Page 1

TKS User’s manual

1

988924FeedMixer EN, V1.8X, 2018-04

User’s manual

TKS

Controller

Program version: V1.8X

Page 2

TKS User’s manual

2

We,

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

declare that the product:

TKS Kuhn - FeedMixer

has been built in conformity with the Machine Directive and meets the relevant fundamental health

and safety requirements.

Kverneland, 2 May 2018

Tønnes Helge Kverneland

General Manager

Enter the serial number

of the machine here :

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specifi cation of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

1 General safety instructions

1.1 CE - Declaration of conformity

Page 3

TKS User’s manual

3

1.2 Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/ or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to TKS

or TKS’s distributor/ importer within the 10th of the month following the one in which the defect was

reported.

The defective parts shall be marked with the claim number and be kept for up to 6 months so that

TKS or TKS’s distributor/ importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any consequential

damage.

The guarantee is not valid if:

a) third party spare parts are used, or the product is repaired or altered without the

approval of TKS

b) the operating and servicing instructions have not been followed.

c) the machine has been used for other purposes than those for which it is designed.

The guarantee does not cover damage due to normal wear and tear.

Offi cial safety regulations specify requirements that apply to the users/ owners and manufacturers

of this machine, relating to the careful review of safety hazards that may arise when this type of

machine is used correctly. Therefore, TKS and our importer/ distributor are not responsible for the

functioning of components that are not shown in the spare parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number; see page 7 on Machine identifi cation.

Page 4

TKS User’s manual

4

Content

1 GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 USING THE SCREEN AND PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1

General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 CE - Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Machine identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.1 General safety instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.2 Additional safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.3 The control cabinet must be secured with padlock. . . . . . . . . . . . . . . . . . . . . . 11

2 Using the screen and PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Numeric keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Selecting a value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 On / off key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 5

TKS User’s manual

5

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Activate FeedMixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2.2 Perform a mixing operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Perform a feedout operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.4 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.5 Manual control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.6 Recipe fi lling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.1 Settings for mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3.2 Settings for feedout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.3 Settings for activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.4 Settings for fi lling sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.3.5 Automatic fi lling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.6 Settings options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.7 Door settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.8 Weigt settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.9 Maintenance / Energy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.10 Feedout timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3.11 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5 Doors 2 and 3 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 6

TKS User’s manual

6

1.3 Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. A network of helpful dealers will be able to advise you on its use, as well as provide

servicing and spare parts.

All TKS products are designed, tested and built in close cooperation with farmers and machine

workshops to ensure optimal effi ciency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine‘s manner

of operation before starting to use it. There are many conditions and variables that can aff ect the

machine’s functionality and manner of operation. It is therefore vital that you consider all known

conditions and adapt usage according to these. A good understanding of the machine‘s manner of

operation and performance, together with a high degree of knowledge with regard to feeding and

feed types/consistencies will ensure the best possible result. The machine is a highly advanced

feed robot that operates without the need for supervision and must be used in accordance with the

applicable instructions from the manufacturer and other regulations in force at any given time.

By being thorough and making the necessary adaptations to local conditions, you will ensure the

best possible results.

Yours faithfully

T. Kverneland & Sønner AS

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

e-post : post@tks-as.no

Phone : + 47 51 77 05 00

Fax : + 47 51 48 72 28

Page 7

ICM_02

TKS User’s manual

7

1.4 Machine identifi cation

The machine’s serial number and the address of the manufacturer are written on the machine.

See the illustration on this page.

Please use the information on the name plate when making any enquiries about spare parts or

servicing.

This product is CE marked. This mark, along with the associated written EU confi rmation, means

that the product fulfi ls current health and safety requirements, and complies with the following

directives.

Page 8

TKS User’s manual

8

1.5

Safety

Please pay particular attention to this symbol. It

designates a safety risk, and describes

precautions that must be taken to avoid

accidents. The control cabinet must be powered

off and locked with padlock when maintenance

is performed.

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Pay attention and be careful when handling

agricultural machinery. Read and take note of

the safety instructions in this manual.

Safety at work is your responsibility!

Please read and understand these general

safety instructions.

1.5.1

General safety

instructions

In order to be able to load the bale into the

hopper, the machine must be open.

This means that people may come into contact

with moving parts if they are standing in the

immediate vicinity of the machine while it is in

use.

Warning! Once the auger is running, never

lean over the top edge of FeedMixer or enter

the hopper when the machine is operating.

If the machine is placed in a sunken fl oor,

the distance from the fl oor to the top of

FeedMixer must not be less than 1.5 m.

It is a conditional requirement of using the

machine that no one must be in the immediate

vicinity of the machine during use.

In addition, in terms of machine type,

FeedMixer is of conventional agricultural design

and, from a safety perspective, the solutions

choosen are considered to be on a par with or

superior to existing products on the market.

Use of the machine

The machine must only be used for the purpose

for which it is designed.

Operating

The machine operator must remain at the end

of the machine where the control box and the

associated operating panel are mounted.

Supervision

The owner/operator must ensure that the area

is suffi ciently signposted and that there is no

unauthorised access.

Page 9

TKS User’s manual

9

Automation

The machine is equipped with devices to automate the entire operation or select parts of the

operation for this purpose. The machine can operate based on a preset schedule set in the

software by the operator, and start at certain times without human presence.

The area in which the machine is operating

Must be physically sealed off or locked to prevent danger to humans or animals.

The machine’s method of operation

The operator must familiarise himself with the machine’s method of operation and function so

that the machine can be used in a safe and appropriate manner.

Keep a safe distance

Humans and animals must be kept away from the machine when it is in operation.

Keep your distance from working, rotating and moving parts.

Think safety at work

Never climb on the machine while it is operating. When performing maintenance, the power supply

must be disconnected

Warning – audio and illuminated

indicator

The control system (software) has been updated for safe start-up. A built-in buzzer sounds for

30 seconds before start-up of the machine. This audio signal is accompanied by a light signal that

fl ashes during the entire period of operation.

Protective guards

Check that all guards are in place and installed correctly. Do not start the machine until this has

been done. Damaged guards must be repaired or replaced immediately.

Spare parts

For safety reasons we recommend that you only use original spare parts. The use of third-party

spares invalidates the product guarantee.

Maintenance

Ensure that the machine is properly maintained and is kept in good condition. Never attempt to

change the mechanical workings of the machine.

Control panel

The power supply must be cut off before opening the panel.

Page 10

TKS User’s manual

10

1.5.2

Additional safety

instructions

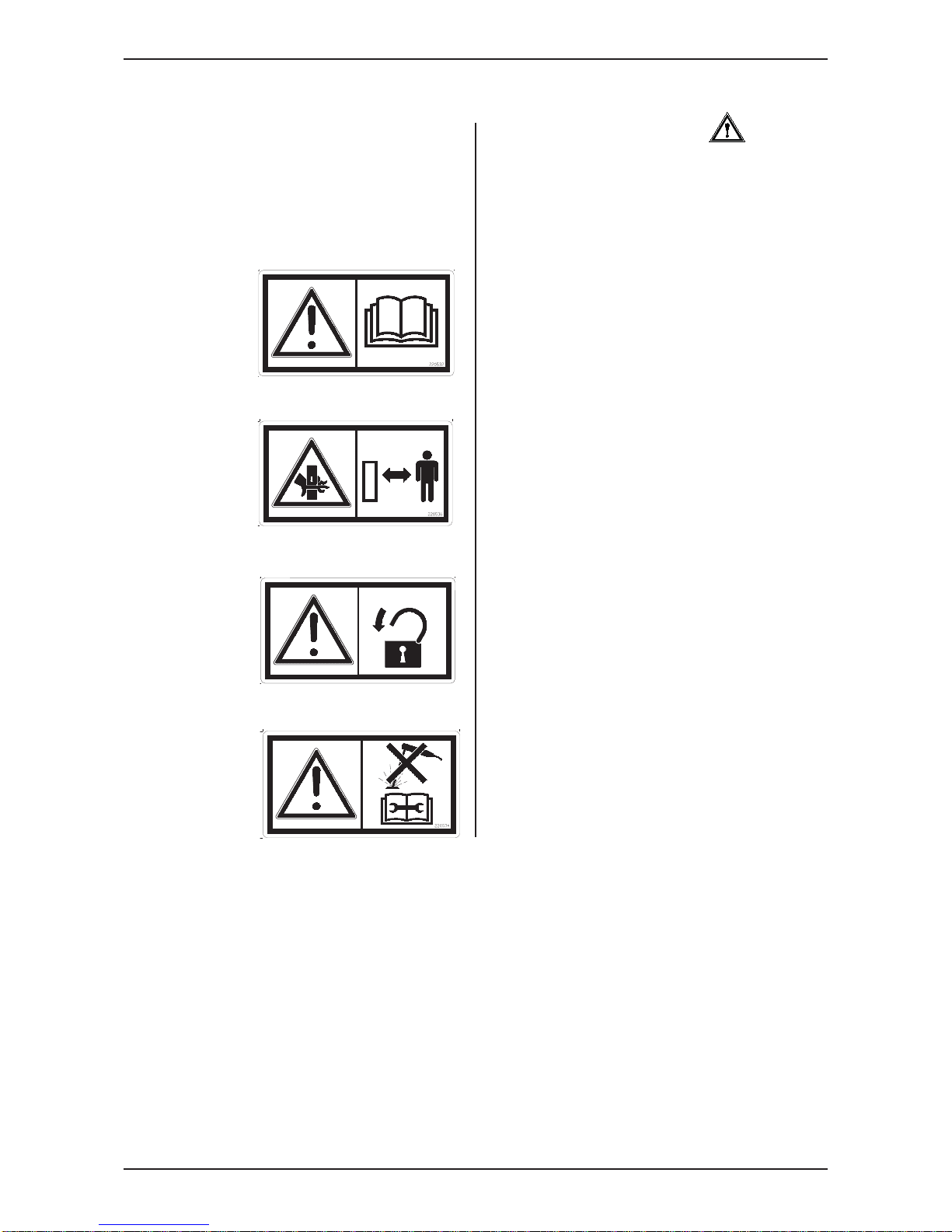

The machine is marked with a warning

signs. If these signs are damaged, they must

be replaced.

Warning sign UH220532 (Fig. 1)

Be careful! Ensure that you read and

understand the instruction manual before using

the machine, and before making any

adjustments or performing any maintenance.

Warning sign UH220536 (Fig. 2)

Risk of crushing hand.

Keep away from the counter knives.

Warning sign 988346 (Fig. 3)

The main power switch must be secured by a

padlock.

Work should only be performed by

authorised personnel.

Warning sign UH220534 (Fig. 4)

Disconnect all electrical connections before

carrying out welding work or maintenance.

Fig. 2

Fig. 1

Fig. 4

Fig. 3

Page 11

UH220536

TKS User’s manual

11

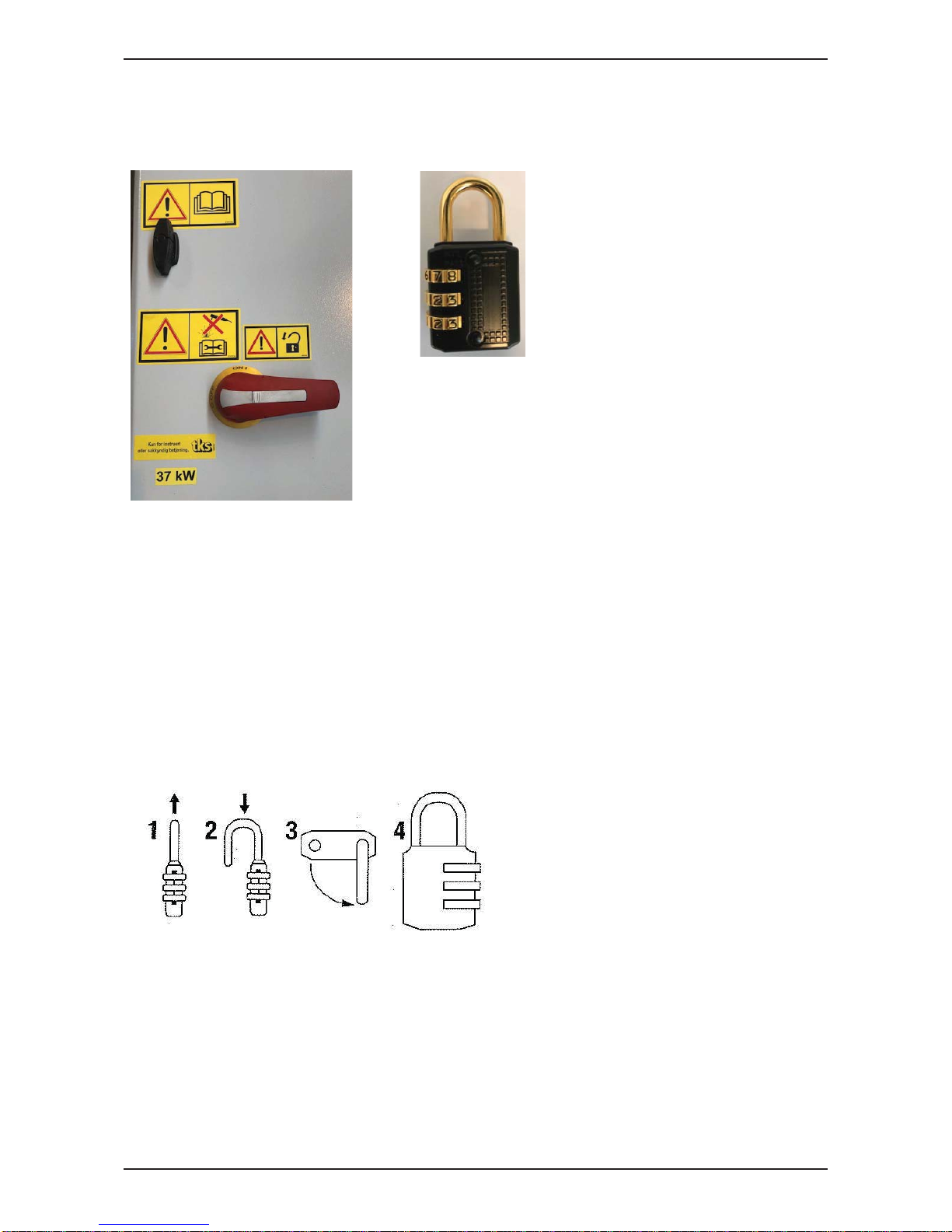

1.5.3 The control cabinet must be secured with padlock

Important!

The control cabinet must be powered off and locked with padlock when maintenance is performed,

especially when knives are sharpened or beeing replaced.

The padlock can be found inside the control cabinet.

Enter your personal code:

1. Set the three code pads so that 0-0-0 is set in the middle of the arrow marker on the short edge

of the padlock and raise the handlebar.

2. Turn the hoop 90O counterclockwise and push it down as far as it goes.

3. While holding the hoop down, enter your personal code using the three code discs.

4. Release the hoop and turn it back to its original position.

NB! The padlock are now ready for use with your personal code.

Page 12

TKS User’s manual

12

2 Using the screen and PLC

2.1 Screen

The control system has a touchscreen, meaning that you can control it by touching the

screen directly. Touch the screen with your fi ngers or use a soft-touch stylus located in the control

cabinet.

Do not press too hard, as this can damage the screen.

If the screen has not been active for a few minutes, it will enter screen saver mode.

The screen will be off in this mode. Touch any part of the screen in order to reactivate it.

The menu keys are displayed on the left-hand side of the screen. Close windows by pressing the X

in the upper right-hand corner to go to the Home screen.

NB! Clean the screen using a moist cloth.

2.2 Numeric keypad

Values in fi elds with blue borders can be

changed. Touch the number and a numeric

keypad will display on the screen.

The top of the screen shows the Max/Min value

that can be entered in this fi eld.

Enter a new value using the number keys.

If an incorrect value was entered, press the

<─ key and delete the most recently entered

number. Press CLR to delete everything.

To enter a negative value, press - before

entering the value.

Once you have selected a value, press the

ENTER button.

This will save the value and close the keypad

window.

To cancel, press X in the upper right-hand

corner. The old value will continue to be active.

To enter times in the feedout schedule

window, begin by entering the hours – then

press period. Then enter the minutes.

Make sure that the time is right.

For example, if you enter 12:65, this will be

ignored – enter 13:05 instead.

Picture 1

Page 13

TKS User’s manual

13

2.3 Selecting a value

Selecting pre-programmed values from a list.

• Open the list – Press the value or the down

arrow

• Select a value from the list

2.4 On / off key

Picture 2

Picture 3

Enable or disable a function using the on/off

key.

• Unchecked means off , disabled

• A checkmark means on, enabled

Page 14

TKS User’s manual

14

3.2 Menus

Picture 5

Picture 4

Picture 6

When FEEDMIXER is switched on, or when the

emergency stop button is pressed, screen

picture will display.

Read the instructions on the screen and make

sure that the machine can be used properly.

Release the emergency stop button if it has

been tripped.

Press “ACTIVATE FEEDMIXER” and hold it

down for three seconds before Home screen

appears.

3.2.1 Home

When FeedMixer is activated, the Home screen

displays. The following displays:

• Menu on the left

• Start keys for mixing and feeding on the right

• The load of the content in the mixer is shown

at the bottom

• The current menu selection is indicated by a

key highlighted in green

• The red line at the top shows FeedMixer

activity

• AUTO – shows when the Feedout timer is

activated.

Clock settings

Hold on the selected area up in the right corner

of the screen for 3 seconds for clock settings.

Time

Hours hh, minutes mm, seconds ss, adjusted

individually.

Date

• Day DD, month MM, year YY adjusted

individually.

• Day of the week chosen from the list

• Press Apply to save

3 Operation

3.1 Activate FeedMixer

Page 15

TKS User’s manual

15

3.2.2 Perform a mixing operation

• Load FeedMixer with feed

• Feed weight shows the number of kg loaded

• Adjust desired mixing time

• Tap the number on the

START MIXING key

• Enter the number of minutes and then press

Enter

• Press and hold the START MIXING key for

three seconds

• The motor goes through its start-up

sequence and mixing begins

Once mixing has commenced, the

START MIXING key changes to a

red STOP key.

Below the keys is a fi eld with a Mixing time left

It can be changed if desired.

The START FEEDOUT key is locked, but the

number of kilograms to be dispensed can be

changed. Once mixing is complete,

FeedMixer stops on its own and the screen

displays two green start keys.

3.2.3 Perform a feedout operation

After mixing, a feedout operation can be started

In the fi eld on the

• START FEEDOUT key, enter the Feedout

quantity in kg.

• Press and hold the START FEEDOUT key

for three seconds,

• FeedMixer begins the feedout sequence.

• The door opens, the counter knives retreats,

the conveyor starts and the feed discharges.

Once the feedout operation has commenced,

the START FEEDOUT key changes to a red

STOP key. Two fi elds display below the keys.

The fi rst fi eld shows the quantity discharged so

far in kg, and the second shows the quantity for

this feedout session in kg.

The START MIXING key is locked, but the

Mixing time can be changed.

Once the feedout operation is complete,

FeedMixer stops on its own and the screen

displays two green start keys.

To empty FeedMixer completely, enter 0 kg in

Feedout quantity before commencing the

feedout operation.

Picture 7

Picture 8

Page 16

TKS User’s manual

16

3.2.4 Settings

Open the settings using Settings in the menu.

Twelve sub-menus display for FeedMixer

settings:

• Mixing – settings for mixing

• Feedout – settings for feedout

• Manual control – control seperate functions

• Activation – settings for remote control

• Filling sources – settings for fi lling sources

• Automatic fi lling – automatic settings

• Options – settings for the motor and

equipment

• Door – door settings

• Weighting system – weight settings

• Maintenance/energy – shows maintenance

intervals, hour meters and energy

consumption

• Time schedule – schedule for automatic feed

dispensing

• Language - select display language

The program version of the

PLC is displayed at the bottom: PLC 1.XX and

screen: HMI v1.XX

3.2.5 Manual control

Open manual control by touching Manual in the

menu.

Operation of the door

• Open the door using the up arrow

• Close the door using the down arrow

• The door is operated when the arrow key is

pressed, and stops when the arrow key is

released

• The arrow key lights up green on activation

• The door stops once the end position is

reached

• The door also moves on the screen

Picture 9

Picture 10

Operation of counter knives

• Counter Knife 1 is moved in position using the right arrow key. (Plate 1)

• Counter Knife 1 is retracted using the left arrow key. (Plate 1)

• Counter Knife 2 is moved in position using the left arrow key. (Plate 2)

• Counter Knife 2 is retracted using the right arrow key. (Plate 2)

• The arrow key lights up green on activation

• The counter knives stops once the end position is reached.

• The bedknife also moves on the screen

Page 17

TKS User’s manual

17

Operation of motor

• In manual operation, the motor rotates in the

forward direction.

• Start motor at pre-defi ned speeds

• Lo = low speed

• M = medium speed

• Hi = high speed

• The motor runs for as long as the key is held

down, and stops when it is released.

• The key lights up green on activation.

Operation of conveyors

• Two conveyors can be operated

individually.

• 1 – operates conveyor 1

• 2 – operates conveyor 2

• The conveyors run for as long as the key is

held down, and stop when it is released.

Control of fi lling sources

• Open separate window using the double

chevrons at the top right.

• Displays fi lling sources 1–12

• Filling sources indicate whether they are

manual or automatic (PLC A3:) (Option)

• Test drive the fi lling source by holding in the

key

Picture 11

Page 18

TKS User’s manual

18

3.2.6 Recipe fi lling

Open Recipe fi lling in the menu

Recipe fi lling can be used manually or

automatically.

For manual use, this is a guide to help fi ll in the

correct quantity of each feed component based

on weight.

For automatic operation, the connected fi lling

sources start and fi ll the specifi ed quantity in

order from a recipe. For automatic fi lling,

electrical equipment must be installed in the

electrical cabinet.

Contact your dealer.

The recipes can consist of both manual and

automatic fi lling sources.

Selection of recipe

This window shows programmed and blank

recipes 1–23

The ingredients box shows the content in the

container now

Select a recipe.

To create a new recipe, press inside a blank

box.

After selection, a new screen will be shown.

To exit without changing, press the red cross.

Ingredients

The window shows the content in the container

now. Unspecifi ed consists of feed that is loaded

outside automatic fi lling, or residual feed from

previous feed dispensing.

Unspecifi ed loaded feed can be moved to a

diff erent ingredient manually.

• Press the blue fi gure to the desired

ingredient

• Enter the desired amount to be moved

All ingredients can be removed from the list.

The weight of these ingredients will be

transferred with unspecifi ed quantity.

Press – Reset all and HOLD for three seconds.

Picture 12

Picture 13

Picture 14

Page 19

TKS User’s manual

19

Recipe fi lling

• Write the name of the recipe.

• Enter the types of feed. Press on the fi elds.

Select from the list in the next window.

(Programming of fi lling sources must be

done in advance in Menu-> Settings->

Filling sources)

• To remove a ingredients, select 0 None.

• The lightest feed should be fi lled fi rst.

See chapter 3.2 about fi lling order.

• Intermediate mixing can be added between

feed ingredients using selection 13. Enter

number of minutes mixing time.

• Enter the amount

• Switch between kg and %. Press on the unit.

When loading bales, it is diffi cult to achieve

an exact number of kg gross feed so it is

useful to use % for quantity when fi lling with

grain feed.

All recipes can consist of up to 12 ingredience.

A specifi c feed ingredient can be repeated

several times to add diff erent layers.

Switch to the last six feed ingredient using the

Line 7–12 key

• When fi lling is fi nished, the mixer can

automatically start to mix and cut the feed.

• Enter the appropriate mixing time.

Mixing after fi lling

• If you do not want automatic mixing, enter 0

min.

• Perform a fi lling sequence

Press START FILLING

Picture 15

Picture 16

Page 20

TKS User’s manual

20

Recipe fi lling in progress

• This window shows the recipe fi lling in

progress.

• The current recipe is shown at the top.

• The status indicator shows in per cent how

much of the feed component has been fi lled.

• The weight of the fi lling loaded so far/how

much to be loaded is shown underneath.

• During fi lling an audible warning will be given

when 80% of the weight of the feed

component has been achieved.

• The audible signal becomes more intense up

to 100%.

• At 95% the indicator changes colour from

yellow to green.

• The fi lling is complete when the sound stops.

• In the event of overloading, the indicator will

turn red from 105%

• When fi lling from a fi lling source is complete,

the indicator changes to the next component

in the recipe within 10 seconds (plus any

additional pause time).

• It is important that the mixer does not move

unnecessarily after the feed component has

been loaded. This will result in a longer

waiting time before the next component

starts.

• When an intermediate mix is in progress, the

mixing process is shown in the status

window

At the bottom of the screen there are keys to

stop the process.

Stop this process

• Stops the ongoing feed component and

moves on to the next component in the

recipe.

• This key should be used if no more of this

component is to be loaded

• The key is used when loading whole bales

when the set weight has not been achieved.

• When the last feed component in the recipe

stops, the pre-programmed Mix after fi lling

will start.

Stop recipe fi lling

• Stops all fi lling and returns to the home

screen without starting mixing.

Picture 17

Picture 18

Picture 19

Page 21

TKS User’s manual

21

Picture 21

Picture 20

3.3 Settings

3.3.1 Settings for mixing

Choose mixing speed by setting a predefi ned

motor speed.

• Low – Low

• Med – Medium

• High – High

• Auto – Automatically adjusts the engine

speed between low and high. FeedMixer

always adjusts to the lowest load.

• Motor load target for auto speed -

the motor’s specifi ed load is entered here as

a percentage. This fi gure is converted to real

amperage (A).

• When new material is loaded into FeedMixer,

the load will increase. You can choose to

start the mixing process from the beginning.

A sound warning is given.

• Enable / disable – Automatically reset mixing

time after FeedMixer is loaded.

3.3.2 Settings for feedout

Choose a feedout speed by setting a

predefi ned engine speed.

• Low – Low

• Med – Medium

• High – High

• Auto – Automatically adjusts the engine

speed between low and high.

FeedMixer always adjusts to the lowest load.

When FeedMixer is used together with

FeedRobot or FeedBelt, the feedout speed

must be set to Medium or Low.

This is important in order to achieve an even

feeding process.

FeedMixer can automatically adjust the speed

to dispense feed evenly.

• Set desired feed quantity in kg per 10

seconds.

• Last calculated feed quantity gives an

indication of how much feed is expected to

come out.

• This function is reserved for FeedBelt and

other conveyors in the feed system.

Page 22

TKS User’s manual

22

Picture 23

Conveyor

It is possible to connect up to two conveyors

to FeedMixer. The conveyors start each time

discharging, and stop after the specifi ed length

of time when the auger has stopped.

• Specify stop delay (time for emptying the

conveyors)

Level of empty containers

• When the mixer is almost empty, it is

possible to set a function to clean the

container.

• This can be set for the function to start at a

fi xed or automatic level.

• Select level

• Set weight limit for level.

• With automatic level, the function will start

when weight reduction does not occur.

• Activate high speed clean. High speed clean

causes the motor to operate at a high speed

to eject any feed left on the screw

• Specify cleaning speed.

• Delay time – specify how long the screw

needs to rotate after the function is

complete.

3.3.3 Settings for activation

Settings for remote control of feed dispensing

on FeedMixer are confi gured here.

Activating the hold signal

FeedMixer can start dispensing feed in

response to external signals issued by feed

dispensing machines.

The start signal must be an active signal for the

entire time the feed is being dispensed A

so-called hold signal.

When the signal is interrupted, feed dispensing

stops.

Feeding and conveyors can be controlled

independently of one another.

• Feedout – enable/disable (circuit diagram

-X3:1)

• Conveyor 1 enable/disable (circuit diagram

-X3:3)

• Conveyor 2 enable/disable (circuit diagram

-X3:3)

Conveyors 1 and 2 start at the same time, but

may have diff erent stop times confi gured.

• Adjust stop delay.

Picture 22

Page 23

TKS User’s manual

23

Picture 24

Activation by pulse signal

FeedMixer can start the feedout process in

response to machines with a pulse signal.

This means that FeedMixer starts with one

signal and stops with another.

In order to prevent FeedMixer from starting in

response to the wrong signal, the signals must

have a minimum duration.

• Enable/disable pulse signal

• Shortest start signal – adjust signal length

(circuit diagram -X3:5)

• Shortest stop signal – adjust signal length

(circuit diagram -X3:6)

• Select desired door

Activation with photocells and switches

When FeedMixer is used together with an

external feed cart or mashine, such as a

FeedRobot or EasyFeed, FeedMixer can be

started using a photocell and switch.

• Enable/disable the function

• Photocell act/deact. delay

Photocell activating/diactivating delay –

how long the photocell must have a stable

signal before FeedMixer reacts.

• Photocell react. delay

Delay until reactivating of photocell

– period of time after the end of the feedout

process until the next feed may begin.

• Switch act. delay

Switch activation delay – how long

Feed Robot must be in the switch position

before the feedout process begins.

• Switch deact. delay

Switch deactivating delay – time to elapse

before FeedMixer stops the feeding

process if FeedRobot leaves the position.

• Select desired door

Picture 23

Page 24

TKS User’s manual

24

3.3.4 Settings for fi lling sources

The settings for the fi lling sources for recipe

fi lling are found here.

• This screen shows the programmed and

blank feed components/fi lling sources.

• Each feed component/fi lling source has its

own settings.

• Select a fi lling source.

• To create a new one, press an empty line.

• The settings window for this component will

open.

Filling source name

Enter the name of the fi lling source / feed

component.

Output

Select whether the fi lling source will be manual

or automatic (PLC A3:).

For automatic, separate electrical equipment

must be connected to the electrical cabinet.

A3:02 refers to the circuit diagram.

Contact TKS for installation and connection.

Picture 25

Picture 26

Page 25

TKS User’s manual

25

Picture 27

Maximum fi lling time

Specifi es how long the fi lling source will be

active before it stops and moves on to the next

fi lling source.

Weight timeout error

When the weight does not increase in this time,

the fi lling source will stop and move on to the

next fi lling source.

This parameter is only active for automatic

fi lling sources.

Stop fi lling source before

Stops the fi lling source before the desired

weight in the recipe is achieved. This is

useful when manually loading bales. If you do

not want overloading according to

the recipe, but still want the automatic fi lling to

move on to the next fi lling source without

pressing the screen, set the value to e.g. 400

kg.

Pause after complete

Any additional waiting time can be set here

before the next fi lling source is activated.

3.3.5 Automatic fi lling

The window shows settings for receptors

associated with automatic fi lling. The function

controls when the container will be fi lled.

• Activate

• Select recipe

• Specify weight limit for remaining feed in the

container before fi lling starts.

• Specify delay before fi lling starts when

weight limit is reached. The timer starts

counting when the mixer stops.

Picture 28

Page 26

TKS User’s manual

26

Picture 29

3.3.6 Settings options

Other settings and enabling/disabling of various

functions can be performed here.

• Door enabled/disabled

– Enable the door to allow FeedMixer to

automatically open/close the door when

feeding. If disabled, the door must be

controlled manually.

• Door 1 opening time

– Confi gure the desired opening height for

the door during automatic feedout. Enter

opening time in seconds it takes to open the

door to the level desired. Enter value 0 and

door opens completely.

• Plate 1 or 2 enabled (Counter knife 1 or 2)

– Enable counter knives to allow FeedMixer to automatically move counter knives in position

when mixing and retract them during the feedout process. When counter knives are disabled,

they are stationary, and can be moved manually to the desired position

• Motor reverse enabled/disabled

– When mixing and feedout, the auger will rotate in reverse approximately a quarter revolution

in order to loosen the feed before rotating in the working direction. This avoids overloading the

motor on start-up. This function must be used when FeedMixer is loaded to the limit.

• Freezing protection enabled/disabled

– During cold times of year, the feed may freeze to the auger and sides, and make it diffi cult for

the auger to turn. You can prevent feed from freezing to surfaces by setting the auger to turn at

defi ned intervals. Confi gure the desired interval.

• Maximum feedout time

– To avoid overloading, the maximum feedout time is limited to 60 minutes.

This time can be lowered as desired.

Blockage detection

If the weight of the content is not reduced during feedout, FeedMixer will stop after the set amount

of time and sound an alarm. It is useful to use this function during automatic feedout when a

connected machine may lead to blockages if it stops

• Activate with check box

• Confi gure the desired time before stop. The time should not be less than 60 seconds.

• Conveyor sensor

When a conveyor is connected, this can be secured with a guard to prevent feed piling up if the

conveyer stops.

• The function can be activated with connected sensor.

Shift to next screen with arrows to the right

Page 27

TKS User’s manual

27

Picture 30

• External alarm input Off / NO / NC

– Used when a connected machine may give

an error message. This signal causes

FeedMixer to stop. (Connected to -X3:4).

NO - normally open signal

NC - normally closed signal

• Motor overload alarm - activate / disable

– emits an audio alarm when the load on the

motor is too high. Do not load any feed until

the alarm stops sounding.

• Web app password

Set a password for access to the website

from a mobile phone.

• Group feed logging

Enables logging of data on feeding to

diff erent groups.

3.3.7 Door settings

The window shows door settings.

If there are several active doors, these are

displayed.

If a door is opened and closed automatically,

the door must be activated and an opening time

must be set for each individual door.

• Enable door

• Close door after feedout Activate / disable

• Door opening time

• Activate which conveyer, 1 or 2, will be

connected to the relevant door.

If you want feed to be dispensed evenly when

the container is emptied, set the function –

Reduce door opening gradually.

The door must be activated automatically.

Three steps can be set.

• Activate step.

• Specify weight at which the door will close

• Specify closing time

When high-speed cleaning is used, the door

can be closed before cleaning starts.

The weight limit for start is specifi ed in the

function

Level of empty containers in the settings

menu for feed dispensing

Picture 31

Picture 32

Page 28

TKS User’s manual

28

3.3.8 Weight settings

The window shows settings for the weighing

system.

• Automatically resets weight when the mixer

is empty. Activate/disable. The mixer is

empty when the motor stops after any

high-speed cleaning.

Any feed residue in the container is then

ignored.

• Now reset weight. Press HOLD for three

seconds.

• Set factory systems for the weighing system.

Press HOLD for three seconds. Transfers

factory data from PLS to the weighing cell

amplifi er.

If the weighing system does not function

correctly, the factory settings can be set, to

rectify any faults.

• Deactivate weight. Can be used in the event

there is a delay in repairing the weighing

system.

Calibrate weight

• Empty FeedMixer before doing the

calibration

• Tare weight system now

• After that the Feedmixer will show value 0 kg

• A known weight will be loaded in the

FeedMixer, for example 1000 kg.

• The weight will show the load

• If scale shows diff erent value than your

loaded weight – weight system needs to be

calibrated

• Adjust the weight of what is loaded.

• For rought adjustment use ++ / --

• Fine tuning with + / -

• When the load is removed, the weight should

show 0 kg

Weight signal forwarding

Settings for forwarding signals to other

systems.

Choose signal type

• Modbus

• Analogue

Set

• Node ID

• Max weight

Picture 34

Picture 33

Page 29

TKS User’s manual

29

Picture 35

3.3.9 Maintenance/Energy

The window has two tabs for information on

maintenance hours and energy consumption.

Maintenance

FeedMixer has a maintenance timer that

generates a message on the screen when

maintenance needs to be performed.

• Lubrication must be applied every month or

every 50 hours.

• Gear oil must be changed every year or

every 1,000 hours

• Maintenance must be carried out at the fi rst

possible opportunity.

• When maintenance is completed, the

maintenance timer must be reset.

• Press HOLD to reset.

Hour meter

• Motor operating time

• Number of times door is opened

• Number of counter knife (Plate) movements

in/out.

Energy consumtion

FeeMixer calculates the energy

consumption of the last mix, over the last

24 hours, the last seven days, and total

consumption.

• Enter the price of energy in EUR/kW.

FeedMixer calculates the cost of

consumption.

Picture 36

Page 30

TKS User’s manual

30

Picture 38

3.3.10 Feedout timer

FeedMixer can be set to dispense feed

automatically according to a time schedule.

Up to 16 diff erent times can be confi gured

individually. It is appropriate to use this function

if a feed dispensing machine does not have a

separate feedout timer.

• Time - set the desired feed dispensing time.

• Kg - specify the feed quantity for each time

• En - enable this feed dispensing with check

box.

• D - specify the door to be used.

• Press the fi gure to switch between

door 1, 2 or 3.

When at least one feedout session is enabled,

a green lamp with the text AUTO will be

displayed at the top of the Home screen.

When automatic feed dispensing is used, the

feed must still be mixed manually. Mixing must

be performed at a time between two automatic

feed dispensing sessions. If FeedMixer is

empty when dispensing, FeedMixer will stop

and an alert will appear on the screen.

3.3.11 Language

Select display language

Picture 37

Page 31

TKS User’s manual

31

Picture 39

3.4 Alarms

FeedMixer stops when an alarm is triggered.

The screen shows the alarm window and which

alarm was triggered.

The window can be closed by pressing the X in

the upper right-hand corner.

A yellow symbol displays on the Home screen.

Touch the symbol to open the alarm window

again.

• Reset the alarms using the

Reset alarm - key

• If the error has not been corrected, the alarm

will trigger again shortly

The following error messages may display:

• Frequency inverter fault

• Conveyor fault

• Door fault

• Limit switch fault, counter knife 1 (Plate 1)

• Limit switch fault, counter knife 2 (Plate 2)

• Feedout process fault

• External alarm input

• Error in feeding

• Perform maintenance

• Error on logging

Page 32

TKS User’s manual

32

3.5 Doors 2 and 3 (Option)

FeedMixer can be equipped with the

operation of up to three doors.

Dispensing with multiple doors is appropriate

where several feed dispensing machines are

connected. All the doors can be controlled

automatically from the connected machine or

they can be operated manually. Door settings,

see chap. 3.3.7

Feedout

Select the desired door before feedout. Press

the desired door: 1, 2, 3. Then start the feedout.

When feedout to another door is desired, the

door that was last activated closes

automatically and the desired door opens

before the feedout starts.

Manual control

First select the desired door on the screen.

The door in red is active.

Open and close the door using the up and

down arrow keys.

Picture 40

Picture 41

Page 33

TKS User’s manual

33

4 Troubleshooting

Fault Causes Procedure – error correction

Auger does not rotate

• The shear bolt in the boltconnection in front of the

planet gear has sheared.

• Replace the shear bolt.

Weight system, door or conveyor belt not working

•

Voltage too high.

•

Power cut.

• Check the fuses.

• Turn off the mains supply for 30

seconds. Motor, door and

counter knives will be reset

automatically.

Scales are showing incorrect

values

Scales are not working

• The settings on the

load cell amplifi er are

incorrect.

• The load cell amplifi er must be

confi gured correctly.

• Auger connections on the

scales’ components have

come loose.

• Retighten the augerconnections.

• The switch is moist.

• Insuffi cient contact in

cables.

• Clean and dry the switch

• (do not use contact spray).

Alarm!

Door fault

•

El. actuator does not reach

top or bottom endpointswithin 30 seconds.

•

Silage in channel to door.

• Clean the outlet.

• Check clearance in the slot of the

door.

Alarm!

Fault on limit switch for the

counter knifes

• Both of the limit switches

in the el. actuator give a

signal.

• Check the cables for faults.

Alarm!

Frequency inverter fault

• Power supply to the motor.

• Overload/overheating on

motor.

• Check the power supply.

• Wait until the engine has cooled.

• Press Reset alarms to reset the

Alarm!

Conveyor fault

• Power supply to the motor.

Overload on motor.

• Check the conveyor.

• Enable motor protection.

Alarm!

Feed feeding fault

• When there is no

reduction in weight during

the discharging process.

• Check the door outlet.

Alarm!

External alarm input

• Fault in connected

machine.

• Check connected machine.

Page 34

TKS User’s manual

34

Page 35

TKS User’s manual

35

Notes

Page 36

www.tks-as.no

TKS is a family owned company

with a strong brand name.

We are providing our customers with a

unique and complete range and high

quality products.

TKS User’s manual

36

www.tks-as.no

TKS is a family owned company

with a strong brand name.

We are providing our customers with a

unique and complete range and high

quality products.

Loading...

Loading...