Page 1

RW1600

Operatio n ma nual

Issue 04/2009

Date of printing 6.2009

Language EN

From machinenumber (PIN) VGEW000365

Serial number (PSN) 03EW01

Reference number ZNA012EN

Page 2

Identifica ti on of the m achine

To support you as soon as possible your dealer requires several details of your machine.

Please enter the information here.

Designation

PIN

Software version

Assembled

options

Dealer's address

RW1600

VGEW........................

Manufacturer's

address

KUHN-GELDROP B.V., retains all copyrights and rights of usage. The contents of this operating manual are subject to change without notice. All

rights reserved. The right to technical revision is reserved.

KUHN-GELDROP B.V.

Nuenenseweg 165

5667 KP Geldrop

The Netherlands

Phone +31 40 2893300

Page 3

Table of contents

Preface .............................................................5

Target group of this operation manual 5

Symbols used 6

Safety instructions .........................................7

For your safety 7

Safety decals at the machine 8

Who is allowed to operate the machine? 12

General 12

Hitching the machine 13

Road transport 14

Working with the machine 15

Unhitching the machine 16

Care and maintenance 17

Further prescriptions 18

Table of contents

Preparation at the field ................................ 46

Safety 46

Performing settings 46

Prior to wrapping 46

Placing into working position 47

Use at the field .............................................. 48

Safety 48

Checks before use 48

Film wrap recommendations 49

Start position mode 50

Wrapping 50

Loading a second bale during

wrapping 53

Emergency stop 54

Acquaintance with the machine .................19

Destination of the machine 19

Characteristics of the machine 19

Description of the components 20

Technical specifications 21

Delivery and preparation .............................25

Safety 25

Checking the delivery 25

Hitching the machine ...................................26

Safety 26

General 26

Hitching 27

Support jack 29

Installation cable control 30

Installation joystick control 31

Installation control box 32

Connections 33

Road lighting [+] 35

Preparation for use .......................................36

Safety 36

Table roller adjustment 37

Support roller 38

Loading arm width 39

Pre-stretcher 40

Film installation 41

Film overlap 42

Check at beginning of the season 43

Running 43

Road transport ..............................................44

Safety 44

Before road transport 44

Road transport 45

Wrap and bale counter ................................. 55

General 55

Wrap and bale counter box 55

Parameter change 56

Parameter settings 57

Joystick control ............................................ 59

General 59

Joystick control 59

Control mode 61

Parameter settings 62

Electronic control system ........................... 65

General 65

Control box 65

Control mode 68

Parameter change 70

Parameter settings 71

Cleaning and caring ..................................... 76

Safety 76

Cleaning 76

Caring 76

Storing the machine ..................................... 77

Safety 77

Unhitching and securing of the machine 77

After the season 77

Maintenance .................................................. 78

Safety 78

General 80

Attaching elements 82

Tightening torques 83

Pre-stretcher 84

Wheels/tyres 85

Hydraulics 86

Table 87

Applicutter 88

Lubrication 89

3

Page 4

Table of contents

Optional equipment ......................................92

General 92

Film roll holder 92

Film roll magazine 92

Wheel chock set 93

Bale turner 93

Hydraulic bale turner 93

Bale stop arm 93

Drop mat 94

Drop plate 94

Road lighting set 94

Remote control 94

Troubleshooting ...........................................95

Safety 95

Electronic control system 95

Applicutter 96

Pre-stretcher 98

Hydraulics 98

Film 99

Bale 99

Disposal of the machine ............................100

EC Declaration of conformity .................... 101

Index ............................................................102

4

Page 5

Preface

Preface

Target group of

this operation

manual

This operation manual is meant for those concerned with the control,

use and maintenance of the machine. It contains all data required for

a safe handling, use and maintenance of the machine.

For your safety

Before starting to adjust and use your machine, familiarise yourself

with this operation manual. By doing so your safety and the best

performance are assured. It is very important to read this manual

carefully before using the machine and to keep it handy. In this way,

you will

• avoid accidents

• respect the warranty conditions

• always have a functional machine in perfect working order

For the employer

All personnel are to be trained in the use of the machine regularly (at

least once a year) in accordance with employers’ liability insurance

association guidelines. Untrained or unauthorised individuals are not

permitted to use the machinery.

You are responsible for the safe operation and maintenance of your

machine. You must ensure that you and anyone else who is going to

operate, maintain or work around the unit be familiar with the

operating and maintenance procedures and related safety information

contained in this manual.

5

Page 6

Preface

Symbols used

In this operation manual the following symbols and terms are used:

• A bullet stands at enumerations

> A triangle stands at steps, which you must do

→ An arrow shows cross-references at other text passages

[+] The plus sign shows that it involves optional equipment, which

does not belong to the standard model.

Besides these symbols, pictograms are used, which will help you with

locating of text passages:

TIPThe word “Tip“ shows tips and advices to the use.

The triangle refers to danger at assembling or (adjusting) work.

The key refers to tips at assembling or adjusting work.

0

The star shows examples, which are needed for a better

understanding.

6

Page 7

Safety instructions

Safety instructions

For your safety

This chapter contains all general safety instructions. Subject-specific

safety instructions are located per chapter. Take care of the safety

instructions

• because of your own safety

• because of the safety of your fellow man

• to guarantee the machine safety

When handling agricultural machinery, wrong behaviour can lead to a

lot of danger. Therefore work with special care and never under

pressure of time.

For the employer

Inform the one who works with this machine frequently about these

safety instructions and according to the legal regulations.

7

Page 8

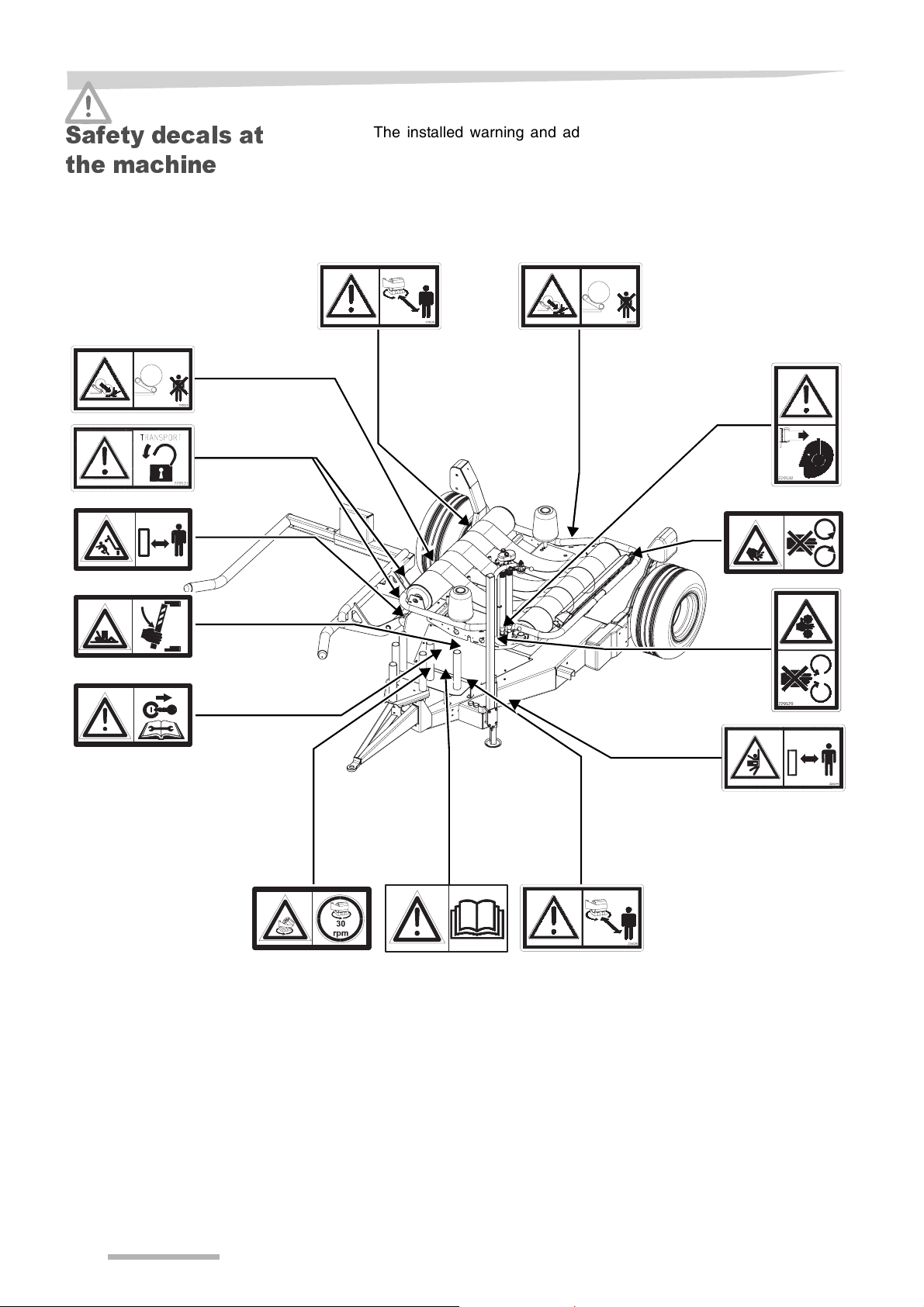

Safety instructions

Safety decals at

the machine

The installed warning and advisory signs give important hints for a

safe operation; adhering to serves your own safety. Keep safety

decals and signs clean and legible at all times. Replace safety decals

and signs that are missing or have become illegible. If original parts on

which a safety decal or sign was installed are replaced, be sure that

the replacement part also displays the current decal or sign.

8

Page 9

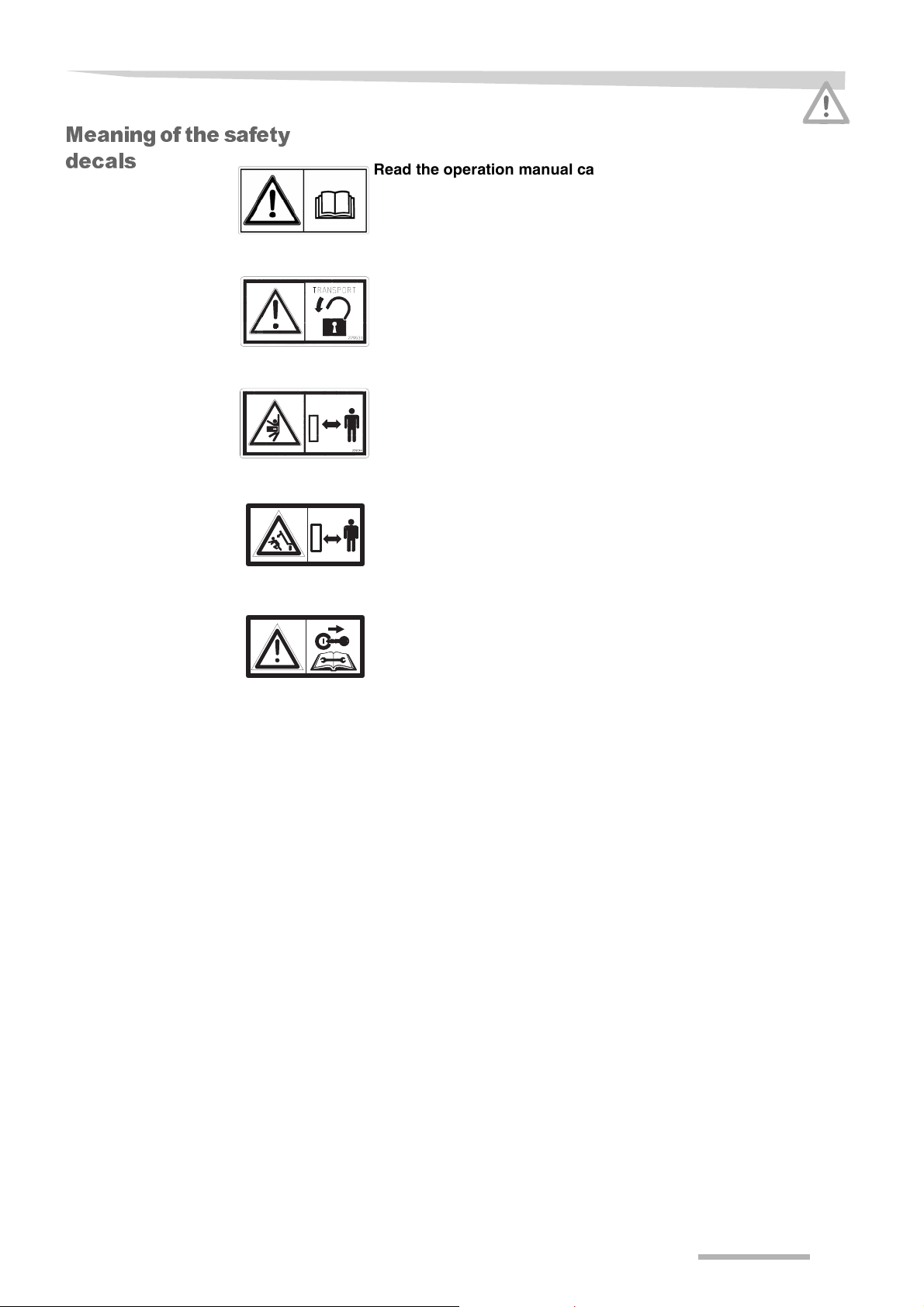

Meaning of the safety

decals

Safety instructions

Read the operation manual carefully

Read the operation manual carefully before taking the machine into

operation. Read and obey the safety instructions.

Use the transport lock

Before road transport, the transport lock must be used to secure the

loading arm. A non-secured loading arm can cause serious or deadly

injuries or damages.

Stay clear of the pre-stretcher

Stay clear of the pre-stretcher area while the wrapper arms are

rotating. Serious injuries can occur.

Stay clear of the loading arm area

Stay clear of the moving loading arm area. A loading arm moving

down can cause serious personal injuries.

Stop the tractor engine

Prior to any maintenance, repair and adjustment work, stop the tractor

engine and remove the ignition key. Otherwise serious or deadly

injuries can occur.

9

Page 10

Safety instructions

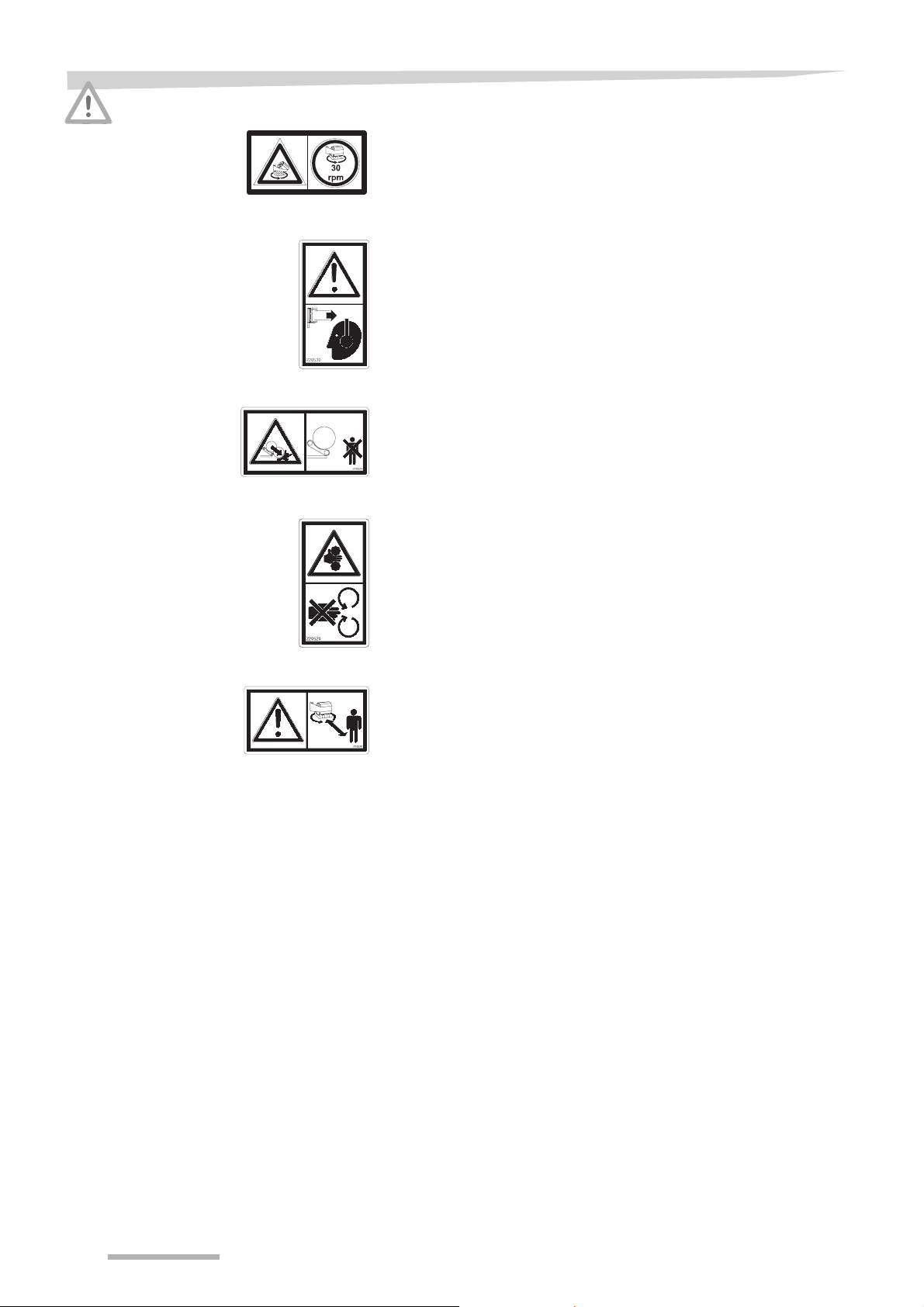

Pre-stretcher rotation 30 rpm

The prescribed pre-stretcher rotation of maximum 30 rpm may not be

exceeded.

Use ear protection

Use adequate ear protection during wrapping. Serious hearing injuries

can occur.

Never stay behind the machine while unloading

Stay clear of the table area while unloading a bale. An outcoming,

rolling bale has a heavy mass and a high speed. A rolling bale can

cause serious or deadly injuries.

Stay clear of pre-stretcher rollers

Stay clear of the pre-stretcher rollers. Hands can be squeezed

between the rollers. Personal injuries can occur.

Stay clear of the pre-stretcher area

Stay clear of the pre-stretcher area while the wrapper arms are

rotating. Serious injuries can occur.

10

Page 11

Safety instructions

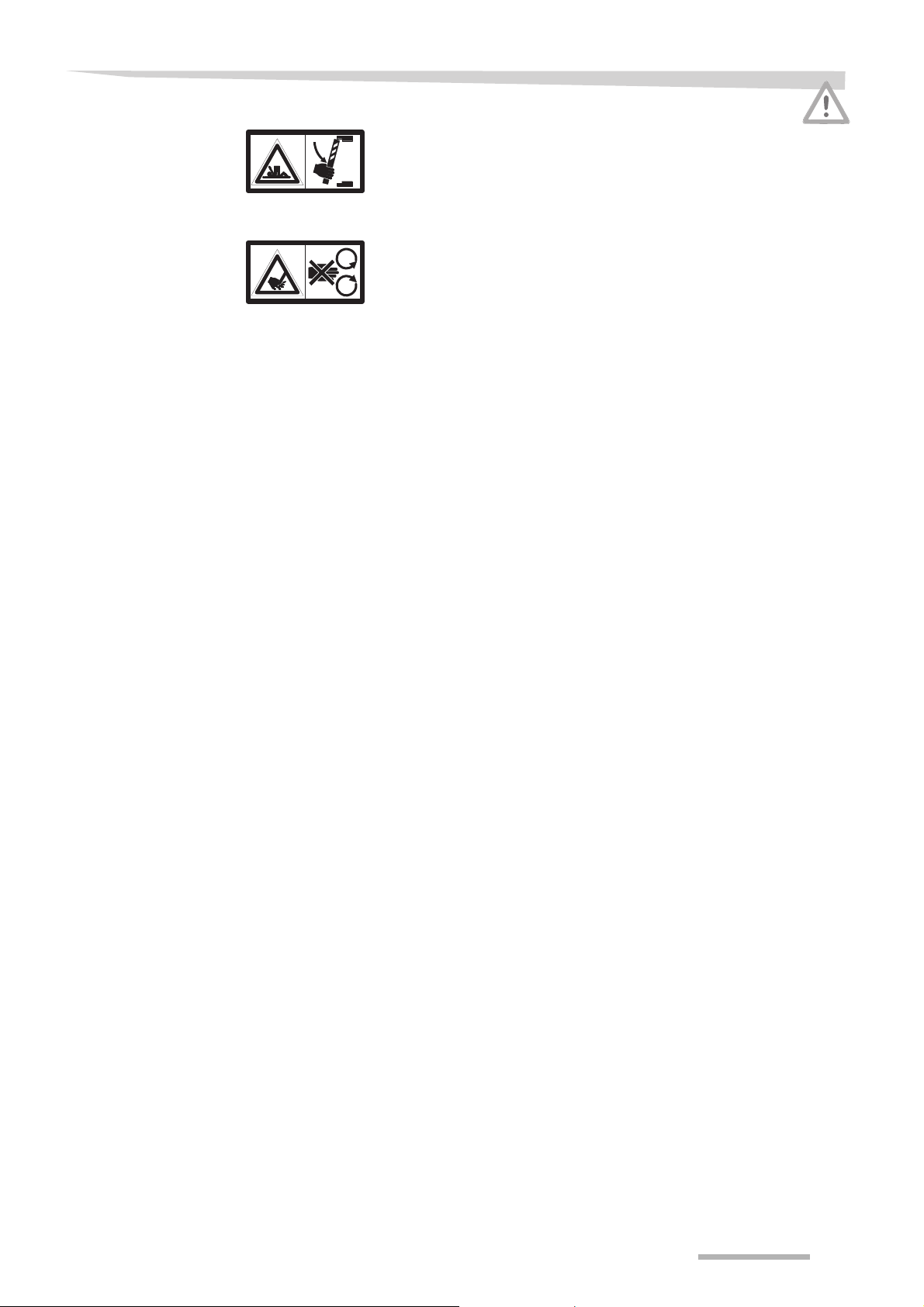

Use the table safety bar

Prior to any maintenance, repair and adjustment work on the tipped

table, place the table safety bar. A non-secured table can cause

serious or deadly injuries.

Stay clear of the applicutter rollers

Stay clear of the applicutter rollers. Hands can be squeezed between

the rollers. Personal injuries can occur.

11

Page 12

Safety instructions

Who is al lo w e d to

operate the

machine?

General

Authorised people only

The machine may only be used, maintained or repaired by authorised

people who have been informed about the dangers when handling the

machine.

Usually such persons have an agricultural or equal intensive

education.

Safety is your responsibility

Apply and insist upon application of the safety instructions. Most

accidents are avoidable. Do not run the risk of serious or fatal

accidents through ignorance of these safety instructions.

Wear close fitting clothing

Avoid wearing loose fitting clothing.

Loose clothing can get stuck between rotating parts. Danger of

serious injury.

Keep the machine clean

Always keep the machine clean to avoid fire risk. Equip the machine

with a 10 litre pressurised water fire extinguisher to be prepared in

case of fire.

Running in an enclosed area

Do not run the machine in an enclosed area. Exhaust fumes can be

dangerous.

Never work on a running machine

Never work on the machine while it is running. Severe injuries can

occur.

No modification of the machine

Do not modify the machine in any way. Unauthorised modifications

may impair the function and/or safety and could affect the life of the

machine.

12

Page 13

Safety instructions

Hitching the

machine

Hydraulics

Increased danger of injury

While hitching the machine onto the tractor an increased danger of

injury occurs. Therefore:

• prevent the tractor from rolling away, shut down the engine and

remove the ignition key

• never stay between tractor and machine during hitching

In case of negligence damages to the machine or serious personal

injuries can occur.

Hydraulic couplings only pressureless

Only couple the hydraulic hoses to the tractor when both tractor and

machine hydraulics are pressureless. Hydraulics under pressure can

cause accidental movements of the machine.

High pressure in the hydraulic system

The hydraulic system is under high pressure. All tubes, hoses and

couplings must be controlled regularly for leaks and external

damages. Only use suitable tools when searching for leaks.

Immediately repair damages. Leaking oil can cause injuries and fire.

When having injuries visit a doctor immediately.

13

Page 14

Safety instructions

Road transport

Pay attention to a road-safe condition

When driving on the local roads, the machine must correspond to the

current traffic prescriptions. To which e.g. belongs:

• mounting of lighting, warning and protection installations

• comply with the permittable transport dimensions and weights,

maximum permittable axle loads, tyre carrying capacity, total

weights and national speed limits

• taking care of the maximum permitted speed of 25 km/h

In case of negligence, driver and owner of the machine are fully liable.

Prohibition of transporting people on the machine

Nobody and nothing shall be transported on the machine during

transport. Transporting of people or objects on the machine is perilous

and prohibited.

Changed driving and braking handling

Because of the hitched machine the driving and braking handling

changes. Especially when driving curves the dimensions and mass of

the machine have to be taken into account. A not adapted driving style

can lead to accidents.

Adapted driving speed

Under bad road circumstances and at high driving speeds very high

crafts can appear, which load or overload the tractor and machine to

much. Adapt the driving speed according to the road circumstances.

A not adapted driving speed can lead to accidents.

14

Page 15

Safety instructions

Working with the

machine

First use only after instruction

The machine may at the first time of use only be brought into use by

employees of the dealer, factory representatives or employees of the

manufacturer. False use after bringing the machine into use without

instructions can cause damages to the machine or accidents.

Take care of technical correct condition

Only bring the machine into use in a technical correct condition. Check

all important parts and replace defective parts before use. Defective

parts can cause material or personal damages.

Do not remove protective covers

The protective covers should not be removed or evaded. Check all

protective covers before using. Unprotected machine parts can cause

heavy or deadly accidents.

Prohibition of transporting people on the machine

Nobody and nothing shall be transported on the machine during

transport. Transporting of people or objects on the machine is perilous

and prohibited.

Check the direct surroundings

Before driving and bringing into use of the machine the direct

surroundings must be checked. Take care of sufficient view. Only start

driving when no persons or objects are in the direct surroundings.

Perilous injuries can occur.

Tighten bolts and nuts

Check bolts and nuts regularly for being tight and tighten if necessary.

Because of using the machine bolts can get loose. Damages to the

machine or accidents can be caused.

Behaviour at troubles

At functional troubles stop and secure the machine immediately.

Remedy the trouble immediately or commission a workshop.

Continuing working with the machine cause accidents or damages.

Blockage or operation of a security device

In case of a blockage or operation of a security device, never work on

the machine without

• stopping the engine and

• removing the ignition key

Never be tempted to hand feed or unblock the machine while it is

running. Serious or deadly injuries can occur.

15

Page 16

Safety instructions

Unhitching the

machine

Increased danger of injury

While unhitching the machine from the tractor an increased danger of

injury occurs. Therefore:

• prevent the tractor from rolling away, shut down the engine and

remove the ignition key

• never stay between tractor and machine during unhitching

• take care of a level and secure surface for the machine

• take care of a secure lock of the support jack

• only detach the hydraulic hoses when the hydraulic system at both

tractor and machine is pressureless

In case of negligence heavy or deadly injuries can be the

consequence.

16

Page 17

Safety instructions

Care and

maintenance

Observe the care and maintenance intervals

Observe the prescribed intervals and those stated in the operation

manual for recurring checks and inspections. In case of negligence of

the intervals damages to the machine or accidents can be caused.

Use original parts only

Lots of components have special properties which decides for the

stability and the function of the machine. Only the parts and options

delivered from the manufacturer have been tested and released.

Other products can interrupt the function of the machine or can harm

the security. When using not original parts the warranty and liability of

the manufacturer reduces to nil and void.

At all care and maintenance work:

• make the hydraulics pressureless

• switch off the engine and remove the ignition key

• make sure the tractor and machine are positioned on a firm and

level area, support if necessary

• unhitch the tractor if possible

• do not use parts of the machine as climbing help, use suitable

climbing helps on the contrary

Only when observing these prescriptions a secured working during

care and maintenance work is guaranteed.

Interrupt electric power supply

Before working on the electrical device, separate this from the electric

power supply. Supplies being charged can cause material or personal

damages.

Exchange hydraulic hoses

Hydraulic hoses can age without external recognizable indications.

We therefore recommend to exchange all hydraulic hoses every six

years. Defective hydraulic hoses can cause heavy or deadly injuries.

Careful when cleaning with high-pressure cleaner

The machine can partly be cleaned with water or steam. Clean

bearings, plastic parts and hydraulic hoses with low pressure only. Too

high pressure can damage these parts.

17

Page 18

Safety instructions

Careful when cleaning with compressed air cleaner

The machine can partly be cleaned with compressed air. Clean

electric parts and the hydraulic valve block with low pressure only. Too

high pressure can damage these parts.

No aggressive wax additives

When cleaning do not use aggressive wax additives. Bright metal

surfaces can get damaged.

Before welding work

Before welding to the hitched machine, untie the tractor’s battery and

the dynamo. Therefore you will avoid damages to the electrical

installation.

Tighten bolted links

After care and maintenance work all loose bolted links must be

tightened. Because of loose bolted links material damages can be

caused.

Further

prescriptions

Observe the prescriptions

Please observe besides these safety instructions

• the accident prevention prescriptions

• the general accredited safety-technical, industrial medicinal and

road traffic law rules

• the tips in this operation manual

• the work, care and maintenance prescriptions

18

Page 19

Acquaintance with the machine

Destination of the

machine

Intended use of the

machine

Characteristics of

the machine

This chapter contains general information about your machine and

information about:

Acquaintance with the mach ine

• characteristics

• technical specifications

This machine is exclusively appropriate designed for film wrapping of

round bales of ligneous plants, mainly grasses, taking into account all

prescriptions, procedures, etc. as stated herein and/or through decals

or other signs on the machine.

This machine shall be exclusively used for the normal agricultural

work.

Any use beyond the one stipulated above requires written

authorization of the manufacturer, this may be required for film

wrapping unusual, non-grass plants as well.

The loading arm picks up, lifts the bale and puts it onto the table. The

table starts rotating. The bale is being wrapped with film. When the

desired number of film wraps is reached, the table stops rotating. The

bale will be unloaded by tipping backward the table. During unloading

the film is cut by the applicutter.

19

Page 20

Acquaintance with the machine

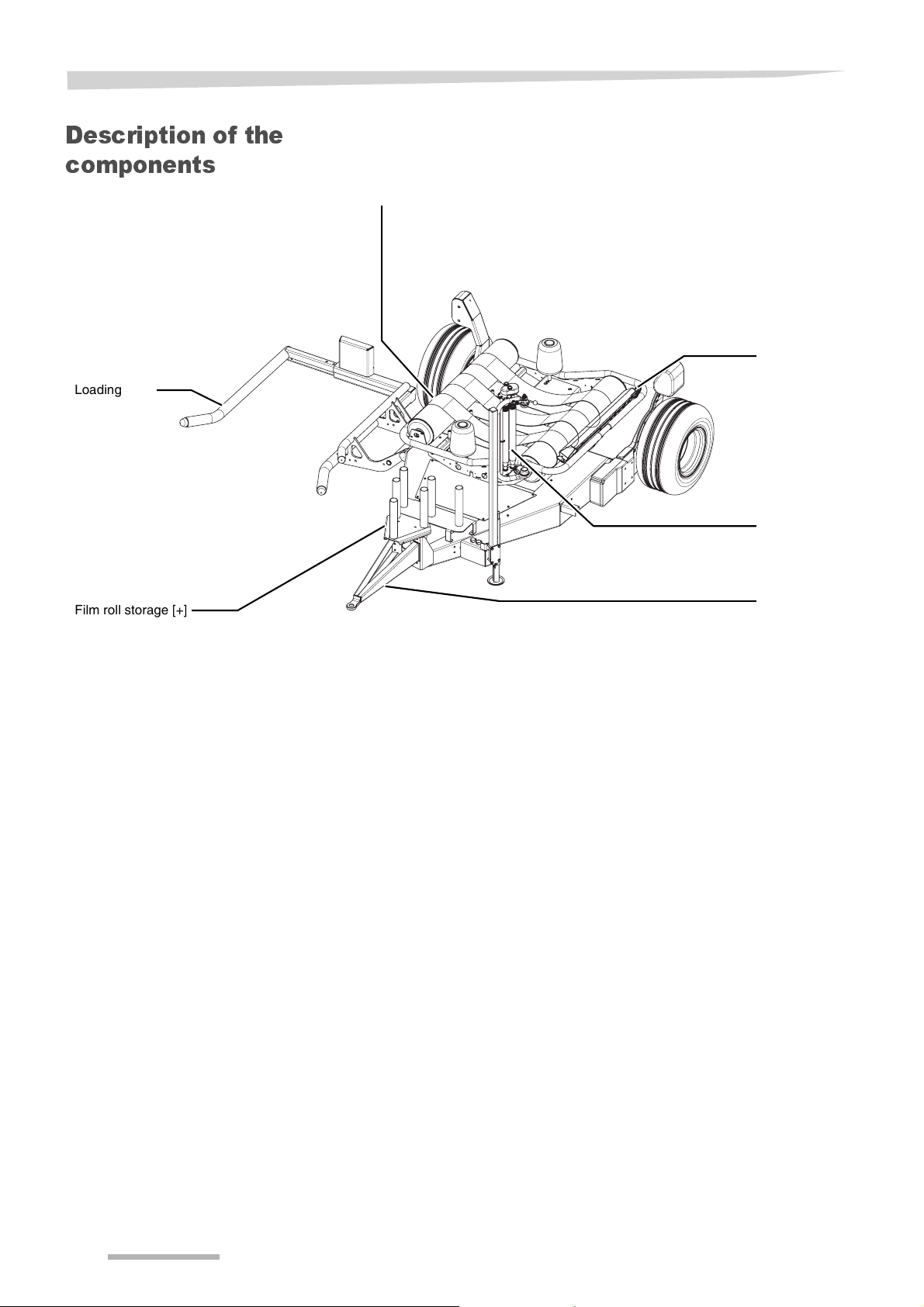

Description of the

components

Table

Loading arm

Applicutter

Film roll storage [+]

Pre-stretcher

Drawbar

20

Page 21

Acquaintance with the machine

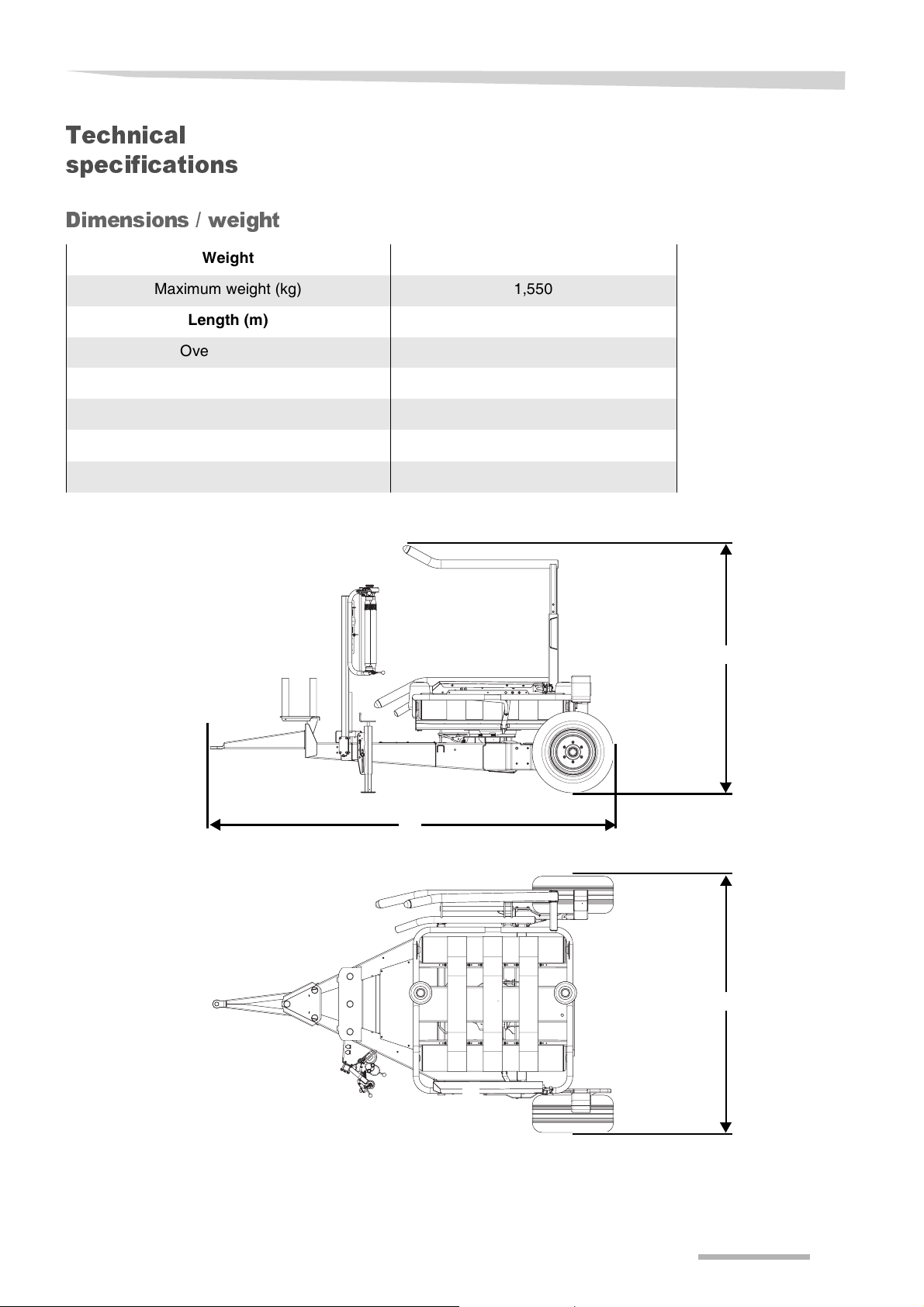

Technical

specifications

Dimensions / weight

Weight

Maximum weight (kg) 1,550

Length (m)

Overall length 4.20 (L)

Width (m)

Overall width 2.69 (W)

Height (m)

Overall height with loading arm folded out 2.58 (H)

H

L

W

L

21

Page 22

Acquaintance with the machine

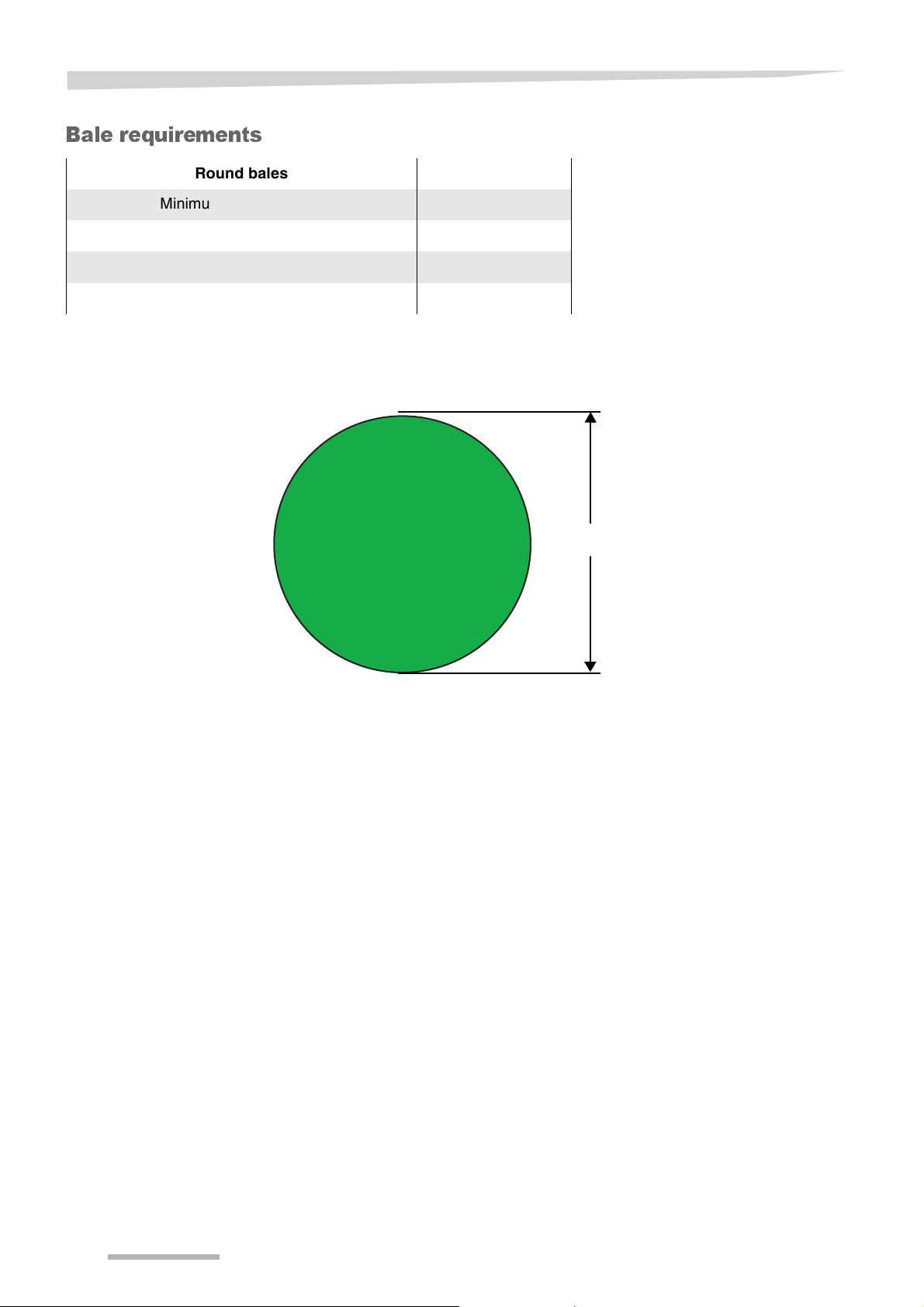

Bale require m ents

Round bales

Minimum diameter (cm) 100

Maximum diameter (cm) 150

Maximum width (cm) 120

Maximum weight (kg) 1.200

Maximum

150 cm

22

Page 23

Optional equipment

Film roll holder

Road lighting set

Film roll magazine

Film end kit (for manual control only)

Drop mat

Bale turner

Additional counter weights

Adapter for 500 mm film rolls

Remote control

Adapter belt drive sprocket

Gear kit pre-stretcher

Wheel chock kit

Acquaintance with the machine

Bale wrap counter

Filmend sensor kit (for electronic con-

trol only)

Hydraulic tip arm for bale turner

Stop arm for bale turner

23

Page 24

Acquaintance with the machine

Tractor requirem e nts

Tractor requirements

Electronics 12 V (DC) coupling for control box

(DIN 9680)

12 V (DC) coupling for road lighting

(DIN ISO 1724) [+]

Hydraulics 1 single acting control valve with pres-

sureless return

with hydraulic bale turner [+] 1 single acting control valve with pres-

sureless return

Pump capacity (l/min) 26

Pressure (bar) 160

Machine

requirements

Tyres

standard 15.0/55-17 10PR-AW

Maximum transport speed (km/h) 25

Maximum table rpm 30

Film requ ire m ent

Film width (mm) 750

Alternative film width (mm) 500

Film thickness (μm) minimum 25

Quality 3-layer blown film

24

Page 25

Delivery and preparation

Delivery and preparation

Safety

Checking the

delivery

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

Completely delivered

The machine is delivered completely. In case parts are not present,

please contact your dealer.

The machine must be checked after delivery. The machine is

equipped with:

• Operation manual

• Spare parts manual

• Hydraulic hose with coupling

• Electronic control system (control box / joystick, fixing brackets,

power cable)

25

Page 26

Hitching the machine

Hitching the machine

Safety

General

Increased danger of injury

• Prevent the tractor from rolling away

• Never stay between the tractor and the machine during hitching

• Operate the three-point hitch slowly and carefully

In case of negligence serious or deadly injuries can occur.

Use a proper tractor

Make sure the tractor

• is in safe operating condition

• has adequate braking capabilities for this machine

• is suitable for carrying and transporting this machine

Using a tractor which is not suitable can cause serious personal and

material damages.

Fix the tractor lower links

Fix the tractor lower links after hitching of the machine. Lateral

movement of the lower links causes leads to unstable driving

characteristics during road transport and can cause accidents.

The machine is ex works provided for hitching onto the tractor towing

hook.

To prepare the machine for hitching, the following items are

necessary:

• Both tractor and machine must be placed on a firm level

• The machine must be levelled

• The electronic control box must be installed

• The hydraulic hoses must be coupled

• The lighting cables [+] must be coupled

26

Page 27

Hitching the machine

Hitching

Drawbar adjustment

Drawbar

Hitch eye Handle

Remove tractor lower links

Remove the tractor lower links to avoid them touching the drawbar.

During turning, the lower links can touch the drawbar and the machine

can tip over. Personal or machine damages can occur.

The machine is ex works provided for hitching to the tractor towing

hook.

Before the machine can be hitched onto the towing hook, the correct

height of the hitch eye to the towing hook must be determined.

> Place both tractor and machine in line on a firm level, with a

distance between the towing hook and the hitch eye of about 15 cm

The drawbar can be turned upside down. Doing this the drawbar can

be set for high and low attachment.

Four types of drawbars exist:

• standard drawbar

• drawbar with eye

• drawbar with double tongue

• high drawbar

The machine must be placed in a horizontal position:

> Turn the handle to the left: drawbar goes upwards

or

> Turn the handle to the right: drawbar goes downwards

> Check the height of the towing hook of the tractor

The drawbar height can be changed by moving the drawbar. The

drawbar can be placed into six positions.

Select the correct position in accordance with your tractor in order to

have tractor and machine lined up correctly.

→ Moving the drawbar, page 28

27

Page 28

Hitching the machine

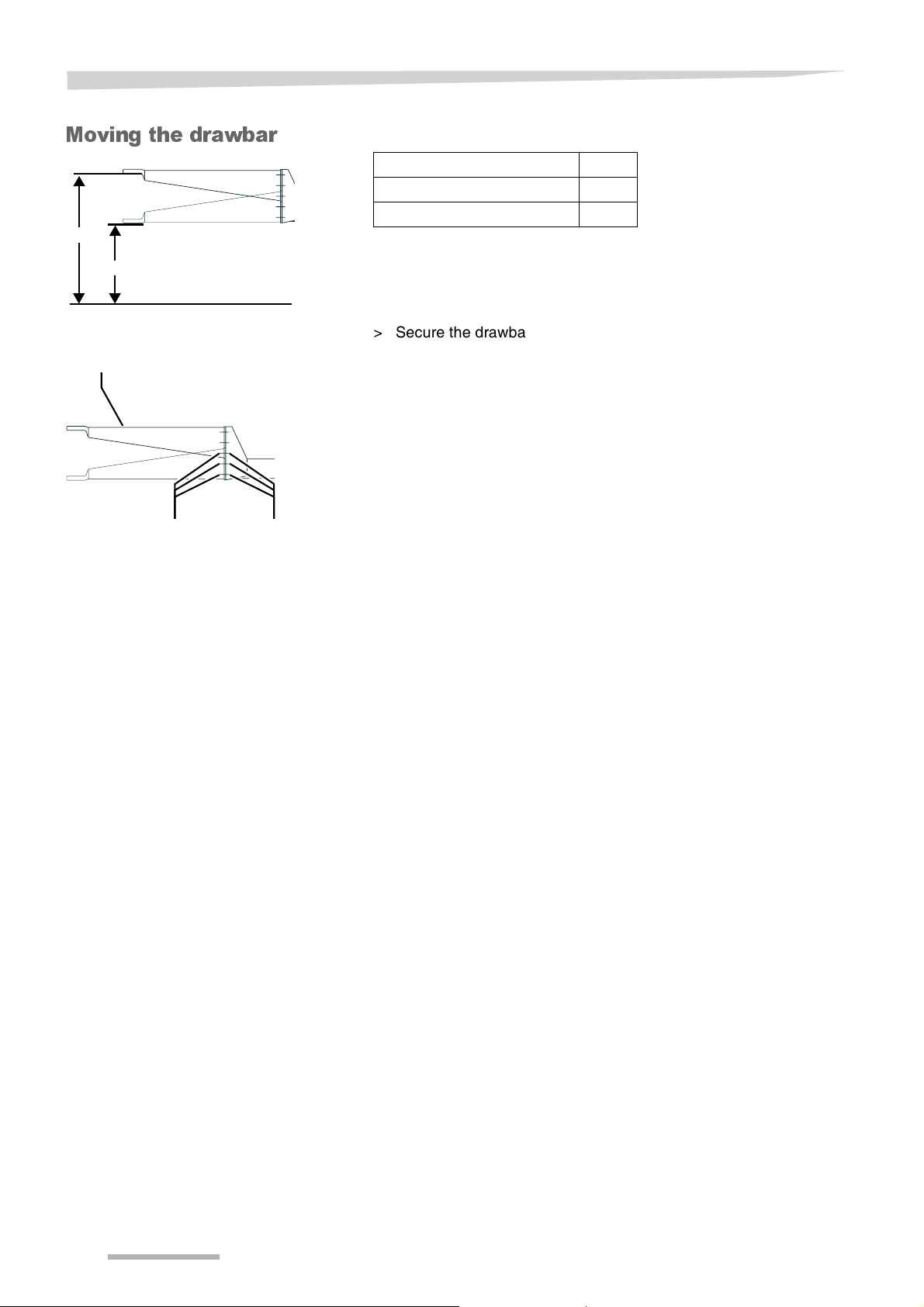

Moving the dra w bar

Towing hook height (cm) Cm

69

36

> Secure the drawbar by placing it in a well suited hoist

Drawbar

> Loosen the bolts and nuts

> Move the drawbar to the desired position

The drawbar must always be fitted with 3 bolts and nuts per side.

> Tighten the bolts and nuts

> Torque the bolts and nuts to 220 Nm

> Remove the hoist

> Hitch the machine to the towing hook of the tractor

Minimum 36

Maximum 69

BoltsNuts

28

Page 29

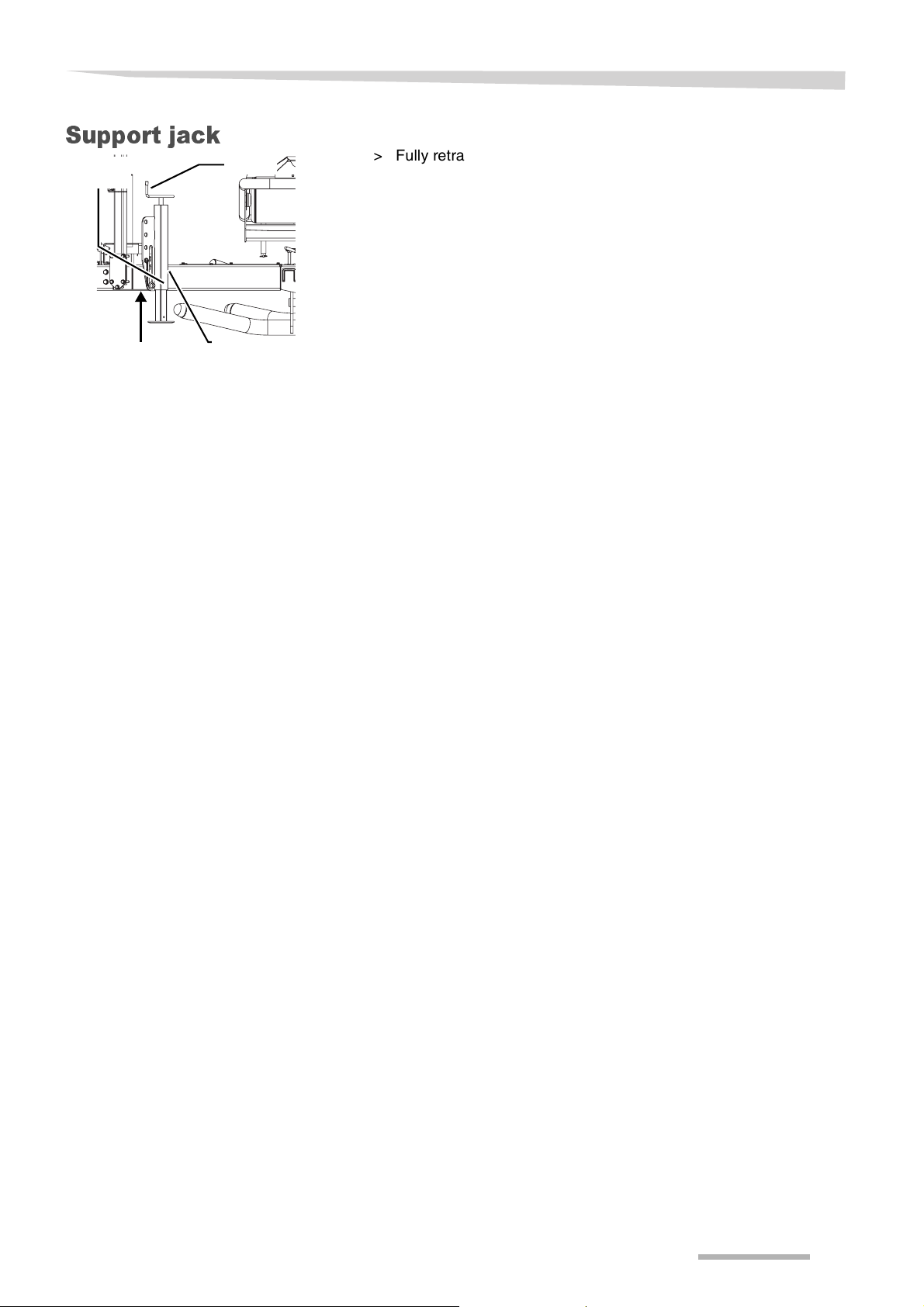

Support jack

Pin /

spring clip

Handle

Support jack

Hitching the machine

> Fully retract the support jack using the handle

> Remove the spring clip

> Remove the pin

> Lift the support jack completely

> Place the pin

> Lock the pin with the spring clip

29

Page 30

Hitching the machine

Installation cable

control

Connection

Cable control

Check correct lying of the cables

Cables may not get stretched or get trapped. Take care of sufficient

free space. Torn or trapped cables can lead to unpredictable

movements of the machine and can lead to serious damages and

injuries.

The cable control must be installed on a support or holder in the tractor

cab.

Take care of the following:

• Ensure the cable control is installed in good manual and visible

reach of the operator

• Do not mount the cable control onto a part that is subject to strong

vibrations

• Ensure the cable control is in an area with less dust

• Avoid sharp bends in the cables

> Place the cable control at the tractor

Rotation and bale

counter

Rotation and

bale counter

30

The rotation and bale counter must be mounted.

Page 31

Hitching the machine

Installation

joystick control

Connection s joystick

control

Connection to

control box

Check correct lying of the cables

Cables may not get stretched or get trapped. Take care of sufficient

free space. Torn or trapped cables can lead to unpredictable

movements of the machine and can lead to serious damages and

injuries.

The joystick must be installed on a support or holder in the tractor cab.

Take care of the following:

• Ensure the joystick is installed in good manual and visible reach of

the operator

• Do not mount the joystick onto a part that is subject to strong

vibrations

> Connect the main power cable of the machine box directly to the

12V battery of the tractor

Cable code Pole

++

--

> Connect the 4-pin connectors of the control box and machine box

to each other

Joystick control

Joystick control

> Place the cable control at the tractor

31

Page 32

Hitching the machine

Installation

control box

Electrical

connections control

box

Connection to

control box

Correct connection of the electronic control system

Never connect the cable to the cigarette lighter because of

interference risk. Always connect the cable directly to the interferencefree power source. Therefore check the functioning of the fuses on the

power cables.

The control box must be installed on a support or holder in the tractor

cab.

Take care of the following:

• Ensure the control box is installed in good manual and visible

reach of the operator

• Do not mount the control box onto a part that is subject to strong

vibrations

• Ensure the control box is in an area with less dust

• Do not install the control box where bright sun or rain may reach it

> Connect the main power cable of the machine box directly to the

12V battery of the tractor

Cable code Pole

++

--

> Connect the 4-pin connectors of the control box and machine box

to each other

32

Page 33

Connections

Hitching the machine

Hydraulic

connections

Hydraulic coupling only pressureless

Only couple the hydraulic hoses to the tractor when both tractor and

machine hydraulics are pressureless. Hydraulics under pressure can

cause accidental movements of the machine.

Avoid oil mixture

When using the machine in combination with different tractors,

improper oil mixture can take place. Improper oil mixture can destroy

tractor parts.

Avoid entering of dirt into the hydraulic system

The hydraulic system can get seriously damaged. Personal injuries or

material damage can be caused.

Check hoses and couplings

Before connecting, prove all hydraulic hoses for damages. After

connecting check all hydraulic couplings for tight connection.

Defective hydraulic hoses or bad connected hydraulic couplings can

cause injuries or unforeseen movements of the machine.

Secure tractor hydraulic devices

In transport position tractor hydraulic devices must be secured against

unintentional movements. Unintentional movements of the hydraulic

device can cause serious injuries or unforeseen movements of the

machine.

Check correct position of hydraulic hoses

Hydraulic hoses may not stick or tighten. Pay attention to sufficient

free space. Torn or stuck hydraulic hoses cause unverifiable

movements of the machine and serious injuries.

Take care of the correct laying of hydraulic hoses

Hydraulic hoses may not stick or tighten. Take care of sufficient free

space. Worn or stuck hydraulic hoses can cause heavy damage to the

machine or severe injuries.

Check the following connections from the tractor to the machine (if

applicable):

• hydraulic connections

• electronic connections

Before coupling, the hydraulic block must be adapted:

• Hydraulic block - open centre

• Hydraulic block - closed centre

• Hydraulic block - load sensing

33

Page 34

Hitching the machine

Hydraulic bl ock -

open centre

Hydraulic bl ock -

closed centre

Cable control

Blocking plug Main plug

Joystick and electronic

control

Main plug

The machine is standardly adjusted for tractors with an open centre

hydraulic system.

No adjustment of the hydraulic block is necessary.

When the tractor is provided with a closed centre hydraulic system,

the hydraulic block must be adjusted accordingly.

When the machine is provided with a cable control the hydraulic block

must be adjusted accordingly.

> Switch off the tractor engine and remove the ignition key

> Remove the main plug

> Mount the blocking plug

> Mount the main plug

When the machine is provided with a joystick or an electronic control

the hydraulic block must be adjusted accordingly.

> Switch off the tractor engine and remove the ignition key

> Turn the plug clockwards fully

34

Page 35

Hitching the machine

Hydraulic block - load

sensing

Hydraulic hose s

Road lighting [+]

The machine is standardly adjusted for tractors with an open centre

hydraulic system.

No adjustment of the hydraulic block is necessary.

The oil flow of the tractor must be adjusted to 26 l/min.

> Make sure the tractor hydraulic device is pressureless

> Couple the hydraulic coupling to a single or to a double acting

hydraulic device with pressureless return

> Connect the 7-pin plug to the trailer lighting socket on the tractor

35

Page 36

Preparation for use

Preparation for use

Safety

Obey safety instructions

Obey the safety instructions at the execution of all work. Ignoring the

safety instructions can lead to serious or deadly injuries.

Guarantee correct hydraulic coupling

Check before using if all hydraulic couplings are coupled correct to the

single and double acting valves. Not correct coupled hydraulic

couplings can cause unpredictable movements of the machine.

Never work on the machine while it is running

Never carry out adjustment work while the machine is running.

• Tractor engine must be switched off and the ignition key must be

removed

• Electronic control box must be switched off

In case of negligence, serious or deadly injuries can occur.

No persons in turning area

During work, no persons may be within the turning area of the

machine, including the table area. Serious personal injuries can be

caused.

Secure the machine

During adjustment, an increased danger of injury exists. Therefore

• secure the machine from accidental commencement of operations

and rolling away

• the machine must have a level, secure position and must be

supported during working if necessary

Unsecured or not supported machines can lead to accidents.

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

Guarantee correct hydraulic coupling

Check definitely, before using the machine, if the hydraulics for the

system are coupled to the correct single acting valves with

pressureless return. Not correct coupled hydraulic hoses can cause

accidental movements of the machine.

36

Page 37

Preparation for use

Table roller

adjustment

Front position Rear position

Table roller Bolts

To ensure good stability of the bale during wrapping, the table roller

must be adjusted for small or large bales.

Recommended setting, depending on the bale diameter:

Bale size (m) Recommended position

until 1.30 front

over 1.30 rear

> Support the roller

> Remove the bolts

> Move the roller to the desired setting

> Tighten the bolts

> Remove the support of the roller

37

Page 38

Preparation for use

Support roller

Support rolle r

adjustment

Support rollers

C C

Support roller

To ensure a good stability of the bale during wrapping, the support

rollers can be adjusted for small or large bales.

The support roller must be adjusted so, that the bale is in the middle

of the table. When the bale is on the table, the clearance C on both

sides between the bale and both support rollers should be maximum

150 mm.

The support roller can be placed in three positions. The middle or the

right hole is recommended.

> Remove the linch pin

> Place the roller in the correct hole, to adjust to clearance C

> Place the linch pin

Bolts

Holes

38

Page 39

Preparation for use

Loading arm width

Loading arm

adjustment

Loading arm

Locking pin Pin

The width of the loading arm can be adjusted depending on the

diameter of the bales to be wrapped.

The loading arm must be adjusted so, that the bale is in the middle of

the loading arm.

> Move up the loading arm a little

> Release the locking pin

> Remove the pin

> Adjust the loading arm to the desired bale diameter

> Place the pin

> Mount the locking pin

39

Page 40

Preparation for use

Pre-stretcher

Pre-stretcher

adjustment

Bolts

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

The pre-stretcher must be adjusted so, that the centre of the film roll

matches the centre of the bale.

> Switch off the tractor engine and remove the ignition key

> Loosen the bolts one turn

Pre-stretcher

Centre of

the bale

> Move the entire pre-stretcher upwards or downwards, depending

on the bale diameter and the kind of bales to be wrapped

The film must now match the centre of the bale.

> Tighten the bolts

40

Page 41

Preparation for use

Film installation

Loading the fil m rol l

Upper

lever

Prestretcher

Hook

Before installing the film:

> switch off the tractor engine

> remove the ignition key

Stay clear of pre-stretcher rollers

Stay clear of the pre-stretcher rollers. Hands can be squeezed

between the rollers. Personal injuries can occur.

Choose a good quality of film in order to ensure troublefree functioning

of the film wrap system. Recommended is

→ Film requirement, page 24

> Move the lower lever to secure the pre-stretcher with the hook

> Release and lift the upper lever

In case a 500-mm film roll is used:

> Place an adapter [+] on top of the film roll

> Place a film roll

> Lower the upper lever

> Guide the film between the pre-stretcher, according to the scheme

> Move the lower lever to unsecure the pre-stretcher from the hook

> Connect the end of the film to the applicutter

Lower

lever

Electronic control only:

> Push at the same time for a counter/programme reset

41

Page 42

Preparation for use

Film overlap

Chain tensionerChain

Sprocket

The film overloap is determined by the rotation speed of the table

belts. The speed of the table belts can be varied by mounting a

different sprocket.

A 12-teeth sprocket is standard mounted. In case a pre-stretcher

adapter for 500 mm film rolls [+] is mounted, an 18-teeth sprocket can

be mounted.

Recommended setting, depending on the desired film roll width:

Film roll width (mm) Sprocket (teeth) Film overlap (%)

500 18 50

750 12 50

Exchanging the sprocket:

> Loosen the chain tensioner

> Remove the chain

> Remove the sprocket

> Mount the desired sprocket

> Mount the chain

> Tighten the chain tensioner

42

Page 43

Preparation for use

Check at

beginning of the

season

Running

The following items have to be checked before using the machine at

the beginning of the season:

• Check the electric connections

→ Electrical connections control box, page 32

• Check the road lighting [+]

• Check the lubrication

→ Maintenance intervals, page 81

• Check the tyre pressure

→ Tyre pressure, page 85

> Run the tractor hydraulics at idle

• Check the correct operation of the components

• Check, if there are no unusual noises

> Switch off the tractor hydraulics

• Check the tightness of the hardware

During the running-in period, a specific maintenance must be done,

confer to maintenance chart

→ Maintenance intervals, page 81

43

Page 44

Road transport

Road transport

Safety

Before road

transport

Loading arm lo ck

Pin Locking pin

Before road transport will take place, please read the following safety

instructions. The compliance is prescribed and helps you to avoid

accidents.

Close valves

Before road transport close all valves. With open valves and false

operation the lifting cylinder can be lowered. Traffic accidents can be

caused.

Clean the machine before road transport

Clean the machine, before every road transport, from crop residues

and heavy dirt. Crop or dirt, falling at the road, can cause a slippery

state of the road. This can lead to fatal accidents.

Road transport must be done in transport position. To bring the

machine into transport position, the following steps are necessary:

• the loading arm transport lock must be applied

• the bale turner [+] must be folded 90° upwards and locked

• the hydraulic bale turner [+] must be folded 90° upwards and

locked

• the stop arm [+] must be folded 90° upwards and locked

The loading arm must be locked into transport position.

> Move up the loading arm completely

> Mount the pin

> Lock the pin with the locking pin

The locking pin must be in the left hole.

44

Page 45

Road transport

Checking the

machine

Road transport

Check the machine before road transport by means of the checklist:

• Tractor hydraulic is switched off?

• All valves are closed?

• Crop residues and heavy dirt are removed?

• Cables and lines are placed in that way they will not tension or get

in touch with the tractor rear tyres during curve driving?

• Before starting driving, check the close environment. Always take

care of a clear view and especially at children in the working

environment of the machine.

• Lock hydraulic valves of the tractor before road transport

• Do not transport any persons or objects at the machine

• Adapt the drive speed to the road conditions

• Do not exceed the maximum speed of 25 km/h. Obey the national

and local speed limits.

• Pay attention to sufficient driving and braking capacity. Then

driving and braking capacity are influenced by the attached

machine (longer braking paths because of larger driving power).

45

Page 46

Preparation at the field

Preparation at the field

Safety

Performing

settings

Prior to w ra p pi ng

Obey the safety instructions

Obey the safety instructions at the execution of all work. Ignoring the

safety information can lead to serious or deadly injuries.

Secure tractor and machine

• Switch off and secure the tractor

• Prevent the machine against accidental commencement of

operations

Unsecured machines and tractors can lead to accidents.

The settings to the machine must be performed in working position.

They are described in the next sections:

• Prior to wrapping

• Placing into working position

Before wrapping can start, the following has to be checked:

• Has the loading arm been placed in working position?

• Has the bale turner [+] been placed in working position?

• Has the hydraulic bale turner [+] been placed in working position?

• Has the stop arm [+] been placed in working position?

The machine has to be adapted to the type of the bale and the size of

the bales wrapped

• Is the number of table rotations ok?

• Is the pre-stretcher height ok?

46

Page 47

Preparation at the field

Placing into

working position

Loading arm lo ck

Pin Locking pin

Right hole

Hydraulic bale turner

Hydraulic bale

turner

The machine must be used in working position. To bring the machine

into working position, the following steps are necessary:

• the loading arm lock must be removed

The loading arm must be placed into working position.

> Remove the locking pin

> Remove the pin

> Move down the loading arm completely

> Mount the pin

> Lock the pin with the locking pin

The locking pin must be in the right hole.

The hydraulic bale turner must be placed into working position.

> Unlock and fold down the hydraulic bale turner in working position

> Lock the hydraulic bale turner

47

Page 48

Use at the field

Use at the field

Safety

Checks before use

Driving along at the machine prohibited

It is never allowed that people or objects drive along at the machine.

Driving along at the machine is perilous and prohibited.

No persons in the turning area

Take care of no people be in the turning and working area of the

machine. People can get grabbed by the machine within this area.

Serious or deadly injuries can occur.

No persons in the folding area

Take care of no people be in the folding area of the machine. People

can get crushed by the machine within this area. Serious or deadly

injuries can occur.

Take care of the field condition

Take care of the field condition especially during driving on slopes

when unloading a round bale. Unloading a round bale on a slope may

only take place in a 90° direction to the slope. Serious or deadly

injuries can occur.

Check that

• the film is hold between the applicutter

• the number of film wraps is set

48

Page 49

Use at the field

Film wrap

recommendations

Recommendation

500 mm fil m

Recommendation

750 mm fil m

The number of table laps decides how many film layers the bale is

wrapped with. It is recommended that a minimum 6 layers of film are

applied to the bale. It may be necessary to increase the number of

layers if the bale has hard and stemmy material.

> Count the number of the table revolutions to cover the bale

completely with film

> Add 1 to this number

> Multiply this with 3, for 6 layers, or with 4, for 8 layers

The table drive is set to give 2+2+2... layers overlap, using 750 mm

film.

The recommended number of film wraps must be 6 film wraps.

Bale diameter (cm) 4 layers 6 layers

120 24 36

150 30 45

The recommended number of film wraps must be 6 film wraps.

Bale diameter (cm) 4 layers 6 layers

120 16 24

150 20 30

49

Page 50

Use at the field

Start p os i ti on

mode

Joystick control

Electronic control

Wrapping

Cable control

Left leverRight lever

The loading arm and the table must be put into start position before

wrapping can get started.

The start position is reached when:

• the loading arm is in the middle position

• the table is fully downwards and in the loading position

> Push the joystick right and hold it to lower the loading arm to the

middle position

> Push the FJ button to move the table in the loading position

> Push to move the loading arm in the middle position and to move

the table in the loading position

The table revolution counter will be reset now.

The wrapping cycle depends on the kind of control on the machine:

• cable control

• joystick control

• electronic control

> Drive to the bale

> Move the right lever forwards to lift the bale using the loading arm

onto the table

> Move the right lever backwards to lower the loading arm

completely

> Hold the middle lever for 1 revelation to start wrapping

The table must turn with maximum 30 rpm.

After the last but one number of film wraps, the buzzer sounds. Than

the final wrap is added.

Extra wraps can be added. The buzzer will sound 2 seconds for every

extra wrap.

> Leave the middle lever to stop wrapping

The bale counter will be reset to zero.

The table must be in tip off position now.

> Move the left lever backwards to unload the bale

With hydraulic bale turner [+]

> use the concerning hydraulic tractor valve

> Push the joystick forward to move the table forwards

> Push the FJ button to move the table into loading position

50

Page 51

Use at the field

Joystick control

Joystick FJ

Automatic mode

> Drive to the bale

> Push the joystick left to lift the bale using the loading arm onto the

table

> Push the joystick right to lower the loading arm completely

> Push the FJ button down and hold it for the pre-set number of table

revelations to start wrapping

The table must turn with maximum 30 rpm.

After the last but one number of film wraps, 3 LED’s in the display will

flash. Than the final wrap is added.

When wrapping is finished, the table automatically moves into the bale

unloading position. The bale will be automatically unloaded,when Tip

Up is set

→ TIP UP, page 63

With hydraulic bale turner [+]

> use the concerning hydraulic tractor valve

> Push the FJ button to move the table into loading position

Joystick FJ

Manual mode

> Drive to the bale

> Push the joystick left and hold it to lift the bale using the loading

arm onto the table

> Push the joystick right and hold it to lower the loading arm

completely

> Push the FJ button down and hold it for the slow table revelations

to start wrapping

> Push the FJ button down and move the joystick to any direction

and hold it for the required number of table revelations

The table must turn with maximum 30 rpm.

After the last number of film wraps:

> Push the F3 button to move the table automatically into the bale

unloading position

> Push the joystick backward to unload the bale

With hydraulic bale turner [+]

> use the concerning hydraulic tractor valve

> Push the joystick forward to move the table forwards

> Push the FJ button to move the table into loading position

51

Page 52

Use at the field

Electronic control

The required number of film wraps must have been set

→ CYC, page 71

> Drive to the bale

Automatic mode

>Push

The entire bale loading, wrapping cycle and bale unloading will be

automatically.

Semi-automatic mode

In case, A2, A4 and A6 are set to 0, every step must be confirmed

manually.

→ Parameter settings, page 71

> Push to activate the programm

> Push to operate the loading arm

> Push to start wrapping

In case the wrapping process is interrupted

> push to restart wrapping

The table must turn with about 30 rpm.

After the last number of film wraps:

> Push to move the table backwards.

The bale will be unloaded.

52

Page 53

Use at the field

Loading a second

bale during

wrapping

Joystick control

Joystick FJ

Electronic control

During wrapping, a second bale can be transported onto the loading

arm.

> Push the FJ button down and hold it and move the joystick to the

right to lower the loading arm completely

Wrapping continues automatically when the joystick is in the middle

position.

> Drive to the bale

> Push the FJ button down and hold it and move the joystick to the

left to lift the loading arm completely

Wrapping continues automatically when the joystick is in the middle

position.

> Hold the joystick forwards to lower the loading arm completely

During holding the joystick, the table stops rotating.

> Drive to the bale

> Push the joystick forwards

The loading arm moves up in carrying position and the table continues

rotating.

53

Page 54

Use at the field

Emergency stop

Joystick control

Electronic control

In case of emergency, wrapping can be stopped immediately.

> Push the joystick in any direction

>Push

54

Page 55

Wrap and bale counter

Wrap and bale counter

General

Wrap and bale

counter box

Control box front

Display

If the machine is equipped with a cable or an joystick control, the wrap

and bale counter can be mounted. This counter controls and monitors

the wrapping of the bale. Furthermore the buzzer sounds when the

pre-set number of wraps has been reached.

The wrap and bale counter box enables supervision of the bale

wrapping procedure from the tractor cab. Especially the following

functions can be monitored:

• Bale counters (1 day counter, 1 total bale counter)

• Film wrap counter

Fuse Buttons

Buttons

Actual mode button

• Selection of the mentioned bale wrap sequence

Clear button

• Change a value

• Reset a value

Set button

• Change a value

55

Page 56

Wrap and bale counter

Parameter change

The parameters can be changed upon desire.

> Push to enter the desired display

> Push until the desired digit flashes

> Push to set the digit

> Push to confirm

56

Page 57

Wrap and bale counter

Parameter

settings

CYK

Via the parameter settings, the entire wrapping process is prescribed.

The current number of table laps can be set. The pre-set number of

table laps can be shown in the display.

Number Recommended number

2 - 99 → Film wrap recommendations, page 49

> Push to enter the display CYK

> Push until the current number of table laps flashes

> Push to set the first digit

> Push for the last digit

> Push to set the last digit

> Push to confirm

BAL

The number of bales wrapped can be shown in the display. The

number of bales wrapped can be reset to zero.

Number

0 - 99999

> Push to enter the display BAL

> Push until the number of bales wrapped flashes

> Push to reset to clear the number of bales wrapped to zero

> Push to confirm

57

Page 58

Wrap and bale counter

BAL +

F.

0

The total number of bales wrapped.

Number

0 - 99999

The total number of bales wrapped can not be reset

The stop position of the table can be set. Which gives the possibility

to leave the lever or joystick until the pre-set number of film wraps is

reached.

Auto stop function must be set

Setting

0.00 -1.99

In case 0.00 is set: the table stops rotating immediately after reaching

the pre-set number of film wraps.

In case 1.00 is set: the table makes one turn after reaching the pre-set

number of film wraps.

> Push to enter the display F.

> Push until the first digit flashes

> Push to set the first digit

> Push until the second digit flashes

> Push to set the second digit

> Push until the last digit flashes

> Push to set the last digit

> Push to confirm

58

Page 59

Joystick control

Joystick control

General

Joystick control

Control box front

F1

F2

F3

Display Lever

The machine can be equipped with the joystick control. This control

system controls and monitors the wrapping and clearing out of the

bale.

The joystick control enables supervision of the total bale wrapping

procedure from the tractor cab. Especially the following functions can

be monitored:

• Bale counters

• Film wrapping process

• Automatic or manual film wrapping control

• Control of several individual parts of the machine

FJ

On / off switch

59

Page 60

Joystick control

Buttons

F1 button

• Short push: selection of manual or automatic control

• Long push: parameter selection

F2 button

• Display selection button

F3 button

• Counter reset

• In manual mode: table to unloading position

• In automatic mode: table to unloading position, when the last

wrapping cycle at slow speed has been interrupted

FJ button

Position Function

Down Start film wrapping

+ joystick to any direction Wrapping in fast speed

+ joystick to the left Loading arm up, during wrapping

+ joystick to the right Loading arm down, during wrapping

On / off switch

To switch the power on or off.

Joystick

Position Function

Forward Table downward

Backward Table unload

Left Loading arm up

Right Loading arm down

60

Page 61

Joystick control

Control mode

Manual mode

M

Semi-automatic

mode

A

The joystick control can be used in the following control modes:

• manual mode

• semi-automatic mode

The set of parameters determines working in semi-automatic mode.

In manual mode, the wrapping cycle is manually controlled by the F

buttons and the joystick.

> Push F2 to select CYK

> Push F1 to select manual mode

The display shows M.

> Push the concerning buttons or joystick

→ Manual mode, page 51

Semi-automatic mode offers the possibility for the following:

• to stop before bale unloading

• to wrap the pre-set number of wraps

• to unload the bale automatically

> Push F2 to select CYK

> Push F1 to select semi-automatic mode

The display shows A.

> Set the desired parameter

→ Parameter settings, page 62

61

Page 62

Joystick control

Parameter

settings

CYK

F1

F2

F3

BAL

F1

F2

Via the parameter settings, the entire wrapping process is prescribed.

The current number of table laps can be set. The pre-set number of

table laps can be shown in the display.

Number Recommended number

2 - 99 → Film wrap recommendations, page 49

> Push F2 to enter the display CYK

> Push and hold F1 until the current number of table laps flashes

> Push joystick forward or backward to set the last digit

> Push joystick left or right to enter the first digit

> Push joystick forward or backward to set the first digit

> Push F2 to confirm

The number of bales wrapped can be shown in the display. The

number of bales wrapped can be reset to zero.

Number

0 - 99999

F3

> Push F2 to enter the display BAL

> Push and hold F1 until the number of bales wrapped flashes

> Push F3 to reset the number of bales wrapped to zero

> Push F2 to confirm

62

Page 63

Joystick control

BAL +

HOLD

F1

F2

F3

TIP UP

F1

F2

The total number of bales wrapped.

Number

0 - 99999

The total number of bales wrapped can not be reset

The total time the FJ button must be held during the start-up wraps at

low table speed, before wrapping continues at normal speed.

Number Recommended number

0 - 5 1

> Push F2 to enter the display HOLD

> Push and hold F1 until the current number of start-up wraps

flashes

> Push joystick forward or backward to set the digit

> Push F2 to confirm

The time the table tips backwards.

Number Recommended number

0,0 - 5,0 0,1

F3

> Push F2 to enter the display TIP UP

> Push and hold F1 until the current time flashes

> Push joystick forward or backward to set the last digit

> Push joystick left or right to enter the first digit

> Push joystick forward or backward to set the first digit

> Push F2 to confirm

TIPIf the time is set to 0,0 sec, the table must be tipped backwards

manually.

63

Page 64

Joystick control

TIP DOWN

F1

F2

F3

The time the table tips downwards.

Number Recommended number

0,0 - 5,0 0,1

> Push F2 to enter the display TIP DOWN

> Push and hold F1 until the current time flashes

> Push joystick forward or backward to set the last digit

> Push joystick left or right to enter the first digit

> Push joystick forward or backward to set the first digit

> Push F2 to confirm

TIPIf the time is set to 0,0 sec, the table must be tipped downwards

manually.

64

Page 65

Electronic control system

Electronic control system

General

Contro l bo x

Control box front

Display

The machine can be equipped with an electronic control system. This

control system controls and monitors the wrapping and clearing out of

the bale. Furthermore the system also provides error indicating

functions.

The control box enables supervision of the total bale wrapping

procedure from the tractor cab. Especially the following functions can

be monitored:

• Bale counters (4 day counters, 1 total counter)

• Film wrapping process

• Automatic or manual film wrapping control

• Control of several individual parts of the machine

Joystick

Upper toggle

switch

Lower toggle

switch

65

Page 66

Electronic control system

Buttons

Auto button

• Selection of automatic control

Stop button

• To stop, interrupt a procedure. Rotation of the table is interrupted.

Programme mode button

• Programming functions

• Counter reset

To neutral position

The loading arm is moved to its neutral position, in front of its sensor.

To start point

To :

• move the loading arm to the middle position

• move the table fully downwards

• reset the revolution counter to zero

Pushing to

• increase a value

• switch the buzzer on

Pushing to

• decrease a value

• switch the buzzer off

Table to bale loading position

This is only possible, if the loading position sensor is mounted on the

machine.

66

Page 67

Electronic control system

Joystick

Pushing up:

• lowering the loading arm

Pushing down:

• raising the loading arm

Pushing to the left:

• parameter selection

• table rotation at normal speed

Pushing to the right:

• parameter selection

• table rotation at low speed

Upper toggle switch

Pushing up:

• lowering the table

Pushing down:

• raising the table

Lower toggle switch

Pushing to the left:

• table to unloading position

Pushing to the right:

• approve

• interrupt the programm before the preset number of foil wraps has

been reached

• reset the revolution counter

67

Page 68

Electronic control system

Control mode

Manual mode

Semi-automatic

mode

The electronic control system can be used in the following control

modes:

• manual mode

• semi-automatic mode

• automatic mode

The set of parameters determines working in semi-automatic or

automatic mode.

In manual mode, the wrapping cycle is controlled by the toggle

switches and the joystick.

> Push to select manual mode

Depending on the requested action

> Push the concerning toggle switches or joystick on the control box

Semi-automatic mode offers the possibility for the following:

• to stop the table before film wrapping starts

• to stop before bale unloading

• to wrap the pre-set number of wraps

• to unload the bale automatically

> Push to select semi-automatic mode

When one or more of the above-mentioned adjustments are selected,

the wrapping cycle will stop at the concerning point(s).

> Push to set the desired parameter

> Push to continue wrapping

68

Page 69

Electronic control system

Automatic mode

In automatic mode, the entire wrapping cycle is automatic.

> Push to select automatic mode

> Push to start wrapping

The machine starts in a programmed cycle.

In case of a failure or correction during wrapping

> Push to select manual mode

> Push to select automatic mode

>Push

Wrapping will continue from the point of failure.

69

Page 70

Electronic control system

Parameter change

The parameters can be changed upon desire.

>Push

> Push joystick left or right to select the desired parameter

> Push to change the parameter value

> Push to return to automatic mode

or

> Push to return to manual mode

The value is stored.

70

Page 71

Electronic control system

Parameter

settings

CYC

BAL

BAL +

Via the parameter settings, the entire wrapping process is prescribed.

The number of table laps can be set.

Number Recommended number

0 - 99 no recommendation

The number of bales wrapped.

Number

0 - 99999

The number of bales can be reset

> Push to confirm

Now the total number of jobs increases with one.

→ JOBS, page 71

The total number of bales wrapped.

Number

0 - 99999

JOBS

The total number of bales wrapped can not be reset

The total number of jobs done.

Setting

0 - 99999 Can be cleared to zero

The total number of jobs can be reset to zero

> Push to confirm

After the number of bales has been cleared to zero, the total number

of jobs done increases with one.

71

Page 72

Electronic control system

A. on / A. off

A1:1 / A1:0

A2:1 / A2:0

A buzzer can be switched on or off for

• a sound after the last sensor by-pass

• when an error occurs

Setting Buzzer

• +

• -

This setting is only valid in case your machine is equipped with the

electronic control system.

The bale loading with the loading arm can be included in the wrapping

procedure.

Setting Recommended setting

• 1 = yes

• on

• off

1

• 0 = no

This setting is only valid in case your machine is equipped with the

electronic control system.

The start of film wrapping after bale loading.

Setting Recommended setting

• 1 = start

1

• 0 = stop

After the bale is loaded

> Push to confirm

72

Page 73

Electronic control system

A3:1 / A3:0

A4:1 / A4:0

A6:1 / A6:0

The bale unloading can be included in the wrapping procedure.

Setting Recommended setting

• 1 = yes

1

• 0 = no

If ‘0’ is chosen, a new loading and wrapping cycle can be started

> Push to confirm

The bale unloading can be done immediately after the wrapping cycle

is finished.

Setting Recommended setting

• 1 = yes

0

• 0 = no

If ‘0’ is chosen, the bale unloading can be done manually

> Push to confirm

This setting is only valid in case your machine is equipped with the

loading position sensor.

After bale unloading the table turns 90°.

A7:1 / A7:0

Setting Recommended setting

• 1 = possible

1

• 0 = impossible

Independent on an optional film sensor is mounted, this setting must

be used.

Setting Recommended setting

• 1 = mounted

0

• 0 = not mounted

73

Page 74

Electronic control system

t1

t2

t3

Start of the flashing light before the automatic wrapping cycle starts.

It is recommended to mount a flashing light when a remote control is

mounted.

Beacon Setting Recommended setting

• mounted

• not mounted

The time can be set before an error message occurs, in case a sensor

does not function.

Setting Recommended setting

0 - 99 15

This setting is only valid in case your machine is equipped with the

electronic control system.

The maximum raising time for the loading arm from the middle position

to the fully lifted position.

Setting Recommended setting

0 - 99 4 - 6

• 0.0 - 9.9

• 0.0 - 9.9

• 2.0

• 0.0

t4

t5

t6

This setting is only valid in case your machine is equipped with the

electronic control system.

The time delay for lowering the loading arm after reaching the sensor.

Setting Recommended setting

0.0 - 9.9 0.5

Before the table rotates at normal speed, a slow-motion start time can

be set.

Setting Recommended setting

0.0 - 9.9 2.5

After the last sensor by-pass, the table speed can be delayed slow

down.

Setting Recommended setting

0.0 - 9.9 1.0 - 2.0

74

Page 75

Electronic control system

t7

t8

t9

t10

The time the table turns at half speed before stopping, after the last

sensor by-pass t6 has taken place.

Setting Recommended setting

0.0 - 9.9 1.5 - 2.5

The time the table is standing still before turning at half speed to the

bale unloading position, after the table has stopped.

Setting Recommended setting

0.0 - 9.9 0.5 - 0.7

The table raising time before bale unloading.

Setting Recommended setting

0 - 99 4 - 6

The time delay before lowering the table.

Setting Recommended setting

0.0 - 9.9 0.3 - 0.5

t11

t12

t14

The time delay after the table is fully lowered.

Setting Recommended setting

0.0 - 9.9 0.3 - 0.5

Not in use.

The maximum interval between the pulses of the film sensor when

wrapping in automatic mode.

Setting Recommended setting

0 - 99 1

> Push to confirm

75

Page 76

Cleaning and caring

Cleaning and caring

Safety

Cleaning

Pre-stretcher rol le rs

For all cleaning and caring activities applies:

Do not penetrate bearings and hydraulic parts

Be careful when cleaning with a high-pressure cleaner. Bearings,

sealings and bolted joints are not waterproof. To avoid machine

damages never penetrate bearings, sealings and bolted joints with

water.

Do not clean bearings and hydraulic parts with high pressure

Do not clean bearings and hydraulic parts with a high-pressure

cleaner. Bright metal parts will get degreased and start rusting. After

every cleaning grease the bearings and grease bright metal parts.

After every time of using the machine:

> Empty and clean the machine of all accumulated crop

Cleaning can be done with low pressure with the high-pressure

cleaner. Do not clean bearings, electronic and hydraulic parts with the

high-pressure cleaner.

The pre-stretcher rollers must be cleaned from particles, dust, crop

and tack.

> Use methylated spirit or similar to clean the rollers

After cleaning

Caring

After cleaning with the high-pressure cleaner

> grease all bearings

When you observe the rules below, you will have a fully operational

machine at the start of the next season:

> Protect all bright metal parts with an oil film. Only use authorized

biological oil, like rape oil

> Repaint any paint damages

76

Page 77

Storing the machine

Storing the machine

Safety

Unhitching and

securing of the

machine

Pin /

spring clip

Handle

Support jack

Obey the safety instructions

Obey the safety instructions at the execution of all work. Ignoring the

safety information can lead to serious or deadly injuries.

Machine is no toy

Store the machine in an area away from human activity. Never allow

children to play on or around the stored machine. Metal edges and

parts of the machine can lead to serious injuries.

> Place the tractor and the machine on a dry and stable ground

> Secure the tractor and the machine from rolling away

> Disconnect the hydraulic connections and store them in the

support at the drawbar

> Disconnect the road lighting connection and store it in the support

at the drawbar

> Remove the spring clip and the pin, lower the support jack to its

lowest position and mount the pin and the spring clip

> Rotate the handle until the hitch eye is free of the tractor’s drawbar

Machine with joystick control only

> Store the joystick control in a dry and dust free room free from

rodents, insects and martens

After the season

Machine with electronic control box only

> Store the control box in a dry and dust free room free from rodents,

insects and martens

> Unhitch the machine

After the season and at longer storage periods, the following work

must be performed:

• Thoroughly clean the machine

→ Cleaning, page 76

• Check all bolted joints and torque them

• Repair or replace damaged parts

• Repaint any paint damages

• Lubricate the machine

• Check the tyre pressure

77

Page 78

Maintenance

Maintenance

Safety

For all maintenance work applies:

Take care of the safety instructions

Definitely take care of the safety instructions during all work. In case

of negligence of the safety instructions serious or deadly accidents

can occur.

Conditions for maintenance work

Only carry out maintenance work if you do dispose of the necessary

professional knowledge and of the suitable tools. Missing professional

knowledge or unsuitable tools can cause accidents or damages.

Use original parts

Use original parts for safety relevant components. Dimensions,

strength, and material quality must be guaranteed. Building in of not

original parts reduces the warranty to nil and void.

Protect the machine against unintentional use

Carry out general repairs, maintenance and repair of function troubles

at the hitched machine, in principle with switched off hydraulics,

switched off engine and removed ignition key! At unintended taking

into use serious accidents can be caused.

Welding work

Before welding work at the tractor and the machine in principal the

electronic circuit must be interrupted. Otherwise damages to the

electronic can not be excluded.

78

Page 79

Maintenance

Protection measures

in contact wi th o il or

lubricants

Additives in oil and lubricants can have, under circumstances, harmful

effects to health. Because an indication according to the danger order

is not necessary, therefore in principle please pay attention to:

Avoid skin contact

Avoid skin contact with these oil and lubricants. Protect your skin by

skin protection creams or oil-resistant gloves. Skin contact can lead to

skin diseases.