Page 1

Complementary instructions

GC003AGB D

Control box

RPB

GC003AGB D

- English - 08-2010

Page 2

Page 3

Control box

RPB

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Dear Owner

1

Page 4

Control box

RPB

$Contents

Dear Owner.....................................................................................................................1

Contents..........................................................................................................................2

Control box identification..............................................................................................4

Front view..........................................................................................................................................4

Manufacturers' marking.................... ... .... ... ... ... ... .... ... ............................................. ... .... ... ... ...........5

Optional equipment..........................................................................................................................6

Safety...............................................................................................................................7

Description of symbols used in this document.............................................................................7

Safety instructions...........................................................................................................................8

General description......................................................................................................10

Description and glossary...............................................................................................................10

Technical specifications............. ... ... ... .... ... ... ... ... .... ............................................. ... ... .... ... ............11

Description of control elements....................................................................................................12

Access and menu navigation.............. .... ... ... ... ... .... ... ... ... .... ... ............................................. ... ......14

Menu tree structure........................................................................................................................16

Assembly and fitting....................................................................................................17

Tractor requirements .....................................................................................................................17

Description of the connection.......................................................................................................17

Positioning and parking.................................................................................................................18

Putting into service......................................................................................................19

Switches on the control box..........................................................................................................19

Standby mode.................................................................................................................................19

2

Contents

Page 5

Control box

Configuration ............................................................................................................... 20

Adjustments before first use.........................................................................................................21

Preliminary adjustments at work..................................................................................................24

Machine use ................................................................................................................. 40

Tank.................................................................................................................................................40

Operating data................................................................................................................................42

Spraying start.................................... ... ... ... .... ... .......................................... ... ... .... ... ... ...................43

Information......................................................................................................................................46

Unfolding/folding of the boom arms ............................................................................................47

Application rate adjustment................ ... ... .... ................................................................................49

AUTO/MAN mode ...........................................................................................................................50

RPB

Opening/shut-off of the spraying sections..................................................................................51

"Menu" key ........................ ... ... ... .... ... ... ... ... .............................................. ......................................57

Optional equipment.....................................................................................................59

Work spotlights and flashing light ...............................................................................................59

Maintenance and storage............................................................................................ 60

Maintenance....................................................................................................................................60

Storage............................................................................................................................................60

Trouble shooting guide...............................................................................................61

Alarms.............................................................................................................................................62

Diagnosis........................................................................................................................................64

Description of fuses.......................................................................................................................65

Factory counters............................................................................................................................70

Version............................................................................................................................................71

Appendix ......................................................................................................................72

Configuration..................................................................................................................................72

Limited warranty..........................................................................................................80

Contents

3

Page 6

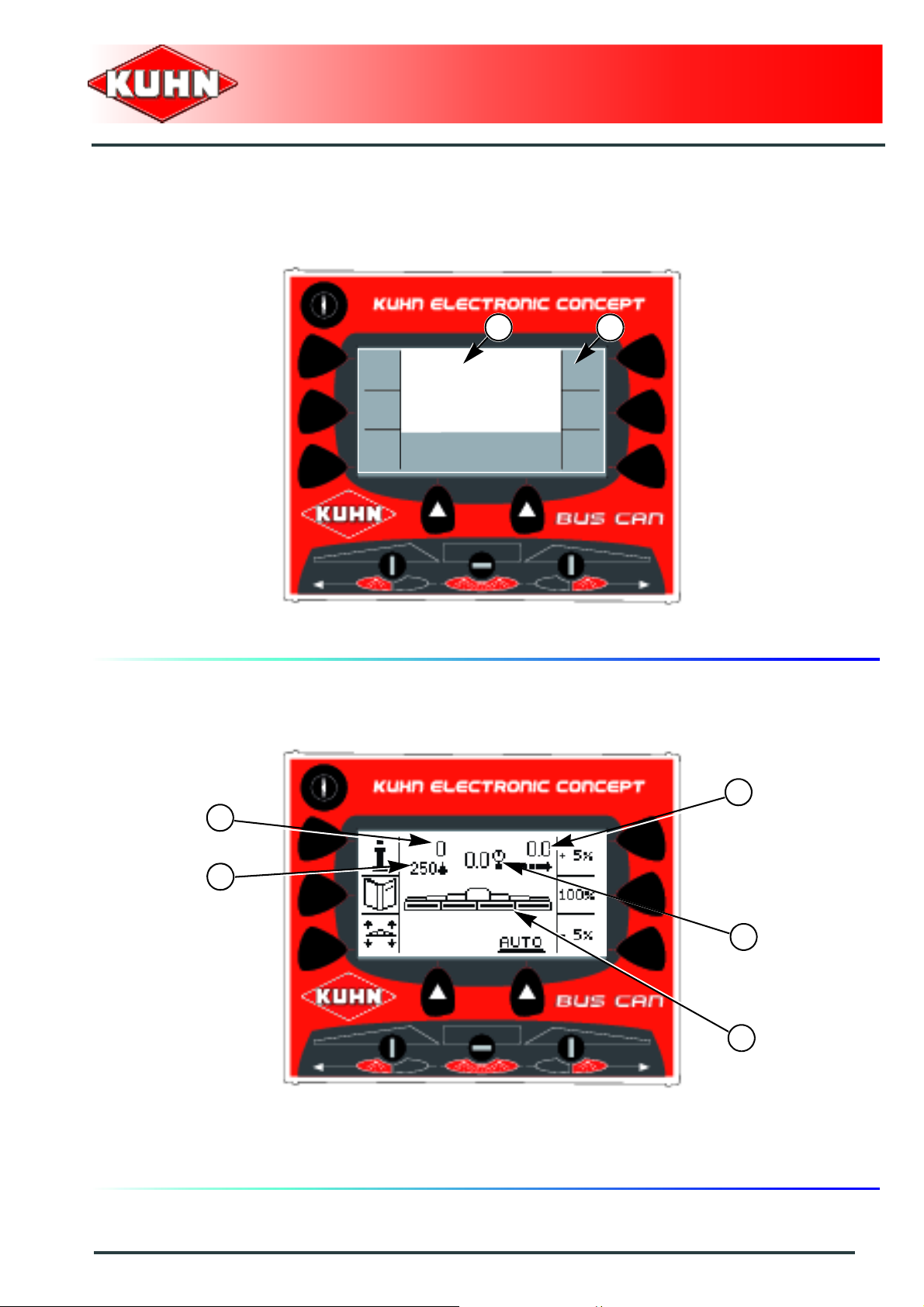

1. Front view

Control box

RPB

$Control box identification

4

Control box identification

Page 7

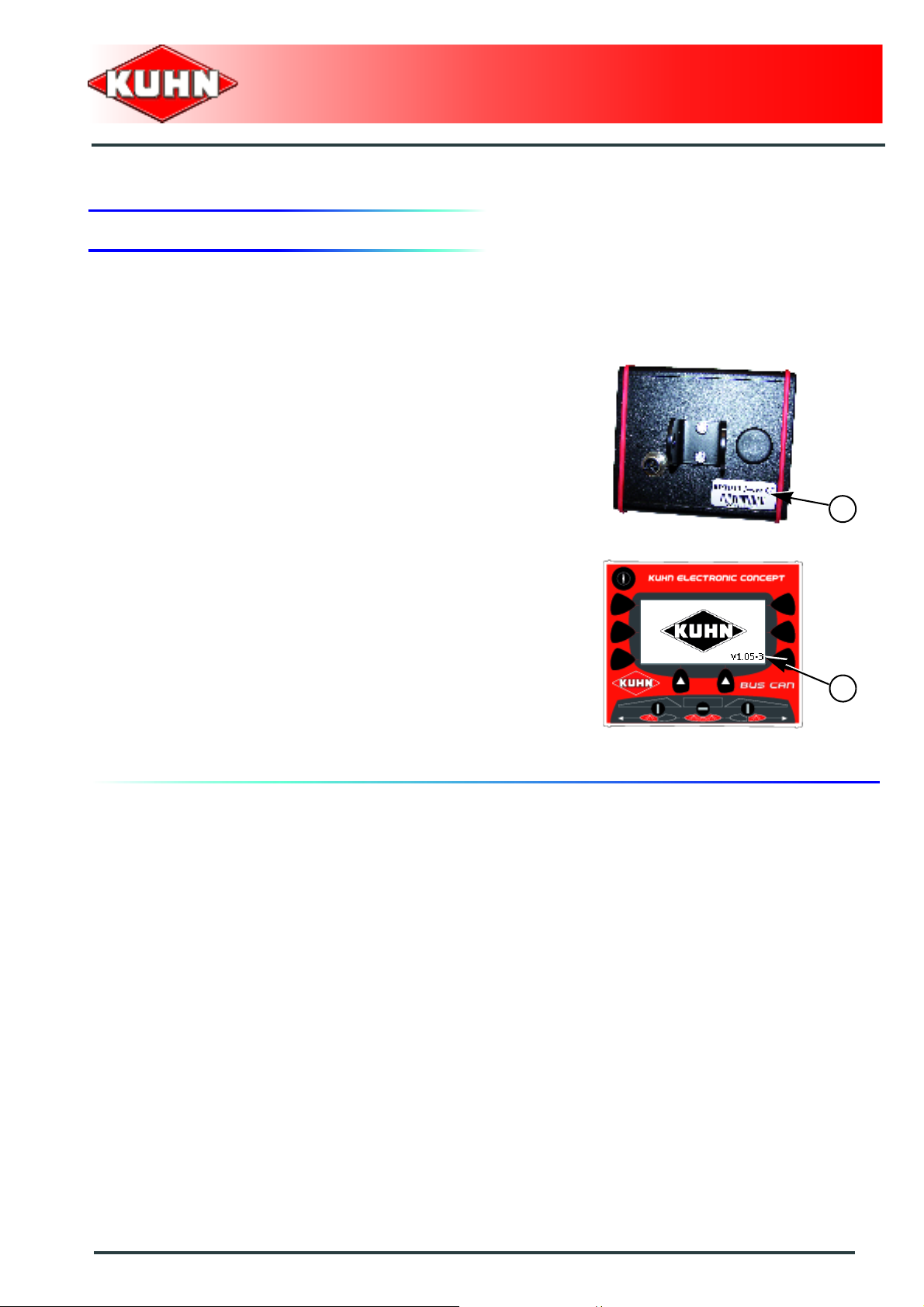

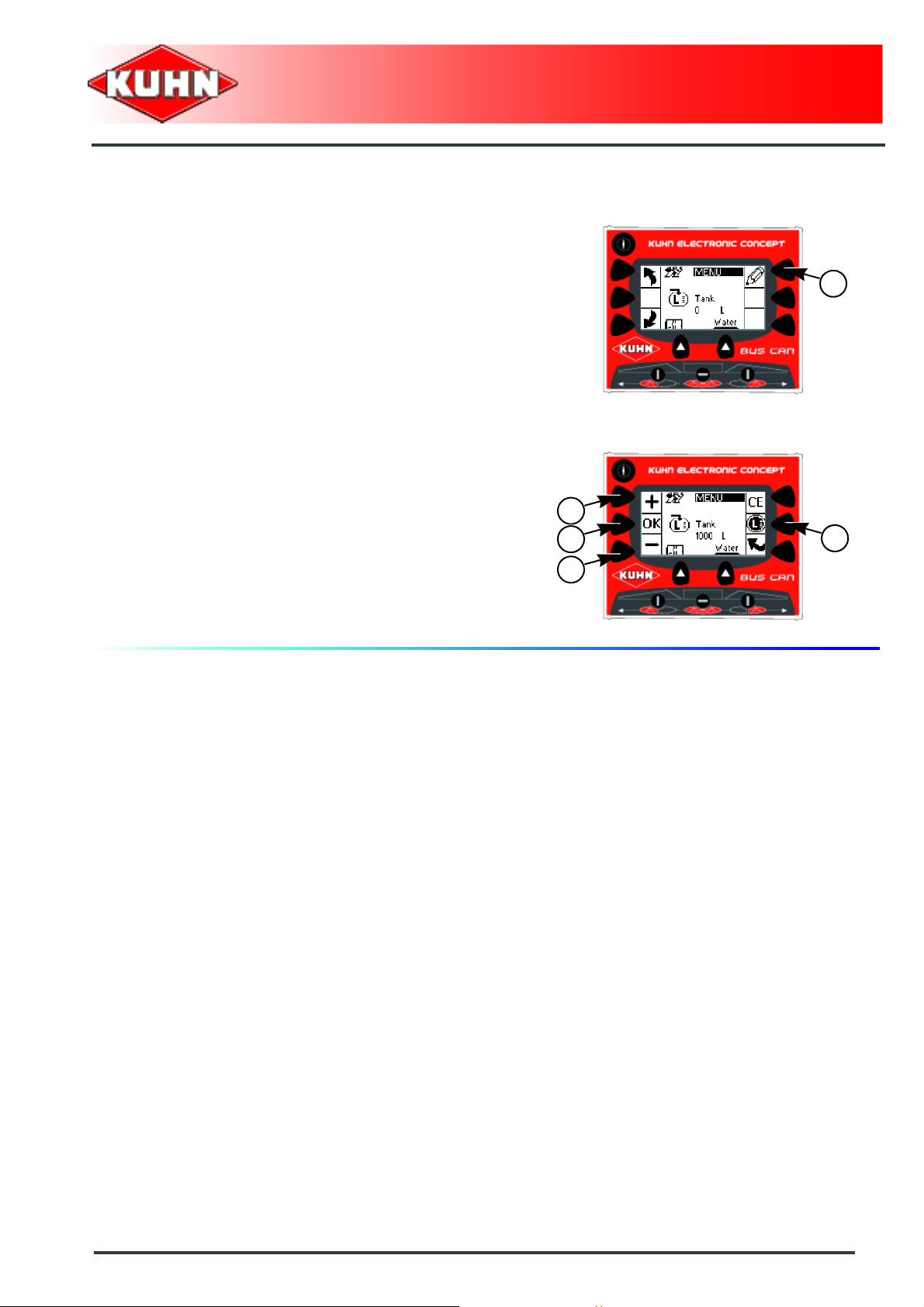

2. Manufacturers' marking

Please note the serial number of your equipment.

This information is to be indicated to the de aler for all

spare parts orders.

- Serial no. (1):

Control box

RPB

1

When switched on, the control box displays the following

information:

- Control box version (1):

1

Control box identification

5

Page 8

3. Optional equipment

All equipments listed below are not always

compatible between each other or with your

machine.

See machine corresponding to a specific

configuration.

Check with your authorized KUHN dealer the

equipment compatibility with your machine.

Prior to using optional equipment, it is necessary

to define the parameters.

See concerned section in the "Configuration"

chapter.

Control box

RPB

Tick box corresponding to the equipment fitted on your

machine:

Working headlights

Flashing light

6

Control box identification

Page 9

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Control box

RPB

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

Safety

7

Page 10

2. Safety instructions

Introduction

The operator must follow the safety instructions in this

manual and in the machine's operator's manual as well

as respect the warnings posted on the machine. The

operator is also obliged to respect current legislation

concerning accident prevention, work safety and public

traffic circulation.

Read and follow the safety instructions

Before using the control box, carefully read all safety

instructions in this manual.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Control box

RPB

Precautions to take before using the

control box

Place the control box so that it cannot interfere with other

tractor controls and be activated inadvertently.

Before switching the control box on, check that nobody

is within the machine pivoting area: switching on the

control box can activate functions on the machine.

8

Safety

Page 11

Precautions to take when using the control box

Do not operate the control box while a person is carrying

out work on the machine.

Switch off control box before carrying out any

maintenance or repair work on the machine.

Precautions when driving

Before transporting the machine on public road s, make

sure no function of the control box or of the control

accessories can be switched on inadvertently. Make

sure tractor valves and power take-off are deactivated

and not inadvertently engaged.

Control box

RPB

Safety

9

Page 12

$General description

1. Description and glossary

0

4

Control box

RPB

3

2

1

5

1 : Machine wiring harness 5-pin connector

2 : Control box mounting

3 : Keyboard with 8 function buttons and 1 On/Off button

4 : Screen

5 : Spraying opening and shut-off switches

10

General description

Page 13

2. Technical specifications

Dimensions:

Control box

RPB

Length

Width

Depth

Operating temperature from -20°C à +60°C

Storage temperature up to +85°C

Voltage input 12 V

Screen 120x 64 pixels

Connector Machine wiring harness 5-pin connector

Wiring harness CAN BUS

125 mm (4.9 ’’)

110 mm (4.3 ’’)

95 mm (3.7 ’’)

General description

11

Page 14

3. Description of control elements

Description of the controls

0

1

Control box

RPB

3

2

3

3

3

4

5

3

6

1 : Start/Stop: Control box

2 : Screen

3 : Selection key

4 : Switch: Left sequential opening/closing of the spraying sections

5 : Switch: Main opening/closing of the spraying sections

6 : Switch: Right sequential opening/closing of the spraying sections

3

3

3

12

General description

Page 15

Description of screen zones

0

Control box

RPB

1

2

1 : Menu and data display 2 : Selection key display

Work screen description

0

5

2

1

3

4

1 : Programmed application rate 2 : Measured application rate

3 : Pressure 4 : Spraying sections

5 : Groundspeed

General description

13

Page 16

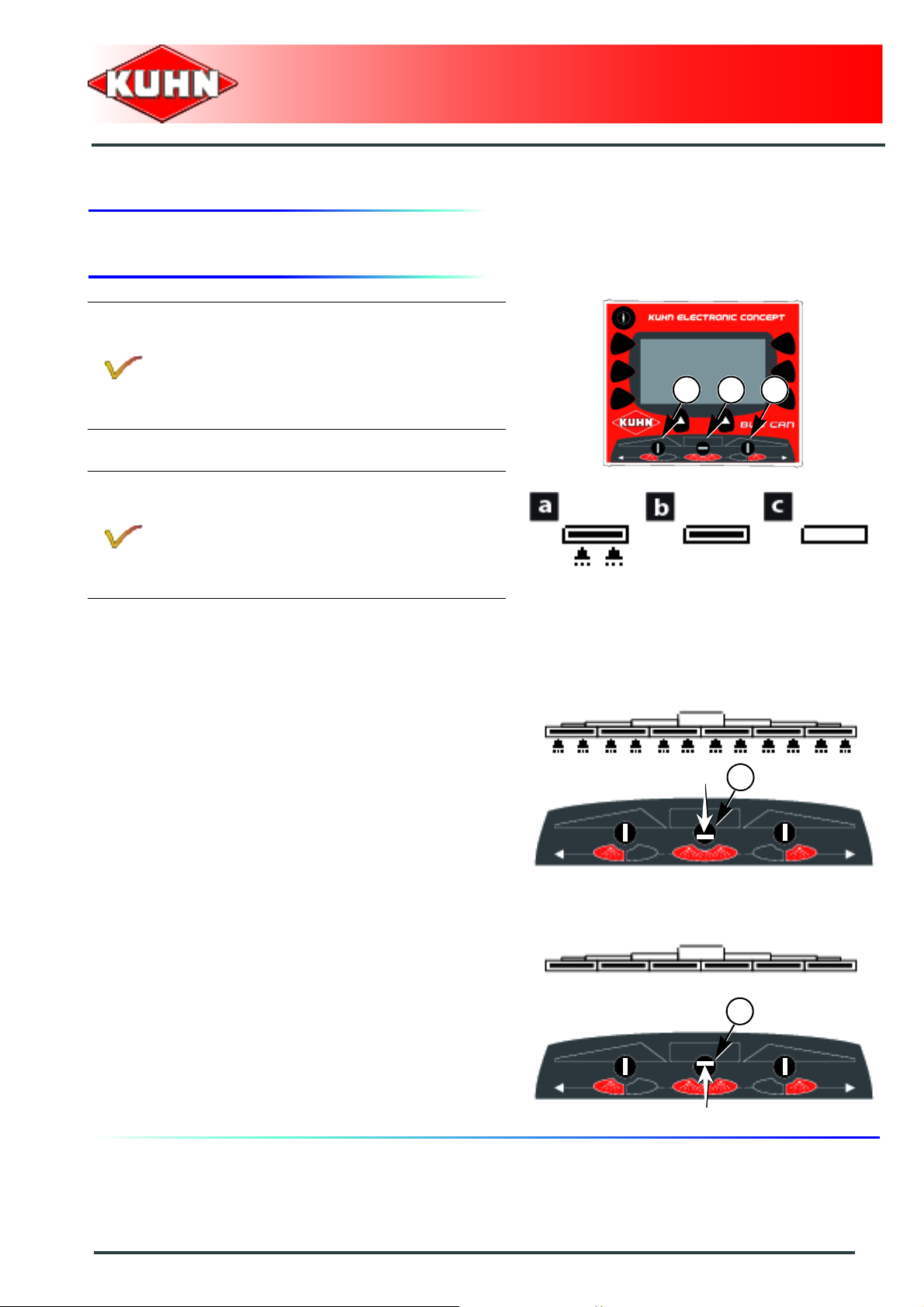

4. Access and menu navigation

Navigation keys

Control box

RPB

To navigate in the menus,use the following keys:

- Menu line change key (1).

- Selection validation key (2).

- Key to return to the previous menu (3).

Menu display (1).

1

2

1

3

1

The RPB control box features circular menus.

14

General description

Page 17

Entry and modification of a value

- Press keys (1) and (2) to select the parameter to

modify:

• Move the cursor upwards (1).

• Move the cursor downwards (2).

Control box

RPB

1

3

- Press key (3) to modify parameter.

Numerical value:

- Press keys (1) or (2) to modify the value:

• Increment a value (1).

• Decrement a value (2).

• Value reset ( 3).

- Validate (4).

or

- Cancel the modification (5).

Alphabetical value:

- Press keys (1) or (2) to select the value to modify:

• Move the cursor to the right (1).

• Move the cursor to the left (2).

2

1

3

4

2

3

5

5

- Press keys (3) or (4) to modify the value:

• Increment a value (3).

• Decrement a value (4).

• Value reset ( 5).

- Validate (6).

or

- Cancel the modification (7).

6

4

2

General description

7

1

15

Page 18

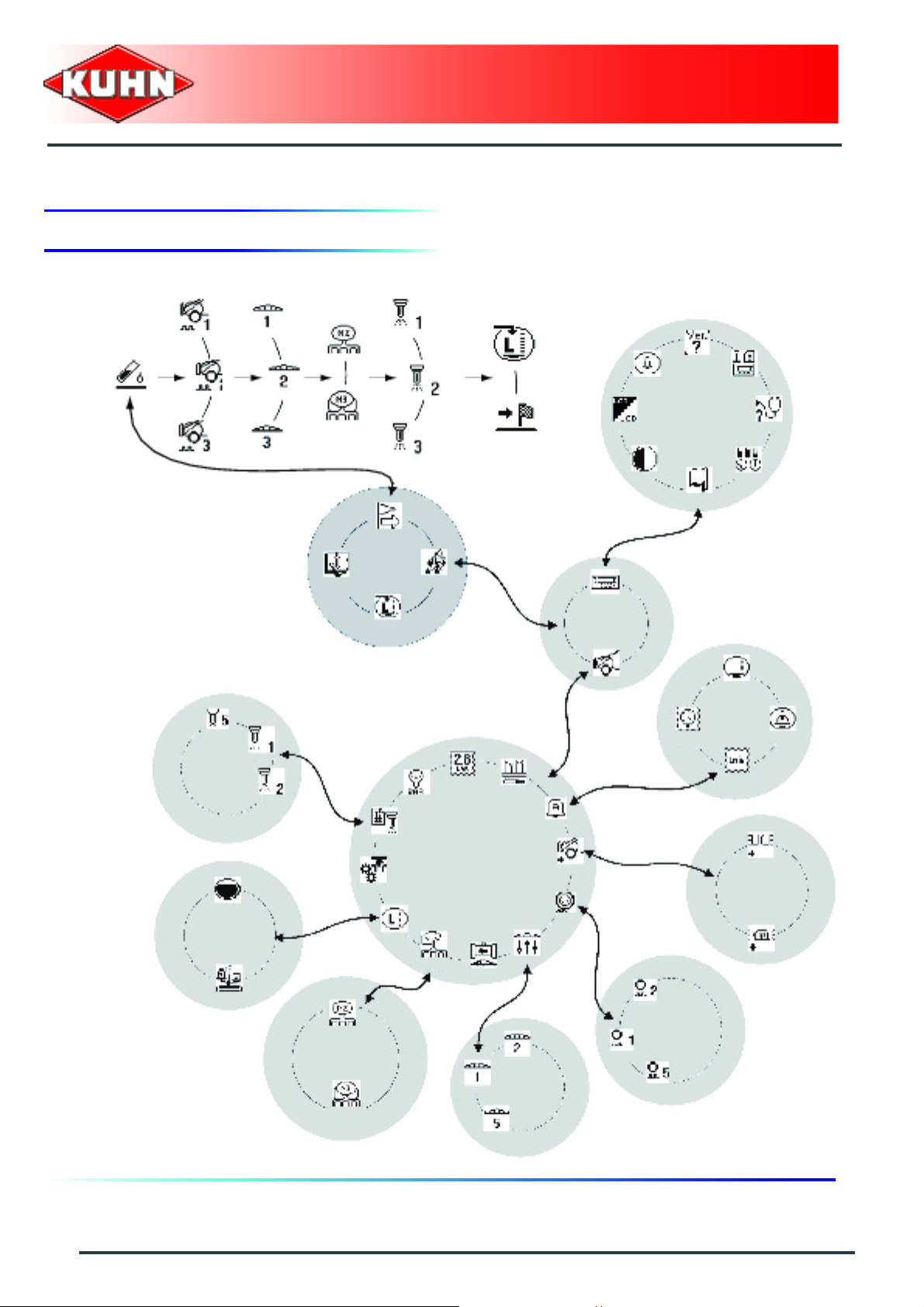

5. Menu tree structure

Control box

RPB

Terminal

Nozzles

Tank

Main menu

Settings

Alarms

Sprayer

Optional equipment

16

General description

Wheels

Circulation

Booms

Page 19

$Assembly and fitting

1. Tractor requirements

The tractor must supply a voltage comprised between

11 V and 14 V.

2. Description of the connection

Control box

RPB

Never connect battery charger or perform

welding tasks without having previously

disconnected the control box.

- Connect the machine 3-pin power plug (1).

- Connect machine CAN BUS wiring harness connector

(2) to the control box.

For increased safety, it is recommended to use the

harness supplied with the machine..

Check that the connectors are in a good

condition and clean.

2

1

- Connect the wiring harness directly to the battery

terminals respecting the polarities.

Assembly and fitting

17

Page 20

3. Positioning and parking

The control box must be easily accessible

from the tractor cab.

The control box must be fitted in a dry place,

safe from bad weather.

Control box mounting

The control box is placed in the tractor cabin on support

(1) to mount.

Control box

RPB

1

Control box removal

Disconnect and store control box in a dry and clean

place.

18

Assembly and fitting

Page 21

$Putting into service

1. Switches on the control box

Control box

RPB

- Press key (1) to switch the control box on.

- Press key (1) for 2 seconds to switch the control box

off.

2. Standby mode

The control box RPB switches to the standby mode

when not used for a few minutes.

- Press on a key to exit the standby mode.

1

Putting into service

19

Page 22

$Configuration

The configuration modification must be

made by your KUHN authorized dealer.

-

Control box

RPB

Main menu

Starting from the main menu:

- Press key (1) to access the "Settings" menu.

- Press key (1) to enter the password.

Settings

1

1

Password: 7

- Press 7 time on key (1).

- Press the button (2) to confirm.

To note user settings, refer to the section

"Appendix".

20

Configuration

1

2

Page 23

1. Adjustments before first use

Control box

RPB

Main menu

As from the "Configuration" menu:

- Press key (1) to access the "Terminal" menu.

- Press on the button (2).

Setting the language

- Press key (1) to access the menu.

- Press key (2) to change the language.

There are 4 different languages available to navigate in

the control box menus. By default, French and English

are always present.

Configuration

Terminal

2

1

1

2

FR: French

GB: English

ES: Spanish

DE: German

RO: Rumanian

DK: Danish

SK: Slovak

PL: Polish

LT: Lithuanian

JP: Japanese

RU: Russian

Configuration

21

Page 24

Setting contrast

- Press key (1) to access the menu.

- Press key (2) to modify the contrast.

Setting back-lighting

- Press key (1) to access the menu.

- Press key (2) to switch from one mode to the other.

No: White text on black background.

Yes: Black text on white background.

Control box

RPB

1

2

1

2

Beep keys

- Press key (1) to access the menu.

- Press key (2) to switch from one mode to the other.

No: No noise.

Beep: Low noise.

Buzzer: Loud noise.

1

2

22

Configuration

Page 25

System

- Press key (1) to access the menu.

- Press on the button (2).

Speed simulator:

The stimulator allows stationary spraying.

- Press key (1) to modify parameter.

Yes: Activated.

No: Deactivated.

Control box

RPB

2

1

1

When starting to move, the speed simulator is

automatically deactivated.

Configuration

23

Page 26

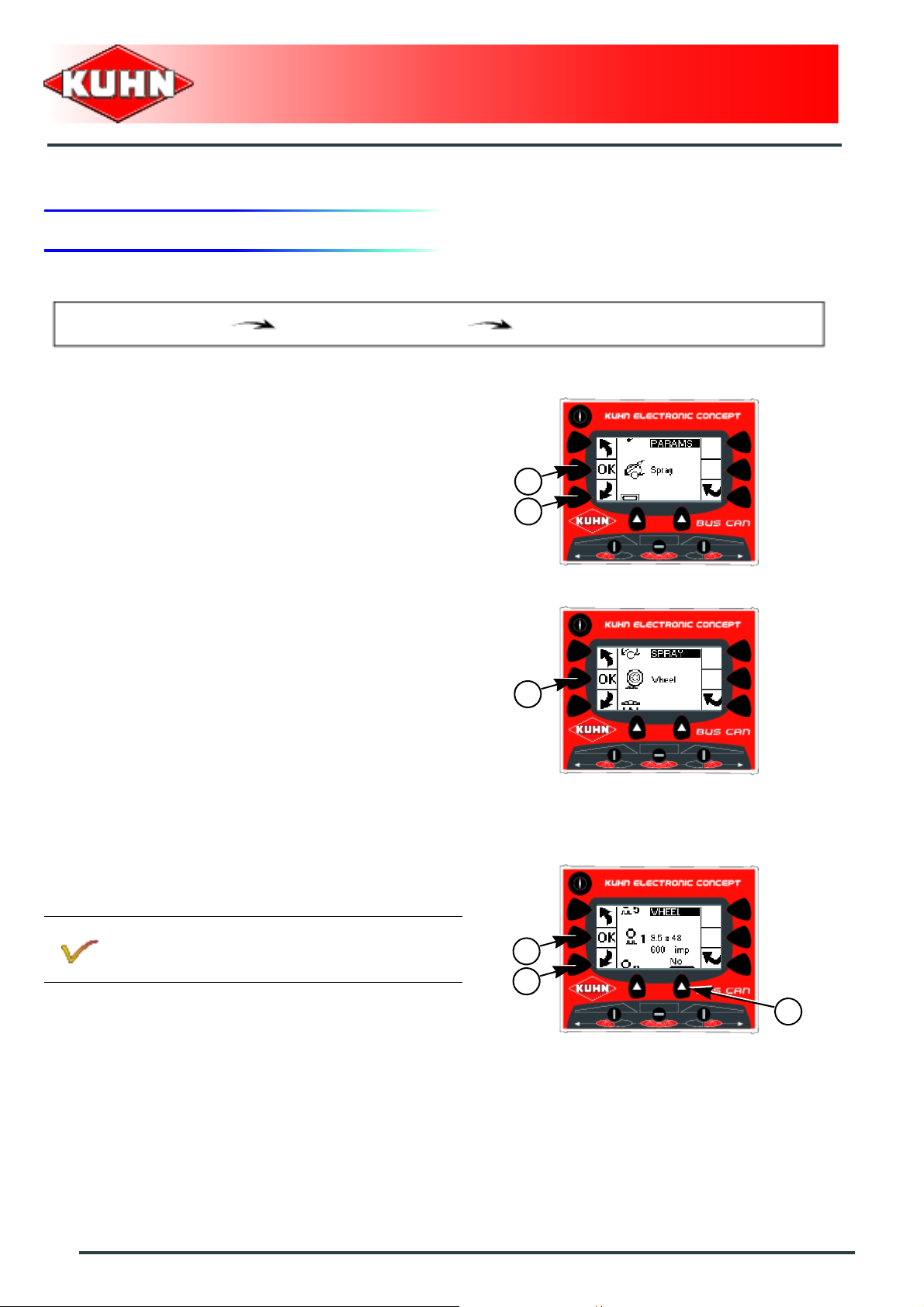

2. Preliminary adjustments at work

Control box

RPB

Main menu

As from the "Configuration" menu:

- Press key (1) to access "Sprayer" menu.

- Press on the button (2).

Wheel

- Press on the button (1).

The control box can save up to 5 different configurations.

All configurations are factory preset. All configurations

can be modified.

Configuration

Sprayer

2

1

1

Activate / deactivate a configuration:

- Press key (1) to select a configuration.

- Press key (2) to switch from one mode to the other.

No: Configuration deactivated.

Yes: Configuration activated.

- Press on the button (3).

24

Configuration

3

1

2

Page 27

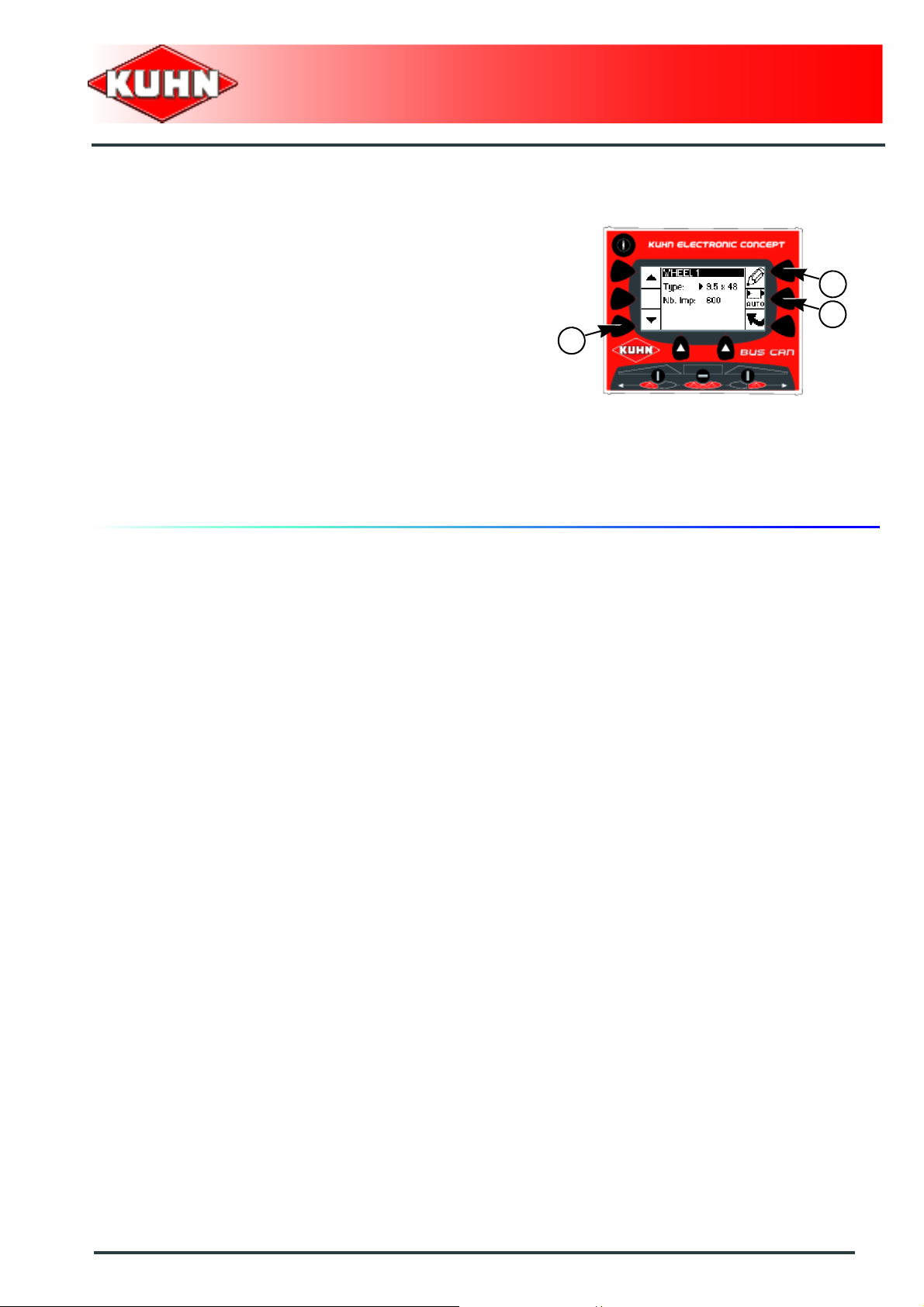

Modifying a configuration:

- Press key (1) to access the parameters to modify.

Control box

RPB

Type:

- Press key (2) to modify parameter.

Number of pulses:

- Press key (2) to modify parameter.

Automatic calibration:

When used for the first time, the equipment must be

calibrated.

- Press key (3) to start the automatic calibration.

- Follow screen instructions.

2

3

1

Configuration

25

Page 28

Boom

- Press on the button (1).

The control box can save up to 5 different configurations.

All configurations are factory preset. All configurations

can be modified.

Activate / deactivate a configuration:

- Press key (1) to select a configuration.

- Press key (2) to switch from one mode to the other.

Control box

RPB

1

No: Configuration deactivated.

Yes: Configuration activated.

- Press on the button (3).

Modifying a configuration:

- Press key (1) to access the parameters to modify.

Name:

- Press key (2) to modify parameter.

Width:

- Press key (2) to modify parameter.

Number of nozzles:

- Press key (2) to modify parameter.

The control box enables managing up to 7

sections.

Section 1 corresponds to the section most to the

left of the boom.

3

1

2

2

1

26

Configuration

Page 29

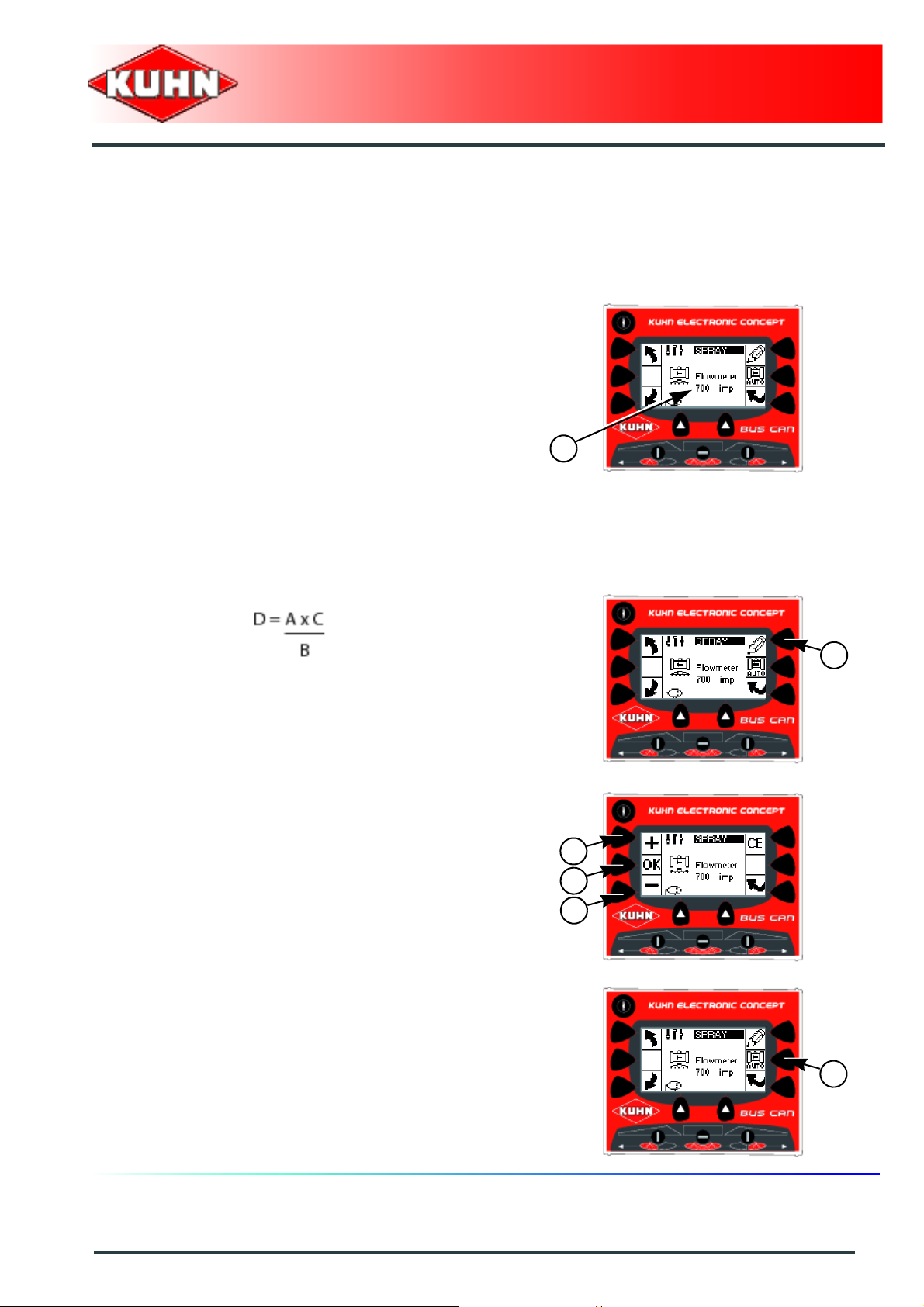

Spraying flowmeter

When used for the first time, the equipment must be

calibrated.

Manual calibration:

- Note the flowmeter coefficient (1) = A.

- Switch to stationary spraying mode.

- Go to manual mode.

- Adjust pressure to 3 bars (44 psi).

- Place a test tube underneath the nozzle.

- Reset counters.

- Open spraying.

- Wait for 10 seconds.

- Shut-off spraying.

- Measure the volume collected in the test tube.

- Multiply the volume collected in the test tube by the

number of nozzles on the boom = B.

- Note the volume displayed by the control box = C.

- Calculate the new coefficient value = D:

Control box

RPB

1

- Press key (1) to modify parameter.

- Pres on keys (1) and (2) to adjust the value.

- Press the button (3) to confirm.

Automatic calibration:

- Press key (1) to start the automatic calibration.

- Follow screen instructions.

1

1

3

2

1

Configuration

27

Page 30

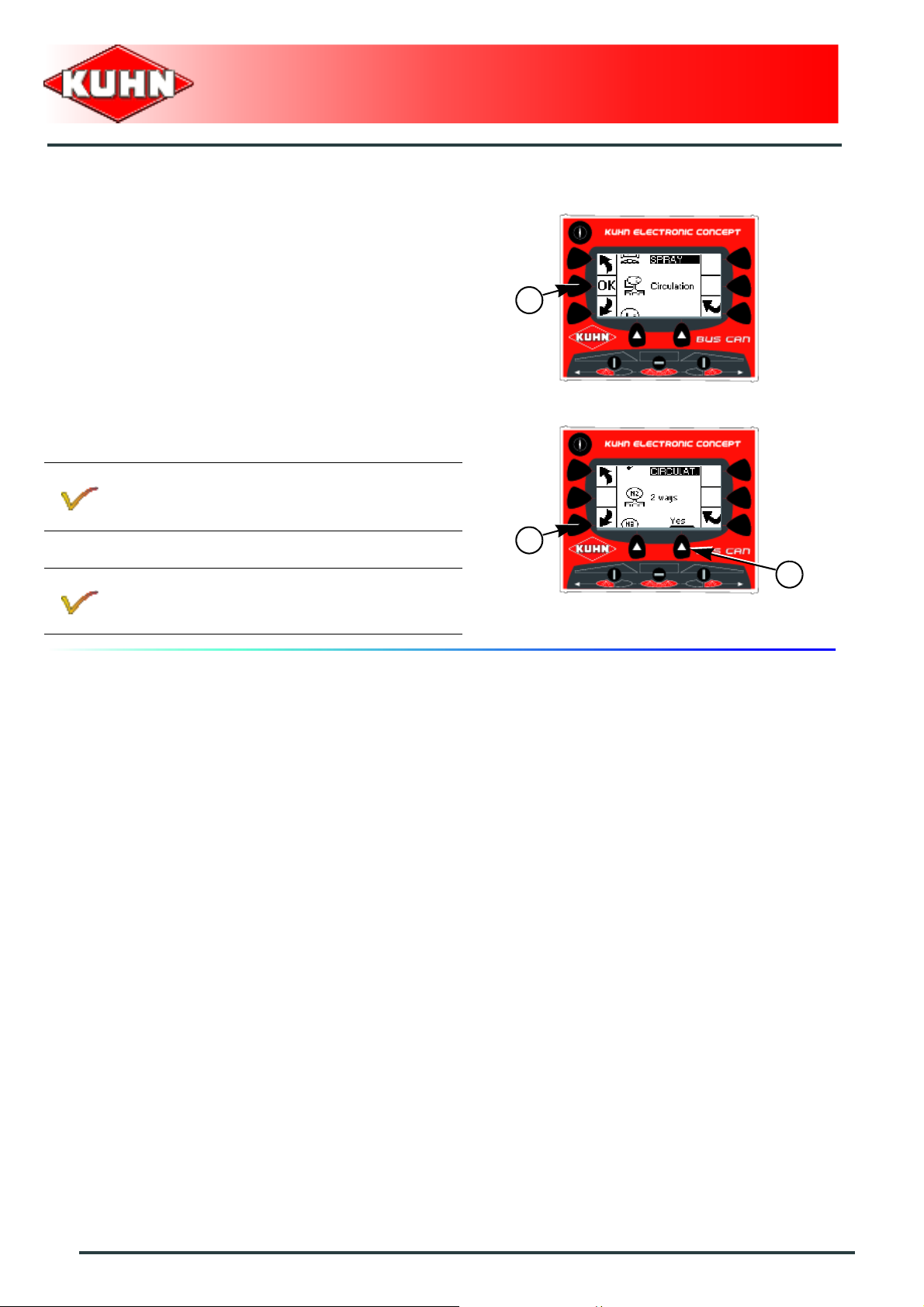

Circulation

- Press on the button (1).

Activate / deactivate a configuration:

- Press key (1) to select a configuration.

- 2-way standard circulation (N2).

- 3-way standard circulation (N3).

Refer to the machine operator's manual.

- Press key (2) to switch from one mode to the other.

Control box

RPB

1

1

No: Configuration deactivated.

Yes: Configuration activated.

2

28

Configuration

Page 31

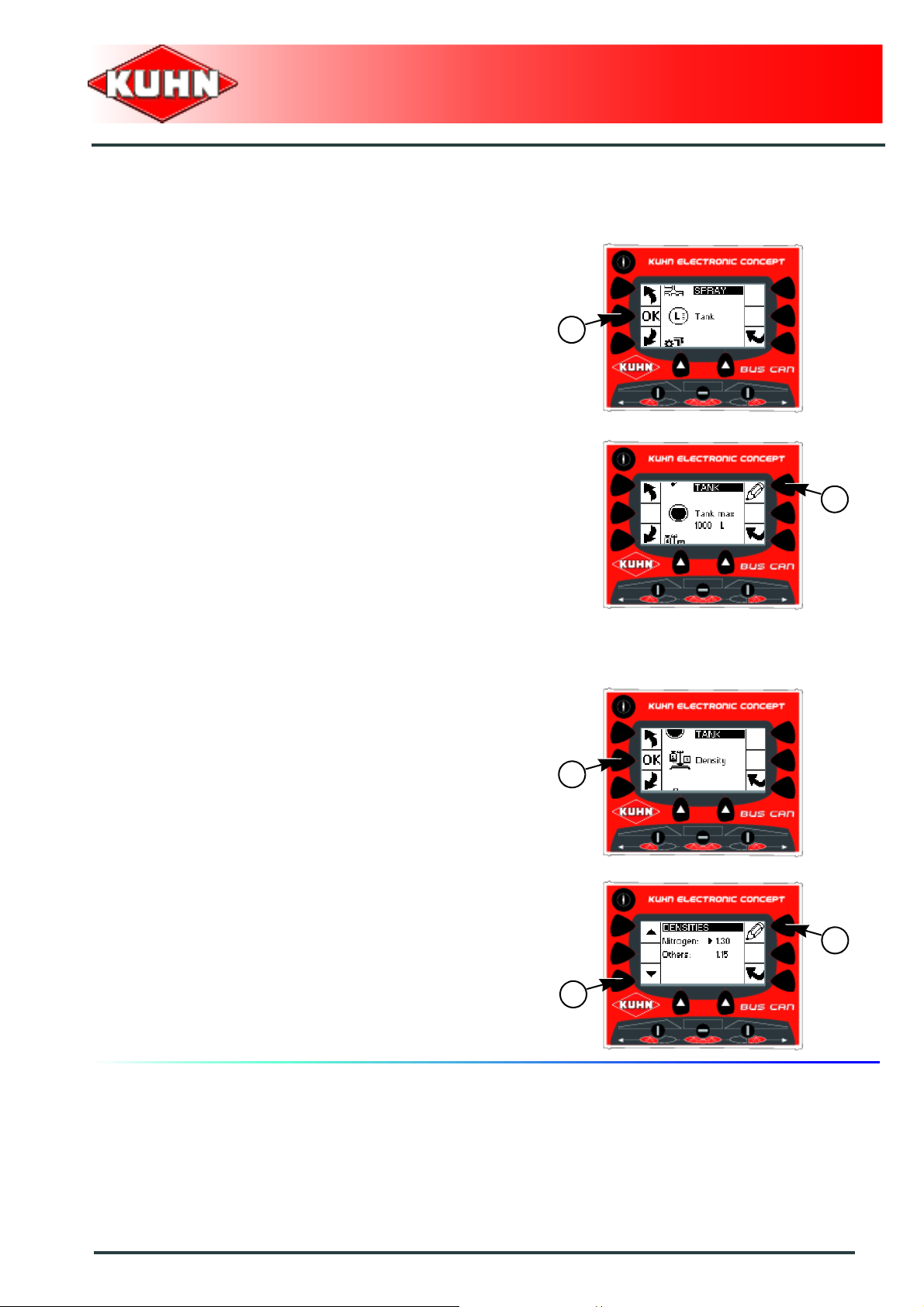

Tank

- Press on the button (1).

Body capacity:

Control box

RPB

1

- Press key (1) to modify parameter.

Density:

- Press on the button (1).

- Press key (1) to access the parameters to modify.

- Press key (2) to modify parameter.

1

1

2

1

Configuration

29

Page 32

Regulation

- Press on the button (1).

- Press key (1) to access the parameters to modify.

Control box

RPB

1

Pump coefficient:

This parameter allows filtering the pump flow variations.

The more the pump flow is varies, the more the

coefficient must be high. The more the pump flow is

stable, the more the coefficient must be low.

- Press key (2) to modify parameter.

Regulation coefficient:

This parameter allows adjusting the regulation speed

according to the regulation valve used. The slower the

valve opening/shut-off, the lower the coefficient must be

set. The faster the valve opens/closes, the higher the

coefficient must be set.

- Press key (2) to modify parameter.

2

1

2

30

Configuration

Page 33

Application rate adjustment:

This parameter allows defining the application rate

adjustment rate:

• 5% or 10% or 15% or 20% or 25%.

- Press key (2) to modify parameter.

Control box

RPB

2

Management of the minimum pressure:

Press key (2) to modify parameter.

No: During work at low speed, the application

rate adjustment is obtained by reducing the

pressure. The pressure goes below the

minimum nozzle working pressure. The spraying

is not even.

Yes: During work at low speed, the regulation

does not go below the minimum nozzle working

pressure. This regulation leads to an

overdosage.

Valve opening time:

This parameter indicates the time taken by the regulation

valve to fully open / close.

- Press key (2) to modify parameter.

2

2

Configuration

31

Page 34

Nozzles

- Press on the button (1).

Control box

RPB

Always calibrate the nozzles using water.

The control box can save up to 5 different configurations.

All configurations are factory preset. All configurations

can be modified.

Activate / deactivate a configuration:

- Press key (1) to select a configuration.

- Press key (2) to switch from one mode to the other.

No: Configuration deactivated.

Yes: Configuration activated.

- Press on the button (3).

Modifying a configuration:

- Press key (1) to access the parameters to modify.

1

3

1

2

Name:

- Press key (2) to modify parameter.

Flow to 3 bar (43.5 psi):

- Press key (2) to modify parameter.

Maximum pressure:

- Press key (2) to modify parameter.

MINIMUM operating pressure:

- Press key (2) to modify parameter.

2

1

32

Configuration

Page 35

Pressure sensor

- Press key (1) to switch from one mode to the other.

No: Sensor off.

Yes: Sensor on.

- Press on the button (2).

We recommend not to modify the initial

setting.

Automatic calibration:

The machine is calibrated at the factory.

Control box

RPB

2

1

For models fitted with a DPI control box:

- Turn off control box DPI.

- Press key (1) to start the automatic calibration.

- Follow screen instructions.

Pressure display

- Press key (1) to switch from one mode to the other.

No: Display deactivated.

Yes: Display activated.

1

1

Configuration

33

Page 36

Hydraulics

- Press key (1) to switch from one mode to the other.

No: For models without 3-function electro-

hydraulic valve

and

For models fitted with a solenoid valve

block.

Yes: For models fitted with a 3-function electro-

hydraulic selector.

For models fitted with a solenoid valve block:

The machine is fitted with a CH10 control box

that groups the hydraulic functions.

- Control box connection CH10.

The control box CH10 functioning and setting

are discribed in the complementary instructions

supplied.

Control box

RPB

1

34

Configuration

Page 37

Alarms

- Press on the button (1).

Flow alarm

This alarm indicates that the preset flow setting is not

reached.

- Press key (1) to switch from one mode to the other.

No: Alarm deactivated.

Beep: Alarm activated. Low noise.

Buzzer: Alarm activated. Loud noise.

Control box

RPB

1

2

- Press on the button (2).

- Press key (1) to modify parameter.

Trip: Time before the alarm is activated.

1

1

Configuration

35

Page 38

Pressure alarm

The alarm indicates the pressure is below/over the set

limit.

Refer to the nozzle configuration.

- Press key (1) to switch from one mode to the other.

No: Alarm deactivated.

Beep: Alarm activated. Low noise.

Buzzer: Alarm activated. Loud noise.

Control box

RPB

2

- Press on the button (2).

- Press key (1) to modify parameter.

Trip: Time before the alarm is activated.

-

1

1

36

Configuration

Page 39

Tank low level prewarning alarm

The alarm indicates that the tank level is below the set

limit.

- Press key (1) to switch from one mode to the other.

No: Alarm deactivated.

Beep: Alarm activated. Low noise.

Buzzer: Alarm activated. Loud noise.

- Press on the button (2).

Control box

RPB

2

1

- Press key (1) to modify parameter.

Trip: Tank level below which the alarm is

activated.

1

Configuration

37

Page 40

Tank low level alarm

The alarm indicates that the tank level is below the set

limit.

- Press key (1) to switch from one mode to the other.

No: Alarm deactivated.

Beep: Alarm activated. Low noise.

Buzzer: Alarm activated. Loud noise.

- Press on the button (2).

- Press key (1) to modify parameter.

Trip: Tank level below which the alarm is

activated.

Control box

RPB

2

1

1

38

Configuration

Page 41

Optional equipment

Do not activate optional equipment that is

not installed.

- Press on the button (1).

Control box

RPB

1

Flashing light

- Press key (1) to switch from one mode to the other.

No: Equipment not installed.

Yes: Equipment installed.

Working headlights

- Press key (1) to switch from one mode to the other.

No: Equipment not installed.

Yes: Equipment installed.

1

1

Configuration

39

Page 42

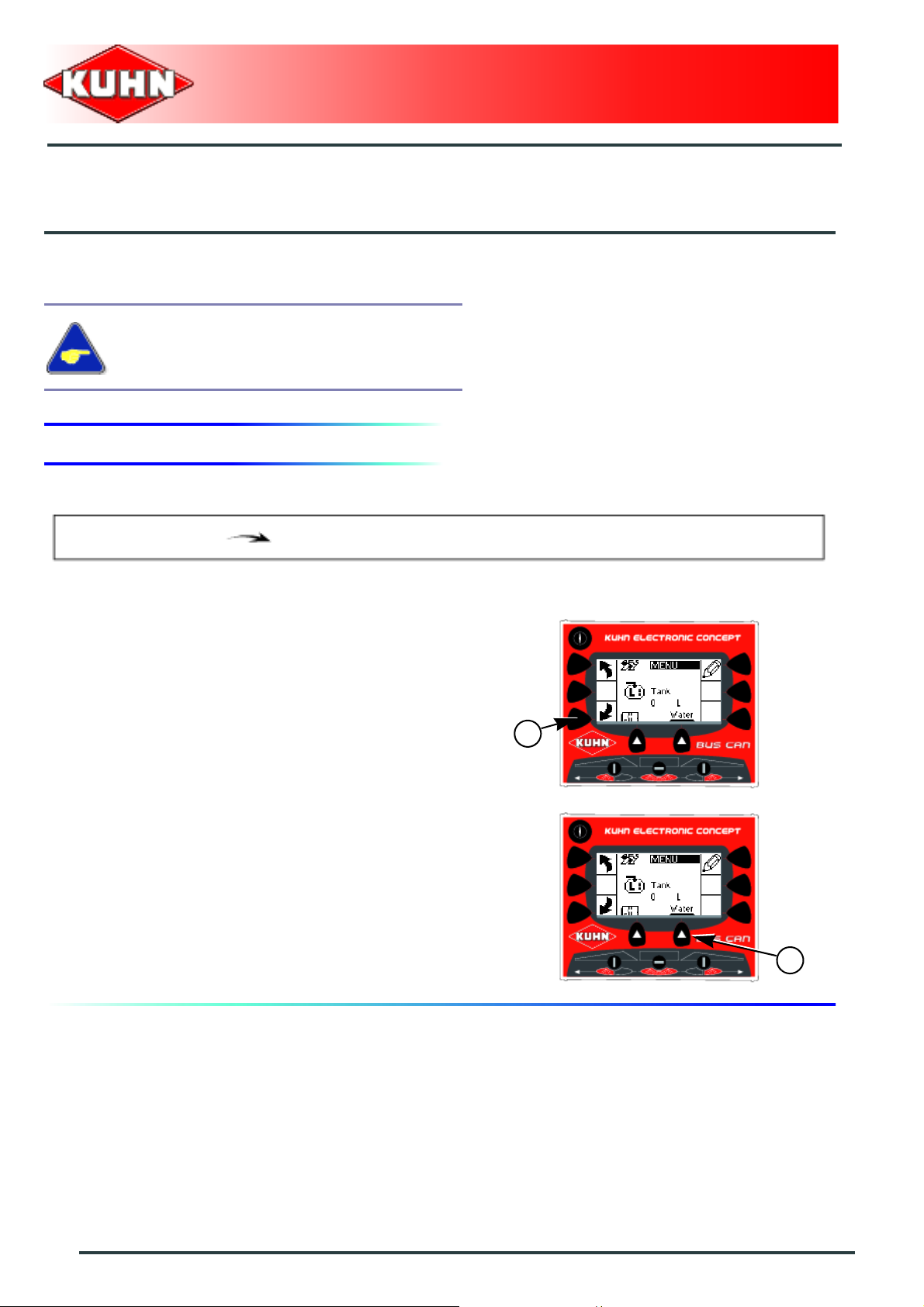

1. Tank

Control box

RPB

$Machine use

Refer to the machine operator's manual.

Main menu

Starting from the main menu:

- Press key (1) to access "Tank" menu.

The control box displays the following information:

- Tank rest.

Density

- Press key (1) to switch from one mode to the other.

Tank

1

1

40

Machine use

Page 43

Filling

- Fill the tank.

- Press key (1) to modify parameter.

Full filling:

- Press on the button (1).

or

Control box

RPB

1

Partial filling:

- Pres on keys (2) and (3) to adjust the value.

- Press the button (4) to confirm.

2

4

1

3

Machine use

41

Page 44

2. Operating data

Control box

RPB

Main menu

Starting from the main menu:

- Press key (1) to access "Counters" menu.

- Press on the button (2).

The control box displays the following information:

- Partial volume.

- Partial area.

- Partial distance.

- Total volume.

- Total area.

- Total distance.

- Press key (1) to select the counter.

- Press key (2) to modify parameter.

Operating data

2

1

2

- Press key (1) for counter reset.

Press key (1) during 3 seconds to reset the

counters.

- Press the button 2 to confirm.

42

Machine use

1

1

2

Page 45

3. Spraying start

Control box

RPB

Main menu

Starting from the main menu:

- Press key (1) to access the "Spraying start" menu.

- Press on the button (2).

According to the configuration, the choices offered are

different:

- If several configurations are activated, the control box

offers a list of choices.

- If only one configuration is activated, the control box

selects automatically the configuration activated.

- If no configuration is activated, an error message is

displayed. Check the control box configuration.

Spraying start

2

1

Ap.rate:

- Press key (1) to modify parameter.

- Press the button (2) to confirm.

1

2

Machine use

43

Page 46

Wheel:

- Press key (1) to select a configuration.

- Press the button (2) to confirm.

Boom:

- Press key (1) to select a configuration.

- Press the button (2) to confirm.

Control box

RPB

2

1

2

1

Circulation:

- Press key (1) to select a configuration.

- Press the button (2) to confirm.

Nozzle:

- Press key (1) to select a configuration.

- Press the button (2) to confirm.

Activate the pressure display to display the list of

nozzles activated. See concerned section in the

"Configuration" chapter.

2

1

2

1

44

Machine use

Page 47

Operating data:

- Press key (1) to select the counter.

- Press key (2) to modify parameter.

- Press key (1) for counter reset.

Press key (1) during 3 seconds to reset the

counters.

Control box

RPB

2

1

1

- Press the button (2) to confirm.

The control box displays the work screen.

2

Machine use

45

Page 48

4. Information

To display the information screen:

- Press on the button (1).

The control box displays the following information:

•Flow.

• Partial area.

• The number of litres spread.

• Tank rest.

The control box automatically redisplays the work screen

after 10 seconds.

Control box

RPB

1

For a continuous information screen display:

- Press for approximately 3 seconds on key (1)

To redisplay the work screen:

- Press key (1) a second time.

46

Machine use

Page 49

5. Unfolding/folding of the boom arms

Check that nobody is within the machine

pivoting area. If there is someone, make su re

the person moves away.

If a speed exceeding 4 km/h is detected, the

control box switches into the slope corrector

mode.

For models fitted with a solenoid valve

block

Control box

RPB

The machine is fitted with a CH10 control box that

groups the hydraulic functions.

Refer to control box operator's manual.

For models fitted with a 3-function electro-

hydraulic selector

The boom activators provide following hydraulic

functions:

- Slope corrector (1).

- Unfolding/folding of the central arms (2).

- Unfolding / folding of the outer arms (3).

At startup, the slope corrector mode is automatically

activated.

Machine use

47

Page 50

Unfold the booms:

Unfold the central arms:

- Press on the button (1).

- Shift the tractor hydraulic valve.

Unfold the outer arms:

- Press on the button (1).

- Shift the tractor hydraulic valve.

- Press on the button (1).

The boom is unfolded.

Control box

RPB

1

1

Fold the booms:

Fold the outer arms:

- Press on the button (1).

- Shift the tractor hydraulic valve.

Fold the central arms:

- Press on the button (1).

- Shift the tractor hydraulic valve.

- Press on the button (1).

The boom is folded.

1

1

48

Machine use

Page 51

6. Application rate adjustment

To adjust the application rate adjustment rate,

see concerned section in the "Configuration"

section.

Control box

RPB

- Press key (1) to increase the programmed application

rate.

- Press key (2) to reduce the programmed application

rate.

To revert to the initial application rate, press key (1).

1

2

1

Machine use

49

Page 52

7. AUTO/MAN mode

- Press key (1) to switch from one mode to the other.

Automatic mode:

- The control box opens/closes the flow regulation valve

to maintain the programmed application rate.

Manual mode:

- Press keys (1) and (2) to open / shut the flow

regulation valve and adjust the spraying pressure.

Control box

RPB

1

1

2

50

Machine use

Page 53

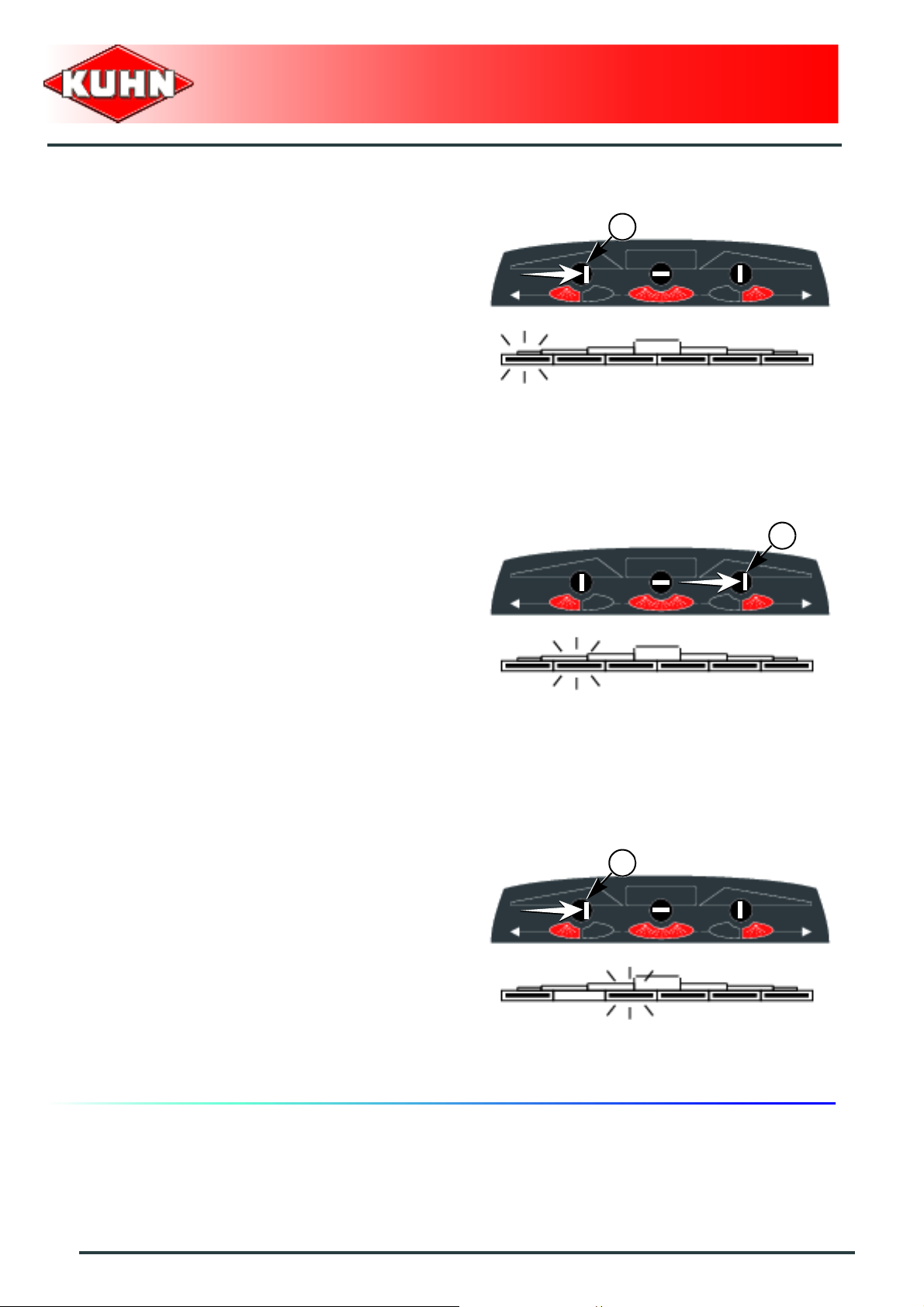

8. Opening/shut-off of the spraying sections

Switch (1): Left sequential opening/closing of the

spraying sections.

Switch (2): Main opening/closing of the spraying

sections.

Switch (3): Right sequential opening/closing of

the spraying sections.

Display a: Spraying open. Spraying section

open.

Display b: Spraying shut-off. Spraying section

open.

Display c: Spraying shut-off. Spraying section

shut off.

Control box

RPB

1 2 3

Spraying opening / shut-off

Spraying main opening:

- Operate switch (1) downwards.

Spraying main shut-off:

- Operate switch (1) upwards.

1

1

Machine use

51

Page 54

Main opening/closing of the spraying

sections

Control box

RPB

Main opening of the spraying sections:

- Operate and maintain switch (1) downwards during 2

seconds.

Main shut-off of the spraying sections:

- Operate and maintain switch (1) upwards during 2

seconds.

1

1

52

Machine use

Page 55

Sequential opening/closing of the spraying sections

Control box

RPB

Left sequential opening of the spraying sections:

- Operate switch (1) to the right.

- Repeat procedure for each section.

Left sequential shutting of the spraying sections:

- Operate switch (1) to the right.

- Repeat procedure for each section.

1

1

Machine use

53

Page 56

Control box

RPB

Right sequential opening of the spraying sections:

- Operate switch (1) to the left.

- Repeat procedure for each section .

Right sequential shutting of the spraying sections:

- Operate switch (1) to the left.

- Repeat procedure for each section .

1

1

54

Machine use

Page 57

Partial opening / shutting of the spraying sections

Section preselection to the right:

- Operate and maintain switch (1) to the left during 2

seconds.

Control box

RPB

1

Open the section:

- Operate switch (1) to the left.

Shut-off the section:

- Operate switch (1) to the left.

1

1

Machine use

55

Page 58

Section preselection to the left:

- Operate and maintain switch (1) to the right during 2

seconds.

Control box

RPB

1

Open the section:

- Operate switch (1) to the right.

Shut-off the section:

- Operate switch (1) to the right.

1

1

56

Machine use

Page 59

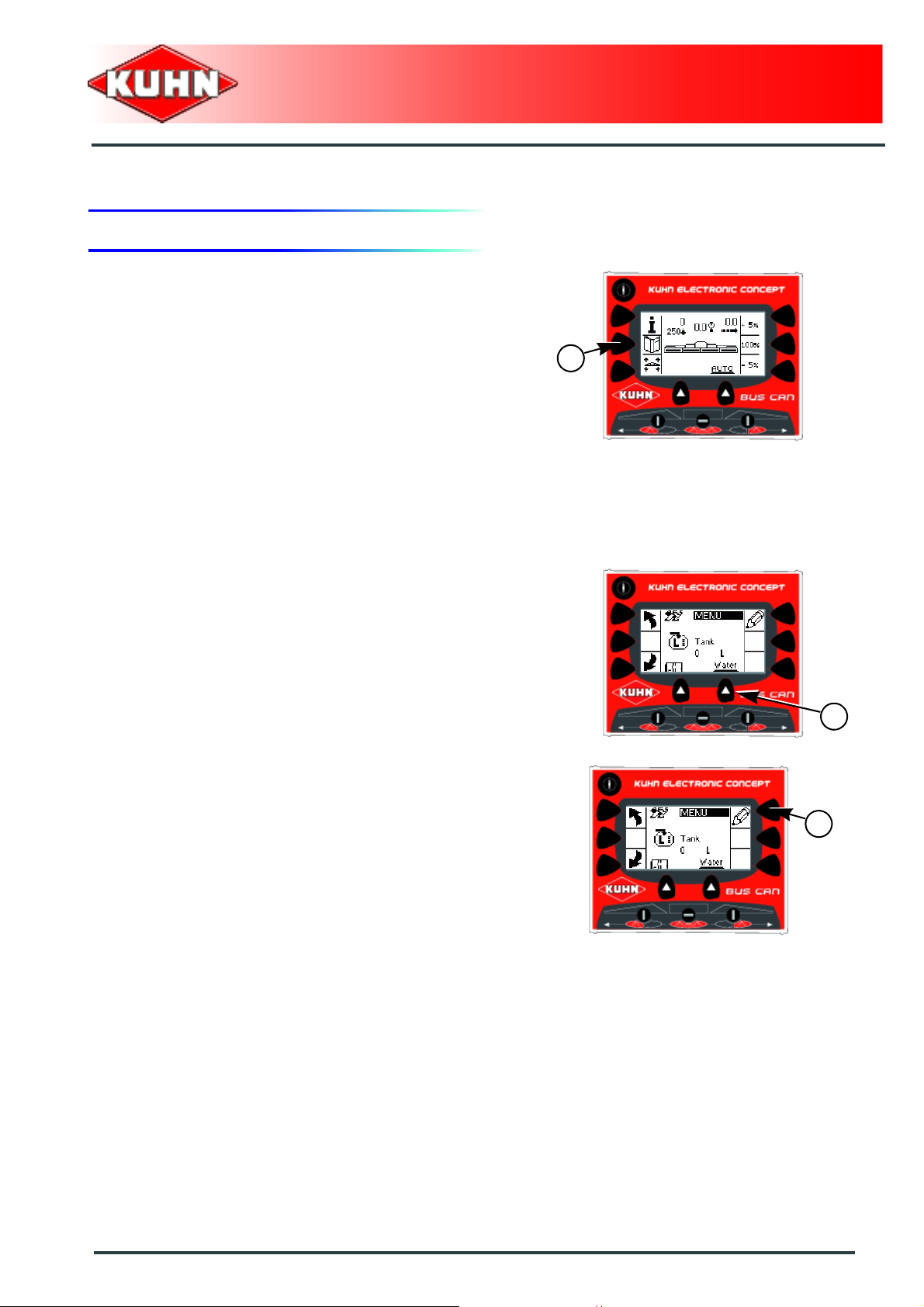

9. "Menu" key

To display the "Menu" screen:

- Press on the button (1).

Tank

The control box displays the following information:

- Tank rest.

Control box

RPB

1

Density

- Press key (1) to switch from one mode to the other.

Filling

- Fill the tank.

- Press key (1) to modify parameter.

1

1

Machine use

57

Page 60

Full filling:

- Press on the button (1).

or

Partial filling:

- Pres on keys (2) and (3) to adjust the value.

- Press the button (4) to confirm.

Work end

- Press on the button (1).

Control box

RPB

2

4

3

1

1

58

Machine use

Page 61

$Optional equipment

1. Work spotlights and flashing light

The work spotlights and flashing light can be

switched on simultaneously.

Working headlights

- Press key (1) to switch from one mode to the other.

Control box

RPB

Display a: Work lights off.

Display b: Work lights on.

Flashing light

- Press key (1) to switch from one mode to the other.

Display a: Flashing light off.

Display b: Flashing light on.

1

1

Optional equipment

59

Page 62

$Maintenance and storage

1. Maintenance

When cleaning the machine, never point the

water jet on the control box.

The control box does not require any particular

maintenance, in the case of a breakdown or a

malfunction call your KUHN technician.

Control box

RPB

2. Storage

At the end of each season

- Store control box in a dry place free of dust.

At the start of each season

- Re-read the operators' manual.

60

Maintenance and storage

Page 63

$Trouble shooting guide

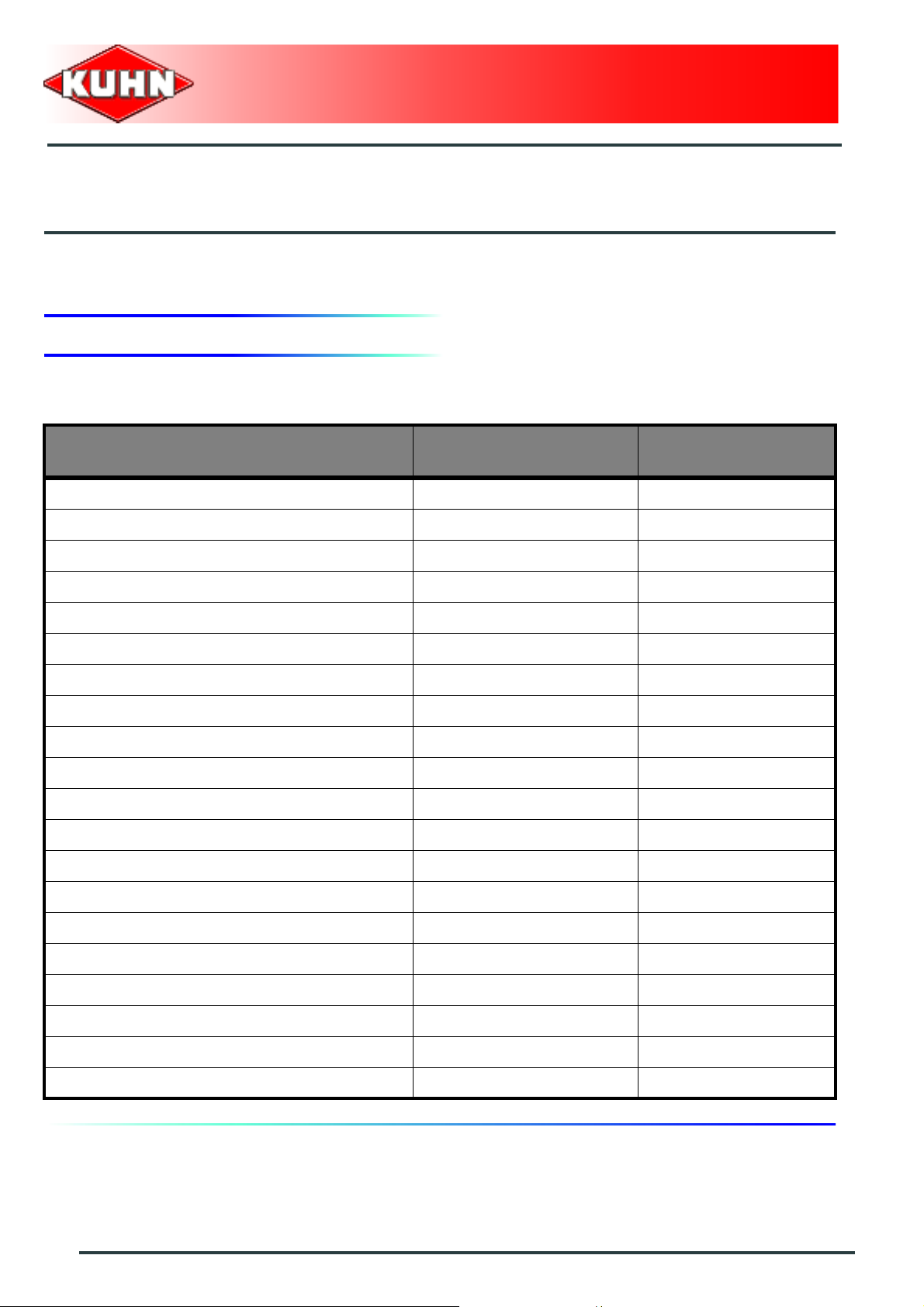

Problem Cause Remedy

Check plug voltage (12V).

Check if the electrical power

The control box does not

come on and controls no

functions.

The speed is incorrect.

Over or underdosage. Incorrect control box setting.

Faulty electric power supply.

The control box is faulty

Faulty sensor.

Incorrect sensor adjustment.

cable of the control box is

connected.

Refer to the section

"Assembly and fitting".

Contact you KUHN

authorized dealer.

Verify speed sensor and

wiring function.

Immediately replace worn or

damaged parts with genuine

KUHN parts.

Carry out the calibration.

See concerned section in the

"Configuration" chapter.

See concerned section in the

"Configuration" chapter.

Contact you KUHN

authorized dealer.

Control box

RPB

Trouble shooting guide

61

Page 64

1. Alarms

To configurate the alarms, see section in the

"Settings" chapter.

If several alarms are activated simultaneously,

the alarm messages are displayed successively.

Flow alarm

This alarm indicates that the preset flow setting is not

reached.

Control box

RPB

Maximum flow alarm

The control box displays an alarm message.

2 "beeps" sound.

Remedy:

- Reduce the pump flow.

or

- Reduce ground speed.

Minimum flow alarm

The control box displays an alarm message.

2 "beeps" sound.

Remedy:

- Increase the pump flow.

or

- Increase forward speed.

62

Trouble shooting guide

Page 65

Pressure alarm

The alarm indicates the pressure is below/over the set

limit.

Maximum pressure alarm

The control box displays an alarm message.

2 "beeps" sound.

Remedy:

- Check the type of nozzle. Replace if necessary.

or

- Reduce ground speed.

Minimum pressure alarm

The control box displays an alarm message.

2 "beeps" sound.

Control box

RPB

Remedy:

- Increase the pump flow.

or

- Increase forward speed.

Tank low level alarm

The alarm indicates that the tank level is below the set

limit.

Tank low level prewarning alarm

The control box displays an alarm message.

2 x 3 "beeps" sound.

Tank low level alarm

The control box displays an alarm message.

5 "beeps" sound.

Trouble shooting guide

63

Page 66

2. Diagnosis

Control box

RPB

Main menu

As from the "Terminal" menu:

- Press key (1) to access the "Diagnosis" menu.

- Press on the button (2).

or

As from any screen:

- Simultaneously press keys (1) and (2) for

approximately 3 seconds.

Configuration

Terminal

2

1

Diagnosis

11

The diagnosis menu enables controlling the machine's

electric system (Battery voltage, Sensors...).

64

Trouble shooting guide

Page 67

3. Description of fuses

Prior to any maintenance or repair on the

junction box, disconnect the machine and

tractor power supply.

Never replace damaged fuse by a fuse of

higher value.

Keep fuses safe from rain and humidity.

The cards are made up of 4 tie-point blocks:

- (1) Signalling.

- (2) Outputs.

- (3) Sensors.

-(4) BUS CAN.

Control box

RPB

4

3

2

The terminal blocks have 3 levels:

(1) High.

(2) Middle.

(3) Low.

1

1

3

2

Trouble shooting guide

65

Page 68

Housing: Powered valves

Outputs:

Gy H: Relay control.

Gy M: +12V Flashing light.

1H: Filling stop valve 1M: Filling stop valve +

2H: Main stop valve 2M: Main stop valve +

3H: Flow regulation valve 3M: Flow regulation valve +

4H: Section valve 1 4M: Section valve 1 +

5H: Section valve 2 5M: Section valve 2 +

6H: Section valve 3 6M: Section valve 3 +

7H: Section valve 4 7M: Section valve 4 +

8H: Section valve 5 8M: Section valve 5 +

9H: Section valve 6 9M: Section valve 6 +

10H: Section valve 7 10M: Section valve 7 +

11H: Section valve 8 11M: Section valve 8 +

12H: Section valve 9 - / Options.

12M: Section valve 9 + / Options.

13H: Section valve 10 - / Options.

13M: Section valve 10 + / Options.

14H: Section valve 11 - / Options.

14M: Section valve 11 + / Options.

15H: Function selector central arms.

15M: Function selector outer arms.

Control box

RPB

4

3

2

1

From 1B to 15B: Ground.

Fuse:

Fuse (1): Flashing light.

Fuse (2): Sensors.

Fuse (3): BUS CAN.

Fuse (4): Supply.

66

Trouble shooting guide

Page 69

Sensors:

1M: Signal frequency: Wheel.

2M: Signal frequency: Flowmeter.

3M: Signal frequency: Return flowmeter.

4M: Signal frequency: Filling flowmeter.

5M: Analog signal: Pressure sensor.

6M: Analog signal: Electronic gauge.

7M: Reserved.

8M: Reserved.

From 1H to 8H: +12V.

From 1B to 8B: Ground.

Control box

RPB

BUS CAN:

Harness connection:

From 1H to 4H.

or

From 1M to 4M.

or

From 1B to 4B.

1: +12V.

2: CAN HIGH.

3: CAN LOW.

4: Ground.

Blue

Brown

White

Black

Trouble shooting guide

67

Page 70

Housing: Solenoid valve block

Outputs:

Gy H: Relay control.

Gy M: +12V Flashing light.

1H: Reserved.

1M: Reserved.

2H: Reserved.

2M: Reserved.

3H: On / Off.

3M: Automatic / Manual.

4H: Left outer arm opening.

4M: Left outer arm closing.

5H: Opening central arms.

5M: Closing central arms.

6H: Right outer arm opening.

6M: Right outer arm closing.

7H: Auxiliary down.

7M: Auxiliary up.

8H: Locking.

8M: Unlocking.

9H: Lowering left variable geometry.

9M: Raising left variable geometry.

10H: Lowering right variable geometry.

10M: Raising right variable geometry.

11H: Lowering height.

11M: Raising height.

12H: Slope left.

12M: Slope right.

13H: Drawbar left.

13M: Drawbar right.

14H: Reserved.

14M: Reserved.

15H: Reserved.

15M: BYPASS valve.

Control box

RPB

Supply

Outputs Sensors BUS CAN

Signalling

From 1B to 15B: Ground.

68

Trouble shooting guide

Page 71

Sensors:

1M: Signal frequency: Wheel.

2M: Analog signal: Gauge.

3M: Analog signal: Follower axle/Self-steering axle:

Front.

4M: Analog signal: Follower axle/Self-steering axle:

Rear.

5M: Reserved.

6M: Analog signal: Height.

7M: Reserved.

8M: Signal frequency: Reverse.

From 1H to 8H: +12V.

From 1B to 8B: Ground.

Control box

RPB

BUS CAN:

Harness connection:

From 1H to 4H.

or

From 1M to 4M.

or

From 1B to 4B.

1: +12V.

2: CAN HIGH.

3: CAN LOW.

4: Ground.

Blue

Brown

White

Black

Trouble shooting guide

69

Page 72

4. Factory counters

Control box

RPB

Main menu

As from the "Terminal" menu:

- Press key (1) to access "Counters" menu.

- Press on the button (2).

The control box displays the following information:

- Total area.

- Total volume.

These counters cannot be deleted.

Configuration

Terminal

2

1

Operating data

70

Trouble shooting guide

Page 73

5. Version

Control box

RPB

Main menu

As from the "Terminal" menu:

- Press key (1) to access the "Version" menu.

The control box displays the following information:

- Control box version.

Configuration

Terminal

1

Version

Trouble shooting guide

71

Page 74

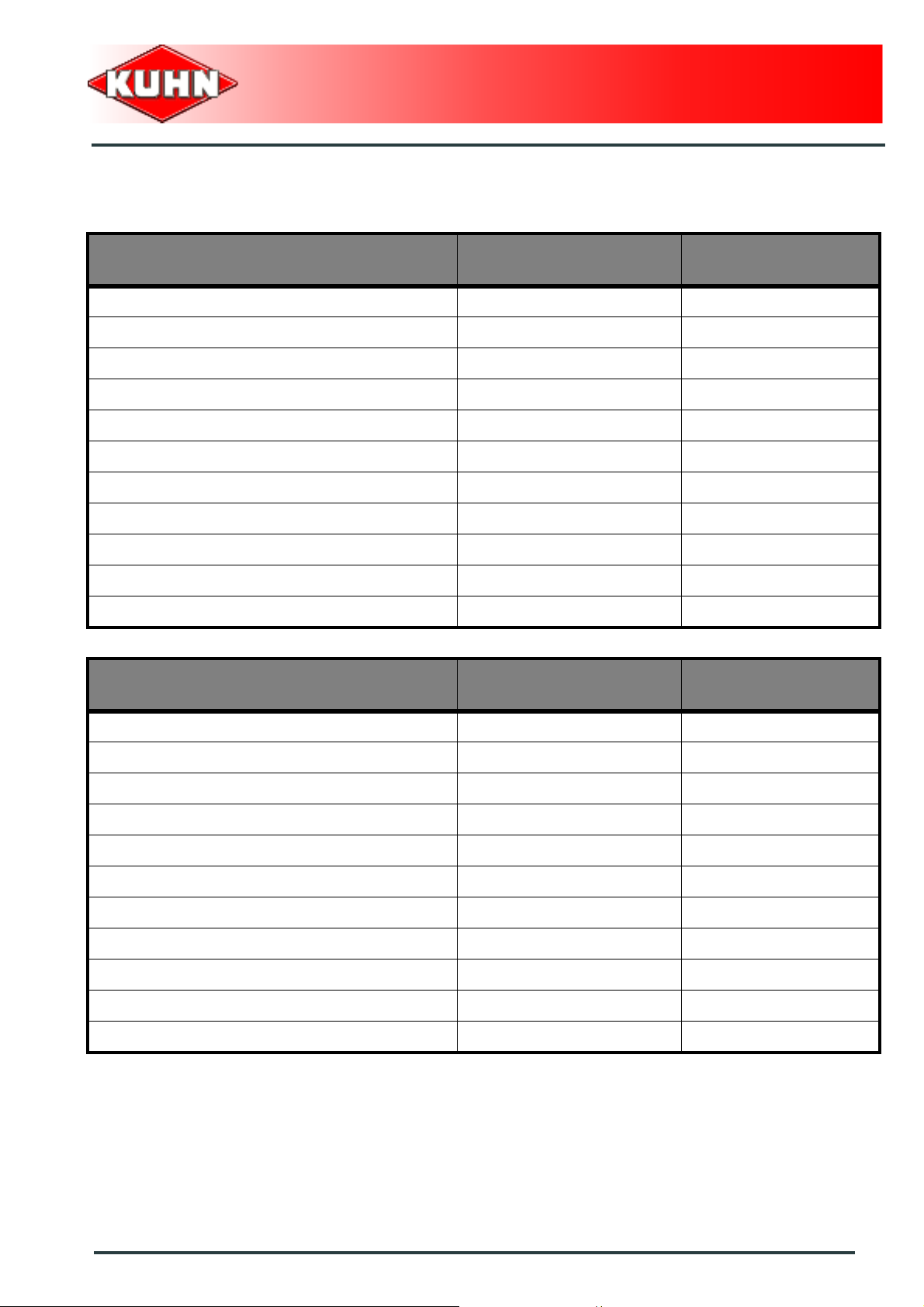

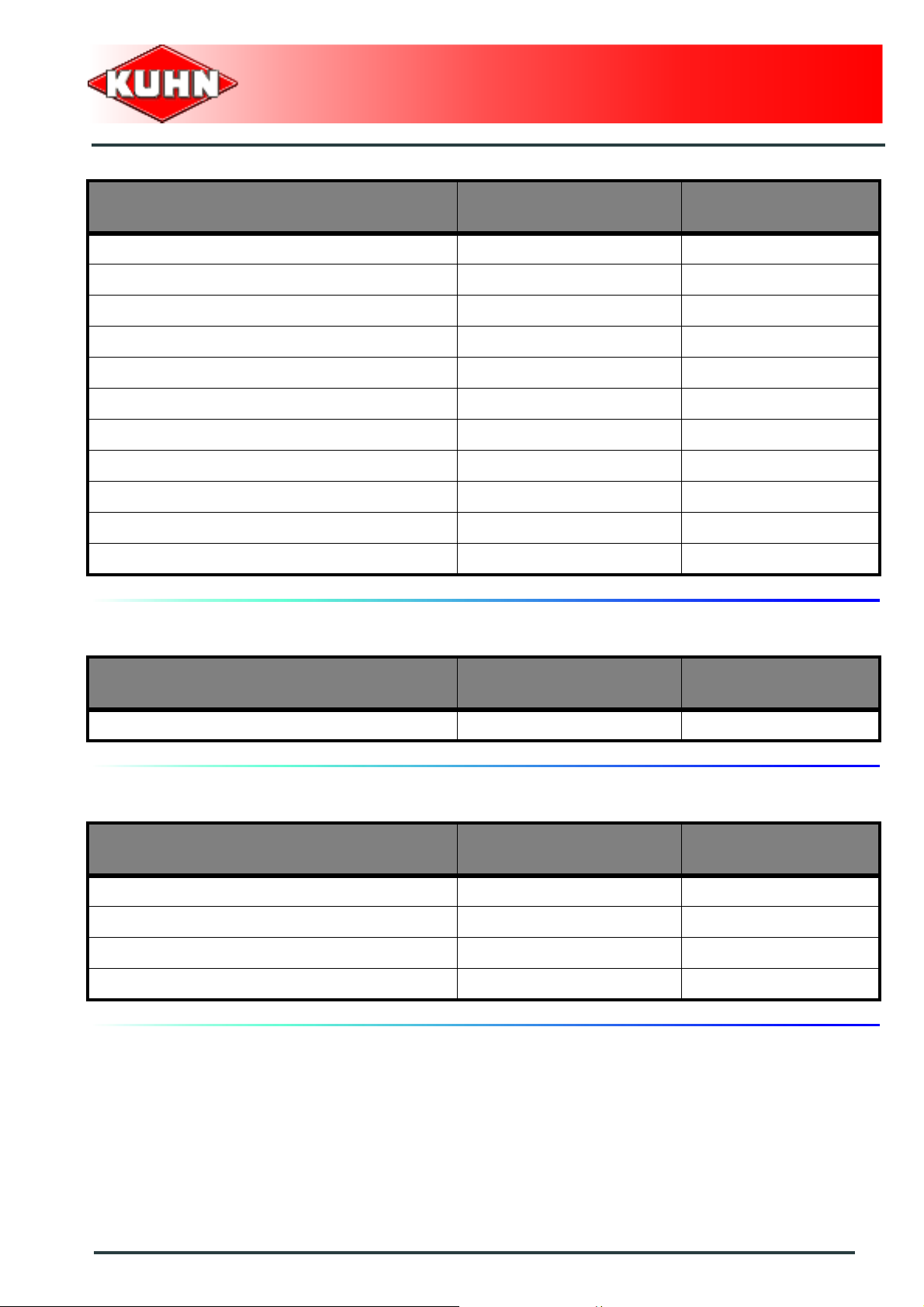

1. Configuration

Wheels

Wheel 1

Status No

Control box

RPB

$Appendix

Factory settings User settings

Wheel 2

Wheel 3

Wheel 4

Wheel 5

Type 9.5 x 48

Number of pulses 600

Status Yes

Type 12.4 x 46

Number of pulses 585

Status No

Type 11.2 x 48

Number of pulses 577

Status No

Type 11.2 x 54

Number of pulses 528

72

Status No

Type 13.6 x 38

Number of pulses 646

Appendix

Page 75

Booms

Boom 1

Control box

RPB

Factory settings User settings

Status No

Name Boom 1

Width 0.5 m (1’8’’)

Number of nozzles section 1 10

Number of nozzles section 2 11

Number of nozzles section 3 11

Number of nozzles section 4 10

Boom 2

Number of nozzles section 5 0

Number of nozzles section 6 0

Number of nozzles section 7 0

Factory settings User settings

Status No

Name Boom 2

Width 1.0 m (3’3’’)

Number of nozzles section 1 2

Number of nozzles section 2 0

Number of nozzles section 3 0

Number of nozzles section 4 0

Number of nozzles section 5 0

Number of nozzles section 6 0

Number of nozzles section 7 0

Appendix

73

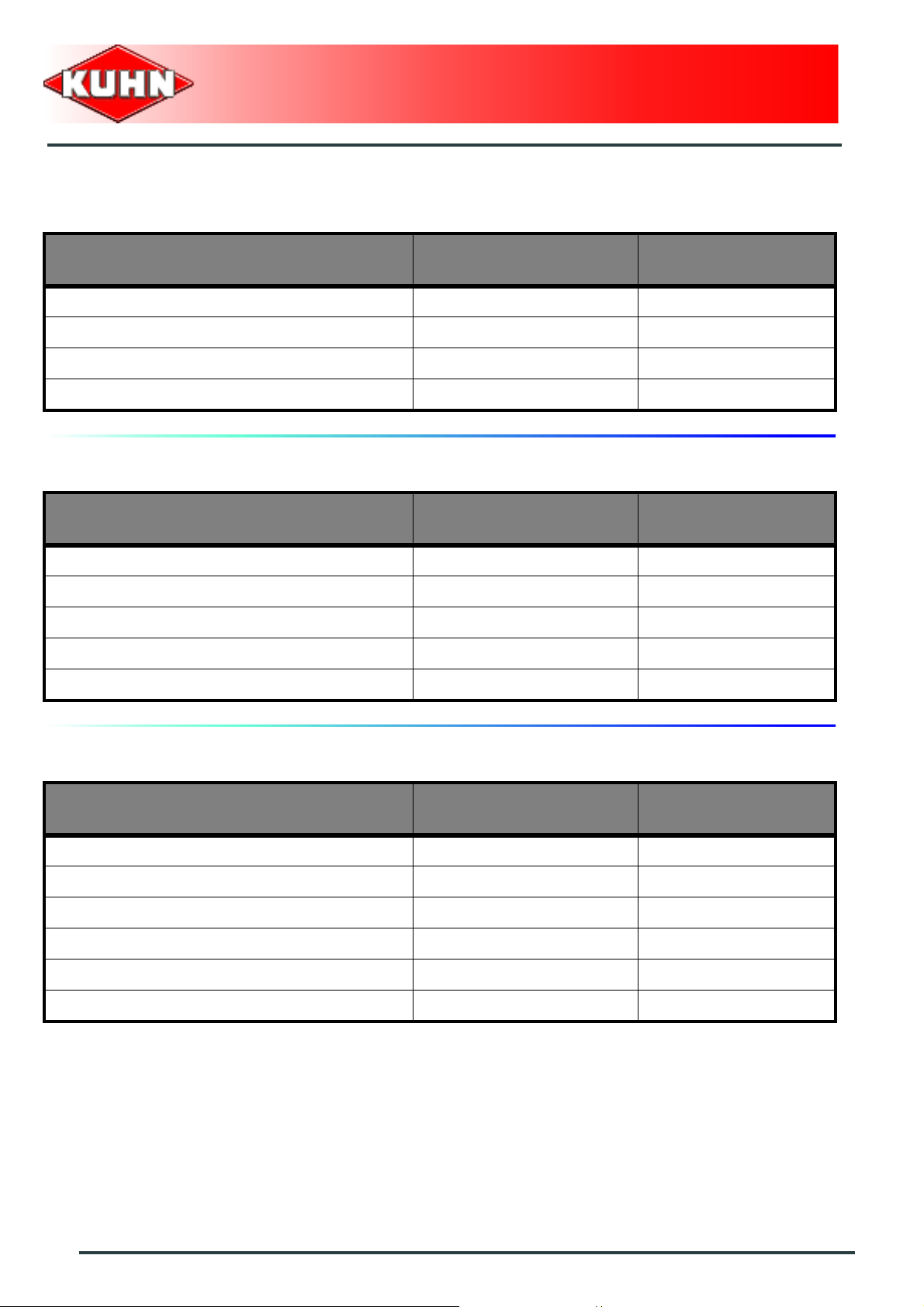

Page 76

Boom 3

Control box

RPB

Factory settings User settings

Status No

Name Boom 3

Width 1.0 m (3’3’’)

Number of nozzles section 1 1

Number of nozzles section 2 1

Number of nozzles section 3 0

Number of nozzles section 4 0

Number of nozzles section 5 0

Number of nozzles section 6 0

Boom 4

Number of nozzles section 7 0

Factory settings User settings

Status No

Name Boom 4

Width 2.0 m (6’7’’)

Number of nozzles section 1 2

Number of nozzles section 2 2

Number of nozzles section 3 0

Number of nozzles section 4 0

Number of nozzles section 5 0

Number of nozzles section 6 0

Number of nozzles section 7 0

74

Appendix

Page 77

Boom 5

Control box

RPB

Factory settings User settings

Status No

Name Boom 5

Width 5.0 m (16’5’’)

Number of nozzles section 1 3

Number of nozzles section 2 2

Number of nozzles section 3 2

Number of nozzles section 4 3

Number of nozzles section 5 0

Number of nozzles section 6 0

Number of nozzles section 7 0

Spraying flowmeter

Factory settings User settings

Number of pulses 680

Circulation

Factory settings User settings

2-way standard circulation (N2)

Status No

3-way standard circulation (N3)

Status No

Appendix

75

Page 78

Tank

Factory settings User settings

Capacity 1000 L (264 US gal)

Density

Nitrogen 1.30

Others 1.15

Regulation

Factory settings User settings

Control box

RPB

Pump coefficient 200

Regulation coefficient 20

Application rate adjustment 5%

Management of the minimum pressure No

Valve opening time 9 s

Nozzles

Factory settings User settings

Nozzle 1

Status Yes

Name Orange

-1

Flow to 3 bar (43.5 psi) 0.4 L/min

Maximum pressure 7 bar (102 psi)

MINIMUM operating pressure 1.5 bar (22 psi)

(0.11 US gal/min-1)

76

Appendix

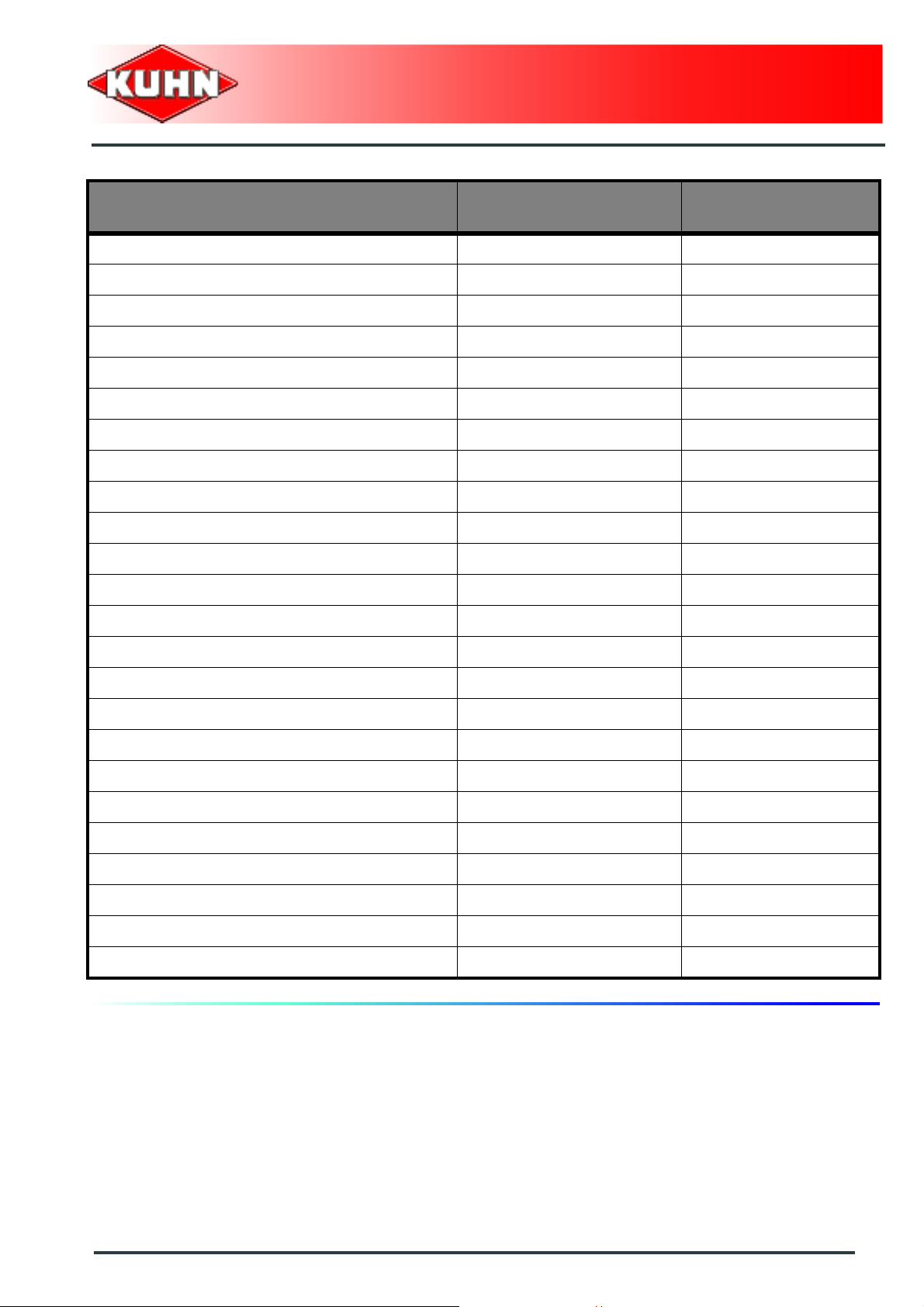

Page 79

Nozzle 2

Nozzle 3

Factory settings User settings

Status No

Name Green

Flow to 3 bar (43.5 psi) 0.6 L/min

Maximum pressure 7 bar (102 psi)

MINIMUM operating pressure 1.5 bar (22 psi)

Status No

Name Yellow

Flow to 3 bar (43.5 psi) 0.8 L/min

-1

(0.16 US gal/min-1)

-1

(0.21 US gal/min-1)

Control box

RPB

Nozzle 4

Nozzle 5

Maximum pressure 7 bar (102 psi)

MINIMUM operating pressure 1.5 bar (22 psi)

Status No

Name Lilac

Flow to 3 bar (43.5 psi) 1 L/min

-1

(0.26 US gal/min-1)

Maximum pressure 7 bar (102 psi)

MINIMUM operating pressure 1.5 bar (22 psi)

Status No

Name Blue

Flow to 3 bar (43.5 psi) 1.2 L/min

-1

(0.32 US gal/min-1)

Maximum pressure 7 bar (102 psi)

MINIMUM operating pressure 1.5 bar (22 psi)

Appendix

77

Page 80

Pressure sensor

Factory settings User settings

Status No

Pressure display

Factory settings User settings

Status No

Control box

RPB

Hydraulic functions

Factory settings User settings

Status No

78

Appendix

Page 81

Alarms

Flow alarm

Status Beep

Trip 5 s

Pressure alarm

Status Beep

Trip 5 s

Tank low level prewarning alarm

Status Beep

Control box

RPB

Factory settings User settings

Trip 0 L (0 US gal)

Tank low level alarm

Status Beep

Trip 0 L (0 US gal)

Optional equipment

Working headlights

Status No

Flashing light

Status No

Factory settings User settings

Appendix

79

Page 82

$Limited warranty

Control box

RPB

80

Limited warranty

Page 83

Control box

RPB

Limited warranty

81

Page 84

Loading...

Loading...