Page 1

Complementary instructions

RC007BGB B

Control box

Software version: 3.70

Quantron S

RC007BGB B

- English - 11-2009

Page 2

Page 3

Control box

Quantron S

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand this manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts are manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The Quantron S control box is exclusively designed for monitoring the application rate of Kuhn seed drills. Any

use outside this application is not permitted.

The intended use of the machine includes following all operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment and accessories, as recommended

by the manufacturer.

The control box must only be operated, maintained and repaired by qualified persons who are familiar with the

machine's specifications and operation as well as safety regulations and procedures for preventing accidents.

The user must conform with the safety regulations given in this manual and the warnings located on the

machine. He must also respect general rules in terms of accident prevention, occupational medicine and road

regulations.

The manufacturer is not held liable for any damage or accidents resulting from control box modifications carried

out by the operator himself or any third party.

Dear Owner

1

Page 4

Control box

Quantron S

$Contents

Dear Owner .....................................................................................................................1

Contents..........................................................................................................................2

Control box identification..............................................................................................5

Front view..........................................................................................................................................5

Manufacturers' marking...................................................................................................................6

Safety...............................................................................................................................7

Description of symbols used in this document.............................................................................7

Safety instructions ...........................................................................................................................8

General description......................................................................................................10

Description......................................................................................................................................10

Technical specifications ................................................................................................................ 11

Description of control elements....................................................................................................12

Menu structure................................................................................................................................ 14

Assembly and fitting ....................................................................................................15

Tractor requirements......................................................................................................................15

Electrical connection .....................................................................................................................15

Control box connection .................................................................................................................16

Putting into service ......................................................................................................17

Switches on the control box..........................................................................................................17

2

Access and menu navigation........................................................................................................18

Basic adjustments..........................................................................................................................19

Contents

Page 5

Control box

Quantron S

Machine use ................................................................................................................. 24

Adjustments before first use......................................................................................................... 24

Calibration of forward speed......................................................................................................... 25

Preliminary adjustments at work ..................................................................................................27

Stationary calibration test ............................................................................................................. 31

Modification of the parameters .....................................................................................................37

Flow test with regards to an area .................................................................................................39

Sowing a seed already stored.......................................................................................................41

Deleting a seed............................................................................................................................... 42

Functioning during work............................................................................................. 43

Distribution stop/start.................................................................................................................... 43

Hydraulic valve bank...................................................................................................................... 46

Tramlining rhythm adjustment...................................................................................................... 47

Operating data ................................................................................................................................ 48

Variation of the seed rate............................................................................................................... 50

Daily counters................................................................................................................................. 51

System/Test.................................................................................................................. 52

Sensor check.................................................................................................................................. 52

Alarm configuration ....................................................................................................................... 54

Service: Machine configuration ................................................................................. 55

Service ............................................................................................................................................ 55

Machine options............................................................................................................................. 56

Contents

3

Page 6

Control box

Quantron S

Alarm messages...........................................................................................................58

Alarm signification .........................................................................................................................58

Deleting a breakdown or an alarm ................................................................................................60

Trouble shooting guide................................................................................................61

Maintenance and storage ............................................................................................63

Connecting diagrams...................................................................................................64

Limited warranty...........................................................................................................69

4

Contents

Page 7

1. Front view

Control box

Quantron S

$Control box identification

Control box identification

5

Page 8

2. Manufacturers' marking

Please write below the type and serial number of the

machine.

This information is to be indicated to the dealer for all

spare parts orders.

Type: QUANTRON S

Serial no.:

Software version:

Control box

Quantron S

6

Control box identification

Page 9

$Safety

1. Description of symbols used in this

document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Control box

Quantron S

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

Safety

7

Page 10

Control box

Quantron S

2. Safety instructions

Introduction

The operator must follow the safety instructions in this manual and in the machine's operator's manual as well

as respect the warnings posted on the machine.

Any use other than the designated operation is at the risk and responsibility of the operator.

The manufacturer is not held liable for any damage or accident resulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

8

Safety

Page 11

Read and follow the safety instructions

Before using the control box, carefully read all safety

instructions in this manual. The operator must be familiar

with all machine controls and their respective functions.

It is too late to learn once work has been started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to take before using the

control box

Place the control box so that it cannot interfere with other

tractor controls and be activated inadvertently.

Before switching the control box on, check that nobody

is within the machine pivoting area: switching on the

control box can activate functions on the machine.

Control box

Quantron S

Precautions to take when using the control

box

Do not operate the control box while a person is carrying

out work on the machine.

Switch off control box before carrying out any

maintenance or repair work on the machine.

Precautions when driving

Before transporting the machine on public roads, make

sure no function of the control box or of the control

accessories can be switched on inadvertently.

Safety

9

Page 12

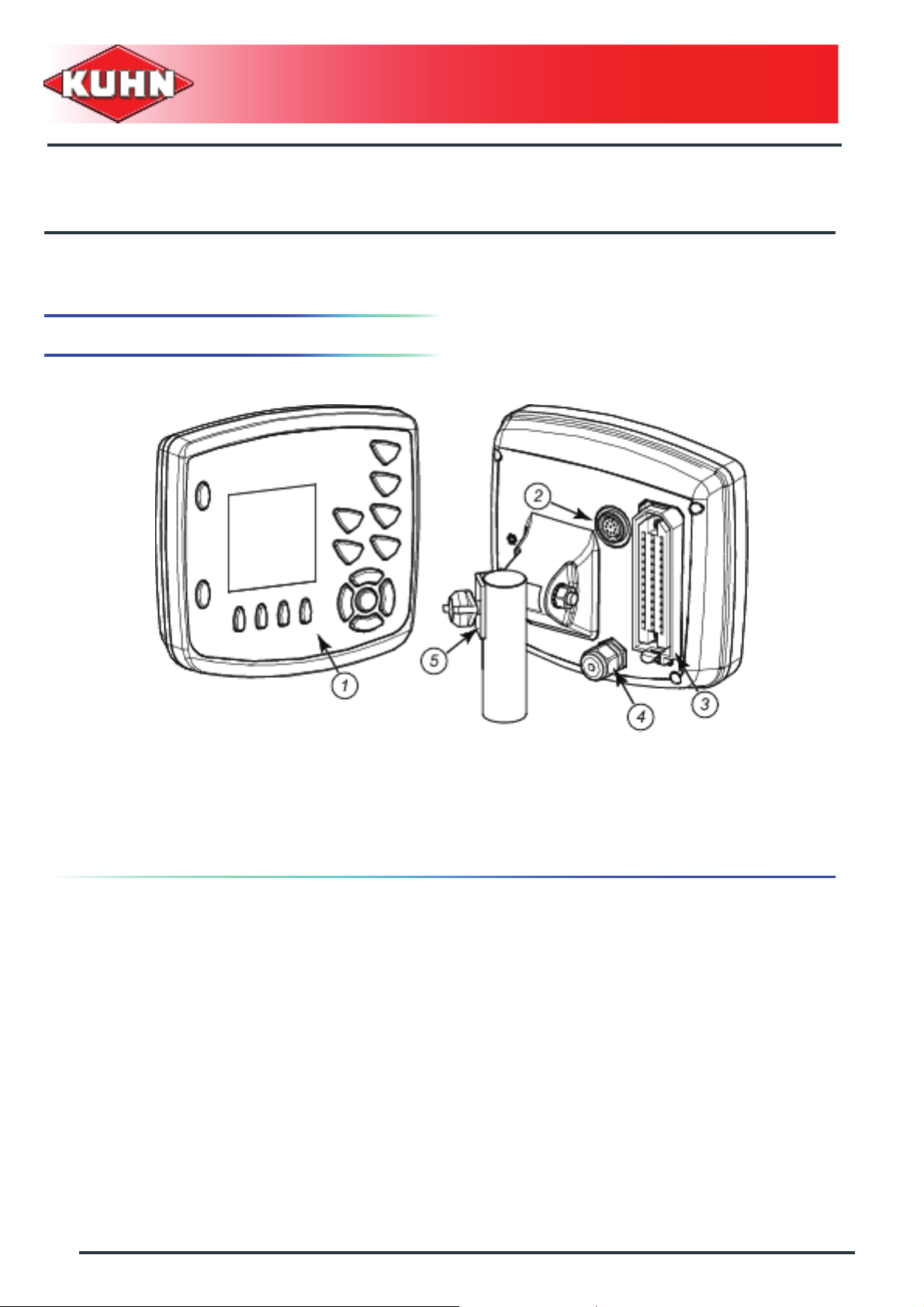

1. Description

0

Control box

Quantron S

$General description

1 : Area of use

2 : Connection pin for data transfer

3 : 39-pin connector: machine wiring harness connection

4 : Power circuit

5 : Holder: 2 x M8

10

General description

Page 13

2. Technical specifications

Operating temperature from -10°C to +60°C

Storage temperature up to +85 °C

Voltage input 12V, range from 10 V to 16 V

Shockproof plastic box, IP65 protection

classification

Screen 160x 160 pixels

CE certification

Control box

Quantron S

22 mm tube holder

Buzzer

Voltage

Maximum intensity

Sound level

Sound frequency

12 V

standby: 250 mA, in service: 15 A

120 dB

from 1.5 to 4 kHz

General description

11

Page 14

3. Description of control elements

Control box

Quantron S

0

1 : Distribution stop/start 2 : Delete / rollback

3 : Switch between the display of the application

rate and the display of the hydraulic valve bank

4 : Rollback to the tramlining counter

position

functions

5 : Access to the general menu 6 : ESC key

7 : Navigating keys with confirmation key 8 : F1 to F4 function keys

9 : Daily counters 10 : Display

11 : On/Off switch 0

When used in MANUAL mode, key Start/Stop is

not operational.

12

General description

Page 15

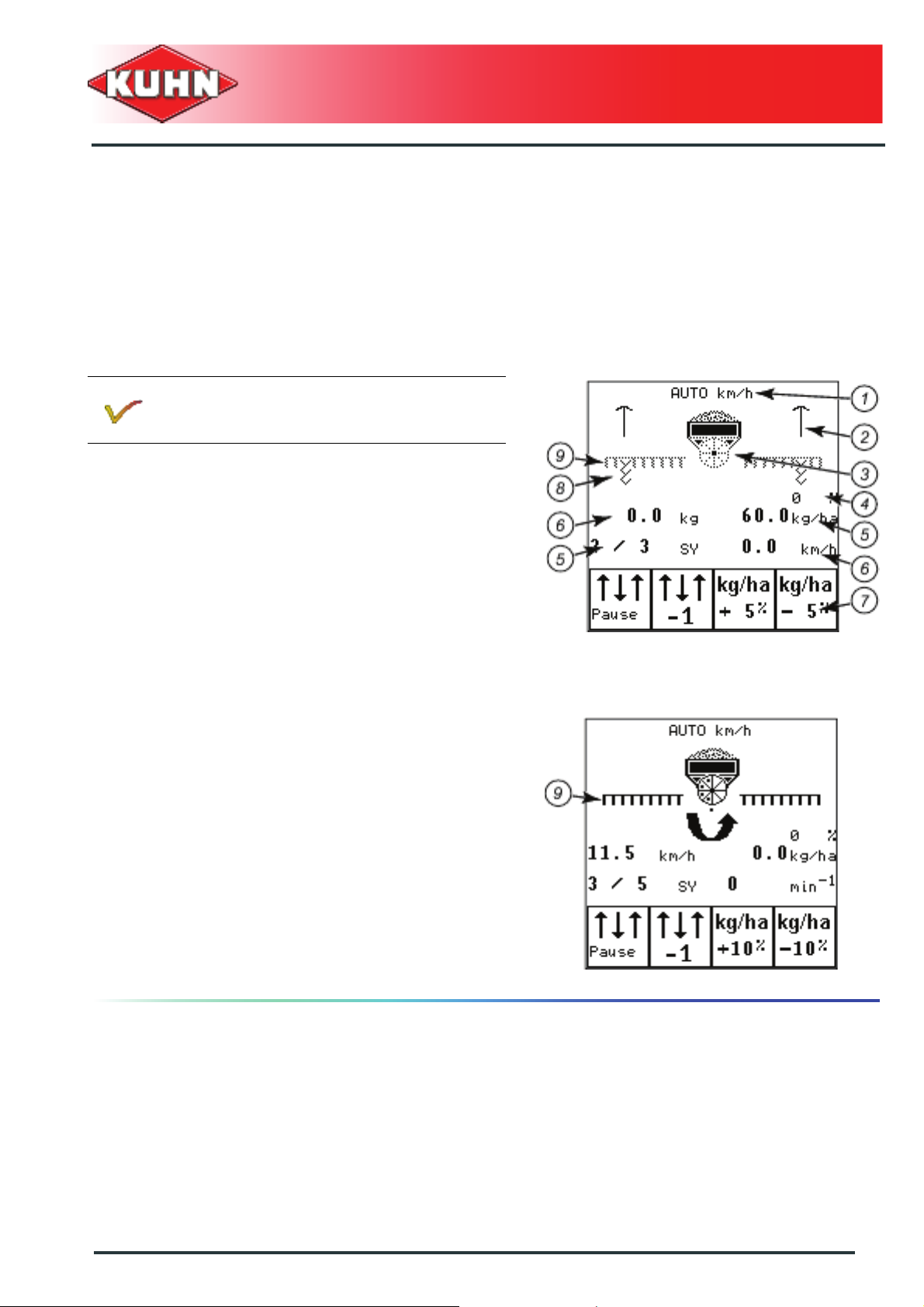

Display

The screen displays information relative to the current

machine status, with the possibility to select of modify

the values.

The main information relative to the machine's use are

displayed during work.

Description of screen zones

The precise definition of the work screen

varies according to the currently set

adjustments.

Meaning of symbols:

- Mode selection (1): Definition of the work mode used.

• AUTO km/h uses the speed signal of the radar or

the wheel impulse sensor.

• Man Km/h: Using the manual mode

The manual working mode can be used for ex. if the

speed sensor is faulty.

- Markers (2)

- Metering unit and hopper (3)

- Application rate adjustment (4)

- Screen areas that can be parameterized at will (6)

- The 2 other zones (5) always display the tramlining

rhythm and the seed application rate.

- Function area (7): the symbols displayed depend on

the machine configuration

• Access to these functions by selecting the function

placed below

- The tramlining (8): The paths for tramlining are being

made.

- Coulter bar (9):

• The work screen shows the coulter bar in a dotted

line. This symbol indicates that the coulter bar is

lowered but not sowing.

• The work screen shows the coulter bar in bold. The

coulter bar is in working position and sowing.

• The coulter bar does not appear on the screen. The

coulter bar is raised.

Control box

Quantron S

General description

13

Page 16

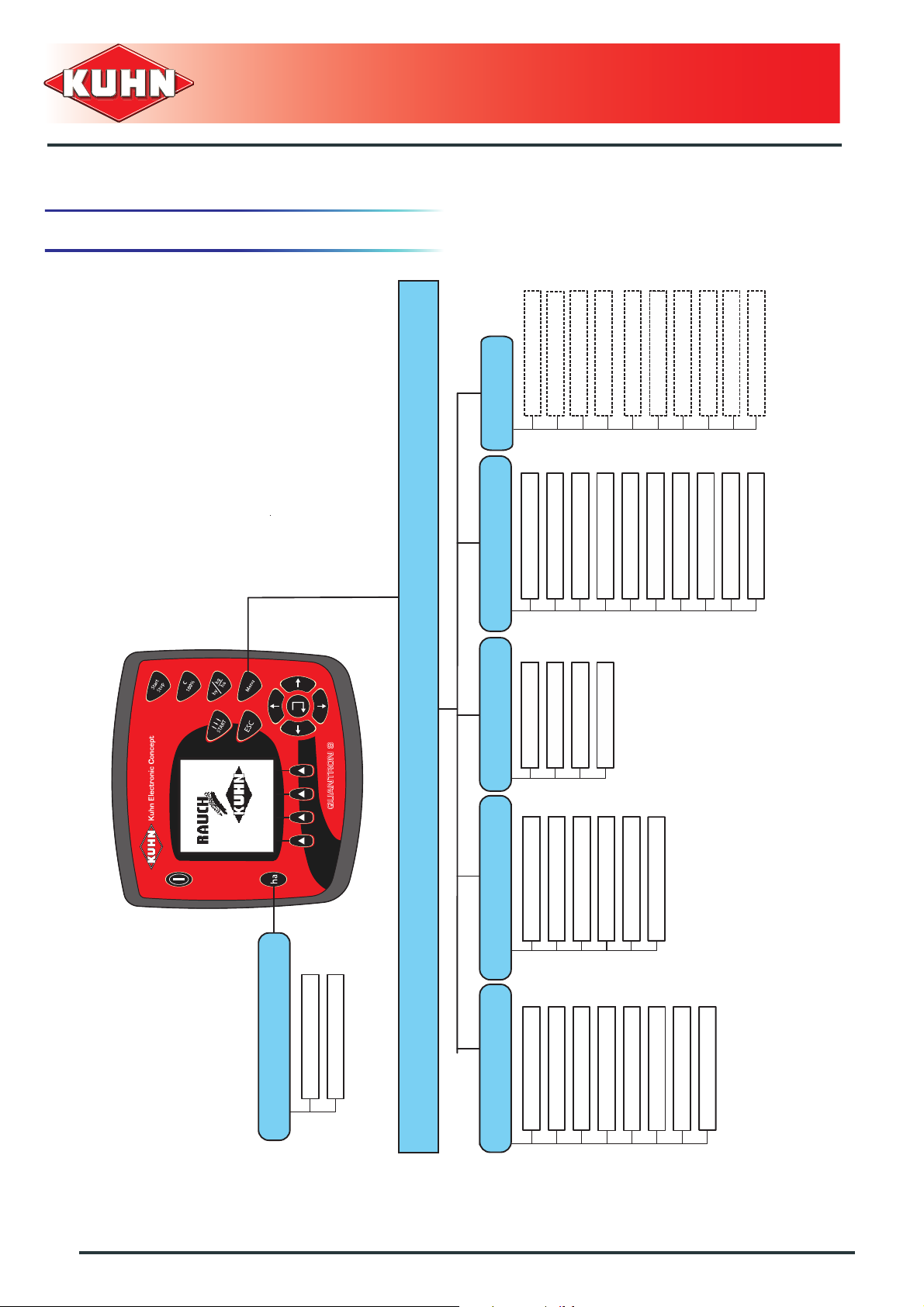

4. Menu structure

Control box

Quantron S

Main menu

Info

Low level sensor

Mach. width (m)

Languages

Choose new file Brightness / Contrast

Create new file

Hydraul. Block

DOSING mode

Tramlining actuat.

Test / Diagnosis

Display configurat.

Delete file

Delete all files

Signal tramlin.

Date

Time

Traml. width

Calibration flap

Data transmission

Total data counter

Alarm configuration

Imp./100 m.

Service

Alarm configuration

14

General description

Trip counter

Area test

Delete trip counter

Seed settings Hopper configuration Field data System / Test

Tramline rythm

Blower speed

Seed list factor

Tramlining

Seed list privat

Seed name

+/- appl. Rate (%)

Working mode

Machine (km/h)

Appl. (kg/ha)

Workingsp. (km/h)

Fine seed slide

Calibration start

Opening (mm)

Page 17

$Assembly and fitting

1. Tractor requirements

Before connecting the control box, make sure the tractor

complies with these conditions:

- Minimum voltage: 12 V: must be ensured even if

several systems are in service (Air conditioning,

Lighting).

Control box

Quantron S

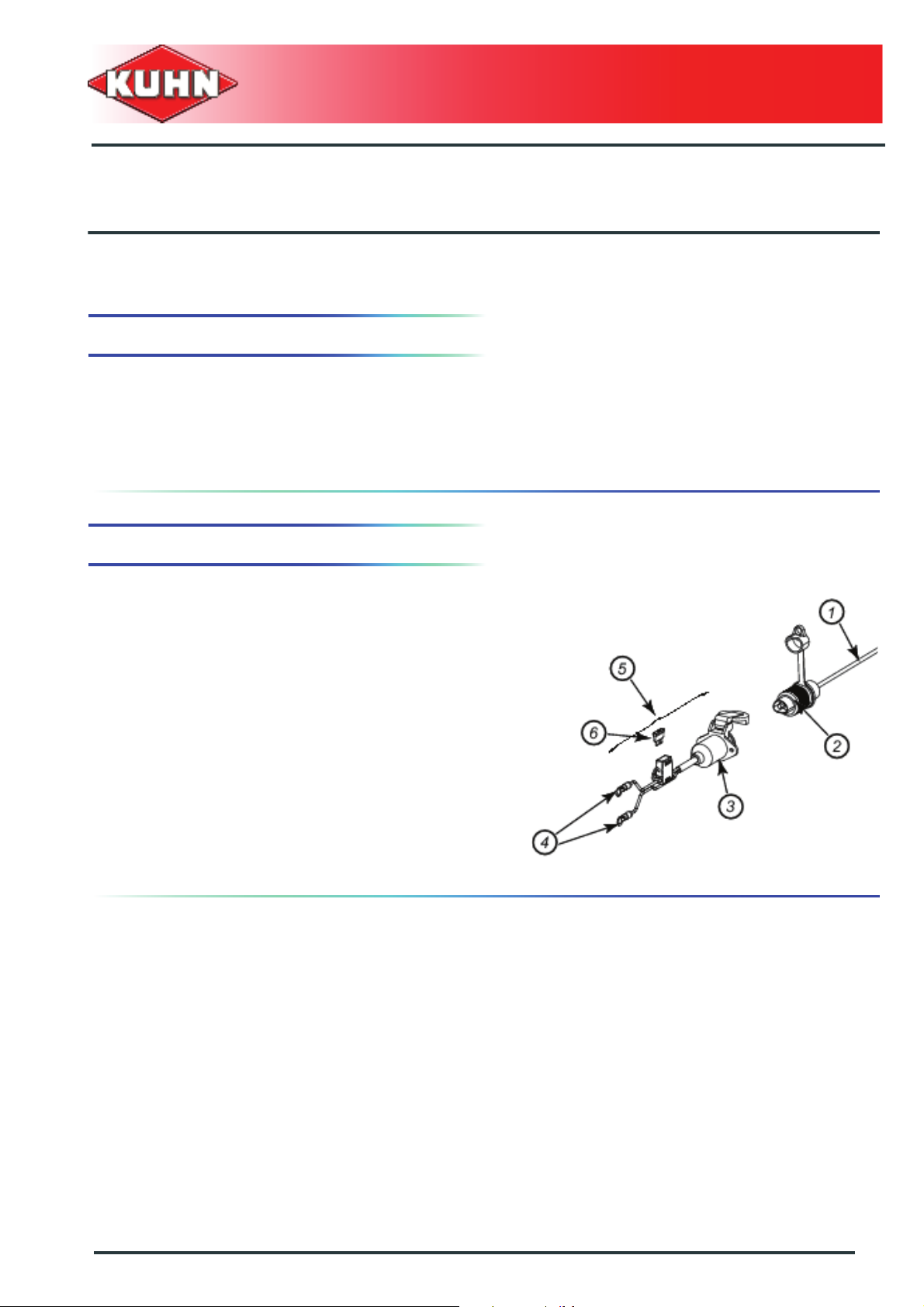

2. Electrical connection

The control box kit comprises:

- A wiring harness (1) pre-assembled on the box with a

male connector (2).

Electrical power supply

An electric power supply cable for another tractor can be

ordered under code 83233002.

The cable is connected by the Kuhn dealer to the plus

lugs (brown) and the tractor battery earth (blue).

For a regular and constant electricity supply for the

machines' controls, connect the electricity power cable

directly to the battery.

Assembly and fitting

15

Page 18

On tractor's fitted as standard with a 3-pin

plug, check the wire polarity to avoid causing

damage to the control box

- Make sure to avoid friction or crushing areas when

installing the power cable.

Control box power supply is from the tractor 3-pin

auxiliary power supply.

3. Control box connection

Carry out following tasks in the given order:

- Fit the control box in a position where the driver can

see it in the tractor cab.

- Connect the machines' 39-pin cable.

- Connect the control box to the power supply (See

chapter Electrical power supply).

Control box

Quantron S

The Quantron S control box is factory set for

the machine supplied.

Only connect the supplied control box to the

concerned machine.

16

Assembly and fitting

Page 19

$Putting into service

1. Switches on the control box

Preconditions:

- The control box is properly connected to the tractor.

- Minimum voltage: 12 V

- Press Quantron S control box Start/Stop button (1).

- The start screen appears after a few seconds.

- A start menu is displayed during a few seconds.

- Then the work screen appears.

Control box

Quantron S

Putting into service

17

Page 20

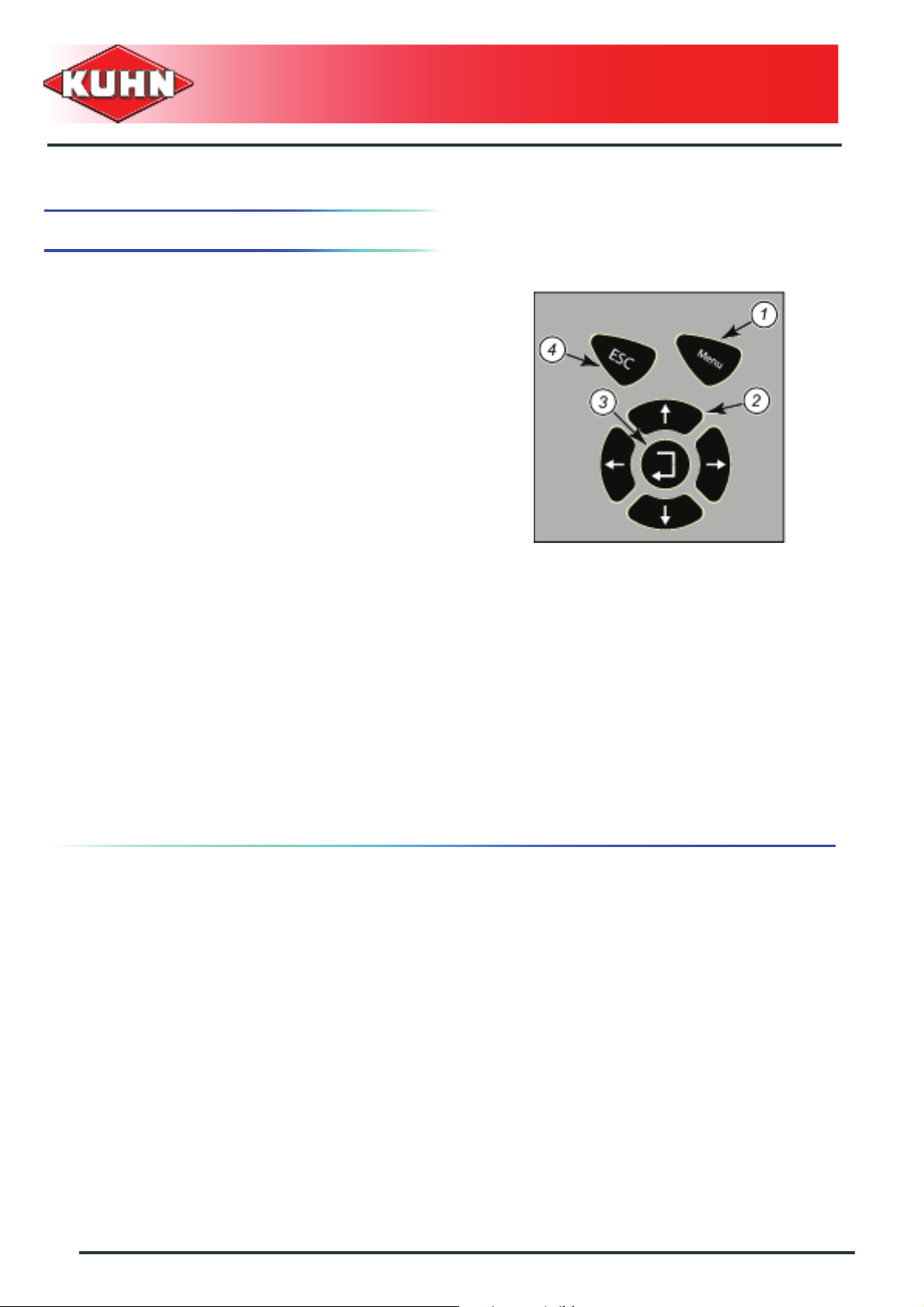

2. Access and menu navigation

MENU key (1)

- From the work screen, is used to access the menu

(see menu tree structure).

- From the menu, is used to return directly to the work

screen.

Warning: a value which was being changed will not be

recorded.

Displays current operations (2)

- "Up" or "+" key

• Used to select the previous line in the menu

• Used to increase a value being changed

- "Down" or "-" key

• Used to select the next line in the menu

• Used to decrease a value being changed

Control box

Quantron S

ENTER key (3)

• Used to select a submenu

• Used to record a modified value and return to the

previous screen

ESC key (4)

- Used to return to the previous screen

Warning: a value which was being changed will not be

recorded.

18

Putting into service

Page 21

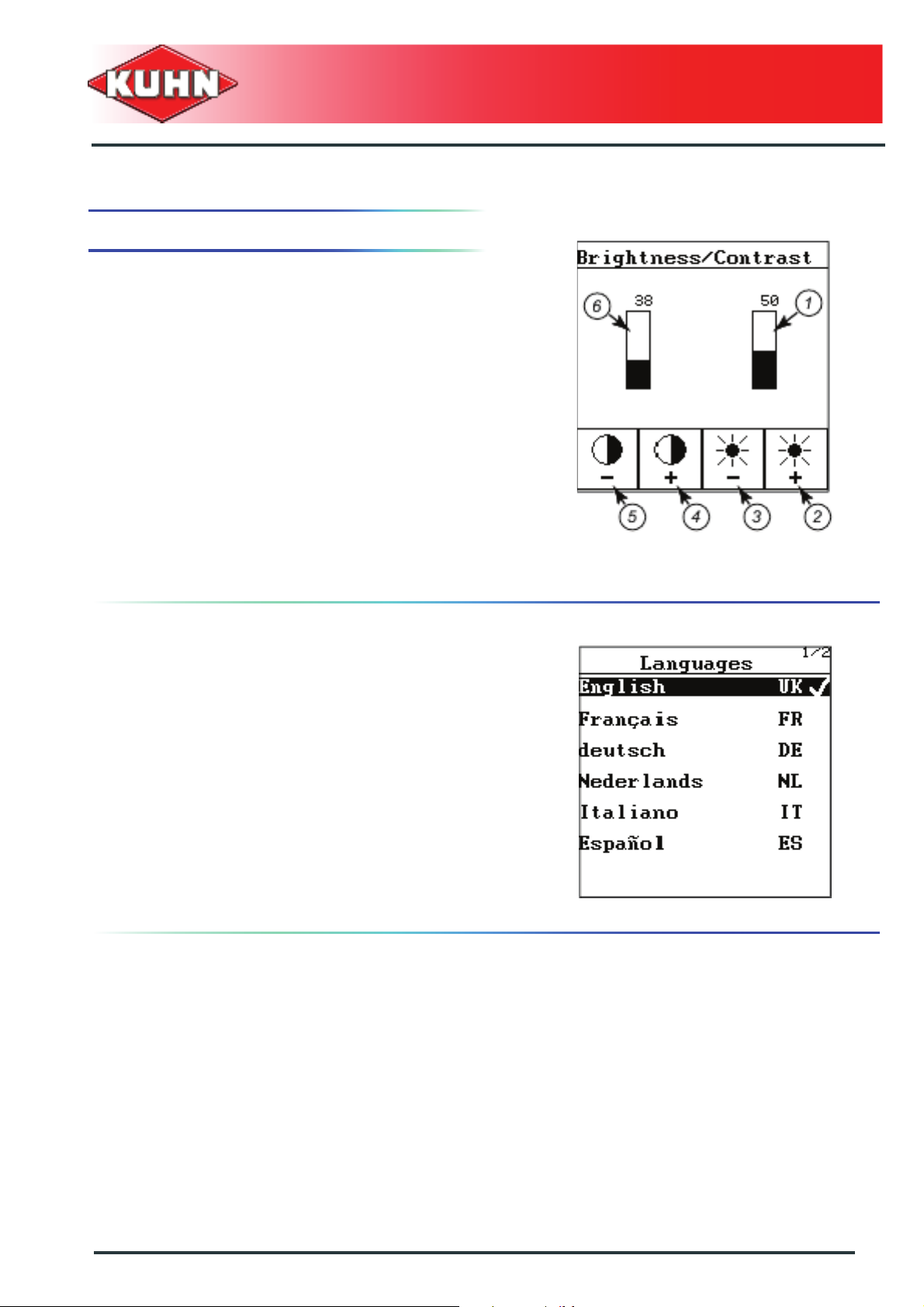

3. Basic adjustments

Basic adjustments are set in the "System/Test" menu.

Brightness/Contrast

- Press on the button «F3 (-)» (3), to reduce the

brightness (1).

- Press on the button «F4 (+)» (2), to increase the

brightness (1).

- Press on the button «F1 (-)» (5) to reduce contrast (6).

- Press on the button «F2 (+)» (4) to increase

contrast (6).

Control box

Quantron S

Language

There are 12 different languages available to navigate in

the control box menus.

- Select the "Language" submenu.

Page 1 out of two appears on the screen.

The other languages are listed on page 2/2.

- Move downwards using the arrow key until page 2/2

appears.

- Choose country language.

- Confirm your choice by pressing Enter key.

The control box comes ON again. The menus are

displayed in the new language.

Putting into service

19

Page 22

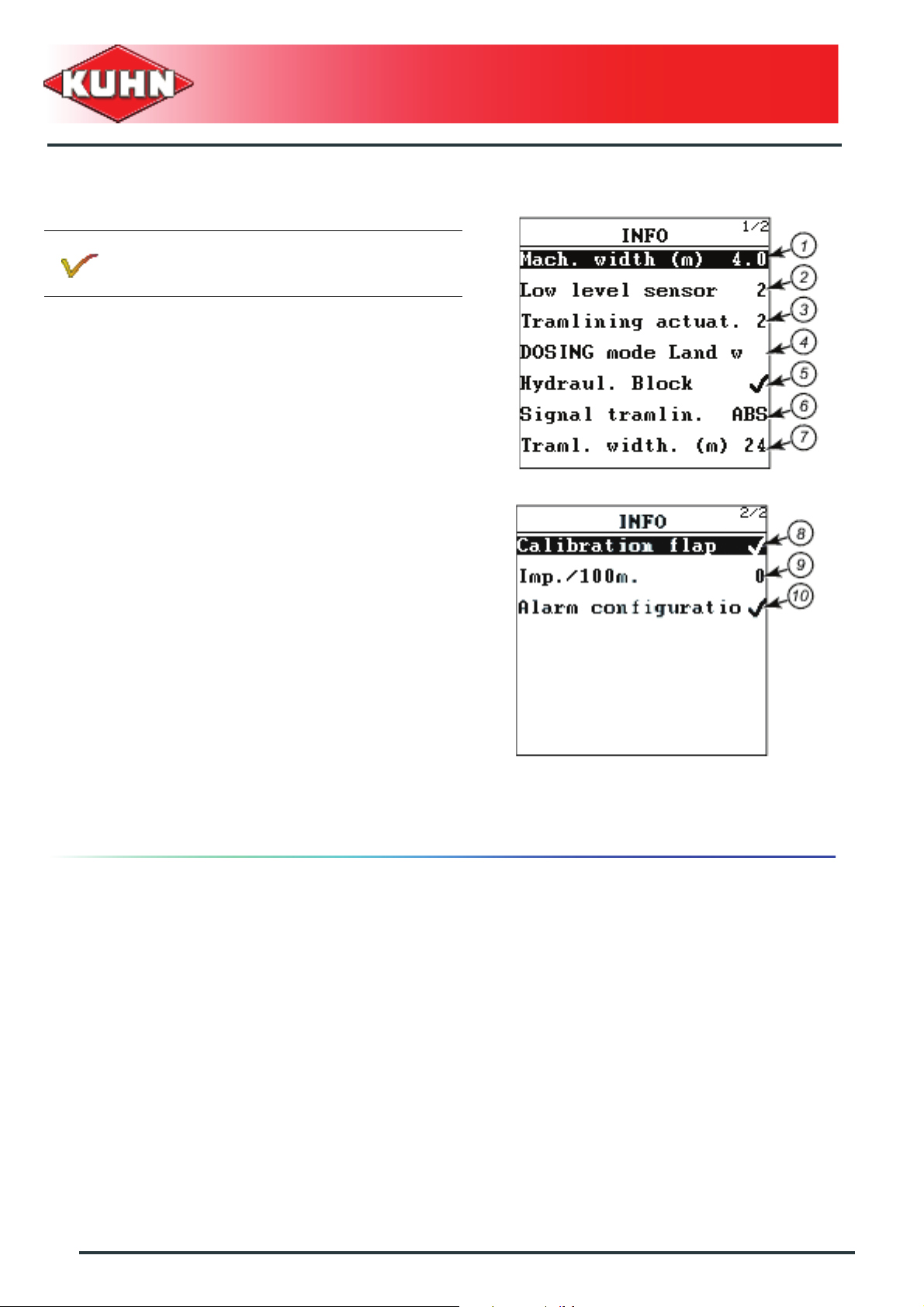

Info

This menu is only used for information purposes.

The menu shows how the machine is equipped.

- 1: Width of seed drill (m)

- 2: Number of low level sensors mounted (1 or 2)

- 3: 2 Cylinder for tramlining: The machine is fitted with

a second cylinder for tramlining.

• Symmetrical and asymmetrical rythms are possible.

- 4: Metering unit drive:

• Electrical drive

• Hydraulic drive

• Mecanical drive through a skeleton wheel

A check mark at the end of the line indicates that this

option is mounted.

- 5: Hydraulic valve bank: The control box is connected

to the hydraulic valve bank.

- 6: Signal for tramlining:

• ABS: The sensor on the chassis or on the coulter

bar counts the impulses for the tramlining counting

• SPR: The side marker sensor controls the tramlining

counting

- 7: The tramlining (m): Treatment width

- 8: Metering unit hatch sensor

- 9: Programmed impulses per 100 m length

(Calibration of forward speed)

- 10: Alarm configuration: A check mark on each line

end means that all alarms are ON.

Control box

Quantron S

20

Putting into service

Page 23

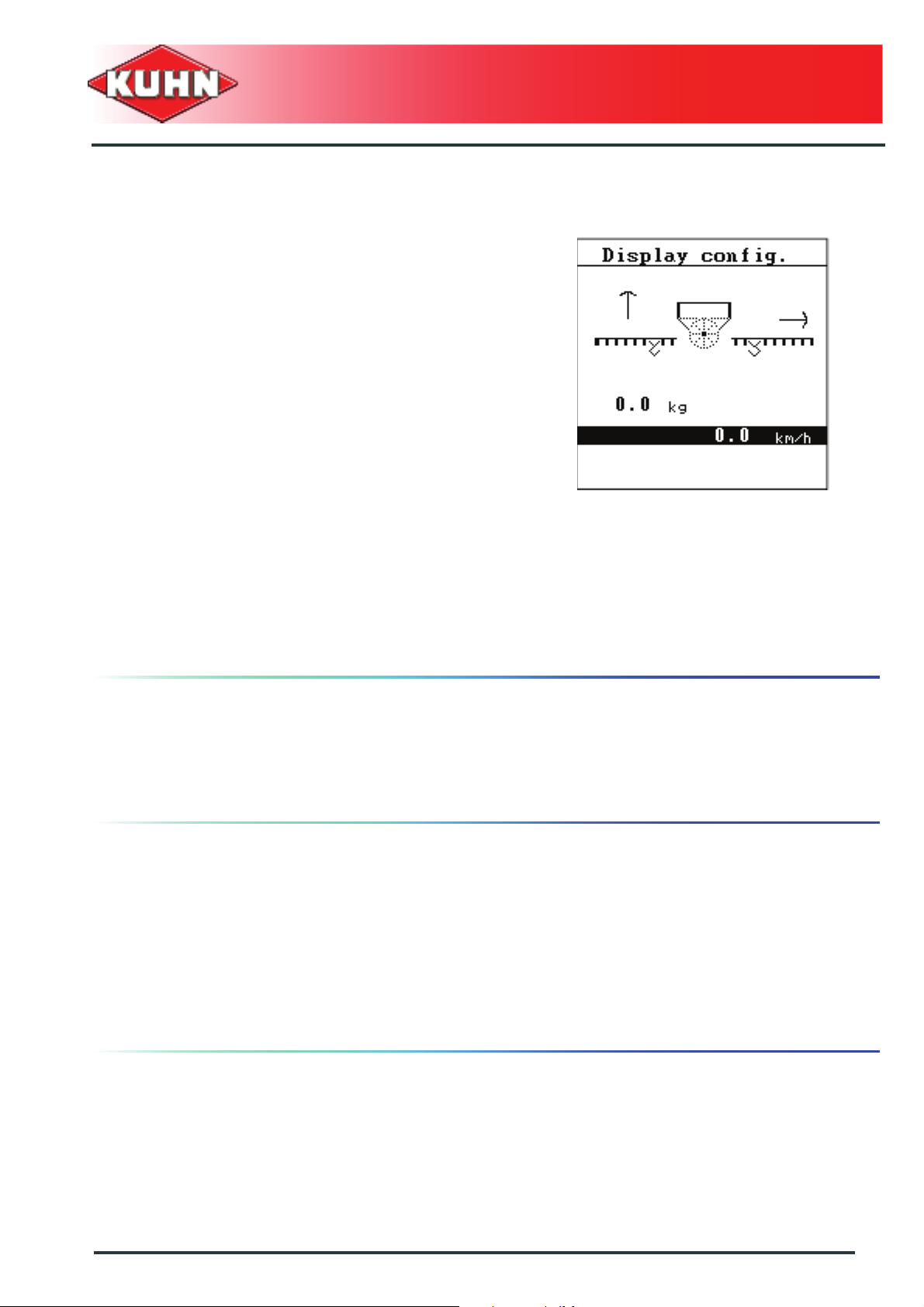

Display configuration

The screen has 2 free display areas. Following values

can be displayed:

- Working speed (Km/h)

- Blower speed

- Metering unit "opening position"

-Time

-Area

- Quantity sown "kg trip"

- Distance covered "m-trip"

- Metering unit rotation speed (min-1)

- As from the "System - Test" menu, select the "display

config" submenu.

- Select the screen area to modify.

- Validate using Enter key.

The list with the functions available appears on the

screen.

- Select the required function that will have to appear.

- Confirm your choice by pressing Enter key.

The screen will now display the required function.

Control box

Quantron S

Date/Time

The date and time are factory set.

If necessary, these parameters can be modified in the

"System - Test" menu.

Field data

This menu, accessible under "System - Test", displays

the following data:

- Quantity sown (independently from the seed variety)

- Area sown (2)

- Number of work hours

- Surface covered

Data displayed cannot be modified or deleted.

Putting into service

21

Page 24

Specific functions

Text entry (Example: seed name)

Some menus enable creating a name.

0

Control box

Quantron S

1 : Entry area 2 : Fully deleting a name

3 : Keys for navigating in the letter area 4 : Key for confirming the letter entry

5 : Function key (OK) for confirming the selected

name and return to the previous menu

6 : Navigation keys in the name entry

area

7 : Area with letters available for printing (depends

on the language)

22

Putting into service

Page 25

Modifying a letter:

- Select the letter in area (1) and position the cursor

using keys (6).

- Using arrow keys (3), move the cursor on the letter

selected in the letter area (7).

- Press Enter key.

The selected letter is positioned in the name creation

area. The cursor moves to the right of one space.

- Repeat procedure until name is completed.

- Press on function OK (5).

The text is memorized in the control box. The screen

displays the previous menu.

Replacing a letter:

An isolated letter can be replaced by another. Deleting

an isolated letter is not possible.

Fully deleting a name:

- Press on the button C/100%.

- Press on function OK.

Control box

Quantron S

Entering values using the arrow keys

Certain menus enable entering numerical values

(Example: Volume).

To move cursor (1), use right and left arrow keys.

Enter the required digit using the vertical arrows:

- Upward arrow: Increasing the selected value.

- Downward arrow: Reducing the value selected.

- Confirm entry by pressing Enter key.

Software updating

Software updating can only be performed by

authorized persons.

Putting into service

23

Page 26

$Machine use

1. Adjustments before first use

Read the operators' manual before using the

machine.

- Make sure that all requested options are set on the

machine.

Proceed with the various pre-controls and adjustments

indicated in the operators' manual.

- Couple the machine to the tractor.

- Check if the electrical power cable of the control box

is connected.

- Check the connection between the machine 39-pin

wiring harness and the control box.

- Switch on the control box.

Control box

Quantron S

- Starting from the "main menu", select "hopper

configuration".

- Select the "Machine km/h" submenu.

- Check machine name.

24

Machine use

Page 27

2. Calibration of forward speed

Factors such as spinning or soil condition can influence

the forward speed measuring and consequently the

application rate.

- Calibrate the speed sensor for 100m to take sowing

conditions into account.

The speed sensor calibration is based on the count of

the sensor impulses over a distance of 100 m.

- Starting from the "main menu", select "hopper

configuration".

- Select the "Machine km/h" submenu.

The speed signal can come from the tractor, the radar

sensor or a wheel sensor.

- Select the speed source:

• F2 (4): Tractor radar

Connect the speed plug wiring harness on one end to the

7-pin plug on the rear of the control box and the other to

the tractor 8-pin plug (DIN9684-1,ISO11786).

Part no. 2056323

• F1 (5): Drill radar or Wheel mounted impulse sensor

When driven mechanically, the travel speed is

indicated by the metering unit sensor.

- Press on function F1 (5).

Control box

Quantron S

Do NOT press F2 (4) if the metering unit is

mechanically driven.

Machine use

25

Page 28

If the number of impulses is known, it can be entered

by hand.

- Select the "Machine km/h" submenu.

- select Imp/100m (2).

- Press Enter key.

- Enter the number of impulses. See chapter Entering

values using the arrow keys.

• Average value for VENTA NC 3000/4000 (Wheel

diameter 400 mm): 970 Imp/100 m

• Average value for MEGANT: 1000 Imp/100 m

• Average value for MODULINER and Radar:

900 Imp/100 m

• Average value for the front hopper; For machines

with serial number as from 11612:

13260 Imp/100 m

- Press Enter key.

If the number of impulses is unknown, proceed with

calibration.

Control box

Quantron S

The calibration must be carried out in the field.

Reference trip: 100 m

- Select the "Machine km/h" submenu.

- Press on function F4 (Auto).

The calibration screen appears.

At the beginning of the reference trip:

- Press key F1 below START (3).

The counter is reset. The control box is ready to count

the impulses.

- Cover 100 m.

At the end of the reference trip:

- Stop moving forward with the tractor.

- Press key F4 below STOP (2).

The number of pulses is displayed on the screen (1).

- Press Enter key.

The new number of impulses is memorized. The screen

displays the previous menu.

26

Machine use

Page 29

3. Preliminary adjustments at work

Working mode

Drilling can be carried out in MANUAL or AUTOMATIC

mode.

The normal working mode is the AUTOMATIC mode.

The manual working mode can be used for ex.

if the speed sensor is faulty.

- Starting from the "main menu", select "hopper

configuration".

- Select the "working mode" submenu.

- Select the required working mode.

- Press Enter key.

Control box

Quantron S

Application rate adjustment

During work, the application rate can be adjusted in

percentage (in addition or deduction) if the conditions

require it (soil condition,...) (See chapter Metering unit

display).

Setting the adjustment rate

This function is only accessible on hydraulically

or electrically driven machines.

The 100% basis is the opening value for the metering

unit.

- Starting from the "main menu", select "hopper

configuration".

- Select the "+/- appl." submenu.

- Enter the percentage rate for adjusting the

application rate during work. See chapter Variation of

the seed rate.

- Press Enter key.

Machine use

27

Page 30

Adjusting the blower alarm limit values

- Starting from the "main menu", select "hopper

configuration".

- Select the "blower speed" submenu.

- Select value (1).

- Press Enter key.

- Indicate the minimum speed alarm value (see table for

values).

- Press Enter key.

- Select value (2).

- Press Enter key.

- Indicate the maximum speed alarm value (see table

for values).

It is very important to maintain the correct blower

rotational speed.

- According to the seed drill type, values are different!.

Control box

Quantron S

Normal use speeds

Minimum

speed

LC 302-452 3600 4500 4250

NC

3000/4000

Small grain

Large grain

Moduliner-

Solo

TF 702

Small grain

Large grain 2800 3500 3200

MEGANT 2800 3500 3200

Respect the indicated values. In case of

excessive speed, there are risks of damaging

the machine.

2700 3300 3000

3500 4500 4200

2800 3500 3200

2000 2800 2500

Maximum

speed

Nominal

speed

28

Machine use

Page 31

Tramlining rhythm

Setting the tramlining rhythm according to the wheel

track and the treatment width.

- Starting from the "main menu", select "hopper

configuration".

- Press Enter key.

- Selecting the "tramlining" sub-menu.

- Press Enter key.

- Select the "Trav.alley rhythm" submenu (1).

- Enter the treatment width.

- Validate using Enter key.

The screen displays the previous menu.

The control box displays the various rhythm possibilities.

If the machine is only fitted with one

tramlining control cylinder: only symmetrical

rhythms are possible.

Control box

Quantron S

Example 1

With a treatment width of 28 m, the control box

calculates the SY 7 rhythm (2).

Drilling starts with the rhythm in position 4 (3).

- Drilling start with the total seed drill width (4).

The field edge can be to the right or left

when using odd symmetrical rythms

(SY3,SY5,SY7,SY9,SY11).

If the drilling start is made with the total seed drill

width, the field edge can be to the right or left.

Example 2: Symmetrical rhythm

With a treatment width of 24 m, the control box

calculates the SY 6 rhythm (2).

Drilling starts with the rhythm in position 3 (3).

- Shut-off the left half-width at the beginning of the

field (4).

The field edge can be to the right or left

when using odd symmetrical rythms

(SY3,SY5,SY7,SY9,SY11).

If the drilling start is made with the total seed drill

width, the field edge can be to the right or left.

Machine use

29

Page 32

Example 3: Asymmetrical rhythms

- Press on function F2 (6).

- With a treatment width of 24 m, the control box

calculates the AS 6 rhythm (2)

Drilling starts with the rhythm in position 4 (3).

Select the field edge side to start drilling using

keys F3, F4 (5).

- Drilling start with the total seed drill width (4).

Control box

Quantron S

Tramlining

This menu is established to set the tramlining.

On headlands, the counting for the tramlining is only

possible if a continuous signal from the sensor is

emitted.

• Press Enter key.

• Indicate the time delay required after which the

tramlining counting is accepted.

Choice of where the signal comes from:

• ABS (3): The sensor on the chassis or on the coulter

bar counts the impulses for the tramlining counting.

A time delay of 2 to 5 is recommended.

-

• SPR (2): The side marker sensor controls the

tramlining counting.

The time delay can be set to 0.

- (4): Choice of tramlining correction on working screen.

See chapter Tramlining rhythm adjustment.

30

Machine use

Page 33

4. Stationary calibration test

Before loading the seeds and carrying out the

flow test, set the metering unit in the position

adapted to the seed variety (small or large

seeds).

Select type of seed

- As from the "main menu", select the "seed settings"

submenu.

- Select "Seed list Factory " sub-menu (1).

- Press Enter key.

A list comprising 14 seeds is stored in

alphabetical order.

Control box

Quantron S

- Select the required seed variety.

If the required seed is not included in the Factory

list, select a seed with similar specifications

(Seed weight, Volume).

For small and large seed mix (ex. oat and grass

mix) to seed at low application rate,

we recommend to use the Grass seed < 25kg in

the Factory list.

For maize, select a variety with a high Thousand

Grain Weight. Required application rate:

minimum 22 kg/ha.

- Press Enter key.

The selected seed will be saved in the "PRIVATE" list.

The screen displays the previous menu.

The control box indicates the required metering

unit outlet or small seed slide position.

- For small seeds, the "small seed" slide must be

positioned by hand in the metering unit (3).

Values relative to this seed variety are stored in the

"PRIVATE" list.

Machine use

31

Page 34

- If needed, change the seed name.

• Select the name line (2).

• Press Enter key.

We recommend to rename the seed to

differentiate the various seeds stored.

Control box

Quantron S

32

Machine use

Page 35

Volume

- Select the "Appl. (kg/ha)" submenu.

- Press Enter key.

- Enter the required application rate using

the arrow keys. See chapter Entering values using the

arrow keys, Page 23.

- Confirm entry by pressing Enter key.

Working speed

Control box

Quantron S

- Select the "working (km/h)" submenu.

- Indicate the planned working speed.

- Press Enter key.

This entry is not possible if the metering unit is

mechanically driven.

Machine use

33

Page 36

Carry out the calibration test

The metering unit opening is set to determine the density

of seeds sown.

Carry out regular calibration tests to check that

the seed drill is properly adjusted.

Carry out the calibration test with the

machine lowered, the power take-off

disengaged and the tractor stopped.

Carry out the calibration test:

• Before drilling

• If the seed quality is modified (humidity, dust,

impurities)

• When the seed variety is changed

Control box

Quantron S

- Move browser down to position yourself on the "Test

start" sub-menu.

- Press Enter key.

- Open the seed drill metering unit to the value

indicated.

- Position a container under the metering unit to collect

the seeds.

- Press Enter key.

34

Machine use

Page 37

- Shortly rotate the metering unit in order to fill the cells.

- Press on the button Start/Stop.

On machine driven hydraulically or electrically,

the metering unit will automatically rotate by one

turn to fill the cells.

- Empty the container and reinstall it underneath the

metering unit.

- Press Enter key.

- Press on the button Start/Stop.

- Rotate metering unit by at least 30 turns.

If necessary, the test can be stopped (e.g. to

empty the container before it overflows), and

resumed using Start/Stop key.

• After 30 metering unit rotations, a short sound alarm

will resound. This minimum quantity is required to

accept the calibration test.

The minimum quantity is reached. The seed flow can be

stopped.

Control box

Quantron S

Wheat: Rotate metering unit by at least 50 turns.

Rape: Rotate metering unit by at least 100 turns.

The screen displays:

• Number of metering unit rotations

• Distribution cylinder rotation speed

• The number of metering unit rotations required

to simulate the application rate corresponding to

1/10 ha

- Press on the button Start/Stop.

- Press Enter key.

- weigh the seeds collected during the test.

- Input collected weight.

- Press Enter key.

Machine use

35

Page 38

The control box calculates the new opening required and

displays it on the screen.

- Adapt metering unit opening according to the value

displayed on the screen (See corresponding manual).

In most cases, it is not necessary to adjust the

metering unit opening, as the electric or

hydraulic drive adjusts the rotation speed.

- Press Enter key.

- Shut-off the calibration flap.

- Press Enter key.

Control box

Quantron S

The calibration test is accepted. Settings will be stored in

the Private list under the saved name.

- Press Enter key.

The machine is ready for work.

If a new calibration test is required, repeat

procedure with the new metering unit opening.

36

Machine use

Page 39

Proceed with a new calibration test

After presetting the metering unit opening, run a

calibration test to know the exact density of

seeds.

- Select the "Seed settings" sub-menu.

- Press Enter key.

- Move browser down to position the cursor on the

"Optimize and calibrate" sub-menu.

- Follow screen instructions.

- Proceed with a new calibration test. See chapter

Carry out the calibration test, Page 34.

Control box

Quantron S

5. Modification of the parameters

A modification of the planned application rate or work

speed of an already calibrated seed requires

confirmation.

- Select values to modify and validate each

modification.

- Select the "Seed settings" sub-menu.

- Press Enter key.

Machine use

37

Page 40

The screen displays:

• Metering unit "opening position"

• Required small seed slide position

• Minimum and maximum application rate values

• Minimum and maximum travel speed values

Accept

- If the possible working zones (outlined values) are

convenient, confirm by selecting "Accept".

- Press Enter key.

The regulation adapts the application rate or speed

modification by means of the drive speed. The new

opening is identical to the former one.

Optimizing the working zone

Control box

Quantron S

If the working zones (outlined values) must be optimized,

there are two possibilities.

Optimize

- Select "Optimize".

- Press Enter key:

• The control box calculates the new opening

required and displays it on the screen.

• According to the application rate or travel speed

modification, the control box will suggest a new

optimized working zone.

- Adapt metering unit opening according to the value

displayed on the screen (See corresponding manual).

- Press Enter key.

38

Machine use

Page 41

The calibration test is accepted. Settings will be stored in

the Private list under the saved name.

- Press Enter key.

- The machine is ready for work.

Optimize and test

- Select "Optimize and test".

- Press Enter key.

• The control box calculates the new opening

required and displays it on the screen.

• According to the application rate or travel speed

modification, the control box will suggest a new

optimized working zone.

- Proceed with a new calibration test. See chapter

Carry out the calibration test, Page 34.

Control box

Quantron S

6. Flow test with regards to an area

For this function, a seed flow for a set area can be

simulated.

- Press on the button ha.

- Select "Area test" sub-menu.

- Press Enter key.

Machine use

39

Page 42

- Choose test area using the corresponding key.

• Example: F2 for 1/10 ha

- Position a container under the metering unit to collect

the seeds.

- Press Enter key.

- Press on the button Start/Stop.

If necessary, the test can be stopped (e.g. to

empty the container before it overflows), and

resumed using Start/Stop key.

Control box

Quantron S

The metering unit rotates until the set theoretical area

is reached.

The metering unit stops automatically.

- Weigh the container and deduct the container weight

(tare) in order to know the quantity collected for the

area of reference used.

- Compare the collected seed quantity with the

instructions in the "Seed settings" menu.

If the quantity collected varies with regards to

the required application rate, proceed with a new

calibration test.

- Press Enter key.

- Shut-off the calibration flap.

- Press Enter key.

40

Machine use

Page 43

7. Sowing a seed already stored

When selecting a seed already stored, the screen

displays the latest values stored.

- As from the "main menu", select the "seed settings"

submenu.

- Select the "Seed list privat" sub-menu (1).

- Press Enter key.

- Select the required seed variety.

The screen indicates the values stored with this seed:

• Dose per hectare

• Work speed in km/h

• Required small seed slide position

- Select the "Seed settings" sub-menu.

- Press Enter key.

Control box

Quantron S

The screen displays:

• Metering unit "opening position"

• Required small seed slide position

• Minimum and maximum application rate values

• Minimum and maximum travel speed values

Accept

- If the possible working zones (outlined values) are

convenient, confirm by selecting "Accept".

- Press Enter key.

If the working zones (outlined values)must be optimized,

there are two possibilities:

• Optimize

• Optimize and test

See chapter Modification of the parameters, Page 37.

Machine use

41

Page 44

8. Deleting a seed

A seed stored in the "Seed list privat" can be deleted in

the following cases:

• The "Seed list privat" is full.

• The seed will no longer be sown.

- As from the "main menu", select the "seed settings"

submenu.

- Select the "Seed list privat" sub-menu.

- Press Enter key.

- Using the browser, select the seed to delete.

- Press on function F2 (1).

The seed will be deleted.

Control box

Quantron S

42

Machine use

Page 45

$Functioning during work

1. Distribution stop/start

- Lower the marker and the coulter bar.

Sowing start

- Start metering unit in the following situations:

• Sowing start

• Power on.

- Press on the button Start/Stop.

The metering unit will run for 6 seconds in a premetering

function.

If the tractor starts to move forward during these

6 seconds, the machine will automatically switch into

work application rate.

If the tractor moves forward at a speed of less than

1,5 km/h, the application rate is stopped.

Control box

Quantron S

The metering unit only starts if following

conditions are met:

- The machine is in working position

- The blower rotates

- The calibration flap is closed.

- The low level sensor indicates the

presence of seed inside the hopper.

- The minimum blower speed is exceeded

(1,5 km/h).

Impulse mode

In automatic mode, the metering unit automatically stops

when lifting and starts when lowering the drill.

The metering function on the headlands is controlled by

the working position sensor (ABS).

Functioning during work

43

Page 46

Drilling in field corners

To maintain the seed quality in the corners, use the

premetering function.

- Press 2 times Start/Stop key.

The metering unit will run for 6 seconds in a premetering

function.

Move forward with the tractor while premetering is

running.

Momentary drilling stop

- Press button Start/Stop in the following situations:

• At the end of work

• Filling the hopper.

Press Start/Stop button when seeding should

start again.

Control box

Quantron S

Using the manual mode

In the manual mode (MAN km/h), the premetering is

impossible. The programmed speed is the reference

speed.

Respect the reference speed during work.

Otherwise over and underdosing will occur.

- Press on the button Start/Stop.

44

Functioning during work

Page 47

Stopping tramlining temporarily

The button "Pause" avoids that the counting is continued

whilst going around an obstacle.

Condition: the working screen must be displayed.

- Press key F1 (1) (REST).

If the seed drill is fitted with a circuit selector:

- Press on the button hy: The screen displays the

hydraulic selector functions.

- Press on function F3 (1) : Confirm the marker lift

function.

- After goind round the obstacle, press key F3

Lower marker and coulter bar.

Control box

Quantron S

- Press key F1 (2) (REST).

The tramlining counting will continue. Quantity and

distance counting will carry on.

Functioning during work

45

Page 48

2. Hydraulic valve bank

Functions available For Speedliner

3000/4000/6000.

- Press on the button hy: The screen displays the

hydraulic selector functions.

Functions not activated:

• (1): The side markers can be controlled by the

tractors' hydraulic outlet.

• (2): The preparation tools can be lowered or raised

using the tractors' hydraulic valve

Control box

Quantron S

Functions activated (Black background):

• Roller pressure (1)

• Hydraulic roll folding (2)

46

Functioning during work

Page 49

Functions available for the BTFR coulter

bar

- Press on the button hy: The screen displays the

hydraulic selector functions.

• (1): Side marker control

• (2): Coulter bar control

White background: Functions not activated

Black background: Markers (1) and coulter bar (2) can

be operated.

Control box

Quantron S

3. Tramlining rhythm adjustment

The tramlining rhythm can be modified by hand if

necessary.

Condition: the working screen must be displayed.

- Use key F2 (1) until correct rhythm position is

obtained.

The correction direction for the tramlining is adjustable in

the menu "tramlining" under "Machine Configuration".

See chapter Tramlining.

Functioning during work

47

Page 50

4. Operating data

This menu is used for saving data of 200 fields.

- As from the "Main menu", select the "Field data"

menu.

Data can be saved either in field file already saved

(resuming work that had been stopped) or by creating a

new file.

Creating a new file (2)

- Select "Create new file".

- Press Enter key.

- Enter the field name in the allocated space.

The field name can be entered freely. See chapter

Text entry.

The number of letters is limited to 40.

Page 1 out of two appears on the screen.

Control box

Quantron S

Selecting a file (1)

Values saved in a file are not deleted, but completed with

new values.

- Select "Choose new file" submenu (2).

- Press Enter key.

The screen displays the field names saved in

alphabetical order.

- Select the required field.

- Press Enter key.

Page 1 out of two appears on the screen.

48

Functioning during work

Page 51

Starting field data

0

1 : Display of the number of files still available

2 : Submenu used for starting the field data

3 : Identification area

4 : Values saved

5 : Display of date and time of drilling start

6 : Display of date and time of drilling end

7 : Display of the seed name used

8 : Submenu used to delete values saved in a file

- Select the "Field data start" submenu (1).

- Press Enter key.

The data recording starts.

The working screen displays the cassette symbol during

the field file recording (9).

Control box

Quantron S

Stopping the recording

- As from the "Field data" menu, enter the file currently

used.

- Select the "Field data stop" submenu.

- Press Enter key.

The file recording is stopped.

Functioning during work

49

Page 52

Deleting one or several files

Deleting a file:

- As from the "Field data" menu, select the "Delete file

data" submenu.

- Press Enter key.

- Select the file to delete in the list

- Delete the file by pressing Enter key.

The screen displays the previous menu.

Deleting all files

- As from the "Field data" menu, select the "Delete all

files" submenu.

- Press Enter key.

A buzzer sounds. An alarm message appears.

- Validate using START key.

- Press on the button ESC: all files will be deleted.

Control box

Quantron S

5. Variation of the seed rate

During work, the application rate can be adjusted using

keys F3/F4. See chapter Application rate adjustment.

Key C/100% cancels the adjustment and the normal

application rate restarts.

Use during work:

- Press on function F3: The normal applicartion rate is

increased by the programmed adjustment rate.

- Press on function F4: The normal applicartion rate is

decreased by the programmed adjustment rate.

• The applied variation of seed rate is indicated above

the seed rate (1).

50

Functioning during work

Page 53

6. Daily counters

- Press on the button ha.

The screen displays:

- Quantity sown (independently from the seed

variety) (1)

- Area sown (2)

- Surface covered (3)

since the last reset.

Deleting the daily counter (4)

- Move browser downwards to select the "Delete trip

counter" sub-menu.

- Press Enter key.

All daily counter values are reset.

- Press on the button ha.

Deleting the daily counter values does not affect the

field data files.

Control box

Quantron S

Functioning during work

51

Page 54

$System/Test

1. Sensor check

The "Test/diagnosis" menu monitors and indicates the

status of the machine sensors or actors.

This menu is only used for information purposes.

- As from the "System - Test" menu, select the "Test diagnosis" menu.

- To choose the desired function.

Control box

Quantron S

The list of sensors depends from the machine

equipment. Following sensors are controlled by the

control box.

- Blower sensor/Working position sensor

- Metering unit sensor,

- Metering unit hatch sensor:

• Sensor is deactivated: The calibration flap is closed

- Low level sensors (UP/DOWN)

- The power supply

- Tramlining: Position of tramlining motor (Left, Right)

-Markers

• Sensor is deactivated: Markerarm is lifted

- Power harrow sensor

• Sensor is deactivated: Power harrow rotating. The

sensor controls the rotation of the power harrow.

- Electric motor

52

System/Test

Page 55

Example: Metering unit

0

1 : Sensor short circuit (Function not switched on)

2 : Wire cut

3/4 :

Sensor function area

3 : Sensor is deactivated

4 : Sensor is activated

Control box

Quantron S

Example: Electric motor

- Press on the button F1 (2) and keep it pressed down.

When the electric motor rotates, the power supply is

represented by the black bar.

System/Test

53

Page 56

2. Alarm configuration

The submenu Alarm configuration allows to deactivate

following sensors if they are broken. The machine can

continue to work.

• Blower

• Calibration flap

• Low level sensors (UP/DOWN)

• Power harrow sensor

Only the sensors which are mounted and

stored in the menu "Machine options" are shown

on the screen. See chapter Service: Machine

configuration

- Uncheck the box corresponding to the faulty sensor:

Press Enter key.

Control box

Quantron S

Replace broken sensors as soon as possible.

Reactivate the required alarm configuration.

54

System/Test

Page 57

$Service: Machine configuration

1. Service

The configuration of the control box through the

"Service" menu is required in following situations:

• New options are mounted on the machine.

• Old or broken equipment are removed.

• The control box is used on several machines.

The "Service" menu under "System-tests" requires a

password to avoid accidental changes of factory

settings.

Control box

Quantron S

Contact your authorised Kuhn dealer to get

the password.

- (1): The Quantron S control box is factory set for the

machine supplied.

- (2): This menu is reserved and accessible only by a

KUHN technician.

- (3): Access to factory settings menu

• Press Enter key.

• Save: The options installed by the user are stored.

The factory adjustments will be rewritten. The

previous machine settings will no longer be

possible

• Recreate: The previous programmed machine

settings can be reinstalled.

- (4): The values stored in the total counters are reset.

Service: Machine configuration

55

Page 58

2. Machine options

Check the equipments mounted on the drill,

before changing values in the menu

"Machine options".

Wrong entries may influence the working

quality and even provoke damage the

machine.

Contact your authorised Kuhn dealer to get

the password.

(1) Identification area: Check machine name.

- Press Enter key.

- Enter new designation.

(2): Width of seed drill (m)

- Press Enter key.

- Enter machine width.

(3): Number of low level sensors mounted

- Press Enter key.

- Enter number of sensors.

(4): One or two tramlining motors are mounted

• Press Enter button to select one of the 2 possible

values.

(5): Power harrow sensor

• A check mark at the end of the line indicates that this

option is mounted.

(6): Not used

(7): Metering unit drive:

- Press successively key Enter to select the functioning

mode.

• Electrical drive

• Hydraulic drive

• Mecanical drive through a skeleton wheel

Control box

Quantron S

56

Service: Machine configuration

Page 59

Move downwards using the arrow key until page 2/2

appears.

(1) Check width of mounted metering unit.

- There are 2 values possible: 150 mm or 200 mm.

- Press Enter button to select one of the 2 possible

values.

A check mark at the end of the line indicates that this

option is mounted.

(2): Hydraulic valve bank: The control box is connected

to the hydraulic valve bank.

(3): Metering unit hatch sensor

(4): Side marker sensors

(5): Enter the serial number of the machine connected to

the control box.

(6): Programming the theoretical number of pulses

(without slippage) of the metering unit sensor for a travel

of 100 m. This value is only used with seed drills fitted

with a mechanically driven metering unit

- Enter value depending on machine type:

Control box

Quantron S

VENTA EC

VENTA LC

SPEEDLINER

Radar

Working

width (m)

impulse/100m

(Distribution

sensor)

3750

3 750

3,5 875

4 1000

4,5 1125

3 1290

41280

6 1290

Service: Machine configuration

57

Page 60

$Alarm messages

When an anomaly is detected, an alarm screen is

displayed and a permanent buzzer sounds.

1. Alarm signification

Control box

Quantron S

Nr. Error messages

1 Fault in metering unit!

2

3

4 Volume outside limits

5

Maximum application rate reached!!

Forward speed or metering volume too high

Minimum application rate reached!

Forward speed or metering volume too low

Description

• Possible causes

• The metering unit does not rotate

although the machine is lowered.

Alarm only possible on machines driven by an

electric or hydraulic motor

• The maximum motor speed has been

reached.

Alarm only possible on machines driven by an

electric or hydraulic motor

• Forward speed or metering volume too

low.

• The quantity collected does not reach or

exceeds by 20 % the theoretical value to

collect.

Only on machine with a low level sensor

• Hopper empty

6

7

58

Alarm messages

Data is deleted!

Delete = START

Abort = ESC

Only on machine with 2 low level sensors

• Right hopper empty

Alarm message for preventing inadvertent

deleting of all data

Page 61

Control box

Quantron S

Nr. Error messages

8

9 Blower speed too high

1

0

1

1

1

2

1

3

Forward speed or metering volume too high

1

4

1

5

1

6

Blower speed too low

Pre-metering stopped

Data transfer error

No RS232 connection

Desired weight outside limits

max. 20 km/h

Calibration flap not closed

Memory full

Deletion of a private table

Description

• Possible causes

Only on machine with 2 low level sensors

• Left hopper empty

• The blower exceeds the maximum

authorized speed value.

The alarm disappears automatically if the

speed decreases below the maximum

authorized speed value.

• The blower does not reach the minimum

authorized speed value.

The alarm automatically disappears when the

speed exceeds the minimum authorized

speed value.

Alarm only possible on machines driven by an

electric or hydraulic motor:

• The pre-metering is activated by pressing

the start/stop key but the blower has not

reached the minimum authorized speed

value.

Alarm only possible on machines driven by an

electric or hydraulic motor:

• The pre-metering is stopped and there

was no forward signal sent before 5

seconds.

• A fault has occured during the data

transfer towards/as from the control box

• The maximum and minimum alarm values

depend on the seed variety.

• The speed value is hoo high for calibration

test.

• The flap is still in calibration test position

and the blower is rotating.

• The maximum number of 46 seed

adjustment charts has been reached.

Alarm messages

59

Page 62

2. Deleting a breakdown or an alarm

An alarm on the screen is simultaneously combined with

a sound alarm.

Deleting an alarm

Look for the cause, and do what is needed.

Refer to the seed drill operator's manual.

- Press on the button C/100%.

The alarm disappears.

Control box

Quantron S

60

Alarm messages

Page 63

$Trouble shooting guide

-

Problem Cause Remedy

The electric or hydraulic drive

rotates non stop during the

calibration test.

The electric or hydraulic drive

does not rotate during

calibration test.

Irregular rotation of the electric

or hydraulic drive

The control box does not receive

the rotation sensor signal.

The stored machine options are

incorrect (Mechanical metering

unit drive).

The rotations pulses are not

properly picked up.

Sowing has been stopped.

The hopper is empty

- Verify the distance between the sensor

and the tips of the metal teeth on the

pinion.

- Replace sensor.

- check current settings using INFO

menu.

- Check control box programming.

- Adapt if necessary.

- Verify the distance between the sensor

and the tips of the metal teeth on the

pinion.

- Press on the button Start/Stop.

- Start sowing using key Start/Stop after

having started the control box.

- Reconfigure alarm condition of the

seed level sensors.

Control box

Quantron S

When sowing, the metering

unit electric or hydraulic drive

does not start.

The electric or hydraulic motor

continues rotating when

turning round.

Incorrect speed is memorized - Adjust blower speed.

- If the blower sensor is faulty, do not

Faulty blower rotation sensor

Coulter bar or power harrow not

lowered

Calibration flap not closed - Shut-off the calibration flap.

No speed signal

Faulty speed sensor

Faulty work position sensor

forget to deactivate it in the "diagnostic

menu".

- Check work position sensor on the

frame or coulter bar.

- Check speed signal source.

- The speed signal can come from the

tractor, the radar sensor or a wheel

sensor.

- Select the "Machine km/h" submenu.

- Select the speed source.

- The manual working mode can be

used for ex. if the speed sensor is

faulty.

- Check work position sensor on the

frame or coulter bar.

Trouble shooting guide

61

Page 64

Problem Cause Remedy

- Check the power connection

The pre-emergence marker

solenoid valve does not

function.

The tramlining rhythm is not

counted.

Bad connection

The PAUSE key has been

activated.

The marker manoeuvre does not

affect the tramlining counting.

Faulty side marker sensor

- Connect wire marked L of wiring

harness Y to the solenoid valve.

- The wire marked R of wiring harness Y

must be connected to a second

solenoid valve for special rhythms.

- Press key F1 (REST).

- The pulses for tramlining are sent by

the wrong sensors.

- In the "tramlining" sub-menu of the

"Hopper configuration" menu, activate

counter on SPR (markers).

- Test the sensors using the diagnosis

menu.

Control box

Quantron S

62

Trouble shooting guide

Page 65

$Maintenance and storage

The control box does not require any particular

maintenance, in the case of a breakdown or a

malfunction call your KUHN technician.

For any welding operation on the machine,

disconnect the electricity supply of the

machine and the tractor (battery and

alternator).

When cleaning the machine, never point the

water jet on the control box.

Control box

Quantron S

Maintenance and storage

63

Page 66

E-M otor

R2055972

Control box

Quantron S

$Connecting diagrams

Sponrad

Landwheel

R2056714

Kabel

R2056569

Roue squelette

L= Links- gauche - left

Wire

Câble

N

Allgemein – En général – Generally

O

R = Rechts – droit - right

MEGANT

VENTA NC

R2055842

Aktuator rechts

Actuator right

OPTION

Kabel

R2055838

Vérin électrique droit

Wire

Câble

Hy-Bloc

Hy-Block

R2055148

Traceur de prélevée

Vorauf laufma rkierung

Pre-emergence marker

E-Drive

Moteur électr ique

R2055148

Trémie

Hopper

Bloc hydraulique

Fullstand

R2055637

N

OPTION

O

DAT

VAM

HYD

LMR

FMR

KMH

R2055844

FML

GEB

SPL

SPR

DOS

LML

ABS

DOK

KEG

O

N

Wire

Kab el

Câble

R2055838

R2055848

64

Connecting diagrams

Geblä se

R2055639

Trémie

Doseur

Turbine

Fan unit

R2055638

R2055639

Dosiereinheit

Metering system

R2055639

Spuranreißer

Side markers

Arbeitsstellung

Traceurs latéraux

Hopper

Fullstand

R2055637

Frame position

Position chassis

R2055842

Aktuator links

Vérin électrique G

Injektor

Injector

Injecteur

Actuator left

R2055639

Kreiselegge

R2055639

Power ha rrow

Herse rotative

Page 67

E-M otor

R2055972

Control box

Quantron S

Bloc

Hy-Bloc

Hy-Block

hydraulique

R2055148

Sponrad

Landwheel

R2055639

Roue squelette

Trémie

Hopper

Fullstand

R2055637

E-Drive

Moteur électr ique

R2055848

EC 3000

OPTION

R2055639

Arbe itsste llung

Frame position

Position chassis

SPEEDLINER

Wire

Kabel

Câble

R2055838

N

O

HYD

ABS

DAT

LMR

KMH

R2055047

SPL

R2055639

Spuranreißer

Side markers

Traceurs laté raux

R2055845

KEG -

FML6 -

FML2 -

VAM

KEG +

FML7 -

FML8 -

SPL -

VAM -

SPR -

SPL +

SPR +

FML3 -

FML4 -

SPR

FML5 -

FML5 +

FML6 +

FML7 +

FML8 +

VAMR +

R2055846

FML1 +

FML2 +

FML3 +

FML4 +

VAML +

FML1 -

LML

GEB

DOK

DOS

L= Links- gauche - left

R = Rechts – droit - right

Gebläse

R2055639

Allgem ein – En général – Generally

R2055047

Trémie

Turbine

Fan unit

R2055638

Injektor

Doseur

Injecteur

R2055639

Dosiereinheit

Me terin g system

Hopper

Injector

Fullstand

R2055637

R2055148

Vorauflaufmarkierung

Traceur de prélevée

Pre-emergence marker

R2055639

Spuranreißer

Side ma rkers

Traceurs latéraux

Connecting diagrams

65

Page 68

R2055839

Kab el fü r Prop Ve ntil

Control box

Quantron S

Bloc

Hy-Bloc

Hy-Block

hydraulique

R2055148

R2055639

Arbe itsste llung

Frame position

Position chassis

Trémie

Hopper

Fullstand

R2055637

Wire for p rop. valve

Câble pour valve prop.

RADAR

DICKEY-JOHN

R2055848

MODULINER 1

SPEEDLINER 1

OPTION

SPL

R2055639

Spuranreißer

HYD

Side markers

Traceurs latéraux

N

Adapter

Adaptateur

R2055841

O

DAT

LMR

KMH

R2055047

ABS

R2055845

KEG -

FML6 -

FMR2-

VAM

KEG +

FML7 -

FML8 -

SPL -

VAM -

SPR -

SPL +

FMR3-

FMR4-

SPR +

SPR

FML5 -

FML5 +

FML6 +

FML7 +

FML8 +

VAMR +

FMR1+

FMR2+

R2055846

LML

GEB

DOK

DOS

FMR1-

FMR3+

FMR4+

VAML +

66

Connecting diagrams

Gebläse

R2055639

L= Links- gauche - left

R = Rechts – droit - right

Allgem ein – En général – General ly

Trémie

Turbine

Fan unit

R2055638

Injektor

Doseur

Injecteur

R2055639

Dosiereinheit

Me terin g system

Hopper

Injector

Fullstand

R2055637

R2055047

R2055148

Vorauflaufmarkierung

Traceur de prélevée

Pre-emergence marker

R2055639

Spuranreißer

Side ma rkers

Traceurs latéraux

Page 69

R2055839

Kabel für Prop Ventil

Control box

Quantron S

R2055639

Spuranreißer

Side markers

R2055047

FMR3+

FMR4+

FMR3 -

FMR4 -

SPR -

SPR +

FMR1+

FMR2+

R2055847

FMR1 -

FMR2 -

Trémie

Hopper

Fullstand

R2055637

Wire f or pr op. va lve

Câble pour valve prop.

Adaptateur

R2055841

RADAR

DICKEY-JOHN

N

Adapter

O

R2055848

R2055148

OPTION

Bloc

Hy-Bloc

Hy-Block

hydraulique

R2055639

Arbeit sste llun g

Frame position

Position chassis

R2055047

Traceurs latéraux

SPR

DAT

Geblä se

R2055639

LMR

KMH

HYD

ABS

VAM

R2055845

R2055047

LML

R2055638

Dosiereinheit

DOK

DOS

Trémie

Doseur

R2055639

Met ering system

Hopper

Injektor

Injector

Injecteur

Fullstand

R2055637

GEB

Turbine

Fan unit

FML3 +

FML1 +

R2055847

R2055148

Voraufla ufma rkierung

FML4 +

FML2 +

Traceur de prélevée

Pre-emergence marker

FML3 -

FML4 -

SPL -

SPL +

FML1 -

FML2 -

SPL

L= Links- gauche - left

R = Rechts – droit - right

All gemein – En général – General ly

R2055639

Spuranreißer

Side markers

Traceurs latéraux

67

SPEEDLINER 2

R2055047

MODULINER 2

Connecting diagrams

Page 70

Fullstand

R2055637

Control box

Quantron S

Sponrad

Landwheel

R2056714

Roue squelette

Trémie

Hopper

Hy-Block

R2055148

Bloc

Hy-Bloc

hydraulique

E-Drive

E-M otor

R20564 30

Moteur électr ique

R2055848

OPTION

VENTA TF + BTF

Adapter

Adaptateur

R2056723

N

O

DAT

LMR

KMH

R2055047

R2055639

SPL

R2056041

KEG -

FML5 -

FML5 +

FML6 +

FML7 +

FML8 +

VAMR +

KEG +

FML6 -

FML7 -

FML8 -

HYD

Spuranreißer

Side ma rkers

Traceurs latéraux

68

Connecting diagrams

GEB

Gebläse

R2055639

SPL -

VAM -

SPR -

FMR1-

FMR1+

FMR2+

FMR3+

R2055846

DOS

Turbine

Doseur

Fan u nit

R2055638

R2055637

Dosiereinheit

Me terin g system

DOK

LML

Trémie

Hopper

Fullstand

ABS

R2055639

Arbe itsste llung

L= Links- gauche - left

R = Rechts – droit - right

Allgem ein – En général – General ly

Frame position

Positio n cha ssis

R2055047

FMR2-

FMR4+

VAML +

VAM

R2055148

Traceur de prélevée

Vorauflaufmarkierung

SPL +

FMR3-

FMR4-

SPR +

SPR

R2055639

Spuranreißer

Side ma rkers

Traceurs latéraux

Pre-emergence marker

Page 71

$Limited warranty

Control box

Quantron S

Limited warranty

69

Page 72

Control box

Quantron S

70

Limited warranty

Page 73

Page 74

Page 75

Page 76

Loading...

Loading...