Page 1

PZ 320FC

Operatio n ma nual

Issue 04/2009

Date of printing 7.2009

Language EN

From machine number (PIN) VGRA000041

Serial Number (PSN) 03RA01

Reference number ZNA037EN

Page 2

Identifica ti on of the m achine

To support you as soon as possible your dealer requires several details of your machine.

Please enter the information here.

Designation

PIN

Mounted options

Dealer's address

PZ 320FC

VGRA ...............................

Manufacturer’s

Adress

KUHN-GELDROP B.V. retains all copyrights and rights of usage. The contents of this operating manual are subject to change without notice. All

rights reserved. The right to technical revision is reserved.

KUHN-GELDROP BV

Nuenenseweg 165

5667 KP Geldrop

The Netherlands

Phone +31 40 2893300

Page 3

Table of contents

Preface..............................................................4

Target group of this operation manual 4

Symbols used 5

Safety instructions ..........................................6

For your safety 6

Safety decals at the machine 7

Who is allowed to operate the machine? 10

Hitching the machine 11

Road transport 12

Working with the machine 13

Unhitching the machine 15

Care and maintenance 16

Further prescriptions 18

Acquaintance with the machine...................19

Designation of the machine 19

Characteristics of the machine 19

Description of the components 20

Technical specifications 21

Delivery and preparation ..............................23

Checking the delivery 23

Hitching the machine ....................................24

Safety 24

General 24

Preparation before hitching 25

Hitching to the 3-point front hitch 26

Coupling the pto drive shaft 27

Connections 28

Preparation for use........................................29

Safety 29

General 30

Top and draft link adjustment 30

Running 31

Table of contents

Parking the machine ..................................... 41

Safety 41

Prior to parking 41

Parking 41

Cleaning of drum skirts/skid discs 41

Cleaning, caring and storing the

machine.......................................................... 42

Preparing for winter 42

Winter storage 42

Maintenance................................................... 43

Safety 43

General 44

Attaching elements 46

Tightening torques 47

Pto drive shaft 48

Lubrication 49

Mowing blades 51

Moving / renewing blade holders 52

Flexible top link 54

Gearboxes 55

Optional equipment....................................... 60

General 60

Troubleshooting ............................................ 61

General 61

Troubleshooting table 61

Disposal of the machine ...............................62

EC Declaration of conformity....................... 63

Index ............................................................... 64

Road transport...............................................32

Safety 32

Before road transport 32

Preparation for road transport 33

Preparation at the field..................................34

Safety 34

Performing settings 34

Prior to mowing 34

Placing into working position 35

Cutting height adjustment 35

Ground pressure 36

Conditioner 37

Use at the field............................................... 39

Safety 39

Using the machine 39

End of mowing 40

3

Page 4

Preface

Preface

Target group of

this operation

manual

This operation manual is meant for those concerned with the control,

use and maintenance of the machine. It contains all data required for

a safe handling, use and maintenance of the machine.

For your safety

Before starting to adjust and use your machine, familiarise yourself

with this operation manual. By doing so your safety and the best

performance are assured. It is very important to read this manual

carefully before using the machine and to keep it handy. In this way,

you will

• avoid accidents

• respect the warranty conditions and

• always have a functional machine in perfect working order

For the employer

All personnel are to be trained in the use of the machine regularly (at

least once a year) in accordance with employers’ liability insurance

association guidelines. Untrained or unauthorised individuals are not

permitted to use the machinery.

You are responsible for the safe operation and maintenance of your

machine. You must ensure that you and anyone else who is going to

operate, maintain or work around the unit be familiar with the

operating and maintenance procedures and related safety information

contained in this manual.

4

Page 5

Preface

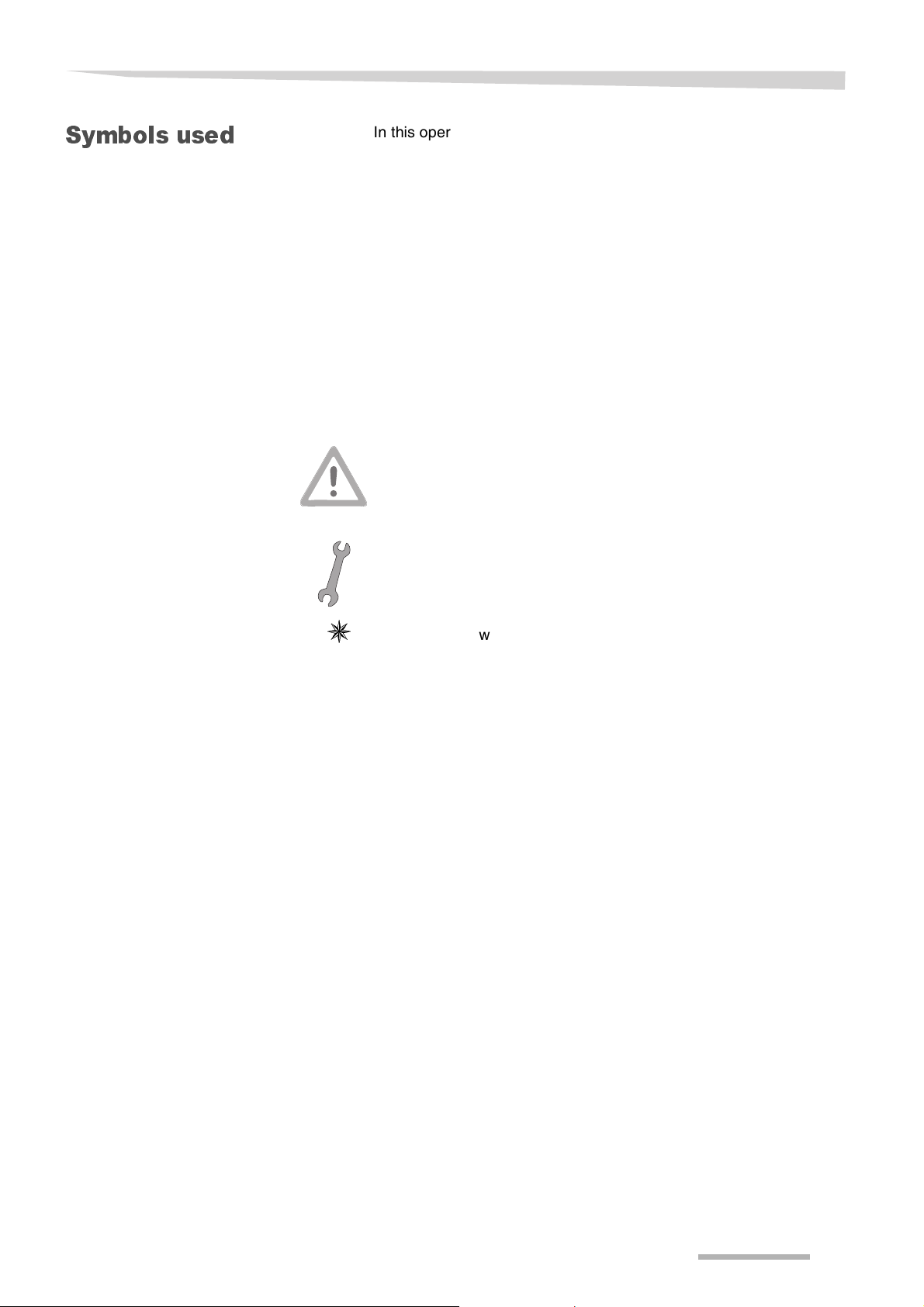

Symbols used

In this operation manual the following symbols and terms are used:

• A bullet stands at enumerations

> A triangle stands at steps, which you must do

→ An arrow shows cross-references at other text passages

[+] The plus sign shows that it involves optional equipment, which

does not belong to the standard model.

Besides these symbols, pictograms are used, which will help you with

locating of text passages:

TIPThe word “Tip“ shows tips and advices to the use.

The triangle refers to danger at assembling or (adjusting) work.

The key refers to tips at assembling or adjusting work.

0

The star shows examples, which are needed for a better

understanding.

5

Page 6

Safety instructions

Safety instructions

For your safety

This chapter contains all general safety instructions. Subject-specific

safety instructions are located per chapter. Take care of the safety

instructions

• because of your own safety

• because of the safety of your fellow man

• to guarantee the machine safety

When handling agricultural machinery, wrong behaviour can lead to a

lot of danger. Therefore work with special care and never under

pressure of time.

For the employer

Inform the one who works with this machine frequently about these

safety instructions and according to the legal regulations.

6

Page 7

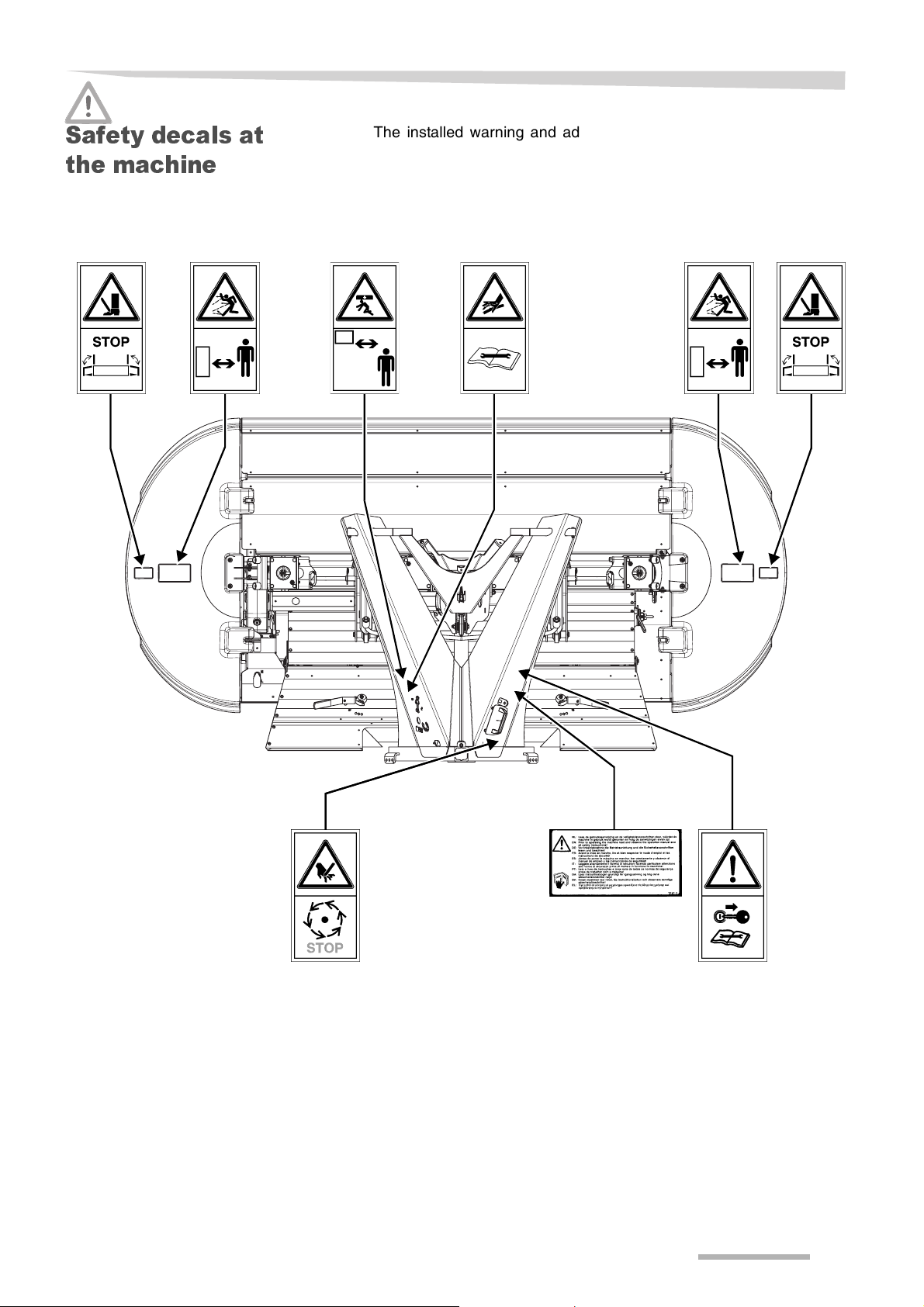

Safety instructions

Safety decals at

the machine

The installed warning and advisory signs give important hints for a

safe operation; adhering to serves your own safety. Keep safety

decals and signs clean and legible at all times. Replace safety decals

and signs that are missing or have become illegible. If original parts on

which a safety decal or sign was installed are replaced, be sure that

the replacement part also displays the current decal or sign.

7

Page 8

Safety instructions

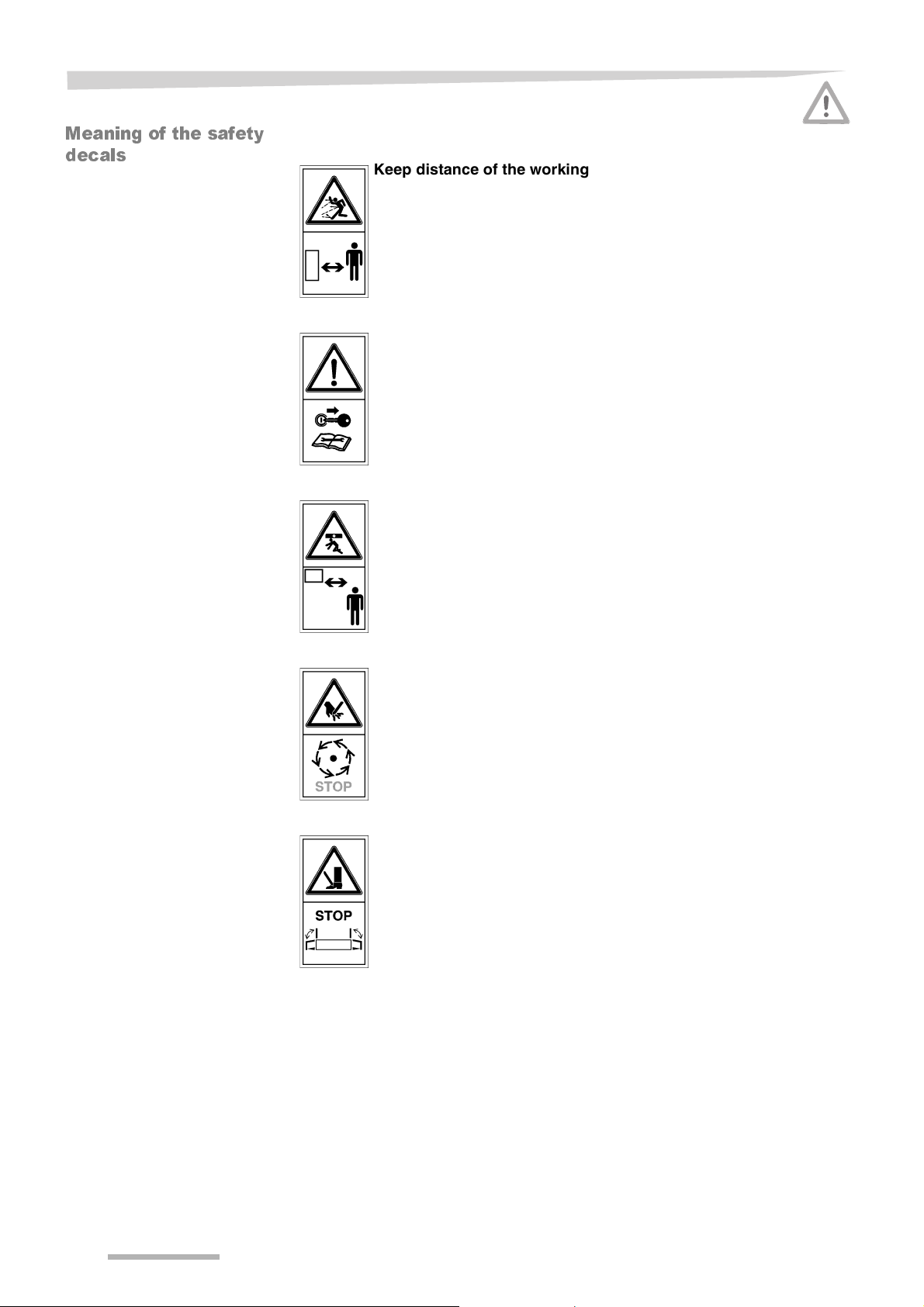

Meaning of the safety

decals

Keep distance of the working machine

Objects can be flung away at very high speed (250 - 300 km/h).

Flunging objects at this speed can not be seen. Flunging objects can

cause serious or deadly injuries.

Shut off engine and remove ignition key

Shut off engine and remove ignition key before performing

maintenance or repeair work. Unintended starting and/or working can

be possible if the engine is not shut off and the ignition key is not

removed. Serious or deadly injuries can be caused.

Do not be situated below a lifted machine

A lifted machine must be adequately supported. A machine can sink

while being below or under it. A sinking machine can cause serious or

deadly injuries.

Do not enter machine components before they have completely

stopped

Wait until all machine components have completely stopped before

touching them. Moving machine components move at high speed and

are not visible. Moving machine components can cause serious

injuries.

Do not move the shielding before complete standstill

Wait until all machine components have completely stopped before

entering the machine. Rotating knives can not be seen. Serious

injuries can occur.

8

Page 9

Safety instructions

Read the operation manual carefully

Read the operation manual carefully before taking the machine into

operation. Various setup and maintenance procedures require special

settings. Not following these special settings can cause serious or

deadly injuries or machine damage.

Do not find or stop a hydraulic leakage by hand

The hydraulic system is under high pressure. Never attempt to find or

even to stop a hydraulic leakage with your hands. High pressure fluid

easily penetrates skin and clothes, causing severe injuries: visit a

doctor immediately when injured.

9

Page 10

Safety instructions

Who is al lo w e d to

operate the

machine?

General

Authorised people only

The machine may be used by authorised people only.

Everyone must be given operating instructions before starting to

operate the machine. It is your responsibility to ensure that anyone

carrying out maintenance or operating the machine is first conversant

with the safety instructions and the operating and maintenance advice

contained in this manual.

Safety is your responsibility

Apply and insist upon application of the safety instructions. Most

accidents are avoidable. Do not run the risk of serious or fatal

accidents through ignorance of these safety instructions.

Wear close fitting clothing

Avoid wearing loose fitting clothing.

Loose clothing can get stuck between rotating parts. Danger of

serious injury.

Keep the machine clean

Always keep the machine clean to avoid fire risk.

Equip the machine with a 10 litre pressurised water fire extinguisher

to be prepared in case of fire.

Running in an enclosed area

Do not run the machine in an enclosed area. Exhaust fumes can be

dangerous.

Never work on a running machine

Never work on the machine while it is running. Severe injuries can

occur.

No modification of the machine

Do not modify the machine in any way. Unauthorised modifications

may impair the function and/or safety and could affect the life of the

machine.

10

Page 11

Safety instructions

Hitching the

machine

Increased danger of injury

While hitching the machine onto the tractor an increased danger of

injury occurs. Therefore:

• prevent the tractor from rolling away, shut down the engine and

remove the ignition key

• never stay between tractor and machine during hitching

• mount and secure the pto drive shaft at the pto

In case of negligence damages to the machine or serious personal

injuries can occur.

Pto drive shaft operation manual

Regard to the operation manual of the pto drive shaft manufacturer.

Here you find instructions for correct handling of the pto drive shaft.

Negligence can lead to damages at the pto drive shaft and to the

machine.

Fix and check pto drive shaft protection

The rotating pto drive shaft is secured by a pto drive shaft protection.

Take care that the pto drive shaft protection is not damaged. Pto drive

shaft protection must be fixed through the chains, both at tractor and

machine side. Unprotected pto drive shafts can cause serious

personal injuries.

Hydraulics

Hydraulic couplings only pressureless

Only couple the hydraulic hoses to the tractor when both tractor and

machine hydraulics are pressureless. Hydraulics under pressure can

cause accidental movements of the machine.

High pressure in the hydraulic system

The hydraulic system is under high pressure. All tubes, hoses and

couplings must be controlled regularly for leaks and external

damages. Only use suitable tools when searching for leaks.

Immediately repair damages. Leaking oil can cause injuries and fire.

When having injuries visit a doctor immediately.

11

Page 12

Safety instructions

Road transport

Pay attention to a road-safe condition

When driving on the local roads, the machine must correspond to the

current traffic prescriptions. To which e.g. belongs:

• mounting of lighting, warning and protection installations

• comply with the permittable transport dimensions and weights,

maximum permissible axle loads, tyre carrying capacity, total

weights and national speed limits

• taking care of the maximum permitted speed of 40 km/h

In case of negligence, driver and owner of the machine are fully liable.

Prohibition of transporting people on the machine

Nobody and nothing shall be transported on the machine during

transport. Transporting of people or objects on the machine is perilous

and prohibited.

Changed driving and braking handling

Because of the hitched machine the driving and braking handling

changes. Especially when driving curves the dimensions and mass of

the machine have to be taken into account. A not adapted driving style

can lead to accidents.

Adapted driving speed

Under bad road circumstances and at high driving speeds very high

crafts can appear, which load or overload the tractor and machine to

much. Adapt the driving speed according to the road circumstances.

A not adapted driving speed can lead to accidents.

12

Page 13

Safety instructions

Working with the

machine

First use only after instruction

The machine may at the first time of use only be brought into use by

employees of the dealer, factory representatives or employees of the

manufacturer. False use after bringing the machine into use without

instructions can cause damages to the machine or accidents.

Take care of technical correct condition

Only bring the machine into use in a technical correct condition. Check

all important parts and replace defective parts before use. Defective

parts can cause material or personal damages.

Do not remove protective covers

The protective covers should not be removed or evaded. Check all

protective covers before using. Unprotected machine parts can cause

heavy or deadly accidents.

Prohibition of transporting people on the machine

Nobody and nothing shall be transported on the machine during

transport. Transporting of people or objects on the machine is perilous

and prohibited.

Check the direct surroundings

Before driving and bringing into use of the machine the direct

surroundings must be checked. Take care of sufficient view. Only start

driving when no persons or objects are in the direct surroundings.

Perilous injuries can occur.

Tighten bolts and nuts

Check bolts and nuts regularly for being tight and tighten if necessary.

Because of using the machine bolts can get loose. Damages to the

machine or accidents can be caused.

13

Page 14

Safety instructions

Behaviour at troubles

At functional troubles stop and secure the machine immediately.

Remedy the trouble immediately or commission a workshop.

Continuing working with the machine cause accidents or damages.

Pto rotates after disengaging

After disengaging or switching off the pto, the machine will continue

running because of inertia. Keep a safe distance to the machine until

all moving parts really stand still.

Blockage or operation of a security device

In case of a blockage or operation of a security device, never work on

the machine without

• disengaging the tractor pto first

• stopping the engine and

• removing the ignition key

Never be tempted to hand feed or unblock the machine while it is

running. Serious or deadly injuries can occur.

14

Page 15

Safety instructions

Unhitching the

machine

Increased danger of injury

While unhitching the machine from the tractor an increased danger of

injury occurs. Therefore:

• prevent the tractor from rolling away, shut down the engine and

remove the ignition key

• never stay between tractor and machine during unhitching

• take care of a level and secure surface for the machine

• place the pto drive shaft at the support or hang it in the chain

• only detach the hydraulic hoses when the hydraulic system at both

tractor and machine is pressureless

In case of negligence heavy or deadly injuries can be the

consequence.

15

Page 16

Safety instructions

Care and

maintenance

Observe the care and maintenance intervals

Observe the prescribed intervals and those stated in the operation

manual for recurring checks and inspections. In case of negligence of

the intervals damages to the machine or accidents can be caused.

Use original parts only

Lots of components have special properties which decides for the

stability and the function of the machine. Only the parts and options

delivered from the manufacturer have been tested and released.

Other products can interrupt the function of the machine or can harm

the security. When using not original parts the warranty and liability of

the manufacturer reduces to nil and void.

At all care and maintenance work:

• switch off pto

• make the hydraulics pressureless

• unhitch the tractor if possible

• switch off the engine and remove the ignition key

• make sure the tractor and machine are positioned on a firm and

level area, support if necessary

• do not use parts of the machine as climbing help, use suitable

climbing helps on the contrary

Only when observing these prescriptions a secured working during

care and maintenance work is guaranteed.

Interrupt electric power supply

Before working on the electrical device, separate this from the electric

power supply. Supplies being charged can cause material or personal

damages.

16

Page 17

Safety instructions

Exchange hydraulic hoses

Hydraulic hoses can age without external recognizable indications.

We therefore recommend to exchange all hydraulic hoses every six

years. Defective hydraulic hoses can cause heavy or deadly injuries.

Careful when cleaning with high-pressure cleaner

The machine can be cleaned with water or steam. Clean bearings,

plastic parts and hydraulic hoses with low pressure only. Too high

pressure can damage these parts.

No aggressive wax additives

When cleaning do not use aggressive wax additives. Bright metal

surfaces can get damaged.

Before welding work

Before welding to the hitched machine, untie the tractor’s battery and

the dynamo. Therefore you will avoid damages to the electrical

installation.

Tighten bolted links

After care and maintenance work all loose bolted links must be

tightened. Because of loose bolted links material damages can be

caused.

17

Page 18

Safety instructions

Further

prescriptions

Observe the prescriptions

Please observe besides these safety instructions

• the accident prevention prescriptions

• the general accredited safety-technical, industrial medicinal and

road traffic law rules

• the tips in this operation manual

18

Page 19

Acquaintance with the machine

Designation of the

machine

Intended use of the

machine

Characteristics of

the machine

This chapter contains general information about your machine and

information about:

Acquaintance with the mach ine

• characteristics

• technical specifications

This machine is exclusively appropriate designed for cutting and

conditioning of non or insignificantly ligneous plants, mainly grasses,

taking into account all prescriptions, procedures, etcetera as stated

herein and/or through decals or other signs on the machine.

This machine shall be exclusively used for the normal agricultural

work.

Any use beyond the one stipulated above requires written

authorization of the manufacturer, this may be required for mowing

unusual, non-grass plants as well.

The rotating knives cut the crop. Via the drums the crop is forwarded

to the conditioner. The conditioner bruises the crop and the crop is

formed into a swath.

19

Page 20

Acquaintance with the machine

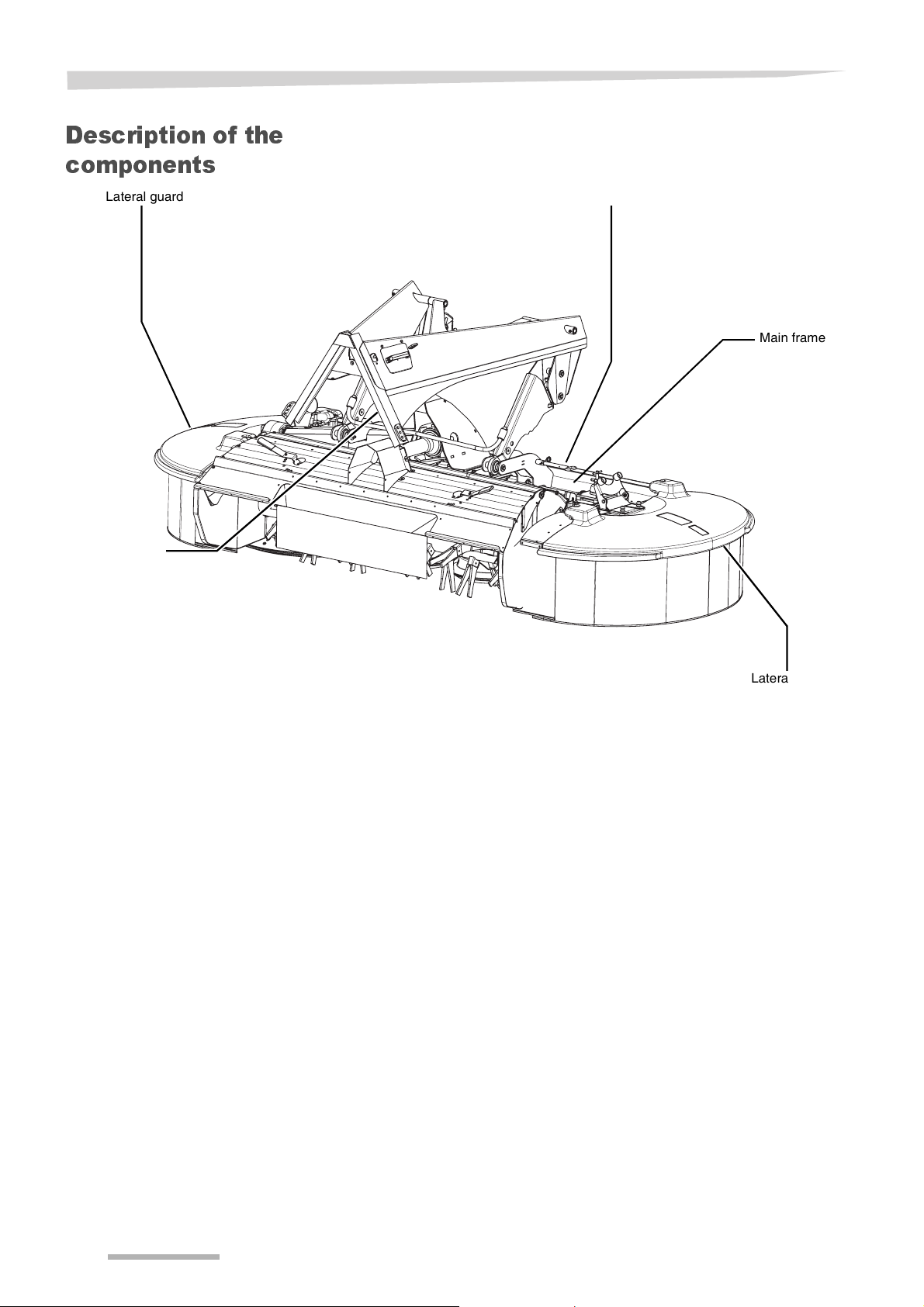

Description of the

components

Lateral guard

Hitching frame

Front guard

Main frame

Lateral guard

20

Page 21

Acquaintance with the machine

Technical

specifications

Dimensions / weight

Weight

Weight (kg) 1,000

Length (m)

Overall length in transport position 1.95 (L)

Overall length in working position 1.87

Width (m)

Transport width 3.00

Cutting width 3.09 (W)

Height (m)

Overall height 1.57 (H)

L

W

H

21

Page 22

Acquaintance with the machine

Tractor requirem e nts

Tractor requirements

PTO horsepower 59 kW (80 hp) and up

PTO speed (rpm) 1000

Hitching category II

Machine

requirements

Mowing drums 4

Blades 12

Skid discs 4

Cutting height adjustment 30 mm continuously

22

Page 23

Delivery and preparation

Delivery and preparation

Checking the

delivery

Completely delivered

The machine is delivered completely. In case parts are not mounted,

please contact your dealer.

The machine must be checked after delivery. The machine is

equipped with:

• Operation manual

• Spare parts manual

• Pto drive shaft assembly

• Blade detachment tool

23

Page 24

Hitching the machine

Hitching the machine

Safety

General

Increased danger of injury

• Prevent the tractor from rolling away

• Never stay between the tractor and the machine during hitching

• Operate the 3-point hitch slowly and carefully

In case of negligence serious or deadly injuries can occur.

Use a proper tractor

Make sure the tractor

• is in safe operating condition

• has adequate braking capabilities for this machine

• is suitable for carrying and transporting this machine

Using a tractor which is not suitable can cause serious personal and

material damages.

The machine is provided for hitching onto the tractor’s 3-point hitch.

To prepare the machine for hitching, the following items are

necessary:

• Both tractor and machine must be placed on a firm level

• The lower link pins must be adjusted if necessary

• The pto drive shaft must be adapted

• The machine must be levelled

• The hydraulic hose must be coupled

24

Page 25

Hitching the machine

Preparation before

hitching

Accord quick hi tch

adjustment

Hitching frame

Cam

Lock nut

Nut

Bolt

In case your tractor is provided with an Accord quick hitch, this quick

hitch must be adjusted before hitching.

The cam of the hitching frame must be adjusted to guarantee an

optimal locking of the Accord quick hitch.

> Loosen lock nut

> Loosen nut

> Turn bolt to the left: cam moves down

or

> Turn bolt to the right: cam moves up

> Tighten nut

> Tighten lock nut

25

Page 26

Hitching the machine

Hitching to the 3-

point front hitch

Hitching frame

Hitching frame

The machine is ex works provided for hitching to a category I or II

Accord quick front hitch.

Fix the tractor lower links

Fix the tractor lower links after hitching of the machine. Lateral

movement of the lower links causes leads to unstable driving

characteristics during road transport and can cause accidents.

Before hitching the machine:

> set the control lever of the 3-point front hitch in a position that

prevents from inadvertent actuation of any function

The machine can be attached to tractors with a category I or II Accord

front quick hitch.

Tractor with an Accord

quick hitch

Spring clip

Hitching frame

> Hitch the machine onto the Accord front quick hitch

> Mount spring clip of the hitching frame onto the Accord quick hitch

> Fix the stabilisers or check chains to prevent sideways movement

of the machine

In some cases the lifting height must be limited in order to avoid

damage to the pto drive shaft, machine protection guards and/or

tractor.

26

Page 27

Hitching the machine

Depth limiting chains

Depth limiting chains

Coupling the pto

drive s h af t

If used, both depth limiting chains must be attached to a fix point at the

tractor.

Do not use a hammer

The pto drive shaft may not be mounted using a hammer or other

equivalent tools. Using these, the pto drive shaft can get seriously

damaged. A damaged pto can cause both machine and tractor

damages.

> Check, before coupling the pto drive shaft, if the pto drive shaft has

to be shortened

> Shorten the pto drive shaft if necessary

→ »Pto drive shaft«, page 48

> Ensure the pto is clean and greased

> Couple the pto drive shaft at both tractor and machine side

> Ensure the shaft sliding ring catches with the slot of the pto

> Fit the chains to rigid positions at both tractor and machine to

prevent the protection covers from turning with the entire pto drive

shaft

27

Page 28

Hitching the machine

Connections

Hydraulic

connections

Hydraulic coupling only pressureless

Only couple the hydraulic hoses to the tractor when both tractor and

machine hydraulics are pressureless. Hydraulics under pressure can

cause accidental movements of the machine.

Avoid oil mixture

When using the machine in combination with different tractors,

improper oil mixture can take place. Improper oil mixture can destroy

tractor parts.

Avoid entering of dirt into the hydraulic system

The hydraulic system can get seriously damaged. Personal injuries or

material damage can be caused.

Check hoses and couplings

Before connecting, check all hydraulic hoses for damages. After

connecting check all hydraulic couplings for tight connection.

Defective hydraulic hoses or bad connected hydraulic couplings can

cause injuries or unforeseen movements of the machine.

Secure tractor hydraulic devices

In transport position tractor hydraulic devices must be secured against

unintentional movements. Unintentional movements of the hydraulic

device can cause serious injuries or unforeseen movements of the

machine.

Coupling

Check correct position and laying of hydraulic hoses

Hydraulic hoses may not stick or tighten. Pay attention to sufficient

free space. Torn or stuck hydraulic hoses cause serious damages of

the machine and serious injuries.

> Ensure the quick coupler is clean

> Make sure the tractor hydraulic valve is pressureless

> Couple the hydraulic coupling to a single acting hydraulic valve

28

Page 29

Preparation for use

Preparation for use

Safety

Obey safety instructions

Obey the safety instructions at the execution of all work. Ignoring the

safety instructions can lead to serious or deadly injuries.

Guarantee correct hydraulic coupling

Check before using if all hydraulic couplings are coupled correct to the

single and double acting valves. Not correct coupled hydraulic

couplings can cause unpredictable movements of the machine.

Never work on the machine while it is running

Never carry out adjustment work while the machine is running.

• Pto must be switched off

• Tractor engine must be switched off and the ignition key must be

removed

In case of negligence, serious or deadly injuries can occur.

No persons in turning area

During work, no persons may be within the turning area of the

machine. Serious personal injuries can be caused.

Secure the machine

During adjustment, an increased danger of injury exists. Therefore

• secure the machine from accidental commencement of operations

and rolling away (use wheel chocks)

• the machine must have a level, secure position and must be

supported during working if necessary

Unsecured or not supported machines can lead to accidents.

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

29

Page 30

Preparation for use

General

Top and draft link

adjustment

Top link adj u stm en t

For the realization of all preparations counts:

• Secure the machine

• Check the tractor’s tyre pressure

The following settings have to be realized before using the machine:

• top and lower link adjustment

• hitching frame adjustment

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

The mowing angle is set via the top link and the draft link adjustment.

The top link and the draft links must be positioned with respect to each

other in order to ensure the mowing unit stays horizontally when lifted

in working position.

> Fit the top link so, that the machine is horizontal and does not tilt

backward

Top link length

Height

Top link

Adjust the top link to ensure the machine is level or slightly tilted

forward. Adjust the top link as follows:

> Turn the top link out = machine tilts forwards

> Turn the top link in = machine tilts backwards

TIPTo avoid recutting, the mowing unit shall never be tilted backwards.

Top link and draft links must be positioned with respect to each other

in order to ensure the mowing unit stays horizontally when lifted in

working position.

After adjusting the top link, the cutting height must be adjusted.

→ »Cutting height adjustment«, page 35

30

Page 31

Preparation for use

Check at beginning of

the season

Running

• Check the blade holders

→ »Checking blade holders«, page 52

• Check the blade pins

→ »Checking blade holders«, page 52

> Run the tractor pto at idle

• Check correct operation of the components

• Check if there are no unusual noises

> Run the machine at 1000 rpm for some minutes

> Stop the pto

• Check the tightness of the hardware

During the running-in period, a specific maintenance must be done,

confer to maintenance chart

→ »Maintenance intervals«, page 45

31

Page 32

Road transport

Road transport

Safety

Before road

transport

Before road transport will take place, please read the following safety

instructions. The compliance is prescribed and helps you to avoid

accidents.

Close valves

Before road transport close all valves. With open valves and false

operation the lifting cylinder can be lowered. Traffic accidents can be

caused.

Clean the machine before road transport

Clean the machine, before every road transport, from crop residues

and heavy dirt. Crop or dirt, falling at the road, can cause a slippery

state of the road. This can lead to fatal accidents.

Road transport must be done in transport position. To bring the

machine into transport position, the following steps are necessary:

> Remove crop residues and heavy dirt

> The lock must be placed in transport position

> The lateral guard must be folded up and locked

> The machine must be placed into transport position

32

Page 33

Road transport

Preparation for

road transport

Moving into transport

position

Lateral guards

The machine has to be prepared before road transport can take place.

Ensure sufficient visibility during all operation and transport.

> Fold up and lock both lateral guards

> Use the hydraulic valve to lift the machine fully

33

Page 34

Preparation at the field

Preparation at the field

Safety

Performing

settings

Prior to m o wing

Obey the safety instructions

Obey the safety instructions at the execution of all work. Ignoring the

safety information can lead to serious or deadly injuries.

Secure tractor and machine

• Switch off and secure the tractor

• Prevent the machine against unintentional commencement of

operations

Unsecured machines can lead to accidents.

The settings to the machine must be performed in working position.

They are described in the next sections:

• Cutting height adjustment

• Ground pressure compensation

Before mowing can start, the following has to be checked:

• Has the lateral guard been folded down?

• Has the front guard been folded down?

• Are the blades correctly seated over the blade pins?

34

Page 35

Preparation at the field

Placing into

working position

General

Lateral guards

Hitching frame

height

Hitching frame

Before use, the machine must be placed into working position.

> Unlock and fold down both lateral guards

> Use the tractor hydraulic valve to lower the machine fully

When in working position, the hitching frame must be at a fixed height.

When the machine is lowered at the ground, height H from the top of

the hitching frame to the ground must be 157 cm.

> Use the front hitch to achieve height H

H

Cuttin g he ig h t

adjustment

Blade detachment

tool

Check-nut

Pin

The cutting height is adjusted continuously by the outer drums.

Before adjusting the cutting height, the mowing unit must be

positioned horizontally.

→ »Top link length«, page 30

> Hold the pin and loosen the check-nut with help of the blade

detaching tool

> Turn the pin to the right; the cutting height increases

or

> Turn the pin to the left; the cutting height decreases

> Hold the pin and tighten the check-nut with help of the blade

detaching tool

35

Page 36

Preparation at the field

Ground pressure

Ground pressure

check

Ground pressure

adjustment

Valve Manometer

Closed

Open

The ground compensation of the machine takes place by the cylinder,

located between the mowing unit and the hitching frame.

The machine must be equally lifted from the ground.

The ground pressure must be about 75 - 100 kg at both sides.

The hitching frame must be at the correct height.

→ »Hitching frame height«, page 35

> Open the valve near the manometer

> Use the hydraulic tractor valve to lift the machine fully to put

pressure on the system

> Close the valve near the manometer

The system pressure, shown at the manometer, must be 80 until 100

bar.

> Put the hydraulic tractor valve in floating position

> Use the valve near the manometer to adjust the ground

compensation pressure for the machine

36

Page 37

Preparation at the field

Conditioner

Swath guid es

adjustment

Wide swath

Narrow swath

The conditioner can be adjusted depending on the crop conditions

and the required conditioning result.

The conditioner can be adjusted by:

• the swath guides

• the swath doors

• the conditioning effect

• the conditioner rpm

The swath width can be adjusted with the swath guides. Either a wide

or a narrow swath can be created:

• wide swath: 3 upper holes

• narrow swath: 4 lower holes

> Move the lever to the desired swath width

Lever

Swath door

adjustment

Swath door

Lever

The swath width can be adjusted with the swath doors. Either a wide

or a narrow swath can be created:

• wide swath: move lever up

• narrow swath: move lever down

> Move the lever up and hold it

> Move the lever and the swath door to the desired swath width

> Leave the lever

37

Page 38

Preparation at the field

Bruising pl ate

adjustment

Ring bolt

Condition er rpm

Lever

HLever

L

The bruising plate can be adjusted. The bruising plate can be set in 4

positions between:

• forward position: decrease the conditioning effect

• backward position: increase the conditioning effect

> Pull the ring bolt and hold it

> Move the lever forwards to decrease the conditioning effect

or

> Move the lever backwards to increase the conditioning effect

> Release the ring bolt

Never work on a running machine

Never work on the machine while it is running. Severe injuries can

occur.

The conditioner rpm is set with the lever at the conditioner gearbox.

The condtioning effect can be adjusted.

> Turn the lever, depending on the requested conditioner rpm, to:

• H: high conditioner rpm

• L: low conditioner rpm

38

Page 39

Use at the field

Use at the field

Safety

Usin g th e m a ch in e

Pto

Driving along at the machine prohibited

It is never allowed that people or objects drive along at the machine.

Driving along at the machine is perilous and prohibited.

No persons in the turning area

Take care of no people be in the turning and working area of the

machine. People can get grabbed by the machine. Serious or deadly

injuries can occur.

Pto speed constant 1000 rpm

The pto speed may not exceed 1000 rpm and must be adapted to the

condition of the crop. A higher rpm can cause damages to the

machine.

Please take care of the following during use:

• the pto must be switched on

• drive at the correct working speed, between 8 and 12 km/h

The pto may only be switched on at a low motor rpm.

> Switch on the pto

> Use the manual throttle to maintain constant rpm speed of 1000

rpm

Working spe ed

Top link

No persons in the working area

Take care of no people be in the turning and working area of the

machine. People can get grabbed by the machine within this area.

Serious or deadly injuries can occur.

The working speed must be adapted according to the crop.

The mowing drums must be rotating at full working speed before

entering crop.

> Select a gear which allows an even stubble to be left

During mowing the machine is pushed forward. Necessary shortening

of the top link length may be possible to avoid tilting forwards.

→ »Top link«, page 39

39

Page 40

Use at the field

Headland driving

End of mowing

Lateral guards

Short turning driving at the field may only take place:

• at slow speed

• with the machine lifted

> Use the hydraulic tractor valve to lift the machine

To continue working:

> put the hydraulic tractor valve in floating position

At the end of the job:

> Switch off the tractor pto

> Use the hydraulic tractor valve to lift the machine fully

The drive of the machine must have completely stopped any rotation

prior to commencing the folding up procedure of the lateral guards.

> Fold up and lock the lateral guards

40

Page 41

Parking the machine

Parking the machine

Safety

Prior to parking

Parking

Pin

Pin +

spring clip

Storage safety

Store the machine in an area away from human activity. Do not allow

children to play on or around the stored machine. Serious injuries can

occur.

Prior to storing the machine perform the following:

> Thoroughly clean the machine, remove all crop residues

> Use oil, grease or a corrosive preventive to protect the bright metal

parts on the piston of the hydraulic cylinder

Park the machine

• in a dry space

• on stable ground

Take care that the machine can not be damaged by rodents or

martens.

The machine must be parked in working position.

> Lock the sliding part with the pin

> Use the hydraulic tractor valve to lower the machine fully

> Place the pins and lock them with the spring clips

> Use the 3-point hitch to lower the machine fully

> Disconnect the chains if connected

> Disconnect the pto drive shaft

> Unhitch the machine from the front hitch

Cleaning of drum

skirts/skid discs

After every working day:

> clean the space between drum skirts and skid discs

41

Page 42

Cleaning, caring and storing the machine

Cleaning, caring and storin g the machine

Preparing for

winter

Winter storage

> Empty and clean the machine of all accumulated crop

> Grease all greasing points

When you observe the rules below, you will have a fully operational

machine at the start of the next season.

• Consult your dealer if you have any questions

• Before taking into use again, all adjustment activities described in

the operation manual must be carried out

> Grease all the components of the machine (pivot points, cylinder

rods, etcetera)

> Protect the outside of the machine (antirust, spray with mixture of

diesel and oil)

> Check

• the condition of the machine

• the tightness of the hardware

> Replace any damaged parts

42

Page 43

Maintenance

Maintenance

Safety

Protection measures

in contact wi th o il or

lubricants

For all maintenance work applies:

Take care of the safety instructions

Definitely take care of the safety instructions during all work. In case

of negligence of the safety instructions serious or deadly accidents

can occur.

Conditions for maintenance work

Only carry out maintenance work if you do dispose of the necessary

professional knowledge and of the suitable tools. Missing professional

knowledge or unsuitable tools can cause accidents or damages.

Use original parts

Use original parts for safety relevant components. Dimensions,

strength, and material quality must be guaranteed. Building in of not

original parts the warranty reduces to nil and void.

Protect the machine against unintentional use

Carry out general repairs, maintenance and repair of function troubles

at the hitched machine, in principle with switched off pto, switched off

engine and removed ignition key! At unintended taking into use

serious accidents can be caused.

Additives in oil and lubricants can have, under circumstances, harmful

effects to health. Because an indication according to the danger order

is not necessary, therefore in principle please pay attention to:

Avoid skin contact

Avoid skin contact with these oil and lubricants. Protect your skin by

skin protection creams or oil-resistant gloves. Skin contact can lead to

skin diseases.

Do not use oil for cleaning

Never use oil and lubricants for hand cleaning! Chips and waste in this

oil and lubricants can extra lead to injuries.

Change dirty clothing

Change extremely filthy oiled clothing as soon as possible. Oil can

cause health injuries.

T

IP

• Waste oil must be collected and recycled

• In case skin diseases by oil or lubricants occur, immediately visit a

doctor

43

Page 44

Maintenance

General

Information of

directions

Direction Description

Left counterclockwards

Right clockwards

Front in the direction of travel

Rear in the direction of travel

Rotation around a horizontal axis as seen at right angles to the direction of travel from left to right

Rotation around a vertical axis as seen from top to bottom

Rotation from bolts, nuts, etcetera always as seen from the operating side

This information is related to all maintenance work. At all maintenance

work the machine must be secured in working position. In case the

transport position is necessary for maintenance, you will find suitable

tips to the maintenance work.

Information of directions (left, right, front, rear, above, below) are to be

seen in the direction of travel.

The direction of rotation has been defined as follows:

44

Page 45

Maintenance

Maintenance

intervals

»Attaching elements«

»Screwing bolts tighter«

»Special torques«

»Pto drive shaft«

»Checking length of the pto drive shaft«

»Shortening the pto drive shaft«

»Lubrication«

»Main pto drive shaft«

»Main pto drive shaft«

»Secondary pto drive shaft«

»Secondary pto drive shaft«

»Arms«

»Flexible top link«

»Mowing blades«

»Mowing blades«

»Moving / renewing blade holders«

»Checking blade holders«

»Renewing blade holders«

»Main frame unit«

»Checking the oil level«

»Changing the oil«

»Filling the main frame unit«

»Conditioner gearbox«

»Checking the oil level«

»Changing the oil«

»Filling the conditioner gearbox«

»L-gearbox«

»Checking the oil level«

»Changing the oil«

»Filling the L-gearbox«

Before doing any maintenance, the following must be obtained:

• Clean the machine before doing any repair work

• Never work on the machine while it is running

• Pto must be switched off

• Tractor engine must be stopped; ignition key must be removed

• Clean the machine with an air jet

Check

Before using the machine

After every working day

After the first 5 working hours

Every 10 working hours

Every 20 working hours

Every 250 working hours

Once per season

After exchange of the blade holders

Grease

If necessary

After every opening

Change

• • • •

••••••

••

• •

• •

••

• •

••

• •

••

•• •

••

• •

• • •

•• •

• • •

• • •

•• •

• • •

• • •

•• •

• • •

Page

46

46

48

48

49

49

49

49

49

50

51

52

53

55

56

56

57

57

58

58

58

59

45

Page 46

Maintenance

Attaching

elements

Screwing bolts

tighter

Special torq ues

100 Nm

All bolts and nuts must be screwed tighter:

• after the first 5 working hours

• depending on the usage frequency of the machine

• at least once per season

Take care of the special torques for the following screwed joints:

• 100 Nm skid saucer bolts

All skid saucer bolts must be screwed tight:

• after five working hours

• once per season

• after exchanging the blade holders

• 140 Nm blade holder nuts of the outer drums

140 Nm

60 Nm

• 60 Nm blade holder nuts of the inner drums

46

Page 47

Maintenance

Tightening

torques

All screwed joints on this machine must be torqued in accordance with

the values given in this table below unless indicated otherwise.

On this machine, 8.8 is both standard and minimum quality used. If not

indicated anyhow use this quality for determination of torque. In most

cases the quality can be found on the head of the respective bolt.

Thread Torque value Spanner

size*

8.8 10.9 12.9

Nm mm

M3 1.3 1.8 2.1 6

M4 2.9 4.1 1.9 7

M5 5.7 8.1 9.7 8

M6 9.9 14 17 10

M8 24 34 41 13

M10 48 68 81 17 (15)

M12 85 120 145 19 (17)

M14 135 190 225 22 (19)

M16 210 290 350 24 (22)

M18 290 400 480 27

M20 400 570 680 30

M22 550 770 920 32

M24 700 980 1180 36

M27 1040 1460 1750 41

M30 1410 1980 2350 46

M33 1910 2700 3200 50

M36 2450 2546 3063 55

M39 3200 4500 5400 60

* Values in brackets = spanner size of lock bolts and nuts with toothed

flange are given in brackets if different from standard.

T

IP

• The listed values are applicable for dry or slightly oiled joints

• Do not use plated bolts/screws/nuts without grease

• When a stiff grease is applied decrease the given value by 10%

• In case lock nuts, lock screws or lock bolts are used increase the

given value by 10%

47

Page 48

Maintenance

Pto drive shaft

Protection tube Profiled tube

Profiled tube

Checking l en gth of

the pto drive shaft

min. 37 cmmin. 5 cm

Protection tube

min. 5 cmA

The length of the pto drive shaft has to be adapted. This depends on

the distance between tractor and machine.

Correct length

To long a pto drive shaft may seriously damage drive bearings of both

tractor and machine. Which is beyond any warranty.

Prior to coupling the pto drive shaft check the length:

> Correctly line-up tractor and machine

> Ensure the tractor pto is clean and greased

> Fit both pto drive shaft halves (not connected!)

> Hold both pto drive shaft halves together, ensure

• the protection tube shall be at least 5 cm shorter

• the overlap of the profiled drive tubes shall be at least 37 cm

Shortening the pto

drive shaft

A = B

> Exactly determine the correct length of the shaft

> Shorten the protection tubes

> Shorten the profiled drive tubes

The length of both cut-off ends shall be identical.

> Clean cut ends of both protection tubes and profile tubes to ensure

they are all smooth and clean

48

Page 49

Maintenance

Lubrication

Main pto driv e sha ft

Joints

Grease nipples

Secondary pto dri ve

shaft

Dust covers Grease nipples

All grease nipples must be greased after every cleaning with a highpressure cleaner.

An own operation manual of the manufacturer has been added to

every pto drive shaft. This operation manual contains detailed

information to the relevant pto drive shaft model.

Check protective parts

All protective parts of the pto drive shaft must be checked visually on

wear and damage. Exchange defective protective parts. An

unprotected pto drive shaft or damaged protective parts can cause

serious injuries during use.

> Disconnect the pto drive shaft

> Grease the grease nipples every 250 working hours

> Check every 10 hours that the tubes of the pto drive shaft are

sliding correctly

> Largely grease the 2 joints of the pto drive shaft before

commissioning the machine

> Remove the dust covers

> Grease the grease nipples every 250 working hours

> Place the dust covers

Arms

Grease nipples

> Grease the 4 grease nipples on both sides of the machine every 10

working hours

49

Page 50

Maintenance

Flexibl e top l in k

Grease nipple

> Grease the grease nipple every 10 working hours

50

Page 51

Maintenance

Mowing blades

Front guard

Wear safety gloves

Mowing blades are very sharp. Always wear safety gloves when

handling mowing blades. Not wearing safety gloves can cause serious

injuries.

TIPAlways exchange all mowing blades per drum.

Ensure there are always

• two mowing blades per inner drums

• four mowing blades per outer drums

Each mowing blade has two cutting edges. As soon as one edge has

been worn, the mowing blade must be fitted upside down in its

position.

An arrow on each mowing blade shows the direction of rotation.

> Lower the machine fully into working position using the 3-point

front linkage

> Fold up and lock the front guard

> Use the blade detachment tool to change the mowing blade

> Fold down the front guard fully

> Regularly check the blade holders

→ »Checking blade holders«, page 52

51

Page 52

Maintenance

Moving / renewing

blade holders

Checking bl a de

holders

Secure the machine from falling down

Before doing any maintenance or adjustment work on a lifted

machine: secure the machine from falling down. Serious injuries can

occur.

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents or decreases the risk of serious injuries.

For both outer and inner drums counts, always:

• exchange all blade holders per drum

• use new bolts and nuts when mounting the blade holders

The blade holders must have a minimum distance X = 0 mm.

The blade pins must have a minimum diameter Y of 7 mm.

The blade holder must be renewed if:

• distance X is smaller than or equal to 0 mm

• the blade pin has a smaller diameter Y than 7 mm

Blade pin

X

ST0301

Y

52

Page 53

Maintenance

Renewin g bl ad e

holders

Front guard

Basic position

1 2 3 4

Proceed as follows:

> Use the hydraulic tractor valve to lower the machine fully into

working position

> Fold up and lock the front guard

> Rotate the drums manually into the basic position

> Use the blade detachment tool to remove the mowing blades

> Fold up the front guard fully

TIPArrow = direction of drive

> Remove the concerning skid disc

> Remove the worn blade holder

> Mount the new blade holder

> Move the blade holders of the other drum skirts in order to produce

the basic position

> Mount the concerning skid disc

> Use the blade detachment tool to place the mowing blades

> Fold down the front guard fully

53

Page 54

Maintenance

Flexible top link

Checking

Spring Pin Plate

A

Adjustment

Pin Plate

The flexible top link is kept at a constant tension by two springs. These

springs must have a constant length.

Distance A between the plate and the pin must be 90 mm.

> Check if distance A is 90 mm

In case distance A is not 90 mm, the distance between the plate and

the pin must be adjusted.

The adjustment of distance A must be adjusted by turning the nut.

> Turn the nut clockwards = distance A increases

or

> Turn the nut counterclockwards = distance A decreases

A

Nut

54

Page 55

Maintenance

Gearboxes

Contents

Main frame unit

The machine contains six gearboxes, which are

• the main frame units

• the conditioner gearbox

• the L-gearbox

All gearboxes are filled with oil. The oil level must be checked and

levelled

• after the first 20 working hours

• once a year

• in case of excessive oil loss

Gearbox Content (l) Specification

Main frame unit 0.3 each SAE 85W-90 API GL-5

Conditioner gearbox 3 SAE 85W-90 API GL-5

L-gearbox 1 SAE 85W-90 API GL-5

Correct checking the oil level

Checking the oil level may only take place when the machine

• has stand still for a long time

• stands horizontal

Otherwise a false oil level can occur. A false oil level can cause

serious machine damages.

Checking the oil level

Oil gauge

Upper line

Lower line

Checking the oil level must be done per main frame unit.

> Remove the oil gauge on top of the main frame unit

The oil level must be between the upper and the lower lines.

> Replace the oil gauge

If the oil is below the lower line, the main frame unit must be filled.

55

Page 56

Maintenance

Changing the oil

Plug

Filling the main frame

unit

Oil gauge Fill opening

Changing the oil must be done per main frame unit.

> Place an oil bin below the change opening

> Remove the plug below the main frame unit

The oil flows into the oil bin.

When the main frame unit is empty

> replace the plug in the main frame unit

Filling the main frame unit must be done per main frame unit.

> Remove the oil gauge

> Fill the requested amount of oil via the fill opening

> Replace the oil gauge

56

Page 57

Condition er gea rbox

Checking the oil level

Plug

Changing the oil

Maintenance

> Remove the plug at the left side of conditioner gearbox

When oil comes out, the oil level is correct.

If no oil comes out, the conditioner gearbox must be filled.

> Replace the plug

> Place an oil bin below the plug

> Remove the plug

The oil flows into the oil bin.

When the conditioner gearbox is empty

> replace the plug

Now the conditioner gearbox must be filled.

→ »Filling the conditioner gearbox«, page 58

Plug

57

Page 58

Maintenance

Filling the conditioner

gearbox

Plug

L-gearbox

Checking the oil level

Plug

> Remove the plug

> Fill the requested amount of oil via the fill opening

> Replace the plug

> Remove the plug at the right side of the L-gearbox

When oil comes out, the oil level is correct.

If no oil comes out, the L-gearbox must be filled.

> Replace the plug

Changing the oil

Plug

> Place an oil bin below the plug

> Remove the plug

The oil flows into the oil bin.

When the L-gearbox is empty

> replace the plug

Now the L-gearbox must be filled.

→ »Filling the L-gearbox«, page 59

58

Page 59

Filling the L-gearbox

Plug

Maintenance

> Remove the plug

> Fill the requested amount of oil via the fill opening

> Replace the plug

59

Page 60

Optional equipment

Optional equipment

General

Where parts are to be changed, only use genuine original spare parts.

When ordering, quote the machine identification numbers. Trained

people must only carry out the use, maintenance and repair of the

machine. Consult your dealer for any additional advice.

In addition, the warranty will be automatically annulled if the machine

has been equipped with accessories or spare parts not authorised by

the manufacturer.

Attach optional equipment in accordance with mounting instructions

and only to the appropriate attaching points.

For details of the optional equipment

→ Spare parts manual

60

Page 61

Troubleshooting

Troubleshooting

General

Troubleshooting

table

Problem Cause Solution Page

Machine does not rotate The slip clutch slips

No restarting before problem solving

Only restart the machine once the cause of the failure has been

identified. Otherwise, parts damaged as a result will not be covered by

warranty.

Before approaching the machine

> switch off the pto

> stop the tractor engine

> remove the ignition key

Troubles can mostly be easily and quickly be remedied. Before you

make an appeal to the service department, please check with help of

the table, if you can remedy the trouble by yourself.

• Lower the working speed

• Remove the blockage

61

Page 62

Disposal of the machine

When the real life of the machine has finished, its separate parts must

be properly disposed. Please observe the local current and valid

waste disposal regulations.

Metal parts

All metal parts have to be delivered to a metal recycling company.

Oil

The hydraulic oil must be disposed at a used-oil recycling company.

Plastic parts

All plastic parts can be recycled.

Rubber

Rubber parts, like hoses and tyres, have to be delivered at a rubber

recycling company.

Disposal of the machine

62

Page 63

In accordance with EU

Directive, 98/37/EC

Identification plate

EC Declaration of conformity

EC Declaration of confor mity

We

KUHN-GELDROP BV

Nuenenseweg 165

5667 KP Geldrop

The Netherlands

declare under our sole responsibility that the product

PZ 320FC and accessories

to which this declaration relates, conforms to the relevant basic safety

and health requirements of EU Directive 98/37/EC.

For the relevant implementation of the safety and health requirements

mentioned in the EU Directive, the following standards have been

taken into account:

• EN 12100-1;2 (04/2004);

• EN 294 (06/1992)

KUHN-GELDROP BV

Geldrop, 21.07.2009

Anthony van der Ley

Business area manager

63

Page 64

Index

Index

A

Acquaintance with the machine

Characteristics of the machine

Designation of the machine 19

Attachment of the machine

29

19

C

Cleaning, caring and storing the machine

Preparing for winter 42

Winter storage

42

D

Disposal of the machine 62

E

EC Certificate of conformity 63

H

Hitching the machine

Coupling the pto drive shaft

27

M

Maintenance 43

Attaching elements

Gearboxes

General 44

Information of directions

Lubrication

Maintenance intervals 45

Mowing blades

Pto drive shaft

Safety

Tightening torques 47

55

49

43

46

44

51

48

O

Optional equipment 60

P

Parking the machine

Parking

Prior to parking 41

Safety

Preface

Symbols used

Preparation at the field

Conditioner speed

Conditioning effect adjustment 38

Cutting height adjustment

General

Ground pressure 36

Hitching frame height

Swath guides adjustment

Preparation for road transport 33

Preparation for use

Check at beginning of the season

Top link adjustment 30

41

41

5

38

35

35

35

37

29

31

R

Road transport 33

Moving into transport position

Placing into transport position 33

Preparation for road transport

33

32

T

Technical specifications 21

Trouble shooting 61

Troubleshooting

General

Troubleshooting table 61

61

U

Use at the field

End of mowing

Headland driving

Pto 39

39

Safety

Top link

Using the machine 39

Working speed

39

40

40

39

64

Loading...

Loading...