Page 1

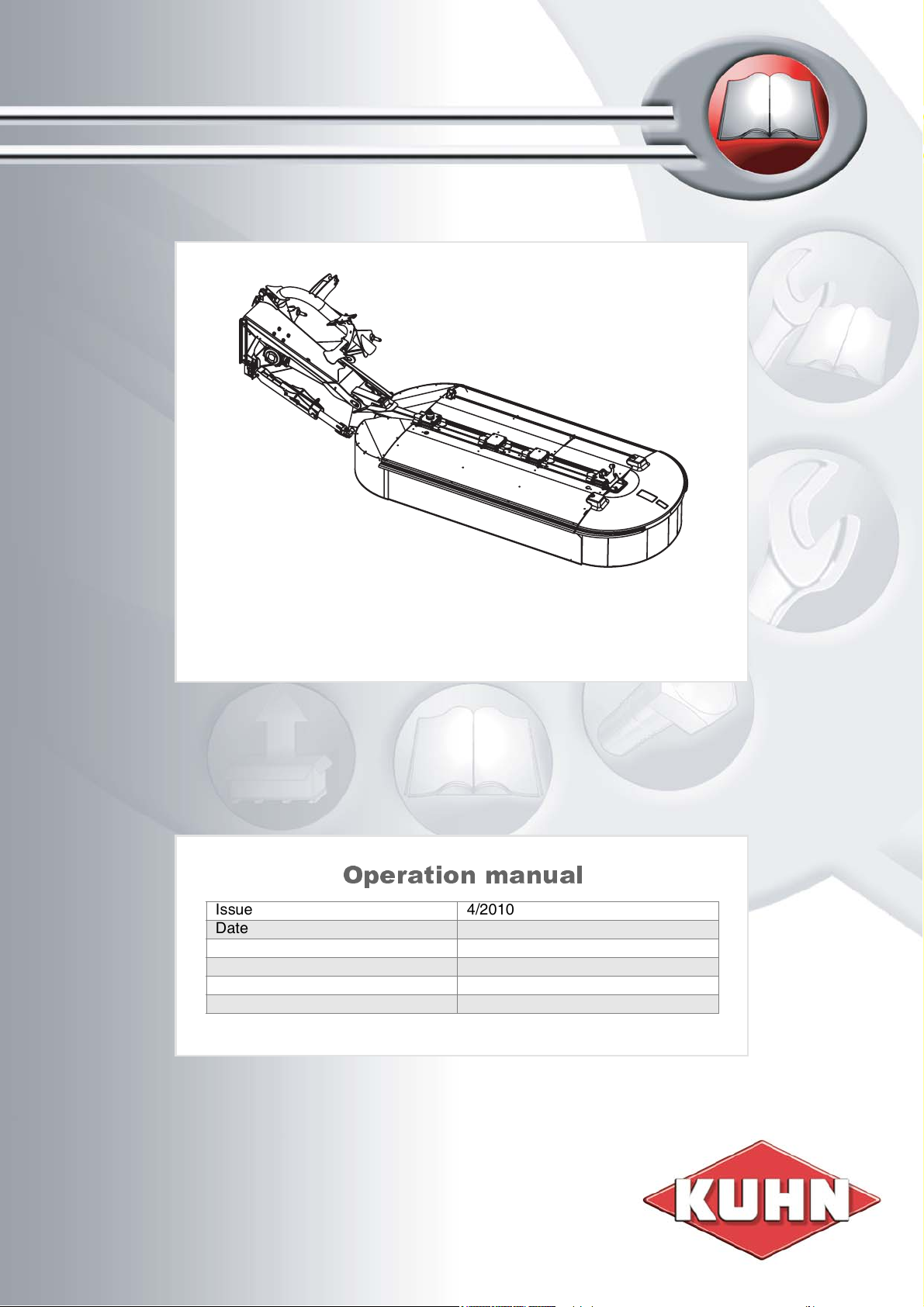

PZ320

Operatio n ma nual

Issue 4/2010

Date of printing 4.2010

Language EN

From machine number (PIN) VGPP000001

Serial Number (PSN) 01PP01

Reference number ZNA048EN

Page 2

Identifica ti on of the m achine

To support you as soon as possible your dealer requires several details of your machine.

Please enter the information here.

Designation

PIN

Mounted options

Dealer's address

PZ320

VGPP ...............................

Manufacturer’s

address

KUHN-GELDROP BV

Nuenenseweg 165

5667 KP Geldrop

The Netherlands

Phone +31 40 2893300

KUHN is continually striving to improve its products and, therefore, reserves the right to make improvements or changes when it becomes practical

to do so, without incurring any obligations to make changes or additions to the equipment sold before.

Copyright 2010 KUHN-GELDROP B.V..

Page 3

BG

ÀɤȠ ɬȠɜa pɔƸȠɜȠȾcɬɜȠ e ɩoɥyɱɟɧɨ ɧɚ ɟɡɢɤ, ɤɨɣɬɨ ɧɟ ɦɨԓɟ ɞɚ ɛɴɞɟ ɪɚɡɛɪɚɧ ɨɬ ɨɩɟɪɚɬɨɪɚ ɧɚ

ɦɚɲɢɧɚɬɚ, ɫɜɴɪԓɟɬɟ ɫɟ ɫ ɜɚɲɢɹ ɞɢɥɴɪ.

CS

Pokud obdr_íte tento návod v jazyce, kterému pracovník obsluhy stroje nerozumí, spojte se s

Vašim prodejcem.

DA

Hvis du har modtaget manualen på et sprog, som operatøren af maskinen ikke forstår, skal du

kontakte forhandleren.

DE

Sollten Sie diese Betriebsanleitung in einer Sprache erhalten haben, die der Bediener dieser

Maschine nicht versteht, kontaktieren Sie bitte Ihren Händler.

EL

EȐv ĮȣIJȩ IJo EȖȤİȚȡȓįȚȠ OįȘȖȚȫv XȡȒıȘȢ, İȓvĮȚ ıİ ȖȜȫııĮ ʌȠȣ įİv ȝʌoȡİȓ vĮ

IJov ȤİȚȡıIJȒ IJoȣ ȝȘȤĮvȒȝĮIJoȢ, ʌĮȡĮțĮȜȠȪȝİ vĮĮʌİȣșȣvșİȚIJİ ıIJov IJoʌȚțȩ ıĮȢ ĮvIJȚʌȡȩıȦʌo.

EN

If this manual is received in a language which cannot be understood by the operator of the

machine, contact your dealer.

ES Si recibe este manual en un idioma que no pueda ser entendido por el usuario de la máquina,

póngase en contacto con su proveedor.

įȚĮȕĮıIJİȓ Įʌȩ

ET

Kui käesolev juhend saadakse keeles, millest masinajuht ei saa aru, siis pöörduge edasimüüja

poole

FI

Jos käyttöohjeen kieli on sellainen, jota koneenkäyttäjä ei ymmärrä, on otettava yhteys

jälleenmyyjään

FR

Si vous recevez ce manuel dans une langue que l’opérateur de la machine ne comprend pas,

veuillez contacter votre concessionnaire.

GA

Má fhaightear an lámhleabhar seo i dteanga nach dtuigeann oibreoir an mheaisín, téigh i

dteagmháil le do cheannaí.

HR

Ako je ovaj priruþnik dostavljen na jeziku koji rukovatelj stroja ne razumije, kontaktirajte Vašeg

prodavaþa.

HU

Ha ez a gépkönyv olyan nyelven készült, amelyet a gép kezelĘ

a forgalmazóval

IS

Ef handbókin er á tungumáli sem notandinn skilur ekki, skal hafa samband við söluaðila.

je nem ért, vegye fel a kapcsolatot

IT

Se l’utente della macchina riceve il presente manuale in una lingua che non comprende,

suggeriamo di contattare il rivenditore.

Page 4

LT

Jei šƳ vadovą gavote kalba, kurios mašinos operatorius nesupranta, kreipkitơs Ƴ platintoją.

LV

Ja saĖemtâ rokasgrâmata ir maÿînas operatoram nesaprotamâ valodâ, sazinieties ar tirgotâju.

MT

Jekk dan il-manwal jiƥi rƛevut f’lingwa li ma tkunx tista’ tinftiehem mill-operatur tal-magna,

ikkuntattja lill-aƥent tiegƫek

NL

Als u deze handleiding heeft ontvangen in een taal die voor de bediener van de machine niet

begrijpelijk is, raadpleeg uw dealer.

NO

Kontakt forhandleren hvis denne bruksanvisningen er på et språk som maskinoperatøren ikke

forstår.

PT

Se este manual for recebido num idioma que não seja entendido pelo operador da alfaia,

contacte o seu concessionário.

PL Ja saĖemtâ rokasgrâmata ir maÿînas operatoram nesaprotamâ valodâ, sazinieties ar tirgotâju.

RO Dacă prezentul manual este primit într-o limbă care nu poate fi înĠeleasă de către operatorul

maúinii, contactaĠi distribuitorul dumneavoastră.

RU

ȿɟɥɢ ɨɩɟɪɚɬɨɪ ɩɨɥɭɱɢɥ ɪɭɤɨɜɨɞɟɫɬɜɨ ɧɚ ɹɡɵɤɟ, ɤɨɬɨɪɵɣ ɨɧ ɧɟ ɩɨɧɢɦɚɟɬ, ɧɟɨɛɯɨɞɢɦɨ

ɨɛɪɚɬɢɬɖɫɹ ɤ ɞɢɥɟɪɭ.

SK

Ak dostanete túto príruþku v jazyku, ktorému operátor stroja nerozumie, spojte sa so svojím

predajcom.

SL

ýe ta priroþnik prejmete v jeziku, ki ga upravljavec stroja ne razume, se obrnite na svojega

trgovca.

SV

Kontakta återförsäljaren om denna manual tagits emot på ett språk, som inte förstås av

maskinoperatören.

Page 5

Inhoudsopgave

Preface .............................................................6

Target group of this operation manual 6

Training 6

Symbols used 7

Inhoudsopgave

Operation ...................................................... 45

Safety 45

Start position 45

Mowing 46

Safety instructions .........................................8

For your safety 8

Safety decals 9

Who is allowed to operate the machine? 12

General 12

Hitching the machine 14

PTO drive shaft 14

Tractor loads 15

Hydraulics 18

Road transport 19

Operation 20

Unhitching the machine 22

Maintenance 23

Further prescriptions 24

Warranty and responsibility 24

Familiarize yourself with the machine ........ 25

General 25

Product description 25

Main components overview 25

Technical specifications 26

Delivery and preparation .............................28

Check the scope of delivery 28

Hitching the machine ...................................29

Safety 29

Hydraulic connections 29

Hitching to the 3-point hitch 30

Hitching 31

Coupling the pto drive shaft 33

Pto drive shaft 33

Electronic connections[+] 34

Cleaning ........................................................ 47

Cleaning 47

Parking and storage ..................................... 48

Safety 48

Unhitching the machine 48

After the season 50

Maintenance .................................................. 51

Safety 51

General 53

Maintenance table 54

Complete machine 55

Bolted connections 55

Torques for bolted connections 56

Drums 57

Gearboxes 60

Drive shafts 64

Hitch frame 67

Troubleshooting ........................................... 68

General 68

Mowing unit 69

Hydraulics 69

Optional equipment ...................................... 70

General 70

Road lighting set 70

Disposal of the machine .............................. 71

EC Declaration of conformity ...................... 72

Index .............................................................. 73

Preparation for use .......................................35

Safety 35

Top link adjustment 35

Hitch frame adjustment 35

Checklist 36

Road transport ..............................................37

Safety 37

General conditions 38

Place the machine into transport

position 38

Checklist 40

Preparation at the field .................................41

Safety 41

Change settings 41

Set the machine into operating mode 41

Mowing unit 42

5

Page 6

Preface

Preface

Target group of

this operation

manual

Training

This operation manual is directed at trained farmers and individuals

who are otherwise qualified to perform agricultural activities and who

have received instruction to handle the machine.

For your safety

You have to familiarize yourself with the contents of this operation

manual before assembly or initial operation of the machine. In this

way, operating and work safety are optimized. The operation manual

is an integral part of the machine and must always be kept to hand.

This will allow:

• Accidents to be avoided.

• The warranty conditions to be met.

• A well-functioning machine in good working order.

N

OTE

If anything in this manual is unclear or is incomprehensible, contact

your dealer.

Your dealer will give you instruction about operation and care of the

machine.

Employer information

All personnel has to be regularly instructed how to operate the

machine. At least once a year, in accordance with the regulations of

the national organization for Health and Safety at Work. Untrained or

unauthorized individuals are not allowed to use this machine.

You are personally responsible for the safe operation and

maintenance of the machine. Always ensure all personnel that

operate or maintain the machine are familiar with the operation and

maintenance instructions and the relevant safety instructions from this

operation manual.

6

Page 7

Preface

Symbols used

In this operation manual the following symbols and terms are used:

• A dot accompanies each item in a list.

> A triangle indicates operating functions which have to be executed.

→ An arrow indicates a cross-reference to another section of this

manual.

[+] A plus sign indicates an accessory, which is not included in the

basic version.

(X) A number between brackets within the text refers to the number in

the drawing(s) belonging to the paragraph.

Next to these symbols, pictographs are used to help you locate other

sections of this manual.

N

OTE

The term “Note“ indicates tips and notes on operation.

The warning triangle indicates important safety instructions. Failure to

observe these safety instructions can result in:

• Serious faults in the correct operation of the machine.

• Damage to the machine.

• Personal injuries or accidents.

0

The wrench indicates tips during assemby or adjustments.

A star indicates examples that assist comprehension of the

instructions.

7

Page 8

Safety instructions

Safety instructions

For your safety

This chapter contains general safety instructions. Each chapter of the

operation manual contains additional specific safety instructions

which are not described in this chapter. Observe the safety

instructions:

• In the importance of your own safety.

• In the importance of the safety of others.

• To ensure the safety of the machine.

Numerous risks can result from incorrect handling of agricultural

machines. Therefore, always work with special care and never under

pressure.

For the employer

At regular intervals, inform those who work with the machine about

these safety instructions and the statutory regulations.

8

Page 9

Safety instructions

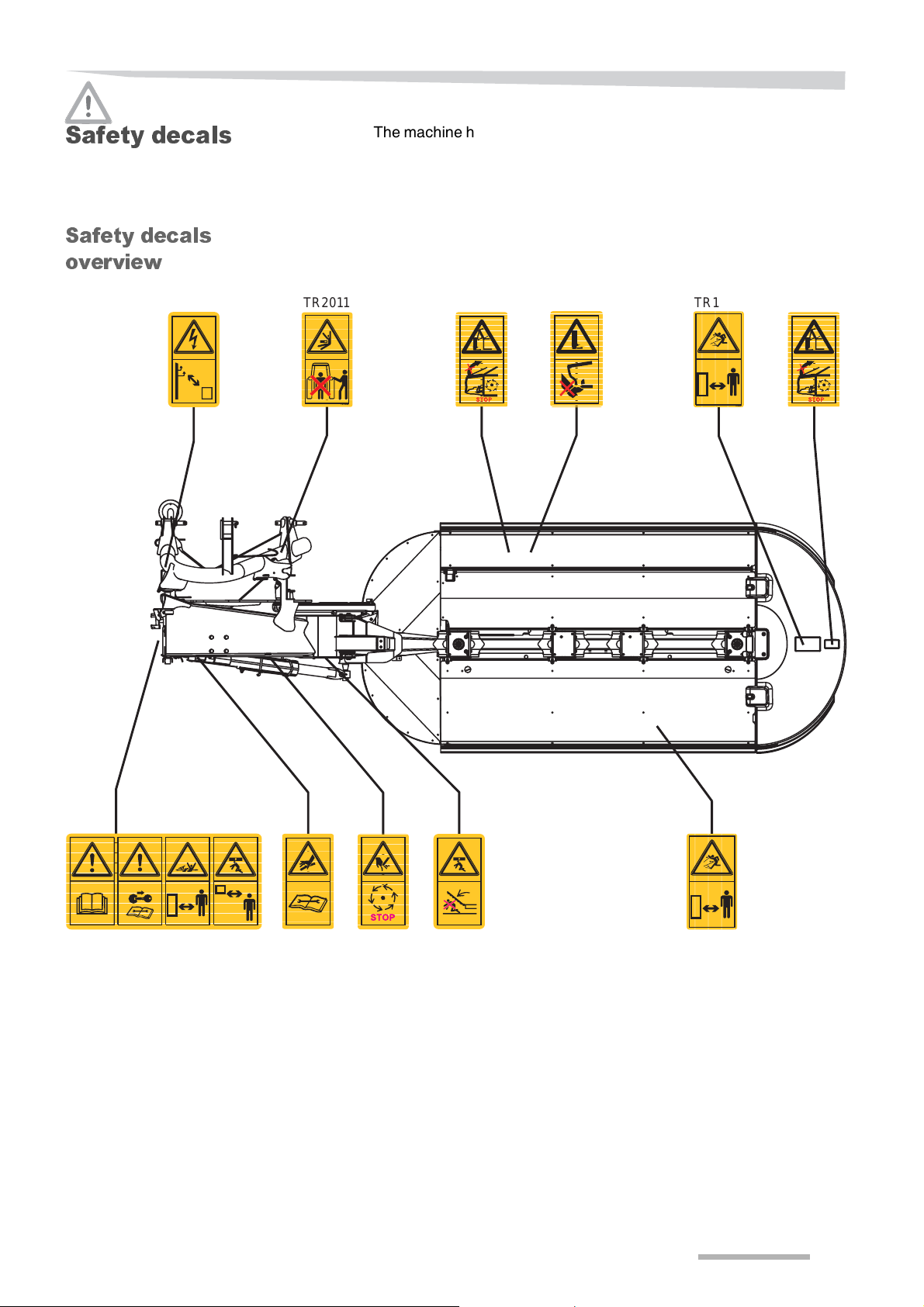

Safety decals

Safety decals

overview

TR2025

TR 2025

TR2011

The machine has safety decals for indicating attention to dangers. The

labels may not be removed. Keep all safety decals clean and legible.

In case safety decals are damaged, perished or lost, order new decals

as spare parts and affix them on the machine.

TR2095TR2097 TR2097

TR 2011

TR2097 TR2097

TR2095

TR1009

TR1009

TR3183

TR 3183

TR2055

TR2023

TR 2023

TR2007

TR 2007

TR1009

TR1009

TR 2055

9

Page 10

Safety instructions

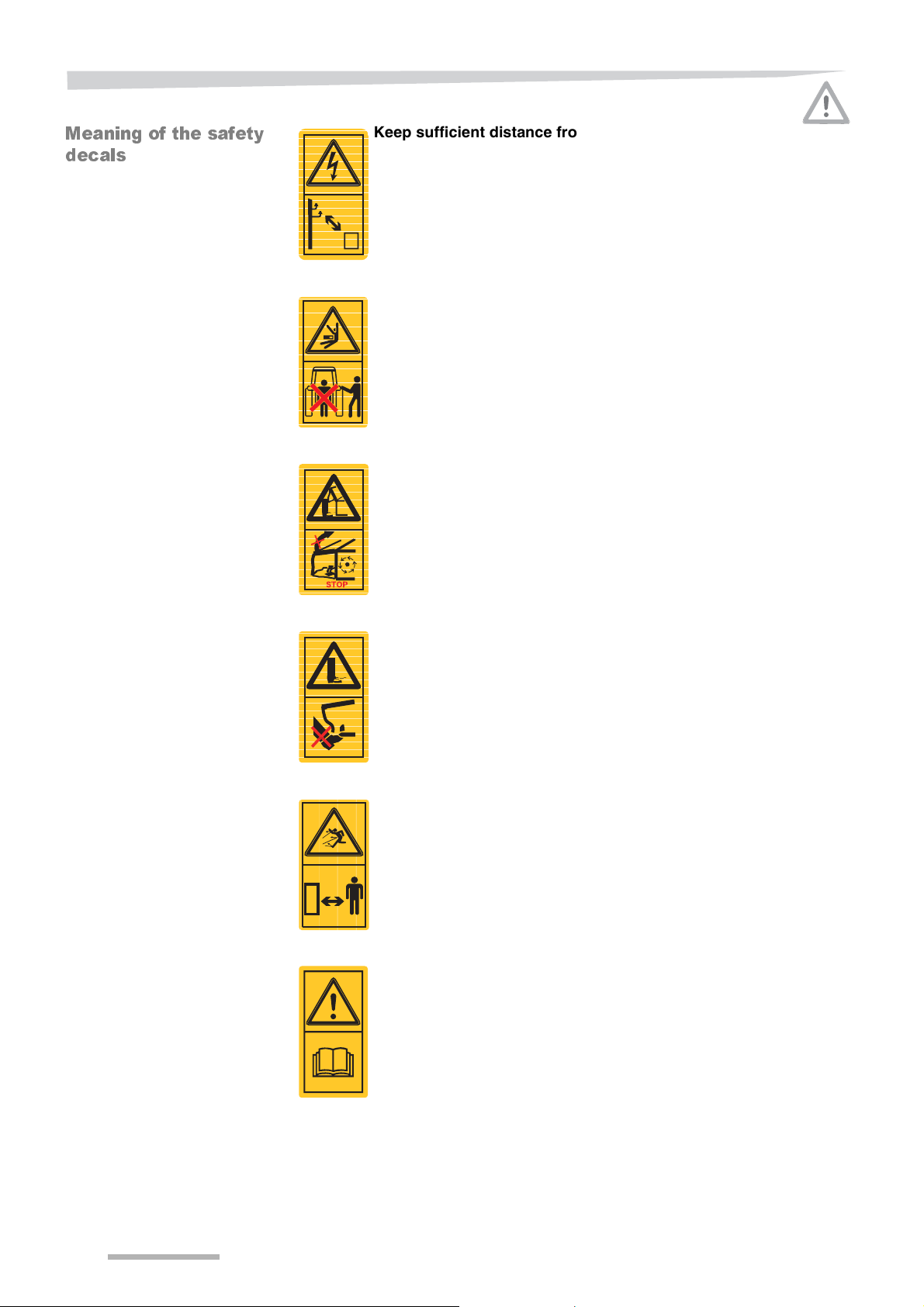

Meaning of the safety

decals

Keep sufficient distance from electrical power lines

Keep sufficient distance from electrical powerlines, especially when

driving with the machine in transport position.

TR 2025

Do not stand between the tractor and machine

During attachment/detachment of the machine, it is not allowed to stay

between the machine and the tractor. Danger of crushing.

TR 2011

Close shields and guards prior to operate the machine

Keep al shields and covers closed while the machine is running.

Do not open or remove any shield or guard untill the machine has come

to a complete standstill. Danger of serious injuries

TR2097

Never bring your feet under the machine

Never bring your feet under the machine while parts are running.

Feet can be cut off. Danger of serious injuries.

TR2095

Stay clear of a running machine

Keep at a safe distance of the machine; objects like stones and other

debris, may fly away at very high speed (250 - 300 km/h).

Danger of serious injuries

TR1009

Read the operation manual

The machine may only be commissioned once the operation manual

has been read and fully understood. This applies in particular to the

safety instructions.

10

TR 2085

Page 11

Safety instructions

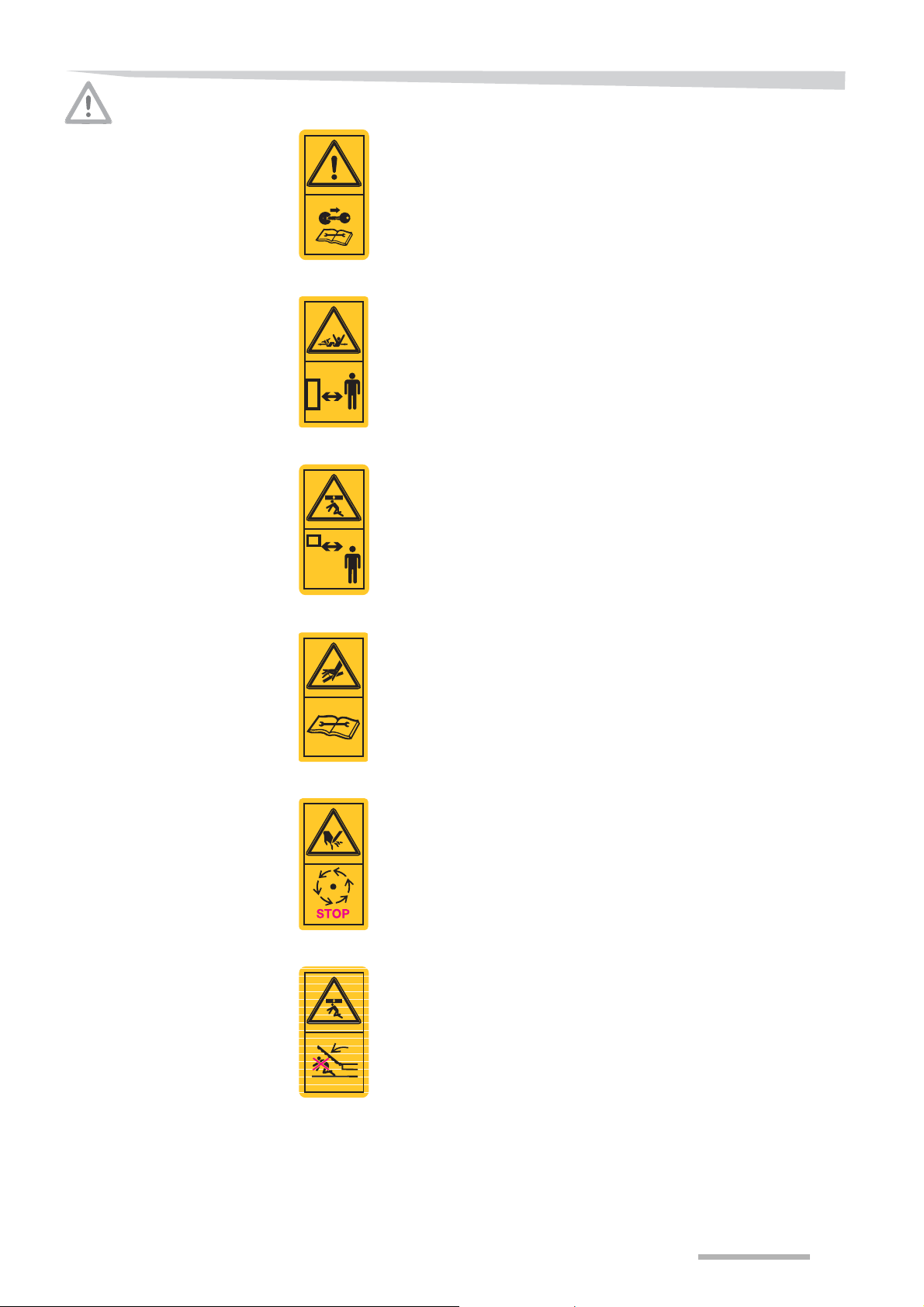

Switch off the tractor engine

Carry out all maintenance, repair and adjusting jobs only when the

machine is at a complete standstill. Switch off electric systems,

hydraulic systems and the engine and remove the ignition key.

Otherwise serious or fatal injuries can occur.

TR 2005

Stay clear of a rotating drive line

Stay clear of the drive line, you may get grabbed by rotating machine

parts. Danger of serious or fatal injuries.

TR 2029

Stay clear of a raised machine

Keep distance from a raised machine, you may get hit when the

machine will be lowered. Danger of serious or fatal injuries.

TR 2015

Do not search for hydraulic leaks by hand

Never search for leaks by touching hydraulic hoses and hydraulic

connections, even when your hands are protected with a protective

skin cream or oil-resistant gloves.

Due to high pressure and very little holes in case of leakages, the

hydraulic oil will go through protection devices and your skin!

Hydraulic oil may come into your bloodstream, which is

TR 2055

lifethreatening!

Mass inertia of the machine

Due to mass inertia of the machine, the machine keeps running for a

while after switching off the PTO.

Stay clear of the machine until the machine has come to a complete

standstill. Danger of serious injuries.

TR 2023

Stay clear of the swinging area of the machine

Stay clear of the swinging area of the machine. Danger of crushing.

TR 2007

11

Page 12

Safety instructions

Who is al lo w e d to

operate the

machine?

General

Only qualified personnel

Only qualified personnel who have been informed about the dangers

associated with handling the machine are permitted to operate,

service or repair the machine. This knowledge can be gained by

agricultural training, technical training or intensive instruction.

Safety is your responsibility

Follow the safety regulations. Ensure you are always in compliance

with the safety regulations. Most accidents can be avoided by

observing the safety instructions.

Use a suitable tractor

Ensure that the tractor meets the listed minimum requirements of the

machine. Ensure that the tractor for safely operating the machine for

all your specific conditions.

→ »Tractor requirements«, see page 27.

Prescribed workwear

Do not wear loose, baggy clothing to avoid being caught by the

rotating parts. Wear workwear and protective clothing as prescribed

by the trade’s mutual indemnity association. Otherwise there is a high

risk of serious or fatal injury.

Oils, lubricants and chemicals

Observe all safety instructions and directions for use for oils,

lubricants and chemicals (like paint, cleaning agents, solvents etc.), as

mentioned on the original packaging or chemical cards.

Fire hazard

Ensure the machine is always clean and remove any remaining crop

to avoid fire hazards.

Fire extinguisher

Equip the machine with a multipurpose ABC fire extinguisher with a

capacity of at least 10 kg. Always use a fire extinguisher which is

approved by the relevant authorities.

Proper operating condition

Ensure that the machine and your tractor are always in a proper

operating condition. Always work with a clean machine, remove any

dirt before operation. Observe the information and technical data in

the operation manual of your tractor.

Running in enclosed space

A machine connected and coupled to the tractor may never be used

in enclosed spaces. Combustion engine exhaust fumes are

dangerous, and may cause asphyxiation.

Never work on a running machine

Never work on the machine while it is running. Objects or personnel

can be caught, drawn in or crushed. Fatal injuries can occur.

12

Page 13

Safety instructions

Do not modify the machine

No modifications whatsoever may be made to the machine.

Unauthorized modifications can impair safety and effect the life time of

the machine. It even renders the manufacturer’s guarantee null and

void and frees the manufacturer from all liability.

Fire hazards when welding

When welding, be careful of any fire or combustion hazards caused by

sprayed metal and sparks. Work away from flammable objects or cover

them. Seal off any gaps or chinks. Ensure there is a suitable fire

extinguisher device and check the working premises; check them again

at the end of the welding process.

13

Page 14

Safety instructions

Hitching the

machine

PTO drive shaft

Increased risk of injury

While hitching the machine to the tractor there is an increased danger

of injury. Therefore always:

• Secure the tractor and the machine from rolling and sliding away.

• Switch off all hydraulic systems.

• Switch off all electronic systems.

• Switch off the engine.

• Remove the ignition key.

• Never stay between the tractor and the machine during hitching.

Failure to comply may cause damage to the machine and even life

threatening injuries.

PTO drive shaft

Only use the PTO drive shaft complying with the manufacturer’s

specification. Other PTO drive shafts with overload clutches can

permit higher torques, which can damage the machine.

PTO drive shaft operation manual

Regard to the manufacturer’s operation manual of the PTO drive shaft

for correct use. Obey all instructions, particularly the safety and

maintenance instructions mentioned in the PTO drive shaft manual.

Negligence can lead to damages at the PTO drive shaft and to the

machine.

Fix and check PTO drive shaft protection

The rotating PTO drive shaft is secured by a PTO drive shaft

protection. Take care that the PTO drive shaft protection is not

damaged. Fix the PTO drive shaft protection both to the tractor and the

machine, to prevent the protection cover from rotating. Unprotected

PTO drive shafts can cause serious personal injuries.

PTO speed 540 rpm

The prescribed PTO speed of maximum 540 rpm may not be

exceeded. Higher PTO speeds can damage the machine.

Do not compress the PTO drive shaft

During operation or transport the PTO drive shaft may not be

compressed. Compressed PTO drive shafts can cause damages to the

tractor and machine.

14

Page 15

Safety instructions

Tractor loads

Check all m a xi m um

and mini m um l oad s

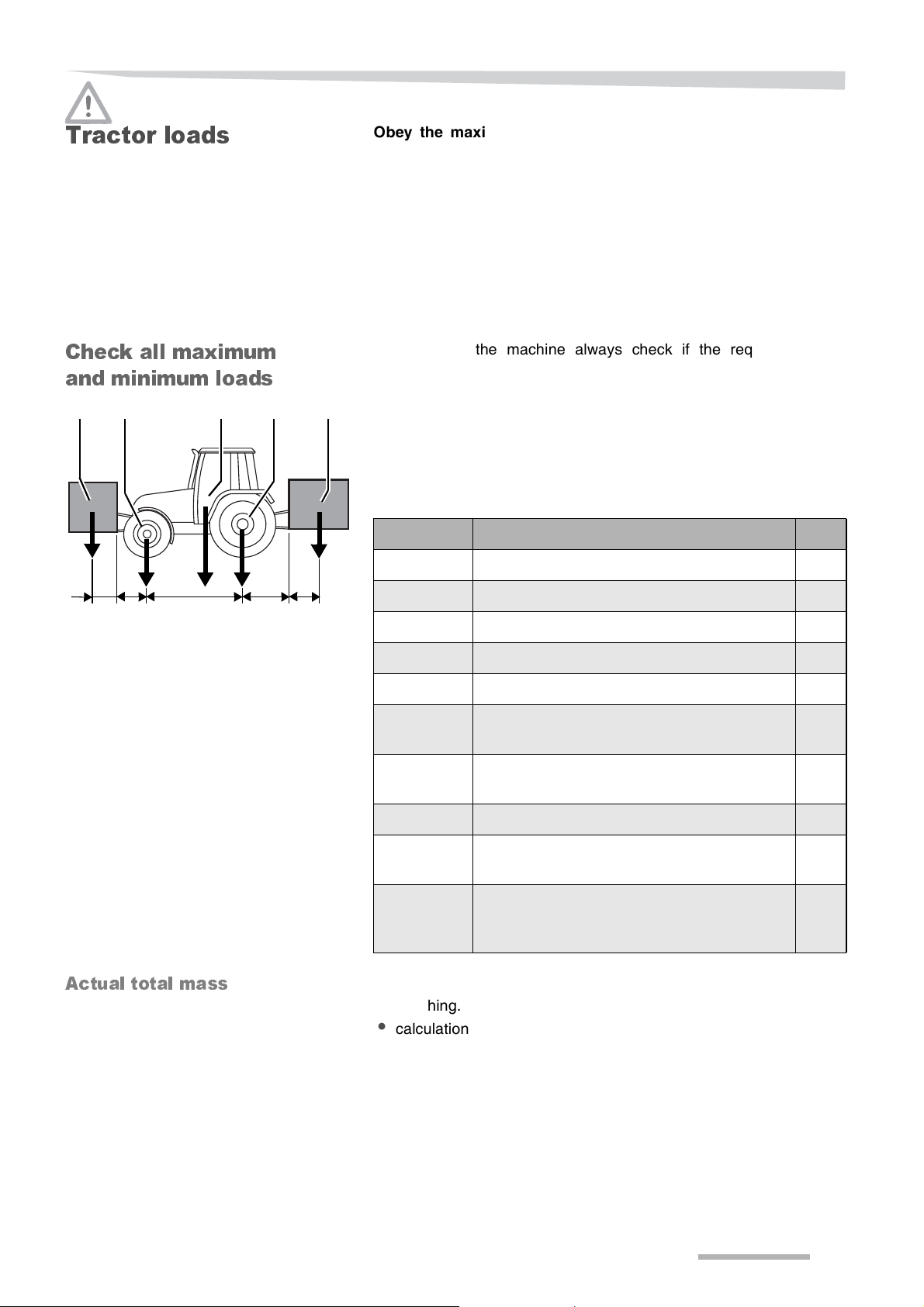

B CA

D E

*

*

*

*

Obey the maximum permissible mass, permissible axle loads

and permissible tyre loads.

Attaching machines to the front or to the rear 3-point linkage may

never result in:

• Exceeding the maximum permissible mass.

• Exceeding the maximum permissible axle load.

• Exceeding the maximum permissible tractor tyre load.

• Not complying with the minimum front axle load.

• Not complying with the minimum rear axle load.

Before using the machine always check if the requirements as

mentioned above are met.

Most of the dimensions and masses in the figure at the left can be

found in the tractor manual or in the corresponding machine manual.

In case this data can not be found, contact the corresponding dealer

or measure or calculate this value.

Legend:

*

Dimension Description Unit

A Unladen tractor mass kg

F G

Actual total mass

IH J

B Unladen front axle load kg

C Unladen rear axle load kg

D Total mass front attachment kg

E Total mass rear attachment kg

F Distance from the lower link ball point centre

to the front attachment’s centre of gravity

G Distance from the front axle centre to the

lower link ball point centre

H Tractor wheel base mm

I Distance from the rear axle centre to the

lower link ball point centre

J Distance from the lower link ball point centre

to the rear attachment’s centre of gravity

→ »Technical specifications«, see page 26

The actual total mass can be determined by:

• weighing.

• calculation:

This value may never exceed the maximum permissible mass.

mm

mm

mm

mm

A + D + E = ........... kg

15

Page 16

Safety instructions

Actual front axle load

The actual front axle load can be determined by:

• weighing.

• calculation:

D x (F + G + H)

B +

H

The actual front axle load may never exceed the maximum

permissible front axle load.

The actual front axle load may never be less than the minimum front

axle load (M). In case the minimum front axle load (M) is not

mentioned in the tractor manual, the minimum front axle load (M) has

to be at least 20% of the unladen tractor mass (A).

In case the minimum front axle load is not met, you have to add front

ballast.

To calculate the minimum required front ballast:

E x (I + J) - (B x H) + (M x H)

F + G + H

N

OTE

In case front ballast is mounted directly at the tractor, replace “F + G”

in the formula by the “Distance from the centre point of the front axle

to the gravity point of the ballast”.

D x (F + G +H)

H

= .......... kg

= .......... kg

Actual rear axle load

Always check the maximum permissible mass, permissible axle load

and permissible tractor tyre load after mounting front ballast.

The actual rear axle load can be determined by:

• weighing.

• calculation:

E x (H + I + J)

C +

H

The actual rear axle load may never exceed the maximum permissible

rear axle load.

The actual rear axle load may never be less than the minimum rear

axle load (N). In case the minimum rear axle load (N) is not mentioned

in the tractor manual, the minimum rear axle load (N) has to be at least

45% of the unladen tractor mass (A).

In case the minimum rear axle load is not met, you have to add rear

ballast.

To calculate the minimum required rear ballast:

D x (F + G) - (C x H) + (N x H)

H + I + J

D x (F + G)

H

= .......... kg

= .......... kg

16

N

OTE

In case the front ballast is mounted directly at the tractor, replace “F +

G” in the formula by the “Distance from the centre point of the front

axle to the gravity point of the front ballast”.

Always check the maximum permissible mass, permissible axle load

and permissible tractor tyre load after mounting rear ballast.

Page 17

Safety instructions

Actual tyre load

The actual tyre load can be found by dividing the corresponding actual

axle load by 2.

The actual tyre load may never exceed the maximum permissible tyre

load.

N

OTE

The maximum permissible tyre load is depending on the tyre pressure

and the driving speed.

17

Page 18

Safety instructions

Hydraulics

Hydraulic couplings only pressureless

Only connect hydraulic hoses to the tractor hydraulic system if the

tractor and machine’s hydraulic system is pressureless. A pressurized

hydraulic system can trigger unforeseen movements at the machine

and may cause serious damage or fatal injury.

High pressure in the hydraulic system

The hydraulic system is under high pressure. All pipes, hoses,

couplings and connecting passageways have to be checked for leaks

and other damage on a regular basis. Only use suitable tools when

checking for leaks. Repair any damage immediately. Escaping oil can

cause injuries and burns. Seek medical care immediately when

injuries occur.

→ »Maintenance«, see page 51.

Searching for hydraulic oil leaks

Never search for leaks by touching hydraulic hoses and hydraulic

connections, even when your hands are protected with a protective

skin cream or oil-resistant gloves.

Due to high pressure and very little holes in case of leakages, the

hydraulic oil will go through protection devices and your skin!

Hydraulic oil may come into your bloodstream, which is

lifethreatening!

18

Page 19

Safety instructions

Road transport

Ensure road safety

If you intend to transport the machine on public roads, the machine

and the combination of tractor and machine have to comply to current

Road Traffic Act’s requirements. This to guarantee your own safety

and the safety of other road users.

For example ensure:

• The license plate, road lighting, warning and protective equipment

is properly installed, clean and functioning.

• Compliance with the permissible transport dimensions and weights

and axle loads.

• Compliance with the brake requirements of the tractor-machine

combination.

Failure to meet the Road Traffic Act’s requirements can result in fatal

accidents.

Block all hydraulic valves

To avoid inadvertently activation of machine components, activate all

machanical and/or hydraulic valve locks at the machine. Also lock the

hydraulic valves at the tractor, or disconnect the hydraulic hoses.

Carrying people and objects on the machine is prohibited

Neither persons nor objects are allowed to be transported at the

machine at any time. Only parts stored in their dedicated storage

locations are alllowed to be transported at the machine. Riding on the

machine is hazardous and strictly prohibited.

Altered driving and braking performance

Driving and braking performances will change when the machine is

attached to the tractor. Take the width and balance weight of the

machine into account, especially when cornering. A driving style that

is not adapted to altered conditions can cause accidents.

Adapted speed

In the event of bad road conditions and excessive speed, very high

forces can occur that subject can overload the tractor and machine.

Adapt the driving speed according to the road circumstances to avoid

accidents with serious or fatal injuries.

19

Page 20

Safety instructions

Operation

First use only after instruction

It is not allowed to operate the machine until distribution company

employees, company representatives or manufacturer’s employees

have given instruction. If initial operation is performed without

instruction, damage to the machine can be caused by operating errors

and accidents can occur.

Ensure that the machine is in perfect technical condition

Do not operate the machine unless it is in perfect condition. Check all

important components and (let) replace any defective component

before start operating. Defective parts can cause damage to materials

and injuries to persons.

Do not remove protective equipment

The protective equipment should not be removed or by-passed.

Check all protective equipment before operation. Unprotected

machine parts can cause serious or fatal injuries.

Carrying people and objects on the machine is prohibited

Neither persons nor objects are allowed to be transported at the

machine at any time. Only parts stored in their dedicated storage

locations are alllowed to be transported at the machine. Riding on the

machine is hazardous and strictly prohibited.

Make sure the direct surrounding is clear

Check the surrounding of the machine before starting and continually

during operation. Make sure that the operator has an adequate view

of the work area. Only start working if the direct surrounding is cleared

from any persons and objects to avoid serious or fatal injuries.

Tighten all bolts and nuts

Tighten all bolts and nuts regularly. Bolts and nuts may come loose by

using the machine. Loose or missing bolts and nuts can cause

damages to the machine or accidents.

Instructions in case of malfunctions

In case of a malfunction, stop the machine immediately:

• Switch off tractor hydraulics.

• Switch off electrical systems.

• Turn off tractor engine and.

• Remove the ignition key.

Perhaps the malfunction can be eliminated immediately, otherwise

contact your dealer. Using a faulty machine can cause accidents or

damage.

Observe the field conditions

Proceed with the utmost caution on hilly terrain or shifting subsoil.

Keep to both the maximum permissible engine load and the gross

working weight limit. A driving style which is not adapted to conditions

can cause accidents with serious or fatal injuries.

20

Page 21

Safety instructions

Cornering and turning manoeuvres

Centrifugal forces will occur during cornering. The machine’s centre of

gravity at the rear end of the tractor will be displaced. Be aware of the

turning radius and the moment of inertia.

PTO rotates after disengaging

After disengaging or switching off the PTO, the machine will continue

running because of inertia. Keep a safe distance to the machine until

all moving and rotating parts are at a complete stand still.

Blockage of a security device

In case of a blockage of a security device, never work on the machine

without

• Disengaging the PTO first.

• Switching off the tractor hydraulics.

• Switching off electronic systems.

• Switching off the tractor engine.

• Removing the ignition key.

Never try to repair a blockage or malfunction on a running machine.

Serious or fatal injuries can occur.

21

Page 22

Safety instructions

Unhitching the

machine

Increased risk of injury

An increased risk of injuries occurs when unhitching the machine from

the tractor. Therefore:

• Prevent the tractor and machine from rolling away.

• Switch off tractor hydraulics.

• Switch off electronic systems.

• Turn off tractor engine and remove the ignition key.

• Never stay between tractor and machine during unhitching.

• Take care of a level and secure surface for the machine.

• Take care of a secured support jack.

• Place the PTO drive shaft at the support or place it in the chain.

• Only detach the hydraulic hoses when the hydraulic system at the

tractor and the machine are pressureless.

In case of negligence heavy or deadly injuries can be the

consequence.

22

Page 23

Safety instructions

Maintenance

Observe the care and maintenance instructions

Observe the prescribed intervals for maintenance, checks and

inspections specified in this manual. If maintenance, checks and

inspections are not complied with, damage to the machine or

accidents can occur.

→ »Maintenance«,see page 51.

Use genuine parts

Only genuine parts are specially designed and thoroughly tested for

the use at this machine. Only genuine parts will guarantee the

reliability and safety of the machine. Other products can interrupt

functioning of the machine or make the machine unsafe. When using

non-genuine parts the warranty and liability of the manufacturer

reduces to nil and void.

Prevent the machine from inadvertent operating

Before carrying out maintenance and repair jobs always:

• Unhitch the machine from the tractor if possible and prevent it from

sliding away.

Otherwise always:

• Switch off the PTO.

• Switch off the tractor hydraulics.

• Switch off the electronic systems.

• Switch off the tractor engine.

• Remove the ignition key.

• Make sure the tractor and machine are positioned on a firm and

level area, support and prevent them from rolling or sliding away.

In case of negligence material damages and serious injuries can

occur.

Switch off electrical supply

Prior to carry out jobs at electrical equipment, disconnect it from the

power supply. Equipment under electrical power can cause damage

to equipment and injury to persons.

Climbing aids

Use suitable climbing aids only, never use components of the machine

as a climbing aid.

Replace hydraulic hoses every six years

Hydraulic hoses can age without any visible indications, therefore

replace all hydraulic hoses every six years. Defective hydraulic hoses

can cause serious or fatal injuries.

Searching for hydraulic oil leaks

Never search for leaks by touching hydraulic hoses and hydraulic

connections, even when your hands are protected with a protective

skin cream or oil-resistant gloves.

Due to high pressure and very little holes in case of leakages, the

hydraulic oil will go through protection devices and your skin!

Hydraulic oil may come into your bloodstream, which is

lifethreatening!

23

Page 24

Safety instructions

Caution when cleaning with a high-pressure cleaner

Avoid damage to the machine; bearings, seals and pipe unions may

not be contacted by the high pressure water jets.

No corrosive washing additives

Do not use any corrosive washing additives for cleaning. Bright metal

surfaces can be damaged.

Prior to carry out welding jobs

Unhitch the machine from the tractor if possible and prevent it from

rolling way before start welding. Otherwise always:

• Switch off the tractor hydraulics.

• Switch off electrical control system.

• Turn off tractor engine and remove ignition key.

• Disconnect all electrical and hydraulic connections from the tractor

to ensure the safety when carrying out welding jobs at the attached

machine.

In case of negligence material damages and serious injuries can occur.

Tighten bolted connections

Tighten all bolts and nuts that had to be unscrewed for maintenance

and repair jobs. Loose bolts and nuts can cause material damages

and serious personal injuries.

→ »Torques for bolted connections«, see page 56.

Further

prescriptions

Warranty and

responsibility

Observe the prescriptions

In addition to the safety instructions above, please also observe the

following:

• Accident prevention regulations.

• Generally recognized safety regulations, occupational health

requirements and road traffic regulations.

• Instructions given in this manual.

• Regulations pertaining to operation, maintenance and repair.

The warranty and manufacturer’s responsibility will no longer be valid

if:

• The safety instructions given in this manual are not obeyed.

• Maintenance and repair is carried out inadequate, incorrect, or not

carried out at all.

• Unqualified or untrained people carrye out maintenance anr repair.

• If the machine is overloaded.

• If the machine is used for other purposes for which it is intended.

• Unauthorized modifications are made to the machine.

24

Page 25

Familiarize yourself with the machine

Familiarize yourself w ith the machine

General

Product

description

Improper use of the

machine

Main components

overview

1

This chapter contains the following information:

• Range of applications and properties.

• Technical specifications.

This machine is designed for cutting of (non-)ligneous plants, mainly

grasses. Rotating knives cut the crop. By the drums a swath will be

created.

This machine is only designed for the use of agricultural purposes.

Any use whatsoever other than the above mentioned is improper use.

Neither the manufacturer nor the dealer is liable for any damage

resulting from improper use of the machine. In some cases, for

mowing unusual non-grassy plants a written authorization of the

manufacturer is required.

2

3 4 5

76

1Hitch frame

2 Hydraulic fold cylinder

3 Front guard

4 Mowing unit

5 Lateral Guard

6 Support jack

7 Hydraulic lift cylinder

25

Page 26

Familiarize yourself with the machine

Technical

specifications

Dimensions / Mass

Mass (kg) 800

L Lenght (mm) 1675

MW Mowing Width (mm) 3100

TW1 Transport Width 1 (mm) 1130

TW2 Transport Width 2 (mm) 1240

TH Transport Height (mm) 3220

J Distance lower tractor links to gravity point (mm) 850

PZ320

TH

TW1

J

TW2

MW

*

L

26

Page 27

Familiarize yourself with the machine

Machine

specifications

Number of mowing drums 4

Number of blades 12

Number of skid saucers 4

Cutting height adjustment 30 mm (continuously)

Cutting slope between -30° and +30°

Tractor requirem e nts

Minimum PTO power (kW / hp) 51 / 70

PTO speed (rpm) 540

PZ320

PZ320

Hitching category II

Minimum hydraulic oil pressure (bar) 180

Hydraulic connections 1 single acting control valve

Lighting power supply* 12V (DC) connector, 7 pin socket (DIN ISO 1724)

Optional equipment

Road lighting set

1 double acting control valve with pressureless return

* = Only necessary when road lighting [+] is installed.

27

Page 28

Delivery and preparation

Delivery and preparation

Check the scope

of delivery

The machine will arrive fully assembled. Check the machine after

delivery for loose or missing parts. In case parts are not assembled

please contact your dealer.

N

OTE

In case parts are missing or the machine got damaged during

transport, please submit a complaint immediately at your dealer,

importer, or the manufacturer.

.

Check list for parts Quantity

Operating manual 1

Spare part manual 1

Special accessories see delivery note

28

Page 29

Hitching the machine

Hitching the machine

Safety

Hydraulic

connections

Wear safety shoes

During all work at the machine never bring your feet under the

machine and always wear safety shoes. Wearing safety shoes

prevents and decreases the risk of serious injuries.

Before hitching the machine always:

• Prevent the tractor and machine from rolling away.

• Switch off all hydraulic systems.

• Switch off the tractor engine.

• Remove the ignition key.

• Never stand between the tractor and the machine during hitching.

In case of negligence serious or deadly injuries can occur.

Ensure the tractor is safe to use

Make sure that the tractor:

• Is in safe and good operating condition.

• Has adequate braking capabilities for the machine.

• Is able to carry and transport the machine.

A tractor which is not in a proper working condition can cause serious

personal and material damages.

Hydraulic connections only pressureless

Only connect hydraulic hoses to the tractor when all hydraulic systems

are pressureless. Hydraulics under pressure can cause accidental

movements of the machine with serious damage and injuries as a result.

Avoid oil mixture

If the machine is used at different tractors improper oil mixtures can

occur, which may destroy tractor and machine parts.

Avoid entering of dirt into the hydraulic system

The hydraulic system can get seriously damaged by dirt. Personal

injuries or material damage can be caused.

Check hoses and connections

Before connecting, check all hydraulic hoses for damages. After

connecting, check all hydraulic hoses for tight connection. Defective

hydraulic hoses or incorrect positioned hydraulic connectors can

cause unforeseen movements of the machine. Serious damage or

fatal injuries can occur.

Secure hydraulic devices

In transport position, secure the hydraulic control devices at the tractor

against unintended actuation and lock if possible. Unintended

actuation of the hydraulic device may lead to unexpected movements

of the machine. Fatal injuries and serious damage can be caused.

Check correct position and layout of hydraulic hoses

Hydraulic hoses may not be jammed or under tension. Pay attention

to sufficient play. Twisted or jammed hydraulic hoses can cause serious

injuries and damages to the machine.

29

Page 30

Hitching the machine

Hitching to the

3-point hitch

Lower link s

1

A

2

The machine is suitable for a catagory II 3-point hitch.

The lower link pins can be set according to:

• The track width of the tractor.

• An optional front mower

Before attaching the machine to the tractor, set the lower links pins in

the required position.

Setting Hitch catagory II

1 A = 1,04 m

2 B = 1,24 m

B

2

1

To set the lower link pins:

> Place the machine at the support jack.

> Loosen the bolts (2).

> Remove the lower link pins (1).

> Install the lower link pins (1) in the required position.

> Apply sealant agent to the screw thread of the bolts (2).

> Tighten the bolts (2).

30

Page 31

Hitching the machine

Hitching

1

4

2

3

> Before hitching the machine, ensure that both tractor lower links

are set at the same heigth.

> Hitch the machine to the tractor lower links and top link.

> Fix the tractor lower links to prevent the machine from moving

sideways. Use stabilisers or chains.

• Connect the blue marked hydraulic hoses (1) and (2), to the double

acting control valve.

• Connect the non-marked hydraulic hose (3) to the single acting

control valve.

> Use the lever (4) in the tractor to place the valve connected to the

blue marked hoses in floating position.

5 6

> Use the 3 point hitch to lift the machine fully.

> Remove the spring clip (6).

> Rectract the support jack (5).

31

Page 32

Hitching the machine

6

798

7

5

9

> Secure the support jack (5) with the spring clip (6).

> Remove the locking pin (9).

> Lift the locking device (7).

> Place back the locking pin (9) in the upper hole and secure the

locking pin.

10

32

11

10

11

> Use the 3-point hitch to place the hitch frame at the correct height.

The correct height is reached when the plate (11) points to the

indicator (10).

Page 33

Hitching the machine

Coupling the pto

drive s h af t

Pto drive shaf t

1

2

Do not use a hammer

It is not allowed to use a hammer or equivalent tools to mount the PTO

drive shaft. By using a hammer the PTO drive shaft can get seriously

damaged, which may lead to machine and tractor damages.

> Check the length of PTO drive shaft, before coupling.

> Shorten the PTO drive shaft if necessary, as described in the next

paragraphs.

> Ensure the tractor PTO is clean and greased.

> Connect the PTO drive shaft at both tractor and machine side.

> Ensure the shaft sliding ring catch with the slot of the PTO.

Fit the chains to rigid positions at both tractor and machine to prevent

the protection covers from rotating.

In some cases the length of the PTO drive shaft has to be adapted.

This is depending on the distance between tractor and machine

2

1 Protection tube

2 Profiled tube

1

Check length of the

PTO drive shaft

min. 37 cmmin. 5 cm

min. 5 cmA

Shortening the pto

drive shaft

Correct length

Never use a PTO drive shaft which is too long, this seriously damage

drive bearings of both tractor and machine.

Prior to coupling the PTO drive shaft check the length:

> Correctly line-up tractor and machine.

> Ensure the tractor PTO is clean and lubricated.

> Fit both PTO drive shaft halves (not connected!).

> Hold both PTO drive shaft halves together, ensure that:

• The protection tube shall be at least 5 cm shorter.

The overlap of the profiled drive tubes shall be at least 37 cm.

Make sure the PTO drive shaft is not damaged.

> Exactly determine the correct length of the shaft.

> Shorten the protection tubes.

> Shorten the profiled drive tubes.

The length of both cut-off ends has to be identical.

Clean cut ends of both protection and profile tubes to ensure they are

all smooth and clean.

A = B

33

Page 34

Hitching the machine

Electronic

connections[+]

Road lighting [+]

Check the cable layout

Take care of enough free space to avoid cables from getting stretched

twisted or torn. Stretched, twisted or torn cables may lead to machine

and tractor damages.

Check the cables and connections

Before connecting check all electronic cables for damages. After

connection check the electronic cables for tight connections.

Damaged or incorrect connected plugs may lead to machine and

tractor damages.

Connect the 7-pin connector (DIN ISO 1724) to the road lighting

connector at the tractor.

34

Page 35

Preparation for use

Preparation for use

Safety

Obey safety instructions

Obey the safety instructions at the execution of all work. Any disregard

for safety instructions can lead to serious or fatal injuries.

→ »Safety instructions«, see page 8.

Wear safety shoes

During all jobs at the machine never bring your feet under the machine

and always wear safety shoes, to decrease the risk of serious injuries.

Switch off the tractor and secure it

Never work at a running machine, make sure that:

> All hydraulic systems are switched off.

> The engine is switched off.

> The ignition key is removed.

> The electronic systems are switched off.

> The tractor is secured from rolling away.

In case of negligence, serious or deadly injuries can occur.

Check all hydraulic connections

Before use, check if all hydraulic connections are fitted correctly to the

corresponding single acting valves at the tractor. Incorrect connected

hydraulic hoses can cause unpredictable movements of the machine,

which may result in serious or fatal injuries.

Hitch frame

adjustment

1

2

Top link

adjustment

1

> Use the 3-point hitch to place the hitch frame at the correct height.

The correct height is reached when the plate (2) points to the

indicator (1).

2

The mowing angle can be adjusted by setting the top link of the tractor.

> Adjust the top link of the tractor in such a way that the machine

always stays horizontal or slightly tilts forward.

> Check if the machine only can tilt forward.

> Adjust the cutting height.

→ »Cutting height adjustment«, see page 43.

N

OTE

To avoid recutting, the mowing unit may never be tilted backwards.

35

Page 36

Preparation for use

Checklist

> Run the tractor hydraulics at idle.

> Run the machine for 540 rpm for some minutes.

> Check the components for operating correctly.

> Check for unusual noises.

> Switch off the tractor hydraulics.

> Switch off the PTO.

> Switch off the tractor engine and remove the ignition key.

> Tighten all bolted connections.

→ »Torques for bolted connections«, see page 56.

During the running-in period, special maintenance has to be carried

out.

→ »Maintenance table«, see page 54.

36

Page 37

Road transport

Road transport

Safety

Before road transport will take place, please read the following safety

instructions. The compliance is mandatory and helps you to avoid

accidents.

Observe safety instructions

Observe the safety instructions for carrying out all kind of jobs. Any

disregard for safety instructions may lead to serious or fatal injuries.

→ »Safety instructions«, see page 8.

Switch off all electronic controls and the hydraulic circuit

Always switch off the electronic systems, and switch off all hydraulic

systems. Inadvertently operating will be prevented this way, otherwise

material damages and fatal injuries can occur.

Make sure the machine is clean before road transport

Before transportation by road, make sure that the machine is clear and

clean from heavy dirt, remaining crop and soil. Crop, dirt or soil that

drops on the road, can cause slippery road conditions. Ensure that all

lighting equipment is free from remaining crop and dirt. Clean the

machine to avoid to traffic accidents.

Block all hydraulic valves

To avoid inadvertently activation of machine components, activate all

mechanical and/or hydraulic valve locks at the machine. Also lock the

hydraulic valves at the tractor or disconnect the hydraulic hoses.

Install and close all protective equipment

All protective covers and doors have to be installed, closed and secured

during road transportation. Material damages and personal injuries can

be caused.

Carrying people and objects on the machine is prohibited

Neither persons nor objects are allowed to be transported at the

machine at any time. Only parts stored in their dedicated storage

locations are alllowed to be transported at the machine. Riding on the

machine is hazardous and strictly prohibited.

Do not compress the PTO drive shaft

During operation or transport the PTO drive shaft may not be

compressed. Compressed PTO drive shafts can cause damages to

the tractor and machine.

Be aware of the transport height

Be aware ot the transport height of the combination of tractor and

machine, especially when driving under high-voltage cables and low

underpasses. Serious personal damages and heavy machine

damages can occur.

37

Page 38

Road transport

General

conditions

Place the machine

into transport

position

1

You have to put the machine into the transport position before road

transport may take place.

Next steps are necessary:

• Remove crop residues and heavy dirt.

• Install, close and secure all protective covers, unless stated

otherwise.

• Place the mowing unit into transport position.

• Switch off the electronic systems.

• Switch off all hydraulic systems.

• Close all hydraulic valves.

Before road transport may take place, the mowing unit has to be

placed in the transport position.

> Fold up and lock the lateral guard (1).

2

4

3

> Pull the rope (2) to lift the locking device of the hydraulic lift cylinder

(3). Keep the locking device lifted.

> Use the lever (4) in the tractor to extend the hydraulic lift cylinder.

The machine will be tilted to halfway position.

38

Page 39

Road transport

4

2

3

> Release the rope (2) and lower the locking device of the hydraulic

lift cylinder (3).

> Use the lever (4) in the tractor to retract the hydraulic fold cylinder.

The machine will be placed in transport position.

> Use the 3-point hitch to place the machine at the required transport

height.

39

Page 40

Road transport

Checklist

Prior to transport the machine on public roads, check if all conditions

of this checklist are met:

• Cables and hoses are routed in such a way that they can not get

stuck, nog get tensioned or interfere with other tractor and/or

machine parts?

• The tractor hydraulics are switched off?

• All hydraulic valves are closed?

• The PTO is switched off.

• The lateral guard is folded up and locked.

• Remaining crop and dirt is removed?

40

Page 41

Preparation at the field

Preparation at the field

Safety

Change settings

Obey the safety instructions

Obey the safety instructions at the execution of all work. Any disregard

for safety instructions can lead to serious or deadly injuries.

→ »Safety instructions«, see page 8.

Wear safety shoes

During all jobs at the machine never bring your feet under the machine

and always wear safety shoes, to decrease the risk of serious injuries.

Switch off the tractor and secure it

Never work at a running machine, make sure that:

> All hydraulic systems are switched off.

> The engine is switched off.

> The ignition key is removed.

> The electronic systems are switched off.

> The tractor is secured from rolling away.

In case of negligence, serious or deadly injuries can occur.

Only adapt the machine settings in the operating mode, as described

in the sections:

• Set the machine into operating mode.

• Checklist prior to operation.

Set the machine

into operating

mode

Set the machine in the operating mode;

• Place the mowing unit in operating position.

• Set the cutting height.

• Set the ground pressure compensation.

41

Page 42

Preparation at the field

Mowing unit

Place the mowing

unit into operating

position

1

> Use the lever (4) in the tractor to extend the hydraulic fold cylinder.

The machine will be lowered to halfway position.

2

1

3

> Pull the rope (2) and lift the locking device of the hydraulic lift

cylinder (3). Keep the locking device lifted.

> Use the lever (1) in the tractor to place the hydraulic system of the

tractor in floating position.

42

Page 43

2

4

3

Preparation at the field

> Release the rope to lower the locking device of the hydraulic lift

cylinder (3).

> Unlock and fold down the lateral guard (4).

> Use the 3-point front hitch to place the machine at correct height.

→ »Hitch frame adjustment«, see page 35.

Cutting heig ht

adjustment

2

1

3

The cutting height can be set by adjusting both outer drums.

Always place the mowing unit horizontal, before adjusting the cutting

height.

> Loosen the lock nut (2) with use of the blade detachment tool (3).

> Turn the bolt (1) clockwise to increase the cutting height (or

counterclockwise to decrease the cutting height).

> Tighten the lock nut (2) with use of the blade detachment tool (3).

43

Page 44

Preparation at the field

A

B

Ground pressure

adjustment

Ground pressure check

21

A

3

The ground pressure compensation can be set by an hydraulic

cylinder.

Always check the ground pressure before working with the machine:

> Lift the machine from the ground and make sure that the machine

stays fully horizontal.

> The ground pressure should be between 70 - 120 kg at each side.

> Adjust the ground pressure if required.

The ground pressure compensation will be set by putting an

accumulator under hydraulic pressure:

> Make sure that the machine is set at the correct height.

→ »Hitch frame adjustment«, see page 35.

→ »Place the mowing unit into operating position«, see page 42.

> Place the lever (2) in position B to open the ball valve (1) in the

hydraulic hose.

> Place the double acting control valve (at the tractor), which is

connected to the blue marked hoses, in the floating position.

> Open the hydraulic valve which is connected to the hose with the

ball valve (1) to put the accumulator under hydraulic pressure.

> Place the lever (2) in position A to close the ball valve (1).

> Place the corresponding hydraulic valve in floating position.

> Move lever (2) slowly towards position B until the pressure is

between 70 and 85 bar.

> The hydraulic pressure, displayed at the manometer (3), should be

between 70 and 85 bar.

> Check the ground pressure.

44

Page 45

Operation

Operat ion

Safety

Obey the safety instructions

Obey the safety instructions at the execution of all work. Any disregard

for safety instructions can lead to serious or fatal injuries.

→ »Safety instructions«, see page 8.

Carrying people and oblects on the machine is prohibited

Neither persons nor objects are allowed to be transported at the

machine at any time. Only parts stored in their dedicated storage

locations are allowed to be transported at the machine. Riding on the

machine is hazardous and strictly prohibited.

Take care for a clear view at the machine

Always take care for a clear view at the machine and monitor the

machine during mowing. Only start mowing if the direct surrounding is

free from any persons and objects, to avoid serious or fatal injuries.

Note the contour of the terrain

Be carefull when working on a slope. Avoid slopes on which the

combination of tractor and machine could slip away or turn over. Fatal

injuries and material damages can occur.

Tractor PTO speed maximum 540 rpm

The tractor PTO speed may never exceed 540 rpm, adapt the tractor

PTO speed to the crop condition. A higher rpm can cause machine

damages.

Start p os i ti on

Place the machine in the start position, the start position is reached

when:

• The tractor engine is running idle.

• The machine is in the operation position

• The 3-point hitch is in operating position.

45

Page 46

Operation

Mowing

Start mowing

1

Headland driving

1

End of the job

> Switch on the PTO at a low tractor engine rpm, to avoid damages

to the machine driveline due to the mass inertia of machine parts.

> Use the manual throttle at the tractor to keep a constant PTO

speed of 540 rpm.

> Lower the machine by using the hydraulic lift cylinder (1) and be

sure that the mowing drums are rotating at full speed (PTO at max.

540 rpm) before entering the crop.

> Start driving with a recommended speed between 8 and 12 km/h.

> Use the hydraulic lift cylinder (1) to lift the machine fully.

> Take curves always with a low speed, especially when making tight

curves and during turning around.

> Switch off the tractor PTO.

> When the machine has come to a complete stand still, place the

machine into transport position.

→ »Place the machine into transport position«, see page 38.

46

Page 47

Cleaning

Cleaning

Cleaning

Maintenan ce a fter

cleaning

After every use of the machine, empty and clean the machine off all

accumulated crop and dirt.

Cleaning can be done with a high pressure cleaner. Avoid bearings,

seals, hydraulic parts and bolted joints from water permeation.

Clean also the space between the drum skirts and the skid saucers.

After cleaning with a high pressure cleaner:

> Grease all bearings according to the maintenance instructions.

> Use oil or grease to protect the bright metal parts on the hydraulic

cylinders against corrosion.

> Repaint any damages.

→ »Maintenance table«, see page 54.

47

Page 48

Parking and storage

Parking and storage

Safety

Unhitching the

machine

1

Obey the safety instructions

Obey the safety instructions at the execution of all work. Any disregard

for safety instructions can lead to serious or fatal injuries.

→ »Safety instructions«, see page 8.

The machine is no toy

Store the machine in an area away from human activity. Never allow

children to play on or around the parked machine. Serious injuries can

occur.

Store the machine in the “operating position“.

> Place the machine in the operating position.

→ »Place the mowing unit into operating position«, see page 42.

> Before unhitching the machine, secure the tractor from rolling

away.

> Switch off the tractor PTO.

> Use the lever (1) in the tractor to place the valve connected to the

blue marked hoses in floating position.

243

> Use the 3 point hitch to lift the machine fully.

> Remove the locking pin (4) from the upper hole.

48

Page 49

Parking and storage

243

6

5 6

> Release the rope (3) to lower the locking device (2).

> Place the locking pin (4) in the lower hole.

> Remove the spring clip (6).

5

> Lower the support jack (5).

> Place the back the spring clip (6).

> Use the 3-point hitch to place the machine at the ground.

> Switch off the tractor hydraulics.

> Switch off the tractor engine.

> Disconnect the tractor lower links and the top link.

> Remove the PTO drive shaft, and place the PTO drive shaft in its

chains.

> Disconnect the hydraulic hoses.

> Disconnect the road lighting cable [+].

> Hang the hydraulic hoses and the road lighting cable over the

machine to prevent it from damages.

Recommendation:

Store the machine in a location which is free from rodents, insects and

martens.

49

Page 50

Parking and storage

After the season

At the end of the season or when the machine will be stored for a

longer period, carry out next jobs:

• Thoroughtly clean the machine.

→ »Cleaning«, see page 47.

• Carry out the prescibed maintenance.

→ »Maintenance table«, see page 54.

• Repair or replace all damages parts.

• Repaint any paint damages.

• Cover all bright metal parts with an oil film. Only use approved

biodegradable oil, like rape oil.

> Prevent the machine from sliding away.

50

Page 51

Maintenance

Maintenance

Safety

Obey the safety instructions

Obey the safety instructions at the execution of all work. Any disregard

for safety instructions can lead to serious or fatal injuries.

»Safety instructions«, see page 8.

Searching for hydraulic oil leaks

Never search for leaks by touching hydraulic hoses and hydraulic

connections, even when your hands are protected with a protective

skin cream or oil-resistant gloves.

Due to high pressure and very little holes in case of leakages, the

hydraulic oil will go through protection devices and your skin! Hydraulic

oil may come into your bloodstream, which is lifethreatening!

Wear safety shoes

During all jobs at the machine never bring your feet under the machine

and always wear safety shoes, to decrease the risk of serious injuries.

Conditions for maintenance jobs

Only carry out maintenance jobs if you have the required expertise

and the suitable tools. The absence of technical knowledge or

unsuitable tools can cause accidents or damages.

Use genuine parts

Only genuine parts are specially designed and thoroughly tested for

the use at this machine. Only genuine parts will guarantee the reliability

and safety of the machine. Other products can interrupt functioning of

the machine or make the machine unsafe. When using non-genuine

parts the warranty and liability of the manufacturer reduces to nil and

void.

Prevent the machine from inadvertent operating

Before carry out maintance and repair jobs always:

• Unhitch the machine from the tractor if possible and prevent the

machine from sliding away.

• Disconnect the hydraulic hose.

→ »Unhitching the machine«, see page 48 .

Otherwise always:

• Switch off the PTO.

• Switch off the hydraulic system.

• Switch off the tractor engine and remove the ignition key.

• Be sure that the tractor and machine combination is positioned on

a firm and lever surface. Prevent the combination of rolling away.

In case of negligence material damages and serious injuries can occur.

51

Page 52

Maintenance

Prior to carry out welding jobs

Unhitch the machine from the tractor if possible and prevent it from

rolling and sliding away before start welding. Otherwise always:

• Switch off all hydraulic systems.

• Switch off the engine and remove the ignition key.

• Disconnect all electrical and hydraulic connections to ensure the

safety when carrying out welding jobs at the attached machine.

In case of negligence material damages and serious injuries can

occur.

Climbing aids

Use suitable climbing aids only, never use components of the machine

as a climbing aid.

Protection m eas ures

Additives in oil and lubricants may have harmful effects to health. Be

always aware of the safety instructions, warnings and cautions

mentioned at the original package of the oil and lubricants.

Because an indication according to the danger order is not necessary,

therefore pay attention to the instructions below.

Avoid skin contact

Avoid skin contact with oil and lubricants. Always use a protective skin

cream or oil-resistant gloves. In case skin deseases occur due to skin

contact with oil or lubricants, contact a doctor immediately.

Discard contaminated cleaning cloths

Discard all oil contaminated cleaning cloths immediately. Oils may

cause damages to your health.

Do not use oil for cleaning

Never use oil and lubricants for hand cleaning! Chips and waste in this

oil and lubricants can extra lead to injuries.

N

OTE

Collect wasted oil, lubricants and oil contaminated cloths, and dispose

them according to local and national environmental regulations.

52

Page 53

Maintenance

General

Directions

Direction Description

Left Counterclockwise

Right Clockwise

Rotation around a horizontal axis As seen at right angles to the direction of travel from left to right

Rotation around a vertical axis As seen from top to bottom

Maintenan ce term s

Task Explanation

Grease Apply grease to the sliding surface by using a brush

At all maintenance tasks, secure the machine in the operating

position. In case the transport position is required, this is mentioned

separately.

Direction specifications (left, right, front, rear) are always meant in

relation to direction of travel.

In the table below you will find some short explanations of the most

common maintenance tasks.

Lubricate One or two presses with a grease gun, unless stated otherwise.

Oil Apply an oil film (to the sliding face).

Replenish Fill up fluids, oil or lubricants to the indicated maximum level.

Replace Remove a part and install a new part. Drain fluids, oils or lubricants

and replenish to the indicated maximum level.

Check Check the condition of parts and components, and replace if

necessary. Check the levels of all fluids, oils and lubricants,

replenish to the indicated maximum level if necessary.

Lubricants

specifications

Lubricant Specifications

Oil Class NLGI2, K2k in accordance with DIN51825

Gearbox Oil SAE 85W-90 API GL-5

Grease Multipurpose, grade EP 2

53

Page 54

Maintenance

Maintenance table

After the first 5 operating hours

»Complete machine«

»Complete machine«

»Safety decals«

»Road lighting [+]«

»Road lighting [+]«

»Bolted connections«

»Bolts and nuts«

»Drums«

»Mowing blades«

»Mowing blade holders«

»Bevel gearbox«

»Oil level«

»Oil change«

»Inner gearboxes and outer gearboxes«

»Oil level«

»Oil change«

»Drive shafts«

»PTO drive shaft«

»Secondary drive shaft«

»Propulsion shaft«

»Overload clutch«

»Hitch frame«

»Hitch frame«

• • • • •

• • • •

Before carry out maintenance or repairs always:

• Clean the machine.

→ »Cleaning«, see page 47.

• Obey all safety instructions.

→ »Safety instructions«, see page 8.

→ »Safety«, see page 51.

• Obey all protection measures.

• »Protection measures«, see page 52.

Oil

Grease

Lubricate

road transport

After operation

Every 10 operating hours

Every 20 operating hours

Every 50 operating hours

Every 150 operating hours

After the first 10 operating hours

Before operation and/or

Every 250 operating hours

At the start of each season

At the end of each season /

before storage

Tighten

Check

Clean

Change / Replace

• • • •

••• •

• • •

• ••• •

••

• • •

••

• • •

••

• • • • • • •

••• • ••

• • • • • •

••

• • • •

Page

55

55

55

55

55

57

57

61

62

62

63

64

65

65

66

67

54

Page 55

Maintenance

Complete machine

Safety decals

Road lighting [+]

Clean the machine always:

• After operation.

• At the start of each season.

• At the end of each season.

• Before storage.

→ »Cleaning«, see page 47.

→ »Parking and storage«, see page 48.

Keep all safety decals clean and legible. In case safety decals are

damaged, perished or lost, order new decals as spare parts and affix

them on the machine.

→ »Safety decals overview«, see page 9.

Always clean the machine before checking the safety decals.

→ »Cleaning«, see page 47.

Check the safety decals:

• After operation.

• At the start of each season.

• At the end of each season.

Check road lighting for proper working:

• Before road transport.

• At the start of each season.

Repair defect road lighting immediately.

Bolted

connections

Bolts and nuts

Clean all lighting equipment:

• Before road transport.

• After operation.

• At the start of each season.

• At the end of each season.

Replace a missing or broken bolt or nut, always by a genuine part.

Standard bolts and nuts may look the same, but can have different

qualities and properties. Non-genuine parts may change the

properties of the machine, and may make the machine unsafe.

Material damages or serious injuries can occur.

Always use a suitable torque wrench to tighten bolts and nuts.

Always check for missing bolts and nuts, install new bolts and nuts if

necessary.

Tighten all bolts and nuts:

• After the first 5 operating hours.

• After the first 10 operating hours.

• Every 150 operating hours.

• At the start of each new season.

• After a bolt or nut has been unscrewed.

→ »Torques for bolted connections«, see page 56.

55

Page 56

Maintenance

Torques for bolted

connections

Thread Torque value Spanner

size*

8.8 10.9 12.9

Nm mm

M3 1.3 1.8 2.1 6

M4 2.9 4.1 1.9 7

M5 5.7 8.1 9.7 8

M6 9.9 14 17 10

M8 24 34 41 13

M10 48 68 81 17 (15)

M12 85 120 145 19 (17)

M14 135 190 225 22 (19)

M16 210 290 350 24 (22)

M18 290 400 480 27

M20 400 570 680 30

M22 550 770 920 32

M24 700 980 1180 36

M27 1040 1460 1750 41

M30 1410 1980 2350 46

M33 1910 2700 3200 50

M36 2450 2546 3063 55

M39 3200 4500 5400 60

* Values in brackets: spanner size for locking bolts and nuts with

toothed flange.

N

OTE

• The values listed apply to dry or slightly lubricated connections.

• Do not use galvanized (plated) bolts and nuts without grease.

• When using a stiff grease, reduce the value in the table with 10%.

• When using (self-)locking bolts and nuts increase the value in the

table with 10%.

56

Page 57

Drums

Maintenance

Mowing blades

Wear safety gloves

Mowing blades are very sharp. Always wear safety gloves when

handling mowing blades to prevent serious injuries.

Check the mowing blade cutting edges for sharpness:

• Before operating.

• After the first 5 operating hours.

• At the start of the season.

Replace or change the mowing blades if required. Always change or

replace all mowing blades per drum.

Ensure there are always 4 mowing blades mounted per outer drum

and 2 blades mounted per inner drum.

Each mowing blade has two cutting edges. As soon as one edge of

the mowing blades has been worn, mount the mowing blades upside

down.

An arrow at each mowing blade shows the direction of rotation.

> Place the machine in the operating position.

→ »Place the mowing unit into operating position«, see page 42.

> Place the blade detachment tool (2) between the drum skirt (1) and

21

the blade holder (3).

> Move the blade detachment tool (2) upwards to release the

mowing blade.

> Keep the blade detachment tool (2) upwards and replace the

mowing blade.

> Lower the blade detachment tool (2) to lock the mowing blade.

Mowing blade

holders

1

3

Check the condition of the mowing blade holders:

• At the start of the season.

• After change or replacement of mowing blades.

Replace the mowing blade holders if:

• Distance X is equal to 0 mm or the blade pin is worn off.

• The diameter Y of the blade pin (1) is less than 7 mm.

X

Y

Always replace the blade holders per drum.

Always use new bolts and nuts when replacing blade holders.

57

Page 58

Maintenance

Inner drums blade holder

replacement

BYXA

1 2

3

4

5

6

To replace the blade holders of the inner drums (A) and (B):

Use the 3-point hitch to lift the

>

> Rotate the drums manually into the basic position as shown in the

picture at the left.

> Unscrew the skid saucer bolts (1).

> Remove the skid saucer (2).

> Unscrew the blade holder bolts (8).

> Discard the blade holder bolts (8) and the spring washers (7).

> Remove the blade holders (6), the bushings (5), the wear plate (4)

and the covers (3).

> Install the covers (3), the wear plate (4), the bushings (5), the new

blade holders (6).

> Place new spring washers (7) and new blade holder bolts (8).

> Tighten the blade holder bolts (8) to 85 Nm.

> Place back the skid saucer (2).

> Apply locking agent to the screw thread of the skid saucer bolts (1).

> Place back the skid saucer bolts (1) and tighten the bolts (1) to 80

Nm.

machine fully and secure the machine.

58

7

8

Page 59

Maintenance

Outer drums blade holder

replacement

BYXA

321

4

5

6

7

To replace the blade holders of the outer drums (X) and (Y):

Use the 3-point hitch to lift

>

> Rotate the drums manually into basic position as shown in the

picture at the left.

> Unscrew the skid saucer bolts (1).

> Remove and discard the spring washers (2).

> Remove the skid saucer (3).

> Unscrew and discard the blade holder bolts (4) and nuts (7).

> Remove the wear plate (3) and the blade holders (6).

> Install the wear plate (3) and the new blade holders (6).

> Place new blade holder bolts (4) and nuts (7.

> Tighten the blade holder (7) to 135 Nm.

> Place back the skid saucer (3).

> Apply locking agent to the thread of the skid saucer bolts (1).