Page 1

OPERATOR'S MANUAL

KN093CGB C

Merger

Merge Maxx 900

KN093CGB C

- English - 04-2010

Page 2

Page 3

Merger

Merge Maxx 900

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The MERGE MAXX 900 must only be used for the work for which it has been designed:

- Raking of previously cut green or wilted forage.

Document illustrations

The illustrations in this manual may be based on one typ e of machine only. However, all instructions apply to all

machines covered in this manual.

Dear Owner

1

Page 4

Merger

Merge Maxx 900

$Contents

Dear Owner.....................................................................................................................1

Contents .........................................................................................................................2

Identification of the machine.........................................................................................4

Front view (working position) .........................................................................................................4

Rear view (working position)...........................................................................................................4

Model identification plate ................................................................................................................5

Optional equipment..........................................................................................................................5

Safety...............................................................................................................................6

Description of symbols used in this document.............................................................................6

Safety instructions...........................................................................................................................7

Location and description of safety decals on the machine .......................................................19

Road safety equipment and recommendations...........................................................................22

Machine specifications................................................................................................25

Description and glossary...............................................................................................................25

Technical specifications............. ... ... ... .... ... ... ... ... .... ............................................. ... ... .... ... ............26

Sound levels ......... ... ... .... ... ... ... .... ............................................. ......................................................28

Required equipment.......................................................................................................................27

Putting into service......................................................................................................29

Description of control elements....................................................................................................29

Coupling and uncoupling..............................................................................................................35

Instructions for transport............................................................................................46

Putting the machine into transport position................................................................................46

Conformity with the road regulations...........................................................................................49

2

Contents

Page 5

Merger

Merge Maxx 900

Instructions for work...................................................................................................50

Putting the machine into work position............. ..........................................................................50

Adjustments in working position..................................................................................................53

Machine use....................................................................................................................................66

Optional equipment.....................................................................................................78

Wide wheels ... ... .... ... ... ... .... ... .......................................... ... ... .... ... ... ... ... ..........................................78

Maintenance and storage............................................................................................ 79

Frequency chart .............................................................................................................................79

Lubrication............................................................................................ ..........................................81

Maintenance....................................................................................................................................89

Storage............................................................................................................................................96

Trouble shooting guide...............................................................................................97

Appendix ....................................................................................................................101

Limited warranty........................................................................................................ 107

Contents

3

Page 6

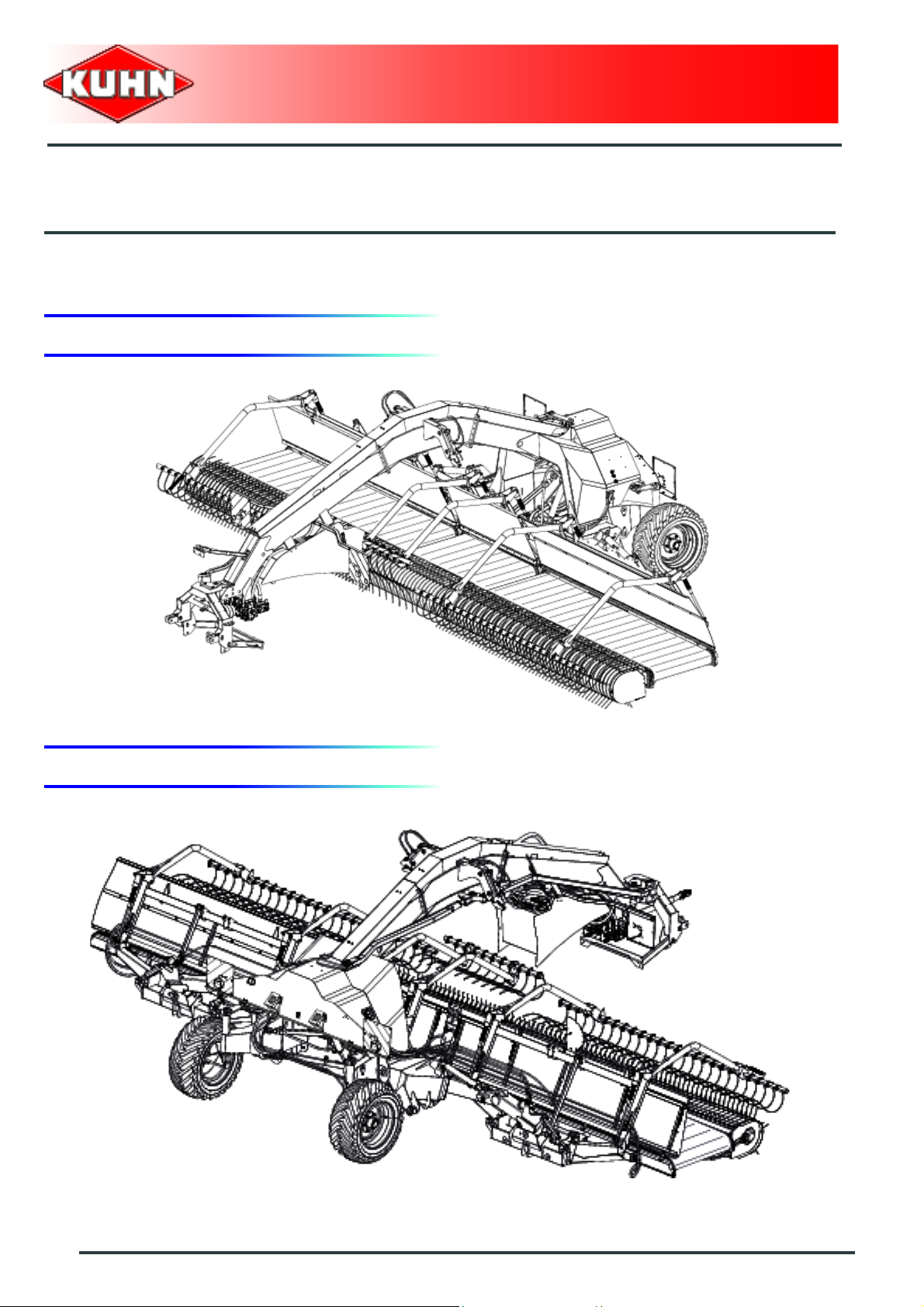

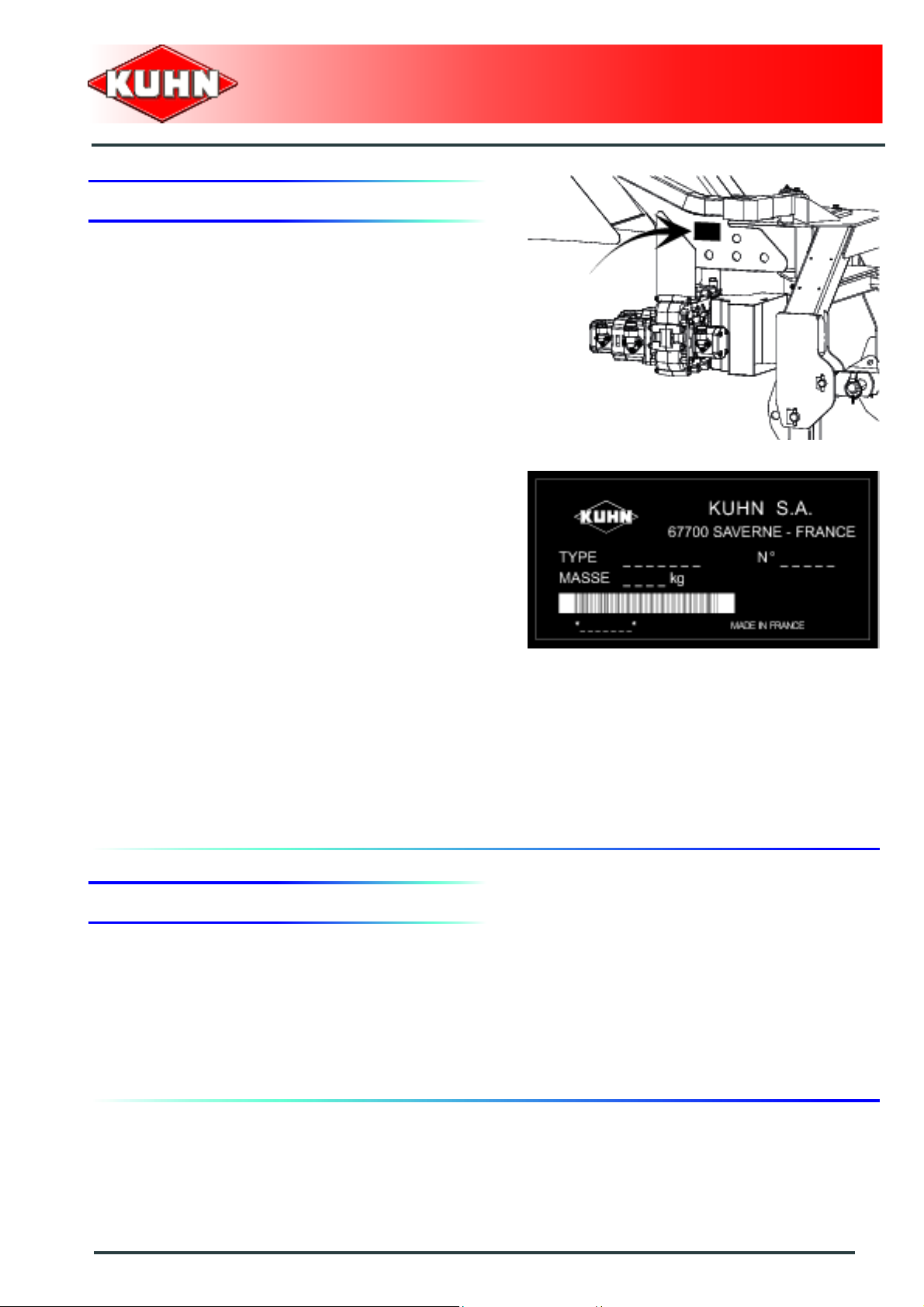

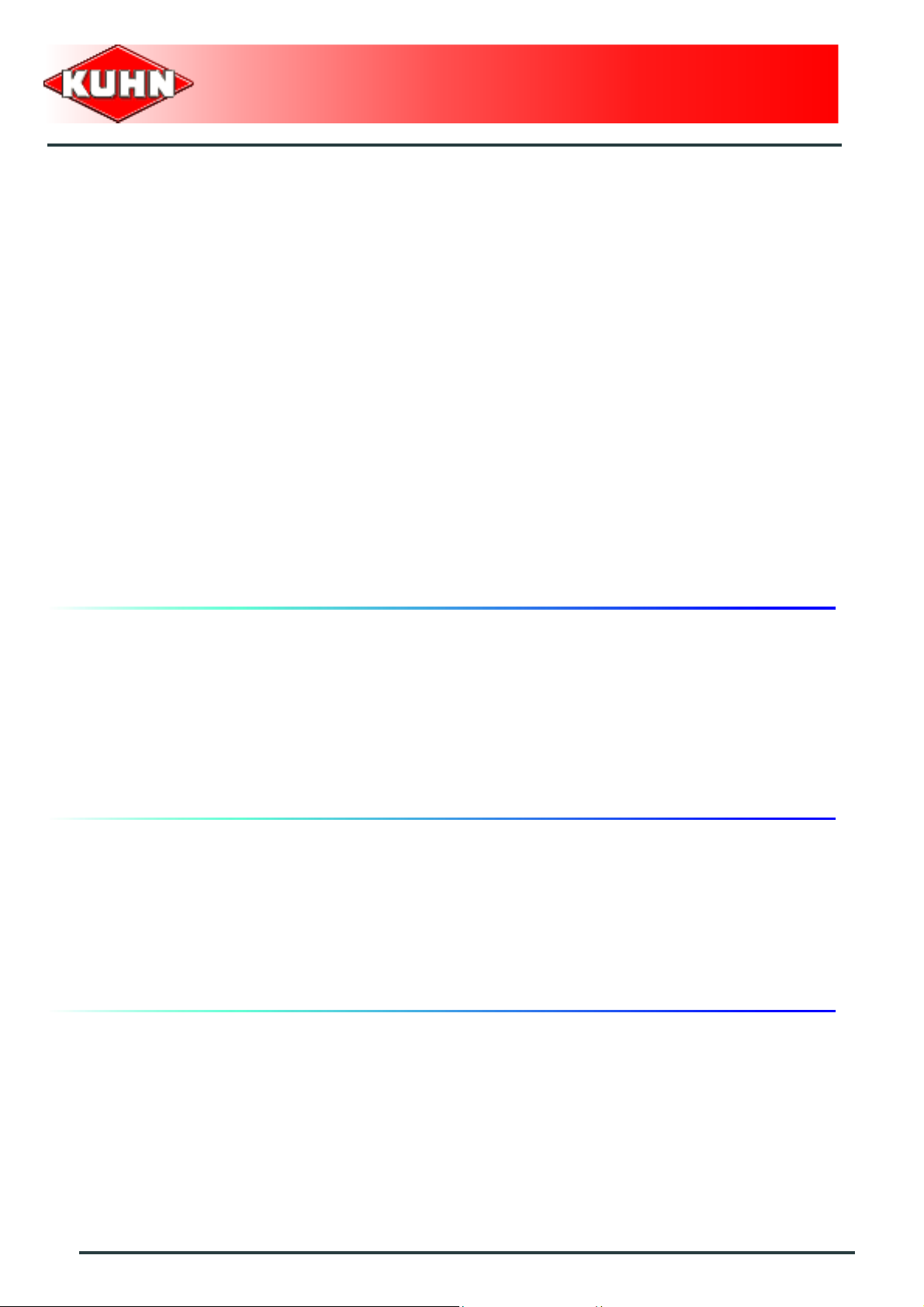

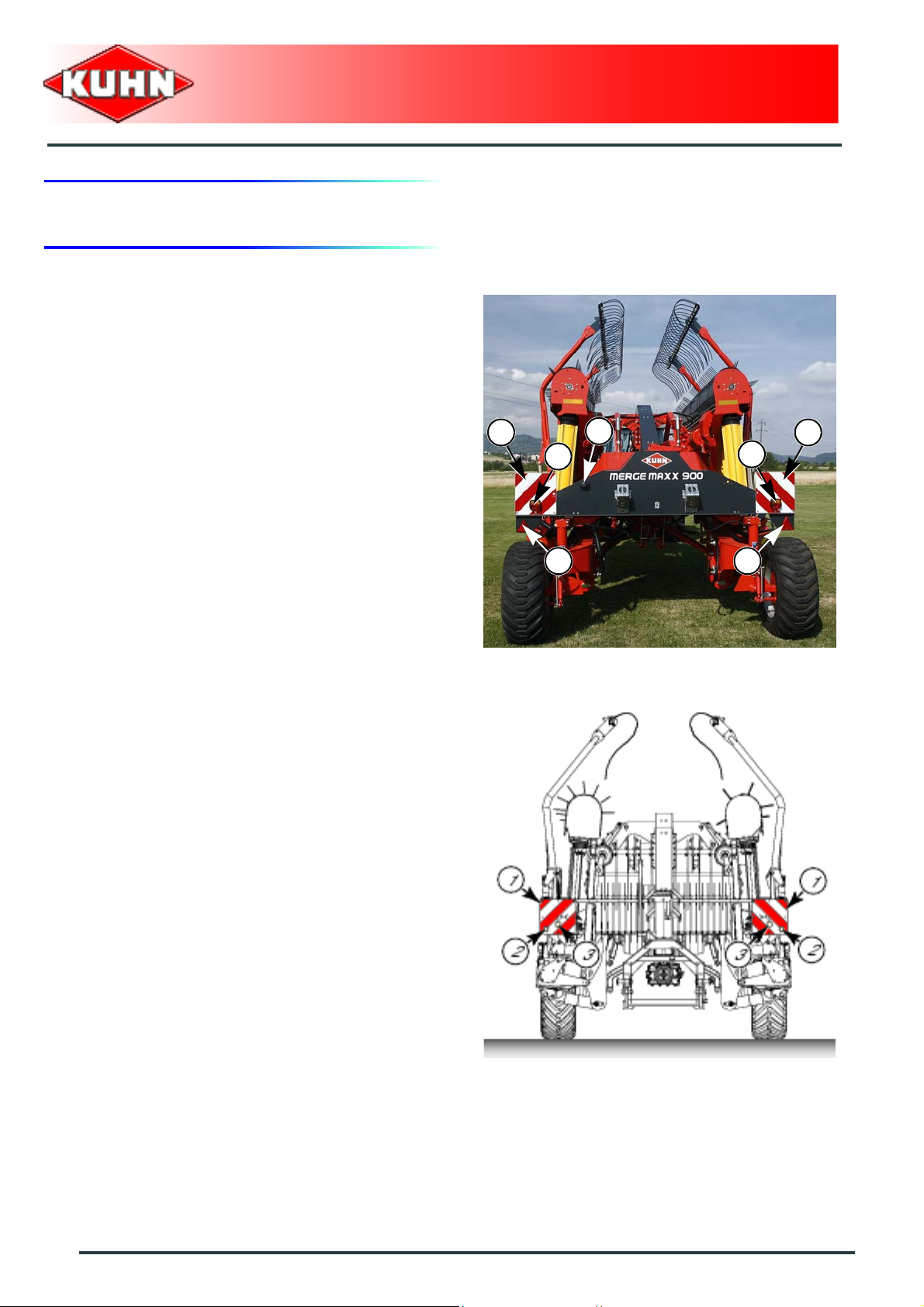

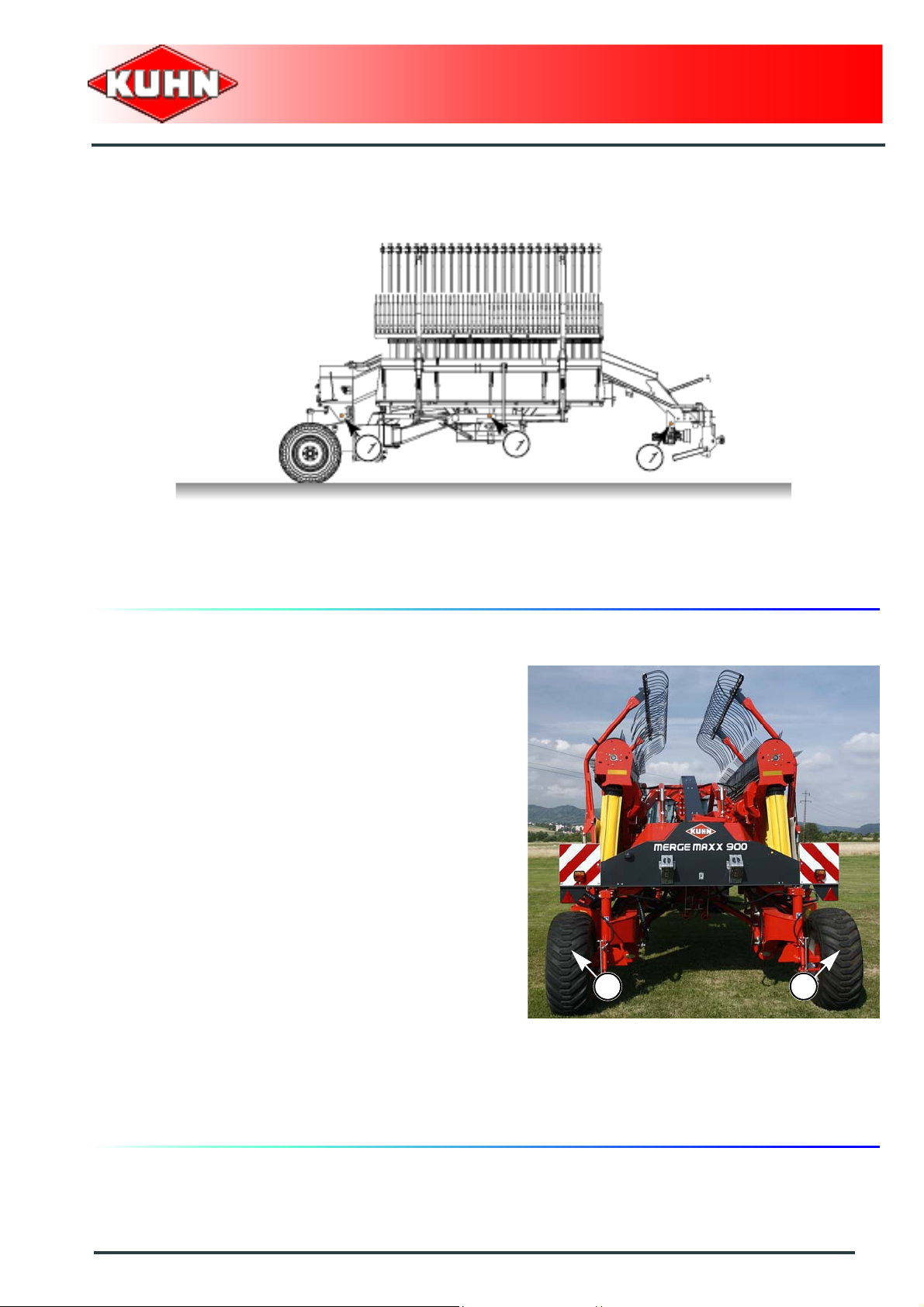

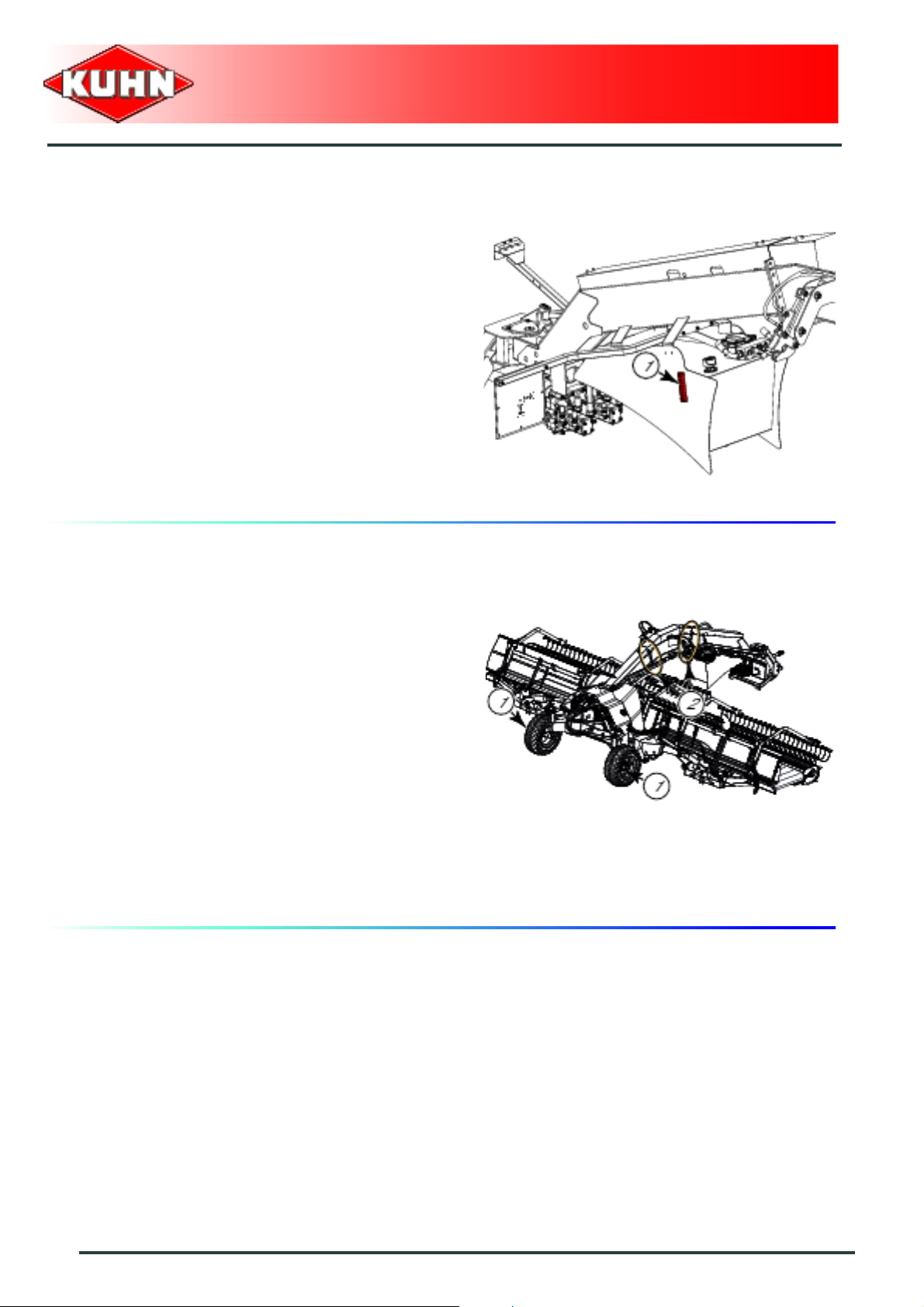

$Identification of the machine

1. Front view (working position)

Merger

Merge Maxx 900

2. Rear view (working position)

4

Identification of the machine

Page 7

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Merger

Merge Maxx 900

Type: MERGE MAXX 900

Serial no.:

4. Optional equipment

Tick box corresponding to the equipment fitted on your

machine:

Kit no. 1146870: Wide wheels (500/45-22.5 14 ply).

Part no. 1409957: Suction-grip holder..

Identification of the machine

5

Page 8

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Merger

Merge Maxx 900

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

6

Safety

Page 9

Merger

Merge Maxx 900

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations fo r preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect current le gislation concerning accident prevention, wo rk safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment a nd acce sso ries, as r ecom mended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident re sulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not traine d

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Safety

7

Page 10

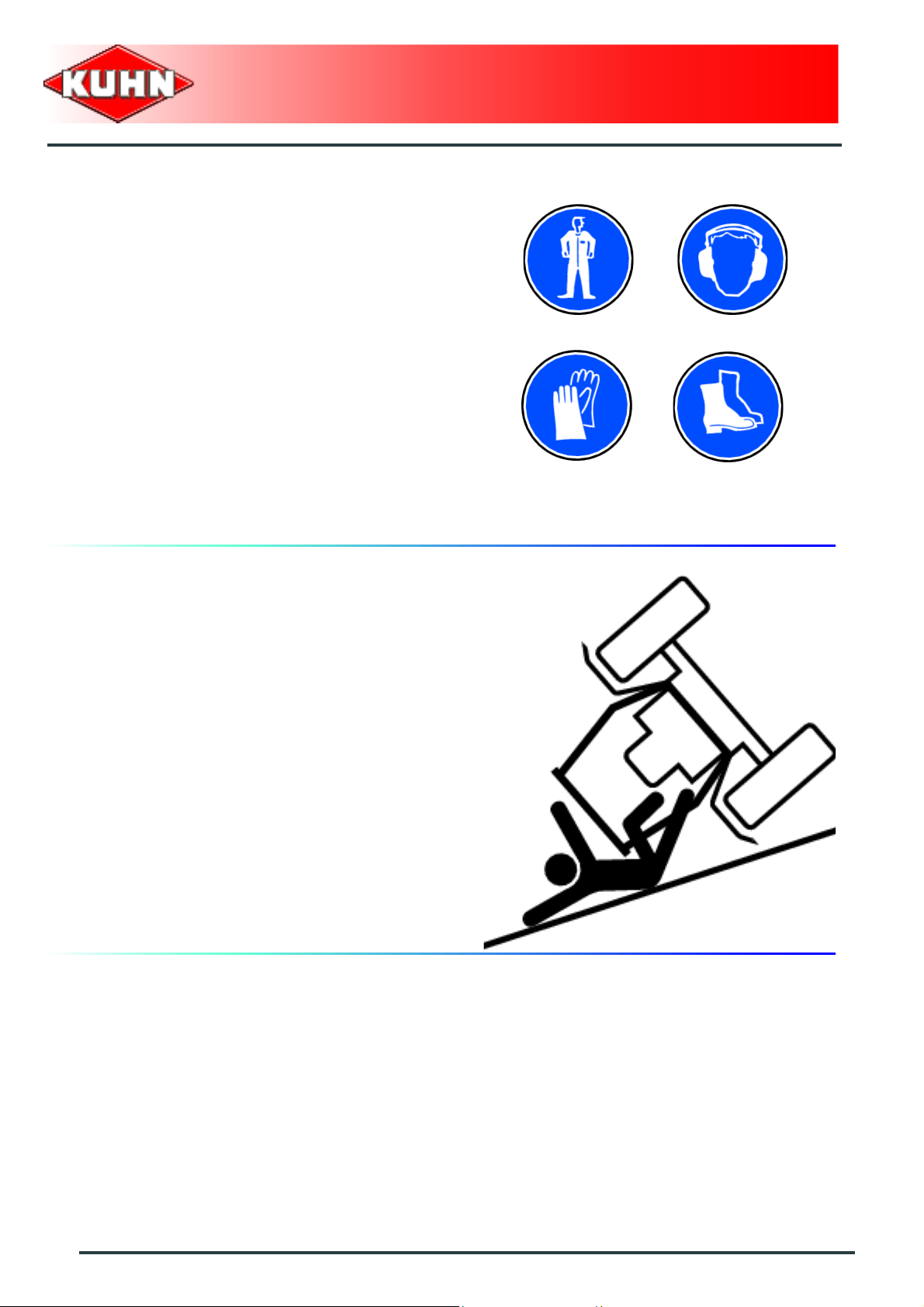

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Merger

Merge Maxx 900

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt change s

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

8

Safety

Page 11

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transportation of oversize

equipment.

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lights and indicators

Before transporting the machine on public road s, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Merger

Merge Maxx 900

Always obey current regulations for driving

on roads.

Gross weight and weight per axle

The drawings are not legally binding, their only aim is to illustrate the method to use.

Prior to driving on public roads, check t hat criteria are met t o be in conformity with the count rie's

regulations:

- When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized

payload must not be exceeded.

- When coupling tools to the front and rear 3-point lift linkages, the maximum load on each

axle's tires must not be exceeded.

- The load on the tractor front axle must al ways represe nt 20 % of the tractor unla den weight.

Safety

9

Page 12

For machines with hoppers or tanks:

- If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance

with the countrie's legislation, empty the hopper to travel on public roads.

- In any case, we recommend to travel on public roads with empty hoppers and tanks.

Description of symbols

Description Units Description

T kg Tractor unladen weight

PTAC kg Gross Combined Weight Rating

T1 kg Unladen load on tractor front axle

T2 kg Empty load on tractor rear axle

Merger

Merge Maxx 900

t kg Axle loads (Tractor + machine)

t1 kg Load on front axle (Tractor + machine)

t2 kg Load on rear axle (Tractor + machine)

t1 max kg Maximum load authorized on the tractor front axle according to the tires

t2 max kg Maximum load authorized on the tractor rear axle according to the tires

M1 kg Total weight of front tool or front ballast

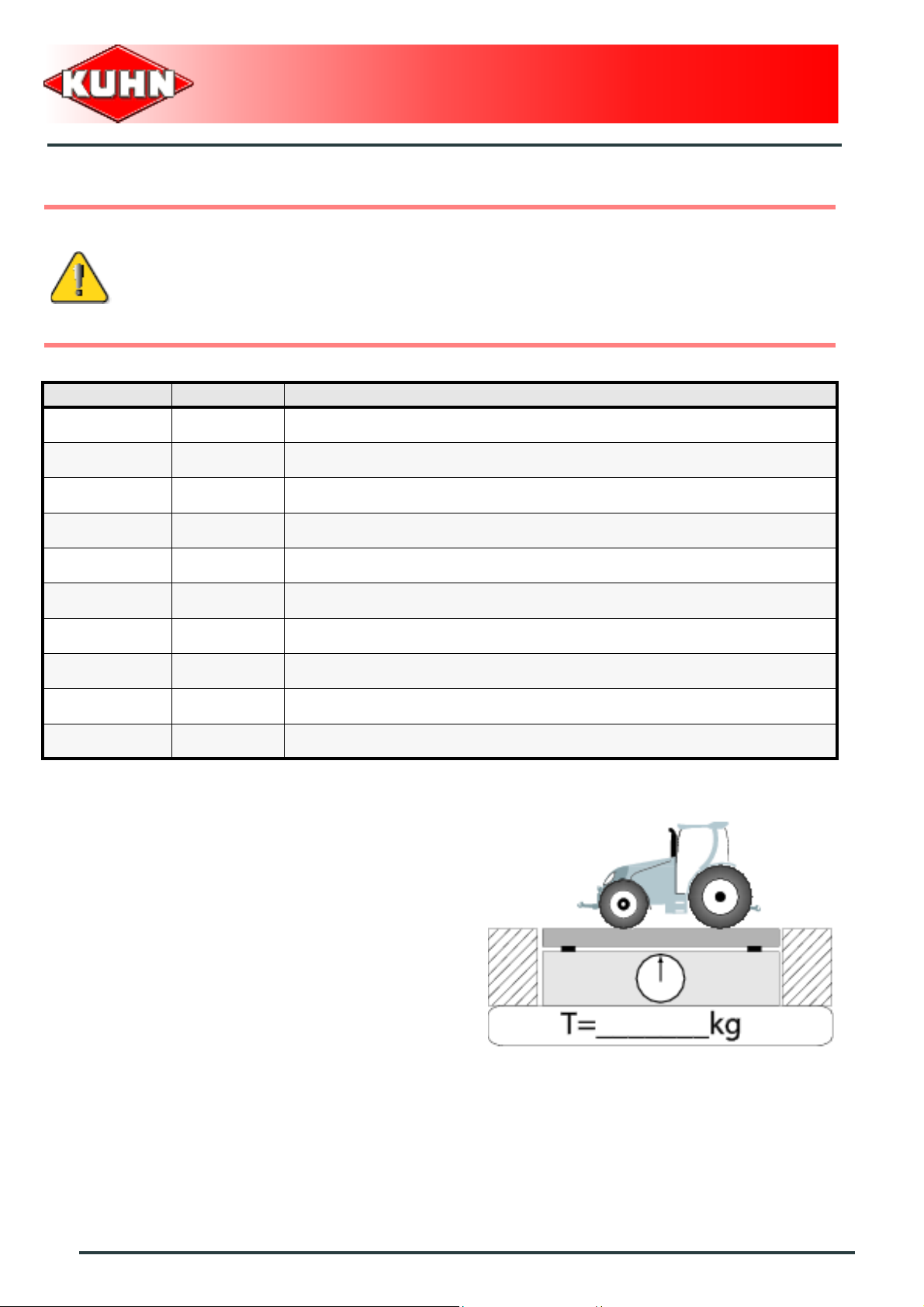

Stage 1:

To measure:

- Tractor tare (T).

10

Safety

Page 13

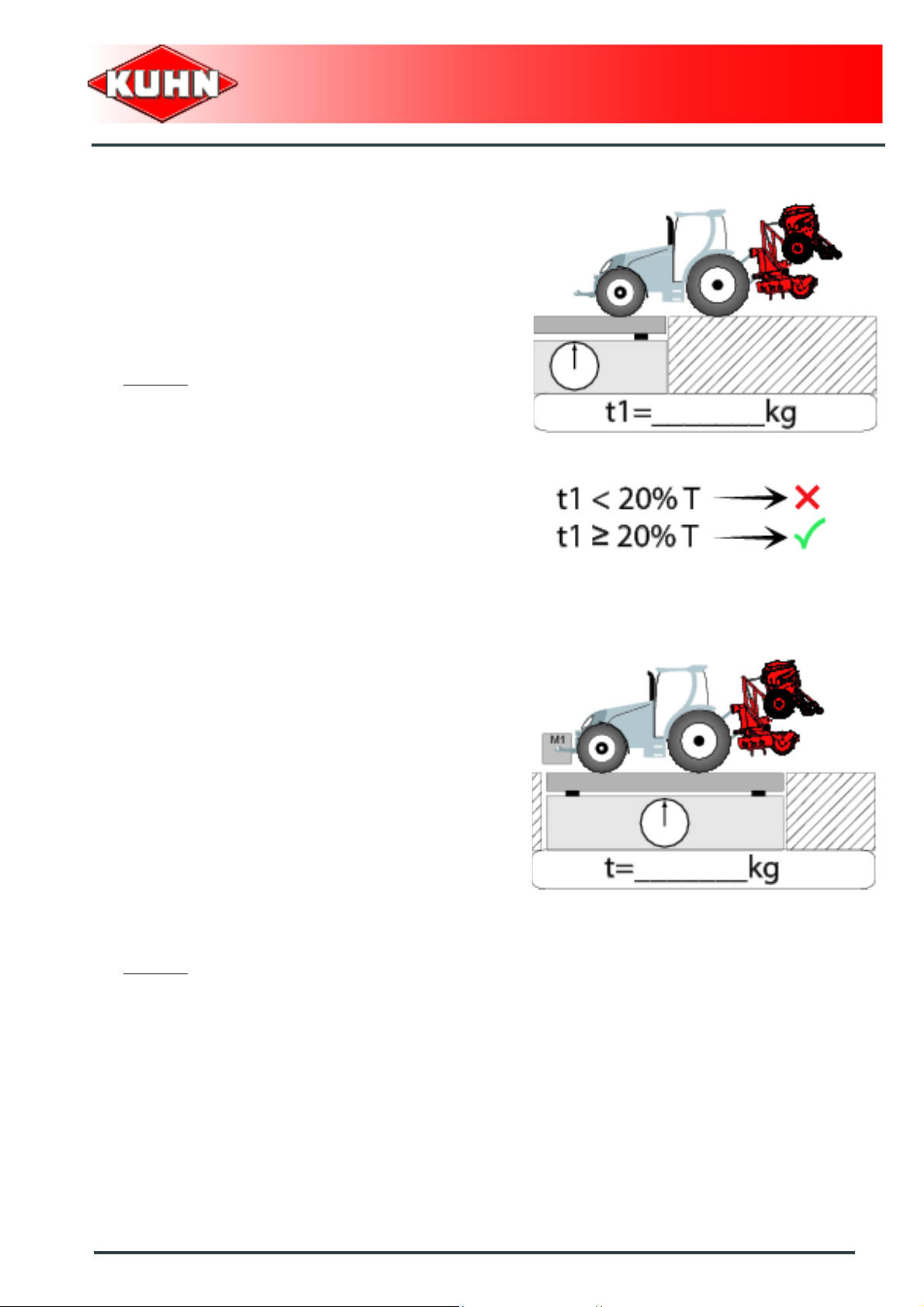

Stage 2:

- Couple the machine to the tractor.

To measure:

- Load on front axle (t1):

• Tractor + machine (transport position).

To do:

- If the front axle load (t1) is below 20% of the tractor

tare (T), add ballast weights (M1) to exceed the

minimum load on the front axle.

Example:

• (T) = 7500 kg (16535 lb)

• The front axle load must be of minimum 1500 kg

(3300 lb).(20% of T)

• (t1) = 700 kg (1545 lb).

• 700 kg (1545 lb) < 1500 kg (3300 lb).

• Add ballast weights until the minimum front axle

load is exceeded.

• Repeat checking procedure.

Merger

Merge Maxx 900

Stage 3:

To measure:

- Total weight (t):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- To go to the next stage:

• Check in the tractor's operator's manual that the

value measured is below the tractor's Gross

Combined Weight Rating.

To do:

- If t < PTAC go to the next stage.

- If the total unit weight exceeds the tractor Gross

Combined Weight Rating in accordance with the

countrie's legislation, empty the hopper to travel on

public roads.

Example:

• (t) = 10000 kg (24250 lb)

• PTAC = 13000 kg .

• t < PTAC : Go to the next stage.

Safety

11

Page 14

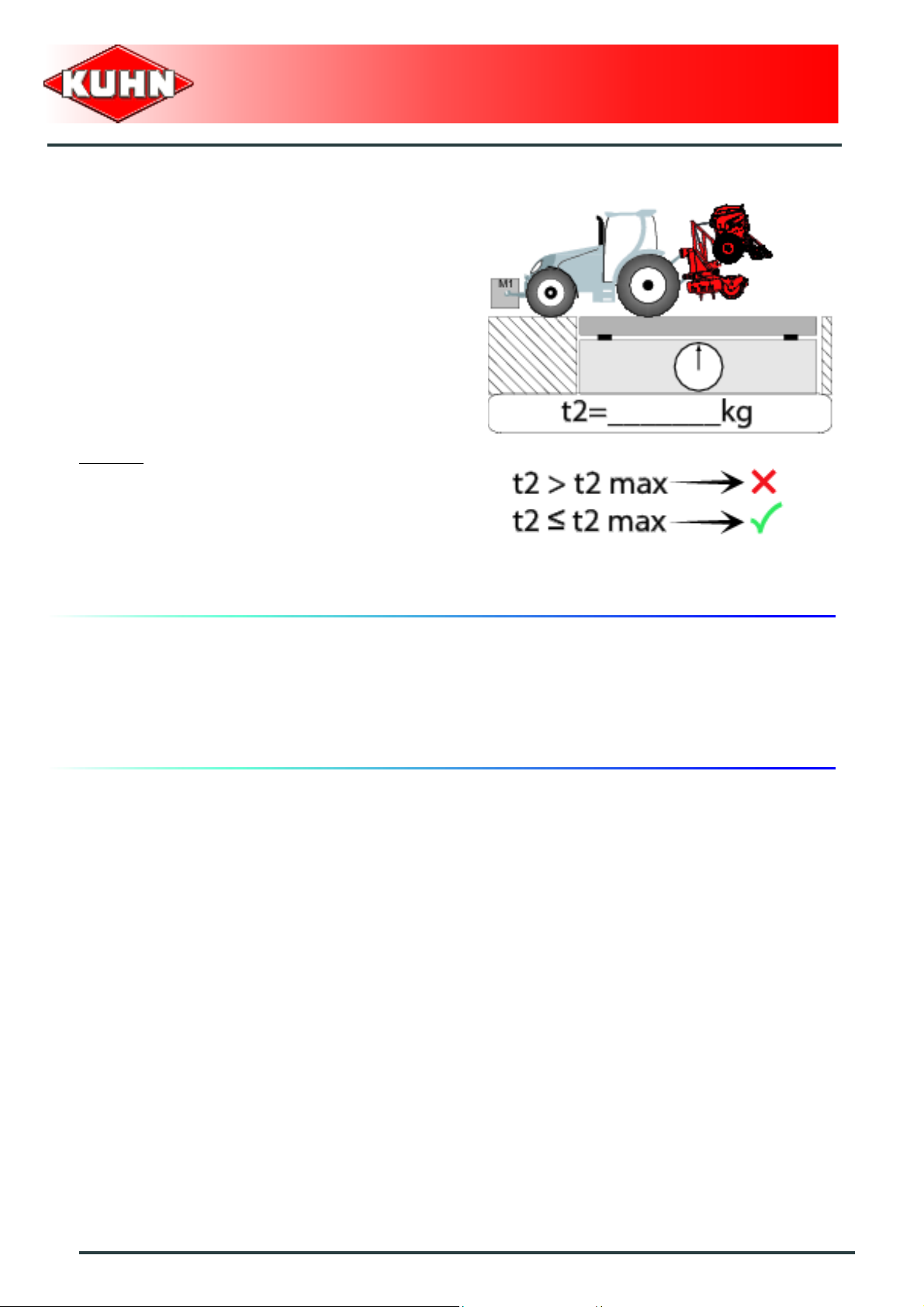

Stage 4:

To measure:

- Load on rear axle (t2):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- Check in the tractor's operator's manual that the value

measured is below the maximum allowed tractor rear

axle load.

- Check that tyre and rim specifiations are in conformity

with the requirements of the tractor manufacturer.

Example:

• Load on rear axle (t2) = 8500 kg (18740 lb)

• Check in the tractor's operator's manual that the

value measured is below the maximum allowed

tractor rear axle load.

• Check that tyre and rim specifiations are in

conformity with the requirements of the tractor

manufacturer.

Merger

Merge Maxx 900

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

12

Safety

Page 15

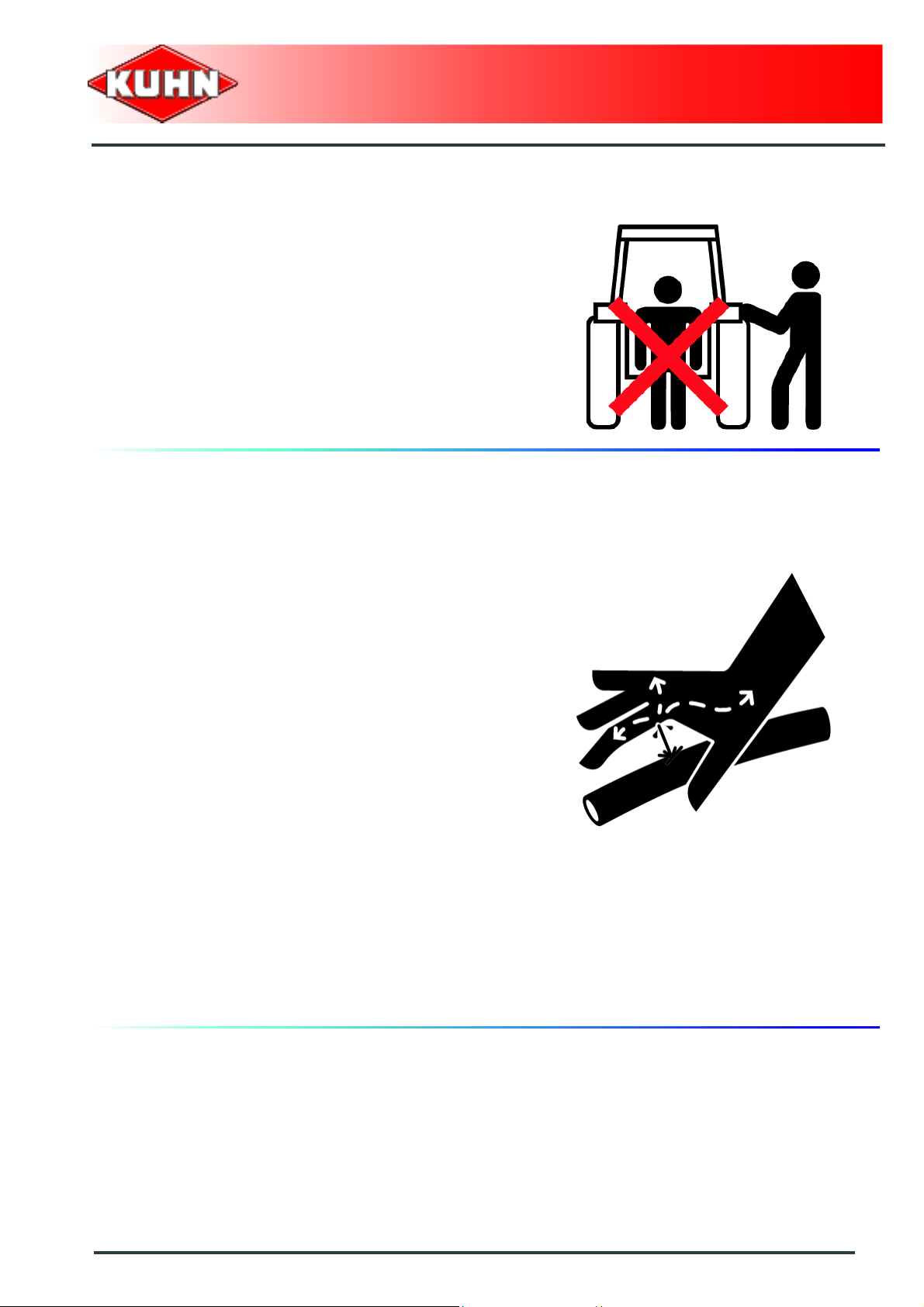

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Hydraulic circuit

Caution! The hydraulic circuit is under high pressure.

Maximum pressure at work: 200 bar.

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making incorrect connectio ns, mark hydraulic

couplers and corresponding hoses with colors.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In case of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be r eplaced.

When replacing the hydraulic hoses, only use hoses with

the specification recommended by the manufacturer of

the machine.

To locate a leak, use appropriate means. Protect body

and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine to the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

Merger

Merge Maxx 900

Safety

13

Page 16

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are secured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately. A worn guard or an unpro tecte d PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendat ion s.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's manual

provided with the PTO shaft.

Merger

Merge Maxx 900

14

Safety

Page 17

Precautions during manoeuvres

When moving the machine from the transport position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Tyres

Regularly check the tyre pressure. Respect

manufacturers' recommendations on pressure.

Assembly, disassembly and repair of wheels and tyres

must only be carried out by competent persons who are

equipped with standardized tools. Before any work is

performed on the wheels, ensure that the machine rests

on the ground and is perfectly stable so that it cannot

move accidentally (put chocks in place).

Merger

Merge Maxx 900

Hydro-pneumatic accumulator

A hydro-pneumatic accumulator contains nitrogen under

pressure (risk of suffocation in closed rooms).

Repairs, maintenance or commissioning may only be

carried out by competent persons. Wait for the

accumulator to cool down before handling it. Only use

nitrogen to precharge it.

Depressurize the gaz and oil sides of the hydraulic

accumulator before opening it.

It is strictly forbidden to weld, grind or drill onto a hydropneumatic accumulator.

Make sure that the accumulator and its' fittings are in

good condition.

Safety

15

Page 18

Safety decals

Safety warning decals are placed in pictorial form on

various parts of the machine. They are ther e to warn you

of potential dangers and to tell you how to avoid

accidents.

Always keep the safety decals clea n and readable, and

replace them when they are worn, damaged, missing or

illegible.

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters, etc.) on the ground, never pour them

down the drain and never discard them in any other

place where they could pollute the environment. Never

throw away or burn a tyre. Always take waste to

specialized recycling or waste disposal centers.

Merger

Merge Maxx 900

16

Safety

Page 19

Precautions for maintenance and repair work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the ground, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

Merger

Merge Maxx 900

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab. Never start a gyrorake when there are people

nearby. Even when the machine is used in accordance

with its purpose, objects may be projected. Stones and

other foreign objects projected by the moving parts can

travel a considerable distance. Keep all persons and

animals away from the danger zone.

Safety

17

Page 20

Precautions for machine use

After each use, check the seeding tools (shares,

coulters) and their attachment hardware in accordance

with the instructions given in the present manual.

Check the guards regularly. Immediately replace any

damaged or missing elements.

Make sure all the guards are in place. Keep all persons

and animals away from the danger zone.

Stay a safe distance from the machine when the cutting

tools are in movement.

Never reverse while raking.

After disengaging the PTO drive, tools can continue

rotating for some time. Stay away from the machine until

all moving parts have come to a complete standstill.

If the machine hits an obstacle, disengage the PTO

drive, stop the tractor engine, remove the ignition key

and wait for all moving parts to come to a complete

standstill. Check the entire machine for any damage

before resuming work.

Merger

Merge Maxx 900

Precautions to take before using the

control box

Place the control box so that it cannot interfere with other

tractor controls and be activated inadvertently.

Before switching the control box on, check that nobody

is within the machine pivoting area: switching on the

control box can activate functions on the machine.

Precautions to take when using the control

box

Do not operate the control box while a person is carrying

out work on the machine.

Switch off control box before carrying out any

maintenance or repair work on the machine.

18

Safety

Page 21

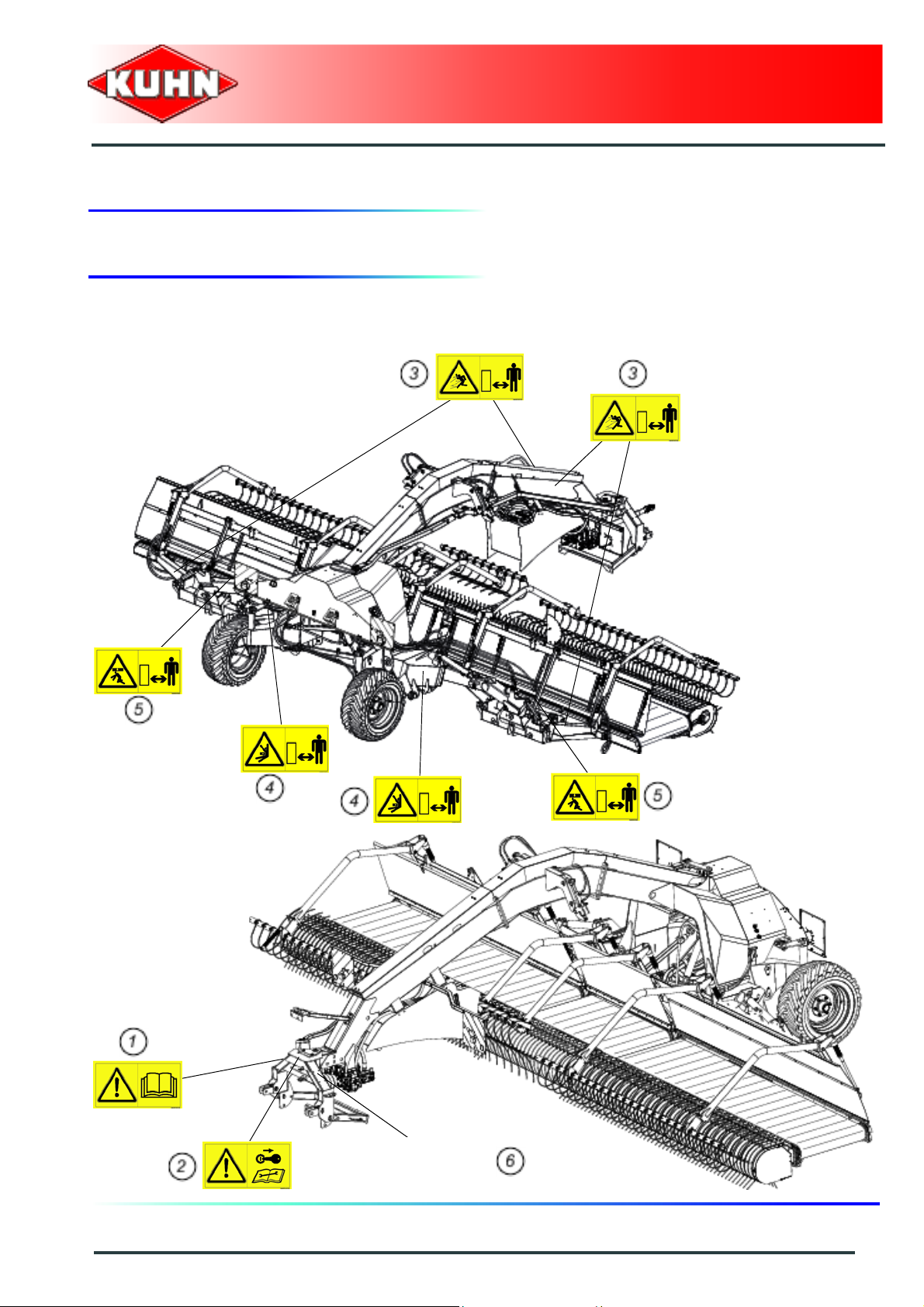

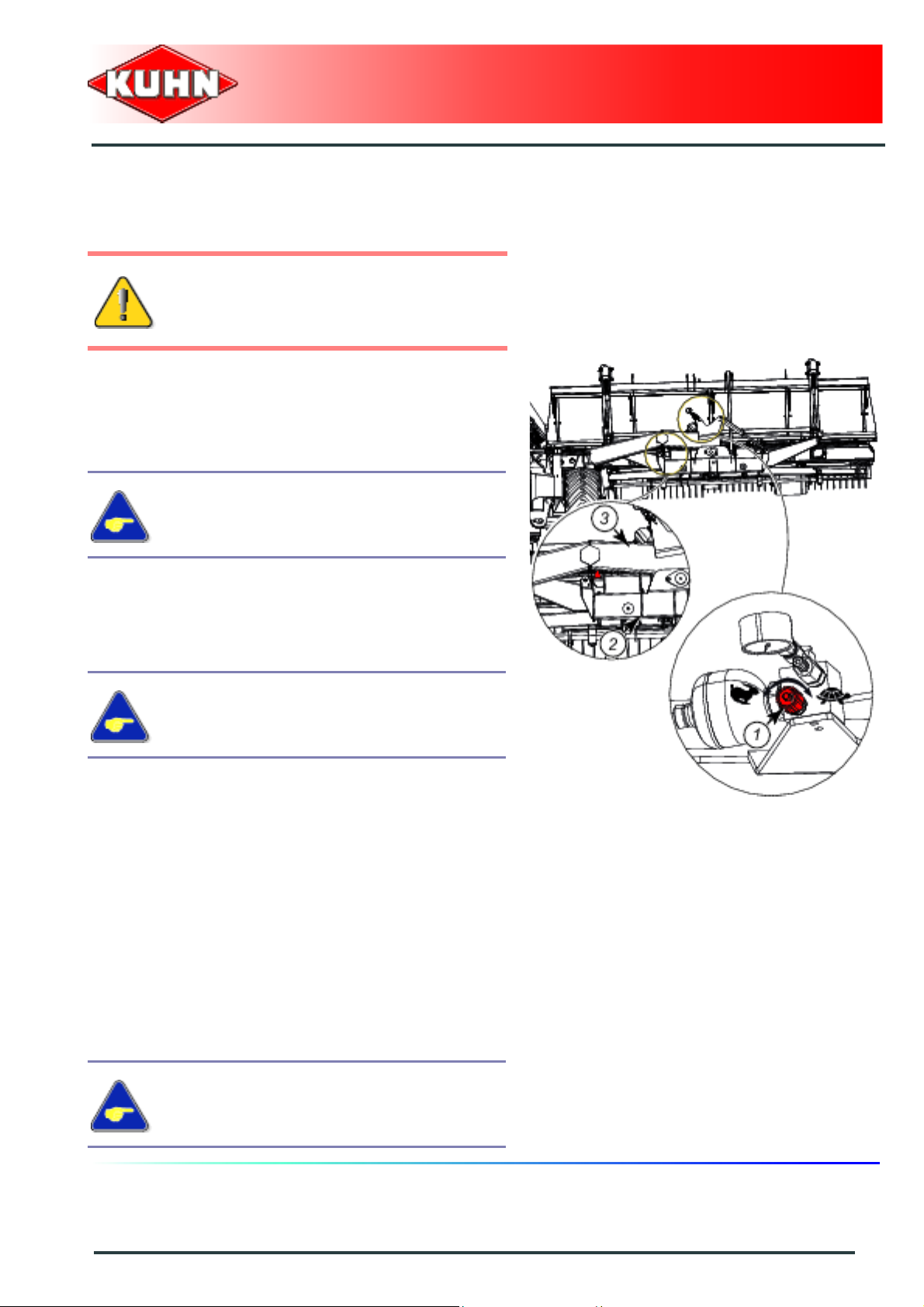

3. Location and description of safety decals on the machine

Location of safety decals

Merger

Merge Maxx 900

Safety

19

Page 22

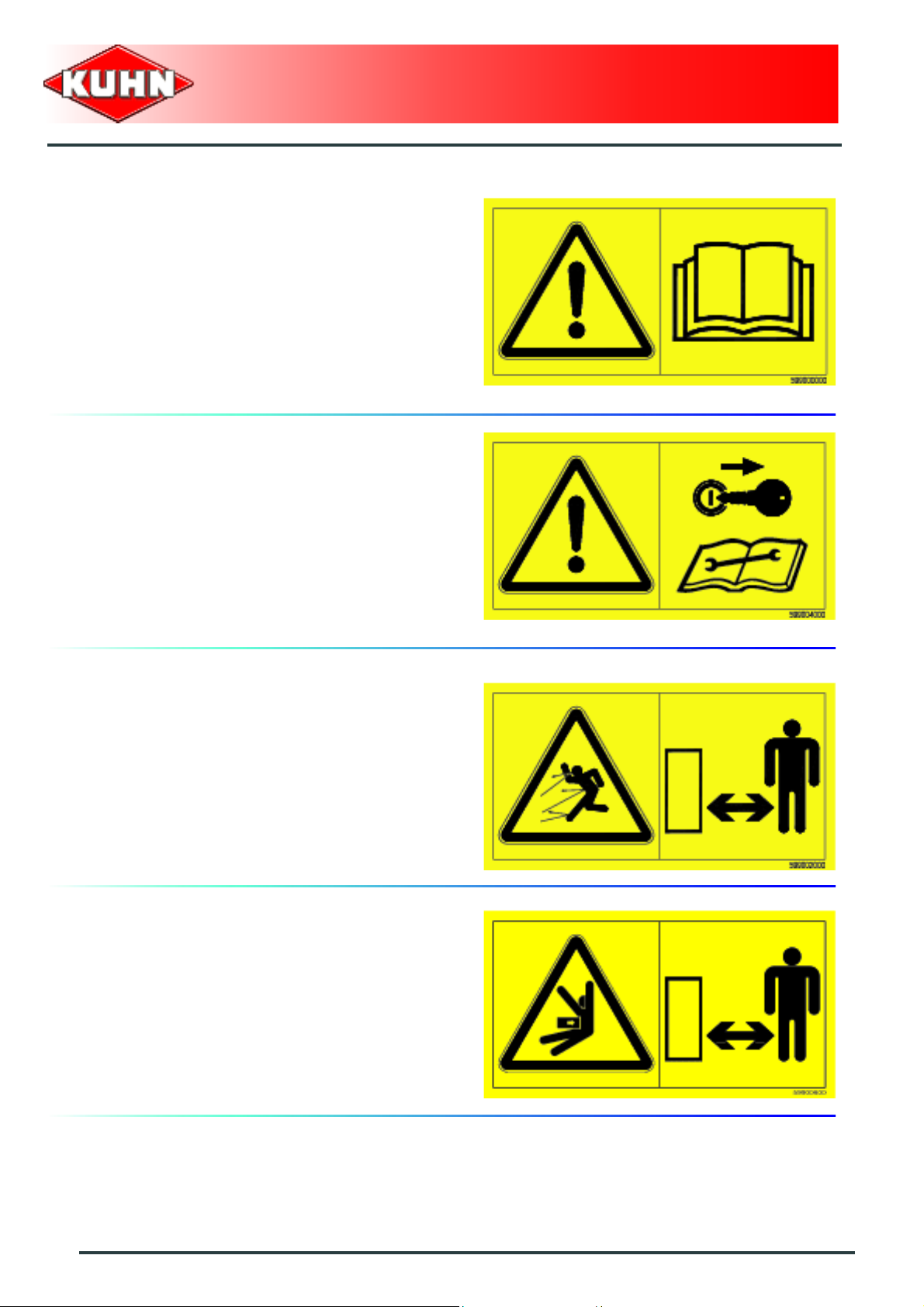

Description of safety decals

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Merger

Merge Maxx 900

Projections (3)

Stones and other debris pro jected by the moving parts

can travel a long distance. Always stay at a safe distance

from the machine.

Manoeuvring area (4)

Stay a safe distance from the machine. Crushing hazard.

20

Safety

Page 23

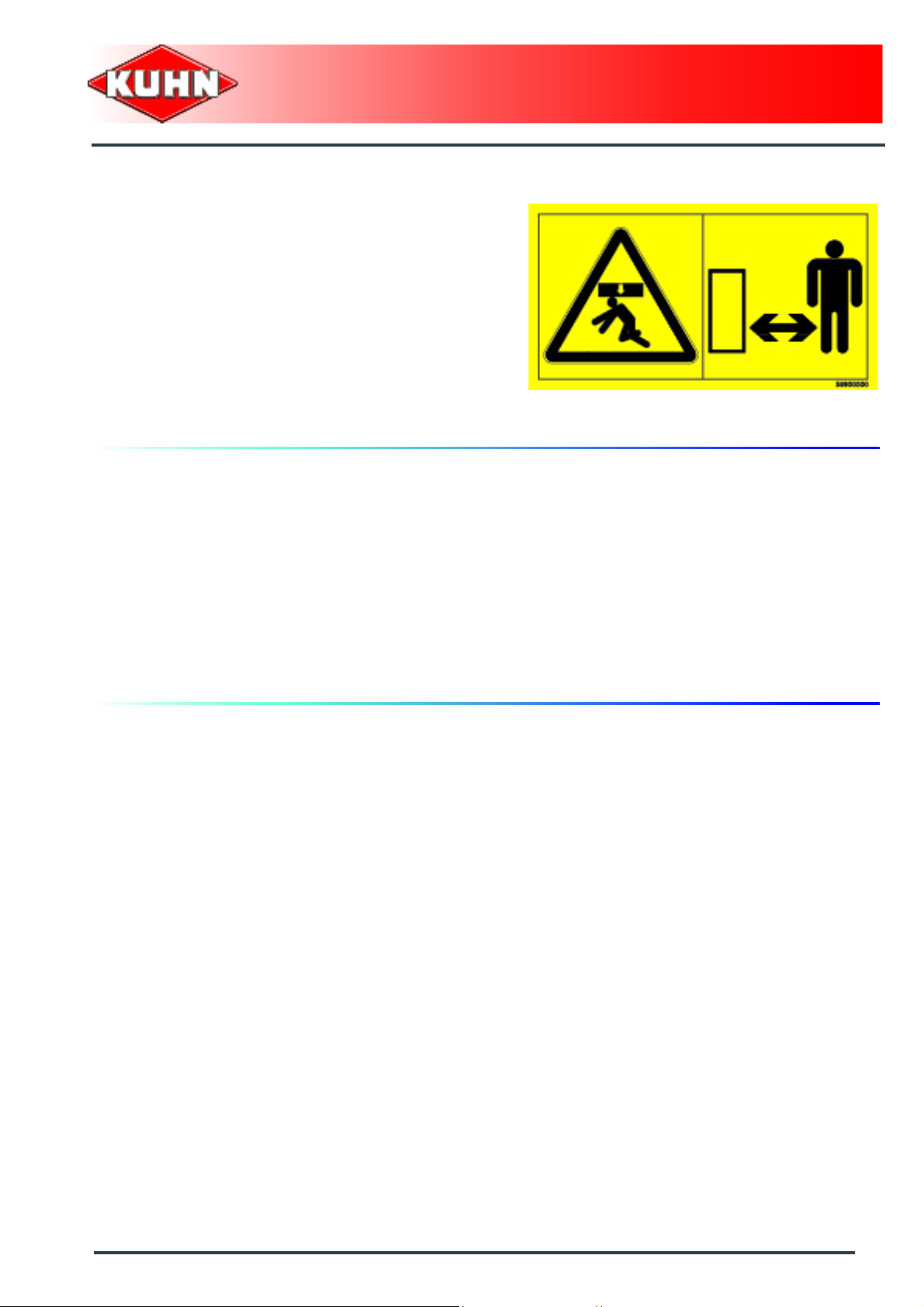

Body crushing (5)

Stay a safe distance from the machine.

Crushing hazard.

Coupling device (6)

Couple the machine to a tractor that is equi pped with a

system for locking the lift arms laterally and vertically.

To drive on roads, respect the attachment height

specified in the operator's manual and lock the lift

linkage.

Merger

Merge Maxx 900

Safety

21

Page 24

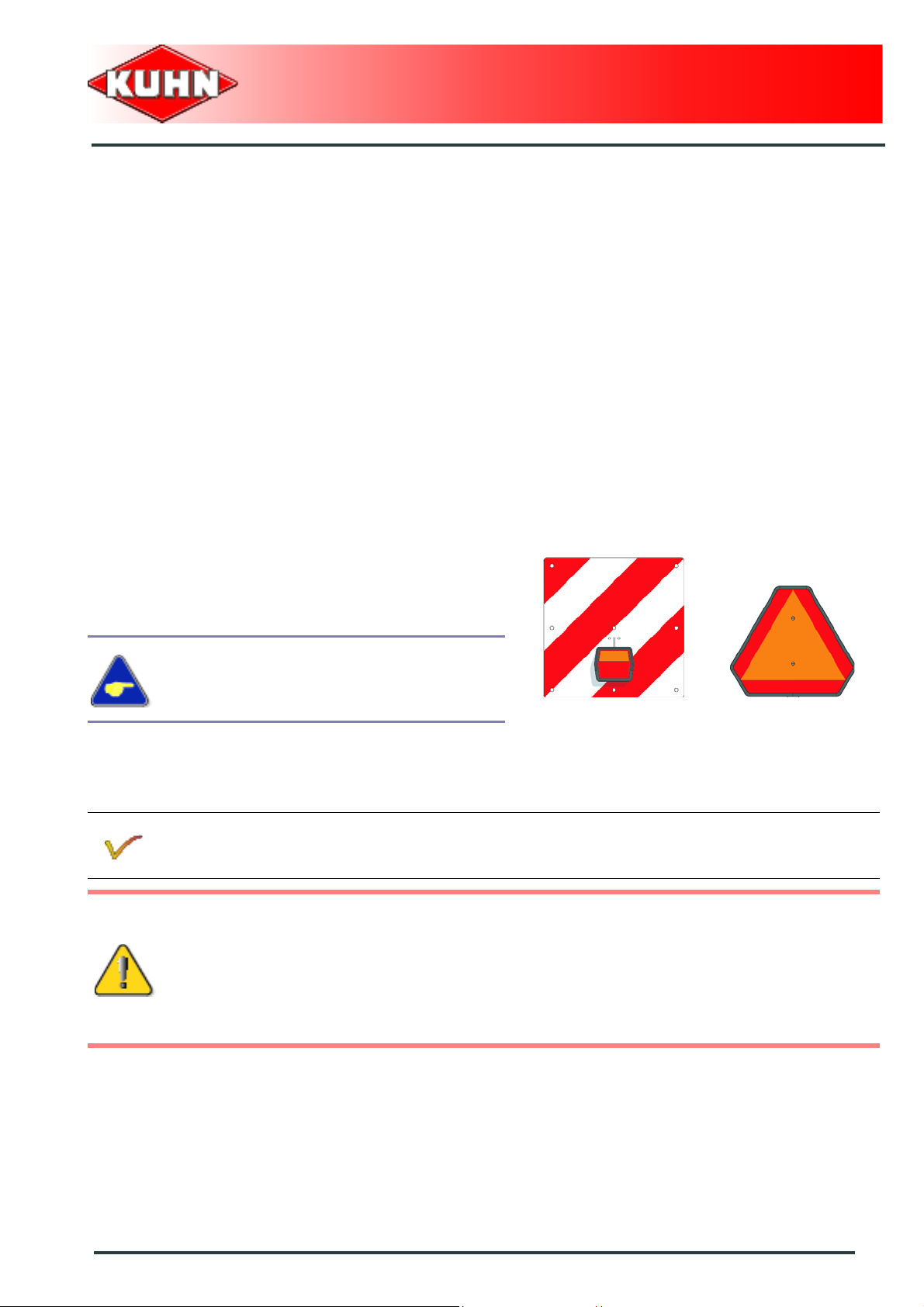

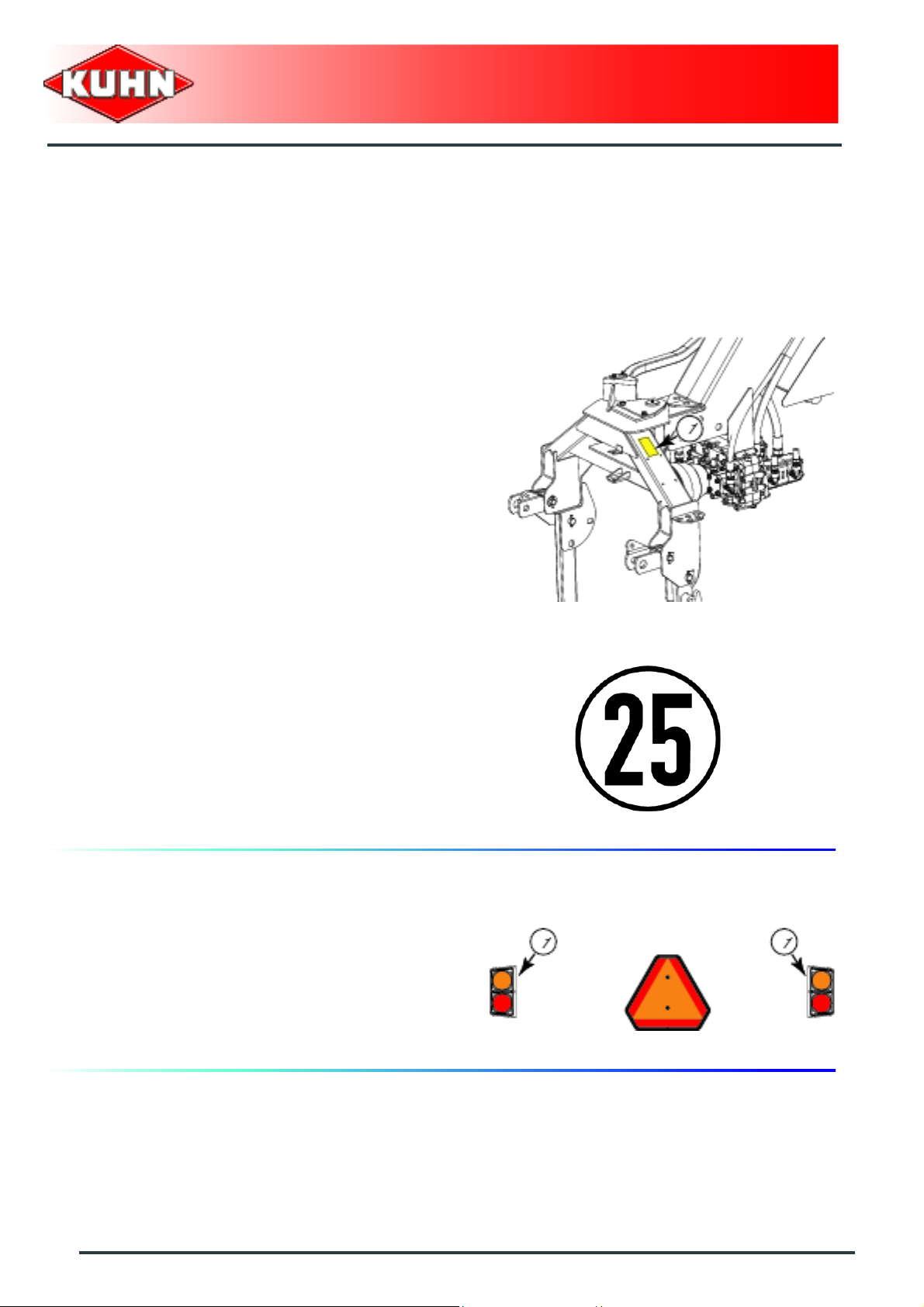

4. Road safety equipment and recommendations

The road safety equipment is mounted in the factory or

by your authorized Kuhn dealer according to current

safety regulations. Always keep to the legal speed limit

for driving a tractor-machine assembly on public roads.

Whatever the speed, we recommend, for everyones'

safety, not to exceed a maximum speed of 25 km/h

(15 mph).

The rear safety device comprises:

- 2 signalling panels (1).

- 2 signalling lights (2) (red light / stop light / turn signal

light).

- 2 red reflectors (3).

- 1 identification plate light (4).

Merger

Merge Maxx 900

4

2

2

11

The front safety device comprises:

- 2 signalling panels (1).

- 2 white reflectors (2).

- 2 white lights (3).

3 3

22

Safety

Page 25

The side device comprises:

- 3 amber reflectors (1) on each machine side.

Merger

Merge Maxx 900

Tyre pressure (1)

- Standard wheels: 2 bar (29 psi)

- Wide wheels: 1.6 bar (23 psi).

- Wheel nut torque:

• 27 daN m (199 lbf ft)

1 1

Safety

23

Page 26

Instructions specific to France

Coupling device (1)

Couple the machine to a tractor that is equipped with a

system for locking the lift arms laterally and vertically.

To drive on roads, respect the attachment height

specified in the operator's manual and lock the lift

linkage.

Merger

Merge Maxx 900

Speed (1)

Always keep to the legal speed limit of 25 km/h (15 mp h)

for driving a tractor-machine assembly on public roads.

Instructions specific to the following

countries: The United States, Canada.

The rear safety device comprises:

- 2 signalling lights (1) (Hazard warning lights).

- 1 support for a SMV emblem (Triangle not supplied).

24

Safety

Page 27

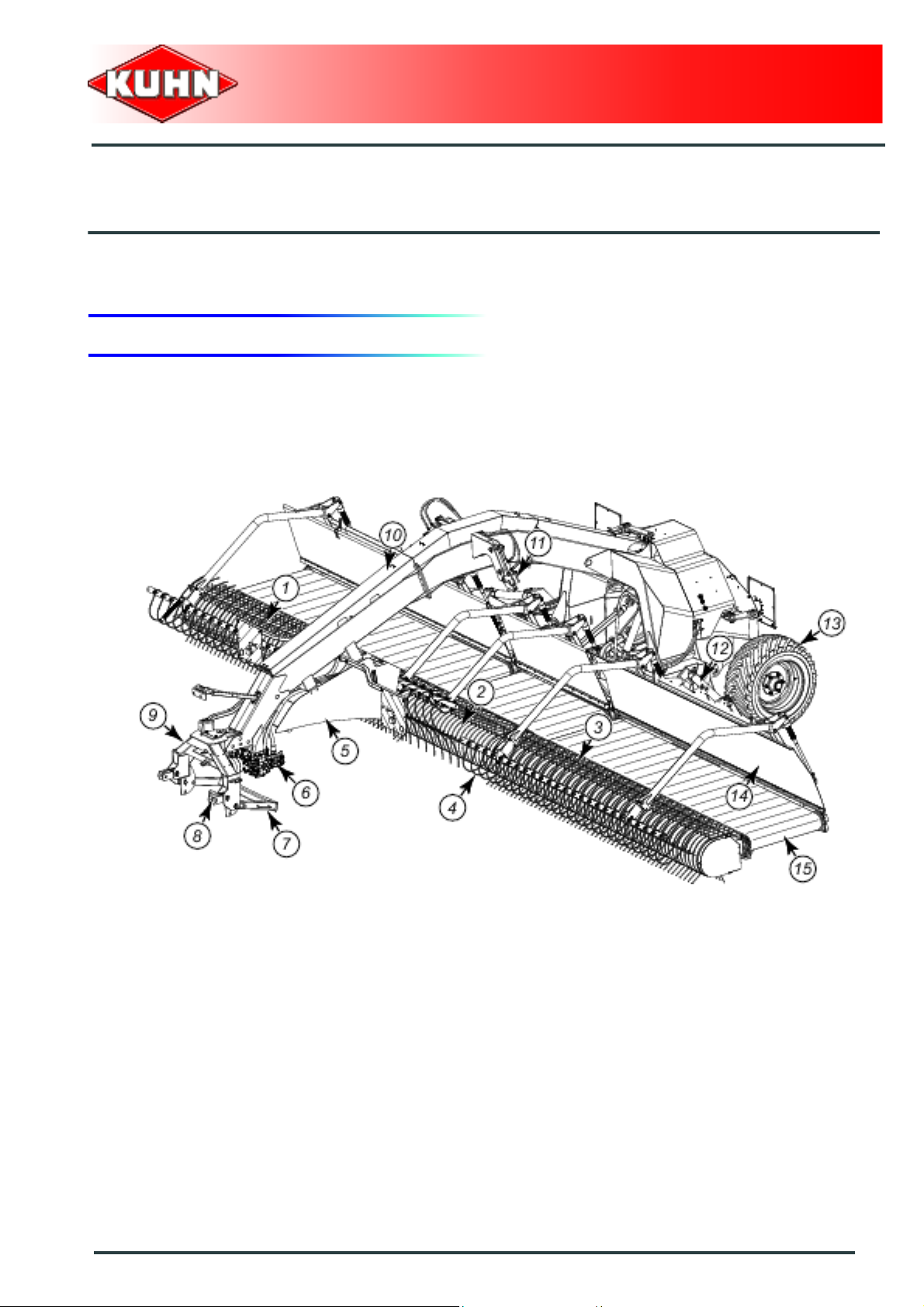

$Machine specifications

1. Description and glossary

0

Merger

Merge Maxx 900

1 : Right pick-up 2 : Central pick-up

3 : Left pick-up 4 : Comb

5 : Hydraulic fluid reservoir 6 : Step up gearbox

7 : Parking stand 8 : Coupling device

9 : Three-point hitch coupler 10 : Drawbar

11 : Transport lock 12 : Folding cylinder

13 : Wheel 14 : Deflector

15 : Conveyor

Machine specifications

25

Page 28

Merger

Merge Maxx 900

2. Technical specifications

Merge Maxx 900

Coupling device 2 point linkage category 2 and 3

Working width (DIN11220)

- Central windrow delivery

- Side windrow delivery

Swath width from 1.40 to 1.80 m (4’7’’ - 5’11’’) (approximately)

Width in working position 9.50 m (31’2’’)

Length in working position 7.13 m (23’5’’)

Height in working position 2.70 m (8’10’’)

10.50 m (34’5’’) (approximately)

9.10 m (29’10’’)

Width in transport position

- with transport wheel: 400/55 - 22.5 14

- with transport wheel: 500/45 - 22.5 14

Length in transport position 7.13 m (23’5’’)

Height in transport position 3.96 m (13’)

Minimum PTO power requirement 50 kW (70 hp)

PTO speed 1000 min

Weight 6600 kg (14550 lb)

Tyres

- Transport wheels

Tyre pressure (Transport wheels)

400/55 - 22.5 14

500/45 - 22.5 14

3.00 m (9’10’’)

3.10 m (10’2’’)

-1

400/55 - 22.5 14 ply

500/45 - 22.5 14 ply

2 bar (29 psi)

1.6 bar (23 psi)

26

Machine specifications

Page 29

3. Required equipment

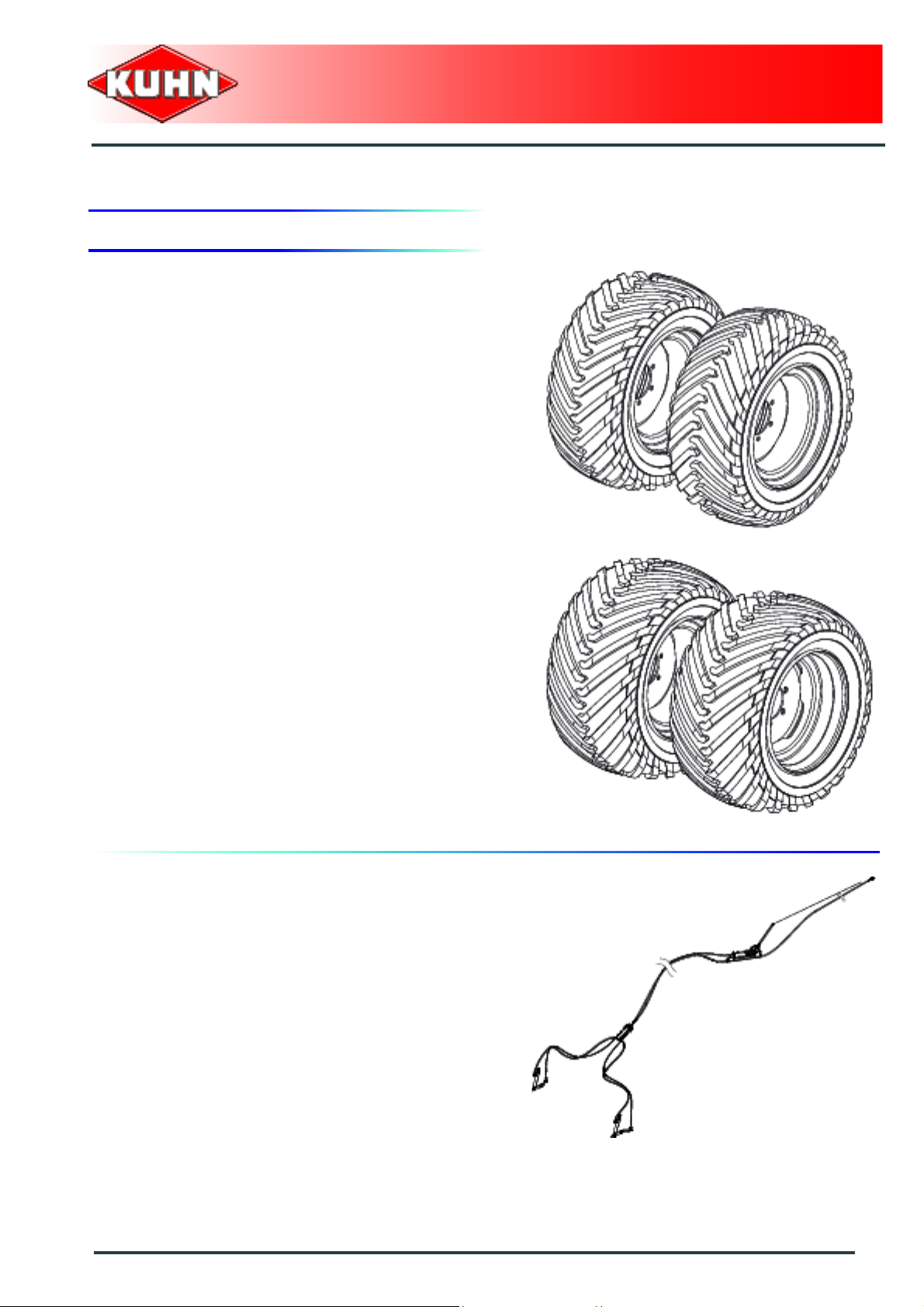

Wheels

The machine is factory supplied with the following set of

tires:

- Standard wheels (400/55-22.5 14 ply)

Merger

Merge Maxx 900

or

- Wide wheels (500/45-22.5 14 ply)

Braking system

This equipment is fitted on the machine transport

wheels, in conformity with the legislation in force in the

country concerned.

The machine is factory fitted with one of the following

braking systems:

- Hydraulic braking system.

Machine specifications

27

Page 30

or

- Pneumatic braking system.

Merger

Merge Maxx 900

4. Sound levels

Sound levels have been measured in accordance with the measuring methods as defined in:

NF EN 1553 "Agricultural machinery - Self-propelled, mounted, semi-mounted and trailed - Common

safety recommendations".

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L (A) eq:

Tractor only: 71.8 dB(A).

Tractor + machine: 72.2 dB(A).

28

Machine specifications

Page 31

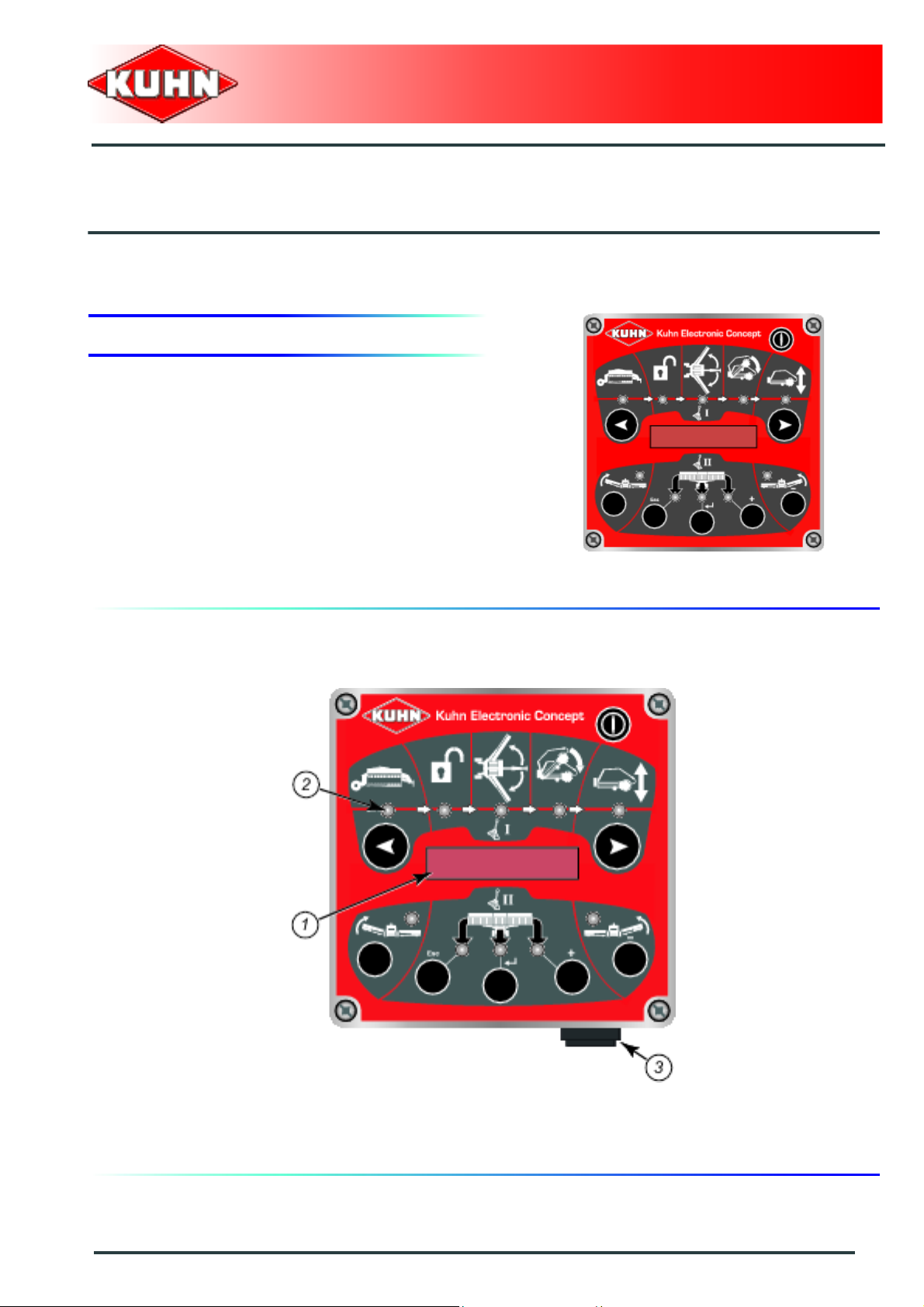

$Putting into service

1. Description of control elements

The machine is fitted with a control box to monitor all

functions.

- Model: T15M

Merger

Merge Maxx 900

Description of the box

0

1 : Display

2 : Indicator light

3 : 7-pin CAN connector for the connection to the on board computer

Putting into service

29

Page 32

Description of the functions

0

Merger

Merge Maxx 900

1 : Transport mode

2 : Machine locking/unlocking function

3 : Machine unfolding/folding function

4 : Pick-up pivoting function

5 : Pick-up height adjustment function

6 : Function for setting the left pick-up in headland turn position

7 : Function for selecting the windrow delivery mode

8 : Function for setting the right pick-up in headland turn position

30

Putting into service

Page 33

The control box is made up of 2 areas (a) and (b):

- The functions of area (a) are controlled by tractor

valve I.

- The functions of area (b) are controlled by tractor

valve II.

Merger

Merge Maxx 900

The functions of area (b) are available when the

"Pick up height ajdusmtent" function is activated

(Indicator light (1) on).

Putting into service

31

Page 34

Description of the controls

Key: On / Off

The T15M control box displays the following messages

when started:

- Software version (T15M): v2.5.

Then

- The "ECU" message is displayed when the

connection is activated to the on board comp ut er .

Then

- Software version (M400): v3.0.

Left (1) and right (2) navigation keys:

These keys enable navigating between the various

functions controlled by tractor valve I.

Merger

Merge Maxx 900

Keys for setting the machine into headland turn

position:

- (1) Left pick-up.

- (2) Right pick-up.

Keys for selecting the windrow delivery mode:

- Left windrow delivery (1).

- Central windrow delivery (2).

- Right windrow delivery (3).

- Left and right windrow delivery (1) and (3).

- Windrow delivery two thirds to the left and one third to

the right (1) and (2).

- Windrow delivery two thirds to the right and one third

to the left (2) and (3).

32

Putting into service

Page 35

Particularity:

In certain adjustment modes, the following keys have a

different function:

-Keys - (1) and + (2):

• Enable modifying a mode or a value.

- (3) key:

• Enables validating an adjustment.

- (4) key:

• Enables to quit the adjustment mode or to delete the

error message.

Emergency stop

Merger

Merge Maxx 900

The control box is fitted with an emergency stop for

switching off the module and stopping all electric

functions on the machine actuators.

Swiftly press ON/OFF key to activate

emergency stop.

2. Assembly and fitting

Control box mounting

The control box must be easily accessible from the

tractor cab.

- Clean the glass surface before installation.

- Position holder (1) on the window and lock it using

lever (2).

Putting into service

33

Page 36

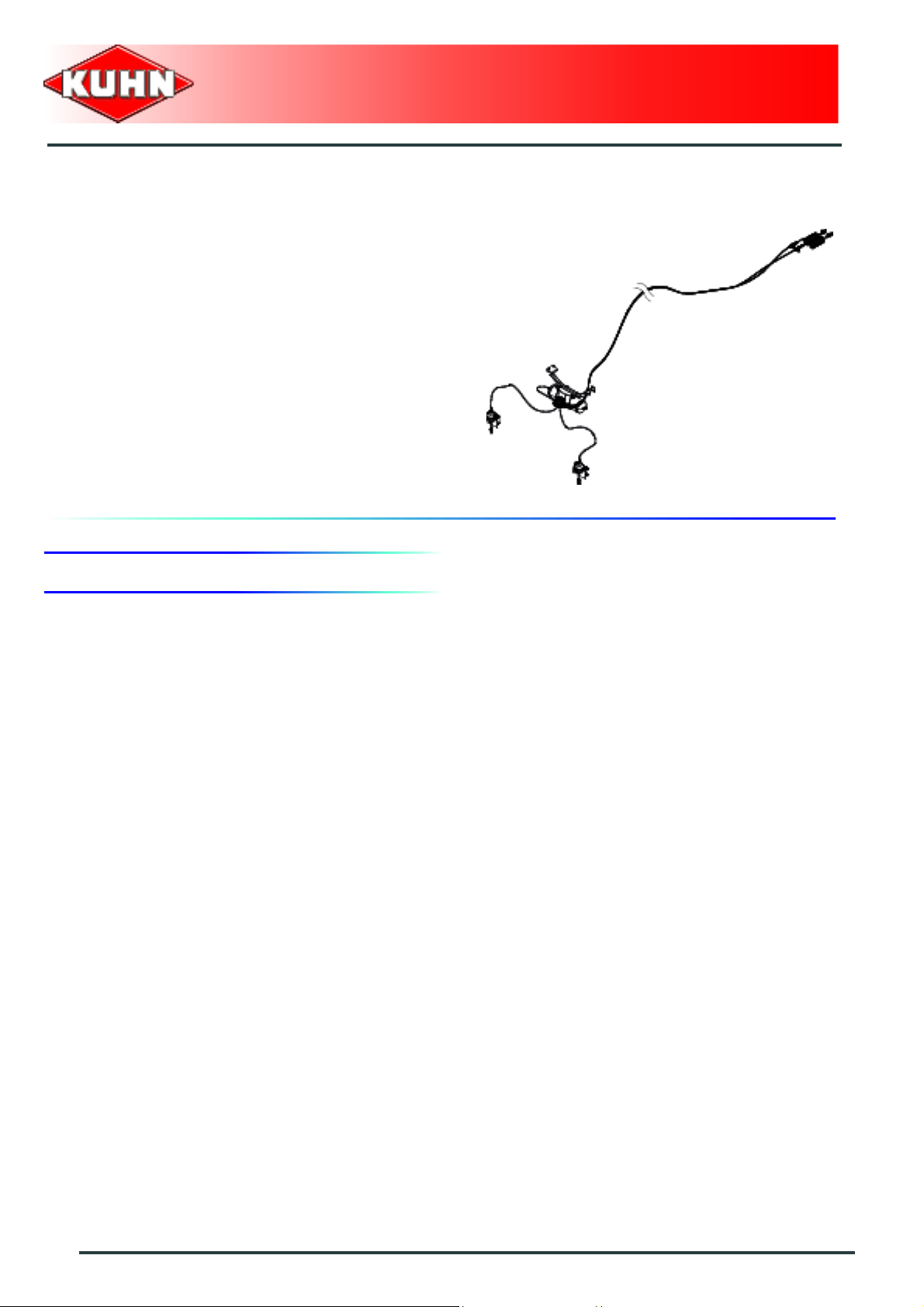

Electrical power supply

The box is energized by the tractor's 3-pin socket (DIN

9680, ISO 12369) or the battery power cable supplied.

Number of contact Colour of cable Function

(1) - 82 Brown +12V

(2) - 15/30 Brown +12V

(3) - 31 Blue Ground

Some tractors are factory equipped with a 3pin socket, to prevent any malfunction, check

the polarity of this socket before connecting

the control box.

Check presence of voltage on pin (1).

Merger

Merge Maxx 900

For tractors not fitted with a 3-pin socket, a wiring

harness is supplied with the machine (Part

no. 83233051).

The wiring harness is fitted with 3 fuses:

- 2 ATO type 30 ampere fuses (Part no. 83233031)

(Fuses (1)).

- 1 ATO type 5 ampere fuses (Part no. 83233014)

(Fuse (2)).

For connection to the tractor's own socket,

make sure tractor fuses are of correct

amperage.

34

Putting into service

Page 37

Merge Maxx 900

Harness connection:

- Connect wire (1) to the battery + terminal.

- Connect wire (2) to the battery + terminal.

- Connect wire (3) to the battery - terminal.

Do not connect the wiring harness to the starter connections.

For tractors fitted with a battery isolation switch, the supply cable must be connected just after

the latter.

Never connect the battery charger or carry out welding tasks without having previously

disconnected the 3-pin plug from the control box.

Check that the connectors are in a good condition and clean.

Merger

3. Coupling and uncoupling

Description of coupling elements

- A pto shaft drives the machine's hydraulic pump for

driving the pick-ups and the conveyor belts.

- An electric 7-pin plug for the signalling equipment.

- A 3-pin plug for the on-board computer po we r su pply.

- 4 hydraulic hoses connected to the hydraulic valve

bank that controls the various functions.

- 1 hydraulic hose to supply the braking system circuit

(depending upon specification).

- 2 pneumatic hoses to supply the brake actuation

system (depending upon specification).

Putting into service

35

Page 38

Preparing the tractor

The machine adapts to tractors fitted with a 3-point hitch

coupler category 2 or 3.

The tractor must be fitted with lower link

stabilizers.

Merger

Merge Maxx 900

The tractor nominal PTO speed must be 1000 min

-1

.

The tractor must be equipped with:

- 1 double acting valve with float position.

- 1 double acting valve with or without float position.

- An electric 7-pin plug for the signalling equipment.

- A 3-pin electric plug for the control box.

When the machine is fitted with a hydraulic brake

actuation system:

- 1 hydraulic connection for the braking system.

When the machine is fitted with a pneumatic brake

actuation system:

- 2 pneumatic plugs for the braking system.

The front axle load (1) must never, under any

circumstances, be less than 20% of the

tractor's unladen weight.If necessary, add

ballast weights to the front or to the rear to

preserve the steering and braking efficiency.

Hitch pin parallelism

Adjust tractor lift rods so that hitch pins are parallel to the

ground.

36

Putting into service

Page 39

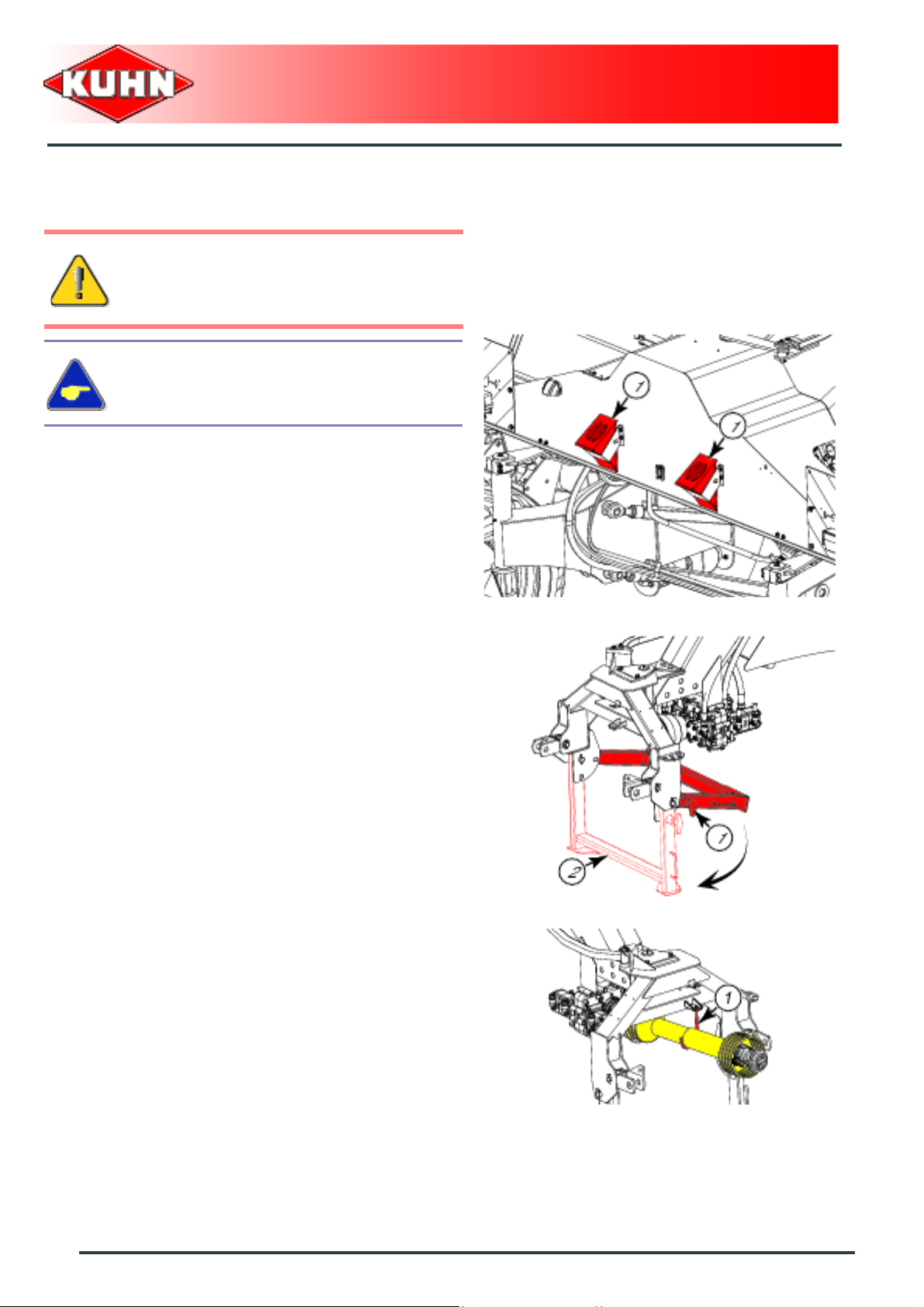

Coupling the machine

- Lower the tractor three-point linkage.

- Place the lower links as close as possible under the

hitch pins.

- Attach lower links to the hitch pins on the inside of the

yokes.

• Category 2 (a)

• Category 3 (b):

Merger

Merge Maxx 900

2 bushes diameter 37 mm (1.45’’) are supplied

with the machine.

- Secure each hitch pin with lynch pin.

- Raise tractor lift linkage to free parking stand.

- Pull on handle (1) to unlock parking stand (2).

- Fold parking stand (2) upwards and lock it in place.

- Remove and store wheel chocks on their holders.

Putting into service

37

Page 40

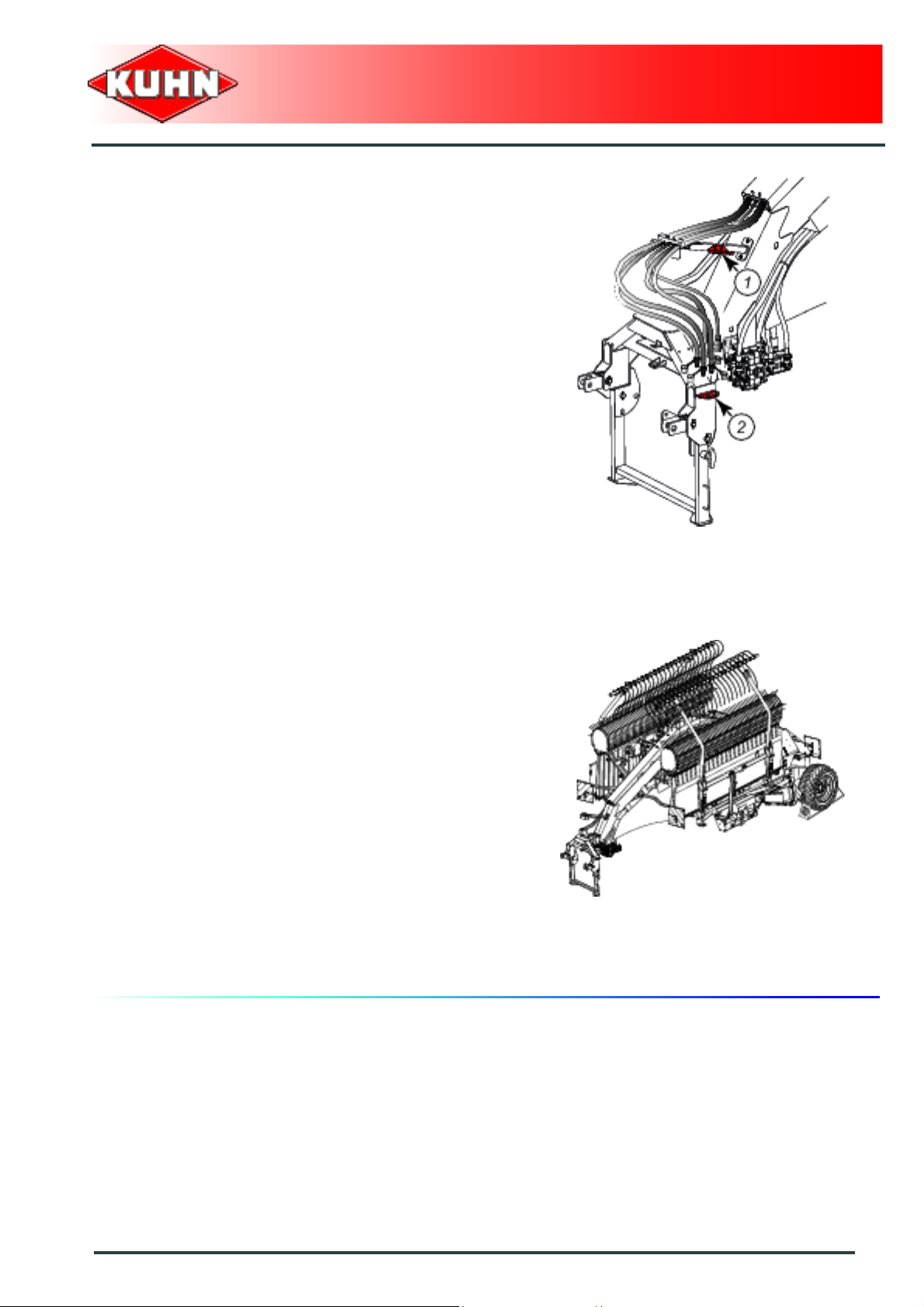

Hydraulic connections

The tractor must be equipped with 2 double acting

valves.

Connect hydraulic hoses (a) and (b) of diameter 16 mm

(0.6’’) on the same tractor double acting valve.

Hoses (a) and (b) supply the following cylinders:

- Transport lock cylinders.

- Machine unfolding/folding cylinders.

- Pick-up pivot cylinders.

- Pick-up height adjustment cylinders.

Connect hydraulic hoses (c) and (d) of diameter 20 mm

(0.8’’) on the same tractor double acting valve.

This valve must have a floating position.

Merger

Merge Maxx 900

Hoses (c) and (d) supply the following cylinders:

- Cylinders for setting the machine into headland turn

position.

After connecting the hoses, check that there is no risk of

catching them during operation.

Before connecting hoses to the tractor

hydraulics, ensure that tractor and machine

circuits are not under pressure.

Before disconnecting a hose, depressurize

the hydraulic circuit.

38

Putting into service

Page 41

Connections for the hydraulic braking (depending upon specification)

Connect hydraulic hose for braking system to the tractor

"trailor brake" coupler.

After connecting the hose, check that there is no risk of

it getting caught during operation.

Check that the brakes work correctly.

Pneumatic braking connections

(depending upon specification)

Merger

Merge Maxx 900

Check connector cleanliness prior to

connecting the hoses.

- Connect the coiled air brake hoses to the tractor.

Respect hose colour when connecting them:

- Red (a): Feed line.

- Yellow (b): Actuating line.

After connecting the lines, check that there is no risk of

them getting caught in operation.

- Check that the brakes work correctly.

When the braking hoses are not connec ted to

the tractor's braking system, the machine's

brakes are automatically engaged.

- Press valve (1) to disengage brakes by hand.

- Pull valve (1) to engage brakes by hand.

A maximum of 3 brake engagement/

disengagement cycles are possible with the

volume of air contained in the container.

Putting into service

39

Page 42

Electrical connections

Control box

- Connect 7-pin plug (1) of module (3) to control box (2).

- Connect the module M400 (3) wiring harness (4) to

the tractor 3-pin plug (5).

Merger

Merge Maxx 900

Lighting

- Connect 7-pin plug to the tractor.

After making the connections, check that there is no risk

of the cables being caught during operation.

40

Putting into service

Page 43

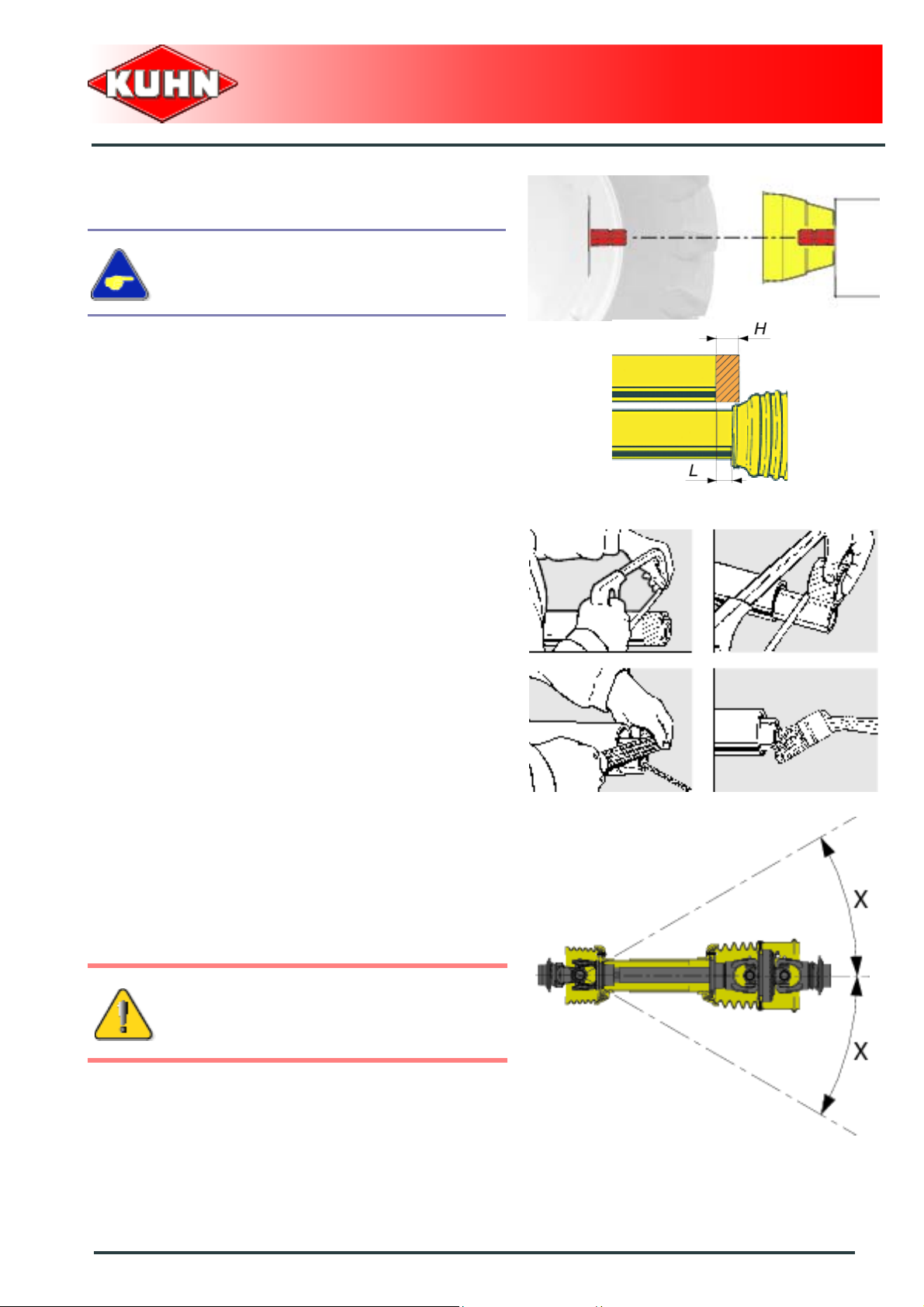

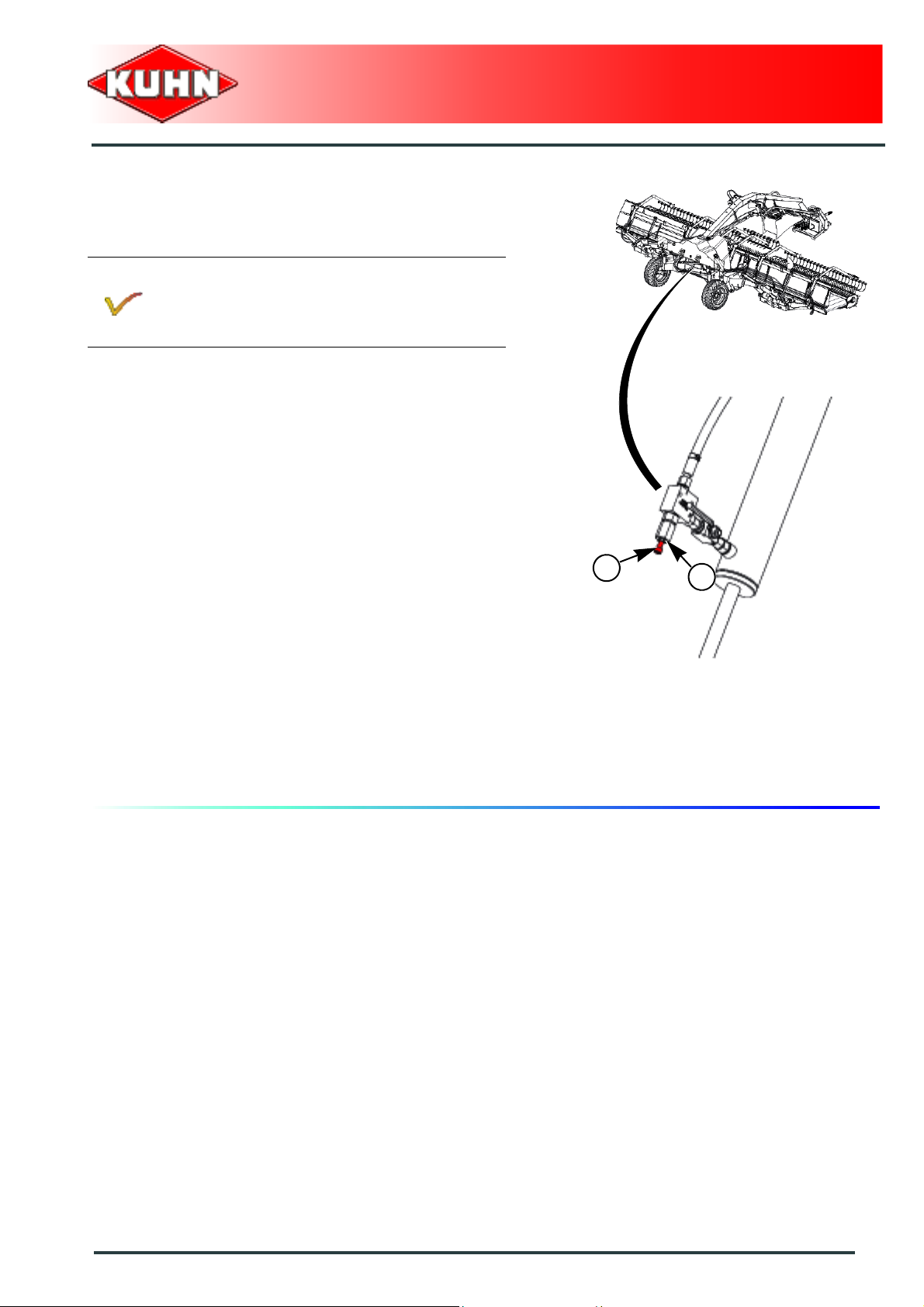

Primary PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

The tractor PTO stub must rotate at a speed of 1000 min-1.

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- Check the maximum overlap when tractor and

machine PTO stubs are in line.

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes. As a safety measure, a clearance (L) of at least

10 mm (0.4’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

250 mm (10’’).

Merger

Merge Maxx 900

If this is not the case:

- Mark length (H) to cut when the transmission is the

maximum overlap position

- Shorten the guard tubes and the transmission tubes

by the same length.

- Bevel and clean the tubes.

- Grease the inside of the outer tube.

Never operate the PTO shaft at an angle X exceeding

30°.

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

Putting into service

41

Page 44

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

Attach PTO shaft guard chain in hole (1) on machine

side.

Immediately replace any worn or damaged

guard.

Merger

Merge Maxx 900

1

Unfold pto shaft support (1).

42

Putting into service

Page 45

Adjusting the machine

Lateral adjustment of the lower linkage arms

Balance the play on either sides of the lift linkage and

lock lower link stabilizers.

Merger

Merge Maxx 900

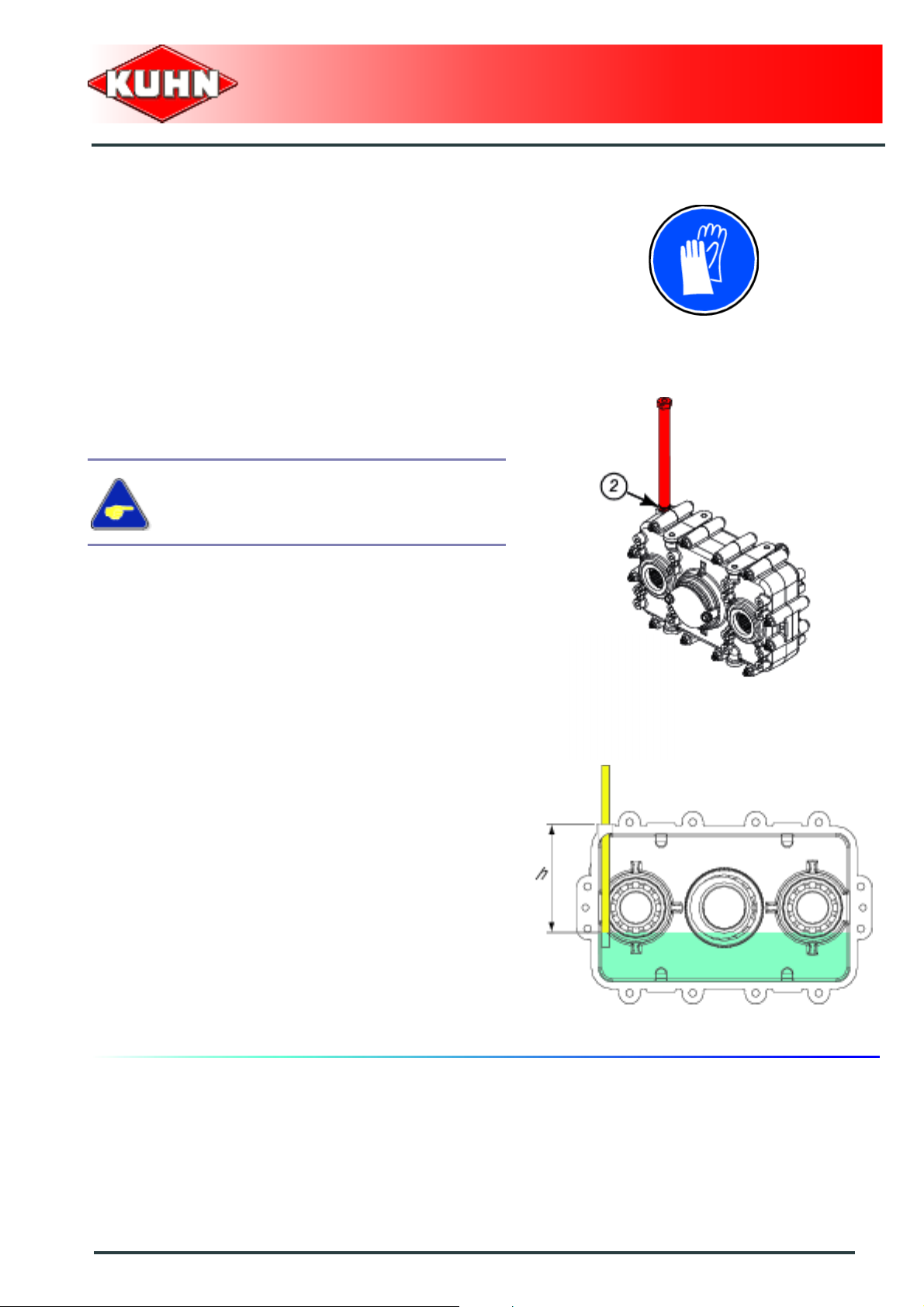

Frame height

- Lower the tractor lift linkage so that hitch pins are at a

distance H = 630 mm (2’1’’) from the ground.

Putting into service

43

Page 46

Uncoupling the machine

Park the machine on an even fairly level

ground.

Preferably park the machine in transport

position.

- Block machine with wheel chocks (1).

Merger

Merge Maxx 900

- Release and lower parking stand (2).

- Secure parking stand using lock (1).

- Uncouple and place PTO shaft in support (1).

44

Putting into service

Page 47

- Disconnect and store brake system hydraulic hoses

on holder.

- Disconnect and store hydraulic hoses on holder (2).

- Disconnect and store signalling electric plug on holder

(2).

- Disconnect and store module electric supply plug.

- Disconnect and store control box in a dry and clean

place.

Merger

Merge Maxx 900

- Lower the tractor three-point linkage to rest the

machine on the ground.

- Release the lower links.

- Lower the tractor three-point linkage.

The machine is uncoupled.

Putting into service

45

Page 48

$Instructions for transport

Before placing the machine into transport

position:

- Wait until the rotating parts have come

to a complete stop.

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

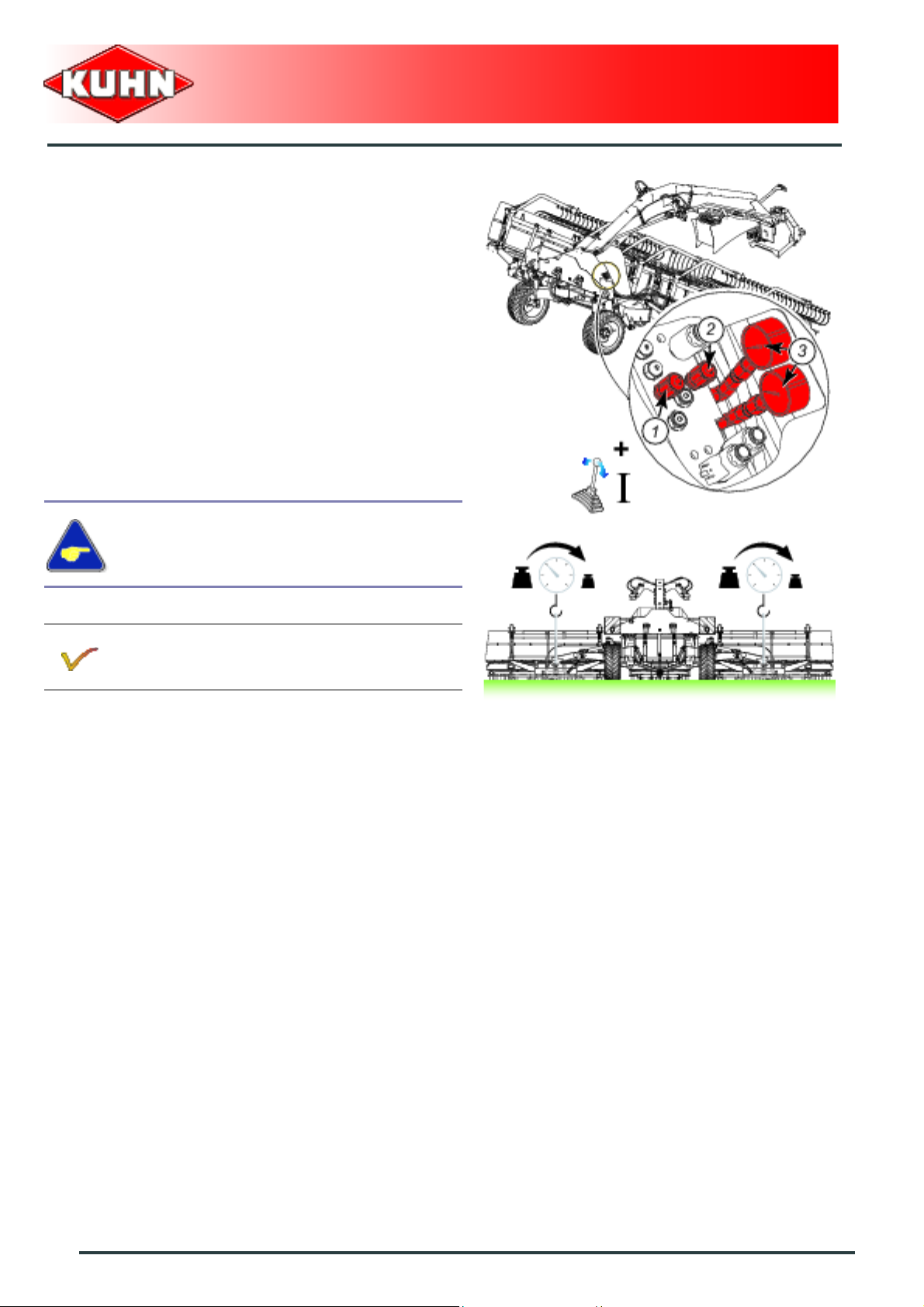

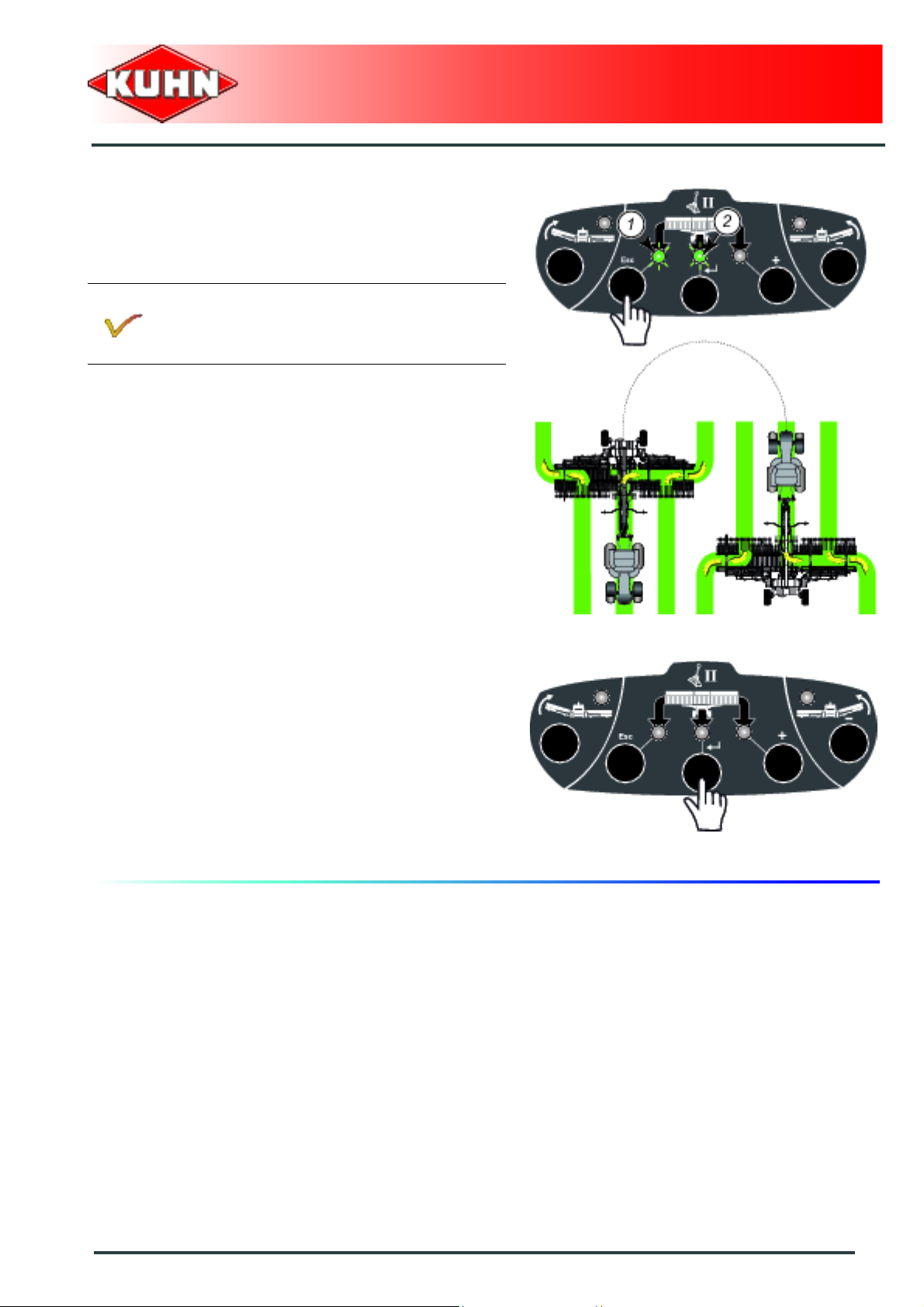

1. Putting the machine into transport position

Merger

Merge Maxx 900

From the working position:

- Place the machine in headland turn position (Valve II).

- Operated hydraulic valve during 5 seconds to position

the central pick-up in transport position.

The side pick-ups cannot be raised if the

machine is not in headland turn position.

The central pick-up must be in transport

position.

The screen flashes.

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 3 - - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The side pick-ups lift.

46

Instructions for transport

Page 49

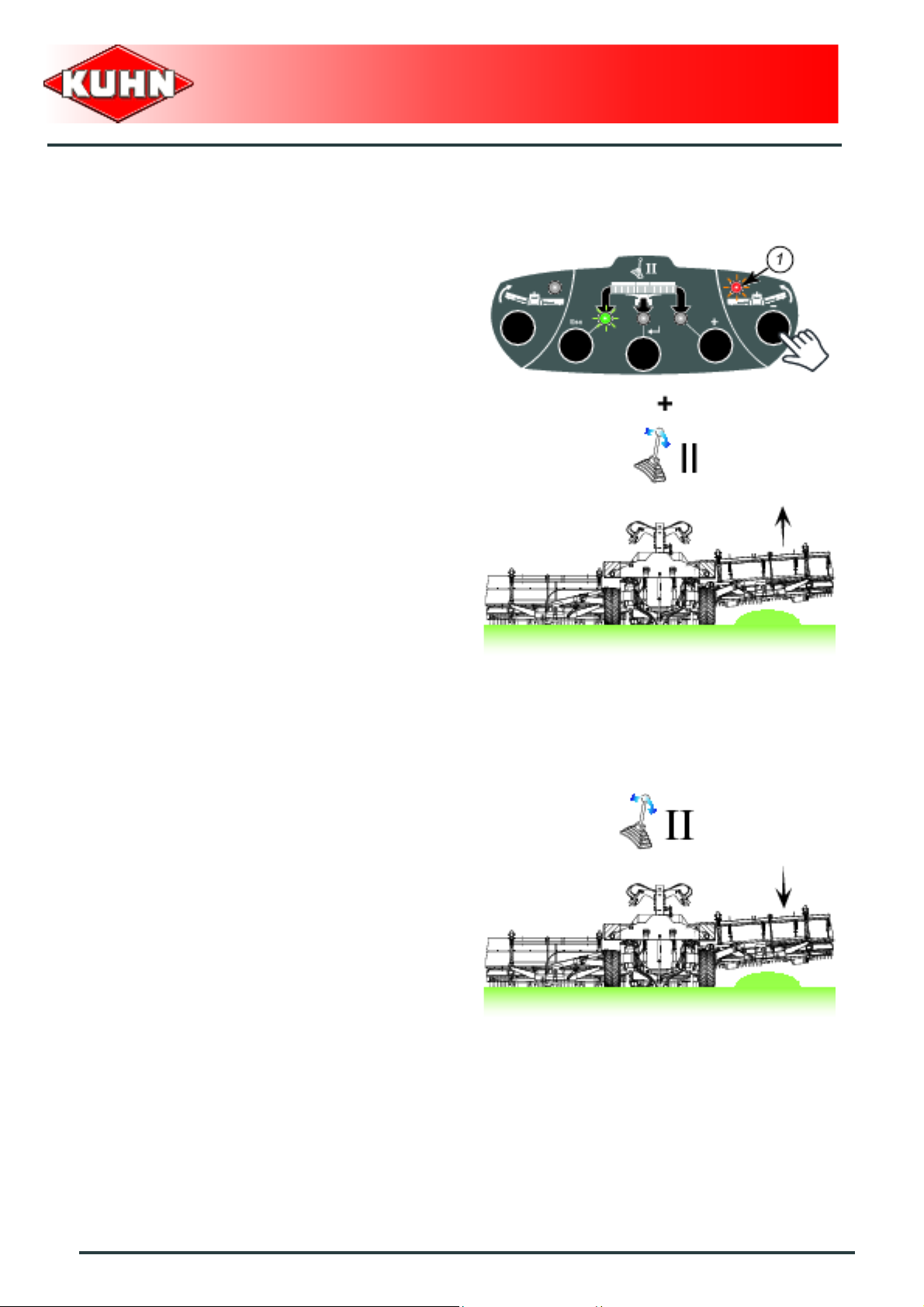

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 2 - - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The machine folds.

Merger

Merge Maxx 900

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 1 - - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The machine locks.

Check that transport locks (1) are fully

engaged.

Instructions for transport

47

Page 50

- Press approximately 1 second on key (a):

• Indicator light (1) flashes.

• The hour counter is displayed.

• all machine functions are deactivated.

- Press on the button ON/OFF (b).

Merger

Merge Maxx 900

The machine is in transport position.

Never engage the tractor PTO drive when the

machine is in transport position.

48

Instructions for transport

Page 51

2. Conformity with the road regulations

Before driving the machine on public roads,

ensure that the machine complies with

current highway code regulations.

Check that the light boards are clean and that the lighting

equipment functions before transporting the machine on

public roads.

Immediately replace any worn or damaged

signalling panels or lights.

Merger

Merge Maxx 900

Check that transport locks (1) are fully

engaged.

Instructions for transport

49

Page 52

$Instructions for work

Before placing the machine in working

position:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

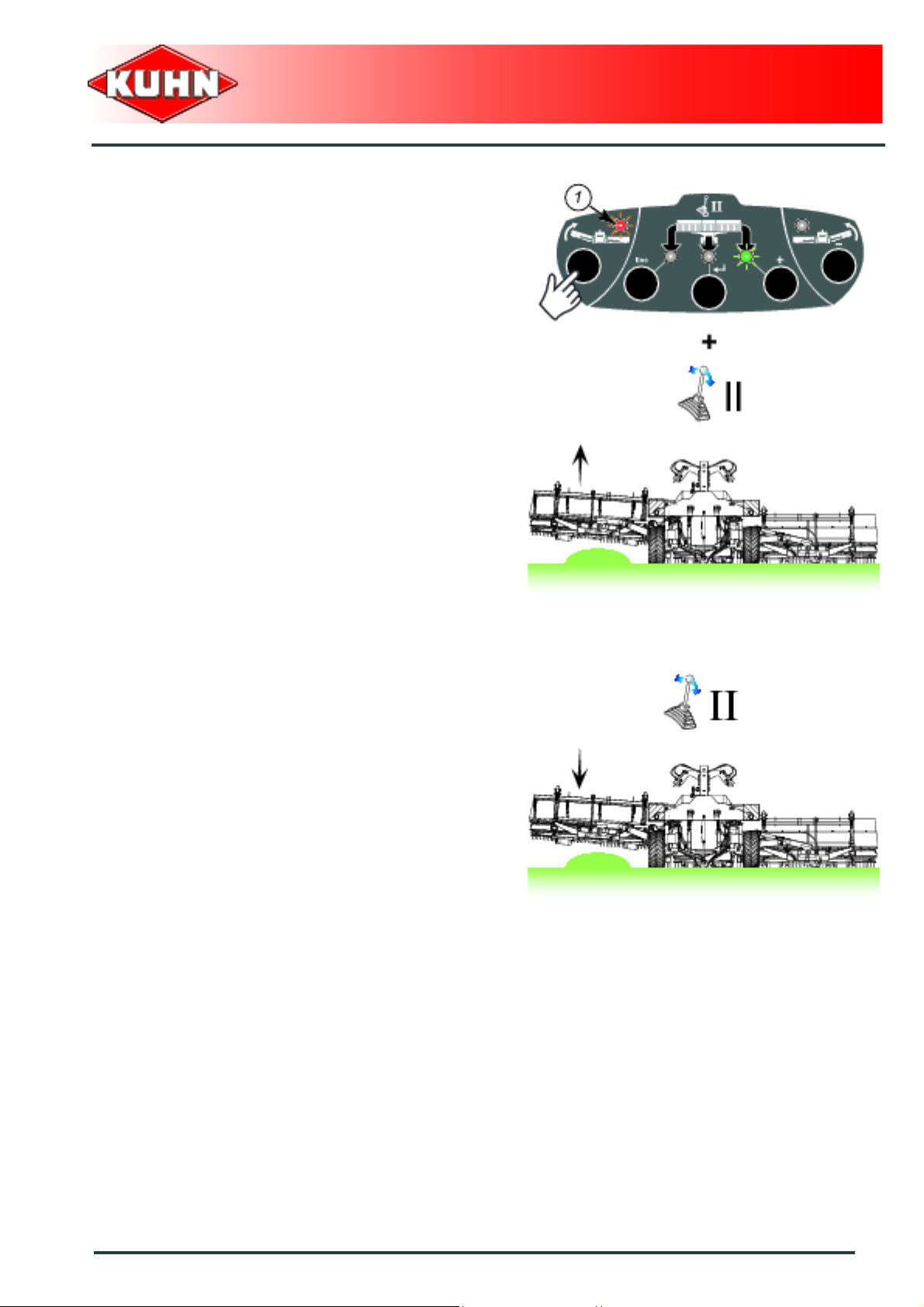

1. Putting the machine into work position

Merger

Merge Maxx 900

From the transport position:

- Press on the button ON/OFF.

• Indicator light (1) flashes.

Wait for the hour counter to appear on the screen.

- (a): hour (0 to 9999).

- (b): minute (0 to 59).

If the hour counter is not displayed, contact your

Kuhn dealer.

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 1 - - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The machine is unlocked.

50

Instructions for work

Page 53

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 2- - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The machine unfolds.

Merger

Merge Maxx 900

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• - - 3 - - is displayed on the screen.

- Operate tractor hydraulic valve I:

• The pick-ups are lowered.

The 1, 2 and 3 modes are active during 60

seconds.

After 60 seconds, the screen flashes.

- Press shortly on arrow keys to reactivate

the mode during 60 additional seconds.

- Without an impulse, the control box

automatically deactivates the function and

switches to the transport mode.

Instructions for work

51

Page 54

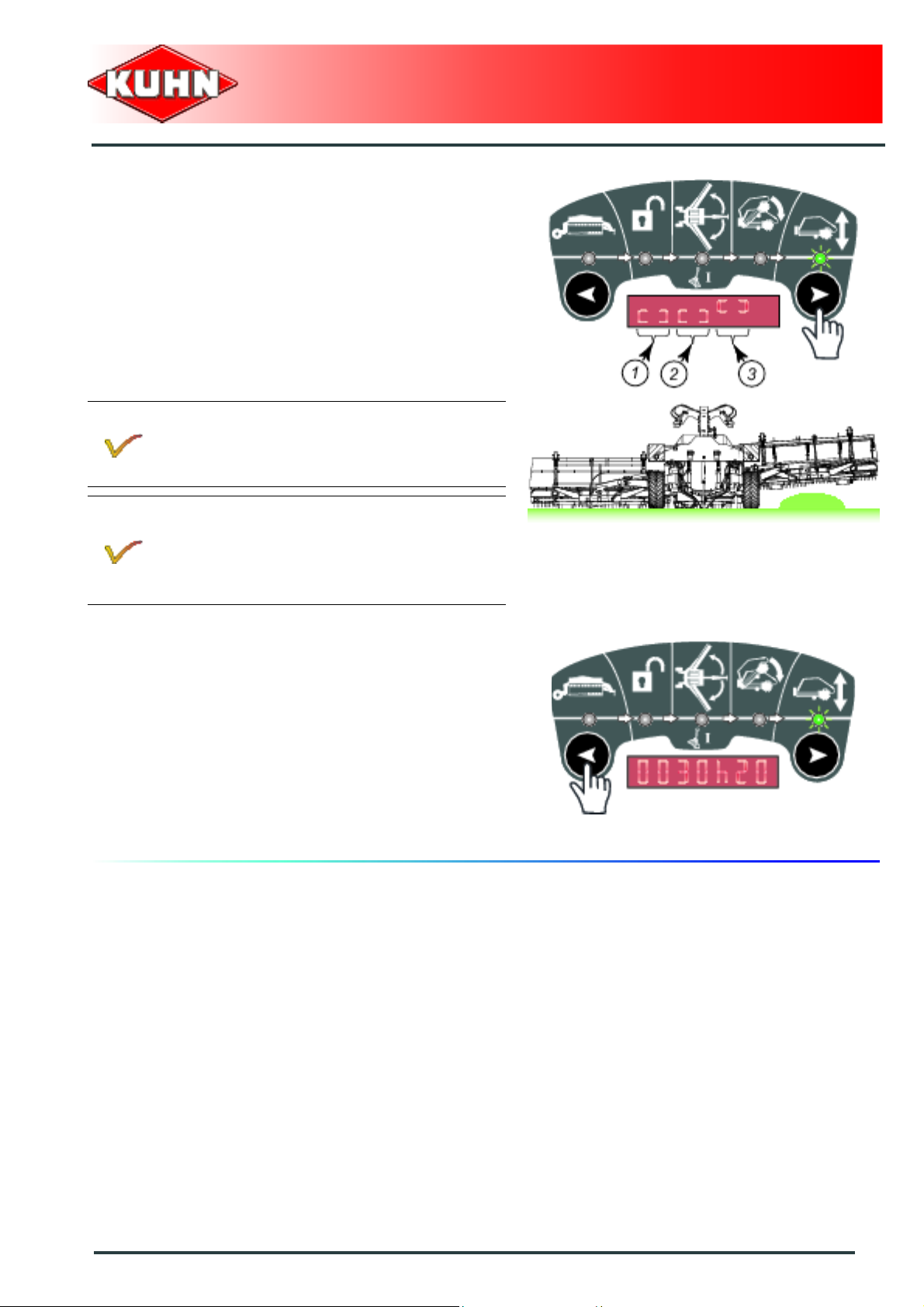

- Press for approximately 1 second on the navigation

key:

• Indicator light (1) comes ON.

• The hour counter is displayed.

• The work functions are activated.

- Activate tractor hydraulic valve II to lower the pickups.

Merger

Merge Maxx 900

The machine is in working position.

52

Instructions for work

Page 55

2. Adjustments in working position

Before making any adjustment:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

Adjusting the pick-up working height

- Select the "Pick-up height adjustment" function using

navigation keys:

• Indicator light (1) comes ON.

• The hour counter is displayed.

- Activate tractor hydraulic valve I to adjust the pick-up

height.

Merger

Merge Maxx 900

Tine to ground distance D can vary from 0 mm to

110 mm (0’’ - 4.33’’).

The pick-up height can be adjusted any time

during work.

Activate tractor hydraulic valve I to adjust the

pick-up height.

Indicator (1) enables to visualize the pick-up working

height.

The difference between 2 notches corresponds

to a 20 mm (0.8’’) variation in the working height

of the pick-ups.

Instructions for work

53

Page 56

Adjusting the aggressiveness of the combs

Various settings are possible:

Adjustment 1:

- Loosen screw (1).

- Remove screw (2).

- Place comb in the required position:

• Position (a): More aggressive position.

• Position (b): Intermediate position.

• Position (c): Less aggressive position.

- Repeat procedure on each comb .

- Fit screw (2).

- Tighten screw (1).

• Torque : 8.5 daN m (63 lbf ft).

Merger

Merge Maxx 900

Adjustment 2:

- Loosen nuts (1).

- Place comb in the required position.

- Tighten nuts (1).

• Torque : 2.5 daN m (18 lbf ft).

54

Instructions for work

Page 57

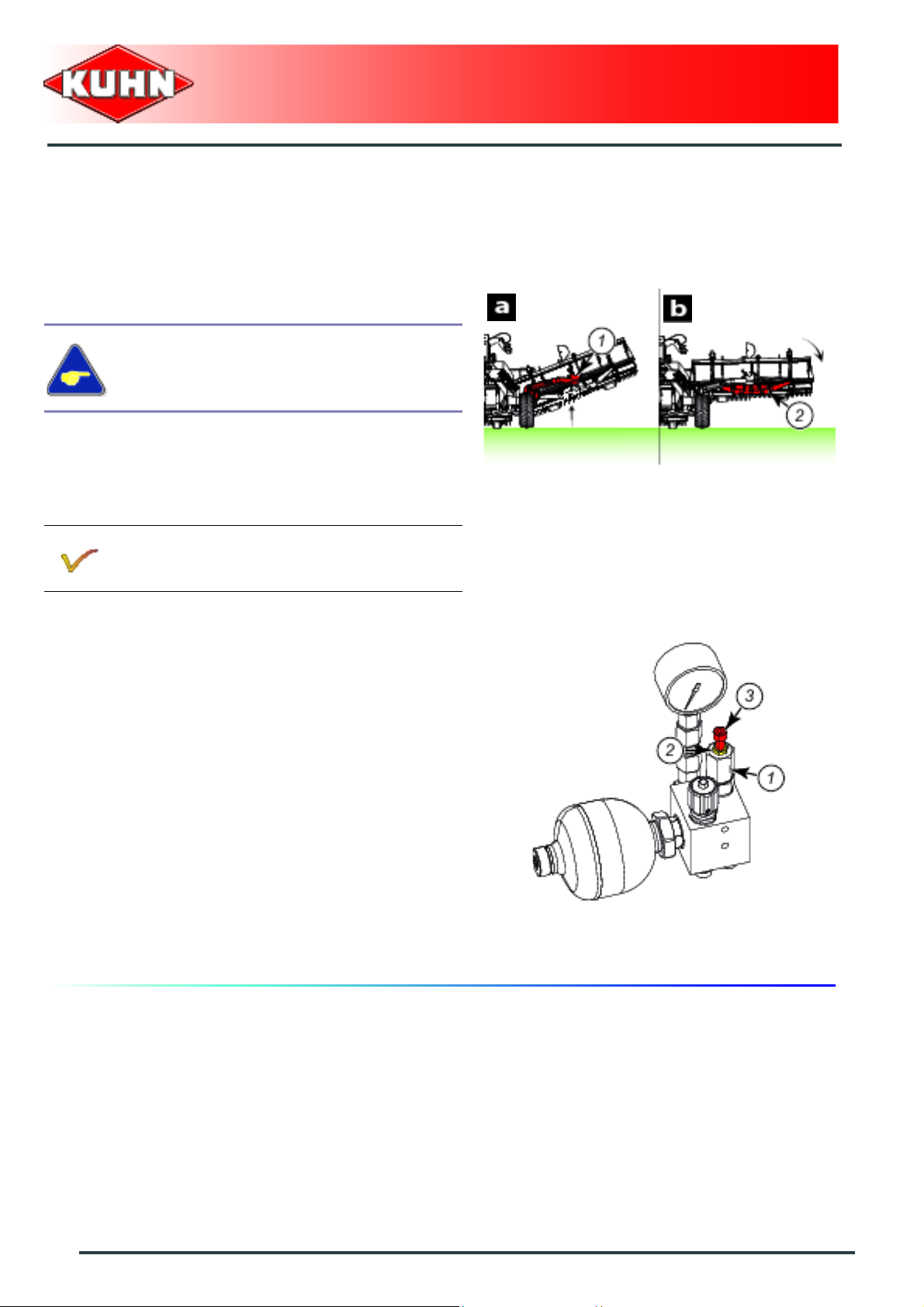

Ground pressure adjustment of the side pick-ups

The side pick-up ground pressure is obtained by 2 hyd ropneumatic accumulators.

By modifying the accumulator pressure, the side pick-up

ground pressure varies.

The pressure must be adapted to the nature and

moisture degree of the ground.

Conditions required:

- The pick-ups are fully raised.

- Select the "Pick-up height adjustment"

function using navigation keys (1).

The machine hydraulic suspension circuit is

pressurized at the factory at 135 bar

(1958 psi):

- max.: 140 bar (2030 psi)

- minimum: 130 bar (1885 psi)

Never adjust machine to a pressure not

comprized between the limit values.

Merger

Merge Maxx 900

1

- Park the machine on an even fairly level ground:

• All pick-ups must rest on the ground.

- Select the "Pick-up height adjustment" function using

navigation keys.

- Activate the tractor hydraulic valve to fully raise the

pick-ups

- Select the "Machine locking/unlocking" function using

the navigation keys.

- Indicator light (1) comes ON.

The function is activated during 60 seconds.

After 60 seconds, the screen flashes.

- Press shortly on arrow keys to reactivate

the mode during 60 additional seconds.

Without an impulse, the control box

automatically deactivates the function and

switches to the transport mode.

Instructions for work

55

Page 58

Ground pressure reduction

Increase pressure in the hydro-pneumatic accumulators

to reduce the pick-up ground pressure:

- Check that valves (1) and (2) are shut-off.

- Operate and maintain hydraulic valve I control lever to

pressurize the circuit.

- Slowly open hydraulic unit valve (2).

- Check pressure increase on gauges (3).

- When the required pressure is reached, close the

valve (2).

Merger

Merge Maxx 900

Tighten valve by hand.

When proceeding to the adjustment, the

pressure exceeds the required value, refer to

"Ground pressure increase" section.

56

Instructions for work

Page 59

Ground pressure increase

Reduce pressure in the hydro-pn eumatic accumulators

to increase pick-up ground pressure:

- Check that valves (1) and (3) are shut-off.

- Place hydraulic valve control lever I in floating position

(or in the "oil returns to the tractor tank" position).

- Slowly open hydraulic unit valve (1).

- Check pressure decrease on gauges (2).

- When the required pressure is reached, close the

valve (1).

Tighten valve by hand.

When proceeding to the adjustment, the

pressure is below the required value, refer to

"Ground pressure decrease" section.

Merger

Merge Maxx 900

When the pressure in the ground pressure

circuit goes below 125 bar (1812 psi), an

alarm message is displayed on the control

box.

In the direction of travel:

- ’’ Press L ’’ = Pressure in the ground

pressure circuit left side.

- ’’ Press R ’’ = Pressure in the ground

pressure circuit right side.

Immediately increase the ground pressure in

the concerned circuit to the recommended

value as soon as the message appears.

See section: ’’ Ground pressure adjustment of

the side pick-ups ’’

Press on the control box "Esc" key to delete the

message momentarily.

Instructions for work

57

Page 60

Adjustment of the central pick-up ground

pressure

2 springs enable adjusting the central pick-up ground

pressure.

Adjustment

The pressure must be adapted to the na ture and

moisture degree of the ground.

Merger

Merge Maxx 900

The springs are factory set to a minimum ground

pressure (1).

Position (2):

- Ground pressure increase (+ 34 kg (75 lb).

Position (3):

- Ground pressure increase (+ 68 kg (15 0 lb).

- Raise the central pick-up:

• See section: ’’

- Shut-off the central pick-up cylinder valve.

- Remove roll pin (1) and washer (2).

- Remove pin (3).

- Place the springs in the hole corresponding to the

required setting.

• The 2 springs must adjusted to the same measure.

- Reinstall pin (3).

- Reinstall washer (2) and roll pin (1).

- Open the central pick-up cylinder valve

Central windrow delivery ’’.

1

3

2

2

3

1

58

Instructions for work

Page 61

Adjustment of the balancing pressure of the side pick-ups

During the first adjustment, increase

pressure to 175 bar (2538 psi) and then

reduce pressure to (0 bar).

Repeat procedure 5 times to bleed the circuit.

- Check that valve (1) is shut-off.

- Operate tractor hydraulic valve II in the headland turn

position direction:

• The side pick-ups lift.

The pick-up holding frame (2) must be at

travel end against side arm (3).

Merger

Merge Maxx 900

- Press hydraulic valve control lever II to pressurize the

circuit.

- Slowly open valve (1).

- When the pressure reaches 175 bar (2538 psi) bar on

the pressure gauge, close the valve.

Tighten valve by hand.

Adjust both sides to the same setting.

Reducing the balancing pressure of the side pick-ups

- Activate tractor hydraulic valve II to lower the pickups.

- Place hydraulic valve control lever II in floating

position (or in the "oil returns to the tractor tank"

position).

- Slowly open valve (1).

- Shut-off valve when the pressure reaches the

required value on the manometer.

Tighten valve by hand.

Instructions for work

59

Page 62

Adjusting the synchronisation of the side

arm lift and the pick-up holding frame

rotation

The pick-up holding frame (2) rotation must

be made after raising side arm (1):

- a: Side arm lift.

- b: Rotation of the pick-up holding frame.

Merger

Merge Maxx 900

The sequencing valve is factory preset at (1).

To delay the rotation movement of the pick-up holding frame:

- Loosen counter nut (2).

- Tighten screw (3) by an eighth of a turn.

- Check movement synchronisation.

- Repeat procedure if necessary .

- Tighten the counter nut.

To put the pick-up holding frame rotation movement forward:

- Loosen counter nut (2).

- loosen screw (3) by an eighth of a turn.

- Check movement synchronisation.

- Repeat procedure if necessary .

- Tighten the counter nut.

60

Instructions for work

Page 63

Synchronization of the lift of the side pick-

ups with regards to the central pick-up

The lift of the 3 pick-ups must occur

approximately at the same moment.

The sequencing valve is factory preset at (1).

To delay the central pick-up raising:

- Loosen counter nut (1).

- Tighten screw (2) by an eighth of a turn.

- Check movement synchronisation.

- Repeat procedure if necessary.

- Tighten counter nut (1).

Merger

Merge Maxx 900

To advance the central pick-up raising:

- Loosen counter nut (1).

- loosen screw (2) by an eighth of a turn.

- Check movement synchronisation.

- Repeat procedure if necessary.

- Tighten counter nut (1).

2

1

Instructions for work

61

Page 64

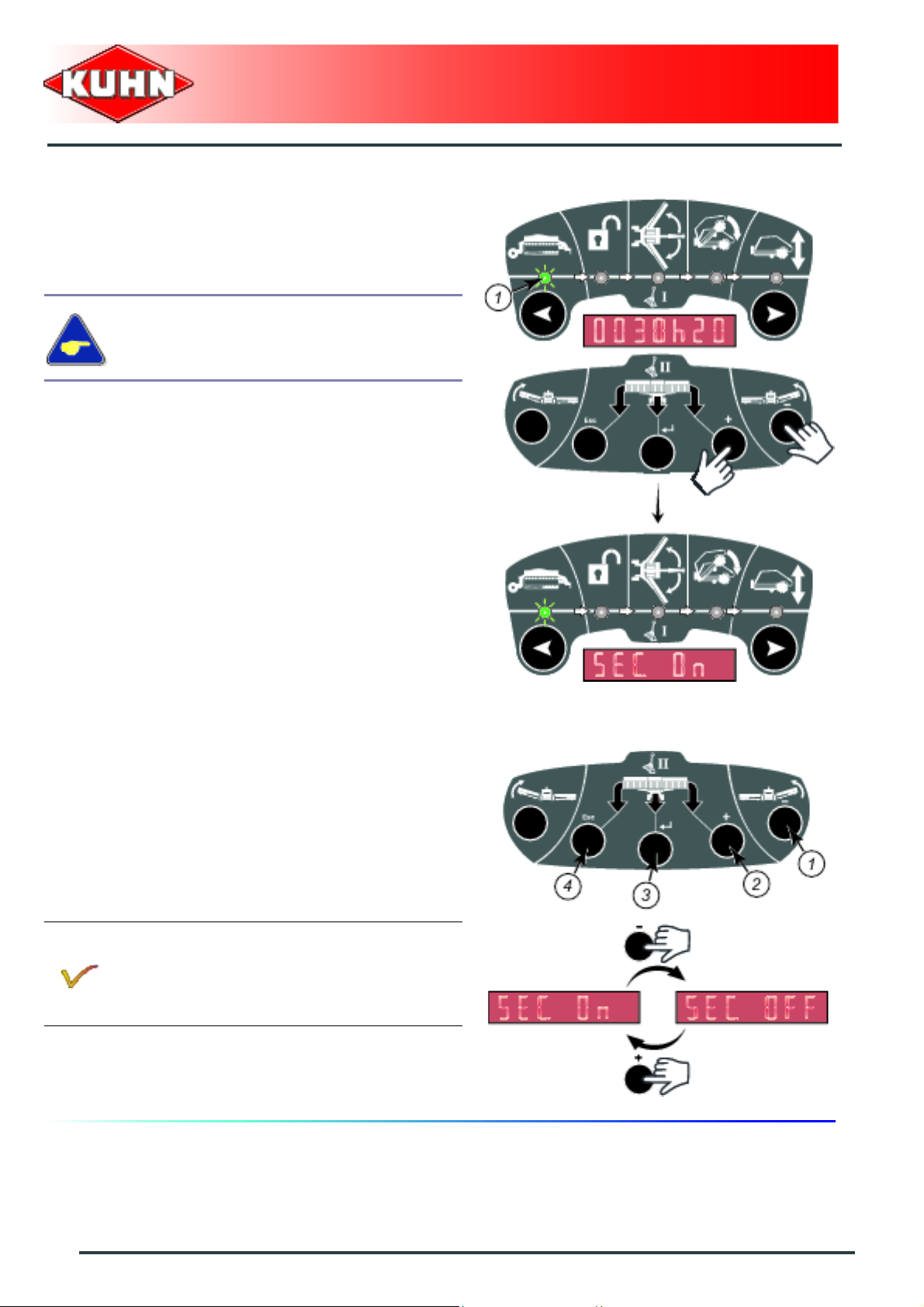

Adjustment of the time delay when

inverting the conveyor belt direction of

rotation (t2)

To access the time delay adjustment:

- Select transport mode:

• Indicator light (1) flashes.

- Simultaneously press keys + and - for approximately

5 seconds:

• The message "SEC. ON" is displayed.

Merger

Merge Maxx 900

- Shortly press navigation key:

• The message "t2 . 5" is displayed.

Adjusting the central pick-up time delay to the intermiate position (t3)

- Shortly press navigation key:

• The message "t3 . 5" is displayed.

62

Instructions for work

Page 65

Modification of the t2 or t3 value

- Press key - (1) to reduce the time delay:

• 2 seconds (minimum).

or

- Press key + (2) to increase the time delay:

• 10 seconds (max.).

- Press on validation key (3) to save the modifications

and return to the transport mode.

The modifications are saved permanently:

- Press "Esc" key (4) to quit without saving the

modifications and return to the transport mode.

Merger

Merge Maxx 900

Instructions for work

63

Page 66

Steering system adjustment

Should the transport wheels hit an obstacle,

check that the steering system is not

damaged.

Check the wheel toe-in (2.4°):

- Measure distance A on the front edges of the wheel

rims.

- Measure distance B on the rear edge of the wheel

rims.

• B = A + 24 mm (1’’).

Merger

Merge Maxx 900

The procedure consists in adjusting the wheel

alignment and toe-in.

Remove steering rod (1):

- Remove nut (2).

- Remove screw (3).

- Remove roll pin (4).

- Remove washer (5)

- Remove pin (6).

- Position headstock (1) at 90° in relation to beam (2).

64

Instructions for work

Page 67

- Pivot areas S and S’ in an angle X of 90° in relation to

beam (1).

Adjusting the wheel alignment ( Perform the operation

on each side of the machine ):

- Loosen counter nut (1).

- Remove nut (2).

- Remove screw (3).

- Remove roll pin (4).

- Remove washer (5)

- Remove pin (6).

- Adjust yoke (7).

- Reinstall pin (6).

- Check wheel parallelism.

Adjusting the wheel toe-in:

- Remove pins (6).

- Tighten yokes by 3.5 turns.

- Check the wheel toe-in (2.4°), B = A + 24 mm (1’’).

Readjust if necessary.

- Reinstall pins (6).

- Reinstall washers (5)

- Reinstall roll pins (4).

- Reinstall bolts (3).

- Reinstall nuts (2).

- Tighten counternuts (1).

Merger

Merge Maxx 900

Reinstall steering rod (1):

- Loosen counter nut (2).

- Adjust yoke (3).

- Reinstall pin (4).

- Tighten counter nut (2).

- Reinstall washer (5)

- Reinstall roll pin (6).

- Reinstall screw (7).

- Reinstall nut (8).

Instructions for work

65

Page 68

3. Machine use

Before working:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

- The machine is fitted with a steering device to:

• allow the machine to follow the same track as the

tractor.

• Facilitate headland turn manoeuvres and speed up

its realignment with regards to a machine not

equipped with this device.

• drive onto a field difficult to access.

Merger

Merge Maxx 900

The headstock is designed to turn at an angle

of maximum 65 degrees to the right of left.

To preserve the steering system, never

exceed this angle.

Groundspeed

The machine can work at a speed of up to

15 km/h (9 mph) in very good working conditions.

Groundspeed must be adapted to the encountered

working conditions.

66

Instructions for work

Page 69

Selecting the windrow delivery mode

Left windrow delivery

- Press approximately 1 seconds on selection key:

• The indicator light flashes for the whole period

during which the conveyor belt direction of rotation

is inverted and then stays on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

Merger

Merge Maxx 900

Right windrow delivery

- Press approximately 1 seconds on selection key:

• The indicator light flashes for the whole period

during which the conveyor belt direction of rotation

is inverted and then stays on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

Instructions for work

67

Page 70

Left and right windrow delivery

- Press simultaneously the selection keys for

approximately 1 second:

• The indicator lights flash for the whole period duri ng

which the conveyor belt direction of rotation is

inverted and then they stay on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

- Operate tractor hydraulic valve II to lift the pick-ups .

The central pick-up must be in transport position.

- Activate tractor hydraulic valve II to lower the pickups:

• Only the side pick-ups are lowered.

Merger

Merge Maxx 900

Central windrow delivery

- Press approximately 1 seconds on selection key:

• The indicator light flashes for the whole period

during which the conveyor belt direction of rotation

is inverted and then stays on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

- Operate tractor hydraulic valve II to lift the pick-ups .

The central pick-up must be in transport position.

- Activate tractor hydraulic valve II to lower the pickups:

• Only the side pick-ups are lowered.

68

Instructions for work

Page 71

Windrow delivery two thirds to the left and one

third to the right

- Press simultaneously the selection keys for

approximately 1 second.

- The indicator lights flash for the whole period during

which the conveyor belt direction of rotation is inverted

and then they stay on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

Merger

Merge Maxx 900

- On headlands, press key activating the inversion of

the conveyor direction of rotation.

- The indicator lights flash for the whole period during

which the conveyor belt direction of rotation is inverted

and then they stay on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

Instructions for work

69

Page 72

By pressing and holding down key allows leaving the

windrow delivery mode.

Windrow delivery two thirds to the right and one

third to the left

- Press simultaneously the selection keys for

approximately 1 second.

- The indicator lights flash for the whole period during

which the conveyor belt direction of rotation is inverted

and then they stay on.

Merger

Merge Maxx 900

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

70

Instructions for work

Page 73

- On headlands, press key activating the inversion of

the conveyor direction of rotation.

- The indicator lights flash for the whole period during

which the conveyor belt direction of rotation is inverted

and then they stay on.

The time delay during which the conveyor belt

direction of rotation is inverted can be adjusted

(See section "Adjustment of the time delay when

inverting the conveyor belt direction of rotation").

Merger

Merge Maxx 900

By pressing and holding down key allows leaving the

windrow delivery mode.

Instructions for work

71

Page 74

Putting the machine in headland turn

position

Right pick-up:

Putting the machine in headland turn position:

- Press selection key:

• Indicator light (1) comes ON.

- Operate tractor hydraulic valve II in the headland turn

position direction:

• The right pick-up is raised.

Merger

Merge Maxx 900

Putting the machine into work position:

- Operate tractor hydraulic valve II in the working

position direction:

• The right pick-up is lowered.

To deactivate the control, press again on selection key.

72

Instructions for work

Page 75

Left pick-up

Putting the machine in headland turn position:

- Press selection key:

• Indicator light (1) comes ON.

- Operate tractor hydraulic valve II in the headland turn

position direction:

• The left pick-up is raised.

Merger

Merge Maxx 900

Putting the machine into work position:

- Operate tractor hydraulic valve II in the working

position direction:

• The left pick-up is lowered.

To deactivate the control, press again on selection key.

Instructions for work

73

Page 76

All pick-ups:

Putting the machine in headland turn position:

If one of the "putting the machine in headland turn

position" function has been activated previously

(Example: Right pick-up):

- Press concerned pick-up selection key to deactivate

the function.

• Indicator light (1) is OFF.

Merger

Merge Maxx 900

- Operate tractor hydraulic valve II in the headland turn

position direction:

• All the pick-ups are raised.

The central pick-up stops in the intermediate

position.

Operated hydraulic valve during 5 seconds to

position the central pick-up in transport position.

Putting the machine into work position:

- Operate tractor hydraulic valve II in the working

position direction:

• All the pick-ups are lowered.

74

Instructions for work

Page 77

Viewing the position of the pick-ups

During work, the pick-up position can be viewed on the

screen.

- Shortly press navigation key.

• Symbols (1) and (2) indicate that the pick-ups are in

lower position.

• The symbol (3) indicates the pick-up is in raised

position.

When symbol (2) is steady, the central pick-up

can be controlled.

When symbol (2) flashes, the central pick-up is

no longer controlled.

When the machine functions in deteriorated

mode, all pick-ups appear in low position.

Deteriorated mode: See section: Use in

deteriorated mode.

Merger

Merge Maxx 900

- Press shortly on the navigation key to quit viewing th e

pick-up position and to return to the hour counter.

Instructions for work

75

Page 78

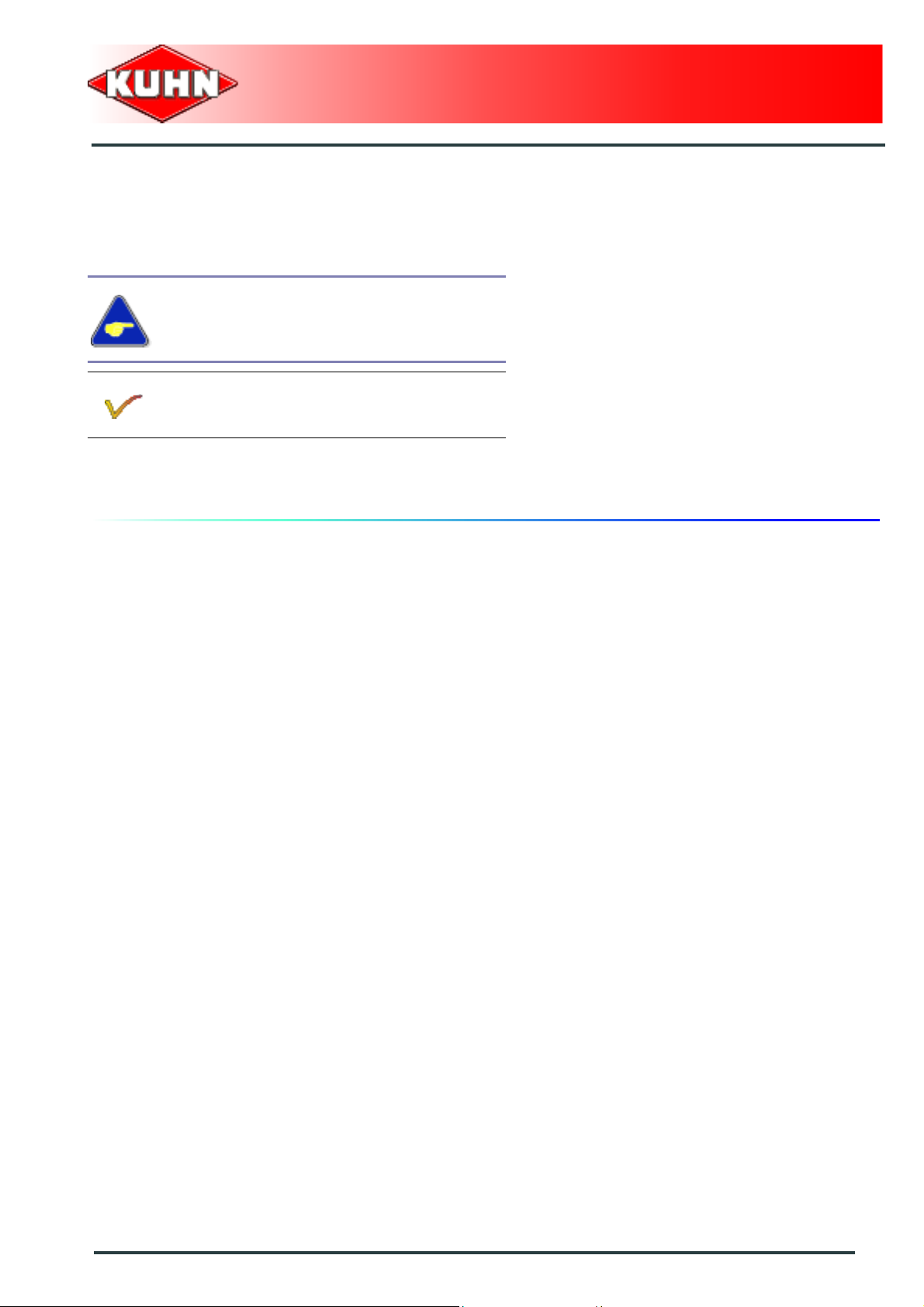

Use in deteriorated mode

This mode enables neutralizing the position sensors

when one of the sensors is faulty. This allows continuing

to work and to fold/unfold the machine.

In deteriorated mode, the time delay for

placing the central pick-up in headland turn

position is neutralized.

To access the deteriorated mode:

- Select transport mode.

• Indicator light (1) flashes.

- Simultaneously press keys + and - for approximately

5 seconds.

• The message "SEC. ON" is displayed.

Merger

Merge Maxx 900

- Press key - (1) to switch to the deteriorated mode.

• The message "SEC. OFF" is displayed.

or

- Press key + (2) to switch back to the normal use

mode.

• The message "SEC. ON" is displayed.

- Press on validation key (3) to save the modifications

and return to the transport mode.

Each time the control box is energized, the

machine automatically switches into normal use

mode (SEC. ON).

If necessary, re-parametize the machine in

deteriorated mode.

- Press "Esc" key (4) to quit without saving the

modifications and return to the transport mode.

76

Instructions for work

Page 79

Error messages

If an error code is displayed on the screen, contact your

Kuhn dealer.

Note the sofware versions of th e T15M and

M400 before contacting your Kuhn dealer.

Press "Esc" key to delete error code.

Merger

Merge Maxx 900

Instructions for work

77

Page 80

1. Wide wheels

Kit no. 1146870

Merger

Merge Maxx 900

$Optional equipment

Technical specifications

When fitting this equipment, following technical specifications are modified

Width in transport position 3.10 m (10’2’’)

Tyres 500/45-22.5 (14 PLY)

Tyre pressure 1.6 bar (23.20 psi)

In certain countries the machine excee ds the

maximum legal size to drive on public roads.

78

Optional equipment

Page 81

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

remove PTO shaft.

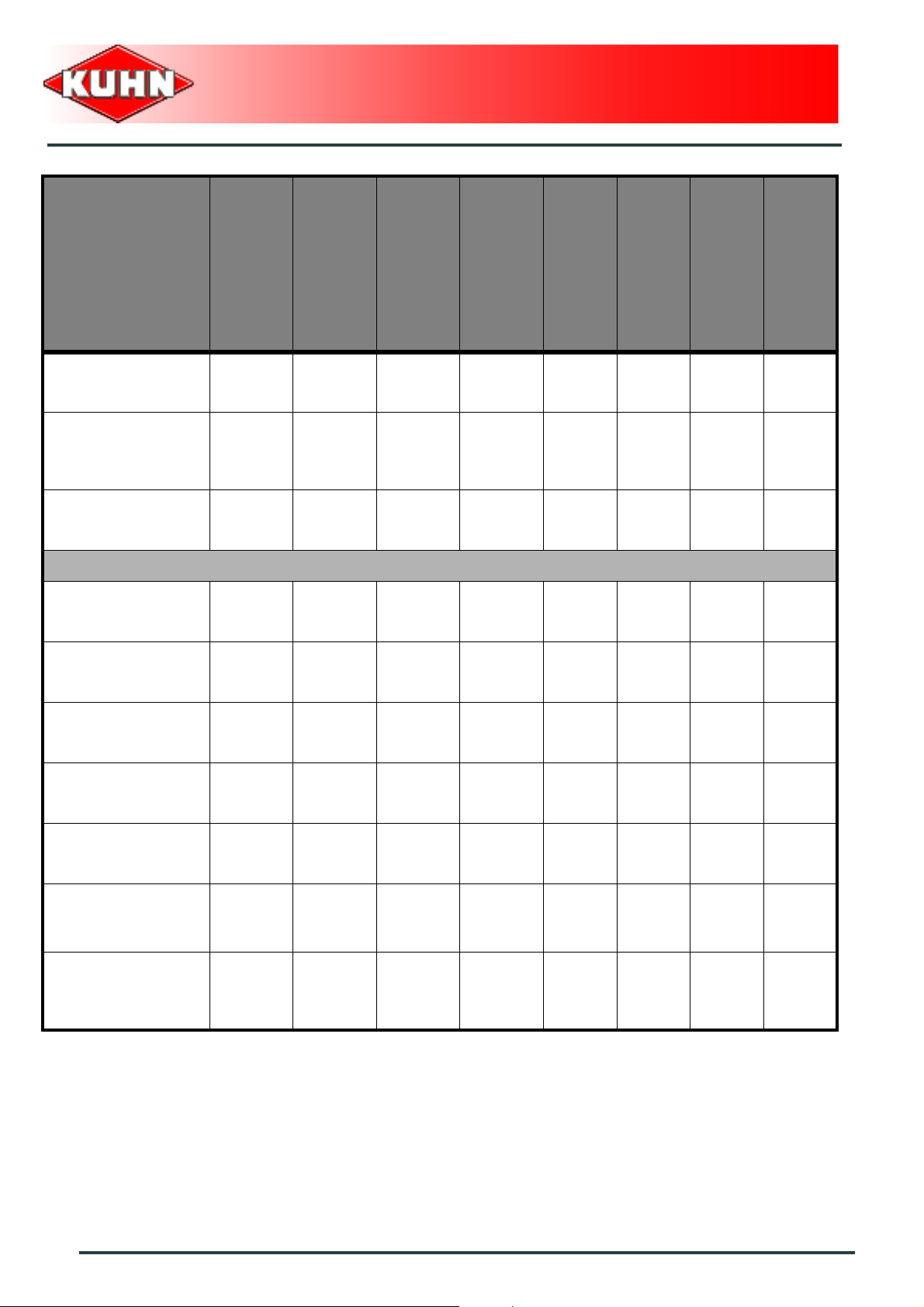

1. Frequency chart

Merger

Merge Maxx 900

$Maintenance and storage

Maintenance intervals are indicated for

normal conditions of use.

Lubrication

Oil change:

- Drive oil tank

- Step-up gearbox

Grease:

first time

machine for the

Before using the

hours of use

After the first 10

hours of use

After the first 20

hours of use

After the first 100

Once per week

Every 50 hours

Every 200 hours

Every 2 years

3

3

- The steering

system

- The left arm pivot

points

- The right arm pivot

points

3

3

3

Maintenance and storage

79

Page 82

- The undercarriage

articulations

Oil:

first time

machine for the

Before using the

hours of use

After the first 10

hours of use

After the first 20

hours of use

After the first 100

Merge Maxx 900

Once per week

Every 50 hours

3

Merger

Every 200 hours

Every 2 years

- The coupling

yokes

- The parking stand

Maintenance

Check:

- The belt tension

- Step up gearbox

oil level

- Tank oil level

- Braking system

- Fixing elements

- Check transport

wheel bolts for

tightness

3

3

33

33

3

33

33

33 3

Replace:

- Hydraulic tank

filter cartridge

80

Maintenance and storage

333

Page 83

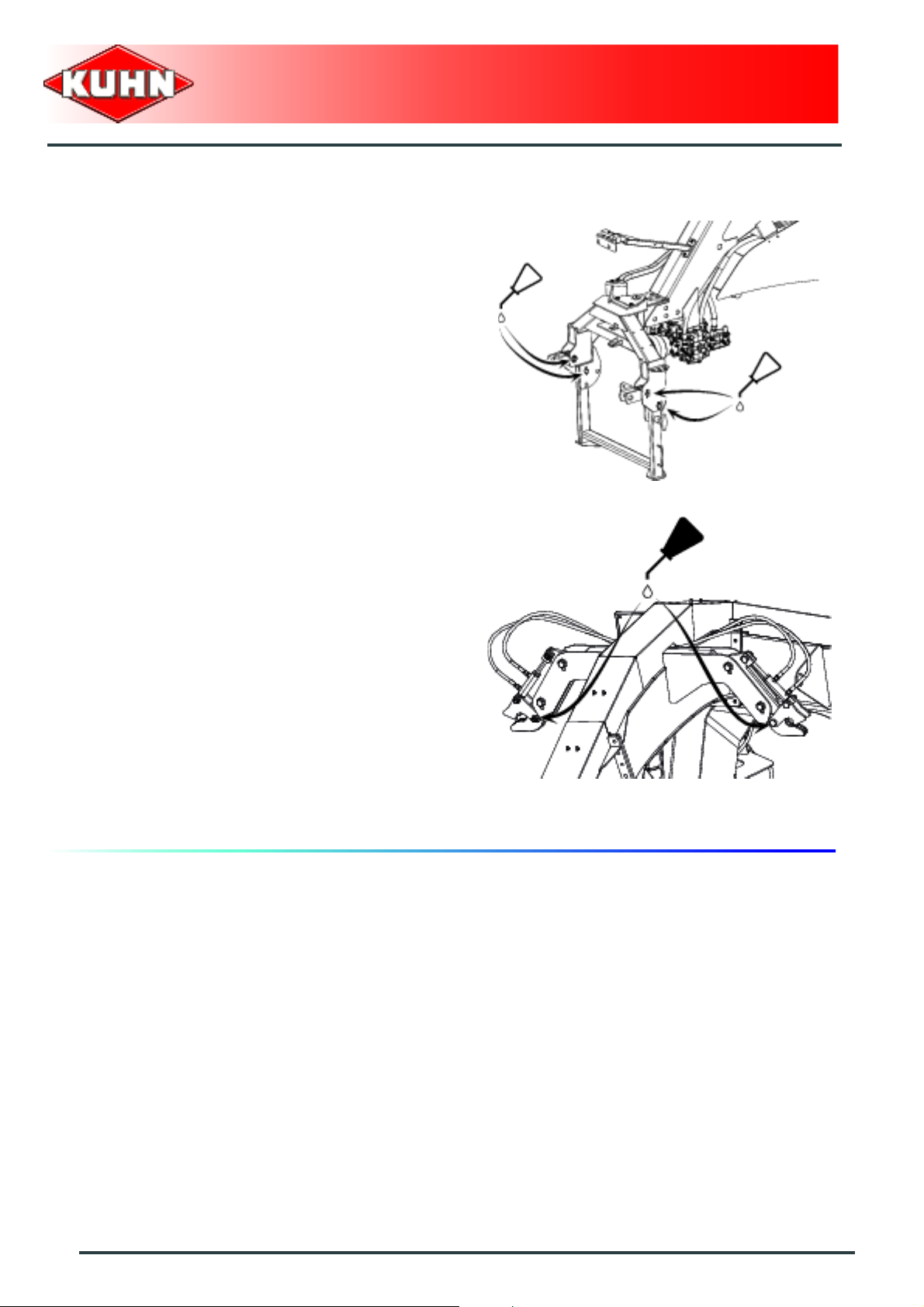

2. Lubrication

The pictorials show the points to be greased (Part

no. 09905400).

Clean grease nipples before greasing.

Lubricate with SHELL multi-purpose grease

grade NLGI 2.

Oil with SHELL SAE 90 gear oil.

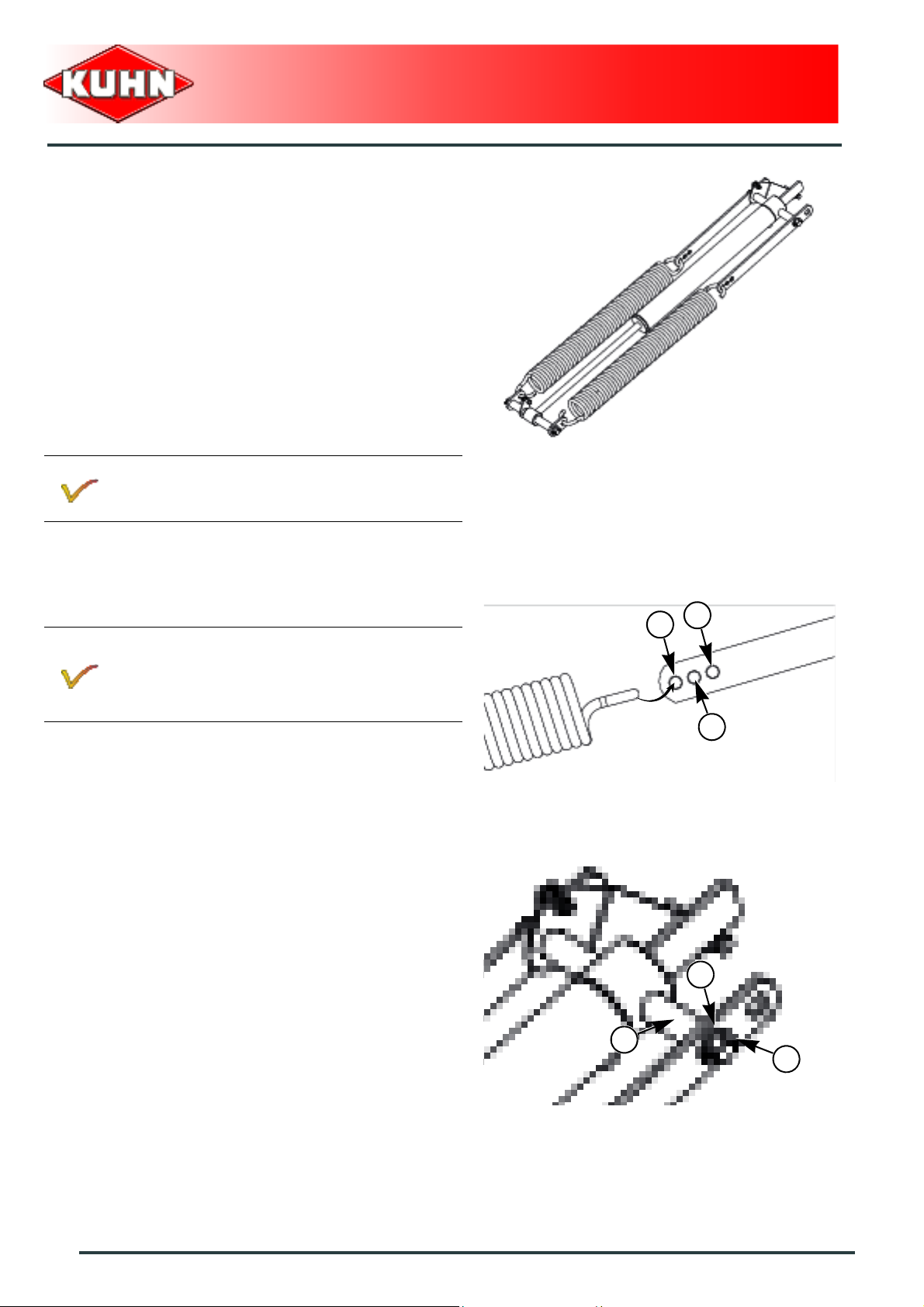

PTO shaft

Merger

Merge Maxx 900

- Every 8 hours:

• The U-joints (1).

• constant velocity joint (4).

- Every 20 hours:

• The transmission tube (2).

- Every 40 hours:

• Guide rings (3).

Maintenance and storage

81

Page 84

Oil change:

Hydraulic tank

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

The oil tank contains 200 L (53 US gal) of SHELL TELLUS 46 oil.

When draining and refilling, it is recommended to use either SHELL TELLUS 46 oil or a mineral base oil

with viscosity grade conform with ISO 46 standard category HM.

- Unscrew filler plug (5).

- Place a container of sufficient capacity under drain

plug (7).

- Remove drain plug (7).

- Allow oil to drain completely.

- Wait for dripping to stop.

- Clean and reinstall drain plug (7) and its washer (6).

Replace it if necessary. (Part no. 82102229).

- Loosen bolts (1).

- Remove cover (2), spring (3) and oil filter (4).

- Replace the oil filter (4) (Part no. A4079112).

- Reassemble all components.

- Pour the correct oil quantity and quality through the

opening of the filler plug.