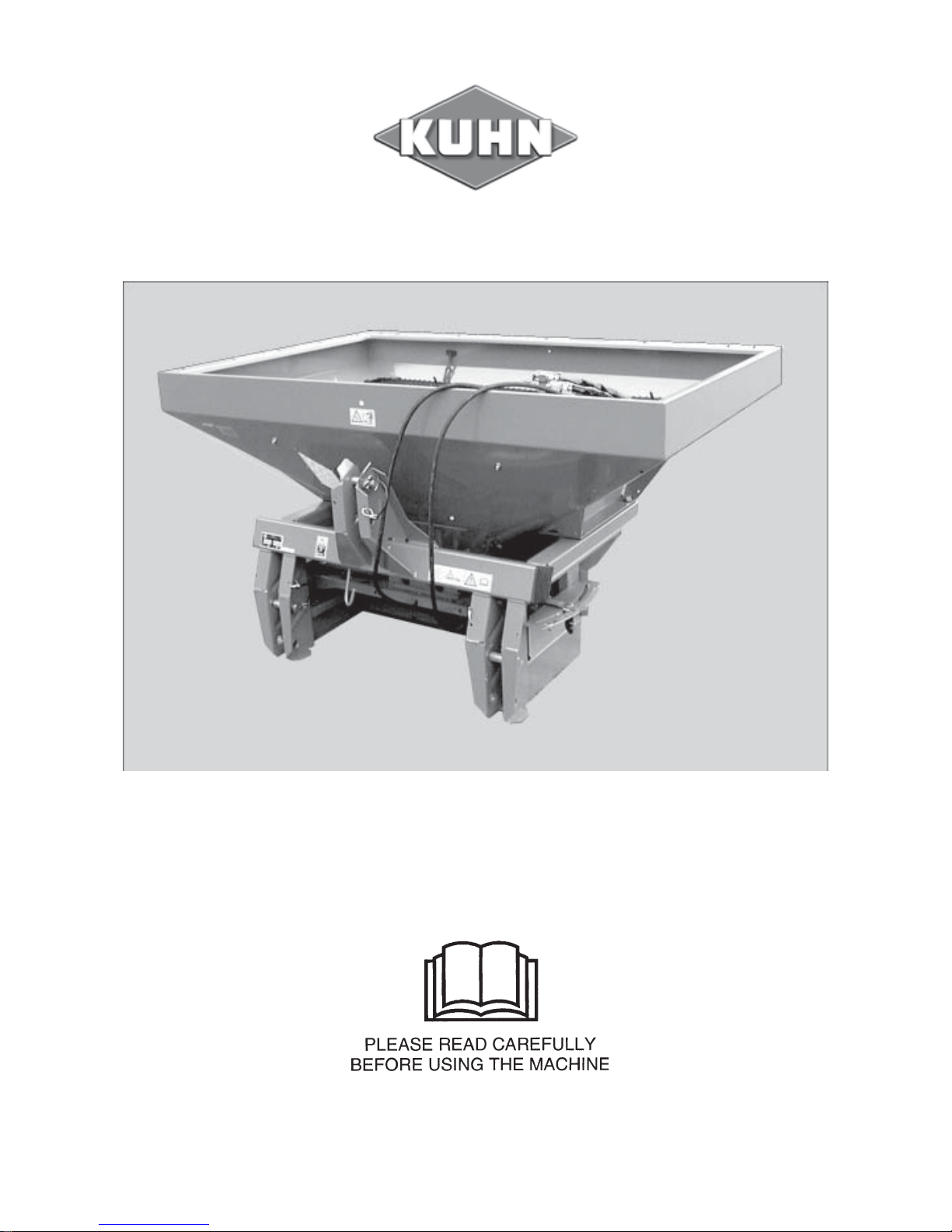

Page 1

OPERATOR’S MANUAL

FERTILISER SPREADER

MDS 55 - 65 - 85 - 735 - 935

N° 95743 A.GB - 07.2003

Page 2

Introduction

Dear Customer,

By purchasing this precision fertiliser spreader you have shown confidence in our products that we are convinced will be justified through its performance and reliability. Thank you. We have made every effort to

provide you with a high performance machine but should any problems occur our service personnel are on

call at all times.

It is very important that you read and thoroughly understand this Operator Manual, taking careful note of the Safety Information, BEFORE operating the machine. This manual provides a comprehensive

guide to the machine controls and all the information necessary for efficient and safe operation, maintenance

and care of your machine.

PLEASE NOTE: Warranty claims which arise from damage due to operator errors and misuse, cannot be

accepted.

NOTE: We recommend that you make a note of the machine model, serial number and construction year in

the spaces below. You will find this information on the serial number plate fixed to the frame of the machine.

Always quote this information when ordering spare parts, optional equipment and accessories, or when making any claims under warranty.

Model: Serial No.: Construction year:

Technical improvements

We are committed to a policy of constant improvement on all our products. We therefore reserve the

right to carry out, without prior notice, any improvements or changes which we feel will benefit our

products, without any obligation on our part to carry out such improvements or changes to machines which have already been sold.

If you have any questions about these, or any of our products, please do not hesitate to contact us.

With kind regards

KUHN FARM MACHNERY

Page 3

Contents

I

Contents

Introduction............................................................................................................................................ 2

Technical improvements ...................................................................................................................... 2

Contents .................................................................................................................................................. I

1 Explanation of warning and safety decals ............................................................................... 5

2 Correct use .................................................................................................................................. 6

2.1 Operational safety ......................................................................................................................... 7

2.2 No liability is accepted for crop, property or environmental damage ............................................ 7

2.3 Public road safety.......................................................................................................................... 8

2.4 Lighting (applicable for Germany)................................................................................................. 8

2.5 Towing of trailers........................................................................................................................... 9

3 Accident prevention and safety issues................................................................................... 10

3.1 General safety recommendations for the hydraulic system........................................................ 13

3.2 Warning and instruction decals ................................................................................................... 13

4 Machine specifications............................................................................................................. 16

4.1 Technical specifications MDS 55 / 65 / 85 / 735 / 935 ................................................................ 16

5 Preparation of the fertiliser spreader ...................................................................................... 17

5.1 Taking delivery of the fertiliser spreader ..................................................................................... 17

5.2 Assembly of the MDS 55-935 fertiliser spreader ........................................................................ 18

5.3 Assembly of the MDS 55 M / 65 M / 85 M / 735 M / 935 M fertiliser spreaders.......................... 18

5.4 Assembly of MDS 55 K / 55 R / 55 D / 65 K / 65 R / 65 D / 735 K / R / D / 935 K / R / D

fertiliser spreaders....................................................................................................................... 19

5.5 Assembling the hopper to the frame and fitting the agitator ....................................................... 20

5.6 Attaching to the tractor ................................................................................................................ 21

5.7 Fitting the pto shaft...................................................................................................................... 22

5.8 Fitting and connecting the hydraulic metering slide controls ...................................................... 24

5.8.1 Single acting hydraulic metering control for MDS 55 K / 65 K / 85 K / 735 K / 935 K ......... 24

5.8.2 Double acting hydraulic metering control for MDS 55 D / 65 D / 85 D / 735 D / 935 D........ 25

5.8.3 Single acting hydraulic metering control with double acting mechanism for MDS 55 R / 65

R / 85 R / 735 R / 935 R.............................................................................................................. 25

5.8.4 Fitting the single acting hydraulic metering slide control FHK 4

and the double acting

hydraulic metering slide control FHD 4

.................................................................................. 26

5.8.5 Position indicator function: (only for MDS K / R / D)............................................................. 28

6 Adjusting the fertiliser spreader.............................................................................................. 29

6.1 General........................................................................................................................................ 29

6.2 Attachment height ....................................................................................................................... 30

6.2.1 Attachment height for normal spreading ............................................................................... 30

6.2.2 Attachment height for late top dressing ................................................................................. 30

Page 4

Contents

II

6.3 Hopper capacity / Hopper extension sets ................................................................................... 31

6.3.1 Calculation of maximum loading ............................................................................................. 31

6.3.2 Hopper level scale..................................................................................................................... 31

6.4 Setting application rates on the MDS 55 M / MDS 65 M / MDS 85 M / 735 M / MDS 935 M .... 32

6.5 Setting application rates on the MDS 55 K / R / D MDS 65 K / R / D MDS 85 K / R / D MDS

735 K / R / D and MDS 935 K / R / D .......................................................................................... 33

6.6 Adjustment of the multi-disc spreading discs.............................................................................. 34

6.6.1 Principle of operation ............................................................................................................... 34

6.6.2 Adjusting the disc vanes .......................................................................................................... 35

6.6.3 Adjustment according to the spreading charts ..................................................................... 37

6.6.4 Setting disc vanes for fertilisers not listed in the spreading charts.................................... 39

6.6.5 DiS 39

6.6.6 PtK 39

6.7 One-sided spreading................................................................................................................... 44

6.7.1 One-sided spreading MDS 55 M / MDS 65 M / MDS 85 M / MDS 735 M / MDS 935 M .......... 44

6.7.2 One-sided spreading MDS 55 K / MDS 65 K / MDS 85 K / MDS 735 K / MDS 935 K ............ 44

6.7.3 One-sided spreading MDS 55 D / MDS 65 D / MDS 85 D / MDS 735 D / MDS 935 D ............ 44

6.7.4 One-sided spreading MDS 55 R / MDS 65 R / MDS 85 R / MDS 735 R / MDS 935 R ............ 44

6.8 Yield and environmental optimised border spreading................................................................. 44

6.8.1 Yield optimised border spreading in the first tramline ......................................................... 44

6.8.2 Environmental and yield border spreading using the border spreading limiter GSE 7

(optional equipment). Only one metering slide is opened.................................................... 45

6.8.3 Environmental and yield border spreading using the border spreading limiter TELIMAT

T1 (optional equipment) ........................................................................................................... 45

The Tellimat T1 is deployed from the first tramline (1/2 working width from the field edge)................. 45

6.9 Spreading on small field strips .................................................................................................... 45

7 Calibration check / Purging unused fertiliser ........................................................................ 45

7.1 Calculating the mean application rate......................................................................................... 45

7.2 The calibration check process..................................................................................................... 47

7.3 Purging unused fertiliser ............................................................................................................. 48

8 Service and maintenance ......................................................................................................... 50

8.1 Cleaning ...................................................................................................................................... 50

8.2 Lubrication................................................................................................................................... 50

8.2.1 Pto shaft ..................................................................................................................................... 50

8.2.2 Agitator shaft and agitator ....................................................................................................... 51

8.2.3 Metering slides, positioning levers, links and adjustment scale segment ......................... 51

8.2.4 Disc hubs ................................................................................................................................... 51

8.3 Gearbox oil level.......................................................................................................................... 51

8.4 Wearing parts .............................................................................................................................. 52

8.5 Checking and setting the metering slide balance and specially checking the metering slides for

seed and slug pellet spreading ................................................................................................... 52

8.5.1 Checking the metering slide .................................................................................................... 52

8.5.2 Rebalancing the metering slides MDS 55 M / MDS 65 M / MDS 85 M / 735 M / 935 M ....... 53

8.5.3 Rebalancing the metering slides MDS 55 K / R / D MDS 65 K / R / D MDS 85 K / R / D

MDS 735 K / R / D and MDS 935 K / R / D ............................................................................... 54

9 Changing the spreading discs................................................................................................. 55

Page 5

Contents

III

9.1 Spreading disc removal............................................................................................................... 55

9.2 Replacing the extension vanes ................................................................................................... 56

9.3 Replacing the main vane or the complete vane assembly ......................................................... 58

9.4 Replacing the MDS vane with an X-vane ................................................................................... 64

9.5 Refitting the spreading discs ....................................................................................................... 65

10 Valuable tips for precision spreading..................................................................................... 66

10.1 Spreading procedure on headlands ............................................................................................ 67

11 Fault diagnosis.......................................................................................................................... 68

11.1 Uneven spread pattern................................................................................................................ 68

11.2 Fault diagnoses for hydraulic metering controls ......................................................................... 68

11.3 Disc vane wear............................................................................................................................ 68

12 Optional equipment................................................................................................................... 69

12.1 Hopper extension sets ................................................................................................................ 69

12.2 Hopper cover............................................................................................................................... 69

12.3 Hopper sieve ............................................................................................................................... 69

12.4 RFZ 7M (all MDS fertiliser spreaders except MDS 55)............................................................... 69

12.5 Double acting mechanism........................................................................................................... 69

12.6 Tele-Space .................................................................................................................................. 69

12.7 Practical Test Kit PtK................................................................................................................... 69

12.8 Fertiliser identification system FiS............................................................................................... 69

12.9 Row spreading unit RV 2M for hopyards and orchards .............................................................. 70

12.10 Boundary spreading limiter GSE 7.............................................................................................. 70

12.11 Electronic remote control EF 24.................................................................................................. 70

12.12 Hydraulic remote control FHZ 10 ................................................................................................ 70

12.13 Lighting without warning shield BLO1 (for rear profile lighting security) for MDS 65 / MDS 85)

71

12.14 Lighting without warning shield BLO2 (for rear profile lighting security) ..................................... 71

12.15 Lighting with warning shield BLW 1 (for rear profile lighting security) for MDS 65 / MDS 85 ..... 71

12.16 Lighting with warning shield BLW 8 (for rear profile lighting security) ........................................ 71

12.17 TELIMAT T1 ................................................................................................................................ 71

12.18 Hydraulic metering slide control FHK 4....................................................................................... 71

12.19 Hydraulic metering slide control FHD 4....................................................................................... 71

12.20 Agitator for grass seeds RWK 7.................................................................................................. 71

12.21 Agitator RWK 15.......................................................................................................................... 71

13 Axle load calculation ................................................................................................................ 72

14 Warranty conditions.................................................................................................................. 75

Page 6

Page 7

Erreur ! Style non défini. Erreur ! Style non défini.

5

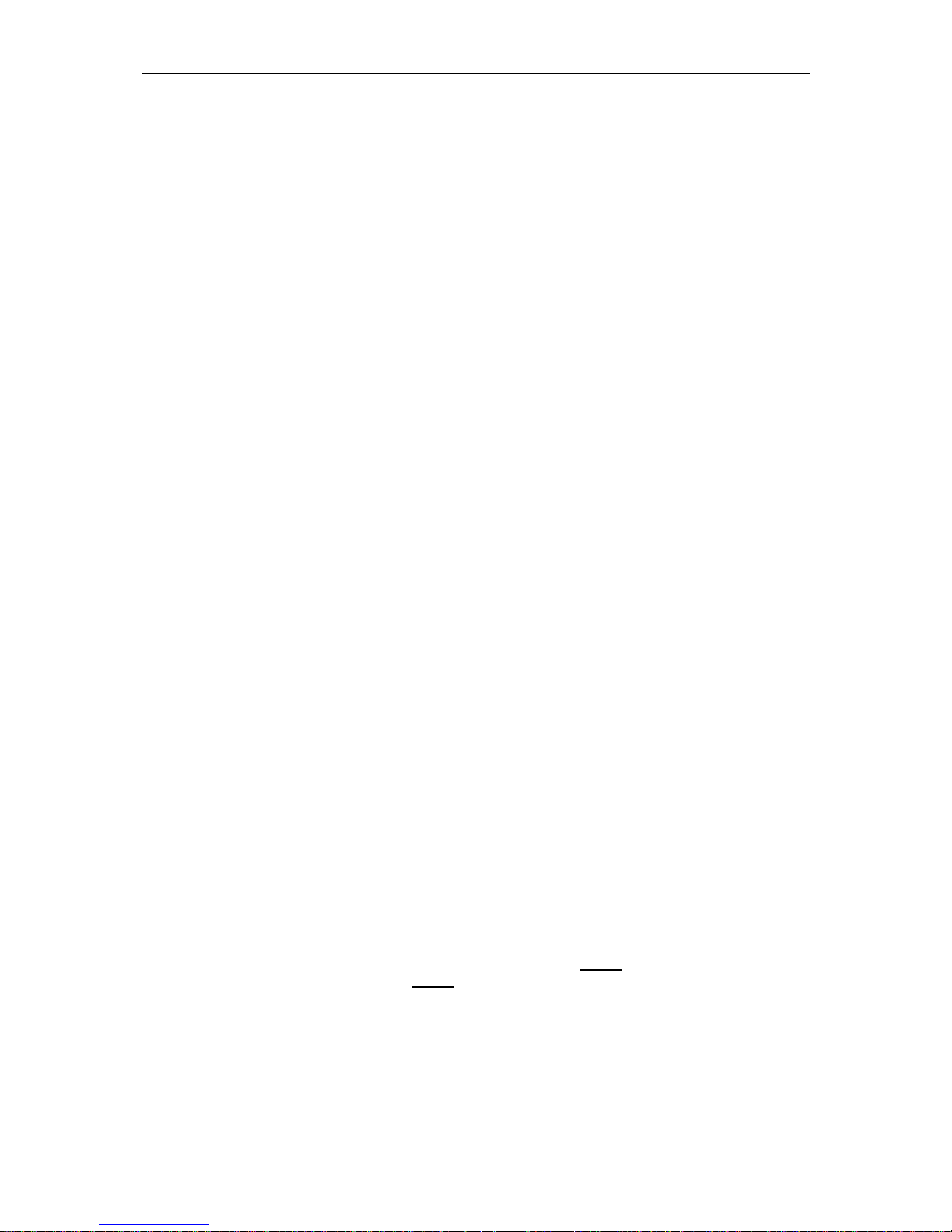

1 Explanation of warning and safety decals

The following table shows symbols and their levels of hazard classification.

A safety symbol appears in the manual when the safety of the operator, or any

other person, or the normal operation of the machine, could be in danger. It is

essential that all safety symbols, safety and accident prevention instructions,

are observed.

It is vital that all users have the opportunity to read and thoroughly understand

these instructions.

Symbol Classification

DANGER

DANGER !

Non observance can result in death or serious injury.

WARNING

WARNING !

Non observance can result in injury or damage to the machine.

IMPORTANT

IMPORTANT !

Non observance can result in damage to the machine or the

immediate environment.

ATTENTION

ATTENTION !

User tips for optimal implement operation and other useful information.

Page 8

Erreur ! Style non défini. Erreur ! Style non défini.

6

2 Correct use

The MDS fertiliser spreader is designed to spread dry, prilled and granular fertiliser, as well as seeds.

Any other use is inappropriate and any defects arising therefrom will invalidate

the manufacturer's warranty and relieve both manufacturer and supplier of any

liability.

Correct use also entails the full compliance with all operating, maintenance and

repair instructions issued by the manufacturer as well as the exclusive usage of

original spare parts.

KUHN original spare parts and accessories are especially designed and manufactured for fertiliser spreaders. Parts and accessories not supplied by KUHN

have not been subjected to our tests and quality control, essential to ensure

correct operation. KUHN is relieved of any liability for damage caused by the

use of non-original parts and/or accessories. The employment of non-original

parts and/or accessories can have a negative influence on the construction characteristics of the fertiliser spreader which could endanger the safety of both

people and the machine.

Any warranty or liability claims against the manufacturer for damage resulting

from unauthorised alterations to the fertiliser spreader will not be accepted.

The fertiliser spreader is built to current technical and accepted safety standards. However, potential risks of injury to the operator or to third parties, or

damage to the machine, or other property during operation, do exist. The fertiliser spreader is only in a correct technical condition, meeting accepted safety

and warning criteria, when all information and instructions in the operator manual are observed. Any faults which develop must be rectified immediately.

The MDS fertiliser spreader should only be used, maintained and repaired by

persons who are familiar with the machine and who have received instructions

with regard to potential dangers.

All current appropriate accident prevention requirements and all other general

recognised safey, technical work-related and road traffic legislation, must be

observed.

Page 9

Erreur ! Style non défini. Erreur ! Style non défini.

7

2.1 Operational safety

The MDS fertiliser spreader should only be put into operation after instructions

have been received from KUHN's business partners, employees and/or representatives, or KUHN's own personnel

Before starting up the machine, read the operator manual and carefully observe

all information and safety instructions.

Only start up the MDS fertiliser spreader when all protection and safety guards,

including any detachable protection devices, have been installed and are functioning correctly.

Check all nuts, bolts and locking elements regularly for correct tightness, and

tighten where necessary.

Regularly check all hydraulic hoses at the beginning of the season for mechanical defects (e.g. cuts, abrasions, crushed sections, kinks, tears, leaks, porosity,

etc.).

The useful life of an undamaged hose should be limited to six years, including a

possible maximum two-year stocking period. The manufacturing date of a

hydraulic hose is indicated on its outer surface in month and year.

If operational faults develop on the fertiliser spreader, stop immediately. Ensure

that the unit is safely parked and secured, rectify the problem. If the problem

cannot be safely rectified by the operator, have the matter rectified by trained

personnel.

2.2 No liability is accepted for crop, property or environmental damage

The MDS fertiliser spreader is carefully manufactured by KUHN. In spite of this,

even when correctly using the unit, variations in output or total output failure can

occur, for example:

• Variations in the physical characteristics of fertiliser and seed products (e.g.

variations in granule sizes, density, granule forms, surface, causticity, packaging and humidity).

• Blockage or bridging around hopper outlets caused by foreign particles,

contaminated seeds, sticky causticity, moist fertiliser, etc.).

• Component wear.

• Damage from outside influences.

• Incorrect operational speed or forward speed.

• Incorrect settings of the fertiliser spreader (i.e. incorrect metering slide

control setting, non-observance of spreading charts).

Before each field operation, as well as during operation, check that the fertiliser

spreader is functioning correctly and that the correct application rate and spread

pattern is being achieved at all times. No claims are accepted for any damages

other than on the fertiliser spreader itself. No liability can be accepted for

consequential loss or damage due to spreading errors.

Page 10

Erreur ! Style non défini. Erreur ! Style non défini.

8

2.3 Public road safety

When driving on public roads, or along tracks, or in public parks, observe all

traffic rules and regulations.

Make sure that the fertiliser spreader complies with all public traffic rules and

specifications.

Observe all maximum transport width laws and equip the unit with all correct

lighting and traffic warning shields.

Make sure tractor steering and braking efficiency is not impaired in any

way!

Due to the combined weight of the fertiliser spreader and material in the hopper,

it is possible that the tractor/fertiliser spreader combination could become

unstable.

Attaching units to either front or rear 3-point tractor linkages must not exceed

the maximum permissible total weight, individual permissible axle weight or maximum tyre loads. The front axle must be ballasted to achieve a minimum load

of 20% of total unloaded weight (see chapter 13: Axle Load Calculation).

• Ensure that all these conditions can be entirely met before the fertiliser

spreader is attached. Observe all instructions and recommendations relating to weight and axle loading, as given in the tractor operator manual.

• Steering characteristics can deteriorate when implements are attached.

• Be aware that implements need more room when driving through curves

due to their long overhang, and can negatively affect stability due to their

large mass.

DANGER

Make sure tractor steering and braking efficiency is not impaired in

any way!

Steering and braking efficiency is influenced when attaching a fertiliser spreader

and its load. Ensure that steering and braking efficiency is correct and reduce

forward speed to suit load conditions!

2.4 Lighting (applicable for Germany)

General

If part of the tractor lighting system or official number plate is obscured, it is necessary to equip the spreader with an auxilliary system, even if only operated in

daylight hours.

Attachment height

When driving on public roads running lights must not exceed a height of

1500mm and reflectors a height of 900mm, above ground level.

Rear warning shield requirements

If the fertiliser spreader extends more than 1000mm beyond the tractor running

lights, a rear warning shield is required.

DANGER

Page 11

Erreur ! Style non défini. Erreur ! Style non défini.

9

Front and rear warning shield requirements

If the fertiliser spreader protrudes more than 400mm from the tractor's outermost light position, the outermost body area or its running light, additional running lights and warning shields must be positioned on the outermost point of the

fertiliser spreader, facing both forwards and rearwards.

Night or poor light conditions

If transporting at night or in poor light conditions, additional lighting is required in

both the forward and rear facing positions.

For lighting requirements in other countries

The fertiliser spreader's lighting and warning system must conform to local public highway traffic regulations. Check with your local authorities and your dealer

that the unit conforms to all regulations.

2.5 Towing of trailers

Note the following :

• When towing trailers, 25 kph must not be exceeded.

• The trailer must be equipped with a hand brake or a braking system that

can be operated by the driver from the tractor cab.

• The total loaded weight of rigid drawbar trailers must not exceed the weight

of the pulling vehicle, and jockey wheels, if used to support the drawbar

weight, should transmit the load to the ground in such a way that the pulling

vehicle can safely steer and brake.

• Articulated drawbar trailers can only be used when the actual total loaded

weight of the trailer does not exceed 1.25 times the weight of the pulling

vehicle. However, the total weight should not exceed 5 tonnes.

Page 12

Erreur ! Style non défini. Erreur ! Style non défini.

10

3 Accident prevention and safety issues

Most accidents happen because someone ignores the most elementary safety

rules during operation, maintenance or transport. It is vital that all persons coming in contact with the machine - the purchaser himself/herself, a member of

his/her family, an employee, a bystander - strictly obey the following safety rules. Other safety instructions are to be found on the decals placed in various

prominent positions on the machine. The machine should only be set up for

operation, operated and maintained by persons who have received instructions

with regard to potential dangers.

• Observe all safety notes contained in this operator manual and all current

statutory safety and accident prevention regulations!

• Warning and instruction decals give important information to operate the

fertiliser spreader without danger and to serve to increase the safety of the

operator.

• Before every operation, check nuts and bolts and other fixings for tightness,

especially those of the spreading discs and spreading vanes. If necessary,

tighten to recommended torque settings.

• Before using the machine, operators must familiarise themselves with all

parts of the equipment and the function of all controls and adjustments.

Finding out during operation may be too late.

• Before every operation, ensure that the tractor/spreader combination

complies with all relevant road traffic, as well as health and safety, regulations.

• When filling the hopper, lower the spreader and switch off the tractor engi-

ne. Remove ignition key before leaving the tractor cab. Make sure metering and shutter slide controls are closed.

• Before adjusting or undertaking other work such as cleaning, lubricating or

carrying out operations on the spreader, disengage the pto drive, switch off

the tractor engine, wait until all moving parts have come to a stop and remove the ignition key. During control or repair work, make sure no one can

start the unit by mistake.

Crushing hazard from power driven parts!

Rotating machine elements (discs, agitator, pto shaft) can cause serious injury

or death.

• Only start the machine when the hopper sieve, disc guards, pto shrouds

and all other guards, are in place!

• Always avoid wearing loose clothing or clothing with loose parts that are li-

able to come into contact with moving parts.

• Avoid wearing clothes with belts, fringes or other items that could get

caught up in moving parts.

• Never get close to revolving parts. Keep hands, feet and clothing well away.

• Never reach into the hopper or touch the rotating discs.

• Never climb onto the spreader when it is operating.

• Keep the hopper free of any foreign objects (e.g. nuts or bolts).

DANGER

Page 13

Erreur ! Style non défini. Erreur ! Style non défini.

11

• Before starting the spreader, make sure that there is no-one within the dan-

ger area around the machine. Make sure you have a good view all round

and keep a special watch out for children!

• Only start up the spreader when all safety devices and guards have been

properly fitted (e.g. pto guards and disc shrouds).

Danger from fast moving spreading material!

Fast moving spreading material can lead to serious injury (e.g. eye injuries).

• Before engaging the pto drive/spreading discs, make sure no-one is within

the spreading zone around the spreader!

• Never leave the spreader running unattended.

• It is illegal and dangerous to carry passengers when using or transporting

the spreader.

• Do not use any parts of the fertiliser spreader as a step (e.g. disc, rear rail

guard).

• Before leaving the tractor seat, lower the spreader to the ground, switch the

tractor off and remove the ignition key. With single acting hydraulic shutter

operations, close the hydraulic shut-off valve.

• Parking the fertiliser spreader when it is not attached to the tractor: only with

an empty hopper and on firm, level ground.

• Never allow anyone to enter the space between the tractor and spreader

without first making sure that the tractor is prevented from moving by means

of a parking brake and/or wheel chocks!

• Before attaching or removing the spreader from the tractor 3-point linkage,

make sure that the operating system is positioned so that inadvertent lowering or raising of the linkage is impossible.

• It is recommended that the condition of the spreader is checked by a re-

commended dealer at the end of every season. Especially disc vanes, fixings and hydraulic parts.

• In the event of a failure during operation, switch off the spreader immediate-

ly. Stop engine and remove the ignition key before checking and repairing

the damage.

• Ill advised choice or use of fertiliser or other spreading material can cause

serious damage to people, animals, plants and the environment. Choose

the correct material for your application. Handle with care and carefully follow the manufacturer's instructions. Wear protective clothes and a protective breathing mask.

• Respect all recommended service periods as well as any inspection or test

recommendations to be carried out from time to time, which are given in

the operator manual.

• Before any cleaning, servicing or repair work, relieve all hydraulic pressure,

disengage the pto drive, switch off the engine and remove the ignition key.

Detach unit from the tractor.

• Only commence cleaning, servicing or repair work when the unit is on firm

level ground and is prevented from moving or jack-knifing (parking

legs/rollers).

WARNING

Page 14

Erreur ! Style non défini. Erreur ! Style non défini.

12

• Any pto damage should be repaired immediately before continuing sprea-

ding operations.

• Do not operate the machine with unguarded pto components. Only start up

the unit when all guards are correctly in place and functioning.

• Before cleaning the fertiliser spreader with a high pressure water or steam

jet, or any other cleaning material, make sure all openings or areas, that for

safety or operational reasons should not come into contact with water or other cleaning materials, are sealed off and adequately protected. For example: electrical elements or exposed bearings. After cleaning, make sure any temporary protection covers are removed.

• After cleaning, check all hydraulic hoses for leaks, loose connections, cuts

and other damage. Any damage should be repaired immediately!

• Disconnect the current supply before working on any electrical installations.

• Disconnect tractor battery cables before undertaking any welding operati-

ons on the fertiliser spreader.

Maximum attachment height of the fertiliser spreader

Danger of injury by unintentional contact with the spreading discs.

• The maximum allowable distance from ground level

to the underside of

the frame when the unit is operating in normal spreading mode : must not

exceed 85 cm at point A and 85 cm at point B.

• The maximum allowable distance from ground level

to the underside of

the frame when the unit is operating in late top dressing mode must not

exceed 77 cm at point A and 83 cm at point B.

IMPORTANT

B

(85 cm)

A

(85 cm)

B

(83 cm)

A

(

77 cm

)

Ground level Ground level

Max. allowable attachment

height in normal spreading

mode

Max. allowable attachment

height in late top dressing

Page 15

Erreur ! Style non défini. Erreur ! Style non défini.

13

3.1 General safety recommendations for the hydraulic system

• Hydraulic circuits contain oil under high pressure.

• The maximum operating pressure (tractor hydraulic system) should not ex-

ceed 200 bar.

• Pay attention to specified hydraulic hose connections when connecting

hydraulic cylinders and hydraulic motors.

• When connecting up the hydraulic hoses to the tractor hydraulics, make su-

re that all hydraulic pressure has been relieved from both the tractor and the

fertiliser spreader.

• All male and female connections should be correctly labelled to eliminate

any possibility of incorrect operation when connecting various hydraulic operating elements between the tractor and fertiliser spreader.

• Regularly check all hydraulic hoses for signs of damage and age, and

replace if in any doubt. Replacement hoses must meet the manufacturers'

technical specifications.

• Even when carefully stored and correctly used, hoses and hose connecti-

ons undergo a natural aging process. Therefore, their stocking and operational periods should not be exceeded.

• The useful life of an undamaged hydraulic hose should be limited to 6

years, including a possible maximum two-year stocking period.

• The hydraulic hose manufacturing date is indicated on the hose with the

month and year of manufacture (e.g. SLP 8 / 00).

• Use suitable protection (gloves and protective eye-glasses, etc.) when loca-

ting oil leaks, in order to avoid injury.

• Hydraulic fluid escaping under high pressure can penetrate the skin and

cause serious injuries. In case of injury, immediately consult a doctor, as

there is a high risk of infection!

• Before carrying out any service or maintenance work on the hydraulic sys-

tem, lower the fertiliser spreader to the ground, relieve the system of pressure, switch off the engine and remove the ignition key.

3.2 Warning and instruction decals

Warning and instruction decals give important information to operate the MDS

fertiliser spreader without danger.

Warning decals are situated at various points on the fertiliser spreader and give

important information for your safety and the safety of others. They also contain

information on correct operation. The text on each decal explains the message

that the symbol is giving.

• Replace any decal as soon as it is damaged or unreadable.

• Replacement decals can be obtained from the spare parts service dept.

• Before placing the new decal on the machine, make sure the surface is free

from dust, dirt and oil, and is totally dry.

• Make sure that any new part or component is correctly equipped with any

corresponding warning decal.

Page 16

Erreur ! Style non défini. Erreur ! Style non défini.

14

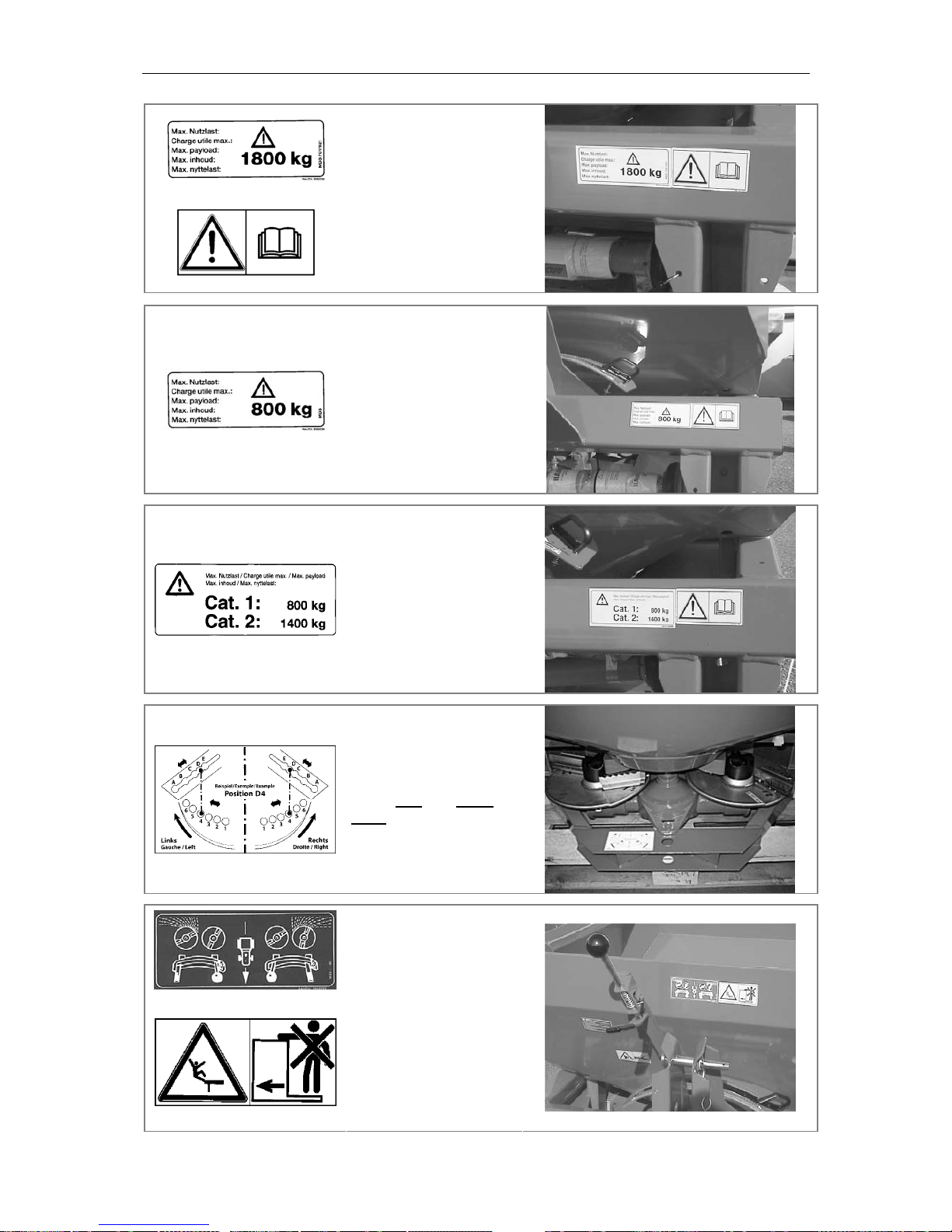

Maximum payload for

MDS 735 - 935.

Before starting up the

machine, read the operator manual and safety

instructions carefully.

Maximum payload for

MDS 55.

Maximum payload for

MDS 65 and MDS 85 :

Cat I : 800 kg

Cat II : 1400 kg

Disc vane adjustment

of the left-

and right-

hand spreading discs.

One-sided spreading.

It is not permitted, and

also very dangerous, to

carry persons on the

fertiliser spreader, or

be accompanied by any

persons while the machine is in operation.

Page 17

Erreur ! Style non défini. Erreur ! Style non défini.

15

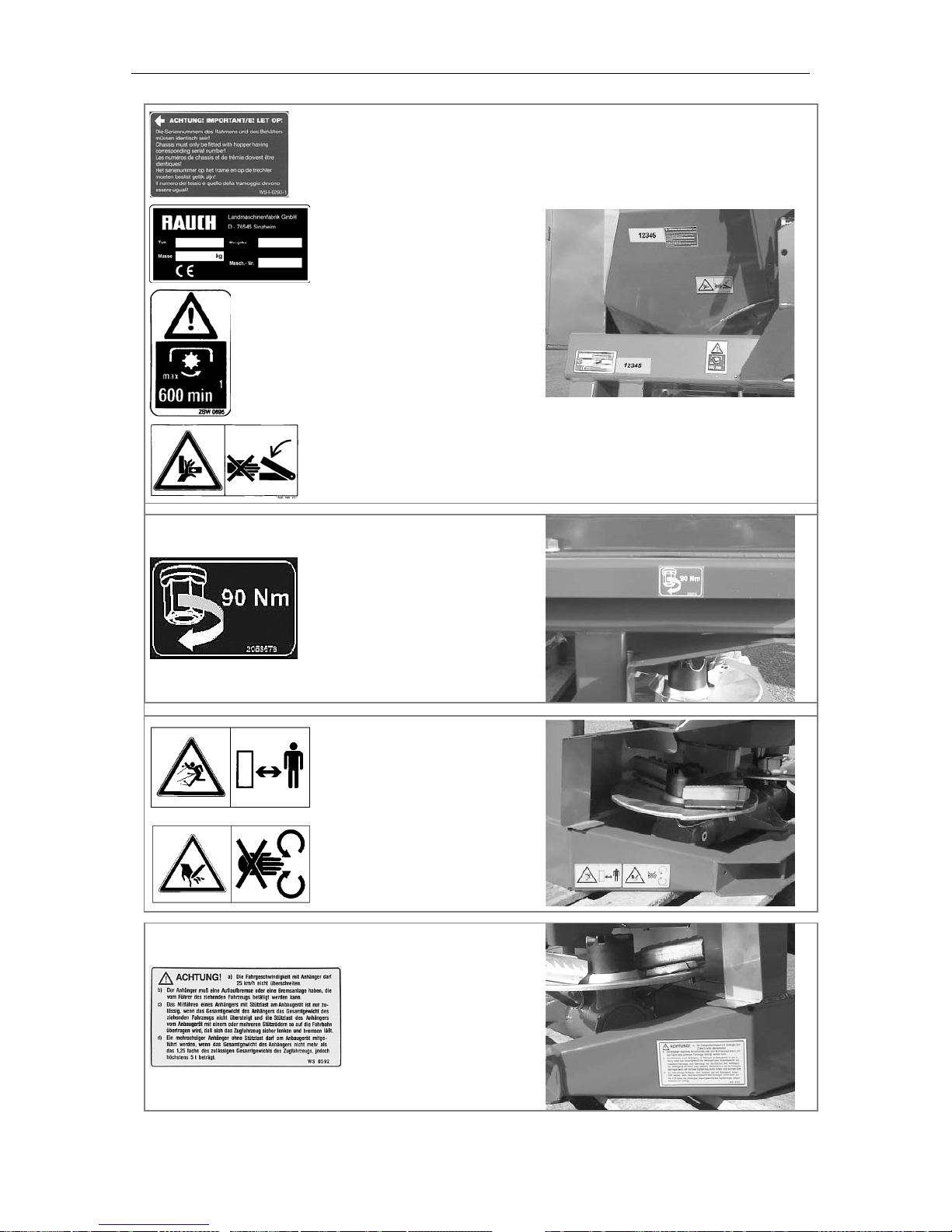

Serial number on frame

and hopper must be identical.

Serial number plate.

Pto speed.

Crushing and amputation hazard in region of

adjustment segments.

Torque setting

hopper to frame attachment.

Danger from fast moving spreading material. Make sure no-one is

within the spreading

zone before engaging

spreading discs!

Never reach into the

spreading disc or agitator zone.

Towing trailers behind

the implement (only for

Germany).

Page 18

Erreur ! Style non défini. Erreur ! Style non défini.

16

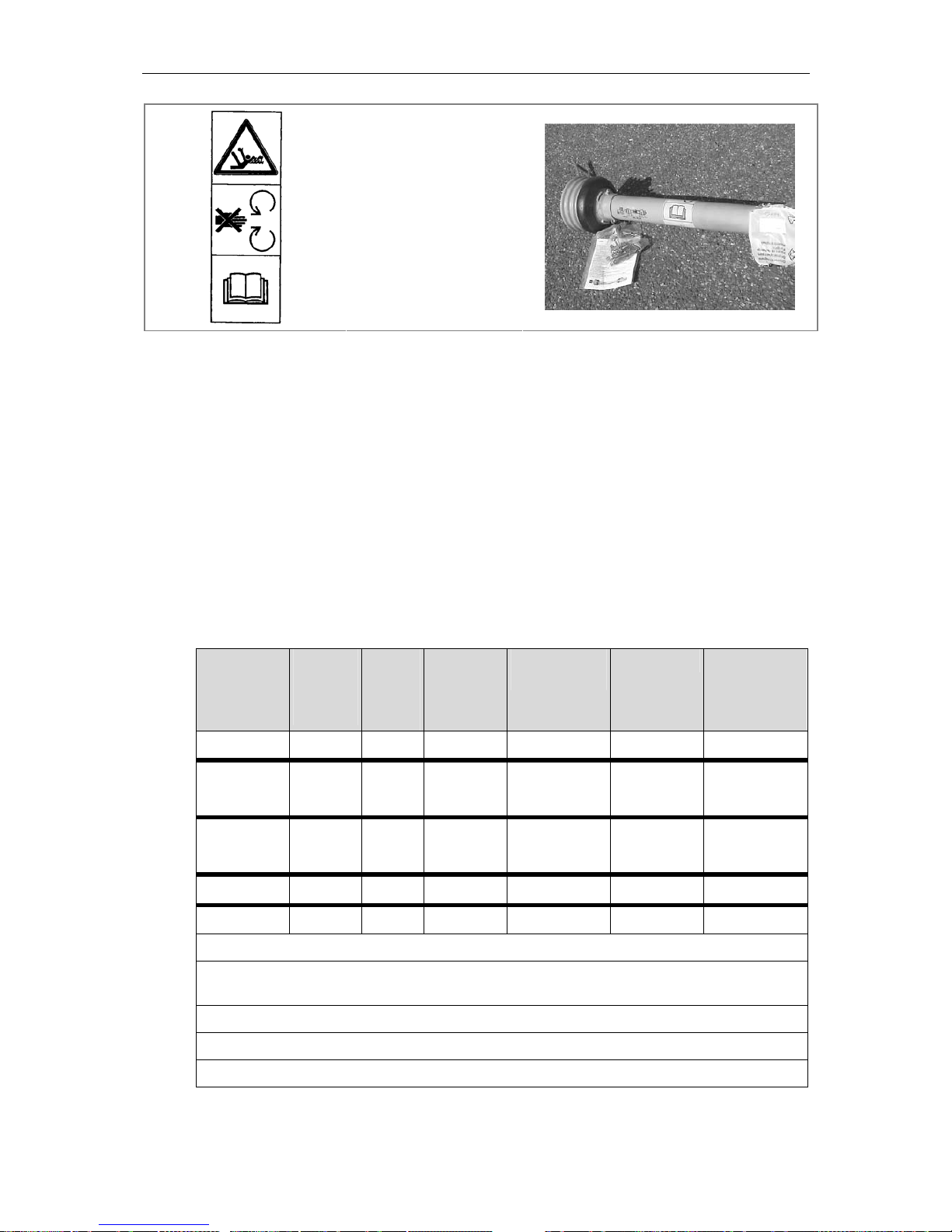

Do not stand near rotating elements.

This is a hazard which

can cause serious injury or death!

Observe all instructions in the pto manufacturers' operator manual!

4 Machine specifications

Manufacturer

RAUCH Landmaschinenfabrik GmbH

Landstraße 14 Postfach 1165

D-76547 Sinzheim D-76545 Sinzheim

Tel.: +49-7221 / 985-0 Fax: +49-7221 / 985-200

Service Centre: Tel.: +49-7221 / 985-250 Fax: +49-7221 / 985-203

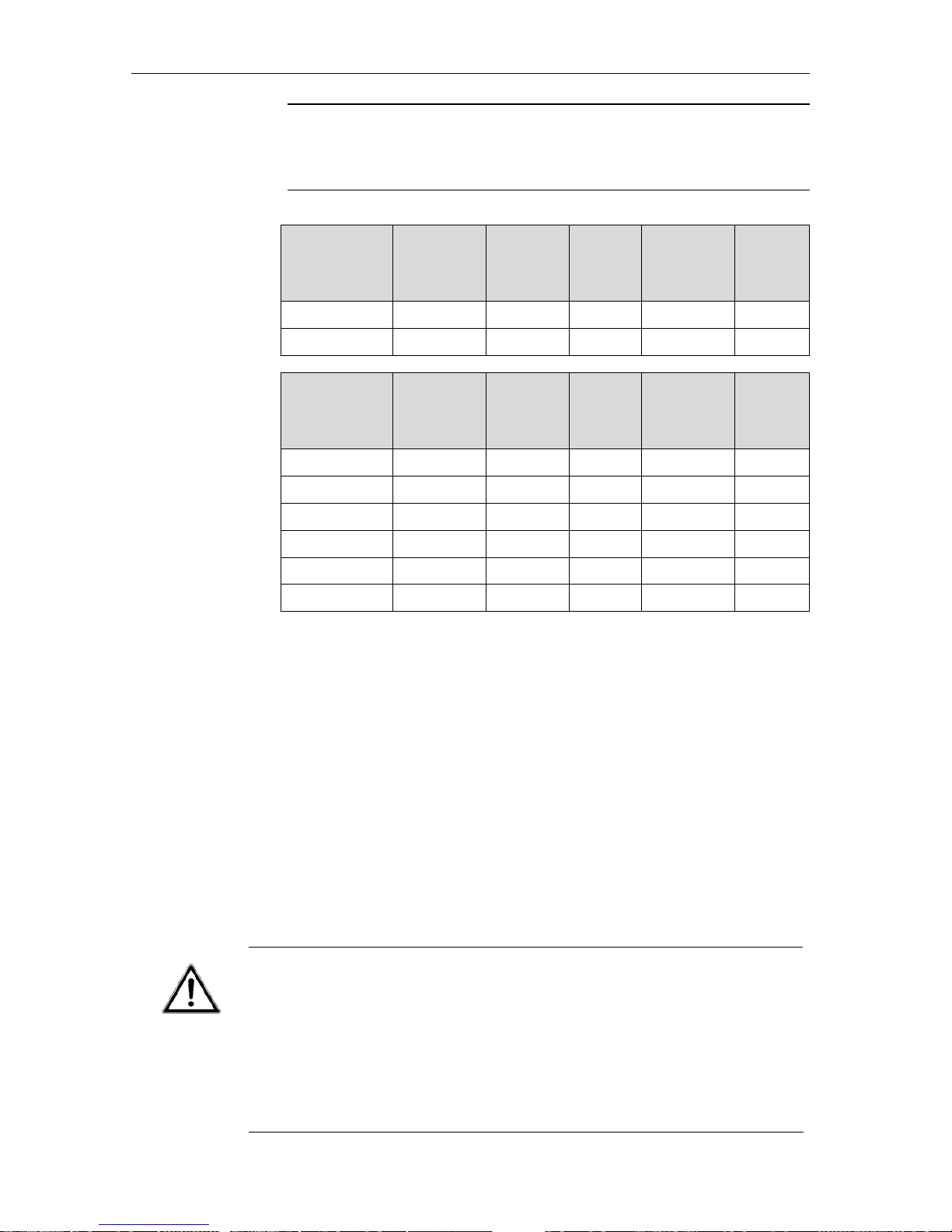

4.1 Technical specifications MDS 55 / 65 / 85 / 735 / 935

Model Hopper

size

approx.

cm

Filling

height

approx.

cm

Filling width

approx. cm

Hopper capacity

approx. litres

Payload Kg Empty weight

approx. Kg

MDS 55 108x108

92 98 500 800 200

MDS 65

140x115

92 130 600

800 (Cat I)

1400 (Cat II)

210

MDS 85

140x115

104 130 800

800 (Cat I)

1400 (Cat II)

220

MDS 735 190x120

93 180 700 1800 250

MDS 935 190x120 101

180 900 1800 250

Centre of gravity distance from the lower linkage point is 55 cm with the hopper empty

Working width, depending on fertiliser type and spreading discs employed, is between 10m and 18m

(24m)

Maximum hydraulic pressure 200 bar

Pto speed 540 rpm

Noise level: 78 dB (A) measured with the tractor cab closed

Page 19

Erreur ! Style non défini. Erreur ! Style non défini.

17

Empty weight data is given on the fertiliser spreader serial number plate.

The weight of the fertiliser spreader when empty, varies according to equipment

fitted. The weight indicated on the serial number plate applies to the most

commonly used specification. It can, however, be higher or lower.

Hopper extension kit for MDS

65 / 85

Hopper size

approx. cm

Filling

height

approx. cm

Filing

width

approx.

cm

Additional

hopper capacity approx. litres

Extension

kit weight

approx.

Kg

M 20

140x115 +12,5 130 +200 +19

M 40

140x115 +24,5 130 +400 +28

Hopper extension kit for MDS

735 / 935

Hopper size

approx. cm

Filling

height

approx. cm

Filling

width

approx.

cm

Additional

hopper capacity approx. litres

Extension

kit weight

approx.

Kg

M 223

190x120 + 0 180 + 200 + 20

M 420

190x120 + 18 180 + 400 + 30

M 423

190x120 + 8,5 180 + 400 + 30

M 650

190x120 + 30 180 + 600 + 40

M 653

240x120 + 16 230 + 600 + 40

M 863

240x120 + 26 230 + 850 + 50

5 Preparation of the fertiliser spreader

5.1 Taking delivery of the fertiliser spreader

When the fertiliser spreader is delivered, please check that it is complete.

The following items are included as standard equipment:

• Operator manual / spreading charts

• Calibration kit

• Agitator

• Top and bottom 3-point linkage pins

• Set of spreading discs with adjusting lever

• Pto shaft, including pto instruction book

Also carefully check all ordered optional equipment

IMPORTANT

Check all nuts and bolts

• Check all nuts and bolts and other fixings for tightness, especially those of the

spreading discs and spreading vanes!

Positioning of the spreading discs on their hubs

• When positioning the spreading discs on their hubs, do not invert the spreading

disc (L) and spreading disc (R)!

• Place the spreading discs carefully onto their hubs with the right-hand disc (R)

on the right-hand side and the left-hand disc (L) on the left-hand side, when

viewed in direction of travel.

ATTENTION

Page 20

Erreur ! Style non défini. Erreur ! Style non défini.

18

Check for any transport damage or any missing parts. Claims can only be accepted if notification is made at time of delivery. Ask the haulier to acknowledge

any transport damage. In case of doubt, contact your dealer or the manufacturer direct.

5.2 Assembly of the MDS 55-935 fertiliser spreader

To reduce the transport volume, hopper and carrying frames are packed separately.

Use a fork-lift truck or front-end loader with suitable slings to unload the hopper

(see photo below).

Likewise, use a fork-lift truck or front-end loader with suitable slings to unload

the frame.

Both hopper and frame have a serial number printed on the right-hand side,

when viewed in the direction of travel. Numbers on both the frame and hopper

must be matched when assembling (see photo, section 3.2).

5.3 Assembly of the MDS 55 M / 65 M /

85 M / 735 M / 935 M fertiliser spreaders

Close the metering slide and place the hopper carefully on the frame. Bolt the

frame and hopper together (see photos 1 and 2, section 5.5).

Page 21

Erreur ! Style non défini. Erreur ! Style non défini.

19

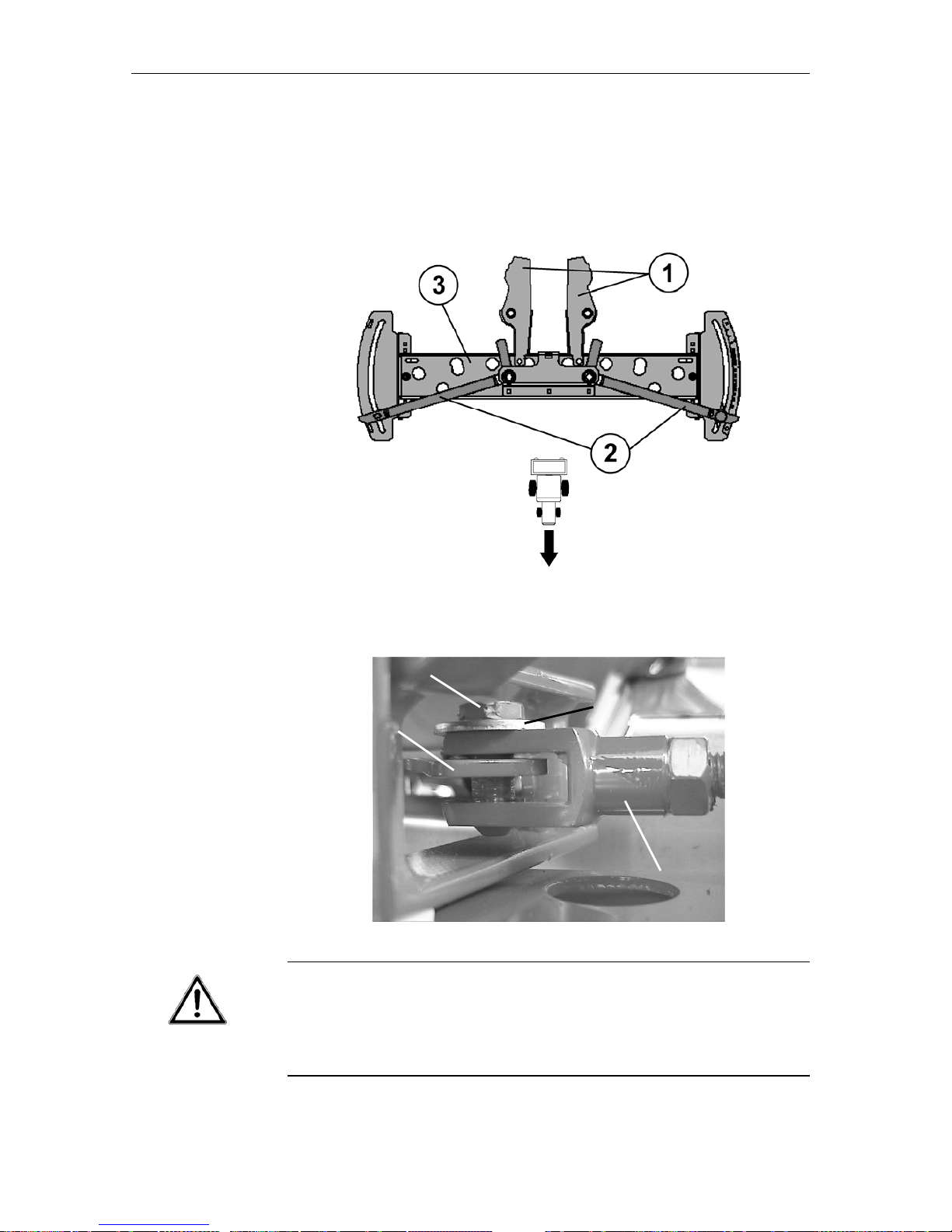

5.4 Assembly of MDS 55 K / 55 R / 55 D / 65 K / 65 R / 65 D /

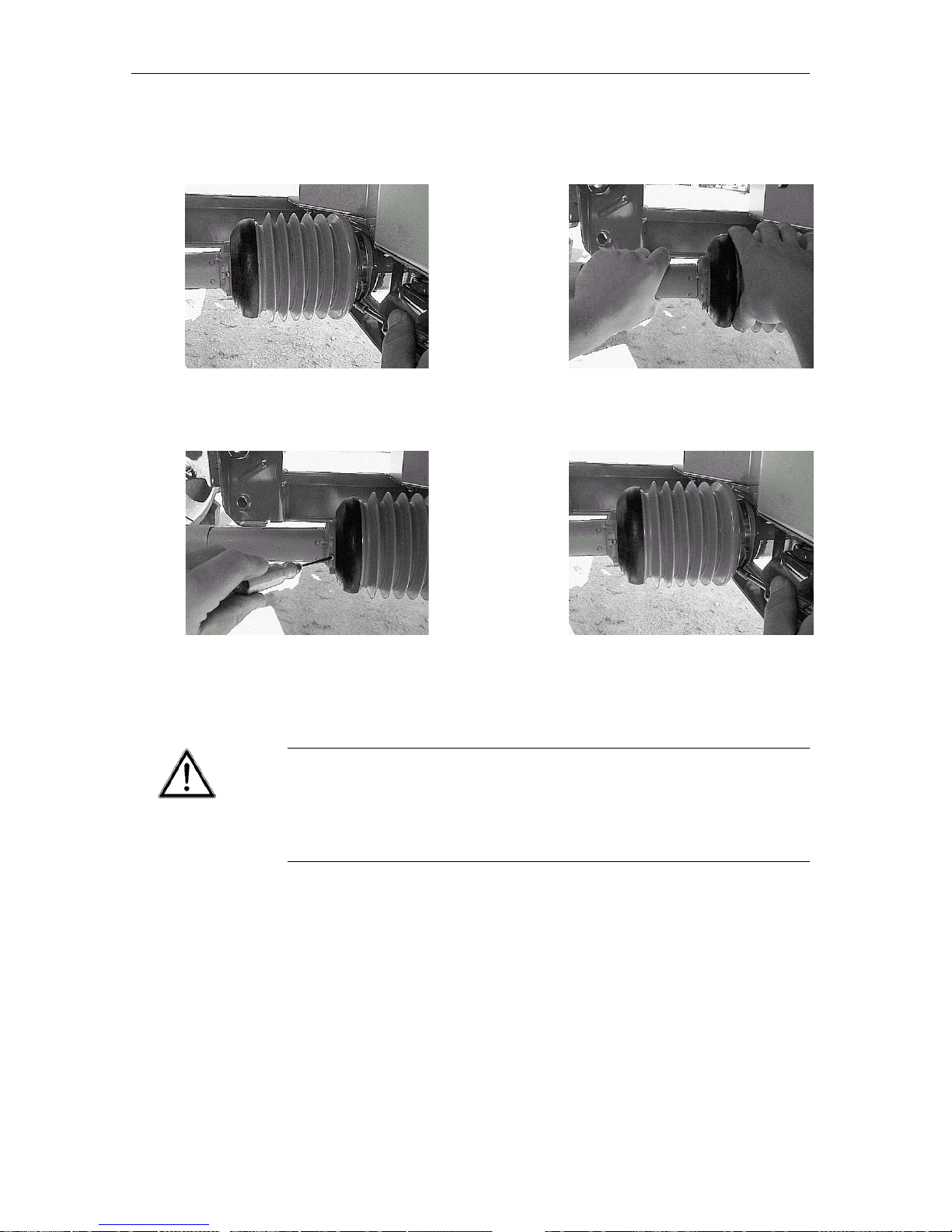

735 K / R / D / 935 K / R / D fertiliser spreaders

Manually position both metering slides (1) parallel to the direction of travel. Place both left- and right-hand side positioning levers (2) into the highest position

(550). Position both hydraulic cylinders attached to the bridge frame (3) in the

direction of travel.

Connect the metering slides (8) to the hydraulic piston fork yokes (9) using retaining washers (11) and retaining pins (10).

Danger of crushing from machine components!

By unintentional operation of the control valve or shut-off valve, the open metering slides could close leading to crushing or amputation injuries.

• Before any assembly or adjustment, close the metering slides and close the

hydraulic shut-off valve.

WARNING

9

10

11

8

Page 22

Erreur ! Style non défini. Erreur ! Style non défini.

20

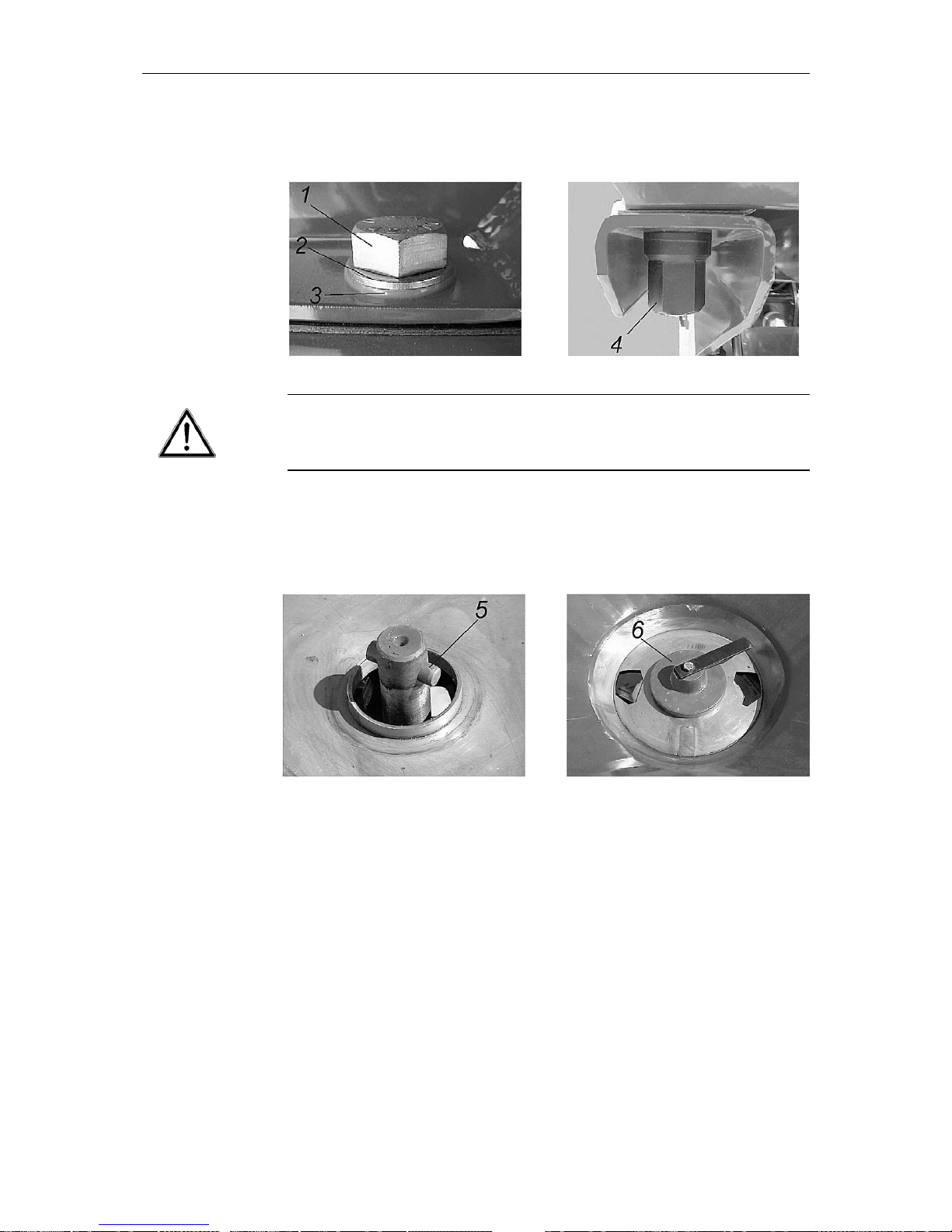

5.5 Assembling the hopper to the frame and fitting the agitator

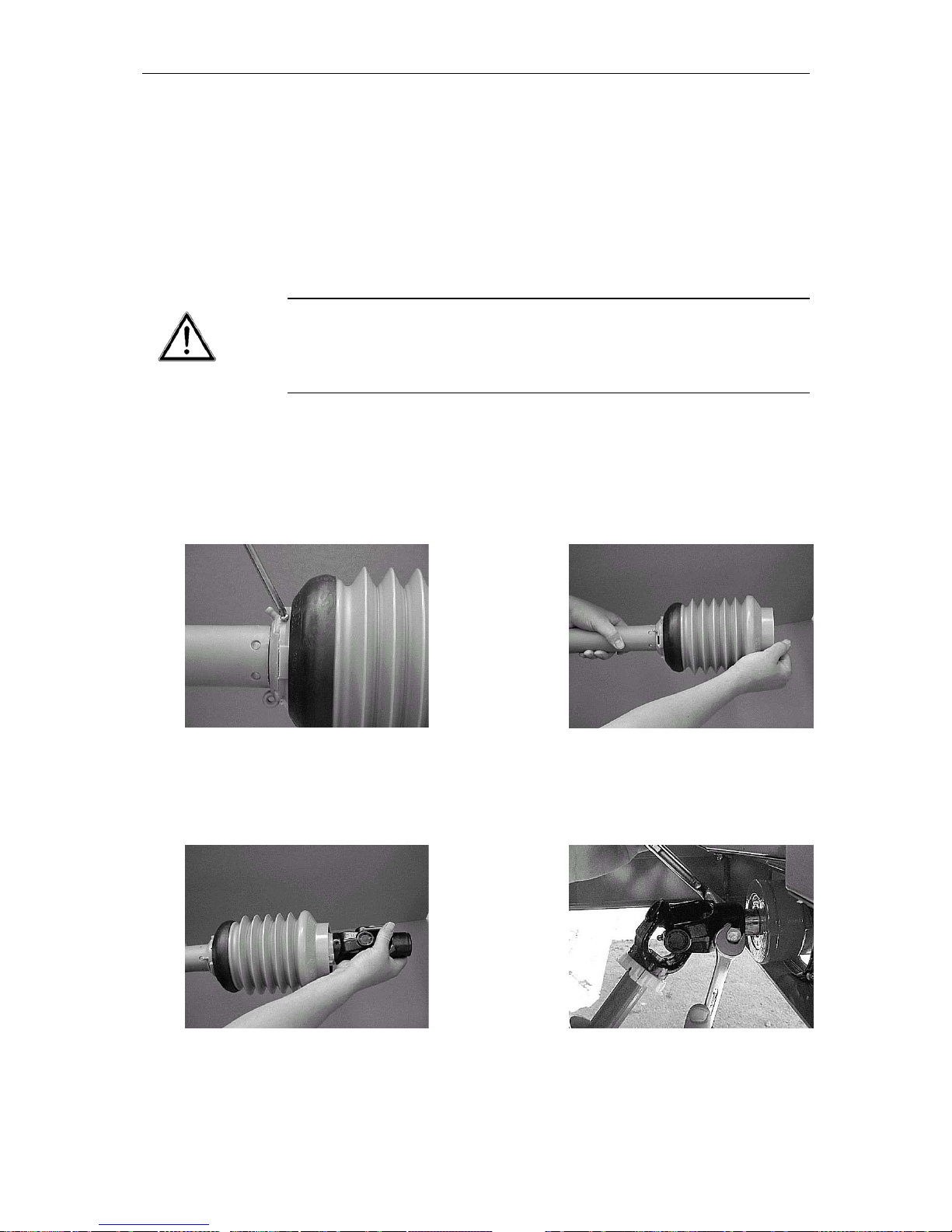

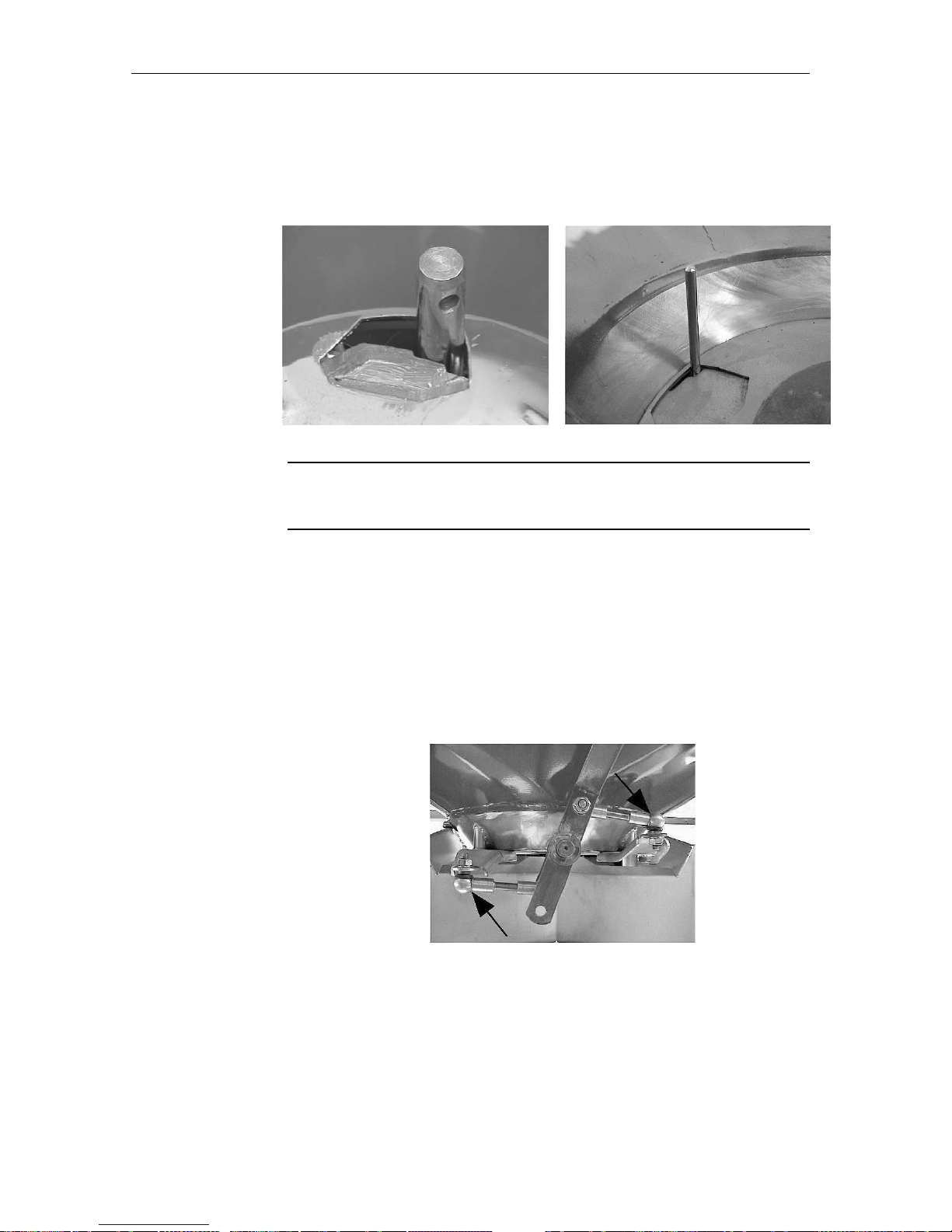

Photo 1 Photo 2

Torque setting

The thread of the synthetic nut can be damaged if overtightened.

• Bolt the hopper to the frame using a torque setting of 90 Nm.

Grease the agitator shaft (5) around the dowel pin with graphite grease (see

photo 3). Likewise, grease the agitator head bore (6) with graphite grease and

place over the shaft, ensure correct engagement by rotating (see photo 4).

Photo 3 Photo 4

1. M 20 bolt

2. Metal washer

3. Synthetic washer

4. Synthetic nut

IMPORTANT

Page 23

Erreur ! Style non défini. Erreur ! Style non défini.

21

5.6 Attaching to the tractor

3-point linkage

Respect correct attachment procedures when coupling the fertiliser spreader to

the tractor and only couple the unit to approved attachment elements.

Non-observance of the correct 3-point linkage category can lead to injury or

damage to the machine, as well as the environment.

• The 3-point linkage of the tractor and fertiliser spreader must be the same

category, or must be adapted to suit (contact your dealer, if in doubt).

• Make sure no-one is standing between the machine and the tractor when

backing the tractor up to the fertiliser spreader.

• If there is not enough free room between the fertiliser spreader and the trac-

tor to easily connect drive and control elements, it is recommended to fit a

telescopic (Tele-Space) pto drive shaft, available as optional equipment.

Payload

Non-respect of maximum payload can lead to injury or damage to the fertiliser

spreader as well as the surrounding environment.

• Pay careful attention to all payload information given in section 4 !

The fertiliser spreader is attached to the tractor 3-point linkage. Attachment to

Cat.III tractor linkages is only possible using Cat.III geometry and placing reduction sleeves over the upper and lower linkage pins. A second lower link connection is provided as standard and allows a higher attachment height on the

tractor of approx. 140mm.

3-point linkage positions

• If the lower link pins are in the upper connection point, then the top link pin

must also be placed in its upper connection point, to avoid poor load distribution between upper and lower links.

• Both lower and top link pins must be secured in place with the linchpin provided!

For correct horizontal spreading of fertiliser, the fertiliser spreader must be attached to the tractor, according to the dimensions given in the calibration charts.

Pay attention that the spreader is mounted at right-angles to the direction of travel, is perfectly horizontal and that the 3-point frame is correctly restrained from

sideways movement to avoid the unit swinging from side to side during operation.

ATTENTION

If there is not enough free room between the tractor and spreader to easily connect the drive or control elements, an extendable Tele-space pto shaft can be

supplied as optional equipment to facilitate extra working space.

For safety and comfort reasons, the use of lower linkage pick-up hooks in connection with a hydraulic top link is highly recommended.

IMPORTANT

IMPORTANT

IMPORTANT

Page 24

Erreur ! Style non défini. Erreur ! Style non défini.

22

5.7 Fitting the pto shaft

Only pto shafts supplied or recommended by the manufacturer should be used.

When first attaching the spreader to the tractor, the length of the shaft must be

matched to the tractor. Read the pto manufacturer's operator manual care-

fully, taking special note of the instructions concerning the shortening of

the shaft. This operator manual is found attached to the pto shaft. If the shaft

is too long, both pto drive and spreader may be damaged when the unit is raised.

Fitting and removing the pto shaft

Injury or death hazard due to rotating shaft

• Before fitting or removing the pto shaft, make sure that the pto drive is disengaged, the tractor engine switched off and the ignition key removed.

Always fit the shaft the correct way round. The end marked with a tractor symbol must be fitted on the tractor side.

1.

Unscrew the locking screw

2.

Turn the guard muff into its unlocked

position

3.

Pull the shaft out

4.

Remove the guard muff and grease

the pto spline shaft. Place the pto

shaft in position and tighten the bolt

DANGER

Page 25

Erreur ! Style non défini. Erreur ! Style non défini.

23

5.

Pull the guard muff over the pto CV

joint onto the housing boss and place the banjo clip into position (do not

tighten).

6.

Turn the guard muff into its locked

position.

7.

Screw in locking screw.

8.

Tighten banjo clip.

• Before engaging the pto drive, make sure that the correct tractor pto speed

is selected to match the recommended speed of the implement. (Respect

all details given in the spreading chart and the max. allowable pto speed.)

Drive shaft damage when engaging the pto drive

The pto drive shaft and the agitator drive can suffer damage if the pto drive is

engaged at high tractor engine speeds.

• Engage the pto drive at lower tractor engine speeds to avoid sudden overload to the drive shaft and agitator drive.

• Make sure that pto shafts, protector tube and end gaiter, as well as extension gaiters on the side

of the fertiliser spreader, are correctly in place and in good condition!

• When detaching the pto shaft, place it in the holder provided on the fertiliser spreader.

• Do not use the safety chain to support the shaft when not in use.

IMPORTANT

Page 26

Erreur ! Style non défini. Erreur ! Style non défini.

24

5.8 Fitting and connecting the hydraulic metering slide

controls

Injury hazard through crushing from remote control elements

The remote control elements (positioning lever, metering slides) can cause

crushing and amputation injuries.

• When activating control levers i.e. metering slides, ensure that no one is in

the vicinity of any moving parts.

Injury hazard due to defective or incorrectly sealed hydraulic hoses

Hydraulic fluid escaping under high pressure can penetrate the skin and cause

serious injuries.

• Regularly check all hoses at least every six months and before each season

commences, for mechanical defects e.g. cuts, abrasions, crushed sections,

kinks, tears, leaks, porosity, etc. Replace any suspect hoses immediately

before operating the machine.

• Even when carefully stored and correctly used, hoses and hose connecti-

ons undergo a natural aging. Therefore, their stocking and operational periods should not be exceeded.

• The useful life of an undamaged hose should be limited to six years, inclu-

ding a possible maximum two-year stocking period.

• The hydraulic hose manufacturing date is indicated on the hose with the

month and year of manufacture (e.g. SLP 8/00).

• Use suitable protection when locating leaks (safety goggles, gloves, etc.) in

order to avoid injury.

• In case of injury, immediately consult a doctor, as there is a risk of serious

infection!

Storing hydraulic hoses when fertiliser spreader is uncoupled from the

tractor

Hydraulic hoses can be laid between the upper link point and the hopper.

5.8.1 Single acting hydraulic metering control for MDS 55 K /

65 K / 85 K / 735 K / 935 K

The MDS 55 K / 65 K / 85 K / 735 K / 935 K metering slides operate with two

hydraulic cylinders fitted complete with exterior mounted return springs.

Oil pressure closes - Spring tension opens

Connecting the hydraulic metering slide control:

The following hydraulic valves are needed on the tractor:

• Two single acting valves, or

• Two double acting valves with free return, or

one single and one double acting valve with free return

WARNING

WARNING

ATTENTION

ATTENTION

Page 27

Erreur ! Style non défini. Erreur ! Style non défini.

25

Prior to long transport journeys or when filling, close both shut-off valves in the

hydraulic circuit to prevent subsequent opening of the metering slides, should

oil inadvertently escape through the control valves.

If the spreader is to be stored for any length of time, it is recommended that the

metering slides are left open so that spring tension is not weakened. Proceed

as follows :

1. Hydraulically close the metering slides

2. Adjust positioning lever stops to their highest scale level.

3. Open metering slides.

5.8.2 Double acting hydraulic metering control for MDS 55 D

/ 65 D / 85 D / 735 D / 935 D

The metering slides operate with two double acting hydraulic cylinders.

Oil pressure closes – Oil pressure opens

Connecting the hydraulic metering slide control:

The following hydraulic valves are needed on the tractor :

Two double acting control valves

5.8.3 Single acting hydraulic metering control with double

acting mechanism for MDS 55 R / 65 R / 85 R / 735 R /

935 R

The MDS 55 R / 65 R / 85 R / 735 R / 935 R metering slides operate with two

single acting hydraulic cylinders complete with externally mounted return

springs.

Oil pressure closes – Spring tension opens

Connecting the hydraulic metering control:

The folowing hydraulic valves are needed on the tractor:

• One single acting or one double acting valve with free return.

Attach the holder brackets for the shut-off valves to a suitable place on the tractor.

Prior to long transport journeys or when filling, close both shut-off valves to the

double acting mechanism to prevent subsequent opening of the metering slides,

should oil inadvertently escape through the control valves.

If the spreader is to be stored for long periods, it is recommended that the metering slides are left open so that spring tension is not weakened. Proceed as follows:

1. Hydraulically close the metering slides.

2. Adjust positioning lever stops to their highest scale level.

3. Open metering slides.

ATTENTION

ATTENTION

Page 28

Erreur ! Style non défini. Erreur ! Style non défini.

26

5.8.4 Fitting the single acting hydraulic metering slide

control FHK 4 and the double acting hydraulic metering

slide control FHD 4

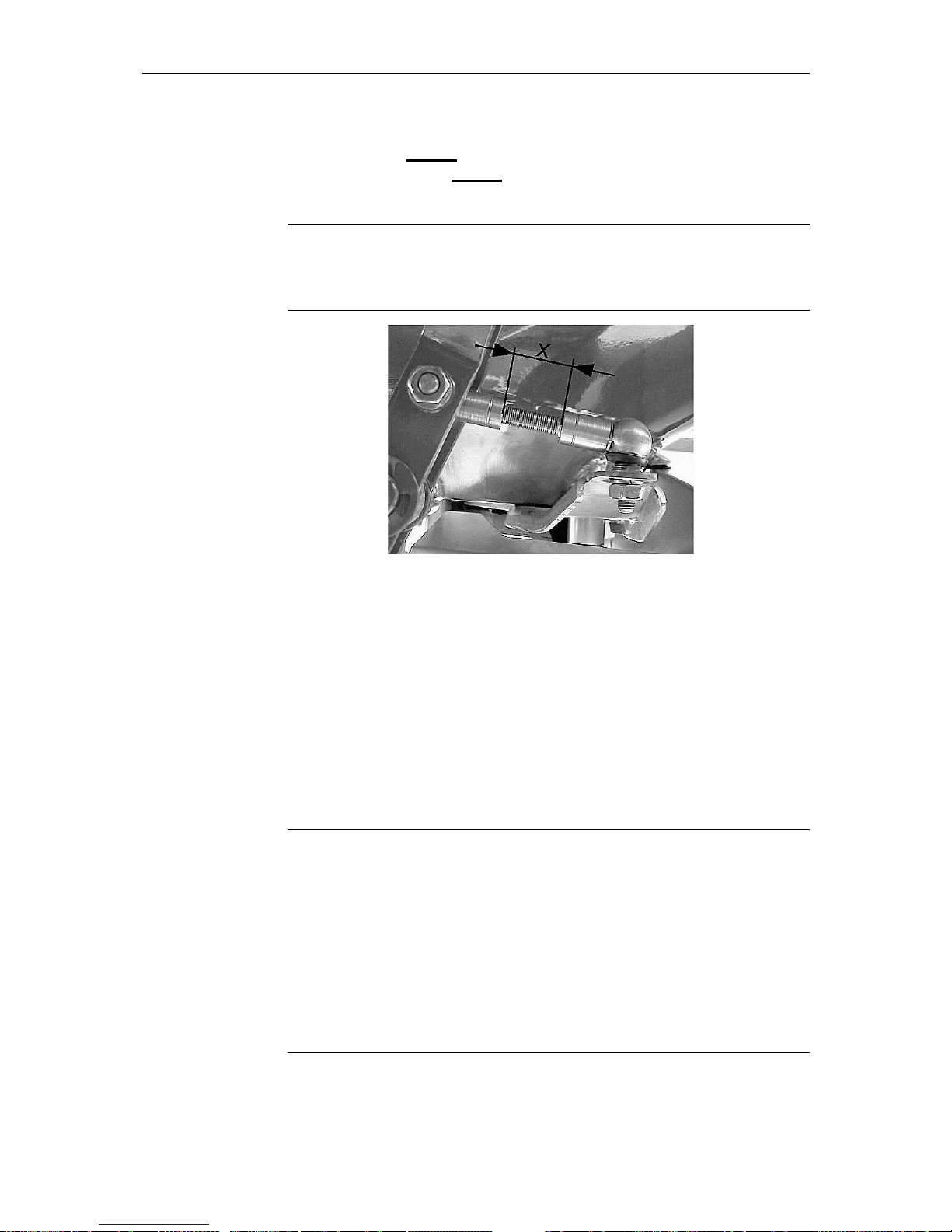

Adjusting the knuckle joints

The setting dimension "x" of the knuckle joints (viewed from the left-hand side in

direction of travel) must be reduced by 1 mm (one turn in a clockwise direction)

before fitting the hydraulic cylinder.

5.8.4.1 Fitting the single acting hydraulic metering slide

control FHK 4 (Optional equipment for MDS 55 M / 65

M / 85 M / 735 M / 935 M)

This metering slide control operates with one single acting control valve (trailer

connection).

Oil pressure closes – Spring tension closes

Connecting the hydraulic metering control:

The cylinder for the hydraulic metering slide control FHK4 is fitted to the righthand side of the spreader (viewed in direction of travel).

Before connecting the hydraulic cylinder to the positioning lever, check that its

assembly length is correct when metering slides are closed and the cylinder is

fully extended.

The cylinder length can be adjusted by releasing the locknut and rotating the

piston fork yoke.

Incorrect assembly of the hydraulic cylinder can result in bent positioning levers and pins. (See separate assembly information.)

Prior to long transport journeys or when filling, close the shut-off valve where

the hydraulic circuit is connected, to prevent subsequent opening of the metering slides.

ATTENTION

ATTENTION

Page 29

Erreur ! Style non défini. Erreur ! Style non défini.

27

If the spreader is to be stored for long periods, it is recommended that the metering slides are opened, so that the spring tension is not weakened.

If the positioning lever's hydraulic cylinder fails to completely open, then the

lever's leaf spring, to which the hydraulic cylinder is attached, can be unscre-

wed.

5.8.4.2 Fitting the double acting hydraulic metering slide

control FHD 4 (Optional equipment for MDS 55 / MDS

65 / MDS 85 / 735 M / 935 M)

This hydraulic metering slide control operates with one double acting control

valve.

Oil pressure closes - Oil pressure opens

Connecting the hydraulic metering control:

The cylinder for the hydraulic metering slide control FHD 4 is fitted to the righthand side of the spreader (when viewed in direction of travel).

Before connecting the hydraulic cylinder to the positioning lever, check that its

assembly length is correct when metering slides are closed and the cylinder is

fully extended.

The cylinder length can be adjusted by releasing the locknut and rotating the

piston fork yoke.

Incorrect fitting of the hydraulic cylinder can result in bent positioning levers

and pins. (See separate assembly information.)

If the positioning lever's hydraulic cylinder fails to completely open, the lever's

leaf spring, to which the hydraulic cylinder is attached, can be unscrewed.

ATTENTION

Page 30

Erreur ! Style non défini. Erreur ! Style non défini.

28

5.8.5 Position indicator function: (only for MDS K / R / D)

This indicator allows the position of the shutter slide to be seen from the driver's seat, avoiding unintentional loss of fertiliser.

Shutter slide closed

Shutter slide open

Shutter slide completely open

Page 31

Erreur ! Style non défini. Erreur ! Style non défini.

29

6 Adjusting the fertiliser spreader

6.1 General

Values provided in the spreading charts are derived from practical tests in the

manufacturer's purpose built fertiliser spreader research centre. Settings are

obtained using fertiliser in perfect condition from each respective manufacturer

and spread over the stated spreading width.

We would particularly emphasise that physical characteristics of fertiliser can

vary, even within the same type and brand, due to differences in size of granules, density, surface texture, specific weight and quality of granules, etc.

These variations can influence spreading characteristics quite markedly, which

result in differences in the fertiliser application rates as well as changes in

spread patterns predicted in the spreading charts, therefore making it necessary to recalibrate the fertiliser.

The data provided in the spreading charts can only be used as a guideline. To

ensure greater accuracy the unit should be recalibrated for application rate, and

the spread pattern should be checked over the desired width with the help of

the practical test kit, every time fertiliser is changed, even when using different

bags of the same fertiliser.

We suggest the use of only quality fertiliser from well-known suppliers, preferably those fertilisers listed in the spreading charts. If you need to use fertiliser

not listed, please contact us.

Spreading of Urea

This highly concentrated nitrogen fertiliser has a wide variation of quality and

particle sizes, due to the great number of importers handling this product.

It is therefore essential to recalibrate the unit every time this fertiliser is used.

Also note that Urea is very susceptible to wind variations and moisture absorbtion.

Pay special attention when setting the spreader. Even a very small error in setting can result in a large change in spread pattern.

We must stress that no liability can be accepted for consequential losses

or damages due to spreading errors.

ATTENTION

Page 32

Erreur ! Style non défini. Erreur ! Style non défini.

30

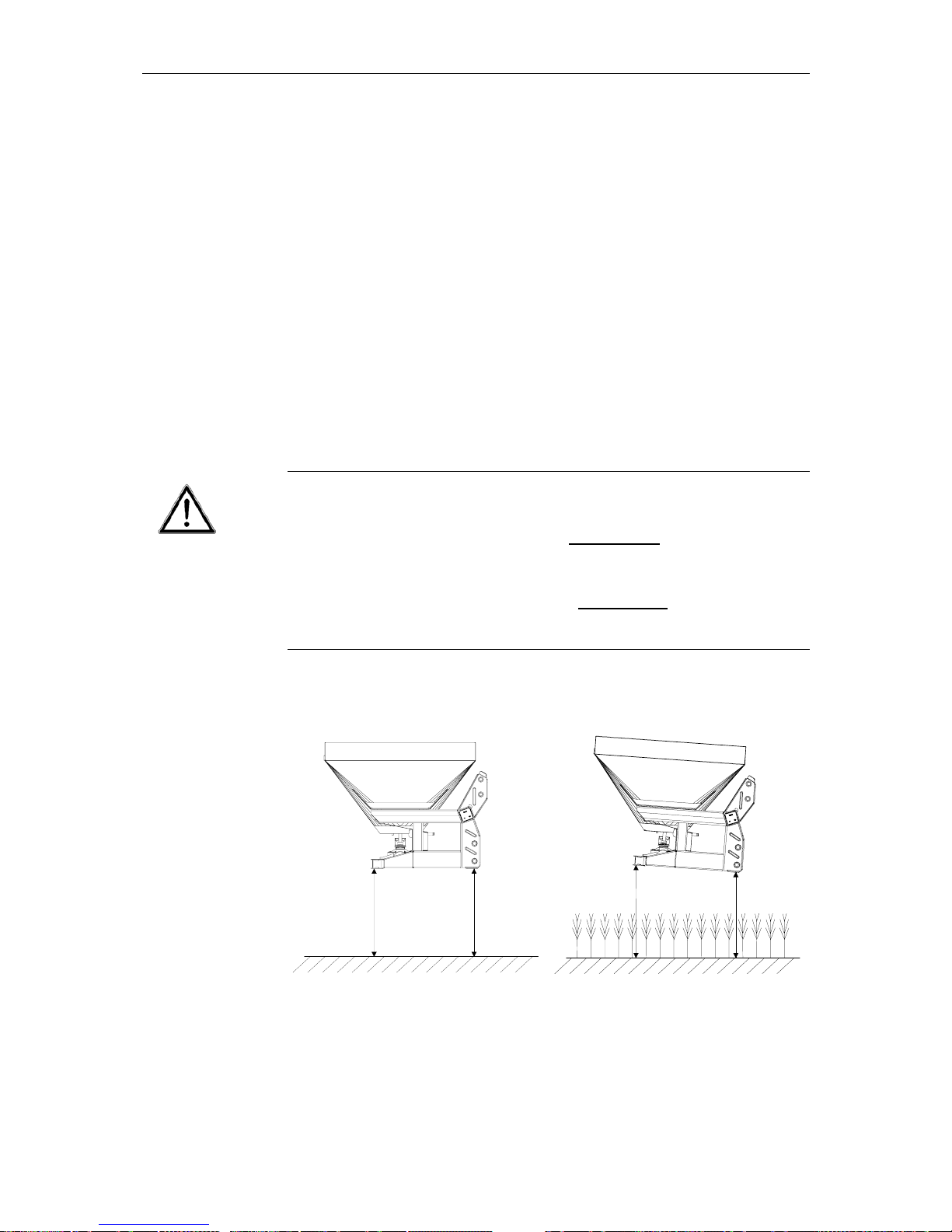

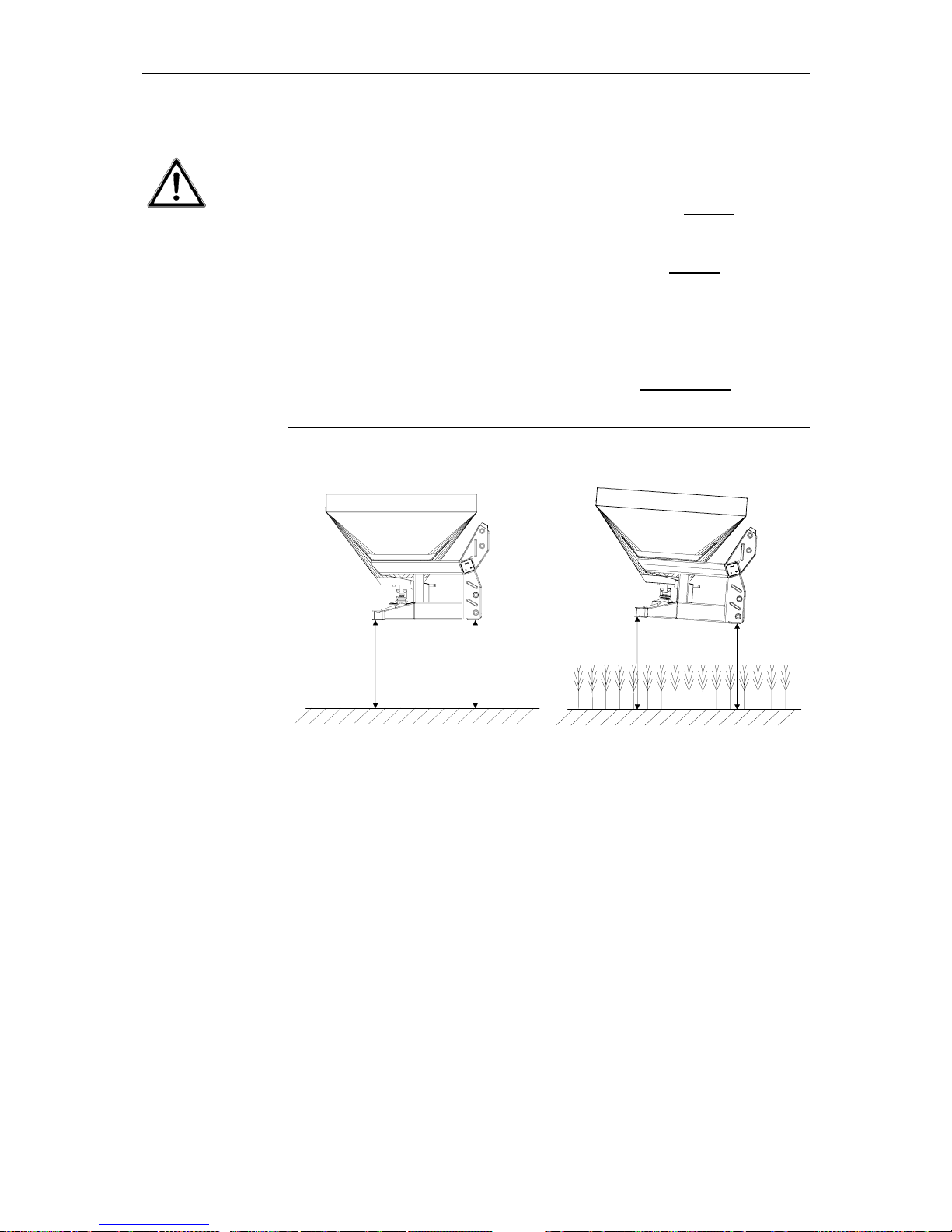

6.2 Attachment height

Attachment height of the fertiliser spreader

Danger of injury from unintentional contact with spreading discs.

• Max. allowable attachment height measured from the ground

to the un-

derside of the frame in normal spreading mode: Dimension A 85 cm and

Dimension B 85 cm.

• Max. allowable attachment height measured from the ground

to the un-

derside of the frame in late top dressing mode: Dimension A 77 cm and

Dimension B 83 cm.

• The dimensions given in the spreading charts are always taken in the field

from the top of the crop to the underside of the frame (Dimension at points

A and B).

• If the max. allowable attachment height from ground level

in normal

spreading mode is exceeded, the unit should be set up using the values

for late top dressing.

6.2.1 Attachment height for normal spreading

Attach the fertiliser spreader to the tractor using the settings given in the spreading chart.

Settings from the spreading chart:

Attachment height above crop level A + B e.g. 50 / 50

The fertiliser spreader attachment height dimension at both points A and B is 50

cm above crop level.

6.2.2 Attachment height for late top dressing

Attach the fertiliser spreader to the tractor using the settings given in the spreading chart.

Settings from the spreading chart:

Attachment height above crop level A + B e.g. 0 / 6

The fertiliser spreader attachment height dimension at point A is 0 cm (i.e. same height as crop level) and the dimension at point B is 6 cm above crop level.

WARNING

Attachment example

Attachment example

B

(85 cm)

A

(85 cm)

B

(83 cm)

A

(

77 cm

)

Ground level-

Ground level

Maximum allowable attachment

height in normal spreading mode

Maximum allowable attachment

height in late top dressisng mode

Page 33

Erreur ! Style non défini. Erreur ! Style non défini.

31

6.3 Hopper capacity / Hopper extension sets

The basic hopper capacity of the fertiliser spreader is between 500 and 900

litres, depending on spreader model. Capacity can be increased by adding one

or more extension sets in various sizes.

When increasing hopper capacity by adding extension sets, take note of the following:

• When filling, the maximum payload must not be exceeded. If the loading

height exceeds 1250 mm a suitable mechanical loading system should be

used e.g. front-end loader.

• When fitting the extension sets, only use the self-locking nuts provided.

Checking the hopper contents

• An inspection window is provided on all MDS fertiliser spreaders (except

MDS 55 / 65 / 85). The M653 and M863 extension sets are also equipped

with inspection windows. These inspection windows facilitate the control of

the hopper contents e.g. when checking what is left in the hopper.

6.3.1 Calculation of maximum loading

The specific weight of Thomas potash = 1.36 kg/l. As the maximum payload of

the MDS 935 fertiliser spreader is 1800 kg, the spreader should not be loaded

with more than a maximum of 1323 litres of Thomas potash.

litres

lkg

kg

ge

fertiliserofweightspec

payload

capacityMax 1323

./36.1

1800

:..

.

.max

. ==

6.3.2 Hopper level scale

For control of the hopper level i.e. amount of product left to be spread in litres.

(Accuracy of each mark max. +/- 10 %.)

The scale allows the operator to calculate how long

spreading can continue before refilling is necessary.

This avoids unnecessary refilling, leading to a reduction in the amount of product remaining after

field operations are completed.

IMPORTANT

Page 34

Erreur ! Style non défini. Erreur ! Style non défini.

32

6.4 Setting application rates on the

MDS 55 M / MDS 65 M / MDS 85 M / 735 M / MDS 935 M

A potential crushing and amputation hazard exists when carrying out

adjustments or other work on the fertiliser spreader.

Rotating parts (e.g. spreading discs, pto shaft) and remote controlled machine

elements (e.g. adjusting lever, metering slides) can cause serious injuries.

• Before carrying out adjustments or other general work such as maintenance

or cleaning, disengage the pto drive, stop engine and remove the ignition

key.

• Wait until the rotating parts have come to a standstill before approaching

the machine.

Application rates are adjusted by means of an adjusting lever stop (1) on a large

scale segment, which is extremely easy and positive to use.

An application rate with its corresponding position on the scale segment is selected from the calibration charts, according to the desired forward speed. The

stop on the segment is positioned so that its edge is aligned to the position selected. (Marked edge (2) aligned to the selected position.)

The stop adjustment of one hole position corresponds to two scale segment positions. If only a single segment position adjustment is needed, this can be achieved by turning the handle (3) over the stop and slotting it into the offset holes (see photos 1 and 2).

Due to the proportional scale segmentation, not every value can be selected.

Select the nearest higher or lower selectable position. As the scale segmentations are so small, application rate variations will be minimal.

Photo 1 Metering slide position 350 Photo 2 Metering slide position 130

Closing the shut-off valves (only valid for single acting metering slide

control)

Close the shut-off valves before all transport journeys and before parking or

disconnecting the unit, as most valves are not entirely oil tight, thus allowing the

spring tension of the hydraulic metering control to overcome oil pressure, resulting in the metering slides opening and fertiliser escaping from the hopper.

WARNING

ATTENTION

Page 35

Erreur ! Style non défini. Erreur ! Style non défini.

33

6.5 Setting application rates on the

MDS 55 K / R / D MDS 65 K / R / D MDS 85 K / R / D

MDS 735 K / R / D and MDS 935 K / R / D

A potential crushing and amputation hazard exists when carrying out

adjustments or other work on the fertiliser spreader.

Rotating parts (e.g. spreading discs, pto shaft) and remote controlled machine

elements (e.g. adjusting lever, metering slides) can cause serious injuries.

• Before carrying out adjustments or other general work such as maintenance

or cleaning, disengage the pto drive, stop engine and remove the ignition

key.

• Wait until all rotating parts have come to a standstill before approaching the

machine.

An application rate with its corresponding position on the scale segment is selected from the calibration charts, according to the desired forward speed. The

stop on the segment is positioned so that its edge is aligned to the position selected. (Marked edge (2) aligned to the selected position.)

Both left- and right-hand side stops must be equally adjusted to the same scale

position and securely locked in place.

Closing the cut-off valves (only valid for single acting metering slide

control)

Close the shut-off valves before all transport journeys and before parking or

disconnecting the unit, as most valves are not entirely oil tight, thus allowing the

spring tension of the hydraulic metering control to overcome oil pressure, resulting in the metering slides opening and fertiliser escaping from the hopper.

WARNING

ATTENTION

Page 36

Erreur ! Style non défini. Erreur ! Style non défini.

34

6.6 Adjustment of the multi-disc spreading discs

6.6.1 Principle of operation

The disc vanes on the spreading discs can be adjusted to accept various types

of fertiliser, different fertiliser operations, as well as different working widths.

Different spreading operation mode possibilities are :

1. Normal spreading.

2. Border spreading either to the left- or right-hand side when in the normal

spreading mode.

3. Late season top dressing.

4. Border spreading either to the left- or right-hand side when in the late sea-

son top dressing mode.

• Each disc is equipped with two identical disc vanes.

• Each vane consists of a main vane with an extension vane.

• The main vane of the right-hand spreading disc is identified with the letters

BR and its corresponding extension vane with the letters AR.

• The main vane of the left-hand spreading disc is identified with the letters

BL and its corresponding extension vane with the letters AL.

• Each vane angle can be increased or decreased. Also, the vane's effective

length can be shortened or increased.

Decreasing the vane angle means that the vane is moved from higher to lower

numbers. The numbers are stamped into the discs.

Increasing the vane angle means that the vane is moved from lower to higher

numbers. The numbers are stamped into the discs.

Shortening the vane length means that the slidable vane extension is moved

towards the disc centre and locked in place.

Increasing the vane length means that the slidable vane extension is moved

away from the disc centre and locked in place.

Decreasing the vane

angle

Increasing the vane

angle

Shortening the vane

length

Increasing the vane

length

Page 37

Erreur ! Style non défini. Erreur ! Style non défini.

35

6.6.2 Adjusting the disc vanes

Obtain recommended setting positions of the disc vanes from the calibration

charts in accordance with the fertiliser to be used, the type of fertiliser operation

mode to be undertaken, as well as the desired working width.

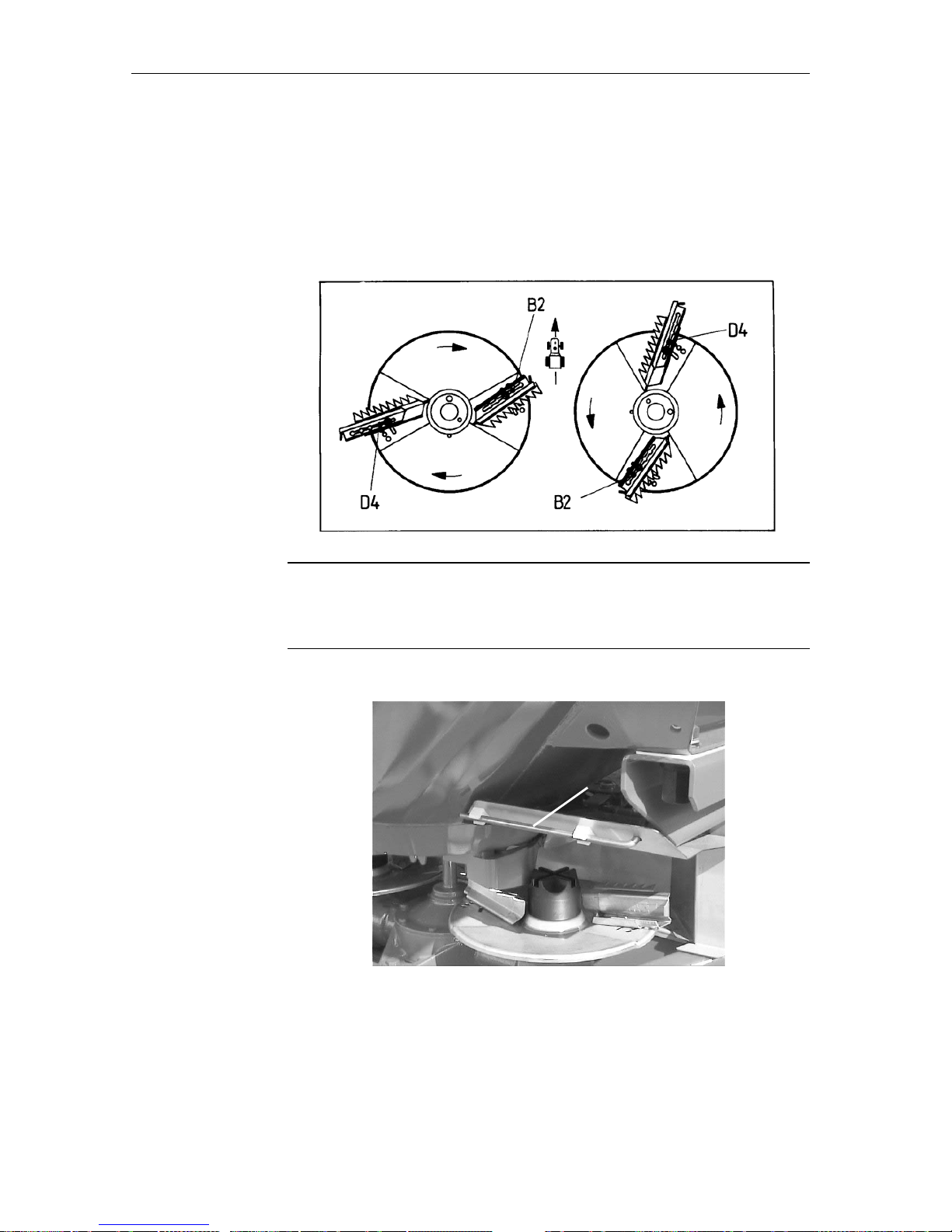

Disc vanes on both discs must be positioned so that one vane is at the D4 position with the other set at the B2 position (see diagram).

Positioning the vanes

Positioning of the vanes on the right-hand disc must correspond exactly to the

same positions of the vanes on the left-hand disc (border spreading is the exception to this rule).

An adjusting lever will be found on the right-hand frame side (1).

This adjusting lever is used to adjust the vane positions as well as for changing

the discs.

When changing or checking that the discs are securely fitted, protective gloves

should be used as there is a danger of injury due to hands coming into contact

with sharp edges.

Example: D4-B2

ATTENTION

1

Page 38

Erreur ! Style non défini. Erreur ! Style non défini.

36

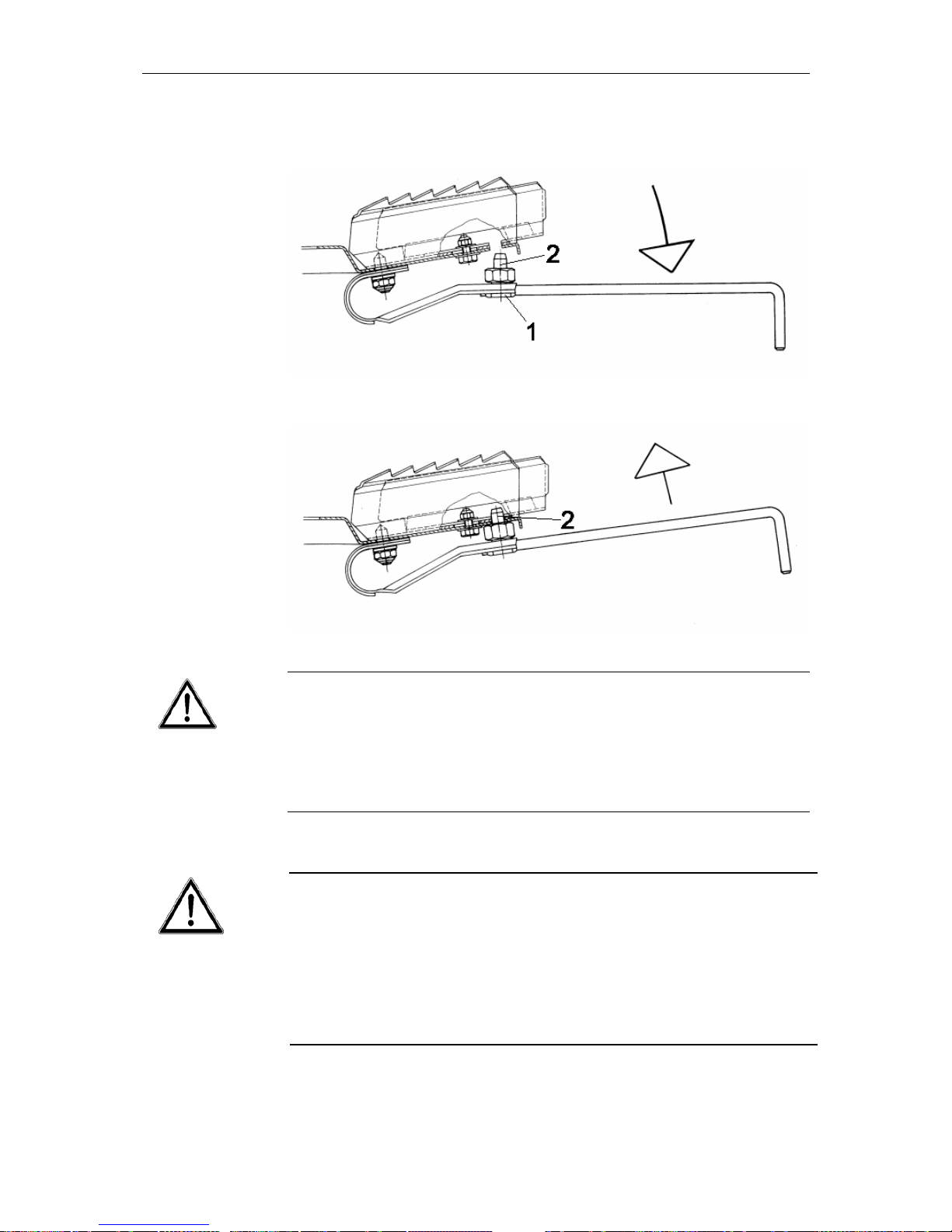

Slot the adjusting lever into the leaf spring under the disc and press downwards

to disengage the notch pin (2).

Adjust vane angle and length and re-engage the notch pin.

Engaging the disc vanes and replacing the adjusting lever

Serious injury hazard from incorrectly attached components.

• After adjusting the vanes, the notch pin must be completely returned into its

locked position.

• The adjusting lever must be securely reclipped into place on the frame befo-

re the pto drive is engaged.

WARNING

The left spring should only be pressed down just enough to disengage the

notch stop.

Over tensioning of the leaf spring will result in loss of necessary tension to safely secure the disc vane.

Check leaf spring tension regularly!! If tension is too weak it means the

notch stop is not fully engaged and the leaf spring should be immediately replaced for security reasons.

WARNING

Page 39

Erreur ! Style non défini. Erreur ! Style non défini.

37

6.6.3 Adjustment according to the spreading charts

Depending on :

• Type of fertiliser,

• Working width and the

• Mode of operation.

The

• Spreading disc type,

• Vane setting,

• Spreader attachment height and the

• Pto speed

must be set according to the spreading chart. Spreader attachment height is

always measured from the top of the crop.

Normal spreading mode:

Example: C3-B2

Both discs have one vane mounted in the C3 position and the other in the B2

position.

Example: A2-A2

Both vanes on the disc nearest the border are placed in the A2 position. The

vanes on the other disc remain in their normal spreading mode.

Late top dressing mode

Example: C3-C2

Mounting height is measured from the top of the crop e.g. when 0/6 is indicated:

Dimension A = distance from the top of the crop is 0 cm. Dimension B = distance from the top of the crop is 6 cm. Both discs have one vane mounted in

the C3 position and the other mounted in the C2 position.

Example: A3-A3

Both vanes on the disc nearest the border are placed in the A3 position. The

vanes on the other disc remain in their late top dressing mode.

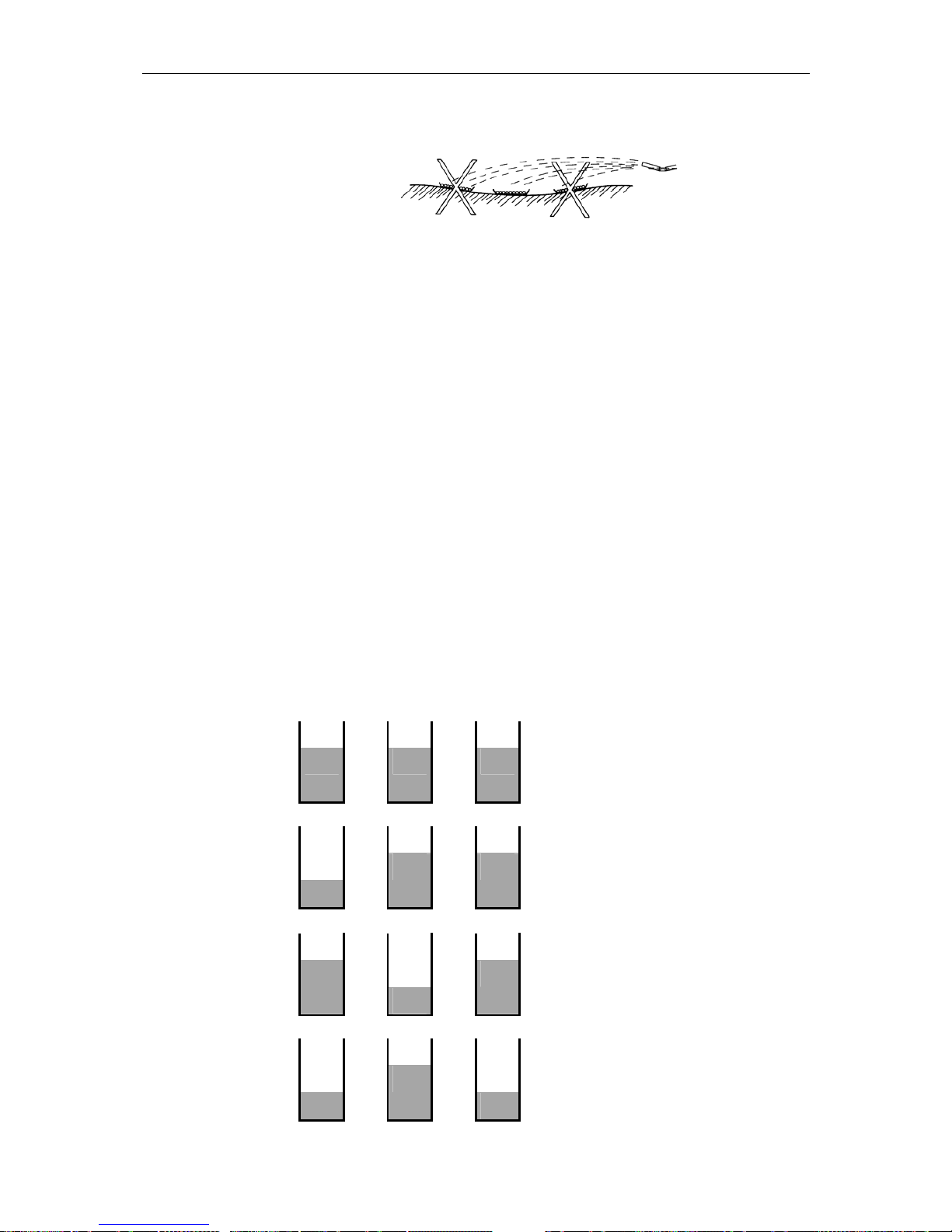

Normal spreading

Border spreading du-

ring normal sprea-

ding

Late top dressing

Boundary spreading

during late top dres-

sing

Page 40

Erreur ! Style non défini. Erreur ! Style non défini.

38

Page 41

Erreur ! Style non défini. Erreur ! Style non défini.

39

6.6.4 Setting disc vanes for fertilisers not listed in the sprea-

ding charts

6.6.5 DiS

The KUHN fertiliser identification kit DiS (optional equipment) gives quick and

easy help in determining the correct spreader settings for numerous unknown

fertiliser products.

Designed to fit in normal size pockets the kit can also be used in the field.

The fertiliser to be identified is first grouped according to its chemical makeup. Then, using "mug shot" reference photos, the actual granules are identified and the fertiliser characteristics can be determined. After identification

the fertiliser spreader setting can be determined from the accompanying

table.

6.6.6 PtK

A practical test kit, supplied as optional equipment, offers a simple and quick

method for checking the spread pattern. By using this kit it is possible to obtain settings for fertilisers not listed in the spreading charts.

For a quick check of the spreader settings a one-pass method is recommended.

To obtain more accurate results and reduction of negative calibration error influences, such as side wind, a three-pass method is recommended.

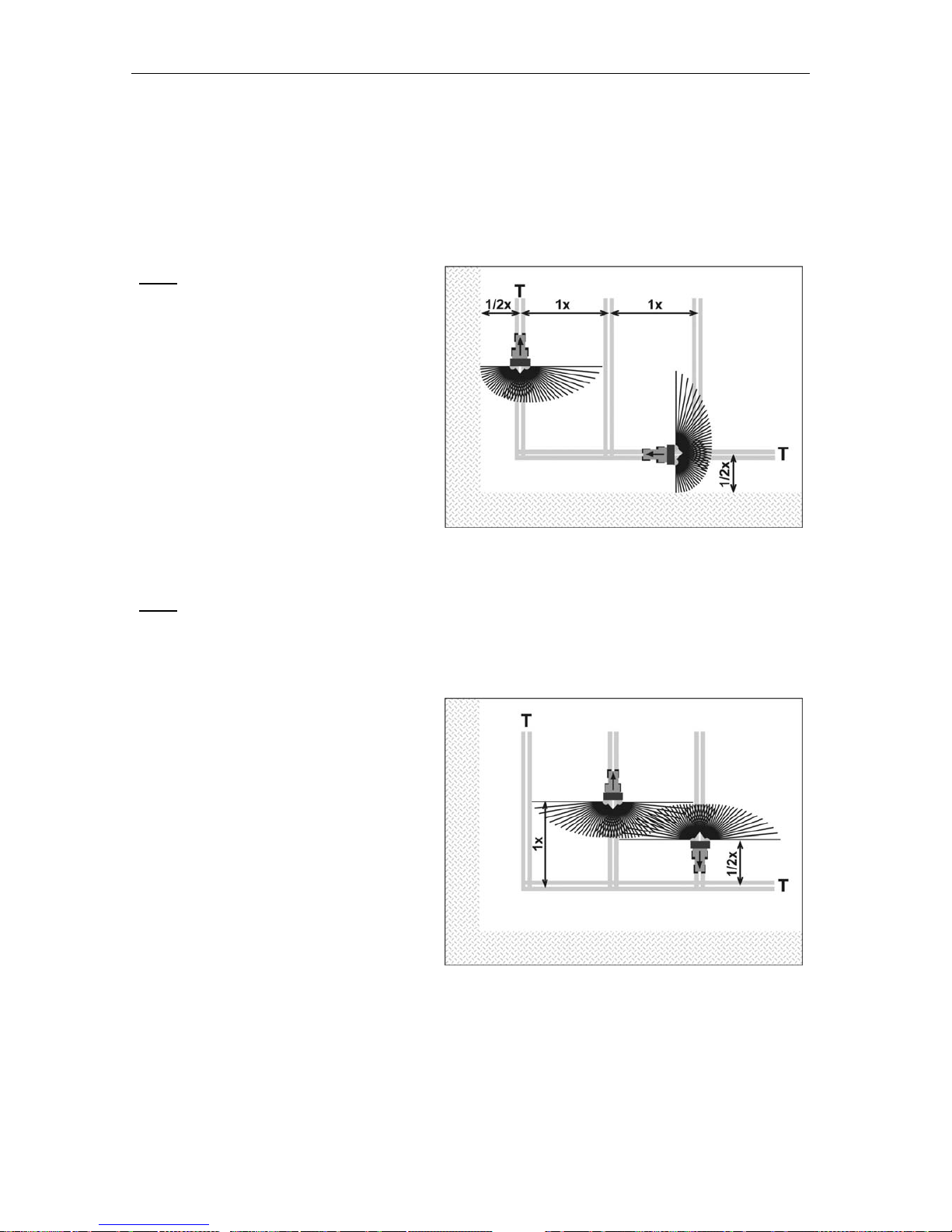

6.6.6.1 Three-pass method (PtK):

• Choose a fertiliser from the spreading charts that has the nearest characte-

ristics to the one that needs to be used and adjust the fertiliser spreader to

these settings.

• Test on a dry calm day so that weather conditions do not influence the re-

sults.

• A test area should be chosen which is horizontal in both directions and is

large enough to achieve 3 tramlines over a length of approx. 60 - 70 m.

• Carry out the test, either on freshly mown grass or in a field with low vegeta-

tion (max. 10cm), and make sure that the 3 tramlines run parallel to each

other. When carrying out a test without pre-set tramlines the tracks must be

measured using a tape measure and marked with suitable post markers.

• The three tracks must not contain any notable bumps or hollows as these

could cause a shift in spread pattern.

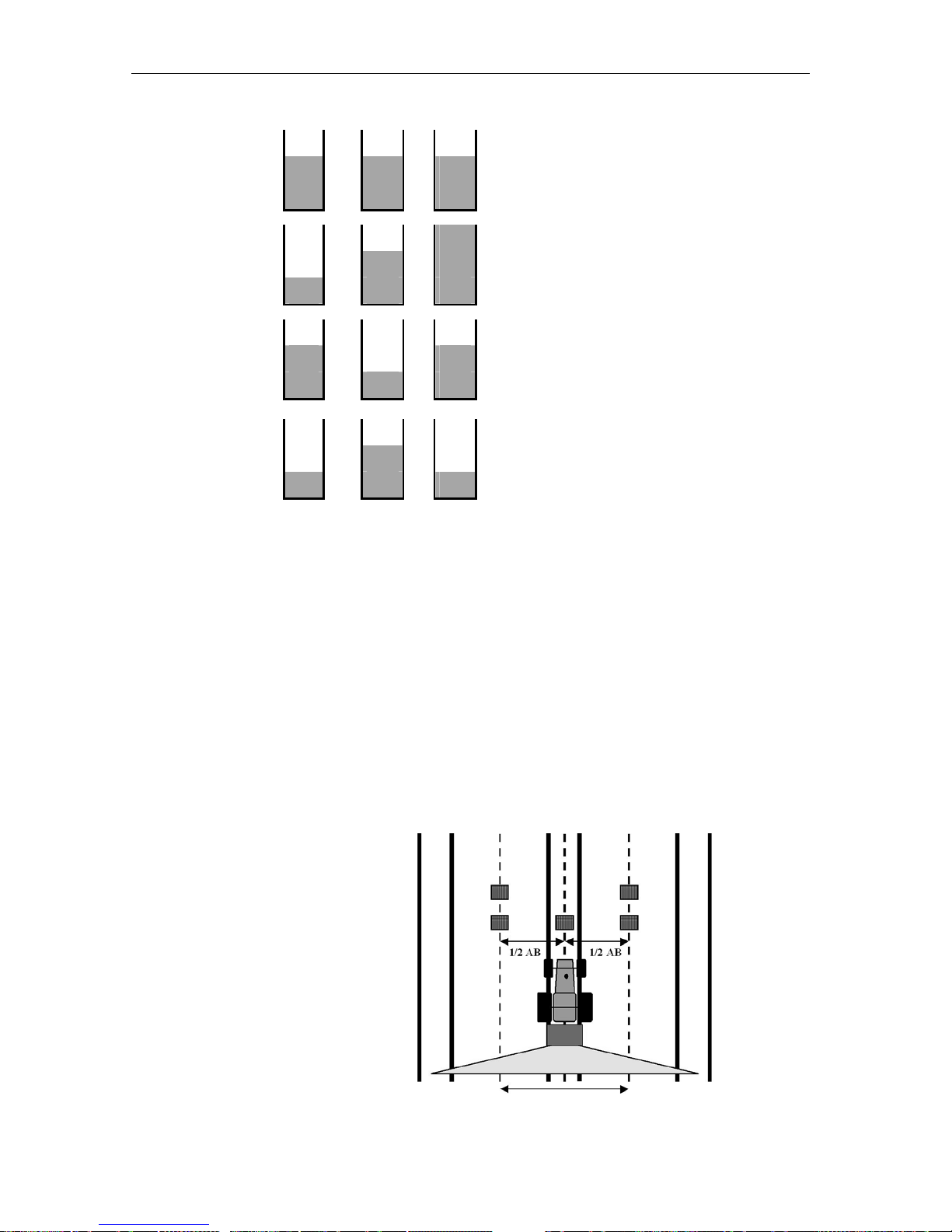

• Place two collecting containers one behind the other (1m apart) as per the

following sketch. One pair in each overlap zone and one pair in the centre

of the middle tramline.

Page 42

Erreur ! Style non défini. Erreur ! Style non défini.

40

1/2

Working width

1/2

123

• Make sure individual containers are level. Containers set at an angle can

lead to measuring errors.

• Set the fertiliser spreader at the same height on the left- and right-hand si-

des in accordance with the information in the spreading charts, paying attention that the mounting height is taken from the top edge of the collecting

trays.