Page 1

OPERA TOR'S MANUAL

MDC

Application rate monitoring

system

No 95738 B.GB - 01. 2005

for VENTA

Page 2

DEAR OWNER,

In buying a KUHN machine you have chosen wisely. Into it have gone years of thought,

research and improvements. You will find, as have thousands of owners all over the world, that

you have the best that engineering skill and actual field testing can produce. You have

purchased a dependable machine, but only by proper care and operation can you expect to

receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your

machine. The performance you get from this machine is largely dependant upon how well you

read and understand this manual and apply this knowledge. Please DO NOT ASSUME THAT

YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR MACHINE before reading this

manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE.

Your KUHN dealer will instruct you on the general operation of your machine. He is interested

that you get the best performance possible and will be glad to answer any special questions

that may arise regarding the operation of the KUHN machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts.

These parts are manufactured and carefully inspected in the same factory that builds the

machine to assure high quality and accurate fitting of any necessary replacements.

When ordering service parts it is important that you indicate the type of machine concerned

and its serial number.

For this reason please complete the model identification plate diagram below with the required

information. This will provide you with an easy reference for future service parts orders.

ABOUT IMPROVEMENTS

KUHN is continually striving to improve its products and, therefore, reserves the right to make

improvements or changes when it becomes practical to do so, without incurring any

obligations to make changes or additions to the equipment sold previously.

Page 3

TABLE of CONTENTS

A Description............................................................................................................. 3

B Summary of use .................................................................................................... 4

C Detailed description of the system...................................................................... 6

C 1 Electric power supply................................................................................... 6

C 2 Design.......................................................................................................... 6

D Work and display settings ................................................................................... 8

D 1 Setting the point of reference ...................................................................... 8

D 2 Opening calibration (flow control)................................................................. 9

D 2.1 Setting the seed type........................................................................9

D 2.2 Setting the opening......................................................................... 10

D 2.3 Flow control ................................................................................... 10

D 3 Programming the nominal application rate (100% )...................................11

D 4 Adjustment to the nominal application rate (100%).................................... 12

D 5 Setting the application rate adjustment level.............................................. 12

D 6 Application rate adjustment in %................................................................ 12

D 7 Setting the null flow rate ............................................................................ 13

E Connection to a « Master » terminal (GPS mode)

E 1 Description................................................................................................. 14

E 2 Work and display settings..........................................................................15

F System adjustment and calibration .................................................................. 16

F 1 Adjusting the opening pulses......................................................................16

F 2 Adjustment of the opening limit points........................................................17

F 3 Screen test................................................................................................. 18

F 4 Rotation sensor test ................................................................................... 18

F 5 Motor and sensor pulse test....................................................................... 18

F 6 Setting the maximum amperage................................................................. 19

F 7 Setting the maximum functioning time under maximum amperage............ 19

G Trouble shooting guide ..................................................................................... 20

H Symbols ............................................................................................................. 21

2

Page 4

A Description

9

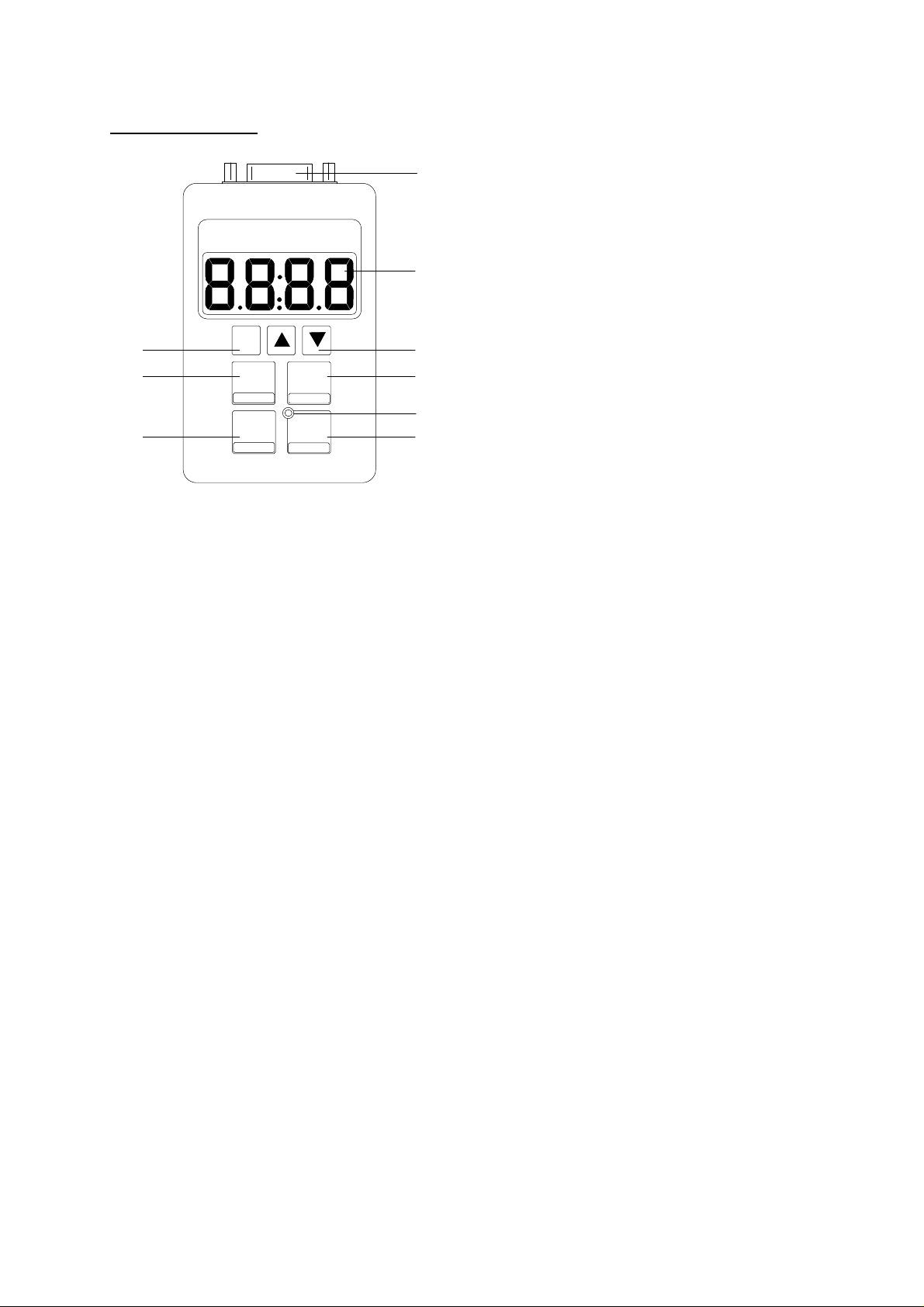

1 – Screen

2 – « Arrow » keys

F

CAL

SP

kg / ha

2 « Arrow » keys

3 « Function » key

MDC

+

STEP %

-100%

REF

1

3 – « Function » key

4 – « Plus » key

5 – « Flow control » key

23

45

6

78

?? Modification of the value.

?? Sets system by pressing this key when switching

on.

?? Second function of keys when pressing this key

simultaneously.

?? Store the selected function by pressing and

holding

6 – « Movement » display

7 – « Minus » key

8 – « 100% application rate » key

9 – Standard connection socket

4 « Plus » key

5 « Flow control » key

6 « Movement » display

7 « Minus » key

8 « 100% application rate » key

?? Increase in % of the application rate.

?? Setting the application rate monitoring level (dual

function key).

?? Setting the seed type (small or large seeds).

?? Programming the opening for carrying out a flow

control .

?? Setting the null flow rate (dual function key).

?? LED lights when metering unit rotates.

?? Reduction in % of the application rate.

?? Setting the point of reference (double function).

?? Adjustment to the nominal application rate

(100%)

?? Programming the application rate (dual function

key)

3

Page 5

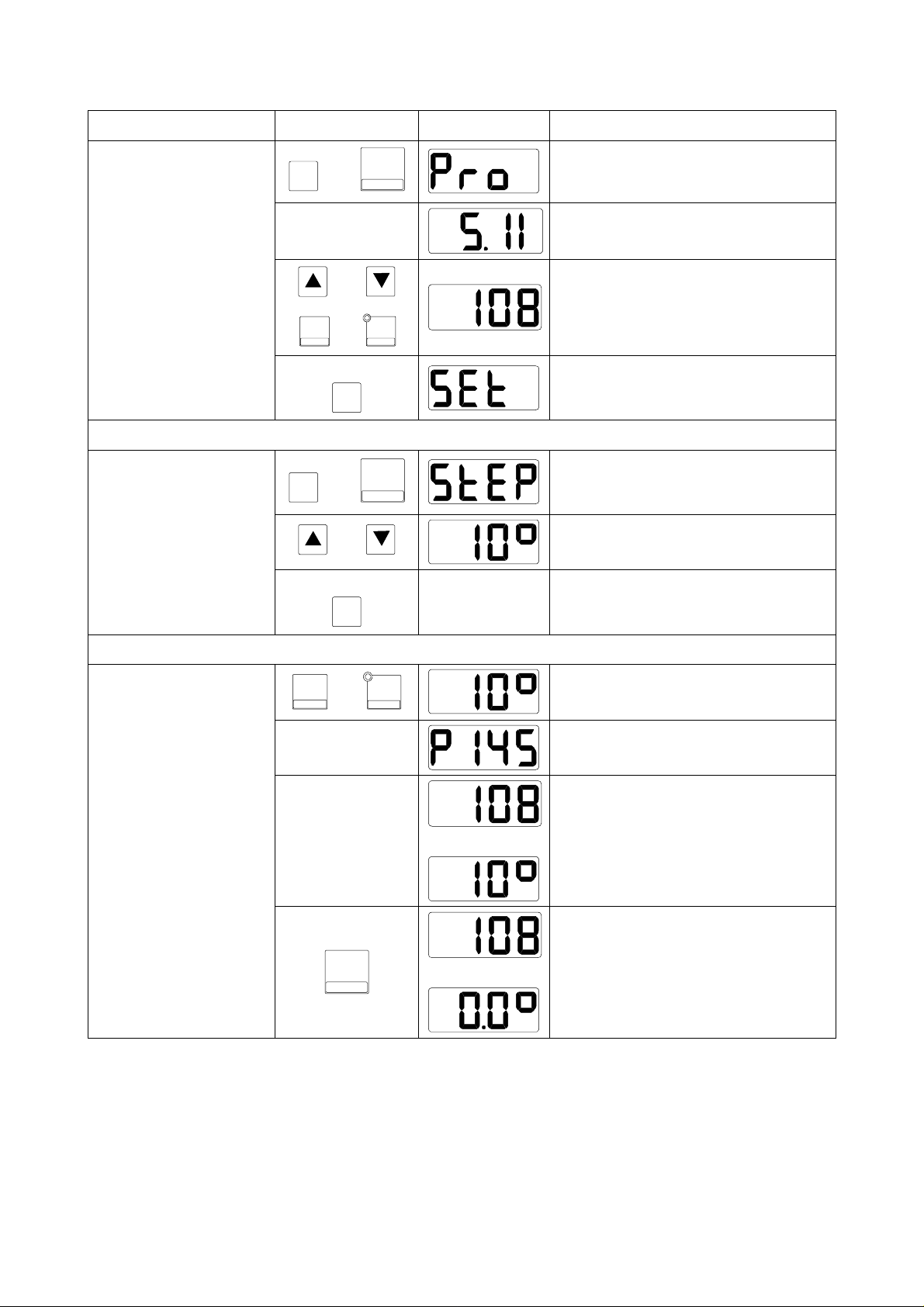

B Summary of use

When moving the metering unit by more than 30 mm, rotate metering

unit to avoid crushing seeds !

IMPORTANT

Action

Checking the opening position

(task to carry out at

work begin, in case

of seed change, at

least once per day)

When seeding in « small seed » position, the control box must also be

set on the « small seed » position!

Control Screen Result

Automatically goes to next screen

after 2 seconds

Metering unit moves to the required

opening

Automatically goes to next screen

after 2 seconds

F

and

and

F

-

REF

Calibration of the

seed type

Setting the opening

(flow control)

or

or

3 seconds

F

3 seconds

CAL

SP

or

3 seconds

F

or

Setting an opening position

Storing the opening

Automatically goes to next screen

after 2 seconds

Setting « small seeds »

Setting « large seeds »

Storing the choice of seed type

Setting the metering opening according to chart

F

or

or

F

-

REF

4

+

STEP %

3 seconds

Programming the nominal application rate /ha !

Automatically goes to next screen

after 2 seconds

Entering weight in kg/ha

Storing the collected weight

Page 6

Action

Setting the nominal

application rate /ha

(100%)

Control Screen Result

Automatically goes to next screen

after 2 seconds

Automatically goes to next screen

after 2 seconds

F

and

100%

kg / ha

Setting the application rate monitoring

level

Adjustment of the

application rate (in

%)

+

STEP %

3 seconds

F

3 seconds

+

STEP %

or

-

REF

ou

F

+

STEP %

and

or

F

-

REF

or

Setting the nominal application rate

(100 %) in kg/ha

Storing the nominal application rate

Automatically goes to next screen

after 2 seconds

Adjustment of the level to

5%, 10% or 15%

Storing the monitoring level

The application rate is adjusted of

the displayed level (max. ? 60%)

The metering unit position is displayed for 2 seconds

The adjusted application rate and

100%

kg / ha

alternately

alternately

the adjustment level are displayed

alternately.

Setting the nominal application rate

5

Page 7

The MDC control box is supplied by a 3 pin plug

O 12369) connection onto the tractor

posed

tween

the tractor and the machine, a sensor and a driving

pin

pin plug (5) if

ctric power supply is

3 2 4 5 6

7

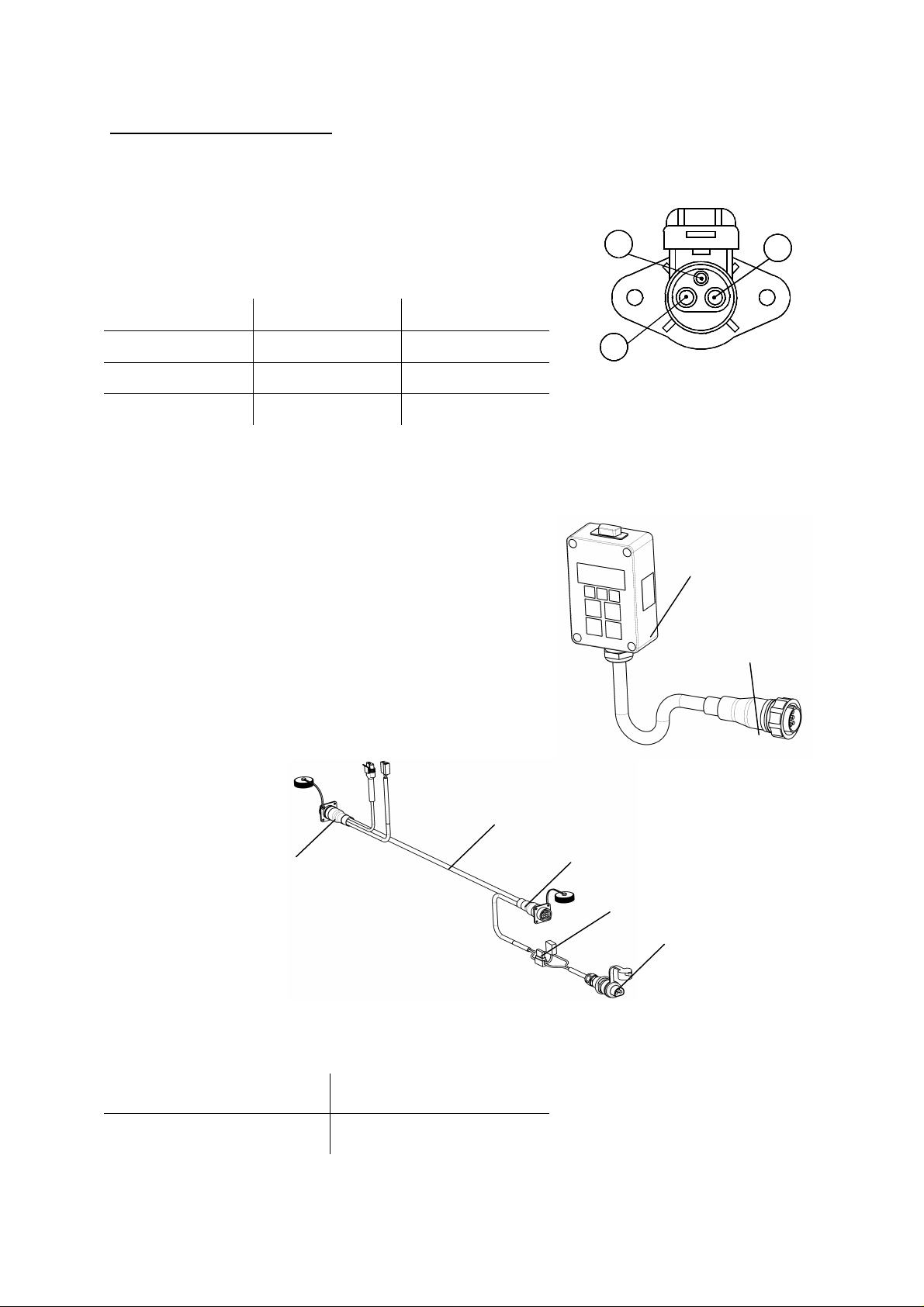

C System description

C 1 Electric power supply

(DIN 9680, IS

network

Pin number Wire colour Function

15 / 30 Brown + 12 Volt

31 Blue Mass

81 - Not used

C 2 Design

The MDC electronic monitoring system is com

of a control box (1), a wiring harness (2) be

motor.

The MDC control box is connected either by its 9-

plug (3) in the cabin to the 9-pin plug (4) of the wiring harness connector or on the 9moved to the machine. The ele

made through plug (6).

The control box is protected by a fuse of 15 A (7).

1

15/30

31

82

2

3

1

Recommended distance of sensor (with regards

to the notched wheel metal stud)

Sensor Distance

From motor position 0,4 – 0,8 mm

6

Page 8

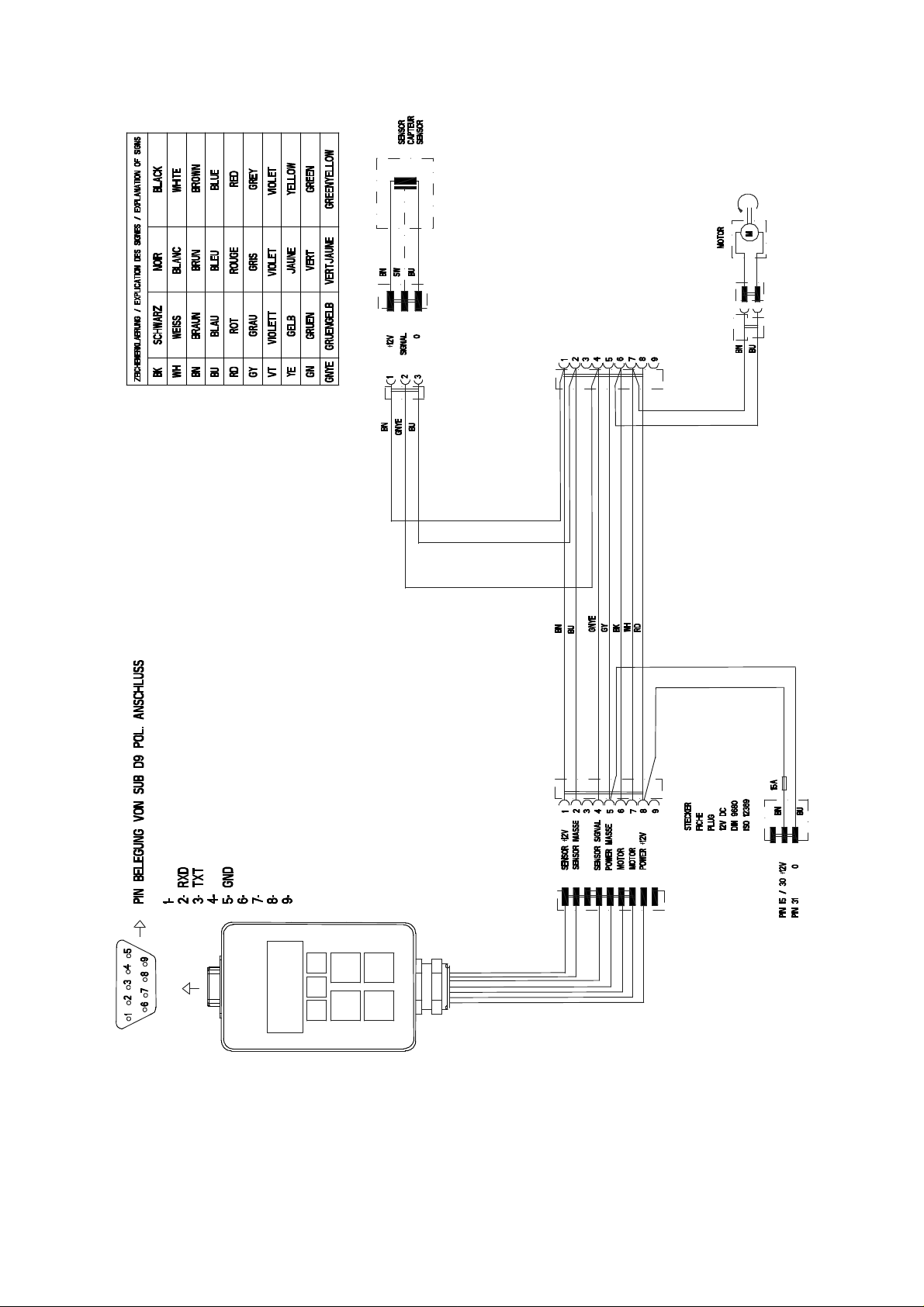

VENTA MDC connection plan

7

Page 9

D Work and display settings

The following settings and displays are vital (bold) or can be made in view of the work to

carry out :

1) Setting the point of reference

2) Calibration of the opening (flow control)

3) Programming the nominal seed application rate (100%)

4) Adjusting the metering unit to the nominal seed application rate

5) Programming the seed application rate adjustment level

6) Distribution adjustment of the chosen seed application rate

7) Setting the null flow rate (in case of maintenance)

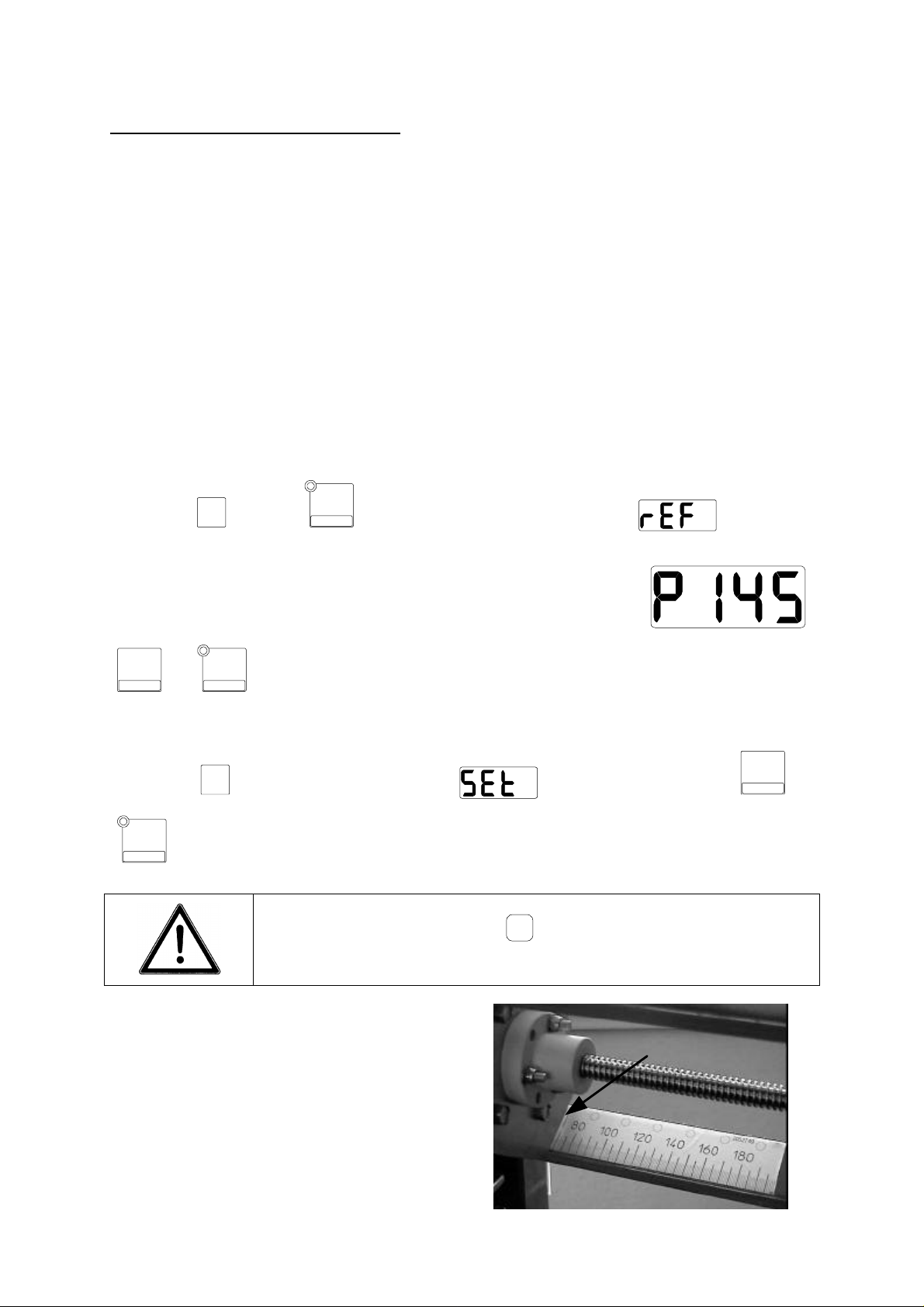

D 1 Setting the point of reference

Should their be a power cut during a motor manoeuvre or due to its removal, the point of

reference must be newly calibrated.

It must be checked at work begin, when changing the seed type or at least once a day!

Press key

The screen displays the theoretical point of reference: it must be

adjusted to an identical position corresponding to the current real

opening position of the metering unit.

+

STEP %

or

easier reading of the graduation). This manoeuvre is not compulsory !

and key

-

REF

keys enable changing the metering unit opening position (for ex. : for an

F

-

REF

to recalibrate the point of reference:

F

Press key

-

REF

to obtain the required value.

: the screen briefly displays . Now, modify with keys

Store this value by pressing

flashes briefly!

F

key for 3 seconds until the display

+

STEP %

or

1

1) Metering unit position (ex. : 70)

8

Page 10

D 2 Calibration of the opening (flow control)

CAL

Press for approx. 3 seconds key

(selection of the seed type, choice of opening for the flow control).

For seeding with the metering unit in « small seed » position

(rapeseed, clover, rye-grass,… i.e. with metering unit reduc-

SP

to carry out calibration for the flow control

tion slide engaged), the MDC must also be set on « small

seed » position if you do not want to risk damaging the me-

IMPORTANT

tering unit during work !

D 2.1 Setting the seed type

Use keys to select the seed type:

Small seed (clover, rapeseed, grass, etc.)

Large seed (wheat, barley, peas, horse beans, etc,)

Store this value by pressing

play flashes briefly!

F

key for 3 seconds until the dis-

The type of seeds memorized is briefly displayed on the screen:

Small seed (clover, rapeseed, grass, etc.)

Large seed (wheat, barley, peas, horse beans, etc,)

9

Page 11

the

D 2.2 Setting the opening

The current value of the metering unit position is displayed:

Opening position

Select from the adjustment chart the required opening in order to carry out a flow

control. It depends of the seed type and the required application rate (ex. : rate required in wheat 180 kg/ha, opening position at 90).

-

REF

to reach the desired opening position.

Use key

IMPORTANT

Press key

+

STEP %

or key

When moving the metering unit by more than 30 mm, rotate

F

metering unit to avoid crushing seeds !

to go onto the next step.

D 2.3 Flow control

After having selected the opening and pressed on key

screen briefly displays the scale symbol :

You may now carry out the flow control (see seed drill operator’s manual).

Weigh the quantity collected during test, convert it in kg/ha and enter it using

F

keys .

Store this value by pressing

play flashes briefly!

10

F

key for 3 seconds until the dis-

Page 12

The nominal seed application rate must now be programmed by pressing on key

100%

F

and at the same time briefly on key

NOTE : An alarm is displayed if the metering unit opening limits are reached when

setting the nominal application rate. The desired value cannot be reached, the screen

shows alternately the obtained seed application rate and the corresponding adjustment level.

kg / ha

.

D 3 Programming the nominal application rate (100%)

To programme the nominal application rate (i.e. the average value or 100%) press

100%

key

F

together with key

kg / ha

. The screen briefly displays

+

Use keys or

application rate in kg/ha.

Example of nominal seed application rate in kg/ha

Note: a message appears if the metering unit opening limits are reached when programming the application rate, the maximum seed application rate which can be

reached will be displayed.

Alarm Point of Limit « small seed » reached

STEP %

or keys or

Store this value by pressing

stored when the display shows before switching to the

work screen!

-

REF

to display the desired nominal

F

key for 3 seconds, the value is

Alarm Point of Limit « large seed » reached

11

Page 13

tion that the metering unit opening limit is not reached.

D 4 Adjustment to the nominal application rate (100%)

100%

Press key

kg / ha

to adjust the metering unit opening to the nominal application rate.

D 5 Setting the application rate monitoring level

The monitoring level in % can be adjusted by pressing key

+

STEP %

key

Use keys

15%.

.

+

STEP %

-

and

REF

to choose the adjustment level in steps of 5%, 10% or

Store this value by pressing

play flashes briefly!

F

key for 3 seconds until the dis-

D 6 Adjustment in % of the application rate at work

+

Use keys

application rate.

STEP %

or

-

REF

to adjust the nominal seed application rate to a different

F

together with

The display alternately shows the application rate reached and

the current adjustment level :

The maximum seed application rate adjustment range is ± 60%

on condi

An alarm appears if the opening limits are reached, the maximum seed application

rate which can be reached and the corresponding adjustment level will show alternately.

Alarm Point of Limit « small seed » reached

Alarm Point of Limit « large seed » reached

12

Page 14

This programming must imperatively be made for SP1 and

D 7 Setting the null flow rate:

This adjustment is specific to the seed drill type (mechanical or pneumatic) and is

only to be carried out when fitting the equipment or should the MDC control box

be replaced.

The calibrations of the null flow rate (in small or large seeds) is carried out by press-

CAL

SP

.

ing simultaneously on keys

F

and

F

Use keys to choose the one to programme. Press key

+

or

Value of the null flow rate in « small

seeds » for VENTA seed drills

Value of the null flow rate in « large

seeds » for VENTA seed drills

STEP %

-

REF

to modify these values.

??

SP2.

and use keys

?? Store this value by pressing

the display flashes briefly!

F

key for 3 seconds until

13

Page 15

E Connections with a « MASTER » terminal (GPS mode)

The standard connection plug enables connecting the MDC control box to a terminal.

This link enables monitoring the application rate within the field (Precision Farming).

The GPS positioning and the corresponding application rate are transmitted by the

« master » terminal to the MDC control box.

Depending on the « master » terminal, the MDC control box will transmit in return

information on the work achieved, to the « master » terminal. Information on the use

of the « master » terminal is indicated in its operator’s manual.

E 1 Description

Following terminals, fitted with a standard RS232 plug, can be connected using a

cable 0 Modem Sub D9 (female/female) for connection to the MDC control box. The

wiring plan in the cable can be checked at point C2.

PRO SERIES

(RDS)

(AGROTRONIX)

FIELD

OPERATOR

(WTK)

ACT

(MÜLLER /

CLAAS)

cable 0 Modem Sub D9 (fe-

male/female)

MDC Control box

FIELDSTAR

(AGCO)

14

Page 16

E 2 Work and display settings

Prior to connecting the terminal and the MDC control box, select the connection

protocol in the « master » terminal.

This protocol is in one way the « language » which will enable communication between both control boxes. Refer to the « master » terminal operator’s manual to adjust this selection.

« Master » Terminal Connection protocol

PRO SERIES 8000 (RDS) Modus B, FIELDSTAR

AGRO PILOT (AGROTRONIX) MDC

FIELD OPERATOR (WTK) FIELDSTAR

ACT 2-40 (MÜLLER / CLAAS) LH AGRO

FIELDSTAR (AGCO) FIELDSTAR

The MDC monitoring must be calibrated prior to the connection with the « master »

terminal, see points D1 to D7 in this manual.

The MDC control box keys are secured and are therefore inaccessible when working

in GPS mode.

If the connection is properly made between both control boxes,

the display shows the symbol opposite. Furthermore the LED

light flashes on the control box.

When switching off the « master » terminal, removing the connection cable or if there is a connection breakdown between

the 2 control boxes, the MDC control box screen displays the

symbol opposite after 10 seconds. The LED light is off.

The LED light is on without flashing if the « master » terminal modifies the application

rate and the motor adjusts the opening.

15

Page 17

Note: a message appears if the metering unit opening limits are reached when adjusting the seed application rate, the rate planned in GPS cannot be reached.

Alarm Point of Limit « small seed » reached

Alarm Point of Limit « large seed » reached

F System adjustment and calibration

Adjustments relative to the system’s good functioning can be accessed by pressing

key

can be checked and modified if necessary:

To go onto the next point to check/modify, press key

To leave this menu, press any other key.

To adjust the amperage limit, simultaneously press key and activate the control

box (12 V).

To adjust the maximum functioning time under maximum amperage, simultaneously

F

and simultaneously placing it under a 12 Volt tension. Following parameters

1) Opening pulses

2) Opening limit points

3) Checking the display screen

4) Checking the sensor

5) Checking the motor and pulses

Store these values by pressing

display flashes briefly!

F

key for 3 seconds until the

F

.

press key and activate control box (12V).

F 1 Adjusting the opening pulses

Use keys and to modify the displayed values:

16

Page 18

Adjustment for VENTA seed drills : 100 (100 pulses from the

impulse wheel with 30 teeth for a 10 mm metering unit movement)

Store these values by pressing

To go onto the next point to check/modify, press key

To leave this menu, press any other key.

display flashes briefly!

F

key for 3 seconds until the

F

.

F2 Adjustment of opening limit points

The maximum opening values of the metering unit must be programmed for the

« small seed » and « large seed » position.

+

Use keys or

the metering unit limit points according to the metering unit position. To go onto the

next screen, press key

STEP %

F

.

-

REF

to modify the displayed values corresponding to

Position (for VENTA) Display Required value

Minimum position

Position of limit « small

seed »

Position of limit « large

seed »

Store these values by pressing

To go onto the next point to check/modify, press key

To leave this menu, press any other key.

display flashes briefly!

F

key for 3 seconds until the

F

.

17

Page 19

F 3 Screen test

Press key

limit points to check the proper functioning of the screen

F

for 2 seconds after having adjusted the opening

F 4 Rotation sensor test

This test is automatically activated after the screen test. Check if the display changes

when metal passes in front of the sensor:

Sensor Display

Sensor deactivated

Sensor activated

To go onto the next point to check/modify, press key

To leave this menu, press any other key.

F

.

F 5 Motor test and sensor pulse count

+

Press keys

The number of pulses is displayed on the screen: it must increase or decrease according to the metering unit movement.

When moving the metering unit, pay attention to the pulse count. If the display

does not change: check the sensor/tooth wheel distance (0,4 to 0,8 mm) and

the sensor connection.

STEP %

and

-

REF

to open or shut the metering unit splines.

To go onto the next point to check/modify, press key

To leave this menu, press any other key.

18

F

.

Page 20

F6 Setting the maximum authorized amperage

To adjust the amperage limit, simultaneously press key and activate the control

box (12 V).

The keys now enable modifying the value indicated on the screen:

Adjustment for VENTA : 6A

Store this value by pressing

play flashes briefly!

F

key for 3 seconds until the dis-

F7 Adjustment of maximum functioning time under maximum a mperage

To adjust the maximum functioning time under maximum amperage, simultaneously

press key and activate control box (12V).

The keys maximum functioning time under maximum amperage:

Adjustment required for VENTA : 1.0 (1.0 second maximum

amperage)

Store this value by pressing

play flashes briefly!

19

F

key for 3 seconds until the dis-

Page 21

G Trouble shooting guide

Display Description of the incident or default

Closed position of the metering unit reached

“small seed” Opening limit position reached

“large seed” Opening limit position reached

Maximum functioning time under maximum amperage rea-

ched.

The motor must have reached an opening position stop.

The point of reference must be calibrated (see point D1).

The motor is perhaps jammed due to a foreign body:

check the metering unit, the point of reference must be

calibrated (see point D1).

No sensor signals although the 12 V motor rotates.

Check sensor: attachment, distance to the tooth wheel

(distance 0.4 – 0.8 mm). The point of reference must be

calibrated (see point D1).

The sensor is damaged: replace it and calibrate the point

of reference (see point D1).

In case of a control box defect, the hood covering the gearwheels which connect the

motor to the metering unit can be removed. Then turn gearwheel by hand to obtain

the desired metering unit opening.

After repair and depending on the part replaced, check all

parameters described in points F6, F7, F1, F2, F3, F4 , F5

IMPORTANT

and then D1 (calibration of the point of reference). !

20

Page 22

H Symbols

When activating functions or in case of incidents, the following symbols may appear :

below a summary of their signification :

Symbols Signification

Metering unit position : 145

Adjustment percentage applied : – 10%

Adjustment of opening pulses

Adjustment of the shutting point of limit

Adjustment of the « small seed » opening point of limit

Adjustment of the « large seed » opening point of limit

Sensor and motor test

Start of the flow control menu

Small seed setting

Large seed setting

Memorizing the « small seed » setting

Memorizing the « large seed » setting

Setting the « small seed » null flow rate

Setting the « large seed » null flow rate

Prior to memorizing the weight collected during test

Memorizing the nominal application rate

21

Page 23

Setting the point of reference

Memorizing the nominal application rate

Functioning time under maximum amperage reached

No signal from sensor

Connection with GPS terminal

Connection defect with the GPS terminal

Setting the maximum authorized amperage (6 amperes)

Adjustment of the maximum functioning time under maximum

amperage (1 second)

22

Page 24

LIMITED WARRANTY

KUHN S.A. of 4 Impasse des Fabriques, 67706 SAVERNE CEDEX, France (hereinafter called the

«Company») warrants, in accordance with the provisions below, to each original retail purchaser of

KUHN new equipment of its own manufacture, from an authorized KUHN dealer, that such equipment

is, at the time of delivery to such purchaser, free from defects in material and workmanship and that

such equipment will be warranted for a period of one year starting from the date the goods are delivered

to the end user and during this period up to a limit of 500 hours use, providing the machine is used and

serviced in accordance with the recommendations in the Operator’s Manual.

THESE CONDITIONS ARE SUBJECT T O THE FOLLOWING EXCEPTIONS :

1. Parts of machines which are not of our manufacture i.e. tyres, belts, P.T.O. shafts, clutches etc., are not

covered by this Limited Warranty but are subject to the warranty of the original manufacturer. Any claim

falling into this category will be taken up with the manufacturer concerned.

2. Warranty claims applying to these types of parts must be handled in the same way as if they were parts

manufactured by KUHN. However, compensation will be paid in accordance with the warranty agreement of the manufacturer concerned in as much as the latter justifies such a claim.

3. This Limited Warranty will be withdrawn if any equipment has been used for purposes other than for

which it was intended or if it has been misused, neglected or damaged by accident or let out on hire. Nor

can claims be accepted if parts other than those manufactured by us have been incorporated in any of

our equipment. Furthermore, the Company shall not be responsible for damage in transit or handling by

any common carrier and under no circumstances within or without the warranty period will the Company

be liable for damages for loss of use or damages resulting from delay or any consequential damage.

We cannot be held responsible for loss of earnings caused by a breakdown or for injuries either to the owner

or to a third party, nor can we be called upon to be responsible for labor charges, other than originally

agreed, incurred in the removal or replacements of components.

THE CUSTOMER WILL BE RESPONSIBLE FOR AND BEAR THE COSTS OF:

1. Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc.

2. Transportation of any kind of any KUHN product to and from the place the warranty work is performed.

3. Dealer travel time to and from the machine or to deliver and return the machine from the workshop for

repair.

4. Dealer travelling costs.

Parts defined as normal wearing items are listed as follows and are not in any way covered under this

Limited Warranty :

V belts, discs, knives, wear plates, disc guards, tires, torque limiters, hydraulic hoses, pitman shafts, swath

sticks, blades, tines and tine holders.

KUHN Limited Warranty will not apply to any product which is altered or modified without the expressed

permission of the Company and/or repaired by anyone other than Authorized Service Distributors or

Authorized Service Dealers.

Page 25

LIMITED WARRANTY IS DEPENDENT UPON THE STRICT OBSERVANCE BY THE

PURCHASER OF THE FOLLOWING PROVISIONS :

- That this Limited Warranty shall not be assigned or transferred to anyone unless the Company’s consent in

writing has first been obtained.

- The warranty/product registration form has been correctly completed by dealer and purchaser with their

names and addresses, dated, signed and returned to the appropriate address as given on the warranty/

product registration form.

- The claim form sent to KUHN has been correctly completed stating:

* dealer’s name and address

* owner’s name and address

* type of machine

* machine serial number

* delivery date to buyer

* date of failure

* tractor make and type

* description of the failure and its cause

* quantity , reference number and name of the damaged p art s

* reference number, quantity and date of the invoice for the replacement p arts.

- The judgement of the Company in all cases of claims under this Limited Warranty shall be final and conclu-

sive and the purchaser agrees to accept its decisions on all questions as to defect and to the exchange of

any part or parts.

- That all safety instructions in the Operator’s Manual shall be followed and all safety guards regularly inspected

and replaced where necessary .

No warranty is given on second-hand products and none is to be implied. Persons dealing in the Company’s

products are in no way legal agents of the Company and have no right or authority to assume any obligation

on their behalf, express implied, or to bind them in any way .

KUHN S.A. reserves the right to incorporate any change in design in its products without obligation to make

such changes on units previously manufactured.

Moreover, because of the constant progress in technology, no guarantee is given to the descriptions of

equipment published in any document by the company .

DISCLAIMER OF FURTHER WARRANTY

There are no warranties, expressed or implied, except as set forth above. There is no

warranty of merchantability. There are no warranties which extend beyond the description

of the product contained herein. In no event shall the company be liable for indirect, special

or consequential damages (such as loss of anticipated profits) in connection with the retail

purchaser’s use of the product.

Page 26

- N O T E S -

Page 27

This machine complies with the safety requirements of the European machinery directive.

The Operator should respect all Health and Safety regulations as well as the Highway

Code. For your own safety, use only genuine KUHN spare parts. The manufacturer

disclaims all responsibilities due to incorrect use or non-compliance with the

recommendations given in this manual.

Page 28

For your safety

and to get the best from your machine,

use only genuine KUHN parts

KUHN S.A. 4 Impasse des Fabriques F - 67706 SAVERNE CEDEX (FRANCE)

Tél. : + 33 (0) 3 88 01 81 00 - Fax : + 33 (0) 3 88 01 81 03

www.kuhnsa.com - E-mail : info@kuhnsa.com

Société Anonyme au Capital de 19 488 000 Euros

Printed in France by KUHN

Loading...

Loading...