Page 1

OPERATOR'S MANUAL

KN175BGB A

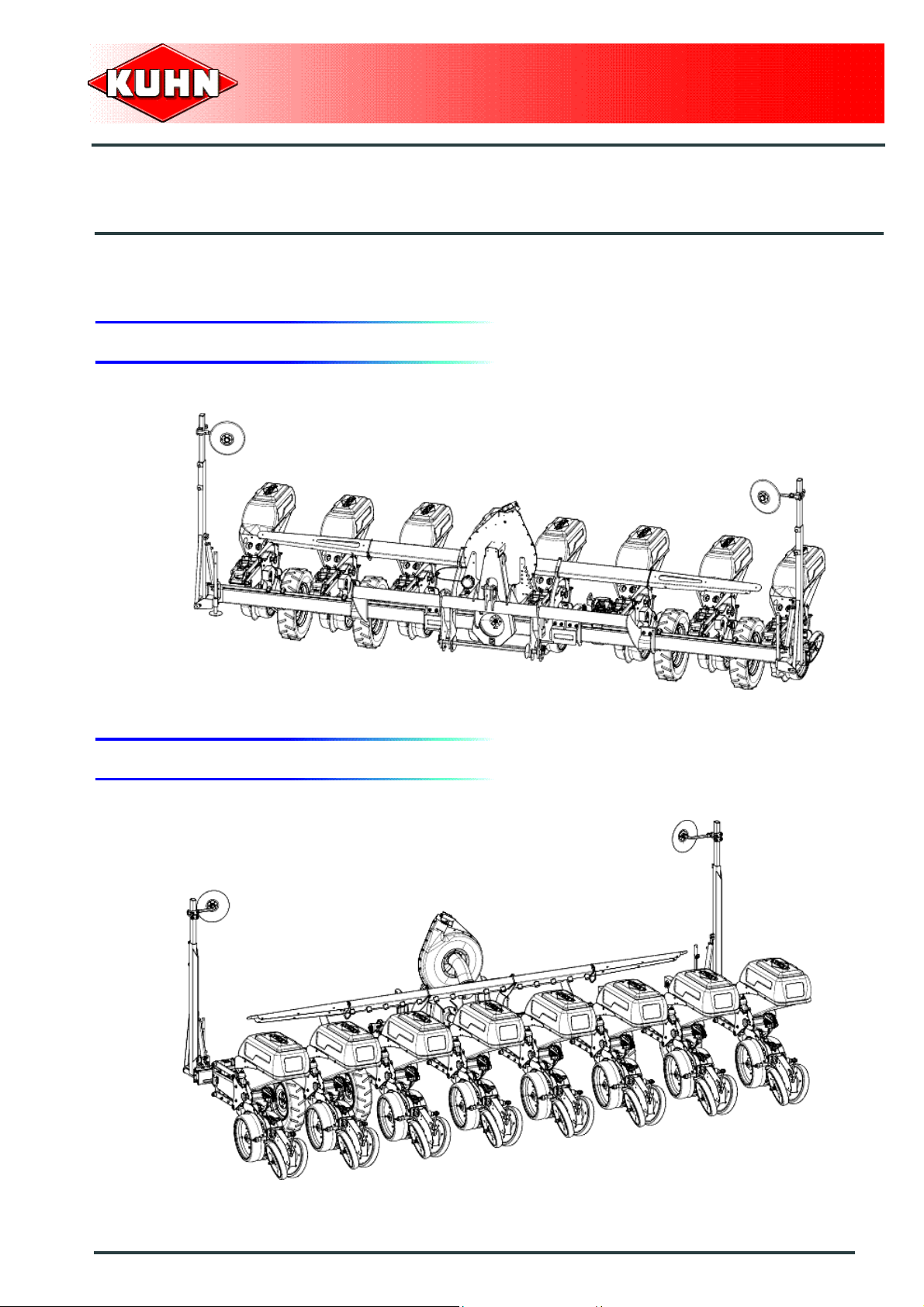

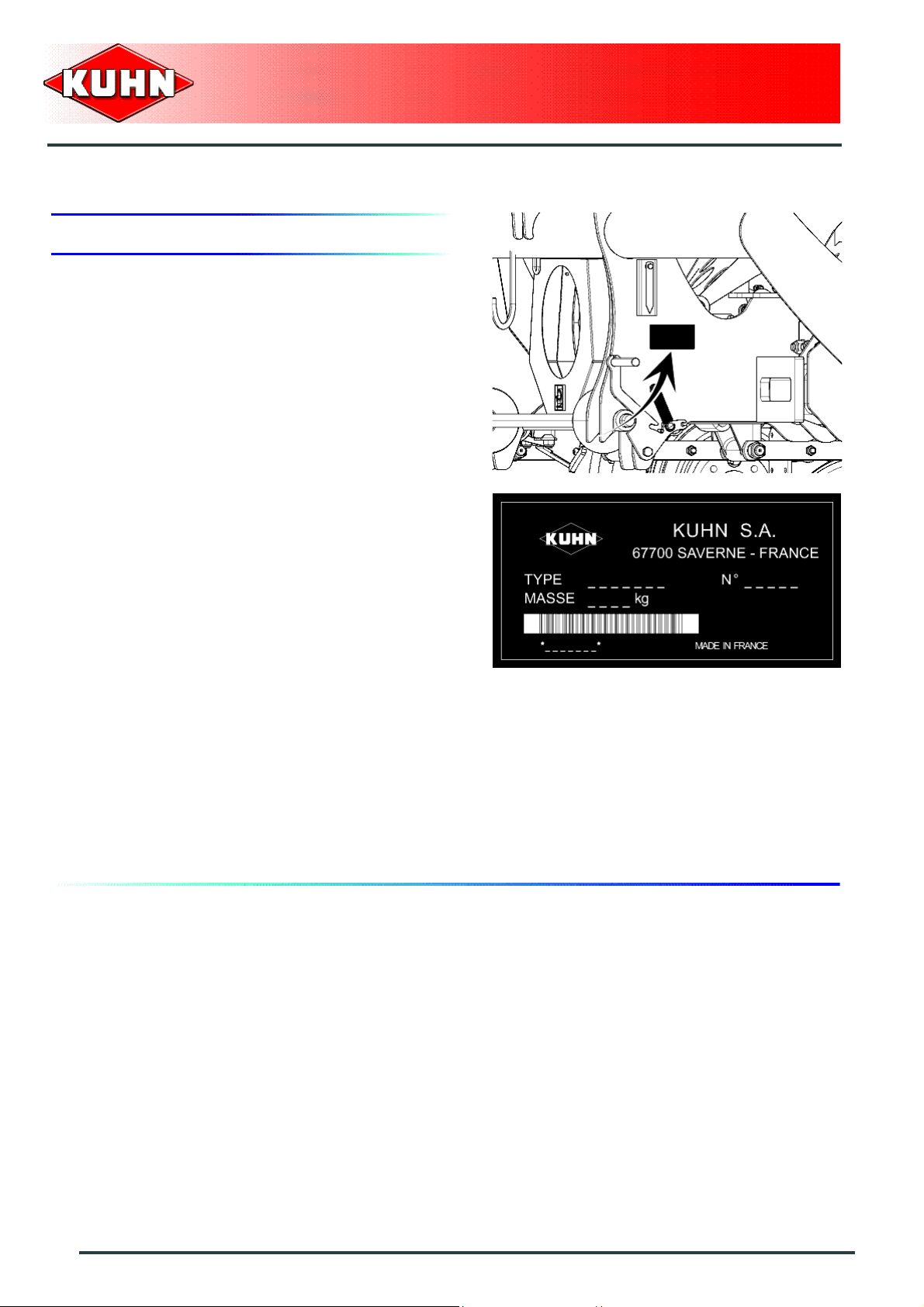

Precision Seed Drills

MAXIMA 2

Single bar frame exceeding 4.40 m

KN175BGB A

- English - 09-2008

Page 2

Page 3

Precision Seed Drills

MAXIMA 2

$DEAR OWNER

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understa nd this manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts are manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurr ing any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The MAXIMA 2 precision seed drill must only be used for work for which it has been designed:

- Precision drilling.

- Mineral fertilizer placement (depending upon equipment).

- Application of microgranules in combination with drilling (depending upon equipment).

Document illustrations

The illustrations in this manual may be based on one type of machine only. However, all instructions apply to all

machines covered in this manual.

Dear Owner

1

Page 4

Precision Seed Drills

MAXIMA 2

$CONTENTS

Dear Owner.....................................................................................................................1

Contents .........................................................................................................................2

Identification of the machine........................................................................................5

Front view (Basic machine) ............................................................................................................ 5

Rear view (Basic machine).............................................................................................................. 5

Model identification plate................................................................................................................ 6

Optional equipment................... ... ... ... .............................................. ............................................... 7

Safety............................................................................................................................16

Description of symbols used in this document............ .... ... ... ... .... ... ... ... ... .... ... ... ....................... 16

Safety instructions......................................................................................................................... 17

Location and description of safety decals on the machine....................................................... 27

Machine specifications................................................................................................30

Description and glossary.............................................................................................................. 30

General technical specifications.................................................................................................. 31

Technical specifications per model ............................................................................................. 32

Sound levels................................................................................................................................... 52

Putting into service......................................................................................................53

Description of control elements................................................................................................... 53

Control box description ................................................................................................................ 53

Coupling and uncoupling.............................................................................................................. 57

Instructions for transport............................................................................................71

Putting the machine into transport position ............................................................................... 71

Conformity with the road regulations.......................................................................................... 73

2

Contents

Page 5

Precision Seed Drills

MAXIMA 2

Instructions for work....................................................................................................74

Putting the machine into work position ...................................................................................... 74

Adjustments in working position.................................................................................................75

Machine use................................................................................................................................. 105

Optional equipment....................................................................................................114

Clod clearer................................................... ... ... ... .... .......................................... ... ... ...................118

Spring assisted clod clearer........................................................................................................119

Star shaped trash remover......................................................................................................... 121

Furrow opening disk ................................................................................................................... 123

Covering scraper......................................................................................................................... 125

Composite intermediate axial press wheel............................................................................... 126

Stainless steel intermediate axial press wheel......................................................................... 128

Furrow closing disks................................................................................................................... 131

Standard V-shaped roller............................................................................................................ 132

HD V roller.................................................................................................................................... 136

"OTIFLEX" 370 x 165 roller......................................................................................................... 141

"OTIFLEX" 500 x 175 roller......................................................................................................... 143

Left and right rear drive wheels 5 x 15 ...................................................................................... 145

Left and right rear drive wheels 6.5 x 15 ................................................................................... 145

Left and right rear drive wheels 26 x 12 .................................................................................... 145

Microgranulator ........................................................................................................................... 146

Fertilizer unit.................... .......................................... ... ... ... .... ..................................................... 164

Low flow kit for the fertilizer unit ............................................................................................... 180

Filling auger ................................................................................................................................. 181

Distribution disks ........................................................................................................................ 183

Rear PTO output stub...................................... ... ... .... ... ............................................................... 184

Vacuometer.................................................................................................................................. 185

HECTOR 3000 electronic control box......... ... ... ... .... ... ... ... .... ... ... ... ... ......................................... 185

Contents

3

Page 6

Precision Seed Drills

MAXIMA 2

Passage control box kit KMS208................................................................................................ 185

Sowing control box kit KMS412 ................................................................................................. 186

Electronic disengagement kit..................................................................................................... 186

65 x 400 depth control wheels.................................................................................................... 187

45 mm (1.8 ’’) spacer and 5 mm (0.2’’) levelling pad................................................................. 187

82 mm (3.2’’) spacer and 5 mm (0.2’’) levelling pad.................................................................. 187

Wheel footbridges............................... .... ... ... ... ... .... ... ... ... .... ... ... .................................................. 188

Track eradicators......................................................................................................................... 189

Marker working depth limitors.................................................................................................... 190

Mechanical hectare counter........................................................................................................ 191

Maintenance and storage..........................................................................................193

Frequency chart........................................................................................................................... 193

Cleaning the machine.................................................................................................................. 195

Lubrication ................................................................................................................................... 196

Maintenance................................................................................................................................. 198

Storage.......................................................................................................................................... 207

Trouble shooting guide .............................................................................................209

Limited warranty........................................................................................................212

4

Contents

Page 7

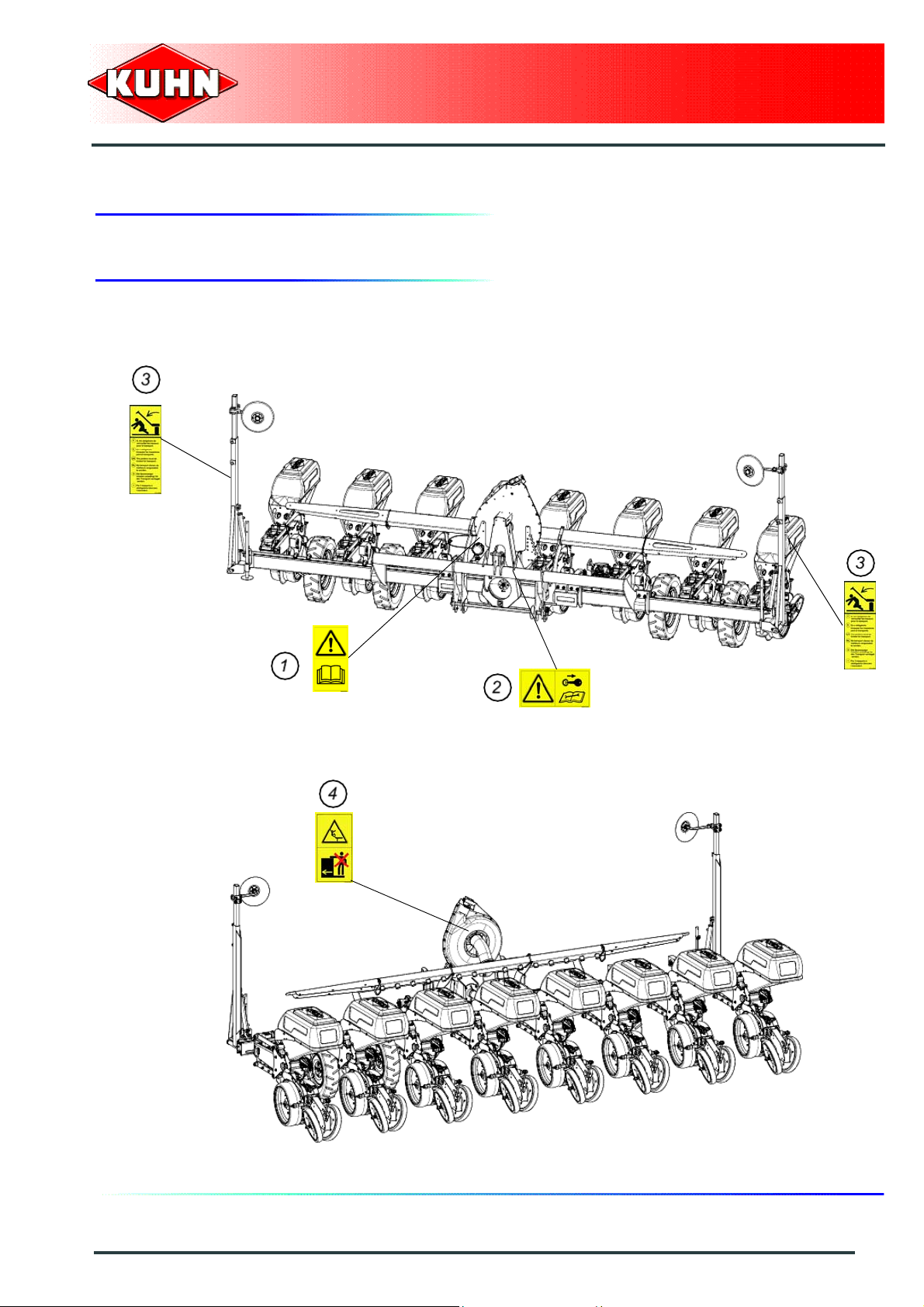

$IDENTIFICATION OF THE MACHINE

1. Front view (Basic machine)

Precision Seed Drills

MAXIMA 2

2. Rear view (Basic machine)

Identification of the machine

5

Page 8

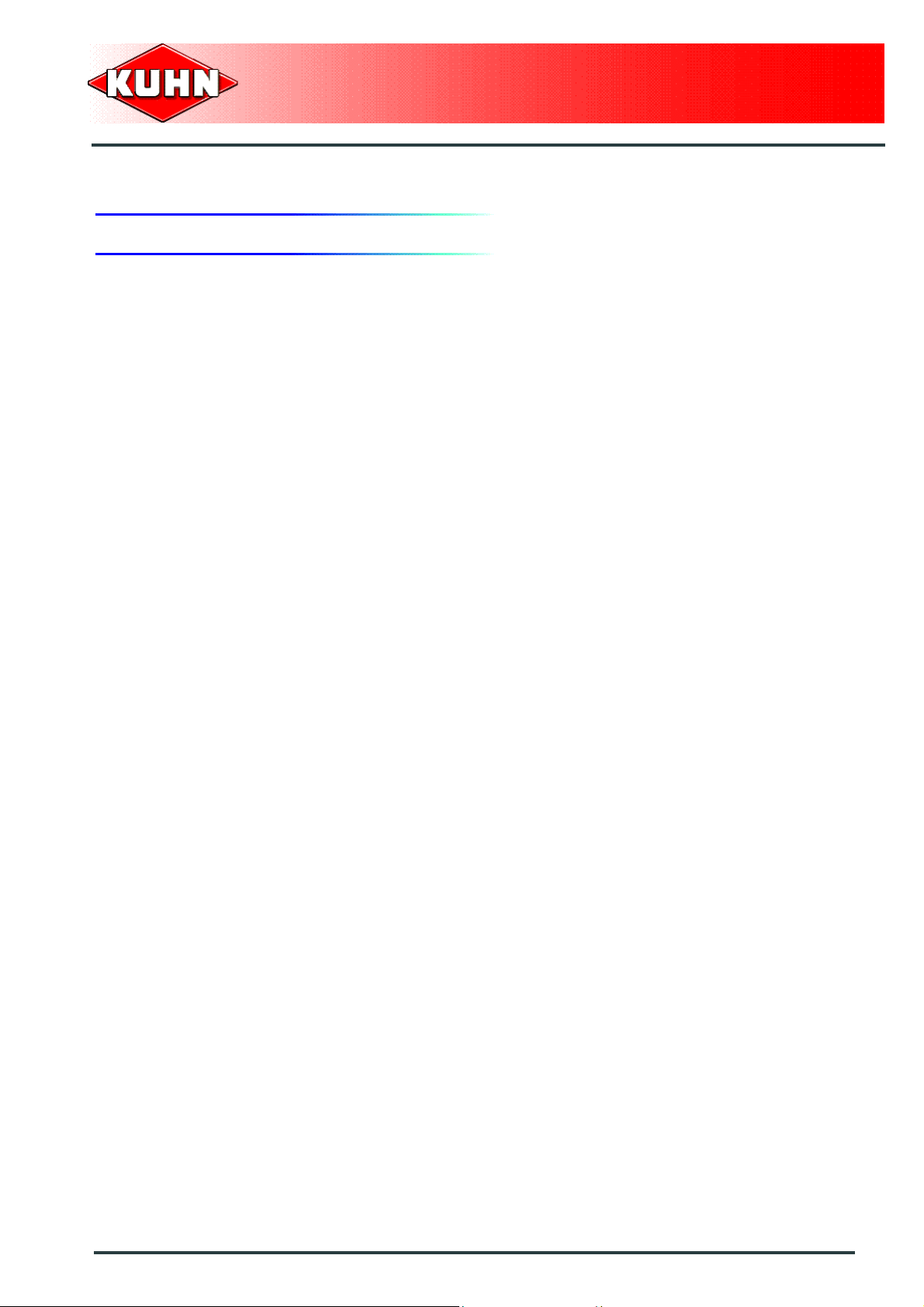

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Precision Seed Drills

MAXIMA 2

Type: MAXIMA 2

Serial no.:

6

Identification of the machine

Page 9

4. Optional equipment

Tick box corresponding to the equ ipment fitted on your

machine:

Sowing component

Kit no. 1676801: Clod clearer with disk coulter for * 1 gauge wheels.

Kit no. 1676802: Clod clearer with disk coulter for * 1 gauge wheels.

Kit no. 1676803: Spring assisted clod clearer.

Kit no. 1676783: Star shaped trash remover.

Kit no. 1676775: Opener disc solo.

Precision Seed Drills

MAXIMA 2

Kit no. 1676780: Furrow opening disk with star-shaped trash remover.

Kit no. 1676761: Covering scraper.

Kit no. 1676762: Composite intermediate axial press wheel.

Kit no. 1676766: Stainless steel intermediate axial press wheel.

Kit no. 1676790: Furrow closing disks.

Kit no. 1677235: Standard Rubber V roller 1’’.

Kit no. 1677234: Standard Rubber V roller 2’’.

Kit no. 1677237: Standard smooth steel V roller.

Kit no. 1677236: Standard notched steel V roller.

Kit no. 1677241: HD Rubber V roller 1’’.

Kit no. 1677240: HD Rubber V roller 2’’.

Kit no. 1677239: HD smooth steel V roller.

Kit no. 1677238: HD notched steel V roller.

Kit no. 1676757: 370 x 165 OTIFLEX roller and covering scrapers.

Kit no. 1676859: 370 x 165 OTIFLEX roller and furrow closing disks.

Kit no. 1676758: 500 x 175 OTIFLEX roller and covering scrapers.

Kit no. 1676863: 500 x 175 OTIFLEX roller and furrow closing disks.

Identification of the machine

7

Page 10

Drive

Kit no. 1676503: Left and right rear drive wheels 5 x 15.

Kit no. 1676502: Left and right rear drive wheels 6.5 x 15.

Kit no. 1676501: Left and right rear drive wheels 26 x 12.

Microgranulator

For the following models:

M2B12MB600C001

M2B12MB600C002

M2M12MB900C002

First equipment microgranulator

Precision Seed Drills

MAXIMA 2

Kit no. 1677175: Insecticide microgranulator 12 rows, 2x80 L (2x21 US gal) hoppers with front blower and fitting

on air duct.

Kit no. 1677176: Slug pellet microgranulator 12 rows, 2x80 L (2x21 US gal) hoppers with front blower and fitting

on air duct.

Kit no. 1677177: Herbicide microgranulator 12 rows, 2x150 (2x40 US gal) hoppe rs with front bl ower and fitting on

air duct.

Second equipment microgranulator

Kit no. 1677178: Insecticide microgranulator 12 rows, with 2x80 L (2x21 US gal) hoppers and fitting on air duct.

Kit no. 1677179: Slug pellet microgranulator 12 rows, with 2x80 L (2x21 US gal) hoppers and fitting on air duct.

Kit no. 1677180: Herbicide microgranulator 12 rows, with 2x150 (2x40 US gal) hoppers and fitting on air duct.

For the following models:

M2B12MB600CG01

M2B12MB600CG02

M2M12MB900CG02

First equipment microgranulator

Kit no. 1677181: Insecticide microgranulator 12 rows with 2x80 L (2x21 US gal) hoppers and upper fitting.

Kit no. 1677182: Slug pellet microgranulator 12 rows with 2x80 L (2x21 US gal) hoppers and upper fitting.

Kit no. 1677183: Herbicide microgranulator 12 rows with 2x150 L (2x40 US gal) hoppers and upper fitting.

8

Identification of the machine

Page 11

Precision Seed Drills

MAXIMA 2

For the following models:

M2B18MB900C001

M2B18MB900C002

First equipment microgranulator

Kit no. 1677184: Insecticide microgranulator 18 rows, 2x100 L (2x26 US gal) hoppers with front blower an d fitting

on air duct.

Kit no. 1677185: Slug pellet microgranulator 18 rows, 2x100 L (2x26 US gal) hoppers with front blowe r and fitting

on air duct.

Kit no. 1677186: Herbicide microgranulator 18 rows, 2x190 (2x50 US gal) hoppers with front blower and fitting o n

air duct.

Second equipment microgranulator

Kit no. 1677187: Insecticide microgranulator 18 rows, with 2x100 L (2x26 US gal) hoppers and fitting on air duct.

Kit no. 1677188: Slug pellet microgranulator 18 rows, with 2x100 L (2x26 US gal) hoppers and fitting on air duct.

Kit no. 1677189: Herbicide microgranulator 18 rows, with 2x190 (2x50 US gal) hoppers and fitting on air duct.

For the following models:

M2M08MB600C002

First equipment microgranulator

Kit no. 1677163: Insecticide microgranulator 8 rows, 100 L (2x26 US gal) hopper with front blower and fitting on

air duct.

Kit no. 1677164: Slug pellet microgranulator 8 rows, 100 L (26 US gal) hopper with front blower and fitting on air

duct.

Kit no. 1677165: Herbicide microgranulator 8 rows, 190 (50 US gal) hopper with front blower and fitting on air duct.

Second equipment microgranulator

Kit no. 1677139: Insecticide microgranulator 8 rows with 100 L (26 US gal) hopper and fitting on air duct.

Kit no. 1677140: Slug pellet microgranulator 8 rows with 100 L (26 US gal) hopper and fitting on air duct.

Kit no. 1677292: Herbicide microgranulator 8 rows with 190 L (50 US gal) hopper and fitting on air duct.

For the following models:

M2M08MB600CG02

First equipment microgranulator

Kit no. 1677145: Insecticide microgranulator 8 rows with 100 L (21 US gal) hopper and fitting in high position.

Kit no. 1677146: Anti-slug pellet microgranulator 8 rows with 100 L (21 US gal) hopper a nd fitting in h igh position.

Kit no. 1677147: Herbicide microgranulator 8 rows with 190 L (40 US gal) hopper and fitting in high position.

Identification of the machine

9

Page 12

Precision Seed Drills

MAXIMA 2

Second equipment microgranulator

Kit no. 1677145: Insecticide microgranulator 8 rows with 100 L (21 US gal) hopper and fitting in high position.

Kit no. 1677146: Anti-slug pellet microgranulator 8 rows with 100 L (21 US gal) hopper and fitting in high position.

Kit no. 1677147: Herbicide microgranulator 8 rows with 190 L (40 US gal) hopper and fitting in high position.

For the following models:

M2S11MB440C002

M2S11MB440CF02

M2S11MB500C003

First equipment microgranulator

Kit no. 1677148: Insecticide microgranulator 11 rows, 2x80 L (2x21 US gal) hoppers with front blower and fitting

on air duct.

Kit no. 1677149: Slug pellet microgranulator 11 rows, 2x80 L (2x21 US gal) hoppers with front blower and fitting

on air duct.

Kit no. 1677150: Herbicide microgranulator 11 rows, 2x1 50 (2x40 US gal) hoppe rs with front bl ower and fitting on

air duct.

Second equipment microgranulator

Kit no. 1677151: Insecticide microgranulator 11 rows, with 2x80 L (2x21 US gal) hoppers and fitting on air duct.

Kit no. 1677152: Slug pellet microgranulator 11 rows, with 2x80 L (2x21 US gal) hoppers and fitting on air duct.

Kit no. 1677153: Herbicide microgranulator 11 rows, with 2x150 (2x40 US gal) hoppers and fitting on air duct.

For the following models:

M2S11MB500CG03

First equipment microgranulator

Kit no. 1677154: Insecticide microgranulator 11 rows with 2x80 L (2x21 US gal) hoppers and upper fitting.

Kit no. 1677155: Slug pellet microgranulator 11 rows with 2x80 L (2x21 US gal) hoppers and upper fitting.

Kit no. 1677156: Herbicide microgranulator 11 rows with 2x150 L (2x40 US gal) hoppers and upper fitting.

For the following models:

M2T09MB500C002

M2T09MB600C002

First equipment microgranulator

10

Identification of the machine

Page 13

Precision Seed Drills

MAXIMA 2

Kit no. 1677157: Insecticide microgranulator 9 rows, 100 L (2x26 US gal) hopper with front blower and fitting on

air duct.

Kit no. 1677158: Slug pellet microgranulator 9 rows, 100 L (26 US gal) hopper with front blower and fitting on air

duct.

Kit no. 1677159: Herbicide microgranulator 9 rows, 190 (50 US gal) hopper with front blower and fitting on air duct.

Second equipment microgranulator

Kit no. 1677160: Insecticide microgranulator 9 rows with 100 L (26 US gal) hopper and fitting on air duct.

Kit no. 1677161: Slug pellet microgranulator 9 rows with 100 L (26 US gal) hopper and fitting on air duct.

Kit no. 1677162: Herbicide microgranulator 9 rows with 190 L (50 US gal) hopper and fitting on air duct.

Fertilizer unit

For the following models:

M2B12MB600C001

M2B12MB600C002

M2M12MB900C002

Kit no. 1677327: Fertilizer 12 rows with front mounted hopper and applicators with standard Suffolk coulters.

Kit no. 1677328:Fertilizer 12 rows with front mounted hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677329: Fertilizer 12 rows with front mounted hopper and applicators with non-stop disk coulters.

For the following models:

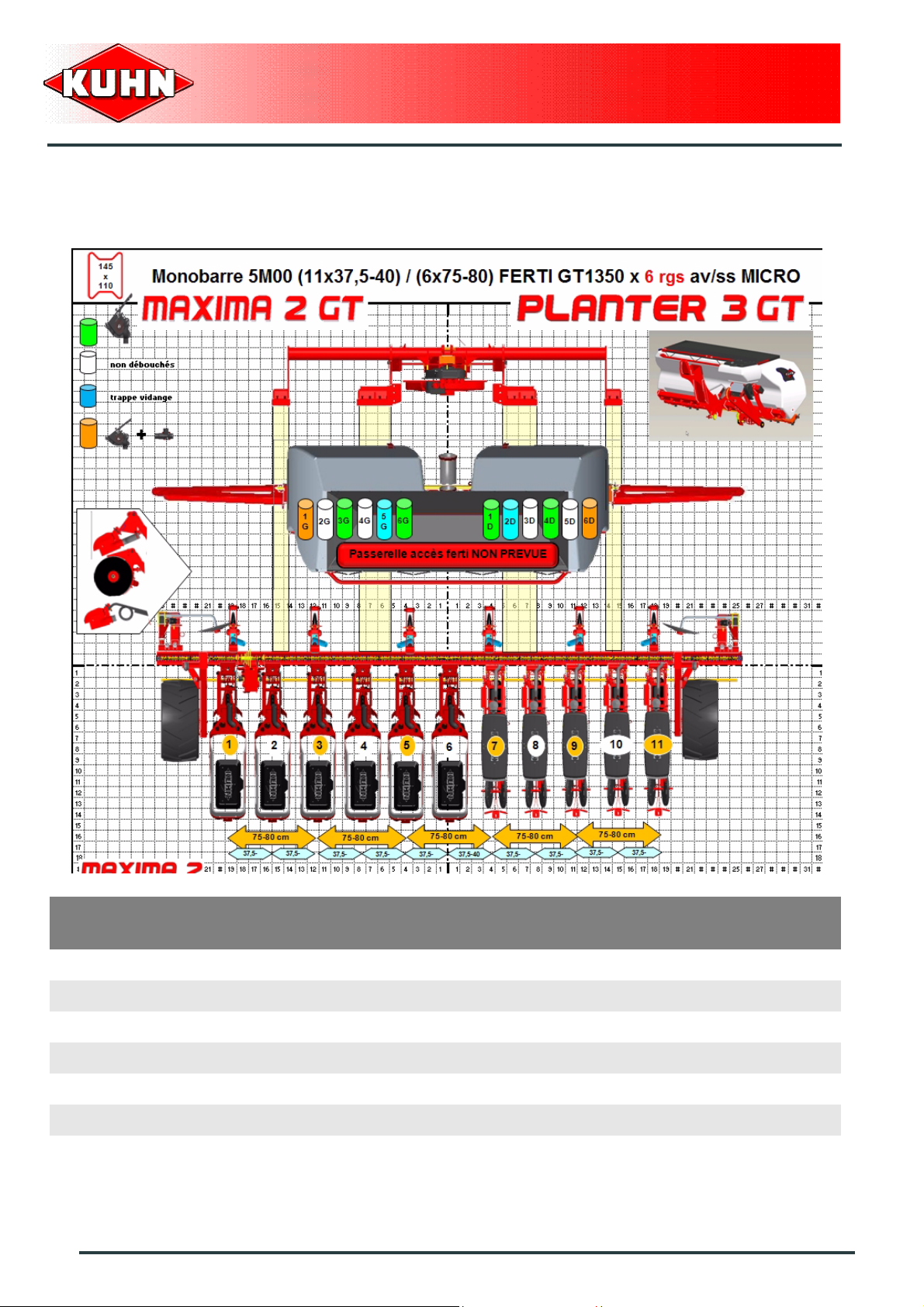

M2B12MB600CG01

M2B12MB600CG02

Kit no. 1677049: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with standard Suffolk coulters.

Kit no. 1677050: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677051: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with non-top disk coulters.

For the following models:

M2M08MB600C002

Kit no. 1677324: Fertilizer 8 rows with front mounted hopper and applicators with standard Suffolk coulters.

Kit no. 1677325: Fertilizer 8 rows with front mounted hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677326: Fertilizer 8 rows with front mounted hopper and applicators with non-stop disk coulters.

Identification of the machine

11

Page 14

Precision Seed Drills

MAXIMA 2

For the following models:

M2M08MB600CG02

Kit no. 1677046: Fertilizer 8 rows with 1350 L (356 US gal) hopper and applicators with standard Suffolk coulters.

Kit no. 1677047: Fertilizer 8 rows with 1350 L (356 US gal) hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677048: Fertilizer 8 rows with 1350 L (356 US gal) hopper and applicators with non-top disk coulters.

For the following models:

M2M12MB900CG02

Kit no. 1677055: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with standard Suffolk coulters.

Kit no. 1677056: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677057: Fertilizer 12 rows with 1350 L (356 US gal) hopper and applicators with non-top disk coulters.

For the following models:

M2S11MB440CF02

Kit no. 1677022: Fertilizer 6 rows with 2X280 L (2X74 US gal) hoppers and applicators with standard Suffolk coulter.

Kit no. 1677023: Fertilizer 6 rows with 2X280 L (2X74 US gal) hoppers and applicators with non-stop Suffolk coulter.

Kit no. 1677024: Fertilizer 6 rows with 2X280 L (2X74 US gal) hoppers and applicators non-stop disk coulters.

For the following models:

M2S11MB500CG03

Kit no. 1677043: Fertilizer 6 rows with 1350 L (356 US gal) hopper and applicators with standard Suffolk coulters.

Kit no. 1677044: Fertilizer 6 rows with 1350 L (356 US gal) hopper and applicators with non-stop Suffolk coulters.

Kit no. 1677045: Fertilizer 6 rows with 1350 L (356 US gal) hopper and applicators with non-top disk coulters.

Kit no. 1677228: Low flow kit for the fertilizer unit.

Kit no. 1677225: Loading screw for fertilizer equiped with 2x280 L (2x74 US gal) hoppers.

Kit no. 1677226: Loading screw for fertilizer unit fitted with a 1350 L (356 US gal) hopper.

Distribution disks

SP = Disk without agitator blades.

AP = Disk with agitator blades.

Kit no. N1503620: Distribution disk 12 holes of diameter 1.5 mm (0.06’’) AP.

Kit no. N04343B0: Distribution disk 12 holes of diameter 2.5 mm (0.1’’) AP.

12

Identification of the machine

Page 15

Precision Seed Drills

Kit no. N1502090: Distribution disk 12 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N04286B0: Distribution disk 18 holes of diameter 1.5 mm (0.06’’) SP.

Kit no. N00846B0: Distribution disk 18 holes of diameter 2.5 mm (0.1’’) AP.

Kit no. N04318B0: Distribution disk 18 holes of diameter 3 mm (0.12’’) AP.

Kit no. N00847B0: Distribution disk 18 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N00856B0: Distribution disk 22 holes of diameter 2.1 mm (0.08’’) SP.

Kit no. N1503810: Distribution disk 22 holes of diameter 2.1 mm (0.08’’) AP.

Kit no. N04341B0: Distribution disk 22 holes of diameter 2.5 mm (0.1’’) AP.

Kit no. N03840B0: Distribution disk 22 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N00851B0: Distribution disk 22 holes of diameter 4.5 mm (0.18’’) AP.

MAXIMA 2

Kit no. N02511B0: Distribution disk 22 holes of diameter 5 mm (0.2’’) AP.

Kit no. N00852B0: Distribution disk 22 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. N1503140: Distribution disk 27 holes of diameter 2.5 mm (0.1’’) AP.

Kit no. N1500670: Distribution disk 27 holes of diameter 3 mm (0.12’’) SP.

Kit no. N03823B0: Distribution disk 27 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N00843B0: Distribution disk 27 holes of diameter 4.5 mm (0.18’’) AP.

Kit no. N00905B0: Distribution disk 27 holes of diameter 5 mm (0.2’’) AP.

Kit no. N00844B0: Distribution disk 27 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. N1500340: Distribution disk 30 holes of diameter 7 mm (0.28’’) AP.

Kit no. N00845B0: Distribution disk 31 holes of diameter 2.1 mm (0.08’’) SP.

Kit no. N00855B0: Distribution disk 33 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N04107B0: Distribution disk 33 holes of diameter 4.5 mm (0.18’’) AP.

Kit no. N04282B0: Distribution disk 33 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. N1503380: Distribution disk 35 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N1503390: Distribution disk 35 holes of diameter 4.5 mm (0.18’’) AP.

Kit no. N1503400: Distribution disk 35 holes of diameter 5 mm (0.2’’) AP.

Kit no. N1503410: Distribution disk 35 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. K3601440: Distribution disk 48 holes of diameter 1.25 mm (0.05’’) SP.

Kit no. N02951B0: Distribution disk 48 holes of diameter 2.5 mm (0.1’’) AP.

Identification of the machine

13

Page 16

Precision Seed Drills

Kit no. N00848B0: Distribution disk 48 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N04305B0: Distribution disk 48 holes of diameter 4.5 mm (0.18’’) AP.

Kit no. N1503130: Distribution disk 48 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. N1500061: Distribution disk 54 holes of diameter 3 mm (0.12’’) SP.

Kit no. N1500681: Distribution disk 54 holes of diameter 4.5 mm (0.18’’) AP.

Kit no. N1500691: Distribution disk 54 holes of diameter 5.5 mm (0.22’’) AP.

Kit no. N1500431: Distribution disk 70 holes of diameter 1.25 mm (0.05’’) SP.

Kit no. N02851B0: Distribution disk 70 holes of diameter 2.5 mm (0.1’’) AP.

Kit no. N04342B0: Distribution disk 70 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N00850B0: Distribution disk 70 holes of diameter 4.5 mm (0.18’’) AP.

MAXIMA 2

Kit no. N1502170: Distribution disk 80 holes of diameter 2.5 mm (0.1’’) AP.

Kit no. N1501591: Distribution disk 80 holes of diameter 3.5 mm (0.14’’) AP.

Kit no. N1501051: Distribution disk 100 holes of diameter 0.8 mm (0.03’’) SP.

Kit no. N00849B0: Distribution disk 100 holes of diameter 1.25 mm (0.05’’) SP.

Kit no. N1500701: Distribution disk 100 holes of diameter 1.75 mm (0.07’’) AP.

Kit no. N04293B0: Distribution disk 100 holes of diameter 3.5 mm (0.14’’) AP.

Blower

Kit no. 1677287: 470 min

Kit no. 1676731: 870 min

Kit no. 1676738: 1000 min

-1

pulley and belt unit

-1

pulley and belt unit

-1

pulley and belt unit

Kit no. 1676730: Rear PTO output stub.

Kit no. 1677223: Vacuometer.

Control units

Kit no. 1676822: HECTOR 3000 electronic unit.

Passage control box kit KMS208:

Kit no. 1676648: For machine with 8 rows.

Sowing control box kit KMS412:

Kit no. 1676408B: For machine with 8 rows.

14

Identification of the machine

Page 17

Kit no. 1676409B: For machine with 9 rows.

Kit no. 1676411B: For machine with 11 rows.

Kit no. 1676412B: For machine with 12 rows: Sowing Beet.

Kit no. 1676413B: For machine with 12 rows: Sowing maize.

Kit no. 1676418B: For machine with 18 rows.

Electronic disengagement kit:

Kit no. 1677299: For machine with 8 rows

Kit no. 1677300: For machine with 9 rows

Kit no. 1677301: For machine with 11 rows

Kit no. 1677302: For machine with 12 rows

Precision Seed Drills

MAXIMA 2

Sundry

Kit no. 1676520: 65 x 400 depth control wheels.

Kit no. 1677293: 45 mm (1.8’’) spacer and 5 mm (0.2 ’’) levelling pad.

Kit no. 1676792: 82 mm (3.2’’) spacer and 5 mm (0.2 ’’) levelling pad.

Kit no. 1676825: Wheel footbridges.

Kit no. 1626614: Track eradicators.

Kit no. 1676815: Marker working depth limitors.

Kit no. 1676820: Mechanical hectare counter.

Identification of the machine

15

Page 18

$SAFETY

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Precision Seed Drills

MAXIMA 2

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

16

Safety

Page 19

Precision Seed Drills

MAXIMA 2

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations for preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect cu rrent legislation concerning accident pr evention, work safety

and public traffic circulation.

Designated use of the machine al so means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuin e spa re parts, e quip ment and accesso rie s, as re commen de d

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident resulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine , remove ignition k ey and

wait until all moving parts have come to a complete stop

and apply park brake.

Safety

17

Page 20

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Precision Seed Drills

MAXIMA 2

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of the great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt changes

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

18

Safety

Page 21

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow th e

local regulations for special transportation of oversize

equipment.

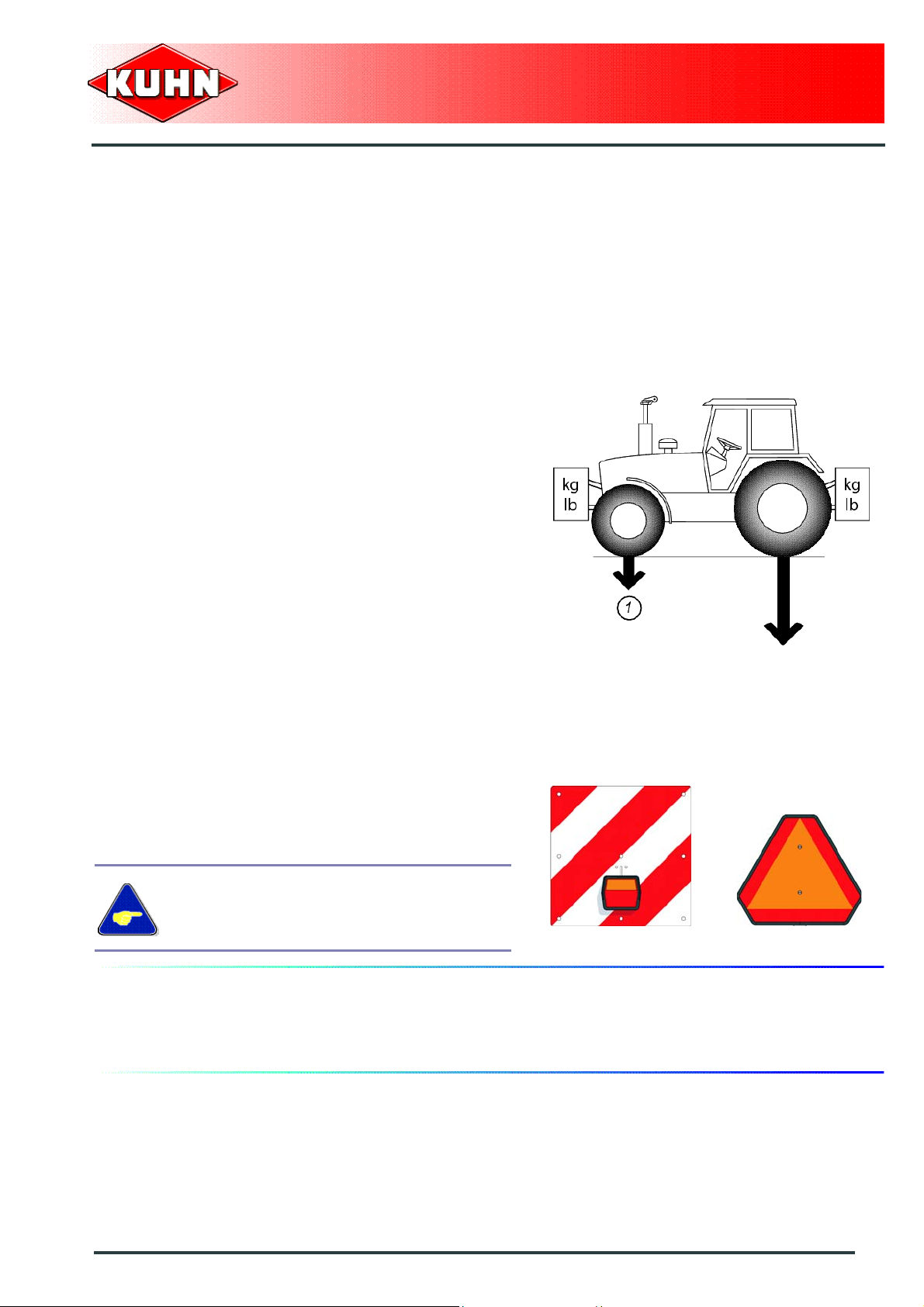

Gross weight and weight per axle

Check that the tractor's authorized gross weight as well

as its lift capacity and maximum weight per axle are not

exceeded.

The front axle load (1) must never, under any

circumstances, be less than 20% of the tractor's unladen

weight. If necessary, add ballast weights to the front or

to the rear to preserve the steering and braking

efficiency.

Precision Seed Drills

MAXIMA 2

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lightings and signallings

Before transporting the machine on public roads, e nsure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Always obey current regulations for driving

on roads.

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

Safety

19

Page 22

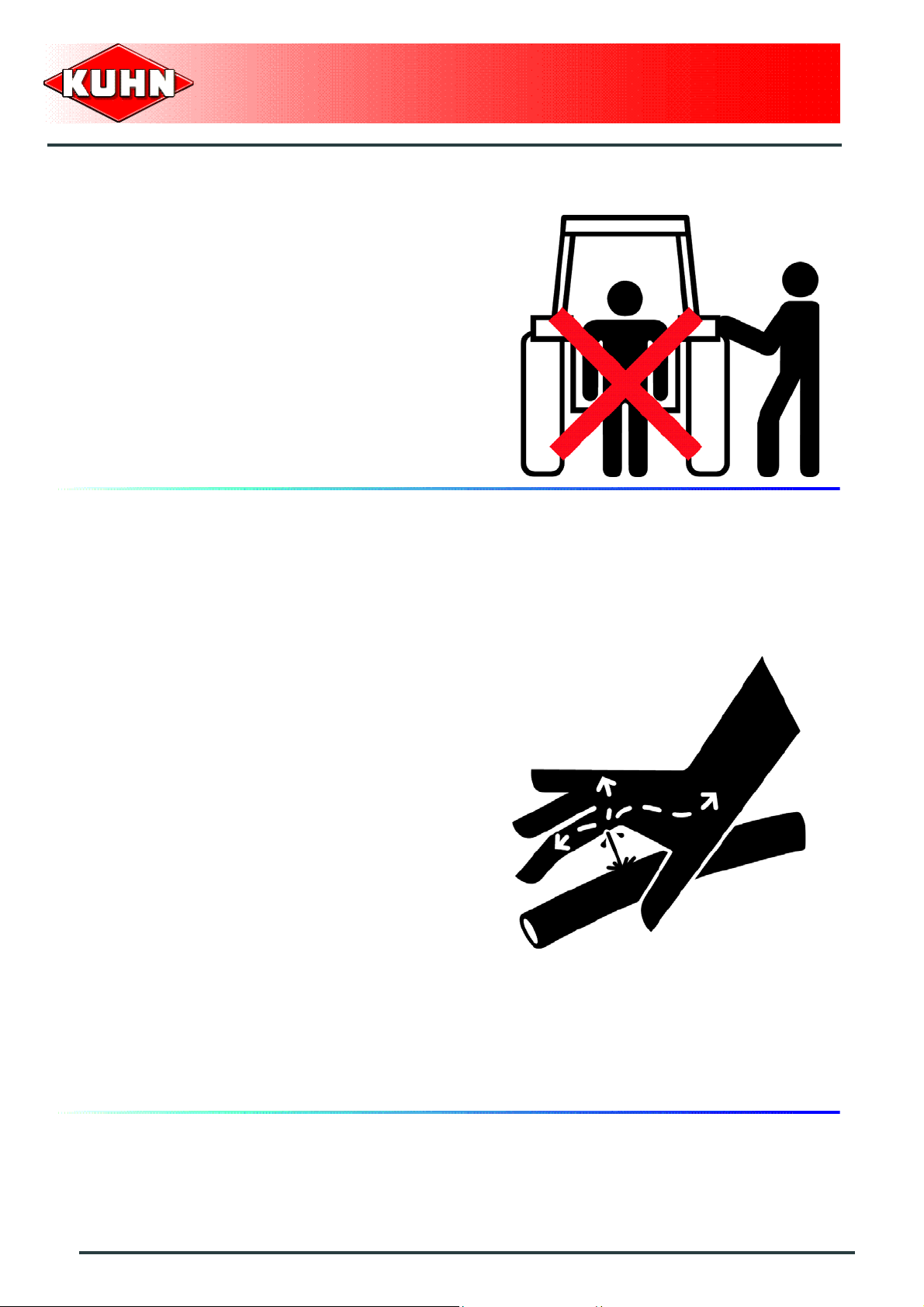

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Hydraulic circuit

Precision Seed Drills

MAXIMA 2

Beware : The hydraulic circuit is under pressure.

Maximum pressure at work: 200 bar (2857 psi).

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making incorrect connections, mark hydraulic

couplers and corresponding hoses with colors.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In cas e of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be replaced.

When replacing the hydraulic hoses, make sure to use

hoses with the specifications and quality recommended

by the manufacturer of the machine.

To locate a leak, use appropriate means.

Protect body and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine on the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

20

Safety

Page 23

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are secured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately. A worn guard or an unprotected PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendations.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective co ver

on the PTO stub of the tractor.

Read and follow the instructions in the operator's m anual

provided with the PTO shaft.

Precision Seed Drills

MAXIMA 2

Safety

21

Page 24

Precautions during manoeuvres

When moving the machine from the transp ort position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Safety decals

Safety warning decals to respect, are placed in pictorial

form on various parts of the machine. They are there to

warn you of potential dangers and to tell you how to

avoid accidents.

Always keep the safety decals clean and readable, and

replace them when they are worn, damaged, missing or

illegible.

Precision Seed Drills

MAXIMA 2

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters etc.) on the ground neither pour them

down the drain or discard them in any other place where

they could pollute the environment. Never throw away or

burn a tire. Always take waste to specialized recycling or

waste disposal centers.

22

Safety

Page 25

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine , remove ignition k ey and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the ground, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on th e electric circ uit or befo re

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

It is strongly recommended to have your machine

checked by your Kuhn dealer after each season,

especially tools and their attaching hardware.

Precision Seed Drills

MAXIMA 2

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab. Never start the machine when there are people

nearby. Even when the machine is used in accordance

with its purpose, objects may be projected. Stones and

other foreign objects projected by the moving parts can

travel a considerable distance. Keep all persons and

animals away from the danger zone.

Safety

23

Page 26

Precautions for machine use

Before use, check the condition of the fasteners in

accordance with the instructions contained in this

manual.

Keep all persons and animals away from the danger

zone. Check that nobody is within the side marker

operating area on headlands.

Stay a safe distance from the machine when the cuttin g

tools are in movement.

Never work in reverse.

Stay away from the machine until all moving parts have

come to a complete standstill.

Check the entire machine for any damage before

resuming work.

Never engage the tractor PTO drive when the machine

is in transport position.

If the machine hits an obstacle, disengage the PTO

drive, stop the tractor engine, remove the ignition key

and wait for all moving parts to come to a complete

standstill. Check the entire machine for any damage

before resuming work.

Precision Seed Drills

MAXIMA 2

Precautions to take with crop protection

products

Keep crop protection products away from children.

Do not clean outlets, spreaders, tubes or other small

parts by blowing with the mouth. When using crop

protection products, never smoke or eat.

All precautions must be taken to prevent hopper from

overflowing and products from flowing outside the

treatment area.

Booms and tanks are to be drained in all cases over the

areas under cultivation in accordance with regulatory

provisions.

Keep machine control and handling devices clean and

make sure to wash your hands prior to using these

devices.

Rinse and pierce packagings to prevent them from being

reused.

Find out about and comply with the instructions on the

use of crop protection products with regards to their

possible harmfulness for insects and wildlife, especially

for pollinating insects.

24

Safety

Page 27

Consulting and respecting the rules given in the

operating instructions, the safety files and in the advice

documents is the basis of behaving responsibly.

Store crop protection products in a place with a leakproof

floor enabling to recover product leaks.

Body protection

Wear waterproof clothing whenever there is a risk of

splashing from or contact with crop protection products,

even in diluted form. Wear specific protective clothing

(suit, gloves, boots, glasses, mask) when handling

phytosanitary products).

Wear gloves that are resistant to the various

components contained in the products (ultranitrile

gloves). Neoprene gloves are required in the presence

of ketone in the formulations.

Strictly avoid certain materials such as late x or PVC. A

watertightness indicator is insufficient.

Replace gloves as soon as they present signs of wear.

Store the gloves in a place well away from the products.

Precision Seed Drills

MAXIMA 2

Use special protection suits resistant to the products.

Wear a respiratory protection when preparing the spray

mixture or spraying certain products.

Check that the respiratory protections are fitted with

filters.

Change cartridges every 40h during intensive use

periods.

Replace respiratory protection at least once per year.

Anti-dust masks do not protect sufficiently

against phytosanitary products.

Safety

25

Page 28

Toxic substances

It is recommended to have a first-aid kit within reach.

Avoid all skin, eyes and mouth contact with products

such as fuels, oils, solvents, antifreeze and cleaning

products. Most of them contain harmfull substances.

In case of an incident, seek medical advice.

Follow to the letter all instructions given on the safety

decals of toxic substance containers.

Compatibility of phytosanitary products

and microgranulators

There are no known contraindication of incompatibility

between solid phytosanitary products and the material

used in the microgranulator assembly.

Precision Seed Drills

MAXIMA 2

26

Safety

Page 29

3. Location and description of safety decals on the machine

Location of safety decals

Precision Seed Drills

MAXIMA 2

Safety

27

Page 30

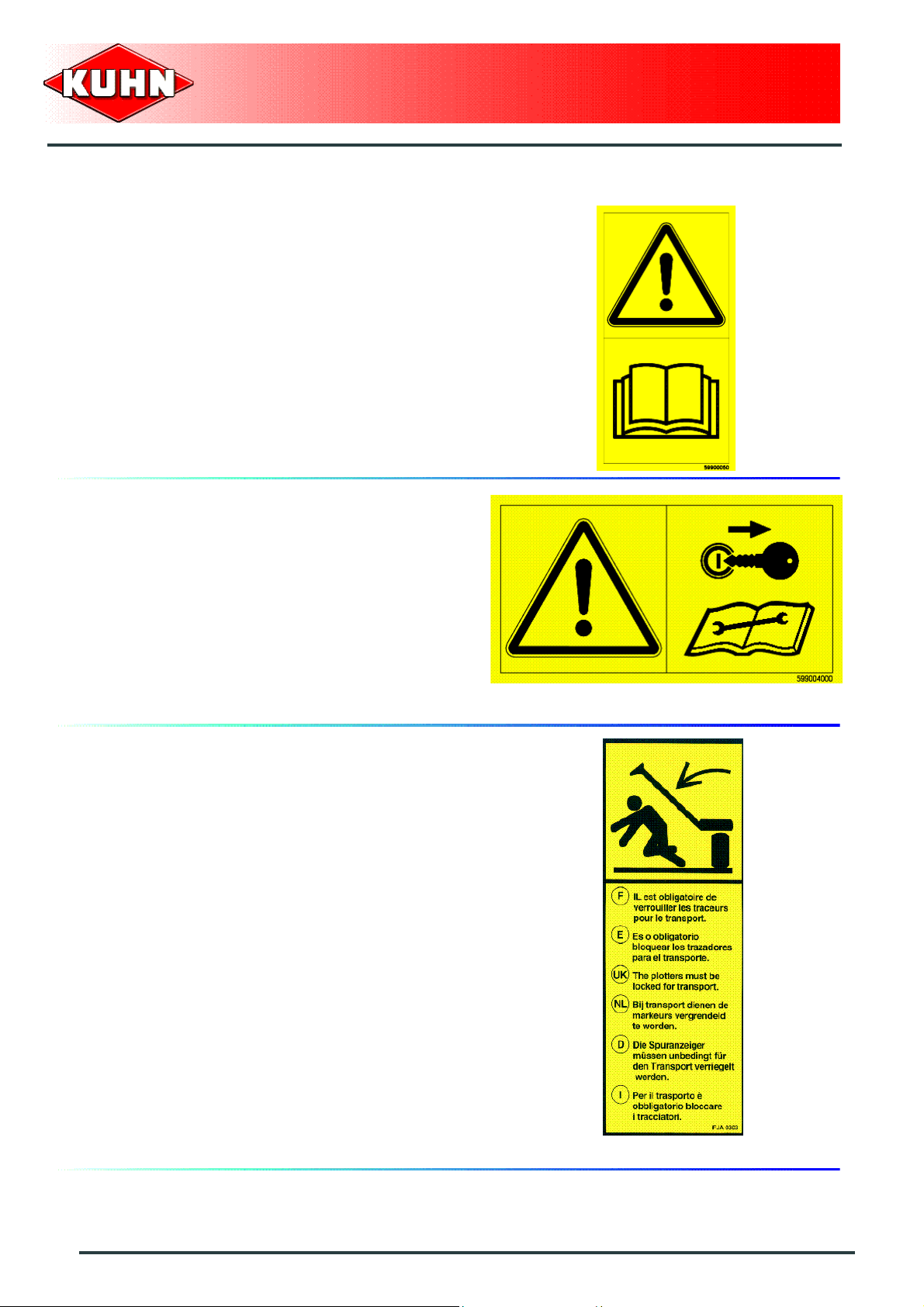

Description of safety decals

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Precision Seed Drills

MAXIMA 2

Body crushing (3)

The side markers must always be locked for transport.

28

Safety

Page 31

Risk of falling (4)

Do not ride on the machine when it is moving. There is a

risk of falling.

Precision Seed Drills

MAXIMA 2

Safety

29

Page 32

$MACHINE SPECIFICATIONS

1. Description and glossary

0

Precision Seed Drills

MAXIMA 2

1 : Pull bar 2 : Three-point hitch coupler

3 : Vacuum turbine 4 : Drive wheel

5 : Sowing component 6 : Gearbox

7 : Side marker 8 : Parking stand

9 : Seeding unit hopper 10 : Control hatch

11 : Distribution disc 12 : Selector

13 : Sowing depth adjustment handle 14 : Gauge wheel

15 : Press wheel 16 : Pressure spring

30

Machine specifications

Page 33

2. General technical specifications

Precision Seed Drills

MAXIMA 2

Maxima 2

Single bar frame exceeding 4.40 m

Attachment type

PTO speed 540 min

Unit hopper capacity 52 L (3 US gal)

Minimum PTO power requirement

- When starting the PTO

-At work

Torque

- When starting the PTO

-At work

Tyre pressure

-5 x 15

- 6.5 x 15

-26 x 12

Semi-automatic attachment category 2

Category 3 linkage

8.2 kW (11 ch) (approximately)

4.4 kW (6 ch) (approximately)

From 12 to 15 daN m (88 - 110 lbf ft)

From 8 to 9 daN m (59 - 66 lbf ft)

1.7 bar (24 psi)

2.7 bar (39 psi)

1.4 bar (20 psi)

-1

Machine specifications

31

Page 34

3. Technical specifications per model

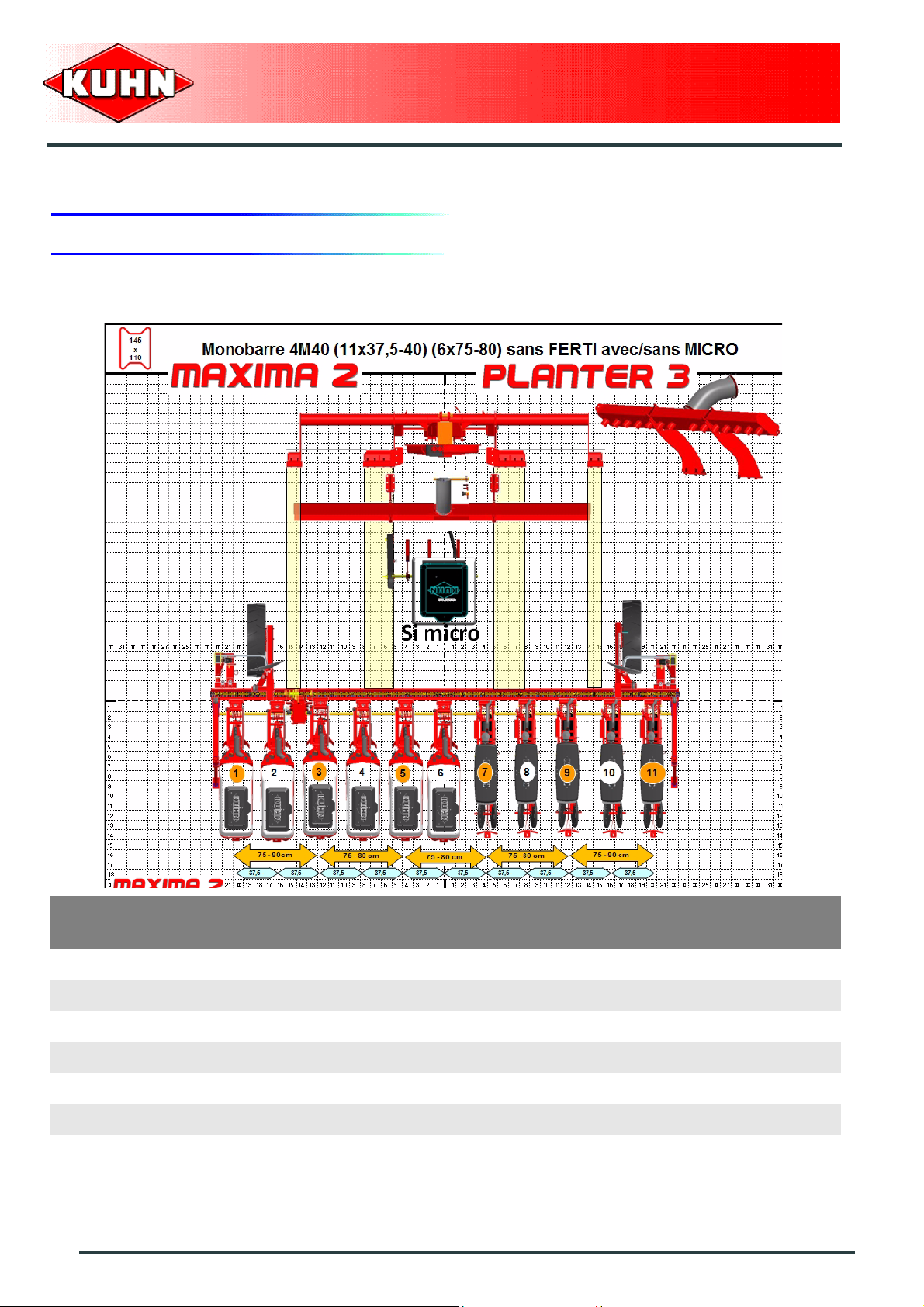

M2S1 1MB440C002

Precision Seed Drills

MAXIMA 2

M2S11MB440C002

Distance between sowing components 37.5 - 40 cm (1’3’’ - 1’4’’)

Number of rows 11

Width in transport position 4400 mm (14’5’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 1803 kg (3975 lb)

32

Machine specifications

Page 35

M2S11MB440CF02

Precision Seed Drills

MAXIMA 2

M2S11MB440CF02

Distance between sowing components 37.5 - 40 cm (1’3’’ - 1’4’’)

Number of rows 11

Width in transport position 4400 mm (14’5’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2131 kg (4698 lb)

Machine specifications

33

Page 36

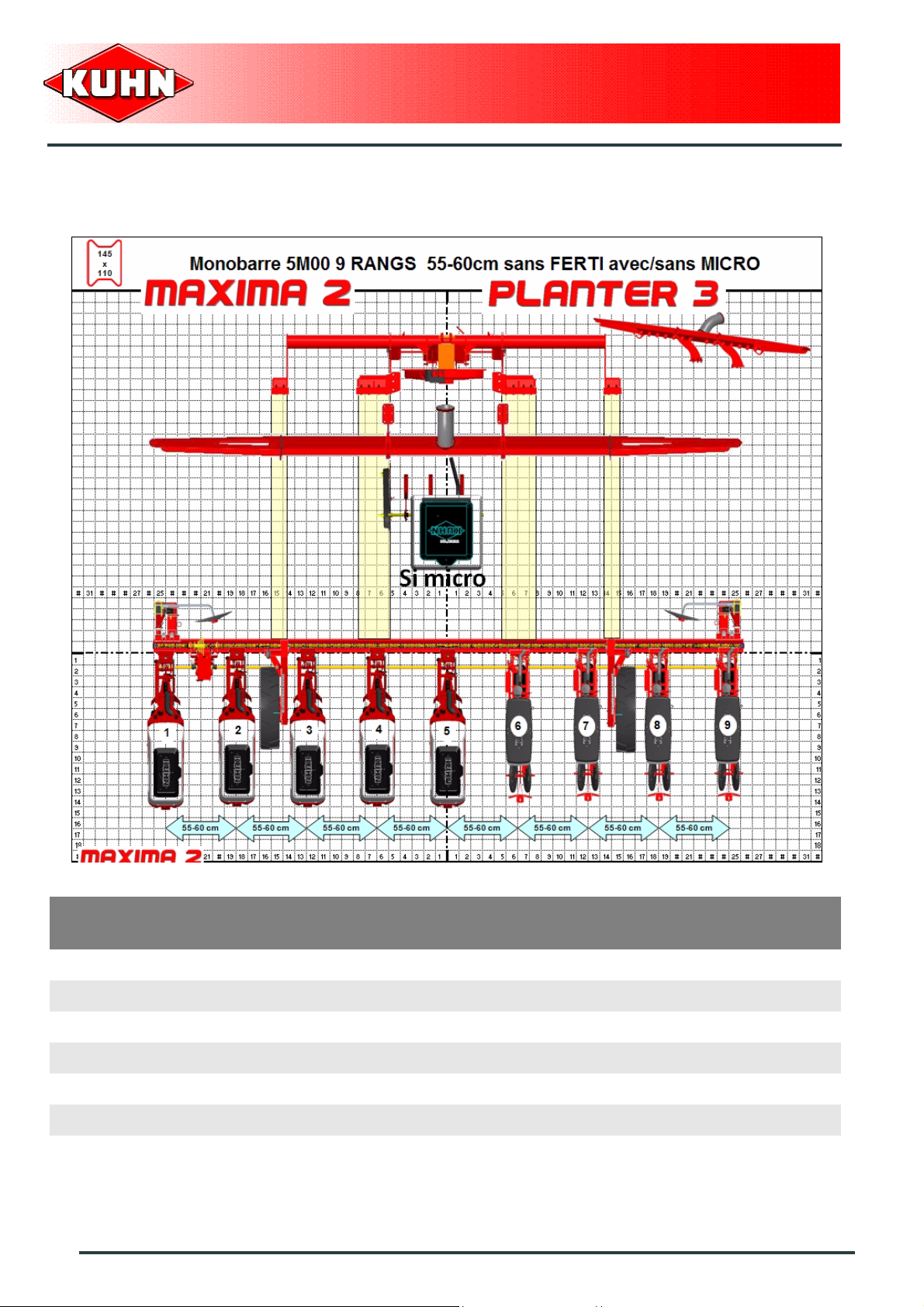

M2T09MB500C002

Precision Seed Drills

MAXIMA 2

M2T09MB500C002

Distance between sowing components 55 - 60 cm (1’9’’ - 2’)

Number of rows 9

Width in transport position 5000 mm (16’5’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 1629 kg (3591 lb)

34

Machine specifications

Page 37

M2S11MB500C003

Precision Seed Drills

MAXIMA 2

M2S11MB500C003

Distance between sowing components 37.5 - 40 cm (1’3’’ - 1’4’’)

Number of rows 11

Width in transport position 5000 mm (16’5’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 1820 kg (4012 lb)

Machine specifications

35

Page 38

M2S11MB500CG03

Precision Seed Drills

MAXIMA 2

M2S11MB500CG03

Distance between sowing components 37.5 - 40 cm (1’3’’ - 1’4’’)

Number of rows 11

Width in transport position 5000 mm (16’5’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2235 kg (4927 lb)

36

Machine specifications

Page 39

M2M08MB600C002

Precision Seed Drills

MAXIMA 2

M2M08MB600C002

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 8

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 1662 kg (3664 lb)

Machine specifications

37

Page 40

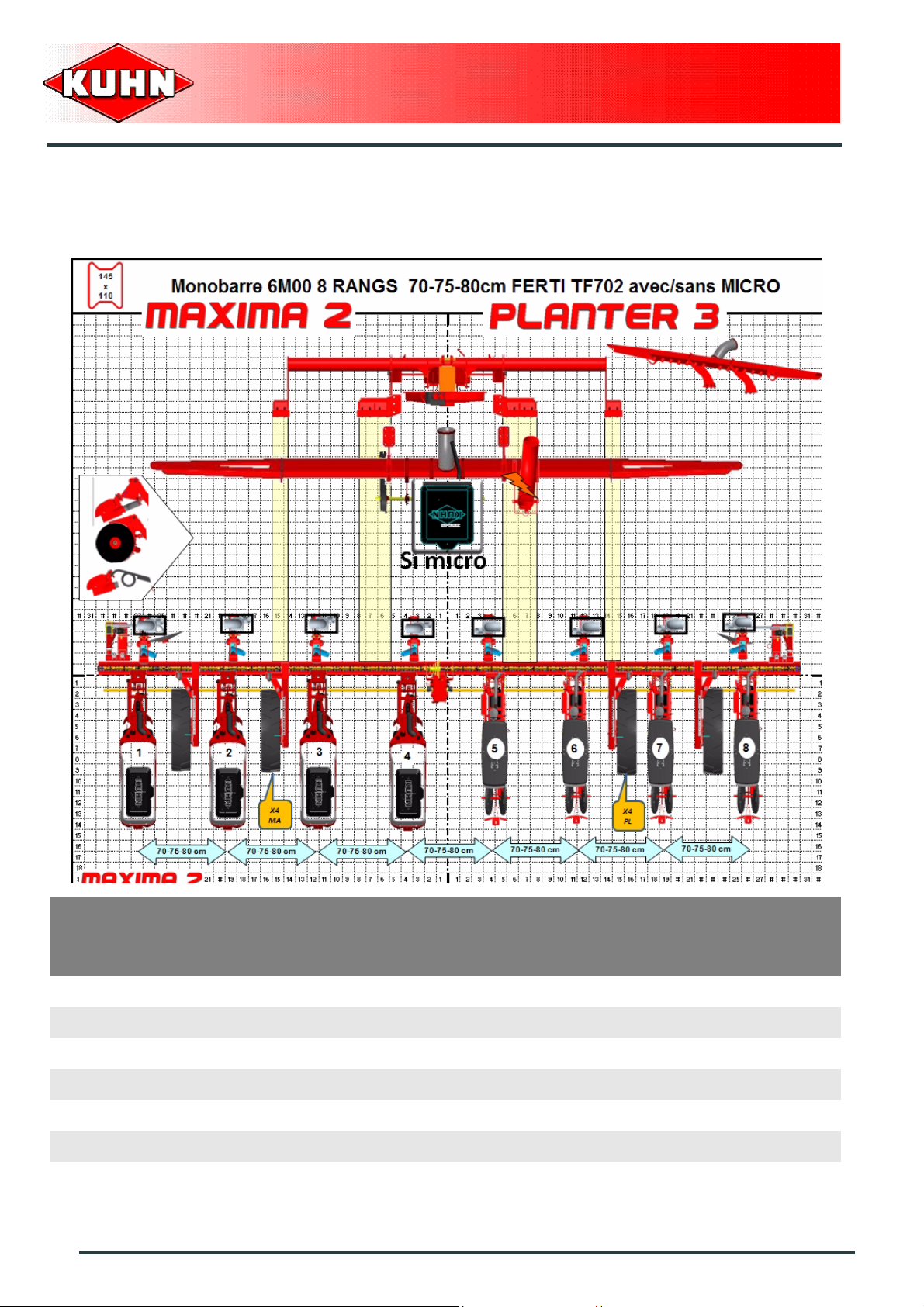

M2M08MB600C002 With TF702 front

hopper

Precision Seed Drills

MAXIMA 2

M2M08MB600C002

With TF702 front hopper

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 8

Width in transport position 6000 mm (19’8’’)

Length in transport position Height in transport position 1900 mm (6’3’’)

Weight -

38

Machine specifications

Page 41

M2M08MB600CG02

Precision Seed Drills

MAXIMA 2

M2M08MB600CG02

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 8

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2100 kg (4630 lb)

Machine specifications

39

Page 42

M2B12MB600C001

Precision Seed Drills

MAXIMA 2

M2B12MB600C001

Distance between sowing components 45 - 50 cm (1’6’’ - 1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2046 kg (4511 lb)

40

Machine specifications

Page 43

M2B12MB600C001 With TF702 front hopper

Precision Seed Drills

MAXIMA 2

M2B12MB600C001

With TF702 front hopper

Distance between sowing components 45 - 50 cm (1’6’’ - 1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position Height in transport position 1900 mm (6’3’’)

Weight -

Machine specifications

41

Page 44

M2B12MB600C002

Precision Seed Drills

MAXIMA 2

M2B12MB600C002

Distance between sowing components 50 cm (1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2052 kg (4524 lb)

42

Machine specifications

Page 45

M2B12MB600C002 With TF702 front hopper

Precision Seed Drills

MAXIMA 2

M2B12MB600C002

With TF702 front hopper

Distance between sowing components 50 cm (1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position Height in transport position 1900 mm (6’3’’)

Weight -

Machine specifications

43

Page 46

M2B12MB600CG01

Precision Seed Drills

MAXIMA 2

M2B12MB600CG01

Distance between sowing components 45 - 50 cm (1’6’’ - 1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2560 kg (5644 lb)

44

Machine specifications

Page 47

M2B12MB600CG02

Precision Seed Drills

MAXIMA 2

M2B12MB600CG02

Distance between sowing components 50 cm (1’8’’)

Number of rows 12

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2566 kg (5657 lb)

Machine specifications

45

Page 48

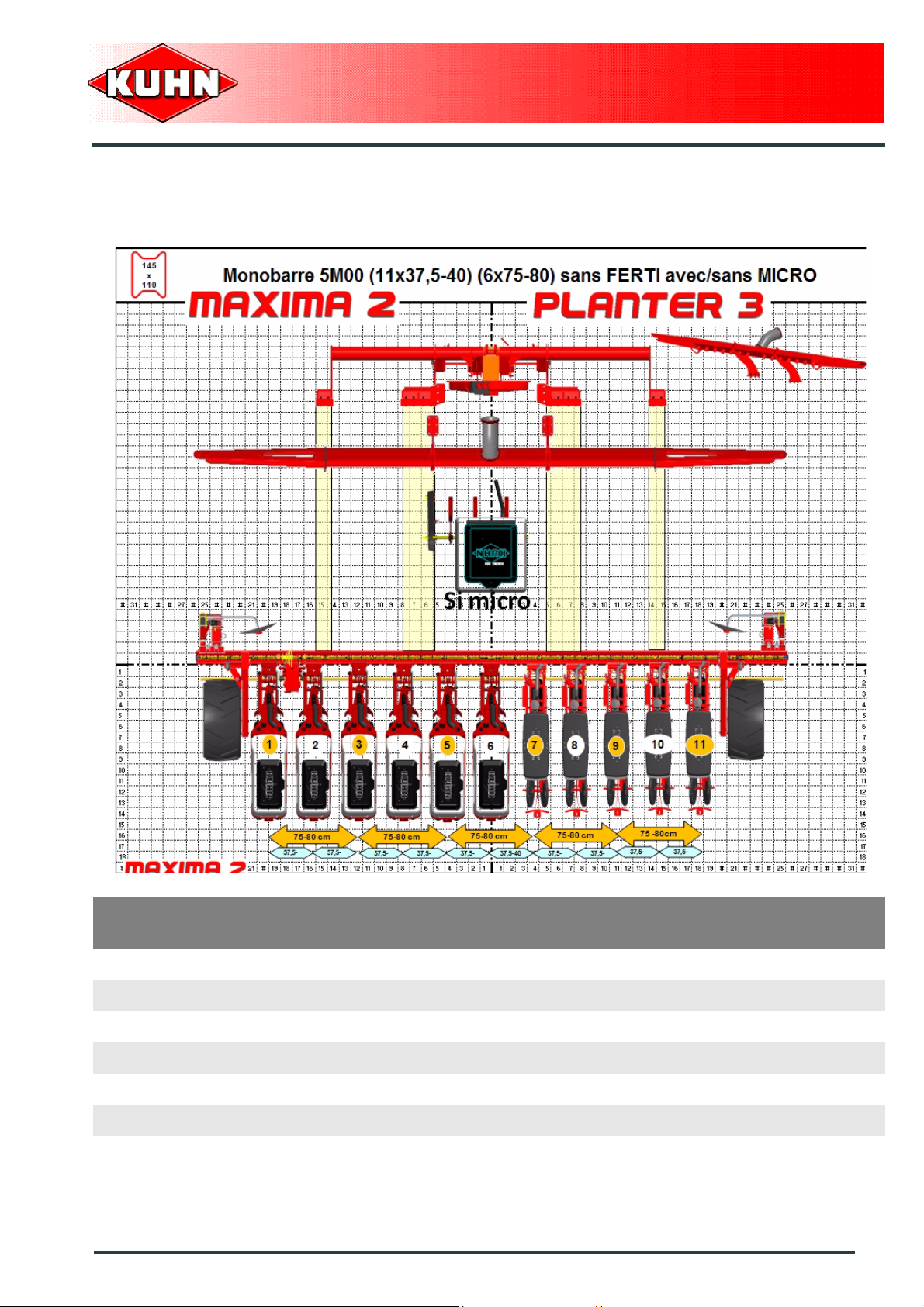

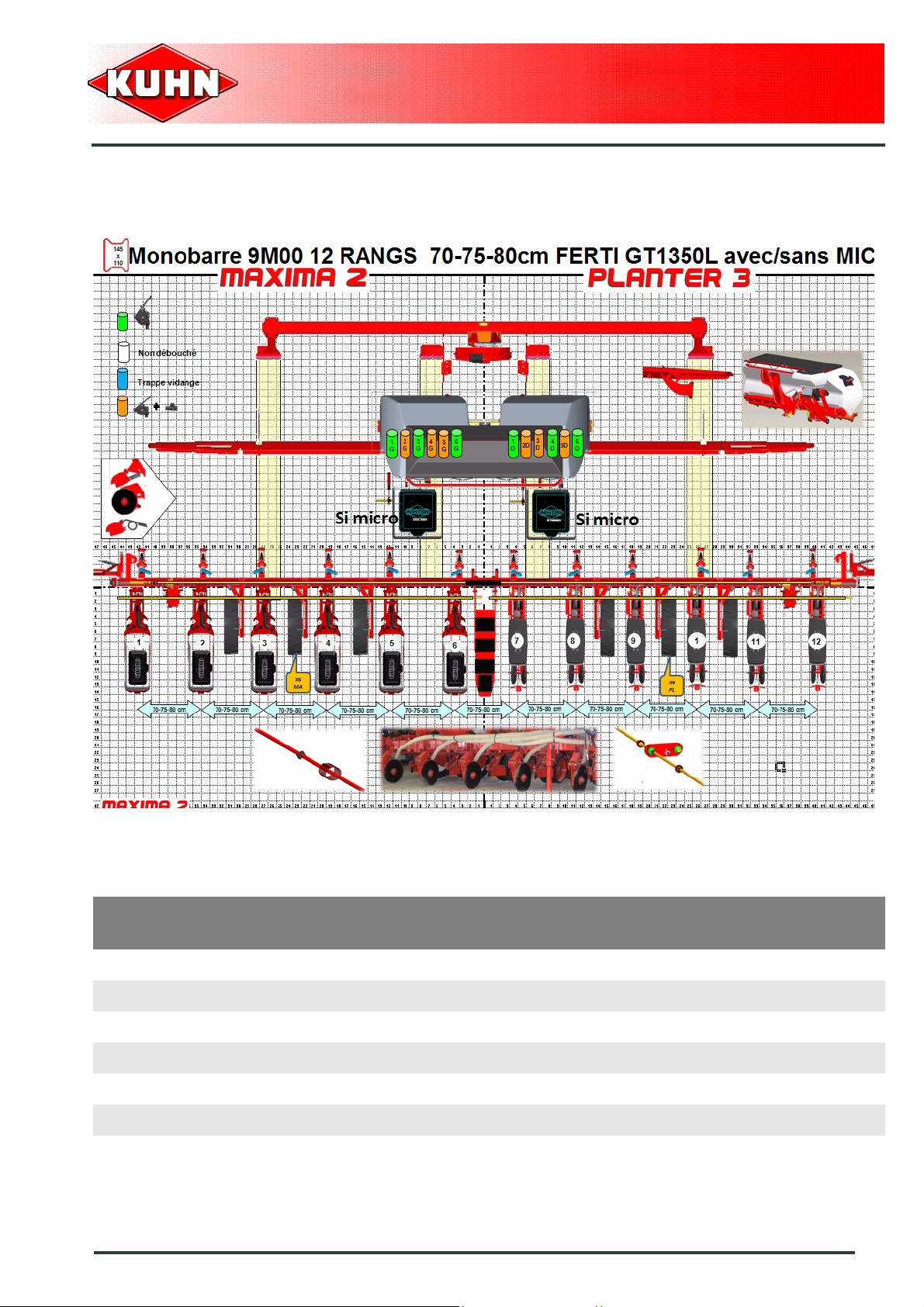

M2M12MB900C002

Precision Seed Drills

MAXIMA 2

M2M12MB900C002

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 12

Width in transport position 9000 mm (29’6’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 2527 kg (5571 lb)

46

Machine specifications

Page 49

M2M12MB900CG02

Precision Seed Drills

MAXIMA 2

M2M12MB900CG02

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 12

Width in transport position 9000 mm (29’6’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 3113 kg (6863 lb)

Machine specifications

47

Page 50

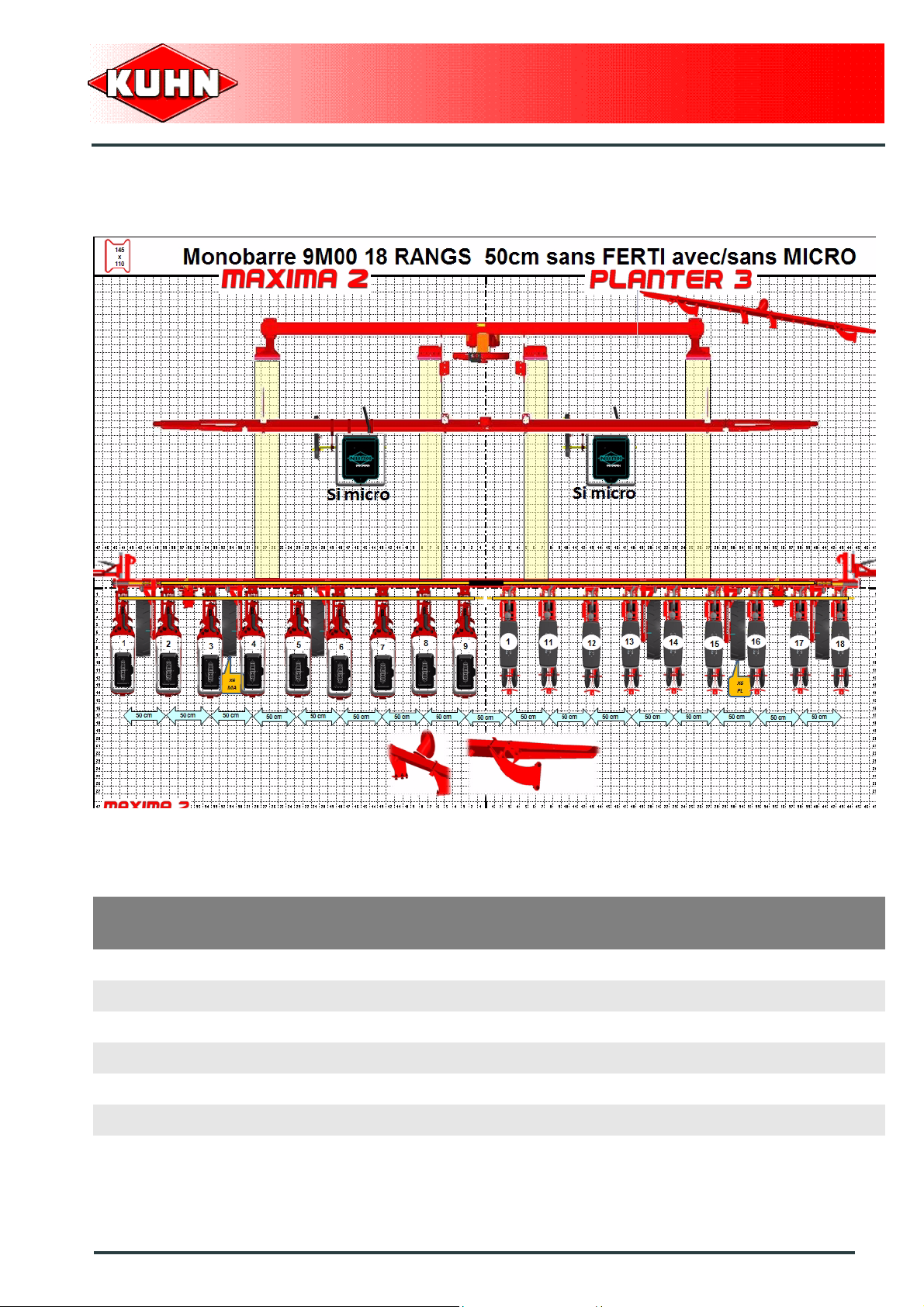

M2B18MB900C001

Precision Seed Drills

MAXIMA 2

M2B18MB900C001

Distance between sowing components 45 - 50 cm (1’6’’ - 1’8’’)

Number of rows 18

Width in transport position 9000 mm (29’6’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 3100 kg (6834 lb)

48

Machine specifications

Page 51

M2B18MB900C002

Precision Seed Drills

MAXIMA 2

M2B18MB900C002

Distance between sowing components 50 cm (1’8’’)

Number of rows 18

Width in transport position 9000 mm (29’6’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

Weight 3110 kg (6856 lb)

Machine specifications

49

Page 52

Precision Seed Drills

M2T09MB600C002

M2T09MB600C002

Distance between sowing components 55 - 60 cm (1’9’’ - 2’)

Number of rows 9

Width in transport position 6000 mm (19’8’’)

Length in transport position 2000 mm (6’7’’)

Height in transport position 1900 mm (6’3’’)

MAXIMA 2

Weight 1671 kg (3684 lb)

50

Machine specifications

Page 53

Precision Seed Drills

MAXIMA 2

M2M12MB900C002 With TF702 front

hopper

M2M12MB900C002

With TF702 front hopper

Distance between sowing components 70 - 75 - 80 cm (2’4’’ - 2’6’’ - 2’8’’)

Number of rows 12

Width in transport position 9000 mm (29’6’’)

Length in transport position Height in transport position 1900 mm (6’3’’)

Weight -

Machine specifications

51

Page 54

Precision Seed Drills

MAXIMA 2

4. Sound levels

Sound levels have been measured in accordance with the measuring methods as defined in:

NF EN 1553 "Agricultural machinery - Self-propelled, mounted, semi-mounted and trailed - Common

safety recommendations"

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L (A) eq:

Tractor only: 69.4 dB(A)

Tractor + machine:

70.1 dB(A)

52

Machine specifications

Page 55

$PUTTING INTO SERVICE

1. Description of control elements

The machine can be fitted with several contro l boxes to

monitor all functions.

Precision Seed Drills

MAXIMA 2

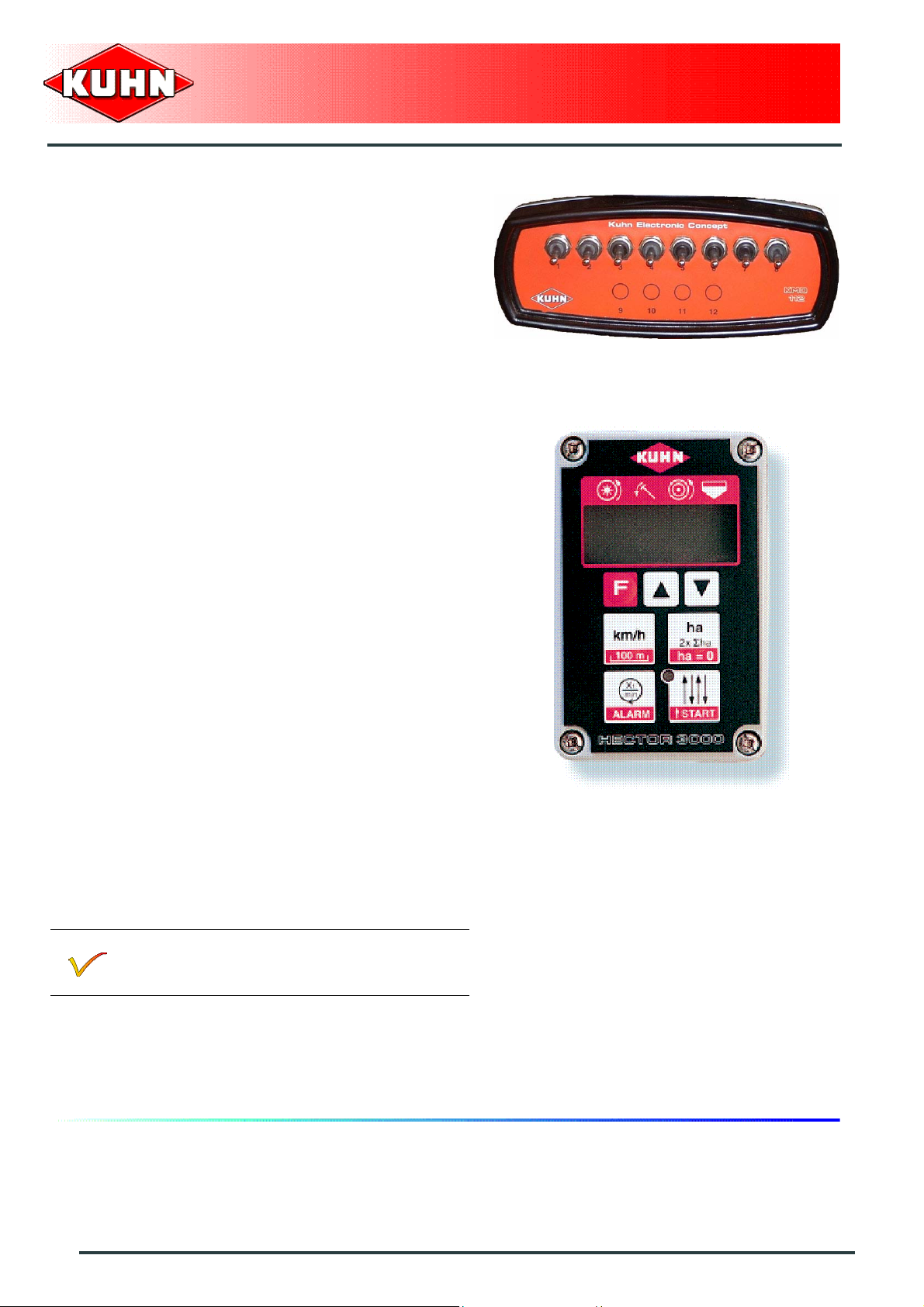

2. Control box description

The KMS412 control box enables monitoring the seed

population.

The KMS208 control box enables controlling the seed

passage.

Putting into service

53

Page 56

The KMD112 disengagement control box can only

function in combination with control boxes KMS208 or

KMS412.

The KMD112 disengagement control box allows

electrical disengagement of one or several rows at any

time

The HECTOR 3000 electronic control box is used to::

- Count the area sown (daily and total counter).

- Indicate forward speed.

Precision Seed Drills

MAXIMA 2

54

Putting into service

The functioning and setting of the control boxes

are indicated in the complementary instructions

supplied.

Page 57

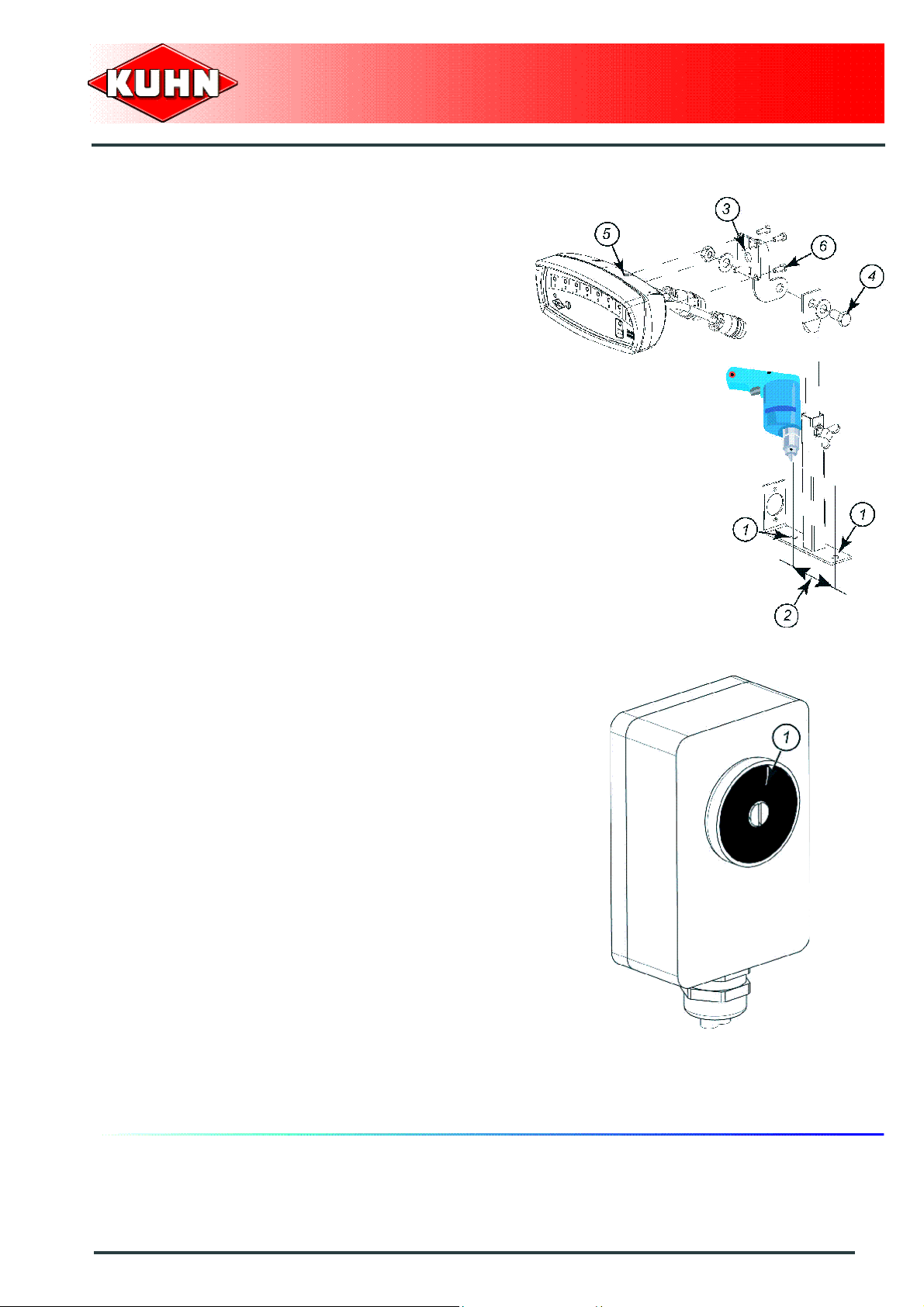

Positioning and parking

Fitting the control boxes

The control boxes must be easy to access from the

tractor cab.

Control boxes KMS412/KMS208 and KMD112:

- Drilling of 2 holes diameter 11 mm (1).

- 100 mm Hole to hole distance (2).

- Fit holder (3) using screws, washers and nuts (4).

- Position control box (5) using screws (6).

Precision Seed Drills

MAXIMA 2

Control box HECTOR 3000:

The attachment is ensured by magnet (1).

Removing the control boxes

The control boxes must be stored in a dry place free of

dust.

Putting into service

55

Page 58

3 pin plug

The box is energized by the tractor's 3-pin socket(DIN

9680, ISO 12369) or the battery power cable supplied.

Pin Wire color Function

15 / 30 (1) Brown + 12 Volt

31 (2) Blue Earth

82 (3) - -

Precision Seed Drills

MAXIMA 2

Description of the connection

Never connect battery charger or perform

welding tasks without having previously

disconnected the control box.

The control boxes are connected to:

- A tractor 3-pin socket.

- a supplied battery power cable.

To use the machine with another tractor, a

second tractor-side power harness can be

ordered under p/n 83233001.

Do not connect the wiring harness to the

starter connections.

Check that the connectors are in a good

condition and clean.

If the tractor is not fitted with a battery isolation switch:

Connect the wiring harness directly to the battery

terminals respecting the polarities.

If the tractor is fitted with a battery isolation switch:

Connect the wiring harness to the battery isolation

switch output.

The wiring harness is fitted with a 15 Amp ATO type

fuse: Part no. 82333017(2).

+

-

56

Putting into service

Page 59

3. Coupling and uncoupling

Description of coupling elements

The machine is equipped with:

- 1 PTO shaft 1 3/8’’ - 6 splines.

- 1 3-pin socket.

- 1 7-pin plug for the signalling equipment.

- 2 hydraulic hoses to supply the side marker cylinders.

Precision Seed Drills

MAXIMA 2

When optional equipment is used, follow

specific procedures mentioned in the related

section: Filling auger.

Preparing the tractor

The machine is for use with tractors equipped with a

standard category 2 or 3 3-point hitch.

The tractor must be fitted with a double acting hydraulic

outlet.

Putting into service

57

Page 60

The tractor PTO stub must rotate at a speed of 540 min-1.

Belt and pulley assemblies are available to adapt

the blower speed to the tractor PTO speed.

- 470 min

-1

pulley and belt unit: Kit

no. 1677287

- 870 min

-1

pulley and belt unit: Kit

no. 1676731

- 1000 min

-1

pulley and belt unit: Kit

no. 1676738

Precision Seed Drills

MAXIMA 2

The front axle load (1) must never, under any

circumstances, be less than 20% of the

tractor's unladen weight.

The tractor must be fitted with lower link

stabilizers.

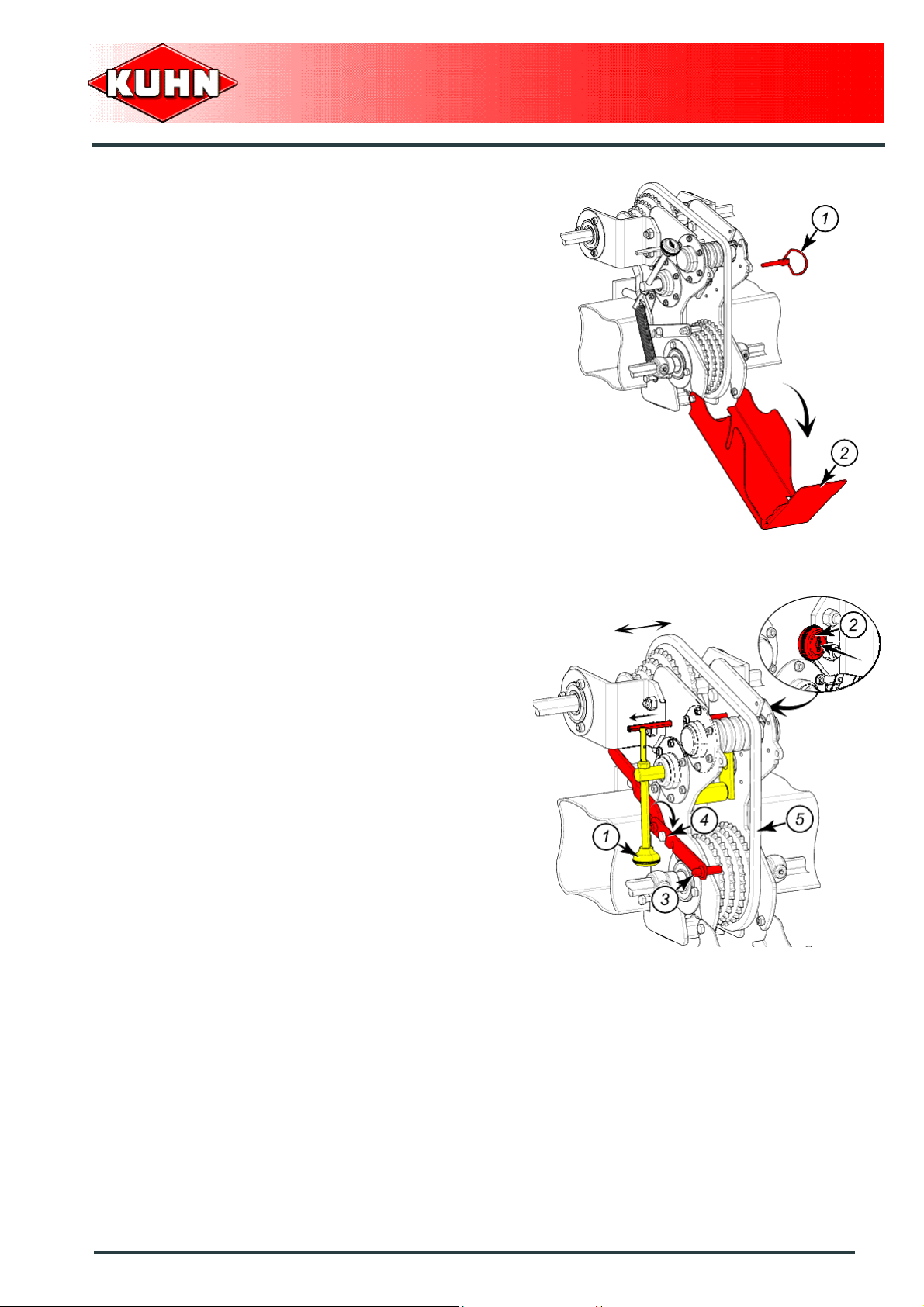

Fitting a pull bar

A pull bar must be fitted when the machine is

equipped with a semi-automatic attachment

category 2.

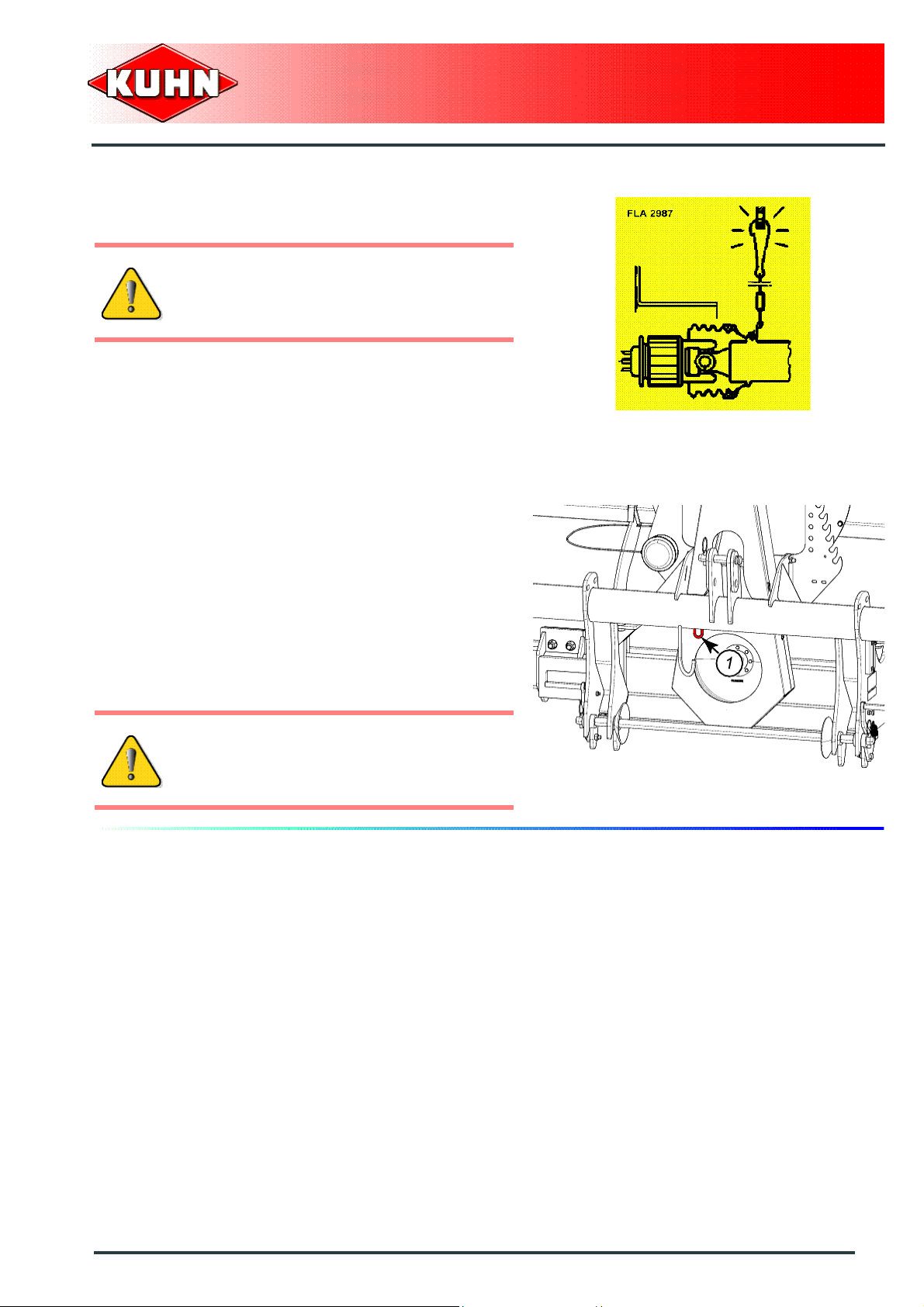

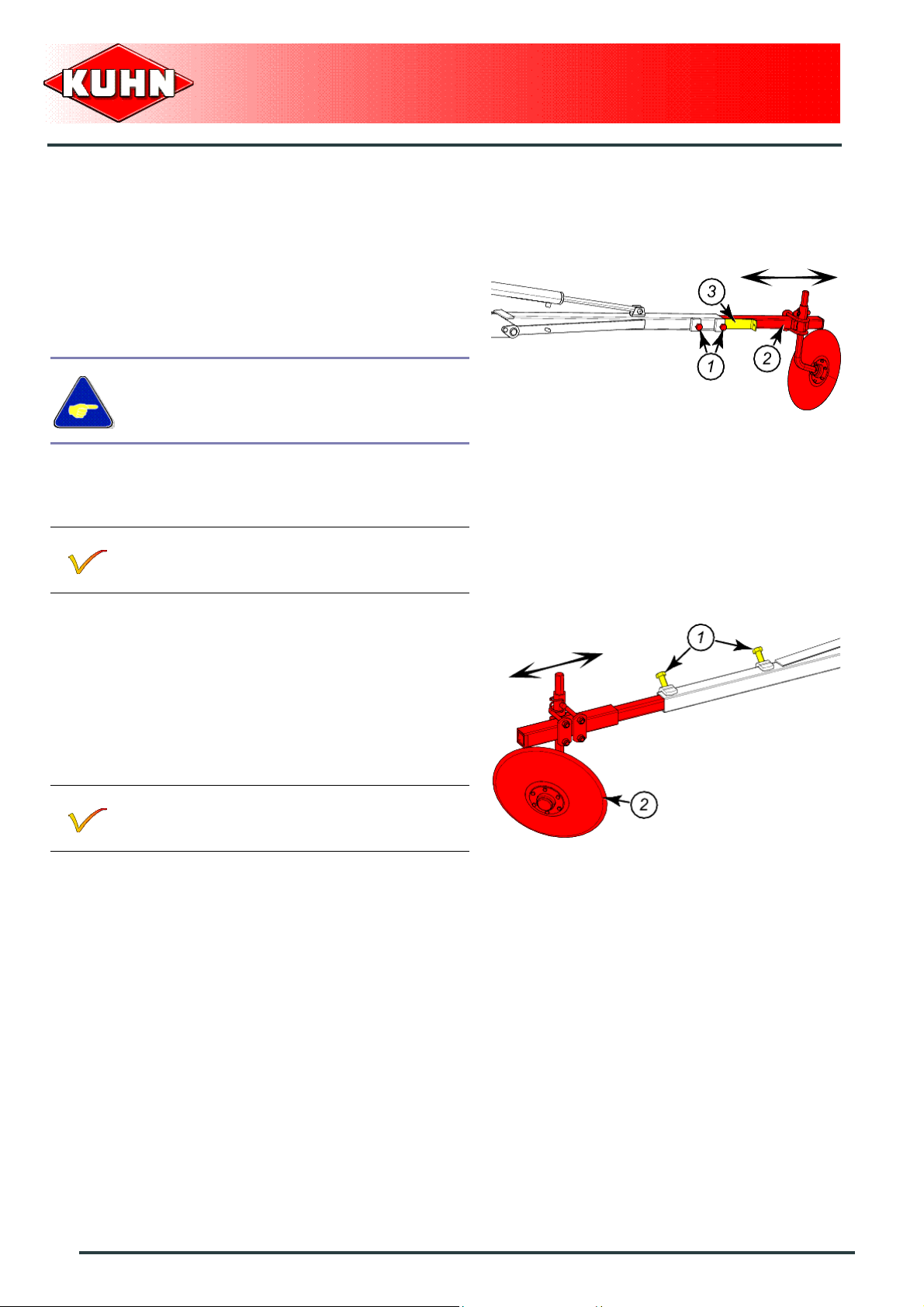

- Fit pull bar (1) on lower links (2).

- Install spacer (3).

- Insert and lock lynch pin (4).

Proceed the same way on the other side.

58

Putting into service

Page 61

Lateral adjustment of the lower linkage arms

Balance the play on either sides of the lift linkage and

lock lower link stabilizers.

Parallelism of lower linkage arms

Adjust tractor lift rods so that lower linka ge arms are at

equal height from ground.

Precision Seed Drills

MAXIMA 2

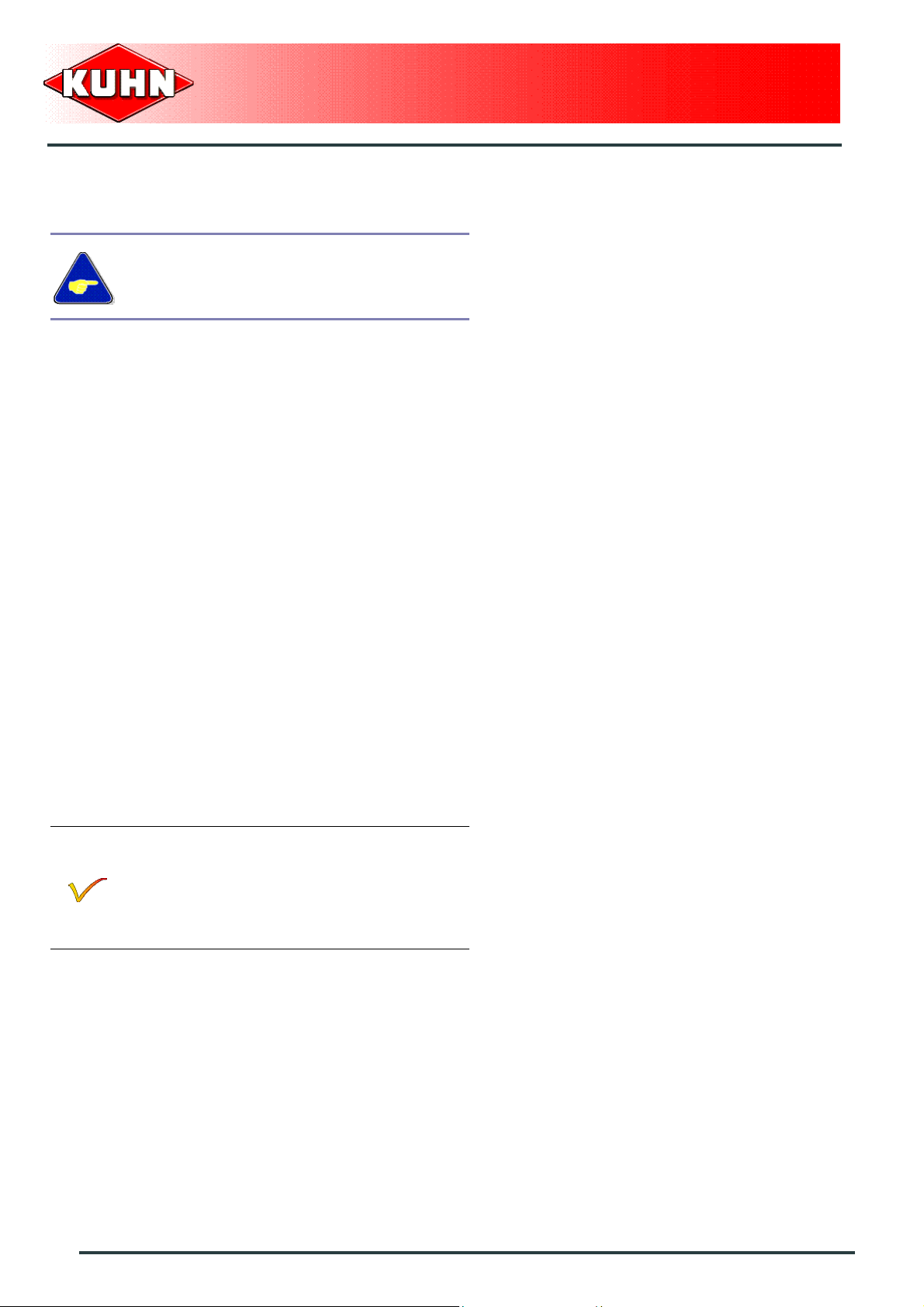

Placing the tractor lift linkage in floating position

Adjust turn buckles (1) in order to obtain floating position

of the lower link arms.

This position enables free machine adaptation to the

ground contours.

Putting into service

59

Page 62

Tyres

If compatible with the seed drill configuration, we

recommended fitting the tractor with dual wheels or

extra-wide wheels in order to reduce the ground

pressure.

Make sure that the seed drill never interferes

with the tractor wheels.

Precision Seed Drills

MAXIMA 2

Tractor tire pressure

To ensure that tractor can be driven safely and that

machine gives the desired finish, each tyre must be

inflated to the correct pressure for the load supported.

- Slightly lift the machine from the ground.

- Measure the load on each wheel (or the load of one

axle divided by 2) using a weight indicator or a scale.

- Refer to the tyre manufacturer's pressure chart.

- Adjust the tyre pressure to the measured loads.

The tyre pressure must be identical on each side of the

tractor.

60

Putting into service

Page 63

Coupling the machine

For attachment category 2:

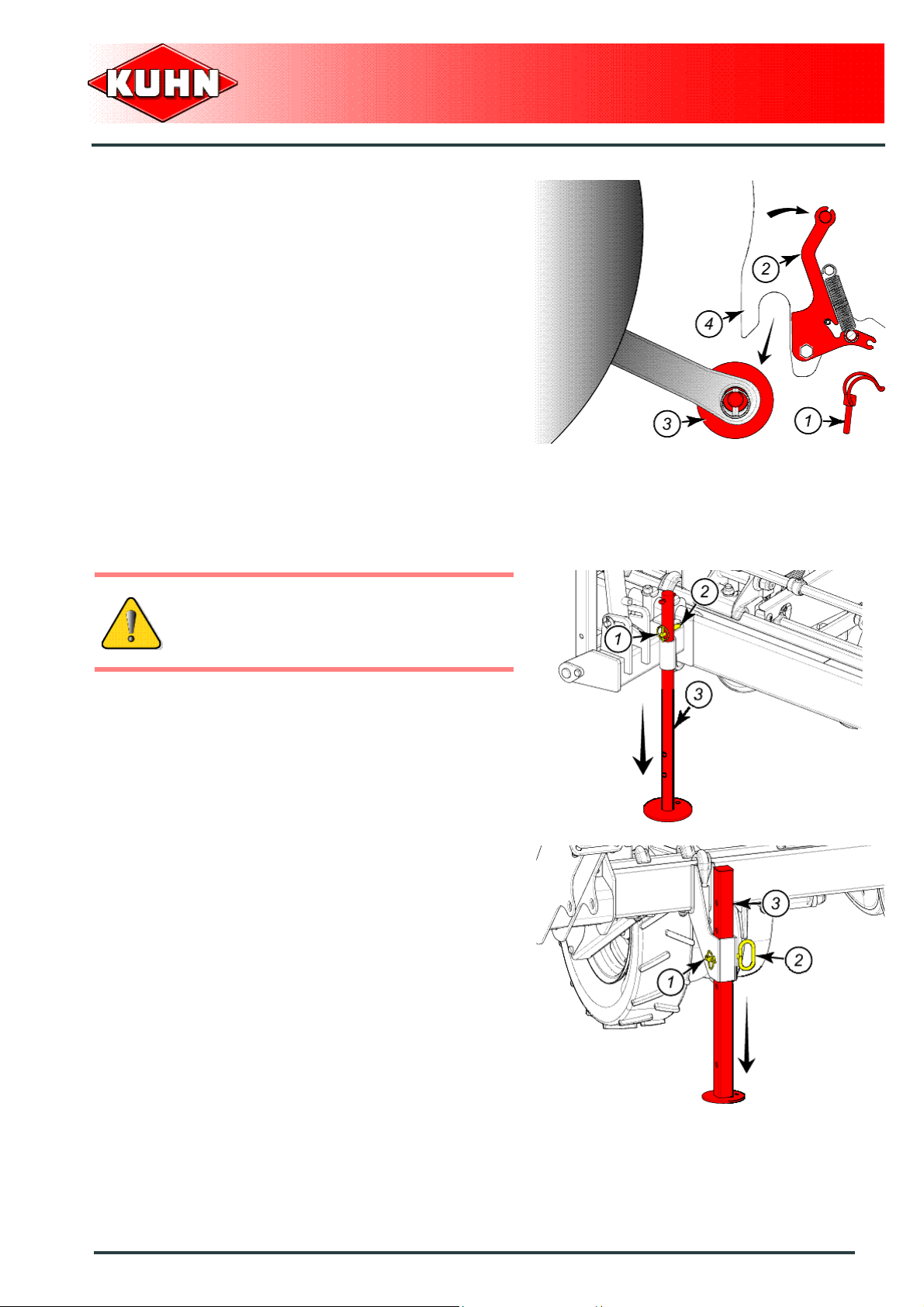

- Position hitch bar closest to the semi-automatic

attachment.

- Remove lynch pins (1) (1 on each machine side).

Precision Seed Drills

MAXIMA 2

- Raise tractor lower links to engage hitch bar (1) in th e

machine's semi-automatic attachment (2).

- The lock (3) automatically engages.

- Insert and lock lynch pin (4). (1 on each machine

side).

- Attach top link with hitch pin.

- Use tractor and machine attachment holes to adjust

the top link position.

- Raise machine using the tractor lift linkage until

parking stands no longer rest on the ground.

To obtain optimum PTO shaft angles and

tractor lift capacity, the top link must be

parallel to the lower links or slightly pointing

downwards towards the tractor.

Putting into service

61

Page 64

- Remove lynch pin (1) and pin (2).

- Raise parking stand (3).

- Insert pin (2) and lock using lynch pin (1).

- Repeat procedure on the other parking stand.

For attachment category 3:

- Lower the tractor three-point linkage.

- Position ball joints of tractor lower links in line with

holes of machine lower yokes.

- Insert pins (1) and lock using lynch pins (2).

Precision Seed Drills

MAXIMA 2

- Remove lynch pin (1) and pin (2).

- Raise parking stand (3).

- Insert pin (2) and lock using lynch pin (1).

- Proceed the same way on each parking stand.

62

Putting into service

Page 65

- Attach top link with hitch pin.

- Use tractor and machine attachment holes to adjust

the top link position.

- Raise machine using the tractor lift linkage until

parking stands no longer rest on the ground.

To obtain optimum PTO shaft angles and

tractor lift capacity, the top link must be

parallel to the lower links or slightly pointing

downwards towards the tractor.

Precision Seed Drills

MAXIMA 2

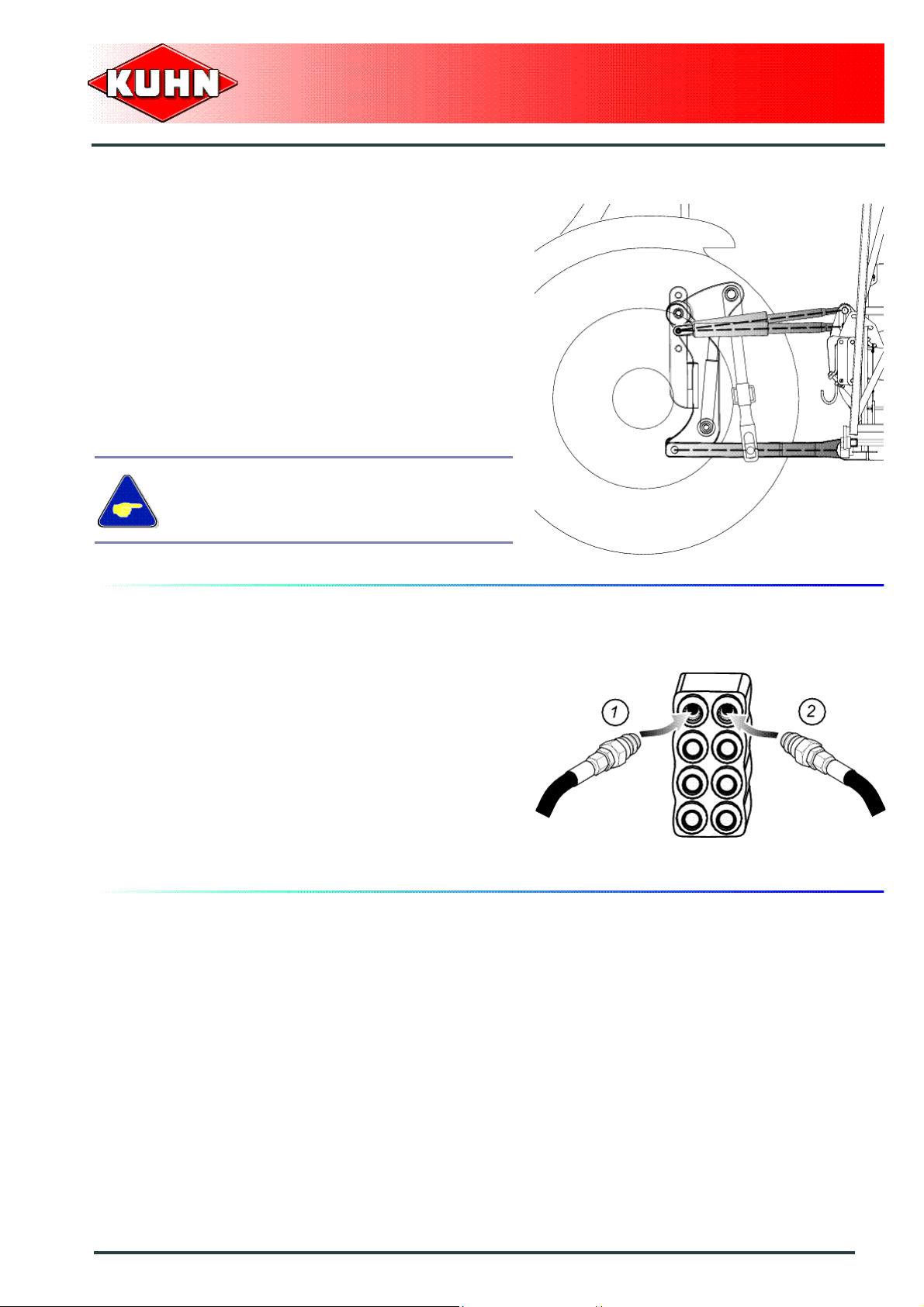

Hydraulic connections

Connect hydraulic hoses (1) and (2) to a double acting

outlet.

Hoses (A) and (B) supply the side marker

folding/unfolding cylinders.

Putting into service

63

Page 66

Adjusting the machine

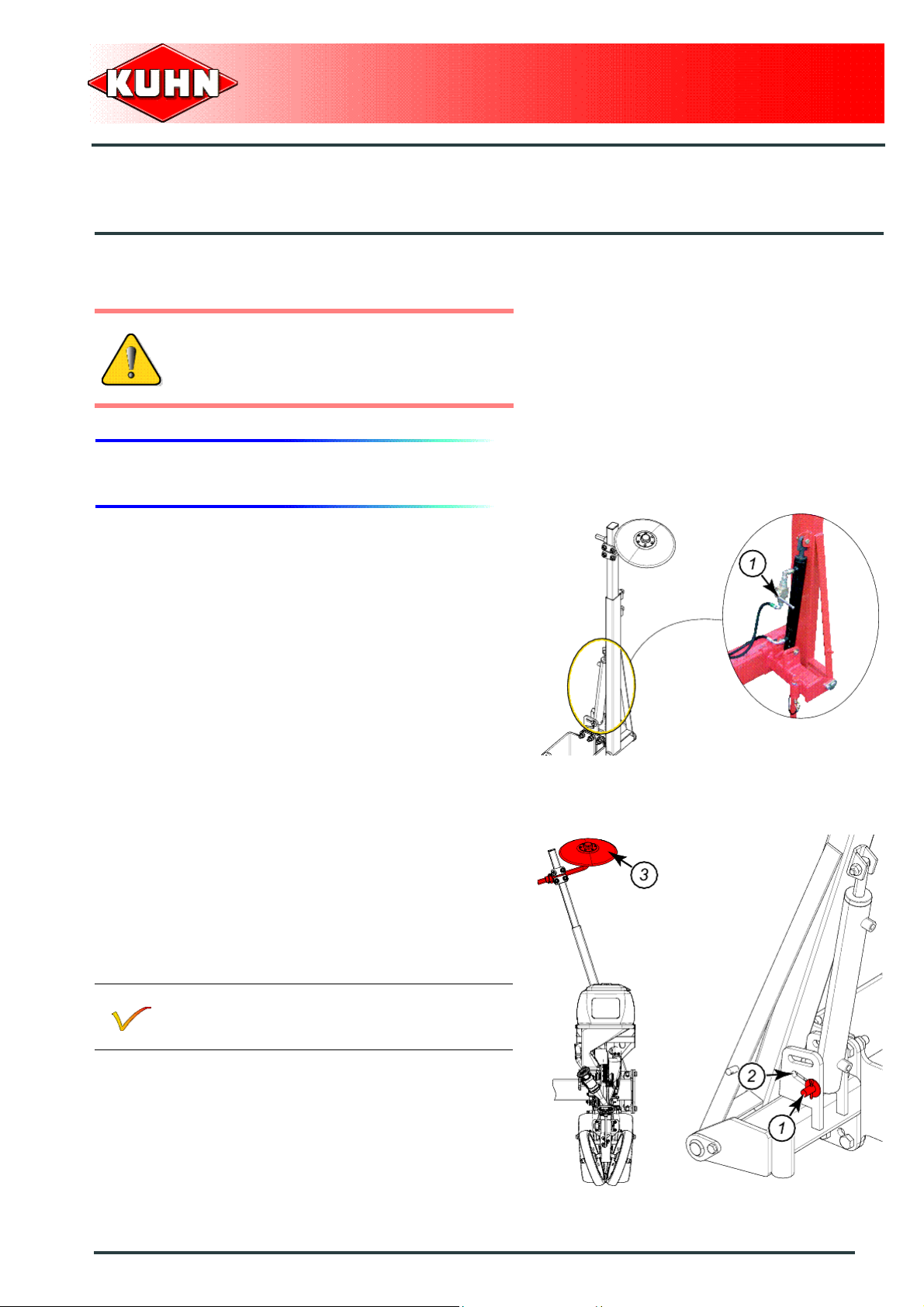

Adjusting the vertical setting

Adjust the top link length so that the machine is

horizontal with regards to the ground.

This setting can be checked with the seed drill level

gauge (1).

Check setting over the first few metres sown.

Precision Seed Drills

MAXIMA 2

Adjusting the scrapers of the side gauge wheels

The scrapers remove soil build-up on the rubber tread of the side gauge wheels.

- Loosen bolts (1).

- Adjusting scrapers (2):

Lateral adjustment

Adjust scraper to obtain play (X) of approximately 3 mm

(0.12 ’’) between scraper (2) and the inside rubber tread

of gauge wheel (3).

Lengthways adjustment

Adjust scraper (2) as close as possible to the gauge

wheel, without touching it. Rotate gauge wheel once to

check that it is not in contact.

- Tighten screws (1).

In certain wet conditions with plant debris, it may

be necessary to remove the scrapers to continue

working without risking stopping the gauge

wheels from turning.

64

Putting into service

Page 67

Setting the seed row spacing

For machine with 8 - 12 - 18 rows.

Adjusting the central sowing units:

- Raise machine using tractor lift.

- Measure the frame middle.

- Loosen nuts (1).

- Adjust position of the two central sowing units in order

to obtain a spacing (D) with regards to the frame

middle equalling half of spacing (E) required between

rows.

- Tighten nuts (1).

• Torque: 13 daN m (96 lbf ft).

Precision Seed Drills

MAXIMA 2

Setting sowing components:

- Loosen nuts (1).

- Adjust position of the seeding units to obtain required

spacing (E) between rows.

- Tighten nuts (1).

• Torque: 13 daN m (96 lbf ft).

Repeat procedure on each seeding unit.

For machine with 9 - 11 rows.

Setting sowing components:

- Raise machine using tractor lift.

- Measure the frame middle.

- Check that central unit (1) is positioned in the frame

middle.

- Loosen nuts (2).

- Adjust position of the seeding units to obtain required

spacing (E) between rows.

- Tighten nuts (2).

• Torque: 13 daN m (96 lbf ft).

Repeat procedure on each seeding unit.

Putting into service

65

Page 68

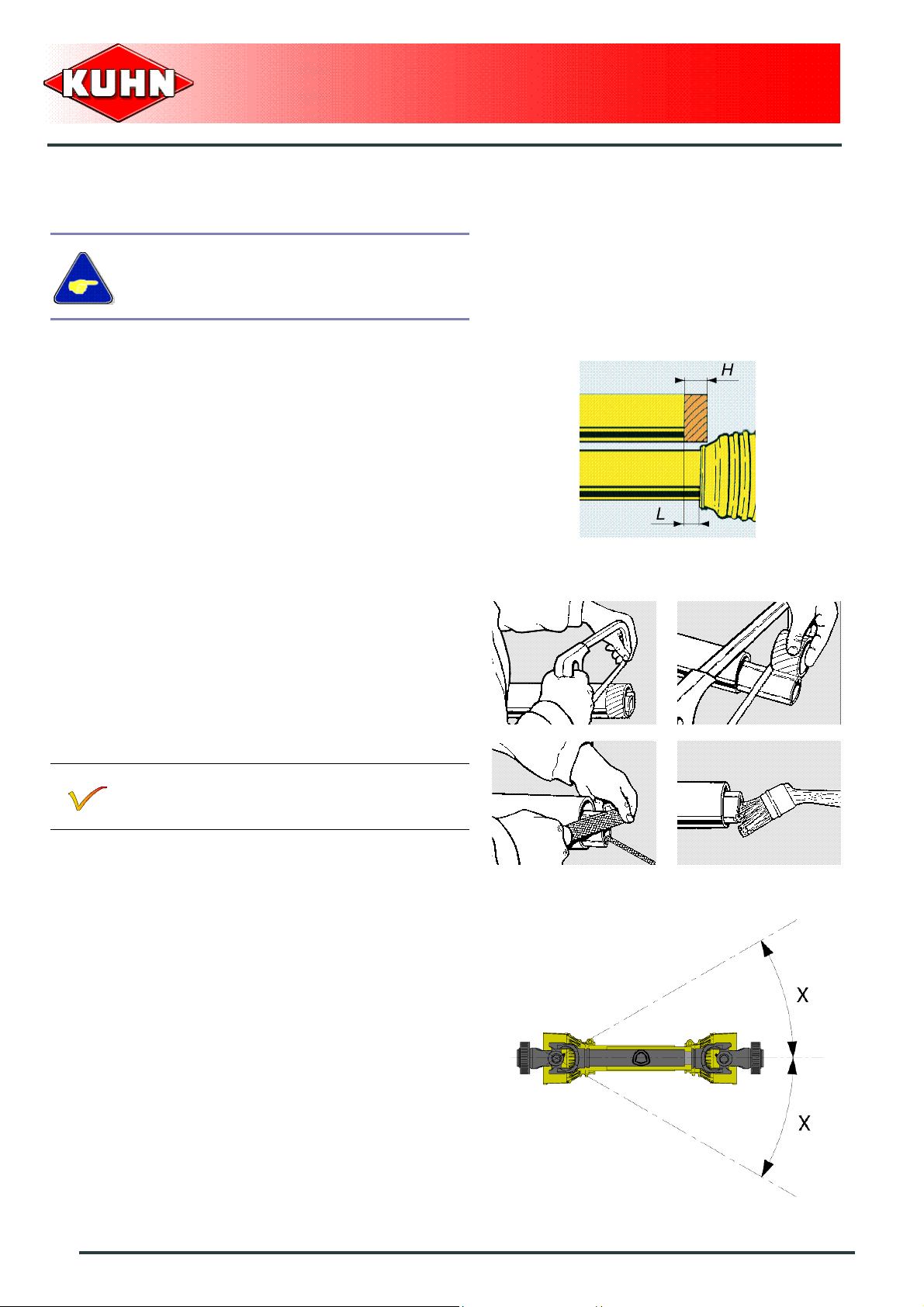

Primary PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes.

- As a safety measure, a clearance (L) of at least

25 mm (1’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

250 mm (10’’).

Precision Seed Drills

MAXIMA 2

If this is not the case:

- Mark length (H) to cut when the transmission is the

maximum overlap position.

- Shorten the guard tubes and the transmission tubes

by the same length.

- Bevel and clean the tubes.

- Grease the inside of the outer tube.

Check that there is still a minimum overlap of

250 mm (10’’) when the machine is in working

position and the tractor in line with the machine.

Never operate the PTO shaft at an angle X exceeding

30°.

66

Putting into service

Page 69

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

Precision Seed Drills

MAXIMA 2

On machine side, hook drive guard chain to ring (1).

Immediately replace any worn or damaged

guard.

Putting into service

67

Page 70

Uncoupling the machine

For attachment category 2:

Park the machine on an even fairly level

ground.

- Remove lynch pin (1) and pin (2).

- Lower parking stand (3).

- Insert pin (2) and lock using lynch pin (1).

- Repeat procedure on the other parking stand.

Precision Seed Drills

MAXIMA 2

- Lower the tractor three-point linkage to rest the

machine on the ground.

- Uncouple and place PTO shaft in support (1).

- Disconnect and store hydraulic hoses in holder (2).

- Disconnect and store control boxes in a dry and clean

place.

- Detach the top link from the machine end.

68

Putting into service

Page 71

- Remove lynch pins (1) (1 on each machine side).

- Pivot lock (2).

- Lower tractor lower links to disengage hitch bar (3)

from the machine semi-automatic attachment (4).

- Insert and lock lynch pin (1) (1 on each machine side).

The machine is uncoupled.

Precision Seed Drills

MAXIMA 2

For attachment category 3:

Park the machine on an even fairly level

ground.

- Lower parking stands:

• Remove lynch pin (1).

• Lower parking stand (2).

• Insert and lock lynch pin (1).

• Repeat procedure on the other parking stand.

Putting into service

69

Page 72

- Lower the tractor three-point linkage to rest the

machine on the ground.

- Uncouple and place PTO shaft in support (1).

- Disconnect and store hydraulic hoses in holder (2).

- Disconnect and store control boxes in a dry and clean

place.

- Detach the top link from the machine end.

- Remove lynch pins (2).

- Remove the 2 pins (1).

- Lower the tractor three-point linkage.

Precision Seed Drills

MAXIMA 2

The machine is uncoupled.

70

Putting into service

Page 73

$INSTRUCTIONS FOR TRANSPORT

Before placing the machine into transport

position:

Wait until the rotating parts have come to a

complete stop.

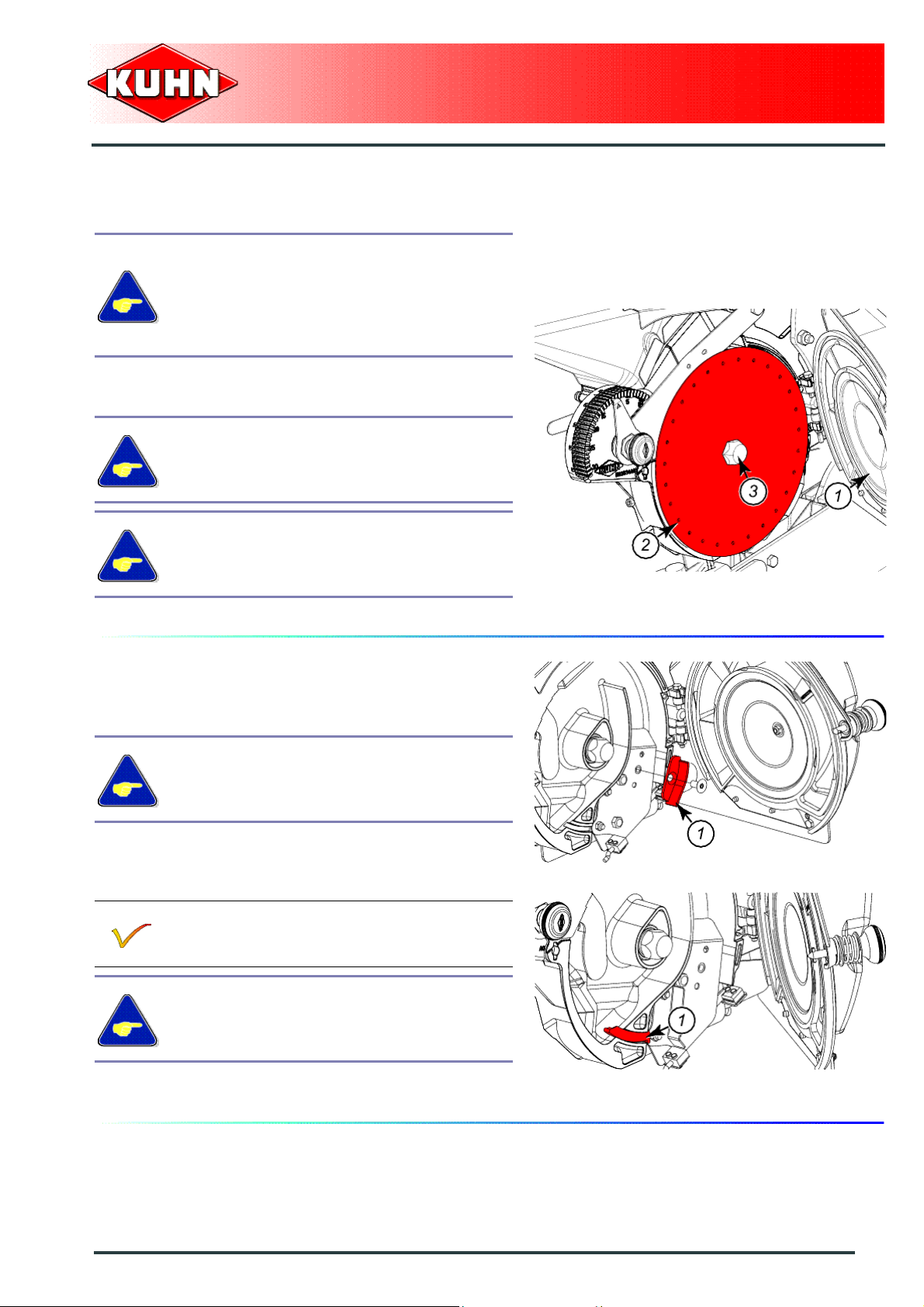

1. Putting the machine into transport position

Precision Seed Drills

MAXIMA 2

From the working position:

If the machine is fitted with a fertilizer or if the

machine is fitted with a fertilizer with a 1350 L

(356 US gal) hopper:

- Activate cylinders to fold side markers.

- Lock side markers using valves (1) (1 on each

marker).

- Position pin (1) in lower hole (2).

this position enables leaving the marker disks (3)

pointing outwards.

Instructions for transport

71

Page 74

If the machine is equipped with a fertilizer with

2x280 l (2x74 US gal) hoppers:

- Activate cylinders to fold side markers.

- Lock side markers using valves (1) (1 on each

marker).

- Remove tube clip (1).

- Position side marker disc towards the machine inside.

- Insert and lock tube clip (1).

Repeat procedure for the other marker.

Precision Seed Drills

MAXIMA 2

- Position pin (1) in upper hole (2).

The machine is in transport position.

Never engage the tractor PTO drive when th e

machine is in transport position.

72

Instructions for transport

Page 75

2. Conformity with the road regulations

For driving on public roads, due to its width,

the machine must be transported on a trailer.

Check that the lilght boards are clean and that the

lighting equipment functions before transporting the

machine on public roads.

Immediately replace any worn or damaged

signalling panels or lights.

Precision Seed Drills

MAXIMA 2

During transport, adapt the travel speed to

suit the road conditions.

Instructions for transport

73

Page 76

$INSTRUCTIONS FOR WORK

Before placing the machine in working

position:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

1. Putting the machine into work position

Precision Seed Drills

MAXIMA 2

From the transport position:

If the machine is equipped with a fertilizer with

2x280 l (2x74 US gal) hoppers:

- Lower tractor lift linkage to position the machine near

to the ground.

- Remove tube clip (1).

- Position side marker disc on the machine outside.

- Insert and lock tube clip (1).

Repeat procedure for the other marker.

- Unlock side marker valve (1). (1 on each marker).

- Deploy the right or left side marker.

The machine is in working position.

74

Instructions for work

Page 77

2. Adjustments in working position

Adjusting the seeding unit ground

pressure

The seeding unit ground pressure is modified by

changing the position of springs (1).

Precision Seed Drills

MAXIMA 2

Coupling device (a):

By moving one spring (1) rearwards, the seeding unit

ground pressure is increased by 20 kg (44 lb).

Coupling device (b):

By moving 2 springs (1) rearwards, the seeding unit

ground pressure is increased by 40 kg (88 lb).

When the 2 springs (1) are positioned in

configuration (b), check that the frame is

sufficiently ballasted.

The drive wheels must not slip. If necessary

ballast the frame.

Instructions for work

75

Page 78

Whe the machine is fitted with electronic

seeding unit disengagement system (1),

never position springs (2) in configuration

(c). There is a risk of interference.

Precision Seed Drills

MAXIMA 2

76

Instructions for work

Page 79

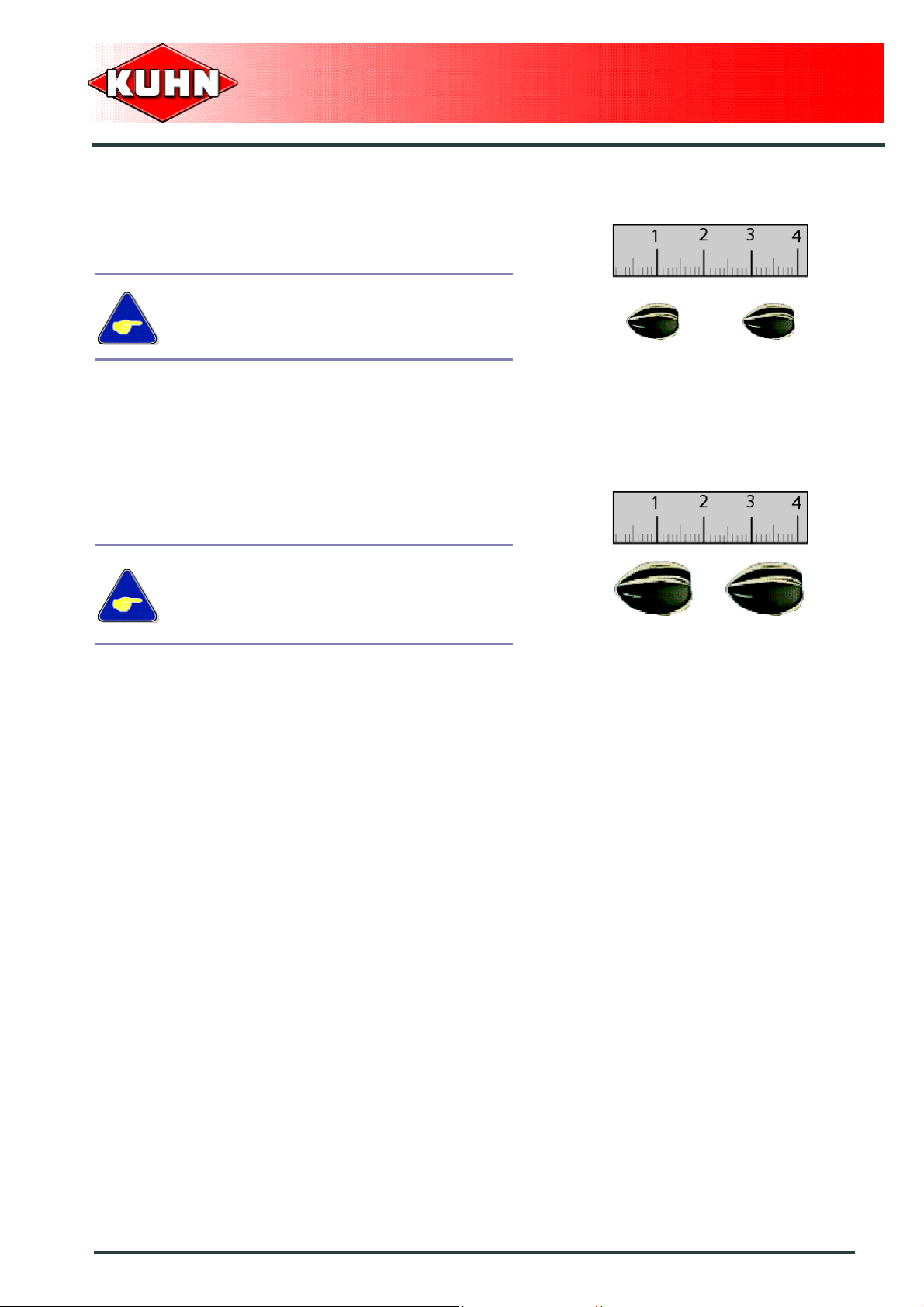

Adjusting the sowing depth

Handle (1) enables adjusting the sowing depth.

The sowing depth can be adjusted from 0 to

8.5 cm (0’’ - 3.34’’) (app ro xim a te ly).

Precision Seed Drills

MAXIMA 2

Adjustment:

Refer to the decal applied on the machine to determine

handle (1) setting position.

Settings are only indicated for your

information.

The seeding unit setting must be adjusted

according to the sowing conditions (Soil

preparation and nature).

Example:

To adjust the sowing depth at 4.5 cm (1.77’’), place

adjustment handle in position D-E.

- Repeat procedure on each seeding unit.

The marking enables identical setting of each

seeding unit.

Instructions for work

77

Page 80

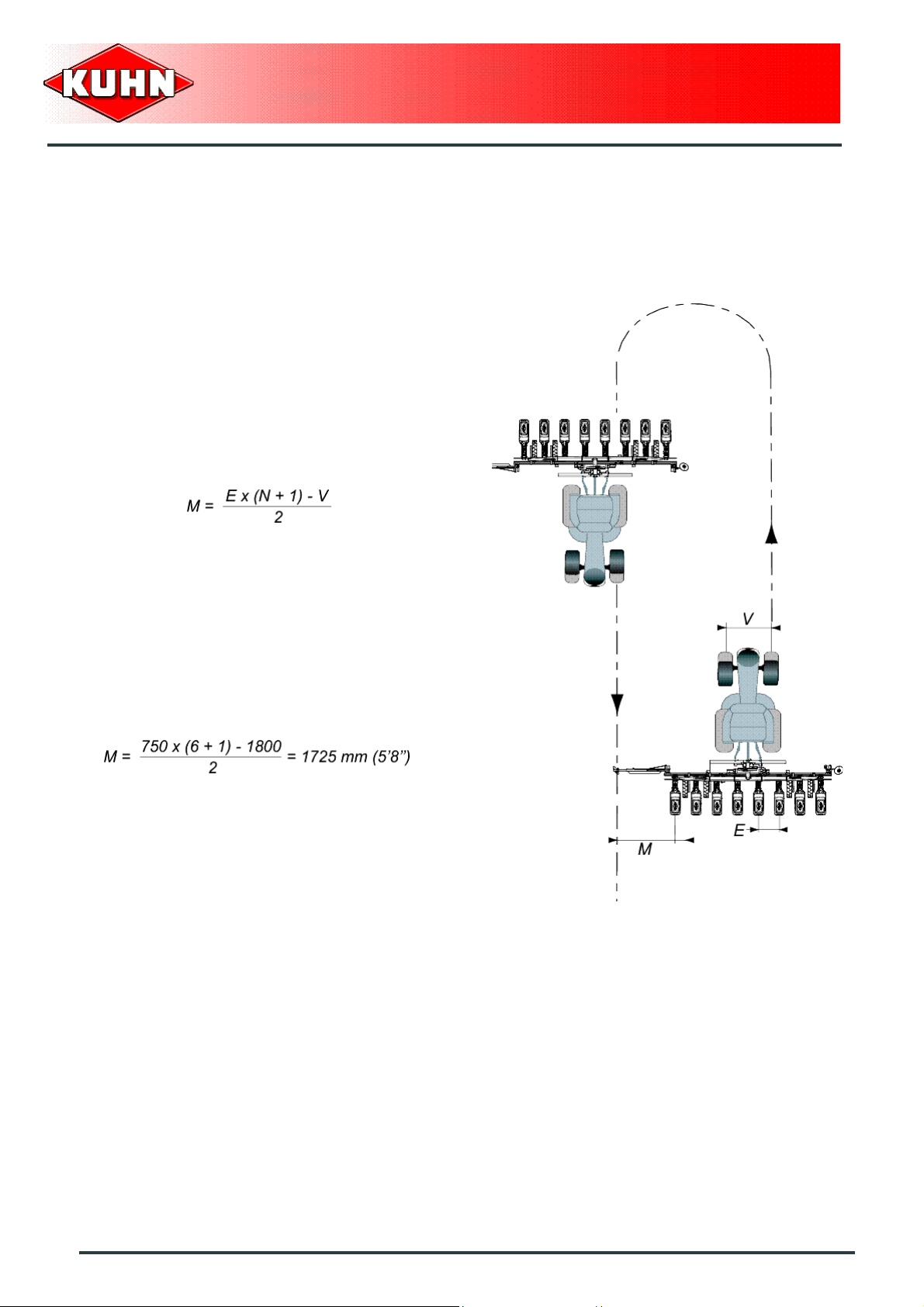

Adjusting the markers

The side markers are designed to provide marking in the

tractor center or wheel track.

Marking to the tractor wheel

Calculating the distance (M):

- M: distance between the marker disk and the outer

seeding unit.

- N: Number of rows.

- E: distance between rows.

- V: Tractor wheel track.

Precision Seed Drills

MAXIMA 2

Example:

N = 6 rows

E = 750 mm (2.5’’)

V = 1800 mm (5’11’’)

78

Instructions for work

Page 81

Marking in line with the tractor

Calculating the distance (M):

- M: distance between the marker disk and the outer

seeding unit.

- N: Number of rows.

- E: distance between rows.

Example:

Precision Seed Drills

MAXIMA 2

N = 6 rows

E = 750 mm (2.5’’)

Instructions for work

79