Page 1

Complementary instructions

KC0012GB F

Pneumatic seed drills

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

KC0012GB F

- English - 10-2008

Page 2

Page 3

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understa nd this manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts are manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurr ing any obligations to make changes or additions to

the equipment sold previously.

Dear Owner

1

Page 4

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

$Contents

Dear Owner.....................................................................................................................1

Contents .........................................................................................................................2

Control box identification .............................................................................................4

Front view......... ... ... .......................................... ... .... .......................................... ... ... ......................... 4

Manufacturer's marking .................................................................................................................. 5

Optional equipment...................................... ... ................................................................................ 5

Safety..............................................................................................................................6

Description of symbols used in this document............................................................................ 6

Safety instructions........................................................................................................................... 7

Specifications.................................................................................................................9

Technical specifications ................................................................................................................. 9

Description of the box................................................................................................................... 10

Meaning of symbols ............................................... ... .......................................... ... ... .... ... ............. 11

Description of the controls........................................................................................................... 11

Assembly and fitting....................................................................................................14

Description of the connection...................................................................................................... 14

Electrical diagrams........................................................................................................................ 18

Positioning and parking................................................................................................................ 21

2

Contents

Page 5

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Putting into service......................................................................................................22

Switches on the control box......................................................................................................... 22

Machine use..................................................................................................................23

Adjustments before first use............. ... ....... ................................................................................. 23

Preliminary adjustments at work .................................................................................................28

Use during work............................................................................................................................. 51

Simple maintenance .....................................................................................................55

Error codes....................................... ... ... .......................................... ... .... ... ... ................................. 55

Adjusting the sensors..... ... ... ... .......................................... .... ... ... ... ... .... ... ... ................................. 57

Optional equipment......................................................................................................58

Pre-emergence marker.................................................................................................................. 58

Maintenance and storage ............................................................................................59

Limited warranty...........................................................................................................60

Contents

3

Page 6

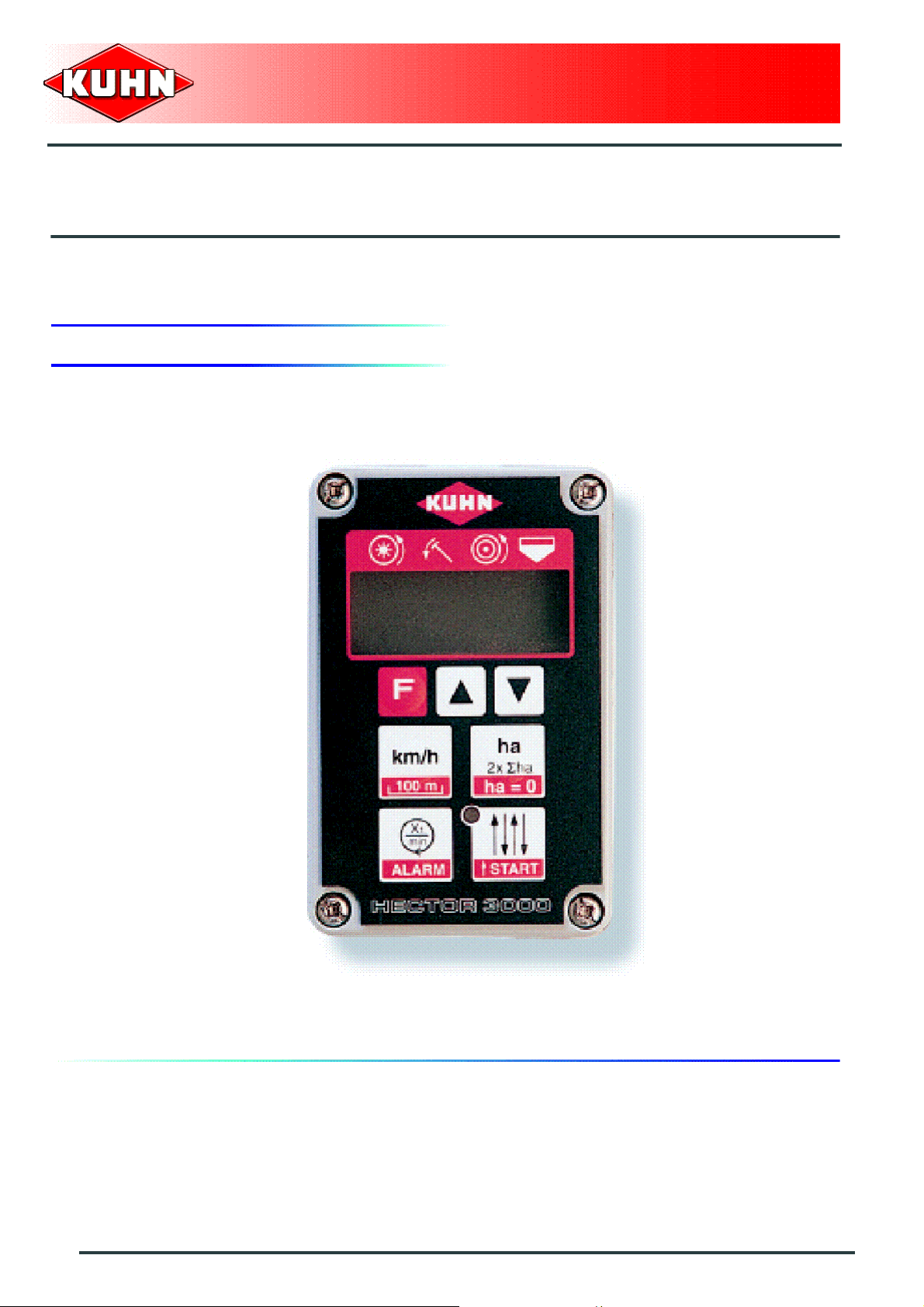

1. Front view

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

$Control box identification

4

Control box identification

Page 7

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

2. Manufacturer's marking

Please note the serial number of your equipment. This

information is to be indicated to the dealer for all spare

parts orders.

Type:

Serial no.:

KUHN reference:

The software version: 2.2

HECTOR 3000

3. Optional equipment

Tick box corresponding to the equ ipment fitted on your

machine:

Pre-emergence marker

Control box identification

5

Page 8

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

HECTOR 3000

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

6

Safety

Page 9

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

2. Safety instructions

Introduction

The operator must follow the safety instructions in this manual and in the machine's operator's manual as well

as respect the warnings posted on the machine.

Read and follow the safety instructions

Before using the control box, carefully read all safety

instructions in this manual.

The operator must be familiar with all machine controls

and their respective functions. It is too late to learn once

work has been started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to take before using the

control box

Place the control box so that it cannot interfere with other

tractor controls and be activated inadvertently.

Before switching the control box on, check that nobody

is within the machine pivoting area: switching on the

control box can activate functions on the machine.

Precautions to take when using the control

box

Do not operate the control box while a person is carrying

out work on the machine.

Switch off control box before carrying out any

maintenance or repair work on the machine.

Safety

7

Page 10

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Precautions when driving

Before transporting the machine on public roads, make

sure no function of the control box or of the control

accessories can be switched on inadvertently. Make

sure tractor valves and power take-off are deactivated

and not inadvertently engaged.

HECTOR 3000

8

Safety

Page 11

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Specifications

1. Technical specifications

Hector 3000

The HECTOR 3000 electronic control box is used to:

- Control the pre- and post-emergence marker system.

- Count the area sown (daily and total counter).

- Check metering unit rotation.

- Indicate forward speed.

- The minimum grain level.

- Checking the rotational speed of the blower.

- Check marker positions during work.

HECTOR 3000

Specifications

9

Page 12

2. Description of the box

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

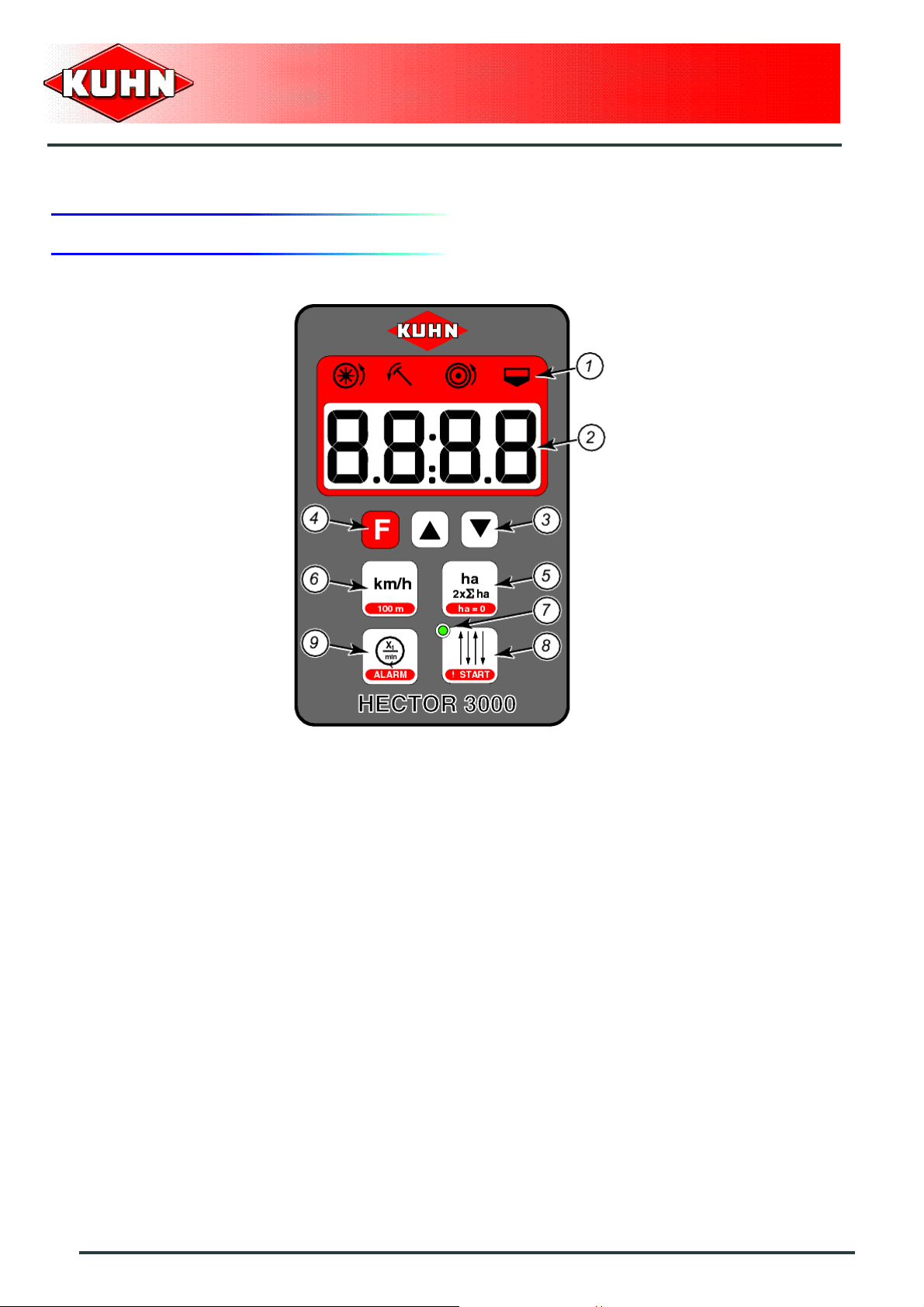

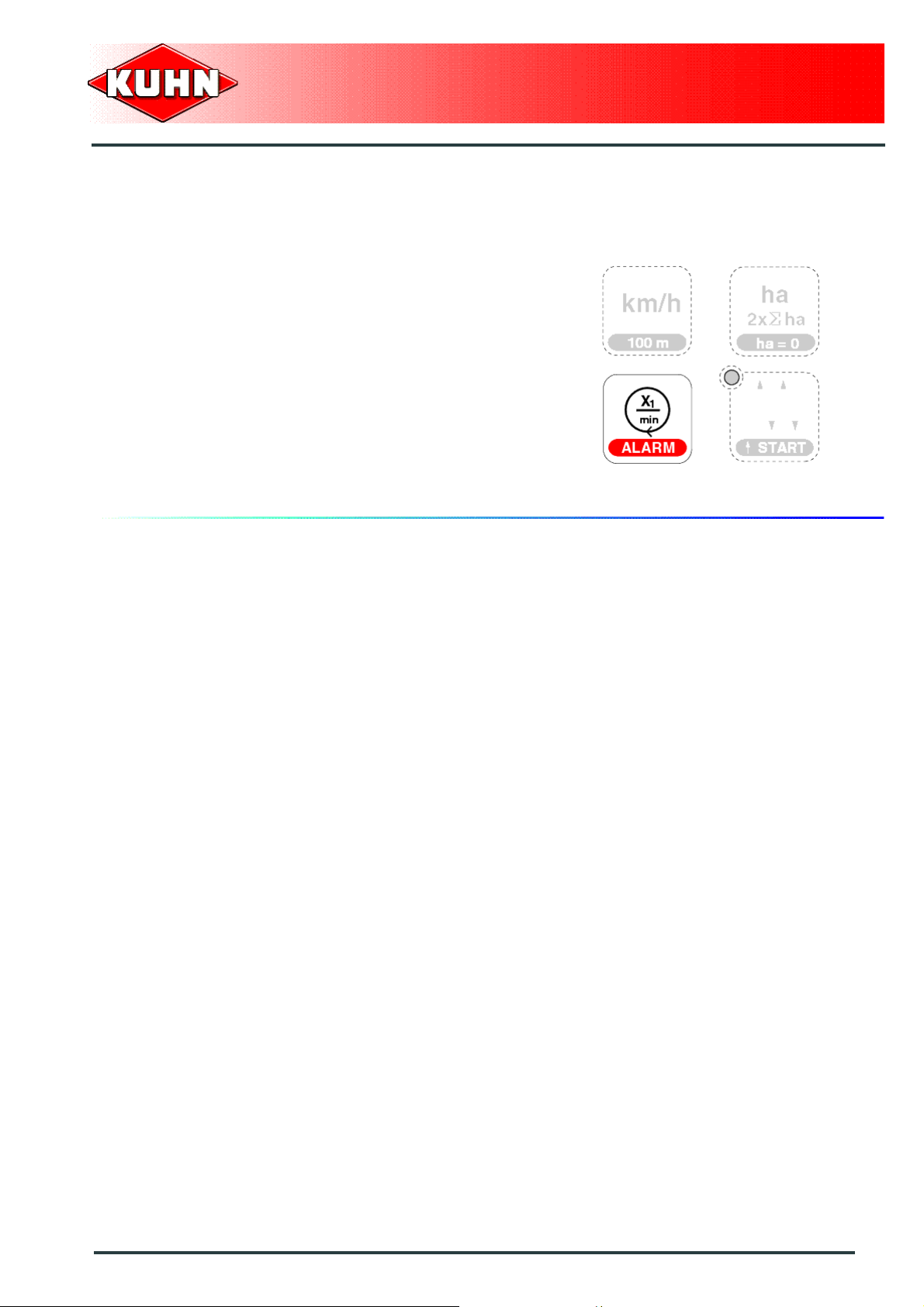

1 : Symbols 2 : Screen

3 : Data modification keys 4 : Function key

5 : Area button 6 : Speed button / Calibration

7 : Marker display 8 : Marker button

9 : Alarm keys / Blower

10

Specifications

Page 13

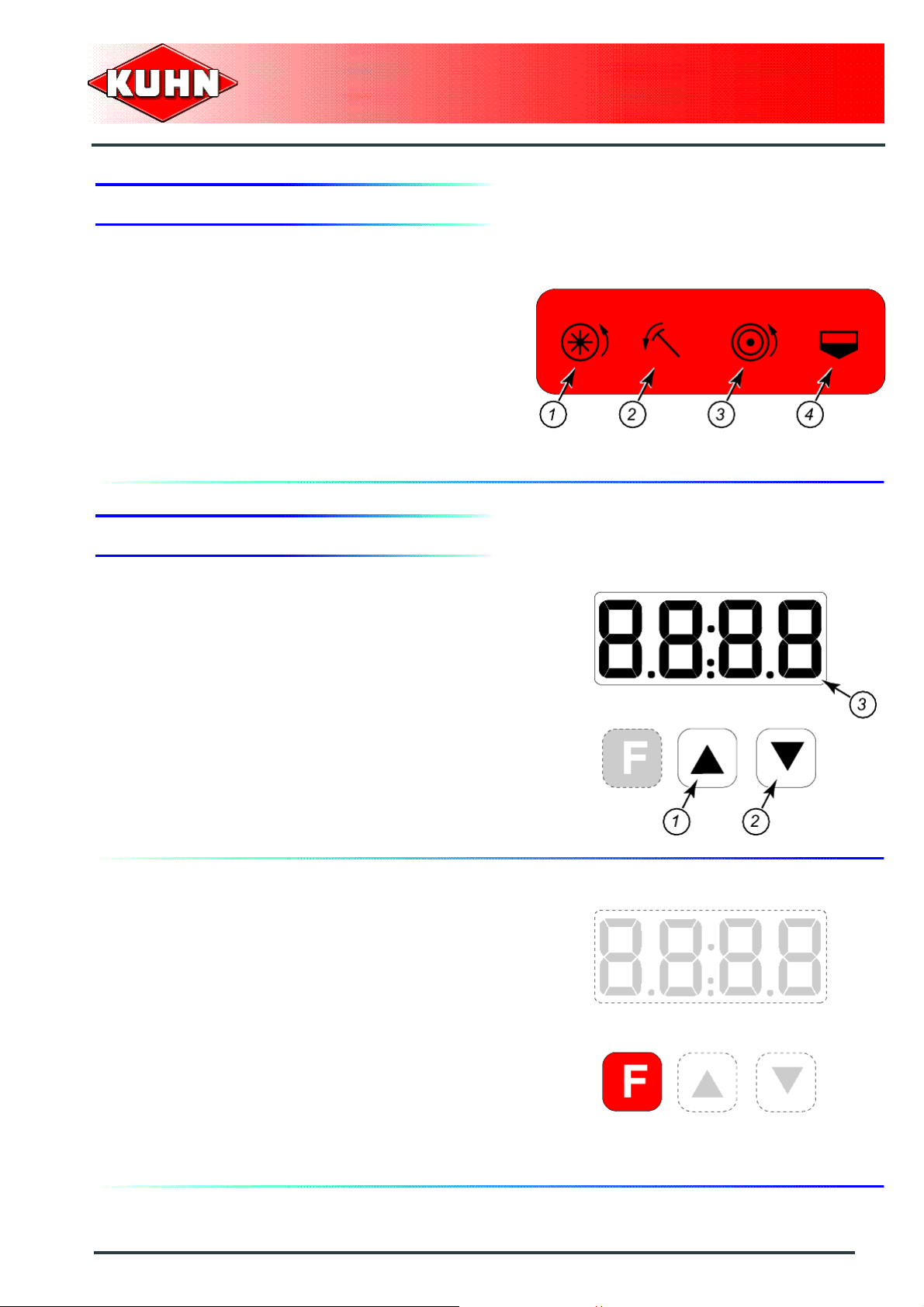

3. Meaning of symbols

Symbol (1):

• Blower.

Symbol (2):

• Side markers.

Symbol (3):

• Metering unit.

Symbol (4):

• Seed level.

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

4. Description of the controls

Data modification keys

Keys (1) and (2) enable modifying data displayed on

screen (3).

Function key

- Selecting adjustment parameters.

- Memorizing the adjustments.

Specifications

11

Page 14

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

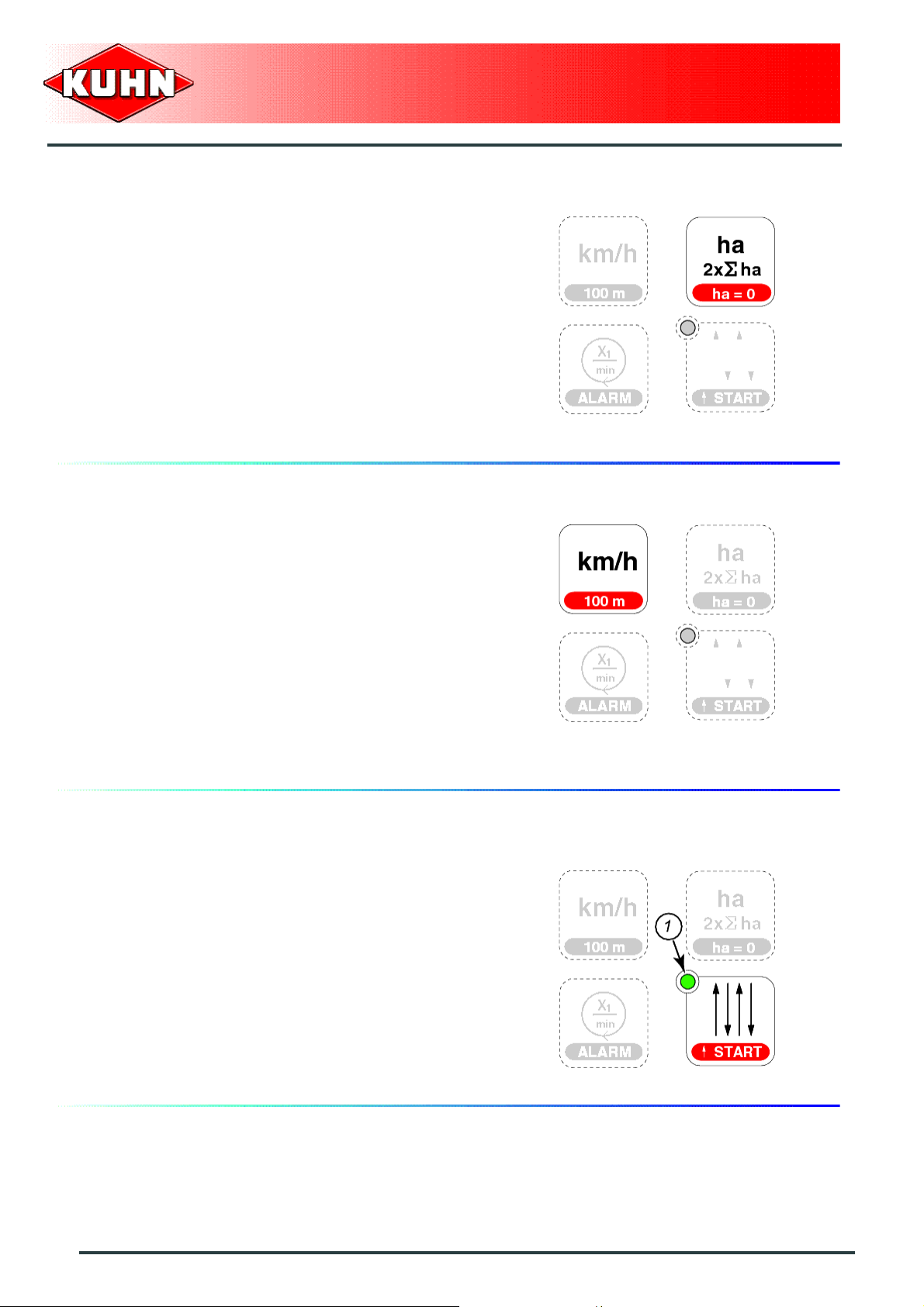

Area button

- Working width adjustment.

- Displaying and adjusting the counters:

• Displaying the daily area counter (ha).

• Displaying the total area counter (ha).

• Counter reset.

Speed button

- Displays the speed.

- Memorization and calibration of the forward travel

impulses.

HECTOR 3000

Marker button

- Tramlining shutters closing indicator light (1).

- Displaying the tramlining rhythm.

- Adjusting the tramlining rhythm.

- Tramlining start and stop.

12

Specifications

Page 15

Alarm keys / Blower

- Alarm activation and deactivation.

- Blower rotational speed is on display.

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Specifications

13

Page 16

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Assembly and fitting

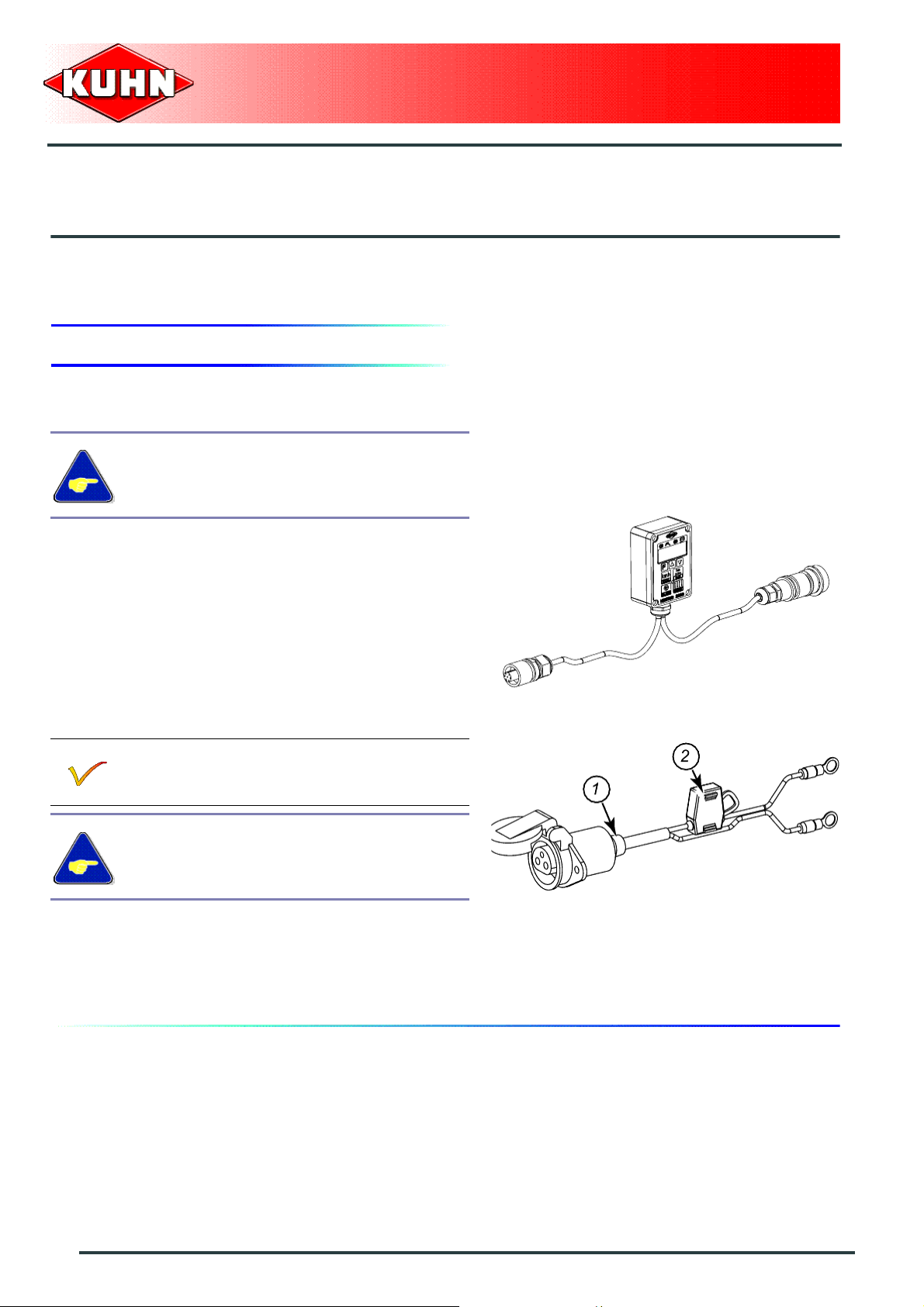

1. Description of the connection

Electrical power supply

Never connect battery charger or perform

welding tasks without having previously

disconnected the control box.

HECTOR 3000

The control box is connected to:

- A tractor 3-pin socket.

- A 7-pin plug of the Hector 3000 junction box.

For tractors not fitted with a 3-pin socket, a wiring

harness can be ordered under (1):

Part no. 83233002.

Do not connect the wiring harness to the

starter connections.

Check that the connectors are in a good

condition and clean.

Connect the wiring harness directly to the battery

terminals respecting the polarities.

The wiring harness is fitted with a 15 Amp ATO type

fuse: Kit no. 82333017 (2)

14

Assembly and fitting

Page 17

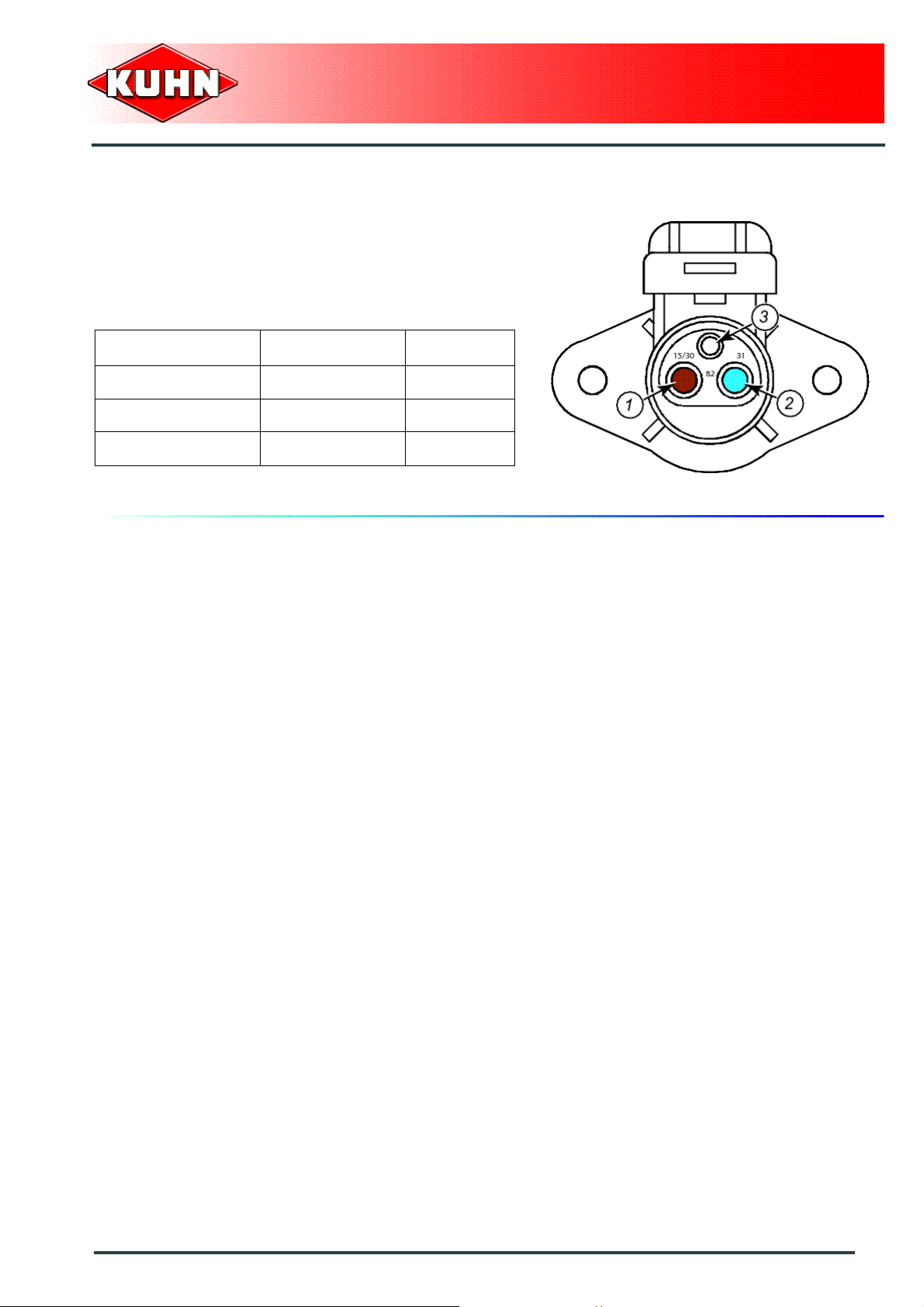

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

3 pin plug

The box is energized by the tractor's 3-pin socket

(DIN 9680, ISO 12369) or the battery power cable

supplied.

Pin Wire color Function

HECTOR 3000

15 / 30 (1)

31 (2)

82 (3)

Brown

Blue Earth

+ 12 Volt

--

Assembly and fitting

15

Page 18

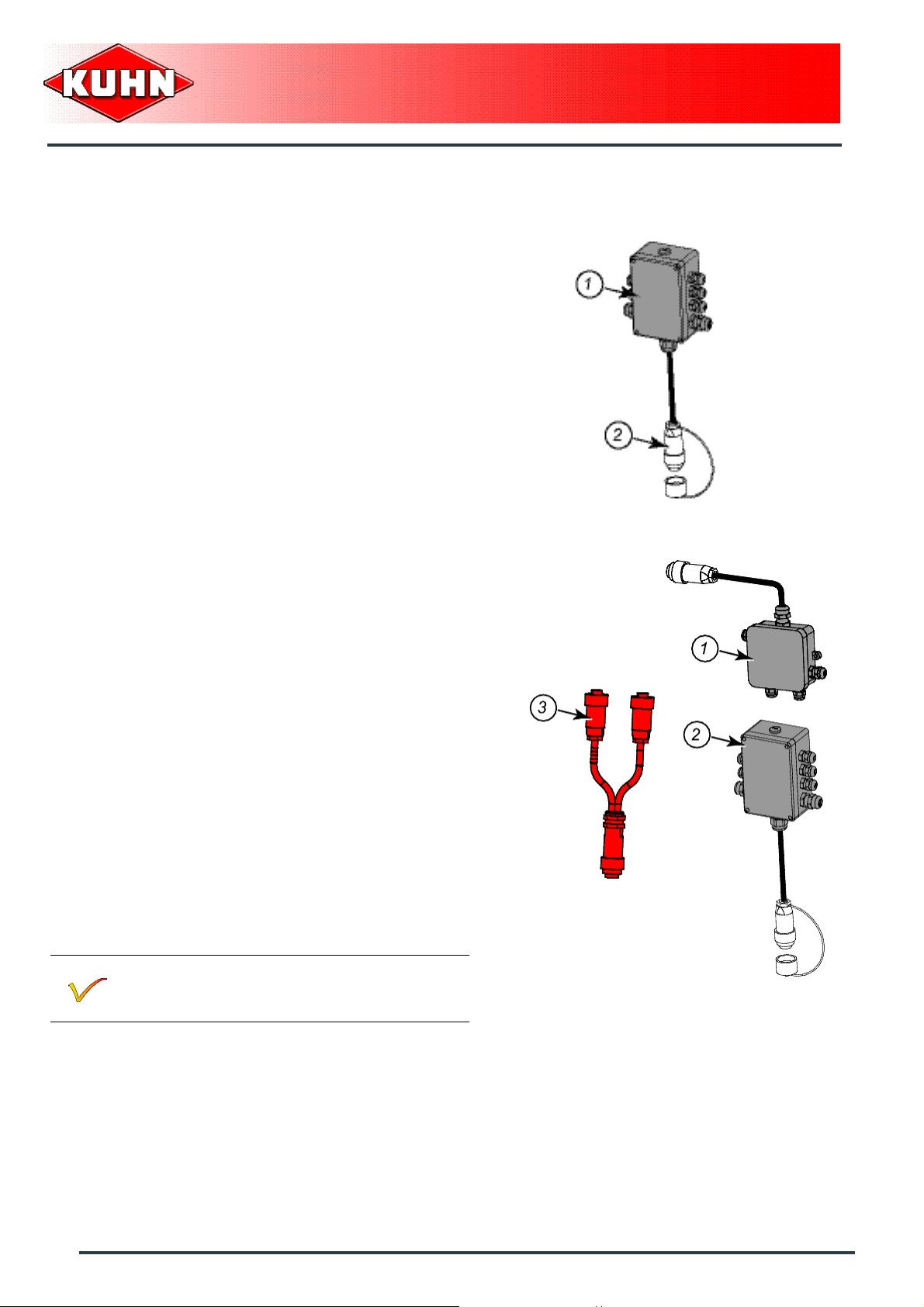

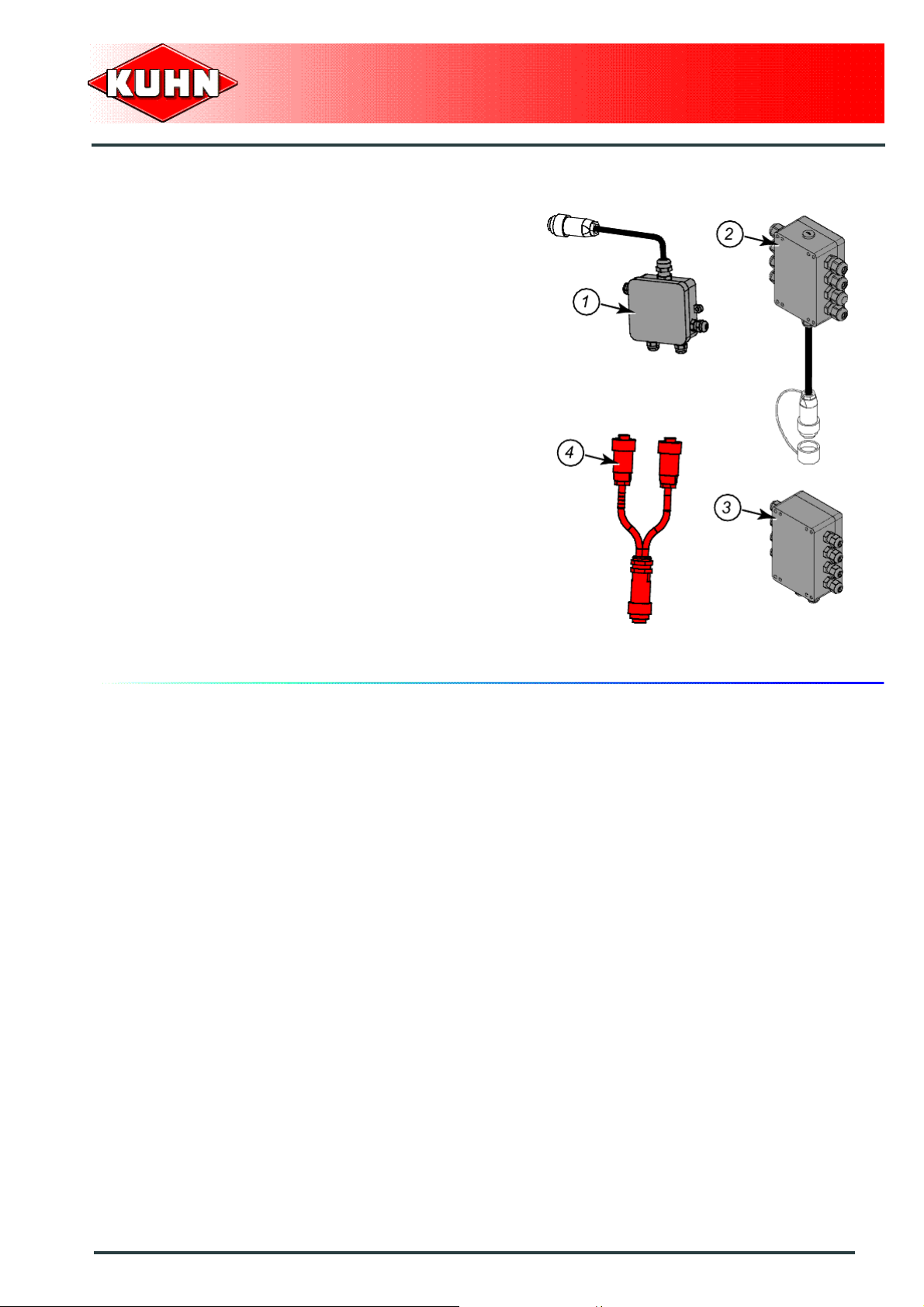

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Junction box

VENTA EC LC AL and MEGANT

The Hector 3000 on the seed drill is composed of:

- 1 junction box (1).

- 2 marker sensors.

- 1 blower sensor.

- 1 metering unit sensor.

- 1 electric tramlining control cylinder.

- 1 seed level sensor.

The junction box is connected to the control box with a 7-pin

plug (2).

HECTOR 3000

VENTA TF702 BTF and BTFR from 3.00 to 5.00 m

(9’10’’ - 16’5’’)

The Hector 3000 on the seed drill is composed of:

- 1 front junction box (1).

- 1 rear junction box (2).

- 2 marker sensors.

- 1 blower sensor.

- 1 metering unit sensor.

- 1 skeleton wheel sensor.

- 1 or 2 control cylinders.

- 1 electric tramlining control cylinder.

The junction boxes (1) and (2) are connected to the

control box by means of a

- The markings on the

• Yellow / green: Front junction box (1).

• Red: Rear junction box (2).

When the TF702 hopper is used in solo, the front

junction box is connected to the control box by

means of an extension cord.

Y (3) connector.

Y connector correspond to:

16

Assembly and fitting

Page 19

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

VENTA TF702 and CS6003R/CS6004R 6 m

(19’8’’)

The Hector 3000 on the seed drill is composed of:

- 1 front junction box (1).

- 1 rear junction box (2).

- 1 electromagnet connecting box for tramlining control

(3)

- 2 marker sensors.

- 1 blower sensor.

- 1 metering unit sensor.

- 1 skeleton wheel sensor.

- 1 or 2 control cylinders.

- 4 tramlining control electromagnets.

The junction boxes (1) and (2) are connected to the

control box by means of a

- The markings on the

• Yellow / green: Front junction box (1).

• Red: Rear junction box (2).

Y (4) connector.

Y connector correspond to:

HECTOR 3000

Assembly and fitting

17

Page 20

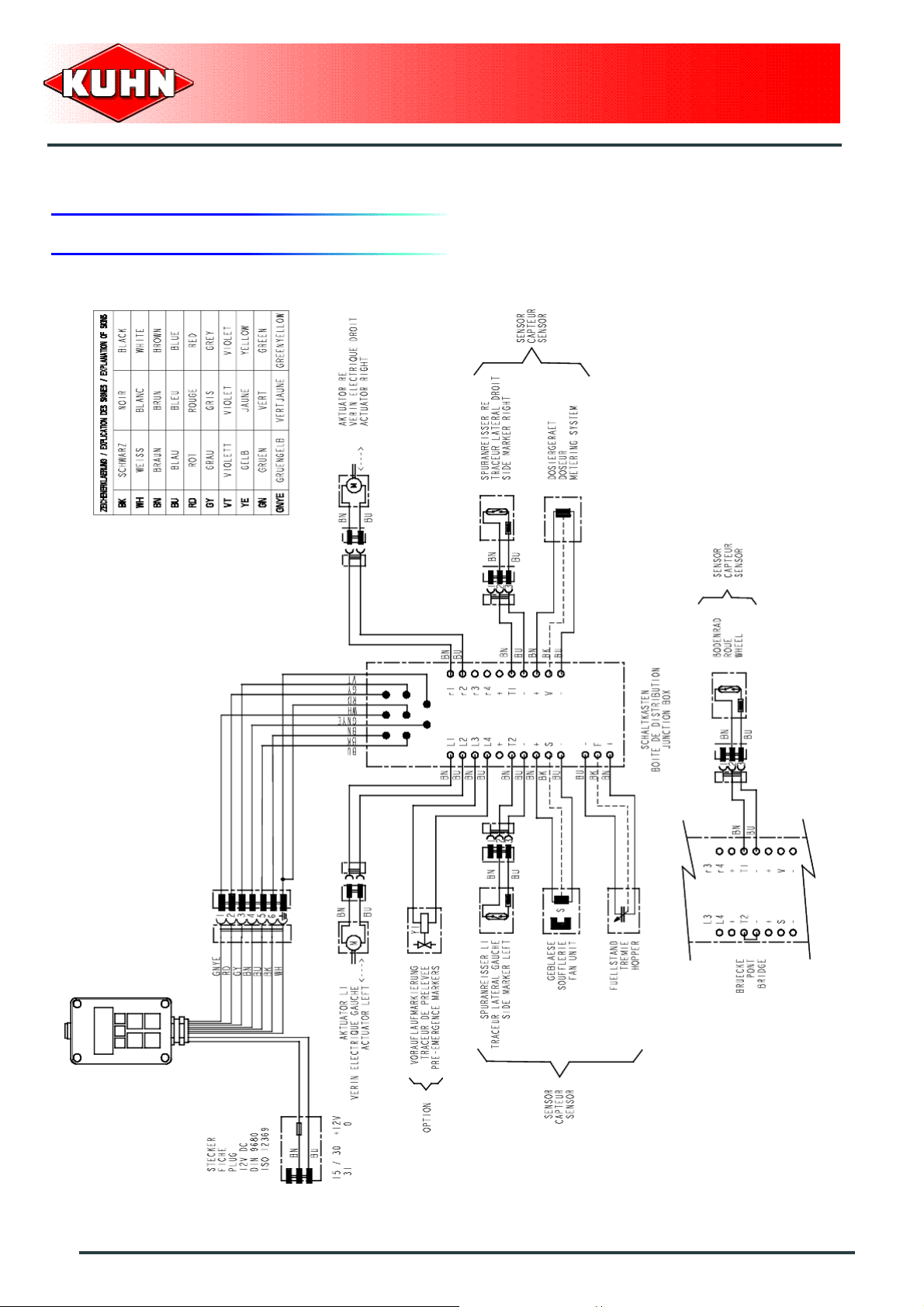

2. Electrical diagrams

VENTA EC LC AL and MEGANT

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

18

Assembly and fitting

Page 21

VENTA TF702 BTF and BTFR

from 3.00 to 5.00 m (9’10’’ - 16’5’’)

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Assembly and fitting

19

Page 22

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

VENTA TF702 and CS6003R/CS6004R

6 m (19’8’’)

HECTOR 3000

20

Assembly and fitting

Page 23

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

3. Positioning and parking

The control box must be easily accessible from the

tractor cab.

Control box mounting

It is held by means of a magnet (1).

HECTOR 3000

Control box removal

Store control box in a dry place free of dust.

Assembly and fitting

21

Page 24

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Putting into service

1. Switches on the control box

Before switching the control box on, check

that nobody is within the machine pivoting

area: switching on the control box can

activate functions on the machine.

Connect control box to the 3-pin electric plug.

HECTOR 3000

22

Putting into service

Page 25

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Machine use

1. Adjustments before first use

Introduction

On switching on the control box press simultaneously

key (1).

- Following parameters can be modified:

• Type of seed drill.

• Number of magnets or tramlining control cylinders.

(Only one on mechanical seed drills).

• Checking the screen.

• Checking sensors.

• Marker sensor signal time delay.

Press key (1) to access the parameters to modify.

HECTOR 3000

The adjustable parameter flashes.

- Press keys (2) and (3) to modify the parameters.

Press for approximately 3 seconds on key (1).

- The selection flashes shortly.

The parameter is memorized.

Press on one of the other keys to leave the configuration

menu.

Machine use

23

Page 26

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Configuration of the type of seed drill

The digits displayed below the symbols mean the

following:

Symbols Displays

- t = Pneumatic seed drills. (Blower sensor)

-

-

Side markers:

-

-

Speed sensor:

-

-

HECTOR 3000

d = Mechanical seed drills. (Distribution sensor)

E = Precision Seed Drills.

1 = Activated.

0 = Deactivated.

1 = Activated.

0 = Deactivated.

Level sensor:

-

1 = Activated.

-

0 = Deactivated.

- On switching on the control box press simultaneously

key (1).

• The adjustable parameter flashes.

- Press key (3) to modify parameter.

- Press key (2) to access the next parameter.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

- Press key (1) to access the next adjustment.

Configuration for:

-VENTA.

- MEGANT.

24

Machine use

Page 27

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Configuration of the number of cylinders

Number of tramlining control cylinders.

- Press keys (3) and (2) to modify the parameter.

Factory setting: 1 Cylinder.

For special rhythms: 2 Cylinder (optional

equipment).

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

- Press key (1) to access the next adjustment.

HECTOR 3000

Checking the screen

Allows checking the screen durin g 2 seconds, then the

screen passes automatically to the next adjustment.

Machine use

25

Page 28

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Checking sensors

Allows to check the various seed drill sensors.

- Switch on the blower.

• The top segment of the first digit flashes.

- Raise wheel (TF702) or markers (EC LC AL MEGANT

BTF BTFR CS6003R).

• The top segment of the second digit is ON.

- Rotate the distribution drive wheel.

• The top segment of the third digit flashes.

- Cover the hopper sensor.

• The top segment of the fourth digit is ON.

- Press key (1) to access the next adjustment.

HECTOR 3000

26

Machine use

Page 29

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Marker sensor signal time delay

The sensor signal time delay can be adjusted for the

following positions:

-Raised

- Lowered

An increase in the time delay is requir ed for particular

cases where the sensor is not fitted on the marker

The time can be adjusted from 0.0 to 9.9

seconds.

- Press keys (3) and (2) to modify the parameter.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

- Repeat procedure for:

- Press on one of the other keys to leave the

configuration menu.

t 1.

t 2.

t 2.

HECTOR 3000

.

Recommended factory setting with markers:

- t1: 0.5 seconds.

- t2: 2.0 seconds.

Recommended factory setting with sensor fitted

on the wheel arm:

- t1: 3.0 seconds.

- t2: 3.0 seconds.

Machine use

27

Page 30

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

2. Preliminary adjustments at work

Introduction

The following settings which are specific to the machine are to be carried out:

- Working width.

- Memorization and calibration of the forward travel impulses.

- Tramlining rhythm.

- Alarm activation and deactivation.

- Blower rotational speed is on display.

Working width adjustment

HECTOR 3000

- Press for approximately 3 seconds on key (4).

•Symbol

• The adjustable parameter flashes.

- Press keys (2) and (3) to modify the parameter.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

Lt is displayed during 2 seconds.

Press on one of the other keys to leave the

configuration menu.

28

Machine use

Page 31

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Memorization and calibration of the forward travel impulses

In order to display the correct speed and for the hectare

counter to calculate correctly, it is necessary to program

the number of pulses over a distance of 100 m (328’1’’).

There are two possible settings:

- An average value.

- In the field.

In field calibration provides increased accuracy

in the number of impulses.

Setting an average value

- Simultaneously press keys (1) and (5).

• Symbol

- Press keys (2) and (3) to modify the parameter.

• See the adjustment chart.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

InP is displayed during 2 seconds.

HECTOR 3000

Press on one of the other keys to leave the

configuration menu.

VENTA EC, LC, AL / MEGANT

Width Impulses/100 m (328’)

2.50 m (8’22’’) 660 3:00 m (9’10’’) 780 -

3.50 m (11’6’’) 920 -

4.00 m (13’1’’) 1050 1050

4.50 m (14’9’’) 1200 1200

4.80 m (15’9’’) - 1210

5.00 m (16’5’’) 1300 1258

5.60 m (18’4’’) - 1410

6.00 m (19’8’’) 1580 1499

VENTA EC, LC, AL MEGANT

Machine use

29

Page 32

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

VENTA TF702 with 600 mm (2’) diameter wheel

Width Gear Z1 Gear Z2 Impulses/100m (328’1’’)

3:00 m (9’10’’) 10 32 780

3.50 m (11’6’’) 10 28 890

4.00 m (13’1’’) 10 24 1040

4.50 m (14’9’’) 10 21 1190

5.00 m (16’5’’) 10 19 1320

6.00 m (19’8’’) 10 16 1560

HECTOR 3000

Fertiliser

17 17 2500

10 20 1250

Field calibration

The field calibration is carried out over a

distance of 100 m (328’).

- Simultaneously press keys (1) and (5).

•Symbol

• The memorized parameter appears.

- Simultaneously press keys (2) and (3).

•Symbol

The calibration mode is activated.

- Press key (2) to start the counting.

- Press key (3) to stop the counting.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

LnP is displayed during 2 seconds.

CAL is displayed during 2 seconds.

Cover a distance of 100 m (328’).

30

Press on one of the other keys to leave the

configuration menu.

Machine use

Page 33

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Adjusting the tramlining rhythm

Before starting sowing, set the tramlining rhythm.

This rhythm depends on the seed drill widths and the

treatment machine.

- See the adjustment chart.

Adjustment chart

Special rhythms 50 to 62 require 2 control

cylinders (optional equipment).

- In symmetrical rhythms SY, the wheel track marking

will be done in a single sowing strip.

Asymmetrical rhythms SY2 SY4 SY6 SY8

SY10 SY12 require to start with a half seed

drill.

HECTOR 3000

Asymmetrical rhythms

AS perform the wheel track

marking over two consecutive sowing strips.

Width of

seed drill

2.50 m

(8’2’’)

3.00 m

(9’10’’)

3.50 m

(11’6’’)

4.00 m

(13’1’’)

4.50 m

(14’9’’)

4.80 m

(15’9’’)

5.00 m

(16’5’’)

12.00 m

(39’4’’)

SY4 / AS4 SY5 62 SY6 / AS6 SY7 SY8 / AS8 SY9

SY3 SY4 / AS4 52 SY5 SY6 / AS6

58 54 SY4 / AS4 60 62 SY6 / AS6

15.00 m

(49’3’)

SY6 / AS6 SY8 / AS8

SY3

16.00 m

(52’6’’)

Treatment width

18.00 m

(59’1’’)

SY4 / AS4

20.00 m

(65’7’’)

21.00 m

(68’11’’)

SY6 / AS6

24.00 m

(78’9’’)

SY5

27.00 m

(88’7’’)

5.60 m

(18’4’’)

6.00 m

(19’8’’)

SY2 / AS2 50 58 SY3 54 56 SY4 / AS4 52

Machine use

31

Page 34

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Treatment width

Width of

seed

drill

2.50 m

(8’2’’)

3.00 m

(9’10’’)

3.50 m

(11’6’’)

4.00 m

(13’1’’)

4.50 m

(14’9’’)

4.80 m

(15’9’’)

5.00 m

(16’5’’)

5.60 m

(18’4’’)

6.00 m

(19’8’’)

28.00 m

(91’10’’)

SY8 /

AS8

SY7

SY5

60 SY5 62

30.00 m

(98’5’)

SY12 /

AS12

SY10 /

AS10

SY6 /

AS6

32.00 m

(105’)

SY8 /

AS8

33.00 m

(108’3’’)

SY11

36.00 m

(118’1’’)

SY12 /

AS12

SY9

SY8 /

AS8

SY6 /

AS6

40.00 m

(131’3’’)

SY10 /

AS10

SY8 /

AS8

42.00 m

(137’10’’)

SY7

44.00 m

(144’4’’)

SY11

48.00 m

(157’6’’)

SY8 /

AS8

Adjustment procedure

- Press for approximately 3 seconds on key (6).

• The stored rhythm flashes.

- Using keys (2) and (3), select the required tramlining

rhythm.

• See the adjustment chart.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

According to the tramlining rhythm chosen, select the

side on which the sowing job is to be started.

- Press on the button (1).

- Select the start side using keys (2) or (3).

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized

32

Machine use

Page 35

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Rhythm 3 symmetrical

- 3.00 m (9’10’’) sowing.

- 9.00 m (29’6’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 12.00 m (39’4’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY3 (a).

HECTOR 3000

Display at start of work:

- Full seed drill (b).

Wheel tracks:

- Rhythm 3 / Position 3 (c).

- Position 3: On 2 sides (d).

Rhythm 4 symmetrical

- 3.00 m (9’10’’) sowing.

- 12.00 m (39’4’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 16.00 m (52’6 ’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY4 (a).

Display at start of work:

- Half seed drill (b).

Wheel tracks:

- Rhythm 4 / Position 4 (c).

- Position 4: On 2 sides (d).

Machine use

33

Page 36

Rhythm 4 asymmetrical

- 3.00 m (9’10’’) sowing.

- 12.00 m (39’4’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 16.00 m (52’6’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm AS4 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 3 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Rhythm 4 / Position 4 (e).

- Position 4/1: Left side (f).

Sowing start: Edge to the right

Programming:

- Rhythm AS4 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 3 (c).

- Full seed drill (d).

Wheel tracks:

- Rhythm 4 / Position 4 (e).

- Position 4/1: Right side (f).

34

Machine use

Page 37

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Rhythm 5 symmetrical

- 3.00 m (9’10’’) sowing.

- 15.00 m (49’3’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 20.00 m (65’7’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY5 (a).

HECTOR 3000

Display at start of work:

- Full seed drill (b).

Wheel tracks:

- Rhythm 5 / Position 5 (c).

- Position 5: On 2 sides (d).

Rhythm 6 symmetrical

- 3.00 m (9’10’’) sowing.

- 18.00 m (59’1’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 24.00 m (78’9’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY6 (a).

Display at start of work:

- Half seed drill (b).

Wheel tracks:

- Rhythm 6 / Position 6 (c).

- Position 6: On 2 sides (d).

Machine use

35

Page 38

Rhythm 6 asymmetrical

- 3.00 m (9’10’’) sowing.

- 18.00 m (59’1’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 24.00 m (78’9’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm AS6 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 4 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Rhythm 6 / Position 6 (e).

- Position 6/1: Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm AS4 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 4 (c).

- Full seed drill (d).

Wheel tracks:

- Rhythm 6 / Position 6 (e).

- Position 6/1: Left side (f).

36

Machine use

Page 39

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Rhythm 7 symmetrical

- 3.00 m (9’10’’) sowing.

- 21.00 m (68’11’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 28.00 m (91’10’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY7 (a).

HECTOR 3000

Display at start of work:

- Full seed drill (b).

Wheel tracks:

- Rhythm 7 / Position 7 (c).

- Position 7: On 2 sides (d).

Rhythm 8 symmetrical

- 3.00 m (9’10’’) sowing.

- 24.00 m (78’9’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 32.00 m (105’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY8 (a).

Display at start of work:

- Half seed drill (b).

Wheel tracks:

- Rhythm 8 / Position 8 (c).

- Position 8: On 2 sides (d).

Machine use

37

Page 40

Rhythm 8 asymmetrical

- 3.00 m (9’10’’) sowing.

- 24.00 m (78’9’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 32.00 m (105’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm AS8 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 5 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Rhythm 8 / Position 8 (e).

- Position 8/1: Left side (f).

Sowing start: Edge to the right

Programming:

- Rhythm AS8 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 5 (c).

- Full seed drill (d).

Wheel tracks:

- Rhythm 8 / Position 8 (e).

- Position 8/1: Right side (f).

38

Machine use

Page 41

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Rhythm 9 symmetrical

- 3.00 m (9’10’’) sowing.

- 27.00 m (88’7’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 36.00 m (118’1’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY9 (a).

HECTOR 3000

Display at start of work:

- Full seed drill (b).

Wheel tracks:

- Rhythm 9 / Position 9 (c).

- Position 9: On 2 sides (d).

Rhythm 10 symmetrical

- 3.00 m (9’10’’) sowing.

- 30.00 m (98’5’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 40.00 m (131’3’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY10 (a).

Display at start of work:

- Half seed drill (b).

Wheel tracks:

- Rhythm 10 / Position 10 (c).

- Position 10: On 2 sides (d).

Machine use

39

Page 42

Rhythm 10 asymmetrical

- 3.00 m (9’10’’) sowing.

- 30.00 m (98’5’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 40.00 m (131’3’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm AS10 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 6 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Rhythm 10 / Position 10 (e).

- Position 10/1: Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm AS10 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 6 (c).

- Full seed drill (d).

Wheel tracks:

- Rhythm 10 / Position 10 (e).

- Position 10/1: Left side (f).

40

Machine use

Page 43

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Rhythm 11 symmetrical

- 3.00 m (9’10’’) sowing.

- 33.00 m (108’3’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 44.00 m (144’4’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY11 (a).

HECTOR 3000

Display at start of work:

- Full seed drill (b).

Wheel tracks:

- Rhythm 11 / Position 11 (c).

- Position 11: On 2 sides (d).

Rhythm 12 symmetrical

- 3.00 m (9’10’’) sowing.

- 36.00 m (118’1’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 48.00 m (157’6’’) treatment.

Sowing start: Edge on the left or right

Programming:

- Rhythm SY12 (a).

Display at start of work:

- Half seed drill (b).

Wheel tracks:

- Rhythm 12 / Position 12 (c).

- Position 12: On 2 sides (d).

Machine use

41

Page 44

Rhythm 12 asymmetrical

- 3.00 m (9’10’’) sowing.

- 36.00 m (118’1’’) treatment.

Or

- 4.00 m (13’1’’) sowing.

- 48.00 m (157’6’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm AS12 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 7 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Rhythm 12 / Position 12 (e).

- Position 12/1: Left side (f).

Sowing start: Edge to the right

Programming:

- Rhythm AS12 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 7 (c).

- Full seed drill (d).

Wheel tracks:

- Rhythm 17 / Position 17 (e).

- Position 17/1: Right side (f).

42

Machine use

Page 45

Rhythm 50

- 6.00 m (19’8’’) sowing.

- 15.00 m (49’3’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 50 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 9 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 2/5 : Left side (e).

- Position 10/7 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 50 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 9 (c).

- Full seed drill (d).

Wheel tracks:

- Position 5/2 : Right side (e).

- Position 7/10 : Left side (f).

Machine use

43

Page 46

Rhythm 52

- 4.00 m (13’1’’) sowing.

- 18.00 m (59’1’’) treatment.

Or

- 6.00 m (19’8’’) sowing.

- 27.00 m (88’7’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 52 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 16 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 18/13 : Left side (e).

- Position 4/9 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 52 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 16 (c).

- Full seed drill (d).

Wheel tracks:

- Position 18/13 : Right side (e).

- Position 4/9 : Left side (f).

44

Machine use

Page 47

Rhythm 54

- 6.00 m (19’8’’) sowing.

- 20.00 m (65’7’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 54 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 9 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 7/10 : Left side (e).

- Position 3/4 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 54 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 9 (c).

- Full seed drill (d).

Wheel tracks:

- Position 10/7 : Right side (e).

- Position 3/4 : Left side (f).

Machine use

45

Page 48

Rhythm 56

- 6.00 m (19’8’’) sowing.

- 21.00 m (68’11’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 56 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 13 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 11/14 : Left side (e).

- Position 4/7 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 56 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 13 (c).

- Full seed drill (d).

Wheel tracks:

- Position 11/14 : Right side (e).

- Position 4/7 : Left side (f).

46

Machine use

Page 49

Rhythm 58

- 4.50 m (14’9’’) sowing.

- 12.00 m (39’4’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 58 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 7 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 2/3 : Left side (e).

- Position 8/5 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 58 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 7 (c).

- Full seed drill (d).

Wheel tracks:

- Position 2/3 : Right side (e).

- Position 8/5 : Left side (f).

Machine use

47

Page 50

Rhythm 60

- 4.50 m (14’9’’) sowing.

- 21.00 m (68’11’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 60 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 12 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 14/9 : Left side (e).

- Position 4/5 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 60 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 12 (c).

- Full seed drill (d).

Wheel tracks:

- Position 14/9 : Right side (e).

- Position 4/5 : Left side (f).

48

Machine use

Page 51

Rhythm 62

- 4.50 m (14’9’’) sowing.

- 24.00 m (78’9’’) treatment.

Sowing start: Edge to the left

Programming:

- Rhythm rt 62 (a).

- Start on the left (b).

Display at start of work:

- Start on the left. Position 14 (c).

- Full seed drill (d).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Wheel tracks:

- Position 5/6 : Left side (e).

- Position 16/11 : Right side (f).

Sowing start: Edge to the right

Programming:

- Rhythm rt 62 (a).

- Start on the right (b).

Display at start of work:

- Start on the right. Position 14 (c).

- Full seed drill (d).

Wheel tracks:

- Position 5/6 : Right side (e).

- Position 16/11 : Left side (f).

Machine use

49

Page 52

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Alarm activation and deactivation

Alarms can be activated or deactivated separately.

- Simultaneously press keys (1) and (7).

- Press key (3) to access the next parameter.

• The adjustable parameter flashes.

- Press key (2) to modify parameter.

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

Recommended configuration:

-VENTA.

- MEGANT

HECTOR 3000

Symbols Functions

Blower.

Side markers.

Metering unit.

Seed level.

Alarms

Activated Deactivated

50

Machine use

Page 53

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Blower rotational speed is on display

- Press for approximately 3 seconds on key (7).

• Symbol

• The adjustable parameter flashes.

- Switch on the blower at the nominal speed.

• VENTA EC : 4250 min

• VENTA LC : 4250 min

• VENTA AL : 2900 min

• VENTA TF702 (Work on flat grounds): 3000 min

• VENTA TF702 (On slopes): 3200 min

• VENTA TF702 (Small grain): 2500 min

• MEGANT : 2900 min

- Press for approximately 3 seconds on key (1).

• The selection flashes shortly.

- The parameter is memorized.

tUA is displayed during 2 seconds.

-1

-1

-1

-1

-1

-1

Press on one of the other keys to leave the

configuration menu.

HECTOR 3000

-1

3. Use during work

Introduction

The following functions are accessible during work:

- Area counter.

- Displays the speed.

- Tramlining start and stop.

- Displaying the tramlining rhythm.

- Blower rotational speed is on display.

Machine use

51

Page 54

Area counter

The counter values remain stored even if the

control box power supply is cut.

Displaying the daily area counter:

- Press 1 time on key (4).

To reset:

- Simultaneously press keys (1) and (4).

Displaying the total area counter:

- Press key (4) a second time.

To reset:

- Simultaneously press keys (1) and (4).

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

The daily area counter will be reset at the

same time.

Displays the speed

- Press 1 time on key (5).

52

Machine use

Page 55

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Tramlining start and stop

Tramlining start:

- Press simultaneously keys (1) and (6) to start sowing.

- The screen displays alternately:

• The side on which the sowing will start.

• Half seed drill / Full seed drill.

Displaying the tramlining rhythm:

- Press on the button (6).

- The screen displays:

• The tramlining rhythm programmed.

• The position in this tramlining rhythm.

- Press keys (2) or (3) or manipulate markers to scroll

the position counting.

HECTOR 3000

Stopping tramlining temporarily:

- Press key (6) to stop the counting.

Pressing key (6) suspends the tramlining rhythm

progress and deactivates keys (2) and (3).

- The screen displays:

- Press key (6) to reactivate the counting.

StOP.

Machine use

53

Page 56

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Blower rotational speed is on display

- Press on the button (7).

- The screen displays:

• The blower speed.

HECTOR 3000

54

Machine use

Page 57

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Simple maintenance

1. Error codes

Alarm messages

Depending on alarm configuration, the following

messages may appear in the event of a fault:

Blower speed

• The alarm is displayed if the blower speed varies of

+/- 200 min

3400 min

• The alarm is displayed if the blower speed varies of

+/- 400 min

3400 min

-1

with a speed memorized below

-1

.

-1

with a speed memorized over

-1

.

HECTOR 3000

The alarm is deactivated when the seed drill is

OFF.

Side markers or wheel arm on TF702

- The alarm is displayed if the wheel has been rotating

for 10 seconds and the marker is not lowered.

Metering unit

- The alarm is displayed if one of th e markers or the

TF702 wheel arm is lowered and the metering unit has

not been rotating for 10 seconds.

Seed level

- The alarm is activated as soon as the sensor is not

covered with seeds.

The alarm is deactivated when the seed drill is

OFF.

Simple maintenance

55

Page 58

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

Press following keys to cancel the alarm message

temporarily.

During headland turn maneuvers if the wheel or

the markers are raised, the alarm messages are

inoperative.

- If the minimum seed level alarm message is

interrupted during work, it will come on again every

time that:

• Headland turns are reached: The metering units no

longer rotate.

• The user resumes sowing after having made the

headland turn: Metering units start rotating again.

HECTOR 3000

56

Simple maintenance

Page 59

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

2. Adjusting the sensors

VENTA EC LC AL and MEGANT

Blower sensor (VENTA AL and MEGANT)

The distance between the sensor sensitive side and the

metal part must be comprised between 2 and 4 mm

(0.07’’ - 0.15’’).

Blower sensor (VENTA EC and LC)

The distance between the sensor sensitive side and the

metal part must be comprised between 1 and 2 mm

(0.11’’ - 0.07’’).

HECTOR 3000

Marker sensor

The distance between the sensor sensitive side and the

metal part must be comprised between 3 and 5 mm

(0.11’’ - 0.19’’).

Metering unit sensor

The distance between the sensor sensitive side and the metal part must be comprised between 0.4 and 0.8 mm (0.01’’ - 0.03’’).

VENTA TF702 BTF and BTFR

Blower sensor

The distance between the sensor sensitive side and the

metal part must be comprised between 2 and 4 mm

(0.07’’ - 0.15’’).

Metering unit sensor

The distance between the sensor sensitive side and the metal part must be comprised between 0.4 and 0.8 mm (0.01’’ - 0.03’’).

Wheel sensor

The distance between the sensor sensitive side and the

metal part must be comprised between 3 and 5 mm

(0.11’’ - 0.19’’).

Simple maintenance

57

Page 60

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Optional equipment

1. Pre-emergence marker

Connect the electromagnet wires to the junction box

contacts:

- Brown wire : Pin L3.

- Blue wire: Pin L4.

HECTOR 3000

58

Optional equipment

Page 61

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

$Maintenance and storage

The control box does not require any particular

maintenance, in the case of a breakdown or a

malfunction call your KUHN repairman.

When cleaning the machine, never point the

water jet on the control box or the junction

box.

HECTOR 3000

For any welding operation on the machine,

disconnect the electricity supply of the

machine and the tractor (battery and

alternator).

Position the earth as close as possible to the

part to be welded. Never put it on the chassis

to weld on the body or vice-versa. This could

be fatal for the sensors which connect the

body to the chassis.

Washing with a high-pressure cleaner is

strongly advised against, as there is a risk of

water penetrating inside the junction box and

the sensors.

Maintenance and storage

59

Page 62

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

$Limited warranty

60

Limited warranty

Page 63

VENTA \ MEGANT \ HR6003CSR \ HR6004CSR

HECTOR 3000

Limited warranty

61

Page 64

Loading...

Loading...