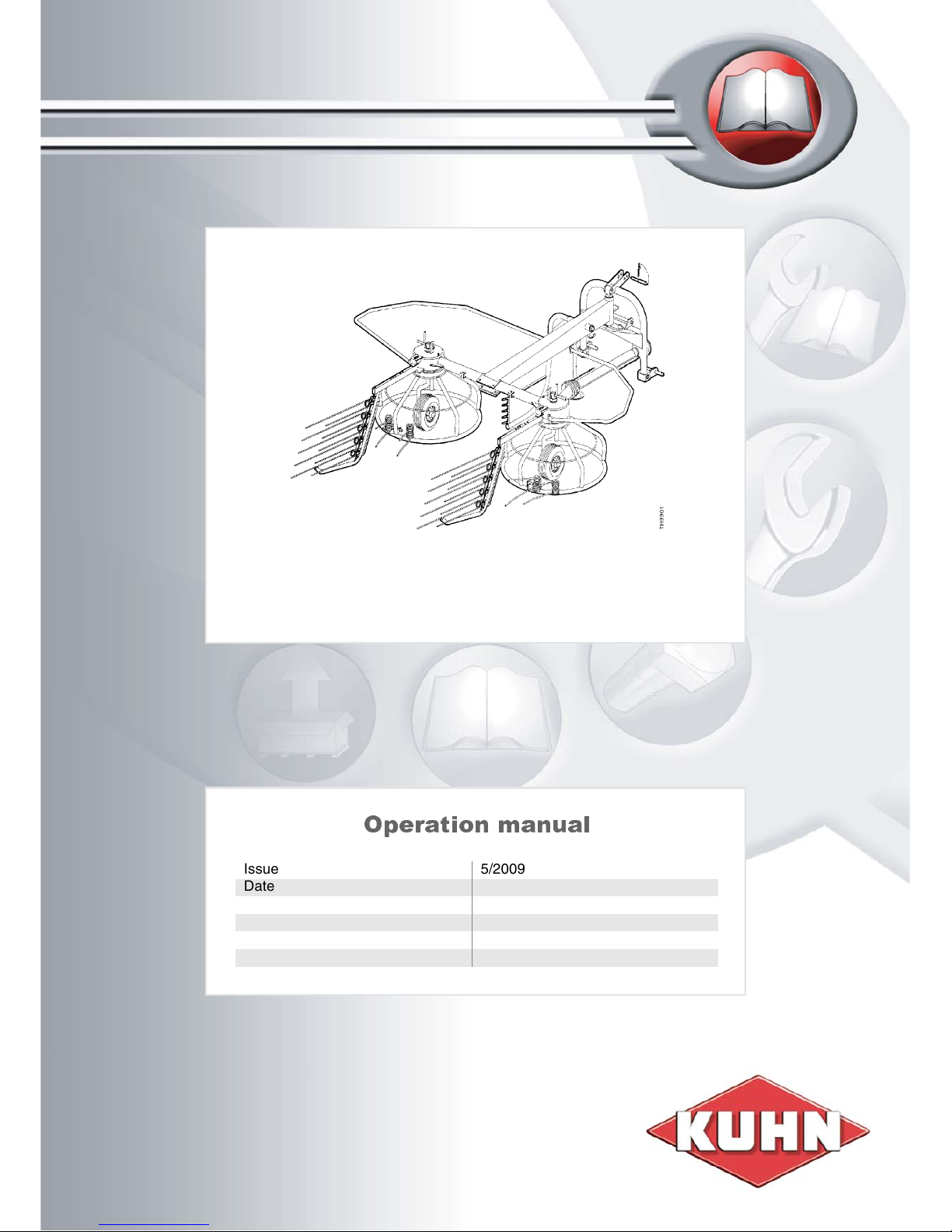

Page 1

Operatio n manual

Issue 5/2009

Date of printing 6.2009

Language EN

Ex machine no. (PIN) VGTH222624

Serial number (PSN) 67TH01

Reference No. ZNA016EN

HAYBOB 300

Page 2

Identifica tion of the m achi ne

To support you as soon as possible your dealer requires several details of your machine.

Please enter the details here.

Designation

PIN

Software

version

Accessories

Address of

dealer

Address of

manufacturer

KUHN-GELDROP BV retains all copyrights and rights of usage. The contents of this operating manual are subject to change without notice. All

rights reserved. The right to technical revision is reserved.

HAYBOB 300

VGTH....................

KUHN-GELDROP BV

Nuenenseweg 165

5667 KP Geldrop

The Netherlands

Phone +31 40 2893300

Page 3

Table of contents

3

Table of contents

Preface............................................................. 4

Used terms and symbols ...............................5

General 5

Destination and intended use ....................... 6

General 6

Safety and reliability .......................................7

Safety instructions 3-point rotary hay

making machines 7

Safety and reliability .....................................12

Tractor loads 12

Pre-operation ................................................15

Attachment to the tractor 15

Transport 15

Operation .......................................................16

General instructions for use 16

Maintenance ..................................................20

General 20

Torque values for international metric

thread joints 22

Conversion table for units of measurement 24

Maintenance ..................................................25

Optional equipment ......................................26

EC Certificate of conformity ........................ 27

Index ..............................................................28

Page 4

4

Preface

Preface

The range of your machinery has now been improved which

incorporates the latest developments in hay making. It is a first class

engineering product backed by a widespread distributor/dealer

organisation to give you an efficient after sales service.

This machine shall be exclusively used for the normal agricultural

work as described in section "Destination and intended use" on page

6.

In this context we want to draw your special attention to “Preoperation” on page 15 and to the “Safety Decals” on page 10.

You will find all illustrations of the operation manual on the fold-out

page at the very end.

This manual has been prepared to enable you to obtain the best

results from your machine. Please read it carefully and follow the

instructions. Your dealer will be pleased to help if any problems arise.

Please keep this manual for reference. Fill in the receipt of delivery,

send it to your dealer and keep the copy well. Enter the machine

number (PIN) you find on the identification plate of the machine in the

frame on page 2 of this manual: it is important in case of any service

contact and when ordering parts, etc.

Page 5

Used terms and symbols

5

Used terms and symbols

General

Specifications are subject to change without previous notice.

Directional indications such as 'right', 'left', 'front' and 'rear', etc. are to

be interpreted when facing in direction of travel.

Parts are numbered from left to right.

This is also the basic position for defining the direction in connection

with which:

- rh (rotation) = clockwise rotation

- lh (rotation) = counter or anti-clockwise rotation

Rotation around a vertical axis is defined when looking from top to

bottom.

Rotation around a horizontal axis almost perpendicular to the direction

of travel is defined when looking from the left to the right.

Rotation of bolts, nuts, hand cranks, etcetera is defined when looking

from the position of operation.

Units of measurement are given both in Imperial/US and international

metric units; the metric value shall be decisive.

Abbreviations used are:

* = you can find this numbers on the identification plate of the machine.

DANGER:

When you see this safety alert heading be alert to the danger of injury

of death of men and animals!

Attention:

When you see this heading, be alert to the possibility of damage to

equipment, crop, buildings, etc., but to financial and/or juridical

problems (warranty, product liability) as well!

This heading indicates a remark to make a job easier, better and safer.

Abbreviation Explanation

cw clockwise

ccw counter-clockwise, anti clockwise

IPL IIlustrated spare Parts Lists

IPB Illustrated Parts Book

PIN* Product Identification No.

PSN* Production Series Number

Page 6

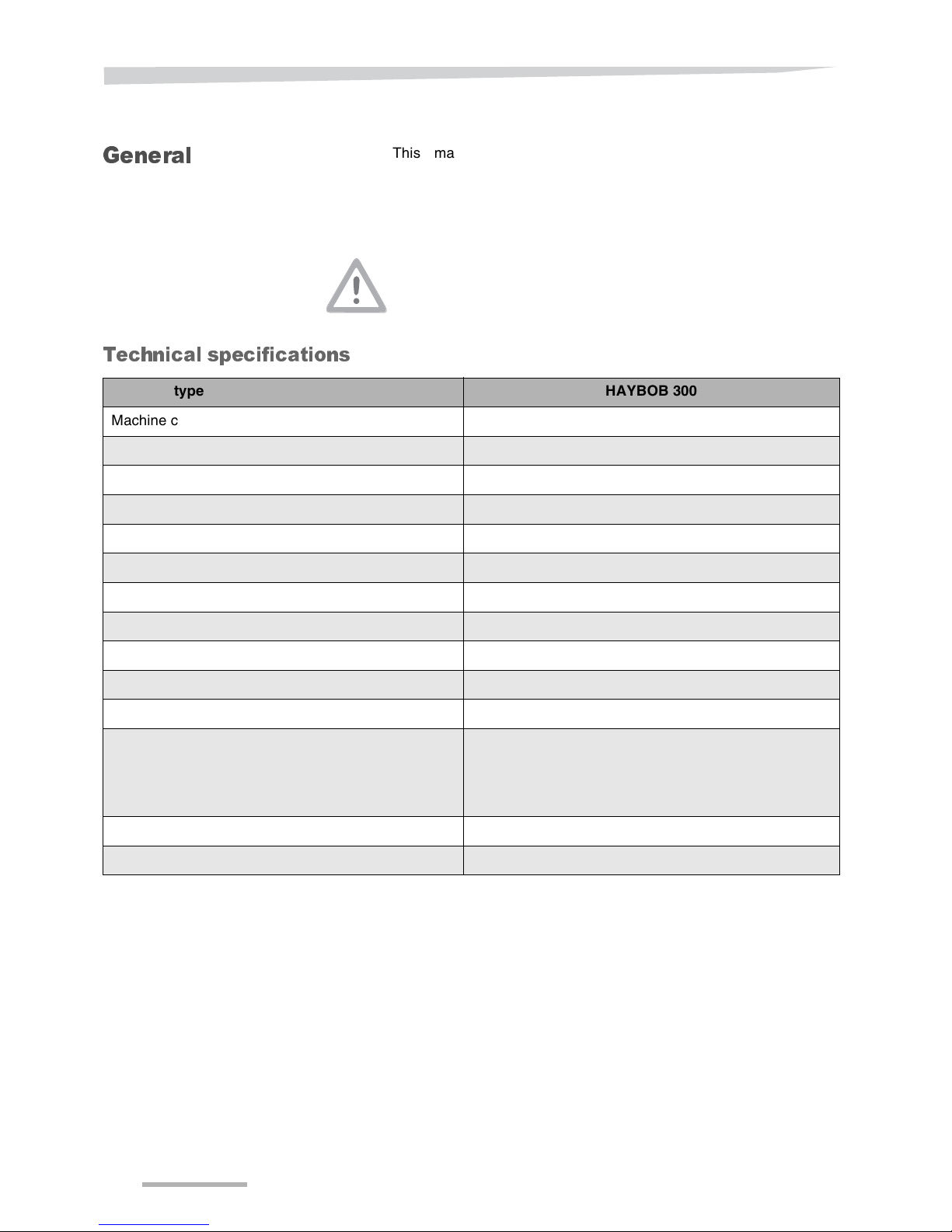

6

Destination and intended use

Destination and intended u se

General

This machine is exclusively appropriate-designed for raking,

spreading and tedding of loose plant parts, mainly cut grasses and

herbs for agricultural forage production, taking into account all

prescriptions, procedures, etcetera as stated herein.

This machine shall be exclusively used for normal agricultural work.

Attention:

Any use beyond the one stipulated above requires written

authorization of the manufacturer; refer also to the reliability and

warranty chapter in this manual!

Technical spe cific ati ons

Machine type HAYBOB 300

Machine code TH

Working width: 300 cm

Transport width 280 cm

Height 125 cm

Distance lower tractor links - gravity point 120 cm

Weight (mass) 300 kg

Lubrication points 2 (except PTO drive shaft)

Rotors 2

Double tines 20

Tyres 15x6.00-6 (4PR)

Tyre pressure 1.5 bar

Drive:

- PTO speed 350 - 540 rpm

- PTO drive shaft with slip clutch (700 Nm)

PTO drive shaft with slip clutch, 730 Nm (539 ft-lb)

Linkage cat. I and II

Page 7

Safety and reliability

7

Safety and reliability

Avoid accidents! Don't learn safety the hard way! Stay alert!

Think SAFETY! Work SAFELY!

Prior to operating the machine read and observe this operation

manual and all safety instructions and decals

Everyone must be given operating instructions before starting to

operate the equipment. Pass on all safety advices also to other users!

Safety instructions

3-point rotary hay

making machines

General

You are responsible for the SAFE operation and maintenance of your

equipment. It is the operator's responsibility to read and understand

ALL safety and operating instructions in the manual and to follow

these. You must ensure that you and anyone else who is going to

operate, maintain or work around the unit be familiar with the

operating and maintenance procedures and related SAFETY

Information contained in this manual. The manual will take you stepby-step through your working day and alert you to all good safety

practices that should be adhered to while operating this equipment.

Remember, you are the key to safety. Good safety practices not only

protect you but also the people around you. Make these practices a

working part of your safety programme. Be certain EVERYONE

operating this equipment is familiar with the recommended operating

and maintenance procedures and follow all safety precautions. Most

accidents can be prevented.

Do not risk injury or death by ignoring good safety practices.

• Machines must never be tested on a tractor in an enclosed space

because of the danger form exhaust fumes!

• Always check traffic and operational safety before any putting the

machine into operation!

• Adhere to the general rules of health and safety precautions

besides the advice of this manual!

• The installed warning and advisory signs give important hints for a

safe operation; adhering to serves your own safety!

• When making use of public roads adhere to applicable traffic rules!

• Become acquainted with all installations and control devices as

well as with their function before beginning the operation. Doing

this during operation would be too late!

• The clothing of the operator should be tight. Avoid wearing any

loose clothing!

• Before beginning to drive and/or operate check surrounding area

(children!). Ensure sufficient visibility during all operation and

transport!

• Nobody shall ride on the machine during transport and/or

operation!

• Attach accessories in accordance with mounting instructions and

only to the appropriate attaching points!

• Special care shall be taken when (dis)mounting the machine on/off

the tractor!

• When attaching/detaching the machine place the jack stand into

Page 8

8

Safety and reliability

the corresponding position!

• Always fit front weights to the fixing points provided for that

purpose.

• Adhere to maximum permissible axle loads, total weights and

transport dimensions!

• Install and check transport equipment, e.g. lighting, warning

devices, guards!

• For road transport bring machine in a transport position and secure

it!

• Never leave the operator's seat during operation or transport.

• Moving behaviour, steerability and braking performance are

influenced by mounted implements and ballast weight! Ensure

sufficient braking effect and safe manageability!

• Always adapt the speed to the local conditions! When making short

turns note the larger radius because of increased width and/or

length of the combination as well as mass and inertia changes due

to the other center of gravity position!

• Do not operate a machine unless all protection is installed and in

functional position!

• Never stay or allow anyone to stay within the operating area!

• Never stay or allow anyone to stay within the turning and slewing

area!

• Before leaving the tractor lower the machine onto the ground,

apply the parking brake, shut down the engine and remove the

ignition key!

• Allow nobody to stay between tractor and machine unless the

tractor is prevented from inadvertent rolling away by applied

parking brake and or placed chocks!

• Before (un)hitching the machine on the three-point linkage set the

controls in a position that prevents from inadvertent lifting/lowering!

• Ensure hitching category of machine corresponds to tractor: adapt

if required!

• Keep clear of three-point linkage area: danger of crushing and

scissoring!

• Do not stand between tractor and machine when handling the

external three-point linkage controls!

• Always use stabilizers or check chains to prevent sideways

movement of the machine, especially during transport!

• During road transport the three-point linkage control lever must be

secured against lowering!

• The protection of the machine prevents from penetrating into

danger areas! Therefore all protection must be kept in optimal

condition and moved into the functional position prior to starting to

work!

• Before performing any work on the machine ensure the tines have

stopped all rotation, shut down the engine and remove the ingition

key!

DANGER:

Machine continues rotation due to inertia: wait until tines really stand

still.

Page 9

Safety and reliability

9

• Do not modify the equipment in any way. Unauthorised

modifications may impair the function and/or safety and could

affect the life of the equipment!

• Repair damages prior to next operation.

Drive through un iv ersa l

joint drive sh afts

• Only use universal joint drive shafts complying with the

specification of the machine manufacturer for that specific use!

DANGER:

In order to ensure protection of both man and machine excise extreme

caution when working at a universal joint drive shaft other then

described in this manual and/or on the instruction at the instruction at

the univ. joint drive shaft. Modification of and other special jobs on

universal joint shafts require written explicit order and procedure of

both machine and univ. joint drive shaft manufacturer is available!

Use the correct tools and genuine parts to ensure the right

performance and max. safety (also see Reliability and Warranty

section 1.2)! This also in accordance with the EU-safety prescriptions

of the Machine Directive 89/392/EU!

• Externally accessible univ. joint drive shafts (e.g. PTO drive shafts)

as well as tractor PTO and machine input shaft must be equipped

with appropriate guards and cones! All the parts shall be kept in a

proper condition!

• Univ. joint drive shaft guard tubes shall overlap sufficiently (and as

safely advised) in all transport and working positions!

• Do not (dis)connect or work on a univ. joint drive shaft unless the

engine has been shut down and stopped and the ignition key has

been removed!

• Ensure univ. joint drive shaft is connected correctly and safetied by

the lock!

• Prevent shaft guard from spinning by attaching the safety chain(s)

to a static part (e.g. not used top link hole).

• Prior to engaging or switching on the PTO ensure nobody stays in

the danger area of the machine!

• Do not engage or switch on the PTO while engine is stopped!

• Prior to engaging or switching on the PTO ensure the PTO speed

cannot exceed 540 rpm!

• When working with PTO drive do not allow anyone to stay near any

spinning univ. joint drive shaft!

• Always stop PTO when it is not needed and when the max.

universal joint angle might be exceeded.

DANGER:

After disengaging or switching off the PTO, the PTO driven machine

will continue running because of inertia! Keep a safe distance to the

machine untill the tines really stand still: the fast rotating tines are

invisible for men's eye!

• Do not clean and/ord grease the PTO driven machine and

universal joint drive shafts unless PTO and engine have stopped

and the inginiton key has been removed!

• Place the uncoupled PTO drive shaft on the retaining device

provided!

Page 10

10

Safety and reliability

• After removal of PTO drive shaft place protective cover/cap

over PTO!

Wheels an d tyres

• When working on the wheels make sure that the machine has been

placed on the ground safely (jack stand) and that it is secured by

chocks against unintentional rolling!

• Mounting wheels and tyres requires sufficient knowledge and

availability of prescribed tools and equipment being in perfect

condition; repairs on tyres may only be performed by trained staff

with suitable tools!

• Check air pressure regularly: ensure prescribed value!

Safety Decals

Attention:

Good safety practice requires that you become familiar with the

various safety decals, the type of warning and the area, or particular

function related to that area, requiring your SAFETY AWARENESS!

Attention:

This machine has been marked with safety decals of the new

generation in acc. with ISO11684, i.e. without text. The decals are

shown below!

TR2005

Stop the engine and ensure it cannot be re-started during performance

of work on the machine!

TR2011

When three point linkage is controlled from outside ensure nobody is

between tractor and machine!

Storage safety

• Store the unit in an area away from human activity.

• Do not permit children to play on or around the stored unit.

• Use the provided jack stand supports, store in stable machine

mode.

Page 11

Safety and reliability

11

Liabili ty and w arran ty

In order to ensure safety all persons working at and/or with this

machine must read and understand this operation manual.

Furthermore this machine shall always be used, handled and stored

in accordance with the design and construction destination (intended

use) which also means:

• Exclusively work in accordance with the instructions given in the

appropriate Assembly, Operation and Repair Instructions

(manuals) including all valid Errata and Supplements as well as

taking into account the relevant Service Bulletins; exclusively use

correct tools and equipment being in a perfect condition!

• Strictly observe the applicable local regulations concerning safety

and accident prevention, generally acknowledged and approved

technical, medical and traffic rules as well as the functional

limitations and safety instructions stated in above mentioned

technical documentation!

• Do not use any parts (spares, accessories, lubricants) other then

those complying with manufacturer requirements. A part complies

with manufacturer requirements when either genuine or approved

by the manufacturer or when all its properties can be proven to

meet with the appropriate manufacturer requirements for that very

use/function!

• Only well instructed people being familiar with all possible danger

shall work with or at the machine!

• The machine shall not be used nor transported unless all safety

devices (covers, plates, rails, curtains, locks, etc.) are correctly

installed and in a perfect condition and set in the appropriate safety

position! All safety decals and signs shall be legible and in the

correct place!

• Unauthorised modification of or arbitrary changes on the machine

or parts of it exclude any responsibility and reliability of the

machine manufacturer for the consequences of that operation!

Attention:

Those disregarding above mentioned rules act grossly negligent

(careless) through which all manufacturers warranty and reliability for

damages and all other consequences become extinct. The negligent

person carries all risks!

Page 12

12

Safety and reliability

Safety and reliability

Tractor loads

Attention:

Obey the maximum permissible mass, permissible axle loads and

permissible tyre loads.

Attaching machines to the front or to the rear 3-point linkage may

never result in:

• Exceeding the maximum permissible mass.

• Exceeding the maximum permissible axle load.

• Exceeding the maximum permissible tractor tyre load.

• Not complying with the minimum front axle load.

• Not complying with the minimum rear axle load.

Check all m a xi m um

and mini m um l oad s

Before using the machine always check if the requirements as

mentioned above are met.

Most of the dimensions and masses in the figure at the left can be

found in the tractor manual or in the corresponding machine manual.

In case this data can not be found, contact the corresponding dealer

or measure or calculate this value.

Legend:

Actual total mass

The actual total mass can be determined by:

• weighing.

• calculation:

This value may never exceed the maximum permissible mass.

F G

B CA

*

*

*

*

*

IH J

D E

Dimension Description Unit

A Unladen tractor mass kg

B Unladen front axle load kg

C Unladen rear axle load kg

D Total mass front attachment kg

E Total mass rear attachment kg

F Distance from the lower link ball point centre

to the front attachment’s centre of gravity

mm

G Distance from the front axle centre to the

lower link ball point centre

mm

H Tractor wheel base mm

I Distance from the rear axle centre to the

lower link ball point centre

mm

J Distance from the lower link ball point centre

to the rear attachment’s centre of gravity

mm

A + D + E = ........... kg

Page 13

Safety and reliability

13

Actual front axle load

The actual front axle load can be determined by:

• weighing.

• calculation:

The actual front axle load may never exceed the maximum

permissible front axle load.

The actual front axle load may never be less than the minimum front

axle load (M). In case the minimum front axle load (M) is not

mentioned in the tractor manual, the minimum front axle load (M) has

to be at least 20% of the unladen tractor mass (A).

In case the minimum front axle load is not met, you have to add front

ballast.

To calculate the minimum required front ballast:

Attention:

In case front ballast is mounted directly at the tractor, replace “F + G”

in the formula by the “Distance from the centre point of the front axle

to the gravity point of the ballast”.

Always check the maximum permissible mass, permissible axle load

and permissible tractor tyre load after mounting front ballast.

Actual rear axle load

The actual rear axle load can be determined by:

• weighing.

• calculation:

The actual rear axle load may never exceed the maximum permissible

rear axle load.

The actual rear axle load may never be less than the minimum rear

axle load (N). In case the minimum rear axle load (N) is not mentioned

in the tractor manual, the minimum rear axle load (N) has to be at least

45% of the unladen tractor mass (A).

In case the minimum rear axle load is not met, you have to add rear

ballast.

To calculate the minimum required rear ballast:

Attention:

In case the front ballast is mounted directly at the tractor, replace “F +

G” in the formula by the “Distance from the centre point of the front

axle to the gravity point of the front ballast”.

Always check the maximum permissible mass, permissible axle load

and permissible tractor tyre load after mounting rear ballast.

B +

D x (F + G + H)

H

-

D x (F + G +H)

H

= .......... kg

E x (I + J) - (B x H) + (M x H)

F + G + H

= .......... kg

C +

E x (H + I + J)

H

-

D x (F + G)

H

= .......... kg

D x (F + G) - (C x H) + (N x H)

H + I + J

= .......... kg

Page 14

14

Safety and reliability

Actual tyre load

The actual tyre load can be found by dividing the corresponding actual

axle load by 2.

The actual tyre load may never exceed the maximum permissible tyre

load.

Attention:

The maximum permissible tyre load is depending on the tyre pressure

and the driving speed.

Page 15

Pre-operation

15

Pre-operation

Attach me nt to th e

tractor

Since the hitch brackets are reversible, the hitch frame is suitable for

both cat. I and II.

- Cat. I: small diameter pins on the outside.

- Cat. II: large diameter pins on the outside.

Prior to attaching the machine to the tractor, ensure the draft links are

on equal level!

If necessary the PTO drive shaft between the tractor and machine

should be shortened to prevent damage when it is in its shortest

position.

> Check the length of the PTO drive shaft, shorten the drive shaft if

necessary.

Care must be taken to ensure the PTO drive shaft is not shortened too

much, see the instructions that come with the PTO drive shaft.

Always use stabilisers or check chains when attaching the machine to

the tractor, to prevent sideways movement of the hitch frame

damaging the pto drive shaft.

Dependent on the length of the top link, either the front or the rear hole

in the hitch frame can be used.

Transport

Set machine as follows:

> Lift and secure jack stand (1) (if jack had been lowered before).

> Lower machine and start a rh turn. Then pull up and engage lever

(2) under bracket pin (3) from tractor seat using cord (4).

> Ensure both deflectors (5) are positions max. inward and secured;

lift machine to transport position.

Page 16

16

Operation

Operatio n

General instructions

for use

To enable the machine to follow ground contours correctly, the

hydraulic lift lever should be in float position during work, so that the

lift arms can move freely up and down.

For a good action, the speed of the PTO should be between 400 and

540 rpm depending on the circumstances. This prevents excessive

wear, limits leaf losses and reduced crop pollution.

To limit the working angle of the PTO drive shaft, it is advisable to

make left-hand turns only, especially when raking.

Always make sure that the tines have been fitted correctly.

Adjustme nts for spreading

and tedding

> Lower machine and start a rh turn.

> Then pull cord (4) to disengage lever (2) from bracket pin (3).

> Set all tines to tedding position (6).

> Use the lower holes (7) for wheel height adjustment: to avoid strips

being left between the rotors (e.g. in a short and difficult crop) it is

advisable to use a higher hole.

Page 17

Operation

17

> Then lower machine completely and drive a little forward, until the

centre slot at front of hitch frame appears clearly visible (arrow,

fig.).

In this position the forward side of the rotors is nearest the ground.

> Now operate machine at full working speed (350-540 rpm at the

pto) and adjust top link, so that the tine tips are just touching the

stubble in front of the rotors.

Forward inclination of rotors can be set as required for the

circumstances by varying wheel height in conjunction with top link

length!

To prevent the crop being moved too far to the side, especially when

working around the boundary of the field, the tedding width of the

machine can be restricted by the deflectors (5) which can be set

laterally, using stays (8).

Each deflector (5) also can be set into two vertical positions by rotating

the nylon blocks (11) through 180°. Use the upper position under

abrasive conditions.

Page 18

18

Operation

Adjustme nt for raki ng

> Lower machine and start a rh turn.

> Then pull cord (4) to disengage lever (2) from bracket pin (3).

> Set all tines to raking position (9).

> Use the upper holes (10) for wheel adjustment. In long stubbles the

use of the lower holes can be advantageous for better pick-up and

clean raking.

> Lower machine completely and drive a little forward, until the

centre slot at front of hitch frame appears clearly visible (arrow,

fig.).

In this position the forward side of the rotors is nearest the ground.

> Now operate machine at full working speed (350-540 rpm at the

pto) and adjust top link, so that the tine tips are just touching the

stubble in front of the rotors.

Forward inclination of rotors can be set as required for the

circumstances by varying wheel height in conjunction with top link

length!

Page 19

Operation

19

> Set deflectors as required using stays (8).

Always make certain that the distance between the deflectors is large

enough, especially in a heavy crop to prevent material from being

pulled out of the swath. When you place the deflectors as shown in fig.

the swaths are laid down close together in the first operation. These

swaths are easily put together afterwards.

Each deflector also can be set into two vertical positions. This can be

achieved by rotating the nylon blocks (11) through 180°. Use the upper

position under abrasive conditions.

Page 20

20

Maintenance

Maintenance

Attention:

Warranty and liability claims of damages caused by inadequate

maintenance (e.g. insufficient lubrication) will be rejected!

General

After a few hours of a new or overhauled machine check that all nuts

and bolts are tight. Special attention should be paid to those holding

the tines and bolts securing the rotors, located under the top of the

rotors. Recheck regularly.

Tines

The HAYBOB 300 has 4 different tines

• 'PZ 107E' (5x) = lh, narrow

• 'PZ 110E' (5x) = lh,wide

• 'PZ 224E' (5x) = rh, narrow

• 'PZ 225E' (5x) = rh, wide

Above mentioned tines are Super C quality tines. The cheaper and

lower quality "B"-tines can be obtained by adding an "E" to the part no.

(e.g. PZ107E).

Always ensure that these tines have been fitted correctly, for example:

• The blue marked tines on the left-hand rotor, the yellow marked

tines on the right-hand rotor.

• Narrow and wide alternately fitted.

• Short finger to the top, long finger to the bottom.

• The bend of the tine should be pushed close to the attachment bolt

(see arrow).

Page 21

Maintenance

21

Lubrication

Attention

Always use a good and adhesive multi-purpose grease for lubrication

of both machine and PTO drive shaft!

The following points need the attention:

• Machine

• PTO drive shaft

Attention

Ensure profiles tubes of pto drive shafts are well greased at all times!

Check a new or repaired machine and/or drive shaft prior to first run

and then every 20 working hours!

Also ensure sliding surfaces of the protection tubes are greased!

Page 22

22

Maintenance

Torque values for

international metric

thread joints

All bolted joints on this machine must be torqued in accordance with

the values given in this table below unless indicated otherwise (e.g. in

Parts List or Installation Instruction, etc.)

On this machine 8.8 is both standard and minimum quality used. If not

indicated anyhow use this quality for determination of torque (in most

cases the quality can be found on the head of the respective bolt).

* Material quality in acc. with DIN ISO 898.

** Value in brackets means inch-pounds (in-lb).

*** Size of jaw of lock bolts and nuts with toothed flange are given

(metric values only) in brackets if different from standard.

• The listet values are applicable for dry or slightly oiled joints.

• When a stiff grease is applied decrease the given value by 10%.

Do not use plated bolts/screws/nuts without grease.

• In case lock nuts, lock screws or lock bolts are used the given value

has to be increased by 10%.

• Torque value of wheel nuts M18x1,5 shall be 270 Nm (200 ft-lb)!

Thread Torque value Size of jaw***

8.8* 10.9* 12.9*

Nm ft-lb** Nm ft-lb** Nm ft-lb** mm inch

M3 1.3 (11.5) 1.8 (16) 2.1 (18.6) 6 7/32

M4 2.9 (25.5) 4.1 (36.5) 4.9 (43.5) 7 9/32

M5 5.7 (50.5) 8.1 (71.5) 9.7 (86) 8 5/16

M6 9.9 7.3 14 10.3 17 12.5 10 13/32

M8 24 17.7 34 25 41 30.3 13 33/64

M10 48 35.4 68 50.2 81 59.8 17 (15) 11/16

M12 85 62.7 120 88.6 145 107 19 (17) 3/4

M14 135 99.6 190 140 225 166 22 (19) 7/8

M16 210 155 290 214 350 258 24 (22) 1 21/128

M18 290 214 400 295 480 354 27 1 9/128

M20 400 295 570 421 680 502 30 1 3/16

M22 550 406 770 568 920 679 32 1 17/64

M24 700 517 980 723 1180 871 36 1 27/64

M27 1040 767 1460 1077 1750 1291 41 1 79/128

M30 1410 1041 1980 1461 2350 1734 46 1 13/16

M33 1910 1410 2700 1996 3200 2362 50 1 31/32

M36 2450 1808 3450 2546 4150 3063 55 2 11/ 64

M39 3200 2362 4500 3321 5400 3985 60 2 3/8

Page 23

Maintenance

23

Tensile strength Material quality acc. to DIN ISO 898

8.8 10.9 12.9

up to and incl. M16 over M16

N/mm

2

808 830 1040 1220

lbf/sq.in. 117,222 120,414 150,880 176,994

Page 24

24

Maintenance

Conversion table for

units of measurement

Length

1m 1000 mm 39 3/8 in 3.2809 ft

1 mm 0.03937 in 5/128 in

1km 3280.9 ft 0.6214 mi 0.5396 NM

1 mi 1.6093 km 1609.3 m

1NM 1.8532 km 1.1515 mi 6080 ft

1yd 36in 3ft 0.914m

1in 1” 25.4 mm 0.0833 ft 1/12 ft

1 ft 1’ 12 in 304.8 mm 30.48 cm

Area

1m² 0.01 a 10.764 sq.ft.

1 a 100 m² 1076.4 sq.ft.

1ha 100 a 2.47 acre

1acre 0.4ha

Volume

1m³ 1000 dm³ 35.3 cu.ft.

1 dm³ 1 l 1.057 US qt(fl) 0.88 Imp.qt.

1cu.in. 16.387 cm³

1 cu.ft. 28.317 dm³

1 Imp.bu. 8 Imp.gal. 36.368 l

1 US bu 8 US gal(dry) 9.308 US gal(fl) 35.232 l

Force and weight

1N 0.102 kg(f) 0.22487 lb(f)

1 kg(f) 9.8 N 2.2046 lb(f)

1lb(f) 4.4447 N

Pressure and tension

1 bar 1.02 at 0.987 atm 14.5 psi 100 kPa

1psi 0.0689 bar 6.89 kPa

Page 25

Maintenance

25

Maintenance

Torque

1Nm 1J 0.102 kg(f)m 1Ws 0.738 ft-lb(f)

1 ft-lb(f) 1.356 Nm 12 in-lb(f)

1in-lb(f) 0.113 Nm

Power

1kW 1000 W 0.738 ft-lb(f)/s 1.359 pk 1.359hp

1 pk 1 PS 1 cv 1 cf 0.73575 kW

1hp 0.73575 kW

1 Btu/h 0.2930 W

Speed of rotation

1rpm 1/min 1/60 Hz

1Hz 1cps 1/s 60rpm

Forward speed

1km/h 0.27778 m/s 0.6214 mph 1kph 0.9113 fps

1 mph 1.609 km/h 0.4470 m/s 1.466 fps

Page 26

26

Optional equipment

Optional equipment

Parts listed below can be standard equipment in your area: contact

your dealer.

Install in accordance with the assembly/installation instructions of the

respective option.

Install in accordance with the assembly/installation instructions of the

respective option.

For spare parts see IPL.

Instructions for ordering

spare parts

Your order for spare parts should contain the following information:

• Machine type and product identification number (PIN) or the PSN,

• Description, part number (see IPL) and quantity in question.

If in doubt send a rough sketch of the part clearly marked with your

name and address.

Attention

Take into account valid Errata and other supplements!

Guards (complete)

Part no. ‘VGTH00267K0’

Tine saver

Part no. ’VGGZ280V’ 20 each required (not shown)

Set of lamp supports

Part no. ‘VGRT00133’ (not shown)

You may require 3 sets, depending on your local regulations.

Page 27

EC Certificate of conformity

27

EC Certificate of confor mity

Conformin g to EE C

Directive 89 /3 92

We

KUHN-GELDROP B.V.

Nuenenseweg 165

NL-5667KP Geldrop

The Netherlands

declare in sole responsibility, that the product

to which this certificate relates, conforms to the basic safety and

health requirements of the Directives 89/392/EEC (amended with 91/

368/EEC, 93/44/EEC and 93/68/EEC) and 98/37/EC.

To effect correct application of the safety and health requirements

stated in the EEC Directives, the following standard(s) and/or

technical specification(s) has (have) been respected:

• EN292

• EN294

KUHN-GELDROP B.V.

Geldrop, 08-05-2009

Anthony van der Ley

General Manager

Rotary Hay Making Machine HAYBOB 300 and accessories

Page 28

Index

28

Index

A

Adjustments for raking 18

Adjustments for spreading and tedding

16

Attachment to the tractor 15

D

Destination and intended use

General

6

Technical specifications 6

M

Maintenance

Conversion table for units of measurements

24

General 20

Lubrication

21

Tines

20

Torque values for international metric thread

joints

22

O

Operation

Adjustments for raking 18

Adjustments for spreading and tedding

16

General instructions for use

16

Optional equipment

Guards (complete)

26

Instructions for ordering spare parts

26

Set of lamp supports 26

Tine Saver

26

P

Pre-operation

Attachment to the tractor

15

S

Safety and reliability

Drive through universal joint drive shafts

9

General

7

Liability and warranty 11

Safety decals

10

Storage safety

10

Tractor loads 12

Wheels and tryres

10

T

Technical specifications 6

Tines 20

Tractor loads

12

U

Used terms and symbols 5

W

Wheels and tyres

Safety and reliability 10

Loading...

Loading...