Page 1

OPERATOR'S MANUAL

KN198KGB D

Disc mower

-FF

GMD800GII

KN198KGB D

- English - 04-2010

Page 2

Page 3

Disc mower

GMD800GII-FF

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The GMD800 GII mower must only be used for the pur pose for which it was manufactured: mowing on the

ground of hay fields, grass silage fields and improved past ures for the purp ose of harve sting fodd er fo r feeding

livestock.

Dear Owner

1

Page 4

Disc mower

GMD800GII-FF

$Contents

Dear Owner.....................................................................................................................1

Contents .........................................................................................................................2

Identification of the machine.........................................................................................4

Front view..........................................................................................................................................4

Rear view.. .................................................... ................................................... ..................................4

Model identification plate ................................................................................................................5

Optional equipment..........................................................................................................................5

Safety...............................................................................................................................6

Description of symbols used in this document.............................................................................6

Safety instructions...........................................................................................................................7

Location and description of safety decals on the machine .......................................................17

Road safety equipment and recommendations...........................................................................22

Machine specifications................................................................................................23

Description and glossary...............................................................................................................23

Technical specifications...................... .... ... ... ....................................................... ... ... .... ... ............24

Sound levels ......... ... ... .... ... ... ... .... ................................................... .... ... ... ... ... .... ... .........................24

Putting into service......................................................................................................25

Description of control elements....................................................................................................25

Coupling and uncoupling..............................................................................................................26

Instructions for transport............................................................................................35

2

Putting the machine into transport position................................................................................35

Conformity with the road regulations...........................................................................................36

Contents

Page 5

Disc mower

GMD800GII-FF

Instructions for work...................................................................................................37

Putting the machine into work position.......................................................................................37

Adjustments in working position..................................................................................................39

Machine use....................................................................................................................................41

Optional equipment.....................................................................................................45

Raised skid shoes..........................................................................................................................45

Side deflector........................... ... .... ... ... ... ... .... ... .................................................... ... ... ...................45

Side deflector with high cone disk..................................... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ...46

Lighting and signalling..................... ... ....................................................... ... ... .... ... ......................46

Lateral signalling equipment.........................................................................................................47

1000 min-1 drive kit........................................................................................................................48

Longer hitch pins...........................................................................................................................49

Maintenance and storage............................................................................................ 50

Frequency chart .............................................................................................................................50

Lubrication............................................................................................ ..........................................51

Maintenance....................................................................................................................................54

Storage............................................................................................................................................74

Trouble shooting guide...............................................................................................75

Appendix ......................................................................................................................77

Calculating the load on an axle.....................................................................................................77

Limited warranty..........................................................................................................83

Contents

3

Page 6

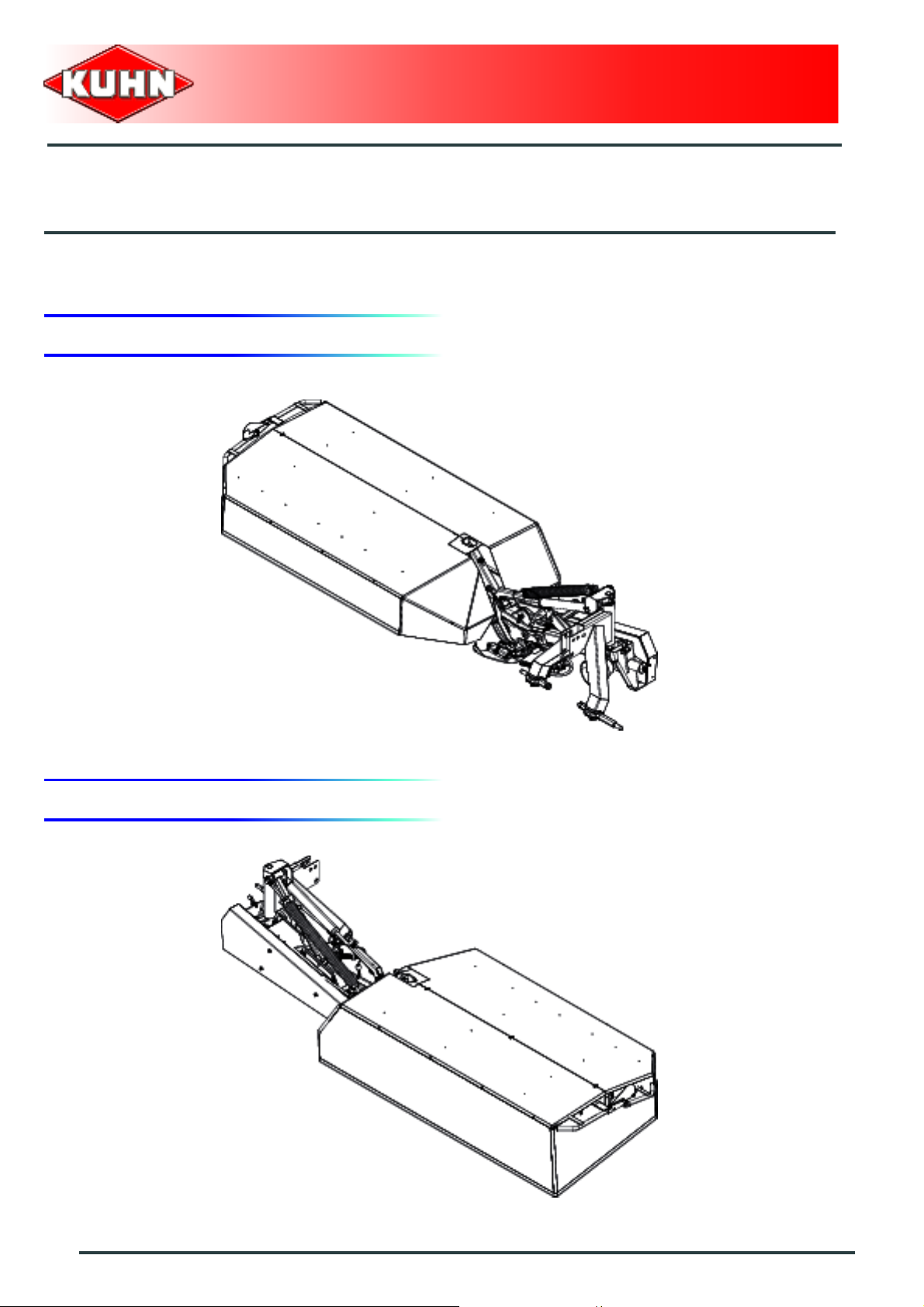

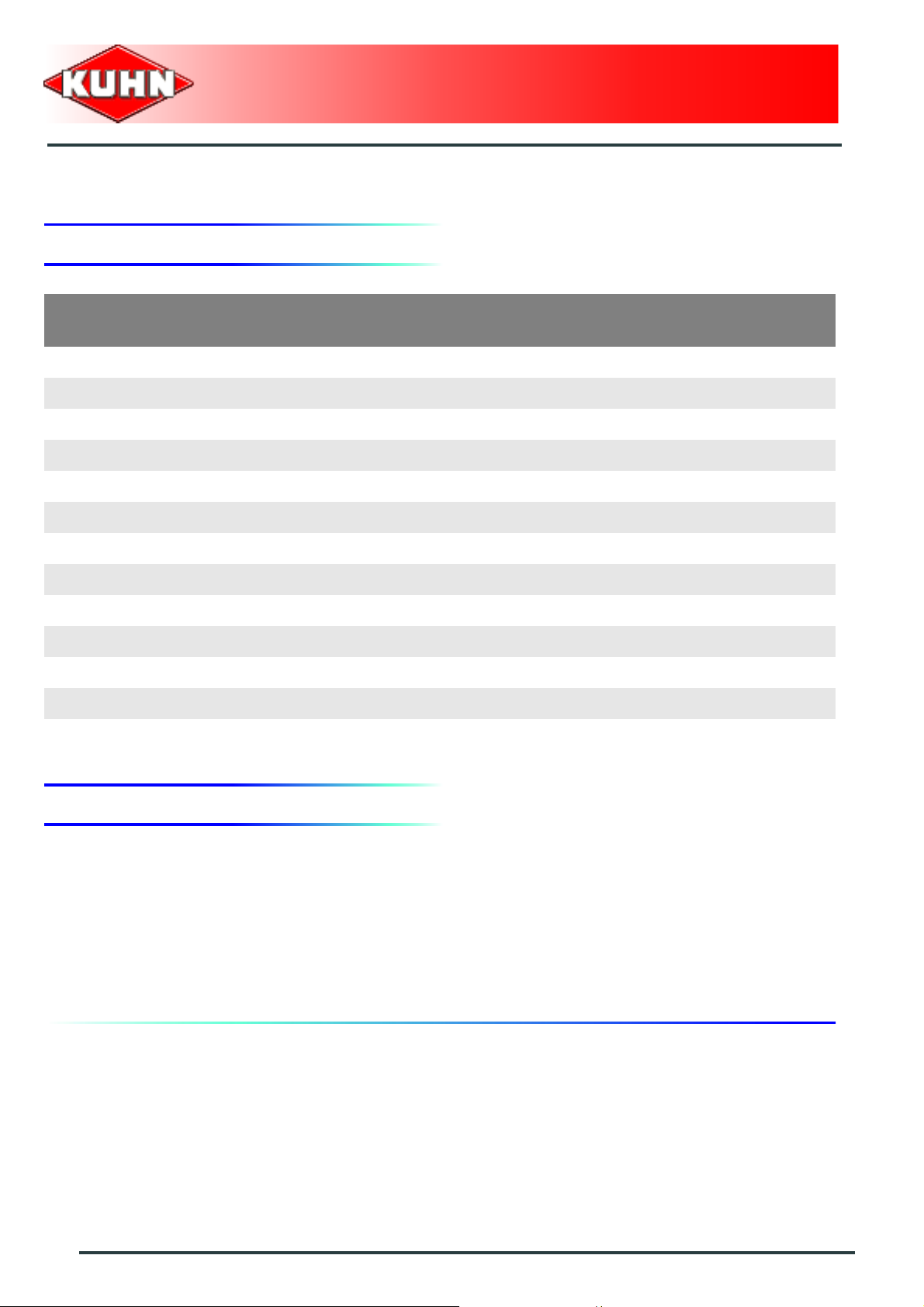

1. Front view

Disc mower

GMD800GII-FF

$Identification of the machine

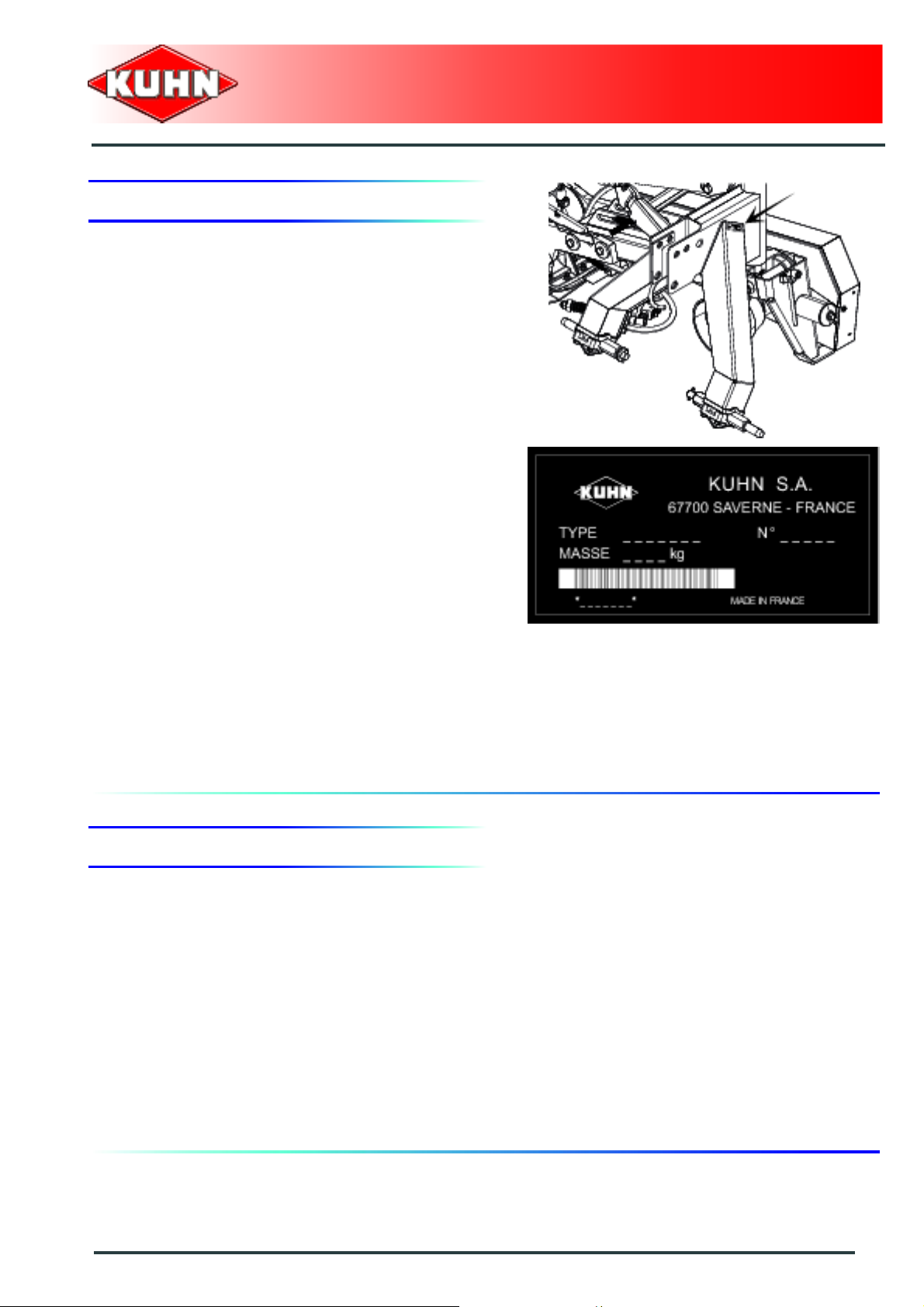

2. Rear view

4

Identification of the machine

Page 7

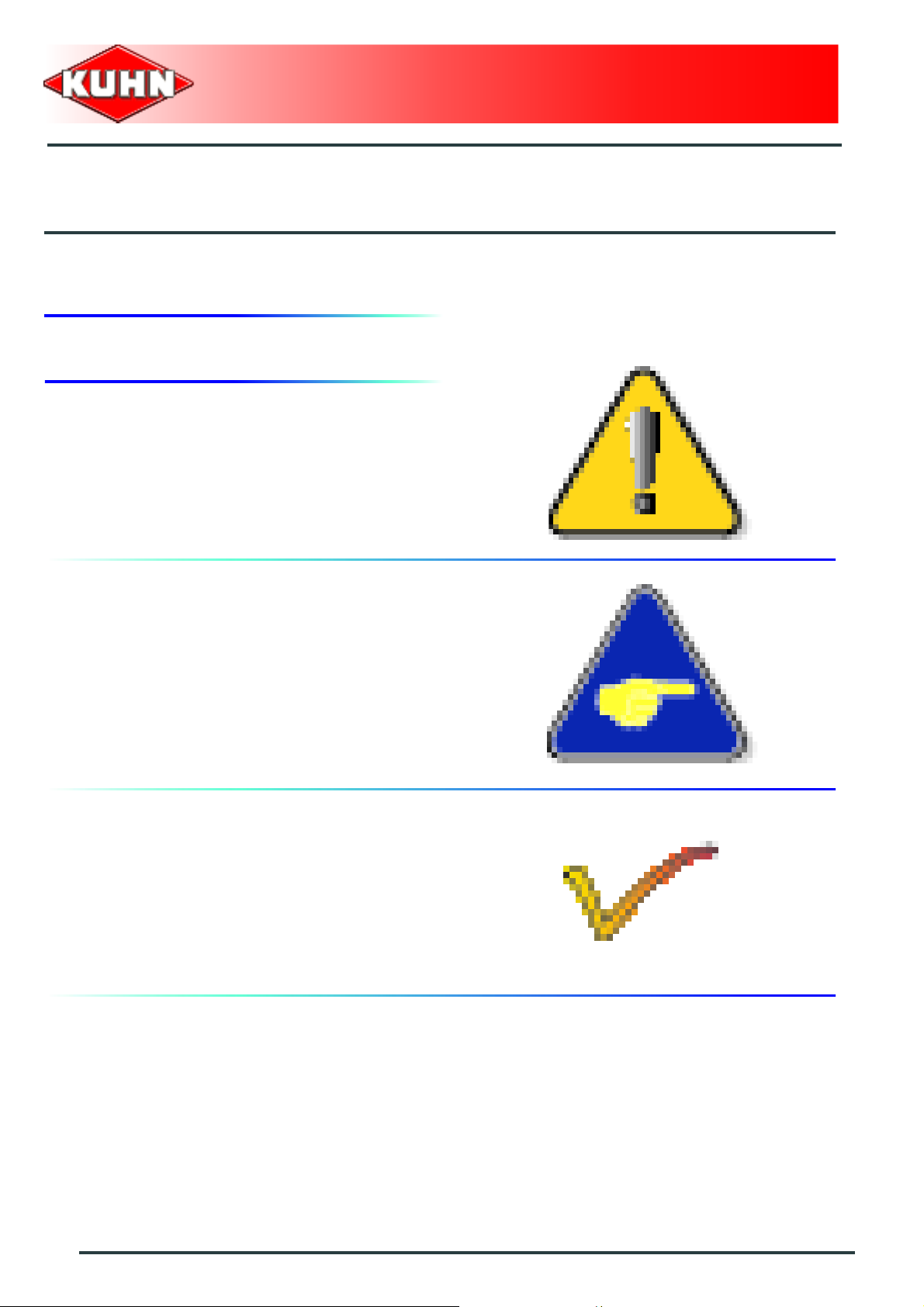

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Type: GMD800GII

Disc mower

GMD800GII-FF

Serial no.:

4. Optional equipment

Tick box corresponding to the equipment fitted on your

machine:

Kit no. 1036230: Raised skid shoes 90 mm (3.54’’).

Kit no. 1036340: Side deflector.

Kit no. 1036290: Side deflector with high cone disk.

Kit no. 1026100: Lighting and signalling.

Kit no. 1016440: Lateral signalling equipment.

Kit no. 1066010: 1000 min

-1

drive kit.

Kit no. 56820700: Longer hitc h pins.

Identification of the machine

5

Page 8

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Disc mower

GMD800GII-FF

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

6

Safety

Page 9

Disc mower

GMD800GII-FF

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations fo r preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect current le gislation concerning accident prevention, wo rk safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment a nd acce sso ries, as r ecom mended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident re sulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not traine d

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Safety

7

Page 10

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Disc mower

GMD800GII-FF

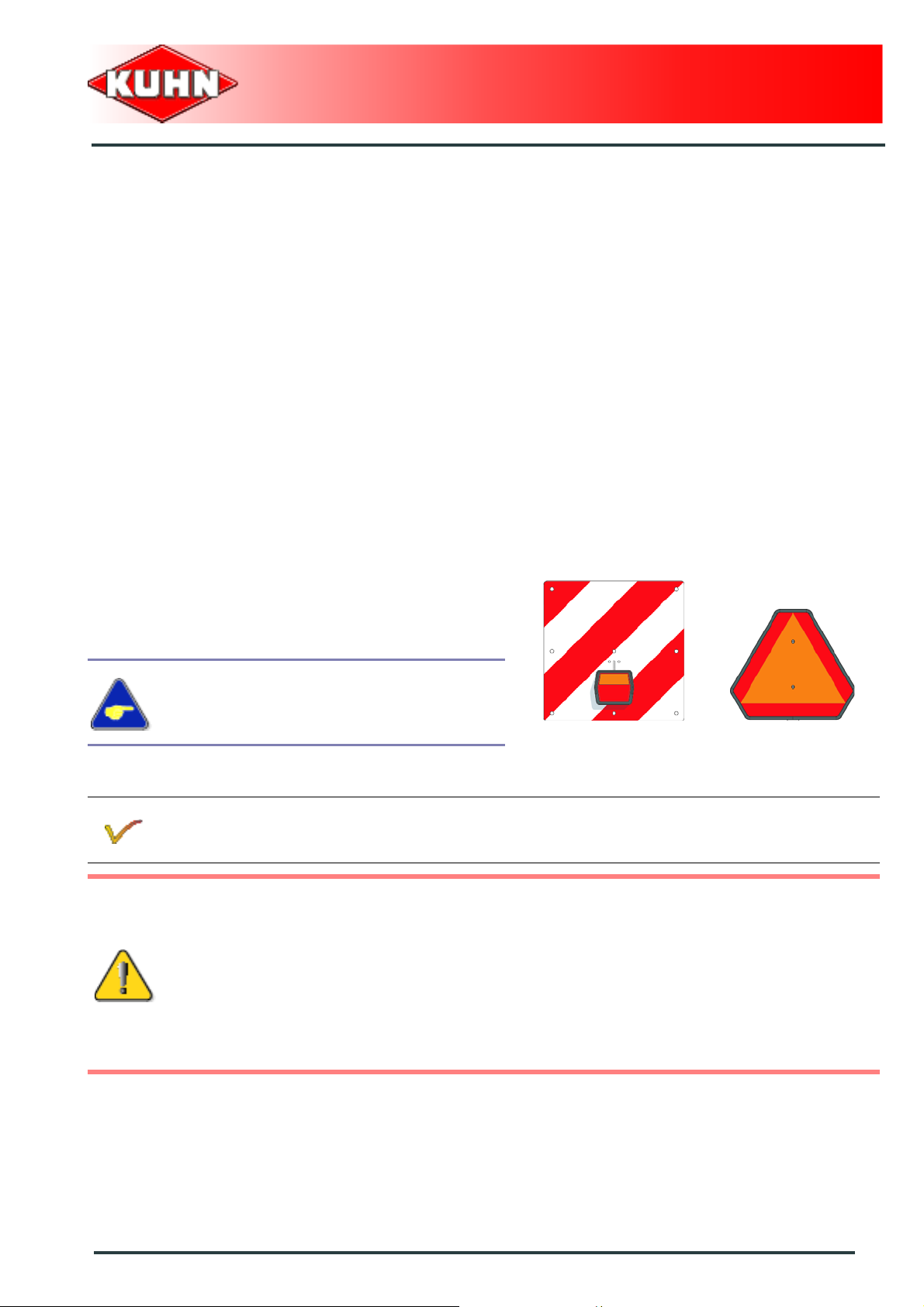

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt change s

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

8

Safety

Page 11

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transportation of oversize

equipment.

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lights and indicators

Disc mower

GMD800GII-FF

Before transporting the machine on public road s, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Always obey current regulations for driving

on roads.

Gross weight and weight per axle

The drawings are not legally binding, their only aim is to illustrate the method to use.

Prior to driving on public roads, check t hat criteria are met t o be in conformity with the count rie's

regulations:

- When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized

payload must not be exceeded.

- When coupling tools to the front and rear 3-point lift linkages, the maximum load on each

axle's tires must not be exceeded.

- The load on the tractor front axle must always repr esent 20 % of the tr actor unladen we ight.

Safety

9

Page 12

For machines with hoppers or tanks:

- If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance

with the countrie's legislation, empty the hopper to travel on public roads.

- In any case, we recommend to travel on public roads with empty hoppers and tanks.

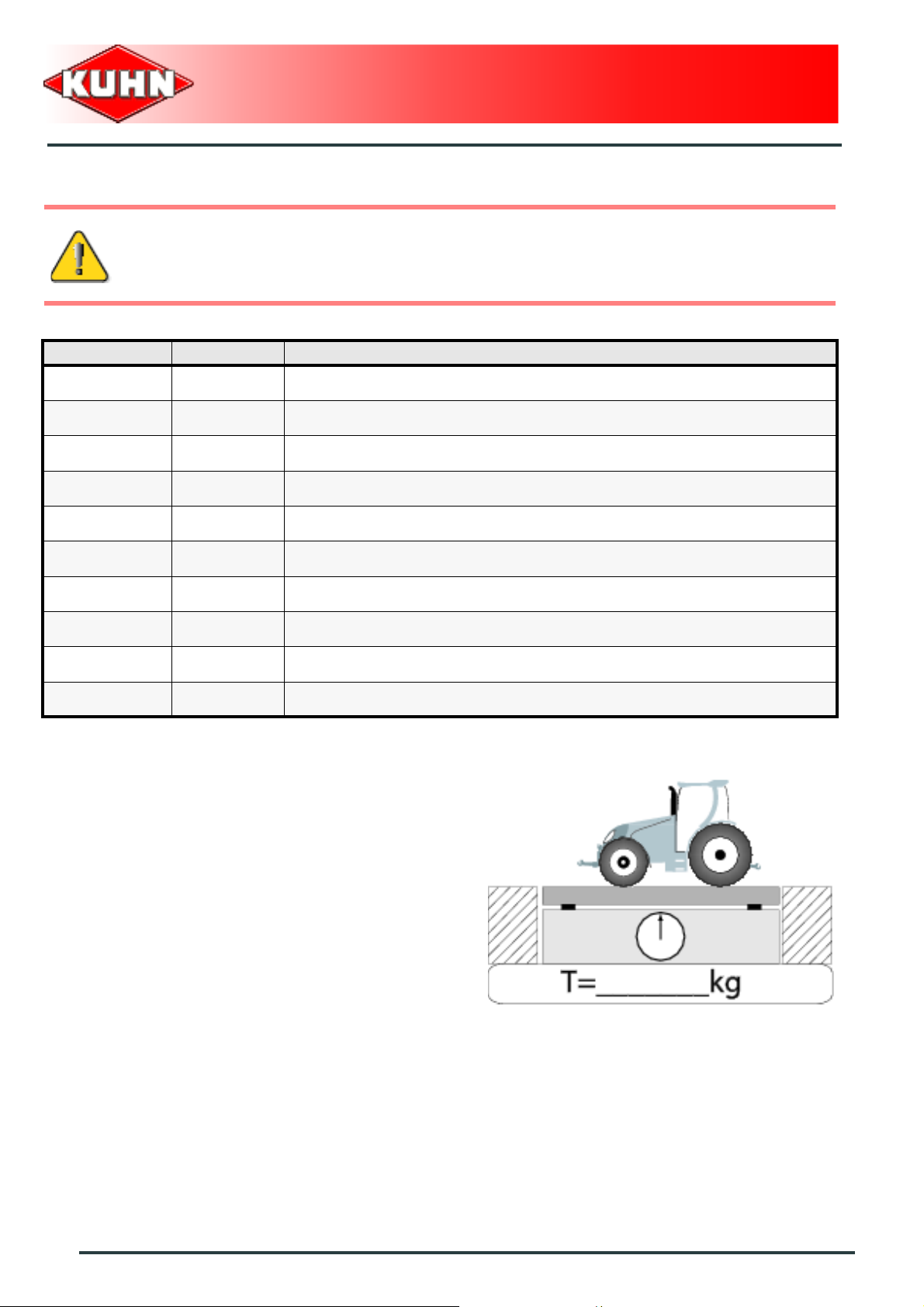

Description of symbols

Description Units Description

T kg Tractor unladen weight

PTAC kg Gross Combined Weight Rating

T1 kg Unladen load on tractor front axle

T2 kg Empty load on tractor rear axle

t kg Axle loads (Tractor + machine)

Disc mower

GMD800GII-FF

t1 kg Load on front axle (Tractor + machine)

t2 kg Load on rear axle (Tractor + machine)

t1 max kg Maximum load authorized on the tractor front axle according to the tires

t2 max kg Maximum load authorized on the tractor rear axle according to the tires

M1 kg Total weight of front tool or front ballast

Stage 1:

To measure:

- Tractor tare (T).

10

Safety

Page 13

Stage 2:

- Couple the machine to the tractor.

To measure:

- Load on front axle (t1):

• Tractor + machine (transport position).

To do:

- If the front axle load (t1) is below 20% of the tractor

tare (T), add ballast weights (M1) to exceed the

minimum load on the front axle.

Example:

• (T) = 7500 kg (16535 lb)

• The front axle load must be of minimum 1500 kg

(3300 lb).(20% of T)

• (t1) = 700 kg (1545 lb).

• 700 kg (1545 lb) < 1500 kg (3300 lb).

• Add ballast weights until the minimum front axle

load is exceeded.

• Repeat checking procedure.

Disc mower

GMD800GII-FF

Stage 3:

To measure:

- Total weight (t):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- To go to the next stage:

• Check in the tractor's operator's manual that the

value measured is below the tractor's Gross

Combined Weight Rating.

To do:

- If t < PTAC go to the next stage.

- If the total unit weight exceeds the tractor Gross

Combined Weight Rating in accordance with the

countrie's legislation, empty the hopper to travel on

public roads.

Example:

• (t) = 10000 kg (24250 lb)

• PTAC = 13000 kg .

• t < PTAC : Go to the next stage.

Safety

11

Page 14

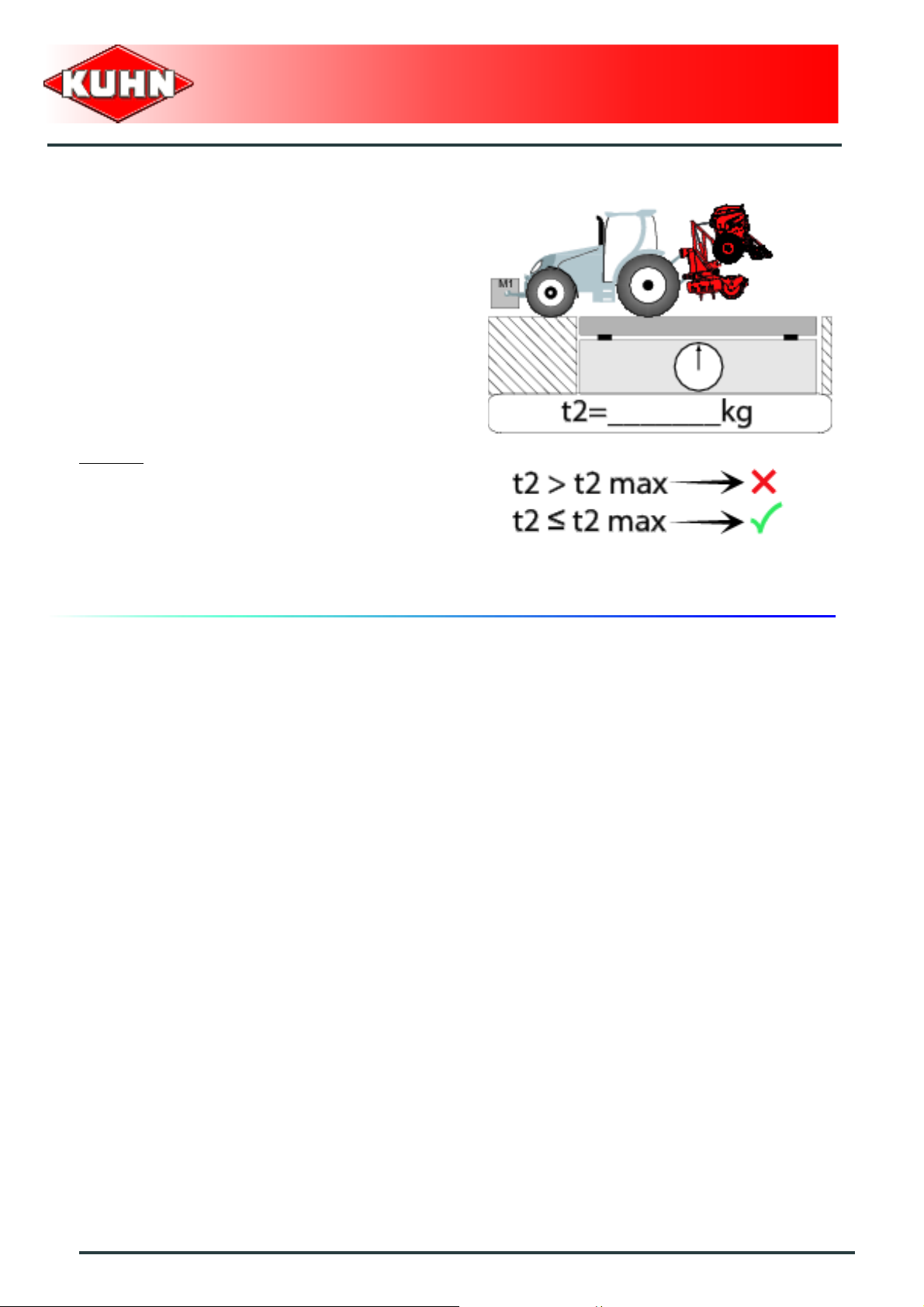

Stage 4:

To measure:

- Load on rear axle (t2):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- Check in the tractor's operator's manual that the value

measured is below the maximum allowed tractor rear

axle load.

- Check that tyre and rim specifiations are in conformity

with the requirements of the tractor manufacturer.

Example:

• Load on rear axle (t2) = 8500 kg (18740 lb)

• Check in the tractor's operator's manual that the

value measured is below the maximum allowed

tractor rear axle load.

• Check that tyre and rim specifiations are in

conformity with the requirements of the tractor

manufacturer.

Disc mower

GMD800GII-FF

12

Safety

Page 15

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

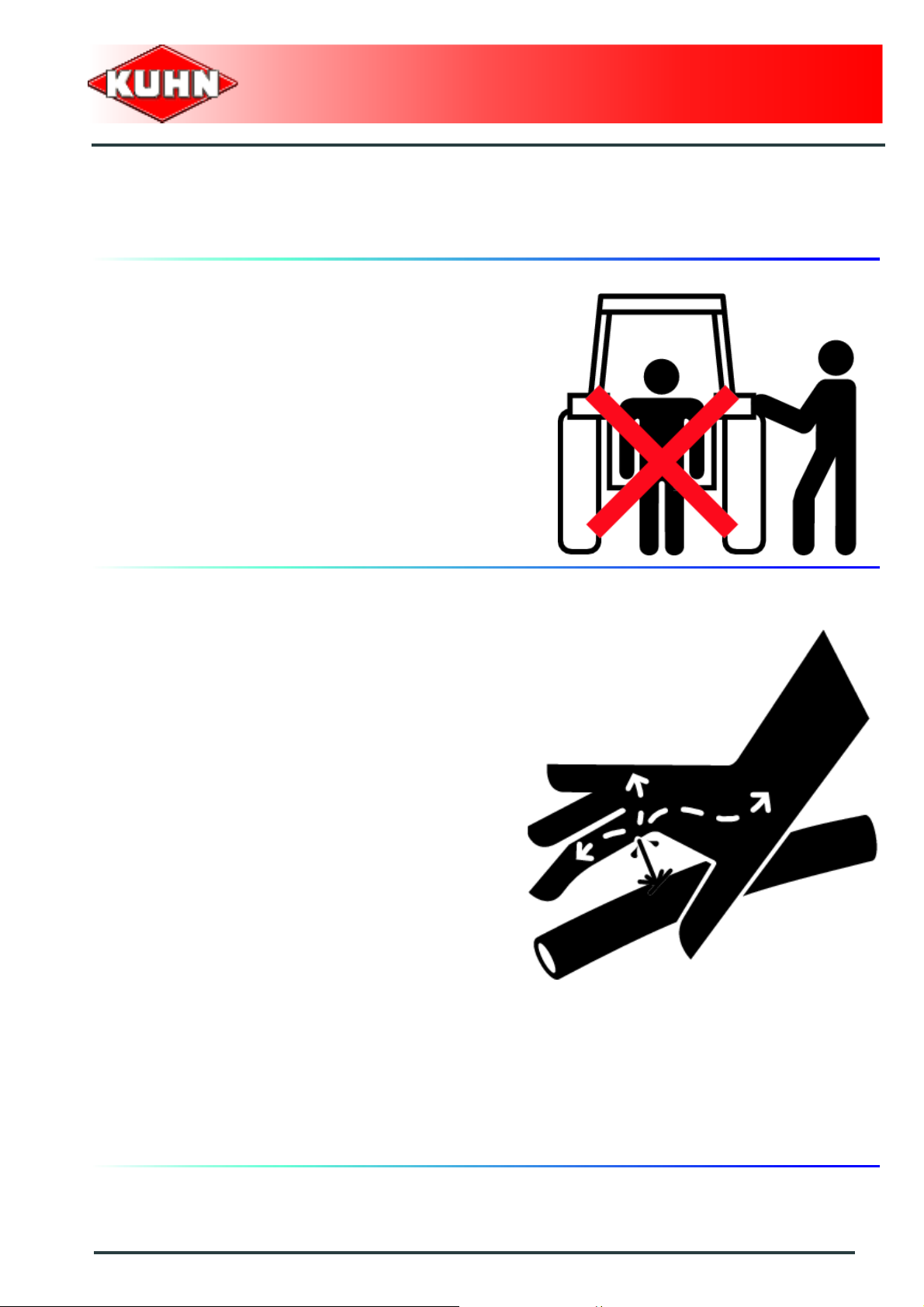

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Disc mower

GMD800GII-FF

Hydraulic circuit

Caution! The hydraulic circuit is under high pressure.

Maximum pressure at work: 200 bar (2900 psi).

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making incorrect connectio ns, mark hydraulic

couplers and corresponding hoses with colors.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In case of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be r eplaced.

When replacing the hydraulic hoses, only use hoses with

the specification recommended by the manufacturer of

the machine.

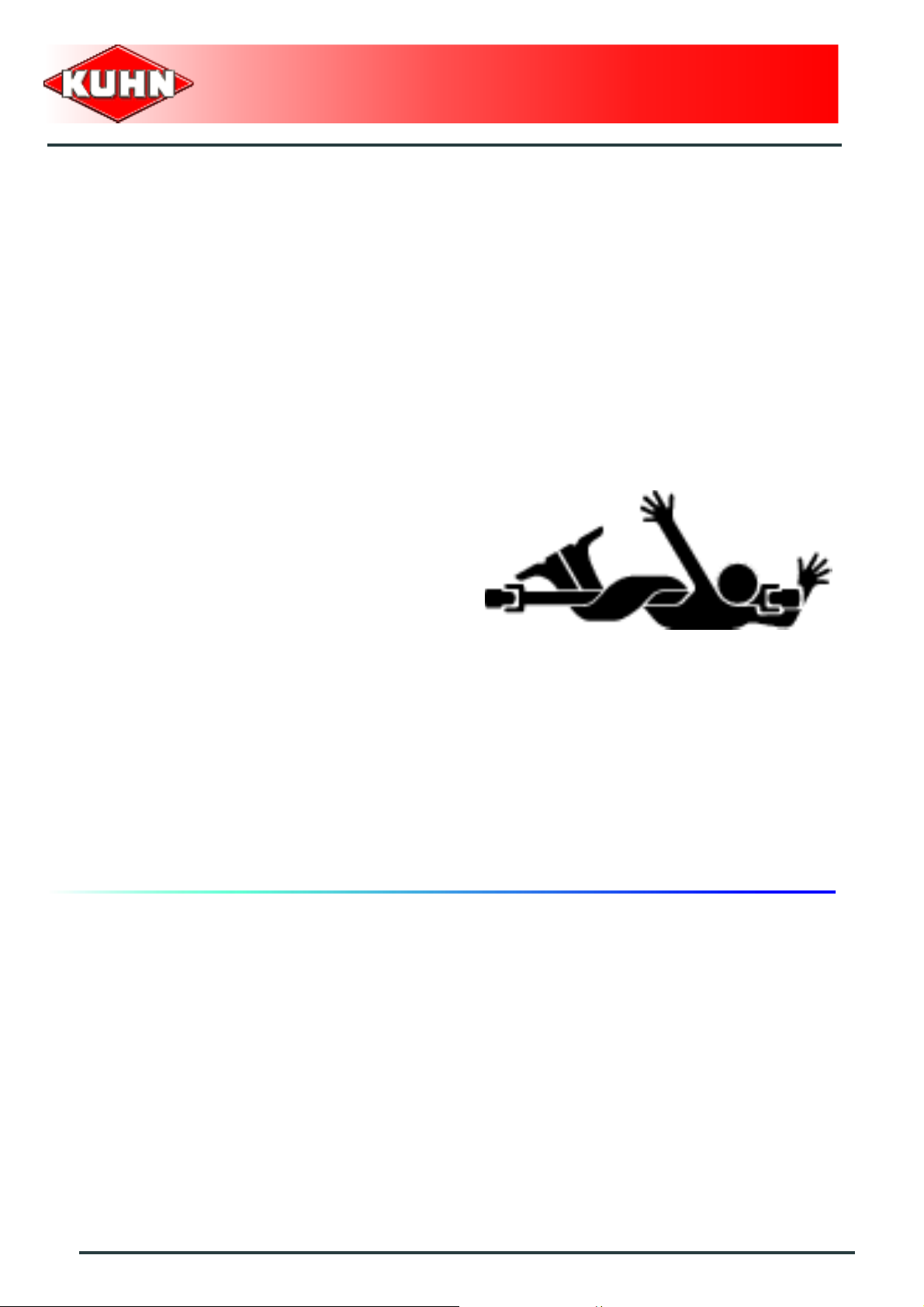

To locate a leak, use appropriate means. Protect body

and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine to the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

Safety

13

Page 16

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are secured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately. A worn guard or an unpro tecte d PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendat ion s.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's manual

provided with the PTO shaft.

Disc mower

GMD800GII-FF

14

Safety

Page 17

Precautions during manoeuvres

When moving the machine from the transport position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Safety decals

Safety warning decals are placed in pictorial form on

various parts of the machine. They are there to warn you

of potential dangers and to tell you how to avoid

accidents.

Always keep the safety decals clean and readable, and

replace them when they are worn, damaged, missing or

illegible.

Disc mower

GMD800GII-FF

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters, etc.) on the ground, never pour them

down the drain and never discard them in any other

place where they could pollute the environment. Never

throw away or burn a tyre. Always take waste to

specialized recycling or waste disposal centers.

Safety

15

Page 18

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the gr ound, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

It is strongly recommended to have your machine

checked by your Kuhn dealer after each season,

especially tools and their attaching hardware.

Disc mower

GMD800GII-FF

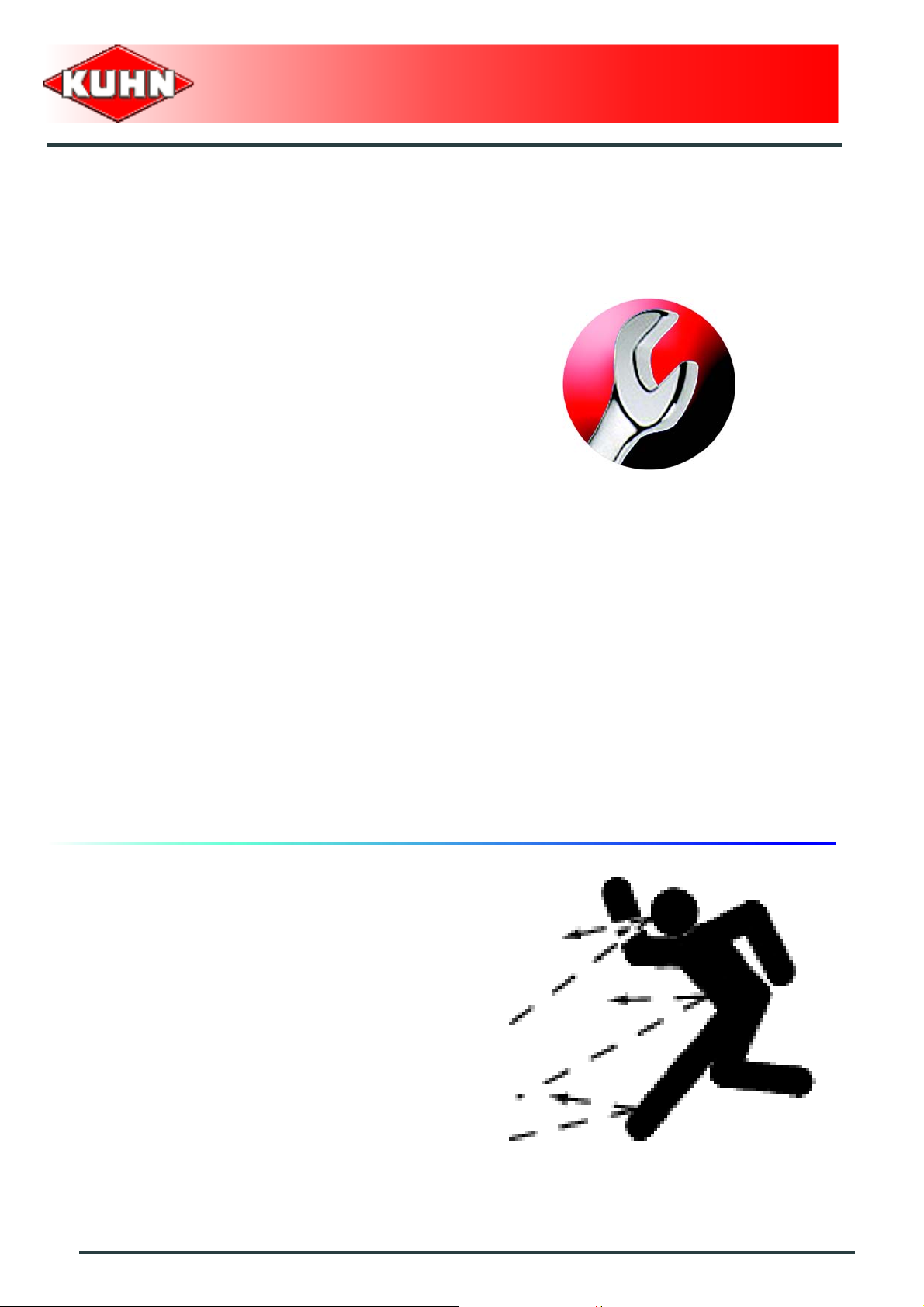

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab. Keep the ground to mow free of foreign bodies.

Avoid mowing on stony or rocky grounds. If this is not

possible, take extra safety precautions, such as:

- Fit polycarbonate screens inside the tractor cab's side

and rear windows, or install narrow mesh guards on

their exterior.

- Increase the cutting height to avoid contact with

stones or rocks.

Never start the machine when there are people nearby.

16

Safety

Page 19

Even when the machine is used in accordance with its

purpose, objects may be projected. Stones and other

foreign objects projected by the movin g parts can tr avel

a considerable distance. Keep all persons and animals

away from the danger zone.

The protection covers help reducing risks of projections.

Therefore, make sure t hat all mower protection devices

are in place and good condition prior to using the

machine.

Regularly check the condition of th e protection covers.

Immediatly replace any worn, damaged or missing

cover.

Precautions for machine use

After each use, check the cutting tools (discs, knives)

and their attachment hardware in accordance with the

instructions given in the present manual. Immediately

replace any worn, damaged or missing cutting tool or

element. To do this, use the tool outfit supplied with the

machine. For your safety, only use genuine parts !

Regularly check the condition of th e protection covers.

Immediatly replace any worn, damaged or missing

cover. Before engaging the PTO, rest the cutterbar on

the ground. Make sure all the guards are in place. Keep

all persons and animals away from the danger zone.

Stay a safe distance from the machine when the cutting

tools are in movement.

Never work in reverse.

After disengaging the PTO drive, cuttings tools can

continue rotating for some time. Stay away from the

machine until all moving parts have come to a complete

standstill.

If the machine hits an obstacle, disengage the PTO

drive, stop the tractor engine, remove the ignition key

and wait for all moving parts to come to a complete

standstill. Check the entire machine for any damage

before resuming work.

Disc mower

GMD800GII-FF

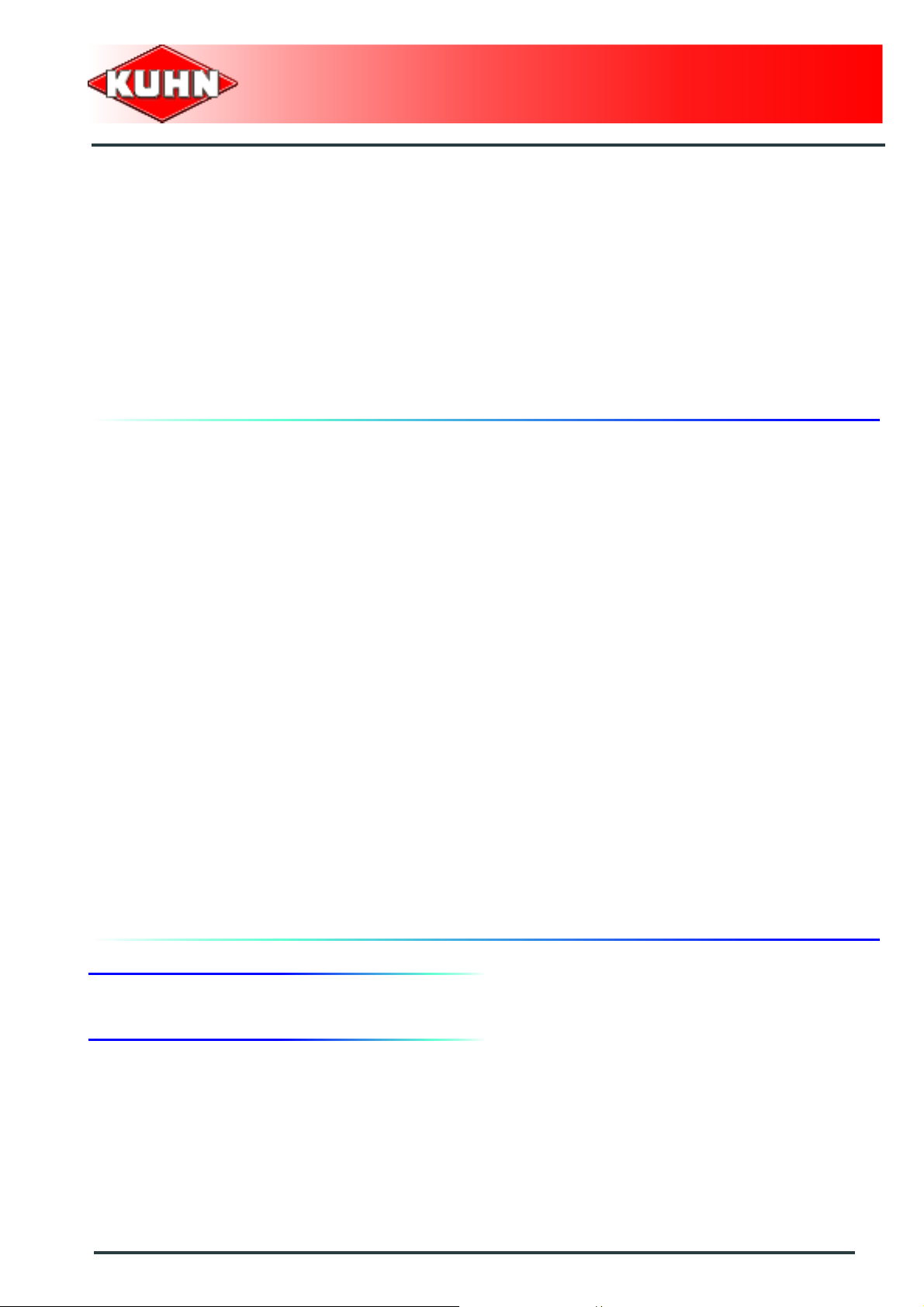

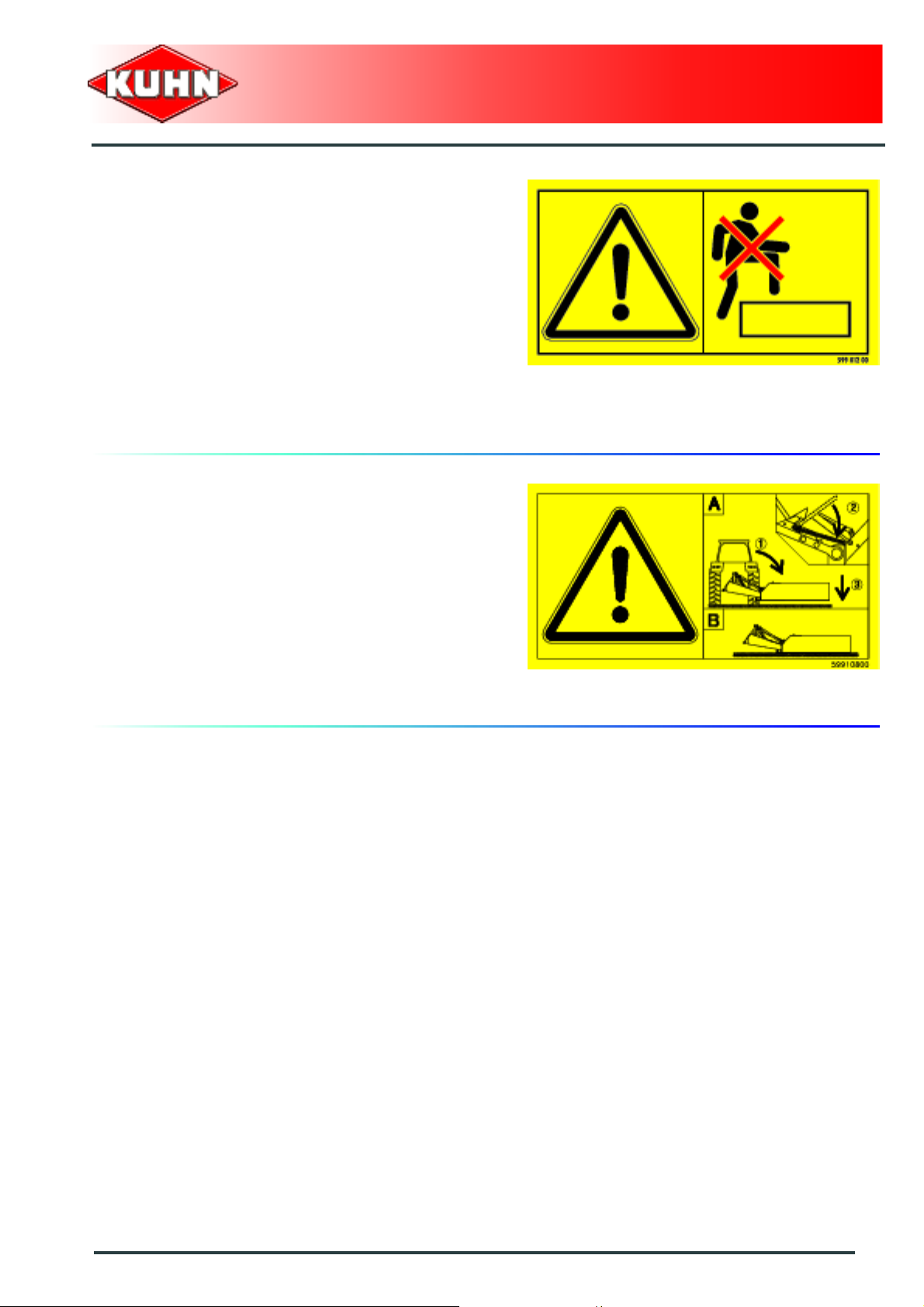

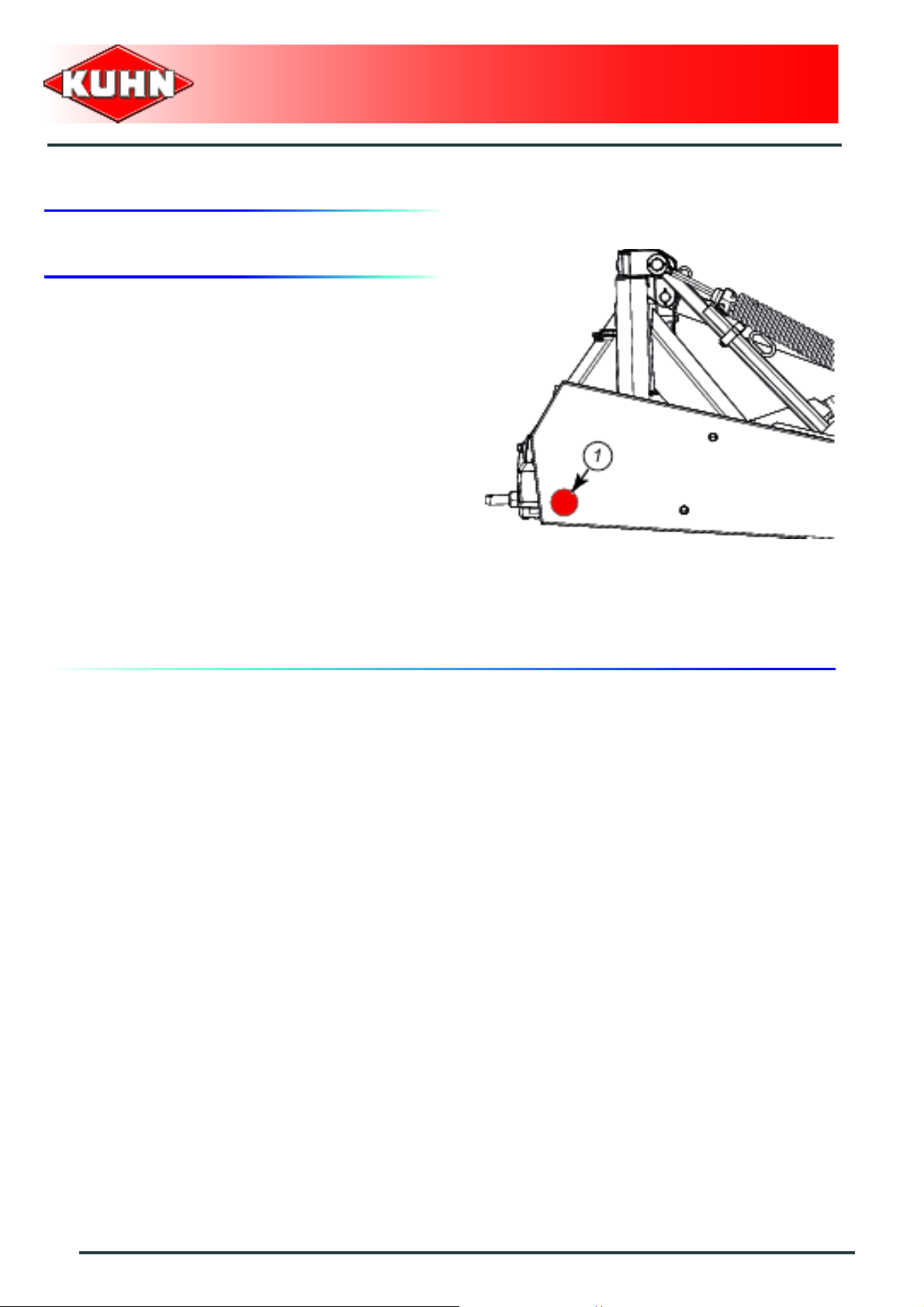

3. Location and description of safety decals on the machine

Location of safety decals

Safety

17

Page 20

Disc mower

GMD800GII-FF

18

Safety

Page 21

Description of safety decals

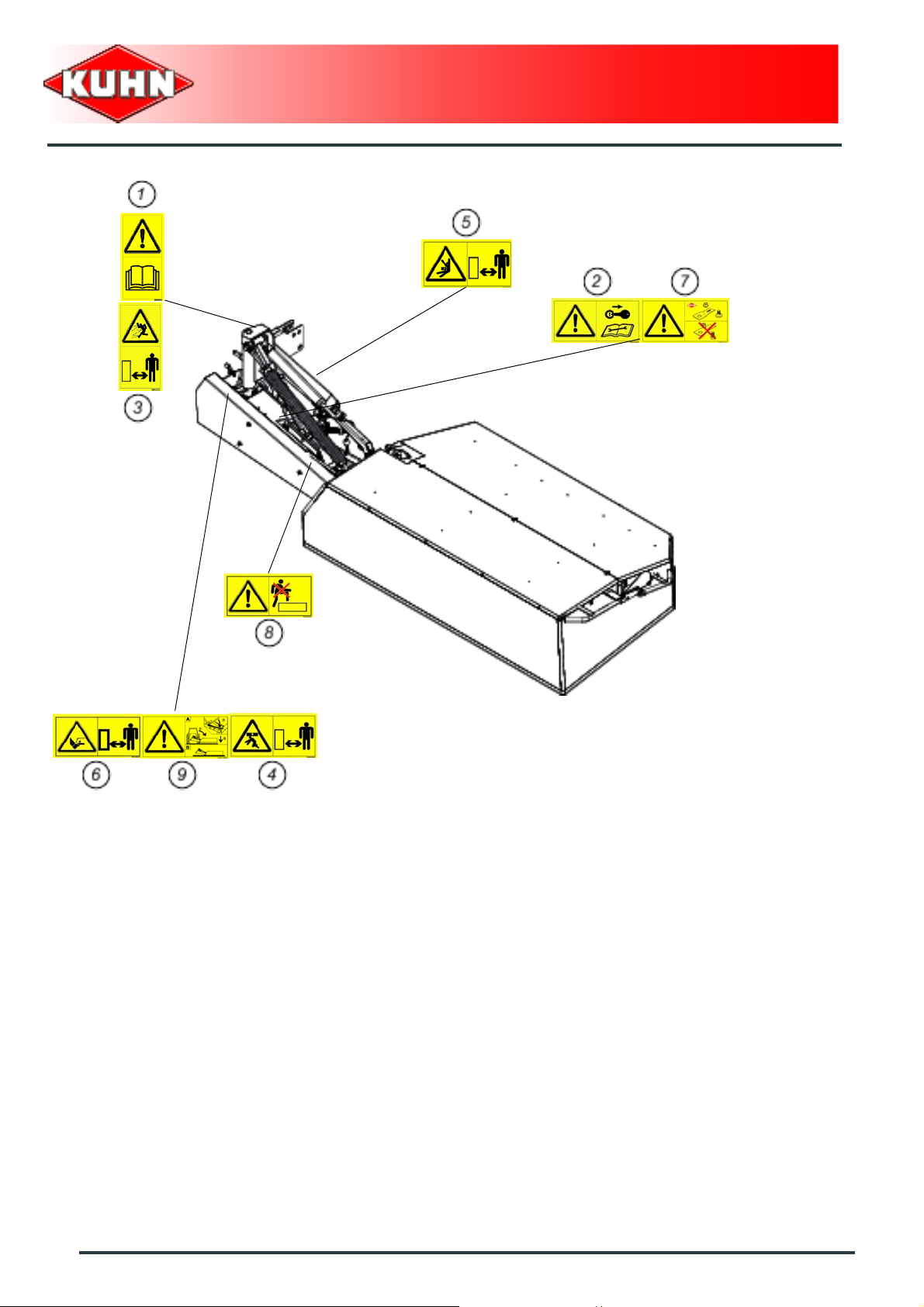

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Disc mower

GMD800GII-FF

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

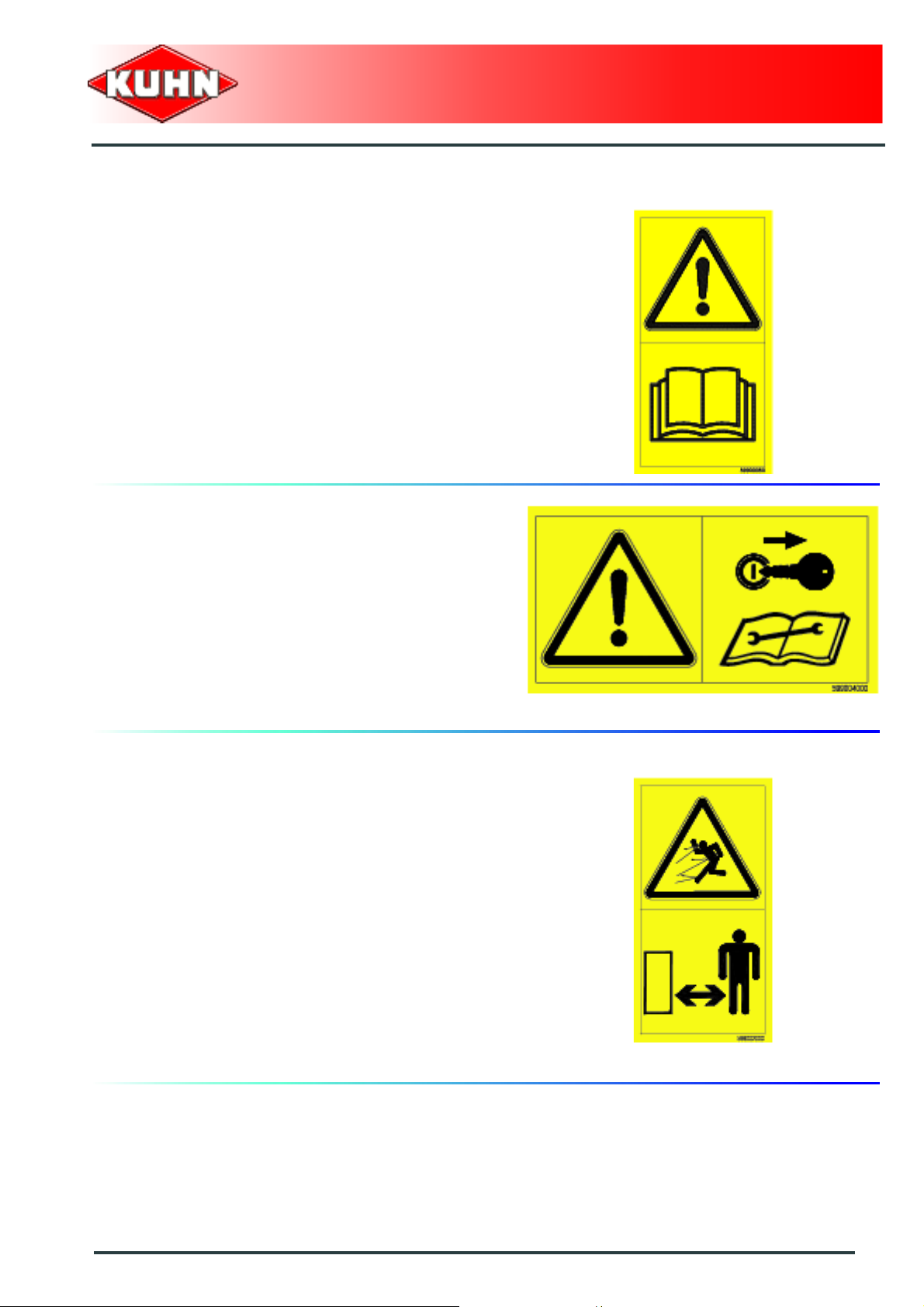

Projections (3)

Stones and other debris projected by the moving parts

can travel a long distance. The protection covers must

always be in position and in good condition. Always stay

at a safe distance from the machine.

Safety

19

Page 22

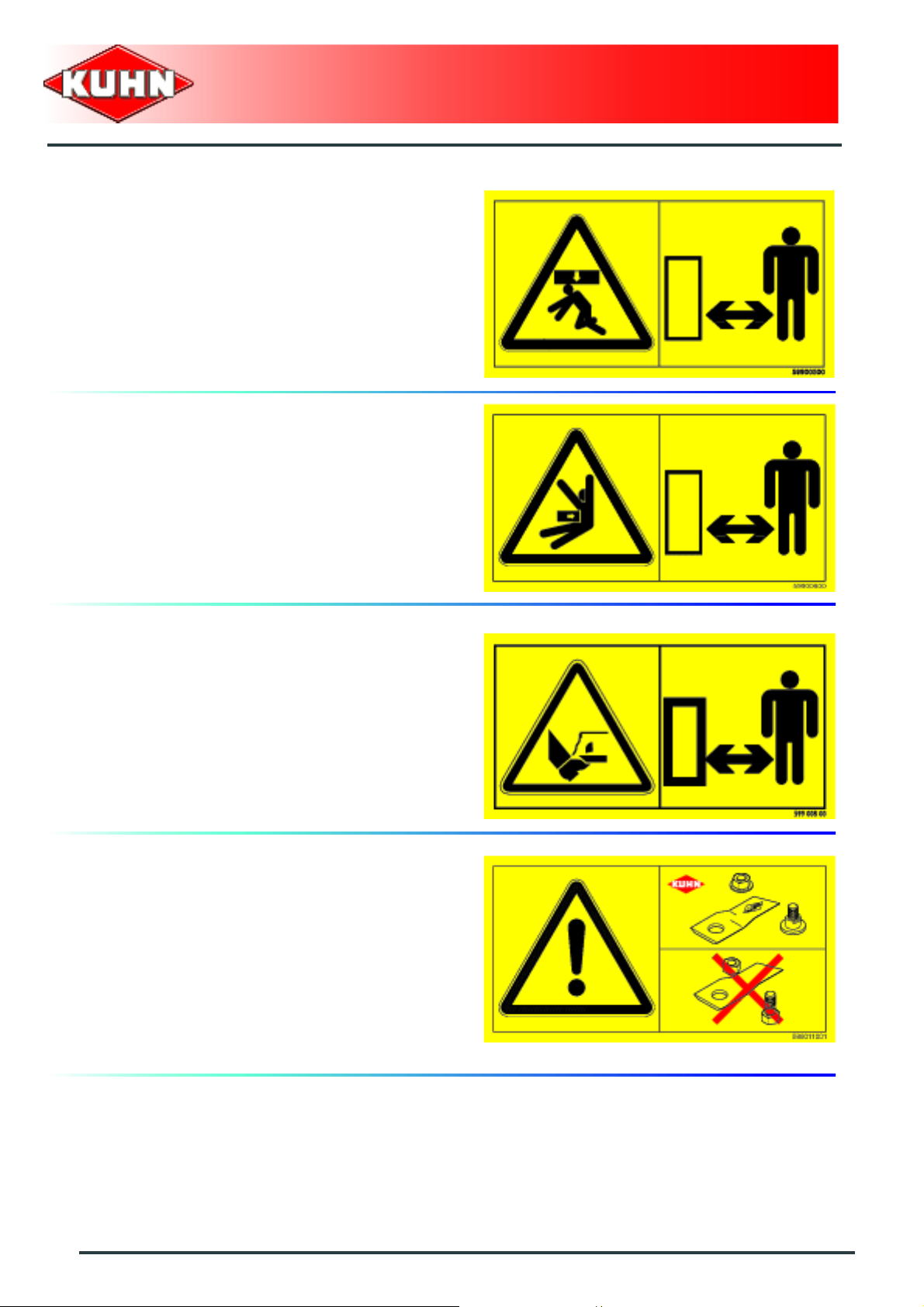

Crushing area (4)

Never operate in an area where there is a crushing risk

before all moving parts have come to a complete stop.

Manoeuvring area (5)

Stay a safe distance from the machine. Crushing hazard.

Disc mower

GMD800GII-FF

Rotating cutting tools (6)

Keep away from the mower knives all the time the engine

is running, the PTO drive engaged and the moving parts

have not come to a complete stop.

Cutting tools (7)

The cutting tools and their attachment hardware meet

safety and reliability criteria set by standards and by the

manufacturer. For your own safety and for correct

machine operation, only use original manufacturer parts.

20

Safety

Page 23

Do not step on the machine (8)

Do not step on the machine : Risk of falling or damaging

the protection device.

Prior to uncoupling the machine (9)

- Place the cutterbar in horizontal position.

- Lower parking lock.

- Lower the machine.

The machine must always be parked with the cutter bar

in horizontal position (B).

Disc mower

GMD800GII-FF

Safety

21

Page 24

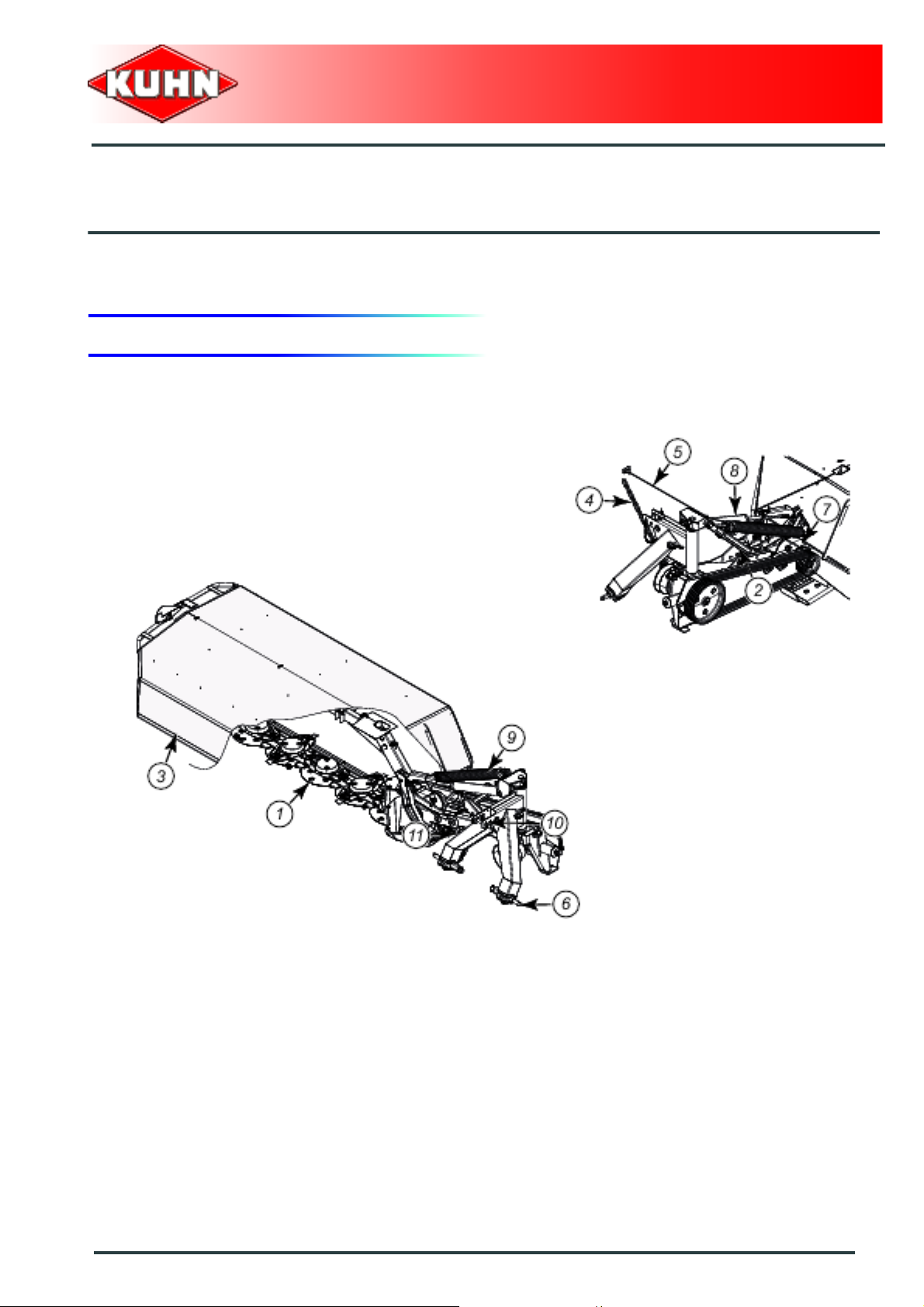

4. Road safety equipment and recommendations

The road safety equipment is mounted in the factory or

by your authorized Kuhn dealer according to current

safety regulations.

The device is composed of:

- 1 red reflector (1).

Always keep to the legal speed limit for driving a tractormachine assembly on public roads. Whatever this

speed, we recommend, for everyone's safety, not to

exceed a speed of 40 km/h (25 mph).

Disc mower

GMD800GII-FF

22

Safety

Page 25

$Machine specifications

1. Description and glossary

0

Disc mower

GMD800GII-FF

1 : Cutterbar 2 : Parking lock

3 : Front guard 4 : Check chain

5 : Release cord 6 : Hitch pin

7 : Gearbox 8 : Lift cylinder

9 : Compensating spring 10 : Upper coupling yoke

11 : Safety breakback

Machine specifications

23

Page 26

2. Technical specifications

Attachment type 3 point, Category 2

Number of discs 8

Working width 3.10 m (10’2’’)

Width in working position 4.98 m (16’4’’)

Height in working position 1.17 m (3’98’’)

Length in working position 1.33 m (4’41’’)

Disc mower

GMD800GII-FF

Width in transport position 1.635 m (5’4’’)

Height in transport position 3.665 m (12’)

Length in transport position 1.38 m (4’63’’)

Disc rotational speed 2986 min

PTO speed 540 min

Weight 710 kg (1565 lb)

Minimum PTO power requirement 41 kW (55 hp)

3. Sound levels

Sound levels have been measured in accordance with the measuring methods as defined in:

NF EN ISO 4254-1

«Agricultural machinery - Safety - Part 1: General requirements»

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L (A) eq:

Tractor only: 76 dB(A)

Tractor + machine: 80.3 dB(A)

-1

-1

24

Machine specifications

Page 27

$Putting into service

1. Description of control elements

The machine is fitted with a release cord operated from

the tractor cab.

Disc mower

GMD800GII-FF

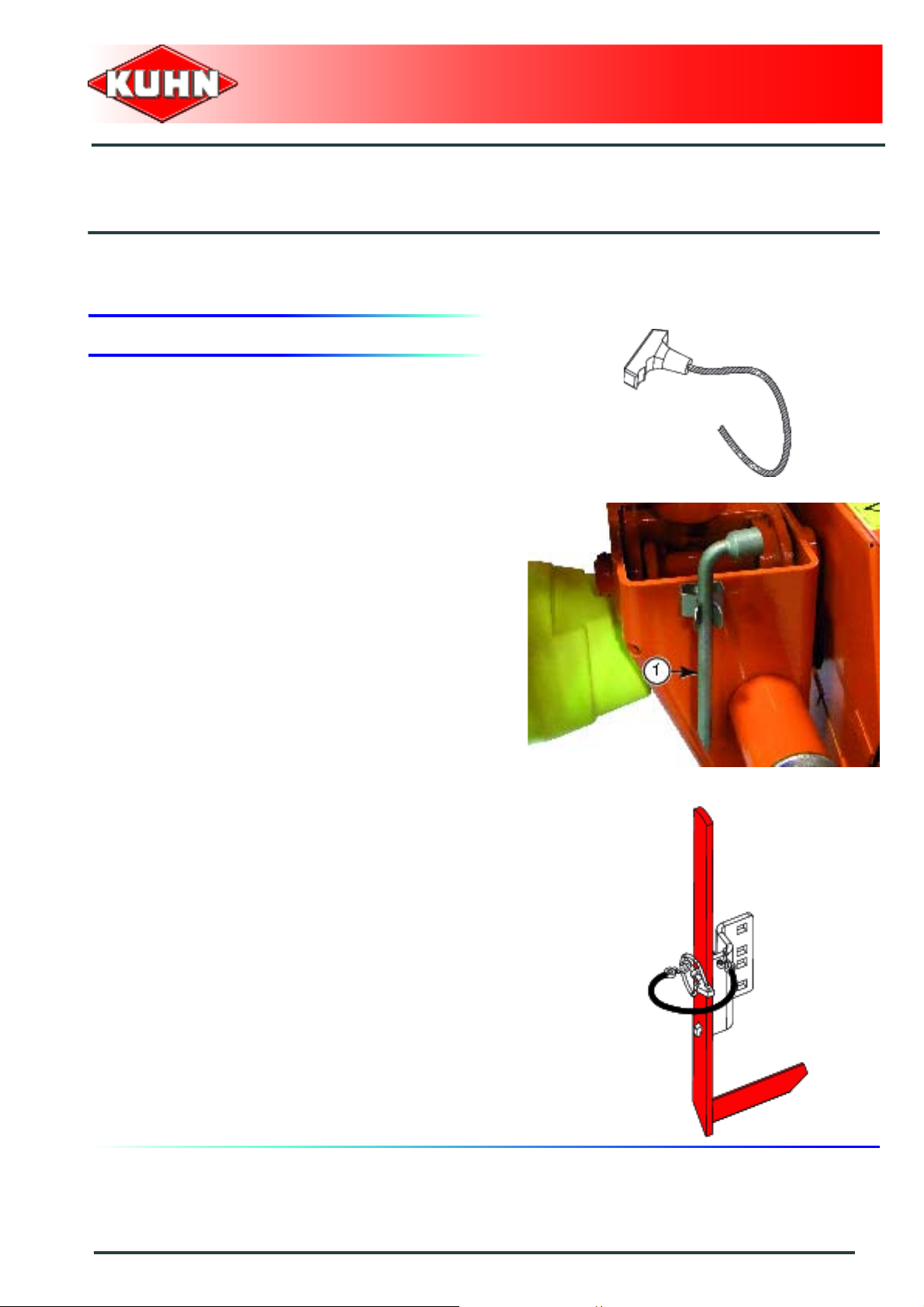

The machine is supplied with an 18 mm box wrench (1)

to carry out certain adjustment and maintenance tasks.

The machine is supplied with a tool for replacing the

knives.

Putting into service

25

Page 28

2. Coupling and uncoupling

The machine adapts to tractors fitted with a 3 point

linkage category 2.

Description of coupling elements

- A PTO shaft 1 3/8’’ - 6 splines.

- A check chain.

- A release cord.

- 1 hydraulic hose controlling the machine

transport/work position cylinder.

Disc mower

GMD800GII-FF

Preparing the tractor

Check that the tractor's authorized gross

weight as well as its lift capacity and

maximum weight per axle are not exceeded.

The front axle load (1) must never, under any

circumstances, be less than 20% of the

tractor's unladen weight. Add ballast weights

to the front in order to preserve the steering

and braking efficiency.

-

The tractor must be fitted with lower link

stabilizers.

-

The tractor PTO stub must rotate at a speed of 540 min-1.

The tractor must be fitted with a single acting hydraulic

outlet with float position.

26

Putting into service

Page 29

Hitch pin parallelism

Adjust tractor lift rods so that hitch pins are parallel to th e

ground.

Disc mower

GMD800GII-FF

Lateral adjustment of the lower links

- Balance the play on either sides of the lift linkage and

lock lower link stabilizers.

Putting into service

27

Page 30

Preparing the machine

Positioning of lower links

- Measure dimension E.

- Adjust tractor lower link stabilizers to measure E =

50 mm (2").

Linkage adjustment

Disc mower

GMD800GII-FF

E

- Measure dimension A.

If measure A is below 2.10 m (6’11’’):

- Place lower links in position a:

Adjust machine lower hitch pin position:

- Loosen the 8 screws (3).

- Position hitch pin (1) at measure F = 10 mm (0.4").

- Tighten 4 hitch pin screws (1).

• Torque : 12 daN m (89 lbf ft).

- Position hitch pin (2) at measure (X = 825 mm (2’8").

- Tighten 4 hitch pin screws (2).

• Torque : 12 daN m (89 lbf ft).

A

F

X

28

Putting into service

Page 31

If measure A is comprised between 2.10 m (6’11")

and 2.25 m (7’04"):

- Place lower links in position b:

Adjust machine lower hitch pin position:

- Loosen the 8 screws (3).

- Centre hitch pin (1) with regards to the mounting plate.

- Tighten 4 hitch pin screws (1).

• Torque : 12 daN m (89 lbf ft).

- Position hitch pin (2) at measure (X = 825 mm (2’8").

- Tighten 4 hitch pin screws (2).

• Torque : 12 daN m (89 lbf ft).

If measure A is comprised between 2.25 m (7’04")

and 2.40 m (7’10"):

- Place lower links in position c:

Adjust machine lower hitch pin position:

- Loosen the 8 screws (3).

- Position hitch pin (2) at measure G = 10 mm (0.4").

- Tighten 4 hitch pin screws (2).

• Torque : 12 daN m (89 lbf ft).

- Position hitch pin (1) at measure (X = 825 mm (2’8").

- Tighten 4 hitch pin screws (1).

Torque : 12 daN m (89 lbf ft).

Disc mower

GMD800GII-FF

X

G

X

Putting into service

29

Page 32

Coupling the machine

- Lower the tractor three-point linkage.

- Position ball joints of tractor lower links in line with

machine lower yokes.

- Attach the lower links to the hitch pins.

- Secure each hitch pin with lynch pin.

Disc mower

GMD800GII-FF

- Attach top link (1) in one of the upper holes on the

tractor side.

- Insert and lock top link lynch pin.

- Place release cord handle in the tractor cab.

- Lift machine using tractor hydraulic lift linkage.

- Fold and lock parking latch (1) using spring (2).

30

Putting into service

The parking latch must always be locked for

work and transport.

Page 33

Hydraulic connections

Connect hydraulic hose (1) of the transport/work cylinder

to a single acting valve with float position.

Fit check chain

See chapter:’’Frame height and check chains’’.

Disc mower

GMD800GII-FF

Putting into service

31

Page 34

Primary PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

The tractor PTO stub must rotate at a speed of 540 min-1.

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes. As a safety measure, a clearance (L) of at least

25 mm (1’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

250 mm (10’’).

Disc mower

GMD800GII-FF

If this is not the case:

• Mark length (H) to cut when the transmission is the

maximum overlap position.

• Shorten the guard tubes and the tran smission tubes

by the same length.

• Bevel and clean the tubes.

• Grease the inside of the outer tube.

Never operate the PTO shaft at an angle X exceeding

30°.

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

32

Putting into service

Page 35

-

On machine side, attach guard chain to the main frame.

Immediately replace any worn or damaged

guard.

Adjusting the machine

Frame height and check chains.

- Tractor fitted with a hydraulic position control function:

• Lower tractor lift linkage in order to engage lift stop

(1) in its housing.

• Respect a lift stop functional play A of 3 mm (0.1’’).

• Note the corresponding lever position in the tractor

cab.

Disc mower

GMD800GII-FF

It is not necessary to use the check chain

supplied with the machine.

Tractor not fitted with a hydraulic position control

function:

• Attach hook of check chain supplied with the

machine in one of the upper holes of the tractor top

link yoke.

• Lower the machine until the check chain is under

tension.

• Respect a lift stop functional play A of 3 mm (0.1’’).

The tractor lift linkage is in working position.

The frame height is correct when:

• The cutterbar is resting on the ground.

• The check chain is under tension.

• The lift stop has a functional play of approximately

3 mm (0.1’’) in its housing.

• The 2 hitch pins are parallel to the ground.

Close hook eyelet with roll pin when properly adjusted.

Putting into service

33

Page 36

Uncoupling the machine

For tractors not fitted with a hydraulic

position control function, unhook and attach

check chain to its support.

- Place the cutterbar in horizontal position.

- Release parking lock (1).

- Engage parking latch behind the bevel gearbox

mounting plate (2).

- Lower the tractor three-point linkage to rest the

machine on the ground.

Make sure no foreign material is located on

the bevel gearbox.

Disc mower

GMD800GII-FF

- Uncouple the PTO shaft.

- Place PTO shaft in holder (1).

- Disconnect hydraulic hose.

- Position hydraulic hose on holder (2).

- Remove cord from tractor and store it in its holder on

the machine.

- Detach the top link from the machine end.

- Release the lower links.

- Lower the tractor three-point linkage.

The machine is uncoupled.

Always park the machine with the cutter bar

in horizontal position.

34

Putting into service

Page 37

$Instructions for transport

Before placing the machine into transport

position:

Wait until the rotating parts have come to a

complete stop.

Check that nobody is locate d in the machine

pivoting area. If there is someone, make su re

the person moves away.

1. Putting the machine into transport position

Disc mower

GMD800GII-FF

When optional equipment is used, follow specific

procedures mentioned in the related section:

- Lighting and signalling.

- Lateral signalling equipment.

From the working position:

- Unlock and lift front guard using 18mm box spanner

supplied with the machine.

- The guard locks automatically.

- Pull release cord until lift stop (1) is free.

- Lift the machine using the tractor's lift linkage.

- Activate the transport/work cylinder to bring the

mowing unit in transport position.

- As cutter bar is being pivoted, wait until lift stop end (1)

passes over lock (2) and release cord.

- The machine automatically locks in transport position.

Instructions for transport

35

Page 38

The machine is in transport position.

Never engage the tractor PTO drive when the

machine is in transport position.

2. Conformity with the road regulations

Disc mower

GMD800GII-FF

Before driving the machine on public roads,

ensure that the machine complies with

current highway code regulations.

Check that the retroreflective signalling equipment is

clean before going on public roads.

Replace worn or damaged reflectors.

Make sure the release cord cannot be

operated inadvertently.

Make sure that transport lock (1) is fully

engaged.

36

Instructions for transport

Page 39

$Instructions for work

Before placing the machine in working

position:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

1. Putting the machine into work position

Disc mower

GMD800GII-FF

When optional equipment is used, follow specific

procedures mentioned in the related section:

- Lighting and signalling.

- Lateral signalling equipment.

From the transport position:

- Fully lift tractor lift linkage.

- Operate transport/work position cylinder to relieve

pressure on the transport lock.

- Pull the release cord until transport lock is released.

- Lower the mowing unit onto the ground using the

mowing unit lift cylinder.

- Press lock (1) and lower front guard (2).

- The guard locks automatically.

Instructions for work

37

Page 40

- Shift the mowing unit lift cylinder directional control

valve in float position.

- Lower the tractor lift linkage in working position.

The machine is in working position.

During work, only use the mowing unit lift

cylinder to place the machine in headland

turn position.

Disc mower

GMD800GII-FF

38

Instructions for work

Page 41

2. Adjustments in working position

Before leaving the tractor or before

adjusting, maintaining or repairing the

machine, disengage the PTO drive, turn off

the engine, remove ignition key and wait until

all moving parts have come to a complete

stop and apply park brake.

Cutting height

The desired cutting height is obtained directly by

adjusting the top link length. The height can be adjusted

from 30 to 50 mm (1.1" - 1.9").

To obtain a different cutting height:

- Place the machine in working position.

- Lower the machine on the ground to remove weight

from the top link.

- Modify the top link length to alter the machine tilt

angle.

- Check cutting height.

Disc mower

GMD800GII-FF

The maximum cutting height (L1 = 50 mm (1.9’’))

is obtained when the discs are parallel to the

ground.

The minimum cutting height must not be below

(L2 = 30 mm (1.1’’)).

Too low a cutting height can lead to:

Excessive disc and knife wear.

Crop being contaminated by soil.

Delay in regrowth.

-

Instructions for work

39

Page 42

Swathing system

The swathing system comprises:

- 1 outer swath wheel (Adjustable).

Position the swath wheel in order to obtain an angle

between 16° (A) and 32° (A’).

Disc mower

GMD800GII-FF

Check that there is a minimum clearance (J)

of 15 mm (0.59’’) between the cone rib and

the swath wheel.

40

Instructions for work

Page 43

Compensating spring tension

The mowing unit is suspensed by means of

compensating spring (1).

In difficult working conditions, the compensating spring

adjustment can be modified.

- Place the machine in working position.

- Lift mowing unit to release tension on the spring.

- Loosen counter nut (2).

- Rotate spring (1) to modify the mowing unit

suspension:

• Reduce measure (X) to increase the suspension.

• Increase measure (X) to reduce suspension.

Disc mower

GMD800GII-FF

The measure (X) is factory set at 90 mm (3.5").

- Tighten counter nut (2).

3. Machine use

Before mowing and to reduce risks of

projections, lower the front guard.

Keep all persons and animals away from the

machine danger zone.

Never lean or step on the protection cover.

At work, the tractor hydraulic valve must

always be in floating position to ensure good

ground contour adaptation.

Before the machine engages the crop:

- Engage the tractor PTO and slowly increase the

speed up to 540 min

-1

.

Instructions for work

41

Page 44

Groundspeed

Adapt the forward speed to the working

conditions.

Headland turn maneuvers

Operate the cutterbar using the "pivot into

transport/work" position cylinder.

- Activate the transport/work cylinder control valve in

the "pivot into transport" position. The cylinder lock (1)

bottoms.

Disc mower

GMD800GII-FF

The lift linkage clears simultaneously the

main frame and cutter bar off the ground.

42

Instructions for work

Page 45

Machine safety

When hitting an obstacle:

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

The break-away latch allows the cutter bar to pivot to the

rear when hitting an obstacle.

In case an obstacle has been struck, check

that the mowing unit has not been damaged.

Disc mower

GMD800GII-FF

The safety breakback is reset by reversing (a).

Instructions for work

43

Page 46

If the break-away latch r eleases too easily after reset,

tighten nut (1) to increase spring washer compression

slightly.

Respect spring washer layout.

Basic adjustment:

L= 95 mm (3.7’’)

For normal functioning of the break-away latch,

measure L must never be below 91 mm (3.60").

In case of clogging:

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Disc mower

GMD800GII-FF

- Lift and lock front guard.

- Remove foreign body.

- Check that the mowing unit has not been damaged.

- Check rotating components for damage.

- Lower and lock front guard.

44

Instructions for work

Page 47

$Optional equipment

1. Raised skid shoes

Kit no. 1036230

The raised skid shoes enable mowing higher, between

35 and 90 mm (1.4’’ - 3.5’’).

Replace the end disc skids by the 2 raised skid shoes.

The use of raised skid shoes is also

recommended on sticky grounds.

Disc mower

GMD800GII-FF

2. Side deflector

Kit no. 1036340

The side deflectors enables mowing dense or down

crops with long stems.

Fit side deflector on the outer side plates o f the cutterbar

stiffener.

Optional equipment

45

Page 48

3. Side deflector with high cone disk

Kit no. 1036290

Large cone discs allow mowing dense or down crops

with long stems.

The side deflector prevents crop from wrapping around

the outer large cone disk when mowing in dense or down

crops with long stems.

Disc mower

GMD800GII-FF

4. Lighting and signalling

Kit no. 1026100

The machine can be fitted with specific signalling lights

to comply with the road regulations.

Electrical connection

Connect machine 7-pin plug on the tractor 7-pin socket.

After making the connections, check that there is no risk

of the cables being caught during operation.

46

Optional equipment

Page 49

Instructions for transport

- Position rear signalling device.

- Connect signalling device wiring harness.

Disc mower

GMD800GII-FF

Instructions for work

- Disconnect signalling device wiring harness.

- Position rear signalling device.

5. Lateral signalling equipment

Kit no. 1016440

The machine can be fitted with specific signalling lights

to comply with the road regulations.

Optional equipment

47

Page 50

1 on each machine side.

Disc mower

GMD800GII-FF

1 in combination with signalling panel.

Lighting and signalling:

Kit no. 1026100

6. 1000 min-1 drive kit

Kit no. 1066010

Belt and pulley assembly for tractors with a pto speed of

1000 min

-1

.

48

Optional equipment

Page 51

7. Longer hitch pins

Kit no. 56820700

The longer hitch pin enables offsetting the machine by

200 mm (7.9’’).

Linkage adjustment

Disc mower

GMD800GII-FF

- Measure dimension A.

If measure A exceeds 2.40 m (7’10"):

Position lower links.

Adjust machine lower hitch pin position:

- Loosen the 8 screws (3).

- Position hitch pin (2) at measure H = 10 mm (0.4").

- Tighten 4 hitch pin screws (2).

• Torque : 12 daN m (89 lbf ft).

- Position left longer hitch pin (1) at a distance of X =

825 mm (2’8").

- Tighten 4 hitch pin screws (1).

• Torque : 12 daN m (89 lbf ft).

A

Optional equipment

49

Page 52

$Maintenance and storage

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Disc mower

GMD800GII-FF

1. Frequency chart

Maintenance intervals are indicated for

normal conditions of use.

Cutterbar draining and refilling

Lubricate moving parts and

articulations

Changing angle gearbox oil

After the first 10

hours of use

33

33

Every 50 hours

3

Every 200 hours

or at the end of

the season

50

Maintenance and storage

Page 53

2. Lubrication

Lubricate with SHELL multi-purpose grease

grade NLGI 2.

PTO shaft

Primary PTO shaft

- Every 8 hours:

• universal joints (1).

- Every 20 hours:

• transmission tube (2).

- Every 40 hours:

• guide rings (3).

Disc mower

GMD800GII-FF

Place the machine in working position.

Stop the tractor engine and remove ignition

key.

Maintenance and storage

51

Page 54

Cutterbar draining and refilling.

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

The cutterbar is lubricated with 2.25 L (0.5 9 US gal) of SHELL SPIRAX A extreme-pressure gear oil

with viscosity grade SAE 80W90 and API grade GL5.

When draining and refilling, it is recommended to use either a mineral base oil with viscosity grade

SAE 80W90 and API grade GL5, or a synthetic base oil, type PAO (Poly-Alpha-Olefin s) with a viscosity

grade equivalent to SAE 80W90.

Never use an oil of viscosity SAE 90 in the

cutterbar.

From the transport position:

Disc mower

GMD800GII-FF

For safety reasons, hook check chain as high as

possible.

- Place a container of sufficient capacity under drain

plug.

- Remove filler plug (1) and its washer.

- Unscrew drain plug (2) and its seal.

- Allow oil to drain completely.

- Wait for dripping to stop.

- Clean and reinstall drain plug (2) and its washer.

Replace if necessary.

- Pour the correct oil quantity and quality through the

opening of the filler plug.

- Clean and reinstall filler plug (1) and its washer.

Replace if necessary.

- Check angle gearbox oil level:

• The oil level must reach the lower edge of the

emptying hole.

- Clean and reinstall drain plug (2) and its washe r .

- Clean and reinstall filler plug (1) and its washer.

52

Maintenance and storage

Page 55

Changing angle gearbox oil.

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

The angle gearbox is lubricated with 0.45 L (0.12 US gal) of SHELL SPIRAX A extre me-pressure oil for

mechanical transmissions with viscosity grade SAE 80W90 and API grade GL5.

When draining and refilling, it is recommended to use either a mineral base oil with viscosity grade

SAE 80W90 and API grade GL5, or a synthetic base oil, type PAO (Poly-Alpha-Olefins) with a viscosity

grade equivalent to SAE 80W90.

From the transport position:

- Remove filler plug (1) and its washer.

- Place a container of sufficient capacity under drain

plug.

- Remove drain plug (2) and its washer.

- Allow oil to drain completely.

- Wait for dripping to stop.

- Place the cutterbar in horizontal position.

- Pour the correct oil quantity and quality through the

opening of the filler plug (1).

Disc mower

GMD800GII-FF

- Check angle gearbox oil level:

- Place the cutterbar in horizontal position.

• The oil level must reach the lower edge of the

emptying hole.

- Clean and reinstall drain plug (2) and its washer.

- Clean and reinstall filler plug (1) and its washer.

Maintenance and storage

53

Page 56

3. Maintenance

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Belt tension

Regularly check belt tension and in particular

during the first hours of use.

Never replace belts individually.

Replace belts in full sets.

Disc mower

GMD800GII-FF

Adjusting the tension:

- Tighten screw (1) using the 18mm box spanner

supplied with the machine.

- Spacer tube (2) must be in contact with main frame (3)

and washer (4).

During the initial assembly or when installing

a new set of belts, give screw (1) 2 additional

turns to compensate for the inital stretch of a

new set of belts.

Breather plug checking and cleaning

From the working position:

Remove breather plug (1) and its seal.

Clean and check breather plug for good functioning (1).

Reinstall breather plug (1) and its seal.

54

Maintenance and storage

Page 57

Checking cutterbar oil level

Regularly check the cutterbar oil level:

• Place cutter bar in vertical position.

• Remove filler plug (1) and its washer.

• Check the oil level.

• Top up if necessary.

• Clean and reinstall filler plug (1) and its

washer. Replace if necessary.

Disc mower

GMD800GII-FF

• The oil must reach the lower edge of the filling hole.

• Top up if necessary.

• Clean and reinstall filler plug (1) and its

washer. Replace if necessary.

If it is found that the transmission case is very hot

to touch by hand, there is no cause of alarm

provided:

- Lubrication recommendations have been

respected.

- Discs can be rotated freely by hand when

the machine is hot.

Before checking that the discs rotate freely by hand:

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Maintenance and storage

55

Page 58

Check angle gearbox oil level

Regularly check the oil level:

• Place the cutterbar in horizontal position.

• Remove drain plug (1) and its washer.

• Check the oil level.

• Top up if necessary.

• Clean and reinstall drain plug (1) and its washer.

Disc mower

GMD800GII-FF

Replace if necessary.

- Check angle gearbox oil level:

• The oil level must reach the lower edge of the

emptying hole.

- Clean and reinstall drain plug (1) and its washe r .

- Clean and reinstall filler plug (2) and its washer.

56

Maintenance and storage

Page 59

Inspection of knives and securing

elements

Immediately replace worn or damaged parts with genuine KUHN parts.

The following procedures take into account the 2 machine configuration possibilities:

Disc mower

GMD800GII-FF

I ) For machines up to serial number K0211

II ) For machines up to serial number K0211

or For machines with serial number as from K0212

Coupling device (a) Coupling device (b)

New spring plate New spring plate

+ Coupling device (a).

+ Coupling device (b)

Never mount a knife in configuration (b) with a spring plate in configuration (a).

Never fit a bolt in configuration (a) with spring plate in configuration (b)

Maintenance and storage

57

Page 60

I ) For machines up to serial number K0211 + Coupling device (a).

Knives

Inspect systematically all knives before the machine is

operated to:

- guarantee the cutting quality.

- guarantee safety in use.

- Prevent cutterbar damage risks.

Replace knives in the following cases:

- Damaged knives.

• Very rough conditions can cause knives to crack

and become deformed.

- Worn knives.

Knife length C must exceed 65 mm (2.6’’).

Knife width B, measured at a distance A of 10 mm (0.4’’)

from the disc edge must exceed 20 mm (0.78’’).

Disc mower

GMD800GII-FF

The hole L for the securing bolt must not become oval by

more than 22 mm (0.86’’).

Always replace both knives per disc to avoid creating an

out-of-balance force.

58

Maintenance and storage

Page 61

Fixing elements

Check the fixing elements:

- After hitting an obstacle.

- When replacing knives.

- At the beginning of each season.

Disc mower

GMD800GII-FF

The fixing bolts should be changed in the following

cases (2):

- When there is visible distortion.

- When the locking compound is worn or inoperational.

- When diameter D of the bolt shoulder is less than

11 mm (0.43’’).

See section: ’’Disc replacement’’.

The radial play between a worn bolt and a new

knife must not exceed d = 10 mm (0.4’’).

Maintenance and storage

59

Page 62

Replace nuts in the following cases (1):

- When nut wear reaches a = 5 mm (0.2’’).

Check the condition of the fixing elements

regularly and also the torque of the knife-fix ing

bolt:

- Torque: 12 daN m (89 lbf ft).

Replace spring plate in the following cases (3):

- When there is visible distortion.

- When you have noticed important wear on a spring

plate:

• Width B of a spring plate, measured at A =

20 mm (0.8’’), must exceed 74 mm (2.9’’).

Disc mower

GMD800GII-FF

See section: ’’Spring plate replacement’’.

Knife replacement

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Replace immediately all worn or distorted

knives.

Never straighten a bent knife.

Always replace both knives per disc.

60

Maintenance and storage

Page 63

Parking

- Clean the top side of the disk guard.

- Clean cavities between disc and spring plate.

- Fully insert special tool between disc and spring plate.

Disc mower

GMD800GII-FF

- Pivot special tool downwards to free spring plate from

screw head.

- Make sure that the securing nut and bolt are in good

condition and if necessary, replace them:

• Torque: 12 daN m (89 lbf ft).

Bolt: Part no. K6801010 (2).

Nut: Part no. 80201262 (1).

Dull knives require more horse power and have a

negative effect on the cut quality.

Maintenance and storage

61

Page 64

Fitting

Knives can be turned over on the same disc to use the

other cutting edge or replaced. On each knife , an arrow

indicates the disc's direction of rotation.

Knife for disk rotating to the left: Part

no. K6801410

Knife for disk rotating to the right: Part

no. K6801420

- Pivot special tool downwards to free spring plate from

screw head.

- Insert the new knife on the screw head.

Disc mower

GMD800GII-FF

Press knife upwards and pull it towards

yourself before releasing the special tool.

- (a), (b), (c)

Checking the full locking and free rotation of

the knife on the screw head.

62

Maintenance and storage

Page 65

- Check that screw head (2) is free to slide in spring

plate hole (3).

- Remove special tool.

- Rotate disk by half a turn.

- Repeat previous tasks.

- Repeat previous tasks on the other disks.

Disc mower

GMD800GII-FF

After replacing the last knife, check that the

tool has been removed and put away.

Maintenance and storage

63

Page 66

Disc replacement

Inner disc:

The replacement of the inner disk must be

carried out by your Kuhn authorized dealer.

Intermediate disc:

- Place a wooden wedge (2) between two discs to stop

them from moving.

- Remove 2 bolts (1) and their spring washers using the

box spanner supplied with the machine.

- Remove the disc conical cover.

Disc mower

GMD800GII-FF

- Remove the 2 screws (1) and their spring washers.

- Remove the disc (2).

When remounting:

- Position their largest diameters at right angles to each

other.

- Position conical centre of spring washer at the top.

- Tighten screws:

• Torque: 12 daN m (89 lbf ft).

64

Maintenance and storage

Page 67

Spring plate replacement

The inner disk spring plate:

The replacement of the inner disc spring

plate must be carried out by a Kuhn

authorized dealer.

Intermediate disk spring plate:

- Remove the disc.

• See section: ’’Disc replacement’’.

Disc mower

GMD800GII-FF

- Remove spring plate (1).

Spring plate Part no. K6801090.

- Refit the disc.

• See section: ’’Disc replacement’’.

Maintenance and storage

65

Page 68

II ) For machines up to serial number K0211 + Coupling device (b)

or For machines with serial number as from K0212.

Knives

Inspect systematically all knives before the machine is

operated to:

- guarantee the cutting quality.

- guarantee safety in use.

- Prevent cutterbar damage risks.

Replace knives in the following cases:

- Damaged knives.

• Very rough conditions can cause knives to crack

and become deformed.

- Worn knives.

Knife length C must exceed 65 mm (2.6’’).

Knife width B, measured at a distance A of 10 mm (0.4’’)

from the disc edge must exceed 20 mm (0.78’’).

Disc mower

GMD800GII-FF

The hole L for the securing bolt must not become oval by

more than 22 mm (0.86’’).

Always replace both knives per disc to avoid creating an

out-of-balance force.

66

Maintenance and storage

Page 69

Fixing elements

Check the fixing elements:

- After hitting an obstacle.

- When replacing knives.

- At the start of each season.

The fixing bolts should be changed in the following

cases (2):

- When there is visible distortion.

- When the locking compound is worn or inoperational.

- When diameter D of the bolt shoulder is less than

11 mm (0.43’’).

Disc mower

GMD800GII-FF

See section: ’’Disc replacement’’.

The radial play between a worn bolt and a new

knife must not exceed d = 10 mm (0.4’’).

Maintenance and storage

67

Page 70

Replace nuts in the following cases (1):

- When nut wear reaches a = 5 mm (0.2’’).

Check the condition of the fixing elements

regularly and also the torque of the knife-fix ing

bolt:

- Torque: 12 daN m (89 lbf ft).

Replace spring plate in the following cases (3):

- When there is visible distortion.

- When you have noticed important wear on a spring

plate:

• Width B of a spring plate, measured at A =

20 mm (0.8’’), must exceed 60 mm (2.4’’).

Disc mower

GMD800GII-FF

See section: ’’Spring plate replacement’’.

Knife replacement

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

Replace immediately all worn or distorted

knives.

Never straighten a bent knife.

Always replace both knives per disc.

68

Maintenance and storage

Page 71

Parking

- Clean the top side of the disk guard.

- Clean cavities between disc and spring plate.

- Fully insert special tool between disc and spring plate.

Disc mower

GMD800GII-FF

- Pivot special tool downwards to free spring plate from

screw head.

- Make sure that the securing nut and bolt are in good

condition and if necessary, replace them.

• Torque: 12 daN m (89 lbf ft).

Bolt: Part no. K6801011.

Nut: Part no. 80201262.

Dull knives require more horse power and have a

negative effect on the cut quality.

Maintenance and storage

69

Page 72

Fitting

Knife for disk rotating to the left:

- Part no. K6802970

Knife for disk rotating to the right:

- Part no. K6802980

- Pivot special tool downwards to free spring plate from

screw head.

- Insert the new knife on the screw head.

Disc mower

GMD800GII-FF

Press knife upwards and pull it towards

yourself before releasing the special tool.

- (a), (b), (c)

Checking the full locking and free rotation of

the knife on the screw head.

70

Maintenance and storage

Page 73

- Check that screw head (2) is free to slide in spring

plate hole (3).

- Remove special tool.

- Rotate disk by half a turn.

- Repeat previous tasks.

- Repeat previous tasks on the other disks.

Disc mower

GMD800GII-FF

After replacing the last knife, check that the

tool has been removed and put away.

Maintenance and storage

71

Page 74

Disc replacement

Inner disc:

The replacement of the inner disk must be

carried out by your Kuhn authorized dealer.

Intermediate disc:

- Place a wooden wedge (2) between two discs to stop

them from moving.

- Remove 2 bolts (1) and their spring washers using the

box spanner supplied with the machine.

- Remove the disc conical cover.

Disc mower

GMD800GII-FF

- Remove the 2 screws (1) and their spring washers.

- Remove the disc (2).

When remounting:

- Position their largest diameters at right angles to each

other.

- Position conical centre of spring washer at the top.

- Tighten screws:

• Torque: 12 daN m (89 lbf ft).

72

Maintenance and storage

Page 75

Spring plate replacement

The inner disk spring plate:

The replacement of the inner disc spring

plate must be carried out by a Kuhn

authorized dealer.

Intermediate disk spring plate:

- Remove the disc:

• See section: ’’Disc replacement’’.

- Remove spring plate (1).

Disc mower

GMD800GII-FF

Spring plate Part no. K6803410.

- Refit the disc.

• See section: ’’Disc replacement’’.

Outer and inner cones

- Check torque of attachment bolts (1) of outer and

inner cone covers (2) and (3):

• Torque: 6 daN m (44 lbf ft).

Replace any lost or damaged cover.

- (2) Part no. 56803420.

- (3) Part no. 56803400.

Maintenance and storage

73

Page 76

4. Storage

At the end of each season

- Clean the machine thoroughly.

- Drain gearbox and cutterbar and refill with new oil.

- Touch up any areas of damaged paintwork.

- Store machine with the cutter bar in horizontal position

in a sheltered dry place.

- Inspect and replace worn knives and bolts (See

section "Inspection of knives and securing elements").

- Release belt tension.

At the start of each season

- Re-read the operators' manual.

- Inspect and replace worn knives and bolts (See

section "Inspection of knives and securing elements").

- Check that all nuts and bolts are sufficiently tightened.

- Check belt condition. Replace them if necessary.

- Check belt tension. Retension if necessary

- Make sure that all protection devices are in place and

in good condition.

Disc mower

GMD800GII-FF

74

Maintenance and storage

Page 77

$Trouble shooting guide

-

Problem Cause Remedy

Dull or broken knives. Replace knives.

Make sure the arrow on the

Uneven stubble.

Soil build up in front of the

cutterbar.

Bad ground contour

adaptation.

Stubble too long.

Too frequent safety breakback

release.

Knives not installed correctly.

Insufficient disk speed. Check belt tension.

Too low PTO speed

(rotational frequency).

Cutter bar pitch angle too high. Reduce angle.

Too much cutterbar down

pressure.

Very wet working conditions.

Incorrect main frame setting.

Excessive ground speed. Reduce ground speed.

Hydraulic cylinder blocked.

Incorrect compensating spring

adjustment.

Cutter bar pivot bushes are

worn or seized.

Incorrect cutter bar pitch angle.

Machine too light.

Insufficient spring washer

compression.

knife upper face is pointing in

the disc's direction of rotation.

Increase speed to 540 min

Adjust compensating spring

tension.

Adjust main frame height with

regards to the ground.

Fit raised skid shoes.

Adjust main frame height with

regards to the ground.

Set hydraulic valve in floating

position.

Adjust compensating spring

tension.

Check condition of pivot

bushes. Replace if necessary.

Modify pitch angle using top

link.

Adjust compensating spring

tension.

Check frame position.

Increase spring washer

compression.

Disc mower

GMD800GII-FF

-1

.

Interference between tractor

and front guard.

Incorrect cam adjustment. Adjust machine pivot moment.

Trouble shooting guide

75

Page 78

Disc mower

GMD800GII-FF

Incorrect mowing unit

positioning with regards to the

tractor when placed in working

position.

The tractor valve double acting

position has not been used to

lower the mowing unit.

Use the tractor double acting

position to lower the mowing

unit.

76

Trouble shooting guide

Page 79

$Appendix

1. Calculating the load on an axle

When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized payload must

not be exceeded.

The load on the tractor front axle must always represent 20 % of the tractor unladen weight.

Prior to use, check that these conditions are satisfied by making this calculation or by weighing the

tractor-machine unit

Define the total weight, axle loads, tyre

capacity and minimum additional mass:

Disc mower

GMD800GII-FF

The following values are required for the calculation:

Description Units Description

T kg Tractor unladen weight

T1 kg Unladen load on tractor front axle

T2 kg Empty load on tractor rear axle

t kg Axle loads (Tractor + machine)

t1 kg Load on front axle (Tractor + machine)

t2 kg Load on rear axle (Tractor + machine)

M1 kg Total weight of front tool or front ballast

M2 kg Total weight of rear tool or rear ballast

am

b m Distance between the tractor axles

cm

d m

Distance between the tools' centre of gravity or the front ballast and

the front axle centre

Distance between the rear axle center and the center of the lower link

ball joints

Distance between the centre of the lower link ball joints and the centre

of gravity of the rear tool or rear ballast

Obtained

by

Refer to the tractor operators' manual Refer to the machine price-list or operators' manual

Dimensions Measure on scale

Appendix

77

Page 80

Rear tool or front-rear combination:

Disc mower

GMD800GII-FF

1) Calculation of the minimum front ballast weight M1

minimum

M2 x (c+d) - T1 x b + 0.2 x T x b

M1

minimum

=

a+b

Write the minimal additional weight in the chart.

Front tool:

2) Calculation of the minimum rear ballast weight M2

minimum

M1 x a - T2 x b + 0.45 x T x b

M2

minimum

=

b+c+d

Write the minimal additional weight in the chart.

3) Calculation of the actual load on the front ax le T1

If the front tool (M1) is lighter than the minimum load required at the front (minimum), increase tool weight until the required minimum

front load is reached

real

M1 x (a+b) + T1 x b - M2 x (c+d)

T1

=

real

b

Indicate front axle calculated load value and the one indicated in the tractor op erators' manual.

4) Calculation of the total weight M

If the rear tool (M2) is lighter than the minimum load required at the rear(minimum), increase tool weight until the required minimum

rear load is reached

real

M

= M1 + T + M2

real

Indicate calculated total load value and the o ne author ized as indicated in the tractor oper ator's manual.

5) Calculation of the actual rear axle load T2

T2

= M

real

real

real

- T1

real

Indicate rear axle calculated load value and the one indicated in the tractor operator's manual.

6) Tyre carrying capacity

Indicate double (2 tyres) the authorized load value (see tyre manufacturer indications).

78

Appendix

Page 81

Table:

Disc mower

GMD800GII-FF

Actual value obtained

by calculation

Minimum front/rear

ballasting

Total weight kg ≤ kg

Load on front axle kg ≤ kg ≤ kg

Load on rear axle kg ≤ kg ≤ kg

The minimum ballasting must be made by fitting a tool or an additional mass to the

tractor.

The values obtained must be below or equal the authorized values.

kg

Value authorized

according to

operator's manual

Double value of the

authorized capacity

per tyre (2 tyres)

Appendix

79

Page 82

Determining the machine weight (M2) and

the position of its centre of gravity (d)

If the data required to calculate the total

weight, axle loads and minimum ballasting

are not supplied, use the following method.

Tractor only:

Disc mower

GMD800GII-FF

- T1: Load on front axle.

• Tractor only.

- T2: Load on rear axle.

• Tractor only.

80

Appendix

Page 83

- T: Axle loads.

•Tractor only.

Disc mower

GMD800GII-FF

Appendix

81

Page 84

Disc mower

GMD800GII-FF

Rear tool or front-rear combination:

If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance with th e

countrie's legislation, empty the hopper to travel on public roads.

In any case, we recommend to travel on public roads with empty hoppers and ta nks.

- Measure dimension (b).

- Measure dimension (c).

- t1: Load on front axle.

• Tractor + machine.

• Hopper empty.