Page 1

OPERATOR'S MANUAL

KN244AGB B

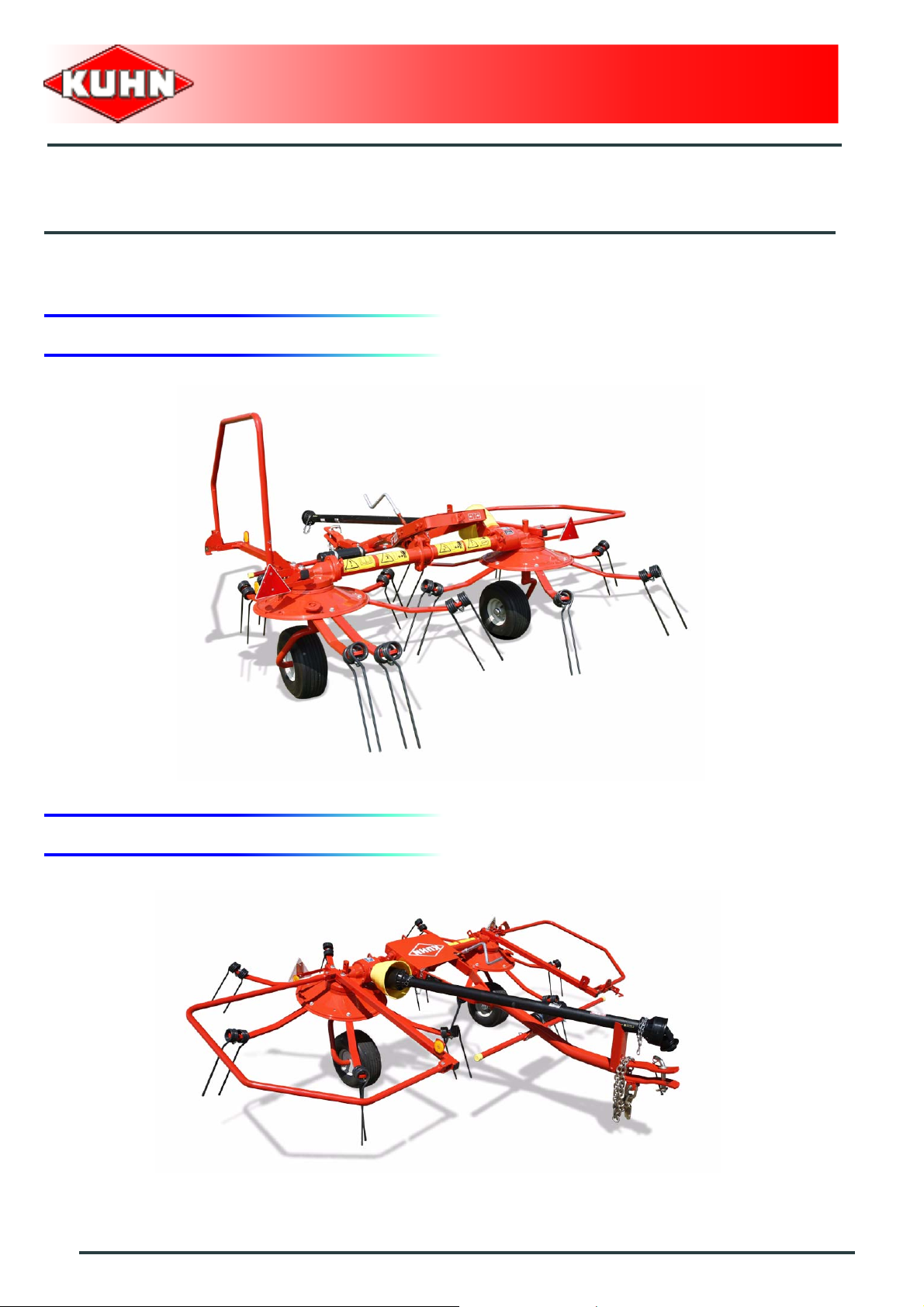

Gyrotedder

GF222T

KN244AGB B

- English - 10-2009

Page 2

Page 3

Gyrotedder

GF222T

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The GF222T gyrotedder must only be used for the purpose for which it was manufactured: spreading and

tedding previously cut forage or straw.

Dear Owner

1

Page 4

Gyrotedder

GF222T

$Contents

Dear Owner.....................................................................................................................1

Contents..........................................................................................................................2

Identification of the machine.........................................................................................4

Rear view.. .................................................................... .....................................................................4

Front view..........................................................................................................................................4

Model identification plate ................................................................................................................5

Safety...............................................................................................................................6

Description of symbols used in this document.............................................................................6

Safety instructions...........................................................................................................................7

Location and description of safety decals on the machine .......................................................15

Road safety equipment and recommendations...........................................................................17

Machine specifications................................................................................................18

Description and glossary...............................................................................................................18

Technical specifications................................................................................................................19

Sound levels ................................................... ... ... .... ... ... ... .... .........................................................19

Putting into service......................................................................................................20

Description of control elements....................................................................................................20

Coupling and uncoupling..............................................................................................................21

Instructions for transport............................................................................................25

2

Putting the machine into transport position................................................................................25

Conformity with the road regulations...........................................................................................27

Contents

Page 5

Gyrotedder

GF222T

Instructions for work...................................................................................................28

Putting the machine into work position.......................................................................................28

Adjustments in working position.................................................................................................. 29

Machine use....................................................................................................................................30

Maintenance and storage............................................................................................ 31

Frequency chart .............................................................................................................................31

Lubrication............................................................................................ ..........................................32

Maintenance....................................................................................................................................34

Storage............................................................................................................................................37

Limited warranty.......................................................................................................... 38

Contents

3

Page 6

1. Rear view

Gyrotedder

GF222T

$Identification of the machine

2. Front view

4

Identification of the machine

Page 7

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Gyrotedder

GF222T

Type: GF222T

Serial no.:

Identification of the machine

5

Page 8

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Gyrotedder

GF222T

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

6

Safety

Page 9

Gyrotedder

GF222T

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations fo r preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect current le gislation concerning accident prevention, wo rk safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment a nd acce sso ries, as r ecom mended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident re sulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!.

Never let anyone operate the machine who is not traine d

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Safety

7

Page 10

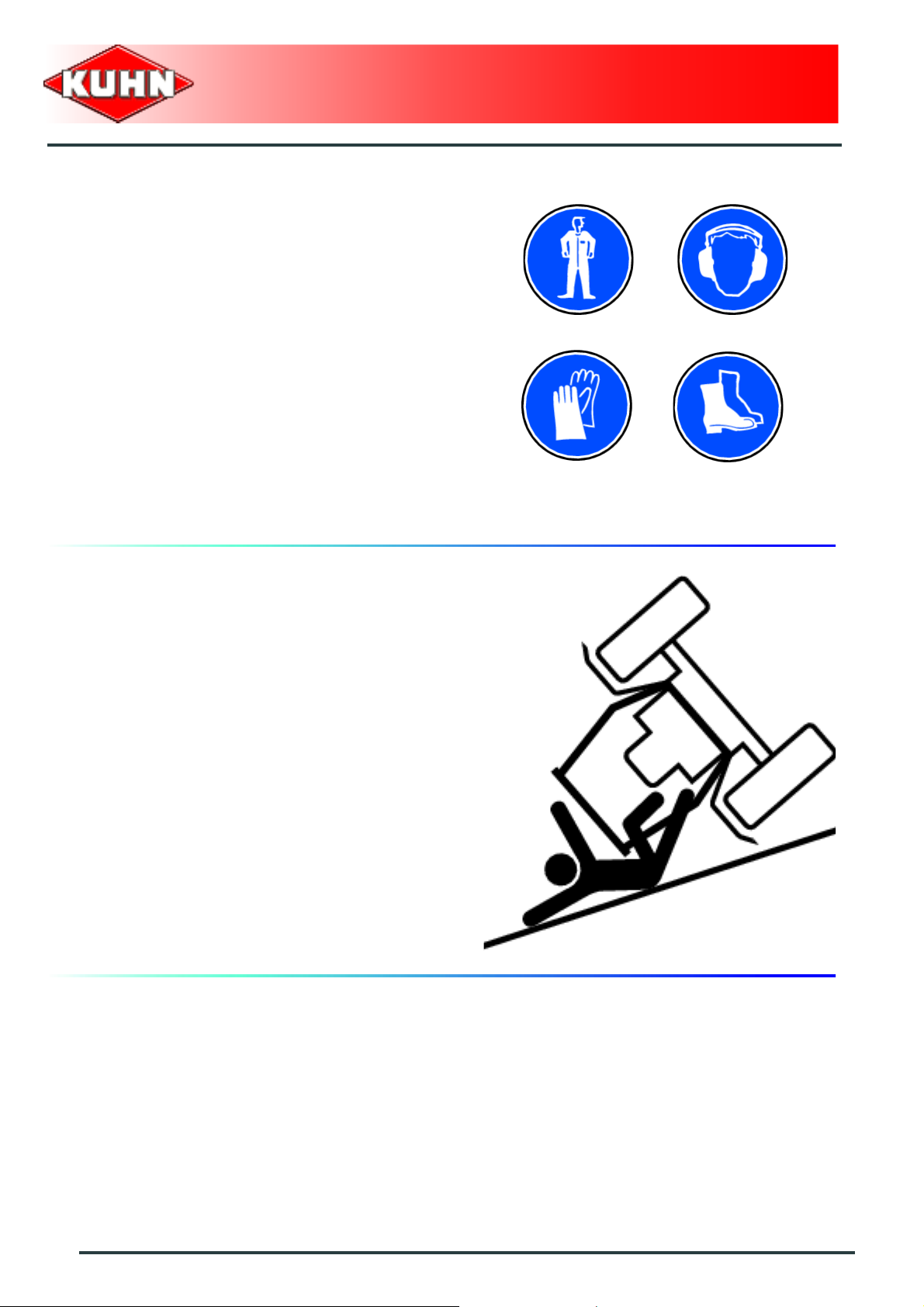

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Gyrotedder

GF222T

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of the great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt change s

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

8

Safety

Page 11

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transportation of oversize

equipment.

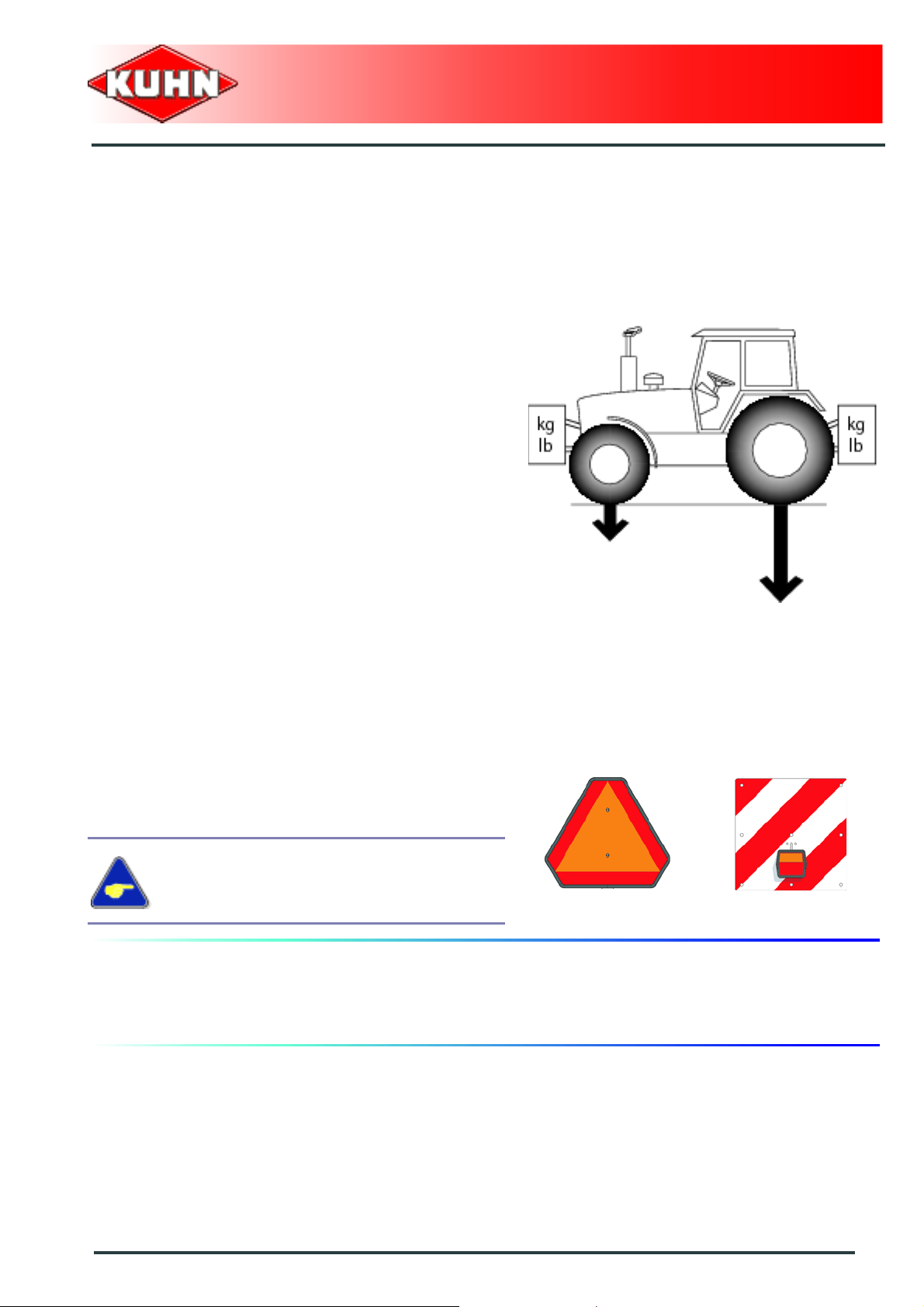

Gross weight and weight per axle

Check that the tractor's authorized gross weigh t as well

as its lift capacity and maximum weight per axle are not

exceeded.

The front axle load (1) must never, under any

circumstances, be less than 20% of the tractor's unladen

weight. If necessary, add ballast weights to the front or

to the rear to preserve the steering and braking

efficiency.

Gyrotedder

GF222T

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lightings and signallings.

Before transporting the machine on public road s, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Always obey current regulations for driving

on roads

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

Safety

9

Page 12

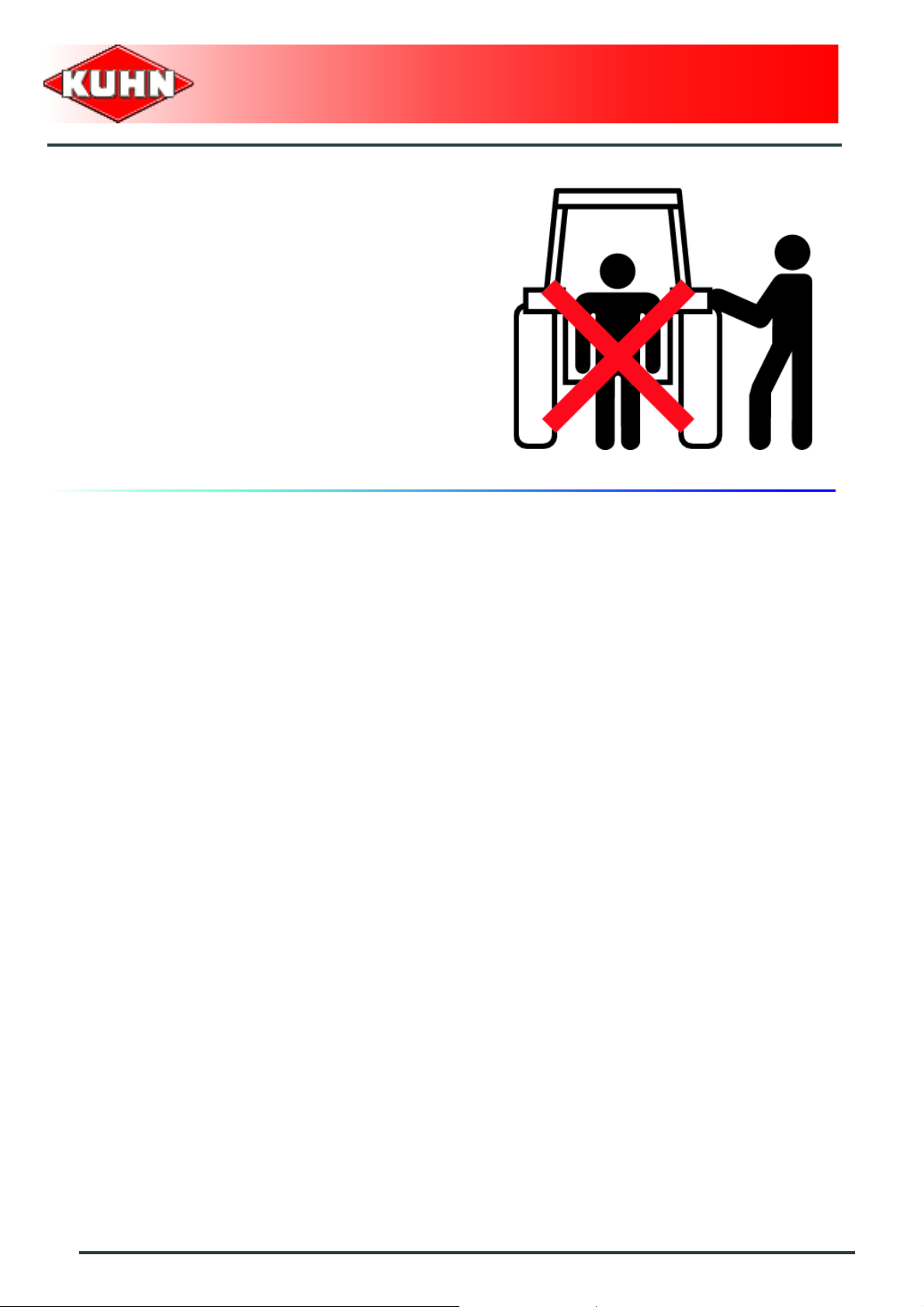

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Gyrotedder

GF222T

10

Safety

Page 13

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are se cured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately.A worn guard or an u nprotected PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendations.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's ma nual

provided with the PTO shaft.

Gyrotedder

GF222T

Safety

11

Page 14

Precautions during manoeuvres

When moving the machine from the transport positio n to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Tyres

Regularly check the tyre pressure. Respect

manufacturers' recommendations on pressure.

Assembly, disassembly and repair of wheels and tyres

must only be carried out by competent persons who are

equipped with standardized tools. Before any work is

performed on the wheels, ensure that the machine rests

on the ground and is perfectly stable so that it cannot

move accidentally (put chocks in place).

Gyrotedder

GF222T

Safety decals

Safety warning decals to respect, are placed in pictorial

form on various parts of the machine. They are there to

warn you of potential dangers and to tell you how to

avoid accidents.

Always keep the safety decals clea n and readable, and

replace them when they are worn, damaged, missing or

illegible.

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters, etc.) on the ground, never pour them

down the drain and never discard them in any other

place where they could pollute the environment. Never

throw away or burn a tire. Always take waste to

specialized recycling or waste disposal centers.

12

Safety

Page 15

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the ground, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear-protectors,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

It is strongly recommended to have your machine

checked by your Kuhn dealer after each season,

especially tools and their attaching hardware (nuts,

bolts, etc.).

Gyrotedder

GF222T

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab. Never start the machine when there are people

nearby.

Even when the machine is used in accordance with its

purpose, objects may be projected. Stones and other

foreign objects projected by the movin g parts can tr avel

a considerable distance. Keep all persons and animals

away from the danger zone.

Safety

13

Page 16

Precautions for machine use

Before using the machine, check tools ( tines) and their

attachment hardware in accordance with the instructions

of the present manual.

Check the guards regularly. Immediately replace any

damaged or missing elements.

Before engaging the pto drive, lower the rotors onto the

ground. Make sure all the guards are in place. Keep all

persons and animals away from the danger zone.

Keep a safe distance from the Gyrotedder when the

rotors are in movement.

Never work in reverse.

After the power source has stopped, the rotors can

continue turning for a time. Stay away from the machine

until all moving parts have come to a complete standstill.

If an obstacle is hit, disengage the PTO drive, stop the

tractor engine, remove the ignition key and wait for all

moving parts to come to a complete standstill. Check the

entire machine for any damage before resuming work.

Gyrotedder

GF222T

14

Safety

Page 17

3. Location and description of safety decals on the machine

Location of safety decals

Gyrotedder

GF222T

Safety

15

Page 18

Description of safety decals

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Gyrotedder

GF222T

Projections (3)

Stones and other debris pro jected by the moving parts

can travel a long distance. Always stay at a safe distance

from the machine.

Rotary tools (4)

To prevent entanglement keep a safe distance from the

machine.

16

Safety

Page 19

4. Road safety equipment and recommendations

The road safety equipment is mounted in the factory or

by your authorized Kuhn dealer according to current

safety regulations. Always keep to the legal speed limit

for driving a tractor-machine assembly on public roads .

Whatever this speed, we recommend, for everyone's

safety, not to exceed a speed of 40 km/h (25 mph).

The rear safety device comprises:

- 2 red triangular reflectors (1).

Gyrotedder

GF222T

1

1

The side device comprises:

- 2 amber reflectors (1) on each machine side.

Tyre pressure

-

Transport wheels (1): 2 bar (29 psi)

1

1

1

1

Safety

17

Page 20

$Machine specifications

1. Description and glossary

0

5

Gyrotedder

GF222T

3

7

1

4

1 : Drawbar 2 : Hitch pin

3 : Guard (Folding) 4 : Guard (Fixed)

5 : Central gearbox 6 : Drive shaft support

7 : Pitch angle adjustment handle

6

2

18

Machine specifications

Page 21

Gyrotedder

2. Technical specifications

Attachment type Drawbar attached to the tractor pull bar

Number of rotors 2

Number of tine arms per rotor 6

Working width (DIN11220) 2.60 m (8’6’’)

Width in working position x.xx m (y’)

Length in working position 2.46 m (8’)

Height in working position 1.4 m (4’7’’)

Width in transport position 2.60 m (8’6’’)

Length in transport position 2.50 m (8’)

GF222T

Height in transport position x.xx m (y’)

Minimum PTO power requirement 15 kW (20 hp)

PTO speed 540 min

Weight 225 kg (496 lb)

Tyres 15x6.00 - 6

Tyre pressure 2 bar (29 psi)

-1

3. Sound levels

Sound levels have been measured in accordance with th e me as ur ing meth od s as de fin ed in:

NF EN 1553

"Agricultural machinery - Self-propelled, mounted, semi-mounted and trailed - Common safety

recommendations"

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L (A) eq:

Tractor only: 78.7 dB(A)

Tractor + machine: 77.7 dB(A)

Machine specifications

19

Page 22

$Putting into service

1. Description of control elements

The machine is fitted with the following components:

- 1 handle to adjust the pitch angle.

Gyrotedder

GF222T

1

20

Putting into service

Page 23

2. Coupling and uncoupling

Preparing the tractor

The machine adapts to tractors fitted with a pull bar.

The tractor nominal PTO speed must be 540 min

Coupling the machine

- Couple machine to tractor and secure hitch pin.

Gyrotedder

GF222T

-1

.

Safety chain

The machine is supplied with a ANSI/ASAE safety chain

type with a minimum ultimate system strength of

45 kN (10100 lbf).

The safety chain is intended to keep the

machine under control in the event of a loss

or failure of the hitch pin.

The safety chain must be tied around a tractor

attachment point other than the attachment bar.

Putting into service

21

Page 24

PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

Gyrotedder

GF222T

The tractor PTO stub must rotate at a speed of 540 min

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- Check the maximum overlap when the machine is in

work position and the tractor turned to the direction

which provides maximum overlap.

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes. As a safety measure, a clearance (L) of at least

25 mm (1’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

250 mm (10’’).

If this is not the case:

• Mark length (H) to cut when the transmission is the

maximum overlap position

• Shorten the guard tubes and the transmission tubes

by the same length.

• Bevel and clean the tubes.

• Grease the inside of the outer tube.

-1

Check that there is still a minimum overlap of

250 mm (10’’) when the machine is in working

position and the tractor in line with the machine.

Never operate the PTO shaft at an angle X exceeding

30°.

22

Putting into service

Page 25

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

On the machine side, attach PTO shaft guard chain

around the drawbar (1).

Immediately replace any worn or damaged

guard.

Gyrotedder

GF222T

1

Lower the pto shaft holder (1).

Adjusting the machine

The machine adjustment must be made every

time another tractor is used.

From the transport position:

- Place the machine on flat ground.

- Adjust machine pitch angle with handle ( 1) so that the

tines are at a distance D = 10 mm (0.4’’) from

the ground.

1

Putting into service

23

Page 26

Uncoupling the machine

Park the machine on an even fairly level

ground.

From the transport position:

- Remove and store safety chain on the drawbar.

Gyrotedder

GF222T

- Unfold pto shaft support (1).

- Uncouple and place PTO shaft in support (1).

- Remove hitch pin.

- Move forward with the tractor.

The machine is uncoupled.

1

24

Putting into service

Page 27

$Instructions for transport

Before placing the machine into transport

position:

- Before leaving the tractor or before

adjusting, maintaining or repairing the

machine, disengage the PTO drive, turn

off the engine, remove ignition key and

wait until all moving parts h ave c ome t o

a complete stop and apply park brake.

1. Putting the machine into transport position

Gyrotedder

GF222T

From the working position:

- Rotate tedder rotor to position hole in line with the

transport lock (1).

- Pull handle (1) to unlock left side guard (2).

- Fold left side guard (2) until automatically locked.

Check guard is fully locked.

1

2

1

Instructions for transport

25

Page 28

- Remove the 2 handles (1).

- Pivot tine arms towards the machine inside.

- Reinstall the 2 handles (1).

- Proceed the same way on the other side.

- Position rotors horizontally using pitch angle

adjustment crank handle.

Gyrotedder

GF222T

1

1

1

The machine is in transport position.

Never engage the tractor PTO drive when the

machine is in transport position.

26

Instructions for transport

Page 29

2. Conformity with the road regulations

Before driving the machine on public roads,

ensure that the machine complies with

current highway code regulations.

- Check that the retroreflective signalling equipment is

clean before going on public roads.

Never tow the machine at a speed exceeding

40 km/h (25 mph).

Gyrotedder

GF222T

Check guard is fully locked

Regularly check the tyre pressure (1).

1

1

Instructions for transport

27

Page 30

$Instructions for work

1. Putting the machine into work position

Gyrotedder

GF222T

From the transport position:

- Place the machine on flat ground.

- Remove the 2 handles (1).

- Pivot tine arms towards the machine outside.

- Reinstall the 2 handles (1).

- Proceed the same way on the other side.

- Adjust machine pitch angle with handle (1) so that the

tines are at a distance D = 10 mm (0.4’’) from

the ground.

1

1

- Pull handle (1) to unlock left side guard (2).

- Unfold left side guard until automatically locked.

Check guard is fully locked.

The machine is in working position.

28

Instructions for work

2

1

Page 31

2. Adjustments in working position

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

- Adjust machine pitch angle with handle (1).

Gyrotedder

GF222T

1

The distance between tines and soil is a very

important factor with regards to the machine

work quality and tine service life.

Instructions for work

29

Page 32

3. Machine use

Keep all persons and animals away from the

danger zone.

Before the machine engages the crop:

- Engage the tractor PTO and slowly increase the

speed up to 540 min

Groundspeed

Adapt the forward speed to the working

conditions.

-1

.

Gyrotedder

GF222T

The following factors determine the forward speed:

- The humidity level (This factor is particularly

determining when wilting).

- The crop density.

- The crop composition (blade length).

- The ground contours.

General advice:

In dense and average length crop:

- When wilting a crop with low humidity level.

• the speed is approximately of 7 to 8 km/h (4.4 -

5mph).

- When tedding a more or less dry crop.

• the speed is approximately of 10 to 12 km/h (6.3 -

7.5 mph).

• The dryer the crop, the more the PTO speed must

be reduced.

• For a very dense, humid crop composed of very

long blades, the forward speed must be reduced.

For difficult working conditions, it is

recommended to operate at a lower forward

speed.

30

Instructions for work

Page 33

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

1. Frequency chart

Gyrotedder

GF222T

$Maintenance and storage

Lubrication

Grease:

- The rotor housings

- The tedding rotor locking system

- The guard lock

- The pitch angle adjustment handle and its

pivot pin

Maintenance

Check:

- Tightness of all bolts and nuts

After the

first 10 hours

of use

Once per week

Every

200 hours or

at the end

of the season

3

33

Maintenance and storage

31

Page 34

2. Lubrication

Before carrying out any maintenance or

repairs on the machine, switch off the trac tor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

The pictorials show the points to be greased

(Part no. 09905400).

Clean grease nipples before greasing.

Gyrotedder

GF222T

Lubricate with SHELL multi-purpose grease

grade NLGI 2.

Lubrication

Lubricate the central disc of each universal

joint with PTO shaft positioned so that it is

straight.

- Every 20 hours:

• U-joints (1).

• Transmission tube (2).

- Every 100 hours:

• Guide rings (3).

32

Maintenance and storage

Page 35

Grease

The rotor housings.

The tedding rotor locking system.

Gyrotedder

GF222T

The guard lock.

The pitch angle adjustment handle and its pivot pin.

Maintenance and storage

33

Page 36

Oil

Oil with SHELL SAE 90 gear oil.

3. Maintenance

Central gearbox

The main gearbox is lubricated for life and does not

require regular maintenance.

The main gearbox is lubricated for life with 0.2 kg

(0.44 lb) of SHELL multi-purpose semi-fluid

grease grade NLGI 2.

Gyrotedder

GF222T

Checking the fixing elements

Check that all nuts and bolts are sufficiently tightened.

34

Maintenance and storage

Page 37

Replacing a tine

Before leaving the tractor or before

adjusting, maintaining or repairing the

machine, disengage the PTO drive, turn off

the engine, remove ignition key and wait until

all moving parts have come to a complete

stop and apply park brake.

2 types of tines are fitted on the machine:

- Tines (1) for rotors rotating clockwise

- Tines (2) for rotors rotating

Check that the tines are f itted properly with

regards to the rotor direction of rotation.

(a).

counterclockwise (b).

Gyrotedder

GF222T

1

2

Respect mounting instructions so that the

crop's pressure (a) closes the coils.

From the working position:

- Remove attachment screw (1).

- Replace tine.

Maintenance and storage

35

Page 38

Check attachment bolt, washer and nut. Replace

if necessary.

- Reassemble the unit.

Check that the tine is properly embedded in

the tine arm.

- Tighten attachment screw:

• Torque: 20 daN m (148 lbf ft).

Gyrotedder

GF222T

Tyre pressure

-

Transport wheels (1): 2 bar (29 psi)

1

1

36

Maintenance and storage

Page 39

4. Storage

At the end of each season:

- Clean the machine thoroughly.

- Lubricate the whole machine.

- Check tyre pressure:

• 2 bar (29 psi).

- Touch up any areas of damaged paintwork.

- Check and replace worn or damaged tines.

- Put the machine under cover in a dry place.

At the start of each season:

- Read through the operator's manual again.

- Check tyre pressure:

• 2 bar (29 psi).

- Check and replace worn or damaged tines.

- Check that all nuts and bolts are sufficiently tightened.

- Make sure that all protection devices are in place and

in good condition.

Gyrotedder

GF222T

Maintenance and storage

37

Page 40

$Limited warranty

Gyrotedder

GF222T

38

Limited warranty

Page 41

Gyrotedder

GF222T

Limited warranty

39

Page 42

Page 43

Page 44

Loading...

Loading...