Page 1

ASSEMBLY / OPERATOR'S

MANUAL

FC 240 P - FC 280 P

Mower conditioner

PLEASE READ CAREFULLY

BEFORE USING THE MACHINE

N° 95100 B.GB - 02.98

Page 2

DEAR OWNER,

In buying a KUHN machine you have chosen wisely. Into it have gone years of thought,

research and improvements. You will find, as have thousands of owners all over the world, that

you have the best that engineering skill and actual field testing can produce. You have

purchased a dependable machine, but only by proper care and operation can you expect to

receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your

machine. The performance you get from this machine is largely dependant upon how well you

read and understand this manual and apply this knowledge. Please DO NOT ASSUME THAT

YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR MACHINE before reading this

manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE.

Your KUHN dealer will instruct you on the general operation of your machine. He is interested

that you get the best performance possible and will be glad to answer any special questions

that may arise regarding the operation of the KUHN machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts.

These parts are manufactured and carefully inspected in the same factory that builds the

machine to assure high quality and accurate fitting of any necessary replacements.

When ordering service parts it is important that you indicate the type of machine concerned

and its serial number.

For this reason please complete the model identification plate diagram below with the required

information. This will provide you with an easy reference for future service parts orders.

ABOUT IMPROVEMENTS

KUHN is continually striving to improve its products and, therefore, reserves the right to make

improvements or changes when it becomes practical to do so, without incurring any

obligations to make changes or additions to the equipment sold previously.

Page 3

- 1 -

CONTENTS

Page

Contents 1

Safety 2

Safety decals 8

Technical specifications 10

Handling and unpalleting 11

Assembly instructions 16

General information 22

Adapting to the tractor 23

P.T.O. shaft 25

Transport 26

Working position 27

Adjustments 29

Safety breakaway 31

Parking the machine 32

Operating the mower conditioner 33

Lubrication 35

Maintenance 39

Inspection of knives & securing elements 42

Optional accessories 44

Trouble shooting guide 46

Storing the mower conditioner 47

Limited warranty 48

Copyright 1998 KUHN S.A.

Page 4

- 2 -

SAFETY

The above symbol is used throughout this manual every time recommendations are made concerning your safety,

the safety of others, or the good operation of the machine.

These recommendations must be made known to all machine operators.

DESIGNATED USE OF THE MACHINE

FC 240 P - F C 280 P Mower Conditioners must only be used for the work which they have been designed

: mowing on the ground of hay fields, grass silage fields and improved pastures for the purpose of harvesting fodder

for feeding livestock.

The manufacturer is not held liable for any damage resulting from machine applications other than those specified

by the manufacturer.

Any use other than the designated operation is at the risk and responsibility of the operator.

Designated use of the machine also means :

- following operation, maintenance and repair recommendations given by the manufacturer ;

- using only genuine spare parts, equipment and accessories as designated by the manufacturer.

FC 240 P - FC 280 P Mower Conditioners must only be operated, maintained and repaired by competent persons

who are familiar with machine specifications and operation and are aware of any danger involved.

The operator must imperatively respect current legislation concerning :

- accident prevention,

- work safety,

- public traffic circulation.

All safety advice indicated on the machine must be strictly observed.

The manufacturer is not held liable for any damage resulting from machine modifications carried out by the operator

himself or by a third party without previous written agreement from the manufacturer.

GENERAL SAFETY RECOMMENDATIONS

Before operating the machine, always ensure that tractor and machine are in accordance with work safety and road

traffic regulations.

Page 5

- 3 -

BASIC PRINCIPLES

1. In addition to the recommendations given in this manual, legislation on work safety and accident prevention must

also be respected.

2. Advice is indicated on the machine, specifying safety recommendations in order to prevent accidents.

3. Before travelling on public roads, the operator must ensure that the machine conforms to road traffic regulations.

4. Before starting work, the operator must be familiar with all machine controls, handling devices and their

functions. Once at work, it is too late to do so !

5. Do not wear loose clothing which could become caught up in moving elements.

6. Use a tractor equipped with a safety cab. Keep windows and roof hatch closed for reduced sound level while

operating the PTO driven implement.

7. Before starting up the machine and beginning work, check the surrounding area (beware of children !). Make

sure there is sufficient visibility. Keep all people and animals away from the danger zone of the machine (risk

of projection!)

8. Carrying people or animals on the machine when working or in transport is strictly forbidden.

9. Machine must only be attached to tractor using means provided and in accordance with current safety

standards.

10. When attaching or removing the machine, place the parking stand into the corresponding position.

11. Special care should be taken when attaching or removing the machine from the tractor.

12. Before attaching the machine, make sure that the maximum permitted front axle weight and gross weight of

the combination are not exceeded.

13. Do not exceed the maximum permitted length and width authorized by road traffic regulations.

14. Before transporting the machine on public roads, ensure that all legally required guards and indicators (lights,

reflectors ...) are in place and in good operation.

15. All operating controls (cords, cables, rods ...) must be positioned so that they cannot be set off accidently,

risking accident or damage.

16. Before travelling on public roads, put the machine into its transport position as instructed in this operators

manual.

17. Never leave the tractor seat while the machine is operating.

18. Drive speed must be adapted to ground conditions as well as to roads and paths.

Always avoid abrupt changes of direction.

19. Precision steering, tractor adherence, road holding and efficient braking are influenced by the type of implement,

weight, ballast of front axle, ground or road conditions. It is therefore of utmost importance to be cautious in

every given situation.

Page 6

- 4 -

20. Be particularly cautious when turning corners, paying attention to machine overhang, length, height and weight.

21. Before operating the machine, ensure that all safety guards are firmly in place and in good condition. If worn

or damaged, replace immediately.

22. Before operating the machine, check the tightness of all nuts and bolts, particularly on tool fixing elements

(blades, tines, knives, spades ...). Retighten if necessary.

23. Keep clear of the machine operating area.

24. WARNING ! Danger of crushing and shearing can exist when components are operated by hydraulic or

pneumatic controls.

25. Before leaving the tractor or before adjusting, maintaining or repairing the machine, turn off the engine, remove

the ignition key and wait until all moving parts have come to a complete stop.

26. Do not stand between the tractor and the machine unless the hand brake is tight and/or stops have been placed

under the wheels.

27. Before any adjustments, maintenance or repairs are carried out, ensure that the machine cannot be started

up accidentally.

ATTACHMENT

1. When attaching or removing the machine from the tractor, position hydraulic lift control lever in such a way that

it cannot be set off accidentally.

2. WARNING ! Danger of crushing and shearing can exist in the lifting zone of the 3-point linkage !

3. Do not stand between the tractor and the machine when operating the outer control lever of the lift mechanism.

4. In transport, the machine lift mechanism should be stabilized by tractor tie rods to avoid floatation and side

shifting.

5. When transporting the machine in the raised position, lock the lift control lever in place.

POWER TAKE-OFF

1. Use only the PTO shaft supplied with the machine or recommended by the manufacturer.

2. PTO guards must always be in place and in good condition.

3. Check for correct PTO overlap when at work and in transport.

4. Before attaching or removing the PTO shaft, disengage PTO shaft, turn off engine and remove ignition key.

Page 7

- 5 -

5. If a primary PTO shaft is equipped with a slip clutch or a free wheel, these must be fitted on the machine PTO.

6. Ensure that PTO shaft is always correctly fitted and locked into place.

7. Make sure guards are correctly in place and secured with the safety chains provided.

8. Before engaging PTO, ensure that PTO speed and direction are in accordance with manufacturer's

recommendations.

9. Before engaging PTO, keep all people and animals clear from the machine.

10. Never engage PTO shaft when tractor motor is turned off.

11. Never surpass the PTO angle recommended by the manufacturer.

12. WARNING ! Rotating elements can continue turning momentarily after PTO is disengaged. Keep clear until all

rotating elements are at a standstill.

13. When removing the machine, place PTO shaft on the supports provided.

14. Fit the safety cap on tractor PTO.

15. Replace any worn or damaged PTO guards immediately.

HYDRAULIC SYSTEM

1. WARNING ! Hydraulic system is under pressure (maximum working pressure : 200 bars / 2900 psi).

2. When fitting hydraulic motors or cylinders, ensure that connections have been made correctly, as per

manufacturers instructions.

3. Before connecting hoses to the tractor hydraulics, ensure that tractor and machine circuits are not under

pressure.

4. It is strongly recommended that the operator marks the hydraulic connections between tractor and machine to

avoid making a wrong connection. WARNING ! Functions could be reversed (for example : lift/lower).

5. Regularly check the hydraulic hoses ! In case of normal wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be replaced .

When replacing the hydraulic hoses, make sure to use hoses with the specifications and quality recommended

by the manufacturer of the machine.

6. Should a leak be found, take all necessary precautions to avoid accidents.

7. Any liquid under pressure (particularly oil from hydraulics) can penetrate the skin and cause severe injury. If

injured, see a doctor immediately, there could be danger of infection.

8. Before any adjustments, maintenance or repairs are carried out, lower the machine, depressurize the circuit,

turn off the engine and remove ignition key.

Page 8

- 6 -

MAINTENANCE

1. Before checking for any machine malfunction and before adjusting, maintaining or repairing the machine,

disengage PTO, turn off engine and remove ignition key.

2. Check tightness of nuts and bolts regularly. Retighten if necessary.

3. If the machine is raised, prop it up in a stable position before carrying out any maintenance work.

4. When replacing a working part, wear protection gloves and only use standardized tools.

5. It is forbidden to discard any oil, grease or filters. These must be given to waste disposal organisations to protect

the environment.

6. Disconnect power source before any work is done to the electric system.

7. Check safety guards regularly, particularly those that are subject to wear. Replace immediately if damaged.

8. Spare parts used must be in accordance with specifications and standards as defined by the manufacturer. Use

only genuine KUHN parts !

9. Before any electric welding is carried out on tractor or attached machine, disconnect generator and battery

terminals.

10.Repairs on elements under pressure or tension (springs, accumulators etc.) must only be carried out by

competent persons with standardized equipment.

SPECIAL SAFETY RECOMMENDATIONS

1. Use a tractor equipped with an enclosed cab with windows made of safety glass and kept closed. It is

recommended to fit polycarbonate screens inside the tractor safety cab's side and rear windows or to install mesh

guards on the exterior of them.

2. Stay a safe distance away from the mower conditioner when discs are rotating.

3. For safe machine operation, it is imperative that cutting tools be fitted in accordance with the manufacturers

recommendations. Use only the tool outfit supplied with the machine.

4. Each time before using the mower conditioner, inspect condition of cutting elements (knives, discs). Replace

any missing, worn or damaged cutting elements immediately. Use only genuine KUHN spare parts.

5. To avoid creating dangerous out of balance forces, always replace missing, damaged or worn knives in pairs.

6. When replacing knives or discs, systematically inspect their securing elements as per the manufacturers

recommendations.

7. Regularly inspect the disc mowers protection cover. Worn or damaged protection covers must be replaced

immediately.

8. Protection devices (such as guards, shields etc.) are intended to prevent stones, rocks or other foreign objects

from being projected. They also prevent access to the machines danger zones. Therefore, it is imperative that

protection devices are put in place and properly secured each time before using the machine.

Page 9

- 7 -

9. Crushing and shearing zones which could cause serious bodily injury when changing the machine from

transport to work position and vice versa may exist. To prevent possible injury, be extra careful when

maneuvering and ensure that everyone is at a safe distance away from the machine.

10. PTO drive to the mower conditioner must never be engaged unless the cutterbar skid shoes are in contact

with the ground and the protective cover is folded down.

11. Ground of the pastures to be mown must be free of foreign objects.

12. Even when the machine is used in accordance with it purpose, objects may be projected. It is therefore

imperative that everyone be kept away from the danger zone, that extra care be taken and that extra precaution

(such as safety indicators) be taken when mowing pastures alongside roads or near public areas (parks,

schools etc.).

13. Never mow in reverse.

14. When disengaging the PTO drive, moving parts continue to rotate for some time. Wait for all moving parts to

come to a complete stop before approaching the machine.

15. If an obstruction is hit, stop the tractor immediately, disengage PTO drive, turn off engine, remove ignition key

and wait for all moving parts to come to a complete stop.

Check the entire machine for any damage before resuming work.

16. It is strongly recommended to have your machine checked by your dealer after each season, especially blades

and discs and their fixing devices (nuts, bolts etc.).

Page 10

- 8 -

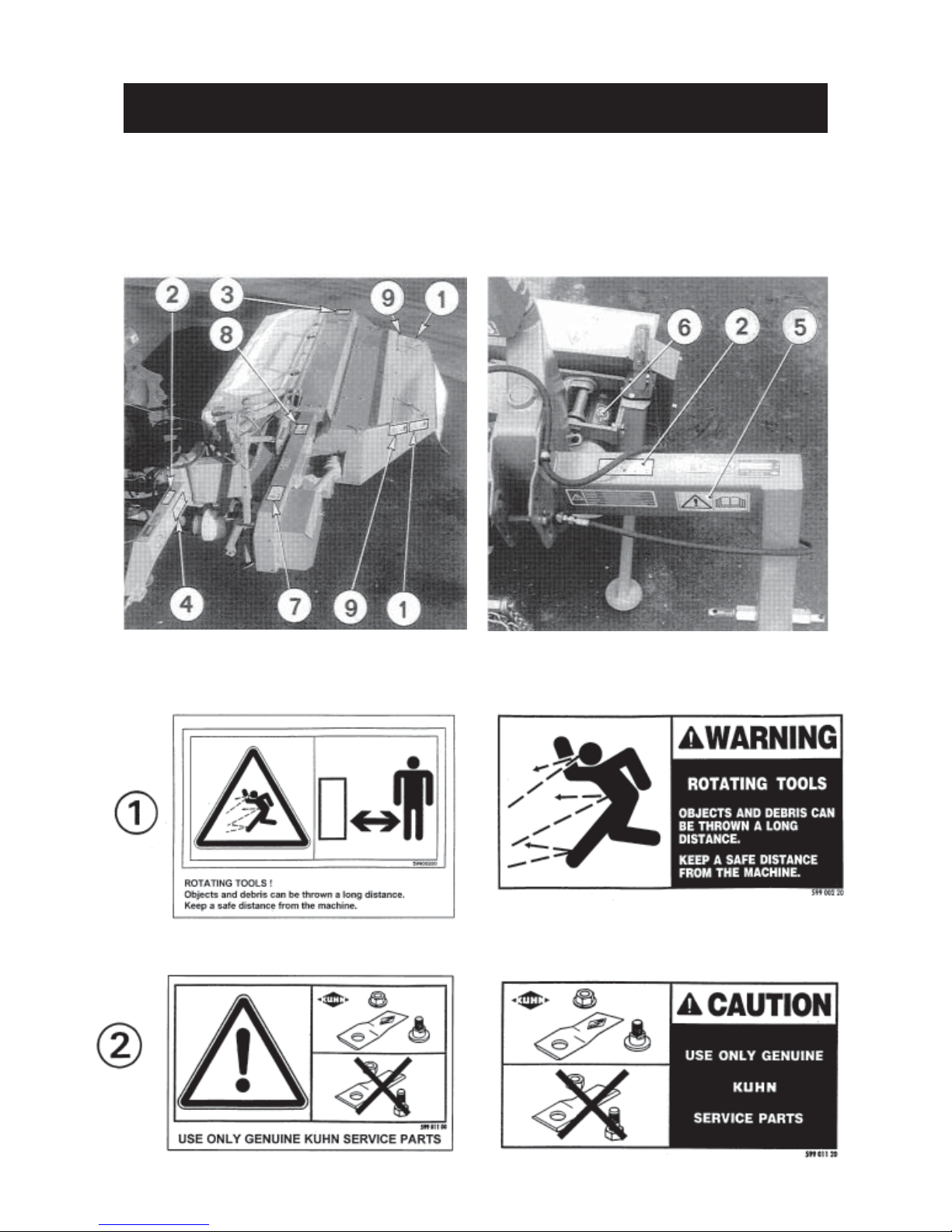

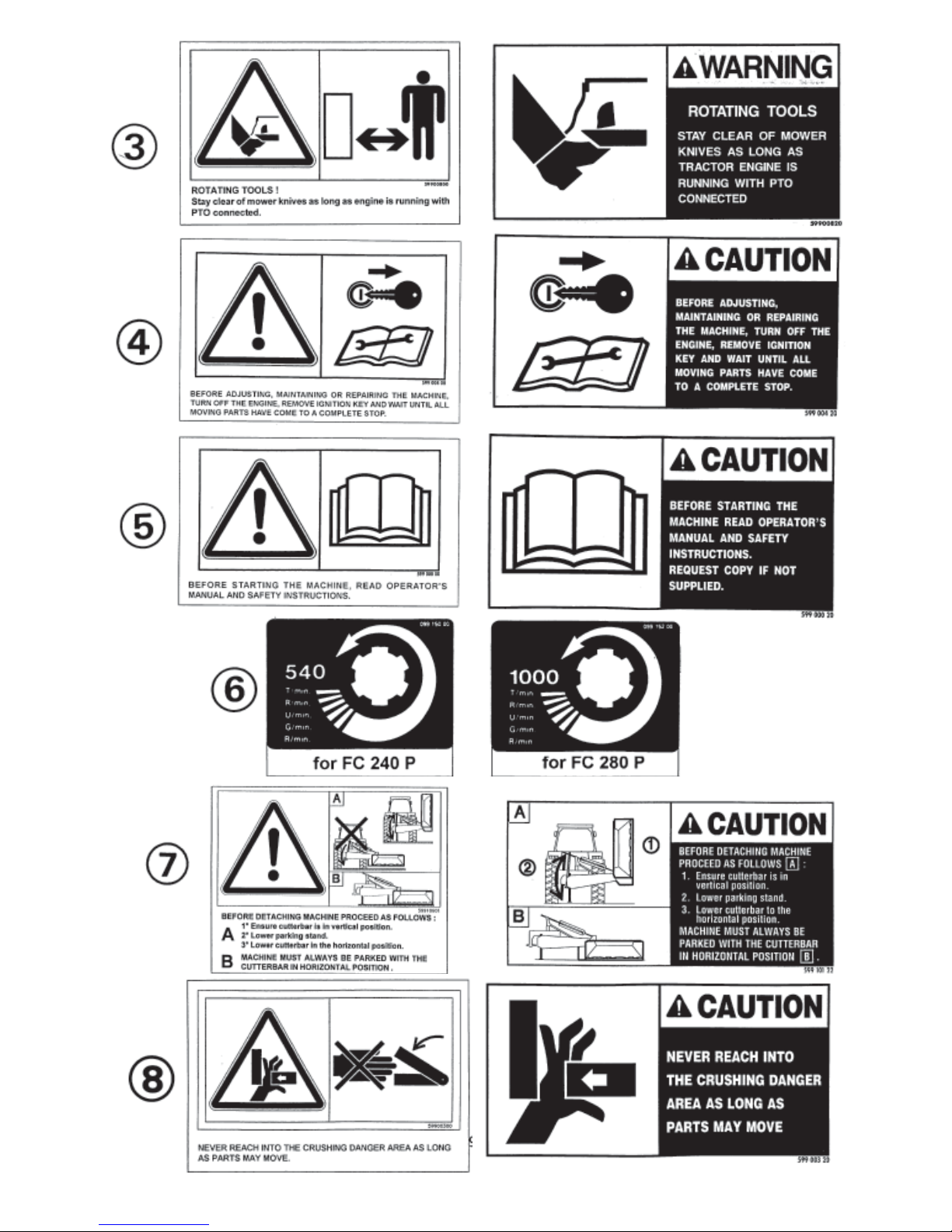

SAFETY DECALS

THE FOLLOWING SAFETY PICTORIALS HAVE BEEN PLACED ON YOUR MACHINE IN THE AREAS

INDICATED. THEY ARE INTENDED FOR YOUR PERSONAL SAFETY AND FOR THE SAFETY OF THE

PEOPLE WORKING WITH YOU. THE TEXT SHOWN ON THEM GIVES THEIR PRECISE MEANING.

ENSURE THAT THESE PICTORIALS ARE ALWAYS LEGIBLE. IF THEY ARE NOT, REPLACE THEM.

Page 11

- 9 -

Page 12

- 10 -

1 l

2 US pint

1.75 Imp pint

TECHNICAL SPECIFICATIONS

Number of discs 6 7

Width of cut 2.40 m / 7' 10" 2.80 m / 9' 2"

Width in transport position (1) 0.35 m (13' 7 ") wider than tractor width

Disc speed 2991 rpm

Rotor speed 888 and 615 rpm

Rotor width 1,80 m / 5' 30" 2,21 m / 6' 50"

Tractor DIN power requirement (as from) 51 kW (70 hp) 60 kW (80 hp)

P.TO. speed 540 rpm 1000 rpm

Lift system hydraulic

Tractor attachment 3 point - cat. 2

Weight (approx.) 900 kg / 1980 lbs 965 kg / 2123 lbs

Bevel gearbox oil capacity

Oil quality : SAE 80 W EP (GL4)

Cutterbar oil capacity 1.7 l 2 l

Oil quality : SAE 80 W EP (GL4) 3.4 US pint 4 US pint

3 Imp pint 3.5 Imp pint

Rotor gearbox oil capacity 0.5 l

Oil quality : SAE 80 W EP (GL4) 1 US pint

0.875 Imp pint

(1) Applicable if machine is attached in such a way that a 5 cm / 2" distance "A" is respected (see page 23).

TYPE FC 240 P FC 280 P

Page 13

- 11 -

ASSEMBLY INSTRUCTIONS

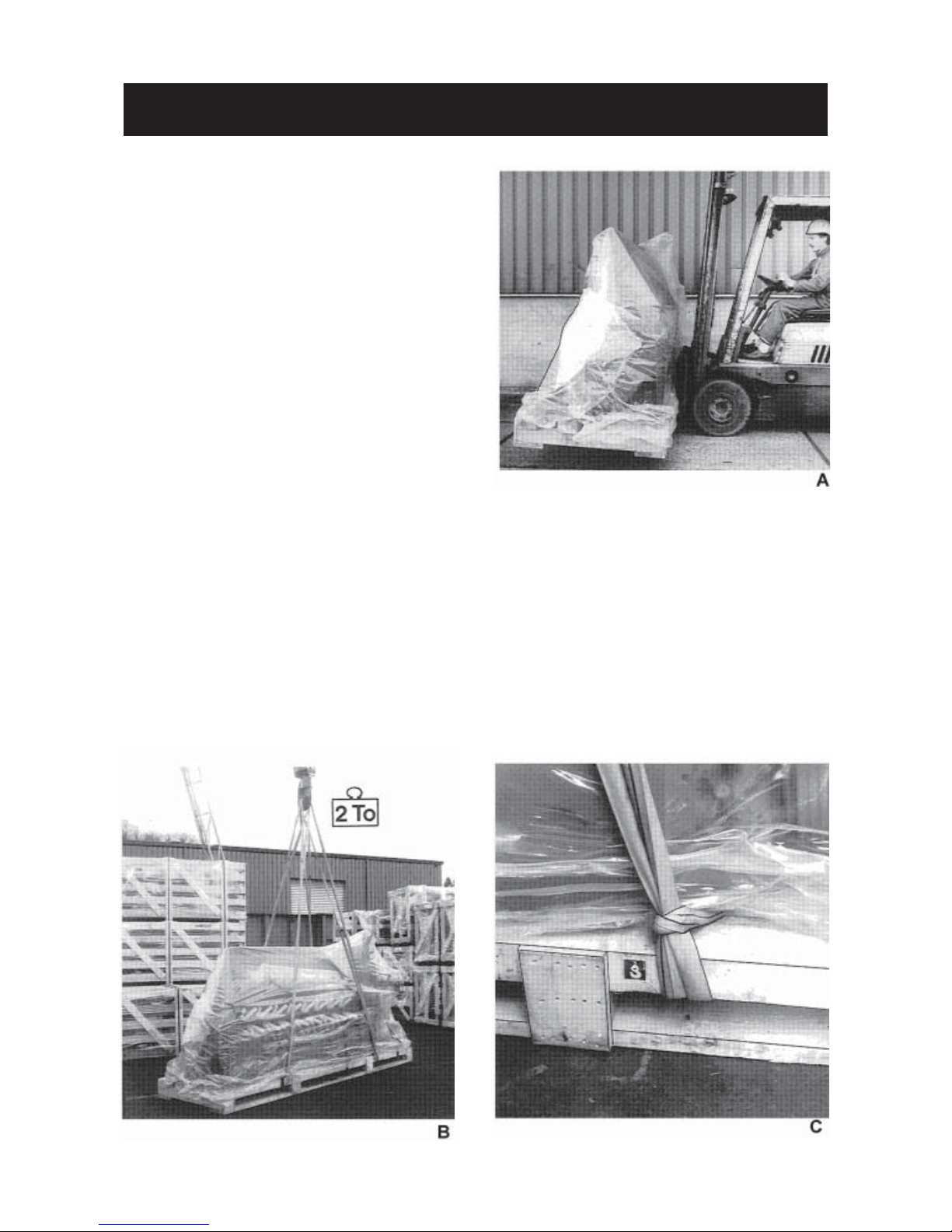

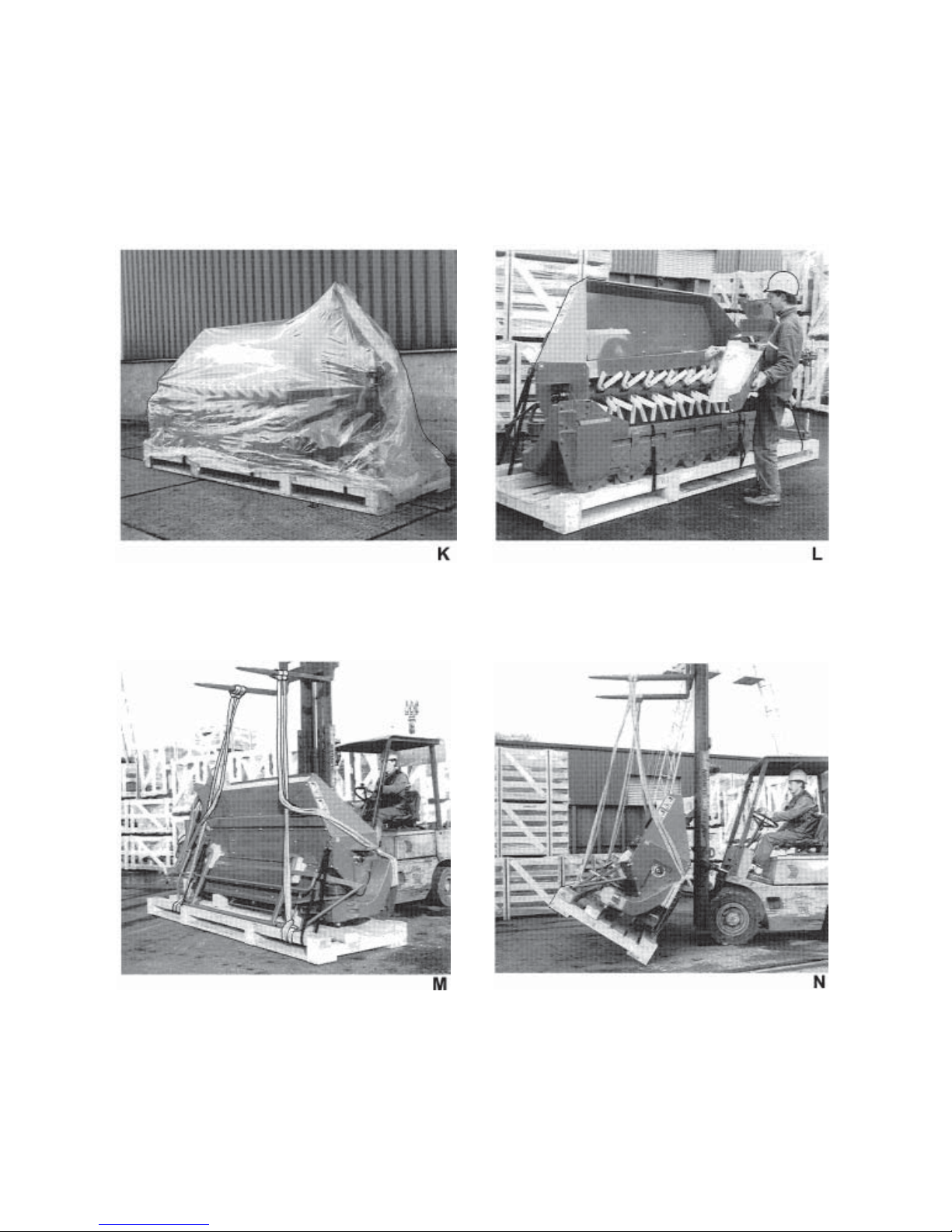

A) HANDLING

1° To facilitate shipping, certain FC 240 P, FC 280 P

are secured on a wooden pallet.

This pallet is designed to be handled by a fork lift

truck or a tractor fitted with a front end loader having

forks no longer than 1.20 m (4') and with a

minimal lift capacity of 2 000 kg (4400 lbs) at 0.60

m (2') from the heel of the forks (1 000 kg / 2200 lbs

at 1.20 m / 4').

Weight of packed machine : :

FC 240 P : 1 120 kg / 2464 lbs

FC 280 P : 1 185 kg / 2607 lbs

To lift the pallet, engage the fork lift/front end loader

crosswise from the cutterbar side only (photo A).

2° The machine can also be unloaded using a lifting device fitted with a hook (hoist, crane, etc) having a minimum

capacity of 2 000 kg (4400 lbs).

Weight of packed machine : FC 240 P : 1 120 kg / 2464 lbs

FC 280 P : 1 185 kg / 2607 lbs

2.1. Handling the machine with the four textile straps :

Attach a textile strap to each of the pallets four corners as shown on photo B (minimum capacity of the two

strands per strap 1500 kg / 3307 lbs ; maximum angle between strands : 90°).

Tie slipknots as shown in photo C to avoid slipping when moving.

Page 14

- 12 -

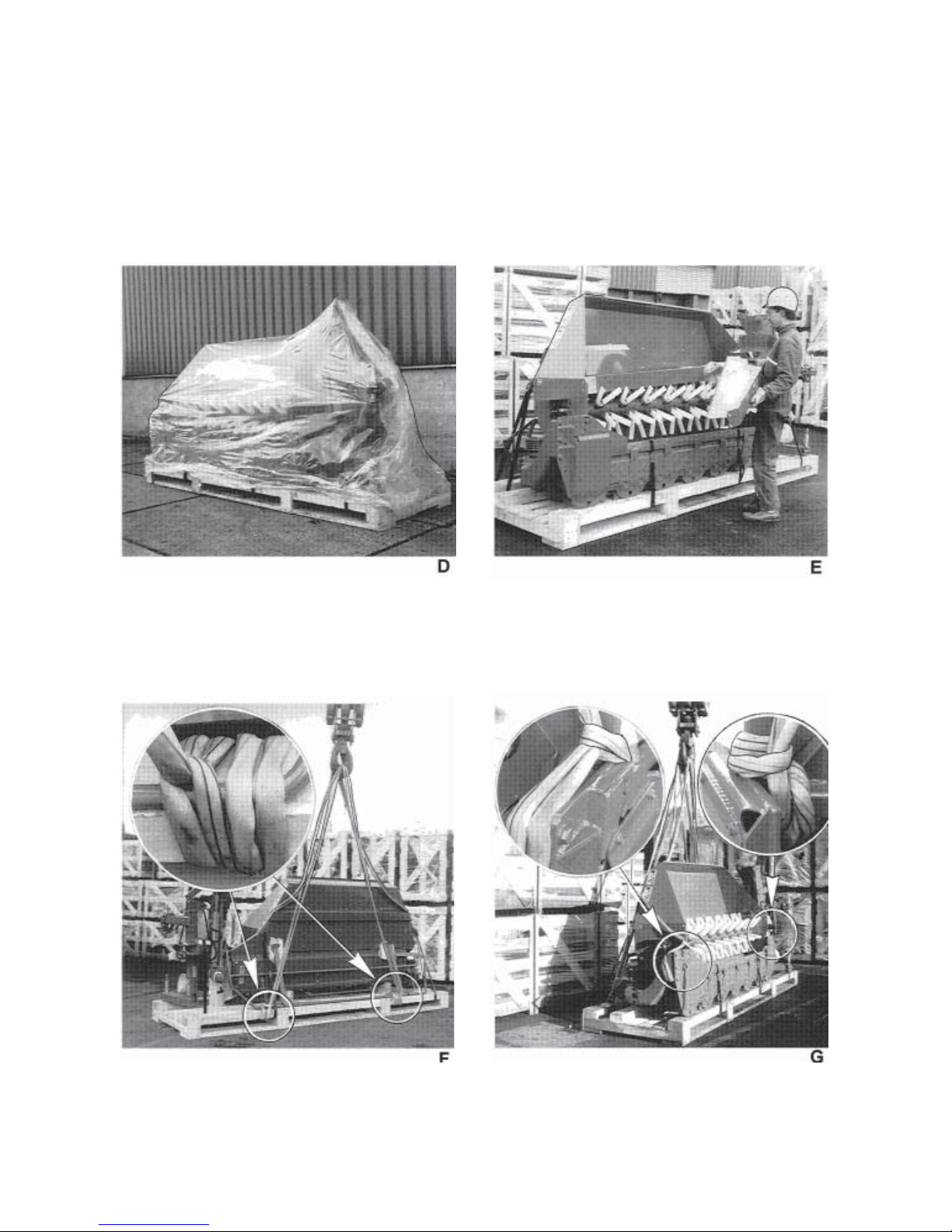

B) INSTRUCTIONS FOR UNPALLETING

1° By means of a lift mechanism equipped with a hook :

1.0. Use of a crane or hoist with a minimum lift capacity of 2 000 kg (4400 lbs).

Overall weight of the packed machine :

FC 240 P : 1 120 kg / 2464 lbs

FC 280 P : 1 185 kg / 2607 lbs

1.3. Fasten the machine using the 4 identical length textile slings as shown in photos F and G (here, minimum lift

capacity 2000 kg / 4400 lbs on the 2 strands of each sling).

- Position slipknots as shown above (circled) to prevent hoops from sliding aside when maneuvering.

1.1. Place the pallet on flat, horizontal ground

(photo D).

Check that all tension hoops are in place and in

good condition. Replace any that are missing or

damaged.

1.2. Take off the protective cover and remove all

unassembled items from the pallet (photo E).

Page 15

- 13 -

Note : If textile slings as pictured are not available, use only slings with a sufficient capacity and that are also well

protected against sharp edges. Never make slipknots with chain type slings.

1.4. Keep all people clear from the zone of the load. Lift

slowly until the machine starts to tilt (photo

H).

1.5. Slowly tip over the machine/pallet assembly until

the machine rests entirely on the ground (photo

I).

1.6. Remove the tension hoops taking the usual precautions (beware of lash) to unfasten the machine from the pallet

(photo J).

Page 16

- 14 -

2° By means of a fork lift truck or a tractor equipped with a front end loader :

2.0. Use of a fork lift truck or a tractor equipped with a front end loader : Length of the forks should not exceed

1.20 m (4') and the lift capacity of the machine should be at least 2 000 kg (4400 lbs) at a distance of 0.6

m (2') away from the heel of the forks.

Overall weight of the packed machine : FC 240 P : 1 120 kg / 2464 lbs

FC 280 P : 1 185 kg / 2607 lbs

2.1. Place the pallet on flat, horizontal ground

(photo K).

Check that all tension hoops are in place and in

good condition. Replace any that are missing or

damaged.

2.2. Take off the protective cover and remove all

unassembled items from the pallet (photo L).

2.3. Fasten the machine using 4 identical length slings

(photo M) (minimum capacity 2000kg / 4400 lbs

on the 2 strands of each sling).

Moor textile slings two at a time to the fork lift truck

tines as shown in photo M.

Keep to the slipknot positions as indicated in the

inset of photos F and G, page 12 to prevent

slipping when operating.

2.4. Move all persons away from the lifting area.

Lift and reverse the fork lift truck until the machine

starts to tilt (photo N).

Page 17

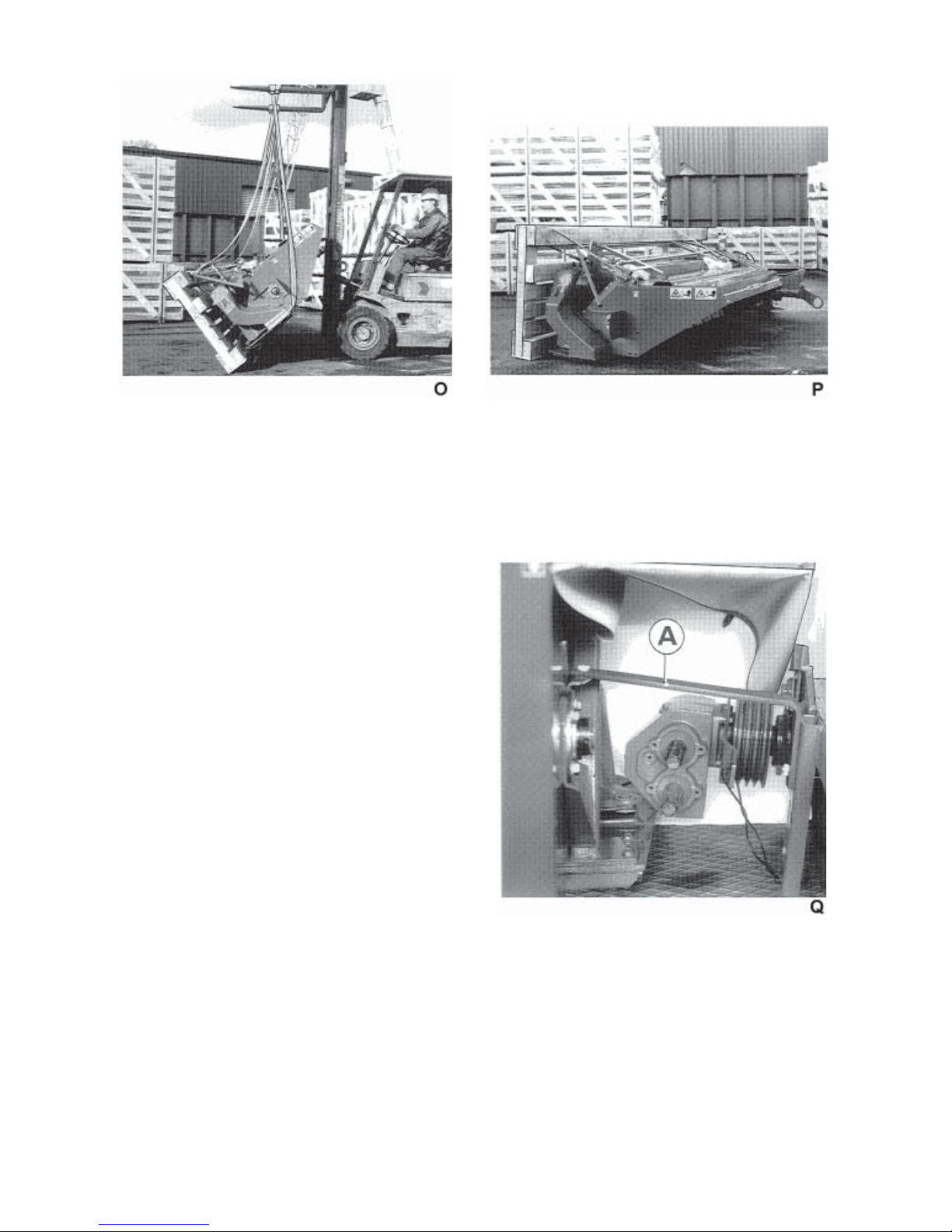

- 15 -

2.5. Slowly lower the forks while progressively

reversing the truck loader (photo O).

2.6. Remove the tension hoops taking the usual

precautions (beware of lash) to unfasten the

machine from the pallet (photo P).

3° Operating before assembly

Before beginning assembly, remove the maintaining

brace (A) linking the 3-point frame to the hooding (photo

Q).

Page 18

- 16 -

ASSEMBLY INSTRUCTIONS

1° Assembling the pivoting cylinder and

the safety breakaway (photo 1)

Fix the pivoting cylinder (1) onto the frame (2) using pin

(3) and 2 roll pins (4) (diameter 6 x 40). Insert the

cylinder guard (5) plain washer (6) (diameter 30.5 x 50

x 2) between the upper roll pin (4) and the mounting

yoke (see photo 1).

Fix the safety breakaway (7) onto the main frame (8)

using pin (9), 2 plain washers (10) (diameter 23 x 40 x

7) and 2 roll pins (11) (diameter 6 x 36). Insert the chain

end (12) between the lower roll pin (11) and the

mounting yoke (see photo 1).

2° Assembling the frame onto the cutting/

conditioning unit

(photo 2)

Check that the nylon bush bore is clean and well

greased. Remove the protection paint on the mating

area of the gear housing front cover. Fix the frame to the

cutting/conditioning unit using 2 self locking screws

(B) (M 16 x 50) and 2 washers (A) (diameter 17 x 61 x

8) as illustrated in photo 2.

Torque : 30 daNm / 220 ft.lbs.

FOR SAFETY, PLACE WEDGES

UNDER THE MACHINE.

3° Assembling the compensating spring

rod housing (photo 3)

Using a chain hoist or a fork lift truck slightly raise the

frame and lower the parking stand.

Then lower the unit so that the weight of the 3-point

frame rests on the parking stand.

Link the rod (13) to the upper frame casting (14) using

pin (15) and 2 roll pins (16) (diameter 8 x 45).

Page 19

- 17 -

4° Assembling the lifting cylinder and

compensating spring

(photo 4)

Attach the cylinder connecting rod (20) to the lift

bracket (21) using pin (22) and 2 roll pins (diameter 6

x 40).

Fix the compensating spring (23) on the safety guard

frame (24) with pin (25) and 2 roll pins (diameter

6 x 40) using the upper connecting hole for the FC

280 P (photo 4) and the lower connecting hole for

the FC 240 P. Make sure that the lower sliding rod is

assembled the right way up (23) (see enlargement).

5° Fixing the inner guard and front belt shield (photos 5 and 6)

Fix the inner guard (28) onto the pivoting housing (29) using a screw (M 8 x 25) and a clamp nut (M 8) (photo

5).

Fix the front belt shield (30) in position using 3 spacers (31) and 2 self-locking nuts (M 12) (photo 6). Do not use

the hole closed with a plastic plug.

Fix the guard (32) onto the front belt shield (30) using 2 clamp nuts (33) and 2 self locking screws (M 8 x 12)

(photo 6).

Attach the support link (35) on the main frame with a self locking bolt (M 12 x 35) and a plain washer (dia.

12.5 x 25 x 1.5).

Connect gearbox (34) to the support link (35) using self locking screw (36) (M 16 x 35) and conical spring washer

(diameter 17 x 32 x 3.4) (torque 22 daNm) (162 ft.lbs) (photo 6). This operation is made easier by using a screwdriver

(37) for example to prevent the link pin from moving (photo 6). The screwdriver must be removed after this

operation.

Page 20

- 18 -

6° Assembling the power band belt, rear belt shield and input shaft guard

Install the power band belt (38) on the pulleys (photo 7) and tension (see specific instructions on page 39). Fix the

rear belt guard (39) using 2 self locking screws (40) (M 8 x 12) and 2 clamp nuts (M 8) on one part and 3 self locking

nuts (41) and 3 lock washers (diameter 12.4 x 27 x 1.8) on the other part (photo 8).

Fix the gearbox guard (42) on to the rear belt shield (39) using 4 self locking screws (43) (M 10 x 16) (photo 8).

7° Fitting the pulley guard (photo 9)

Fit the guard (44) on the belt shield using 4 self locking

screws (45) (M 8 x 12) and 4 clamp nuts (M 8).

Page 21

- 19 -

8° Fitting the secondary PTO trans-

mission shaft

Connect the secondary PTO transmission shaft (46) to

the conditioning rotor input shaft and fix the protection

cover (47) on the flange (48) using a clamp collar (49)

(photo 10).

Note : Position the cover (47) so that the opening (50)

for greasing the U-joint is pointing upwards

(photo 10).

According to the required conditioning rotor rotating

speed, connect the secondary PTO transmission

shaft (46) to the upper or lower output shaft of the

gearbox (photo 11) (see specific instructions page 33).

Link the safety chain (51) (photo 11). Fix the guard (52)

in front of the output shaft not being used using a wing

nut (53) (photo 11).

9° Fixing the safety curtain retaining rod

(photo 12)

Fix the retaining rod (54) at the end of the frame (55)

using 2 original nuts and bolts (56) (photo 12).

Page 22

- 20 -

10° Assembling safety curtain and front guard

- Pre-assemble the safety curtain (1). To do this loosely fasten rod (3) with the straps (2) (photo 13).

- Spread out safety curtain and arrange in correct position. Attach straps located at (5) around the guard tube (photos

13 and 14). All straps are attached to the underside of the safety curtain.

- Attach both hinges (6) with cup square bolts (7) (M 10 x 20) (photo 13 and figure 15).

- Install the front safety guard with its curtain to the main frame (8) with rod (9) (photo 14 and fig. 15) which must

be inserted successively through the following holes : safety guard lug (10), curtain hem and hinges (11),

PVC cord loops (12). Secure the rod in place with 2 roll pins (14) (dia. 4 x 30) (photo 16).

Page 23

- 21 -

Note : - Slide rod (9) in place so that the holes for roll pins (14) are located on the gearbox side

(photo 16).

- Attach front and side curtains to one another with 2 straps (15) (photo 14).

- Attach springs to their respective anchorage points with the small chains (16 and 17) (photos 13, 16 and

fig. 15) and close the eyelets

.

12° Attaching rear curtain

Remove both end bolts (23) (photo 19). Install the rear curtain (24) (red stripe visible from the rear) under hood (25)

with bar (26) and 5 cup square bolts (23) (M 10 x 20), 5 plain washers (27) (dia. 11 x 24 x 2) and 5 self-locking nuts

(M 10) (28) (see photo 18 and fig. 19).

The lower hitch pins should stay parallel to the ground when the machine is parked. If this

is not the case the lift cylinder should be bled in extended position.

11° Attaching swath shields

Attach both swath shields (18) with axles (19), plain

washers (20) (dia. 16.5 x 25.5 x 4) and roll pins (21)

(dia. 5 x 30) (fig. 17).

Install lock handles (2) with 2 cup square bolts (M

10 x 35), 2 washers (diameter 36 x 11 x 2) and 2 selflocking nuts (M 10) (photo 18).

Then tighten the 4 self-locking nuts (M 10) on the swath

shields.

Page 24

- 22 -

(T).

GENERAL INFORMATION

1. Minimum tractor engine power used should be

51 kW / 70 hp for the FC 240 P and 60

kW / 80 hp for the FC 280 P. If tractor power is

insufficient, quality of work will be unsatisfactory.

2. - FC 240 P mower conditioner can be

adapted to all tractors having a PTO speed of

540 rpm and equipped with a normalized Cat.

2 three-point hitch.

- FC 280 P mower conditioner can be

adapted to all tractors having a PTO speed of

1000 rpm and equipped with a normalized

Cat. 2 three-point hitch.

3. FC 240 P and FC 280 P are equipped with

adjustable lower hitch pins allowing the machine to be offset +/- 50 mm (2") to the left and

to the right.

4. To adjust lower hitch pins (T) (photo A), loosen

the 4 hexagonal screws (U) of collar flanges (V)

on each side.

Reposition lower hitch pins respecting :

825 mm (28") dimension (page 23) and retighten

screws (U). Torque : 12 daNm / 88 ft.lbs.

Check tightness of screws (U) after the first

ten hours of use.

Note : 825 mm dimension is correct when the

distance (X) is the same for the two lower hitch pins

The parking stand on the FC 240 P and FC 280 P machines has been designed to support the

weight of the 3-point frame only and the following points must be respected :

1) If at any time it becomes necessary to move the machine with a fork lift or loader type

vehicle it is very important that the 3-point frame is :

a) lifted from the ground first, when lifting the machine

b) lowered onto the ground last when lowering the machine.

Failure to comply with the above points will result in damage being caused to the parking

stand / operating lever.

2) If at any time it becomes necessary to transport the machine on a lorry or trailer then some

form of support must be used i.e. a piece of wood, to take the weight of the 3-point frame,

so relieving the weight on the parking stand. This action will prevent damage being

caused to the parking stand when the machine is secured by load straps.

Page 25

- 23 -

ADAPTING TO TRACTOR

A) Attachment of lower links and

positioning of hitch pins :

Follow fig. B for category 2 tractors with narrow wheel

tracks.

Follow fig. C for category 2 tractors with standard

wheel tracks.

Follow fig. D for category 2 tractors with wide wheel

tracks.

NOTE : Always attach machine in such a way that

distance (A) is approximately 50 mm (2").

Page 26

- 24 -

B) Attaching the machine

- Attach the lower links (A) to the hitch pins and

secure with linchpins (photo E).

Select the attachment holes of the turn buckle

(P) on the tractor side and machine side (D) so

that it is approximately parallel with the tractor

lower draught arms (A) in working position and

in raised position (photo E).

- Connect hydraulic hose (H) to the tractors single

acting valve (photo E). First make sure that the

hydraulic connection is clean ; if not, cylinders may

not function correctly.

C) Adjusting cutting / conditioning unit

horizontal position

- Activate the tractors hydraulic lift mechanism and

check that the 3-point frame is lifted parallel to the

ground (photo F). If necessary, adjust levelling rods

(F) (photo E).

If, once this adjustment has been made, the cutting/

conditioning unit is still not parallel to the 3-point

frame, level it by adjusting threaded cylinder rod (V)

(photo F).

D) Raising cutting / conditioning unit

and parking stand

NOTE : ONLY OPERATE THE PARKING STAND

(L) WHEN THE CUTTING CONDITIONING

UNIT IS IN THE VERTICAL TRANSPORT

POSITION (COMPENSATING SPRING

IS RELEASED).

- Activate the machines hydraulic cylinders to bring

the cutting/conditioning unit into its vertical position.

- With the machine in the transport position (cutterbar vertical), raise the stand (E) and connect it to the

suspension rod (F) using pin (L) (photo G).

(

Note : The PTO shaft must be adapted

at a later stage. Correct length cannot be checked as long as the cutting / conditioning unit is in horizontal position.

Page 27

- 25 -

P.T.O. SHAFT

THE LENGTH OF THE PTO SHAFT MUST BE ADAPTED TO THE TRACTOR BEING USED WITH

THE CUTTERBAR LATCHED IN VERTICAL TRANSPORT POSITION (PRESSURE IN CUTTERBAR

LIFT CYLINDER RELEASED).

Proceed as follows to check that the PTO shaft length is correct when coupling the machine to a tractor for the

first time and when using another tractor.

1° Remove the PTO shaft and separate the two half transmission tubes.

2° Raise the cutting / conditioning unit to its full vertical transport position, then release hydraulic pressure

to engage latch (I) (photo 21).

3° Set the tractor 3-point lift to the position where the distance between tractor and machine PTO stub is as short

as possible.

4° Connect the half transmission tubes to their corresponding PTO stubs (free wheel clutch on machine side,

tractor end yoke on the 540 rpm PTO for FC 240 P and on the 1000 rpm PTO for FC 280 P). Hold both

shaft halves next to one another. The outer guard tube should remain clear of the protection cone by "a" =

40 mm (1 1/2") (see photo H). If this is not the case, shorten the two transmission tubes and the two guard tubes

by the same length (photos I and J). Deburr, bevel and clean the tubes (photo K). Grease the inside of the outer

tube (photo I).

5° Lower the cutting / conditioning unit to its horizontal working position and check that the overlap is

at least 150 mm (6") by keeping both shaft halves next to one another. Reassemble the PTO sliding tubes and

connect the PTO shaft in place while the cutterbar is in its horizontal position.

Page 28

- 26 -

These recommendations and adjustments must be respected to avoid damage or

premature wear of the PTO. Repeat these checks when the machine is fitted to any other

tractor.

Only attach the FC 240 P to the 540 rpm PTO and the FC 280 P to the 1000 rpm PTO.

To avoid accidents which could be serious, make sure that the guards are always correctly

in place and secured with the safety chains (C). On the machine side the chain should be

fixed onto the oscillating arm grommet (photo N). Replace the guards immediately as soon

as they have been damaged.

TRANSPORT

WARNING : WAIT UNTIL DISCS AND ROTOR COME TO A COMPLETE STOP BEFORE

RAISING THE CUTTING CONDITIONING UNIT INTO THE VERTICAL POSITION.

BE SURE THAT EVERYONE IS AT A SAFE DISTANCE FROM THE MOWER CONDITIONER

PIVOTING AREA.

WARNING : BEFORE TRANSPORTING THE MACHINE ON THE PUBLIC HIGHWAY, THE

OPERATOR SHOULD MAKE SURE THAT THE MACHINE CONFORMS TO THE HIGHWAY

CODE.

To transport the machine on public roads or from one field to another, proceed as follows :

- Make sure discs and rotor have come to a complete stop.

- Lift the machine using the tractor 3-point linkage

- Pressurize the hydraulic cylinders to lift the cutting conditioning unit into its vertical position.

- The cutting conditioning unit will lift and simultaneously pivot towards the rear.

- Once the cutterbar has reached the end of its trajectory, release hydraulic pressure and the cutterbar will be

automatically locked in place (photo 20).

Never operate the PTO shafts at too great an angle (X = 25° maximum) (fig. M).

Page 29

- 27 -

WORKING POSITION AND ADJUSTMENTS

1) Pressurize hydraulic cylinders and pull cord (A) to

free lock (I) (photo 21).

2) Lower cutting conditioning unit into the work posi-

tion by releasing the hydraulic pressure. As soon

as the cutting conditioning unit starts to pivot,

release pressure on the cord (A).

When the cutting conditioning unit is in the horizontal position [cylinder (V) is fully extended], lower

machine with the hydraulic lift until the roll pin

(F) is exactly centered in its aperture (H) (photo

23).

Page 30

- 28 -

Adjustment of chassis height from the

ground :

1. For tractors equipped with hydraulic position

control function : set lower link height so that roll

pin (F) is exactly centered in its aperture (H) (photo

23).

This gives height E = 400 mm approximately

(photo 22), which corresponds to a cutting height of

30 mm.

2. For tractors not equipped with hydraulic

position control function, the stop-chain (L) which

is delivered with the machine must be used.

Proceed as follows to install this chain (L) (photos

24 and 25) :

- Remove roll pin (K) from right hitch pin, attach

chain (L) and washer (M) and reinstall roll pin (K).

- Lower machine until hitch pins (T) are 400 mm

(16") or slightly more from the ground [roll pin (F)

is slightly excentered in regard to its aperture (H)].

- Attach stop-chain (L) with its hook (O) to the

uppermost free holes at the tractors top link

attachment clevis (photo 25).

- Lower the machine into working position. Chassis

height is correct when :

- The cutting conditioning unit is resting

on the ground

- Stop-chain (L) is tight.

- Roll pin (F) is exactly centered in its

aperture (H) (photo 23).

- To keep this adjustment permanently, close hook

eyelet (O) with roll pin.

WARNING : BEFORE LOWERING THE MACHINE IN WORK POSITION, ENSURE ALL

PERSONS ARE WELL CLEAR OF THE MOWER-CONDITIONER PIVOTING AREA.

Page 31

- 29 -

INNER DEFLECTOR

Conditioning degree is governed by an inner deflector adjustable in 3 different positions (O) with lever (C). Each time

conditioning is readjusted do not forget to reinstall the two spring cotters (E) (photo 28 and figure 29).

- For maximum conditioning select the intermediate or lower position of deflector.

- For minimum conditioning when mowing leguminous crops, deflector can be adjusted in the highest position giving

the greatest distance between deflector and rotor fingers.

ADJUSTMENTS

BEFORE CARRYING OUT ANY OPERATION SUCH AS MAINTENANCE OR ADJUSTMENT ON

THE MACHINE, STOP THE TRACTOR ENGINE, REMOVE IGNITION KEY AND WAIT FOR

ROTATING DISCS AND ROTOR TO STOP.

Cutting height

Maximum cutting height (80 mm / 3") (fig. 26) is achieved when the discs are parallel to the ground. Adjustment of

cutting height is achieved by altering the cutterbar tilt angle. This is effected by varying top link length (P) (photo

25) until desired cutting height is achieved. To minimize blade and disc wear, improve grass regrowth and get

maximum nutritive value from the crop, minimum cutting height should never be adjusted less than 30 mm

/ 1 1/4" (fig. 27).

A raised skid shoe kit (set no. 107 6100) available as an optional equipment provides a cutting height adjustable

between 60 mm and 120 mm (2.5" and 5") (see page 45).

MAXIMUM CUTTING HEIGHT MINIMUM CUTTING HEIGHT

Page 32

- 30 -

Swath screens

Desired swath width is obtained by adjusting swath screens (T) (figure 30). Swath screens are locked in position

by means of 2 handles (M) (figure 30).

Adjustment of compensating spring

tension

The compensating spring or system is factory adjusted

so that dimension (X) (photo 32) is:

- 25 mm (1") for the FC 240 P

- 55 mm (2 1/6") for the FC 280 P.

When working conditions are difficult, adjustment can

be modified as follows :

- Put machine in parking position, which releases

compensating springs (P) (photo 32).

- Loosen lock nut (H) and adjust rod (F).

- After adjustment retighten lock nut (H).

Maxi length of dimension (X) must not exceed :

- 115 mm / 4"1/2 for the FC 240 P

- 75 mm / 3" for the FC 280 P.

Page 33

- 31 -

A breakaway latch allows the cutting conditioning unit

to swing back if an obstruction is hit (photo 33).

IF THE LATCH RELEASES, STOP THE TRACTOR

IMMEDIATELY AND DISENGAGE THE PTO.

To reset the cutterbar, back up the mower conditioner

until the cutterbar is in its normal position.

The factory setting of the latch is adapted to most

working conditions.

NOTE : Before using the mower conditioner, the breakaway linkage must be checked for good operation

making sure all components slide correctly and are

well greased. Check for any cutting conditioning unit

damage if an obstruction is encountered.

The stack (Y) of spring washers should be compressed to 95 mm ( 3 3/4") (fig. 35). Observe spring washer

arrangement in fig. 35 carefully.

If after resetting the cutterbar continues to break away, the pressure of spring assembly (A) (photo 34) can be

increased but stacking (Y) must never be less than 91 mm (3 2/3"), otherwise safety disengagement cannot function.

SAFETY BREAKAWAY

Page 34

- 32 -

PARKING THE MACHINE

1° THE CUTTING/CONDITIONING UNIT

MUST BE RAISED INTO ITS VERTICAL POSITION SO THAT THE

COMPENSATING SPRING(S) ARE

RELEASED.

2° Take out pin (L) which links the stand (E) to the

suspension rod (F) (photo 36). Lower and lock the

stand (E) with pin (L) in its support (R) (photo 37).

3° Release hydraulic pressure to lower cutting/

conditioning unit to the horizontal position

[cylinder (V) is fully extended].

4° With the hydraulic 3-point lift, lower the machine to

the ground and disconnect the top link and the

hydraulic hose.

Then disconnect lower links and the PTO shaft.

5° Place the PTO shaft (A) in its support (U)

(photo 37).

FOR YOUR SAFETY : ALWAYS PARK THE MACHINE WITH THE CUTTING CONDITIONING

UNIT IN THE HORIZONTAL POSITION.

Page 35

- 33 -

OPERATING THE MOWER CONDITIONER

GENERAL

Before engaging the machine into the grass, lower the cutting conditioning unit to the ground and bring the PTO shaft

up to its nominal speed (540 rpm for the FC 240 P and 1000 rpm for the FC 280 P).

Do not allow the PTO to drop to too low a speed as this would reduce cutting quality and cause rotor plugging. If

this should occur, immediately disconnect the PTO, stop the tractor engine and remove the ignition key. Clear crop

from the rotor and make sure fingers and belts are in good condition and the belts are well tensioned.

Forward speed should be determined in accordance with work conditions.

We recommend that forward speed be reduced when working in high density crops or in difficult conditions.

Check that covers (14-15) (photos 51 and 51 A, page 33) of inner and outer cones are securely attached. Replace

immediately if worn or damaged.

ROTOR SPEED

The mower conditioner is equipped with a 2 speed rotor : 888 and 615 rpm. These speeds are obtained by connecting

the PTO shaft to one of the two rotor drive shafts (photo 38).

FC 280 P (1000 rpm drive gearbox) (fig. 39, p. 34)

- High speed (upper drive shaft, fig. 39) is recom-

mended for conditioning gramineous crops.

- Low speed (lower drive shaft, fig. 39) is recom-

mended for conditioning leguminous crops.

FC 240 P (540 rpm drive gearbox) (fig. 40, p. 34)

- High speed (lower drive shaft, fig. 40) is recommended for conditioning gramineous crops.

- Low speed (upper drive shaft, fig. 40) is recommended for conditioning leguminous crops.

MAKE SURE THAT THE DRIVE

SHAFT NOT IN USE IS ALWAYS

COVERED BY GUARD (E) SUPPLIED

FOR THIS PURPOSE (PHOTO 38).

THE POSITIONING OF THE GUARD (E)

IS CARRIED OUT BY PIVOTING

DOWNWARDS OR UPWARDS

WITHOUT COMPLETELY REMOV-ING

THE WING NUT.

BEFORE STARTING WORK BRING THE GUARD DOWN INTO THE CORRECT POSITION.

FASTEN THE FRONT SAFETY CURTAIN TO THE LATERAL CURTAINS USING THE

STRAPS PROVIDED.

DO NOT STAND ON OR LEAN AGAINST THE GUARD.

BEFORE BEGINNING WORK, KEEP ALL PEOPLE AND ANIMALS AWAY FROM THE

DANGER ZONE OF THE MACHINE (RISK OF PROJECTION)

Page 36

- 34 -

FC 280 P FC 240 P

Lift the mower conditioner using the 3-point linkage when maneuvering on field edges. When mowing

embankments, make sure there is never more than

a 15° angle (A) (see photo 41) between cutting

conditioning unit (G) and frame (E).

MANEUVERING ON FIELD EDGES AND

MOWING EMBANKMENTS

ADVERSE FIELD CONDITIONS

NEVER MOW IN STONY OR ROCKY GROUNDS.

Extra care and precautions should be taken in rough or debris-ridden fields. The following adjustments should be

made to the mower conditioner in these conditions to minimize the possibility of foreign objects being deflected by

the cutting knives.

1° Tilt the angle of the cutterbar back towards the horizontal position by turning the top link handle (P) (photo 25,

page 28) to raise the cutting height of the knives.

2° Reduce the forward speed.

3° Make sure the cutting knives can pivot if an obstruction is hit.

Page 37

- 35 -

LUBRICATION

It is forbidden to discard oil, grease or filters of any type. These must be given to specialised

waste disposal organisations to protect the environment.

BEFORE CARRYING OUT ANY OPERATION SUCH AS MAINTENANCE OR ADJUSTMENT

ON THE MACHINE, STOP THE TRACTOR ENGINE, REMOVE IGNITION KEY AND WAIT

FOR ROTATING DISCS AND ROTOR TO STOP BEFORE LEAVING THE TRACTOR.

IMPORTANT !

After the first 10 hours of use imperatively change oil [SAE 80 W EP (GL4)] in : - cutterbar

- lateral gearbox

- rotor gearbox.

Thereafter, oil must be changed after every 200 hours of work and at least once per year.

CHANGING CUTTERBAR OIL

Before changing the oil of the cutterbar, let the machine run a few minutes so the oil gets hot.

Proceed as follows to change the cutterbar oil :

1° Lift the cutterbar into its vertical position by means of the hydraulic cylinders (photo 42).

2° Remove inner shoe (18) of main gearcase (photo 42).

3° Remove magnetic oil plug and its washer (19, 20) (photo 42 and fig. 43A) and let the old oil drain out into an

appropriate container.

4° Remove inner plug (21) (fig. 43).

5° Clean magnetic plug and its washer (19, 20) and fit

back into place.

6° Fit inner shoe (18) back into place.

7° Lower the cutterbar so that it is horizontal to the

ground and pour the quantity of fresh oil prescribed

below into the fill plug hole (21) (fig. 43).

8° Clean plugs (21) and their washers (22) and fit back

into place (fig. 43).

QUANTITY OF OIL IN CUTTERBAR

FC 240 P : 1,7 l / 3.4 US pint / 3 Imp pint

FC 280 P : 2,0 l / 4 US pint / 3.5 Imp pint

SAFETY CLUTCH WITH SHEAR BOLT

If during work the conditioning rotor stops rotating but

the discs are still driven, disengage the P.T.O., stop

the tractor engine, remove ignition key and wait for all

rotating parts to stop before leaving the tractor.

Remove the 2 broken parts of the shear bolt and

replace it by a new bolt (V) (part no. 800 608 50)

(specification H.M 8 x 50 grade 8.8) and self locking nut

(part no. 802 008 40). Insert the bolt in the direction

of arrow (F) as shown in the photo opposite. Fix

the secondary PTO shaft back in place after the

operation and attach the security chains.

Page 38

- 36 -

CHECKING OIL IN THE CUTTERBAR (fig. 43 and 43 A)

Cutterbar oil level can be checked by measuring oil

level through both filler plugs (21) when the cutterbar is

perfectly horizontal lengthways and crosswise (X and

Y).

Use a spirit level to ascertain that this is the case.

Correct oil level is 6 to 7 mm (1/4") at both filler

plugs (21) (fig. 43).

If in doubt as to the amount of oil contained in the

cutterbar, do not add oil. Drain the oil completely and

refill with the prescribed quantity.

NOTE : Provided above instructions are strictly observed, there is no cause for alarm if it is found that the

transmission case is very hot to touch, provided that the discs turn freely by hand.

Attention : Make sure that the tractor engine is shut off, ignition key removed and PTO shaft

disconnected before carrying out this operation.

Page 39

- 37 -

CHANGING GEARBOX OIL

Check gearbox oil level daily. Top up with SAE 80 W

EP (GL4) oil if necessary by filling up through plug (B)

(photo 44).

MAXIMUM AMOUNT OF OIL IN GEARBOX :

1 l / 2 US pint / 1.75 Imp pint

NEVER EXCEED THIS QUANTITY.

Check oil level through plug (C) (photo 44) when the

cutterbar is horizontal to the ground. Oil level is correct

when the oil reaches the edge of the hole. When the

cutterbar is in the vertical position, oil can be drained

through plug (C).

CHANGING ROTOR GEARBOX OIL (photos 45 and 45 A)

Change oil of rotor gearbox as follows :

- Disassemble gearbox cover (E) by removing the 4 fixing bolts (G) (photo 45).

- Unscrew drain plug (D) (photo 45 A).

Fill through plug (F) (photo 45 A).

Check oil level through plug (N) (photo 45 A). The level is correct when oil reaches the opening.

MAXIMUM AMOUNT OF OIL IN ROTOR GEARBOX

0,5 l / 1 US pint / 0.875 Imp pint

Page 40

- 38 -

P.T.O. SHAFTS

Lubricate all PTO shafts with SHELL Multi-Purpose

grease NLGI grade 2 at the hourly intervals indicated in

fig. opposite.

To reach the U-joint grease fitting (rotor side) of the

secondary PTO shaft, disconnect the PTO shaft on the

gearcase side and tilt down the PTO shaft to gain

access to the lubricating hole located in the protection

cover (photo 46).

GREASE FITTING

- Clean fittings before applying grease.

- Grease breakaway sliding components as required.

- Regularly lubricate 3-point frame pivot (E) (photo 46

A)

- After every 50 hours of operation, oil all moving parts

and pivot points.

THE RECOMMENDED GREASE AND OIL CHANGE PERIODS ARE BASED ON NORMAL

FIELD AND WORK CONDITIONS.

SEVERE OR UNUSUAL CONDITIONS MAY REQUIRE MORE FREQUENT LUBRICATION

OR OIL CHANGES.

RESPECT SPECIFIED OIL QUANTITIES AND GRADES : SAE 80 W EP (GL4) OIL

ONLY.

[In certain countries SAE 80 W EP (GL4) oil may not be available. In this case a GL4 or GL5 grade

SAE 80 W 90 oil may be used as a replacement. Never use a straight EP 90 oil].

Page 41

- 39 -

MAINTENANCE

BEFORE CARRYING OUT ANY OPERATION SUCH AS MAINTENANCE OR ADJUSTMENT

ON THE MACHINE, STOP THE TRACTOR ENGINE, REMOVE IGNITION KEY AND WAIT

FOR ROTATING DISCS AND ROTOR TO STOP COMPLETELY BEFORE LEAVING THE

TRACTOR.

BELT

Belt must be properly tensioned at all times to prevent

excessive slipping and flopping. A loose belt will cause

poor cutting and premature failures.

Check powerband tension as follows :

- Remove belt guard.

- Unlock counter-nut (E) (photo 47) and loosen belt (C)

(photo 48).

- Draw two marks on the belt (A), 1000 mm (39 1/3")

apart (photo 48).

- Tighten adjustment screw (D) (photo 47). Belt ten-

sion is correct when distance between marks (A) is

1007 mm (39 2/3").

- Retighten counter-nut (E) (photo 47) after the adjust-

ment has been made and refit the belt guard.

This precise adjustment should be made when a belt

is replaced and also when retensioning a belt

loosened for storage purposes.

A brief belt tension check should be made after the first

3 hours of use and periodically throughout the season.

To do so it is not necessary to remove the belt guard.

This check is made through the opening (F) located

above the guard after having removed the cover plate

(photo 48A).

Tension is correct when the belt does not deflect more

than 21 mm (4/5") when a force of 28 daN (60 lbs) is

applied mid-way between pulleys onto the whole width

of the belt.

Do not forget to replace the cover plate (P) (photo

48 A) after having made this check.

Note : If damaged, replace the belt :

Part No. 831 116 77 for FC 280 P

Part No. 831 116 78 for FC 240 P

MAKE SURE BELT GUARD IS ALWAYS KEPT IN PLACE.

Page 42

- 40 -

DISCS AND KNIVES

Discs, knives and securing elements are manufactured from high quality steel and have been subjected to a heattreatment to assure a high resistance to wear.

Worn or damaged items must immediately be replaced with genuine KUHN parts as otherwise warranty will be

withdrawn.

CAUTION : ONLY USE GENUINE

KUHN SPARE PARTS.

Worn knives should either be turned over on the same

disc to use the other cutting edge, or replaced. When

turning or replacing the knifes, make sure there is a 1

mm minimum gap between the knives or their mounting

bolts and the cutterbar wear plates. If otherwise, insert

one (maximum two) distance spacer(s) (code 568 071

00) between the discs and the disc bearing stations

(see fig. 50 A). Dull knives require more horse power to

cut the crop and will leave an uneven stubble. To

replace or turn over knives, first clean the area around

nut (A) (photo 49) and remove nut with the box spanner

supplied with the machine. Ensure securing elements

are in good condition and fit knives so that the arrow on

their upper face is pointing in the direction of rotation of

the disc it is fitted to.

Torque locknut to 12 daNm (90 ft.lbs).

IMPORTANT : ALWAYS REPLACE

SECURING ELEMENTS (LOCKNUTS AND BOLTS) WHEN THEY

HAVE BEEN REMOVED 5 TIMES.

CAUTION : ALWAYS REPLACE

DAMAGED KNIVES, NEVER

STRAIGHTEN A BENT KNIFE.

NEVER REPLACE ONE KNIFE ONLY

PER DISC, ALWAYS REPLACE

BOTH OF THEM TO AVOID CREATING AN OUT-OF-BALANCE FORCE.

Discs are secured by 4 nipple screws (B) and 4 conical

spring washers (C) on a hub (fig. 50).

Two of these diametrically opposite bolts are also used

to secure the conical covers on top of the discs.

Tighten all 4 bolts to a torque of 12 daNm (90 ft.lbs).

The discs must have their largest diameters positioned

at right angles to each other (photo 49). This positioning must be scrupulously respected so as to avoid

interference between the knives. Take extra care when

fitting the conical spring washers (C) (fig. 50), which

must be positioned with the conical centre at the top.

Page 43

- 41 -

DISCS SUPPLIED THROUGH OUR

SPARE PARTS DEPARTMENT

COME WITH A 1 MM SPACER (PART

no. 568 071 00) (fig. 50 A)

ATTACHED TO THEM. WHEN

INSTALLING A NEW DISC CHECK

IF THE GAP BETWEEN THE

BLADES OR THEIR MOUNTING

BOLTS AND THE CUTTERBAR PROTECTION SHIELDS IS AT LEAST 1

MM. IF THIS IS NOT THE CASE FIT

THE 1 MM SPACER BETWEEN THE

DISC AND ITS MOUNTING HUB FOR

INCREASED CLEARANCE (fig. 50

A).

Make sure cone lids (14 - 15) are properly secured in place (photos 51 and 51 A). Tightening torque of bolts (V) is

8 daNm (60 ft.lbs).

ROTOR CONDITIONING FLANGES

When replacing rotor conditioning fingers (16), make

sure fixing plates (17) are positioned correctly and

bolts (18) are tightened to 8.5 daNm (60 ft.lbs)

(photo 52).

REGULARLY CKECK ALL NUTS AND BOLTS FOR CORRECT TIGHTNESS,

PARTICULARLY THOSE SECURING DISCS AND BLADES.

Page 44

- 42 -

INSPECTION OF KNIVES AND SECURING ELEMENTS

A. KNIVES : Should be inspected

systematically each time before the machine

is operated.

Cutting quality as well as safe operation depend on the

regular inspection and care given to the knives. Knives

should be replaced in the following cases :

1. Damaged knives

Very rough conditions can cause knives to crack

and become deformed leading to :

- increased risk of accidents ;

- deterioration of cutting quality ;

- risk of damage to the cutterbar.

2. Worn knives

Length (A) of a knife should be greater than 65 mm.

The width (B) of a knife, measured at a distance

of 10 mm away from the edge of the disc should

be greater than 34 mm

The hole (L) for the securing bolt must not become

oval by more than 20 mm for an 18 mm hole.

B. SECURING ELEMENTS : To be

inspected regularly !

(particularly the tightening torque of the nut:

12 daNm / 90 ft.lbs).

- Inspect immediately after hitting an obstruction.

- Inspect when replacing knives.

- Check at the beginning of each season.

Page 45

- 43 -

1. The securing bolt must be replaced:

- When a visible deformation is found.

- When the locking compound on the threads

has worn away or if the locking compound has

become inoperational due to infiltration of water,

oil or dirt.

- When wear on the head reaches the contact

area of the knife.

- When the diameter (D) of the bolt shoulder

is less than 15 mm (5/8 ").

2. The nuts must be replaced :

- When the contact washer has lost its elasticity

or when it becomes loose from the nut.

- When wear on the nut reaches a = 5 mm.

FOR THE CORRECT OPERATION OF YOUR MACHINE,

ALWAYS USE GENUINE KUHN SPARE PARTS

Page 46

- 44 -

OPTIONAL EQUIPMENT

1. HYDRAULIC ADAPTATOR (photo 53)

Code No. 823 012 06

An adaptator M 16 x 1.5 / 1/2 NPT - 24 is available on

request.

2. PTO SHAFT YOKE 1 3/8" - 21 SPLINES

Kit No 460 3256

This yoke is available for tractors with 1 3/8" - 21

splines PTO shafts (photo 54).

3. SIGNALLING ELEMENTS (photo 55)

Kit No. 107 6030

Signalling elements can be ordered as an optional

extra for the FC 240 P and FC 280 P. To install this kit

proceed as follows :

- Attach tail lamp (N) to panel (A).

- Bolt panel (A) to support (S) with 3 hexagon screws

(E) (M 10 x 20), 3 plain washers (dia. 11 x 24 x 2) and

3 self-locking nuts (M 10).

- Attach guide (H) to the left side shield (L) with 2 cup

square bolts (T) (M 10 x 20), 2 plain washers (dia. 11

x 24 x 2) and 2 self-locking nuts (M 10).

- Plug electric cable (O) into the lamp terminal (N).

In transport position mount the panel (A) with its

support (S) in the guide (H) with lock (U) and plug

electric cable at the rear of the tractor.

Before putting the machine in

work position, dont forget to

unbolt the panel.

Page 47

- 45 -

4. SAFETY GUARD FOR GREAT BRITAIN

(Kit No. 107 6050)

FC 240 P - FC 280 P mower-conditioners marketed in

the United Kingdom are supplied with a safety guard

extension.

Attach guard (U) to the outside end of the safety

canvas frame using the 2 cup square bolts (E) (M

10 x 35) already mounted (photo 56).

5. 1.20 m / 4' SWATH KIT (for FC 240 P

only) (fig. 57)

Code n° 107 6090

This equipment enables swaths of 1.20 m width to be

formed using the FC 240 P.

To use this kit the original swath shields must first be

removed.

The kit is made up of two deflectors (1) and a left and

a right swath shield (2) which are to be fixed on the side

plates (3) of the hooding using 12 cup square bolts (4)

(M 10 x 20), 12 flat washers (diameter 11 x 24 x 2) and

12 self locking nuts (M 10).

When assembling, ensure that the deflectors (1) are

fixed on the outside and the swath shields (2) on the

inside of the side plates (3).

6. RAISED SKIDS (fig. 58)

(Kit No. 107 6180)

A raised skid shoe kit comprising 2 raised skids is

available as an optional equipment. This kit serves 2

purposes :

- providing a cutting height adjustable between 60 mm

and 120 mm (2.5" and 5"),

- operating on sticky grounds.

This 2 raised skids are installed instead of the 2 regular

end skids.

Page 48

- 46 -

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE REMEDY

Uneven stubble Too much tilt on cutterbar Reduce tilt (see page 29)

Low PTO speed Increase engine speed to run PTO at

1000 rpm for FC 280 P or

540 rpm for FC 240 P

Knives not installed Make sure that the arrow on the knife

correctly upper face is pointing in the direction

of rotation of the disc (see page 40)

Low disc speed Check belt for correct tension

(see page 39)

Dull or broken knives Replace knives (see page 40)

Stubble too long Incorrect angle on cutterbar Change cutterbar angle using

tractor top link (see page 29)

Insufficient cutterbar Adjust compensating spring tension

down pressure (see page 30)

Soil build up in front of Very wet conditions Adjust main frame height by

cutterbar shortening chain as necessary

(see pages 27 - 28)

Too much cutterbar Adjust compensating spring tension

down pressure (see page 30)

Cutterbar not floating Main frame setting incorrect Adjust main frame as described

on pages 27 and 28

Machine breaking back Insufficient tension on Tighten breakaway spring

too easily breakaway spring washers washers (see page 31)

Obstruction of conditioning Insufficient PTO speed Increase PTO speed to

rotor 1000 rpm for the FC 280 P or to

540 rpm for the FC 240 P

Shear bolt broke Replace shear bolt (see page 35)

Badly shaped windrows Insufficient PTO speed Run PTO speed at

1000 rpm for the FC 280 P or at

540 rpm for the FC 240 P

Incorrectly adjusted swath Adjust both swath screens

screens (see page 30)

Forward speed too high Reduce forward speed

Page 49

- 47 -

Machine does not lower The hydraulic hose coupler Replace coupler

into its work position connecting the machine to the

tractor is worn

Vibrations of main rotor Incorrect attachment Check :

gearcase - that the turn buckle and the lower

arms are approx. parallel in working position and in raised position

(page 24)

- that the 3-point frame is horizontal

Improper handling Avoid lifting the cutting/conditioning

unit using the machines hydraulic

cylinder while the machine is operating

Cutting height difficult Excessive pressure on top link Rest the machine on its parking stand

to adjust (see page 32 for correct procedure)

Machine cannot be coupled The 3-point frame is not hori- - Check the cutting/conditioning unit

or uncoupled easily zontal in detached position horizontal position (page 24)

- Use the correct procedure for

detaching machine (page 32)

PROBLEM CAUSE REMEDY

1. Thoroughly clean the mower conditioner.

2. Drain oil from gearbox and cutterbar and refill with new oil to correct level.

3. Inspect and replace worn knives and their fixation hardware.

4. Repaint rusted parts and all areas from which the paint has worn.

5. Inspect and replace damaged fingers on the rotor.

6. Loosen the belt.

7. Park the mower-conditioner in the horizontal position.

8. Store the machine in a dry place.

STORING THE MOWER CONDITIONER

Page 50

- 48 -

SOUND LEVELS

Sound levels given out by : FC 240 P - FC 280 P Mower conditioners

Sound levels have been measured in accordance with the measuring methods as defined in :

HM Agricultural Inspectorate

AGRICULTURAL MACHINERY NOISE

Legislation and guidance on methods of testing

(Annex to AIC 1896/117 REV)

February 1988

Health and Safety Executive

The method employed corresponds to the method No. 4 in this document. Unspecified testing

conditions comply with ISO 5131 standard.

Measuring equipment conforms to NF S 31-009 standard. The tractors used have a power of 66 kW

(FC 240 P) and 84 kW ( FC 280 P) respectively.

A-weighted emission sound pressure level L (A) eq inside tractor cab (with closed windows) :

FC 240 P FC 280 P

Tractor only 72.9 dB (A) 76.0 dB (A)

Tractor + machine 78.2 dB (A) 82.9 db (A)

Page 51

LIMITED WARRANTY

KUHN S.A. of 4 Impasse des Fabriques, 67706 SAVERNE CEDEX, France (hereinafter called the

«Company») warrants, in accordance with the provisions below, to each original retail purchaser of

KUHN new equipment of its own manufacture, from an authorized KUHN dealer, that such equipment

is, at the time of delivery to such purchaser, free from defects in material and workmanship and that

such equipment will be warranted for a period of one year starting from the date the goods are delivered

to the end user and during this period up to a limit of 500 hours use, providing the machine is used and

serviced in accordance with the recommendations in the Operators Manual.

THESE CONDITIONS ARE SUBJECT TO THE FOLLOWING EXCEPTIONS :

1. Parts of machines which are not of our manufacture i.e. tyres, belts, P.T.O. shafts, clutches etc., are not

covered by this Limited Warranty but are subject to the warranty of the original manufacturer. Any claim

falling into this category will be taken up with the manufacturer concerned.

2. Warranty claims applying to these types of parts must be handled in the same way as if they were parts

manufactured by KUHN. However, compensation will be paid in accordance with the warranty agreement of the manufacturer concerned in as much as the latter justifies such a claim.

3. This Limited Warranty will be withdrawn if any equipment has been used for purposes other than for

which it was intended or if it has been misused, neglected or damaged by accident or let out on hire. Nor

can claims be accepted if parts other than those manufactured by us have been incorporated in any of

our equipment. Furthermore, the Company shall not be responsible for damage in transit or handling by

any common carrier and under no circumstances within or without the warranty period will the Company

be liable for damages for loss of use or damages resulting from delay or any consequential damage.

We cannot be held responsible for loss of earnings caused by a breakdown or for injuries either to the owner

or to a third party, nor can we be called upon to be responsible for labor charges, other than originally

agreed, incurred in the removal or replacements of components.

THE CUSTOMER WILL BE RESPONSIBLE FOR AND BEAR THE COSTS OF:

1. Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc.

2. Transportation of any kind of any KUHN product to and from the place the warranty work is performed.

3. Dealer travel time to and from the machine or to deliver and return the machine from the workshop for

repair.

4. Dealer travelling costs.

Parts defined as normal wearing items are listed as follows and are not in any way covered under this

Limited Warranty :

V belts, discs, knives, wear plates, disc guards, tires, torque limiters, hydraulic hoses, pitman shafts, swath

sticks, blades, tines and tine holders.

KUHN Limited Warranty will not apply to any product which is altered or modified without the expressed

permission of the Company and/or repaired by anyone other than Authorized Service Distributors or

Authorized Service Dealers.

Page 52

LIMITED WARRANTY IS DEPENDENT UPON THE STRICT OBSERVANCE BY THE

PURCHASER OF THE FOLLOWING PROVISIONS :

- That this Limited Warranty shall not be assigned or transferred to anyone unless the Companys consent in

writing has first been obtained.

- The warranty/product registration form has been correctly completed by dealer and purchaser with their

names and addresses, dated, signed and returned to the appropriate address as given on the warranty/

product registration form.

- The claim form sent to KUHN has been correctly completed stating:

* dealers name and address

* owners name and address

* type of machine

* machine serial number

* delivery date to buyer

* date of failure

* tractor make and type

* description of the failure and its cause

* quantity, reference number and name of the damaged parts

* reference number, quantity and date of the invoice for the replacement parts.

- The judgement of the Company in all cases of claims under this Limited Warranty shall be final and conclusive and the purchaser agrees to accept its decisions on all questions as to defect and to the exchange of

any part or parts.

- That all safety instructions in the Operators Manual shall be followed and all safety guards regularly inspected

and replaced where necessary.

No warranty is given on second-hand products and none is to be implied. Persons dealing in the Companys

products are in no way legal agents of the Company and have no right or authority to assume any obligation

on their behalf, express implied, or to bind them in any way.

KUHN S.A. reserves the right to incorporate any change in design in its products without obligation to make

such changes on units previously manufactured.

Moreover, because of the constant progress in technology, no guarantee is given to the descriptions of

equipment published in any document by the company.

DISCLAIMER OF FURTHER WARRANTY

There are no warranties, expressed or implied, except as set forth above. There is no

warranty of merchantability. There are no warranties which extend beyond the description

of the product contained herein. In no event shall the company be liable for indirect, special

or consequential damages (such as loss of anticipated profits) in connection with the retail

purchasers use of the product.

Page 53

- N O T E S -

Page 54

Page 55

This machine complies with the safety requirements of the European machinery directive.

The Operator should respect all Health and Safety regulations as well as the Highway

Code. For your own safety, use only genuine KUHN spare parts. The manufacturer

disclaims all responsibilities due to incorrect use or non-compliance with the

recommendations given in this manual.

Page 56

Printed in France by KUHN

KUHN S.A. 4 Impasse des Fabriques F - 67706 SAVERNE CEDEX (FRANCE)

Tél. : + 33 (0) 3 88 01 81 00 - Fax : + 33 (0) 3 88 01 81 03

www.kuhnsa.com - E-mail : info@kuhnsa.com

Société Anonyme au Capital de 19 488 000 Euros

For your safety

and to get the best from your machine,

use only genuine KUHN parts

Loading...

Loading...