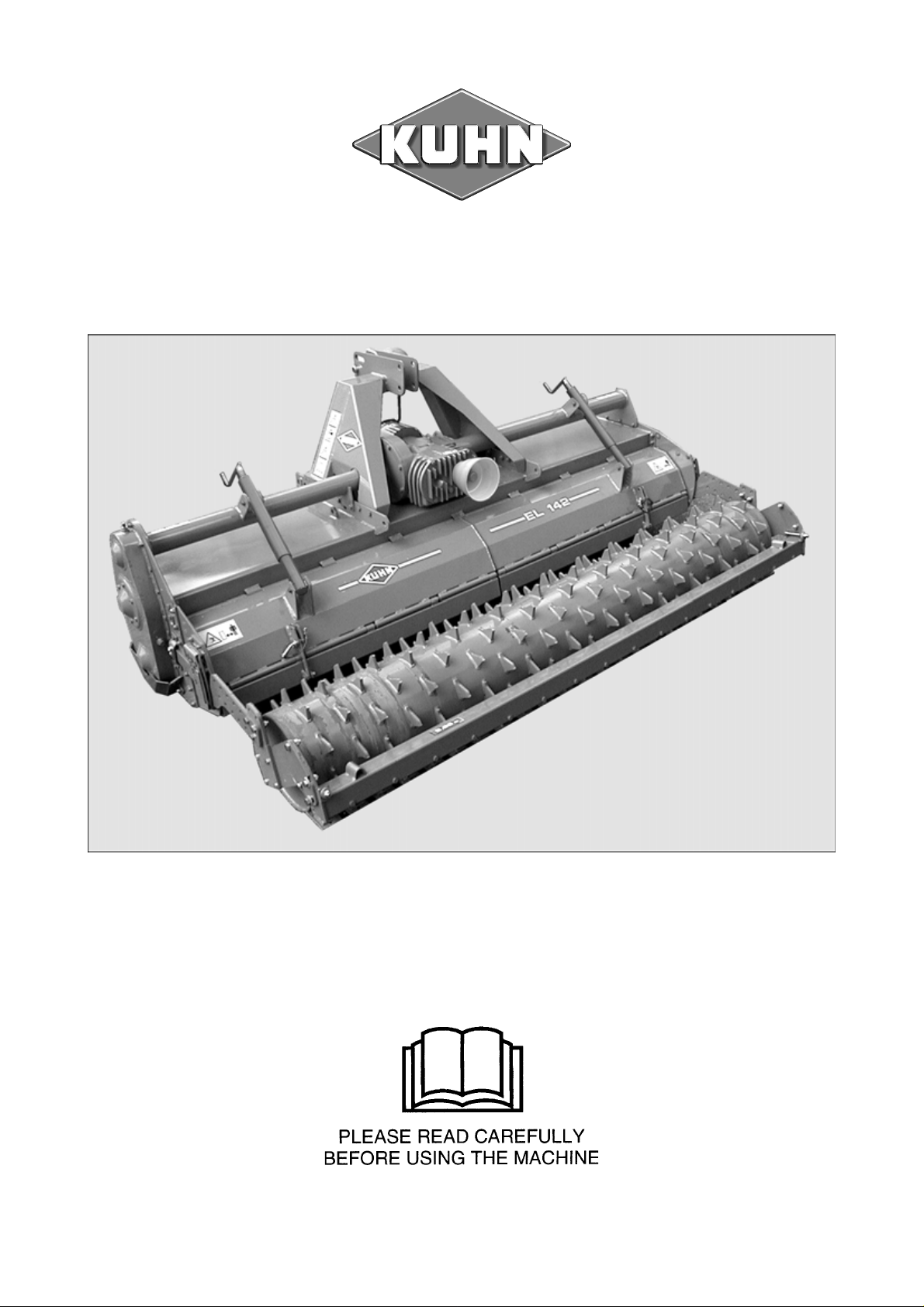

Page 1

ASSEMBLY / OPERATOR'S MANUAL

EL 142

POWER TILLER / CULTITILLER / CULTIPLOW

No. 95461CGB A 08.2003

Page 2

DEAR OWNER,

In buying a KUHN machine you have chosen wisely. Into it have gone years of thought,

research and improvements. You will find, as have thousands of owners all over the world, that

you have the best that engineering skill and actual field testing can produce. You have

purchased a dependable machine, but only by proper care and operation can you expect to

receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your

machine. The performance you get from this machine is largely dependant upon how well you

read and understand this manual and apply this knowledge. Please DO NOT ASSUME THAT

YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR MACHINE before reading this

manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE.

Your KUHN dealer will instruct you on the general operation of your machine. He is interested

that you get the best performance possible and will be glad to answer any special questions

that may arise regarding the operation of the KUHN machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts.

These parts are manufactured and carefully inspected in the same factory that builds the

machine to assure high quality and accurate fitting of any necessary replacements.

When ordering service parts it is important that you indicate the type of machine concerned

and its serial number.

For this reason please complete the model identification plate diagram below with the required

information. This will provide you with an easy reference for future service parts orders.

ABOUT IMPROVEMENTS

KUHN is continually striving to improve its products and, therefore, reserves the right to make

improvements or changes when it becomes practical to do so, without incurring any

obligations to make changes or additions to the equipment sold previously.

Page 3

TABLE OF CONTENTS

PAGE

Safety 2

Safety Decals - Model identification plate 8

Technical Specifications 10

Guards 12

Fitting to the tractor 1 3

PTO shaft 14

Slip clutch 16

Rotor speeds (rotational frequencies) 17

Adjustment of the rear hood 1 9

Use 20

Equipment 22

1) Rollers 2 2

2) Skids + stand 2 6

3) Gauge wheel kit 2 7

4) Side separating discs 2 8

5) Rear wheel kit 2 9

6) Track eradicators 30

7) Rear hydraulic lift linkage 3 1

8) A-frame kit for VENTA AL and Ti integrated seeder attachment 3 4

9) Semi-automatic hitch 3 4

10 ) Hard coated packer roller scraper plates 3 4

11 ) Nylon cleaning plates for standard packer roller, packer roller

PK2 and maxipacker roller scrapers 3 5

12 ) P.T.O. shafts 3 5

13 ) Rotors complete 35

14 ) Signalling elements 36

Maintenance 37

1) Lubrication 37

2) Fitting blades 3 8

3) Changing the rotor 4 1

Trouble Shooting 42

Conditions of Limited Warranty 45

Copyright 2003 KUHN S.A.

- 1 -

Page 4

SAFETY

The symbol above is used throughout this manual every time recommendations are made concerning your safety,

the safety of others, or the good operation of the machine.

These recommendations must be made known to all machine operators.

DESIGNATED USE OF THE MACHINE

The EL 142 must only be used for the work for which it has been designed :

- Seedbed preparation on ploughed or unploughed ground with or without simultaneous seeding (machine can

be equipped with an integrated or a 3-point mounted seeder).

- Stubble ploughing or reclamation of grassland.

The manufacturer is not held liable for any damage resulting from machine applications other than those specified

by the manufacturer.

Any use other than the designated operation is at the risk and responsibility of the operator.

Designated use of the machine also means :

- following operation, maintenance and repair recommendations given by the manufacturer ;

- using only genuine spare parts, equipment and accessories as designated by the manufacturer.

The EL 142 must only be operated, maintained and repaired by competent persons who are familiar with machine

specifications and operations and are aware of any danger involved.

The operator must imperatively respect current legislation concerning :

- accident prevention,

- work safety,

- public traffic circulation.

All safety advice indicated on the machine must be strictly observed.

The manufacturer is not held liable for any damage resulting from machine modifications carried out by the

operator himself or by a third party without previous written agreement from the manufacturer.

- 2 -

Page 5

GENERAL SAFETY RECOMMENDATIONS

Before operating the machine, always ensure that tractor and machine are in accordance with work safety and

road traffic regulations.

BASIC PRINCIPLES

1. In addition to the recommendations given in this manual, legislation on work safety and accident prevention

must also be respected.

2. Advice is indicated on the machine, specifying safety recommendations in order to prevent accidents.

3. Before travelling on public roads, the operator must ensure that the machine conforms to road traffic

regulations.

4. Before starting work, the operator must be familiar with all machine controls, handling devices and their

functions. Once at work, it is too late to do so !

5. Use a tractor equipped with a safety cab. Keep windows and roof hatch closed for reduced sound level while

operating the PTO driven implement.

6. Before starting up the machine and beginning work, check the surrounding area (beware of children !). Make

sure there is sufficient visibility.

Keep all people and animals away from the danger zone of the machine (risk of projection !)

7. Carrying people or animals on the machine when working or in transport is strictly forbidden.

8. Machine must only be attached to tractor using means provided and in accordance with current safety

standards.

9. Special care should be taken when attaching or removing the machine from the tractor.

10. Before attaching the machine, ensure that the front tractor axle is sufficiently ballasted.

Ballast is to be placed on the supports provided in accordance with instructions of the tractor manufacturer.

11. Do not surpass the maximum axle load or the overall transport weight as prescribed by the tractor

manufacturer.

12. Do not surpass the maximum transport width authorized by road traffic regulations.

13. Before transporting the machine on public roads, ensure that all legally required guards and indicators (lights,

reflectors ...) are in place and in good operation.

14. All operating controls (cords, cables, rods...) must be positioned so that they cannot be set off accidently,

risking accident or damage.

15. Before transporting on public roads, locate the machine into its transport position as instructed in this

operator’s manual.

16. Never leave the tractor seat while the machine is operating.

- 3 -

Page 6

17. Drive speed must be adapted to ground conditions as well as roads and paths.

Always avoid abrupt changes of direction.

18. Precision steering, tractor adherence, road holding and efficient braking are influenced by the type of

implement, weight, ballast of front axle, ground or road conditions. It is therefore of utmost importance to be

cautious in every given situation.

19. Be particularly cautious when turning corners, paying attention to machine overhang, length, height and

weight.

20. Keep clear of the machine operating area.

21. WARNING ! Danger of crushing and shearing can exist when components are operated by hydraulic or

pneumatic controls.

22. Before leaving the tractor or before adjusting, maintaining or repairing the machine, turn off the engine,

remove ignition key and wait until all moving parts have come to a complete stop.

23. Do not stand between the tractor and the machine unless the hand brake is tight and/or stops have been

placed under the wheels.

24. Before any adjustments, maintenance or repairs are carried out, ensure that the machine cannot be started

up accidentally.

PRECAUTIONS TO BE TAKEN BEFORE OPERATING THE MACHINE

1. Do not wear loose clothing which could become caught up in moving elements.

2. Wear the individual protection equipment corresponding to the work which is planned (gloves, shoes, eye

protection, helmet, ear protectors...).

3. All operating controls (cords, cables, rods ...) must be positioned so that they cannot be set off accidentally,

causing accident or damage.

4. Before operating the machine, check the tightness of all nuts and bolts, particularly on rotating parts (blades,

tines, knives, spades ...)

5. Before operating the machine, ensure that all safety guards are firmly in place and in good condition. If worn

or damaged, replace immediately.

ATTACHMENT

1. When attaching or removing the machine from the tractor, position hydraulic lift control lever in such a way that

it cannot be set off accidentally.

2. When attaching the machine to tractor hydraulic linkage, ensure that diameter of link pins corresponds to

diameter of ball joints.

3. WARNING ! Danger of crushing and shearing can exist in the lifting zone of the tractor hydraulic linkage !

4. Do not stand between the tractor and the machine when operating the outer control lever of the lift mechanism.

5. In transport, the machine lift mechanism should be stabilized by tractor tie rods to avoid floatation and side

shifting.

6. When transporting machine ensure that it can not be lowered accidentally.

- 4 -

Page 7

POWER TAKE-OFF

1. Only use PTO shaft supplied with the machine or recommended by the manufacturer.

2. PTO guards must always be in place and in good condition.

3. Check for correct PTO overlap when at work and in transport.

4. Before attaching or removing the PTO shaft, disengage PTO shaft, turn off engine and remove ignition key.

5. If a primary PTO shaft is equipped with a slip clutch or a free wheel, these must be fitted on the machine PTO.

6. Ensure that PTO shaft is always correctly fitted and locked into place.

7. Make sure guards are correctly in place and secured with the safety chains provided.

8. Before engaging PTO, ensure that PTO speed (rotational frequency) and direction are in accordance with

manufacturer's recommendations.

9. Before engaging PTO, keep all people and animals clear from the machine.

10. Never engage PTO shaft when tractor engine is turned off.

11. Never surpass PTO angle recommended by the manufacturer.

12. WARNING ! Rotating elements can continue turning momentarily after PTO is disengaged. Keep clear until

all rotating elements are at a standstill.

13. When removing the machine, locate PTO shaft on the supports provided.

14. Fit safety cap on tractor PTO.

15. Replace any worn or damaged PTO guards immediately.

Rotation speed ... rpm (American Measure) is also expressed in metric measure : Rotational frequency ... min

Both units are equivalent, for example : Rotation speed 540 rpm equals Rotational frequency 540 min-1.

ROAD TRANSPORT

Dimensions

-1

.

Depending upon the machine’s dimensions, the user should check with the relevant authority that it can be

transported legally on public roads.

If maximum authorised size is exceeded, the user should act according to the legislation in force regarding

transport of oversize equipment.

Load per axle and gross weight

When transporting the machine or combined machines, check that :

- the tractor’s authorised gross weight as well as the maximum weight per axle is not exceeded.

- In all circumstances, the weight on the tractor’s front axle is never below 20% of the tractor’s unladen

weight. If the case arises, fit front ballast weights.

- 5 -

Page 8

HYDRAULIC SYSTEM

1. WARNING ! Hydraulic system is under pressure.

2. When fitting hydraulic motors or cylinders, ensure that connections have been made correctly, as per

manufacturer’s instructions.

3. Before connecting hoses to the tractor hydraulics, ensure that tractor and machine circuits are not under

pressure.

4. It is strongly recommended that the operator marks the hydraulic connections between tractor and machine to

avoid making a wrong connection. WARNING ! Functions could be reversed (for example : lift/lower).

5. Check hydraulic hoses regularly ! Worn or damaged hoses must be replaced immediately.

Replacement parts must be in accordance with manufacturer’s recommendations concerning specifications

and quality.

6. Should a leak be found, take all necessary precautions to avoid accidents.

7. Any liquid under pressure (particularly oil from hydraulics) can penetrate the skin and cause severe injury. If

injured, see a doctor immediately, there could be danger of infection.

8. Before any adjustments, maintenance or repairs are carried out, lower the machine, depressurize the circuit,

turn off the engine and remove ignition key.

- 6 -

Page 9

MAINTENANCE

1. Before checking any machine malfunction and before adjusting, maintaining or repairing the machine,

disengage PTO, turn off engine and remove ignition key.

2. Check tightness of nuts and bolts regularly. Retighten if necessary.

3. If the machine is raised, prop it up in a stable position before carrying out any maintenance work.

4. When replacing a working part, wear protection gloves and only use standardized tools.

5. It is forbidden to discard any oil, grease or filters. These must be given to waste disposal organisations to

protect the environment.

6. Disconnect power source before any work is done on the electric system.

7. Check safety guards regularly, particularly those that are subject to wear. Replace immediately if damaged.

8. Spare parts used must be in accordance with specifications and standards as defined by the manufacturer.

Use only genuine KUHN parts !

9. Before any electric welding is carried out on tractor or attached machine, disconnect generator and battery

terminals.

10. Repairs on elements under pressure or tension (springs, accumulators etc...) must only be carried out by

competent persons with standardized equipment.

- 7 -

Page 10

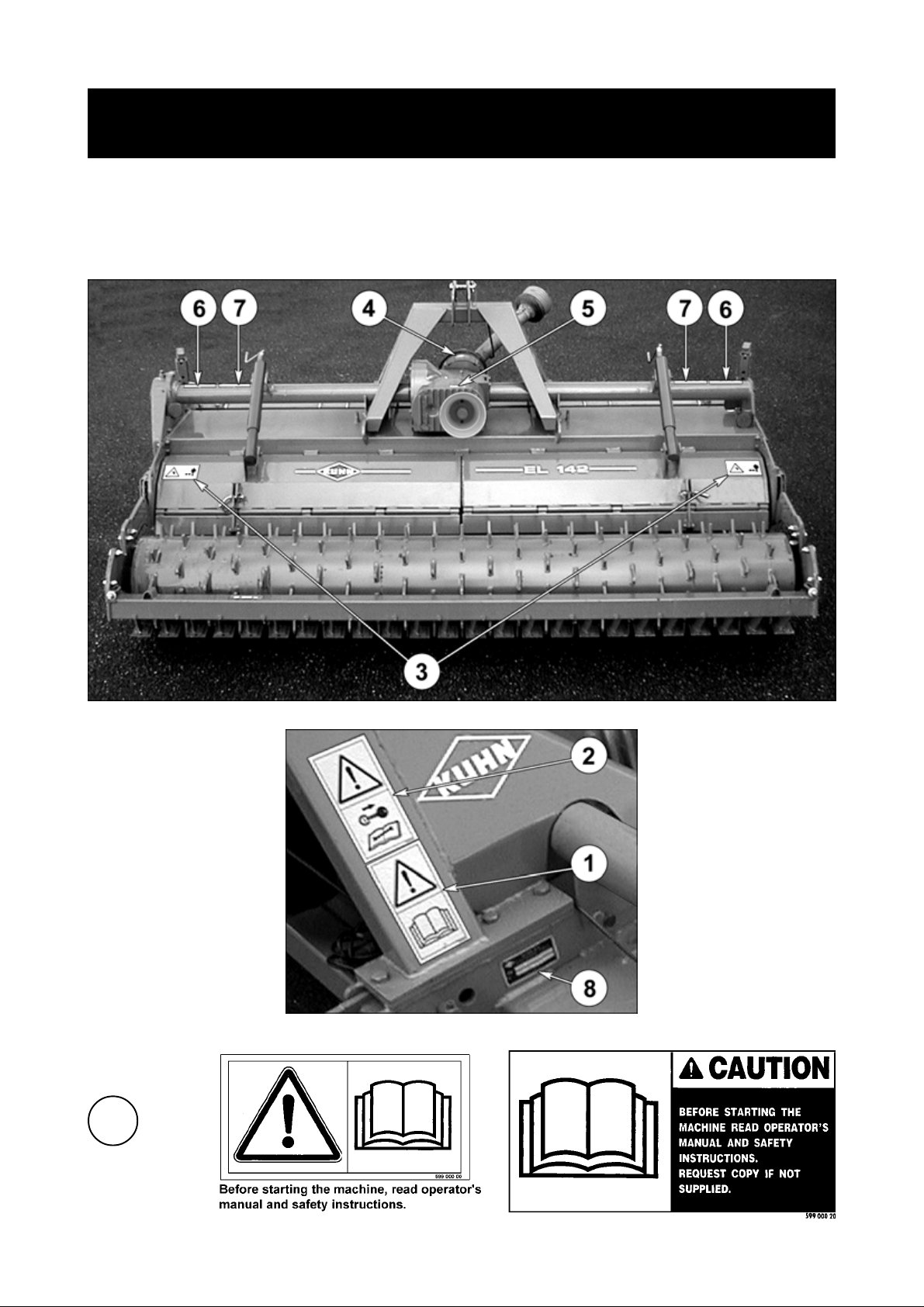

SAFETY DECALS

MODEL IDENTIFICATION PLATE

The following safety pictorials have been placed on your machine in the areas indicated. They

are intented for your personal safety and for the safety of the people working with you. The text

shown on them gives their precise meaning. Keep the pictorials clean. Replace them when they

are faded.

1

- 8 -

Page 11

2

3

4

6

7

5

8

- 9 -

Page 12

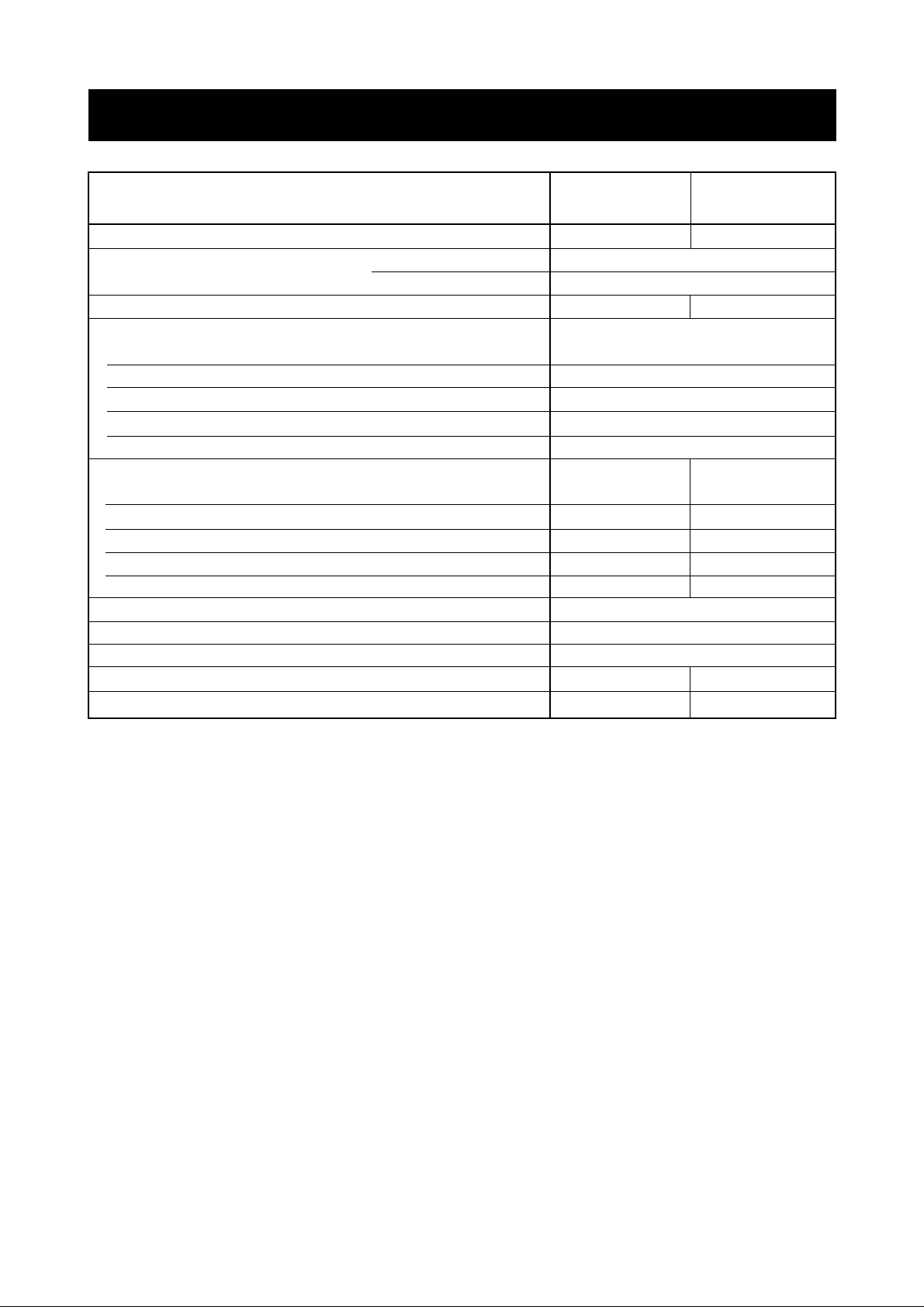

TECHNICAL SPECIFICATIONS

SPECIFICATIONS EL 142 EL 142

250 300

Working width m (ft) 2.50 (8’2") 3.00 (9’10")

Maxi. allowable DIN power P.T.O. 750 rpm (min

kW (hp) P.T.O. 1000 rpm (min-1) 103 (140)

Minimum power requirement kW (hp) 66 (90) 73 (100)

Rotor diameter mm (")

- POWER TILLER with standard diameter C-blade rotor 550 (1'9")

- POWER TILLER with larger diameter L-blade rotor 590 (1'11")

- CULTIPLOW rotor with 2 bolts per blade 570 (1'10")

- CULTIPLOW rotor with 1 bolt per blade 570 (1'10")

- CULTITILLER rotor with Fast-Fit blades 570 (1'10")

Number of blades :

POWER TILLER with standard diameter C-blade rotor 60 72

POWER TILLER with larger diameter L-blade rotor 60 72

CULTIPLOW rotor with 2 bolts per blade 84 100

CULTIPLOW rotor with 1 bolt per blade 84 100

CULTITILLER rotor with Fast-Fit blades 56 66

Working depth adjustable min. / max. mm (") 8 (1/3") / 25 (1")

Working depth control with skids, gauge wheels or roller

Attachment cat. 2 and 3N

Overall machine transport width cm (ft) 277 (9'1") 325 (10'8")

Overall machine working width (with safety guards) cm (ft) 293 (9'7") 341 (11'2")

-1

) 77 (105)

*

* Optional equipment (see page 13).

- 10 -

Page 13

SPECIFICATIONS EL 142 EL 142

250 300

Weight with packer roller : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1400 (3080) 1560 (3432)

- POWER TILLER with larger diameter L-blade rotor 1450 (3190) 1615 (3553)

- CULTIPLOW rotor with 2 bolts per blade 1510 (3322) 1675 (3685)

- CULTIPLOW rotor with 1 bolt per blade 1495 (3289) 1665 (3663)

- CULTITILLER rotor with Fast-Fit blades 1405 (3091) 1565 (3443)

Weight with packer roller PK2 : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor - 1595 (3509)

- POWER TILLER with larger diameter L-blade rotor - 1650 (3630)

- CULTIPLOW rotor with 2 bolts per blade - 1710 (3762)

- CULTIPLOW rotor with 1 bolt per blade - 1700 (3740)

- CULTITILLER rotor with Fast-Fit blades - 1600 (3520)

Weight with maxipacker roller : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1455 (3201) 1625 (3575)

- POWER TILLER with larger diameter L-blade rotor 1505 (3311) 1680 (3696)

- CULTIPLOW rotor with 2 bolts per blade 1565 (3443) 1740 (3828)

- CULTIPLOW rotor with 1 bolt per blade 1550 (3410) 1730 (3806)

- CULTITILLER rotor with Fast-Fit blades 1460 (3212) 1630 (3586)

Weight with crumbler roller : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1260 (2772) 1390 (3058)

- POWER TILLER with larger diameter L-blade rotor 1310 (2882) 1445 (3179)

- CULTIPLOW rotor with 2 bolts per blade 1370 (3014) 1505 (3311)

- CULTIPLOW rotor with 1 bolt per blade 1355 (2981) 1495 (3289)

- CULTITILLER rotor with Fast-Fit blades 1265 (2783) 1395 (3069)

Weight with maxicrumbler roller : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1270 (2794) 1400 (3080)

- POWER TILLER with larger diameter L-blade rotor 1320 (2904) 1455 (3201)

- CULTIPLOW rotor with 2 bolts per blade 1380 (3036) 1515 (3333)

- CULTIPLOW rotor with 1 bolt per blade 1365 (3003) 1505 (3311)

- CULTITILLER rotor with Fast-Fit blades 1275 (2805) 1405 (3091)

Weight with skids : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1075 (2365) 1200 (2640)

- POWER TILLER with larger diameter L-blade rotor 1125 (2475) 1255 (2761)

- CULTIPLOW rotor with 2 bolts per blade 1185 (2607) 1315 (2893)

- CULTIPLOW rotor with 1 bolt per blade 1170 (2574) 1305 (2871)

- CULTITILLER rotor with Fast-Fit blades 1080 (2376) 1205 (2651)

Weight with gauge wheels : (kg / lbs)

- POWER TILLER with standard diameter C-blade rotor 1095 (2409) 1225 (2695)

- POWER TILLER with larger diameter L-blade rotor 1145 (2519) 1280 (2816)

- CULTIPLOW rotor with 2 bolts per blade 1205 (2651) 1340 (2948)

- CULTIPLOW rotor with 1 bolt per blade 1190 (2618) 1330 (2926)

- CULTITILLER rotor with Fast-Fit blades 1100 (2420) 1230 (2706)

- 11 -

Page 14

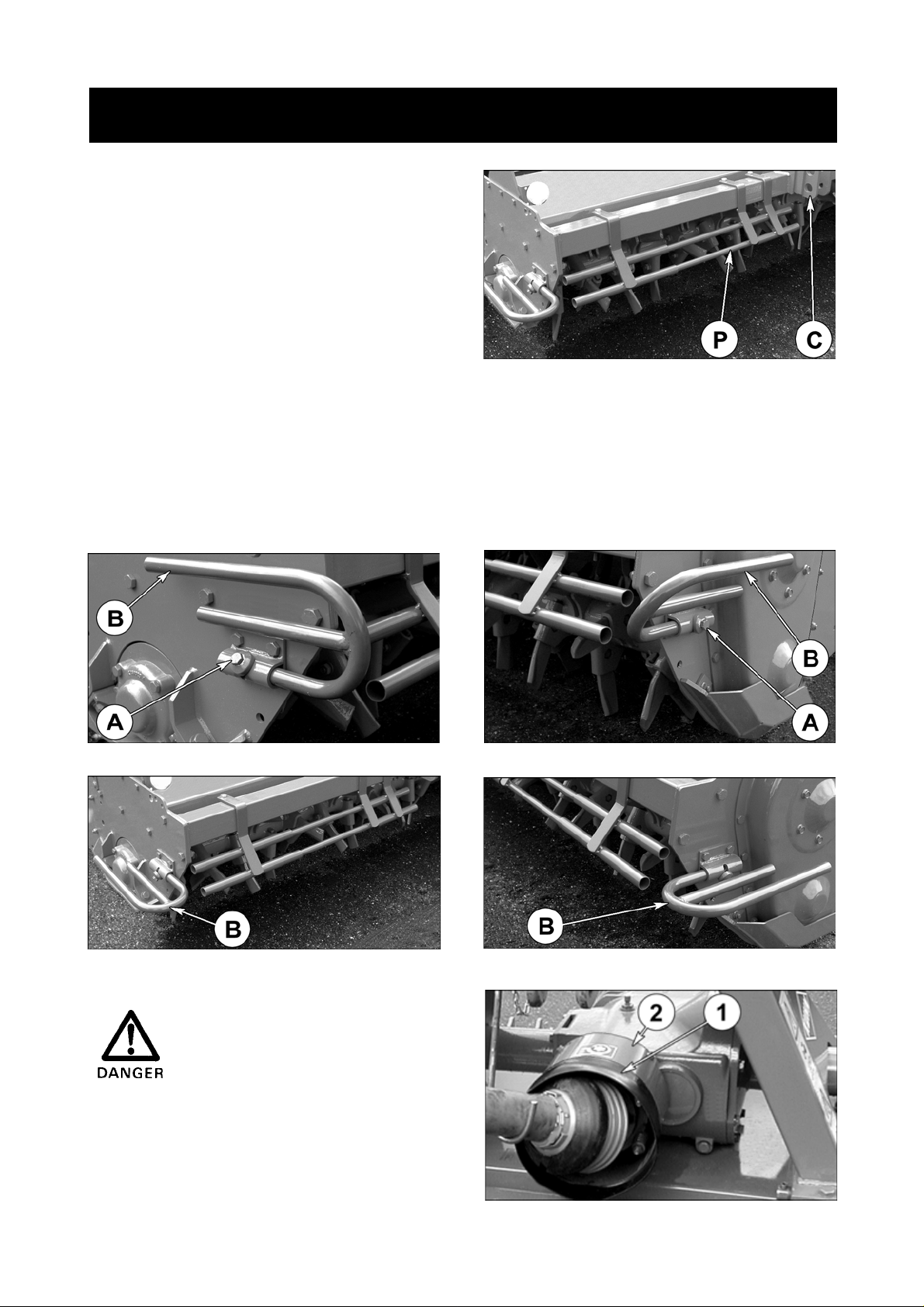

GUARDS

1) Front safety guards

The safety guards increase the safety of the machine.

The 2 front safety guards (P) are made up of 3 parts,

one fixed and 2 sliding sections. They are factory

fitted as shown on photo 1.

The sliding sections of the safety guards may need to

be repositioned (front wheels, track eradicators…).

Whatever the accessories the machine is equipped

with, the guards must remain fixed and cover the

whole length of the machine from the outside of the

adjustable lower link brackets (C) (photo 1).

2) Side safety guards

To reduce the machine width for road transport, proceed as follows :

- loosen the screws (A) of guards (B) (photos 2 and 3)

- pivot guards (B) upwards (photos 2 and 3),

- tighten screws (A).

1

2

4

Side guards (B) are safety

elements, they must be always

folded downwards at work (photos 4 and 5).

3) Guard extension

Fit the guard extension (1) over the sheet metal guard

(2) of the torque limiter (see photo 6).

3

5

- 12 -

6

Page 15

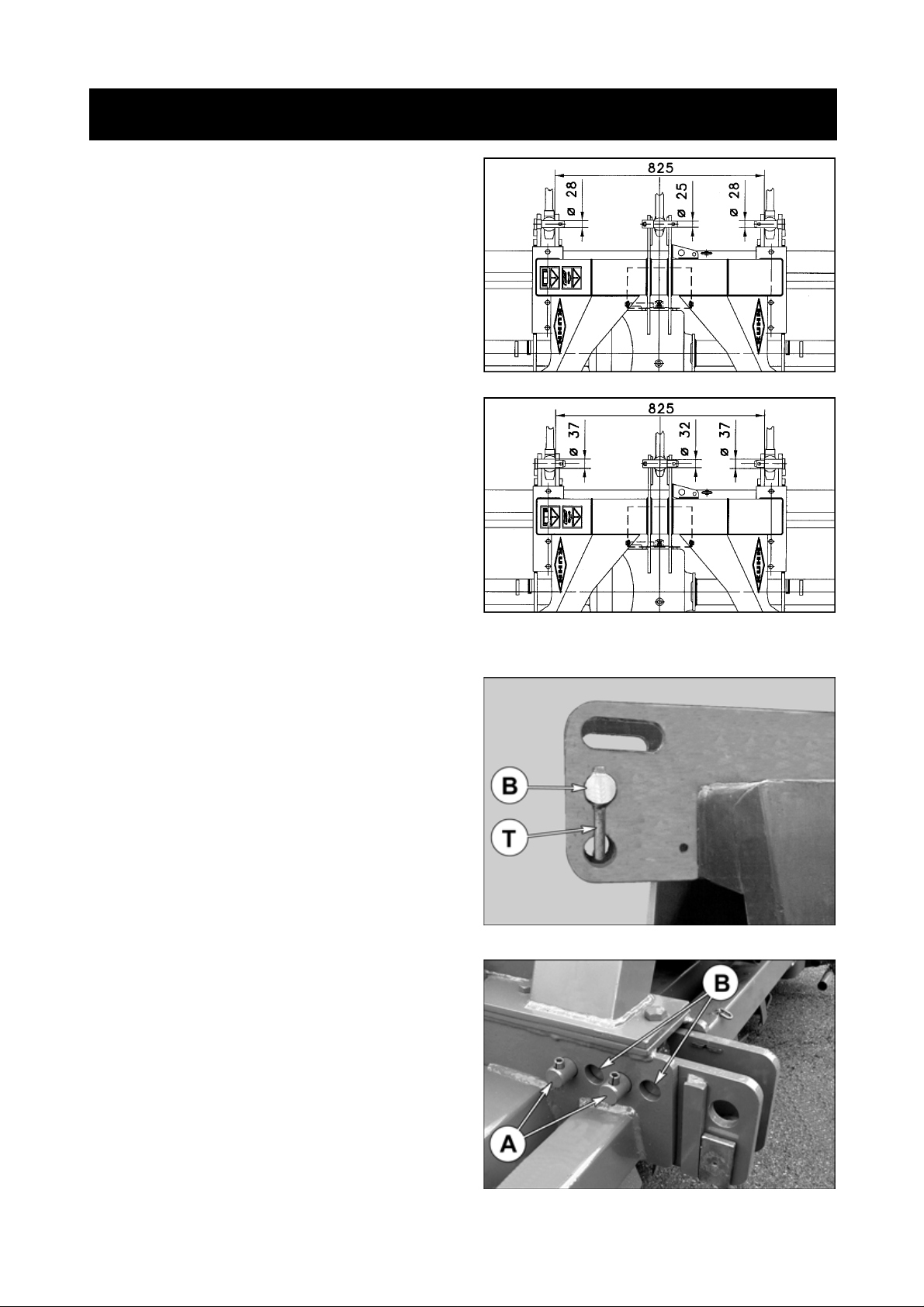

FITTING TO THE TRACTOR

The EL 142 can be fitted to all tractors equipped with

a standard Cat. 2 or Cat. 3 three-point hitch (figure 7).

Category "2"

- original equipment

Alternative attachment :

Category “ 3 N ”

(with a cat.2 space between lower lift arms)

Recommended with a EL 142/seed drill combination.

The top hitch pin (code 525 970 00) and the lower hitch

pins cat.3 (code 525 925 00) are available through the

Kuhn Service Parts Department.

7

Note : The top link pin (B) has an anti-turn arm (T). It

should be fitted as shown in photo 8.

The lower attachment yokes can be placed in 2

different positions on the main frame.

1) Towards the rear (A) (photo 9) (original fitting) : to

bring the centre of gravity of the machine as close to

the tractor as possible (in combination with a seed

drill for example).

7A

8

2) Towards the front (B) (photo 9) : to avoid any

clashing with the tractor wheels when fitting certain

equipments such as front gauge wheels or track

eradicators.

9

- 13 -

Page 16

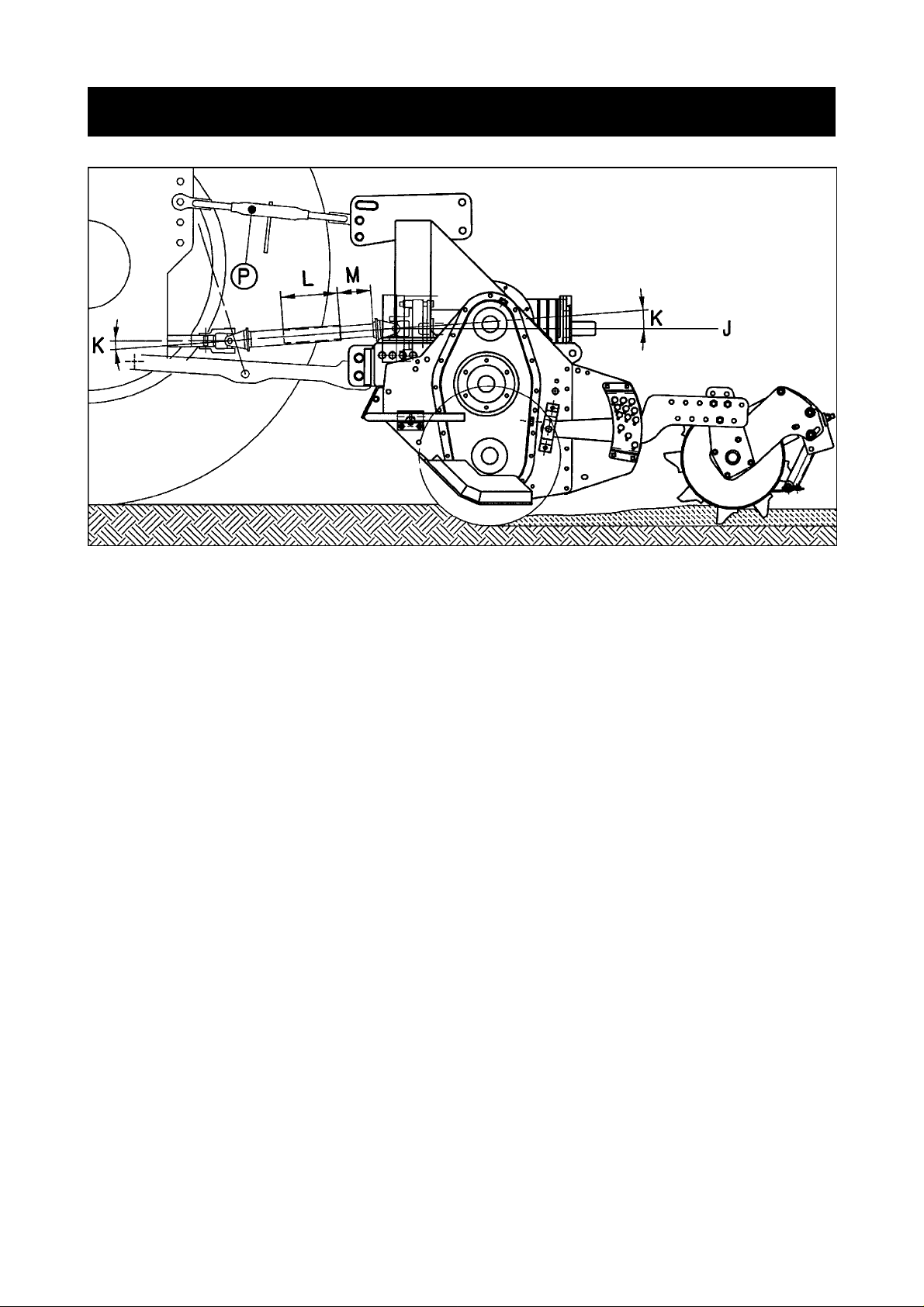

P.T.O. DRIVE SHAFT

10

Make sure the EL 142 is resting on the ground and is maintained in a stable position. Clean and lubricate the

gearbox input shaft and slide the mating PTO shaft yoke in place. Before attaching the PTO shaft to the slip clutch

flange, it is essential that both mating surfaces are thoroughly cleaned.

Bring both components together and fix in place using the self-locking screws provided. Tighten all the studs to

a torque setting of 10 daNm (75 ft.lbs) at the same time making sure that the flange is centrally seated.Tightness

has to be checked regularly.

After mounting the EL 142, stabilize the tractor 3-point linkage with whatever means are recommended i.e. the

bars, chains, etc.

Be sure the tractor P.T.O. shaft drive is disengaged and stop engine.

Couple the P.T.O. shaft to the tractor P.T.O stub.

Attachment is correct when machine is horizontal in work position.

With the machine resting on the ground, adjust the top link (P) length to a position where the tractor PTO stub and

the tiller input shaft are parallel.

In working position :

- The 2 angles (K) formed by the centre lines of the yoke and the sliding tubes must be equal and not exceed a

combined angle of 30° when working.

- The sliding tube overlap (L) must be at least 22 cm (8.5") (fig. 10).

With the machine fully raised on the tractor hydraulic linkage :

- The 2 sliding tubes must not completely overlap each other ; a gap (M) of 1 cm (3/8") should exist between end

of sliding tube and yoke.

- Both U joints (K) should operate approximately at the same bent angles which must never exceed 40°

(fig. 10).

Should the above mentioned conditions not exist :

- Shorten both tubes by an equal length (fig. A and B), chamfer edges (fig. C) and grease liberally (fig. D) before

refitting.

- To avoid noisy running of the PTO shaft when lifting the machine out of work, attach top link (P) so that it is almost

parallel to the lower links (fig. 10).

Important : Always disconnect the tractor PTO drive before lifting the machine into the transport position,

otherwise permanent damage can be caused to the transmission shaft.

Repeat these adjustments each time the machine is mounted to a different tractor.

- 14 -

Page 17

A

B

C

A hook (C) is supplied with the machine to support

the PTO shaft (T) when disconnected to avoid

damage or deterioration due to contact with the

ground (photo 11).

To avoid accidents which could be serious, make sure that the guards are always

correctly in place and secured with the safety chains. On the machine side, attach

restraining chain (H) to the corresponding hole on the right side of the hitch frame (photo

11). All worn or damaged guards must be replaced immediately.

D

11

- 15 -

Page 18

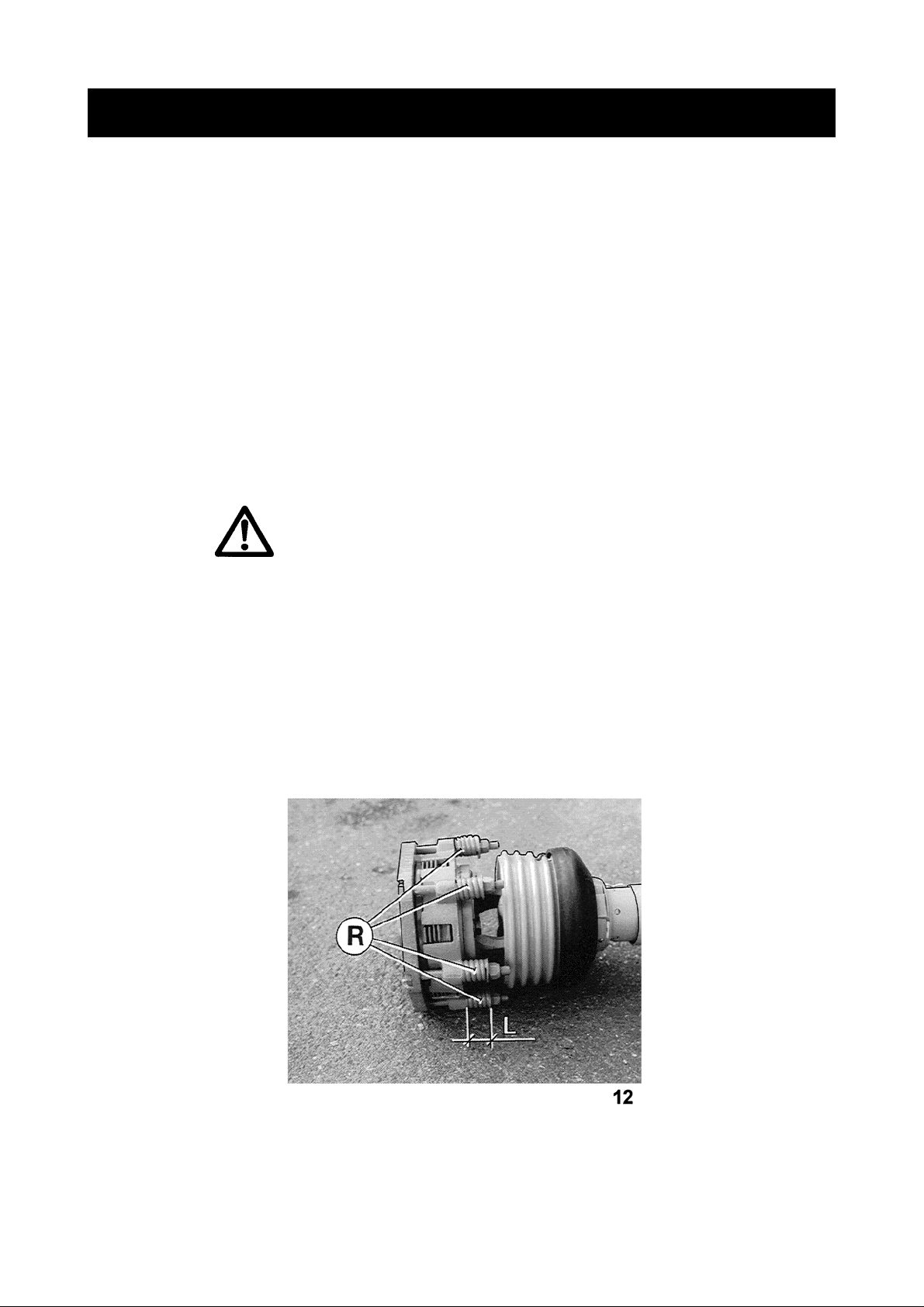

FRICTION SLIP CLUTCH

The EL 142 is factory equipped with an adjustable friction slip clutch.

Spring pressure is factory pre-set (L = 32 mm / 1 1/4") for 103 kW (140 hp) tractors at 1000 rpm (min-1) PTO (photo

12).

The theoretical average length of springs (R) (L = 32 mm / 1 1/4") is only an indication and can be slightly modified

according to machine width, work conditions and tractor. Too light a spring pressure will allow the plates to slip

continuously or intermittently at frequent intervals, resulting in overheating and rapid wear of the friction plates.

On the other hand, over pressured or completely coil bound springs will provide no protection to the drive

components (this occurs at 31 mm spring length).

IMPORTANT : * Always check if the clutch is set correctly for the work to be carried out. It should feel warm

to the touch during work.

* If the clutch slips excessively (too light a spring pressure, obstacles, etc.), readjust if

necessary and wait until the temperature of the clutch drops to a normal work temperature of

approximately 40°C (104 °F) before getting back to work. If the clutch overheats it will slip more

easily, thus increasing disc wear.

* With L = 31 mm the springs (R) will be completely coil bound and the clutch cannot operate.

Never work with springs fully locked as this risks deteriorating drive line components if an

obstruction jams the rotor. Always loosen at least half a turn.

NEVER FULLY LOCK THE SPRINGS.

Check clutch setting regularly, especially after the machine hasn’t worked for a long time. Completely slacken

off the 6 springs (R) by unscrewing their securing nuts, let the friction plates slip for a few seconds then retighten

springs as explained above (to L = 32 mm / 1 1/4").

Note : We recommend that the clutch guard be removed for easier access when carrying out slip clutch

adjustments. Don’t forget to bolt guard back in place after adjustments have been made.

- 16 -

Page 19

ROTOR SPEED (ROTATIONAL FREQUENCY)

The EL 142 is fitted with a speed gearbox which adapt the rotor speed (rotational frequency) to the working

conditions.

To change the PTO speed (rotational frequency) invert or replace the sets of matching gearwheels located at the

rear of the gearbox. The machine is standard equipped with 2 sets of gearwheels.

To invert the pinions proceed as follows. Tilt the machine forward to avoid oil leaking out of the gearbox when

removing the cover.

To do this :

- uncouple the PTO shaft

- shorten the turn buckle

- raise the machine in order to obtain a satisfactory angle

- remove bolts (U) from cover plate (V) and pull the cover and gearwheel assembly out of the gearbox (photo 13),

- invert the set of matching gears (A and B) or replace it by the set (C and D), according to the desired rotor speed

(rotational frequency) (photo 14),

- always store the non used set of matching gears inside the gearbox by placing gearwheel (D) on the rear PTO

shaft and gearwheel (C) on the cover plate (photo 14),

- reinstall the cover plate making sure to position the O-ring (E) in its groove correctly (photo 14).

13

Rotor speed (rotational frequency) chart EL 142 in rpm (min-1) :

P.T.O.

speed

(rotational

frequency)

750 rpm (min-1) 183 214 - 273

1000 rpm (min-1) 244 286 191 364

* Ex-Works setting

Position of

gears

*

26 24 24 26 29 21 21 29

1st gear set

Recommended PTO speed (rotational frequency)

14

2nd gear set

- 17 -

Page 20

The gearbox is factory fitted with a rear PTO shaft (S) which rotates at the same speed (rotational frequency) as

the tractor PTO shaft (photo 16). An extra implement can be driven by a secondary PTO shaft which should be

assembled and used according to the legislation in force at the time.

Remove the PTO shaft cover (O) (photos 15 and 16). The rear PTO shaft is 1 3/8" 6 spline profile, and must not

be used to transmit more than 37 kW (50 hp).

If the rear PTO shaft is not used, always put cover (O) in place (photo 15).

15

16

- 18 -

Page 21

ADJUSTMENT OF THE REAR HOOD

The rear hood unit consists of:

- Hood (Q) the position of which can be adjusted by

cranked handles (P) (photo 17)

- Flap (R) which can be adjusted and locked by

inserting pins (B) into holes (S) (photos 18 and 19)

The desired tilth can be obtained by adjusting the

position of rear hood (Q):

- lowering the hood increases the working of the

ground (see arrow C, figure 20) giving a finer tilth

- raising the hood reduces the working of the ground

giving a coarser tilth (figure 21).

17

18

Flap (R) must always be set to ensure that it levels the ground according to the flow of soil behind the rotor (figures

20 and 21). In order to keep the machine stable it is essential that the ground is well levelled in front of the roller.

If the flap is not correctly adjusted the ground surface will be undulating which can result in the machine pitching

or rolling in work, especially when travelling fast.

19

20 21

- 19 -

Page 22

USE

Before carrying out any operation on the machine, stop the tractor engine,

remove ignition key and wait for all rotating parts to stop before leaving the tractor.

Clod size should be different depending on the job to be done.

The following features determine clod size :

- Choice of rotor (either POWER TILLLER, CULTITILLER or CULTIPLOW)

- Rotor speed (rotational frequency)

- Working depth

- Hood position.

- Position of the flap.

- Forward speed.

- Number of passes.

The rear hood/flap unit must be set to ensure that there is no risk of it touching the roller

during work.

To obtain fine clods :

- High rotor speed (rotational frequency)

- Hood (Q) lowered (figure 20, page 19)

- Set the position of flap (R) in relation to the working depth to ensure that it performs its function of levelling (figure

20, page 19)

- Low forward speed

- Choice of the rotor in accordance with given work conditions :

. CULTITILLER rotor with angled blades

. CULTIPLOW rotor with curved blades : a greater shattering effect to get even finer clods.

. POWER TILLER rotor with "three pairs of blades per flange".

To obtain coarser clods :

- Low rotor speed (rotational frequency)

- Hood (Q) raised (figure 21, page 19)

- Set the position of flap (R) in relation to the working depth to ensure that it performs its function of levelling (figure

21, page 19)

- Higher forward speed

- Choice of the rotor in accordance with given work conditions (CULTITILLER, CULTIPLOW or POWER TILLER

with "2 pairs of blades per flange").

EL 142 CULTITILLER or CULTIPLOW

With the EL 142 CULTITILLER or CULTIPLOW, clods are shattered vertically without modifying their natural

structure : not too many clods, nor too much fine soil !

Points are spirally mounted, working and aerating the ground over the entire rotor width ; no panning. They engage

into the ground with a digging action without risk of gathering up vegetable residue. The angle at which the blades

of the CULTITILLER rotor enter the ground has the effect of a pickaxe. The “trailing” position of the blades in

CULTIPLOW version eliminates nearly all risks of clogging and building up of plant residues.

The roller controls working depth and levels and packs the seedbed behind the machine.

The EL 142 CULTITILLER or CULTIPLOW is a very versatile machine offering a wide range of applications :

- turning in stubble

- soil preparation after ploughing

- and in some cases, direct soil preparation without ploughing.

- 20 -

Page 23

EL 142 POWER TILLER

The POWER TILLER rotor fitted with mulch blades "BH" is world renown for its excellent incorporation of organic

matter into the ground.

The POWER TILLER rotor can be equipped with either 2 or 3 spades, depending on the soil profile required. When

it comes to turning in stubble and reclaiming old pastures, the Power Tiller rotor is at it’s best.

The Power Tiller rotor fitted with mulch blades "BH" is recommended for :

- turning in green manure, dung, harvest residues

- reclaiming old pastures

- orchard maintenance

- turning in stubble

- market gardening.

Note : Before working in vegetable residue, an independant shredder must be used first to obtain a fine

shred and even distribution of residue so that it can then be easily incorporated into the ground, getting

a good mix. The more residue there is, the more important this is.

Hints on use :

- Allow the rotor to rotate at ist working speed before engaging it into the soil. Gradually lower the machine while

pulling forward with the tractor.

- Always work in a straight line. When turning, lift machine out of work.

- Never work in reverse, otherwise damage could occur to some component parts.

- Do not disengage the PTO drive unless the machine has been lifted out of work.

Important remarks :

Like many farm machines, use of the EL 142 entails limits which must be respected in all situations. These limits

are often tied in with :

- meteorological conditions : avoid working during and immediately after rainfall, wait until ground to be worked

is completely drained,

- soil types : smooth clods indicate too malleable or too humid soil to be worked in. Wait until ground is completely

drained. Soil consistency is ideal when clods crumble without sticking,

- tractor power : adapt working depth, forward speed and rotor speed (rotational frequency) to power available

and type of work to be done. Never exceed the maximum allowable tractor DIN power : 103 kW (140 hp).

- hood adjustment : The machine should not be operated with the hood (Q) (photo 17, page 19) completely

closed. The hood should always be sufficiently open so that worked ground can flow out freely. If the rotor is

operating deep down in the soil and the hood is closed, the large amount of worked ground could clog the rotor

and deteriorate the hoods.

- 21 -

Page 24

EQUIPMENT

1) ROLLERS

The operator may choose to equip the EL 142 with :

- either a packer roller (studs welded onto a cylinder),

- either a packer roller PK2 (studs welded onto a cylinder) (only for EL 142 - 3,00 m),

- either a maxipacker roller (rows of discontinuous studs welded on a large diameter cylinder),

- either a crumbler roller (welded tubes and removable bars)

- or a maxicrumbler roller (welded tubes).

The roller :

- adjusts and controls rotor working depth

- packs the ground behind the rotor to create an ideal seedbed

- increases crumbling efficiency by breaking down the clods

- improves ground levelling.

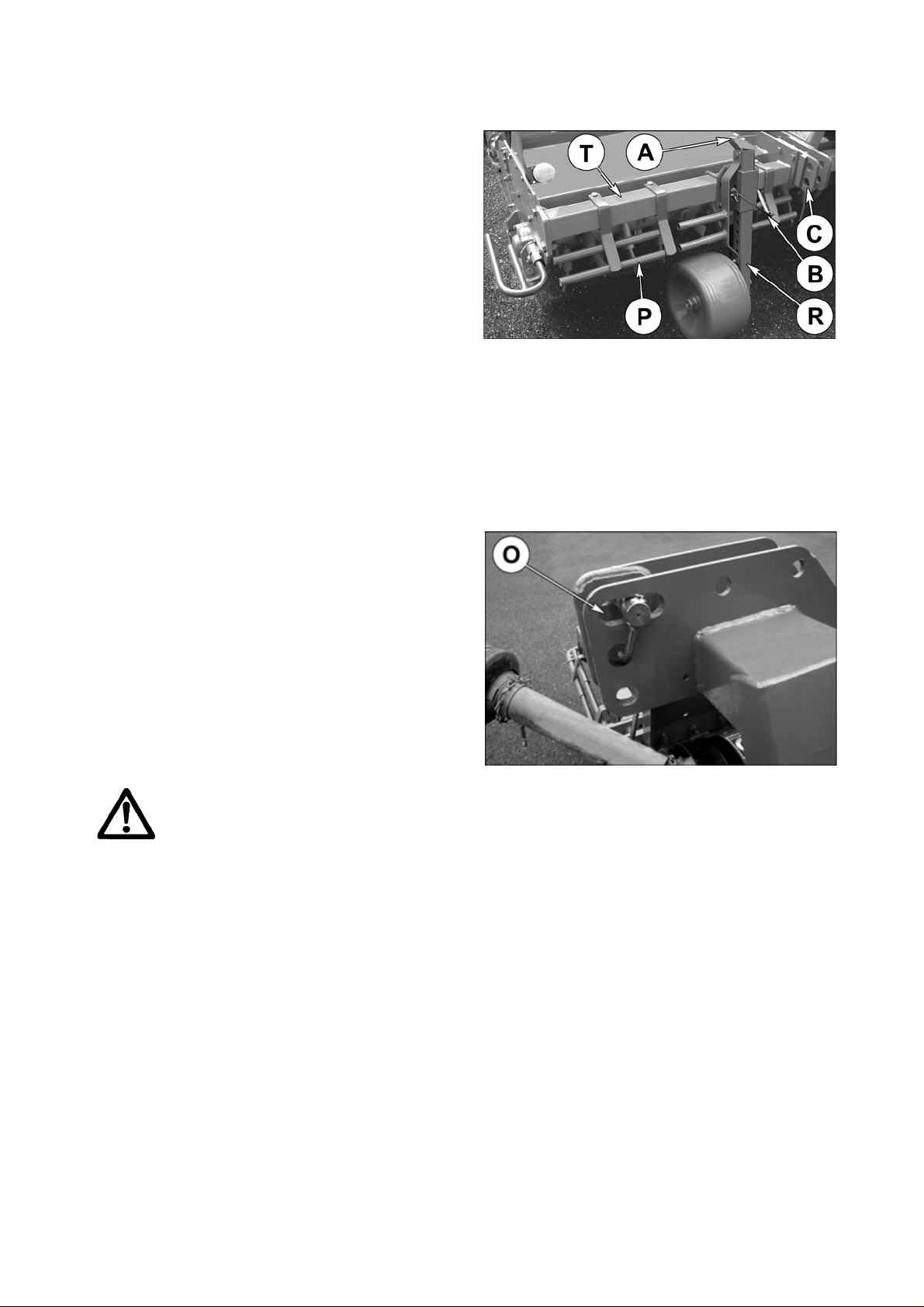

Adjusting the roller (photo 23)

Adjustment in direction of travel :

The roller can be placed in six different horizontal

positions so that the overhang is reduced to a minimum in relation to the hood. This shift is carried out

with the 3 screws (C) on the multi-hole arms (A) and

plates (B) (photo 23).

23

Height adjustment :

The roller height is adjusted at (P) (photo 23).

To adjust, proceed as follows:

- Lift the machine behind the tractor,

- Place pin (T) in the hole corresponding to the required height (photo 23). Make sure that the same hole is used

on each side of the machine.

To limit the roller downward movement when manoeuvring on field end, a 2nd pin (T) may be ordered under part

number 517 070 00 (2 x) and be inserted in holes (O) of the adjustment plate (P) (photo 23). Do not restrain the

roller movement if the machine is equipped with a Venta seed drill resting on the roller arms.

To raise the roller completely out of work, lift the roller, then place the original pins (T) in holes (O).

Fitting of the adjustment sectors and roller arm mounting brackets (photo 23)

Fit the adjustment sectors (P) on the side plates using 8 cup square bolts (I) (M12 x35) and 8 self-locking nuts (M

12) (screw heads positioned on the inner side of the side plates).

Fit the roller arm mounting brackets (K) on the side plates using 4 hexagonal screws (M) (M 12x35) and 4 selflocking nuts (M 12).

- 22 -

Page 25

A) STANDARD PACKER ROLLER AND PACKER ROLLER PK2 :

- EL 142 - 2.50 m : Kit No.121 6650 (standard)

- EL 142 - 3.00 m : Kit No.121 6600 (standard), Kit No. 121 7080 (PK2)

This rollers are particularly intended for use in wet or sticky soils. Efficient packing, proper levelling and good

crumbling are always achieved. Mud scrapers are an integral part of the standard packer roller and of the packer

roller PK2. These scrapers, placed between the rows of studs, ensure that the roller is cleaned.

a) Assembly of the packer rollers and their scrapers

When assembling the roller, take particular care concerning the direction of rotation. The direction of rotation is

indicated on the decal affixed to the side of the roller (see arrow, figure 24).

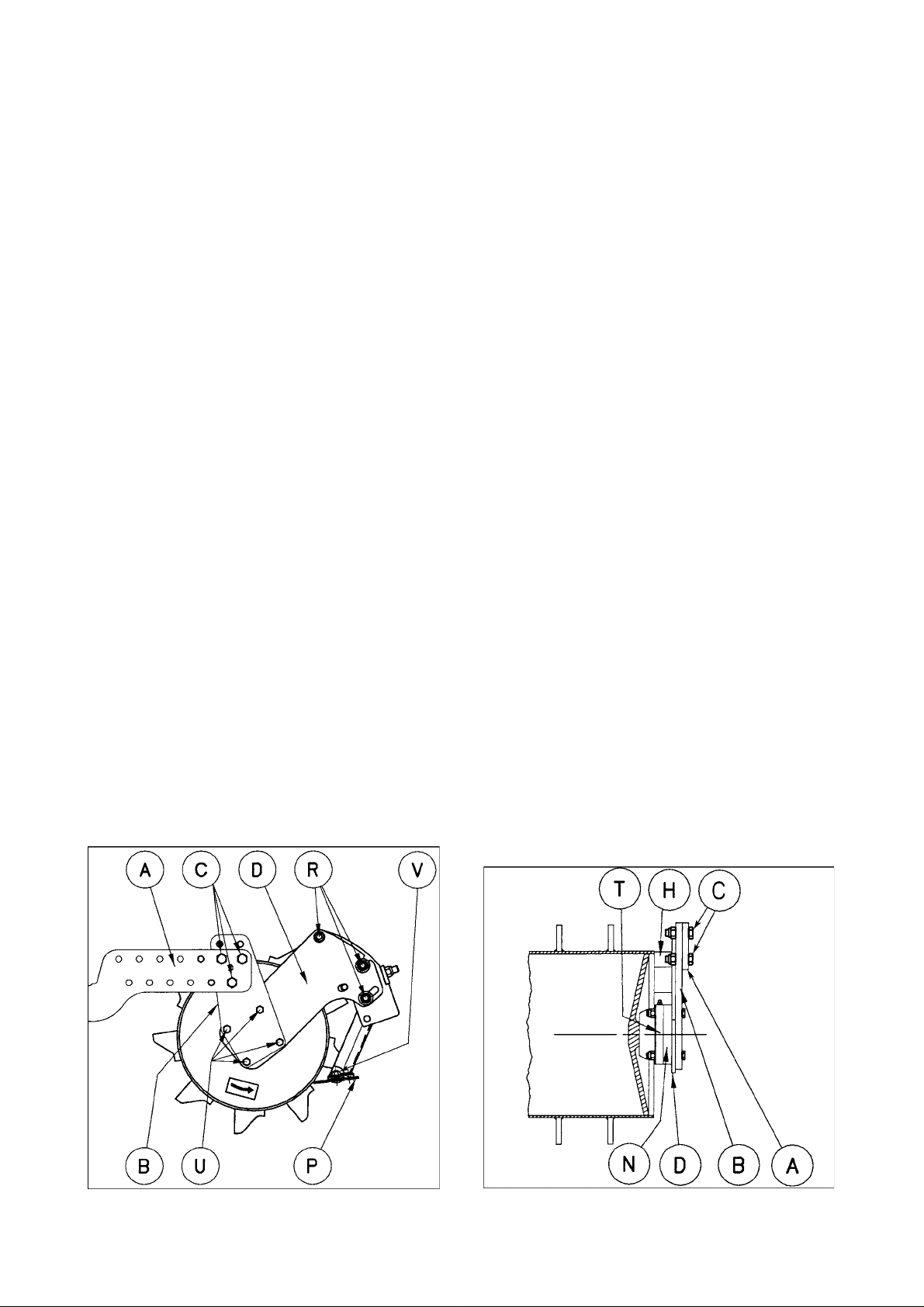

Using 8 bolts (U) and M 12 nuts and mount roller arms (B) and scraper bar arms (D) on the bearing housings (T)

placing spacer (N) as shown on drawings 24 and 25 (torque 10 daNm / 74 ft.lbs).

Then fit the swinging arms (A) on roller arms (B) with 6 bolts (C) and M16 nuts using the 3 holes (C) (torque 22

daNm / 160 ft.lbs) (fig. 26).

Then bolt the scraper bar (H) onto holders (D) using the 4 screws (R) (figure 24). Do not fully tighten these bolts

at this stage. Check that all the cleaners (P) of the scraper are in the retracted position.

Position the 2 eybolts (Q) (photo 27). Using the two nuts (S) tighten against the tensioners to pivot the scraper

towards the roller until the two elongated holes almost butt out (photo 27). Thereafter tighten the four bolts (R) and

adjust the scraper plates (P) as described below (torque 22 daNm / 160 ft.lbs).

Then mount the complete roller assembly with arms (A) on the roller arm brackets (K) by means of 2 pins (X)

secured with 2 self-locking screws (J) (M10 x 16) (photo 23, page 22).

24

26

25

27

- 23 -

Page 26

b) Adjusting scraper plates

- Slightly loosen fixing bolts (V) of the scrapers (P) so that they slide freely (figure 24, page 23).

- Check that their position is central relative to the rows of roller teeth. The scraper supports have elongated holes

to allow readjustment if necessary.

- After having checked that the scraper bar is in its furthest forward position (photo 27, page 23), position scraper

plates one at a time so that they are all in contact with the roller. Retighten bolts (V) to 8 daNm / 50 ft.lbs (figure

24, page 23). Make sure that the plates only lightly touch the roller and do not interfere with its rotation.

c) Cleaning the scrapers

In case of crop or soil build-up, to clean, it is recommended that the scraper assembly be pivoted to the rear around

the two upper bolts (R) (photo 27, page 23).

- Loosen the self-locking nuts (S) (photo 27, page 23).

- Release the two eyebolts (Q).

- Remove the two lower bolts (R) (photo 27, page 23).

- To facilitate pivoting the scraper assembly, use a lever in each of the two holes (L) situated at each end of the

connecting tube (H) (photo 27, page 23).

B) MAXIPACKER ROLLER 2,50 m - Kit No. 121 6690

3,00 m - Kit No. 121 6700

This roller is suitable for all soil types and especially humid and sticky soils. It provides an efficient ground packing,

a good levelling and crumbling.

Due to its large diameter cylinder, it provides a large ground contact area, hence reduced sinking and less

resistance to rolling, meaning a reduced traction power is needed. The scraperbar is part of the maxipacker roller.

The scraper plates located between the rows of studs ensure the cleaning of the roller. They are hard coated to

further increase their service life.

In case of blocking with crop residues, the scraper bar can be easily pivoted to permit cleaning.

a) Fitting the maxipacker roller and its scraper (figures 28 and 29 and photo 30).

When fitting the roller, be sure to check its direction of rotation. The direction of rotation is indicated by a sticker

on the side of the roller (see arrow on figure 28).

Using 8 bolts (U) and M12 nuts and mount roller arms (B) and scraper bar arms (D) on the bearing housings (T)

placing spacer (N) as shown on drawings 24 and 25 (torque 10 daNm / 74 ft.lbs).

Then fit the swinging arms (A) on roller arms (B) with 6 bolts (C) and M16 nuts using the 3 holes (C) (torque 22

daNm / 160 ft.lbs) (fig. 26, page 23).

Then fit scraper supporting bar (H) onto the 2 support arms (D) with the 6 bolts (R). Do not tighten the bolts at this

stage (figure 28).

28

29

- 24 -

Page 27

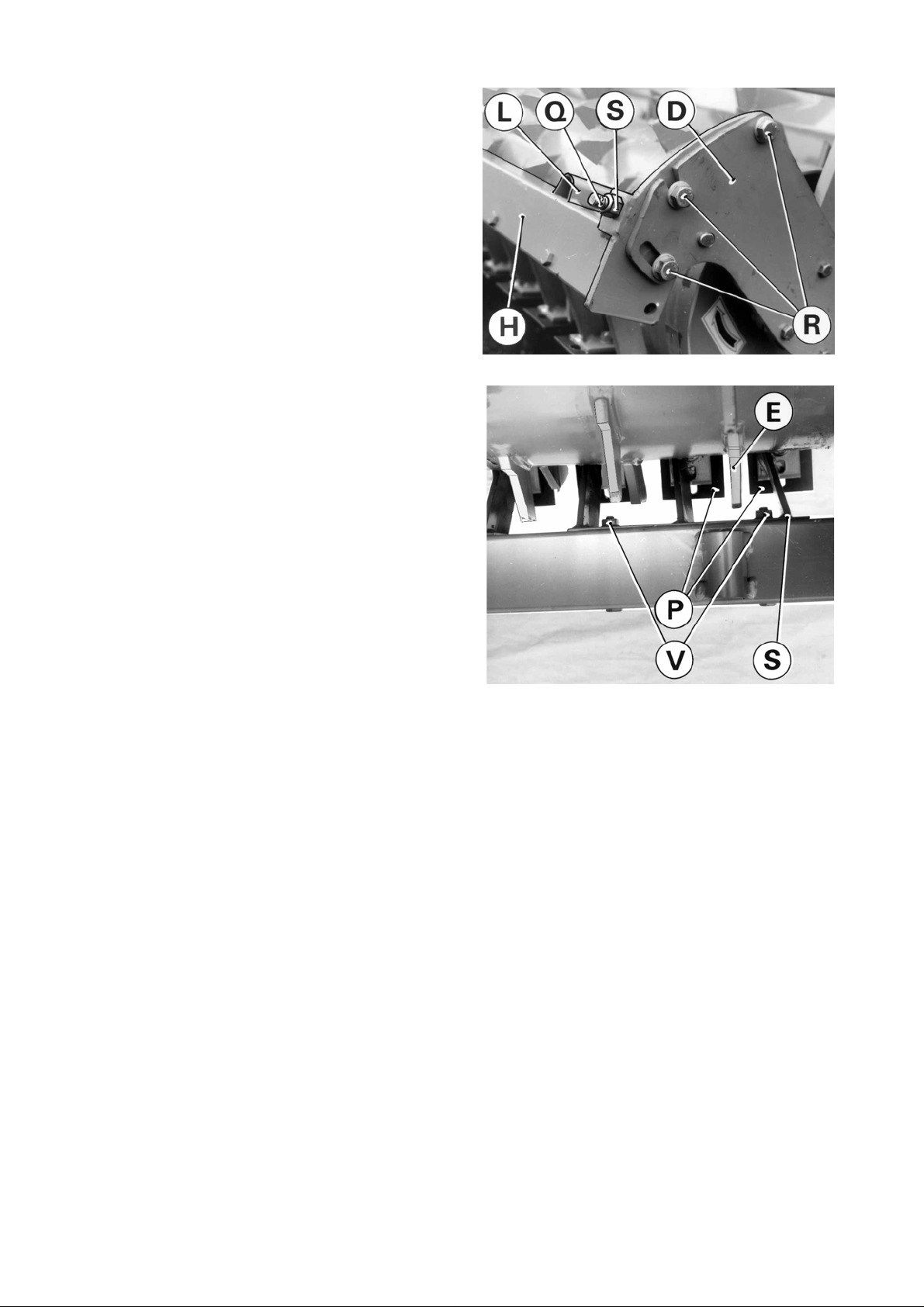

Fit the 2 adjusters (Q) (photo 30). Using the 2 nuts (S)

on the adjusters, bring the scraper bar towards the

roller until it is almost bottomed-out in the 2 slots of the

support arms (D) (photo 30). Then tighten the 6 bolts

(R) to a torque of 22 daNm / 160 ft.lbs, and if required

adjust the position of the scraper plates (P) as shown

thereafter.

Then mount the complete roller assembly with arms

(A) on the roller arm brackets (K) by means of 2 pins

(X) secured with 2 self-locking screws (J) (M10 x 16)

(photo 23, page 22).

b) Adjusting the scraper plates

- The hard coated thick scraper plates have been factory

pre-set on a reference roller. Therefore, they are nearly

in the correct working position after mounting the scraper

bar (paragraph a, page 24).

- If necessary, adjust the scraper plates so that they are in

contact with the roller and tighten the screws (torque 8

daNm / 50 ft.lbs). Make sure that the scraper plates

only lightly touch the roller and do not interfere with

its rotation.

- Also make sure that the scraper plates (P) are well

centred with regards to the stud rows (E) (photo 31). The

scraper plate supports (S) are equipped with oblong

holes enabling to recentre them by sliding them crosswise at the screw level (V) (torque 10 daNm / 74 ft.lbs).

30

c) Cleaning the scrapers

In case of crop residue build-up, it is recommended for cleaning that the scraper be pivoted backwards around

the 2 upper bolt holes (R) (figure 28, page 24). To do this, untighten the 4 lower bolts (R) and release the 2 adjusters

(Q) after loosening their self-locking nuts (S) (photo 30).

To ease pivoting of the scraper bar towards the rear, use a lever in holes (L) (photo 30) placed at each side of the

scraper bar (H).

31

C) CRUMBLER ROLLER : 2,50 m - Kit No. 121 6670

3,00 m - Kit No. 121 6680

The crumbler roller is ideal for dry and slightly humid conditions. It is made up of fixed welded tubes (F) and

removable bars (G), held in place by round support rings (figure 32, page 26).

With removable bars in place :

Recommended in dry conditions for fine tillage and levelling with good ground packing.

Without removable bars in place :

Recommended in more humid ground, less risk of roller clogging. Tillage and levelling are coarser.

Bars can be removed as follows :

- Remove inside roll pins

- loosen the bars using a hammer

- pull out the bars.

- 25 -

Page 28

Using 8 bolts (U) and M12 nuts, mount the roller arms (B) together with the covers (D) on the roller bearing housings

(T) placing a spacer (N) as shown on drawings 32 and 33 (torque 10 daNm / 74 ft.lbs). Then fit the swinging arms

(A) on roller arms (B) with 6 bolts (C) and M16 nuts using the 3 holes (C) (torque 22 daNm / 160 ft.lbs) (fig. 26,

page 23).

Then mount the complete roller assembly with arms (A) on the roller arm brackets (K) by means of 2 pins (X)

secured with 2 self-locking screws (J) (M10 x 16) (photo 23, page 22).

32

D) MAXICRUMBLER ROLLER (photo 34)

2.50 m - Kit no. 121 6950

3.00 m - Kit no. 121 6870

The maxicrumbler roller is ideal for dry or slightly

humid conditions. It is not advisable to use it in

conjunction with an integrated seed drill.

It is made up of fixed tubes (F) welded on round

support rings (photo 34).

2) SKIDS + STAND (photos 35 and 35 A)

Kit no 120 9210

The EL 142 can be equipped with 2 skids which must be mounted on each side of the machine.

This equipment is recommended in Cultirotor version when no roller for working depth control is fitted.

Depth control is adjusted by means of 6 hole skid bars (T) (photo 35).

Assemble skids following photo 34. First remove the wear plate of the lateral housing.

A stand (E) is supplied with the skids to ensure stability when machine is parked (photo 35 A).

33

34

35

35A

- 26 -

Page 29

3)FRONT GAUGE WHEELS

(photo 36)

The EL 142 can be equipped with a gauge wheel kit.

Wheels (R) are fitted on cross tube (T) in front of the

machine. This equipment is recommended either in

Cultirotor version when no roller is fitted, or for all

versions combined with a roller in order to improve the

machine’s stability.

Wheels (R) can easily be adjusted in height inside

their supports using pins (B).

Handles (A) make it easier to handle the gauge

wheels (R).

Kit no 121 6640

36

NOTE : - When mounting the front wheels, slide guards (P) (photo 36) so that they cover the complete

front part of the machine located at the exterior of the 3-point frame’s mounting yokes (C). The

gap between guards (P) and the wheels columns (R) must be of less than 60 mm.

- In addition, on 230 and 250 models, dismount the front safety guard inner part on each side

of the headstock in order to obtain the space required to fit the front gauge wheels.

IMPORTANT NOTE CONCERNING THE USE OF

FRONT GAUGE WHEELS

When the EL 142 is used with front gauge wheels

combined with a roller, the tractor top link must be

connected to the oblong hole (O) on the machine’s 3point frame (photo 37). With this method of hitching

the machine adapts freely to the ground contours,

independently of the tractor.

Coupling the top link to the oblong hole (O) on the machines headstock is only intended for

work. It is strictly forbidden to use this hole during transportation.

37

- 27 -

Page 30

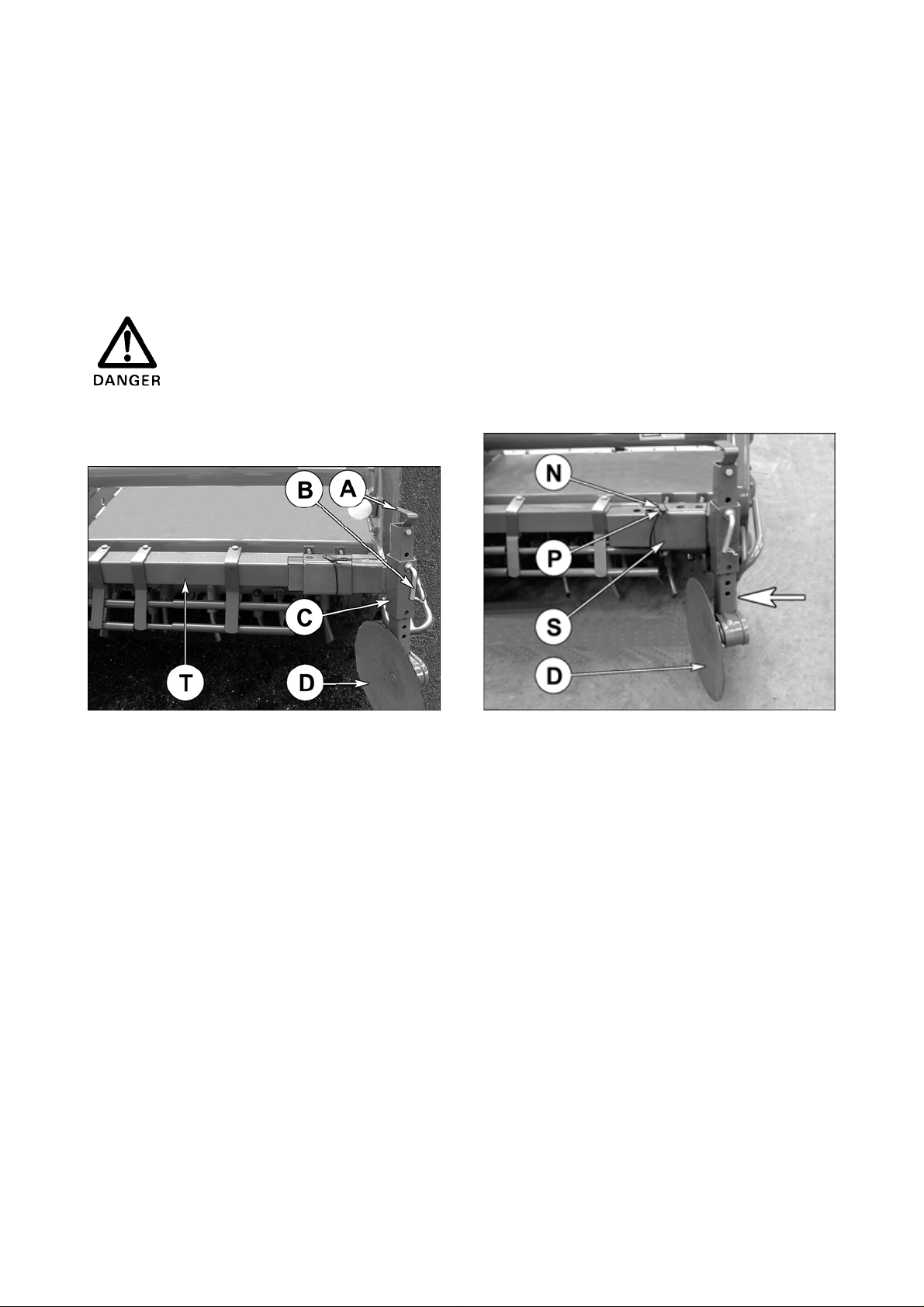

4) SIDE SEPARATING DISCS (photos 38 and 38A)

Kit no. 121 6630

These discs improve soil movement towards the rotor and thus achieve a better definition between worked and

unworked land. The side separating discs also help to stabilize the machine during surface work. Fit the side

separating discs (D) to the cross bar (T) as shown in photo 38. They are adjustable in height on the inside of their

supports (C) using pins (B).

They are also adjustable laterally. Make sure to set both side discs (D) in the same position.

Handles (A) make it easier to handle the side separating discs (D) and also act as a stop to prevent accidents.

At transport, in order to reduce the overall width, the side separating discs (D) must be

completely retracted into their supports (S) (see arrow) and locked in the holes (N) using the

pins (P) (photo 38A).

38

38A

- 28 -

Page 31

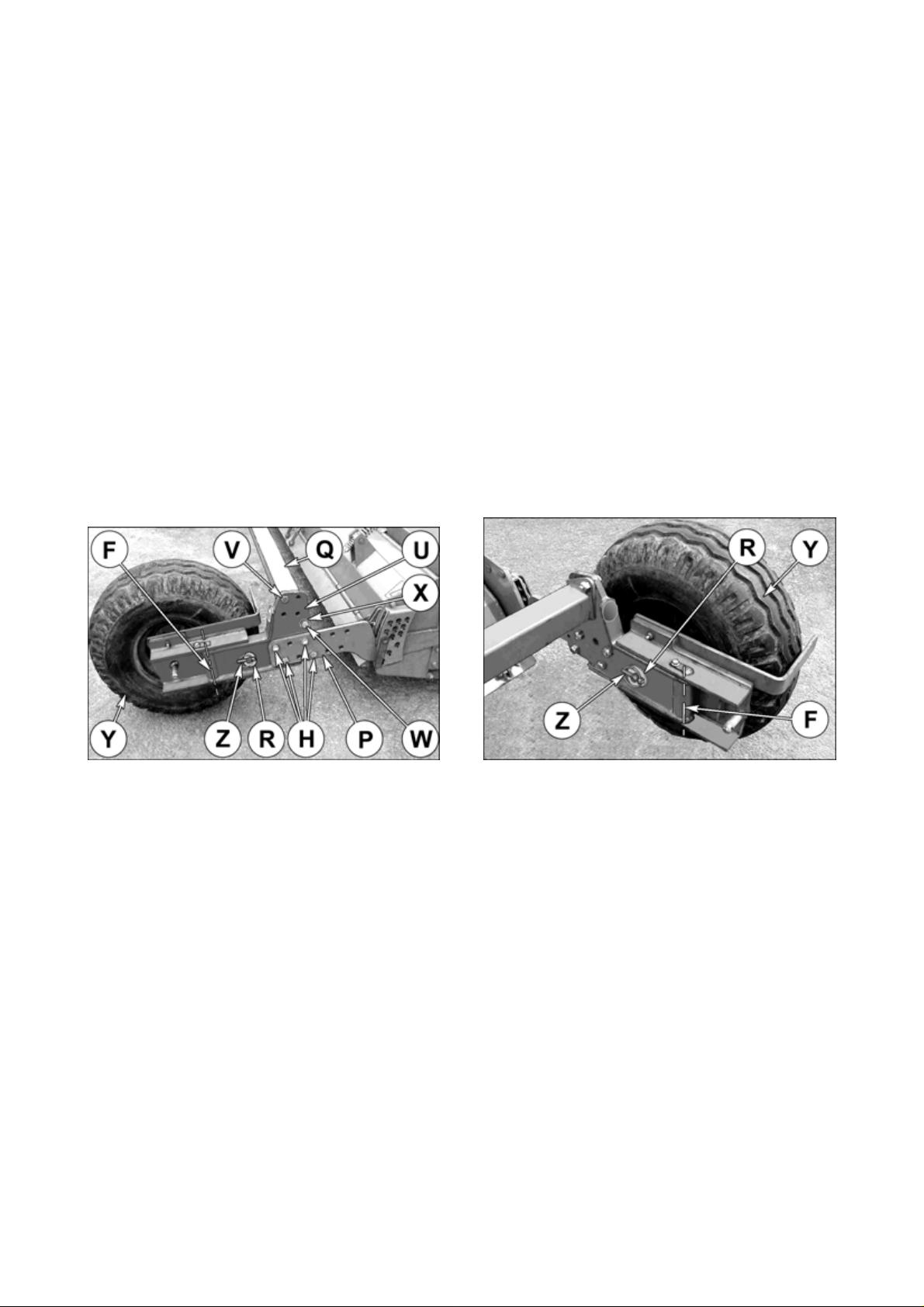

5) REAR WHEEL KIT (photos 39 and 40)

Kit no. 121 6360 for EL 142 - 2.50 m

Kit no. 121 6370 for EL 142 - 3.00 m

Rear wheels can be fitted in place of the roller for certain surface operations (for example, stubble clearing or

turning over pastures).

The rear wheel kit can be fitted in various positions (lengthways) on the roller arms (P) delivered with the kit by

means of 8 hexagon bolts (H) (M 16 x 55) and 8 self-locking nuts (M 16).

Next fit cross bar (Q) on the fixed arms (U) of the rear wheels using 2 hexagon bolts (V) (M 16 x 55), 2 hexagon

bolts (W) (M 16 x 55), 2 flat washers (X) (diameter 16 x 30 x 3) and 4 self-locking nuts (M 16). The cross bar can

be fitted either in the upper position (as shown on photos 39 and 40) or the lower position (when working with an

integrated seeder or separate seeding system). When fitting in the lower position use the 2 longer hexagon bolts

(W) (M 16 x 80) supplied.

Rear wheels (Y) should face inside the machine for transport to reduce machine width (photo 39). They should

face outside during work so as not to roll over the ground worked by the rotor (photo 40).

It may, however, be useful to work on field edges with the wheels in their transport position. In this case the wheel

scraper should be pivoted to the rear of the machine (seen in the forward direction).

To put the rear wheels into their transport position (photo 39) or work position (photo 40), pivot them inside or out

on vertical axle (F). Lock them in place using linchpin (Z), do not forget to insert washer (R) (diameter

23 x 54 x 6).

39

40

- 29 -

Page 32

6) TRACK ERADICATORS

In order to reduce the tractor wheel marks left on the seedbed, the EL 142 may be equipped with wheel track

eradicators. Depending upon the working conditions and machine widths, various types of track eradicators may

be ordered : - Kit no. 121 6610 for the traction bolt overload mechanism

- Kit no. 121 6620 for the adjustable spring overload mechanism

The eradicator tine mounting yokes (C) are to be fitted on the cross tube (T) as shown on photos 41 and 41 A.

The height of the leg (L) with reversible share (F) can be adjusted according to the depth of the wheel tracks by

means of a pin (N) (photos 41 and 41 A). Nevertheless, the working depth of the shares must never

exceed 100 mm (4").

The track eradicators are equipped with an overload mechanism should they encounter an obstacle :

- with traction bolt (T) (photo 41) : breakage of the bolt (ref. 801 310 51) with its nut (ref. 802 010 30)

- with adjustable spring (U) (photo 41 A) : the tine clears the obstacle and regains automatically its position.

Recommended in difficult or stony grounds.

41

The track eradicators must be mounted centred with regards to the tractor wheels, one per wheel (photos 42

and 42 A). In the case of dual wheels or large tyres, additional track eradicator tines can be fitted (to be ordered

under n° 121 6610 or 121 6620).

41A

42A42

NOTE : - Track eradicators are only to be used for secondary tillage work.

- When mounting the track eradicators, slide guards (P) (photos 41 and 41 A) in order to cover

the complete front part of the machine located at the exterior of the 3-point frame’s mounting

yokes. The gap between guards (P) and the track eradicators must be of less than 60 mm.

- 30 -

Page 33

7) 3-POINT LINKAGE WITH HYDRAULIC LIFT FOR ADDITIONAL IMPLEMENTS

(photo 43) Kit no. 121 6720

43

The 3-point linkage with hydraulic lift cylinders (V) reduces the overhang of a combination (EL 142 - seeder, for

example) by lifting back the combined machine over the EL 142 (see photo 45 on page 33).

a) Assembly :

The hydraulic lift linkage is fitted to the EL 142 by means of axle (Q) and pins (U) (photo 43). A spacer washer

(Ø 20 x 45 x 8) must be added on each side of the headstock mounting plates in order to minimise the lateral play

at (U).

Hydraulic cylinders (V) necessitate at least one single acting valve on the tractor.

Attach hydraulic hoses (K) to cross bar by means of 2 hose clamps (N) and connect hoses to the cylinders (V)

as shown in photo 43.

To allow adaptation of Category 1 and Category 2 implements, hooks (A) and spacers (B) can be assembled in

different ways : either to the inside or to the outside of rear frame (C) to obtain desired span.

The hooks (A) can also be adjusted in height (two positions). The locks (D) are used to secure the secondary

implement's lower link pins inside hooks (A) (photo 43 and fig. 44 on page 30).

- 31 -

Page 34

44

In order to reduce combination overhang as much as possible, the 3-point frame lower linkage hooks (A) can be

adjusted horizontally through a range of 22 cm (8,5") (photo 43 on page 31).

Depending upon application, the standard position (as set in factory) can be changed. The alternative positions

can be achieved as follows :

- towards the rear : by combining the two rear positions of linkage arm (W) with the four holes (F) of arm (G) (photo

43 on page 31)

- towards the front : by first moving rear frame (C) into position (Y) and by combining the two front positions of

linkage arm (W) with the four holes (F) of arm (G) (photo 43 on page 31).

Note : In the position (Y), the 2 plates (Z) must be removed.

Tractor

hydraulic

pressure

150 bar 1800 daN 1300 daN

180 bar 2200 daN 1800 daN

Max. frontward Max. rearward

position position

- 32 -

Lift capacity

Page 35

b) Combination with a machine with PTO drive

(for example a pneumatic seed drill - photo 45)

Set of two chain stroke limiters Kit no. 124 6040

For the combination of the EL 142 with a PTO powered

machine, it is necessary to fit a set of two chain

stroke limiters (E) available as an optional extra to

prevent the PTO shaft sliding tubes (T) from butting

together and to protect the PTO shaft from being

subject to excessive angles.

Proceed as follows when adapting the seeder for the

first time :

- Connect transmission (T),

- progressively lift the combined machine up to the

maximum overlap of the transmission tubes, at the

same time ensuring that there is always a safety

clearance (W) of 1-2 cm (1/2"-1"),

- position the chain stroke limiters (E) as shown in

photo 45, adjust tensioners (R) in order to prevent

the two cylinders (V) from lifting any higher.

The rear hydraulic linkage can then be operated with

total safety.

Bump stops :

45

In the transport position, rear PTO shaft must be disconnected and chain stroke limiters (E) (photo 45) removed.

This will allow lower lift arms to rest against the bump stops (M) (photo 43), preventing accidental over-raising and

damping vibrations which reduces loading on structural parts.

c) Safety chain

A safety chain (H) prevents the hydraulic lift linkage from lowering accidentally during

transport if, for example, there is an oil leak (see photo 45).

This safety chain (H) is supplied as standard with all the hydraulic lift linkages and must be connected to the chassis

(S) and the rear 3-point frame (C) with 2 pins (A) as shown on photo 45.

d) Maintenance of the linkage

Periodically grease the different pivot points equipped with 8 grease nipples.

When parking the combined unit (EL 142 / seed drill, for example) make sure that the

additional implement is lowered first.

Always put cover in place if the rear P.T.O. shaft is not used.

NOTE : All gearboxes are fitted with a rear PTO shaft (P) (photo 43) which rotates at the same speed (rotational

frequency) as the tractor PTO. The rear PTO shaft is 1 3/8" 6 spline profile and must not be used to

transmit more than 37 kW (50 hp).

There are two adhesive safety decals (O) and (O') on the 3-point frame as shown in photo 43, page 31. Their aim

is to contribute to your safety and the safety of the people working with you. Check their location and read them

carefully. Always keep the decals clean and legible ; replace them if they are not.

- 33 -

Page 36

O

8) ADAPTATION KIT FOR VENTA AL AND TI INTEGRATED SEEDER

There are two kits for EL 142 - 3.00 m

- Floating adapter : Kit no. 121 6730

- Fixed adapter : Kit no. 121 6750

For assembling and operating instructions see the VENTA AL and TI instructions booklets.

9) SEMI-AUTOMATIC HITCH (photo A)

Kit no. 121 6770 - Category 2

Kit no. 121 6780 - Category 3

The semi-automatic linkage consists especially of a

cross-shaft (L), 2 linkage hooks (M) and 2 bushes (N).

The cross-shaft (L) should be fitted to the tractor lower

links, and the linkage hooks (M) should be fitted to the

machine chassis in place of the standard lower attachment brackets.

Do not forget to install the 2 spacers (N).

A

10)HARD COATED PLATES FOR STANDARD PACKER ROLLER AND

PACKER ROLLER PK2

These scraper plates, which are particularly resistant to wear and tear, are available as replacement parts under

part n° 525 600 10.

- 34 -

Page 37

11) NYLON CLEANING PLATES FOR STANDARD PACKER ROLLER,

PACKER ROLLER PK2 AND MAXIPACKER ROLLER SCRAPERS

Part No. 525 702 00 for the standard packer roller and the packer roller PK2

Part no. 525 923 00 for the maxipacker roller

These cleaning plates are made from a supple synthetic

material which enables them to be slightly pre

compressed against the roller for improved cleaning

action.

a) Installation and adjustment (photo 46) :

The nylon cleaning craper plates (R) are to be placed :

- between two new standard steel scraper plates (S)

(525 321 30) for standard and PK2 packer rollers by

using a longer screw (V) (part No 500 073 00),

- between two non hardcoated steel scraper plates (S)

(525 989 10) on maxipacker rollers by using a longer

screw (V) (part No 800 312 40).

46

Allow the nylon cleaning plate (R) to stick out of the carrier plates (S) by 10 mm and press it slightly against the

roller so that its leading edge is in contact with the roller segment across its full width. Rotate the roller one complete

turn to check that there is no gap between roller and nylon cleaning plate. Re-adjust the plate if this is not the case.

Also check that the upper carrier plate is set parallel to the roller segment and does not come into contact with it.

b) Use :

The nylon cleaning plate is particularly recommended for light, loamy or chalky grounds with little crop residue or

stones. A correct cleaning plate adjustment results in a clean and shiny roller area across the full width of the

cleaning plates.

Soil deposit on the roller will result in premature cleaning plate wear. Readjust them quickly. The cleaning plate

is reversible for increased service life.

12) P.T.O. SHAFTS

The PTO shaft is available in the following versions to fit the tractor PTO :

- W 2500 1”3/8, 6 splines : Part no. 4600 502

- W 2500 1”3/8, 21 splines : Part no. 4600 504

- W 2500 1”3/4, 6 splines : Part no. 4600 506

- W 2500 1”3/4, 20 splines : Part no. 4600 508

13) ROTORS COMPLETE

Standard diameter Power Tiller rotor : Kit no. 121 6810 for 2.50 m / 8’2"

Kit no. 121 6820 for 3.00 m / 9’10"

Larger diameter Power Tiller rotor : Kit no. 121 6970 for 2.50 m / 8’2"

Kit no. 121 6980 for 3.00 m / 9’10"

CULTITILLER rotor : Kit no. 120 6830 for 2.50 m / 8’2"

Kit no. 120 6840 for 3.00 m / 9’10"

CULTIPLOW rotor with 2 bolts per blade : Kit no. 120 6850 for 2.50 m / 8’2"

Kit no. 120 6860 for 3.00 m / 9’10"

CULTIPLOW rotor with 1 bolt per blade : Kit no. 120 7010 for 2.50 m / 8’2"

Kit no. 120 7020 for 3.00 m / 9’10"

- 35 -

Page 38

14) SIGNALLING ELEMENTS

Kit no. 120 8840

Install the signalling elements as described below :

- Fix the 4 supports (A) and (B) on the 2 adapter plates (C), at the rear of the right side plate, and on the rear left

plate using 4 bolts (S) (M 16 x 35) and nuts (M 16) (torque 16 daNm) (see photos 47 and 48).

- Fix the four reflector boards (D) onto the four supports (A and B) with 12 bolts (T) (M 10) (torque to 10 daNm

/ 75 ft.lbs) as shown in photos 47 and 48 making sure that the red and white stripes are positioned correctly (the

top outer corners must be red, photos 49 and 50).

- Fit pilot lights (K) to the front reflector boards (see photo 50).

- Fit the left tail light (I) (marked "L" on the connector terminal) to the left rear reflector board (photo 49). The left

tail light's connector terminal is also white.

- Fit the right tail light (M) (marked "R" on the connector terminal) to the rear right reflector board (photo 49).

- Layout the wiring harness referring to photos 47, 48 and 50 and attach it in place with self-sticking collar holders

and clamp collars (O).

NOTES : - A 7 pin socket is required at the rear of the tractor in order to operate these signalling elements.

47

49

48

50

- 36 -

Page 39

MAINTENANCE

BEFORE CARRYING OUT ANY OPERATION SUCH AS MAINTENANCE OR ADJUSTMENT

ON THE MACHINE, STOP THE TRACTOR ENGINE, REMOVE IGNITION KEY AND WAIT

FOR ROTATING PARTS TO STOP BEFORE LEAVING THE TRACTOR.

1) LUBRICATION

. PTO Shaft (fig. 51) :

Grease PTO shaft telescopic tubes (A), universal

joint bearings (B) and guard tubes (C) : every 8 hours

of use with SHELL Multi-Purpose grease NLGI

grade 2.

. Roller :

Grease the bearing housings at each roller end every 20 hours with SHELL Multi-Purpose grease NLGI grade

2 until the old grease spills out of the housing (2 grease zerks).

. Gearbox and side gearbox (photos 52, 53 and 53A) :

First oil change after 10 hours of work ; then every 100 hours. To change the oil of the side gearbox, the protective

guards (3) must be removed. Use extreme pressure oil SHELL SPIRAX of grade SAE 85W 140 (in intensive

working conditions) or SAE90 oil (API GL4 or GL5) for work in less demanding applications. Check the oil level

on a weekly basis.

51

53

52

GEARBOX SIDE GEARBOX

Filler and breather plug item 1 item 2

Drain plug item 4 item 5

Level plug item 6 item 7

Oil quantity 6 litres/10.5 Imp.Pint/12 US Pint 3,5 litres/6.3 Imp.Pint/7 US Pint

FOR TROUBLEFREE OPERATION OF YOUR MACHINE,

WE RECOMMEND THE USE OF SHELL PRODUCTS.

53A

- 37 -

Page 40

2) FITTING THE BLADES

a) POWER TILLER with standard diameter C- blade rotor (fig. 54 and photo 55)

The blades can be fitted in two different ways, depending on the job to get done :

- 3 pairs of blades per flange

3 right blades (D) and 3 left blades (G) (as fitted at factory)

- 2 pairs of blades per flange

2 right blades (D) and 2 left blades (G)

NUMBER OF BLADES

Number of rotor flanges 11 13

TYPE OF TYPE OF NUMBER OF

FORMATION BLADES BLADES

2 pair RIGHT 20 24

formation LEFT 20 24

3 pair RIGHT 30 36

formation LEFT 30 36

To recognise if blades are right or left, point the cutting

edge in the direction of rotation (F) and note the

direction of their curved portion.

A = machine forward direction

To fit blades helicoidally, proceed as follows :

- Always start fitting each flange with a left blade,

placing it opposite mark (R), shown by a chamfer or

a hollow (see fig. 54) ;

- all blades should be fitted on the left face of the

flanges (see photo 55).

- Fixing bolt heads should face the blades, washers

and nuts should face the flanges.

54

MODEL 250 300

End blades : depending on the way the blades have

been fitted (2 or 3 pairs of blades per flange), the left

end flange is fitted with 2 right blades diametrically opposite to each other or 3 right blades. Likewise, the right end

flange will be fitted with 2 left blades diametrically opposite to each other or 3 left blades (photo 55).

Tighten nuts to a torque of 30 daNm / 220 ft.lbs.

- 38 -

55

Page 41

b) POWER TILLER with larger diameter L- blade rotor (fig. 56 and photo 57)

The blades can be fitted in two different ways, depending on the job to get done :

- 3 pairs of blades per flange

3 right blades (D) and 3 left blades (G) (as fitted at factory)

- 2 pairs of blades per flange

2 right blades (D) and 2 left blades (G)

56

NUMBER OF BLADES

Number of rotor flanges 11 13

TYPE OF TYPE OF NUMBER OF

FORMATION BLADES BLADES

2 pair RIGHT 20 24

formation LEFT 20 24

3 pair RIGHT 30 36

formation LEFT 30 36

To recognise if blades are right or left, point the cutting

edge in the direction of rotation (F) and note the

direction of their curved portion.

A = machine forward direction

To fit blades helicoidally, proceed as follows :

- Always start fitting each flange with a left blade,

placing it opposite mark (R), shown by a chamfer or

a hollow (see fig. 56),

- all blades should be fitted on the left face of the

flanges (see photo 57).

- Fixing bolt heads should face the blades, washers

and nuts should face the flanges.

MODEL 250 300

57

End blades : depending on the way the blades have been fitted (2 or 3 pairs of blades per flange), the left end

flange is fitted with 2 right blades diametrically opposite to each other or 3 right blades. Likewise, the right end flange

will be fitted with 2 left blades diametrically opposite to each other or 3 left blades (photo 57).

Tighten nuts to a torque of 30 daNm / 220 ft.lbs.

- 39 -

Page 42

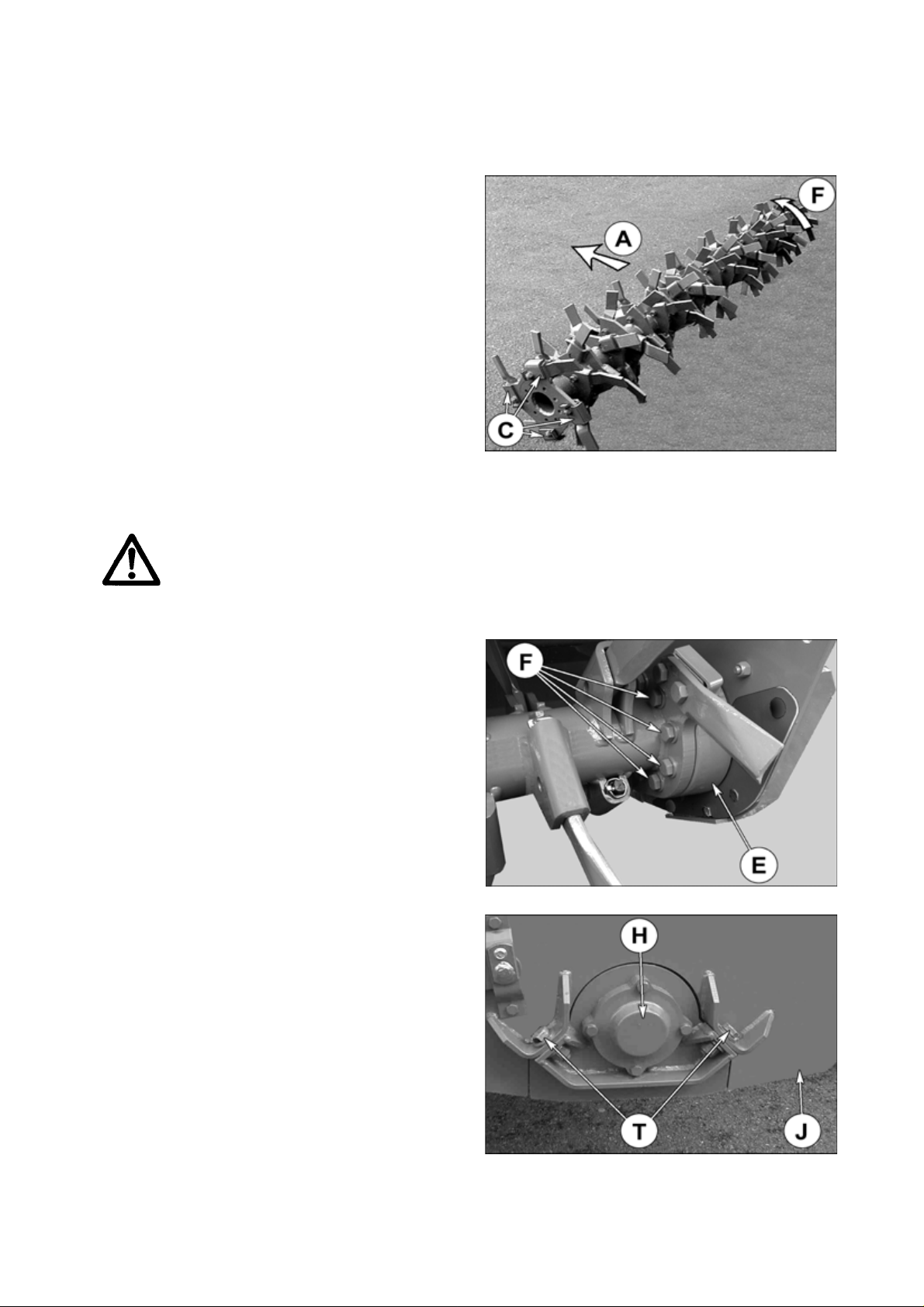

c) CULTITILLER rotor with Fast-Fit blades

The CULTITILLER rotor is equipped with angled left

and right blades, solidly housed in individual supports

welded on the rotor tube (photos 58 and 58A).

Start fitting blades on the support nearest the side

gearbox. A left blade should be fitted first (cutting

edge facing the left in the forward direction [A]) (photo

58). Then fit a right blade on the support opposite the

left blade. Fit all blades like this, alternately left and

right The last blades fitted should be the one nearest

the right end shield.

The cutting edges of all blades should face the direction of rotor rotation (F) (in forward direction [A])

(photo 58).

To facilitate the removal of the lynch pins (M), use the

special key (N) supplied with the machine (photo

58A).

End blades : The left end flange is fitted with 2 angled

blades and 2 left guard caps (B) (photo 58). The right

end flange is fitted with 2 right angled blades and 2

right guard caps. The blades must be fitted on the

flange inner side and the guard caps on the outer side

using 2 screws (M 16) (torque : 30 daNm/220 ft.lbs.).

58

When replacing blades, also change

guard caps (B) located on both rotor

end flanges (photo 58).

d) CULTIPLOW rotor with 2 bolts per blade

(photo 59)

This CULTIPLOW rotor is fitted with right and left

angled blades bolted onto flanges welded on the rotor

tube. To distinguish the left blades from the right

blades, note the cutting edge of the blade which is

facing towards the left in the rotor rotating direction

(F) (seen in the direction of travel (A) of the machine).

Each rotor flange is equipped with two left angled

blades and two right angled blades. On the end

flanges, 4 angled blades are mounted on the inner

sides.

On intermediate flanges the 2 right angled blades are

mounted on the right side and the 2 left angled blades

are mounted on the left side.

Fit all blades like this so that left and right blades are

fitted helicoidally.

The mounting bolts heads must be on the blade side,

the washers and bolts on the flange side.

58A

59

Tighten the nuts to a torque of 40 daNm / 295 ft.lbs

on all CULTIPLOW blades.

- 40 -

Page 43

e) CULTIPLOW rotor with 1 bolt per blade

(photo 60)

This CULTIPLOW rotor is fitted with left and right

angled blades. To distinguish left blades from right

blades, refer to part number marked on the back of

each blade (K1631030 = left blade, K1631040 = right

blade).

Each rotor flange is equipped with 2 left angled blades

mounted in holders welded to the flange left face and

2 right angled blades mounted in holders welded to

the flange right face.

On the end flanges, all holders are welded on the inner

face of the flanges.

Make sure to place the end flange blades in such a

way that they continue the spiral formed by the other

blades.

To replace blades, slightly unscrew fixing nuts, remove blades from holders, insert new blades and

tighten nuts.

Bolt torque : 30 daNm/220 ft.lbs.

When replacing blades, also replace

guard caps (C) located on both rotor

end flanges (photo 60).

60

3) CHANGING ROTORS

Detach rotor by proceeding as follows :

- Remove the 9 special hexagonal bolts (M16 x 43)

and their conical spring washers at F (photo 61).

- Remove the 2 hexagonal bolts (T) (M16 x 55)

(photo 62).

- Lift the machine. The complete rotor with housing

(H) now separates from drive flange (E) and side

shield (J) (photo 62).

Fit an alternative rotor :

Install the rotor by following the disassembly procedure in reverse order.

- Tighten the 2 hexagonal screws (T) (M16 x 55) (photo

62) to a torque of 30 daNm (221 ft.lbs).

- On drive flange (E) side, assemble 9 special hexagonal bolts (M16 x 43) and their conical spring

washers at F (photo 61). Tighten to a torque of 30

daNm (221 ft.lbs).

61

- 41 -

62

Page 44

TROUBLE SHOOTING

CAUSE REMEDYPROBLEM

Noisy drive when lifting Top link of 3-point hitch badly Position the top link parallel

the machine positioned/adjusted to the lower lift arms (page 14)

Excessive lifting height - Reduce lifting height

- Should the problem persist, disengage the PTO shaft when lifting the machine.

Noisy drive during work Machine is tilted to the front Lengthen or shorten top link to set

or rear the machine horizontally during

work. (The tractor PTO stud and

machine input shaft must be

parallel to each other) (page 14)

Machine insufficiently stabilized Tighten the tractor's anti-sway

and moves from side to side stabilisers

Too much power needed Too much worked ground Adjust the machine to a higher

when working in dry setting by means of the roller, the

conditions wheels or the skids (pages 22 & 26)

Working depth too deep Make sure it is set no deeper

than necessary.

Blades too worn Change the complete set of

blades so that the rotor stays

balanced.

Rotor speed (rotational frequency) Reduce rotor speed (rotational

is too high frequency) (see page 17)

Choose the appropriate rotor See important remarks

(pages 20 and 21)

Soil is thrown too far to Hood is badly positioned Alter the positions of the hoods

the rear and their flaps (page 19)

Too much power needed Too much worked ground Adjust the machine to a higher

when working in humid setting by means of the roller or

conditions the wheels (pages 22 and 26)

Working depth too deep Make sure it is set no deeper

than necessary.

Hood or rotor clogged Open the hoods so that the

ground can flow more freely.

Raise the hood flaps (page 19)

Rotor speed (rotational frequency) Reduce rotor speed (rotational

is too high frequency) (see page 17)

Choose the appropriate rotor See important remarks

(pages 20 and 21)

- 42 -

Page 45

PROBLEM CAUSE REMEDY

Tilth produced is too coarse Insufficient rotor speed (rotational Increase the rotor speed (rotation-

frequency) al frequency) (see page 17)

Hoods too open Close the hoods and if necessary

lower the hood flaps (page 19)

Forward speed too high Reduce forward speed

Choose the appropriate rotor See important remarks

(pages 20 and 21)

Irregular mix of Insufficient working depth Adjust the roller or the wheels

vegetable residue to increase the amount of ground

to be worked (pages 22 and 26)

Rotor speed (rotational frequency) Increase rotor speed (rotational

is too slow frequency) (page 17)

Choose the appropriate rotor See important remarks

(pages 20 and 21)

Seedbed ground is Not enough pressure on the Lengthen the top link

over-aerated roller

Soil is too fine, due to rotor Reduce rotor speed (rotational

over-working the soil frequency) (see page 17)

Choose appropriate rotor See important remarks

(pages 20 and 21)

Vegetable residue build up Poor shredding and distribution Operate an independant shredder

on seed drill coulters when of vegetable residue first

using an EL 142 / seed Use a seed drill specially

drill combination. equipped for seeding in

vegetable residue.

Ridging across Machine jerks and jolts Make necessary adjustment on :

the pass width during work. - forward speed (reduce slightly)

- rotor speed (rotational frequency)

(page 17)

- working depth (increase slightly)

(pages 22 and 26)

- opening or closing the hoods and

their flaps (page 19)

- 43 -

Improve machine stabilisation by

using the following optional equipment (see page 28) :

- side separating discs

- front gauge wheels (with the roller)

Page 46

PROBLEM CAUSE REMEDY

Erratic packer roller Worn or incorrectly adjusted Position scraper plates closely

function scraper plates to the roller

(see pages 24 and 25)

Rely on hard coated scraper plates

or nylon cleaning plates in case of

excessive wear (pages 34 and 35)

Scrapers jammed by trash Clean the scrapers by pivoting

them to the rear (pages 24 and 25)

Scraper bar incorrectly Make sure that the scraper bar

positioned is in its furthest forward position.

Plates must only be slid forward

one at a time (pages 24 and 25)

Plugging from ground build Sandy soil Close the hoods and if necessary

up in front of the packer roller lower the hood flaps (page 19)

Slightly lenghten the top link

Reduce forward speed

Use a maxipacker roller

Maxicrumbler roller clogging Humid conditions Use a packer roller

- 44 -

Page 47

SOUND LEVELS

Sound levels given out by : EL 142 Power Tiller / Cultitiller / Cultiplow

Sound levels have been measured in accordance with the measuring methods as defined in:

EN 1553

<< Agricultural machinery - Agricultural self-propelled, mounted, semi-mounted and trailed machines -

Common safety requirements >>

A-weighted emission sound pressure level L (A) eq inside tractor cab (with closed windows) :

Tractor only : 75.1 dB (A)

Tractor + machine : 77.4 db (A)

- 45 -

Page 48

LIMITED WARRANTY

KUHN S.A. of 4 Impasse des Fabriques, 67706 SAVERNE CEDEX, France (hereinafter called the

«Company») warrants, in accordance with the provisions below, to each original retail purchaser of

KUHN new equipment of its own manufacture, from an authorized KUHN dealer, that such equipment

is, at the time of delivery to such purchaser, free from defects in material and workmanship and that

such equipment will be warranted for a period of one year starting from the date the goods are delivered

to the end user and during this period up to a limit of 500 hours use, providing the machine is used and

serviced in accordance with the recommendations in the Operator’s Manual.

THESE CONDITIONS ARE SUBJECT TO THE FOLLOWING EXCEPTIONS :

1. Parts of machines which are not of our manufacture i.e. tyres, belts, P.T.O. shafts, clutches etc., are not

covered by this Limited Warranty but are subject to the warranty of the original manufacturer. Any claim

falling into this category will be taken up with the manufacturer concerned.

2. Warranty claims applying to these types of parts must be handled in the same way as if they were parts