Page 1

OPERATOR'S MANUAL

JN033AGB A

Shredders

BKE 280-305 SUPER

JN033AGB A

- English - 05-2010

Page 2

Page 3

Shredders

BKE 280-305 SUPER

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

BKE 280-305 SUPER shredders must only be used for the work for which they have been d esigned: shredding

of crop residues, set-aside land and green spaces.

Dear Owner

1

Page 4

Shredders

BKE 280-305 SUPER

$Contents

Dear Owner.....................................................................................................................1

Contents .........................................................................................................................2

Identification of the machine.........................................................................................4

Model identification plate ................................................................................................................5

Optional equipment..........................................................................................................................5

Safety...............................................................................................................................6

Description of symbols used in this document.............................................................................6

Safety instructions...........................................................................................................................7

Location and description of safety decals on the machine .......................................................19

Machine specifications................................................................................................25

Description and glossary...............................................................................................................25

Technical specifications............. ... ... ... .... ... ... ... ... .... ............................................. ... ... .... ... ............26

Required equipment.......................................................................................................................27

Sound levels ......... ... ... .... ... ... ... .... ............................................. ......................................................28

Putting into service......................................................................................................29

Coupling and uncoupling..............................................................................................................29

Coupling the machine....................................................................................................................34

Uncoupling the machine................................................................................................................37

2

Contents

Page 5

Shredders

BKE 280-305 SUPER

Instructions for transport............................................................................................ 40

Putting the machine into transport position................................................................................40

Conformity with the road regulations ... ... .... ... .............................................................................41

Instructions for work...................................................................................................42

Putting the machine into work position............. ..........................................................................42

Adjustments in working position..................................................................................................43

Machine use....................................................................................................................................45

Optional equipment.....................................................................................................46

Wear skids ......................................................................................................................................46

Maintenance and storage............................................................................................ 47

Frequency chart .............................................................................................................................47

Lubrication............................................................................................ ..........................................48

Maintenance....................................................................................................................................51

Storage............................................................................................................................................57

Machine recycling..........................................................................................................................58

Trouble shooting guide...............................................................................................59

Appendix ......................................................................................................................60

Calculating the load on an axle.....................................................................................................60

Limited warranty..........................................................................................................66

Contents

3

Page 6

Front view

Shredders

BKE 280-305 SUPER

$Identification of the machine

Rear view

4

Identification of the machine

Page 7

1. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Type: BKE 280 SUPER

Serial no.:

Type: BKE 305 SUPER

Shredders

BKE 280-305 SUPER

Serial no.:

2. Optional equipment

Tick box corresponding to the equipment fitted on your

machine:

Kit no. 1556444: Wear skids (BKE 280 SUPER).

Kit no. 1556445: Wear skids (BKE 305 SUPER).

Identification of the machine

5

Page 8

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Shredders

BKE 280-305 SUPER

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

6

Safety

Page 9

Shredders

BKE 280-305 SUPER

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations fo r preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect current le gislation concerning accident prevention, wo rk safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment a nd acce sso ries, as r ecom mended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident re sulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not traine d

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Safety

7

Page 10

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Shredders

BKE 280-305 SUPER

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt change s

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

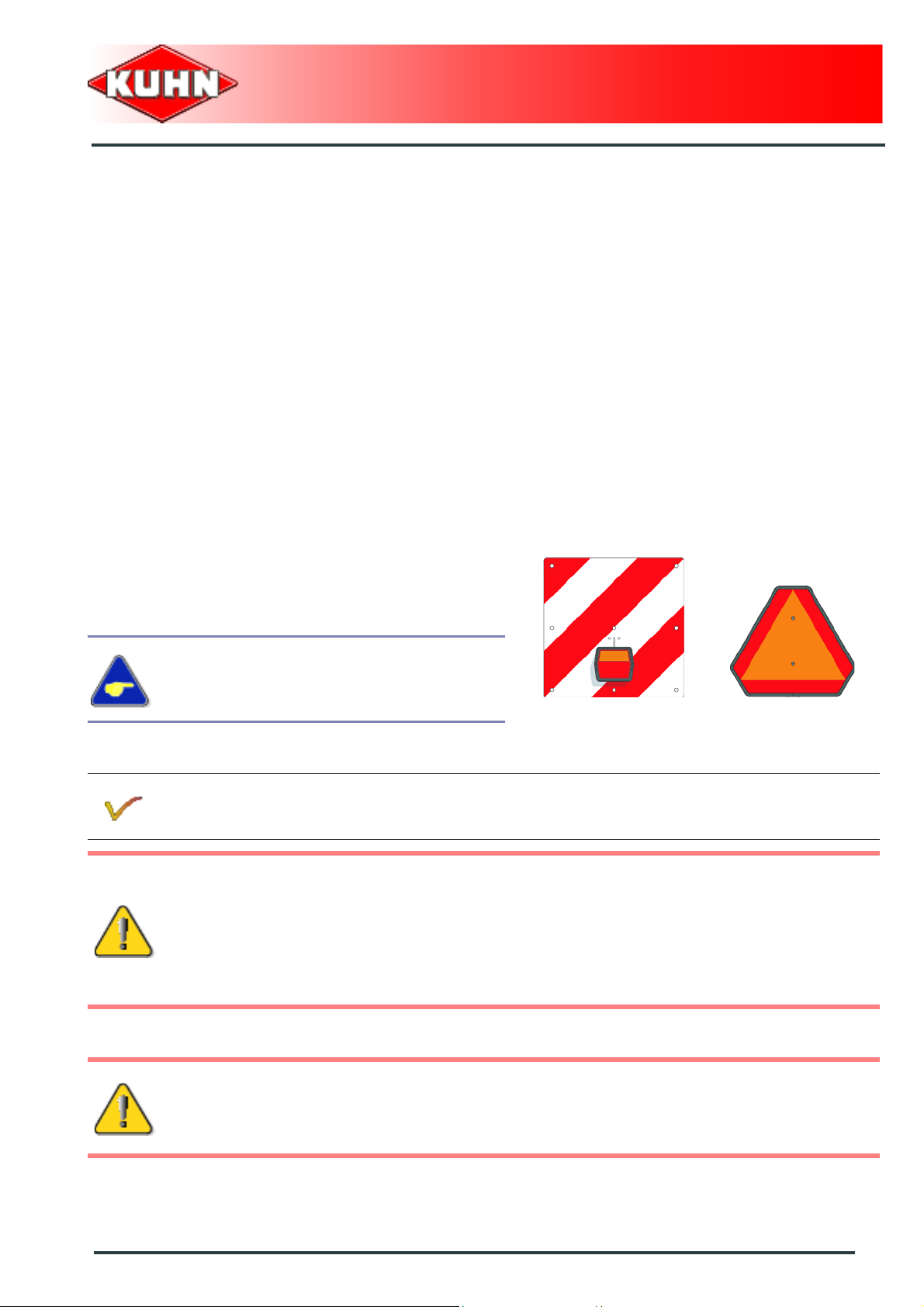

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

8

Safety

Page 11

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transportation of oversize

equipment.

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lights and indicators

Before transporting the machine on public road s, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Shredders

BKE 280-305 SUPER

Always obey current regulations for driving

on roads.

Gross weight and weight per axle

The drawings are not legally binding, their only aim is to illustrate the method to use.

Prior to driving on public roads, check t hat criteria are met t o be in conformity with the count rie's

regulations:

- When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized

payload must not be exceeded.

- When coupling tools to the front and rear 3-point lift linkages, the maximum load on each

axle's tires must not be exceeded.

- The load on the tractor front axle must always represent 2 0 % of the tr actor unladen we ight.

For machines with hoppers or tanks:

- If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance

with the countrie's legislation, empty the hopper to travel on public roads.

- In any case, we recommend to travel on public roads with empty hoppers and tanks .

Safety

9

Page 12

Shredders

BKE 280-305 SUPER

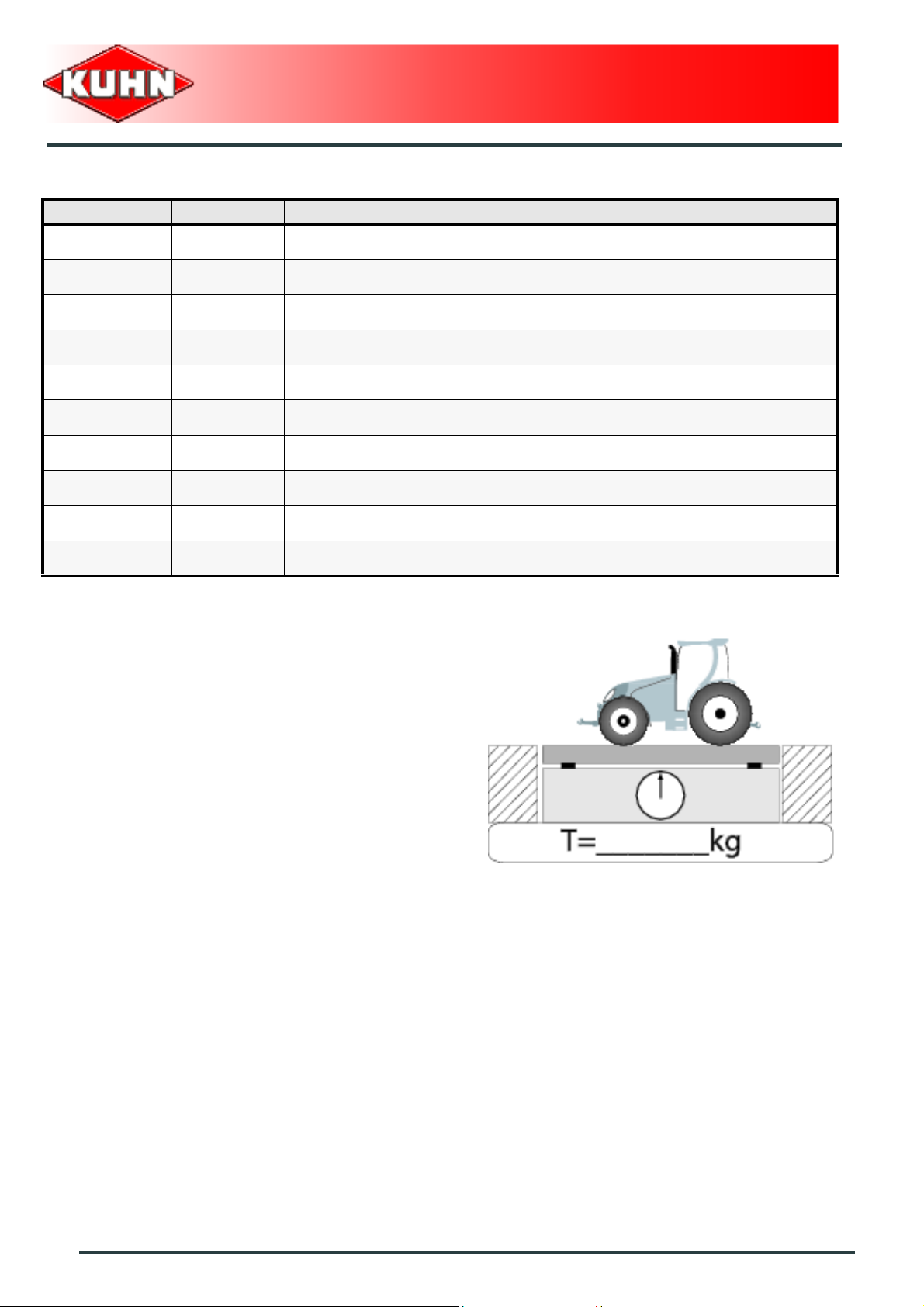

Description of symbols

Description Units Description

T kg Tractor unladen weight

PTAC kg Gross Combined Weight Rating

T1 kg Unladen load on tractor front axle

T2 kg Empty load on tractor rear axle

t kg Axle loads (Tractor + machine)

t1 kg Load on front axle (Tractor + machine)

t2 kg Load on rear axle (Tractor + machine)

t1 max kg Maximum load authorized on the tractor front axle according to the tires

t2 max kg Maximum load authorized on the tractor rear axle according to the tires

M1 kg Total weight of front tool or front ballast

Stage 1:

To measure:

- Tractor tare (T).

10

Safety

Page 13

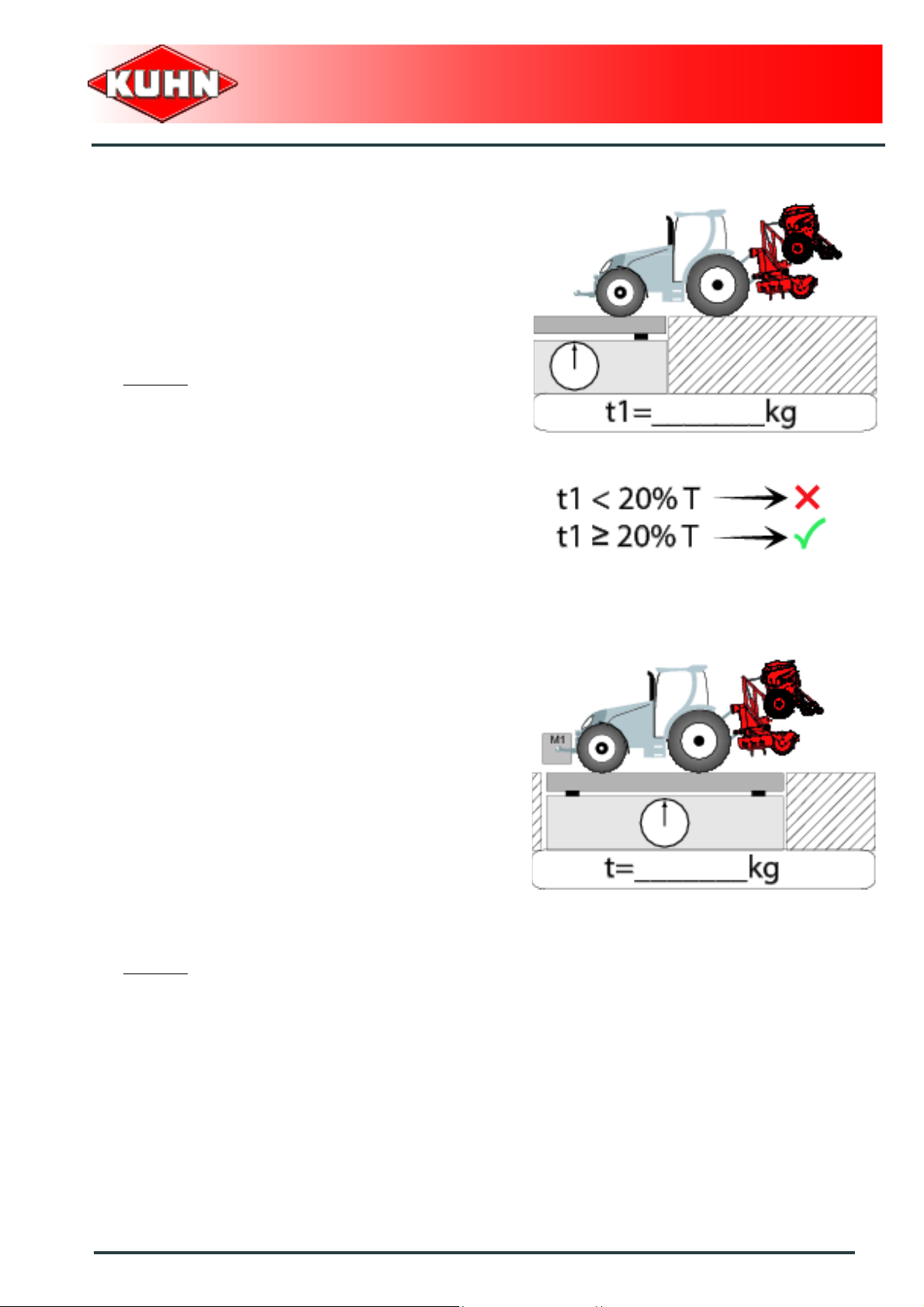

Stage 2:

- Couple the machine to the tractor.

To measure:

- Load on front axle (t1):

• Tractor + machine (transport position).

To do:

- If the front axle load (t1) is below 20% of the tractor

tare (T), add ballast weights (M1) to exceed the

minimum load on the front axle.

Example:

• (T) = 7500 kg (16535 lb)

• The front axle load must be of minimum 1500 kg

(3300 lb).(20% of T)

• (t1) = 700 kg (1545 lb).

• 700 kg (1545 lb) < 1500 kg (3300 lb).

• Add ballast weights until the minimum front axle

load is exceeded.

• Repeat checking procedure.

Shredders

BKE 280-305 SUPER

Stage 3:

To measure:

- Total weight (t):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- To go to the next stage:

• Check in the tractor's operator's manual that the

value measured is below the tractor's Gross

Combined Weight Rating.

To do:

- If t < PTAC go to the next stage.

- If the total unit weight exceeds the tractor Gross

Combined Weight Rating in accordance with the

countrie's legislation, empty the hopper to travel on

public roads.

Example:

• (t) = 10000 kg (24250 lb)

• PTAC = 13000 kg .

• t < PTAC : Go to the next stage.

Safety

11

Page 14

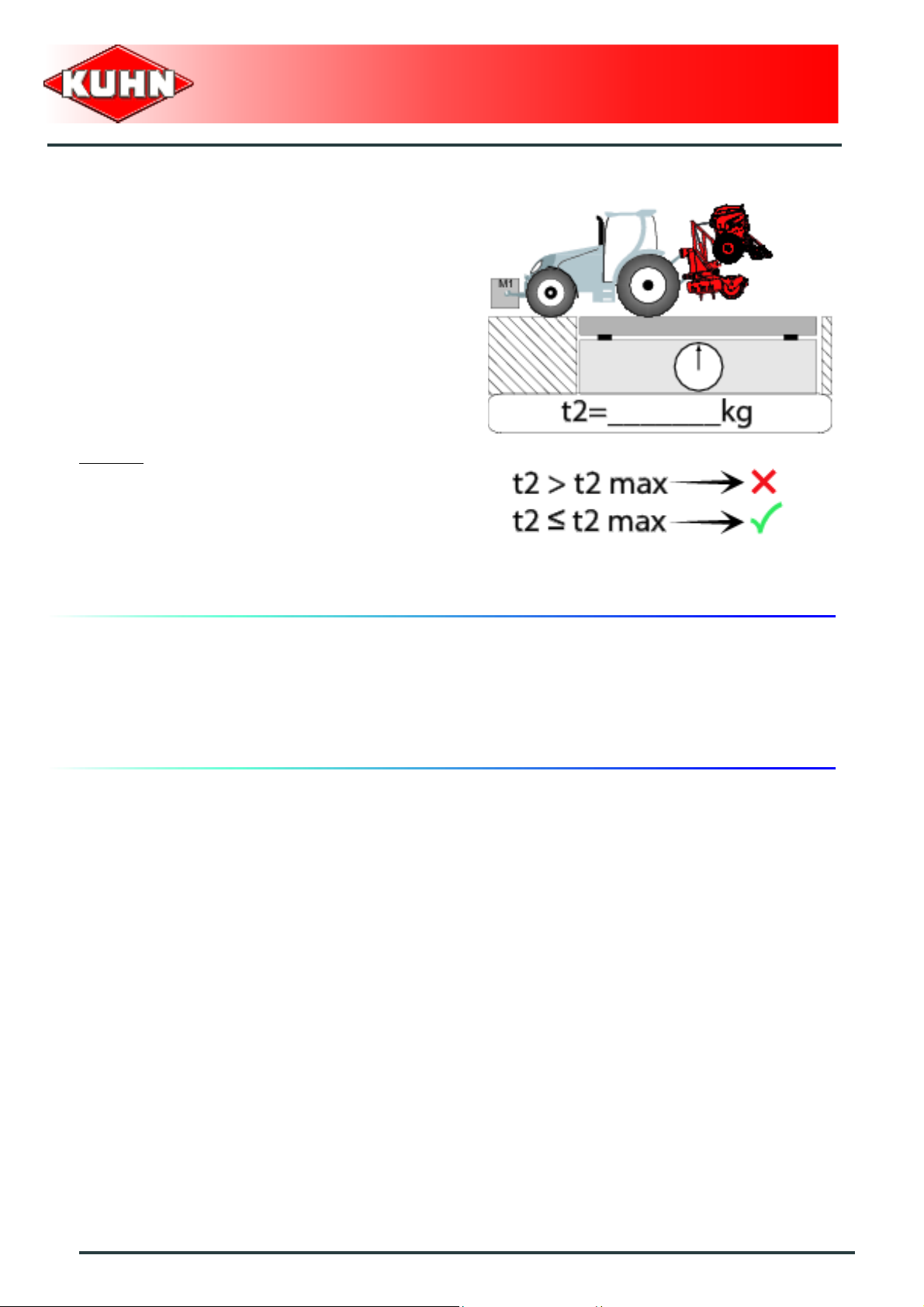

Stage 4:

To measure:

- Load on rear axle (t2):

• Tractor + machine (transport position).

• Ballast weights.

Checking:

- Check in the tractor's operator's manual that the value

measured is below the maximum allowed tractor rear

axle load.

- Check that tyre and rim specifiations are in conformity

with the requirements of the tractor manufacturer.

Example:

• Load on rear axle (t2) = 8500 kg (18740 lb)

• Check in the tractor's operator's manual that the

value measured is below the maximum allowed

tractor rear axle load.

• Check that tyre and rim specifiations are in

conformity with the requirements of the tractor

manufacturer.

Shredders

BKE 280-305 SUPER

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

12

Safety

Page 15

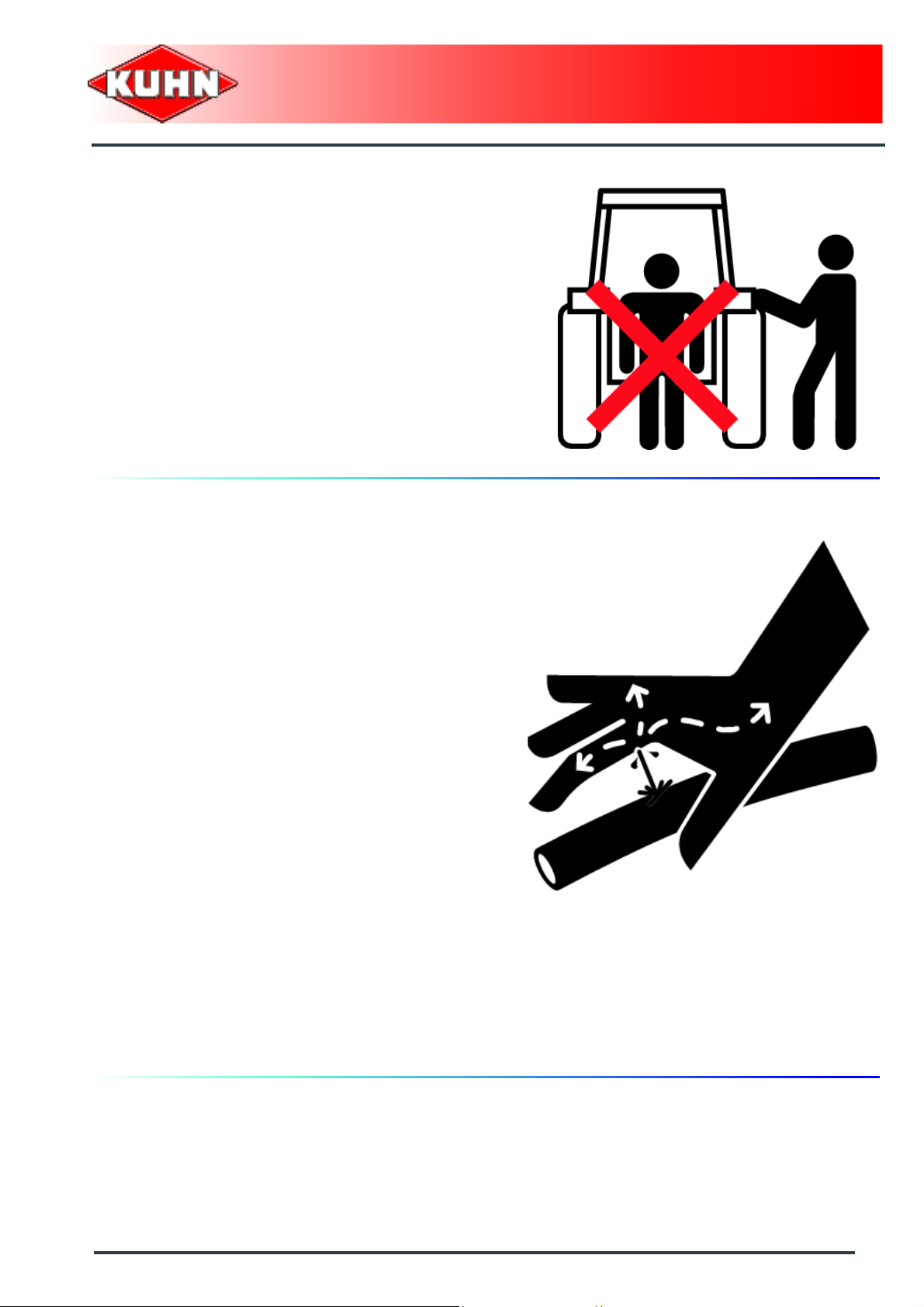

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

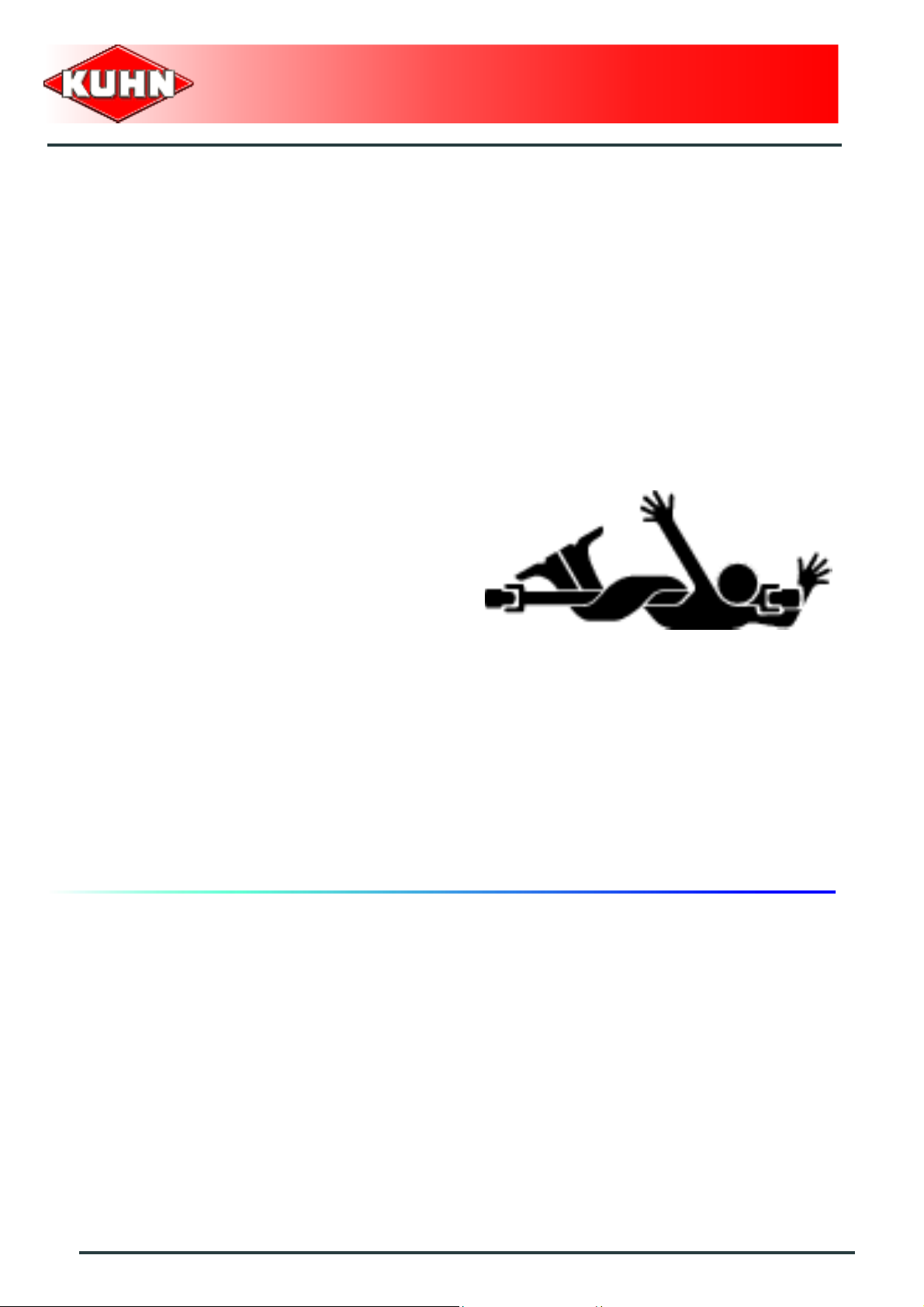

Hydraulic circuit

Shredders

BKE 280-305 SUPER

Caution! The hydraulic circuit is under high pressure.

Maximum pressure at work: 200 bar.

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making incorrect connectio ns, mark hydraulic

couplers and corresponding hoses with colors.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In case of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be r eplaced.

When replacing the hydraulic hoses, only use hoses with

the specification recommended by the manufacturer of

the machine.

To locate a leak, use appropriate means. Protect body

and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine to the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

Safety

13

Page 16

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are secured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately. A worn guard or an unpro tecte d PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendat ion s.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's manual

provided with the PTO shaft.

Shredders

BKE 280-305 SUPER

14

Safety

Page 17

Precautions during manoeuvres

When moving the machine from the transport position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Safety decals

Safety warning decals are placed in pictorial form on

various parts of the machine. They are there to warn you

of potential dangers and to tell you how to avoid

accidents.

Always keep the safety decals clean and readable, and

replace them when they are worn, damaged, missing or

illegible.

Shredders

BKE 280-305 SUPER

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters, etc.) on the ground, never pour them

down the drain and never discard them in any other

place where they could pollute the environment. Never

throw away or burn a tyre. Always take waste to

specialized recycling or waste disposal centers.

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the ground, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

Safety

15

Page 18

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

It is strongly recommended to have your machine

checked by your Kuhn dealer after each season,

especially tools and their attaching hardware.

Projection of stones and foreign objects

Shredders

BKE 280-305 SUPER

For driver safety, always use a tractor equipped with a

cab. Keep the ground to be shredded free from foreign

objects. Avoid using the shredder on stony or rocky

ground. If this is not possible, take extra safety

precautions, such as:

- Fit polycarbonate screens inside the tractor cab's side

and rear windows, or install narrow mesh guards on

their exterior.

- Increase the cutting height to avoid contact with

stones or rocks.

Never start the shredder when there are people nearby.

Even when the machine is used in accordance with its

purpose, objects may be projected. Stones and other

foreign objects projected by the moving parts can travel

a considerable distance. Keep all persons and animals

away from the danger zone.

The guard plates/covers on the machine help reduce the

risks of projection. Therefore, make sure that all

shredder protection devices are in place and good

condition prior to using the machine.

Regularly check the condition of the guard plates/covers.

Immediatly replace any worn, damaged or missing

guard plate/cover.

Precautions for machine use

Before using the shredder, inspect shredding tools

(knives, rotors) and their attachment hardware in

accordance with the instructions given in the present

manual. Immediatly replace any worn, damaged or

missing guard plate/cover. Before engaging the pto

drive, lower the shredder onto the ground. For your

safety, only use genuine parts !

16

Safety

Page 19

Regularly check the condition of the guard plates/covers.

Immediatly replace any worn, damaged or missing

cover. Before engaging the PTO drive, lower the

machine on the ground. Make sure all the guards are in

place. Keep all persons and animals away from the

danger zone.

Stay a safe distance from the machine when the cutting

tools are in movement.

Never work in reverse.

After disengaging the PTO drive, cuttings tools can

continue rotating for some time. Stay away from the

machine until all moving parts have come to a complete

standstill.

If the machine hits an obstacle, disengage the PTO

drive, stop the tractor engine, remove the ignition key

and wait for all moving parts to come to a complete

standstill. Check the entire machine for any damage

before resuming work.

Shredders

BKE 280-305 SUPER

Safety

17

Page 20

Precautions to take to prevent rotor from

clogging

Foreign bodies in the field (wire,...) can cause clogging.

Avoid shredding close to roads, dumps or inert material

dumps.

To eliminate cloggings, take the following safety

measures:

- Switch off the engine.

- Lift the machine using the tractor's lift linkage.

- Put on gloves and protective glasses.

- Wait until all rotating parts have come to a complete

stop.

- Checked concerned parts for overheating.

- Prop up frame using trestles.

- Remove foreign body with adequate equipment (lever

and pliers).

Shredders

BKE 280-305 SUPER

18

Safety

Page 21

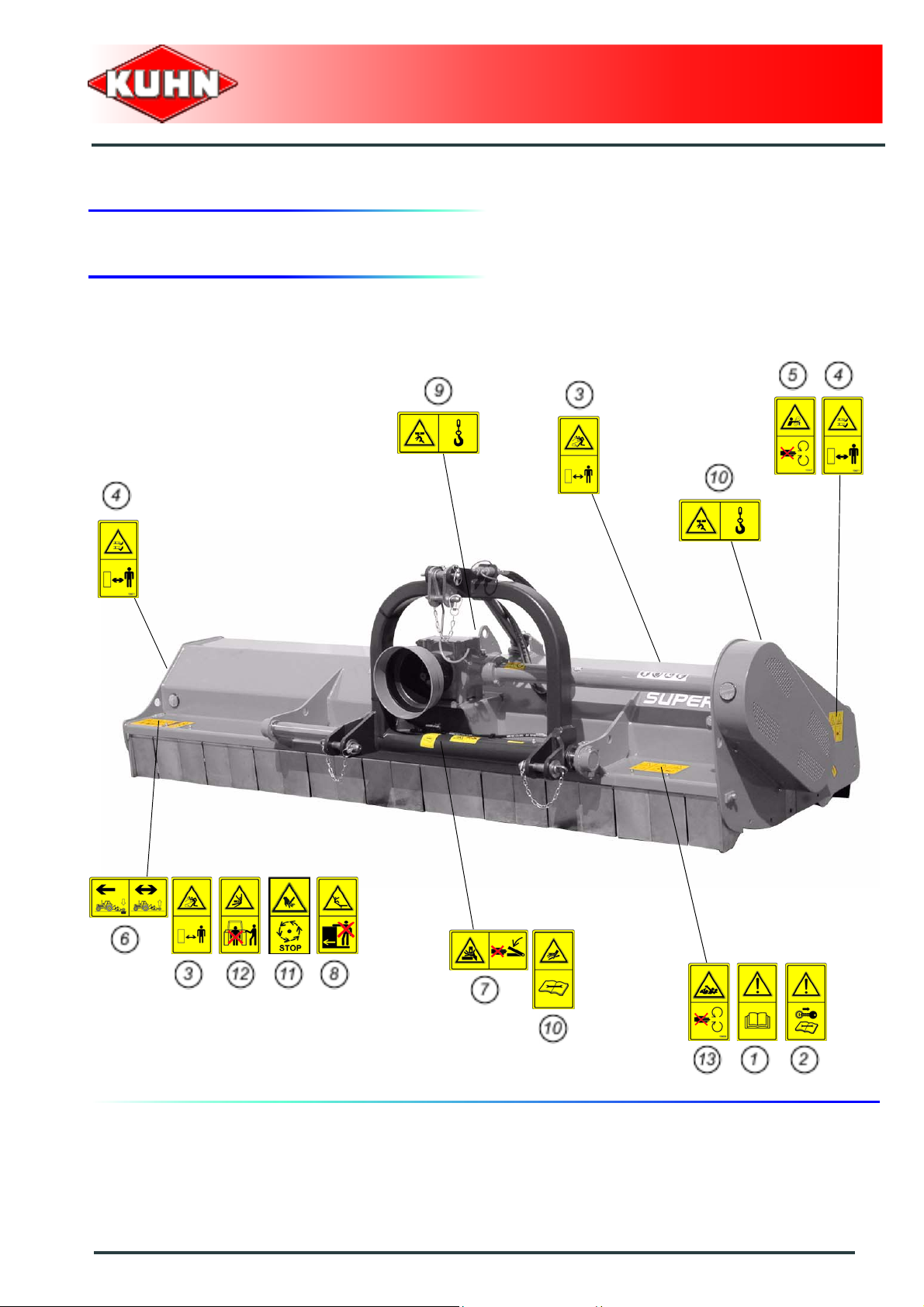

3. Location and description of safety decals on the machine

Location of safety decals

Shredders

BKE 280-305 SUPER

Safety

19

Page 22

Description of safety decals

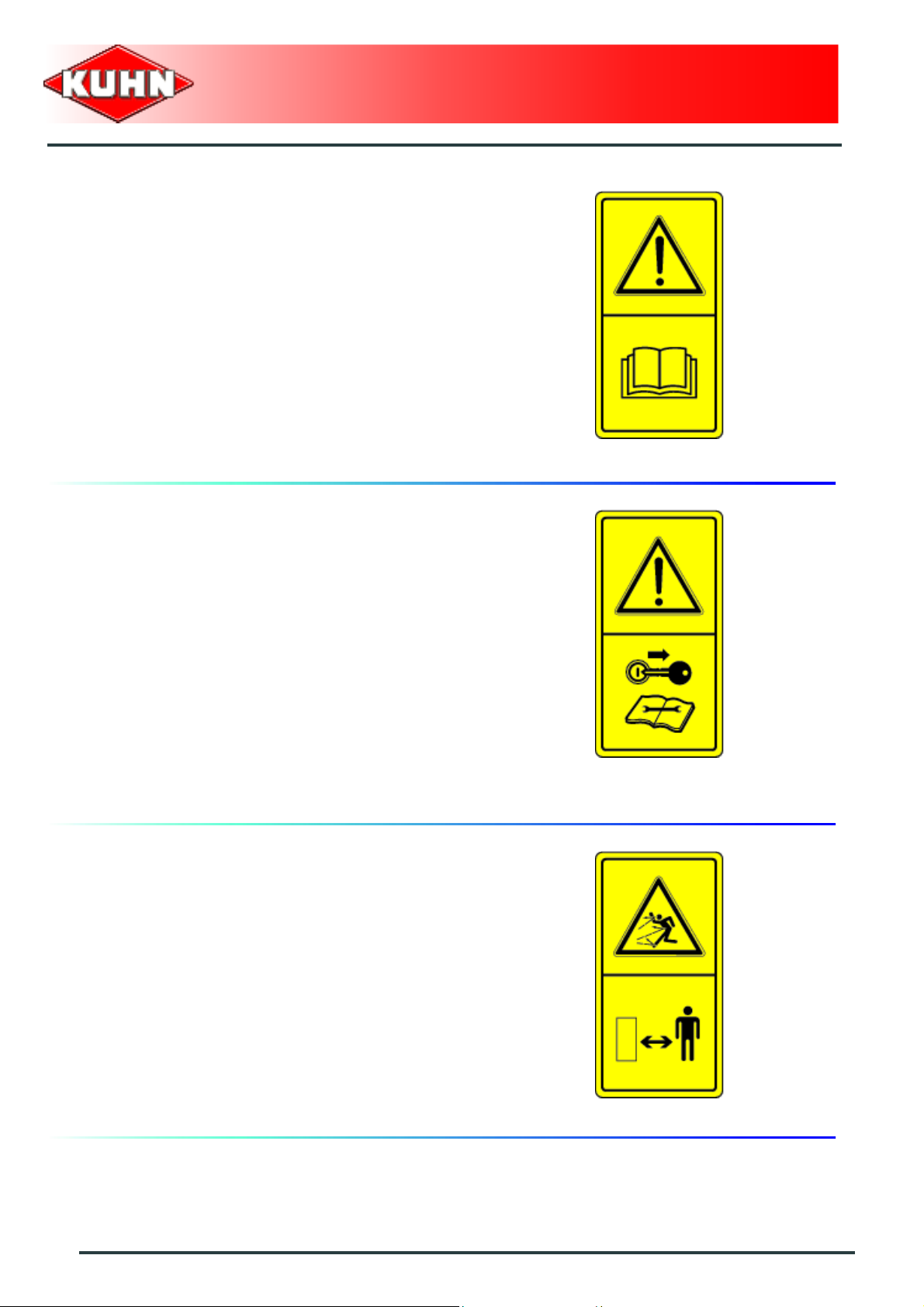

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Shredders

BKE 280-305 SUPER

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Projections (3)

Stones and other debris pro jected by the moving parts

can travel a long distance. The guard plates/covers must

always be in position and in good condition. Always sta y

at a safe distance from the machine.

20

Safety

Page 23

Rotating cutting tools (4)

Keep away from the machine tools all the time the

engine is running, the PTO drive engaged and the

moving parts have not come to a complete stop.

Moving elements (5)

Shredders

BKE 280-305 SUPER

Do not open or remove guards when the engine is

running.

Support wheels (6)

At work, the support wheels must rest on the

ground. During manoeuvres, raise the machine to lift the

wheels off the ground.

Safety

21

Page 24

Crushing area (7)

Never operate in an area where there is a crushing risk

before all moving parts have come to a complete stop .

Danger of falling (8)

Do not ride on the machine.

Shredders

BKE 280-305 SUPER

Anchoring point (9)

Indicates anchoring points for handling the machine.

22

Safety

Page 25

Hazard: high-pressure fluids (10)

Oil jets under pressure.

Shredders

BKE 280-305 SUPER

Risk of injuries (11)

Before adjusting, maintaining or repairing the machine,

wait until all moving parts have come to a complete stop.

Risk of being crushed (12)

Do not stay between the machine and the tractor.

Safety

23

Page 26

Risk of entanglement (13)

Stay clear of rotating drive line.

Shredders

BKE 280-305 SUPER

24

Safety

Page 27

$Machine specifications

1. Description and glossary

0

8

Shredders

BKE 280-305 SUPER

4

9

3

1

7

6

2

8

3

3

Three-point hitch coupler

1 :

Hitch pin

3 :

PTO shaft support

5 :

Side drive shaft

7 :

Semi-pivoting wheels (Optional equipment)

9 :

Side guard

2 :

Parking stand

4 :

Central gearbox

6 :

Roller (Optional equipment)

8 :

Machine specifications

25

Page 28

BKE 280-305 SUPER

2. Technical specifications

BKE SUPER 280 305

Shredders

Coupling device

Lateral offset 450 mm (1’6’’)

Working width 2793 mm (9’2’’) 3034 mm (9’ 11’’)

Maximum width 2959 mm (9’8’’) 3186 mm (10’5’’)

Required tractor power 49 kW (67 hp) 58 kW (78 hp)

Allowable tractor power 92 kW (125 hp)

Free wheel Inside central gearbox

Power takeoff rotation frequency 540-1000 min

Quantity / type of belts N°4 SPBX 1600

Rotor speed 1833-1960 min

Knives peripherical speed

Cutting diameter 465 mm (1’6’’)

Number of knives:

01 56 64

[m/s]

3 point, Category 2

( Hydraulic offset )

-1

-1

44 - 48

06 28 32

08 56 64

09L 28 32

Distance d ( Distance between the centre of the

lower link ball joints and the centre of gravity of the

rear tool or rear ballast )

- See chapter: «Appendix».

Weight ( including equipment ) 890 kg (1962 lb) 920 kg (2028 lb)

26

Machine specifications

700 mm (2’4’’)

Page 29

3. Required equipment

Rear support unit

Roller

The roller can be used for work on gras s cover ed area s,

set-aside land or pasture land.

or

Shredders

BKE 280-305 SUPER

Semi-pivoting wheels

The semi-pivoting wheels are recommended for work in

wet conditions.

Machine specifications

27

Page 30

Shredders

BKE 280-305 SUPER

4. Sound levels

Sound levels have been measured in accordance with the measuring methods as defined in:

NF EN ISO 4254-1 «Agricultural machinery - Safety - Part 1: General requirements»

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L(A)eq according to

standard UNI EN ISO 11201: 1997

BKE 280 SUPER BKE 305 SUPER

93.5 dB (A) 94.0 dB (A)

Measured weighed volume level Lw(A) according to standard UNI EN ISO 3744: 1997 for machines that exceed

a pressure of 85dB(A) in the driver's post

BKE 280 SUPER BKE 305 SUPER

110.0 dB (A) 108.5 dB (A)

Wear ear protectors !

28

Machine specifications

Page 31

$Putting into service

1. Coupling and uncoupling

Description of coupling elements

- A PTO shaft 1 3/8’’ - 6 splines (1).

- Attachment configuration category 2.

Preparing the tractor

Shredders

BKE 280-305 SUPER

The tractor must be fitted with lower link

stabilizers.

The tractor PTO must rotate at a speed of 540 min-1 or

1000 min

Hitch pin parallelism

Adjust tractor lift rods so that hitch pins are parallel to th e

ground.

-1

.

Lateral adjustment of the lower links

Balance the play on either sides of the lift linkage and

lock lower link stabilizers.

Putting into service

29

Page 32

Adjusting the machine

Invert drive pulleys to obtain a different machine PTO

speed.

Inverting the pulleys

- Remove the 3 nuts (2).

- Remove screw (3).

- Remove side gearbox (1).

Shredders

BKE 280-305 SUPER

- Loosen screw (3).

- Loosen the 4 screws (4) that hold the central gearbox.

- Loosen counter nut (5).

- Loosen adjustment screws (6) and (7) to slacken

belts.

- Remove belts (9).

- Unscrew and remove the 7 screws (10).

- Insert and screw 3 out of the 7 screws in the 3

threaded holes (11)

Insert screws in threaded holes (11) to extract Tclamps.

.

- Remove T-clamp (12).

30

Putting into service

Page 33

- Remove pulley (A).

- Repeat procedure on pulley (B).

- Invert and reinstall pulleys (A) and (B).

Shredders

BKE 280-305 SUPER

- Reinstall T-clamp (12) of pulley (A).

- Reinstall the 7 bolts (10).

- Tighten screws (10)

• Torque: 4,2 daNm (31 lbf ft).

- Reinstall T-clamp (12) of pulley (B).

Putting into service

31

Page 34

- Using a ruler, check that pulleys are in line (8).

Shredders

BKE 280-305 SUPER

- Reinstall the 7 bolts (10).

- Tighten screws (10)

• Torque: 4,2 daNm (31 lbf ft).

- Reinstall belts (9).

- Turn the adjustment screws (6) and nuts (7) equally

until reaching the optimum tension.

By adjusting (6) and (7) equally, the central

transmission shaft is kept parallel to the rotor.

- Tighten screws (3) and (4).

- Tighten counter nut (5).

32

Putting into service

Page 35

- Using a ruler, check that pulleys are in line (8).

- Repeat procedure until perfect pulley alignment is obtained.

- Reinstall side gearbox (1).

- Reinstall screws (3) and nuts (2).

- Tighten screws (3) and nuts (2)

• Torque:2.5 daN m (18 lbf ft)

Shredders

BKE 280-305 SUPER

Putting into service

33

Page 36

2. Coupling the machine

The input machine rotation direction must

correspond to the tractor PTO rotation

direction.

Check that tractor PTO rotates clockwise.

- Lower the tractor three-point linkage.

- Place the lower links as close as possible under the

hitch pins.

- Attach the lower links to the hitch pins (1).

- Secure with lynch pins.

Shredders

BKE 280-305 SUPER

- Attach top link (2).

- Lock the upper hitch attachment using lynch pin (3).

- Lift the machine using the tractor's lift linkage.

Hydraulic connection

Connect hydraulic hoses (a) and (b) to the same

hydraulic double acting outlet.

34

Putting into service

Page 37

Primary PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

The tractor PTO stub must rotate at a speed of 540 min-1.

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes. As a safety measure, a clearance (L) of at least

25 mm (1’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

250 mm (10’’).

Shredders

BKE 280-305 SUPER

If this is not the case:

- Mark length (H) to cut when the transmission is the

maximum overlap position.

- Shorten the guard tubes and the transmission tubes

by the same length.

- Bevel and clean the tubes.

- Grease the inside of the outer tube.

Never operate the PTO shaft at an angle X exceeding

30°.

Putting into service

35

Page 38

On machine side, attach PTO shaft guard chain to the

gear box guard fastener 1.

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

Immediately replace any worn or damaged

guard.

Shredders

BKE 280-305 SUPER

Length of the top link

- Adjust the height of the lift linkage an d the length of

the top link until the machine is horizontal or only

slightly higher at the front.

- Adjust the length of the top link in order to set the

swinging yoke (1) at an angle of X=45° when the

machine is in the working position.

36

Putting into service

Page 39

3. Uncoupling the machine

Park the machine on an even fairly level

ground.

With roller:

From the working position:

- Lower and lock parking stand (1).

- Lower the tractor three-point linkage to rest the

machine on the ground.

- Uncouple and place PTO shaft in support (2).

- Detach the top link from the machine end (3).

- Release the lower links (4).

- Lower the tractor three-point linkage.

Shredders

BKE 280-305 SUPER

The machine is uncoupled.

Position hydraulic hoses on holder (5).

Putting into service

37

Page 40

With semi-pivoting wheels:

From the working position:

- Pivot wheels (1) in transport position.

- Lock semi-pivoting wheels.

- Secure pin (2) using R-clip.

- Lower and lock parking stand (3).

- Lower the tractor three-point linkage to rest the

machine on the ground.

Shredders

BKE 280-305 SUPER

- Uncouple and place PTO shaft in support (4).

- Block machine with wheel chocks (5).

- Detach the top link from the machine end (6).

- Release the lower links (7).

- Lower the tractor three-point linkage.

The machine is uncoupled.

Position hydraulic hoses on holder (8).

38

Putting into service

Page 41

Handling

Shredders

BKE 280-305 SUPER

When lifting this equipment, use appropriate

lift straps, chains or any other equipment, in

perfect working order, complying with safety

standards in force for this type of equipment,

and with capacities that exceed the total

weight of the unit, as listed in this manual:

- BKE 280 SUPER: 890 kg (1962 lb).

- BKE 305 SUPER: 920 kg (2028 lb).

Putting into service

39

Page 42

$Instructions for transport

Before placing the machine into transport

position:

- Wait until the rotating parts have come

to a complete stop.

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

1. Putting the machine into transport position

Shredders

BKE 280-305 SUPER

From the working position:

- Lift the machine with the tractor's three point linkage.

When the following equipment is fitted:

Semi-pivoting wheels.

- Unlock and remove pin (1).

- Pivot semi-pivoting wheel in transport

position.

- Insert pin (1).

- Secure with lynch pin.

- Repeat the operation on the second wheel.

- Activate offset cylinder to put the machine in line with

the tractor.

The machine is in transport position.

Never engage the tractor PTO drive when the

machine is in transport position.

40

Instructions for transport

Page 43

2. Conformity with the road regulations

Before driving the machine on public roads,

ensure that the machine complies with

current highway code regulations.

- Check that the light boards are clean and that the

lighting equipment functions before transporting the

machine on public roads.

Shredders

BKE 280-305 SUPER

In offset position, the machine juts out with

regards to the tractor.

Follow the local regulations in terms of

oversize equipment signalling and be careful

when driving on roads.

Instructions for transport

41

Page 44

$Instructions for work

Before placing the machine in working

position:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

1. Putting the machine into work position

Shredders

BKE 280-305 SUPER

From the transport position:

If the machine is equipped with semi-pivoting wheels.

Unlock semi-pivoting wheels:

- Unlock and remove pin (1).

- Fit pin (1) in its holder (2).

- Secure with lynch pin.

- Repeat the operation on the second wheel.

Lower the tractor's lift linkage until the rear support unit

touches the ground.

The machine is in working position.

42

Instructions for work

Page 45

2. Adjustments in working position

Working height

The cutting tools must never touch the

ground.

The working height is set by the position of the rear

support unit.

With roller:

Shredders

BKE 280-305 SUPER

- Slightly lift the machine from the ground.

- Loosen bolts (1)(2)(3).

- Remove screw ((3)).

- Proceed the same way on the other side

- Position roller in holes corresponding to the required

adjustment.

- Reinstall bolts (3).

- Tighten bolts (2) and (3)

• Torque: 13.5 daN m (99 lbf ft)

- Tighten screws (1)

• Torque: 21 daN m (155 lbf ft)

Relationship between the working height and the

roller position:

- Hole (a) = 30 mm (1.2’’).

- Hole (b) = 60 mm (2.4’’).

- Hole (c) = 86 mm (3.4’’).

- Hole (d) = 110 mm (4.3’’).

- Hole (e) = 131 mm (5.2’’).

Instructions for work

43

Page 46

With semi-pivoting wheels:

- Slightly lift the machine from the ground.

- Loosen screw (1).

- Remove screw (2).

- Position wheel arm in hole corresponding to the

required setting.

- Reinstall and tighten screw (2):

• Torque: 21 daN m (155 lbf ft).

- Tighten screw (1).

• Torque: 21 daN m (155 lbf ft).

Relations between the working height and the

position of the wheels:

- Hole (a) = 28.5 mm (1.1’’).

- Hole (b) = 52 mm (2.0’’).

- Hole (c) = 83 mm (3.3’’).

- Hole (d) = 96 mm (3.8’’).

- Hole (e) = 125 mm (4.9’’).

Shredders

BKE 280-305 SUPER

Height of the tractor's lift linkage

- Lower the 3 point lift of the tractor until the rear support

element rests on the ground.

- Adjust lift linkage height to obtain a perfectly

horizontal position.

Avoid modifying the linkage height to tilt the

machine frontwards.

When tilting the rear part of the machine

downwards, there is an increased risk of

material being ejected towards the operator.

e

44

Instructions for work

Page 47

3. Machine use

Before shredding:

- Keep all persons and animals away from

the machine danger zone.

This zone is defined by a radius (R) of

10 m (33’) around the working line of the

machine.

If using a tractor with a cab that is not soundproofed or pressurized, the operator must

use individual protection equipment:

Ear protections, if the noise exceeds normal

exposure limits.

Anti-dust mask if working in very dry

conditions or when large quantities of dust

are lifted.

Shredders

BKE 280-305 SUPER

If the machine starts vibrating oddly during

work, immediately stop and check the

condition of the rotor, the cutting tools and

the balancing ballast. Excessive vibration

can cause physical harm to the user.

The top link is in floating position during work to

provide good ground adaptation in irregular

grounds.

Groundspeed

Adapt the forward speed to the working conditions.

Instructions for work

45

Page 48

1. Wear skids

Kit no. 1556444 (BKE 280 SUPER)

Kit no. 1556445 (BKE 305 SUPER)

Fitting

- Place the skid.

- Insert screws and nuts (1).

- Tighten nuts

• Torque : 5 daN m (37 lbf ft).

- Proceed the same way on the other side.

Shredders

BKE 280-305 SUPER

$Optional equipment

46

Optional equipment

Page 49

Before carrying out any maintenance or

repairs on the machine, switch off the tractor

engine, remove ignition key, wait until all

moving parts have come to a standstill and

apply park brake.

1. Frequency chart

Shredders

BKE 280-305 SUPER

$Maintenance and storage

Lubrication

Draining:

- Central gearbox

Grease:

- The wheel pins

- Hitch sliding tubes

- Roller removable bottoms

Oil:

- Cardan cross joints

- PTO shaft tubes

Every 4

hours

Every 8

hours

3

Every 20

hours

3

Every 50

hours

3

Every

250

hours or

at the

end of

the

season

3

- The PTO shaft guiding bushes

- Roller removable bottoms

- Pivot points

- Rotor bearings

3

3

Maintenance and storage

47

Page 50

2. Lubrication

The pictorials show the points to be greased Part

no. 09905400

- Clean grease nipples before greasing.

Lubricate with AGIP GR MU EP/2 multi-purpose

lithium grease.

Shredders

BKE 280-305 SUPER

PTO shaft

Primary PTO shaft

- Every 8 hours:

• universal joints (1).

- Every 20 hours:

• transmission tube (2).

- Every 50 hours:

• guide rings (3).

48

Maintenance and storage

Page 51

Grease

- The wheel pins (1).

Shredders

BKE 280-305 SUPER

- Hitch sliding tubes (2).

- Roller removable bottoms (3)

Maintenance and storage

49

Page 52

Oil change

Central gearbox

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

Lubricate with AGIP SAE 90 EP (ISO220) gear oil.

- BKE 280 SUPER: 2.2L(0.58USgal).

- BKE 305 SUPER: 2.3L(0.61USgal).

- Park the machine on an even fairly level ground.

- Remove drain plug (2).

- Use an oil syringe to drain the gearbox.

- Remove filler plug (1).

- Pour the correct oil quantity and quality through the

opening of the filler plug (1).

- Clean and reinstall drain plug (2) and its washer.

Replace if necessary.

- Reinstall filler plug (1).

- Check central gearbox oil level.

Shredders

BKE 280-305 SUPER

50

Maintenance and storage

Page 53

3. Maintenance

Checking the oil levels

Place the machine on level ground.

Check central gearbox oil level:

- Place the machine on level ground.

- Remove level plug (1).

Shredders

BKE 280-305 SUPER

- The oil level must reach lower part of level plug hole.

- Reinstall level plug (1).

Maintenance and storage

51

Page 54

Check cutting tools and their fixing

elements

Cutting tools:

Universal knives Type 01 (1)

Hammer knives Type 06 (2)

Shredders

BKE 280-305 SUPER

Pivoting universal knives Type 08 (3)

Articulated hammer knives Type 09L (4)

52

Maintenance and storage

Page 55

Check cutting tools before each use in order to:

• ensure shredding quality.

• guarantee safety in use.

• avoid risk of damaging the fixing elements.

Replace cutting tools in the following cases:

- Damaged cutting tools:

• Very uneven ground can cause the knives to crack

or warp.

- Important wear.

Universal knives

- The length (L1) of the universal knives must exceed

90 mm (3.54’’).

- Ovalisation of the mounting hole L2 must not exceed

18 mm (0.71’’).

Shredders

BKE 280-305 SUPER

Hammer knives

- The cutting tool length L1 must exceed

90 mm (3.54’’).

- Ovalisation of the mounting hole L2 must not exceed

18 mm (0.71’’).

Fixing elements

- Check the condition of the fixing elements regularly

and also the torque of the knife-fixing bolt.

• Torque: 10.5 daN m (77.4 lbf ft).

- Check the fixing elements:

• After hitting an obstacle.

• When knives are replaced.

• At the start of each season.

- The fixing bolts should be changed in the following

cases:

• When there is visible distortion.

• When the thread is damaged or worn.

• When a groove (H) of over 2 mm (0.08’’) has

developed.

Maintenance and storage

53

Page 56

Replacing knives and pallet knives

Immediately replace worn or damaged parts

with genuine KUHN parts.

Replace self-locking nuts after each removal

operation:

Torque: 10.5 daN m (77.4 lbf ft).

From the transport position:

- Uncouple PTO shaft on machine side.

Partial replacement:

- Lift the machine using the tractor's lift linkage.

- Prop up frame using trestles.

- Replace damaged or worn knives.

- Replace the knives that are diametrically opposite to

maintain the existing balance.

- Check that there is still 1 to 2 mm (0.04’’ - 0.08’’) play

between the pair of knives and the supports.

Shredders

BKE 280-305 SUPER

In parking position:

- Slightly lift machine off the ground using an adapted

lifting device.

- Tip the machine forward.

- Lower the lifting device until the attachment yokes

touch the ground.

Keep the slings under tension.

- Weigh cutting tools.

- Pair up equally weighted cutting tools so that they can

be placed diametrically opposite.

Put the lighter pairs in the center of the rotor and

the heavier pairs to the edges.

54

Maintenance and storage

Page 57

• Fit the knives according to the direction of travel of

the machine.

• Check that there is still 1 to 2 mm (0.04’’ - 0.08’’)

play between the pair of knives and the supports.

- Checking the balance:

• Couple PTO shaft on machine side.

• Slightly lift the machine from the ground.

• Start the PTO drive and increase speed

progressively up to a steady speed of 540 min

• When mounted correctly, the rotor must rotate

without causing the machine to vibrate.

Belt tension

Check belt tension:

After the first 3 hours of use.

Every 8 hours.

Shredders

BKE 280-305 SUPER

-1

.

Checking the tension:

Through the belt guard slot:

- Apply a force of 35 N (1.6 lbf) on the belt: the belt

should not deflect more than H = 7 mm (0.3’’).

Maintenance and storage

55

Page 58

Adjusting the tension:

- Remove the 3 nuts (2).

- Remove screw ((3)).

- Remove side gearbox (1).

Replace belts, if proper tension can no

longer be obtained.

Shredders

BKE 280-305 SUPER

Always replace the complete belt set if one of

them is damaged.

- Loosen screw (3).

- Loosen the 4 screws (4) that hold the central gearbox.

- Loosen counter nut (5).

- Turn the adjustment screws (6) and nuts (7) equally

until reaching the optimum tension.

By adjusting (3) and (4) equally, the central

transmission shaft is kept parallel to the rotor.

- Tighten screws (3) and (4).

- Tighten counter nut (5).

- Using a ruler, check that pulleys are in line (8).

- Repeat procedure until perfect pulley alignment is obtained.

56

Maintenance and storage

Page 59

- Reinstall side gearbox 1.

- Reinstall bolts 2:

• Torque: 2,5 daN m (18 lbf ft).

- Reinstall the 2 nuts (3):

• Torque: 2,5 daN m (18 lbf ft).

Shredders

BKE 280-305 SUPER

4. Storage

At the end of each season

- Clean the machine thoroughly:

• The rotor.

• The inner panels.

• Rotor housings.

• Roller housings.

- Touch up any areas of damaged paintwork.

- Lubricate all mechanical components correctly to

protect them from corrosion.

- Put the machine under cover in a dry place.

- Check the condition of the fixing elements regularly

and also the torque of the knife-fixing bolt. Replace if

necessary.

- Check that the original safety decals are in their

original location, undamaged and legible.

- Drain bevel gearbox and fill with new oil.

- Slacken V-belts and check their condition.

Maintenance and storage

57

Page 60

At the start of each season

- Re-read the operators' manual.

- Check that the machine is greased.

- Check all the knives and fixings, and replace if

necessary.

- Check that all nuts and bolts are sufficiently tightened.

- Retension V-belts.

- Check belt guard condition and if it is firmly secured in

place.

- Make sure that all protection devices are in place and

in good condition.

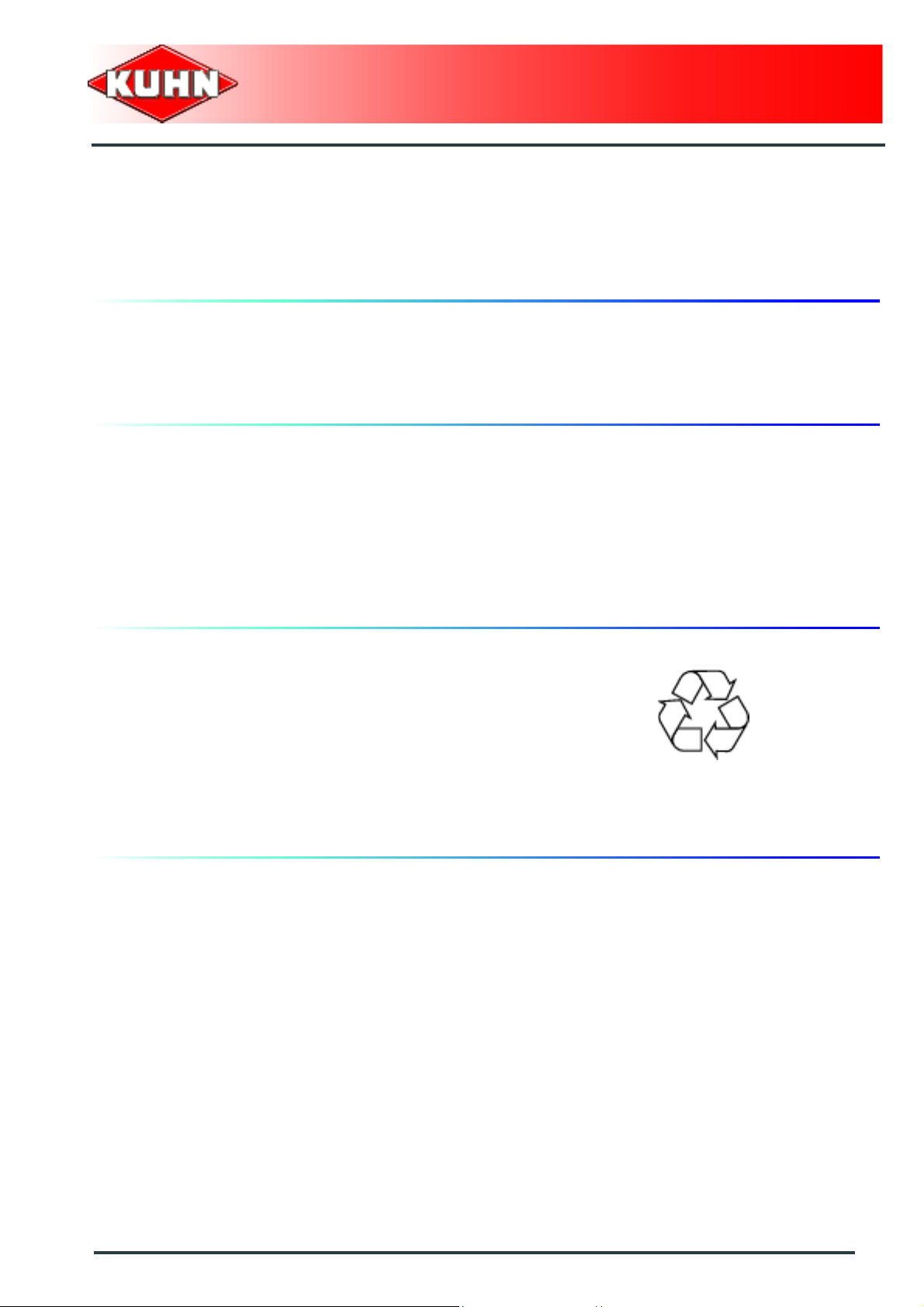

5. Machine recycling

In case of recycling, the machine will have to be recycled in

conformity with the legislation in force in the country

concerned.

Prior to proceeding with the recycling, remove all plastic or

rubber parts, electric or electronic equipment.

Collect possible residual oil and give it to an appropriate

processing center.

Parts only made up of plastic, aluminium, steel can be recycled

if they are collected by an appropriate center.

Shredders

BKE 280-305 SUPER

58

Maintenance and storage

Page 61

BKE 280-305 SUPER

$TROUBLE SHOOTING GUIDE

Problem Cause Remedy

Excessive vibrations.

Poor cutting quality due to a drop

in the rotor speed.

Belt overheating.

A) Breakage or excessive wear

of knives or hammer knives.

B) Knife or hammer knife

jamming on the pivot point.

C) Incorrect rotor balance.

A) Insufficient belt tension.

B) Excessive belt wear.

A) incorrect belt tension.

B) The angle gearbox axle is no

longer in line with the rotor axle.

Replace worn or damaged parts.

Clean and grease pivot points.

Check weight of knives and

hammer knives.

Adjust tension.

Replace belts.

Check tension.

Check alignment.

Shredders

Angle gearbox overheating.

Fast knife or hammer knife wear.

Drive shaft oil loss on the belt

side.

Distortion of roller or wheel

supports.

Distortion of the front pivoting

safety flaps.

Rotor jamming during work.

A) Lack of oil.

B) No oil.

A) Working position too low,

interference with the ground.

A) Seal wear or breakage. Replace seal.

A) The roller or wheel supports

have been subject to lateral

forces.

A) The machine has been

lowered onto the residues to

shred from the raised position

(transport position).

A) Clogging due to foreign bodies

(example: wire, plastic material).

Top up until proper oil level is

reached.

Replace gearbox.

Adjust working height.

Raise machine off the ground

when inverting the direction of

travel or steering the wheels.

The machine must be in working

position before coming into

contact with the residues to

shred.

Put on gloves and remove

foreign bodies with adequate

tools.

Trouble shooting guide

59

Page 62

$Appendix

1. Calculating the load on an axle

When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized payload must

not be exceeded.

The load on the tractor front axle must always represent 20 % of the tractor unladen weight.

Prior to use, check that these conditions ar e satisfied by making this calculation or by weighing the

tractor-machine unit

Define the total weight, axle loads, tyre

capacity and minimum additional mass:

Shredders

BKE 280-305 SUPER

The following values are required for the calculation:

Description Units Description

T kg Tractor unladen weight

T1 kg Unladen load on tractor front axle

T2 kg Empty load on tractor rear axle

t kg Axle loads (Tractor + machine)

t1 kg Load on front axle (Tractor + machine)

t2 kg Load on rear axle (Tractor + machine)

M1 kg Total weight of front tool or front ballast

M2 kg Total weight of rear tool or rear ballast

am

b m Distance between the tractor axles

cm

d m

Distance between the tools' centre of gravity or the front ballast and

the front axle centre

Distance between the rear axle center and the center of the lower link

ball joints

Distance between the centre of the lower link ball joints and the centre

of gravity of the rear tool or rear ballast

Obtaine

d by

60

Refer to the tractor operators' manual Refer to the machine price-list or operators' manual

Dimensions Measure on scale

Appendix

Page 63

Rear tool or front-rear combination:

Shredders

BKE 280-305 SUPER

1) Calculation of the minimum front ballast weight M1

minimum

M2 x (c+d) - T1 x b + 0.2 x T x b

M1

minimum

=

a+b

Write the minimal additional weight in the chart.

Front tool:

2) Calculation of the minimum rear ballast weight M2

minimum

M1 x a - T2 x b + 0.45 x T x b

M2

minimum

=

b+c+d

Write the minimal additional weight in the chart.

3) Calculation of the actual load on the front axle T1

If the front tool (M1) is lighter than the minimum load required at the front (minimum), increase tool weight until the required minimum

front load is reached

real

M1 x (a+b) + T1 x b - M2 x (c+d)

T1

=

real

b

Indicate front axle calculated load value and the one indicated in the tractor operators' manual.

4) Calculation of the total weight M

If the rear tool (M2) is lighter than the minimum load required at the rear(minimum), increase tool weight until the required minimum

rear load is reached

real

M

= M1 + T + M2

real

Indicate calculated total load value and the one autho rized as indicated in the tractor operator's manual.

5) Calculation of the actual rear axle load T2

T2

= M

real

real

real

- T1

real

Indicate rear axle calculated load value and the one indicated in the tractor operator's manual.

6) Tyre carrying capacity

Indicate double (2 tyres) the authorized load value (see tyre manufacturer indications).

Appendix

61

Page 64

Table:

Shredders

BKE 280-305 SUPER

Actual value obtained

by calculation

Minimum front/rear

ballasting

Total weight kg ≤ kg

Load on front axle kg ≤ kg ≤ kg

Load on rear axle kg ≤ kg ≤ kg

The minimum ballasting must be made by fitting a tool or an additional mass to the

tractor.

The values obtained must be below or equal the authorized values.

kg

Value authorized

according to

operator's manual

Double value of the

authorized capacity

per tyre (2 tyres)

62

Appendix

Page 65

Determining the machine weight (M2) and the position of its centre of gravity (d)

If the data required to calculate the total

weight, axle loads and minimum ballasting

are not supplied, use the following method.

Tractor only:

Shredders

BKE 280-305 SUPER

- T1: Load on front axle.

•Tractor only.

- T2: Load on rear axle.

•Tractor only.

Appendix

63

Page 66

- T: Axle loads.

• Tractor only.

Shredders

BKE 280-305 SUPER

64

Appendix

Page 67

Shredders

BKE 280-305 SUPER

Rear tool or front-rear combination:

If the total unit weight exceeds the tractor Gross Combined We ight Rating in accordance wit h the

countrie's legislation, empty the hopper to travel on public roads.

In any case, we recommend to travel on public roads with empty hoppers and tanks.

- Measure dimension (b).

- Measure dimension (c).

- t1: Load on front axle.

• Tractor + machine.

• Hopper empty.

- t: Axle loads.

• Tractor + machine.

• Hopper empty.

Calculating the rear tool weight (M2):

M2 = T - t

Calculating the distance (d):

d = (( b x ( T1 - t1) ) / M2 ) - c

Appendix

65

Page 68

$Limited warranty

Shredders

BKE 280-305 SUPER

66

Limited warranty

Page 69

Shredders

BKE 280-305 SUPER

Limited warranty

67

Page 70

Page 71

Page 72

Loading...

Loading...