Page 1

OPERATOR'S MANUAL

RN001CGB A

Fertilizer spreaders

AXIS

Original instructions

RN001CGB A

- English - 08-2010

Page 2

Preface

Dear customer,

You have shown your trust in our product by purchasing the solid fertiliser broadcaster s of the

AXIS series Thank You! We want to live up to your expectations. You have acquired an efficient

and dependable solid fertiliser broadcaster .

Our customer service is always at your disposal, should any problems arise.

Please read these operating instructions and follow them carefully before taking the solid

fertiliser broadcaster into service.

The operating instructions offer a comprehensive operative overview and gives you valuable information regarding assembly, maintenance and care of the product.

This instruction manual may also contain descriptions of equipment which is not included in the

solid fertiliser broadcaster kit.

You should be aware that damage caused by incorrect operation or improper use may not be covered by warranty claims.

n CAUTION

Please enter the model and serial number, as well as the year of manufacture of your solid fertiliser broadcaster.

You can find this information either on the manufacturer's nameplate or on the

frame of the product.

Please state this information whenever you wish to order spare parts, accessories or in case of complaints.

Model: Serial number: Year of manufacture:

Technical improvements

We are continuously improving our products. For this reason, we reserve the right to make any

improvements and necessary changes to our product line without prior notice. However, we are

not obligated to apply such improvements or changes on machines that have already been sold.

We will be pleased to answer any other questions that you might have.

Yours sincerely

KUHN S.A.

Farm Machinery

Page 3

AXIS-GENERAL

AXIS 20.1

AXIS 30.1 (W), AXIS 40.1 (W)

AXIS 50.1 W

AXIS-MAINTENANCE

The chapter AXIS-General deals with general instructions regarding the operation of the entire

AXIS model range. Please read this chapter carefully before taking the solid fertiliser broadcaster

into service.

The chapter Safety deals with safety instructions, as well as occupational and traffic safety regulations associated with the handling and operation of the solid fertiliser broadcaster AXIS. The

consideration of and adherence to the instructions in this chapter is the basic requirement for

the safe handling and trouble free operation of the solid fertiliser broadcaster.

At the end of the instruction manual, you will find the chapters dealing with disposal of the product

and terms/conditions of warranty for all models.

The chapter AXIS 20.1 contains specific information about the solid fertiliser broadcaster of the

model type AXIS 20.1.

The chapter AXIS 30.1, AXIS 40.1 contains specific information about the solid fertiliser broad-

caster of the model types AXIS 30.1 and AXIS 40.1.

The chapter AXIS 50.1 W contains specific information about the solid fertiliser broadcaster of the

model type AXIS 50.1 W.

The chapter AXIS-Maintenance describes the general maintenance and repair tasks which apply

to all solid fertiliser broadcasters of the AXIS series.

Page 4

Page 5

Contents

Preface

AXIS-GENERAL

1 Intended use 1

2 User instructions 3

2. 1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. 2 Structure of the operator's manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. 3 Depictions in the text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.1 Directions and instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.2 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.3 References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Safety 5

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Significance of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 General safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Operator instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.1 Personnel qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.2 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.3 Accident prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Operating safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.1 Shutting down the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.2 Filling the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.3 Inspection before startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.4 During operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Fertiliser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Service and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8.1 Maintenance personnel qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8.2 Parts subject to wear and tear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8.3 Service and repair tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9 Traffic safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.9.1 Checks before driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.9.2 Transport with the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . 13

3.10 Protective equipment built into the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.10.1 Positioning of the protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.10.2 Protective device functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.11 Warning and instruction message stickers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.11.1 Warning stickers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.11.2 Instruction stickers and factory plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.12 Reflectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

I

Page 6

Contents

4 Technical data 21

4. 1 Machine information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.1 Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.2 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.3 Specifications of base equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.4 Specifications of extensions and extension combinations . . . . . . . . . . . . . . 23

4. 2 List of available optional equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Hopper covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3 Hopper cover supplement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.4 TELIMAT T 25, T 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.5 Two way unit (only for AXIS 20.1/30.1/40.1) . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.6 Tele-Space universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.7 Universal drive shaft with radial ratchet brace (only for AXIS 20.1) . . . . . . . 26

4.2.8 Auxiliary lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.9 ASR 25 transport wheels with bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.10 Border spreading unit GSE 25 (only for AXIS 20.1/30.1/40.1) . . . . . . . . . . . 27

4.2.11 Hydraulic remote controller FHZ 25 for GSE 25

(only for AXIS 20.1/30.1/40.1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.12 Hydraulic remote controller FHZ 26 for GSE 25

(only for AXIS 30.1 W/40.1 W)27

4.2.13 Dirt deflector SFG 30 (only for AXIS 20.1) . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.14 Dirt deflector extension SFG-E 30 (only for AXIS 30.1/40.1) . . . . . . . . . . . . 27

4.2.15 Spreading vane set Z14, Z16, Z18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.16 Inspection kit PPS5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.17 Fertiliser Identification System DiS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Axle load calculation 29

5.1 Calculation of the total weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Axle loads table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Transport without tractor 33

6.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Loading and unloading, parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Instructions regarding the spreading process 35

8 Standard operating procedure (all models) 37

8. 1 Taking delivery of the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8. 2 Tractor requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8. 3 Mounting the drive shaft on the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . 38

8.3.1 Fitting and removing the drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8. 4 Attaching solid fertiliser broadcaster to the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.4.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.4.2 Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8. 5 Preset the mounting height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5.2 Maximum approved hopper mounting height at front (V) and rear (H). . . . . 47

8.5.3 Hopper mounting heights A and B as per the spreading calibration chart . . 48

II

Page 7

Contents

8. 6 Using the spreading calibration chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.6.1 Information on the calibration chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.6.2 Settings as per calibration chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8. 7 Spreading at the headland. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8. 8 Calibration of the border spreading unit GSE (optional equipment)

(only for AXIS 20.1, AXIS 30.1, AXIS 40.1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.8.1 Calibration of the border spreading unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8. 9 Calibration of the TELIMAT T 25, T 50 (optional equipment) . . . . . . . . . . . . . . . . . 62

8.9.1 Calibrating the TELIMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.9.2 Correcting the spreading distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.9.3 Instructions for spreading with the TELIMAT . . . . . . . . . . . . . . . . . . . . . . . . 64

8. 10 Adjustments for unlisted fertiliser types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.10.1 Requirements and conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.10.2 Running one pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.10.3 Running three passes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

III

Page 8

Contents

AXIS 20.1

A Commissioning 73

A.1 Mount universal drive shaft with shear bolt coupling on the AXIS 20.1.. . . . . . . . . . 73

A.1.1 Mounting the universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

A.1.2 Demounting the drive shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

A.2 Connecting the slide feed controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

A.2.1 Connecting hydraulic slide feed controls: AXIS 20.1, versions K + D. . . . . . 77

A.2.2 Connecting the hydraulic slide feed controls: AXIS 20.1, version R. . . . . . . 77

A.2.3 Connecting the electric slide actuator controls: AXIS 20.1, version R . . . . . 79

A.3 Filling up the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

B Spreading Operation 82

B.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

B.2 Using the calibration charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

B.3 Spreading at the headland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

B.4 Setting the application rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

B.5 Setting the working width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

B.5.1 Choosing the correct spreading disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

B.5.2 Removing and mounting spreading discs. . . . . . . . . . . . . . . . . . . . . . . . . . . 86

B.5.3 Set drop point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

B.6 Calibration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

B.6.1 Determine nominal output volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

B.6.2 Running calibration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.7 Check mounting height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

B.8 Setting the PTO speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

B.9 Faults and possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

B.10 Discharging residue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

B.11 Decoupling and parking the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . 102

C Maintenance and repair 104

C.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

C.2 Adjusting the metering slide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

C.3 Adjusting the fertiliser drop point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

IV

Page 9

Contents

AXIS 30.1, AXIS 40.1

A Commissioning 109

A.1 Connecting the slide feed controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.1.1 Connecting hydraulic slide feed controls: AXIS 30.1/40.1,

versions K + D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.1.2 Connecting the hydraulic slide feed controls: AXIS 30.1/40.1,

version R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.1.3 Connecting the electric slide actuator: AXIS 30.1/40.1, . . . . . . . . . . . . . . . . .

versions Q + W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.2 Filling up the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

B Spreading Operation 114

B.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

B.2 Using the calibration charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.3 Spreading at the headland. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.4 Setting the application rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.5 Setting the working width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

B.5.1 Choosing the correct spreading disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

B.5.2 Removing and mounting spreading discs . . . . . . . . . . . . . . . . . . . . . . . . . 118

B.5.3 Setting the fertiliser drop point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.6 Calibration test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.6.1 Determine nominal output volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.6.2 Running calibration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

B.7 Check mounting height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

B.8 Setting the PTO speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

B.9 Faults and possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

B.10 Discharging residue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

B.11 Decoupling and parking thesolid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . 135

C Maintenance and repair 137

C.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C.2 Weight spreader lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

C.3 Check the screw connections in the weighing cell. . . . . . . . . . . . . . . . . . . . . . . . . 138

C.4 Metering slide adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

C.5 Fertiliser drop point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

V

Page 10

Contents

AXIS 50.1 W

A Commissioning 145

A.1 Connecting electric slide feed actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2 Filling up the solid fertiliser broadcaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

B Spreading operation 147

B.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

B.2 Using the calibration charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

B.3 Spreading at the headland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

B.4 Setting the application rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

B.5 Setting the working width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

B.5.1 Choosing the correct spreading disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

B.5.2 Removing and mounting spreading discs. . . . . . . . . . . . . . . . . . . . . . . . . . 150

B.5.3 Setting the fertiliser drop point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

B.6 Calibration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

B.6.1 Running calibration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

B.7 Check mounting height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

B.8 Setting the PTO speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

B.9 Faults and possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

B.10 Discharging residue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

B.11 Decoupling and parking thesolid fertiliser broadcaster. . . . . . . . . . . . . . . . . . . . . . 163

C Maintenance and repair 164

C.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

C.2 Using the steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

C.2.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

C.2.2 Folding out step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

C.2.3 Folding in the step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

C.3 Weight spreader lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

C.4 Check the bolted connections in the weighing cell. . . . . . . . . . . . . . . . . . . . . . . . . 167

C.5 Metering slide adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

C.6 Fertiliser drop point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

D Appendix 179

D.1 Deactivating the actuator control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

D.2 Set drop point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

VI

Page 11

Contents

AXIS-MAINTENANCE

9 General maintenance and service (all models) 183

9.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

9.2 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

9.3 Opening the protective grid in the hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

9.4 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

9.5 Lubrication chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

9.6 Wearing parts and bolted connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

9.6.1 Checking wearing parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

9.6.2 Checking bolted connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

9.7 Checking the position of the spreading disc hub . . . . . . . . . . . . . . . . . . . . . . . . . . 189

9.8 Checking agitator drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

9.9 Changing spreading vanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

9.10 Gear oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

9.10.1 Quantity and types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

9.10.2 Checking oil level, changing oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

AXIS-GENERAL

10 Disposal (all models) 197

10.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

10.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

11 Guarantee and warranty (all models) 199

VII

Page 12

Contents

VIII

Page 13

AXIS-GENERAL

1 Intended use

The solid fertiliser broadcaster of the AXIS series should only be used in strict accordance to the specifications given in the instruction manual.

The solid fertiliser broadcaster of the AXIS series are built according to their specified use, therefore they should be exclusively used for the following purposes:

for conventional agricultural use

for the spreading of dry, granular and crystalline fertilisers, seeds and pest

control agents

Any use beyond these specifications is considered as contrary to the intended

use. The manufacturer is not liable for any damage resulting from misuse. The

operator bears the entire risk.

The intended use also includes compliance with the operating, maintenance and

service conditions according to manufacturer specifications. Only genuine spare

parts from the manufacturer may be used as replacements.

The solid fertiliser broadcaster of the AXIS series should be operated, serviced

and maintained solely by persons who are thoroughly familiar with the machine

and are aware of the hazard.

Intended use

1

The instructions regarding the operation, service and safe handling of the machine as described in this manual and declared by the manufacturer in the form

of warning signs and symbols on the machine, must be strictly followed during operation.

The relevant accident prevention regulations and the other generally recognised

safety, occupational health and road traffic regulations must be strictly observed

when using the machine.

Unauthorised modifications to the solid fertiliser broadcaster of the AXIS series

are not allowed. The manufacturer is not liable for any resulting damage.

Foreseeable misuse

The manufacturer has indicated foreseeable misuse of the solid fertiliser broadcaster AXIS series by affixing warning signs and symbols on the machine. These

warning signs and symbols must be observed at all times in order to avoid non

intended use of the solid fertiliser broadcaster of the AXIS series as specified in

the operating manual.

1

Page 14

Intended use 1

AXIS-GENERAL

2

Page 15

AXIS-GENERAL

2 User instructions

2. 1 About this manual

This operator’s manual is a part of the solid fertiliser broadcaster of the AXIS series.

The manual contains important directions for a safe, proper and efficient usage

and maintenance of the solid fertiliser broadcaster. Attention to the given directions will help to avoid hazards, to minimise maintenance costs and downtime,

as well as to increase the reliability and the life of the machine.

The complete documentation, comprising this operator’s manual and all supplier

documentation, must be kept easily accessible at the place of operation of the

solid fertiliser broadcaster (e.g. in the tractor).

When the machine is sold, the operator’s manual must go with it.

The operator’s manual is meant for the operator of the solid fertiliser broadcaster

of the AXIS series and their operating and maintenance staff. It must be read, understood and applied by every person who is entrusted with the following work on

the machine:

User instructions

2

Operation,

Maintenance and cleaning,

Repairing faults.

At the same time, particular attention must be paid to the following:

the issue of safety,

the warnings in the various chapters.

The operator’s manual does not replace your individual responsibility as the

operator and operating staff of the solid fertiliser broadcaster of the AXIS series.

2. 2 Structure of the operator's manual

The content in the operator’s manual is arranged according to six focal points:

user instructions,

safety instructions,

machine details,

instructions for operation of the solid fertiliser broadcaster,

instructions for finding and correcting faults and

maintenance and repair instructions.

3

Page 16

User instructions 2

AXIS-GENERAL

2. 3 Depictions in the text

2.3.1 Directions and instructions

Steps that the operator must carry out are shown as a numbered list.

1. Instruction for action step 1

2. Instruction for action step 2

Directions involving a single step are not numbered. The same applies to actions

which do not have to be carried out in a particular sequence.

The following directions are preceded by a bullet point :

Handling instruction

2.3.2 Lists

Lists without a specific sequence are shown as lists with bullet points (level 1) and

dashes (level 2):

Property A

Property B

2.3.3 References

References to other sections in the document are shown as paragraph number,

header text and page number:

Please note also chapter 3: Safety, page 5.

References to other documents are made without mentioning the exact chapter

or page number:

Please also observe the instructions contained in the universal drive shaft

- Point A

- Point B

manual.

4

Page 17

AXIS-GENERAL

3 Safety

3.1 Introduction

The chapter on safety contains basic safety instructions and safety regulations for

working and operation in traffic when using the solid fertiliser broadcaster AXIS.

Observance of the instructions given in this chapter is a prerequisite for ensuring

safe handling and trouble free operation of the solid fertiliser broadcaster.

In the other chapters of the operator’s manual further warnings are to be found,

which should also be taken into account. The warnings are always given before

the description of the respective action.

Warnings regarding third party supplier components are given in the respective

supplier documents. Please observe these warnings as well.

3.2 Significance of warnings

In this operator’s manual, the warnings are arranged according to the severity of

the risk and the probability of its occurence.

Safety

3

The warning symbols draw attention to the unavoidable residual risks inherent in

the operation of the solid fertiliser broadcaster. The warning messages are structured in the following way:

Signal word

Symbol Explanation

Example

n DANGER

Risk to life if warning is disregarded

Description of the danger and possible consequences.

Disregard of this warning can lead to the most extreme injury,

resulting in possible death.

Always take the specified measures to avoid this risk.

5

Page 18

Safety 3

AXIS-GENERAL

Warning severity level

The risk level is determined through the signal word. The risk levels are classified

as follows:

n DANGER

Type and source of danger

This is a warning against an immediate threat to the health and life

of persons.

Disregard of this warning can lead to the most extreme injury,

resulting in possible death.

Always take the specified measures to avoid this risk.

n WARNING

Type of danger

This is a warning against possible danger to the health of persons.

Disregard of this warning can lead to severe injury.

Always take the specified measures to avoid this risk.

n CAUTION

Type of danger

This is a warning against possible danger for the health of persons

or damage to the environment and property.

Disregard of this warning can lead to injury as well as damage to

the product or the surrounding area.

Always take the specified measures to avoid this risk.

NOTICE

General instructions contain usage tips and particularly useful information but

no warnings.

6

Page 19

AXIS-GENERAL

3.3 General safety information

The solid fertiliser broadcaster of the AXIS series is designed and built according

to state of the art technology and recognised technical regulations. Nevertheless,

operation and maintenance of the machine may pose a risk to the life and limb of

the operator or other persons, as well as cause damage to the machine or other

assets in the surrounding area.

Therefore, please operate the solid fertiliser broadcaster of the AXIS series

only when it is in a proper and roadworthy condition,

safety-conscious and risk-aware.

Therefore, it is imperative that you read and understand the contents of the operator’s manual thoroughly. You know the relevant accident prevention measures

as well as the generally recognised safety related, occupational health and road

traffic laws and that you are in a position to practically apply this knowledge also.

3.4 Operator instructions

The operator is responsible for the designated use of the solid fertiliser broadcaster AXIS.

Safety

3

3.4.1 Personnel qualification

The personnel which are to be assigned the task of operating, maintaining and

servicing the solid fertiliser broadcaster must have read and understood the contents of the operator’s manual before using the product.

The machine should be operated by trained and authorised personnel only.

Personnel under training may work on the machine only if an experienced col-

league is present.

Maintenance and repair work must be carried out by appropriately qualified

persons.

3.4.2 Orientation

Resellers, factory representatives or staff of manufacturer shall provide training

in operation and maintenance of the solid fertiliser broadcaster to the relevant

personnel.

It is the responsibility of the operating company to ensure that new or inexperienced personnel thoroughly understand the contents of the operator’s manual

before starting work on the machine.

7

Page 20

Safety 3

AXIS-GENERAL

3.4.3 Accident prevention

Safety and accident prevention regulations are regulated by law according to

each country. The company operating the machine is responsible for compliance

to the regulations of the country of deployment.

Please note the following:

Never leave the solid fertiliser broadcaster operating without supervision.

Do not ride on the solid fertiliser broadcaster while it is working or it is being

transported (no passengers).

Do not use machine components of the solid fertiliser broadcaster to climb up

on the machine.

Do not wear loose clothing. Avoid workwear with belts, fringes or other parts

which can get caught in the machinery.

Follow the manufacturer's directions when working with chemicals. It may be

necessary to wear personal protective equipment.

3.5 Operating safety instructions

The solid fertiliser broadcaster should only be operated in a reliable condition to

avoid dangerous situations.

3.5.1 Shutting down the solid fertiliser broadcaster

Park the solid fertiliser broadcaster with empty hopper on a firm, horizontal

surface.

If the solid fertiliser broadcaster is parked without tractor, the metering valve

should be left completely open. The retaining springs of the valve operating

mechanism are de-tensioned.

3.5.2 Filling the solid fertiliser broadcaster

Never fill the solid fertiliser broadcaster with the tractor engine running. Take

the ignition key out to make sure the motor cannot be started.

Use suitable equipment for filling (e.g. front-end loader, auger).

Fill up the solid fertiliser broadcaster only till the specified rim height. Check

the filling level, e.g. through the viewing window in the hopper (depending on

model).

Fill up the solid fertiliser broadcaster only with the protective grid closed. This

way you will avoid operating problems caused by clumping of the grit or other

foreign bodies.

8

Page 21

AXIS-GENERAL

3.5.3 Inspection before startup

Before the first and every subsequent operation, thoroughly inspect the solid fertiliser broadcaster to make sure that it is safe to operate.

Is all safety equipment on the solid fertiliser broadcaster installed and func-

tional?

Are all attachments and load bearing assemblies tight and in a proper condi-

tion?

Are the spreading discs and their fasteners in good condition?

Are the protective grids in the hopper closed and locked?

Is the test dimension of the protective grid interlock within the proper range?

See figure 9.3

Is there anyone in the danger zone of the solid fertiliser broadcaster?

Is the shaft cover in proper condition?

on page 186.

3.5.4 During operation

Safety

3

If the solid fertiliser broadcaster malfunctions, turn the machine off and se-

Never climb up on to the solid fertiliser broadcaster when it is operating.

Use the solid fertiliser broadcaster only with protective grid in the hopper

Rotating parts of the machine can cause severe injury. Therefore, always

Do not place any objects (such as screws, nuts) in to the spreader hopper.

Grit is flung from the machine at a high speed and can cause serious injury,

If the wind speed is too high, you should stop the spreading operation, as the

Never climb up the solid fertiliser broadcaster or the tractor if you are beneath

3.6 Fertiliser

Improper selection or use of fertiliser may cause serious injury or environmental

damage.

cure it immediately. Have the machine repaired by qualified personnel.

closed. The safety guard must not be opened or removed during operation.

make sure that body parts or items of clothing never come close to the rotating parts of the machine.

e.g. to the eyes. Make sure that there are no persons within the spreading

range of the solid fertiliser broadcaster.

spreading accuracy cannot be ensured.

a high tension power line.

When you choose a fertiliser, make sure you are properly informed about its

effects on humans, the environment and the machine.

Please note the fertiliser manufacturers instructions.

9

Page 22

Safety 3

AXIS-GENERAL

3.7 Hydraulics

The hydraulic system is under high pressure.

Fluid escaping under high pressure can cause serious injuries and environmental

damage. To avoid danger, please note the following:

The maximum allowed operating pressure should never be exceeded.

Release the pressure from the hydraulic system before all maintenance

Always wear safety goggles and safety gloves when looking for leaks.

If injury occurs due to contact with hydraulic fluid, seek medical attention

When connecting the hydraulic hoses to the tractor hydraulics, make sure

The hydraulic hoses from the tractor and spreader should be connected with

Keep the hydraulic circuitry clean. Always hang the couplings in their special

work. Turn the tractor motor off and make sure it cannot be started during

maintenance work.

immediately, otherwise serious infections can occur.

that the hydraulic systems are unpressurised on both tractor and spreader.

the specified couplings only.

brackets. Use the dust caps. Clean the connections before coupling.

Check the hydraulic components and hydraulic lines regularly for mechanic

defects, such as cuts and worn positions, crushing, cracking, porous sections

etc.

Pipes and pipe couplings undergo a natural ageing process even if they are

stored and used properly. This is the reason their shelf and service life is limited.

The service life of the hose line should not exceed 6 years, including a storage

period of a maximum of 2 years.

The date of manufacture of the hose line is stamped on the hose coupling in

month and year

Replace the hydraulic pipes if they are damaged or old.

Replacement hydraulic lines must meet the technical requirements of the

equipment manufacturer. Pay particular attention to the maximum pressure

specifications of the pipes to be replaced.

10

Page 23

AXIS-GENERAL

3.8 Service and maintenance

During service and maintenance tasks, you have to take additional dangers into

account which cannot occur during normal operation.

Carry out the service and maintenance tasks carefully and with full concen-

tration. Always work with full awareness of the risks involved.

3.8.1 Maintenance personnel qualification

Welding and work on the electrical and hydraulic systems must be carried out

by qualified technicians only.

3.8.2 Parts subject to wear and tear

Observe the maintenance and repair intervals specified in this operator's

manual exactly.

Also observe the maintenance and repair intervals for the supplied compo-

nents. See the supplier documentation for the relevant intervals

It is our recommendation that you should get the solid fertiliser broadcaster,

particularly fastening parts, safety relevant plastic components, hydraulic

system, measuring parts and casting blades inspected after every season by

a certified specialist.

Safety

3

Replacement parts should meet the minimum technical standards specified

by the manufacturer. The technical standards can be guaranteed by using

genuine replacement parts, for example.

Self-locking nuts are designed to be used only once. Always use new self-

locking nuts to fasten components (e.g. when replacing spreading vanes).

3.8.3 Service and repair tasks

Turn the tractor motor off before starting any cleaning, maintenance, repair or

service tasks. Wait for all rotating parts to come to a stop.

Make sure that no unauthorised person can switch on the solid fertiliser

broadcaster. Take out the tractor ignition key.

Check that the tractor with the solid fertiliser broadcaster is correctly parked.

Park the fertiliser broadcaster with an empty hopper on level, solid ground

and secure it to prevent it from moving.

Depressurise the hydraulic system before starting service or maintenance

work.

Disconnect the electrical system from the main power supply before starting

work on it.

If you have to work on the rotating tractive unit, please make sure nobody is

in the vicinity of the PTO unit or the drive shaft.

11

Page 24

Safety 3

AXIS-GENERAL

Never clear blockages in the broadcaster hopper by hand or with the foot but

always use a suitable tool. To prevent blockages always use the safety guard

when filling the hopper.

Before cleaning the solid fertiliser broadcaster with water, steam or other

cleaning agents cover all components that must be prevented from getting

wet (e.g. bearings, electrical connections).

Check the nuts and bolts regularly for tightness and tighten loose contacts.

3.9 Traffic safety

When travelling on public roads and tracks the tractor with the attached solid fertiliser broadcaster must comply with the traffic regulations of the country in which

it is operating. The owner and driver are responsible for compliance with these

regulations.

3.9.1 Checks before driving

A pre-operational check is an important contribution to traffic safety. Before every

trip check compliance with the operating conditions, traffic safety and the regulations of the country of operation.

Make sure that the approved total weight is not exceeded. Note the approved

axle load, the approved braking load and the approved tyre load capacity;

See also „Axle load calculation“ on page 29

Is the solid fertiliser broadcaster correctly attached?

Could spreading material be lost while travelling?

.

- Check the fill level of the fertiliser in the hopper.

- The metering slides must be closed.

- The locks must also be closed on single-action hydraulic cylinders.

- Turn off electronic controls.

Check the tyre pressure and the function of the tractor brake system.

Do the lighting and identification markings on the solid fertiliser broadcaster

comply with the your country regulations for use on public roads? Make sure

to make the fittings according to the regulations .

12

Page 25

AXIS-GENERAL

3.9.2 Transport with the solid fertiliser broadcaster

The handling and the steering and braking characteristics of the tractor change

when the solid fertiliser broadcaster is attached to it. So it can happen that, for

example, due to the excessive weight of the solid fertiliser broadcaster, the front

axle of the tractor becomes unloaded, resulting in a decrease in tractor steering

reliability.

Adjust your driving behaviour according to the load on the vehicle.

Always make sure you have unencumbered sight. If this is not possible (e.g.

while reversing), another person is required to direct the driver.

Do not exceed the legal speed limit.

Avoid sudden turns when driving uphill or downhill or across a slope. Due to

the change in the centre of gravity there is a risk of tipping over. Travel over

uneven, soft ground (e.g. entering a field, over road edges) with great care.

Set the lower link on the three-point linkage so it is rigid to prevent the ma-

chine from rocking.

Passengers are prohibited on the solid fertiliser broadcaster during transport

and operation.

Safety

3

13

Page 26

Safety 3

AXIS-GENERAL

3.10 Protective equipment built into the machine

3.10.1 Positioning of the protective equipment

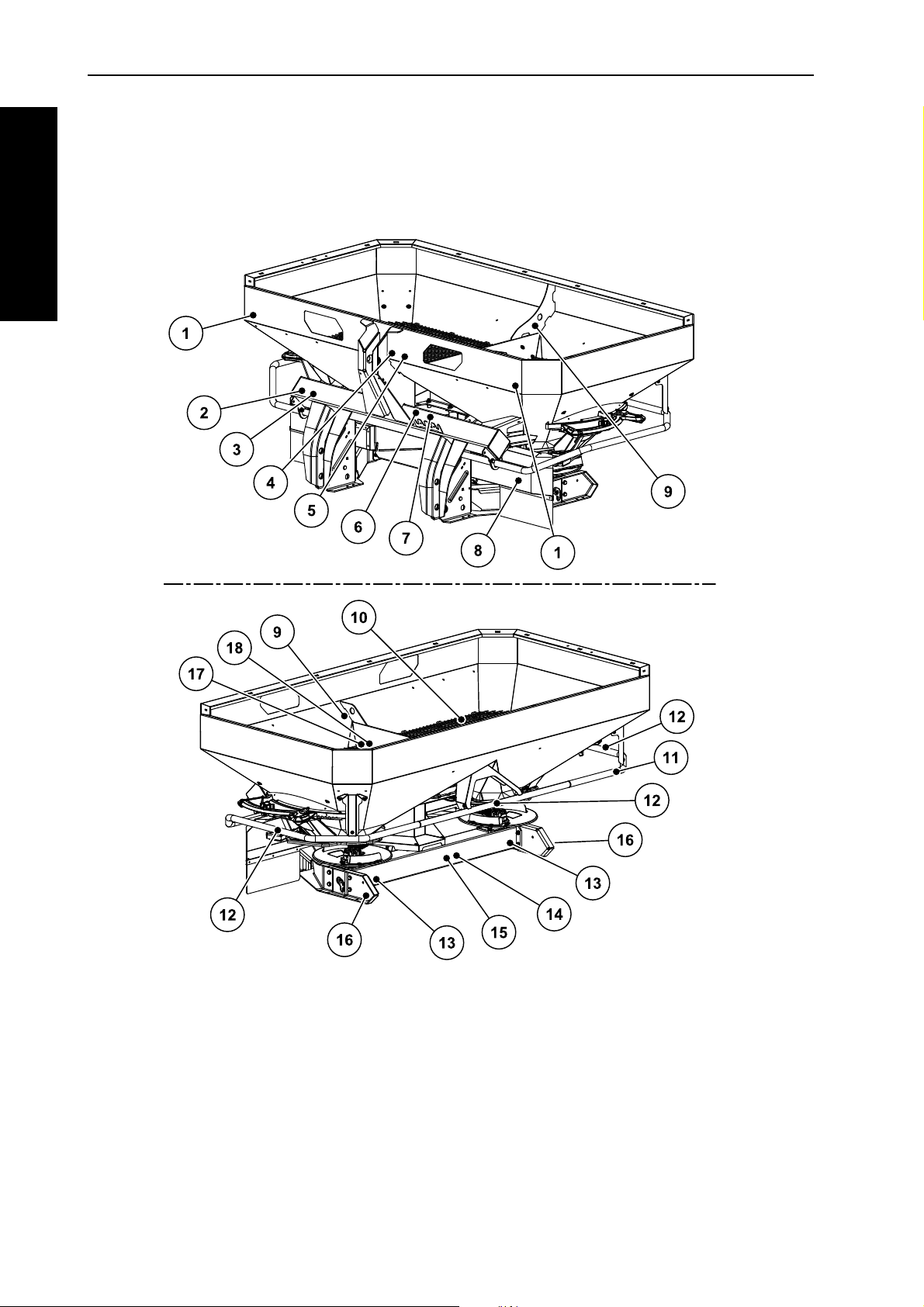

AXIS 20.1/30.1/40.1

Figure 3.1: Position of protection devices, warning and instruction notices and reflectors

[1] White reflector in front

[2] Nameplate

[3] Serial number

[4] Warning: read operator's manual

[5] Warning: material throw-out

[6] Warning: maximum payload

[7] Warning: PTO speed

[8] Spreading disc cover

[9] Instructions: eyelet in hopper

14

[10] Protective grid in hopper

[11] Deflector bracket

[12] Instructions: no climbing

[13] Red reflector

[14] Warning: remove ignition key

[15] Warning: moving parts

[16] Yellow side reflector

[17] Protective grid lock

[18] Instructions: protective grid lock

Page 27

AXIS-GENERAL

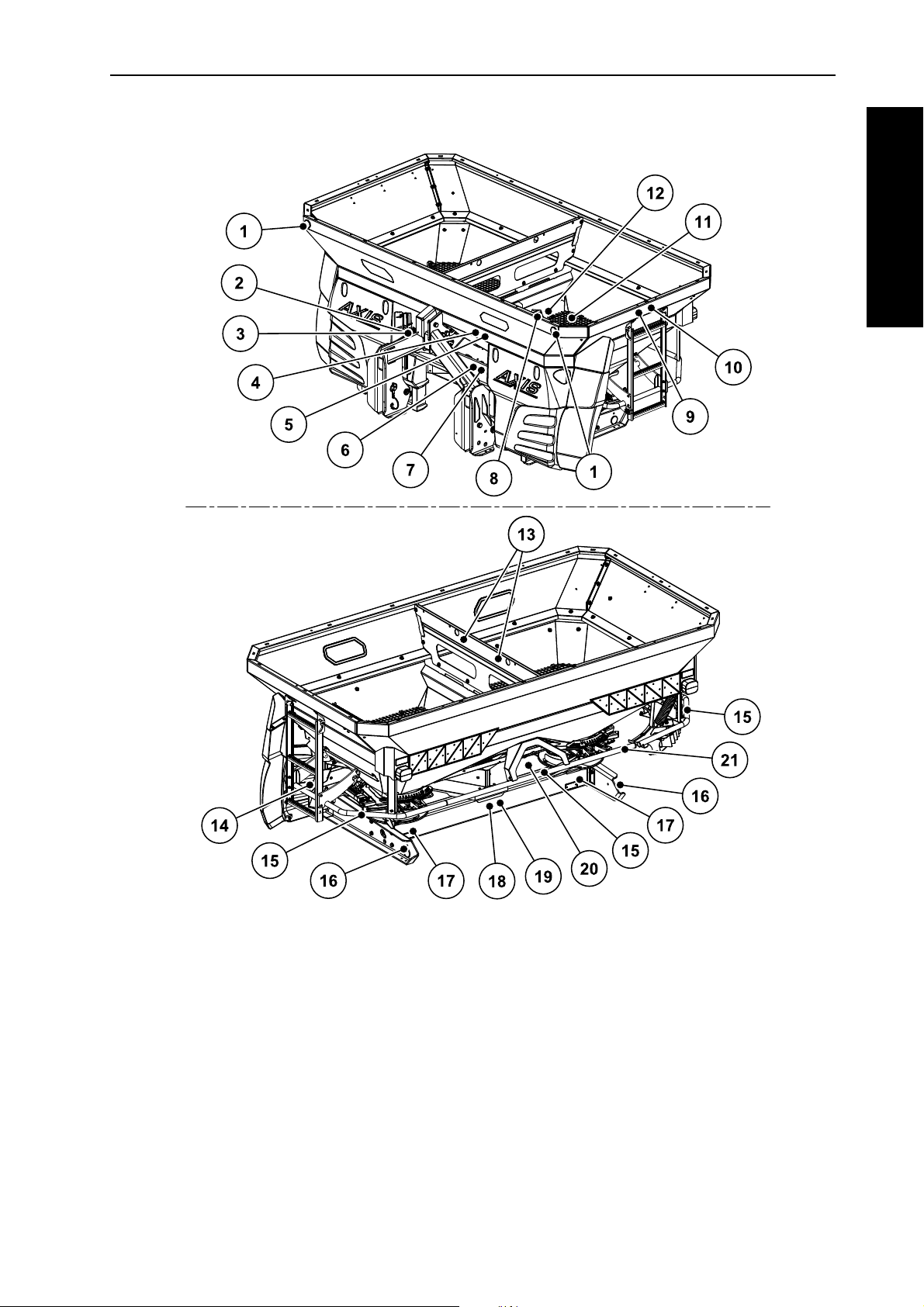

AXIS 50.1 W

Safety

3

Figure 3.2: Position of protection devices, warning and instruction notices and reflectors

[1] White reflector in front

[2] Nameplate

[3] Serial number

[4] Warning: read operator's manual

[5] Warning: material throw-out

[6] Warning: maximum payload

[7] Warning: PTO speed

[8] Protective grid lock

[9] Instructions on going uphill

[10] Warning: passenger transport prohibited

[11] Protective grid in hopper

[12] Instructions: protective grid lock

[13] Instructions: eyelet in hopper

[14] Spreading disc cover

[15] Instructions: no climbing

[16] Yellow side reflector

[17] Red reflector

[18] Warning: moving parts

[19] Warning: remove ignition key

[20] Gear protective cover

[21] Deflector bracket

15

Page 28

Safety 3

AXIS-GENERAL

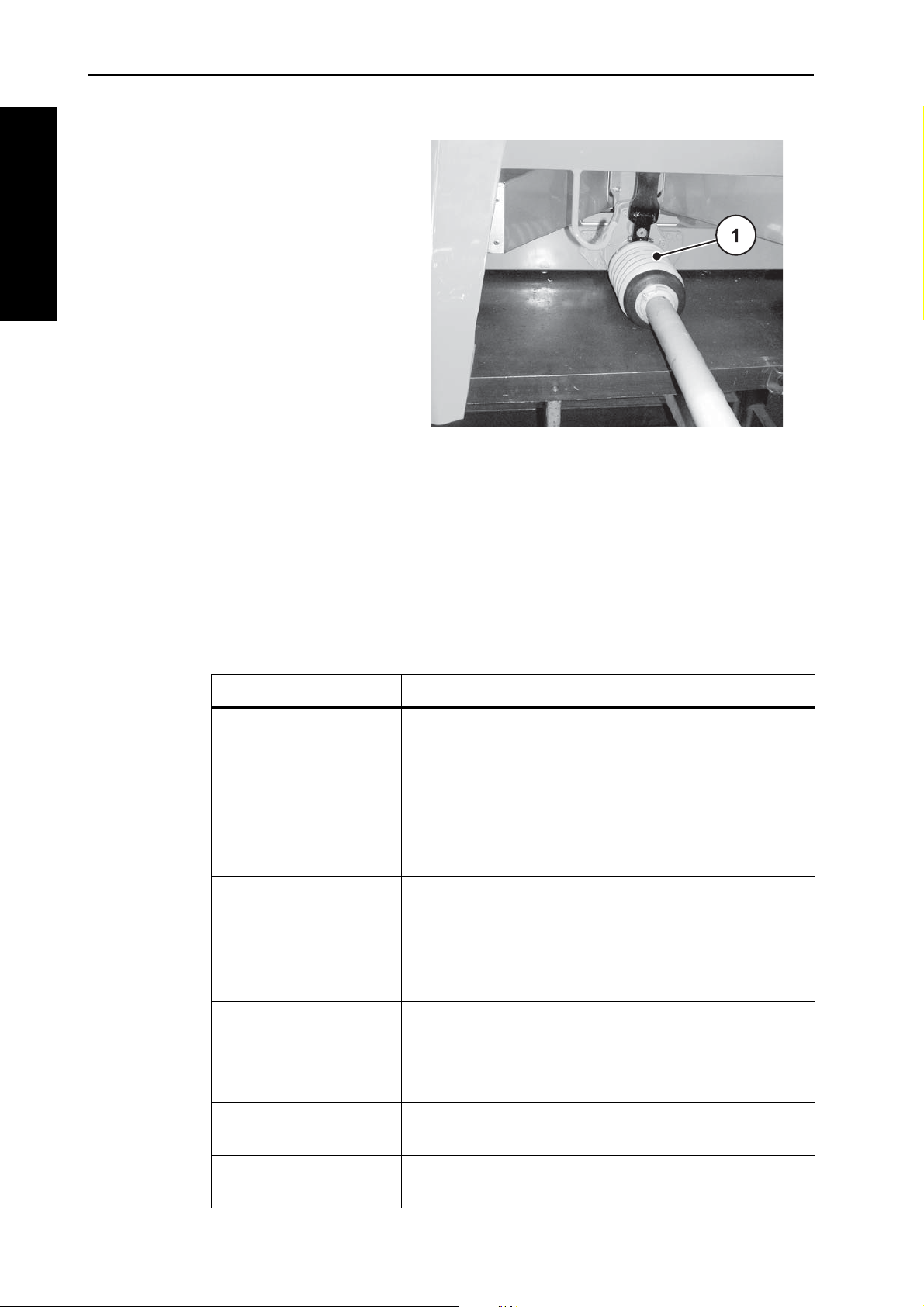

[1] Drive shaft cover

3.10.2 Protective device functions

Figure 3.3: Drive shaft

The protective devices protect your life and limb.

Always operate the solid fertiliser broadcaster with effective protective equip-

ment.

Do not use the deflector bracket to climb up on the machine. It is not designed

for this. You may be in danger of falling.

Designation Function

Protective grid in the

hopper

Prevents the intake of body parts by the rotating agitator.

Prevents body parts from being cut off by the metering

slide.

Prevents faults caused by lumps in the spreading material, large stones or other large-scale objects

(screening effect) during the spreading process.

Protective grid lock Prevents the inadvertent opening of the protective grid

in the hopper. Engages mechanically if protective grid

is closed properly. Can be opened by using a tool.

Deflector bracket Protection against getting caught by the rotating

spreading discs from behind and from the side.

16

Spreading disc cover Protection against getting caught by the rotating discs

from the front.

Prevents the casting of fertiliser towards the front side

(in the direction of the tractor and driver).

Drive shaft shield Prevents the intake of body parts into the rotating drive

shaft.

Toothed segment protective cover

Only included with AXIS 50.1 W: prevents body

parts from getting crushed by moving machinery parts.

Page 29

AXIS-GENERAL

3.11 Warning and instruction message stickers

The solid fertiliser broadcaster of the AXIS series has various warning and instruction messages affixed to it (for an illustration please see figure 3.1

figure 3.2

These warning and instruction messages are a part of the machine. They may

neither be removed nor modified. Missing or unreadable warning and instruction

stickers must be replaced immediately.

If parts have been replaced with new ones, it should be made sure that the new

parts have the same warning and instruction stickers as the previous ones.

The correct warning and instruction notices can be obtained from the spare

parts service.

).

NOTICE

Safety

and

3

17

Page 30

Safety 3

AXIS-GENERAL

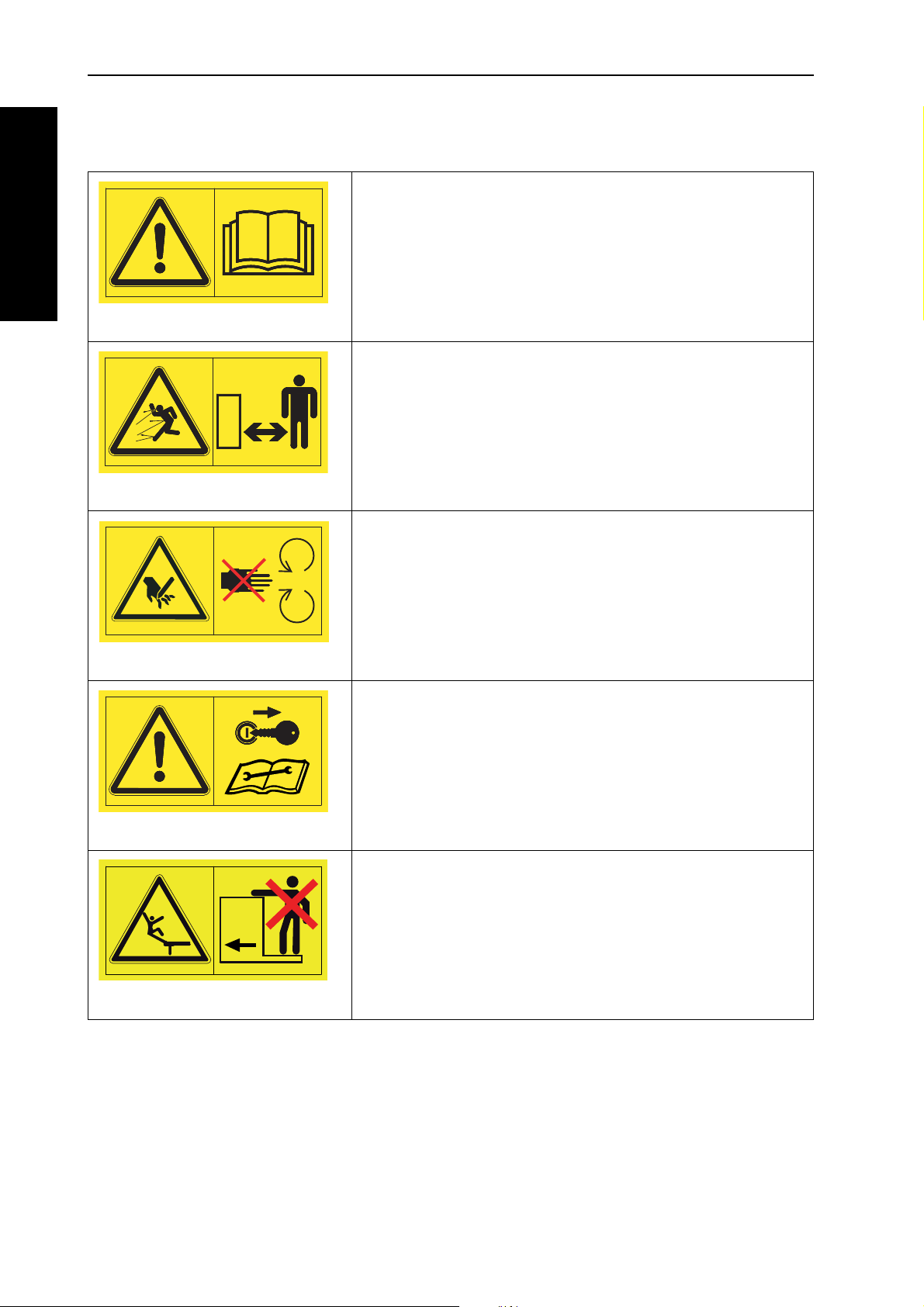

3.11.1 Warning stickers

Read instruction manual and warning messages.

Read and understand the instruction manual before operating the machine.

The operator's manual explains in detail how to operate the

spreader and contains valuable information on operation,

care and maintenance.

Danger through ejection of material

Risk of injury to the entire body through rapidly ejected

spreading material

Please direct all persons out of the danger zone (spreading

zone) before operating the solid fertiliser broadcaster.

Danger from moving parts

Danger of amputation of body parts

Reaching into the danger areas of the rotating spreading

discs, the agitator or the drive shaft is prohibited.

Before carrying out repair and adjustment work, shut off engine and remove the key.

Remove the ignition key.

Before carrying out repair and maintenance work, shut off

engine and remove the key.

Only for AXIS 50.1 W: Riding prohibited

Risk of slipping and injury. Do not climb on the steps of the

solid fertiliser broadcaster during spreading and transport.

18

Page 31

AXIS-GENERAL

3.11.2 Instruction stickers and factory plate

2056545

2055689

Safety

Only for AXIS 50.1 W: Steps

Climbing on the retracted steps is prohibited.

Only climb on the steps when it is extended.

Only travel on the road with the steps retracted.

Ring eyelets on the hopper

The brackets used for the fastening of the lifting

gear

3

2052291

Climbing prohibited

Climbing on the deflector bracket is prohibited.

Protective grid lock

The grid lock is automatically locked when the

protective grid in the hopper is closed properly.

It can only be unlocked by using a tool.

Rated speed of PTO shaft

The rated speed of the PTO shaft is 540 r.p.m.

540

min

-1

19

Page 32

Safety 3

AXIS-GENERAL

2056779

750

min

-1

2100 kg

2055654

max.

3000 kg

2052173

max.

4000 kg

2056096

max.

Landmaschinenfabrik GmbH

D-76545 Sinzheim

Typ:

Masse: Baujahr:kg

12345

Rated speed of PTO shaft

(optional, gearbox at 750 r.p.m.)

The rated speed of the PTO shaft is 750 U/min.

Maximum loading capacity (depending on

model)

3.12 Reflectors

The solid fertiliser broadcaster of the AXIS series is factory fitted with front, back

and side identification (For an illustration of the positioning on the machine, see

figure 3.1

Nameplate

Serial number

and figure 3.2).

20

Page 33

Technical data

AXIS-GENERAL

4 Technical data

4. 1 Machine information

4.1.1 Manufacturer

KUHN SA

F-67706 Saverne Cedex

Tel.: +33 (0)3 88 01 81 00

Fax.: +33 (0)3 88 01 81 01

Internet: www.kuhn.com

4.1.2 Versions

Model AXIS 20.1 AXIS 30.1 AXIS 40.1 AXIS

50.1 W

4

Function Q KRDQKRDWQKRDW W

Spreading speed, depending

on travellingspeed

Single-acting hydraulic cylinder

Single-acting hydraulic cylinder with two way unit

Double-acting hydraulic cylinder

Weighing spreader

Electrical application point

adjustment

21

Page 34

Technical data 4

AXIS-GENERAL

4.1.3 Specifications of base equipment

Dimensions:

Data AXIS

20.1

Overall width 240 cm

Overall length 141.5 cm

Fill height (basic ma-

95 cm

chine)

Distance of centre of

65.5 cm

gravity from lower

steering arm

Fill width 230 cm

Working width

PTO speed

2

1

12 - 28 m 12 - 42 m 12 - 42 m 12 - 42 m 12 - 42 m 18 - 50 m

min. 450 450 450 450 450 450

max. 650

Capacity 1000 l

Mass flow

3

Hydraulic pres-

max. 400 kg/min 500 kg/min 500 kg/min 500 kg/min 500 kg/min 500 kg/min

max. 200 bar

sure

Noise level

(measured

75 dB (A) 75 dB (A) 75 dB (A) 75 dB (A) 75 dB (A) 75 dB (A)

4

in the closed tractor

driver's cab)

AXIS

30.1

AXIS

30.1 W

AXIS

40.1

AXIS

40.1 W

AXIS

50.1 W

240 cm 240 cm 240 cm 240 cm 290 cm

141.5 cm 145,0 cm 141.5 cm 145,0 cm 161,0 cm

101 cm 101 cm 101 cm 101 cm 125 cm

65.5 cm 72.5 cm 65.5 cm 72.5 cm 74.5 cm

230 cm 230 cm 230 cm 230 cm 270 cm

650 650 650 650 650

1200 l 1200 l 1200 l 1200 l 2000 l

200 bar 200 bar 200 bar 200 bar 200 bar

1. Working width dependent on fertiliser and casting disc type

2. Optional: gearbox with 750 rpm, max. 900 rpm

3. Max. mass flow dependent on fertiliser type

4. Since the noise level of the solid fertiliser broadcaster can only be determined when the tractor is running, the actual

measured value is greatly dependent on the tractor type being used.

22

Page 35

Technical data

AXIS-GENERAL

Weights and loads:

NOTICE

The unladen weight (mass) of the solid fertiliser broadcaster varies depending

on the feature package and attachment combination. The unladen weight

(mass) shown on the factory plate refers to the standard version.

4

Data AXIS

20.1

Unladen weight 295 kg 320 kg 375 kg 330 kg 385 kg 680 kg

Fertiliser loading capacity

4.1.4 Specifications of extensions and extension combinations

Solid fertiliser broadcaster AXIS can be operated with different extensions and

combinations of extensions. Depending on the feature package the capacity, dimensions and weights may change.

Extension combination AXIS 20.1

Change in capacity + 600 l + 800 l + 1100 l

Change in fill height 0 + 26 cm + 24 cm

Extension size max. 240 x 130 cm 280 x 130 cm

Extension weight 30 kg 45 kg 60 kg

max.

2100 kg 3000 kg 4000 kg

L603 L800 XL1103

AXIS

30.1

AXIS

30.1 W

AXIS

40.1

AXIS

40.1 W

AXIS

50.1 W

Notes 3-side 4-side 3-side

23

Page 36

Technical data 4

AXIS-GENERAL

AXIS 30.1, AXIS 40.1

Extension combination L603 L800 L1500 XL1103 XL1300 XL1800

Change in capacity + 600 l + 800 l + 1500 l + 1100 l + 1300 l + 1800 l

Change in fill height 0 + 26 cm + 50 cm + 24 cm + 38 cm + 52 cm

Extension size max 240 x 130 cm 280 x 130 cm

Extension weight 30 kg 45 kg 75 kg 60 kg 65 kg 85 kg

Notes 3-side 4-side 4-side3-side4-side4-side

AXIS 50.1 W

Extension combination GLW1000 GLW2000

Change in capacity + 1000 l + 2000 l

Change in fill height + 22 cm + 44 cm

Extension size max. 290 x 150 cm

Extension weight 52 kg 86 kg

Notes 4-side 4-side

24

Page 37

AXIS-GENERAL

4. 2 List of available optional equipment

We recommend that you have the extra equipment fitted and mounted on the

basic machine by your supplier or an authorised service centre .

4.2.1 Extensions

The holding capacity of the spreader can be increased by extending the main

hopper by an hopper extension.

The extensions are bolted to the standard unit.

For an overview of extensions and extension combinations see Chapter

4.1.4:

Specifications of extensions and extension combinations, page 23.

NOTICE

NOTICE

Technical data

4

4.2.2 Hopper covers

A hopper cover can be installed to protect the spreader material from rain and

moisture.

The hopper covers are screwed both to the main hopper and to the hopper extension.

Hopper covers Application

AP-L 25, foldable

AP-XL 25, foldable Attachments: XL11031, XL1300, XL1800

AP-L 50, foldable

1. A supplementary hopper cover is necessary for this attachment.

4.2.3 Hopper cover supplement

For the hopper extensions L603 and XL1103, a supplementary cover is necessary in addition to the hopper cover.

Standard unit

Attachments: L603

Attachments: GLW1000, GLW2000

1

, L800, L1500

Cover supplements Application

APE-L 25, foldable

APE-XL 25, foldable

Extension: L603

Extension: XL1103

25

Page 38

Technical data 4

AXIS-GENERAL

4.2.4 TELIMAT T 25, T 50

The Telimat is used for remote-controlled boundary spreading from the track

(right).

A single action valve is required for the operation of the TELIMAT T 25 or T 50.

4.2.5 Two way unit (only for AXIS 20.1/30.1/40.1)

The two way unit can be used to connect the solid fertiliser broadcaster to tractors

with only one single-acting control valve.

4.2.6 Tele-Space universal drive shaft

The Tele-Space universal drive shaft is extendable and provides additional space

(approx. 300 mm) for easier coupling of the solid fertiliser broadcaster to the tractor.

A separate assembly manual is supplied with the Tele-Space universal drive

shaft.

4.2.7 Universal drive shaft with radial ratchet brace (only for AXIS 20.1)

The radial ratchet brace coupling limits the torque in case of overloading.

4.2.8 Auxiliary lighting

The solid fertiliser broadcaster can be fitted with auxiliary lighting.

Lighting Application

BLO 25/50

BLW 20/25/50

BLF 25/50

BLF

Lighting for rear

without warning sign

Lighting for rear

with warning sign

Lighting for front

with warning sign

for wide attachments

Lighting for front

without warning sign

26

for wide attachments

NOTICE

Attachments are subject to the lighting regulations specified in the traffic regulations. Observe the traffic regulations of your country.

Page 39

Technical data

AXIS-GENERAL

4.2.9 ASR 25 transport wheels with bracket

For parking and manually pushing the empty solid fertiliser broadcaster.

The transport wheels consist of two turning wheels in front and two non turning

wheels at the rear without wheel lock.

4.2.10 Border spreading unit GSE 25 (only for AXIS 20.1/30.1/40.1)

Limits the spreading width (either towards the left or right) to the range between

approx. 0.5 m and 2 m from the centre of the tractor track to the outer edge of the

field. The metering slide that points to the field edge is closed.

Fold the border spreading unit downwards for border spreading.

The border spreading unit must be hinged up again before two-sided spread-

ing.

4.2.11 Hydraulic remote controller FHZ 25 for GSE 25 (only for AXIS 20.1/30.1/40.1)

This remote controller is used, from the tractor cab, to hydraulically swing the

GSE 25 border spreading unit into position or to swing it from border spreading

position to the both side spreading position.

4

For operating the hydraulic remote controller FHZ 25, a single action valve is required

4.2.12 Hydraulic remote controller FHZ 26 for GSE 25 (only for AXIS 30.1 W/40.1 W)

This remote controller is used, from the tractor cab, to hydraulically swing the

GSE 25 border spreading unit into position or to swing it from border spreading

position to the both side spreading position.

For operating the hydraulic remote controller FHZ 26, a single action valve is required.

4.2.13 Dirt deflector SFG 30 (only for AXIS 20.1)

This attachment prevents the solid fertiliser broadcaster and extra equipment

from getting dirty by dirt thrown up by the wheels of the tractor.

Apart from that, the dirt deflector also prevents foreign bodies from being caught

and flung out by the spreading discs.

4.2.14 Dirt deflector extension SFG-E 30 (only for AXIS 30.1/40.1)

If the deflector SFG 30 does not perform satisfactorily, the SFG-E 30 extension

can be mounted additionally.

27

Page 40

Technical data 4

AXIS-GENERAL

4.2.15 Spreading vane set Z14, Z16, Z18

This set of spreading vanes is used for spreading snail bait. The snail bait spreading vane replaces the short spreading vane on the right and left spreading discs.

Set Application

Z14

Z16

Z18

4.2.16 Inspection kit PPS5

For checking cross-distribution in the field.

4.2.17 Fertiliser Identification System DiS

Rapid, uncomplicated determination of spreader settings with unfamiliar fertilisers.

Spreading disc S4

Spreading disc S6

Spreading disc S8

28

Page 41

AXIS-GENERAL

5 Axle load calculation

5.1 Calculation of the total weight

Overload danger

Mounted units on the front or rear three-point linkage must not

cause the approved total weight to be exceeded. The front axle of

the tractor must always be loaded with at least 20 % of the

unladen weight of the tractor.

Before using the unit make sure that it meets these require-

ments by performing the following calculations or weighing

the tractor-unit combination.

n CAUTION

Axle load calculation

5

Calculation of the

total weight, the

axle loads and the

tyre capacity and

the required ballast weights.

G

V

T

V

abcd

Bild 5.1: Loads and weights

G

H

T

H

29

Page 42

Axle load calculation 5

AXIS-GENERAL

You will need the following data for the calculation:

Character

[unit]

T

[kg] Unladen weight of tractor. [1]

L

[kg] Front-axle load of the unladen tractor. [1]

T

V

[kg] Rear-axle load of the unladen tractor. [1]

T

H

[kg] Total weight of front-mounted unit or front bal-

G

V

Meaning Calculation

by

[2]

last.

[kg] Total weight of rear-mounted unit or rear ballast. [2]

G

H

a [m] Distance between centre of gravity of front-

[2], [3]

mounted unit or front ballast and centre of front

axle.

b [m] Wheel base of tractor. [1], [3]

c [m] Distance between centre of rear axle and centre

[1], [3]

of lower link ball.

d [m] Distance between centre of lower link ball and

[2]

centre of gravity of rear-mounted unit or rear

ballast.

[1] See tractor operator's manual

[2] See equipment price list and/or operator's manual

[3] Measuring

30

Page 43

AXIS-GENERAL

Rear-mounted unit or front-rear combinations

G

Vmin

G

H

cd+()• TVb02TLb••,+•–()

ab+

---------------------------------------------------------------------------------------------=

G

Hmin

GVa• THb 0 45 TLb••,+•–()

bcd++

----------------------------------------------------------------------------------=

T

Vtat

G

V

ab+()• TVbG

H

–cd+()••+()

b

-------------------------------------------------------------------------------------------=

Calculation of minimum ballast at

front G

V min

Enter the calculated minimum ballast requirement in the table.

Front-mounted unit

Calculation of the minimum ballast at

rear G

H min

Axle load calculation

5

Enter the calculated minimum ballast requirement in the table.

If the front-mounted unit (GV) is lighter than the minimum ballast at the front (G

), the weight

V min

of the front-mounted unit must be increased to at least the weight of the minimum front ballast.

Calculation of the actual front-axle

load T

V tat

Enter the calculated actual and approved front-axle load as specified in the tractor operator's

manual in the table.

31

Page 44

Axle load calculation 5

AXIS-GENERAL

G

tat

G

V

TLG

H

++()=

T

H

tat

G

tat

G

Vtat

–()=

If the rear-mounted unit (GH) is lighter than the minimum ballast at the rear (G

), the weight

Hmin

of the rear-mounted unit must be increased to at least the weight of the minimum rear ballast.

Calculation of the actual total weight

G

tat

Enter the calculated actual and approved total weight as specified in the tractor operator's manual

in the table.

Calculation of the actual rear-axle

load T

H tat

Enter the calculated actual and approved rear-axle load as specified in the tractor operator's manual in the table.

Tyre load capacity

Enter double the value (two tyres) of the approved tyre load capacity (for example, see tyre manufacturer's documentation) in the table.

5.2 Axle loads table

Actual value from

calculation

Minimum ballast

kg ⎯⎯

front/rear

Total weight kg ≤ kg ⎯

Front-axle load kg ≤ kg ≤ kg

Rear-axle load kg ≤ kg ≤ kg

Approved value

from operator's

manual

Twice approved

tyre load capacity

(two tyres)

32

The minimum ballast weight must be mounted on the tractor as an attachment

or as ballast.

The calculated values must be less than or equal to the permitted values.

Page 45

AXIS-GENERAL

6 Transport without tractor

6.1 General safety instructions

Before transporting the solid fertiliser broadcaster observe the following

instructions:

The solid fertiliser broadcaster must only be transported without the tractor if

the hopper is empty.

The operation must only be carried out by suitable, trained and expressly au-

thorised personnel.

Suitable means of transportation and lifting equipment (e.g. crane, fork lift

truck, cable devices...) are to be used for transport purposes.

Establish the transportation route in good time and remove possible obsta-

cles.

A check must be made to ascertain that all safety and transport devices are

fit for operation.

Cordon off all danger areas accordingly, even if they are only briefly in exist-

ence.

Transport without tractor

6

The person responsible for the transportation is required to make certain, that

the transport of the solid fertiliser broadcaster can be carried out routinely.

Unauthorised persons are to be excluded from the transport route. The areas

concerned are to be cordoned off!

The solid fertiliser broadcaster is to be handled and transported carefully.

Make sure that allowance is made for the centre of gravity! If necessary, ad-

just the cables such that the machine is correctly aligned on the means of

transport.

Transport the solid fertiliser broadcaster to the set-up location as close to the

ground as possible.

6.2 Loading and unloading, parking

1. Determine the weight of the solid fertiliser broadcaster.

Check the details on the factory type plate.

If applicable, note the weight of the special built-on accessories.

2. Hang suitable lifting tackle in both ring eyelets.

3. Lift the machine carefully using suitable lifting equipment.

4. Place the machine carefully on the loading platform of the transport vehicle or

on solid ground.

33

Page 46

Transport without tractor 6

AXIS-GENERAL

34

Page 47

Instructions regarding the spreading process

AXIS-GENERAL

7 Instructions regarding the spreading process

The intended use of the solid fertiliser broadcaster includes compliance with the

operating, maintenance and service conditions according to manufacturer specifications. Spreading therefore always includes the work of preparation and

cleaning/maintenance.

Conduct spreading as described below.

Preparation

Attach spreader to tractor page 42

Close metering slide

Preset the mounting height page 46

Fill hopper Chapter A.2 or Chapter A.3

Set application rate Chapter B.2

Setting the working width

Chapter B.5

7

1

1

1

- Choosing the correct spreading disc

- Set fertiliser drop point

Chapter B.5.3

Spreading

Travel to the spreading location

Check mounting height

Engage PTO shaft

Open slide and start spreading

Finish spreading run and close the outlets

Disengage PTO shaft

Discharge residue Chapter B.10

Cleaning/maintenance

Open metering slide

Unhitch spreader from tractor

Maintenance and lubrication Chapter C

1

and AXIS-Main-

tenance

1

1

1. See the solid fertiliser broadcaster register (AXIS 20.1, AXIS 30.1/40.1 or AXIS 50.1 W)

35

Page 48

Instructions regarding the spreading process 7

AXIS-GENERAL

36

Page 49

Standard operating procedure (all models)

AXIS-GENERAL

8 Standard operating procedure (all models)

8. 1 Taking delivery of the solid fertiliser broadcaster

Please check that all parts are included when the solid fertiliser broadcaster is delivered.

The standard equipment includes

1 solid fertiliser broadcaster of the AXIS series,

1 operator’s manual AXIS 20.1, AXIS 30.1, AXIS 40.1, AXIS 50.1 W

1 calibration chart (Paper or CD),

1 calibration kit comprising chute and calculator,

lower and upper steering arm pins,

1 spreading disc set (according to order),

1 universal drive shaft (including operator's manual).

1 agitator

8

1 protective grid in the hopper

version Q or W of the solid fertiliser broadcaster: electronic control

Please check any accessories that you ordered.

Check and make sure that no damage occured to the machine during transport

and that no parts are missing. Have the transport damages be confirmed by the

transport company.

When receiving the machine, check that all attached components are correctly

and tightly seated.

The right and left casting discs must be mounted facing the direction of travel.

In case of doubt, please contact your dealer or our factory.

8. 2 Tractor requirements

The tractor must meet the required mechanical, hydraulic and electrical requirements for safe and correct operation of the solid fertiliser broadcaster of the AXIS

series.

NOTICE

universal drive shaft connection: 1 3/8 inches, 6-spline, 540 rpm,

Oil feed: max. 200 bar, single or double action valve (depending on equip-

ment)

On board voltage: 12 V,

Three point linkage category II.

37

Page 50

Standard operating procedure (all models) 8

AXIS-GENERAL

8. 3 Mounting the drive shaft on the solid fertiliser broadcaster

n CAUTION

Danger from unsuitable drive shaft.

The solid fertiliser broadcaster is fitted with a universal drive shaft

type designed for the unit and the power.

Use only universal drive shafts approved by the manufacturer.

Follow the directions in the shaft manufacturer's manual!

The solid fertiliser broadcaster can be delivered with various kinds of drive shafts,

depending on model:

universal drive shaft with shear bolt clutch,

universal drive shaft with radial pin clutch,

Tele-Space universal drive shaft with radial pin clutch.

The drive shaft with shear pin attachment can only be mounted on the solid

fertiliser broadcaster of the type AXIS 20.1. See „

with shear bolt coupling on the AXIS 20.1.“ on page 73.

8.3.1 Fitting and removing the drive shaft

Attachment:

1. Check the attachment position.

The end of the shaft with the tractor symbol must be at the tractor end of

the shaft.

2. Release the drive shaft [1]

locking screw.

3. Turn the drive shaft shield to

the demounting position.

NOTICE

Mount universal drive shaft

38

4. Pull the universal drive shaft

out.

Figure 8.1: Remove drive shaft shield

Page 51

Standard operating procedure (all models)

AXIS-GENERAL

5. Remove the spigot protec-

tion and grease the transmission spigot. Mount the

drive shaft onto the transmission spigot.

8

6. Tighten hexagonal screw

and nut with size 17 wrench

(max. 35 Nm).

Figure 8.2: Mount the drive shaft onto the

transmission spigot

Figure 8.3: Tighten drive shaft

39

Page 52

Standard operating procedure (all models) 8

AXIS-GENERAL

7. Slide drive shaft shield with

hose clamp over the universal drive shaft and place on

the gearbox neck (do not

tighten).

8. Turn the drive shaft shield to

the locking position.

9. Tighten locking screw.

10. Tighten hose clamp.

Figure 8.4:

Figure 8.5: Secure universal drive shaft

Put the drive shaft shield back on

shield

40

Page 53

Standard operating procedure (all models)

AXIS-GENERAL

Instructions for removal:

Remove the universal drive shaft in reverse order of attachment.

Do not use safety chain to suspend the universal drive shaft.

Store uncoupled universal drive shaft on the bracket.

8