Page 1

OPERATOR'S MANUAL

AN055AGB C

Silo unloader - Straw

Spreader

ALTOR 6070

AN055AGB C

- English - 02-2010

Page 2

Page 3

Silo unloader - Straw Spreader

ALTOR 6070

$Dear Owner

In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and

improvement. You will find, as have thousands of owners all over the world, that you have the best that

engineering skill and actual field testing can produce. You have purchased a dependable machine, but only

through proper care and operation can you expect to receive the performance and long service built into it.

This manual contains all the necessary information for you to receive full efficiency from your machine. The

performance you get from this machine is largely dependent on how well you read and understand th is manual

and apply this knowledge. Please DO NOT ASSUME YOU KNOW HOW TO OPERATE AND MAINTAIN YOUR

MACHINE before reading this manual carefully. KEEP THIS MANUAL AVAILABLE FOR REFERENCE. Pass

it on to the next owner if you re-sell the machine.

Your KUHN dealer can offer a complete line of genuine KUHN service parts. These parts ar e manufactured and

carefully inspected in the same factory that builds the machine to assure high quality and accurate fitting of any

necessary replacements.

About improvements

We are continually striving to improve our products. It therefore reserves the right to make improvements or

changes when it becomes practical to do so, without incurring any obligations to make changes or additions to

the equipment sold previously.

Designated use of the machine

The silo unloader-straw spreader ALTOR 6070 must only be used for the purpose for which it is designed:

unloading silage from the silo, loading round or rectangular bales, transport, distribution in feeding areas and

spreading straw in animal bedding areas.

Dear Owner

1

Page 4

Silo unloader - Straw Spreader

ALTOR 6070

$Contents

Dear Owner.....................................................................................................................1

Contents..........................................................................................................................2

Identification of the machine.........................................................................................5

Front view..........................................................................................................................................5

Rear view.. .......................................... ... .... ... ... .......................................... ... ... .... ... ... ........................5

Model identification plate ................................................................................................................6

Optional equipment..........................................................................................................................6

Safety...............................................................................................................................7

Description of symbols used in this document.............................................................................7

Safety instructions...........................................................................................................................8

Location and description of safety decals on the machine .......................................................18

Road safety equipment and recommendations...........................................................................21

Machine specifications................................................................................................22

Description and glossary...............................................................................................................22

Technical specifications................................................................................................................24

Sound levels ......... ... ... .... ... ... ... .... ............................................. ......................................................27

Putting into service......................................................................................................28

Description of control elements....................................................................................................28

Coupling and uncoupling..............................................................................................................37

Walkway with dual control.............................................................................................................41

2

Swivel chute....................................................................................................................................42

Mixing hopper.................................................................................................................................43

Contents

Page 5

Silo unloader - Straw Spreader

ALTOR 6070

Instructions for transport............................................................................................ 49

Conformity with the road regulations ... ... .... ... .............................................................................49

Instructions for work...................................................................................................50

Preliminary checks.........................................................................................................................50

Functional check, no load.............................................................................................................51

Silage unloading.............................................................................................................................53

Loading bales.......................................... ............................................. ..........................................55

Adjustment setting.........................................................................................................................57

Distribution.....................................................................................................................................58

Straw blowing.................................................................................................................................63

Optional equipment.....................................................................................................65

Hydraulic unit .................................................................................................................................65

Leg with holes ................................................................................................................................67

Homokinetic transmission with free wheel and friction limiter .................................................68

Weighing unit..................................................................................................................................68

Maintenance and storage............................................................................................ 69

Greasing and oil change................................................................................................................69

Control storage...............................................................................................................................75

Cleaning the conveyor...................................................................................................................77

Conveyor chain tension.................................................................................................................78

Checking and adjusting the sections. ... ... .... ... ... ... ................................................. ... ... ................79

Contents

3

Page 6

Silo unloader - Straw Spreader

ALTOR 6070

Belt tension.....................................................................................................................................80

Changing oil and checking levels.................................................................................................82

Tyres................................................................................................................................................83

Storage............................................................................................................................................84

Maintenance....................................................................................................................................85

Trouble shooting guide................................................................................................86

Limited warranty...........................................................................................................91

4

Contents

Page 7

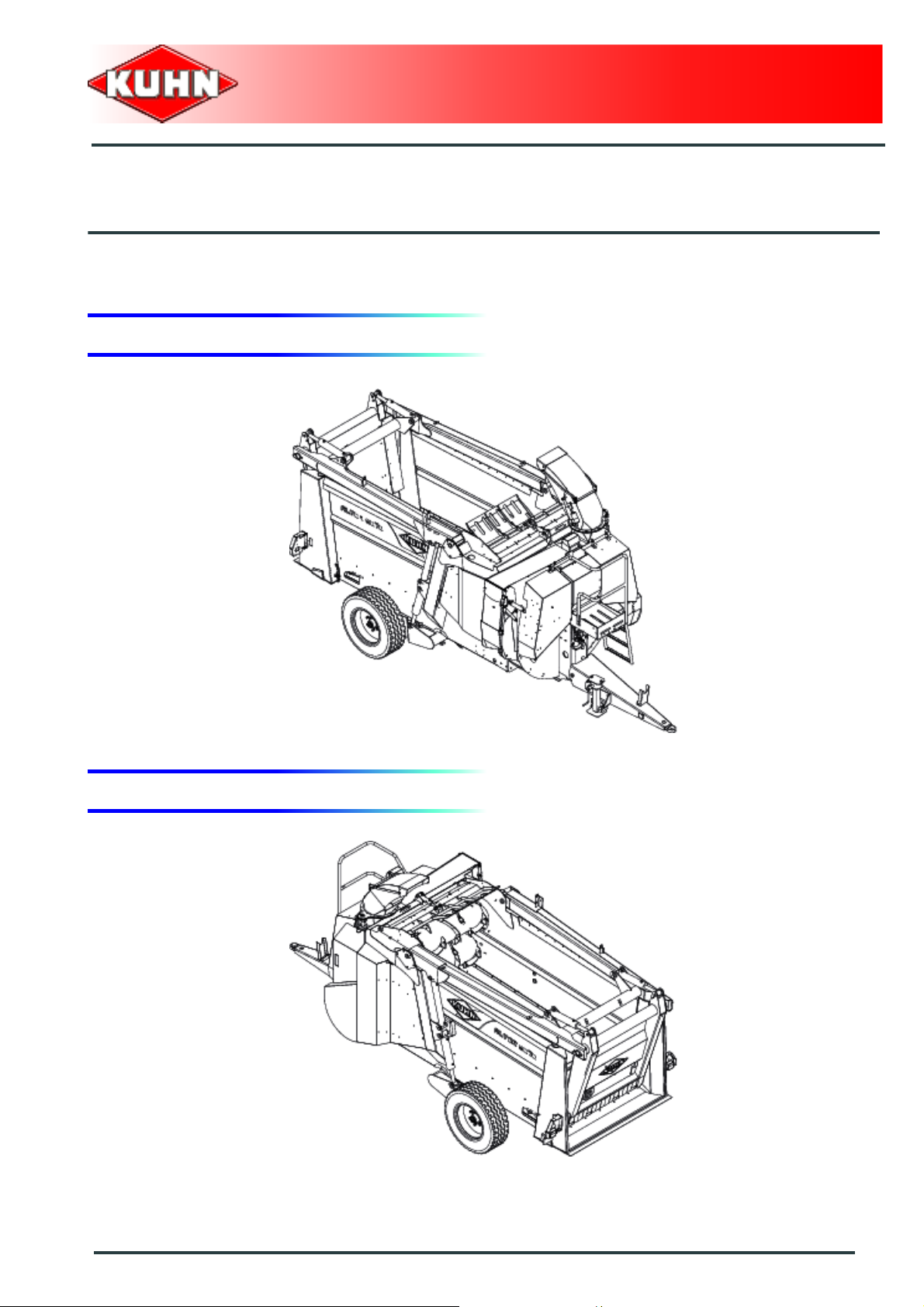

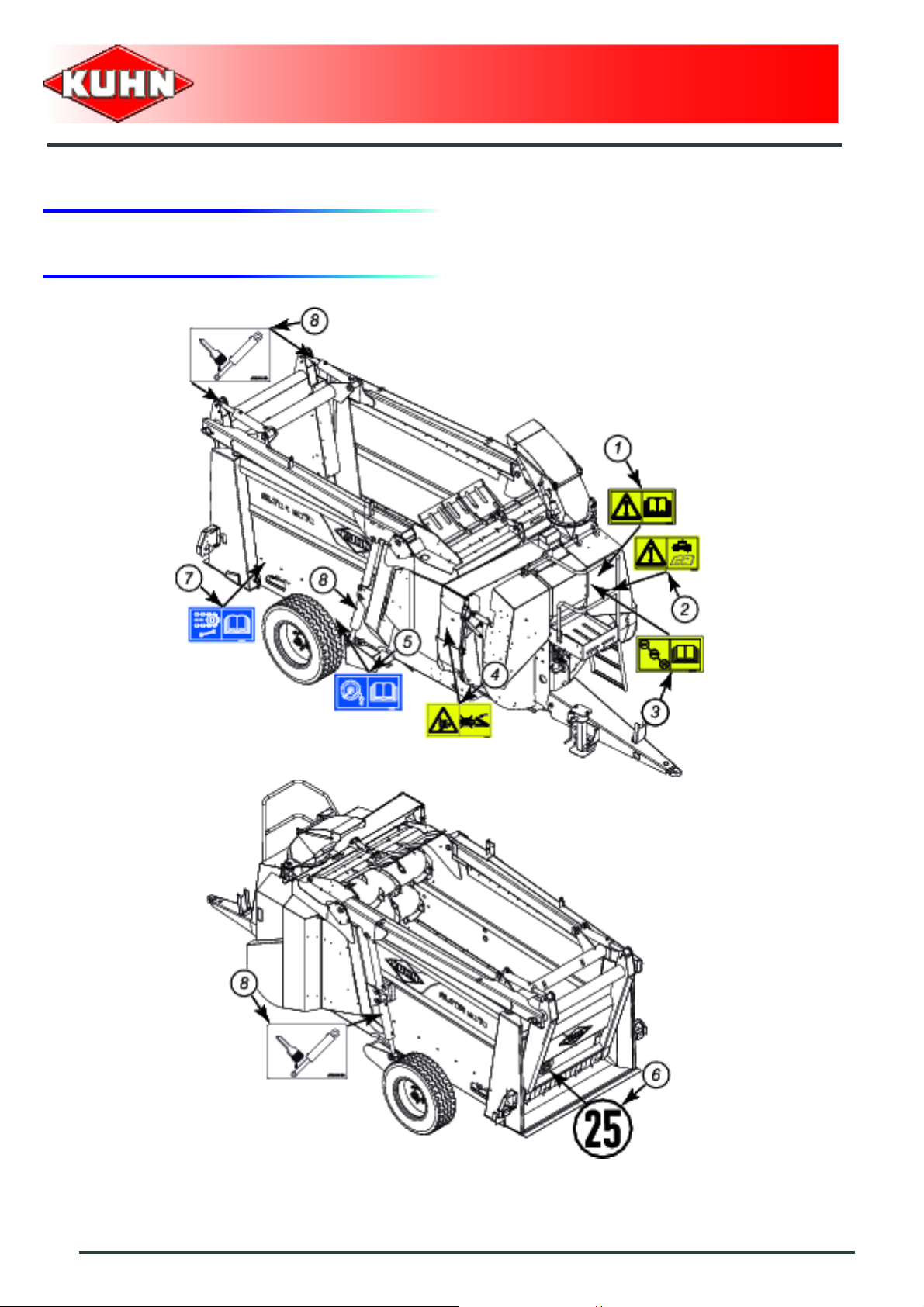

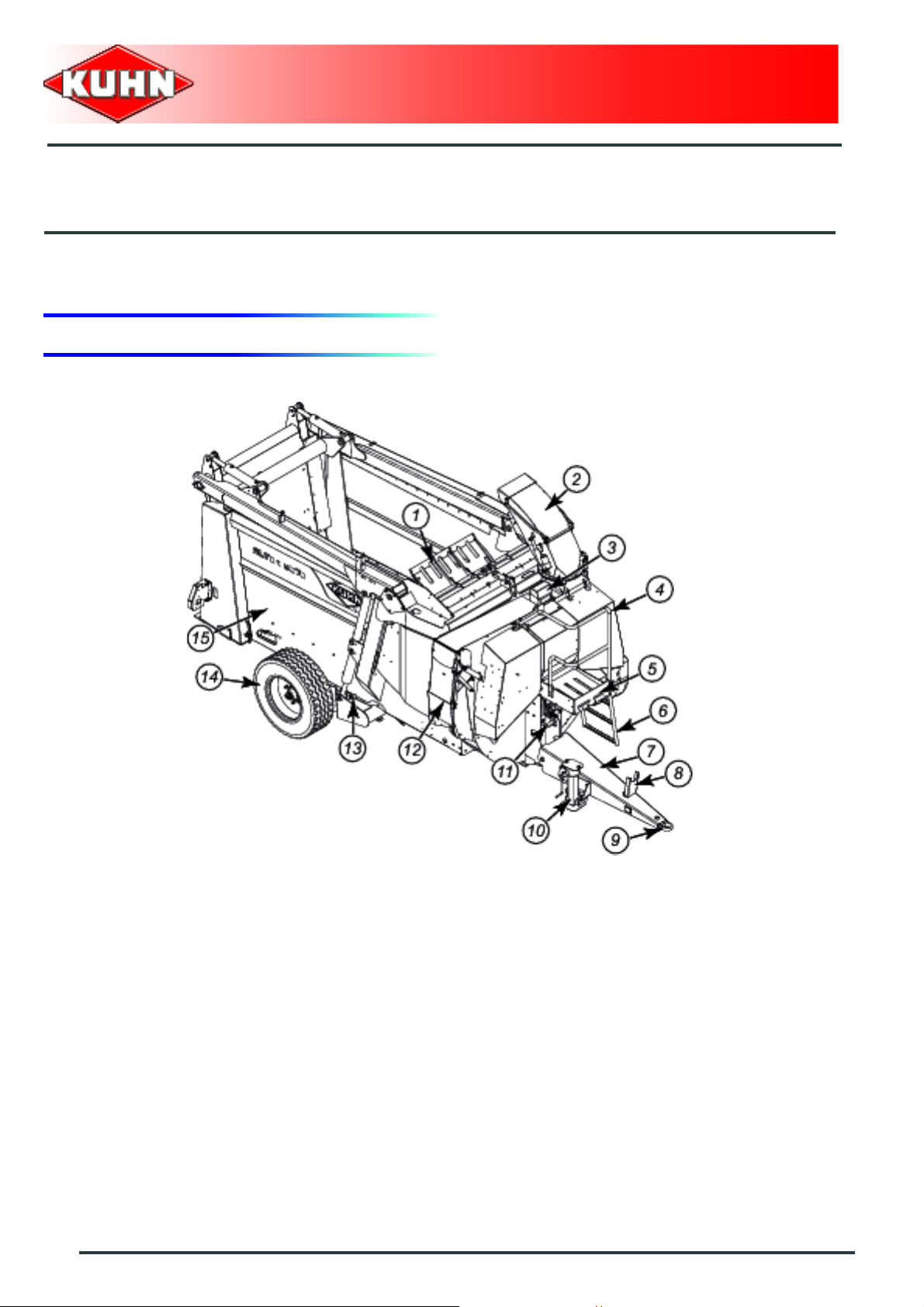

1. Front view

Silo unloader - Straw Spreader

ALTOR 6070

$Identification of the machine

2. Rear view

Identification of the machine

5

Page 8

3. Model identification plate

Please write below the type and serial number of the

machine. This information is to be indicated to the dealer

for all spare parts orders.

Type:

Serial no.:

Silo unloader - Straw Spreader

ALTOR 6070

4. Optional equipment

Tick box corresponding to the equipment fitted on your

machine:

Kit no. 1926193: Hydraulic unit

Kit no. 1926207: Weighing unit

Kit no. 1936023: Programmable weighing unit

Kit no. 1926178: Homokinetic transmission with free wheel and friction limiter

Kit no. 1926174: Leg with holes

6

Identification of the machine

Page 9

$Safety

1. Description of symbols used in this document

This symbol indicates a potentially hazardous situation

that if not avoided, could result in serious bodily injury.

Silo unloader - Straw Spreader

ALTOR 6070

This symbol is used to identify special instructions or

procedures which, if not followed strictly, could result in

machinery damage.

This symbol is used to communicate technical

information of particular interest.

Safety

7

Page 10

Silo unloader - Straw Spreader

ALTOR 6070

2. Safety instructions

Introduction

The machine must only be operated, maintained and repaired by competent persons who are familiar with

machines' specifications and operation and aware of safety regulations for preventing accidents.

The operator must imperatively respect safety instructions in this manual and in the warnings posted on the

machine. The operator is also obliged to respect curren t legislation concerning accident prevention, wor k safety

and public traffic circulation.

Designated use of the machine also means following operation, maintenance and repair recommendations

given by the manufacturer, and using o nly ge nuine spa re parts, e qu ipme nt an d accessori es, as reco mme nde d

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident resulting from ma chine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding certain

parts in this manual, please contact your KUHN dealer.

Precautions to be taken before carrying out

any operations on the machine

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

8

Safety

Page 11

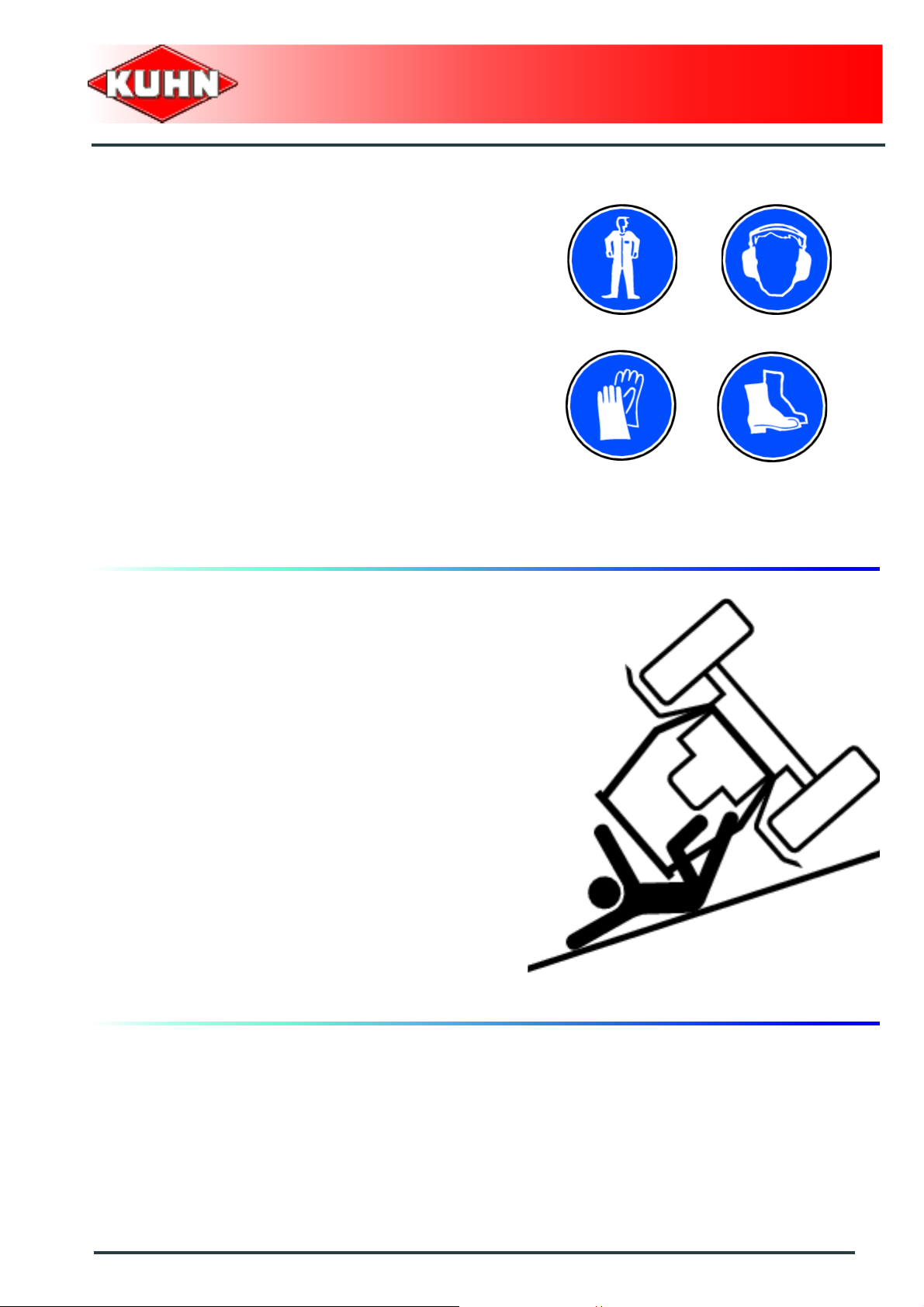

Precautions to take before using the machine

Do not wear loose clothing which could become caught

up in moving parts.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on fixing elements (tines, forks,

blades, knives, etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Silo unloader - Straw Spreader

ALTOR 6070

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of great importance that the

operator exercises caution in every given situation.

Groundspeed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt changes

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.

Safety

9

Page 12

Precautions when driving on public roads

Dimensions

Depending on the dimensions of the machine, contact

the relevant authorities to ensure that it can be legally

transported on public roads.

If the machine is over the maximum legal size, follow the

local regulations for special transportation of oversize

equipment.

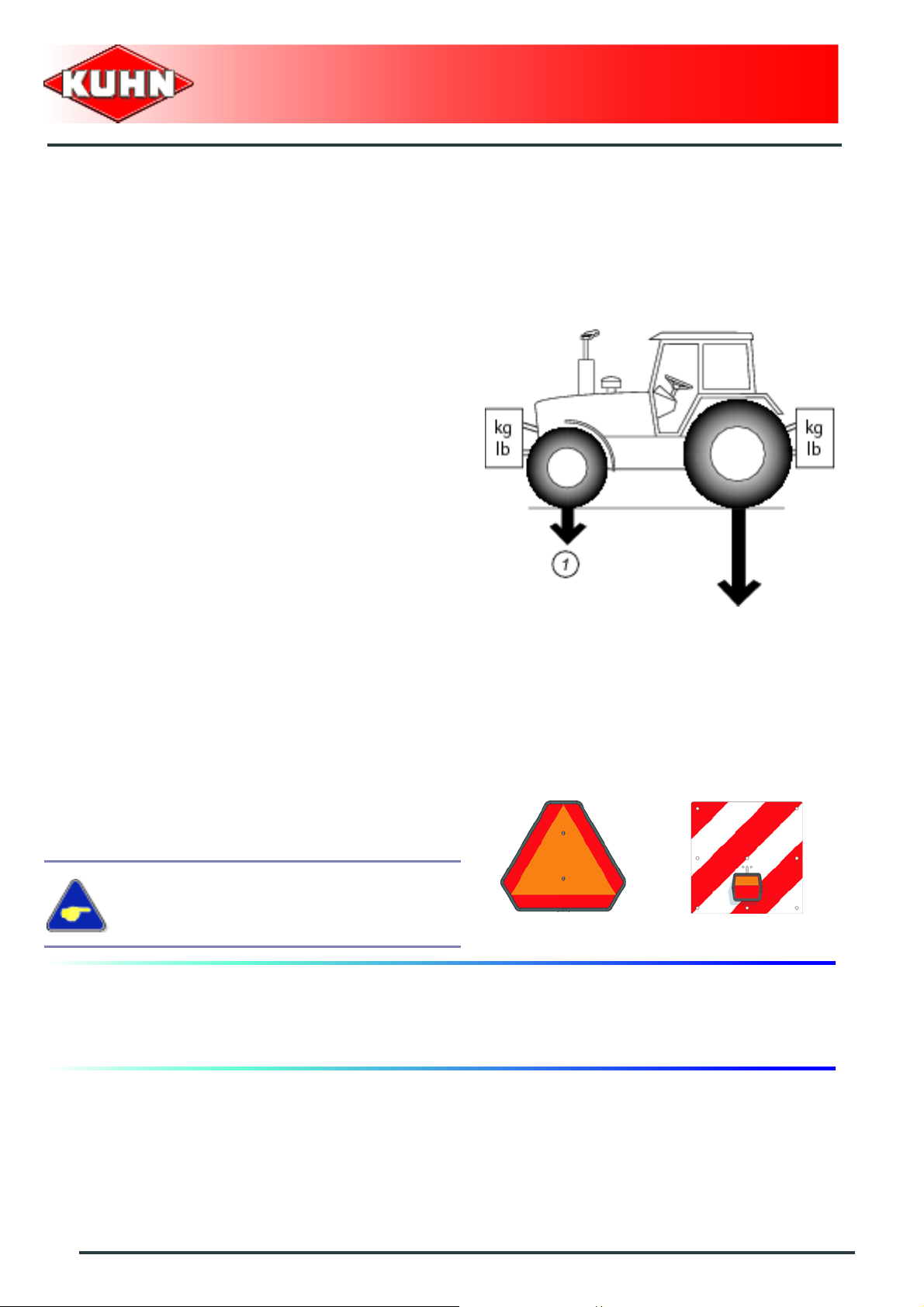

Gross weight and weight per axle

Check that the tractor's authorized gross weight as well

as its lift capacity and maximum weight per axle are not

exceeded.

The front axle load (1) must never, under any

circumstances, be less than 20% of the tractor's unladen

weight. If necessary, add ballast weights to the front or

to the rear to preserve the steering and braking

efficiency.

Silo unloader - Straw Spreader

ALTOR 6070

Transport position

Before transporting the machine on public roads, place

the machine into its transport position, according to the

instructions in this manual.

Lights and indicators.

Before transporting the machine on public roads, ensure

that all legally required lightings and signallings are in

place.

Ensure that lightings and signallings are clean and in

good working order. Replace any missing or broken

equipment.

Always obey current regulations for driving

on roads

Maximum speed

Always keep to the legal speed limit for driving a tractormachine assembly on public roads.

10

Safety

Page 13

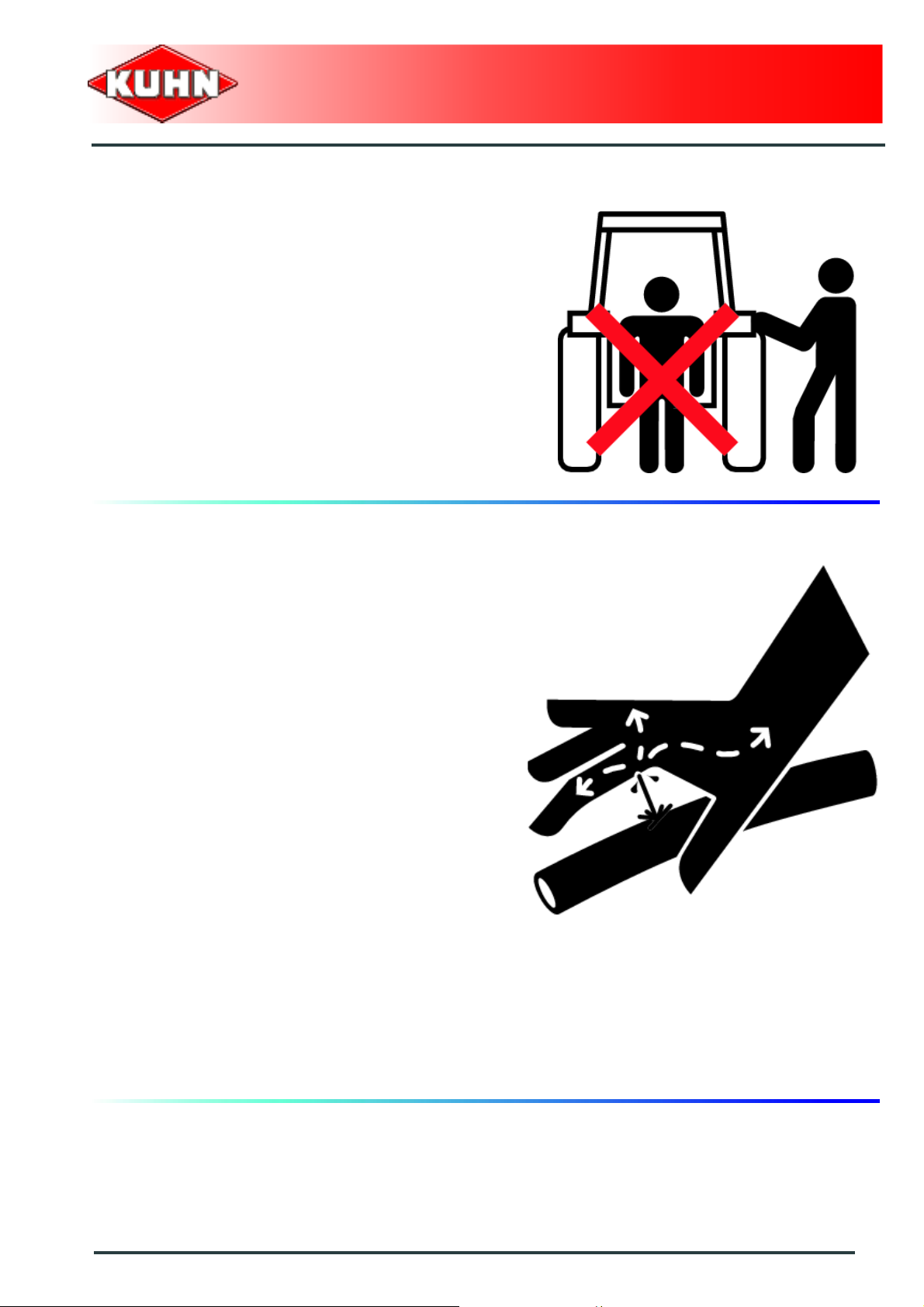

Precautions when coupling

Before attaching the machine, make sure that it cannot

accidentally start moving (chock the wheels) and that the

parking stand is in the right position.

The machine must only be attached to the hitch points

provided for this purpose.

Never stand between the tractor and the machine when

operating the three point linkage.

Do not stand between the tractor and the machine

without ensuring that the parking brake is applied.

Hydraulic circuit

Silo unloader - Straw Spreader

ALTOR 6070

Caution! The hydraulic circuit is under high pressure.

Maximum pressure at work: 215 bar.

Before connecting hoses to the tractor hydraulics,

ensure that tractor and machine circuits are not under

pressure. Before disconnecting a hose, depressurize the

hydraulic circuit.

To avoid making incorrect connectio ns, mark hydraulic

couplers and corresponding hoses with colors.

WARNING! Functions could be reversed (for example:

lift/lower) and cause accidents.

Regularly check the hydraulic hoses. In case of normal

wear, replace the hydraulic hoses every 5 years.

Damaged or worn hoses must immediately be r eplaced.

When replacing the hydraulic hoses, only use hoses with

the specification recommended by the manufacturer of

the machine.

To locate a leak, use appropriate means. Protect body

and hands from liquid under pressure.

Any liquid under pressure (particularly oil from

hydraulics) can penetrate the skin and cause severe

injury. If injured, see a doctor immediately, there could

be danger of infection.

Before any adjustments, maintenance or repairs are

carried out, lower the machine to the ground,

depressurize the hydraulics, turn off the engine, remove

ignition key and wait until all moving parts have come to

a complete stop.

Safety

11

Page 14

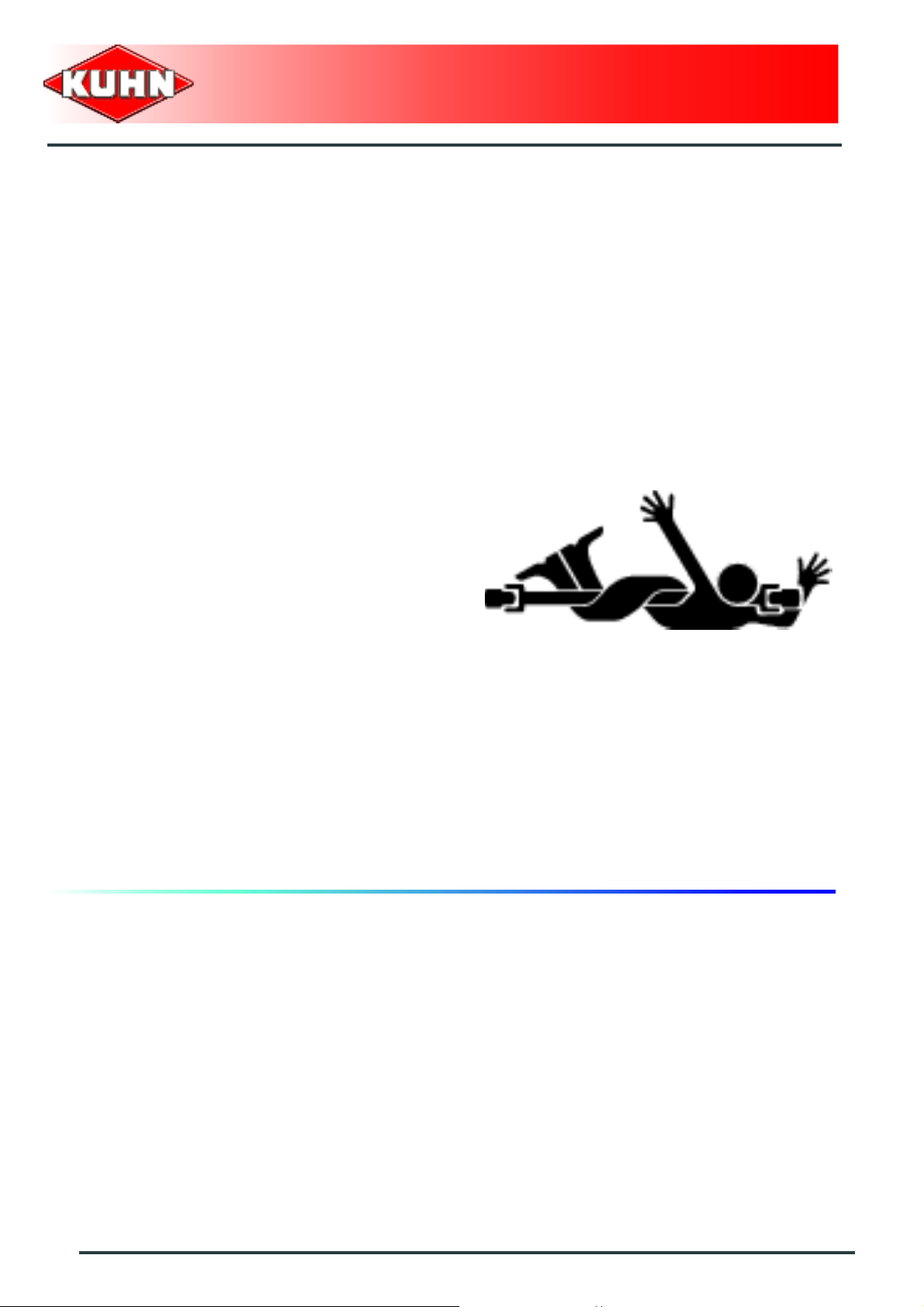

PTO shaft

Use only PTO shafts supplied with the machine or

recommended by the manufacturer.

The protective shield of the tractor PTO stub, the PTO

shaft guards and the protective covering of the machine

input shaft must always be in place and in good

condition.

Make sure that the PTO shaft guards are secured with

the safety chains provided.

Any worn or damaged guards must be replaced

immediately. A worn guard or an unpro tecte d PTO shaft

can cause a serious or even a lethal accident.

Do not wear loose clothing that could be caught in the

rotating PTO shaft.

Before attaching or removing a PTO shaft, or before

doing any work on the machine, disengage the PTO

drive, turn off the engine, remove ignition key and wait

for all moving parts have come to a complete stop.

If the primary PTO shaft is equipped with a slip clutch or

a free wheel, these must be fitted on the machine side.

Ensure that the PTO shaft is always correctly fitted and

locked into place.

Before connecting the PTO shaft, ensure that the PTO

speed (rotational frequency) and directions of rotation

are in line with manufacturer's recommendat ion s.

Before engaging the PTO drive, make sure all people

and animals are clear from the machine. Never engage

the PTO drive when the tractor engine is stopped.

When uncoupling the machine, rest the PTO shaft on the

support specially provided, and replace protective cover

on the PTO stub of the tractor.

Read and follow the instructions in the operator's manual

provided with the PTO shaft.

Silo unloader - Straw Spreader

ALTOR 6070

12

Safety

Page 15

Precautions during manoeuvres

When moving the machine from the transport position to

the working position and vice versa, make sure that

nobody is within the machine pivoting area.

Remote controlled components

Danger of crushing and shearing can exist when

components are operated by hydraulic or pneumatic

controls. Keep away from these danger zones.

Tyres

Contrôler régulièrement la pression des pneumatiques.

Respecter la pression indiquée par le constructeur. Le

montage, le démontage et la réparation de roues et des

pneumatiques ne doivent être réalisés que par des

personnes ayant les connaissances nécessaires pour le

faire et disposant de l’outillage réglementaire approprié.

Avant toute intervention sur les roues ou sur les

pneumatiques, faire reposer la machine au sol et mettre

en place des cales de roues pour éviter un déplacement

accidentel.

Silo unloader - Straw Spreader

ALTOR 6070

Safety decals

Safety warning decals are placed in pictorial form on

various parts of the machine. They are there to warn you

of potential dangers and to tell you how to avoid

accidents.

Always keep the safety decals clean and readable, and

replace them when they are worn, damaged, missing or

illegible.

Safety

13

Page 16

Waste disposal

Respect the environment! Never spill pollutants (oil,

grease, filters, etc.) on the ground, never pour them

down the drain and never discard them in any other

place where they could pollute the environment. Never

throw away or burn a tyre. Always take waste to

specialized recycling or waste disposal centers.

Precautions for maintenance and repair

work

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Rest the machine on the gr ound, release the pressure

from the hydraulic circuit and leave the machine to cool

down.

Make sure that the parts of the machine that need to be

lifted for maintenance or repair work are firmly propped

up.

Before any work is done on the electric circuit or before

any electric welding is carried out on the attached

machine, disconnect the machine from the tractor

electrical circuit. Also disconnect alternator and battery

terminals.

Repairs on elements under pressure or tension (springs,

pressure accumulators, etc.) must only be carried out by

competent persons with regulation equipment.

Wear the appropriate protective clothing for the work in

hand (gloves, shoes, goggles, helmet, ear defenders,

etc.).

Do not solder, weld or use a blow torch near fluids under

pressure or inflammable products.

For your own safety and for correct machine operation,

only use original manufacturer parts.

Silo unloader - Straw Spreader

ALTOR 6070

14

Safety

Page 17

Projection of stones and foreign objects

For driver safety, always use a tractor equipped with a

cab. Even when the machine is used in accordance with

its purpose, objects may be projected. Stones and other

foreign objects projected by the movin g parts can tr avel

a considerable distance. Keep all persons and animals

away from the danger zone.

Precautions for machine use

Silo unloader - Straw Spreader

ALTOR 6070

Before using the machine, check tools (tines) and their

attachment hardware in accordance with the instructions

of the present manual.

Check the guards regularly. Immediately replace any

damaged or missing elements.

Before engaging the pto drive, lower the rotors onto the

ground. Make sure all the guards are in place. Keep all

persons and animals away from the danger zone.

After the power source has stopped, the rotors can

continue turning for a time. Stay away from the machine

until all moving parts have come to a complete standstill.

If an obstacle is hit, disengage the PTO drive, stop the

tractor engine, remove the ignition key and wait for all

moving parts to come to a complete standstill. Check the

entire machine for any damage before resuming work.

Safety

15

Page 18

Precautions and prevention of fire risk

Your machine works with moving parts (bale

separator(s), turbine) and highly inflammable products.

There is therefore a real risk of fire resulting from:

- Overheating of the power takeoff friction limiter.

Please do not use this limiter excessively. If smoke

issues from the transmission, stop the machine

immediately and leave the limiter to cool outside the

buildings.

- Winding strink or products at the ends of the bale

separator(s). Each time, before using the machine,

check the ends of the bale separator(s) to remove

products which have become wound round or have

accumulated in this area.

- Worn bearing. Grease bearings regularly and check

their condition.

- Sparks caused by pebbles or metal objects in the

straw.

Silo unloader - Straw Spreader

ALTOR 6070

It is highly recommended to have an extinguisher which

has been checked and maintained, on your tractor.

Recommended types: sprayed water + additive, ABC

powder.

It is strictly prohibited to use your machine stationary

inside a building.

16

Safety

Page 19

Silo unloader - Straw Spreader

ALTOR 6070

Safety

17

Page 20

3. Location and description of safety decals on the machine

Silo unloader - Straw Spreader

ALTOR 6070

18

Safety

Page 21

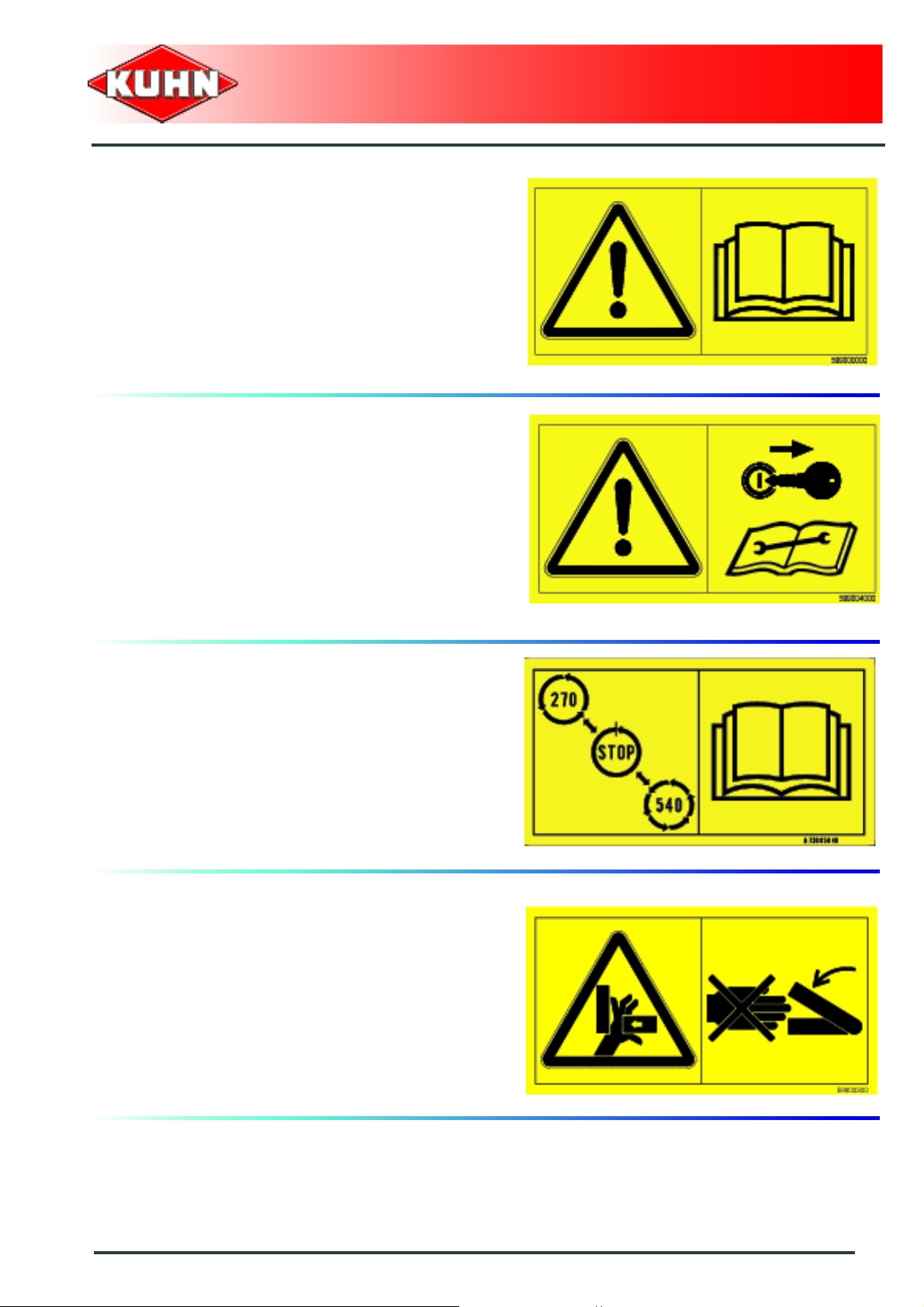

Description of safety decals

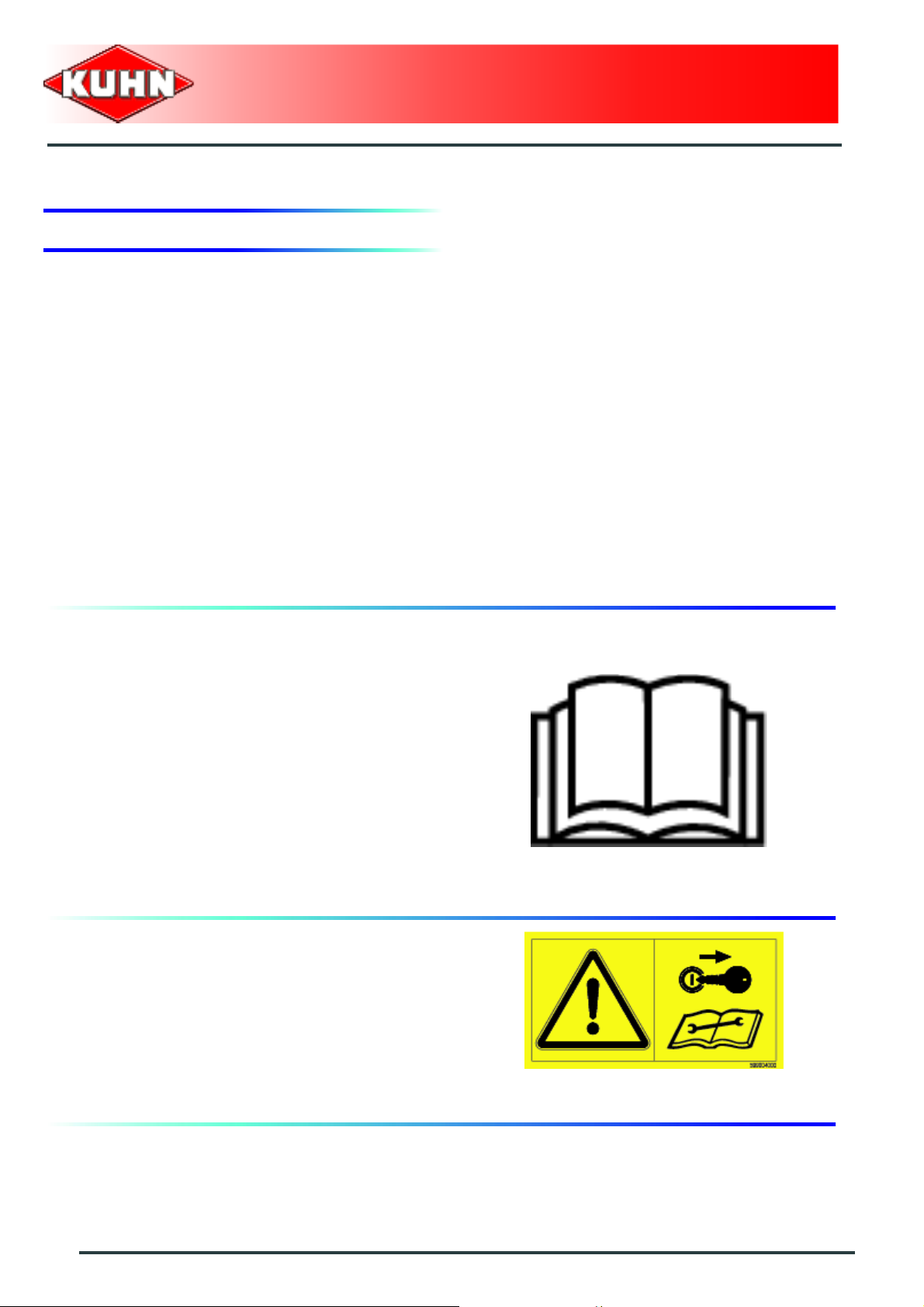

Operating instructions (1)

The operators' manual contains all the information

necessary for using the machine safely. It is imperative

to read and comply with all instructions.

Working on the machine (2)

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, disengage the

PTO drive, turn off the engine, remove ignition key and

wait until all moving parts have come to a complete stop

and apply park brake.

Silo unloader - Straw Spreader

ALTOR 6070

You must totally stop the machine before changing speed (3)

Crushing area (4)

Never operate in an area where there is a crushing risk

before all moving parts have come to a complete stop.

Safety

19

Page 22

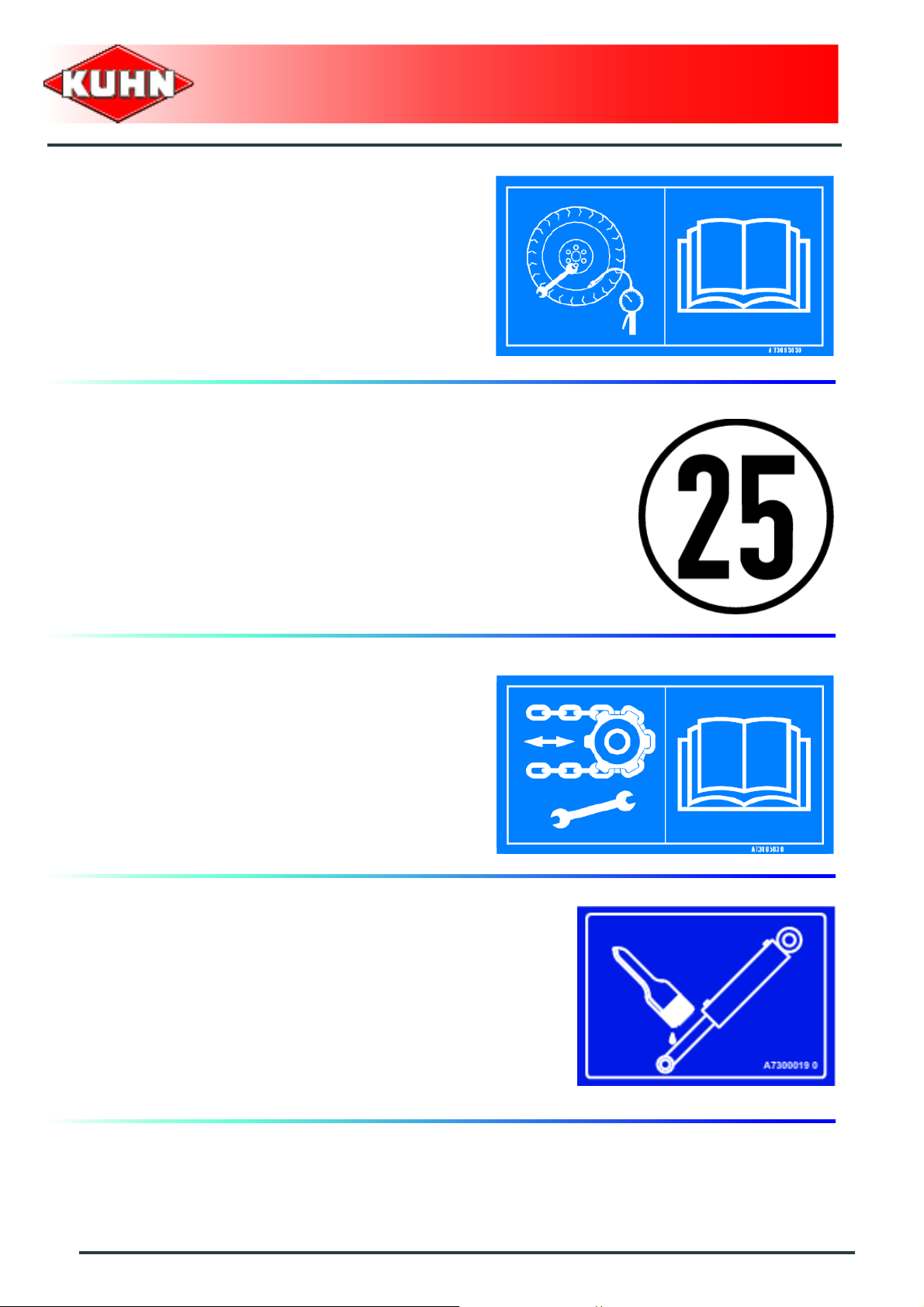

Tire pressure (5)

Check the fixing of the wheels and the tire pressure

regularly.

Speed (6)

Always keep to the legal speed limit of 25 km/h for

driving a tractor-machine assembly on public roads.

Silo unloader - Straw Spreader

ALTOR 6070

Conveyor chain tension (7)

Check the tension of the conveyor chains regularly.

Greasing the cylinder rod (8)

Grease the cylinder rods in contact with the outside.

20

Safety

Page 23

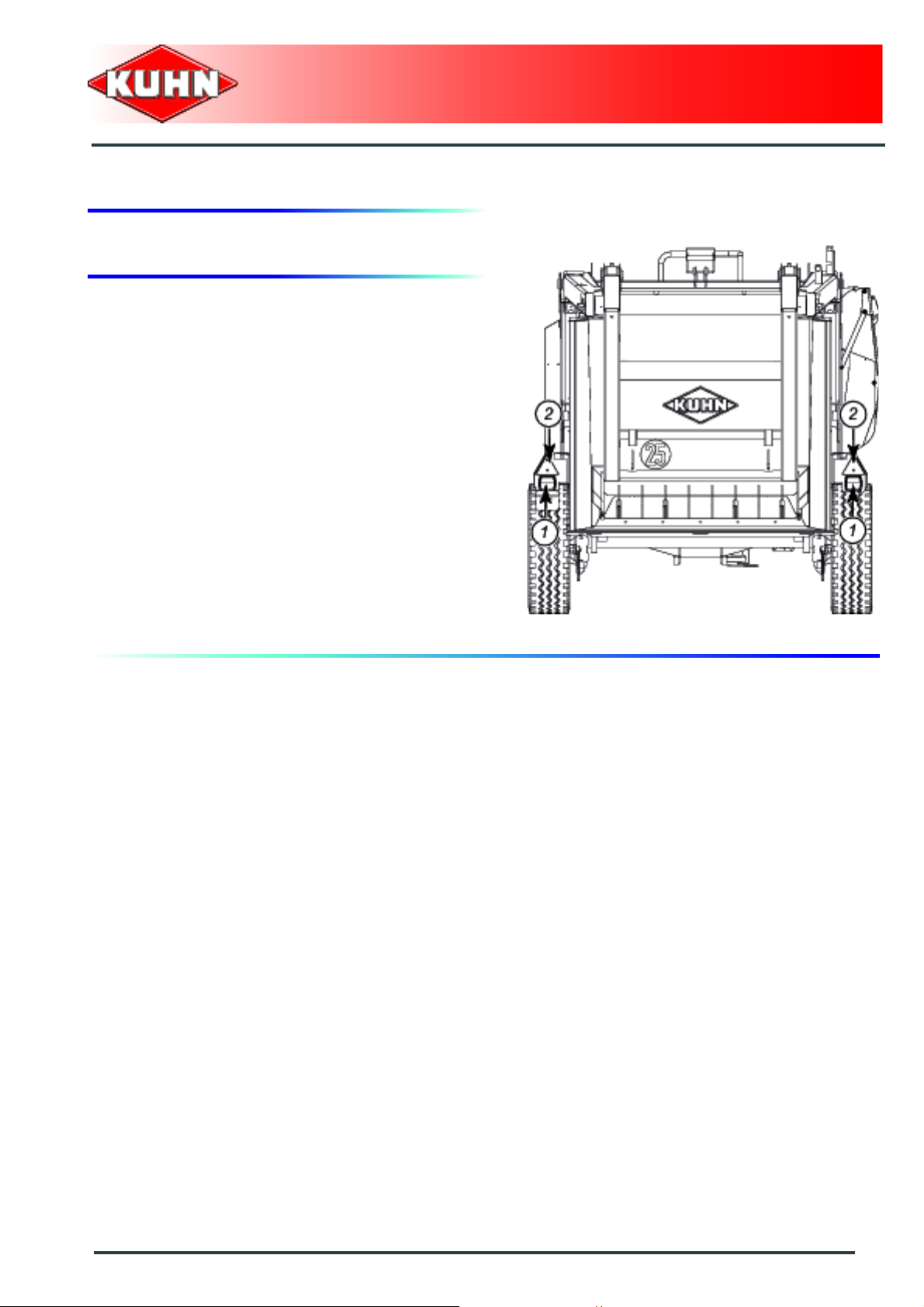

4. Road safety equipment and recommendations

The road safety equipment is mounted in the factory or

by your authorized Kuhn dealer according to current

safety regulations. Always keep to the legal speed limit

for driving a tractor-machine assembly on public roads .

Whatever the speed, we recommend, for everyones'

safety, not to exceed a maximum speed of 25.

- The lighting consists of:

• 2 Tail lights

• 2 reflective triangles (2)

Silo unloader - Straw Spreader

ALTOR 6070

Safety

21

Page 24

$Machine specifications

1. Description and glossary

0

Silo unloader - Straw Spreader

ALTOR 6070

1 : Deflector 2 : Swivel chute

3 : Walkway with dual control 4 : Hand rail

5 : Platform 6 : Ladder

7 : Drawbar 8 : Drive shaft support

9 : Towing eye 10 : Parking stand

11 : Gearbox 12 : Discharge chute

13 : Axle 14 : Wheel

15 : Body

22

Machine specifications

Page 25

Silo unloader - Straw Spreader

ALTOR 6070

0

1 : Bale separator 2 : Hook cylinder

3 : Hook 4 : Hook scraper

5 : Rear lights 6 : Body cylinder

7 : Arm cylinder

Machine specifications

23

Page 26

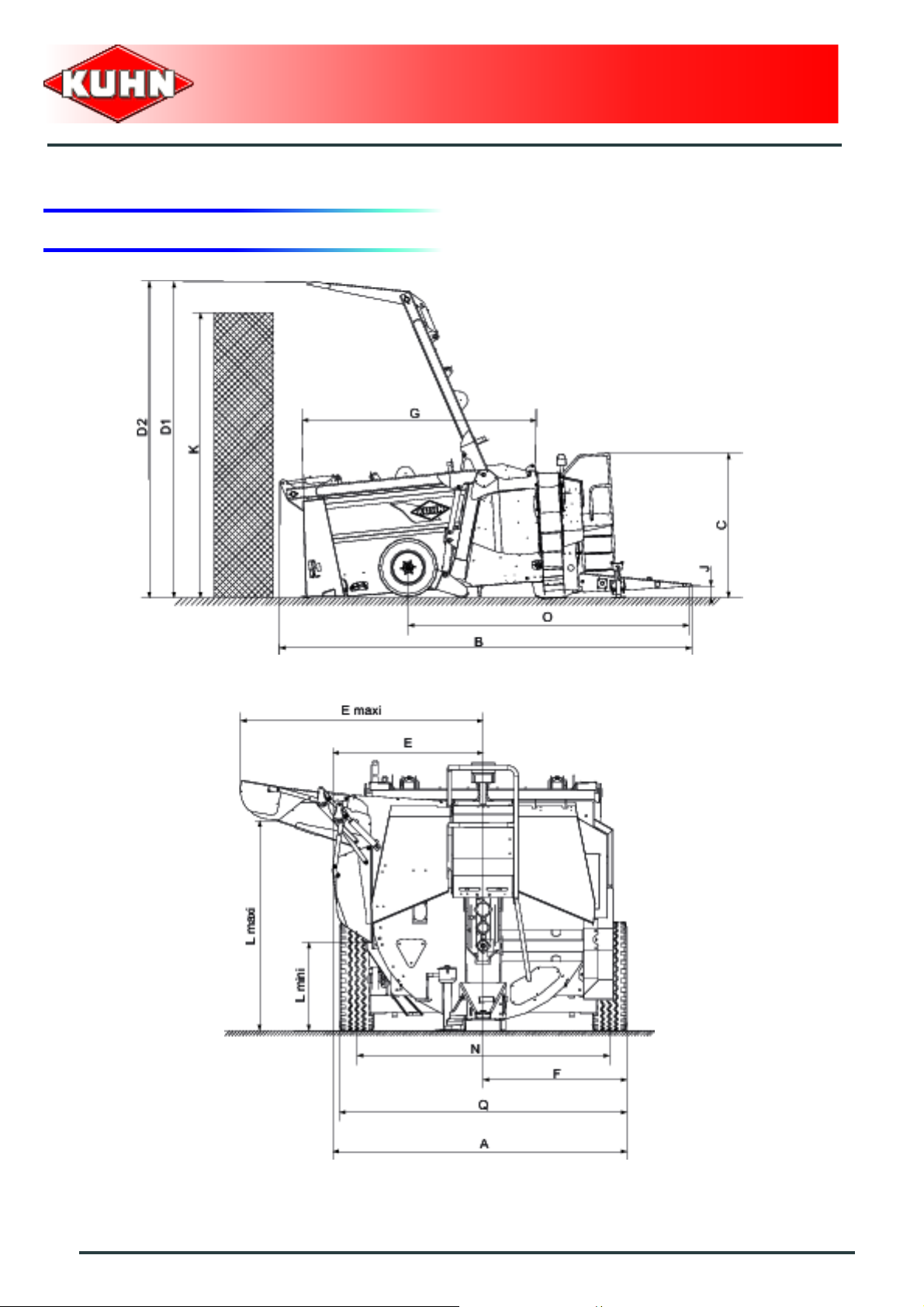

2. Technical specifications

Silo unloader - Straw Spreader

ALTOR 6070

24

Machine specifications

Page 27

Silo unloader - Straw Spreader

ALTOR 6070

Ref. Description ALTOR 6070

A Overall width 2,42 m (7’11’’)

B Overall length on the machine on the ground 6,25 m (20’6’’)

C Overall height with machine on the ground 2,22 m (7’3’’)

D1* Maximum height of the machine on the ground 4,81 m ( 15’9’’)

D2* Maximum dimensions with axle at highest setting 5,64 m (18’6’’)

E Lateral offset on chute side (closed) 1,24 m (4’1’’)

E Lateral offset on chute side (maximum) 2,00 m (6’7’’)

F Left lateral offset 1,18 m (3’10’’)

G Length inside body 3,57 m (11’9’’)

H Width inside body 1,50 m (4’11’’)

I Height inside body without arms 1,32 m (4’4’’)

Height inside body with arms 1,52 m (5’)

J Min. height of coupling 0,04 m (0’2’’)

K

L* Distribution height:

M Recommended maximum silage unloading height 3,38 m (11’1’’)

N Track 2,06 m (6’9’’)

O Wheelbase 4,25 m (13’11’’)

P Height in transport position 2,66 m (8’9’’)

Q Width at wheels 2,36 m (7’9’’)

Maximum height of silage unloading with the machine on the

ground

Minimum 0,73 m (2’5’’)

max. 2,29 m (7’6’’)

Unloaded weight in working order 3960 kg (8730 Lb)

Weight on the axle:

4.40 m (14’5’’)

Unladen 3080 kg (6790 Lb)

Maximum 4800 kg (10582 Lb)

Weight on the ring:

Unladen 880 kg (1940 Lb)

Maximum 910 kg (2006 Lb)

Total loaded weight 5710 kg (12588 Lb)

Machine specifications

25

Page 28

Silo unloader - Straw Spreader

ALTOR 6070

Ref. Description ALTOR 6070

Capacity 6,5 m3 (230 cu.ft)

Working load 1750 kg (3858 Lb)

Tyres 285 x 70 R 19.5

Tyre pressure 6,5 bar (94 psi)

Minimum drawbar power 65 hp / 48 kW

Minimum drawbar power with belt 80 hp / 59 kW

Traction pressure required:

Minimum 170 bar (2466 psi)

Maximum 190 bar (2756 psi)

Minimum tractor output: Machine without hopper 30 l/mn (8 gal/mn)

Minimum tractor output: Machine with hopper 45 l/mn (11 gal/mn)

Maximum tractor output 60 l/mn (16 gal/mn)

Optional equipment

Mixing hopper

Loading height with machine horizontal 1,55 m (5’1’’)

Loading height with machine on the ground 1.42 m (4’8’’)

Overall length of the machine with hopper 6.25 m (20’6’’)

Swivel chute

Height of machine horizontal, with chute retr acted 2.66 m (8’9’’)

Height of machine horizontal, with chute not retracted 2.93 m (9’7’’)

Hydraulic unit

Flow 45 l/mn (11 gal/mn)

Tank capacity 60 L (16 gal)

* Depending on the tractor. (Take account of the lift

height)

26

Machine specifications

Page 29

Silo unloader - Straw Spreader

ALTOR 6070

3. Sound levels

Sound levels have been measured in accordance with th e me as ur ing meth od s as de fin ed in:

NF EN 1553 "Agricultural machinery - Self-propelled, mounted, semi-mounted and trailed - Common

safety recommendations"

Weighted equivalent continuous acoustic pressure level at the driver's seat (closed cabin) L (A) eq:

Tractor only: 68,1 dB (A)

Tractor + machine: 73 dB (A)

Machine specifications

27

Page 30

$Putting into service

1. Description of control elements

ELECTRICAL CONTROLS

For standard machines and adjustable chute

Silo unloader - Straw Spreader

ALTOR 6070

Machine with hopper

28

Putting into service

Page 31

Box On/Off switch (A)

Active controls with working light (1)

Controls in neutral (0)

Controls active (2)

Raising / lowering the arm and body (B)

Silo unloader - Straw Spreader

ALTOR 6070

Arm raising

Arm lowering

Raising the body

Lowering the body

Putting into service

29

Page 32

Raising / lowering the distribution chute and opening / closing the hook (C)

Raising the chute

Lowering the chute

Silo unloader - Straw Spreader

ALTOR 6070

Opening the hook

Closing the hook

30

Putting into service

Page 33

Beater bar On/Off (D)

Beater bar clutch engaged

Silo unloader - Straw Spreader

ALTOR 6070

Beater bar clutch disengaged

The beater bar clutch is hydraulically controlled.

Hold the lever in the required position for a few

moments until the beater bar is fully engaged or

disengaged. The green control indicator lights up

when the beater bar is fully engaged.

Conveyor forward/reverse (E)

Conveyor in forward motion

Conveyor in reverse

The conveyor only works in forward motion when

the bale separator is in fully engaged position.

Putting into service

31

Page 34

Adjusting the conveyor speed (F)

The speed is adjusted by a knob graduated from 0 to 10.

Position 0 corresponds to zero conveyor speed.

The conveyor speed is not exactly proportional to the

graduation.

The conveyor movement indicator is at the front

of the machine, on the right, just under the

distribution chute.

Silo unloader - Straw Spreader

ALTOR 6070

Deflector (G)

Regulator in low position (hay, wrapped)

Regulator in high position (recyclin g, silage distribution,

straw spreading)

32

Putting into service

Page 35

Flap closing the swivel chute and for recycling (H)

Position of distribution chute

Position of adjustable chute

Flap installation is hydraulically controlled.

This maneuver takes several seconds, so

hold the lever in the required position for a

few moments.

Silo unloader - Straw Spreader

ALTOR 6070

Electrical controls for optional equipment

Swivel chute controls

Raising / lowering the cap (I)

Raising the deflector

Lowering the deflector

Rotating the swivel chute (I)

Rotating to the left

Rotating to the right

Putting into service

33

Page 36

Mixing hopper controls

Mixing screw rotation (J)

- The lever is at top right, the conv eyor-bale separator

is running alone in forward gear.

- The lever is at bottom right, the conveyor-bale

separator is running alone in reverse.

- The lever is at bottom left, the conveyor-bale

separator is running in reverse and the mixing screw

is working.

- The lever is at center left, the mixing screw is running

alone.

- The lever is at top left, the conveyor-bale separator is

running in forward gear and the mixing screw is

working.

Silo unloader - Straw Spreader

ALTOR 6070

Adjusting the injection speed (K)

- The speed is adjusted by a knob graduated from 0 to

10.

- Position 0 is for 0 injection screw speed.

The output at the injection screw exit is not

absolutely proportional to the graduation.

Calibration by product type may be necessary.

See the mixing hopper instructions supplied with

the machine.

34

Putting into service

Page 37

Walkway electric controls

Raising / lowering the arm and body (B)

Arm raising

Arm lowering

Silo unloader - Straw Spreader

ALTOR 6070

Lowering the body

Raising the body

Opening / closing the hook (C)

Opening the hook

Closing the hook

Putting into service

35

Page 38

Changing the blower speed

The speed change lever is at the front of the machine.

The lever has three positions (for a PTO speed of 540

-1

min

):

- 0: Loading using a machine fitted with a hydraulic unit.

-540 min

-270 min

-1

: straw blowing

-1

: feeding

Follow this procedure to change gear:

• Stop the tractor PTO.

• Set the lever to the required position.

• Engage the power takeoff gently until the new gear

can be engaged.

Silo unloader - Straw Spreader

ALTOR 6070

36

Putting into service

Page 39

2. Coupling and uncoupling

Before hitching the machine, make sure that

there is sufficient ballast on the front axle of

the tractor.

Ballast may need to be added to the front of

the tractor at the right place and in

conformity with the tractor manufacturer's

recommendations. The front axle load must

not be below 20 % of the tractor's tare.

Silo unloader - Straw Spreader

ALTOR 6070

Hooking up the machine for use on the

public highway

- Position the linkage ring at the desired height using

the leg.

- Reverse the tractor and raise the leg after coupling.

- Lock the linkage with the system provided.

- Connect the linkage rupture cable to a fixed point on

the tractor frame using a quick-release link.

Hooking up the machine to be used

exclusively inside the farm

- Mount the hitch bar (1) on the lift arms (3) of the

tractor.

- Lock the drawbar (1) with clip pins 8 mm (2)

- Reverse the tractor until the coupling ring is opposite

the hole through which the drawbar passes.

- Reinstall and lock pin.

- With the machine coupled, stabilize the drawbar

laterally with the device provided for the purpose (rod,

chains, chocks...).

Putting into service

37

Page 40

Machines equipped with a weighing system

with this type of coupling, when turning

tightly, don't catch the coupling bar (or lifting

arms) against the drawbar: there is a strong

risk of damaging the tongue weight indicator.

Silo unloader - Straw Spreader

ALTOR 6070

38

Putting into service

Page 41

Setting the coupling drawbar

Adjusting the drawbar allows you to position the body at

the desired level no matter which tractor is used.-

For a good mixture, the back of the body must be

slightly lower than the front.

- Adapt the height of the drawbar to the tractor used as

follows:

• 6 height settings are possible for 2 positions of the

drawbar support plate (4) et (5).

• Dismantle the drawbar by removing shaft (6).

• Loosen the 8 bolts (7) and (8) on each side of the

drawbar (24 wrench).

• Set plates (4) and (5) in the desired position.

• Reinsert the bolts (7) (8) in the holes required

(torque 29 daNm.

• Raise the drawbar.

• Reinstall shaft (6).

Silo unloader - Straw Spreader

ALTOR 6070

To change from position (A) to position (B), or

the revers, rotate the drawbar (4) (5) support

plates by 180°. Reverse the two plates: put the

right hand plate on the left and the left ha nd plate

on the right.

The different coupling height s according to the

position of the drawbar support plate: position

(A) or (B) and orifices (1) (2) or (3) are given for

standard wheels.

Putting into service

39

Page 42

Positioning the controls

In the case of electrical controls, the unit can be placed

where the user wants in the cab.

The gear lever can be pl aced on the tractor or on the

machine.

Silo unloader - Straw Spreader

ALTOR 6070

40

Putting into service

Page 43

3. Walkway with dual control

The walkway provides users with optimal visibility of the

working surface during silage unloading, no matter what

type of tractor or machine equipment is being used.

The base control recall makes loading operations easy

(arms, hook, body).

Operating tips

- Set the machine in silage unloading position.

- Before climbing onto the walkway:

• Check the machine for proper oil supply.

• Make sure that nobody can use the main controls in

the cab.

Silo unloader - Straw Spreader

ALTOR 6070

For safety reasons, climb down from the

walkway when the machine is being moved.

It is strictly forbidden to carry personnel on

the walkway.

To protect the walkway dual electric cont rols, close the

lid of the control box after each use.

Putting into service

41

Page 44

4. Swivel chute

The maximum distance of straw spreading with the

swivel chute is 13 m (4’3’’).

The swivel chute is indispensable in buildings with a

single central alley and only one entrance.

The wide rotation angle makes it possible to work in all

directions without blowing the product onto the tractor

cab.

The straw blowing device can be used on the right or the

left.

Silo unloader - Straw Spreader

ALTOR 6070

The distance of straw spreading is controlled from the

cab via an electric cylinder.

To avoid any error during handling and incorrect use of

the chutes, do not use the swival chute to distribute

wrapped grass.

The machine is equipped with a flap position indicator.

Before moving the arm, the adjustable chute

must be positioned to avoid any risk of

collision with the arm.

42

Putting into service

Page 45

5. Mixing hopper

The mixing hopper with a volume of 575 L (151.9 gal)

can be used to add minerals and concentrate to rough

fodder (grass or maize silage...).

Incorporation takes place in the turbine.

With its extra low profile and two side filler hatches,

loading takes place with no particular accessories.

For maximum accessibility, position the machine on the

ground and lower the tractor lifting mechanism as far as

possible when the machine is coupled to the hitching

bar.

Silo unloader - Straw Spreader

ALTOR 6070

Putting into service

43

Page 46

Hydraulic connections

To use the machine with a tractor with a hydraulic output

in excess of 60 l/min (15.9 gal/min) ; a flow divider must

be fitted to prevent the circuit overheatin g.

If your tractor is fitted with a closed-center

hydraulic circuit, make a return to the filter.

Machine without a hydraulic system

In order to power the machine's independent distributor,

the machine can be connected to the tractor hydraulics

in one of three ways:

1. Connection to a single-acting control valve and

direct return to the tank.

2. Connection to a double-acting distributor. The first

port is used to connect the pressure hose and the

second for the return hose. On fitting, make sure

that the direction of the oil flow is correct..

3. Connection to a line from the tractor.

Silo unloader - Straw Spreader

ALTOR 6070

- For maximum user-friendliness, the original hydraulic

distributor on the tractor must be equipped with a

continuous pumping position.

- The operating pressure of the hydraulic circuit is 190.

- The minimum and maximum hydraulic oil flow for a

standard machine is 30 l/min (7.9 gal/min) and

60 l/min (15.9 gal/min) respectively.

- The pressure and return hoses are fitted with a male

push/pull coupler (ISO 7241).

- The pressure hose has a white arrow on a red

background (1), pointing from the tractor to the

machine.

- The return hose (2) is marked by a white arrow on a

blue background, pointing from the distributor toward s

the tractor.

44

Putting into service

Page 47

Before connecting, make sure that the couplers are

clean. The plastic caps MUST be used when the

machine is not hitched to the tractor.

After connecting the hoses, check that there

is no risk of catching them during operation.

When the machine is not hitched to the tractor, all

hydraulic hoses must be put back in the special support.

Machine with hydraulic power unit

Optional equipment

This option makes the machine independent of the

tractor hydraulic circuit: no hydraulic connection to be

made before using the machine.

Silo unloader - Straw Spreader

ALTOR 6070

Putting into service

45

Page 48

Electrical connections

Lighting

Connect to the standardized 7-pin socket located at the

back of the tractor.

Control and Weighing Unit Power Supply

On tractors equipped with a 3 terminal female connector

in accordance with the standard DIN 9680A, connect the

control and weighing unit directly.

For other tractors, a harness to be connected directly to

the battery is delivered with the machine.

The wiring harness is fitted with a 15 Amp ATO type

fuse.

Silo unloader - Straw Spreader

ALTOR 6070

To use the machine with another tractor, a

second tractor-side power harness can be

ordered under p/n A7040170.

Control box Harness on tractor side

Machine Fuse type ATO Fuse 30 A Harness references

6070 Standard 15 A 83233017 83233020 A7040170

6070 Adjustable chute 20 A 83233018 83233020 A7040170

6070 Mixer hopper 15 A 83233017 83233020 A7040170

46

Putting into service

Page 49

PTO shaft

Make sure that the PTO shaft is correctly

adjusted, to avoid premature wear and tear.

Separate the two half PTO shafts and connect them to

the machine's input shaft and to the tractor PTO stub.

Check the length of the PTO shaft:

- Check the maximum overlap when the machine is in

transport position and the tractor turned to the

direction which provides maximum overlap.

- When the PTO shaft is in its maximum overlap

position (retracted), tubes should not butt against the

yokes. As a safety measure, a clearance (L) of at least

25 mm (1’’) must be maintained.

- When the PTO shaft is in its maximum extended

position, the tube overlap must be more than

330 mm (13’’)

Silo unloader - Straw Spreader

ALTOR 6070

If this is not the case:

• Mark length (H) to cut when the transmission is the

maximum overlap position.

• Shorten the guard tubes and the transmission tub es

by the same length.

• Bevel and clean the tubes.

• Grease the inside of the outer tube.

Check that there is still a minimum overlap of

330 mm (13’’) when the machine is in working

position and the tractor in line with the machine.

- The cardan drive shaft must not work at an angle X:

• More than 15° for a standard joint

• More than 25° for a homokinetic joint.

Putting into service

47

Page 50

To avoid serious accidents, the PTO drive

shaft guards must be properly in place and

fixed with the chains provided.

Attach PTO shaft guard chain in hole (1) on machine

side.

Immediately replace any worn or damaged

guard.

Silo unloader - Straw Spreader

ALTOR 6070

48

Putting into service

Page 51

$Instructions for transport

1. Conformity with the road regulations

Before driving the machine on public roads,

ensure that the machine complies with

current highway code regulations.

Check that the braking and lighting systems are in good

condition.

Silo unloader - Straw Spreader

ALTOR 6070

Instructions for transport

49

Page 52

Before placing the machine in working

position:

Check the immediate surroundings before

starting up the machine. Make sure that the

visibility is adequate and that there are no

obstacles in the machine working area.

1. Preliminary checks

Silo unloader - Straw Spreader

ALTOR 6070

$Instructions for work

Carry out the following checks before using the machine:

- Check the wheelnuts and tighten them if necessar y to

25 daNm (184.39 Lb.ft) daNm.

- Check the tension of the conveyor chain and adjust it

if necessary.

- Check that the screws and nuts are tightened,

including the ones that fix the tools (knives, conveyo r

bars).

- When the distribution is finished.

- Grease all moving parts. Use only lubricants

recommended by the manufacturer.

- Check the oil level in the gearbox.

- Check the oil level in the conveyor gearbox.

- Check the oil level in the hydraulic unit and the

cleanliness of the oil filter (optional).

50

Instructions for work

Page 53

2. Functional check, no load

Before using the machine for the first time

with a load, make sure that the tractormachine combination is in working order.

Make sure there are no foreign bodies inside

the machine.

- Make sure you can change PTO speed. (Caution: this

is not synchronised).

- For a machine with a hydraulic unit, check whether the

gearbox can be set to neutral.

Silo unloader - Straw Spreader

ALTOR 6070

- Select a PTO speed (270 m i n

- Align the tractor and the machine, then engage the

PTO drive and leave the tractor idling.

- Gradually increase the engine speed until the PTO

reaches 540 min

- Start the beater bar then the conveyor (test in both

directions).

- Now check that the machine is running smoothly and

free from vibration.

- Reduce the engine speed once again until it is idling.

If the machine is noisy or vibrating abnormally,

stop the PTO immediately and refer to the

troubleshooting section or contact your Kuhn

dealer. When the problem has been solved, start

the test procedure again from the beginning.

-1

.

-1

or 540 min-1).

Instructions for work

51

Page 54

- Operate the hydraulically-controlled elements and

check that the machine is functioning properly.

- Stop the PTO, switch off the control unit and switch off

the tractor engine.

If one of the hydraulic functions is not working, or

is running in the wrong direction, check the h ose

connections and start the test procedure again

from the beginning.

- Test the operation of the lighting and signalling

system (sidelights, brake lights and indicators).

Precautions and prevention of fire risk

Your machine works with moving parts (bale

separator(s), turbine) and highly inflammable products.

There is therefore a real risk of fire resulting from:

- Overheating of the power takeoff friction limiter.

Please do not use this limiter excessively. If smoke

issues from the transmission, stop the machine

immediately and leave the limiter to cool outside the

buildings.

- Winding strink or products at the ends of the bale

separator(s). Each time, before using the machine,

check the ends of the bale separator(s) to remove

products which have become wound round or have

accumulated in this area.

- Worn bearing. Grease bearings regularly and check

their condition.

- Sparks caused by pebbles or metal objects in the

straw.

Silo unloader - Straw Spreader

ALTOR 6070

It is highly recommended to have an extinguisher which

has been checked and maintained, on your tractor.

Recommended types: sprayed water + additive, ABC

powder.

It is strictly prohibited to use your machine stationary

inside a building.

52

Instructions for work

Page 55

3. Silage unloading

For a machine equipped with a hydraulic unit,

you must set the gearbox to neutral..

Approaching the silo

- Set the hydraulic distributo control to continuous

pumping mode.

- Raise the arm and the hook as far as possible to

ensure good visibility and avoid crushing the heap

following a collision.

Silo unloader - Straw Spreader

ALTOR 6070

- Lower the machine as far as it will go, taking care to

avoid scraping the heel along the ground, then

reverse towards the front of the silo.

- Set the heel of the machine on the ground before

contacting the silage to be unloaded.

For a corridor silo, position the machine slightly on the

bias so as to load as close to the wall as possible.

Never attempt to penetrate the silo by

reversing forcefully.

Instructions for work

53

Page 56

Loading the machine

Always start unloading the product from the top.

- From the tractor cab or walkway, position the hook so

as to take the product over a depth of about 40 cm

(1’4’’).

- Move the hook in a to and fro movement while

lowering the arm gently.

- When the hook is down, take it inside the body while

raising the arm to ensure proper filling.

- Raise the arm with the hook retracted and repeat the

loading operation until the machine is properly filled.

Silo unloader - Straw Spreader

ALTOR 6070

- At the end of loading, set the hook in the position of

rear door without compressing the product against the

bale separator.

Never compress the product against the bale

separator.

54

Instructions for work

Page 57

4. Loading bales

For a machine equipped with a hydraulic unit,

you must set the gearbox to neutral..

Round bales

- Raise the arm and hook for good visibility.

- Reverse the machine near to the bale.

- Extend the hook as far as possible and lower the arm

until it comes into contact with the bale and covers it.

Silo unloader - Straw Spreader

ALTOR 6070

- Keep the arm in contact with the bale while reversing

slowly. Once the bale is engaged in the body, finish

loading with the hook and arm.

- Raise the back of the machine to hold the bale in the

body.

- Raise the arm slightly to decompress the bale.

- Remove the binding, then lower the arm again.

To make it easier to spread the hay or straw with

a round bale, load the bale so that it can unroll

naturally. This allows the blower-beater bar

assembly to be fed more easily, and improves

the straw blowing or feeding.

Instructions for work

55

Page 58

Rectangular bales

- Raise the arm and hook for good visibility.

- Reverse the machine near to the bale.

- Extend the hook as far as it will go and lower the arm

until it contacts the middle of the bale.

- Keep the arm in contact with the bale while reversing

slowly. Once the bale is engaged in the body, finish

loading with the hook and arm.

- Once the bale is loaded into the machine, position the

hook to hold it in place without compressing it against

the bale separator.

Silo unloader - Straw Spreader

ALTOR 6070

- Raise the back of the machine to hold the b ale in the

body.

- Raise the arm slightly to decompress the bale.

- Remove the binding, then lower the arm again.

It is easier to remove the bindings when the bale

has been loaded with the bindings on the side.

- Position the hook so that the marker rod fits into the

notch.

56

Instructions for work

Page 59

5. Adjustment setting

The product adjustment system, place above the 2 bale

separators and at the turbine inlet, has 2 working

positions:

Low position:

- Used to adjust and split the product.

This position is mandatory for distributing

wrapped bales and hay.

Silo unloader - Straw Spreader

ALTOR 6070

High position:

- Leaves a maximum inlet for the product in the turbine.

This position is recommended for silage and

straw distribution.

Instructions for work

57

Page 60

6. Distribution

Select the blower speed for feeding: 270 min-1.

Always start the tractor PTO before engaging the

beater bar. Stop the beater bar be fore stopping

the PTO. If you do not do this in the right order,

you are very likely to block up the blower.

The distribution chute on the right of the machine is used

for 2 purposes.

For optimal quality of work and product positioning in the

designed place, the distribution chute cap can be set to

three positions.

Silo unloader - Straw Spreader

ALTOR 6070

For easy manual adjustment of the position, open the

chute halfway.

Pull the handle down.

Put the spindle into the desired notch (the most external

one sets the cap to the greatest angle of tilt).

Operating tips:

To stop the distribution (posts, obstacles) disenga ge the

beater bar. (The conveyor stops at the same time).

To avoid clogging the machine in difficult conditions,

watch the engine speed carefully. Slow down conveyor

speed or even reverse the direction if the engine speed

drops or the belt starts to slip. If it becomes overloaded,

allow it to empty before making the conveyor move

forward again.

58

Instructions for work

Page 61

Never attempt to clear the product by hand or

with a tool (fork, etc.) while the machine is

running.

If the blower or bale separator is blocked, use

the hook (1) inside the left hand machine

casing, to remove any product which is stuck

in the distribution chute or bale separator.

Afterwards, use a lever to turn the blower

freely.

Silo unloader - Straw Spreader

ALTOR 6070

When the machine is loaded, we strongly

advise you to not leave the conveyor running

in reverse longer than is necessary.

Before starting the beater bar, make sure the conveyor

speed is set to position 0 to prevent a load being fed into

the blower.

The product flow rate is adjusted by:

• Changing the tractor engine speed: this regulates

the hydraulic flow and the PTO rotation speed.

• The conveyor speed.

Instructions for work

59

Page 62

Silage distribution

- Start up the tractor PTO and bring the engine up to

nominal speed.

- Switch the tractor's hydraulic distributor to continuous

pumping.

- Point the delivery chute downwards so that the forage

should be properly channelled to the ground or into a

trough.

- Start the bale separator by engaging it until the light

indicator comes on.

- To distribute the product, start the conveyor running

forward and adjust the speed:

• Set the conveyor to forward.

• Adjust its speed.

- Rake product regularly onto the conveyor using the

hook.

- The conveyor speed is set at the control box

according to the forward speed and product

distribution criteria and the type of product.

- When the distribution is finished:

• Retract the arm and hook as far as they will go.

• Stop the conveyor and disengage the beater bar.

• Disengage the bale separator.

• Close the distribution chute.

• Disengage tractor PTO.

Silo unloader - Straw Spreader

ALTOR 6070

To distribute light products (maize silage, food

supplements), reduce the tractor engine speed

and hence the turbine rotation speed as far as

possible to limit spraying product onto the

ground.

60

Instructions for work

Page 63

Hay and haylage

Never distribute hay or haylage with hooks fitted

to the beater bar.

- Start up the tractor PTO and bring the engine up to

nominal speed.

- Switch the tractor's hydraulic distributor to continuous

pumping.

- Point the delivery chute downwards so that the forage

should be properly channelled to the ground or into a

trough.

Silo unloader - Straw Spreader

ALTOR 6070

- Start the bale separator by engaging it until the light

indicator comes on.

- To distribute the product, start the conveyor running

forward and adjust the speed:

• Set the conveyor to forward.

• Adjust its speed.

- The conveyor speed is set at the control box

according to the forward speed and product

distribution criteria and the type of product.

- When the distribution is finished:

• Retract the arm and hook as far as they will go.

• Stop the conveyor and disengage the beater bar.

• Disengage the bale separator.

• Close the distribution chute.

• Disengage tractor PTO.

Instructions for work

61

Page 64

Operating tips

- To facilitate feeding the turbine from the bale

separator, let the bale turn freely under the action of

the separators.

- Reduce engine speed when feeding is over to limit

projections.

During feeding, raise the back of the body in order to:

• keep round bales up against the beater bar when

the product requires little power.

• facilitate the rotation of round bales against the

beater bar when the product is tougher.

- The conveyor speed is set at the control box

according to the forward speed and product

distribution criteria and the type of product.

Silo unloader - Straw Spreader

ALTOR 6070

- If you are using the equipment with 2 round bales,

make sure the first bale is turning freely before

engaging the separators. Reverse the conveyor if

necessary.

62

Instructions for work

Page 65

7. Straw blowing

Select the blower speed for straw blowing: 540 min-1.

- Start up the tractor PTO and bring the engine up to

nominal speed.

- Switch the tractor's hydraulic distributor to continuous

pumping.

- Position the distribution chute or the swivel chute

(optional equipment) so that the straw is sprayed

where you want it.

Silo unloader - Straw Spreader

ALTOR 6070

- Start the bale separator by engaging it until the light

indicator comes on.

- To distribute the product, start the conveyor moving

forward. Adjust the conveyor speed according to the

type of straw. The conveyor speed is adjusted from

the control unit. It will depend on several things: how

fast the tractor is moving, the rate of distribution and

the type of product.

- Use the hook to keep the bale in contact with the

separator.

- When the distribution is finished:

• Retract the arm and hook as far as they will go.

• Stop the conveyor and disengage the beater bar.

• Disengage the bale separator.

- Put the tractor's distributor lever back to neutral,

disengage the PTO and switch off the engine.

In certain cases, the first part of rectangular

bales tends to shoot upwards at the start of straw

blowing. The guides push the product towards

the back of the machine. For this reason it is

important not to stop the conveyor and to let the

product drop naturally to the back.

Instructions for work

63

Page 66

Operating tips

- To blow the straw regularly, the bale must remain in

permanent contact with the beater bar, but must not

be blocked too hard by the gate.

- Lift the back of the machine slightly to avoid the bale

being thrown to the back of the beater bar.

- During straw blowing, adjust the height of the body in

order to:

• keep round bales up against the beater bar when

the product requires little power.

• facilitate the rotation of round bales against the

beater bar when the product is tougher.

- To improve product feed into the blower, up to 3 hooks

can be mounted on the beater bar in place of the

sections.

Silo unloader - Straw Spreader

ALTOR 6070

Keep an angle of 120° between the hooks.

Never distribute hay or haylage with hooks fitted

to the beater bar.

You are strongly recommended to spread straw

after distributing feed to the animals: this helps

clean and dry the machine (straw absorbs silage

acids) and thereby limit corrosion of the machine

by acid attack..

To spread straw in stalls, use a turbine rotation

speed of 270 min

-1

.

64

Instructions for work

Page 67

$Optional equipment

1. Hydraulic unit

Kit no.: 1926193

The hydraulic unit can be mounted on machines

already in service.

The hydraulic unit is designed to provide the hydraulic

power needed to run the machine.

It is suitable for use with tractors of low hydraulic power,

while guaranteeing optimal operation of its functions.

Silo unloader - Straw Spreader

ALTOR 6070

Description

- Auxiliary hydraulic unit

- Driven by the tractor power take-off

- Pump 55 cm

-1

min

: 45 l/min (11.9 gal/min)

- 60 L (15.9 gal) tank with filter and level

- Circuit protected by valve calibrated to 190 bar

(2755.8 psi)

- Recommended oil: type ISO VG 46 (HV), for example:

SHELL HYDRAU PW

A slight gear noise may be heard at low

speed. Use the hydraulic unit at a minimum

power take-off rate of 300 min

Functioning

- Before starting the machine, check the oil level in the

tank.

- Connect the tractor power take-off transmission and

the pump step-up gearbox drive shaft, then lock.

- The machine must be driven at a rated power-take-off

rate of 540 min

3

, speed at a power take-off rate of 540

-1

.

-1

.

Optional equipment

65

Page 68

Silo unloader - Straw Spreader

ALTOR 6070

Under no circumstances must you use the

tractor power take-off 1000 min

-1

.

- Start the tractor, then gradually engage the power

take-off until the pump turns.

- Check that all machine functions are operational.

Make sure the pump flanges and various hydraulic

connections are tight.

- With the gear lever, the hydraulic unit can be used in

three ways:

• In neutral, without engaging the blower, for all

loading operations.

• At a blower speed of 270 min

• At a blower speed of 540 min

-1

for distribution.

-1

for straw feeding.

Maintenance

- Follow the safety regulations concerning machine

servicing.

- Check the oil level in the tank periodically. The oil level

must not fall below the upper 1/3 on the indicator.

- Change the hydraulic oil every 1500 hours.

- Replace the filter cartridge after the first 50 hours of

operation, then every 500 hours. For that purpose::

• Unscrew the cap.

• Take the filter handle and remove the filter-bowl

unit.

• To remove the filter:Turn the handle a quarter turn

anticlockwise and remove the filter from its

cartridge.

• Clean the bowl.

• Put in a new filter and lock its position, turning it a

quarter turn clockwise.

• Replace the cap and reposition the seal properly to

ensure tightness.

66

Optional equipment

Page 69

2. Leg with holes

Kit no.: 1926174

Not available in certain countries.

The height of this leg cannot be adjusted when it is

supporting the machine.

The leg is designed for users who never need to couple

the machine to the tractor eye-bolt.

Silo unloader - Straw Spreader

ALTOR 6070

3. Leg with manual holes

This optional equipment provides continuous adjustment

of the drawbar height to position the linkage and

adjustment using a pin.

Optional equipment

67

Page 70

4. Homokinetic transmission with free wheel and friction limiter

Kit no.: 1926178

The transmission can be mounted on machines already

in service.

The homokinetic transmission pr ovide s a wider angle of

displacement and free rotation of the blower.

Before using this equipment, read manual supplied with

the PTO.

Silo unloader - Straw Spreader

ALTOR 6070

5. Weighing unit

Kit no.: 1936023

This unit weighs and programs the animals' feed rations.

Read the instructions carefully before

weighing.

68

Optional equipment

Page 71

$Maintenance and storage

1. Greasing and oil change

Frequency chart

Silo unloader - Straw Spreader

ALTOR 6070

Greasing

Grease:

- Greasing points from (1) to

(17)

Draining

Oil change:

- Gearbox

- Conveyor reducing gearbox

- The hydraulic system

Maintenance

- Changing the filter cartridge in

the hydraulic unit

- Check the conveyor chain

tension

After 2 hours

After 50

hours

Every 100

hours

Every 500

hours

Every 1500

hours

33

33

33

3

33

33

- Check belt tension

- Check the gearbox level

- Verification of the level of the

conveyor reducing gearbox

- Tighten the linkage bar eyebolts

- Check that the screws and

nuts are tight, including the

ones that fix the tools (tines,

forks, blades etc.)

33

33

33

3

33

Maintenance and storage

69

Page 72

Silo unloader - Straw Spreader

ALTOR 6070

- Check that the wheel studs

are tightened to 25 daN m and

the tire pressure is 5 bars

- Check the state of wear of the

moving parts, replace them if

necessary with KUHN parts

- Clean the machine (body,

gate and chute). Avoid

splashing the electrical

components, the belt, etc.

Greasing points

After 2 hours

After 50

hours

Every 100

hours

Every 500

hours

33

3

3

Every 1500

hours

70

Maintenance and storage

Page 73

Silo unloader - Straw Spreader

ALTOR 6070

0

1 : Deflector cylinder pin 2 : Swivel chute

3 : Side chute cylinder pin 4 : flap cylinder pin

5 : Parking stand 6 : Conveyor rotation indicator

7 : Conveyor shaft 8 : Bale separator bearing

9 : Axle pin 10 : Body lifting cylinder pin

11 : Arm cylinder pin 12 : Arm pin

13 : Hook cylinder pin 14 : Hook pin

15 : Clutch release cylinder pin 16 : Clutch tension rod

17 : Small pulley bearing

Maintenance and storage

71

Page 74

Greasing

The greasing points are shown by a white picture on a

blue background.

Some greasers are situated under cases or protective

plugs.

Upon delivery, take the time to open all the cases in

order to find all the different greasing points.

Regular greasing allows the life span of the rotating parts

to be significantly increased.

Silo unloader - Straw Spreader

ALTOR 6070

Lubricant chart

Description Recommended lubricants Equivalent standard

Gearbox

Capacity 5 L (1.3 gal)

Gearbox

Capacity 1.5 L (0.4 gal)

Central hydraulic tank

Capacity 60 L (15.9 gal)

Greasing SHELL RETINAX EP 2 NLG1

SHELL OMALA 150 ISO CKC 150/ SAE 80 W 90

SHELL OMALA 150 ISO CKC 150/ SAE 80 W 90

ISO 46 SHELL HYDRAU PW SAE 15 W-40

72

Maintenance and storage

Page 75

PTO shaft

The transmission must be greased with the

"transmission in line".

Every 8 hours

• universal joints (1)

Every 20 hours

• transmission tube (2)

Silo unloader - Straw Spreader

ALTOR 6070

Every 40 hours

• guide rings (3)

• locking pins (4)

• constant velocity joint (5)

Maintenance and storage

73

Page 76

2. Checking friction limiter settings

Torque calibration is provided by the pressure of the

spring-washers on the friction disks.

- The collar (1) is used as a reference for calibrating the

limiter correctly.

- Tighten the bolts (2), until the flange (3) is in contact

with the collar (1) without blocking it:

• Tighten the bolts (2) until the collar is blocked, then

unscrew them by a quarter turn.

- The collar must not be blocked or deformed by

excessive tightening of the bolts.

Silo unloader - Straw Spreader

ALTOR 6070

Do not over-tighten the bolts because the

limiter function could be compromised.

Do not change the calibration: risk of

damaging the machine, cardan drive and

tractor.

Friction may raise the temperature, do not

touch them.

To prevent the risk of fire, do not bring

inflammable products into the area around

the friction and avoid prolonged sliding.

74

Maintenance and storage

Page 77

3. Control storage

ELECTRICAL CONTROLS

Make sure the controls are put away after every use to

protect them from the weather.

Machine without hopper

A fastening hook (1) is located under the front right

casing.

Silo unloader - Straw Spreader

ALTOR 6070

Machine with hopper

Store the control in the protective casing (1).

Maintenance and storage

75

Page 78

Walkway dual control

To protect the walkway dual electric controls, close the

lid of the control box after each use.

Silo unloader - Straw Spreader

ALTOR 6070

76

Maintenance and storage

Page 79

4. Cleaning the conveyor

The conveyor is contained in a unit to keep it clean.

Open the emptying hatch once a week to remove

product accumulated at the back of the unit.

How to proceed:

• Set the tractor distribution lever to the continuous

pumping position.

• Engage the tractor PTO and the beater bar.

• Put the conveyor into forward for a few seconds to

bring out any product accumulated at the back of the

unit.

• Stop the conveyor; disengage the beater bar then

the tractor PTO.

• Stop the tractor engine and remove ignition key.

Silo unloader - Straw Spreader

ALTOR 6070

Wait for a few moments until the machine has

completely stopped.

• Pull on the locking handles (1).

• Release the hooks holding the ring (2).

• Open the hatch as wide as possible (3).

• Use a broom or similar to remove any product left

inside.

• Raise the hatch and put the two hooks into the rings

before lifting the handles.

• Lock the hatch by lifting the handles.

Maintenance and storage

77

Page 80

5. Conveyor chain tension

Check the chain tension after every 100 hours of use.

If the arrow is over 150 mm (4’11’’) mm, tighten the

chains.

Never completely tighten the chains. Leave a

minimum play of 50 mm mm

Silo unloader - Straw Spreader

ALTOR 6070

How to proceed:

• Open the hatch (3) using the procedure described

for cleaning the conveyor.

• Loosen counter nut (1).

• Unscrew the conveyor extension nuts (4).

• Tension the unit with nuts (2).

• Tighten the counter nut.

• Tighten the conveyor extension nuts (4).

• Tension both sides of conveyor belt identically.

• Close the hatch as shown in the section on

"Cleaning the conveyor".

When the chain tension indicator has stopped, shorten

the chains (right and left) by 2 links.

78

Maintenance and storage

Page 81

6. Checking and adjusting the sections

Regularly check the position of the regulator

combs relative to the sections.

- External regulator combs (1):

• They must be centered relative to the sections

passing on each side.

- Internal regulator combs (2):

• The distance 'd'' between these regulator combs

and the sections must be less than 10 mm.

Silo unloader - Straw Spreader

ALTOR 6070

- The unbevelled side must be on th e regulator comb

side to obtain optimal product cutting.

To adjust the position of the regulator combs relative to

the sections, add or remove spacer shims (Part no.:

A5204400).

To guarantee optimum cutting, the edges of the sections

must be kept sharp. Sharpen or replace them as

necessary..

You can also swap sections around in order to use both

cutting edges of each section.

Be very careful when replacing sections. You

run a very serious risk of cutting yourself

(between the regulating tines and the

sections).

Maintenance and storage

79

Page 82

7. Belt tension

In order to guarantee optimal operation, belt tension

must be checked and adjusted if necessary every 100

hours (or more often in case of frequent feeding with

tough products).