OPERATOR’S MANUAL

RC015AGB A

Control box

Quantron E2

Original instructions

RC015AGB A

- English - 04-2012

Foreword

Dear customer,

By purchasing the control unit Quantron E2 for the mineral fertiliser spreader AXIS, you have

shown confidence in our product. Thank you! We want to justify your trust. You have purchased

a powerful and reliable control unit. Our customer service is always at your disposal, should any

problems arise.

Please read this operating manual carefully before commissioning the mineral fertiliser

spreader and follow the advice given.

This manual could also describe equipment and options that are not included in your control unit.

You should be aware that damage caused by incorrect operation or improper use may not be covered by warranty claims.

n CAUTION

Note the serial number of the control unit and of the machine

The control unit Quantron E2 has been calibrated at the factory for the mineral

fertiliser spreader with which it was supplied. It cannot be connected to another

mineral fertiliser spreader without requiring calibration.

Please enter the serial number of the control unit and of the mineral fertiliser

spreader here. When connecting the control unit to the mineral fertiliser spreader, these numbers must be checked.

Serial number control unit: Serial number mineral fertiliser

spreader:

Year of manufacture:

Technical improvements

We are continuously improving our products. Therefore, we reserve the right to make any

improvements and changes to our machine that we consider necessary without notice.

This constitutes no obligation to make such improvements or changes on machines that

have already been sold.

We will be pleased to answer any other questions that you might have.

Yours sincerely

KUHN S.A.

Farm Machinery

Table of contents

Foreword

Technical improvements

1 User instructions 1

1.1 About this operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Notes on the depiction of information in this manual. . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.1 Significance of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.2 Instructions and procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.3 Listings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Layout and function 5

2.1 Overview of the supported AXIS versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Layout of the control unit - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Structural overview of Easy Mode menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Structural overview of Expert Mode menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Attachment and installation 13

3.1 Requirements for the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Connections, sockets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 7-pin plug connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Connecting the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Preparation of metering slide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Operation of the Quantron E2 21

4.1 Switching on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Weighing-trip counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

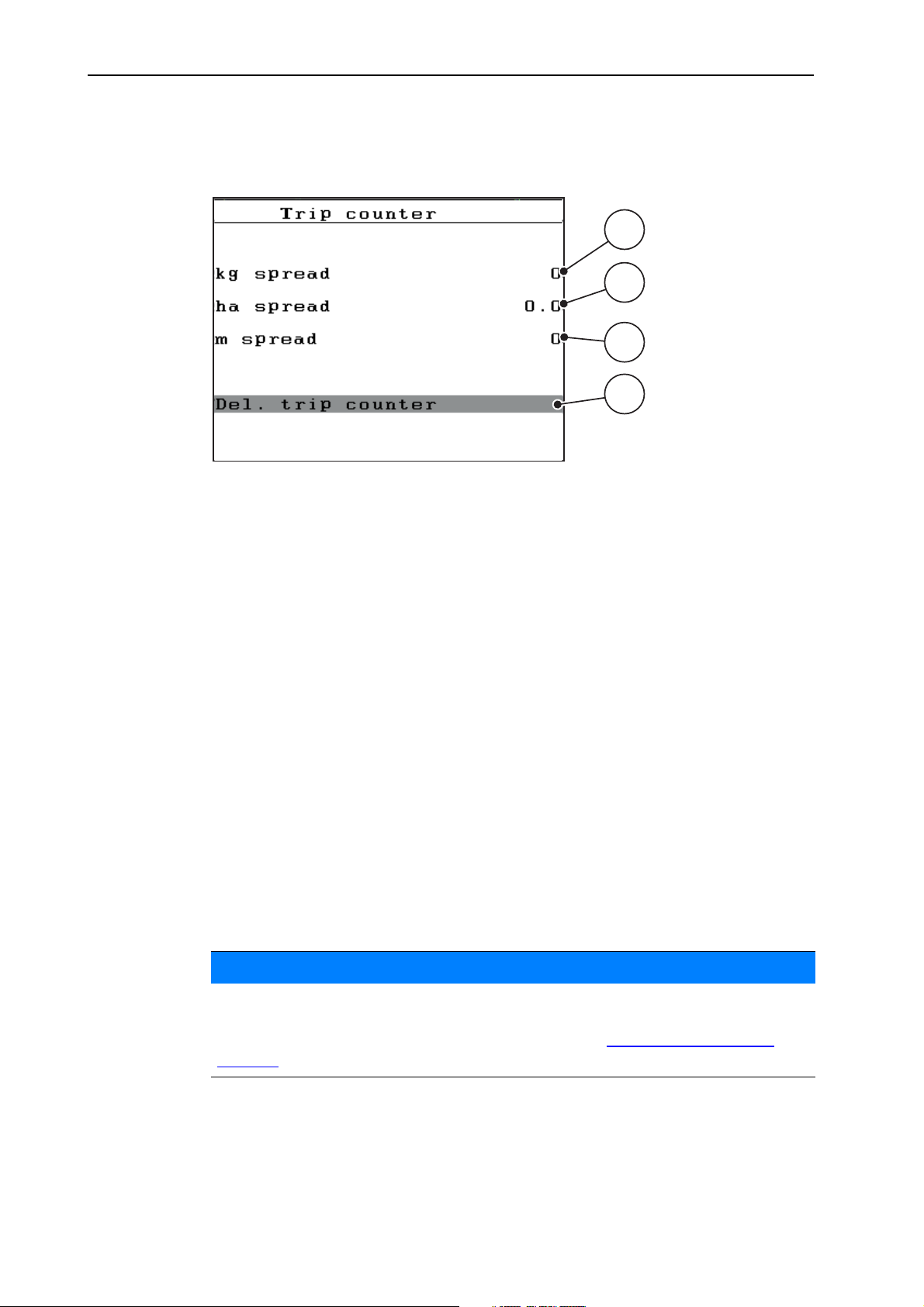

4.2.1 Trip counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.2 Determining the applied fertiliser quantity . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3 Remaining fertiliser quantity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.4 Weigh quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.5 Machine tare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.6 Telimat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Fertiliser settings in Easy mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5 Fertiliser settings in Expert mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.1 Application rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5.2 Working width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.5.3 Flow factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.5.4 Drop point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.5 Telimat quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.6 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.7 Fertiliser chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

I

Table of contents

4.6 Machine settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.6.1 Speed calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.2 AUTO/MAN mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.6.3 +/- appl. rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.6.4 kg counter cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.7 Fast emptying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.8 Field data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.8.1 Selecting a field data file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.8.2 Starting recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.8.3 Stopping recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.8.4 Importing and exporting field data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.8.5 Deleting field data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.9 System/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.9.1 Setting the language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.9.2 Display config. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.9.3 Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.9.4 Test/Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.9.5 Data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.9.6 Total data counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.9.7 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4.10 Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4.11 Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.11.1 Text input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.11.2 Input of values using the cursor keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5 Alarm messages and possible causes 91

5.1 Meaning of alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.2 Clearing a fault/alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.2.1 Acknowledging an alarm message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.2.2 Resolving problems with the flow factor regulation (only AXIS W). . . . . . . . 95

6 Special equipment/options 97

7 Guarantee and warranty 99

8 EC Declaration of Conformity 101

II

1 User instructions

1.1 About this operating manual

This operating manual is a constituent part of the control unit Quantron E2.

The manual contains important instructions for safe, proper and economic use

and maintenance of the control unit. Adherence to the manual helps to avoid

dangers, reduce repair costs and downtime and to increase the machine's reliability and service life.

The operating manual is a part of the machine. The complete documentation

must be kept in an easily accessible location close to where the control unit is

used (e. g. on the tractor).

The manual does not replace your own responsibility as the operator and op-

erating personnel of the control unit Quantron E2.

1.2 Notes on the depiction of information in this manual

1.2.1 Significance of warnings

User instructions

1

The warning instructions in this manual have been structured according to the degree of danger and the probability of their occurrence.

Danger signs and symbols inform the user about other construction-related and

unavoidable remaining dangers that may be encountered when operating the

control unit. The safety warnings are structured as follows:

Signal word

Icon with Explanation

Example

n DANGER

Description of the sources of danger

Description of the danger and possible consequences.

Ignoring these warnings will result in very serious or even fatal

injury.

Measures to prevent the danger.

1

User instructions 1

Warning severity level

The degree of danger is indicated by the signal word. The levels are classified as

follows:

n DANGER

Type and source of danger

This note warns of a danger posing an immediate threat to the

health and life of persons.

Ignoring these warnings will result in very serious or even fatal

injury.

Always observe the measures described to prevent this

danger.

n WARNING

Type of hazard

This note warns of a possible dangerous situation for the health of

persons.

Ignoring these warnings will result in very serious or even fatal

injury.

Always observe the measures described to prevent this

danger.

n CAUTION

Type of hazard

This note warns of a potentially dangerous situation for personal

health or of material and environmental damage.

Ignoring these warnings can result in damage to the product or the

general area.

Always observe the measures described to prevent this

danger.

NOTICE

General information containing application tips and particularly useful information do not constitute a hazard warning.

2

1.2.2 Instructions and procedures

Action steps that the operator must carry out are shown as a numbered list.

1. Instruction for action step 1

2. Instruction for action step 2

Instructions involving only one step are not numbered. The same applies to action steps that do not have to be carried out in a specific sequence.

A bullet is placed in front of these instructions:

Instruction.

1.2.3 Listings

Listings without a specific sequence are shown with bullet points (level 1) and

dashes (level 2):

Property A

- Point A

- Point B

User instructions

1

Property B

3

User instructions 1

4

2 Layout and function

2.1 Overview of the supported AXIS versions

Function/options AXIS W

Layout and function

2

Weighing spreader

Electrical adjustment of drop point

AXIS 20.1 W

AXIS 30.1 W

AXIS 40.1 W

AXIS 50.1 W

AXIS 50.1 W

5

Layout and function 2

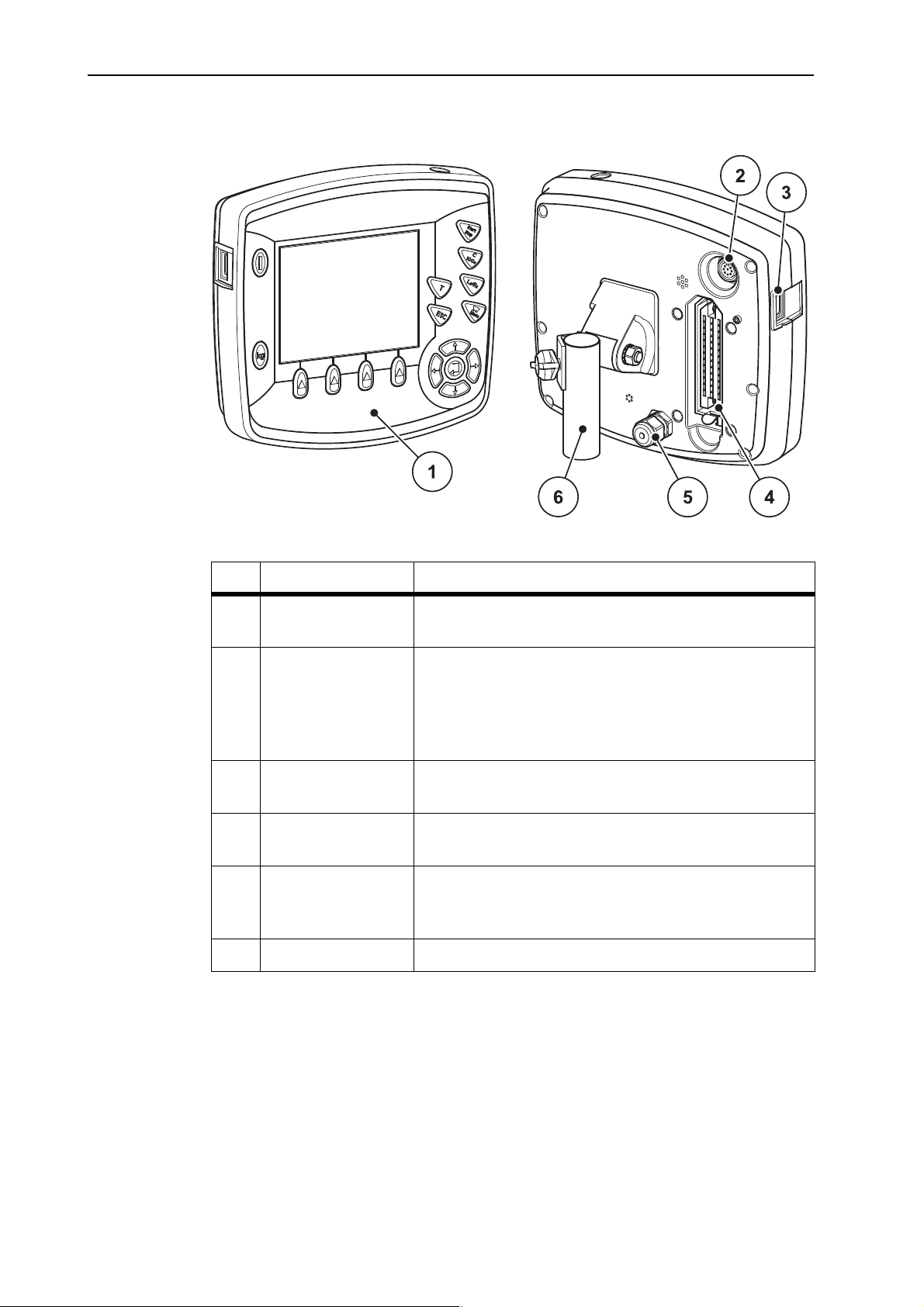

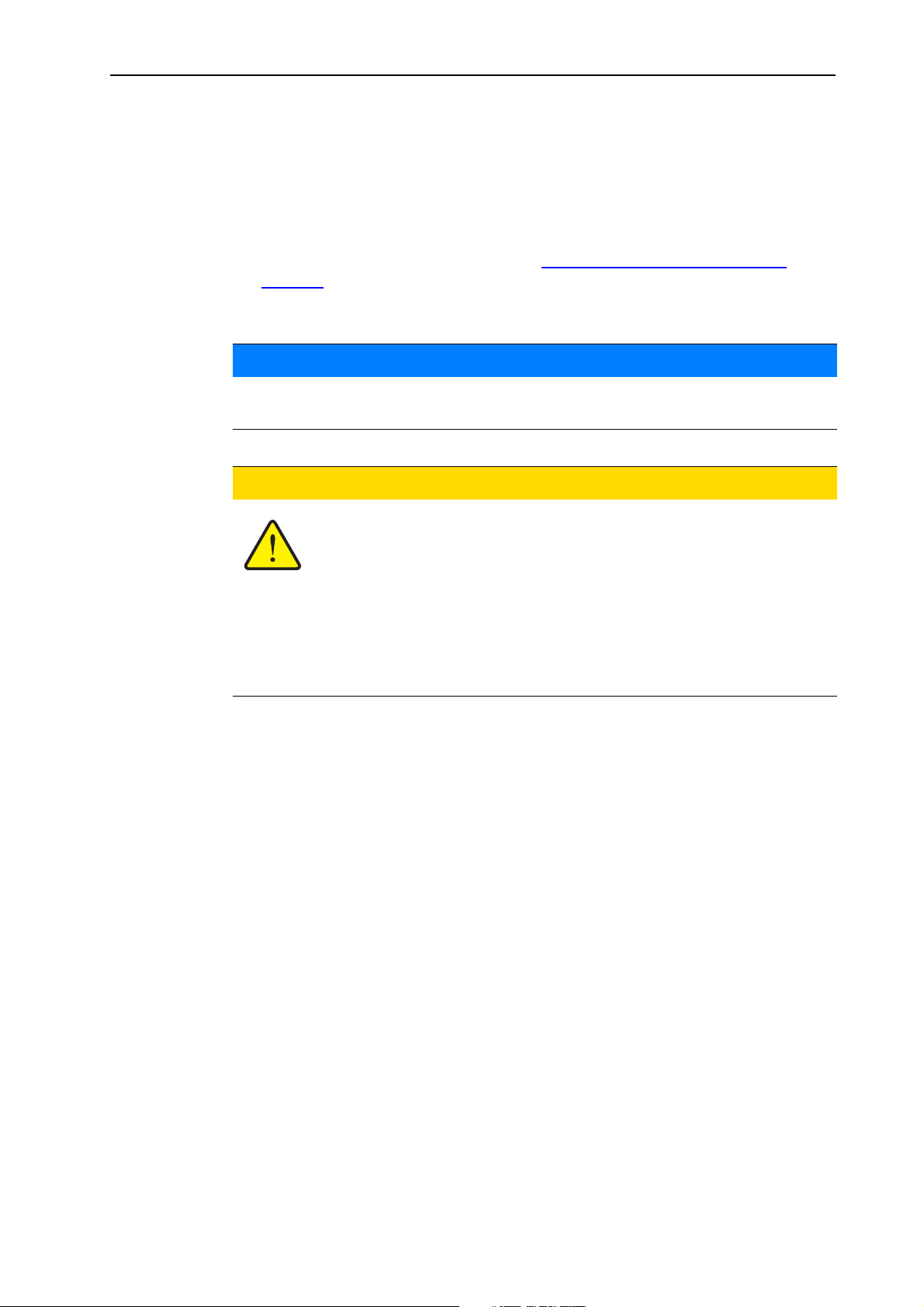

2.2 Layout of the control unit - overview

Figure 2.1: Control unit Quantron E2

No. Designation Function

1 Control panel Consisting of foil buttons used to operate the device

and the display for operating screens.

2 V24 data port Serial interface (RS232) with LH 5000 and

ASD protocol, designed for connecting an Y-RS232

cable for the connection to a remote terminal.

Plug connection (DIN 9684-1/ISO 11786) for connecting the 7-pin to 8-pin cable for the speed sensor.

3 USB port with cov-erFor exchanging data and updating the PC. Cover

serves as protection against contamination.

4 Machine cable plug

connector

39-pin plug connector for connecting the machine

cable to sensors and actuating cylinders.

5 Power supply 3-pin plug connector conforming to

DIN 9680/ISO 12369 for connecting the power supply.

6 Bracket Attaches the control unit to the tractor.

6

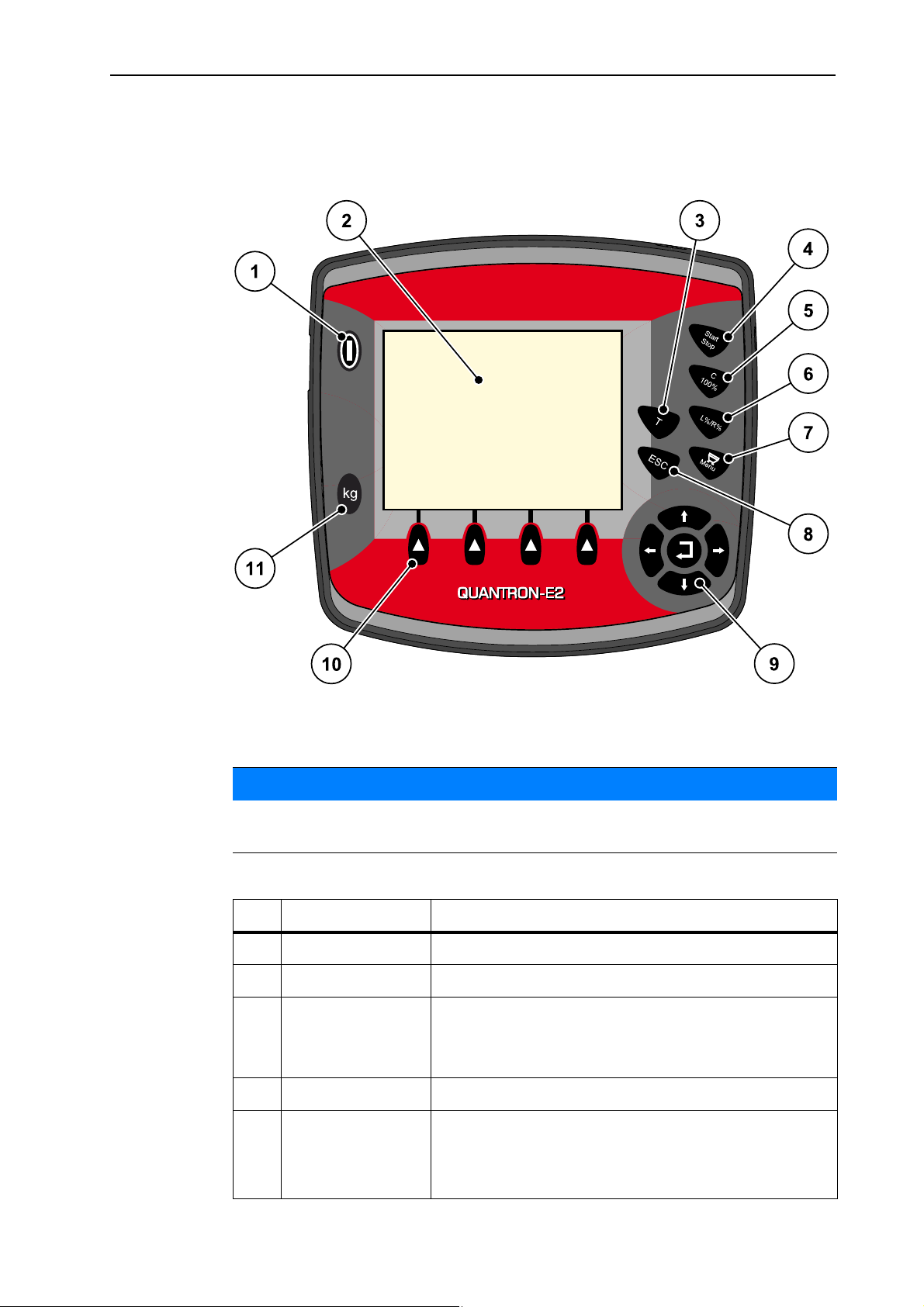

2.3 Control elements

The Quantron E2 is operated via 17 foil buttons (13 strictly defined and 4 freely

assignable foil buttons).

Layout and function

2

Figure 2.2: Control panel on the front panel of the unit

NOTICE

The operating manual describes the functions of the control unit Quantron E2

as of software version 1.20.00.

No. Designation Function

1 On/Off Switches the device on/off

2 Display Display of operating screens

3 T key (Telimat)

Key to display the Telimat settings,

Electrical Telimat automatically moves to border,

spreading position.

4 Start/Stop Start/stop spreading.

5 Clear/Reset

Clear an input in an input field,

Reset the excess quantity to 100 %,

Acknowledge alarm messages.

7

Layout and function 2

No. Designation Function

6 Preselected sec-

tion setting

Preselect sections for changing the application rates

(Left or Right or Left +Right).

7 Menu Switch between operating screen and main menu.

8 ESC For aborting information input and/or returning to the

previous menu at the same time.

9 Navigation field 4 arrow keys and one enter key for navigating

through the menus and input fields.

Arrow keys for moving the cursor on the display

or to highlight an input field.

Enter key to confirm an input.

10 Function keys F1

to F4

11 Weighing-trip

counter

Selection of the functions displayed above the function keys.

Display of the remaining fertiliser that is still in the

hopper.

Trip counter

kg left

Metre counter

8

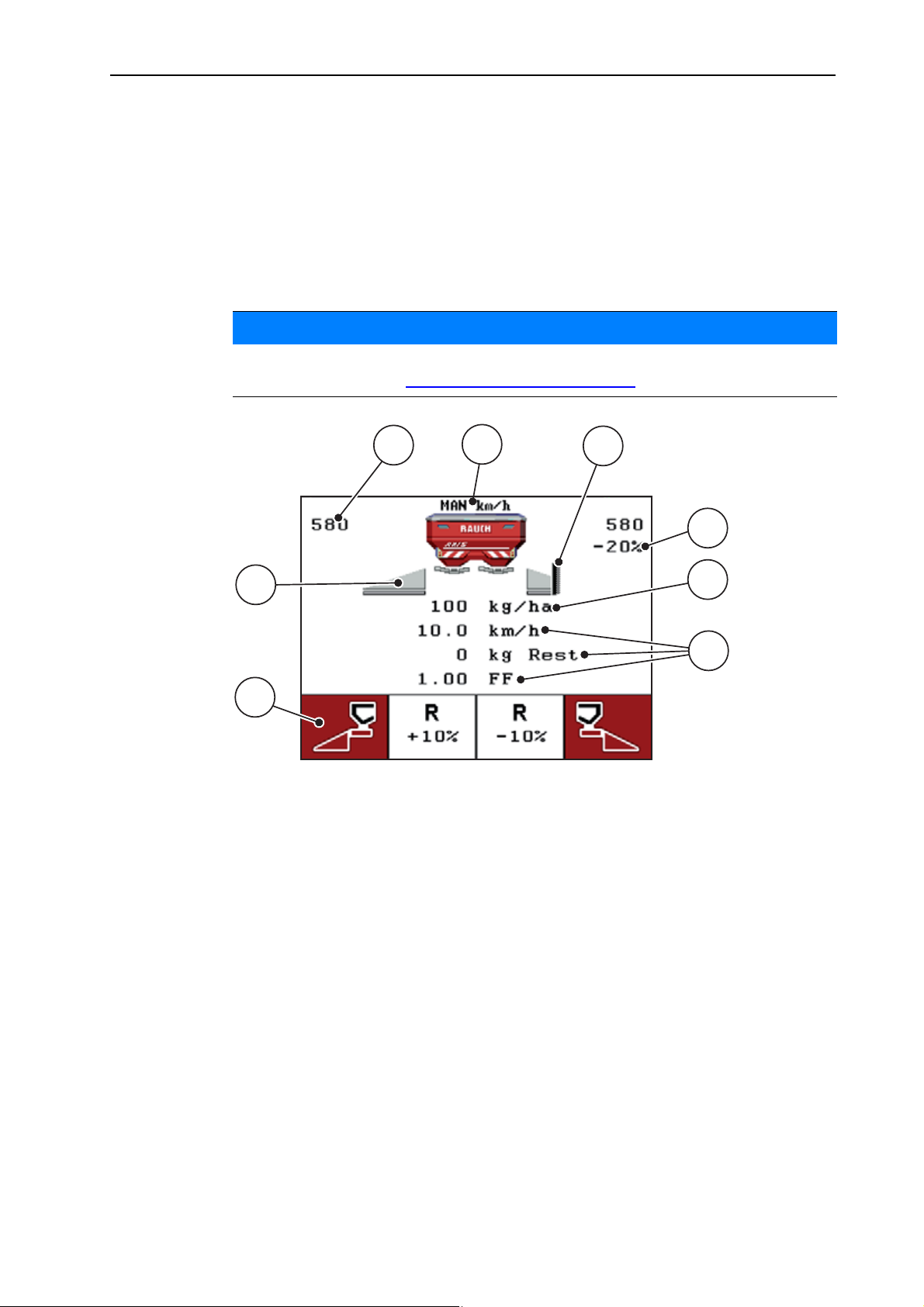

2.4 Display

1

8

7

2

3

4

5

6

Layout and function

The display shows the current status information and the selection and input options for the control unit.

The most important information on the operation of the mineral fertiliser spreader

is displayed in the operating screen.

Description of the operating screen

NOTICE

The exact representation of the operating screen depends on the actual settings

selected, see chapter 4.9.2: Display config., page 80

.

2

Figure 2.3: Control unit display

9

Layout and function 2

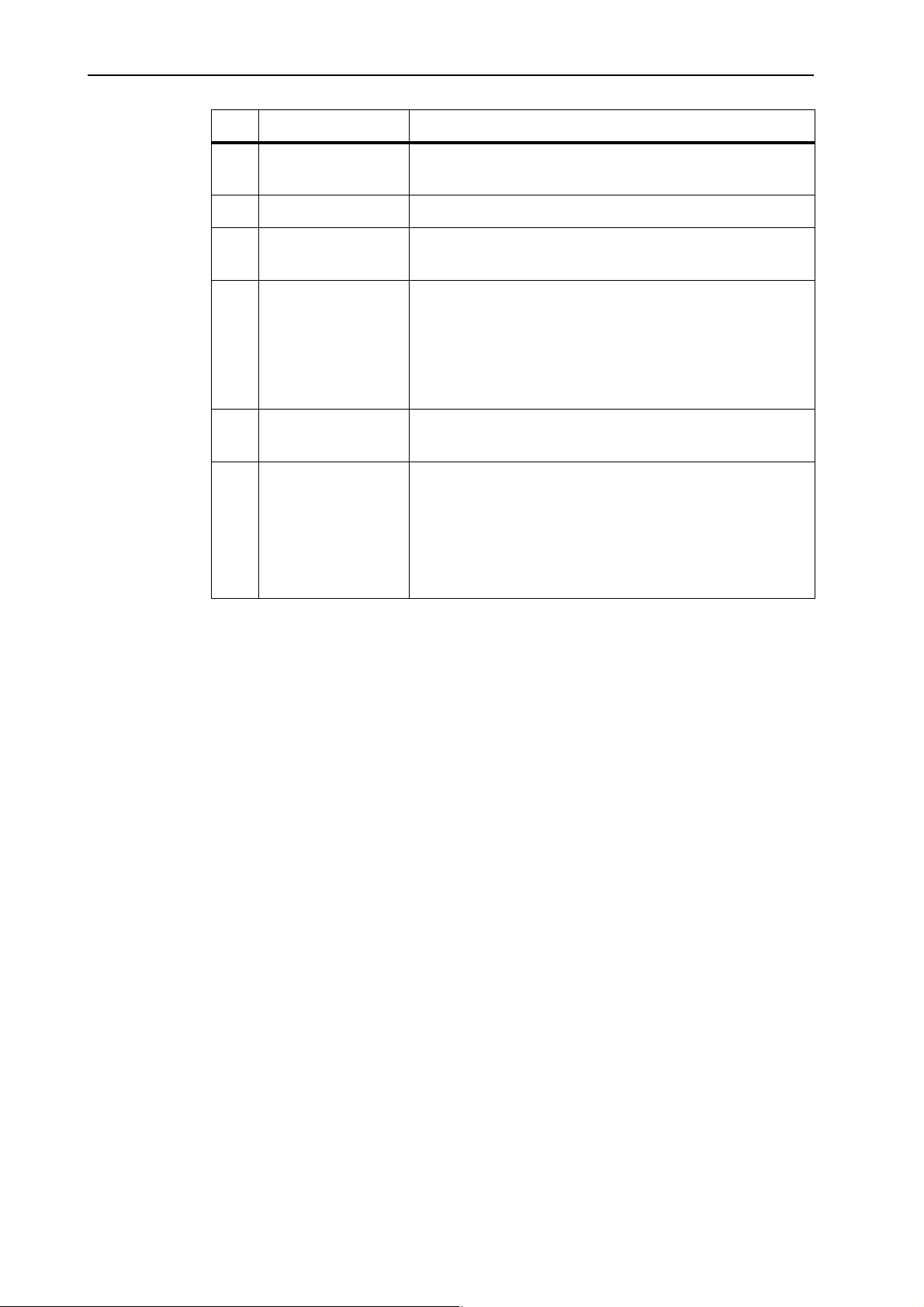

The icons and displays in the example have the following meaning:

No. Icon/Display Meaning (in the example)

1 Metering slide

Current opening position of the left metering slide.

scale opening left

2 Operating mode Shows the current operating mode.

Auto km/h uses the radar signal or wheel signal

for determining the speed.

3 Telimat icon This symbol appears if the Telimat sensors are fitted

and the Telimat function is activated (factory setting) or the T key has been activated.

4 Quantity change

right

Quantity change (+/- ) in percent.

Display of quantity changes.

Range of values +/- 1..99 % possible.

5 Application rate Preset application rate.

6 Display fields Configurable display fields (here: forward speed, flow

factor).

Possible configuration: see

chapter

4.9.2: Display config., page 80.

7 Icon fields Icons assigned to fields depending on the menu.

Selection of the function by means of the func-

tion keys located underneath.

8 Section left Display of status of left section.

Bar icon: Section left not selected.

Empty icon (contour): Section left selected but

not active.

Icon with red background: Section in spreader

operation.

10

7 pol.

8 pol.

fr

Fertilizer settings Hopper Configuration Field data

Info

Fast emptying System / Test

Main menu

Metre counter

kg rest (kg, ha, m)

Appl. (kg/ha)

Work width (m)

Flow factor

Telimat Quantity

Calibration start

Drop Point

Tractor (km/h)

AUTO / MAN mode

+/- appl. rate (%)

kg counter cradle

Brightness

Languages

Display config.

Mode

Test/Diagnosis

Date

Time

Data transmission

Total data counter

Service

en

Trip counter (km/h)

Fertiliser name

Weighing - Tripcounter

Machine tare

Weigh quantity

Compare kg counter

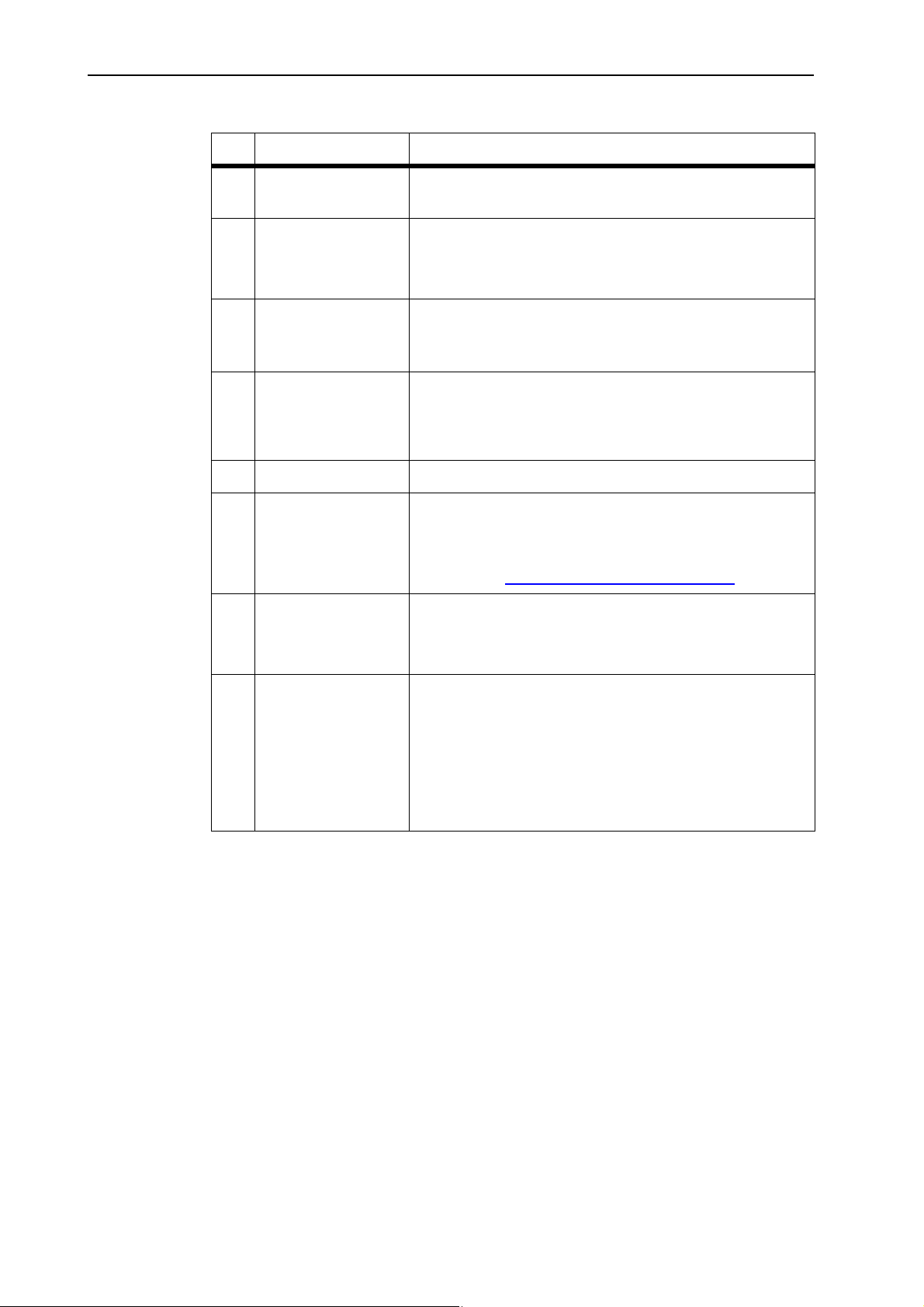

2.5 Structural overview of Easy Mode menu

Setting the mode is described in section 4.9.3: Mode, page 81.

Layout and function

2

11

7 pol.

8 pol.

fr

Fertilizer settings Hopper Configuration Field data

Info

Fast emptying System / Test

Main menu

Metre counter

kg rest (kg, ha, m)

Appl. (kg/ha)

Work width (m)

Flow factor

Telimat Quantity

Calibration start

Drop Point

Tractor (km/h)

AUTO / MAN mode

+/- appl. rate (%)

kg counter cradle

Brightness

Languages

Display config.

Mode

Test/Diagnosis

Date

Time

Data transmission

Total data counter

Service

en

Trip counter (km/h)

Fertiliser name

Weighing - Tripcounter

Machine tare

Weigh quantity

Compare kg counter

Disc type

PTO

Bound sprdg type

Telimat boundary

Way to spread

Height setting

Composition

Fertiliser chart

Manufacturer

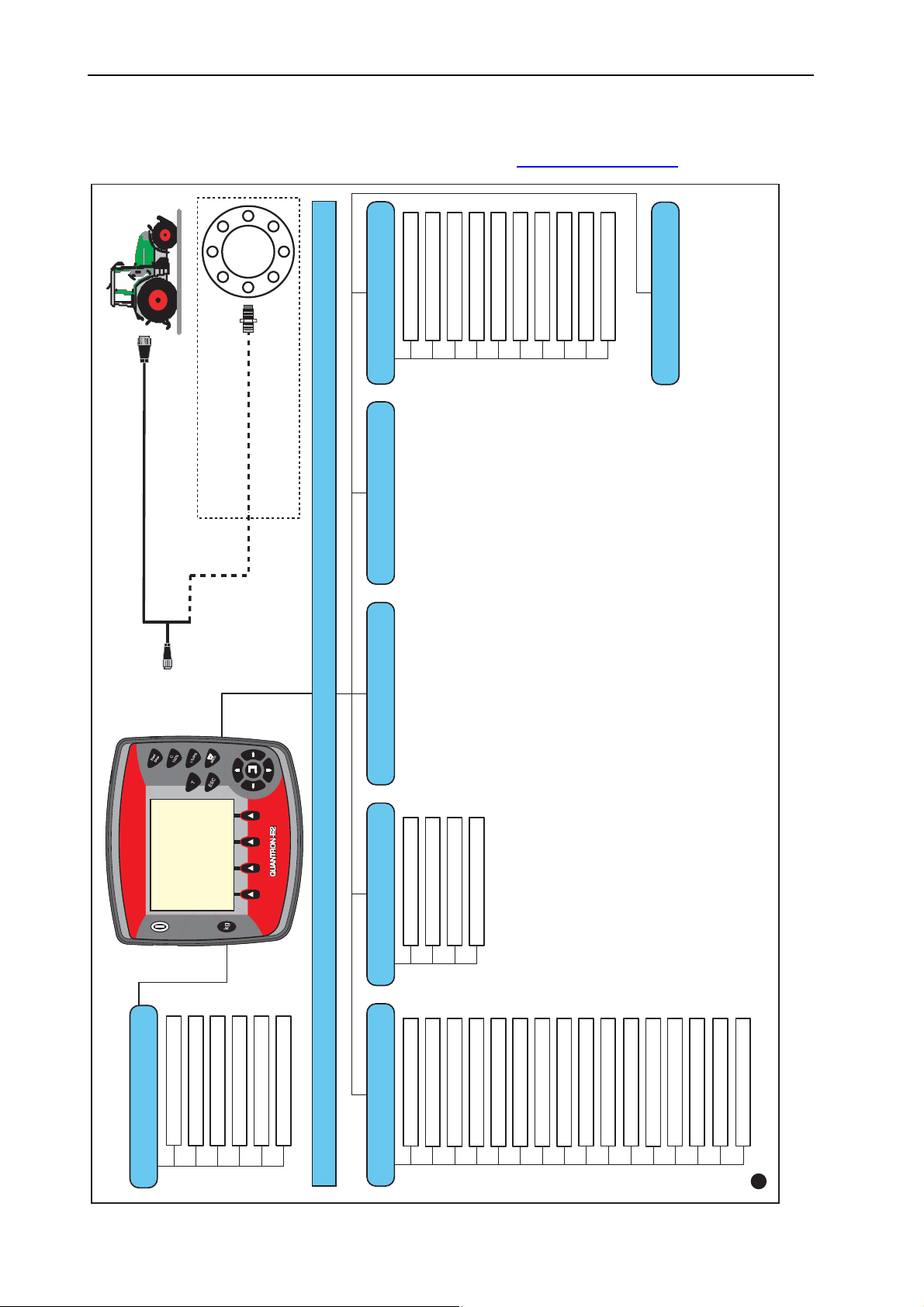

Layout and function 2

2.6 Structural overview of Expert Mode menu

Setting the mode is described in section 4.9.3: Mode, page 81.

12

3 Attachment and installation

3.1 Requirements for the tractor

Before installing the control unit, check to make sure your tractor meets the following requirements:

A minimum voltage of 11 V is essential at all times, even if multiple loads are

connected simultaneously (e. g. air conditioning system, lights).

The PTO speed can be set to 540 rpm and must be maintained (basic re-

quirement for correct working width).

On tractors without load-switchable gears, the forward speed must be selected

by using the correct gear ratio in such a way that it corresponds to a PTO speed

of 540 rpm.

A 7-pin socket (DIN 9684-1/ISO 11786). The control unit receives the pulse

for the current forward speed through this socket.

NOTICE

Attachment and installation

3

The 7-pin socket for the tractor and the forward speed sensor can be obtained

as an expansion kit (option), see figure 3.3

3.2 Connections, sockets

3.2.1 Power supply

The control unit is supplied with power from the tractor via the 3-pin power supply

socket (DIN 9680/ISO 12369).

NOTICE

to figure 3.5.

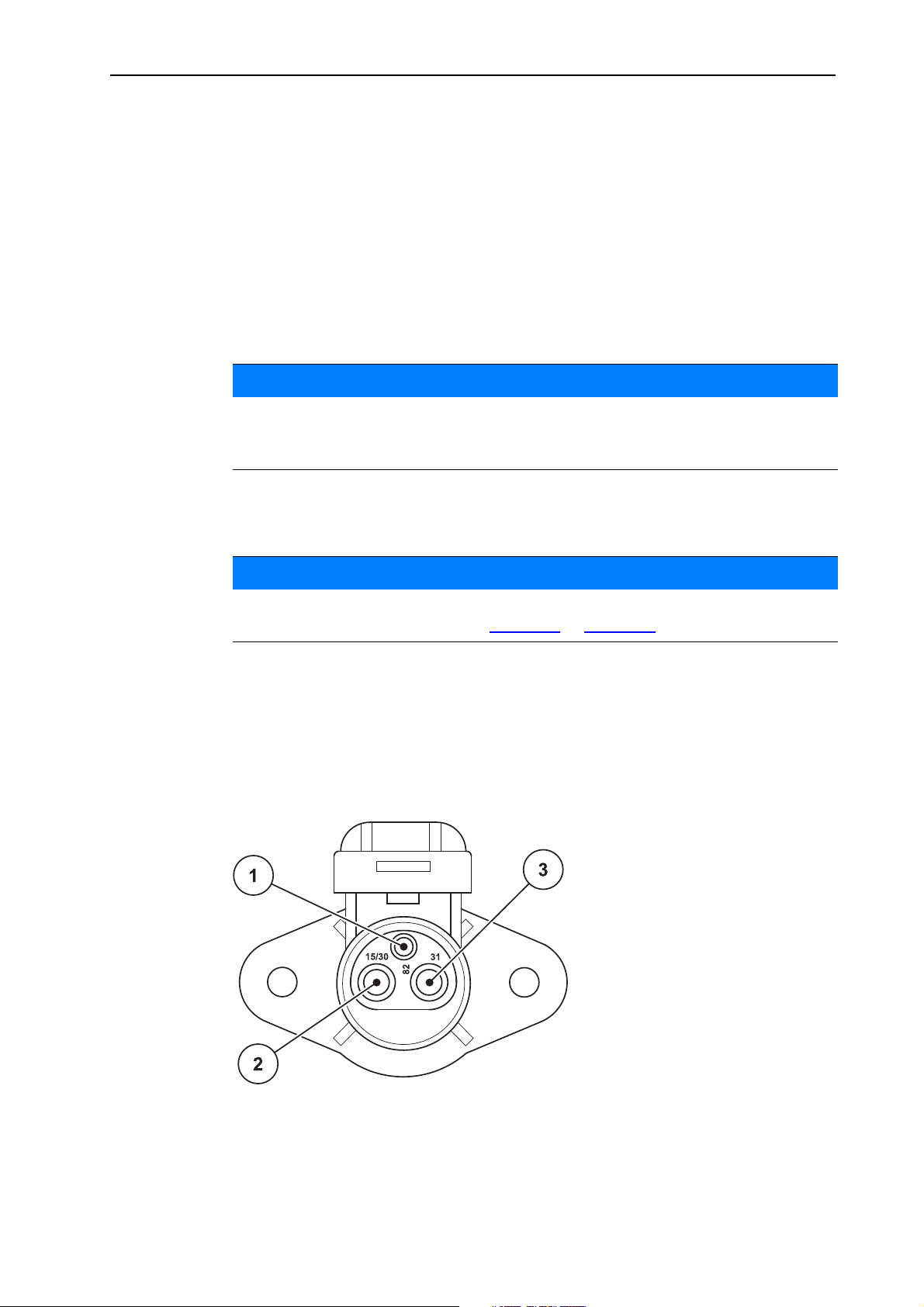

Figure 3.1: PIN assignment of power socket

[1] PIN 1: is not required

[2] PIN 2: (15/30): +12 V

[3] PIN 3: (31): Earth

13

Attachment and installation 3

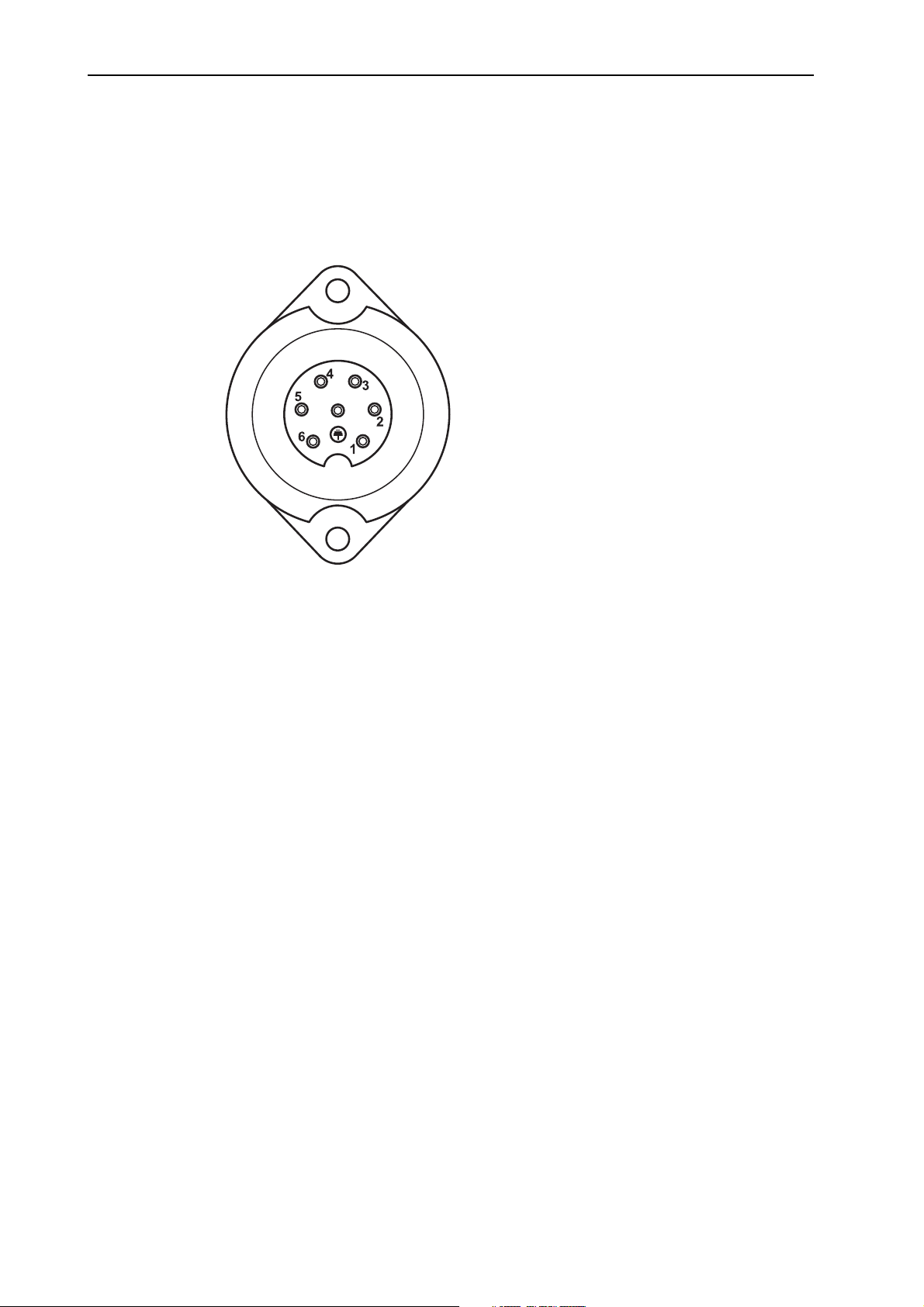

3.2.2 7-pin plug connector

The control unit receives the pulses for the current forward speed via the 7-pin

plug connector 9684-1/ISO 11786). For this purpose, the 7-pin to 8-pin cable (accessory) is connected to the forward speed sensor at the plug connector.

[1] PIN 1: actual forward speed (radar)

[2] PIN 2: theoretical forward speed (e. g.

gearbox, wheel sensor)

Figure 3.2: PIN assignment for 7-pin plug connector

14

3.3 Connecting the control unit

After the control unit Quantron E2 has been switched on, the machine number

will be shown in the display for a short period of time!

Note machine number!

The control unit Quantron E2 has been calibrated at the factory for the mineral fertiliser spreader with which it was supplied.

Connect the control unit to the correct mineral fertiliser

spreader only.

NOTICE

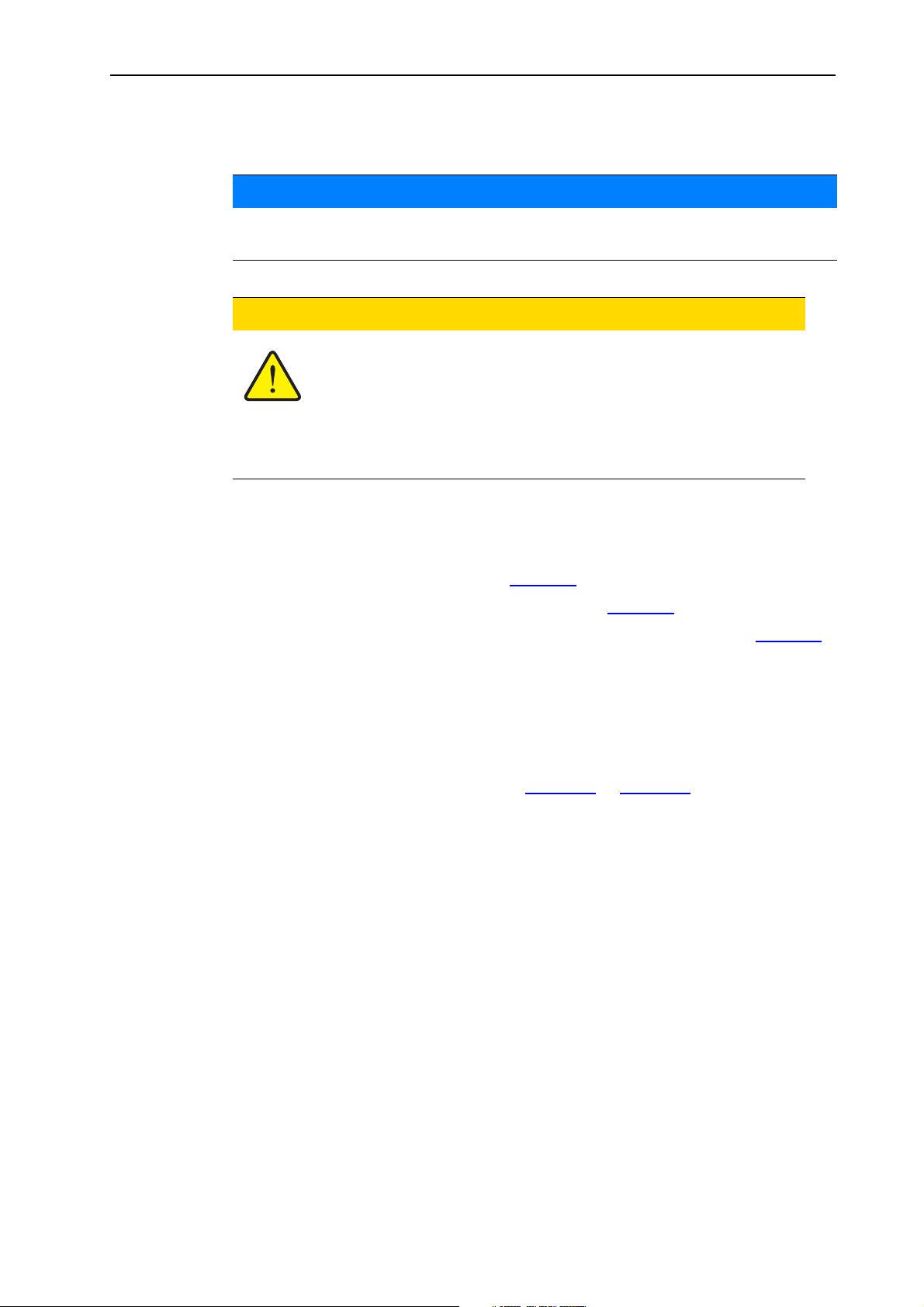

n CAUTION

Attachment and installation

3

Depending on the equipment, there are different methods of attaching the control

unit to the mineral fertiliser spreader. For schematic connection diagrams see below:

for the standard connection, see page 16,

for the connection with the wheel sensor, see page 17,

for the connection with the wheel sensor and machine cable, see page 18.

Carry out the installation in the following order.

Select a suitable position in the tractor cabin (in the driver's field of view) to

attach the control unit.

Install the control unit in the tractor cabin using the bracket.

Connect the control unit to the 7-pin socket or to the forward speed sensor

(depending on the equipment, see figure 3.3

Connect the control unit to the actuating cylinders of the mineral fertiliser

to figure 3.5).

spreader using the 39-pin machine cable.

Connect the control unit to the tractor's power supply using the 3-pin plug con-

nector.

15

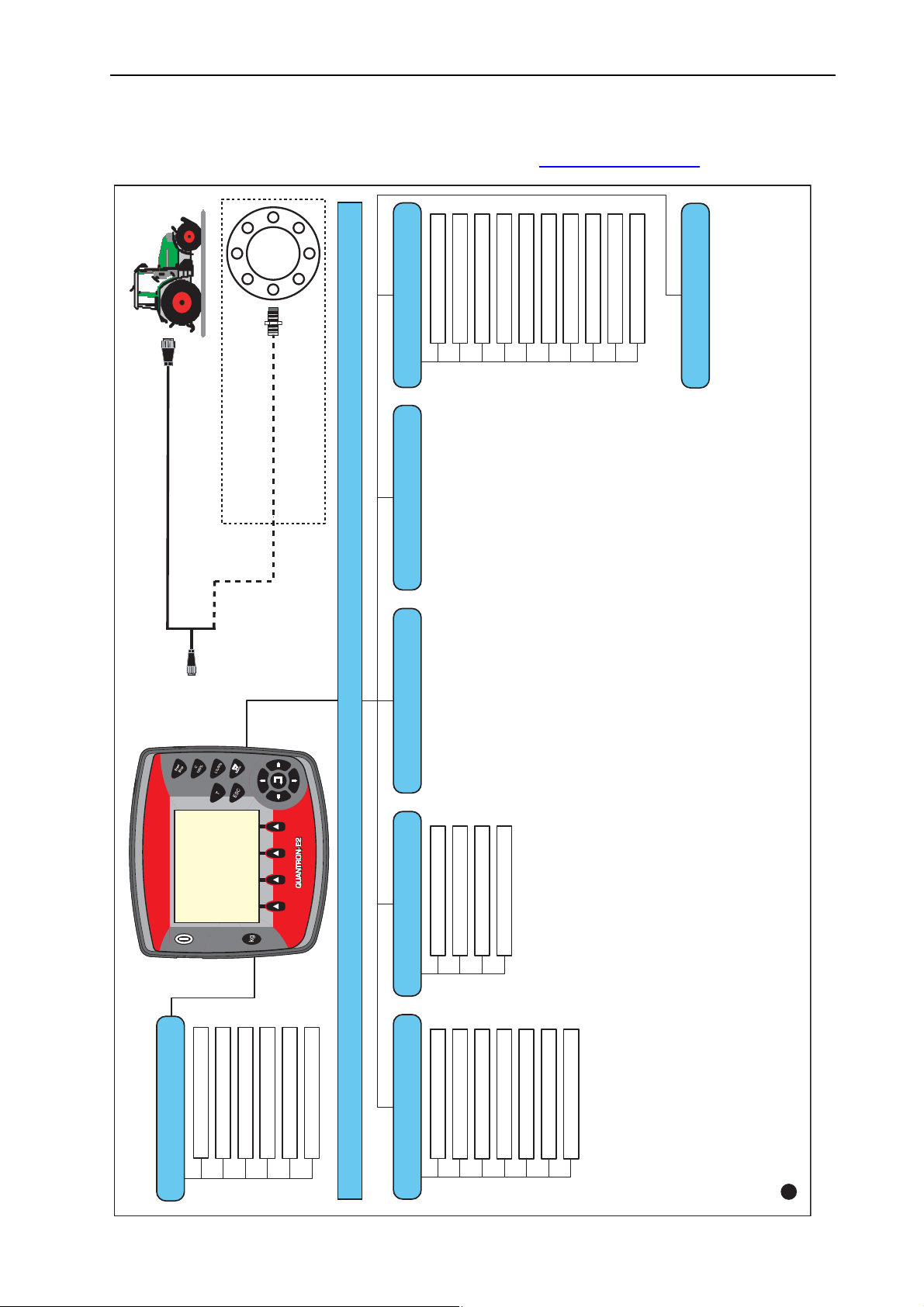

Attachment and installation 3

km/h

+

-

3

2

7

8

5

4

6

12

9

10

11

13

1

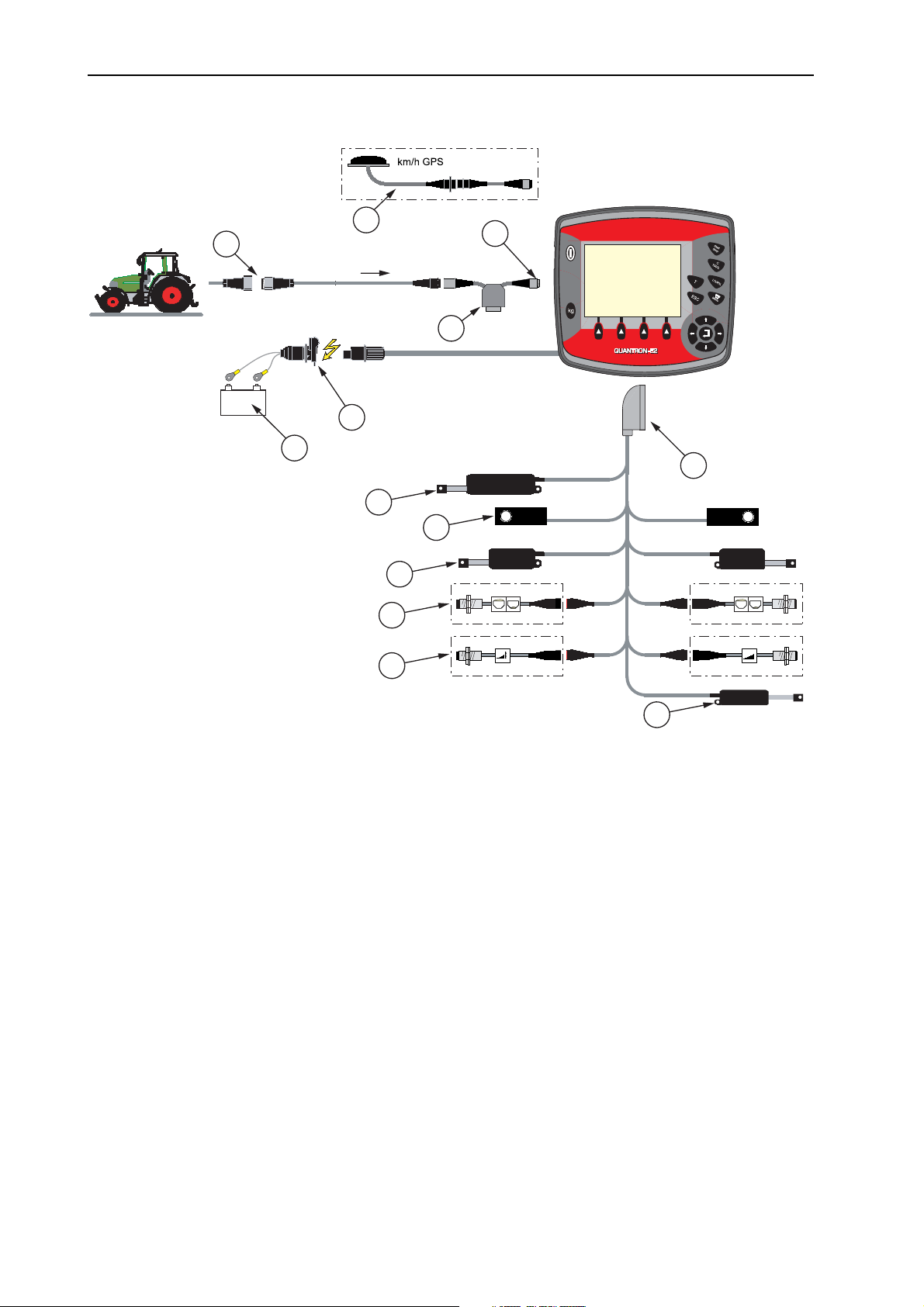

Standard schematic connection diagram:

Figure 3.3: Schematic connection diagram Quantron E2

[1] Serial interface RS232, 8-pin plug connector

[2] 39-pin machine plug

[3] Optional: Drop point adjustment (only for AXIS 50.1 W)

[4] Optional: Telimat sensor top/bottom

[5] Optional: Fill level sensor left/right

[6] Metering slide actuator left/right

[7] Weigh cell left/right

[8] Optional: electrical Telimat

[9] Battery

[11] Optional: Y-cable (V24 RS232 interface for storage medium)

[10] 3-pin plug connector conforming to DIN 9680/ISO 12369

[12] 7-pin plug connector conforming to DIN 9684

[13] Optional: GPS cable and receiver

16

Attachment and installation

km/h

+

-

12

3

2

7

5

4

6

9

10

11

13

1

8

Schematic connection diagram for wheel sensor:

3

Figure 3.4: Schematic connection diagram Quantron E2

[1] Serial interface RS232, 8-pin plug connector

[2] 39-pin machine plug

[3] Optional: Drop point adjustment (only for AXIS 50.1 W)

[4] Optional: Telimat sensor top/bottom

[5] Optional: Fill level sensor left/right

[6] Metering slide actuator left/right

[7] Weigh cell left/right

[8] Optional: electrical Telimat

[9] Battery

[10] 3-pin plug connector conforming to DIN 9680/ISO 12369

[11] Optional: Y-cable (V24 RS232 interface for storage medium)

[12] Forward speed sensor

[13] Optional: GPS cable and receiver

17

Attachment and installation 3

Standard schematic connection diagram for machine cable:

13

15

14

1

12

k m / h

k m / h

11

-

+

10

9

2

8

7

6

5

4

3

Figure 3.5: Schematic connection diagram Quantron E2

[1] Serial interface RS232, 8-pin plug connector

[2] 39-pin machine plug

[3] Optional: Drop point adjustment (only for AXIS 50.1 W)

[4] Optional: Telimat sensor top/bottom

[5] Optional: Fill level sensor left/right

[6] Metering slide actuator left/right

[7] Weigh cell left/right

[8] Optional: electrical Telimat

[9] Battery

[10] 3-pin plug connector conforming to DIN 9680/ISO 12369

[11] Optional: Y-cable (V24 RS232 interface for storage medium)

[12] Forward speed sensor

[13] Optional: Quantron E2 power supply via ignition lock

[14] 7-pin plug connector conforming to DIN 9684

[15] Optional: GPS cable and receiver

18

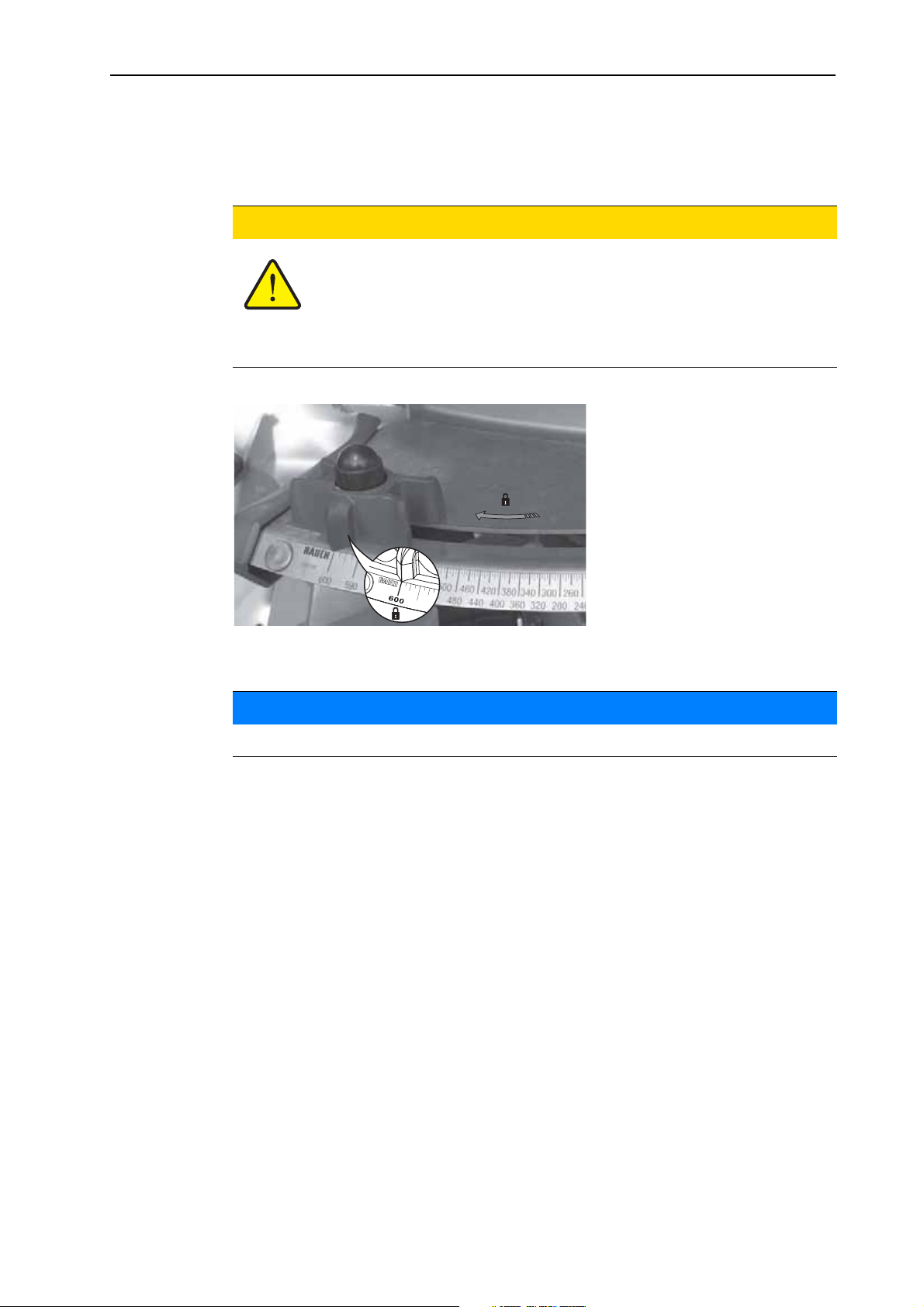

3.4 Preparation of metering slide

The AXIS W mineral fertiliser spreaders are provided with an electronic slide actuation for adjusting the application rate.

Check the position of the metering slide!

Operation of the actuators by the Quantron E2 can cause damage

to the metering slides if the stop levers are incorrectly positioned.

Always clamp the stop levers at the maximum scale posi-

tion.

n CAUTION

Attachment and installation

3

Figure 3.6: Preparation of the metering slide (example)

NOTICE

Observe the operating manual of the fertiliser spreader.

19

Attachment and installation 3

20

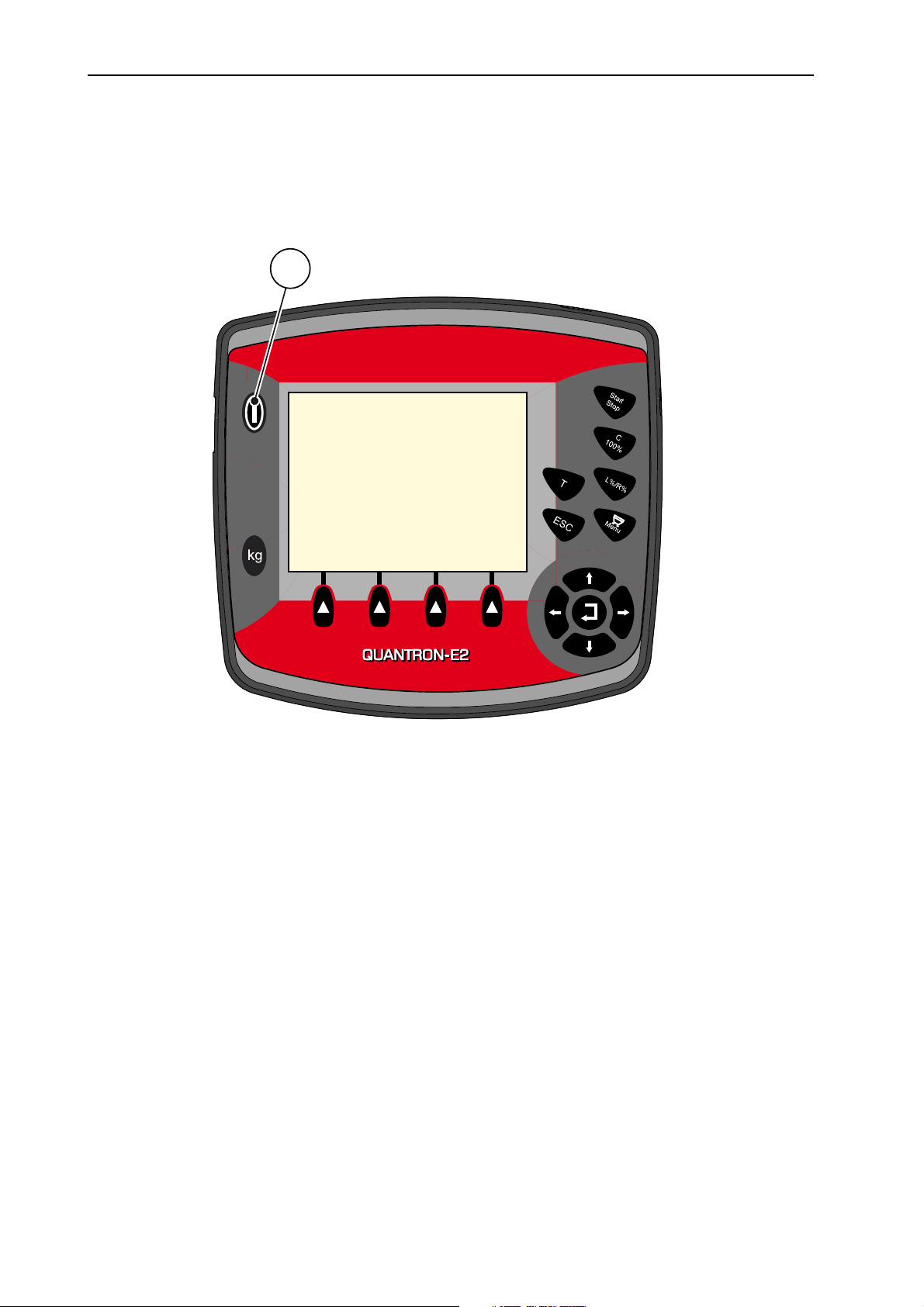

4 Operation of the Quantron E2

4.1 Switching on the control unit

Requirements:

The control unit is correctly connected to the mineral fertiliser spreader and

the tractor (for example, see chapter

page 15).

A minimum voltage of 11 V is applied.

The operating manual describes the functions of the control unit Quantron E2

as of software version 1.20.00.

Operation of the Quantron E2

3.3: Connecting the control unit,

NOTICE

n CAUTION

4

Risk of injury due to ejected fertiliser!

Only for mineral fertiliser spreaders with electronic control unit

In the case of a fault, it is possible that the metering slide unexpectedly opens during road transport to the spreading location.

There is a danger of slipping and injury to persons due to ejected

fertiliser.

Before transporting the unit to the spreading location,

always switch off the electronic control unit Quantron E2.

21

Operation of the Quantron E2 4

Switching the unit on:

Press the ON/OFF switch.

After a few seconds, the start interface appears on the control unit.

Then the boot menu is displayed for a few seconds.

Then the operating screen appears.

1

Figure 4.1: Start Quantron E2

[1] ON/OFF switch

22

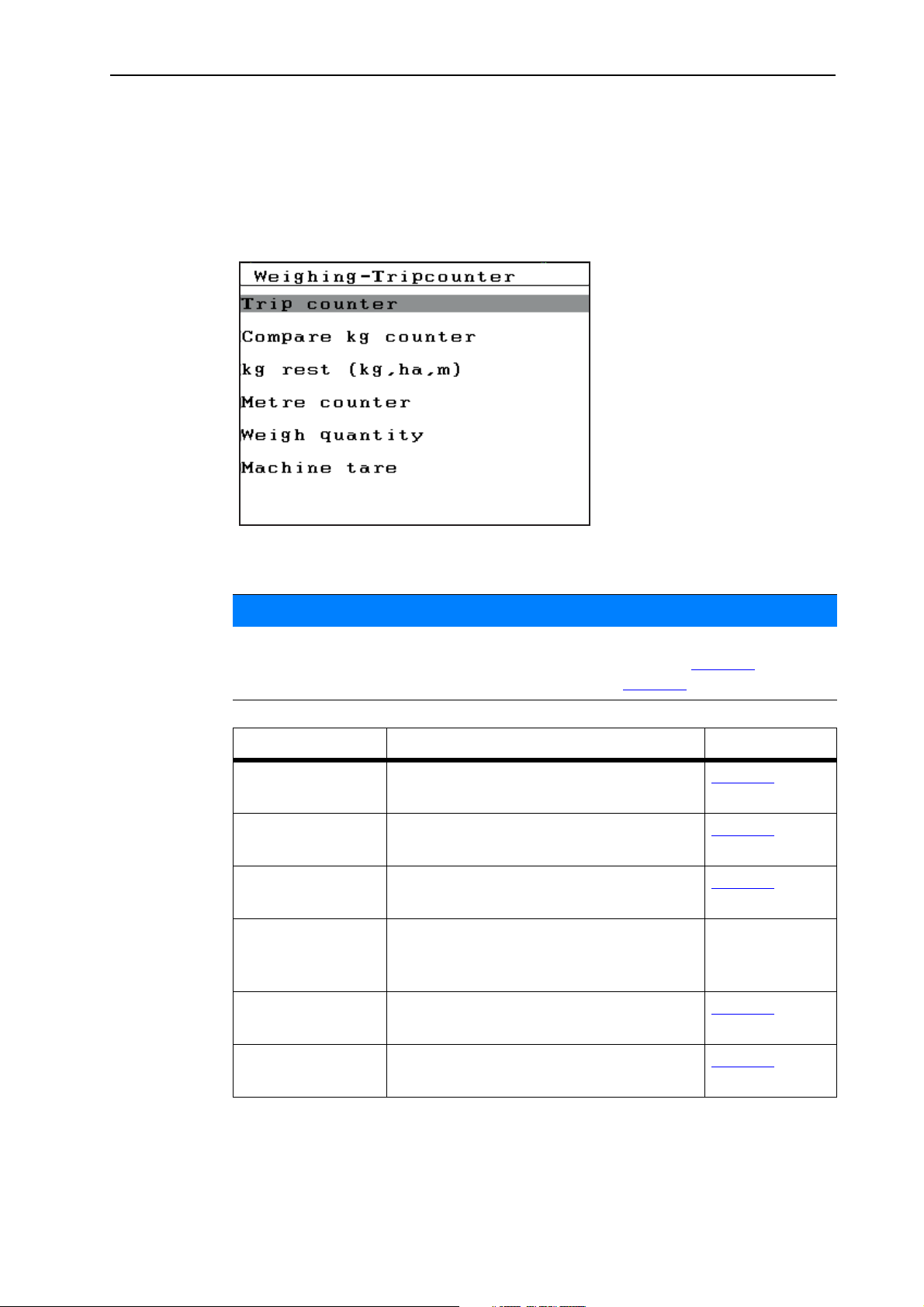

4.2 Weighing-trip counter

In this menu, you can have the values of the spreading work carried out displayed

and you can perform functions for the weighing operation.

Press the kg key on the control unit.

The weighing-trip counter menu opens.

Operation of the Quantron E2

4

Figure 4.2: Weighing-trip counter menu

NOTICE

The menu item Compare kg counter will only be displayed in the operating

modes AUTO km/h + Stat. kg and AUTO km/h + Auto kg (Page 56

tion was activated in the machine settings menu (Page 66

).

) if the op-

Submenu Meaning Description

Trip counter Display of the applied spread quantity,

Page 24

area spread and spread distance.

Compare kg counter

kg left (kg, ha, m) Display of the remaining spread quantity,

Display and comparison of fertiliser applied according to the scale.

Page 25

Page 26

area and distance.

Metre counter Display of the distance travelled since the

last reset of the metre counter.

Reset (zeroing)

by pressing the

key C100%

Weigh quantity The window weigh quantity appears in

Page 28

the display.

Machine tare Weighing value for empty scales is set to

Page 31

"0 kg".

How to select a submenu:

1. Highlight the submenu with the black bar in the display. The highlight bar can

be moved up and down with the arrow keys.

2. Open the highlighted submenu with the enter key.

23

Operation of the Quantron E2 4

1

2

4

3

4.2.1 Trip counter

You can find values for the completed spreading work (quantity, area, distance)

in this menu.

Figure 4.3: Trip counter menu

[1] Display of spread quantity since the last reset

[2] Display of spread area since the last reset

[3] Display of spread distance since the last reset

[4] Clearing the trip counter: all values to 0

Clearing the trip counter:

1. Switch from the weighing-trip counter menu to the trip-counter menu.

The values determined for the spread quantity, the spread area and the

spread distance since the last deletion appear in the display.

2. Highlight the field Del. trip counter in the display.

3. Confirm with the enter key.

All values of the trip counter are reset to 0.

4. Press the kg key once.

This returns you to the operating screen.

Checking the trip counter during spreading:

You can switch to the trip counter menu and read the current values, i.e. with

open slides.

NOTICE

If you should wish to constantly observe the values during the spreading procedure, you can also assign the freely selectable display fields on the operating

screen with kg trip, ha Trip or mTrip, see chapter 4.9.2:

Display config.,

page 80.

24

4.2.2 Determining the applied fertiliser quantity

In the Compare kg counter menu, you can display and compare the fertiliser

quantity applied according to the scale after the spreading.

The menu will display the applied fertiliser quantity in kg.

Figure 4.4: Compare kg counter menu

Operation of the Quantron E2

1

2

3

4

[1] Applied fertiliser quantity display field

[2] Start comparison

[3] Forward speed display field

NOTICE

The function Compare kg counter can only be carried out if the machine is at

a standstill and in a horizontal position.

Comparing the kg counter

1. Switch from the weighing-trip counter menu to the compare kg counter

menu.

2. How to start the comparison: Highlight the field start comparison in the dis-

play. Confirm with the enter key.

The applied fertiliser quantity is transferred to the trip counter, to the field

data and to the total data counter.

3. Press the kg key once.

This returns you to the operating screen.

NOTICE

When refilling the mineral fertiliser spreader, the function compare kg counter

is automatically carried out!

25

Operation of the Quantron E2 4

1

2

4

5

3

4.2.3 Remaining fertiliser quantity

In the kg left menu, you can call up or enter the remaining fertiliser quantity in

the hopper.

The menu shows the possible area (ha) and distance (m) that can be spread

with the remaining fertiliser quantity. Both displays are calculated based on the

following values:

Fertiliser settings

the entered kg value,

application rate,

working width.

Figure 4.5: kg left menu

[1] Remaining fertiliser quantity input field

[2] Application rate (display field from fertiliser settings)

[3] Working width (display field from fertiliser settings)

[4] Display of possible area that can be spread with the remaining fertiliser quantity

[5] Display of possible distance that can be spread with the remaining fertiliser quantity

26

Operation of the Quantron E2

Entering the remaining fertiliser quantity when refilling:

1. Switch from the weighing-trip counter menu to the kg left menu.

The remaining fertiliser quantity from the last spreading process appears

in the display.

2. Fill the hopper.

3. Enter the new total weight of the fertiliser in the hopper. Confirm the input by

pressing the enter key.

4

See also chapter

4.11.2:

Input of values using the cursor keys, page 89.

The device calculates the values for the possible spread area and the pos-

sible spread distance.

NOTICE

The values for application rate and working width cannot be changed in this

menu. They are for information only.

4. Press the kg key once.

This returns you to the operating screen.

Calling up the remaining fertiliser quantity during spreading:

During spreading, the remaining fertiliser quantity is continuously recalculated

and displayed.

You can switch to the kg left menu during spreading, i.e. with open slides, and

read of the remaining quantity in the hopper.

NOTICE

If you should wish to constantly observe the values during the spreading procedure, you can also assign the freely selectable display fields on the operating

screen with kg left, ha left or m left, see chapter 4.9.2:

Display config.,

page 80.

27

Operation of the Quantron E2 4

5

1

2

4

3

4.2.4 Weigh quantity

In this menu, you can weigh the fertiliser quantity contained in the hopper and set

the parameters for controlling the flow factor.

Figure 4.6: Weigh quantity menu

[1] Display of spreader's forward speed

[2] Weighed quantity in the hopper

[3] Filling options

[4] Weigh remnant (only displayed for the operating mode Auto km/h + Stat. kg)

[5] Quit

NOTICE

The function weigh quantity can only be carried out if the machine is at a standstill and in a horizontal position.

The menu shows the remaining fertiliser quantity. This volume depends on the

following values:

Menu item weigh quantity

Menu item machine tare

NOTICE

The function weigh quantity is only effective if the system is using either the

Auto km/h + Auto kg or Auto km/h + Stat. kg operating modes.

For the control unit supplied with the AXIS W fertiliser spreader, the Auto km/h

+ Auto kg operating mode is preset as standard at the factory.

28

Operation of the Quantron E2

When weighing the quantity, ensure that:

the fertiliser spreader is at a standstill,

the PTO is switched off,

the mineral fertiliser spreader is in a horizontal position and off the ground,

the tractor is at a standstill,

the Quantron E2 is switched on.

Weighing the fertiliser quantity in the hopper:

1. Fill the hopper.

A window appears in the display which shows the remaining fertiliser

quantity.

2. Highlight the type of filling carried out on the display:

Refill: Continue spreading with the same fertiliser.

New fertiliser: Flow factor is set to 1.0 and a new flow factor regulation will

follow.

ESC: Quit

4

3. Confirm with the enter key.

The operating screen appears on the display. The weighted quantity can

be displayed on the display field.

NOTICE

In order to display the remaining fertiliser quantity on the operating screen, the

display option kg left must be selected (4.9.2:

Display config., page 80).

Figure 4.7: Operating screen with weighed quantity

29

Operation of the Quantron E2 4

Working with the weighed fertiliser quantity, refilling the hopper:

1. Tare the scale.

See chapter

4.2.5:

Machine tare, page 31.

2. Select the fertiliser type to be used.

See chapter 4.5.7:

Fertiliser chart, page 49.

3. Fill the hopper.

4. Weigh the fertiliser quantity in the hopper.

See chapter 4.2.4:

Weigh quantity, page 28.

5. Start the work. If the hopper is empty, refill it. To do so, repeat steps 2 to 5.

NOTICE

If the hopper is empty and filled with less than 200 kg of fertiliser, the flow factor is fixed and flow factor regulation does not take place, see

chapter 4.5.3:

Flow factor, page 41. Switch to operating mode Auto Km/h.

NOTICE

If the hopper is full and if less than 200 kg of fertiliser is added, press the kg

key when the machine is at a standstill and select, while in the weigh quantity

menu, the function refill.

30

4.2.5 Machine tare

In this menu, set the weighing value for the empty weighing spreader to 0 kg.

When taring the scale, ensure that:

the hopper is empty,

the fertiliser spreader is at a standstill,

the PTO is switched off,

the mineral fertiliser spreader is in a horizontal position and off the ground,

the tractor is at a standstill.

Machine tare:

1. Switch from the weighing-trip counter menu to the machine tare menu.

The machine tare menu appears on the display.

2. Confirm with the enter key.

The weighing value for the empty scale is now set to 0 kg.

3. Press the ESC key to return to the previous menu.

Operation of the Quantron E2

4

NOTICE

Tare the scale before each use in order to ensure problem-free calculation of

the remaining fertilizer quantity.

Figure 4.8: Machine tare menu

31

Operation of the Quantron E2 4

4.2.6 Telimat

Attachment options for the AXIS W mineral fertiliser spreader

NOTICE

The Telimat option is preset for the control unit at the factory!

Telimat with hydraulic remote control

The Telimat is hydraulically moved to its working or idle position. Pressing the

T key will activate or deactivate the Telimat. Depending on the position, the Tel-

imat symbol is shown or hidden in the display of the control unit.

Telimat with hydraulic remote control and Telimat sensors

If Telimat sensors are connected and activated, the Telimat symbol will be

shown in the display of the control unit once the Telimat has been hydraulically

moved to its working position. If the Telimat is moved back to the idle position, the

Telimat symbol will disappear again. The sensors monitor the Telimat adjustment and activate or deactivate the Telimat automatically. The T key has no func-

tion for this option.

If the status of the Telimat setting cannot be verified for more than 5 seconds, the

alarm message 14 will be displayed; see chapter

5.1:

Meaning of alarm messag-

es, page 91.

Figure 4.9: Display of Telimat alarm message

n CAUTION

Risk of injury due to automatic adjustment of the Telimat!

32

After pressing the T key, the unit will automatically be moved to

the border spreading position by means of actuating cylinders.

This can cause injuries and material damage.

Before pressing the T key, ensure that no one is in the dan-

ger area of the machine.

Operation of the Quantron E2

Telimat with electrical remote control

By pressing the T key, the electrical Telimat will automatically move to the border

spreading position. During the adjustment, an "?" symbol will appear in the dis-

play of the control unit, which will disappear again once the working position has

been reached. A sensor monitoring of the the Telimat position is not required,

since the actuator was calibrated at the factory.

4

If the Telimat is blocked, alarm 23 appears; see chapter

5.1:

Meaning of alarm

messages, page 91.

NOTICE

The Telimat symbol shown in the display is the same for each of the different

Telimat options!

1

?

2

Figure 4.10: Telimat display

[1] Telimat symbol

[2] "Telimat not yet in working position" symbol

33

Operation of the Quantron E2 4

4.3 Main menu

Press the menu key in the operating screen.

Figure 4.11: Main menu Quantron E2

The main menu opens on the display.

The main menu shows the following submenus.

Submenu Meaning Description

Fertiliser settings Settings for fertiliser and spreader opera-

Page 36

tion.

Hopper configuration Settings for tractor and mineral fertiliser

Page 52

spreader.

Fast emptying Direct access to the menu for fast empty-

Page 67

ing of the fertiliser spreader.

Field data Opens the menus for selecting, creating

Page 69

or deleting field data.

System/Test Settings and diagnosis of the control unit. Page 77

Info Display of machine configuration. Page 86

How to select a submenu:

1. Highlight the submenu with the black bar in the display. The highlight bar can

be moved up and down with the arrow keys.

2. Open the highlighted submenu with the enter key.

34

4.4 Fertiliser settings in Easy mode

The mode settings are described in section 4.9.3: Mode, page 81.

You can adjust the settings for the fertiliser and spreader operation in this menu.

Switch from the main menu to the Fertiliser settings menu.

Operation of the Quantron E2

4

Figure 4.12: Fertiliser settings menu

The main menu shows the following submenus.

Submenu Meaning/Possible values Description

Name of fertiliser Selected fertiliser.

Application rate Input of target value for the application

Page 39

rate in kg/ha.

Working width Determination of the working width to be

Page 40

spread.

Flow factor Input of flow factor of the fertiliser used. Page 41

Drop point Input of the drop point. This display is only

for information.

For AXIS 50.1 W: electrical setting of the

drop point (DP).

Observe the operating instructions for the

mineral fertiliser spreader.

Page 43

Telimat quantity Pre-setting the quantity reduction for bor-

der spread.

Only for mineral

fertiliser spreaders with Telimat.

Calibration start Calling up the submenu for executing the

Page 45

calibration.

How to select a submenu:

1. Highlight the submenu with the black bar in the display. The highlight bar can

be moved up and down with the arrow keys.

2. Open the highlighted submenu with the enter key.

35

Operation of the Quantron E2 4

4.5 Fertiliser settings in Expert mode

The mode settings are described in section 4.9.3: Mode, page 81.

In this menu, you can enter the settings for the fertiliser and spreader operation.

In comparison to the Easy mode, this menu contains further setting pages as well

as the fertiliser chart.

Switch from the main menu to the fertiliser settings menu.

36

Figure 4.13: Fertiliser settings menu

Operation of the Quantron E2

The main menu shows the following submenus.

Submenu Meaning/Possible values Description

4

Name of fertiliser Fertiliser selected from the fertiliser chart.

Application rate Input of target value for the application

Page 49

Page 39

rate in kg/ha.

Working width Determination of the working width to be

Page 40

spread.

Flow factor Input of flow factor of the fertiliser used. Page 41

Drop point Input of the drop point. This display is only

for information.

For AXIS 50.1 W: electrical setting of the

drop point (DP).

Observe the operating instructions for the

mineral fertiliser spreader

Page 43

Telimat quantity Pre-setting the quantity reduction for bor-

Page 44

der spread.

Calibration start Calling up the submenu for executing the

Page 45

calibration.

Disc type Selection list:

S2

Selection using

the arrow keys.

Confirmation

S4

S6

with enter key.

S8

S10

S12

PTO 540 rpm

Bound. sprdg type Selection list:

Border

Boundary

Telimat boundary Saving the Telimat settings for boundary

fertilisation.

Way to spread Selection list:

Normal

Late

Height setting Input in cm

Selection list: 0/6 40/40 50/50 60/60 70/70

70/76

Selection using

the arrow keys.

Confirmation

with enter key.

Only for mineral

fertiliser spreaders with Telimat.

Selection using

the arrow keys.

Confirmation

with enter key.

Manufacturer Entering the manufacturer of the fertiliser.

37

Operation of the Quantron E2 4

Submenu Meaning/Possible values Description

Composition Percentage content of chemical composi-

tion.

Fertiliser chart Management of fertiliser charts.

Page 49

How to select a submenu:

1. Highlight the submenu with the black bar in the display. The highlight bar can

be moved up and down with the arrow keys.

2. Open the highlighted submenu with the enter key.

NOTICE

Not all parameters are shown simultaneously in one operating screen. You can

switch to the adjacent operating screen using the arrow keys.

38

4.5.1 Application rate

In this menu, you can enter the desired target value for the application rate.

Figure 4.14: Appl. rate menu

Entering the application rate:

Operation of the Quantron E2

4

1. Switch from the Fertiliser settings menu to the Application rate menu.

The display shows the currently specified application rate.

2. Enter the new value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

Arrow to the left/right: Cursor moves to the left/right.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89

3. Confirm the input by pressing the enter key.

The new value is saved in the control unit.

4. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

39

Operation of the Quantron E2 4

4.5.2 Working width

You can set the working width (in metres) in this menu.

Figure 4.15: Working width menu

Entering the working width:

1. Switch from the Fertiliser settings menu to the Working width menu.

The display shows the currently set working width.

2. Enter the new value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

Arrow to the left/right: Cursor moves to the left/right.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89

3. Confirm the input by pressing the enter key.

The new value is saved in the control unit.

4. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

40

4.5.3 Flow factor

The flow factor is within the range of 0.4 to 1.9. The following applies under the

same basic conditions (km/h/, working width, kg/ha):

If the flow factor is increased, the dosing quantity is reduced.

If the flow factor is reduced, the dosing quantity is increased.

If you know the flow factor from earlier calibrations or from the fertiliser chart, you

can enter it manually in this menu.

Via the calibration menu, the flow factor can be determined and entered using

the Quantron E2. See chapter 4.5.6:

Operation of the Quantron E2

NOTICE

Calibration, page 45.

4

Figure 4.16: Flow factor menu

With the weighing spreader, the calculation of the flow factor is performed

through dynamic weighing. However, the data can also be entered manually.

NOTICE

The flow factor calculation depends on the operating mode used. For further

information about the flow factor, refer to chapter 4.6.2:

AUTO/MAN mode,

page 56.

Entering the flow factor:

1. Switch from the fertiliser settings menu to the flow factor menu.

The display shows the currently set flow factor.

2. Enter the new value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

Arrow to the left/right: Cursor moves to the left/right.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89.

41

Operation of the Quantron E2 4

NOTICE

If your fertiliser is not listed in the fertiliser chart, enter the flow factor 1.00.

In the AUTO km/h and MAN km/h operating modes, we strongly recommend

that you perform a calibration to precisely determine the flow factor for this fertiliser.

3. Confirm the input by pressing the enter key.

The new value is saved in the control unit.

4. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

NOTICE

On AXIS W (Auto km/h + Auto kg), we recommend displaying the flow factor

on the operating screen in order to observe the flow factor regulation during

spreading. See chapter 4.9.2:

chapter 4.6.2:

AUTO/MAN mode, page 56.

Display config., page 80 and

Resolving problems with the flow factor regulation (only AXIS W):

Under certain conditions, the display of the flow factor can freeze despite having

carried out the weigh quantity function. The following alarm message appears

in the display.

Figure 4.17: Flow factor error message

n CAUTION

42

Possible spreading error

This alarm message can lead to spreading errors which have a

negative impact on the environment.

immediately stop the spreading process.

Resolving the fault, see chapter

5.2:

Clearing a fault/alarm, page 94.

4.5.4 Drop point

If the Quantron E2 is connected to a AXIS 50.1 W mineral fertiliser spreader, the

drop point is electrically confirmed and set.

Entering the drop point for AXIS 20.1 W, AXIS 30.1 W or AXIS 40.1 W is merely informative and does not affect the settings of the fertiliser spreader.

1. Switch from the Fertiliser settings menu to the Drop point menu.

2. Determine the position for the drop point using the fertiliser chart.

3. Enter the determined value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

Operation of the Quantron E2

NOTICE

4

See also chapter

4.11.2:

Input of values using the cursor keys, page 89

4. Press the enter key.

A message appears in the display asking for the new setting to be con-

firmed.

See chapter 5.1:

Meaning of alarm messages, page 91

n CAUTION

Risk of injury due to automatic adjustment of the drop point!

On the AXIS 50.1 W the alarm move to drop point intervenes.

After pressing the start/stop key, the drop point is automatically

moved to the preset value using the electrical actuating cylinders.

This can cause injuries and material damage.

Before pressing the start/stop key, ensure that no one is in

the danger area of the machine.

The fertiliser settings window appears with the new drop point on the display.

NOTICE

Emergency actuation on the AXIS 50.1 W must not stop the adjustment of the

drop point. Otherwise the setting unit of the drop point can be damaged.

If the drop point is blocked, alarm 17 appears; see chapter 5.1:

messages, page 91.

Meaning of alarm

43

Operation of the Quantron E2 4

4.5.5 Telimat quantity

In this menu, you can determine the Telimat quantity reduction (in percent) that

will be used during the activation of the border spread function by means of the

Telimat sensor or the T key.

Figure 4.18: Telimat quantity menu

NOTICE

Recommended quantity reduction of 20 % on border spreading side %.

Entering the Telimat quantity:

1. Switch from the fertiliser settings menu to the Telimat quantity menu.

2. Enter the determined value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89

3. Press the enter key.

The fertiliser settings window appears with the new Telimat quantity on the display.

44

4.5.6 Calibration

In this menu, you can determine the flow factor based on a calibration and save

it in the control unit.

Carry out a calibration:

before spreading for the first time.

if the fertiliser quality has changed significantly (moisture, high dust content,

if a new fertiliser type is used.

The calibration must be conducted with engaged PTO at a standstill or during

travel over a test section.

Remove both spreading discs and move the drop point to the calibration po-

Entering the working speed:

1. Switch from the Fertiliser settings menu to the Calibration start menu.

2. Enter the average working speed.

cracked grain).

sition (DP 0).

Operation of the Quantron E2

4

This value is required for calculating the slide position during the calibration.

3. Enter the new value in the input field using the arrow keys:

Arrow up: Value increases.

Arrow down: Value decreases.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89

Figure 4.19: Working speed menu

4. Confirm the input by pressing the enter key.

The new value is saved in the control unit.

The operating screen prepare calibration will appear on the display.

45

Operation of the Quantron E2 4

3

2

1

Figure 4.20: Prepare calibration operating screen

[1] Symbol above function key F4 to select right spreading side

[2] Symbol above function key F1 to select left spreading side

[3] Display of section

Selecting the section:

1. Set the spreading side on which you wish to conduct the calibration.

Press function key F1 to select the left spreader side or

press function key F4 to select the right spreader side.

The symbol of the selected spreader side has a red background.

Running the calibration:

n WARNING

Risk of injury when performing the calibration

Rotating machine components and ejected fertiliser may cause

injury.

46

Before starting the calibration, make sure that all require-

ments have been met. Observe the calibration chapter in

the operating manual of the mineral fertiliser spreader.

2. Press the start/stop key.

The opening slide of the previously selected section is opened. The cali-

bration is started.

The run calibration operating screen is displayed.

NOTICE

The calibration can be stopped at any time by pressing the ESC key. The open-

ing slide is then closed and the fertiliser settings menu appears in the display.

Operation of the Quantron E2

2

1

Figure 4.21: Run calibration operating screen

[1] Display of elapsed time since starting the calibration

[2] Active section (in this case: left side)

4

NOTICE

The calibration time is not relevant to the accuracy of the results. However, at

least 20 kg must be spread.

3. In order to end the calibration, press the start/stop key again.

The opening slide is closed.

The Input collected weight menu is displayed.

Figure 4.22: Input collected weight menu

n WARNING

Risk of injury due to rotating machine components.

Contact with rotating machine components (shafts, hubs) may

cause bruises, abrasions and crushing injuries. Body parts or

objects may be caught or pulled in.

Switch off the PTO and the tractor engine and lock them to

prevent unauthorized activation.

47

Operation of the Quantron E2 4

1

2

Recalculating the flow factor

1. Weigh the discharged fertiliser quantity.

2. Enter the weight of the discharged fertiliser quantity in the input field of the

Input collected weight menu.

See also chapter

4.11.2:

Input of values using the cursor keys, page 89.

3. Confirm the input by pressing the enter key.

The new value is saved in the control unit.

The display shows the Flow factor calculation menu.

Figure 4.23: Flow factor calculation menu

[1] Display of previously saved flow factor

[2] Display of newly calculated flow factor

NOTICE

The flow factor must lie between 0.4 and 1.9.

4. Specify the flow factor.

To accept the newly calculated flow factor, press the enter key.

To confirm the previously saved flow factor, press the ESC key.

The flow factor is saved.

The fertiliser settings menu is displayed.

5. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

48

4.5.7 Fertiliser chart

1

2

3

In the Expert mode, you can use this menu to create and manage, see

chapter

The selection of a fertiliser chart has an effect on the fertiliser settings, the control unit and the mineral fertiliser spreader. The setting of the application rate remains unaffected.

Creating a new fertiliser table

You have the option of creating up to 30 fertiliser charts in the control unit.

1. Switch from the Fertiliser settings menu to the Fertiliser chart menu.

Operation of the Quantron E2

4.9.3: Mode, page 81, the fertiliser charts.

NOTICE

4

Figure 4.24: Fertiliser chart menu

[1] Display of fertiliser chart filled with values

[2] Display of active fertiliser chart

[3] Name field fertiliser chart

2. Highlight the name field of a fertiliser chart that is not filled with values.

This field consists of the name of the fertiliser, the working width, and the disc

type.

49

Operation of the Quantron E2 4

3. Press the enter key.

The selection menu is displayed.

Figure 4.25: Selection menu

4. Highlight the function open element.

5. Press the enter key.

The display shows the Fertiliser settings menu and the selected element

is loaded as active fertiliser chart in the fertiliser settings.

6. Process the parameter in the Fertiliser chart.

See chapter

4.5:

Fertiliser settings in Expert mode, page 36.

NOTICE

We recommend naming the fertiliser chart with the fertiliser name to improve the

classification of the fertiliser chart.

Selecting an existing fertiliser chart:

1. Switch from the Fertiliser settings menu to the Fertiliser chart menu.

The Fertiliser chart operating screen is displayed.

2. Select the fertiliser chart using the arrow keys and press the enter key.

The selection menu is displayed in the operating screen.

3. Highlight the function Open element...

4. Press the enter key.

The display shows the Fertiliser settings menu and the selected element

is loaded as active fertiliser chart in the fertiliser settings.

50

5. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

Operation of the Quantron E2

Copying an existing fertiliser chart

1. Select the desired fertiliser chart in the Fertiliser chart operating screen and

confirm the selection with the enter key.

The selection menu is displayed.

Figure 4.26: Selection menu

4

2. Select the function Copy element.

3. Confirm the selection by pressing the enter key.

The fertiliser chart is copied to the first free position in the list.

Deleting an existing fertiliser chart

1. Select the desired fertiliser chart in the Fertiliser chart operating screen and

confirm the selection with the enter key.

The selection menu is displayed.

Figure 4.27: Selection menu

2. Select the function Delete element .

3. Confirm the selection by pressing the enter key.

The fertiliser chart is deleted.

51

Operation of the Quantron E2 4

4.6 Machine settings

You can adjust the settings for the tractor and mineral fertiliser spreader in this

menu.

Switch from the main menu to the Hopper configuration menu.

Figure 4.28: Hopper configuration

NOTICE

The menu item kg counter cradle will only be displayed in the operating modes

AUTO km/h + Stat. kg and AUTO km/h + Auto kg, see

chapter 4.6.2:

AUTO/MAN mode, page 56 and can be activated here!

Submenu Meaning Description

Tractor (km/h) Determining or calibrating the speed sig-

Page 53

nal.

AUTO/MAN mode Determining the automatic or manual oper-

Page 56

ating mode.

+/- appl. rate Pre-setting the quantity reduction for the

Page 65

different spreading types.

kg counter cradle Activating the Compare kg counter function Page 66

How to select a submenu:

52

1. Highlight the submenu with the black bar in the display. The highlight bar can

be moved up and down with the arrow keys.

2. Open the highlighted submenu with the enter key.

4.6.1 Speed calibration

The speed calibration is the basic requirement for an exact spreading result. Factors such as tyre size, a different tractor, all-wheel drive, slippage between tyres

and ground, ground characteristics and tyre pressure influence the speed measurement and therefore the spreading result.

Preparing the speed calibration:

The exact calculation of the number of speed pulses over 100 m is very important

for the precise discharge of the fertiliser quantity.

Run the calibration in the field. This reduces the influence of the ground char-

acteristics on the calibration result.

Measure a 100 m reference distance as accurately as possible.

Engage the four-wheel drive.

If possible, only fill the mineral fertiliser spreader until it is half-full.

Calling up the speed settings:

In the control unit Quantron E2 up to 4 different profiles for type and number of

pulses can be saved. You can assign names to these profiles (e. g. tractor name).

Operation of the Quantron E2

4

Before spreading, check that the correct profile is opened in the control unit.

1

2

3

4

5

Figure 4.29: Tractor (km/h) menu

[1] Tractor type

[2] Transducer display for the speed signal

[3] Display of number of pulses over 100 m

[4] Calibrate tractor submenu

[5] Symbols for saving locations of profiles 1 to 4

1. Switch from the Hopper configuration menu to the tractor (km/h) menu.

The displayed values for name, origin and number of pulses refer to the

profile highlighted in black.

2. Press the function key (F1-F4) under the saving location symbol to switch the

tractor profile.

53

Operation of the Quantron E2 4

Recalibrating the speed signal:

You can either overwrite an existing profile or create a profile in an empty memory

location.

1. Highlight the desired memory location using the function key below it in the

Tractor (km/h) menu.

2. In the Tractor (km/h) menu, highlight the New calibration field using the arrow keys.

3. Press the enter key.

The Tractor (km/h) calibration menu is displayed.

1

2

6

5

Figure 4.30: Tractor (km/h) calibration menu

[1] Tractor name field

[2] Display of origin of speed signal

[3] Display of number of pulses over 100 m

[4] Automatic calibration submenu

[5] Radar pulse transducer

[6] Wheel pulse transducer

4. Highlight the tractor name field and press the enter key.

5. Enter the name of the profile.

NOTICE

3

4

54

The name is limited to 16 characters.

We recommend using the name of the tractor for ease of understanding.

Entering text into the control unit is described in section

4.11.1: Text input,

page 87.

6. Select the transducer for the speed signal.

For radar pulses press the function key F1.

For wheel pulses press the function key F2.

The transducer is shown in the display.

Operation of the Quantron E2

1

2

3

The number of pulses of the speed signal must still be specified below. If you

know the exact number of pulses, you can enter it directly:

7. Highlight the Imp/100m submenu and press the enter key.

The pulses menu is displayed for manual input of the number of pulses.

4

Entering values into the control unit is described in section

4.11.2:

Input of values

using the cursor keys, page 89.

If you do not know the exact number of pulses, you can start the calibration run.

8. Press the function key F4 (Auto).

The calibration run operating screen is shown in the display.

Figure 4.31: Calibration run speed signal operating screen

[1] Pulse display

[2] Stop recording pulses

[3] Start recording pulses

9. At the starting point of the reference distance, press the function key F1.

The pulse display is set to zero.

The control unit is ready for counting pulses.

10. Drive the 100 m reference distance. Stop the tractor at the end of the reference distance.

11. Press the function key F4.

The display shows the number of received pulses.

12. Press the enter key.

The new pulse count is saved. This returns you to the calibration menu.

13. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

55

Operation of the Quantron E2 4

4.6.2 AUTO/MAN mode

The default operating mode is the AUTO mode. The control unit automatically

controls the actuators based on the speed signal.

Only work in manual mode, if:

there is no speed signal (radar or wheel sensor not available or defective),

slug pellets or seeds (fine seeds) are to be applied.

When working in manual mode, you must always operate at a constant forward speed to ensure even spreading.

NOTICE

1

2

3

4

5

Figure 4.32: AUTO/MAN mode menu

[1] Metering slide adjustment for manual mode

[2] Adjustment of forward speed for manual mode

[3] Selecting automatic mode

[4] Selecting automatic mode with static weighing

[5] Selecting automatic mode with automatic weighing

Automatic mode with automatic weighing (AUTO km/h + Auto kg)

The AUTO km/h + Auto kg operating mode allows for continuous weighing of

the fertiliser quantity in the hopper during spreader operation. The flow factor regulation is corrected at regular intervals on the basis of this information. This optimises the metering of the fertiliser.

NOTICE

56

The AUTO km/h + Auto kg menu only appears on the display if the AXIS W

mineral fertiliser spreader was configured in the factory.

With the AXIS W setting, the AUTO km/h + Auto kg operating mode is preselected as standard at the factory.

Operation of the Quantron E2

a) Selecting AUTO km/h + Auto kg:

1. Switch on the control unit Quantron E2.

2. Switch from the machine settings menu to the AUTO/MAN mode menu.

3. Highlight the AUTO km/h + Auto kg selection field.

4. Press the enter key.

The weigh quantity window appears.

5. Case a: Refill

The flow factor setting is retained.

The remaining fertiliser quantity is increased by the refilling quantity.

Case b: New fertiliser

The flow factor is reset to 1. If necessary, you can enter the required flow

factor value later on. See chapter

4.5.3:

Flow factor, page 41.

6. Highlight the required type of filling and press the enter key to return to the

operating screen.

n CAUTION

4

Incorrect metering by pressing the ESC key

The ESC key must not be pressed. Doing so will result in serious

errors in the application rate/metering.

To confirm the weighing function, always press the enter

key.

b) Procedure when spreading with Auto km/h + Auto kg:

1. Each time you switch on the Quantron E2, use the kg key to switch to the

weigh quantity menu and weigh the fertiliser quantity using refill or new fer-

tiliser.

See chapter 4.2.4:

Weigh quantity, page 28

2. Press the enter key.

3. Adjust the fertiliser settings:

Application rate (kg/ha)

Working width (m)

4. Pour the fertiliser in.

NOTICE

If the fertiliser quantity added to an empty hopper is less than 200 kg switch to

the AUTO km/h + Stat. kg or Auto km/h mode.

The weigh quantity window appears in the display.

57

Operation of the Quantron E2 4

5. Highlight the action carried out in the display:

Refill:

Continue spreading with the same fertiliser.

The flow factor setting is retained.

The remaining fertiliser quantity is increased by the refilling quantity.

New fertiliser: Flow factor is set to 1.0 and a new flow factor regulation

will follow.

ESC: Quit

The remaining fertiliser quantity is increased by the refilling quantity.

6. Press the start/stop key.

The spreading starts.

NOTICE

On uneven, hilly terrain, application rates below 30 kg/min should be spread in

the Auto km/h + Stat. kg (weighing spreader) or Auto Km/h (other mineral fer-

tiliser spreader types) mode.

NOTICE

If, after confirming the Weigh quantity window, the fertiliser settings are

changed before spreading is started, then these changes to the settings must

be made with the spreader stopped and horizontal.

NOTICE

If during travel (i. e. travelling to the field), a change is made to the fertiliser settings, you must press the kg key with the vehicle stopped and before starting to

spread and, while in the Weigh quantity menu, select the function New ferti-

liser.

NOTICE

We recommend that the flow factor be displayed in the operating screen (see

Display config., page 80) in order to watch the flow factor regulation while

4.9.2:

spreading.

58

NOTICE

In the event of problems with the regulating behaviour of the flow factor (blockages,...), at a standstill and after resolution of the fault, use the kg key to switch

to the Weigh quantity menu and call up the New fertiliser function.

Operation of the Quantron E2

Automatic mode with static weighing (AUTO km/h + Stat. kg)

The AUTO km/h + Stat. kg operating mode is recommended for spreading on

uneven, hilly terrain and/or for low application rates. Automatic flow factor regulation does not take place during spreading. However, you can use the Weigh

remnant function to recalculate the flow factor.

NOTICE

The AUTO km/h + Stat. kg menu only appears on the display if the AXIS W

mineral fertiliser spreader has been configured in the factory.

a) Selecting AUTO km/h + Stat. kg:

1. Switch on the control unit Quantron E2.

2. Fill the hopper with fertiliser.

3. Switch from the machine settings menu to the AUTO/MAN mode menu.

4. Highlight the AUTO km/h + Stat. kg selection field.

5. Press the enter key.

4

The Weigh quantity window appears.

6. Confirm the New fertiliser selection field with the enter key.

The flow factor is reset to 1.0.

The control unit switches to the operating screen.

59

Operation of the Quantron E2 4

b) Procedure when spreading with Auto km/h + Stat. kg:

1. Each time you switch on the Quantron E2, use the kg key to switch to the

Weigh quantity menu and weigh the fertiliser quantity using Refill or New

fertiliser.

See chapter

4.2.4:

Weigh quantity, page 28

2. Press the enter key.

3. Adjust the fertiliser settings:

Application rate (kg/ha)

Working width (m)

4. Pour the fertiliser in.

The Weigh quantity window appears in the display.

5. Highlight the action carried out in the display:

Refill: Continue spreading with the same fertiliser. All saved values (flow fac-

tor) are retained.

New fertiliser: Flow factor is reset to 1.0. If necessary, you can enter the required flow factor value later on.

ESC: Quit

6. Press the enter key.

7. Refer to the fertiliser chart or empirical values for the flow factor and enter it

manually.

8. Press the start/stop key.

The spreading starts.

9. After at least 150 kg of fertiliser have been applied, press the start/stop key.

10. Stop the tractor on a level surface.

The mineral fertiliser spreader must be horizontal.

11. Switch to the Weigh quantity menu using the kg key.

12. Highlight the Weigh remnant field.

13. Press the enter key.

The quantity applied is compared to the actual remaining fertiliser quantity

in the hopper.

The flow factor is then recalculated accordingly.

14. Specify the flow factor.

To accept the newly calculated flow factor, press the enter key.

To accept the previously saved flow factor, press the ESC key.

60

Operation of the Quantron E2

n CAUTION

Risk of injury due to automatic adjustment of the drop point!

On the AXIS 50.1 W the alarm move to drop point intervenes.

After pressing the start/stop key, the drop point is automatically

moved to the preset value using the electrical actuating cylinders.

This can cause injuries and material damage.

Before pressing the start/stop key, ensure that no one is in

the danger area of the machine.

NOTICE

If during travel (i. e. travelling to the field), a change is made to the fertiliser settings, you must press the kg key and Weigh quantity with the vehicle stopped

and before starting to spread.

Automatic mode (Auto km/h)

4

a) Selecting Auto km/h:

1. Switch on the control unit Quantron E2.

2. Switch from the Hopper configuration menu to the AUTO/MAN mode

menu.

3. Highlight the AUTO km/h selection field.

4. Press the enter key.

The operating mode setting is saved.

5. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

61

Operation of the Quantron E2 4

b) Procedure when spreading with Auto km/h:

1. Adjust the fertiliser settings:

Application rate (kg/ha)

Working width (m)

2. Pour the fertiliser in.

3. Carry out a calibration to determine the flow factor

or

Refer to the fertiliser chart for the flow factor and enter it manually.

4. Press the start/stop key.

The spreading starts.

NOTICE

In order to achieve an optimum spreading result, you should carry out a calibration before starting to spread.

62

Operation of the Quantron E2

Manual operation (MAN km/h)

1. Switch from the Hopper configuration menu to the AUTO/MAN mode

menu.

2. Highlight the MAN km/h selection field.

The forward speed menu is displayed.

3. Enter the value for the forward speed during spreading. Confirm the input by

pressing the enter key.

4. Press the ESC key to return to the previous menu

or

press the menu key to return to the operating screen.

NOTICE

The specified operating mode is displayed in the operating screen.

4

NOTICE

In order to achieve an optimum spreading result, you should carry out a calibration before starting to spread.

Manual operation scale (MAN scale)

1. Switch from the Hopper configuration menu to the AUTO/MAN mode

menu.

2. Highlight the MAN scale selection field.

The slide opening menu is displayed.

3. Enter the scale value for the metering slide opening. Confirm the input by