Kubuta BX1800, BX2200 Workshop Manual

WORKSHOP MANUAL

KiSC issued 07, 2006 A

TRACTOR

BX1800,BX2200

TO THE READER

KiSC issued 07, 2006 A

This Workshop Manual has been prepared to provide servicing personnel with

information on the mechanism, service and maintenance of KUBOTA Tractors BX1800

and BX2200. It is divided into two parts, “Mechanism” and “Servicing” for each section.

■ Mechanism

Information on the construction and function are included. This part should be

understood before proceeding with troubleshooting, disassembling and servicing.

■ Servicing

Under the heading “General” section comes general precautions, check and

maintenance and special tools. Other section, there are troubleshooting, servicing

specification lists, checking and adjusting, disassembling and assembling, and servicing

which cover procedures, pr ecauti ons , fac tor y spe cifi ca tion s and allowa bl e limits .

All information illustrations and specifications contained in this manual are based on

the latest product information available at the time of publication.

The right is reserved to make changes in all information at any time without notice.

January 2000

© KUBOTA Corporation 2000

BX1800 · BX2200, WSM

SAFETY FIRST

KiSC issued 07, 2006 A

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

This symbol, the industry’s “Safety Alert Symbol”, is used throughout this manual and on labels on

the machine itself to warn of the possibility of personal injury. Read these instructions carefully.

It is essential that you read the instructions and safety regulations before you attempt to repair or use

this unit.

DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

■ IMPORTANT : Indicates that equipment or property damage could result if instructions are not

followed.

■ NOTE : Gives helpful information.

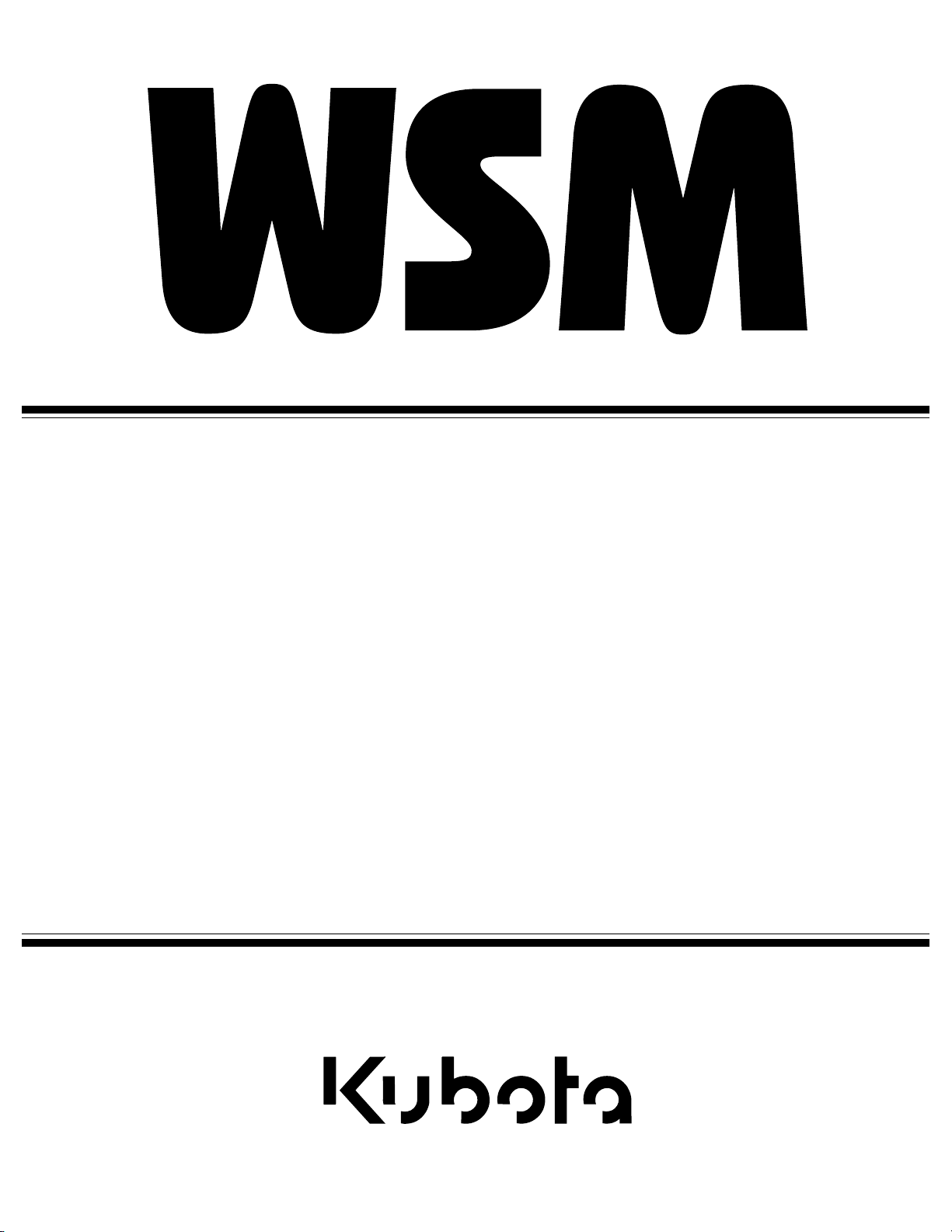

BEFORE SERVICING AND REPAIRING

• Read all instructions and safety instructions in this

manual and on your machine safety decals.

• Clean the work area and machine.

• Park the machine on a firm and level ground, and set

the parking brake.

• Lower the implement to the ground.

• Stop the engine, and remove the key.

• Disconnect the battery negative cable.

• Hang a “DO NOT OPERATE” tag in operator

station.

1

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

SAFETY INSTRUCTIONS

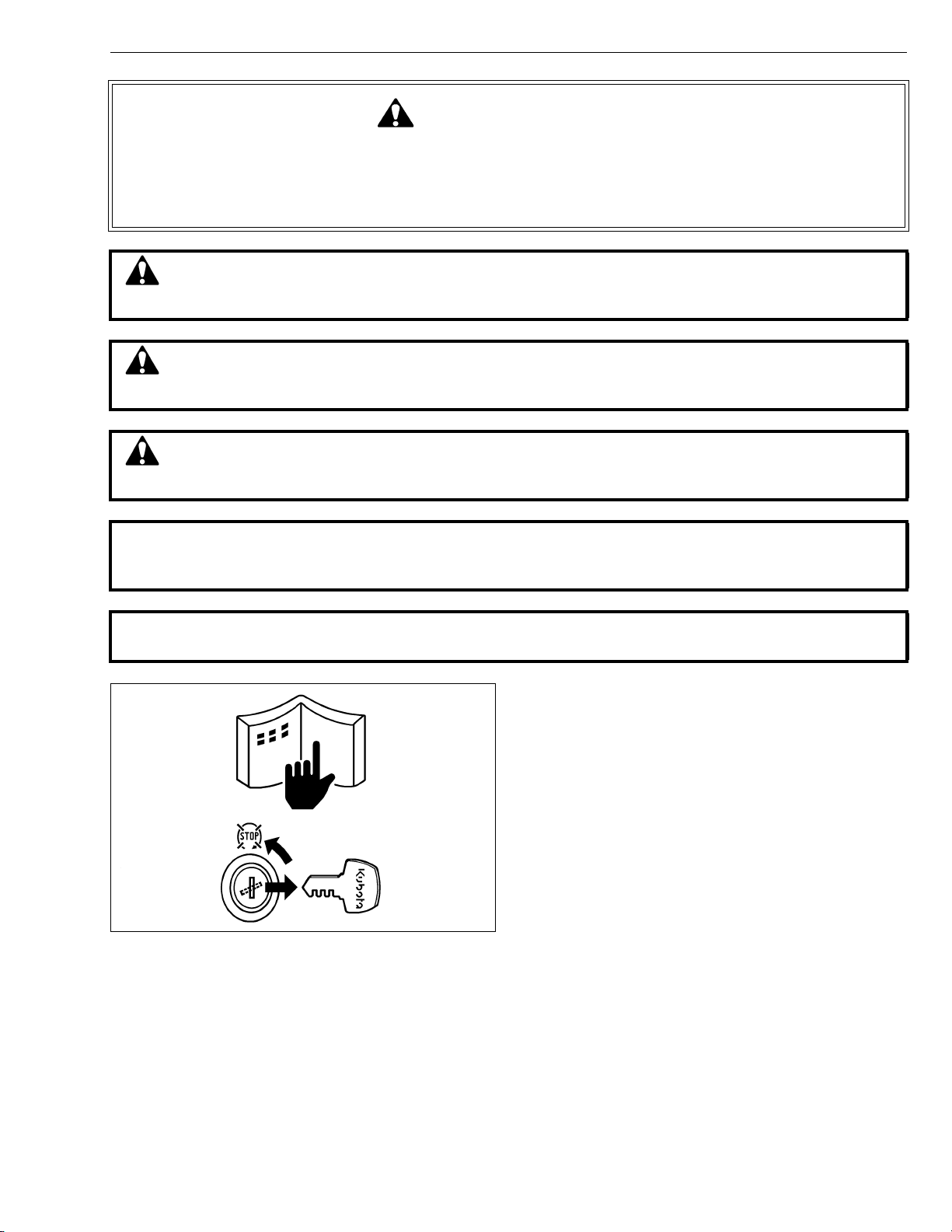

SAFETY STARTING

• Do not start the engine by shorting across starter

terminals or bypassing the safety start switch.

• Do not alter or remove any part of machine safety

system.

• Before starting the engine, make sure that all shift

levers are in neutral positions or in disengaged

positions.

• Never start the engine while standing on ground.

Start the engine only from operator’s seat.

SAFETY WORKING

• Do not work on the machine while under the influence

of alcohol, medication , or other substances or while

fatigued.

• Wear close fitting clothing and safety equipment

appropriate to the job.

• Use tools appropriate to the work. Makeshift tools,

parts, and procedures are not recommended.

• When servicing is performed together by two or more

persons, take care to perform all work safely.

• Do not work under the machine that is supported

solely by a jack. Always support the machine by

safety stands.

• Do not touch the rotating or hot parts while the engine

is running.

• Never remove the radiator cap while the engine is

running, or immediately after stopping. Otherwise, hot

water will spout out from radiator. Only remove

radiator cap when cool enough to touch with bare

hands. Slowly loosen the cap to first stop to relieve

pressure before removing completely.

• Escaping fluid (fuel or hydraulic oil) un der pressure

can penetrate the skin causing serious injury. Relieve

pressure before disconnecting hydraulic or fuel lines.

Tighten all connections before applying pressure.

AVOID FIRES

• Fuel is extremely flammable and explosive under

certain conditions. Do not smoke or allow flames or

sparks in your working area.

• To avoid sparks from an accidental short circuit,

always disconnect the battery negative cable first and

connect it last.

• Battery gas can explode. Keep sparks and open

flame away from the top of b attery, especially when

charging the battery.

• Make sure that no fuel has been spilled on the engine.

2

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

SAFETY INSTRUCTIONS

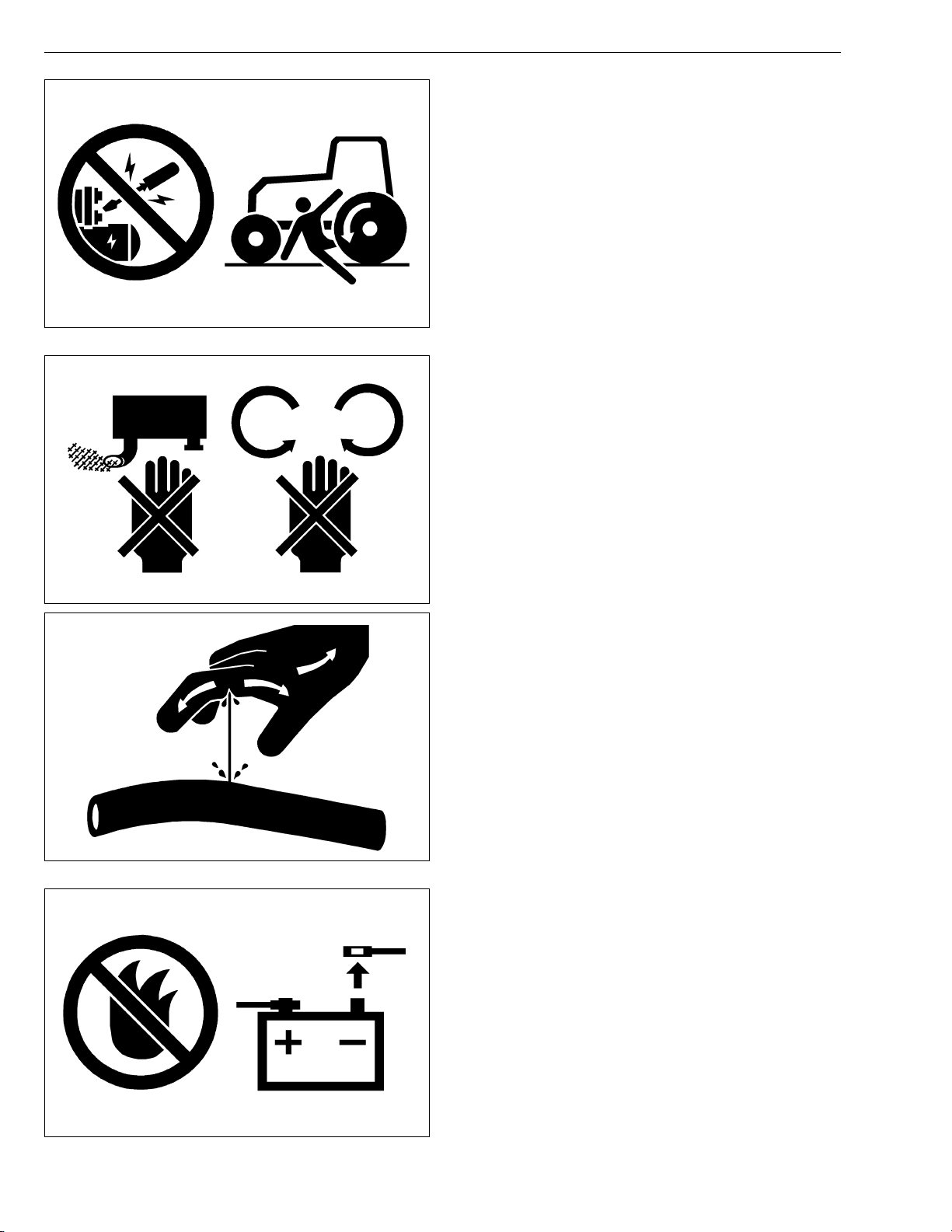

VENTILATE WORK AREA

• If the engine must be running to do some work, make

sure the area is well ventilated . Neve r run the eng ine

in a closed area. The exhaust gas contains poisonous

carbon monoxide.

PREVENT ACID BURNS

• Sulfuric acid in batte ry electrolyte is poisonou s. It is

strong enough to burn skin, clothing and cause

blindness if splashed into eyes. Keep electrolyte

away from eyes, hands and clothing. If you spill

electrolyte on yourself, flush with water, and get

medical attention immediately.

DISPOSE OF FLUIDS PROPERLY

• Do not pour fluids into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental prot ectio n regulati ons whe n disp osing

of oil, fuel, coolant, electrolyte and other harmful

waste.

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extingui sher handy at all

times.

• Keep emergency numbers for doctors, ambulance

service, hospital and fire department near your

telephone.

3

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

SAFETY INSTRUCTIONS

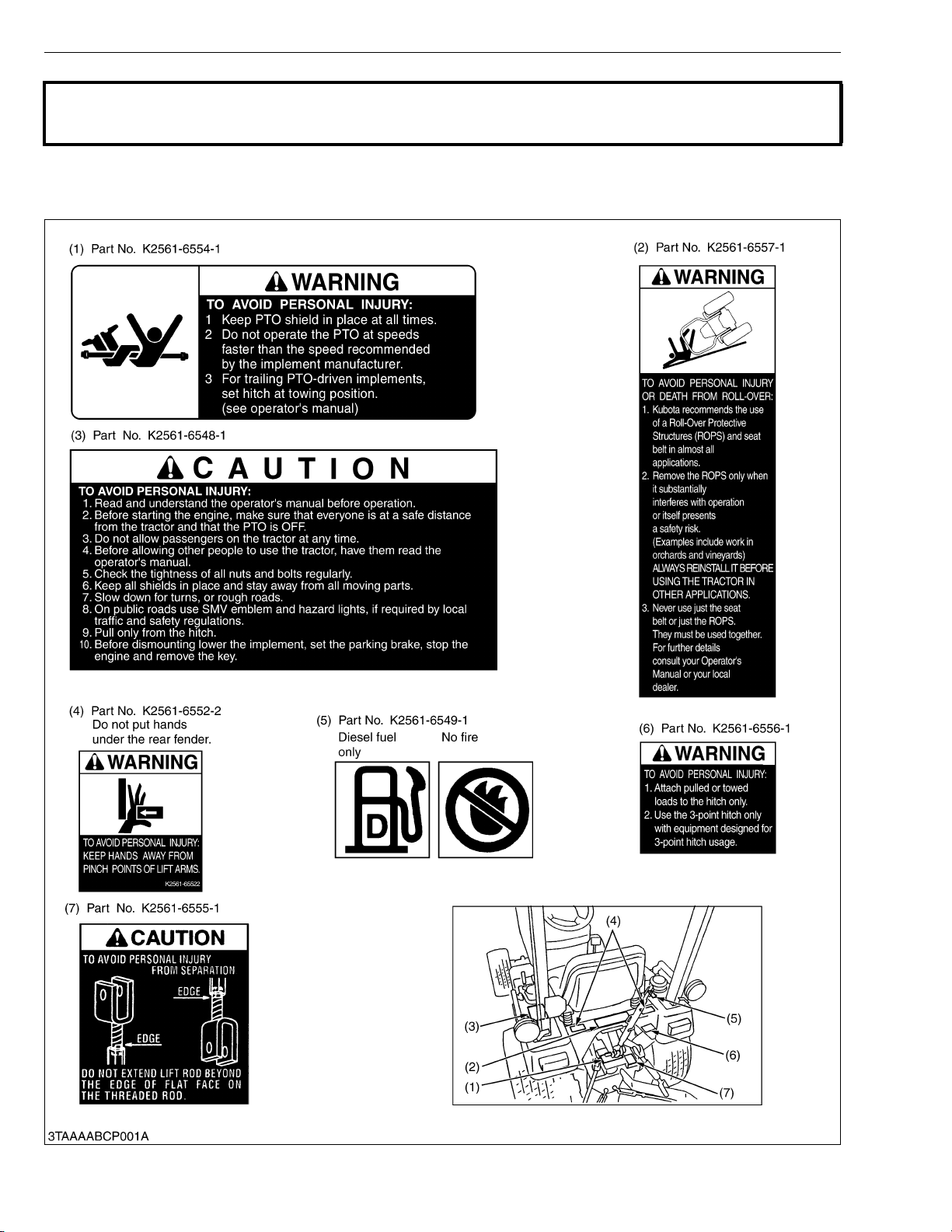

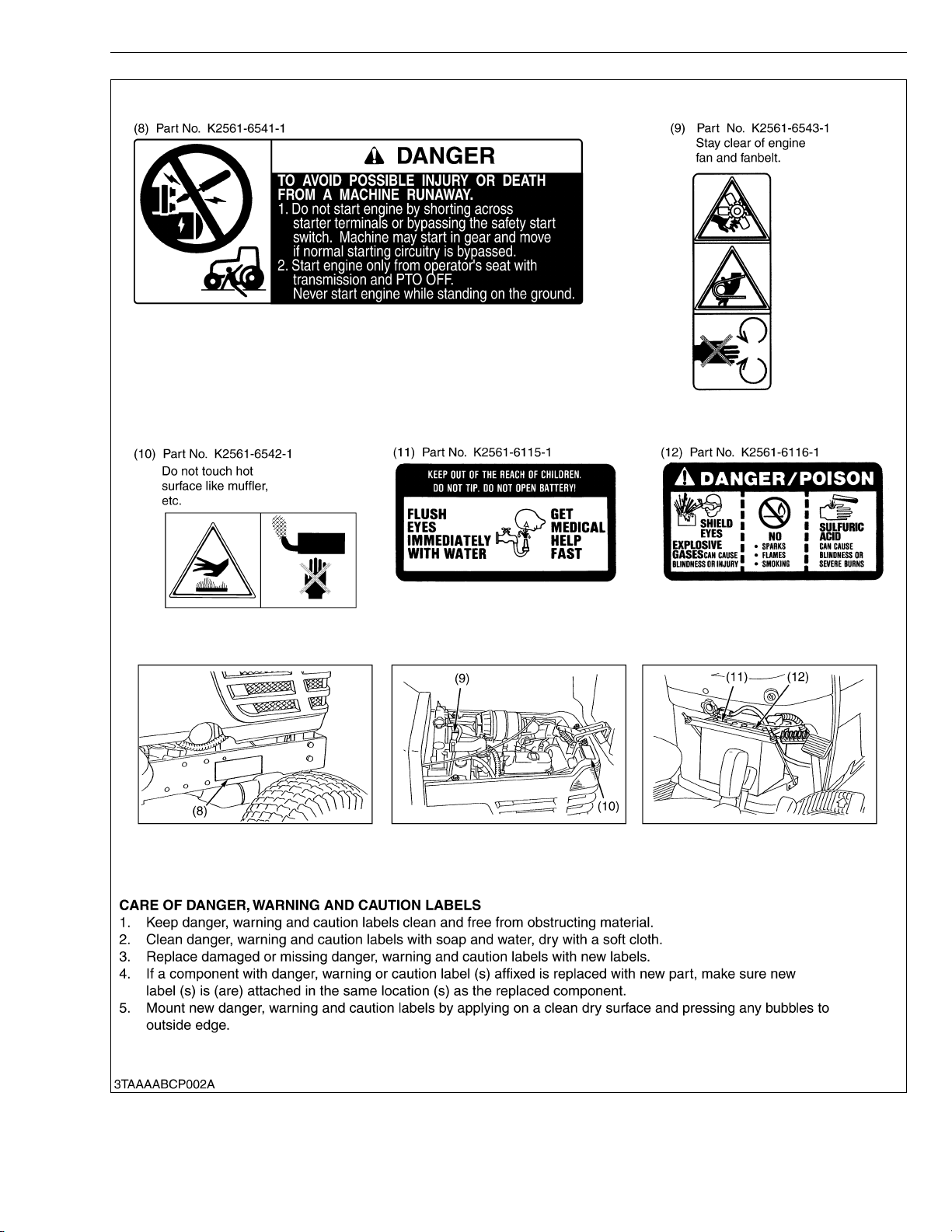

SAFETY DECALS

The following safety decals are installed on the machine.

If a decal becomes damaged, illegible or is not on the machine, replace it. The decal part number is listed in

the parts list.

4

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

SAFETY INSTRUCTIONS

5

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

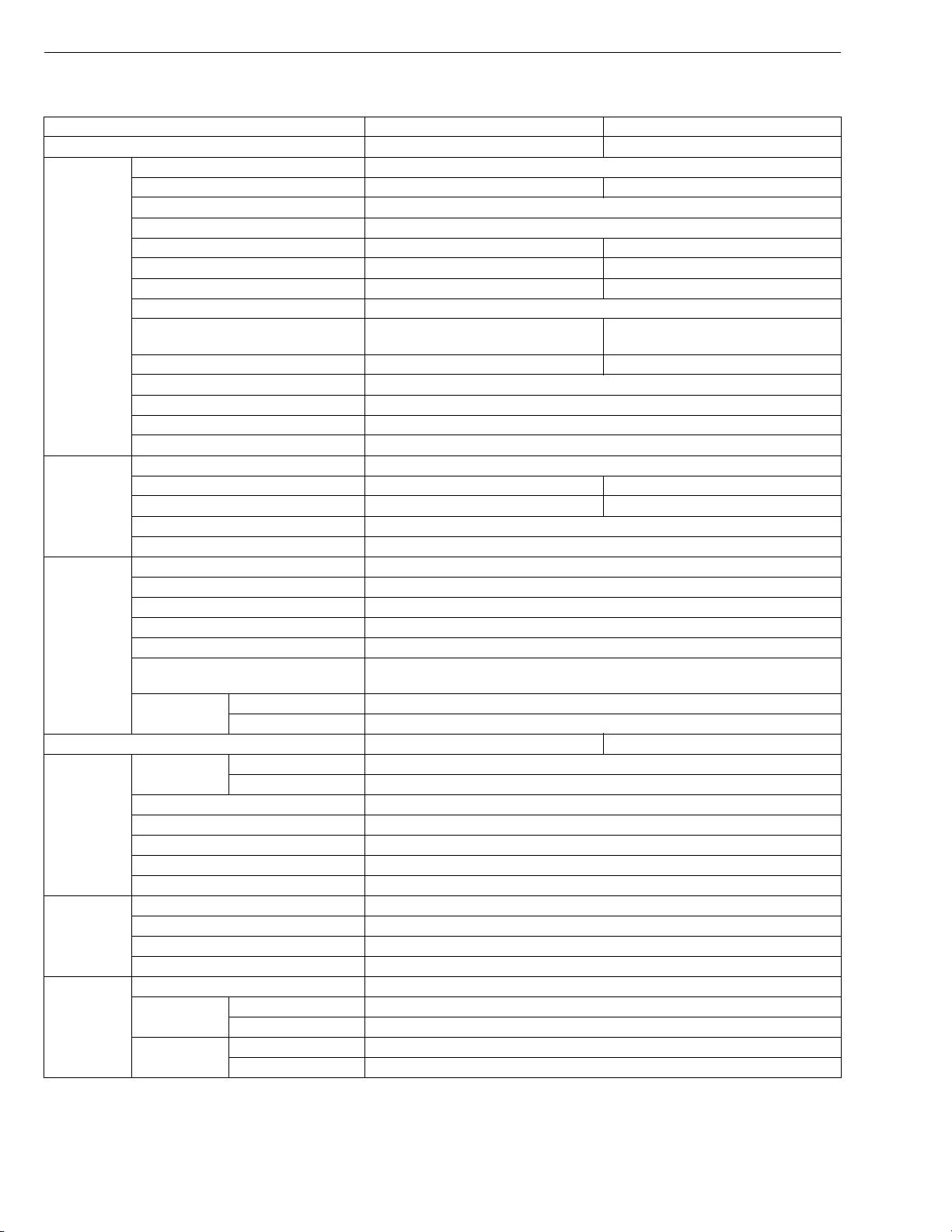

SPECIFICATIONS

SPECIFICATIONS

Model BX1800 BX2200

PTO power 10.2 kW (13.7 HP)* 12.4 kW (16.7 HP)*

Maker KUBOTA

Model D722-E-BX D905-E-BX

Type Indirect Injection. Vertical, water-cooled, 4-cycle diesel

Number of cylinders 3

Bore and stroke 67 × 68 mm (2.64 × 2.68 in.) 72 × 73.6 mm (2.83 × 2.90 in.)

Total displacement 719 cm

Engine gross power (DIN) 13.4 kW (18.0 HP) 16.4 kW (22.0 HP)

Engine

Capacities

Dimensions

Weight 570 kg (1257 lbs) 590 kg (1301 lbs)

Travelling

system

Hydraulic

system

PTO system

NOTE: * Manufacture’s estimate

The company reserves the right to change the specifications without notice.

Rated revolution 53.3 r/s [3200 min

Maximum torque

Battery 12 V, CCA : 435 A, RC : 62 min. 12 V, CCA : 535 A, RC : 80 min.

Starting system Electric starting with cell starter, 12 V, 1.4 kW

Lubrication system Forced lubrication by trochoidal pump

Cooling system Pressurized radiator, forced circulation with water pump

Fuel Diesel fuel No. 2-D [above −10 °C (14 °F)], Diesel fuel No. 1 [below −10 °C (14 °F)]

Fuel tank 21 L (5.5 U.S.gals, 4.6 Imp.gals.)

Engine crankcase (with filter) 1.9 L (2.01 U.S.qts., 1.67 Imp.qts.) 2.5 L (2.64 U.S.qts., 2.20 Imp.qts.)

Engine coolant (with recovery tank) 2.9 L (3.06 U.S.qts., 2.55 Imp.qts.) 3.5 L (3.70 U.S.qts., 3.08 Imp.qts.)

Transmission case 10.1 L (2.7 U.S.gals, 2.2 Imp.gals.)

Front axle case 4.7 L (4.97 U.S.qts., 4.14 Imp.qts.)

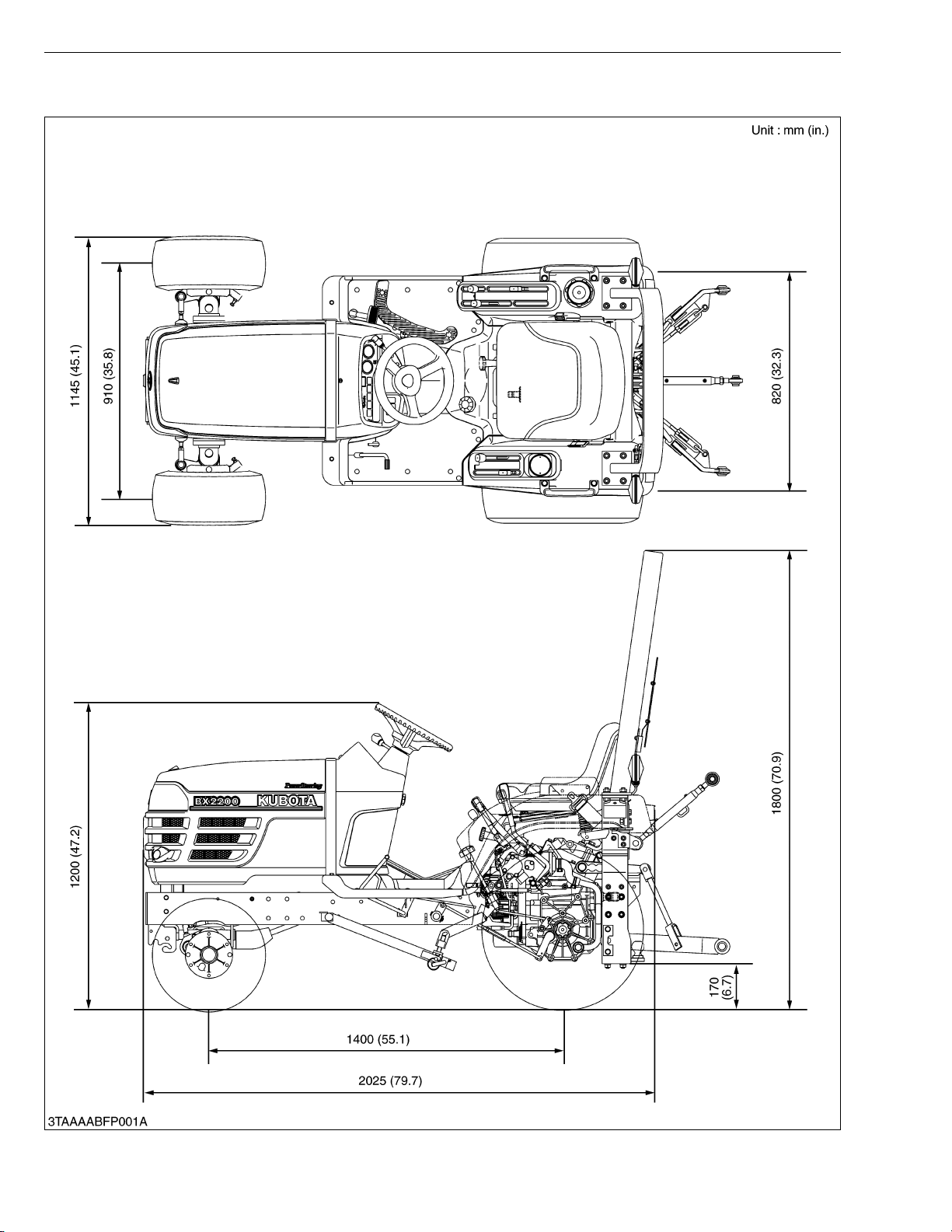

Overall length (without 3P) 2025 mm (79.7 in.)

Overall width 1145 mm (45.1 in.)

Overall height (with ROPS) 1800 mm (70.9 in.)

Overall height (top of steering wheel) 1200 mm (47.2 in.)

Wheel base 1400 mm (55.1 in.)

Minimum ground clearance (bottom of

hitch bracket)

Tread

Tires

Steering Hydrostatic power steering

Transmission Main-hydrostatic transmission, Range gear shift (2 forward and 2 reverse)

Brake Wet disc type

Min. turning radius (without brake) 2.3 m (7.5 feet)

Differential Bevel gear

Hydraulic control system Directional control, auto-return lever system

Pump capacity 21.0 L/min. (5.5 U.S.gals./min., 4.6 Imp.gals./min.)

Three point hitch SAE Category I

Max. lift force (24 in. behind lift points) 3040 N (310 kg, 684 lbs)

Clutch Wet type, multiple discs

Mid

Rear

Front 910 mm (35.8 in.)

Rear 820 mm (32.2 in.)

Front 18 × 8.50 – 8 (Turf)

Rear 26 × 12.00 – 12 (Turf)

PTO shaft

Revolution

PTO shaft

Revolution

41.5 N·m (4.23 kgf·m, 30.6 ft-lbs) / 36.7

to 43.3 r/s [2200 to 2600 min

3

(43.9 cu.in.) 898 cm3 (54.8 cu.in.)

-1

(rpm)]

-1

(rpm)]

170 mm (6.7 in.)

USA No. 5 (KUBOTA 10-tooth) involute spline

41.7 r/s [2500 min

9.0 r/s [540 min

-1

(rpm)] / engine 52.1 r/s [3125 min-1 (rpm)]

SAE 1-3/8, 6 splines

-1

(rpm)] / engine 51.1 r/s [3068 min-1 (rpm)]

54.9 N·m (5.6 kgf·m, 40.5 ft-lbs) / 36.7

to 43.3 r/s [2200 to 2600 min-1 (rpm)]

W1028103

6

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

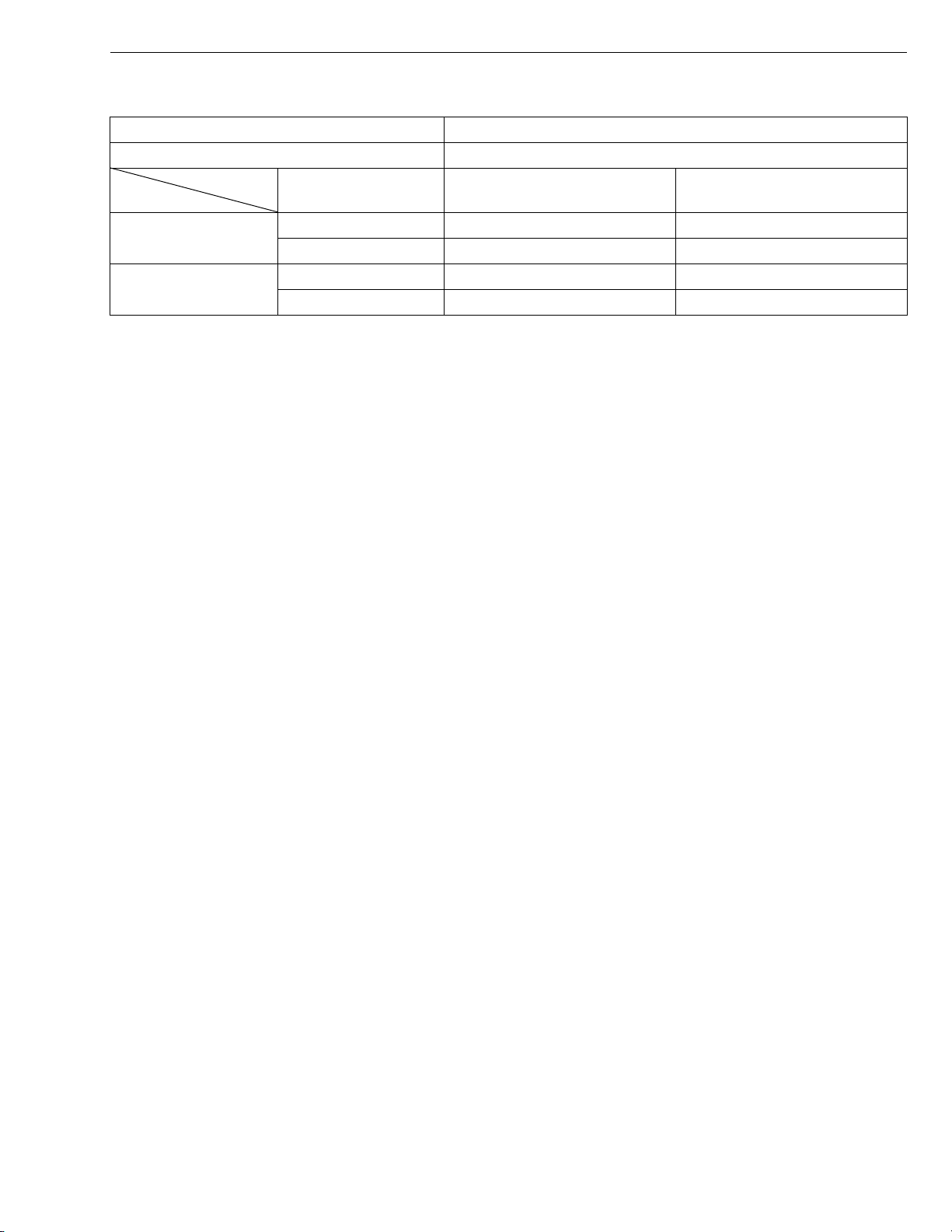

TRAVELLING SPEEDS

Model BX1800, BX2200

Tire size (Rear) 26 × 12.00 – 12

Range gear shift

lever

Low 0 to 5.9 0 to 3.7

Forward

High 0 to 13.0 0 to 8.1

Low 0 to 4.5 0 to 2.8

Reverse

High 0 to 10.0 0 to 6.2

The company reserves the right to change the spe cifi ca tion s with out notic e.

km/h mile/h

TRAVELLING SPEEDS

W1035065

7

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

DIMENSIONS

DIMENSIONS

8

G GENERAL

KiSC issued 07, 2006 A

GENERAL

KiSC issued 07, 2006 A

CONTENTS

1. TRACTOR IDENTIFICATION ......................................................................... G-1

2. GENERAL PRECAUTIONS ............................................................................ G-2

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING..G-3

[1] WIRING...................................................................................................... G-3

[2] BATTERY................................................................................................... G-5

[3] FUSE.......................................................................................................... G-5

[4] CONNECTOR............................................................................................ G-5

[5] HANDLING OF CIRCUIT TESTER......................................................... G-6

4. LUBRICANTS, FUEL AND COOLANT ......................................................... G-7

5. TIGHTENING TORQUES ............................. ....... ...... ....... ...... ....... ...... ....... .... G- 8

[1] GENERAL USE SCREWS, BOLTS AND NUTS................................... G-8

[2] STUD BOLTS............................................................................................ G-8

[3] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH UNC

OR UNF THREADS ................................................................................. G-9

6. MAINTENANCE CHECK LIST..................................................................... G-10

7. CHECK AND MAINTENANCE......... ...... ...... ....... ...... ....... ...... ....... ............... G-11

[1] DAILY CHECK........................................................................................ G-11

[2] CHECK POINTS OF INITIAL 50 HOURS........................................... G-12

[3] CHECK POINTS OF EVERY 50 HOURS........................................... G-14

[4] CHECK POINTS OF EVERY 100 HOURS......................................... G-15

[5] CHECK POINTS OF EVERY 200 HOURS......................................... G-20

[6] CHECK POINTS OF EVERY 300 HOURS......................................... G-21

[7] CHECK POINTS OF EVERY 400 HOURS......................................... G-22

[8] CHECK POINTS OF EVERY 500 HOURS......................................... G-23

[9] CHECK POINTS OF EVERY 800 HOURS......................................... G-23

[10]CHECK POINTS OF EVERY 1500 HOURS....................................... G-23

[11]CHECK POINTS OF EVERY 3000 HOURS....................................... G-23

[12]CHECK POINTS OF EVERY 1 YEAR................................................ G-23

[13]CHECK POINTS OF EVERY 2 YEARS.............................................. G-24

[14]OTHERS .................................................................................................. G-25

8. SPECIAL TOOLS.......................................................................................... G-27

[1] SPECIAL TOOLS FOR ENGINE .......................................................... G-27

[2] SPECIAL TOOLS FOR TRACTOR....................................................... G-34

9. TIRES............................................................................................................. G-35

[1] TIRE PRESSURE................................................................................... G-35

[2] TREAD..................................................................................................... G-35

[3] TIRE LIQUID INJECTION...................................................................... G-36

10. IMPLEMENT LIMITATIONS.......................................................................... G-38

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

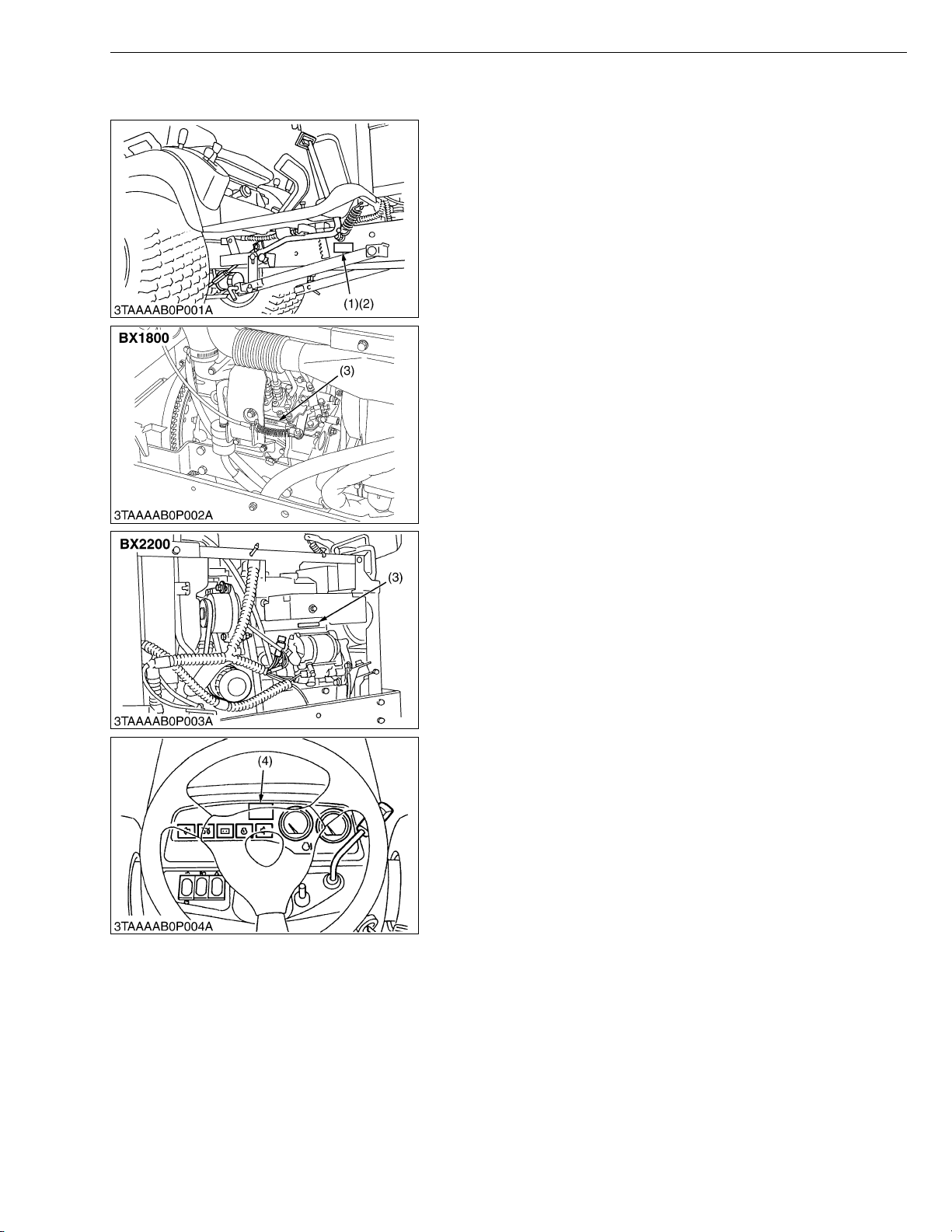

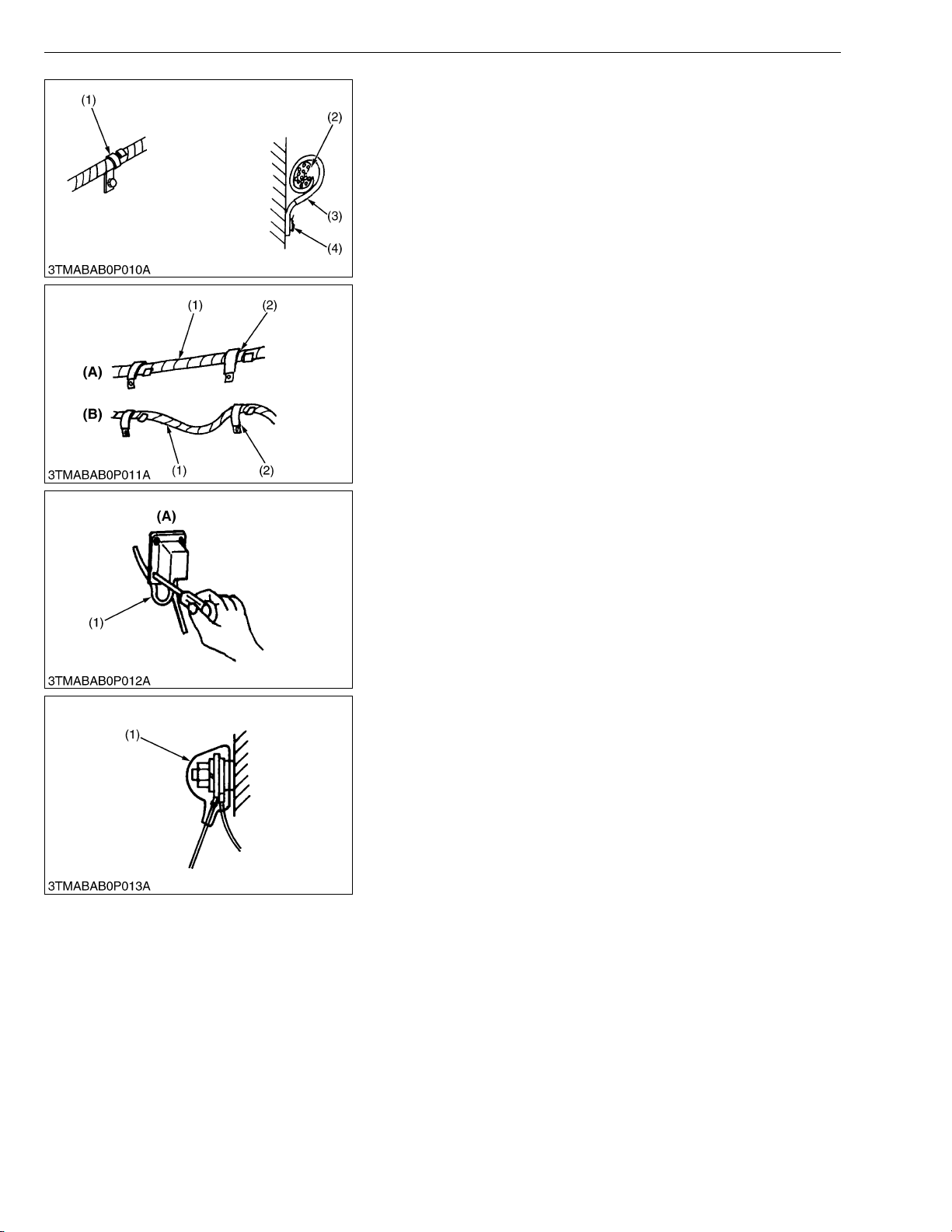

1. TRACTOR IDENTIFICATION

When contacting your loca l KUBOTA distr ibutor, alway s specify

engine serial number, tractor serial number and hour meter reading.

(1) Tractor Identification Plate

(2) Tractor Serial Number

G GENERAL

(3) Engine Serial Number

(4) Hour Meter

W1010590

G-1

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

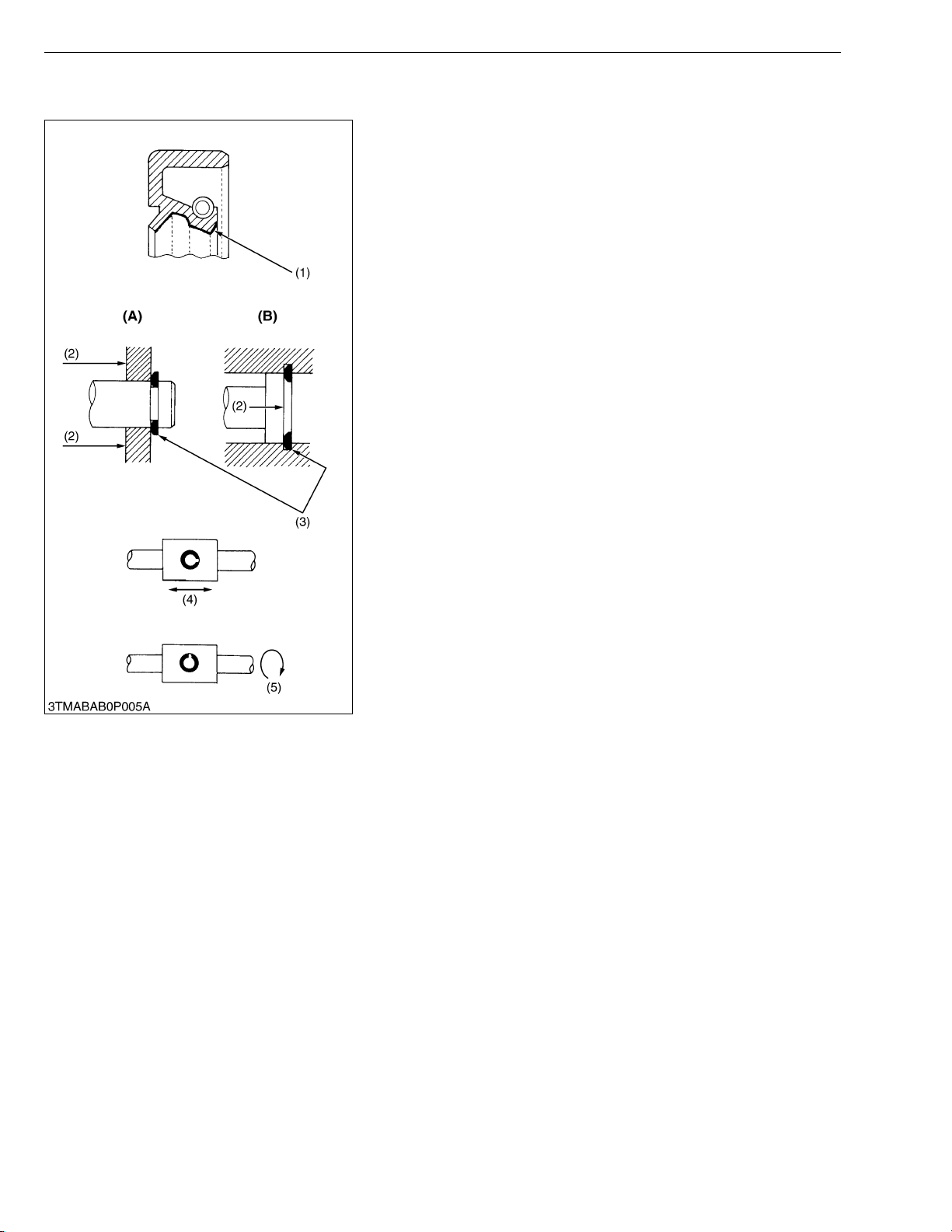

2. GENERAL PRECAUTIONS

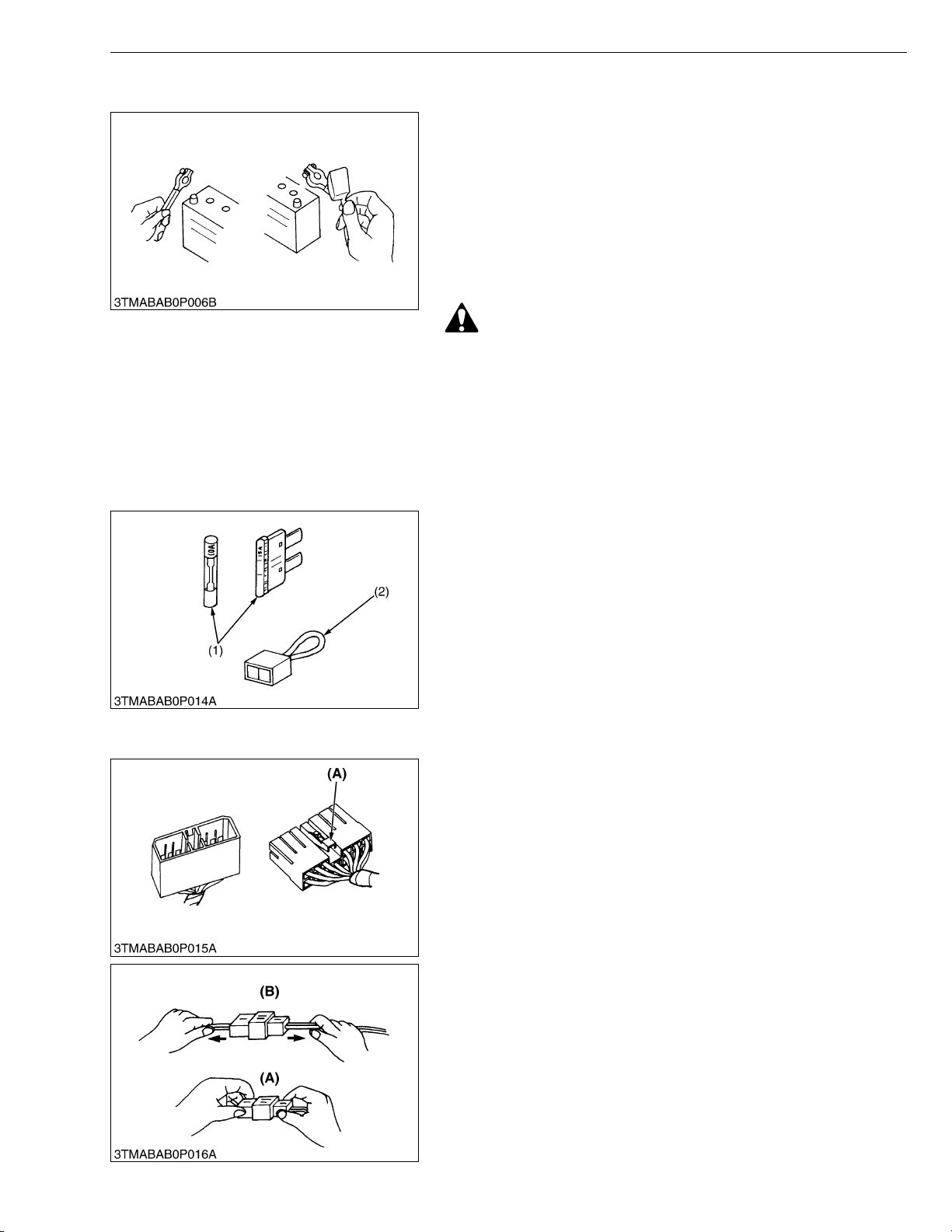

• During disa ssembly, ca refully ar range removed parts in a cle an

area to prevent confusion later. Bolts and nuts should be

installed in their original position to prevent reassembly errors.

• When special tools are requi red, use KUBOT A genuine speci al

tools. Special tools which are not frequently used should be

made according to the drawings provided.

• Before disassembling or servicing electrical wires, always

disconnect the ground cable from the battery first.

• Remove oil and dirt from parts before measuring.

• Use only KUBOTA genuine parts for parts replacement to

maintain tractor performance and to assure safety.

• Gaskets and O-rings must be replaced during reassembly.

Apply grease to new O-rings or oil seals before assembling.

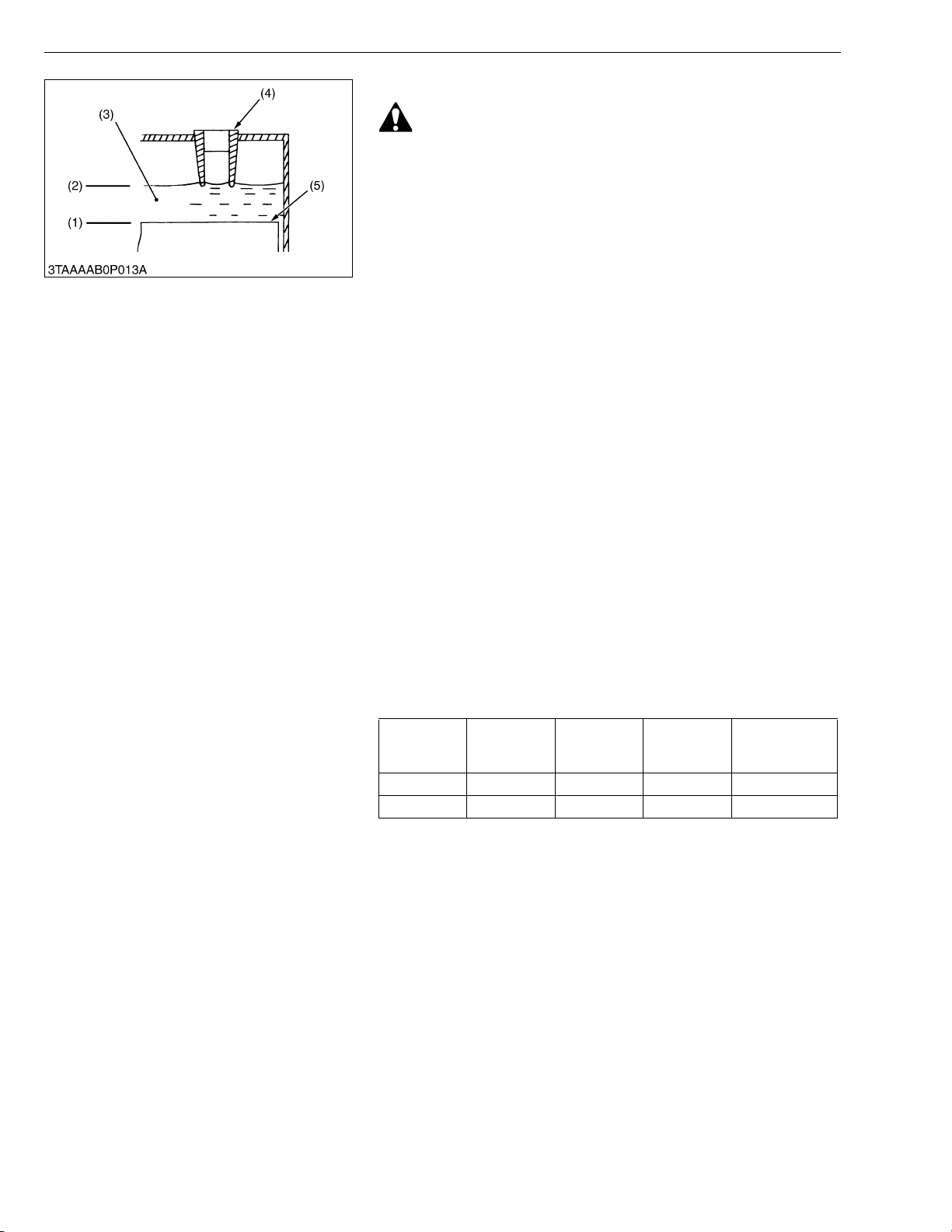

See the figure left side.

• When reassem bling external snap rings or inte rnal snap rings,

they must be positioned so that sharp edge faces against the

direction from which a force is applied. See the figure left side.

• When insert ing spring pins, their splits must face the direction

from which a force is applied. See the figure left side.

• To prevent dam age to the hydraulic s ystem, use only sp ecified

fluid or equivalent.

(1) Grease

(2) F orce

(3) S harp Edge

(4) Axial Force

(5) Rotating Movement

G GENERAL

(A) External Snap Ring

(B) Internal Snap Ring

W10109040

G-2

BX1800 · BX2200, WSM

IMPORTANT■

KiSC issued 07, 2006 A

G GENERAL

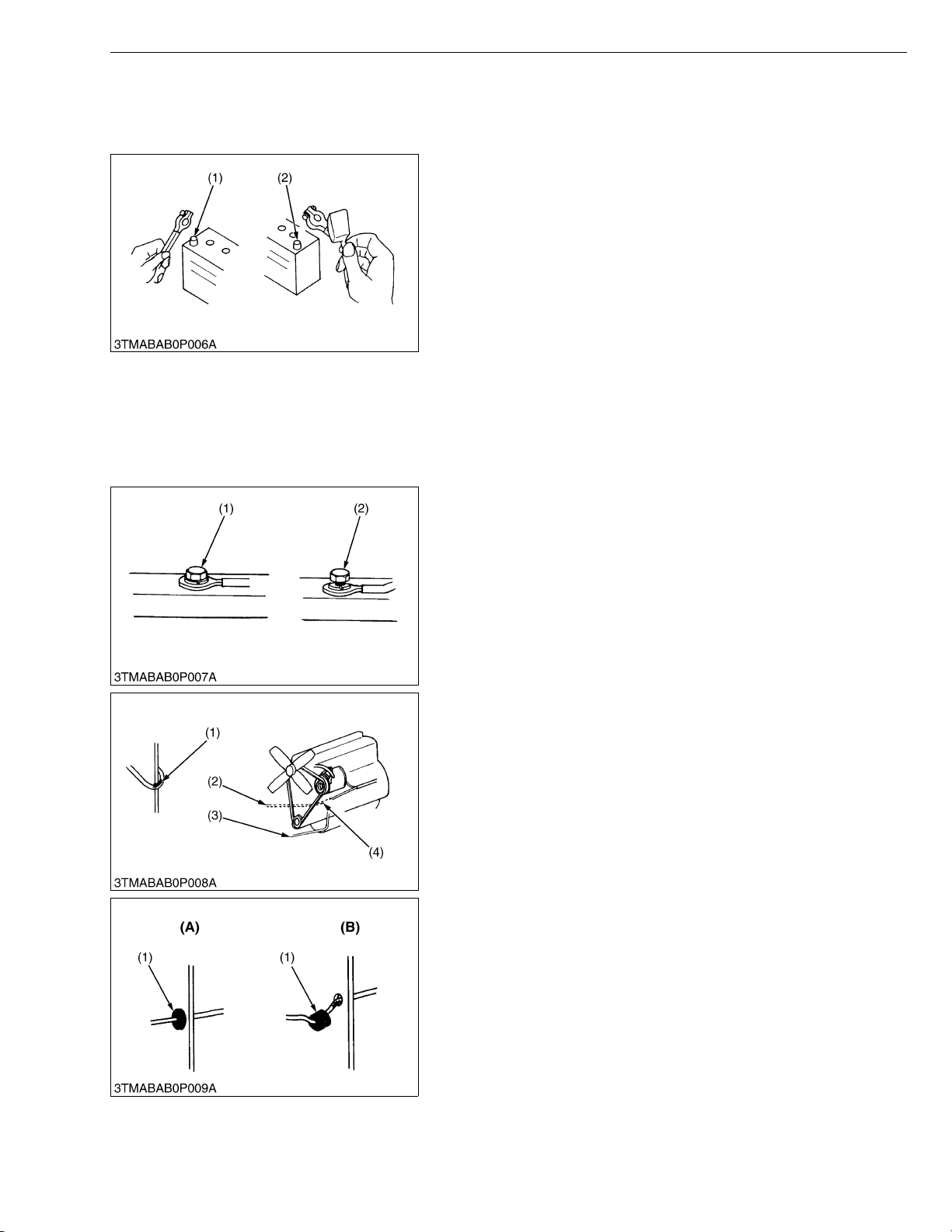

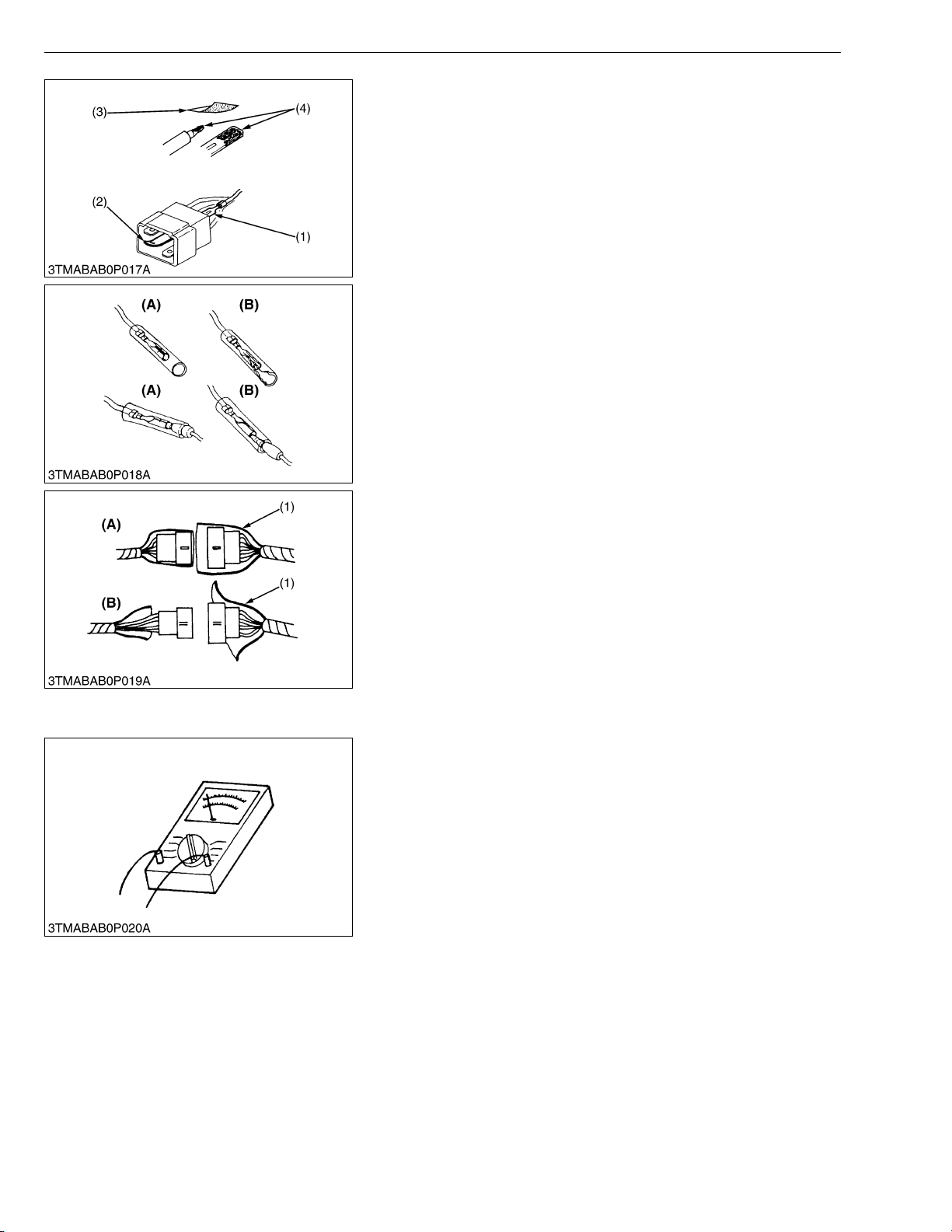

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS

AND WIRING

To ensure safety and prevent damage to the machine and

surrounding equipm ent, heed the following pr ecautions in handling

electrical parts and wiring.

• Check electrical wiring for damage and loosened

connection every year. To this end, educate the customer to

do his or her own check and at the s ame time recommend

the dealer to perform periodic check for a fee.

• Do not attempt to modify or remodel any electrical parts and

wiring.

• When removing th e ba tter y cab le s, dis co nn ect t he n egat ive

cable first. When in stalling the b attery cables, c onnect the

positive cable first.

(1) Negative Terminal (2) Positive Terminal

W10111140

[1] WIRING

• Securely t ighten wiring terminals.

(1) Correct

(Securely Tighten)

(2) Incorrect

(Loosening Leads to Faulty Contact)

W10112160

• Do not let wiring contact dangerous part.

(1) Dangerous Part

(2) Wiring (Incorrect)

(3) Wiring (Correct)

(4) Dangerous Part

• Securely insert grommet.

(1) Grommet (A) Correct

(B) Incorrect

W10113130

W10113880

G-3

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

• Securely clamp, being careful not to damage wiring.

(1) Clamp

• Wind Clamp Spirally

(2) Wire Harness

(3) Clam p

(4) Welding Dent

W10114580

• Clamp wiring so that there is no twist, unnecessary sag, or

excessive tension, except for movable part, where sag be

required.

(1) Wiring

(2) Clamp

(A) Correct

(B) Incorrect

W10115870

• In installing a part, take care not to get wiring caught by it.

(1) Wiring (A) Incorrect

W10116700

• After installing wiring, check protection of terminals and clamped

condition of wiring, only connect battery.

(1) Cover

• Securely Install Cover

W10117350

G-4

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

[2] BATTERY

[3] FUSE

G GENERAL

• Take care not to confuse positive and negative terminal posts.

• When removing b attery cables, disconnect negative cable first.

When installing battery cables, check for polarity and connect

positive cable first.

• Do not install a ny battery with capacity other than is specified

(Ah).

• After connecting cables to battery terminal posts, apply high

temperature grease to them a nd sec urely in stall t erminal covers

on them.

• Do not allow dirt and dust to collect on battery.

CAUTION

• Take care not to let battery liquid spill on your skin and

clothes. If contaminated, wash it off with water immediately.

• Before recharging the battery, remove it from the machine.

• Before recharging, remove cell caps.

• Do recharging in a well- ventilated place where there is no

open flame nearby, as hydrogen gas and oxygen are formed.

W10118160

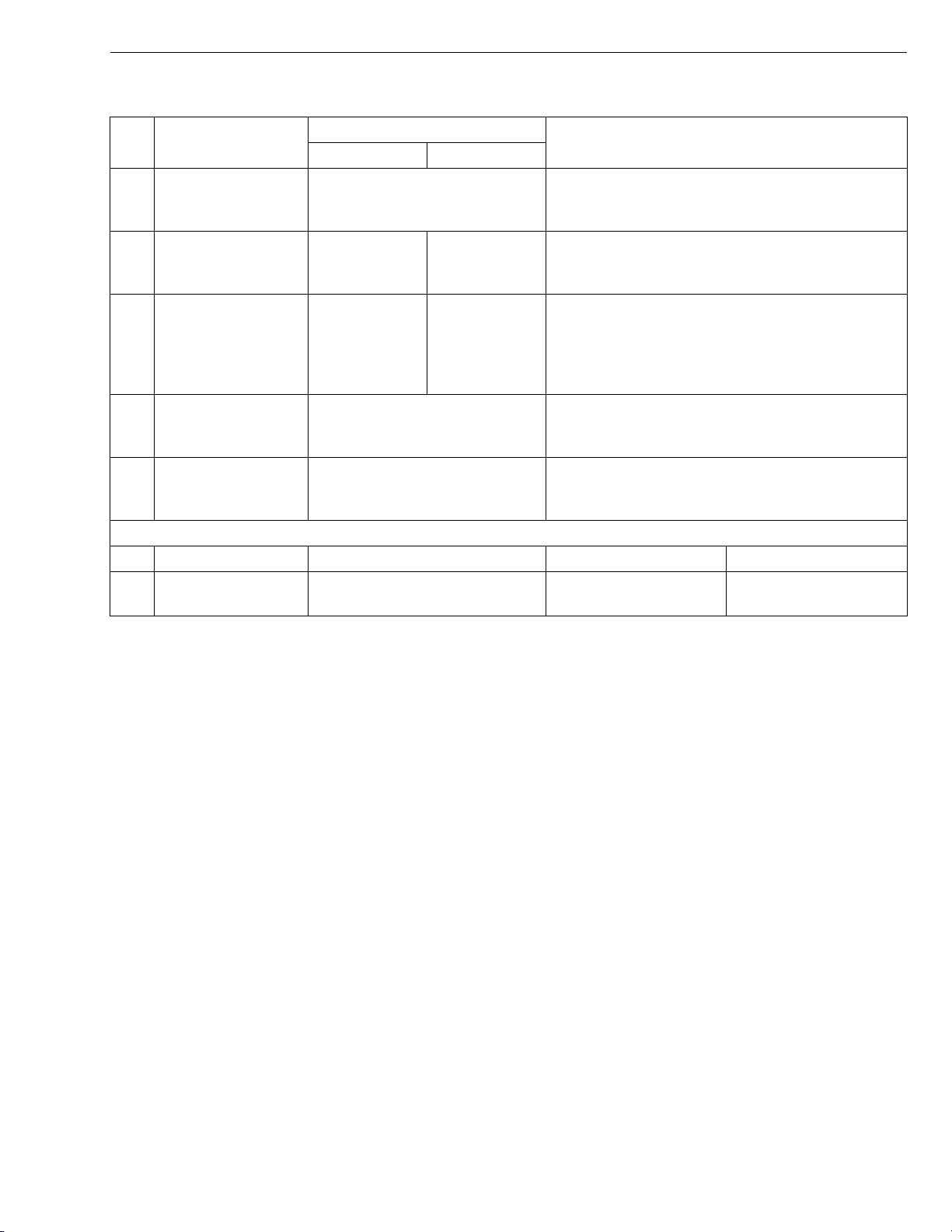

[4] CONNECTOR

• Use fuses with specified capacity.

Neither too large or small capacity fuse is acceptable.

• Never use steel or copper wire in place of fuse.

• Do not install working light, radio set, etc. on machine which is not

provided with reserve power supply.

• Do not install accessories if fuse capacity of reserve power

supply is exceeded.

(1) Fuse (2) Fusible Link

W10120920

• For connector with lock, push lock to separate.

(A) Push

W10122110

• In separating connectors, do not pull wire harnesses.

• Hold connector bodies to separate.

(A) Correct (B) Incorrect

W10122720

G-5

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

• Use sandpaper to remove rust from terminals.

• Repair deformed terminal. Make certain there is no terminal

being exposed or displaced.

(1) Exposed Terminal

(2) Bend Terminal

(3) Sandpaper

(4) Rust

W10123460

• Make certain that there is no female connector being too open.

(A) Correct (B) Incorrect

W10124300

• Make certain plastic cover is large enough to cover whole

connector.

(1) Cover (A) Correct

[5] HANDLING OF CIRCUIT TESTER

• Use tester correctly following manual provided with tester.

• Check for polarity and range .

(B) Incorrect

W10125190

W10126840

G-6

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

4. LUBRICANTS, FUEL AND COOLANT

G GENERAL

No. Place

1 Fuel tank

Cooling system

2

with recovery tank

3 Engine crankcase

4 Transmission case

5 Front axle case

No. Place No. of greasing point Capacity Type of grease

6 Battery terminal 2 Moderate amount

* KUBOTA original transmission hydraulic fluid.

BX1800 BX2200

3.06 U.S.qts.

2.55 Imp.qts.

2.01 U.S.qts.

1.67 Imp.qts.

Capacity

5.5 U.S.gals.

4.6 Imp.gals.

2.9 L

1.9 L

2.7 U.S.gals.

2.2 Imp.gals.

4.97 U.S.qts.

4.14 Imp.qts.

21.0 L

3.70 U.S.qts.

3.08 Imp.qts.

2.64 U.S.qts.

2.20 Imp.qts.

10.1 L

4.7 L

3.5 L

2.5 L

Greasing

Lubricants, fuel and coolant

No. 2-D diesel fuel

No. 1-D diesel fuel if temperature is below −10 °C

(14 °F)

Fresh clean water with anti-freeze

Engine oil : API Service CC or CD

Below 0 °C (32 °F) : SAE10W, 10W-30 or 10W-40

0 to 25 °C (32 to 77 °F): SAE20, 10W-30 or

10W-40

Above 25 °C (77 °F): SAE30, 10W-30 or 10W-40

KUBOTA SUPER UDT fluid*

KUBOTA SUPER UDT fluid* or SAE80, 90 gear

oil

Multipurpose type

grease

G-7

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

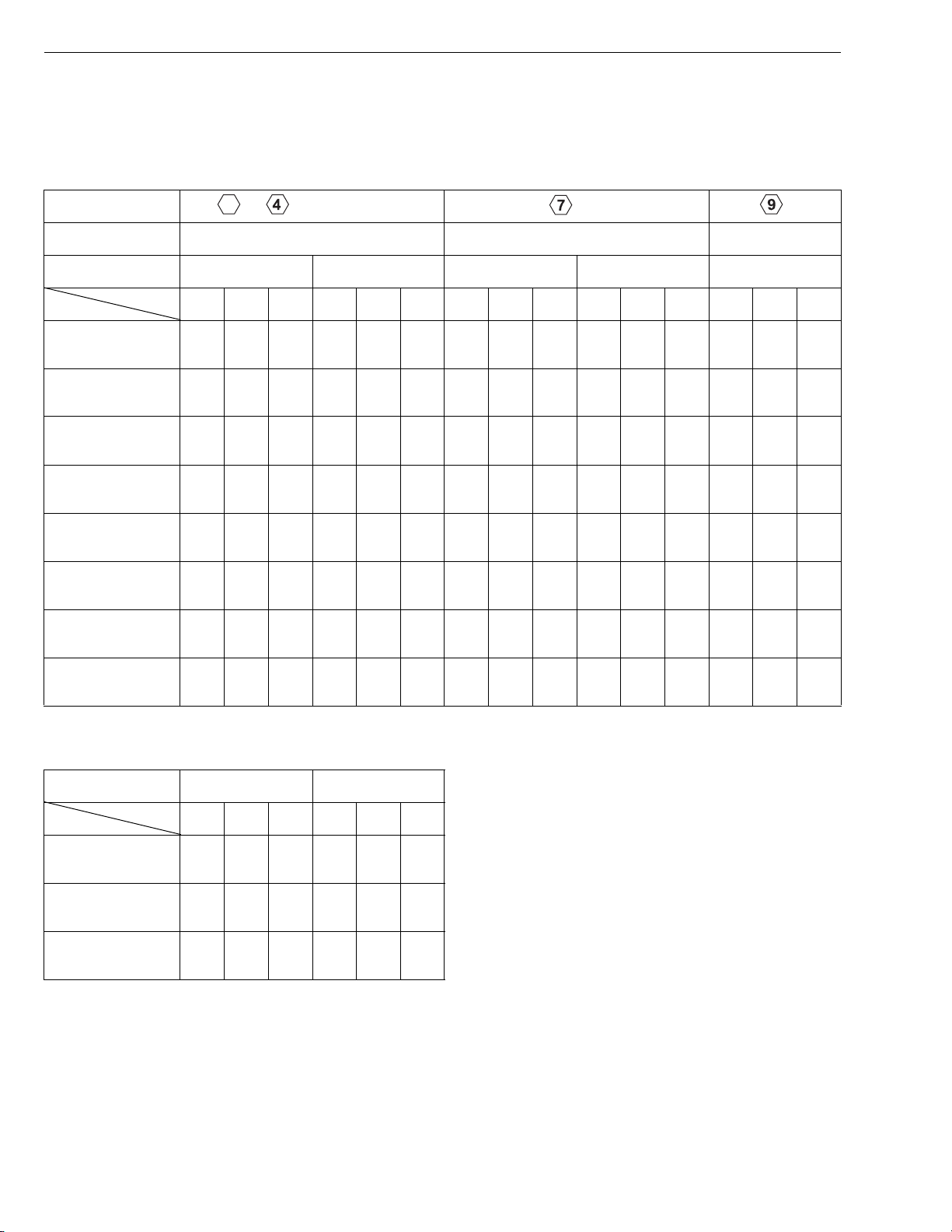

5. TIGHTENING TORQUES

[1] GENERAL USE SCREWS, BOLTS AND NUTS

Screws, bolts and nuts whos e tightening torques are not spec ified i n this W orkshop Ma nual sho uld be tig htened

according to the table below.

Indication on top of

bolt

Material of bolt SS400, S20C S43C, S48C

Material of opponent

part

Unit

Diameter

M6

(6 mm, 0.24 in.)

M8

(8 mm, 0.31 in.)

M10

(10 mm, 0.39 in.)

M12

(12 mm, 0.47 in.)

M14

(14 mm, 0.55 in.)

M16

(16 mm, 0.63 in.)

M18

(18 mm, 0.71 in.)

M20

(20 mm, 0.79 in.)

No-grade or 4T 7T 9T

SCr435,

SCM435

Ordinariness Aluminum Ordinariness Aluminum Ordinariness

N·m kgf·m ft-lbs N·m kgf·m ft-lbs N·m kgf·m ft-lbs N·m kgf·m ft-lbs N·m kgf·m ft-lbs

7.85

0.80

5.79

7.85

0.80

5.79

9.81

1.00

7.24

7.85

0.80

5.79

12.3

to

9.31

17.7

to

20.5

39.3

to

45.1

62.8

to

72.5

108

to

125

167

to

191

246

to

284

334

to

392

to

0.95

1.8

to

2.1

4.0

to

4.6

6.4

to

7.4

11.0

to

12.8

17.0

to

19.5

25.0

to

29.0

34.0

to

40.0

to

6.87

13.1

to

15.1

29.0

to

33.2

46.3

to

53.5

79.6

to

92.5

123

to

141

181

to

209

246

to

289

to

to

to

8.82

0.90

6.50

16.7

19.6

31.4

34.3

1.7

12.3

to

to

2.0

3.2

to

3.5

–––

–––

–––

–––

–––

to

14.4

23.2

to

to

25.3

to

11.2

23.6

to

27.4

48.1

to

55.8

77.5

to

90.2

124

to

147

197

to

225

275

to

318

368

to

431

to

1.15

2.4

to

2.8

4.9

to

5.7

7.9

to

9.2

12.6

to

15.0

20.0

to

23.0

28.0

to

32.5

37.5

to

44.0

to

8.31

17.4

to

20.2

35.5

to

41.2

57.2

to

66.5

91.2

to

108

145

to

166

203

to

235

272

to

318

to

to

to

8.82

0.90

6.50

17.7

20.5

39.3

44.1

62.8

72.5

1.8

13.1

to

to

2.1

4.0

to

4.5

6.4

to

7.4

–––

–––

–––

–––

to

15.1

29.0

to

to

32.5

46.3

to

to

53.5

to

14.2

29.5

to

34.3

60.9

to

70.6

103

to

117

167

to

196

260

to

304

344

to

402

491

to

568

1.25

to

1.45

3.0

to

3.5

6.2

to

7.2

10.5

to

12.0

17.0

to

20.0

26.5

to

31.0

35.0

to

41.0

50.0

to

58.0

W1034542

9.05

to

10.4

21.7

to

25.3

44.9

to

52.0

76.0

to

86.7

123

to

144

192

to

224

254

to

296

362

to

419

[2] STUD BOLTS

Material of opponent

part

Unit

Diameter

M8

(8 mm, 0.31 in.)

M10

(10 mm, 0.39 in.)

M12

(12 mm, 0.47 in.)

Ordinariness Aluminum

N·m kgf·m ft-lbs N·m kgf·m ft-lbs

11.8

to

15.6

24.6

to

31.3

29.5

to

49.0

1.2

to

1.6

2.5

to

3.2

3.0

to

5.0

8.68

8.82

to

11.5

18.1

23.1

21.7

36.1

to

11.8

19.7

to

to

25.4

to

31.4 3.2 23.1

0.90

to

1.2

2.0

to

2.6

6.51

to

8.67

14.5

to

18.8

W10481390

G-8

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

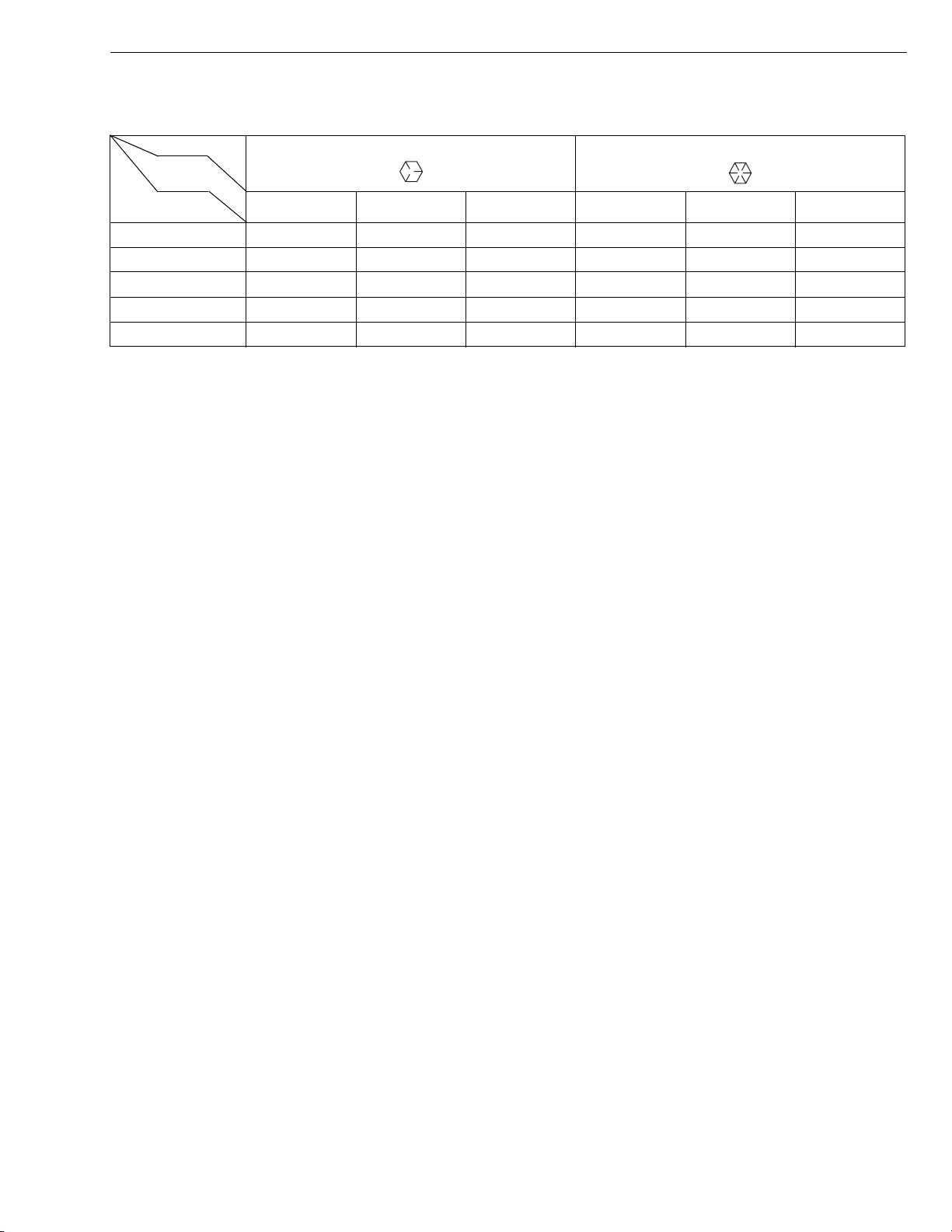

G GENERAL

[3] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH UNC OR

UNF THREADS

Grade

Unit

Nominal Diameter

5/16 23.1 to 27.8 2.35 to 2.84 17.0 to 20.5 32.5 to 39.3 3.31 to 4.01 24.0 to 29.0

3/8 47.5 to 57.0 4.84 to 5.82 35.0 to 42.0 61.0 to 73.2 6.22 to 7.47 45.0 to 54.0

1/2 108.5 to 130.2 11.07 to 13.29 80.0 to 96.0 149.2 to 179.0 15.22 to 18.27 110.0 to 132.0

9/16 149.2 to 179.0 15.22 to 18.27 110.0 to 132.0 217.0 to 260.4 22.14 to 26.57 160.0 to 192.0

5/8 203.4 to 244.1 20.75 to 24.91 150.0 to 180.0 298.3 to 358.0 30.44 to 36.53 220.0 to 264.0

SAE GR.5 SAE GR.8

N·m kgf·m ft-lbs N·m kgf·m ft-lbs

W1022485

G-9

BX1800 · BX2200, WSM

IMPORTANT■

KiSC issued 07, 2006 A

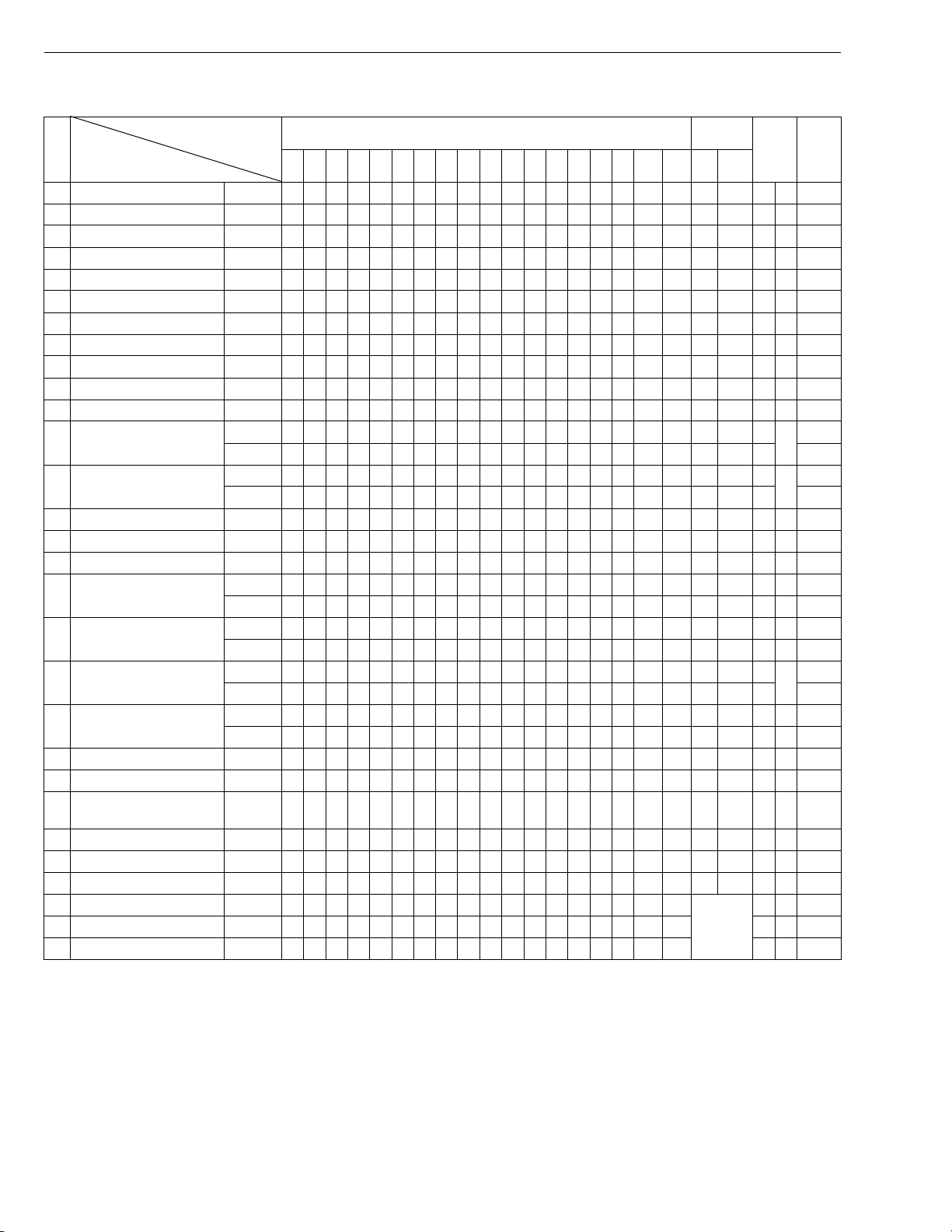

6. MAINTENANCE CHECK LIST

G GENERAL

Period

No.

Item

1 Engine oil C hange ★✩ ✩ ✩ ✩

2 Engine oil filter Replace ★✩ ✩ ✩ ✩ G-12

3 T ransmission oil filter Replace ★✩ ✩ G-13

4 T ransmission fluid Change ★✩ ✩ G-13

5 T ransmission strainer Clean ✩✩ G-22

6 Front axle case oil Change ✩✩ G-22

7 Front axle pivot Adjust ✩✩ G-22

8 Engine start system Check ✩✩✩✩

9 Greasing – ✩✩✩✩

10 Wheel bolt torque Check ✩✩✩✩

11 Battery condition Check ✩✩✩✩

12 Air cleaner element

13 Fuel filter element

14 Fan belt Adjust ✩✩✩✩

15 HST neutral spring Adjust ✩✩✩✩

16 Brake Adjust ✩✩✩✩

17 Radiator hose and clamp

18 Power steering oil line

19 Fuel line

20 Intake air line

21 Toe-in Adjust ✩✩✩✩ G-21

22 Engine valve clearance Adjust ✩ 1-S22

Fuel injection nozzle

23

injection pressure

24 Injection pump Check ✩ @1-S30

25 Cooling system Flush ✩ G-24

26 Coolant Change ✩

27 Fuel system Bleed

28 Fuse Replace G-26

29 Light bulb Replace G-26

Clean ✩✩✩✩

Replace ✩ *2 G-17

Check ✩✩✩✩

Replace

Check ✩✩✩✩ G-20

Replace ✩ G-20

Check ✩✩✩✩ G-20

Replace ✩ G-20

Check ✩✩✩✩

Replace ✩ G-18

Check ✩✩✩✩ G-21

Replace ✩ *3 G-21

Check ✩✩ @1-S20

50 10015020025030035040045050055060065070075080015003000

Indication on hour meter

✩

✩

✩

✩

✩

✩

✩

✩✩✩✩✩✩✩

✩

✩

✩✩✩✩✩✩✩

✩

✩

✩✩✩✩✩✩✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩ G-12

✩ G-14

✩ G-14

✩ G-15

✩

✩ *4 G-15

✩

✩ *1

✩

✩

✩

✩ G-18

✩

✩ G-19

✩

✩ G-19

✩

✩

After

purchase

1

year2 years

Service as

required

Impor-

tant

@

@

@

Refer-

ence

page

G-17

G-18

G-18

G-18

G-24

G-25

• The jobs indicated by ★ must be done after the first 50 hours of operation.

• *1 : Air cleaner should be cleaned more often in dusty conditions than in normal conditions.

• *2 : Every year or every 6 times of cleaning.

• *3 : Replace only if necessary.

• *4 : When the battery is used for less than 100 hours per year, check the fluid level annually.

• The items listed above (@ marked) are registered as emission related critical parts by KUBOTA in the U.S.EPA nonroad emission

regulation. As the engine owner, you are responsible for the performance of the requi red maintenance on the en gine according t o

the above instruction.

Please see the Warranty Statement in detail.

W1035769

G-10

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

7. CHECK AND MAINTENANCE

CAUTION

• Be sure to check and service the tractor on a flat place with engine shut off, the parking brake on and chock

the wheels.

[1] DAILY CHECK

To prevent trouble from occurring, it is important to kno w the condition of the tractor. Che ck the following items

before starting.

Checking

• Check areas where previous trouble was experienced.

• Walk around the tractor.

1. Check the tire press ure, and check for wear and damage.

2. Check for oil and water leaks.

3. Check the engine oil lev el.

4. Check the transmi ssio n flui d level.

5. Check the coola nt lev el .

6. Check the condition of seat belt and ROPS attaching hardware.

7. Check and clean the radiator screen and grill.

8. Check the bolts and nuts of tires are tight.

9. Check the number plate or SMV emblem for damage and cleaner replace as necessary if equipped.

10.Care of danger, warning and caution labels.

11.Clean around the exhaust manifold and the muffler of the engine.

• While sitting in the operator’s seat.

1. Check the HST pedal and brake pedals.

2. Check the parking brake.

3. Check the steering wheel.

• Turning the key switch.

1. Check the performance of the easy checker lights.

2. Check head lights, tail lights and hazard lights. Clean if necessary.

3. Check the performance of the meters and gauges.

• Starting the engine.

1. Check to see that the lights on the Easy Checker go off.

2. Check the color of the exhaust gas.

3. Check the brakes for proper operation.

G-11

BX1800 · BX2200, WSM

■

IMPORTANT■

KiSC issued 07, 2006 A

[2] CHECK POINTS OF INITIAL 50 HOURS

Changing Engine Oil

CAUTION

• Be sure to stop the engine before changing engine oil.

1. Start and warm up the engine for approx. 5 minutes.

2. Place an oil pan underneath the engine.

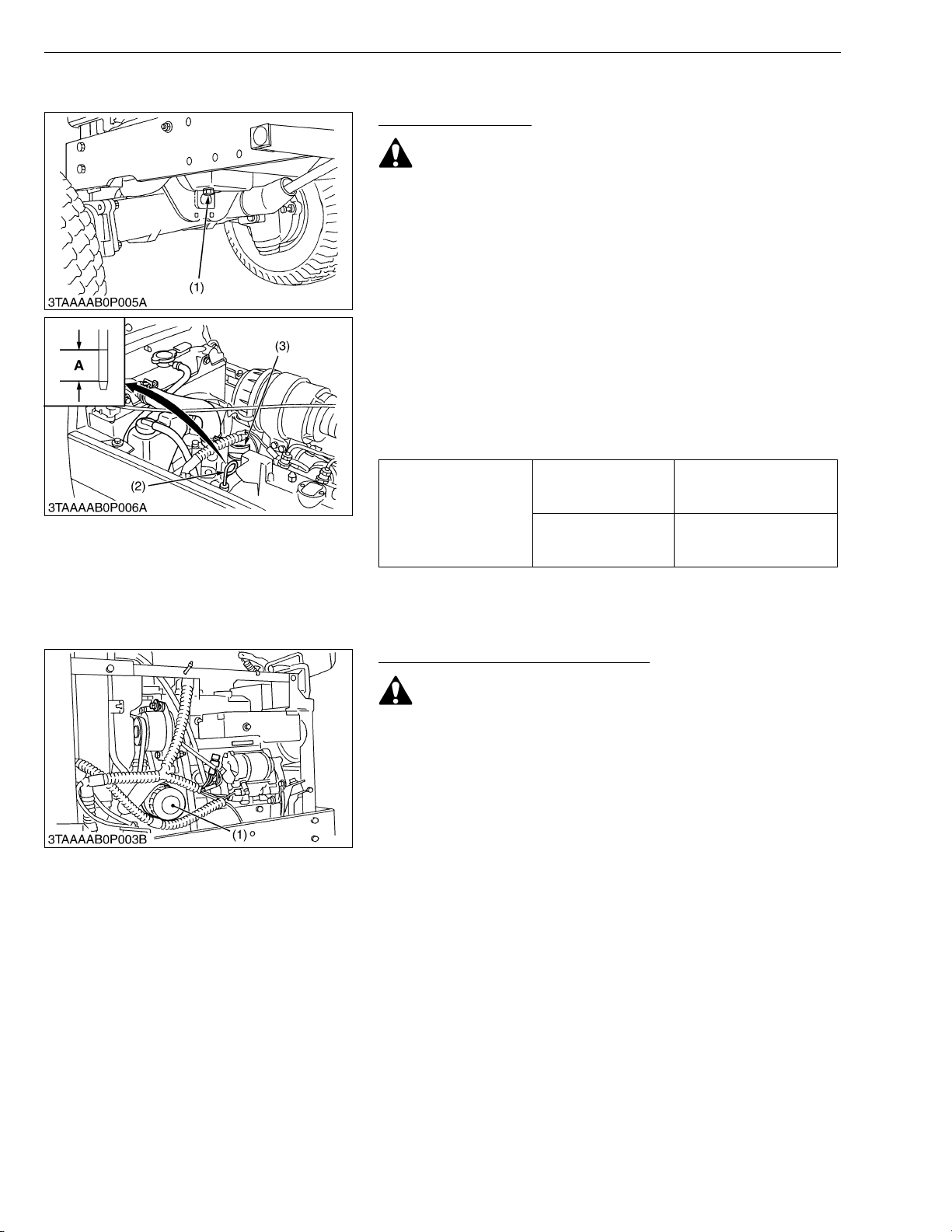

3. To drain the us ed oi l, remov e the d rain plug (1 ) at th e bottom of

the engine and drain the oil completely.

4. Screw in the drain plug (1).

5. Fill new oil up to upper line on the dipstick (2).

IMPORTANT

• When using an oil of different manufacture or viscosity from

the previous one, remove all of the old oil.

• Never mix two different types of oil.

• Use the proper SAE Engine Oil according to ambient

temperatures.

• Refer to “LUBRICANTS, FUEL AND COOLANT”. (See page

G-7.)

Engine oil capacity

BX1800

BX2200

G GENERAL

1.9 L

2.01 U.S.qts.

1.67 Imp.qts.

2.5 L

2.64 U.S.qts.

2.20 Imp.qts.

(1) Drain Plug

(2) Dipstick

(3) Oil Inlet

A : Oil level is acceptable within this

range.

W1014065

Replacing Engine Oil Filter Cartridge

CAUTION

• Be sure to stop the engine before changing oil filter

cartridge.

1. Remove the oil filter cartridge with the filter wrench.

2. Apply a slight coat of oil onto the cartridge gasket.

3. To install the new cartridge, screw it in by hand. Over tightening

may cause deformation of rubber gasket.

4. After the new cartridge has been replaced, the engine oil

normally decrease a little. Thus see that the engine oil does not

leak through the seal and be sure to read the oil level on the

dipstick. Then, replenish the engine oil up to the specified level.

• To prevent serious damage to the engine, replacement

element must be highly efficient. Use only a KUBOTA

genuine filter or its equivalent.

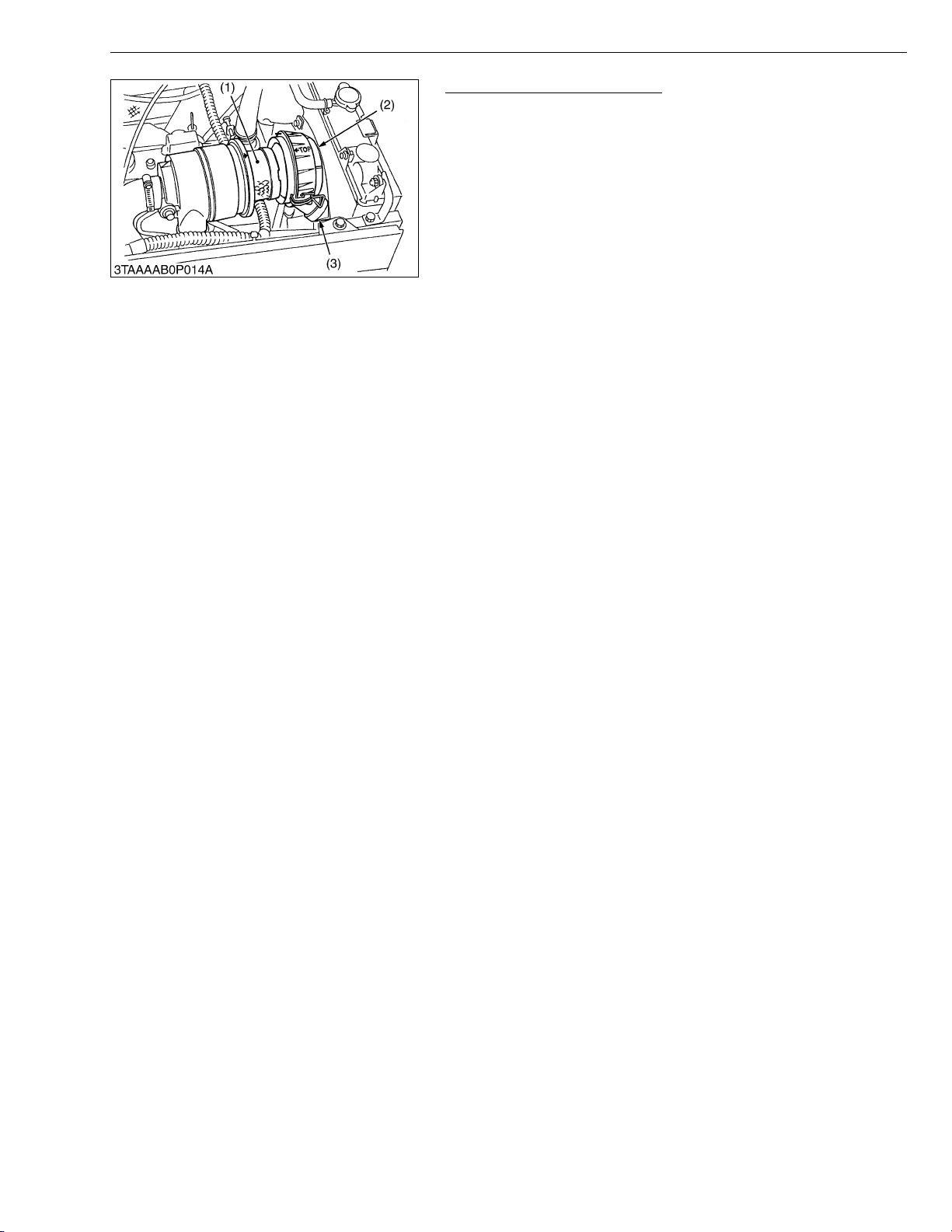

(1) Engine Oil Filter Cartridge

W1014316

G-12

BX1800 · BX2200, WSM

■

IMPORTANT■

KiSC issued 07, 2006 A

G GENERAL

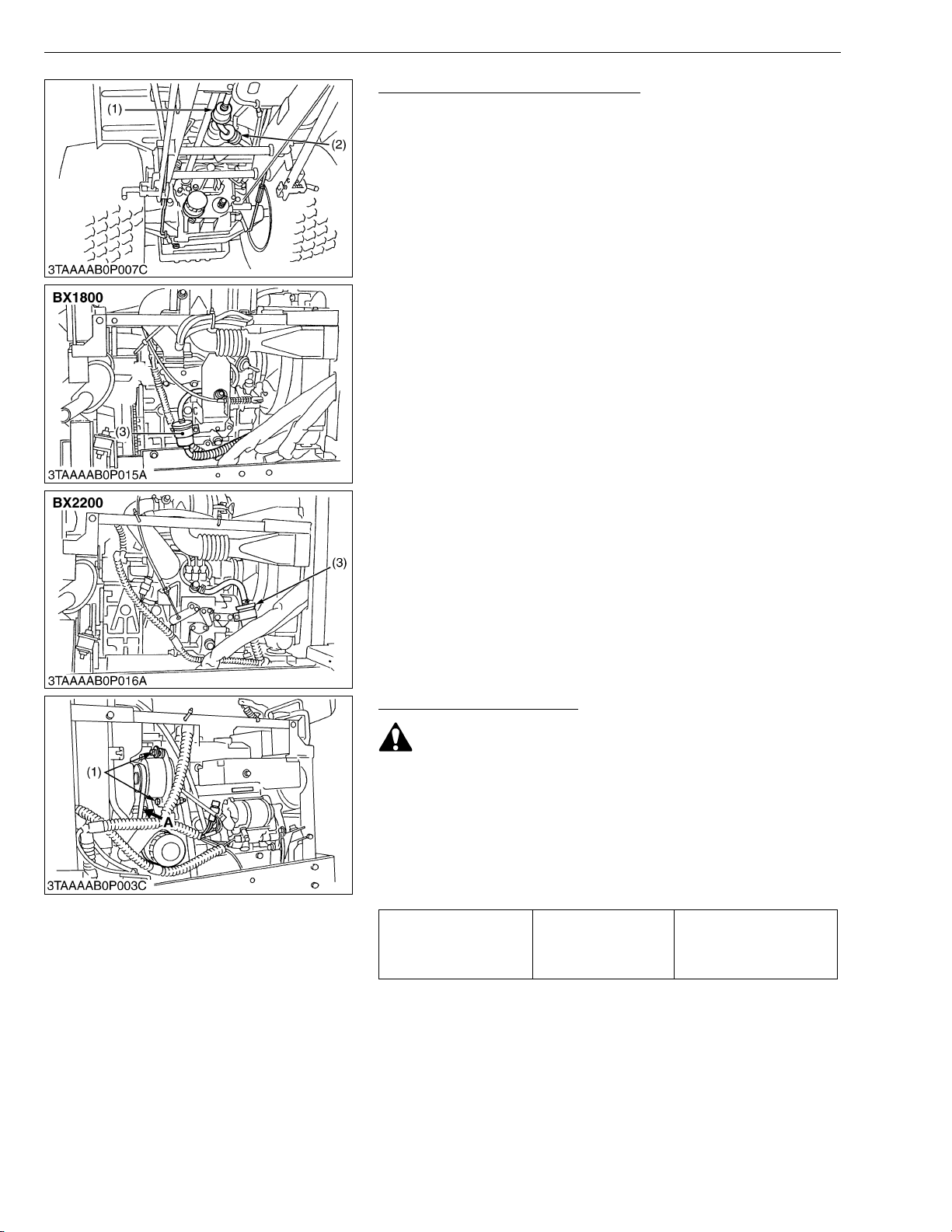

Replacing Transmission Oil Filter Cartridge

CAUTION

• Be sure to stop the engine before changing the oil filters.

1. Remove the oil filter cartridge by using a filter wrench.

2. Apply a slight coat of oil onto the cartridge gasket.

3. To install the new cartridge, screw it in by hand. Over tightening

may cause deformation of rubber gasket.

4. After the new cartridge has been replaced, the transmission fluid

level will normally decrease slightly. Make sure that the

transmission fluid does not leak through the seal. Check the fluid

level.

IMPORTANT

• To prevent serious damage to the hydraulic system. Use

only a genuine KUBOTA filter or its equivalents.

(1) Transmission Oil Filter Cartridge

W1014458

Changing Transmission Fluid

CAUTION

• Be sure to s top the engine be fore ch anging t he transm ission

fluid.

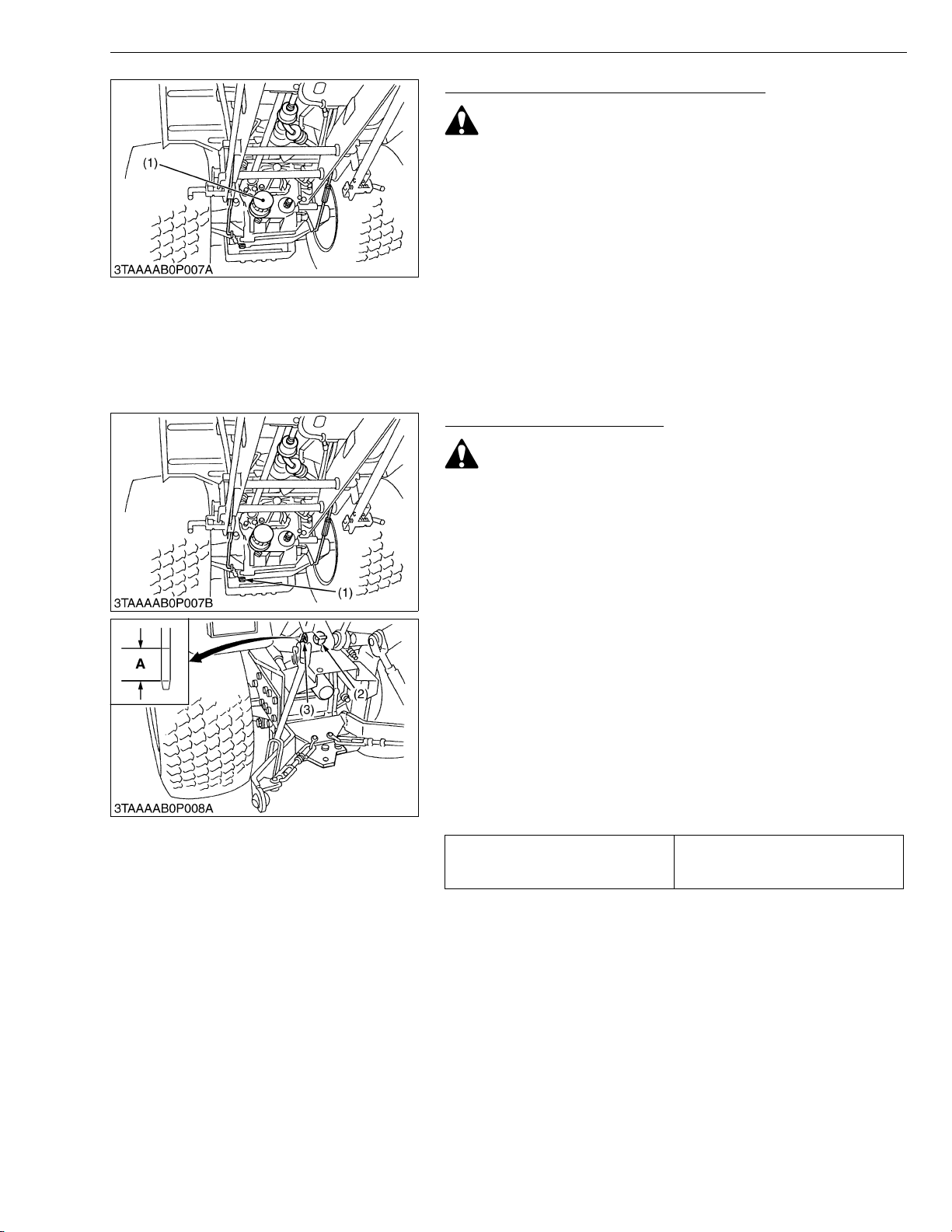

1. Place an oil pan under the tractor.

2. Remove the drain plugs (1) at the bottom of the transmission

case and drain the oil completely.

3. After draining, screw in the drain plug.

4. Fill new oil from filling port after removing the filling plug (2) up to

the upper notch on the dipstick.

5. After running the engine for a few minutes, stop it and check the

oil level again, if low, add oil to prescribed level.

• Use only multi-grade transmission oil. Use of other oils may

damage the transmission or hydraulic system.

Refer to “LUBRICANTS, FUEL AND COOLANT”. (See page

G-7.)

• Never work the tractor immediately after changing the

transmission oil. Keeping the engine at medium speed for a

few minutes to prevents damage to the transmission.

• Do not mix different blands oil together.

Transmission fluid capacity

(1) Drain Plug

(2) Filling Plug

(3) Dipstick

10.1 L

2.7 U.S.gals.

2.2 Imp.gals.

A : Oil level is acceptable within this

range.

W1014665

G-13

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

[3] CHECK POINTS OF EVERY 50 HOURS

Checking Engine Start System

CAUTION

• Do not allow anyone near the tractor whil e testing.

• If the tractor does not pass the test do not operate the

tractor.

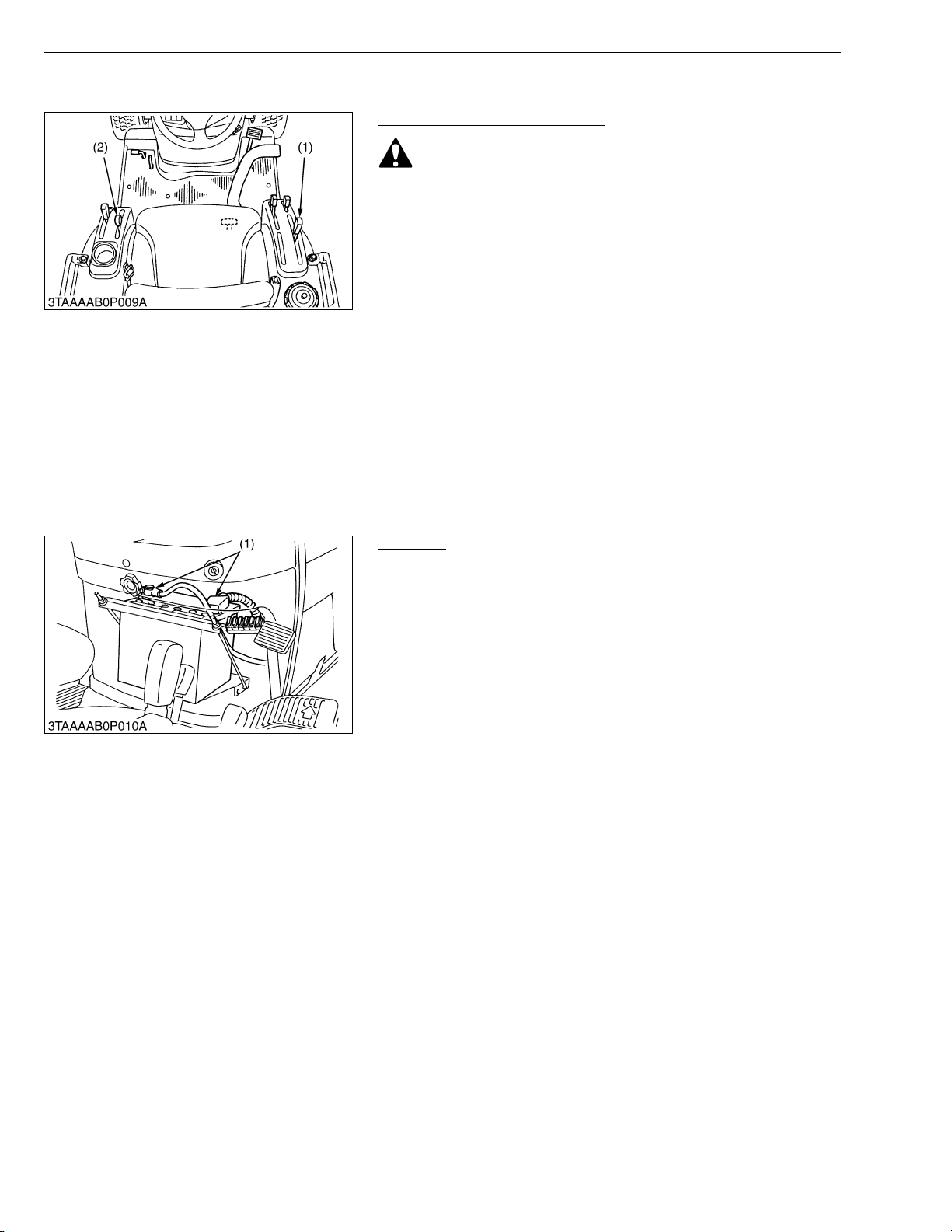

■ Preparation before testing.

1. Sit on operator’s seat.

2. Set the parking brake and stop the engine.

3. Shift the range gear shift lever in “NEUTRAL” position.

4. Shift the PTO clutch lever to “OFF” position.

■ Test 1 : Safety switch on the range gear shift linkage

1. Shift the range gear shift lever to “LOW” or “HIGH” position.

2. Turn the key to “START” position.

3. The engine must not crank.

■ Test 2 : Safety switch on the PTO clutch lever

1. Shift the range gear shift lever to “NEUTRAL” posit ion .

2. Shift the PTO clutch lever to “ON” position.

3. Turn the key to “START” position.

4. The engine must not crank.

(1) Range Gear Shift Lever (2) PTO Clutch Lever

Greasing

1. Apply a small amount of grease to the battery terminals (1).

(1) Battery Terminal

G GENERAL

W1014904

W1015242

G-14

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

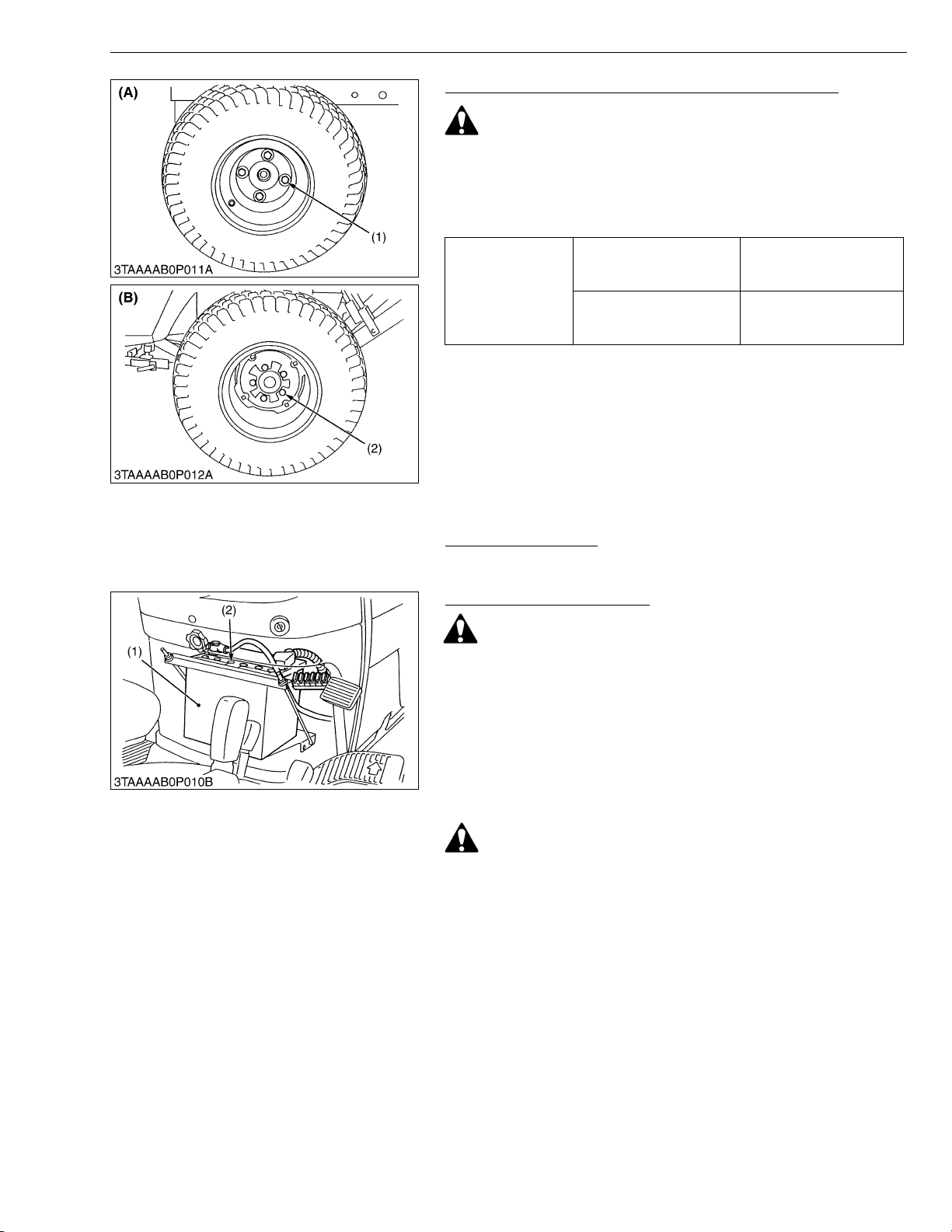

Checking Wheel Mounting Screws Tightening Torque

CAUTION

• Never operate tractor with a loose rim, wheel, or axle.

• Any time screws are loosened, retighten to specified torque.

• Check all screws frequently and keep them tight.

1. Check wheel screws regularly especially when new. If there are

loosened, tighten as follows.

Front wheel mounting

screws

Tightening torque

Rear wheel mounting

screws

149.2 to 179.0 N·m

15.3 to 18.2 kgf·m

110 to 132 ft-lbs

108.5 to 130.2 N·m

11.1 to 13.2 kgf·m

80 to 96 ft-lbs

(1) Front Wheel Mounting Screw

(2) Rear Wheel Mounting Screw

[4] CHECK POINTS OF EVERY 100 HOURS

Changing Engine Oil

1. See page G-12.

Checking Battery Condition

DANGER

To avoid the possibility of battery explosion:

For the refillable type battery, follow the instructions below.

• Do not use or charge the refillable type battery if the fluid

level is below the LOWER (lower limit level) mark.

Otherwise, the battery component parts may prematurely

deteriorate, which ma y shorten the batte ry’s service life or

cause an explosion. Check the fluid level regularly and add

distilled water as required so that the fluid level is between

the UPPER and LOWER levels.

(A) Front

(B) Rear

W1015311

W1015501

CAUTION

• Never remove the vent plugs while the engine is running.

• Keep electrolyte away fr om eyes, h and s and clothe s. If you

are spattered with it, wash it away completely with water

immediately and get medical attention.

• Wear eye protection and rubber gloves when working

around battery.

1. Mishandling the battery shortens the service life and adds to

maintenance costs.

2. The original battery is maintenance free type battery, but need

some servicing.

If the battery is weak, the engine is difficult to start and the lights

become dim. It is important to check the battery periodically.

(1) Battery (2) Vent Plug

W1015551

G-15

BX1800 · BX2200, WSM

KiSC issued 07, 2006 A

G GENERAL

■ Battery Charging

CAUTION

• When the battery is being activated, hydrogen and oxygen

gases in the battery are extremely explosive. Keep open

sparks and flames away from the battery at all times,

especially when charging the battery.

• When charging the battery, ensure the vent caps are

securely in place (if equipped).

• When disconnecting the cable from the battery, start with

the negative terminal first.

When connecting the cable to the battery, start with the

positive terminal first.

• Never check battery charge by placing a metal object across

the posts.

Use a voltmeter or hydrometer.

1. Make sure each e lec trol yte lev el is to the bottom of vent wells, if

necessary add distilled water in a well-ventilated area.

2. The water in the electrolyte evaporates during recharging. Liquid

shortage damage s the battery . Excessiv e liquid s pills over a nd

damages the tractor body.

3. To slow charge the battery, connect the battery positive terminal

to the charger positive terminal and the negative to the negative,

then recharge in the standard fashion.

4. A boost ch arge is only f or emergen cies. It will par tially c harges

the battery at a high rate and in a short time.

When using a boost-charged battery, it is necessary to recharge

the battery as early as possible.

Failure to do this will shorten the battery’s service life.

5. When the specific gravity of electrolyte become betwee n 1.27

and 1.29 charge has completed.

6. When exchanging an old battery into new one, use battery of

equal specification shown in table 1.

Table 1

Reserve

Tractor Type Battery Type Volts (V)

BX1800 26/26R 12 62 435

BX2200 526RA 12 80 535

Capacity

(min.)

Cold Cranking

Amps

■ Direction for Storage

1. When storing the tractor for long periods of time, remove the

battery from tractor, adjust the electrolyte to the proper level and

store in a dry place out of direct sunlight.

2. The battery self-discharges while it is stored.

Recharge it once every three months in hot se asons and once

every six months in cold seasons.

(1) Lowest Level

(2) Highest Level

(2) Electrolyte

(4) Vent Well

(5) Separator

W1019057

G-16

BX1800 · BX2200, WSM

IMPORTANT■

KiSC issued 07, 2006 A

G GENERAL

Cleaning Air Cleaner Element

1. Remove the air cleaner cover (2) and element (1).

2. Clean the element if:

- When dry dust adheres to the element, blow compressed air

from the inside, turn ing the element. Pres su re o f c omp r ess ed

2

air must be under 205 kPa (2.1 kgf/cm

, 30 psi).

- When carbon or oil adheres to the element, soak th e element

in detergent for 15 minutes then wash it several times in water,

rinse with clean water and dry it naturally. After element is fully

dried, inspect inside of the element with a light and check if it is

damaged or not.

3. Replace the element (1) once a year or after every six ti mes of

cleaning, whichever comes first.

• The air cleaner uses a dry element, never apply oil.

• Do not run the engine with filter element removed.

• Be sure to refit the dust cup with the arrow ↑ upright. If the

dust cup is improperly fitted, evacuator valve will not

function and dust will adhere to the element.

■ Evacuator Valve

Open the evacuator valve once a week under ordinary conditions

or daily when used in a dusty place to get rid of large particles of dust

and dirt.

(1) Element

(2) Cover

(3) Evacua tor Valve

W1017166

G-17

BX1800 · BX2200, WSM

IMPORTANT■

NOTE■

KiSC issued 07, 2006 A

G GENERAL

Checking Fuel Lines and Fuel Filter

1. The fuel line is made of rubber an d ages regardless of service

period.

2. After inspection, if the fuel line and clamps are found damaged or

deteriorated, replace them.

3. Check fuel filter, if it is clogged by debris or contaminated by

water, replace it.

• When the fuel line is disconnected for maintenance or

repair, plug both ends of the fuel line with a clean plug of

suitable size to prevent dust and dirt from entering.

Particular care must be taken not to admit dust a nd dirt into

the fuel system. Entrance of dust and dirt causes

malfunction of the fuel pump.

• If the fuel line is removed, be sure to properly bleed the fuel

system (see page G-25).

(1) Fuel Pump

(2) Fuel Filter

(3) Fuel Filter

W1017546

Checking Fan Belt Tension

CAUTION

• Be sure to stop engine before checking belt tension.

1. Stop the engine and remove the key.

2. Apply moderate thumb pressure to belt between pulleys.

3. If tension is incorrect, loosen the alternator mounting bolts and

using a lever placed between the alternator and the engine block,

pull the alternator out until the deflection of the be lt falls within

acceptable limits.

4. Replace fan belt if it is damaged.

A deflection of between 7

Fan belt tension Factory spec .

(1) Mounting Bolt A : Check the belt tension

to 9 mm (0.28 to 0.34 in.)

when the belt is pressed

in the middle of the span.

W1017708

G-18

Loading...

Loading...