ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

1 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

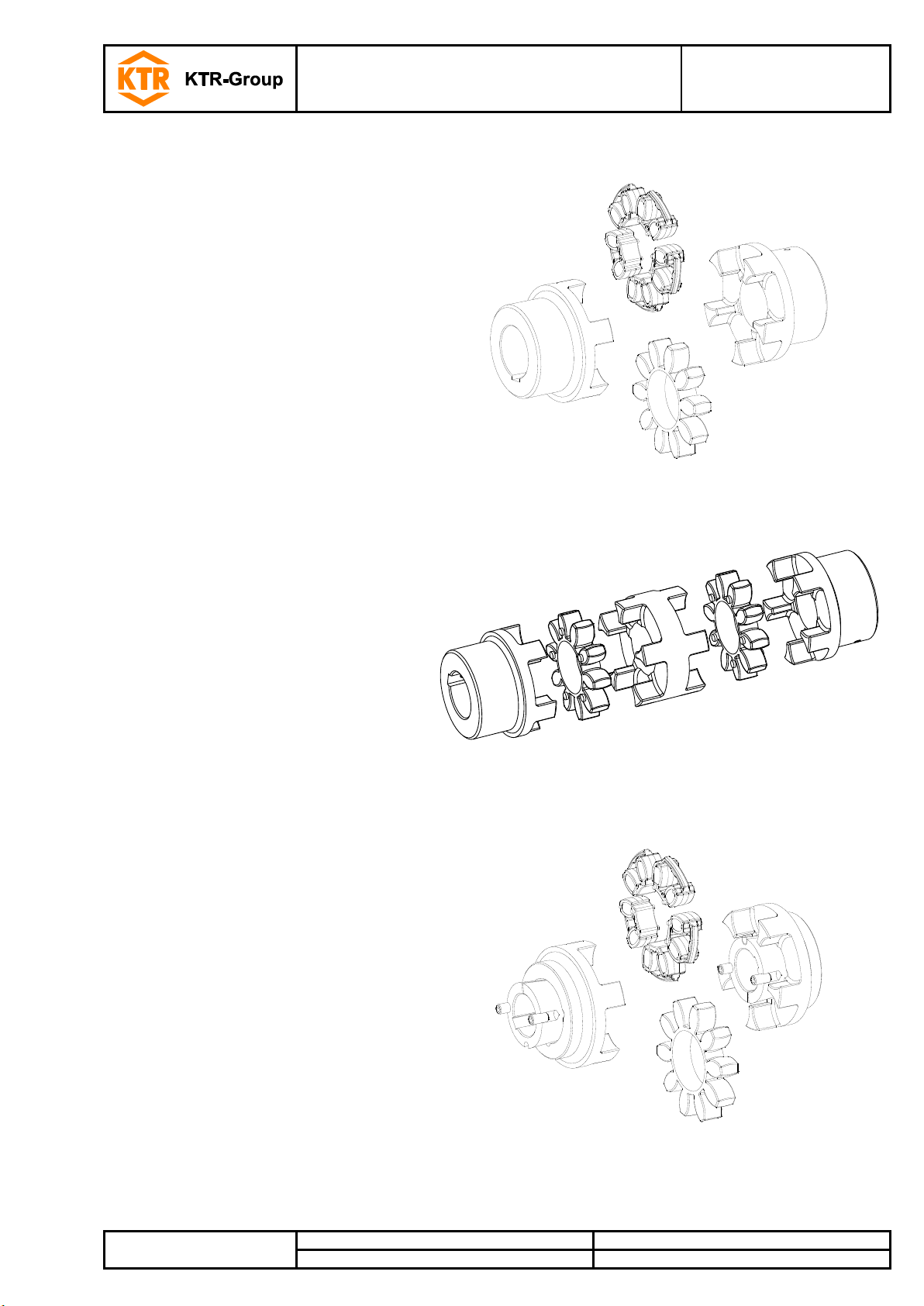

ROTEX®

Torsionally flexible jaw-type couplings

No. 001 – shaft coupling,

No. 018 – DKM,

with taper clamping sleeve

and their combinations

according to directive 2014/34/EU

for finish bored, pilot bored and

unbored couplings

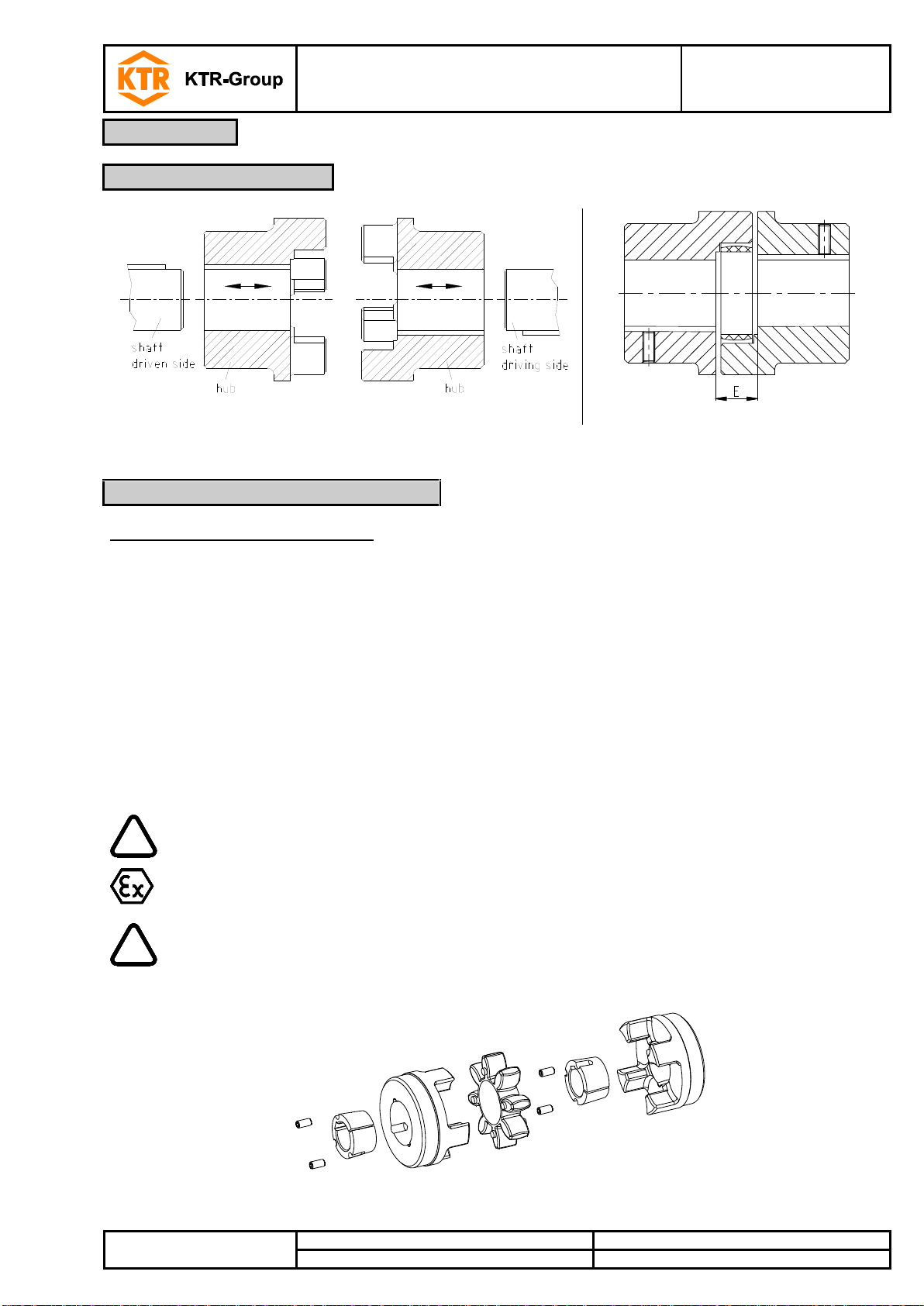

Type No. 001 – shaft coupling

Type No. 018 – DKM

double-cardanic coupling

Type with taper clamping sleeve

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

2 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Table of contents

ROTEX® is a torsionally flexible jaw coupling. It is able to compensate for shaft misalignment, for

example caused by manufacturing inaccuracies, thermal expansion, etc.

1 Technical data 3

2 Advice 5

2.1 General advice 5

2.2 Safety and advice symbols 6

2.3 General hazard warnings 6

2.4 Intended use 6

2.5 Coupling selection 7

2.6 Reference to EC Machinery Directive 2006/42/EC 7

3 Storage, transport and packaging 7

3.1 Storage 7

3.2 Transport and packaging 7

4 Assembly 8

4.1 Components of the coupling 8

4.2 Advice for finish bore 9

4.3 Assembly of the hubs 10

4.4 Assembly of taper clamping sleeve 11

4.5 Displacements - alignment of the couplings 12

5 Start-up 14

6 Breakdowns, causes and elimination 15

7 Disposal 17

8 Maintenance and service 17

9 Spares inventory, customer service addresses 17

10 Enclosure A

Advice and instructions regarding the use in hazardous locations 18

10.1 Intended use in hazardous locations 18

10.2 Inspection intervals for couplings in hazardous locations 19

10.3 Standard values of wear 20

10.4 Permissible coupling materials in hazardous locations 21

10.5 marking of coupling for hazardous locations 21

10.6 EU Certificate of conformity 22

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

3 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

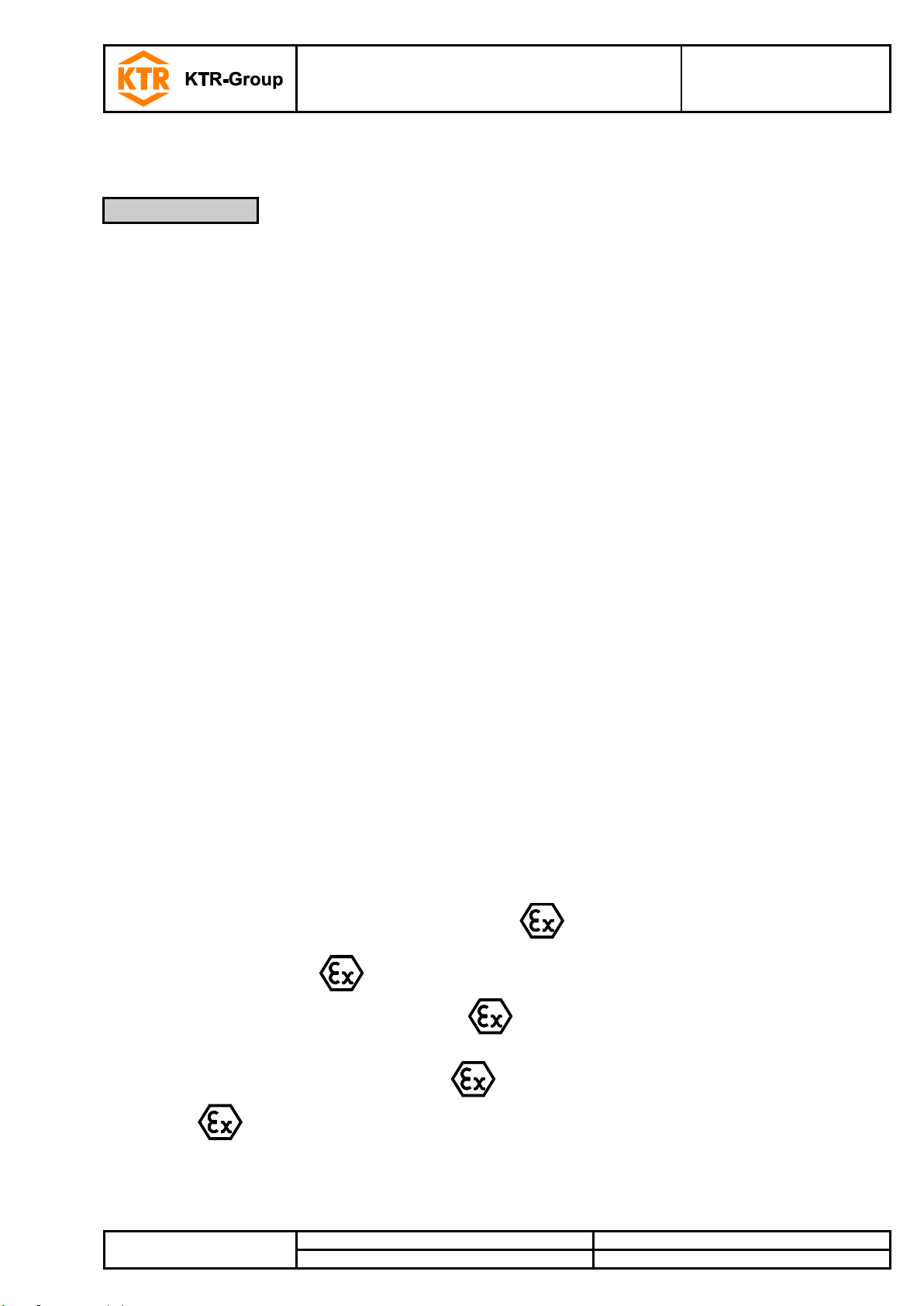

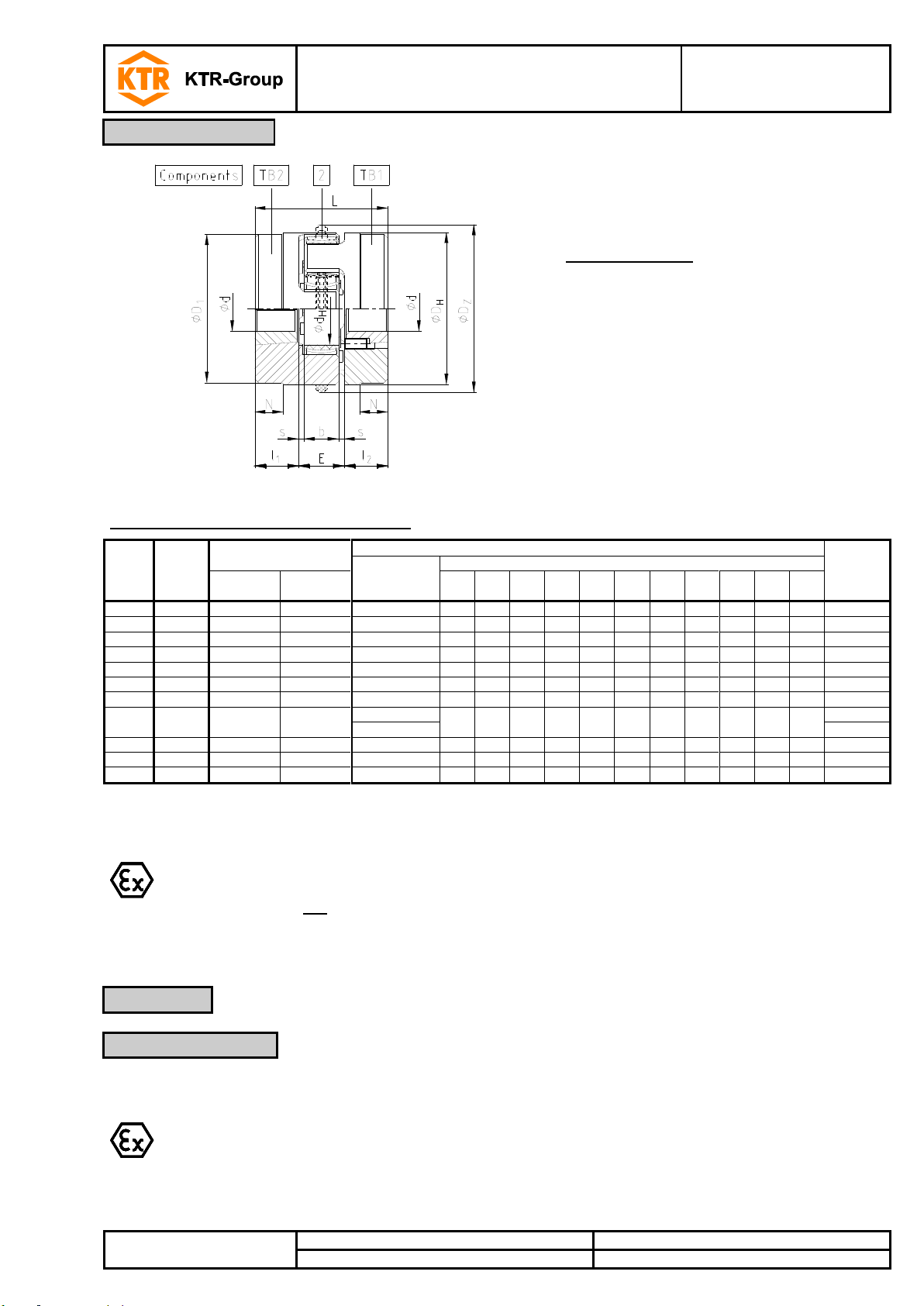

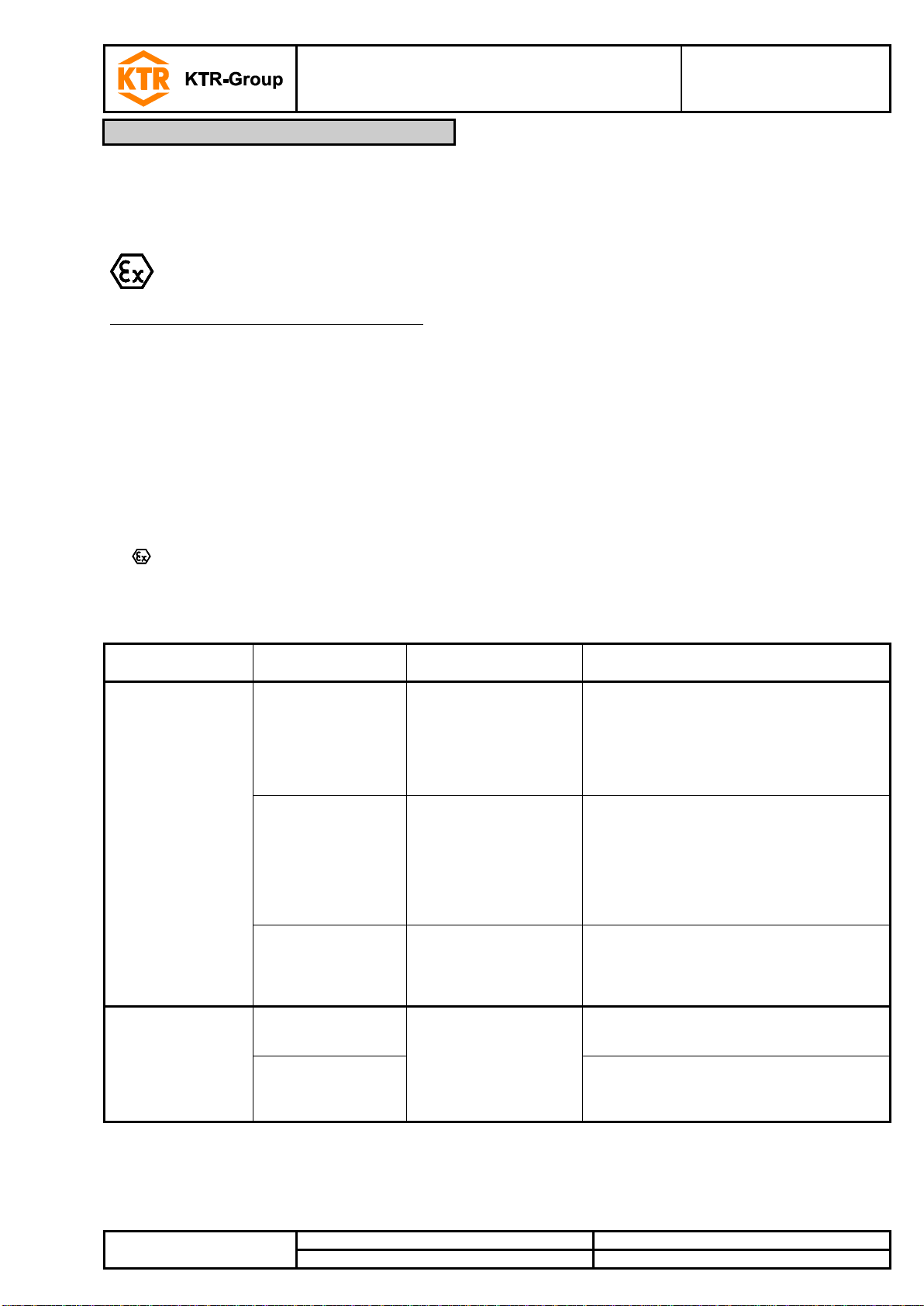

Illustration 1: ROTEX® (material: Al-D)

Illustration 2: ROTEX® (material: EN-GJL-250/EN-GJS-400-15)

Size

Compo

nent

Spider 1) (component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore 2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l1; l2 E b s DH

DZ

DZ1 4)

dH

D;D1 N 14

1a

7.5

12.5 - 6 - 16

35

11

13

10

1.5

30 - -

10

30

-

19 1 10

17

6 - 19

66

25

16

12

2.0

41 - -

18

32

20

1a

19 - 24

41

24 1 35

60

9 - 24

78

30

18

14

2.0

56 - -

27

40

24

1a

22 - 28

56

28 1 95

160

-

10 - 28

90

35

20

15

2.5

67 - -

30

48

28

1a

28 - 38

67

Size

Compo

nent

Spider 1) (component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore 2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l1; l2 E b s DH

DZ

DZ1 4)

dH

D;D1

N

Cast iron EN-GJL-250

38 1 190

325

405

12 - 40

114

45

24

18

3.0

80 - -

38

66

37

1a

38 - 48

78

1b

12 - 48

164

70

62

42 1 265

450

560

14 - 45

126

50

26

20

3.0

95 - -

46

75

40

1a

42 - 55

94

1b

14 - 55

176

75

65

48 1 310

525

655

15 - 52

140

56

28

21

3.5

105 - -

51

85

45

1a

48 - 62

104

1b

15 - 62

188

80

69

55 1 410

685

825

20 - 60

160

65

30

22

4.0

120 - -

60

98

52

1a

55 - 74

118

65 1 625

940

1175

22 - 70

185

75

35

26

4.5

135 - -

68

115

61

75 1 1280

1920

2400

30 - 80

210

85

40

30

5.0

160 - -

80

135

69

90 1 2400

3600

4500

40 - 97

245

100

45

34

5.5

200

218

230

100

160

81

Nodular iron EN-GJS-400-15

100 1 3300

4950

6185

50 - 115

270

110

50

38

6.0

225

246

260

113

180

89

110 1 4800

7200

9000

60 - 125

295

120

55

42

6.5

255

276

290

127

200

96

125 1 6650

10000

12500

60 - 145

340

140

60

46

7.0

290

315

330

147

230

112

140 1 8550

12800

16000

60 - 160

375

155

65

50

7.5

320

345

360

165

255

124

160 1 12800

19200

24000

80 - 185

425

175

75

57

9.0

370

400

415

190

290

140

180 1 18650

28000

35000

85 - 200

475

185

85

64

10.5

420

450

465

220

325

156

1 Technical data

Table 1: Material Al-D

Table 2: Material EN-GJL-250 (GG 25)/EN-GJS-400-15 (GGG 40)

1) Maximum torque of the coupling T

2) Bores H7 with keyway to DIN 6885 sheet 1 [JS9] and thread for setscrew

3) For dimensions G and t see table 6; threads for setscrews are located opposite the keyway with material Al-D and on the keyway with

material EN-GJL-250/EN-GJS-400-15

4) DZ1 = internal diameter of housing

= rated torque of the coupling T

Kmax.

K rated

x 2

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

4 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

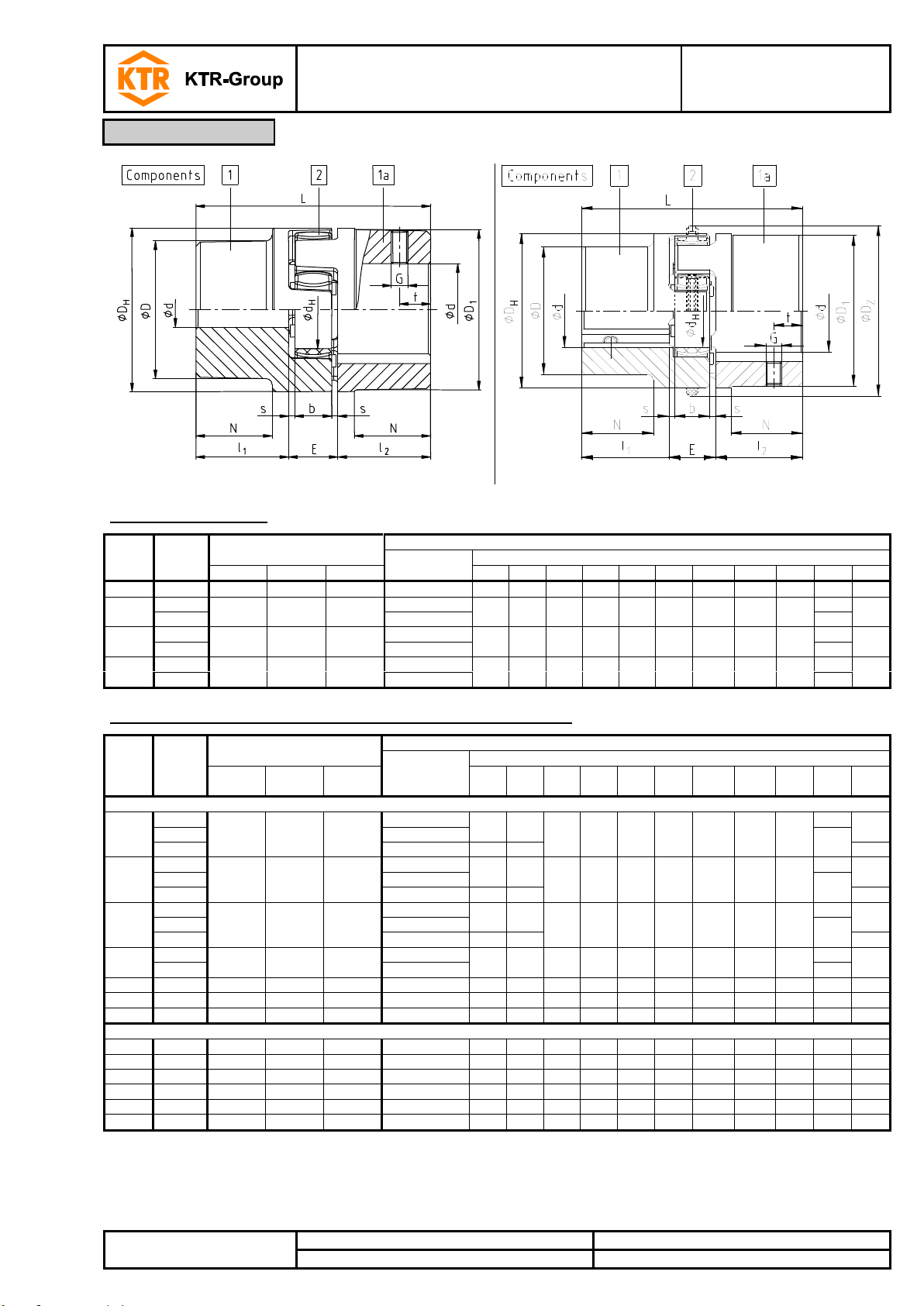

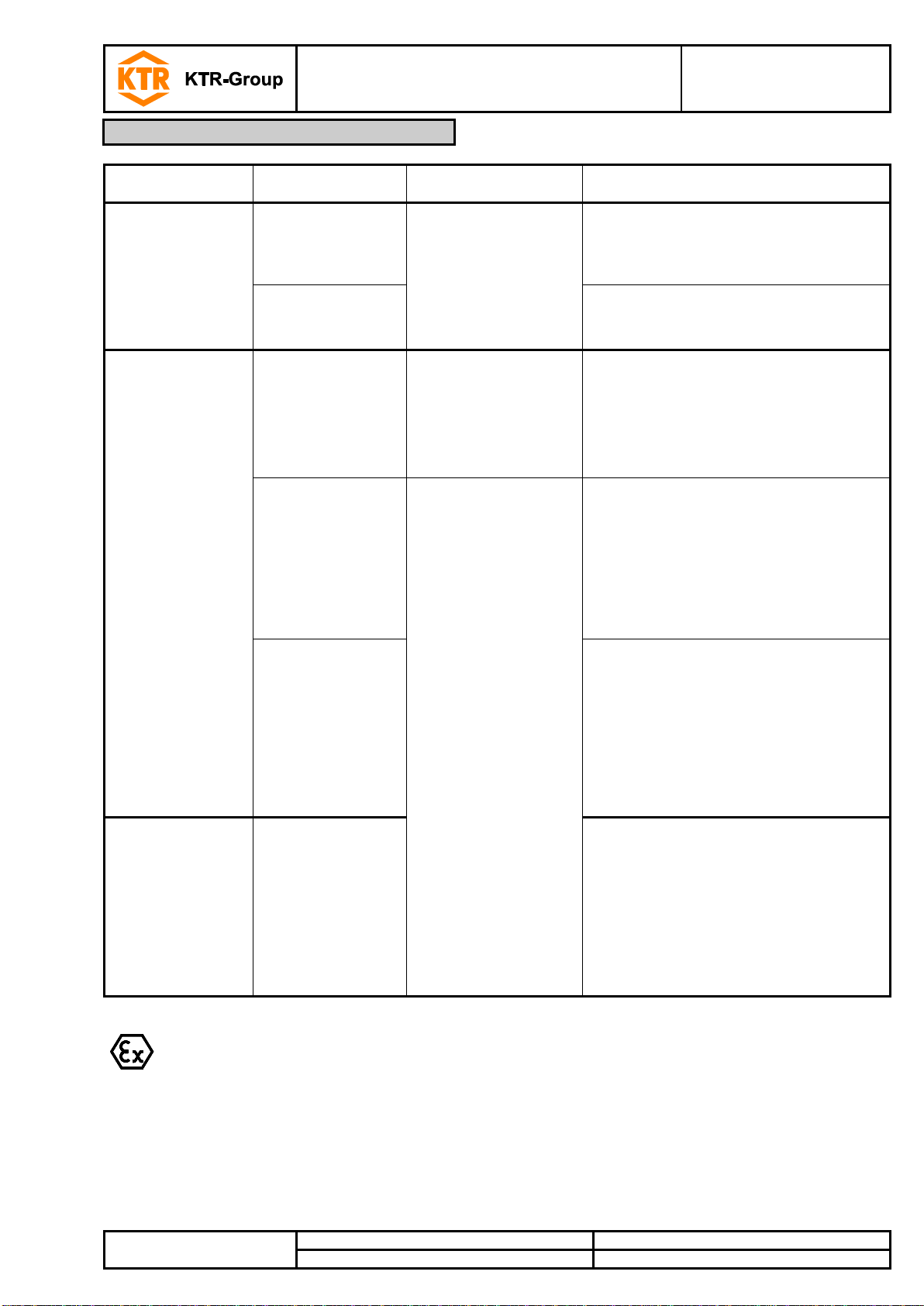

Illustration 3: ROTEX® (material: steel)

Illustration 4: ROTEX®, type DKM 5)

Size

Compo

nent

Spider 1) (component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore 2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l1; l2 E b s DH

DZ

DZ1 4)

dH D N

14

1a

7.5

12.5

16

0 - 16

35

11

13

10

1.5

30 - -

10

30

1b

50

18.5

19

1a

10

17

21

0 - 25

66

25

16

12

2.0

40 - -

18

40

1b

90

37

24

1a

35

60

75

0 - 35

78

30

18

14

2.0

55 - -

27

55

1b

118

50

28

1a

95

160

200

0 - 40

90

35

20

15

2.5

65 - -

30

65

1b

140

60

38 1 190

325

405

0 - 48

114

45

24

18

3.0

80 - -

38

70

27

1b

164

70

80

-

42 1 265

450

560

0 - 55

126

50

26

20

3.0

95 - -

46

85

28

1b

176

75

95

-

48 1 310

525

655

0 - 62

140

56

28

21

3.5

105 - -

51

95

32

1b

188

80

105

-

55 1 410

685

825

0 - 75

160

65

30

22

4.0

120 - -

60

110

37

1b

210

90

120

-

65 1 625

940

1175

0 - 80

185

75

35

26

4.5

135 - -

68

115

47

1b

235

100

135

-

75 1 1280

1920

2400

0 - 95

210

85

40

30

5.0

160 - -

80

135

53

1b

260

110

160

-

90 1 2400

3600

4500

0 - 110

245

100

45

34

5.5

200

218

230

100

160

62

1b

295

125

200

-

Size

Spider 1) (component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Dimensions

d, D, D1

General

92 ShA

98 ShA

L

DKM

l1; l2 E b s DH

dH

l11

l12

19

10

17

see table 1 to 3

92

25

16

12

2.0

40

18

10

42

24

35

60

112

30

18

14

2.0

55

27

16

52

28

95

160

128

35

20

15

2.5

65

30

18

58

38

190

325

158

45

24

18

3.0

80

38

20

68

42

265

450

174

50

26

20

3.0

95

46

22

74

48

310

525

192

56

28

21

3.5

105

51

24

80

55

410

685

218

65

30

22

4.0

120

60

28

88

65

625

940

252

75

35

26

4.5

135

68

32

102

75

1280

1920

286

85

40

30

5.0

160

80

36

116

90

2400

3600

330

100

45

34

5.5

200

100

40

130

1 Technical data

Table 3: Material steel

Table 4: Type DKM 5)

1) Maximum torque of the coupling T

2) Bores H7 with keyway to DIN 6885 sheet 1 [JS9] and thread for setscrew

3) For dimensions G and t see table 6; threads for setscrews are located opposite the keyway with material Al-D and on the keyway with

material EN-GJL-250/EN-GJS-400-15

4) DZ1 = internal diameter of housing

5) Type DKM not available with DZ elements.

= rated torque of the coupling T

Kmax.

x 2

K rated

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

5 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

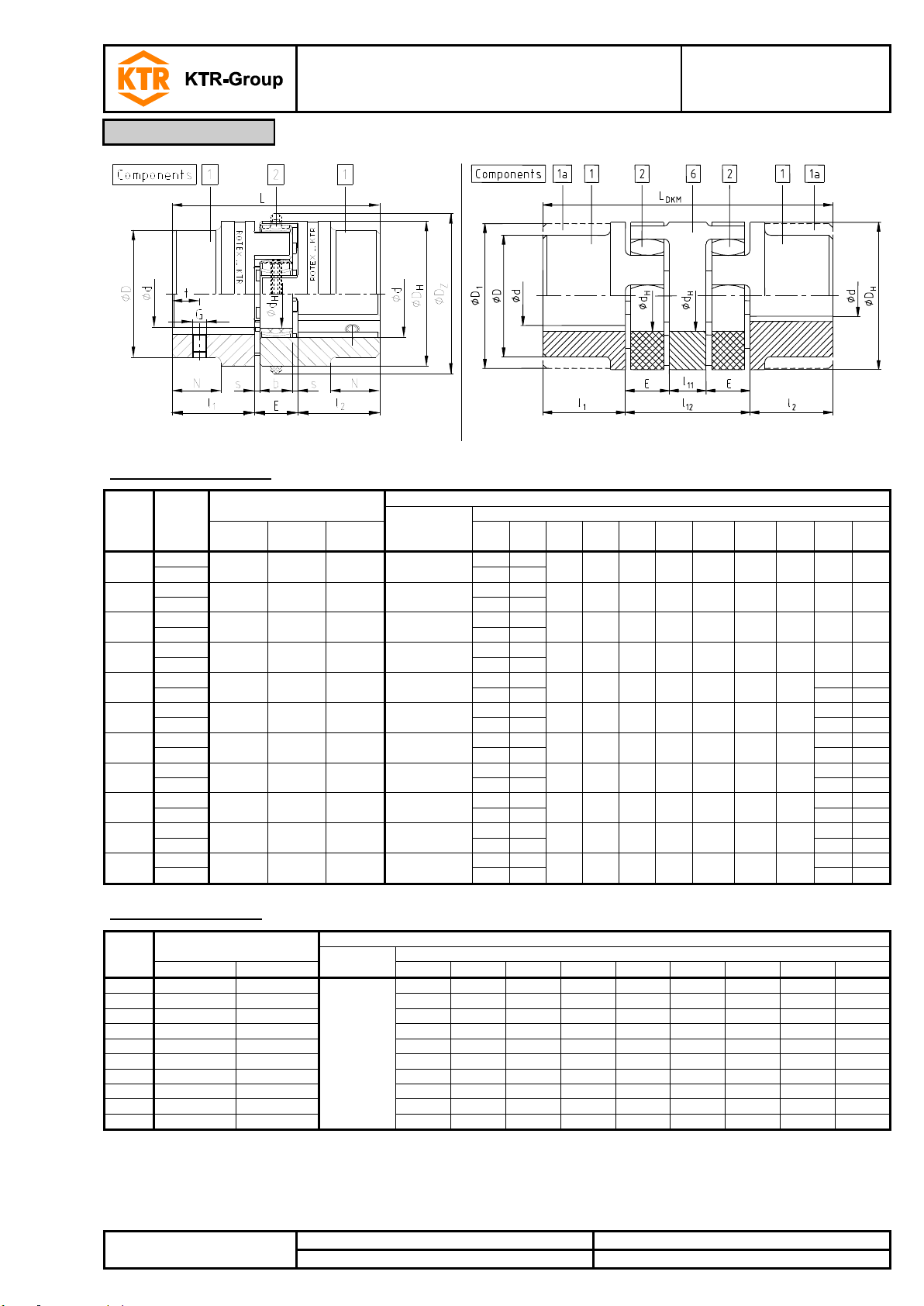

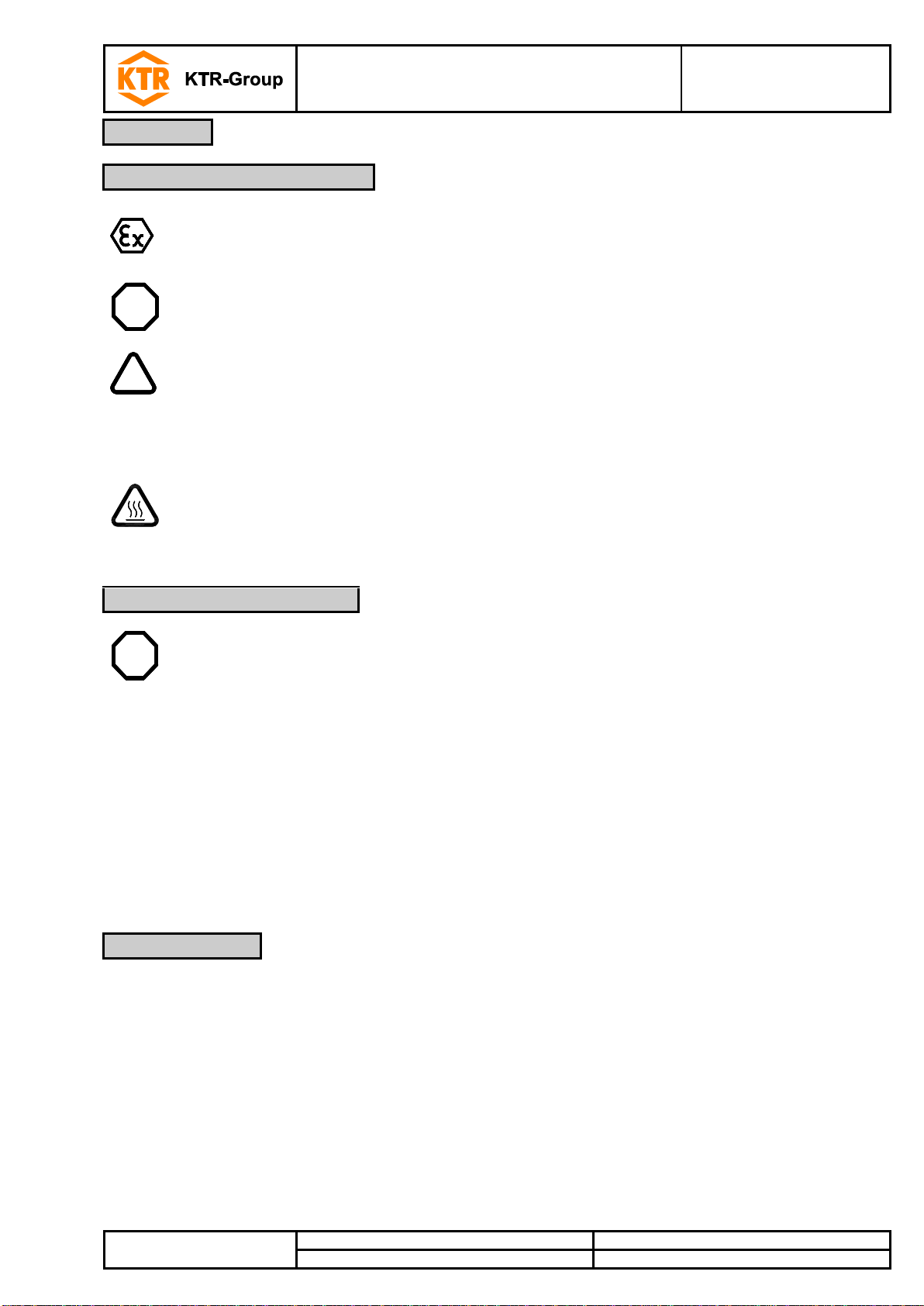

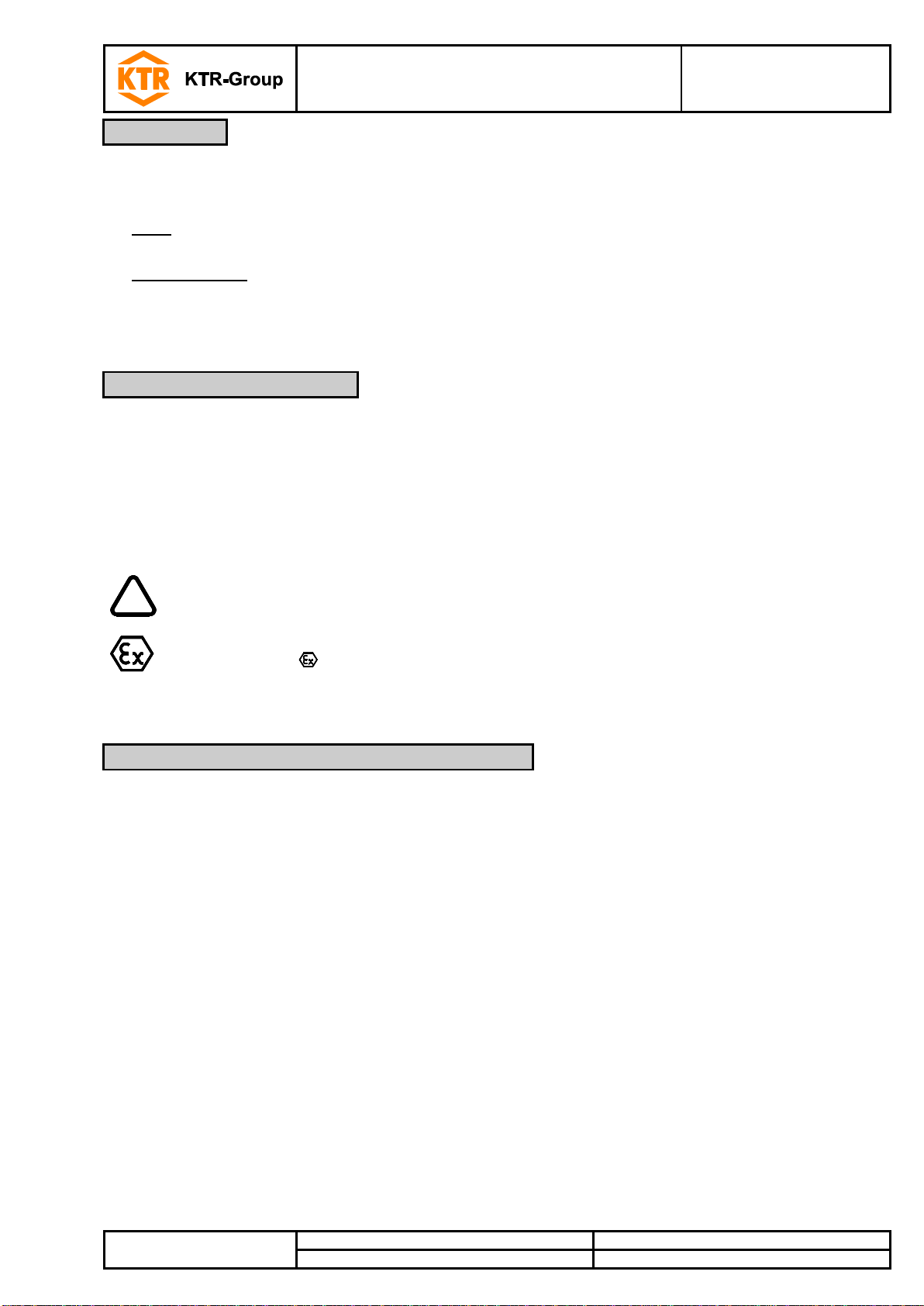

Coupling design:

TB1 Screwing on cam side

TB2 Screwing on collar side

Different combinations of types TB1 and TB2

are possible.

Illustration 5: ROTEX®, type with taper clamping sleeve

Size

Compo

nent

Spider 1) (component 2)

Rated torque [Nm]

Dimensions [mm]

Taper

clamping

sleeve

Finish bore

d (min-max)

General

92 ShA

98 ShA

L

l1; l2 E b s DH

DZ

DZ1

2)

dH

D1

N

24

1a

35

60

10 - 25

64

23

18

14

2.0

55 - -

27 - -

1008

28

1a

95

160

10 - 25

66

23

20

15

2.5

65 - -

30 - -

1108

38

1a

190

325

10 - 25

70

23

24

18

3.0

80 - -

38

78

15

1108

42

1a

265

450

14 - 25

78

26

26

20

3.0

95 - -

46

94

16

1610

48

1a

310

525

14 - 40

106

39

28

21

3.5

105 - -

51

104

28

1615

55

1a

410

685

14 - 50

96

33

30

22

4.0

120 - -

60

118

20

2012

65 1 625

940

14 - 50

101

33

35

26

4.5

135 - -

68

115 5 2012

75 1 1280

1920

16 - 60

144

52

40

30

5.0

160 - -

80

158

36

2517

25 - 75

3020 3)

90 1 2400

3600

25 - 75

149

52

45

34

5.5

200

218

230

100

160

14

3020

100 1 3300

4950

35 - 90

230

90

50

38

6.0

225

246

260

113

180

69

3535

125 1 6650

10000

55 - 110

288

114

60

46

7.0

290

315

330

147

230

86

4545

ROTEX® couplings with attachments that can generate heat, sparks and static charging

(e. g. combinations with brake drums, brake disks, overload systems like torque limiters,

fans etc.) are not permitted for the use in hazardous areas.

A separate analysis must be performed.

The ROTEX® coupling is suitable and approved for the use in hazardous locations. When using the

coupling in hazardous locations, please observe the special advice and instructions regarding safety

in enclosure A.

1 Technical data

2 Advice

2.1 General advice

Table 5: Type with taper clamping sleeve

1) Maximum torque of the coupling T

2) DZ1 = internal diameter of housing

3) Available for type TB2 only

= rated torque of the coupling T

Kmax.

K rated

x 2

Please read through these operating/assembly instructions carefully before you start up the coupling.

Please pay special attention to the safety instructions!

The operating/assembly instructions are part of your product. Please store them carefully and close to the

coupling. The copyright for these operating/assembly instructions remains with KTR.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

6 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Warning of potentially explosive

atmospheres

This symbol indicates notes which may contribute to

preventing bodily injuries or serious bodily injuries that

may result in death caused by explosion.

STOP

Warning of personal injury

This symbol indicates notes which may contribute to

preventing bodily injuries or serious bodily injuries that

may result in death.

!

Warning of product damages

This symbol indicates notes which may contribute to

preventing material or machine damage.

General advice

This symbol indicates notes which may contribute to

preventing adverse results or conditions.

Warning of hot surfaces

This symbol indicates notes which may contribute to

preventing burns with hot surfaces resulting in light to

serious bodily injuries.

STOP

With assembly, operation and maintenance of the coupling it has to be made sure that the

entire drive train is secured against accidental switch-on. You may be seriously hurt by

rotating parts. Please make absolutely sure to read through and observe the following

safety indications.

2 Advice

2.2 Safety and advice symbols

2.3 General hazard warnings

2.4 Intended use

All operations on and with the coupling have to be performed taking into account "safety first".

Please make sure to switch off the power pack before you perform your work on the coupling.

Secure the power pack against accidental switch-on, e. g. by providing warning signs at the place of switch-on

or removing the fuse for current supply.

Do not reach into the operation area of the coupling as long as it is in operation.

Please secure the coupling against accidental contact. Please provide for the necessary protection devices

and covers.

You may only assemble, operate and maintain the coupling if you

have carefully read through the operating/assembly instructions and understood them

had technical training

are authorized by your company

The coupling may only be used in accordance with the technical data (see chapter 1). Unauthorized modifications

on the coupling design are not admissible. We will not assume liability for any damage that may arise. In the

interest of further development we reserve the right for technical modifications.

The ROTEX® described in here corresponds to the technical status at the time of printing of these

operating/assembly instructions.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

7 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

!

For a permanent and failure-free operation of the coupling it must be selected according to

the selection instructions (according to DIN 740 part 2) for the particular application (see

catalogue drive technology "ROTEX®").

If the operating conditions (performance, speed, modifications on engine and machine)

change, the coupling selection must be reviewed.

Please make sure that the technical data regarding torque refer to the spider only. The

transmittable torque of the shaft-hub-connection must be reviewed by the customer and is

subject to his responsibility.

!

The storage rooms must not include any ozone-generating devices like e. g. fluorescent

light sources, mercury-vapour lamps or electrical high-voltage appliances.

Humid storage rooms are not suitable.

Please make sure that condensation is not generated. The best relative air humidity is less

than 65 %.

!

In order to avoid any injuries and any kind of damage please always make use of proper

transport and lifting equipment.

2 Advice

2.5 Coupling selection

2.6 Reference to EC Machinery Directive 2006/42/EC

3 Storage, transport and packaging

3.1 Storage

3.2 Transport and packaging

For drives subject to torsional vibrations (drives with cyclic stress due to torsional vibrations) it is necessary to

perform a torsional vibration calculation to ensure a reliable selection. Typical drives subject to torsional vibrations

are e. g. drives with diesel engines, piston pumps, piston compressors etc. If requested, KTR will perform the

coupling selection and the torsional vibration calculation.

The couplings supplied by KTR should be considered as components, not machines or partly completed

machines according to EC Machinery Directive 2006/42/EC. Consequently KTR does not have to issue a

declaration of incorporation. For details about safe assembly, start-up and safe operation please refer to the

present operating/assembly instructions considering the warnings.

The coupling hubs are supplied in preserved condition and can be stored at a dry and covered place for 6 - 9

months.

The features of the coupling spiders (elastomers) remain unchanged for up to 5 years with favourable storage

conditions.

The couplings are packed differently each depending on size, number and kind of transport. Unless otherwise

contractually agreed, packaging will follow the in-house packaging specifications of KTR.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

8 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

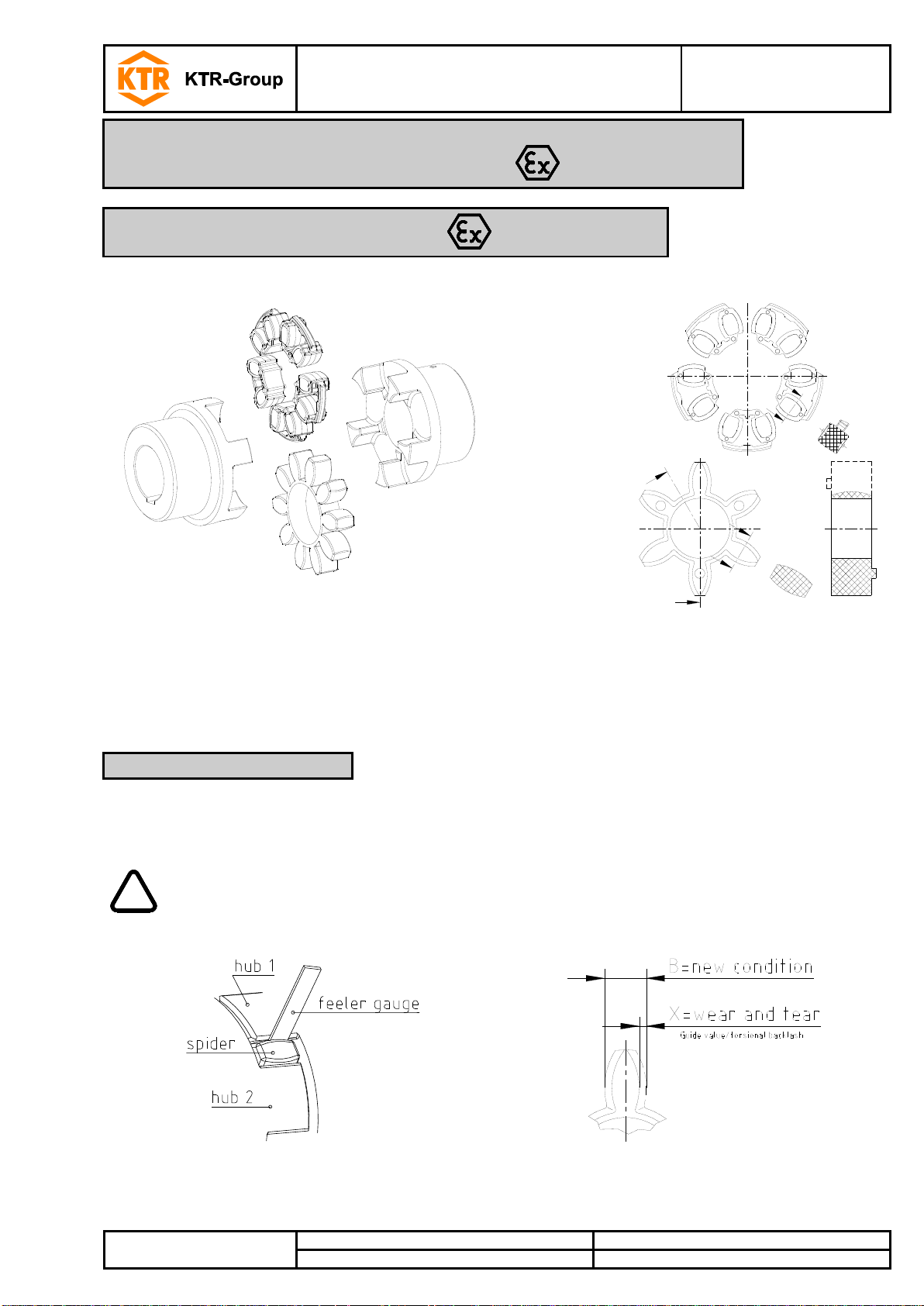

Component

Quantity

Description

Illustration 6: ROTEX®

1

2

Hub 2 1

Spider 1)

3

5 2)

DZ elements 1)

4

2

Setscrews

DIN EN ISO 4029

1) Optionally spider or DZ elements

2) With size 180 the quantity is 6.

Component

Quantity

Description

Illustration 7: ROTEX® DKM

1

2

Hub

2

2

Spider 3 1

DKM spacer

4

2

Setscrews

DIN EN ISO 4029

1) Type DKM not available with DZ elements.

Component

Quantity

Description

Illustration 8: ROTEX® type with taper clamping sleeve

TB1/TB2

2

Hub for taper

clamping sleeve

1

2

Taper clamping

sleeve 2 1

Spider 1)

3

5 2)

DZ elements 1)

4

4

Setscrews

DIN EN ISO 4029

1) Optionally spider or DZ elements

2) With size 180 the quantity is 6.

4 Assembly

4.1 Components of the coupling

The coupling is generally supplied in individual parts. Before assembly the coupling has to be inspected for

completeness.

Components of ROTEX®, shaft coupling type No. 001

Components of ROTEX®, type DKM

1)

Components of ROTEX®, type with taper clamping sleeve

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

9 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

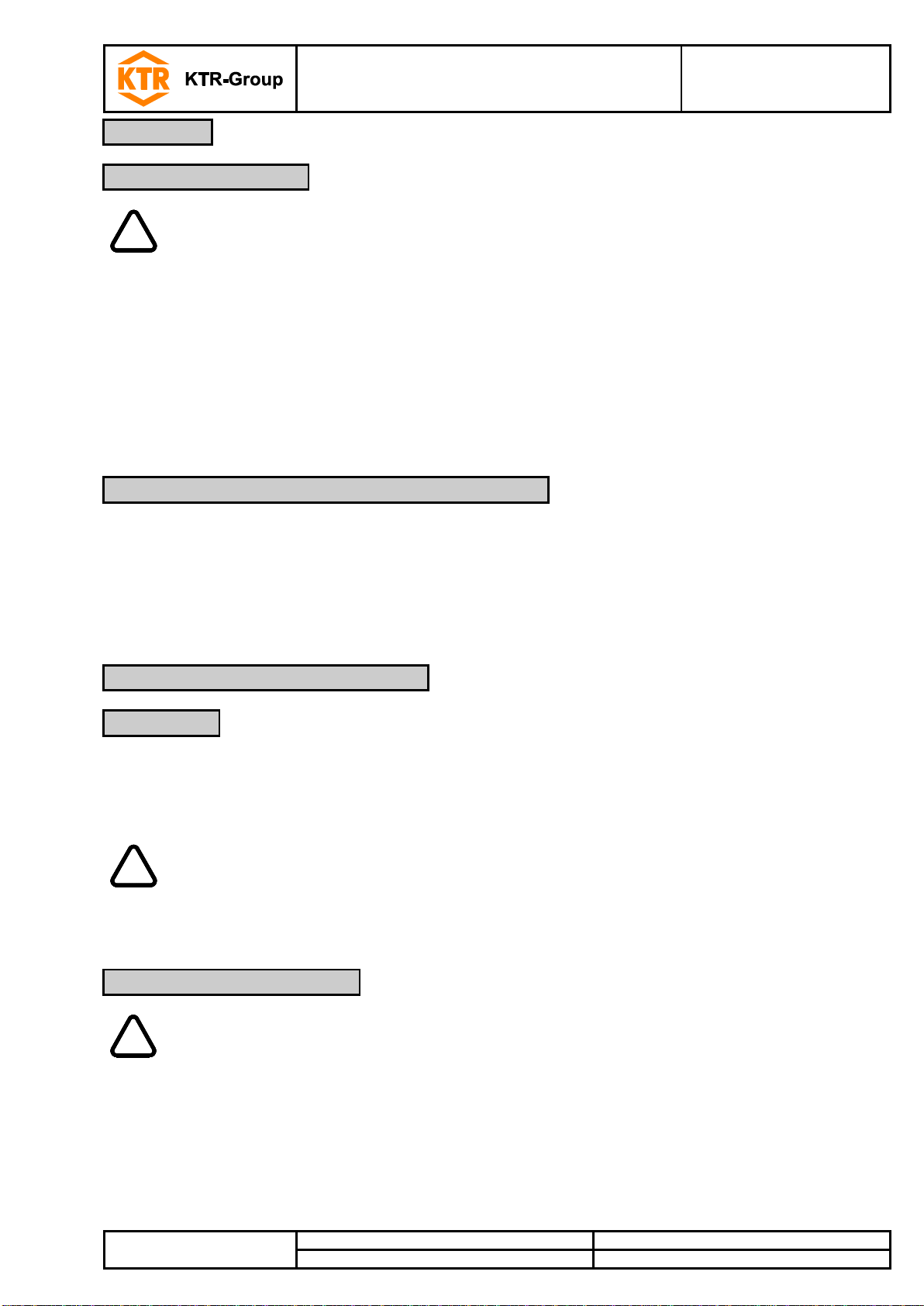

Spider hardness

(Shore)

92 Shore A

95/98 Shore A

64 Shore D

T-PUR®

(orange)

PUR

(yellow)

T-PUR®

(purple)

PUR

(red)

T-PUR®

(light green)

PUR

(natural white 1))

Marking

(colour)

STOP

The maximum permissible bore diameters d (see table 1

to 5 in chapter 1 - technical data) must not be exceeded.

If these figures are disregarded, the coupling may tear.

Rotating particles may cause danger to life.

Hub bores machined by the customer have to observe

concentricity or axial runout, respectively (see illustration

9).

Please make absolutely sure to observe the figures for

Ø d

max

.

Carefully align the hubs when the finish bores are drilled.

Please provide for a setscrew according to

DIN EN ISO 4029 with a cup point or an end plate to fasten

the hubs axially.

Illustration 9: Concentricity and axial runout

!

The customer bears the sole responsibility for all machining processes performed

subsequently on unbored or pilot bored as well as finish machined coupling components

and spare parts. KTR does not assume any warranty claims resulting from insufficient

remachining.

KTR supplies unbored or pilot bored coupling components and spare parts only upon

explicit request of the customer. These parts are additionally labelled with the symbol

.

Size

14

19

24

28

38

42

48

55

65

75

90

100

110

125

140

160

180

Dimension G

M4

M5

M5

M8

M8

M8

M8

M10

M10

M10

M12

M12

M16

M16

M20

M20

M20

Dimension t

5

10

10

15

15

20

20

20

20

25

30

30

35

40

45

50

50

Tightening

torque TA [Nm]

1.5 2 2

10

10

10

10

17

17

17

40

40

80

80

140

140

140

4 Assembly

4.1 Components of the coupling

4.2 Advice for finish bore

Features of standard spiders

1) Natural white with green marking of teeth

Table 6: Setscrews DIN EN ISO 4029

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

10 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Bore [mm]

Shaft tolerance

Bore tolerance

above

up to

50

k6

H7

(KTR standard)

50 m6

We recommend to inspect bores, shaft, keyway and feather key for dimensional accuracy

before assembly.

Heating the hubs lightly (approx. 80 °C) allows for an easier mounting on the shaft.

Please pay attention to the ignition risk in hazardous locations!

STOP

Touching the heated hubs causes burns.

Please wear safety gloves.

!

With the assembly please make sure that the distance dimension E (see table 1 to 5) is

observed to allow for axial clearance of the spider when in operation.

Disregarding this advice may cause damage to the coupling.

If the shaft diameters with inserted feather key are smaller than dimension dH (see table 1

to 5) of the spider, one or two shaft ends may protude into the spider.

If used in hazardous locations the setscrews to fasten the hubs as well as all screw

connections must be secured against working loose additionally, e. g. conglutinating with

Loctite (average strength).

4 Assembly

4.2 Advice for finish bore

4.3 Assembly of the hubs

Table 7: Recommended fit pairs acc. to DIN 748/1

If a feather keyway is intended to be used in the hub, it should correspond to the tolerance ISO JS9 (KTR

standard) with normal operating conditions or ISO P9 with difficult operating conditions (frequently alternating

torsional direction, shock loads, etc.). The keyway should preferably be located between the cams. With axial

fastening by setscrews the tapping should be located on the keyway with the exception of Al-D which should be

located opposite to the keyway.

The transmittable torque of the shaft-hub-connection must be reviewed by the customer and is subject to his

responsibility.

Mount the hubs on the shaft of driving and driven side (see illustration 10).

Insert the spider or DZ elements into the cam section of the hub on the driving or driven side.

Shift the power packs in axial direction until the distance dimension E is achieved (see illustration 11).

If the power packs are already firmly assembled, shifting the hubs axially on the shafts allows for adjusting the

distance dimension E.

Fasten the hubs by tightening the setscrews DIN EN ISO 4029 with a cup point (tightening torques see

table 6).

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

11 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Illustration 10: Assembly of the hubs

Illustration 11: Assembly of coupling

!

If used in hazardous locations the setscrews to fix the taper clamping sleeves have to be

secured against working loose additionally, e. g. conglutinating with Loctite (average

strength).

The use of taper clamping sleeves without a feather key is not permitted in hazardous

locations.

!

Oils and greases with molybdenum disulphide or high-pressure additives, additives of

Teflon and silicone as well as internal lubricants reducing the coefficient of friction

significantly must not be used.

4 Assembly

4.3 Assembly of the hubs

4.4 Assembly of taper clamping sleeve

Assembly of taper clamping sleeve:

Clean the contact surfaces of the taper clamping sleeves and of shaft and hub and afterwards apply thin fluid oil

lightly (e. g. Ballistol Universal oil or Klüber Quietsch-Ex).

The taper clamping sleeves have axially parallel, cylindrical and smooth blind holes. Only half of these holes are

located in the material of the sleeve. The other half located in the hub has threads.

Fit the coupling element and the taper clamping sleeve into each other, make sure that the bores cover each

other and tighten the setscrews lightly. Fit the coupling element along with the taper clamping sleeve on the shaft

and tighten the setscrews at the tightening torque specified in table 8.

During the process of screwing the hub is mounted onto the taper sleeve and thus the sleeve is pressed onto the

shaft. By light blows of the hammer the taper clamping sleeve must be pushed further into the taper bore by

means of a suitable sleeve. Afterwards please re-tighten the setscrews at the tightening torque indicated in table

8. This process must be performed at least once.

After the drive has operated under load for a short while please inspect if the setscrews have unscrewed.

An axial fixing of the Taper Lock hub (coupling hub with taper clamping sleeve) is obtained by proper assembly

only.

Illustration 12: ROTEX®, type with taper clamping sleeve

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

12 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Taper

clamping

sleeve

Screw dimensions

Quantity

Illustration 13: Withworth setscrew (BSW)

G

[inch]

L

[inch]

SW

[mm]

TA

[Nm]

1008

1/4

1/2 3 5.7

2

1108

1/4

1/2 3 5.7

2

1610

3/8

5/8 5 20 2 1615

3/8

5/8 5 20 2 2012

7/16

7/8 6 31 2 2517

1/2

7/8 6 49

2

3020

5/8

1 1/4 8 92

2

3535

1/2

1 1/2

10

115 3 4545

3/4

1 3/4

12

170

3

!

In order to ensure a long service life of the coupling and avoid dangers with the use in

hazardous locations, the shaft ends must be accurately aligned.

Please absolutely observe the displacement figures indicated (see table 9 to 11). If the

figures are exceeded, the coupling will be damaged.

The more accurate the alignment of the coupling, the longer is its service life.

If used in hazardous locations for the explosion group IIC (marking II 2GD c IIC T X), only

half of the displacement figures (see table 9 to 11) are permissible.

Angular displacements

Radial displacements

Axial displacements

Kw = L

1max.

- L

1min.

[mm]

L

max

= L + Ka [mm]

4 Assembly

4.4 Assembly of taper clamping sleeve

4.5 Displacements - alignment of the couplings

Disassembly of taper clamping sleeve:

The taper clamping sleeve is released by removing the setscrews. Afterwards one of the setscrews used as

forcing screw is screwed in the thread of the sleeve and tightened.

The coupling hub detached in this way can be manually removed from the shaft with the taper clamping sleeve.

Table 8:

The displacement figures shown in tables 9 to 11 provide for sufficient safety to compensate for external

influences like, for example, heat expansion or foundation settling.

Please note:

The displacement figures specified in table 9 to 11 are maximum figures which must not arise in parallel. If

radial and angular displacements arise at the same time, the permissible displacement values may only be

used proportionally (see illustration 15).

Please inspect with a dial gauge, ruler or feeler whether the permissible displacement figures of tables 9 to 11

can be observed.

Illustration 14: Displacements

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

13 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Examples of the displacement combinations

specified in illustration 15:

Example 1:

Kr = 30 %

Kw = 70 %

Example 2:

Kr = 60 %

Kw = 40 %

Illustration 15:

Combinations of

displacement

K

total

= Kr + Kw 100 %

Size

14

19

24

28

38

42

48

55

65

75

90

100

110

125

140

160

180

Max. axial displacement Ka

[mm]

-0.5

-0.5

-0.5

-0.7

-0.7

-1.0

-1.0

-1.0

-1.0

-1.5

-1.5

-1.5

-2.0

-2.0

-2.0

-2.5

-3.0

+1.0

+1.2

+1.4

+1.5

+1.8

+2.0

+2.1

+2.2

+2.6

+3.0

+3.4

+3.8

+4.2

+4.6

+5.0

+5.7

+6.4

Max. radial

displacement

Kr [mm] with

1500 rpm

0.17

0.20

0.22

0.25

0.28

0.32

0.36

0.38

0.42

0.48

0.50

0.52

0.55

0.60

0.62

0.64

0.68

3000 rpm

0.11

0.13

0.15

0.17

0.19

0.21

0.25

0.26

0.28

0.32

0.34

0.36

0.38 - - - -

Kw [degree]

max. angular displacement

with n=1500 rpm

Kw [mm]

1.2

1.2

0.9

0.9

1.0

1.0

1.1

1.1

1.2

1.2

1.2

1.2

1.3

1.3

1.2

1.2

1.2

0.67

0.82

0.85

1.05

1.35

1.70

2.00

2.30

2.70

3.30

4.30

4.80

5.60

6.50

6.60

7.60

9.00

Kw [degree]

max. angular displacement

with n=3000 rpm

Kw [mm]

1.1

1.1

0.8

0.8

0.9

0.9

1.0

1.0

1.1

1.1

1.1

1.1

1.2 - - - -

0.60

0.70

0.75

0.85

1.10

1.40

1.60

2.00

2.30

2.90

3.80

4.20

5.00 - - - Size

14

19

24

28

38

42

48

55

65

75

90

100

110

125

140

160

180

Max. axial displacement Ka

[mm]

-0.5

-0.5

-0.5

-0.7

-0.7

-1.0

-1.0

-1.0

-1.0

-1.5

-1.5

-1.5

-2.0

-2.0

-2.0

-2.5

-3.0

+1.0

+1.2

+1.4

+1.5

+1.8

+2.0

+2.1

+2.2

+2.6

+3.0

+3.4

+3.8

+4.2

+4.6

+5.0

+5.7

+6.4

Max. radial

displacement

Kr [mm] with

1500 rpm

0.11

0.13

0.15

0.18

0.21

0.23

0.25

0.27

0.30

0.34

0.36

0.37

0.40

0.43

0.45

0.46

0.49

3000 rpm

0.08

0.09

0.10

0.13

0.15

0.16

0.18

0.19

0.21

0.24

0.25

0.26

0.28 - - - -

Kw [degree]

max. angular displacement

with n=1500 rpm

Kw [mm]

1.1

1.1

0.8

0.8

0.9

0.9

1.0

1.0

1.1

1.1

1.1

1.1

1.2

1.2

1.1

1.1

1.1

0.57

0.77

0.77

0.90

1.25

1.40

1.80

2.00

2.50

3.00

3.80

4.30

5.30

6.00

6.10

7.10

8.00

Kw [degree]

max. angular displacement

with n=3000 rpm

Kw [mm]

1.0

1.0

0.7

0.7

0.8

0.8

0.9

0.9

1.0

1.0

1.0

1.0

1.1 - - - -

0.52

0.70

0.67

0.80

1.00

1.30

1.60

1.80

2.20

2.70

3.50

4.00

4.90 - - - -

Size

19

24

28

38

42

48

55

65

75

90

Max. axial displacement Ka [mm]

+1.2

+1.4

+1.5

+1.8

+2.0

+2.1

+2.2

+2.6

+3.0

+3.4

-1.0

-1.0

-1.4

-1.4

-2.0

-2.0

-2.0

-2.0

-3.0

-3.0

Max. radial displacement

Kr [mm] with n =

1500 rpm

0.45

0.59

0.66

0.77

0.84

0.91

1.01

1.17

1.33

1.48

3000 rpm

0.40

0.53

0.60

0.70

0.75

0.82

0.81

1.05

1.19

1.33

Kw [degree] max. angular

displacement with n =

1500 rpm

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

3000 rpm

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

4 Assembly

4.5 Displacements - alignment of the couplings

Table 9: Displacement figures for 92 and 95/98 Shore A

Table 10: Displacement figures for 64 Shore D

Table 11: Displacement figures for type DKM only

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

14 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

If used in hazardous locations the setscrews to fasten the hubs as well as all screw

connections must be secured against working loose additionally, e. g. conglutinating with

Loctite (average strength).

If the couplings are used in locations subject to dust explosion and in mining the user must

make sure that there is no accumulation of dust in a dangerous volume between the cover

and the coupling. The coupling must not operate in an accumulation of dust.

For covers with unlocked openings on the top face no light metals must be used if the

couplings are used as equipment of equipment group ll (if possible, from stainless steel).

If the couplings are used in mining (equipment group l M2), the cover must not be made of

light metal. In addition, it must be resistant to higher mechanical loads than if it is used as

equipment of equipment group ll.

Openings

Cover [mm]

Top side

Lateral components

Distance „Sr“

Circular - max. diameter

4

8

10

Rectangular - max. lateral length

4

8

10

Straight or curved slot - max. lateral

length/height

not permissible

8

20

!

If you note any irregularities with the coupling during operation, the drive unit must be

switched off immediately. The cause of the breakdown must be specified by means of the

table „Breakdowns“ and, if possible, be eliminated according to the proposals. The potential

breakdowns mentioned can be hints only. To find out the cause all operating factors and

machine components must be considered.

If coated (priming, paintings, etc.) couplings are used in hazardous locations, the requirements on

conductibility and coating thickness must be considered. In case of paintings up to 200 µm

electrostatic load does not have to be expected. Multiple coatings exceeding 200 µm are prohibited

for explosion group llC.

5 Start-up

Before start-up of the coupling, please inspect the tightening of the setscrews in the hubs, the alignment and the

distance dimension E and adjust, if necessary, and also inspect all screw connections for the tightening torques

specified, dependent on the type of coupling.

Finally the coupling protection against accidental contact must be fitted.

The cover must be electrically conductive and included in the equipotential bonding. Bellhousings (magnesium

share below 7.5 %) made of aluminium and damping rings (NBR) can be used as connecting element between

pump and electric motor. The cover may only be taken off with standstill of the unit.

During operation of the coupling, please pay attention to

different operating noise

vibrations occurring.

The minimum distance „Sr“ between the protective device and the rotating parts must at least correspond to the

figures specified below.

If the protective device is used as cover, regular openings can be arranged from the point of view explosion

protection that must not exceed the following dimensions:

Coating of coupling:

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

15 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

If used other than intended the coupling can become a source of ignition.

EU directive 2014/34/EU requires special care by the manufacturer and the user.

Breakdowns

Causes

Hazard notes for

hazardous locations

Elimination

Different operating

noise and/or

vibrations occuring

Misalignment

Increased temperature on

the spider surface; ignition

risk by hot surfaces

1) Set the unit out of operation

2) Eliminate the reason for the misalignment

(e. g. loose foundation bolts, breaking of the

engine mount, heat expansion of unit

components, modification of the installation

dimension E of the coupling)

3) For inspection of wear see item inspection

Wear of spider, short-

term torque

transmission due to

metal contact

Ignition risk due to

sparking

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

Screws for axial

fastening of hubs

working loose

Ignition risk due to hot

surfaces and sparking

1) Set the unit out of operation

2) Inspect alignment of coupling

3) Tighten the screws to fasten the hubs and

secure against working loose

4) For inspection of wear see item inspection

Breaking of cams

Wear of spider, torque

transmission due to

metal contact

Ignition risk due to

sparking

1) Set the unit out of operation

2) Replace complete coupling

3) Inspect alignment

Breaking of the cams

due to high impact

energy/overload

1) Set the unit out of operation

2) Replace complete coupling

3) Inspect alignment

4) Find out the reason for overload

6 Breakdowns, causes and elimination

The below-mentioned failures can lead to a use of the ROTEX® coupling other than intended. In addition to the

specifications given in these operating and assembly instructions please make sure to avoid such failures.

The errors listed can only be clues to search for the failures. When searching for the failure the adjacent

components must generally be considered.

General failures with use other than intended:

Important data for the coupling selection were not forwarded.

The calculation of the shaft-hub-connection was not considered.

Coupling components with damage occurred during transport are assembled.

If the heated hubs are assembled, the permissible temperature is exceeded.

The clearance of the components to be assembled is not coordinated with one another.

Tightening torques have been fallen below/exceeded.

Components are mixed up by mistake/assembled incorrectly.

A wrong or no spider/DZ elements are inserted in the coupling.

No original KTR components (purchased parts) are used.

Old/ spiders/DZ elements already worn off or spiders/DZ elements stored for too long are used.

: The coupling used/the coupling protection used is not suitable for the operation in hazardous locations

and does not correspond to EU directive 2014/34/EU, respectively.

Maintenance intervals are not observed.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

16 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Breakdowns

Causes

Hazard notes for

hazardous locations

Elimination

Breaking of cams

Operating parameters

do not meet with the

performance of the

coupling

Ignition risk due to

sparking

1) Set the unit out of operation

2) Review the operating parameters and select

a bigger coupling (consider mounting space)

3) Assemble new coupling size

4) Inspect alignment

Operating error of the

unit

1) Set the unit out of operation

2) Replace complete coupling

3) Inspect alignment

4) Instruct and train the service staff

Early wear of spider

Misalignment

Increased temperature on

the spider surface; ignition

risk by hot surfaces

1) Set the unit out of operation

2) Eliminate the reason for the misalignment

(e. g. loose foundation bolts, breaking of the

engine mount, heat expansion of unit

components, modification of the installation

dimension E of the coupling)

3) For inspection of wear see item inspection

e. g. contact with

aggressive liquids/oils,

ozone influence, too

high/low ambient

temperatures etc.

causing physical

modification of the

spider

Ignition risk due to

sparking with metallic

contact of the cams

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Make sure that further physical

modifications of the spider are excluded

Ambient/contact

temperatures which

are too high for the

spider, max.

permissible

e. g. with T-PUR®

T4 = - 50 °C/

+ 120 °C

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Inspect and adjust ambient/contact

temperature (possibly corrective by using

different spider materials)

Early wear of spider

(liquefaction of

material inside the

spider cam)

Vibrations of drive

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Find out the reason for the vibrations

(possibly corrective by spider with lower or

higher Shore hardness)

If you operate with a worn spider/DZ elements (see item 10.3) and with the subsequent

contact of metal parts a proper operation meeting the explosion protection requirements

and acc. to directive 2014/34/EU is not ensured.

6 Breakdowns, causes and elimination

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

17 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

!

Having started up the coupling the tightening torques of the screws have to be inspected

during the usual inspection intervals.

With the use in hazardous locations please observe chapter 10.2 Inspection intervals for

couplings in - hazardous locations.

KTR does not assume any liability or warranty for the use of spare parts and accessories

which are not provided by KTR and for the damages which may incur as a result.

7 Disposal

8 Maintenance and service

9 Spares inventory, customer service addresses

In respect of environmental protection we would ask you to dispose of the packaging or products on termination of

their service life in accordance with the legal regulations and standards that apply, respectively.

Metal

Any metal components have to be cleaned and disposed of by scrap metal.

Nylon materials

Nylon materials have to be collected and disposed of by a waste disposal company.

ROTEX® is a low-maintenance coupling. We recommend to perform a visual inspection on the coupling at least

once a year. Please pay special attention to the condition of the spider of the coupling.

Since the flexible machine bearings of the driving and driven side settle during the course of load, please

inspect the alignment of the coupling and re-align the coupling, if necessary.

The coupling parts have to be inspected for damages.

The screw connections have to be inspected visually.

A basic requirement to ensure the operational readiness of the coupling is a stock of the most important spare

parts on site.

Contact addresses of the KTR partners for spare parts and orders can be obtained from the KTR homepage at

www.ktr.com.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

18 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Type

Hub design

Sizes

Material

001

Standard

1.0, 1.1, 1.3

1a (large hub)

clamping set 4.1, 4.2, 4.3

38 - 90

Cast iron (GJL)

100 - 180

Nodular iron (GJS)

14 - 180

Steel

Clamping sleeve

Taper clamping sleeve

24 - 125

019

Clamping ring hub

6.0, 6.5

19 - 90

Clamping hub

2.0, 2.1, 2.3

19 - 180

018

DKM

1.0, 1.1

spacers for drop-out center lengths 10

to 40 mm

19 - 90

Hubs, clamping hubs or similar types without feather keyways may be used in category 3

only.

T-PUR®

PUR

Temperature class

Ambient or

operating

temperature Ta

Max. surface

temperature

Temperature class

Ambient or

operating

temperature Ta

Max. surface

temperature

T3, T2, T1

- 50 °C to

+ 120 °C 1)

+ 140 °C 2)

T4, T3, T2, T1

- 30 °C to

+ 90 °C 1)

+ 110 °C 2)

T4

- 50 °C to + 115 °C

+ 135 °C

T5

- 30 °C to + 80 °C

+ 100 °C

T5

- 50 °C to + 80 °C

+ 100 °C

T6

- 30 °C to + 65 °C

+ 85 °C

T6

- 50 °C to + 65 °C

+ 85 °C

10 Enclosure A

Advice and instructions regarding the use in hazardous locations

10.1 Intended use in hazardous locations

ROTEX® DKM and ROTEX® ZS-DKM only with spacer made of steel or aluminium semi-finished products with a

yield point of R

≥ 250 N/mm2.

p0.2

Conditions of operation in hazardous locations

ROTEX® couplings are suitable for the use according to EU directive 2014/34/EU.

1. Industry (with the exception of mining)

Equipment group II of category 2 and 3 (coupling is not approved for equipment group 1)

Media class G (gases, fogs, steams), zone 1 and 2 (coupling is not approved for zone 0)

Media class D (dusts), zone 21 and 22 (coupling is not approved for zone 20)

Explosion group IIC (explosion class IIA and IIB are included in IIC)

Temperature class:

Explanation:

The maximum surface temperatures each result from the maximum permissible ambient or operating temperature Ta plus the maximum

temperature increase T of 20 K which has to be taken into account.

1) The ambient or operating temperature Ta is limited to + 90 °C (valid for T-PUR® only: + 120 °C) due to the permissible permanent

operating temperature of the elastomers used.

2) The maximum surface temperature of + 110 °C (valid for T-PUR® only: + 140 °C) applies for the use in locations which are potentially

subject to dust explosion, too.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

19 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Explosion group

Inspection intervals

3G

3D

For couplings which are classified in category 3G or 3D the operating and assembly

instructions that are usual for standard operation apply. During the standard operation

which has to be subject to the ignition risk analysis the couplings are free from any ignition

source. Merely the temperature increase produced by self-heating and depending on the

coupling type has to be considered:

for ROTEX®: T = 20 K

II 2GD c IIB

T4, T5, T6

An inspection of the torsional backlash and a visual inspection of the flexible spider/DZ

elements must be performed after 3,000 operating hours for the first time, at the latest after

6 months after start-up of the coupling.

If you note insignificant or no wear on the spider/DZ elements upon this initial inspection,

further inspections can each be performed after 6,000 operating hours or at the latest after

18 months, provided that the operating parameters remain the same.

If you note significant wear during the initial inspection so that it would be recommendable

to replace the spider/DZ elements, please find out the cause according to the table

„Breakdowns“, if possible.

The maintenance intervals must be adjusted to the modified operating parameters without

fail.

II 2GD c IIC

T4, T5, T6

An inspection of the torsional backlash and a visual inspection of the flexible spider/DZ

elements must be performed after 2,000 operating hours for the first time, at the latest after

3 months after start-up of the coupling.

If you note insignificant or no wear on the spider/DZ elements upon this initial inspection,

further inspections can each be performed after 4,000 operating hours or at the latest after

12 months, provided that the operating parameters remain the same.

If you note significant wear during the initial inspection so that it would be recommendable

to replace the spider/DZ elements, please find out the cause according to the table

„Breakdowns“, if possible.

The maintenance intervals must be adjusted to the modified operating parameters without

fail.

Hubs, clamping hubs or similar types without feather keyways may be used in category 3

only.

10 Enclosure A

Advice and instructions regarding the use in hazardous locations

10.1 Intended use in hazardous locations

10.2 Inspection intervals for couplings in hazardous locations

2. Mining

Equipment group I of category M2 (coupling is not approved for equipment group M1).

Permissible ambient temperature - 30 °C to + 90 °C (valid for T-PUR® only: - 50 °C to + 120 °C).

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

20 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

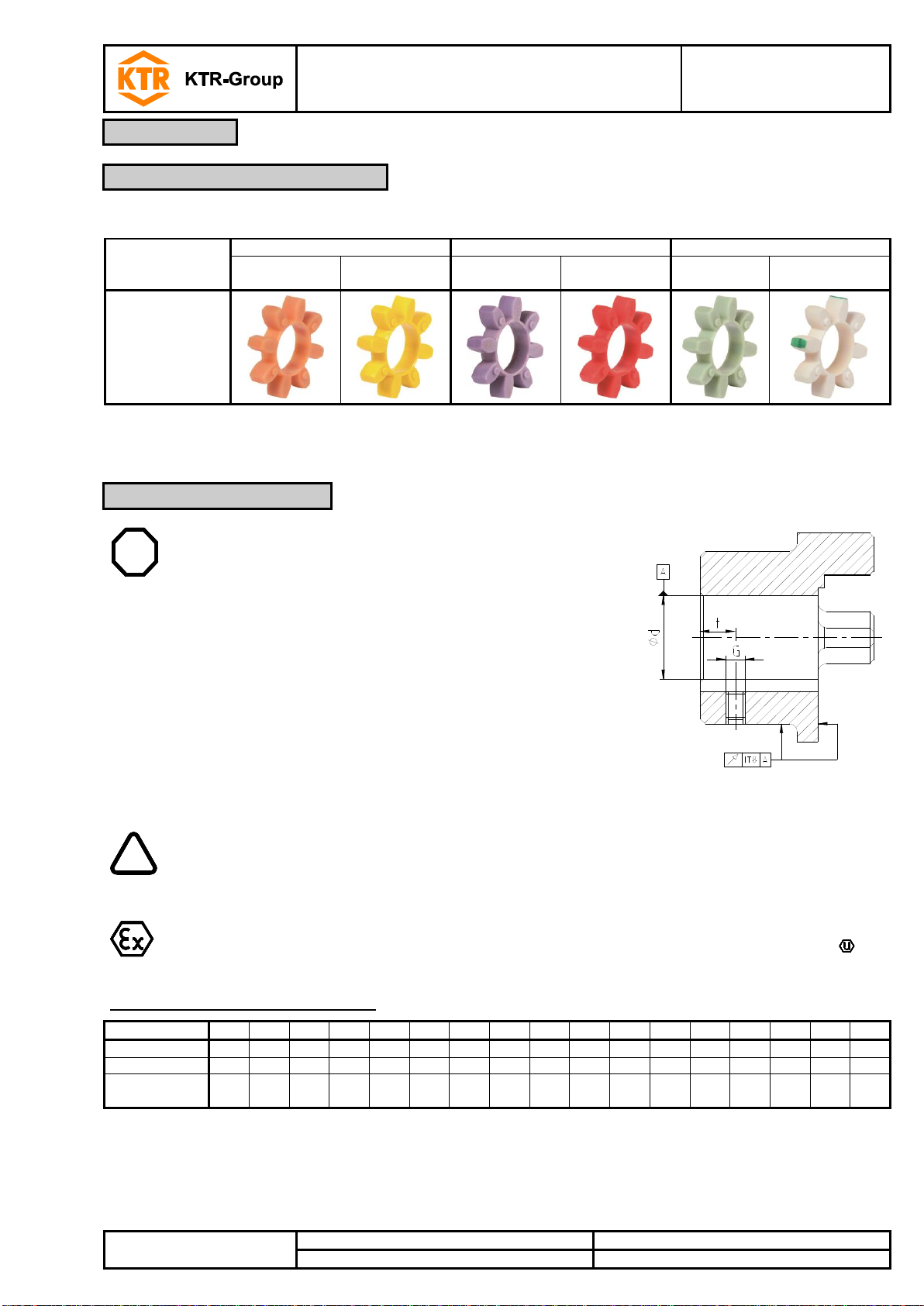

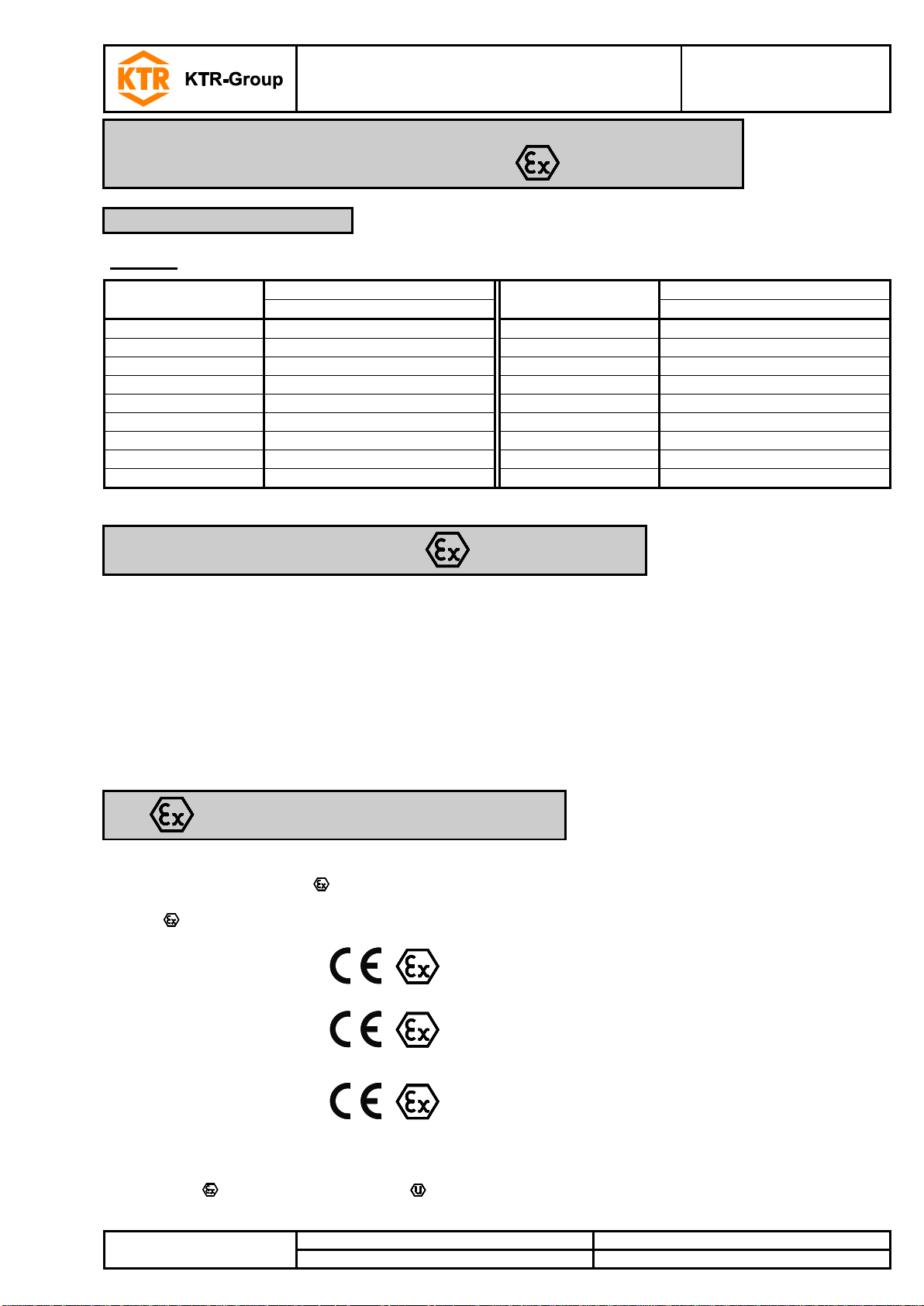

Illustration 17.1:

ROTEX® DZ

elements

Illustration 17.2:

ROTEX® spider

Illustration 16: ROTEX® coupling

!

In order to ensure a long service life of the coupling and avoid dangers with the use in

hazardous locations, the shaft ends must be accurately aligned.

Please absolutely observe the displacement figures indicated (see table 9 to 11). If the

figures are exceeded, the coupling will be damaged.

Illustration 18: Inspection of the limit of wear

Illustration 19: Wear of spider

10 Enclosure A

Advice and instructions regarding the use in hazardous locations

10.2 Inspection intervals for couplings in hazardous locations

10.3 Standard values of wear

ROTEX® coupling

Here the backlash between the cams of the coupling and the flexible spider/DZ element must be inspected by

means of a feeler gauge.

When reaching the wear limit maximum friction, the spider/DZ element must be replaced immediately,

irrespective of the inspection intervals.

In case of backlash > X mm, the flexible spider/DZ elements must be replaced.

Reaching the limits for replacing depends on the operating conditions and the existing operating parameters.

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

21 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

Size

Limits of wear (friction)

Size

Limits of wear (friction)

X

max.

[mm]

X

max.

[mm]

9 2 65 5 14 2 75 6 19 3 90 8 24 3 100 9 28 3 110 9 38 3 125

10

42 4 140

12

48 4 160

14

55 5 180

14

Short labelling:

(standard)

II 2GD c IIC T X/I M2 c X

Complete labelling:

(valid for T-PUR® only)

II 2G c IIC T6, T5, T4 resp. T3 - 50 °C Ta + 65 °C, + 80 °C,

+ 115 °C resp. + 120 °C

II 2D c T 140 °C/I M2 c - 50 °C Ta + 120 °C

Complete labelling:

(valid for PUR only)

II 2G c IIC T6, T5 resp. T4 - 30 °C Ta + 65 °C, + 80 °C resp.

+ 90 °C

II 2D c T 110 °C/I M2 c - 30 °C Ta + 90 °C

10 Enclosure A

Advice and instructions regarding the use in hazardous locations

10.3 Standard values of wear

10.4 Permissible coupling materials in hazardous locations

10.5 marking of coupling for hazardous locations

Table 12:

In the explosion groups IIA, IIB and IIC the following materials may be combined:

EN-GJL-250 (GG 25)

EN-GJS-400-15 (GGG 40)

Steel

Stainless steel

Semi-finished products of aluminium with a magnesium share of up to 7.5°% and a yield point of

R

≥ 250 N/mm2 are permitted for the use in hazardous locations.

p0.2

Aluminium diecast is generally excluded for hazardous locations.

Couplings for the use in hazardous locations are marked on at least one component completely and on the

remaining components by an label on the outside diameter of the hub or on the front side each for the

operating conditions permitted. The flexible spider or DZ element is excluded. For reason of limited space only the

symbol is stamped up to size 19.

The labelling with explosion group llC includes the explosion groups llA and llB.

If the symbol was stamped in addition to

KTR.

, the coupling component was supplied unbored or pilot bored by

ROTEX®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

22 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

EU Certificate of conformity

corresponding to EU directive 2014/34/EU dated 26 February 2014

and to the legal regulations

The manufacturer - KTR Systems GmbH, D-48432 Rheine - states that the

flexible ROTEX® couplings

in an explosion-proof design described in these operating/assembly instructions are devices

corresponding to article 2, 1. of directive 2014/34/EU and comply with the general safety and health

requirements according to enclosure II of directive 2014/34/EU.

The coupling described in here complies with the specifications of the following standards/guidelines:

DIN EN 1127-1

DIN EN 1127-2

DIN EN 13463-1

DIN EN 13463-5

CLC/TR 50404

The ROTEX® is in accordance with the specifications of the directive 2014/34/EU. One or several

directives mentioned in the corresponding type examination certificate IBExU13ATEXB016 X were in

part replaced by updated versions.

KTR Systems GmbH being the manufacturer confirms that the product mentioned above is in

accordance with the specifications of the new directives, too.

According to article 13 (1) b) ii) of directive 2014/34/EU the technical documentation is deposited with

the institution:

IBExU

Institut für Sicherheitstechnik GmbH

Fuchsmühlenweg 7

09599 Freiberg

Rheine,

2017-01-02

i. V.

i. V.

Place

Date

Reinhard Wibbeling

Engineering/R&D

Michael Brüning

Product Manager

10 Enclosure A

Advice and instructions regarding the use in hazardous locations

10.6 EU Certificate of conformity

Loading...

Loading...