KTM POWDER DISCHARGE SYSTEM (PDS) METALTITE® BALL VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be read fully and understood

Please use the valves according to warnings

and cautions described in this document.

Failure to do so could result in an accident

due to wrong storage, installation, operation,

maintenance and disassembling and/or serious

damage.

Please keep this manual in a handy place for

immediate reference; be sure to provide it to

purchaser, contractor, piping designer, user,

operator or maintenance technician.

KTM reserves the right to discontinue the

manufacture of, change or modify design and/

or construction of any KTM product during the

manufacturing procedure, without incurring

any obligation to accept for credit, to replace or

furnish or install such changes or modifications

on products previously or subsequently sold.

This document is subject to changes without

TABLE OF CONTENTS

notice.

1. Safety precautions ......................................... 1

2. Specifications ................................................ 2

3. Range of application...................................... 3

4. Storage and preservation before

installation ..................................................... 4

5. Transportation ............................................... 4

6. Installation ..................................................... 4

7. Operation ....................................................... 5

8. Maintenance .................................................. 6

9. Troubleshooting ............................................ 7

10. Valve disassembly ......................................... 7

11. Warranty ....................................................... 9

Please read through this manual completely

before operating the valves.

Powder Discharge System (PDS) Metaltite

Valves are usable for ON-OFF powder service

such as polyethylene, polypropylene and

hydrocarbon vapor etc.

®

Ball

1 SAFETY PRECAUTIONS

Precautions for using KTM valves safely are

highlighted with the following two warning

signs to indicate the level of danger posed.

Please read the postscript carefully to ensure

safety and prevent any damage before starting

to use the product.

WARNING

A potentially hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING

A potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Emerson.com/FinalControl © 2020 Emerson. All rights reserved. VCIOM-14921-EN 20/01

KTM POWDER DISCHARGE SYSTEM (PDS) METALTITE® BALL VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

2 SPECIFICATIONS

The safety of the valves and conformity with your equipment should be checked by the design

engineer or those who determine the specification based on the catalog or other technical data.

Upon arrival, the applicable conditions (temperature, pressure, fluid-characteristics,

environmental conditions, mounting gauge etc.) should be first checked to make sure they

are correct.

For the standard specifications, refer to the table below and the catalog.

SELECTION GUIDE

Example E0126 M K 62 BY A30 RF 200 PX

Valve code

E0105 Full bore, trunnion type, JIS 10K, ASME CL150, (DN 250 - 350)

E0106 Full bore, trunnion type, JIS 20K, ASME CL300, (DN 250 - 350)

E0125 Full bore, trunnion type, JIS 10K, ASME CL150, (DN 50 - 200)

E0126 Full bore, trunnion type, JIS 20K, ASME CL300, (DN 50 - 200)

E0108 Full bore, trunnion type, ASME CL600, (DN 50 - 350)

Sub code

M Metaltite

Special feature

K Powder service

Body code

32 JIS SCS14A (316SS), ASTM CF8M (316SS)

62 JIS SCPH2, ASTM WCB

Trim code Ball Description Seat Packing Stem

BY SCS14A / SFNi CF8M / SFNi 316 SS Stellited RTFE SCM 435 ENP

BG SCS14A / SFNi CF8M / SFNi 316 SS Stellited Graphite SCM 435 ENP

WY SCS14A / WC CF8M / WC 316 SS WC RTFE SCM 435 ENP

WG SCS14A / WC CF8M / WC 316 SS WC Graphite SCM 435 ENP

Flange code

A15 ASME Class 150 J10 JIS 10K

A30 ASME Class 300 J20 JIS 20K

A60 ASME Class 600 JPI Also available

Connection code

RF Raised face (smooth finish 125 to 250 AARH)

RJ Ring joint

Size

50 DN 50 (NPS 2) 100 DN 100 (NPS 4) 200 DN 200 (NPS 8) 300 DN 300 (NPS 12)

80 DN 80 (NPS 3) 150 DN 150 (NPS 6) 250 DN 250 (NPS 10) 350 DN 350 (NPS 14)

Option code

PX Powder proof devices around seat and stem areas

®

seat

NOTES

SFNi Nickel alloy overlay

ENP Electroless nickel plating

WC Tungsten carbide coating

2

KTM POWDER DISCHARGE SYSTEM (PDS) METALTITE® BALL VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

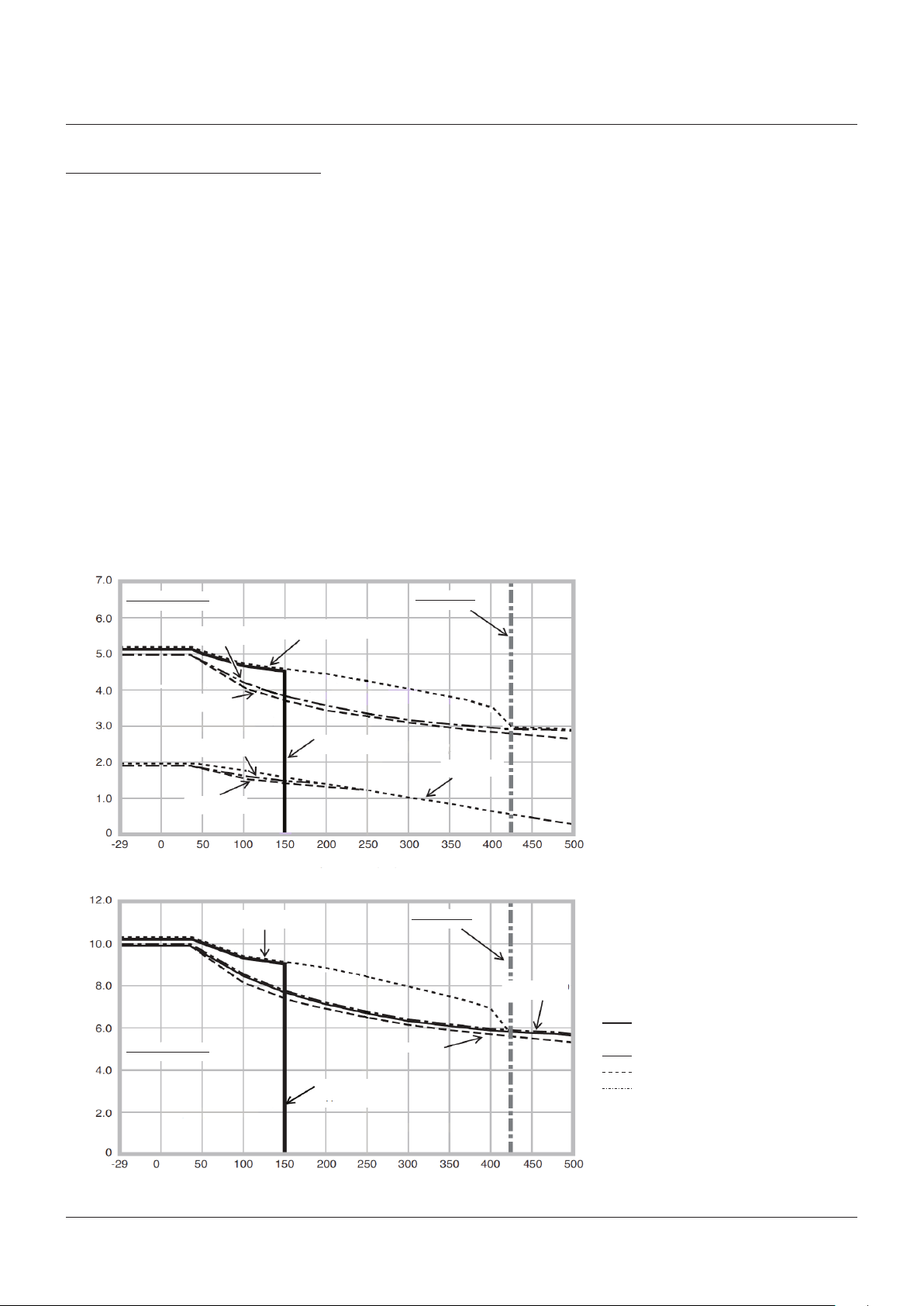

3 RANGE OF APPLICATION

Pressure/temperature rating

Powder Discharge System (PDS) Metaltite

®

Ball Valves have a range of application defined

by temperature and pressure. Please operate

the valve within the range shown below.

Operating the valve outside that range may

result in failure of valve body or parts and

leakage of the fluid.

(The pressure/temperature rating is defined

by body and seal ring material.)

WCB (SCPH2)

Lower limit -29°C (-5°C)

CF8M (SCS 14A)

Class 300

WCB (SCPH2) Class 300

BY, BG, WY, WG type

WARNING

Do not use valves beyond specifications or limits

indicated in the catalog.

CAUTION

1. These models may be used indoors or

outdoors. If however used in an environment

exposed to gas, an appropriate type and

material should be used to prevent corrosion

or rusting. (Details on the component

materials are provided in the catalogs.)

2. To prevent accidents, custom-made valves

for special treatment and operation should be

ordered for specific applications using oxygen

and hydrogen peroxide.

Class 150 and 300

WCB (SCPH2)

Upper limit 425°C

Pressure (MPa)Pressure (MPa)

WCB (SCPH2)

Lower limit -29°C (-5°C)

CF8 (SCS 13A)

Class 300

CF8M (SCS 14A)

Class 150

CF8 (SCS 13A)

Class 150

WCB (SCPH2)

BY, BG, WY, WG type

BY, BG, WY, WG type

Upper limit

Temperature (°C)

Class 600

BY, BG, WY, WG type

Upper limit

WCB (SCPH2)

Upper limit 425°C

CF8 (SCS 13A)

WCB (SCPH2)

Class 150

CF8M (SCS 14A)

BX type

Solid line indicate trim rating.

Dashed lines indicate body ratings.

WCB

CF8

CF8M

Materials in parentheses indicate equivalent JIS

material.

Lower limit temperature for SCPH2 is -5°С,

WCB is -29°С.

Temperature (°C)

3

Loading...

Loading...