KTM 450 SMR 2012 Owner's manual

OWNER'S MANUAL 2012

450 SMR

Art. no. 3211729en

DEAR KTM CUSTOMER 1

DEARKTM CUSTOMER

Congratulations on your decision to purchase a KTM motorcycle. You are now the owner of a state-of-the-art sports motorcycle that will

give you enormous pleasure if you service and maintain it accordingly.

We wish you a lot of enjoyment in riding this vehicle!

Enter the serial numbers of your vehicle below.

Chassis number ( p. 9) Dealer's stamp

Engine number ( p. 9)

The owner's manual corresponded to the latest state of this series at the time of printing. Slight deviations resulting from continuing

development and design of our motorcycles can however not be completely excluded.

All specifications are non-binding. KTM Sportmotorcycle AG specifically reserves the right to modify or delete technical specifications, prices, colors, forms, materials, services, designs, equipment, etc., without prior notice and without specifying reasons, to adapt

these to local conditions, as well as to stop production of a particular model without prior notice. KTM accepts no liability for delivery

options, deviations from illustrations and descriptions, as well as printing and other errors. The models portrayed partly contain special

equipment that does not belong to the regular scope of delivery.

© 2011 KTM-Sportmotorcycle AG, Mattighofen Austria

All rights reserved

Reproduction, even in part, as well as copying of all kinds, is permitted only with the express written permission of the copyright

owner.

ISO 9001(12 100 6061)

According to the international quality management standard ISO 9001, KTM uses quality assurance processes that lead

to the maximum possible quality of the products.

Issued by: TÜV Management Service

KTM-Sportmotorcycle AG

5230 Mattighofen, Austria

TABLE OF CONTENTS 2

TABLEOF CONTENTS

MEANS OF REPRESENTATION ............................................ 4

IMPORTANT INFORMATION ................................................ 5

VIEW OF VEHICLE............................................................... 7

Vehicle view, front left ..................................................... 7

Vehicle view, rear right..................................................... 8

SERIAL NUMBERS.............................................................. 9

Chassis number............................................................... 9

Type label....................................................................... 9

Engine number................................................................ 9

Fork part number............................................................. 9

Shock absorber part number ............................................. 9

CONTROLS....................................................................... 10

Clutch lever .................................................................. 10

Hot start lever ............................................................... 10

Hand brake lever ........................................................... 10

Throttle grip.................................................................. 10

Kill switch .................................................................... 10

Electric starter button .................................................... 11

Opening filler cap.......................................................... 11

Closing filler cap ........................................................... 11

Fuel tap........................................................................ 12

Choke........................................................................... 12

Shift lever..................................................................... 12

Foot brake lever............................................................. 13

Plug-in stand ................................................................ 13

PREPARING FOR USE ....................................................... 14

Advice on first use ......................................................... 14

Running-in the engine ................................................... 15

RIDING INSTRUCTIONS .................................................... 16

Checks and maintenance when preparing for use.............. 16

Starting ........................................................................ 16

Starting off ................................................................... 17

Shifting, riding.............................................................. 17

Braking ........................................................................ 17

Stopping, parking .......................................................... 18

Refueling...................................................................... 18

SERVICE SCHEDULE......................................................... 19

Service schedule ........................................................... 19

Service work (as additional order).................................... 20

TUNING THE CHASSIS...................................................... 21

Checking the basic suspension setting against the rider's

weight .......................................................................... 21

Compression damping of shock absorber.......................... 21

Adjusting the low-speed compression damping of the

shock absorber .............................................................. 21

Adjusting the high-speed compression damping of the

shock absorber .............................................................. 22

Adjusting the rebound damping of the shock absorber....... 22

Measuring rear wheel sag unloaded ................................. 23

Checking static sag of shock absorber.............................. 23

Checking riding sag of shock absorber ............................. 23

Adjusting the spring preload of the shock absorber x ...... 24

Adjusting the riding sag x............................................. 24

Checking basic setting of fork ......................................... 25

Adjusting the compression damping of the fork ................ 25

Adjusting the rebound damping of the fork....................... 25

Fork offset .................................................................... 26

Adjusting the fork offset x ............................................ 26

Handlebar position ........................................................ 26

Adjusting handlebar position x...................................... 26

SERVICE WORK ON THE CHASSIS ..................................... 28

Raising the motorcycle with the lift stand ........................ 28

Removing the motorcycle from the lift stand .................... 28

Bleeding fork legs.......................................................... 28

Cleaning the dust boots of the fork legs ........................... 28

Removing the fork legs x.............................................. 29

Installing the fork legs x............................................... 29

Removing the fork protector............................................ 30

Installing the fork protector ............................................ 30

Removing the lower triple clamp x ................................ 30

Installing the lower triple clamp x................................. 31

Checking steering head bearing play................................ 32

Adjusting play of steering head bearing x....................... 32

Greasing the steering head bearing x............................. 33

Removing the start number plate .................................... 33

Installing the start number plate ..................................... 33

Removing the front fender .............................................. 34

Installing the front fender............................................... 34

Removing the shock absorber x..................................... 34

Installing the shock absorber x ..................................... 35

Removing the seat ......................................................... 35

Mounting the seat ......................................................... 36

Removing the air filter box lid......................................... 36

Installing the air filter box lid.......................................... 36

Removing the air filter x............................................... 36

Installing the air filter x ............................................... 37

Cleaning the air filter and air filter box x........................ 37

Removing main silencer ................................................. 37

Installing the main silencer ............................................ 38

Changing the glass fiber yarn filling of the main

silencer x ................................................................... 38

Removing the fuel tank x ............................................. 39

Installing the fuel tank x .............................................. 39

Checking for chain dirt accumulation .............................. 40

Cleaning the chain......................................................... 40

Checking the chain tension ............................................ 41

Adjusting the chain tension ............................................ 41

Checking the chain, rear sprocket, engine sprocket and

chain guide................................................................... 42

Adjusting the chain guide x.......................................... 44

Checking the frame x................................................... 44

Checking the swingarm x ............................................. 44

Checking the throttle cable routing.................................. 45

Checking the rubber grip ................................................ 45

Additionally securing the rubber grip ............................... 45

Adjusting basic position of clutch lever............................ 45

Checking the fluid level of hydraulic clutch...................... 46

Changing the hydraulic clutch fluid x ............................ 46

BRAKES........................................................................... 47

Checking free travel on hand brake lever.......................... 47

Adjusting the basic position of the hand brake lever.......... 47

Checking the brake discs................................................ 47

Checking the front brake fluid level ................................. 48

Adding front brake fluid x ............................................ 48

Checking the front brake linings...................................... 49

Changing the front brake linings x................................. 49

Checking the free travel of the foot brake lever ................. 51

Adjusting the basic position of the foot brake lever x ...... 51

Checking rear brake fluid level ........................................ 52

Adding brake fluid to the rear brake circuit x ................. 52

Checking rear brake linings ............................................ 53

Changing the rear brake linings x.................................. 53

TABLE OF CONTENTS 3

WHEELS, TIRES ............................................................... 54

Removing the front wheel x .......................................... 54

Installing the front wheel x........................................... 54

Removing the rear wheel x ........................................... 55

Installing the rear wheel x ............................................ 56

Checking the tire condition............................................. 57

Checking the tire air pressure ......................................... 57

Checking spoke tension.................................................. 57

ELECTRICAL SYSTEM ....................................................... 59

Removing the battery x ................................................ 59

Installing the battery x................................................. 59

Recharging the battery x .............................................. 59

Removing the main fuse................................................. 60

Installing the main fuse ................................................. 61

COOLING SYSTEM ............................................................ 62

Cooling system .............................................................. 62

Checking the anti-freeze and coolant level ....................... 62

Checking the coolant level.............................................. 62

Draining the coolant x.................................................. 63

Refilling coolant x ....................................................... 63

TUNING THE ENGINE ....................................................... 64

Checking the play in the throttle cable............................. 64

Adjusting the play in the throttle cable x ....................... 64

Carburetor - idle ............................................................ 64

Carburetor - adjusting the idle speed x .......................... 65

Emptying the carburetor float chamber x ....................... 65

Ignition curve plug connection ........................................ 66

Changing the ignition curve ............................................ 66

Checking the basic position of the shift lever.................... 66

Adjusting the basic position of the shift lever x .............. 67

Antihopping clutch ........................................................ 67

Adjusting the antihopping clutch .................................... 68

SERVICE WORK ON THE ENGINE ...................................... 70

Checking engine oil level................................................ 70

Changing the engine oil and oil filter, cleaning the oil

screen x ..................................................................... 70

Adding engine oil .......................................................... 72

CLEANING, CARE ............................................................. 73

Cleaning motorcycle ...................................................... 73

STORAGE ......................................................................... 74

Storage......................................................................... 74

Preparing for use after storage ........................................ 74

TROUBLESHOOTING......................................................... 75

TECHNICAL DATA - ENGINE .............................................. 77

Capacity - engine oil ...................................................... 77

Capacity - coolant.......................................................... 77

TECHNICAL DATA - ENGINE TIGHTENING TORQUES .......... 78

TECHNICAL DATA - CARBURETOR..................................... 80

TECHNICAL DATA - CHASSIS ............................................ 81

Tires ............................................................................ 81

Capacity - fuel............................................................... 82

TECHNICAL DATA - FORK.................................................. 83

Capacity - fork oil .......................................................... 83

TECHNICAL DATA - SHOCK ABSORBER ............................. 84

TECHNICAL DATA - CHASSIS TIGHTENING TORQUES ........ 85

SUBSTANCES................................................................... 86

AUXILIARY SUBSTANCES.................................................. 88

STANDARDS..................................................................... 90

INDEX .............................................................................. 91

MEANS OF REPRESENTATION 4

Symbols used

The symbols used are explained below.

Indicates an expected reaction (e.g. to a work step or a function).

Indicates an unexpected reaction (e.g. to a work step or a function).

All work marked with this symbol requires specialist knowledge and technical understanding. In the interest of

your own safety, have these jobs performed in an authorized KTM workshop. There, your motorcycle will be serviced optimally by specially trained experts using the specialist tools required.

Identifies a page reference (more information is provided on the specified page).

Formats used

The typographical and other formats used are explained below.

Specific name Identifies a proprietary name.

®

Name

Brand™ Identifies a trademark.

Identifies a protected name.

IMPORTANT INFORMATION 5

Use definition

KTM sport motorcycles are designed and built to withstand the normal stresses and strains of competitive use. The motorcycles comply with currently valid regulations and categories of the top international motorsport organizations.

Info

The motorcycle must be used only in closed off areas remote from public road traffic.

Service

A prerequisite for perfect operation and prevention of premature wear is that the service, care and tuning work on the engine and

chassis is properly carried out as described in the owner's manual. Poor adjustment and tuning of the engine and chassis can lead to

damage and breakage of components.

Using the vehicle in difficult conditions such as on sand or very muddy or wet terrain can lead to above-average wear of components

such as the drive train or the brakes. For this reason, it may be necessary to service or replace worn parts before the limit specified in

the service schedule is reached.

Pay careful attention to the prescribed running-in period and service intervals. If you observe these exactly, you will ensure a much

longer service life for your motorcycle.

Warranty

The work prescribed in the service schedule must be carried out by an authorized KTM workshop only and confirmed in the customer's

service record and in the KTM dealer.net; otherwise, all warranty claims will be void. No warranty claim can be honored for damage

resulting from manipulation and/or other changes to the vehicle.

Fuel, oils, etc.

You should use the fuels, oils and greases according to specifications as listed in the owner's manual.

Spare parts, accessories

For your own safety, only use spare parts and accessory products that have been approved and/or recommended by KTM and have

them installed by an authorized KTM workshop. KTM accepts no liability for other products and any resulting damage or loss.

Some spare parts and accessories are specified in brackets in the respective descriptions. Your KTM dealer will be happy to advise

you.

You will find the current KTM PowerParts for your vehicle on the KTM website.

International KTM Website: http://www.ktm.com

Work rules

Special tools are necessary for some of the work. These are not included with the vehicle and can be ordered under the number in

parentheses. Ex: valve spring compressor (59029019000)

During assembly, non-reusable parts (e.g. self-locking screws and nuts, seals and seal rings, O-rings, pins, lock washers) must be

replaced by new parts.

If thread lock (e.g. Loctite®) is used for screw connections, be sure to comply with the manufacturer's specific instructions on its

usage.

Parts that you want to reuse following repairs and servicing should be cleaned and checked for damage and wear. Change damaged or

worn parts.

Ensure that the vehicle is safe to operate after completing repair and maintenance work.

Transport

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

Note

Fire hazard Some vehicle components become very hot when the vehicle is operated.

– Do not park the vehicle near flammable or explosive substances. Do not place objects on the vehicle while it is still warm from

being run. Always let the vehicle cool first.

– Switch off the engine.

– Turn the handle of the fuel tap to the OFF position. (Figure 500178-10 p. 12)

– Use straps or other suitable devices to secure the motorcycle against accidents or falling over.

IMPORTANT INFORMATION 6

Environment

Motorcycling is a wonderful sport and we naturally hope that you can enjoy it to the full. However, it is a potential problem for the

environment and can lead to conflicts with other persons. But if you use your motorcycle responsibly, you can ensure that such problems and conflicts do not have to occur. To protect the future of motorcycle sport, make sure that you use your motorcycle legally, display environmental consciousness, and respect the rights of others.

Notes/warnings

Pay close attention to the notes/warnings.

Info

Various information and warning labels are affixed to the vehicle. Do not remove information/warning labels. If they are missing, you or others may not recognize potential hazards and may therefore be injured.

Grades of risks

Danger

Identifies a danger that will immediately and invariably lead to fatal or serious permanent injury if the appropriate measures

are not taken.

Warning

Identifies a danger that is likely to lead to fatal or serious injury if the appropriate measures are not taken.

Caution

Identifies a danger that may lead to minor injuries if the appropriate measures are not taken.

Note

Identifies a danger that will lead to considerable machine and material damage if the appropriate measures are not taken.

Warning

Identifies a danger that will lead to environmental damage if the appropriate measures are not taken.

Owner's manual

– It is important that you read this owner's manual carefully and completely before making your first trip. It contains information and

tips to help you operate and handle your motorcycle. Only then will you learn how to best adjust the motorcycle for your own use

and how to protect yourself from injury. The owner's manual also contains important information on servicing the motorcycle.

– The owner's manual is an important component of the motorcycle and should be handed over to the new owner if the vehicle is

sold.

VIEW OF VEHICLE 7

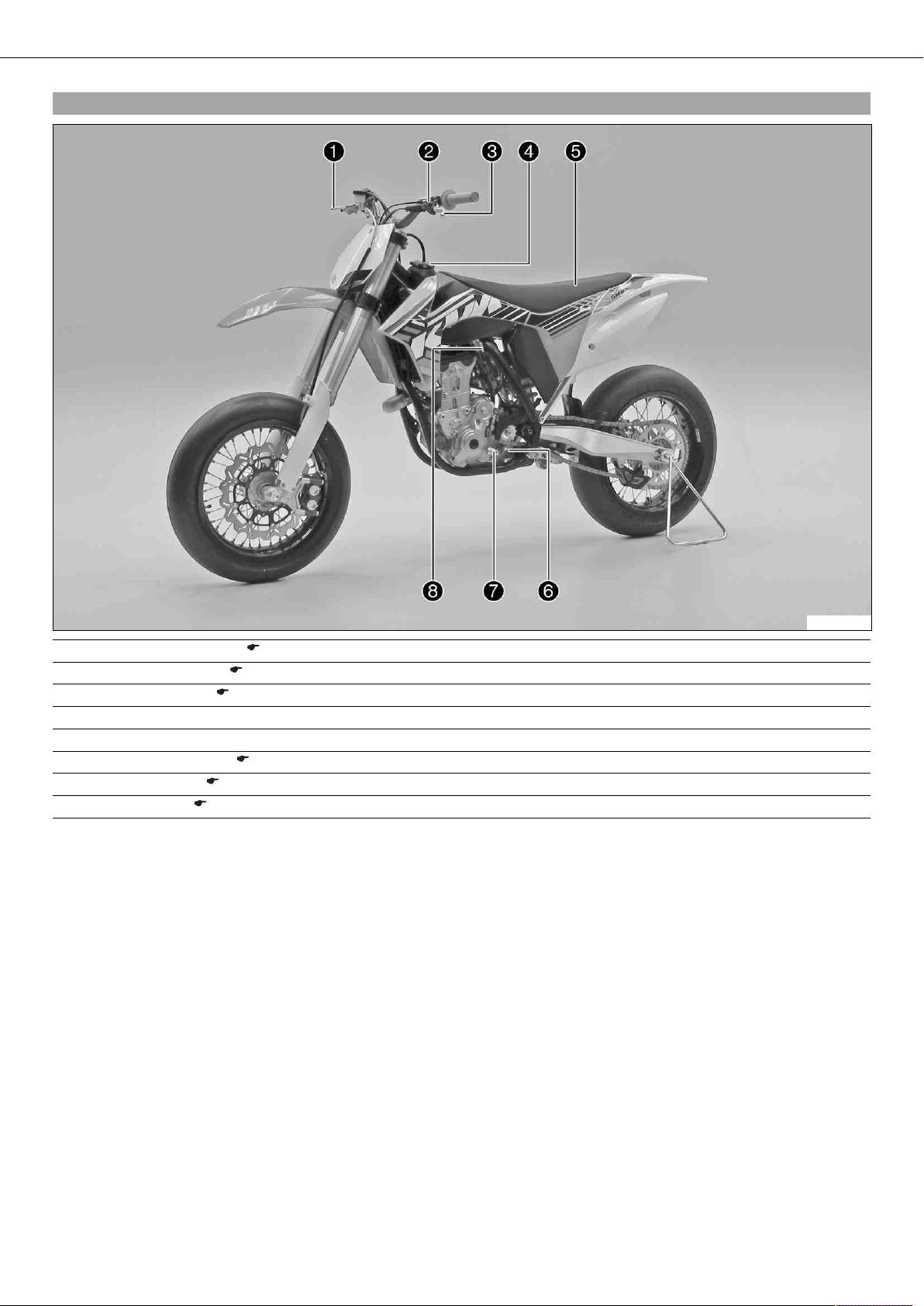

3.1Vehicle view, front left

1 Hand brake lever ( p. 10)

2 Hot start lever ( p. 10)

3 Clutch lever ( p. 10)

4 Filler cap

5 Seat

6 Engine number ( p. 9)

7 Shift lever ( p. 12)

8 Fuel tap ( p. 12)

B00837-10

VIEW OF VEHICLE 8

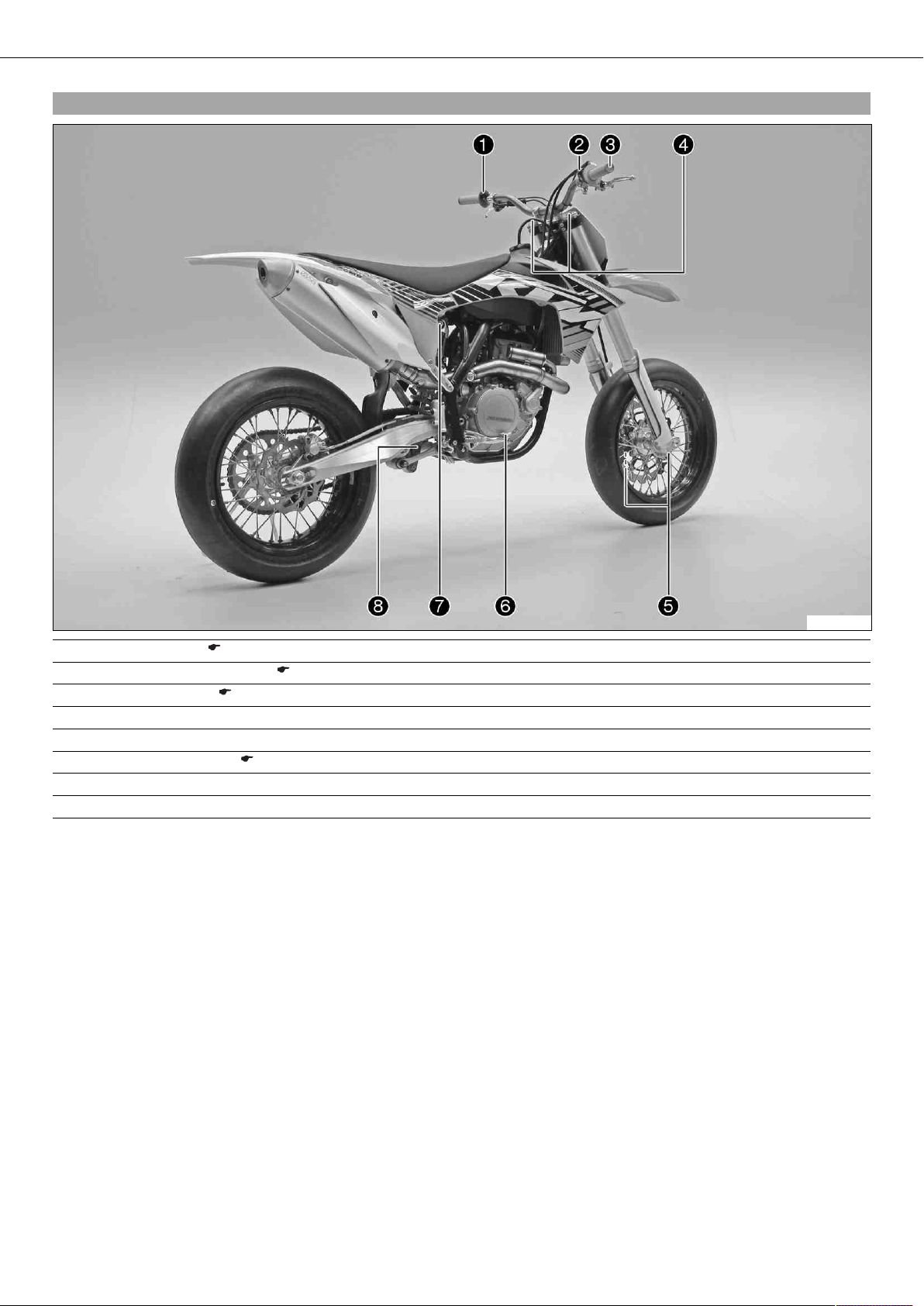

3.2Vehicle view, rear right

1 Kill switch ( p. 10)

2 Electric starter button ( p. 11)

3 Throttle grip ( p. 10)

4 Fork compression adjustment

5 Fork rebound adjustment

6 Foot brake lever ( p. 13)

7 Shock absorber compression adjustment

8 Shock absorber rebound adjustment

B00838-10

SERIAL NUMBERS 9

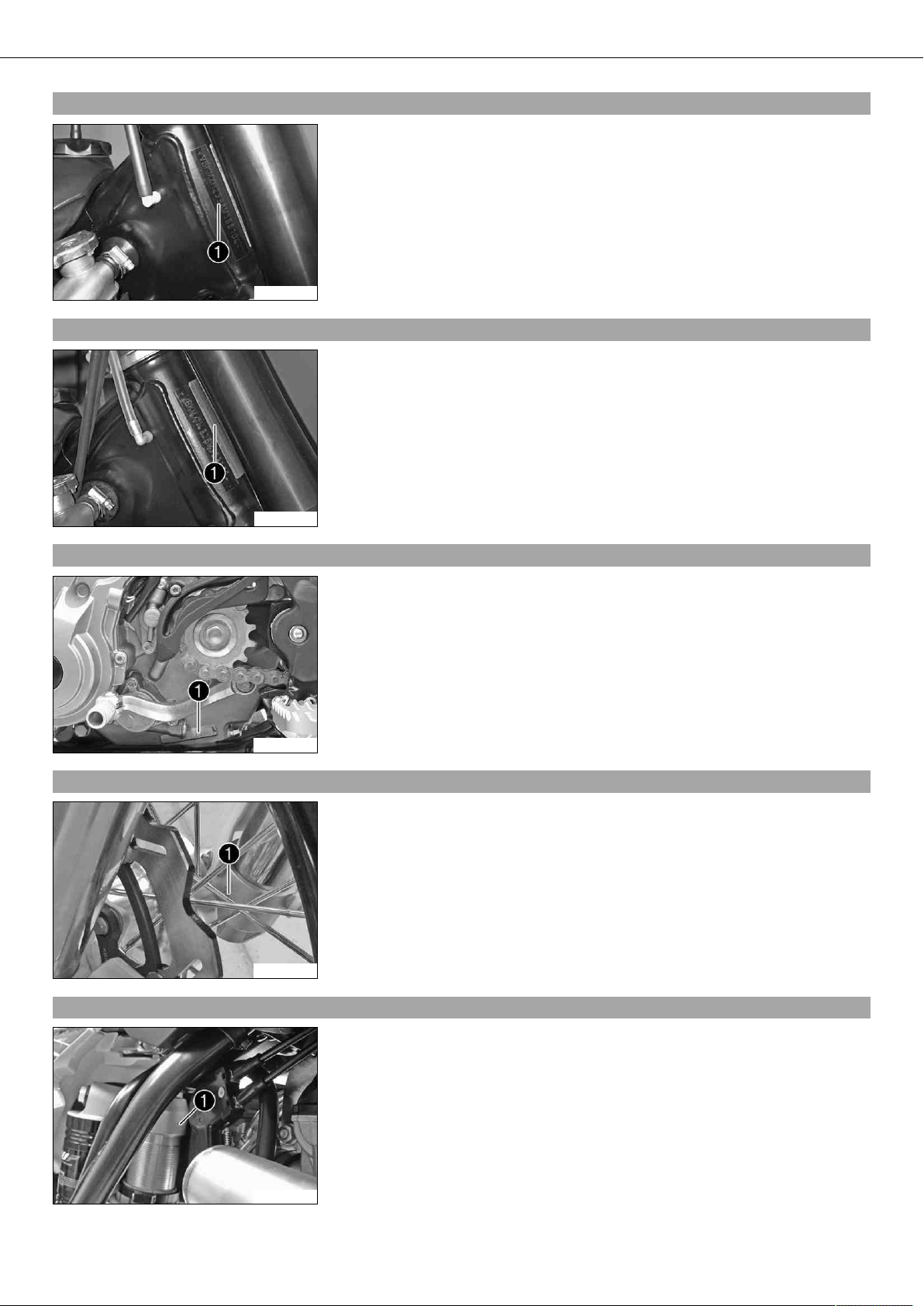

4.1Chassis number

The chassis number is stamped on the steering head on the right.

400193-10

4.2Type label

The type label is fixed to the front of the steering head.

4.3Engine number

4.4Fork part number

400284-10

The engine number is stamped on the left side of the engine under the engine

sprocket.

B00425-10

The fork part number is stamped on the inner side of the fork stub.

4.5Shock absorber part number

B00879-10

The shock absorber part number is stamped on the top of the shock absorber above

the adjusting ring on the engine side.

B00840-10

CONTROLS 10

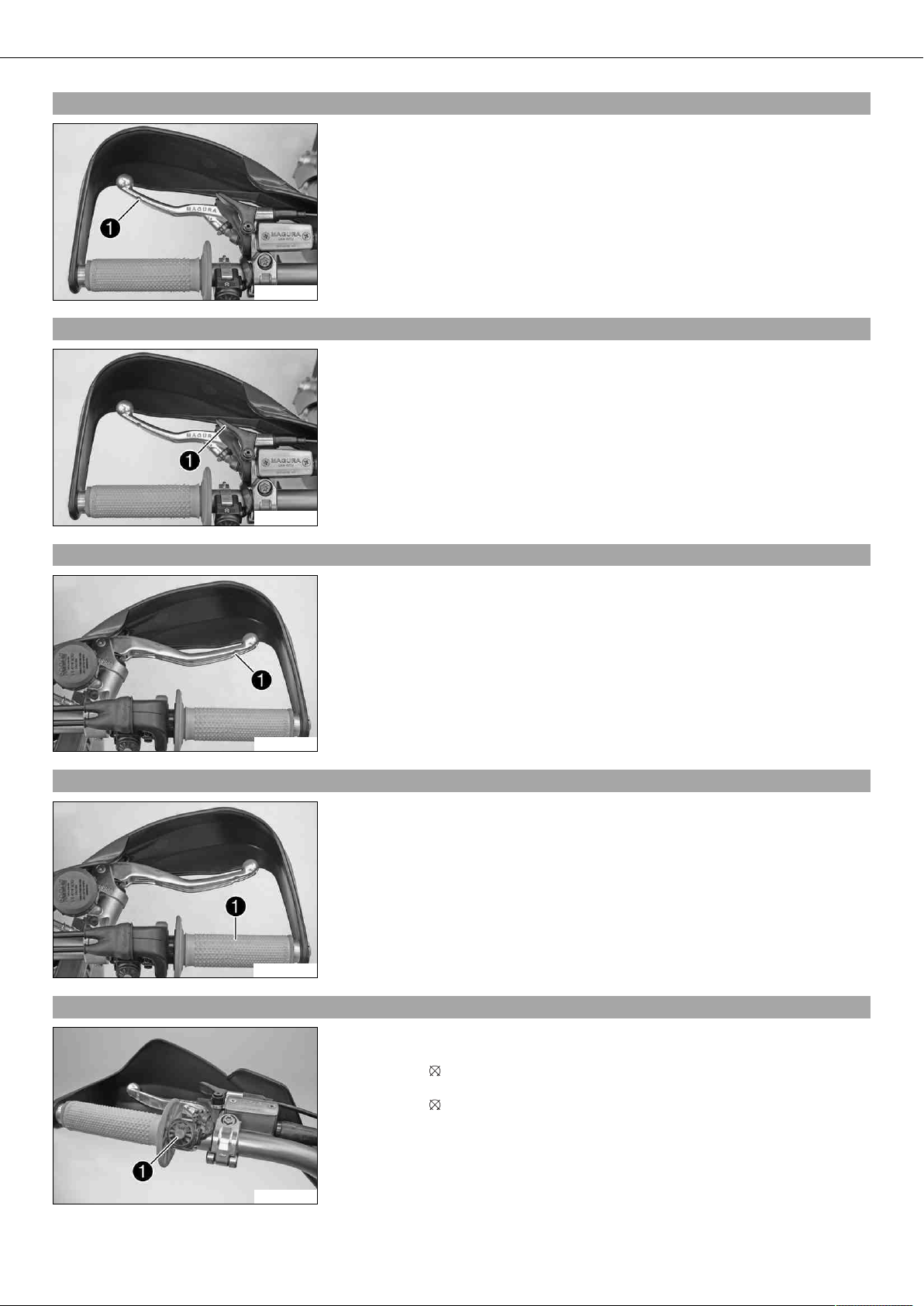

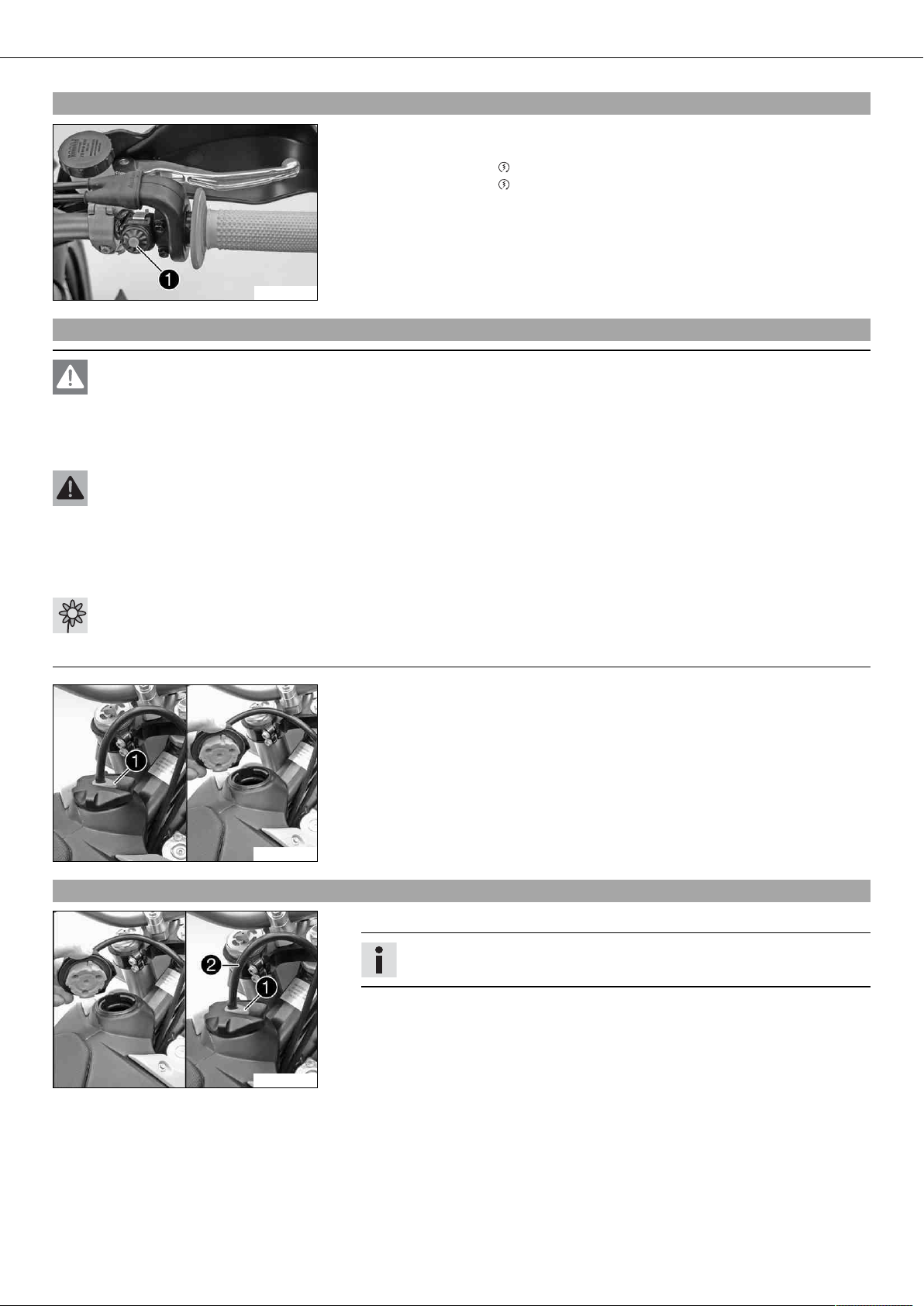

5.1Clutch lever

The clutch lever is fitted on the left side of the handlebar.

The clutch is hydraulically operated and self-adjusting.

100826-10

5.2Hot start lever

The hot start lever is fitted on the left side of the handlebar.

If you pull the hot start lever to the handlebar during the start procedure, a bore is

opened in the carburetor through which the engine can draw in extra air. This gives a

leaner fuel-air mixture, which is needed for a hot start.

Possible states

• Hot start function activated – Hot start lever is pulled out to the stop.

• Hot start function deactivated – Hot start lever is pushed back to the stop.

5.3Hand brake lever

5.4Throttle grip

100826-11

Hand brake lever is located on the right side of the handlebar.

The hand brake lever is used to activate the front brake.

100827-10

The throttle grip is fitted on the right side of the handlebar.

5.5Kill switch

B00839-10

Kill switch is fitted on the left side of the handlebar.

Possible states

• Kill switch in basic position – In this position, the ignition circuit is closed, and

the engine can be started.

• Kill switch pressed – In this position, the ignition circuit is interrupted, a running engine stops, and a non-running engine will not start.

100825-10

CONTROLS 11

5.6Electric starter button

Electric starter button is fitted on the right side of the handlebar.

Possible states

• Electric starter button in basic position

• Electric starter button pressed – In this position, the electric starter is actuated.

100828-10

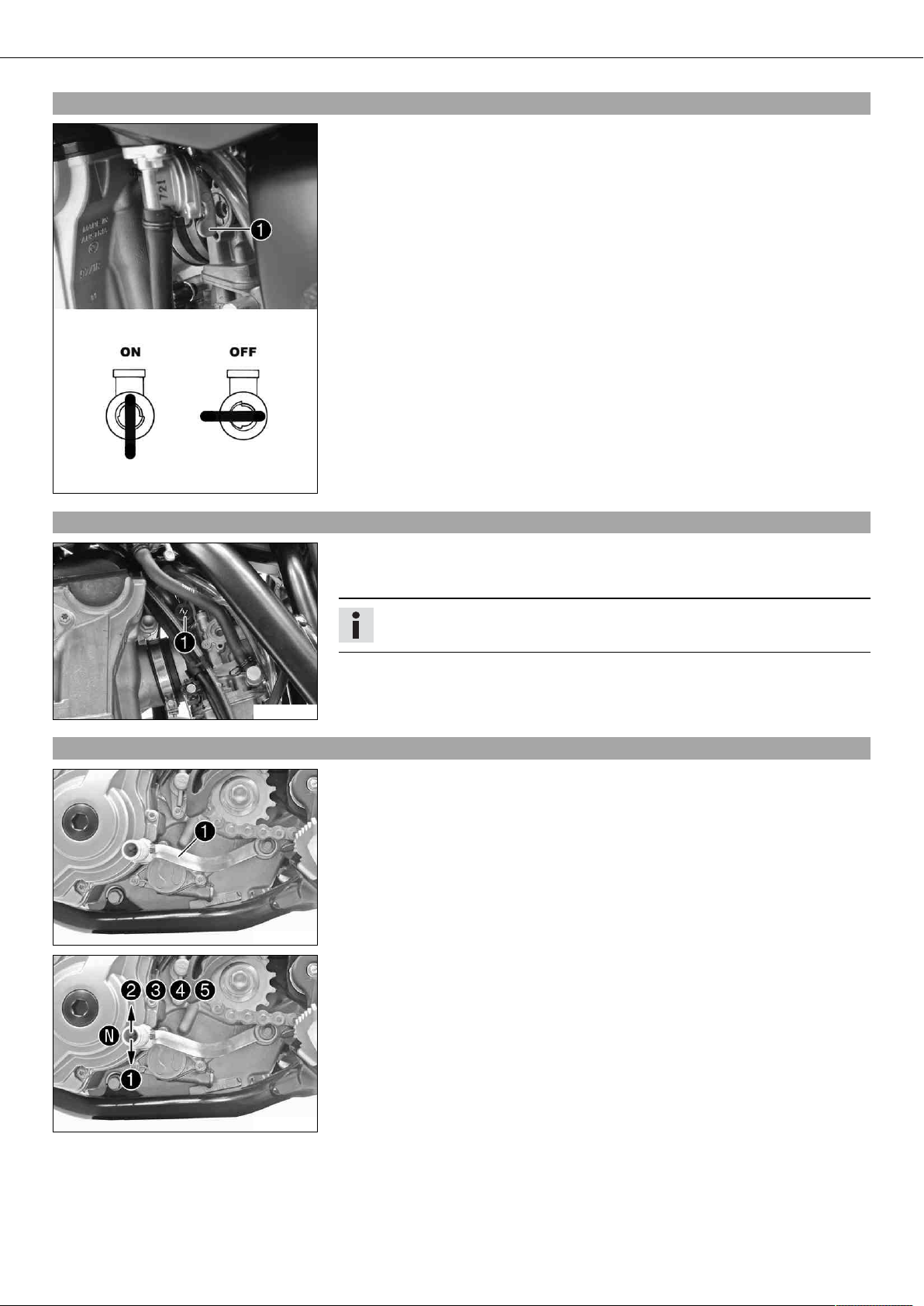

5.7Opening filler cap

Danger

Fire hazard Fuel is highly flammable.

– Never refuel the vehicle near open flames or burning cigarettes, and always switch off the engine first. Be careful that no

fuel is spilt, especially on hot vehicle components. Clean up spilt fuel immediately.

– Fuel in the fuel tank expands when warm and can escape if the tank is overfilled. See the notes on refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

– Avoid contact between fuel and skin, eyes and clothing. Do not inhale fuel vapors. If fuel gets into your eyes, rinse immedi-

ately with water and contact a doctor. Wash affected skin areas immediately with soap and water. If fuel is swallowed, contact a doctor immediately. Change clothing that has come into contact with fuel. Store fuel in a suitable canister according

to regulations and keep it out of the reach of children.

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

– Do not allow fuel to get into the ground water, the ground, or the sewage system.

– Press release button , turn filler cap counterclockwise and lift it upwards and

remove.

B00841-10

5.8Closing filler cap

– Replace the filler cap and turn clockwise until the release button locks in place.

Info

Route the fuel tank breather hose without kinking.

B00842-10

CONTROLS 12

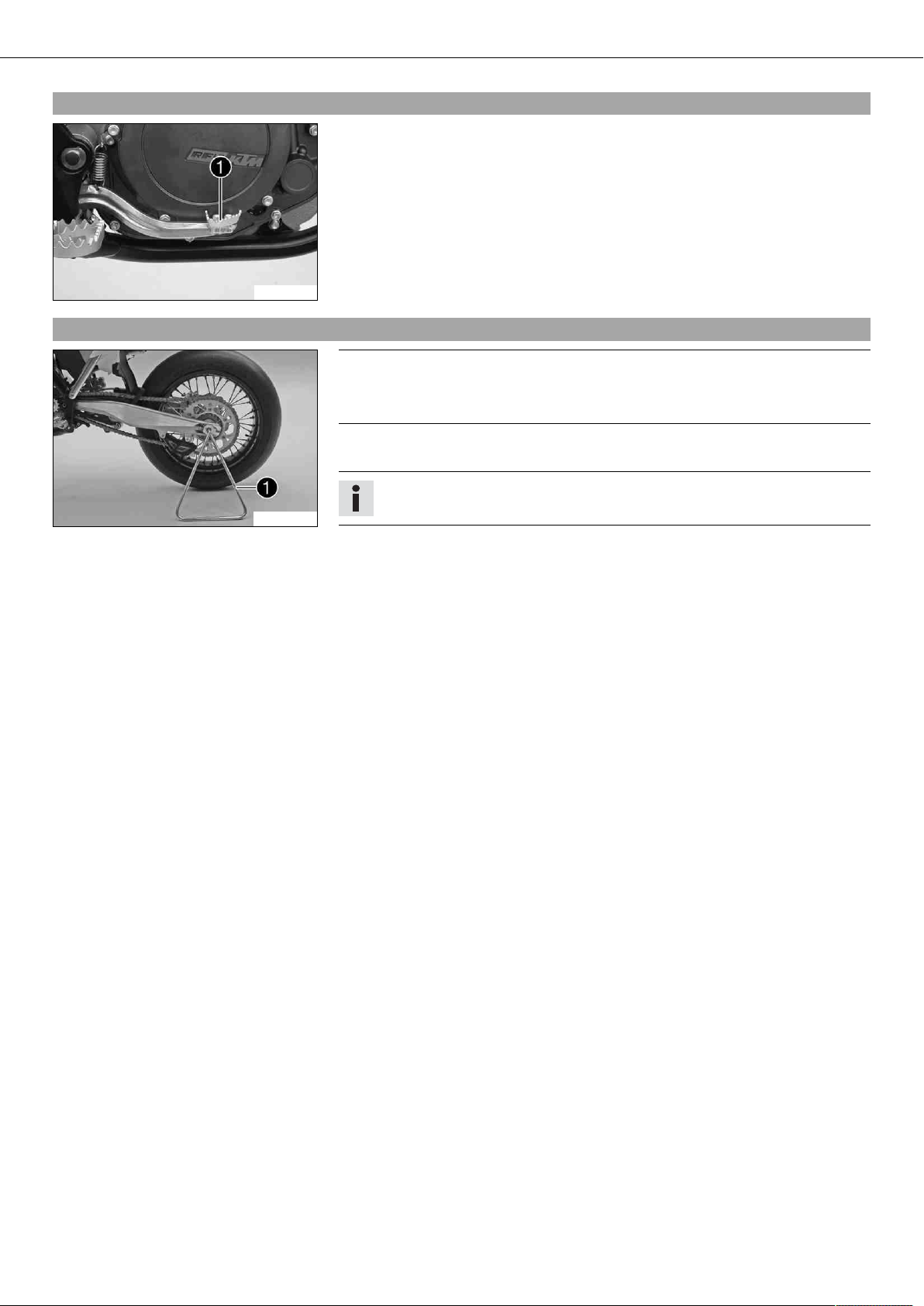

5.9Fuel tap

With the tap handle on the fuel tap, you can open or close the supply of fuel to the

carburetor.

Possible states

• Fuel supply closed OFF – No fuel can flow from the tank to the carburetor.

• Fuel supply open ON – Fuel can flow from the tank to the carburetor. The fuel tank

empties completely.

500178-10

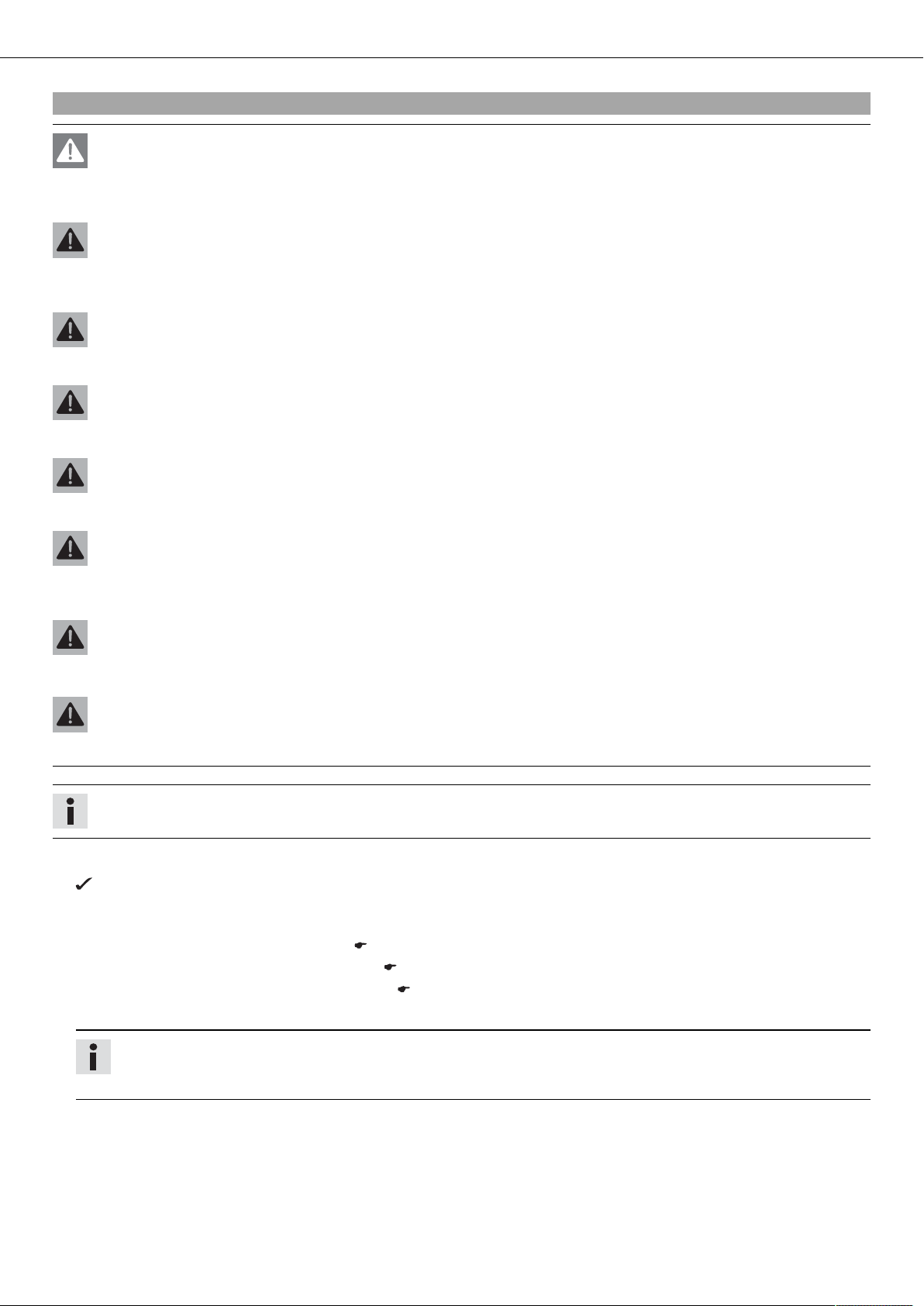

5.10Choke

5.11Shift lever

B00843-10

B00426-11

Choke is fitted on the left side of the carburetor.

Activating the choke function frees an opening through which the engine can draw

extra fuel. This gives a richer fuel-air mixture, which is needed for a cold start.

Info

If the engine is warm, the choke function must be deactivated.

Possible states

• Choke function activated – The choke lever is pulled out to the stop.

• Choke function deactivated – The choke lever is pushed in to the stop.

The shift lever is mounted on the left side of the engine.

The gear positions can be seen in the photograph.

The neutral or idle position is between the first and second gears.

B00426-10

CONTROLS 13

5.12Foot brake lever

Foot brake lever is located in front of the right footrest.

The foot brake lever is used to activate the rear brake.

400205-10

5.13Plug-in stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

To stand the motorcycle, plug the plug-in stand into the left side of the wheel spindle.

Info

B00844-10

Before riding, remove the plug-in stand.

PREPARING FOR USE 14

6.1Advice on first use

Danger

Danger of accidents Danger arising from the rider's judgement being impaired.

– Do not operate the vehicle while under the influence of alcohol, drugs and certain medications or physically or mentally

impaired.

Warning

Risk of injury Missing or poor protective clothing present an increased safety risk.

– Wear protective clothing (helmet, boots, gloves, pants and jacket with protectors) every time you ride the vehicle. Always

wear protective clothing, which must be undamaged and meet legal requirements.

Warning

Danger of crashing Poor vehicle handling due to different tire tread patterns on front and rear wheels.

– The front and rear wheels must be fitted with tires with similar tread patterns to prevent loss of control over the vehicle.

Warning

Danger of accidents Critical riding behavior due to inappropriate riding.

– Adapt your riding speed to the road conditions and your riding ability.

Warning

Danger of accidents Accident risk caused by presence of a passenger.

– Your vehicle is not designed to carry passengers. Do not ride with a passenger.

Warning

Danger of accidents Failure of brake system.

– If the foot brake lever is not released, the brake linings drag continuously. The rear brake may fail due to overheating. Take

your foot off the foot brake lever when you are not braking.

Warning

Danger of accidents Unstable riding behavior.

– Do not exceed the maximum permissible weight and axle loads.

Warning

Risk of misappropriation Usage by unauthorized persons.

– Never leave the vehicle while the engine is running. Secure the vehicle against use by unauthorized persons.

Info

When using your motorcycle, remember that others may feel disturbed by excessive noise.

– Make sure that the pre-delivery inspection work has been carried out by an authorized KTM workshop.

You receive a delivery certificate and the service record at vehicle handover.

– Before your first trip, read the entire operating instructions carefully.

– Get to know the controls.

– Adjust the basic position of the clutch lever. ( p. 45)

– Adjust the basic position of the hand brake lever. ( p. 47)

–

Adjust the basic position of the foot brake lever. x ( p. 51)

– Get used to handling the motorcycle on a suitable piece of land before making a longer trip.

Info

Your motorcycle is not authorized for riding on public roads.

Offroad, you should be accompanied by another person on another machine so that you can help each other.

– Try also to ride as slowly as possible and in a standing position to get a better feeling for the vehicle.

– Do not make any offroad trips that over-stress your ability and experience.

– Hold the handlebar firmly with both hands and keep your feet on the footrests when riding.

– Do not exceed the overall maximum permitted weight and the axle loads.

PREPARING FOR USE 15

Guideline

Maximum permissible overall weight 335 kg (739 lb.)

Maximum permissible front axle load 145 kg (320 lb.)

Maximum permissible rear axle load 190 kg (419 lb.)

– Run in the engine. ( p. 15)

6.2Running-in the engine

– During the running-in phase, do not exceed the specified engine speed and engine performance.

Guideline

Maximum engine speed

During the first operating hour 7,000 rpm

Maximum engine performance

During the first 3 operating hours ≤ 75 %

– Avoid fully opening the throttle!

RIDING INSTRUCTIONS 16

7.1Checks and maintenance when preparing for use

Info

Before every trip, check the condition of the vehicle and ensure that it is safe to operate.

The vehicle must be in perfect technical condition when used.

– Check the engine oil level. ( p. 70)

– Check the front brake fluid level. ( p. 48)

– Check the rear brake fluid level. ( p. 52)

– Check the front brake linings. ( p. 49)

– Check the rear brake linings. ( p. 53)

– Check that the brake system is functioning properly.

– Check the coolant level. ( p. 62)

– Check for chain dirt accumulation. ( p. 40)

– Check the chain, rear sprocket, engine sprocket and chain guide. ( p. 42)

– Check the chain tension. ( p. 41)

– Check the tire condition. ( p. 57)

– Check the tire air pressure. ( p. 57)

– Check the spoke tension. ( p. 57)

– Clean the dust boots of the fork legs. ( p. 28)

– Bleed fork legs. ( p. 28)

– Check the air filter.

– Check the settings of all controls and ensure that they can be operated smoothly.

– Check all screws, nuts and hose clamps regularly for tightness.

– Check the fuel reserves.

7.2Starting

Danger

Danger of poisoning Exhaust gases are poisonous and inhaling them may result in unconsciousness and/or death.

– When running the engine, always make sure there is sufficient ventilation, and do not start or run the engine in an enclosed

space without an effective exhaust extraction system.

Note

Engine failure High engine speeds in cold engines have a negative effect on the service life of the engine.

– Always warm up the engine at low engine speeds.

Info

If the motorcycle is unwilling to start, the cause may be old fuel in the float chamber. The flammable elements of the fuel

evaporate after a long time of standing.

If the float chamber is filled with fresh fuel, the engine starts immediately.

Press the starter for a maximum of 5 seconds. Wait for a least 5 seconds before trying again.

Engine has been out of use for more than 1 week

–

Empty the carburetor float chamber. x ( p. 65)

– Turn the handle of the fuel tap to the ON position. (Figure 500178-10 p. 12)

Fuel can flow from the fuel tank to the carburetor.

– Remove the motorcycle from the stand.

– Shift transmission to neutral.

The engine is cold

– Pull choke lever out as far as possible.

400733-01

The engine is hot

– Pull the hot start lever out to the stop.

– Press the electric starter button .

Info

Do not open the throttle.

RIDING INSTRUCTIONS 17

The engine is hot and running

– Push back the hot start lever to the stop with the engine running.

7.3Starting off

– Pull the clutch lever, engage 1st gear, release the clutch lever slowly and simultaneously open the throttle carefully.

7.4Shifting, riding

Warning

Danger of accidents If you change down at high engine speed, the rear wheel can lock up.

– Do not change into a low gear at high engine speed. The engine races and the rear wheel can lock up.

Info

If you hear unusual noises while riding, stop immediately, switch off the engine and contact an authorized KTM workshop.

First gear is used for starting off or for steep inclines.

– When conditions allow (incline, road situation, etc.), you can shift into a higher gear. To do so, release the throttle while simulta-

neously pulling the clutch lever, shift into the next gear, release the clutch and open the throttle.

– If the choke function was activated, deactivate it after the engine has warmed up.

– When you reach maximum speed after fully opening the throttle, turn back the throttle to about ¾ of its range. This barely reduces

vehicle speed but lowers fuel consumption considerably.

– Always open the throttle only as much as the engine can handle – abrupt throttle opening increases fuel consumption.

– To shift down, brake and close the throttle at the same time.

– Pull the clutch lever and shift into a lower gear, release the clutch lever slowly and open the throttle or shift again.

– Switch off the engine if you expect to be stationary for a long time.

Guideline

≥ 2 min

– Avoid frequent and prolonged slipping of the clutch. This causes heat build-up in the engine oil, the engine and the cooling sys-

tem.

– Ride at lower engine speeds instead of high revs and a slipping clutch.

7.5Braking

Warning

Danger of accidents If you brake too hard, the wheels can lock.

– Adapt your braking to the traffic situation and the road conditions.

Warning

Danger of accidents Reduced braking efficiency caused by spongy pressure point of front or rear brake.

– Check the brake system and do not continue riding. (Your authorized KTM workshop will be glad to help.)

Warning

Danger of accidents Reduced braking efficiency due to wet or dirty brakes.

– Clean or dry dirty or wet brakes by riding and braking gently.

– On sandy, wet or slippery surfaces, use the rear brake.

– Braking should always be completed before you go into a bend. Change down to a lower gear appropriate to your road speed.

– On long downhill stretches, use the braking effect of the engine. Change down one or two gears, but do not overstress the engine.

In this way, you have to brake far less and the brakes do not overheat.

RIDING INSTRUCTIONS 18

AA

7.6Stopping, parking

Warning

Risk of misappropriation Usage by unauthorized persons.

– Never leave the vehicle while the engine is running. Secure the vehicle against use by unauthorized persons.

Warning

Danger of burns Some vehicle components become very hot when the vehicle is operated.

– Do not touch hot components such as exhaust system, radiator, engine, shock absorber and brakes. Allow these compo-

nents to cool down before starting work on them.

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

Note

Fire hazard Some vehicle components become very hot when the vehicle is operated.

– Do not park the vehicle near flammable or explosive substances. Do not place objects on the vehicle while it is still warm from

being run. Always let the vehicle cool first.

– Brake the motorcycle.

– Shift transmission to neutral.

– Press and hold the kill switch while the engine is idling until the engine stops.

– Turn the handle of the fuel tap to the OFF position. (Figure 500178-10 p. 12)

– Park the motorcycle on firm ground.

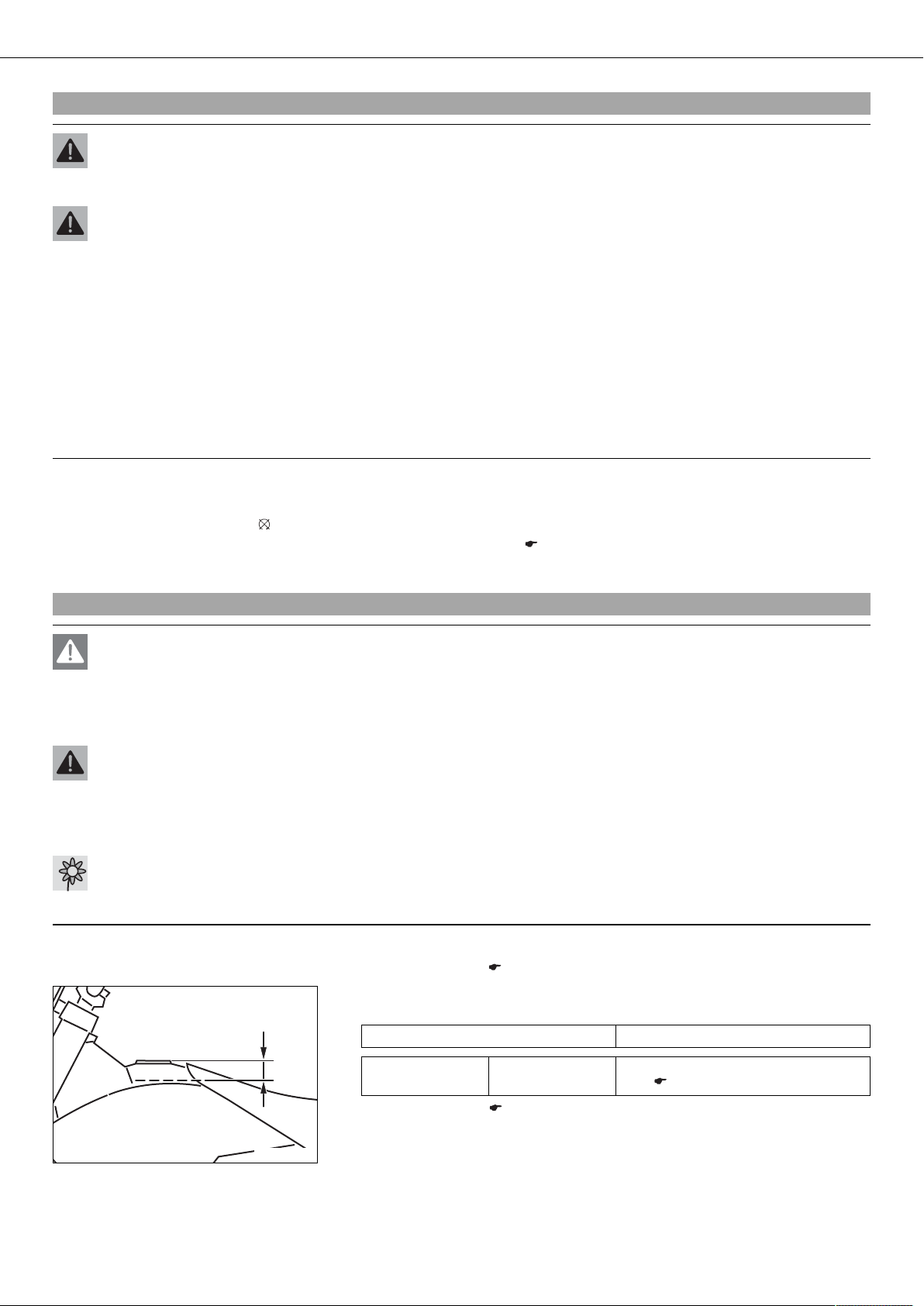

7.7Refueling

Danger

Fire hazard Fuel is highly flammable.

– Never refuel the vehicle near open flames or burning cigarettes, and always switch off the engine first. Be careful that no

fuel is spilt, especially on hot vehicle components. Clean up spilt fuel immediately.

– Fuel in the fuel tank expands when warm and can escape if the tank is overfilled. See the notes on refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

– Avoid contact of the fuel with skin, eyes and clothing. Do not inhale fuel vapors. If fuel gets into your eyes, rinse imme-

diately with water and contact a doctor. Wash affected skin areas immediately with soap and water. If fuel is swallowed,

contact a doctor immediately. Change clothing that has come into contact with fuel.

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

– Do not allow fuel to get into the ground water, the ground, or the sewage system.

– Switch off engine.

– Open the filler cap. ( p. 11)

– Fill the fuel tank with fuel up to measurement .

Guideline

Measurement of 35 mm (1.38 in)

400382-10

Total fuel tank

capacity, approx.

– Close the filler cap. ( p. 11)

7.5 l

(1.98 US gal)

Super unleaded (ROZ 95/RON 95/PON

91) ( p. 87)

SERVICE SCHEDULE 19

8.1Service schedule

S1N S10A S20A S30A

Check and charge the battery. x

Change the engine oil and oil filter, clean the oil screen. x ( p. 70)

Check the front brake linings. ( p. 49) • • •

Check the rear brake linings. ( p. 53) • • •

Check the brake discs. ( p. 47) • • •

Check the brake lines for damage and leakage. • • •

Check the rear brake fluid level. ( p. 52) • • •

Check the free travel of the foot brake lever. ( p. 51) • • •

Check the frame and swingarm. x

Check the swingarm bearing. x

Check the shock absorber linkage. x

Conduct a minor fork service. x

Conduct a major fork service. x

Check the tire condition. ( p. 57) • • • •

Check the tire air pressure. ( p. 57) • • • •

Check the wheel bearing for play. x

Check the wheel hubs. x

Check the rim run-out. x

Check the spoke tension. ( p. 57) • • • •

Check the chain, rear sprocket, engine sprocket and chain guide. ( p. 42) • • •

Check the chain tension. ( p. 41) • • • •

Lubricate all moving parts (e.g., hand lever, chain, ...) and check for smooth operation. x

Check the fluid level of the hydraulic clutch. ( p. 46) • • •

Check the front brake fluid level. ( p. 48) • • •

Check the free travel on the hand brake lever. ( p. 47) • • •

Check the steering head bearing play. ( p. 32) • • • •

Check the valve clearance. x

Check the clutch. x

Check all hoses (e.g. fuel, cooling, bleeder, drainage, etc.) and sleeves for cracking, leaks and

correct routing. x

Check the anti-freeze and coolant level. ( p. 62) • • • •

Check the cables for damage and routing without sharp bends. x

Check that the cables are undamaged, routed without sharp bends and set correctly. • • • •

Clean the air filter and air filter box. x ( p. 37)

Change the glass fiber yarn filling of the main silencer. x ( p. 38)

Check the screws and nuts for tightness. x

Check idle. x

Final check: Check the vehicle for safe operation and take a test ride. • • • •

Make the service entry in KTM DEALER.NET and in the service record. x

• • • •

• • • •

• •

• • • •

• • • •

• • • •

• • • •

• • • •

• • •

• • •

•

• • •

• • •

•

• • •

• • •

• • •

• • •

• • •

• • •

S1N: Once after 1 operating hour - corresponds to about 7 liters of fuel (1.8 US gal)

S10A: Every 10 operating hours - corresponds to about 70 liters of fuel (18.5 US gal) / after every race

S20A: Every 20 operating hours - corresponds to about 140 liters of fuel (37 US gal)

S30A: Every 30 operating hours - corresponds to about 210 liters of fuel (55.5 US gal)

SERVICE SCHEDULE 20

8.2Service work (as additional order)

S20N S20A S40A S80A J1A

Change the front brake fluid. x

Change the rear brake fluid. x

Change the hydraulic clutch fluid. x ( p. 46)

Grease the steering head bearing. x ( p. 33)

Check/set the carburetor components. • • •

Service the shock absorber. x

Change the spark plug and spark plug connector. x

Change the piston. x

Change the piston. (in difficult operating conditions) x

Check/measure the cylinder. x

Check the cylinder head. x

Change the valves, valve springs and valve spring seats. x

Check the camshaft and cam lever. x

Change the connecting rod, conrod bearing and crank pin. x

Change the crankshaft bearing. x

Check the transmission and shift mechanism. x

Check the oil pressure regulator valve. x

Check the oil pumps and lubrication system. x

Check the timing assembly. x

Change all engine bearings. x

• • •

• •

• •

• • •

• •

• •

•

• •

• •

• •

• •

• •

• •

• •

•

•

•

•

•

S20N: Once after 20 operating hours - corresponds to about 140 liters of fuel (37 US gal)

S20A: Every 20 operating hours - corresponds to about 140 liters of fuel (37 US gal)

S40A: Every 40 operating hours - corresponds to about 280 liters of fuel (74 US gal)

S80A: Every 80 operating hours - corresponds to about 560 liters of fuel (148 US gal)

J1A: Annually

TUNING THE CHASSIS 21

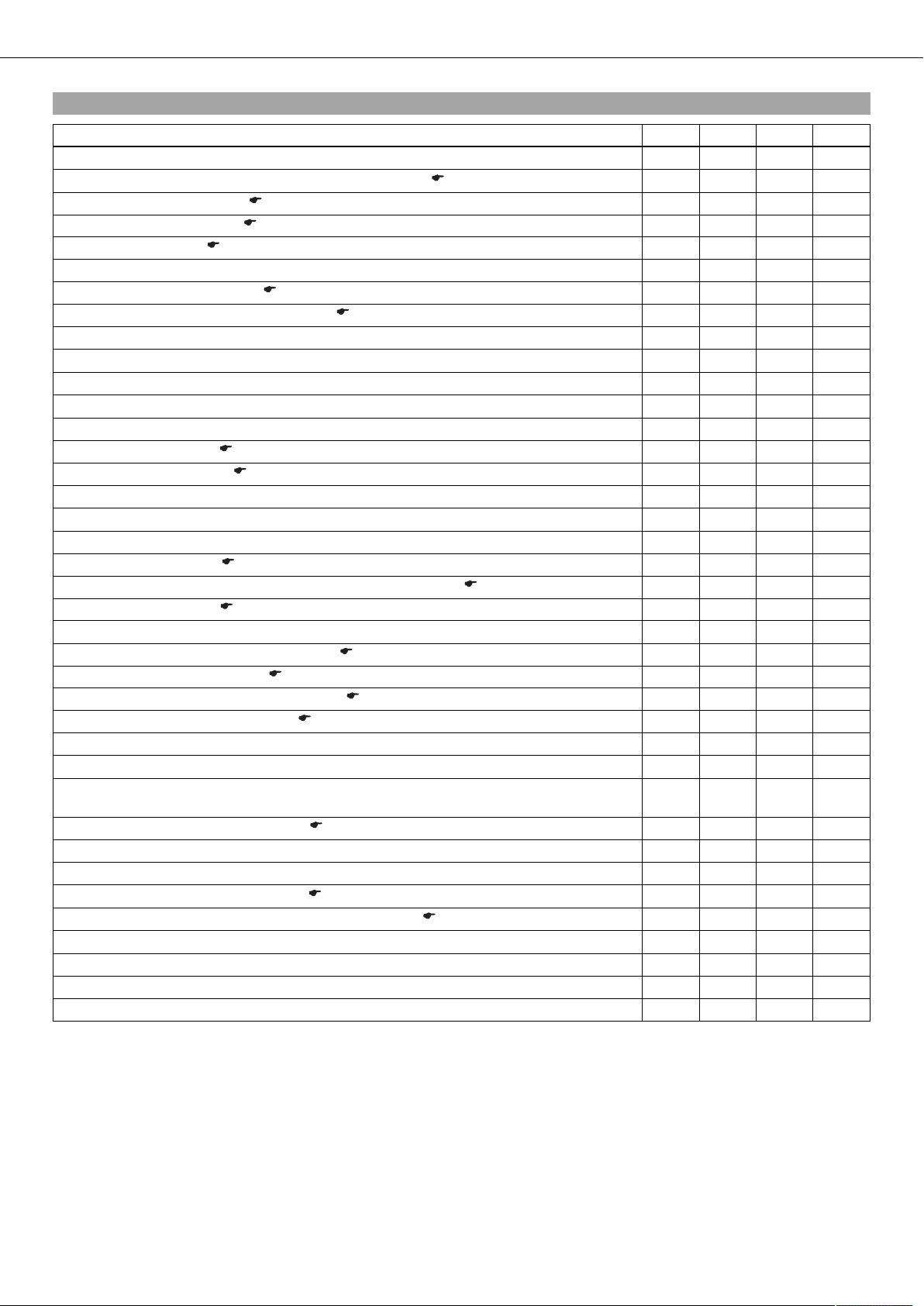

9.1Checking the basic suspension setting against the rider's weight

Info

When adjusting the basic suspension setting, first adjust the shock absorber and then the fork.

– For optimal motorcycle riding characteristics and to avoid damage to forks, shock

absorbers, swingarm and frame, the basic settings of the suspension components

must match the rider's weight.

– As delivered, KTM offroad motorcycles are adjusted for a standard rider weight

(with full protective clothing).

Guideline

Standard rider weight 75… 85 kg (165… 187 lb.)

– If the rider's weight is above or below the standard range, the basic setting of the

suspension components must be adjusted accordingly.

– Small weight differences can be compensated by adjusting the spring preload, but

in the case of large weight differences, the springs must be replaced.

401030-01

9.2Compression damping of shock absorber

The compression damping of the shock absorber is divided into two ranges: high-speed and low-speed.

High-speed and low-speed refer to the compression speed of the rear wheel suspension and not to the vehicle speed.

The high-speed setting, for example, has an effect on the landing after a jump: the rear wheel suspension compresses more quickly.

The low-speed setting, for example, has an effect when riding over long ground swells: the rear wheel suspension compresses more

slowly.

These two ranges can be adjusted separately, although the transition between high-speed and low-speed is gradual. Thus, changes in

the high-speed range affect the compression damping in the low-speed range and vice versa.

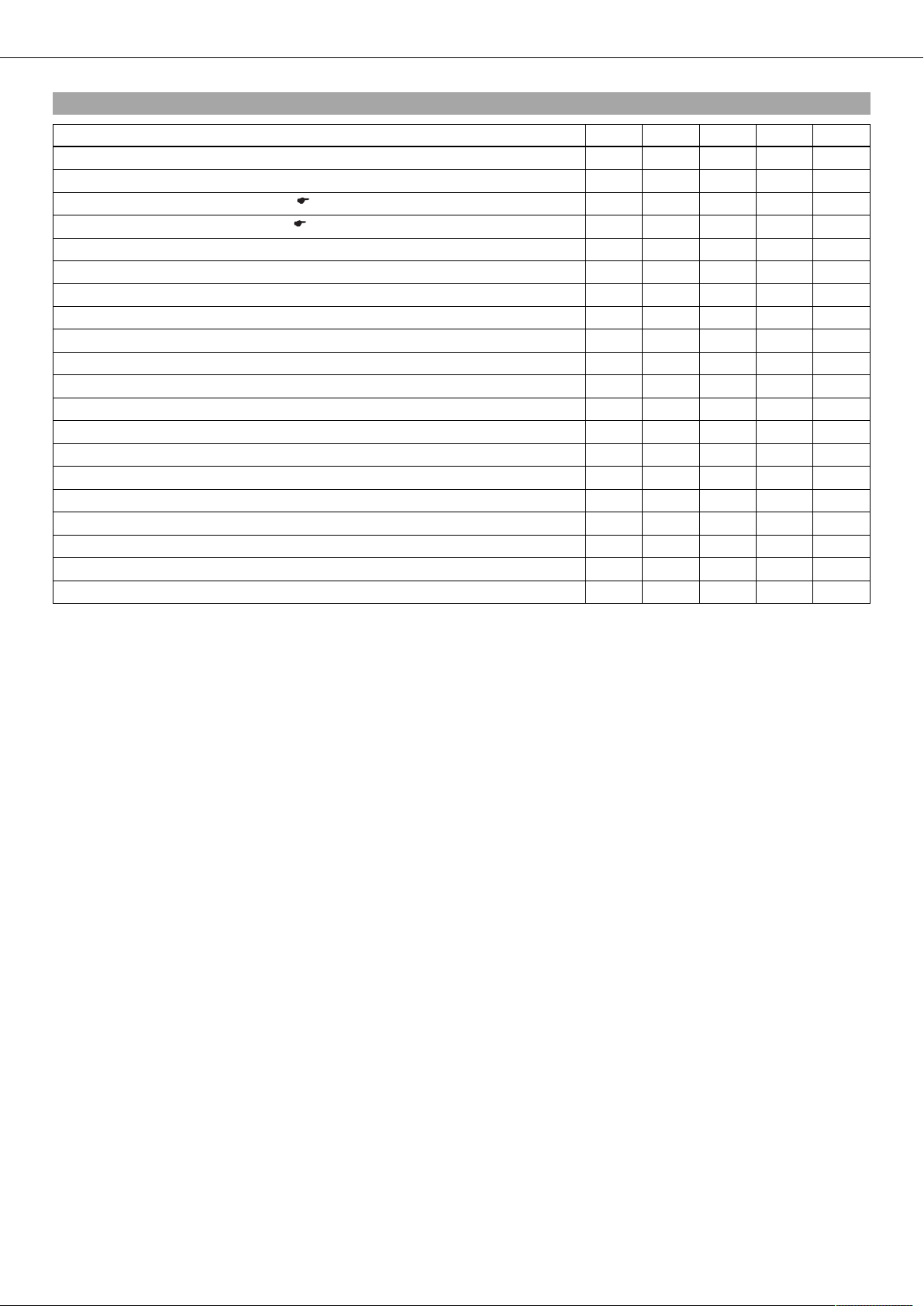

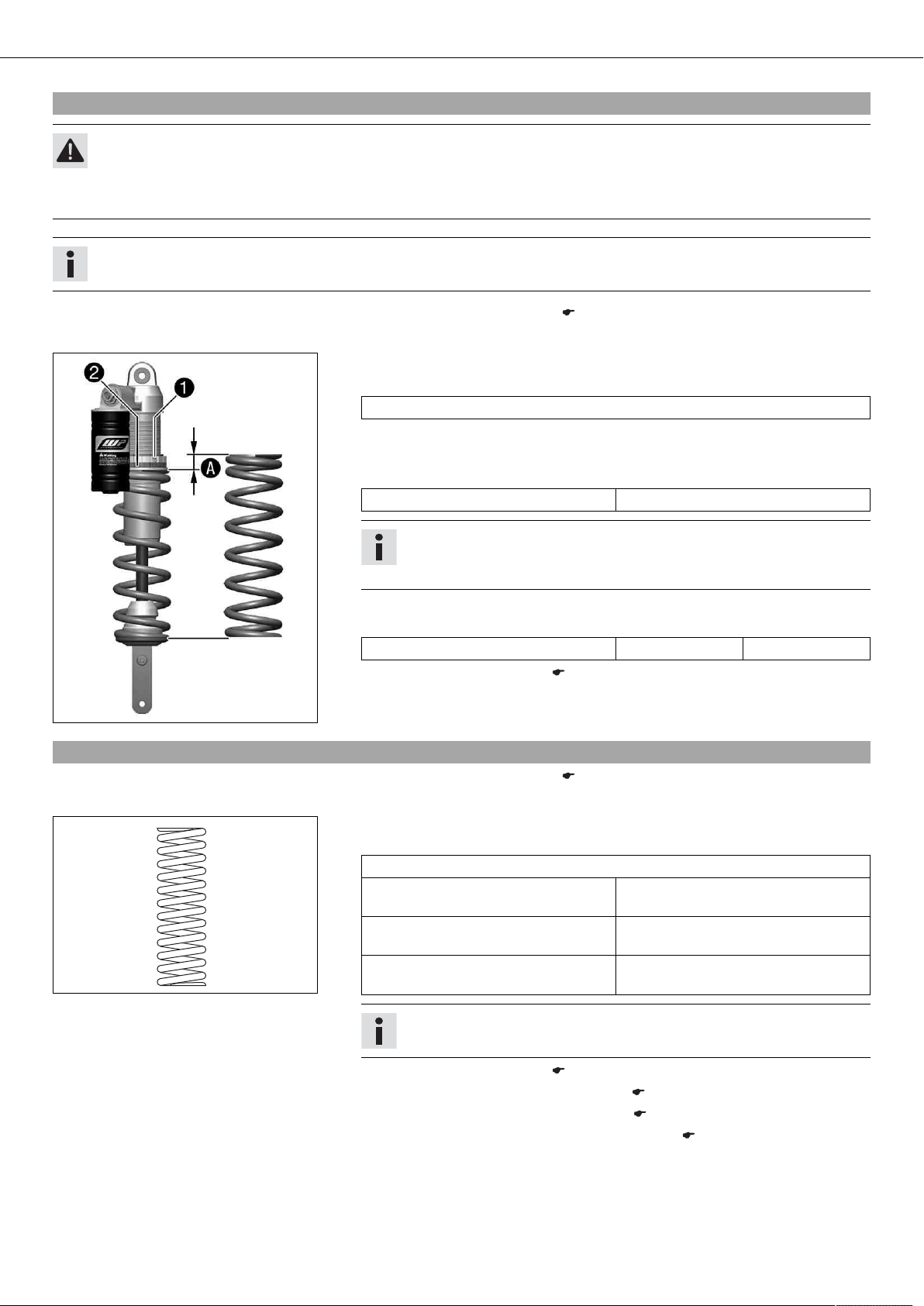

9.3Adjusting the low-speed compression damping of the shock absorber

Caution

Danger of accidents Disassembly of pressurized parts can lead to injury.

– The shock absorber is filled with high density nitrogen. Adhere to the description provided. (Your authorized KTM workshop

will be glad to help.)

Info

The low-speed setting can be seen during the slow to normal compression of the shock absorber.

– Turn adjusting screw clockwise with a screwdriver up to the last perceptible

click.

B00290-10

Info

Do not loosen nut !

– Turn back counterclockwise by the number of clicks corresponding to the shock

absorber type.

Guideline

Compression damping, low-speed

Comfort 21 clicks

Standard 18 clicks

TUNING THE CHASSIS 22

Info

Turn clockwise to increase damping; turn counterclockwise to reduce damping.

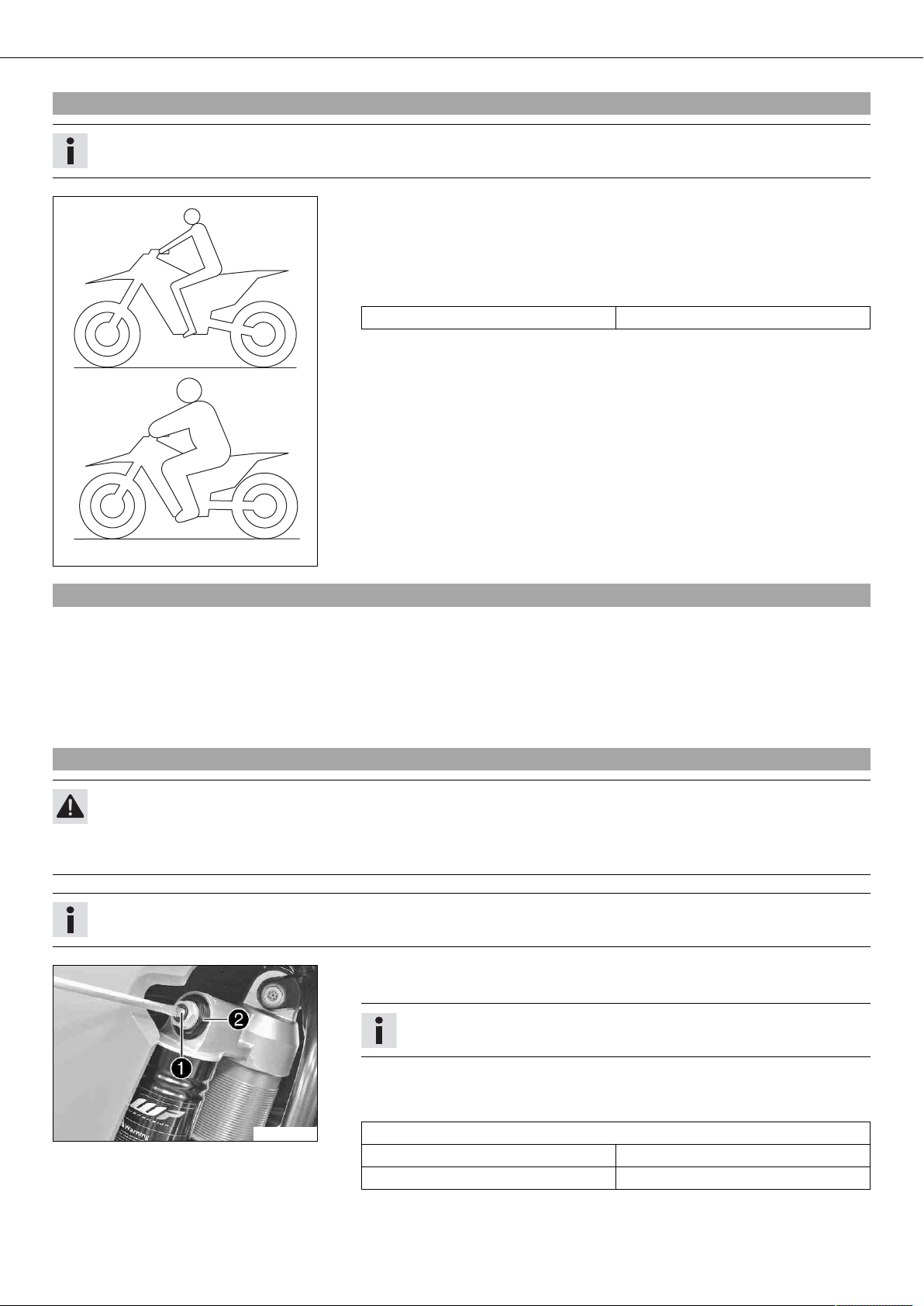

9.4Adjusting the high-speed compression damping of the shock absorber

Caution

Danger of accidents Disassembly of pressurized parts can lead to injury.

– The shock absorber is filled with high density nitrogen. Adhere to the description provided. (Your authorized KTM workshop

will be glad to help.)

Info

The high-speed setting can be seen during the fast compression of the shock absorber.

– Turn adjusting screw all the way clockwise with a socket wrench.

Info

Do not loosen nut !

– Turn back counterclockwise by the number of turns corresponding to the shock

absorber type.

Guideline

Compression damping, high-speed

B00289-10

Comfort 2 turns

Standard 1.5 turns

Info

Turn clockwise to increase damping; turn counterclockwise to reduce damping.

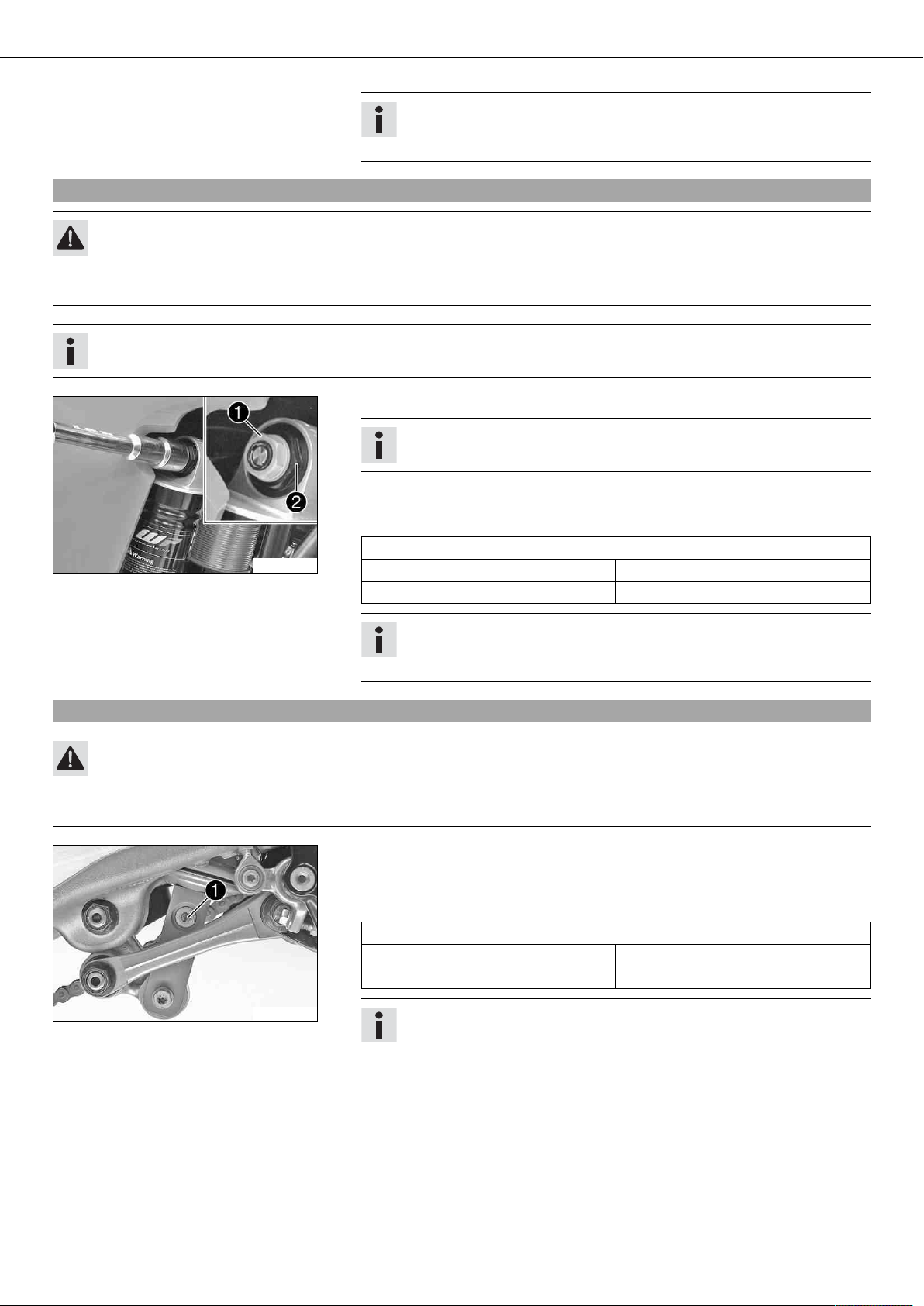

9.5Adjusting the rebound damping of the shock absorber

Caution

Danger of accidents Disassembly of pressurized parts can lead to injury.

– The shock absorber is filled with high density nitrogen. Adhere to the description provided. (Your authorized KTM workshop

will be glad to help.)

– Turn adjusting screw clockwise up to the last perceptible click.

– Turn back counterclockwise by the number of clicks corresponding to the shock

absorber type.

Guideline

Rebound damping

Comfort 14 clicks

Standard 12 clicks

B00291-10

Info

Turn clockwise to increase damping; turn counterclockwise to reduce damping.

TUNING THE CHASSIS 23

00AA

000BB

0

0

AA

CC

0

0

AA

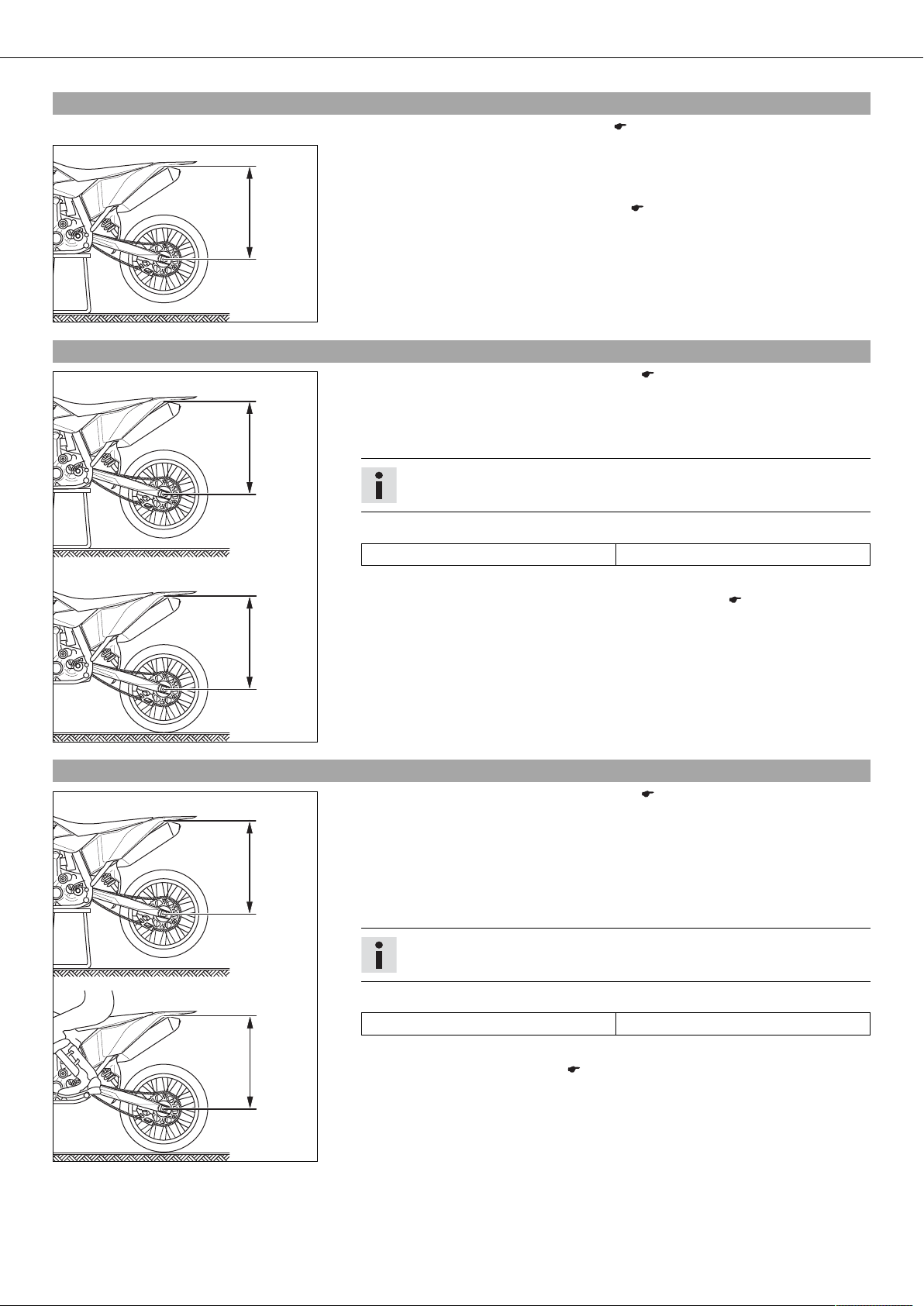

9.6Measuring rear wheel sag unloaded

– Raise the motorcycle with the lift stand. ( p. 28)

– Measure the distance – as vertically as possible – between the rear axle and a fixed

point, such as a mark on the side cover.

– Make note of the value as measurement .

– Remove the motorcycle from the lift stand. ( p. 28)

400389-10

9.7Checking static sag of shock absorber

– Measure distance of rear wheel unloaded. ( p. 23)

– Ask someone to help you by holding the motorcycle upright.

– Measure the distance between the rear axle and the fixed point again.

– Make a note of the value as measurement .

Info

The static sag is the difference between measurements and .

400383-10

9.8Checking riding sag of shock absorber

– Check the static sag.

Static sag 20 mm (0.79 in)

» If the static sag is less or more than the specified value:

–

Adjust the spring preload of the shock absorber. x ( p. 24)

– Measure distance of rear wheel unloaded. ( p. 23)

– With the help of another person holding the motorcycle, the rider, wearing com-

plete clothing, sits on the motorcycle in a normal position (feet on footrests) and

rocks up and down a few times so that the rear wheel suspension levels out.

– Another person now measures the distance between the rear axle and the fixed

point.

– Make a note of the value as measurement .

Info

The riding sag is the difference between measurements and .

400384-10

– Check the riding sag.

Riding sag 75 mm (2.95 in)

» If the riding sag differs from the specified measurement:

–

Adjust the riding sag. x ( p. 24)

TUNING THE CHASSIS 24

9.9Adjusting the spring preload of the shock absorber x

Caution

Danger of accidents Disassembly of pressurized parts can lead to injury.

– The shock absorber is filled with high density nitrogen. Adhere to the description provided. (Your authorized KTM workshop

will be glad to help.)

Info

Before changing the spring preload, make a note of the present setting, e.g., by measuring the length of the spring.

–

Remove the shock absorber. x ( p. 34)

– After removing the shock absorber, clean it thoroughly.

– Loosen screw .

– Turn adjusting ring until the spring is no longer under tension.

Hook wrench (T106S)

– Measure the overall spring length when not under tension.

– Tighten the spring by turning adjusting ring to measurement .

Guideline

Spring preload 19 mm (0.75 in)

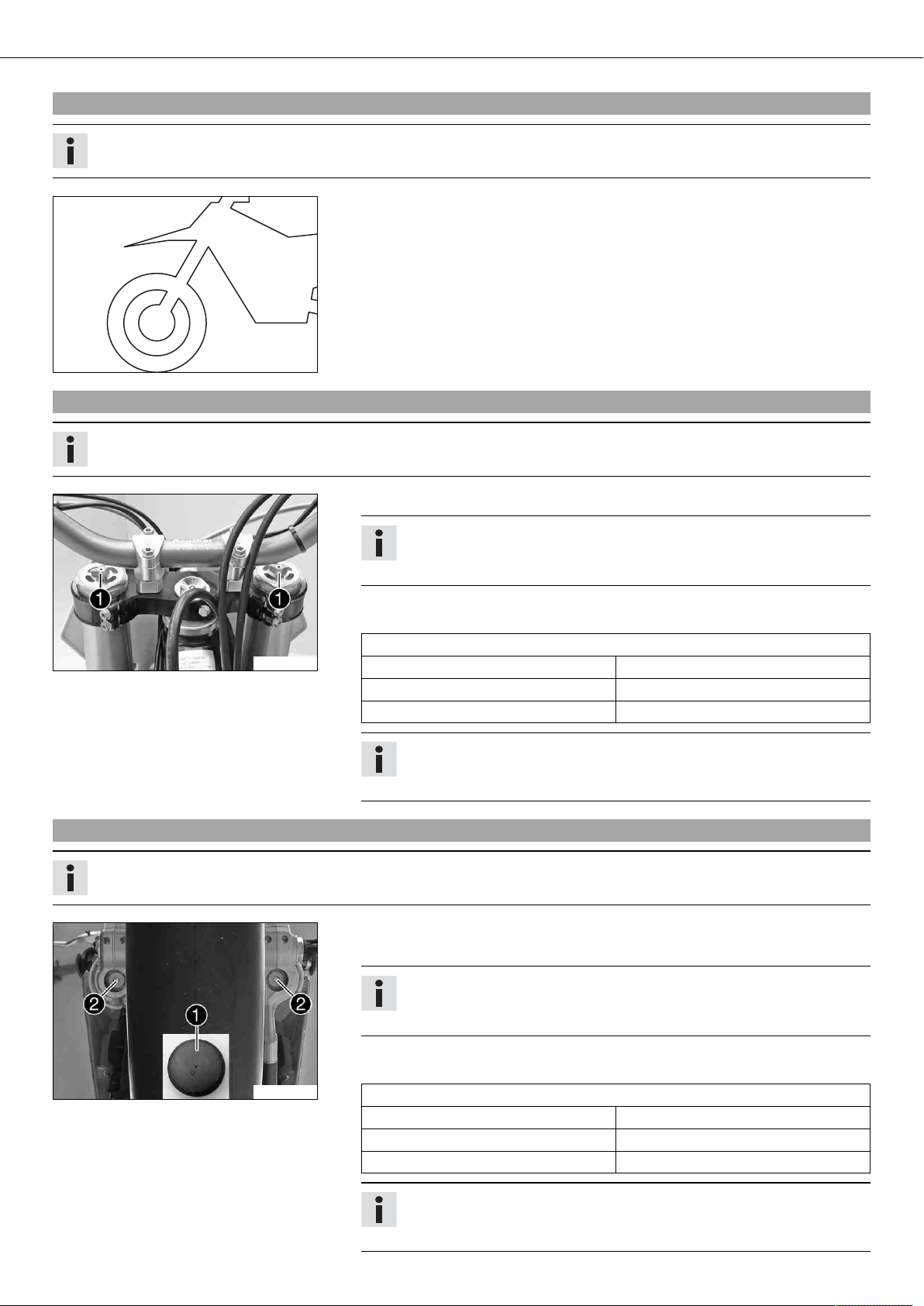

9.10Adjusting the riding sag x

401025-10

B00292-10

Info

Depending on the static sag and/or the riding sag, it may be necessary to

increase or decrease the spring preload.

– Tighten screw .

Guideline

Screw, shock absorber adjusting ring M5 5 Nm (3.7 lbf ft)

–

Install the shock absorber. x ( p. 35)

–

Remove the shock absorber. x ( p. 34)

– After removing the shock absorber, clean it thoroughly.

– Choose and mount a suitable spring.

Guideline

Spring rate

Weight of rider: 65… 75 kg (143…

165 lb.)

Weight of rider: 75… 85 kg (165…

187 lb.)

Weight of rider: 85… 95 kg (187…

209 lb.)

54 N/mm (308 lb/in)

57 N/mm (325 lb/in)

60 N/mm (343 lb/in)

Info

The spring rate is shown on the outside of the spring.

–

Install the shock absorber. x ( p. 35)

– Check the static sag of the shock absorber. ( p. 23)

– Check the riding sag of the shock absorber. ( p. 23)

– Adjust the rebound damping of the shock absorber. ( p. 22)

TUNING THE CHASSIS 25

9.11Checking basic setting of fork

Info

For various reasons, no exact riding sag can be determined for the forks.

– As with the shock absorber, smaller differences in the rider's weight can be com-

pensated by the spring preload.

– However, if the fork is often overloaded (hard end stop on compression), harder

springs must be fit to avoid damage to the fork and frame.

401000-01

9.12Adjusting the compression damping of the fork

Info

The hydraulic compression damping determines the fork suspension behavior.

– Turn adjusting screws clockwise all the way.

Info

Adjusting screws are located at the top end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise by the number of clicks corresponding to the fork type.

Guideline

Compression damping

B00848-10

Comfort 14 clicks

Standard 12 clicks

Sport 10 clicks

Info

Turn clockwise to increase damping; turn counterclockwise to reduce damping.

9.13Adjusting the rebound damping of the fork

Info

The hydraulic rebound damping determines the fork suspension behavior.

– Remove protection caps .

– Turn adjusting screws clockwise all the way.

B00849-10

Info

Adjusting screws are located at the bottom end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise by the number of clicks corresponding to the fork type.

Guideline

Rebound damping

Comfort 14 clicks

Standard 12 clicks

Sport 10 clicks

Info

Turn clockwise to increase damping; turn counterclockwise to reduce damping.

TUNING THE CHASSIS 26

00BB

0

0

AA

0022

0

0

11

0

0

22

11

– Mount protection covers .

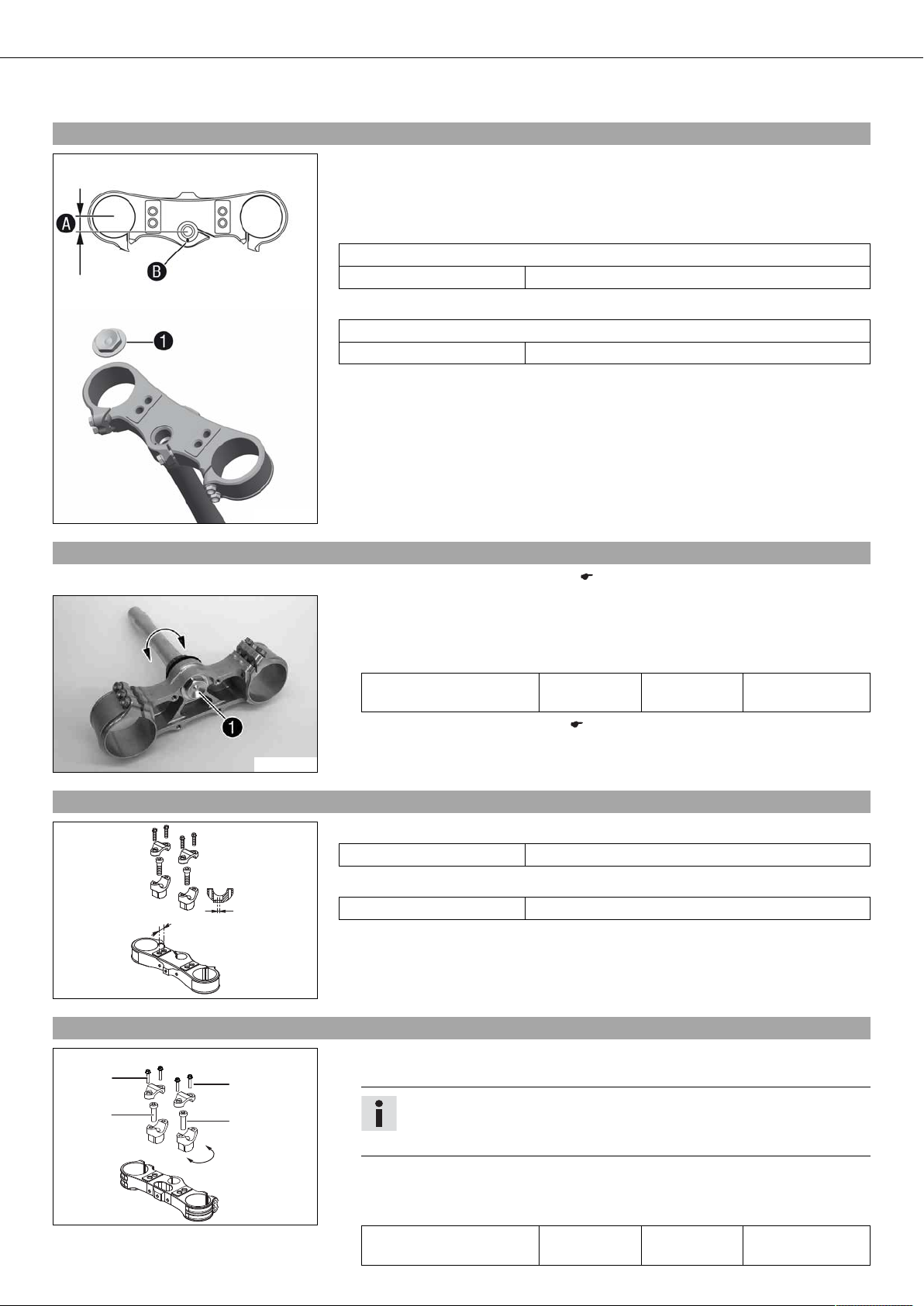

9.14Fork offset

You can see the currently set offset if you remove screw .

The fork offset has an impact on the handling of the vehicle. It is calculated from

the center of the fork leg to the center of the steering head bearing.

The fork offset can optionally be adjusted.

Marking to the front gives greater stability on fast racetracks.

Fork offset

Front marking 14 mm (0.55 in)

Marking to the rear gives better handling in bends.

Fork offset

Rear marking 16 mm (0.63 in)

9.15Adjusting the fork offset x

9.16Handlebar position

800009-10

500104-10

–

Remove the lower triple clamp. x ( p. 30)

– Remove screw . Remove the steering stem.

– Rotate the steering stem 180° and insert into the triple clamp. Mount and tighten

screw .

Guideline

Screw, bottom steering

head

–

Install the lower triple clamp. x ( p. 31)

On the upper triple clamp, there are 2 holes at a distance of to each other.

Hole distance A 15 mm (0.59 in)

The holes on the handlebar support are placed at a distance of from the center.

Hole distance B 3.5 mm (0.138 in)

The handlebar can be mounted in four different positions. In this way, the handlebar

can be mounted in the position that is most comfortable for the rider.

M20x1.5 60 Nm

(44.3 lbf ft)

Loctite®243™

9.17Adjusting handlebar position x

400271-11

B00375-10

– Remove the four screws . Remove the handlebar clamp. Remove the handlebar

and lay it to one side.

Info

Protect the motorcycle and its attachments from damage by covering them.

Do not bend the cables and lines.

– Remove screws . Remove the handlebar support.

– Place the handlebar support in the required position. Mount and tighten screws .

Guideline

Screw, handlebar support M10 40 Nm

(29.5 lbf ft)

Loctite®243™

TUNING THE CHASSIS 27

Info

Position the left and right handlebar supports evenly.

– Position the handlebar.

Info

Make sure cables and wiring are positioned correctly.

– Position the handlebar clamp. Fit and evenly tighten the four screws .

Guideline

Screw, handlebar clamp M8 20 Nm

(14.8 lbf ft)

Loading...

Loading...