KTM 1190 RC8 2008 Repair manual

REPAIR MANUAL 2008

1190 RC8 EU

1190 RC8 AUS/UK

1190 RC8 FR

1190 RC8 JP

Article no. 3206057en

INTRODUCTION 1

INTRODUCTION

Read this repair manual carefully and thoroughly before beginning work.

Only use ORGINAL KTM SPARE PARTS.

The vehicle will only be able to meet the demands placed on it if the specified service work is performed regularly and properly.

This repair manual was written to correspond to the latest state of this series. We reserve the right to make changes in the interest of

technical advancement without at the same time updating this manual.

We shall not provide a description of general workshop methods. Likewise, safety rules that apply in a workshop will not be specified

here. It is assumed that the repair work will be performed by a fully trained mechanic.

All specifications are non-binding. KTM Sportmotorcycle AG specifically reserves the right to modify or delete technical specifications, prices, colors, forms, materials, services, designs, equipment, etc., without prior notice and without specifying reasons, to adapt

these to local conditions, as well as to stop production of a particular model without prior notice. KTM accepts no liability for delivery

options, deviations from illustrations and descriptions, as well as printing and other errors. The models portrayed partly contain special

equipment that does not belong to the regular scope of delivery.

© 2008 by KTM-Sportmotorcycle AG, Mattighofen Austria

All rights reserved

Reproduction, even in part, is permitted only with the express written permission of the copyright owner.

ISO 9001(12 100 6061)

Within the meaning of the international quality management standard ISO 9001, KTM uses quality assurance processes

that lead to the maximum possible quality of the products.

Issued by: TÜV Management Service

KTM-Sportmotorcycle AG

5230 Mattighofen, Austria

CONTENTS 2

CONTENTS

MEANS OF REPRESENTATION ............................................ 5

IMPORTANT NOTES............................................................ 6

LOCATION OF SERIAL NUMBERS ........................................ 7

Chassis number/type label................................................ 7

Key number .................................................................... 7

Engine number................................................................ 7

Fork part number............................................................. 7

Shock absorber part number............................................. 7

Steering damper part number ........................................... 8

MOTORCYCLE..................................................................... 9

Jacking up motorcycle front.............................................. 9

Taking front of motorcycle off work stand........................... 9

Jacking up motorcycle rear ............................................... 9

Taking rear of motorcycle off work stand ............................ 9

Starting ........................................................................ 10

01/FORK, TRIPLE CLAMP.................................................. 11

Adjusting compression damping of fork ........................... 11

Adjusting rebound damping of fork.................................. 11

Adjusting spring preload of fork ...................................... 12

bleeding fork legs .......................................................... 12

Vehicle level ................................................................. 13

Adjusting front vehicle level............................................ 13

02/HANDLEBAR, CONTROLS AND INSTRUMENTS.............. 15

Adjusting basic position of clutch lever............................ 15

Adjusting the steering damper ........................................ 15

Adjusting the handlebar height ....................................... 15

Adjusting gas Bowden cable ........................................... 16

03/FRAME........................................................................ 17

Footrest position............................................................ 17

Adjusting footrest position.............................................. 17

Rear frame position ....................................................... 18

Adjusting the rear frame position .................................... 18

04/SHOCK ABSORBER, SWINGARM................................... 21

Adjusting the low-speed compression damping of the

shock absorber.............................................................. 21

Adjusting high-speed compression damping of the shock

absorber ....................................................................... 21

Adjusting rebound damping of the shock absorber ............ 22

Adjusting spring preload of shock absorber ...................... 22

Adjusting the vehicle level at the rear .............................. 23

05/EXHAUST .................................................................... 24

Removing the exhaust cover completely........................... 24

Installing the exhaust cover completely............................ 24

Removing the exhaust system ......................................... 24

Installing the exhaust system.......................................... 26

06/AIR FILTER.................................................................. 28

Removing the air filter ................................................... 28

Installing the air filter .................................................... 28

Removing the filter box bottom ....................................... 28

Installing the filter box bottom........................................ 30

07/FUEL TANK, SEAT, TRIM.............................................. 32

Removing the seat......................................................... 32

Fitting the seat.............................................................. 32

Removing passenger seat ............................................... 32

Fitting the passenger seat .............................................. 32

Dismounting the fuel tank .............................................. 32

Installing the fuel tank................................................... 33

Removing the fuel tank guard ......................................... 34

Installing the fuel tank guard.......................................... 35

08/MASK, FENDER, DECAL ............................................... 36

Removing the side covers ............................................... 36

Installing the side covers................................................ 36

Removing the inside cover.............................................. 36

Installing the inside cover .............................................. 37

09/FRONT WHEEL ............................................................ 38

Removing front wheel .................................................... 38

Fitting front wheel ......................................................... 38

Tire condition checking.................................................. 39

Checking tire air pressure............................................... 39

Checking the front brake discs........................................ 40

10/REAR WHEEL .............................................................. 41

Removing rear wheel...................................................... 41

Installing the rear wheel................................................. 41

Installing the rear wheel - when installing the engine ........ 42

Tire condition checking.................................................. 44

Checking tire air pressure............................................... 44

Checking the rear brake disc........................................... 45

Checking for chain dirt................................................... 45

Cleaning the chain......................................................... 45

Checking the chain tension ............................................ 45

Adjusting the chain tension ............................................ 46

Checking rear sprocket / engine sprocket for wear............. 47

Checking chain wear...................................................... 47

Checking chain sliding guard.......................................... 47

Checking rear hub shock absorbers ................................. 47

11/WIRING HARNESS, BATTERY ....................................... 49

Removing the battery..................................................... 49

Installing the battery...................................................... 49

Recharging the battery................................................... 50

Changing the main fuse ................................................. 51

Changing the fuses of individual power consumers............ 52

13/BRAKE SYSTEM........................................................... 53

Brake linings................................................................. 53

Checking the front brake linings...................................... 53

Checking brake fluid level of front brake .......................... 53

Topping up brake fluid of front brake............................... 54

Adjusting the basic position of the handbrake lever........... 54

Checking the rear brake linings....................................... 54

Checking rear brake fluid level........................................ 55

Topping up rear brake fluid ............................................ 55

Adjusting the footbrake pedal stub.................................. 56

Adjusting the footbrake pedal ......................................... 56

Removing the rear brake system...................................... 57

Installing the rear brake system ...................................... 57

14/LIGHT SYSTEM, INSTRUMENTS ................................... 58

Activating/deactivating ignition key ................................. 58

Setting ROAD or RACE mode.......................................... 59

Setting the clock with SET CLOCK .................................. 60

Adjusting shift speed RPM1/2 ........................................ 60

Setting the blank time of the LAP button LAP BLANK T.... 61

Setting number of laps SET NUM LAPS........................... 61

Setting fuel reserve display TRIPF RESET........................ 62

Setting kilometers/miles SET KM/MILES.......................... 62

Setting temperature unit SET °C/°F ................................. 63

Switching external temperature display on/off................... 63

Resetting the Service display.......................................... 63

Checking headlight adjustment....................................... 64

Adjusting headlamp range.............................................. 64

Changing the parking light bulb ...................................... 65

Changing the low beam bulb........................................... 66

Change the high beam bulb............................................ 67

30/ENGINE....................................................................... 70

Removing the engine ..................................................... 70

CONTENTS 3

Preparing the engine for installation................................ 72

Installing the engine ...................................................... 72

Setting the engine to ignition top dead center of the rear

cylinder ........................................................................ 76

Setting the engine to ignition top dead center of the front

cylinder ........................................................................ 76

30/DISASSEMBLING THE ENGINE..................................... 77

Clamping the engine into the engine work stand............... 77

Draining the engine oil................................................... 77

Removing the front valve cover ....................................... 77

Removing the rear valve cover......................................... 77

Setting the engine to ignition top dead center of the rear

cylinder ........................................................................ 78

Removing the starter motor ............................................ 78

Removing the oil filler tube ............................................ 78

Removing the heat exchanger ......................................... 79

Removing the rear timing chain tensioner ........................ 79

Removing the rear camshaft ........................................... 79

Removing the rear cylinder head ..................................... 80

Removing the rear piston................................................ 80

Setting the engine to ignition top dead center of the front

cylinder ........................................................................ 80

Removing the front timing chain tensioner....................... 80

Removing the front camshafts ........................................ 81

Removing the front cylinder head.................................... 81

Removing the front piston .............................................. 81

Removing the generator cover ......................................... 82

Removing the ignition pulse generator ............................. 82

Removing the torque limiter and idler.............................. 82

Removing the rotor ........................................................ 82

Removing the idler and timing chain on the left ............... 83

Removing the oil filter.................................................... 84

Removing the balancer shaft .......................................... 84

Removing the drive wheel of the balancer shaft ................ 84

Removing the gear position sensor .................................. 84

Removing the left suction pump ..................................... 85

Removing the water pump wheel..................................... 86

Removing the clutch cover ............................................. 86

Removing the idler and timing chain on the right.............. 86

Removing the clutch facing ............................................ 87

Removing the outer clutch hub ....................................... 87

Removing the primary gear ............................................. 88

Removing the force pump .............................................. 88

Removing the shift shaft ................................................ 89

Removing the shift drum locating.................................... 89

Removing the locking lever............................................. 89

Removing the left engine case ........................................ 90

Removing the crankshaft................................................ 90

Removing the middle suction pump ................................ 90

Removing the transmission shaft..................................... 91

Removing the oil spray tube ........................................... 92

Removing the timing chain rails of the right engine case

section ......................................................................... 92

Removing the timing chain rails of the left engine case

section ......................................................................... 92

30/ENGINE - WORK ON INDIVIDUAL PARTS....................... 93

Work on the right section of the engine case .................... 93

Removing the main bearing of the right engine case

section ......................................................................... 94

Selecting the main bearing shells.................................... 95

Installing the right main bearing ..................................... 95

Work on the left section of the engine case ...................... 96

Removing the left main bearing ...................................... 98

Installing the left main bearing ....................................... 98

Changing the conrod bearing .......................................... 99

Work on the clutch cover.............................................. 100

Changing the step bearing of the crankshaft................... 101

Checking the radial clearance of the bottom connecting

rod bearing ................................................................. 102

Checking/measuring the cylinder................................... 102

Checking/measuring the piston ..................................... 103

Checking the piston ring end gap .................................. 104

Checking the piston/cylinder mounting clearance............ 104

Work on the cylinder head ............................................ 104

Checking the cylinder head .......................................... 107

Work on the right idler ................................................. 108

Checking the timing assembly ...................................... 109

Preparing the timing chain tensioner for installation ....... 109

Checking the oil pressure regulator valve........................ 110

Checking the oil pumps................................................ 110

Checking the clutch..................................................... 111

Checking the shift mechanism...................................... 112

Preassembling the shift shaft........................................ 113

Dismantling the main shaft .......................................... 113

Dismantling the countershaft........................................ 114

Checking the transmission............................................ 115

Assembling the main shaft ........................................... 116

Assembling the countershaft......................................... 116

30/ASSEMBLING THE ENGINE........................................ 118

Installing the timing chain rails of the left engine case

section ....................................................................... 118

Installing the timing chain rails of the right engine case

section ....................................................................... 118

Installing the oil spray tube .......................................... 119

Installing the transmission shaft ................................... 119

Installing the middle suction pump ............................... 120

Installing the crankshaft............................................... 120

Installing the left engine case....................................... 121

Installing the locking lever............................................ 122

Installing the shift drum locating .................................. 122

Installing the shift shaft ............................................... 122

Installing the force pump ............................................. 123

Installing the left suction pump .................................... 124

Setting the engine to ignition top dead center of the

rear cylinder................................................................ 124

Installing the primary gear............................................ 125

Installing the outer clutch hub...................................... 125

Installing the clutch facing........................................... 126

Installing the idler and timing chain on the right ............ 127

Installing the clutch cover ............................................ 127

Installing the water pump wheel ................................... 128

Installing the gear position sensor ................................. 128

Installing the drive wheel of the balancer shaft............... 128

Installing the balancer shaft ......................................... 129

Installing the idler and timing chain on the left .............. 129

Installing the oil filter .................................................. 130

Installing the rotor....................................................... 130

Installing the torque limiter and idler ............................ 131

Installing the ignition pulse generator............................ 131

Installing the generator cover........................................ 131

Installing the oil drain plug........................................... 131

Installing the rear piston .............................................. 132

Installing the rear cylinder head.................................... 133

Installing the rear camshaft.......................................... 134

CONTENTS 4

Installing the rear timing chain tensioner....................... 134

Setting the engine to ignition top dead center of the

front cylinder .............................................................. 135

Installing the front piston ............................................. 135

Installing the front cylinder head................................... 137

Installing the front camshafts ....................................... 137

Installing the front timing chain tensioner...................... 138

Installing the heat exchanger........................................ 138

Installing the oil filler tube ........................................... 139

Installing the starter motor ........................................... 139

Checking the rear valve clearance ................................. 139

Adjusting the rear valve clearance ................................. 140

Checking the front valve clearance ................................ 140

Adjusting the front valve clearance................................ 140

Installing the front valve cover ...................................... 141

Installing the rear valve cover ....................................... 141

32/CLUTCH .................................................................... 142

Checking fluid level of hydraulic clutch ......................... 142

Correcting fluid level of hydraulic clutch........................ 142

34/SHIFT MECHANISM ................................................... 143

Adjusting shift lever stub.............................................. 143

Adjusting shift lever..................................................... 143

35/WATER PUMP, COOLING SYSTEM .............................. 145

Checking the coolant level............................................ 145

Checking the antifreeze................................................ 145

Removing the radiator.................................................. 146

Installing the radiator................................................... 146

Adding coolant/bleeding the cooling system ................... 147

Filling the cooling system compensating tank................. 148

36/CYLINDER HEAD........................................................ 149

Checking the valve clearance........................................ 149

Adjusting the rear valve clearance ................................. 150

Adjusting the front valve clearance................................ 150

Removing the rear camshaft ......................................... 151

Installing the rear camshaft.......................................... 151

Removing the front camshafts ...................................... 152

Installing the front camshafts ....................................... 152

Removing the rear timing chain tensioner ...................... 152

Installing the rear timing chain tensioner....................... 153

Removing the front timing chain tensioner..................... 153

Installing the front timing chain tensioner...................... 153

38/LUBRICATION SYSTEM .............................................. 154

Oil circuit ................................................................... 154

Checking engine oil level.............................................. 155

Changing engine oil and filter, cleaning oil screen .......... 155

Draining engine oil, cleaning oil screens ........................ 155

Removing oil filter ....................................................... 157

Fitting oil filter............................................................ 158

Filling up with engine oil.............................................. 158

Topping up engine oil .................................................. 159

IMMOBILIZER FLASH CODE ............................................ 160

ENGINE CONTROL ERROR CODE..................................... 161

TECHNICAL DATA - ENGINE............................................ 163

Capacity- engine oil ..................................................... 163

Capacity - coolant........................................................ 163

TECHNICAL DATA - TOLERANCE, WEAR LIMITS OF

ENGINE ......................................................................... 164

TECHNICAL DATA - ENGINE TIGHTENING TORQUES........ 166

TECHNICAL DATA - CHASSIS .......................................... 168

Lighting equipment ..................................................... 169

Capacity - fuel............................................................. 169

TECHNICAL DATA - FORK................................................ 170

TECHNICAL DATA - SHOCK ABSORBER ........................... 171

TECHNICAL DATA - CHASSIS TIGHTENING TORQUES ...... 172

CLEANING/CONSERVATION............................................. 174

Cleaning motorcycle .................................................... 174

Conservation for winter operation .................................. 174

STORAGE ....................................................................... 175

Storage....................................................................... 175

Putting into operation after storage ............................... 175

GREASING AND SERVICE TABLE..................................... 176

Important service tasks to be carried out by an

authorized KTM-RC8 workshop. .................................... 176

Important service tasks to be carried out by an

authorized KTM-RC8 workshop. (as additional job) ......... 177

WIRING DIAGRAM .......................................................... 178

1 of 3......................................................................... 178

2 of 3......................................................................... 182

3 of 3......................................................................... 188

SUBSTANCES................................................................. 192

AUXILIARY SUBSTANCES................................................ 194

SPECIAL TOOLS.............................................................. 195

STANDARDS................................................................... 203

INDEX ............................................................................ 204

MEANS OF REPRESENTATION 5

1MEANSOFREPRESENTATION

Symbols used

The following explains the meaning of specific symbols.

Identifies an expected reaction (e.g., of an operation or a function).

Identifies an unexpected reaction (e.g., of an operation or a function).

Identifies a page reference (more information is provided on the specified page).

Formats used

The type formats used are explained here.

Specific name Identifies a name.

®

Name

Brand™ Identifies a trademark.

Identifies a protected name.

IMPORTANT NOTES 6

2IMPORTANTNOTES

Warranty

The maintenance work described in the greasing and service table must be carried out exclusively in an authorized KTM-RC8 workshop and confirmed in the service record, since otherwise any warranty claim is meaningless. No warranty claim can be met for damage resulting from manipulation and/or other changes to the vehicle.

Materials

The fuels, lubricants and other materials named in this repair manual must be used according to specifications.

Spare parts, accessories

Only use spare parts and accessories approved and/or recommended by KTM. KTM accepts no liability for other products and any

resulting damage.

You will find the current KTM PowerParts for your vehicle on the KTM website.

International KTM Website: http://www.ktm.com

Work rules

During assembly, non-reusable parts (e.g. self-locking screws and nuts, seals and seal rings, O-rings, pins, lock washers) must be

replaced by new parts.

If a thread lock (e.g. Loctite®) is used for screw connections, be sure to comply with the manufacturer's specific advice on its usage.

Parts that you want to reuse following repairs and servicing should be cleaned and checked for damage and wear. Change damaged or

worn parts.

Following servicing, the vehicle must be checked for roadworthiness.

Notes/warnings

Be sure to pay attention to the notes and warnings given here.

Info

Various notes and warning stickers are attached to the vehicle. Do not remove any notes and warning stickers. If they are missing, you or others may not recognize dangers and may therefore be injured.

Grades of risks

Danger

Danger that leads immediately and certainly to severe and permanent injury or death.

Warning

Danger that will probably lead to severe and permanent injury or death.

Note

Danger of serious damage to machine or material.

Warning

Risk of environmental damage.

Repair manual

– Read this repair manual carefully and thoroughly before beginning work. It contains useful information and tips that will help you

repair and service your motorcycle.

– This manual assumes that the necessary special KTM tools and workplace and workshop equipment are available.

LOCATION OF SERIAL NUMBERS 7

3LOCATIONOFSERIALNUMBERS

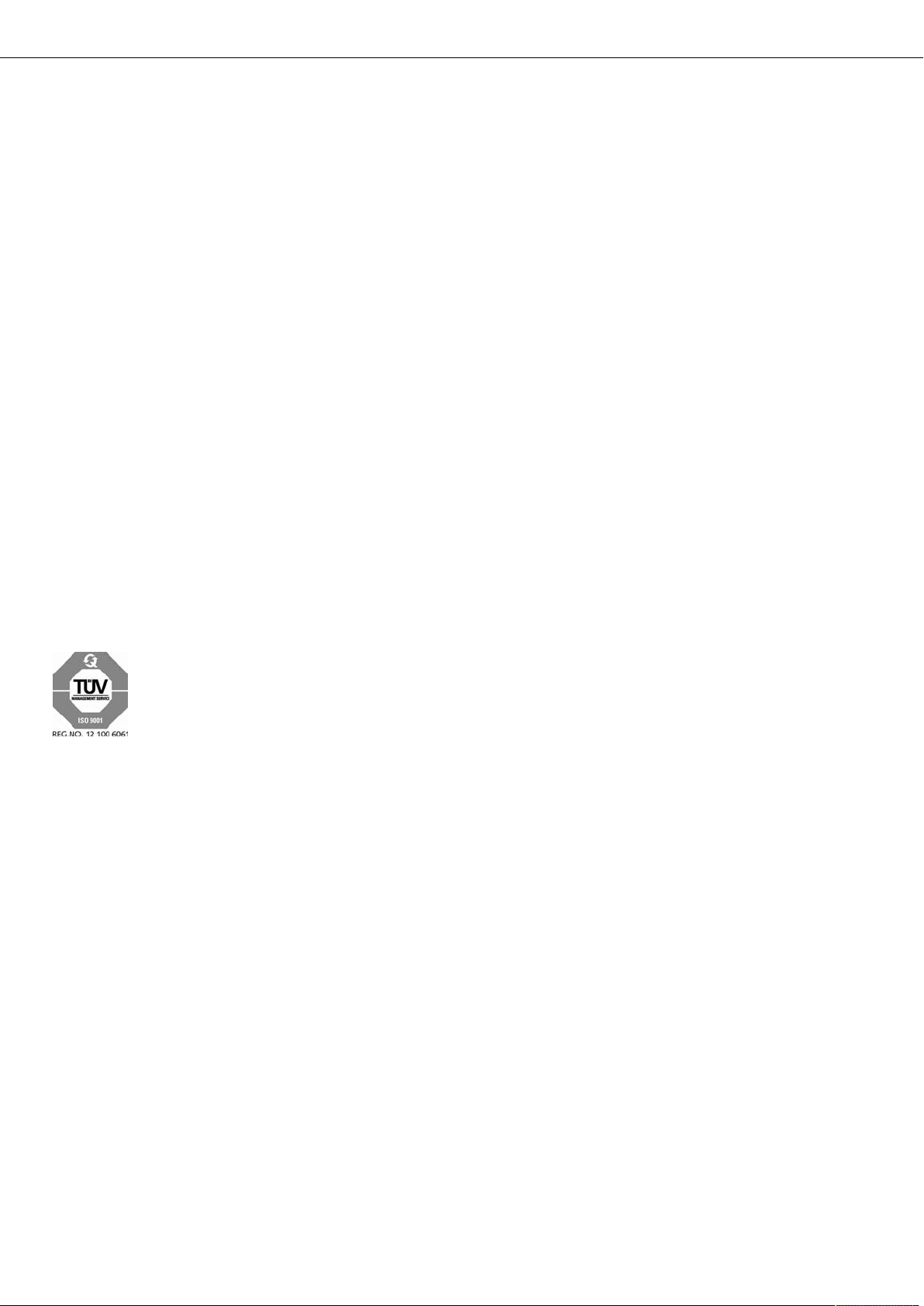

3.1Chassis number/type label

The chassis number is stamped on the frame behind the steering head on the right.

The type label is on the frame above the chassis number.

700231-01

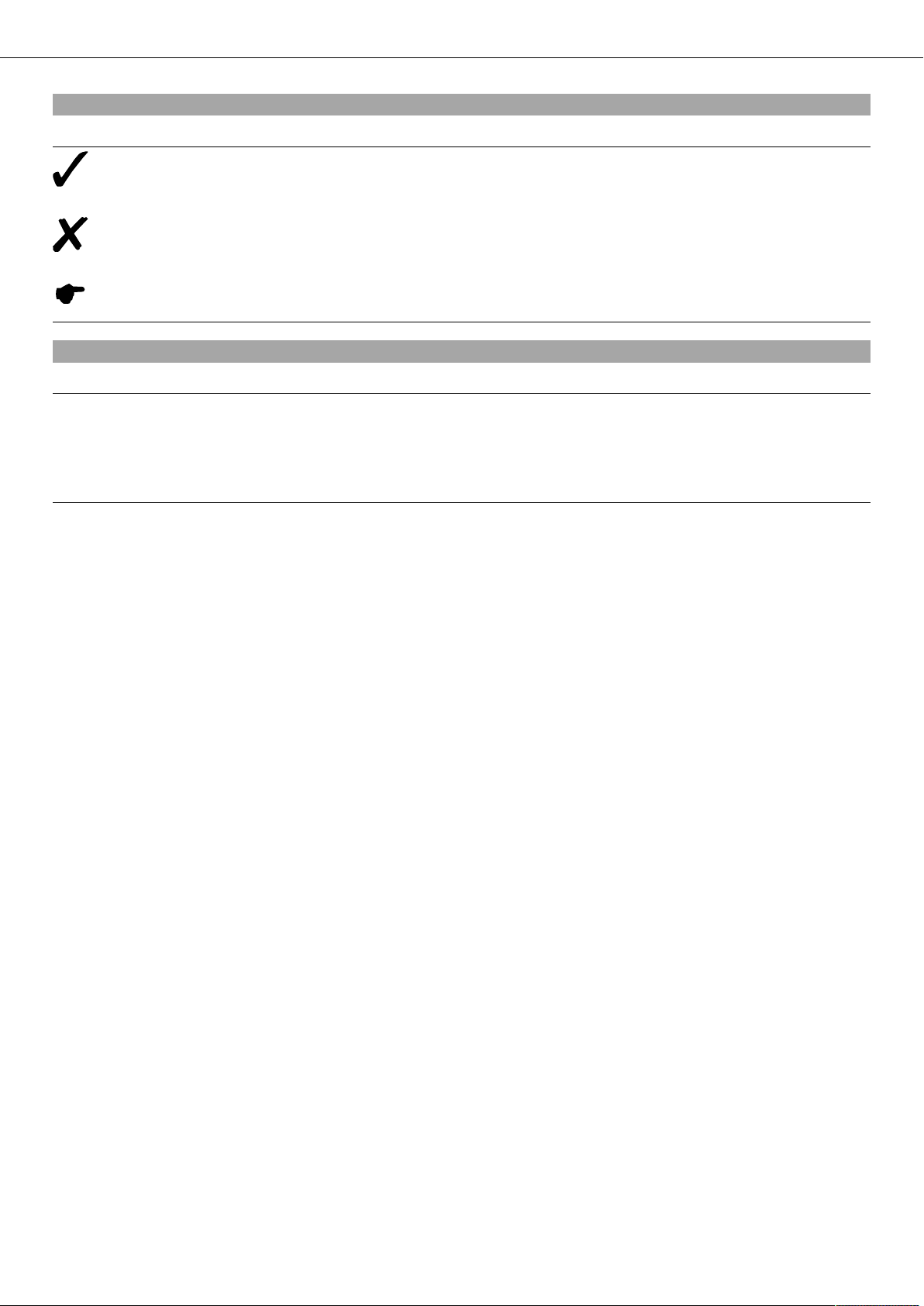

3.2Key number

The key number Code number can be found on the KEYCODECARD.

Info

You need the key number to order a spare key. Keep the KEYCODECARD in a safe

place.

Use the orange programming key to activate and deactivate the black ignition

key. Keep the orange programming key in a safe place: it must only be used for

learning and programming functions.

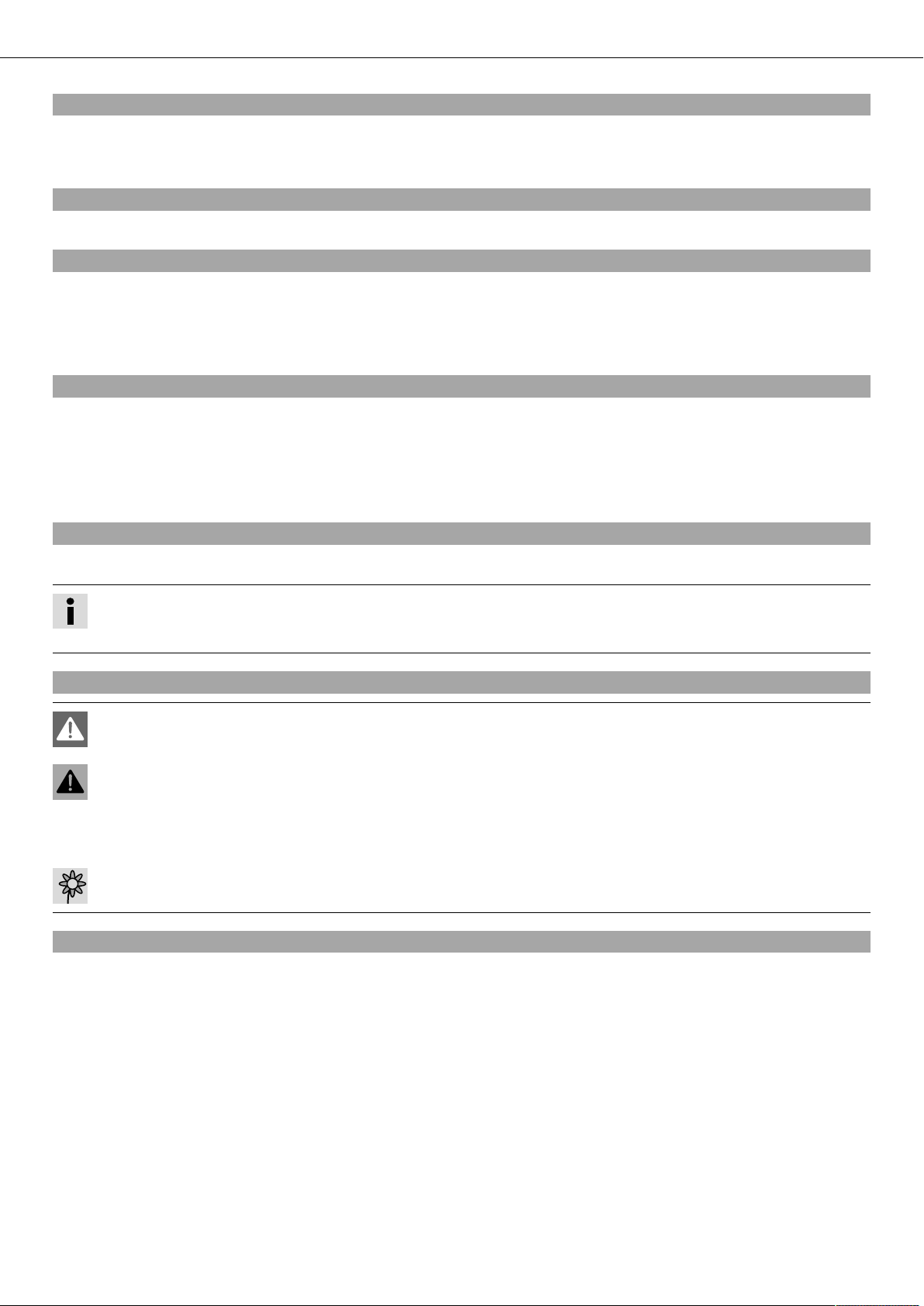

3.3Engine number

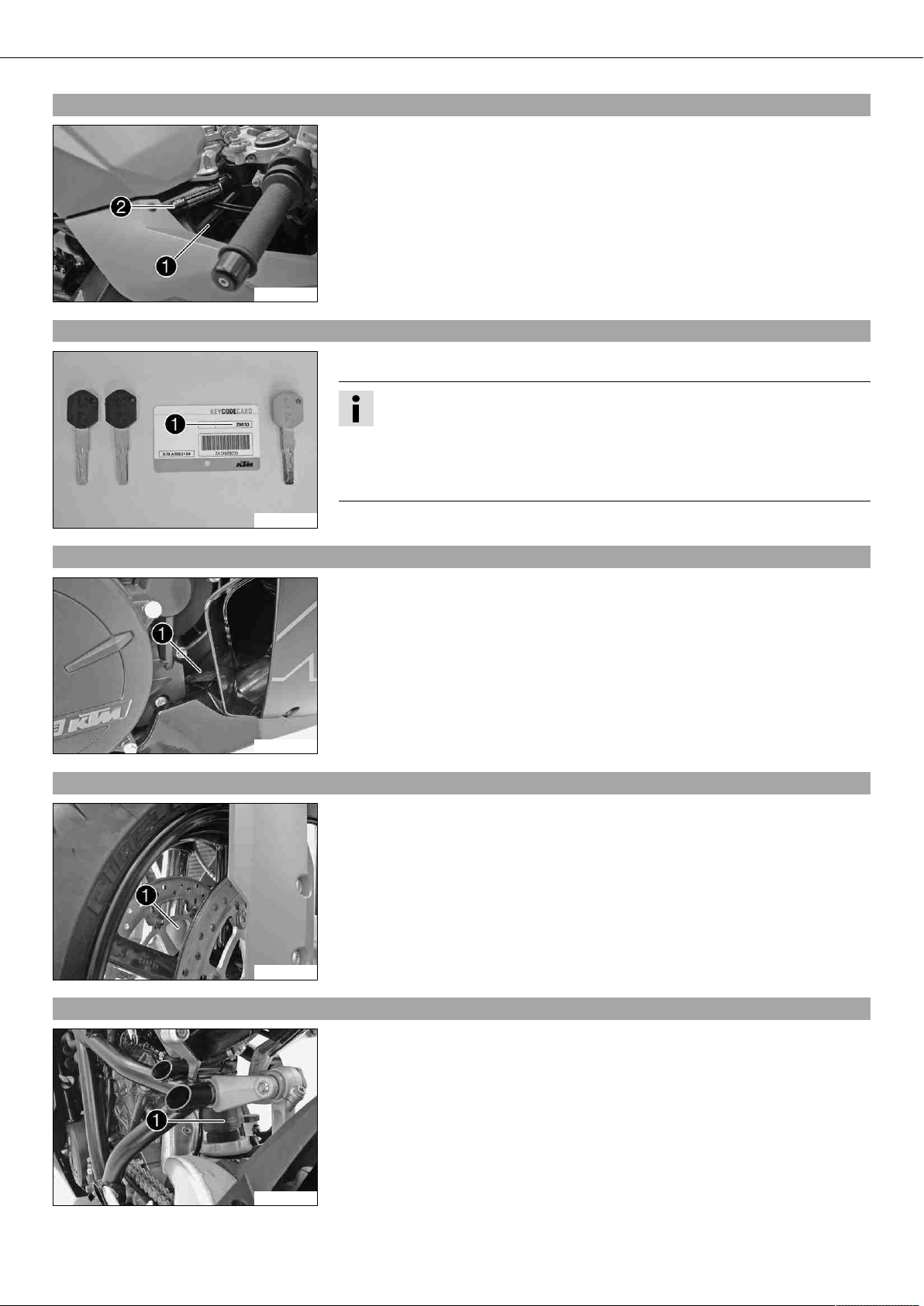

3.4Fork part number

700222-01

The engine number is stamped on the right side of the engine.

700223-01

The fork part number is stamped on the inner side of the fork stub.

3.5Shock absorber part number

700224-01

The shock absorber part number is stamped on the upper part of the shock absorber

above the adjusting ring towards the rear.

700225-01

LOCATION OF SERIAL NUMBERS 8

3.6Steering damper part number

The steering damper part number is stamped on the top of the steering damper.

700226-01

MOTORCYCLE 9

4MOTORCYCLE

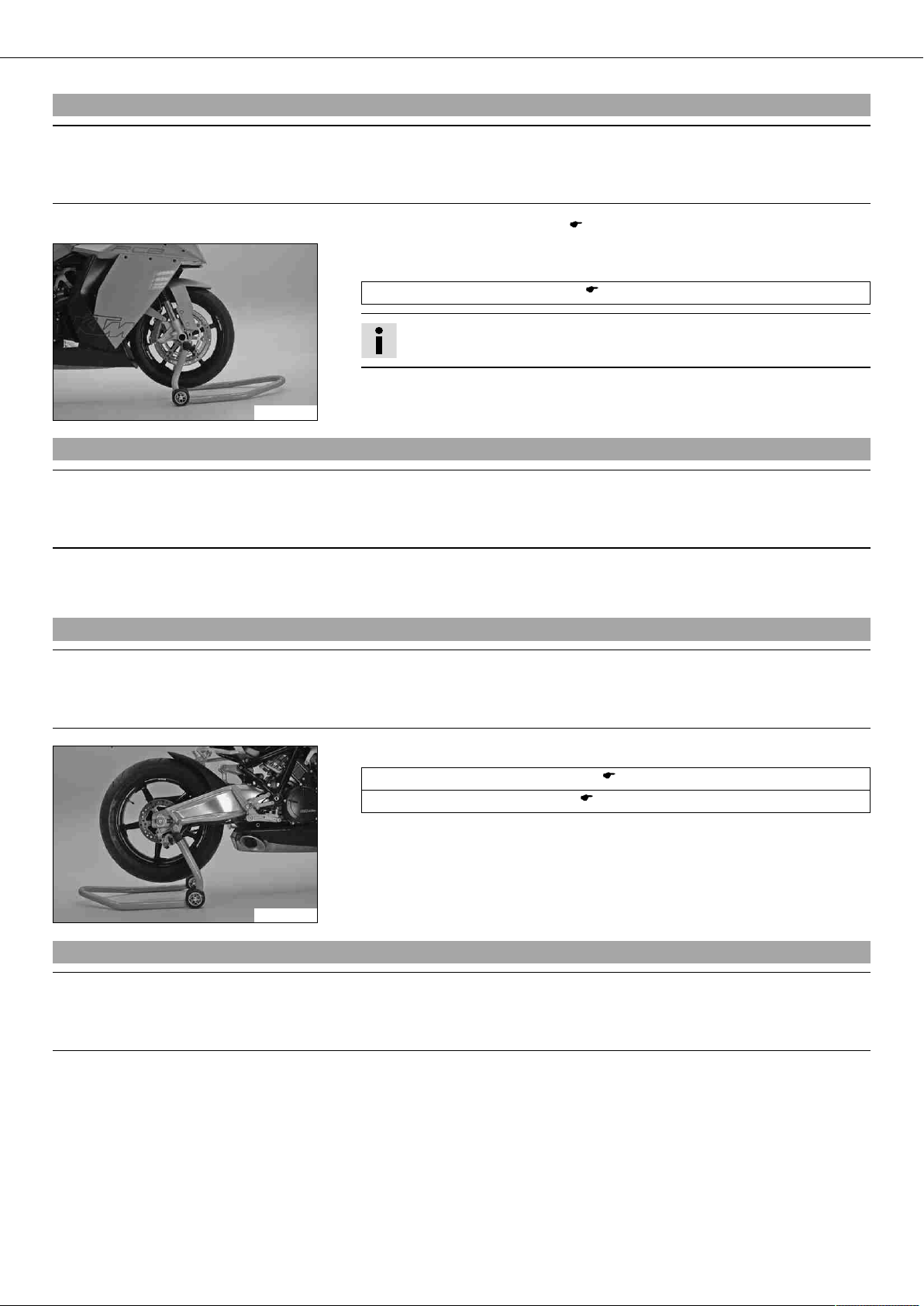

4.1Jacking up motorcycle front

Note

Danger of damage Danger of damage by the vehicle running away or falling over.

– Always place the vehicle on a firm and even surface.

– Jack up the motorcycle rear end. ( p. 9)

– Move the handlebar to the straight-ahead position. Align the work stand at the front

with the adapters to the fork legs.

Work stand front (61029055300) ( p. 198)

Info

Always jack up the rear of the motorcycle first.

– Jack up the motorcycle at the front.

700250-01

4.2Taking front of motorcycle off work stand

Note

Danger of damage Danger of damage by the vehicle running away or falling over.

– Always place the vehicle on a firm and even surface.

– Secure the motorcycle against falling over.

– Remove the work stand from the front.

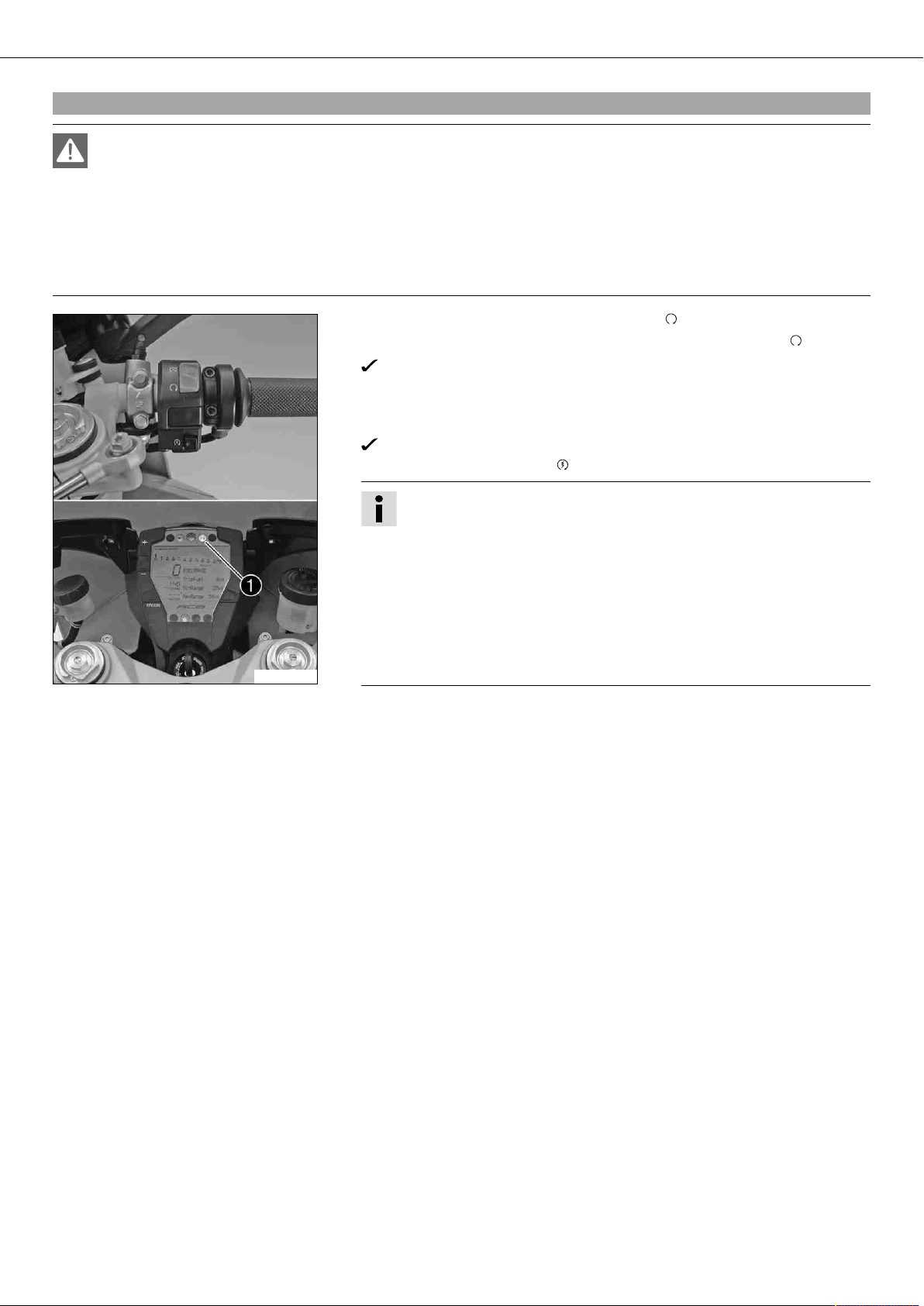

4.3Jacking up motorcycle rear

Note

Danger of damage Danger of damage by the vehicle running away or falling over.

– Always place the vehicle on a firm and even surface.

– Insert the work stand adapter in the rear of the work stand.

Work stand adapter (61029055120) ( p. 197)

Work stand rear (61029055100) ( p. 197)

– Stand the motorcycle upright, align the work stand to the link fork and the

adapters, and jack up the motorcycle.

700251-01

4.4Taking rear of motorcycle off work stand

Note

Danger of damage Danger of damage by the vehicle running away or falling over.

– Always place the vehicle on a firm and even surface.

– Secure the motorcycle against falling over.

– Remove the work stand from the rear and lean the vehicle on the sidestand.

MOTORCYCLE 10

4.5Starting

Danger

Danger of poisoning Exhaust gases are poisonous and can result in unconsciousness and/or death.

– When running the engine, always make sure there is sufficient ventilation, and do not start or run the engine in a closed

space.

Note

Engine failure High engine speeds in cold engines have a negative effect on the service life of the engine.

– Always warm up the engine at low engine speeds.

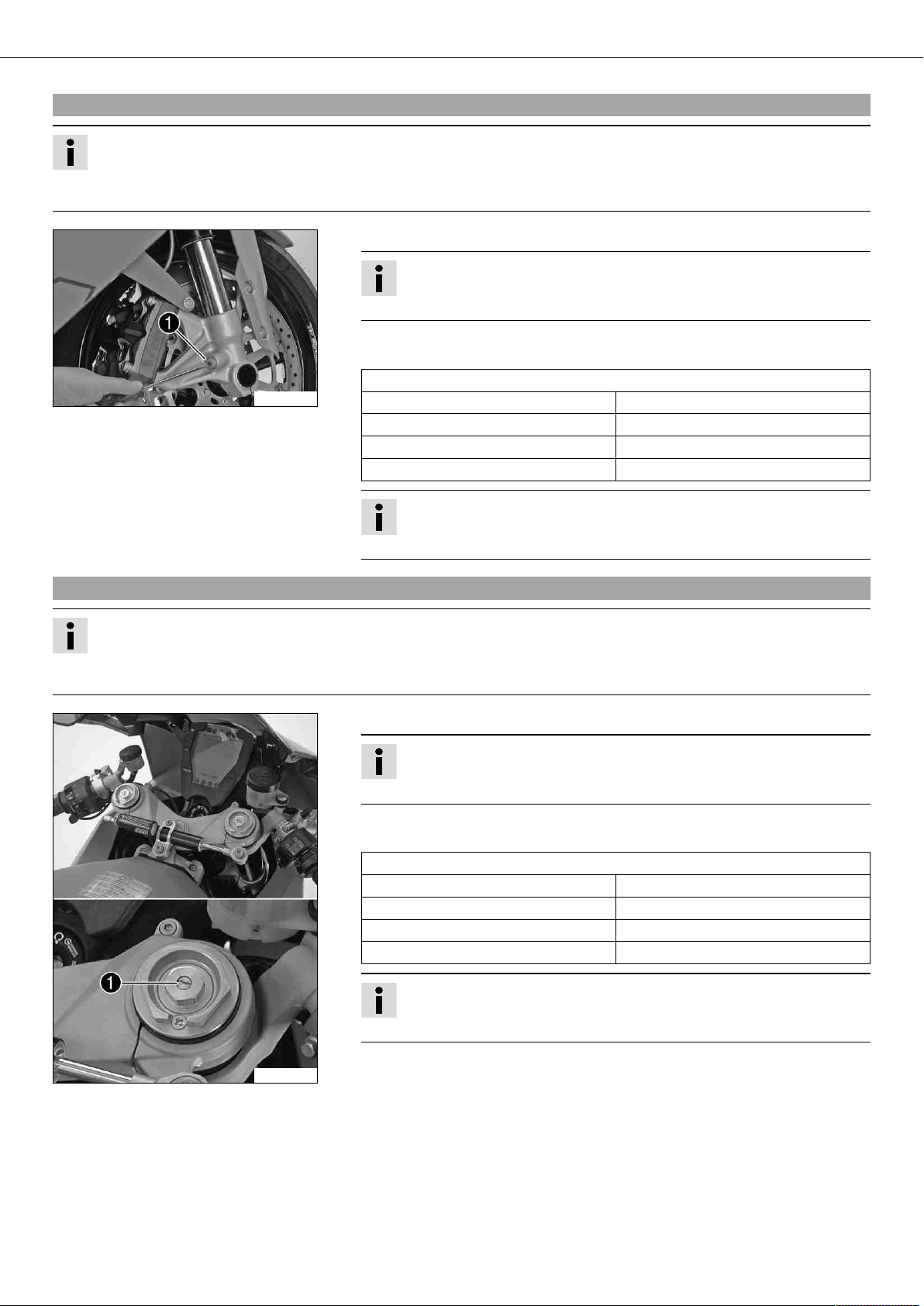

– Press the emergency OFF switch into the position .

– Switch on the ignition by turning the black ignition key to the position .

When you switch on the ignition, you hear the fuel pump working for about 2

seconds. At the same time, the function test of the combination instrument is

run.

– Shift into neutral.

The green idling speed indicator lamp N lights up.

– Press the electric starter button .

Info

Do not press the electric starter button until the combination instrument

function test finishes.

Do not open the throttle to start. If you open the throttle during starting, the

engine management does not supply any fuel, so the engine cannot start.

Press the starter for a maximum of 5 seconds without a break. Wait at least

5 seconds before trying to start again.

This motorcycle is equipped with a safety start system. The engine will only

start if in neutral or, if a gear is engaged, when the clutch lever is pulled. If

the sidestand is out and the machine is in gear and you release the clutch

700248-01

– Take the weight off the side stand and swing it upwards with your foot as far as it

lever, the engine stops.

will go.

01/FORK, TRIPLE CLAMP 11

501/FORK,TRIPLECLAMP

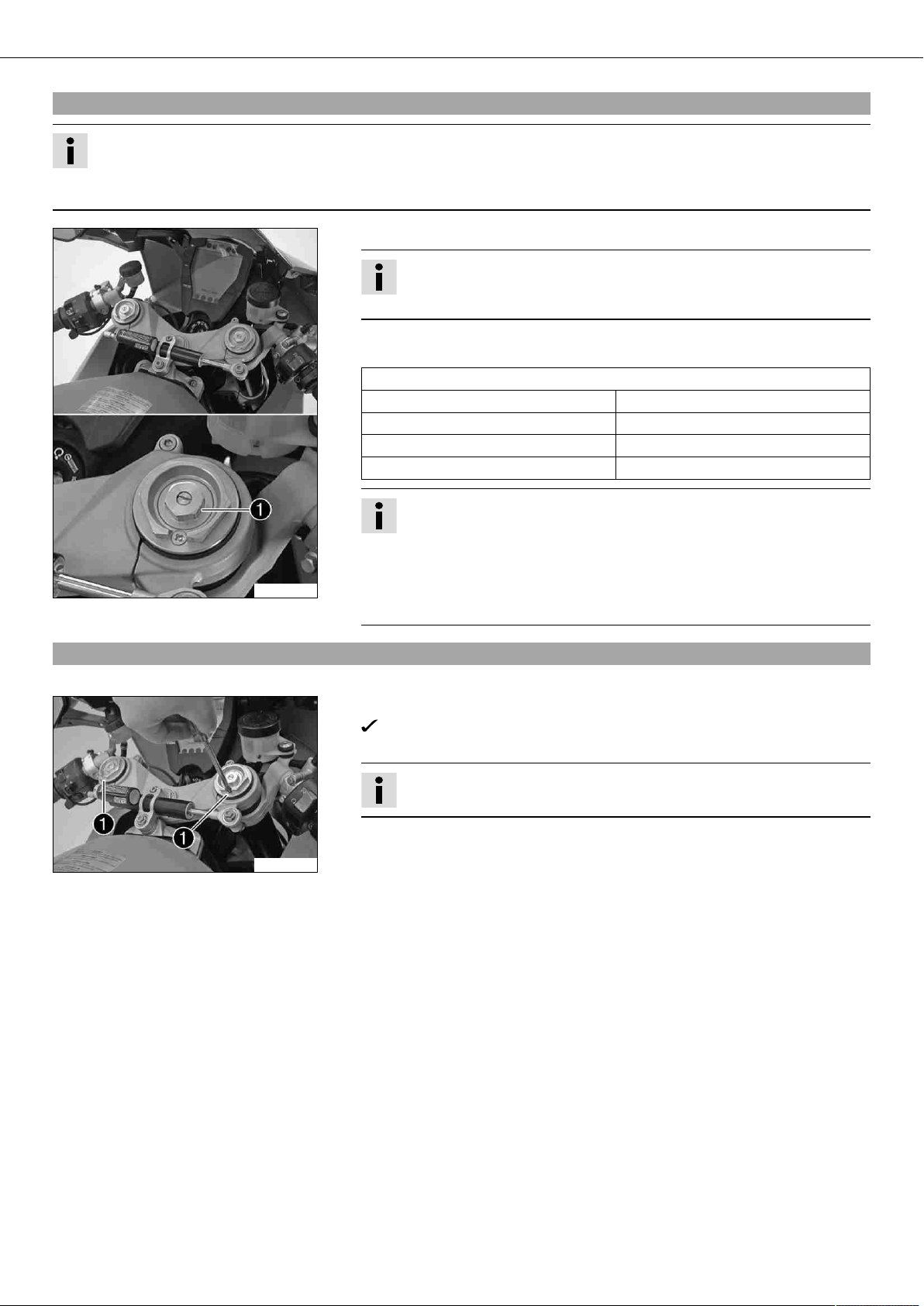

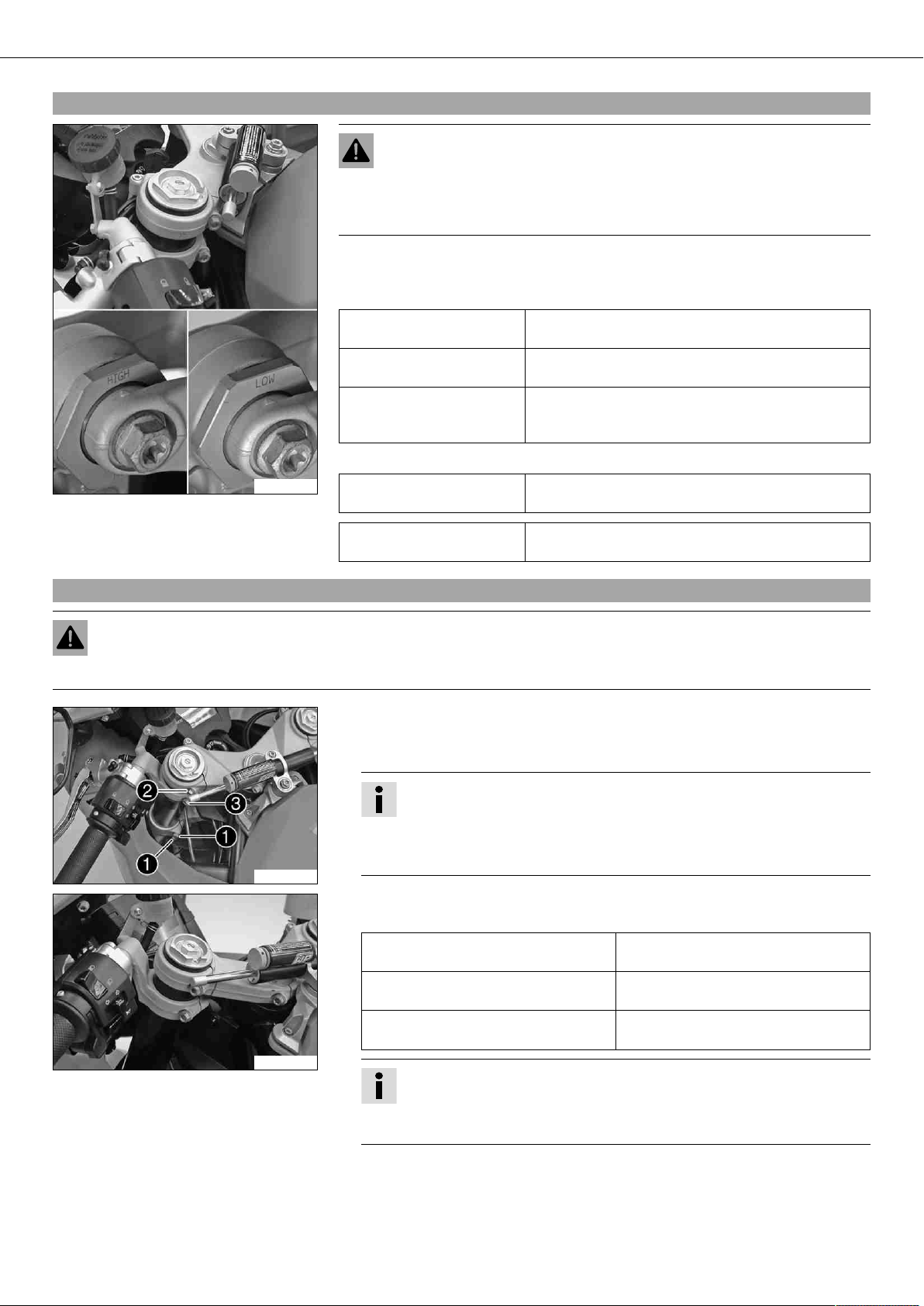

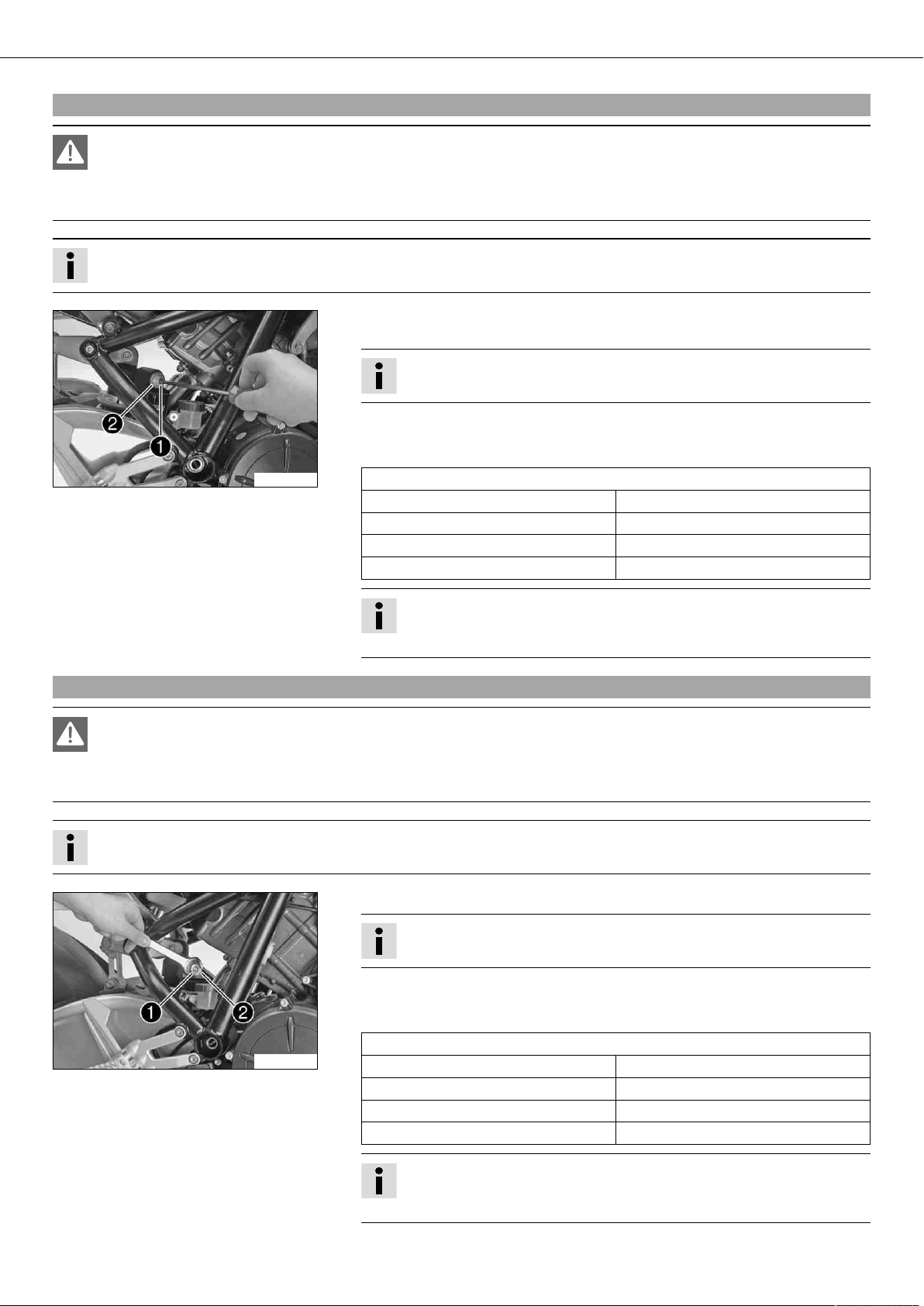

5.1Adjusting compression damping of fork

Info

The hydraulic compression damping determines the fork suspension behavior.

An optimally adjusted compression damping ensures that the fork does not compress too far and fast when you brake hard or

when the load shifts very fast. It gives the rider good feedback about the road conditions.

– Turn adjusting screws clockwise until they stop.

Info

The adjusting screws are located at the bottom end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise the number of clicks corresponding to the fork type.

Guideline

Compression damping

700253-01

Comfort 15 clicks

Standard 10 clicks

Sport 5 clicks

full payload 5 clicks

Info

Turn clockwise to increase damping, turn counterclockwise to reduce suspension damping.

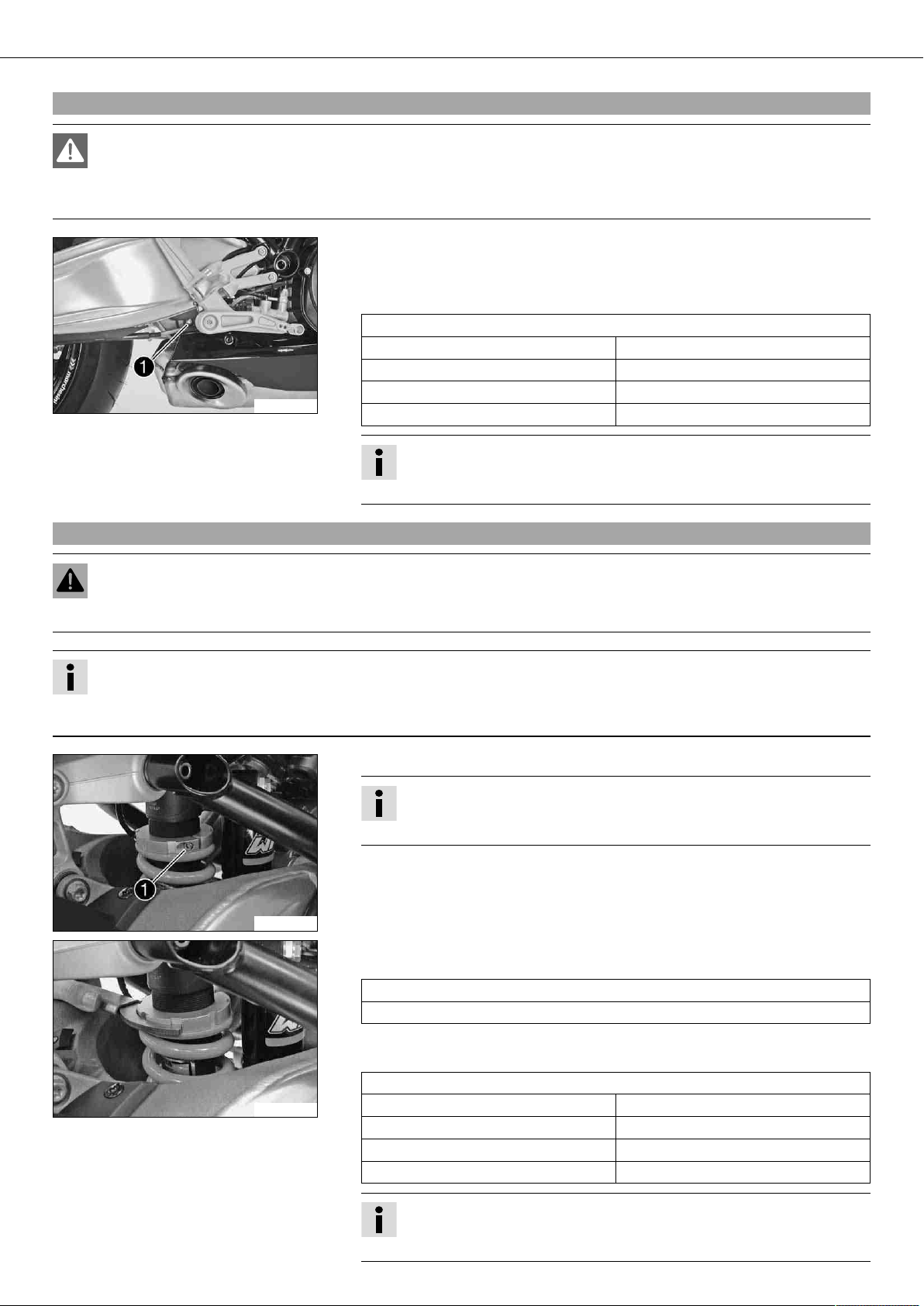

5.2Adjusting rebound damping of fork

Info

The hydraulic rebound damping determines the fork suspension behavior.

An optimally adjusted rebound damping brakes the springing energy and enables a fast, vibration-free resetting of the fork to

the zero position.

– Turn adjusting screws clockwise until they stop.

Info

The adjusting screws are located at the top end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise the number of clicks corresponding to the fork type.

Guideline

Rebound damping

Comfort 15 clicks

Standard 10 clicks

Sport 5 clicks

Full payload 5 clicks

700347-01

Info

Turn clockwise to increase damping, turn counterclockwise to reduce suspension damping.

01/FORK, TRIPLE CLAMP 12

5.3Adjusting spring preload of fork

Info

The spring preload defines the initial situation of the spring process of the fork.

An optimally adjusted spring preload is adapted to the rider's weight and ensures a compromise between easy handling and

stability.

– Turn the adjusting spindles clockwise until they stop.

Info

The adjusting spindles are located at the top end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise the number of turns corresponding to the fork type.

Guideline

Spring preload - Preload Adjuster

Comfort 5 turns

Standard 5 turns

Sport 3 turns

full payload 3 turns

5.4bleeding fork legs

700348-01

700259-01

Info

Turn clockwise to increase preload, turn counterclockwise to reduce spring

preload.

Changing the spring preload has no influence on the rebound damping

although the adjusting screws turn during the adjustment work. However,

you should also adjust the rebound damping when you alter the spring

preload.

– Lean the motorcycle on the side stand.

– Remove bleeder screws briefly.

Any excess pressure escapes from the interior of the fork.

– Mount and tighten bleeder screws.

Info

Perform this action on both fork legs.

01/FORK, TRIPLE CLAMP 13

5.5Vehicle level

Warning

Danger of accidents Modifications to the chassis can seriously alter the vehi-

cle's handling characteristics.

– Following modifications, ride slowly at first to get the feel of the new han-

dling characteristics.

The vehicle level can be adjusted at the front by means of the fork leg clamp and at

the rear by the eccentric shaft.

The fork legs can be clamped at three positions in the triple clamps.

Upper triple clamp flush

0 mm (0 in)

with upper edge of fork legs

Upper triple clamp flush

2.5 mm (0.098 in)

with 1st ring of fork legs

Upper triple clamp flush

5 mm (0.2 in)

with 2nd ring of fork legs

(standard)

The chassis height can be adjusted steplessly by turning the eccentric shaft.

700333-01

Chassis height difference

7 mm (0.28 in)

HIGH - LOW

Maximum adjustment range

180°

between HIGH - LOW

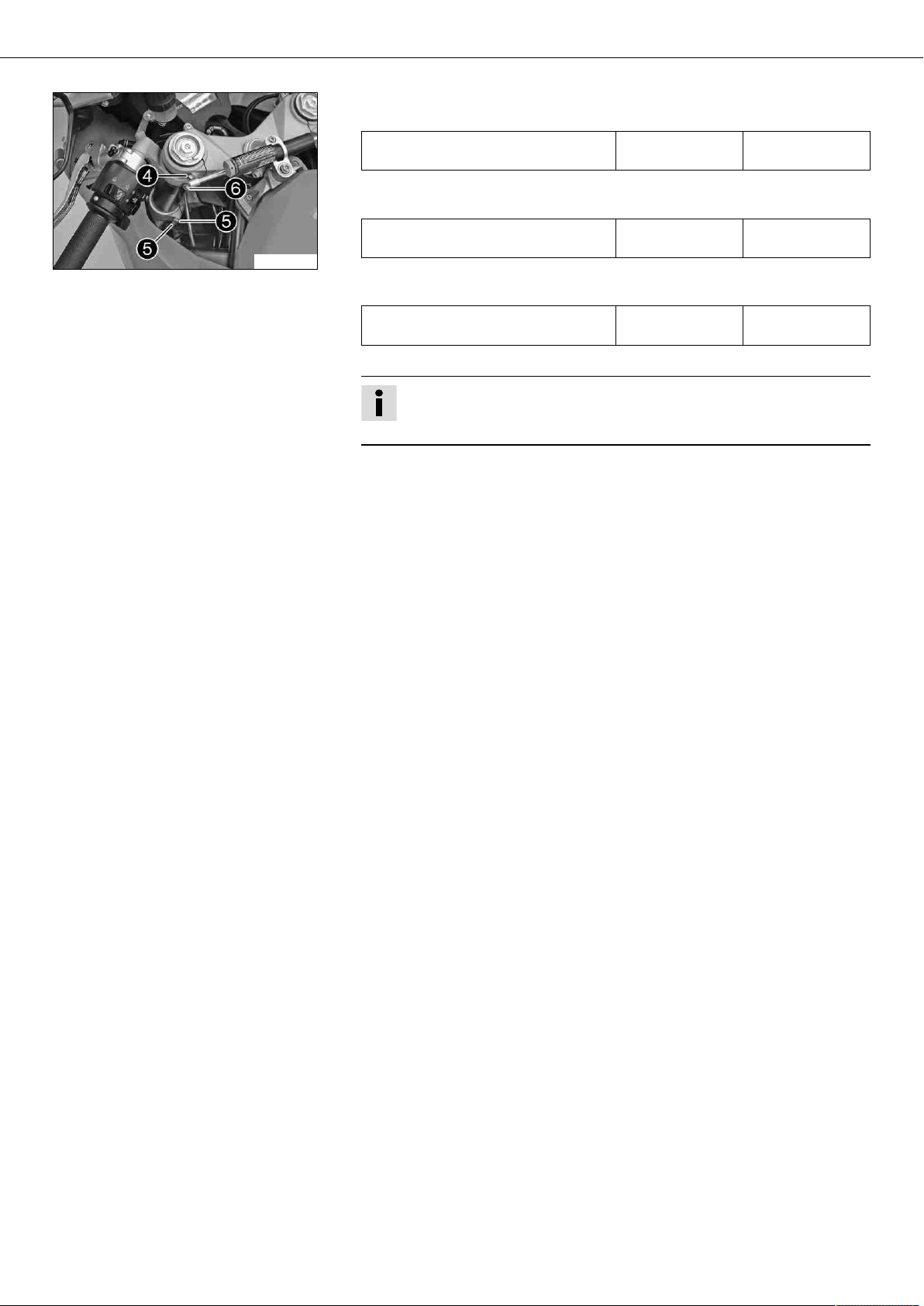

5.6Adjusting front vehicle level

Warning

Danger of accidents Modifications to the chassis can seriously alter the vehicle's handling characteristics.

– Following modifications, ride slowly at first to get the feel of the new handling characteristics.

– Loosen screws on the lower triple clamp.

– Loosen screw on the upper triple clamp.

– Loosen screw of the handlebar stub.

700352-01

700353-01

Info

Loosen the screws far enough to prevent damage to the lacquer when the

fork legs are moved.

Make the adjustments first on one fork leg and then on the other. When the

screws of both fork legs are loosened, the vehicle sags toward the front.

– Align the fork leg in the desired position by means of the fork rings.

Guideline

Upper triple clamp flush with upper

0 mm (0 in)

edge of fork legs

Upper triple clamp flush with 1st ring

2.5 mm (0.098 in)

of fork legs

Upper triple clamp flush with 2nd ring

5 mm (0.2 in)

of fork legs (standard)

Info

The standard adjustment is the setting that provides the best vehicle handling. When the fork is compressed, the chassis setting changes, causing

the vehicle to become more stable but also more difficult to handle.

01/FORK, TRIPLE CLAMP 14

– Tighten screw .

Guideline

Screw, top triple clamp M8 17 Nm

(12.5 lbf ft)

– Tighten screws .

Guideline

Screw, bottom triple clamp M8 15 Nm

700352-10

– Tighten screw .

Guideline

Screw, handlebar stub M8 20 Nm

– Repeat the adjustment on the other fork leg.

Info

The setting of the vehicle level via the fork legs must be identical on both

fork legs.

(11.1 lbf ft)

(14.8 lbf ft)

02/HANDLEBAR, CONTROLS AND INSTRUMENTS 15

602/HANDLEBAR,CONTROLSAND INSTRUMENTS

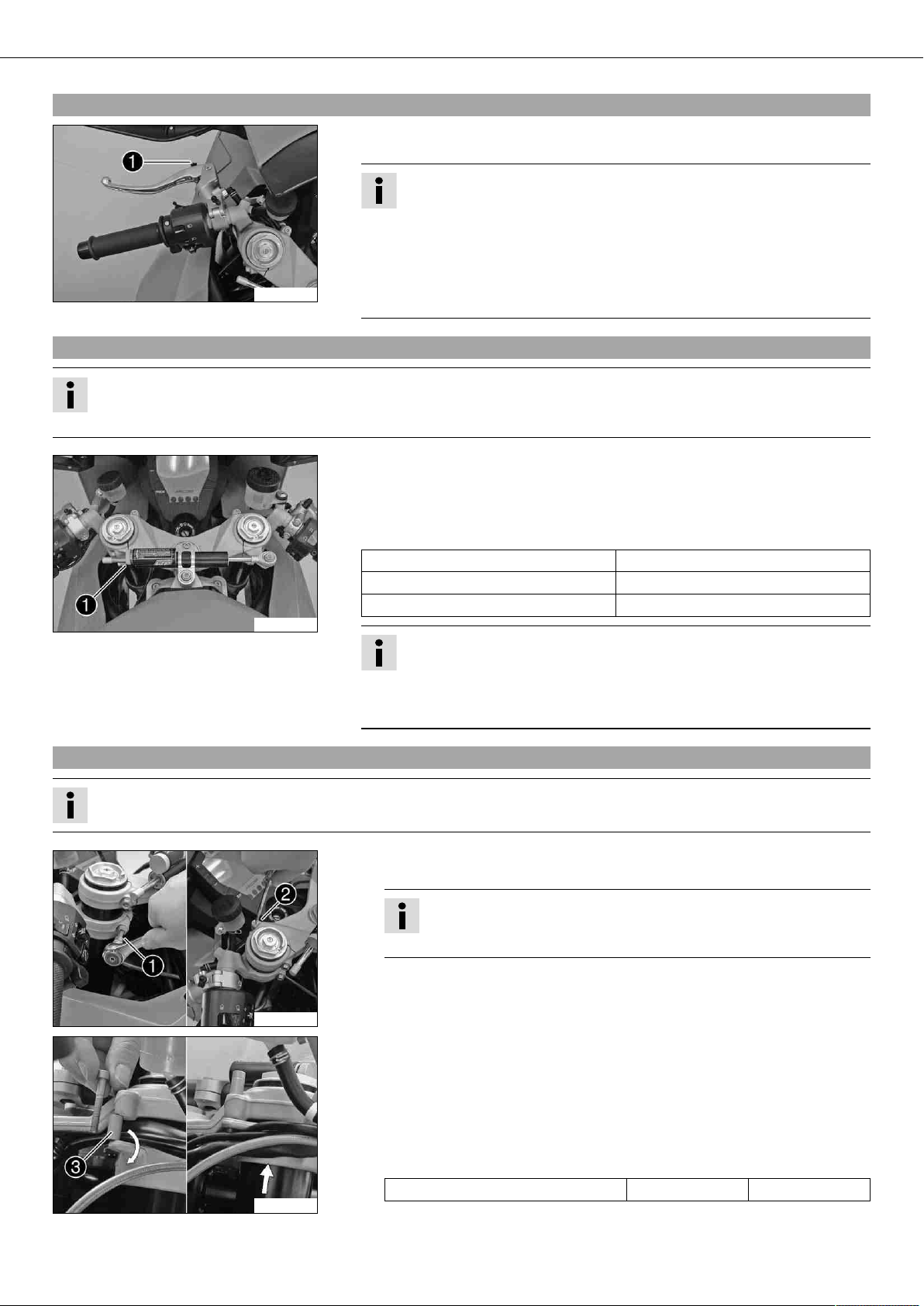

6.1Adjusting basic position of clutch lever

– Adjust the basic setting of the clutch lever to your hand size by turning adjusting

screw .

Info

Turn the adjusting screw clockwise to increase the distance between the

clutch lever and the handlebar.

Turn the adjusting screw counterclockwise to decrease the distance between

the clutch lever and the handlebar.

The range of adjustment is limited.

700227-10

6.2Adjusting the steering damper

Info

The hydraulic steering damper stabilizes the steering if the front wheel is raised off the ground or carries no load.

In contrast to other damping elements, the steering damper is adjusted with the damping element open.

– Turn the adjusting screw anticlockwise towards "–" as far as the last perceptible

– Adjust the steering damper according to your riding style and the road conditions

700339-10

Turn the adjusting screw by hand only, and do not apply any force.

Do not make any adjustments while riding!

click.

by turning the adjust screw clockwise towards "+".

Guideline

Steering damper adjustment range 1… 32 clicks

Recommended range for use 1… 20 clicks

Standard 1 click

Info

Do not change the adjustment of the steering damper during the journey!

After adjusting the steering damper, check the steering for smooth operation, making sure that the handlebar can be moved from extreme left to

extreme right without a tendency to lock.

6.3Adjusting the handlebar height

Info

The handlebar stub position must be identical on the left and right of the vehicle.

Adjusting the high position of the handlebar stubs:

– Loosen screw .

Info

Loosen the screw several turns to prevent damage to the fork lacquer

when moving the handlebar stub.

– Remove screw .

700318-01

– Remove distance sleeve .

– All cables routed under the upper triple clamp must now be routed under the

handlebar stub.

– Push the handlebar stub carefully up to the upper triple clamp.

– Position the distance sleeve above the triple clamp.

– Mount and tighten the screw.

Guideline

700319-01

Remaining chassis screws M5 5 Nm (3.7 lbf ft)

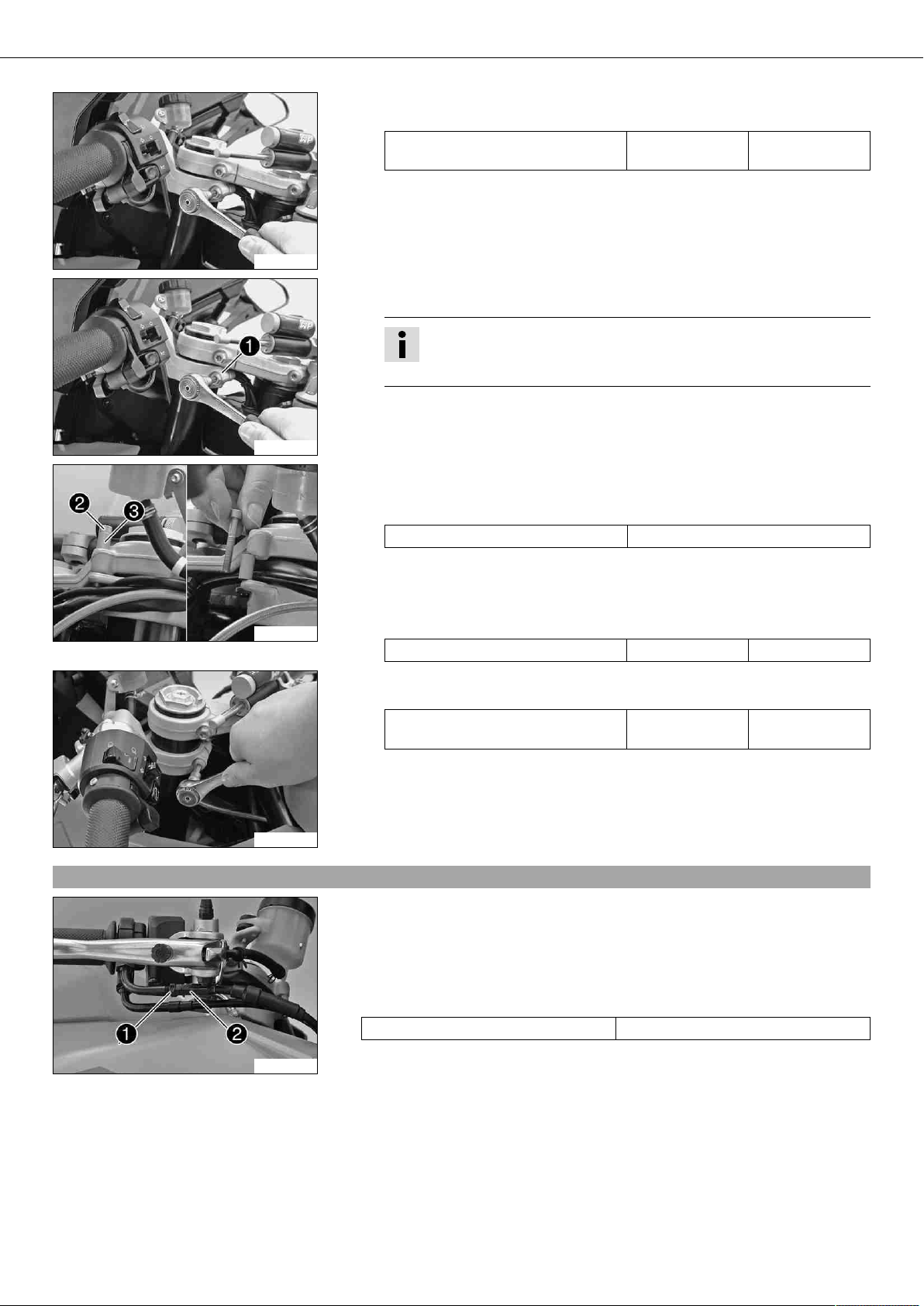

02/HANDLEBAR, CONTROLS AND INSTRUMENTS 16

– Tighten the screw.

Guideline

Screw, handlebar stub M8 20 Nm

(14.8 lbf ft)

– Repeat the adjustments on the other handlebar stub.

– Move the handlebar to and fro over the entire steering range.

» If the cables restrict the freedom of movement of the steering:

700320-01

Adjusting the low position of the handlebar stubs:

700320-11

– Correct the cable routing.

– Loosen screw .

Info

Loosen the screw several turns to prevent damage to the fork lacquer

when moving the handlebar stub.

– Remove screw with distance sleeve .

– Carefully shift the handlebar stub by the length of the distance sleeve.

Guideline

Long distance sleeve 15 mm (0.59 in)

6.4Adjusting gas Bowden cable

700319-11

700362-01

– Lay all cables between the upper triple clamp and the handlebar stub.

– Position the distance sleeves.

– Mount and tighten the screw.

Guideline

Remaining chassis screws M5 5 Nm (3.7 lbf ft)

– Tighten the screw.

Guideline

Screw, handlebar stub M8 20 Nm

(14.8 lbf ft)

– Repeat the adjustments on the other handlebar stub.

– Move the handlebar to and fro over the entire steering range.

» If the cables restrict the freedom of movement of the steering:

– Correct the cable routing.

– Move the handlebar to the straight-ahead position.

– With the diagnostics tool KTM DIA, place the control motor for the throttle valve

position into the neutral position.

– Loosen the counter nut .

– Adjust the gas Bowden cable with the adjusting screw .

Guideline

Play in gas Bowden cable 3… 5 mm (0.12… 0.2 in)

700317-01

– Tighten the counter nut .

03/FRAME 17

703/FRAME

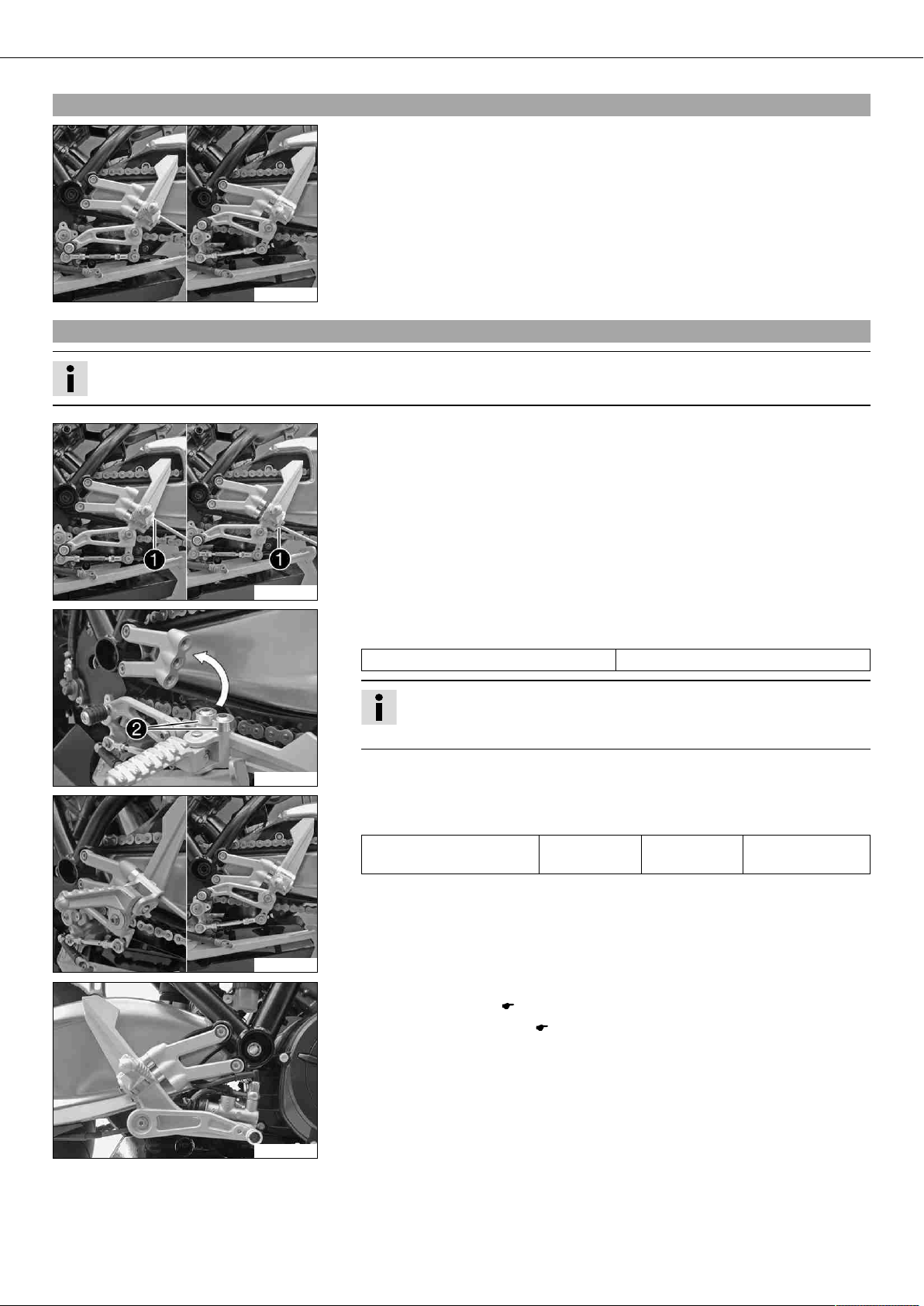

7.1Footrest position

The adjustable footrest system enables an individual setting of the footrest height and

an individual adjustment of the operating elements.

The lower footrest position enables a more comfortable knee angle, the upper footrest

position a sporting sitting position and more forward-leaning freedom for use in racing.

700328-01

7.2Adjusting footrest position

Info

The footrest position must be identical on the left and the right.

– Remove screws .

700307-01

700308-01

700306-01

– Position the footrest bracket with spacers and screws.

Guideline

Standard Lower position

Info

The adjustable footrest bracket enables a more comfortable lower footrest

position or a sporting upper footrest position.

– Mount and tighten screws.

Guideline

Screw, front footrest

bracket

– Repeat adjustment work on the footrest bracket on the other side.

– Adjust the shift lever. ( p. 143)

– Adjust the footbrake pedal. ( p. 56)

M8 25 Nm

(18.4 lbf ft)

Loctite®243™

700309-01

03/FRAME 18

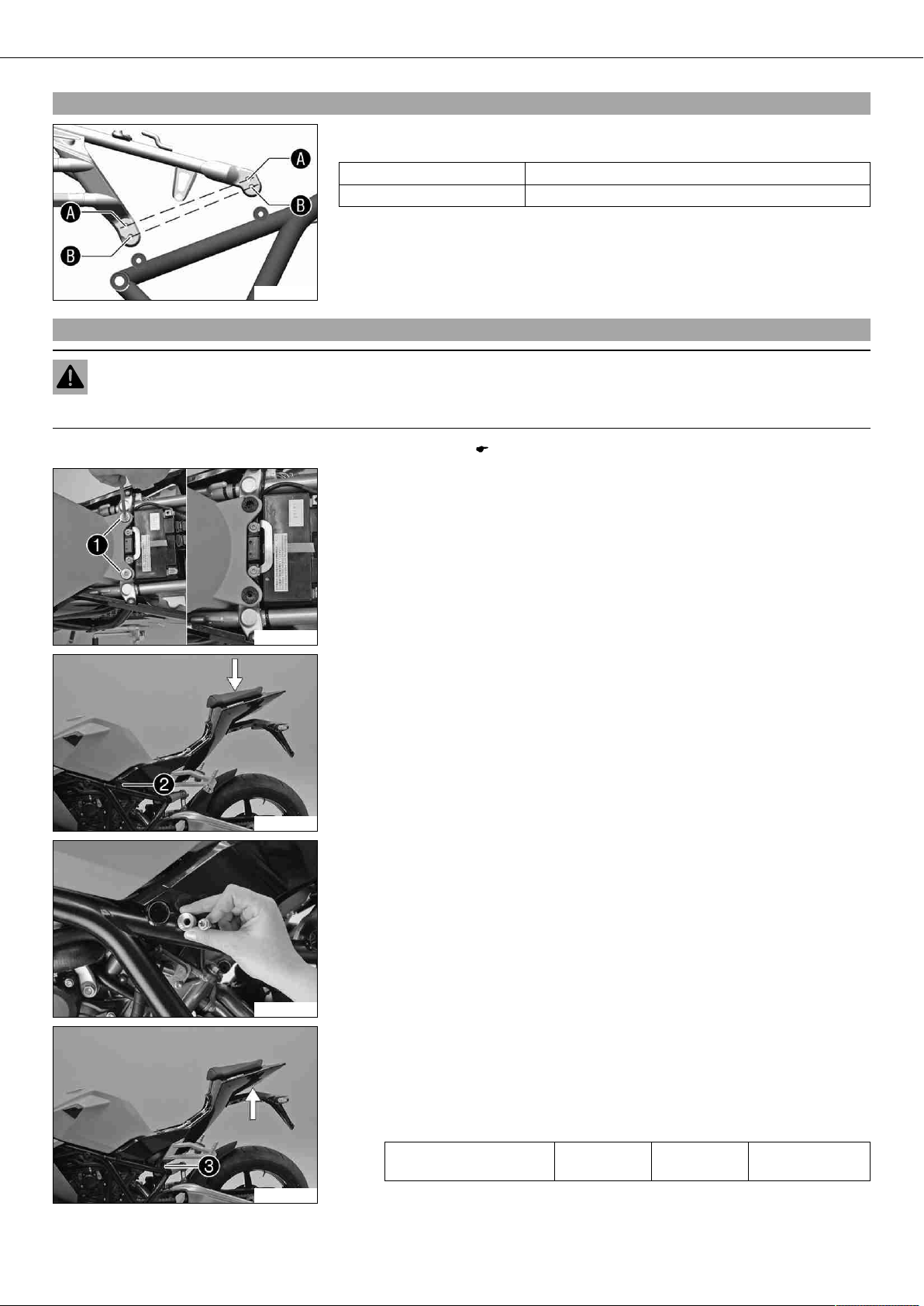

7.3Rear frame position

The frame rear height can be set to two different positions, enabling ergonomic adjustment of the seat height.

Seat height (standard) 805 mm (31.69 in)

Seat height 825 mm (32.48 in)

400439-10

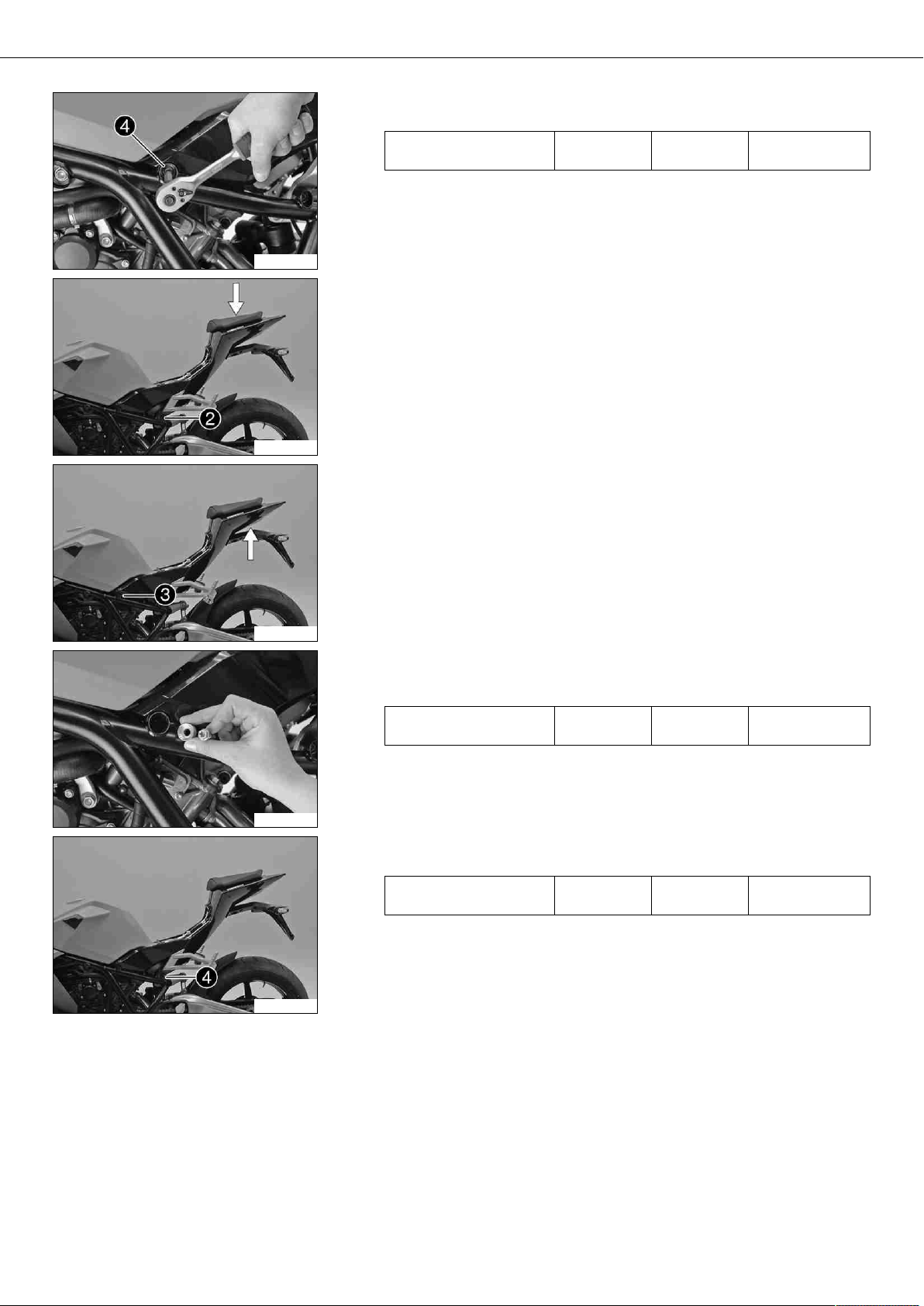

7.4Adjusting the rear frame position

Warning

Danger of accidents Modifications to the chassis can seriously alter the vehicle's handling characteristics.

– Following modifications, ride slowly at first to get the feel of the new handling characteristics.

– Remove the seat. ( p. 32)

– Remove screws with the bushings.

700363-01

700327-10

700329-01

700327-11

Setting a higher seat position:

– Remove screw with washer on the left and right sides of the vehicle.

– Push the rear end down until the drill holes of the frame are level with the

lower front drill holes of the rear.

– Mount the screw and washer on the left and right sides of the vehicle, but do

not tighten.

– Remove screw with washer on the left and right sides of the vehicle.

– Push the rear end up until the drill holes of the frame are level with the lower

rear drill holes of the rear.

– Mount the screw and washer on the left and right sides of the vehicle, and

tighten.

Guideline

Screw, subframe M8 25 Nm

Loctite®243™

(18.4 lbf ft)

03/FRAME 19

– Tighten screw on the left and right sides of the vehicle.

Guideline

Screw, subframe M8 25 Nm

(18.4 lbf ft)

700330-01

Setting a lower seat position:

– Remove screw with washer on the left and right sides of the vehicle.

– Push the rear end down until the drill holes of the frame are level with the

upper rear drill holes of the rear.

– Mount the screw and washer on the left and right sides of the vehicle, but do

not tighten.

700327-12

– Remove screw with washer on the left and right sides of the vehicle.

– Push the rear end up until the drill holes of the frame are level with the upper

front drill holes of the rear.

Loctite®243™

700327-14

700329-01

700327-13

– Mount the screw and washer on the left and right sides of the vehicle, and

tighten.

Guideline

Screw, subframe M8 25 Nm

Loctite®243™

(18.4 lbf ft)

– Tighten screw on the left and right sides of the vehicle.

Guideline

Screw, subframe M8 25 Nm

Loctite®243™

(18.4 lbf ft)

03/FRAME 20

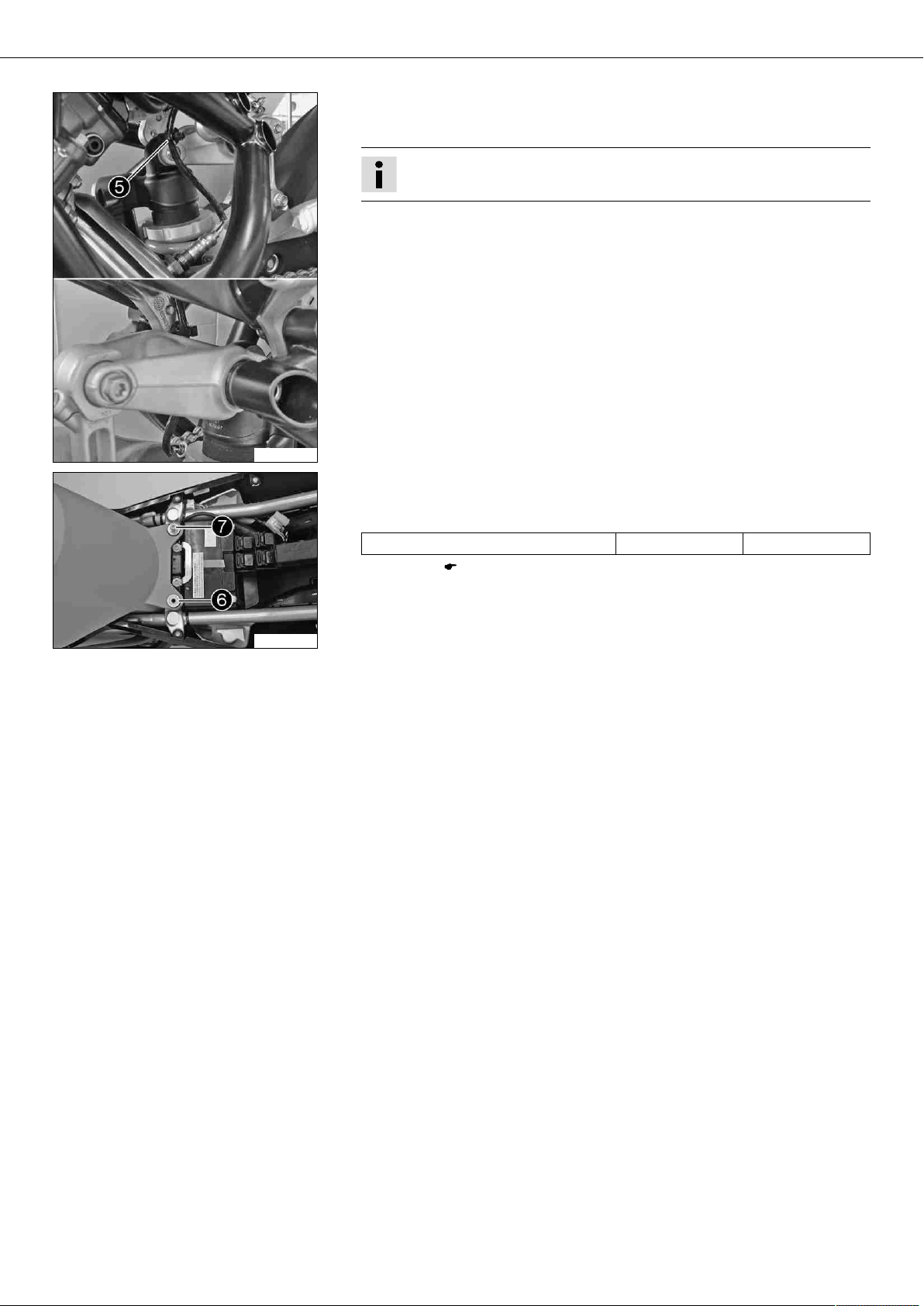

– When you screw in the rear left fixing screw, the plug-in cable binder is pushed

out of the thread. To reposition the cable of the lambda probe, fix the plug-in cable

binder in the remaining free drill hole.

Info

Check the cable routing. The cable of the lambda probe should not be taut.

700338-01

– Position bushings .

– Mount and tighten screws .

Guideline

Remaining chassis screws M6 10 Nm (7.4 lbf ft)

700364-01

– Fit the seat. ( p. 32)

04/SHOCK ABSORBER, SWINGARM 21

804/SHOCKABSORBER,SWINGARM

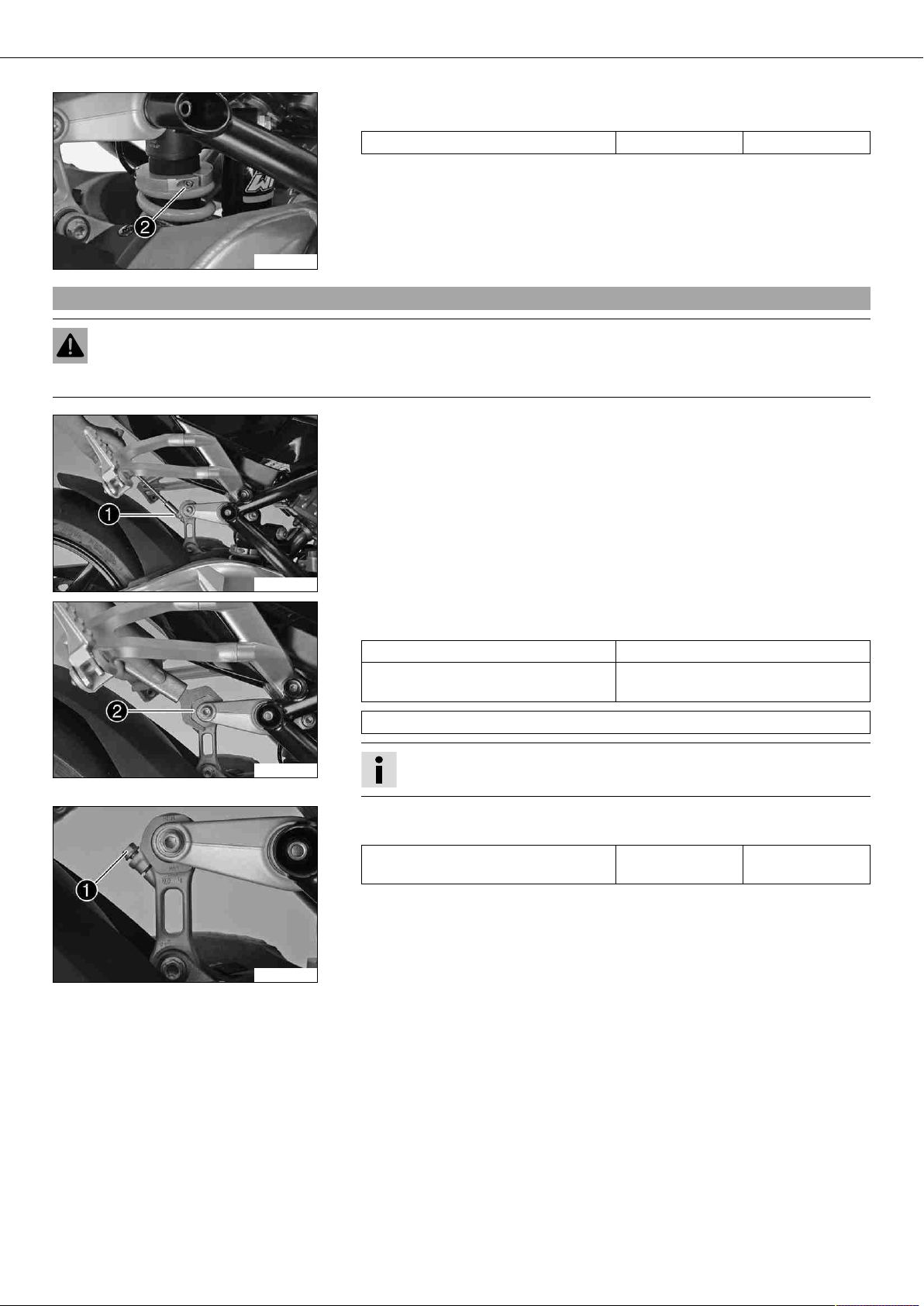

8.1Adjusting the low-speed compression damping of the shock absorber

Danger

Danger of accidents The shock absorber is under high pressure.

– The shock absorber is filled with highly compressed nitrogen, so never dismantle the shock absorber or carry out any main-

tenance on it yourself.

Info

The low-speed setting can be seen during the slow to normal compression of the shock absorber.

– Turn the adjusting screw clockwise with a screwdriver up to the last perceptible

click.

Info

Do not loosen nut !

– Turn back counterclockwise the number of clicks corresponding to the shock

absorber type.

Guideline

700255-01

Compression damping, low-speed

Comfort 20 clicks

Standard 15 clicks

Sport 10 clicks

full payload 10 clicks

Info

Turn clockwise to increase damping, turn counterclockwise to reduce suspension damping.

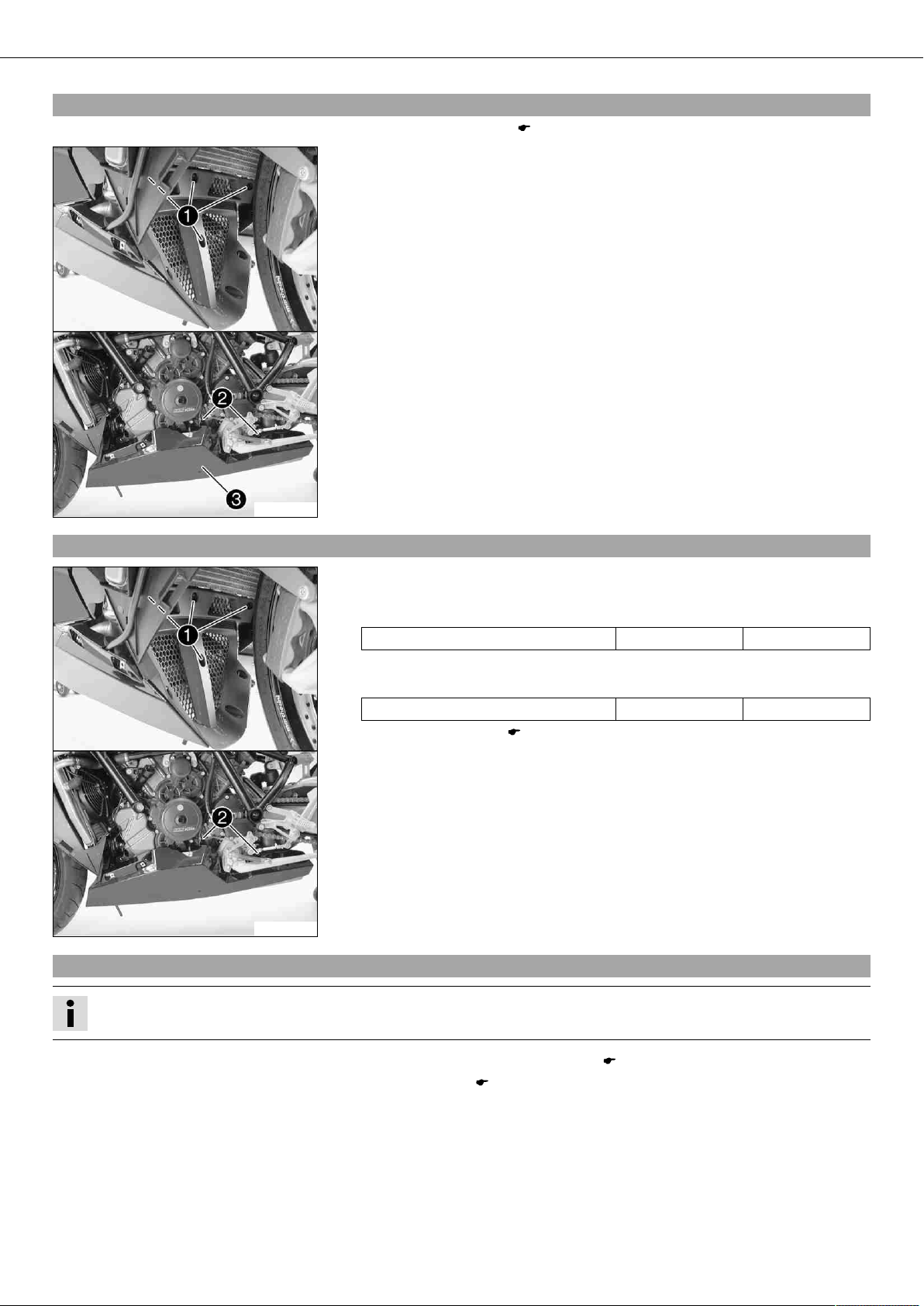

8.2Adjusting high-speed compression damping of the shock absorber

Danger

Danger of accidents The shock absorber is under high pressure.

– The shock absorber is filled with highly compressed nitrogen, so never dismantle the shock absorber or carry out any main-

tenance on it yourself.

Info

The high-speed setting can be seen during the fast compression of the shock absorber.

– Turn the adjusting screw clockwise with an open-ended spanner until it stops.

Info

Do not loosen nut !

– Turn back counterclockwise the number of turns corresponding to the shock

absorber type.

Guideline

Compression damping, high-speed

700256-01

Comfort 2 turns

Standard 1.5 turns

Sport 1 turn

full payload 1 turn

Info

Turn clockwise to increase damping, turn counterclockwise to reduce suspension damping.

04/SHOCK ABSORBER, SWINGARM 22

8.3Adjusting rebound damping of the shock absorber

Danger

Danger of accidents The shock absorber is under high pressure.

– The shock absorber is filled with highly compressed nitrogen, so never dismantle the shock absorber or carry out any main-

tenance on it yourself.

– Turn the adjusting screw clockwise up to the last perceptible click.

– Turn back counterclockwise the number of clicks corresponding to the shock

absorber type.

Guideline

Rebound damping

Comfort 15 clicks

Standard 10 clicks

700257-01

Sport 5 clicks

full payload 10 clicks

Info

Turn clockwise to increase damping, turn counterclockwise to reduce suspension damping.

8.4Adjusting spring preload of shock absorber

Warning

Danger of accidents Modifications to the chassis can seriously alter the vehicle's handling characteristics.

– Following modifications, ride slowly at first to get the feel of the new handling characteristics.

Info

The spring preload defines the initial situation of the spring process on the shock absorber.

An optimally adjusted spring preload is adapted to the rider's weight and ensures a compromise between easy handling and

stability.

– Take the weight off the rear wheel and swingarm.

Info

The spring preload can be adjusted correctly only if the rear wheel and the

swingarm are fully relieved of weight.

– Loosen screw two turns, but do not remove.

700341-10

– Turn the adjusting ring anticlockwise with the toolset wrench until the spring is

completely relaxed.

700342-01

Hook wrench (69012022000)

Extension (60012060000)

– Turn the adjusting ring clockwise and tension it to the specified value.

Guideline

Spring preload

Comfort 6 mm (0.24 in)

Standard 6 mm (0.24 in)

Sport 8 mm (0.31 in)

full payload 8 mm (0.31 in)

Info

Turn clockwise to increase preload, turn counterclockwise to reduce spring

preload.

04/SHOCK ABSORBER, SWINGARM 23

– Tighten screw .

Guideline

Remaining chassis screws M5 5 Nm (3.7 lbf ft)

700341-11

8.5Adjusting the vehicle level at the rear

Warning

Danger of accidents Modifications to the chassis can seriously alter the vehicle's handling characteristics.

– Following modifications, ride slowly at first to get the feel of the new handling characteristics.

– Loosen screw but do not remove it.

700331-01

700332-01

700334-01

– Turn eccentric shaft to the desired position using the tool from the tool set.

Guideline

Standard LOW

Maximum adjustment range between

180°

HIGH - LOW

Open end wrench SW 38 (69012021000)

Info

The chassis height can be adjusted in both directions.

– Tighten screw .

Guideline

Remaining chassis screws M8 25 Nm

(18.4 lbf ft)

05/EXHAUST 24

905/EXHAUST

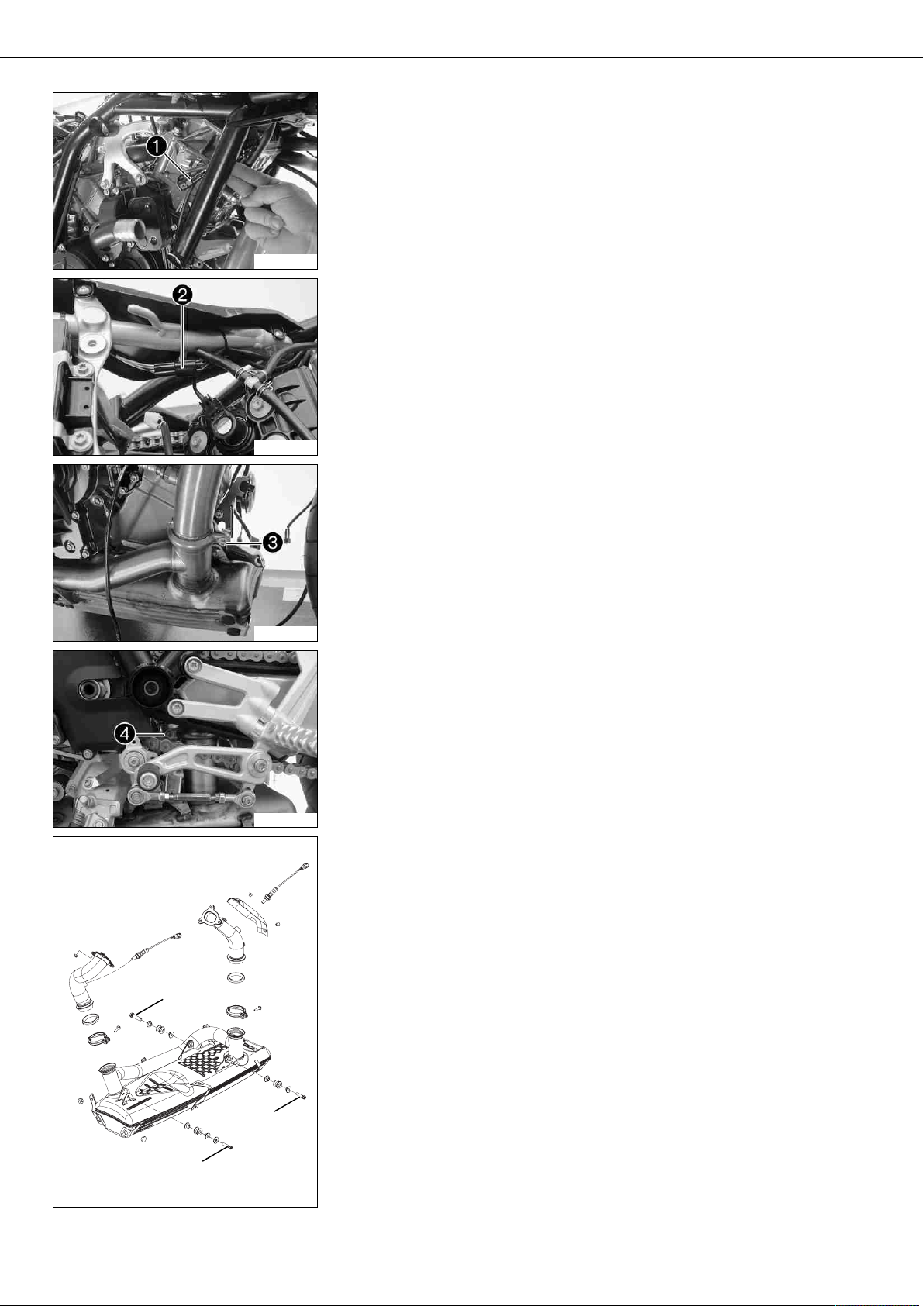

9.1Removing the exhaust cover completely

– Remove the side covers. ( p. 36)

– Remove screws .

– Remove screws on both sides.

– Take off exhaust cover completely.

200532-10

9.2Installing the exhaust cover completely

200532-11

– Position the exhaust cover.

– Mount and tighten screws .

Guideline

Remaining chassis screws M5 5 Nm (3.7 lbf ft)

– Mount and tighten screws on both sides.

Guideline

Remaining chassis screws M5 5 Nm (3.7 lbf ft)

– Install the side covers. ( p. 36)

9.3Removing the exhaust system

Info

The radiator has only been removed to illustrate the procedure more clearly.

– Remove the exhaust cover completely. ( p. 24)

– Remove the seat. ( p. 32)

0055

0055

0055

05/EXHAUST 25

– Unplug connector of the lambda probe (2nd cylinder). Open the cable binder.

200513-10

– Unplug connector of the lambda probe (1st cylinder).

200514-10

– Remove screw . Slide the clamp upward.

200515-10

200516-10

– Remove screw . Slide the clamp upward.

– Remove screws with the washers. Take off the main silencer.

200517-01

05/EXHAUST 26

– Remove nuts . Remove the manifold at the front with the seals.

200518-10

– Remove nuts . Remove the manifold at the rear with the seals.

200519-10

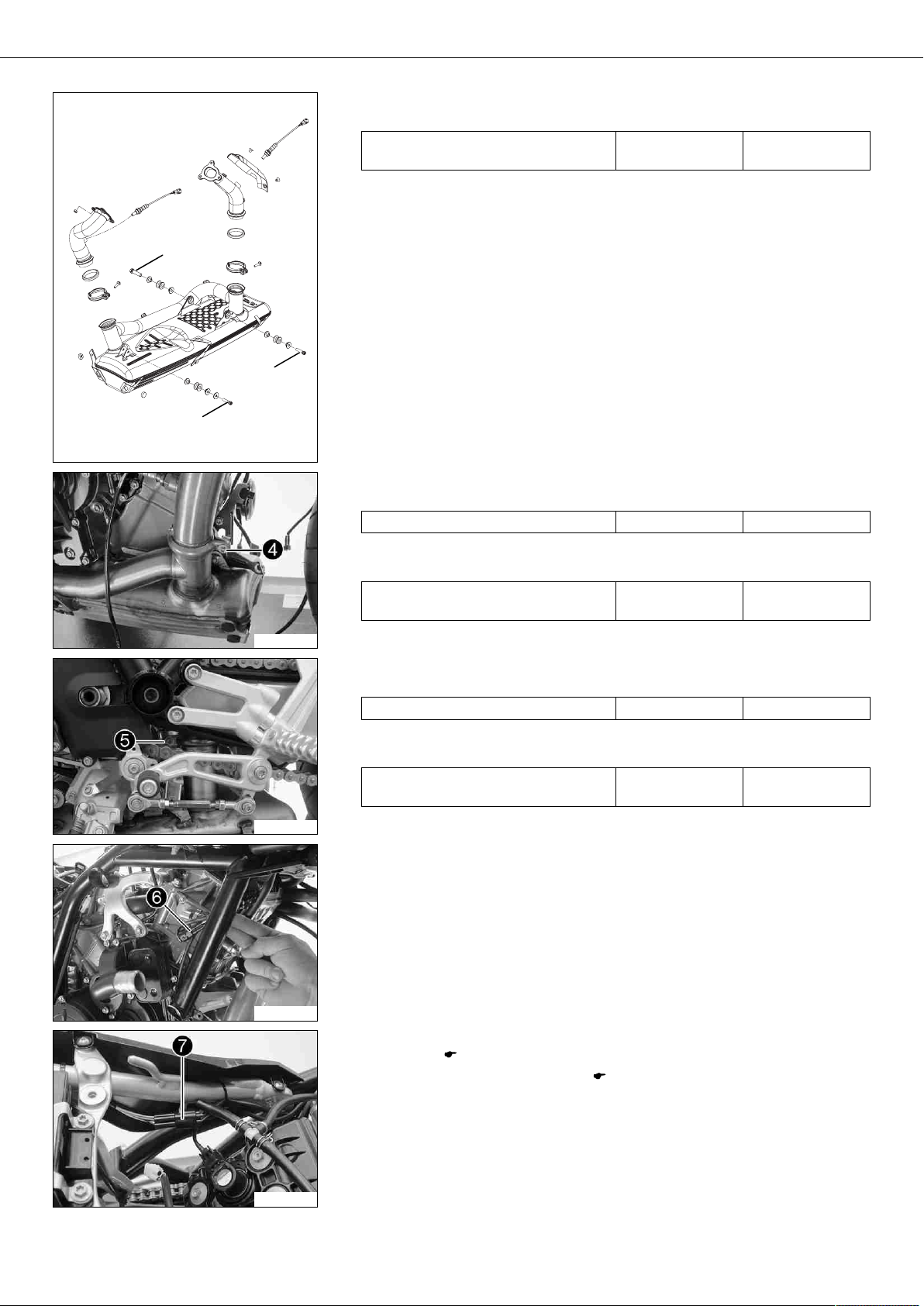

9.4Installing the exhaust system

Info

The radiator has only been removed to illustrate the procedure more clearly.

– Position the manifold at the front with the seals. Mount nuts but do not tighten

them yet.

200518-11

– Position the manifold at the rear with the seals. Mount nuts but do not tighten

them yet.

200519-11

0033

0033

0033

05/EXHAUST 27

– Position the main silencer. Mount and tighten screws with the washers.

Guideline

Remaining chassis screws M8 25 Nm

(18.4 lbf ft)

200517-02

– Position the clamp. Mount and tighten screw .

Guideline

Screw, exhaust clamp M6 8 Nm (5.9 lbf ft)

200515-11

200516-11

– Tighten nuts .

Guideline

Remaining chassis nuts M8 30 Nm

(22.1 lbf ft)

– Position the clamp. Mount and tighten screw .

Guideline

Screw, exhaust clamp M6 8 Nm (5.9 lbf ft)

– Tighten nuts .

Guideline

Remaining chassis nuts M8 30 Nm

(22.1 lbf ft)

– Plug in connector of the lambda probe (2nd cylinder). Secure the cable with the

cable binders.

200513-11

– Plug in connector of the lambda probe (1st cylinder).

– Fit the seat. ( p. 32)

– Install the exhaust cover completely. ( p. 24)

200514-11

06/AIR FILTER 28

1006/AIRFIL TER

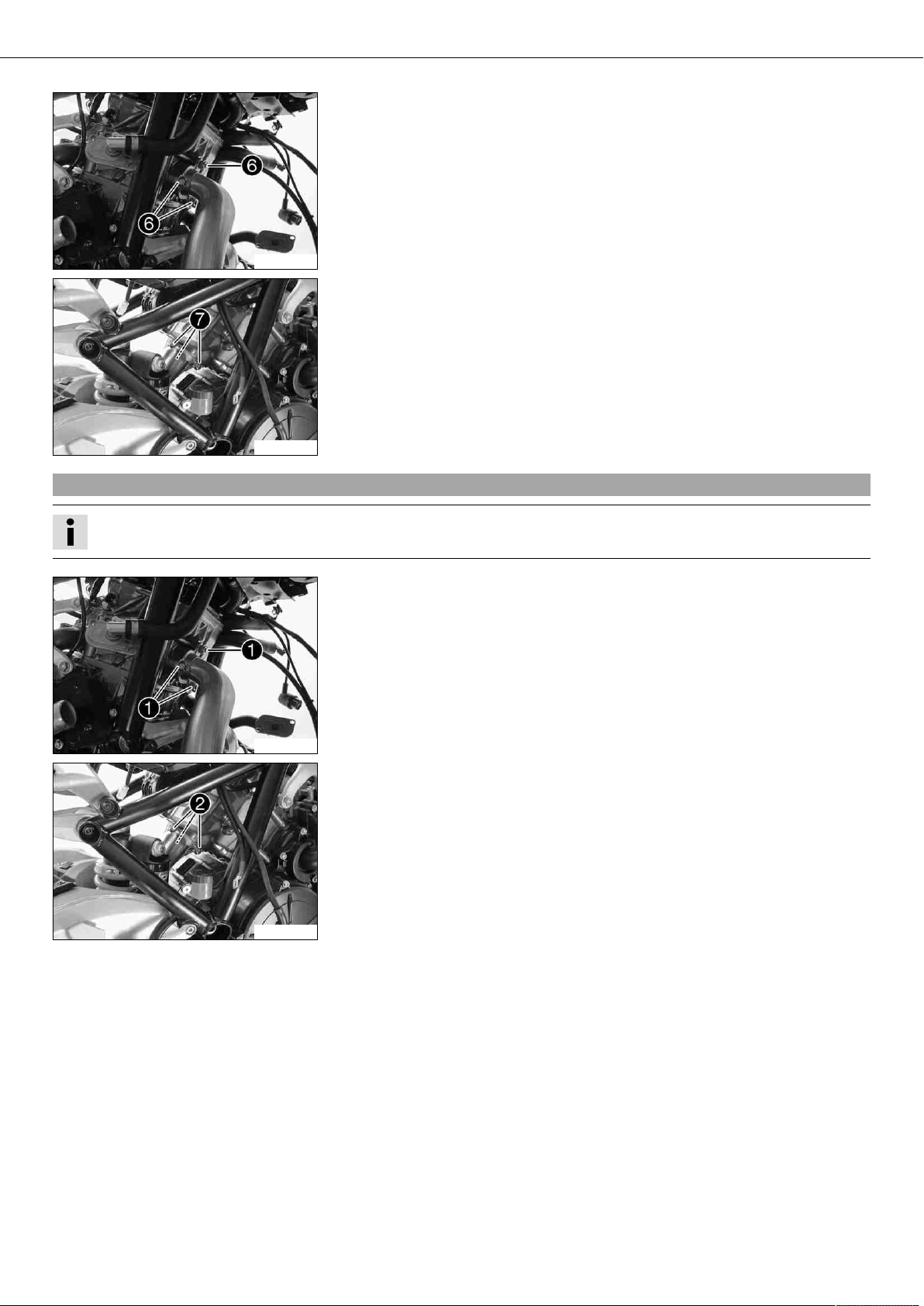

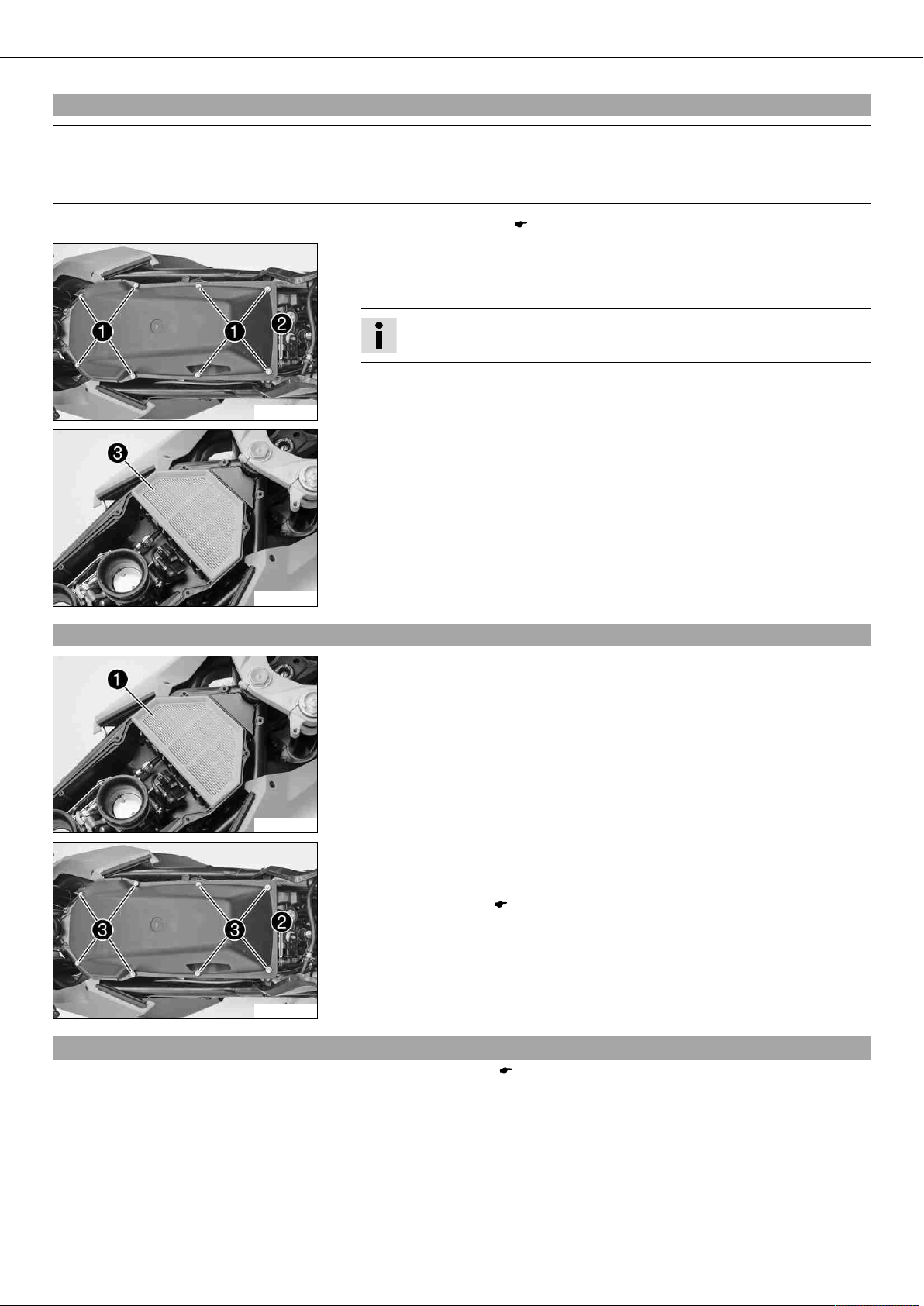

10.1Removing the air filter

Note

Engine failure Unfiltered intake air has a negative effect on the service life of the engine.

– Never ride the vehicle without an air filter since dust and dirt can get into the engine and result in increased wear.

– Dismount the fuel tank. ( p. 32)

– Remove screws .

– Slide back clamp . Pull off the engine breather hose and take off the clamp.

– Take off the filter box top.

Info

Watch out for the engine breather hose.

200496-10

– Remove air filter .

– Clean the air filter box.

10.2Installing the air filter

200497-10

– Position air filter .

200497-11

– Position the filter box top with the engine breather hose. Mount clamp with the

engine breather hose.

– Tighten screws .

– Install the fuel tank. ( p. 33)

200496-11

10.3Removing the filter box bottom

– Remove the air filter. ( p. 28)

Loading...

Loading...