Page 1

INDUSTRIAL

1000BASE-T TO 1000BASE-X

MEDIA CONVERTERS

KCD-400 Series

Installation Guide

DOC.060227-KCD-400

-1-

Page 2

(C) 2005 KTI Networks Inc. All rights reserved. No part of this documentation may be reproduced in any form or by any means or used to make

any directive work (such as translation or transformation) without permission from KTI Networks Inc.

KTI Networks Inc. reserves the right to revise this documentation and to

make changes in content from time to time without obligation on the part

of KTI Networks Inc. to provide notification of such revision or change.

For more information, contact:

United States KTI Networks Inc.

P .O. BOX 631008

Houston, T exas 77263-1008

Phone: 713-2663891

Fax: 713-2663893

E-mail: kti@ktinet.com

URL: http://www.ktinet.com/

International Fax: 886-2-26983873

E-mail: kti@ktinet.com.tw

URL: http://www.ktinet.com.tw/

-2-

Page 3

The information contained in this document is subject to change without

prior notice. Copyright (C) All Rights Reserved.

TRADEMARKS

Ethernet is a registered trademark of Xerox Corp.

FCC NOTICE

This device complies with Class B Part 15 the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received including the interference that may cause.

CE NOTICE

Marking by the symbol indicates compliance of this equipment to

the EMC directive of the Europea n Community . Such marking is indica-

tive that this equipment meets or exceeds the following technical standards:

EMC Class B

EN 50081-1/1992 : EN55022:1994/A1:1995/A2:1997 Class B

EN61000-3-2:2000

EN61000-3-3:1995/A1:2001

EN 55024:1998/A1:2001

IEC 61000-4-2:1995

IEC 61000-4-3:1995

IEC 61000-4-4:1995

IEC 61000-4-5:1995

IEC 61000-4-6:1996

IEC 61000-4-8:1993

IEC 61000-4-11:1994

-3-

Page 4

Table of Contents

1. Introduction.........................................................5

1.1 Features ........................................................................................ 6

1.2 Specifications ................................................................................ 7

1.3 Special Functions ......................................................................... 11

2. Installation.........................................................13

2.1 Unpacking ................................................................................... 13

2.2 Safety Cautions .......................................................................... 14

2.3 DIN-Rail Mounting ....................................................................... 1 5

2.4 Panel Mounting............................................................................ 1 7

2.5 Applying Power ........................................................................... 19

2.6 Power Failure Relay Output ........................................................ 22

2.7 Making Twisted Pair Copper Port Connection ............................ 23

2.8 Making Fiber Port Connection..................................................... 24

3 LED Indicators ...................................................25

3.1 LED Indicators............................................................................. 25

Appendix: Model Optical Specifications ............26

-4-

Page 5

1. Introduction

The industrial 1000BASE-T to 1000BASE-X media converter series provides industrial strength Ethernet copper-to-fiber media conversion, allowing for 1000Base-T-to-1000Base-X over multi-mode or optional singlemode fiber optical media.

For industrial environment, the converters are designed with the following enhanced features exceeding that of commercial media converters:

• High a nd wide operating Temperature

• Wide operating voltage range for DC power input

• Power input interface: Industrial screw terminal block and DC

power jack for external commercial power adapter as option

• DIN rail mounting support for industrial enclosure

• Screw panel mounting support for industrial enclosure

• Industrial-rated Emission and Immunity performance

-5-

Page 6

1.1 Features

• Gigabit copper to fiber conversion: 1000Base-T-to-1000Base-SX/LX

over multimode or single-mode fiber

• SFP design : For flexibility , a n SFP (Mini-GBIC) connector is

provided for the fiber port to accommodate any type of SFP fiber

transceiver when needed.

• Support full wire speed copper to fiber conversion

• Auto MDI/MDI-X detection function on the copper port

• Auto-negotiation support

• Plug and play : no configuration settings is required

• Link Fault Pass Through : this function allows link fault status

passes through between copper link and fiber link transparently.

• Far End Fault function on fiber port

• Transparent conversion to any type of packet frame

• No packet length limitation

• Diversified mounting support : desktop mounting, wall mounting,

optional Din-Rail support

• Low power consumption

• T wo power interface type: screw terminal block and DC jack

• Wide operating voltage input range : +7 ~ 30V DC

• Support DIN rail mounting

• Support panel mounting

• High and wide operating temperature range : -20oC to 70oC

• Industrial-rated Emission and Immunity performance

-6-

Page 7

1.2 Specifications

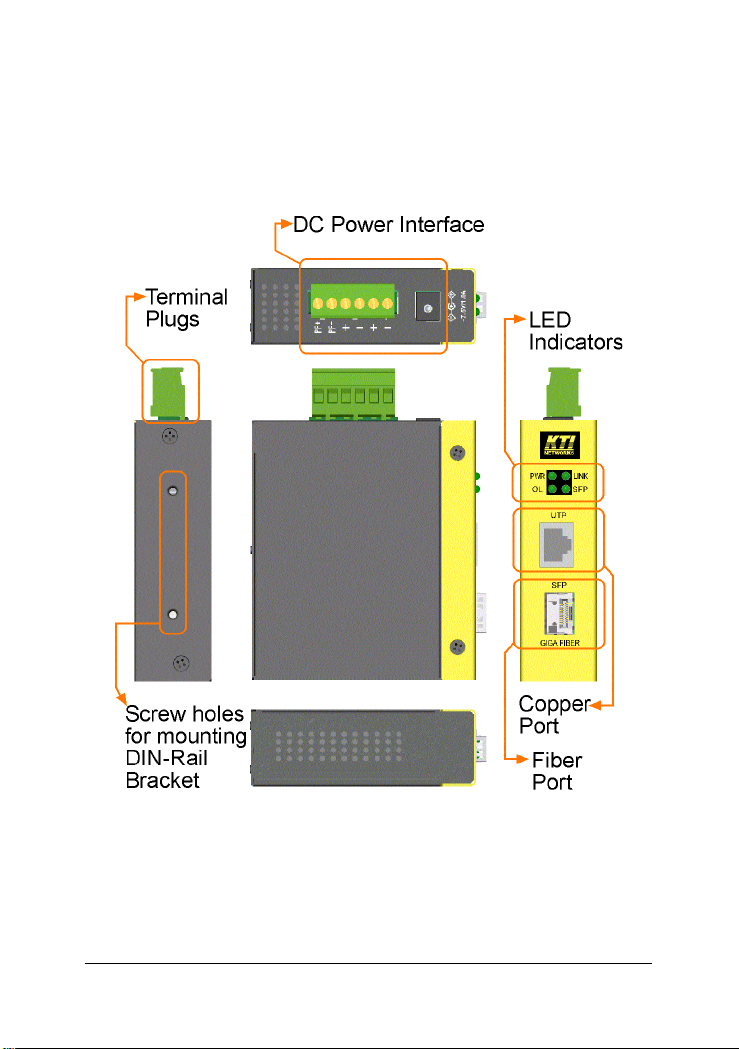

This figure shows the important components of the converter:

-7-

Page 8

Twisted-Pair Interface (Copper Port)

Connector Shielded RJ-45

Signal Compliance IEEE 802.3ab 1000BASE-T std.

Pin Assignments Auto MDI/MDI-X detection

Data Speed 1000Mbps

Duplex Mode Half-duplex or Full-duplex

Configuration Auto-negotiation support

Cable T ypes Category 5 or higher UTP

Link Distance Up to 100 meters

Fiber Optic Interface (Fiber Port)

Signal Compliance IEEE 802.3z 1000BASE-SX/LX std.

Connector SFP for pluggable fiber transceiver

Data Speed 1000Mbps

Duplex Mode Full d uplex

Cable Types MMF - 50/125, 62.5/125

SMF - 9/125

Link Distance MMF up to 500m

SMF -model dependent

Eye Safety compliance IEC825 Class 1

Refer to Appendix for detailed optical specifications.

LED Indicators

LED DISPLA Y ST ATE INTERPRET ATION

PWR Power status ON Power on

OF F Power off

SF P SFP slot status ON SFP transceiver is installed.

OF F No SFP transceiver is installed.

LINK Link status ON Copper-fiber link up

OF F Copper-fiber link down

BLINK Copper-fiber link with data traffic

OL Optical status ON Fiber port optical signal detected

OFF Fiber port no optical signal

-8-

Page 9

DC Power Interface

Interface Screw-type terminal block

1. T wo pairs f or power wire ca scading

2. One pair for power failure relay output

DC Jack (-D6.3mm/+D2.0mm)

Operating Input Voltages +7V ~ +30V(+5%)

Power consumption 2.25W @+7.5VDC input

2.3W @+24VDC input

2.5W @+30VDC input

Basic Information

Conversion Full wire speed

1000Mbps - 1,488,00pps at 64-byte packets

Packet Types Transparent and no modification for

- IEEE 802.3 standard packets

- IEEE 802.1Q VLAN tagged packets

Packet Length No limit

Mechanical

Dimension (base) W 28mm x D 82mm x H 95mm

Housing Enclosed metal with no fan

Mounting Support DIN-rail mounting, Panel mounting

Weight 252g

Environmental

Operating T emperature T ypical -20oC ~ 70oC (model dependent)

Storage T emperature - 20oC ~ 85oC

Relative Humidity 5% ~ 90%

-9-

Page 10

Certificate

F C C Part 15 Class B

CE/EMC EMI EN50081-1 Class B

EMS EN55024

CE/L V D Safety EN 60950

EN 50081-1/1992 :

EN55022:1994/A1:1995/A2:1997

EN61000-3-2:2000

EN61000-3-3:1995/A1:2001

EN 55024:1998/A1:2001

IEC 61000-4-2:1995 ESD T est

IEC 61000-4-3:1995 RS T est

IEC 61000-4-4:1995 EFT/BURST Test

IEC 61000-4-5:1995 Surge Test

IEC 61000-4-6:1996 CS T est

IEC 61000-4-8:1993 Magnetic Field

IEC 61000-4-11:1994 V olatge Int. Dips

-10-

Page 11

1.3 Special Functions

Auto MDI/MDI-X Function

This function allows the copper port to auto-detect the twisted-pair signals and adapts itself to form a valid MDI to MDI-X connection with the

remote connected device automatically .

Link Fault Pass Through Function

When a link fault is detected on the copper port, the device will force a

link down on the fiber port immediately . Si milarly , a link fault detected on

the fiber port will also force a link down on the copper port. As illustrated

in the following figure, this function allows to pass copper link fault to

the remote link partner and makes the converter like a twisted pair cable

extender.

-11-

Page 12

Far End Fault Function

The fiber port is facilitated with this function. When the fiber port detects

a link failure on its receiving circuitry , it will send out an FEFI (Far End

Fault Indication) signal to the remote connected device to indicate a

remote fault is detected.

It also is capable to receive FEFI signal sent from the remote link partner

if the link partner detected a receiving fault. Upon receiving an FEFI

signal, it indicates a link failure occurred on the transmitting path. This

function allows the converter to report a fiber link fault even when a link

failure occurred on transmitting fiber cable.

-12-

Page 13

2. Installation

2.1 Unpacking

Check that the following components have been included:

• Information CD

• The Media Converter unit

• DIN-rail mounting bracket

If any item is found missing or damaged, please contact your local reseller

for replacement.

The following are available optional accessories:

• Panel Mounting Bracket

The bracket is used for mounting the converter on a panel surface.

• Commercial-rated AC power adapters:

- Rated AC120V/60Hz DC7.5V 1A

- Rated AC230V/50Hz DC7.5V 1A

- Rated AC100V/50-60Hz DC7.5V 1A

- Rated AC240V/50Hz DC7.5V 1A

The adapters are used for supplying DC power to the converter

via DC power jack interface.

-13-

Page 14

2.2 Safety Cautions

T o reduce the risk of bodily injury, electrical shock, fire, and damage to

the equipment, observe the following precautions.

• Do not service any product except as explained in your system

documentation.

• Opening or removing covers may expose you to electrical shock.

Only a trained service technician should service components inside

these compartments.

• If a ny of the f ollowing conditions occur, unplug the product from the

electrical outlet and replace the part or contact your trained service

provider:

- The power cable, extension cable, or plug is damaged.

- An object has fallen into the product.

- The product has been exposed to water.

- The product has been dropped or damaged.

- The product does not operate correctly when you follow the

operating instructions.

• Do not push any objects into the openings of your system. Doing

so can cause fire or electric shock by shorting out interior components.

• Operate the product only from the type of external power source

indicated on the electrical ratings label. If you are not sure of the

type of power source required, consult your service provider or local

power company.

-14-

Page 15

2.3 DIN-Rail Mounting

In the product package, a DIN-rail bracket is installed on the device for

mounting the converter in a industrial DIN-rail enclosure.

The steps to mount the device onto a DIN rail are:

1. Install the mounting bracket onto the device unit as shown below:

2. Attach bracket to the lower edge of the DIN rail and push the unit

upward a little bit until the bracket can clamp on the upper edge of

the DIN rail.

3 .Clamp the unit to the DIN rail and make sure it is mounted securely.

4. Make sure that there are proper heat dissipation from and adequate

ventilation around the device.

-15-

Page 16

The final mechanical dimensions after installing DIN rail mounting bracket

are:

-16-

Page 17

2.4 Panel Mounting

The device is provided with an optional panel mounting bracket. The

bracket support mounting the device on a plane surface securely. The

mounting steps are:

1 .Install the mounting bracket on the device unit.

2 .Screw the bracket on the device unit.

3 .Screw the device unit on a panel.

4. Make sure that there are proper heat dissipation from and adequate

ventilation around the device. Do not place heavy objects on the

device.

-17-

Page 18

The screw locations and final dimension are shown below:

-18-

Page 19

2.5 Applying Power

The power specifications of the device are:

Operating V oltage +7 ~ +30VDC

Power Consumption Max. 2.5W @30VDC

The device provides two types of power interfaces, terminal block and DC

power jack for receiving DC power input from external power supply .

Using T erminal Blocks

Either DC1 interface or DC2 interface can be used to receive DC power

from an external power system. Or, DC2 also can be used to deliver the

power received on DC1 to next device in ca scading way .

DC1 + Vdc Positive (+) terminal

DC1 - Vdc Negative (-) terminal

DC2 + Vdc Positive (+) terminal

DC2 - Vdc Negative (-) terminal

Three 2P terminal plugs are provided together with the device. T wo of the

three plugs are used for DC1 a nd DC2 interface s respectively . The plug is

shown below:

-19-

Page 20

Power wires: 24 ~ 12A W G (IEC 0.5~2.5mm2)

Install the power source wires with the plug properly . Screw the wire with

plug securely. Then, plug in DC1 contacts.

If cascading the power to next device is needed, install the power wires

and plug for another switch. Then, use DC2 contacts.

Note: Only up to four device units can be cascaded to receive power

from one main power input source.

-20-

Page 21

Using DC Power Jack

DC Jack Connector: Jack D 6.3mm D 2.0mm

AC Power Adapters: Optional commercial rated adapters are available

for purchasing.

Rated AC120V/60Hz DC7.5V 1A

Rated AC230V/50Hz DC7.5V 1A

Rated AC100V/50-60Hz DC7.5V 1A

Rated AC240V/50Hz DC7.5V 1A

Connect power adapter DC plug to the DC power jack of the converter

before connecting to the AC outlet. Connect the power adapter to the

AC outlet.

Note: Before you begin the installation, check the AC voltage of your

area. The AC power adapter which is used to supply the DC power

for the unit should have the AC voltage matching the commercial

power voltage in your area.

-21-

Page 22

2.6 Power Failure Relay Output

The device provides a relay output to report power failure event to a

remote alarm monitoring system. The replay output is provided with two

contacts labeled PF+ and PF- in the terminal block interface.

Use the provided 2P terminal plug for signal wiring and plug into the PF+/

- contacts. The function is designed as :

Power is normal PF+ contact is shorted with PF- contact.

Power failure PF+ contact is disconnected with PF- contact.

Note: Be sure the voltage applied on PF+/- contacts is within the

specification of 30VDC/1A max. or 120VAC/0.5A max.

-22-

Page 23

2.7 Making Twisted Pair Copper Port Connection

Copper port is featured to support connection to :

• Auto-negotiation devices

• Auto-negotiation incapable 10BASE-T devices

• Auto-negotiation incapable 100BASE-TX devices

Network Cables

1000BASE-T: 4-pair UTP Cat. 5e or 6, EIA/TIA-568B 100-ohm STP

Link distance: Up to 100 meters

Note: The copper port is featured with auto MDI/MDI-X crossover de-

tection and configuration function. No matter a straight through

cable or crossover cable is connected, the copper port can sense

the receiving pair automatically and configure itself to match

the connection.

-23-

Page 24

2.8 Making Fiber Port Connection

The mini-GBIC (SFP) port must be installed with an SFP fiber transceiver for making fiber connection. The device may come with an SFP

tra nsce iver pre-installed when it is shipped from factory.

Installing SFP F iber Transceiver

Turn off the power to the device. Insert the SFP fiber transceiver into the

mini-GBIC port. Normally, a bail is provided for every SFP transceiver.

Hold the bail and make insertion. Until the SFP transceiver is seated

securely in the slot, place the bail in lock position.

Connecting Fiber Cables

LC connectors are commonly equipped on most SFP transceiver modules. Identify TX and RX connector before making cable connection.

The following figure illustrates a connection example between two fiber

ports:

Make sure the RX-to-TX connection rule is followed on the both ends of

the fiber cable.

Note: For Bi-Di (Bidirectional) SFP transceivers which use two differ-

ent wavelengths for TX and RX respectively over single fiber

cable, only one connector is provided on the fiber port and only

one fiber cable is used.

Network Cables

Multimode (MMF) - 50/125, 62.5/125

Single mode (SMF) - 9/125

-24-

Page 25

3 LED Indicators

The following figure shows the locations of the configuration switches

and LED indicators:

3.1 LED Indicators

LED DISPLA Y ST ATE INTERPRET ATION

PW R Power status O N The device is powered on.

OFF The device is powered off.

SF P SFP slot status O N An SFP transceiver is installed.

OF F No SFP transceiver is installed.

LINK Link status ON Copper-fiber link up

OF F Copper-fiber link down

BLINK Copper-fiber link with data traffic

OL Optical status ON Fiber port optical signal detected

OFF Fiber port no optical signal

-25-

Page 26

Appendix: Model Optical Specifications

The media converter series provides the following fiber options:

Model Specifications

Reference Operating

KCD-400-xx FX Wavelength Fiber Distance Temperature

-SX L C 850nm 50/125 MMF 500m -20 ~ 70oC

62.5/125 MMF 200m

-LX L C 1310nm MMF 550m -20 ~ 70oC

SMF 10km

-LX20 LC 1310nm SMF 20km -20 ~ 70oC

Optical Specifications

KCD-400-xxx FX Tx Power Sensitivity Max. Rx Power

-SX L C -9.5 ~ -4 dBm -18dBm -1 d Bm

-L X L C -9.5 ~ -3 dBm -20dBm -3 dBm

-LX20 L C -7 ~ 0 dBm -24dBm -3 dBm

-26-

Loading...

Loading...