Page 1

Solar controller

SOL3-7

Installation and operating

manual

Firmware version 1.07

June 2011

Page 2

Installation and operating manual KT-Elektronik

Warranty

We permanently enhance our products, therefore we reserve the right to make changes to

our products at any time and without prior notice.

We take no responsibility for the accuracy or completeness of this manual. No liability can

be accepted for the use of our products for a buyer specific purpose. Buyer claims,

especially claims for damages including lost profits or other financial losses are excluded.

This does not apply if the damage caused by intent or gross negligence. In case of

negligent violations of major contractual obligations, our liability is limited to the

foreseeable damage

Security advices

Only qualified personnel that is familiar with installation and

commissioning of this product is allowed to mount and put into operation

the device. Appropriate shipping and storage are assumed.

The product is designated for use in heavy current equipment. Installation

and maintenance have to be performed according to the corresponding

safety regulations.

2 EB_37388_SOL3-7_EN001

Page 3

KT-Elektronik SOL3-7

Table of contents

1 Operation .......................................................................................................................... 6

1.1 Controls ...................................................................................................................... 6

1.1.1 Rotary switch ....................................................................................................... 7

1.1.2 Rotary pushbutton .............................................................................................. 7

1.2 Operating .................................................................................................................. 8

1.3 Display ...................................................................................................................... 8

1.3.1 System scheme ................................................................................................... 9

1.3.2 Operating Mode ................................................................................................ 10

1.4 Retrieving data – Information level .......................................................................... 11

1.5 Setting the system time ............................................................................................ 12

1.6 Adjust usage schedule settings ............................................................................... 13

1.7 Setting the party mode (heating circuit/auxiliary heating) ........................................ 15

1.8 Setting holidays ........................................................................................................ 16

1.9 Setting vacation times .............................................................................................. 17

1.10 Access advanced information level ........................................................................ 18

1.11 Trend show – Data logging .................................................................................... 20

2 Commissioning ............................................................................................................... 22

2.1 Set language ........................................................................................................... 22

2.2 Setting the system variant ID ................................................................................... 23

2.3 Activate and deactivate functions ............................................................................ 24

2.4 Edit settings ............................................................................................................. 26

2.5 Sensor calibration .................................................................................................... 28

2.6 Reset to factory default settings ............................................................................... 29

3 Manual operating mode .................................................................................................. 30

4 System variants .............................................................................................................. 31

4.1 Extending the basic system variant representations ................................................ 40

5 Solar circuit functions ..................................................................................................... 43

5.1 Basic Control function .............................................................................................. 43

5.2 Storage .................................................................................................................... 45

5.3 Swimming pool ......................................................................................................... 46

5.4 Collector return flow sensor, Collector flow sensor .................................................. 47

5.5 Measurement of solar power and solar energy ........................................................ 48

5.6 Rotation speed control ............................................................................................. 49

5.7 Collector overheating protection .............................................................................. 50

5.8 Collector minimum temperature ............................................................................... 51

5.9 Start up function ....................................................................................................... 51

5.10 Forced pump operation (blocking protection) ........................................................ 51

5.11 Collector Antifreeze ................................................................................................ 52

5.12 Two collector arrays ............................................................................................... 52

EB_37388_SOL3-7_EN001 3

Page 4

Installation and operating manual KT-Elektronik

5.13 External heat exchanger ........................................................................................ 53

5.14 Auxiliary heating with secondary heat generator ................................................... 53

6 Heating circuit functions ................................................................................................. 55

6.1 Prescribing the room temperature set-points ........................................................... 55

6.2 Weather-compensated control ................................................................................. 55

6.2.1 Gradient characteristic ..................................................................................... 55

6.2.2 4-point characteristic ......................................................................................... 57

6.3 3-point control .......................................................................................................... 59

6.4 Two-point control ..................................................................................................... 59

6.5 Underfloor heating/screed drying ............................................................................. 60

6.6 Deactivation depending on the outdoor temperature ............................................... 61

6.6.1 OT deactivation temperature for daytime operating mode ................................ 61

6.6.2 OT deactivation temperature for night-time operating mode ............................. 61

6.6.3 OT activation temperature for daytime operating mode .................................... 61

6.6.4 Summer operating mode (OM) .......................................................................... 62

6.7 Delayed outside temperature compensation ........................................................... 62

6.8 Remote operation .................................................................................................... 63

6.9 Optimization ............................................................................................................. 63

6.10 Raise return flow of external heating system ........................................................ 64

6.10.1 Main principle .................................................................................................. 64

6.10.2 Implementation ................................................................................................ 65

7 Domestic water circuit functions ..................................................................................... 66

7.1 Domestic water heating in storage tank ................................................................... 66

7.2 Thermal Disinfection of the storage tank ................................................................. 66

8 System wide functions - all system variants ................................................................... 67

8.1 Automatic summer/winter switching ......................................................................... 67

8.2 Antifreeze ................................................................................................................. 67

8.3 Locking manual operating mode .............................................................................. 68

8.4 Locking the rotary switch ......................................................................................... 68

8.5 Enter a valid individual access code ........................................................................ 68

8.6 Temperature difference controller ............................................................................ 69

9 Malfunction ..................................................................................................................... 70

9.1 Error list .................................................................................................................... 70

9.2 Sensor failure ........................................................................................................... 70

9.3 Temperature monitoring ........................................................................................... 71

9.4 Error status register ................................................................................................. 71

9.5 SMS delivery in case of a system failure ................................................................. 72

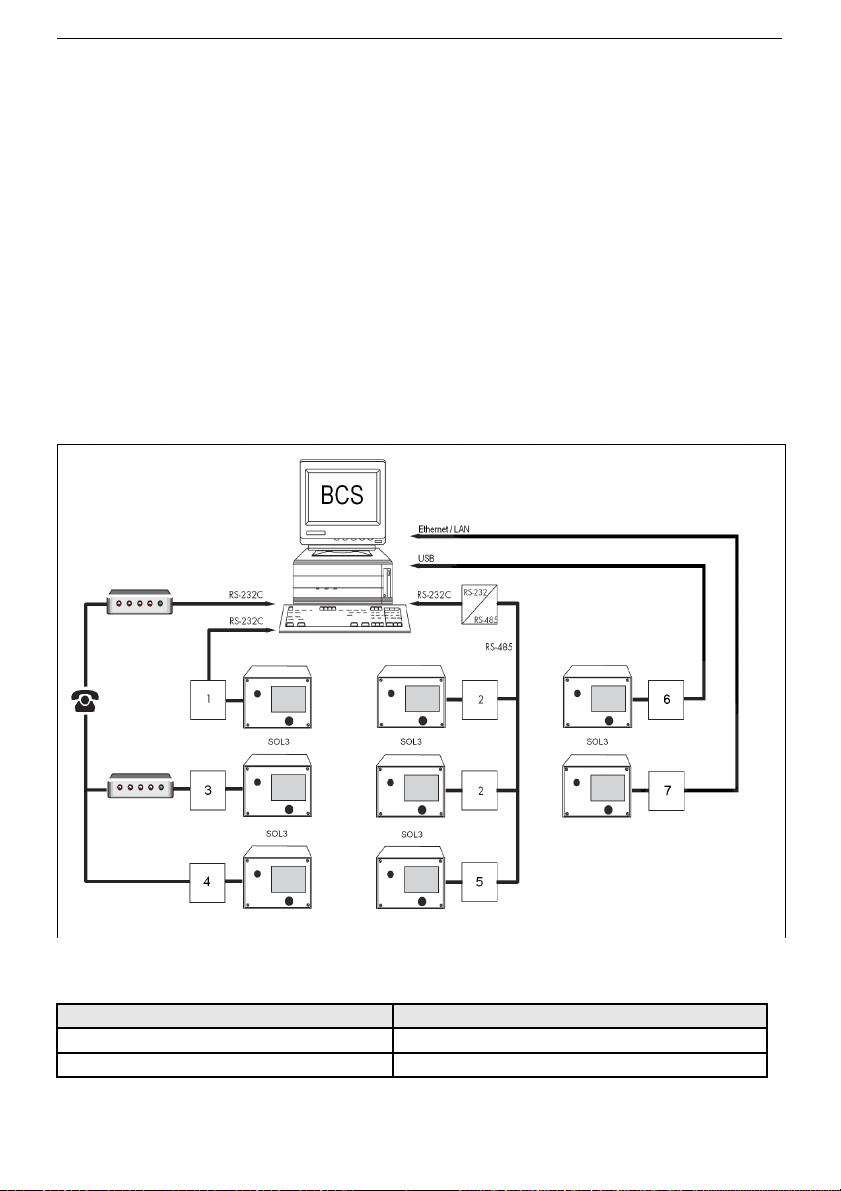

10 Communication ............................................................................................................ 73

10.1 Communication module KOM232PC .................................................................... 74

10.2 Communication module iCon485 .......................................................................... 74

4 EB_37388_SOL3-7_EN001

Page 5

KT-Elektronik SOL3-7

10.3 Communication module KOM232M ...................................................................... 76

10.4 Data Modem DataMod11 ...................................................................................... 77

10.5 ModBus-MBus-Gateway ....................................................................................... 78

10.6 USB communication cable USB-L3 ...................................................................... 79

10.7 Modbus-TCP-Gateway ......................................................................................... 80

10.8 Description of the adjustable communication settings .......................................... 80

10.9 Memory module .................................................................................................... 81

10.10 55Viewer for visualization and remote maintenance. ......................................... 82

10.11 Data Logging ....................................................................................................... 83

11 Mounting ....................................................................................................................... 84

12 Electrical connection ..................................................................................................... 86

12.1 Notes for wire installation ....................................................................................... 86

12.2 Surge Protection Measures ................................................................................... 86

12.3 Connecting the controller ....................................................................................... 86

12.3.1 Connecting the sensors ................................................................................... 87

12.3.2 Connecting the pumps .................................................................................... 87

12.3.3 Legend for connection diagram ....................................................................... 87

12.3.4 Wiring diagram ................................................................................................ 88

12.3.5 Terminal assignment for Outputs .................................................................... 89

12.3.6 Terminal assignment for inputs ....................................................................... 92

13 Appendix ....................................................................................................................... 93

13.1 Function block lists ................................................................................................. 93

13.2 Parameter list ......................................................................................................... 97

13.3 Resistance values ................................................................................................ 100

13.4 Technical specifications ....................................................................................... 101

13.5 Accessories .......................................................................................................... 102

13.6 Function block settings in configuration levels ..................................................... 103

13.7 Einstellungen in den Parameterebenen .............................................................. 104

13.8 Abbreviations ....................................................................................................... 106

13.9 Access codes ....................................................................................................... 107

13.10 Notes .................................................................................................................. 108

EB_37388_SOL3-7_EN001 5

Page 6

Installation and operating manual KT-Elektronik

1 Operation

The controller is factory-provided with standard temperature settings and timing programs

and therefore ready for use.

The current date and time have to be set at initial operation of the controller (Chapter

1.5).

1.1 Controls

The operational controls are located on the front side of the controller.

The user is guided by means of rotary switches and pressing the control button described

below control levels.

6 EB_37388_SOL3-7_EN001

Bedienknopf

Drehschalter

Anzeige

Page 7

KT-Elektronik SOL3-7

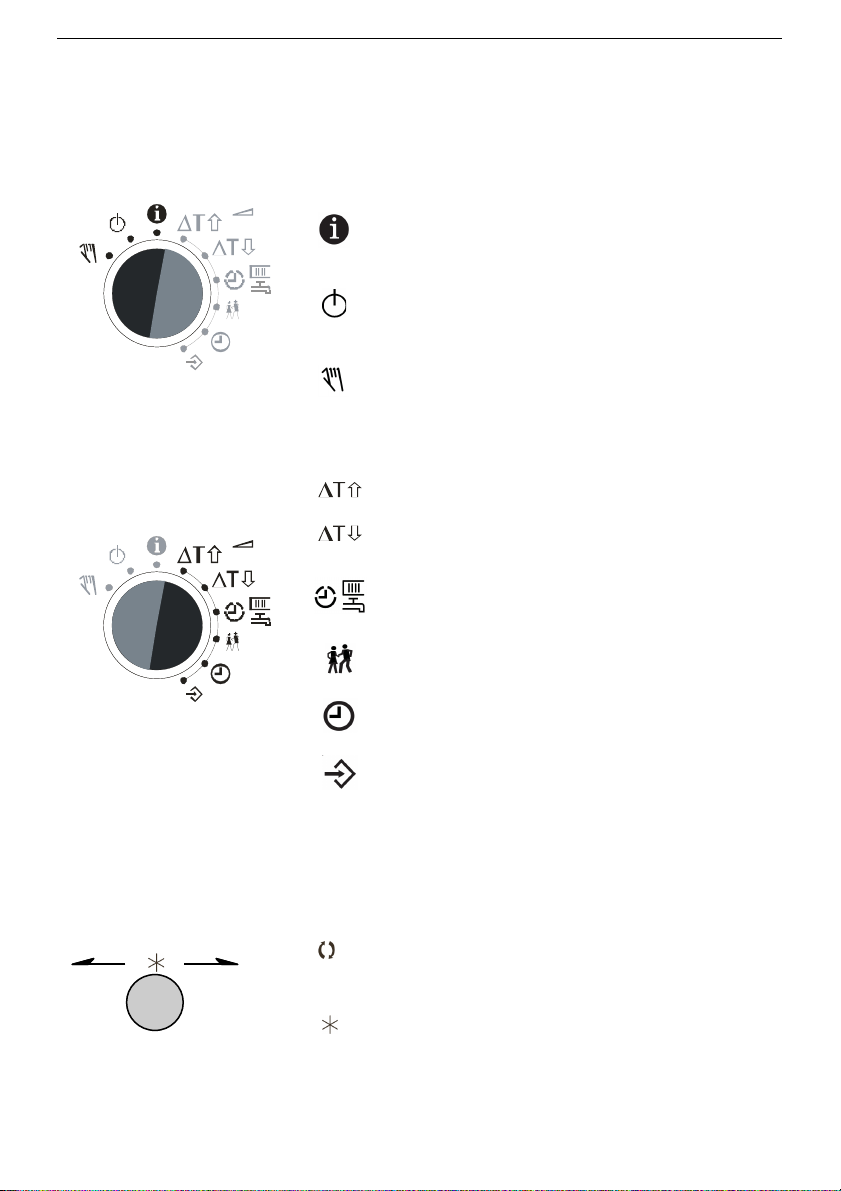

1.1.1 Rotary switch

The rotary switch is used to select the operating mode on the left hand and the basic

settings of the controller on the right hand.

Rotary switch – operating mode

Control on, display informations about

operating behaviour of unit (standard position)

Turning off the control functions

(Controller remains in operation)

Manual operating mode:

manual switching of pumps and valves,

position presetting in percent

Rotary switch – Settings

Solar-Turn-on threshold

Solar-Turn-off threshold

Scheduled time ranges and operating modes for

heating circuit (1), aux. heating (2) and hot water

circulation (3)

Party mode

System time:

Setting time, date and year

Configuration and settings level

1.1.2 Rotary pushbutton

The rotary pushbutton is an integral part of the intuitive operating concept, with only one

button.

Turn :

Display, select settings and function blocks

Push :

confirm selection or setting

EB_37388_SOL3-7_EN001 7

Page 8

Installation and operating manual KT-Elektronik

1.2 Operating

The operation of the device SOL3-7follows a continuous uniform display and operating

philosophy.

Values and display texts are shown in black characters with no background. Elements for

direct input or selection are shown with white characters on black background. Choice

elements in rows oriented menus are shown with black characters on a gray background.

With the help of the rotary switch, a control level is set. The rotary pushbutton is used to

select and adjust.

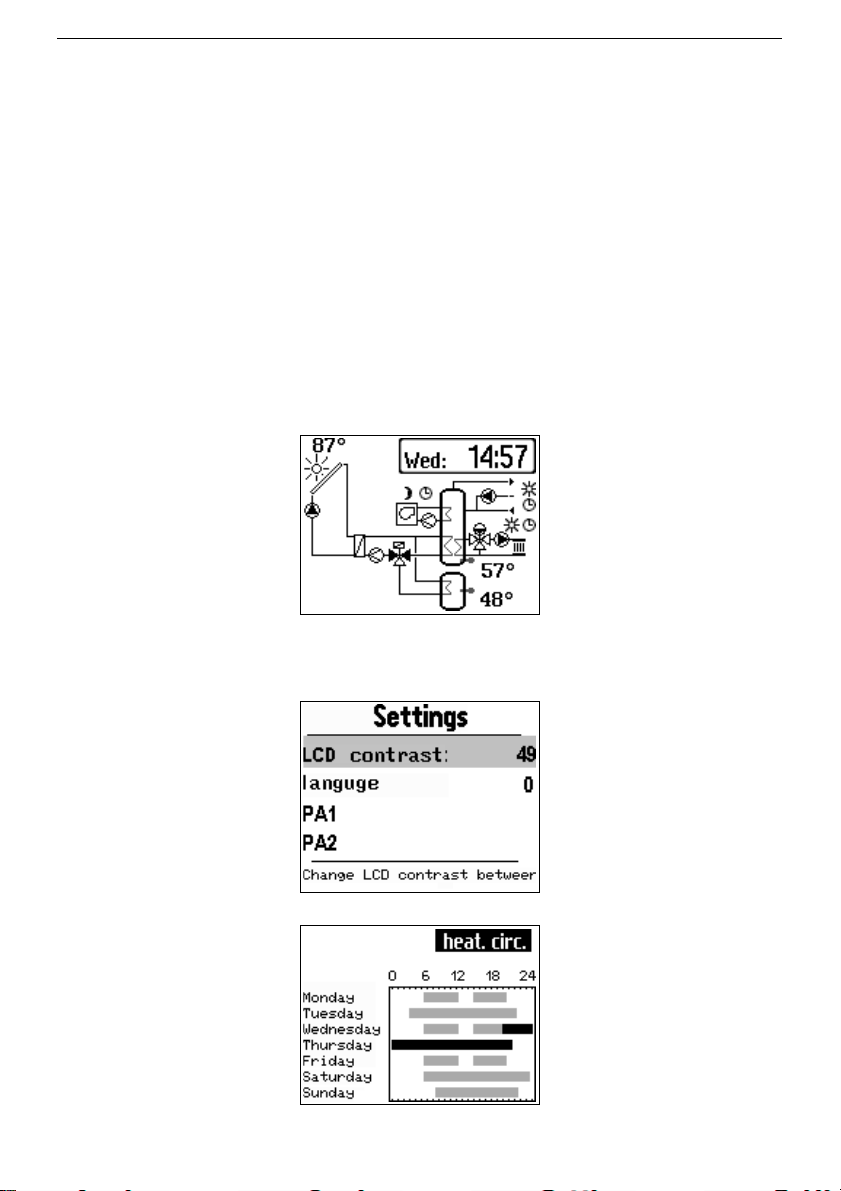

1.3 Display

The controller SOL3-7 it equipped with a graphical display. The display allows it to

visualize the current system scheme with all relevant sensor informations as welll as state

informations of pumps and valves for a quick overview of the operating condition of the

system.

Example of display in the information level:

For the use of the device the user is facilitated in operating levels for display and input of

operating parameters with clear text menus and explanatory texts.

Example of display in the setting level:

Example of display for checking and modifying of times-of-use (weekly schedule):

8 EB_37388_SOL3-7_EN001

Page 9

KT-Elektronik SOL3-7

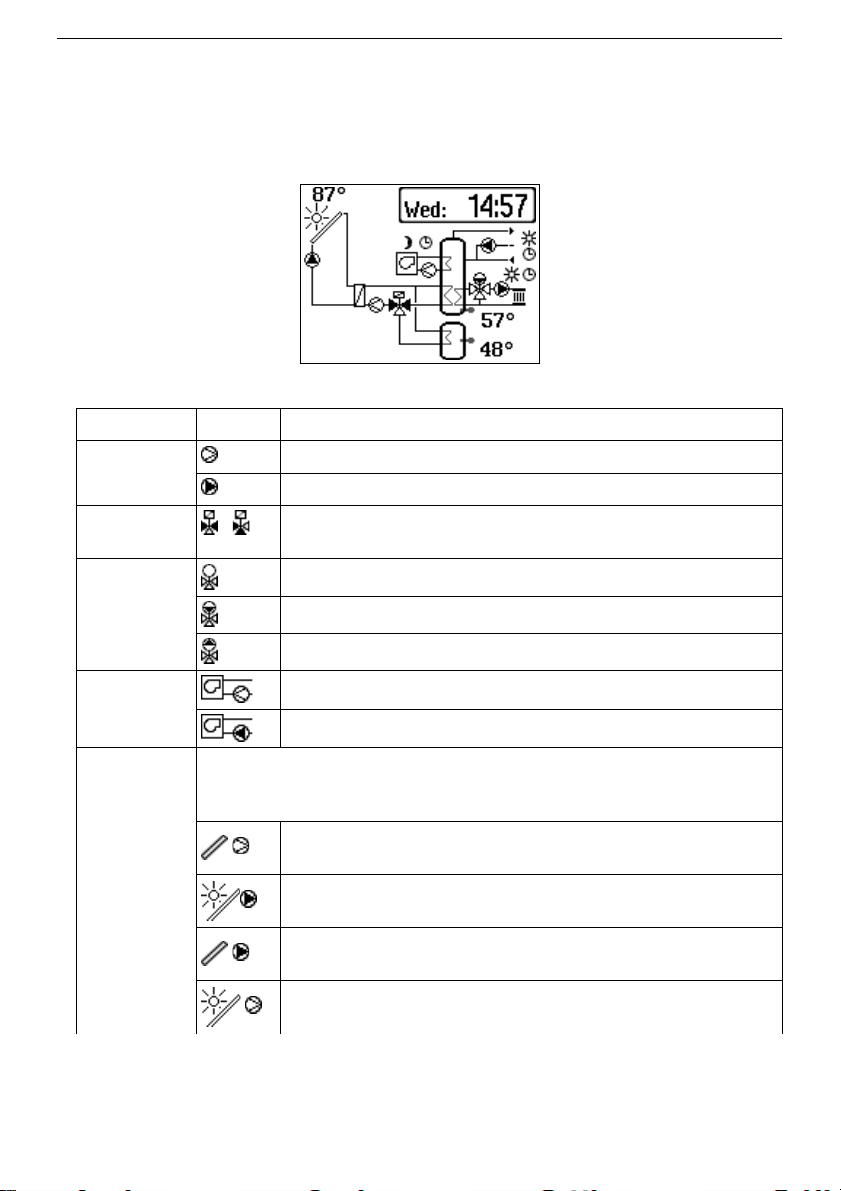

1.3.1 System scheme

With the on the display shown system scheme, the relevant sensor information, the

operating mode of the control circuits and state information of pumps and valves for a

quick overview of the operating condition can be visualized.

Among the symbols used in the system scheme are the following:

Element Symbol Meaning

Pump

Pump is in operation

Pump is not in operation

Switching

valve

Switching valve is showen with filled triangles

Valve

Valve is not in operation

Valve 'CLOSE' is in operation

Valve 'OPEN' is in operation

Auxilary

heating

Auxilary heating is not in operation

Auxilary heating is in operation

Collector

pump

A temporarily shown sun above a collector represents an

operating state indication of the pump belonging to the

collector.

Condition for the activation of the pump is not met and the

pump is not operating.

Condition for the activation of the pump is met and the pump

is operating.

The condition for switching off the pump is met, but pump is

due to the minimum ON time still in operation.

Condition for switching on the pump is met, but pump is due

to the minimum OFF time yet in operation.

EB_37388_SOL3-7_EN001 9

Page 10

Installation and operating manual KT-Elektronik

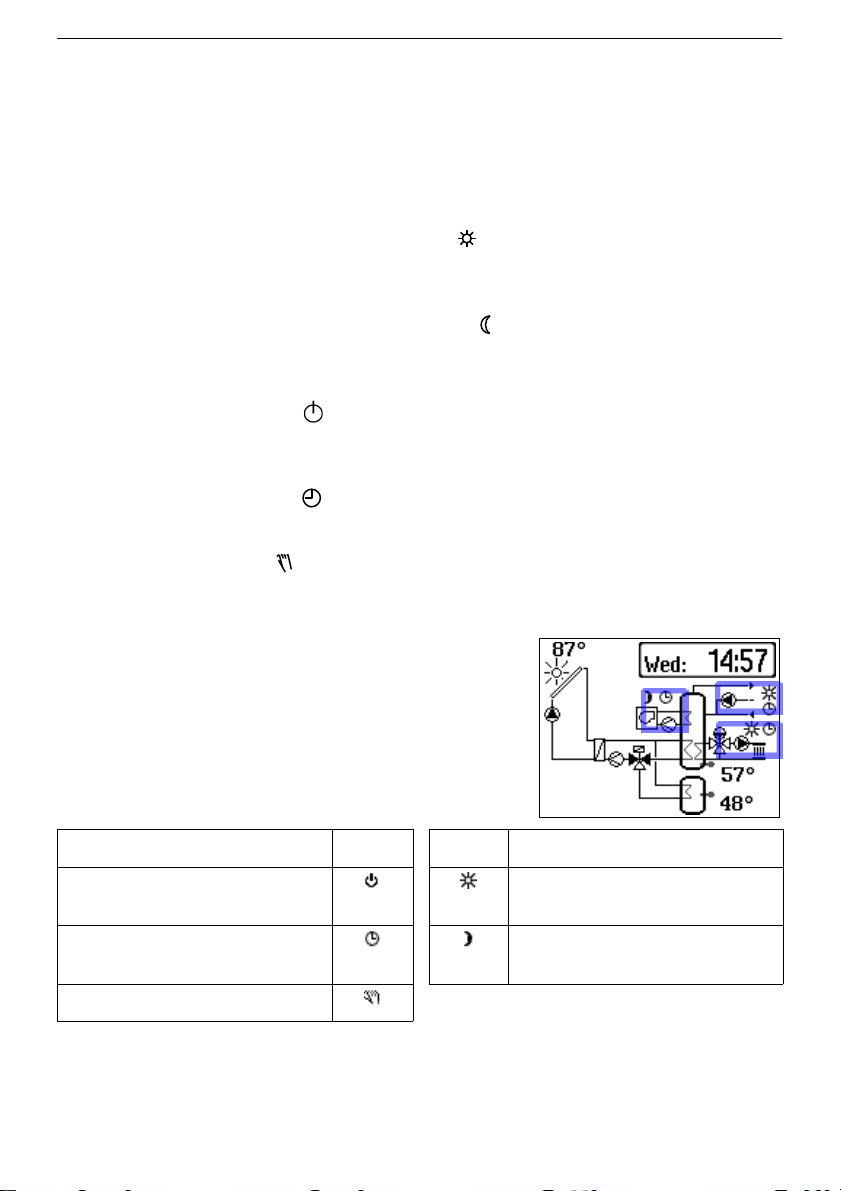

1.3.2 Operating Mode

The operation of the heating circuit, hot water circulation and auxilary heating can be

affected depending on time and day of week. There are two different set-points for night

and day exist. A usage schedule determines when to operate in day-time operating mode

or night-time operating mode. It is possible to deactivate schedules (without deleting them)

and to specify manually to operate permanently in day-time or night-time operating mode.

Icons on the display indicate the current operating mode for each function of the controller:

Daytime operating mode (nominal operation)

Values are permanently adjusted to meet the set-points entered for nominal operating

mode regardless of scheduled time ranges or summer operating mode settings.

Night-time operating mode (reduced operation)

Values are permanently adjusted to meet the set-points entered for reduced operation

regardless of scheduled time ranges.

Normal operating mode off

Normal operating mode is deactivated regardless of the scheduled time ranges. Only

equipment anti-freeze is ensured (if activated).

Automatic operating mode

The controller automatically switches between both modes depending on the time.

Manual operating mode

Manual control of valves and pumps (Chapter 3).

The operating modes of heating circuit, hot water

circulation and auxilary heating are in the system scheme,

context-sensitive arranged and allow capture at a glance

the current function of the system part.

Operating mode Symbol Symbol Time phase

Standby Nominal operation

(Day mode)

Automatic mode Reduced operation

(Night mode)

Manual mode

10 EB_37388_SOL3-7_EN001

Page 11

KT-Elektronik SOL3-7

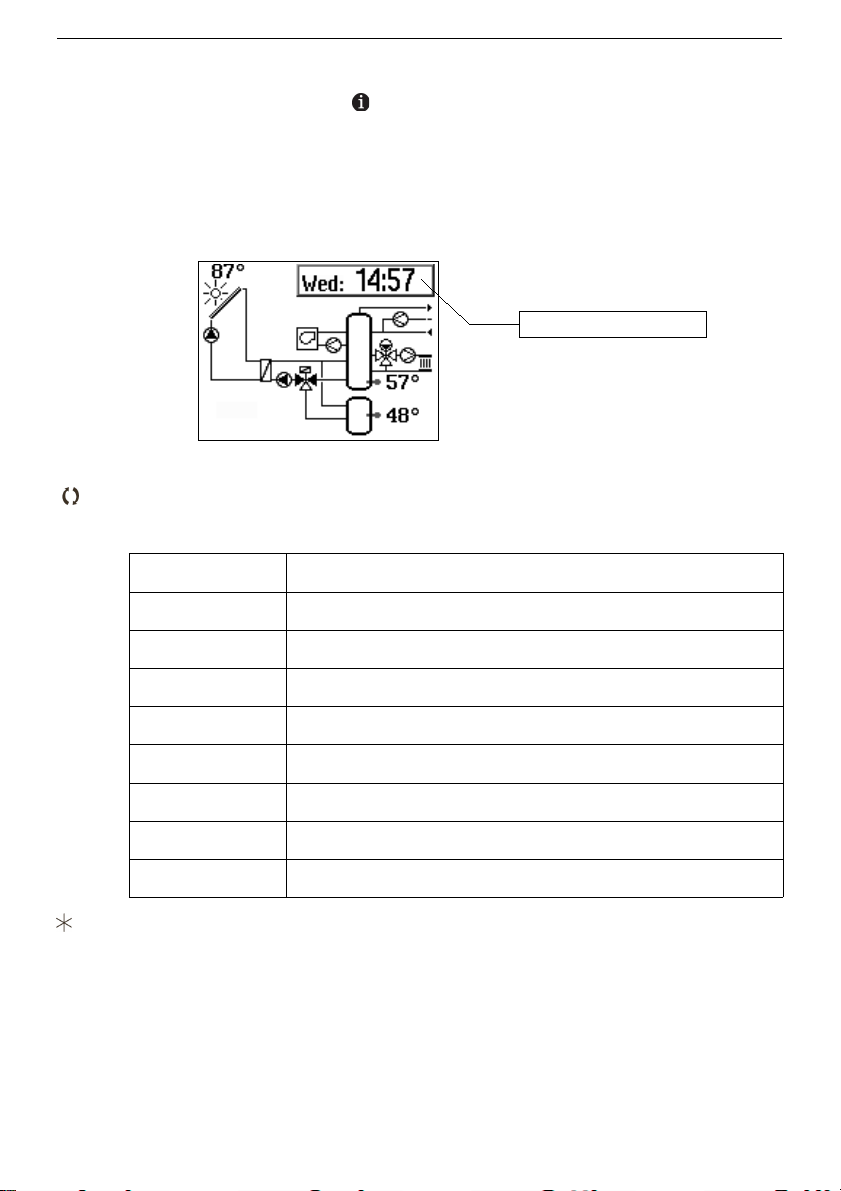

1.4 Retrieving data – Information level

At the normal rotary switch position ,„Information level“, the system scheme, time, date

as well as relevant temperatures measured by the connected sensors and state

informations of pumps and valves of the selected hydraulc schema.

By turning and pushing the rotary pushbutton it is possible to show time, date, temperature,

and query the values of connected sensors and their setpoints.

Procedure:

Select value:

In the display appears, depending on system configuration, successively the

different data points, which are described by an acronym:

Sample displays Meaning

So: 14:57 Time

AF: -5.3°C Outdoor temperature AF

RF: 20.4°C Room temperature RF

VF: 34.1°C

Temperature at flow sensor of heating circuit VF

SF1: 52.9°C Temperature at storage tank sensorr SF1

CF1: 27.3°C Temperature at collector sensor CF1

coll 12 h Operating hours of solar circiut

trend show Graphical presentation of logged system data

Setpoint or limit value compared to the displayed value.

Pushing the rotary pushbutton in the clock display shows the date and year.

Additional values can be displayed in the optional, advanced level of information (Kapitel

1.10).

EB_37388_SOL3-7_EN001 11

Display area

Page 12

Installation and operating manual KT-Elektronik

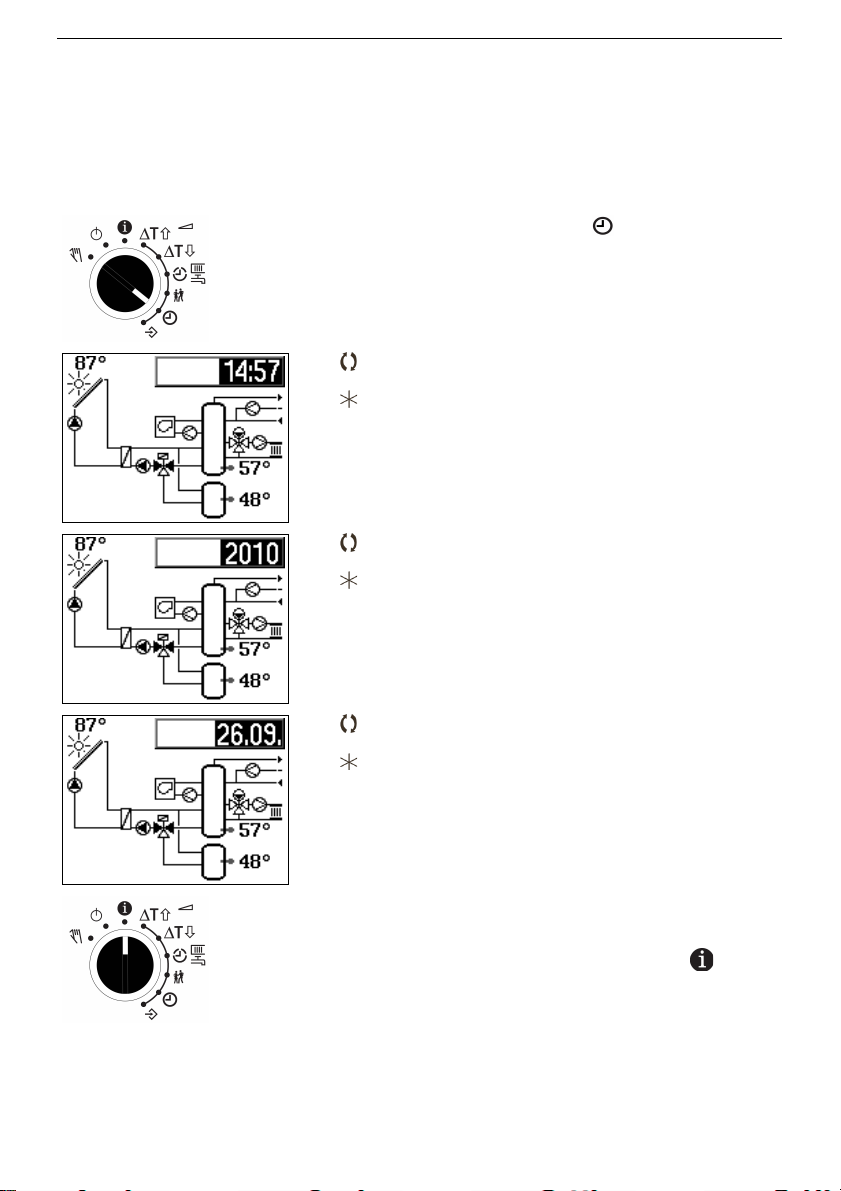

1.5 Setting the system time

The current time and date must be set immediately after the commision and after a power

failure of more than 24 hours. In this case, the system time on the clock 01/01/2000 10:00

preset and is displayed inverted (white on black) .

Procedure:

Set rotary switch to time

Display: System scheme and time(inverted)

Edit time

Confirm time

Display: System scheme and year (inverted)

Edit year

Confirm year Jahreszahl übernehmen.

Display: System scheme and year (inverted)

Format: day.month

Edite date

Confirm date

Display: System scheme and time (inverted)

Set rotary switch to Information level

12 EB_37388_SOL3-7_EN001

Page 13

KT-Elektronik SOL3-7

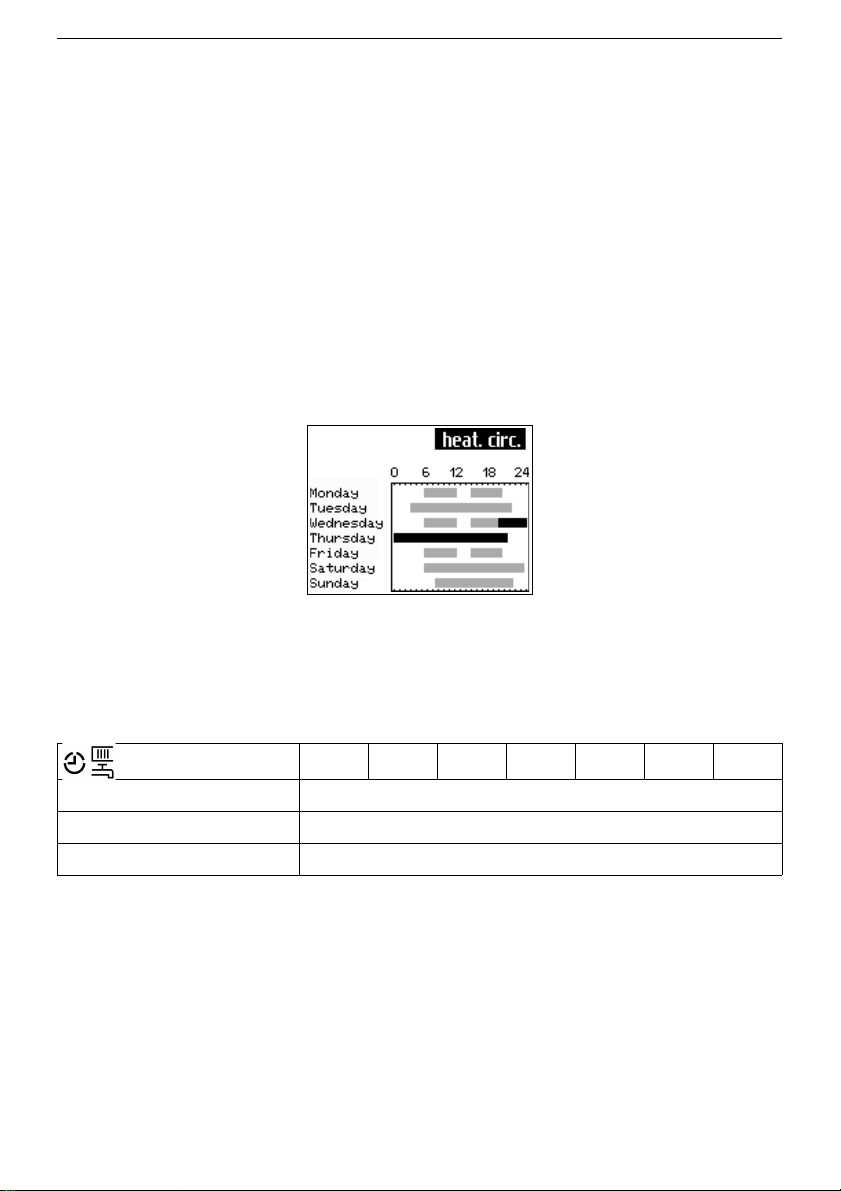

1.6 Adjust usage schedule settings

There are three separate usage schedules for

• Heating circuit

• Auxiliary heating

• Domestic water circulation

For systems that do not contain the functional groups mentioned, this chapter has no

meaning, the display and input of times-of-use is not offered by the SOL3-7.

The following applies to each usage schedule:

For each day of the week, three time ranges can be programmed. If only one time range is

needed, the start and end time of the second range have to be set to the same value. The

third range will then not be shown any more.

A usage schedule is presented as a weekly schedule. For each day there is shown every

interval (time-to-use) for nominal operation (day) by a gray bar chart. A black bar indicates

a time in addition to the party program set-operation (chapter 1.7).

To check the set times of use should the group of days (Monday to Sunday, Monday to

Friday, Saturday and Sunday) are not used. If this menu, even after adjustment of

schedule settings opened, the times-of-use of Monday will transfered to all other days of

week.

Factory defaults

Times Mo Tue Wed Thu Fr Sa Su

Heating circuit 06:00 – 22:00

Auxiliary heating - - : - - – - - : - Domestic water circulation 00:00 – 24:00

EB_37388_SOL3-7_EN001 13

Page 14

Installation and operating manual KT-Elektronik

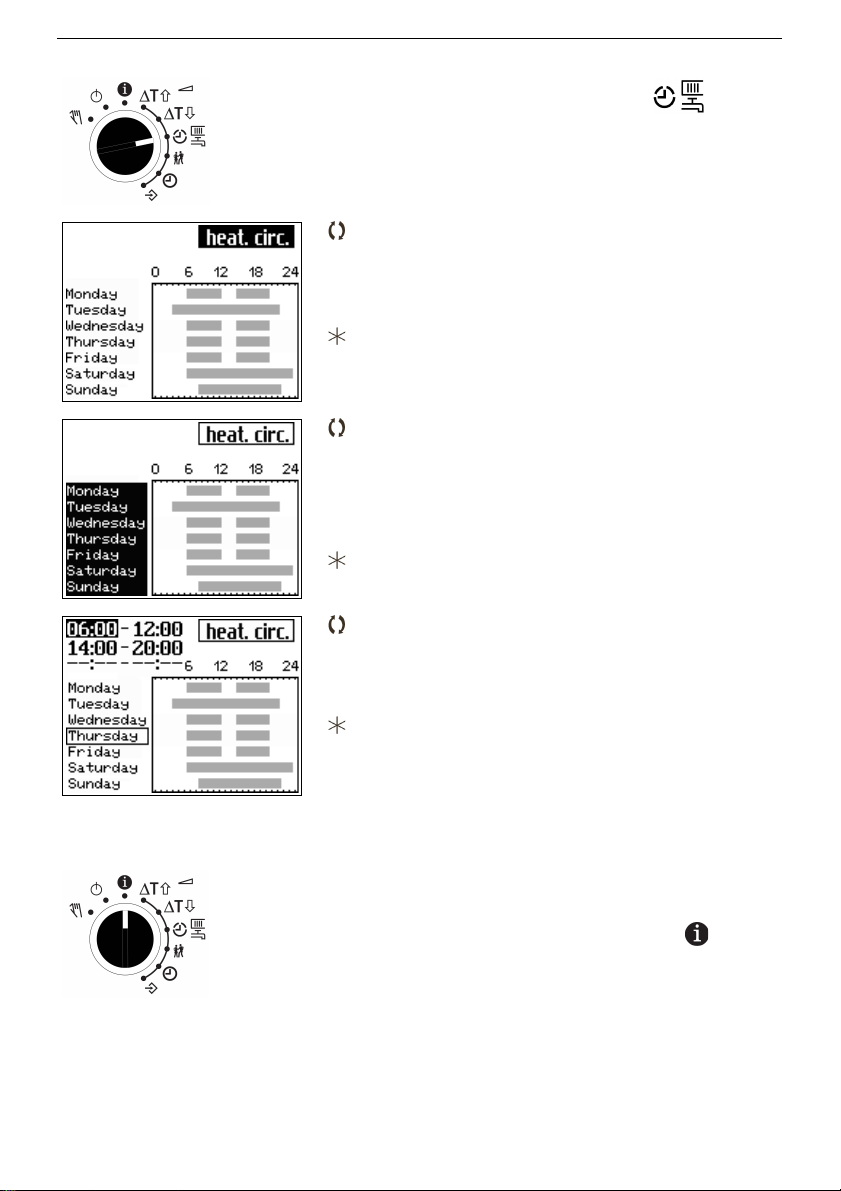

Procedure:

Set rotary switch to times-of-use

Times-of-use for heating circiut is graphicaly

shown, name of times-of-use is displayed

inverted.

Select times-of-use to view

• heating circuit

• hot water circulation

• auxilary heating

Confirm times-of-use to modify

Display:

Selection 'Monday to Sunday' (inverted)

Select day of week (inverted):

• Monday to Sunday

• Monday to Friday

• Saturday to Sunday

• single day

Confirm day of week (interval)

Display: Start and stop time for day of week

Edit start time (inverted):

• 15 minute increment

• 00:00 to 24:00

• - - : - - deaktivated

Confirm Start or stop time

Anzeige: next start or stop time

After confirming the maximum 6 times the

selection of the day of week starts again.

Repeat these steps for the daily input in the

same order.

Set rotary switch to Information level

14 EB_37388_SOL3-7_EN001

Page 15

KT-Elektronik SOL3-7

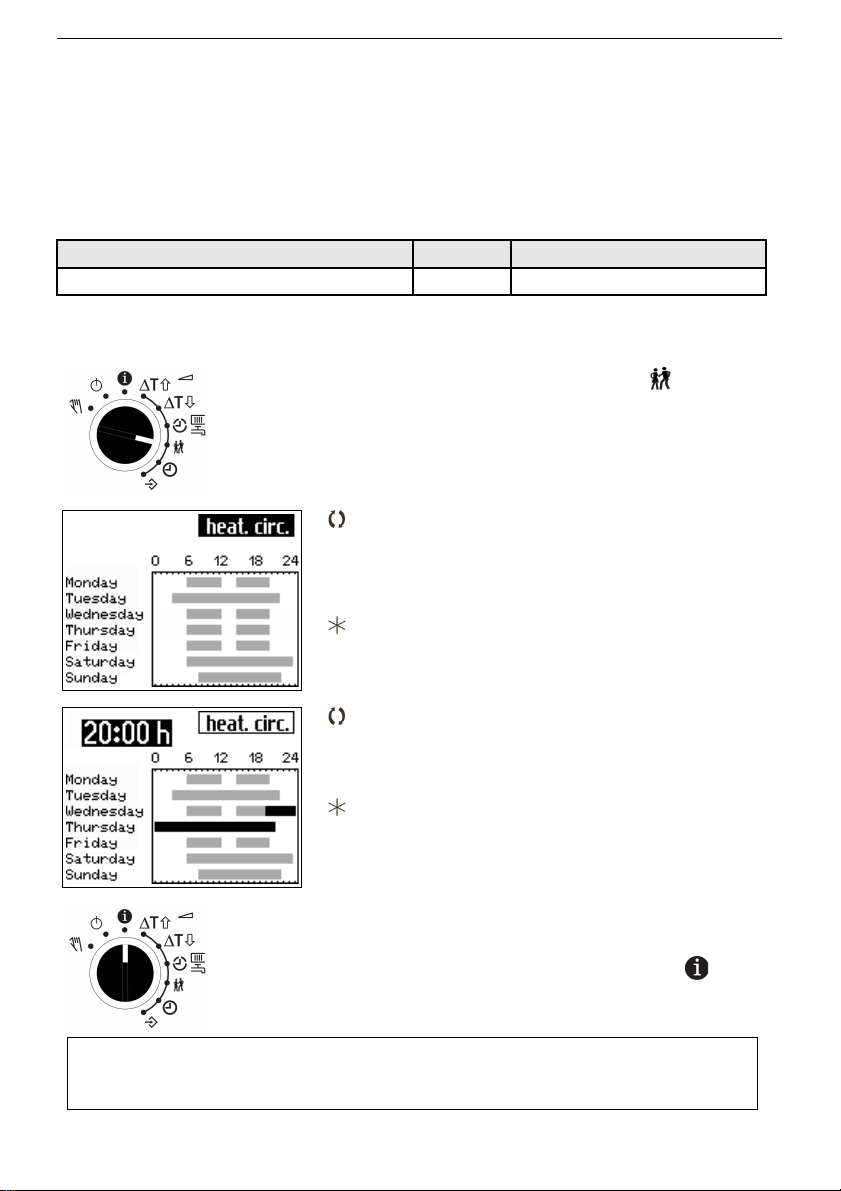

1.7 Setting the party mode (heating circuit/auxiliary heating)

Using the Party mode function, the controller continues or activates the nominal operating

mode (day) during the time when the party timer is active, regardless of the programmed

times-of-use. The activation of the party mode (count down) starts with turning the rotary

switch to any operating mode position (e.g.information level). When the party timer has

elapsed, the party mode timer is reset to 00:00 and the controller continue working as

programmed times-of-use.

Setting FS Value range

initiate or continue nominal operation 0 h 0 to 48 h

Procedure:

Set rotary switch to party mode

Display: weekly schedule

(name of times-of-use is displayed inverted.)

Select times-of-use

• heating circuit

• auxilary heating

Confirm times-of-use

Display: Current Party timer (inverted)

Edit desired duration of time-of-use

The party time is displayed across days.

Confirm Party timer

Display: weekly schedule

(name of times-of-use is displayed inverted.)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 15

Note:

The lapse of time of the party timer is displayed in 15 minute increments.

Page 16

Installation and operating manual KT-Elektronik

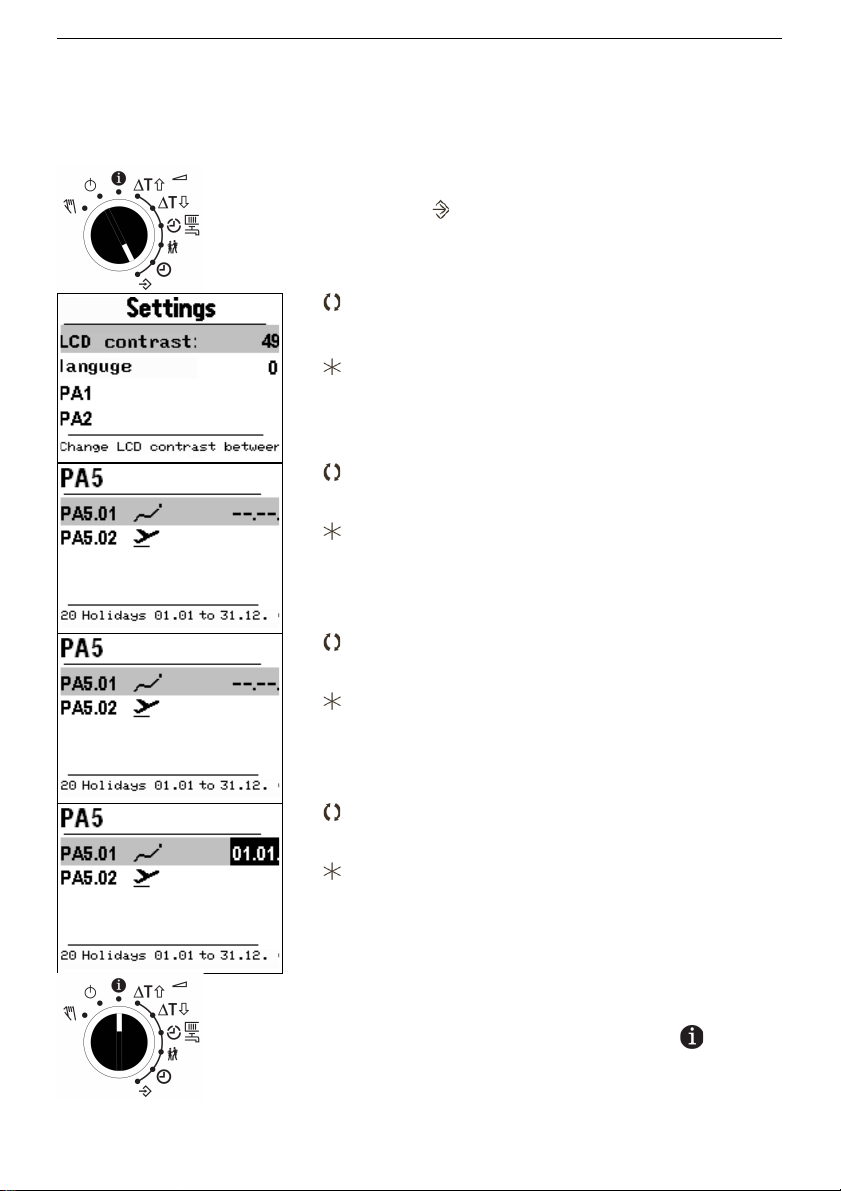

1.8 Setting holidays

On public holidays the times-of-use entered for Sunday apply. The number of programmable holidays is limited to 20. Once programmed the holidays are valid every year.

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast selected)

Select item 'PA5'

Confirm selection

Select item 'PA5.01'

Confirm selection

Display: date of holiday or placeholder

Select date of holiday or placeholder

Confirm date or placeholder to modify

Display: Date of holiday (inverted)

Edit date of holiday (day.month) or erase the date

by select placeholder '--.--' (01.01 to 31.12)

Confirm input

Display: Modified date or placeholder

(edit further holidays)

Set rotary switch to Information level

16 EB_37388_SOL3-7_EN001

Page 17

KT-Elektronik SOL3-7

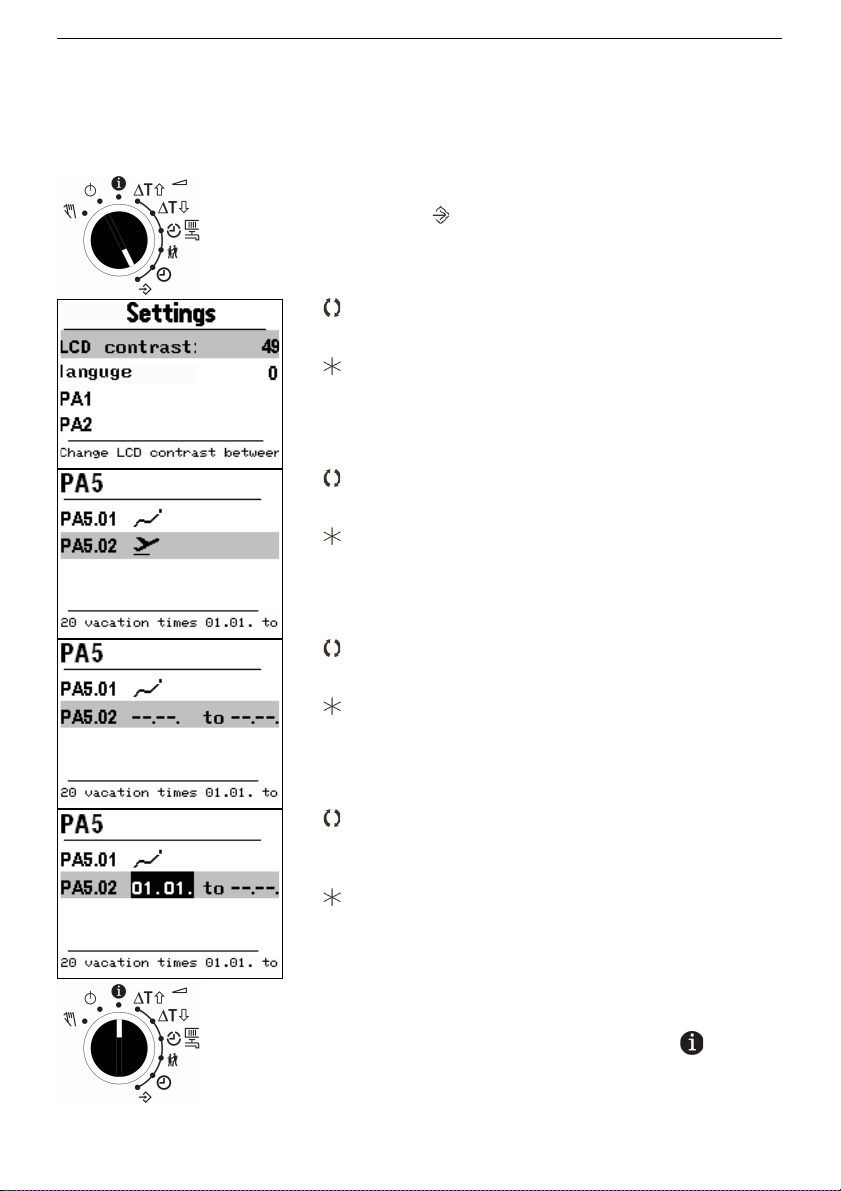

1.9 Setting vacation times

During vacation times the system is set to permanent reduced operation. The number of

programmable vacation times is limited to 10.

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast selected)

Select item 'PA5'

Confirm selection

Select item 'PA5.02'

Confirm selection

Display: vacation time or placeholder

Select vacation time or placeholder

Confirm vacation time or placeholder to modify

Display: Vacation time (inverted)

Edit vacation time by set first and last day of

vacation period (day.month) or erase the date by

select placeholder '--.--' (01.01 to 31.12)

Confirm input

Display: Modified date or placeholder

(edit further vacation time)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 17

Page 18

Installation and operating manual KT-Elektronik

1.10 Access advanced information level

After entering the access code 1999 the following informations are accessible through the

menu items as described in chapter 1.4:

•Measured values for not needed sensor inputs of current system layout

•Valve positions

•Binary input switching status

•Modem state

•Data of M-Bus meters

•Info II - The following values are sequentially displayed:

ID Controller ID

Logg Memory usage of data logging-module (Kapitel 10.11)

MBAd Station address

Koll Operating hours of solar circuit

V' Volume flow rate of flow sensor in solar circui

Pakt Current performance of solar circuit

Wtot Total gain (rate) of solar circuit

WTag Daily gain of solar circuit

18 EB_37388_SOL3-7_EN001

Page 19

KT-Elektronik SOL3-7

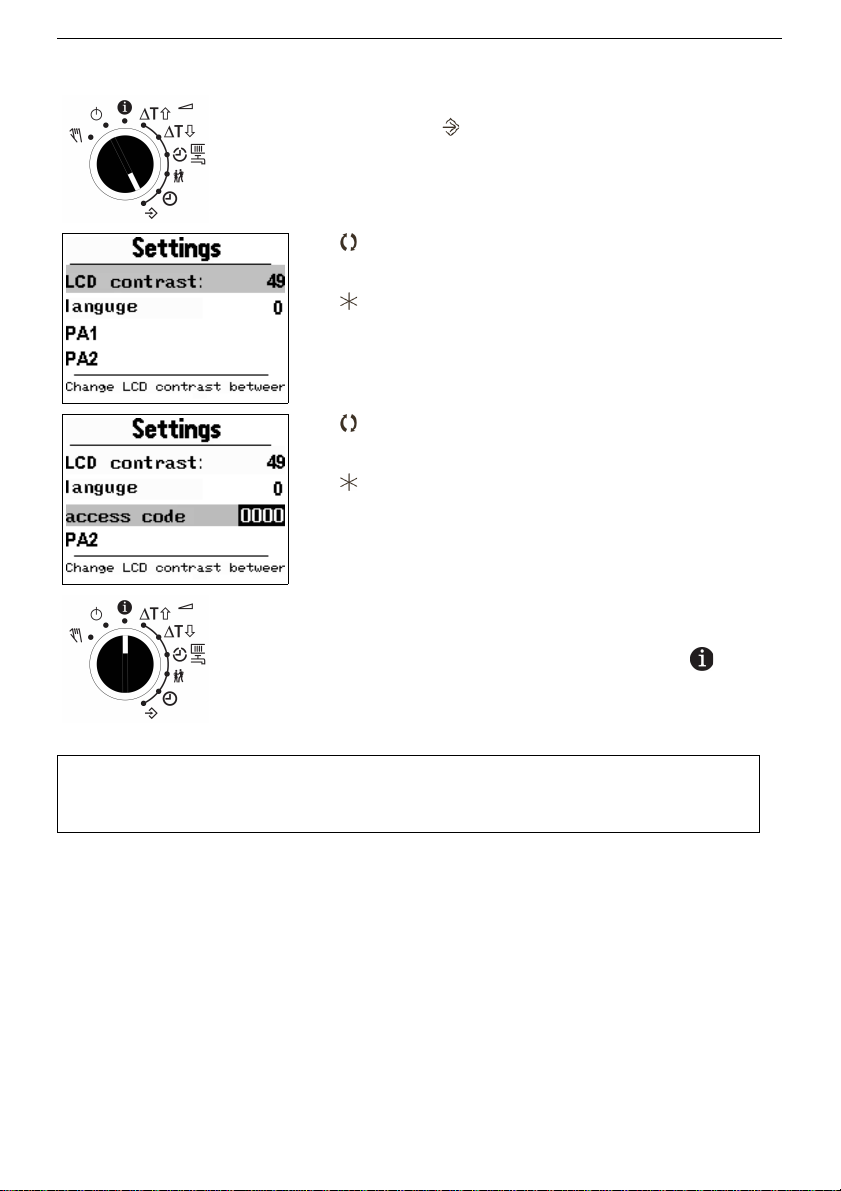

Provide advanced information level:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected)

Select item 'PA1' (respectively 'PA3')

Confirm selection

Set access code (key number) 1999

Confirm access code (key number) 1999

Display: Settings menue ('PA1' selected)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 19

Note:

Re-entering the access code 1999 hides the advanced informations.

Page 20

Installation and operating manual KT-Elektronik

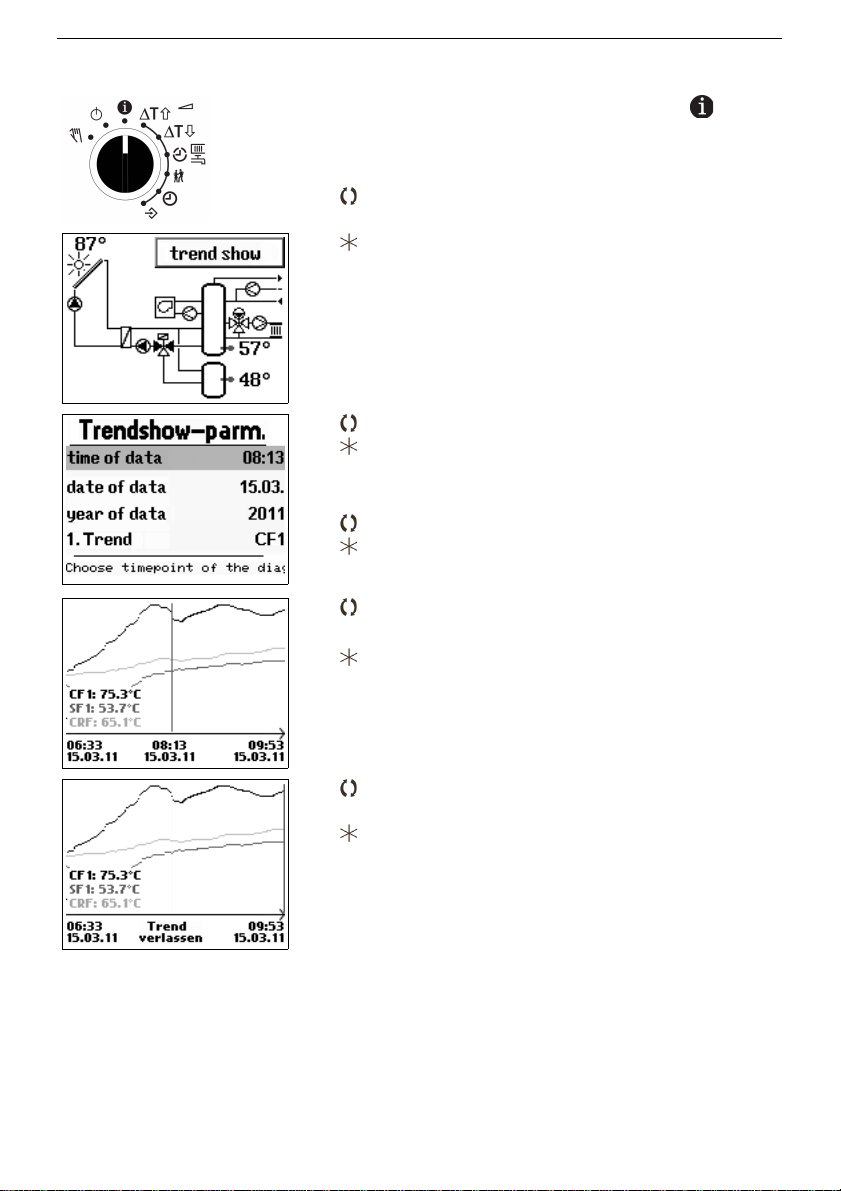

1.11 Trend show – Data logging

The device SOL3-7 is equipped with an internal memory capacity. Every minute the

controller saves data into this memory, in order to analyze in retrospect the operation of the

device without use of additional tools.

The internal backup includes:

• Sensor readings

• States of the switching outputs

• Error Status Register and archive

• Access to controller settings

• user-defined data points

The trend display shows a graph of up to 3 selectable data points with exactly 160 values.

The display area is determined based on the variable minimum and maximum values in the

range of 160 displayed records.

One record will be selected through a focus (vertical line in the display area). The recording

time stamp below the center and the values in plain text on the left side of the display area

are displayed.

With the control button, the displayed time range can be changed and adjusted to the

middle of the display area.

20 EB_37388_SOL3-7_EN001

Page 21

KT-Elektronik SOL3-7

Usage of the trend show

Set rotary switch to Information level

Display: System scheme

Select 'trend show'

Confirm Selection 'trend show'

Display: Trend show settings

Select item

Confirm selection to modify the item

Select 'end'

Confirm selection 'end'

Display: Trend show

Move focus to show values of records

Set focus to the middle of the display area

(readjust time domain)

Moving the focus to the right or left edge

Leave trend show

Display: System scheme

EB_37388_SOL3-7_EN001 21

Page 22

Installation and operating manual KT-Elektronik

2 Commissioning

The configuration procedures and parametrization described in this chapter can only be

performed by entering a valid controller access code.

The access code provided by the factory for first time use can be found in the appendix. To

avoid an unauthorized use, it is recommended to cut out or black out the code. Additionally

the standard code can be replaced by an individual one (Chapter 8.5).

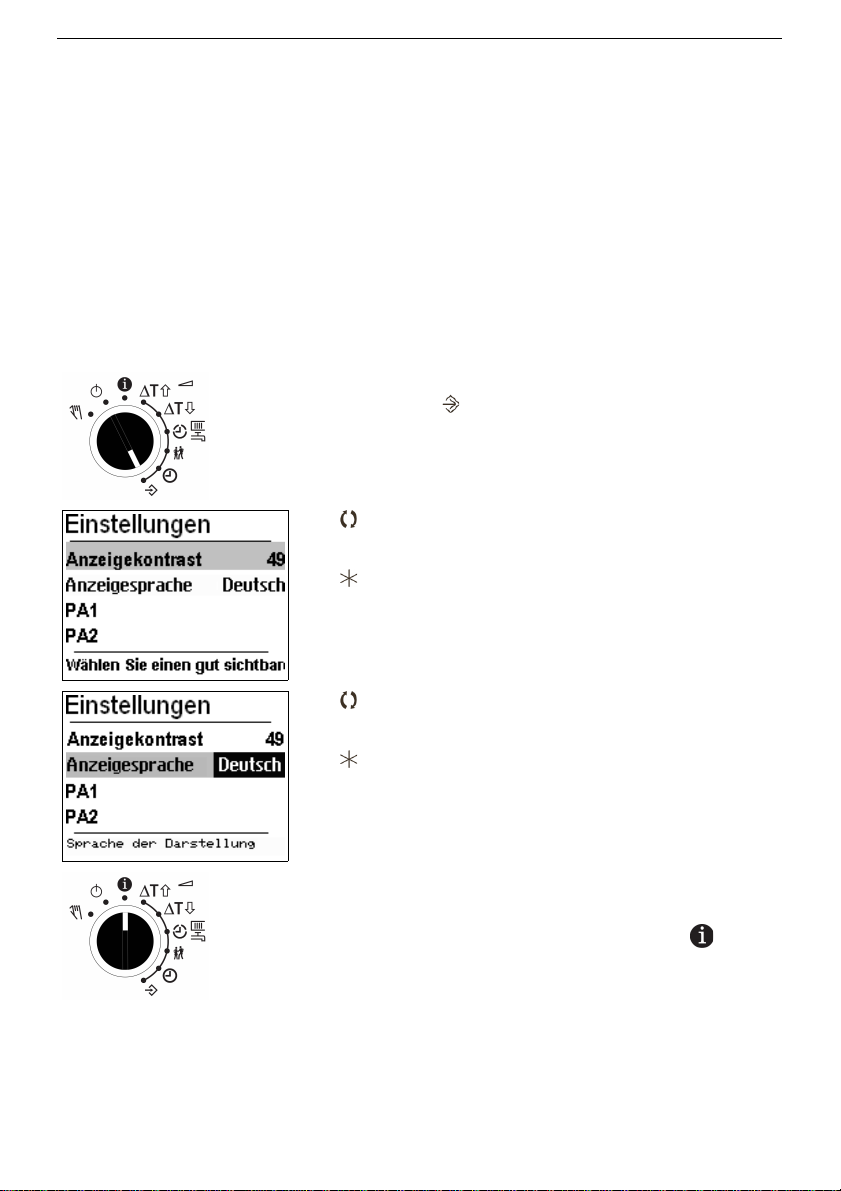

2.1 Set language

The device SOL3-7 will delivered with german language as factory default language. It is

possible to use other languages.

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected- Language German as default)

Select 'Anzeigesprache' in Settings menue

Confirm selection

Display: Current languages (inverted)

Select your prefered language

Confirm language

Display:

Settings menue in the chosen language

Set rotary switch to Information level

22 EB_37388_SOL3-7_EN001

Page 23

KT-Elektronik SOL3-7

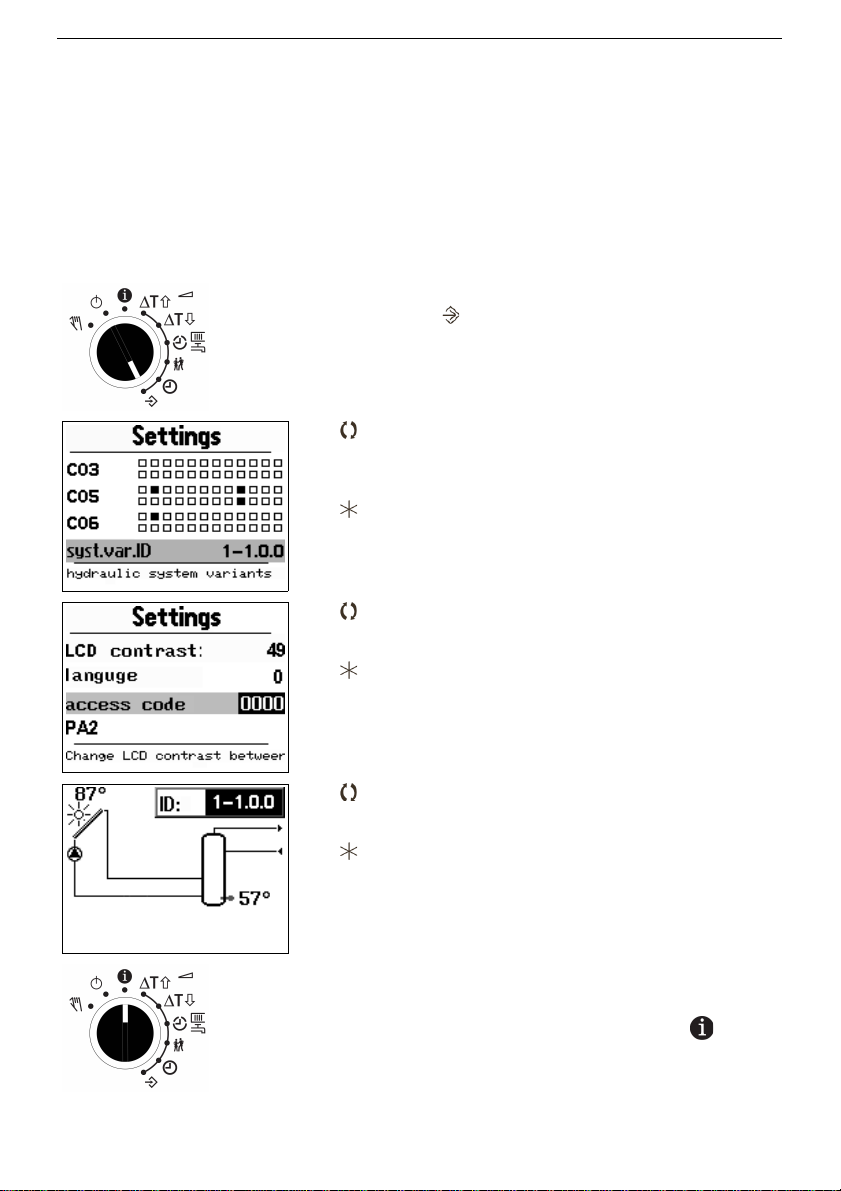

2.2 Setting the system variant ID

Several hydraulic system variants are available. Each variant is represented by an

identification number. The variants are illustrated in chapter 4. The available controller

functions are described in chapters 5, 6 and 7.

Editing the variant ID resets previously entered function blocks to factory default settings.

At parameter level, function block parameters and settings will be preserved. The variant

ID can be set at configuration level.

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected)

Select 'syst.var.id' in Settings menue (system

code number)

Confirm selection

Display: Access code (Key number)

Set valid key number (chapter13.9)

Confirm key number

Display: System scheme

(system code number inverted)

Select system scheme

Confirm system

Display: Settings menue

(Item 'syst.var.id' selected)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 23

Page 24

Installation and operating manual KT-Elektronik

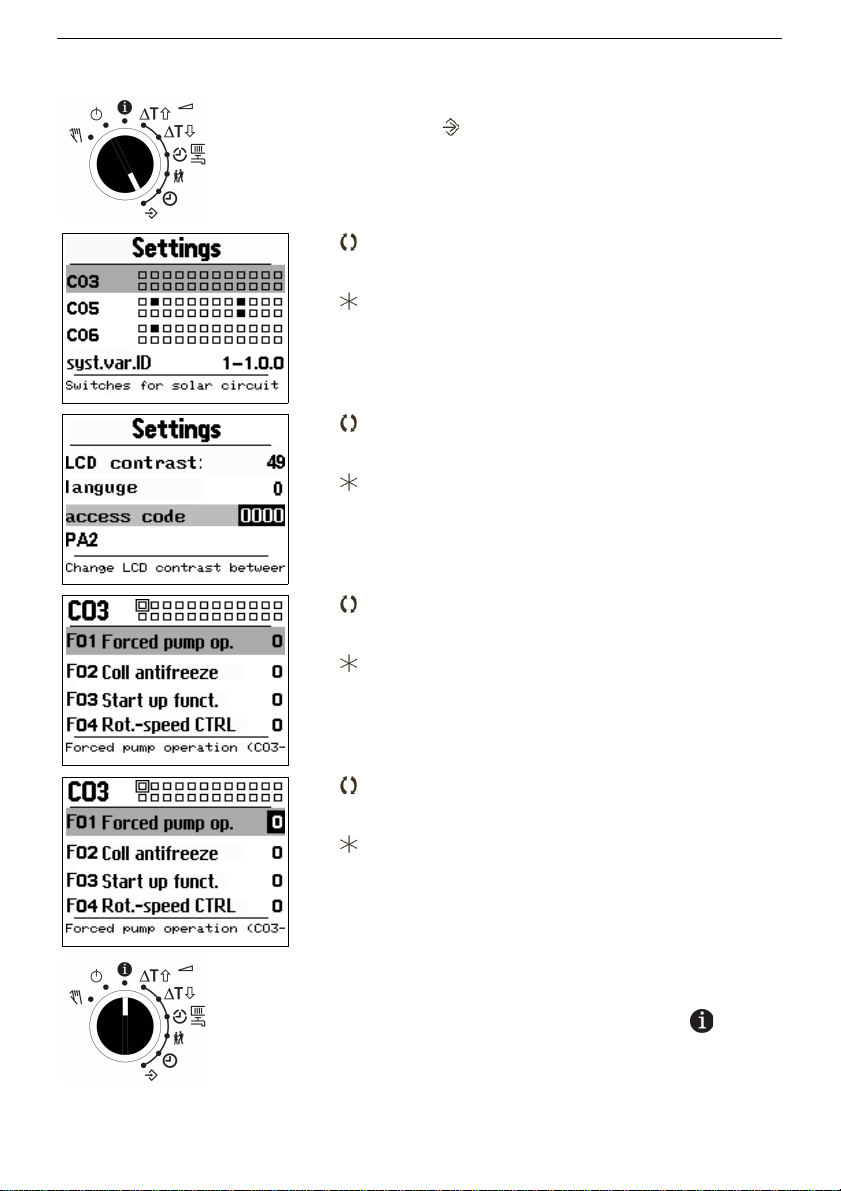

2.3 Activate and deactivate functions

Each function can be activated within its related function block. The sequence of numbers

shown at the head of the display (0 to 24) represent the function block numbers. When

accessing the configuration level, a black square is displayed right hand below active

function block numbers. The function blocks are described in chapter 13.1.

The functions are grouped by topic:

CO1: Heating circuit

CO3: Solar circuit

CO4: Domestic water circuit/auxiliary heating

CO5: System wide

CO6: Modbus-Communication

Function block parameters

Some functions that can be configured via function blocks require additional parameters.

This function block parameter will queried to edit or to confirm in the line of the function

block after function block is activated or deactivated.

24 EB_37388_SOL3-7_EN001

Page 25

KT-Elektronik SOL3-7

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected)

Select 'CO3' in Settings menue

Confirm selection

Display: Access code (Key number)

Set valid key number (chapter13.9)

Confirm key number

Display: Configuration menue 'CO3'

Select funktion to activate or deactivate function

(1/0)

Confirm selection

Display: 'F01 Forced pump op. 0'

(Function block value inverted)

Activate or deactivate function (1/0)

Selektion bestätigen

Anzeige: Configuration menue 'CO3'

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 25

Page 26

Installation and operating manual KT-Elektronik

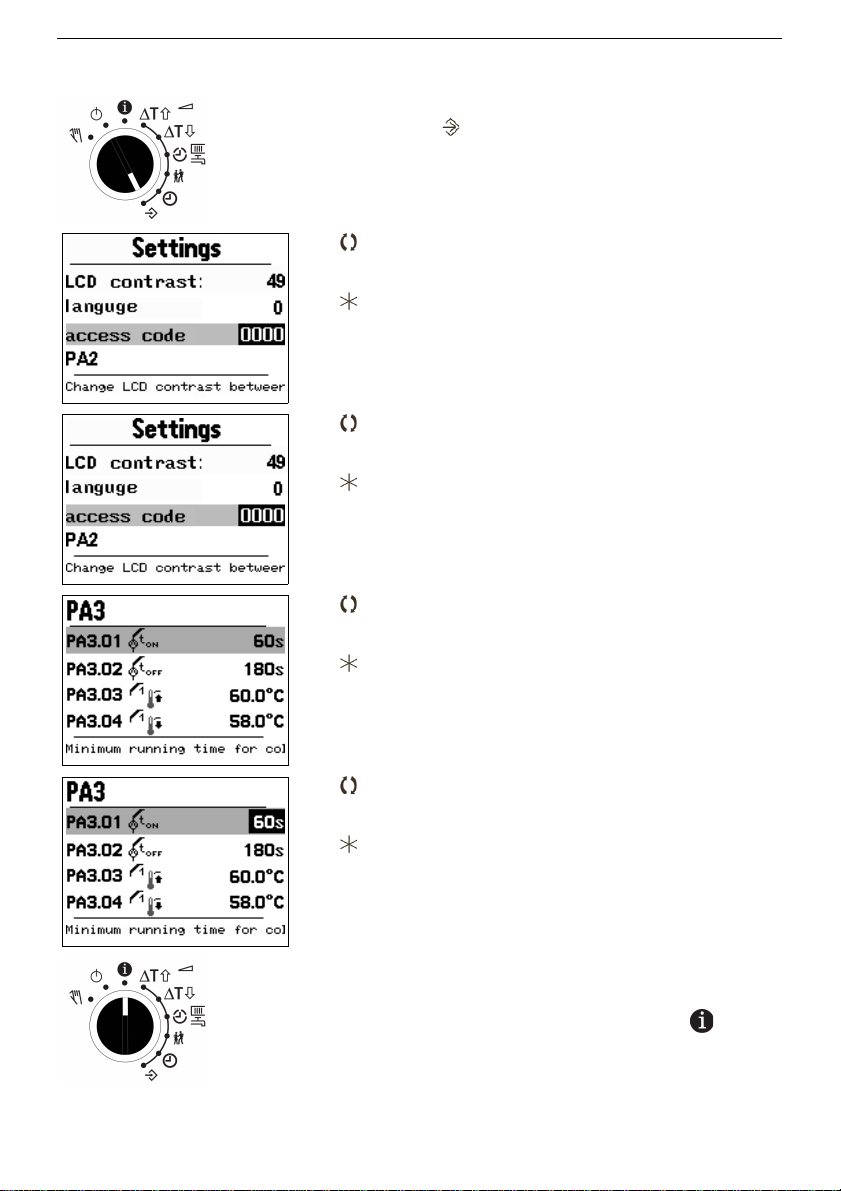

2.4 Edit settings

Depending on the current system variant ID and active functions, not all parameters listed

in the parameter list in the Appendix will be accessible (Chapter 13.2). The functions are

grouped by topic:

PA1: Heating circuit

PA3: Solar circuit

PA4: Domestic water circuit / auxiliary heating

PA5: System wide

PA6: Modbus Communication

26 EB_37388_SOL3-7_EN001

Page 27

KT-Elektronik SOL3-7

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected)

Select 'PA3' in Settings menue

Confirm selection

Display: Access code (Key number)

Set valid key number (chapter13.9)

Confirm key number

Display: Settings menue 'PA3'

Select setting

Confirm setting to modify

Display: Setting menue 'PA3'

(Value inverted)

Edit setting

Confirm setting

Display: Setting menue 'PA3

(Line 'PA3.01' selected)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 27

Page 28

Installation and operating manual KT-Elektronik

2.5 Sensor calibration

The controller is designed for connection of Pt1000-sensors. The sensor values of

resistance are listed on page 100.

If the temperature values displayed by the controller do not match the real temperatures,

the measured values of the connected sensors can be adjusted. The temperature value

displayed has to be replaced by the value measured directly at the measuring point

(reference value). The adjustment has to be activated in CO5, function block F20. A wrong

adjustment can be deleted (for all inputs) by setting - 0 in F20.

Procedure:

Select the function block according to chapter 2.3 CO5.F20 "Sensor calibrat" and activate

or confirm the function block set.

As a function block parameter are viewed with turning the rotary pushbutton all in the

chosen hydraulic system used temperature sensor inputs. If the rotary pushbutton is

pushed, the displayed value is inverted for input.

By turning the rotary pushbutten edit the reference value as an actual temperature of a

thermometer directly at the measuring point and confirm by pressing the rotary pushbutton.

Proceed in this manner to be aligned with each temperature sensor input.

28 EB_37388_SOL3-7_EN001

Page 29

KT-Elektronik SOL3-7

2.6 Reset to factory default settings

All parameters set by means of the rotary switch as well as the parameters set in level PA1

to PA5 can be reset to factory default settings, except the maximum flow temperature and

return flow temperature thresholds in level PA1.

Procedure:

Set rotary switch to configuration and settings

level

Display: Settings menue (LCD contrast

selected)

Select item 'PA1' (respectively 'PA3')

Confirm selection

Set access code (key number) 1991

Confirm access code (key number) 1991

Display: Settings menue ('PA1' selected)

Set rotary switch to Information level

EB_37388_SOL3-7_EN001 29

Note: The error message "Error 2" will be generated while resetting to the factory

default settings. It will be removed automatically shortly after midnight.

Page 30

Installation and operating manual KT-Elektronik

3 Manual operating mode

The manual operating mode allows the configuration of all outputs

(chapter 12).

Procedure:

Set rotary switch to manual mode

Display: System scheme and 'Collector 1'

Select switching output or valve

Confirm selected output

Display: System scheme and current state of

collector pump 1 (inverted)

Edit state of output

Confirm state of output

Display: System scheme and 'Collector 1'

Set rotary switch to Information level

The manual operating mode of the affected control circuit can be deactivated by selecting

any other operating mode.

30 EB_37388_SOL3-7_EN001

Note:

Just by moving the rotary switch to the position “manual operating mode”, the

outputs of the controller are not affected. Only the specific change of position

respectively switching status will influence them.

In manual operating mode the antifreeze function can not be guaranteed (Chapter 8.2).

Page 31

KT-Elektronik SOL3-7

4 System variants

117 hydraulic system variants are available. They differ in the first instance in:

• Number of collector arrays,

• Number of storages,

• Switching between several collectors or storages by means of switching valves or

several pumps,

• Internal (or none) or external heat exchanger.

The following section shows 17 system variants, all other1 differ only by the presence or

absence of extensions as:

• Heating circuit

• Auxiliary heating (e.g boiler, electric cartridge heater),

• Domestic water circulation pump

The system images shown are just basic variant representations missing any kind of cut-off

and safety devices or check valves for example.

System variant I I.0.0 One collector, one storage tank

1 Als system variant IDs are listed at page 89 in the list of output terminal configuration.

EB_37388_SOL3-7_EN001 31

Page 32

Installation and operating manual KT-Elektronik

System variant 2 I.0.0

Two collectors (switching valve), one storage tank

System variant 3 I.0.0

Two collectors (two pumps), one storage tank

32 EB_37388_SOL3-7_EN001

Page 33

KT-Elektronik SOL3-7

System variant I o I.0.0

One collector, one storage, external heat exchanger

System variant 2 o I.0.0

Two collectors (switching valve), one storage tank, external heat exchanger

EB_37388_SOL3-7_EN001 33

Page 34

Installation and operating manual KT-Elektronik

System variant 3 o I.0.0

Two collectors (two pumps), one storage tank, external heat exchanger

System variant I 2.0.0

One collector, two storage tanks (switching valve)

34 EB_37388_SOL3-7_EN001

Page 35

KT-Elektronik SOL3-7

System variant 2 2.0.0

Two collectors (switching valve), two storage tanks (switching valve)

System variant 3 2.0.0

Two collectors (two pumps), two storage tanks (switching valve)

EB_37388_SOL3-7_EN001 35

Page 36

Installation and operating manual KT-Elektronik

System variant I o 2.0.0

One collector, two storage tanks (switching valve), external heat exchanger

System variant 2 o 2.0.0

Two collectors (switching valve), two storage tanks (switching valve), external heat

exchanger

36 EB_37388_SOL3-7_EN001

Page 37

KT-Elektronik SOL3-7

System variant 3 o 2.0.0

Two collectors (two pumps), two storage tanks (switching valve), external heat exchanger

System variant I 3.0.0

One collector, two storage tanks (two pumps)

EB_37388_SOL3-7_EN001 37

Page 38

Installation and operating manual KT-Elektronik

System variant 2 3.0.0

Two collectors (switching valve), two storage tanks (two pumps)

System variant I o 3.0.0

One collector, two storage tanks (two pumps), external heat exchanger

38 EB_37388_SOL3-7_EN001

Page 39

KT-Elektronik SOL3-7

System variant 2 o 3.0.0

Two collectors (switching valve), two storage tanks (two pumps), external heat exchanger

System variant 3 o 3.0.0

Two collectors (two pumps), two storage tanks (switching valve), external heat exchanger

EB_37388_SOL3-7_EN001 39

Page 40

Installation and operating manual KT-Elektronik

4.1 Extending the basic system variant representations

Each system image shown can be enlarged to include other functions. These additional

functions can be combined with each other.

The functions heating circuit, auxiliary heating and circulation are identified by the last two

digits of the system variant ID:

xxx.0.0 no additional function

xxx. I.0 Auxiliary heating

xxx.2.0 Circulation pump

xxx.3.0 Auxiliary heating and circulation pump

xxx.0. I Heating circuit

xxx. I. I Auxiliary heating and heating circuit

xxx.2. I Circulation pump and heating circuit

xxx.3. I Auxiliary heating and circulation pump and heating circuit

2

Example of all additional functions with system variant I o 2:

System variant I o 2.0. I (with heating circuit)

One collector, two storage tanks (switching valve), external heat exchanger

2 Not available for each system variant

40 EB_37388_SOL3-7_EN001

Page 41

KT-Elektronik SOL3-7

System variant I o 2. I.0 (with auxiliary heating)

One collector, two storage tanks (switching valve), external heat exchanger

System variant I o 2.2.0 (with circulation pump)

One collector, two storage tanks (switching valve), external heat exchanger

EB_37388_SOL3-7_EN001 41

Page 42

Installation and operating manual KT-Elektronik

System variant I o 2. I. I (with heating circuit and auxiliary heating)

One collector, two storage tanks (switching valve), external heat exchanger

42 EB_37388_SOL3-7_EN001

Page 43

KT-Elektronik SOL3-7

5 Solar circuit functions

5.1 Basic Control function

The controller monitors the collector temperature (sensor CF) as well as the storage

temperature (sensor SF) and turns the collector pump (CP) on once enough solar energy

is available to heat up the storage.

The temperature chart shows how regulation works under consideration of the parameters:

EB_37388_SOL3-7_EN001 43

Figure 1: temperature chart

Page 44

Installation and operating manual KT-Elektronik

A) The collector temperature exceeds the storage temperature by more than the

turn-on threshold (8 K). The collector pump is turned on.

B) The collector temperature dropped below the turn-off threshold (SF + 4 K). The

collector pump is turned off.

C) The collector temperature exceeds the turn-on threshold again. The pump is

turned on as soon as the minimum idle time elapses.

D) The collector temperature dropped and falls below the turn-off threshold again

(SF + 4 K). The collector pump is turned off.

E) The collector temperature exceeds the storage temperature by more than the

turn-on gap (8 K). The collector pump is turned on.

F) The collector temperature quickly dropped below the turn-off threshold again. The

pump remains running as long as the minimum running time has not elapsed.

Parameters for the basic function:

Setting FS Value range Description

Direct input

8 K 1 to 50 K Turn-on threshold

Direct input

4 K 1 to 50 K Turn-off threshold

Minimum run time

PA3.01

60 s 0 to 1800 s Minimum run time for collector pump

Minimum idle time

PA3.02

180 s 0 to 1800 s Minimum idle time for collector pump

44 EB_37388_SOL3-7_EN001

Note:

The turn-on condition only applies if the actuator to be turned on is turned off. The

turn-off condition only applies if the actuator to be turned off is turned on.

By placing sensors at positions which only allow an insufficient measurement of

relevant temperatures and by an inadequate selection of settings at run-time

respectively by delaying control signals, it may be possible to bring the controller to

operate switches that conflict with the goal of a maximum solar energy.

Page 45

KT-Elektronik SOL3-7

5.2 Storage

The storage is only charged until the maximum allowed temperature is reached. Using

factory default settings, charging the storage already ends at 60°C. Falling below 58°C

would initiate a new charging cycle. If the water is routed to extraction points directly, there

is a scalding danger at higher temperatures. If using additional components – such as

mixing taps – and therefore is no risk, higher storage temperatures can and should be

allowed.

Too high temperatures may cause limescale that can negatively affect the performance of

the heat exchanger.

Setting FS Value range Description

Storage tank 1Max A

PA3.03

60 °C 20...160 °C maximum storage tank temperature 1

(turn-off condition)

Storage tank 1Max E

PA3.04

58 °C 20...160 °C maximum storage tank temperature 1

(turn-on condition)

The controller supports the selective charging of two storages, e.g. a storage tank and a

heating buffer storage. Depending on the achievable and the allowed storage temperature,

the solar heat is lead to the storage by means of a switching valve respectively two

separate pumps. The two (logically existing) storages can also be realized by using a

stratified storage with alternative adapters for thermal layering.

Setting FS Value range Description

Storage tank 2Max A

PA3.05

60 °C 20...160 °C maximum storage tank temperature 2

(turn-off condition)

Storage tank 2Max E

PA3.06

58 °C 20...160 °C maximum storage tank temperature 2

(turn-on condition)

The solar thermal controller SOL3-7 is used to transfer the usable solar energy into the

storage tanks in systems with two storage tanks according to the priority presetting and the

programmed parameters. The scope of application of the saved energy is irrelevant for this

process. Differing from the system variants shown in chapter 4, the domestic water heating

and/or the heating circuit can be feeded by storage tank 1 (with SF1) and/or storage tank 2

(with SF2). Additional equipment for charge reversal can be also provided.

EB_37388_SOL3-7_EN001 45

Page 46

Installation and operating manual KT-Elektronik

Storage tank priority

Depending on the usage, it could make sense to reach a higher temperature in one of both

storage tanks or to reach a uniform allocation of the collected energy. The parameter Type

of storage tank priority is used to determine the solar controller mode of operation.

Setting FS Value range Description

Type of storage tank

priority

PA3.07

3 1...5 The following table

Priority

mode

Function Description

1 hard priority

Max

Storage tank 2 is only charged if the maximum temperature in

storage tank 1 has been reached

2 hard priority

Min.

Storage tank 2 is only charged if the minimum temperature in

storage tank 1 has been exceeded.

PA3.08 - Minimum storage tank temperature for charging

3 soft priority Storage tank 1 is always charged if the collector temperature is

sufficient to charge it. If not sufficient to charge storage tank 1 but

sufficient to charge storage tank 2, charging of storage tank 2 is

initiated.

PA3.09 - Charging time for low priority storage tank

After the lapse of the specified time (Charging time for low

priority storage tank, FD 15 minutes), charging is interrupted for

the minimum idle time (see section 5.1). At the end of this

interruption it is newly decided if the temperature is sufficient to

charge storage tank 1.

4 alternating

charge

The storage with the lowest temperature is charged first. Once

the currently charged storage tank becomes warmer by more

than 5K compared to the other one, charging is switched to the

colder storage tank. Switching can occur several times.

5 no priority Both storages tank are charged having equal priority, that is, the

storage tank with the lower temperature is charged first. If

charging is not interrupted, the storage tank is charged to its

maximum temperature and only then switched to charge the

other storage tank.

5.3 Swimming pool

The solar controller SOL3-7 is suitable for the solar heating of swimming-pools. Any usable

solar energy is transferred in a swimming pool, which can be selected as a storage tank 1

or storage tank 2 with the given storage tank priority mode.

The maximum storage tank temperature (temperature of the swimming-pool) is to the need

to adapt.

46 EB_37388_SOL3-7_EN001

Page 47

KT-Elektronik SOL3-7

5.4 Collector return flow sensor, Collector flow sensor

In several systems, the sensors for collector temperature and for storage tank temperature

are not really appropriate to decide if the collector pump should be already turned off or

not. It is possible that fluid with a higher temperature than measured by the storage tank

sensor flows from the storage tank to the collector, e.g. because of layering in the storage

tank. It is also possible that the temperature measured by the collector sensor differs from

the one of the heat carrier medium entering the storage tank. Both can result to a

senseless continued operation of the collector pump even without sunshine, until the

temperatures have changed.

A reliable turn-off criteria can be obtained by using a return flow sensor (CRF), and even

better by using both, a flow sensor (CVF) and a return flow sensor (CRF). By activating the

function block CO3-FB08 collector return flow sensor, turning off the collector pump is not

based on the difference between CF and SF any more, but on the difference between CF

and CRF.

If a collector flow temperature sensor is also present (function block CO3-FB08 = On), the

temperature difference between CVF and CRF is also relevant to turn off the pump.

Function FS Description

CVF

CRF

0

0

CO3 -> F07 Collector flow sensor active

CO3 -> F08 Collector return flow sensor active

EB_37388_SOL3-7_EN001 47

Page 48

Installation and operating manual KT-Elektronik

5.5 Measurement of solar power and solar energy

To document the solar gain of the solar system, a heat meter has been implemented,

which determines the heat quantity provided by the solar system by means of the flow and

return flow temperature and a flow volume sensor (quantity impulse generator) respectively

a flow volume sensor replacement value.

The temperature difference between flow and return flow is proportional to the energy

transferred into the storage at a given flow rate. The controller displays the current solar

energy and the current day total if the function block CO3-FB05 energy measuring has

been activated.

If the flow volume sensor (VST) is missing, a fixed flow rate can be set. This value is used

as substitute for the flow volume value when the pump is running.

The following alternatives are possible depending on the existing sensors:

Sensors Turn-off criteria Power and energy measurement

CF, SF CF - SF not available

CF, SF, CRF CF - CRF A fixed flow rate value is assumed (not

available with rotation speed control),

eventual measurement errors at CF

CF, SF, CRF, CVF CVF - CRF A fixed flow rate value is assumed (not

available with rotation speed control)

CF, SF, CRF, VST CF - CRF Flow rate is measured, eventual

measurement errors at CF

CF, SF, CRF, CVF, VST CVF - CRF Flow rate is measured, highest accuracy

achievable

In order to calculate the power and energy, the controller has to know the heat capacity of

the heat carrier medium. This value depends on an eventually used antifreeze fluid, its

concentration and the temperature. The heat capacity of water is approx. 1.16 Wh/(lK)

respectively. 4.18 kJ/(kgK) at 25 °C and approx. 1.12 Wh/(lK) respectively 4.03 kJ/(kgK) at

100°C. The necessary specifications when using antifreeze fluid (solar fluid) can be

obtained from the antifreeze manufacturer.

The impulse factor specifies the flow rate in litre, after which an impulse is sent by the

sensor. This value should be found on the package or in the data sheet of the flow sensor.

If the sensor expects impulses/m³ instead of l/Impulse, the value has to be converted:

e. g. 100 impulses/m³ are equivalent to 0.01 m³/impulse respectively 10 l/impulse

If the capacity is given in Wh/(kgK), the value has to be converted to Wh/(lK) by means of

the fluid density. Some general notes on the conversion of heat capacity values:

• 1 watt hour (Wh) = 3600 watt seconds (Ws)

• 1 watt hour (Wh) = 3600 joules (J)

• 1 kilowatt hour (kWh) = 1000 watt hours (Wh)

48 EB_37388_SOL3-7_EN001

Page 49

KT-Elektronik SOL3-7

Function FS Description

Energy measurement

Heat capacity 25°C

Heat capacity 100°C

Correcting factor

0

1.16

1.12

1.00

CO3 -> F05 – 1 – Heat meter active

Heat capacity of carrier medium at 25 °C in Wh/

(Litre*K) / 0.3 to 2.5 Wh/(LK)

Heat capacity of carrier medium at 100 °C in Wh/

(Litre*K) / 0.3 to 2.5 Wh/(LK)

Correction factor / 0.2 to 2.5

Volume flow rate

Impulse factor

Volume flow

replacement value

0

10

0

500

CO3 -> F06 – 1 – impulse capture active

Impulse factor for flow volume sensor / 1 to 250

litre/impulse

CO3 -> F06 – 0 – Flow replacement value active

Flow volume sensor replacement value/ 10 to

5000 litre/h

5.6 Rotation speed control

It might make sense to run the pump with a lower flow rate at low solar radiation. By doing

so, the following can be achieved:

–a higher temperature is reached at the collector. This impairs the efficiency of the

collector, but allows to heat up a small amount of water in the storage.

–the power consumption of the pump is reduced.

Basically, the turn on and off conditions for the pumps apply as without rotation speed

control. Additionally, the 0...10V-output is provided with rotation speed information when

the pump is running.

The following speed control modes are available:

1 - Constant temperature difference

The rotation speed is regulated such that the temperature at the collector is higher by a

certain value (factory default setting 8K) than at the storage. The programmed value is

usually exceeded at high solar radiation, what causes the pump to run at 100%. Once the

difference drops below the set-point, the flow rate is reduced. The temperature in the

collector flow thereby increases again and the difference remains at the set-point.

If a return flow sensor is present, the temperature difference between the collector sensor

and the return flow sensor is corrected, if flow and return flow sensor exist, then the

difference between these two is corrected.

2 - Constant collector temperature

Only the collector temperature (or collector flow sensor, if present) is considered. It is

adjusted to the programmed set-point (e.g. 60°C). The programmed value is usually

exceeded at high solar radiation, the controller runs the pump at 100%. If the solar

radiation becomes weaker, so that the temperature drops below the set-point, the

controller reduces the rotation speed of the pump, thereby the heat carrier medium

remains for a longer period in the collector and the temperature increases again. In case

the solar radiation decreases such that the temperature can't even be hold at the minimum

rotation speed set (e.g. 30%), then the controller signalizes 0% which equals 0V which

turns the pump off if this has not been done yet by means of a normal turn-off condition.

EB_37388_SOL3-7_EN001 49

Page 50

Installation and operating manual KT-Elektronik

A rotation speed control is only available for one single pump. This might therefore not be

reasonable for system variants with more than one pump. In system variants with external

heat exchanger, the storage circuit rotation speed is always regulated whereas the pump (s) in the collector circuit are run with a constant rotation speed. A uniform temperature

distribution in the collector is achieved this way, which improves the collector efficiency.

The SOL3 controller has a 0...10V-output that can be connected to the input of a

corresponding pump. Parameter settings can curtail the voltage range of this variable:

If the calculated value is above the programmed maximum rotation speed value, a signal

for 100% is sent (corresponding to 10 V output). If the calculated value is below the

programmed minimum rotation speed a signal for 0% (corresponding to 0 V output) is sent.

The calculation is based on a PID algorithm, whose parameters can be customized.

Function FS Description

Rotation speed mode

Rotation speed set-point

Minimum rotation speed

Maximum rotation speed

PID control parameters

1

10

0%

100%

2.0

120 s

0 s

CO3 -> F04 Mode of rotation speed control / 1...2

Set-point for rotation speed control / 1...100 °C

respectively K (Differential or absolute value)

Minimum rotation speed / 0 ... 50%

Maximum rotation speed / 50 ... 100%

KP (boost) / 0.1 to 50.0

TN (reset time) / 1 to 999 s

TV (retention time) / Do not change value!

5.7 Collector overheating protection

If the collector temperature exceed this maximum value (default factory setting is 130°C), it

is assumed that steam is already in the system, and therefore no circulation takes place

any more. The collector pump is turned off in this case until the temperature dropped to a

lower value (default factory setting is 110°C).

Setting FS Value range Description

Collector-Max A

PA3.10

130 °C 90 ... 160 °C Maximum collector temperature

(turn-off condition)

Collector-Max E

PA3.11

110 °C 90 ... 160 °C Maximum collector temperature

(turn-on condition)

50 EB_37388_SOL3-7_EN001

Page 51

KT-Elektronik SOL3-7

5.8 Collector minimum temperature

A minimum collector temperature can be set, underneath which the pump is not turned on

at all. This can be reasonable in cases where it is known that the solar gain ratio lays

below the pump power ratio.

A very low temperature can be set if this function is not desired (e.g. -20°C)

Setting FS Value range Description

Collector-Min A

PA3.12

30 °C -20 ... 50 °C minimum collector temperature

(turn-off condition)

Collector-Min E

PA3.13

35 °C -20 ... 50 °C minimum collector temperature

(turn-on condition)

5.9 Start up function

There are collectors, in particular vacuum tube collectors, but also conventional flat-laying

collectors, where measuring of the carrier medium temperature is insufficiently supported.

A start-up function makes sense for systems with such collectors in order to determine the

carrier medium temperature.

The temperature at the collector sensor only slowly increases even if the collector is

illuminated by the sun. The start-up function can be activated for these cases:

This function can only be used if the collector temperature is below the turn-on threshold

but above the collector minimum temperature. In case that the temperature at the collector

sensor increases by 5K within 10 minutes, the pump is turned on briefly (20 s). This leads

to a transport of heat, and with sufficient radiation to an excess of the turn-on condition at

the collector sensor. This start-up function is repeated every 20 min if necessary.

Function FS Description

Start up function

CO3 -> F03- 1

0 Cyclic test-step switching of the collector pump (s)

5.10 Forced pump operation (blocking protection)

If the pumps have not been turned on for 24 hours, they are turned on by force on midday

to prevent that they get stuck in long term idle periods.

Function FS Description

Forced pump operation

CO3 -> F01- 1

0 Regular forced pump operation

The forced collector pump operation is suppressed if the related collector sensor measures

a temperature below 10 °C.

EB_37388_SOL3-7_EN001 51

Page 52

Installation and operating manual KT-Elektronik

5.11 Collector Antifreeze

Solar systems with no antifreeze medium can be run in regions where frost just appears

sporadically. In case that the temperature really should drop below the dew point, the

controller is able to turn on the pump in order to prevent a freezing of the collector.

Operation: The collector pump is turned on if the temperature at the collector sensor drops

below 5 °C. At 6 °C it is turned off again, but only after the minimum running time set

elapsed.

The following icon additionally appears if the pump is turned on for antifreeze purpose.

Function FS Description

Collector antifreeze

CO3 -> F02- 1

0 Collector antifreeze

In system variants with two collector arrays and switching valve (system variant 2.... ), the

collector array where the temperature falls below the dew point last is not flown through

before the temperature in the first array has increased.

5.12 Two collector arrays

Depending on the structural conditions, it may be necessary to install the two collectors

each pointing in a different direction. The controller can be used in systems operating in

parallel mode with two collector arrays with one array having priority over the other. This is

basically predetermined by configuring the system to operate with two collector pumps or

with one pump and a switching valve.

The heat transport is controlled independently for each array according to the above

described criteria. In system variants with two collector arrays and switching valve, the

array with the higher energy supply has precedence.

In system variants with two collector arrays and two collector pumps, it is generally

recommended to install a collector return flow sensor CRF. Only by knowing the return flow

temperature, it can't reliably be determined whether the power is delivered to the storage

or not.

Setting FS Value range Description

Array minimum

running time

PA3.14

60 s 0...1800 s Minimum running time for array before

switching

52 EB_37388_SOL3-7_EN001

Notes:

This function leads to transferring the heat out of the storage to the collector. It is

only suitable for regions with mild climate. The storage may not be able to provide

sufficient energy during strong freeze periods to protect the collector from freezing.

This function should not be used in systems with antifreeze.

Page 53

KT-Elektronik SOL3-7

5.13 External heat exchanger

When operating installations with system separation of collector and storage tank, an

external heat exchanger may be installed. An additional exchanger pump CTP is required

in this case.

Turn-on condition: The start of the exchanger pump CTP is delayed by the setting 'turn-on

delay CTP', if the temperature difference between collector and storage still matches the

turn-on condition after one of the collector pumps CP1/CP2 have been turned on. If the

temperature difference drops below the turn-on condition after the collector pump CP1 or

CP2 has been turned on, the exchanger pump is not turned on.

Turn-off condition: The exchanger pump CTP is turned off with a defined delay 'CTP postrun time' once the turn-off condition for the collector pump CP1 or CP2 has been reached.

The turn-on delay and the post-run time depend on the system (pipe length, flow rate,

exchanger capacity).

Setting FS Value range Description

Turn-on delay CTP

PA3.15

120 s 0 to 250 s Turn-on delay for the collector exchanger

pump CTP

Post-run time CTP

PA3.16

10 s 0 to 250 s Post-run time for the collector exchanger

pump CTP

An optional collector flow temperature sensor CVF located in the collector circuit may be

used to reduce the turn-on delay and the post-run time in order to increase the efficiency of

the solar system. The exchanger pump CTP is turned on once the collector flow sensor

has reached the turn-on condition (temperature difference between collector flow and

storage tank) and one of the collector pumps CP1/CP2 is running.

Function FS Description

CVF for CTP

CO3 -> F09- 1

0 Collector flow temperature sensor CVF for heat

exchanger pump CTP active

CO3 -> F07 – 1 - (CVF) required

5.14 Auxiliary heating with secondary heat generator

An additional heat generator is required in several systems where a solar fraction of 100%

can't be expected. The secondary heat generator may be an oil or gas boiler, an electric

cartridge heater or a district heating network.

Scheduled time ranges to hold a specific stand-by temperature can be set for nominal

(day-time) and reduced (night-time) operating mode.

Once the temperature falls below the programmed set-point for the storage tank, the

secondary heat generator is activated and remains active until the temperature at the

storage tank sensor SF1 reaches the set-point again.

The setting 'Offset with CP On' can be used to specify that the auxiliary heating is only

turned on if the storage temperature is considerably too low (e.g. 20K), in cases where one

of the collector pumps CP1/CP2 is running. Hereby it is possible to use an energetically

EB_37388_SOL3-7_EN001 53

Page 54

Installation and operating manual KT-Elektronik

more favourable heat source with just a slight impairment of comfort. The collector circuit

has no impact on auxiliary heating if this parameter is set to 0K (default factory setting).

Secondary heat generators allow thermal disinfection.

Setting FS Value range Description

Day-time

storage tank

set-point

PA4.01

45 °C 5 to 90 °C Storage tank temperature set-point

for nominal operating mode (day-time)

Night-time

storage tank

set-point

PA4.02

10 °C 5 to 90 °C Storage tank temperature set-point

for reduced operating mode (night-time)

Hysteresis

PA4.03

5 K 0 to 30 K Hysteresis for storage tank temperature

Offset with

CP On

PA4.04

0 K 0 to 20 K Auxiliary heating delay temperature difference

with running collector pump

54 EB_37388_SOL3-7_EN001

Page 55

KT-Elektronik SOL3-7

6 Heating circuit functions

The following sensors are available for the heating circuit:

VF Flow sensor

AF Outdoor sensor

RF Ambient/Room sensor

AF and RF can individually be activated and deactivated at configuration level CO1.

All available controller functions can only be used if all sensors are installed. A weather-

compensated control is not available without an outdoor sensor, a room control is not

available without a room sensor. The flow sensor is always required.

6.1 Prescribing the room temperature set-points

The controller can be programmed with changes in temperature for the flow temperature of

night (set-point night) and day (set-point day) of the heating circuit, for which fictitious setpoints are used. An increase of the standard room temperature (20 °C for the day and

15 °C for the night) will cause an increase of the flow temperature - a reduction will cause

the opposite.

The domestic water circuit allows setting the desired temperature the water should be

heated up to by means of auxiliary heating.

6.2 Weather-compensated control

In weather-compensated control mode, the flow temperature is adjusted depending on the

outdoor temperature. The heating characteristic of the controller defines the flow

temperature as a function of the outdoor temperature (page 56). The outdoor temperature

needed to control the temperature is measured by the outdoor sensor.

Function FS Description

Outdoor sensor AF

CO1 -> F02 - 1

1 Outdoor sensor is present

6.2.1 Gradient characteristic

Basically, the following relation applies: when the outdoor temperature drops, the flow

temperature rises. By varying the gradient and level parameters, the characteristic may be

adjusted to meet custom needs. The "level" parameter shifts the characteristic in parallel

up or down. Outside scheduled time ranges reduced set-points are used for control: The

reduced flow rate set-point is calculated as the difference between the entered values for

daytime operation and the flow temperature drop. The parameters for maximum and

minimum flow temperature limit the temperature up- and downwards.

EB_37388_SOL3-7_EN001 55

Page 56

Installation and operating manual KT-Elektronik

Advices to adjust gradient and level:

• If the room temperatur in cold season don't rises up to the room temparture

setpoint the Gradient needs to be increased.

• If the room temperatur in cold season rises over to the room temparture set-point

the Gradient needs to be increased.

• If the room temperatur in mild season don't rises up to the room temparture

setpoint the Level needs to be increased and Gradient needs to be decreased.

• If the room temperatur in mild season rises over to the room temparture set-point

the Level needs to be decreased and Gradient needs to be increased.

Functions FS Configuration

4-point heating characteristic 0 CO1 -> F11 - 0

Setting FS Parameter level / Value range

Gradient, flow

PA1.01

1,8* PA1 / 0,2 to 3,2

Level, flow

PA1.02

0 °C 0 to 30 °C

Minimum flow temperature

PA1.06

20 °C PA1 / 5 to 130 °C

Maximum flow temperature

PA1.07

50 °C* PA1 / 5 to 130 °C

* for CO1 -> F05 - with value 1 applies to: gradient, flow / 0.2 to 1.0 (1.0)

Maximum flow temperature / 5 to 50 °C (50 °C)

56 EB_37388_SOL3-7_EN001

Page 57

KT-Elektronik SOL3-7

Example characteristic settings:

-Old building, radiator performance/layout 90/70: gradient approx. 1.8

-New building, radiator performance/layout 70/55: gradient approx. 1.4

-New building, radiator performance/layout 55/45: gradient approx. 1.0

-Underfloor heating depending on laying: gradient below 0.5

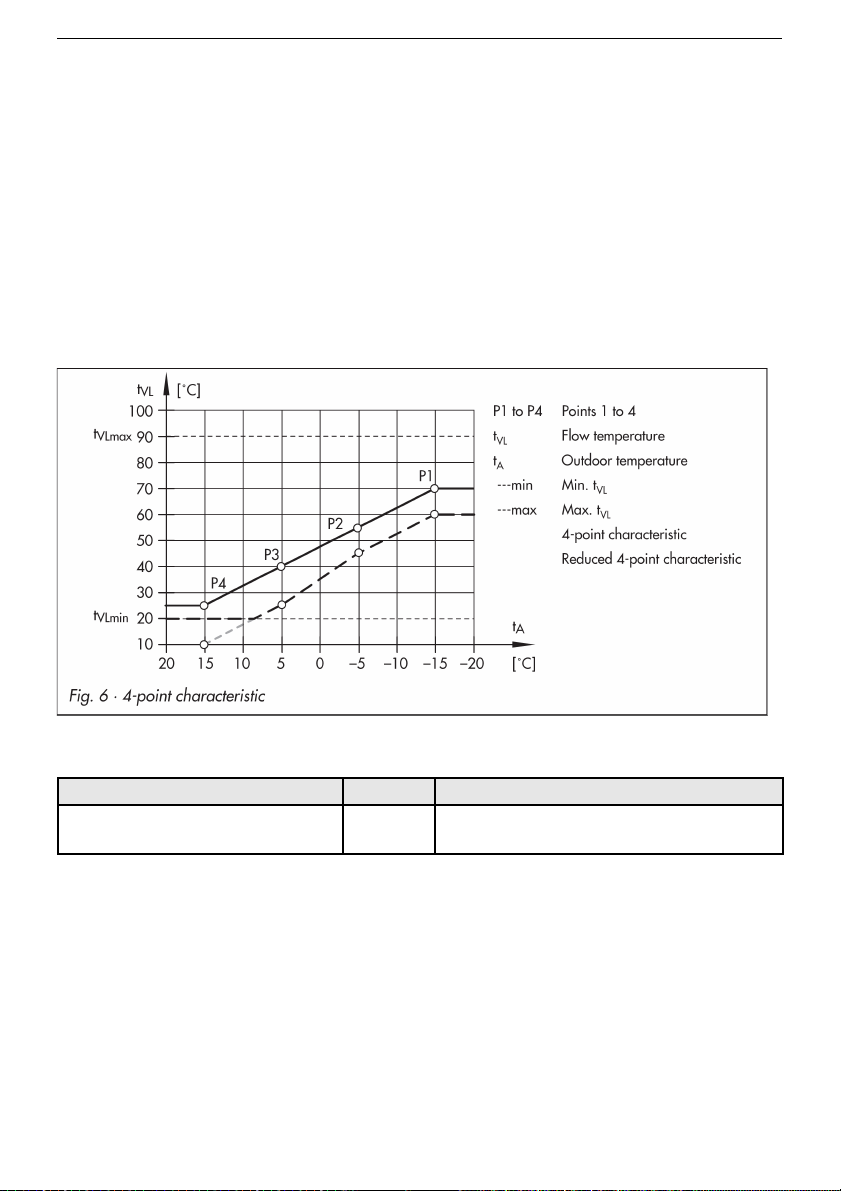

6.2.2 4-point characteristic

By means of the 4-point characteristic one can define its own heating characteristic. The

characteristic is determined by 4 points each of the outdoor temperature, the flow

temperature, the reduced flow temperature and the return flow temperature. The

parameters for maximum and minimum flow temperature limit the temperature up- and

downwards.

Functions FS Configuration

4-point characteristic

characteristic

0 CO1 -> F11 - 1

EB_37388_SOL3-7_EN001 57

Page 58

Installation and operating manual KT-Elektronik

Setting FS Parameter level / Value range

Outdoor temperature

Point 1 (P1)

Point 2 (P2)

Point 3 (P3)

Point 4 (P4)

–15 °C

–5 °C

5 °C

15 °C

PA1 / -40 to 50 °C

Flow temperature

Point 1 (P1)

Point 2 (P2)

Point 3 (P3)

Point 4 (P4)

70 °C

55 °C

40 °C

25 °C

PA1 / 5 to 130 °C

Reduced flow temp.

Point 1 (P1)

Point 2 (P2)

Point 3 (P3)

Point 4 (P4)

60 °C

40 °C

20 °C

20 °C

PA1 / 5 to 130 °C

Minimum flow temperature

PA1.06

20 °C PA1 / 5 to 130 °C

Maximum flow temperature

PA1.07

90 °C* PA1 / 5 to 130 °C

*for CO1 -> F05 -with value 1 applies to: Maximum flow temperature / 5 to 50 °C (50 °C)

6.3 3-point control

The flow temperature can be regulated by means of a PI algorithm. The valve responds to

impulses sent out by the controller in case of deviations. In particular, the length of the first

impulse depends on the size of the deviation and the boost KP (the impulse length grows

with increasing KP). The length of the impulse and the pauses in between change

continuously until the deviation is corrected. The pause duration mainly depends on the

reset time TN (pause duration increases with increasing TN). The valve transit time TY

specifies the time the valve needs to open or close from 0 to 100 %.

Functions FS Configuration

3-point control mode 1

2.0

120 s

0 s

45 s

CO1 -> F12 - 1

KP (boost) / 0.1 to 50.0

TN (reset time) / 1 to 999 s

TV (retention time) / Do not change value!

TY (valve transit time) / 5, 10, 15, , 240 s

58 EB_37388_SOL3-7_EN001

Note: The 4-point characteristic can only be activated as long as the function

adaptation is deactivated (CO1 -> F08 - 0).

Page 59

KT-Elektronik SOL3-7

6.4 Two-point control

The flow temperature can, for example, be controlled by switching a valve on and off. The