MT5000-0200-1 Rev f (10-2010) DCN0528

TABLE OF CONTENTS

1.0 Introduction ................................................................................................................................ 3

2.0 Overview .................................................................................................................................... 4

2.1 Storage and Handling Information ..................................................................................... 4

2.2 Ambient Temperature ........................................................................................................ 4

2.3 Description and Principle of Operation .............................................................................. 4

3.0 Installation .................................................................................................................................. 6

3.1 Mechanical Installation ....................................................................................................... 6

3.2 Shortening of the Probe ..................................................................................................... 7

3.3 Electrical Installation .......................................................................................................... 7

4.0 Commissioning .......................................................................................................................... 8

4.1 Display Operation ............................................................................................................... 8

4.1.1. Jumper Settings .................................................................................................... 9

4.1.2. Push Buttons ......................................................................................................... 9

4.2 MT5000 Menu Flow Chart .................................................................................................. 10

4.3 Basic Setup ........................................................................................................................ 11

4.3.1. Units ....................................................................................................................... 11

4.3.2. Probe Type ............................................................................................................. 11

4.3.3. Probe Length .......................................................................................................... 12

4.3.4. Mounting Type ....................................................................................................... 13

4.3.5. Nozzle Length ........................................................................................................ 14

4.3.6. Offset ...................................................................................................................... 14

4.3.7. Dielectric ................................................................................................................. 16

4.3.8. Measure Mode ....................................................................................................... 16

4.3.9. Language ............................................................................................................... 17

4.4 Quick Calibration ................................................................................................................ 18

4.5 mA Output Setup ................................................................................................................ 18

4.5.1. Output ..................................................................................................................... 19

4.5.2. LRV 4mA ................................................................................................................ 19

4.5.3. URV 20mA ............................................................................................................. 19

4.5.4. Dampening ............................................................................................................. 20

4.5.5. Alarm Delay ............................................................................................................ 20

4.5.6. DAC Trim (4mA and 20mA) ................................................................................... 21

4.5.7. LOOP Test ............................................................................................................. 21

4.5.8. HART Address ....................................................................................................... 22

4.5.9. LRS (HART version only) ...................................................................................... 22

4.6 Extended Setup .................................................................................................................. 23

4.6.1. Waveform Display .................................................................................................. 23

4.6.2. Functions ................................................................................................................ 25

4.6.3. Temperature ........................................................................................................... 26

4.6.4. Linearization Menu ................................................................................................. 27

4.6.5. SOR (HART version only) ...................................................................................... 31

5.0 Troubleshooting ......................................................................................................................... 32

5.1 Valid Current Loop Outputs ................................................................................................ 32

5.2 Symptoms and Solutions ................................................................................................... 32

5.3 Electronics Module Replacement ...................................................................................... 33

6.0 Installation Drawings for Intrinsic Safety & Standard Wiring ..................................................... 34

7.0 Installation Drawings for Explosion Proof.................................................................................. 36

8.0 CE Certificate of Conformity ...................................................................................................... 37

9.0 Customer Support ..................................................................................................................... 38

9.1 K-TEK RMA Form .............................................................................................................. 39

10.0 Warranty .................................................................................................................................. 40

MT5000-0200-1 Rev f (10-2010) DCN0528 2

1.0 INTRODUCTION

Thank you for using the K-TEK MT5000 Guided Wave Radar Liquid Level Transmitter. The MT5000 series is a

second generation of products which have been designed for simplicity of setup while offering extensive

configuration capabilities. You are invited and urged to review this instruction manual in its entirety prior to use of

the transmitter. This will eliminate most installation problems due to improper configuration.

We, the K-TEK Family, sincerely hope you receive many years of reliable use from the MT5000 transmitter and

welcome your feedback to consistently improve our all of our products. It is our desire to provide you, the user, with

the most reliable, customer friendly device to suit your application needs.

When it comes to measuring the level of liquids, guided wave radar technology now offers more level-detection

capabilities than ever before. For an ever-widening range of previously hard-to-measure products such as molten

sulfur, liquid ammonia and petrochemicals, guided wave radar transmitters provide accurate level measurements

even under harsh chemical environments, wide variations in operating temperatures and pressures, and low

dielectric constants. Great strides have also been taken in making these units easier to configure to a variety of process applications coupled with the simplicity of integrating these devices with most digital communication protocols.

These improvements come as a welcome relief to process engineers that seek solutions to measuring the contents

of tanks, silos, hoppers, bins, mixing basins, and vessels in an expanded range of level applications across several

different industries.

Because a guided wave radar transmitter has no moving parts, it has established itself as a level measurement

technology that has distanced itself from traditional mechanical means, which don't hold up as well in dirty service.

Guided wave radar achieves its non-mechanical level detection capability by measuring the time of flight of the

transmitted signal.

Known more accurately as Time Domain Reflectometry (TDR), the process involves:

1. Sending microwave energy down into a vessel guided by an antenna.

2. When the pulse of radar energy reaches the product (indicated by a change in impedance), part of the

pulse is reflected back toward the transmitter.

3. A receiver measures the exact duration of time between the transmitted and reflected signal—the "time

of flight."

4. The device analyzes this time and ultimately displays the level of the product as a distance in inches,

feet, meters, or other engineering units.

The MT5000 transmitter was developed with ease of operation in mind. We made use of a graphic display to provide a more user friendly aspect to the transmitter configuration. The graphic display allowed us to incorporate multiple language options in the setup menu such as English, Spanish and Chinese. In the incorporation of the graphic

display, the electronics were converted to a digital format. This provided a greater signal recognition capability

and an ability to include an ―onboard oscilloscope‖ as an aid in troubleshooting tough applications.

The emphasis on simplicity extended itself beyond the use of multiple languages. The Basic Setup menu has been

designed with a series of multiple choice questions which, when answered correctly, will configure the transmitter to

the installation. The mA Output Setup menu has been expanded to include Loop Test and HART® Address

capabilities.

Coupled with the development of the MT5000 series was the development of the KCOM™ software. KCOM™ is a

diagnostic tool which allows the MT5000 to be remotely configured using a computer and HART® interface modem.

Beyond the Basic Setup parameters, the software will allow the user to view the return signal of the MT5000 on the

computer screen. As a trouble shooting tool, a screen shot of the waveform may be taken and sent to the factory for

analysis. The KCOM™ software is free and may be downloaded from our website at www.ktekcorp.com.

For more information on the MT5000 series including liquid/liquid interface and bulk solids measurement visit our

website at www.ktekcorp.com.

MT5000-0200-1 Rev f (10-2010) DCN0528 3

2.0 OVERVIEW

2.1 Storage and Handling Information

If possible, storage prior to installation should be indoors at ambient temperature, not to exceed the following:

Temperature range: -40 to 150 degrees F.

Humidity: 0 to 100% R.H. non-condensing.

To avoid probe damage:

Do not transport or support the weight of the MT5000 by means of the probe.

Installation of rigid probes and flange mounted transmitters may require the use of lifting equipment.

Avoid sharp bending of cable probes which can result in poor instrument operation.

The lids on the MT5000 housing are sealed with o-rings. To avoid damage to the electronics, both lids should be

closed tightly before and after installation.

2.2 Ambient Temperature

The MT5000 electronics temperature may not exceed 170°F / 77°C. For higher ambient temperatures due to radiant

process heat, a high temperature extension option is required. The coupler process temperature shall not exceed

the temperature stated in the datasheet specifications for the given coupler.

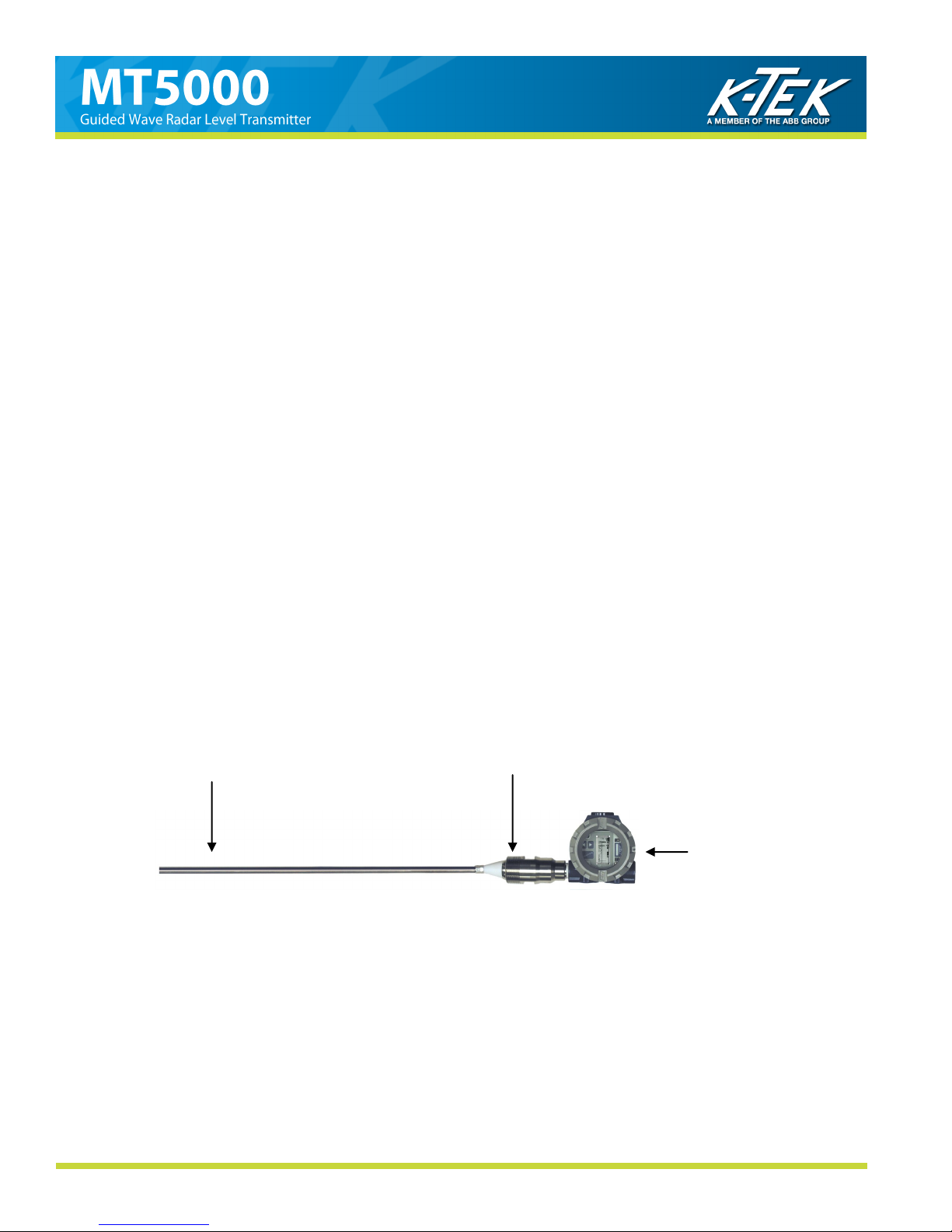

2.3 Description & Principle of Operation

The MT5000 is a 4-20mA loop powered Smart Level Transmitter, which is microprocessor based and is available

with HART® communication. It uses very low power microwave energy to determine the level of the product being

measured. In order to obtain optimum performance, it is important to understand the basic principle of operation. The

electronics housing is typically fitted with a special adapter ―Coupler‖ serving as a process connection and seal, and

holding a solid rod or a cable. The rod or cable ―Probe‖ hangs into the vessel and acts as a wave-guide, i.e. the

microwave energy stays concentrated around the probe and along its length, instead of being dispersed in a cone,

as it would be if there was no probe.

PROBE

COUPLER

HOUSING

MT5000-0200-1 Rev f (10-2010) DCN0528 4

A measurement cycle consists of the following:

1. A very short ―pulse‖ of microwave energy is applied at the cou-

pler, to the Probe.

2. The pulse travels along the length of the probe and when it encounters a discontinuity that is a dielectric constant change,

such as the product surface, some of the energy is reflected

and travels back towards the coupler.

3. When the reflected energy reaches the coupler, it is sensed by

the electronics. By measuring the time elapsed between the

initial pulse and the reflected one, the electronics can calculate the product level.

4. Since the microwave energy travels at the speed of light, one

complete measurement cycle is made up of several thousands

of Pulses. The electronics uses Time Domain Reflectometry

(TDR), a sampling technique to reconstruct a waveform duplicating the actual real time signal, but at a much lower speed, so

that it can be processed by the microprocessor. This process

can be compared to using the stroboscope effect as when observing a piece of machinery turning at high speed with a

strobe light.

5. The measurement cycles are made 2 times per second and

processed by special filtering techniques, before generating a

current output proportional to the level of the product.

5

1

4

2 3

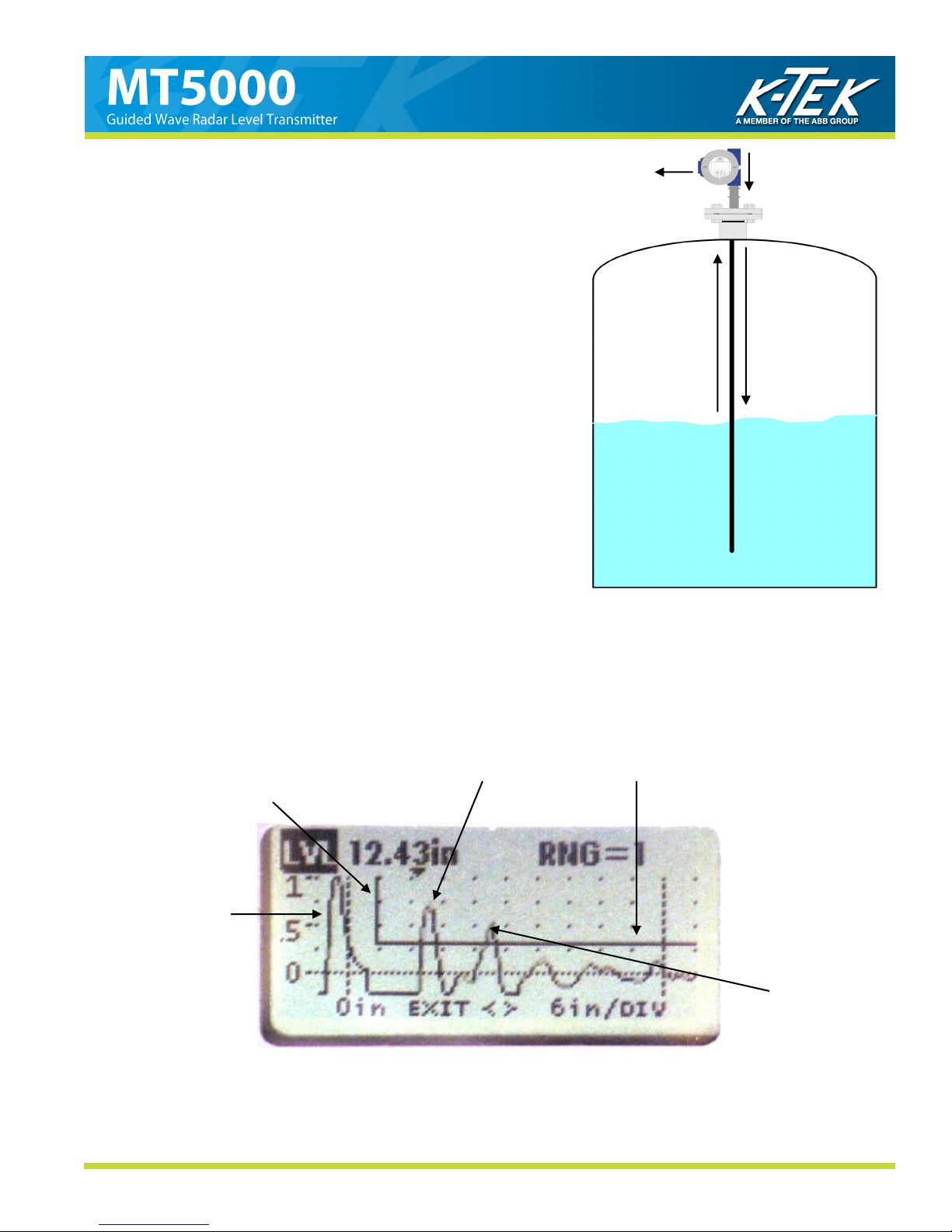

A simplified signal trace as seen on the graphic display (Figure 1) can be divided into three identifiable sections:

Coupler Reflection, Signal Reflection and End of Probe Reflection.

The measurement principle using TDR is based on the fact that a dielectric constant discontinuity or geometric

change will yield a positive pulse having certain amplitude above the baseline. The greater the dielectric constant

difference, the greater the positive amplitude of the return signal. This means that a signal will show up on the baseline if there is a substantial change from a nozzle diameter to an open tank, for example, as signal plot at the process connection. This fact will be taken into account in the configuration of the MT5000 (Consult Basic Setup

(Section 4.3) on Commissioning).

Signal Reflection

Threshold

Blanking

Coupler Reflection

End of Probe Reflection

Figure 1

Note: Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

MT5000-0200-1 Rev f (10-2010) DCN0528 5

3.0 INSTALLATION

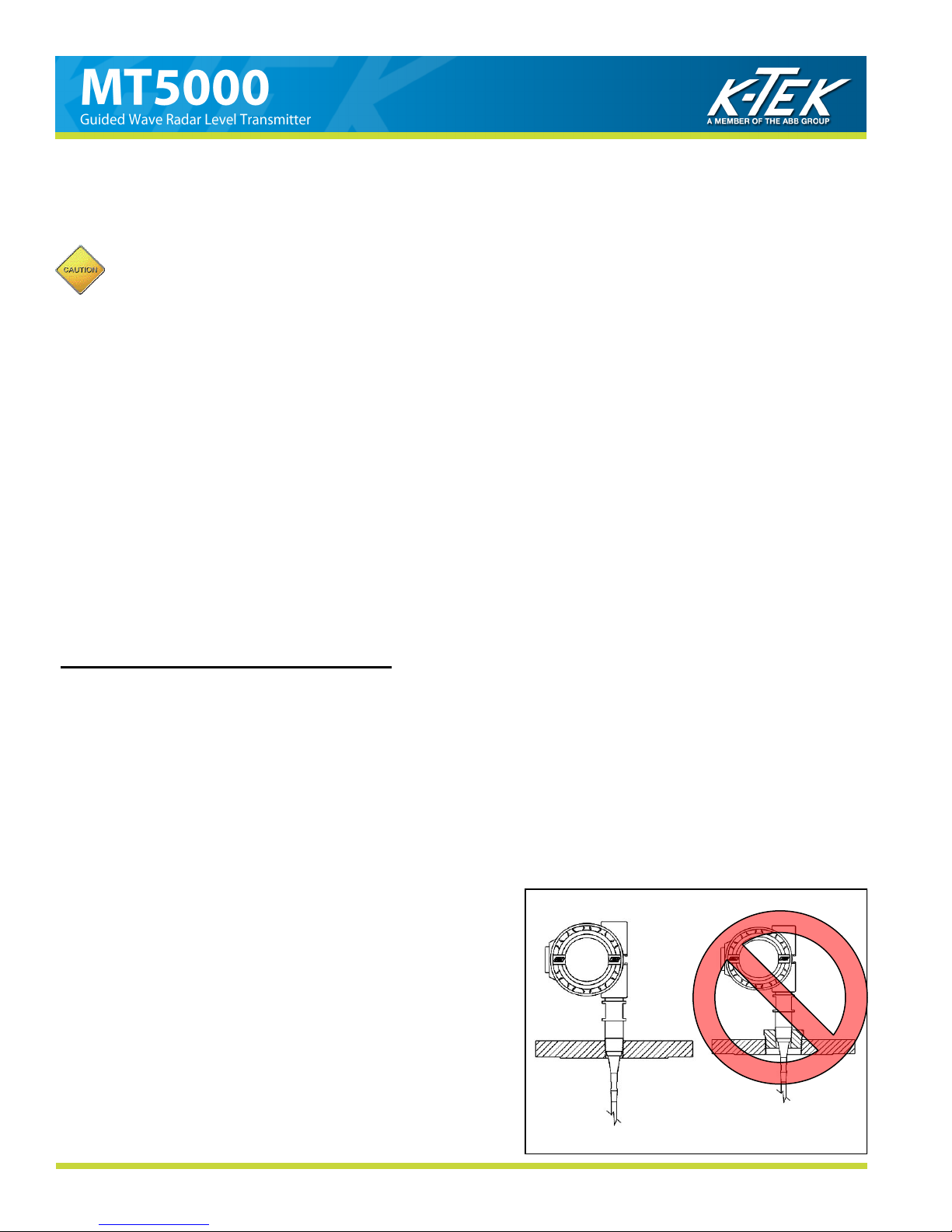

3.1 Mechanical Installation

Guidelines and Warnings for MT5000 installation:

Do not tamper or remove coupler from transmitter housing as this will damage the coupler.

All Installations

1. Do not mount the MT5000 in the product fill stream.

2. To obtain the best return signal from the product level mount the MT5000 coupler directly into the top of the vessel.

3. Do not mount MT5000 single probes using bushings. (Figure 2)

4. Ideally, probes should be mounted in the center of the vessel to provide the maximum measuring range.

5. Avoid internal obstructions such as tubing, ladders or agitators.

6. An MT5000 installed in a nozzle whose height is greater than its width will have an increased non-linear zone at

the top of the probe.

7. Cable probes with weights should be allowed to hang under the tension of the weight within the vessel. Shortening of the probe may be required.

8. To avoid excessive movement of the MT5000 probe in an agitated process, or where installation close to the

vessel wall is required, secure the bottom end of the probe to the vessel. Probes installed from top of the vessel

may require the use of a stilling well.

9. Probes installed in side vessel connections require additional probe support within the nozzle connection.

10. Threaded connections should be installed with thread sealant approved for use by the consumer. Flanged connections should be made using materials (bolts, studs, nuts, and gaskets) and procedures (torque specifications)

approved by the consumer.

Assembly Instructions for Loose Shipments:

At times, the rigid probe (i.e. P01 or P02) or flexible cable (i.e. P11 or P12) will be shipped as a loose (separate) assembly. In this case, an identification tag will be attached to the probe/cable to identify the serial number/transmitter

it is associated with.

1. Locate the top end of the probe/cable that has a threaded FNPT connection.

2. Locate the bottom end of the transmitter coupler that has a threaded MNPT connection.

3. Apply LOCTITE 222MS to the MNPT connection.

4. Fasten the probe/cable hand tight to the MNPT connection and allow this to cure for 15 minutes.

5. Ready for installation.

Plastic Tanks, Fiberglass Tanks, and Open Air Installations

1. Single probe units require the use of a metal mounting flange or plate to launch the microwave energy down

length of the probe. A minimum 6 inch (150mm) OD, 3/8 inch (10mm) thick plate should be used.

2. A MT5000 installed in a non-metallic vessel or open air environment will be subject to interference from other electromagnetic devices such as radios. Stilling wells may be required to

eliminate this interference.

Concrete Tanks

1. Tanks constructed of concrete require probe mounting be:

1 ft. / 0.3 m from wall with up to 20 ft. / 6.1 meter measuring length

2 ft. / 0.61 m from wall over 20 ft. / 6.1 meter measuring

length

2. Single probe units require the use of a metal mounting flange

or plate to launch the microwave energy down length of the

CORRECT

Figure 2

NOT

RECOMMENDED

MT5000-0200-1 Rev f (10-2010) DCN0528 6

3.2 Shortening of Probe

The MT5000 single rod and cable probe can be cut to length prior to installation. If shortening of the probe is necessary, cut the rod or cable to the desired length using a hacksaw.

Shortening of coaxial probes in the field is not recommended.

The centering disc or weight at the end of the probe must be reattached for proper operation.

The Probe Length parameter in the Basic Setup menu will need to be adjusted for the new probe length.

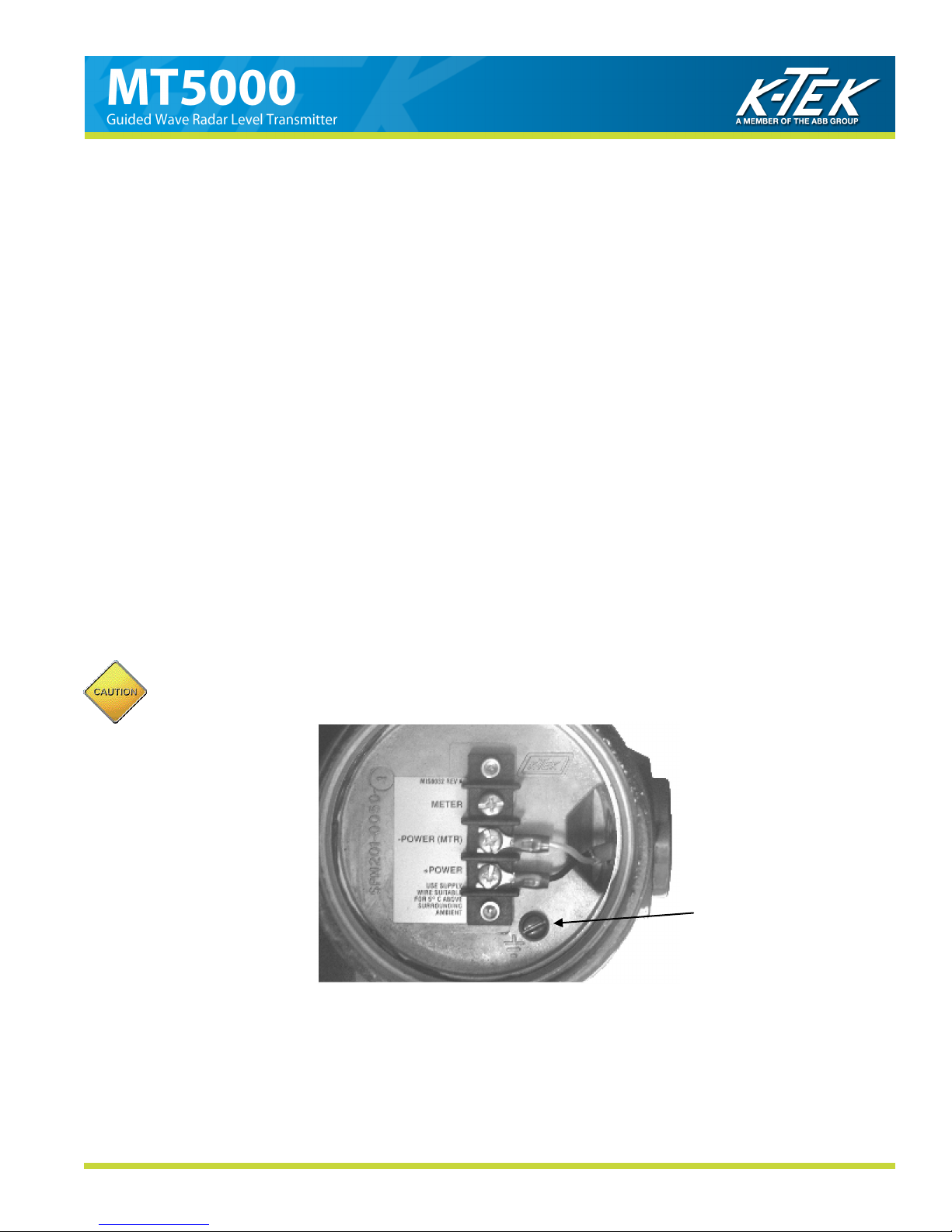

3.3. Electrical Installation

Electrical connection to the MT5000 should approach the transmitter head from below the conduit opening to provide

a drain for moisture. Install conduit to ½‖ NPT port and run 18 gauge twisted, shielded pair to housing. Refer to Sec-

tion 4 wiring diagram ELE1015 for typical loop wiring diagram and to ELE1014 for instructions applicable to intrinsic

safety installation.

Apply loop power to the transmitter as follows:

Terminal Block + 14 VDC minimum to 36 VDC Maximum

Terminal Block - To control System Input

Ground Screw GROUND

Note: The ―+Meter‖ and ―-Meter‖ terminals are available to hook up a mA meter to monitor loop current, without

breaking the loop.

The housing cover can only be removed when the unit is installed in a non-hazardous area, when installed with intrinsic safety barrier, or when power is removed from the transmitter.

Ground

Screw

MT5000-0200-1 Rev f (10-2010) DCN0528 7

4.0 COMMISSIONING

The MT5000 transmitter has been designed with a simple easy to follow setup menu. To make this unit operational,

at a minimum, the items in the BASIC SETUP menu must to be entered. If further setup is required, a Quick Calibration may be used or additional menu items will need to be entered.

4.1 Display Operation

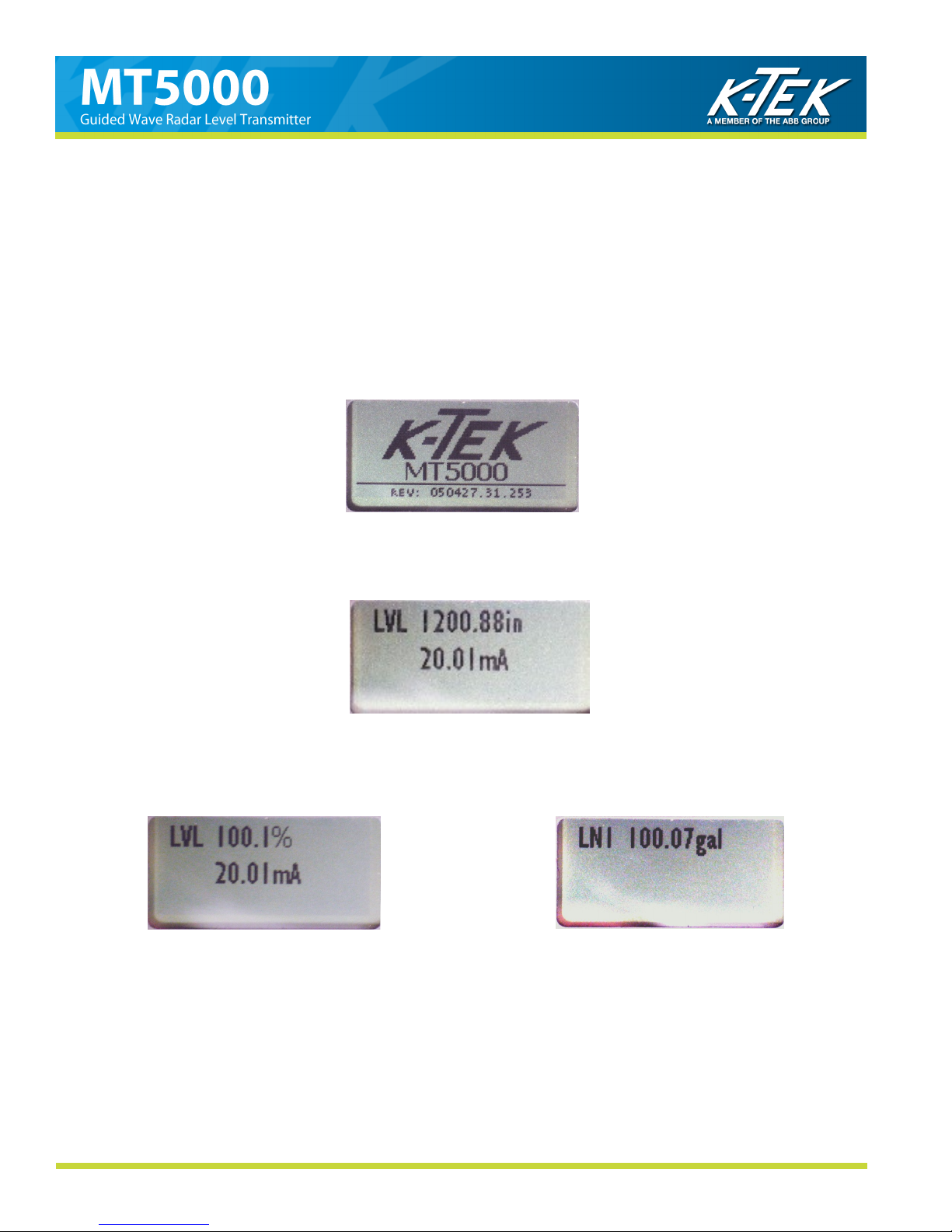

When power is applied to an MT5000 series transmitter, the display will light up with a title screen which shows the

model type and the software revision. (Figure 4) This initial power up cycle will last for 3 seconds and the current

output of the transmitter will hold at 4.00 mA.

Figure 4

After the initial power up cycle, the display will change to show the Measured Level and the Current Output. The

output will also shift to the current corresponding to the level. (Figure 5)

Figure 5

By pushing the UP or Down button, the main display can be scrolled to display the level in terms of a percentage of

calibrated range (Figure 6) or in terms of a linearized / strapped measurement. (Figure 7).

Figure 6 Figure 7

MT5000-0200-1 Rev f (10-2010) DCN0528 8

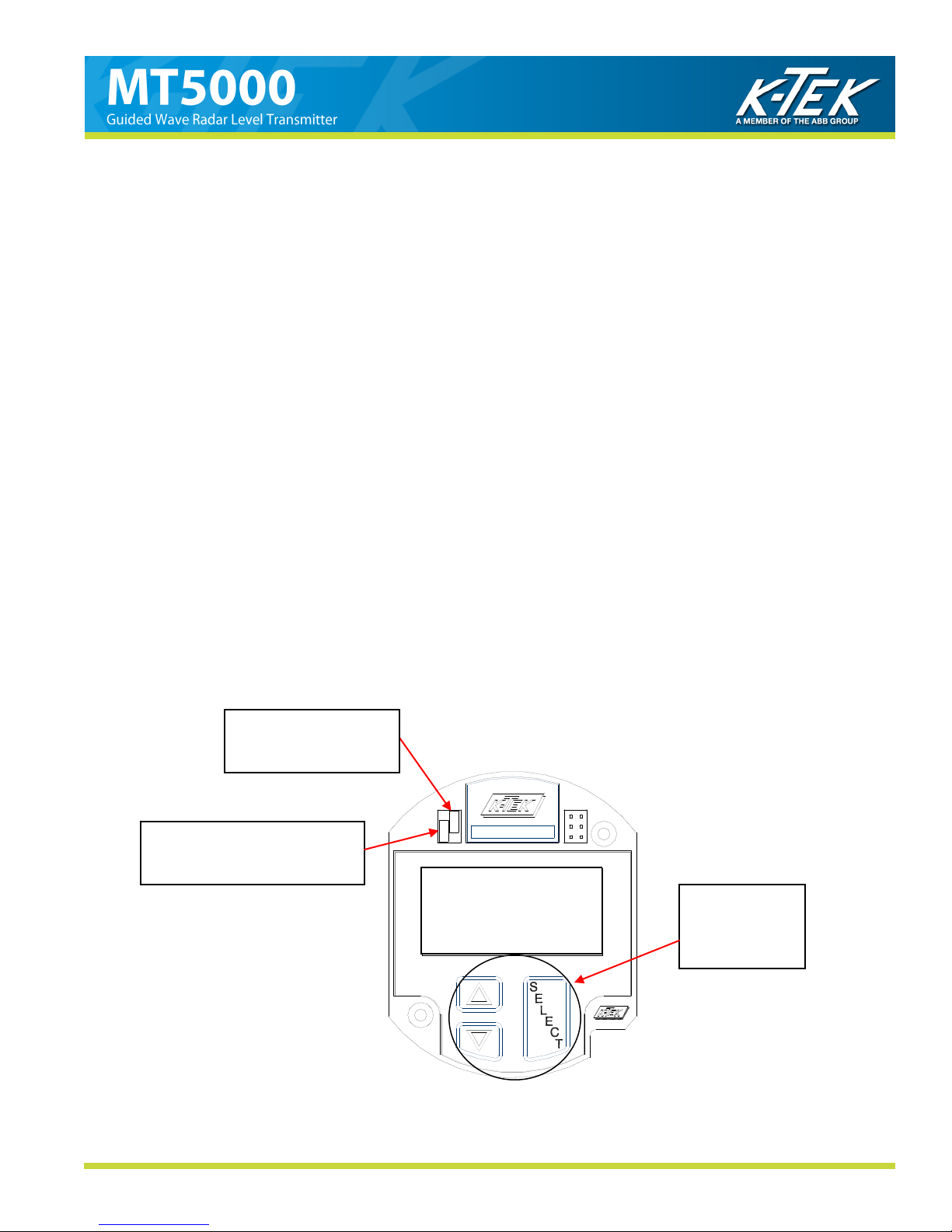

4.1.1. JUMPER SETTINGS

The jumper switches are located on the face of the electronics module and can be set up as follows (Figure 8).

ALARM (Left Jumper)

Placing the jumper to the lower position causes the output to go to 21.00 mA when there is a loss of signal or transmitter malfunction.

Placing the jumper to the upper position causes the output to go to 3.62 mA when there is a loss of signal or transmitter malfunction.

The alarm output works in conjunction with the ALARM DELAY setting available in the mA OUTPUT menu. The output will go to alarm state only if there is a loss of signal that lasts at least the duration of the alarm delay. The alarm

delay default value is two seconds. For instance the output will hold the last measured value if there is a loss of signal lasting less than two seconds and will go into the alarm condition if the loss signal exceeds two seconds.

WRITE PROTECT (Right Jumper)

When the jumper is in the lower position the transmitter configuration cannot be changed manually or via HART®

communication. (Figure 8).

Placing the jumper in the upper position will allow the configuration parameters to be changed manually or via

HART® communication. (Figure 8).

4.1.2. PUSHBUTTONS

Three pushbuttons are located on the lower portion of the module faceplate (Figure 8). These buttons will be used

to navigate through the setup and configuration menu of the MT5000. Some operations will require the pushbuttons

to be used together or held for a period of time to affect a change.

Write Protect Jumper:

UP = OFF

DOWN = ON

Fault Jumper:

UP = Fail Low = 3.6 mA

DOWN =Fail High = 21.00 mA

Figure 8

LVL XX.XX in

XX.XX mA

Pushbuttons:

UP

DOWN

SELECT

MT5000-0200-1 Rev f (10-2010) DCN0528 9

4.2 MT5000 Menu Flow Chart

LVL: XXXX.XX”

XX.XX mA

S

BASIC SETUP

LVL: XX.XX in XX.XX mA

S S S

UNITS

inches

LVL: XX.XX in XX.XX mA

PROBE TYPE

Single Rod / Cable

LVL: XX.XX in XX.XX mA

PROBE LENGTH

XX.XX in

LVL: XXXX.XX “ XX.XX mA

MOUNTING TYPE

Plate

LVL: XX.XX in XX.XX mA

NOZZLE LENGTH

XX.XX in

LVL: XX.XX in XX.XX mA

OFFSET

XX.XX in

LVL: XX.XX in XX.XX mA

DIELECTRIC

XX.XX

LVL: XX.XX in XX.XX mA

MEASURE MODE

Media Level

LVL: XX.XX in XX.XX mA

LANGUAGE

English

LVL: XX.XX in XX.XX mA

LVL XXX.X%

XX.XX mA

mA OUTPUT SETUP

LVL: XX.XX in XX.XX mA

OUTPUT

Level

LVL: XX.XX in XX.XX mA

LRV 4mA

XX.XX in

LVL: XX.XX in XX.XX mA

URV 20mA

XX.XX in

LVL: XX.XX in XX.XX mA

DAMPING

X.X sec

LVL: XX.XX in XX.XX mA

ALARM DELAY

XX sec

LVL: XX.XX in XX.XX mA

4mA DAC TRIM

LVL: XX.XX in XX.XX mA

20mA DAC TRIM

LVL: XX.XX in XX.XX mA

LOOP TEST

LVL: XX.XX in XX.XX mA

HART ADDRESS

XX

LVL: XX.XX in XX.XX mA

LRS

3.85 mA

LVL: XX.XX in XX.XX mA

LNI XX.XX gal

EXTENDED SETUP

LVL: XX.XX in XX.XX mA

WAVEFORM AT

COUPLER

LVL: XX.XX in XX.XX mA

WAVEFORM AT

LVL

LVL: XX.XX in XX.XX mA

WAVEFORM AT

XXXX in

LVL: XX.XX in XX.XX mA

WAVEFORM AT

END OF PROBE

LVL: XX.XX in XX.XX mA

TEMPERATURE

XXX.X F/C

LVL: XX.XX in XX.XX mA

LINEARIZATION

MENU

LVL: XX.XX in XX.XX mA

SOR

LVL: XX.XX in XX.XX mA

LRM*

LVL: XX.XX in XX.XX mA

END MENU

LVL: XX.XX in XX.XX mA

NAVIGATION

SELECT

S

button

S

S

S

S

Section 4.6.4

S

* Used only if SOR is set to ALARM.

UP or DOWN

button

END MENU

LVL: XX.XX in XX.XX mA

END MENU

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 10

Pressing the SELECT button at each END MENU

will return to the MAIN DISPLAY.

4.3 BASIC SETUP

BASIC SETUP is a menu of items that are used to adapt the internal settings of the MT5000

to a particular application. Certain fields are required entry items and will be needed for

proper operation of the device. Other entry items are not used for the setup of the transmitter

and are listed as optional. At a minimum, the items in the BASIC SETUP menu will need to

be entered for the MT5000 to operate. BASIC SETUP menu items include the PROBE

TYPE, PROBE LENGTH and MOUNTING TYPE.

From the main display, press the SELECT button to access the items in the BASIC SETUP

menu.

4.3.1. UNITS

This function will allow the user to select the UNIT of measure for the process variable of the

unit and provide a basis for all of the setup functions. Selectable engineering UNITS include:

inches, feet, meters, millimeters and centimeters.

To select the required unit of measure:

1. Press the SELECT button.

2. Scroll UP or DOWN to the desired measurement unit.

3. Press the SELECT button to set the new UNIT.

4. Scroll UP to END MENU.

5. Pressing the SELECT button now will return you to the main screen.

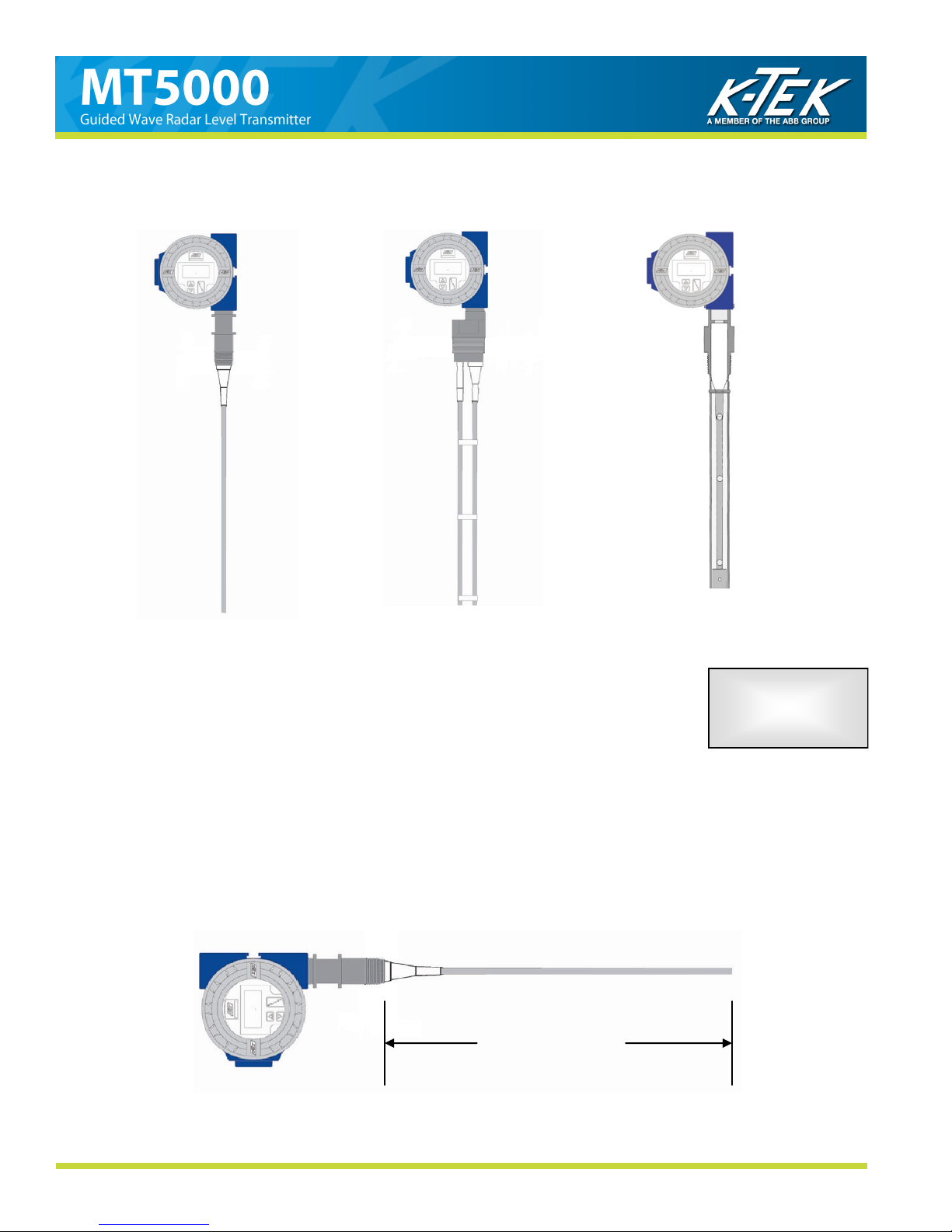

4.3.2. PROBE TYPE

This function will help adjust the transmitter setting for the installed configuration. Certain

aspects of the transmitter setup will be adjusted to the probe type entered in this location.

Selectable probe types include: Single Rod/Cable, Dual Rod/Cable or Coaxial. Select only

the type of probe included with the MT5000 transmitter. Failure to set the actual probe type

could result in measurement errors.

To set the PROBE TYPE:

1. Press and hold the SELECT button for two seconds.

2. Scroll UP or DOWN to the PROBE TYPE as it corresponds to Figure 9 on the following

page.

3. Press the SELECT button to set the new PROBE TYPE.

4. Scroll UP to END MENU.

5. Pressing the SELECT button now will return you to the main screen.

BASIC SETUP

LVL: XX.XX in XX.XX mA

UNITS

inches

LVL: XX.XX in XX.XX mA

PROBE TYPE

Single Rod / Cable

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 11

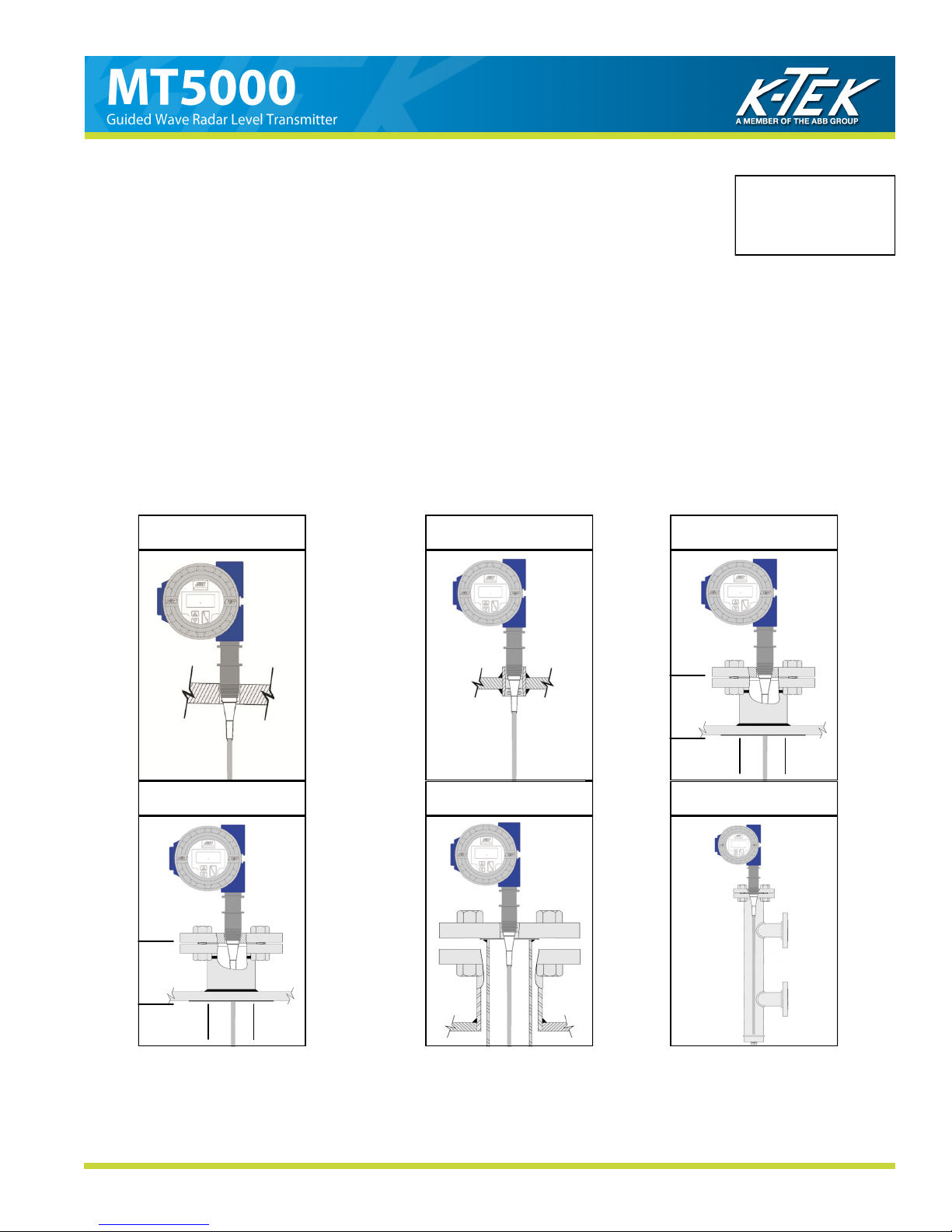

Figure 9

Single Rod/Cable Dual Rod/Cable Coaxial

4.3.3. PROBE LENGTH

Also described as insertion length, PROBE LENGTH is defined as the measured distance

from the first thread of the coupler (or the face of the flange) to the end of the probe. This

value must be entered in units that correspond to the UNITS of the process variable.

To set the PROBE LENGTH:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to set each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new PROBE LENGTH.

5. Scroll UP or DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

Figure 10

Probe Length

PROBE LENGTH

XX.XX in

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 12

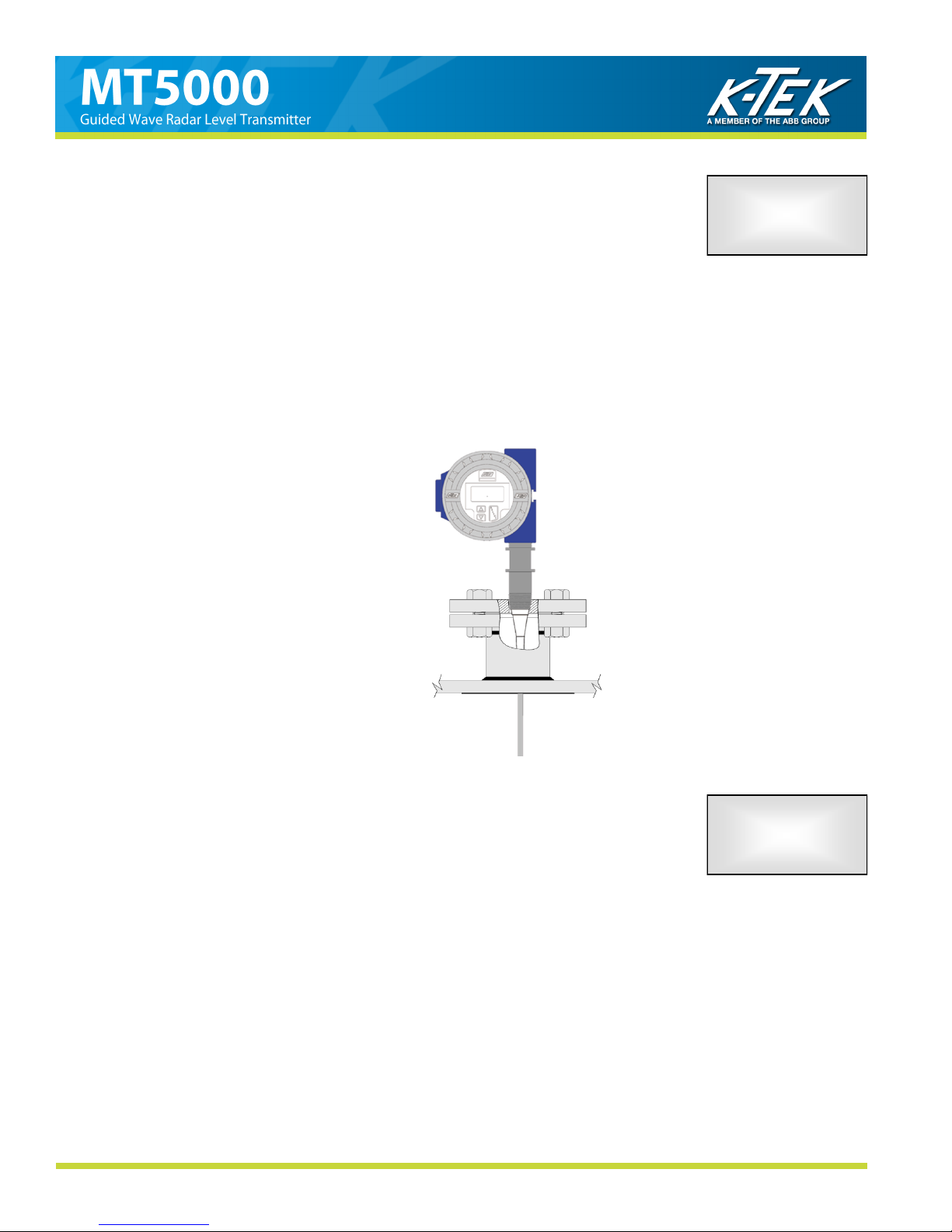

4.3.4. MOUNTING TYPE

Different mounting configurations will affect each probe type in different ways. A coupler

mounted on a nozzle whose length is greater than its width will have a reduced signal capacity that must be accounted for by the MT5000. In order to help maximize the range ability of the MT5000, the MOUNTING TYPE corresponding to the installation must be entered.

The MOUNTING TYPE should fall into one of the categories listed below. (Figure 11)

To set the MOUNTING TYPE:

1. Review the installation and determine which class of mounting configuration the unit

will be installed in.

2. Press and hold the SELECT button for 2 seconds.

3. Scroll UP or DOWN to the required MOUNTING TYPE.

4. Press the SELECT button to set the new MOUNTING TYPE.

5. Scroll DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen

Figure 11

MOUNTING TYPE

Plate

LVL: XX.XX in XX.XX mA

Plate

Coupling / Plate Nozzle/Flange H>S

H

Nozzle/Flange H<S Stilling Well Ext. Chamber

H

S

S

MT5000-0200-1 Rev f (10-2010) DCN0528 13

4.3.5. NOZZLE LENGTH

In this selection you will enter the length of the mounting nozzle from the face of the coupler to the top of the tank. Transmitters with a Mounting Type of Plate will have a Nozzle

Length of 0. This entry will tell the transmitter to ignore any reading within the nozzle area.

(Figure 12)

To enter the NOZZLE LENGTH:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to set each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new NOZZLE LENGTH.

5. Scroll UP or DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

Figure 12

NOZZLE LENGTH

XX.XX in

LVL: XX.XX in XX.XX mA

Nozzle Length

4.3.6. OFFSET

Offset is a value in engineering UNITS which may be entered to compensate for an unmeasureable area below a probe or to align the measurement of the MT5000 with another

device. The value entered in the Offset will be Added to or subtracted from the LVL indication on the main display. (Figure 13)

To enter the LVL OFFSET:

1. Press the SELECT button.

2. Scroll UP or DOWN to set each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new LVL OFFSET.

5. Scroll DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

OFFSET

XX.XX in

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 14

Example:

If the end of the probe, in Figure 13, were 4 inches

off the bottom of the tank the Offset would be 4

inches. If the Measured Level were 21 inches after

entering the OFFSET, the local indicator would

indicate 25 inches (21 +4) and the 4-20 mAdc signal

would indicate a level of 25 inches.

Figure 13

Measured

Level

LVL OFFSET

MT5000-0200-1 Rev f (10-2010) DCN0528 15

4.3.7. DIELECTRIC (OPTIONAL)

The DIELECTRIC setting is an optional entry. It is not used to set or establish any

operating parameters within the unit. It will not be necessary to know the exact dielectric constant of the process or to enter a valid value in this setting.

To enter the DIELECTRIC:

1. Press and hold the SELECT button.

2. Scroll UP or DOWN to set each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the DIELECTRIC.

5. Scroll UP or DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main display.

4.3.8. MEASURE MODE

The MT5000 can be used to measure Media Level or Ullage. Media Level refers to a

Level Measurement from the end of the probe to the surface of the liquid level that is

measuring the amount of liquid in the tank. Ullage refers to a Level Measurement

from the face of the coupler to the surface of the liquid that is measuring the amount

of vapor space in the tank. From the factory the MEASURE MODE will be Media

Level.

To select the MEASURE MODE:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to change the MEASURE MODE between Media Level and Ullage.

3. Press the SELECT button.

4. Scroll DOWN to END MENU.

5. Pressing the SELECT button now will return you to the main display.

DIELECTRIC

XX.XX

LVL: XX.XX in XX.XX mA

MEASURE MODE

Media Level

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 16

Figure 14

0%

ULLAGE

MEDIA

LEVEL

0%

4.3.9. LANGUAGE

The MT5000 has been equipped with several different operating languages to assist in the

setup of the unit. When a specific language is selected, the titles of the menu items will be

translated. Abbreviations specific to the MT5000 will remain unchanged as icons regardless

of language selection.

Available LANGUAGES include:

English

French

Spanish

Portuguese

Italian

Russian

Chinese (Mandarin)

To change the menu LANGUAGE:

1. Press the SELECT button.

2. Scroll UP or DOWN to find the new LANGUAGE.

3. Press the SELECT button to set the new LANGUAGE.

4. Scroll DOWN to END MENU.

5. Pressing the SELECT button now will return you to the main screen.

LANGUAGE

English

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 17

4.4 QUICK CALIBRATION

Note to User

After the BASIC SETUP menu items have been entered, the MT5000 will be operational. The 4 milliamp output point

of the transmitter will be set at the 0 measurement point and the 20 milliamp point will be set at the highest measured value. The location of the 4 and 20 milliamp points will be determined by the Measurement Mode. If the probe

is measuring the level of the process accurately but is not returning the desired milliamp output, it is possible to

quickly recalibrate the MT5000 based on the measured level from the transmitter.

Procedure

Setting the 4 milliamp output.

1. Raise or lower the liquid level to the desired 4 milliamp point.

2. Press the UP and DOWN buttons on the MT5000 at the same time.

3. Press the DOWN button to set the 4 milliamp point.

Setting the 20 milliamp output.

1. Raise or lower the liquid level to the desired 20 milliamp point.

2. Press the UP and DOWN buttons on the MT5000 at the same time.

3. Press the UP button to set the 20 milliamp point.

The MT5000 will now be fully operational. If a further detailed setup is required you may proceed to the mA OUTPUT menu, or the Extended Setup menu. If the output of the MT5000 is required to match that of another device, the

following alternate procedure may be used.

Setting the 4 milliamp output.

1. Raise or lower the liquid level to the 4 milliamp point of the primary transmitter.

2. Press the UP and DOWN buttons on the MT5000 at the same time.

3. Press the DOWN button to set the 4 milliamp point.

Setting the 20 milliamp output.

1. Raise or lower the liquid level to the 20 milliamp point of the primary transmitter .

2. Press the UP and DOWN buttons on the MT5000 at the same time.

3. Press the UP button to set the 20 milliamp point.

4.5 mA OUTPUT SETUP

The mA OUTPUT SETUP is a menu of items used to control the output signal from the

MT5000. In this menu you will find entries for the 4mA point, 20mA point and Damping

along with other output related items.

To access the items in the mA OUTPUT SETUP menu from the main display:

1. Press the SELECT button.

2. Scroll DOWN to mA OUTPUT SETUP

3. Press the SELECT button.

MT5000-0200-1 Rev f (10-2010) DCN0528 18

mA OUTPUT SETUP

LVL: XX.XX in XX.XX mA

4.5.1. OUTPUT

OUTPUT is a function which allows the user to determine which variable the mA OUTPUT of the MT5000 will be based upon. Selections for OUTPUT are Level and LIN

Level. Level is the actual linear measurement the MT5000 is interpreting from its configuration. LIN Level is the measurement of the MT5000 as it is filtered through the LINEARIZATION TABLE (Section 4.6.4.)

To access the items in the mA OUTPUT SETUP menu from the main display:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to the desired OUTPUT variable.

3. Press the SELECT button to set the new OUTPUT.

4. Scroll UP to END MENU.

5. Pressing the SELECT button now will return you to the main screen.

4.5.2. LRV 4mA

OUTPUT

Level

LVL: XX.XX in XX.XX mA

LRV 4mA is a value in engineering UNITS which determines at which measured value

the MT5000 will generate a mA OUTPUT of 4.00mA. Traditionally this is known as the

zero point. From the factory the LRV 4mA will be set to 0.00 inches.

To enter the LRV 4mA:

1. Press the SELECT button.

2. Scroll UP or DOWN to select each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new LRV 4mA.

5. Scroll UP to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

4.5.3. URV 20mA

URV 20mA is a value in engineering UNITS which determines at which measured value

the MT5000 will generate a mA OUTPUT of 20.00mA. Traditionally, this is known as the

span point. From the factory the URV 20mA will be set to the PROBE LENGTH.

To enter the URV 20mA:

1. Press the SELECT button.

2. Scroll UP or DOWN to select each digit.

3. Press the SELECT button to set the digit and move to the next digit in

sequence.

4. After the last digit is set, press the SELECT button to set the new URV

20mA.

5. Scroll UP to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

LRV 4mA

00.00 in

LVL: XX.XX in XX.XX mA

URV 20mA

000.00 in

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 19

4.5.4. DAMPING

Figure 15

Typical Settings for Range Values

URV 20mA =

Probe Length MEDIA LEVEL 0 inches

0 inches ULLAGE Probe Length

MEASURE MODE = LRV 4mA =

DAMPING is a setting designed to delay the mA OUTPUT response to a change in

measured level. It is a value set in seconds at .5 second intervals. If the process is agitated or splashing of the liquid is possible, a higher DAMPING value may be required. If

the process changes rapidly, a lower DAMPING value may be needed to increase the

response time to a level change. The highest DAMPING allowable is 36 seconds.

To change the DAMPING:

1. Press the SELECT button.

2. Scroll UP or DOWN to select each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

(The last digit will scroll between .0 and .5)

4. After the last digit is set, press the SELECT button to set the new DAMPING.

5. Scroll UP or DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

4.5.5. ALARM DELAY

If the MT5000 does not pick up a return signal crossing the threshold it will return an

ALARM signal (Section 4.1.1) In an application where the surface of the product may be

subject to a change in physical state (such as flashing,) the return signal from the product

will appear and disappear as the product boils. To prevent the mA OUTPUT from spiking

to ALARM in these conditions, an ALARM DELAY may be set. This delay time will allow

the MT5000 to hold the last good value it received for a given time before returning an

alarm indication. From the factory the ALARM DELAY will be set to 2 seconds.

To enter the ALARM DELAY:

1. Press the SELECT button.

2. Scroll UP or DOWN to select each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new ALARM DELAY.

5. Scroll DOWN to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

DAMPING

0.5 sec

LVL: XX.XX in XX.XX mA

ALARM DELAY

2 sec

LVL: XX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 20

4.5.6. DAC TRIM

The MT5000 is designed as a 2 wire loop powered device. It will generate a mA OUTPUT

over a range of 3.61 to 21.00 mA. When an MT5000 is calibrated at the factory, the output

of the unit will be set to correspond to a calibrated multi-meter. The exact output is set using the DAC TRIM function. When an MT5000 is installed and wired, the field wiring and

other loop components may affect the mA OUTPUT that is received at the point of control.

The DAC TRIM will be used to compensate for the loop components and allow the point of

control to receive a true 4 and 20 mA.

To adjust either the 4 or 20 mA DAC TRIM:

1. A means of measuring the current output must be established in the control loop.

2. Scroll to the desired function.

3. Press and hold the SELECT button for 2 seconds. (the output will change to what the

transmitter interprets as 4 or 20 mA.)

4. Using the SELECT, UP and DOWN buttons to enter the measured current value.

5. Press the SELECT button to set each digit and move to the next digit in sequence.

6. After the last digit is set, the mA OUTPUT will adjust to exactly 4 or 20 mA.

7. Scroll DOWN to END MENU.

8. Pressing the SELECT button now will return you to the main screen.

4.5.7. LOOP TEST

LOOP TEST is a function designed to simulate transmitter output at various levels and

confirm readings from a separate location. The LOOP TEST may be performed at any mA

OUTPUT between 3.61 and 21.00.

To perform a LOOP TEST:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to select each digit for the desired mA OUTPUT.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set the mA OUTPUT will change to the desired level. (Another

mA OUTPUT may be selected by repeating steps 1 through 4.)

5. Scroll DOWN to END MENU. (The mA OUTPUT will return to normal operation after

pushing the DOWN arrow)

6. Pressing the SELECT button now will return you to the main screen.

4mA DAC TRIM

LVL: XX.XX in XX.XX mA

20mA DAC TRIM

LVL: XXXX.XX “ XX.XX mA

LOOP TEST

LVL: XXXX.XX “ XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 21

4.5.8. HART ADDRESS

HART ADDRESS is a selection which will allow the user to assign a numerical address to the MT5000. Setting the address of the unit will allow the MT5000 to be

HART ADDRESS

XX

polled when installed in a string of transmitters. The HART ADDRESS may be set

to any number from 0 to 15. As a default value, the MT5000 is set with an address

LVL: XX.XX in XX.XX mA

of 0. This allows the MT5000 to operate normally. If an address other than 0 is set

in the MT5000, the mA output of the transmitter will hold at 4.00mA and the measured level will continue to operate as normal.

To enter a HART ADDRESS:

1. Press and hold the SELECT button for 2 seconds.

2. Scroll UP or DOWN to set each digit.

3. Press the SELECT button to set the digit and move to the next digit in sequence.

4. After the last digit is set, press the SELECT button to set the new PROBE

LENGTH.

5. Scroll UP to END MENU.

6. Pressing the SELECT button now will return you to the main screen.

NOTE: For more information on HART® communications and addressing visit www.hartcomm.org.

4.5.9. LRS (HART VERSION ONLY)

Low Range Saturation is the lowest current output that the transmitter can attain in normal operation (not

in alarm condition), regardless of the actual measurement value. The LRS limit has no effect on the ―Fail

Low‖ alarm current (3.60mA if selected) with the Fail Hi/Lo jumper position on the face of the module.

Should the transmitter lose its echo, the transmitter will immediately enter its low alarm state (no damping

effect) of 3.60mA. LRS has two selections:

3.85 sets 3.85mA as the low limit for the mA signal. As the level decreases below the LRV, the output

current will change proportionally, down to the limit.

4.0 sets 4.0mA as the low current limit from the transmitter, preventing a ―negative‖ level in the control

system.

MT5000-0200-1 Rev f (10-2010) DCN0528 22

4.6 EXTENDED SETUP

EXTENDED SETUP is a menu containing features designed to fine tune the operation of

the MT5000. This menu contains WAVEFORM options which allow access to a graphic

representation of the return signal and a LINEARIZATION MENU.

To access the items in the EXTENDED SETUP menu from the main display:

1. Press the SELECT button.

2. Scroll DOWN to EXTENDED SETUP.

3. Press the SELECT button.

EXTENDED SETUP

LVL: XX.XX in XX.XX mA

4.6.1. WAVEFORM DISPLAY

The first four menu options in the EXTENDED SETUP, will allow access to a graphic display of the return signal

from the sensor of the MT5000. Each of these WAVEFORM screens has the same configuration and will allow access to the same functions. Figure 4.6.1. outlines the features of the WAVEFORM screens.

Figure 16

Return Signal

a. Measured Level or

Raw Counts at

Blanking

End of Probe

d. Access to

Functions

b. Volts DC

c. Reference

Measurement

h. Return to

EXTENDED

g. Signal

Threshold

Voltage

e. Measurement

Per Division

f. Scroll

Left or

MT5000-0200-1 Rev f (10-2010) DCN0528 23

After entering each of the WAVEFORM screens you may navigate through them by using the UP and DOWN buttons. To make adjustment to an item, highlight the item and press the SELECT button. Certain functions will require

holding the SELECT button for 2 seconds to enter the field. Functions on the WAVEFORM screen will only affect the

appearance of the graphic display not the operation of the MT5000.

a. Measured Level / Raw Counts - Displays the Media Level or Ullage as determined by the transmitter. Press-

ing the SELECT button here will scroll this portion of the display between the Measured Level and the Raw

Counts at the Measured Level.

b. Volts DC - Scaling of the graphic display from 0 to 1 VDC. The return signal will rise up from 0 volts towards 1

volt.

c. Reference Measurement - The dotted vertical line to the left of the display provides a reference measurement

for the WAVEFORM. The measured value at this dotted line will be displayed in the bottom left hand portion of

the screen and provide a starting point for determining the position of the signal. Regardless of the MEASURE

MODE, reference measurements are made from the face of the coupler or the mounting flange.

d. Access to Functions - This section will allow entry to separate menu items to adjust the appearance of the

signal and the signal detection capabilities. Some of these settings will be determined by the values entered in

the BASIC SETUP menu and adjustments made to these settings are to be made only when absolutely necessary. (Section 4.5.2.)

e. Measurement per Division - The WAVEFORM display will be divided into horizontal sections or divisions.

The separations in the divisions will remain constant on the display. Variation in the appearance of the signal

will be based on the Measurement per Division. The available measurements per division will be dependant

upon the UNITS set in the BASIC SETUP menu. To adjust the Measurement per Division, scroll down to highlight the setting and press the SELECT button.

f. Scroll Left or Right - This function will allow the Reference Measurement to be shifted based on the Measure-

ment per Division giving access to the full WAVEFORM. Shifting the Reference will not affect the operation of

the MT5000. Pressing the SELECT button with < highlighted will shift the reference 5 divisions to the left. Pressing the SELECT button with > highlighted will shift the reference 5 divisions to the right. The displayed reference

may not be shifted to a value less than 0 measurement.

g. Signal - The actual return signal from the antenna of the MT5000. The signal from the measured level will ap-

pear as a rising wave that moves up from 0 volts toward 1 volt then falls back down towards 0. This signal must

cross the Threshold Voltage to the right of the blanking to be registered as a measurement by the MT5000.

h. Return to EXTENDED SETUP - Pressing the SELECT button while EXIT is highlighted will back out of the

WAVEFORM screen and revert back to the EXTENDED SETUP menu.

UNITS Available Measurement per Division

inches 6 in / div 12 in / div 24 in / div

feet .5 ft / div 1 ft / div 2 ft / div

millimeters 100 mm / div 250 mm / div 500 mm / div

centimeters 10 cm / div 25 cm / div 50 cm / div

meters .1 m / div .25 m / div .5 m / div

Table 1

MT5000-0200-1 Rev f (10-2010) DCN0528 24

4.6.2. FUNCTIONS

Adjustments to the settings which control the shape of the signal and what part of the signal is accepted as the

measurement may be accessed through the WAVEFORM screens. By highlighting the function in the top right corner of the WAVEFORM screen and pressing the SELECT button, you can scroll through each of these functions. To

adjust a certain function, when the function appears, press and hold the SELECT button for 2 seconds. The WAVEFORM screen will change to a field entry screen which corresponds to the function.

Functions Available from the WAVEFORM screen:

1. LTV = Threshold (in DC Volts)

The Threshold voltage provides a method of signal detection

along the waveform. Digitally set from 0 to 2 volts, the return

signal from the process must cross this barrier to be detected

as a signal. The MT5000 is designed to detect the first pulse

crossing the Threshold. The Threshold may need to be raised

to avoid baseline interference or lowered to detect the correct

pulse.

2. BLK = Blanking (in terms of UNITS)

Blanking is a measured area which the MT5000 will be set to

ignore. This will be set based on the NOZZLE LENGTH from

the BASIC SETUP menu. It may be necessary to extend the

Blanking further past the nozzle to ignore reflections from the

top portion of the probe. Blanking is set in terms of UNITS. To

adjust the Blanking enter the distance from the Reference

Measurement to be ignored.

3. GAIN = Signal Amplification (1 thru 99)

GAIN is a factory set function designed to adjust the return

pulse to the best possible signal to noise ratio. The GAIN setting will be optimized by the MT5000 based on the entries from

the BASIC SETUP menu. Increasing the GAIN setting will amplify the noise as well as the return pulse. Lowering the GAIN

setting will decrease the return pulse as well as the noise.

4. SHAPE = 1 or 2

The SHAPE function will be set based on the mounting

configuration. Like the GAIN function it is designed to create the

best signal to noise ratio from the return pulse. The SHAPE setting will determine how the signal is amplified.

5. RNG = 1 or 2

The RANGE setting is determined by the PROBE LENGTH.

Probes shorter than 100 feet will be set to RANGE 1. Probes

from 100 to 200 feet will be set to RANGE 2. Changing the

RANGE setting will erase all factory trim settings and calibration

values. Changing the RANGE setting is not recommended

unless a commitment to changing the physical probe length has

been made.

Access to

Functions

Blanking

Threshold

Signal

THRESHOLD

X.XX

LVL: XX.XX in XX.XX mA

BLANKING

XX.XX inches

LVL: XX.XX in XX.XX mA

GAIN

XX

LVL: XX.XX in XX.XX mA

SHAPE

1

LVL: XX.XX in XX.XX mA

RANGE

1

LVL: XX.XX in XX.XX mA

Note: After setting the value of each function, pressing the SELECT button will return you to the WAVEFORM screen.

MT5000-0200-1 Rev f (10-2010) DCN0528 25

4.6.3. TEMPERATURE

The TEMPERATURE indication in the EXTENDED SETUP menu is an indication of temperature internal to the electronics module. It is not used for temperature compensation.

The TEMPERATURE will toggle between Celsius and Fahrenheit.

TEMPERATURE

XX.X F/C

LVL XXX.XX in XX.XX mA

MT5000-0200-1 Rev f (10-2010) DCN0528 26

4.6.4. LINEARIZATION MENU

The LINEARIZATION function of the MT5000 is a multi-purpose tool designed to enhance the operating capabilities

of the MT5000 transmitter. The format of the LINEARIZATION TABLE allows a set of values to be assigned to

measured level points along the PROBE LENGTH. The points in the table can be assigned exact measured values

to linearize the measured level for increased accuracy at the top and bottom of the probe, assigned volume points

for tank strapping, or assigned flow rates for measurement of flow in an open channel.

LINEARIZATION MENU items:

1. LIN UNITS

Allows the selection of the desired output UNITS based on the values of the lin-

earization table. LIN UNITS include measurement selections such as meters,

volume selections such as gallons, and flow selections such as liters/hour.

(Table 2)

2. LIN MINIMUM

The value assigned to the lowest measurable point along the PROBE LENGTH.

Typically this will be set to 0, although it is not required.

3. LIN MAXIMUM

The value assigned to the highest measurable point along the PROBE

LENGTH. This value will be greater than the largest point in the Linearization

Table.

4. LIN MODE

This will determine how the values in the table will be assigned. Manual Mode

allows the entry of the values along with the respective measured level. Automatic requires the level of the product to be at the measured level when the respective value is set.

5. LINEARIZATION TABLE

The set of parameters used to collate Measured Level and a user selected set

of values for those Measured Levels. Table points will be entered based on the

LIN MODE. Table points must be entered from smallest value to largest value

from point 01 to point 20. In Manual Mode, the table will ask for Output Point 01

-20 then ask for the corresponding Input Point 01-20. The Output Point is the

desired reading. The Input Point is the Measured Level. In Automatic Mode, the

table will only ask for the Output Point 01-20. The corresponding Input Point will

be gained by setting the level to the correct location along the PROBE LENGTH.

LIN OUTPUT

Level

LVL XX.XX in XX.XX mA

LIN UNITS

inches

LVL XX.XX in XX.XX mA

LIN MINIMUM

XX.XX

LVL XX.XX in XX.XX mA

LIN MAXIMUM

XXX.XX

LVL XX.XX in XX.XX mA

LIN MODE

Manual

LVL XX.XX in XX.XX mA

LINEARIZATION

TABLE

LVL XX.XX in XX.XX mA

Changing the UNITS in the BASIC SETUP menu will automatically change the UNITS of the Input Points. Changing

the LIN MAXIMUM after table points are set will cause the table points to change based on the percentage change

of the LIN MAXIMUM.

MT5000-0200-1 Rev f (10-2010) DCN0528 27

Table 2

Linearization Output Units

Level Flow Volume

inches gallons cubic yards cubit ft/sec cubic meters/sec liters/sec

feet liters cubic feet cubic ft/min cubic meters/min liters/min

millimeters imperial gallons cubic inches cubic ft/hr cubic meters/hr liters/hr

centimeters cubic meters liquid barrels cubic ft/day cubic meters/day million liters/day

meters barrels hectoliters gallons/sec barrels/sec imperial gallons/sec

percent (%) bushels gallon/min barrels/min imperial gallons/min

gallons/hr barrels/hr imperial gallons/hr

gallons/day barrels/day imperial gallons/day

million gallons/day

LINEARIZATION for LEVEL

Due to the nature of the microwave energy and the physics involved in the measurement of the MT5000, measurements return signals on the top and bottom end of the probe may be non-linear. The degree of non-linearity will depend upon the dielectric of the material being measured, the configuration of the probe, and the proximity of the material to the ends of the probe. A typical table setup for measurement linearity will only contain a few Output Points.

Points not used will be left set to 0.00. Below is an example of Linearization set up for Measurement Linearity.

SETTINGS

LIN OUTPUT

Level

LIN UNITS

inches

LIN MINIMUM

00.00

LIN MAXIMUM

48.00

LIN MODE

Auto

PROBE LENGTH

51.00

NOZZLE HEIGHT

3.00 inches

LINEARIZATION TABLE

MEASURED

LEVEL

0.25” 01 1.00”

1.50” 02 2.00”

2.75” 03 3.00”

3.88” 04 4.00”

NOT USED 05 thru 16 0.00”

43.88” 17 44.00”

44.75” 18 45.00”

45.50” 19 46.00”

46.25” 20 47.00”

OUTPUT POINT

MT5000-0200-1 Rev f (10-2010) DCN0528 28

LINEARIZATION for VOLUME

The MT5000 is designed to measure level in a linear fashion over the length of the probe. If the transmitter is installed in a straight sided tank, the volume of the tank may be calculated by knowing the amount of product per unit

of measurement. However, if the MT5000 is installed in a tank with round sides, like a sphere or bullet tank, the

amount of product per unit measurement will change from one point to the next. For this reason the Linearization

has been designed with the flexibility to accept a strapping table as an output. With the LIN MODE set to Manual, a

20 point strapping table may be entered into the Linearization Table to allow the MT5000 to display a volume measurement. If a strapping table is not available for the tank, with the LIN MODE set to Automatic, a given amount of

liquid may be added to the tank and the Output Points set based on that given amount. Below is an example of a

Linearization setup for Volume using the Manual Mode.

SETTINGS

LIN OUTPUT

Volume

LIN UNITS

gallons

01 5.00‖ 115.86

LIN MINIMUM

00.00

05 13.00‖ 456.80

LIN MAXIMUM

2010.00

09 21.00‖ 876.49

LIN MODE

Manual

13 30.00‖ 1368.89

PROBE LENGTH

98.00 in

17 38.00‖ 1761.10

3.00 inches

LINEARIZATION TABLE

02 7.00‖ 188.53

03 9.00‖ 270.37

04 11.00‖ 361.70

06 15.00‖ 556.56

07 17.00‖ 662.40

08 19.00‖ 818.75

10 23.00‖ 988.07

11 25.00‖ 1097.32

12 27.00‖ 1206.04

14 32.00‖ 1472.69

15 34.00‖ 1575.34

16 36.00‖ 1671.05

18 40.00‖ 1845.96

19 42.00‖ 1919.85 NOZZLE HIEGHT

20 43.00‖ 1952.56

INPUT

POINT

OUTPUT

POINT

MT5000-0200-1 Rev f (10-2010) DCN0528 29

LINEARIZATION for FLOW

Fluid flow in a flume or open channel will present some of the same characteristics as a level in a tank. If you examine a cross section of a liquid flowing at a particular rate through a channel, it will rise to a certain level in that channel. As the flow increases, the level in the cross section of channel will rise. Knowing the aspects of the channel, we

can create a correlation between the measured level of the fluid and the rate of flow through the channel.

Due to the method of operation of the MT5000 and the physics of flow, there are specific mounting requirements

when using a Guided Wave Radar transmitter in a flow application.

1. A rigid probe must be used and it must be secured to the bottom of the flow channel.

2. A single rod probe design will require the use of a metal launch plate mounted to the MT5000 coupler.

3. The MT5000 probe and transmitter must be mounted 3 times the head height upstream from the end of the

channel or from the flow change.

Below is a typical Linearization setup for channel flow.

SETTINGS

LIN OUTPUT

Flow

LIN UNITS

gallons/min

LIN MINIMUM

00.00

LIN MAXIMUM

80.00

LIN MODE

Manual

PROBE LENGTH

24.00

LINEARIZATION TABLE

01 0.50‖ 10.00

03 1.00‖ 20.00

05 2.00‖ 30.00

07 3.00‖ 40.00

09 4.00‖ 50.00

11 5.00‖ 60.00

Points 02,04,06,08,10 and

Input

Point

12-20 are not used

OUTPUT

POINT

MT5000-0200-1 Rev f (10-2010) DCN0528 30

User Functions

At the end of the Output / Input Points there are three User Functions for the Linearization Table. These Functions are here to assist the user with the Linearization Table values.

1. BACK UP Table - Selecting this Function will store all of the values in the Linearization

Table to a Back Up file in the Eprom of the MT5000.

2. RELOAD Table - Selecting this Function will reinstall the values of a Linearization Table

that have been stored in the Back Up file of the MT5000.

3. CLEAR Table - Selecting this Function will completely erase all values from the Lineariza-

tion Table.

These functions will only affect the Linearization Table values. They will not affect any other

settings of the MT5000.

BACK UP

Table

LVL XX.XX in XX.XX mA

RELOAD

Table

LVL XX.XX in XX.XX mA

CLEAR

Table

LVL XX.XX in XX.XX mA

4.6.5. SOR (HART VERSION ONLY)

Signal Out of Range: SOR has two selections – SATURATION = Saturation; ALARM = Alarm. This function prevents

the abrupt mA output change that is common in applications of low dielectric constant fluids in EC chambers. To

take advantage of this programming, the module’s Failure Alarm jumper should be set HIGH, and SOR Set to

ALARM.

Description: SATURATION (normal operation) and ALARM selections are described below.

A. SATURATION – (Existing transmitter normal operation with a low D.C. fluid): When the chamber level exceeds

the URV, the output will continue to track the level until the output saturates at 20.56mA. Should the level continue to increase to the point that the level echo is lost, the next echo that the module immediately recognizes is

the centering disc at the end of the antenna. Since the centering disc echo is being detected through the low DC

fluid, it appears significantly below the actual distance and the output drives to 3.85mA (saturated output) causing significant control problems. This situation is generally not a problem with a high DC fluid application be-

cause when the transmitter loses its echo, it cannot ―see‖ the centering disc through the fluid and therefore enters the transmitter’s ―alarm‖ mode (generally set High @ 21 mA).

B. ALARM – As the level increases as described in SATURATION above, when the level increases such that the

transmitter loses the echo from the real level (output is 20.56 mA), the transmitter is prevented from ―seeing‖ the

centering disc below the engineering units entered in LRM. If the transmitter sees no echo, it will enter its alarm

state (21 mA) as programmed by the jumpers on the face of the module. The transmitter’s output now simply

increases from 20.56 mA (out of range saturation – high) to 21 mA (Transmitter Failure Alarm – High), preventing any control upset. When the level drops and the transmitter re-acquires the true level echo, the transmitter’s

output will change from 21 mA (Failure Alarm high) to 20.56 mA (measurement out of range –high), and then

track the level downward to 20 mA (URV) and normal operation.

LRM (only if SOR is set to ALARM) – Low Range Margin – the limiting distance below LRV (4.0 mA

value) at which a valid echo will be recognized. This value is displayed and can be changed only when

ALRM is selected. LRM is a positive value and can be up to 50% of sensor trim span. This value is not

critical and is typically set at 4.0‖ (10cm).

MT5000-0200-1 Rev f (10-2010) DCN0528 31

5.0 Troubleshooting

Use a milliamp (mA) meter to measure the output current. When power is applied the output will go to 4.00 mA for

at least one (1) second and then to either the measured level or an alarm condition output. If this does not happen

the transmitter may not be receiving enough power or the main electronic is defective. Excessive current above

21.00 mA is an indication of defective electronics or improper wiring, disconnect the power supply immediately to

avoid further damage to the MT5000.

5.1 Valid Current Loop Outputs

21.00 mA

20.58 mA

If the top board jumper is set to HI ALARM a loss of signal, a problem with the configuration

or a malfunction will cause the output to be set to the alarm condition of 21.00mA

When the level increases above the 20.0 mA point the output will continue up to 20.6 mA and

then latch until the level returns below the 20.6 mA level.

4.0 mA to 20.0 mA Normal output range

3.85 mA

3.61 mA

When the level decreases below the 4.0 mA point the output will continue down to 3.8 mA

and then latch until the level returns above the 3.8 mA level.

If the top board jumper is set to LOW ALARM a loss of signal, problem with the configuration,

or a malfunction will cause the output to be set to the alarm condition of 3.61mA

5.2 Symptoms and Solutions

Symptom Possible Cause Solution

Output spiking high

Output too low

Blanking area too short Verify proper Nozzle Length in BASIC

Threshold voltage too high From the WAVEFORM display readjust the

Inadequate supply voltage Check Power Supply Voltage

SETUP menu. (SECTION 4.3.5)

From the WAVEFORM AT COUPLER dis-

play extend the Blanking (BLK) past obstructions. (Section 4.6.1)

LTV for the return signal. (Section 4.6.1)

Current drain in wiring Check Wiring for Ground Faults or Water in

No display and no mA Output

Inadequate supply voltage Check Power Supply Voltage

Electronics failure Replace Electronics Module (Section 5.3)

No display with mA Output

Actual mA Output does not match

displayed Value

Electronics failure Replace Electronics Module (Section 5.3)

Improper DAC Trim Perform DAC Trim (Section 4.5.7)

Shorted RFI Filters in terminal

Unit worked until new IS barrier was

installed

Upon power up current output drops to

4mA before reading correct level

Barrier does not meet

Normal Operation Normal Operation

MT5000-0200-1 Rev f (10-2010) DCN0528 32

strip

requirements for the transmitter

Conduit

Check Wiring Connections to Transmitter

and Power Supply

Replace Terminal Strip

Verify Barrier Specifications to Match

ELE1014

5.3 Electronics Module Replacement

A defective electronics module can be replaced as follows:

1. Disconnect the supply power from the MT5000.

2. Remove the existing module by unscrewing the two slotted screws holding the module in the housing.

3. Note the orientation of the module and unplug from the housing base.

4. Carefully unplug the coax cable connector from side of the module.

5. Plug the coax cable into the new module.

6. Plug module onto the housing base.

7. Secure the module to the housing by screwing the two flat screws.

8. Reconnect the supply power the MT5000.

9. If a minor error in measured level is detected, the error may be compensated for using the LVL OFFSET function

in the BASIC SETUP menu. (Section 4.3.6.)

The MT5000 is now ready for use without further calibration.

MT5000-0200-1 Rev f (10-2010) DCN0528 33

6.0 Installation Drawings for Intrinsic Safety & Standard Wiring

Reference K-TEK drawing ELE1014 MT2000 Series, Intrinsically Safe Electrical Interconnection Diagram.

MT5000-0200-1 Rev f (10-2010) DCN0528 34

Installation Drawings for Intrinsic Safety & Standard Wiring (continued)

Reference K-TEK drawing ELE1014 MT2000 Series, Intrinsically Safe Electrical Interconnection Diagram.

MT5000-0200-1 Rev f (10-2010) DCN0528 35

7.0 Installation Drawings for Explosion Proof

Reference K-TEK drawing ELE1015 MT2000 or MT5000 Loop Powered TX Hookup Dual Compartment Housing.

MT5000-0200-1 Rev f (10-2010) DCN0528 36

8.0 CE Certificate of Conformity

MT5000-0200-1 Rev f (10-2010) DCN0528 37

9.0 CUSTOMER SUPPORT

18321 Swamp Road

Prairieville, LA 70769 USA

Tel: +(1) 225.673.6100

Fax: +(1) 225.673.2525

Email: service@ktekcorp.com

Website: ktekcorp.com

MT5000-0200-1 Rev f (10-2010) DCN0528 38

9.1 K-TEK RMA FORM

K-TEK

18321 Swamp Road

Prairieville, LA 70769

Phone: +1 (225) 673-6100

Fax: +1 (225) 673-2525

Email: service@ktekcorp.com

Toll Free: (800) 735-5835

*** IMPORTANT CUSTOMER NOTICE: PLEASE READ PRIOR TO RETURNING PRODUCTS TO K-TEK***

Be sure to include the Return Authorization (RA) number on the shipping label or package to the attention: Customer Service. A

copy of this document should also be included with the packing list. K-TEK wants to maintain a safe work environment for its employees. In the event, the returned product or material has been in contact with a potentially hazardous chemical, per federa l regulations, the customer must provide evidence of decontamination and the related chemical composition and characteristics. In o rder

to expedite your return, please include the applicable Material Safety Data Sheets (MSDS) and decontamination tags by affixing

these documents in close proximity to the shipment label for identification purposes. (January 18, 2006)

Return Authorization Form

Customer:

Contact Name:

Contact Email:

Contact Phone:

Contact Fax:

Completed by Customer

Reason

Problem Found: None

Action: None

Requested:

Is expedited return shipping requested? Yes

If yes, please provide a purchase order or your shipper’s account number (ex. FedEx or UPS). K-TEK pays return transport via

standard ground shipments only.

If purchase order is issued, a copy of purchase order must be included with return documentation.

Is K-TEK authorized to repair items determined to be non-warranty? Yes

If yes, a copy of purchase order must be included with return documentation.

Customer PO:

Has product been in contact with any potentially hazardous chemical? Yes

If yes, documentation product and forward MSDS to K-TEK, “ATTN: Customer Service”

Return Repaired Product to Address

Date:

Product:

Serial No:

Job No:

Service Rep:

□

□

Date:

Account #:

□

Shipping Address:

MT5000-0200-1 Rev f (10-2010) DCN0528 39

Billing Address:

Ship Via:

10.0 WARRANTY

5 YEAR WARRANTY FOR:

KM26 Magnetic Liquid Level Gauges; MagWave Dual Chamber System; LS Series Mechanical Level Switches (LS500, LS550,

LS600, LS700, LS800 & LS900); EC External Chambers, STW Stilling Wells and ST95 Seal Pots.

3 YEAR WARRANTY FOR:

KCAP300 & KCAP400 capacitance switches. BETA Pressure and Temperature Switches have a limited factory guarantee, excluding wetted parts & consumables.

2 YEAR WARRANTY FOR:

AT100, AT100S and AT200 series transmitters; RS80 and RS85 liquid vibrating fork switches; RLT100 and RLT200 reed switch

level transmitters; TX, TS, TQ, IX and IM thermal dispersion switches; IR10 and PP10 External Relays; MT2000, MT5000,

MT5100 and MT5200 radar level transmitters; RI100 Repeat Indicators; KP paddle switches; A02, A75 & A77 RF capacitance

level switches and A38 RF capacitance level transmitters; Buoyancy Level Switches (MS50, MS10, MS8D & MS8F); Magnetic

Level Switches (MS30, MS40, MS41, PS35 & PS45).

1 YEAR WARRANTY FOR:

KM50 gauging device; AT500 and AT600 series transmitters; LaserMeter and SureShot series laser transmitters; LPM200 digital

indicator; DPM100 digital indicators; APM100 analog indicators; KVIEW series digital indicators and controllers; SF50 and SF6 0

vibrating fork switches, KB Electro-Mechanical Continuous Measuring Devices, KSONIK ultrasonic level switches, transmitters &

transducers, ChuteMaster Microwave Transmitter / Receiver and TiltMaster Switches.

SPECIAL WARRANTY CONSIDERATIONS:

K-TEK does not honor OEM warranties for items not manufactured by K-TEK (i.e. Palm Pilots). These claims should be handled

directly with the OEM.

K-TEK will repair or replace, at K-TEK’s election, defective items which are returned to K-TEK by the original purchaser within the

period specified above from the shipment date of the item and which is found, upon examination by K-TEK, to its satisfaction, to

contain defects in materials or workmanship which arose only under normal use and service and which were not the result of either alterations, misuse, abuse, improper or inadequate adjustments, applications or servicing of the product. K -TEK’s warranty

does not include onsite repair or services. Field service rates can be supplied on request.

If a product is believed to be defective, the original purchaser shall notify K-TEK and request a Returned Material Authorization

before returning the material to K-TEK, with transportation prepaid by the purchaser. (To expedite all returns/repairs from outside

of the United States, consult K-TEK’s customer service team (service@ktekcorp.com) to determine an optimal solution for ship-

ping method and turnaround time.) The product, with repaired or replaced parts, shall be returned to the purchaser at any point in

the world with transportation prepaid by K-TEK for best-way transportation only. K-TEK is not responsible for expedited shipping

charges. If the product is shipped to K-TEK freight collect, then it will be returned to the customer freight collect.

If inspection by K-TEK does not disclose any defects in material or workmanship, K-TEK’s normal charges for repair and ship-

ment shall apply (minimum 250.00 USD).

The materials of construction for all K-TEK products are clearly specified and it is the responsibility of the purchaser to determine

the compatibility of the materials for the application.

THE FOREGOING WARRANTY IS K-TEK'S SOLE WARRANTY AND ALL OTHER WARRANTIES EXPRESSED, IMPLIED, OR

STATUTORY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE, ARE EXCLUDED AND NEGATED TO THE MAXIMUM EXTENT PERMITTED BY LAW. NO PERSON OR REPRESENTATIVE IS AUTHORIZED TO EXTEND ANY OTHER WARRANTY OR CREATE FOR K-TEK ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF K-TEK’S PRODUCTS. THE REMEDIES SET FORTH IN THIS WARRANTY ARE EXCLUSIVE

OF ALL OTHER REMEDIES AGAINST K-TEK. K-TEK SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL,

OR SPECIAL DAMAGES OF ANY KIND. K-TEK’S SOLE OBLIGATION SHALL BE TO REPAIR OR REPLACE PARTS (FOUND

TO BE DEFECTIVE IN MATERIALS OR WORKMANSHIP) WHICH ARE RETURNED BY THE PURCHASER TO K-TEK.

MT5000-0200-1 Rev f (10-2010) DCN0528 40

MT5000-0200-1 Rev f (10-2010) DCN0528 41

MT5000-0200-1 Rev f (10-2010) DCN0528 42

MT5000-0200-1 Rev f (10-2010) DCN0528 43

MT5000-0200-1 Rev f (10-2010) DCN0528 44

Loading...

Loading...