MG26-F2

Please read this manual seriously before using !

USER's MANUAL

Made in China

Add.: Middle of Binnan Street, Dongbin Industrial Zone, Donghai Bincheng,

Quanzhou, Fujian 362000,

China

Tel.: +86-595 22391040

Fax: +86-595 22391048

E-mail: sales@ksj.cn

Website:www.ksj.cn

sales@hidea.cn

www.glossmeter.cn

1.

Brief Introduction

Specifications

Main Functions

Construction

Measurement

Warning And Notice

Menu Operation

Using Software

Trouble shooting

Warranty

Packing List

2

3

5

7

11

16

17

25

33

37

38

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

CONTENTS

2.

All kinds of coating and finishing surfaces, such as paints, varnishes,

printing ink, etc.

Decorative materials, such as marble, granite, polishing brick, ceramic

tile and so on.

The other kinds of materials and objects, such as plastic, woodenware,

paper, etc.

MG26-F2 is designed and manufactured according to ISO2813 and

GB9754. It is also compatible with the standards of ASTM , ASTM

, GB/T13891, GB7706, and GB8807. The technical parameters

conform with JJG696-2002. The gloss values can be traced to the those

of the National Primary Standards in SIMT in the P.R.China.

D523

D2457

Thanks for your choice to purchase MG26-F2.

Main Applications:

BRIEF INTRODUCTION

3.

Specifications

Unit

MG26-F2

Glossmeter

Measuring Range

Resolution

Reproducibility

Repeatability

GU

GU

GU

GU

GU

GU

+10 +40

Gs 20

Gs 60

0.0 119.9

0.0 119.9

Gs 20

Gs 60

120 2000

120 1000

0.1

1

0.2

0.2

0.5

0.2

0.5

Zero-point Deviation

Operating Temperature

Deviation

1.5

1.5%

SPECIFICATIONS

4.

Specifications

Unit

MG26-F2 Glossmeter

-10 +60

Gs 20

Gs 60

910

916

Storage Temperature

Relative Humidity

Up to 85%, no moisture condensation, for operation

Measuring Spot

g

400 ( with a battery and a holder)

155 48 75 ( without a holder)

mm

3

mm

2

One AA-sized battery, 1.2V 1.5V,Rechargeable or alkaline.

Power Supply

Consumption

Volume

Weight

It's different to battery types. An alkaline battery

may support 20000 measurements or more.

SPECIFICATIONS

5.

MG26-F2 has the main functions as below:

One key to get 2 gloss values at a measurement. The result will be automatically stored

into memory.

Optional angle groups. You may complete a measurement at the both angles. You can

also choose to do a measurement at a single angles.

Self-diagnosis and self-calibration.This function help to find some faults, and so you can

deal with them in time.

Friendly display interface. In measurement mode, current values, averages and other

information are synchronously shown on the Display Window. The clear characters and

simple menus make operation more easily.

Presettable measurement number in a group. According a requirement you can choose

a proper number between 1 to 99 for a group. A correct choice will make measurement

and data processing easier.

Large memory for measurement data. In 2-angle mode, more than10000 measurements

or 999 groups can be allowed to stored in MG26-F2.

Inquiry for data in memory. Through menu operation you can browse the data in memory.

MAIN FUNCTIONS

6.

Deleting defective measurements. By pressing Measuring Button for two seconds or

more, the measurement displaying on the Display Window will be deleted. This function

is only effective in current group.

RS232 port (9 pins). Through this series port MG26-F2 can communicate with a PC.

Practical and friendly software. KSJ Data Operator is not only friendly but practical. It

can help you to upload the data from MG26-F2, preset the measuring conditions, make

a printout, perform data processing and export the data to an Excel document.

Low power consumption. MG26-F2 needs only a 1.2v to 1.5v DC power supply. You

can choose a piece of AA battery which may be alkaline or rechargeable. An alkaline

battery will support more than 20000 measurements. The power for communicating is

taken from a PC.

Prompt for low battery and full memory.

Automatic shutoff. If no operation MG26-F2 will be turned off by itself in a preset time

interval.

MAIN FUNCTIONS

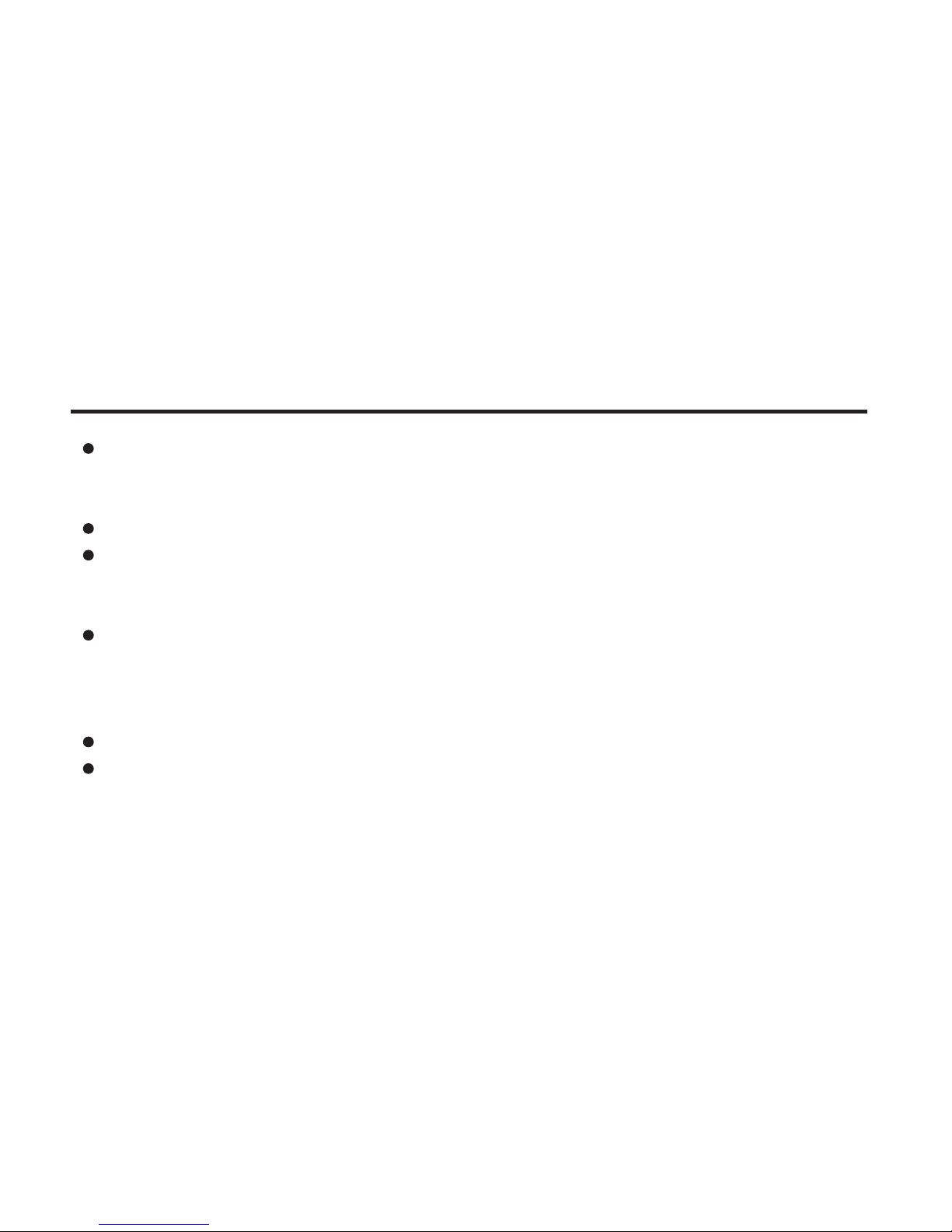

Ô

Display Window

Front Shell

Holder

Bat. Chamber Cover

Rear Shell

Menu Wheel

7.

Whole set of MG26-F2

CONSTRUCTION

8.

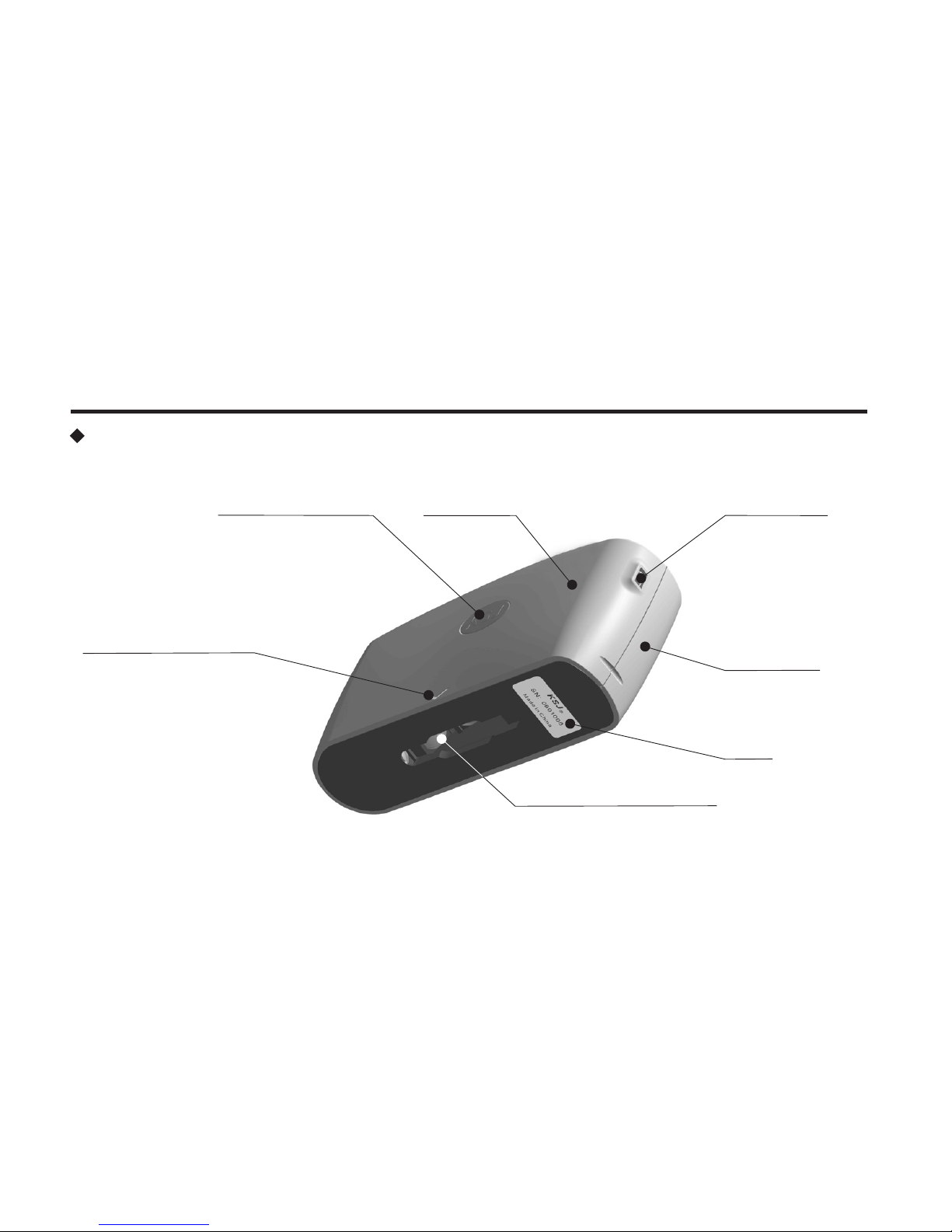

Rear Shell

Measuring Button

Mark For Location

Incidence Direction

Front Shell

RS232 Port

Label

Measurement Aperture

Main Device

CONSTRUCTION

Holder

Calibrating Standard

Gloss Value Label

9.

Holder With Calibrating Standard

CONSTRUCTION

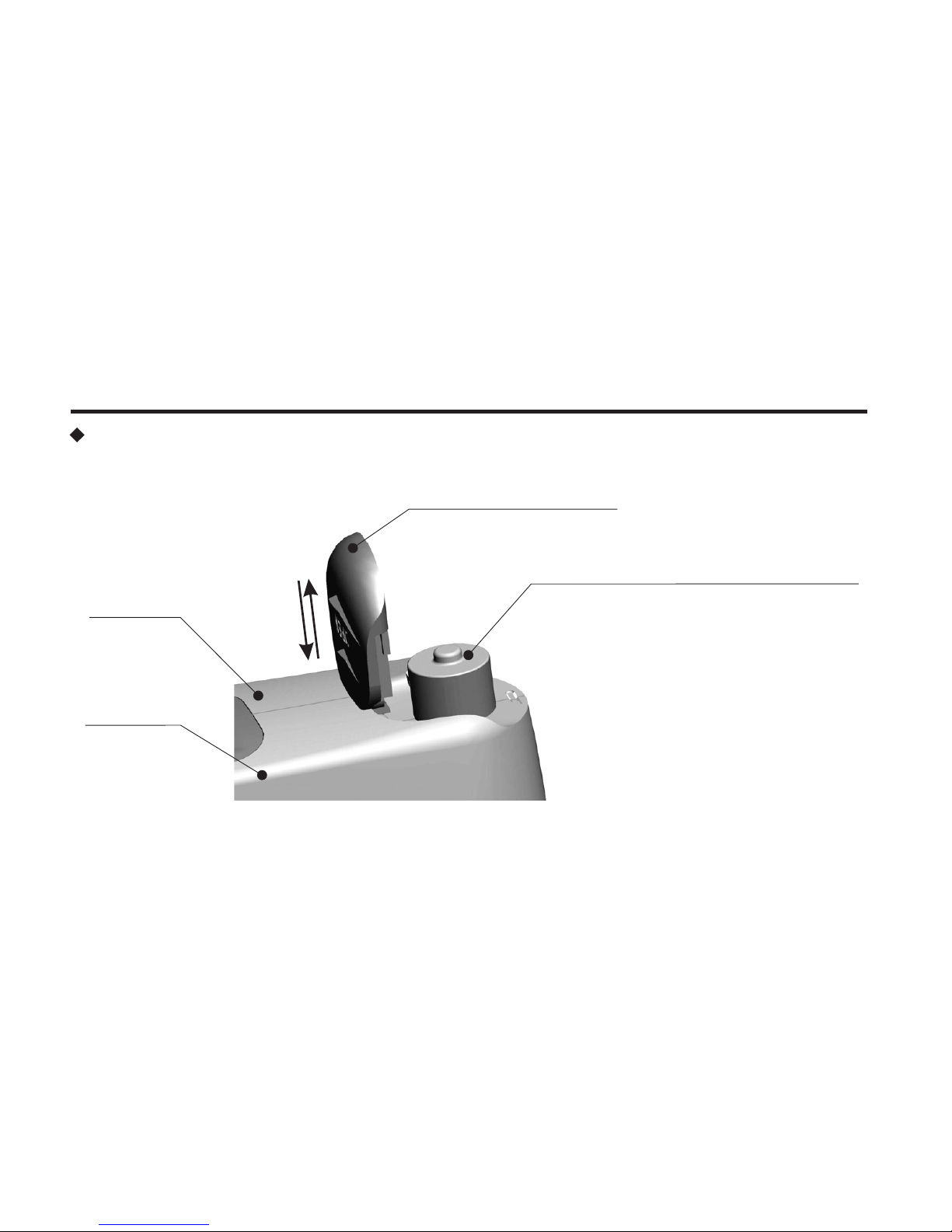

10.

Battery in Position

Battery Chamber Cover

Front Shell

Rear Shell

Battery With Positive Pole Up!

AA or LR6, Alkaline or Rechargeable.

CONSTRUCTION

11.

Please

1.CleanSTD.

2.SetHolder.

3.Recalibrate.

MEASUREMENT

Turn on the meter

Notes

If the main unit don't lay into the holder, it is possible to turn on the meter by pushing

down the Menu wheel. But it will skip the

self-diagnose and self-calibrating.

Battery installing can also turn on the meter directly.

Lay the main unit into the holder, then push down the Menu Wheel t .

The infos of model and series number will be shown in the Display Window, meanwhile

the meter performs self-diagnose and self-calibrating. After passing this procedure the

display should turn to measuring mode, the meter would be ready for operation. Or else

it shows as below:

o turn on the meter

The messages prompt you to confirm that:

1) The calibrating Standard (STD) is clean;

2) The main device is set into the holder properly;

3) Recalibrating is required when environment temperature change is great. In this case

the meter needs some time to establish a balance of temperature before calibrating.

12.

MEASUREMENT

008/03/05

X

20

!

" 91.9 91.8

" 87.4 87.5

60

Measuring and measurement interface

Notes

008/03/05 express that the current measuement is the third of five measurements in

the eighth group.

Angle mode is shown in the first column, the values of A current measurement in the

second and the averages in the third.

Remove the holder ement

Then push the Measuring Button. Within 2 seconds a measurement will

be completed. Meanwhile the result in Window as below

and stored into the memory automatically.

and lay the Measur Aperture just against the position that you

want to measure.

will be shown the Display

13.

D

eleting measurements

Turn off the meter

Note

Note

Only the measurements in a current group can be deleted one by one.

After turning off the meter will be in a sleeping state which consume little power. Even so

it is strongly recommended to remove the battery when for a long time interval.no use

To delete a current measurement please push down operation button for more than 2

seconds.

The meter will shut off automatically according to the preset time. See page 25..

MEASUREMENT

14.

Notice

The holder removed from the main device should be kept in a safe and clean place

to prevent from damage or pollution.

please

If necessary, especially under strong light, shade it with a

piece of light-tight cloth.

A big temperature difference between environment and the meter would badly affect

measuring. In this case please wait for a period of time till the temperature get to a

balance and then calibrate the meter again.

If measurement operation last a long time, for example an hour or more, it's necessary

to recalibrate the meter.

Pay attention to keep Calibrating Standard and Measurement Aperture clean. Any dirt,

such as fingermarks, dust, steam and filth, should be cleaned gently with lens paper

or a piece of soft cloth dipped in absolute ethanol.

While measuring keep environment light f rom directly irradiating into the

Measurement Aperture.

MEASUREMENT

15.

MEASUREMENT

If memory is full of data, a prompt would be shown as below in Display Window. In this

case measuring operation will be in order, but the results can't be stored into memory

any more. It is better to upload the data in memory to PC and clear the memory.

When a battery runs out, the following message will be shown. Please replace the old

battery with a new one.

FULL

Low Battery

16.

The whole set of the meter should be kept in dry and non-corrosive environment under

the temperature between

If the meter is not in use, please lay it into the holder.

When moisture condensation occurs, you may be unable to make a correct measurement.

When the battery run out, "Low Battery" will appear on the Display Window, replace the

old battery with a new one at once.

For environment dispose the wasted batteries properly.

The meter should not be taken down at will in order to avoid permanent damage.

-10 to +60 .

Although the exterior parts of the meter are made of good quality plastic, they may not

resist some chemicals, especially some strong solvents, such as acetone and so on.

To avoid damage of the meter due to leak of corrosive liquid, we strongly recommend you

use a high quality battery.

After turning off the meter will be in a sleeping state which consume little power. Even so

it is strongly recommended to remove the battery when no use for a long time interval.

WARNING AND NOTICE

17.

Measurement

Data

Calibration

Setup

{

#

#

#

MENU OPERATION

Menu interface

Hint: Anytime press the Measuring Button to terminate menu operation and return to the

measurement interface.

{ Select to return

*| Select to enter

# Enter the next submenu

} Return to the prior menu

Option selecting

Turn up or down the Menu Wheel to select the options. Push down the Menu Wheel for

entering your option selected. The following describes what the symbols mean.

On the Interface, push the Menu Wheel to enter the interface as

below.

measurement menu

18.

MENU OPERATION

Data

*|

Inquiry

Group No. 001

Delete All

OK

NO

Data

Inquiry

Delete All

{

#

#

Measurement Option

Data menu and its submenu

Select this option and push down the Menu Wheel to return to measurement interface.

19.

MENU OPERATION

N=01/05

20!" 16.5 17.6

6 " 49.4 51.70

submenuInquiry

1)

!

return to the previous interface,

N=01/05

represents the first measurement in a current group that has been preset

to involve five measurements. represents the averages of this group.

2) Turn up and down the Menu Wheel to browse data. Push down the Menu Wheel to

and press the Measuring Button to exit and back to

the measurement interface.

In data menu select inquiry option and push down the Menu Wheel to enter the inquiry

submenu. Turn up and down to set the group number that you want to inquire and

then push down the Menu Wheel to enter the inquiry interface. Here you can browse

all the measurements in this group by turning the Menu Wheel.

Notes:

20.

submenu

Delete All

Enter the submenu and turn the Menu Wheel to select to clear all data in memory.

Or else select

OK

NO

to exit.

Calibration Menu and its submenu

Calibration

*|

Calibration

Modify Values

Calibrate

{

#

}

*_

Modify Values

20" = 94.7

6 " = 96.00

MENU OPERATION

21.

MENU OPERATION

submenuModify Values

optionCalibrate

Notes

1) Before calibrating be sure that the Calibrating Standard is clean!

2) You can also calibrate the meter with Checking Standard that is available for purchase.

Enter the submenu, turn the Menu Wheel to select a value and push down the Menu

Wheel to confirm, then turn the Menu Wheel to modify the value, push down the Menu

Wheel to confirm again. It is the same operation for other values.

In menu, turn the Menu Wheel to select and push

down the Menu Wheel to confirm. The calibrating will be carry out automatically, and

meanwhile the result will be shown in the Display Window. Finally it will return to the

measurement interface.

Calibration Calibrate option

22.

MENU OPERATION

_

Measurements

in a group

N= 05

Setup

Angle Mode

Shutoff Time

Group

{

#

#

#

Setup

*|

Shutoff Time

30 S

60 S

120 S

*

}

*_

Setup menu and its submenu

Angle Mode

20

"

6"

2"6"

0

00

{

23.

MENU OPERATION

}

*_

Single_Angle

20

0

0

"

6"

20"6 "

submenuAngle Mode

submenuShutoff Time

Enter the sub , select an option and push down the Menu Wheel to confirm.

Then it will be changed to the measurement interface automatically.

menu

This menu is for setting a no-operation time interval for which shut

down automatically. In the menu select an option and push down the Menu Wheel to

confirm. And then it will return to the measurement interface.

the meter will be

24.

MENU OPERATION

submenuGroup

Note

The range is between 1 to 99.

Enter the menu, turn the Menu Wheel to set a number of measurements in a group and

confirm. Then it will return to the measurement interface automatically.

25.

USING SOFTWARE

Brief introduction

Software installation and uninstall

To use KSJ Data Operator, you need the following:

an IBM compatible PC with a CD-ROM.

Microsoft Windows XP or later versions.

The software is on the CD that comes with MG26-F2. The procedure of intallation and

uninstall is same as a normal software, and it is unnecessary to be described here.

KSJ Data Operator is a simple software for data processing. Using it, we can perform a

communication between and a PC, and upload the data of measurements.

Then we can process the data uploaded and export them to an E file or as a printout.

We can also operate on a PC to set the measuring conditions for MG26-F2 and clear its

memory.

MG26-F2

xcel

26.

How to connect between MG26-F2 and a PC

There are two connecting cables for MG26-F2 to connect with a PC. One is a RS232

Cable (9 pins), and the other is a USB Adapter ( optional extra).

Using a COM port

Using a USB port

Simply onnect one terminal to MG26-F2 and the other to a COM port on a PC.

Connect a RS232 Cable and a USB Adapter, and then connect separately the other

terminal of the RS232 Cable to MG26-F2 and the USB plug of the USB Adapter to

a USB port on a PC.

Note

It is necessary to install a driver for a USB Adapter. Please find the driver in the CD

which comes with MG26-F2.

USING SOFTWARE

Title Bar

Menu Bar

Tool Bar

Upload Area

Data Area

Function Area

27.

Software interface

Interface of Current Data (default)

USING SOFTWARE

Title Bar

Menu Bar

Tool Bar

Query Area

Data Area

Function Area

28.

Interface of Historical Data

USING SOFTWARE

29.

Menu commands

Connect MG26-F2 and a PC, turn on MG26-F2, run KSJ Data Operator, set the

upload date, then click Upload button to upload data.

Turn to the interface of Historical Data, set a time interval for data inquiring, then

click the Query button to get a result.

The data is uploaded one by one group with sounds and flash indicating..

Uploading troubles can usually be settled according to the hints of a pop-up window.

Data Operation

Current Data

Historical Data

Notes

USING SOFTWARE

30.

This group of commands is used to set the measuring conditions of MG26-F2 in a

communication state.

There are six options to be select including single angle, double angle and treble

angle.

To preset a number of measurements in a group, you can choose from 1 to 99.

This is for modifying the verified values of the Calibrating Standard in the Holder.

Meter Setup

Angle Mode

Group Presetting

Verified Values

Note

It is very important to keep the verified values correct for a calibrating standard. Therefor

don't modify those values at will.

USING SOFTWARE

31.

The contents of help

About the copyright and version of KSJ Data Operator and other informations.

Help

Contents

About KSJ Data Operator

Shutoff Time

Clear Memory

This command is for setting a no-operation time interval for which

shut down automatically. There are three options to be selected.

the meter will be

This is for cllearing all the data stored in the memory of MG26-F2 permanently.

And so It is better to reconsider before clearing.

USING SOFTWARE

32.

Current Data : Equivalent to the corresponding menu command.

Delet Button

To delete selected data shown in the Data Area permanently.

Delet All Button

To delete all data shown in the Data Area permanently.

Excel Button

To export data to an Excel document.

Print Button

To make a printout.

Historical Data : the corresponding menu command.Equivalent to

Print : the function button of print.Equivalent to

Print : the corresponding menu command.Equivalent to

Tool bar

Function Button

USING SOFTWARE

33.

Please

1.CleanSTD.

2.SetHolder.

3.Recalibrate.

TROUBLE SHOOTING

Errors in self-diagnose and self- calibration

When the meter is turned on with the Holder, the

warning message (on right hand side) may come

out. It says something would be wrong.

Please check and settle the troubles in turn:

ny dirt, such as dust

fingermarks, steam and filth, is found, it should be cleaned gently with lens paper or

a piece of soft cloth dipped in absolute ethanol.

self-diagnose and self- calibration

1. Clean STD.

2. Set Holder.

Clean the Calibrating Standard.

Observe the surface of the Calibrating Standard against light. If a

Some abrasion and damage on the

surface will change its verified values. If so, please contact the manufacturer to deal

with.

Set the main unit into the Holder.

Only when the main unit lay in the Holder properly, the meter can pass the procedure

of

34.

A big temperature difference between environment and the meter would badly affect

measuring, and the warning message will be shown. In this case please wait for a

period of time till the temperature get to a balance and then calibrate the meter.

3. Recalibrate. Recalibate the meter.

Moisture condensation

Corrosion caused by a bad battery

When the meter is taken from a cold location to a hot environment, moisture condensation occurs easily. If so don't use the meter any more and wait for the moisture to

evaporate. See above item also.

A bad or over-discharged battery will produce corrosive liquid to damage the electric

poles and elements. When it happens, please remove the battery in time and clean the

poles with a cotton bud dipped in absolute ethanol. If the meter don't work well, please

contact us for repair.

TROUBLE SHOOTING

35.

Problems with communication

It is all right to use a Series Port to carry out a communication. Problems u

occur because :

MG26-F2 don't connect with a PC properly.

MG26-F2 is not in a turn-on state.

No data is in the meter's memory.

sually

Failing to communicate through a Series Port on a PC

Failing to communicate through a USB Port on a PC

Please be sure that:

The driver of the USB adapter has been installed properly.

All connecting cables are connected correctly.

The USB Adapter works in order.

Notes

The .USB Adapter, i.e. a USB Serial Port Convertor, is an optional accessory

TROUBLE SHOOTING

36.

How to verify your glossmeter

A glossmeter is a kind of metrical instruments. It is important and necessary to keep its

accuracy. For this reason the meter must be verified in a period of time, usually a year.

Then, we recommend you to verify the glossmeter as follow:

Send it to a public organization which is authorised by the government and able to

perform the gloss verifying.

Send it to a manufacturer that produces glossmeters.

Purchase certified standards to verify the glossmeter by yourself.

Note:

We also provide some models of Standards for gloss verifying as below:

MG268S-H, high gloss.

MG268S-M, medium gloss.

MG268S-L, low gloss.

TROUBLE SHOOTING

37.

Limited Warranty And Technical Support

The limited warranty period is one year commencing on the date of purchase.

We provide spare parts anytime for distributors and customers.

The inquiries on the gloss measurement may be directed to support@ksj.cn

We also provide glossmeter customizing for a special application.

Notes

If your

meter needs service, carry it to the local reseller or contact us at http://www.ksj.cn

for repair.

The meter should not be taken down at will in order to avoid precision destroying

and maintaining difficulty.

If the breakdown is caused by taking-down or inappropriate use, we reserve the

rights not to guarantee it free in repair.

WARRANTY

38.

Main Device, Model MG26-F2

Holder With Calibrating Standard

RS232 Cable

KSJ Data Operator

Carrying case

User's Manual

Tracable Certificate

1 Unit

1 Unit

1 Piece

1CD

2 Piece

1 Piece

1 Piece

Note:

The USB Adapter is provided as an optional accessory.

PACKING LIST

Loading...

Loading...