KSF CM-340H1, CM-270H1, CM-520H1 Instruction Book

PORTABLE

LI

INSTRUCTION

BOOK

MODEL

M-270H1

CM-340H1

CM-520H1

------------------------------

I

,

,

SAFETY

To

maintain

make

sure

the

read

operation

and

understand

safety,

@ 2009.07/ Copyrighl by KSF.

this

instruction

operating

this

equipment.

book

BEFORE

a _

K.S.F.

CE

According to the

• Machinery Directive :

• Low Voltage Directive : 200tl1ll5i£ C

• Electromagnetic Cornpatibrhly Duscuve : 2DD4/108/EC

We

. Kou Sheng Feng Co., LId,

Add: No

Tel: +886· .' 7-7919·n Fnx' '·8SI;·J 7-79.1877

declare thnt the machines rncnrioned hereafter:

EC Declar ati

followlII)o:

LU

1)11

ccuv,':.,

~ODGl4~ IEC

..

~6,

Chi Shi Rd.. P,li

J)O(]

.~

l c. Tougsbia c ,

~Iit\\llC'

'l " ' . 1,11 ' '.

1111

CE

)1 I I f

(j)Product : Portable Lifter

© Model No.(s) : CM·270H1. CM-340H1, CM-520H1, GLS-340, GLS-G20, C

'~Ser ia

l

No.

I\

.(jOU

"j)Funclions : They are designed and manufaclured to be used for heavy load IIftlli

They are designed and manufactured ill compliance

the Machiucry Directive.

based ou the following

• EN

1494:Z0I)O~AI:c008,

• EN

ISO IclOO-1

PMl I: Bavic termin ology, methodology

• EN ISO IZI00-2:2003+AI

POll

c:

Technical principles

• EN

ISO ]-1121-1:2007.Sa

• ISQ,TR

14121-C:Z007,

of methods

• EN 6020·1-32:200S . Safetyof machinery - Elecnicaleqnipment

Pai

t 32: Requiremeuts for hoisting unchiues

• EN 550 11:2007. Elecrromnguetic compatibility

frequency equipuieut- Radio di

• EN 61000-4-2 :Z009. Electrostatic discharge IESD)

• EN

G l OOO~14: 2 004.

61000·4·6

• EN

low

VoltageDirective aud Electromnguetic Compatibility Directive, and me-

£U101h:~;m

harmonized standards:

Mobile or movablejacks aud associated lifting equipment

:200~

+AI

:2009. Safety of mnchiuery -Basic

:C009

, Safely of maclunery - Basic couccprs, general principles for design •

tet)"

of machinery - Risk assessment Patt I: Principles

Safely of

machinery-

suubauce

Ele

ctric

:2009 , Immuni ty to conducted disturbances. induced by radio-frequency fields (CS)

al Iast transient-burst requirements (EFTiBm'sl)

with

the essential health and safety requiremeru-,III

COUCl1'!s

, general principles fill design.

Risk assessment Part 2: Practical guidance examples

ofmach

ines -

-J

udusrria]. scieurifie

And

medical (ISM) radio-

characteristics- Limit s and methods of measureiueut

Representative:

I Date

Piece

Huang Yu Tal R&D Manager

Misole, Taiwan I Msr.

15.2010

-1-

.

"O rigin al

iU

'-' fm;t i on~ "

~ ~.F

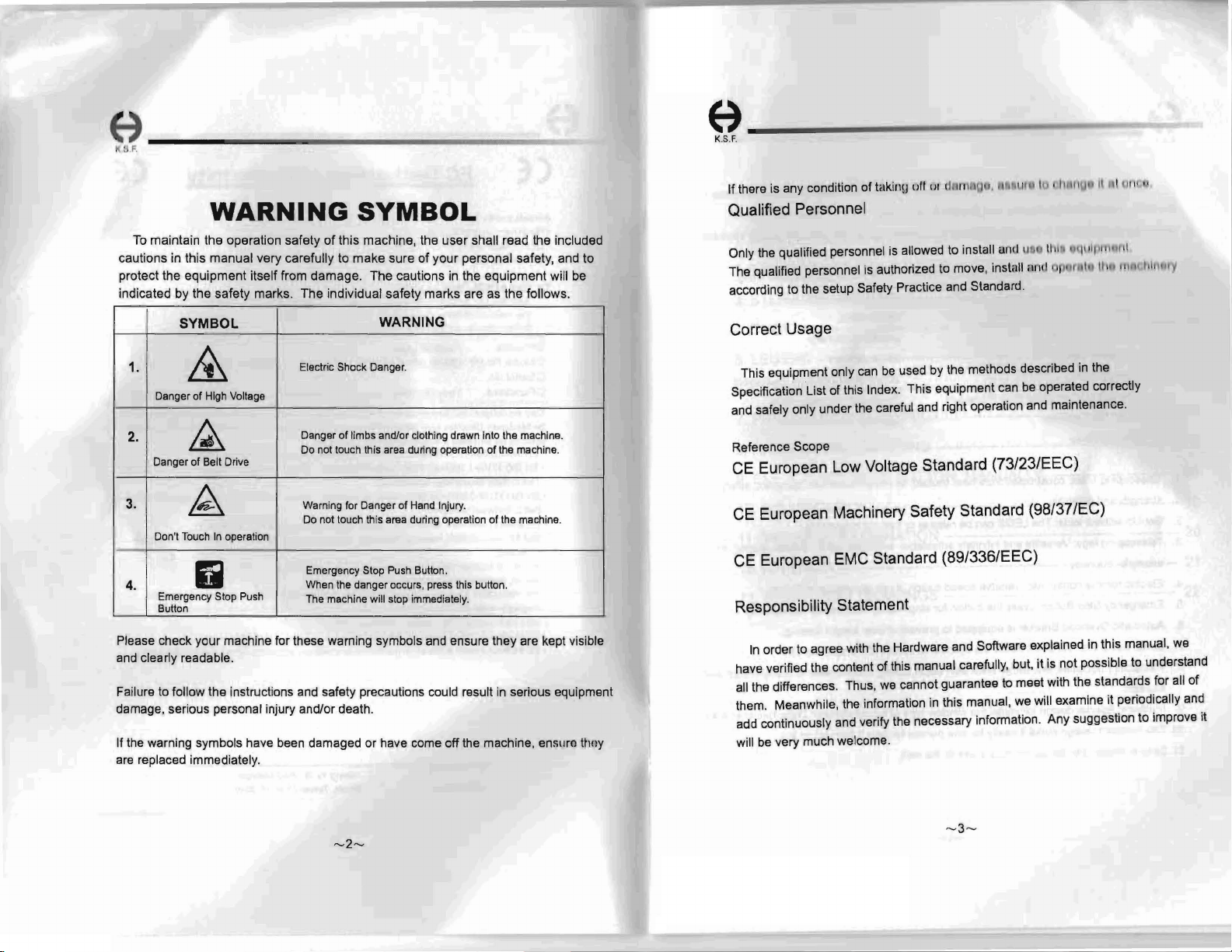

WARNING

To maintain the operation safety of this machine, the user shall read the included

cautions in this manual very carefully to make sure of your personal safety, and to

protect the equipment itself from damage. The cautions in the equipment will be

indicated by the safety marks. The individual safety marks are as the follows

SYMBOL

a_ _ - -

K.S.F.

If there is any condition of

Qualified Personnel

Only the qualified personnel is allowed to install uncllJlllii

The qualified personnel is authorized to move, install

according to the setup Safety Practice and Standard.

takin!J

011

III

II

tll

ll '1I111

i1n

clo\l'lrnh..II'"

It II

lu

lI' .'

11'

1II1

trll

11

1m "hll ll

SYMBOL

1.

2.

3.

4.

Please check your machine for these waming symbols and ensure they are kept visible

and clearly readable .

Failure to follow the instructions and safety precautions could result in serious equipment

damage, serious personal injury and/or death.

If the warning symbols have been damaged or have come off the machine , ensure thoy

are replaced immediately.

&

Danger of High Voltage

~

Danger of Belt Drive

£

Don't Touch In operation

[I

Emergency Stop Push

Button

Electric Shock Danger.

Danger of limbs

Do not touch this area during operation of the machine .

Warning for Danger of Hand Injury.

Do not touch this area during operation of the machine.

Emergency Stop Push Button.

When the danger occurs , press this button .

The machine will stop immediately.

WARNING

andlor clothing drawn Into the machine.

Correct Usage

This equipment only can be used by the methods described in the

Specification List of this Index. This equipment can be operated correctly

and safely only under the careful and right operation and maintenance.

Reference Scope

CE European Low Voltage Standard (73/23/EEC)

CE European Machinery Safety Standard (98/37/EC)

CE European EMC Standard (89/336/EEC)

Responsibility Statement

In order to agree with the Hardware and Software explained in this manual, we

have verified the content of this manual carefully, but, it is not possible to understand

all the differences. Thus, we cannot guarantee to meet with the standards for all of

them. Meanwhile, the information in this manual, we will examine it periodically and

add continuously and verify the necessary information. Any suggestion to improve it

will be very much welcome.

~2~

~ 3~

K r. F.

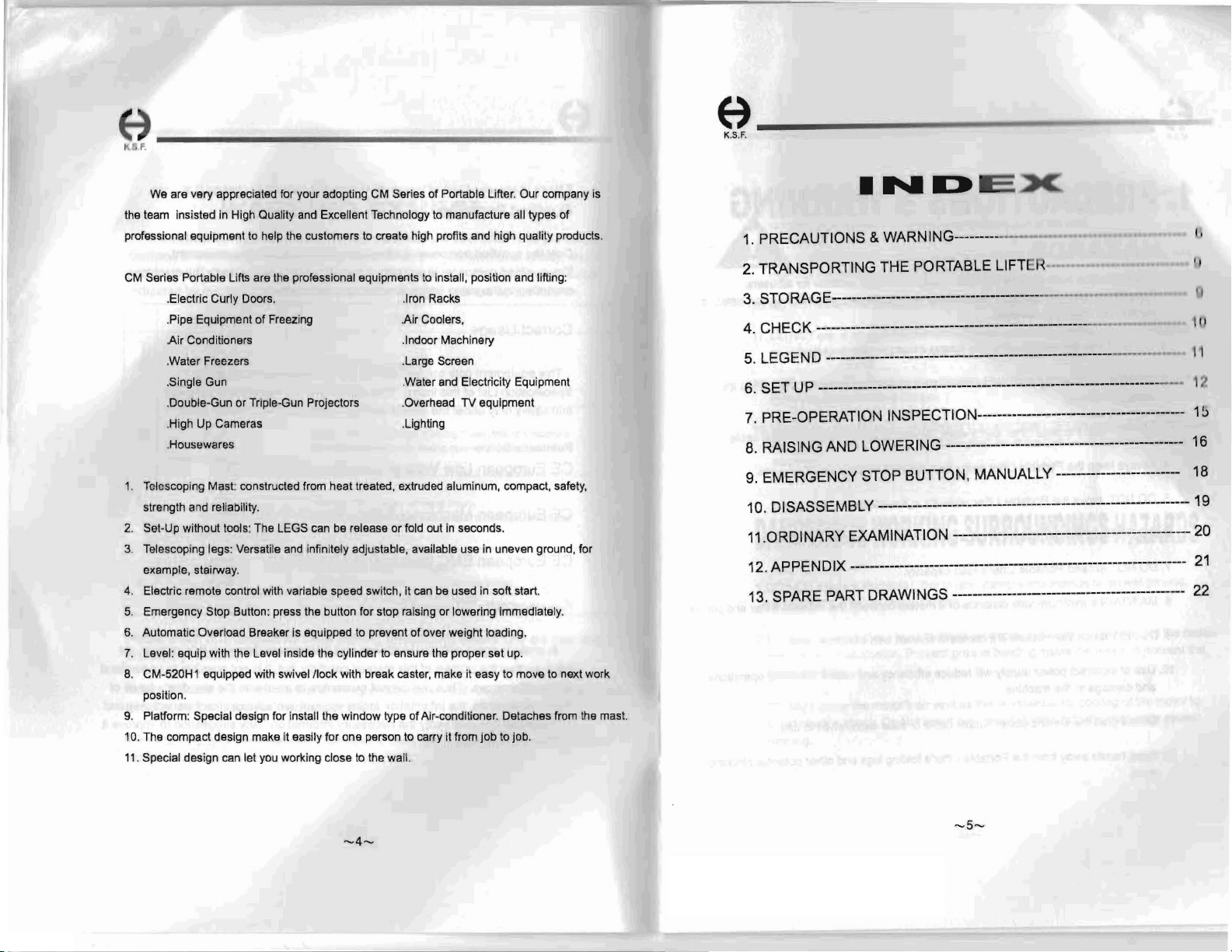

We are very appreciated for your adopting CM Series of Portable Lifter. Our company is

the team insisted in High Quality and Excellent Technology to manufacture all types of

professional equipment to help the customers to create high profits and high quality products .

CM Series Portable Lifts are the professional equipments to install, position and lifting:

.Electric Curly Doors. .Iron Racks

.Pipe Equipment of Freezing .Air Coolers ,

.Air Conditioners .Indoor Machinery

.Water Freezers .Large Screen

Water

.Single Gun

.Double-Gun or Triple-Gun Projectors .Overhead TV equipment

.Hiqf Up Cameras .Lighting

.Housewares

and Electricity Equipment

a

K.S,F.

1.

PRECAUTIONS

TRANSPORTING

2.

3. STO RAG E-------------------------------------------- --

4. CHECK --------------------------------------------------------

5. LEGEND ---------------------------------------------------------- -- - _•

6. SET UP ---------------------------------------------------------------------- ,

7. PRE-OPERATION INSPECTION----------------------------------------- 1

8. RAISING AND LOWERING ------------------------------------------------ 16

--

•

.-.11::»

& WARNING----------

THE PORTABLE L1FTEI{·

-

I ,

I)

1u

l '

~

1. Telescoping Mast: constructed from heat treated, extruded aluminum, compact , safety,

strength and reliab ility.

2. Set-Up without tools : The LEGS can be release or fold out in seconds.

3. Telescoping legs: Versatile and infinitely adjustable, available use in uneven ground, for

example, stairway.

4. Electric remote control with variable speed switch, it can be used in soft start.

5. Emergency Stop Button: press the button for stop raising or lowering immediately.

6. Automatic Overload Breaker is equipped to prevent of over weight loading.

7. Level: equip with the Level inside the cylinder to ensure the proper set up.

8. CM·520H1 equipped with

position .

9. Platform: Special design for install the window type of Air-conditioner. Detaches from the mast.

10. The compact design make it easily for one person to carry it from job to job.

11. Special design can let you working close

swivel/lock

with break caster, make it easy to move to next work

to the wall.

~4~

EMERGENCY

9.

O. DISASSEMBLY -------------------------------

1

11.0 RDINARY EXAMINATION ------------------------------------------------ 20

12. APPEN DIX

13. SPARE PART DRAWINGS ------------

STOP BUTTON, MANUALLY ------------------------- 18

---------------------

-----------------

~5~

-----------

------

--------- 19

21

-------

22

a_

K.S.F.

- - -

1.

PRECAUTIONS

HAZARDS

This instruction book shall be put in an easily accessible location for all users .

FAILURETO OBEYTHE

INJURY AND

1. DO NOT use this equipment to life people or as a ladder or step .

2. DO NOT stand under or allow person to stand under the Portable Lifter while it's

raising or raised .

3. DO NOT use Portable Lifter with a worn , frayed, kinked or damaged steel cable.

4. Always keep the Portable Lifter away from the high voltage electrical wires .

5. DO NOT move the Portable Lifter while it's in the raised position.

6.

00

7. DO NOT exceed Portable Lifter's load capacity.

8. MAINTAIN a minimum safe distance of 3 meters between the Portable Lifter and people.

9.

00

10. Use of incorrect power supply will reduce efficiency and cause abnormal operations

and damage to the machine.

11. Do not grab the electric power supply cable or steel cable when in use .

12. Keep hands away from the Portable Lifter's folding legs and other potential pinching

point.

PROPERTY

NOT use the Portable Lifter on a moving surface or vehicle .

NOT touch the machine if it comes in contact with electrical wires.

INSTRUCTIONS

DAMAGE.

AND

&

SAFETY

WARNltlG

~

RULES

MAY

RESULTINDEATH,

SERIOUS

13. DO NOTlower the load unlessthe area bulow I"

14. DO NOT place ladder or scaffolding against any

15. No untrained or unauthorized personnel to operatu

instruction is needed to maintain safe operations.

16. DO NOT disassemble and part of this unit. Contact distributor

17.DO NOT use or operate the Portable Lifter for operationsoutsides of 'Uwrrll'

specifications in this instruction book.

18.USE only approved tools onthis machine. Use oftools not approved may dalllllllu lh

Portable Lifter and cause danger.

19. PRESS the EMERGENCY STOP BUTTON and TURN OFF the power supply if probtorns

occur during operation. Stop using the machine immediately and contact an authorised

repairer.

DANGEROUS

1

.00

NOT

operate Portable Lifter in rain,

because

2.00

may cause an explosion. Prevent

motor

3

.00

avoid electric shock.

runn ing .

of the risk of electric shock.

NOT

operate close to pertroleum products, gas or oil as operation of the motor

burning.

NOT

cover

WORKING

the motor's air

00

Not

SURROUNDINGS

grease

vent

as this is essential for cool ing of the motor to

insert

any

drill

! of

lJUI

I l·'Il".l lll

p;1I1

"f 1I,Ia unn

11101111'

111,

1," , I'rUI'III Irlllninu

101

damp

surroundings or on

building inside the

metal objects into the

lllOI'I

II\l(,

IIQ

I\

1'1\1

1

"llll"

..1

HAZARDS

wet

ground,

motor

to prevent the

vent

while motor

-6-

-7-

a_ - - -

ro

.

K.S.F.

4.Keep the work space and surroundings clean and tidy. Working in dirty or dark

surroundings could cause an accident.

5. DO NOT operate the machine on any unsteady surface. The machine must be kept

steady and balanced when in use.

6. DO NOT operate the machine in strong or gusty winds.

7. If the loading objects are over-weight or large , it will reduce the balance of the

machine. just as the machine operating under the strong winds . Thus , if the

measurement is too large, must keep the load staying in the center of Platform .

8. Prior to use. check the work area for drop-ofts, holes, bumps. debris, unstable or

slippery surfaces or other possible hazardous conditions .

INCORRECT

t , DO NOT grab the electric cable, or

operating. This will avoid short circuiting the motor.

2. Keep the electric cable away from sharp or hot object.

:J. If tho

electric

repaired or roplaced before operating the Portable

USAGE

cable is damaged, please stop using it immediately. Have the cable

OF

ElECTRIC

pullout

it from a power point while the motor is

CABlE

Lifter

HAZARDS

again.

4. The Portable Lifter is equippUl!willi

Checking if it's in the condition of lovollnu bululll 1

5. Ensure the steel cable is

A): not worn or frayed.

B): not derailed and not caught in obstructions.

C): not hooked by abnormal objects causing unusunl hlt;llo" or 1'

6. Ensure the manual handle IS NOT installed in the manual Sililil.

7. Ensure the power supply is correct voltage before connecting the mochln

8. Check the work area for overhead obstructions or other possible hazards.

2.

TRANSPORTING

, .The export delivery of the Portable Lifters are used the strong packing and put into the

standard carton, and then adopt the proper transportation way to deiiver to the

appointed place.

2.00 not throwing the machine heavily or put the heavy objects on the machine while

transport. When piling up. please go ahead according to the indicated piling numbers

marked in carton.

3.lf this machine will not be operated promptly, please keep it in the proper storage place.

As for the storage condition. please refer to the paragraph of Storage in this manual.

L

ll

v

u I LJ

(J

'I lr'~

THE

PORTABLE

1l1

(I

...

. 1

1I1I

pll'" 1M,,,

t,,llM

"UI

I'"

''

Illllll v"llI

nllll ll"

LIFTER

CHECKING

t . Ensure the legs are fixed fastened .

2.

Ensure

3.

Ensure the

Portable

Lifter is in a safety work area.

load

object

BEFORE

is put in the

center

-8-

RAISING

of Platform.

3.

1. Storage temperature: -5K - 45K .

STORAGE

Humidity control : 90% within non-dewing

-9-

Loading...

Loading...