DYNAMIC CONE PENETROMETERS

USER’S

MANUAL

All rights reserved by

Kessler Soils Engineering Products, Inc.

17775 Running Colt Place, Leesburg, VA 20175

SALES: (703) 569-2583 or (800) 569-7303

www.kesslerdcp.com

Meets ASTM D6951

PATENT NO. 5,313,825

K-100 Models

WITH QUICK CONNECT PIN

KSE DCP

DO NOT

PUT HAND NEAR

THE ANVIL WHEN

HAMMER IS RAISED

KEEP ONE HAND ON

THE HANDLE WHILE

OPERATING

THE DCP

SAFETY NOTICE

ALWAYS SECURE THE HAMMER AND/OR

THE ASSEMBLED DCP INSTRUMENT

WHEN PLACING IT ON ANY FLAT ELEVATED SURFACE TO PREVENT

IT FROM ROLLING OFF AND CAUSING PERSONAL INJURY OR

DAMAGE TO THE INSTRUMENT.

Copyright ©2014 Kessler Soils Engineering Products, Inc.

All Rights Reserved, Printed in the USA

INDEX

Application 1

Description 3

Procedures 7

Correlations 14

Maintenance 28

References 28

Warranty 30

MANUAL FOR IN SITU STRENGTH OF SOILS

USING THE KESSLER DYNAMIC CONE PENETROMETER

PART I: DCP WITH VERTICAL SCALE

PART II: DCP WITHOUT VERTICAL SCALE

Application 18

Description 19

Procedures 20

Correlations 22

Parts List 31

PART III

PART I

DCP With Vertical Scale

1. APPLICATION

1.1 This application describes measurement of the

penetration rate of the KESSLER DCP (Dynamic Cone

Penetrometer) with a Single-Mass or Dual-Mass Hammer

and quick-connect Drive Rod in field soil testing using a

Vertical Scale.

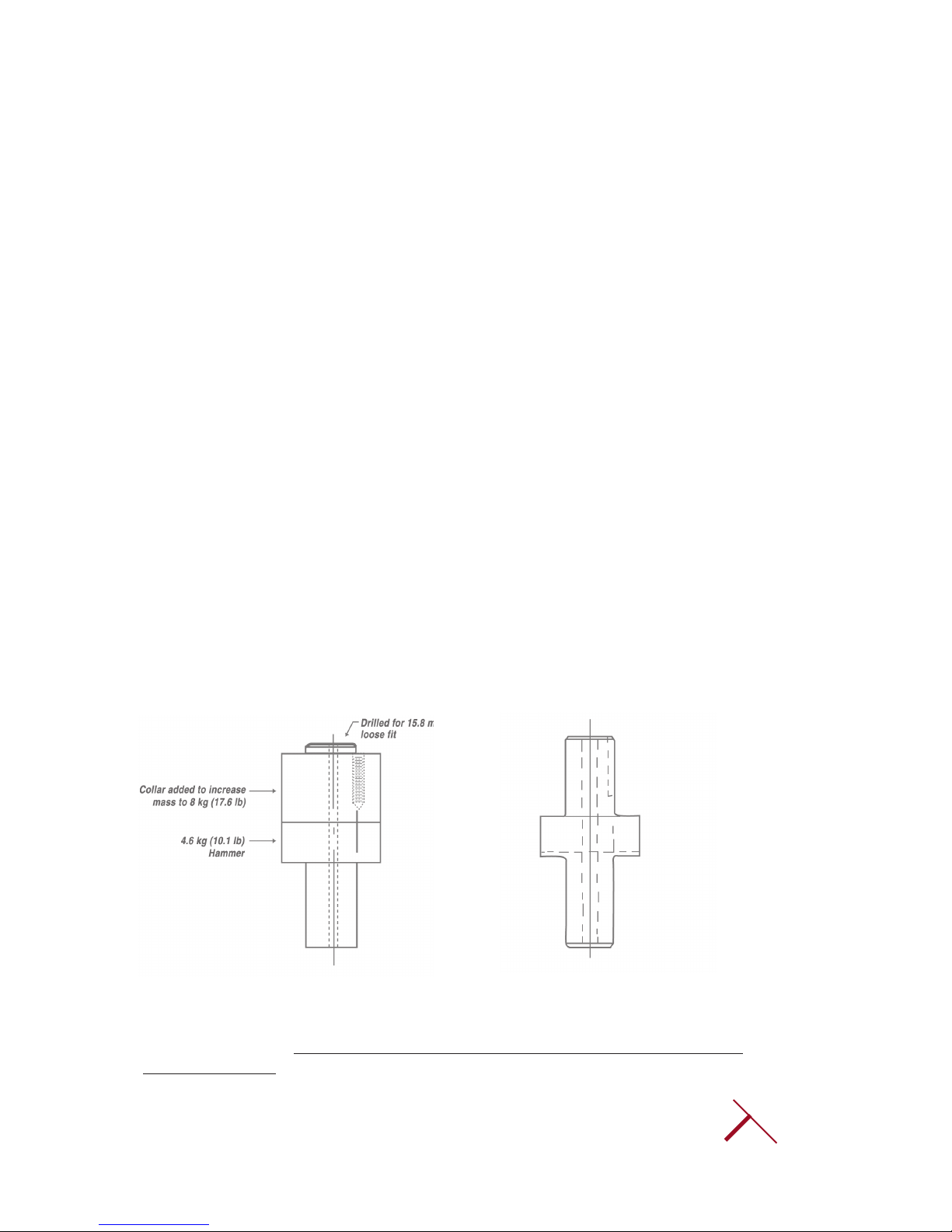

1.2 The KESSLER DCP is driven into the soil by

dropping either a Single-Mass 17.6 lb (8kg) Hammer or a

Dual-Mass Hammer from a height of 22.6 in (575mm). To

convert the Dual-Mass Hammer from a 17.6 lb hammer to

a 10.1 lb Hammer, remove the hexagonal set screw and

the outer steel sleeve (as shown in Fig. 2). The outer steel

sleeve is designed to slide over the DCP handle for ease of

conversion during testing. The cone penetration caused by

one blow of the 17.6 lb (8 kg) hammer is essentially twice

that caused by one blow of the 10.1 lb (4.6 kg) hammer.

The 10.1 lb (4.6 kg) hammer is used in weaker soils having

a CBR value of 10 or less and can be used on soils up to CBR

80. The 17.6 lb (8 kg) hammer penetrates high strength

soils quicker. The depth of cone penetration is measured at

selected penetration or hammer drop intervals and the soil

shear strength is reported in terms of DCP index. The DCP

index is based on the average penetration depth resulting

from one blow of the 17.6 lb (8 kg) hammer. The average

penetration per hammer blow of the 10.1 lb (4.6 kg)

hammer must be multiplied by 2 in order to obtain the DCP

index value from the correlation equation in paragraph 4.

1.3 The KESSLER DCP can be used to estimate the

strength characteristics of fine and grained soils, granular

construction materials and weak stabilized or modified

materials.

APPLICATION

1

Thank you for your purchase of a Kessler DCP (Dynamic Cone

Penetrometer), licensed to Kessler Soils Engineering Products, Inc.

by the U.S. Army Corps of Engineers (Patent No. 5,313,825).

The Kessler DCP is a durable and reliable Penetrometer

designed for field soil testing and measuring.

2

APPLICATION

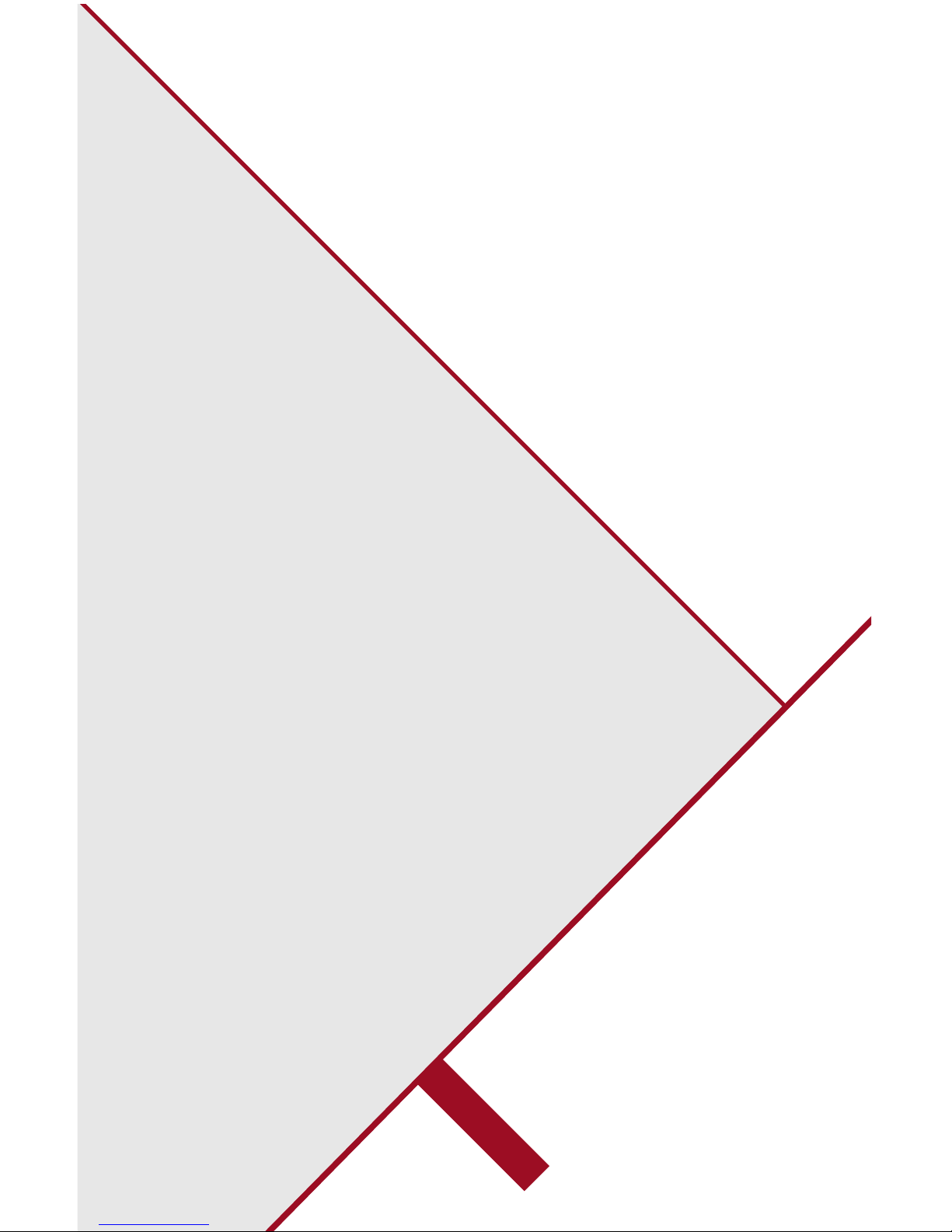

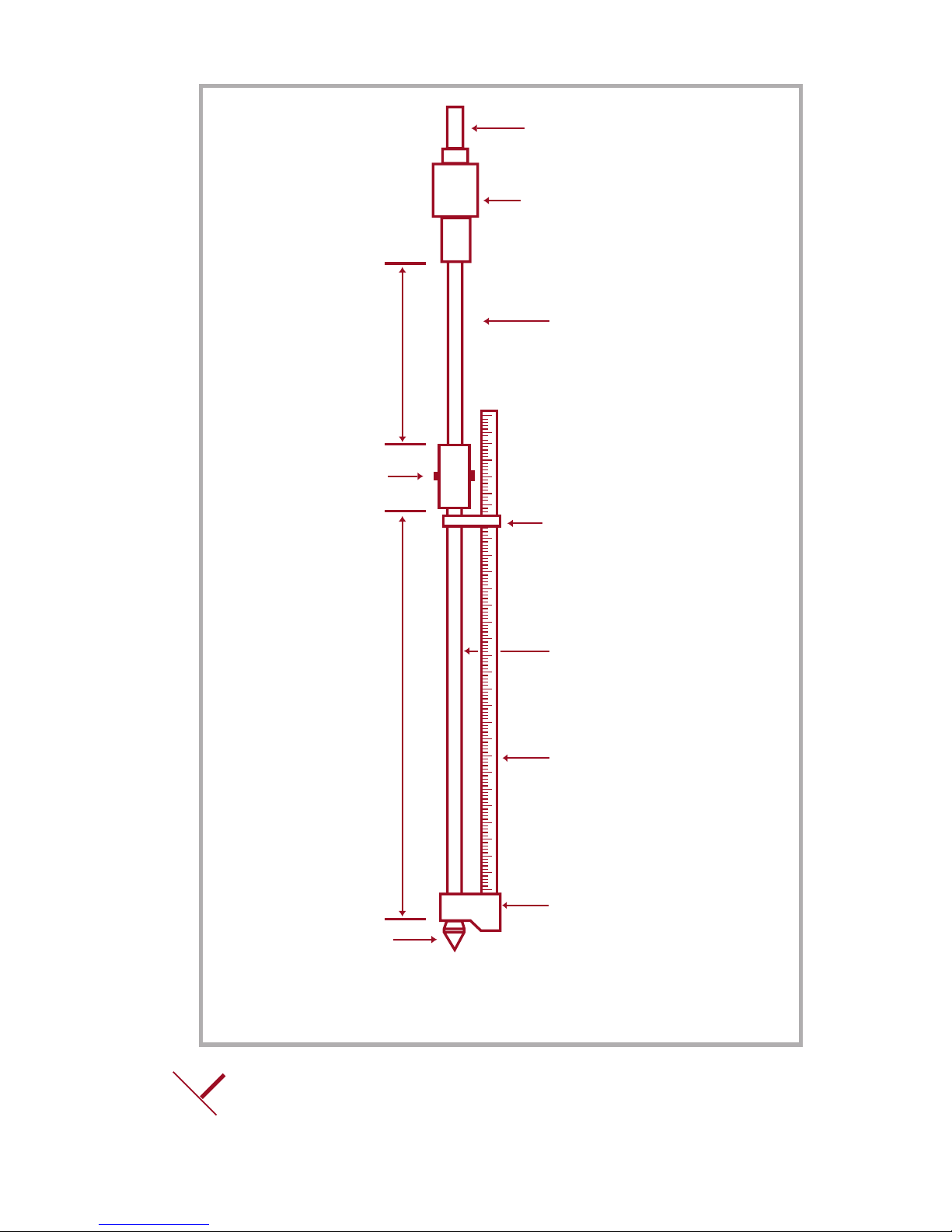

575 mm

22.6 in

Anvil with

Quick-Connect Pin

Ve

Upper Rod

Handle

Upper

Attachment

Foot

Variable

30, 37.75, 40 in

Drive Rod

5/8 in (16 mm) diameter

Single Mass OR Dual-Mass

Hammer

17.6 lb (8 kg) OR 10.1 lb (4.6 kg)

rtical Scale

Tip (Reusable

Hardened Point or

Disposable Cone)

Figure 1–Schematic of DCP Device

1

METHOD ST6 (1984) Measurement of the In Situ Strength of Soils by the Dynamic Cone

Penetrometer (DCP) (1984) Special Methods for Testing Roads, Draft TMH 6, Technical

Methods for Highways (TMH), Pretoria, South Africa. ISBN 0 7988 2289 9,Page 20.

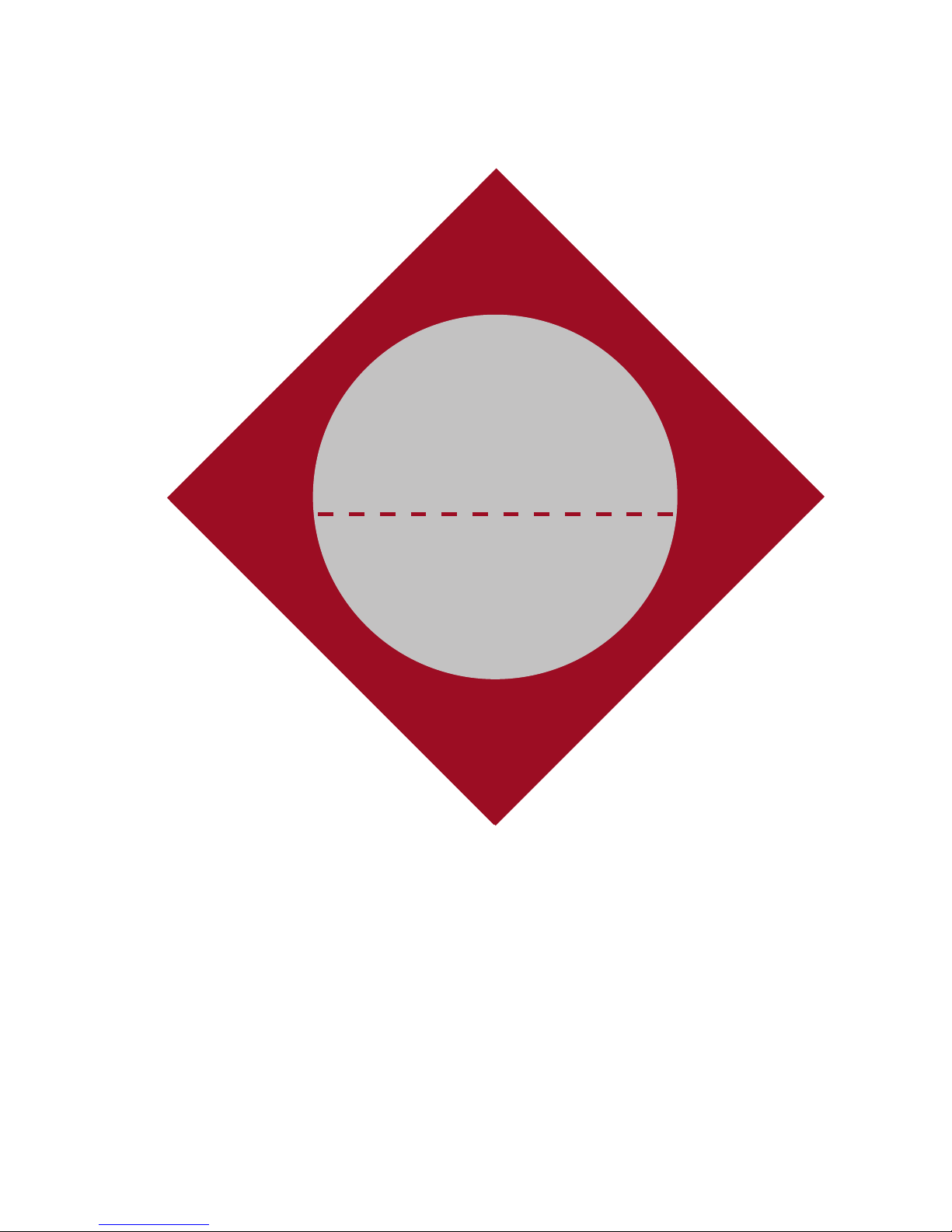

Figure 2–Dual-Mass Hammer

1.4 The KESSLER DCP can be used to estimate the

strength of in situ materials underlying a bound or highly

stabilized layer by first drilling or coring an access hole.

NOTE: The DCP may be used to assess the density of a fairly uniform material by

relating to penetration rate on the same material. In this way under compacted

or ”soft spots“ can be identified, even though the DCP does not measure density

directly.

A field DCP measurement results in a field or in situ CBR and will not

normally correlate with the laboratory or soaked CBR of the same material. The

test is thus intended to evaluate the in situ strength of a material under existing

field conditions.

1

2. DESCRIPTION

2.1 The KESSLER DCP in Fig.1 consists of an upper

assembly with a Single Mass or Dual-Mass Hammer (Fig. 2),

a Drive Rod and a tip. The Drive Rod is held in place with a

Quick-Connect Pin (Fig. 3) through the anvil. The tip consists

of an Adapter and Disposable Cone (Fig. 4) or reusable

Hardened Point (Fig. 5). The DCP is constructed of stainless

steel, with the exception of the tip. The Hardened Points

and the Adapters for the Disposable Cones are heat treated

steel. The Disposable Cones are plated steel.

DESCRIPTION

3

17.6 lb (8kg) Hammer 10.1 lb (4.6kg) Lower Hammer

DESCRIPTION

4

Upper rod

Anvil

Quick connect pin

Drive rod

End cap

Figure 3–Quick Connect Assembly

(Patent Pending)

Figure 4–Adapter with two Disposable Cones

Figure 5– Reusable Hardened Point

2.2 The instrument is manufactured to the following

specifications:

(1) Hammer weight measurement of 17.6 lb (8kg)

tolerance is 0.022 lb(0.010kg).

(2) Hammer weight measurement of 10.1 lb

(4.6kg) tolerance is 0.022 lb (0.010kg).

(3) Drop of hammer measurement of 22.6 in (575

mm) tolerance is 0.039 in (1.0 mm)

(4) Tip included angle measurement of 60

degrees; tolerance is 1 degree.

(5) Tip base diameter measurement of 0.790 in

(20 mm); tolerance is 0.010 in (0.25mm)

DESCRIPTION

5

NOTE: The Disposable Cone tip shown in Figure 4 is held in place with an

o-ring. Use Disposable Cone tips in hard and cohesive soils to allow easy

extraction of the instrument. The Disposable Cone tip is designed to slide off

the Adapter when the Drive Rod is pulled upward after completion of the test.

DESCRIPTION

6

DESCRIPTION

6

DESCRIPTION

6

2.3 Replacement and Optional DCP equipment can be

found at www.kesslerdcp.com, including:

- 12”, 30” and 37.5” Drive Rods

- 48” Drive Rod

- 12” and 24” Extension Rods

- Magnetic Ruler

- Magnetic Ruler Printer

2.4 Other equipment used to make an access hole

through a bound layer may include:

- a rotary hammer drill or coring appartus capable of

drilling a minimum diameter hold of 1 inch (25mm).

A larger hold make be required depending on the

underlying material or the need for additional tests

or sampling.

- a wet/dry vacuum or suitable alternative to

remove loose material and fluid if an access

hole is made before testing.

- a field power supply to power above items.

3. PROCEDURES

3.1 Equipment Check

3.1.1 Before beginning a test, check to ensure the

Drive Rod is straight by rolling the rod on a flat surface.

Note: The Drive Rod may bend if driven beyond refusal

(see para 3.3.3).

3.1.2 The Hardened Point must be checked to ensure

the 3 mm flat is discernible. The flat area will become

rounded after about 250 tests and the tip should be

replaced. Rarely, if ever, does the Hardened Point wear to

the extent that the diameter fails to meet specifications

(see para 2.2).

3.1.3 The Adapter o-ring should be should be clean and

free of cuts or nicks. Each pack of 25 Disposable Cones contains a replacement o-ring.

3.2 Assembling

3.2.1 Vertical Scale- Secure the black delrin Upper

Attachment by tightening the screw just below the end

cap. Next, place the foot over the end of the Drive Rod.

Slide the Vertical Scale through the square hole in Upper

Attachment and into the foot.

3.2.2 Tip- Tighten the tip securely with the wrenches.

3.2.2.1 The reusable Hardened Point is used in soft, non-

cohesive material, i.e. where the DCP advances more than

1/2” per blow (CBR <18%).

3.2.2.2 The Adapter and Disposable Cones should be

used for cohesive material and material where the DCP

advances less than 1/2” per blow (CBR >18%). Attach the

disposable cone to the adapter by applying pressure and

rotating the cone. This will ensure proper seating and

extend the life of the o-ring.

3.2.3 Drive Rod (30”, 37 3/4”, or 48”)- Slide the Drive

Rod into the anvil, insert the Quick-Connect Pin and

retainer clip. Treat the drive rod with a light film of oil

to minimize skin friction. This is especially important in

cohesive soils.

7

PROCEDURES

3.2.4 Drive Rod (12”) with 12” or 24” Extension- Use

only for material where DCP advances more than

1” per blow (CBR < 8%) and always use Disposable

Cones. Screw one 12” or 24” Extension Rod into the

12” Drive Rod and tighten with wrenches. Reassemble

DCP hammer assembly and restart the test. The test can

be conducted to a depth of 6 feet by adding additional

Extensions Rods in a similar manner. If you are using the

US Army Corps of Engineers Excel template we provide

to reduce your data, it will be necessary to book each

22” segment of the test in a separate file as this template

cannot be modified. You may wish to use the equations

provided in paragraph 4.1 to make your own template.

3.2.5 Adding 12” or 24” Extensions- After the 12” Drive

Rod and 24” Extension have been advanced, disconnect

the Drive Rod from the anvil and the Extension Rod. Screw

the second Extension Rod into the rod in the ground and

the Drive Rod using wrenches. Reassemble DCP hammer

assembly and restart the test. The test can be conducted to a

depth of 6 feet by adding the Extensions in a similar manner.

If you are using the Excel template we provide from the

US Army Corps of Engineers to reduce your data, it will be

necessary to book each 22” segment of the test in a separate

file as this template cannot be modified. You may wish to

use the equations provided in paragraph 4.1 to make your

own template.

3.3 Testing Sequence

3.3.1 Dropping the Hammer- Hold the DCP device

in a vertical position. Raise the Hammer until it touches,

but does not impact, the handle. Allow the Hammer to

fall freely and impact the anvil coupler assembly. Record

the number of blows and corresponding penetration as

described in paragraph 3.6.

3.3.2 Depth of Penetration- The depth of penetration

will vary with application. For typical highway applications,

a penetration of less than 692 mm (27 1/4 in) will generally

be adequate. In soft soil, the DCP may be advanced to 6

feet (See

PROCEDURES para 3.2.4 and 3.2.5).

PROCEDURES

8

3.3.3 Refusal- The presence of aggregates > 2” or rock

strata will either stop further penetration or deflect the

drive rod. If, after 3 blows, the device has not advanced

more than 0.08 in (2 mm) or the handle has deflected

more than 3 in (75 mm) from the vertical position, stop

the test and move the device to another test location.

Continuing to drop the hammer will damage the

instrument. The new test location should be a minimum

of 12 in (300 mm) from the prior location to minimize test

error caused by disturbance of the material.

3.3.4 Extraction- Following completion of the test,

extract the device by driving the hammer upward against

the handle. Use a smooth upward movement and do

not throw the hammer against the handle.

3.4 Caution

• DO NOT drop the hammer after refusal.

• DO NOT throw the hammer upwards.

• DO NOT rock the DCP side to side or forward and

backward in an attempt to loosen it from the ground.

3.5 Initial Reading

3.5.1 Testing a surface layer- Hold the DCP vertically

with the top of the widest part of the tip flush with the

surface of the material to be tested. Take an initial reading from the Vertical Scale, measuring the distance to the

nearest 1 mm (0.04 in).

3.5.2 Testing below a bound layer- When testing mate-

rials underlying a bound layer, a rotary hammer drill or

coring apparatus meeting the requirements given in paragraph 2.4 is used to provide an access hole to the layer

to be tested. Wet coring requires that coring fluid be

removed immediately and the DCP test be performed as

soon as possible. The coring fluid must not be allowed to

9

PROCEDURES

soak into or penetrate the material to be tested. A wet/dry

vacuum or suitable alternative is used after completion of

drilling or coring to remove loose material and fluid from

the access hole before testing. To minimize the extent of

the disturbance from the rotary hammer, drilling should

not be taken completely through the bound layer, but

stopped short by about 10 to 20 mm. The DCP is then used

to penetrate the bottom portion of the bound layer. This

can be a repetitive process between drilling and doing DCP

tests to determine the thickness of the layer.

3.5.3 Testing pavement with thin seals — For pavements

with thin seals, the tip is advanced through the seal until

the top of the widest part of the tip is flush with the layer

to be tested.

3.5.4 Once the layer to be tested has been reached- A

reference reading is taken with the cone zero point at the

top of that layer and the thickness of the layer(s) cored

through recorded. This reference reading is the point from

which the subsequent penetration is measured.

3.6 Recording Methods

3.6.1 Two person, traditional method (Figure 6A)-

When many tests are to be taken, it is best to have two

people operating the DCP and recording the data. The

recorder reads the scale at the top of the attachment or

holds the Vertical Scale to the bottom of the widest part

of the hammer and measures/records the cumulative penetration for the number of blows in a set. The set is the

number of blows it takes to advance the DCP about 2 in (50

mm). The data is recorded on the DCP data sheet.

3.6.2 One person with Vertical Scale (Figure 6B)- Apply

blue removable tape along the side of the Vertical Scale

adjacent to the mm markings. Insert the Vertical Scale

through the Upper Attachment and into the Foot. At the

end of each set, the operator marks the position of the top

edge of the Upper Attachment by drawing a line along it

on the blue tape, and writes the number of blows required

next to the line. After the test, the operator enters the

PROCEDURES

10

cumulative penetration and number of blows between

marks on a DCP data sheet or in the Excel template.

11

PROCEDURES

Figure 6A–Two person,

traditional method

One person operates

DCP while the other

person records

penetration rate

Figure 6B–One person

One person operates

DCP, then marks the

tape on the Vertical

Scale.

12

PROCEDURES

3.6.4 Magnetic Ruler (Figure 7)- The optional Magnetic

Ruler is a battery-operated AAA (Qty. 6), data-collection

device for the Dynamic Cone Penetrometer (DCP). It

displays depth, blows, mm/blow, cumulative mm/blow , and

cumulative blow/inch in SI and English. The correlations

are CBR (California bearing ratio) in %; Bearing capacity

in Kips per square foot, and unconfined compression test

in %. A flash drive records the data, information entered

by the operator, and date and time for each test via a

waterproof USB port.

3.7 Data Recording

A form like the one shown in Figure 8 is suggested for data

recording. The recorder enters the header information

before the test.

(1) The actual test data is recorded in column 1

(Number of Blows) and column 2 (Cumulative Penetration

in mm); if the moisture content is available, it is entered in

column 8.

(2) When testing a subsurface layer through a

drilled or cored access hole, the first reading corresponds

to the referenced reading at the top of the layer to be

tested.

(3) The number of blows between readings may

be varied depending on the resistance of the material.

Normally readings will be taken approximately every 50

mm (2”), i.e. 1 blow for soft material, 5 blows for “normal” materials and 10 blows for very resistive materials.

(4) The tip should be advanced a minimum of 25

mm (1.0 in) between readings. The penetration to the

nearest 1 mm (0.04 in) corresponding to the specific number of blows is recorded. A reading is taken immediately

when the material properties or rate of advance change

significantly.

13

PROCEDURES

Figure 7–Magnetic Ruler

Instruction for Data Recording Sheet:

(1) Number of hammer blows between test readings

(2) Cumulative penetration after each set of hammer blows

(3) Difference in cumulative penetration (2) between readings

(4) (3) divided by (1)

(5) Enter 1 for 17.6lb (8kg) hammer; 2 for 10.1 lb (4.6kg) hammer

(6) (4) x (5)

(7) From CBR verses DCP Index correlation

(8) % Moisture content when available

14

CORRELATIONS

4. CORRELATIONS

4.1 The CBR may be estimated using the DCP index

(column 6 on the DCP Data Sheet) and Table 1 for each

set of readings. First, the DCP index is computed for

the respective penetration between readings. The

penetration per blow is then used to estimate in situ CBR

or shear strength using the appropriate correlation for

the reference. For example, the correlation of penetration

per blow (DCP) in Table 1 is derived from the equation

CBR = 292 / PR

1.12

recommended by the US Army Corps

of Engineers. This equation is used for all soils except for

CL soils below CBR 10% and CH soils. For these soils, the

following equations are recommended by the US Army

Corps of Engineers, where PR is the DCP penetration rate

in mm per blow:

3

CL soils CBR < 10: CBR = 1 / (0.017019*PR)2

CH soils: CBR = 1/ (0.002871*PR)

Selection of the appropriate correlation is a matter of

professional judgment.

4.2 The Modulus of Rigidity M

R

may be estimated

using between 1300 to 1500 CBR.

4.3 If a distinct layering exists within the material test-

ed, a change of slope on a graph of penetration/blow vs.

depth will be observed for each layer. The exact interface

is difficult to define because, in general, a transition zone

exists between layers. The layer thickness can be defined

by the intersection of the lines representing the average

slope of adjacent layers. Once the layer thicknesses have

been defined, the average penetration rate per layer is

calculated.

4.4 The EXCEL

™

template on the enclosed CD will graph

the results of the test. (See instruction sheet included on

CD). It will also plot a correlation of CBR to PSF (lbs/sq. ft).

DCP DATA SHEET

Project: Forest Service Road

Location: STA 30+50, 1 M RT of C/L

Depth of zero point below: 0

Material Classification: GW/CL

Pavement conditions: Not applicable

Date: 7 July 2005

Personnel: JLS & PAK

Hammer Weight: 17.6lb (8kg)

Weather: Overcast, 25°C, (72° F)

Water Table Depth: Unknown

(1)

Number

of

Blows

(2)

Cumulative

Penetration

(mm)

(3)

(4)

(5)

Hammer

Blow

Factor

(6)

DCP

Index

mm/blow

(7)

CBR

%

(8)

Moisture

%

0

5

5

15

10

5

5

10

5

5

5

5

0

25

55

125

175

205

230

280

310

340

375

435

--

25

30

70

50

30

25

50

30

30

35

60

--

5.0

6.0

4.7

5.0

6.0

5.0

5.0

6.0

6.0

7.0

12.0

--

1

1

1

1

1

1

1

1

1

1

1

--

5.0

6.0

4.7

5.0

6.0

5.0

5.0

6.0

6.0

7.0

12.0

--

50

40

50

50

40

50

50

40

40

35

18

Figure 8–DCP Data Sheet

2

1

2

3

4

5

6

7

8

9

10

11

12

2

Webster, S.L., Grau, R.H. Williams, T.P., (May 1992), Description and Application of

Dual mass Dynamic Cone Penetrometer, Report GL-92-3, Department of the Army, Washington

D.C., Pg. 19

CORRELATIONS

15

Penetration

Between

Reading

(mm)

Penetration

per

Blow

(mm)

73Webster, S.L., Brown, R.W., Porter, J.R. (April 1994), Force Projection

Site Evaluation Using the Electric Core Protection (ECP) and the Dynamic Cone

Penetrometer (DCP), Technical Report No. GL-94-17, Air Force Civil Engineering

Support Agency, U.S. Air Force, Tyndall Air Force Base, Florida

3

Table 1–Tabulated Correlation of CBR versus DCP Index

DCP Index

mm/blow

CBR

%

DCP Index

mm/blow

CBR

%

DCP Index

mm/blow

CBR

%

<3

3

4

5

6

7

8

9

10-11

12

13

14

15

16

17

18-19

20-21

22-23

24-26

27-29

30-34

35-38

100

80

60

50

40

35

30

25

20

18

16

15

14

13

12

11

10

9

8

7

6

5

39

40

41

42

43

44

45

46

47

48

49-50

51

52

53-54

55

56-57

58

59-60

61-62

63-64

65-66

67-68

4.8

4.7

4.6

4.4

4.3

4.2

4.1

4.0

3.9

3.8

3.7

3.6

3.5

3.4

3.3

3.2

3.1

3.0

2.9

2.8

2.7

2.6

69-71

72-74

75-77

78-80

81-83

84-87

88-91

92-96

97-101

102-107

108-114

115-121

122-130

131-140

141-152

153-166

166-183

184-205

206-233

234-271

272-324

>324

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

>0.5

16

CORRELATIONS

PART II

DCP Without Vertical Scale

5. APPLICATION

5.1 This application describes measurement of

the penetration rate of the KESSLER DCP (Dynamic Cone

Penetrometer) with a Single-Mass Hammer and quick-connect

Drive Rod in field soil testing without a Vertical Scale.

5.2 This procedure is used to assess the in place

strength of undisturbed soil and/or compacted materials. The penetration rate can be used to estimate CBR

(California Bearing Ratio), shear strength of strata, and

thickness of strata. It is ideal for horizontal construction

applications, such as shallow foundations and pavement

shoulders. Typically it is used to assess material properties to a depth of 36 in (914 mm) below the surface. With

extensions the driving rod can be advanced to 6 ft ( 2 m).

5.3 The operator drives the DCP tip into soil by lifting the sliding hammer to the handle then releasing it. The

total number of blows for a given depth( i.e. 2”, 4”, or 6”)

is recorded. This blow count is then used to estimate the

in

situ

shear strength or CBR from an appropriate correlation

chart.

5.4 The Single Mass DCP can be used to estimate the

strength characteristics of fine and grained soils, granular

construction materials and weak stabilized or modified

materials. It should not be used in highly stabilized or

cemented materials or for granular materials containing

aggregates greater than 2 in ( 50 mm).

18

APPLICATION

19

DESCRIPTION

6. DESCRIPTION

6.1 The KESSLER DCP consists of an upper assembly

with a Single Mass Hammer, a Drive Rod and a tip. The

upper rod, drive rod, handle and anvil are stainless steel.

The Drive Rod is held in place with a Quick-Connect Pin

(Fig.3) through the anvil. The tip consists of an Adapter and

Disposable Cone (Fig.4) or reusable Hardened Point (Fig.5).

The DCP hammer is constructed of steel. The Hardened

Points and the Adapters for the Disposable cones are heat

treated then plated. The Disposable cones are plated steel.

6.2 The instrument is manufactured to the following

specifications:

(1) Hammer weight measurement of 10.1lb

(4.6Kg). Tolerance is 0.022lb (0.010K).

(2) Hammer weight measurement of 17.6 lb (8kg)

tolerance is 0.022lb (0.010kg).

(3) Drop of hammer measurement of 22.6in

(575mm). Tolerance is 0.039in ( 1.0mm).

(4) Tip included angle measurement of 60 degrees;

tolerance is 1 degree.

(5) Tip base diameter measurement of 0.790 in (20

mm); tolerance is 0.010 in (0.25 mm).

7. PROCEDURES

7.1 Equipment Check

7.1.1 Before beginning a test, check to ensure the

Drive Rod is straight by rolling the rod on a flat surface.

NOTE: The Drive Rod may bend if driven beyond refusal (see para 3.3.3).

7.1.2 The Hardened Point must be checked to

ensure the 3 mm flat is discernible. The flat area will

become rounded after about 250 tests and the hardened point should be replaced. Rarely, if ever, does the

Hardened Point wear to the extent that the diameter fails

to meet specifications (see para 2.2).

7.2 Testing Sequence

7.2.1

Dropping the Hammer

- Hold the DCP device

in a vertical position. Raise the Hammer until it touches,

but does not impact, the handle. Allow the Hammer to

fall freely and impact the anvil coupler assembly. Count

the number of blows for corresponding penetration for

each 2” increment on the drive rod. Use Tables 3, 4, and

5 for the correlation, the blow count, and the bearing

capacity in PSF (pounds per square foot).

7.2.2

Refusal

- The presence of aggregates > 2”

or rock strata will either stop further penetration or

deflect the drive rod. If, after 3 blows, the device has not

advanced more than 0.08 in (2 mm) or the handle has

deflected more than 3 in (75 mm) from the vertical position, stop the test and move the device to another test

location. Continuing to drop the hammer will dam-

age the instrument. The new test location should be

a minimum of 12 in (300 mm) from the prior location to

minimize test error caused by disturbance of the material.

20

PROCEDURES

21

PROCEDURES

7.2.3

Extraction

- Following completion of the test,

extract the device by driving the hammer upward against

the handle. Use a smooth upward movement and do

not throw the hammer against the handle.

7.3 Caution

•DO NOT drop the hammer after refusal.

•DO NOT throw the hammer upwards.

•DO NOT rock the DCP side to side or forward

and back in an attempt to loosen it from

the ground.

7.4 Use of Disposable Cones

7.4.1 The adapter and disposable cones should be

used for cohesive material and material where the DCP

advances less than 1/2” per blow ( CBR > 18%). Attach the

disposable cone to the adapter by applying pressure and

rotating the cone. This will ensure proper seating and extend the life of the o-ring.

7.5 Initial Reading

7.5.1

Testing a surface layer

- Hold the DCP vertically

with the top of the widest part of the tip flush with the

surface of the material to be tested.

22

CORRELATIONS

8. CORRELATIONS

8.1 Tables 3, 4, and 5 are derived from the

following equation recommended by the US Army Corps of

Engineers, where PR is the DCP penetration rate in mm per

5.2 This procedure is used to assess the in place strength

of undisturbed soil and/or compacted materials. The

penetration rate can blow:

CBR = 292 / PR

1.12

This equation is used for all soils except for CL soils below CBR

10% and CH soils. For these soils, the following equations are

recommended by the US Army Corps of Engineers

3.

Selection

of the appropriate correlation is a matter of professional

judgment.

CL soils CBR < 10: CBR = 1 / (0.017019*PR)

2

CH soils: CBR = 1/ (0.002871*PR)

For analysis of shallow foundations an estimate of bearing

capacity can be made from the following equation adapted from the Portland Cement Association (PCA)

12

showing

the relationship between bearing capacity and CBR.

q= 3.794*CBR

0.664

q = Bearing Capacity (psi) ultimate

8.2 If a distinct layering exists within the material

tested, a change of slope on a graph of penetration/blow

vs. depth will be observed for each layer. The exact interface

is difficult to define because, in general, a transition zone

exists between layers. The layer thickness can be defined

by the intersection of the lines representing the average

slope of adjacent layers. Once the layer thicknesses have

been defined, the average penetration rate per layer is

calculated.

Hammer

17.6 lbs

Blows/2”

Table -3 - Tabulated Correlaltion of blows per 2” penetration verses CBR and PSF

Hammer

10.1 lbs

Blows/2”

Other CL CH Other CL CH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

2

4

6

8

10

12

15

17

19

22

24

27

29

32

34

37

39

42

45

47

50

53

55

58

61

63

66

69

72

74

77

80

83

86

89

91

94

97

100

100

0

1

3

5

8

12

15

17

19

22

24

27

29

32

34

37

39

42

45

47

50

53

55

58

61

63

66

69

72

74

77

80

83

86

89

91

94

97

100

100

3

7

10

14

17

21

24

27

31

34

38

41

45

48

51

55

58

62

65

69

72

75

79

82

86

89

92

96

99

100

760

1270

1720

2130

2520

2880

3240

3570

3900

4220

4530

4830

5130

5420

5700

5980

6260

6530

6800

7060

7320

7580

7840

8090

8340

8580

8830

9070

9310

9550

9780

10020

10250

10480

10710

10930

11160

11380

11600

11820

260

660

1130

1660

2230

2840

3240

3570

3900

4220

4530

4830

5130

5420

5700

5980

6260

6530

6800

7060

7320

7580

7840

8090

8340

8580

8830

9070

9310

9550

9780

10020

10250

10480

10710

10930

11160

11380

11600

11820

1240

1960

2560

3100

3600

4060

4500

4920

5320

5700

6070

6430

6790

7130

7460

7790

8110

8420

8730

9030

9330

9620

9910

10200

10480

10750

11020

11290

11560

11820

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

23

CBR

Soil type

PSF

Soil type

Hammer

17.6 lbs

Blows/4”

Hammer

10.1 lbs

Blows/4”

CL CH Other CL CH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

21

22

23

24

25

27

28

29

30

32

33

34

36

37

38

39

41

42

43

45

46

47

0

0

1

1

2

3

4

5

7

8

11

12

13

15

16

17

18

19

21

22

23

24

25

27

28

29

30

32

33

34

36

37

38

39

41

42

43

45

46

47

2

3

5

7

9

10

12

14

15

17

19

21

22

24

26

27

29

31

33

34

36

38

39

41

43

45

46

48

50

51

53

55

57

58

60

62

63

65

67

69

460

760

1030

1280

1510

1730

1940

2140

2330

2520

2710

2890

3070

3240

3410

3580

3740

3910

4070

4220

4380

4530

4690

4840

4990

5130

5280

5420

5570

5710

5850

5990

6130

6270

6400

6540

6670

6810

6940

7070

110

260

450

660

890

1140

1390

1660

1950

2240

2710

2890

3070

3240

3410

3580

3740

3910

4070

4220

4380

4530

4690

4840

4990

5130

5280

5420

5570

5710

5850

5990

6130

6270

6400

6540

6670

6810

6940

7070

780

1240

1620

1960

2270

2570

2840

3110

3360

3600

3840

4070

4290

4500

4720

4920

5120

5320

5520

5710

5900

6080

6260

6440

6620

6790

6970

7140

7310

7470

7640

7800

7960

8120

8280

8430

8590

8740

8890

9040

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Table -4 - Tabulated Correlation of blows per 4” penetration verses CBR and PSF

24

CBR

Soil type

PSF

Soil type

Other

Hammer

17.6 lbs

Blows/6”

Hammer

10.1 lbs

Blows/6”

Other CL CH Other CL CH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

0

1

2

2

3

4

4

5

6

6

7

8

9

9

10

11

12

12

13

14

15

15

16

17

18

19

19

20

21

22

23

23

24

25

26

27

28

28

29

30

0

0

0

1

1

1

2

2

3

4

4

5

6

7

8

11

18

19

21

22

23

24

25

27

28

29

30

32

33

34

36

37

38

39

41

42

43

45

46

47

1

2

3

5

6

7

8

9

10

11

13

14

15

16

17

18

19

21

22

23

24

25

26

27

29

30

31

32

33

34

35

37

38

39

40

41

42

43

45

46

340

560

760

940

1110

1280

1430

1580

1730

1870

2000

2140

2270

2400

2520

2650

2770

2890

3010

3120

3240

3350

3470

3580

3690

3800

3910

4010

4120

4220

4330

4430

4530

4640

4740

4840

4940

5040

5130

5230

60

150

260

390

520

660

810

970

1140

1310

1480

1660

1850

2040

2240

2650

2770

2890

3010

3120

3240

3350

3470

3580

3690

3800

3910

4010

4120

4220

4330

4430

4530

4640

4740

4840

4940

5040

5130

5230

600

950

1240

1500

1740

1960

2170

2370

2570

2750

2930

3110

3280

3440

3600

3760

3920

4070

4220

4360

4500

4650

4790

4920

5060

5190

5320

5450

5580

5710

5830

5960

6080

6200

6320

6440

6560

6680

6790

6910

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Table -5 - Tabulated Correlation of blows per 6” penetration verses CBR and PSF

CBR

Soil type

PSF

Soil type

25

PART III

Maintenance

References

Warranty

Parts List

28

REFERENCES

9. MAINTENANCE

Testing with the KESSLER DCP causes wear on the metal

parts that make up the device. In order to ensure maximum

service life, periodic inspections of the KESSLER DCP for

fatigue or damage are recommended. Any parts found

to be fatigued or damaged should be repaired by the

manufacturer, or replaced with Kessler DCP parts. The

KESSLER DCP should be kept clean and all soil removed

from the Drive Rod and Hardened Point before each test.

The drive rod should be kept clean and lubricated with oil.

10. REFERENCES

(1) Scala, A.J., (1956), Simple Methods of Flexible Pavement Design

Using Cone Penetrometers, Proceedings of the Second Australian Soil

Mechanics Conference, Christ Church, New Zealand. New Zealand

Engineer. 11(2) pages 34-44.

(2) Kleyn, E.G., (July.1975), The Use of the Dynamic Cone

Penetrometer (DCP), Report 2/74, Transvaal Roads Department,

Pretoria, South Africa. Page 35.

(3) METHOD ST6: Measurement of the In Situ Strength of soils by the

Dynamic Cone Penetrometer (DCP) (1984) Special Methods for Testing

Roads, Draft TMH6, Technical Methods for Highways (TMH), ISBN 0

7988 2289 9, Pages 19 to 24, 1984.

(4) Portland Concrete Association (1995), Design of Concrete Airport

Pavement, Portland Cement Association.

(5) De Beer, M., (1991), Use of the Dynamic Cone Penetrometer (DCP)

in the Design of Road Structures, Research Report DPVT-18, Roads

and Transport Technology, CSIR, South Africa.

(6) Webster, S.L., Grau, R.H. Williams, T.P., (May 1992), Description and

Application of Dual Mass Dynamic Cone Penetrometer, Report GL-923, Department of the Army, Washington DC, Pg 19.

(7) Webster, S.L., Brown, R.W., Porter, J.R. (April 1994), Force

Projection Site Evaluation Using the Electric Core Protection (ECP) and

MAINTENANCE

the Dynamic Cone Penetrometer (DCP), Technical Report No. GL-94-17,

Air Force Civil Engineering Support Agency, U.S. Air Force, Tyndall Air

Force Base, Florida.

(8) Siekmeier, J.A., Young, D., and Beberg, D., (1999),

Comparison of the Dynamic Cone Penetrometer with Other Tests

During Subgrade and Granular Base Characterization in Minnesota,

Nondestructive Testing of Pavements and Backcalculation of Moduli:

Third Volume, ASTM STP 1375, S.D. Tayabji and E.O. Lukanen, Eds.,

American Society for Testing and Materials, West Conshohochen,

Pennsylvania.

(9) Livneh, M,. (1999), The Israeli Experience with the Regular and

Extended Dynamic Cone Penetrometer for Pavement and Subsoil

Strength Evaluation, Nondistructive Testing of Pavements and

Backcalculation of Moduli, ASTM STP 1375, S.D. Tayabji and E.O.

Lukanen, Eds., American Society for Testing and Materials, West

Conshohochen, Pennsylvania.

(10) De Beer M. (March 2000) Dynamic Cone Penetrometer (DCP).

The Development of DCP pavement technology in South Africa. Video

Tape Series from RSA/US Pavement Technology Workshop. Technology

Transfer Office, University of California, Berkeley, California.

(11) ASTM D 6951-03 Standard Test Method of Use of the Dynamic

Cone Penetrometer in Shallow Pavement Applications.

(12) Portland Concrete Association (1955), Design of Concrete Airport

Pavement, Portland Cement Association, P8.

29

REFERENCES

30

WARRANTY

11. WARRANTY

1. KESSLER SOILS ENGINEERING PRODUCTS, INC. guarantees

this product to be manufactured in the U.S. A. to the specifications

and standards developed by the Department of the Army, Corps

of Engineers, Waterways Experiment Station and recorded under

patent number 5,313,825 entitled “Dual Mass Dynamic Cone

Penetrometer.”

2. KESSLER SOILS ENGINEERING PRODUCTS, INC. warrants this

product to be free from defects in material and components for

one (1) year from the date of first purchase, provided the product

is used, operated and maintained in accordance with all applicable

instructions. To claim under this warranty the Bill of Sale and

cancelled check or credit card receipt must be presented.

3. This warranty does not apply to parts that are not in original

condition because of normal wear and tear, or parts that fail or

become damaged as a result of misuse, accidents, lack of proper

maintenance or defects caused by improper use. Shipping costs

relating to repairing a KESSLER DCP will be the responsibility of the

purchaser.

4. To the full extent allowed by the law of the jurisdiction that

governs the sale of the product, this express warranty excludes any

and all other expressed warranties and limits the duration of any

and all implied warranties, including warranties of merchantability

and fitness for a particular purpose to one (1) year from the date

of first purchase. The liability of KESSLER SOILS ENGINEERING

PRODUCTS, INC. is limited to the purchase price of the product and

does not cover any other damages whatsoever including indirect,

incidental or consequential damages.

5. Limitations herein do not apply in states that do not allow

a limitation on how long an implied warranty lasts or an exclusion

or limitation of incidental or consequential damage.

12. PARTS LIST

ITEM DESCRIPTION

K010 K-100 User’s Manual & Software

K1312 Drive Rod, 12” - Stainless

K1330 Drive Rod, 30” - Stainless

K133775 Drive Rod, 37 3/4” - Stainless

K133775S Drive Rod, 37 3/4” - Spring Steel

K1348 Drive Rod, 48” - Stainless

K1348S Drive Rod, 48” - Spring Steel

K1724 Extension Rod, 24” - Stainless

K450 Pin with Clip, 2 per pkg

K500 Vertical Scale, 40

K510 Foot, Vertical Scale holder

K530 Upper Attachment, Vertical Scale

holder

K550 Measuring Rod, 40”, aluminum

K700 Hardened Point with flats, silver

K705 5-Pack, Hardened Points w/ flats

(silver)

K800 Cone Adapter with flats, silver

K900 25 Disposable Cones

31

PARTS LIST

KSE form 300, 20 AUGUST 2014

K100UM300

Loading...

Loading...