Page 1

Operating Instructions

Nº A1766.8E/2

Works Nº: ________________________________

Type series: ______________________________

precautionary notes. Please read the manual

thoroughly prior to installation of unit, connection to

the power supply and commissioning. It is

imperative to comply with all other operating

instructions referring to components of this unit.

These operating instructions contain

fundamental information and

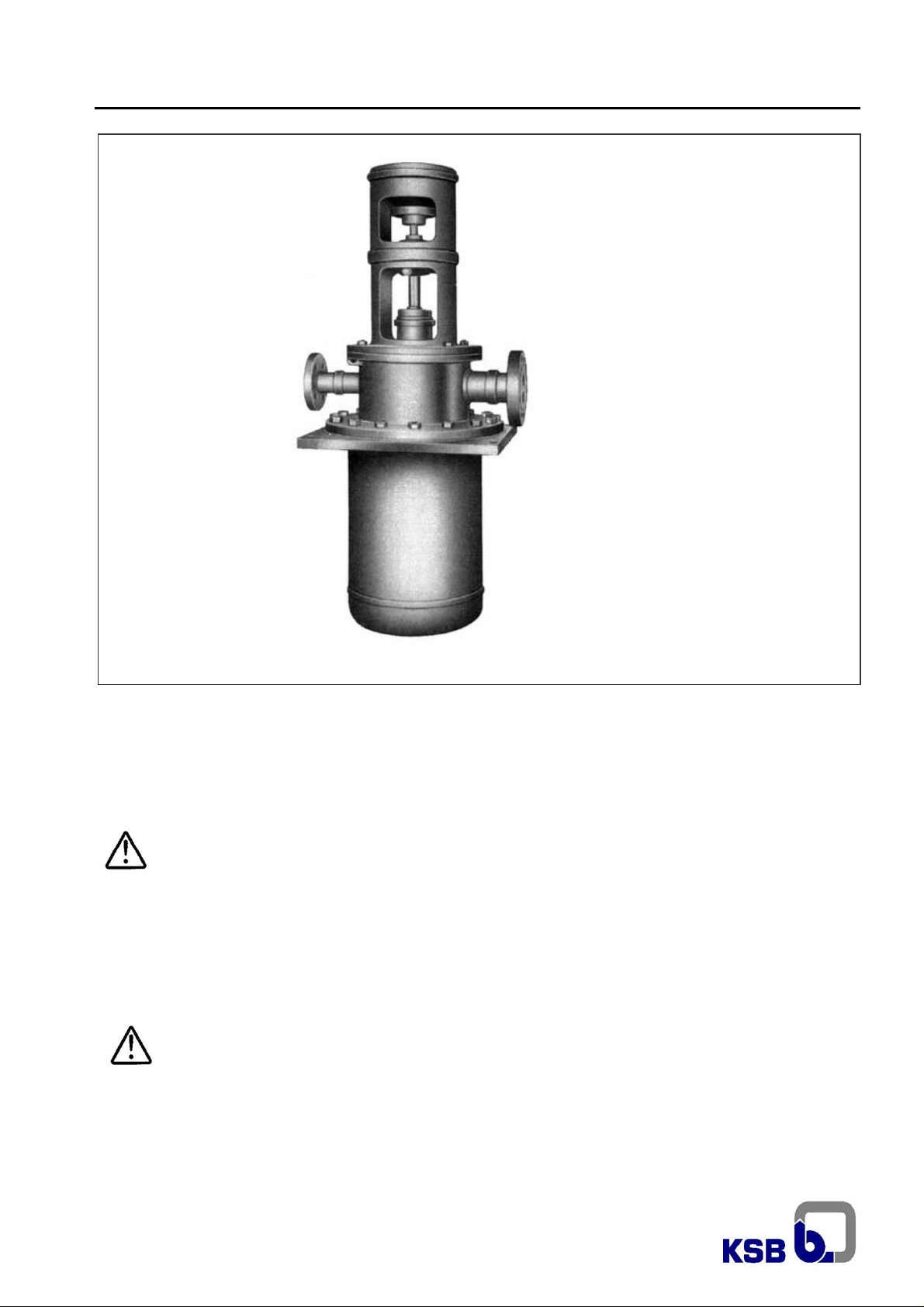

KSB WKT

Vertical Process Pump

according to API 610

as per Directive 94/9/EC

This manual shall always be kept close to

the unit´s location of operation or directly

on the pump set.

Page 2

Contents

Page

1 General 4

2 Safety 4

2.1 Marking of Instructions in the manual 4

2.2 Personnel qualification and training 4

2.3 Non-compliance with safety instructions 4

2.4 Safety awareness 4

2.5 Safety instructions for the operator / user 5

2.6 Safety instructions for maintenance,

inspection and installation work

2.7 Unauthorized modification and manufacture

of spare parts

2.8 Unauthorized modes of operation 5

2.9 Explosion protection 5

2.9.1 Unit fill 5

2.9.2 Marking 5

2.9.3 Checking the direction of rotation 5

2.9.4 Pump operating mode 5

2.9.5 Temperature limits 6

2.9.6 Maintenance 6

3 Transport an d interim storage 6

3.1 Transport 6

3.2 Interim storage (indoors) / preservation 6

3.3 Devolution / discard 7

3.3.1 Devolution 7

3.3.2 Discard 7

4 Description of the product an

accessories

4.1 Technical specification 7

4.2 Designation 7

4.3 Design details 7

4.3.1 Pump casing 7

4.3.2 Impeller 7

4.3.3 Shaft seal 7

4.3.4 Bearing arrangement 8

4.3.5 Permissible forces and moments at the

discharge nozzle

4.3.6 Noise characteristics

4.4 Accessories

4.5 Dimensions and weights

5 Installation at site 10

5.1 Safety regulations

5.2 Checks to be carried out prior to installation 10

5.2.1 Place of installation 10

5.3 Foundation 10

5.4 Barrel cleaning

5.5 Mounting 10

5.6 Aligning the pump / drive

5.7 Connecting the piping

5.7.1 Auxiliary connections 11

5.7.2 Coupling guard 11

5.8 Final check 11

5.9 Connection to power supply 11

5

5

7

9

9

9

9

10

10

10

11

WKT

Page

6 Commissioning, start-up / shutdown 12

6.1 Preparations 12

6.1.1 Recommended safety instrumentation for

pump

6.1.2 Lubrication 12

6.1.3 Pre-comissioning checks 12

6.1.4 Lubrication 12

6.1.5 Shaft seal 13

6.1.6 Priming the pump and checks to be carried

out

6.1.7 Checking the direction of rotation 14

6.2 Start-up 14

6.2.1 Minimum flow 14

6.3 Shutdown

6.4 Operating limits 15

Temperature of the fluid handled, ambient

6.4.1

temperature, bearing temperature

6.4.2 Switching frequency 15

6.4.3 Density or fluid pumped 15

6.4.4 Abrasive fluids

6.4.5 Minimum / Maximum flow

6.5 Shutdown / storage / preservation

6.5.1 Storage of new pumps

Measures to be taken for prolonged

6.5.2

shutdown

6.6 Returning to service after storage

7 Servicing / Maintenance

7.1 General instructions

7.2 Servicing / inspection

7.2.1 Supervision of operation 16

7.2.2 Lubrication and lubricant change 17

7.3 Drainage / disposal 17

7.4 Dismantling 17

7.4.1 Fundamental instructions and

recommendations

7.4.2 Dismantling the pump 17

7.4.3 Examination of individual components 18

7.5 Reassembly 20

7.5.1 General instructions 20

7.5.2 Preparations 21

7.5.3 Tightening torques 24

7.6 Spare parts stock 24

7.6.1 Recommended spare parts stock for 2

years’ operation to DIN 24296

8 Troubleshooting 25

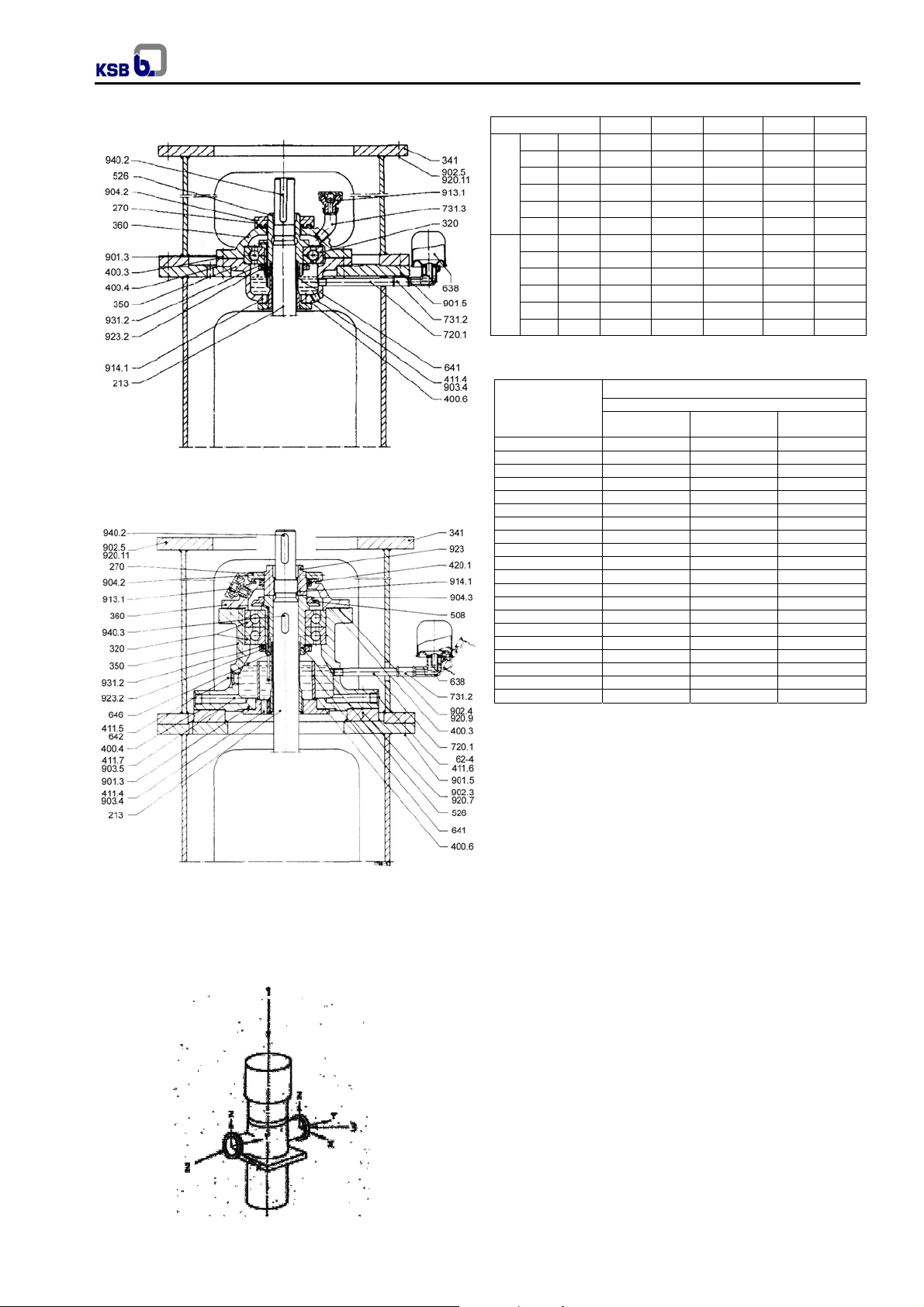

9 Sectional drawing 26

Supplementary sheet 28

Annex 01 29

12

13

15

15

15

15

16

16

16

16

16

16

16

17

24

Page 3

Introduction

KSB has supplied you an equipment that has been designed and manufactured with the latest technology.

Due to its simple and tough construction, it will need few maintenance. With the aim to provide our clients with a

satisfactory, trouble free operation, we recommend to install and care our equipment according to the instructions

contained in this service manual.

This manual has been prepared to inform the end user about construction and operati on of our pumps, describing the

proper procedures for handling and maintenance.

We recommend that this manual should be handled by the maintenance supervision.

This equipment must be used at operation conditions for which it has been selected, suc h as: flow rate, total head, speed,

voltage, frequency and temperature of pumped liquid.

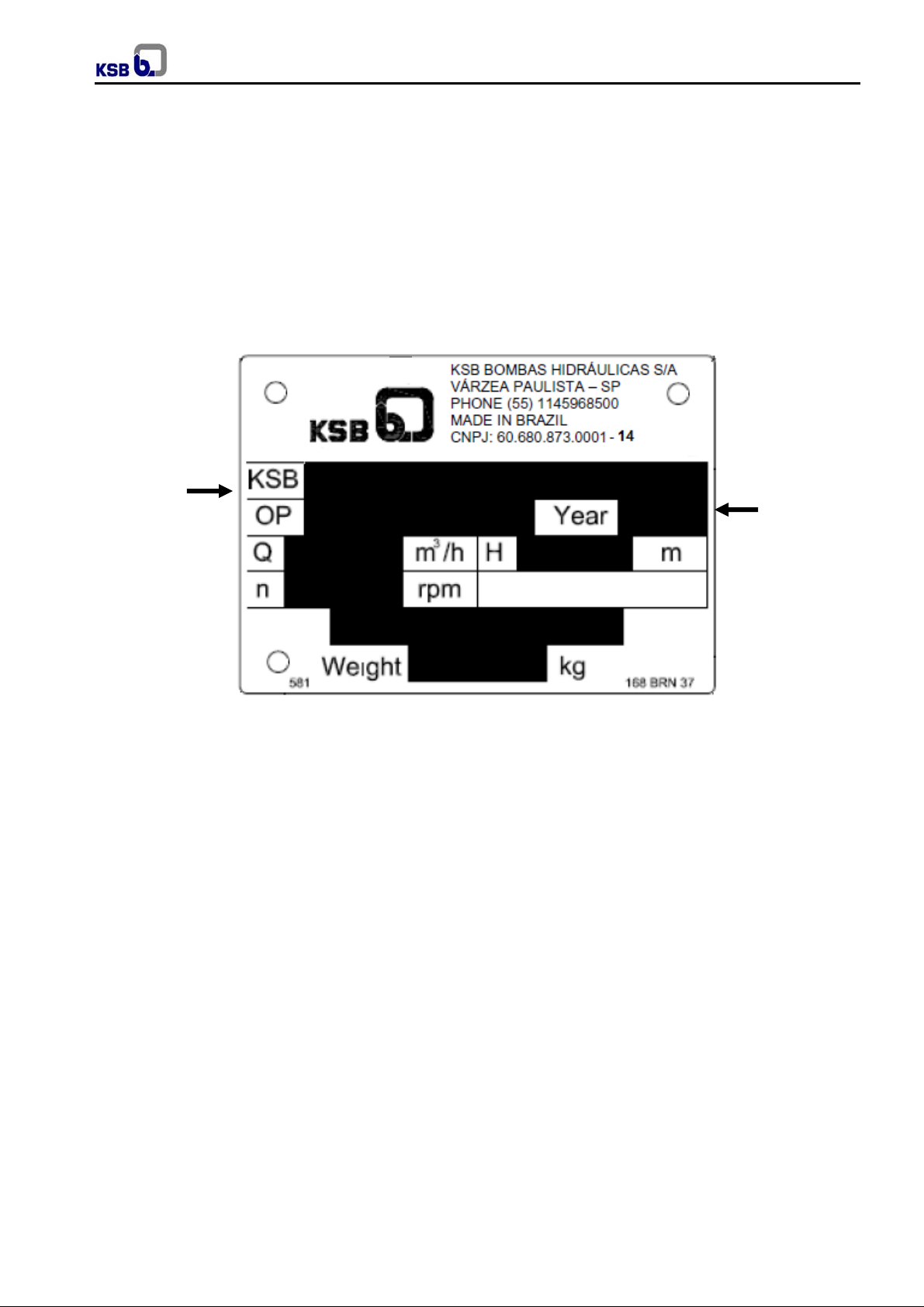

Place for description

of type and size of

the pump

WKT

Place for order

number

Fig. 01 - Nameplate

For requests about the equipment, or when ordering spare parts, please mention the t ype of the pump and

the Production Order number (serial nº). This information can be obtained from the nameplate of each

pump. If the nameplate is not available, the OP number is engraved in low relief o n the suction flange and

on the discharge flange you may find the impeller diameter.

Attention: This manual contains very important recommendations and instructions. Must be carefully read before

installation, electrical connection, first start up and maintenance.

3

Page 4

1. General

Caution

technology; it is manufactured with utmost care and

subject to continuous quality control.

These operating instructions are intended to facilitate

familiarization with the unit and its designated use.

The manual contains important information for reliable,

proper and efficient operation. Compliance with the

operating instructions is of vital importance to ensure

reliability and a long service life of the unit and to avoid

any risks.

These operating instructions do not take into account

local regulations; the operator must ensure that such

regulations are strictly observed by all, including the

personnel called in for installation.

This pump / unit must not be operated beyond

the limit values for the fluid handled, capacity,

speed, density, pressure, temperature and motor

rating specified in the technical documentation. Make

sure that operation is in accordance with the instructions

laid down in this manual or in the contract

documentation. Contact the manufacturer, if required.

The nameplate indicates the type series / size, main

operating data and works number; please quote this

information in all queries, repeat orders and particularly

when ordering spare parts.

If you need any additional information or instructions

exceeding the scope of this manual or in c ase of damage

please contact KSB´s nearest customer service centre.

For noise characteristics please refer to section 4.3.6.

This KSB product has been developed

in accordance with state-of-the-art

2. Safety

These operating instructions contain fundamental

information which must be complied with during

installation, operation, monitoring and maintenance.

Therefore this operating manual must be read and

understood both by the installing personnel and the

responsible trained personnel / operators prior to

installation and commissioning, and it must always be

kept close to the location of operation of the machine /

unit for easy access.

Not only must the general safety instructions laid down in

this chapter on “Safety” be complied with, but also the

safety instructions outlined under specific headings,

particularly if the pump / unit is operated in hazardous

areas (see section 2.9).

2.1 Marking of instructions in the manual

The safety instructions contained in this manual whose

non-observance might cause hazards to persons are

specially marked with the symbol

general hazard sign to ISO 7000-0434

the electrical danger warning sign is

safety sign to IEC 417-5036

WKT

and special instructions concerning explosion protection

are marked

The word

is used to introduce safety instructions whose nonobservance may lead to damage to the machine and its

functions.

Instructions attached directly to the machine, e.g.

- arrow indicating the direction of rotation

- markings for fluid connections

must always be complied with and be kept in a perfectly

legible condition at all times.

2.2 Personnel qualification and training

All personnel involved in the operation, maintenance,

inspection and installation of the unit must be fully

qualified to carry out the work involved.

Personnel responsibilities, competence and supervision

must be clearly defined by the operator. If the personnel

in question is not already in possession of the requisite

know-how, appropriate training and instruction must be

provided. If required, the operator may commission the

manufacturer / supplier to take care of such training. In

addition, the operator is responsible for ensuring that the

contents of the operating instructions are fully un derstood

by the responsible personnel.

2.3 Non-compliance with safety instructions

Non-compliance with safety instructions can jeopardize

the safety of personnel, the environment and the machine

/ unit itself. Non-compliance with these safety instructions

will also lead to forfeiture of any and all rights to claims for

damages.

In particular, non-compliance can, for example, result in:

- failure of important machine / system functions;

- failure of prescribed maintenance and servicing

practices;

- hazard to persons by electrical, mechanical and

chemical effects as well as explosion;

- hazard to the environment due to leakage of

hazardous substances.

2.4 Safety awareness

It is imperative to comply with the safety instructions

contained in this manual, the relevant national and

international explosion protection regulations, and the

operator´s own internal work, operation and safety

regulations.

Ex symbol relates to additional requirements

which must be adhered to when the pump is

operated in hazardous areas.

Caution

4

Page 5

2.5 Safety instructions for the operator / user

- Any hot or cold components that could pose a hazard

must be equipped with a guard by the operator.

- Guards which are fitted to prevent accidental contact

with moving parts (e.g. coupling) must not be

removed whilst the unit is operating.

- Leakages (e.g. at the shaft seal) of hazardous fluids

handled (e.g. explosive, toxic, hot) must be contained

so as to avoid any danger to persons or the

environment. All relevant laws must be heeded.

- Electrical hazards must be eliminated. (In this

respect refer to the relevant safety regulations

applicable to different countries and / or the local

energy supply companies.)

- Any components in contact with the fluid pumped,

especially in the case of abrasive fluids, shall be

inspected for wear at regular intervals and replaced

by original spare parts (see section 2.7) in due time.

If the pumps / units are located in hazardous

areas, it is imperative to make sure that

unauthorized modes of operation are prevented. Non–

compliance may result in the specified t emperature limits

being exceeded.

2.6 Safety instructions for maintenance, inspection

and installation work

The operator is responsible for ensuring that all

maintenance, inspection and installation work be

performed by authorized, qualified specialist personnel

who are thoroughly familiar with the manual.

The pump must have cooled down to ambient

temperature, pump pressure must have been released

and the pump must have been drained.

Work on the machine / unit must be carried out only

during standstill. The shutdown procedure described in

the manual for taking the unit out of service must be

adhered to without fail.

Pumps or pump units handling fluids injurious to health

must be decontaminated.

Immediately following completion of the work, all safetyrelevant and protective devices must be re-installed and /

or re-activated.

Please observe all instructions set out in the chapter on

“Commissioning” before returning the unit to service.

2.7 Unauthorized modification and manufacture of

spare parts

Modifications or alterations of the equipment supplied are

only permitted after consultation with the manufacturer

and to the extent permitted by the manufacturer. Original

spare parts and accessories authorized by the

manufacturer ensure safety. The use of other parts can

invalidate any liability of the manufacturer for

consequential damage.

2.8 Unauthorized modes of operation

The warranty relating to the operating reliability and

safety of the unit supplied is only valid if the equipment is

used in accordance with its designated use as described

in the following sections. The limits stated in the data

sheet must not be exceeded under any circumstances.

WKT

2.9 Explosion protection

If the pumps / units are installed in hazardous

areas, the measures and instructions given in

the following sections 2.9.1 to 2.9.6 must be adhered to

without fail, to ensure explosion protection.

2.9.1 Unit fill

It is assumed that the system of suction and

discharge lines and thus the wetted pump

internals are completely filled with the product to be

handled at all times during pump operation, so that an

explosive atmosphere is prevented.

If the operator cannot warrant this condition,

appropriate monitoring devices must be used.

Caution

systems of the shaft seal and the heating and cooling

systems are properly filled.

2.9.2 Marking

The marking on the pump only refers to the pump

part, i.e. the coupling and motor must be regarded

separately. The coupling must have an EC

manufacturer’s declaration. The driver must be regarded

separately.

Example of marking on the pump part:

The marking indicates the theoretically available

temperature range as stipulated by the respective

temperature classes. The temperatures permitted for the

individual pump variants are outlined in section 2.9.5.

Pumps WKT are designed to meet the requirements of

Zone 1 and Category 2 as per EN1127-1 when sealed

by mechanical seal.

2.9.3 Checking the direction of rotation (see also

6.1.7)

If the explosion hazard also exists during the

installation phase, the direction of rotation must

never be checked by starting up the unfille d pump unit,

even for a short period, to prevent temperature increases

resulting from contact between rotating and stationary

components.

2.9.4 Pump operating mode

Make sure that the pump is always started up with the

suction-side shut-off valve fully open and the dischargeside shut-off valve slightly open. However, the pump can

also be started up against a closed swing check valve.

The discharge-side shut-off valve shall be adjusted to

comply with the duty point immediately following the ru nup process (see 6.2).

Pump operation with the shut-off valves in the

suction and / or discharge pipes closed is not

permitted.

Caution

temperatures after a very short time, due to a rapid

temperature rise in the pumped fluid inside the pump.

In addition, it is imperative to make sure

that the seal chambers, auxiliary

Ex II 2 G T1 - T5

In this condition, there is a risk of the

pump casing taking on high surface

5

Page 6

Additionally, the resulting rapid pressure build-up inside

the pump may cause excessive stresses on the pump

materials or even bursting.

The minimum flows indicated in section 6.4.5 refer to

water and water-like liquids. Longer operating periods

with these liquids and at the flow rates indicated will not

cause an additional increase in the temperatures on th e

pump surface. However, if the physical properties of the

fluids handled are different from water, it is essential to

check if an additional heat build-up may occur and if the

minimum flow rate must therefore be increased. To

check, proceed as described in section 6.4.5.

In addition, the instructions given in section 6 of this

operating manual must be observed.

Both gland packings and mechanical s eals may

exceed the specified temperature limits if run

dry. Dry running may not only result from an

inadequately filled seal chamber, but also from

excessive gas content in the fluid handled.

Pump operation outside its specified operating range

may also result in dry running.

In hazardous areas, gland packings shall only be

used if combined with a suitable temperature

monitoring device.

2.9.5 Temperature limits

In normal pump operation, the highest

temperatures are to be expected on the surface

of the pump and distributor casing, at the shaft seal and

in the bearing areas. The surface temperature at the

pump casing corresponds to the temperature of the fluid

handled.

If the pump is heated, it must be ensured that the

temperature classes stipulated for the plant are observed.

In the bearing bracket area, the unit surfaces must be

freely exposed to the atmosphere.

In any case, responsibility for compliance with the

specified fluid temperature (operating temperature)

lies with the plant operator. The maximum

permissible fluid temperature depends on the

temperature class to be complied with.

The table below lists the temperature classes to EN

13463-1 and the resulting theoretical temperature limits of

the fluid handled. In stipulating these temperatures, any

temperature rise in the shaft seal area has already been

taken into account.

Temperature class to

EN 13463-1:

T5

T4

T3

T2

T1

*) depending on material variant

Safety note:

Caution

data sheet. If the pump is to be operated at a higher

temperature, the data sheet is missing or if the pump is

part of a pool of pumps, the maximum permissible

operating temperature must be inquired from the pump

manufacturer.

Based on an ambient temperature of 40ºC and proper

maintenance and operation, compliance with temperatur e

class T4 is warranted in the area of the rolling element

bearings. A special design is required to comply with

The permissible operating temperature of

the pump in question is indicated on the

Temperature limit of

fluid handled

85ºC

120ºC

185ºC

280ºC

Max. 400ºC *)

WKT

temperature class T6 in the bearing area. In such cases,

and if ambient temperature exceeds 40ºC, contact the

manufacturer.

2.9.6 Maintenance

Only a pump unit which is properly serviced and

maintained in perfect technical condition will give

safe and reliable operation.

This also applies to the reliable function of the rolling

element bearings whose actual lifetime largely depends

on the operating mode and operating conditions.

Regular checks of the lubricant and the running noises

will prevent the risk of excessive temperatures as a result

of bearings running hot or defective bearing seals (also

see section 6.1.4).

The correct function of the shaft seal must be checked

regularly. Any auxiliary systems installed must be

monitored, if necessary, to make sure they function

correctly.

Gland packings must be tightened correctly, to prevent

excessive temperatures due to packings running hot.

3. Transport and interim storage

3.1 Transport

The transport of motor-pump set or only pump should be

made with ability and sound sense, according to safety

standards. By the motor eyebolt should only lift it, never

the motor-pump set.

If the pump / unit slips out of the suspension

arrangement, it may cause personal injury and

damage to property!

Vertical pumps up to about 4 m shipping length are

dispatched completely assembled. Larger pumps are

dispatched in sub-assemblies and must be assembled at

site under KSB´s supervision only.

The stuffing box is not packed and the packing is supplied

loose.

The barrel is normally supplied loose with the pump.

To avoid damage in transit, the motor is usually not

mounted before dispatch.

Please refer packing list received with the pump for more

details.

3.2 Interim storage (indoors) / Preservation

KSB standard storage and preservation procedures

maintain the pump protected for a maximum period of 6

months in an indoor installation. The unit / pump should

be stored in a dry room where the atmospheric humidity

is as constant as possible. When this period is exceeded,

additional storage procedure should be taken. For that,

please use the following conservation liquids:

- Internal parts of ferrous material in contact with

pumped liquid (except mechanical seal contact

surfaces): water repellent of mineral oil basis.

- Bearings: mineral oil for internal conservation.

- Polished parts: mineral oil for internal and external

conservation.

- Mechanical seals: should be cleaned by dry air. Do

not apply any liquid or other conservation material i n

6

Page 7

order to not damage secondary sealings (O´rings

and flat gaskets).

All existing connections, like plugs for external source

liquid, priming, drainage, etc, should be properly covered.

Pump suction and discharge flanges are properly covered

with adhesive, in order to avoid strange contents in its

interior.

Assembled pumps waiting for startup or installation

should have their rotor manually rotated each 15 days. In

case of difficulty, use some adjustable spanner,

protecting the motor shaft surface.

Before conservation liquids application, areas should be

washed with gas or kerosene until they are completely

cleaned.

The conservative liquids can be removed from the areas

in contact with pumped liquid, polished parts and surfaces

like: shaft, salient faces and couplings, by means of

solvents derived from petroleum or clean industrial

liquids. Drain the conservative oil from bearing bracket

before fulfill it with lubricant oil.

3.3 Devolution / discard

3.3.1 Devolution

- Drain the pump correctly.

- Carefully wash and clean the pump, especially in

case of harmful, explosive, hot fluids or other

hazardous fluids.

- In the case fluids are pumped, and they are with

residues which can cause corrosion damage when in

contact with atmospheric humidity or that can ignite

in contact with oxygen, the pump aggregate must be

additionally neutralized and its dry process must be

executed through blowing inert gas without water

through the aggregate.

- Should always be sent with the pump / motor pump

set a certificate of decontamination completely

fulfilled. (Annex 1).

- Please always indicate adopted safety and

decontamination measurements.

3.3.2 Discard

CAUTION

Medium handled is harmful to health.

Hazardous for people and environment!

Collect and dispose of the liquid from

the washing as well as any residual

liquids.

If necessary, use protective clothing and

mask.

Observe the legal disposals related to

the discard of harmful liquids to health.

- Disassemble the pump / moto-pump set.

Collect the masses and lubricants during dismantling.

- Separate materials part of the pump, example:

WKT

Metal

Plastic

Eletronic scrap

Masses and lubricants

4. Description of the product and

accessories

4.1 Technical specification

Fields of application:

Used in the chemical and petrochemical industry as well

as in refineries for handling chemically aggressive media

with low solids content.

As well used in industry in general as for process pump

process gas and condensate.

4.2 Designation

KSB WKT 80 / 3

Trade mark

Type series

Discharge nozzle (mm)

Number of stages

For materials refer to the data sheet.

4.3 Design details

Vertical, radially split shaft-driven sump pump with

multiple stages, in wet installation.

4.3.1 Pump casing

Radially split, multiple stages.

For handling combustible media, the pump casing,

the pipe assembly and the flanged elbow must be

made of ductile material with a maximum magnesium

content of 7.5% (see EN 13463-1). This is a standard

feature in all KSB supplies.

4.3.2 Impeller

Closed radial impeller with multiply curved vanes. Axial

thrust is balanced by means of suction and dischargeside casing wear rings and balancing holes.

4.3.3 Shaft seal

Shaft sealing is effected by gland packing or single or

double acting mechanical seals.

The relevant seal version is shown in the mecha nical seal

drawing.

7

Page 8

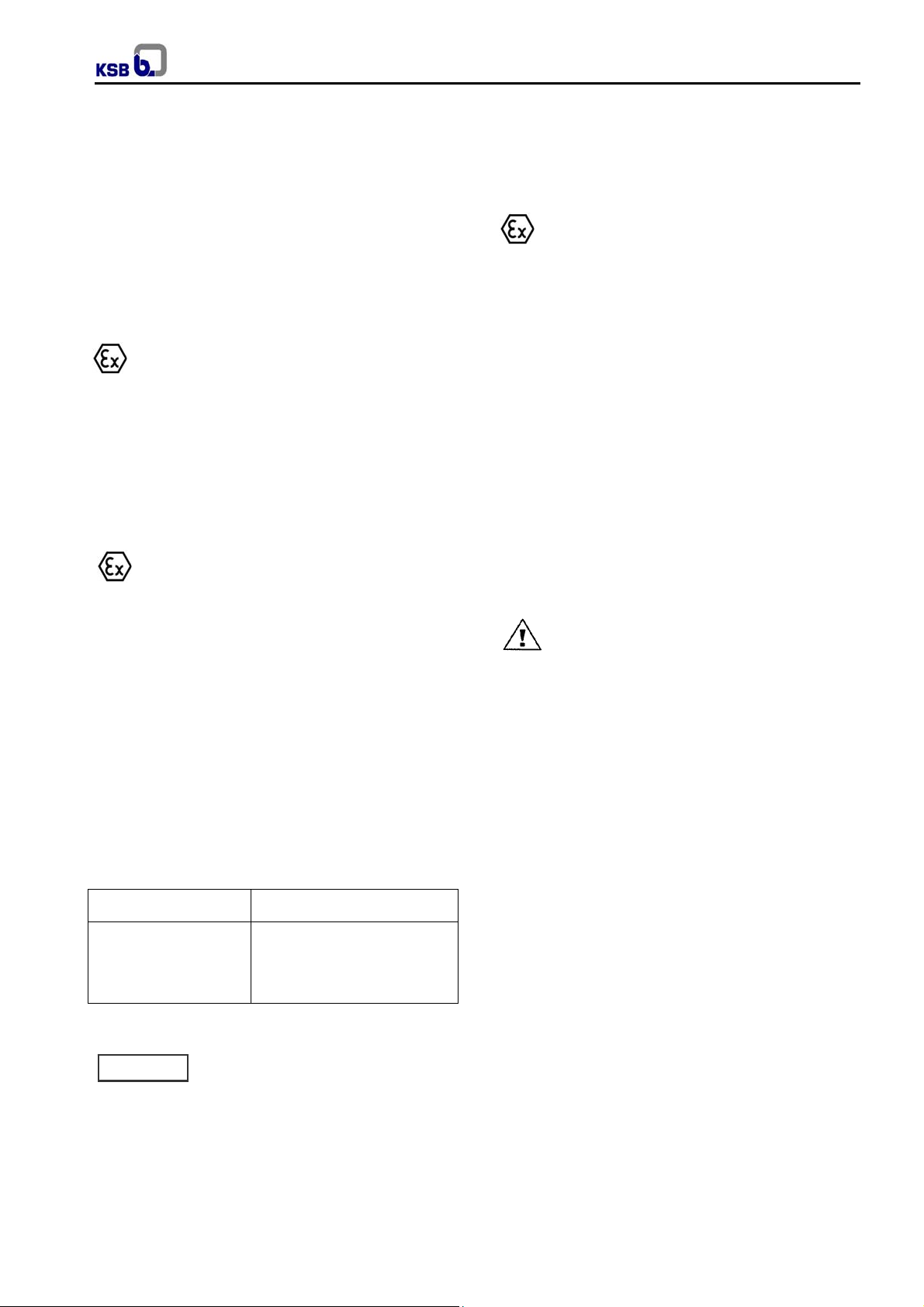

Arragement drawing (examples)

Gland packing (special variant-consult KSB to use in

explosive atmospheres)

WKT

212 Intermediate shaft

383 Bearing spider

400.2 Flat gasket

529.3 Bearing sleeve

545.3 Bearing bush

711.1 Riser pipe

Fig. 02

Mechanical seal

Mechanical seal

Single-acting

Fig. 03

Mechanical seal

Double-acting

Fig. 04

4.3.4 Bearing arrangement

4.3.4.1 Pump bearings

The pump shaft runs in two plain bearings.

The bearing at the suction end is arranged in the suction

casing (106) and the bearing at the discharge end is

arranged in the discharge casing (107). Both these

bearings are lubricated by the product pumped.

4.3.4.2 Intermediate shaft bearings

(See fig. 05)

The intermediate shafts are guided by bearing spiders

(383) with built-in bearing bushes (545.3) between the

lengths of column pipe. Their construction and lubrication

corresponds to that of the pump bearings.

Fig. 05 Intermediate shaft bearing

4.3.4.2.1 Rigid Couplings for intermediate shafts

Depending on the shaft diameter, rotational speed,

switching frequency and type of driver, either rigid

screwed couplings, or split (muff) couplings are used to

connect the intermediate shafts to one another and to

transmit the driving torque.

In order to prevent the unscrewing (slackening) of

screwed couplings during reverse rotation pumping sets

fitted with such couplings must be provided with a revers e

rotation stop device.

Hollow shaft motors and hollow shaft bevel gears are

equipped with such a reverse rotation stop device.

Electric motors of V1 type series are however not so

equipped, and the direction of rotation of such motors

should therefore be checked before connection to the

shafting. It is therefore preferable to use split (muff)

couplings in conjunction with V1 type series electric

motors. The type of coupling applying to your installatio n

can be ascertained from the data sheet attached to the

Order confirmation.

See figures below for construction and arrangement.

Screwed coupling Split (muff) coupling

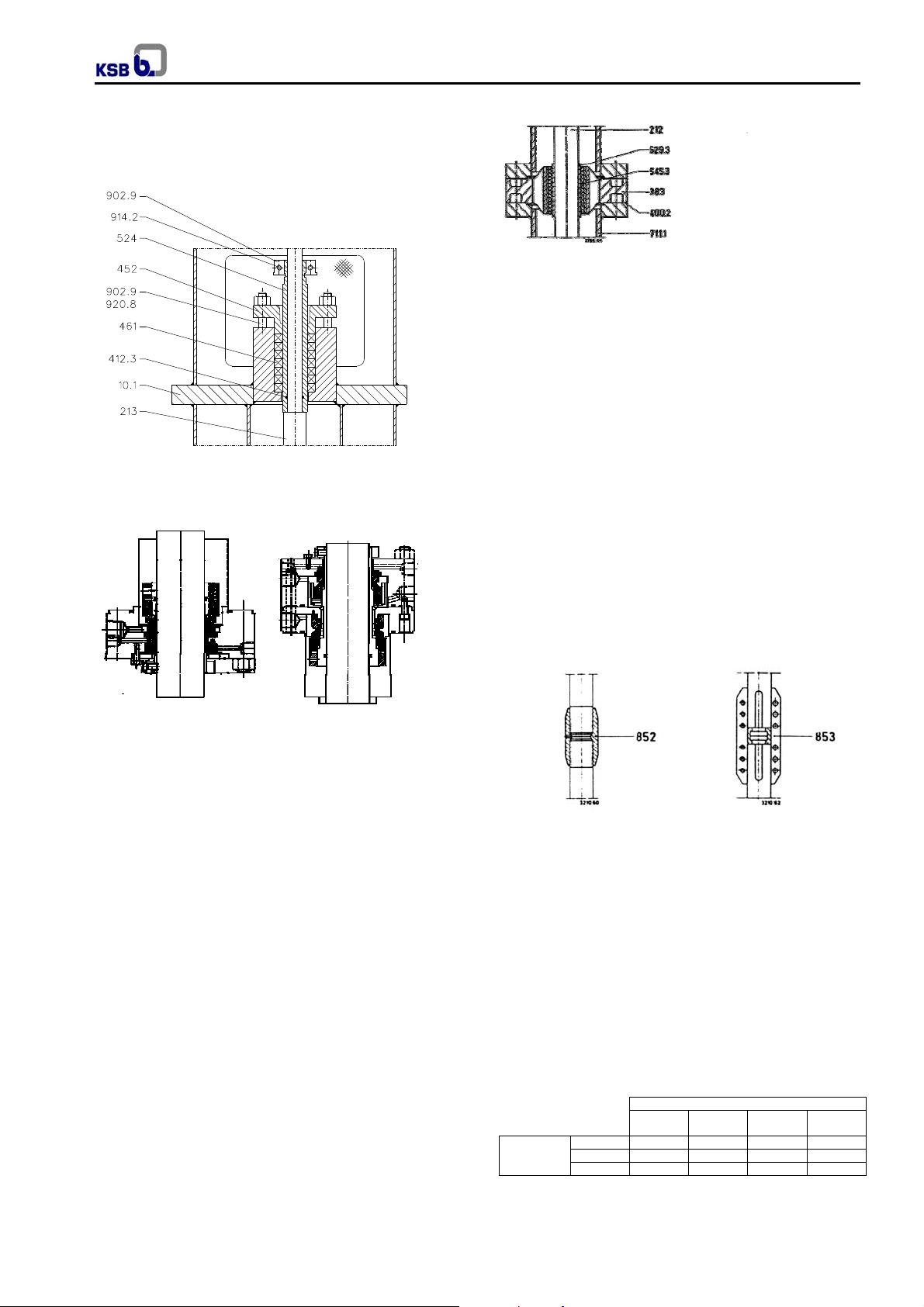

4.3.4.3 Thrust bearing

(See fig. 07 and 08 for construction).

The thrust bearing arranged in the motor lantern absorbs

the weight of the complete pump rotor, including the

weight of the intermediate shafts (212) and drive shaft

(213), and the radial forces which arise, it also absorbs

the residual axial thrust generated, and transmits all these

weights and forces to the motor lantern. Depending on

the values 3 different configurations are available. See

fig. 06. The bearing is oil lubricated, in the normal

execution.

Oil mist lubrication is possible, however it is special and

made up on consult.

Pump sizes

Thrust

bearing

constructions

VÖR 6311 6312 6315 6317

VÖQJ 311 312 315 317

VÖB 25 (7311) 35 (7312) 45 (7315) 60 (7318)

40 50 and 65

80 and

100

125 and

150

Fig. 06

8

Page 9

WKT

p

VÖB and VOQJ

Pump size 40 50/65 80/100 125 150

Fx N 1500 1800 2500 3000 3500

Fy N 1500 1800 2500 3000 3500

Fz N 1500 1800 2500 3000 3500

Mx N.m 1200 1500 2000 2500 3000

Suction

My N.m 1200 1500 2000 2500 3000

Mz N.m 1200 1500 2000 2500 3000

Fx N 800 1500 2000 2500 3000

Fy N 800 1500 2000 2500 3000

Fz N 800 1500 2000 2500 3000

Mx N.m 500 1200 1500 2000 2500

My N.m 500 1200 1500 2000 2500

Discharge

Mz N.m 500 1200 1500 2000 2500

4.3.6 Noise characteristics

Fig. 07 Construction of support bearing VÖB (deep

groove ball bearing and VÖQJ (four point contact

bearing).

VÖB

Fig. 08 Construction of support bearing VÖB

4.3.5 Permissible forces and moments at the

nozzles

For max. permissible forces & moments refer table below.

Fig. 09

Rated power input

P

110,0 79,0 77,0 76,0

132,0 79,5 77,5 76,5

160,0 80,0 78,0 77,0

200,0 81,0 79,0 77,5

250,0 81,5 79,5 78,5

400,0 83,0 81,0 80,0

500,0 84,0 82,0 80,5

750,0 85,0 83,0 81,5

1000,0 86,0 84,0 82,5

Sound pressure level

(kW)

N

2,2 60,0 60,0 -

5,5 65,5 65,0 64,5

11,0 70,0 68,5 67,5

15,0 71,5 70,0 69,0

22,0 73,5 72,0 71,0

30,0 74,5 73,0 72,0

37,0 75,5 74,0 73,0

45,0 76,0 74,5 73,0

55,0 76,5 75,0 73,5

75,0 77,5 76,0 74,5

90,0 78,0 76,5 75,0

2900

1/min

Pump only

1450

1/min

L

(db)

A

980

1/min

Measured at a distance of 1m from the pump outline (as per DIN 45635

Part 1 and 24). Room and foundation influences have not been included.

The tolerance for these factors is 1 to 2 dB.

Increase for 60 Hz operation

Pump without motor: -- Pump with motor:

3500min-1:+3dB, 1750min-1: + 1dB, 1160min-1: ---dB

4.4 Accessories

As a general rule, the following items are supplied with

the pump:

- Motor lantern,

- Special tools and tackles for assembly / disassembly

of conical coupling,

On request the following items can be supplied amongst

others:

- Coupling: flexible coupling with spacer,

- Coupling guard,

- Coupling extractor device,

- Motor,

- Base plate: welded construction,

- Pressure gauges for suction and discharge,

- ARC valve,

- Suction strainer.

4.5 Dimensions and weights

For dimensions and weights please refer to the general

arrangement drawing of the pump.

9

Page 10

5. Installation at site

Pumps should be installed, leveled and aligned by

qualified people. When this service is inappropriate

executed, it can have as consequence, operation

troubles, premature wear and irreparable damage.

Foundation Plan drawing (FU) informs pump dimension,

weights, foundation arrangement, connection sizes and

position of fixation elements.

Assure that all parameters for handling and operation

(access, assembly area, connections for assembly

equipment, cranes, etc) were perfectly established before

pump installation activities.

5.1 Safety regulations

Equipment operated in hazardous locations

must comply with the relevant explosion

protection regulations. This is indicated on the pump

name plate and motor name plate (see 2.9).

5.2 Checks to be carried out prior to installation

All structural work required must ha ve been prepared

in accordance with the dimensions stated in the

dimension table / general arrangement plan.

In case of concrete foundations they shall have

sufficient strength (min.class X0) to ensure safe and

functional installation in accordance with DIN 1045- 2

or equivalent standards.

Make sure that the concrete foundation has set firmly

before placing the unit on it. Its surface shall be truly

horizontal and even. The foundation bolts shall be

inserted in the soleplate.

5.2.1 Place of installation

The distributor casing, the pipe assembly and

certain areas of the soleplate take on roughly the

same temperatures as the medium handled. The motor

stool or bearing bracket lantern must not be insulated.

Take the necessary precautions to avoid burns.

5.3 Foundation

A special base frame must be fitted flush on shims in the

foundation or cover aperture to receive the pump set. T he

concrete base must have set before the base frame is

fitted.

Carefully level the machined seating face for the barrel

flange using a precision spirit level; use stainless steel

shims to compensate for any differences in height.

Do not grout and concrete in the base frame until the

pump set has been installed and the levels rechecked.

5.4 Barrel cleaning

Before mounting of barrel in the pit clean carefully inner

side of the barrel, keeping it horizontally and tilti ng it as

and when required till it is absolutely cleaned up.

5.5 Mounting

Fit the barrel separately in the leveled base frame,

carefully align and secure on the base frame.

WKT

Fit and align pump set and driver as described in section

5.6.

Then concrete in the base frame; re-check the alignment

and secure the barrel flange to the base frame using

studs and nuts.

5.6 Aligning the pump / drive

The pump unit consisting of pump, coupling and drive has

been mounted on a common set and is carefully aligned

in the manufacturing works.

The following instructions also apply to units not mounted

on a common set.

After connecting the piping and priming

Caution

the system, it is essential to re-check

the alignment at operating temperature.

operating behavior and may result in damage to the

bearings and shaft seals as well as premature coupling

wear.

Please note:

The pump set is correctly aligned, if a straight-edge

placed axially on both coupling halves is the same

distance from each shaft at all points around the

circumference. In addition, the distance between the two

coupling halves must remain the same all around the

circumference. Use a feeler gauge, a wedge gauge or a

dial micrometer to verify (see figs. 10 and 11).

Fig. 10 - Aligning the coupling with the help of a gauge

and a straight-edge

Fig. 11 - Aligning a spacer-type coupling

The radial and axial deviation between the t wo coupling

halves must not exceed 0, 1 mm.

The alignment of the pump and drive shall preferably be

checked by means of a dial micrometer. For this purpose

Incorrect alignment and inadmissible

Caution

coupling displacement will affect the

10

Page 11

remove the coupling spacer after having marked its

installation position by dotting marks (balancing

condition).

At the same time check the motor´s direction of rotation,

with the pump decoupled (see 6.1.7). The direction of

rotation must correspond to the direction indicated by the

arrow on the pump. Verify by switching the motor on and

then off again immediately. Fig. 12 ilustrates examples of

possible dial micrometer arrangements.

Fig. 12 - Aligning a spacer-type coupling with a dial

micrometer

Admissible run-out of coupling face (axial) max. 0,1 mm.

Admissible radial deviation, measured over the complete

circumference, max. 0,2 mm.

5.7 Connecting the piping

Never use the pump itself as an

Caution

anchorage point for the piping. The

permissible pipeline forces must not be exceeded (see

section 4.3.5).

The pipelines shall be anchored in c lose proximity to the

pump and connected without transmitting any stresses or

strains. The nominal diameters of the pipelines shall be at

least equal to the nominal diameters of the pump nozzles.

It is recommended to install check and shut-off elements

in the system, depending on the type of plant and pump.

It must be ensured, however, that the pump can still be

drained and dismantled without problems.

Thermal expansions of the pipelines must be

compensated by appropriate measures so as not to

impose any extra loads on the pump exceeding the

permissible pipeline forces and moments.

An excessive, impermissible increase in the

pipeline forces may cause leaks on the pump

where the fluid handled can escape into the atmosphere.

Danger of life when toxic or hot fluids are handled!

The flange covers on the pump suction and discharge

nozzles must be removed prior to installation in the

piping.

After the piping has been connected, it

Caution

must be easy to rotate the pump shaft by

hand at the coupling.

Recommendations for suction

In the pump installation, please consider the following

conditions:

a) Check minimum distance from bottom well up to

suction outlet or strainer according to installation (see

foundation plan).

b) Check liquid minimum level above pump casing, in

order to avoid dry operation, cavitation or vortex.

WKT

c) In case of frequent liquid level variation, it should

foreseen the installation of protection system against

operation below the minimum level.

d) In case of liquid with solids in suspension or with

excessive dirty, it should foreseen strainer in the pump

inlet.

Recommendations for discharge piping

The discharge piping assembly should comply with the

following considerations:

a) It should have disposals for water hammer control,

every time the overpressure values, deriving from liquid

return in long pipings, exceeds the recommended values

for piping and pump.

b) In the points where it is necessary to extract the air it

should foreseen vent valves.

c) It is necessary to foreseen tie bolted assembly joints, to

absorb system reaction efforts, deriving from applicable

loads.

d) Safety valves, relief disposals and other operation

valves, besides those mentioned, should foreseen when

necessary.

5.7.1 Auxiliary connections

The dimensions and locations of the auxiliary

connections (cooling, barrier liquid, flushing liquid, etc.)

are indicated on the general arrangement drawing or

piping layout.

These connections are required for proper

Caution

functioning of the pump and are therefore

of vital importance!

5.7.2 Coupling guard

In compliance with the accident prevention

regulations the pump must not be operated

without a coupling guard.

If the customer specifically requests not to include a

contact guard in our delivery, then the operator must

supply one. In this case, it is important to make sure that

the materials selected for coupling and coupling guard

are non-sparking in the event of mechanical contact.

KSB’s scope of supply meets this requirement.

5.8 Final check

Re-check the alignment as described in section 5.6 and

verify the correct distance between the coupling and the

coupling guard.

It must be easy to rotate the shaft by hand at the

coupling.

5.9 Connection to power supply

Connection to the power supply must be effected

by a trained electrician only. Check available

mains voltage against the data on the motor rating plate

and select appropriate start-up method.

We strongly recommend to use a motor protection device

(motor protection switch).

In hazardous areas, compliance with IEC60079-

14 is an additional requirement for electrical

connection.

11

Page 12

6. Commissioning, start-up / shutdown

Caution

importance. Damage resulting from non-compliance shall

not be covered by the scope of warranty.

6.1 Preparations

6.1.1 Recommended safety instrumentation for pump

a) Level switch for low level in suction tank.

b) Differential pressure indicator with switch across the

suction strainer.

Both these instruments should give trip signal for motor.

6.1.2 Lubrication

Check the bearing lubrication and correctly fill with the

specified amount of lubricant. See 6.1.4 for lubricant fill

and quality.

6.1.3 Pre-commissioning checks

a) Flushing of suction tank, suction pipeline with water

b) Cleaning of suction strainer;

c) Barrel cleaning; see 5.4;

d) Shaft seal;

e) Fit suction and discharge pressure gauges;

f) Check functioning of all interlocks by stimulation

g) Priming – see 6.1.6 for details;

h) Check free rotation of shaft manually.

6.1.4 Lubrication

Oil lubrication

The support bearing is lubricated by the oil fill in the

bearing housing (350). An oil elevator tube (646) inside

the centering sleeve (526) supplies oil to the antifriction

bearing. The requisite oil level is maintained by a

constant level oiler (638). The reservoir of this constant

level oiler must therefore always be kept topped up with

oil.

Filling and topping up (see fig. 13).

Compliance with the following

requirements is of paramount

after chemical cleaning. Take care to blind the pump

suction and discharge nozzles before flushing;

I) Check shaft seal and pack as described in

6.1.5.1 (applicable for gland packing execution

only);

II) Remove auxiliary piping for mechanical seal ie.

cooling, flushing, quenching, etc. It must be

thoroughly cleaned with water, dried and then

refitted.

method;

WKT

Filling and topping

Remove the protective case of the constant level-oiler.

Unscrew vent plug. Pour in the oil through the vent plug

tapping hole after having removed out the reservoir of the

constant level oiler until oil appears in the vertical portion

of the connection elbow. Then fill the reservoir of the

constant level oiler with oil and snap it back into operating

position. Screw vent plug in again. After a short time

check whether the oil level in the reservoir has dropped. It

is important to keep the reservoir properly filled at all

times.

The oil level should always be belo w the level of the vent

opening arranged at the top edge of the connection

elbow.

Fig.13 - Filling with oil

65

80

100

3

125

150

2

/s

12

1. Oil level in bearing housing and in connection elbow.

2. Position for topping up of oil level make-up quantity.

3. Oil level in oil reservoir after filling of same.

Oil changes and oil requirements

The first oil change should take place after the first 300

hours of operation, and subsequent oil changes should

be effected after every 3000 hours of operation, but at

least once a year.

Unscrew and remove the drain plug (903.4) on the

bearing housing and drain the oil. After draining of the

bearing housing, replace the drain plug and fill in fresh oil.

Pump sizes 40 50

Oil fill 1) ltrs 0,3 0,5 0,6 1,2

1)

Oil filling quantity (including constant level oiler and filler

pipe).

Fig. 14 Oil requirements

Oil specification

The oil used should exhibit the following characteristics:

Kinematics viscosity at 50ºC = 30 to 45 mm

Density at 20ºC = 0,9 kg/dm

Flash point = at least 150ºC

Pour point = below -5ºC

Ash content = not exceeding 0,05%

Neutralization number = not exceeding 0,3

Asphaltenes = 0%

Page 13

Lubrication by product pumped

The pump bearings and intermediate shaft bearings ar e

lubricated directly by the product pumped (suction side

bearing by inlet pressure and intermediate shaft bearings

by liquid at pump discharge pressure). No special

maintenance of these bearings is necessary, but the

pump must not be allowed to run dry.

6.1.5 Shaft seal

6.1.5.1 Gland packing

Gland packings supplied with the pump

Caution

have to be installed prior to pump startup

(unless they were fitted prior delivery).

The gland packing must be tightened gently and evenly.

It must be easy to rotate the shaft by hand.

a) Fitting new packing

Thoroughly clean the packing compartment and the shaft

protection sleeve, and coat them with molybdenum

disulphide. Insert neck ring (457), if any, and press it

home until it abuts. Insert the packing rings individually

and push them home with the aid of the stuffing bo x gland

and the seal cage ring. The ring butt of each packing ring

should be offset 90º in relation to the joints of the

adjoining rigid. In case of lubrication by an external

source insert seal cage ring (458) so that it registers

opposite connection 10E.

Then insert the remaining packing rings individually.

Leave a sufficient clearance gap at the entrance of the

stuffing box for the positive guidance of the gland. The

inserted packing rings should only be lightly compressed

by the gland and the nuts.

Then the nuts should be slackened and tig htened again

by hand. The even seating of the gland should be

checked with a feeler gauge, with the pump subjected to

suction pressure.

b) Removing the packing

Slacken clamping ring (184) and remove it from shaft

protection sleeve (524), undo stuffing box gland (452) and

pull it out of stuffing box housing.

Pull the top packing rings out of stuffing box housing

(451) with the aid of a packing ring extractor, pull out seal

cage ring (458), if any, then remove the remaining

packing rings and examine shaft protection sleeve (524)

for signs of damage.

Clean the packing compartment and coat it with

molybdenum disulphide.

Pack the stuffing box as described under a) above.

N.B.

The stuffing box should drip slightly whilst the pump is

running the leakage rate should amount to between 2 and

3 l/h. If your pump has sealing and cooling liquid

connections in use, they should be checked for

unimpeded flow. When the stuffing box gland has been

repeatedly tightened in service until it a buts, it is time to

renew the packing in the stuffing box.

WKT

Packing material

When selecting the packing material, remember to

ascertain its compatibility with the product pumped.

Always use new packing material, preferably material

which has been stored for a certain period, to repack the

stuffing box.

Pump

sizes

40

50

65

80

100

125

150

dws = Outer diameter of shaft protection sleeve

da = Inner diameter of packing compartment

Fig. 15 Dimension of packing compartment and packing.

6.1.5.2 Mechanical seal

Caution

supply tank, the tank must be fitted in accordance with

the general arrangement drawing (see also 6.1.6).

Quench feed must also be provided during pump

shutdown. On variants with pressurized dual mechanical

seals, apply barrier pressure as specified in the g eneral

arrangement drawing prior to starting up the pump (see

6.1.6). Barrier pressure must also be provided during

pump shutdown.

For external liquid supply, the quantities

Caution

and pressure specified in the data sheet

and general arrangement drawing shall be applied.

6.1.6 Priming the pump and checks to be carried out

The barrel must be filled at all times with product.

The pump body must be vented through the discharge

pipe during priming before commissioning.

6.1.6.1 Vacuum balance line

If the pump has to pump liquid out of a vessel under

vacuum it is advisable to install a vacuum balance line.

The suction area (barrel and distributor casing) is vented

via a line which remains open all the time. This line

should have a nominal size of 25 mm minimum. It should

be arranged to lead back into the vacuum vessel in

vapour phase.

Packing

compartment

dws / da

mm

40 / 60

45 / 70

45 / 70

55 / 80

55 / 80

80 / 112

80 / 112

The mechanical seal has been fitted prior

to delivery. On variants with quench

Number of

packing

rings

6

6

6

6

6

5

5

Width of

packing

mm

10

12,5

12,5

12,5

12,5

16

16

Overall

length

mm

1400

1500

1500

1600

1600

1800

1800

13

Page 14

WKT

Back to suction

(in vapour state)

Never run the pump dry!

Caution

Open or switch on all auxiliary lines (cooling, lubricati on,

sealing liquid etc) and ensure they are not blocked.

For water cooling, use suitable non-aggressive cooling

water not liable to form deposits and not containing

suspended solids. (Hardness: on average 5dH; (~1

mmol/l); pH > 8, or conditioned and neutral with regard to

mechanical corrosion).

Inlet temperature t

Outlet temperature t

Caution

Dry running of the pump will result in

mechanical seal failure and must be

= 10 to 30ºC

E

max. 45ºC

A

avoided!

6.1.6.2 Cooling

In general, the shaft seal must be cooled

Caution

if the vaporization pressure of the fluid

handled is higher than the atmospheric pressure.

Depending on the fluid handled, the system pressure and

the mechanical seal material, the limit may change

(example: hot water).

Observe permissible temperature

Caution

classes.

6.1.7 Checking the direction of rotation

When the unit has been connected to the electric power

supply, verify the following (local and national regulations

have to be taken into account separately):

For trouble-free operation of the pump,

Caution

the correct direction of rotation of the

impeller is of paramount importance. If running in the

wrong direction of rotation, the pump cannot reach its

duty point; vibrations and overheating will be the

consequence. The unit or the shaft seal might be

damaged.

Correct direction of rotation:

The direction of rotation must correspond to the direction

indicated by the arrow on the pump.

Never put your hands or any other objects into the

pump.

The motor’s direction of rotation

Caution

must be checked with the

pump/motor coupling removed.

If the motor runs in the wrong direction of rotation,

interchange two of the three phases in the control c abinet

or motor terminal box.

The safety instructions set forth in section 2.9.3 must be

complied with.

Fig. 16 – Decoupled drive

6.2 Start-up

Before starting the pump ensure that the shut-off element

in the suction line (if any) is fully open.

The pump may be started up against a closed dischargeside swing check valve or slightly open shut-off valve.

Only after the pump has reached full rotational speed

shall the shut-off valve in the discharge line be opened

slowly and adjusted to comply with the duty po int. When

starting up against an open discharge-side shut-off valve,

take the resulting increase in input power into account!

Pump operation with the shut-off

Caution

valves in the discharge and

suction pipes closed is not permitted.

The permissible pressure and temperature limits might be

exceeded. In extreme cases, the pump may burst.

After the operating temperature has

Caution

been reached and / or in the event of

leakage, switch off the unit and re-tighten the applicab le

bolts. Permissible tightening torques see 7.5.3.

Caution

Check the coupling alignment at

operating temperature as described in

section 5.6 and re-align, if necessary.

Immediate steps after start up

After start up and with pump in process, please observe

the following items:

a) Control electric power consumption (amperage) and

voltage;

b) Certify that the pump runs free of vibration and

abnormal noises;

c) Control support bearing temperature, which can

reach up to 40ºC above ambient temperature;

however the sum of them cannot exceed 82ºC.

The above items should be controlled each 15 minutes

during the first 2 hours operation. If everything is normal,

new controls should be made each 1 hour, during the first

5 up to 8 hours. If there is anything abnormal during this

period, please consult chapter Functioning Abnormalities

and its eventual Causes.

6.2.1 Minimum flow

(For the protection of the pump when operating at low

loads).

14

Page 15

General

The power absorbed by the pump does not decrease

proportionately with decreasing rate of flow, but on the

contrary still amounts to more than 50% of the power

absorbed at the design duty point at zero flow (pump shut

off point). In order to carry off this energy which is

converted into heat inside the pump, it is necessary to

maintain a minimum rate of low through the pump.

In the case of pumps with discharge nozzles of nominal

sizes between 40 and 150 this minimum rate of flow

normally amounts to 0,15 Qopt, taking the heat conditions

and the pattern of the characteristic curve into account.

In the case of pumps with larger sizes of discharge

nozzle, this minimum rate of flow amounts to 0,2 Qopt.

Qopt = Rate of flow at maximum efficiency of the pump.

The pump should only be operated at

Caution

rates of flow below the minimum rate of

flow during the switching on and switching off process.

Excessive wear and damage to the pump cannot be

excluded under these circumstances.

Minimum flow circulation via a permanent bypass

The permanent bypass recirculation is selected for plants

with relatively low pressures and low minimum flow rates.

This system is very attractive from the point of view of low

first cost, but is uneconomic in operation because the

minimum flow (or bypass flow) has to be circulated over

the entire operating range of the pump. When sizing the

pump, the bypass rate of flow must be added to the pump

capacity.

In order to ensure the minimum flow, an orifice plate is

fitted in the bypass line between the pump and the

suction vessel.

Minimum flow circulation via an automatic

recirculation valve

The automatic recirculation valve ensures the minimum

flow protection requirement simply and reliably. It is

mounted vertically in the discharge line between the

pump discharge nozzle and the isolating valve, in such a

way that the fluid flow through it from bottom to top.

As soon as the rate of flow of the pump falls below a

given minimum value, the bypass outlet on the automatic

recirculation valve opens sufficiently wide for a

predetermined minimum flow quantity to pass through

and be maintained even when the rate of flow through the

main discharge line is reduced to zero.

6.3 Shutdown

Close the shut-off valve in the discharge line.

If the discharge line is equipped with a non-return or

check valve, the shut-off valve may remain open. If shutoff is not possible, the pump will run in reverse direction.

This may cause damage to mechanical

Caution

seals which are not bi-directional!

The reverse runaway speed must be lower than the rated

speed.

Switch off the drive, making sure that the unit runs down

smoothly to a standstill.

Close the auxiliary lines but do not turn off the cooling

liquid supply, if any, until the pump has cooled down.

WKT

Please refer to section 6.1.5.2.

In the event of frost and / or prolonged shutdowns, the

pump – and the cooling chambers, if any – must be

drained or otherwise protected against freezing.

6.4 Operating limits

The pump´s / unit´s application limits regarding

pressure, temperature and speed are stated on

the data sheet and must be strictly adhered to!

If a data sheet is not available, contact KSB!

6.4.1 Temperature of the fluid handled, ambient

temperature, bearing temperature

Caution

sheet or the name plate unless the written consent of

the manufacturer has been obtained. Damage resulting

from disregarding this warning will not be covered by the

KSB warranty.

Bearing bracket temperature see 7.2.1.

The safety instructions set forth in section 2.9 must

be complied with.

6.4.2 Switching frequency

To prevent high temperature increases in the motor and

excessive loads on the pump, coupling, motor, seals and

bearings, the switching frequency shall not exceed the

following number of start-ups per hour (S).

If the above switching frequencies are exceeded, please

contact the motor manufacturer or KSB.

6.4.3 Density or fluid pumped

The power input of the pump will increase in proportion to

the density of the fluid pumped. To avoid overlo ading of

the motor, pump and coupling, the density of the fluid

must comply with the data specified on the purchase

order.

6.4.4 Abrasive fluids

When the pump handles liquids containing abrasive

substances, increased wear of the hydraulic s ystem and

the shaft seal are to be expected. The intervals

recommended for servicing and maintenance shall be

shortened.

6.4.5 Minimum / Maximum flow

Recommended operation flow range is Q = 0,5 up to

1,15 Q

Q

For minimum flow in short periods of operation see 6.2.1.

The data refer to water and water-like liquids. However, if

the physical properties of the fluids handled are different

from water, the calculation formula below must be used to

check if an additional heat build-up may lead to a

Do not operate the pump at temperatures

exceeding those specified on the data

Motor rating (kW) max. S (start –ups / h)

up to 12 15

up to 100 10

more than 100 5

opt.

= optimum efficiency

opt

15

Page 16

dangerous temperature increase at the pump surface. If

necessary, the minimum flow must be increased.

To = Tf +

= g * H / c * * (1 - )

c Specific heat [ J / kg K ]

g Acceleration due to gravity [ m / s

2

]

H Pump head [ m ]

Tf Temperature of fluid handled [ ºC ]

Temperature of casing surface [ ºC ]

T

o

Pump efficiency at duty point [ - ]

Temperature difference [ ºC ]

6.5 Shutdown / storage / preservation

Each KSB pump leaves the factory carefully assembl ed.

If commissioning is to take place some time after delivery,

we recommend that the following measures be taken for

pump storage.

6.5.1 Storage of new pumps

- New pumps are supplied by our factory duly

prepared for storage. Maximum protection for up to 6

months, if the pump is properly stored indoors.

- Store the pump in a dry location.

- Rotate the shaft by hand once a month.

6.5.2 Measures to be taken for prolonged shutdown

1. The pump remains installed; periodic check of

operation

In order to make sure that the pump is always ready

for instant start-up and to prevent the formation of

deposits within the pump and the pump intake area,

start up the pump set regularly once a month or once

every 3 months for a short time (approx. 5 minutes)

during prolonged shutdown periods.

Prior to an operation check run ensure that there is

sufficient liquid available for operating the pump.

2. The pump is removed from the pipe and stored

Before putting the pump into storage, carry out all

checks specified in sections 7.1 to 7.4. Then apply

appropriate preservatives:

- Spray-coat the inside wall of the pump casing,

and in particular the impeller clearance areas,

with a preservative. Spray the preservative

through the suction and discharge nozzles. It is

advisable to close the pump nozzles (e.g. with

plastic caps or similar).

6.6 Returning to service after storage

Before returning the pump to service, carry out all checks

and maintenance work specified in sections 7.1 and 7.2.

In addition, the instructions laid down in the

sections on “ Preparations “ (6.1) and

“Operating Limits “(6.4) must be observed.

Immediately following completion of the work, all

safety-relevant and protective devices must be

re-installed and / or re-activated.

WKT

7. Servicing / maintenance

7.1 General Instructions

The operator is responsible for ensuring that all

maintenance, inspection and installation work be

performed by authorized, qualified specialist personnel

who are thoroughly familiar with the manual.

A regular maintenance schedule will help avoid expensive

repairs and contribute to trouble-free, reliable operation of

the pump with a minimum of maintenance expenditure

and work.

Work on the unit must only be carried out

with the electrical connections disconnected.

Make sure that the pump set cannot be switched on

accidentally (danger to life!).

draining the fluid see to it that there is no risk to

persons or environment or the environment. All

relevant laws must be adhered to (danger to life)!

7.2 Servicing / inspection

7.2.1 Supervision of operation

The pump must never be allowed to run dry.

Always ensure a sufficient liquid level above the pump

inlet.

Prolonged operation against a closed shut-off

valve is not permitted. When operating the pump

set with the shut-off valve in the discharge line slightly

open for a short period of time, the permissible pressure

and temperature limits must not be exceeded.

A special design is required to comply with

temperature class T6 in the bearing area. In

such cases, and if ambient temperature exceeds 40ºC,

contact the manufacturer.

Verify correct oil level as described in section 6.1.4.

The shut-off elements and the auxiliary feed lines must

not be closed during operation.

Any stand-by pumps installed shall be started up

regularly, e.g. once a week, to keep them operational.

Attention shall be paid to the correct functioning of the

auxiliary connections. The cooling system must be

thoroughly cleaned at least once a year to ensure proper

cooling. Take the pump out of service for this purpose.

replaced in due time. Re-align the coupling as descr ibed

in section 5.6.

Supervision during operation

Depending on the labor availability and pump

responsibility, we recommend the following checks, and

in case of any abnormality the maintenance responsible

should be advised immediately.

Pumps handling liquids posing health

hazards must be decontaminated. When

Caution

Caution

The pump must run quietly and free

from vibrations at all times.

If the flexible coupling elements begin to

show signs of wear, they must be

16

Page 17

Weekly supervision

Check:

a) Pump operation point;

b) Motor current consumption and net tension value;

c) Vibration and abnormal noises;

d) Bearing housing temperature;

e) If applicable, the gland packing should drip slightly

whilst the pump is running. The gland should only be

tightened lightly.

Monthly supervision

Check:

a) Oil change interval, (if applicable).

Semestral supervision

Check:

a) Base frame and motor fix bolts;

b) Pump-motor set alignment;

c) Coupling lubrication (when applicable).

Annual supervision

Disassemble the pump for maintenance. After cleaning,

inspect bearings, (do it in detail), retainers and / or

bearing sealings, joints, O´rings, impellers, casing internal

regions (control also thickness), wear areas and coupling.

Note:

In installations with good operation conditions and

pumped liquid not aggressive to the pump materials, the

supervision can be done each 2 years.

7.2.2 Lubrication and lubricant change

See section 6.1.4.

7.3 Drainage / disposal

If the pump was used for handling liquids

Caution

posing health hazards, see to it that

there is no risk to persons or the environment when

draining the fluid. All relevant laws must be heeded. If

required, wear safety clothing and a protective mask!

If the fluids handled by the pumps leave residues which

might lead to corrosion when coming into contact with

atmospheric humidity, or which might ignite when coming

into contact with oxygen, then the unit must be flushed

through, neutralized, and then for drying purposes

anhydrous gas must be blown through the pump.

The flushing fluid used and any liquid residues in the

pump must be properly collected and disposed of without

posing any risk to persons or the environm ent. See also

section Discard (3.3.2).

7.4 Dismantling

Before dismantling the pump, secure it so as to

make sure it cannot be switched on accidentally.

The shut-off valve in the discharge line must be closed.

The pump set must have cooled down to

ambient temperature, pump pressure must

have been released and the pump must have been

drained including oil of bearing housing, if any.

WKT

Dismantling and reassembly must alw ays be carried

out in accordance with the relevant sectional

drawing.

7.4.1 Fundamental instructions and recommendations

Repair and maintenance work to the pump must on ly be

carried out by specially trained personnel; using original

spare parts (see 2.7).

Observe the safety regulations laid down in section

7.1. Any work on the motor shall be governed by the

specifications and regulations of the respective

motor supplier.

Dismantling and reassembly must alw ays be carried

out in accordance with the relevant general assembl y

drawing. The general assembly drawing and other

relevant documents are found in the annex. The

dismantling sequence can be derived from the

general assembly drawing.

In case of damage you can always contact our

service departments.

7.4.2 Dismantling the pump

7.4.2.1 Dismantling the thrust bearing

1. Pull the pump end half coupling off drive shaft (213)

with the aid of puller. Remove key (940.4).

2. Unscrew and remove oil labyrinth (270);

3. Unscrew bearing cover (360), and remove centering

sleeve (526) together with antifriction bearing (320)

and bearing cover (360) from the shaft by twisting the

centering sleeve. Pull the bearing cover (360) off the

centering sleeve (526).

4. Dismantle constant level oiler (638) together with its

connecting pipe.

5. Unscrew bearing housing (350) force it off and pull if off

over shaft (213) together with oil stand pipe (641).

6. Unlock and unscrew withdrawal nut (923.2), push

antifriction bearing (320) off the centering sleeve,

clean it with wash oil and examine it.

7.4.2.2 Dismantling the shaft seal

Gland packing

1. Unscrew screws (914.31) in clamping ring (184).

2. Pull the shaft protection sleeve together with the

clamping ring off the shaft.

3. Unscrew hex nuts (920.31) and remove stuffing box

gland (452).

4. Remove packing rings (461) and seal cage ring (458)

from the stuffing box housing, if any.

Mechanical seal

See specific instructions.

17

Page 18

7.4.2.3 Dismantling the pump body

After a prolonged period of operation, it

Caution

may happen that individual rotor

components (impeller and distance bushes) are difficult to

pull off the shaft, in such cases, do not use force or

hammer blows. First try using a suitable rust solvent or a

puller device. If these measures do not lead to the

desired result, the components concerned can be

warmed up slightly and then pulled off or forced off. The

shaft should remain as cold as possible during the

warming up process. If rotor components are dismantled

by warming up, the shaft should subsequently be

checked for radial run out.

1. Unscrew studs and nuts (902.1 and 920.5) between

distributor casing (10-1) and column pipe main, force

off pump body together with column pipe, and

dismantle distributor casing. Carefully underpin the

drive shaft (213).

2. Dismantle the column pipe.

3. Unscrew the intermediate shaft coupling or

disassemble the muff coupling and remove drive shaft

(213).

4. Unscrew nuts (920.1) of tie rods (905) at suction end,

remove them and pull out the tie rods.

5. Force off suction casing (106).

6. Undo nut (920.2) and remove it together with the lock

washer (931.1).

7. Pull suction impeller (231) off pump shaft (211), and

remove key.

Underpin the stage casing.

8. Force off and remove stage casing (108) including first

stage diffuser (171.1) and suction side bearing. D o not

damage the sealing faces.

9. Pull the stage sleeve (521.1) from the shaft and

remove the split ring (501.2).

10. Pull the impeller (230) off the pump shaft (211) and

remove key. Support the stage casing.

11. Press off and remove the stage casing (108) and

diffuser (171.2).

12. Press the stage sleeve (521) from the shaft.

13. Dismantle all the remaining s tages in the same way

as described in points 10 to 12 above.

In the case of multistage pumps, mark the impellers

and stage casings in their correct sequence, to

facilitate reassembly.

14. Pull discharge casing (107) off the shaft and store the

shaft with due care.

7.4.2.4 Dismantling of pumps installed very deep

down

1. Carry out preparations as described in section 7.4.1.

WKT

2. Dismantle thrust bearing as described in section

7.4.2.1

3. Dismantle shaft seal as described in section 7.4.2.2.

4. Pull the pumping set far enough out of the barrel by

means of the distributor casing (10-1) to enable a pipe

clip to be attached some 50 cm beneath the next

column pipe joint.

Firmly fasten the pipe clip and lower the pumping set

again until the pipe clip rests on top of the barrel.

Unscrew the pipe joint connecting the lengths of

column pipe main, and lift the distributor casing and

the upper length of column pipe main (711.1) over the

drive shaft. Unscrew the intermediate shaft coupling or

disassemble the muff coupling and remove drive shaft

(213). Force off the complete intermediate shaft

bearing and pull it off over the shaft.

Examine the bearing and shaft for signs of galling

(seizure). If necessary, raise the pumping set by a

further length of column pipe main, again fit a pipe clip

and lower the pumping set until the pipe clip rests on

the barrel. Then dismantle the length of column pipe

main and the bearing. Lift the pump body out of the

barrel, then set it down and underpin it in the

horizontal position for dismantling.

5. Dismantle the pump body in accordance with section

7.4.2.3, points 4 to 14.

7.4.3 Examination of individual components

7.4.3.1 Shafts (211, 212, 213)

Inspect the bearing sleeves (529) on the shafts for signs

of galling (seizure). Slight traces of damage can be

removed by grinding within the permissible clearance

limits. If the touching up works should result in the

permissible clearances being exceeded, then new

bearing sleeves (529) must be placed on.

Carry out an out-of-round check on a lathe between dead

centres. The max. permissible shaft whip must not

exceed 0,03 mm.

Caution

readings will be erroneous.

If certain rotor components are replaced by new ones, or

have been touched up, or if a new shaft has been fitted,

the pump rotor must be balanced dynamically, preferabl y

at the max, operating speed of the pump, but at l east at

1000 1/min. The max. permissible residual eccentricity is

5 microns.

7.4.3.2 Bearing arrangement

Antifriction bearings (320)

Even if they only exhibit slight discoloration marks or

specks of rust, or signs of damage to the running

surfaces, the bearings must be replaced by new ones.

Make sure the shaft is accurately

centered on the lathe, as otherwise the

18

Page 19

Observe the greatest cleanliness when mounting the

bearings. Use washing oil to clean the old bearings. After

washing, the bearings should be dried and immediately

sprayed with oil.

Plain bearings (pump and intermediate shafts)

Examine the bearing bushes for signs of galling (seizure).

If necessary, fit new bearing bushes (see table, fig. 20).

7.4.3.3 Shaft seal

Soft packed stuffing box

Use new packing material every time the pump is

overhauled. The shaft protection sleeve (524) may only

be touched up very lightly by grinding.

If it exhibits signs of damage, a new shaft protection

sleeve should be fitted.

(For pump with impeller rings and inter stage bushes, see

supplementary sheet).

7.4.3.4 Pump body

Suction casing (106), discharge casing (107), stage

casings (108), impellers (230, 231), casing wearing rings

(502), bearing bushes (545), stage sleeves (521).

Ensure all the sealing faces are in perfect condition.

Check the plane parallelism of the faces at 4 points on

the circumference with a micrometer. The deviation must

not exceed 0,02 mm. Damaged faces can be machined

on a lathe. The surface roughness must not exceed

0.8 µm (micron meter).

The stage casings (108) and diffusers (171) are fitted with

renewable casing wearing rings (502).

Check the impellers and wearing rings for galling and

check the rotor clearances per fig. 19.

The casing wearing rings must be machined when fitted

and the max. permissible clearances must be respected.

Any increase in clearance must be made uniform at all

wearing points inside the pump.

If the bearing clearances are the same as or greater t han

the max. permissible clearances per Fig. 20. Fit new

oversized wearing parts and re-establish the “as new”

clearances.

Fitting new casing wearing rings (502)

1. Undo the allen grub screw, press the casing wearing

rings in the stage casing and diffuser out of the fit

taking care not to damage the fit. (see fig. 17).

2. Uniformly press new wearing rings.

3. Smooth down all impellers (230, 231) in the region of