KSB WK, WK 40, WK 100, WK 50, WK 65 Series Manual

...

Contents

WK

Point Description Page

No. No.

0 Introduction 1

1 Pump construction 1

1.1 Casing 1

1.2 Rotor 1

1.3 Bearing arrangement 2

1.4 Lubrication 3

1.4.1 Oil lubrication 3

1.4.2 Grease lubrication 4

1.5 Shaft seal 4

1.5.1 Stuffing boxes 4

1.5.1.1 Cooling liquid for stuffing boxes 5

1.5.1.2 Packing the stuffing boxes 5

1.5.1.3 Packing material 7

1.5.2 Mechanical seals 7

1.6 Coupling 7

2 Mode of operation of pump 7

3 Drive 8

4 Transport 8

5 Painting 8

6 Condition of equipment as supplied 8

7 Accessories 9

8 Installing the pumping set 9

8.1 Description of site prior to

commencement of erection 9

8.2 Installation and preliminary levelling up 9

8.3 Aligning the coupling 9

8.4 Grouting in the baseplate 10

8.5 Final alignment 10

9 Piping 11

9.1 Suction lift line and positive

Suction head line 11

9.1.1 Strainers in suction head line/suction lift line 11

9.2 Isolating valves 12

9.3 Non-return valves 12

9.3.1 Automatic recirculation valve 12

9.4 Final coupling check 13

9.5 Measuring instruments 13

10 Commissioning 13

10.1 Preliminary remarks regarding

commissioning 13

10.2 Start-up 13

10.3 Operation and supervision of pump 14

Point Description Page

No. No.

10.4 Shutting the pump down 14

10.5 Preserving the pump 15

10.6 Sending the pump back to our Works 15

11 Dismantling the pump 15

11.1 Preparations prior to dismantling 15

11.2 Dismantling the bearing 15

11.2.1 Dismantling the drive end bearing 15

11.2.2 Dismantling the end side bearing 16

11.2.2.1 Standard bearing construction 16

11.2.2.2 Heavy duty bearing construction 17

11.3 Removing the shaft seal 17

11.3.1 Soft-packed stuffing box construction 17

11.4 Dismantling the pump body 17

11.5 Inspection of individual pump components 19

11.6 Dynamic balancing of pump rotor 20

12 Assembly of pump 20

12.1 Preparations prior reassembly 20

12.2 Assembling the pump body 20

12.3 Assembly of shaft seal 22

12.3.1 Pump construction with soft-packed

stuffing box 22

12.4 Assembly of bearings 23

12.4.1 Assembly of end side bearing 23

12.4.2 Assembly of drive end bearing 23

13 Operating troubles, causes and remedies 25

13.1 Operating troubles 25

13.2 Causes for damage 25

13.3 Suggested remedies 26

14 Spare parts 27

15 Check list 28

15.1 Pre-requisites for initial commissioning 28

15.2 Initial start-up with cold water 28

15.3 Priming the boiler 28

15.4 Initial operation with hot fluid 28

15.5 Supervision of operations & maintenance 28

16 Sectional drawings and list of

components 29

Balancing liquid piping 31

WK

water compartment, which is sealed off against atmosphere

by the stuffing box housing cover (165) with flat gasket (400.3)

and O-ring (412.4) (See Fig. 2)

7A/7E

Fig. 1

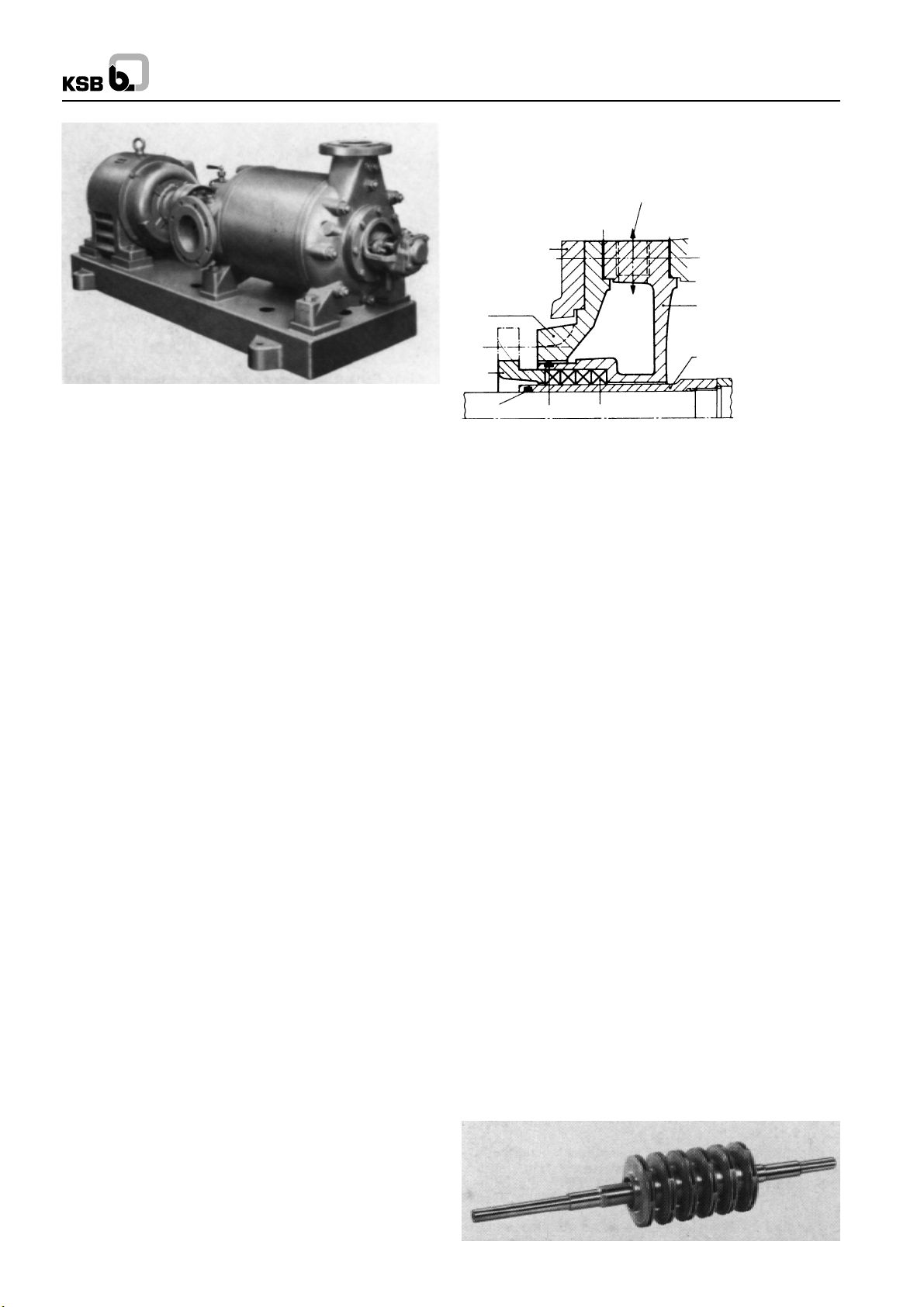

0. Introduction

WK pumps are High Pressure Horizontal Centrifugal Pumps.

In accordance with the latest state of the art of pump design

and construction, our pumps combine favourable hydraulic

characteristics with a long service life, reliability of operation

and simple maintenance and operation.

A pre-requisite for trouble-free operation of the pumps is the

careful observance of the recommendations contained in this

operating instruction manual. It should therefore, always be at

the disposal of the personnel entrusted with the erection,

maintenance and operation of the pump.

It goes without saying that the pumps should only be operated

under the duty conditions specified (see data sheet). The terms

of our Guarantee naturally apply within this range of conditions.

Our Guarantee will become invalid if the pumps are dismantled,

either completely or partially, without our prior consent. The

first assembly and dismantling of the pump should be carried

out by skilled fitters and erectors, and this also applies to the

initial start-up (commissioning) of the pumping set.

400.3

350

165

452

412.3 412.4 461.1

400.3

451

524.2

(524.1)

Fig. 2 Stuffing box housing with cooling compartment cover

Depending on the number of stages and on the temperature

of the product pumped, the pump feet are integrally cast onto

the suction and discharge casings (106 and 107) either at the

bottom, or at shaft centerline height. The suction nozzle can

be arranged to point horizontally to the left or right hand side,

or vertically upwards, if the pump feet are arranged at the

bottom of the pump; if they are arranged at shaft centerling

height, the suction nozzle can only be arranged to point

vertically upwards the discharge nozzle points radially upwards

on both types of pump feet arrangement.

In order to achieve a favourable NPSH required, the suction

nozzles on all sizes of pumps are made one nominal size larger

than the discharge nozzles. The flange construction is specified

in the data sheet.

1.2 Rotor

All the rotating components assembled on the shaft make up

the complete pump rotor (See Fig. 3 and 4)

1. Pump Construction

(For item numbers, see under section 16, Sectional drawings.)

1.1 Casing

WK high pressure centrifugal pumps are single or multistage

centrifugal pumps with a radially split casing. This consists of

the suction and discharge casing (106 and 107) together with

a number of stage casings (108). If the extraction of a given

quantity of the liquid pumped at one of more intermediate

pressures is required, the corresponding stage casings can

be provided with extraction (Bleed off) nozzles. The individual

casing components are sealed off against one another by flat

gaskets (400.2) or by ‘O’ rings (412) and clamped together by

connection rods (905). The diffusers (171.1 and 171.2) are

arranged in the stage casings and in the discharge casing

respectively (108 and 107 respectively). They are centered in

the casings at their outer periphery and secured against

twisting.

The stuffing box housings (451) and bearing housing (350)

are flanged onto the suction and discharge casing respectively

(106 and 107) and attached by studs (902.1). The stuffing box

housings (451) are sealed off from the suction and discharge

casings respectively (106 and 107) by a flat gasket (400.3).

On pumps fitted with special hot water stuffing boxes or with

mechanical seals, the shaft seal is surrounded by a cooling

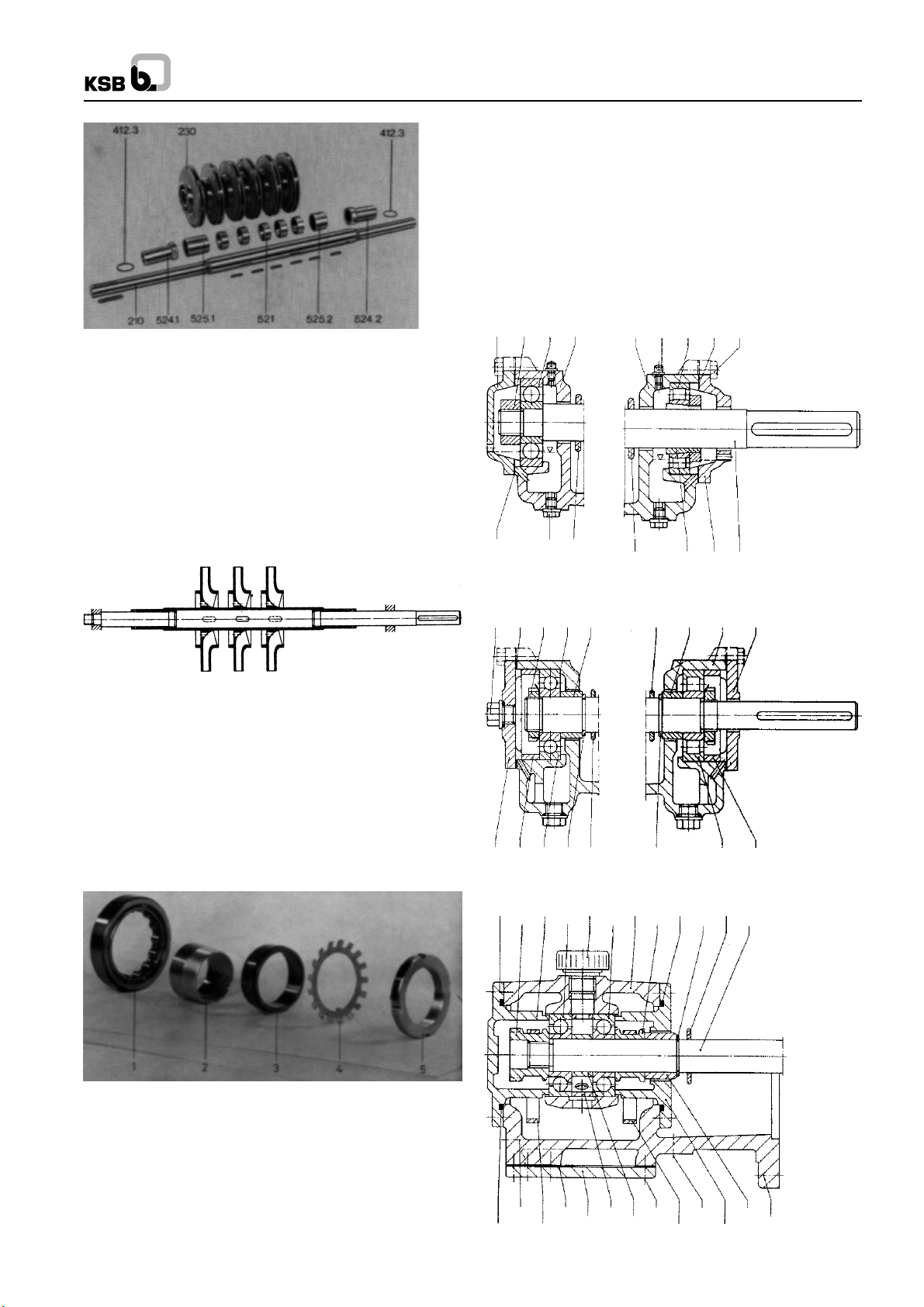

The shaft (210) transmits the torque generated by the drive

onto the impellers. The impellers (230) are mounted is

sequence on shaft (210), and they all point in the same

direction. They are secured against twisting by keys.

The narrow clearance gap between impeller neck and casing

wearing ring (502) at the suction and discharge end of each

impeller prevents the equalization of presure between one

stage and the next.

The shaft (210) is protected inside the pump against attack by

the fluid pumped by means of spacer sleeve (525.1/2) and

distance bushes stage (521). The distance bushes/stage also

serve to locate the impellers axially on the shaft. The shaft

(210) is protected by the shaft protection sleeves (524.1/.2) in

the region of the shaft seal. These protection sleeves are

screwed onto shaft (210) by means of screw threads with

opposed hand to the direction of rotation of the shaft.

Fig. 3 Assembled rotor

1

WK

5412 and standard bearing bracket (No adaptor sleeve

provided on pump size 150).

End side : 1 deep groove ball bearing in accordance with DIN

625 and standard bearing housing (see Figs. 7 and 8).

Heavy Duty Bearing Construction :

Drive end : Same as atandard bearing construction. End

side : 2 matched angular contact ball bearings in accordance

with DIN 628; X arrangement and heavy duty bearing bracket

(see Fig. 9).

Fig. 4 Dismantled rotor

In order to balance the axial thrust, throttling passages are

arranged at the impeller necks at the suction and discharge

end of each impeller, and additional balancing holes are

provided in the impeller necks at the discharge end

(See Fig. 5).

A fixed bearing absorbs the residual axial thrust generated

and also locates the rotor in the axial position; in the standard

bearing construction, this bearing consists of a deep groove

ball bearing (321) and in the pump construction with heavy

duty bearing bracket, it consists of two angular contact ball

bearings (320).

Fig. 5 Rotor

1.3 Bearing Arrangement

WK pumps are fitted with different types of beaings and bearing

housing, depending on the differential head (generated

pressure) of the pump. In the case of low differential heads,

the standard bearing construction is provided. In the case of

higher total heads, the heavy duty bearing construction is

provided to absorb the increased residual thrust.

The pump manufacturer decides which type of bearing

arrangement shall be provided.

361 920.4 321 350 350 731.2 322 400.4 901.2

400.4

903.4

(13B)

507

507 52-1 360 210

Fig. 7 Bearing construction, size 40 to 125

400.4 920.4 350 525.4

903.12

361 543 321 932 507 932 322 543

507 525.4 350 360

Fig. 8 Bearing construction, size 150

Drive end

Fig. 6 Individual bearing components (drive end)

Part 1 = Outer race with cage and rollers

Part 2 = Adaptor Sleeve

Part 3 = Inner bearing race

Part 4 = Locking Washer

Part 5 = Withdrawal Nut

Standard Bearing Construction :

Drive end : 1 Cylindrical roller bearing in accordance with DIN

5412 (see Fig. 6) with adaptor sleeve in accordance with DIN

901.3 361 913 350.2 412.7 507

903.5

(

)

13B

412.7 644 644 360.2

543400.5

525.8160

901.4

720.3

(8B)

210

932508320320923

525.5

902.3

Fig. 9 Bearing construction with heavy duty bearing

bracket size 150.

2

WK

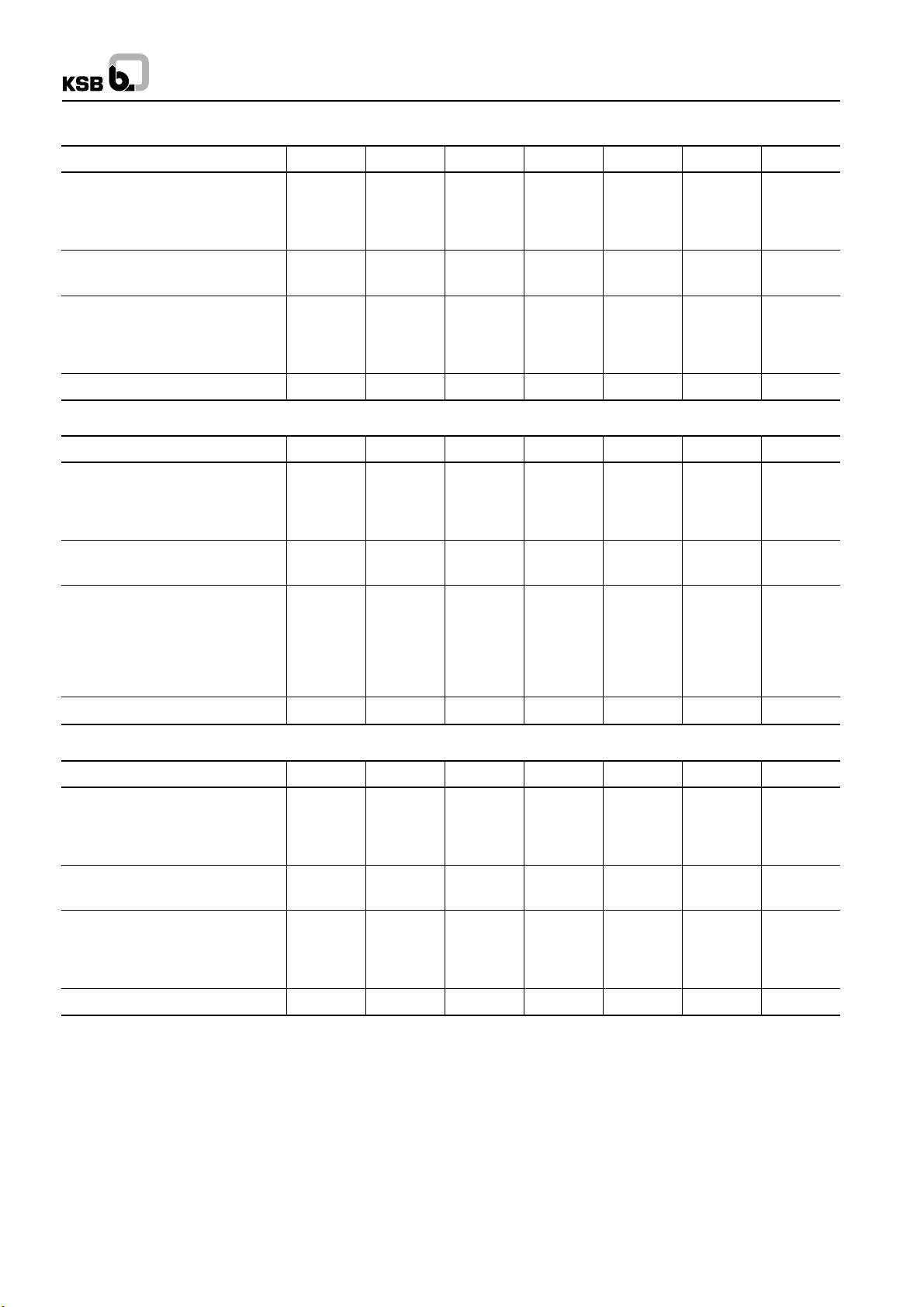

Standard Construction

Pump size 40 50 65 80 100 125 150

Drive end :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5412

Non Drive end :

Deep groove ball bearing

designation in accordance 6403/C 3 6404/C 3 6404/C 3 6405/C 3 6405/C 3 6405/C 3 6410/C 3

with DIN 625

Oil fill in litres 0.16 0.18 0.18 0.25 0.25 0.28 0.45

Heavy Duty Bearing Bracket

Pump size 40 50 65 80 100 125 150

Drive end :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5415

Non Drive end :

Angular contact ball bearing

Din 628, 7305 BG 7306 BG 7306 BG 7307 BG 7307 BG 7309 BG 7310 BG

matched pair, X arrangement

Manufacturer SKF

FAG

Oil fill in litres 0.65 0.70 0.70 0.90 0.90 1.2 1.2

H 206 H 207 H 207 H 208 H 208 H 210 ---

H 206 H 207 H 207 H 208 H 208 H 210 ---

7305 B. UA 7306 B. UA 7306 B. UA 7307 B. UA 7307 B. UA 7309 B. UA 7310 B. UA

Drive at both Ends

Pump size 40 50 65 80 100 125 150

Suction side :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5412

Discharge side :

Deep groove ball bearing

designation in accordance 6305/C 3 6306/C 3 6306/C 3 6307/C 3 6307/C 3 6308/C 3 6410/C 3

with DIN 625

Oil fill in litres 0.16 0.18 0.18 0.25 0.25 0.28 0.45

Fig. 10 Bearing end oil requirement table

In case of the pump construction with drive at both ends, the

bearing arrangement at the suction end corresponds to the

standard construction. At the discharge end, deep groove ball

bearings in accordance with DIN 625 are fitted, but they are of

bearing series 63.

See Fig. 10 ‘‘Bearing and oil requirement table’’ for precise

bearing designation and size for the individual pump sizes.

Splash ring (507) on shaft (210) prevent the penetration of

any leakage liquid from the stuffing box into the bearing

housing.

H 206 H 207 H 207 H 208 H 208 H 210 ---

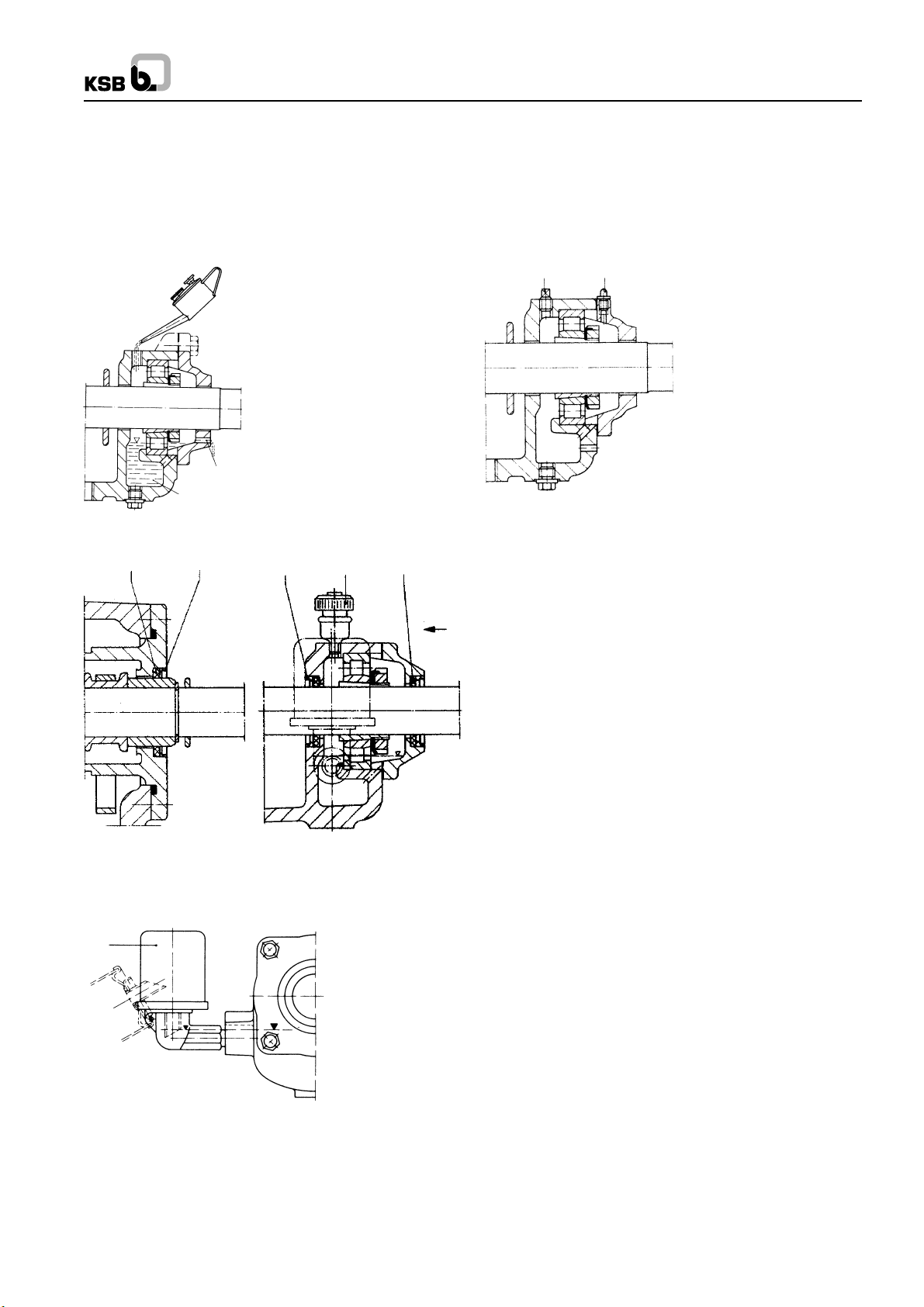

1.4 Lubrication

1.4.1 Oil Lubrication

Standard construction WK pumps are provided with oil splash

lubrication. The antifriction bearings are slightly submerged in

the oil sump, ensuring perfectly satisfactory lubrication at all

times. The max. oil level is automatically attained during topping

up when oil starts pouring out of the over-flow holes in the

bearing covers (360/361).

On request, we can fit constant level oilers (638), which will

necessitate the sealing of the shaft against the bearing bracket

by means of felt rings (422.1) (See Fig. 11 to 13).

3

WK

Oil Quality : Machinery oil possessing good air release

properties and corrosion prevention characteristics; kinematic

viscosity 36 cSt approx. = 4.80E at 500C; flash point 1500C

minimum; pour point lower than -200C.

Lubrication times : First oil change after the first 500 hours of

operation, subsequent oil changes after every 3000 hours of

operation approx., but at least once a year.

Overflow hole

Oil sump

Fig. 11 Oil splash lubrication

422.4

500.4

500.1 913 422.1

X

Portable (mobile) pumps, and pumps installed on board ship

have grease-lubricated bearings (See Fig. 14). Use a good

quality lithium soap ball and roller bearing grease, free of resin

and acid, and possessing rust preventive properties. The

grease should have a penetration number situated between 2

and 3, corresponding to a worked penetration situated between

2220 and 295 mm/10. Its drop point should be not less than

0

C.

175

731.2 636

Fig. 14 Grease lubricated bearing construction

The bearing temperature may be allowed to rise up to 400C

above room temperature, but should not exceed 800C. The

grease fill will last for 15000 hours of operation i.e., for 2 years

approx. If the operating conditions are arduous, the bearings

should be serviced once a year. A grease fill amounts to 10-20

grammes of grease, depending on the pump size. The pump

bearings are packed with grease at our Works before despatch.

End side

(Heavy duty bring bracket)

Drive end

Fig. 12 Construction with constant level oiler and sealing of

the bearing housing.

638

Fig. 13 Constant level oiler viewed from X

Topping up of the oil fill at least once a month.

The bearing temperature may be allowed to rise up to 40

0

above room temperature, but should not exceed 800C.

1.4.2 Grease Lubrication

(Cannot be provided on heavy duty bearing construction

pumps).

1.5 Shaft Seal

The shaft is sealed at its exits through the casings by softpacked

stuffing boxes or by mechanical seals. If the pump is fitted with

special stuffing boxes, mechanical seals can be fitted in lieu of

soft packing (or vice versa) at any time during the service life

of the pump, with a minimum of machining of the cooling

compartment covers. On the other hand, the fitting of

mechanical seals to pumps equipped with standard or hot water

type soft-packed stuffing boxes necesitates the fitting of new

pump components. Particulars can be obtained from the pump

manufacturer.

1.5.1 Stuffing Boxes

Soft-packed stuffing boxes reduce the flow of leakage liquid at

the clearance gap between casing and shaft protection sleeve

when the pressure inside the pump is higher than atmospheric.

Conversely, on pumps which operate on suction lift, the softpacked stuffing box prevents the ingress of air into the pump.

Sealing is effected by means of soft packing (461.1) arranged

in a number of rings in the annular space between the stuffing

box housing (451) and the shaft protection sleeve (524.1/2)

and lightly compressed by the stuffing box gland (452).

Caution : On pumps which have a high discharge pressure,

the stuffing box at the discharge end is relieved of pressure,

via a balance liquid line, down to the suction pressure, provided

that the differential pressure across the pump exceeds 20 bar.

This ensures that the stuffing boxes at the suction and discharge

ends of the pump have the same admission pressure. This

arrangement applies to pump sizes 40 to 65 if the discharge

C

pressure exceeds 20 bar and to pump sizes 80 to 150 if the

discharge pressure exceeds 15 bar.

Single stage pumps require no special pressure relief even at

high discharge pressures. The pressure is relieved via the

balance holes in the impeller.

4

WK

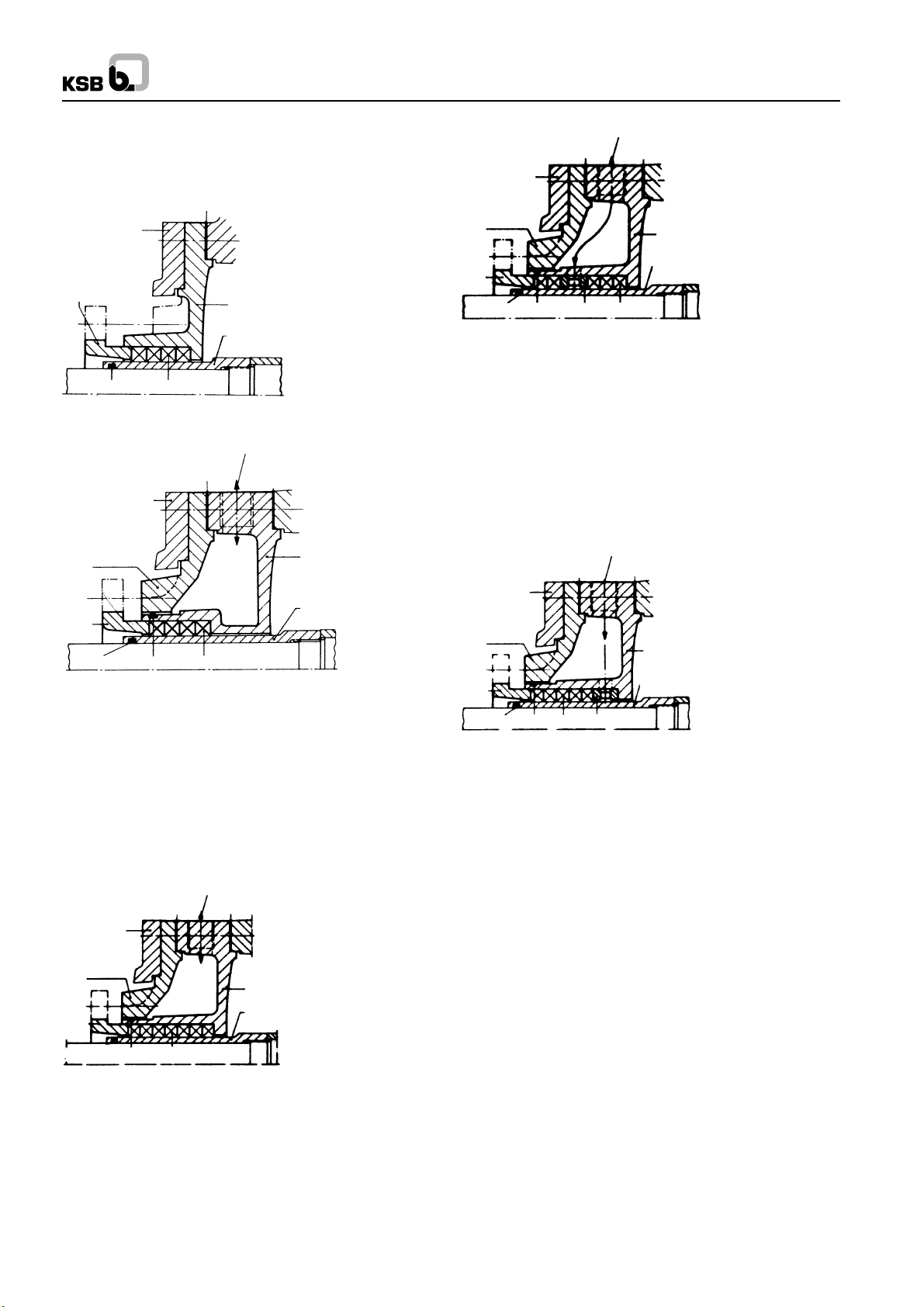

Soft-packed stuffing box, ‘‘Standard’’ (N) construction.

Standard construction with 4 packing rings (461.1) used for

temperatures of the fluid pumped up to 1050C. The stuffing

box compartment cannot be cooled.

400.3

350

452

412.3

461.1

451

524.2

(524.1)

Fig. 15 ‘‘Standard’’ (N) construction stuffing box

7A/7E

400.3

350

165

452

412.3 412.4 461.1

400.3

451

524.2

(524.1)

Fig. 16 ‘‘Hot Water’’ (HW) construction stuffing box

Soft-packed stuffing box, ‘‘Hot Water’’ (HW) construction.

Construction with 4 packing rings (461.1) and cooling of the

stuffing box compartment. Used for temperatures of the fluid

pumped in excess of 105

0

C up to 2300C max.

Special stuffing box, ‘‘Extra-deep’’ (V) construction.

Construction with 7 packing rings (461.1) and cooling of the

stuffing box compartment, used mainly in process industry

applications.

7A/7E

400.3

451

524.2

(524.1)

165

452

412.3

400.3

350

412.4 461.1

Fig. 17 Special soft packed stuffing box ‘‘Extra deep’’ (V)

Special stuffing box, ‘‘VSM’’ Constructed

VSM is the abbreviation (in German) of ‘‘Extra deep with lantern

ring at the centre’’.

Construction with 5 packing rings (461.1) and one seal case

ring (458) arranged at the centre of the packing compartment;

used mainly for operation under vacuum or suction lift, and

where malodorous fluids are pumped. For operation under

vacuum, the lantern ring (458) is fed with a sealing liquid, and

it prevents the ingress of air into the pump.

10A/10E

400.3

350

165

452

412.3 412.4 461.1

458

400.3

451

524.2

(524.1)

Fluids pumped :

Operation under vacuum

or pumping of malodorous

fluids (ammonia and

solvents).

Sealing liquid consumption

1 to 3 litres/hours approx.

Fig. 18 Special stuffing box VSM

Special stuffing box, ‘‘VSH’’ constructed.

VSH is the abbreviation (in German) for ‘‘Extra deep with seal

cage ring at the bottom of the box’’. The construction with 5

packing rings (461.1) and a seal cage ring (458) arranged at

the bottom of the packing compartment is used where fluids

containing abrasive particles are pumped. The flushing liquid,

which should be fed through the cage ring (458) at a pressure

of at least 1 to 4 bar (max.) above the suction pressure,

penetrates inside the pump and protects the stuffing box

packing (461.1) against abrasive substances.

11E

458

400.3

451

524.2

(524.1)

Fluids :

Products containing abrasive

particles, which must be kept

away from the stuffing box

packing, so as not to erode

the latter (oils containing

diatomite (kieselguhr),

fractions from catalytic

cracking containing abrasive

catalyst particles).

Flushing liquid consumption

300 to 500 litres/hour approx.

165

452

412.3

400.3

350

412.4 461.1

Fig. 19 Special stuffing box VSH.

1.5.1.1 Cooling Liquid for Stuffing Boxes

Treated cooling water which does not tend to precipitate salts

causing hardness out of solution should be used as cooling

liquid. The cooling water should be allowed to flow out freely

and visibly, so that it can be checked at any time in respect of

rate of flow and temperature. The temperature differential

between cooling water inlet and outlet should not exceed 10

The max. permissible cooling water outlet temperature should

not exceed 500C. The cooling water pressure should be situated

between 1 bar min. and 10 bar max.

An isolating valve should be incorporated in the cooling water

supply line, to enable the rate of flow of cooling water to be

adjusted, and the supply of cooling water to be turned off when

the pump is shut down. The cooling water should only be turned

off after the temperature of the fluid inside the pump has

dropped to below 80

0

C.

1.5.1.2 Packing the Stuffing Boxes

Caution : The pump is despatched from our works with the

stuffing boxes unpacked. An adequate quantity of packing

material is supplied loose with the pump. The stuffing box will

only be able to perform its vital function satisfactorily on

condition that it is carefully packed and properly maintained

as prescribed.

Before packing, thoroughly clean stuffing box gland (452),

packing compartment and shaft protection sleeve (524.1/.2).

5

0

C.

Fig. 20 Cutting the packing rings of length.

To cut the packing rings to correct length, use a suitable wooden

cutting jig (we can supply same on request), to ensure that the

packing rings are of the correct length and that their ring butts

come into correct contact with one another (see Fig. 20).

WK

Fig. 23 Tightening the stuffing box gland

Fig. 21 Stuffing box packing

If the packing rings are either too long or too short, the stuffing

box will not be able to perform its function properly. In the case

of asbestos-graphite packing material, the rubbing faces of

the individual rings should be lightly coated with molybdenum

disulphide before insertion in the packing compartment. The

first packing ring is then inserted and pushed home into the

compartment with the aid of the stuffing box gland.

The following packing rings are then inserted into the packing

compartment one by one, making sure that the butt joint of

each ring is offset 90

0

approx. in relation to the butt joint of the

preceding ring; the individual rings are pushed home into the

packing compartment with the aid of the stuffing box gland

(see Fig. 21 and 22). The packing rings should only be pressed

lightly against one another. They should not be inserted in the

packing compartment in such a way that a clear gap of 6 to 8

mm is left at the outer end of the compartment for the positive

guidance of the stuffing box gland.

Fig. 24 Information plate regading seal cage ring

The inserted packing rings should then be compressed

moderately with the aid of the stuffing box gland (452) and the

nuts (see Fig. 23). Then the nuts should be slackened again

by one to two complete turns, and thereafter tightened lightly

by hand. The correct and even seating of the stuffing box gland

(452) should be checked when the pump is subjected to suction

pressure, by inserting a feeler gauge between the gland (452)

and the shaft protection sleeve (524.1/.2).

In the case of the special stuffing boxes, a seal cage ring is

also inserted in the packing compartment, viz. at the centre of

the compartment (between the packing rings) in the case of

construction ‘‘VSM’’, and at the bottom of the compartment in

the case of construction ‘‘VSH’’. In these cases, an information

plate (see Fig. 20) is affixed to the stuffing box housing, showing

the position of the lantern ring. The seal cage ring must register

beneath the drilled hole in the stuffing box housing, to enable

the sealing of flushing liquid to flow through the hole and the

ring. The sealing or flushing liquid pressure should be 1 to 4

bar above the pressure reigning in the packing compartment

of the stuffing box.

Fig. 22 Insertion of packing rings with the aid of the stuffing

box gland

The packing of the stuffing boxes should be carried out with

great care, to avoid an excessively high radial pressing force

of the packing rings against the shaft protection sleeve, which

might damage the latter. If the shaft protection sleeve is scored

or grooved, even a new packing cannot be expected to last

very long in service.

6

A newly packed stuffing box should leak profusely at first. If

this leakage does not cease of its own accord after a relatively

short period of operation, the nuts on the gland should be

tightened slowly and evenly while the pump is running, until

the stuffing box only drips tightened evenly and not askew, as

otherwise the shaft protection sleeves (524.1/.2) might be

damaged (see Fig. 23).

The leakage rate in service of a soft-packed stuffing box should

amount to 3 to 5 litres/hours approx.

If the newly packed stuffing boxes start to smoke when the

pump is started up for the first time, the pump should be

switched off. If the smoking persists after the pump has been

started up again and operated several times in succession,

the nuts on the gland should be slackened slightly, or the stuffing

box should be inspected if necessary.

WK

Fig. 31 Mounted spacer-type flexible coupling

1.5.1.3 Packing Material

When selecting the packing material, make sure it is compatible

with the fluid pumped (consult the manufacturer in case of

doubt).

In steam generating plants, the asbestos-graphite packing

material specially developed for hot water service has given

good results. Packing material which has been dept in store

for a certain period has a longer service life than packing

material fresh from the packing manufacturer.

1.5.2 Mechanical Seals

Mechanical seals can be fitted as shaft seals in lieu of softpacked stuffing boxes. If it is intended to replace soft-packed

stuffing boxes by mechanical seals after the pump has been

in service for some time, it is necessary for the pump to be

equipped with stuffing box holdings (451) for ‘‘V’’ special stuffing

boxes. It is also necessary to re-machine two tapped holes in

the cooling cover (165) for the attachment of the seal cover

(471).

1.6 Coupling

The pump on connected to the driver by a flexible coupling.

Fig. 29 illustrated the type of coupling most frequently used.

2. Mode of Operation of Pump

The fluid flows through the suction casing towards the impeller

at a given pressure. Energy is transmitted to the fluid by the

impeller, which is fitted with vanes. From the impeller, the fluid

flows into the diffuser, where kinetic energy is converted into

potential energy, increasing the pressure rise still further.

The return guide vanes arranged on the discharge end cheek

of the diffuser (171.1) guide the fluid under hydraulically

favourable conditions towards the eye of the following stage

impeller (230). This process is repeated from one stage to the

next, and the pressure rise by the same amount in each stage,

viz. by the stage generated pressure. After leaving the final

stage diffuser (171.2), the fluid flows through the discharge

casing (107) into the discharge line connected to this casing.

The generated pressure creates an axial thrust on the pump

rotor of single and multistage centrifugal pumps. By the

provision of narrow throttling gap between the impeller necks

and the casing wearing rings at either side of each impeller,

equal size lateral impeller space, and therefore almost identical

pressure conditions are created at the suction and discharge

ends of each impeller (see Fig. 34).

Fig. 29 Flexible coupling

Spacer type couplings (see Figs. 30 and 31) enable inspections

and minor repairs (e.g. the fitting of new bearings or shaft

protecting sleeves) to be carried out without removing the driver.

Fig. 30 Spacer type flexible coupling

Balance hole

Fig. 34 Axial forces acting on impeller

The balance holes in the discharge side impeller cheeks ensure

a compensation of pressures between the suction and

discharge sides of the impellers in the region situated between

the impeller hub and the throttling gap, thus again preventing

the creation of any appreciable axial thrust in this region of the

impeller. Any residual axial thrust is absorbed by the fixed

bearing in the discharge end bearing housing. This fixed

bearing also locates the axial rotor position.

7

WK

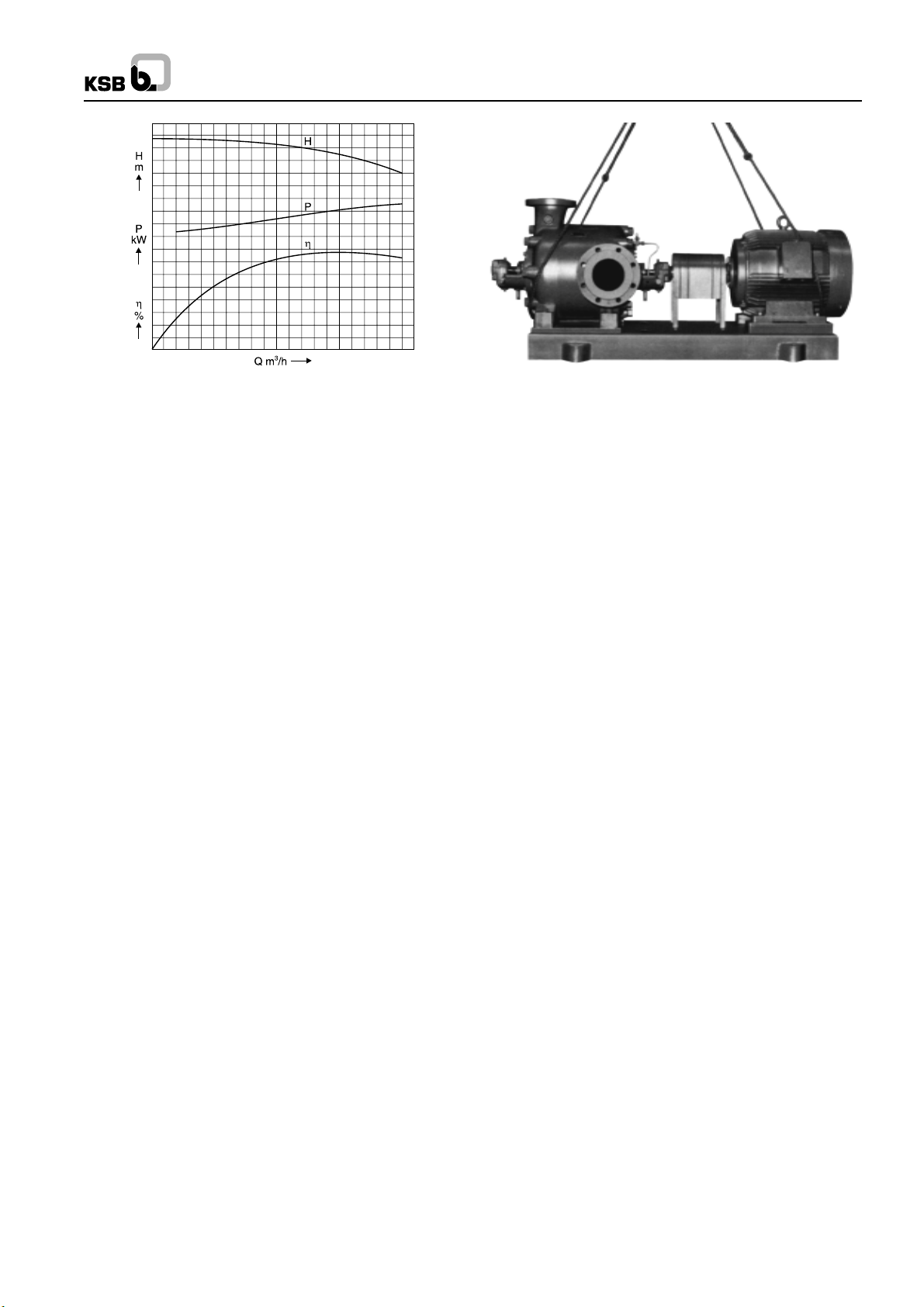

Fig. 35 Characteristics for constant pump rotational speed

As can be seen in the Fig. 35 the power absorbed by the pump

does not decrease proportionately with decreasing rate of flow,

but remains relatively high at the pump shut-off point (capacity

Q = 0).

This absorbed power is almost wholly converted into heat inside

the pump and this heating up process can lead to rapid

evaporation of the fluid inside the pump, particularly if the driving

motor is powerful and the fluid pumped is hot; this happens at

the pump shut-off point (Q = 0) and at very low rate of flow.

In order to avoid such evaporation which might damage the

pump, It is necessary to ensure a given minimum rate of flow

through the pump at all times, which removes the heat

generated.

For this purpose, an automatic recirculation valve (combined

with a non-return valve) is provided (see section 9.3.1); this

valve automatically opens a by-pass line when the rate of flow

drops below a given preset value. If such a valve is not

incorporated in the plant, the pump must not be operated below

a given minimum rate of flow, nor must it be allowed to run

against a closed discharge valve. After start up against a closed

discharge valve, the latter should be opened immediately. If

the pump handles a hot fluid or a fluid with a low boiling point

(highly volatile), or if it operates on suction lift, steps must be

taken to ensure that the fluid at the pump inlet nozzles has

attained the pressure prescribed in the Confirmation of Order,

in order to prevent vapour formation and the resulting damage

caused by cavitation particularly the disintegration of the first

stage impeller). If the back pressure is too low, the capacity of

the pump will increase unduly, and the danger than arise of

overloading and overheating of the driving motor.

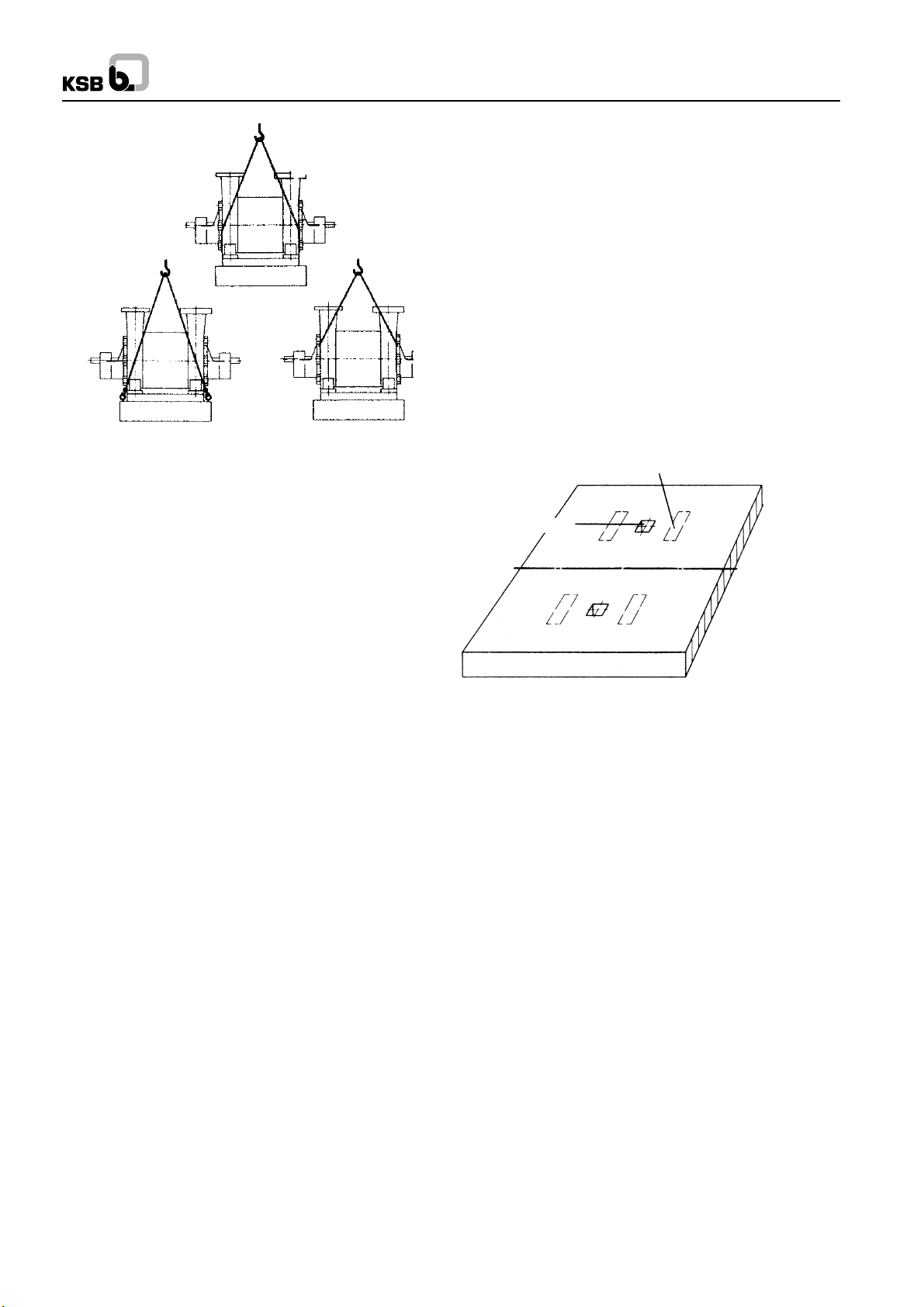

Fig. 36 Slinging the ropes under the pump and driver

mounted on a combine baseplate

5. Painting

Standard construction pumps operating at temperatures below

1400C are provided with a coat of primer and a top coat of

synthetic resin base blue enamel paint (RAL 5001). If the

operating temperature exceeds 1400C, the ‘‘hot’’ pump

components, i.e. casing, pressure gauge piping and connection

rods are provided with a coat of aluminium bronze paint (RAL

9006 silver bronze). All the ‘‘Cold’’ pump components, viz. the

base-plate, bearing brackets etc. receive a coat of primer and

a top coat of blue enamel paint (RAL 5001).

Special painting to customer’s specification can be carried out

on request in accordance with the Confirmation of Order. All

bright aprts and surfaces on the pump are coated with oil

grease.

6. Condition of Equipment as Supplied

The following constructions can be supplied on request (see

Confirmation of Order for certified and binding data) :

1. Pump without baseplate (Fig. 0).

2. Pump mounted on short baseplate (Fig. 4).

(designed to accomodate pump only)

3. Pump and driver mounted on combbined baseplate

(Fig. 3).

If the pump is supplied with a short baseplate or without a

baseplate, the ropes should be slung under the connection

rods as illustrated in Fig. 37.

3. Drive

The driver is usually connected to the stub shaft at the suction

end of the pump. The direction of rotation is clockwise viewed

from the driver into the pump. On request, the drive can be

arranged at the discharge end of the pump (direction of rotation

anticlockwise) or the pump can be provided with a stub shaft

at both ends.

There are too many different types of drivers to allow them to

be described in detail here, and we would therefore refer you

to the operating instructions for the driver, published by the

driver manufacturer, which are attached.

4. Transport

If the pump is supplied as a unit bolted onto a baseplate, the

ropes for handling and transport should be slung under the

pump and driver as illustrated in Fig. 36.

Caution : When slinging the ropes for transport, never sling

them under the pump stub shafts or under the bearing brackets.

The internal interconnecting piping for the pressure relief of

the shaft seal, and any cooling liquid supply and drain lines or

sealing liquid lines, in so far as required, are already laid at

our works prior to despatch, up to the limit of the Extent of

Supply. The coupling and coupling guard are already mounted

on the pump.

When a pump is supplied mounted on a combined baseplate,

only the pump is dowelled to the baseplate, after having been

aligned with the driver.

The driver is dowelled on site with cylindrical dowel pins after

the final alignment on site. The necessary cylindrical dowel

pins are supplied loose with the pump.

8

Fig. 37 Slinging the ropes on a pump with short baseplate

Fig. 4

WK

Our erection staff will check the correct orientation of the

foundations in relation to the space axis after c;earamce fpr

erection has been given. The site management is responsible

for the zero point marking of the foundation (see ‘‘Conditions

of Erection’’).

The areas for the packing plates (shims) should now be marked

out and trued up in accordance with the foundation drawing.

Then thick packing plates should be laid in position and levelled

up with a spirit level.

The packing plates should lie flush on the foundation and be

levelled up as truly horizontal as possible to facilitate the

subsequent alignment and levelling up of the complete pumping

set as accurately as possible. The exact height is of less

importance at this stage, because any difference in heights

can be compensated by the insertion of shims of varying

thickness when the set itself is levelled up. Three point support

should be adopted for the preliminary levelling up.

Surface for shims (packing plates)

Caution :

1. The pump bearings are not filled with oil.

2. The stuffing boxes are not packed.

All apertures are plugged with PVC stoppers.

7. Accessories

As a general rule, the following items are supplied loose with

the pump :

1 set of binding bolts (only supplied loose if the pump is supplied

without a baseplate).

1 set of foundation bolts (if the pump is supplied with a

baseplate).

On request, the following items can be supplied, amongst

others :

Pressure gauge holder or pressure gauge bridge

Pressure gauge

Pressure vacuum gauge

Stop valve for pressure gauge

Coupling extractor device

1 set of shims and packing plates for levelling up

1 wooden cutting jig for packing rings

1 set of special tools

8. Installing the Pumping Set

Foundation bolt

Foundation axis

Fig. 38 Preparation of foundation

8.2 Installation and preliminary Levelling Up

The pumping set should only be placed on the foundation after

the latter has set quite firmly, and the preparations for the

foundation described above should be carefully followed.

Before placing the set on the foundation, suspend the

foundation bolts in the baseplate. Then fix the longitudinal and

lateral directions and the correct height, then carry out a

preliminary levelling up with the aid of a spirit level, and grout

in the foundation bolts.

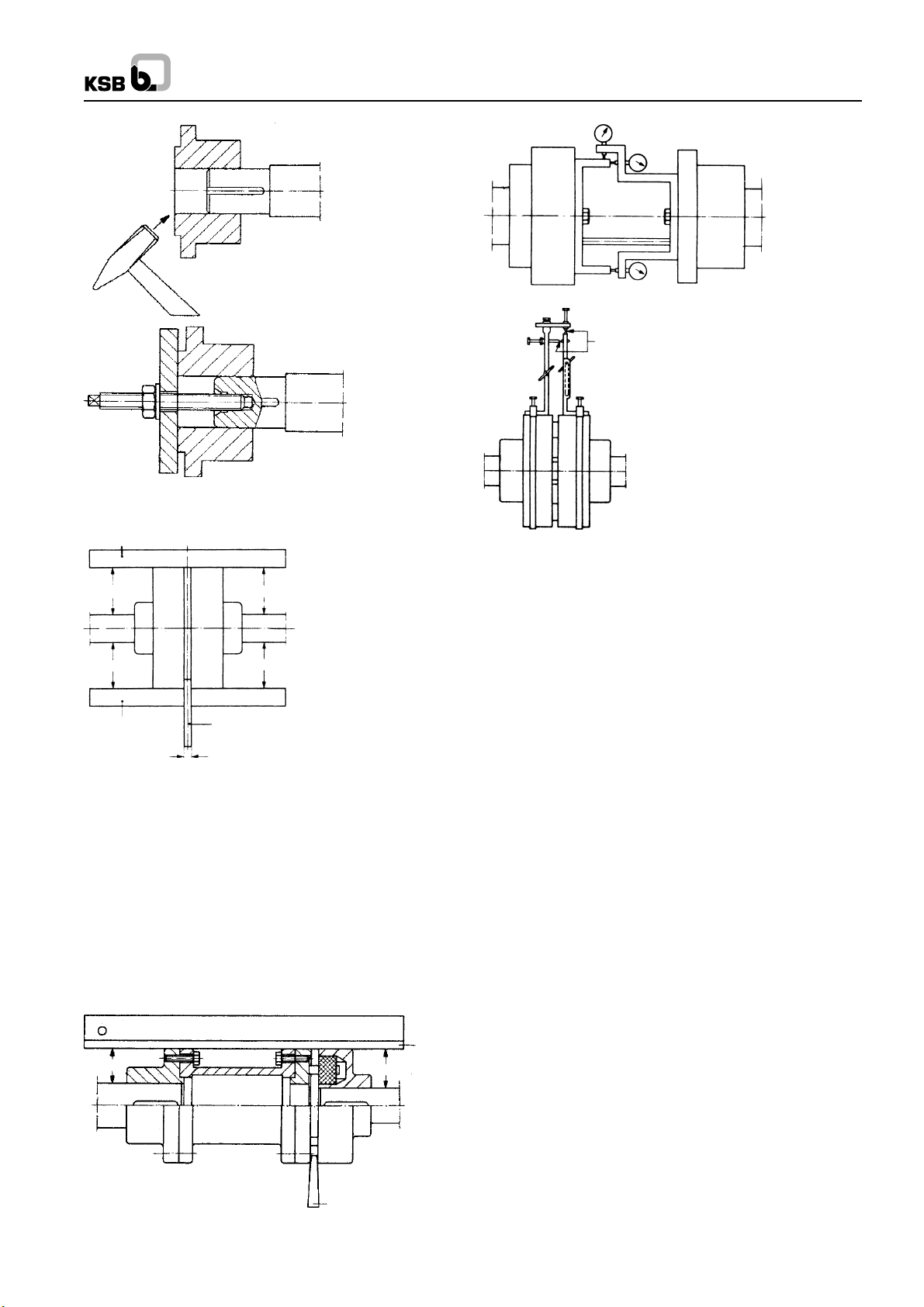

8.3 Aligning the Coupling

If the bare pump only is supplied, i.e. the motor or gearbox are

not mounted, the flexible coupling should be pre-heated to 100-

0

C approx. in an oil bath before mounting on the stub shafts.

120

The flexible elements should be removed beforehand.

8.1 Description of Site prior to Commencement of

Erection

When our erection staff arrive on site, the pump foundation

must have been checked for dimensional conformity with our

foundation drawing data by the site management, and cleared

for erection to preceed. The foundation and its immediate

surroundings must be in a suitable condition to enable the

efficient and speedy erection of the pump and accessories to

proceed with out hindrance.

Our erection staff must be able to make use of customer’s

hoisting gear, e.g. the engine room crane etc. for transport

and erection if required.

Caution : Never drive the half coupling onto the shaft by

hammer blows. Always use a pusher device to mount it on the

shaft. (see Fig. 39).

In order to align the shafts, the pump and driver should be

pushed towards each other until the two coupling halves are

separated by the axial gap specified in the foundation or

installation drawing.

The preliminary alignment of the coupling is effected by means

of a short steel straight edge and feeler gauge.

9

WK

Wrong

Right

Fig. 39 Mounting the coupling

Straight edge

A

B

C

Max. clearance 0.04 mm

Fig. 42 Coupling alignment jig

Spacer type coupling

a

1

ab

Straight edge Gauge

E

b

1

Fig. 40 Aligning the coupling bby means of a straight edge

and gauge

Check the axial gap ‘‘E’’ at various points around the periphery,

with the aid of a feeler gauge, and place a short straight edge

across the outer diameter of the two coupling havles, forming

bridge. If the gap ‘‘E’’ remains constant around the periphery,

and if the straight edge lies flush at all points, the preliminary

alignment can be considered satisfactory (see Fig. 40 and 41).

The accurate coupling alignment requires the manufacturer of

a coupling alignment jig. This can be made from 20 x 20 flat

bar steel or similar, the jig should be attached to the shafts

(see Fig. 42).

Straight

D

edge

D

The coupling can be considered correctly aligned with the aid

of the jigs illustrated if the difference measured does not exceed

0.04 mm both in the radial and axial directions, measurements

being taken in 4 planes at 90

0

intervals. The coupling alignment

check should be repeated after the piping has been connected

to the pump.

8.4 Grouting in the Baseplate

After alignment of the coupling, the holes for the foundations

bolts and the baseplate should be grouted in with a quicksetting

cement mortar in 1:2 ratio (1 part of cement on 2 parts sand

and gravel). Make sure that all the boxes in the baseplate are

completely filled with the cement mortar and that no cavities

remain.

The foundation bolts should be tightened evenly and firmly

after the grout has set firmly. Then check with the aid of a dial

micrometer that the alignment is still correct.

8.5 Final Alignment

After all the pipelines have been connected and the direction

of rotation check has been carried out (with the pump

disconnected from the driver), the final alignment of the

pumping set should be effected. The same procedure would

be followed as for the preliminary alignment, i.e. the relevant

alignment jigs with 3 dial micrometers should be used and the

measurements previously described should be carried out at

the various shaft position (see section 8.3 ‘‘Aligning the

Couplings’’).

Gauge

Fig. 41 Aligning the spacer-type coupling by means of a

straight edge and gauge

Caution : The pump feet must be pulled tight against their

seating on the baseplate. The alignment can be considered

satisfactory if the dimensional deviations do not exceed 0.04

mm both in the case of the radial measurement and in the

case of the axial difference measurement (see section

‘‘Alignment’’).

The final measurement readings should be entered in the

system of coordinates on the erection check list. Any necessary

height adjustments should be effected by inserting shims of

appropriate thickness under the feet of the individual machines.

10

9. Piping

The main piping should be connected to the pump without

transmitting any stresses or strains onto the latter. Any

appreciable piping forces which are transmited to the baseplate via the PUMP can detrimentally affect the alignment and

the running of the pump. Such forces should therefore be kept

to a minimum at all costs.

9.1 Suction Lift Line and Positive Suction Head Line

The pipe line connected to the suction casing (106) is called

either a suction lift line or a (positive) suction head line,

depending on whether the pressure at the pump inlet is below

or above atmospheric pressure. This line should be kept as

short as possible. (see Figs. 43 and 44)

Suction lift lines should rise all the way towards the pump,

they should also be absolutely leak tight and be laid in such a

way as to prevent the formation of air pockets at any point.

(see Fig. 43).

Eccentric reducer (fitted belly down)

>0.5m

Suction strainer basket

>0.5m

Fig. 43 Suction lift line

The nominal size of the pump suction flange is no accurate

guide to the size of the suction lift line. The latter should be

sized, as a first approximation to give a velocity of 2m/sec.

approx. In principle, every pump should be equipped with its

own individual suction lift line. If this is not feasible for particular

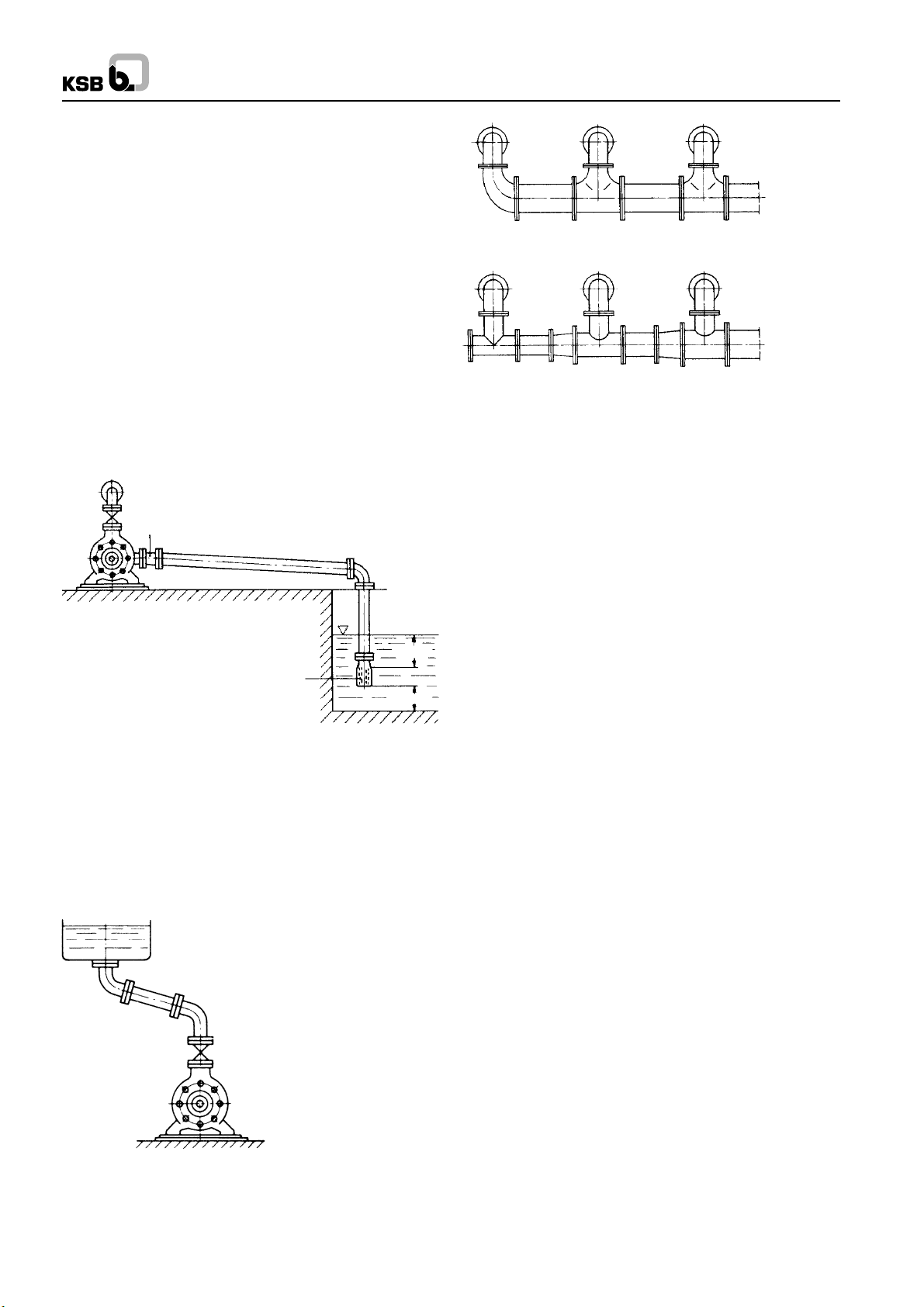

reasons, the common suction lift line should be sized for a s

low a velocity as possible and preferably for a constant velocity

right up to the last pump on the line (see Fig. 45).

WK

Correct

Wrong

Fig. 45 Common suction lift line for several pumps

In addition, pumps connected to a common suction lift line

should be equipped with VSM stuffing boxes.

If the suction lift line is buried, it should be hydrostatically tested

at 3 to 4 bar before burial.

The same remarks as above apply to the nature and laying of

(positive) suction head lines. Horizontal lenngths of suction

head lines should however be laid with a slightly rising slope

towards the suction vessel. If it is not feasible to avoid apexes

in the suction head line, each apex should be equipped with a

vent cock. It is also advisable to avoid any appreciable length

of horizontal suction head line laid close beneath the suction

vessel because of the danger of evaporation (see Fig. 44).

9.1.1 Strainers in Suction Head Line/Suction Lift Line

Before a new pumping installation is commissioned, all the

vessels, piping and connections should be thoroughly cleaned,

flushed through and blown though. It often happens that welding

beads, pipe scal and other dirt only become detached from

inside the piping after a considerable period of service; they

must therefore be prevented from penetrating inside the pump

by the provision of a strainer in the suction head or suction lift

line. This strainer should have a free area of holes equal to 3

times the pipe cross section area approx., in order to avoid an

excessive pressure drop when foreign bodies tend to clog the

strainer.

Conical (hat shaped) strainers have given good results in

service (see DIN 4189), they should have a woven wire insert

of corrosion-resistant material with a 1.0 mm. mesh width of

0.5 mm. diameter wire. The fine strainer should precede the

coarse strainer in respect of direction of flow of the fluid. During

the initial period of commissioning, the suction pressure should

be kept under frequent observation. If the NPSH available is

found to decrease, this may be due to clogged strainers (the

pressure drop acros the strainer should be measured with the

aid of a differential pressure gauge). The strainers should then

be cleaned. (see Figs. 46 and 47).

Fig. 44 Suction head line

Unless anything to the contrary has been specified, the max.

permissible pressure drop across the strainer should not

exceed 3 meters.

11

Loading...

Loading...