KSB Vitastage Operating Manual

Hygienic Pump

Vitastage

Installation/Operating Manual

Legal information/Copyright

Installation/Operating Manual Vitastage

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 15/12/2017

Contents

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 8

2.1 Key to safety symbols/markings.......................................................................................................................8

2.2 General..............................................................................................................................................................8

2.3 Intended use .....................................................................................................................................................8

2.4 Personnel qualification and training...............................................................................................................9

2.5 Consequences and risks caused by non-compliance with this manual .........................................................9

2.6 Safety awareness ..............................................................................................................................................9

2.7 Safety information for the operator/user.....................................................................................................10

2.8 Safety information for maintenance, inspection and installation ..............................................................10

2.9 Unauthorised modes of operation................................................................................................................10

3 Transport/Temporary Storage/Disposal............................................................................................. 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................11

3.4 Return to supplier...........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................13

4 Description of the Pump (Set)............................................................................................................. 14

4.1 General description ........................................................................................................................................14

4.2 Designation.....................................................................................................................................................14

4.3 Name plate......................................................................................................................................................15

4.4 Design details..................................................................................................................................................15

4.5 Configuration and function...........................................................................................................................16

4.6 Noise characteristics .......................................................................................................................................16

4.7 Scope of supply...............................................................................................................................................17

4.8 Dimensions and weights ................................................................................................................................17

5 Installation at Site................................................................................................................................ 18

5.1 Safety regulations...........................................................................................................................................18

5.2 Checks to be carried out prior to installation...............................................................................................18

5.3 Piping ..............................................................................................................................................................18

5.3.1 Connecting the piping.......................................................................................................................18

5.3.2 Permissible forces and moments at the pump nozzles....................................................................20

5.4 Enclosure/insulation .......................................................................................................................................20

5.5 Electrical system..............................................................................................................................................20

5.5.1 Operation on a frequency inverter...................................................................................................20

5.6 Electrical connection ......................................................................................................................................21

5.6.1 Setting the time relay ........................................................................................................................21

5.6.2 Connecting the motor .......................................................................................................................21

5.6.3 Earthing ..............................................................................................................................................22

5.7 Checking the direction of rotation................................................................................................................22

6 Commissioning/Start-up/Shutdown................................................................................................... 23

6.1 Commissioning/Start-up.................................................................................................................................23

6.1.1 Prerequisites for commissioning/start-up ......................................................................................... 23

6.1.2 Priming and venting the pump.........................................................................................................23

6.1.3 Start-up............................................................................................................................................... 23

6.1.4 Checking the shaft seal......................................................................................................................24

6.1.5 Shutdown ...........................................................................................................................................25

Vitastage

3 of 44

Contents

6.2 Operating limits..............................................................................................................................................25

6.2.1 Ambient temperature........................................................................................................................25

6.2.2 Frequency of starts.............................................................................................................................26

6.2.3 Cleaning in place (CIP) ....................................................................................................................... 26

6.2.4 Steaming in place (SIP) ......................................................................................................................27

6.2.5 Fluid handled .....................................................................................................................................27

6.3 Shutdown/storage/preservation ....................................................................................................................28

6.3.1 Measures to be taken for shutdown ................................................................................................28

6.4 Returning to service .......................................................................................................................................29

7 Servicing/Maintenance........................................................................................................................ 30

7.1 Safety regulations...........................................................................................................................................30

7.2 Servicing/inspection........................................................................................................................................31

7.2.1 Supervision of operation ................................................................................................................... 31

7.2.2 Inspection work..................................................................................................................................31

7.3 Drainage/cleaning ..........................................................................................................................................32

7.4 Dismantling the pump set..............................................................................................................................32

7.4.1 General information/Safety regulations...........................................................................................32

7.4.2 Preparing the pump set.....................................................................................................................33

7.4.3 Removing the complete pump set from the piping ........................................................................33

7.4.4 Dismantling the pump.......................................................................................................................33

7.5 Reassembling the pump set...........................................................................................................................34

7.5.1 General information/Safety regulations...........................................................................................34

7.5.2 Reassembling the pump ....................................................................................................................34

7.6 Spare parts stock.............................................................................................................................................35

7.6.1 Ordering spare parts..........................................................................................................................35

7.6.2 Recommended spare parts stock for 2 years' operation to DIN24296...........................................35

8 Trouble-shooting.................................................................................................................................. 36

9 Related Documents.............................................................................................................................. 38

9.1 General assembly drawing with list of components, Vitastage 05/1 - 05/8 - horizontal installation........38

9.2 General assembly drawing with list of components, Vitastage 05/1 - 05/8 - vertical installation .............39

10 EU Declaration of Conformity............................................................................................................. 40

11 Certificate of Decontamination........................................................................................................... 41

Index ..................................................................................................................................................... 42

4 of 44

Vitastage

Glossary

Glossary

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

CIP (cleaning in place)

Procedure during which the inside of the pump is

cleaned with a cleaning agent. The pump does not

need to be dismantled.

Discharge line

The pipeline which is connected to the discharge

nozzle

Hydraulic system

The part of the pump in which the kinetic energy

is converted into pressure energy

Noise characteristics

The noise characteristics are indicated as surface

sound pressure level in dB(A).

Pump

Machine without drive, additional components or

accessories

Pump set

Complete pump set consisting of pump, drive,

additional components and accessories

SIP (steaming in place)

Procedure during which the inside of the pump is

sterilised with steam. The pump does not need to

be dismantled.

Suction lift line/suction head line

The pipeline which is connected to the suction

nozzle

Vitastage

5 of 44

1 General

1 General

1.1 Principles

This operating manual is supplied as an integral part of the type series and variants

indicated on the front cover. The manual describes the proper and safe use of this

equipment in all phases of operation.

The name plate indicates the type series and size, the main operating data, the order

number and the order item number. The order number and order item number

clearly identify the pump set and serve as identification for all further business

processes.

In the event of damage, immediately contact your nearest KSB service centre to

maintain the right to claim under warranty.

Observe the noise characteristics, indicated as surface sound pressure level.

(ðSection4.6,Page16)

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB refer to the sub-sections under

Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.4,Page9)

1.4 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Data sheet Description of the technical data of the pump (set)

General arrangement drawing/

outline drawing

Drawing of auxiliary connections Description of auxiliary connections

Hydraulic characteristic curve Characteristic curves showing head, NPSH

General assembly drawing

1)

Sub-supplier product literature1)Operating manuals and other product literature

Spare parts lists

Piping layout

List of components

Drawing for assembly

1)

1)

1)

1)

For accessories and/or integrated machinery components observe the relevant

manufacturer's product literature.

Description of mating and installation dimensions

for the pump (set), weights

required, efficiency and power input

Sectional drawing of the pump

describing accessories and integrated machinery

components

Description of spare parts

Description of auxiliary piping

Description of all pump components

Sectional drawing of the installed shaft seal

1.5 Symbols

Table2: Symbols used in this manual

Symbol Description

1) If agreed upon in scope of supply

6 of 44

Vitastage

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

1 General

Symbol Description

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

Vitastage

7 of 44

2 Safety

!

DANGER

!

DANGER

!

WARNING

CAUTION

2 Safety

All the information contained in this section refers to hazardous situations.

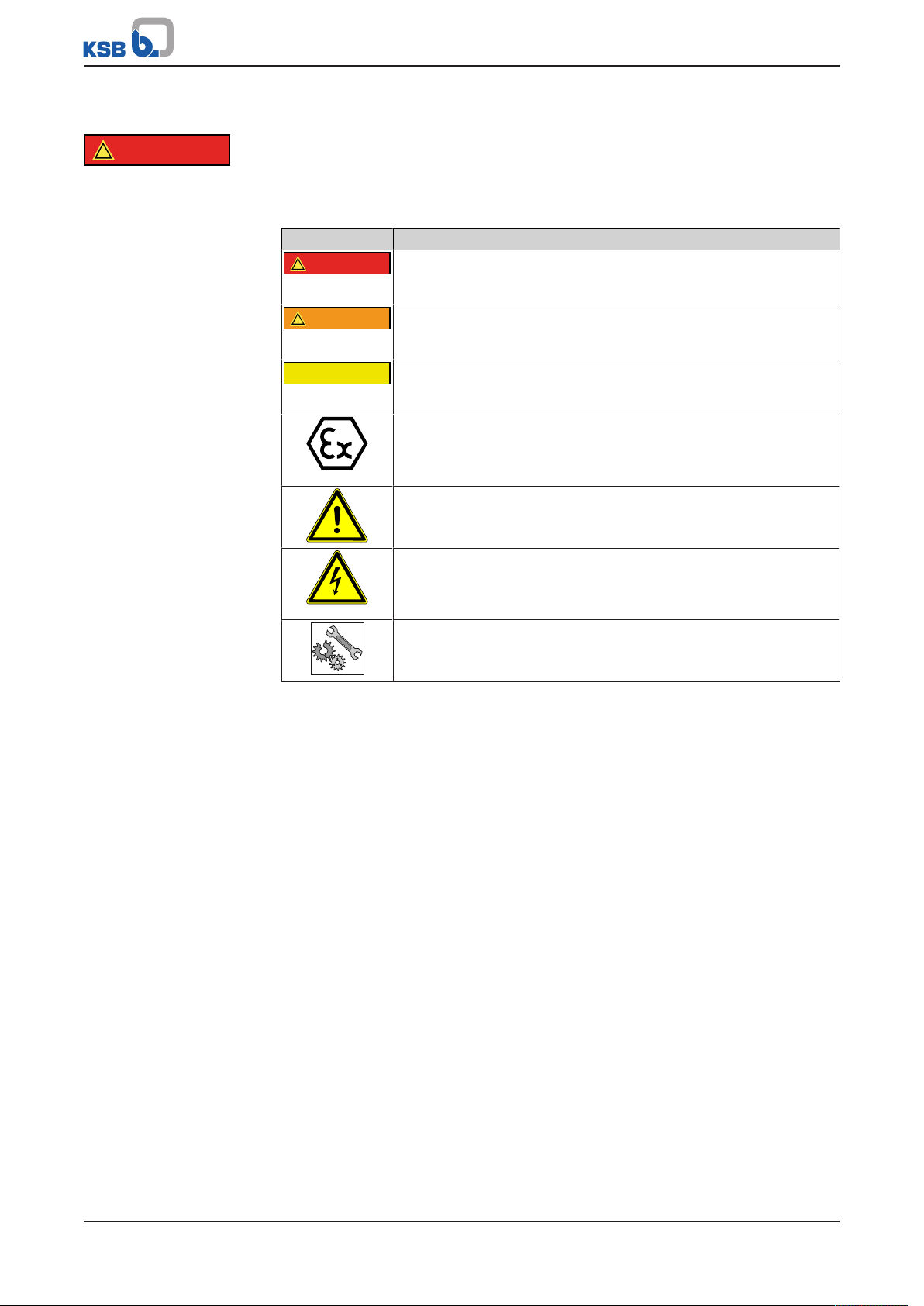

2.1 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EU Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Arrow indicating the direction of rotation

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

8 of 44

2.3 Intended use

▪ The pump (set) must only be operated within the operating limits described in

the other applicable documents. (ðSection1.4,Page6)

▪ Only operate pumps/pump sets which are in perfect technical condition.

▪ Do not operate the pump (set) in partially assembled condition.

Vitastage

2 Safety

▪ Only use the pump to handle the fluids described in the data sheet or product

literature of the pump model or variant.

▪ Never operate the pump without the fluid to be handled.

▪ Observe the minimum flow rates indicated in the data sheet or product literature

(to prevent overheating, bearing damage, etc).

▪ Observe the minimum flow rate and maximum flow rate indicated in the data

sheet or product literature (to prevent overheating, mechanical seal damage,

cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the suction side of the pump (to prevent

cavitation damage).

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

Prevention of foreseeable misuse

▪ Never open the discharge-side shut-off elements further than permitted.

– The maximum flow rates specified in the product literature or data sheet

would be exceeded.

– Risk of cavitation damage

▪ Never exceed the permissible operating limits specified in the data sheet or

product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the pump (set) must always be supervised by technical specialist

personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

Vitastage

9 of 44

2 Safety

2.7 Safety information for the operator/user

▪ The operator shall fit contact guards for hot, cold and moving parts and check

that the guards function properly.

▪ Do not remove any contact guards during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Only carry out work on the pump (set) during standstill of the pump.

▪ Only perform work on the pump set when it has been disconnected from the

power supply (de-energised).

▪ The pump casing must have cooled down to ambient temperature.

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the pump set out of service always adhere to the procedure

described in the manual. (ðSection6.3,Page28)

▪ Decontaminate pumps which handle fluids posing a health hazard.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page23)

10 of 44

2.9 Unauthorised modes of operation

Never operate the pump (set) outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the supplied pump

(set) is only valid if the equipment is used in accordance with its intended use.

(ðSection2.3,Page8)

Vitastage

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

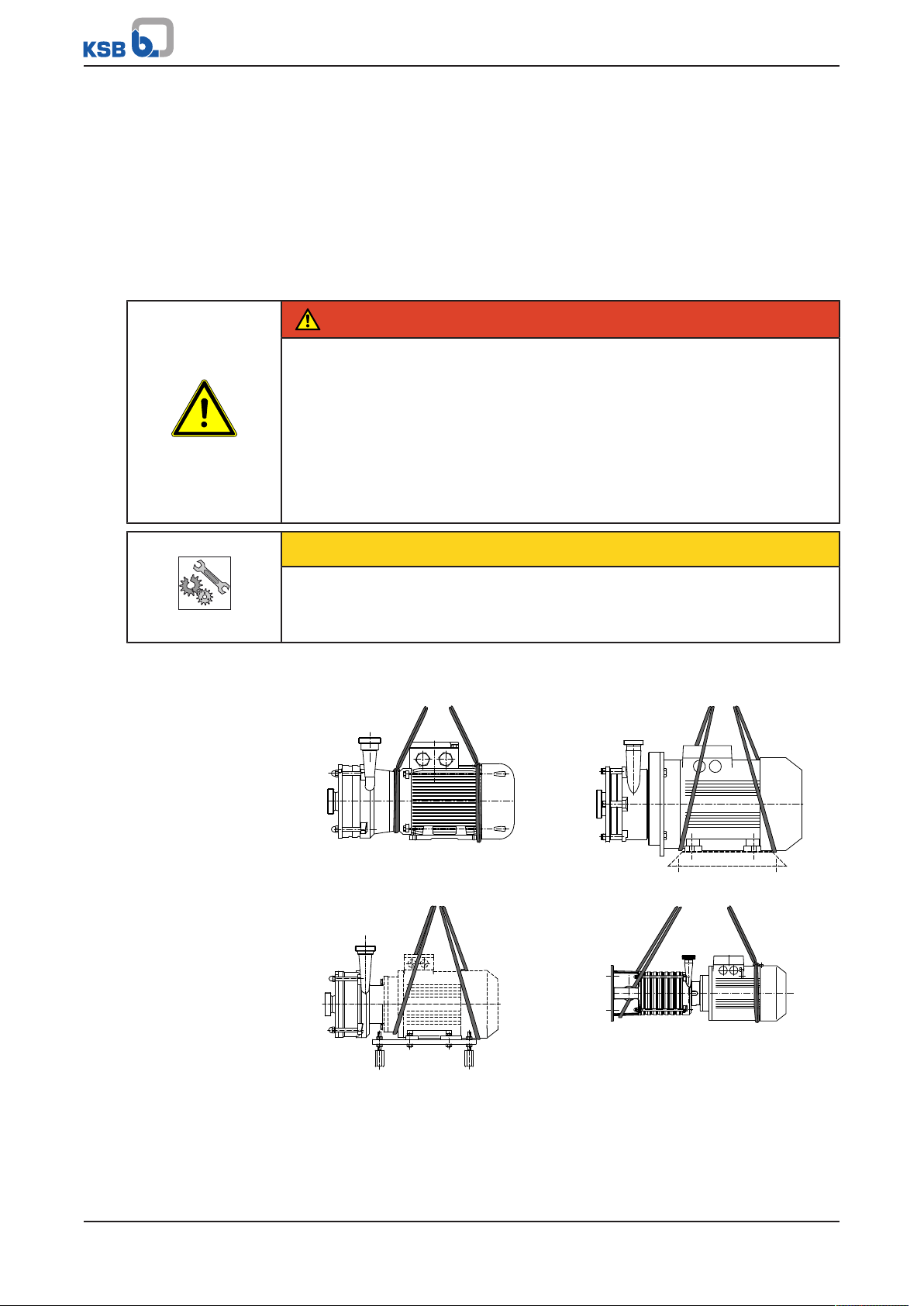

3.2 Transport

DANGER

The pump (set) could slip out of the suspension arrangement

Danger to life from falling parts!

▷ Always transport the pump (set) in the specified position.

▷ Never attach the suspension arrangement to the free shaft end or the motor

eyebolt.

▷ Give due attention to the weight data and the centre of gravity.

▷ Observe the applicable local health and safety regulations.

▷ Use suitable, permitted lifting accessories, e.g. self-tightening lifting tongs.

CAUTION

Deformation of motor shroud during transport

Damage to the pump set!

▷ Remove motor shroud, if included in scope of supply, for transport.

To transport the pump/pump set suspend it from the lifting tackle as shown.

Table4: Transporting the pump (set)

Without motor foot Motor foot

Ball feet Vertical installation

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for pump (set) storage.

Vitastage

11 of 44

3 Transport/Temporary Storage/Disposal

CAUTION

Damage during storage due to humidity, dirt, or vermin

Corrosion/contamination of the pump (set)!

▷ For outdoor storage cover the packed or unpacked pump (set) and accessories

with waterproof material.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage to the pump!

▷ Clean and cover pump openings and connections as required prior to putting

the pump into storage.

Store the pump (set) in a dry, protected room where the atmospheric humidity is as

constant as possible.

Rotate the shaft by hand once a month, e.g. via the motor fan.

If properly stored indoors, the pump set is protected for a maximum of 12 months.

New pumps/pump sets are supplied by our factory duly prepared for storage.

For storing a pump (set) which has already been operated, the shutdown measures

must be adhered to. (ðSection6.3.1,Page28)

3.4 Return to supplier

1. Prior to returning the product to the supplier, flush and clean it, particularly if it

has been used in noxious, explosive, hot or other hazardous fluids.

2. If the product has been used in fluids whose residues could lead to corrosion

damage in the presence of atmospheric humidity or could ignite upon contact

with oxygen, the product must also be neutralised and treated with anhydrous

inert gas to ensure drying.

3. Always complete and enclose a certificate of decontamination when returning

the product. (ðSection11,Page41)

Indicate any safety measures and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

12 of 44

Vitastage

3 Transport/Temporary Storage/Disposal

3.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the pump (set).

Collect greases and other lubricants during dismantling.

2. Separate and sort the pump materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Vitastage

13 of 44

4 Description of the Pump (Set)

4 Description of the Pump (Set)

4.1 General description

▪ Hygienic pump

▪ Multistage centrifugal pump in ring-section design

Pump for handling fluids which are not chemically aggressive, are free from solids

and do not require hermetic sealing.

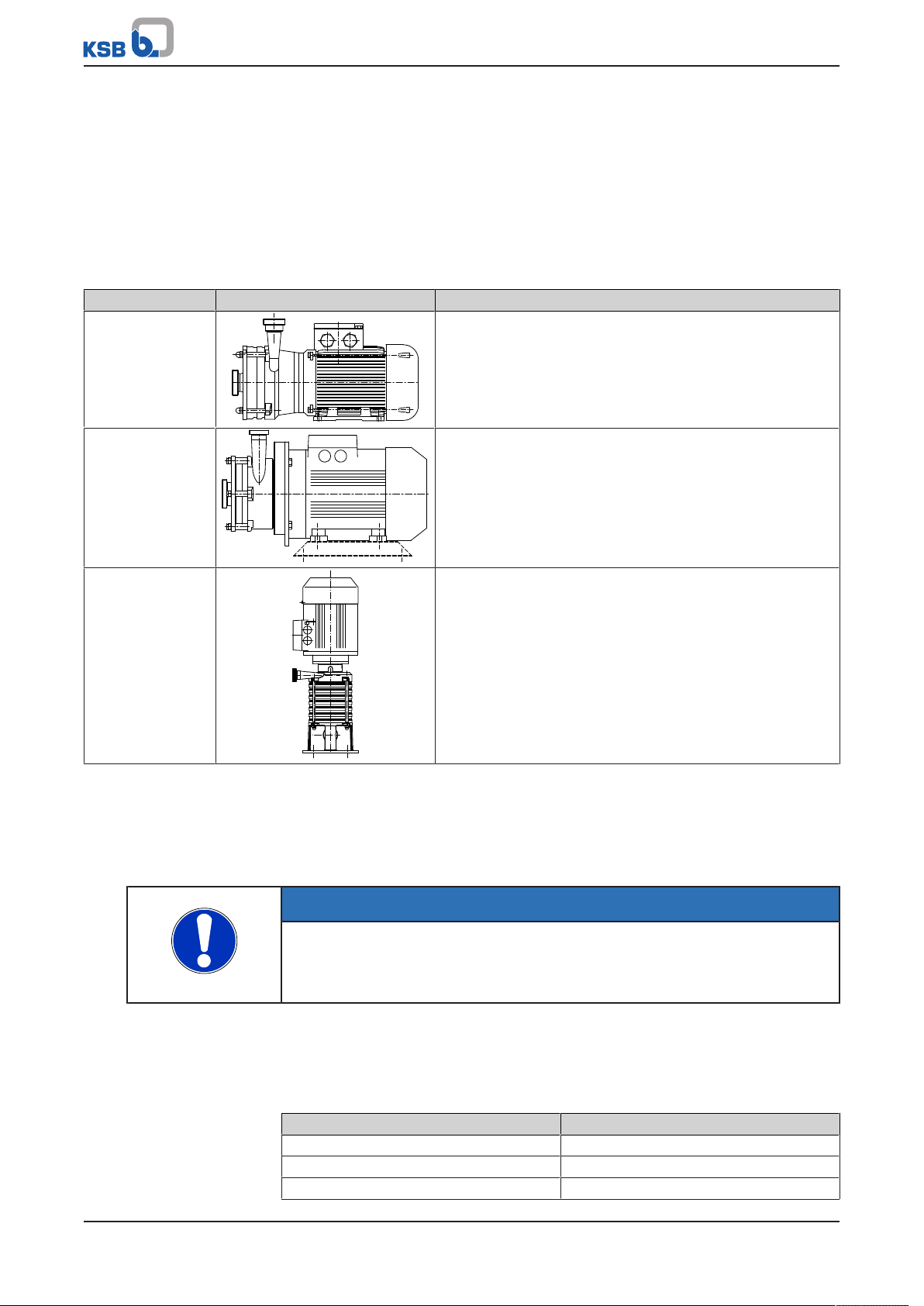

Table5: Installation type

Installation type Illustration Description

B ▪ Horizontal close-coupled pump

▪ Axial suction nozzle

▪ Radial discharge nozzle

BM ▪ Horizontal close-coupled pump

▪ Mounted on motor feet

▪ Axial suction nozzle

▪ Radial discharge nozzle

V ▪ Vertical close-coupled pump

▪ Axial suction nozzle

▪ Radial discharge nozzle

All pumps of this type series are fitted with standardised mechanical seals to

EN12756. This ensures reliable operation and interchangeability.

When different standardised mechanical seals are used, verify the axial length of the

seal.

Type and material of the mechanical seal are specifically selected to match the nature

and composition of the fluid to be handled.

NOTE

Before using the pump for any fluids different to those originally specified, check

that the mechanical seals and joint rings are suitable for that fluid.

If certified seal types or materials are used, make sure that any replacement seals

used also meet the certification requirements.

14 of 44

4.2 Designation

Example: Vitastage 10/3/75 2 B T

Table6: Designation key

Code Description

Vitastage Type series

10 Size

3 Number of stages

Vitastage

Loading...

Loading...