Page 1

Type Series Booklet

3400.5/4--10 G3

50 Hz

Submersible Borehole Pumps

Applications

-- Drinking and service water supply

-- Irrigation and spray irrigation

-- Lowering and maintaining ground water levels

-- Pressure boosting

-- Fountains

-- Mining, offshore, tank farms

-- Building services systems

-- VDS sprinkler systems

Operating Data

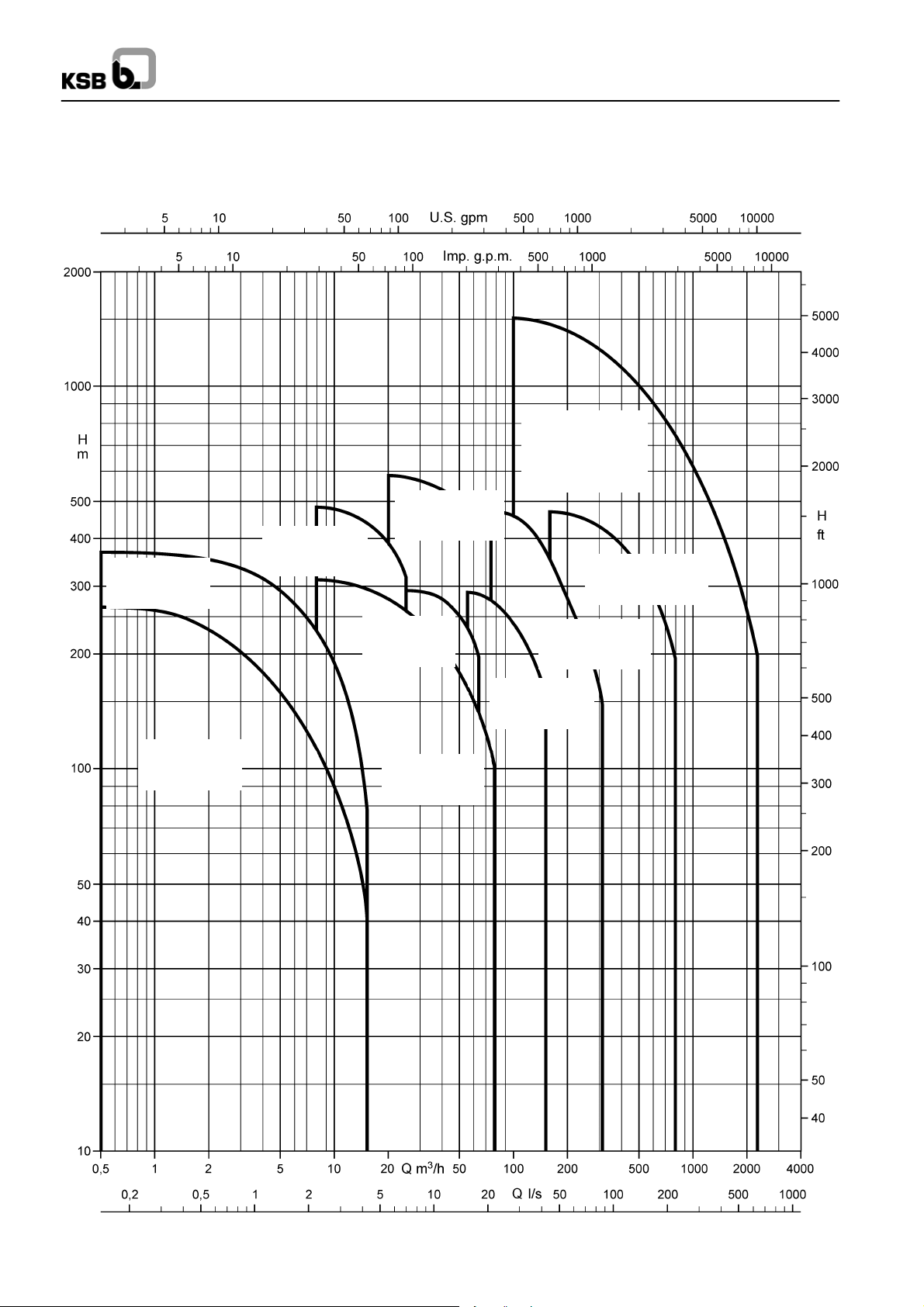

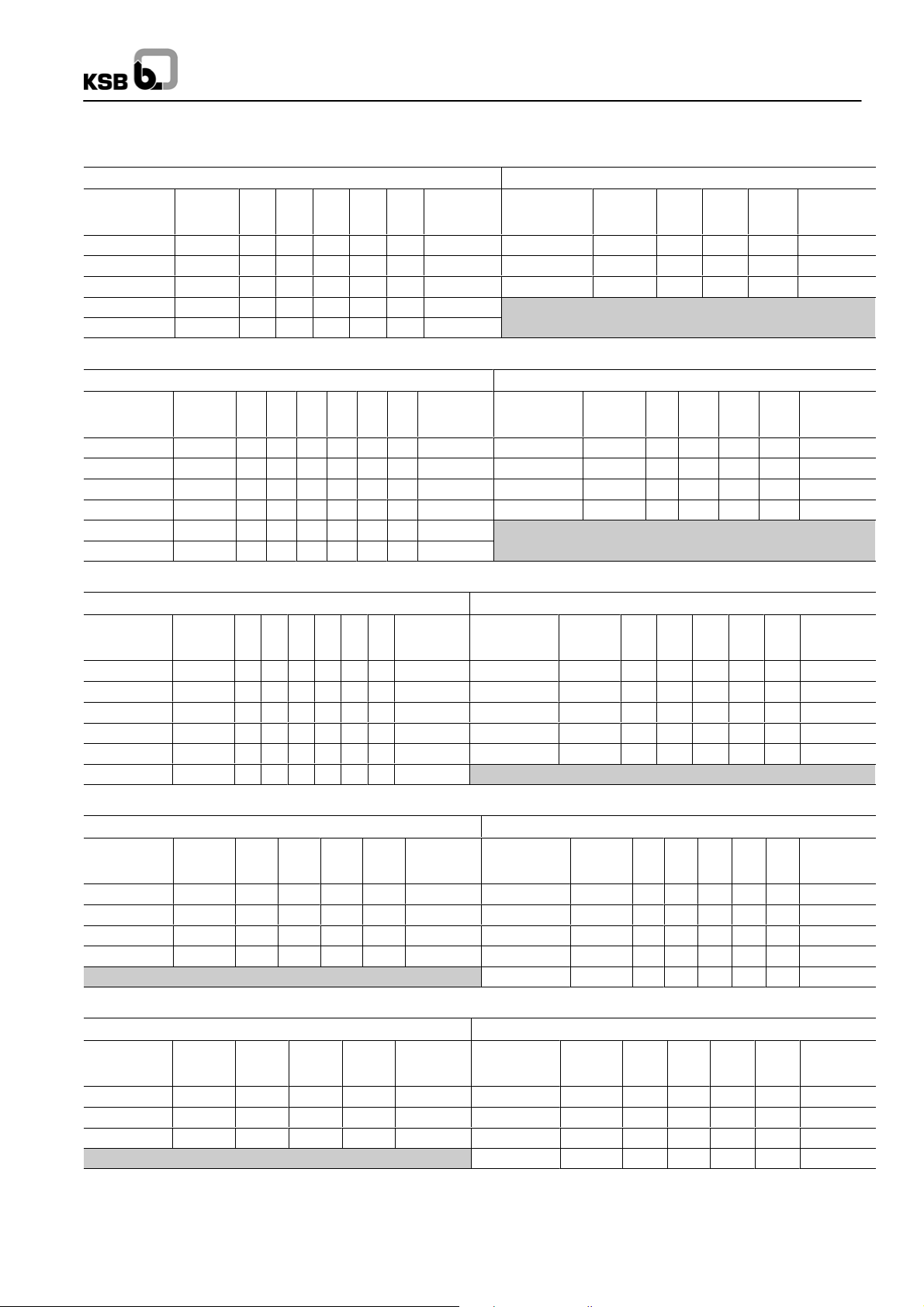

Capacity Q up to 840 m3/h (233 l/s)..................

Head H up to 480 m.....................

Temperature of fluid handled t up to +50 °C..

Speed n ≈ 2900 rpm....................

Supply voltage U up to 10,000 V.............

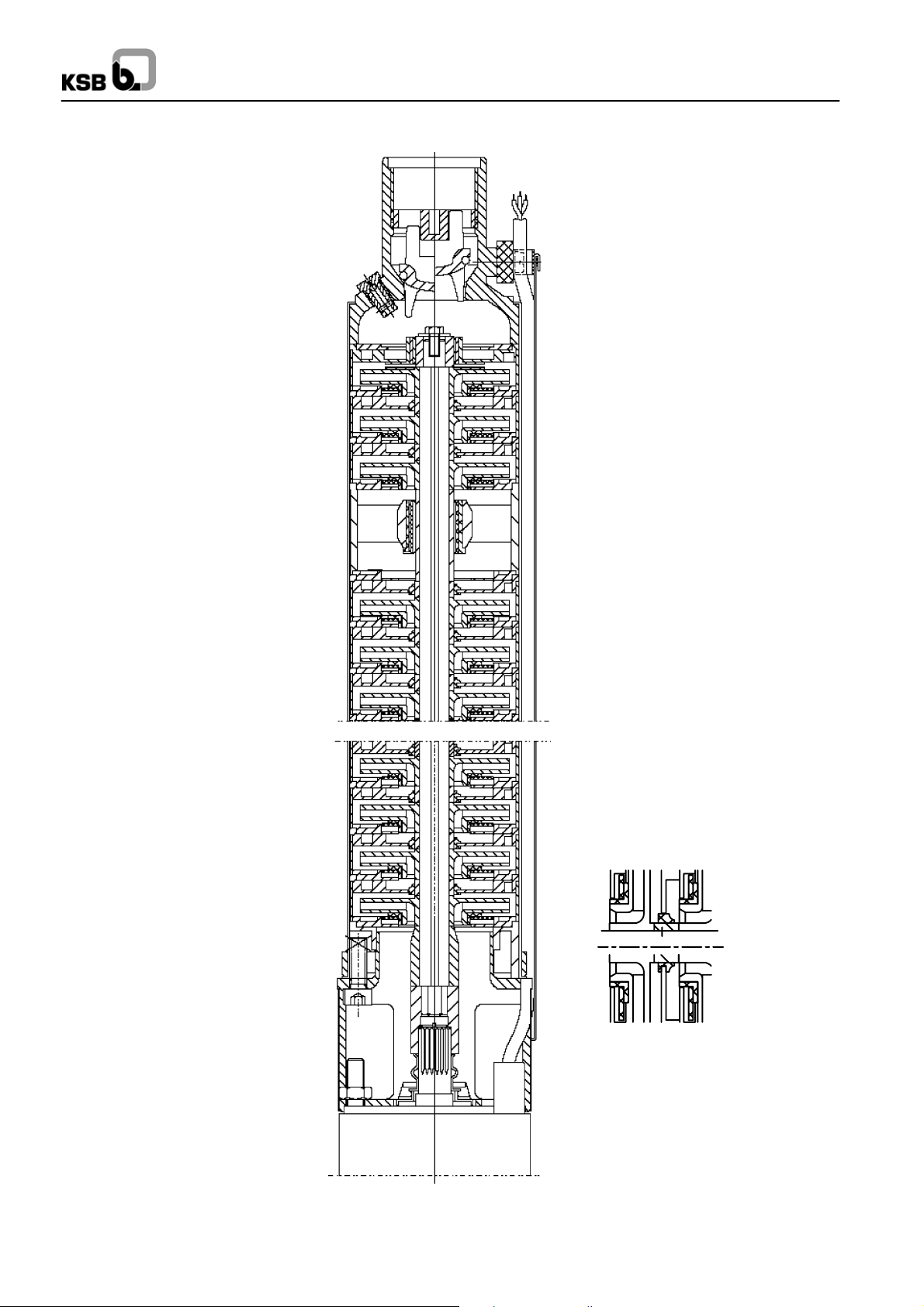

Design

Single-- or multistage centrifugal pumps in pump shroud or in

ring--section design. Radial or mixed flow hydraulic systems;

reduced impeller diameters also available in some cases. The

stage casings of radial pumps are connected by metal straps,

those of mixed flow pumps by stud bolts. Suction casing fitted

between pump and motor. Suction casing equipped with

strainer to protect the pump from coarse particles in the fluid.

Pumps with check valve or connection branch on option.

Available with threaded or flanged end on option.

Particularlysuitable forverticalinstallationinnarrow deepwells.

Submersible Borehole Pumps

S 100D, UPA 100C, UPA 150S, UPA 200,

UPA 200B, UPA 250C, UPA 300,

UPA 350, BSX -- BSF, UPZ

Pump Designation (Example)

UPA 200 B -- 8 0 /5 b

Type series

Minimum well diameter (mm)

(for ex.: 200 mm = 8 inches)

Design status

Capacity Q

Number of stages

Reduced impeller diameters

1)

UPA 200 -11 + 14: Q in l/s.

(m3/h)--(4upto10inches)

opt

(l/s) -- (12 inches and above)

Motor Designation (Example)

UMA 250 D 110 /21

Type series

Well diameter (mm)

(for ex. 250 mm = 10 inches)

Design status

Rated power P

Number of poles

Winding insulation

N

(kW)

Certification

Quality management certified to ISO 9001

1)

Available automation products:

• Hyamaster (UPA 150S -- UPA 350)

• hyatronic (UPA 150S -- UPA 350)

• switch gear (S 100D -- UPA 350)

Complete Range

The complete submersible borehole pump range comprises

pump models for flow rates up to Q = 2500 m

heads up to H = 1500 m.

The submersiblemotor range coverssizes for powerratings up

to P = 3500 kW and voltages up to U = 10,000 V for 50 and

60 Hz.

In addition, a special range is available which features

submersible motors with a higher number of poles.

3

/h (695 l/s) and

Page 2

50 Hz Submersible Borehole Pumps

Contents Page

The Submersible Borehole Pump Range 4.....................................

Operation with Soft Starters 5................................................

Operation with Frequency Inverter 6...........................................

Typical Installation Positions 7................................................

Submersible Borehole Pump Selection for Deep Wells 8............................

Request for Quotation (Form) 9...............................................

Head Losses in the Piping 10.................................................

Pump Sets 4 inches 11 + 23.................................................

Pump Sets 6 inches 33......................................................

Pump Sets 8 inches/10 inches 49.............................................

Pump Sets 12 inches/14 inches 69............................................

Pump Sets 16 inches and above 83 + 87......................................

Typical Tenders: 4 to 14 inches 91.............................................

Submersible Motors 96......................................................

Accessories 98.............................................................

Flow Velocity “v” Past the Motor 108...........................................

2

Page 3

Submersible Borehole Pumps50 Hz

What can you expect from the

“Submersible Borehole Pumps Booklet”?

The information provided can help you make a

-- quick

-- first rough selection

-- on your own

to find a suitable KSB submersible borehole pump for your

application. Wehave kept the volume of the catalogue down to

what we think is the absolute minimum. For the 4 to 14 inch

range, you will find the following information on the pump

selected:

-- pump series, size and number of stages,

-- motor series, size, power, amperage, and allowable

temperature,

-- starting method, supply voltage and type of installation,

-- material variants and

-- major dimensions and weights.

You may also complete, to the extent possible, the request for

quotation on page 9.

You will then receive as soon as possible a detailed quotation

and, if required, additional literature on KSB submersible

borehole pumps from the nearest KSB sales branch.

Benefits at a Glance

+ Full range of products

+ High-tech equipment

+ Optimum material selection

+ Maximum efficiency

+ Functional reliability

+ Long service life

+ No maintenance

+ “Clean” technology

+ Customer focus

General

Information on fields of application, available models, type of

installation, direction of rotation, coating, connection to power

supply and speed controlis provided inthe detailed sectionsfor

the relevant type series.

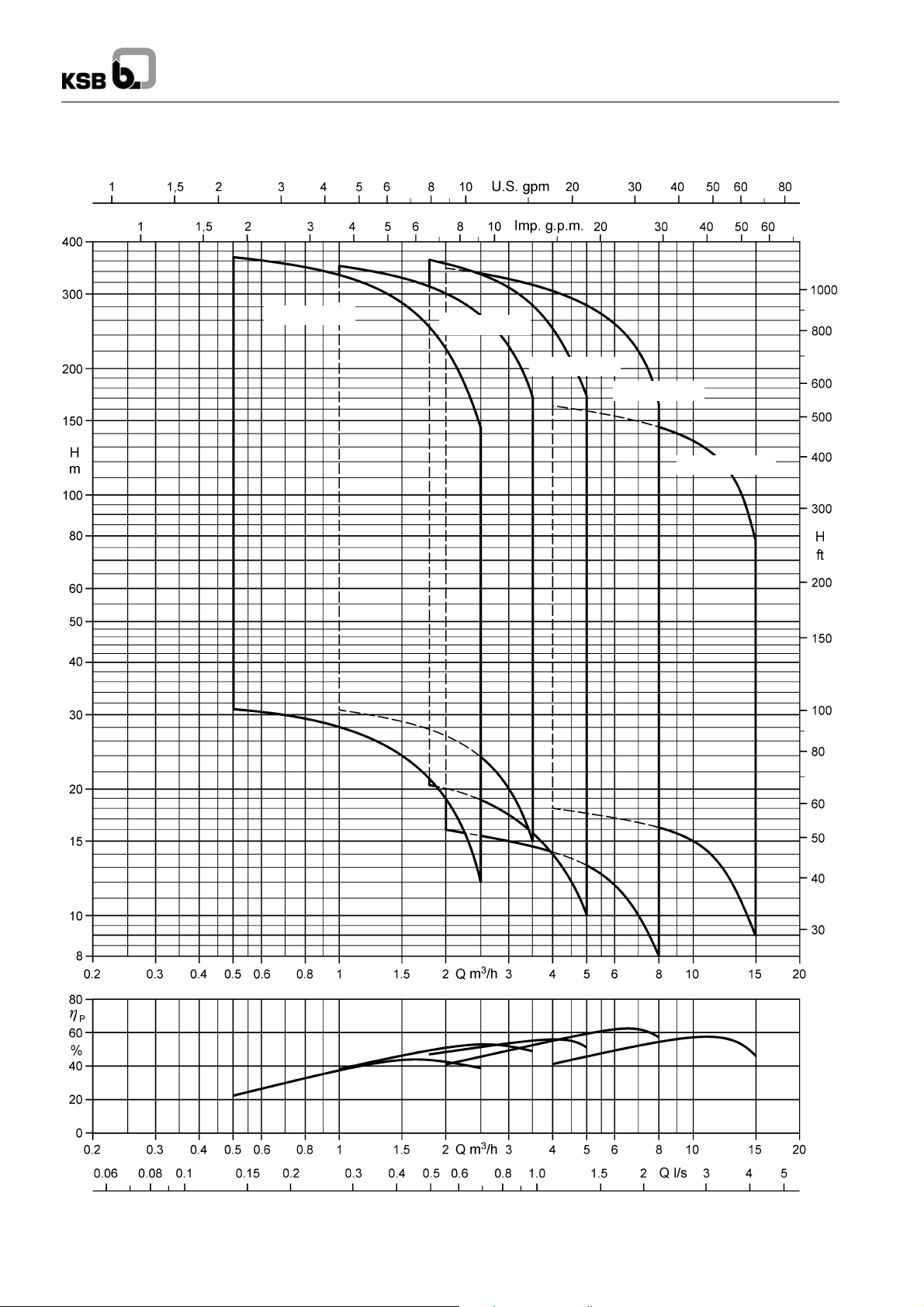

Pump Efficiency

The characteristic curves for UPA 200/200B and larger pumps

show pump efficiency for themaximum and optimum (reduced)

impeller diameter (for ex. ”c”). The efficiency of pumps with a

low number of stages or considerably reduced impeller

diameter (for ex. ”d”, “e”) is lower than the value shown; it is

given in the individual characteristic curves specifically

prepared for the quotation.

Dry Running Protection

For use in wells with marked water level fluctuations or

temporary low yield we strongly recommend installing dry

running protection equipment (”Accessories”).

Application Temperatures

The submersibleborehole pumps are, as a standard, suitablefor

use in water with temperatures of up to t = +30

indispensable requirementfor this isa flow velocityof v = 0.2 m/s

past the motor. This requirement is met, for example, when the

pump is installed in a deep well above the well screen / filter, etc.

With certain restrictions, some motor sizes may also be used

in water with temperaturesof up tot = +50

without an adequate cooling flow of water past the motor, i.e.

v = 0 m/s (for example, when the unit is installed in a deep well

below the screen / filter area or in a pump sump, etc.).

The details below provide data of adequate accuracy for the

allowable temperature as a function of the type of installation,

motor size and flow velocity v past the motor:

Vertical installation:

-- DN 100 / DN 150:

t

allow=tmax

-- UMA 150D/200D:

v= 0m/s t

v ≥ 0.2 m/s t

v ≥ 0.5 m/s t

-- UMA 250D:

v = 0 m/s Please consult manufacturer,......

v ≥ 0.2 m/s t

v ≥ 0.5 m/s t

1)

Values taken from tables on pages 15, 16 etc., 27, 28 etc..

1)

irrespective of flow past the motor.

≈ t

allow

allow

allow

allow

allow

max

=t

max

≈ t

max

=t

max

≈ t

max

o

C and for operation

1)

-- 5oC,......

1)

,.....

1)

+5oC......

1)

,.....

1)

,+5oC......

o

C. An

Horizontal installation:

The principle is the same as for vertical installation.

Exception: Pumps with UMA 250D motors.

These units must always be equipped with a flow inducer

sleeve. The flow inducer sleeve is not required, if the given

pump is equipped with a motor having a 10 % higher power

rating.

For all pump sets:

For a flow velocity of v ≥ 0.5 m/s and horizontalinstallation, check

back with the manufacturer.

3

Page 4

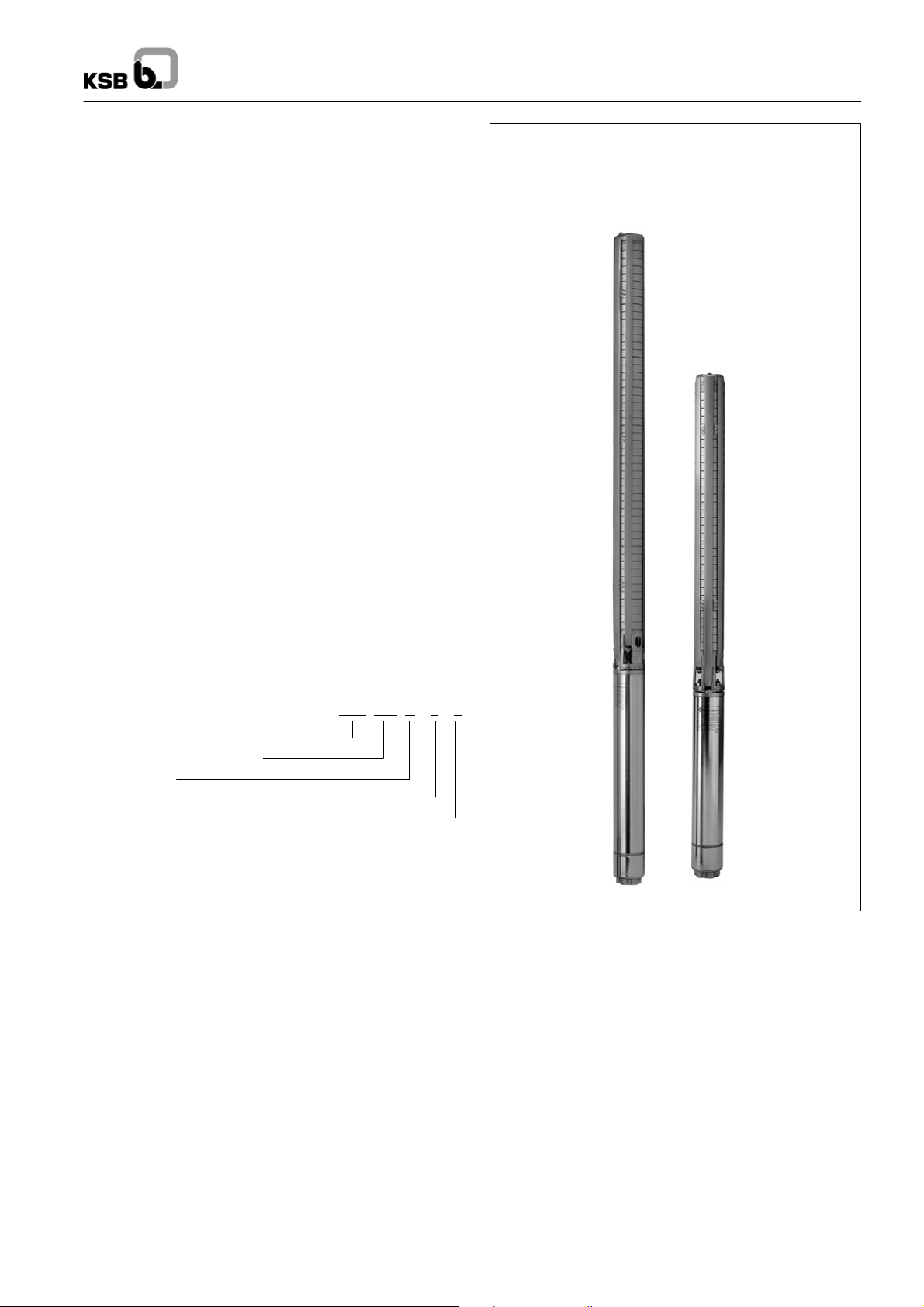

The Submersible Borehole Pump Range

" UPV 200

UPV 150S "

(6 inch)

" UPA 100C

(4 inch)

p. 23 -- 32

on request

50 Hz Submersible Borehole Pumps

" UPZ

BSX - BSF

(≥ 16 inch)

p. 83 -- 90

on request

(8 inch)

on request

" UPA 300, 350

(12/14 inch)

p. 69 -- 82

" S 100D

(4 inch)

p. 11 -- 22

UPA 200 "

(8/10 inch)

p. 49 -- 57

" UPA 150S

(6 inch)

p. 33 -- 48

" UPA 250C

(8/10 inch)

p. 62 -- 68

" UPA 200B

(8/10 inch)

p. 58 -- 61

4

Page 5

Submersible Borehole Pumps50 Hz

Operation of KSB submersible motor pumps with soft starters

Soft starterelectronically reduce the incoming line voltage and,

hence, the initial starting torque and starting current of electric

motors. During run--up they gently ramp up the applied voltage

to the motor.

In the case of submersible motors, the extremely slim design

and consequential small moments of inertia result in special

characteristics, which differ strongly from normal

asynchronous motors.

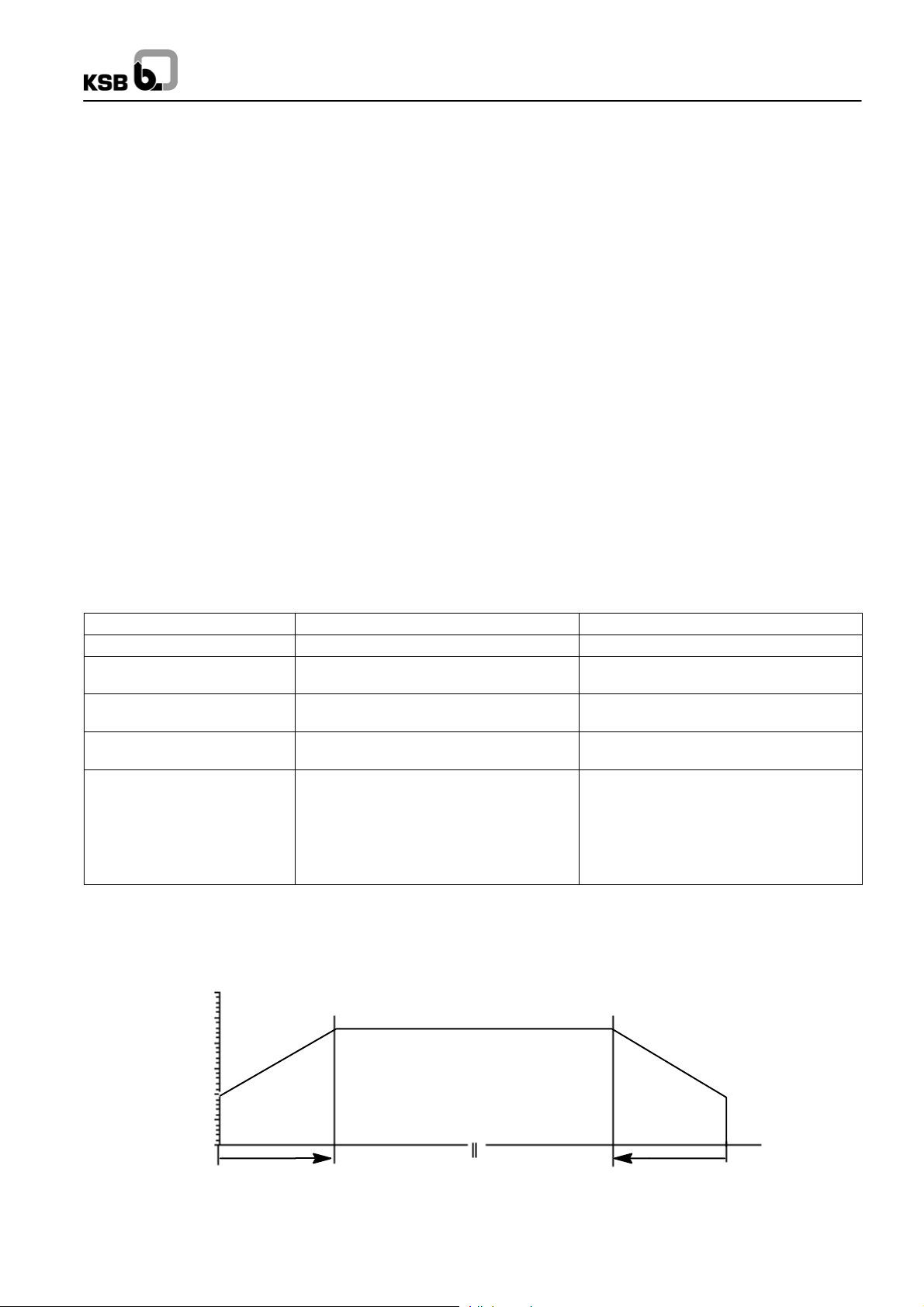

12.3 Soft starter settings

Effects on submersible borehole pumps

-- Starting current ⇒ approx. 40% to 65% of IArequired for

direct-starting.

-- Run-up time t

with approx. 0.2s to 0.5s for direct. starting.

-- Starting torque M

torque.

-- No current or torque peaks (I

switching arrangement.

-- Hydraulic pressure surges (waterhammer) upon starting

and stopping of the pump can be reduced, but not fully

eliminated. Therefore, soft starters are not suitable for

solving water hammer problems.

This would require the use of hydraulic control equipment

or a frequency inverter. To prevent effects due to power

failure, additional measures are required.

increased to approx. 1s to 3s compared

H

roughly 1/4 of the direct-starting

A

), as in star-delta

A,MA

Note

Conspicuous noiseor vibrations duringrun-up could well be an

indication of incorrect settings on the soft starter. This might be

due to exceeded ramp--up periods, incorrect operating mode

(setting), activated special functions, etc.

Parameter / Function Setting Comments

Minimum starting voltage 40% of the motors’ rated voltage

Ramp time / acceleration

(run--up) time

Current limitation IA/INpreset to approx. 3.5 Should only be altered with allowance for

Deceleration (run--down) time /

stop ramp

Special functions, e.g.:

-- special “pump function”

-- kick--start / boost function

-- speed adjustment

-- Current contoller

-- cos ϕ- / economy function

-- delayed starting

During operation the soft starter must be bridged (bypass). This helps to avoid losses at the machine and motor to secure proper

permanent operation.

120

< 4s Ramp time is nor identical with the motor

Deceleration time tA< 4s Better without a ramp.

OFF Do not use, as they tend to be troublesome,

Run--up

Operation

actual run--up time

< 4s

t

H

particulary in submersible borehole applications.

Run--down

100

80

60

40

Voltage [%]

20

0

4s

Time [s]

4s

5

Page 6

Pump Operation with Frequency Inverter

3

0

203

0

50 Hz Submersible Borehole Pumps

In principle, the motors of submersible borehole pumps can

also be run on a frequency inverter. As submersible motors

differ from conventional standardized motors in terms of

bearings, moment of inertia, insulation, temperature increase,

loss distributionand heat distribution, the following parameters

must be observed:

-- Maximum allowable acceleration time (start ramp)

-- Maximum allowable deceleration time (stop ramp)

-- Minimum frequency

-- Maximum operating frequency

-- Maximum permissible voltage increase velocity and peak

voltages

-- Control principle of frequency inverter

Maximum Allowable Acceleration Time (Start

Ramp) and Deceleration Time (Stop Ramp)

The plain bearings of the submersible motor do not tolerate

operation below the minimum frequency f

mixed lubrication range).

For this reason, the acceleration period from standstill to

minimum frequency f

should not exceed 2s. The same

min

applies to the deceleration period.

(operation in

min

Minimum Frequency

Minimum frequency f

Motor size

DN 100

Vertical

installation

30

DN 150

UMA 150D

20 30

UMA 200D

UMA 250D

UMA 300D /2

UMA 300D /4 30 35

(Hz)

min

Horizontal

installation

30

-- --

Maximum Operating Frequency

Frequency inverter operation above the nominal frequency

(50Hz /60Hz) ofthe pumpunit must beavoided soas toprevent

motor overload.

Maximum Permissible Voltage Increase Velocity

and Peak Voltages

Excessive voltage increase velocities and excessive peak

voltages will reduce the service life of the winding insulation.

For this reason, the following limits must be adhered to:

-- Maximum voltage increase velocity:

du/dt ≤ 500 V/µs

-- Maximum peak voltages to earth:

Low-voltage motors ≤ 1 kV: J1 insulation ≤ 600 V

J2 insulation ≤ 800 V

For motor sizes DN 100 and DN 150, the limit values for J1

insulation apply.

Note: Compliance with these limits can usually be assured by

means of a sine filter or

du

/dtfilter.

Control Principle of Frequency Inverter

The control principleof the frequency inverter must correspond

to linear U/f curve control. If other control principles are

employed, such as field-oriented inverters, inverters with DTC

or NOF,the manufacturerof the frequency invertermust ensure

that thespecial requirementsof submersiblemotors (very small

moment of inertia, electrical data) are taken into account.

Note: For details refer to ”Design and Selection Information for

Running Submersible Borehole Pumps on Frequency

Inverters”, Ref. No. 3400.0610--10.

6

Page 7

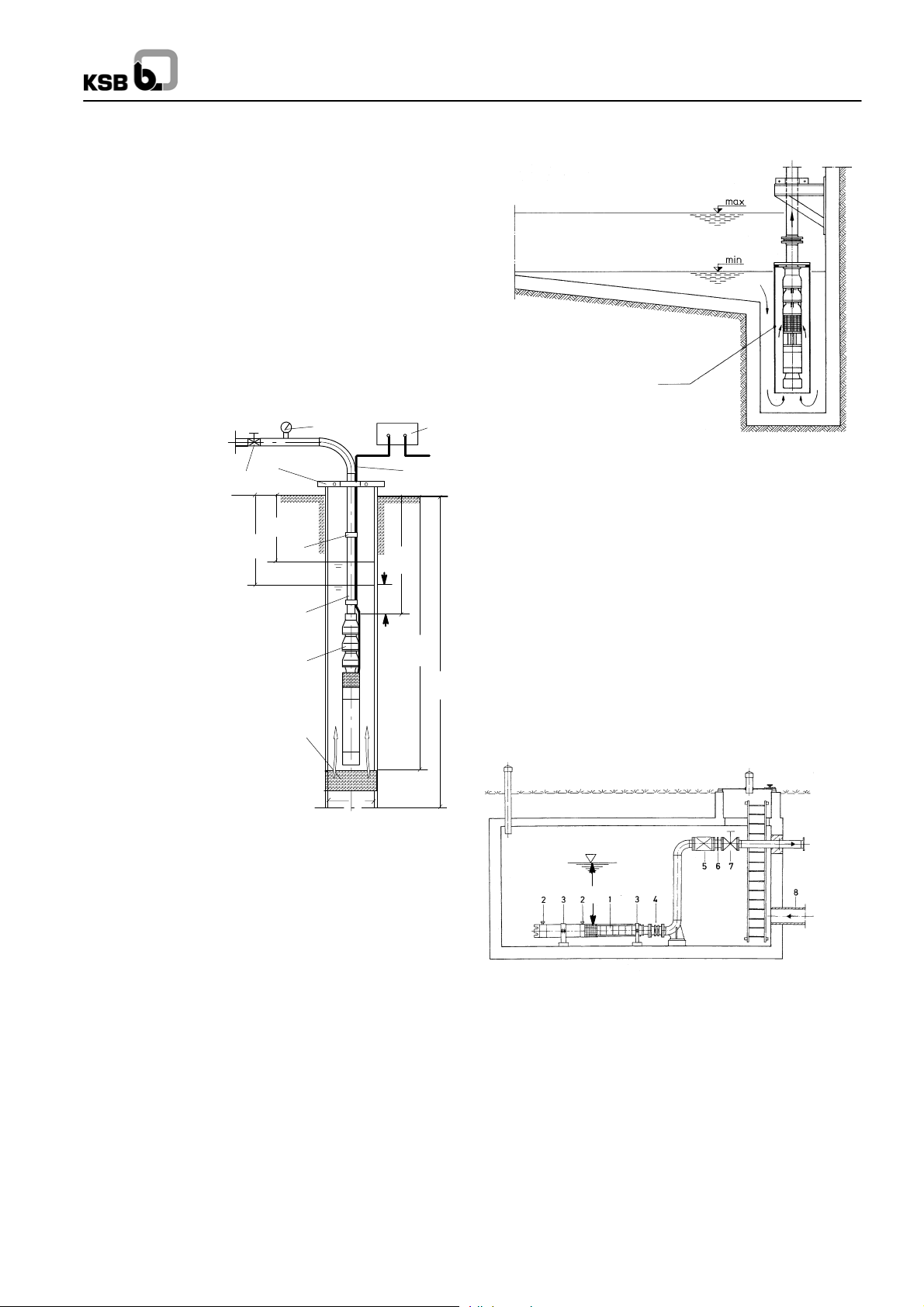

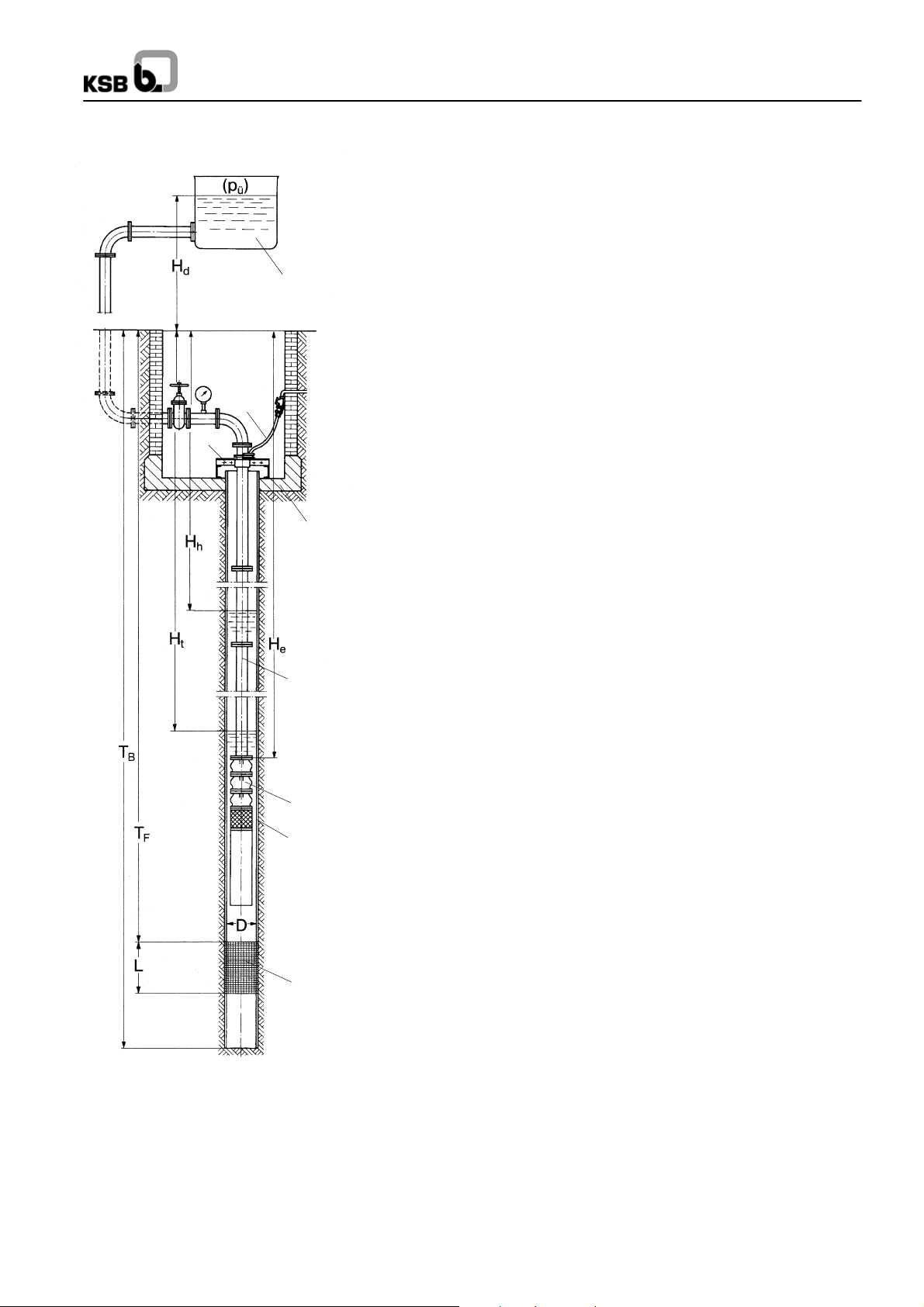

Typical Installation Positions

a) Vertical Installation

(deep well, pump sump, etc.)

CAUTION:

The construction of the well head must meet the relevant

regulations ofthe competent authorities! The unit must never

be installed with its suction strainer exactly at the level of the

well screen / filter!

Before installingthe unitin narrowdeep wells werecommend to

check narrow boreholes for dimensional accuracy over their

entire length, e.g. by inserting a pipe of the length and biggest

outside diameter of the pump unit. Sharp bends or bottlenecks

can make installation difficult or even impossible.

The unit is supported on the well head by supporting clamps

(low-weight unitsand lowsubmergence) ora supportingflange.

The construction of the well head must meet the relevant

regulations of the competent authority.

5

8

Submersible Borehole Pumps50 Hz

Cooling / Suction shroud

Fig. 2 Installation in a pump sump

3400:50

4

6

H

h

H

t

3

B

B

7

H

e

X

2

T

1

1 Submersible borehole pump

F

T

B

2 Riser pipe

3 Cable tie

9

4 Supporting flange / Well head

5 Pressure gauge

6 Shut-off valve

7 Power supply cable

8 Control box

9 Well screen / filter

D

3410:70/4

D = Inside well diameter

T

= Well depth

B

= Well screen / filter depth

T

F

H

= Installation depth

e

H

= Static water level

h

= Dynamic water level (Pumping water level)

H

t

Fig. 1 Vertical installation (in deep well, pump sump, etc.)

The suspension arrangement of the pump unit must be

designed and dimensionedso that allstatic anddynamic forces

can be absorbed and that theriser pipe cannot slip downwards.

The supporting clamps or flanges must be fastened at the well

head so that they cannot shift of lift off the well head.

The unit mustnever be installed with its suction strainer exactly

at the level of the well screen / filter! Excessive flow in the area

of the well screen / filter entails the risk of large amounts of

entrained sand clogging the well screen / filter and causing

excessive wear in the pump.

Pump units installed in a pump sump must generally be

equipped with a cooling or suction shroud (fig. 2).

b) Horizontal Installation

(in reservoirs, mine shafts, etc.)

CAUTION:

The instructions given in ”a) Vertical installation” shall also apply

by analogy to horizontal installation, when the pump unit is fitted

on mounts (pedestals / supporting frame) supplied by us. If the

pump and motor are supplied ready mounted on a supporting

frame, on-site alignment of pump and motor will not be

necessary. If this is not the case, the relevant installation /

assembly drawing must be ordered, giving the following details:

-- installation height (floor clearance),

-- spacing of supports,

-- submergence X

The ground / foundation must be level and of sufficient

load-bearing capacity to accept the weight of the unit with

supports.

Air intake from an inlet arranged above the water level is not

permitted.

X

3410:71/2

Fig. 3 Horizontal installation (in tanks, mine shafts etc.)

1 Submersible borehole pump

2 Water storage tanks (UMA 300D and 14D motors only)

3 Pedestal

4 Expansion joint

5 Check valve

(only if pump unit does not have its own check valve)

6 Dismantling joint

7 Shut-off valve

8 Intake

7

Page 8

50 Hz Submersible Borehole Pumps

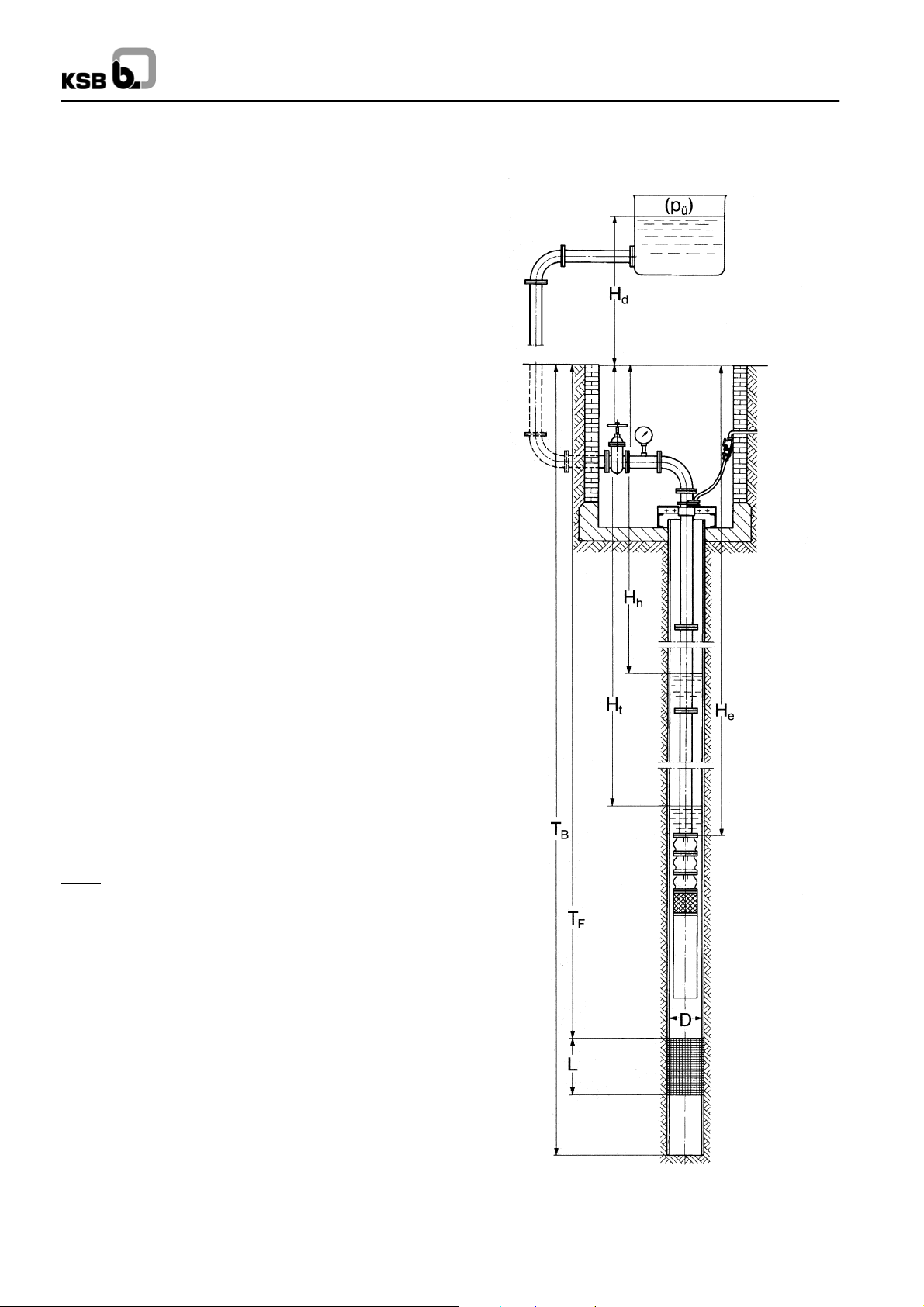

Submersible Borehole Pump Selection for Deep Wells

Pump Selection

The following data are required for a first rough selection of a

submersible borehole pump:

-- Capacity Q in m

-- Pressure at well head H

-- Well diameter in inches or mm

-- Temperature of fluid handled t

-- Pump head HPin m

While Q, H

head H

A

to be developed by the pump needs to be calculated.

P

There are two typical applications to be considered (see the

drawing on the right):

1. Pumping into an open overhead tank

HP=HA+Ht+Hv+HS[m]

where ...

HA= Required pressure at well head

H

= Lowest water level (dynamic water level)

t

Hv= Head losses in the checkvalve (see characteristic

H

= Head losses in riser pipe up to well head

S

H

= Installation depth

e

3

/h (l/s)

in m

A

in °C

A

, D and tAare usually specified bythe customer,the

curves for different stage numbers for UPA 150S

and above).

(see page 10).

2. Pumping into a closed tank

Hp=HA+Ht+Hv+HS+pü[m]

where ...

pü= Gauge pressure (also air cushion) in a tank

Example

Given ...

QA= 120 m3/h,

=95m,

H

A

tA=+15°C,

50 Hz, 400 V and d.o.l. starting,

well diameter D = 250 mm (10 inches).

...

Found

1. step:

pump type UPA 200B/250C

(for Q

2. step:

pump size UPA 200B - 130

(for QAtaken from selection chart on page 50)

3. step:

pump set UPA 200B-130/6b + UMA 200D 45/21

(for Hp=HA+Ht+HV+HS= 95 + 4 + 0.75 + 0.26 = 100 m

with H

numbers on page 61).

Pump efficiency: ηP= 80.5 % (without check valve)

taken from selection chart on page 4)

A

taken from characteristic curves for different stage

V

3300:54/3

Figure:

Deep well with submersible borehole pump and overhead tank

or closedtank at apressure above atmospheric pressureof p

ü.

8

Page 9

50 Hz Submersible Borehole Pumps

Request for Quotation

We should like to test the efficiency and quality of your computer-aided quotation process.

Please let us have a quotation based on the following data. (Fill in the required data and

/ or underline the relevant information, as far as available.)

1. Water quality

Discharge head required at theend of the

piping:

Temperature °C.....................

8

Sand content g/m

..................

H = m ( bar)............. ........

3

Cut-out pressure in the pressure vessel:

Please attach water analysis, if available.

p

= bar............

Ü

2. Type of system

7

6

Well / Mine shaft / Tank

Free discharge above ground

Discharge into an overhead tank

Discharge into a pressure vessel

c)Piping outside well head housing:

Overall length m....................

Nominal diameter mm...............

Number of bends, valves and fittings:

pcs................................

3. Deep well

Well depth(distance from ground level to

5

well base):

T

=m............................

B

Inside diameter at submersible pump

installation depth:

D = mm ( inches).............. ....

4

Well screen / filter:

-- Installation depth T

=m...........

F

Inside diameter reduced by incrustation

to: D = mm........................

6. Installation depth

Ground level to check valve / to

connection branch:

He = m............

Caution: Do not install the submersible

borehole pump at the level of the well

screen / filter!

F

1 Well screen / filter

2 Well casing

3 Submersible borehole pump

4 Riser

5 Well head housing

6 Well head

7 Power supply cable

8 Overhead tank

3

2

1

3300:54/3

-- Length L

=m...................

F

4. Capacity

Q= m3/h ( l/s)............. .......

5. Total head

(including all friction losses)

H= m............................

If H is not known, please provide the

following data:

a)

Water level in well, measured from

ground level:

-- Static water level: H

-- Dynamic water level: H

(at capacity Q = m

b)

Head above ground:

Geodetic altitude up to the highest point

of the pipeline or up to the highest water

level in the overhead tank:

H

=m...........................

d

=m..........

h

=m........

t

3

/h)..............

7. Power supply

Single- / three-phase alternating current.

Mains voltage at well:

U= V.............................

Frequency f = Hz..................

If voltage drops cannot be precluded:

Minimum voltage ...

U

=V...........

min

8. Control box

Manual start-up / remote control / automatic start-up by way of float switch,

pressure switch or dry running protection

equipment.

Other types of switchgear: ...........

...................................

9. Starting method

D.o.l. (without / with autotransformer or

soft starter) or star-delta starting.

9

Page 10

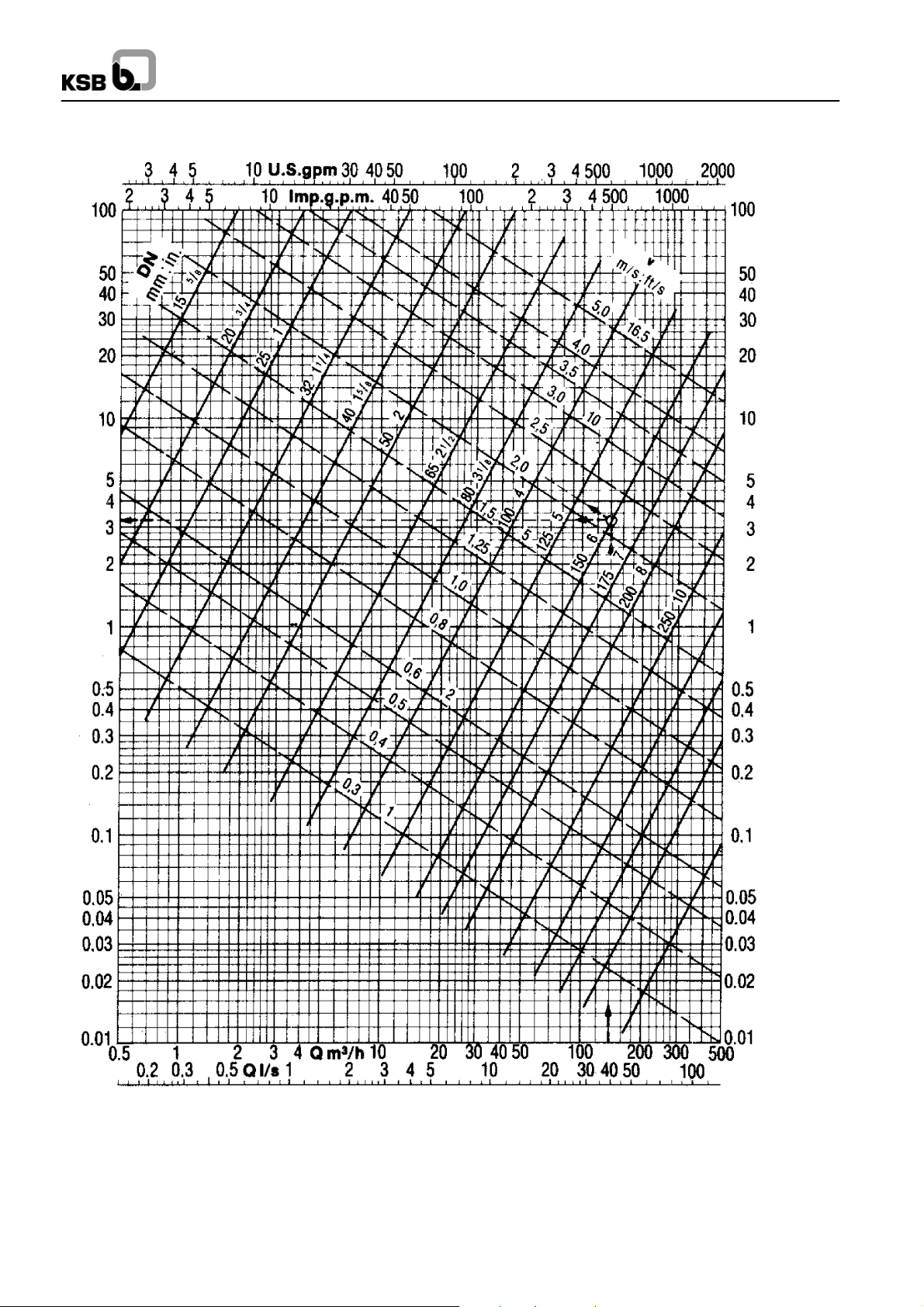

Head losses in the piping

H

V

m/100 m

50 Hz Submersible Borehole Pumps

H

V

ft/100 ft

The frictionlosses givenin theabove chart roughlyapply tonew

cast iron pipes.For newrolled steelor plasticpipes, multiply the

values by approx. 0.8. For old, slightly rusty cast iron pipes,

multiply by approx. 1.25. In pipes with incrustations, friction

losses may rise to 1.7 times the value given in the chart for the

10

3300:103/3-2

diameter reduced by incrustations. For pipes subject to considerable incrustation, the friction losses can only be determined experimentally.

Example: Q = 140 m

H

V

3

/h, new DN 150 cast iron pipe.

= 3.25 m per 100 m of pipe, v = 2.2 m/sec.

Page 11

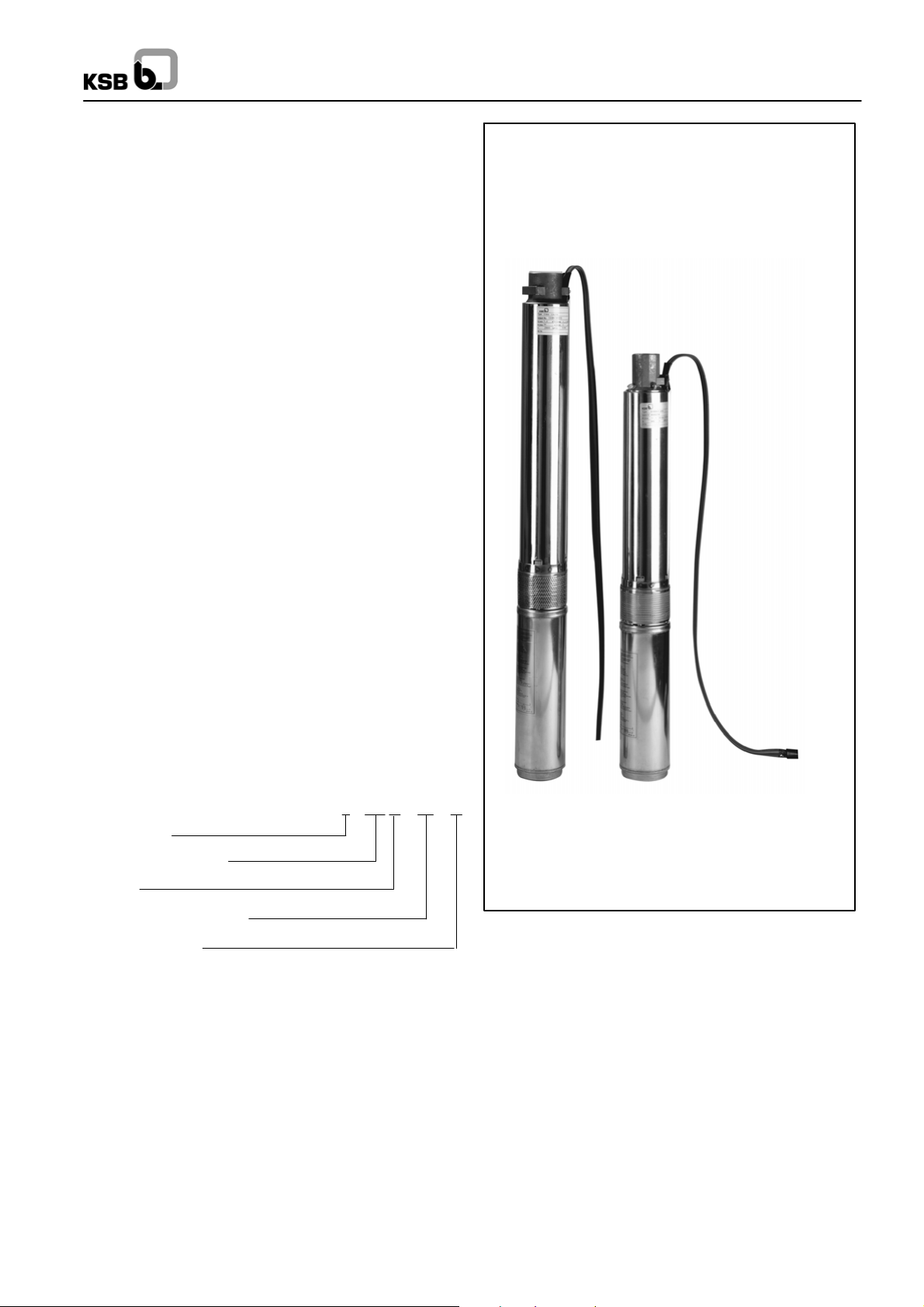

50 Hz S 100D

Applications

-- Domestic and general water supply

-- Irrigation and spray irrigation

-- Lowering groundwater levels

-- Fountains

-- Pressure boosting

-- Air-conditioning systems

-- Fire protection

-- Cooling water cycles

Operating Data

Caoacity Q up to 16 m3/h

Head H up to 300 m

Temperature of fluid handled

tupto+30°C in continuous operation

Power Pn up to 5.5 kW

Pump Type / Design

Pump:

Stainless steel and plastic multistage centrifugal pump.

-- Additional bearing depending on the number of stages

-- Pump sizes D1 and D2 with anti-blockage feature. This consists of a hexagonal polyurethane disc mounted to the back

of the diffuser. A PE-HD ring fitted to the impeller front side

sits closeto thedisc. The impeller hub is protected by apolyurethane ring.This design improves the starting torque of lowcapacity pumps and has the effect that solid particles such as

sand are propelled outside instead of clogging the pump.

Motor:

Submersible canned motor (Franklin), NEMA standard, 50 Hz

-- For single-phase alternating current (type PSC) or threephase current

-- With short cable

-- Connection to power supply mains by means of cable connector (accessories)

-- D.o.l. starting, start-up frequency up to 20/h

-- Type of enclosure IP 68

-- Thermal class B

Submersible Borehole Pumps

for Well Diameters

of 100 mm (4 inch)

Designation

S 100 D -- 4 / 6

Type series

Well diameter (mm)

Status

Capacity (m

Number of stages

3

/h)

Recommended Accessories

UPA Control: Control box for motor and dry running protection

by immersion electrodes.

Automatic control unit: in conjunction with the Controlmatic

E or Cervomatic EDP control and monitoring units, which protect thepump againstdry running, ifthe waterlevel falls,S 100D

can be used for automatic water supply

Certification

Quality management certified to ISO 9001

Available automation products:

• Automatic control unit

Product Features

-- Pumps sizes D1 and D2 with anti-blockage feature

-- Rust-proof

-- Suitable for installation in narrow deep wells

-- High efficiency

-- Hermetically sealed motor

-- Motor designed for maximum pump output

-- Low noise level

-- For vertical, angled or horizontal installation

-- Check valve with anti-blockage valve disc

11

Page 12

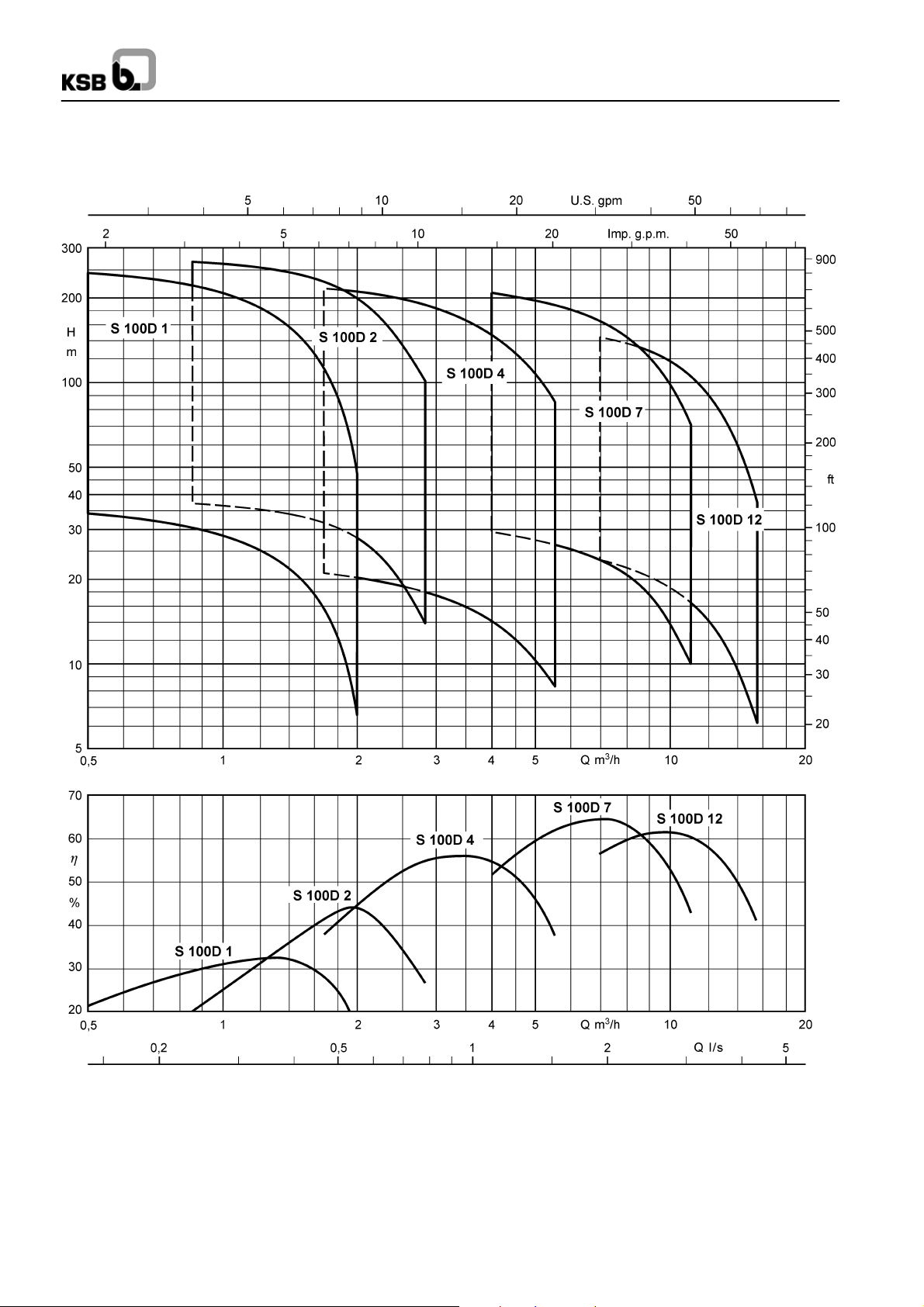

50 Hz S 100D

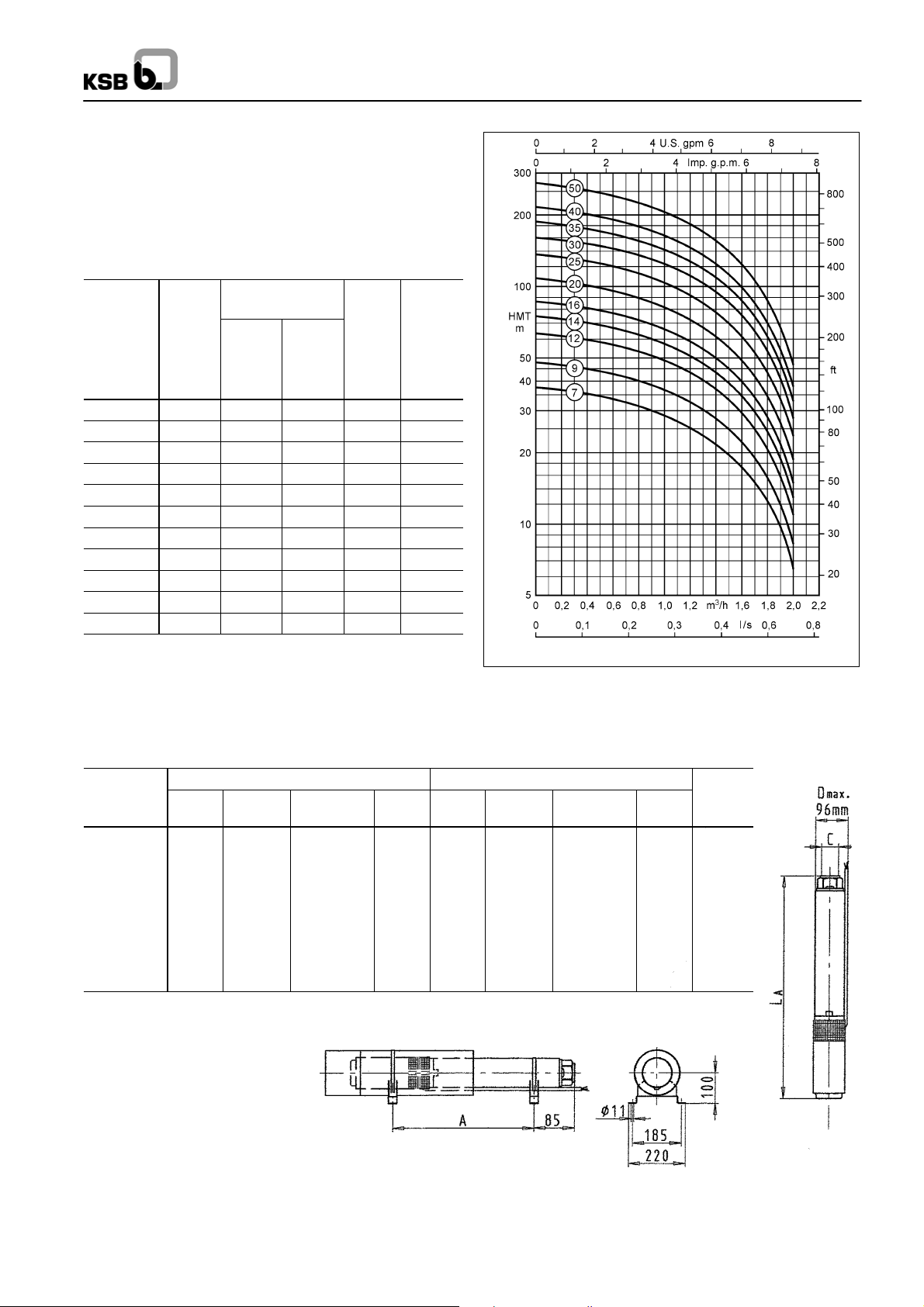

Selection Chart (Ranges on Offer) n ≈ 2900 rpm

Note:

Up to a motor rating of PN= 2.2 kW, all pump sizes can be supplied with either single-phase a.c. or three-phase current motors.

12

Page 13

50 Hz S 100D

Materials

Component

Pump ...

Outer pump casing/

Suction casing /

Valve housing

Stage casing CrNi steel (1.4301)

Stage casing (diffuser) /

Impeller

Shaft Cr-steel (1.4021)

Bearing bush Nitril NBR 80

Screws, bolts and nuts CrNiMo-steel (A4--70)

Motor ...

Shaft CrNi steel (1.4305)

Bearing carrier CrNi steel (1.4301)

Stator case CrNi steel (1.4301)

G (Standard design)

CrNi steel (1.4301)

glass fibre reinforced Noryl

(PPO)

Bearings / Lubrication

Plain bearings, lubricated by the fluid pumped or by the motor

fill liquid. Depending on the number of stages, an additional intermediate bearing is provided in the pump.

The axial thrust is balanced by a thrust bearing in the motor.

The hydraulic thrust is balanced by the pump’s counter thrust

bearing.

Direction of Rotation of the Pump

Clockwise rotation (viewed at the drive shaft end).

Pump End (Discharge Nozzle)

S 100D - 1, 2, 4 + 7: Internal thread G 1’’1/4(DN 32).

S 100D - 12: Internal thread G 2’’ (DN 50).

Drive

Type canned motor in squirrel-....................

cage design, 2 poles

Connection NEMA standard..............

Type of enclosure IP 68........

Frequency 50 Hz..............

Type of current single-phase a.c. (1

or three-phase (3

Rated voltage U 220 ... 230 V (1~) and..........

380 ... 400 V (3~)

Rated power P

Voltage fluctuation up to ± 5 % acc. to VDE........

Frequency of starts up to 20/h.......

Min. delay before restarting 3 min.

A starter for single-phase a.c. motors in PSC design (with

integrated run capacitor and motorprotection) is included inthe

scope of supply.

N

up to 2.2 kW for 1~ and............

up to 5.5 kW for 3~

µ)...........

µ)

Connection to Power Supply

All DN 100 motors are factory-equipped as follows:

1 x 1.5 mflatcable, quality 4x 1.5 mm2(3 phases + 1 earthconductor).

Exception: DN 100 motors with a rating of 5.5 kW, 3~, are

equipped as follows: 2.5 m cable, quality 4 x 1.5 mm

Connection of extensioncable (any length)by meansof a cable

connector

Connected at the factory by means of a standard cable con-

nector (non-separable, shrink tube)

Ident. No. 40 980 708

For cable quality 4 x 1.5 mm

Ident. No. 39 020 536

For cable quality 4 x 4 mm

Connected at the factory with Franklin cable connector

(separable, sealing compound)

Ident. No. 90 049 385

For cable quality 4 x 1.5 mm

2

or 4 x 2.5 mm

2

2

up to 4 x 2.5 mm

2

.

2

2

Installation

Vertical and, depending on the number of stages, also angled

and horizontal installation.

Starting Mode

Only direct on line.

Temperatures

The S 100D submersible borehole pump is designed for use in

water with temperatures of up to t = + 30

o

C.

Variants Available on Request

-- Higher fluid temperatures

-- Higher voltages up to 500 V

-- Other frequencies

13

Page 14

Design Features

50 Hz S 100D

Easy to commission and service

D Vent valve for operation with automatic

control units such as Controlmatic E or

Cervomatic EDP

D Easy to install thanks to plug--type

connection of power cable of Franklin

submersible motor

D The cable guard is easy to fit and remove.

High operating reliability and

long service life

D Maintenance--free and wear--protected

pump bearings

D Special guide feature prevents jamming

or tilting of the check valve

D Cable guard protects cables from damage.

Highly corrosion--resistant

D Suction casing, check valve

housing and outer casing made of

stainless steel

D Hydraulic system made of glass

fibre reinforced Noryl

14

Page 15

S 100D -- 1 ...

(motor)

ith

for well diameters of 100 mm (4 inch)

Pumps with submersible motors for ...

-- Temperature of fluid handled up to + 30oC............

-- Current / Operating voltage 1~/230 V..................

or 3~/400 V.......................................

-- Starting direct......................................

50 Hz S 100D

Rated

power

Current intensity for

...

Installa-

2)

tion

Oper-

ation

w

control

unit

3

Pump unit

S 100D

P

kW

1~

230 V

1)

N

I

N

A

3~

400 V

I

N

A

1/ 7 0.37 3.4 1.3 v+h x

1/ 9 0.37 3.4 1.3 v+h x

1/12 0.55 3.4 1.3 v+h x

1/14 0.55 4.3 1.7 v+h x

1/16 0.55 4.3 1.7 v+h x

1/20 0.75 4.3 1.7 v+h x

1/25 1.10 5.7 2.2 v x

1/30 1.10 5.7 2.2 v x

1/35 1.50 8.6 3.2 v x

1/40 1.50 8.6 3.2 v x

1/50 2.20 10.6 4.0 v x

1)

Capacitor run motors (PSC motors) with starter.

2)

v = vertical and h = inclined / horizontal.

3)

Always check and make sure that the operating pressure of Controlmatic /

Cervomatic units is not exceeded.

4)

3~ only

3)4)

Note : Use a cooling shroud for horizontal installation.

)

3)

3)

3)

3)

3)

3)

Capacity

Dimensions / Weights / Ident. Numbers / Horizontal Installation

1~/ 230 V 3~/ 400 V

Pump unit

S 100D

1/ 7

1/ 9

1/ 12

1/ 14

1/ 16

1/ 20

1/ 25

1/ 30

1/ 35

1/ 40

1/ 50

For information on cooling shroud refer to page 20.

L

A

≈ mm

575

625

720

795

810

925

1100

1210

1395

1505

1805

m

≈ kg

11. 5

11.7

13.4

13.6

13.8

14.3

16.3

16.8

20.0

20.6

22.7

A

Ident No. A

39 022 528

39 022 529

39 022 530

39 022 531

39 022 532

39 022 533

39 022 534

39 022 535

39 022 536

39 022 537

39 022 538

≈ mm

371

425

508

552

597

687

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

L

A

≈ mm

555

605

700

755

780

870

1045

1150

1310

1450

1705

m

≈ kg

10.7

10.9

12.2

12.4

12.6

13.1

14.9

15.4

17.4

18.0

20.3

A

Ident No. A

39 022 565

39 022 566

39 022 567

39 022 568

39 022 569

39 022 570

39 022 571

39 022 572

39 022 573

39 022 574

39 022 575

≈ mm

362

416

492

537

582

672

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

C

G1”1/4

Accessories: UPA Control for dry running protection using 1 or 3 immersion electrodes, see page 21.

15

Page 16

S 100D -- 2 ...

p

for well diameters of 100 mm (4 inch)

50 Hz S 100D

Pumps with submersible motors for ...

-- Temperature of fluid handled up to + 30

-- Current / Operation voltage 1~/230 V..................

or. 3~/400 V......................................

-- Starting direct......................................

Pump unit

S 100D

Rated

power

(motor)

P

kW

N

Current intensity

for ...

1~

230 V

I

N

A

1)

3~

400 V

I

N

A

Instal-

lation

2)

Opera-

tion with

control

unit

3

2/ 7 0.37 3.4 1.3 v+h x

2/11 0.55 4.3 1.7 v+h x

2/15 0.75 5.6 2.2 v+h x

2/18 1.1 8.6 3.2 v+h x

2/20 1.1 8.6 3.2 v+h x

2/22 1.1 8.6 3.2 v+h x

2/27 1.5 10.6 4.0 v+h x

2/30 1.5 10.6 4.0 v x

2/33 2.2 15.5 5.9 v x

2/38 2.2 15.5 5.9 v x

2/44 2.2 15.5 5.9 v x

2/50 3.0 -- 7.8 v x

1)

Capacitor run motors (PSC motors) with starter.

2)

v = vertical and h = inclined / horizontal.

3)

Always check and make sure that the operating pressure of Controlmatic /

Cervomatic units is not exceeded.

4)

3~ only

3)

3)

3)

3)

3)

3)

3)

3)

3)4)

Note : Use a cooling shroud for horizontal installation.

o

C............

)

Capacity

Dimensions / Weights / Ident. Numbers / Horizontal Installation

1~/ 230 V 3~/ 400 V

Pump unit

S 100D

2/ 7

2/11

2/15

2/18

2/20

2/22

2/27

2/30

2/33

2/38

2/44

2/50

For information on cooling shroud refer to page 20.

L

A

≈ mm

570

695

815

940

985

1030

1175

1235

1425

1535

1670

-- -- -- -- --

m

A

≈ kg

11. 3

13.0

14.8

17.7

17.8

18.0

19.5

19.9

23.6

24.1

24.6

-- -- -- -- --

Ident No. A

39 022 539

39 022 540

39 022 541

39 022 542

39 022 543

39 022 544

39 022 545

39 022 546

39 022 547

39 022 548

39 022 549

-- -- -- -- --

≈ mm

371

484

589

684

729

775

901

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

L

A

≈ mm

550

665

790

880

925

970

1120

1180

1325

1435

1570

1770

m

≈ kg

10.5

11.8

13.4

15.1

15.2

15.4

17.1

17.5

19.0

19.5

20.0

23.6

A

Ident No. A

39 022 576

39 022 577

39 022 578

39 022 579

39 022 580

39 022 581

39 022 582

39 022 583

39 022 584

39 022 585

39 022 586

39 022 587

≈ mm

362

470

574

655

701

746

873

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

C

G1”1/4

Accessories: UPA Control for dry running protection using 1 or 3 immersion electrodes, see page 21.

16

Page 17

S 100D -- 4 ...

p

for well diameters of 100 mm (4 inch)

50 Hz S 100D

Pumps with submersible motors for ...

-- Temperature of fluid handled up to + 30

-- Current / Operating voltage 1~/230 V..................

or 3~/400 V......................................

-- Starting direct......................................

Pump unit

S 100D

Rated

power

(motor)

P

kW

N

Current intensity

for ...

1~

230 V

I

N

A

1)

3~

400 V

I

N

A

Instal-

lation

2)

Opera-

tion with

control

unit

3)

4/ 3 0.37 3.4 1.3 v+h x

4/ 6 0.55 4.3 1.7 v+h x

4/ 8 0.75 5.7 2.2 v+h x

4/11 1.10 8.6 3.2 v+h x

4/16 1.50 10.6 4.0 v+h x

4/21 2.20 15.5 5.9 v+h x

4/24 2.20 15.5 5.9 v x

4/33 3.00 -- -- -- 7.8 v x

4/40 3.70 -- -- -- 9.1 v x

1)

Capacitor run motors (PSC motors) with starter.

2)

v = vertical and h = inclined / horizontal.

3)

Always check and make sure that the operating pressure of Controlmatic /

Cervomatic units is not exceeded.

4)

3~ only

3)4)

3)4)

3)4)

3)4)

3)4)

Note : Use a cooling shroud for horizontal installation.

o

C............

Capacity

Dimensions / Weights / Ident. Numbers / Horizontal Installation

1~ / 230 V 3~ / 400 V

Pump unit

S 100D

4/ 3

4/ 6

4/ 8

4/11

4/16

4/21

4/24

4/33

4/40

For information on cooling shroud refer to page 20.

L

A

≈ mm

505

610

690

820

975

1180

1255

-- -- -- --

-- -- -- --

m

≈ kg

11. 5

13.4

15.1

18.2

20.1

24.8

25.3

-- -- -- --

-- -- -- --

A

Ident No. A

39 022 550

39 022 551

39 022 552

39 022 553

39 022 554

39 022 555

39 022 556

-- -- -- -- --

-- -- -- -- --

≈ mm

333

399

489

594

734

900

-- -- -- --

-- -- -- --

-- -- -- --

L

A

≈ mm

485

580

665

760

920

1080

1155

1595

1805

m

≈ kg

10.7

12.2

13.7

15.6

17.7

20.2

20.7

25.5

33.0

A

Ident No. A

39 022 588

39 022 589

39 022 590

39 022 591

39 022 592

39 022 593

39 022 594

39 022 595

39 022 596

≈ mm

324

384

475

566

706

847

-- -- -- --

-- -- -- --

-- -- -- --

C

G1”1/4

Accessories: UPA Control for dry running protection using 1 or 3 immersion electrodes, see page 21.

17

Page 18

S 100D -- 7 ...

p

for well diameters of 100 mm (4 inch)

50 Hz S 100D

Pumps with submersible motors for ...

-- Temperature of fluid handled up to + 30

-- Current / Operating voltage 1~/230 V..................

or 3~/400 V.......................................

-- Starting direct......................................

Pump unit

S 100D

Rated

power

(motor)

P

kW

N

Current intensity

for ...

1~

230 V

I

N

A

1)

3~

400 V

I

N

A

Instal-

lation

2)

Opera-

tion with

control

unit

3)

7/ 4 0.75 5.7 2.2 v+h x

7/ 6 1.10 8.6 3.2 v+h x

7/ 8 1.50 10.6 4.0 v+h x

7/11 2.20 15.5 5.9 v+h x

7/13 2.20 15.5 5.9 v+h x

7/18 3.00 -- -- -- 7.8 v+h x

7/23 3.70 -- -- -- 9.1 v x

7/28 5.50 -- -- -- 13.7 v x

7/33 5.50 -- -- -- 13.7 v x

1)

Capacitor run motors (PSC motors) with starter.

2)

v = vertical and h = inclined / horizontal.

3)

Always check and make sure that the operating pressure of Controlmatic /

Cervomatic units is not exceeded.

4)

3~ only

4)

4)

4)

3)4)

3)4)

3)4)

3)4)

Note : Use a cooling shroud for horizontal installation.

o

C............

Capacity

Dimensions / Weights / Ident. Numbers / Horizontal Installation

1~ / 230 V 3~ / 400 V

Pump unit

S 100D

7/ 4

7/ 6

7/ 8

7/11

7/13

7/18

7/23

7/28

7/33

For information on cooling shroud refer to page 20.

L

A

≈ mm

611

736

831

1011

1076

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

m

≈ kg

14.6

17.7

19.1

23.1

23.6

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

A

39 022 557

39 022 558

39 022 559

39 022 560

39 022 561

Ident No. A

≈ mm

421

517

599

740

808

-- -- -- -- --

-- -- -- -- --

-- -- -- -- --

-- -- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

-- -- -- --

L

A

≈ mm

586

676

776

911

976

1211

1516

1881

2051

m

≈ kg

13.2

15.1

16.7

18.5

19.0

23.1

30.8

38.3

39.4

A

Ident No. A

39 022 597

39 022 598

39 022 599

39 022 600

39 022 601

39 022 602

39 022 603

39 022 604

39 022 605

≈ mm

407

489

571

687

755

958

-- -- -- --

-- -- -- --

-- -- -- --

C

G1”1/4

Accessories: UPA Control for dry running protection using 1 or 3 immersion electrodes, see page 21.

18

Page 19

S 100D -- 12 ...

p

for well diameters for 100 mm (4 inch)

50 Hz S 100D

Pumps with submersible motors for ...

-- Temperature of fluid handled up to + 30

-- Current / Operation voltage 1~/230 V..................

or 3~/400 V.......................................

-- Starting direct......................................

Pump unit

S 100D

Rated

power

(motor)

P

N

kW

Current intensity

for ...

1~

230 V

I

400 V

1)

N

A

3~

I

A

Installa-

tion

2)

Operation

with

control

unit

3)

N

12 / 4 1.1 8.6 3.2 v+h x

12 / 6 1.5 10.6 4.0 v+h x

12 / 10 2.2 15.5 5.9 v+h x

12 / 13 3.0 -- -- -- 7.8 v x

12 / 17 3.7 -- -- -- 9.1 v x

4)

3)4)

12 / 21 5.5 -- -- -- 13.7 v -- -- -12 / 25 5.5 -- -- -- 13.7 v -- -- --

1)

Capacitor run motors (PSC motors) with starter.

2)

v = vertical and h = inclined / horizontal.

3)

Always check and make sure that the operating pressure of Controlmatic /

Cervomatic units is not exceeded.

4)

3~ only

Note : Use a cooling shroud for horizontal installation.

o

C............

Capacity

Dimensions / Weights / Ident. Numbers / Horizontal Installation

1~ / 230 V 3~ / 400 V

Pump unit

S 100D

12 / 4

12 / 6

12 /10

12 /13

12 /17

12 /21

12 /25

For information on cooling shroud refer to page 20.

L

A

≈ mm

865

1000

1295

-- -- --

-- -- --

-- -- --

-- -- --

m

≈ kg

17.3

19.3

24.6

-- -- --

-- -- --

-- -- --

-- -- --

A

Ident No. A

39 022 562

39 022 563

39 022 564

-- -- --

-- -- --

-- -- --

-- -- --

≈ mm

613

739

991

-- -- --

-- -- --

-- -- --

-- -- --

L

A

≈ mm

805

945

1195

1425

1815

2185

2400

m

≈ kg

14.7

16.9

20.0

24.2

32.2

40.2

42.0

A

Ident No. A

39 022 606

39 022 607

39 022 608

39 022 609

39 022 610

39 022 611

39 022 612

≈ mm

585

707

938

-- -- --

-- -- --

-- -- --

-- -- --

C

G2”

Accessories: UPA Control for dry running protection using 1 or 3 immersion electrodes, see page 21.

19

Page 20

50 Hz S 100D

ootoupto05(

)

Ø115(130)x500

9006549

1

p

Ø115(130)x800

9006549

3

Scope of Supply for Single--phase A.C.

Motors DN 100 (1~)

A starter for single-phase a.c. motors in PSC design (with

integrated run capacitor and motorprotection) is included inthe

scope of supply.

Permissible Cable Lengths

∆Uupto3%,directstartingandtupto+30

Current /

Voltage

1~/

230 V

(PSC)

3~/

400 V

Motor

rating

kW 1.5 2.5 4.0 6.0

0.37

0.55

0.75

1.10

1.50

2.20

0.37

0.55

0.75

1.10

1.50

2.20

3.00

3.70

5.50

72 m

60 m

47 m

30 m

26 m

20 m

752 m

483 m

368 m

242 m

194 m

131 m

100 m

80 m

55 m

Cable lengths for

cable cross--section in ... mm

120 m

100 m

79 m

50 m

43 m

32 m

614 m

403 m

322 m

218 m

165 m

135 m

90 m

o

C

2

190 m

159 m

125 m

80 m

68 m

52 m

--

--

645 m

516 m

350 m

265 m

215 m

143 m

284 m

236 m

186 m

118 m

101 m

77 m

--

--

--

--

--

--

--

-525 m

397 m

323 m

215 m

Technical Data -- Cooling Shroud

Pump unit

S 100D

1/7 to 1/20

1/25 to 1/30

2/7 to 2/15

4/3 to 4/8

7/4

1/35 to 1/50 v

2/18 to 2/27

2/30

4/11 to 4/16

7/6 to 7/8

12/4 to 12/6

2/33 to 2/50

4/21

4/24 to 4/33

7/11 to 7/18

12/10

12/13

4/40 v

7/23 to 7/33

12/17 to 12/25

1)

v = vertical, h = inclined / horizontal

Installation1)Dimension (dia. x length)

and motor type (kW)

v+h

v

v+h

v+h

v+h

v+h

v

v+h

v+h

v+h

v

v+h

v

v+h

v+h

v

v

v

Ø115 (130) x 400

for motor up to 0.75 kW (1~)

or up to 0.75 kW (3~)

Weight 1.5 kg

Ø115 (130) x 500 90 065 491

for motor up to 1.5 kW (1~)

or up to 1.5 kW (3~)

Weight 1.7 kg

Ø115 (130) x 625

for motor up to 2.2 kW (1~)

or up to 3.0 kW (3~)

Weight 2.0 kg

Ø115 (130) x 800 90 065 493

for motor up to 5.5 kW (3~)

Weight 2.5 kg

Cooling Shroud

Ident No.

90 065 490

90 065 492

Strainer

Ident No.

90 065 494

Ø115x117

0.3 kg

Support feet

Ident No.

90 065 495

Set = 2 pc.

0.6 kg

20

Page 21

50 Hz S 100D

Accessories: UPA Control for Dry Running Protection (using 3 immersion electrodes)

S 100D-1/.. 1~ S 100D-1/... 3~

Relais

Télémécanique

(A)

2.5to4.0 (3) X 40 980 891 1.0to1.6 (3) X 40 980 887

4.0to6.0 (3) X 40 980 893 1.6to2.5 (3) X 40 980 889

5.5to8.0 (3) X 40 990 895 2.5to4.0 (3) X 40 980 891

7.0to10 (3) X 40 980 897

9.0to13 (3) X 40 980 899

Electrode

(Qty.)

S 100D-2/.. 1~ S 100D-2/... 3~

Relais

Télémécanique

(A)

2.5to4.0 (3) X 40 980 891 1.0to1.6 (3) X 40 980 887

4.0to6.0 (3) X 40 980 893 1.6to2.5 (3) X 40 980 889

5.5to8.0 (3) X 40 990 895 2.5to4.0 (3) X 40 980 891

7.0to10 (3) X 40 980 897 5.5to8.0 (3) X 40 980 895

9.0to13 (3) X 40 980 899

12 to 18 (3) X 40 984 811

Electrode

(Qty.)

7

14

9

16

12

20

7 11 15

253035

18

20

22

Relais

40

50

Ident No.

33

38

27

44

30

Ident No.

Télémécanique

(A)

Relais

Témécanique

(A)

Electrode

(Qty.)

Electrode

(Qty.)

7

14

9

12

30

11

15

7

35

40

to

50

18

33

44

to

50

30

Ident No.

Ident No.

S 100D-4/.. 1~ S 100D-4/... 3~

Relais

Télémécanique

(A)

2.5to4.0 (3) X 40 980 891 1.0to1.6 (3) X 40 980 887

4.0to6.0 (3) X 40 980 893 1.6to2.5 (3) X 40 980 889

5.5to8.0 (3) X 40 990 895 2.5to4.0 (3) X 40 980 891

7.0to10 (3) X 40 980 897 5.5to8.0 (3) X 40 980 895

9.0to13 (3) X 40 980 899 7.0 to 10 (3) X 40 980 897

12 to 18 (3) X 40 984 811

Electrode

(Qty.)

3 6 8

11 16

21

24

Ident No.

Relais

Télémécanique

(A)

Electrode

(Qty.)

681116212433

3

40

Ident No.

S 100D-7/.. 1~ S 100D-7/... 3~

Relais

Télémécanique

(A)

5.5to8.0 (3) X 40 990 895 1.6to2.5 (3) X 40 980 889

7.0to10 (3) X 40 980 897 2.5to4.0 (3) X 40 980 891

9.0to13 (3) X 40 980 899 5.5to8.0 (3) X 40 980 895

12 to 18 (3) X 40 984 811 7.0to10 (3) X 40 980 897

Electrode

(Qty.)

4 6 8

11

13

Ident No.

Relais

Télémécanique

(A)

12 to 18 (3) X 40 984 811

Electrode

(Qty.)

4

11

6

13

8

18

28

33

23

Ident No.

S 100D-12/.. 1~ S 100D-12/... 3~

Relais

Télémécanique

(A)

7.0to10 (3) X 40 980 897 2.5to4.0 (3) X 40 980 891

9.0to13 (3) X 40 980 899 5.5to8.0 (3) X 40 980 895

12 to 18 (3) X 40 984 811 7.0to10 (3) X 40 980 897

Electrode

(Qty.)

4 6 10 Ident No.

Relais

Télémécanique

(A)

12 to 18 (3) X 40 984 811

Electrode

(Qty.)

4

6

13

21

17

10

25

Ident No.

21

Page 22

50 Hz S 100D

22

Page 23

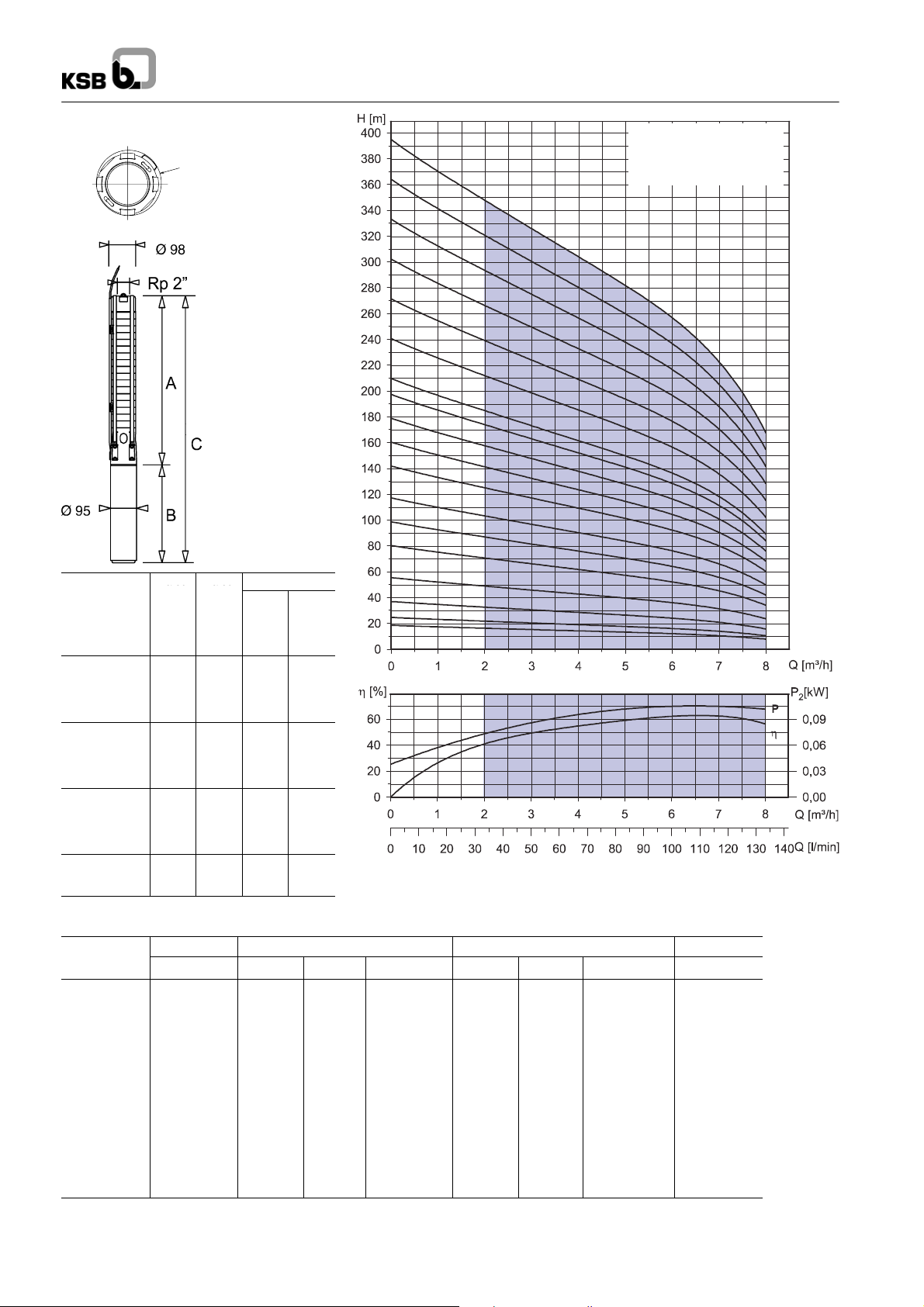

UPA 100C

Applications

-- Domestic and general water supply

-- Irrigation and spray irrigation

-- Lowering ground water levels

-- Fountains

-- Pressure boosting

-- Air-conditioning systems

-- Fire protection

-- Cooling water cycles

Operating Data

Maximal capacities Q up to 15 m3/h

Maximal Head H up to 400 m

Maximum fluid temperature t 30 °C

Motor ratings P

Maximum permissible

amount of suspended sand: 50 g/m

up to 7.5 kW

N

3

Pump Type / Design

Multistage centrifugal pump with components made of

stainless steel and additional bearing for eachstage. The stage

casings are connected by means of tie bolts on radial pumps,

and by means of studs on mixed--flow pumps.

Submersible canned motor: Franklin Electric pre-filled

motors, corrosion free, NEMA shaft end, 50 Hz

-- Single-phase and three-phase motor type Super Stainless

-- With separate lead

-- Direct starting, max starts per hour: 20

-- Type of enclosure: IP 68

-- Insulation: Class B

Submersible Borehole Pumps

for Well Diameters of

100 mm (4 inches)

Pump Designation

Type series

Minimum well diameter (mm)

Design status

Capacity Q

Number of stages

opt

(m3/h)

Certification

Quality management certified to ISO 9001

UPA 100 C –4 6

Product Features

-- Very sturdy design

-- All components made of stainless steel

-- Suitable for installation in narrow deep wells

-- High efficiency

-- Totally enclosed motor

-- Motor designed for maximum pump output

-- Low noise level

-- For vertical or horizontal installation

-- Check valve protected against blocking

-- Pre-filled motor; no risk of contamination of the

pumped water

23

Page 24

UPA 100C

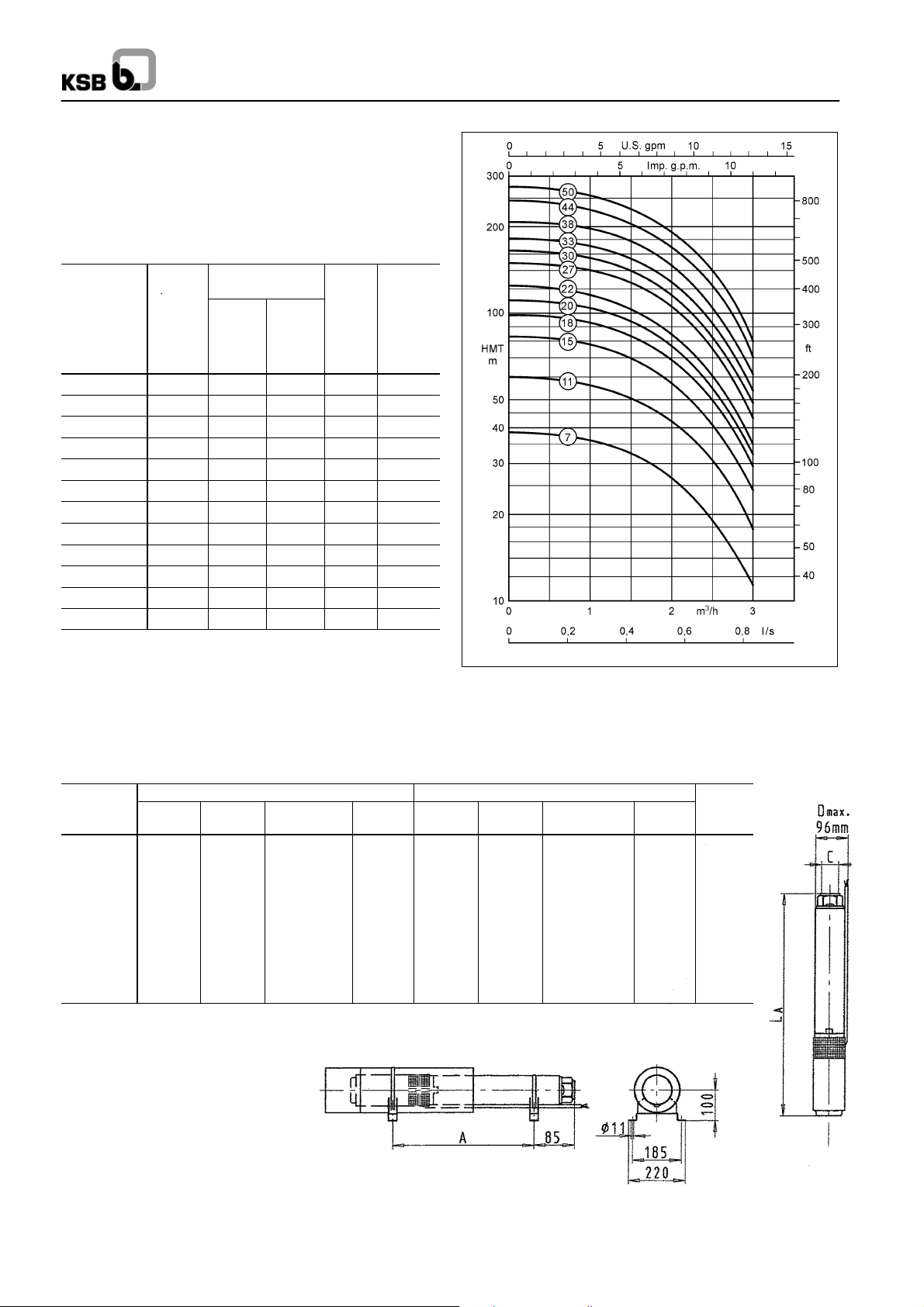

Selection Chart (Ranges on offer) n ≈ 2900 rpm

UPA 100C 2

UPA 100C 3

UPA 100C 4

UPA 100C 7

UPA 100C 12

24

Page 25

UPA 100C

Materials

Component

Pump ...

Diffuser

Upper diffuser

Lower diffuser

Impeller

Pump shaft with Nema

coupling

Suction casing

Suction filter

Discharge casing

Spacer sleeve

Hook

Seal ring NBR + AISI 316

Upper bearing bush NBR + AISI 316

Intermediate bearing bush NBR

Val ve fac e NBR + AISI 316

Motor ...

Shaft stainless steel AISI 304 SS

Bearing housing stainless steel AISI 304 SS

Stator case stainless steel AISI 304 SS

C1 (stainless steel)

stainless steel AISI 304

Direction of Rotation of the Pump

Clockwise rotation (when looking at at the drive shaft end).

Drive

Type submersible canned motor

Connection NEMA standard

Enclosure IP 68

Frequency f 50 Hz

Type of current single-phase and three-phase

Rated voltage U 1~ 230 V,

3~ 400 V,

Rated power P

Voltage fluctuations up to +/-- 10 %

Frequency of starts up to 20 / h

Min. delay

before restarting 3 min

A start box withintegrated phase-shiftingcapacitor andthermal

protection is included in the scope of supply of single-phase

pump sets in PSC design.

N

up to 7.5 kW

Starting Mode

Direct on line.

Temperatures

The UPA 100 Csubmersible boreholepump isdesigned foruse

in water with temperatures of up to +30 °C.

Permissible Cable Lengths

∆U up to 3 % and temperatures up to +30 °C.

Discharge Nozzle

UPA 100C

2 -- 3 -- 4: Rp 1’’

7--12 Rp2’’

1

/

2

Installation

Vertical or horizontal installation without restriction.

In order to guarantee the dissipation of the motor heat it will be

necessary to install a device guiding the flow along the motor

(cooling jacket, flow inducer sleeve, etc.) in horizontal

installation.

Variants Available on Request

-- Higher fluid temperatures

-- Voltages above 500 V

-- Other frequencies

Type of current /

Voltage

1~ 230 V

50 Hz

3~ 400 V

50 Hz

Drive

rating

kW 1.5 2.5 4.0 6.0 10.0

0.37

0.55

0.75

1.10

1.50

2.20

0.37

0.55

0.75

1.10

1.50

2.20

3.30

3.70

4.00

5.50

7.50

Length of cable in m for cross-

section in ... mm

72

120

100

79

50

43

32

--

-614

403

322

218

165

135

124

90

63

190

159

125

80

68

52

--

--

-645

516

350

265

215

195

143

100

60

47

30

26

20

752

483

368

242

194

131

100

80

74

55

38

2

248

236

186

118

101

77

--

--

--

--

-525

397

323

295

215

150

--

--

--

--

--

--

--

--

--

--

--

--

--

--

-597

415

25

Page 26

Design Features

Optimised operating costs:

Check valve, built into the dis-

charge chamber, designed for low

loss of head.

Hydraulic profiles are optimized for

the attainment of high efficiencies.

UPA 100C

Resistance to corrosion and abrasion, i.e. the same inherent qualities

of stainless steel.

Oversized intermediate bearings

located at each pump stage to

align the shaft, specially designed

to optimize lubrication.

Coupling and flange suitable

for motors with pump mounting dimensions in accordance with NEMA standards.

Reliable in service:

Very strong construction: minimum

thickness of stainless sheet steel of

1 mm, 6 spot welding on each vane,

special top bearing for every pump.

Friendly service:

Great ease of dismantling and as-

sembly.

Easy-to-replace wear-rings and

bearings.

26

Page 27

UPA 100C

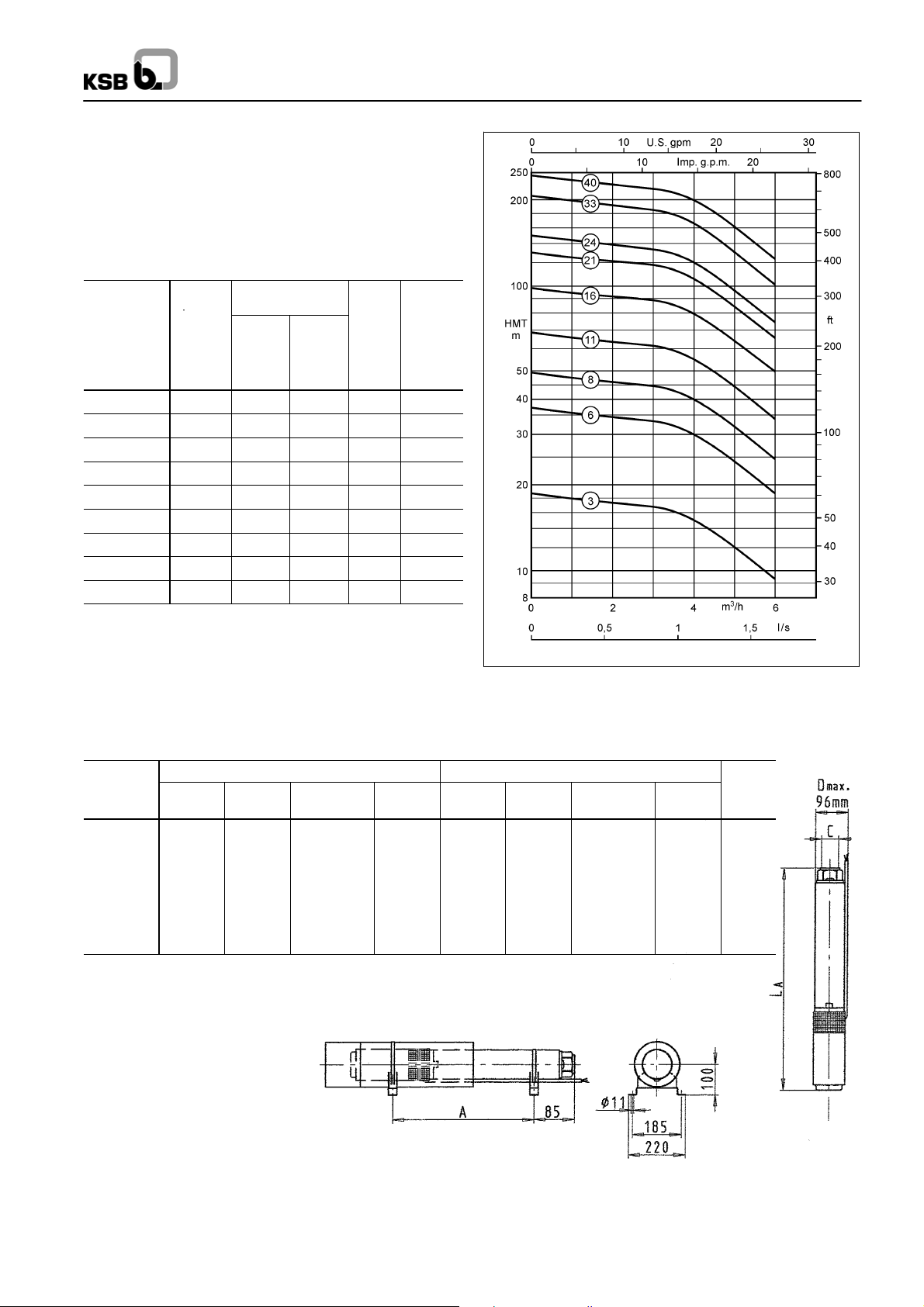

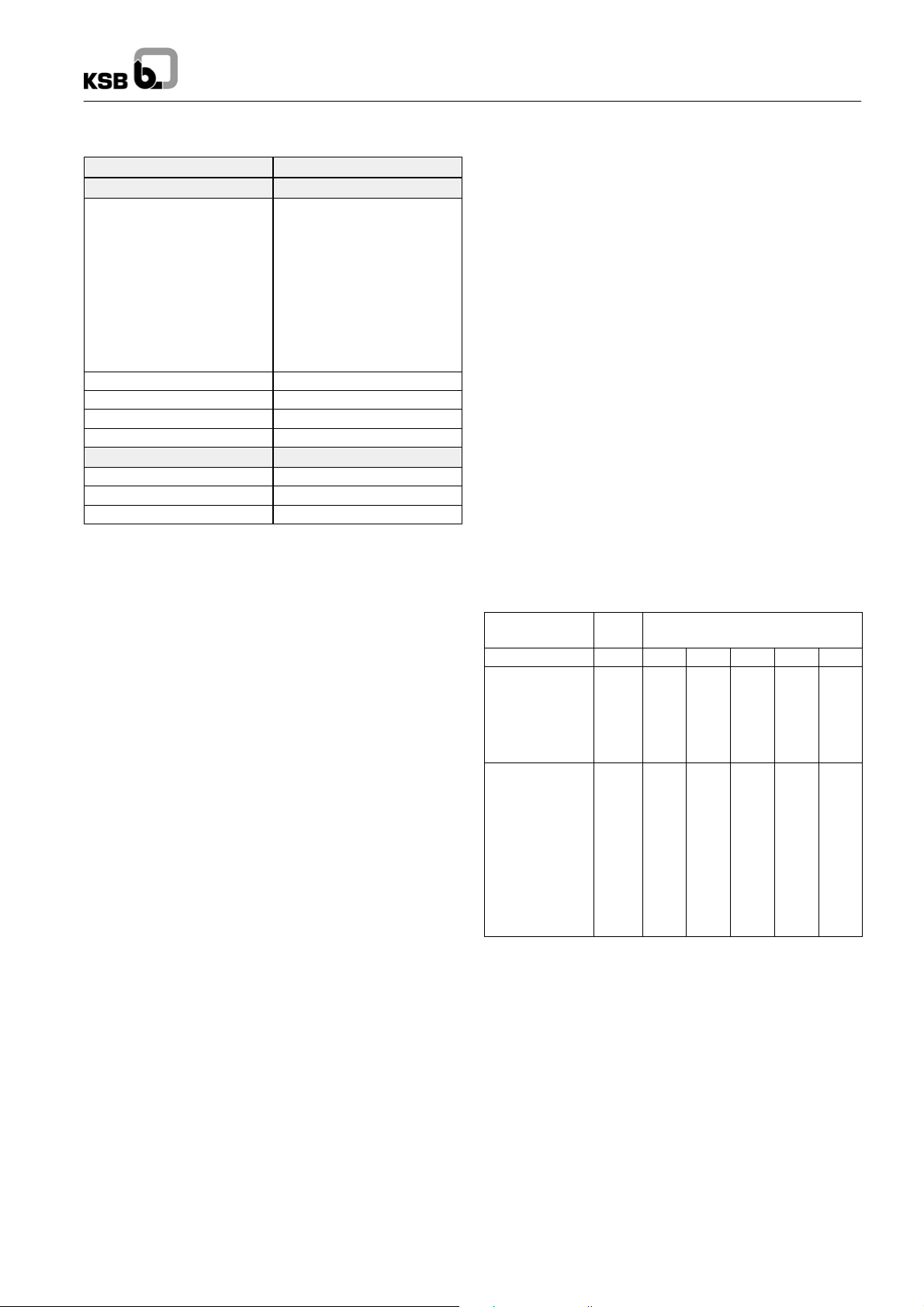

aed

aed

UPA 100C 2 -- ...

D1

ØD1max:

Pump = 96.5 mm

Pump with motor

= 98.0 mm

-- 7 2

-- 6 6

-- 6 0

-- 5 4

-- 4 7

-- 4 0

-- 3 5

-- 3 0

-- 2 1

-- 1 7

-- 1 3

-- 8

UPA 100C 2 -- ...

(Tolerances to ISO 2548

Class C, Annex B)

-- 2 5

-- 6

Rated Rated Rated current for

power

P

kW

0.37

0.37

0.55

0.75

1.1

1.1

1.5

1.5

2.2

2.2

2.2

3.0

3.0

3.0

power

(Motor)

P

N

HP

0.5

0.5

0.75

1.5

1.5

1~

220 V

N

I

3.2

3.6

5.7

1

6.9

8.0

8.9

2

9.5

2

11. 1

3

12.1

3

14.5

3

15.9

4

4

4

3~

400 V

1)

N

I

0.9

1.1

1.5

2.0

2.8

3.0

3.3

3.8

5.1

5.4

5.6

6.8

7.2

7.5

N

A

Operating range:

=0.5--2.5m3/h

Q

min

= End of characteristic curve

Q

max

A

--

--

--

(Motor)

Pump set

UPA 100C 2 --..

6

8

13

17

21

25

30

35

40

47

54

60

66

72

1)

Capacitor run motors (PSC motors) with starter.

Dimensions / Weights / Ident. Numbers

Pump set

UPA 100C 2 --..

6

8

13

17

21

25

30

35

40

47

54

60

66

72

A ≈ mm

349

397

517

623

711

807

928

1048

1169

1338

1506

1651

1796

1941

B ≈ mm C ≈ mm Ident. No. B ≈ mm C ≈ mm Ident. No. mA≈ kg

242

242

271

299

327

327

356

356

460

460

460

--

--

--

For horizontal installation, a device guiding the flow along the motor (cooling shroud, flow inducer sleeve, etc.) will be required.

1~ / 220 V 3~ / 400 V

591

639

788

922

1038

1134

1284

1404

1629

1798

1966

--

--

--

90 065 300

90 065 301

90 065 302

90 065 303

90 065 304

90 065 305

90 065 306

90 065 307

90 065 308

90 065 309

90 065 310

--

--

--

223

223

242

271

299

299

327

327

356

356

356

423

423

423

572

620

759

894

1010

1106

1255

1375

1525

1694

1862

2074

2219

2364

90 065 387

90 065 388

90 065 389

90 065 390

90 065 391

90 065 392

90 065 393

90 065 394

90 065 395

90 065 396

90 065 397

90 065 398

90 065 399

90 065 400

11. 1

11.7

14.3

17.0

19.5

20.8

23.7

25.4

28.1

29.5

32.6

37.0

38.9

40.9

Accessories: UPA Control for dry running protection see page 32.

27

Page 28

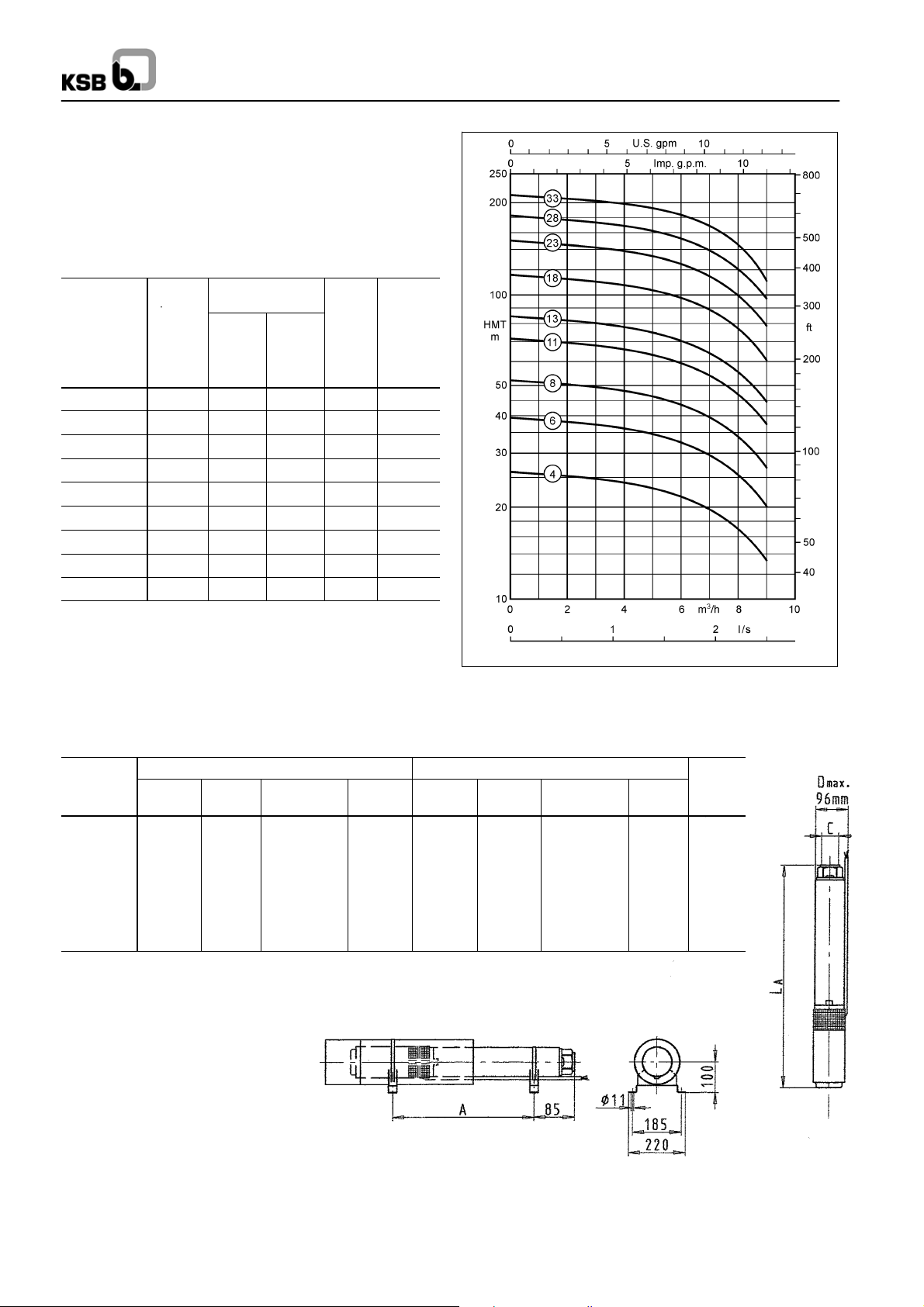

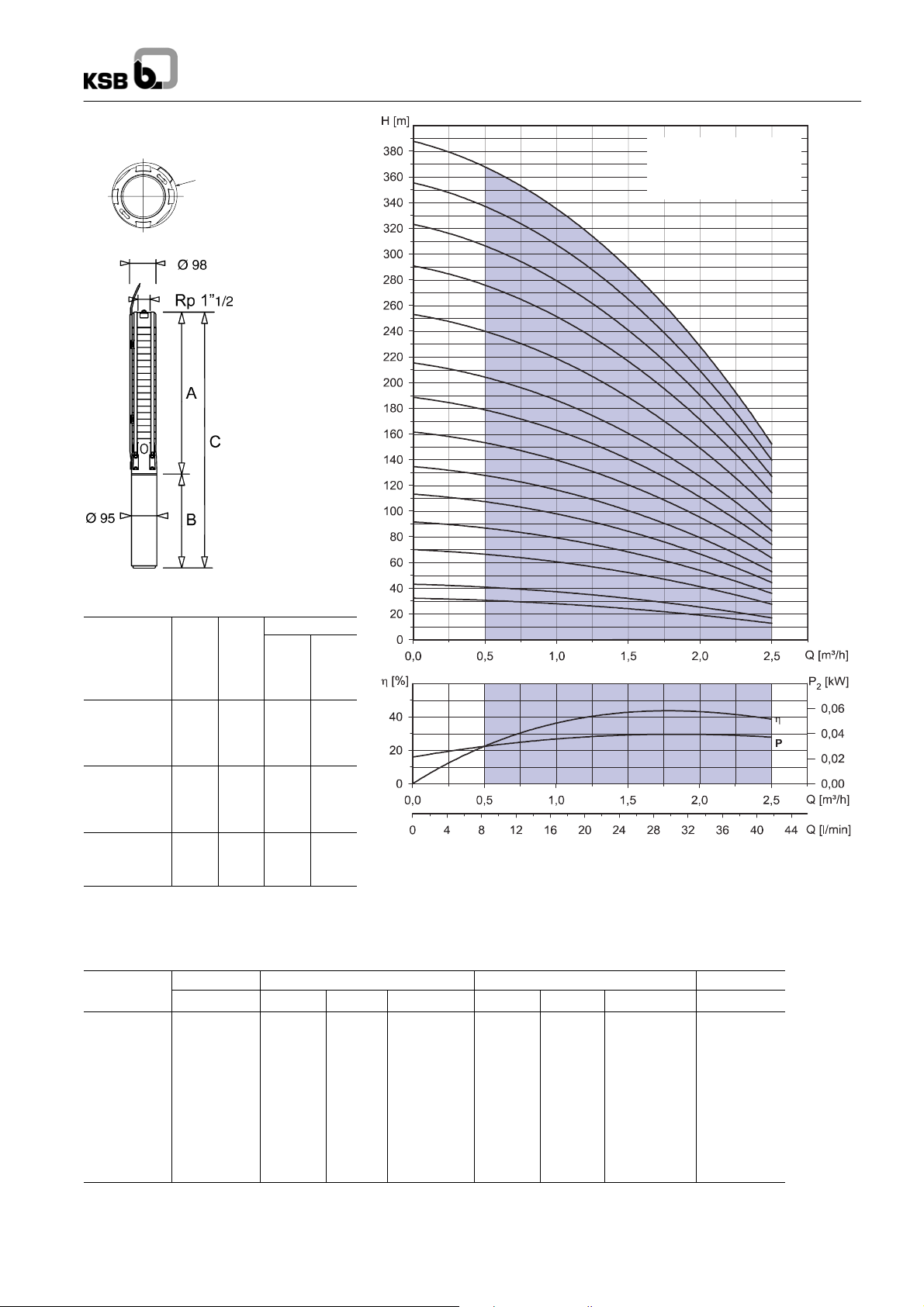

UPA 100C 3 -- ...

aed

aed

D1

ØD1max:

Pump = 96.5 mm

Pump with motor

= 98.0 mm

-- 6 8

-- 6 2

-- 5 7

-- 5 1

-- 4 4

-- 3 6

-- 3 0

-- 2 5

-- 2 2

-- 1 8

-- 1 5

-- 1 2

-- 9

-- 6

UPA 100C

UPA 100C 3 -- ...

(Tolerances to ISO 2548

Class C, Annex B)

Rated Rated

power

(Motor)

Pump set

UPA 100C 3 --..

6

9

12

15

18

22

25

30

36

44

51

57

62

68

1)

Capacitor run motors (PSC motors) with starter.

P

kW

0.37

0.55

0.75

1.1

1.1

1.5

1.5

2.2

2.2

3.0

3.0

3.7

3.7

4.0

N

power

(Motor)

P

N

HP

0.5

0.75

1.0

1.5

1.5

2.0

2.0

3.0

3.0

4.00

4.0

5.0

5.0

5.5

Rated current for

1~

220 V

I

N

3.6

5.7

6.9

8.7

8.9

9.8

11. 1

12.5

15.9

3~

400 V

1)

I

A

N

A

1.1

1.5

2.0

2.9

3.0

3.6

3.8

5.2

5.6

--

7.0

--

7.2

--

8.8

--

9.1

--

10.00

Operating range:

Q

=1.0--3.5m3/h

min

= End of characteristic curve

Q

max

Dimensions / Weights / Ident. Numbers

Pump set

UPA 100C 3 --..

6

9

12

15

18

22

25

30

36

44

51

57

62

68

A ≈ mm

349

421

493

566

638

734

807

928

1072

1265

1434

1579

1699

1844

B ≈ mm C ≈ mm Ident. No. B ≈ mm C ≈ mm Ident. No.

242

271

299

327

327

356

356

460

460

--

--

--

--

--

1~ / 220 V 3~ / 400 V

591

692

792

883

965

1090

1163

1388

1532

--

--

--

--

--

90 065 311

90 065 312

90 065 313

90 065 314

90 065 315

90 065 316

90 065 317

90 065 318

90 065 319

mA≈ kg

223

242

271

299

299

327

327

356

--

--

--

--

--

356

423

423

545

545

583

572

663

764

865

937

1061

1134

1284

1428

1688

1857

2124

2244

2427

90 065 401

90 065 402

90 065 403

90 065 404

90 065 405

90 065 406

90 065 407

90 065 408

90 065 409

90 065 410

90 065 411

90 065 412

90 065 413

90 065 414

11. 1

13.1

15.4

17.1

18.5

21.1

22.1

25.1

27.2

32.3

34.7

41.5

43.2

48.3

For horizontal installation, a device guiding the flow along the motor (cooling shroud, flow inducer sleeve, etc.) will be required.

Accessories: UPA Control for dry running protection see page 32.

28

Page 29

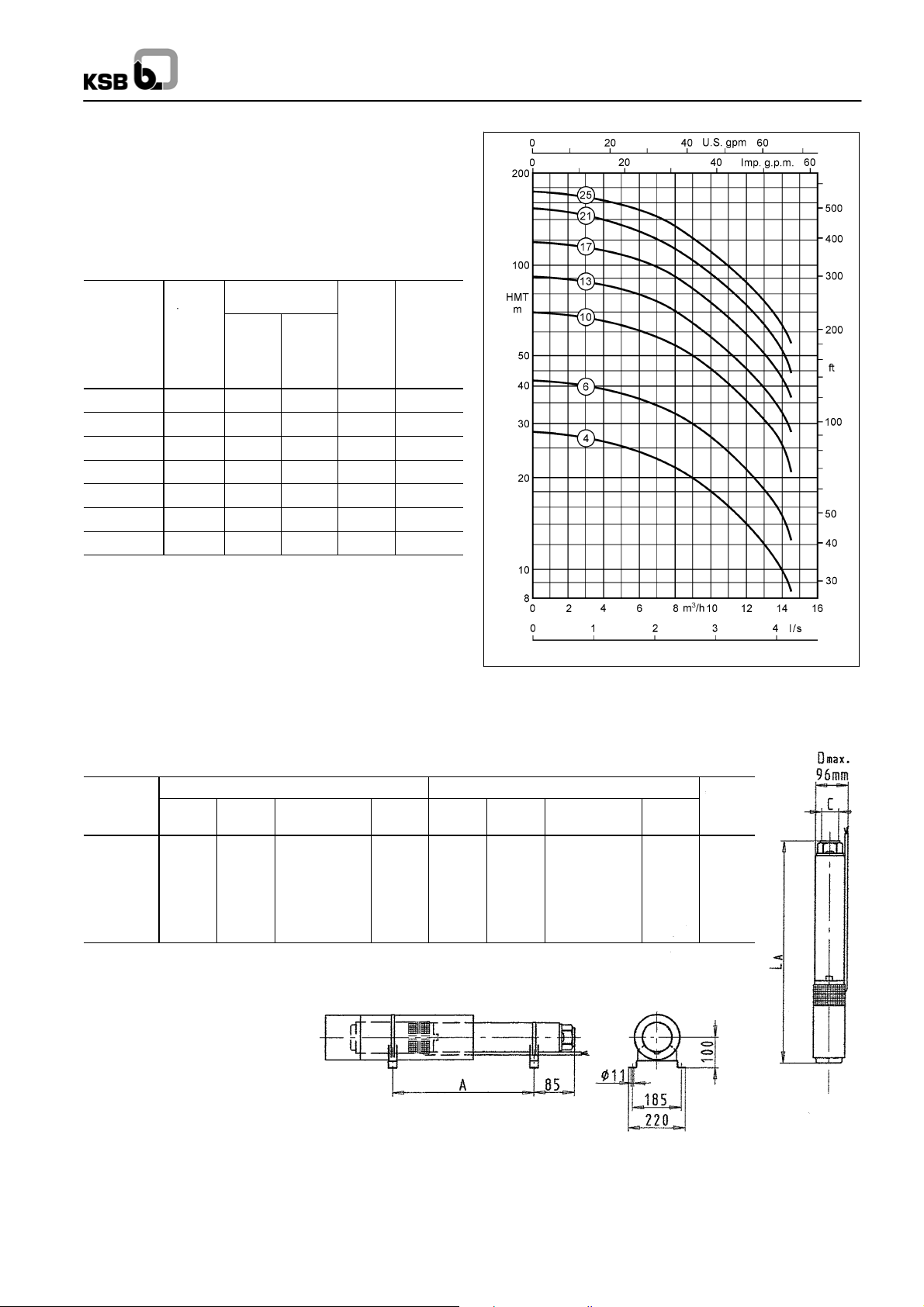

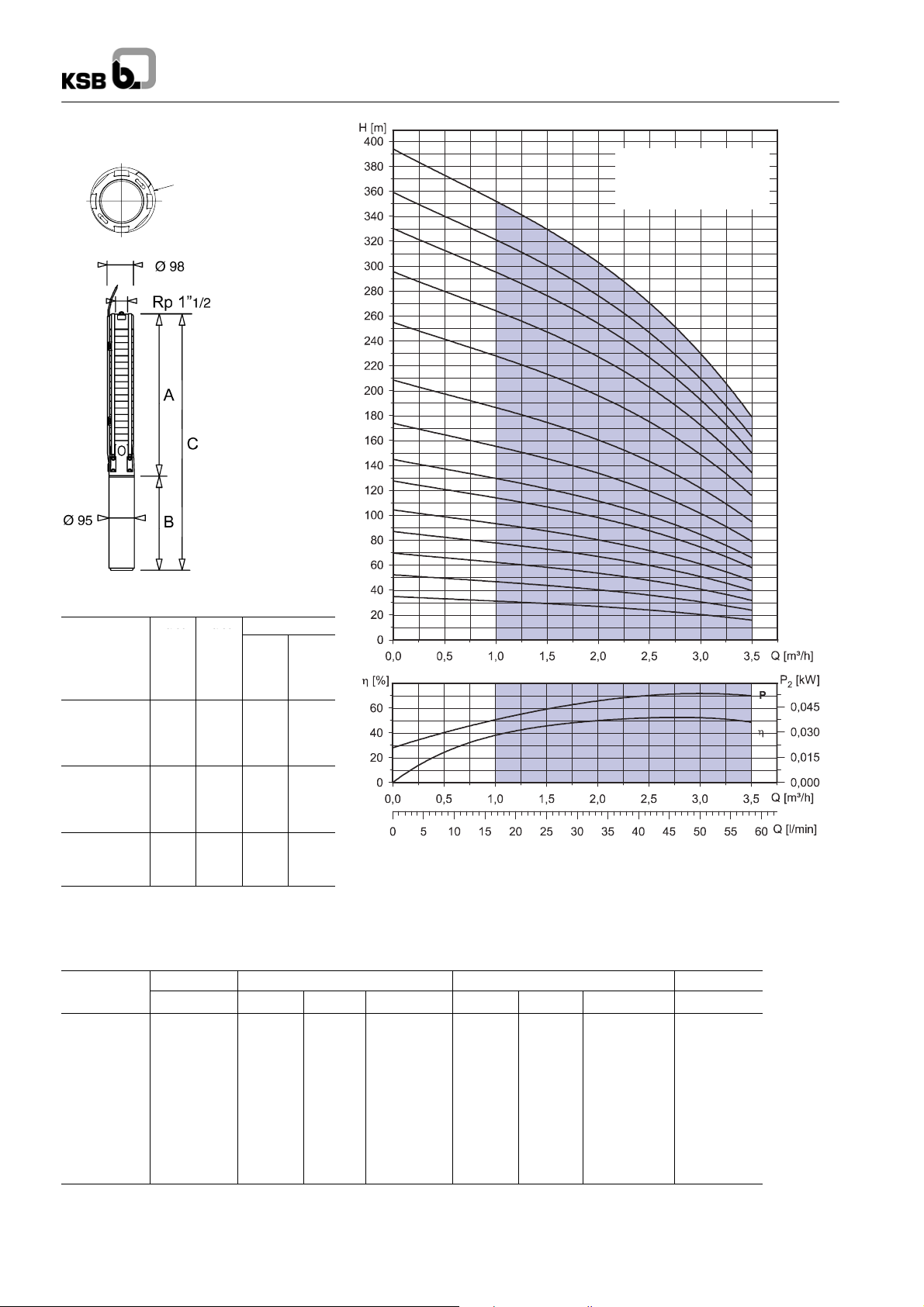

UPA 100C

aed

aed

UPA 100C 4 -- ...

D1

ØD1max:

Pump = 96.5 mm

Pump with motor

= 98.0 mm

Rated Rated

power

(Motor)

Pump set

UPA 100C 4 --..

4

7

9

14

19

24

29

34

39

45

50

54

60

66

72

1)

Capacitor run motors (PSC motors) with starter.

P

kW

0.37

0.55

0.75

1.1

1.5

2.2

2.2

3.0

3.0

3.7

3.7

4.0

5.5

5.5

5.5

N

power

(Motor)

P

N

HP

0.5

0.75

1.0

1.5

2.0

3.0

3.0

4.0

4.0

5.0

5.0

5.5

7.5

7.5

7.5

Rated current for

1~

220 V

I

N

A

3.6

5.7

6.9

8.9

11. 1

12.8

15.9

--

--

--

--

--

--

--

--

-- 7 2

UPA 100C 4 -- ...

(Tolerances to ISO 2548

-- 6 6

-- 6 0

-- 5 4

-- 5 0

-- 4 5

-- 3 9

-- 3 4

-- 2 9

-- 2 4

-- 1 9

-- 1 4

-- 9

-- 7

-- 4

3~

400 V

1)

I

N

A

1.1

1.5

2.0

3.0

3.8

5.3

5.6

7.0

7.2

8.8

9.1

10.0

11. 5

12.5

13.2

Operating range:

=1.0--5.0m3/h

Q

min

= End of characteristic curve

Q

max

Class C, Annex B)

Dimensions / Weights / Ident. Numbers

Pump set

UPA 100C 4 --..

4

7

9

14

19

24

29

34

39

45

50

54

60

66

72

A ≈ mm

300

373

421

542

662

783

903

1024

1145

1289

1410

1506

1651

1796

1941

B ≈ mm C ≈ mm Ident. No. B ≈ mm C ≈ mm Ident. No.

242

271

299

327

356

460

460

--

--

--

--

--

--

--

--

For horizontal installation, a device guiding the flow along the motor (cooling shroud, flow inducer sleeve, etc.) will be required.

Accessories: UPA Control for dry running protection see page 32.

1~ / 220 V 3~ / 400 V

542

644

720

869

1018

1243

1363

--

--

--

--

--

--

--

--

90 065 320

90 065 321

90 065 322

90 065 323

90 065 324

90 065 325

90 065 326

--

--

--

--

--

--

--

--

223

242

271

299

327

356

356

423

423

545

545

583

698

698

698

523

615

692

841

989

1139

1259

1447

1568

1834

1955

2089

2349

2494

2639

90 065 415

90 065 416

90 065 417

90 065 418

90 065 419

90 065 420

90 065 421

90 065 422

90 065 423

90 065 424

90 065 425

90 065 426

90 065 427

90 065 428

90 065 429

mA≈ kg

10.5

12.5

14.5

17.4

20.4

23.5

25.2

29.4

31.1

38.0

39.7

44.3

51.6

53.7

55.7

29

Page 30

UPA 100C

aed

aed

UPA 100C 7 -- ...

D1

ØD1max:

Pump = 96.5 mm

Pump with motor

= 98.0 mm

Rated Rated

power

(Motor)

Pump set

UPA 100C 7 --..

3

4

6

9

13

16

19

23

26

29

32

34

39

44

49

54

59

64

1)

Capacitor run motors (PSC motors) with starter.

P

kW

0.37

0.55

0.75

1.1

1.5

2.2

2.2

3.0

3.0

3.7

3.7

4.0

5.5

5.5

5.5

7.5

7.5

7.5

N

power

(Motor)

P

N

HP

0.5

0.75

1.0

1.5

2.0

3.0

3.0

4.0

4.0

5.0

5.0

5.5

7.5

7.5

7.5

10.0

10.0

10.0

Rated current for

1~

220 V

I

N

3.6

5.7

6.9

8.9

11. 1

12.8

15.9

3~

400 V

1)

I

A

N

A

1.1

1.5

2.0

3.0

3.8

5.2

5.6

--

6.6

--

7.2

--

8.3

--

9.1

--

10.0

--

11. 5

--

12.5

--

13.2

--

17.5

--

18.3

--

19.1

Operating range:

Q

=2.0--8.0m3/h

min

= End of characteristic curve

Q

max

Dimensions / Weights / Ident. Numbers

Pump set

UPA 100C 7 --..

3

4

6

9

13

16

19

23

26

29

32

34

39

44

49

54

59

64

A ≈ mm

276

300

349

421

517

590

662

759

831

903

976

1024

1145

1266

1386

1506

1628

1748

B ≈ mm C ≈ mm Ident. No. B ≈ mm C ≈ mm Ident. No.

242

271

299

327

356

460

460

--

--

--

--

--

--

--

--

--

--

--

1~ / 220 V 3~ / 400 V

519

571

648

748

873

1050

1122

--

--

--

--

--

--

--

--

--

--

--

90 065 327

90 065 328

90 065 329

90 065 330

90 065 331

90 065 332

90 065 333

UPA 100C 7 -- ...

-- 6 4

-- 5 9

-- 5 4

-- 4 9

-- 4 4

-- 3 9

-- 3 4

-- 3 2

-- 2 9

-- 2 6

-- 2 3

-- 1 9

-- 1 6

-- 1 3

-- 9

-- 6

-- 4

-- 3

223

242

271

299

327

356

--

--

--

--

--

--

--

--

--

--

--

356

423

423

545

545

583

698

698

698

774

774

774

500

542

620

720

844

946

1118

1182

1254

1448

1521

1607

1843

1964

2084

2280

2402

2522

(Tolerances to ISO 2548

Class C, Annex B)

90 065 430

90 065 431

90 065 432

90 065 433

90 065 434

90 065 435

90 065 436

90 065 437

90 065 438

90 065 439

90 065 440

90 065 441

90 065 442

90 065 443

90 065 444

90 065 445

90 065 446

90 065 447

mA≈ kg

10.2

11.5

13.5

15.8

18.5

21.0

22.0

25.9

27.0

33.0

34.0

37.9

45.0

46.8

48.6

53.9

55.7

59.5

For horizontal installation, a device guiding the flow along the motor (cooling shroud, flow inducer sleeve, etc.) will be required.

Accessories: UPA Control for dry running protection see page 32.

30

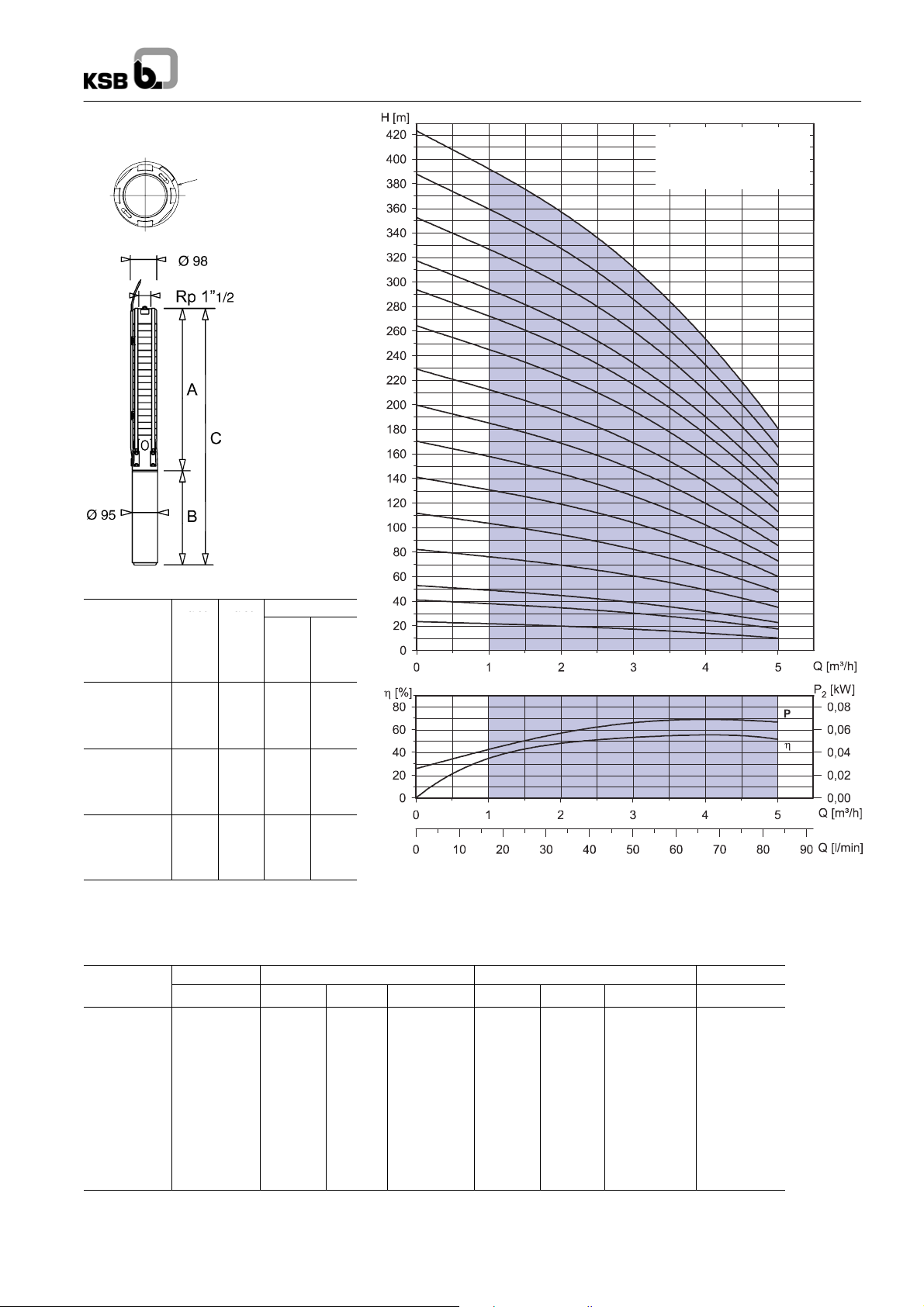

Page 31

UPA 100C

aed

aed

UPA 100C 12 -- ...

D1

ØD1max:

Pump = 96.5 mm

Pump with motor

= 98.0 mm

UPA 100C 12 -- ...

(Tolerances to ISO 2548

Class C, Annex B)

-- 2 7

-- 2 4

-- 2 0

-- 1 7

-- 1 4

-- 1 3

-- 1 0

-- 8

-- 5

Rated Rated

power

(Motor)

Pump set

UPA 100C 12 --..

3

5

8

10

13

14

17

20

24

27

1)

Capacitor run motors (PSC motors) with starter.

P

kW

1.1

1.5

2.2

3.0

3.7

4.0

5.5

5.5

7.5

7.5

N

power

(Motor)

P

N

HP

1.5

2.0

3.0

4.0

5.0

5.5

7.5

7.5

10.0

10.0

Rated current for

1~

220 V

I

N

8.9

11. 1

15.9

3~

400 V

1)

I

A

3.0

3.8

5.6

7.2

9.1

10.0

12.5

13.2

18.3

19.1

N

A

--

--

--

--

--

--

--

Operating range:

= 4.0 -- 15.0 m3/h

Q

min

= End of characteristic curve

Q

max

Dimensions / Weights / Ident. Numbers

Pump set

UPA 100C 12 --..

3

5

8

10

13

14

17

20

24

27

A ≈ mm

327

405

522

600

717

756

873

990

1146

1263

B ≈ mm C ≈ mm Ident. No. B ≈ mm C ≈ mm Ident. No.

327

356

460

--

--

--

--

--

--

--

1~ / 220 V 3~ / 400 V

654

761

982

--

--

--

--

--

--

--

90 065 334

90 065 335

90 065 336

-- 3

mA≈ kg

299

327

--

--

--

--

--

--

--

356

423

545

583

698

698

774

774

626

732

878

1023

1265

1339

1571

1688

1920

2037

90 065 448

90 065 449

90 065 450

90 065 451

90 065 452

90 065 453

90 065 454

90 065 455

90 065 456

90 065 457

13.9

16.0

18.7

22.1

28.4

29.6

36.4

37.7

44.1

45.4

For horizontal installation, a device guiding the flow along the motor (cooling shroud, flow inducer sleeve, etc.) will be required.

Accessories: UPA Control for dry running protection see page 32.

31

Page 32

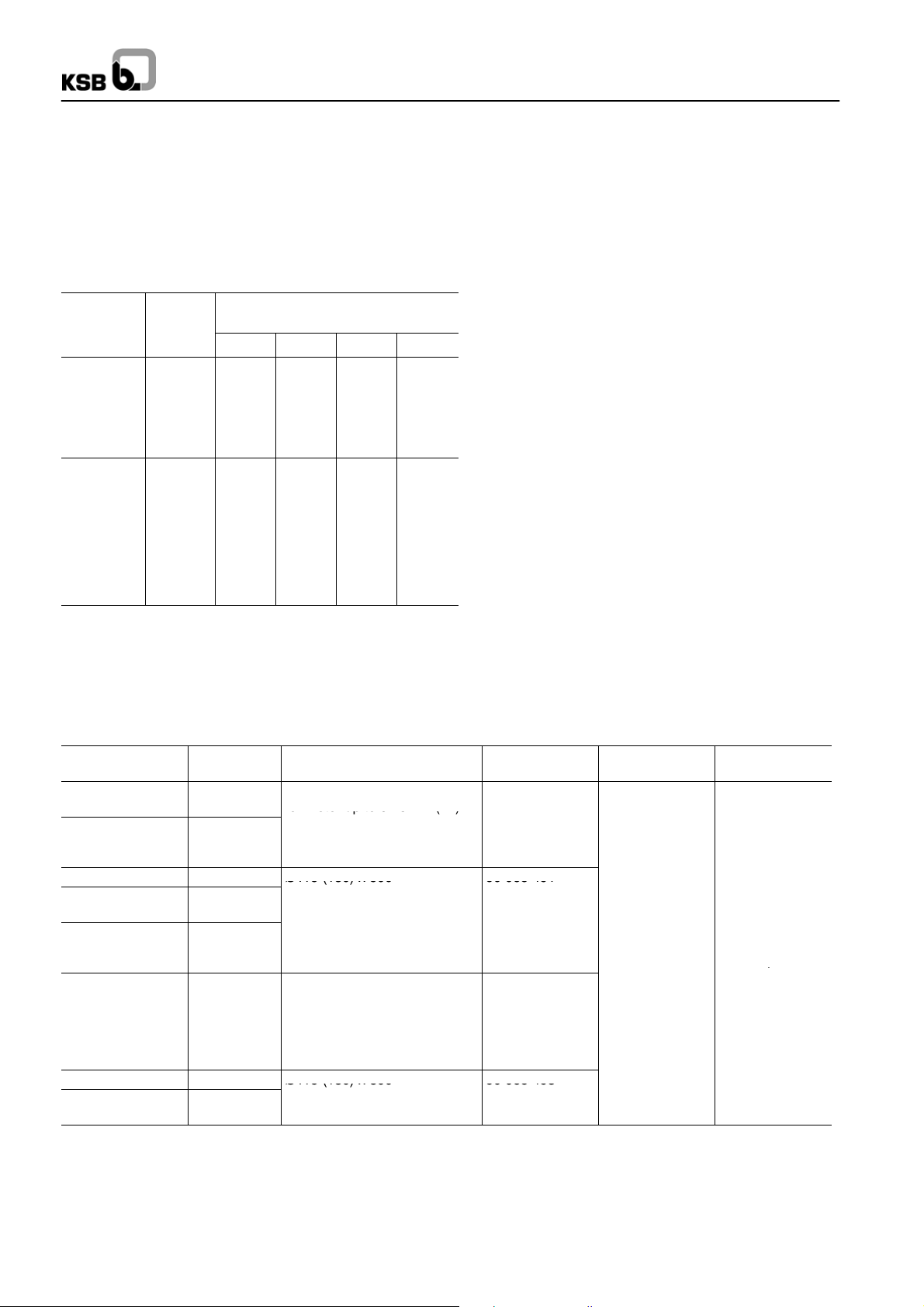

UPA Control

0.3kg0.6k

g

Accessory: UPA Control for dry running protection (using 3 immersion electrodes)

Relay (A) Ident. No.

1.0to1.6 40 980 887