KSB STAAL 40 AKD, STAAL 100 AKGS-A, STAAL 100 ZTS, STAAL 40 AKKS, STAAL 100 AKK Operating Manual

...Page 1

STAAL 40 AKD/AKDS, STAAL 100 AKD/AKDS,

AKG-A/AKGS-A, ZTS,

STAAL 40 AKK/AKKS, STAAL 100 AKK/AKKS,

AKR/AKRS, ZRS, VTS, UGS

Operating Manual

Page 2

Legal information/Copyright

Operating Manual

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 04/10/2018

Page 3

Contents

3 of 68

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Target group.....................................................................................................................................................6

1.3 Other applicable documents............................................................................................................................6

1.4 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 7

2.1 Key to safety symbols/markings.......................................................................................................................7

2.2 General..............................................................................................................................................................7

2.3 Intended use .....................................................................................................................................................8

2.3.1 Prevention of foreseeable misuse.......................................................................................................8

2.4 Personnel qualification and training...............................................................................................................8

2.5 Consequences and risks caused by non-compliance with this manual .........................................................8

2.6 Safety awareness ..............................................................................................................................................9

2.7 Safety information for the operator/user.......................................................................................................9

2.8 Safety information for maintenance, inspection and installation ................................................................9

2.9 Unauthorised modes of operation..................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier...........................................................................................................................................13

3.5 Disposal ...........................................................................................................................................................13

4 Valve Description ................................................................................................................................. 14

4.1 General description ........................................................................................................................................14

4.2 Marking...........................................................................................................................................................14

4.3 Gate Valves .....................................................................................................................................................14

4.3.1 Function of gate valves with bolted bonnet....................................................................................14

4.3.2 Function of gate valves with pressure seal bonnet .........................................................................15

4.3.3 Gate Valves to DIN/EN with Bolted Bonnet .....................................................................................16

4.3.4 Gate Valves to DIN/EN in Pressure Seal Design ................................................................................23

4.4 Body Pressure Relief Valve.............................................................................................................................29

4.4.1 UGS .....................................................................................................................................................29

4.5 Swing check valves .........................................................................................................................................33

4.5.1 Function of swing check valves with bolted cover ..........................................................................33

4.5.2 Function of swing check valves with pressure seal cover ................................................................33

4.5.3 Swing Check Valves with Bolted Cover ............................................................................................34

4.5.4 Swing check valves with pressure seal cover....................................................................................39

4.6 Line Blind Valve ..............................................................................................................................................45

4.6.1 VTS ......................................................................................................................................................45

4.7 Scope of supply...............................................................................................................................................48

4.8 Dimensions and weights ................................................................................................................................48

5 Installation at Site................................................................................................................................ 49

5.1 General information/Safety regulations .......................................................................................................49

5.2 Installation position and location..................................................................................................................50

5.3 Welding into the pipeline..............................................................................................................................51

5.4 Valves with actuator.......................................................................................................................................52

5.5 Insulation ........................................................................................................................................................53

5.6 Body pressure relief valve ..............................................................................................................................54

6 Commissioning/Start-up/Shutdown................................................................................................... 57

6.1 Commissioning/Start-up.................................................................................................................................57

6.1.1 Prerequisites for commissioning/start-up .........................................................................................57

Page 4

Contents

4 of 68

6.1.2 Valve actuation ..................................................................................................................................59

6.1.3 Information on the mechanical components...................................................................................60

6.2 Shutdown........................................................................................................................................................62

6.2.1 Measures to be taken for shutdown ................................................................................................62

6.2.2 Servicing/Maintenance ......................................................................................................................62

7 Servicing/Maintenance........................................................................................................................ 64

7.1 Safety regulations...........................................................................................................................................64

8 Trouble-shooting.................................................................................................................................. 65

9 EU Declaration of Conformity............................................................................................................. 66

9.1 EU Declaration of Conformity for STAAL40, STAAL100, AKG-A/AKGS-A, AKR/AKRS, ZTS, ZRS, VTS ......66

Index ..................................................................................................................................................... 67

Page 5

Glossary

5 of 68

Glossary

Pressure Equipment Directive (PED)

The 2014/68/EU Directive sets out the

requirements to be met by pressure equipment

intended to be placed on the market in the

European economic area.

Technical literature

Refer to the product catalogue for the technical

literature on our products at www.ksb.com.

Page 6

1 General

6 of 68

1 General

1.1 Principles

This operating manual is supplied as an integral part of the type series and variants

indicated on the front cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

In the event of damage, immediately contact your nearest KSB sales organisation

responsible to maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.3 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Type series booklet Description of the valve

Flow characteristics

1)

Information on Kv and zeta values

General assembly drawing

2)

Sectional drawing of the valve

Sub-supplier product literature3)Operating manuals and other product literature

for the accessories

Observe the relevant manufacturer's product literature for the accessories.

1.4 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

1) If any

2) If inclusion in the scope of supply has been agreed; otherwise refer to the type series booklet.

3) If inclusion in the scope of supply has been agreed.

Page 7

2 Safety

7 of 68

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

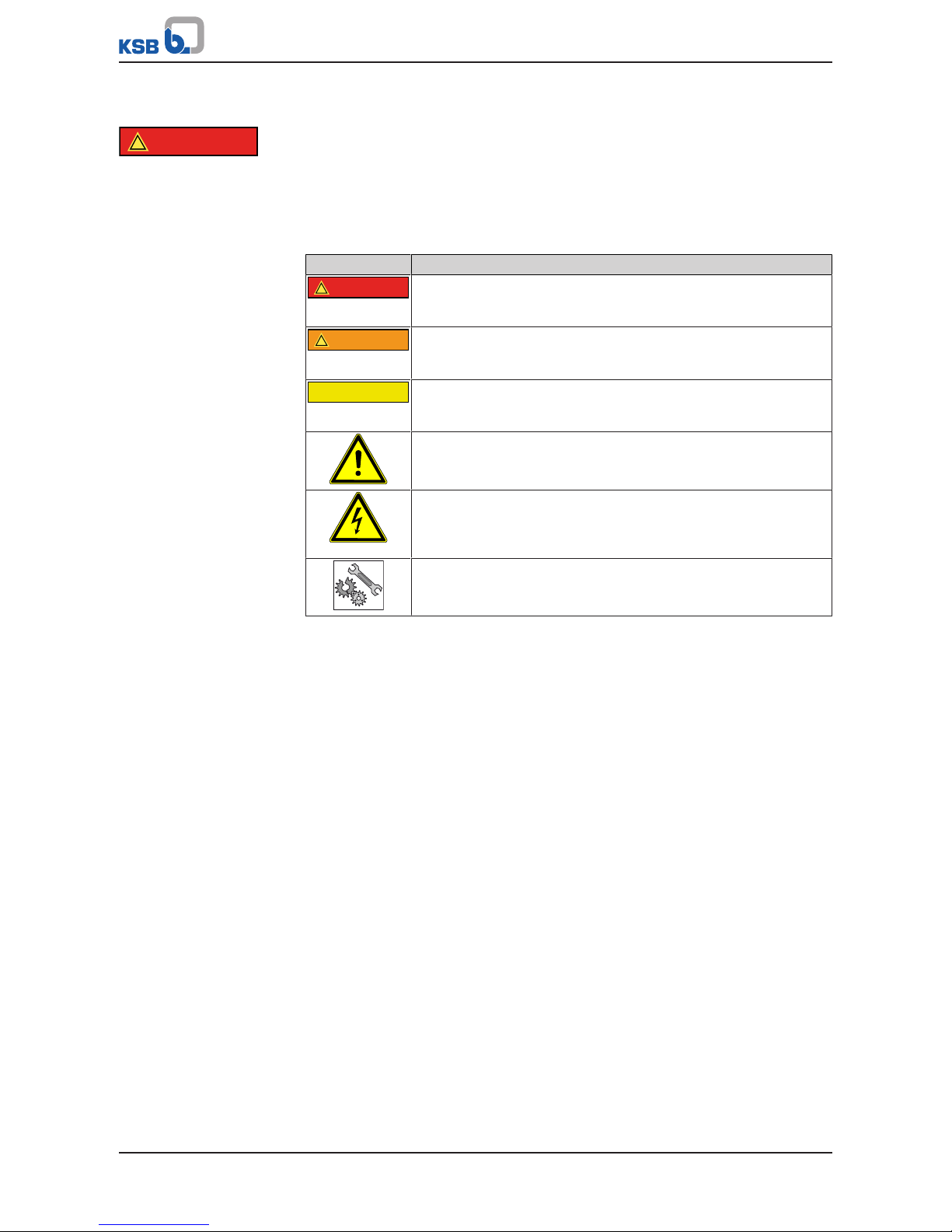

2.1 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information and markings attached directly to the product must always be complied

with and kept in a perfectly legible condition at all times. This applies to, for

example:

▪ Flow direction arrow

▪ Manufacturer

▪ Type designation

▪ Nominal pressure, nominal size

▪ Year of construction

▪ Body material

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

The design, manufacture and the testing of the valve are subject to a QM system to

DINENISO9001 as well as the current European Pressure Equipment Directive.

European Pressure Equipment Directive (PED) Compliance with these requirements,

however, is based on normal, predominantly static loading.

Page 8

2 Safety

8 of 68

Bear in mind that valves exposed to creep-rupture conditions have a limited service

life and have to meet the applicable regulations stipulated in the technical codes.

In the case of customised special variants, further restrictions may apply with regard

to the operating mode and service life. Refer to the relevant sales documentation for

applicable limitations.

This operating manual does not take into account:

▪ Any eventualities or incidents occurring during installation performed by the

customer, operation and maintenance.

▪ Local regulations; the operator must ensure that such regulations are strictly

observed by all, including the personnel called in for installation.

2.3 Intended use

▪ Only operate valves which are in perfect technical condition.

▪ Do not operate the valve in partially assembled condition.

▪ Only use the valve for fluids specified in the product literature. Take the material

variant into account.

▪ Only operate the valve within the operating limits described in the other

applicable documents.

▪ The valve's design and rating are based on predominantly static loading in

accordance with the codes applied. Consult the manufacturer if the valve is

subjected to dynamic loads or any other additional influences.

▪ Consult the manufacturer about any other modes of operation not described in

the product literature.

▪ Do not use the valve as a foothold.

2.3.1 Prevention of foreseeable misuse

▪ Never exceed the permissible application and operating limits specified in the

product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the product this manual refers to and be fully aware of the interaction

between the valve and the system.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Hands-on training at the valve must always be supervised by specialist technical

personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

Page 9

2 Safety

9 of 68

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.7 Safety information for the operator/user

Actuator-operated valves are intended for use in areas which cannot be accessed by

unauthorised persons. Operation of these valves in areas which can be accessed by

unauthorised persons is only permitted if appropriate protective devices are fitted at

the site. This must be ensured by the operator.

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the stem seal) of hazardous fluids (e.g. explosive, toxic,

hot) so as to avoid any danger to persons and the environment. Adhere to all

relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the valve require the manufacturer's prior

consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Carry out work on the valve during standstill only.

▪ The valve body must have cooled down to ambient temperature.

▪ The pressure in the valve body must have been released and the valve must have

been drained.

▪ When taking the valve out of service always adhere to the procedure described

in the manual.

▪ Decontaminate valves which handle fluids posing a health hazard.

▪ Protect the valve body and body bonnet/cover from any impacts.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page57)

2.9 Unauthorised modes of operation

Never operate the valve outside the limits stated in the data sheet and in this

operating manual.

The warranty relating to the operating reliability and safety of the valve supplied is

only valid if the valve is used in accordance with its intended use.

(ðSection2.3,Page8)

Shut-off valves are not suitable for regulating volume flow.

Page 10

2 Safety

10 of 68

Gate valves are used in such a way that they are either fully open or fully closed. An

intermediate position (throttling function) is not permitted.

Page 11

3 Transport/Temporary Storage/Disposal

11 of 68

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

Always close the valve manually before transporting it. The valve is delivered ready

for operation and its line connection ports may still be closed with caps, if applicable.

Original spare parts are only ready for operation following assembly/installation and

subsequent shell and leak testing of the valve.

DANGER

The valve could slip out of the suspension arrangement

Danger to life from falling parts!

▷ Only transport the valve in the specified position.

▷ Never suspend the valve from its handwheel.

▷ Pay attention to the weight data and the centre of gravity.

▷ Observe the applicable local accident prevention regulations.

▷ Use suitable, permitted lifting accessories.

▷ Transport devices (if any) on the actuator may not be suitable for being

attached to a suspension arrangement in order to transport the valve/actuator

assembly. Refer to the actuator operating manual for the permissible loads.

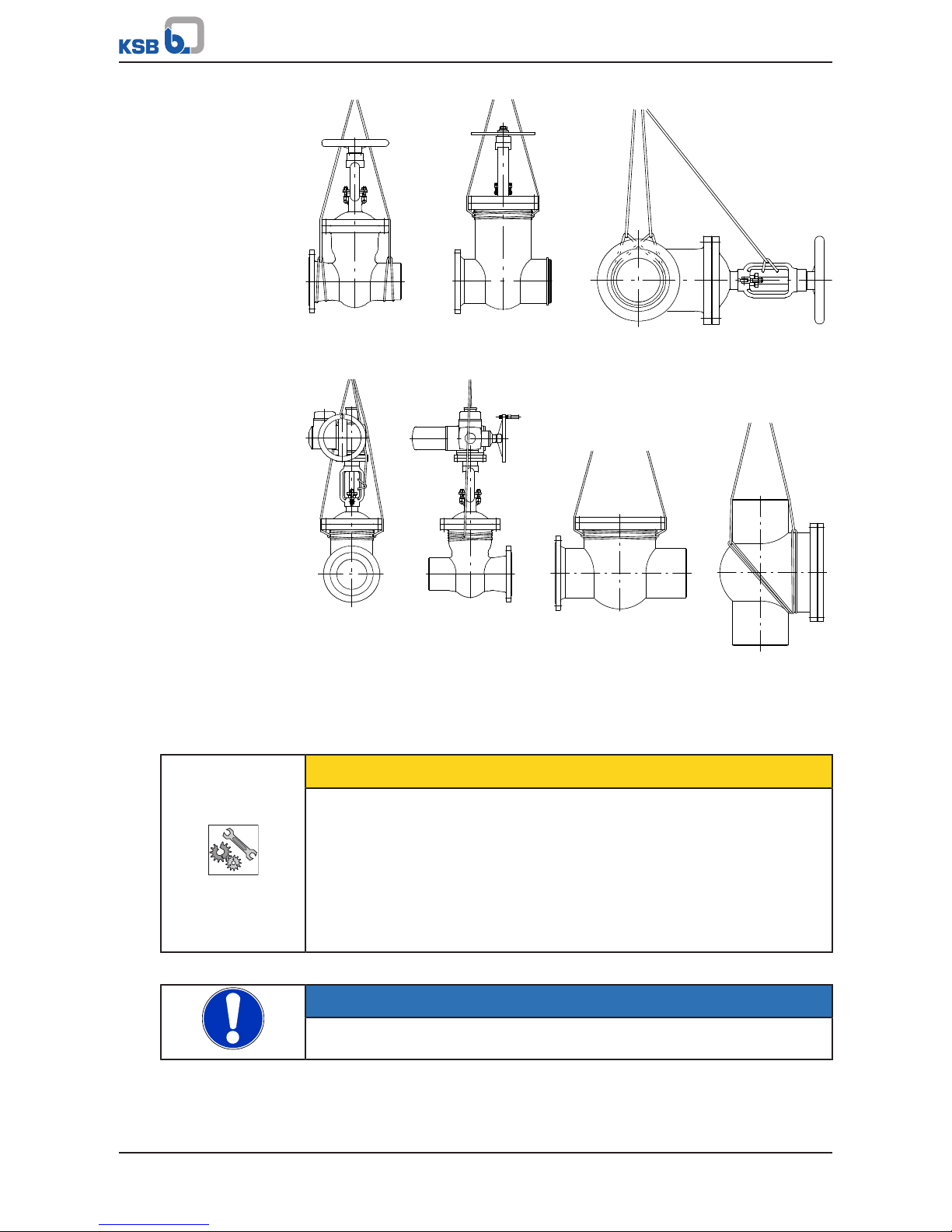

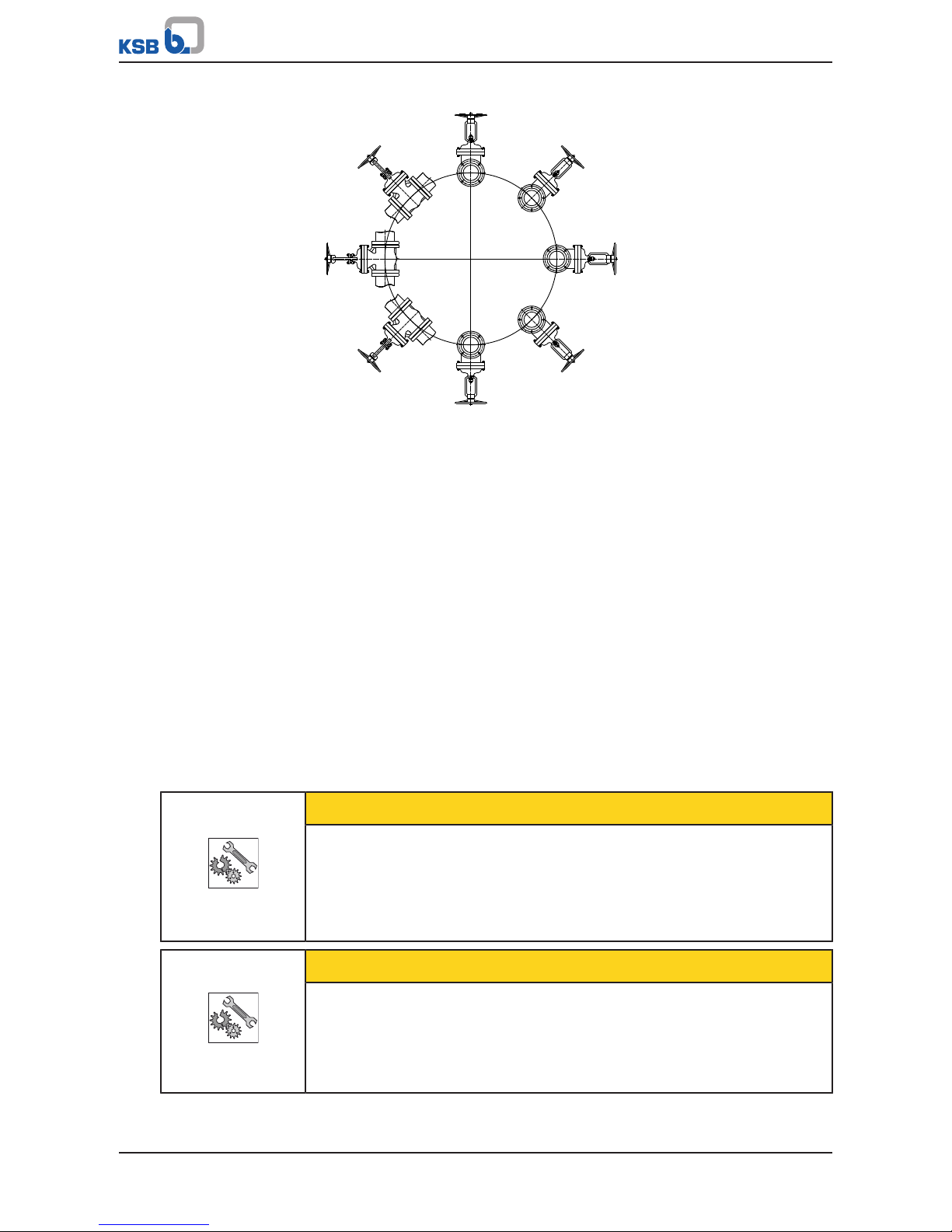

To transport the valve, suspend it from the lifting tackle as illustrated.

Page 12

3 Transport/Temporary Storage/Disposal

12 of 68

Fig.1: Transporting the valve

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for storing the valve:

CAUTION

Incorrect storage

Damage to the valve due to dirt, corrosion, moisture and/or frost!

▷ Store the valve in a dust- and vibration-free, frost-proof room where the

atmospheric humidity is as constant as possible (use suitable caps or film for

protection).

▷ Close the valve using little force and store in the closed position.

▷ Protect the valve from contact with solvents, lubricants, fuels or other

chemicals.

If properly stored indoors, the equipment is protected for a maximum of 12 months.

NOTE

For actuated valves, also observe the actuator's operating manual.

Page 13

3 Transport/Temporary Storage/Disposal

13 of 68

3.4 Return to supplier

1. Drain the valve as described in the manual.

2. Flush and clean the valve, particularly if it has been used for handling noxious,

explosive, hot or other hazardous fluids.

3. If the valve has handled fluids whose residues could lead to corrosion damage in

the presence of atmospheric humidity or could ignite upon contact with oxygen

also neutralise the valve and blow through with anhydrous inert gas to ensure

drying.

4. When returning valves used for handling Fluids in Group1 always complete and

enclose a certificate of decontamination.

Indicate any safety measures and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

3.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot or pose a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the valve.

Collect greases and other lubricants during dismantling.

2. Separate and sort the valve materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Page 14

4 Valve Description

14 of 68

4 Valve Description

4.1 General description

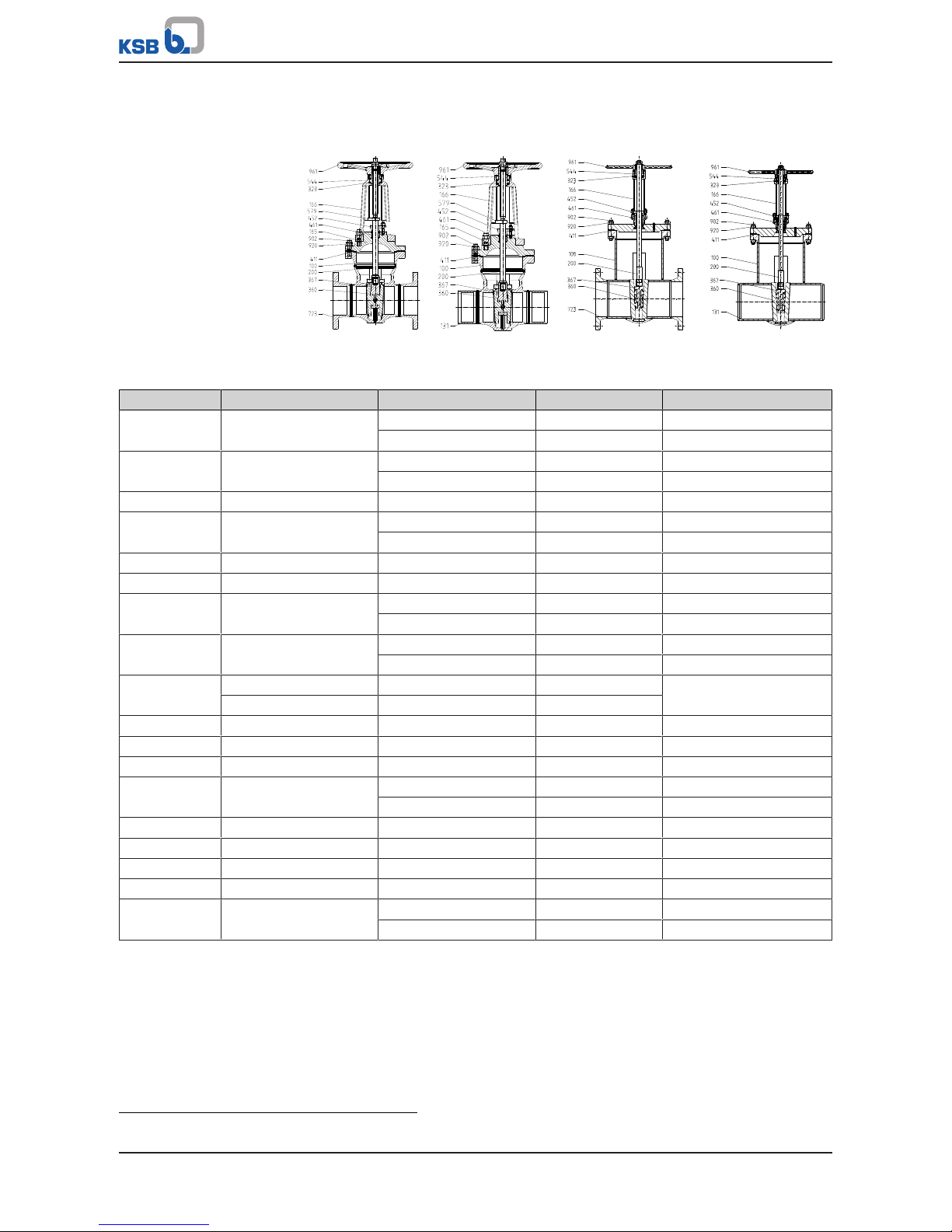

The sectional drawings below provide examples of the general design/configuration

of the valve. For additional and more detailed information, refer to the respective

type series booklet.

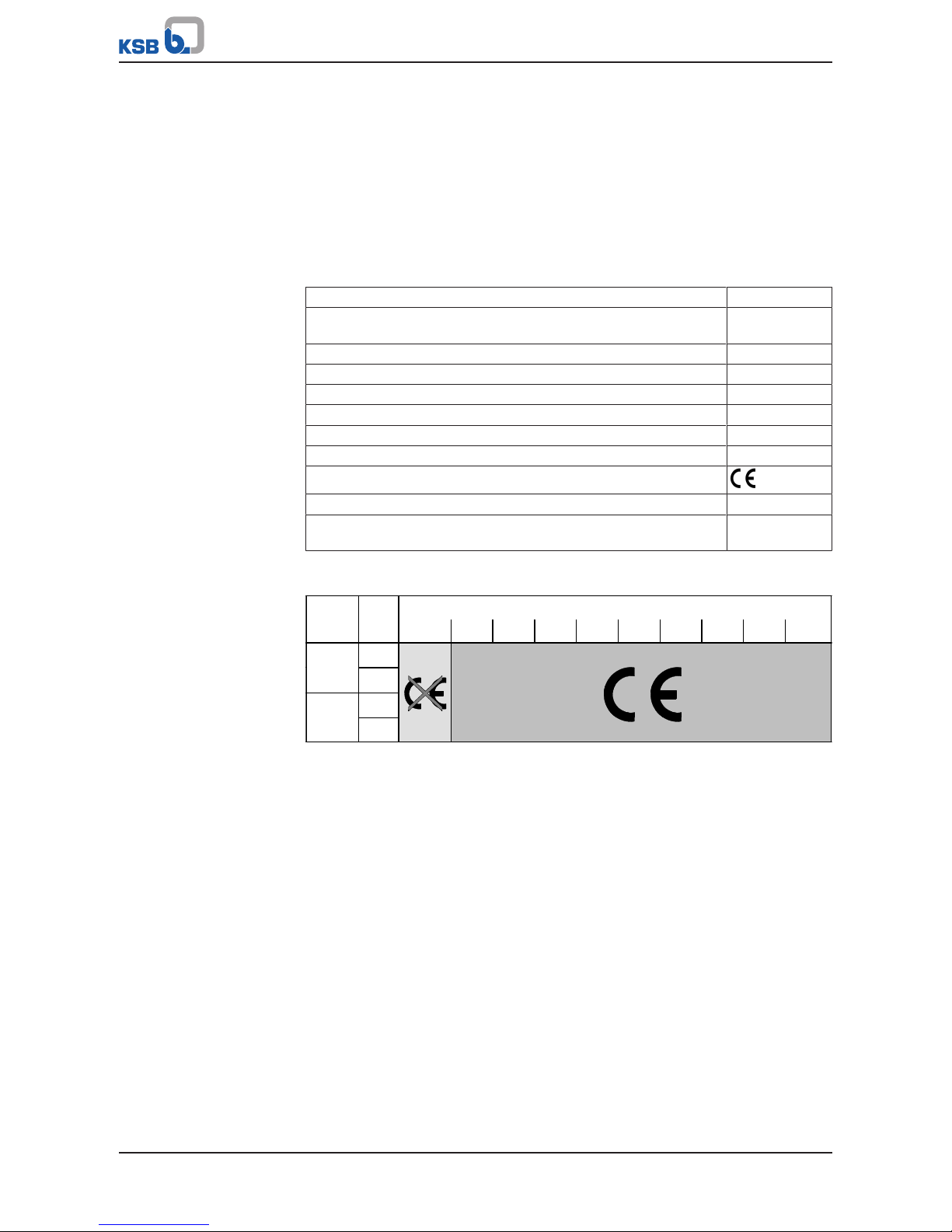

4.2 Marking

Table4: General marking

Nominal size DN ...

Nominal pressure class and/or max. permissible pressure/

temperature

PN ... / ... bar / ...

°C

Manufacturer KSB

Type series/model and/or order number NORI...

Year of construction 20..

Material .......

Flow direction arrow →

Traceability of the material .......

CE marking PED

Identification number of the notified body 0036

Customer's marking e.g. plant/

system No., etc.

The CE marking on the valve indicates that it is in conformity with the European

Pressure Equipment Directive 2014/68/EU.

Fluids in Groups 1 and 2

Class PN DN

≤25 32 40 50 65 80 100 125 150 ≥200

10

16

25

≥

≥40

150

300

Fluid groups In accordance with Article13 Para.1 of Pressure Equipment Directive 2014/68/EU,

Group 1 comprises all fluids posing physical or health hazards, e.g. fluids defined as

▪ Explosive

▪ Extremely flammable

▪ Highly flammable

▪ Flammable: The maximum allowable temperature is above flashpoint

▪ Very toxic

▪ Toxic

▪ Oxidising

Group 2 comprises all other fluids not referred to in Group 1.

4.3 Gate Valves

4.3.1 Function of gate valves with bolted bonnet

The valve consists of the pressure-retaining parts, i.e. body 100 and yoke 166, and the

functional unit.

Body 100 and yoke 166 are connected by studs 902.1 or grub screws 904 and nuts

920.1, and the joint is sealed off by joint ring 411.1.

Page 15

4 Valve Description

15 of 68

The functional unit consists mainly of wedge holder 367, flexibly mounted wedge

discs 360 and stem 200. The actuating element is either a handwheel 961 or an

actuator.

The seating faces of body 100 and wedge discs 360 are hard-faced. Gland packing

461, which seals off stem 200, is tightened via gland follower 452 by means of studs

902.3 or hinged bolts and nuts 920.2.

4.3.2 Function of gate valves with pressure seal bonnet

Gate valves with wedge discs 360 consist of body 100 with welded stellited seat rings

515, wedge discs 360 with stellited seating faces, bonnet 139 with gland packing 461

and yoke 166 with the actuating element.

Shut-off is performed by two wedge discs 360 pressed against seat rings 515; they are

flexibly mounted in wedge holder 367 and supported by replaceable thrust inserts

553 via pins 563.

Wedge holder 367 is screwed onto stem 200. A retainer prevents wedge discs 360

from twisting in wedge holder 367. To prevent twisting of the obturator

components, the wedge holder is guided in the body by lateral guide ribs 752. The

valve is equipped with a pressure seal bonnet.

The pressure inside body 100 presses bonnet 139 against joint ring 411.1, which is

supported by compression ring 501. The studs 902.2 and hexagon nuts 920.6, which

are supported by thrust plate 414 ensure that bonnet 139 is held in position against

joint ring 411.1, even if there is no pressure inside body 100.

For fitting a body pressure relief valve (ðSection4.4.1,Page29) (see type series

booklet 7300.1) a 22/14x74mm connection branch 131.2 is welded to body 100. The

connection branch is closed upon delivery.

Body pressure relief valves, if ordered, are supplied unassembled, i.e. attached loosely

to the gate valve.

Instead of fitting a body pressure relief valve, the operator may also provide a means

of pressure balancing between the body's middle section and the gate valve's

pressurised connection branch, e.g.:

▪ a pressure balancing hole in the seat ring or

▪ an external balancing line.

In this case the gate valve can be used for one flow direction only.

If gate valves and swing check valves in pressure seal design (bonnet 139) are fitted in

close proximity to one another, meaning that the trapped liquid could heat up if the

valves are closed, the operator must fit a body pressure relief valve.

Gland packing 461, which seals off stem 200, is tightened via gland follower 452 by

means of studs 902.3 and nuts 920.1. Stem 200 is moved in axial direction by the

rotating threaded bush 544, which is fitted with cylindrical roller bearings 323. Stem

200 lifts off wedge discs 360 or presses them against seat rings 515.

Threaded bush 544 is positioned in the yoke head by intermediate flange 729 and

hexagon socket head cap screws 914.1. Handwheel 961 sits on threaded bush 544, to

which it is joined via key 940. It is secured by circlip 932.

The stop nut 920.3 fitted on stem 200 serves as a travel stop in closing direction. It

prevents jamming of the wedge assembly in the seat and is secured by parallel pin

562.3.

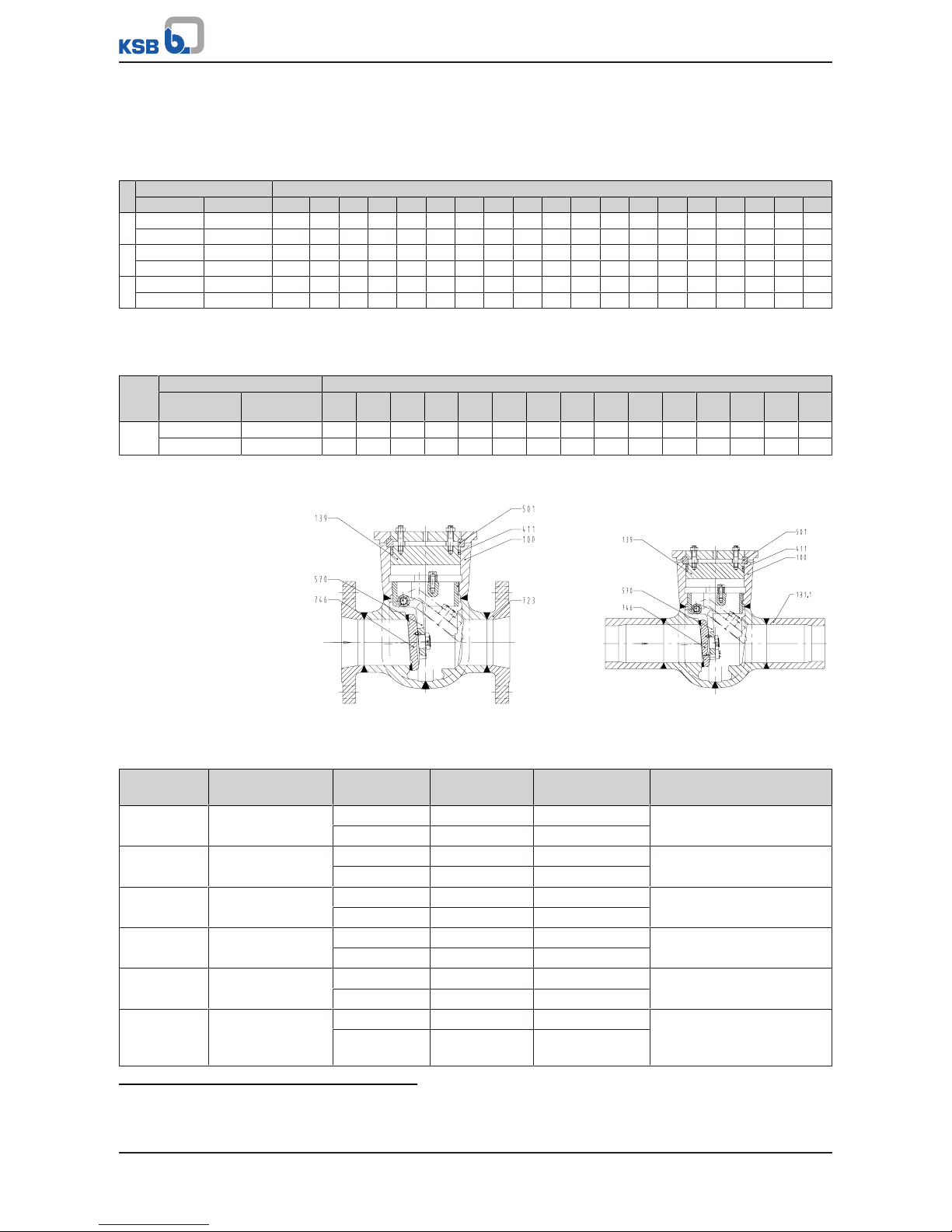

Fig.2: Parallel discs

Unlike wedge gate valve designs, slide gate valves feature two parallel discs 368,

which are flexibly mounted in disc holder 367. The discs are supported by replaceable

disc springs 950.1 via parallel pins 562.1, which press them against seat rings 515.

Page 16

4 Valve Description

16 of 68

4.3.3 Gate Valves to DIN/EN with Bolted Bonnet

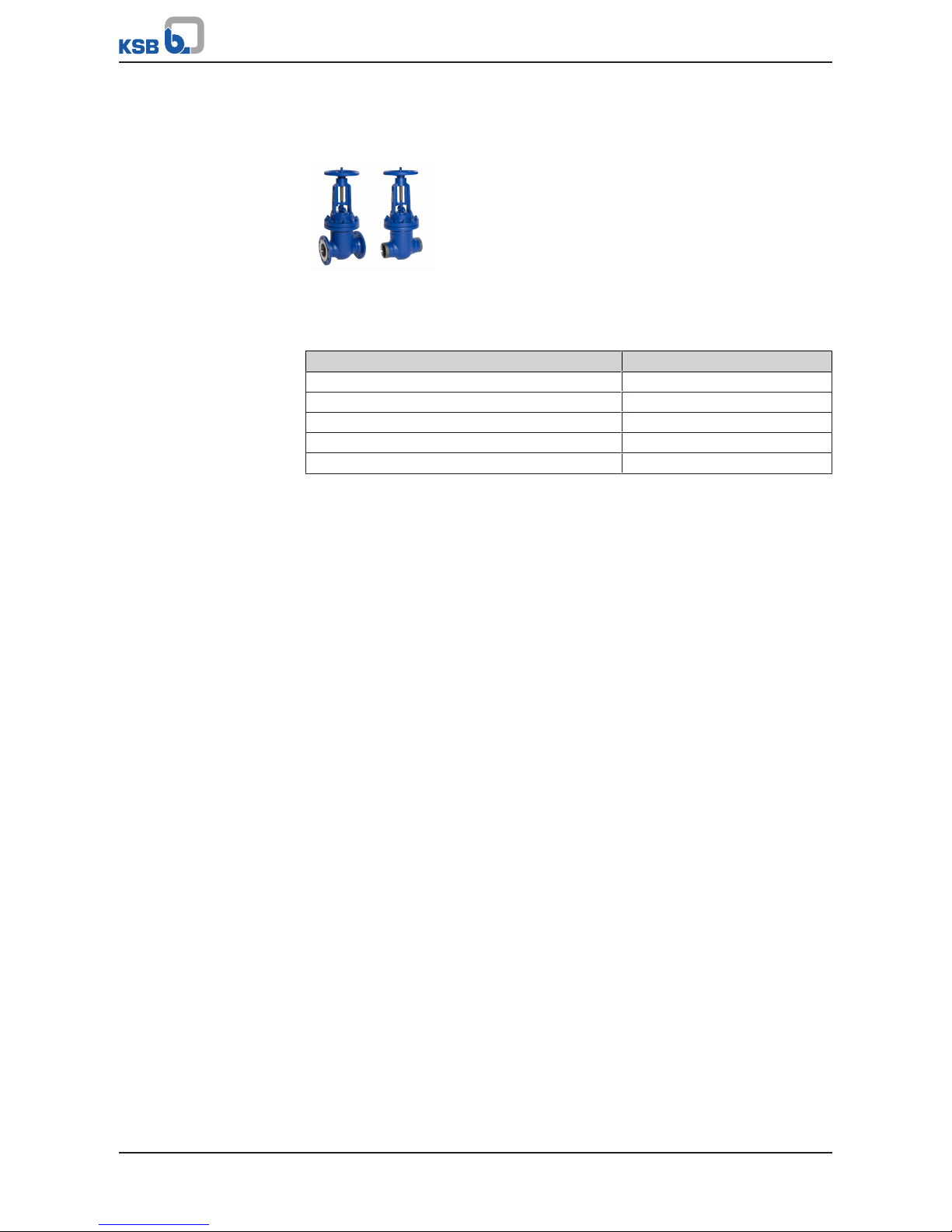

4.3.3.1 STAAL 40 AKD/AKDS

4.3.3.1.1 Operating data

Table5: Operating properties

Characteristic Value

Nominal pressure PN 10 - 40

Nominal size DN 50 - 600

Max. permissible pressure [bar] 40

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+450

Selection as per pressure/temperature ratings (ðSection4.3.3.1.4,Page17)

4.3.3.1.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.3.3.1.3 Design details

Design

▪ Body of forged or welded steel construction

▪ Bolted bonnet

▪ Non-rotating stem with external screw

▪ Split wedge

▪ Standard position indicator ≤ DN200

▪ Yoke head suitable for mounting electric actuators (DINISO5210)

▪ The valves satisfy the safety requirements of AnnexI of the European Pressure

Equipment Directive2014/68/EU (PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Variants

▪ Stem protecting tube

▪ Stem protecting tube with position indicator (≥ DN250)

▪ Stem protecting tube with position switch (≥ DN250)

▪ Position switch(es) mounted on yoke (≤DN200)

▪ Bypass

▪ Drain branch

▪ Barrier water connection

▪ Electric actuators

Page 17

4 Valve Description

17 of 68

▪ Actuator installation kit

▪ Seat/disc interface made of wear-resistant and corrosion-proof Stellite

▪ Stem made of 1.4122

▪ TA-Luft-compliant model (with or without spring loading) for applications to

VDI2440 at temperatures ≤ 250°C and > 250°C (400°C maximum)

▪ Other flange designs or butt weld end designs

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

▪ ≥ DN 700 on request

4.3.3.1.4 Pressure/temperature ratings

Table6: Permissible operating pressure [bar] (to EN 1092-1)

4)

PN Material [°C]

RT

5)

100 150 200 250 300 350 400 450

10 P250GH / P265GH 10,0 9,2 8,8 8,3 7,6 6,9 6,4 5,9 3,2

16 16,0 14,8 14,0 13,3 12,1 11,0 10,2 9,5 5,2

25 25,0 23,2 22,0 20,8 19,0 17,2 16,0 14,8 8,2

40 40,0 37,1 35,2 33,3 30,4 27,6 25,7 23,8 13,1

4) Operating pressures in accordance with DIN 2401 are also permissible.

5) RT: room temperature (-10°C to +50°C)

Page 18

4 Valve Description

18 of 68

4.3.3.1.5 Materials

PN 10 - 40

DN 50 - 200

PN 40

DN 250 - 600

AKD AKDS AKD AKDS

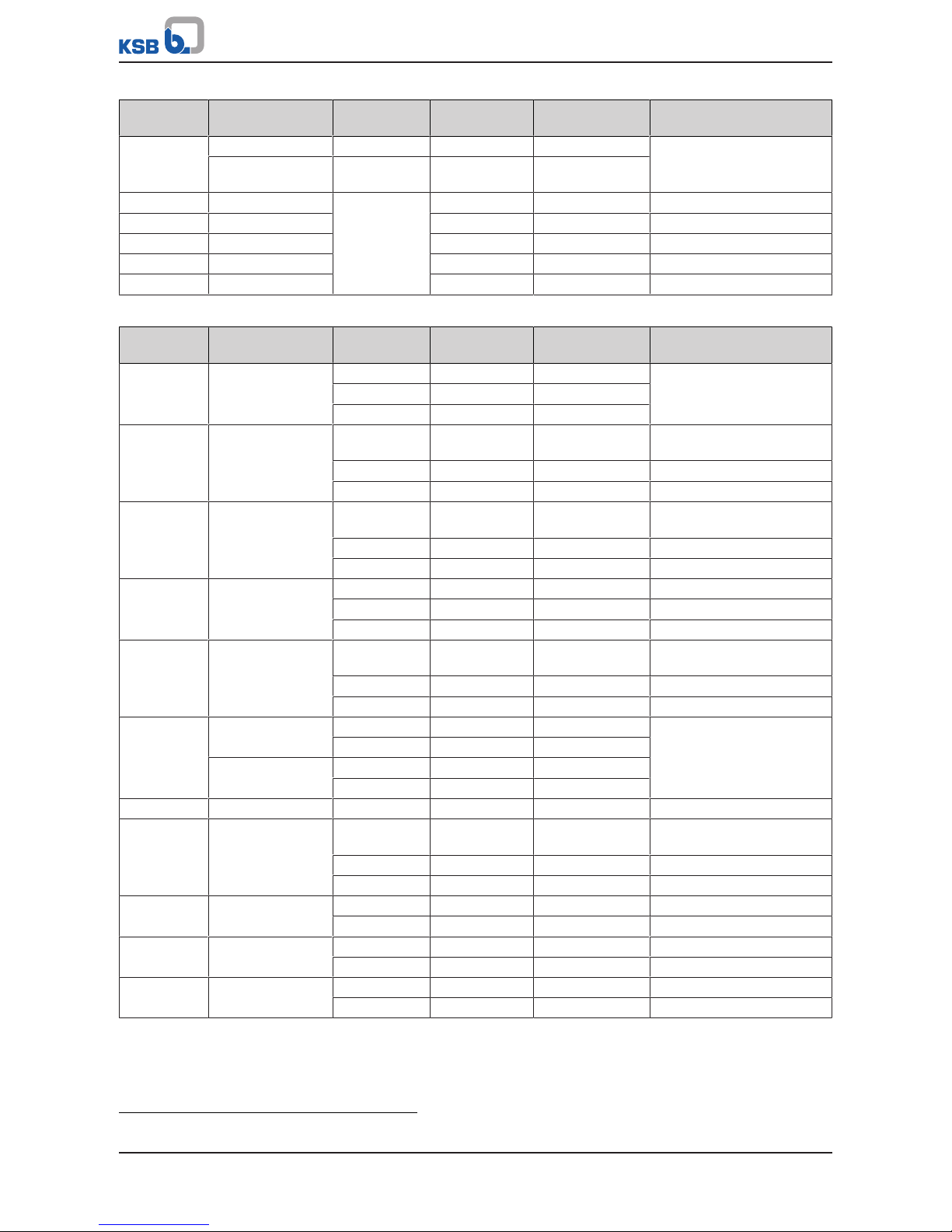

Table7: Parts list

Part No. Description Material Material number Note

100 Body P 250 GH 1.0460 -

P265GH 1.0425 ≥ DN 250

131.1 Connection branch P 235 GH 1.0345 P265GH 1.0425 ≥ DN 500

165 Bonnet P 250GH 1.0460 166 Yoke GP 240 GH+N 1.0619+N -

P265GH 1.0425 ≥ DN 250

200

6)

Stem X 20 Cr 13+QT800 1.4021+QT800 -

323

6)

Thrust bearing Steel - -

360

6)

Wedge discs GP 240 GH+N 1.0619+N -

P265GH 1.0425 ≥ DN 250

367

6)

Disc/wedge holder P 250 GH 1.0460 -

P265GH 1.0425 ≥ DN 250

Seat/disc

interface

Body X20CrMo171 1.4115 17% chrome steel

Wedge discs X8CrTi18 1.4502

411

6)

Joint ring CrNi steel/graphite - 452 Gland follower P250GH/P265GH 1.0460 / 1.0425 461

6)

Gland packing Pure graphite - 544

6)

Threaded bush 46S20+C 1.0727+C DN 50-200, nitrocarburised

11SMn30+C 1.0715+C ≥ DN 250, nitrided

579 Stop S235JR - 723 Flange P 250 GH 1.0460 902 Stud 25CrMo4 1.7218 920 Hexagon nut C35E 1.1181 961 Handwheel EN-GJL-250 5.1301 DN 50-200

Steel - ≥ DN 250

6) Recommended spare parts

Page 19

4 Valve Description

19 of 68

4.3.3.2 STAAL 100 AKD/AKDS

4.3.3.2.1 Operating data

Table8: Operating properties

Characteristic Value

Nominal pressure PN 63 - 100

Nominal size DN 50 - 500

Max. permissible pressure [bar] 100

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+530

Selection as per pressure/temperature ratings (ðSection4.3.3.2.4,Page20)

4.3.3.2.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.3.3.2.3 Design details

Design

▪ Body of forged or welded steel construction

▪ Bolted bonnet

▪ Non-rotating stem with external screw

▪ Split wedge

▪ Yoke head suitable for mounting electric and pneumatic actuators (DINISO5210)

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Page 20

4 Valve Description

20 of 68

Variants

▪ Stem protecting tube

▪ Stem protecting tube with position indicator

▪ Limit switch(es)

▪ Bypass

▪ Drain branch

▪ Hard-faced back seat

▪ Threaded bush free from non-ferrous metals

▪ Electric actuators

▪ Pneumatic actuators

▪ Spur gear

▪ Bevel gear

▪ Actuating bush for remote actuation

▪ Other flange designs or butt weld end designs

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

▪ Die-forged model for DN300/250 on request.

▪ DN 500 and above on request

4.3.3.2.4 Pressure/temperature ratings

Table9: Permissible operating pressure [bar] (to EN 1092-1)

7)

PN Material [°C]

Designation Number RT8)100 150 200 250 300 350 400 450 460 470 480 490 500 510 520 530

63 P250GH 1.0460 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - -

P265GH 1.0425 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - 16Mo3 1.5415 63,0 63,0 63,0 63,0 61,5 54,0 51,0 47,1 43,5 40,3 37,2 34,1 31,0 27,9 - - 13CrMo4-5 1.7335 63,0 63,0 63,0 63,0 63,0 63,0 60,0 56,7 53,1 50,5 47,9 45,4 42,8 41,1 34,8 28,2 23,4

100 P250GH 1.0460 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - -

P265GH 1.0425 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - 16Mo3 1.5415 100,0 100,0 100,0 100,0 100,0 97,6 80,9 74,7 69,0 64,0 59,1 54,2 49,2 44,2 - - 13CrMo4-5 1.7335 100,0 100,0 100,0 100,0 100,0 100,0 95,2 90,0 84,2 80,2 76,1 72,0 68,0 65,2 55,2 44,7 37,1

7) Operating pressures in accordance with DIN 2401 are also permissible.

8) RT: room temperature (-10°C to +50°C)

Page 21

4 Valve Description

21 of 68

4.3.3.2.5 Materials

DN 50/50-250/250 DN 300/300-500/500

AKD AKD

AKDS AKDS

Table10: Parts list DN 50/50-250/250

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450 P 250 GH 1.0460 Body die-forged and

welded

≤ 530 13CrMo4-5 1.7335

723 Flange ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

131.1 Connection

branch

≤ 450 P 250 GH 1.0460 Material can be matched to

pipeline material

≤ 530 13CrMo4-5 1.7335

360

9)

Wedge discs ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

367

9)

Disc/wedge holder ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

166 Yoke ≤ 450 P 250 GH 1.0460 -

9) Recommended spare parts

Page 22

4 Valve Description

22 of 68

Part No. Description Temperature

[°C]

Material Material number Note

166 Yoke ≤ 530 13CrMo4-5 1.7335 Seat/disc

interface

Body ≤ 450 X20CrMo17-1 1.4115 Hard-faced

Wedge discs ≤ 530 Stellite

200

9)

Stem ≤ 530 X39CrMo17-1 1.4122 -

411

9)

Joint ring 1.4541/graphite - Serrated gasket

452 Gland follower P250GH 1.0460 457

9)

Neck ring G-X70CrMo292 1.4136 -

461.1/.2

9)

Gland packing Graphite - Compression-moulded

rings (confined)

544

9)

Threaded bush CuZn35Ni2 2.0540 On axial needle bearing

902.1 Stud 21CrMoV5-7 1.7709 -

920.1 Hexagon nut 25CrMo4 1.7218 961 Handwheel GG-25 0.6025 Non-rising

Table11: Parts list DN 300/300-500/500

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450 P265GH 1.0425 Body of welded steel

construction

≤ 500 16Mo3 1.5415

≤ 530 13CrMo4-5 1.7335

723 Flange ≤ 450 P 250 GH/P 265GH1.0460/1.0425 -

≤ 500 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

131.1 Connection

branch

≤ 450

≤ 500

≤ 530

P265GH

16Mo3

13CrMo4-5

1.0425

1.5415

1.7335

Material can be matched to

pipeline material

360

9)

Wedge discs 367

9)

Disc/wedge holder 166 Yoke Seat/disc

interface

Body ≤ 450 X20CrMo17-1 1.4115 Hard-faced

≤ 530 Stellite -

Wedge discs ≤ 450 X8CrTi18 1.4502

≤ 530 Stellite -

200

9)

Stem ≤ 530 X39CrMo17-1 1.4122 411

9)

Joint ring ≤ 530 1.4541/graphite - Serrated gasket

452 Gland follower P 250 GH/P 265GH1.0460/1.0425 -

461

9)

Gland packing Graphite - Compression-moulded

rings (confined)

544

9)

Threaded bush CuZn35Ni2 2.0540 On axial bearing

900 Screw ≤ 450 25CrMo4 1.7218 -

≤ 530 21CrMoV5-7 1.7709 -

920 Hexagon nut ≤ 450 25CrMo4 1.7218 -

≤ 530 25CrMo4 1.7218 -

961 Handwheel ≤ 530 Steel - Non-rising

Page 23

4 Valve Description

23 of 68

4.3.4 Gate Valves to DIN/EN in Pressure Seal Design

4.3.4.1 AKG-A/AKGS-A

4.3.4.1.1 Operating data

Table12: Operating properties

Characteristic Value

Nominal pressure PN 63 - 160

Nominal size DN 80/80-300/250

Max. permissible pressure [bar] 160

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+550

Selection as per pressure/temperature ratings (ðSection4.3.4.1.4,Page24)

4.3.4.1.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.3.4.1.3 Design details

Design

▪ Pressure seal design

▪ Non-rotating stem

▪ Split wedge

▪ Yoke head suitable for mounting electric and pneumatic actuators (DINISO5210)

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Page 24

4 Valve Description

24 of 68

Variants

▪ Body made of forged steel

▪ Position indicator

▪ Limit switch(es)

▪ Drain branch

▪ Hard-faced back seat

▪ Disc spring supported yoke head

▪ Parallel discs

▪ Bypass

▪ Spur gear

▪ Bevel gear

▪ Electric actuators

▪ Pneumatic actuators

▪ Actuating bush for remote actuation

▪ Other flange designs

▪ Other butt weld end versions

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

4.3.4.1.4 Pressure/temperature ratings

Flanged ends, type AKG-A

Table13: Permissible operating pressures [bar]

10)

(to EN 1092-1)

11)

PN

Material [°C]

Designation Number RT

12)

100 150 200 250 300 350 400 450 460 470 480 490 500 510 520 530 540 550

63

P250GH 1.0460 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - - - 13CrMo4-5 1.7335 63,0 63,0 63,0 63,0 63,0 63,0 60,0 56,7 53,1 50,5 47,9 45,4 42,8 41,1 34,8 28,2 23,4 18,3 14,7

100

P250GH 1.0460 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - - - 13CrMo4-5 1.7335 100,0 100,0 100,0 100,0 100,0 100,0 95,2 90,0 84,2 80,2 76,1 72,0 68,0 65,2 55,2 44,7 37,1 29,0 23,3

160

P250GH 1.0460 160,0 148,5 140,9 133,3 121,9 110,4 102,8 95,2 52,5 - - - - - - - - - 13CrMo4-5 1.7335 160,0 160,0 160,0 160,0 160,0 160,0 152,3 144,0 134,8 128,3 121,8 115,3 108,8 104,3 88,3 71,6 59,4 46,4 37,3

Butt weld ends, unmachined, type AKGS-A

Table14: Permissible operating pressures [bar]

10)

PN

Material [°C]

Designation Number Up to

120

200 250 300 350 400 425 450 475 500 510 520 530 540 550

160

P250GH 1.0460 160 160 140 120 100 80 72 60 - - - - - - 13CrMo4-5 1.7335 160 160 160 160 160 150 147 145 140 118 100 80 67 52 42

10) The valves are suitable for temperatures down to -10 °C.

11) Operating pressures in accordance with DIN2401 are also permissible.

12) RT: room temperature (-10°C to +50°C)

Page 25

4 Valve Description

25 of 68

4.3.4.1.5 Materials

AKG-A AKGS-A

Table15: Parts list DN 50/50-250/200

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450 P 250 GH 1.0460 Body die-forged and welded

≤ 550 13CrMo4-5 1.7335

723 Flange ≤ 450 P 250 GH 1.0460 -

≤ 550 13CrMo4-5 1.7335 -

131.1 Connection branch ≤ 450 P 250 GH 1.0460 Material can be matched to

pipeline material

≤ 550 13CrMo4-5 1.7335

139 Bonnet ≤ 450 P 250 GH 1.0460 -

≤ 550 13CrMo4-5 1.7335

360

13)

Wedge discs ≤ 450 P 250 GH 1.0460 -

≤ 550 13CrMo4-5 1.7335

367

13)

Disc/wedge holder ≤ 450 P 250 GH 1.0460 -

≤ 550 13CrMo4-5 1.7335

162 Yoke bonnet ≤ 550 C22N 1.0402 Welded design

131.2 Connection branch 13CrMo4-5 1.7335 Seat/disc

interface

Body ≤ 450 Hard-faced 1.4115 Hard-faced

Wedge discs ≤ 550 Stellite hard-

faced

-

200

13)

Stem ≤ 550 X39CrMo17-1 1.4122 -

411.1

13)

Joint ring Pure graphite - 452 Gland follower 13CrMo4-5 1.7335 461

13)

Gland packing Pure graphite - With packing end rings

501 Segmental ring 13CrMo4-5 1.7335 544

13)

Threaded bush CuZn35Ni2 2.0540 On cylindrical roller bearings

961

13)

Handwheel EN-GJL-250 5.1301 ≥DN150 made of steel

(welded)

13) Recommended spare parts

Page 26

4 Valve Description

26 of 68

4.3.4.2 ZTS

4.3.4.2.1 Operating data

Table16: Operating properties

Characteristic Value

Design pressure [bar] ~ 600

Nominal size DN 50 - 800

Max. permissible pressure [bar] ~ 600

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+650

Selection as per pressure/temperature ratings (ðSection4.3.4.2.4,Page27)

4.3.4.2.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.3.4.2.3 Design details

Design

▪ Body made of forged steel

▪ Pressure seal design

▪ Non-rotating stem

▪ Split wedge

▪ Yoke head suitable for mounting electric and pneumatic actuators (DINISO5210)

▪ Seat/disc interface made of wear-resistant and corrosion-proof Stellite

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Page 27

4 Valve Description

27 of 68

Variants

▪ Flanged ends

▪ Bypass

▪ Drain branch

▪ Parallel discs (type GTS)

▪ Pressure relief connections (3-branch system)

▪ Balancing hole in seat ring

▪ Hard-faced back seat

▪ Lantern ring in gland packing

▪ Disc spring supported threaded bush

▪ Packing combination for high-temperature applications

▪ Pressure seal joint ring capped with stainless steel

▪ Position indicator

▪ Limit switch(es)

▪ Spur gear

▪ Bevel gear

▪ Electric actuators

▪ Pneumatic actuators

▪ Actuating bush for remote actuation

▪ Threaded bush free from non-ferrous metals

▪ Locking device

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

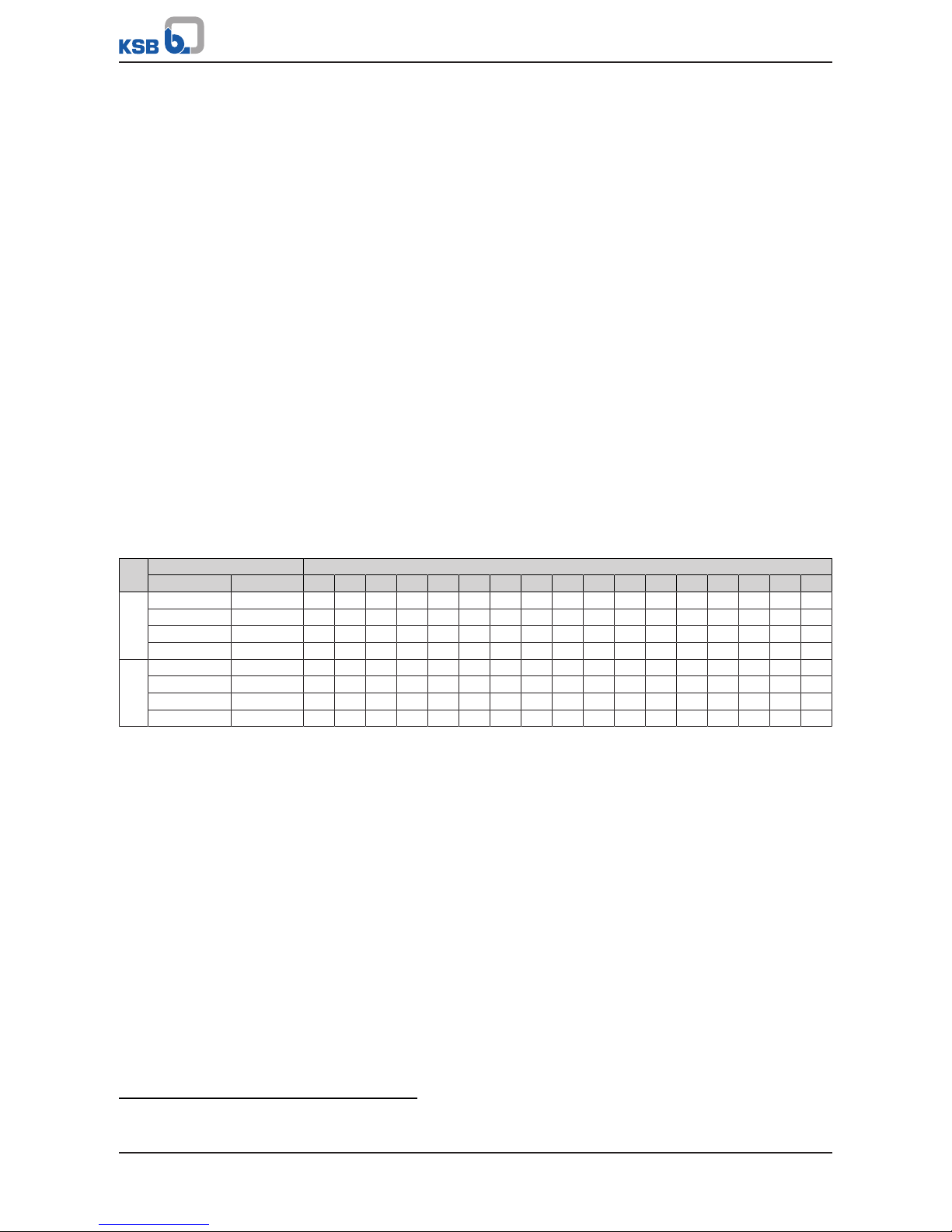

4.3.4.2.4 Pressure/temperature ratings

Subseries B

14)

Table17: Permissible operating pressure [bar]

15)

Material Subseries

16)

[°C]

20 300 350 400 425 450 475 500 510 520 530 540 550 560 570 580 590 600

16Mo3

1.5415

B 100 86 81 75 72 69 57 44 - - - - - - - - - -

13CrMo4-5

1.7335

B 100 100 95 90 87 84 74 65 55 45 37 - - - - - - -

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

B 100 100 98 93 90 88 76 64 56 49 43 37 32 - - - - -

X10CrMoVNb9-1

1.4903

B 100 100 100 100 100 100 100 100 100 100 96 87 79 71 64 57 50 45

Subseries C, D, E and F

Table18: Permissible operating pressure [bar]

15)17)

Material Subseries

16)

[°C]

20

100

150

200

250

300

350

400

425

450

475

500

510

520

530

540

550

560

570

580

590

600

610

620

630

640

650

P250GH

1.0460

C 212 202 181 161 141 126 105 85 76 66 - - - - - - - - - - - - - - - - D 323 308 277 246 215 192 161 130 115 100 - - - - - - - - - - - - - - - - E 426 407 366 325 284 254 213 172 152 132 - - - - - - - - - - - - - - - - -

14) DN 350-800

15) The valves are suitable for temperatures down to -10 °C.

16) The subseries determines the maximum operating pressure per temperature. The gate valve is designed and marked for the

actual design data specified in the purchase order.

17) The test pressure is defined in accordance with the provisions of the technical codes PED2014/68/EC; DINEN12516-2 and

EN12266-1.

Page 28

4 Valve Description

28 of 68

Material Subseries

16)

[°C]

20

100

150

200

250

300

350

400

425

450

475

500

510

520

530

540

550

560

570

580

590

600

610

620

630

640

650

P250GH

1.0460

F 521 496 446 397 347 310 260 210 186 160 - - - - - - - - - - - - - - - - -

15NiCuMoNb5

1.6368

C 367 367 367 367 367 356 341 327 314 242 - - - - - - - - - - - - - - - - CS

18)

445 445 445 445 445 430 415 400 380 300 - - - - - - - - - - - - - - - - -

D

19)

558 558 558 558 558 539 518 498 476 374 - - - - - - - - - - - - - - - - -

E 738 738 738 738 738 711 685 658 629 495 - - - - - - - - - - - - - - - - -

16Mo3

1.5415

C 268 237 214 192 177 151 147 141 140 136 134 94 66 52 42 - - - - - - - - - - - D 408 361 326 292 269 231 223 215 211 207 205 143 100 79 63 - - - - - - - - - - - E 539 478 432 386 356 304 294 284 279 275 269 189 132 104 83 - - - - - - - - - - - F 657 583 527 471 434 372 359 347 341 335 329 231 162 128 102 - - - - - - - - - - - -

13CrMo4-5

1.7335

C 268 243 228 213 202 187 177 167 162 157 155 138 118 95 79 61 49 - - - - - - - - - D 408 369 346 323 308 284 269 254 246 238 235 211 178 145 119 93 75 - - - - - - - - - E 539 488 457 427 407 376 355 335 325 315 310 277 236 191 158 124 100 - - - - - - - - - F 657 596 558 521 496 459 434 409 397 385 378 341 288 233 193 151 121 - - - - - - - - - -

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

C 268 248 232 217 213 202 187 177 173 167 162 136 119 104 91 79 69 58 51 - - - - - - - D 408 377 354 331 323 308 284 269 262 254 246 207 181 158 138 119 104 89 78 - - - - - - - E 539 498 467 437 427 407 376 355 345 335 325 275 239 210 183 158 138 117 103 - - - - - - - F 657 608 570 533 521 496 459 434 422 409 397 335 292 255 223 193 168 144 126 - - - - - - - -

X10CrMoVNb9-1

1.4903

C - - - - - - - - - - - - - 245 225 204 185 166 148 131 116 102 89 78 67 59 50

D - - - - - - - - - - - - - 324 296 270 244 214 195 174 154 135 117 103 87 77 67

E - - - - - - - - - - - - - 470 429 391 353 316 283 251 221 197 170 148 126 112 96

F - - - - - - - - - - - - - 514 472 428 387 347 311 275 244 215 186 162 139 122 105

X10CrWMoVNb9-2

1.4901

C - - - - - - - - - - - - - - - - - - - 134 120 107 94 82 71 61 53

D - - - - - - - - - - - - - - - - - - - 201 180 160 142 123 106 92 79

E - - - - - - - - - - - - - - - - - - - 262 234 208 184 160 138 120 103

F - - - - - - - - - - - - - - - - - - - 314 281 250 221 192 166 144 124

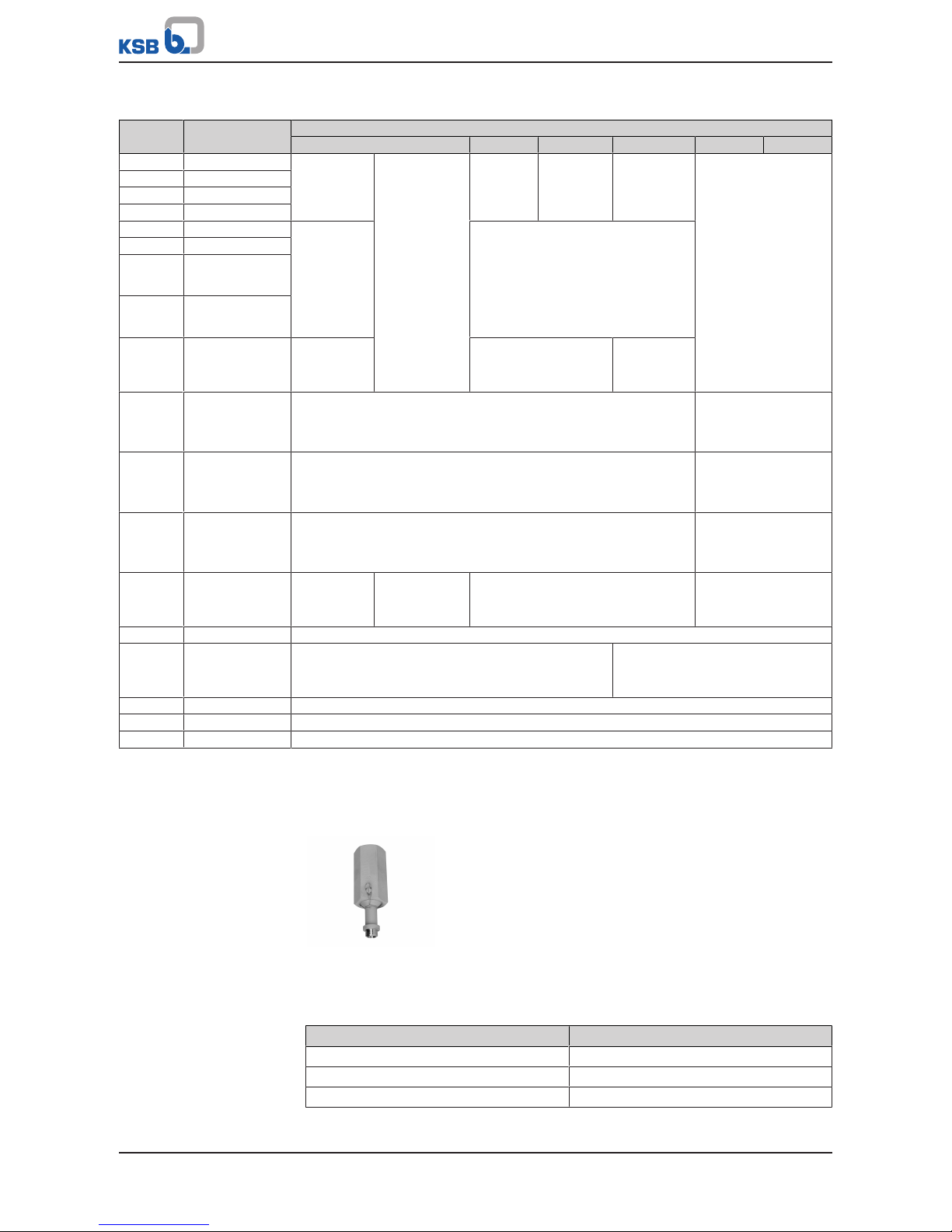

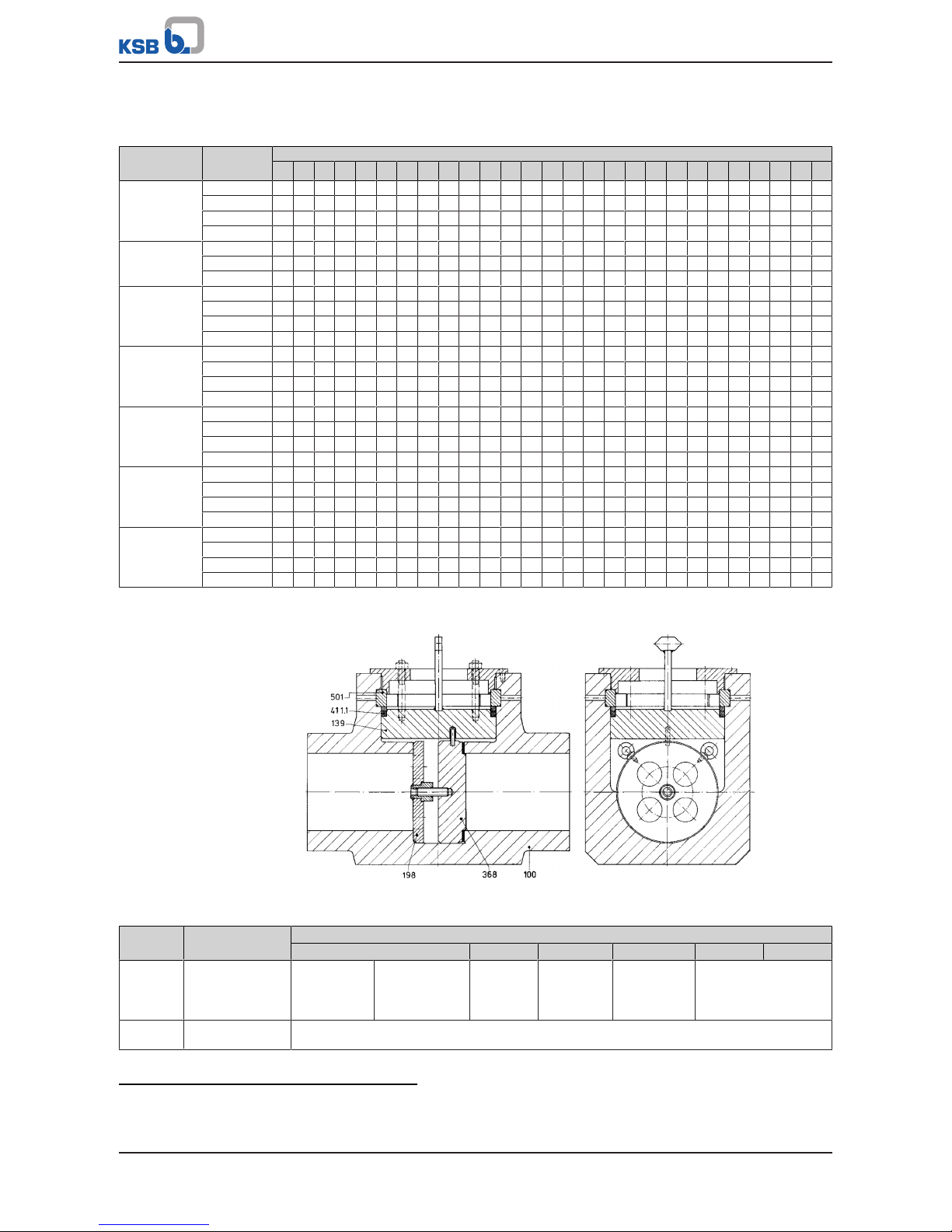

4.3.4.2.5 Materials

DN 50/50 - 200/175 DN 200/200 - 500/450

with connection branch extensions without connection branch

extensions

18) Weights, dimensions and differential pressures on request.

19) Special CD subseries version on request. Depending on the nominal size, permissible operating pressures up to the

subseriesD pressure/temperature ratings are possible (subject to differential pressure limitations compared to subseriesD,

however).

20) Recommended spare parts

Page 29

4 Valve Description

29 of 68

Table19: Parts list

Part No. Description Materials for operating temperatures [°C] up to

450 530 550 570 600 650

101 Lower body section P250 GH

1.0460

15NiCuMoNb5

1.6368

16Mo3

1.5415

13CrMo4-5

1.7335

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

X10CrMoVNb9-1

1.4903

X10CrWMoVNb 9-2

1.4901

102 Upper body section

108 Main body

131.1 Connection branch

139 Bonnet 10CrMo9-10

1.7380/

11CrMo9-10

1.7383

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

501

20)

Segmental ring

360

20)

Wedge discs

hard-faced with

Stellite6

368

20)

Parallel discs

hard-faced with

Stellite6

515 Seat ring

hard-faced with

Stellite6

13CrMo4-5

1.7335

13CrMo4-5

1.7335

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

131.2 Connection branch 13CrMo4-5

1.7335

11CrMo9-10

1.7383

X10CrMoVNb9-1

1.4903

166 Yoke 13CrMo4-5

1.7335

11CrMo9-10

1.7383

X10CrMoVNb9-1

1.4903

200

20)

Stem X39CrMo17-1

1.4122

X22CrMoV11-1

1.4923

X22CrMoV11-1

1.4923

X5NiCrTi2615

1.4980

367

20)

Disc/wedge holder 13CrMo4-5

1.7335

15NiCuMoNb5

1.6368

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

X10CrMoVNb9-1

1.4903

411.1

20)

Joint ring Pure graphite, capped with stainless steel

452 Gland follower 13CrMo4-5

1.7335

10CrMo9-10

1.7380/

11CrMo9-10

1.7383

461

20)

Gland packing Pure graphite/stainless steel capped packing end rings

544

20)

Threaded bush Copper base alloys

961 Handwheel Steel

4.4 Body Pressure Relief Valve

4.4.1 UGS

4.4.1.1 Operating data

Table20: Operating properties

Characteristic Value

Nominal pressure ≥ PN 40

Nominal size DN 15

Max. permissible pressure 25 - 750bar

Page 30

4 Valve Description

30 of 68

4.4.1.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

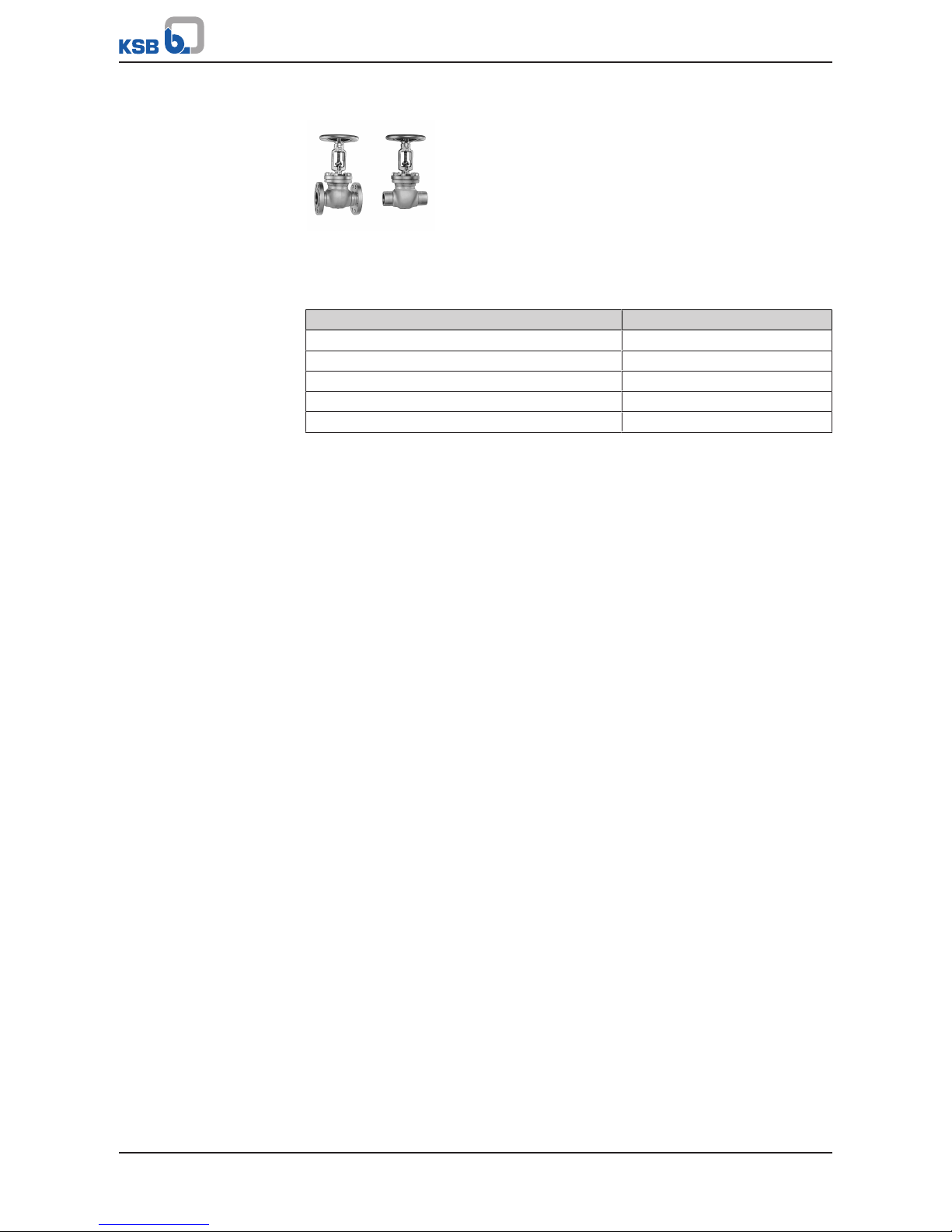

4.4.1.3 Design details

Design

▪ Body made of forged steel

▪ Stainless steel valve disc (UGS and UGSV)

▪ Adjustable, needle bearing supported spring assembly (UGS and UGSV)

▪ Blow-off pressure is set via screw-type body

▪ Stellited seat

▪ Lead-sealed screw prevents unauthorised manipulation of set blow-off pressure

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Variants

▪ Bursting disc (UGSV and UGSVA)

▪ Blocking device

▪ With lockable shut-off valve

Page 31

4 Valve Description

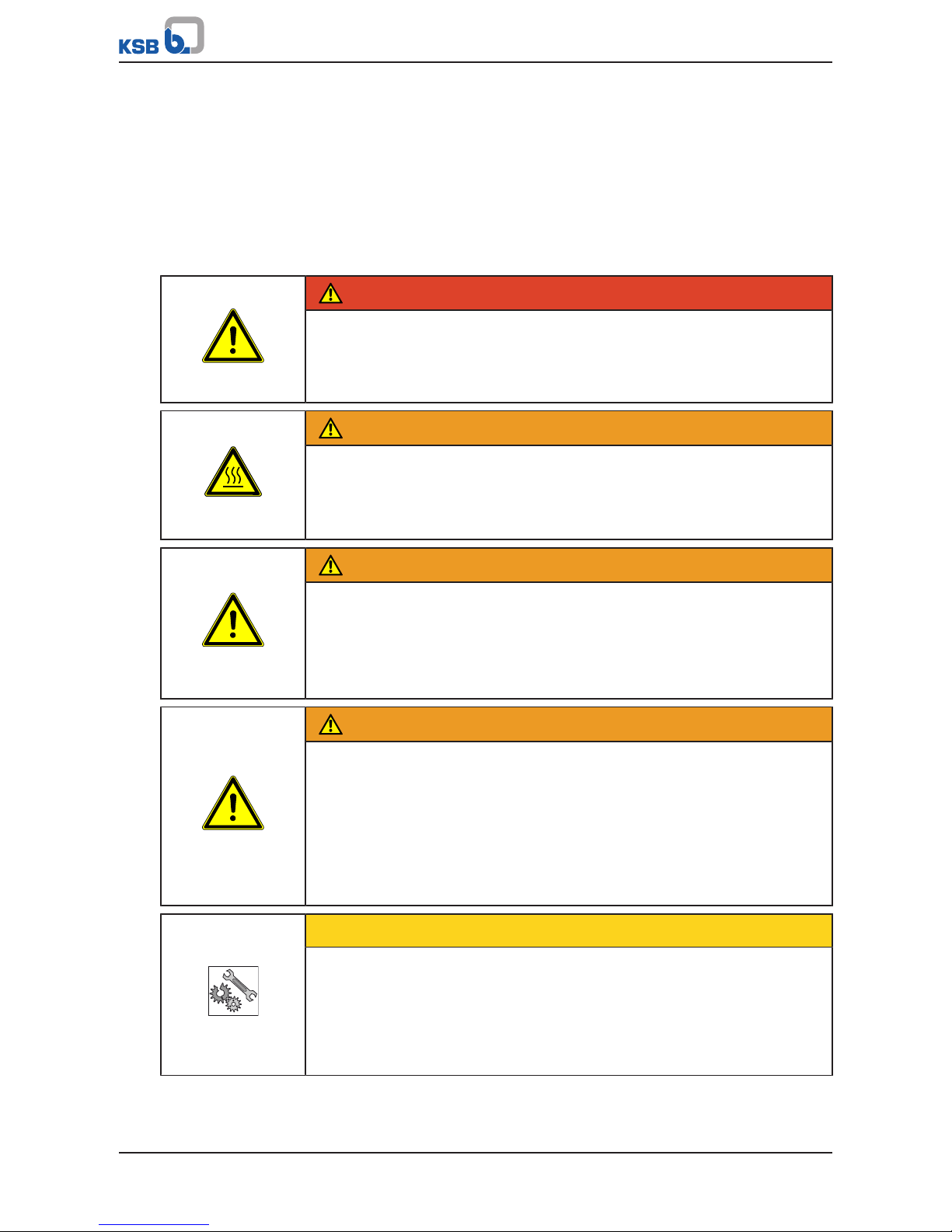

31 of 68

4.4.1.4 Materials

1)

1)

3)

2)

1)

UGS:

without bursting disc, spring-loaded

UGSV:

with bursting disc, spring-loaded

UGSVA:

with bursting disc, without spring

loading

To be used in combination with

lockable globe valve only .

1) Lead-sealed 2) Paint dot

3) Name plate for bursting disc

Table21: Parts list

Part No. Description Material Material number Note

32-2 Axial needle bearing Steel - 160 Cover P250GH 1.0460 350 Valve disc X39CrMo17-1 1.4122 500 Ring X6CrNiTi18-10 1.4541 520 Sleeve 13CrMo4-5 1.7335 Stellited

550.1 Disc X20Cr13 1.4021 -

550.2 Bursting disc 316 SS - 574 Rod X39CrMo17-1 1.4122 731 Pipe union P250GH 1.0460 Stellited

13CrMo4-5 1.7335

10CrMo9-10/

11CrMo9-10

1.7380

1.7383

X10CrMoVNb9-1 1.4903

734 Screw-type body 9 SMn28 k - 900 Screw 5.8 - 901 Hexagon head bolt 8.8 - -

Page 32

4 Valve Description

32 of 68

Part No. Description Material Material number Note

920 Hexagon nut 8 - 950 Disc spring Inconel 718 - -

4.4.1.5 Heating up of trapped liquids

The heating up of trapped liquids primarily occurs inside gate valves.

If liquid remains in the body after pressure testing, for instance, or if condensate

develops due to certain operating conditions, there is a risk of an impermissible

pressure increase if the body is heated up by hot water or steam in one or both the

connected pipes. The potential pressure increase depends both on the temperature

and the extent to which the body is filled with liquid and may reach impermissible

values very quickly.

The problem of trapped liquids heating up inside the valve is particularly dangerous

on gate valves with a pressure seal bonnet as the bonnet seal becomes tighter with

rising pressure. The pressure may reach several times the operating pressure.

On gate valves with a bolted bonnet, an impermissible increase in pressure will be

relieved through leaks developing at the bonnet gasket.

Gate valves with a pressure seal bonnet, by contrast, must be fitted with body

pressure relief valves if excessive heating of trapped liquids is potentially a problem.

The body pressure relief valve ensures that the body is protected against excessive

loads and deformation under all operating conditions, thus avoiding incidents which

may compromise safety.

The likelihood of trapped liquid heating up varies depending on the system and must

be individually assessed for each gate valve by the purchaser. It is therefore necessary

to order the body pressure relief valve and the gate valve separately.

4.4.1.6 Function

Body pressure relief valves are available in three different designs:

▪ Spring-loaded body pressure relief valve (UGS)

▪ Spring-loaded body pressure relief valve with bursting disc (UGSV)

▪ Non-spring-loaded designs with bursting disc in combination with a lockable

globe valve (UGSVA).

Spring-loaded body

pressure relief valve (UGS)

Stainless steel valve disc 350 is pressed onto the stellited seat of pipe union 731 by

means of adjustable spring assembly 950 via disc 550.1 and rod 574, ensuring tight

closure.

The required pre-loading of disc springs 950 is adjusted via screw-type body 734,

supported by needle bearing 32-2. Screw-type body 734 is locked in position by

means of screw 900.

The blow-off pressure is always set at the supplying factory and stamped on the body

pressure relief valve. It is determined by the respective valve type, the operating data

and the max. permissible body load.

Every body pressure relief valve is tested and lead-sealed. Removal of the lead seal

will result in forfeiture of any warranty claims.

Setting and testing are performed on the basis of work instructions or parts list

specifications using special testing equipment. Re-setting can only be performed at

the supplying factory.

Spring-loaded body

pressure relief valve with

bursting disc (UGSV)

The body pressure relief valve with pre-fitted bursting disc basically consists of two

assemblies:

▪ Bursting disc with fastening elements

▪ Downstream spring-loaded body pressure relief valve

Bursting disc 550.2 is clamped between pipe union 731 and sleeve 520 and sealed by

means of intermediate ring 500.

It is combined with the downstream spring-loaded body pressure relief valve

described above.

Page 33

4 Valve Description

33 of 68

If bursting disc 550.2 bursts as a result of excessive pressure inside the gate valve, the

space between bursting disc 550.2 and the body pressure relief valve's seat is also

subjected to this excessive pressure. This causes valve disc 350 to lift off its seat and

the body pressure relief valve to blow off.

Excess pressure is relieved and the body is thus protected against excessive loads.

After blowing off, the body pressure relief valve closes again.

Despite the damaged bursting disc, operation of the gate valve with the body

pressure relief valve can be continued until the next maintenance inspection is due.

The bursting disc must then be renewed.

A paint dot at the point where the rod (574) passes through the screw-type body

(734) serves as a visual indicator. It indicates that the body pressure relief valve has

tripped and the bursting disc must have burst. When the body pressure relief valve

trips, this paint dot will burst open.

The paint dot must therefore be checked at regular intervals. The paint dot does not

affect the body pressure relief valve's functioning.

NOTE

Rupture of the bursting disc always indicates an impermissible pressure increase.

Before replacing the bursting disc, investigate the cause of this malfunction to rule

out any negative effects on the proper functioning of the valve.

Non-spring-loaded design

with bursting disc (UGSVA)

WARNING

Fluid escaping following rupture of bursting disc

Burns/scalding and damage/hazard to the environment!

▷ Take appropriate measures, e.g. fence off area.

Under normal operating conditions, the globe valve is locked in the open position. If

the globe valve is closed, the pressure relief function is not available.

The globe valve must be capable of reducing the amount of fluid escaping after the

bursting has ruptured, e.g. while the system is being shut down.

4.5 Swing check valves

4.5.1 Function of swing check valves with bolted cover

Swing check valves consist of forged body 100 with hard-faced seating faces. Fluid

flow is shut off by hard-faced valve disc 746, which is flexibly mounted on hanger

arm 570. This connection is secured with a nut and a locking pin.

Body 100 is joined to cover 161 by studs 902.1 and sealed to atmosphere by joint ring

411.1. The disc assembly is pivot-mounted on hinge 230 welded to cover 161 or on

hinge pin 210 mounted in the body.

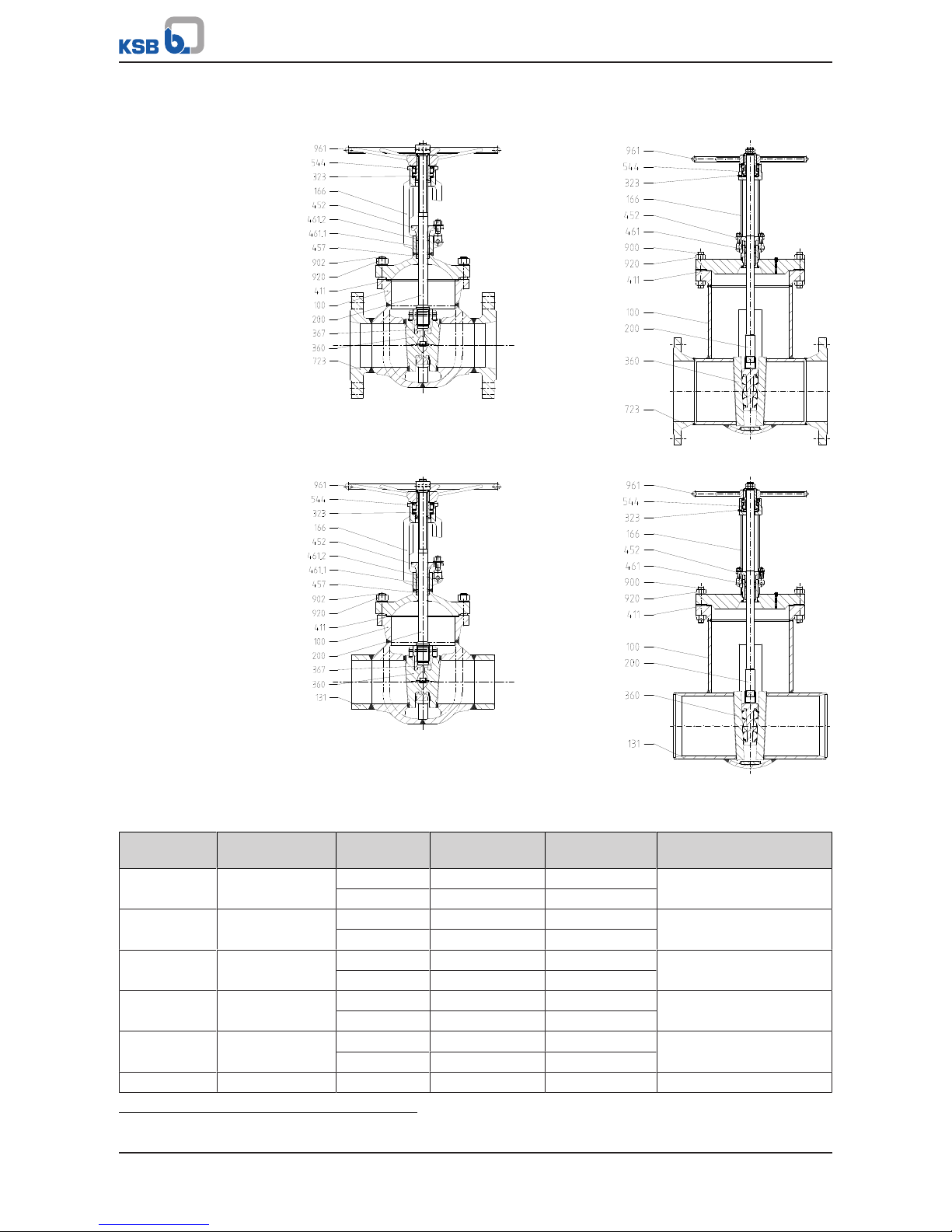

4.5.2 Function of swing check valves with pressure seal cover

The swing check valve is equipped with a pressure seal cover. The pressure inside

body 100 presses bonnet 139 against joint ring 411.1; the latter is supported by

segmental ring 501, which rests in a groove inside the body, via compression ring

500. Studs 902.2 and hexagon nuts 920.6, which are supported by cover 161, ensure

that bonnet 139 is held in place against joint ring 411.1, even if there is no pressure

inside body 100.

Hinge pin 210 held by bearing bushes 545 acts as a pivotal point for hanger arm 570

with valve disc 746. Together with plate 198, the hanger arm forms a complete

assembly that is inserted into body 100 and clamped and locked in place in a

circumferential groove inside the body by locking plates 196.

Page 34

4 Valve Description

34 of 68

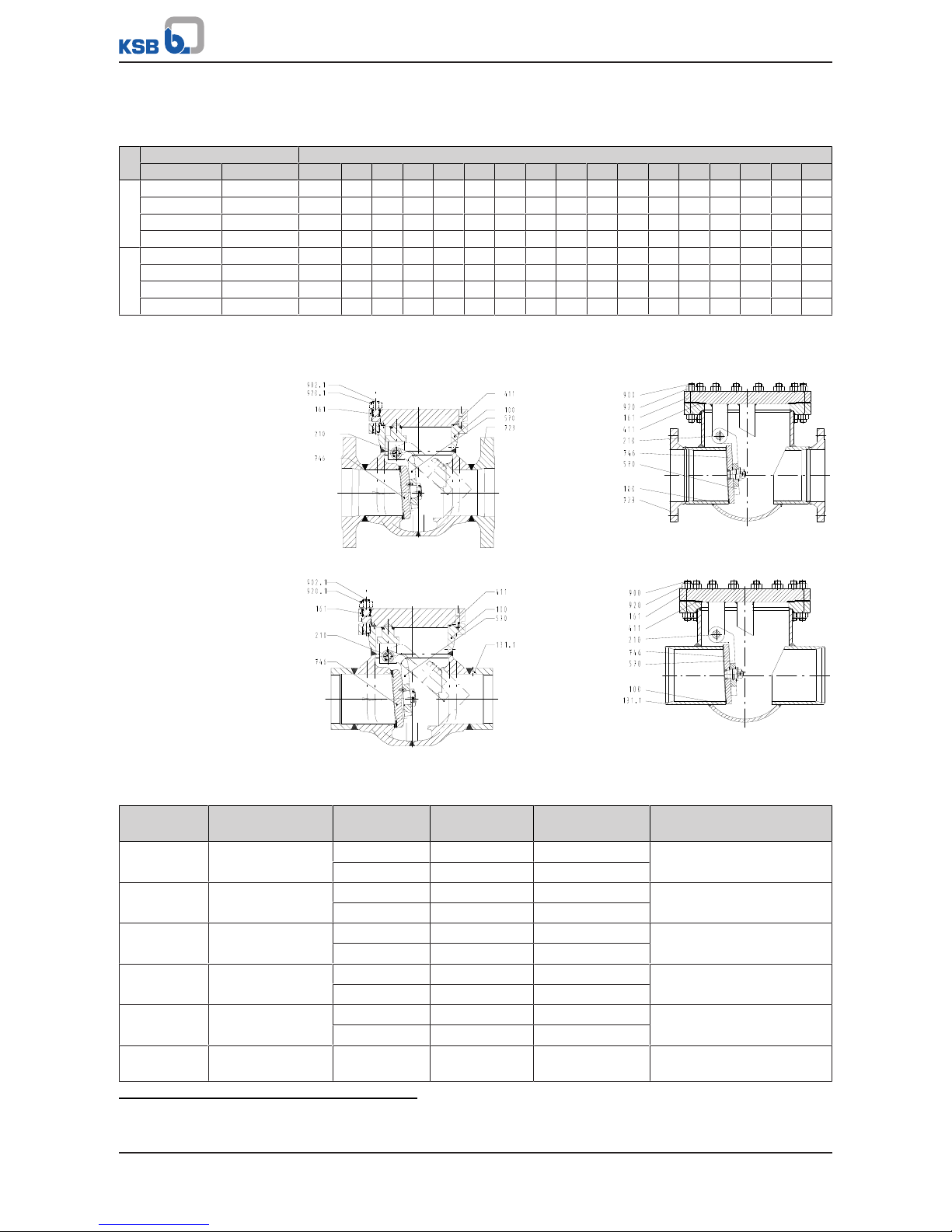

4.5.3 Swing Check Valves with Bolted Cover

4.5.3.1 STAAL 40 AKK/AKKS

4.5.3.1.1 Operating data

Table22: Operating properties

Characteristic Value

Nominal pressure PN 10 - 40

Nominal size DN 80 - 400

Max. permissible pressure [bar] 40

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+450

Selection as per pressure/temperature ratings (ðSection4.5.3.1.4,Page35)

4.5.3.1.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.5.3.1.3 Design details

Design

▪ Body of forged or welded steel construction

▪ Bolted cover

▪ Internally mounted hinge pin

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Variants

▪ Extended hinge pin from DN 250 (for lever and weight operation)

▪ Other flange designs

▪ Other butt weld end versions

▪ Drain branch

▪ Seat/disc interface made of wear-resistant and corrosion-proof Stellite

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

▪ DN 500 and above on request

21) Operating pressures in accordance with DIN2401 are also permissible.

Page 35

4 Valve Description

35 of 68

4.5.3.1.4 Pressure/temperature ratings

Table23: Permissible operating pressure [bar] (to EN 1092-1)

21)

PN Material [°C]

RT

22)

100 150 200 250 300 350 400 450

10 P235GH / P265GH 10,0 9,2 8,8 8,3 7,6 6,9 6,4 5,9 3,2

16 16,0 14,8 14,0 13,3 12,1 11,0 10,2 9,5 5,2

25 25,0 23,2 22,0 20,8 19,0 17,2 16,0 14,8 8,2

40 40,0 37,1 35,2 33,3 30,4 27,6 25,7 23,8 13,1

4.5.3.1.5 Materials

AKK AKKS

Table24: Parts list

Part No. Description Material Material number Note

100 Body P 235 GH 1.0345 -

P265GH 1.0425 -

131.1 Connection branch P 235 GH 1.0305 161 Body cover P265GH 1.0425 210

23)

Hinge pin X 20 Cr 13 1.4021 -

Seat/disc

interface

Body X20CrMo171 1.4115 17% chrome steel

Valve disc X8CrTi18 1.4502

411

23)

Joint ring Pure graphite - -

570

23)

Hanger arm P265GH 1.0425 723 Flange P 250 GH 1.0460 746

23)

Valve disc P265GH 1.0425 900 Screw 25CrMo4 1.7218 920 Hexagon nut C35E 1.1181 -

22) RT: room temperature (-10 °C to +50 °C)

23) Recommended spare parts

Page 36

4 Valve Description

36 of 68

4.5.3.2 STAAL 100 AKK/AKKS

4.5.3.2.1 Operating data

Table25: Operating properties

Characteristic Value

Nominal pressure PN 63 - 100

Nominal size DN 80 - 400

Max. permissible pressure [bar] 100

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+530

Selection as per pressure/temperature ratings (ðSection4.5.3.2.4,Page37)

4.5.3.2.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.5.3.2.3 Design details

Design

▪ Body of forged or welded steel construction

▪ Bolted cover

▪ Internally mounted hinge pin

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Variants

▪ Extended hinge pin from DN 250 (for lever and weight operation)

▪ Other flange designs

▪ Other butt weld end versions

▪ Drain branch

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

▪ DN 50 and DN 65 on request

▪ DN 400 and above on request.

25) RT: room temperature (-10°C to +50°C)

Page 37

4 Valve Description

37 of 68

4.5.3.2.4 Pressure/temperature ratings

Table26: Permissible operating pressure [bar] (to EN1092-1)

25)

PN

Material [°C]

Designation Number RT

25)

100 150 200 250 300 350 400 450 460 470 480 490 500 510 520 530

63

P250GH 1.0460 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - P265GH 1.0425 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - 16Mo3 1.5415 63,0 63,0 63,0 63,0 61,5 54,0 51,0 47,1 43,5 40,3 37,2 34,1 31,0 27,9 - - 13CrMo4-5 1.7335 63,0 63,0 63,0 63,0 63,0 63,0 60,0 56,7 53,1 50,5 47,9 45,4 42,8 41,1 34,8 28,2 23,4

100

P250GH 1.0460 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - P265GH 1.0425 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - 16Mo3 1.5415 100,0 100,0 100,0 100,0 100,0 97,6 80,9 74,7 69,0 64,0 59,1 54,2 49,2 44,2 - - 13CrMo4-5 1.7335 100,0 100,0 100,0 100,0 100,0 100,0 95,2 90,0 84,2 80,2 76,1 72,0 68,0 65,2 55,2 44,7 37,1

4.5.3.2.5 Materials

DN 80/80-250/250 DN 300/300-400/400

AKK AKK

AKKS AKKS

Table27: Parts list DN 80/80-250/250

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450 P 250 GH 1.0460 Body die-forged and welded

≤ 530 13CrMo4-5 1.7335

723 Flange ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

131.1 Connection branch ≤ 450 P 250 GH 1.0460 Material can be matched to

pipeline material.

≤ 530 13CrMo4-5 1.7335

161 Body cover ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

746

26)

Valve disc ≤ 450 P 250 GH 1.0460 -

≤ 530 13CrMo4-5 1.7335

Seat/disc

interface

Body ≤ 450 X20CrMo17-1 1.4115 Hard-faced

24) Operating pressures in accordance with DIN2401 are also permissible.

26) Recommended spare parts

Page 38

4 Valve Description

38 of 68

Part No. Description Temperature

[°C]

Material Material number Note

Seat/disc

interface

Body ≤ 530 Stellite - Hard-faced

Valve disc ≤ 530 X15CrNiMn18-81.4370

411

26)

Joint ring ≤ 530 1.4541/graphite - Serrated gasket

570

26)

Hanger arm 13CrMo4-5 1.7335 -

210 Hinge pin X39CrMo17-1 1.4122 -

902.1 Stud 21CrMoV5-7 1.7709 -

920.1 Hexagon nut 25CrMo4 1.7218 -

Table28: Parts list DN 300/300-400/400

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450 P265GH 1.0425 Body of welded steel

construction

≤ 500 16Mo3 1.5415

≤ 530 13CrMo4-5 1.7335

723 Flange ≤ 450 P 250 GH/P 265GH1.0460/1.0425 -

≤ 500 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

131.1 Connection branch ≤ 450 P265GH 1.0425 Material can be matched to

pipeline material.

≤ 500 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

161 Body cover ≤ 450 P265GH 1.0425 -

≤ 500 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

746

27)

Valve disc ≤ 450 P 250 GH/P 265GH1.0460/1.0425 -

≤ 500 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

Seat/disc

interface

Body ≤ 450 X20CrMo17-1 1.4115 Hard-faced

≤ 530 Stellite -

Valve disc ≤ 450 X8CrTi18 1.4502

≤ 530 Stellite -

411

27)

Joint ring ≤ 530 1.4541/graphite - Serrated gasket

570

27)

Hanger arm ≤ 450 P 250 GH/P 265GH1.0460/1.0425 -

≤ 530 16Mo3 1.5415 ≤ 530 13CrMo4-5 1.7335 -

210

27)

Hinge pin ≤ 450 X20Cr13 1.4021 -

≤ 530 X39CrMo17-1 1.4122 -

900 Screw ≤ 450 25CrMo4 1.7218 -

≤ 530 21CrMoV5-7 1.7709 -

920 Hexagon nut ≤ 450 25CrMo4 1.7218 -

≤ 530 25CrMo4 1.7218 -

27) Recommended spare parts

Page 39

4 Valve Description

39 of 68

4.5.4 Swing check valves with pressure seal cover

4.5.4.1 AKR/AKRS

4.5.4.1.1 Operating data

Table29: Operating properties

Characteristic Value

Nominal pressure PN 63 - 160

Nominal size DN 80/80-300/250

Max. permissible pressure [bar] 160

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+550

Selection as per pressure/temperature ratings (ðSection4.5.4.1.4,Page40)

4.5.4.1.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.5.4.1.3 Design details

Design

▪ Body of forged or welded steel construction

▪ Pressure seal design

▪ Internally mounted hinge pin

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, GroupII, category2 (zones1+21) and

category3 (zones2+22) to ATEX2014/34/EU.

Variants

▪ Other flange designs

▪ Other butt weld end versions

▪ Inspections to technical codes such as TRD/TRB/AD2000 – German Steam Boiler /

Pressure Vessel Regulations – or to customer specification

30) RT: room temperature (-10°C to +50°C)

Page 40

4 Valve Description

40 of 68

4.5.4.1.4 Pressure/temperature ratings

Flanged ends, type AKR (to EN1092-1)

29)

Table30: Permissible operating pressures [bar]

30)

PN

Material [°C]

Designation Number RT

30)

100 150 200 250 300 350 400 450 460 470 480 490 500 510 520 530 540 550

63

P250GH 1.0460 63,0 58,5 55,5 52,5 48,0 43,5 40,5 37,5 20,7 - - - - - - - - - 13CrMo4-5 1.7335 63,0 63,0 63,0 63,0 63,0 63,0 60,0 56,7 53,1 50,5 47,9 45,4 42,8 41,1 34,8 28,2 23,4 18,3 14,7

100

P250GH 1.0460 100,0 92,8 88,0 83,3 76,1 69,0 64,2 59,5 32,8 - - - - - - - - - 13CrMo4-5 1.7335 100,0 100,0 100,0 100,0 100,0 100,0 95,2 90,0 84,2 80,2 76,1 72,0 68,0 65,2 55,2 44,7 37,1 29,0 23,3

160

P250GH 1.0460 160,0 148,5 140,9 133,3 121,9 110,4 102,8 95,2 52,5 - - - - - - - - - 13CrMo4-5 1.7335 160,0 160,0 160,0 160,0 160,0 160,0 152,3 144,0 134,8 128,3 121,8 115,3 108,8 104,3 88,3 71,6 59,4 46,4 37,3

Butt weld ends, machined, type AKRS

28)

Table31: Permissible operating pressures [bar]

29)

PN Material [°C]

Designation Number Up to

120

200 250 300 350 400 425 450 475 500 510 520 530 540 550

63/160 P250GH 1.0460 160 160 140 120 100 80 72 60 - - - - - - -

13CrMo4-5 1.7335 160 160 160 160 160 150 147 145 140 118 100 80 67 52 42

4.5.4.1.5 Materials

AKR AKRS

Table32: Parts list

Part No. Description Temperature

[°C]

Material Material number Note

100 Body ≤ 450°C P 250GH 1.0460 Body die-forged and welded

≤ 550°C 13CrMo4-5 1.7335

723 Flange ≤ 450°C P 250GH 1.0460 -

≤ 550°C 13CrMo4-5 1.7335

131.1 Connection branch ≤ 450°C P 250GH 1.0460 Material can be matched to

pipeline material.

≤ 550°C 13CrMo4-5 1.7335

746

31)

Valve disc ≤ 450°C P 250GH 1.0460 -

≤ 550°C 13CrMo4-5 1.7335

139 Bonnet ≤ 450°C P 250GH 1.0460 -

≤ 550°C 13CrMo4-5 1.7335

Seat/disc

interface

Body ≤ 450°C Hard-faced 1.4115 Hard-faced

≤ 550°C Stellite hard-

faced

-

28) Operating pressures in accordance with DIN2401 are also permissible.

29) The valves are suitable for temperatures down to -10 °C.

31) Recommended spare parts

Page 41

4 Valve Description

41 of 68

Part No. Description Temperature

[°C]

Material Material number Note

Seat/disc

interface

Valve disc ≤ 550°C Stainless steel

hard-faced

1.4370 Hard-faced

411

31)

Joint ring ≤ 550°C Pure graphite - 501 Segmental ring 13CrMo4-5 1.7335 570 Hanger arm 13CrMo4-5 1.7335 -

4.5.4.2 ZRS

4.5.4.2.1 Operating data

Table33: Operating properties

Characteristic Value

Design pressure [bar] ~ 600

Nominal size DN 50/50-500/450

Max. permissible pressure [bar] ~ 600

Min. permissible temperature [°C] ≥-10

Max. permissible temperature [°C] ≤+650

Larger nominal sizes on request.

Selection as per pressure/temperature ratings (ðSection4.5.4.2.4,Page43)

4.5.4.2.2 Fluids handled

▪ Water

▪ Steam

▪ Other non-aggressive fluids such as gas or oil on request.

4.5.4.2.3 Design details

Design

▪ Body made of forged steel

▪ Pressure seal design

▪ Internally mounted hinge pin

▪ Seat/disc interface made of wear-resistant and corrosion-proof Stellite

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 2014/68/EU(PED) for fluids in Groups1and2.