KSB RWCN, RWCP Original Manual

Instructions manual

MIF-4900/02-I [02-2010]

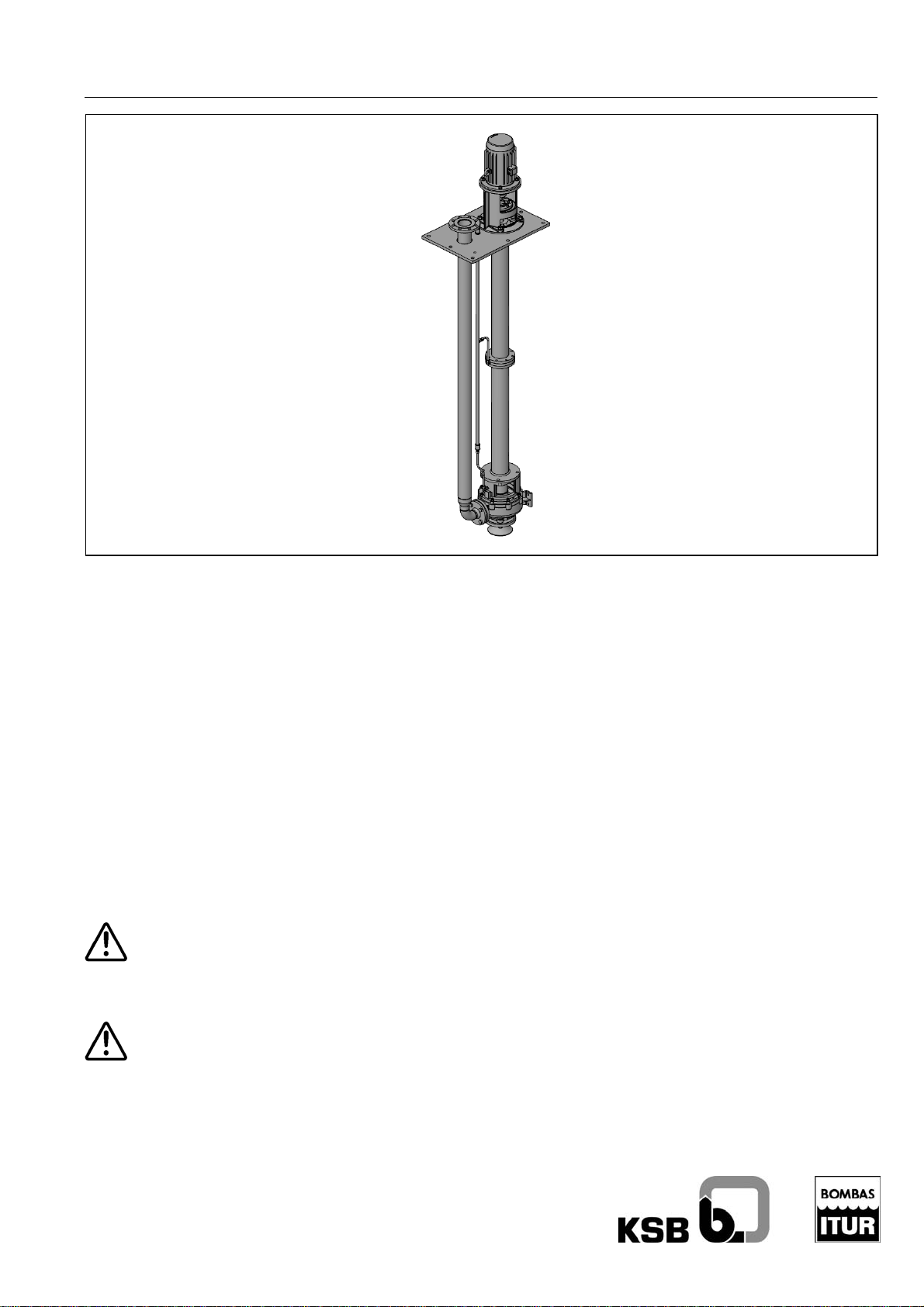

RWCP, RWCN

Vertical pumps for tanks

Original manual

This manual contains important instructions and warnings.

You must read them before mounting, making the electrical

connections and starting up. You must also co mply with the

instructions for the components related to this pump.

You should also remember that it is essential to keep this

Manual close to the motor pump equipment.

Index

RWCP, RWCN

GENERAL.................................................................. 3

1

2 SAFETY ..................................................................... 3

2.1 MARKING OF WARNINGS IN THIS MANUAL..................... 3

2.2 PERSONNEL QUALIFICATIONS AND INSTRUCTION.......... 3

2.3 RISKS OF FAILING TO COMPLY WITH THE SAFETY

INSTRUCTIONS

................................................................. 3

2.4 CONSCIENTIOUS SAFETY AT WORK............................. 3

2.5 SAFETY INSTRUCTIONS FOR USERS AND SERVICE

PERSONNEL

.................................................................... 3

2.6 SAFETY INSTRUCTIONS FOR MAINTENANCE, INSPECTION

AND ASSEMBLY WORK

....................................................... 3

2.7 MODIFICATIONS AND ARBITRARY MANUFACTURE OF

SPARE PARTS

.................................................................. 4

2.8 UNAUTHORISED OPERATION MODES ........................... 4

2.9 WARNINGS FOR EQUIPMENT WITH MARKING ...... 4

3 TRANSPORT AND STORAGE.................................. 5

3.1 TRANSPORT AND HANDLING ...................................... 5

3.2 PROVISIONAL STORAGE/CONSERVATION..................... 5

4 GROUP DESCRIPTION............................................. 5

4.1 GENERAL DESCRIPTION ............................................ 5

4.2 DENOMINATION........................................................ 5

4.3 FORM OF CONSTRUCTION ......................................... 5

4.4 FORCES AND MOMENTS PERMITTED ........................... 6

5 INSTALLATION ......................................................... 7

5.1 CHECK BEFORE ASSEMBLY........................................ 7

5.2 GROUP POSITIONING ................................................ 7

5.2.1 Vertical groups...............................................7

5.3 PIPE JOINT .............................................................. 7

5.3.1 Auxiliary connections.....................................8

5.4 ELECTRICAL CONNECTION:........................................ 8

5.4.1 Motor connection...........................................8

5.4.2 Time relay adjustment...................................9

5.4.3 Rotation direction. Check...............................9

6 START UP.................................................................. 9

6.1 FIRST START-UP ...................................................... 9

6.1.1 Lubricant........................................................9

6.1.2 Filling (priming) of the pump..........................9

6.1.3 Final control...................................................9

6.1.4 Impeller adjustment.....................................10

6.1.5 Start-up........................................................10

6.1.6 Shutdown.....................................................10

6.2 SERVICE LIMITS ......................................................10

6.2.1 Switching frequency ....................................10

6.2.2 Temperature of the liquid to be pumped......10

6.2.3 Density of the liquid to be pumped ..............10

6.2.4 Temperature of the liquid to be pumped......11

6.2.5 Maximum pump speed ................................11

6.3 STARTING UP AFTER STORAGE .................................11

7 MAINTENANCE/CONSERVATION.......................... 11

7.1 GENERAL INSTRUCTIONS.........................................11

7.2 MAINTENANCE/INSPECTION ..................................... 11

7.2.1 Checking instructions.................................. 11

7.2.2 Lubrication .................................................. 11

7.3 EMPTYING/DRAINAGE ............................................. 12

7.4 DI MANTLING......................................................... 12 S

7.4.1 Fundamental instructions/observations....... 12

7.4.2 Coupling...................................................... 12

7.4.3 Mechanical seal (when fitted)...................... 12

7.4.4 Packing (where fitted) .................................12

7.4.5 Pump .......................................................... 13

7.5 ASSEMBLY............................................................. 13

7.5.1 Coupling...................................................... 13

7.5.2 Mechanical seal (when fitted)...................... 14

7.5.3 Packing (where fitted) .................................14

7.5.4 Pump .......................................................... 14

7.5.5 Tightening torque of the screws/nuts.......... 14

7.6 RECOMMENDED SPARE PARTS .................................15

7.7 PREVENTATIVE MAINTENANCE.................................. 15

8 TROUBLE-SHOOTING ............................................16

9 ANNEXES.................................................................17

9.1 SECTIONAL PLANS ..................................................17

9.2 MINIMUM SUBMERGENCE CHART AND EXTERIOR

BEARINGS WATER CONSUMPTION

. .................................... 19

2

1 General

Note

manufactured with great care and put through continuous

Quality Control. The present Instructions Manual will provide

you with knowledge of the pump and the ways it can be

applied.

It contains important instructions to operate the pump

appropriately and profitably. It is important to comply with the

manual in order to guarantee reliability and a long useful life

for the pump, whilst avoiding any possible risks.

This manual does not include any local regulations or any

instructions with regards to assembly personnel, which the

user shall be responsible for.

(rpm), density, pressure and temperature, and with regards to

the motor power or anything else set out in the instructions

manual and contractual documentation. Check with the

manufacturer as appropriate.

The factory plate shows the model/size, the main service data

and the manufacture number of the pump. Please include

these data in any queries, subsequent orders or requests for

spare parts.

If you require any additional information or have problems with

regards to failures, please contact the nearest KSB ITUR

service.

This KSB ITUR pump has been developed in

line with state-of-the-art technology,

This group cannot be used in conditions in excess of

those established in the technical documentation

with regards to the liquid to be pumped, flow, speed

2 Safety

This instructions manual contains fundamental instructions

which must be complied with in assembly, service and

maintenance. It must be read by assembly personnel,

competent technical personnel and users before installing and

starting up, and it must be available at all times at the place of

location of the machine.

Proceed not only in line with this main safety chapter, but also

observing the instructions described in other similarly

important safety points.

2.1 Marking of warnings in this manual

The instructions which may involve hazard if not observed are

highlighted with the following general symbols:

Safety instructions which may involve a hazard to

people and facilities if not complied with in

accordance with ISO 7000-0434.

Safety instructions to prevent electrical hazards in

accordance with IEC 417-5036.

Note

with.

Safety instructions to prevent the risk of explosion.

Only applicable to groups with ATEX plate, specially

designed to satisfy Directive 94/9/EC on the prevention of the

risk of explosion.

The details shown directly on the machine, such as:

- Rotation direction arrow

- Fluid connection identifications

These must be observed, and conserved in a manner which

ensures they are legible.

Safety instructions which may affect the

equipment and its operation if not complied

RWCP, RWCN

2.2 Personnel qualifications and instruction

All Service, Maintenance, Inspection and Assembly personnel

must be duly qualified. The terms regarding responsibility,

competence and supervision of personnel must be regulated

by the user in an exact manner.

Any personnel lacking appropriate know-how must be duly

instructed. This preparation can be obtained upon request by

the machine user to the manufacturer or supplier of the

machine.

Finally, the user must ensure that all personnel have fully

understood the content of the instructions manual.

2.3 Risks of failing to comply with the safety

instructions

Failure to comply with the safety instructions may lead to risks

both for people, the environment and the machine, and may

lead to the loss of any entitlement to claims.

In particular, failure to comply may cause the following

hazards:

- Failure of important machine/facility functions.

- Failure of the prescribed maintenance and conservation

methods.

- Personal hazard resulting from electrical, mechanical or

chemical effects.

- Danger to the environment due to escaping noxious

products.

2.4 Conscientious safety at work

The safety instructions contained in this Manual must be

observed, as must international prescriptions on Health and

Safety at Work and any possible Safety Regulations at the

workplace of the user.

2.5 Safety instructions for users and service

personnel

The operator is responsible for keeping the

temperature of the fluid within the pump classification

temperature limits.

- The installer must ensure that the parts of the machine

which may create danger due to heat or cold are

protected against accidental contact. The operator shall

check as well that the coupling guard is in place and

firmly secured.

- The contact protections of moving parts (e.g. couplings)

must not be removed whilst the machine is in service.

- Provide the personnel with protective equipment and

make sure it is used.

- Any possible leaks (e.g. through the shaft sealing) of

hazardous products must be channelled in such a

manner as they do not present any risk to people or the

environment, in line with corresponding legislation.

- Follow safety instructions due to use of power. In this

respect refer to the applicable national safety regulations

and/or regulations issued by the energy supply comp

2.6 Safety instructions for maintenance,

inspection and assembly work

The user must ensure that all maintenance, inspection and

assembly tasks are carried out by authorised, qualified,

specialised personnel who have been sufficiently informed

through careful study of the instructions manual.

3

It is a fundamental principle that any work on the machine

must be carried out whilst it is shutdown. It is essential to

respect the pump shutdown procedure described in the

instructions manual.

When the pump is stopped it is liable to remain under

pressure. The pump frame must have returned to

environmental temperature. Before dismantling it, is must be

depressurised by making drain openings (or air vents) leading

to a safe area.

All pumps or motor pumps which pump hazardous materials

must be decontaminated.

Connect an earth conductor to the metal casing of the pump

or baseplate if the fluid handled is electrostatically charged.

Never connect the earth of the electric welding equipment to

pump or baseplate.

As soon as the work is complete, all safety and protection

devices must be installed and put into operation.

Before starting up again, all that described in the First Start-Up

section must be fulfilled.

Due to the fact that the unit contains small parts such as

nuts, screws, etc., whose accidental contact may lead to

small cuts on the hands, operators are recommended to

use gloves when handling.

The following additional risk-prevention instructions

shall be fulfilled:

The pumped liquid may cause injuries, burns, poisoning, etc. It

is therefore necessary:

- To check the temperature and amount of leaks occurring

at the mechanical seal or packing area. Conduct such

leaks to a safe area through a controlled drainage

system, specially indicated for the case of break of

mechanical seal.

- To take appropriate measures to avoid direct contact with

the pumped liquid when it is necessary to prime or fill the

pump or unit.

- Before dismantling the pump, if the liquid is toxic or

dangerous, it must be decontaminated. For this purpose

the unit must be cleaned inside by introducing a cleaning

liquid into the pump and emptying it subsequently

through the drainage connection. The cleaning liquid

must not create hazardous situations and must be

compatible with the pump components (CONSULT)

- To take appropriate measures to avoid contact with the

pump if liquids are pumped at temperatures over 40ºC.

- In the event of a liquid with high steam pressure being

used, beware of the danger of explosion due to pressure

confinement with the pump stopped. This confinement

must be avoided by opening inlet or discharge valves, or

by providing a properly conducted air-vent connection in

the pump discharge for liquid evacuation.

For rotating parts:

- The pump should never work without its coupling guard

in place and firmly secured.

- Do not wear loose or baggy clothing or wear long hair

loose near rotation areas to avoid clothes or hair getting

caught and causing serious accidents.

- Do not force jammed rotating parts manually when the

pump is in operation.

When the pump is joined to considerably long piping,

waterhammer may occur when it is stopped. Should this arise,

appropriate anti-waterhammer elements must be put in place.

All the safety regulations indicated by the pump drive

manufacturer must be observed and complied with.

Inappropriate installation may lead to the unit breaking and

consequent risks to persons and/or the environment. It is

therefore necessary to:

- Vent the pumps appropriately before operation, checking

that the pump is full of liquid.

- Check that the pump discharge and suction valves are

fully open and that there is no dirt or foreign bodies in the

piping.

Regarding overload conditions:

- Do not exceed the maximum permitted values

(temperature, suction pressure, discharge pressure,

rpm.) indicated in this instructions manual, offer and

technical catalogue.

- Do not exceed the maximum loads permitted on the

suction and discharge connections.

- The pumps must only be used in the conditions and with

the liquid indicated in the offer and/or order.

An unforeseen failure in the drive power may lead to danger

due to spontaneous start-up of the unit; it is up to the

customer to take the necessary steps to avoid this.

When the CONTROL SYSTEM is not supplied by KSB ITUR,

the customer is responsible for the entire machine complying

with the machine safety directive, including these controls

RWCP, RWCN

2.7 Modifications and arbitrary manufacture of

spare parts

The machine must not be modified or changed without prior

agreement from the manufacturer. Only original spare parts

and accessories approved by the manufacturer can guarantee

safety. The use of other parts invalidates any liability of KSB

ITUR for consequential damage.

2.8 Unauthorised operation modes

The safe service of the supplied pump can only be guaranteed

through correct use, in line with section 0 of the Instructions

Manual. The operation limits established in the Datasheet

must not be exceeded under any circumstance.

2.9 Warnings for equipment with marking

KSB ITUR pumps marked with the ATEX plate are

valid for group II category 2 and 3, zones 1, 21, 2 and

22 temperature class as shown on the plate and Conformity

Certificate.

Reliability may be lost through incorrect use, poor

connections or any modifications, however small.

It is necessary to take into account the rules on the

connection and use of electrical devices in hazardous

areas, in particular national regulations on installation. Only

qualified personnel who are familiar with these rules should

handle this type of machine.

Any repair made by the end user, unless explicitly

approved by KSB ITUR, shall release the

manufacturer from any liability relating to Directive 94/9/EC.

Individual pieces supplied as spare parts must be originals,

supplied and checked by KSB ITUR.

4

P

3 Transport and storage

3.1 Transport and handling

The transport and handling of the equipment must be

carried out using suitable means in line with the

weight to be supported. The weight is generally

shown on the delivery note or on the data plate. If it is not, and

the equipment cannot be handled safely, please contact KSB

ITUR.

Remember that the equipment should never be lifted using the

ring bolts of each of the elements, e.g. the motor and pump

ring bolts, which are exclusively for independent transport.

Note

couplings.

Note

motor and pump support.

Note

the well on the ground, place a wood plug at the height of the

casing in order to prevent the suction hood from being a

support point for the pump.

It is also important not to use the pump and

pipe flanges or joining elements, e.g.

If the equipment is to be lifted using straps,

these must always be run underneath the

Do not position the pump on the filter/suction

hood. When positioning the pump outside of

4 Group description

4.1 General description

Vertical centrifugal pump designed for wells, ditches and

tanks. For neutral or aggressive liquids with significant solid

content.

RWCP, RWCN

When the pumps are dismounted from their transport

pallet, suitable means must be used to ensure the

stability of the equipment, until it is finally secured at

its definitive location.

3.2 Provisional storage/conservation

During provisional storage, it is only necessary to protect with

preservation products those low alloy parts in contact with the

liquid (e.g. grey cast, nodular cast, etc). Preservation products

available on the sector market can be used, in line with the

manufacturer's instructions on application and disposal.

The pump, or motor pump, shall be deposited in a dry site

where the relative humidity is as constant as possible.

When stored outside, it is necessary to keep the pump/motor

pump in an impermeable box, ensuring it does not come into

contact with external humidity.

Note

openings must remain closed, and must not be opened until

necessary during assembly!

The shiny (mechanised) parts and surfaces of the pump must

be protected from corrosion using silicone-free oil or grease.

in vertical position and disconnected.

Protect the stored product from humidity, dirt,

parasites and unauthorised access! All

The electric motor must be disconnected, the

connection cables removed and the terminal box

closed with its cover on. The switchboards must be

RWC

4.2 Denomination

RWCP

RWCN

- 100 / 250 V

Discharge nozzle DN

Series

[mm]

DN impeller [mm]

Impeller type:

- A (semi-open)

- C (channel)

- V (vortex)…

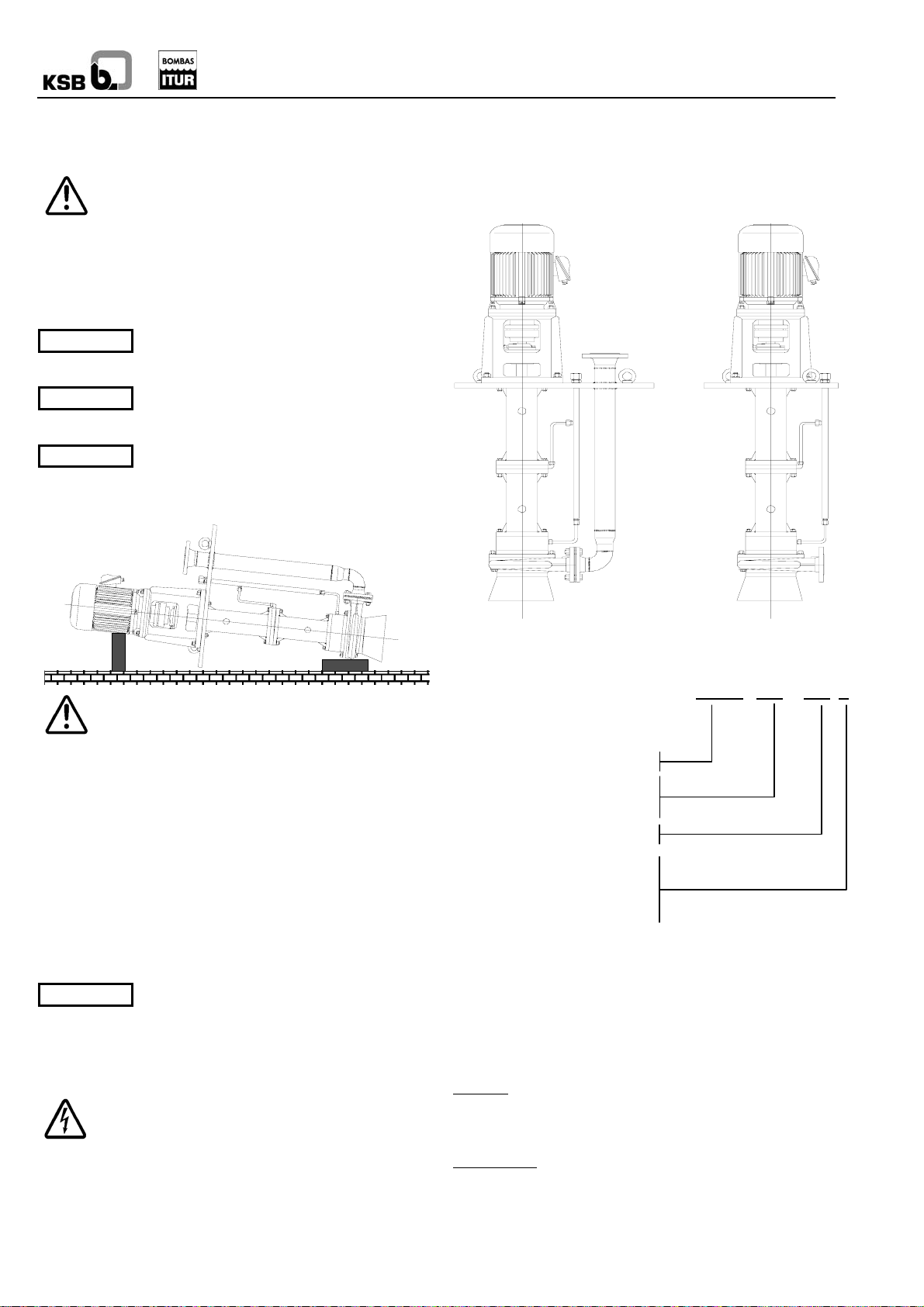

4.3 Form of construction

Volute pump casing with axial suction and radial impulsion.

Single-stage impeller semi-open, channel or vortex. Suction

hood.

The RWCP series has a discharge pipe to the outside of the

base plate.

The RWCN series does not have a discharge pipe.

Bearings

grease-lubricated ballbearings or friction bearings lubricated

by the pumped liquid (when possible) or through the exterior

injection of liquid or grease.

Shaft sealing

retainer. This can be done optionally using a packing or

mechanical seal.

: Both series are fitted with two classes of bearing:

: The standard sealing system is by way of a

5

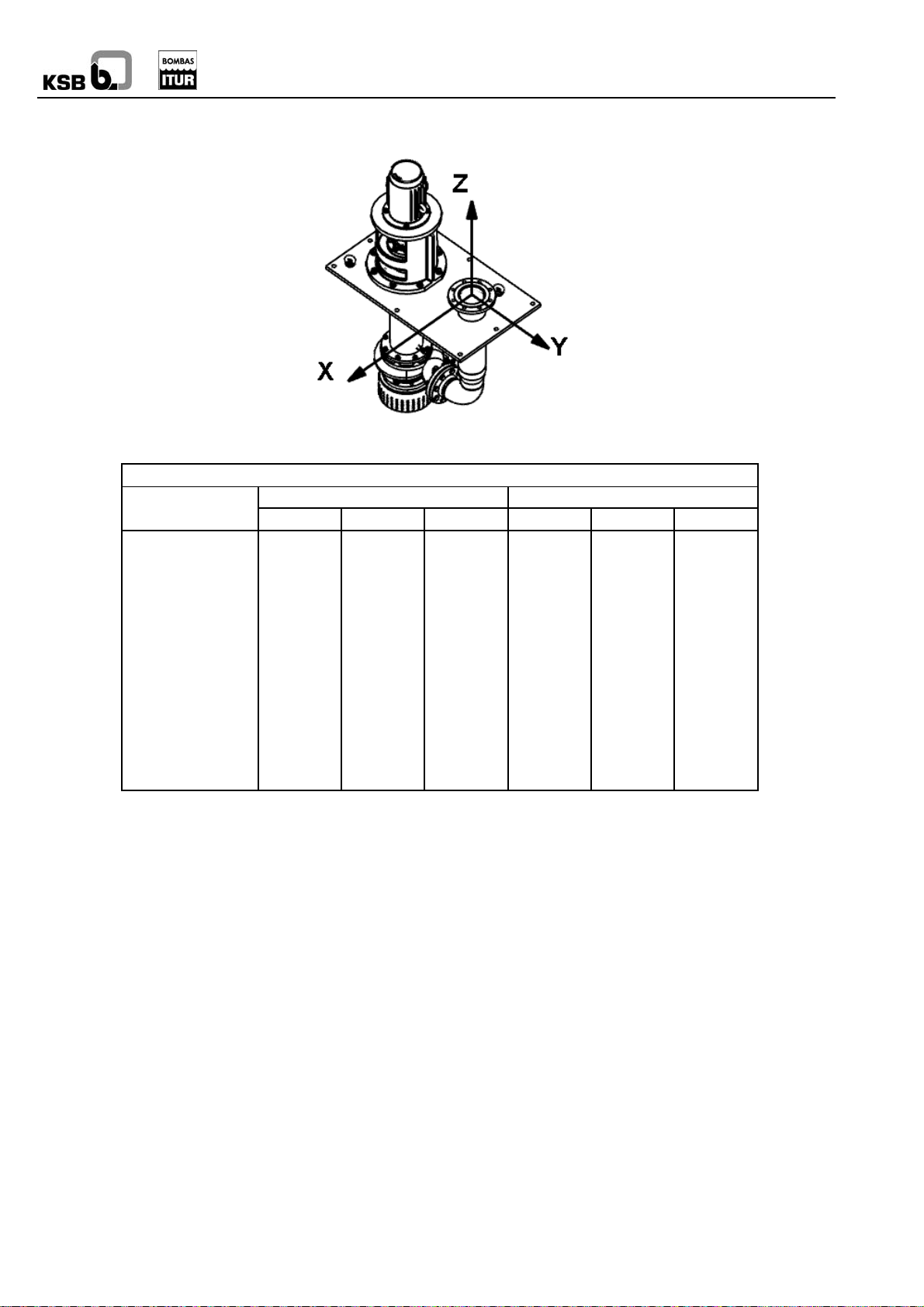

4.4 Forces and moments permitted

Maximum permitted strain in the upper discharge flange, RWCP series exclusively

DN

32 – 1 ¼” 630 510 540 450 510 660

40 – 1 ½” 750 600 660 540 630 780

50 – 2” 990 810 900 600 690 840

65 – 2 ½” 1260 1020 1110 660 720 900

80 – 3” 1500 1230 1350 690 780 960

100 – 4” 2010 1620 1800 750 870 1050

125 – 5” 2370 1920 2130 900 1140 1260

150 – 6” 3000 2430 2700 1050 1230 1500

200 – 8” 4020 3240 3600 1380 1590 1950

250 – 10” 5010 4050 4470 1890 2190 2670

300 – 12” 6000 4830 5370 2580 2970 3630

350 – 14” 6990 5640 6270 3300 3810 4650

400 – 16” 7980 6450 7170 4140 4770 5820

The RWCN series does not admit any strain on the discharge flang e.

Fz Fx Fy Mz Mx My

Force [N] Moment [N·m]

RWCP, RWCN

6

Loading...

Loading...