KSB RPH Series Operating Instructions Manual

Operating instructions

1316.8014/2-10 G3

RPH

RPH process pump

to API 610, 10th edition and DIN ISO 13709

and Directive 94/9/EC

Standard bearing assemblies B 02 to B 06

Tandem bearing assemblies B 02 to B 06

cooled/uncooled

Mechanical seal

Made by KSB

Works No.: __________________________________

Type series: __________________________________

These operating instructions contain fundamental

information and precautionary notes. Please read

the manual thoroughly prior to installation of unit,

connection to the power supply and commissioning. It is

imperative to comply with all other operating instructions

referring to components of this unit.

This manual shall always be kept close to the unit’s

location of operation or directly on the pump set.

Contents

Page

1 General 4

2 Safety 4

2.1 Marking of instructions in the manual 4

2.2 Personnel qualification and training 4

2.3 Non-compliance with safety instructions 4

2.4 Safety awareness 4

2.5 Safety instructions for the operator / user 4

2.6 Safety instructions for maintenance,

inspection and installation work

2.7 Unauthorized modification and manufacture

of spare parts

2.8 Unauthorized modes of operation 5

2.9 Explosion protection 5

2.9.1 Unit fill 5

2.9.2 Marking 5

2.9.3 Checking the direction of rotation 5

2.9.4 Pump operating mode 5

2.9.5 Temperature limits 5

2.9.6 Maintenance 6

3 Transport and interim storage 6

3.1 Transport 6

3.2 Interim storage/Preservation 6

4 Description of the product and

accessories

4.1 Technical specification 6

4.2 Designation 6

4.3 Design details 6

4.3.1 Pump casing 6

4.3.2 Impeller 7

4.3.3 Shaft seal 7

4.3.4 Bearings 7

4.3.5 Permissible forces and moments at the

pump nozzles

4.3.6 Noise characteristics 8

4.4 Accessories 8

4.5 Dimensions and weights 8

5 Installation at site 8

5.1 Safety regulations 8

5.2 Checks to be carried out prior to installation 8

5.3 Installing the pump / unit 9

5.3.1 Aligning the pump / drive 9

5.3.2 Place of installation 9

5.4 Connecting the piping 10

5.4.1 Auxiliary connections 10

5.4.2 Coupling guard 10

5.5 Final check 10

5.6 Connection to power supply 10

6 Commissioning, start-up / shutdown 10

6.1 Commissioning 10

6.1.1 Lubricants 10

6.1.2 Shaft seal 11

6.1.3 Priming the pump and checks to be carried

out

6.1.4 Checking the direction of rotation 11

6.1.5 Cleaning the plant piping 11

6.1.6 Start-up strainer 11

5

6.1.7 Start-up 12

6.1.8 Shutdown 12

5

6.2 Operating limits 12

6.2.1 Temperature of fluid handled / ambient

temperature

6.2.2 Switching frequency 12

6.2.3 Density of fluid pumped 12

6.2.4 Abrasive fluids 12

6.2.5 Minimum/Maximum Flow 12

6.3 Shutdown / Storage /

Preservation

6.3.1 Storage of new pumps 12

6.3.2 Measures to be taken for prolonged

shutdown

6.4 Returning to service after storage 13

6

7 Servicing / maintenance 13

7.1 General instructions 13

7.2 Servicing / inspection 13

7.2.1 Supervision of operation 13

7.2.2 Lubrication and lubricant change 13

7.3 Drainage / disposal 13

7.4 Dismantling 14

7.4.1 Fundamental instructions and

7

7.4.2 Dismantling (general) 14

7.5 Reassembly 14

7.5.1 General instructions 14

7.5.2 Reassembly (general) 15

7.5.3 Tightening torques 15/16

7.5.4 Mechanical seal installation 16

7.5.5 Clearances 17

7.6 Spare parts stock 18

7.6.1 Recommended spare parts stock for 2

7.6.2 Interchangeability of pump components 19

8 Trouble-shooting 20

9 General assembly drawings/lists of

9.1 Material class S, cooled/uncoooled 21

9.2 Bearing bracket B 06, cooled/uncooled 22

9.3 Design variants 23

recommendations

years’ operation

components

RPH

Page

11

12

12

13

14

18

21-24

2

Index

Section Page

Abrasive fluids 6.2.4 12

Accessories 4.4 8

Aligning the pump / drive 5.3.1 9

Auxiliary connections 5.4.1 10

Bearing bracket B 06, cooled/uncooled 9.2 22

Bearings 4.3.4 7

Checking the direction of rotation 2.9.3/

6.1.4

Checks to be carried out prior to installation 5.2 8

Cleaning the plant piping 6.1.5 11

Clearances 7.5.5 17

Commissioning 6.1 10

Commissioning, start-up / shutdown 6 10

Connecting the piping 5.4 10

Connection to power supply 5.6 10

Coupling guard 5.4.2 10

Density of fluid pumped 6.2.3 12

Description of the product and accessories 4 6

Design details 4.3 6

Design variants 9.3 23

Designation 4.2 6

Dimensions and weights 4.5 8

Dismantling 7.4 14

Dismantling (general) 7.4.2 14

Drainage / disposal 7.3 13

Explosion protection 2.9 5

Final check 5.5 10

Fundamental instructions and

recommendations

General 1 4

General assembly drawings/lists of

components

General instructions 7.1/

Impeller 4.3.2 7

Installation at site 5 8

Installing the pump / unit 5.3 9

Interchangeability of pump components 7.6.2 19

Interim storage/Preservation 3.2 6

Lubricants 6.1.1 10

Lubrication and lubricant change 7.2.2 13

Maintenance 2.9.6 6

Marking 2.9.2 5

Marking of instructions in the manual 2.1 4

Material class S, cooled/uncoooled 9.1 21

Measures to be taken for prolonged

shutdown

Mechanical seal installation 7.5.4 16

Minimum/Maximum Flow 6.2.5 12

7.4.1 14

9 21-24

7.5.1

6.3.2 13

11

13/

14

Noise characteristics 4.3.6 8

Non-compliance with safety instructions 2.3 4

Operating limits 6.2 12

Permissible forces and moments at the

pump nozzles

Personnel qualification and training 2.2 4

Place of installation 5.3.2 9

5/

Priming the pump and checks to be carried

out

Pump casing 4.3.1 6

Pump operating mode 2.9.4 5

Reassembly 7.5 14

Reassembly (general) 7.5.2 15

Recommended spare parts stock for

2 years’ operation

Returning to service after storage 6.4 13

Safety 2 4

Safety awareness 2.4 4

Safety instructions for maintenance,

inspection and installation work

Safety instructions for the operator / user 2.5 4

Safety regulations 5.1 8

Servicing / inspection 7.2 13

Servicing / maintenance 7 13

Shaft seal 4.3.3/

Shutdown 6.1.8 12

Shutdown / Storage /

Preservation

Spare parts stock 7.6 18

Start-up 6.1.7 12

Start-up strainer 6.1.6 11

Storage of new pumps 6.3.1 12

Supervision of operation 7.2.1 13

Switching frequency 6.2.2 12

Technical specification 4.1 6

Temperature limits 2.9.5 5

Temperature of fluid handled / ambient

temperature

Tightening torques 7.5.3 15/16

Transport 3.1 6

Transport and interim storage 3 6

Trouble-shooting 8 20

Unauthorized modes of operation 2.8 5

Unauthorized modification and manufacture

of spare parts

Unit fill 2.9.1 5

RPH

Section Page

4.3.5 7

6.1.3 11

7.6.1 18

2.6 5

6.1.2

6.3 12

6.2.1 12

2.7 5

11

7/

3

RPH

1 General

Caution

is manufactured with utmost care and subject to continuous

quality control.

These operating instructions are intended to facilitate

familiarization with the unit and its designated use.

The manual contains important information for reliable, proper

and efficient operation. Compliance with the operating

instructions is of vital importance to ensure reliability and a long

service life of the unit and to avoid any risks.

These operating instructions do not take into account local

regulations; the operator must ensure that such regulations are

strictly observed by all, including the personnel called in for

installation.

This pump / unit must not be operated beyond the limit

values for the fluid handled, capacity, speed, density,

pressure, temperature and motor rating specified in the

technical documentation. Make sure that operation is in

accordance with the instructions laid down in this manual or in

the contract documentation. Contact the manufacturer, if

required.

The name plate indicates the type series / size, main operating

data and works number; please quote this information in all

queries, repeat orders and particularly when ordering spare

parts.

If you need any additional informationor instructions exceeding

the scope of this manual or in case of damage please contact

KSB’s nearest customer service centre.

Noise characteristics see section 4.3.6.

This KSB product has been developed in

accordance with state-of-the-art technology; it

2 Safety

These operating instructions contain fundamental information

which must be complied with during installation, operation,

monitoring and maintenance. Therefore this operating manual

must be read and understood both by the installing personnel

and the responsible trained personnel / operators prior to

installation and commissioning, and it must always be kept

close to the location of operation of the machine / unit for easy

access.

Not only must the general safety instructions laid down in this

chapter on ”Safety” be complied with, but also the safety

instructions outlined under specific headings, particularly if the

pump/unit is operated in potentially explosive atmospheres

(see section 2.9).

The word

Caution

is used to introduce safety instructions whose non-observance

may lead to damage to the machine and its functions.

Instructions attached directly to the machine, e.g.

- arrow indicating the direction of rotation

- markings for fluid connections

must always be complied with and be kept in a perfectly legible

condition at all times.

2.2 Personnel qualification and training

All personnel involved in the operation, maintenance,

inspection and installation of the unit must be fully qualified to

carry out the work involved.

Personnel responsibilities, competence and supervision must

be clearly defined by the operator. If the personnel in question

is not already in possession of the requisite know-how,

appropriate training and instruction must be provided. If

required, the operator may commission the manufacturer /

supplier to take care of such training. In addition, the operator

is responsible for ensuring that the contents of the operating

instructions are fully understood by the responsible personnel.

2.3 Non-compliance with safety instructions

Non-compliance with safety instructions can jeopardize the

safety of personnel, the environment and the machine / unit

itself. Non-compliance with these safety instructions will also

lead to forfeiture of any and all rights to claims for damages.

In particular, non-compliance can, for example, result in:

- failure of important machine/system functions,

- failure of prescribed maintenance and servicing practices,

- hazard to persons by electrical, mechanical and chemical

effects as well as explosion,

- hazard to the environment due to leakage of hazardous

substances.

2.4 Safety awareness

It is imperative to comply with the safety instructions contained

in thismanual, the relevant nationaland international explosion

protection regulations, health and safety regulations and the

operator’s own internal work, operation and safety regulations.

Ex symbol relates to additional requirements which

must be adhered to when the pump is operated in

potentially explosive atmospheres.

2.1 Marking of instructions in the manual

The safety instructions contained in this manual whose

non-observance might cause hazards to persons are specially

marked with the symbol

general hazard sign to ISO 7000-0434

the electrical danger warning sign is

safety sign to IEC 417 - 5036.,

and special instructions concerning explosion protection are

marked

4

2.5 Safety instructions for the operator / user

- Any hot or cold components that could pose a hazard must

be equipped with a guard by the operator.

- Guards which are fitted to prevent accidental contact with

moving parts (e.g. coupling) must not be removed whilst the

unit is operating.

- Leakages (e.g. at the shaft seal) of hazardous fluids

handled (e.g. explosive,toxic, hot) must be contained so as

to avoid any danger to persons or the environment. All

relevant laws must be heeded.

- Electrical hazards must be eliminated. (In this respect refer

to the relevant safety regulations applicable to different

countries and/or the local energy supply companies.)

- Any components in contact with the fluid pumped,

especially in the case of abrasive fluids, shall be inspected

for wear at regular intervals and replaced by original spare

parts (see section 2.7) in due time.

If the pumps/units are located in potentially explosive

atmospheres, it is imperative to make sure that

unauthorized modes of operation are prevented.

Non-compliance may result in the specified temperature limits

being exceeded.

RPH

2.6 Safety instructions for maintenance,

inspection and installation work

The operator is responsible for ensuring that all maintenance,

inspection and installation work be performed by authorized,

qualified specialist personnel who are thoroughly familiar with

the manual.

The pump must have cooled down to ambient temperature,

pump pressure must have been released and the pump must

have been drained.

Work on the machine / unit must be carried out only during

standstill. The shutdown procedure described in the manual for

taking the unit out of service must be adhered to without fail.

Pumps or pump units handling fluids injurious to health must be

decontaminated.

Immediately following completion of the work, all

safety-relevant and protective devices must be re-installed

and/or re-activated.

Please observe all instructions set out in the chapter on

”Commissioning” before returning the unit to service.

2.7 Unauthorized modification and

manufacture of spare parts

Modifications or alterations of the equipment supplied are only

permitted after consultation with the manufacturer and to the

extent permitted by the manufacturer . Original spare parts and

accessories authorized by the manufacturer ensure safety.The

use of other parts can invalidate any liability of the manufacturer

for consequential damage.

2.8 Unauthorized modes of operation

The warranty relating to theoperatingreliability and safety of the

unit supplied is only valid ifthe equipment is used inaccordance

with its designated use as described in the following sections.

The limits stated in the data sheet must not be exceeded under

any circumstances.

2.9 Explosion protection

If the pumps/units are installed in potentially explosive

atmospheres, the measures and instructions given in

the following sections 2.9.1 to 2.9.6 must be adhered to without

fail, to ensure explosion protection.

by starting up the unfilled pump unit, even for a short period, to

prevent temperature increases resulting from contact between

rotating and stationary components.

2.9.4 Pump operating mode

Make sure that the pump is always started up with the

suction-side shut-off valve fully open and the discharge-side

shut-off valve slightly open. However, the pump can also be

started up against a closed swing check valve. The

discharge-side shut-off valve shall be adjusted to comply with

the duty point immediately following the run-up process (see

6.1.7 ).

Pump operation with the shut-off valves in the suction

and/or discharge pipes closed is not permitted.

Caution

after a very short time, due to a rapid temperature rise in the

pumped fluid inside the pump.

Additionally, the resulting rapid pressure build-up inside the

pump may cause excessive stresses on the pump materials or

even bursting.

The minimumflows indicated in section 6.2.5 refer to water and

water-like liquids. Longer operating periods with these liquids

and at the flow rates indicated will not cause an additional

increase in the temperatures on the pump surface. However, if

the physical properties of the fluids handled are different from

water, it is essential to check if an additional heat build-up may

occur and if theminimum flow rate must therefore be increased.

To check, proceed as described in section 6.2.5.

In addition, the instructions given in section 6 of this operating

manual must be observed.

Both gland packings and mechanical seals may

exceed the specified temperature limits if run dry.

Dry running may not only result from an inadequately filled

seal chamber, but also from excessive gas content in the

fluid handled.

Pump operation outside its specified operating range may

also result in dry running.

In potentiallyexplosive atmospheres, gland packingsshall

only be used if combined with a suitable temperature

monitoring device.

In this condition, there is a risk of the pump

casing taking on high surface temperatures

2.9.1 Unit fill

It is assumed that the system of suction and discharge

lines and thus the wetted pump internals are completely

filled with the product to be handled at all times during pump

operation, so that an explosive atmosphere is prevented.

If the operatorcannot warrantthis condition, appropriate

monitoring devices must be used.

Caution

seal and the heating and cooling systems are properly filled.

2.9.2 Marking

The marking on the pump only refers to the pump part,

i.e.the coupling and motor must be regardedseparately.

The coupling must have an EC manufacturer’s declaration.The

driver must be regarded separately.

Example of marking on the pump part:

The marking indicates the theoretically available temperature

range as stipulated by the respective temperature classes.The

temperatures permitted for the individual pump variants are

outlined in section 2.9.5.

2.9.3 Checking the direction of rotation (see also 6.1.4)

If the explosion hazard also exists during the installation

phase, the direction of rotation must never be checked

In addition, it is imperative to make sure that the

seal chambers, auxiliary systems of the shaft

Ex II 2 G T1 - T5

2.9.5 Temperature limits

In normalpump operation, the highest temperatures are

to be expected on the surfaceof the pump casing, at the

shaft seal and in the bearingareas. The surface temperature at

the pump casing corresponds to the temperature of the fluid

handled.

If the pump is heated, it must be ensured that the temperature

classes stipulated for the plant are observed.

In the bearing bracket area, the unit surfaces must be freely exposed to the atmosphere.

In any case, responsibility for compliance with the

specified fluid temperature (operating temperature) lies

with the plant operator. The maximum permissible fluid

temperature depends on the temperature class to be

complied with.

The table below lists the temperature classes to EN 13463-1

and the resulting theoretical temperature limits of the fluid

handled. In stipulating these temperatures, any temperature

rise in the shaft seal area has already been taken into account.

Temperature class

to EN 13463-1:

T5

T4

T3

T2

T1

*) depending on material variant

Temperature limit of fluid handled

85 °C

120 °C

185 °C

280 °C

max. 400 °C

*)

5

Safety note:

Caution

sheet. If the pump is to be operatedat a higher temperature,the

data sheet is missing or if the pump is part of a pool of pumps,

the maximum permissible operating temperature must be

enquired from the pump manufacturer.

Based on an ambient temperature of 40 °C and proper

maintenance and operation, compliance with temperature

class T4 is warranted in the area of the rolling element bearings.

A special design is required to comply with temperature class

T6 in the bearing area. In such cases, and if ambient

temperature exceeds 40 °C, contact the manufacturer.

2.9.6 Maintenance

Only a pump unit which is properly serviced and maintai-

ned in perfect technical condition will give safe and reliable operation.

This also applies to the reliable function of the rolling element

bearings whose actual lifetime largely depends on the operating mode and operating conditions.

Regular checks of the lubricant and the running noises will prevent the risk of excessive temperatures as a result of bearings

running hot or defective bearing seals (also see section

7.2.2.2).

The correct function of the shaft sealmust be checked regularly.

Any auxiliary systems installed must be monitored, if necessary, to make sure they function correctly.

Gland packings must be tightened correctly, to prevent excessive temperatures due to packings running hot.

The permissible operating temperature of the

pump in question is indicated on the data

3 Transport and interim storage

RPH

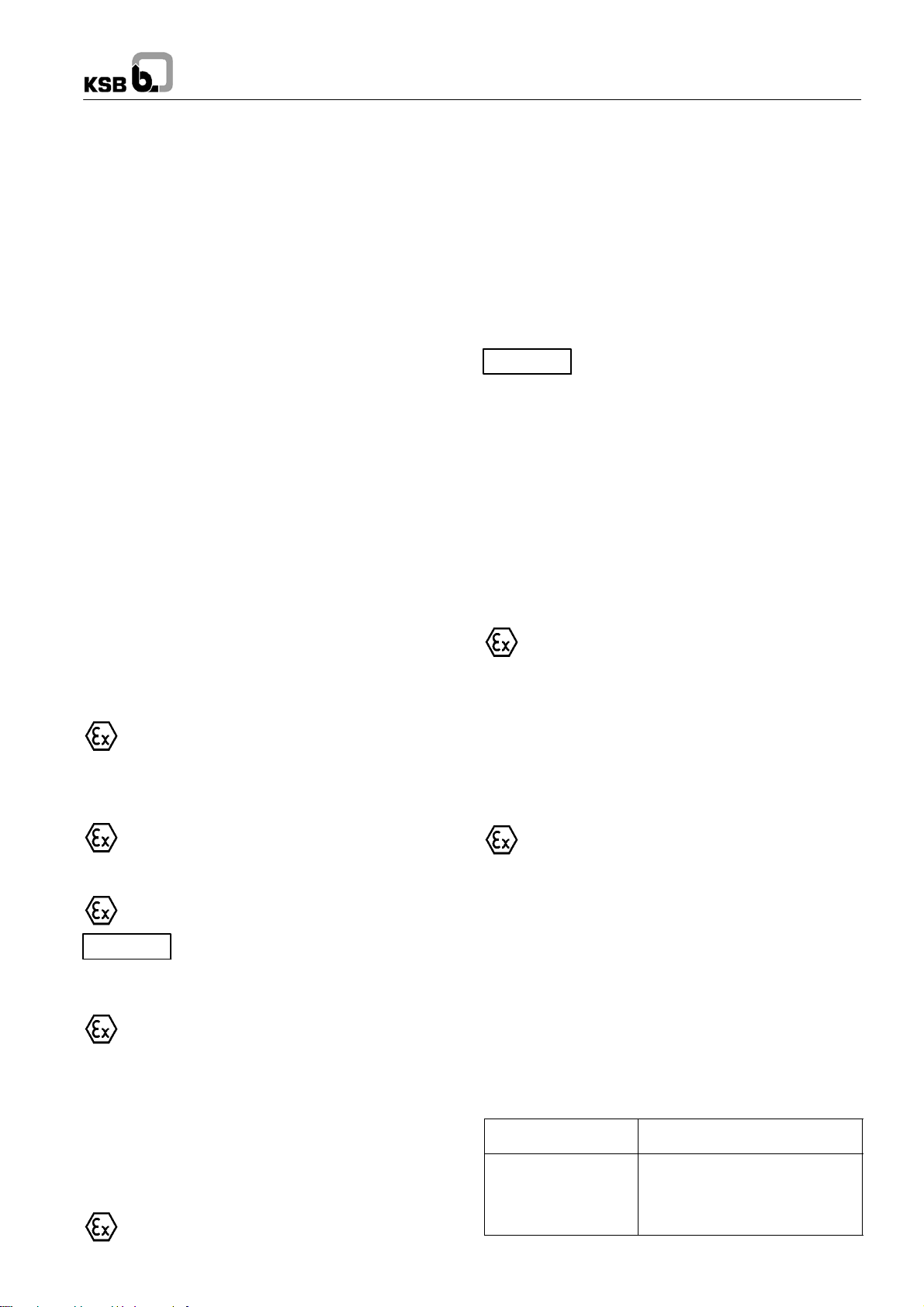

Fig. 2 Transport of the complete unit

3.2 Interim storage (indoors) / Preservation

When the unit is temporarily put into storage, only the wetted

low alloy components (e.g. JL 1040, JS 1030, A 216 Gr. WCB,

etc.) must be preserved. Commercially available preservatives

can be used for this purpose. Please observe the

manufacturer’s instructions for application/removal.

The relevant procedure is described in section 6.3.

The unit / pump should be stored in a dry room where the

atmospheric humidity is as constant as possible.

If stored outdoors, the unit and crates must be covered by

waterproof material to avoid any contact with humidity.

Caution

of the assembled unit components are closed and must onlybe

opened when required during installation.

All blank parts and surfaces of the pump are oiled or greased

(silicone-free oil and grease) to protect them against corrosion.

Protect all stored goods against humidity, dirt,

vermin and unauthorized access! All openings

3.1 Transport

Transport of the unit requires proper preparation and handling.

Always make sure that the pump or the unit remains in

horizontal position during transport and cannot slip out of the

transport suspension arrangement. Do not use a lifting sling on

the free shaft end of the pump or on the motor eyebolt.

If the pump / unit slips out of the suspension

arrangement, it may cause personal injury and damage

to property!

D00311

Fig. 1 Transport of the pump

4 Description of the product and

accessories

4.1 Technical specification

RPH pumps are used for handling the large variety of crude oil

products, mainly in refineries and chemical and petrochemical

plants.

4.2 Designation

RPH S1 I 80 - 280 B

Type series

Material variant

Version with inducer

Discharge nozzle DN

Nominal impeller dia. in mm

Special hydraulics (B-hydraulics)

4.3 Design details

Horizontal, radially split volute casing pumps in back pull-out

design, to API 610, 10th edition and ISO 13709, with radial

impeller, single-flow, single-stage, centreline pump feet.

4.3.1 Pump casing

Radially split, consisting of volute casing with casing wear ring

and casing cover. The volute casing, the casing cover and the

seal cover form the internal pump chamber.

The wall thickness of the casing includes a corrosion allowance

of 3 mm (0.12 in.).

On some pump sizes, pump casings have a double volute, in

order to compensate radial forces.

6

RPH

The casing cover is designed for holding the discharge-side

casing wear ring, ifthis is required for balancing the axial thrust.

The casing cover includes the heating or cooling chamber for

the shaft s eal, if required.

For handling combustible fluids, the pump casing must

be made of ductile material with a maximum magnesium

content of 7.5 % (see EN 13463-1). This is a standard feature

in all KSB supplies.

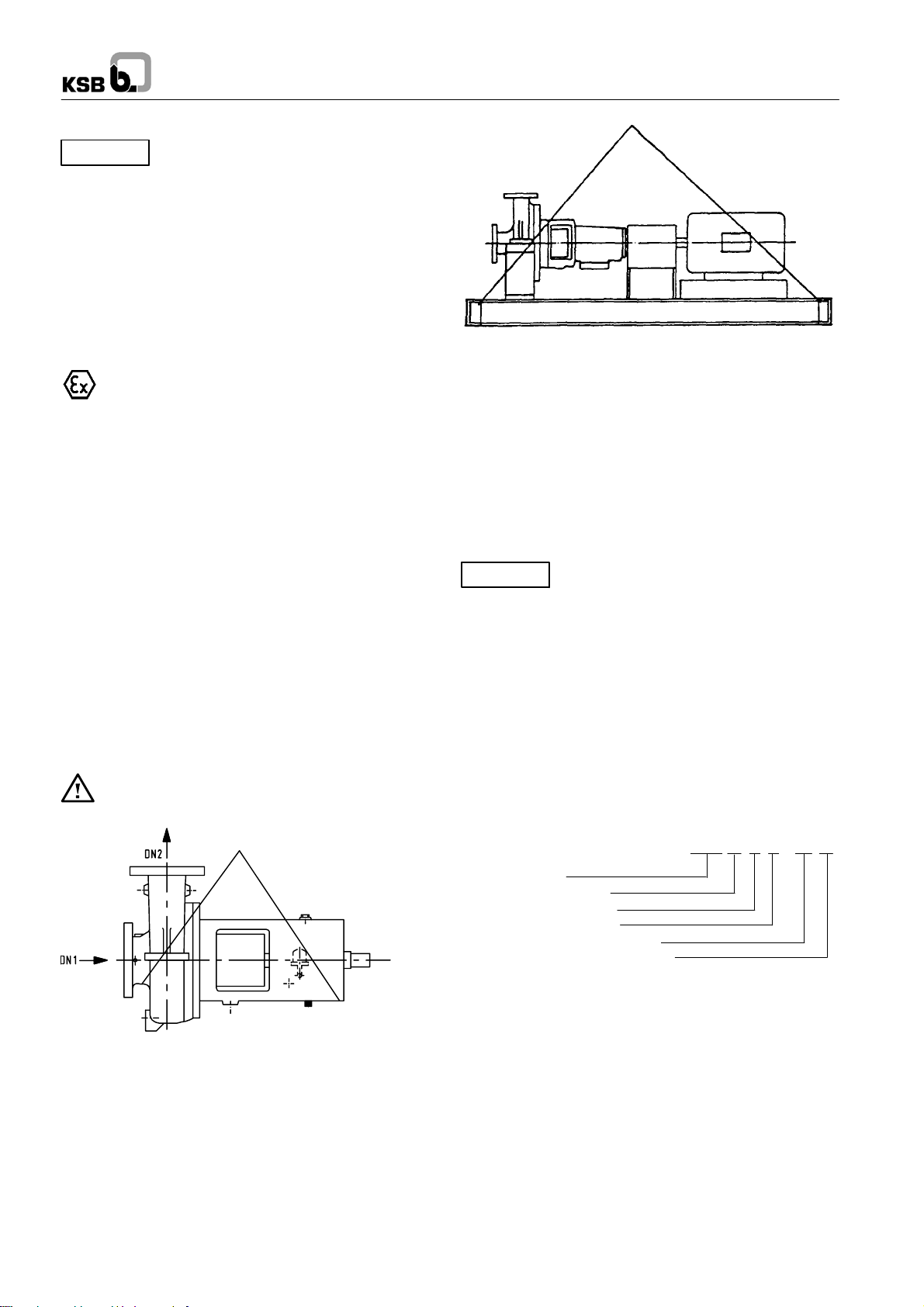

4.3.1.1 Position of pump feet

Generally centreline pump feet.

Centreline pump feet are generally specified by API 610,

10th edition.

Fig. 3 Casing with centreline pump feet

4.3.1.2 Nozzle positions

Axial inlet nozzle, radial discharge nozzle pointing vertically

upwards on pumps from DN 250 or

with a nominal impeller

diameter from 500 and on pump size 200-401. All other pumps

with tangential discharge nozzle pointing vertically upwards.

4.3.2 Impeller

Closed radial impeller. Impellers are supplied with wear rings

both on the suction and the discharge sideor only on the suction

side.

Wear rings are locked with grub screws.

(can also be locked with three weld spots).

Balancing:

Axial thrust is balanced by means of sealing gap and balancing

holes. The size of the balancing holes depends on the inlet

pressure.

For high inlet pressures and thus impellers withoutbalancing of

axial thrust, the discharge-side casing and impeller wear rings

are not fitted.

4.3.4.2 Bearing bracket designation

B03

Back pull-out bearing bracket

Size code (based on dimensions of seal chamber,

shaft end and bearings)

For the applicable bearing bracket version please refer to the

data sheet.

4.3.4.3 Bearings used and bearing design

KSB designation

FAG designation SKF designation

B.MUA B. MP. UA BECBM

Standard bearing assembly

Bearing

bracket

B02

B03

B05

B06

Rolling element bearing

Pump end Motor end

NU 211 C3

NU 213 C3

NU 316 C3

NU 324 C3

2 x 7309 B-MUA

2x7311B-MUA

2 x 7315 B-MUA

2 x 7224 B-MUA

Reinforced bearing assembly (triple bearing assembly)

Bearing

bracket

B02

B03

B05

B06

Rolling element bearing

Pump end Motor end

NU 211 C3

NU 213 C3

NU 316 C3

NU 324 C3

3 x 7309 B-MUA

3x7311B-MUA

3 x 7315 B-MUA

3 x 7224 B-MUA

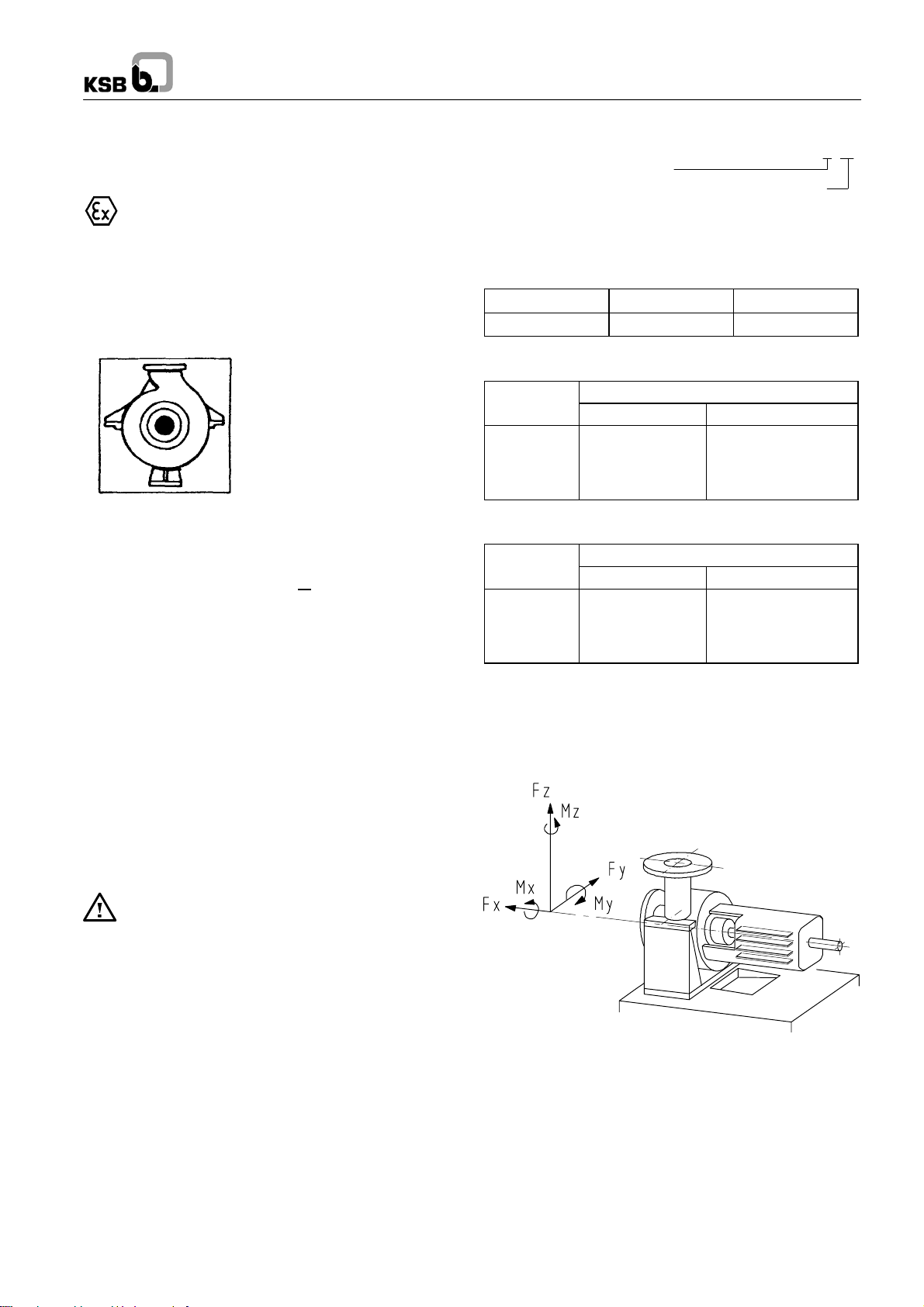

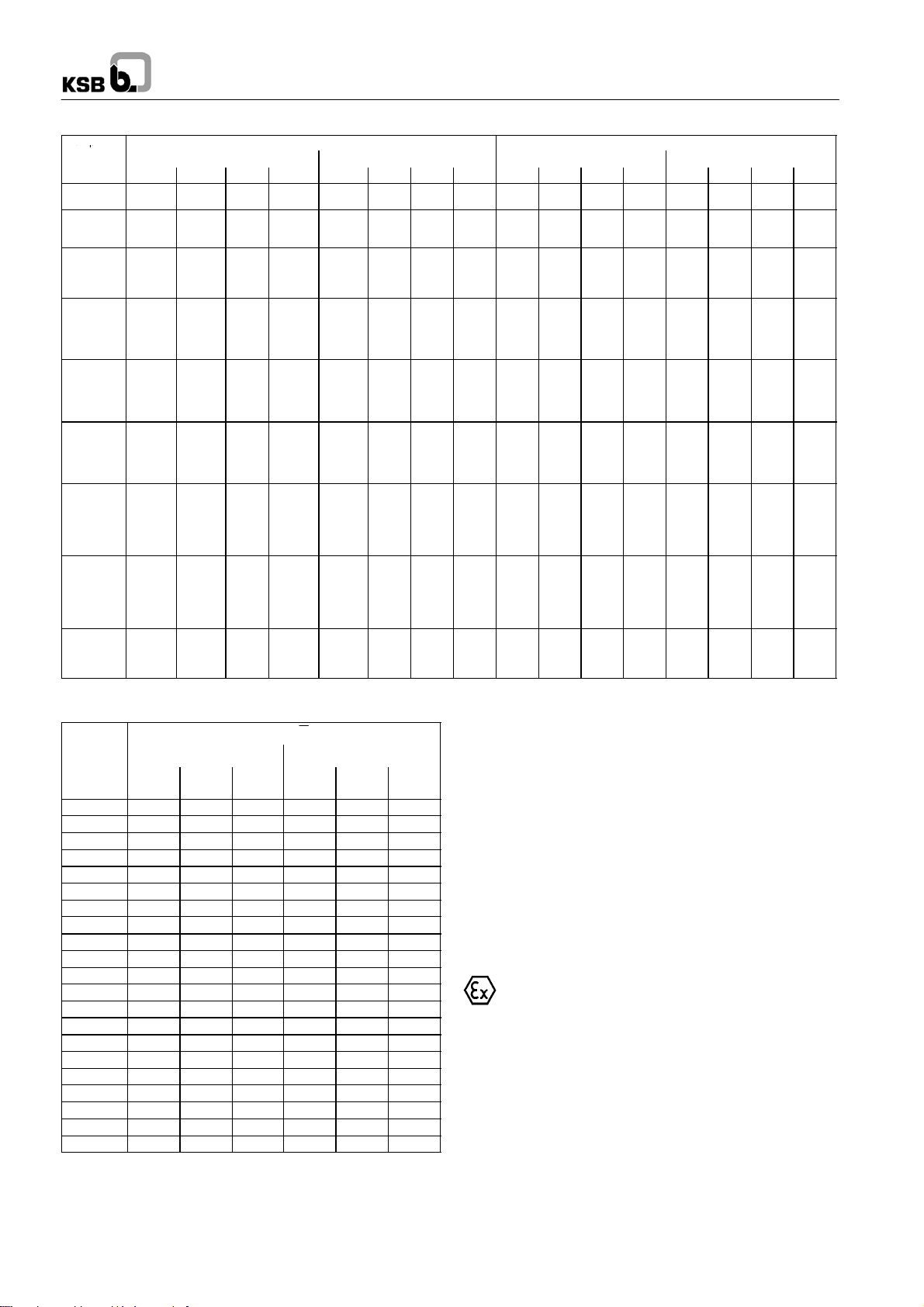

4.3.5 Permissible forces and moments at the pump

nozzles

RPH pumps are designed towithstand higher piping forces and

moments than required by API 610, tables 2-1A and 2-1B.

Forces and moments of RPH

Discharge nozzle

4.3.3 Shaft seal - Mechanical seal

Mechanical seal designs and types other than specified

herein shall only be used in exceptional cases and only

after prior consultation with the KSB factory.

The relevant seal version is shown in the mechanical seal

drawing.

4.3.4 Bearings

4.3.4.1 Design specifications

The shaft is supported byoil lubricatedrolling element bearings.

The motor end bearing is a fixed bearing whose axial bearing

clearance limits the axial movement of the rotor. The standard

motor end bearing is a paired angular contact ball bearing. For

high inlet pressures, a triple bearing assembly is used (see

section 9, design variants).

The bearing bracketsare provided withoil bath lubrication.Both

oil ring lubrication and oil mist lubrication are available as

special pump designs.

On the standard pump design, the bearing bracket is uncooled.

A cooled bearing bracket is available as special pump design.

During pump standstill the oil level can be checked against the

mark next to the oil level sight glass.

Suction nozzle

D01046

7

RPH

Pum

p

Pump

sizes

100-180

100-230

100-280

100-360

100-450

150-230

150-280

150-360

150-450

150-501

150-630

200-280

200-360

200-401

200-450

200-501

200-670

250-401

250-501

250-630

250-710

25-180

25-230

40-180

40-230

40-280

40-181

40-231

40-281

40-361

50-180

50-230

50-280

50-360

50-450

80-180

80-230

80-280

80-360

80-450

Forces (in N) Moments (in Nm) Forces (in N) Moments (in Nm)

F

1780 1430 1160 2560 920 460 710 1250 1430 1160 1780 2560 920 460 710 1250

1780 1430 1160 2560 920 460 710 1250 1430 1160 1780 2560 920 460 710 1250

1780 1430 1160 2560 920 460 710 1250 1430 1160 1780 2560 920 460 710 1250

2670 2140 1780 3860 1900 950 1440 2570 1430 1160 1780 2560 920 460 710 1250

3560 2840 2320 5110 2660 1360 2010 3600 2140 1780 2670 3860 1900 950 1440 2570

6230 4980 4090 8960 4610 2360 3530 6270 2850 2310 3560 5110 2660 1360 2010 3600

9790 7560 6230 13850 7050 3530 5150 9420 4980 4100 6230 8970 4610 2360 3530 6270

13350 10680 8900 19270 10030 4880 7590 13490 7560 6230 9790 13850 7060 3530 5150 9420

16000 13340 10680 23410 12200 5960 9220 16412 10680 8900 13340 19267 10040 4880 7600 13505

F

x

y

Suction nozzle Discharge nozzle

F

F

z

M

M

res

x

y

MzM

F

res

F

x

y

Fig. 4 Forces and moments Coordinate axes as per API 610

4.3.6 Noise characteristics

Rated

power

input P

N

(kW) 2900

Sound pressure level pA (dB)

L

Pump only Pump with motor

1450

1/min

1/min

960/760

1/min

2900

1/min

1.5 53.5 52.5 51.5 63.0 58.0 55.5

2.2 55.5 54.5 53.0 66.0 60.0 58.0

3.0 57.0 56.0 54.5 67.5 61.5 59.5

4.0 59.0 57.5 56.0 69.0 63.0 61.0

5.5 60.5 59.0 57.5 70.5 64.5 62.0

7.5 62.0 61.0 59.0 72.0 66.0 63.5

11. 0 64.0 63.0 61.0 74.0 67.5 65.0

15.0 66.0 64.5 62.5 75.0 69.0 66.5

18.5 67.0 65.5 63.5 76.0 70.0 67.5

22.0 68.0 66.5 64.5 76.5 70.5 68.0

30.0 70.0 68.0 66.0 78.0 72.0 69.5

37.0 71.0 69.5 67.0 78.5 72.5 70.0

45.0 72.0 70.5 68.0 79.5 73.5 71.0

55.0 73.0 71.5 69.0 80.0 74.0 71.5

75.0 74.5 73.0 70.5 81.0 75.5 72.5

90.0 75.5 74.0 71.0 81.5 76.0 73.0

110.0 77.0 75.0 72.0 82.0 76.5 74.0

132.0 78.0 76.0 73.0 82.5 77.0 74.5

160.0 79.0 77.0 74.0 83.5 78.0 75.0

200.0 80.0 78.0 75.0 84.0 78.5 75.5

250.0 80.5 78.5 - 84.5 79.5 -

1) measured at a distance of 1 m from the pump outline as per DIN 45635,

Part 1 and 24. Room and foundation influences have not been

included. The tolerance for these factors is 1 to 2 dB.

2) Increase for 60 Hz operation

Pump without motor: --Pump with motor:

3500min

-1

: +3dB, 1750min-1: +1dB, 1160min-1: --- dB

8

1) 2)

1450

1/min

960/760

1/min

4.4 Accessories

Coupling: flexible coupling with/without spacer

Contact guard: coupling guard

Baseplate: welded for the complete unit (pump

If a complete unit is supplied, coupling and coupling guard

are provided by the supplier.

Special accessories: as required

4.5 Dimensions and weights

For dimensions and weights please refer to the general

arrangement drawing of the pump.

5 Installation at site

5.1 Safety regulations

Equipment operated in potentially explosive

atmospheres must comply with the relevant

explosion protection regulations. This is indicated on the

pump name plate and motor name plate (see 2.9).

5.2 Checks to be carried out prior to installation

All structural work required must have been prepared in

accordance with the dimensions stated in the dimension

table / general arrangement plan.

The concrete foundations shall have sufficient strength

(min. class X0) to ensure safe and functional installation in

accordance with DIN 1045 or equivalent standards.

Make sure that the concrete foundation has set firmly before

placing the unit on it. Its surface shall be truly horizontal and

even. The foundation bolts shall be inserted in the baseplate.

RPH

F

F

M

M

z

res

x

sleeve

and motor), in torsion-resistant design

y

MzM

res

Loading...

Loading...