Page 1

Self-cooling Motor-independent

Frequency Inverter

PumpDrive 2

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual PumpDrive 2

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB Aktiengesellschaft, Frankenthal 21/08/2017

Page 3

Contents

3 of 212

PumpDrive 2

Contents

Glossary .................................................................................................................................................. 5

1 Safety...................................................................................................................................................... 6

1.1 Key to safety symbols/markings.......................................................................................................................6

1.2 General..............................................................................................................................................................6

1.3 Intended use .....................................................................................................................................................6

1.4 Personnel qualification and training...............................................................................................................7

1.5 Consequences and risks caused by non-compliance with this operating manual........................................ 7

1.6 Safety awareness ..............................................................................................................................................7

1.7 Safety information for the user/operator.......................................................................................................7

1.8 Safety information for maintenance, inspection and installation ................................................................7

1.9 Unauthorised modes of operation..................................................................................................................8

1.10 Software Changes.............................................................................................................................................8

1.11 Electromagnetic compatibility (EMC)..............................................................................................................8

1.11.1 Interference emission requirements ...................................................................................................8

1.11.2 Line harmonics requirements..............................................................................................................9

1.11.3 Interference immunity requirements .................................................................................................9

2 Transport/Temporary Storage/Disposal............................................................................................. 10

2.1 Checking the condition upon delivery..........................................................................................................10

2.2 Transport.........................................................................................................................................................10

2.3 Storage............................................................................................................................................................11

2.4 Disposal/recycling ...........................................................................................................................................12

3 General.................................................................................................................................................. 13

3.1 Principles .........................................................................................................................................................13

3.2 Target group...................................................................................................................................................13

3.3 Other applicable documents..........................................................................................................................13

3.4 Symbols ...........................................................................................................................................................13

4 Operation.............................................................................................................................................. 14

4.1 Graphical control panel..................................................................................................................................14

4.1.1 Graphical display................................................................................................................................ 14

4.1.2 Menu keys ..........................................................................................................................................16

4.1.3 Service interface and LED traffic light function...............................................................................21

5 Commissioning report ......................................................................................................................... 23

6 Description............................................................................................................................................ 24

6.1 General description ........................................................................................................................................24

6.2 Designation.....................................................................................................................................................24

6.3 Name plate......................................................................................................................................................26

6.4 Power range and sizes....................................................................................................................................26

6.5 Technical data.................................................................................................................................................27

6.6 Dimensions and weights ................................................................................................................................30

6.7 Mounting options...........................................................................................................................................31

7 Installation at Site................................................................................................................................ 32

7.1 Safety regulations...........................................................................................................................................32

7.2 Checks to be carried out prior to installation...............................................................................................32

7.3 Mounting PumpDrive.....................................................................................................................................32

7.3.1 Motor mounting ................................................................................................................................ 32

7.3.2 Wall/control cabinet mounting.........................................................................................................32

7.4 Electrical connection ......................................................................................................................................33

7.4.1 Safety regulations ..............................................................................................................................33

7.4.2 Information for planning the system ...............................................................................................34

7.4.3 Electrical connection.......................................................................................................................... 38

8 Commissioning/Shutdown.................................................................................................................. 64

8.1 Commissioning wizard ...................................................................................................................................64

Page 4

Contents

4 of 212

PumpDrive 2

8.2 Control point concept ....................................................................................................................................65

8.3 Setting motor parameters..............................................................................................................................65

8.4 Motor control method ...................................................................................................................................66

8.5 Automatic motor adaptation (AMA) of frequency inverter........................................................................67

8.5.1 Automatic motor adaptation (AMA) of frequency inverter for asynchronous motors.................68

8.5.2 Automatic motor adaptation (AMA) of frequency inverter for KSB SuPremE motors .................69

8.6 Entering the setpoint .....................................................................................................................................70

8.7 Pump operation..............................................................................................................................................72

8.7.1 Single-pump operation......................................................................................................................72

8.7.2 Multiple pump configuration ...........................................................................................................82

8.8 Application functions.....................................................................................................................................87

8.8.1 Aligning the frequency inverter with the pump .............................................................................87

8.8.2 Protective functions ...........................................................................................................................89

8.8.3 Flow rate estimation.......................................................................................................................... 96

8.8.4 Energy optimisation...........................................................................................................................98

8.8.5 Ramps ...............................................................................................................................................109

8.8.6 Motor standstill heater.................................................................................................................... 112

8.9 Device functions ...........................................................................................................................................112

8.9.1 Factory and user settings................................................................................................................. 112

8.9.2 Read out PumpMeter ......................................................................................................................113

8.9.3 Date and time ..................................................................................................................................114

8.10 Digital and analog inputs/Digital and analog outputs ..............................................................................114

8.10.1 Digital inputs.................................................................................................................................... 114

8.10.2 Analog inputs................................................................................................................................... 118

8.10.3 Relay outputs ...................................................................................................................................120

8.10.4 Analog outputs ................................................................................................................................ 122

8.10.5 Inputs and outputs of the I/O extension board .............................................................................123

8.11 Parameterising the M12 module.................................................................................................................127

8.12 Parameterising the field bus module..........................................................................................................130

9 Servicing/Maintenance...................................................................................................................... 133

9.1 Safety regulations.........................................................................................................................................133

9.2 Servicing/inspection......................................................................................................................................133

9.2.1 Supervision of operation .................................................................................................................133

9.3 Dismantling...................................................................................................................................................134

9.3.1 Preparing frequency inverter for dismantling ............................................................................... 134

10 Parameter List..................................................................................................................................... 135

10.1 Selection lists.................................................................................................................................................188

11 Trouble-shooting................................................................................................................................ 189

11.1 Faults/malfunctions: Trouble-shooting .......................................................................................................189

11.2 Alerts .............................................................................................................................................................190

11.3 Warnings.......................................................................................................................................................193

11.4 Information messages ..................................................................................................................................195

12 Purchase Order Specifications........................................................................................................... 196

12.1 Ordering spare parts ....................................................................................................................................196

12.2 Accessories ....................................................................................................................................................197

12.2.1 Service software ...............................................................................................................................197

12.2.2 Control panels ..................................................................................................................................197

12.2.3 Motor adapter kits........................................................................................................................... 197

12.2.4 Adapter for wall and cabinet mounting ........................................................................................ 199

12.2.5 M12 module ..................................................................................................................................... 199

12.2.6 Installation options ..........................................................................................................................200

12.2.7 Sensor system ................................................................................................................................... 202

12.2.8 Control cabinet mounting...............................................................................................................205

13 EU Declaration of Conformity........................................................................................................... 207

Index ................................................................................................................................................... 208

Page 5

Glossary

5 of 212

PumpDrive 2

Glossary

Braking resistor

Takes up the braking power produced during

generator operation.

Hydraulic blockage

Undesirable operating situation in which the

pump cannot supply fluid due to a closed inlet or

outlet.

KSB device bus

Proprietary CAN bus that is used in dual and

multiple pump configurations for facilitating

communication among the frequency inverters.

The KSB device bus cannot be used for external

communication or for communication with the

KSB local bus (PumpDrive 1).

Pump

Machine without drive, additional components or

accessories

Pump set

Complete pump set consisting of pump, drive,

additional components and accessories

RCD

Abbreviation for "residual current device"

Page 6

1 Safety

6 of 212

PumpDrive 2

1 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

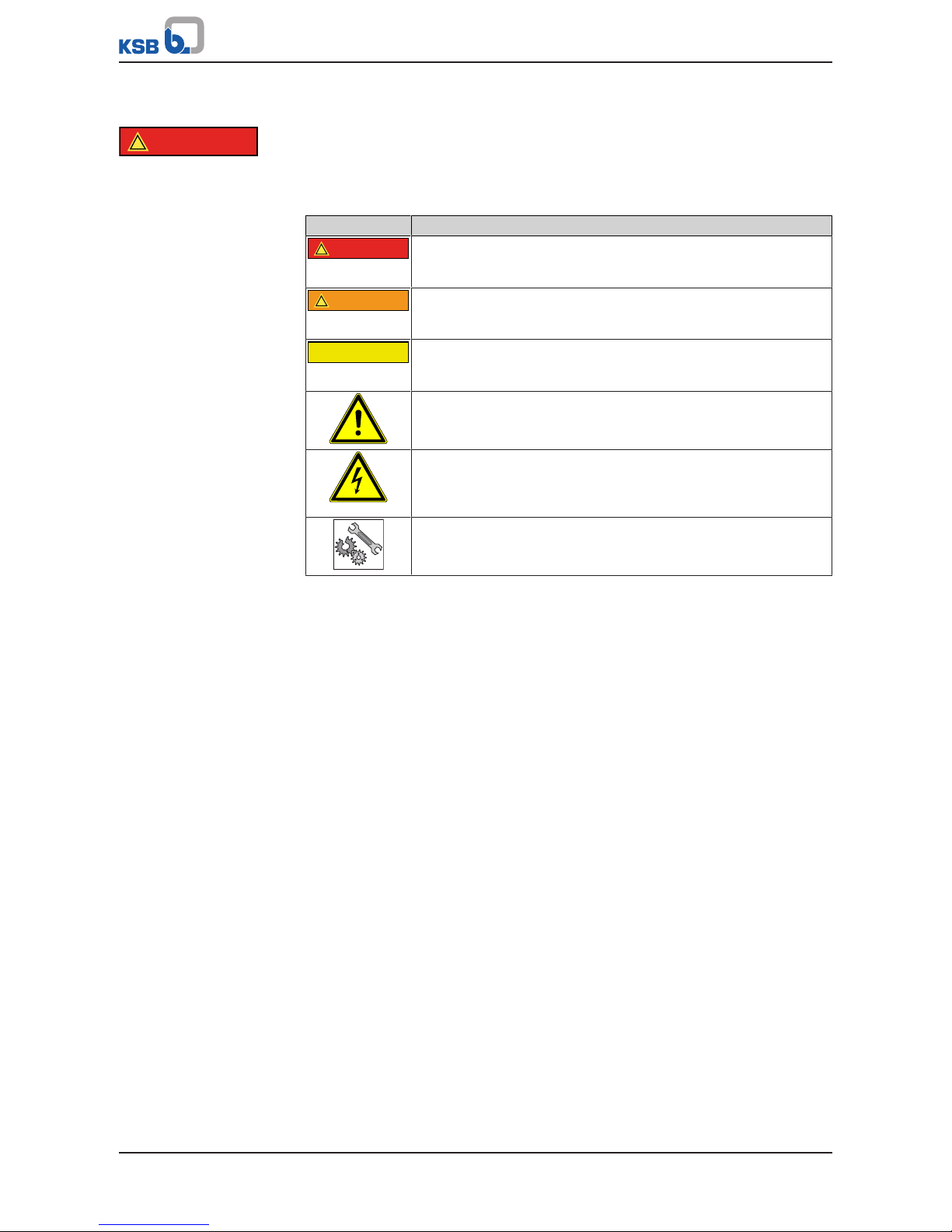

1.1 Key to safety symbols/markings

Table1: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

1.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

1.3 Intended use

▪ This product must only be operated within the limit values stated in the technical

product literature for the mains voltage, mains frequency, ambient temperature,

motor rating, fluid handled, flow rate, speed, density, pressure, temperature and

in compliance with any other instructions provided in the operating manual or

other applicable documents.

▪ The product must not be used in potentially explosive atmospheres.

Page 7

1 Safety

7 of 212

PumpDrive 2

1.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the product this manual refers to. The responsibilities, competence and

supervision of all personnel involved in installation, operation, maintenance and

inspection must be clearly defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the product must always be supervised by specialist technical personnel.

1.5 Consequences and risks caused by non-compliance with this operating

manual

▪ Non-compliance with this operating manual will lead to forfeiture of warranty

cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

1.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and legislation (e.g. EN50110-1)

1.7 Safety information for the user/operator

▪ The operator shall fit contact guards for hot, cold and moving parts and check

that the guards function properly.

▪ Do not remove any contact guards during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

1.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Any work on the product shall only be performed when it has been disconnected

from the power supply (de-energised).

▪ Carry out work on the product during standstill only.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning.

Page 8

1 Safety

8 of 212

PumpDrive 2

1.9 Unauthorised modes of operation

Never operate the product outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the product supplied

is only valid if the product is used in accordance with its intended use.

1.10 Software Changes

The software has been specially created for this product and thoroughly tested.

It is impermissible to make any changes or additions to the software or parts of the

software. Software updates supplied by KSB are excluded from this rule.

1.11 Electromagnetic compatibility (EMC)

The Electromagnetic Compatibility Directive 2004/108/EC defines the requirements

concerning the interference immunity and interference emissions of electric and

electronic equipment.

1.11.1 Interference emission requirements

The EN61800-3 EMC product standard is relevant for electric variable speed drives/

control systems. It specifies all pertinent requirements and refers to the relevant

generic standards for complying with the EMC Directive.

Frequency inverters are commonly used by operators as a part of a system, plant or

machine assembly. It should be noted that the operator bears all responsibility for

the final EMC properties of the equipment, plant or installation.

A prerequisite or requirement for complying with the relevant standards or the limit

values and inspection/test levels referenced by them is that all information and

descriptions regarding EMC-compliant installation be observed and followed.

(ðSection7.4,Page33)

In accordance with the EMC product standard, the EMC requirements to be met

depend on the purpose or intended use of the frequency inverter. Four categories

are defined in the EMC product standard:

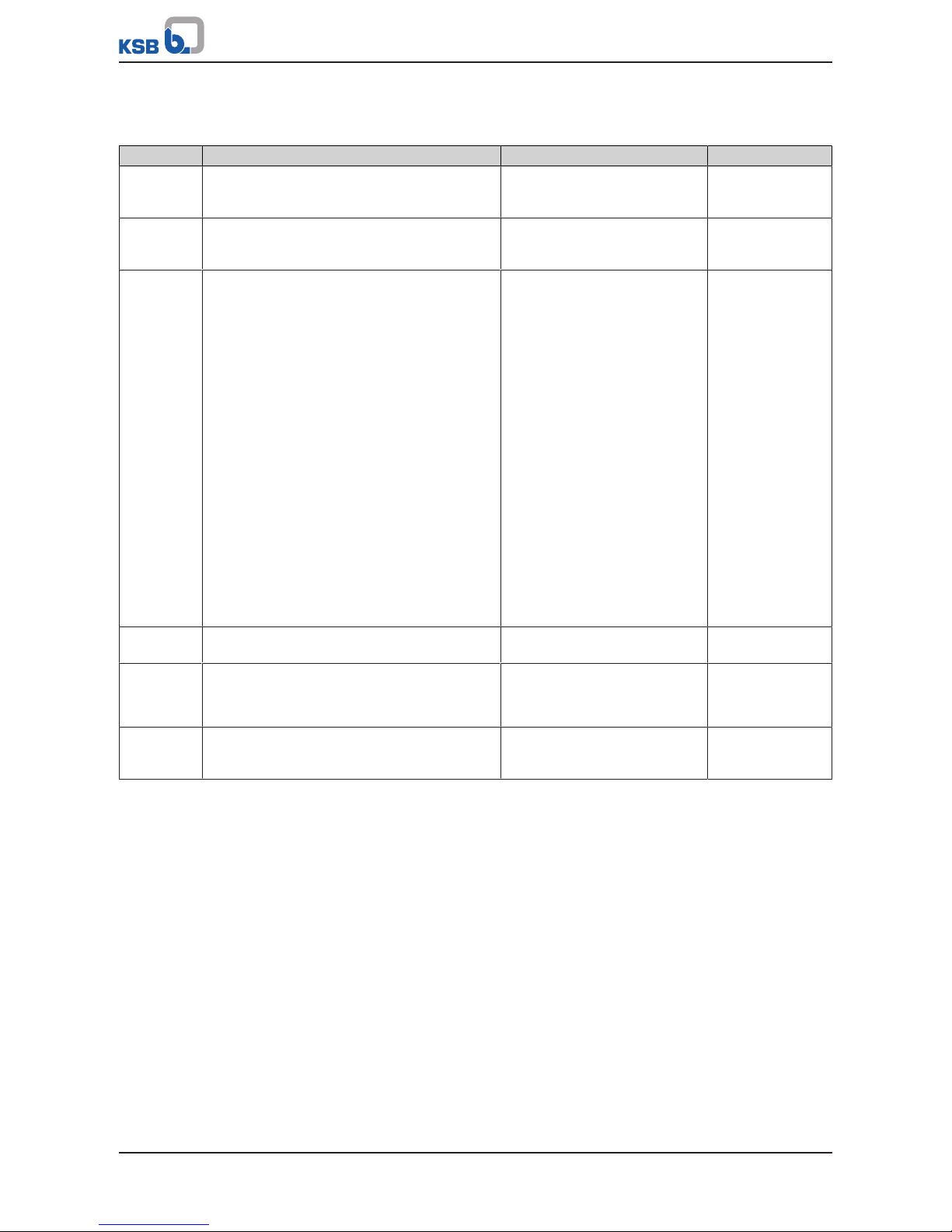

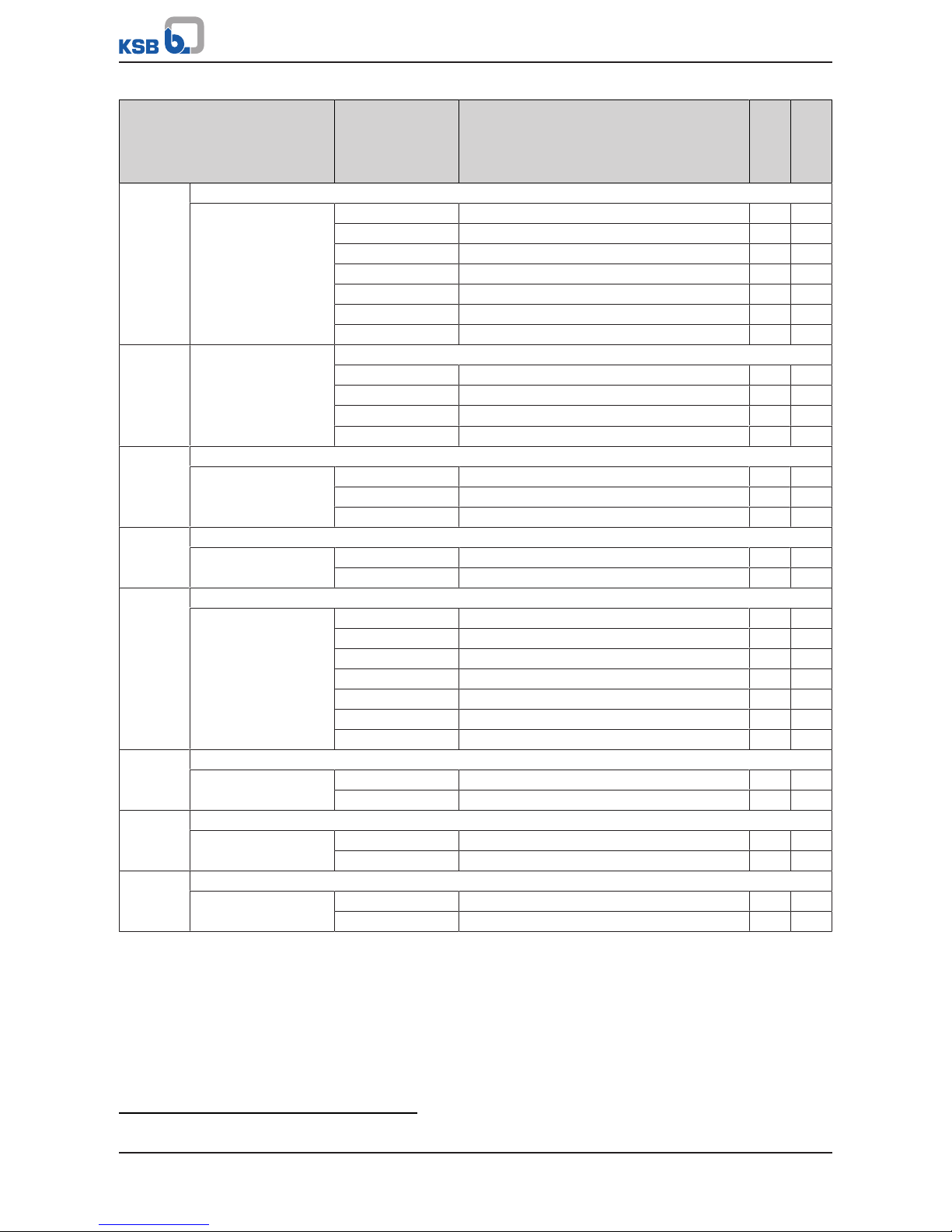

Table2: Categories of intended use

Category Definition Limits to EN55011

C1 Frequency inverters with a supply voltage under 1000V installed in the

first environment (residential and office areas).

Class B

C2 Frequency inverters with a supply voltage under 1000V installed in the

first environment (residential and office areas) that are neither ready to

be plugged in/connected nor are mobile and must be installed and

commissioned by specialist personnel.

Class A, Group 1

C3 Frequency inverters with a supply voltage under 1000V installed in the

second environment (industrial environments).

Class A, Group 2

C4 Frequency inverters with a supply voltage over 1000V and a nominal

current over 400A installed in the second environment (industrial

environments) or that are envisaged for use in complex systems.

No borderline/

boundary

1)

The following limit values and inspection/test levels must be complied with if the

generic standard on interference emissions applies:

Table3: Classification of installation environment

Environment Generic standard Limits to EN55011

First environment (residential and office areas) EN/IEC61000-6-3

for private, business and commercial

environments

Class B

Second environment (industrial environments) EN/IEC61000-6-4

for industrial environments

Class A, Group 1

The frequency inverter meets the following requirements:

1) An EMC plan must be devised.

Page 9

1 Safety

9 of 212

PumpDrive 2

Table4: EMC properties of the frequency inverter

Power

[kW]

Cable length

[m]

Category to EN 61800-3 Limits to EN55011

≤ 11 ≤5 C1 ClassB

> 11 ≤50 C2 ClassA, Group 1

The EN61800-3 standard requires that the following warning be provided for drive

systems that do not comply with category C1 specifications:

This product can produce high-frequency interference emissions that may necessitate

targeted interference suppression measures in a residential or office environment.

1.11.2 Line harmonics requirements

The product is a device for professional applications as defined by EN 61000-3-2. The

following generic standards apply when establishing a connection to the public

power grid:

▪ EN 61000-3-2

for symmetric, three-phase devices (professional devices with a total power of up

to 1kW)

▪ EN 61000-3-12

for devices with a phase current of between 16A and 75A and professional

devices from 1kW up to a phase current of 16 A.

1.11.3 Interference immunity requirements

In general, the interference immunity requirements for a frequency inverter hinge on

the specific environment in which the inverter is installed.

The requirements for industrial environments are therefore higher than those for

residential and office environments.

The frequency inverter is designed such that the immunity requirements for

industrial environments and, thus, the lower-level requirements for residential and

office environments, are met and fulfilled.

The following relevant generic standards are used for the interference immunity test:

▪ EN 61000-4-2: Electromagnetic compatibility (EMC)

– Part 4-2: Testing and measurement techniques – Electrostatic discharge

immunity test

▪ EN 61000-4-3: Electromagnetic compatibility (EMC)

– Part 4-3: Testing and measurement techniques – Radiated, radio-frequency,

electromagnetic field immunity test

▪ EN 61000-4-4: Electromagnetic compatibility (EMC)

– Part 4-4: Testing and measurement techniques – Electrical fast transient/burst

immunity test

▪ EN 61000-4-5: Electromagnetic compatibility (EMC)

– Part 4-5: Testing and measurement techniques – Surge immunity test

▪ EN 61000-4-6: Electromagnetic compatibility (EMC)

– Part 4-6: Testing and measurement techniques – Immunity to conducted

disturbances, induced by radio-frequency fields

Page 10

2 Transport/Temporary Storage/Disposal

10 of 212

PumpDrive 2

2 Transport/Temporary Storage/Disposal

2.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer (as applicable) and the insurer about the

damage in writing immediately.

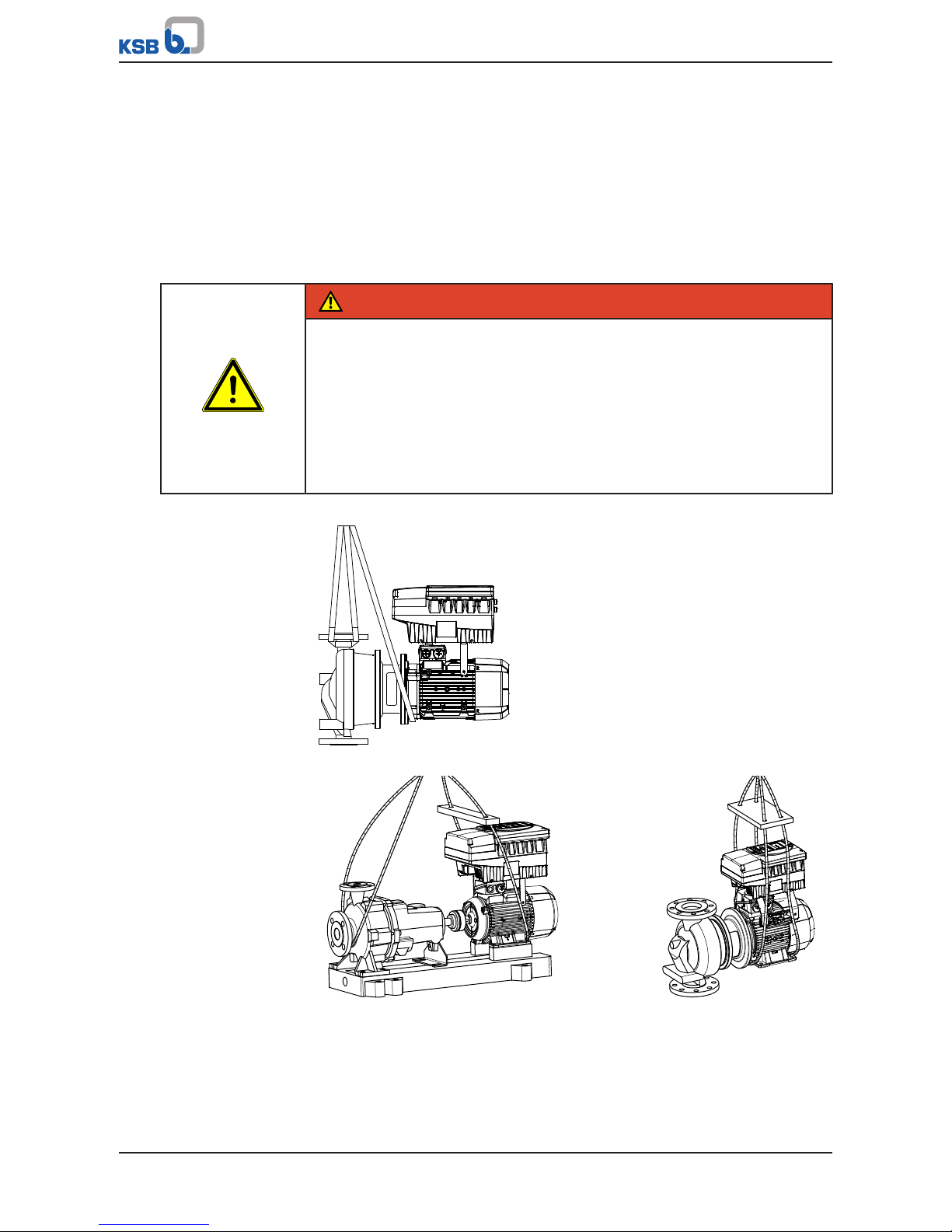

2.2 Transport

DANGER

The pump (set) could slip out of the suspension arrangement

Danger to life from falling parts!

▷ Always transport the pump (set) in the specified position.

▷ Never attach the suspension arrangement to the free shaft end or the motor

eyebolt.

▷ Give due attention to the weight data and the centre of gravity.

▷ Observe the applicable local health and safety regulations.

▷ Use suitable, permitted lifting accessories, e.g. self-tightening lifting tongs.

To transport the pump/pump set suspend it from the lifting tackle as shown.

Fig.1: Transporting a close-coupled pump set

Fig.2: Transporting a horizontal pump set

Page 11

2 Transport/Temporary Storage/Disposal

11 of 212

PumpDrive 2

Fig.3: Transporting a vertical pump set

Fig.4: Transporting the motor with frequency inverter

Fig.5: Transporting the frequency inverter with lifting gear

2.3 Storage

If the ambient conditions for storage are met, the function of the control unit is

safeguarded even after a prolonged period of storage.

Page 12

2 Transport/Temporary Storage/Disposal

12 of 212

PumpDrive 2

CAUTION

Damage during storage by humidity, dirt or vermin

Corrosion/contamination of the control unit!

▷ For outdoor storage cover the (packed or unpacked) control unit and

accessories with water-proof material.

Table5: Ambient conditions for storage

Ambient condition Value

Relative humidity 85% max. (non-condensing)

Ambient temperature -10°C to + 70°C

▪ Store the control unit in dry, vibration-free conditions and, if possible, in its

original packaging.

▪ Store the control unit in a dry room where the level of atmospheric humidity is as

constant as possible.

▪ Prevent excessive fluctuations in atmospheric humidity (see table on ambient

conditions for storage).

2.4 Disposal/recycling

The product is classified as special waste due to several installed components:

1. Dismantle product.

2. Separate materials

e.g.:

- Aluminium

- Plastic cover (recyclable plastic)

- Line chokes with copper windings

- Copper lines for internal wiring

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

PCBs, power electronics, capacitors and electronic components are all special

waste.

Page 13

3 General

13 of 212

PumpDrive 2

3 General

3.1 Principles

This manual is supplied as an integral part of the type series indicated on the front

cover. The manual describes the proper and safe use of this equipment in all phases

of operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB service centre to

maintain the right to claim under warranty.

3.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

3.3 Other applicable documents

Table6: Overview of other applicable documents

Document Contents

Operating manual Description of the proper and safe use of the

pump in all phases of operation

Wiring diagram Description of the electrical connections

Supplementary operating

manual

2)

Description of the proper and safe use of

supplementary product components

For accessories and/or integrated machinery components, observe the relevant

manufacturer's product literature.

3.4 Symbols

Table7: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

2) Optional

Page 14

4 Operation

14 of 212

PumpDrive 2

4 Operation

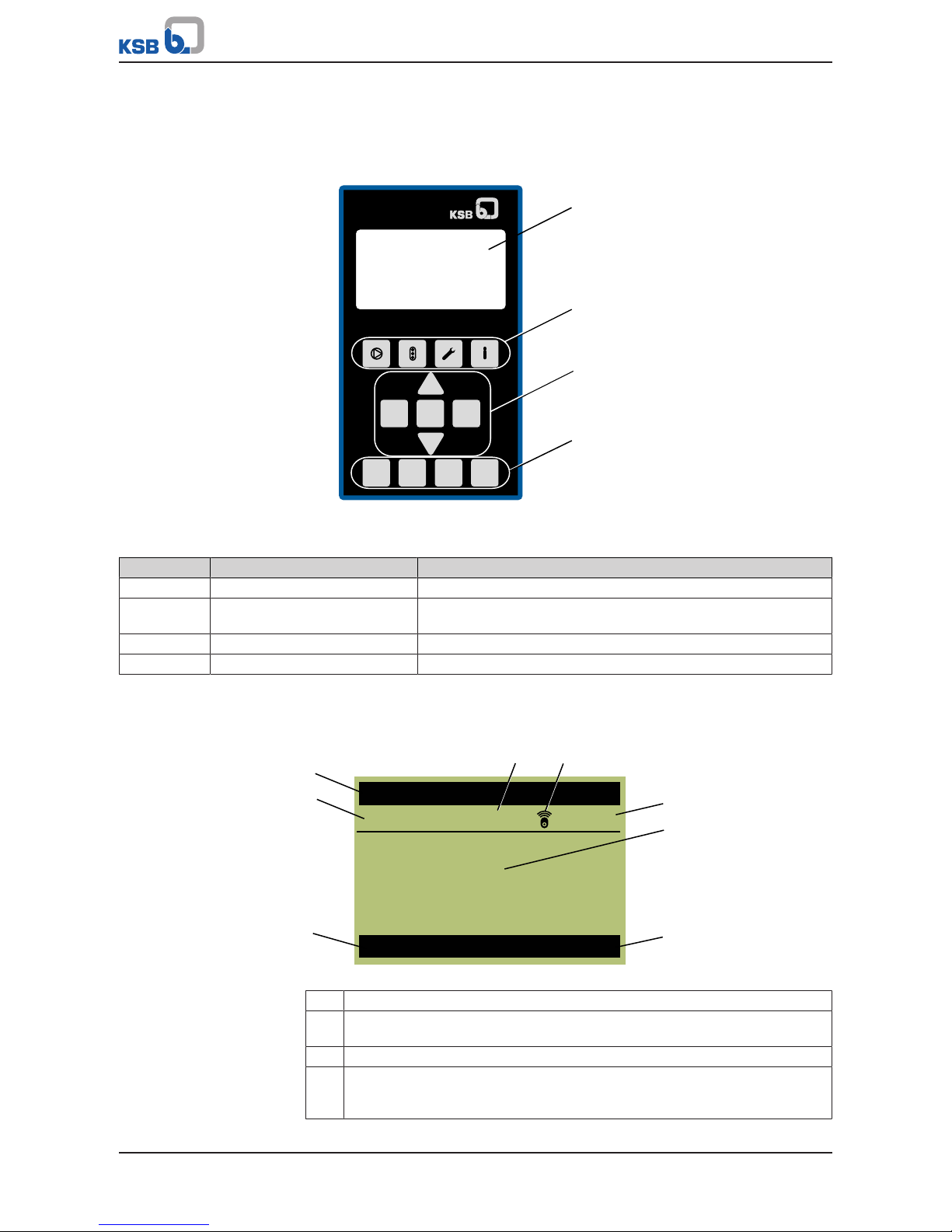

4.1 Graphical control panel

OK

MAN

ESC

?

AUTO FUNC

OFF

3

1

2

3

4

Fig.6: Graphical control panel

Table8: Description of graphical control panel

Position Description Function

1 Graphical display Displays information on frequency inverter operation

2 Menu keys Accessing the elements of the first menu level (Operation,

Diagnosis, Settings and Information)

3 Navigation keys Navigation and parameter setting

4 Operating keys Toggling operating modes

4.1.1 Graphical display

The main screen breaks down into 6areas.

C M

H

1-2-1-1

2893

rpm

17.48 m³/h

4.62 bar 642.9 V

RUN

AUTO

Speed

8

1

4

5

7

6

3

2

Fig.7: Main screen (example)

1 Motor standstill heater is switched on

2 The wireless icon illuminates when the Bluetooth module is inserted. The

wireless icon flashes when communication takes place.

3 Display of the master and login level

4 Display of up to four (4)operating values: One operating value is displayed in

large format. Three (3) operating values are displayed in small format. The

operating values scroll through cyclically.

Page 15

4 Operation

15 of 212

PumpDrive 2

5 Display of operating status

6 Display of the current operating mode

7 Parameter number of the operating value displayed in the centre

8 Name of the operating value displayed in the centre

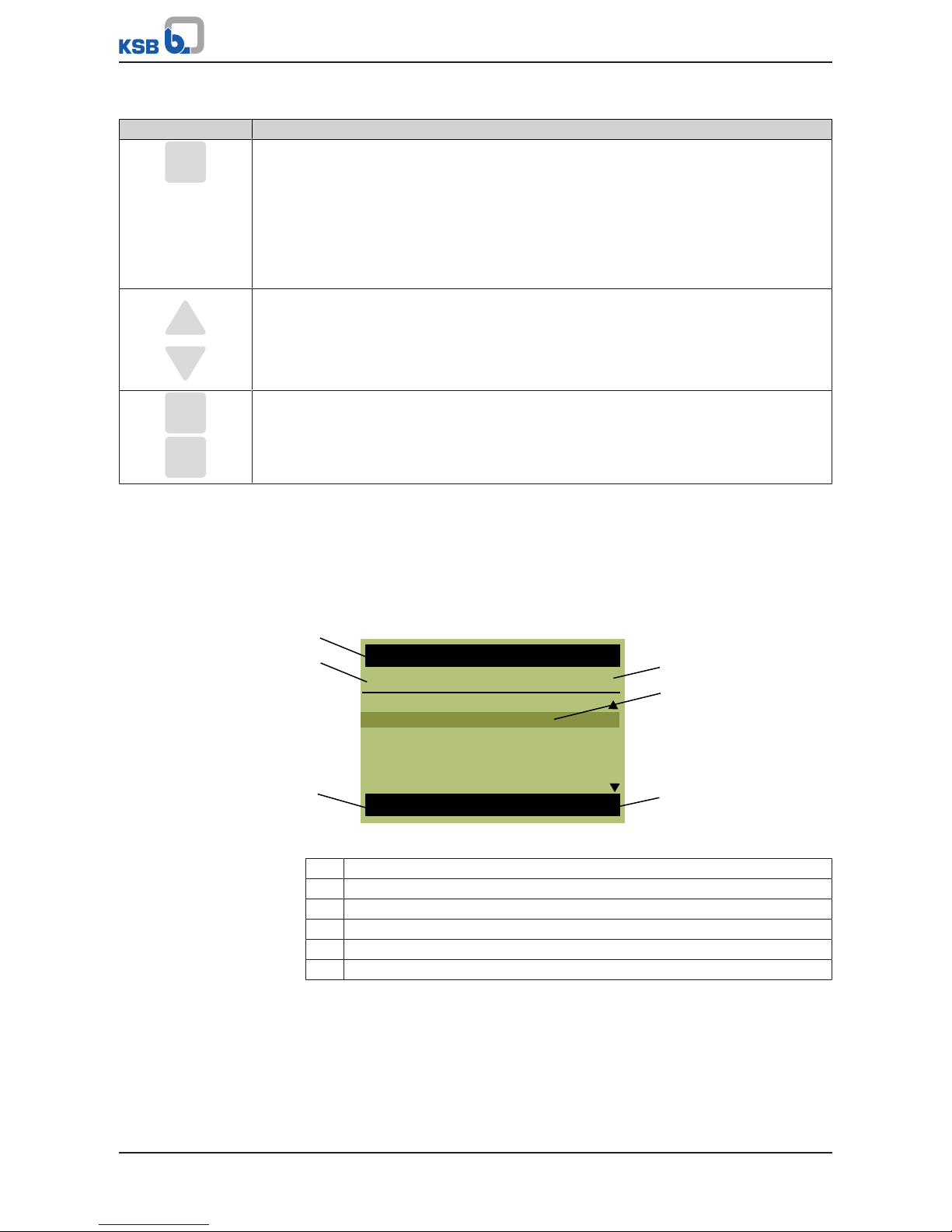

Table9: Assignment of keys

Key Function

Operation menu key

Diagnosis menu key

Settings menu key

Information menu key

Arrow keys:

▪ Move up/down in the menu options.

▪ Increase/decrease the value displayed when you are entering numerals. (When an arrow

key is pressed and held down, the response repeats in ever shorter intervals.)

ESC

Escape key:

▪ Delete/reset entry

(the entry is not saved).

▪ Move up one menu level.

OK

OK key:

▪ Confirm settings.

▪ Confirm menu selection.

▪ Move to the next digit when entering numerals.

▪ Message display: Acknowledge alert.

▪ Measured value display: Go to Favourites menu.

?

Help key:

▪ Displays a help text for each selected menu option.

MAN

MAN operating key:

▪ Starts the frequency inverter in manual operating mode.

OFF

OFF operating key:

▪ Stops the frequency inverter.

AUTO

AUTO operating key:

▪ Switches to automatic operating mode.

FUNC

FUNC operating key:

▪ Parameterisable function key

Manual mode via control panel

NOTE

After a power failure, the frequency inverter reverts to the OFF operating mode.

Manual mode must be restarted.

Page 16

4 Operation

16 of 212

PumpDrive 2

Table10: Assignment of keys for manual mode

Key Function

MAN

MAN operating key:

▪ When switching the operating mode from AUTO to MAN, the current operating speed is

used as control value (Manual) 1-3-4 and is displayed accordingly. The control point 3-6-2

must be set to Local.

▪ When switching the operating mode from OFF to MAN, the frequency inverter operates

at minimum speed. The control point 3-6-2 must be set to Local.

▪ If the control value (Manual) 1-3-4 is defined via an analog input, the analog input speed

is accepted. (ðSection8.2,Page65)

Arrow keys:

▪ Pressing the arrow keys changes and immediately accepts the control value (Manual)

1-3-4. Making a change using the arrow key has a direct effect even when not confirmed

with OK. The speed can only be changed between the set minimum speed and the

maximum speed.

ESC

OK

ESC/OK key:

▪ Press the OK or ESC key to go from digit to digit. Press the ESC key to go back. Changes

are rejected. Pressing the OK key for the right-hand digit takes you back to the main

screen.

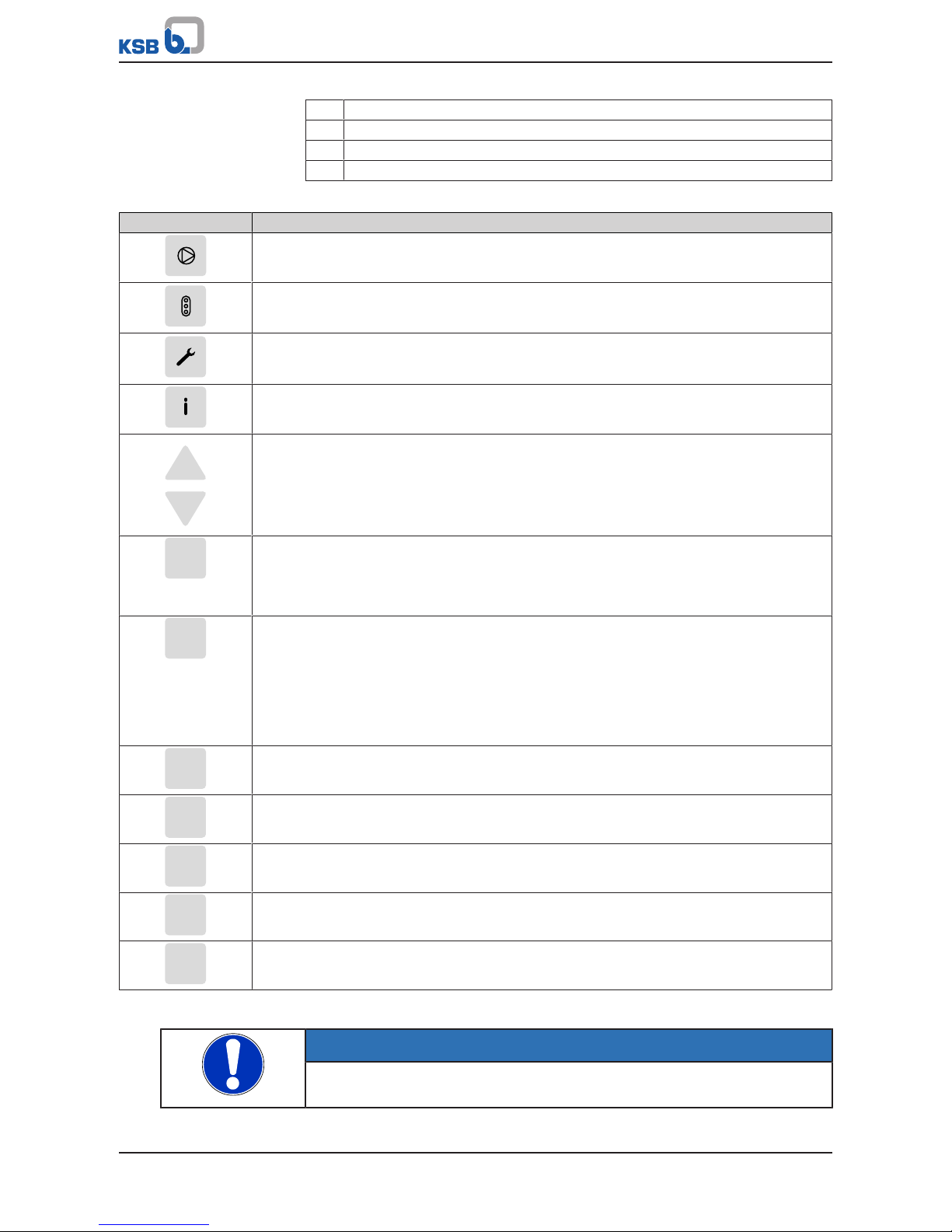

4.1.2 Menu keys

The menu keys allow you to directly access the first menu level (Operation 1-x-x-x,

Diagnosis 2-x-x-x, Settings 3-x-x-x, and Information 4-x-x-x).

The parameter numbers contain the navigation path, which helps you find a

particular parameter quickly and easily. The first digit of the parameter number

indicates the first menu level, which is called up directly via the four menu keys.

C M

STOP

3-6-1

AUTO

OFF (Open-loop Control)

Discharge Pressure

Suction Pressure

Differential Pressure

Flow Rate

Temperature (Cooling)

Type of Control

1

2

3

4

5

6

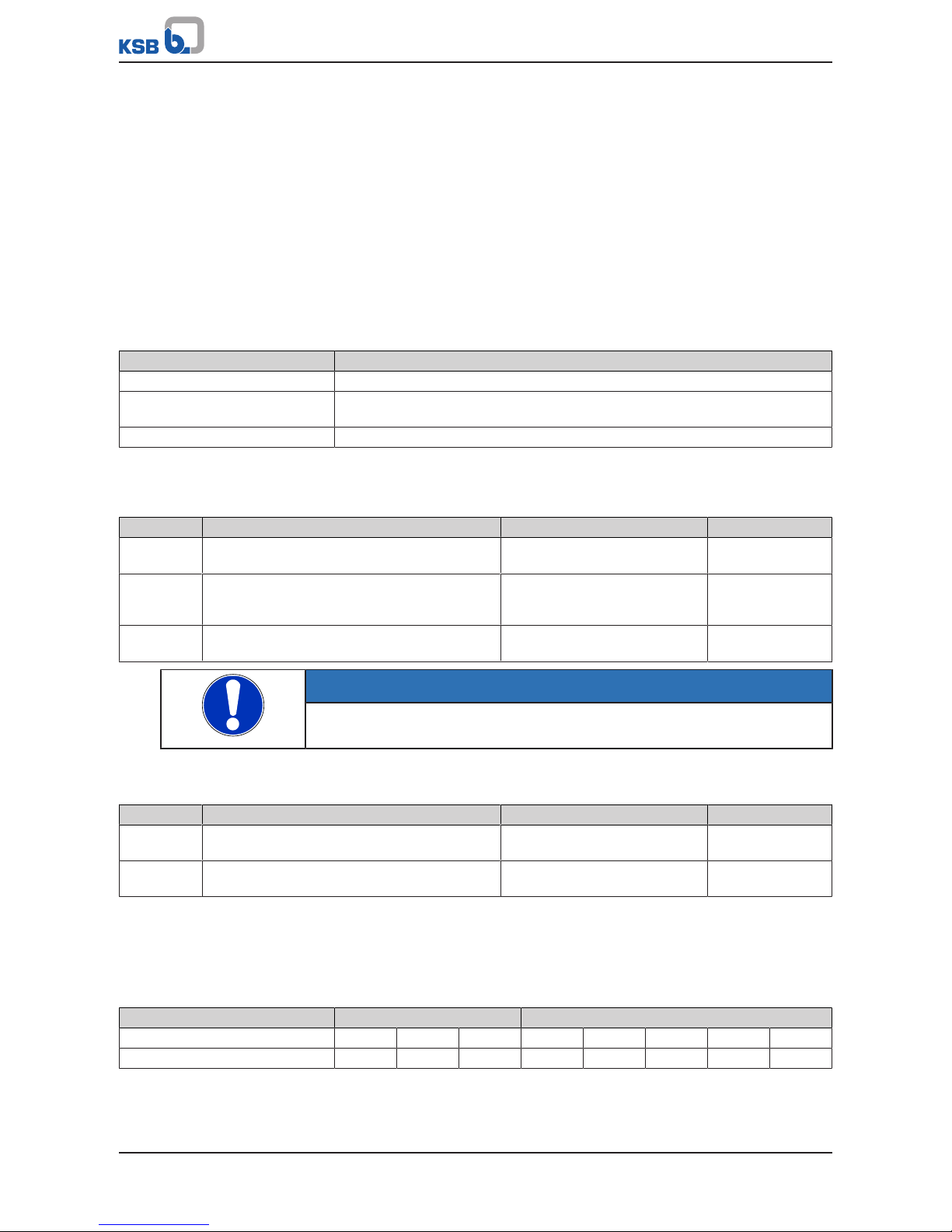

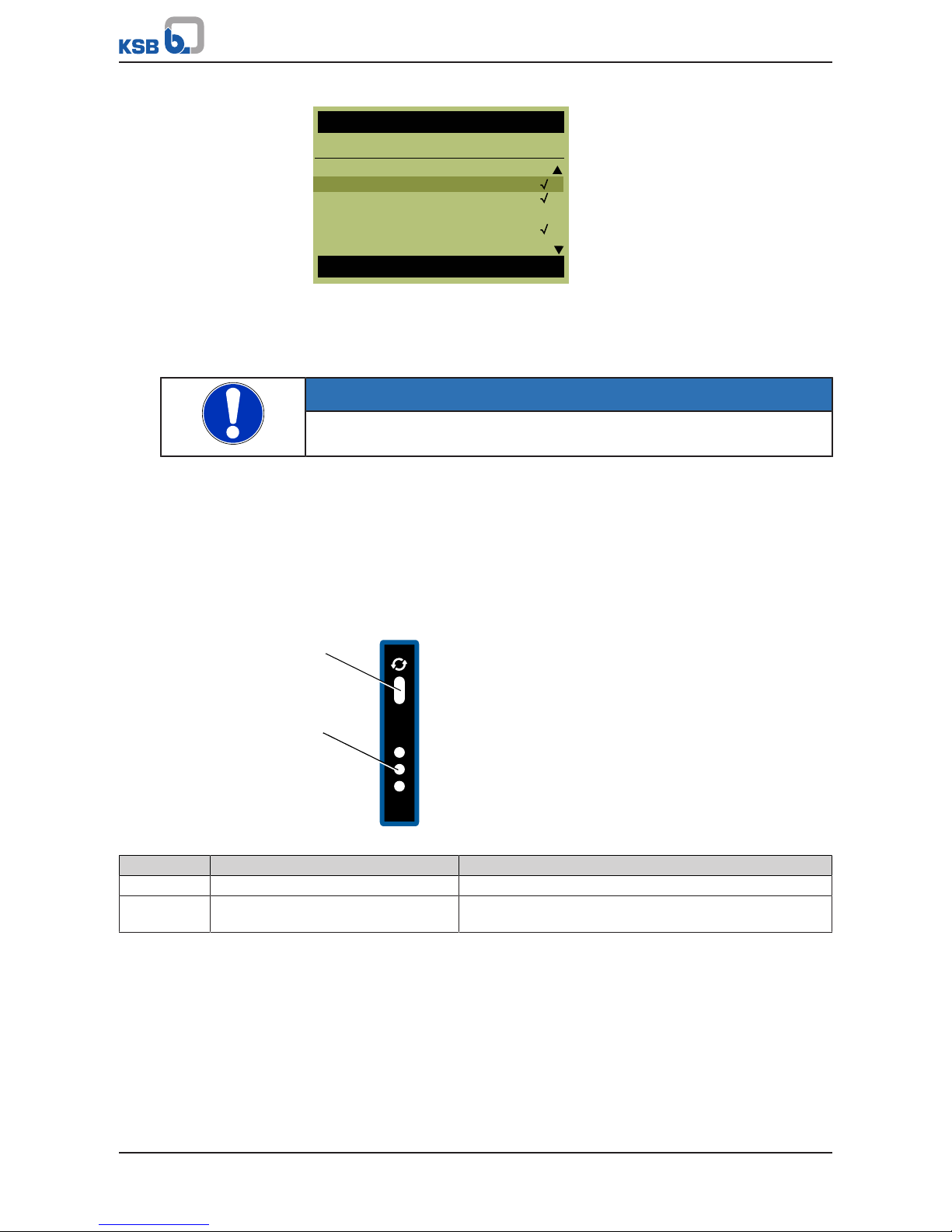

Fig.8: Menu display

1 Name of current menu/parameter

2 Parameter number of parameter selected in selection list

3 Display of the current operating mode

4 Display of the master and login level

5 Parameter/submenu selection list

6 Display of operating status

Page 17

4 Operation

17 of 212

PumpDrive 2

4.1.2.1 Menu: Operation

The Operation section contains all information required for operating the machine

and the process. This includes:

▪ Login to device with password

▪ Operating and measured values for motor, frequency inverter, pump and system

▪ Setpoints and control values

▪ Energy meter and operating hours

4.1.2.1.1 Access levels

Three access levels have been defined to prevent accidental or unauthorised access to

frequency inverter parameters:

Table11: Access levels

Access level Description

Standard (No Login) Access without password entry.

Customer Access level for the expert user with access to all parameters required for

commissioning

Customer service Access level for service personnel.

If a parameter's access level is not explicitly specified, the parameter is always

assigned the customer access level.

Table12: Access level parameters

Parameter Description Possible settings Factory setting

1-1-1 Customer Login

Log in as customer

0000...9999 0000

1-1-2 Service Login

Log in for access to special parameters for KSB

Service

0000...9999 -

1-1-4 Logout

Log out of all access levels

Run -

NOTE

If no keys are pressed for ten minutes, the system will automatically return to the

standard access level.

The password can be changed after entering the factory default password.

Table13: Parameters for changing passwords

Parameter Description Possible settings Factory setting

1-1-5 Customer Access ID

Changing the customer access ID

0000...9999 -

1-1-6 Service Access ID

Changing the service access ID

0000...9999 -

4.1.2.1.2 Operating values for input and output signals

The status of the digital inputs/relay outputs is displayed via the Digital Inputs

(1-2-4-6) and Digital Outputs (1-2-4-7) parameters.

Table14: Example of status of digital inputs (1-2-4-6). 24V is applied to digital input 1: System Start

Optional IO card Standard

Digital input DI8 DI7 DI6 DI5 DI4 DI3 DI2 DI1

Bit pattern on display 0 0 0 0 0 0 0 I

Page 18

4 Operation

18 of 212

PumpDrive 2

Table15: Example of status of digital outputs (1-2-4-7). The following is reported via relay output 1: General fault

message (configurable)

Optional IO card Standard

Digital output R8 R7 R6 R5 R4 R3 DO2 D01 R2 R1

Bit pattern on

display

0 0 0 0 0 0 0 0 0 I

4.1.2.2 Menu: Diagnosis

In the Diagnosis section, the user is provided with information about faults and

warning messages that pertain to the pump set or process. The frequency inverter

can be in fault (standstill) or warning (operational) status. The user can also find

previous messages in the history.

Messages

All monitoring and protective functions trigger warnings or alerts. These are

signalled via the amber or red LED of the LED traffic light function.

A corresponding message is output on the control panel display. If more than one

message is output, the last one is displayed. Alerts have priority over warnings.

AUTO

17.48 m³/h

4.62 bar2893 rpm

W57

rpm

C M

RUN

Low flow

1

5

2

3

4

Fig.9: Message display

1 Name of the message displayed in the centre

2 Display of the master and login level

3 Display of the message: The most recently received message is displayed in

large format on the main screen. Three operating values are displayed in small

format.

4 Display of operating status

5 Displays the current operating mode

Pending messages

If a message has occurred and been acknowledged but has not gone, this message

will be listed in the Pending Messages menu. All current messages can be displayed in

the Diagnosis menu under Pending Messages (2-1). Active warnings and alerts can

also be connected to the relay outputs.

Message history

Only messages that have come, been acknowledged, and gone are listed in the

message history. The message history can be viewed by selecting the Message History

parameter 2-2. The last 100 messages are listed here. You can use the arrow keys and

the OK key to select an entry from the list.

Acknowledging and resetting messages

NOTE

Depending on the combination of settings, the frequency inverter could

conceivably restart automatically after acknowledgement/reset or when the cause

of the malfunction or fault has been eliminated.

Acknowledgement

You can acknowledge the message once the cause has been rectified. Messages can

be acknowledged separately in the Diagnosis menu. A message can also be

acknowledged via a digital input. Digital input 2 is defaulted for this purpose.

Page 19

4 Operation

19 of 212

PumpDrive 2

Overview of warnings and alerts (ðSection11,Page189)

Messages can be acknowledged as follows:

Table16: Acknowledgement types for messages

Property of message Type of acknowledgement

Self-acknowledging Message self-acknowledges if condition for message has gone.

Self-acknowledging

(configurable)

Users can choose between self-acknowledging and acknowledging manually.

Partially selfacknowledging

Alerts that are partially self-acknowledging carry out self-acknowledgement in

increasingly large intervals after the alarm condition has gone. If the alert occurs

repeatedly within a specific time window, no additional self-acknowledgement is

carried out.

As soon as the alarm condition of a pending alert no longer exists, the time interval is

started. When this interval expires, automatic acknowledgement takes place.

If the alert occurs again within 30seconds after the time interval has started, the

interval is extended by one increment. Should this not be the case, the previous

(shorter) time interval is reverted to and corresponding action is taken again in

30seconds. The time intervals are 1second, 5seconds, 20seconds, and endless (i.e.

manual acknowledgement is required). When the 20-second interval is extended, selfacknowledgement no longer takes place.

Non-self-acknowledging Must be acknowledged manually.

Time stamp

If a message is not acknowledged and its condition comes and goes several times in

this time window, the first occurrence of the message is always used for the Message

Come time stamp. The Message Condition Gone time stamp, however, always shows

the last time the message condition was no longer active.

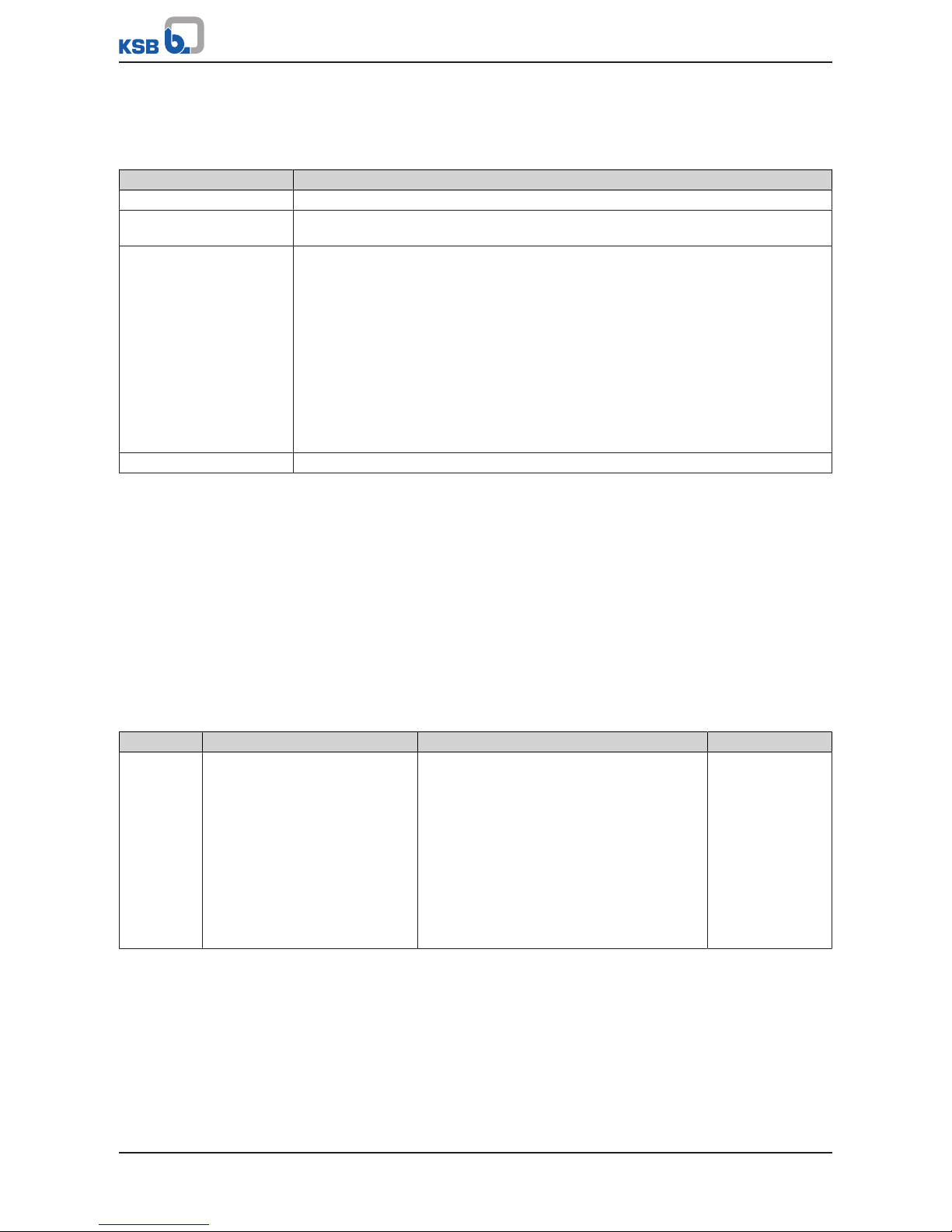

4.1.2.3 Menu: Settings

General settings can be made or the settings for the process optimised in the Settings

section.

4.1.2.3.1 Setting the display language

The display ships from the factory with support for 4languages (language package).

A language package can be changed using the KSB Service Tool:

Table17: Parameters for display language

Parameter Description Possible settings Factory setting

3-1-1 Language

Configurable display language

Depending on the language package:

▪ English, German, French, Italian

▪ English, French, Dutch, Danish

▪ English, Spanish, Portuguese, Turkish

▪ English, Norwegian, Swedish, Finnish

▪ English, Estonian, Latvian, Lithuanian

▪ English, Polish, Hungarian, Czech

▪ English, Slovenian, Slovakian, Croatian

▪ English, Russian, Romanian, Serbian

English, German,

French, Italian

Page 20

4 Operation

20 of 212

PumpDrive 2

4.1.2.3.2 Setting the control panel

Table18: Parameters for setting the control panel

Parameter Description Possible settings Factory setting

3-1-2-1 Operating Values on Main Screen

Display of current operating values on the main

screen

Main screen selection list -

3-1-2-2 Control Keys Require Login

Direct access to the MAN, OFF, AUTO and FUNC

operating keys can be disabled via this parameter.

▪ OFF

▪ ON

OFF

3-1-2-3 Function Key Assignment

Assigning a freely selectable function to the FUNC

key

▪ No Function

▪ System Start / Stop

▪ Setpoint (Closed-loop

Control)

▪ Control Value (Open-loop

Control)

▪ Alternative Setpoint (Closed-

loop Control)

▪ Alternative Control Value

(Open-loop Control)

▪ Immediate Pump

Changeover

▪ Immediate Functional Check

Run

▪ Language

▪ Fixed Speed 1

▪ PumpMeter Upload

▪ Remote/Local Control Point

Language

3-1-2-4 Display Contrast

Configurable contrast for the display

0...100 50

3-1-2-5 Display Backlight

Configuring the display backlight

▪ OFF

▪ ON

▪ Automatic

Automatic

3-1-2-6 Display Backlight Duration

Duration of display backlight on period in

automatic mode

0...600 30

Operating Values on Main

Screen

Up to 4operating values are simultaneously displayed on the main screen. An

operating value is displayed in large format with the associated parameter name,

parameter number and unit. Three (3) operating values are displayed in smaller

format with the associated unit. The arrow keys can be used to cycle through the

operating values. Each operating value passes through all display areas. Up to

10operating values can be selected from the predefined list for the display. The

sequence of the selection list determines the sequence of the operating values on the

main screen. If more than 4parameters are selected, the hidden parameters are also

cycled through in the background.

Selecting operating values for the main screen

1. Open parameter 3-1-2-1 in the Settings menu.

2. Using the arrow keys, select the operating value to be displayed from the list.

3. Press OK key.

4. Select additional, required operating values from the list and confirm by

pressing the OK key.

Page 21

4 Operation

21 of 212

PumpDrive 2

C M

RUN

AUTO

3-1-2-1

Speed

Motor Input Power

Motor Current

Output Frequency

Pump Suction Pressure

Pump Discharge Pressure

Operating Values on Main Scr...

Fig.10: Selecting multiple parameters from the selection list

Locking operating keys

The operating keys of the control panel can be locked via the 3-1-2-2 parameter to

prevent unauthorised operation or unauthorised acknowledgement of alerts.

Function key assignment

The FUNC operating key can be preassigned a function from a selection list.

NOTE

When the FUNC operating key is used in the System Start / Stop role, the system

must be restarted via the FUNC operating key every time the voltage is reset.

Favourites menu

Press the OK key on the main screen to call up the favourites menu, where you can

select various parameters and quickly adapt their configuration settings.

4.1.2.4 Menu: Information

All direct information about the frequency inverter is provided in the Information

section. Important details regarding the firmware version are listed here.

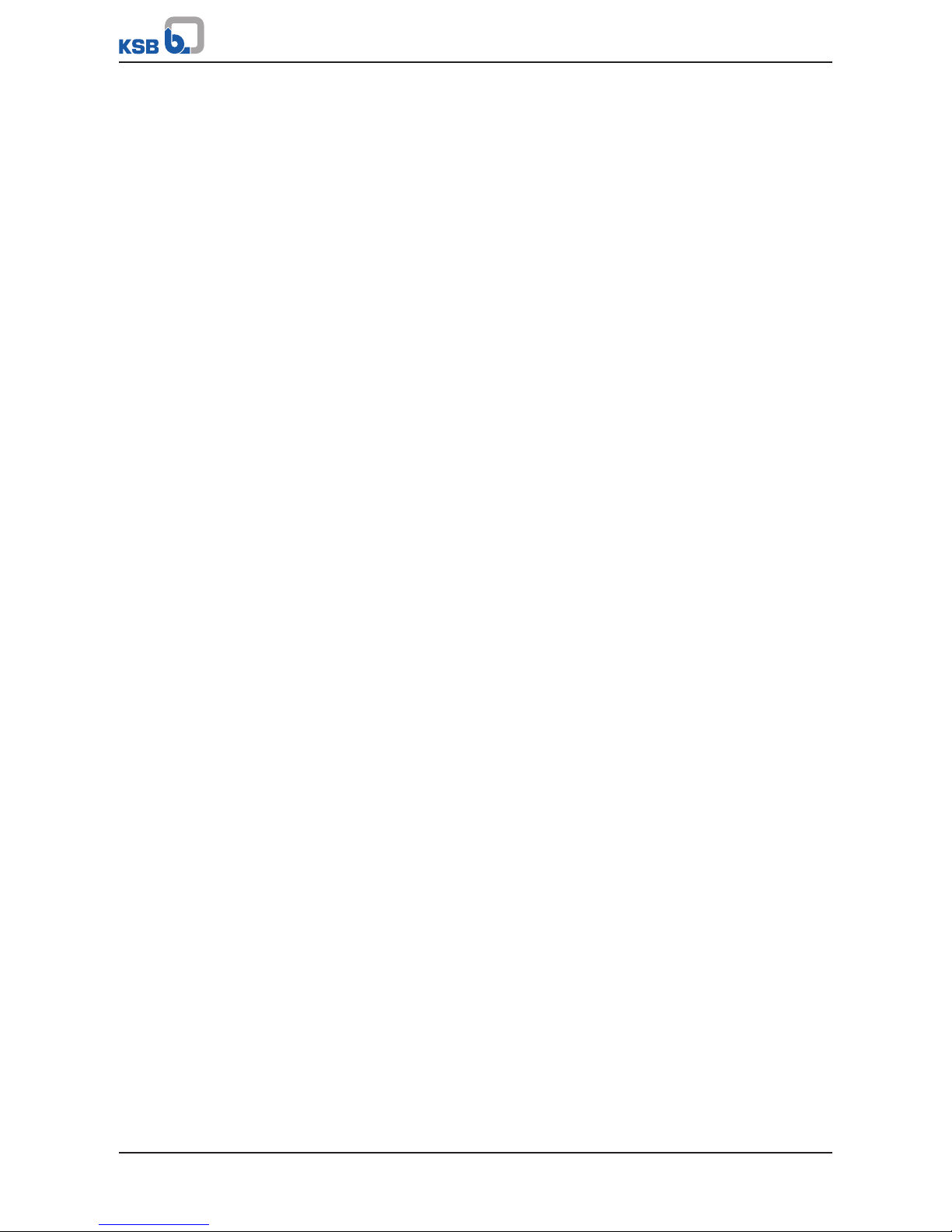

4.1.3 Service interface and LED traffic light function

2

1

Fig.11: Service interface and traffic light LEDs

Item Description Function

1 Service interface Optical interface

2 LED traffic light function The traffic light function provides information about the

system's operating status.

Service interface

The service interface allows a PC/notebook to be connected via a special cable (USB –

optical).

The following action can be taken:

▪ Configuring and parameterising the frequency inverter with the service software

▪ Software update

▪ Saving and documenting set parameters

LED traffic light function

The LED traffic light function provides information about the current PumpDrive

operating status.

Page 22

4 Operation

22 of 212

PumpDrive 2

Table19: LED description

LED Description

Red

One or more than one alert is active

Amber

One or more than one warning is active

Green

Steady light: Trouble-free operation

Page 23

5 Commissioning report

23 of 212

PumpDrive 2

5 Commissioning report

Report number: ...................................................

Purchaser

Order number ........................................................................................................................................

Customer ........................................................................................................................................

Installation location ........................................................................................................................................

Contact ........................................................................................................................................

Product

Pump type .................................................................................................................................................................

Pump works number 1. ................................................. 2. .................................................

3. ................................................. 4. .................................................

5. ................................................. 6. .................................................

Motor data ................. [kW] ..................... [A] ........................ [V] .................... [cos phi] ................... [rpm]

Type code 1. ................................................. 2. .................................................

3. ................................................. 4. .................................................

5. ................................................. 6. .................................................

Serial number 1. ................................................. 2. .................................................

(Name plate), frequency

inverter

3. ................................................. 4. .................................................

5. ................................................. 6. .................................................

Operating mode

Manual mode Application: Pressure/differential pressure/flow rate/temperature

Open-loop control mode Setpoint .......................... [Source] ............. [Unit] ................. [Value]

Closed-loop control mode Sensor .............................[sensor full-scale value]

Multiple pump

configuration

Number of frequency inverters ..... [Quantity] Number of HMIs..... [Quantity]

Master control device Number of master control devices ..... [Quantity]

Bus connection Field bus type ...................... Number of modules ..... [Quantity]

Comments

.................................................................................................................................................................................................

.................................................................................................................................................................................................

.................................................................................................................................................................................................

.................................................................................................................................................................................................

........................................................................................ ........................................................................................

KSB Customer Service/name Client/name

........................................................................................ ........................................................................................

Place, date, signature Place, date, signature

Page 24

6 Description

24 of 212

PumpDrive 2

6 Description

6.1 General description

PumpDrive is a modular, self-cooling frequency inverter which enables the motor

speed to be varied continuously by means of analog standard signals, a field bus or

the control panel.

6.2 Designation

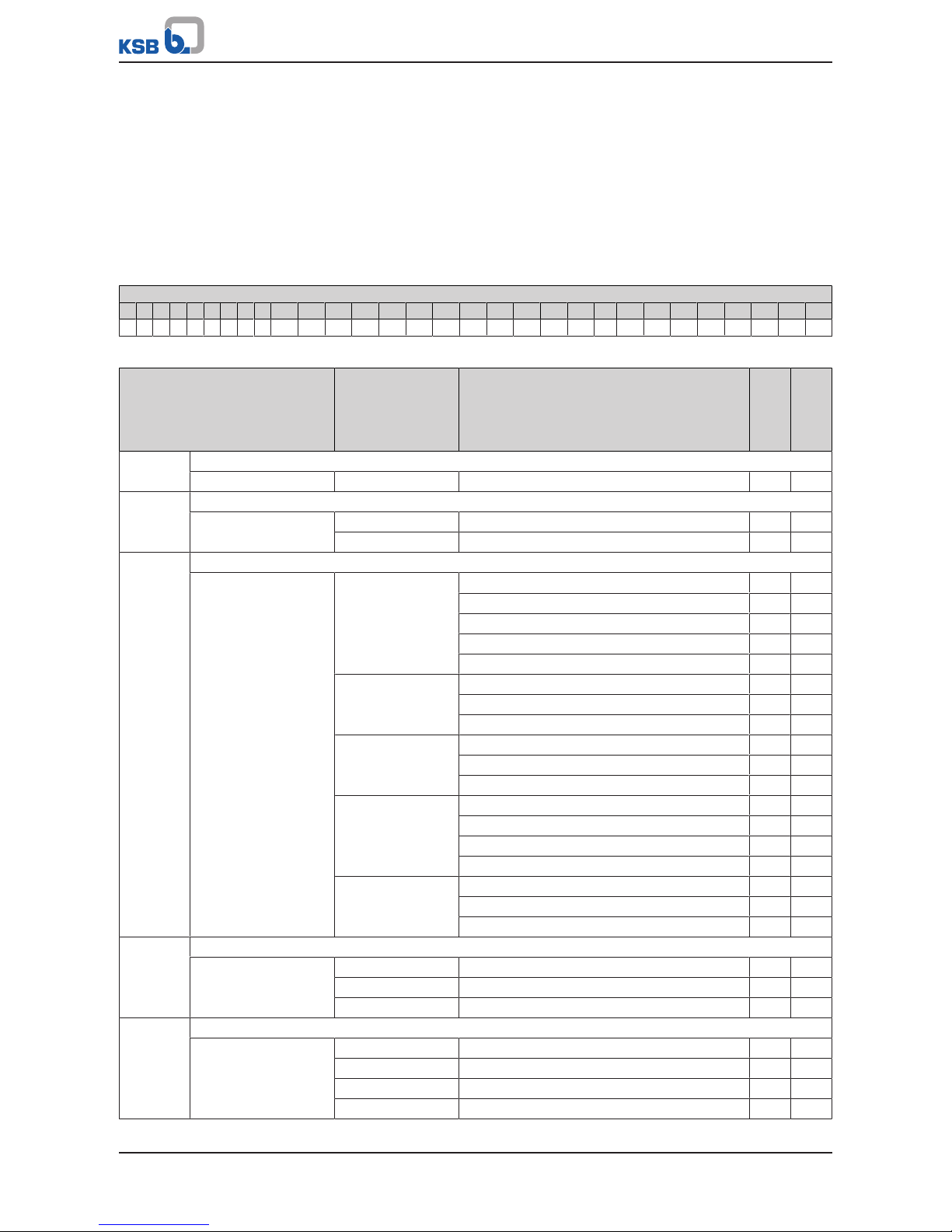

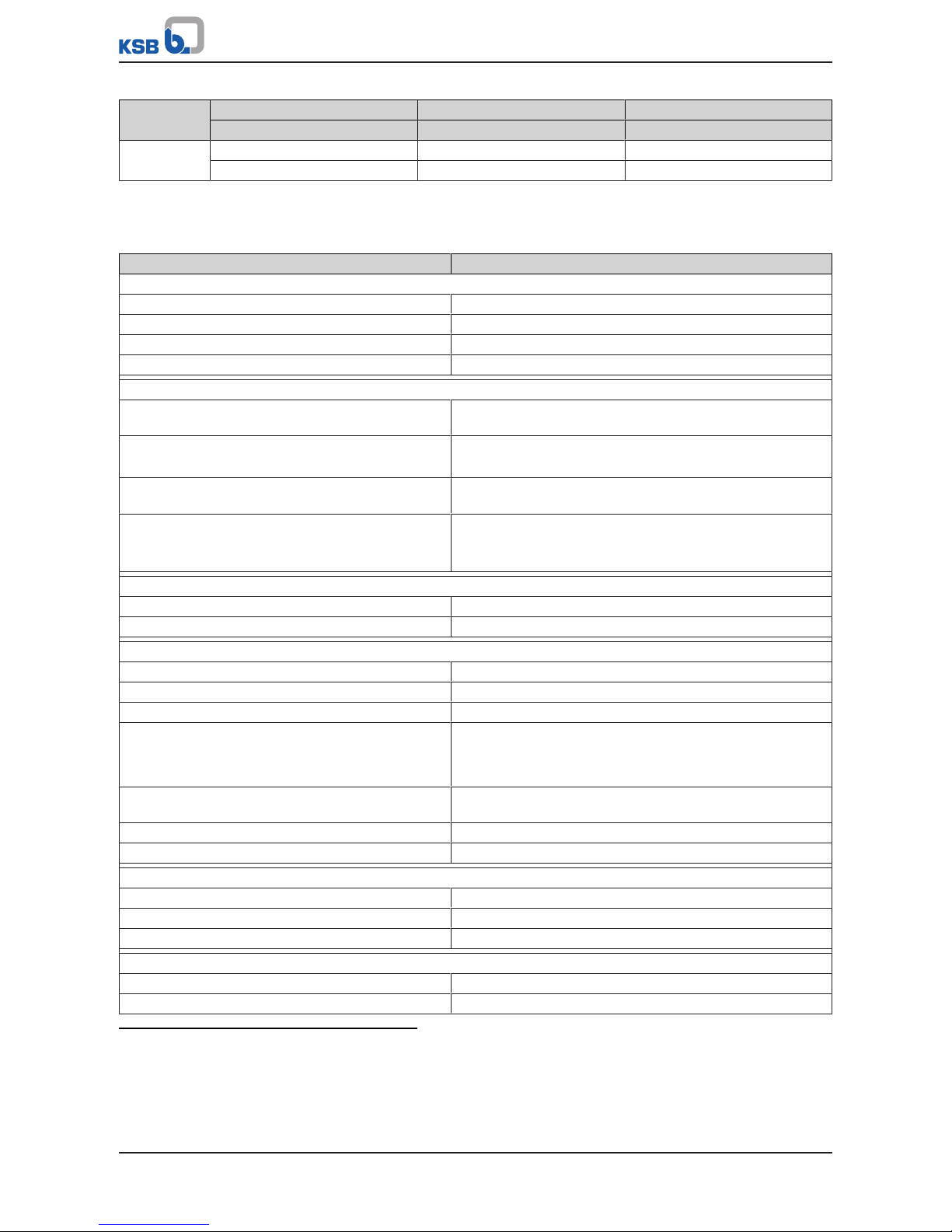

Table20: Designation example

Item

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

P D R V 2 E - 0 1 1 K 0 0 M _ S 1 L E 1 E 2 P 2 _ M O O R O

Table21: Key to the designation

Item Code Description

PumpDrive 2

Eco

PumpDrive2

1-4 Generation

PDRV2 2. PumpDrive generation ✘ ✘

6 Variant

E PumpDrive 2 Eco ✘ -

- PumpDrive2 - ✘

8-13 Power

A 000K37=0,37kW ✘ ✘

000K55=0,55kW ✘ ✘

000K75=0,75kW ✘ ✘

001K10=1,1kW ✘ ✘

001K50=1,5kW ✘ ✘

B 002K20=2,2kW ✘ ✘

003K00=3kW ✘ ✘

004K00=4kW ✘ ✘

C 005K50=5,5kW ✘ ✘

007K50=7,5kW ✘ ✘

011K00=11kW ✘ ✘

D 015K00=15kW - ✘

018K50=18,5kW - ✘

022K00=22kW - ✘

030K00=30kW - ✘

E 037K00=37kW - ✘

045K00=45kW - ✘

055K00=55kW - ✘

14 Mounting option

M Motor mounting ✘ ✘

W Wall mounting ✘ ✘

C Cabinet mounting ✘ ✘

16 Motor manufacturer

K KSB ✘ ✘

S Siemens ✘ ✘

C Cantoni ✘ ✘

W Wonder ✘ ✘

Page 25

6 Description

25 of 212

PumpDrive 2

Item Code Description

PumpDrive 2

Eco

PumpDrive2

17-20 Motor type

1LE1 Siemens 1LE1/ KSB1PC3 ✘ ✘

1LA7 Siemens 1LA7/ KSB1LA7 ✘ ✘

1LA9 Siemens 1LA9/ KSB1LA9 ✘ ✘

1LG6 Siemens 1LG6/ KSB1LG6 ✘ ✘

SUPB KSB SuPremE B ✘ ✘

DMC KSB(DM) Cantoni ✘ ✘

DMW KSB(DM) Wonder ✘ ✘

21-22 Efficiency class

E1 IE1 ✘ ✘

E2 IE2 ✘ ✘

E3 IE3 ✘ ✘

E4 IE4 ✘ ✘

23-24 Number of motor poles

P2 2 poles ✘ ✘

P4 4 poles ✘ ✘

P6 6 poles ✘ ✘

26 M12 module

O None ✘ ✘

M M12 module ✘ ✘

27 Field bus module

O None ✘ ✘

L LON - ✘

P Profibus DP - ✘

M Modbus RTU ✘ ✘

B BACnet MS / TP - ✘

3)

N Profinet - ✘

3)

E Ethernet - ✘

3)

28 Optional component 1

O None ✘ ✘

I I/O extension board - ✘

29 Optional component 2

O None ✘ ✘

R Bluetooth module ✘ ✘

30 Optional component 3

O None ✘ ✘

M Master switch - ✘

3) Consult the manufacturer.

Page 26

6 Description

26 of 212

PumpDrive 2

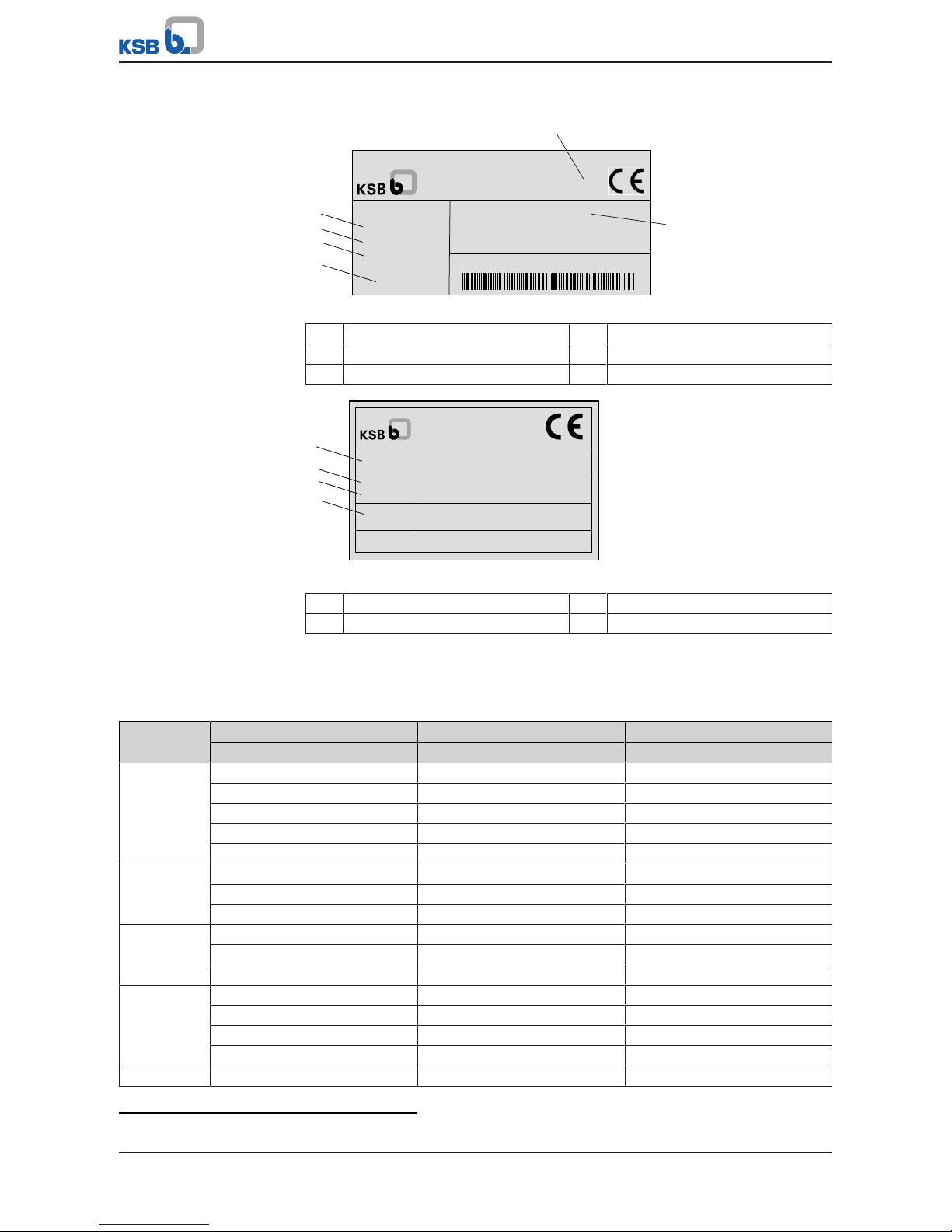

6.3 Name plate

IP55

PumpDrive

3PH 380 : 480 VAC

50-60 Hz

0105000180

18,0 A

7,5 KW

INPUT:

P D R V 2 _ _ 0 0 7K50

1

2

3

4

5

6

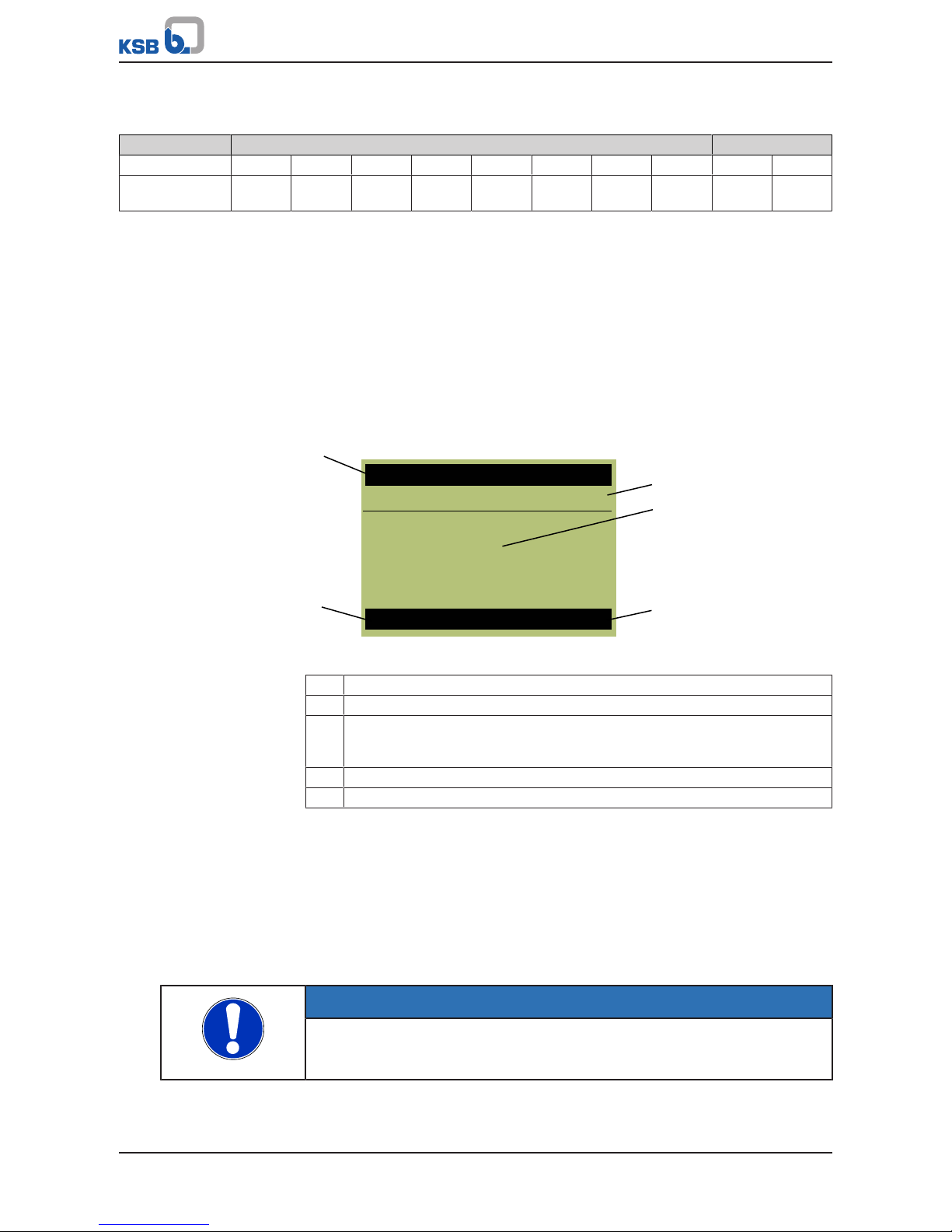

Fig.12: Name plate 1, frequency inverter (example)

1 Enclosure 2 Type series, size

3 Nominal power 4 Nominal current

5 Mains frequency 6 Mains voltage

IP55

PumpDrive

997257666000010002

ETN 080-065-160 GG A 11GD20150

31.07.2014

PDRV2__-015K00M_S1LE1E2P2_MPIRM

3

4

1

2

Fig.13: Name plate 2, frequency inverter (example)

1 PumpDrive type code 2 KSB order number

3 Pump designation 4 Date of manufacture

6.4 Power range and sizes

Table22: Power range4) for 2-pole (3000rpm), 4-pole (1500rpm) and 6-pole (1000) asynchronous motors and KSB

SuPremE

Size Nominal electrical power Nominal output current Mains-side input current

[kW] [A] [A]

A 0,37 1,3 1,4

0,55 1,8 2

0,75 2,5 2,7

1,10 3,5 3,7

1,50 4,9 5,2

B 2,2 6 6,3

3,0 8 8,4

4,0 10 10,4

C 5,5 14 14,6

7,5 18 18,7

11 25 25,9

D 15 33 34,1

18,5 42 43,3

22 51 52,4

30 66 67,7

E 37 81,5 83,4

4) The power ranges specified apply in full to all mounting options.

Page 27

6 Description

27 of 212

PumpDrive 2

Size Nominal electrical power Nominal output current Mains-side input current

[kW] [A] [A]

E 45 97 99

55 120 122,4

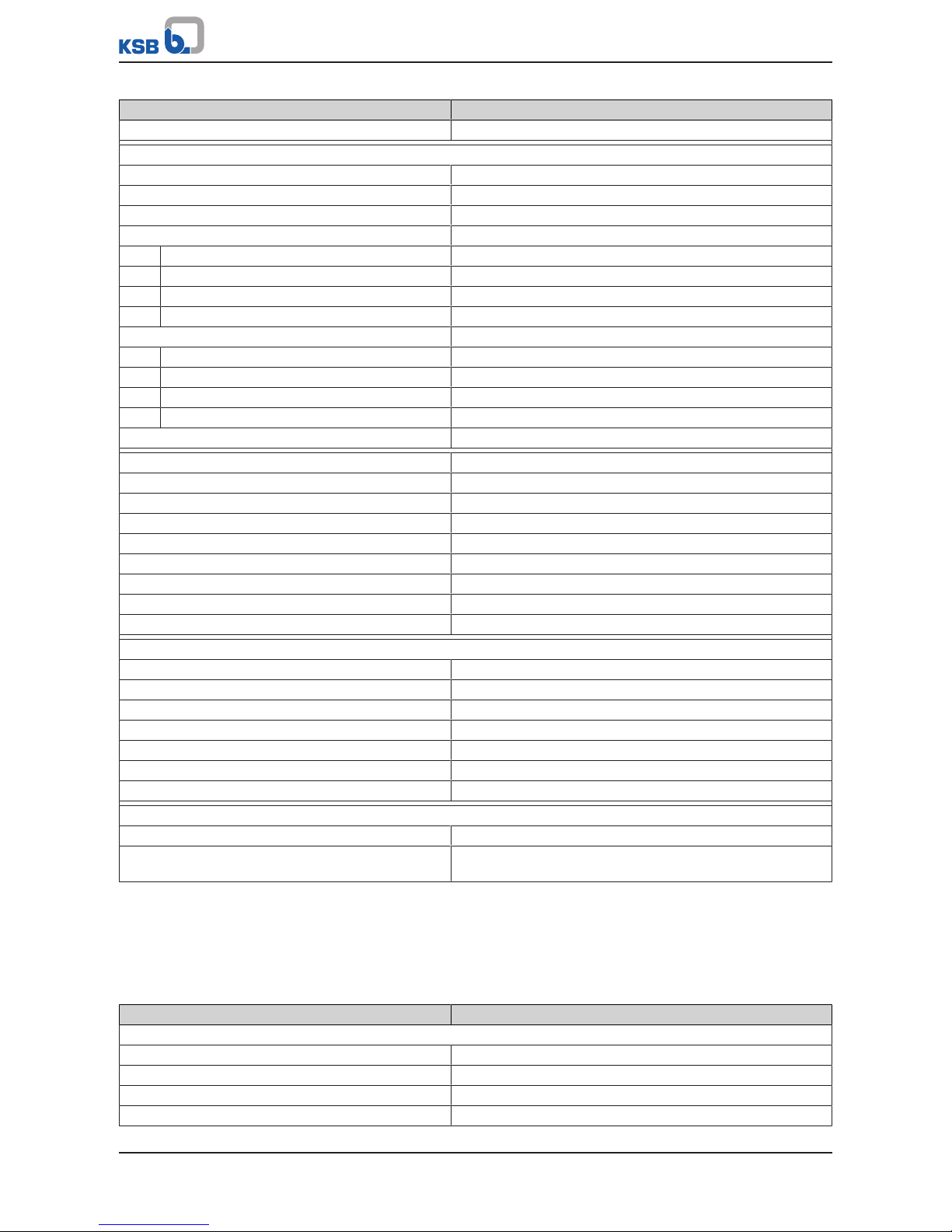

6.5 Technical data

Table23: Technical data of frequency inverter

Characteristic Value

Mains supply

Mains voltage

5)

3 ~ 380VAC - 10% to 480VAC +10%

Voltage difference between the three phases ±2% of the supply voltage

Mains frequency 50 - 60Hz ± 2 %

Mains types TN-S, TN-CS, TN-C, TT and IT mains (to IEC/EN60364)

Output data

Frequency inverter output frequency 0 - 70 Hz for asynchronous motors

0 - 140Hz for KSBSuPremE

PWM carrier frequency Range: 2 - 8 kHz

(Factory setting: 4kHz)

Phase rate of rise dv/dt

6)

5000 V/µs max. (depending on the size of the frequency

inverter)

Peak voltages 2×1,41×V

eff

Lines with a high current-carrying capacity can cause the

voltage to increase up to double the value.

Frequency inverter data

Efficiency 98 % - 95 %

7)

Noise emissions Sound pressure level of pump used + 2.5dB

8)

Environment

Enclosure IP55 (to EN 60529)

In-service ambient temperature -10°C to +50°C

In-storage ambient temperature -10 °C to +70 °C

Relative humidity Operation: 5% to 85% (non-condensing)

Storage: 5% to 95%

Transport: 95%max.

Installation altitude < 1000m above MSL, or 1 % power derating per additional

100m

Vibration resistance 16.7m/s2 max. (to EN60068-2-64)

Fluid temperature -30°C to +140°C

EMC

Frequency inverter ≤11kW EN61800-3 C1/EN55011 Class B/cable length ≤ 5m

Frequency inverter ≥ 15 kW EN 61800-3 C2/EN 55011 Class A, Group 1/cable length ≤50m

Mains feedback Integrated line chokes

Inputs and outputs

Internal power supply unit 24V ± 10 %

Maximum load 600mA DC max., short-circuit and overload-proof

5) If the mains voltage is low, the nominal torque of the motor will be lower.

6) The phase rate of rise (dv/dt) depends on the line capacity.

7) The efficiency at the nominal point of the frequency inverter varies between 98 percent for high power outputs and

95percent for low outputs, depending on the inverter's nominal power.

8) The values are for orientation purposes only. The value refers to the nominal duty point (50Hz) only. Also refer to the

pump's noise characteristics. They, too, are documented for nominal duty operation. Other values may occur during

variable speed operation.

Page 28

6 Description

28 of 212

PumpDrive 2

Characteristic Value

Residual ripple <1%

Analog inputs

Number of parameterisable analog inputs 2 (configurable for current or voltage input)

Input type Differential

Maximum voltage (with reference to GND) ± 10V

Current input 0/4 - 20mA

Input impedance 500Ohm

Accuracy 1% of full-scale value

Signal delay < 10ms

Resolution 12bit

Voltage input 0/2 - 10V

Input impedance ca. 40kOhm

Accuracy 1% of full-scale value

Signal delay < 10ms

Resolution 12bit

Reverse polarity protection Positive and negative polarity reversal possible

Analog outputs

Number of parameterisable analog outputs 1 (toggling 4 output values)

Current output 4-20mA

Maximum external working resistance 850Ohm

Output PNP transistor

Accuracy 2 % of full-scale value

Signal delay < 10ms

Reverse polarity protection Provided

Short-circuit protection and overload protection Provided

Digital inputs

Number of digital inputs 6 in total, 5 of which can be parameterised

ON level 15-30V

OFF level 0-3V

Input impedance Approx. 2 kOhm

Electrical isolation Provided, insulation voltage: 500VAC

Delay < 10ms

Reverse polarity protection Provided

Relay outputs

Number of parameterisable relay outputs 2 changeover contacts

Maximum contact rating AC: Max. 250 VAC/0.25A

DC: Max. 30 VDC/2A

PWM carrier frequency

Power derating for increased carrier frequency

Sizes A, B and C (at PWM carrier frequency > 4kHz):

I

Nominal motor current (PWM)

= I

Nominal motor current

×(1 - [f

PWM

- 4kHz]×2.5 %)

Table24: Technical data of I/O extension board

Characteristic Value

Analog inputs

Number of parameterisable analog inputs 1

Input type Differential

Maximum voltage (with reference to GND) + 10V

Current input 0/4 – 20mA

Page 29

6 Description

29 of 212

PumpDrive 2

Characteristic Value

Input impedance 500Ohm

Accuracy 1% of full-scale value

Signal delay < 10ms

Resolution 11bit

Voltage input 0/2 - 10V

Input impedance ca. 40kOhm

Accuracy 1% of full-scale value

Signal delay < 10ms

Resolution 11 bit + 1 bit sign

Reverse polarity protection Provided

Analog outputs (current output or voltage output)

Number of parameterisable analog outputs 1 (toggling 4 output values)

Current output 4 – 20mA

Maximum external working resistance 850Ohm

Output PNP transistor

Accuracy 2 % of full-scale value

Signal delay < 10ms

Reverse polarity protection Provided

Short-circuit protection and overload

protection

Provided

Voltage output 2 – 10V

Maximum output current 25mA

Output NPN transistor

Accuracy 2 % of full-scale value

Signal delay < 10ms

Reverse polarity protection Provided

Short-circuit protection and overload

protection

Provided

Digital inputs

Number of digital inputs 3 (all parameterisable)

ON level 15-30V

OFF level 0 - 3V

Input impedance Approx. 2 kOhm

Electrical isolation Provided, insulation voltage: 500VAC

Delay < 10ms

Reverse polarity protection Provided

Digital outputs

Number of digital outputs 2

Output PNP transistor

ON level 24V ±10 %

OFF level < 2V

Output current Max. 40 mA

Differential current < 100µA

Reverse polarity protection Provided

Short-circuit protection and overload protection Provided

Relay outputs

Number of parameterisable relay outputs 1 changeover contacts

5 NO contact

Page 30

6 Description

30 of 212

PumpDrive 2

Characteristic Value

Changeover contact, maximum contact rating AC: Max. 250 VAC/0.25A

DC: Max. 30 VDC/3A

NO contact, maximum contact rating AC: Max. 250 VAC/0.25A

DC: Max. 30 VDC/1A

Suitable for switching operations of contactors with a

maximum start-up current of 10A.

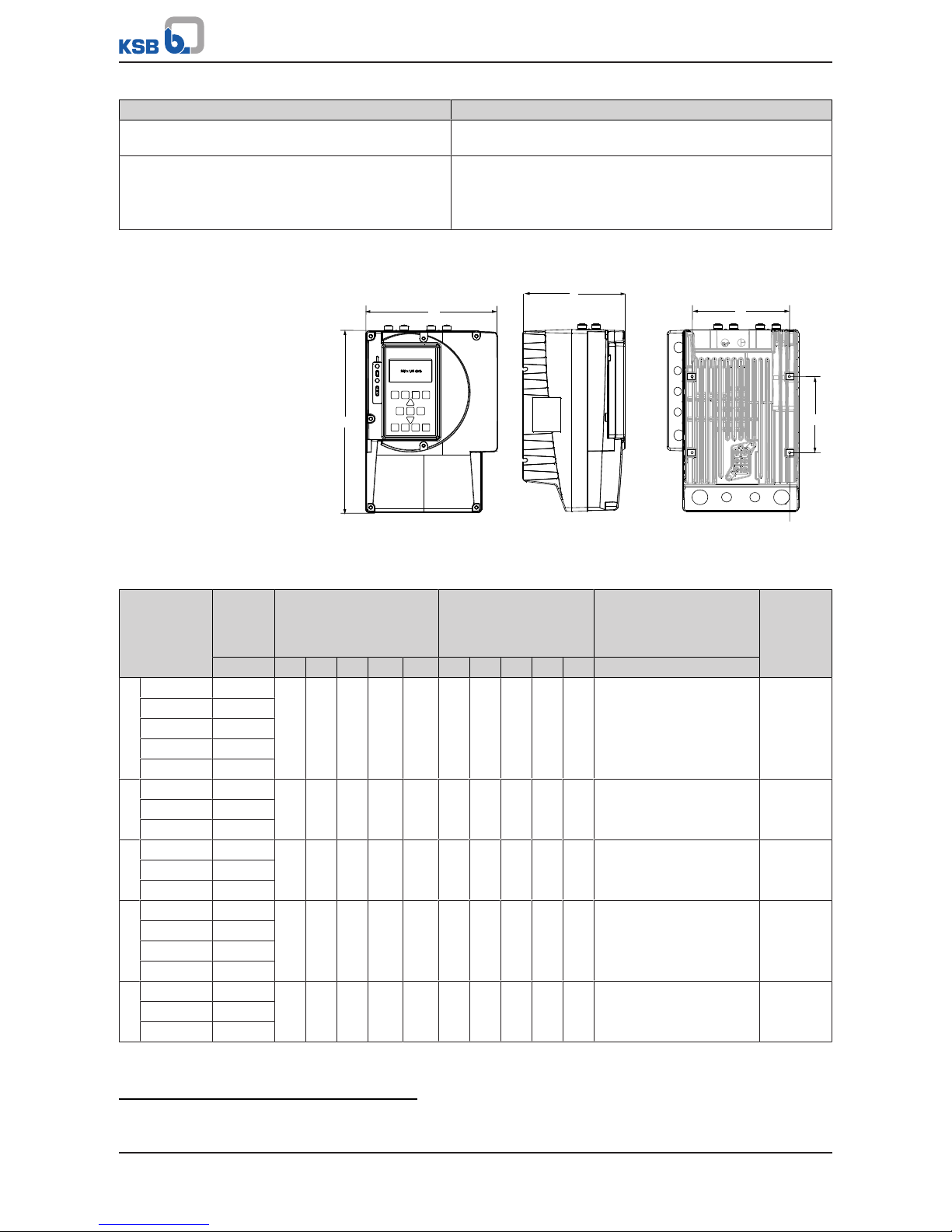

6.6 Dimensions and weights

a

b

c

d

e

F

Fig.14: Dimensions

Table25: Dimensions and weights

Size P Motor-mounted model

[mm]

Wall-/

Cabinet-mounted

model

9)

[mm]

Fastening screws/bolts Weight

10)

[kg]

[kW] a b c d e a b c d e F

A ..000K37.. 0,37 260 190 166 140 141 343 190 166 140 333 M4×10 5

..000K55.. 0,55

..000K75.. 0,75

..001K10.. 1,1

..001K50.. 1,5

B ..002K20.. 2,2 290 211 166 155 121 328 211 166 155 318 M4×10 6,5

..003K00.. 3

..004K00.. 4

C ..005K500.. 5,5 330 280 210 219 205 401 280 210 219 387 M6×12 12,5

..007K500.. 7,5

..011K000.. 11

D ..15K000.. 15 460 350 290 280 309 582 350 290 280 565 M8×14 36

..18K500.. 18,5

..22K00.. 22

..30K00.. 30

E ..37K00.. 37 700 455 340 375 475 819 455 340 375 800 M8×14 60

..45K00.. 45

..55K00.. 55

9) The dimensions provided refer to PumpDrive including the wall-mounting brackets.

10) Without motor adapter

Page 31

6 Description

31 of 212

PumpDrive 2

6.7 Mounting options

The frequency inverter is identical in design and configuration for all 3 mounting

options.

▪ Motor mounting

For the motor mounting option, the frequency inverter is mounted to the motor

via an adapter or to the pump for the Movitec configuration. Adapters for

subsequent conversion to motor mounting for existing pump systems are

available as accessories.

▪ Wall mounting

The installation kit required for the wall-mounted model is included in the scope

of supply. Installation kits for subsequent conversion to wall mounting for

existing pump systems are available as accessories.

▪ Cabinet mounting

The installation kit required for the cabinet-mounted model is included in the

scope of supply. Installation kits for subsequent conversion to cabinet mounting

for existing pump systems are available as accessories.

Page 32

7 Installation at Site

32 of 212

PumpDrive 2

7 Installation at Site

7.1 Safety regulations

DANGER

Incorrect installation

Danger to life!

▷ Install the frequency inverter in a flood-proof location.

▷ Never use the frequency inverter in potentially explosive atmospheres.

7.2 Checks to be carried out prior to installation

Place of installation

The standard configuration has IP55 enclosure protection and may only be used in

environments for which its enclosure provides adequate protection.

The place of installation must meet the following requirements:

▪ Well ventilated

▪ No direct sunlight

▪ Protected from weather

▪ Sufficient clearance for ventilation and dismantling

▪ Flood-proof

Ambient conditions

▪ Operating temperature: -10 °C to +50°C

The service life of the frequency inverter is reduced if an average temperature of

+35°C/24h is exceeded or if the inverter is operated at temperatures below 0°C

or above +40°C.

The frequency inverter switches off automatically if excessively high or low

temperatures occur.

NOTE

Contact the manufacturer if the device is to be used under ambient conditions

other than those described above.

Outdoor installation

Provide the frequency inverter with suitable protection when installed outdoors to

prevent condensation on the electronic equipment and exposure to excessive

sunlight.

7.3 Mounting PumpDrive

Depending on the selected mounting option, an adapter or installation kit is

required.

7.3.1 Motor mounting

The frequency inverter for the motor-mounted model is supplied, together with the

pump, already mounted to the motor via an adapter.

Adapters for subsequent conversion to the motor mounting configuration for

existing pump systems are available from KSB.

7.3.2 Wall/control cabinet mounting

The wall-mounted model is supplied with the installation kit required for wall

mounting as standard. Installation kits for subsequent conversion to the wall

mounting configuration for existing pump systems are available from KSB.

Page 33

7 Installation at Site

33 of 212

PumpDrive 2

The frequency inverter should rest flush against the wall so that the air flow of the

fans is directed through the heat sink.

Make sure to prevent exhaust air produced by other equipment from entering the

device's air intake in order to ensure adequate cooling of the device. The following

minimum distances must be observed:

Table26: Minimum distances for control cabinet mounting

Minimum distance from other devices Distance [mm]

Top and bottom 100

Side 20

The power dissipated in the form of heat when the frequency inverter is operated at

nominal duty values varies between 98percent for high power outputs and

95percent for low outputs, depending on the frequency inverter's nominal power.

7.4 Electrical connection

7.4.1 Safety regulations

DANGER

Incorrect electrical installation

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by specialist personnel.

▷ Observe the technical specifications of the local and national energy supply

companies.

DANGER

Unintentional start-up

Risk of fatal injury due to electric shock!

▷ Disconnect the frequency inverter from the mains before carrying out any

maintenance and installation work.

▷ Prevent the frequency inverter from being re-started unintentionally when

carrying out any maintenance and installation work.

DANGER

Contact with live components

Risk of fatal injury due to electric shock!

▷ Never remove the centre housing part from the heat sink.

▷ Mind the capacitor discharge time.

After switching off the frequency inverter, wait 10minutes until dangerous

voltages have discharged.

WARNING

Direct connection between power supply and motor connection (bypass)

Damage to the frequency inverter!

▷ Never establish a direct connection between the power supply and motor

connection (bypass) of the frequency inverter.

Page 34

7 Installation at Site

34 of 212

PumpDrive 2

WARNING

Simultaneous connection of several motors to the frequency inverter output

Damage to the frequency inverter!

Fire hazard!

▷ Never simultaneously connect several motors to the frequency inverter output.

CAUTION

Improper dielectric test

Damage to the frequency inverter!

▷ Never carry out dielectric tests on frequency inverter components.

▷ Only carry out dielectric tests on the motor, motor connection cable, or power

cable after having disconnected the frequency inverter connections.

NOTE

Depending on the combination of settings, the frequency inverter could

conceivably restart automatically after acknowledgement/reset or when the cause

of the malfunction or fault has been eliminated.

The frequency inverter is equipped with electronic safety devices, which in case of a

disturbance or malfunction, trip and de-energise the inverter, causing it to stop.

Use only the available cable gland holes (if necessary, in combination with double

cable glands) for establishing the cable connections. Any additional drilling could

generate metal chips and damage the equipment.

7.4.2 Information for planning the system

7.4.2.1 Power/connection cables

Selecting the power/connection cables

The type of connection cable you choose depends on various factors such as, for

example, the type of connection, the ambient conditions and the type of system.

Connection cables must be used in accordance with their intended use, and the

manufacturer specifications regarding nominal voltage, current, operating

temperature and thermal effects must be observed.

Power/connection cables must not be routed across or near hot surfaces unless they

have been designed for this kind of application.

When they are used in mobile system components, flexible or highly flexible power/

connection cables must be employed.

The cables used for connections to permanently installed devices should be as short

as possible and be properly connected to these devices.

Different earth bus bars should be used for control and power/motor connection

cables.

Power cable

Unshielded cables can be used as power cables.

The power cables must be designed with a cross-section suitable for the nominal

mains current.

If a mains contactor is used in the power cable (before the frequency inverter), this

must be configured for an AC1 duty rating; the rated current values of the frequency

inverters used are added and the result is increased by 15%.

Motor connection cable

Shielded cables must be used as motor connection cables.

Control cable

Shielded cables must be used as control cables.

Page 35

7 Installation at Site

35 of 212

PumpDrive 2

NOTE

Lines of type J-Y (ST) Y are not suitable for used as control cables.

1 2 3

Fig.15: Structure of electric cable

1 Wire end sleeve 2 Core

3 Cable

Table27: Cable cross-section, control terminals

Control terminal Core cross-section [mm²] Cable diameter

11)

[mm]

Rigid cores Flexible cores Flexible cores with

wire end sleeves

Terminal strip A, B, C 0,2-1,5 0,2-1,0 0,25-0,75 M12: 3,5-7,0

M16: 5,0-10,0

Table28: Power/connection cable properties

Size Power Cable gland for Mains-side

input

current

12)

Maximum

core cross-

section

Cable cross-

section

KSBmotor

cable

Mains

power

cable

Sensor

cable

Motor

cable

PTC

thermistor

[kW] [A] [mm²]

A .. 000K37 .. 0,37 M20 M16 M20 M16 1,4 2,5 2,5

.. 000K55 .. 0,55 2,0

.. 000K75 .. 0,75 2,7

..001K10.. 1,1 3,7

B .. 001K50 .. 1,5 M25 M16 M25 M16 5,2 2,5

.. 002K20 .. 2,2 6,3

.. 003K00 .. 3 8,4

.. 004K00 .. 4 10,4

C ..005K500.. 5,5 M32 M16 M32 M16 14,6 16 4

..007K500.. 7,5 18,7

..011K000.. 11 25,9 6

D ..15K000.. 15 M40 M32 M20 M40 34,1 50 10

..18K500.. 18,5 43,3 16

..22K00.. 22 52,4 16

..30K00.. 30 67,7 25