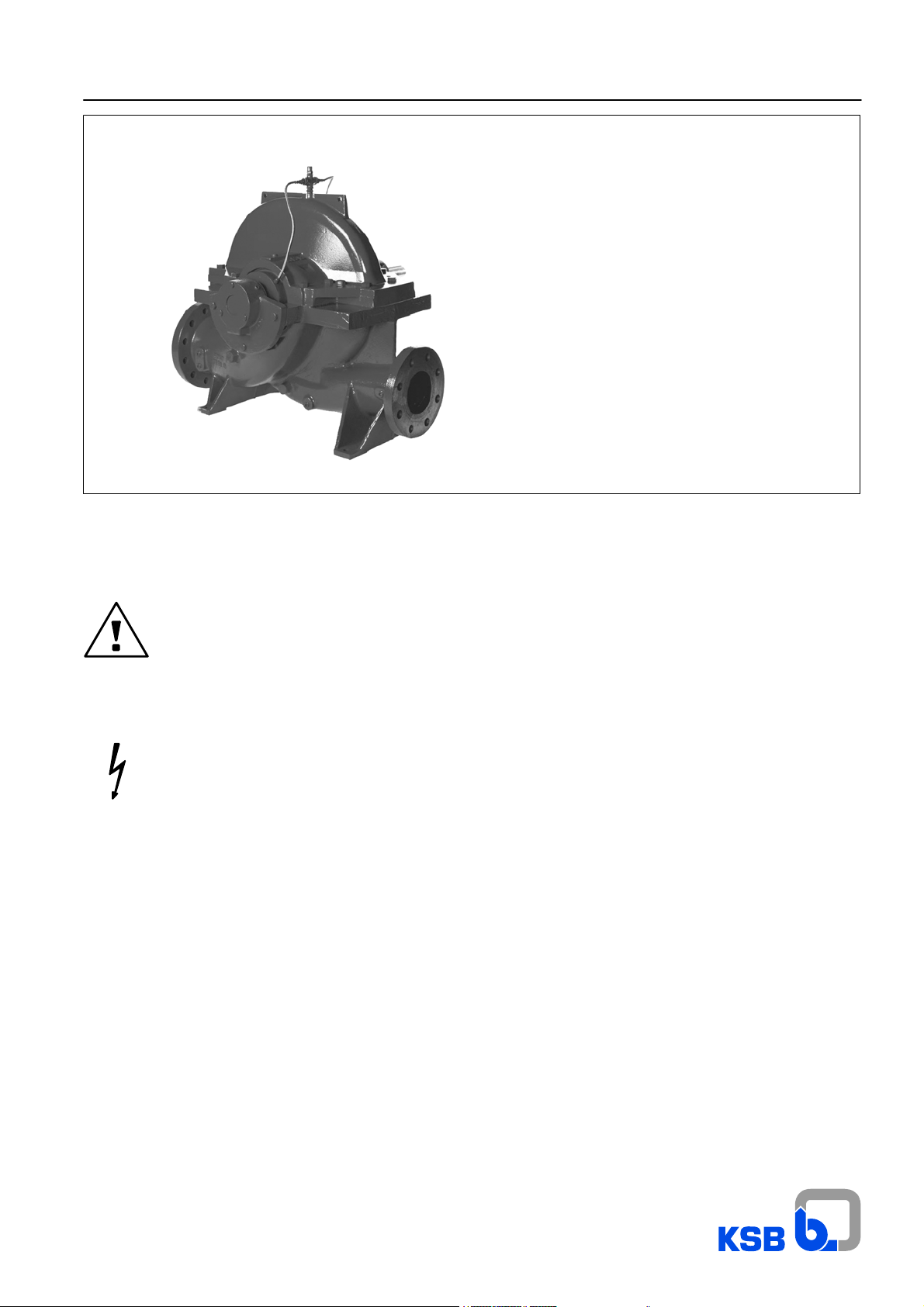

KSB Omega Series Operating Instructions Manual

Operating instructions

Omega1384.8/4--10

Volute casing pump

with radial impeller

Pump set

Horizontal installation -- 3 E

These operating instructions contain fundamental information and precautionary notes.

Please read the manual thoroughly prior to installation of unit, electrical connection and

commissioning. It is imperative to comply with all other operating instructions referring to

components of individual units.

Any work on the unit must only be carried out with the electrical connections (incl. control cable)

disconnected (or unplugged). Make sure that the pump set cannot be switched on accidentally.

Ident--No.: 01 059 616

Omega

For usage in hazardous locations

refer to supplementary operating

instructions 1387.81.

2

Omega

Contents Page

1 General 4...............................................................................

2 Safety 4................................................................................

2.1 Marking of Instructions in the Manual 4.........................................................

2.2 Personnel Qualification and Training 4..........................................................

2.3 Non--Compliance with Safety Instructions 4.....................................................

2.4 Safety Awareness 4..........................................................................

2.5 Safety Instructions for the Operator / User 5.....................................................

2.6 Safety Instructions for Maintenance, Inspection and Installation Work 5.............................

2.7 Unauthorized Modification and Manufacture of Spare Parts 5......................................

2.8 Unauthorized Modes of Operation 5............................................................

3 Transport and Interim Storage 5..........................................................

3.1 Transport 5.................................................................................

3.2 Interim Storage / Preservation 6...............................................................

4 Description of the Product and Accesories 6..............................................

4.1 Technical Specification 6.....................................................................

4.2 Designation 7...............................................................................

4.3 Design Details 7.............................................................................

4.4 Types of Installation 7........................................................................

4.5 Accessories (optional) 7......................................................................

4.6 Dimensions and Weights 7....................................................................

5 Installation at Site 7.....................................................................

5.1 Safety Regulations 7.........................................................................

5.2 Checks to Be Carried out Prior to Installation 7..................................................

5.3 Installing the Pump / Unit 8....................................................................

5.4 Connecting the Piping 8......................................................................

5.5 Final Check 8...............................................................................

6 Commissioning, Start--up / Shutdown 9...................................................

6.1 Commissioning 9............................................................................

6.2 Shaft Seal 9................................................................................

6.3 Venting 9...................................................................................

6.4 Commissioning 9............................................................................

6.5 Shutdown / Storage / Preservation 10...........................................................

6.6 Returning to Service after Storage 10............................................................

7 Maintenance / Repair 10...................................................................

7.1 General Instructions 10........................................................................

7.2 Maintenance / Inspection 11...................................................................

7.3 Dismantling 11...............................................................................

7.4 Reassembly 12...............................................................................

7.5 Instructions for Replacing Subassemblies 14.....................................................

7.6 Monitoring schedule 15........................................................................

8 Special Instructions for Subassemblies (Shaft Seal Variants) 16..............................

8.1 Gland packing 16.............................................................................

8.2 Mechanical Seal Variants (Mech. Seal Size / Pump Size Combinations) 17...........................

9 Spare Parts 32...........................................................................

10 Forces and Moments 34...................................................................

11 Trouble--Shooting 35......................................................................

11.1 General 35...................................................................................

11.2 Trouble--shooting Table 36.....................................................................

12 Routine Maintenance and Inspection Intervals 40...........................................

13 Appendix 41.............................................................................

3

Omega

1 General

This KSB pump has been developed in accordance with

state--of--the--art technology; it is manufactured with utmost care and subject to continuous quality control.

These operating instructions are intended to facilitate familiarization with the pump and its designated use.

The manual contains important information for reliable, proper

and efficient operation. Compliance with the operating instructions is of vital importance to ensure reliability and a long service life of the pump and to avoid any risks.

These operating instructions do not take into account local regulations; the operator must ensure that such regulations are

strictly observed by all, including the personnel called in for installation.

This pump / unit must not be operated beyond the limit values

specified in the technical documentation for the medium handled, capacity, speed, density, pressure, temperature and motor

rating. Make sure that operation is in accordance with the in structions laid down in this manual or in the contract documentation.

The name plate indicates the type series / size, main operating

data and works / series number; please quote this information

in all queries, repeat orders and particularly when ordering

spare parts.

If you need any additional information or instructions exceeding

the scope of this manual or in case of damage please contact

KSB’s nearest customer service centre.

2 Safety

These operating instructions contain fundamental information

which must be complied with during installation, operation and

maintenance. Therefore this operating manual must be read

and understood both by the installing personnel and the responsible trained personnel / operators prior to installation and

commissioning, and it must always be kept close to the location

of operation of the machine / unit for easy access.

Not only must the general safety instructions laid down in this

chapter on ”Safety” be complied with, but also the safety in structions outlined under specific headings.

2.1 Marking of Instructions in the Manual

The safety instructions contained in this manual whose non-observance mightcause hazards to persons are specially marked with the general hazard sign, namely

The word

Caution

is used to introduce safety instructions whosenon--observance

may lead to damage to the machine and its functions.

Instructions attached directly to the machine, e.g.

· arrow indicating the direction of rotation

· markings for fluid connections

must always be complied with and be kept in perfectly legible

condition at all times.

2.2 Personnel Qualification and Training

All personnel involved in the operation, maintenance, inspection and installation of the machine must be fully qualified to

carry out the work involved.

Personnel responsibilities, competence and supervision must

be clearly defined by the operator. If the personnel in question

is not already in possession of the requisite know--how, appropriate training and instruction must be provided. If required, the

operator may commission the manufacturer / supplier to take

care of such training. In addition, the operator is responsible for

ensuring that the contents of the operating instructions are fully

understood by the responsible personnel.

2.3 Non--Compliance with Safety Instructions

Non--compliance withsafety instructionscan jeopardizethe safety of personnel, the environment and themachine itself. Non-compliance with these safety instructions will also lead to forfeiture of any and all rights to claims for damages.

In particular, non--compliance can, for example, result in:

· failure of important machine / unit functions

· failure of prescribed maintenance and servicing practices

· hazard to persons by electrical, mechanical and chemical

effects

· hazard to the environment due to leakage of hazardous

substances

2.4 Safety Awareness

It is imperative to comply with the safety instructions contained

in this manual, the relevant national health and safety regulations and the operator’s owninternal work,operation and safety

regulations.

safety sign in accordance with DIN 4844 -- W9.

The electrical danger warning sign is

safety sign in accordance with DIN 4844 -- W8.

4

Omega

2.5 Safety Instructions for the Operator / User

Any hot or cold components that could pose a hazard must

·

be equipped with a guard by the operator.

· Guards which are fitted to prevent accidental contact with

moving parts (e.g. coupling) must not be removed whilst the

machine is operating.

· Leakages (e.g. at the shaft seal) of hazardous media hand-

led (e.g. explosive, toxic, hot) must be contained so as to

avoid any danger to persons and the environment. Pertinent legal provisions must be adhered to.

· Electrical hazards must be eliminated. (In this respect refer

to the relevant safety regulations applicable to different

countries and/or the local energy supply companies.)

2.6 Safety Instructions for Maintenance,

Inspection and Installation Work

The operator is responsible for ensuring that all maintenance,

inspection and installation work be performed by authorized,

qualified specialist personnel who are thoroughly familiar with

the manual.

Work on the machine must be carried out only during standstill.

The shutdown procedure described in the manual for taking the

machine out of service must be adhered to without fail.

Pumps or pump units handling media injurious to health must

be decontaminated.

Immediately following completion of the work, all safety--relevant and protective devices mustbe re--installed and/or re--activated.

Please observe all instructions set out in the chapter on ”Commissioning” before returning the machine to service.

3 Transport and Interim Storage

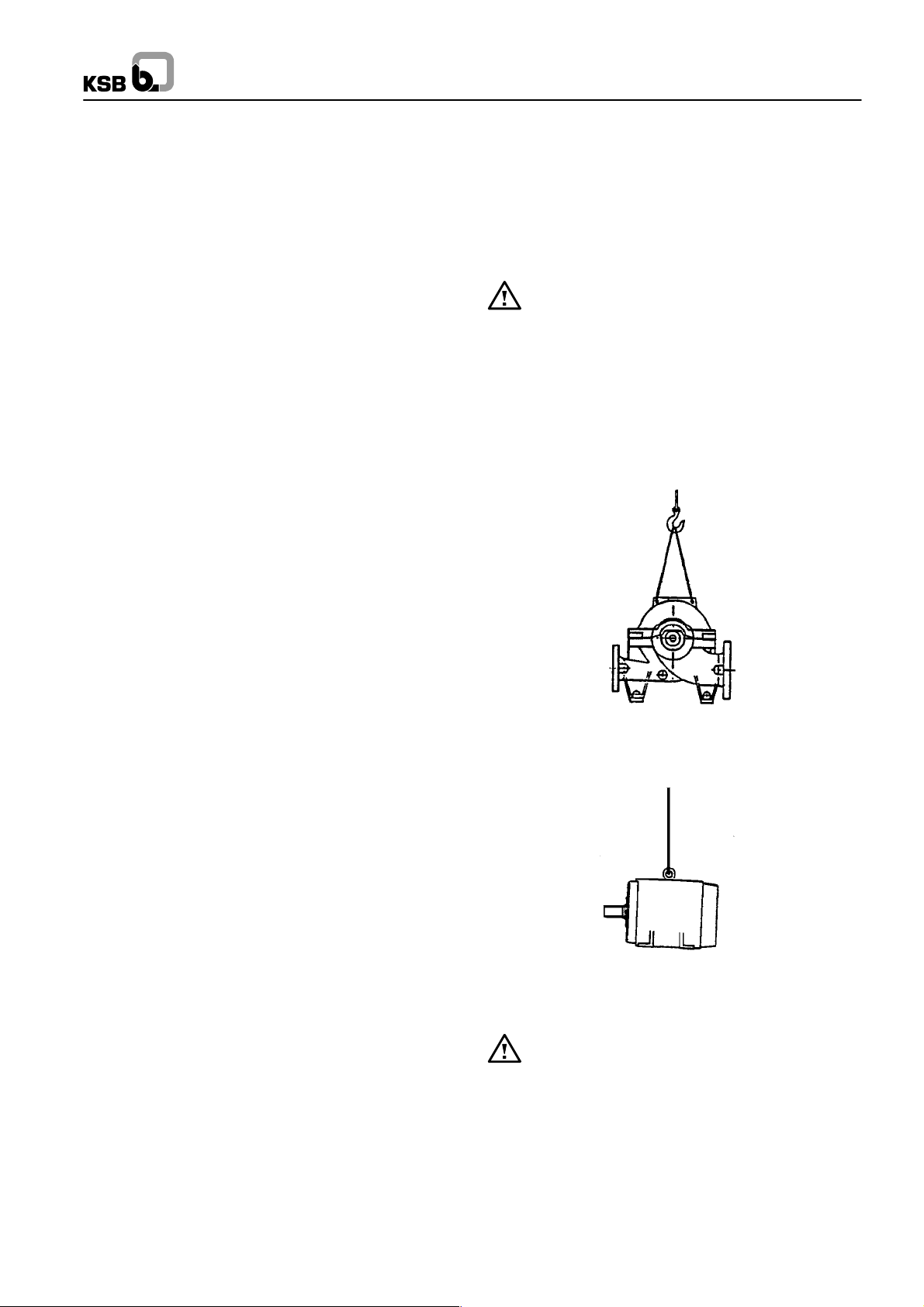

3.1 Transport

Transport of the unit requires proper preparation and handling.

Always make sure that the pump or the unit remains in horizontal position during transport and cannot slip out of the transport

suspension arrangement. Do not use lifting slings on the free

shaft end of the pump or on the motor eyebolt.

Also make sure that the coupling guard is not damaged

by the sling arrangement.If the pump / unit slips out of

the suspension arrangement, it may cause personal injury and damage to property.

Transport in horizontal position is recommended in all cases,

since this ensures stable positioning of the unit without any risk

of accident, whatever the method of transport, e.g. road, rail or

ship, etc.

For transport purposes the unit shall be securedon suitable pallets or sleds. All loose and movable parts must be secured.

2.7 Unauthorized Modification and Manufacture

of Spare Parts

Modifications or alterations of the machine are only permitted

after consultation with the manufacturer. Original spare parts

and accessories authorized by the manufacturer ensure safety.

The use of other parts can invalidate any liability of the manufacturer for consequential damage.

2.8 Unauthorized Modes of Operation

The warranty relating to the operating reliability and safety of

the pump / unit supplied is only valid if the machine is used in

accordance with its designated use as described in section 1

of these operating instructions. The limits stated in the data

sheet must not be exceeded under any circumstances.

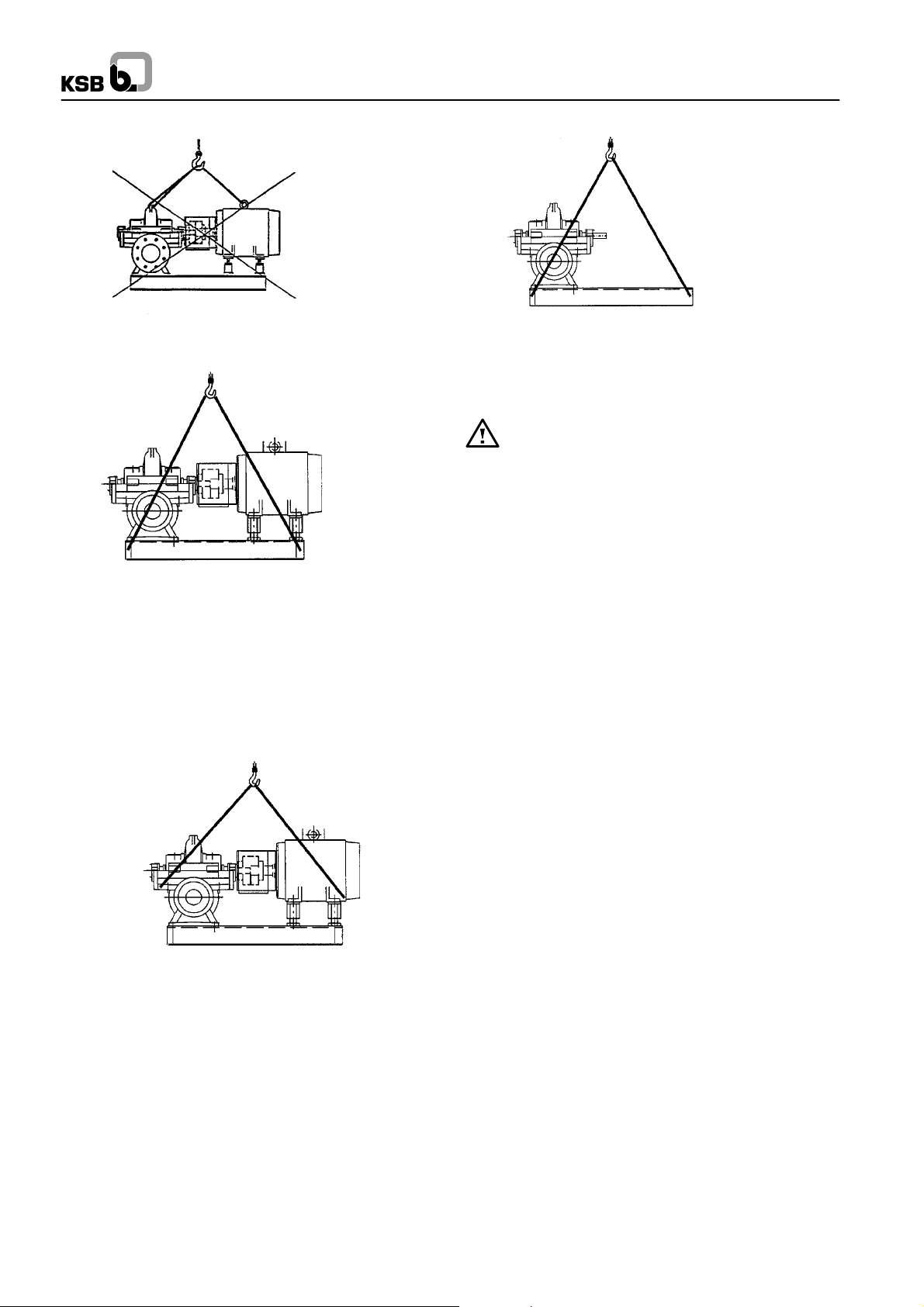

Fig.1: Transport of pump (Fig.0)

Fig.2: Transport of motor

The motor eyebolts must only be used for lifting the motor alone, never for lifting the complete unit.

5

Omega

Fig.3: Never transport the unit as shown above!

Fig.4a: Transport of complete unit

(horizontal installation type 3E)

-- up to motor size 280 (IEC standard)

-- or up to a total weight of 1500 kg

Observe angles of pull when lifting.

Angle of pull > 90_ not permitted.

Use two separate sets of lifting slings!

Fig.4c: Transport of unit (without motor)

-- motor sizes 315 and above

-- or total weight (unit) of 1500 kg and above

Safe transport in horizontal position mustbe ensured by

suitable transport facilities. Make sure the pump cannot

slip out of the transport arrangement.

3.2 Interim Storage / Preservation

When the unit is temporarily put into storage, only the wetted

low alloy components, e.g. JL1040 (GG--25) must be preserved. Commercially available preservatives can be used for this

purpose. Please observe the manufacturer’s instructions for

application / removal.

4 Description of the Product and

Accesories

4.1 Technical Specification

Design

The KSB pump of the Omega series is a horizontally installed,

single--stage, axially split volute casing pump with double--entry radial impeller.Connection flanges are manufactured according to EN, DIN, ISO, BS or ASME, as preferred.

Fig.4b: Transport of complete unit

-- up to motor size 280 (IEC standard)

-- or up to a total weight of 1500 kg

6

Fields of application

In waterworks, irrigation and drainagepumping stations, power

stations, for industrial water supply, dock installations, fire extinguishing systems, refineries, pipelines and tank farms, also

for handling crude oil and refinery intermediates

Omega

g

4.2 Designation

Omega XXX XXX X

Type series

Discharge nozzle DN mm

Nominal impeller dia.

Impeller type (A,B,C)

4.3 Design Details

4.3.1 Pump Casing

Axially split volute casing with replaceable casing wear rings.

Suction and discharge nozzles in lower half of casing are at the

same level (inline version).

4.3.2 Impeller

The double--entry radial impeller is manufacturedfor the operating data provided in each case. Also with impeller wear rings,

if requested.

In double--entry radial impellers the axial thrust is largely balanced.

4.3.3 Pump Shaft

The shaft is fully sealed against the liquidbeing pumped.Shaft -protecting sleeves are fitted in the seal area.

4.3.4 Shaft Seal

The shaft seals at the drive end and non--drive end are gland

packings or mechanical seals, as requested.

4.3.5 Bearings and Lubrication

The pump is fitted with covered deep--groove ball bearings

which are grease--lubricated for life.

The fixed bearing at the non--drive end is located on a bush to

permit rapid changing without removing the rotor or upper half.

4.4 T ypes of Installation

The pump set is installed in configuration 3E -- horizontal installation, direct--coupled (see appendix).

4.5 Accessories (optional)

The following accessories are available:

Configuration Omega

Accessories Fig.0 3E

Motor -- -- x1)

Baseplate/baseframe -- -- x1)

Coupling and coupling guard -- -- x1)

Sealing and flushing water pi-

ping

Set of pressure gauges x x

Cyclone separator with pipework x x

Vent valve (manual or automatic) x x

Temperature sensor for rolling

element bearings (PT 100)

Signal transmitter for PT 100 x x

Drain line x x

2

) included in standard scope of supply

x x

x x

4.6 Dimensions and Weights

For dimensions and weights please refer to the tables in the appendix.

5 Installation at Site

5.1 Safety Regulations

Electrical equipment operated in ”zone 1” hazardous

locations must comply with the explosion protection

regulations. This is indicated on the motor rating plate.

If the equipment is installed in hazardouslocations, the applicable local explosion protection regulations and the regulations of

the test certificate supplied with the equipment and issued by

the responsible approval authorities must be observed and

complied with.

The test certificate must be kept close to the location of operation for easy access (e.g. foreman’s office).

5.2 Checks to Be Carried out Prior to

Installation

All structural work required must have been prepared in accordance with the dimensions and loads stated in the dimension

table / installation plan.

The concrete foundations shall have sufficient strength

(min. BN 25) to ensure safe and functional installation in

accordance with DIN 1045 or equivalent standards.

Make sure that the concrete foundation has set firmly before

placing the unit on it. Its surface shall be truly horizontal and

even.

7

Omega

5.3 Installing the Pump / Unit

Caution Caution

Before setting up the pump, check the

operating data. Ensure that the data on the

5.4 Connecting the Piping

name plate matches the data in the order and the system data,

e.g. operating voltage, frequency, pumped liquid temperature

etc.

Suction lift lines shall be laid with a rising slope towards the

pump and suction head lines with a downward slope towards

the pump. The pipelines shall be anchored in close proximity to

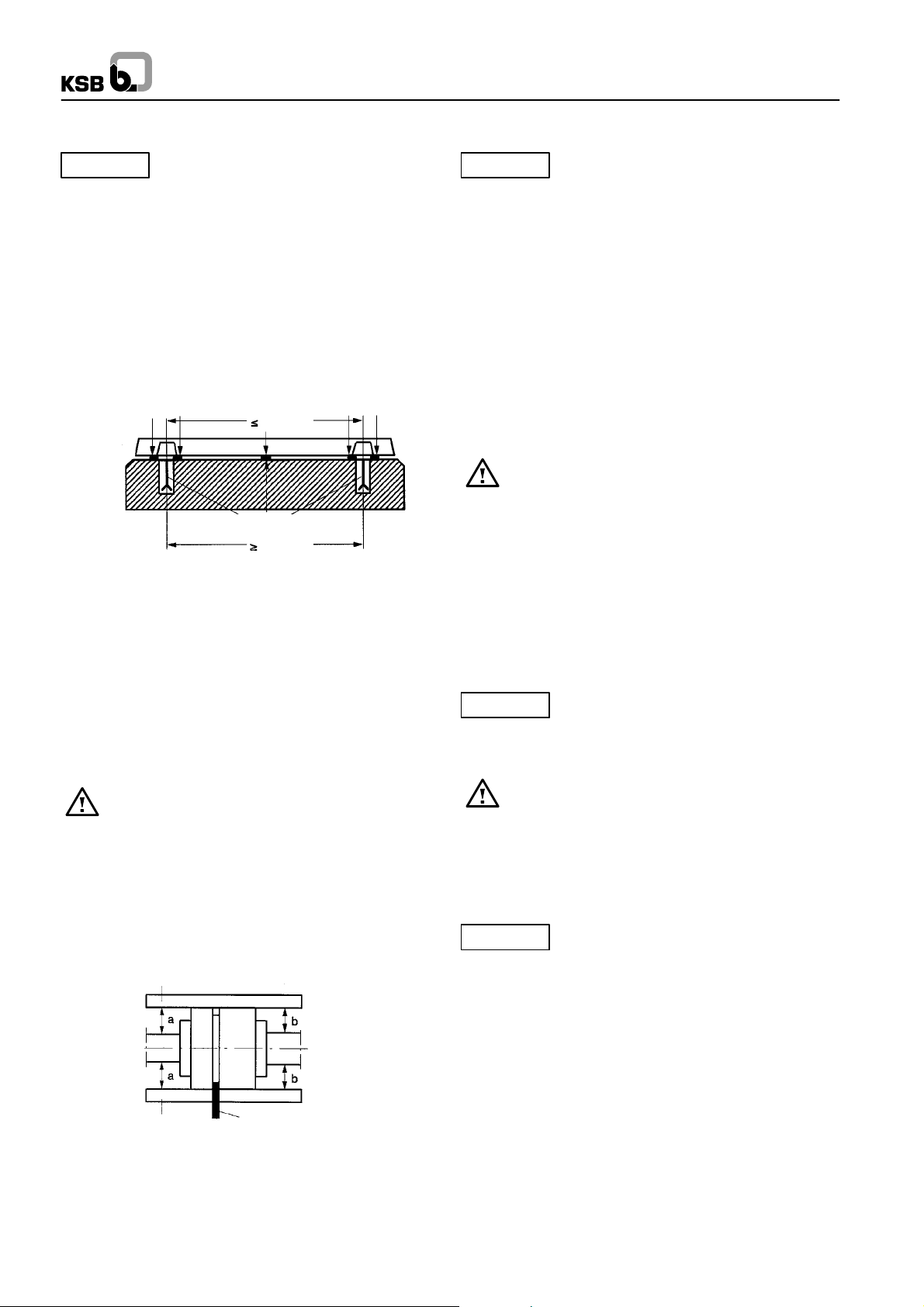

After placing the pump on the foundation, align it with the help

of a spirit level. Shims shall be fitted between the baseplate and

the foundation itself; they shall always beinserted to the left and

right of the foundation bolts and in close proximity to these

bolts. For a bolt--to--bolt clearance of more than 1000 mm, additional shims shall be inserted halfway between the adjoining

holes. All shims must lie perfectly flush.

the pump and connected without transmitting any stresses or

strains. Their weight must not exert any load on the pump. With

short pipelines, the nominal diameters shall be at least equal to

the nominal diameters of the pump nozzles. For long pipelines

the most economical nominal diameter has to be determined

from case to case.

Any additional loads on the discharge and suction nozz-

les, e.g. caused by:

Shim Shim Shim

1000

Weight of the water--filled pipes, changes in the length of pipes

owing to temperaturefluctuations, reactionforces due to unbra-

ced expansion joints must not exceed the values stated in the

installation plan.

Foundation bolts

1000

The flange covers on the pump suction and discharge nozzles

must be removed prior to installation in the piping.

Fig.5: Fitting required shims

Insert the foundation bolts and set them into the foundation

using concrete. When the concrete has set, align the baseplate

as described in section 5.3.2 and tighten the foundation bolts

evenly and firmly. Then grout the baseplateusing lowshrinkage

concrete, making sure no cavities remain.

5.3.1 Removing Rotor Lock

5.4.1 Auxiliary Connections

The locations of the auxiliary connections (sealing liquid, flus-

hing liquid, etc.) are indicated on the installation plan or piping

layout (see appendix).

Please refer to the appendix fordetailed assembly instructions.

Caution

This is not necessary for a horizontally installed pump, since no

locking device is fitted.

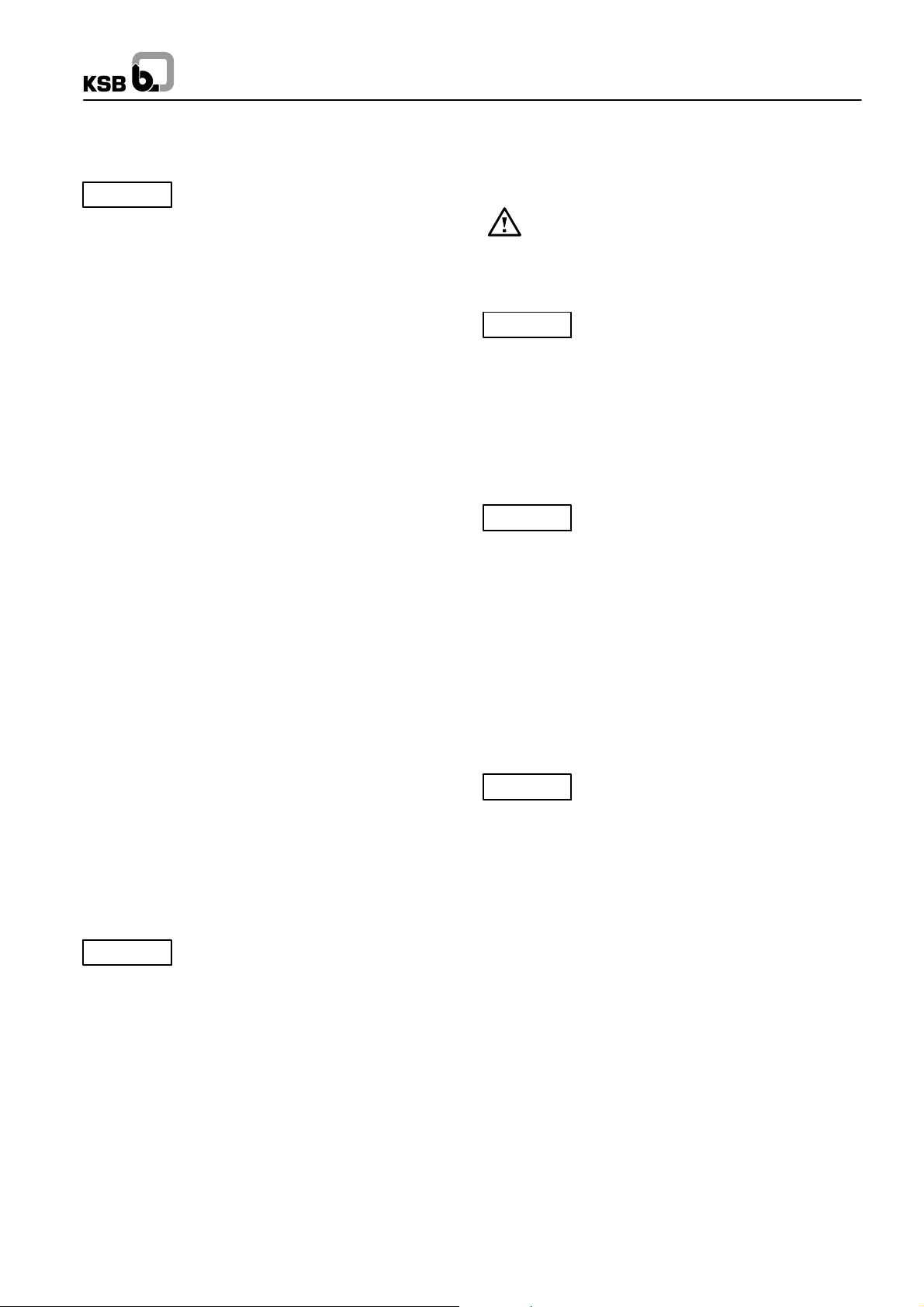

5.3.2 Aligning the Pump / Drive

5.4.2 Coupling Guard

Improper alignment of the unit can cause damage to

both the coupling and the unit itself!

A pump set inhorizontal installation type 3E is correctly aligned,

guard. If the customerspecifically requests not to includea cou-

pling guard in our delivery, then the operator must supply one.

if a straight--edge placed axially on both coupling halves is the

same distance from each shaft at all points around the circumference. In addition, the distance between the two coupling hal ves must remain the same all around the circumference. Use

a feeler gauge, a wedge gauge or a dial micrometer to verify

(see fig. 6).

straight edge

5.5 Final Check

Re--check the alignment as described in section 5.3.2.

It must be easy to rotate the shaft by hand at the coupling.

Caution

Never use the pump itself as an anchorage

point for the piping.

An excessive, impermissible increase in the pipeline

forces may cause leaks on the pump where the medium

handled can escape into the atmosphere.

Danger of life when hot media are handled!

These connections are required for proper

functioning of the pump and are therefore of

vital importance!

In compliance with the accident prevention regulations

the pump must not be operated without a coupling

Check the integrity and proper functioning of all

connections.

straight edge

Fig.6: Coupling alignment, using gauge and straight edge

Special instructions see appendix

gauge

8

Omega

6 Commissioning, Start-- up /

Shutdown

Caution

from non--compliance shall not be covered by the scope of

warranty.

6.1 Commissioning

Before starting up the pump make sure that the following requirements have been checked and fulfilled:

· Has the pump been firmly bolted to the foundation?

· Have the coupling and pump unit been aligned as speci-

fied?

· Can the unit be easily rotated by hand at the coupling?

(Carry out at least one full rotation)

· Are the pipes properly fitted?

· Has the coupling guard been fitted?

· Have staff been informed about sources of danger and

measures been taken to comply with the accident prevention regulations?

· Correct start--up procedure for suction lift operation.

· Is the unit protected against overload (appropriate safety

valve)?

· Have the seals been fitted as described in the appendix?

· Have any additional devices been prepared and fitted as

specified in the appendix?

· Has the pump been vented as specified in section 6.3.?

Compliance with the following requirements is

of paramount importance. Damage resulting

Correct direction of rotation:

The direction of rotation must correspond to the direction indicated by the arrow on the pump. This can be verified by switching the pump on and then off again immediately.

Before checking the direction of rotation make sure that

there is no foreign matter in the pump casing.

Never put your hands or any other objects into the pump!

6.4.2 Start--up

Caution

If a shut--off valve is fitted in the suction line, open it fully.

All additional connections for flushing or sealing liquid etc., if fitted, must be opened fully and the flow must be checked.

Switch on the motor.

As soon as the pump starts to deliver -- this can be recognised

by the rising gauge pressure -- slowly open the discharge--side

gate valve fully.

Caution

otherwise inadmissible temperature rise occurs resulting in

damage.

6.4.3 Pump Operating Range

The flow rate ”Q” adjusts itself automatically to the delivery

head according to the H--Q characteristic. The pump’s permitted operating range is subject to limits, which have separate

causes.

If a non--return valve is not fitted at the di -scharge--side, close the discharge--side

gate valve.

The pump may operate against the closed gate

valve only during start--up and shutdown, as

6.2 Shaft Seal

For commissioning the shaft seal please refer to section 8.1 /

8.2. If the pump has been out of service for a prolonged period,

the measures specified in section 6.6 must be carried out.

6.3 Venting

Before start--up, the pump and the pipes must be vented and

filled with the liquid to be pumped. This is done at the vent plug

on the casing (903). For suction lift operation, the pump must

also be evacuated, i.e. a vacuum must be produced.

6.4 Commissioning

6.4.1 Checking the Direction of Rotation

Caution

paramount importance.

If running in the wrong direction of rotation, the pump c annot reach its duty point; vibrations and overheating will be the consequence. The unit or the shaft seal might be damaged.

For trouble--free operation of the pump, the

correct direction of rotation of the impeller is of

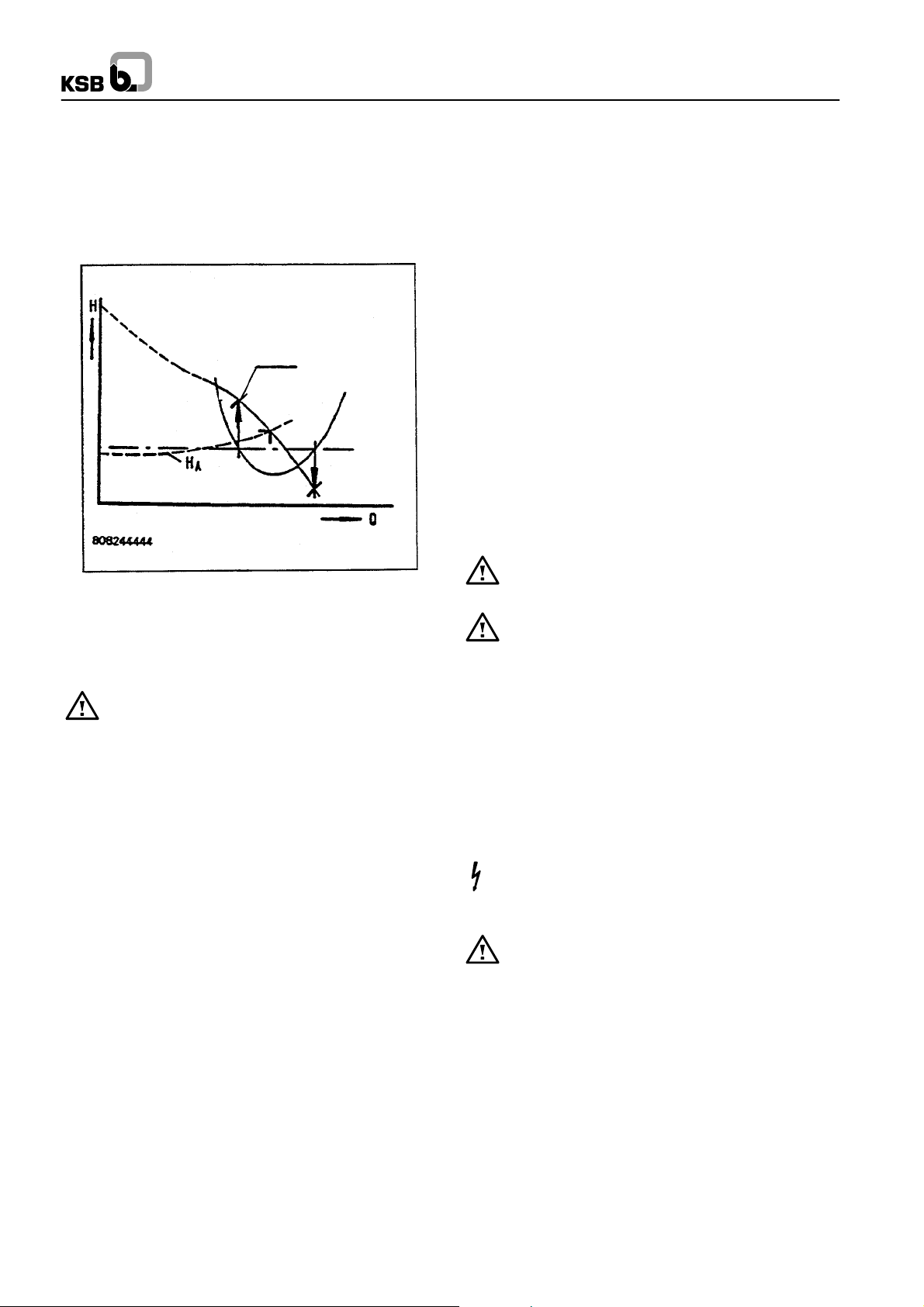

1. Part load operating limit for low flow rate

This limit is indicated in the H--Q characteristic by Q

discontinuation of the characteristic curve.

Caution

in this range causes greatly increased mechanical loads which

the components cannot withstand.

Brief passage through the critical range is permissible, e.g. during start--up

2. NPSH--related limits in the part load and overload ranges

These two limits are determined by the ratio of NPSH

NPSH

available

It is not permissible to operate the pump in the

range from Q=0 to Q

. They are determined as follows:

Prolonged operation

min.

min

required

or by the

to

9

Omega

The intersections of NPSH

required

and NPSH

available

are projected onto the H--Q characteristic, where they indicate theoperating limits (refer to the diagram below). Checking of the

NPSH--related operating limit is notnecessary for operating the

pump under design conditions. If system--related changes occur, an NPSH check must be carried out. If necessary, consult

the nearest after--sales service centre.

Q

min

NPSH

required

NPSH

available

6.4.4 Shutdown

Close the shut--off element in the discharge line. If the discharge line is equipped with a check valve, the shut--off ele ment may remain open, provided there is back pressure in the

line.

The shut--off element in the suction line must not be closed when switching off the pump. Switch off the motor,

making sure that the unit runs smoothly down to a standstill.

Depending on the system the pump shall have an adequate after--run period -- with the heat source switched off -- to allow the

medium handled to cool down sufficiently to avoid any heat

build--up within the pump.

In the case of prolonged shutdown, the shut--off element in the

suction line has to be closed.

Close the auxiliary connections.

In the event of frost and / or prolonged shutdowns, the pump

must be drained or otherwise protected against freezing.

6.5 Shutdown / Storage / Preservation

Each KSB pump leaves the factory carefully assembled.If commissioning is to take place some time after delivery, we recommend that the following measures be taken for pump storage.

6.5.1 Storage of New Pumps

· New pumps are supplied by our factory duly prepared for

storage.

Maximum protection for up to 12 months, if the pump is properly stored indoors.

· Store the pump in a dry location.

6.5.2 Measures to be Taken for Prolonged Shutdown

1. The pump remains installed; periodic check of operation

In order to make sure that the pump is always ready for instant

start--up and to prevent the formation of deposits within the

pump and the pump intake area, start up the pump set regularly

once a month or once every 3 month for a short time (approx.

5 minutes) during prolonged shutdown periods. Prior to an operation check run ensure that there is sufficient liquid available

for operating the pump.

2. The pump is removed from the pipe and stored

Before putting the pump into storage carry out all checks specified in sections 7.1 to 7.4. Then apply appropriate preservatives:

· Spray--coat the inside wall of the pump casing, and in parti-

cular the impeller clearance areas, with a preservative.

Spray the preservative through the suction and discharge

nozzles. It is advisable to close the nozzles (for ex. with plastic caps or similar).

6.6 Returning to Service after Storage

Before returning the pump to s ervice carry out all checks and

maintenance work specified in sections 5.1 and 5.2.

In addition, the instructions laid down in section 6.1

”Commissioning” and section 6.4.3 ”Operating limits”

must be observed.

Upon completion of the work, all safety--related and protective equipment must be properly refitted and / or reactivated before starting the pump set.

7 Maintenance / Repair

7.1 General Instructions

The operator is responsible for ensuring that all maintenance,

inspection and installation work is carried out by authorized,

duly qualified staff who are thouroughly familiar with these operating instructions.

A regular maintenance schedule will help avoid expensive repairs and contribute to trouble--free, reliable operation of the

pump with a minimum of maintenance expenditure and work.

Work on the pump and the motor must only be c ar-

ried out with the electrical connections disconnected. Make sure that the pump set cannot be switched on accidentally (danger of life!).

Pumps handling liquids posing health hazards must be

decontaminated. When draining the medium see to it

that there is no risk to persons or the environment. All relevant

laws must be adhered to (danger of life!).

10

Omega

7.2 Maintenance / Inspection

7.2.1 Supervision of Operation

Caution

Prolonged operation against a closed shut--off element

is not permitted in order to prevent the medium handled

from heating up.

At room temperatures of up to 30 _C(86_F) the bearing temperature shall be below 90 _C (194 _F). At higher room tempera tures, the bearing temperature shall be below100 _C (212 _F).

During pump operation the shut--off element in the inlet

line must not be closed.

Any stand--by pumps installed shall be switched on and then

immediately off again once a week to keep them operational.

Attention shall be paid to the correct functioning of the auxiliary

connections.

Caution

time. See section ”Coupling”.

If an external supply of sealing, flushing or lubricating liquid is

used, make sure supply pressure is 1.0 to 2.0 bar higher than

pressure at the suction nozzle.

On pumps fitted with a gland packing the packing must drip

slightly during operation. The gland cover should therefore only

be gently tightened. (See section 8 ”Special instructions for

subassemblies, shaft seal variants”).

7.2.2 Shaft Seal Maintenance

For required maintenance work on gland packings please refer

to section 8.1. ”Shaft seal”. Mechanical seals are maintenance--free.

7.2.3 Bearing Maintenance

The bearings are maintenance--free and greased for life. No

re--lubrication is required.

The pump shall run quietly and free from

vibrations at all times. The pump must neverbe

allowed to run dry.

If the flexible coupling elements begin to show

signs of wear, they must be replaced in due

7.3 Dismantling

Before dismantling, secure the pump so as to makesure

it cannot be switched on accidentally. The shut--off elements in the suction and discharge lines must be closed. The

pump must have cooled down to ambient temperature, pump

pressure must be released and the pump must be drained.

Dismantling and reassembly must always be carried out in ac cordance with the relevant sectional drawing.

7.3.1 Fundamental Instructions and

Recommendations

Repair and maintenance work to the pump must only be carried

out by specially trained personnel, using original spare parts.

Observe the safety regulations laid down. Any work on the motor shall be governed by the specifications and regulations of

the respective motor supplier.

Dismantling and reassembly must always be carried out in ac cordance with the relevant general drawing. The general drawing and other relevant documents are found in the annex. The

dismantling sequence can be derived from the general drawing.

In case of damage you can always contact our nearest customer service centre.

7.3.2 Preparations for Dismantling

The pump is designed so that the complete rotor can be removed in the sequence described below without removing the suction or discharge pipe or disturbing the alignment of the pump

unit:

· Close the suction anddischarge--side gate valvesand drain

the pump by opening the drain plug (903.01 bottom) and

vent plug (903.01 top).

· Remove any pipes between additional equipment and the

pump.

· Removethe coupling guard. Decouple pump--side coupling

half as described in the appendix.

· Loosen and push back the seal cover (471), if a mechanical

seal is fitted.

· Undo the flange screws (901.01 / 901.02) and separate the

upper casing half (105.02) from the lower casing half

(105.01) with the aid of the forcing screws. Remove with lifting gear. The interior of the pump (impeller with casing

wear rings, shaft seal) is now accessible for inspection.

· Remove the screwed connection (901.04) betweenbearing

housing (350.01) and bearing brackets. Also undo the nuts

(920.05) and bolts (901.07) which secure the bearing cover

(360).

· Press the bearing housing out of the recesses and lift the

rotor out of the lower casing half. For further disassembly,

place securely in horizontal position.

· Pull off the bearing housing of the fixed bearing (opposite

the drive end).

· Undo and remove the keywayed nuts (920.03).

· Remove the deep--groove ball bearing (312) with bush

(520) from the shaft.

· Remove the bearing cover (360).

· Remove the V--ring (412.02) from the shaft--protecting

sleeve (524.01).

· Pull off the shaft--protecting sleeve (524.01).

· Remove the shaft seal housing (441).

· The impeller (234) is located with a sliding fit on the shaft

and can normally be removed easily. In case of difficulty, it

can be loosened by gently tapping the hub with a wooden

hammer.

· Remove the second shaft protection sleeve (524.01) com-

plete with the shaft seal housing (441), if fitted.

· Remove the coupling half.

· Pull off the bearing housing (350.01).

· Remove the circlip (932) and pull off the deep--groove ball

bearing (321).

11

7.4 Reassembly

Reassembly is effected in reverse order to dismantling. For all

work on the pump unit refer to the general drawing, in conjunction with the list of components, for orientation.

The rules of sound engineering practice and also the instructions for removal and installation of shaft seal, bearings, impeller wear rings and casing wear rings (sections 7.5.1 and 7.5.2)

must be observed.

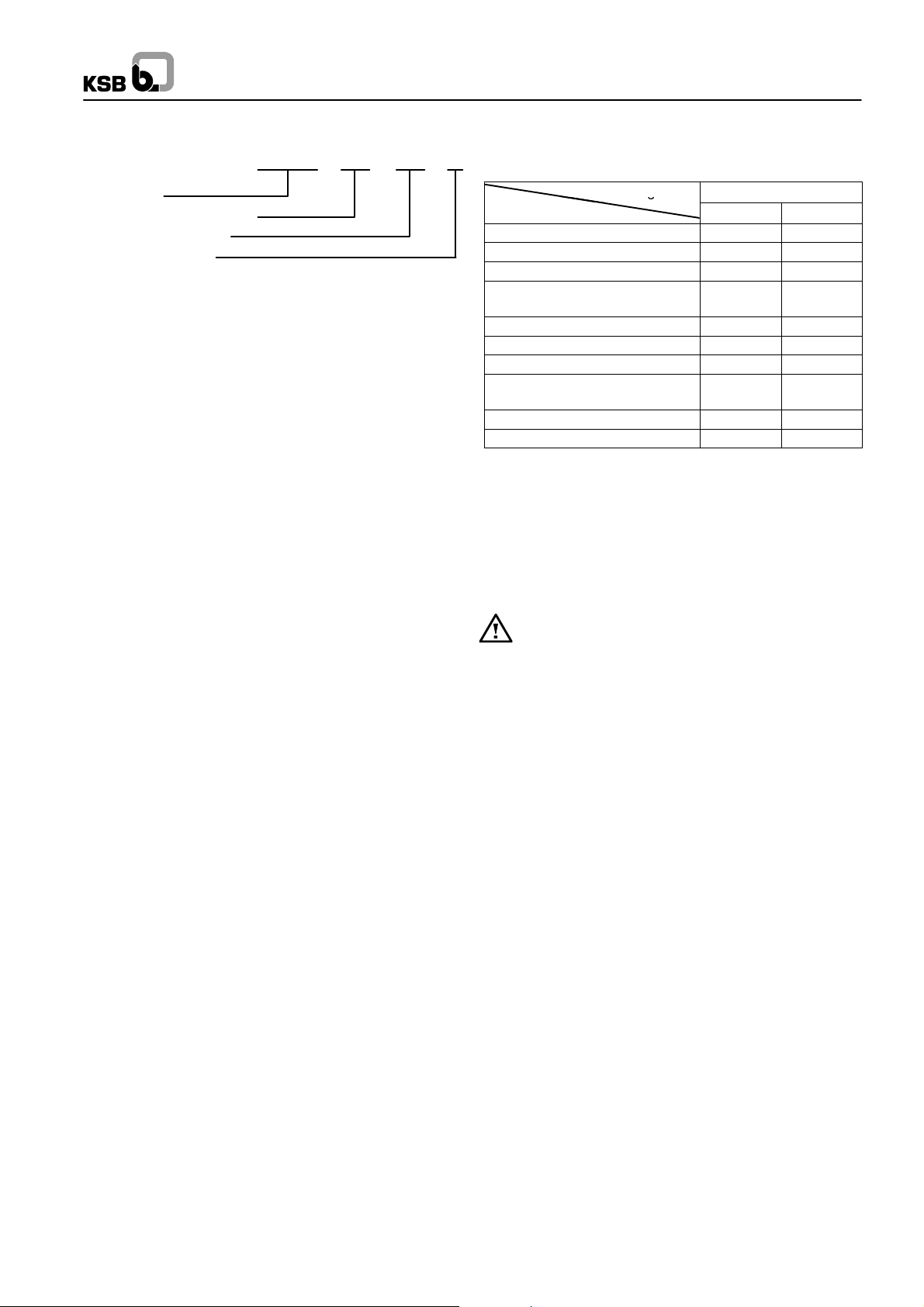

The tightening torques indicated for nuts and bolts shall be observed. The table below indicates the tightening torques for

threads depending on the materials used.

Property class (Material) 8.8 10.9 A.-50 A.-70 1.4462

0,2% yield stress 640 900 210 450

R

p02

in N/mm

2

Metric ISO threads Tightening torque

coarse--pitch- fine--pitch- M

M4 3,1 4,4 1,0 2,15

M5 6,1 8,7 2,00 4,25

M6 10,4 14,9 3,40 7,30

M8 25,2 36,1 8,30 17,7

M10 49,5 71,0 16,2 34,8

M12 85,2 122,2 28,0 59,9

M16 211 302,7 69,2 148

M20 412 591,9 135 290

M24 710 1019,6 233 276 500

M27 1050 1501,3 343 409 736

M30 1420 2036,4 466 554 1000

M33 1940 2779,4 636 -- -- 1360

M36 2480 3552,3 812 -- -- 1740

1

) Nominal values to DIN ISO 898 Part 1, DIN 267 Part 11 and DIN 267 Part 18

1

) 250 450

in Nm

A

M8x1 27,2 39,0 8,90 19,1

M10x1,25 52,5 75,4 17,3 36,9

M12x1,5 89,5 128,5 29,4 62,9

M12x1,25 93,9 134,7 30,8 66,0

M16x1,5 226 324,7 74,3 159

M20x1,5 461 661,0 151 324

M24x2 780 1118,6 256 305 548

M27x2 1130 1627,1 372 443 797

M30x2 1580 2269,9 519 618 1110

M33x2 2130 3062,6 700 -- -- 1500

M36x3 2630 3775,4 863 -- -- 1850

Omega

It is imperative to lock and seal the screwed connections specially marked in the general drawings.

Symbols for screwed connections to be locked and sealed:

12

ALTEMP Q NB 5 0 grease

Sealed with Loctite 574

Omega

O--rings and V--rings must be replaced and their seats on the

shaft must be cleaned. In addition, all the sealing elements

must be fitted into the respective components before installation.

For assembling the rotor, position the pump shaft (211) securely. All fits, threads and sliding fits of the shaft must be cleaned

and coated with assembly paste.

Insert the keys required for assembly into the pump shaft (211).

Mount the impeller (234),which has a sliding fit. When fitting the

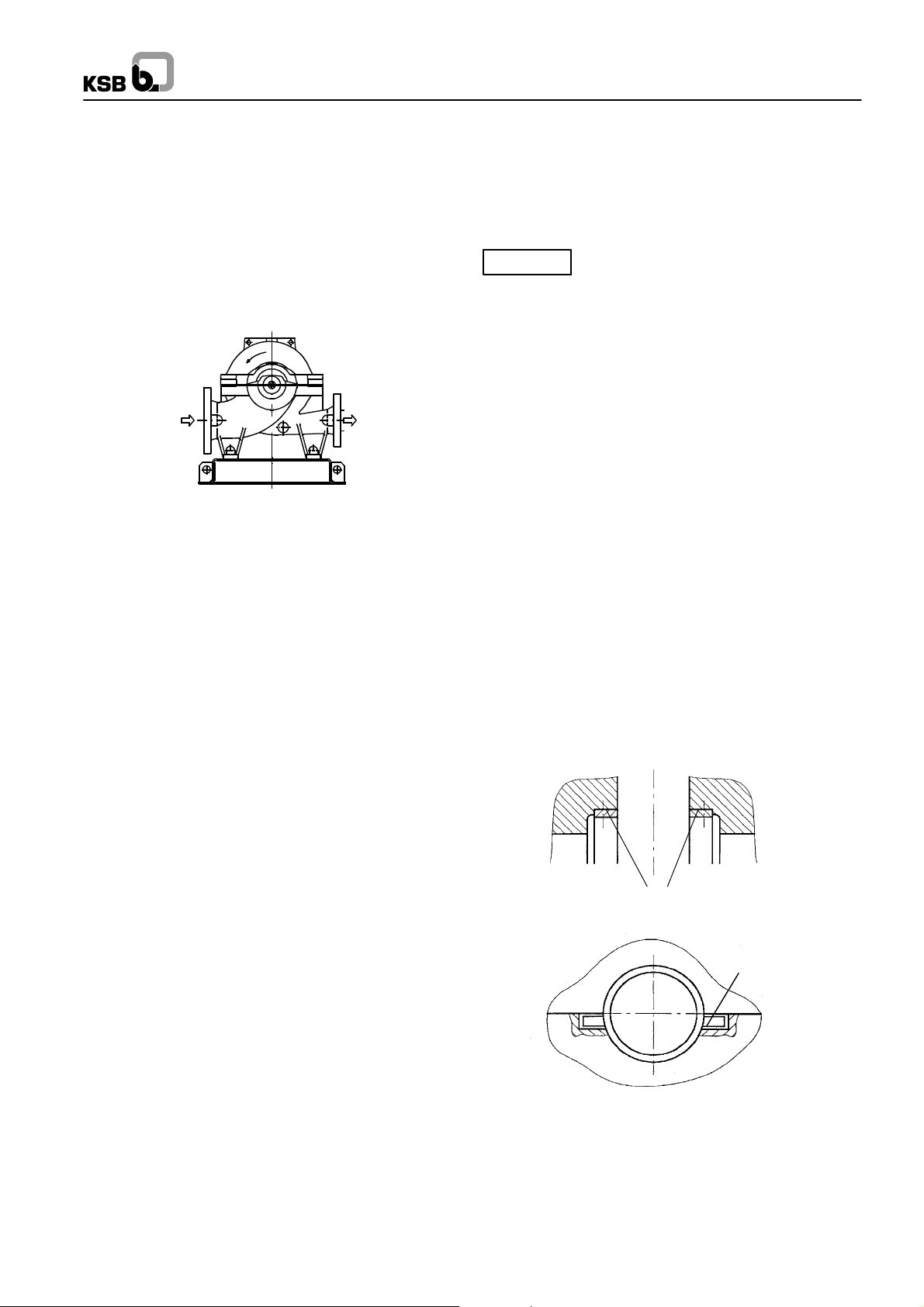

impeller,observe the direction of rotation (see diagram below).

For assembling the casing wear rings (502), observe section

7.5.2 ”Replacing the casing wear rings”.

Put the casing wear rings onto the running surfaces of the impeller.Ensure that the bezels of the rings are on the outside (towards the bearing). Insert the pins required for fixing the casing

wear rings.

The remaining components are fitted first on the movable bearing side (i.e. the drive side) of the pump shaft.

Push the shaft protecting sleeve (524.01) onto the pump shaft

(211). Ensure that the groove provided engages in the key of

the impeller.

Push the shaft seal housing (441) onto the shaft and install

the shaft seal as described in section 8.1, ”Gland packing”.

Slip on V--ring (411.01).

Insert the radial shaft seal ring (421.02) into the bearing cover

(360) and push the bearing cover over the shaft.

Heat the deep--grooved ball bearing (321) and fit it onto the

pump shaft (211). It is essential to avoid one --sided pressure or

hammer blows on the outer races. The bearing is secured by

the disc (550.01) and the circlip (932).

To fit the shaft protecting sleeve (524.01), shaft seal housing

(441), V--ring (411.01) and bearing cover (360) at the non--drive

end, proceed as described above for the drive side.

Heat the deep--groove ball bearing (321) and fit it onto the

sleeve (520).

Push the sleeve (520) with deep--groove ball bearing (321)onto

the pump shaft (211) with key (940.01) inserted.

Tension the rotor parts elastically with keywayed nut (920) and

cup spring (950). For this purpose tension the cup spring (950)

to blocking point and then undo the keywayed nut (920) again

by half a turn (180_).

Caution

This measure is essential to compensate for

differences in thermal expansion between the

pump shaft (211) and the components fitted on it.

Rotor assembly is now complete.

Insert the rotor into the pump casing.

Apply Loctite 574 to the casing wear ring surfaces and the sealing surfaces of the casing.

Install the rotor,making sure that the direction of rotation is correct.

Align the rotor and ensure that the fixing pins are correctly seated in the casing.

The pins (561.01) must be positioned as shown in the diagram

below.

The bearing housings (350.01) must be fastened to the bearing

brackets by means of the screwed connections (901.04), with

the sealing cap (580) inserted at the non--drive end.The seating

positions are determined by the recesses.

Fit the bearing covers.

To assemble the casing cover, apply Loctite 574 to the casing

joint surface of the lower casing half.

Tighten the flange bolts diagonally from the inside towards the

outside.

Insert the key for fitting the coupling into the pump shaft (211).

When fitting the coupling and accessories, refer to the relevant

section of the operating instructions.

Casing wear rings

(502)

561.01

13

Omega

7

0

7.5 Instructions for Replacing Subassemblies

After dismantlingas described in section 7.3.2, the casing wear

rings (502) can be removed. When fitting the rings, ensure that

7.5.1 Replacing the Shaft Seal

Proceed as described in section 8.1 and 8.2.

7.5.2 Replacing Casing Wear Rings and / or Impeller

Wear Rings

1)

The impeller clearance

clearance between impeller 234 and

casing wear ring 502 is given in the table below.

For impeller removal proceed as described in section 7.3,

their bezels are on the outside (towards the bearing). The pins

(561.01) must be positioned as shown in the diagram below.

If the impeller has not been fitted with a wear ring at the factory,

and changing the casing wear ring alone does not achieve anything close to the required impeller clearance (the impeller

neck is badly worn by clearance flows), the impeller neck must

be turned off on a lathe (contact KSB before doing so) and an

impeller wear ring fitted in addition (available as spare part).

Alternatively, a new impeller can be supplied at short notice.

”Dismantling”.

Impeller clearances and trim dimensions for impeller wear rings

Clearance (as--new) Dimensions of impeller wear ring

No. Pump

size

1 80-210 0,3 0,15 0,2 134 r6 18

2 80-270 0,3 0,15 0,2 134 r6 18

3 80-370

4 100-250

5 100-310 0,35 0,17 0,2 163 r6 22

6 100-375 0,35 0,17 0,2 163 r6 22

7 125-230 0,35 0,18 0,23 178 r6 22

8 125-290 0,35 0,18 0,23 178 r6 22

9 125-365

10 125-500

11 150-290 0,45 0,22 0,26 210 r6 30

12 150-360 0,45 0,22 0,26 210 r6 30

13 150-460 0,45 0,22 0,26 210 r6 30

14 150-605

15 200-320

16 200-420 0,5 0,24 0,28 243 r6 30

17 200-520 0,5 0,24 0,28 243 r6 30

18 200-670

19 250-370

20 250-480

21 250-600

22 300-300 70 0,5 0,24 0,28 259 r6 30

23 300-435 80 0,6 0,29 0,35 313 r6 35

24 300-560

25 300-700

26 350-360 80 0,5 0,24 0,28 294 r6 35

27 350-430

28 350-510

Shaft

unit

DW 2 D5 b

40

50

60

70

80

90

90

Nominal clea-

rance

(max. perm.)

D

2-D1

[mm] [mm] [mm] [mm] [mm]

0,3 0,15 0,2 134 r6 18

0,35 0,17 0,2 163 r6 22

0,35 0,18 0,23 178 r6 22

0,35 0,18 0,23 178 r6 22

0,45 0,22 0,26 210 r6 30

0,5 0,24 0,28 243 r6 30

0,5 0,24 0,28 243 r6 30

0,5 0,24 0,28 276 r6 30

0,5 0,24 0,28 276 r6 30

0,5 0,24 0,28 276 r6 30

0,6 0,29 0,35 313 r6 35

0,6 0,29 0,35 313 r6 35

0,6 0,32 0,37 333 r6 35

0,6 0,32 0,37 353 r6 35

Min.

clearance

Smin

Max.

clearance

Smax

b

S (min - max)

14

7.6 Monitoring schedule

For a detailed description of the pump version, components

and accessories supplied by KSB please refer to section 13 of

this operating manual.

Component monitored Action Value required

Omega

Mechanical seal

(if applicable)

Gland packing

(if applicable)

Suction side measuring instrument, ps

(if applicable)

Discharge side measuring instrument, pd

(if applicable)

Thermometer

(suction / discharge nozzle)

(if applicable)

Flushing line sight glass

(if applicable)

Vibration measurement

(if applicable)

Bearing temperature

(if applicable)

Coupling Check weekly

Drive

(if applicable)

Coupling guard Check monthly No contact permitted

Earthing connection Check monthly Connection must be fitted and marked.

Check for leakage (daily) see section 8.2 and *

Check for leakage (daily) 10 to 120 drops / min.

Check pressure (daily) *

Check pressure (daily) *

Check temperature (weekly) *

Check flushing water flow

(weekly)

Check weekly *

Check weekly Section 7.2

See manufacturer’s documentation Ensure contact--free installation

Water flows

Annex from p. 47, detailed manufacturer

information

* see list of measuring points (if applicable) in section 13,

Annex.

In the event of deviations proceed as described in the table given in section 11.2 (Trouble--shooting).

15

Omega

8 Special Instructions for

Subassemblies (Shaft Seal Variants)

The shaft seal variant supplied is shown in the purchase order

and order--processing documents.

8.1 Gland packing

The gland packings used by KSB are asbestos--free and suita ble for drinking water applications.

Installation and commissioning

Before installation, ensure that the gland space is clean (no

packing remnants or corrosion). The shaft protecting sleeve

must be bright and have no scoring. Otherwise a new shaft protecting sleeve must be used.

Cutting the packing rings to size

If moulded packing rings are not available, the rings can best

be cut to size using a special cutting gauge. If no cutting gauge

is available, take a tube with the same diameter as the shaft,

wind the packing around the tube in a spiral and cut the rings

from the spiral. We recommend a straight cut.

Installing the packing rings

Push the packing rings with the stuffing box insertinto the gland

space one by one. The joints of the packing rings must be offset

by 90_. The number of rings and the arrangement of the lantern

ring are shown in the general drawing (see appendix). After fitting all the packing rings, put on the stuffingbox insertand gland

cover and tighten them so that the packing rings adapt to the

gland space. Then loosen the gland cover again to relieve the

load on the packing. This procedure is notnecessary if moulded

packing rings are used.

Also note the following:

Leakage and temperature rise: If necessary, shut down the

pump. After a short cooling period (approx. 10 to 15 minutes)

the pump can be restarted. The necessary minimum leakage

depends on the liquid being pumped, thepressure, sliding velo city and temperature. It is approx. 10 to 120 drops per minute

(20 drops of water correspond to approx. 1 ml).

Disassembly

A packing puller must be used for pulling out the packing rings.

Maintenance

Gland packings must be repacked in accordance with the section ”Installation and commissioning” after prolonged standstill, repair work or heavy leakage. Therefore, the leakage rate

must be observed during operation, alsoto avoid possible overheating.

Commissioning

When the pump is started up,the gland must only be gently tightened (by hand). A high leakage rate (approx. 50 to 200 drops

per minute), depending on the liquid being pumped, must be accepted until the packing material has settled and has adapted

to the temperature conditions (approx. 10 to 15 minutes).

Then the gland cover must be carefully and evenly tightened to

reduce the leakage to a minimum. If there is no leakage, there

is a risk that the packing will run hot.

16

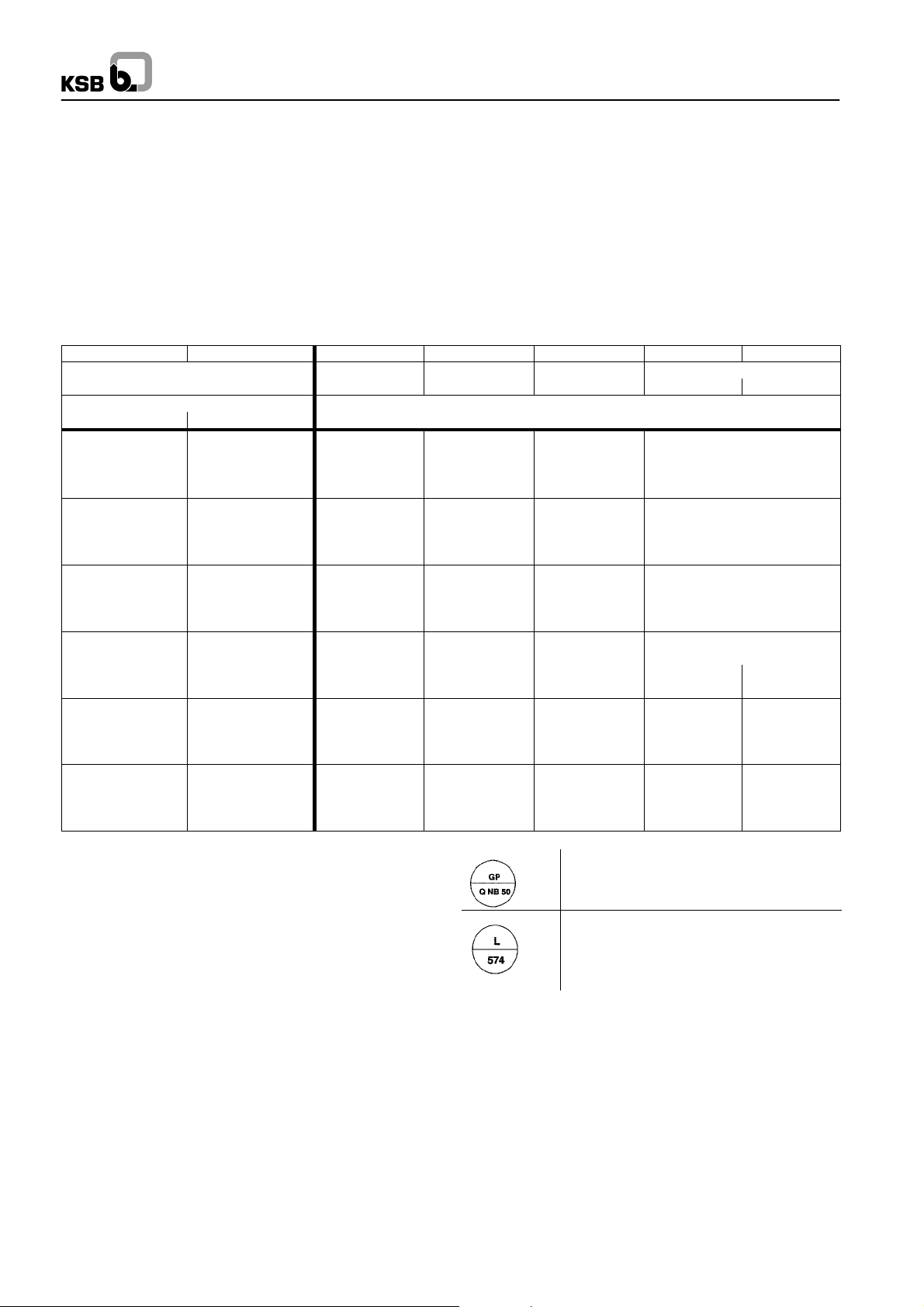

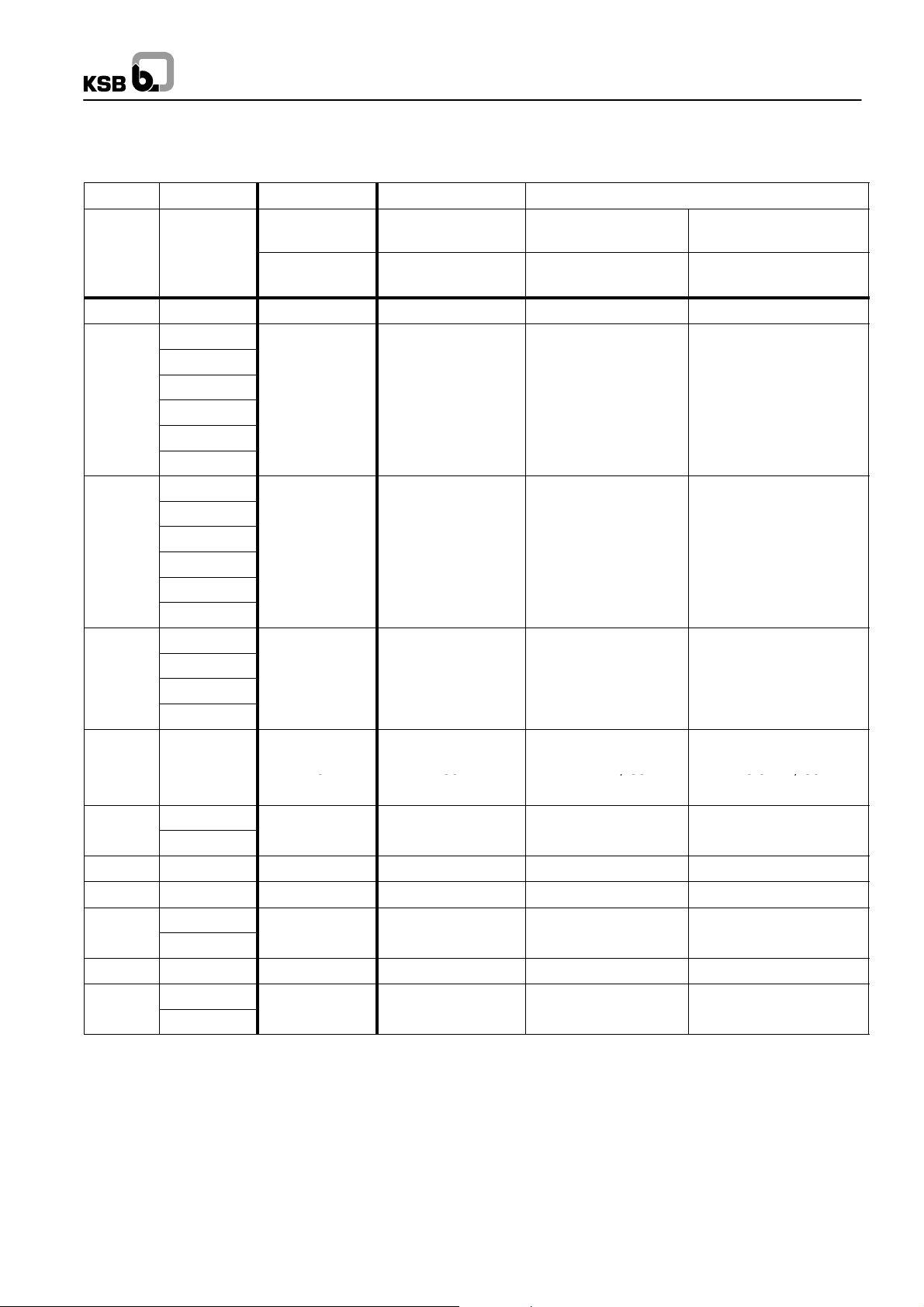

8.2 Mechanical Seal Variants (Mech. Seal Size / Pump Size Combinations)

7080M7N4/80HJ92N/80

Mechanical seal variants

No. Pump size Shaft unit Nom. mech. seal

Non--balanced Balanced

size

d

w

d for operating pres--

suresupto16bar

for operating pressures

> 16 bar

1 80 - 210

2 80 - 270

3 80 - 370

40 50 M7N4/50 HJ 92 N/50

4 100 - 250

5 100 - 310

6 100 - 375

7 125 - 230

8 125 - 290

9 125 - 365

50 60 M7N4/60 HJ 92 N/60

10 125 - 500

11 150 - 290

12 150 - 360

13 150 - 460

14 150 - 605

60 70 M7N4/70 HJ 92 N/70

15 200 - 320

16 200 - 420

17 200 - 520

18 200 - 670

70 80 M7N4/80 HJ 92 N / 80

19 250 - 370

20 250 - 480

80 90 M7N4/90 HJ 92 N/90

21 250 - 600

22 300 - 300 70 80 M7N4/80 HJ 92 N / 80

23 300 - 435 80 90 M7N4/90 HJ 92 N / 90

24 300 - 560

90 110 M74N/110 H75N/110

25 300 - 700

26 350 - 360 80 90 M7N4/90 HJ 92 N / 90

27 350 - 430

90 110 M74N/110 H75N/110

28 350 - 510

Omega

17

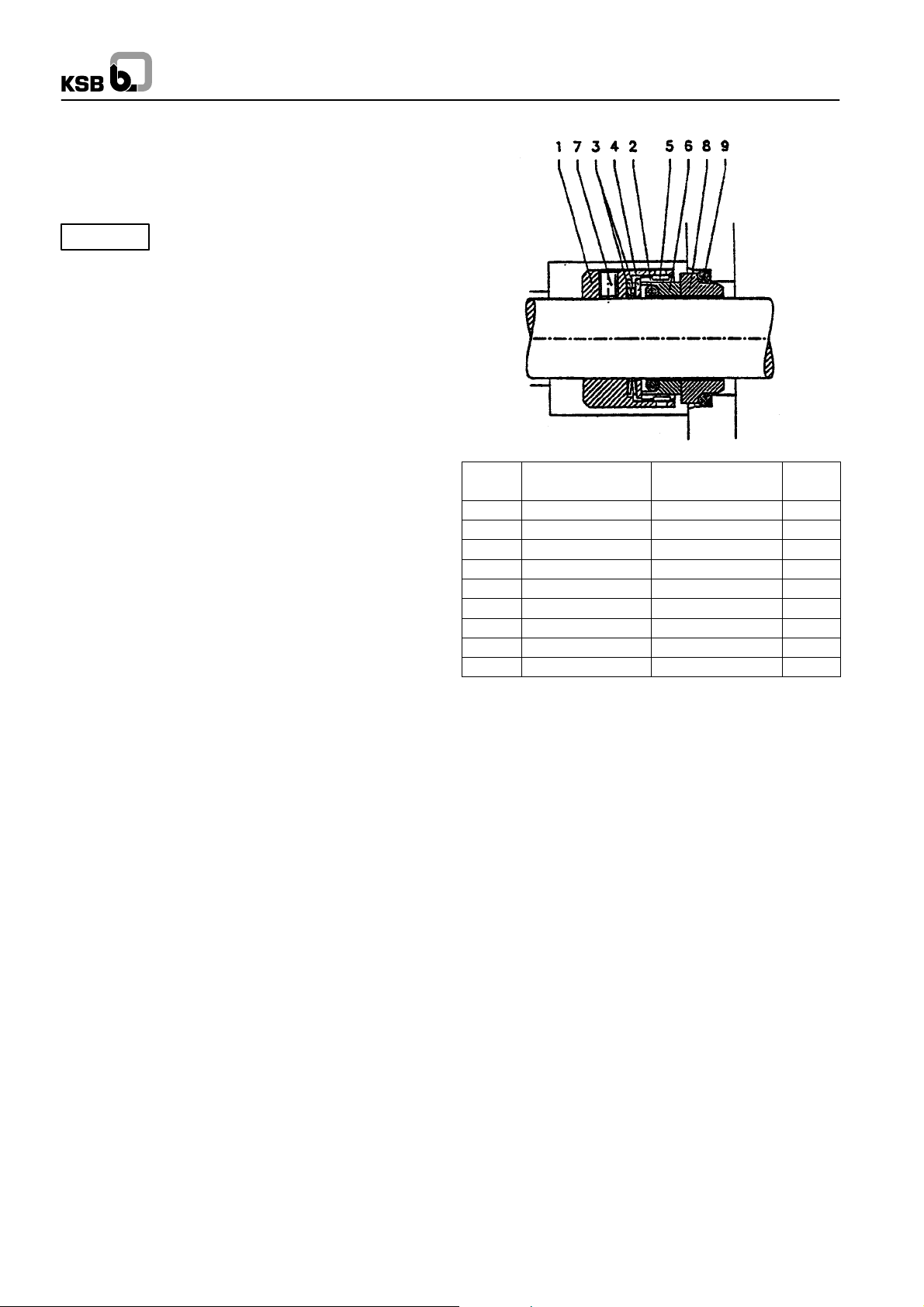

8.2.1 Mechanical Seal ”Type H7N4”

(Shaft unit d

The mechanical seal type H 7 N 4 usedis a single--acting, bi--rotational, non--balanced seal which does not require circulation

pipework in cold water applications, due to the pump design.

Caution

Installation

For the installation of the total seal assembly (mechanical seal,

seal housing) see operating instructions for the pump.

The shaft protection sleevesand also the surfaces ofthe casing

are subjected to accurate finishingprocesses with regard to the

O--ring seats, in order to achieve a complete and reliable seal.

Care must be taken during installation to keep these parts absolutely clean, to avoid the surfaces from being damaged and

prevent entry of foreign particles.

The seat ring (8) together with the relevant O--ring (9), is fitted

into the seal cover (see general drawing). The O--ring can be

lubricated for easy s liding movement. Special attention mustbe

given to ensure that pressure is applied evenly. The contact

surfaces are generally fitted dry.

In mechanical seals of the M7N4 design, the rotating assembly

is supplied as one unit, consisting of a housing and pin ( 1 + 5),

fitted spring loaded ring (6), O --ring (2), spring (3), thrust plate

(4) and grub screws (7). The grub screws (7) must be loosened

so far as to prevent them from protruding from the housing (1)

at the inner diameter. The O--ring (2) can be slightly lubricated

to facilitate assembly.

The complete rotating assembly is pushed onto the shaft protection sleeve in compliance with the installation dimensions

which are given in the mech. seal drawing,or until it reaches the

stop on the shaft protection sleeve. Finally the grub screws are

tightened and secured with LOCTITE.

40 to 80 mm)

w

Dry--running of the seal must be avoided at

all costs!

Omega

Item Description Material No. of

items

1 Housing Cr-Ni-Mo-steel 1

2 O--ring Viton 1

3 Spring Cr-Ni-Mo-steel 1

4 Thrust plate Cr-Ni-Mo-steel 1

5 Pin Cr-Ni-Mo-steel 2

6 Spring--loaded ring Si-SiC 1

7 Grub screw Cr-Ni-Mo-steel 2

8 Seat ring Si-SiC 1

9 O--ring Viton 1

Special instructions for mechanical seal assembly

· The contact faces must only be cleaned with propyl alcohol

and paper tissue.

-- Never use cleaning rags or cloth.

-- Clean carefully to remove any smears.

· Do not touch the contact faces with bare fingers.

· Never use force during mechanical seal assembly.

· Never put the spring--loaded ring and the seat ring face

down on the contact faces without the protective wrapping.

· Cover the contact face with a cardboard washer and press

the seat ring into its position slowly and evenly, lubricating

it with a generous amount of water or alcohol. Use a spacer

sleeve, if necessary. Verify that the seat ring position is nor mal to the shaft axis.

· In the mechanical seal area, the shaft shall be slightly lubri-

cated with water, alcohol or silicone grease. Sealing elements made of EP rubber must never come into contact

with mineral oil base lubricants (swelling, possibly decomposition).

18

Omega

Commissioning

Flood the pump and the seal chamber with the medium to be

handled and vent carefully. The seal is operational now.

On single --acting mechanical seals, the pressure in the seal

chamber of the pump (stuffing box) must always exceed ambient pressure, to prevent any air intake at the seal faces,

which would result in dry running and thus failure of the mechanical seal.

In all operating conditions, the product to be sealed off must

be available in liquid state at the mechanical seal, particularly

during pump start--up and shutdown. This must be ensured by

appropriate facilities on the pump (e.g. heating).

Should the mechanical seal fail, the liquid to be sealed off may

spurt out. Takesuitable precautions to prevent hazards to persons and the environment, e.g. install splash guards, wear safety goggles, etc. Proper disposal of leakage shall be arranged for and supervised by the operator.

Maintenance

Mechanical seals operated in compliance with the manual

are maintenance--free in their entire service life.

The mechanical seal should be inspected in accordance with

the plant inspection schedule.

During planned plant outage periods the spring--loaded rings

and the seat rings should be checked for visible damage in installed condition.

If the mechanical sealis inspected during plant outage,the contact faces should be re--worked.

Dismantling

For dismantling of the mechanical seal assembly please refer

to section 7.3 ”Dismantling”. Grub screws (7) and joint rings

(2+9) shall be replaced whenever the mechanical seal has

been dismantled!

Repair

If the seal needs to be repaired,alwaysreturn the complete

seal to the manufacturer. The manufacturer will know best

which parts can be re--worked andwhich parts have to be replaced to ensure an optimum sealing effect.

If repair on the spot is necessary, it should be carried out in a

clean workshop preferrably byKSB --monteurs or skilled operator staff. Spring--loaded rings, seat rings, all elastomer materials and springs should be replaced in any case.

Make sure to comply with the instructions for handling h a-

zardous substances and the applicable accident preven tion regulations when repairing, dismantling and cleaning

used mechanical seals. If you have any queries in this context

please inform yourself before commencing any repair work.

Spare parts

Only original spare parts shall be used. Non-- compliance

with this requirement entails the risk of seal malfunctions

which may jeopardize the safety of personnel and the environment.

It will also lead to forfeiture of all warranty claims.

Faults

Determine and document the nature of the fault.

In the event of a fault as evidenced by excessive leakage, observe the tendency of the leakage amount. Changes in operating conditions must be documented. If an excessive temperature rise is detected, the mechanical seal must be shut down for

safety reasons.

During the warranty period the mechanical s eal shall only be removed and dismantled with the manufacturer’s approval or under instructions of the mechanical seal manufacturer’s service

engineers.

If the fault cannot be remedied by the operator or if the cause

is unclear, please contact the KSB service center.

19

Omega

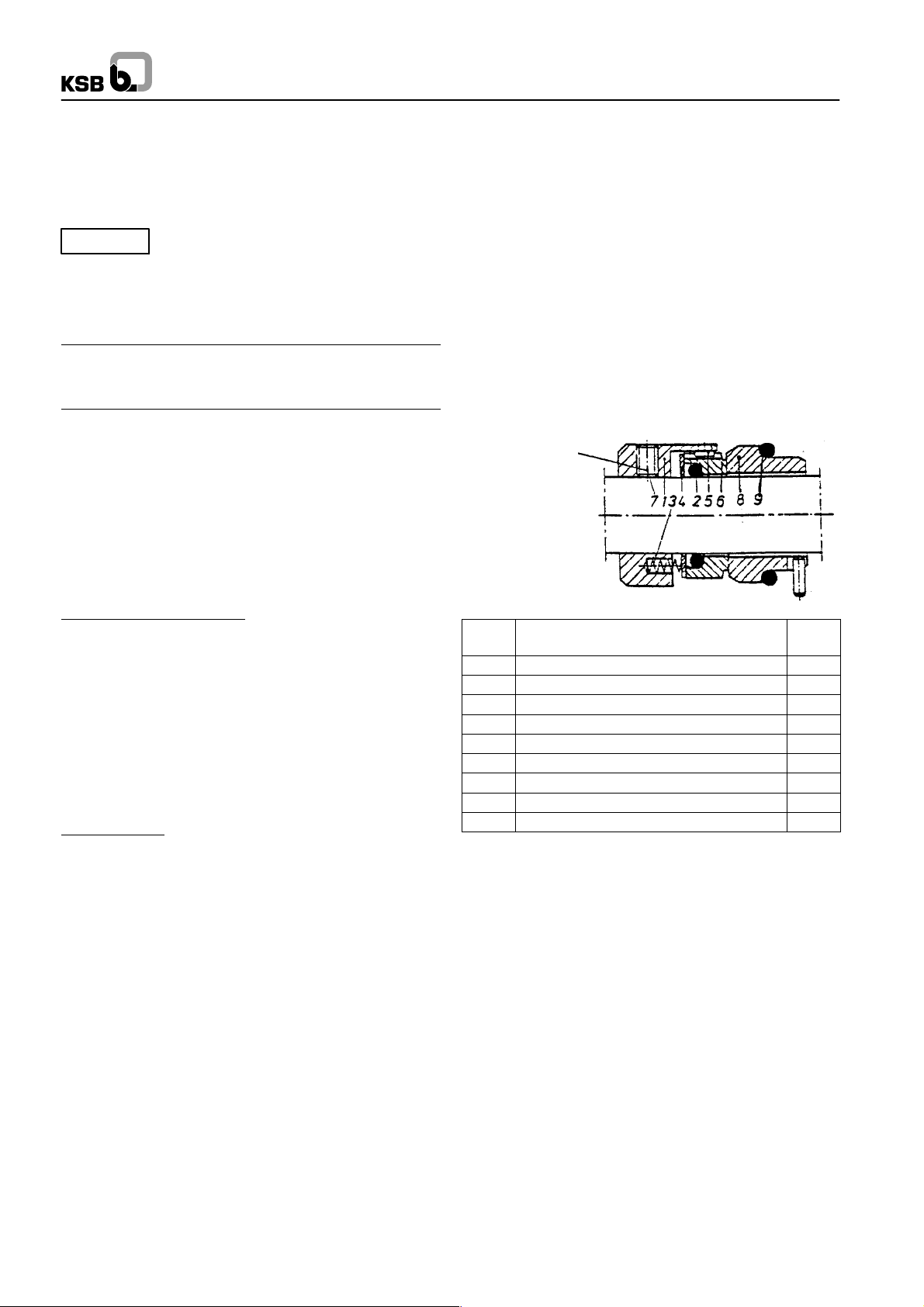

8.2.2 Mechanical Seal -- ”Type M74N ”

(Shaft unit d

This mechanical seal type is a single--acting, bi-- rotational,

non--balanced mechanical seal with multiple spring arrangement.

Caution

Special instructions for mechanical seal installation

= 90 mm)

w

It is imperative to avoid dry running of the

mechanical seal!

· Application limits

Pressure to be sealed off, p max.

Product temperature, t --40...220 °C

Sliding velocity, vg

25 bar

20 m/s

· Safety

Any work on the mechanical seal shall only be performed after the pump has stopped and pump pressure has beenreleased.

In addition to the safety instructions contained in this manual,

the general health and accident prevention regulations

shall be observed.

The seat ring (8) together with the relevant O--ring (9), is fitted

into the seal cover (see general drawing). The O--ring can be

lubricated for easy sliding movement. Special attention must

be given to ensure that pressure is applied evenly. The contact

surfaces are generally fitted dry.

In mechanical seals of the M74Ndesign, the rotating assembly

is supplied as one unit, consisting of a housing and pin ( 1 + 5),

fitted spring loaded ring (6), O--ring (2), spring (3), thrust plate

(4) and grub screws (7). The grub screws (7) must be loosened

so far as to prevent them from protruding from the housing (1)

at the inner diameter. The O--ring (2) can be slightly lubricated

to facilitate assembly.

The complete rotating assembly is pushed onto the shaft protection sleeve in compliance with the installation dimensions

which are given in the mech. seal drawing,or until it reaches the

stop on the shaft protection sleeve. Finally the grub screws are

tightened and secured with LOCTITE.

Degrease the grub

screws and insert

with a thread sealant

(e.g. Loctite). Use

new grub screws

whenever the mechanical seal has

been dismantled!

Preparations for installation

Check pump components

for:

· chamfered edges (sliding cones 2 mm/ 30_ or to DIN

24960).

· radiused transitions

· locating surfaces, surfaces for O--rings: fine finished Rz

10 (DIN 4768)

· Shaft surface in the area of the dynamically loaded joint

ring: roughness depth R

The shaft must be provided with the requisite recesses for

the housing screws of the mechanical seal.

Check pump

for:

max

5 mm.

· damage at the mating surfaces with the mechanical seal

· connecting dimensions, rectangularity and concentricity to

the shaft axis

Installation

For the installation of the total seal assembly (mechanical seal,

seal housing) see operating instructions for the pump.

The shaft protection sleevesand also the surfaces ofthe casing

are subjected to accurate finishingprocesses with regard to the

O--ring seats, in order to achieve a complete and reliable seal.

Care must be taken during installation to keep these parts absolutely clean, to avoid the surfaces from being damaged and

prevent entry of foreign particles.

Item Description Material No. of

items

1 Housing Cr-Ni-Mo-steel 1

2 O--ring Compat. elastomers 1

3 Spring Cr-Ni-Mo-steel 1

4 Thrust plate Cr-Ni-Mo-steel 1

5 Pin Cr-Ni-Mo-steel 2

6 Rotating ring Buka, Buke, Bume 1

7 Grub screw Cr-Ni-Mo-steel 2

8 Seat ring Buke, Buko, Buka 1

9 O--ring Compat. elastomers 1

· Apply a thin coat of grease to the shaft in the mechanical

seal area.

Sealing elements made of EP rubber must never come

into contact with mineral oil base lubricants (swelling,

possibly decomposition).

· Unwrap the mechanical seal and inspect for damage to the

spring--loaded ring and the seat ring, the O--rings and the

mating surfaces.

Never put the spring--loaded ring and the seat ring face

down on the contact faces without the protective wrapping.

· Thoroughly clean all components with alcohol and cellulose

tissue.

20

Omega

Installation

Never use force during mechanical seal installation.

· Slip the degreased O--ring onto the seat ring.

· Cover the contact face with a cardboard washer.

· Push the seat ring slowly and evenly into its seat.Use a spa-

cer sleeve, if necessary. Lubricate with a generous amount

of water or alcohol.

· Verify that the seat ring position is normal to the shaft axis.

· Push the rotating assembly with the degreased joint rings

onto the shaft. Thread in the degreased grub screws with

1 drop of thread sealant each (e.g. Loctite No. 243) and position the mechanical seal by tightening the grub screws.

The installation dimensions given in the drawing must be

adhered to.

· The contact faces must only be cleaned with propyl alcohol

and paper tissue (no cleaning rags or cloth). Clean carefully

to remove any smears. Do not touch the contact faces with

bare fingers afterwards.

The contact faces must not be lubricated; they must be clean

and dry.

· Assemble the seal cover with the installed seat ring.

Commissioning

Flood the pump and the seal chamber with the medium to be

handled and vent carefully. The seal is operational now.

Faults

Determine and document the nature of the fault.

In the event of a fault as evidenced by excessive leakage, observe the tendency of the leakage amount. Changes in operating conditions must be documented. If an excessive temperature rise is detected, the mechanical seal must beshut down for

safety reasons.

A continuous flow of leakage indicates a fault.

During the warranty period the mechanical s eal shall only be removed and dismantled with the manufacturer’s approval or under instructions of the mechanical seal manufacturer’s service

engineers.

If the fault cannot be remedied by the operator or if the cause

is unclear, please contact the KSB service centre.

Maintenance

Mechanical seals operated in compliance with the manual are

maintenance--free; however, wear parts will have to be replaced as required.

The mechanical seal should be inspected in accordance with

the plant inspection schedule. We recommend to have the mechanical seal inspected by KSB service centre.

If the mechanical sealis inspected during plant outage,the contact faces should be re--worked and all elastomer seals and

springs should be replaced.

Reliable seal operation

On single --acting mechanical seals, the pressure in the seal

chamber of the pump (stuffing box) must always exceed ambient pressure, to prevent any air intake at the seal faces,

which would result in dry running and thus failure of the mechanical seal.

In all operating conditions, the product to be sealed off must

be available in liquid state at the mechanical seal, particularly

during pump start--up and shutdown. This must be ensured by

appropriate facilities on the pump (e.g. heating).

If the operating conditions indicated are observed and the instructions given in this operating manual are complied with, the

mechanical seal can be expected to give trouble--free operation.

Should the mechanical seal fail, the liquid to be sealed

off may spurt out.Takesuitable precautions to pre-

vent hazards to persons and the environment, e.g. install

splash guards, wear safety goggles, etc. Proper disposal of

leakage shall be arranged for and supervised by the operator.

Repair

If the seal needs to be repaired,alwaysreturn the complete

seal to the manufacturer. The manufacturer will know best

which parts can be re--worked andwhich parts have to be replaced to ensure an optimum sealing effect.

If repair on the spot is absolutely necessary (e.g. no spare

seal available, longtransport distances,problems with customs

procedures), skilled operator staff may carry out the repair

work in a clean workshop to the directions of KSB service centres.

21

Omega

Mechanical seal removal

Shut down the pump in accordance with the operating

manual, allow to cool down and release pump pressure.

There must be no pumped product at the

mechanical seal ®The pump must be drained.

Secure the pump to prevent inadvertent start--up.

Follow the safety instructions

(safety data sheets)!

Make sure to comply with the applicable accident preven-

tion regulations when removing a mechanical seal. Also observe the instructions for handling hazardous substances

if the mechanical seal has already been in operation. If you

have any queries about the applicable regulations please in-

form yourself before commencing any repair work.

Any work on the mechanical seal is only permitted with the

pump shut down and pump pressure released.

Removal of the mechanical seal shall be performed analogously with mechanical seal installation, but in reverse order.

Removing the subassembly

See section 7.3.

· Grub screw (7) und Dichtringe (2+9) nach jederDemontage

erneuern.

8.2.3 Mechanical Seal ”Type HJ92 N”

(Shaft unit d

Note:

Refer to sections 8.2.1 and 8.2.2 for general recommendations

and instructions for handling this seal type.

For detailed information please refer to the operating manual

for seal type HJ92 N.

=40to80mm)

w

Spare parts

Only genuine spare parts shall be used. Non--compliance

with this requirement entails the risk of seal malfunctions

which may jeopardize the safety of personnel and the environment.

It will also lead to forfeiture of all warranty claims.To keep a

complete spare seal on stock.

22

OPERATING MANUAL

MECHANICAL SEAL (MS)

HJ92N

PLEASE READ this manual carefully and OBSERVE the information contained as to:

H Safety H

Storage H Installation H Start up H Maintenance H Repair

J SAFETY

Any personin the operator’s plant who is involved in the installation, removal, operation, commissioning and maintenance of

the mechanical seal must have read and thoroughly understood these operating instructions, particularly the safety instructions contained therein. It is advisable for the operator to

have this confirmed.

The mechanicalseal isa precision product (ISO 9001) and safe

to operate. However, it may constitute a hazard if it is not used

in accordance with its designated use, or if operatedimproperly

by unskilled personnel.

The operator has to determine the consequences of any mechanical seal failure and decide whether safety precautions

need to be taken to protect personnel or the environment.

The pump shall be installed in such a way that any fluidspurting

out cannot cause personal injury and that leakage can be properly disposed of.

Any operating mode liable to impair the safe and reliable function of the mechanical seal is not permitted.

Mechanical seals shall only be installed, operated, removed or

repaired by authorized, qualified and appropriately instructed

personnel.

Any work on the mechanical seal shall only be performed with

the pump shut down and the pump pressure released.

Staff responsibilities for the work involved must be clearly defined and complied with, to prevent unclear competencies with

regard to safety aspects.

In addition to the instructions contained in this manual, the general occupational health and safety regulations must be adhered to.

Unauthorized modifications and alterations liable to jeopardize

the safe operation of the mechanical seal are not permitted.

J OPERATING LIMITS

Shaft diameter dw: 18 to 100 mm

Press. to be sealed off p max.: 25 bar

Fluid temperature t: -- 40 to 220 °C

Sliding velocity vg: 20 m/s

*)

depending on the seal face materials

The mechanical seal shall not be operated at several application limits at the same time.

Higher loads (pressure, temperature, speed) may lead to increased wear and damage the contact faces or the elastomer

elements.

Such operating conditions would shorten the useful life of the

seal but also entail the risk of sudden seal failure with hazards

to personnel and the environment.

*)

J O PERAT ING DATA

The operating data for the application in question, such as fluid

to be sealed off, operating pressure, operating temperature, rotational speed, etc., are indicated on the respective pump data

sheets.

J DESIGNATED USE

Any operation outside the operating conditions stated in the

”Operating Limits” section is deemed to be non--conforming

with the designated use.

To ensure safe operation of the mechanical seal, check withthe

seal manufacturer before using the seal for other operating

conditions or in a different location of operation.

J MATERIALS

Materials as per drawing and/or order.

J DRAWINGS

General assembly drawing of pump.

The applicable design is shown on the general pump drawing

in the original scale and latest revision, see section 9 of the

pump’s operating manual, which shall be used in conjunction

with this document.

J DECLARATION

within the meaning of EC Directive ”Machinery” 98/37/EC.

A mechanical seal does not function independently. It is intended to be incorporated into or assembled with machinery.

Operating maual mechanical seal

Rev. 0, 13.02.2004

J SPECIFICATION

H Single mechanical seal

H Balanced

H Bi--rotational

H Connecting dimensions to DIN 24960 KB

H Installation dimensions l

1K

23

Loading...

Loading...