Page 1

Waste Water, Condensate and Heat

Transfer Fluid Pump

MK

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual MK

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 11/10/2018

Page 3

Contents

3 of 64

MK

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.2.1 Prevention of foreseeable misuse.......................................................................................................8

2.3 Personnel qualification and training...............................................................................................................8

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation................................................................................................................10

2.9 Explosion protection ......................................................................................................................................10

2.9.1 Marking ..............................................................................................................................................10

2.9.2 Temperature limits.............................................................................................................................10

2.9.3 Monitoring equipment......................................................................................................................11

2.9.4 Operating limits .................................................................................................................................11

3 Transport/Temporary Storage/Disposal............................................................................................. 12

3.1 Checking the condition upon delivery..........................................................................................................12

3.2 Transport.........................................................................................................................................................12

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier...........................................................................................................................................13

3.5 Disposal ...........................................................................................................................................................14

4 Description of the Pump (Set)............................................................................................................. 15

4.1 General description ........................................................................................................................................15

4.2 Designation.....................................................................................................................................................15

4.3 Name plate......................................................................................................................................................15

4.4 Design details..................................................................................................................................................16

4.5 Configuration and function...........................................................................................................................17

4.6 Noise characteristics .......................................................................................................................................19

4.7 Scope of supply...............................................................................................................................................19

5 Installation at Site................................................................................................................................ 20

5.1 Safety regulations...........................................................................................................................................20

5.2 Checks to be carried out prior to installation...............................................................................................20

5.3 Fitting and setting the float switch control (optional) ................................................................................20

5.3.1 Control elements for MK/MKA .........................................................................................................20

5.3.2 Control element for MKY..................................................................................................................23

5.4 Installing the pump set ..................................................................................................................................23

5.5 Connecting the piping ...................................................................................................................................23

5.6 Permissible forces and moments at the pump nozzles ................................................................................24

5.7 Electrical connection ......................................................................................................................................24

5.8 Checking the direction of rotation................................................................................................................25

6 Commissioning/Start-up/Shutdown................................................................................................... 27

6.1 Commissioning/Start-up.................................................................................................................................27

6.1.1 Prerequisites for commissioning/start-up .........................................................................................27

Page 4

Contents

4 of 64

MK

6.1.2 Filling in lubricants.............................................................................................................................27

6.1.3 Start-up...............................................................................................................................................27

6.1.4 Shutdown ...........................................................................................................................................28

6.2 Operating limits..............................................................................................................................................29

6.2.1 Ambient temperature........................................................................................................................29

6.2.2 Frequency of starts.............................................................................................................................29

6.2.3 Fluid handled .....................................................................................................................................30

6.3 Shutdown/storage/preservation ....................................................................................................................31

6.3.1 Measures to be taken for shutdown ................................................................................................31

6.4 Returning to service .......................................................................................................................................32

7 Servicing/Maintenance........................................................................................................................ 33

7.1 Safety regulations...........................................................................................................................................33

7.2 Servicing/Inspection........................................................................................................................................34

7.2.1 Supervision of operation...................................................................................................................34

7.2.2 Lubrication and lubricant change.....................................................................................................35

7.3 Drainage/cleaning ..........................................................................................................................................39

7.4 Dismantling the pump set..............................................................................................................................40

7.4.1 General information/Safety regulations...........................................................................................40

7.4.2 Removing the pump set from the piping.........................................................................................40

7.4.3 Dismantling the pump section ..........................................................................................................41

7.5 Reassembling the pump set...........................................................................................................................43

7.5.1 General information/Safety regulations...........................................................................................43

7.5.2 Reassembling the pump section .......................................................................................................44

7.6 Tightening torques.........................................................................................................................................48

7.7 Spare parts stock.............................................................................................................................................48

7.7.1 Ordering spare parts..........................................................................................................................48

7.7.2 Recommended spare parts stock for 2 years' operation to DIN24296 ..........................................48

8 Trouble-shooting.................................................................................................................................. 50

9 Related Documents.............................................................................................................................. 52

9.1 General assembly drawings/exploded views with list of components........................................................52

9.1.1 MK, MKA ............................................................................................................................................52

9.1.2 MK, MKA - grease-lubricated............................................................................................................53

9.1.3 MK, MKA - internally lubricated by fluid handled ..........................................................................54

9.1.4 MK, MKA - lubricated by an external fluid ......................................................................................55

9.1.5 MKY ....................................................................................................................................................57

10 EU Declaration of Conformity............................................................................................................. 59

11 Certificate of Decontamination........................................................................................................... 60

Index ..................................................................................................................................................... 61

Page 5

Glossary

5 of 64

MK

Glossary

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

Discharge line

The pipeline which is connected to the discharge

nozzle

Pump

Machine without drive, additional components or

accessories

Pump set

Complete pump set consisting of pump, drive,

additional components and accessories

Page 6

1 General

6 of 64

MK

1 General

1.1 Principles

This operating manual is supplied as an integral part of the type series and variants

indicated on the front cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series and size, the main operating data, the order

number and the order item number. The order number and order item number

clearly identify the pump set and serve as identification for all further business

processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB refer to the sub-sections under

Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.3,Page8)

1.4 Other applicable documents

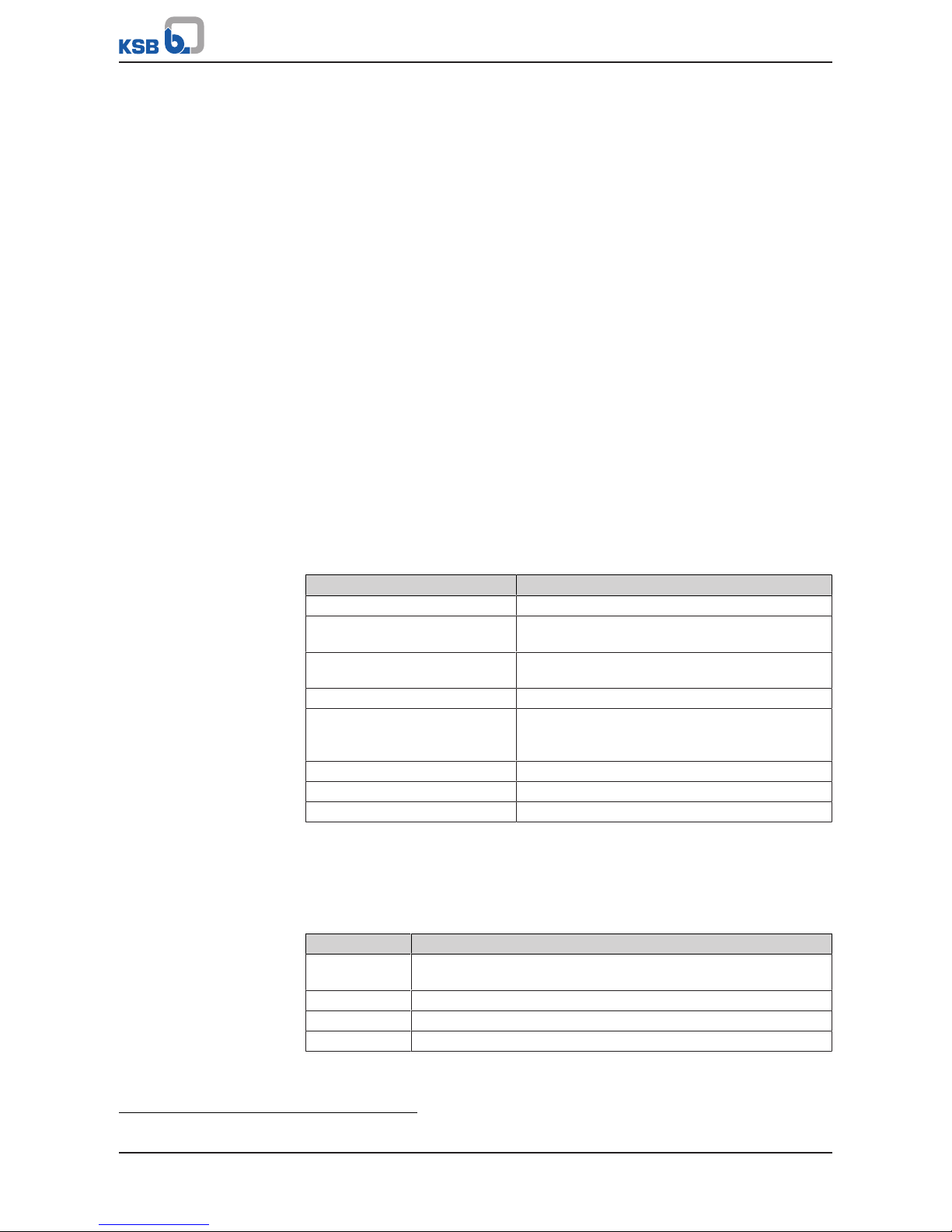

Table1: Overview of other applicable documents

Document Contents

Data sheet Description of the technical data of the pump (set)

General arrangement drawing/

outline drawing

Description of mating and installation dimensions

for the pump (set), weights

Hydraulic characteristic curve Characteristic curves showing head, NPSH

required

,

efficiency and power input

General assembly drawing

1)

Sectional drawing of the pump

Sub-supplier product literature1)Operating manuals and other product literature

describing accessories and integrated machinery

components

Spare parts lists

1)

Description of spare parts

Piping layout

1)

Description of auxiliary piping

List of components

1)

Description of all pump components

For accessories and/or integrated machinery components, observe the relevant

manufacturer's product literature.

1.5 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

Result of an action

⇨ Cross-references

1) If agreed to be included in the scope of supply

Page 7

1 General

7 of 64

MK

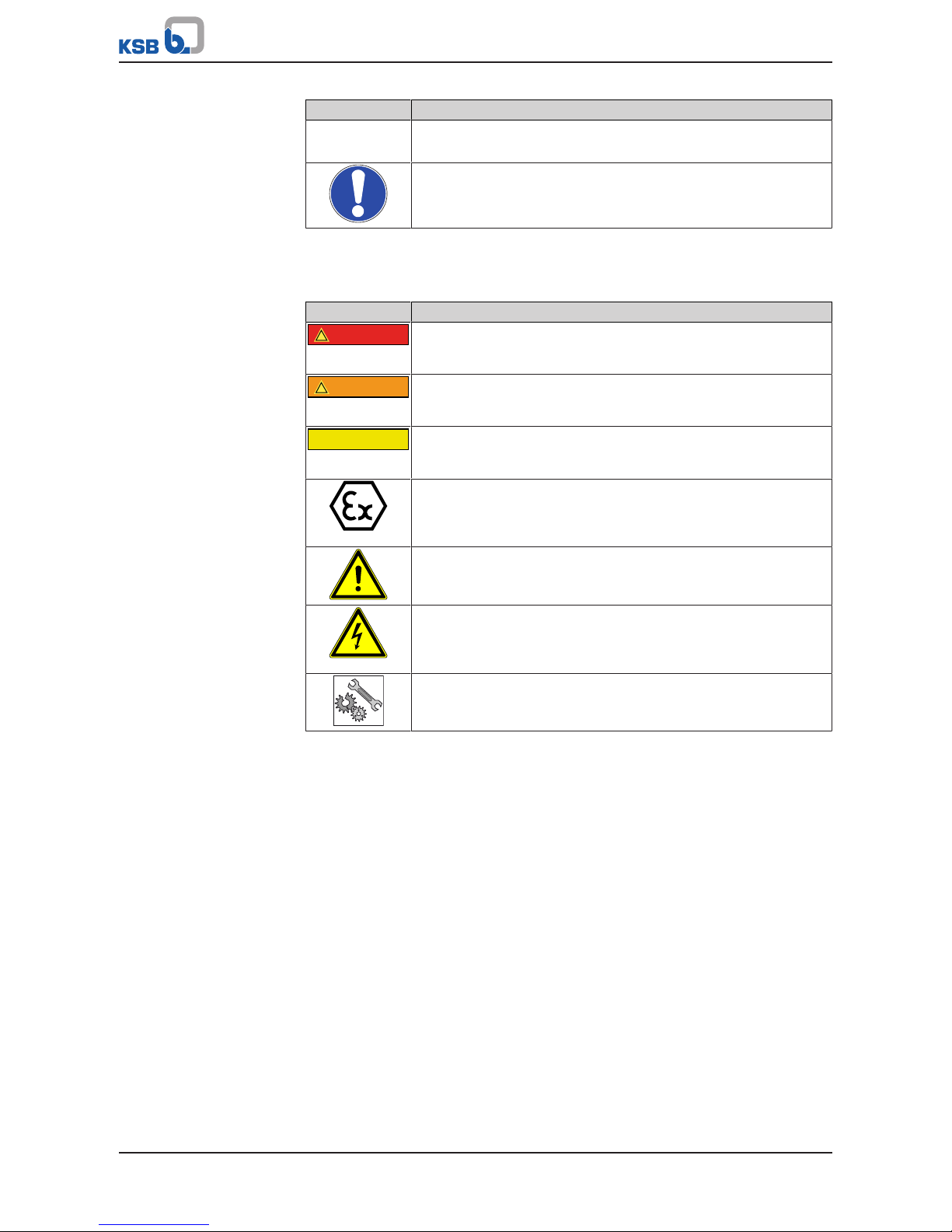

Symbol Description

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

1.6 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EU Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

Page 8

2 Safety

8 of 64

MK

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Arrow indicating the direction of rotation

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

2.2 Intended use

▪ The pump (set) must only be operated in the fields of application and within the

use limits specified in the other applicable documents.

▪ Only operate pumps/pump sets which are in perfect technical condition.

▪ Do not operate the pump (set) in partially assembled condition.

▪ Only use the pump to handle the fluids described in the data sheet or product

literature of the pump model or variant.

▪ Never operate the pump without the fluid to be handled.

▪ Observe the minimum flow rates indicated in the data sheet or product literature

(to prevent overheating, bearing damage, etc).

▪ Observe the minimum flow rate and maximum flow rate indicated in the data

sheet or product literature (to prevent overheating, mechanical seal damage,

cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the suction side of the pump (to prevent

cavitation damage).

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

2.2.1 Prevention of foreseeable misuse

▪ Never open the discharge-side shut-off elements further than permitted.

– The maximum flow rates specified in the product literature or data sheet

would be exceeded.

– Risk of cavitation damage

▪ Never exceed the permissible application and operating limits specified in the

data sheet or product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

2.3 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the machinery this manual refers to.

Page 9

2 Safety

9 of 64

MK

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the pump (set) must always be supervised by technical specialist

personnel.

2.4 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.5 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.6 Safety information for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

2.7 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump (set) are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Only carry out work on the pump (set) during standstill of the pump.

Page 10

2 Safety

10 of 64

MK

▪ Only perform work on the pump set when it has been disconnected from the

power supply (de-energised).

▪ The pump (set) must have cooled down to ambient temperature.

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the pump set out of service always adhere to the procedure

described in the manual. (ðSection6.3,Page31)

▪ Decontaminate pumps which handle fluids posing a health hazard.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page27)

2.8 Unauthorised modes of operation

Never operate the pump (set) outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the supplied pump

(set) is only valid if the equipment is used in accordance with its intended use.

(ðSection2.2,Page8)

2.9 Explosion protection

!

DANGER

Always observe the information on explosion protection given in this section when

operating the product in potentially explosive atmospheres.

Only pumps/pump sets marked as explosion-proof and identified as such in the data

sheet may be used in potentially explosive atmospheres.

Special conditions apply to the operation of explosion-proof pump sets to EU

Directive 2014/34/EU (ATEX).

Especially adhere to the sections in this manual marked with the symbol opposite and

the following sections, (ðSection2.9.1,Page10) to (ðSection2.9.4,Page11)

The explosion-proof status of the pump set is only assured if the pump set is used in

accordance with its intended use.

Never operate the pump set outside the limits stated in the data sheet and on the

name plate.

Prevent impermissible modes of operation at all times.

2.9.1 Marking

Pump The marking on the pump refers to the pump part only.

Example of such marking:

II 2 G c TX (EN 13463-1) or II 2G Ex h IIC T5-T1 Gb (ISO 80079-36)

The pump complies with the requirements of type of protection constructional safety

"c" to ISO80079-37.

Refer to the data sheet for the applicable temperature class.

Motor The motor has its own marking. The marking is maintained on the condition that the

temperatures the pump causes to develop at the motor flange and motor shaft are

permitted by the motor manufacturer.

The motors used by KSB on pumps with ATEX certification meet this condition.

2.9.2 Temperature limits

In normal pump operation, the highest temperatures are to be expected at the

surface of the pump casing, the pipe assembly, the plain bearings and in the bearing

areas.

The surface temperature at the pump casing corresponds to the temperature of the

fluid handled. If the pump is heated in addition, the operator of the system is

responsible for observing the specified temperature class and fluid temperature

(operating temperature).

The table below lists the temperature classes and the resulting theoretical

temperature limits of the fluid handled (a potential temperature rise in the shaft seal

area has been taken into account).

Page 11

2 Safety

11 of 64

MK

The temperature class specifies the maximum permissible temperature at the surface

of the pump set during operation. For the permissible operating temperature of the

pump in question refer to the data sheet.

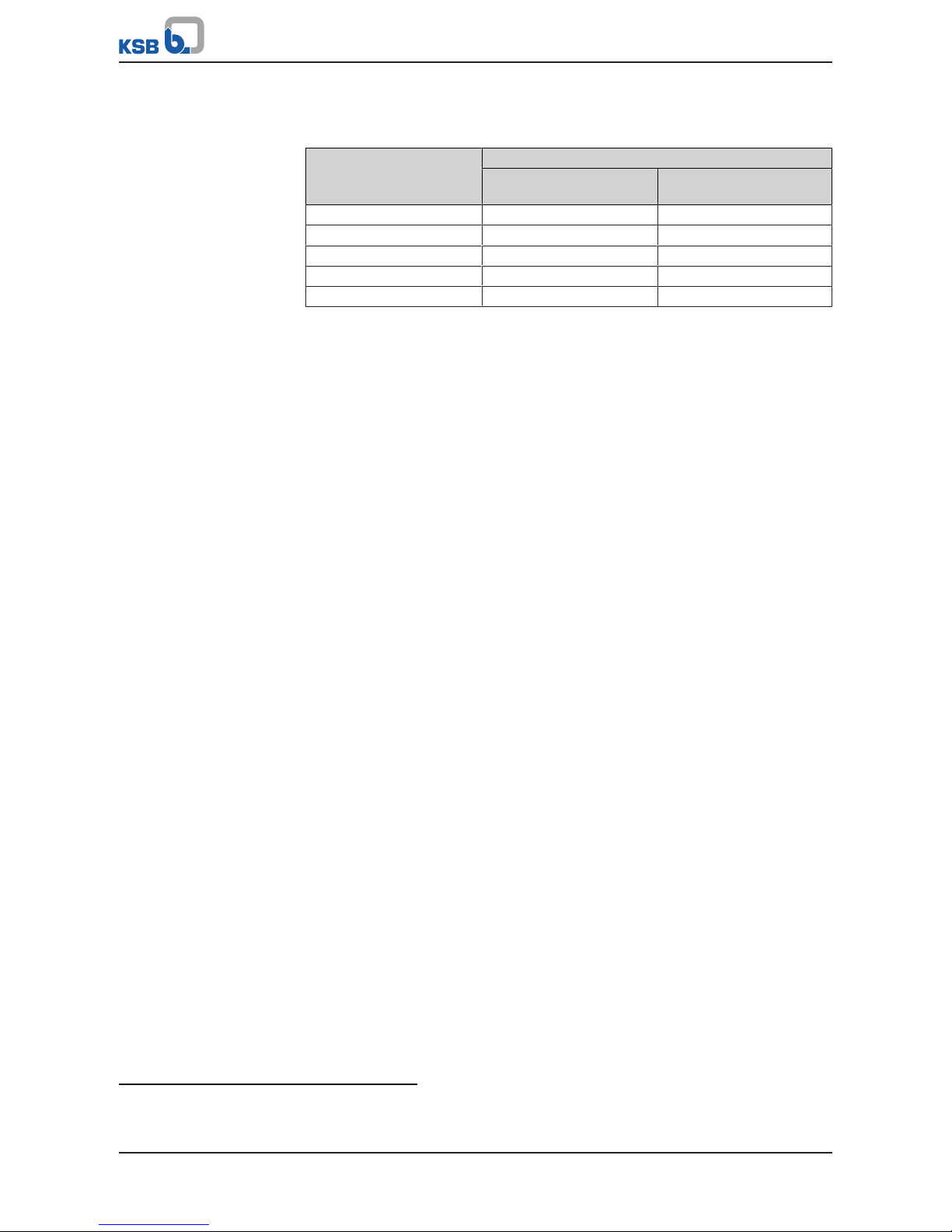

Table4: Temperature limits

Temperature class to EN 13463-1 or ISO

80079-36

Maximum permissible fluid temperature

T1 90°C

T2 90°C

T3 90°C

T4 90°C

T5 80°C

Temperature class T5 Temperature class T5 can only be complied with if the bearing temperature is limited

to 80°C.

Misuse, malfunctions or non-compliance with the instructions may result in

substantially higher temperatures.

If the pump is to be operated at a higher temperature, if there is no data sheet or if

the pump is part of a pool of pumps, contact KSB for the maximum permissible

operating temperature.

2.9.3 Monitoring equipment

The pump (set) must only be operated within the limits specified in the data sheet

and on the name plate.

If the system operator cannot warrant compliance with these operating limits,

appropriate monitoring devices must be used.

Check whether monitoring equipment is required to ensure that the pump set

functions properly.

Contact KSB for further information on monitoring equipment.

Bearing temperature monitoring

If temperature class T5 is to be complied with, the bearing temperature must be

monitored. For this purpose, the pump must be equipped with a temperature sensor

at the drive-end fixed bearing (G 1/8 connection, DIN 3852).

The temperature sensor must be operated with an ATEX-approved transducer

providing explosion protection for the sensor. The bearing temperature must be

monitored so as to ensure it does not exceed 80°C.

2.9.4 Operating limits

The minimum flows indicated in (ðSection6.2.3.1,Page30) refer to water and

water-like fluids handled. Longer operating periods with these fluids and at the flow

rates indicated will not cause an additional increase in the temperatures at the pump

surface. However, if the physical properties of the fluids handled are different from

water, it is essential to check whether an additional heat build-up may occur and if

the minimum flow rate must therefore be increased. The calculation formula in

(ðSection6.2.3.1,Page30) can be used to check whether additional heat build-up

may lead to a dangerous temperature increase at the pump surface.

Page 12

3 Transport/Temporary Storage/Disposal

12 of 64

MK

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

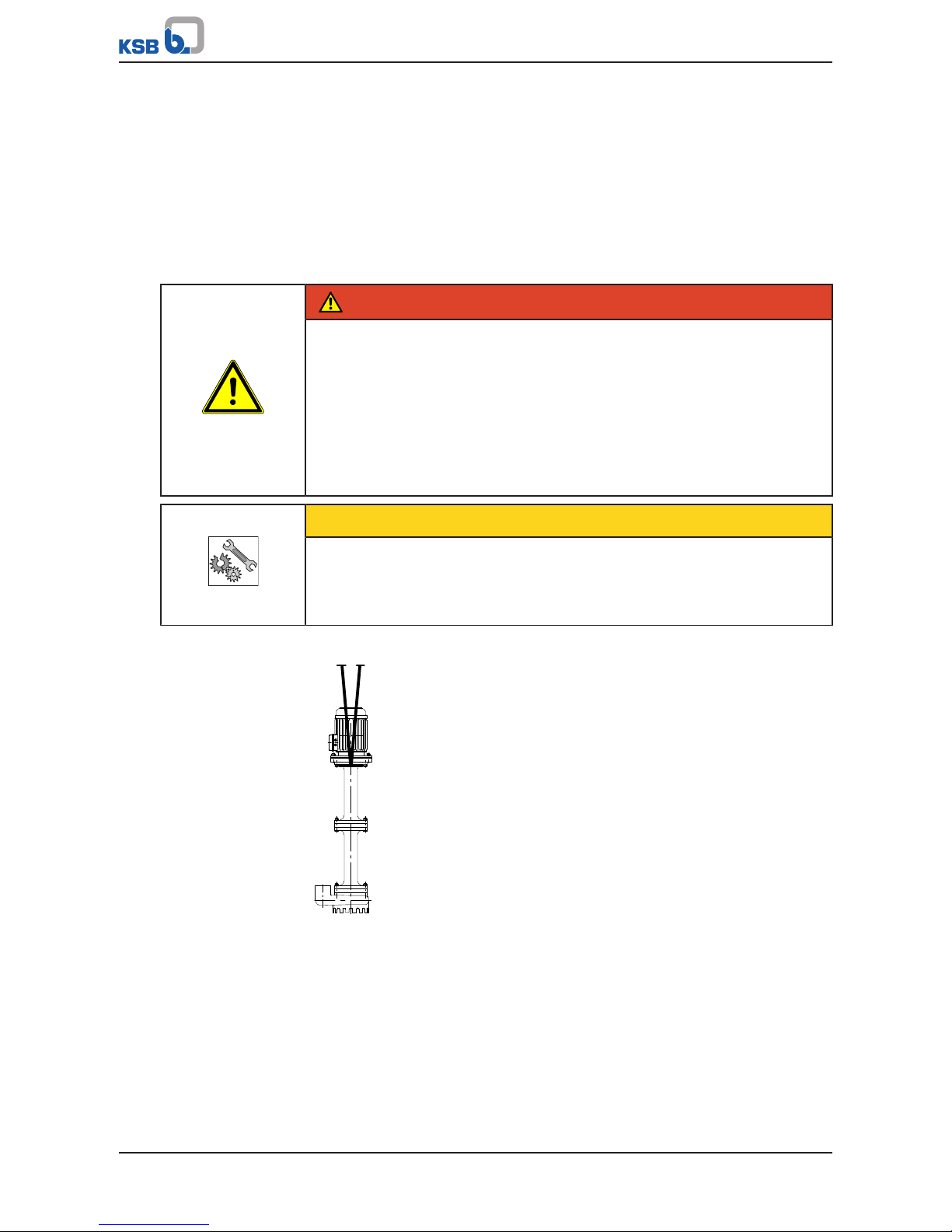

3.2 Transport

DANGER

The pump (set) could slip out of the suspension arrangement

Danger to life from falling parts!

▷ Always transport the pump (set) in the specified position.

▷ Never attach the suspension arrangement to the free shaft end or the motor

eyebolt.

▷ Observe the information about weights, centre of gravity and fastening points.

▷ Observe the applicable local accident prevention regulations.

▷ Use suitable, permitted lifting accessories, e.g. self-tightening lifting tongs.

CAUTION

Incorrect transport of the pump

Damage to the shaft seal!

▷ For transport, lock the pump shaft with a suitable transport lock to prevent any

movement of the shaft.

To transport the pump/pump set suspend it from the lifting tackle as shown.

Fig.1: Transporting the complete pump set

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for pump (set) storage.

Page 13

3 Transport/Temporary Storage/Disposal

13 of 64

MK

CAUTION

Damage during storage due to humidity, dirt or vermin

Corrosion/contamination of the pump (set)!

▷ For outdoor storage cover the pump (set) or the packaged pump (set) and

accessories with waterproof material.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage to the pump!

▷ Clean and cover pump openings and connections as required prior to putting

the pump into storage.

Store the pump (set) in a dry, protected room where the atmospheric humidity is as

constant as possible.

Rotate the shaft by hand once a month, e.g. via the pump impeller.

If properly stored indoors, the equipment is protected for a maximum of 12 months.

New pumps/pump sets are supplied by our factory duly prepared for storage.

For storing a pump (set) which has already been operated, observe the instructions in

(ðSection6.3.1,Page31) .

3.4 Return to supplier

1. Drain the pump as per operating instructions. (ðSection7.3,Page39)

2. Flush and clean the pump, particularly if it has been used for handling noxious,

explosive, hot or other hazardous fluids.

3. If the pump has handled fluids whose residues could lead to corrosion damage

in the presence of atmospheric humidity or could ignite upon contact with

oxygen also neutralise the pump and blow through with anhydrous inert gas to

ensure drying.

4. Always complete and enclose a certificate of decontamination when returning

the pump.

Indicate any safety measures and decontamination measures taken.

(ðSection11,Page60)

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

Page 14

3 Transport/Temporary Storage/Disposal

14 of 64

MK

3.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the pump (set).

Collect greases and other lubricants during dismantling.

2. Separate and sort the pump materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Page 15

4 Description of the Pump (Set)

15 of 64

MK

4 Description of the Pump (Set)

4.1 General description

▪ Waste water, condensate and heat transfer fluid pump

Pump for handling waste water, oils, emulsions, condensate, heat transfer fluids and

aggressive fluids.

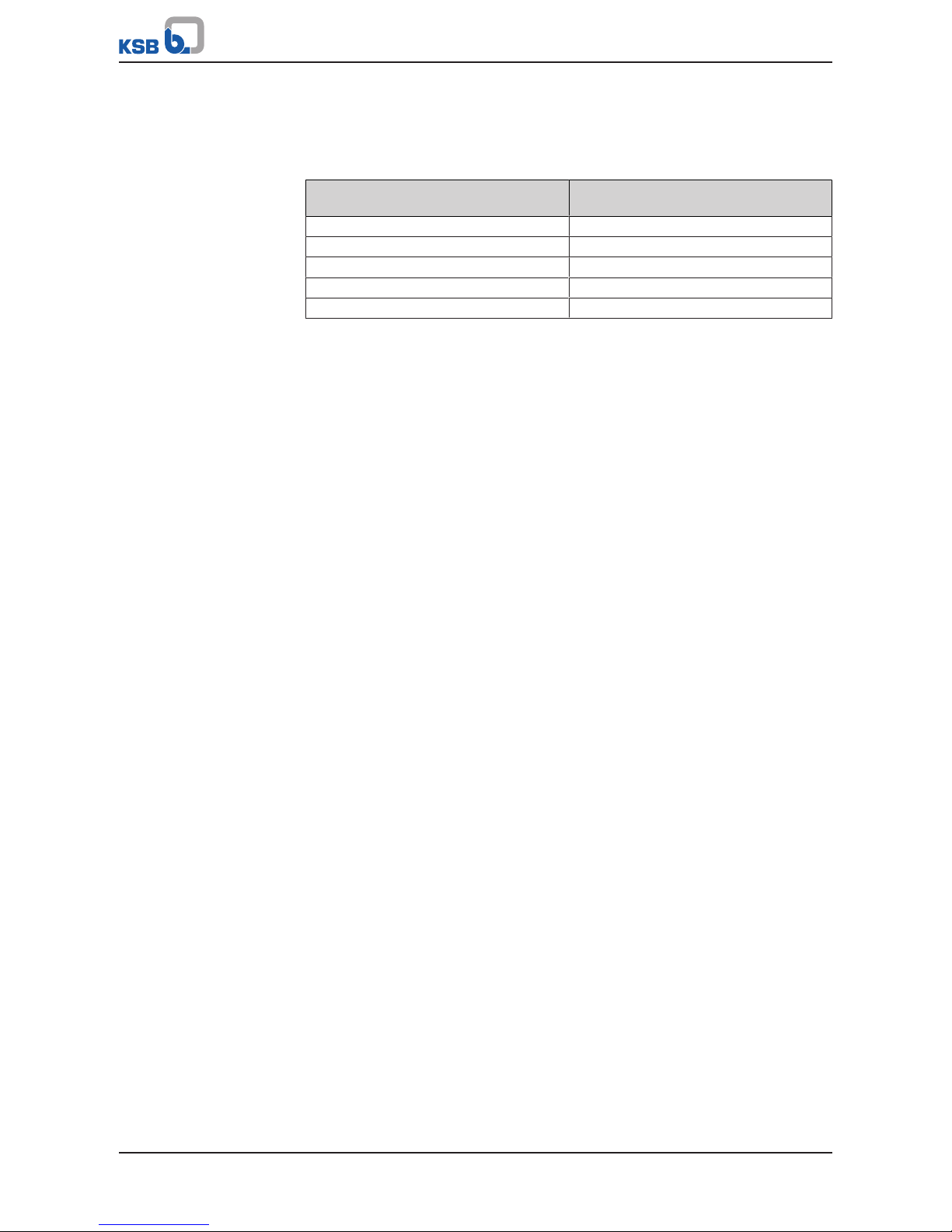

4.2 Designation

MK A - B 20 - 1/ 100

Table5: Designation key

Code Description

MK Type series

A Design

-

2)

Pump without discharge pipe, without cover plate, with motor

A Pump with square mounting/cover plate and discharge pipe, with

motor

Y Pump with round mounting/cover plate and flanged discharge

pipe, with lantern, gland packing and motor

B Casing material

Grey cast iron

B Tin bronze

C Chrome nickel molybdenum cast steel

2 Pipe connection

2 Rp 2

0 Design status

1 Power code (defines the impeller diameter)

1 - 6

100 Installation depth [cm]

100, 190, 280

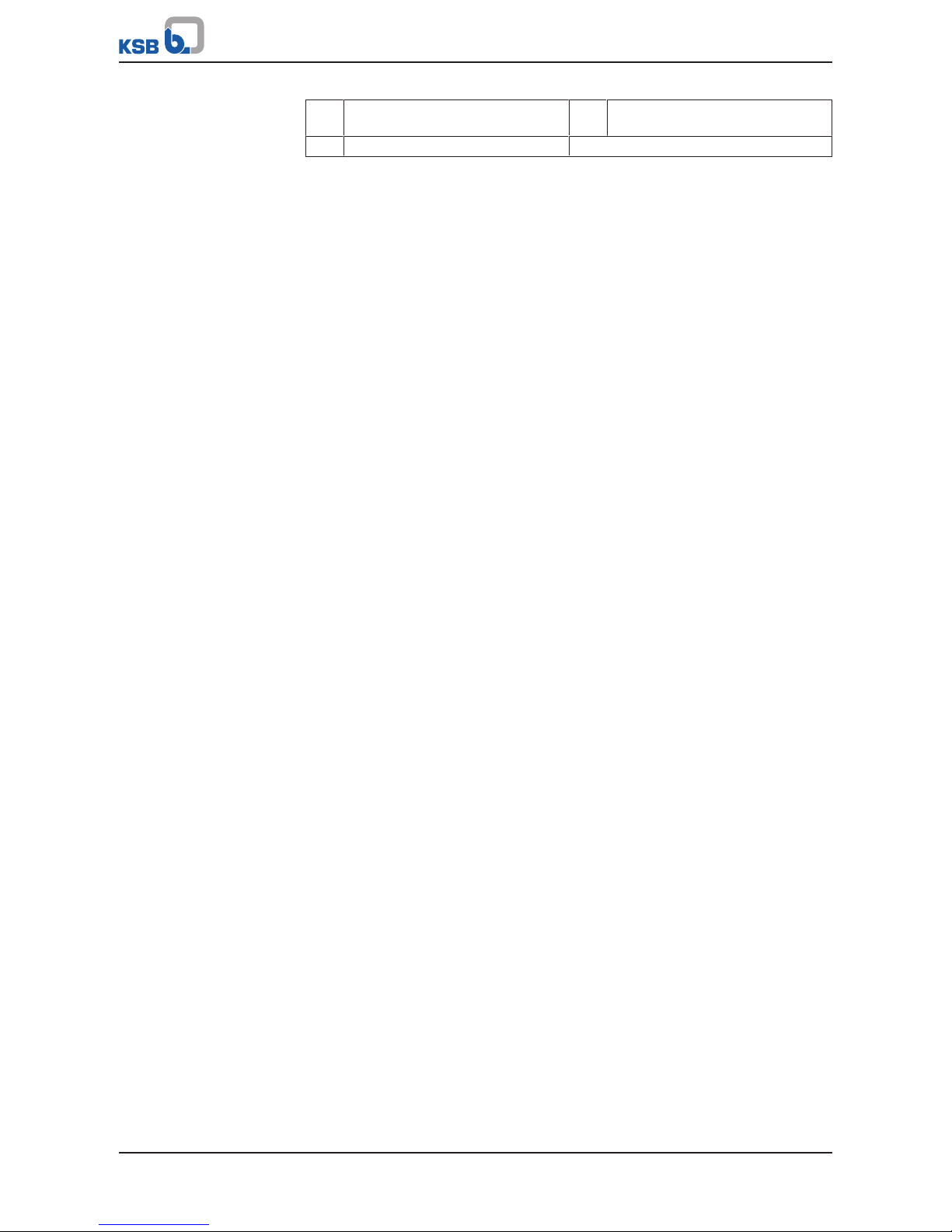

4.3 Name plate

No. 9971402925/ 000200 / 01

Q 10 m3/h H 3 m

n 1450 1/min

Ident.-No. 00 391 209 AN 886-82

2016

MKA-B 20-1/100

1

2

6

5

3

9

8

7

4

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

Fig.2: MK name plate (example)

1 Type series, size and version 2 KSB order number

(ten digits)

3 Flow rate 4 Direction of rotation

5 Year of construction 6 Order item number

(six digits)

2) Blank

Page 16

4 Description of the Pump (Set)

16 of 64

MK

7 Consecutive number

(two digits)

8 Head

9 Speed

4.4 Design details

Design

▪ Volute casing

▪ Vertical installation

▪ Rigid connection between pump and motor

▪ Single-stage

Drive

▪ KSB surface-cooled IEC three-phase current squirrel-cage motor

▪ 230/400V

▪ Type of construction V1

▪ Enclosure IP55

▪ Motors integrated in explosion-proof pump sets are supplied in Ex eb IIB / Ex db

eb IIC type of protection.

Shaft seal

MK, MKA:

▪ Vapour barrier

MKY:

▪ Gland packing

Impeller type

▪ Three-channel impeller

Bearings

Drive end:

▪ Radial ball bearing

▪ Greased for life

Impeller end:

▪ Bearing bush

▪ Product-lubricated

▪ Optional:

– Internal lubrication by fluid handled

– Grease lubrication

– Lubrication by external fluid

Explosion protection

MK, MKA:

▪ Available

▪ For explosion-proof variants one of the optional lubrication types must be used

for the bearing bush.

MKY:

▪ Not available

Page 17

4 Description of the Pump (Set)

17 of 64

MK

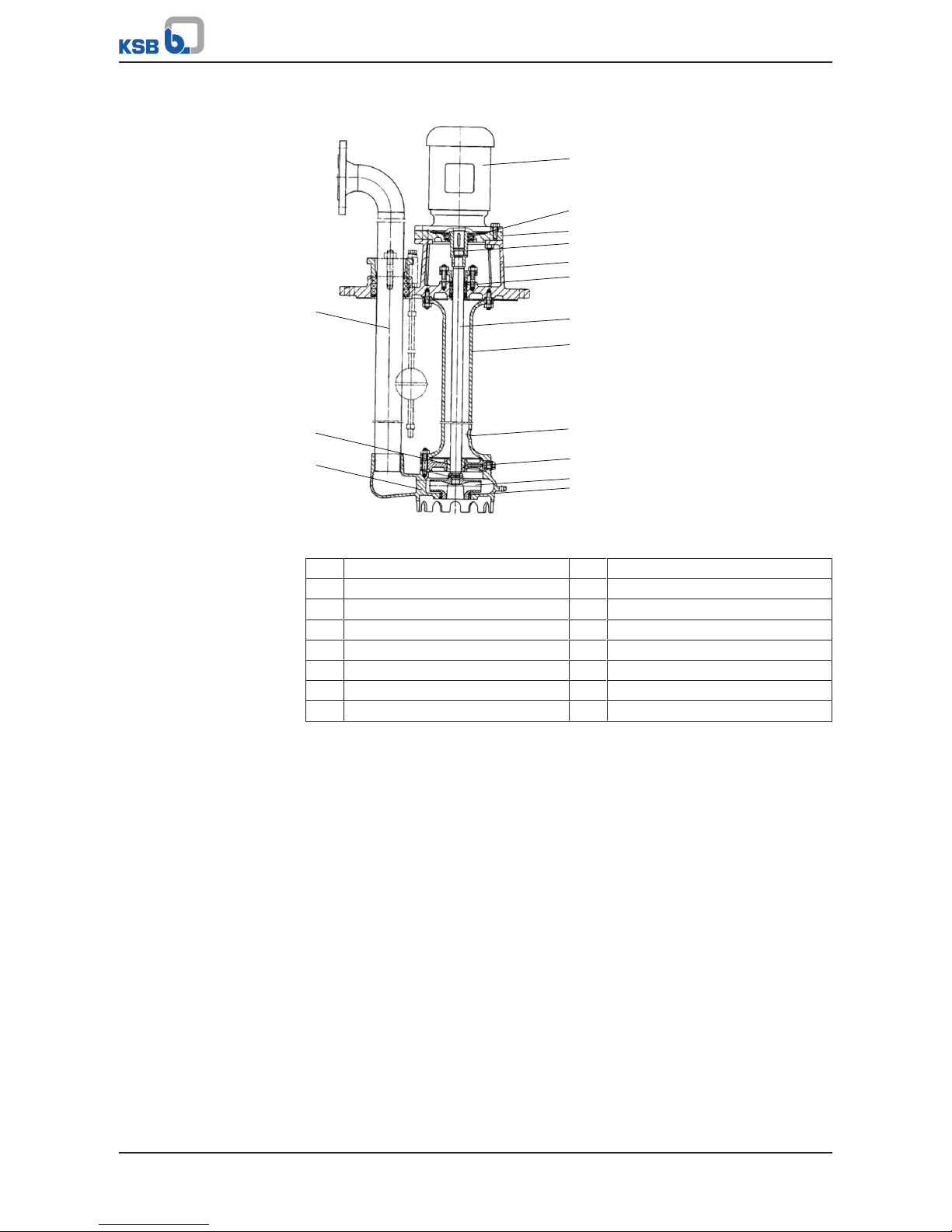

4.5 Configuration and function

MKA

8

9

11

10

12

13

14

15

1

2

3

4

5

6

7

Fig.3: MK, MKA

1 Thrust and radial bearing 2 Radial ball bearing

3 Shaft 4 Support column

5 Discharge pipe 6 Bearing bush

7 Volute casing 8 Motor

9 Cover plate 10 Shaft coupling

11 Vapour barrier 12 Overflow opening

13 Radial bearing 14 Impeller

15 Clearance gap

Design The vertical non-self-priming submerged pump in single-stage, single-entry design

features an axial fluid inlet and a radial fluid outlet.

At the drive end the rotor is axially and radially supported by a radial ball bearing

which is greased for life; at the impeller end it is radially supported by a productlubricated bearing bush. It is connected to the motor by a rigid coupling sleeve.

Various installation depths can be accommodated by up to three support column sets

and matching incremental lengths of the shaft assembly. The required radial bearings

are lubricated by the fluid handled. As an alternative, external lubrication can be

used. To protect the drive-end radial ball bearing the shaft is enclosed by a vapour

barrier below the thrust and radial bearing. For pump sets installed with a cover

plate (MKA) the discharge nozzle of the volute casing is connected to the plate via a

discharge pipe.

Function The uniformly rotating impeller of the submerged pump transfers mechanical energy

to the fluid passing through. The fluid enters the pump set vertically via the suction

nozzle and is accelerated outward by the rotating impeller. In the flow passage of

the volute casing the kinetic energy of the fluid handled is converted into pressure

energy. The fluid leaves the pump set via the discharge nozzle. The clearance gap

minimises the fluid flowing back from the volute casing into the suction nozzle. On

the rear side of the impeller, the hydraulic system extends up to the radial bearing

with bearing bush. The shaft passes through the radial bearing.

Sealing Apart from a vapour barrier protecting the fixed bearing the pump set is seal-less. A

small amount of leakage flows into the support column at the shaft passage and

then through the overflow opening back into the tank.

Page 18

4 Description of the Pump (Set)

18 of 64

MK

MKY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Fig.4: MKY

1 Discharge pipe 2 Bearing bush

3 Volute casing 4 Motor

5 Radial ball bearing 6 Thrust and radial bearing

7 Shaft coupling 8 Drive lantern

9 Shaft seal 10 Shaft

11 Support column 12 Overflow opening

13 Radial bearing 14 Impeller

15 Clearance gap

Design The vertical non-self-priming submerged pump in single-stage, single-entry design

features an axial fluid inlet and a radial fluid outlet.

Above the drive lantern the rotor is axially and radially supported by a radial ball

bearing which is greased for life; at the impeller end, it is radially supported by a

product-lubricated bearing bush. It is connected to the motor by a rigid coupling

sleeve. Various installation depths can be accommodated by up to three support

column sets and matching incremental lengths of the shaft assembly. The pump set is

installed in a drive lantern. The discharge nozzle of the volute casing is connected to

the lantern via a discharge pipe. The discharge pipe ends in a flanged bend.

Function The uniformly rotating impeller of the submerged pump transfers mechanical energy

to the fluid passing through. The fluid enters the pump vertically via the suction

nozzle and is accelerated outward by the rotating impeller. In the flow passage of

the volute casing the kinetic energy of the fluid handled is converted into pressure

energy. The fluid leaves the pump via the discharge nozzle. The clearance gap

minimises the fluid flowing back from the volute casing into the suction nozzle. On

the rear side of the impeller, the hydraulic system extends up to the radial bearing

with bearing bush. The shaft passes through the radial bearing.

Sealing The pump set is sealed towards the fixed bearing with a shaft seal (gland packing).

Page 19

4 Description of the Pump (Set)

19 of 64

MK

4.6 Noise characteristics

Table6: Surface sound pressure level L

pA

3)

Rated power input

PN [kW]

Pump set

1450 rpm

[dB]

2900 rpm

[dB]

0,55 52 0,75 57 64

1,1 - 64

1,5 - 65

2,2 - 66

4.7 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Pump

Drive

▪ Surface-cooled IEC frame three-phase squirrel-cage motor

Special accessories

▪ As required

Soleplate

MK:

▪ Without baseplate

MKA:

▪ Baseplate accommodating pump and motor

MKY:

▪ Baseplate integrally cast with the lantern

Monitoring equipment (optional)

▪ Temperature sensor at the drive-end fixed bearing with G 1/8 threaded

connection

Level control system (optional)

▪ Level control system with rod-actuated float switch

▪ Level control system with magnetic float switch

▪ Level control system with EURO float switch

3) Spatial average; as per ISO 3744; valid for pump operation in the Q/Qopt = 0.80 - 1.1 range and for non-cavitating

operation. If noise levels are to be guaranteed: add +3dB for measuring and constructional tolerance; the above values

apply to the pump set without cover plate. If a cover plate is fitted, this value may increase by up to 2 pA (dB).

Page 20

5 Installation at Site

20 of 64

MK

5 Installation at Site

5.1 Safety regulations

DANGER

Improper installation in potentially explosive atmospheres

Explosion hazard!

Damage to the pump set!

▷ Comply with the applicable local explosion protection regulations.

▷ Observe the information in the data sheet and on the name plates of pump and

motor.

DANGER

Improper cleaning of coated pump surfaces

Explosion hazard by electrostatic discharge!

▷ When cleaning coated pump surfaces in atmospheres of Explosion groupIIC,

use suitable anti-static equipment.

5.2 Checks to be carried out prior to installation

Check the structural requirements.

The structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing and/or general arrangement drawing.

5.3 Fitting and setting the float switch control (optional)

5.3.1 Control elements for MK/MKA

5.3.1.1 Rod-actuated float switch control

The pump set is controlled by a switch fitted on the motor flange. The switch is

actuated by a float via a switch rod with stop clamps.

Page 21

5 Installation at Site

21 of 64

MK

Fitting the rod-actuated float switch

74-4

574

901.52

930.52

575.52

500.50

930.52

920.52

81-45

900.51

550.51

570

900.50

920.50

733.51

481

733.52

68-3

550.51

920.51

575.51

902.12

920.12

710.01

920.11

550.11

400.11

Fig.5: Fitting the rod-actuated float switch

a) b) c)

A A B B C C

Fig.6: Positioning the rod-actuated float switch for installation depth: a) 1000mm; b) 1900mm; c) 2800mm

A 1000 mm B 1900 mm

C 2800 mm

Page 22

5 Installation at Site

22 of 64

MK

Fig.7: Float switch a) installation position; b) switching position

1. Fasten strip 575.51 to the motor flange and strip 575.52 to the pump casing with

hexagon head bolt 901.52, hexagon nut 920.52 and spring washers 930.52.

2. Mount float switch 81-45 on strip 575.51 using hexagon socket head cap screws

900.51, discs 550.51 and nuts 920.51.

3. Fit the lever on float switch 81-45.

4. Assemble guide rod 574 with float 74-4 and the two upper adjusting rings

500.50.

5. Run the guide rod through strip 575.52 and fit adjusting ring 500.50 beneath

the strip.

6. Connect the lever and the guide rod using hexagon socket head cap screw

900.50 and hexagon nut 920.50.

7. If applicable, fit bellows 481 and hose clamp 733.51 on the guide rod.

8. Fasten the bellows on cover plate 68-3 with hose clamp 733.52.

9. Position adjusting rings 500.50 in the desired switching levels above and below

the float, respectively, to start and stop the pump as required.

10. Adjust the switching mechanism of float switch 81-45 such that the lever is

angled 42° off the horizontal in non-actuated position, see illustration of float

switch a) installation position. In installed condition, the lever position must be

as shown in the illustration of the float switch b) switching position.

ð As the float rises, the lever is lifted into the position shown and contact 15-16

closes.

11. Check that the rod-actuated float switch functions properly.

5.3.1.2 Magnetic float switch control (non-ATEX applications only)

Pump sets for installation depths of 1000 and 1900mm are controlled by a magnetic

float switch arrangement. It is equipped with a sensor tube with integrated dry-reed

contacts. The float with integrated permanent magnets can move freely along the

sensor tube and activates the dry-reed contacts when it reaches the minimum and

maximum fluid levels. The fluid levels are permanently pre-set by means of adjusting

rings.

Fitting the magnetic float switch control

1. Remove the plug from the G3/4 through-hole in the cover plate.

2. Tightly screw the magnetic float switch arrangement into the G3/4 hole provided.

Page 23

5 Installation at Site

23 of 64

MK

NOTE

The switching points - measured from the cover plate - are located at 300mm for

"ON" and 800mm (for installation depth 1000mm) or 1700mm (for installation

depth 1900mm) for "OFF" and cannot be altered. The max. contact rating is 1 A;

for MK pumps separately at the tank.

5.3.1.3 EURO float switch control (non-ATEX applications only)

The pump set is started/stopped by the float switch in response to the fluid level.

The free length of the float's connection cable (= length from the attachment point

to the float switch) defines the fluid levels for starting/stopping the pump.

Float switches with 5, 10 or 20 m connection cable must only be used for fluids with a

maximum temperature of 70 °C.

5.3.2 Control element for MKY

Pump sets installed in heat transfer fluid and recirculating systems usually do not

need any control elements.

If the pump set is used for handling condensate at temperatures of up to 110°C and

is installed at installation depths of 1000mm or 1900mm, it can be equipped with

magnetic float switch control. (ðSection5.3.1.2,Page22)

5.4 Installing the pump set

ü The installed motor is protected against flooding.

ü Motor and (optional) float switch are located outside the pit or tank.

ü Motor and (optional) float switch are ventilated and protected against moisture.

1. Remove the transport plugs from the volute casing and the discharge pipe.

2. For pump sets with installation depths of 1900mm and 2800mm without cover

plate (MK) fit the pipe union 731, which is supplied separately strapped to the

pump. (ðSection9.1.2,Page53) (ðSection9.1.4,Page55)

3. Place the pump set on the floor of a pit (approximately 500x500mm) or, if the

pump set is installed in a tank, fit it to the tank edge with a cover plate.

4. If the pump set is installed in a pit without a cover plate and angular frame,

secure it to the pit wall using mounting clamps.

5.5 Connecting the piping

DANGER

Impermissible loads acting on the pump nozzles

Danger to life from leakage of hot, toxic, corrosive or flammable fluids!

▷ Do not use the pump as an anchorage point for the piping.

▷ Anchor the pipes in close proximity to the pump and connect them properly

without transmitting any stresses or strains.

▷ Take appropriate measures to compensate for thermal expansion of the piping.

CAUTION

Incorrect earthing during welding work on the piping

Destruction of rolling element bearings (pitting effect)!

▷ Never earth the electric welding equipment on the pump or soleplate.

▷ Prevent current flowing through the rolling element bearings.

Page 24

5 Installation at Site

24 of 64

MK

NOTE

Installing check and shut-off elements in the system is recommended, depending on

the type of plant and pump. However, such elements must not obstruct proper

drainage or hinder disassembly of the pump.

NOTE

If the pump is used for automatic drainage, fit a non-return or check valve.

ü The nominal diameters of the pipelines are equal to or greater than the nominal

diameters of the pump nozzles.

ü Adapters to larger nominal diameters are designed with a diffuser angle of

approx. 8° to avoid excessive pressure losses.

ü A flow velocity of 2-3m/s is recommended.

ü The pipelines have been anchored in close proximity to the pump and connected

without transmitting any stresses or strains.

1. Thoroughly clean, flush and blow through all vessels, pipelines and connections

(especially of new installations).

2. Before installing the pump in the piping, remove the flange covers on the

suction and discharge nozzles of the pump.

CAUTION

Welding beads, scale and other impurities in the piping

Damage to the pump!

▷ Free the piping from any impurities.

3. If required, fit a suction strainer upstream of the pump nozzle.

4. Connect the discharge-side pump nozzle with the piping.

CAUTION

Aggressive flushing liquid and pickling agent

Damage to the pump!

▷ Match the cleaning operation mode and duration of flushing and pickling to

the casing materials and seal materials used.

5.6 Permissible forces and moments at the pump nozzles

No piping-induced forces and moments (from warped pipelines or thermal

expansion, for example) must act on the pump.

5.7 Electrical connection

DANGER

Incorrect electrical installation

Explosion hazard!

▷ For electrical installation, also observe the requirements of IEC 60079-14.

▷ Observe the manufacturer's product literature supplied with the motor.

▷ Observe the manufacturer's product literature supplied with the float switch if

float switch control is used.

Page 25

5 Installation at Site

25 of 64

MK

DANGER

Electrostatic charging

Explosion hazard!

Damage to the pump set!

▷ Connect the potential equalisation conductor to the earthing terminal

provided.

▷ Make sure that the connection between pump and baseplate is electrically

conductive.

▷ Screws, bolts, nuts and shims must not be coated or the coating must be

removed.

▷ Provide potential equalisation between the pump set and the foundation.

DANGER

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN60079.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

NOTE

A motor protection device is recommended.

1. Check the available mains voltage against the data on the motor name plate.

2. Select an appropriate starting method.

5.8 Checking the direction of rotation

DANGER

Pump set running dry

Explosion hazard!

▷ Check the direction of rotation of explosion-proof pump sets outside

potentially explosive atmospheres.

WARNING

Hands inside the pump casing

Risk of injuries, damage to the pump!

▷ Always disconnect the pump set from the power supply and secure it against

unintentional start-up before inserting your hands or other objects into the

pump.

Page 26

5 Installation at Site

26 of 64

MK

CAUTION

Pump set running dry

Increased vibrations!

Damage to mechanical seals and bearings!

▷ Never operate the pump set for more than 60seconds outside the fluid to be

handled.

CAUTION

Drive and pump running in the wrong direction of rotation

Damage to the pump!

▷ Refer to the arrow indicating the direction of rotation on the pump.

▷ Check the direction of rotation. If required, check the electrical connection and

correct the direction of rotation.

The correct direction of rotation of the motor and pump is clockwise (seen from the

drive end).

1. Start the motor and stop it again immediately to determine the motor's

direction of rotation.

2. Check the direction of rotation.

The motor's direction of rotation must match the arrow indicating the direction

of rotation on the pump.

3. If the motor is running in the wrong direction of rotation, check the electrical

connection of the motor and the control system, if applicable.

Page 27

6 Commissioning/Start-up/Shutdown

27 of 64

MK

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/Start-up

6.1.1 Prerequisites for commissioning/start-up

▪ The pump set has been properly connected to the power supply and is equipped

with all protection devices.

▪ The direction of rotation has been checked.

▪ All auxiliary connections required are connected and operational.

▪ After prolonged shutdown of the pump (set), the activities required for returning

the equipment to service have been carried out.

▪ Float switch control has been installed and set (if applicable).

6.1.2 Filling in lubricants

Thrust and radial bearings The sealed-for-life radial ball bearings are already packed with grease.

Radial bearings The bearing bushes are lubricated by the fluid handled. The start-up point must be

situated above the top bearing. Observe the minimum fluid level

(ðSection6.2.3.2,Page30) . For grease lubrication (optional) fill the lubricators

with grease. For lubrication by external fluid open the flushing liquid connection.

(ðSection7.2.2.2,Page36)

6.1.3 Start-up

DANGER

Non-compliance with the permissible pressure and temperature limits due to a

clogged intake or if the pump is operated with the discharge line closed.

Explosion hazard!

Leakage of hot fluids!

▷ Never operate the pump with the shut-off elements in the discharge line

closed.

▷ Only start up the pump set against a slightly or completely open discharge-side

shut-off element.

▷ Make sure that the intake area is clean and free from foreign objects.

DANGER

Excessive temperatures due to dry running or excessive gas content in the fluid

handled

Explosion hazard!

Damage to the pump set!

▷ Never operate the pump set without liquid fill.

▷ Prime the pump as per operating instructions.

▷ Always operate the pump within the permissible operating range.

▷ If the pump is in slurp mode, stop the pump immediately.

▷ Provide for fill level monitoring to prevent dry running of the pump.

Page 28

6 Commissioning/Start-up/Shutdown

28 of 64

MK

CAUTION

Abnormal noises, vibrations, temperatures or leakage

Damage to the pump!

▷ Switch off the pump (set) immediately.

▷ Eliminate the causes before returning the pump set to service.

ü The system piping has been cleaned.

ü The pump and the inlet tank, if any, have been vented and primed with the fluid

to be handled.

ü The lines for priming and venting have been closed.

CAUTION

Start-up against open discharge line

Motor overload!

▷ Make sure the motor has sufficient power reserves.

▷ Use a soft starter.

▷ Use speed control.

1. Close or slightly open the shut-off element in the discharge line.

2. Start up the motor.

3. Immediately after the pump has reached full rotational speed, slowly open the

shut-off element in the discharge line and adjust it to comply with the duty

point.

6.1.4 Shutdown

1. Close the shut-off element in the discharge line.

2. Switch off the motor and make sure the pump set runs down smoothly to a

standstill.

NOTE

If the discharge line is equipped with a non-return or check valve, the shut-off

element may remain open provided that the system conditions and system

regulations are considered and observed.

NOTE

If shut-off is not possible, the pump will run in reverse direction.

The reverse runaway speed must be lower than the rated speed.

For prolonged shutdown periods:

1. Close the auxiliary connections.

CAUTION

Risk of freezing during prolonged pump shutdown periods

Damage to the pump!

▷ Drain the pump and the cooling/heating chambers (if any) or otherwise protect

them against freezing.

Page 29

6 Commissioning/Start-up/Shutdown

29 of 64

MK

6.2 Operating limits

DANGER

Non-compliance with operating limits

Damage to the pump set!

▷ Comply with the operating data specified in the data sheet.

▷ Avoid operation against a closed shut-off element.

▷ Never operate an explosion-proof pump set at ambient temperatures or fluid

temperatures exceeding those specified in the data sheet and/or on the name

plate.

▷ Never operate the pump set outside the limits specified below.

6.2.1 Ambient temperature

CAUTION

Operation outside the permissible ambient temperature

Damage to the pump (set)!

▷ Observe the specified limits for permissible ambient temperatures.

Observe the following parameters and values during operation:

Table7: Permissible ambient temperatures

Permissible ambient temperature Value

Maximum 40 °C

Minimum - 20 °C

6.2.2 Frequency of starts

DANGER

Excessive surface temperature of the motor

Explosion hazard!

Damage to the motor!

▷ In case of explosion-proof motors, observe the frequency of starts specified in

the manufacturer's product literature.

To prevent high temperature increases in the motor and excessive loads on the

pump, coupling, motor, seals and bearings, the frequency of starts shall not exceed

20 start-ups per hour (h).

CAUTION

Re-starting while motor is still running down

Damage to the pump (set)!

▷ Do not re-start the pump set before the pump rotor has come to a standstill.

Page 30

6 Commissioning/Start-up/Shutdown

30 of 64

MK

6.2.3 Fluid handled

6.2.3.1 Flow rate

Unless specified otherwise in the characteristic curves or in the data sheets, the

following applies:

▪ Short-time operation: Q

min

4)

=0.1×Q

opt

5)

▪ Continuous operation: Q

min

4)

=0.3×Q

opt

5)

▪ 2-pole operation: Q

max

6)

=1.1×Q

opt

5)

▪ 4-pole operation: Q

max

6)

=1.25×Q

opt

5)

The data refer to water and water-like fluids. Longer operating periods with these

fluids and at the flow rates indicated will not cause an additional increase in the

temperatures on the pump surface. However, if the physical properties of the fluids

handled differ from those of water, the calculation formula below must be used to

check if an additional heat build-up may lead to a dangerous temperature increase at

the pump surface. If necessary, the minimum flow must be increased.

×

×

×

Table8: Key

Symbol Description Unit

c Specific heat capacity J/kg K

g Gravitational constant m/s²

H Pump discharge head m

T

f

Fluid temperature °C

T

O

Temperature at the casing surface °C

Pump efficiency at duty point Temperature difference K

6.2.3.2 Minimum level of fluid handled

DANGER

Pump set running dry

Explosion hazard!

▷ Never allow an explosion-proof pump set to run dry!

CAUTION

Fluid level below the specified minimum

Damage to the pump set by cavitation!

▷ Never allow the fluid level to drop below the specified minimum.

Minimum 120mm above the bottom edge of the casing; if handling condensate ~400mm

Maximum 150mm below the plate

Before start-up, the pump set must always be immersed in the fluid to be handled so

it is above the minimum switch-off level (ðSection6.1.2,Page27) .

4) Minimum permissible flow rate

5) Flow rate at best efficiency point

6) Maximum permissible flow rate

Page 31

6 Commissioning/Start-up/Shutdown

31 of 64

MK

6.2.3.3 Temperature of the fluid handled

CAUTION

Incorrect temperature of the fluid handled

Damage to the pump (set)!

▷ Do not operate the pump (set) outside the specified temperature limits.

Table9: Fluid temperature

Design Temperature [°C]

Minimum Maximum

MK, MKA -10 °C 90 °C

7)

MKY -10 °C 200 °C

8)

6.2.3.4 Density of the fluid handled

The pump input power changes in proportion to the density of the fluid handled.

CAUTION

Impermissibly high density of the fluid handled

Motor overload!

▷ Observe the information about fluid density in the data sheet.

▷ Make sure the motor has sufficient power reserves.

6.2.3.5 Gas content of fluid handled

DANGER

Excessive temperatures as a result of bearing bushes running hot

Explosion hazard!

Fire hazard!

Damage to the pump set!

▷ Never pump fluids with excessive gas content.

▷ Allow sufficient time for gases to leave the fluid handled.

6.2.3.6 Abrasive fluids

Do not exceed the maximum permissible solids content specified in the data sheet.

When the pump handles fluids containing abrasive substances, increased wear of the

hydraulic system and shaft seal are to be expected. In this case, reduce the commonly

recommended inspection intervals.

6.3 Shutdown/storage/preservation

6.3.1 Measures to be taken for shutdown

The pump (set) remains installed

ü Sufficient fluid is supplied for the functional check run of the pump.

1. For prolonged shutdown periods, start up the pump (set) regularly between

once a month and once every three months for approximately five minutes.

ð This will prevent the formation of deposits within the pump and the pump

intake area.

7) 80 °C for bearing material 1.4571-NBR

8) 200 °C for bearing material EK 3205; 110 °C when handling water; 80 °C for bearing material 1.4571-NBR

Page 32

6 Commissioning/Start-up/Shutdown

32 of 64

MK

The pump (set) is removed from the pipe and stored

ü The pump has been properly drained.

ü The safety instructions for dismantling the pump have been observed.

1. Spray-coat the inside wall of the pump casing and, in particular, the impeller

clearance areas with a preservative.

2. Spray the preservative through the suction nozzle and discharge nozzle.

It is advisable to then close the pump nozzles (e.g. with plastic caps).

3. Oil or grease all exposed machined parts and surfaces of the pump (with

silicone-free oil or grease, food-approved if required) to protect them against

corrosion.

Observe the additional instructions on preservation.

If the pump set is to be stored temporarily, only preserve the wetted components

made of low-alloy materials. Commercially available preservatives can be used for

this purpose. Observe the manufacturer's instructions for application/removal.

6.4 Returning to service

WARNING

Failure to re-install or re-activate protective devices

Risk of injury from moving parts or escaping fluid!

▷ As soon as the work is completed, re-install and re-activate any safety-relevant

devices and protective devices.

For returning the equipment to service, observe the sections on commissioning/startup (ðSection6.1,Page27) and the operating limits .

In addition, carry out all servicing/maintenance operations before returning the

pump (set) to service. (ðSection7,Page33)

Page 33

7 Servicing/Maintenance

33 of 64

MK

7 Servicing/Maintenance

7.1 Safety regulations

DANGER

Improper cleaning of coated pump surfaces

Explosion hazard by electrostatic discharge!

▷ When cleaning coated pump surfaces in atmospheres of Explosion groupIIC,

use suitable anti-static equipment.

DANGER

Sparks produced during servicing work

Explosion hazard!

▷ Observe the safety regulations in force at the place of installation!

▷ Always perform maintenance work at an explosion-proof pump (set) outside of

potentially explosive atmospheres.

DANGER

Improperly serviced pump set

Explosion hazard!

Damage to the pump set!

▷ Service the pump set regularly.

▷ Prepare a maintenance schedule with special emphasis on lubricants, shaft seal

and coupling.

The operator ensures that maintenance, inspection and installation is performed by

authorised, qualified specialist personnel who are thoroughly familiar with the

manual.

WARNING

Unintentional starting of the pump set

Risk of injury by moving components and shock currents!

▷ Ensure that the pump set cannot be started unintentionally.

▷ Always make sure the electrical connections are disconnected before carrying

out work on the pump set.

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Risk of injury!

▷ Observe all relevant laws.

▷ When draining the fluid take appropriate measures to protect persons and the

environment.

▷ Decontaminate pumps which handle fluids posing a health hazard.

Page 34

7 Servicing/Maintenance

34 of 64

MK

WARNING

Insufficient stability

Risk of crushing hands and feet!

▷ During assembly/dismantling, secure the pump (set)/pump parts to prevent

tilting or tipping over.

A regular maintenance schedule will help avoid expensive repairs and contribute to

trouble-free, reliable operation of the pump, pump set and pump parts with a

minimum of servicing/maintenance expenditure and work.

NOTE

All maintenance work, service work and installation work can be carried out by KSB

Service or authorised workshops. For contact details please refer to the enclosed

"Addresses" booklet or visit "www.ksb.com/contact" on the Internet.

Never use force when dismantling and reassembling the pump set.

7.2 Servicing/Inspection

7.2.1 Supervision of operation

DANGER

Impermissibly high temperatures

Explosion hazard!

Damage to the pump!

▷ Prolonged operation against a closed shut-off element is not permitted

(heating up of the fluid).

▷ Observe the temperature limits in the data sheet and in the section on

operating limits. (ðSection6.2,Page29)

DANGER

Excessive temperatures as a result of bearings running hot or defective bearing

seals

Explosion hazard!

Fire hazard!

Damage to the pump set!

Risk of burns!

▷ Regularly check the lubricant level.

▷ Regularly check the rolling element bearings for running noises.

CAUTION

Fluid level below the specified minimum

Damage to the pump set by cavitation! Dry running of the plain bearings!

▷ Never allow the fluid level to drop below the specified minimum.

While the pump is in operation, observe and check the following:

▪ The pump must run quietly and free from vibrations at all times.

▪ Check the shaft seal.

▪ Check the static sealing elements for leakage.

Page 35

7 Servicing/Maintenance

35 of 64

MK

▪ Check the rolling element bearings for running noises.

Vibrations, noise and an increase in current input occurring during unchanged

operating conditions indicate wear.

▪ Monitor the correct functioning of any auxiliary connections.

▪ Monitor the stand-by pump.

To make sure that stand-by pumps are ready for operation, start them up once a

week.

▪ Make sure that the floats of rod-actuated and magnetic float switch

arrangements can always slide along the guide rods without obstruction.

▪ The minimum fluid level must be observed. (ðSection6.2.3.2,Page30)

▪ Monitor the bearing temperature.

The bearing temperature must not exceed 90 °C (measured on the outside of the

bearing bracket).

For monitoring the bearing temperature, a G 1/8 connection hole (Ø 7 mm) is

provided in thrust and radial bearing 303.1 (max. width across corners of fastener

used: 18 mm).

CAUTION

Operation outside the permissible bearing temperature

Damage to the pump!

▷ The bearing temperature of the pump (set) must never exceed 90 °C (measured

on the outside of the bearing bracket).

NOTE

After commissioning, increased temperatures may occur at grease-lubricated rolling

element bearings due to the running-in process. The final bearing temperature is

only reached after a certain period of operation (up to 48 hours depending on the

conditions).

7.2.2 Lubrication and lubricant change

DANGER

Excessive temperatures as a result of bearings running hot or defective bearing

seals

Explosion hazard!

Fire hazard!

Damage to the pump set!

▷ Regularly check the condition of the lubricant.

7.2.2.1 Lubrication of radial ball bearings

The shaft runs in a radial ball bearing in the thrust and radial bearing. The radial ball

bearing is fitted with sealing washers on both sides and greased for life.

Page 36

7 Servicing/Maintenance

36 of 64

MK

1

2

34

Fig.8: Radial ball bearing (thrust and radial bearing)

1 Radial ball bearing 2 Washer

3 Grease fill 4 Nilos ring

Table10: Bearings used

Sizes Motor Radial ball bearing Nilos ring

MK, MKA 20-1 to 5 80M 6006 2 RS ZJV 6006

MK, MKA 20-6 90 S, L 6008 2 RS ZJV 6008

MKY 20-1 to 4 80M 6006 2 RS ZJV 6006

MKY 20-5 and 6 90 S, L 6008 2 RS ZJV 6008

Grease quality ▪ High-performance lithium soap grease to DIN 51825

▪ Free of resin and acid

▪ Not liable to crumble

▪ With good rust-preventive characteristics

Bearing life With this grease, a theoretical bearing life Lh10 of 25,000 h at an operating

temperature of 75 °C can be achieved. If temperatures are higher, grease life will be

reduced. A temperature increase of 15 K will reduce grease life by half. However,

bearing life may be reduced by vibrations, aggressive gases, humidity, etc.

7.2.2.2 Lubrication of bearing bushes

DANGER

Excessive temperatures as a result of bearing bushes running hot

Explosion hazard!

Fire hazard!

Damage to the pump set!

▷ Make sure the bearing bushes are properly lubricated.

▷ Regularly check the bearing bushes for correct lubrication.

The bearing bushes (radial bearings) in the support column and volute casing are

lubricated by the fluid handled. Bearings must be checked for wear in the following

cases:

▪ When the pump has been operated under dry-running or cavitation conditions

▪ When vibrations, noise and an increase in current input occur during unchanged

operating conditions

Internal lubrication by fluid handled

Lubrication by the fluid handled is used for bearing bushes with a risk of dry running.

Connect pipe union 731.21 between the discharge pipe and the support column.

Page 37

7 Servicing/Maintenance

37 of 64

MK

Grease lubrication

CAUTION

Insufficiently filled grease cups

Damage to the pump set by cavitation and ungreased bearings!

▷ The grease cup must be filled with lubricant.

▷ The grease cup must be screwed down regularly.

Provide each bearing bush in the support column with a separate lubricating device

including a lubricator.

Grease quality

Optimum grease properties:

Table11: Grease quality to DIN 51825

Soap basis NLGI grade Worked penetration at

25° C in mm/10

Drop point

Lithium 2 to 3 220-295 ≥ 175°C

▪ Free of resin and acid

▪ Not liable to crumble

▪ Rust-preventive characteristics

a) b)

Fig.9: a) Grease lubrication; b) Lubrication by fluid handled

Page 38

7 Servicing/Maintenance

38 of 64

MK

Lubrication by external fluid

DANGER

Failure of lubrication by external fluid

Explosion hazard!

▷ Monitor lubrication by external fluid.

DANGER

Risk of potentially explosive atmosphere by mixing of incompatible fluids in the

auxiliary piping

Risk of burns!

Explosion hazard!

▷ Make sure that the barrier fluid or quench liquid are compatible with the fluid

handled.

For lubrication by external fluid provide a flushing water connection which meets the

following conditions:

▪ Maximum flushing water temperature: 40°C

▪ Minimum pressure required: 2.5 bar

▪ Fit connection line with shut-off valve and non-return valve.

▪ Control by a solenoid valve connected in parallel with the motor is

recommended.

Page 39

7 Servicing/Maintenance

39 of 64

MK

Fig.10: Lubrication by external fluid

7.3 Drainage/cleaning

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Always flush the pump if it has been used for handling noxious, explosive, hot

or other hazardous fluids.

2. Always flush and clean the pump before transporting it to the workshop.

Provide a certificate of decontamination for the pump set.

(ðSection11,Page60)

Page 40

7 Servicing/Maintenance

40 of 64

MK

7.4 Dismantling the pump set

7.4.1 General information/Safety regulations

WARNING

Unqualified personnel performing work on the pump (set)

Risk of injury!