Page 1

Operating Instructions

Nº A2742.8E/8

KSB Meganorm

Centrifugal pump for general use

1. Application

The KSB MEGANORM centrifugal pump is suitable for

handling chemical products, aggressive organic and

inorganic liquids, oil, water, condensate and other liquids,

and it is mainly used in the following applications:

- Sugar and alcohol industry

- Water supply

- Irrigation

- Air conditioning

- Fire fighting

- Drainage

2. Design

Horizontal, single-stage, end suction with top centerline

discharge. The “back-pull-out”design allows maintenance

and repair services through the backside, without

dismantling piping supports.

Dimensionally built to ISO 2858/DIN 24256 and

mechanically to ANSI B73.1.

Line :

Standard :

Mega

ISO 2858

3. Designation

Trade Mark

Model / Type

Discharger Nozzle Diameter (mm)

Nominal Impeller Diameter(mm)

KSB Meganorm 80 - 200

4. Operating data

Sizes - DN 25 up to 150 ( 1 ¼” to 6’)

Flow - up to 3,082 gpm (700 m3/h)

Head - to 460 ft (140 m)

Temperature - to 221ºF (105º C)

Max. Suction pressure - to 145 psi (10 bar)

Speed - to 3,500 rpm

Page 2

5. Introduction

KSB has supplied you with equipment that has been

designed and manufactured with the most advanced

technology. Due to its simple and tough construction it will

not need much maintenance. With the aim of provid ing our

clients with a satisfactory, trouble free operation, we

recommend to install and care our equipment according to

the instructions contained in this service manual.

Place for description

of type and size of

the pump.

Meganorm

This manual has been prepared to inform the end user

about the construction and operation of our pumps,

describing the adequate procedures for handling and

maintenance. We recommend that this manual should be

handled by the maintenance supervision.

This equipment should be used in the operational

conditions for which it was selected as to: flow rate, total

head, speed, voltage, frequency, and temperature of

pumped liquid

Place for description

of manufacturer data.

Place for order number

Fig. 1 –Nameplate

For requests about the product, or when ordering spare

parts, please indicate the type of pump and the Production

Order nº (serial nº). This information can be obtained from

the nameplate on the actual pump. If the nameplate is not

available, the PO nº is engraved in low relief on the suction

flange, and on the discharge flange you may find the

Attention

instructions and recommendations. Its careful reading

is an obligation before installation, electrical

connections, first starting and maintenance.

: This manual contains very important

impeller diameter.

Contents

Denomination Chapter Denomination Chapter

Application

Design

Designation

Operating data

Introduction

Technical data

Transportation

Preservation and storage of idle pumps

1

2

3

4

5

6

7

8

Installation

Operation

Maintenance

Explode view/Parts list

Recommended spare parts

Special recommendations

Pressure limit x Maximum temperature

Wearing areas maintenance

9

10

11

12

13

14

15

16

2

Page 3

Meganorm

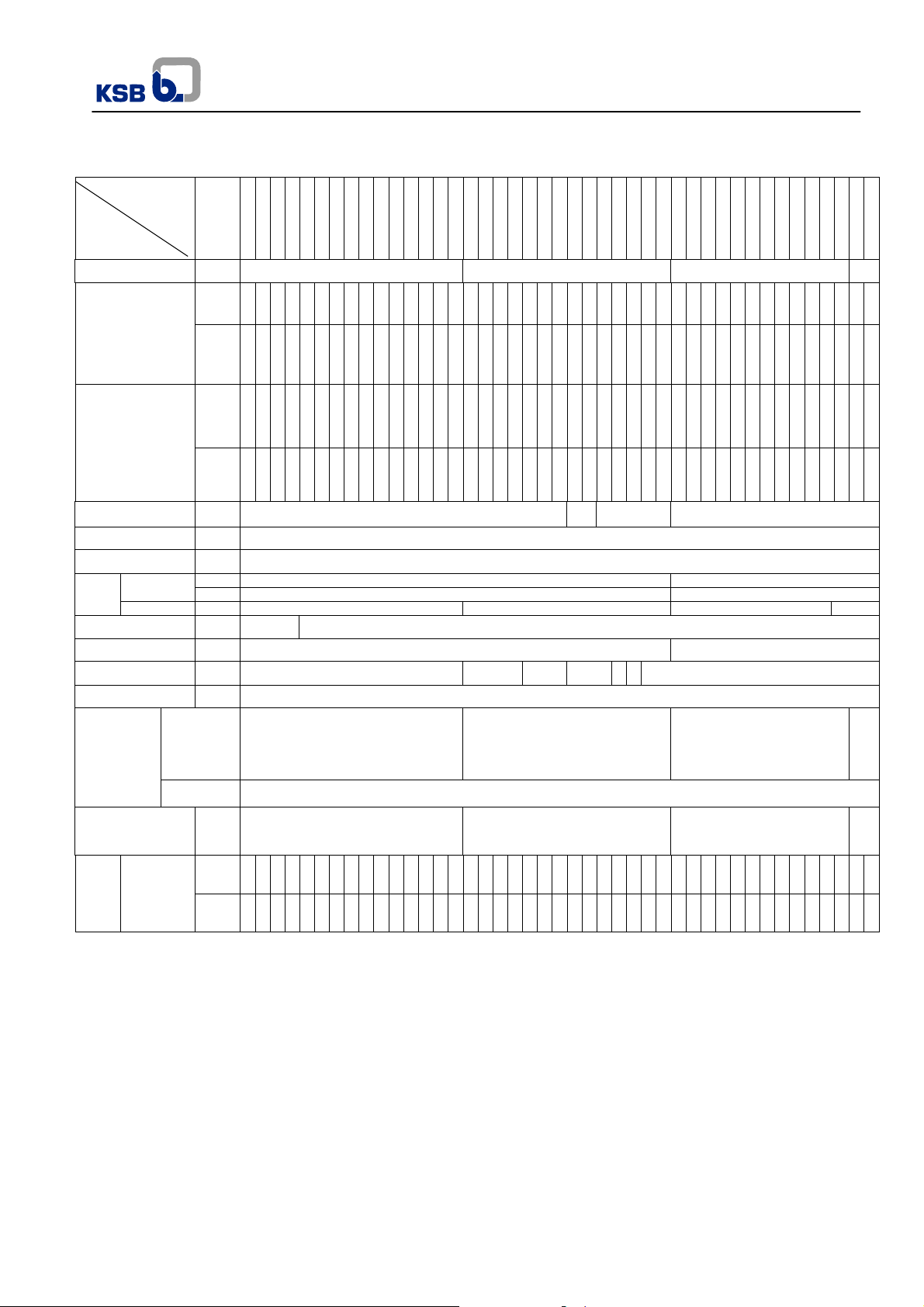

6. Technical data

Pump sizes

Units.

100-250 *

100-315

100-400 e

125-200 *

125-250

125-315

125-400 e

150-200

150-250

100-160

100-200 d

65-315

80-315

40-315

50-315

80-200 d

65-250 d

50-125

32-160

32-200.1 d

32-200 d

40-125

32-125.1

32-125

Technical data

Bearing bracket A 30 A 40 A 50 A60

25-150

32-160.1

25-200 d

40-160

40-200 d

50-160

32-250 d

50-200 d

80-160

65-160

65-200 d

50-250 d

40-250 d

65-125

32-250.1 d

80-250 d

80-400 e

150-315

150-400 e

mm

Width of impeller

passage

WR2 with water

Max. rot. speed rpm 3500 1750 3500 1750

Max. suction pressure bar/(psi) 10 / (145) d e

Max. discharge pressure

x Temp.

Packing

Shaft

Seal

Mech. seal f inch 1 3/8 1 3/4 2 3/8 2 3/4

Axial thrust balance Min./max. flow - 0.1 Qopt / 1.1 Qopt 0.15 Qopt / 1.1 Qopt

Flanges - ANSI B 16.1 125 Lb FF 250 Lb FF

Rotation direction - Clockwise, seen from driver end

Bearings

inch

kg m²

lb.ft

bar/(psi) See table 7

mm 10 12,5

inch 3/8 1/2

Ball bearings 2x

6 7 9 5 5 6 6

5,5

3/16

4/16

0.0214

0.0591

2

0.127

0.350

c

4/16

6/16

0.0140

0.0142

0.083

0.084

14

12 9 20

3/16

3/16

4/16

4/16

9/16

8/16

6/16

13/16

0.0224

0.0238

0.0760

0.0786

0.0144

0.0336

0.0640

0.0189

0.132

0.141

0.451

0.466

0.085

0.199

0.379

0.112

6306 C 3 6308 C 3 6310 C 3

16

11

7/16 1 5/16

10/16

0.0394

0.0750

0.233

0.445

8 8 8

25

0.0263

0.1800

0.156

1.068

12

21

17

5/16

5/16

8/16

13/16

11/16

0.1820

0.1880

0.1920

0.0521

0.0985

1.079

1.115

1.139

0.309

0.584

By bored hole on impeller

125LbFF

9

31

6/16

1 4/16

0.0641

0.4396

0.380

2.608

y y y yy

9

13

6/16

8/16

0.4800

0.2232

2.847

1.324

23

19

14/16

12/16

0.1568

0.2904

0.930

1.722

36

32

1 7/16

1 4/16

0.1040

0.1800

0.617

1.067

13

18

13

27

23

8/16

8/16

10/16

14/16

1 1/16

0.5120

0.5696

1.2788

0.3172

0.6100

3.037

3.379

7.587

1.881

3.619

ANSI B 16.1 125 Lb FF

17

40

11/16

1 9/16

1.3832

0.2230

8.206

1.323

37

30

1 7/16

1 3/16 1 2 5/16

0.4100

0.7740

2.432

4.592

25

59

1.6912

0.2918

1.731

10.033

48

39

1 9/16

1 14/16

0.4656

0.8680

2.762

5.149

6312 C 3

33

1 5/16

1.8600

11.035

Drive (P/n value)

Shaft SAE 1045

Weight Cast iron

Lubrication

HP/rpm 0.0176 0.0458 0.100

kg

32

40

34

35

34

34

42

44

38

38

49

40

42

47

49

68

68

73

lb

70

88

75

77

75

75

92

97

84

84

88

92

108

104

108

150

150

161

72

159

70

154

Oil

61

134

89

196

104

229

108

238

89

196

92

202

106

233

105

231

108

238

126

278

132

291

162

357

132

291

142

313

178

392

136

300

157

346

156

344

Table 1 y125Lb FF yy250 Lb FF

*For sizes 100-250 and 125-200 max. speed = 2.900 rpm.

cFor size 25-200 by bored holes on impeller, for sizes 25-150; 32-125.1 and 32-12 5 without axial thrust balance.

deThe maximum suction pressure for pumps with mechanical seal is 5 bar (73 psi), except for sizes d in 3500 rpm

and e in 1750 rpm which are limited by sum of inlet pressure and work pressure not exceeding 10 bar (145 psi).

fMaterials: stationary face in ceramic, rotating face in carbon, seals in Buna-N.

Not recommended for liquids containing solids.

Other materials upon request.

193

425

183

403

192

423

3

0.158

246

542

280

617

Page 4

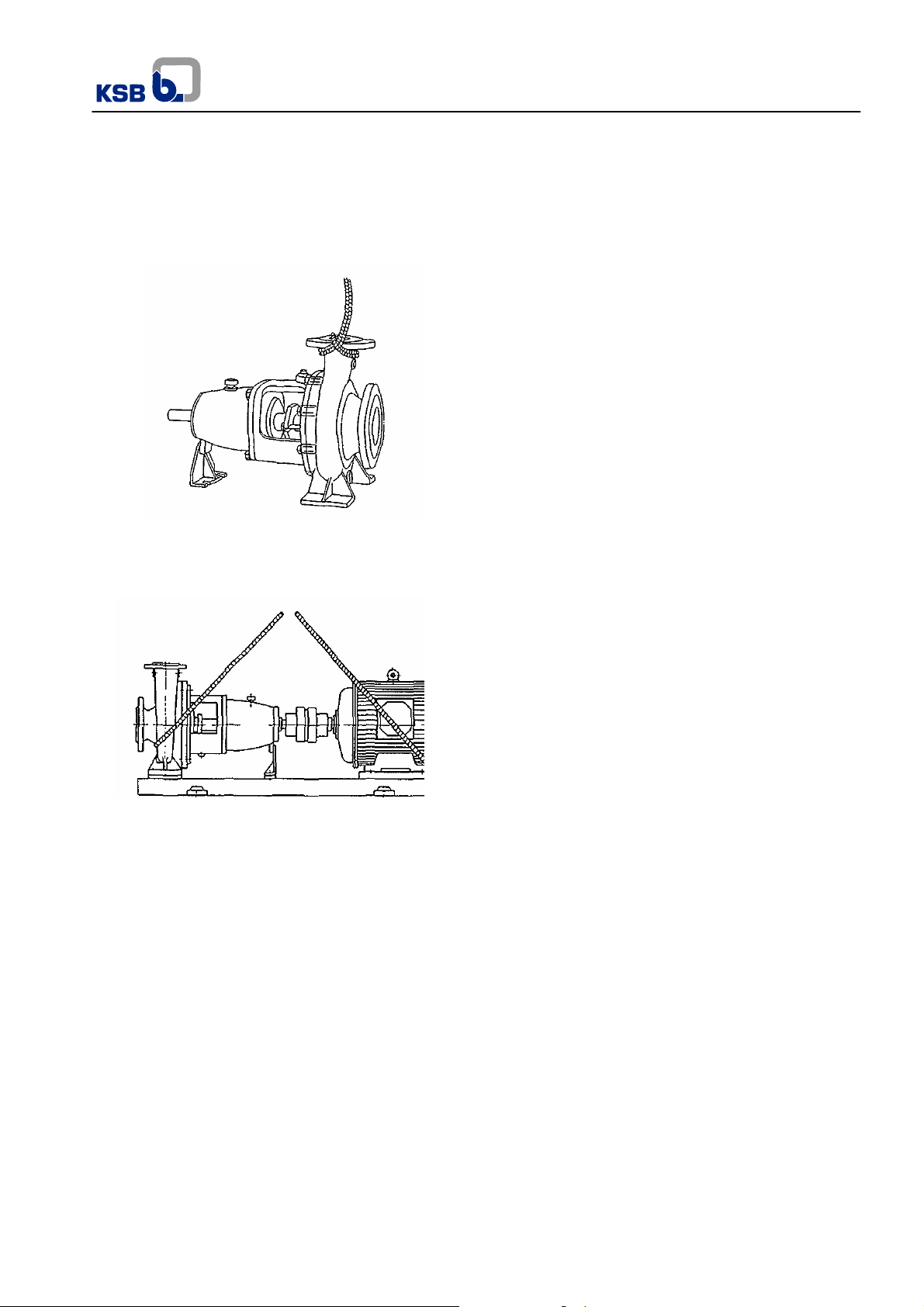

7. Transportation

Skilled, trained personnel should perform the transportation

of the pump-motor assembly or bare shaft pump. Even so,

safety regulations should be observed. On lifting, the motor

lug should be used to carry the motor only and never the

pump-motor assembly.

Fig. 2 – Transportation of the pump through the discharge

flange.

Fig. 3 – Transportation of the pump-motor assembly

Be sure that the coupling guard and foundation bolts

NOTE:

are not lost or damaged during transportation.

8. Preservation and storage of idle

pumps

Following procedures of preservation and storage are made

by KSB and its Dealer Network and protect the equipm ent

up to 6 months in an indoor environment. It is client

responsibility to keep these procedures after receiving the

pump.

When the pump is not subjected to a performance test after

its sale, the areas in contact with the pumped liquid which

are not painted (i.e. stuffing box housing, wear rings, flange

sealing areas, etc), receive an application of RUST ILO DW301 by brush.

When the pump is equipped with packing and is subjected to

a performance test, it is drained after the test without

Meganorm

disassembling it, and then filled up with RUSTILO DW-

301 rotating its rotor assembly in order to improve

RUSTILO application. After this operation, the pump

should be drained again.

Exposed shaft areas (i.e. shaft end, area between the

gland cover and the bearing bracket) receive a brush

application of TECTYL 506.

On oil lubricated bearing brackets, the bearings receive

a layer of MOBILARMA 524 by spray.

The pump must be protected against material damage,

humidity, dust and aggressive environment i n an i ndoor

place.

8.1 Additional procedures of preservation and

storage of idle pumps

- Pumps stored for periods exceeding one year

should be serviced every 12 months. They should

be disassembled, cleaned and the whole

preservation process described below should be

repeated.

- PACKING equipped pumps should have their

packing removed before storage.

- MECHANICAL SEALS should be cleaned by

compressed air. No other liquid or material

should be applied to them in order to prevent

damage to the secondary sealings as to o-ring

gaskets.

- All connections as inlets for liquids from external

sources, priming, draining, flushing and cooling

should be closed. SUCTION AND DISCHARGE

FLANGES SHOULD BE COVERED to prevent the

entry of strange bodies.

- Assembled pumps waiting to be installed or to start

operation should be turned manually every 15

days. If it is difficult to move them by hand, use a

box spanner, protecting the shaft surface at the

point of application.

- Before conservation liquids application, areas

should be washed with gasoline or kerosene until

they are completely cleaned.

4

Page 5

Characteristics of the protecting liquids used for pump preservation purposes:

Protecting liquid

Thickness of the applied

layer (μm)

Drying time Removal Manufacturer

Meganorm

TECTIL 506 from 80 to 100 ½ up to 1 hour

RUSTILO DW 301 from 6 to 10 1 up to 2 hours Gasoline, benzene Castrol

MOBILARMA 524

≤ 6

Table 2 – Protecting liquids

9. Installation

Our pumps should be installed, leveled and aligned b y skill ed

and trained personnel. When this service is done incorrectly,

it will originate operational troubles, premature wear and

damage beyond repair.

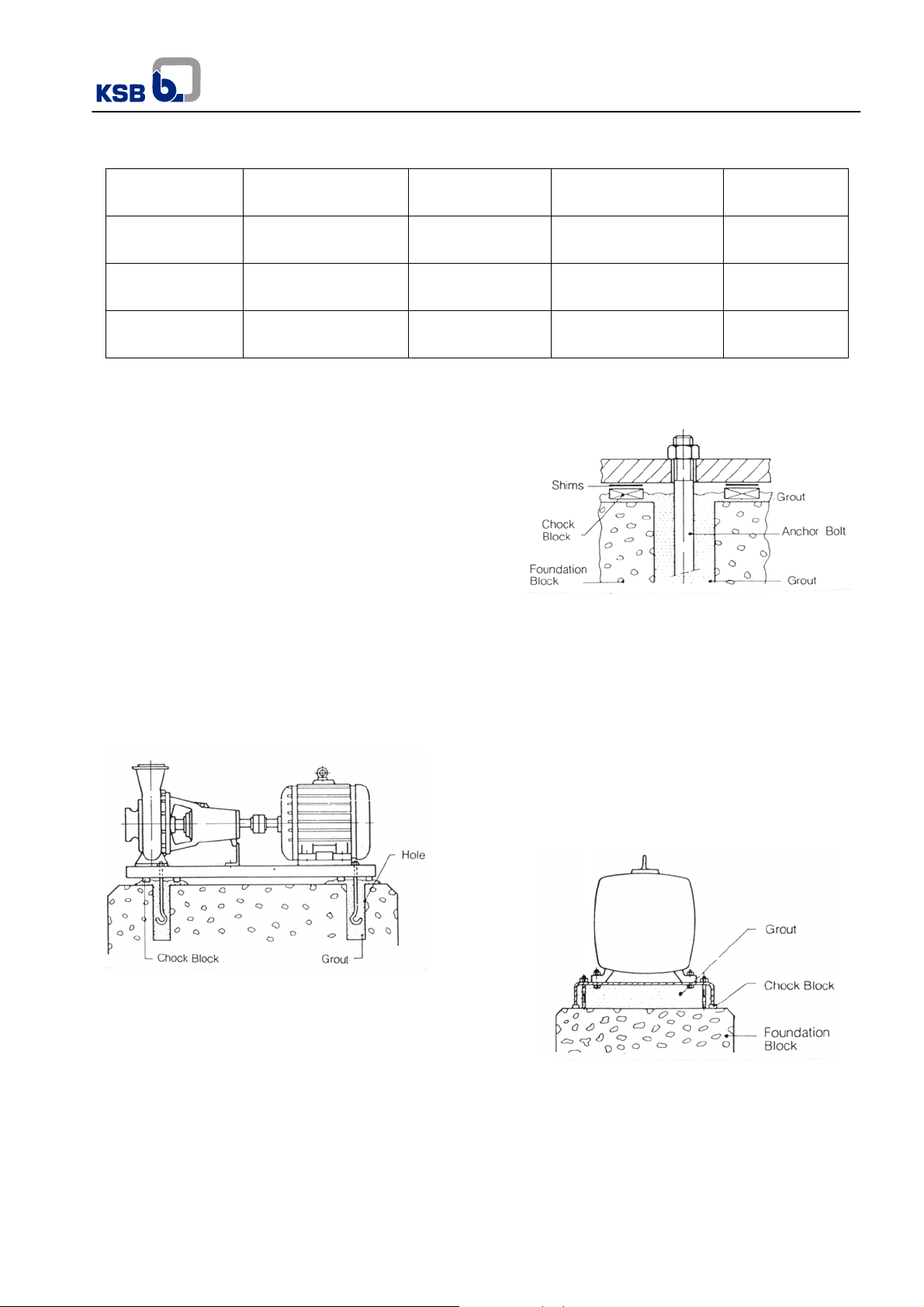

9.1 Base grouting

Place the foundation bolts in the holes or slots of the

foundation block according to boring design as shown on the

foundation drawing.

Between the base and the foundation block and beside the

foundation bolts, metallic chocks of the same height should

be fixed with grout together with the foundation bolts, to

serve as support for the base.

In order to achieve a perfect adherence to the grout, the

chock blocks and foundation bolts should be free of any

grease or oil residues. After the grout set is compl eted, place

the base on the foundation block (non-shrinking mortar is

highly recommended). Please see Fig. 4.

does not dry Not necessary Mobil Oil

.

Note: After leveling the base and before concrete fulfill, the

motor-pump set must be pre-aligned according to the

instructions of item 9.4.

9.3 Grouting

In order to get a good, vibration-free operation, the pump

base plate must be filled with grout.

Grout should be made of specific compounds available in the

civil construction market, which prevent shrinkage through

grout setting process as well as full base filling and does not

allow blanks or gaps. Please see Fig. 6a

Gasoline, benzene

diesel Oil

Fig. 5 – Base leveling

Brascola

Fig. 4 – Base grouting

9.2 Base leveling

Check if the base plate is equally resting on its chock blocks,

if it is correctly set, place and tighten uniformly the nuts on

the foundation bolts. With the help of a precision lev el, check

the leveling of the base longitudinally and transversally.

If the base plate is out of level, loosen the foundation bolt

nuts and insert shims, as necessary, between the metallic

chock block and the base, in order to correct the leveling.

Please see fig.5.

Fig. 6a-Base fulfill with grout

9.3.1 Execution with adjustment screws

When adjustment screws are used under motor side

surrounding areas should be free of concrete. Protecting

tubes should be used, in order permit future adjustments to

align the equipments. See fig.6b.

5

Page 6

Fig. 6b – Grouting inside the baseplates of adjusting screw

type

9.4 Coupling alignment

The useful life of the rotating assembly and its operation free

of irregular vibrations will rely on the perfect alignment

between the pump and the driver.

The alignment performed at the factory must be rechecked

due to the fact that during transportation and handling, the

motor-pump assembly is subjected to deformations, which

may affect the initial alignment.

After the complete set of the grout, perform the alignment, if

possible, with the suction and discharge pipe lines already

connected.

This alignment should be performed with the help of a dial

indicator for the control of the radial and axial displacements.

Fix the button of the instrument to the periphery of on e the

coupling halves, adjust the position of the feeler

perpendicular to the periphery of the other half of the

coupling. Move the dial to zero and move manually the

coupling half in which the instrument button is fixed, making

the dial complete a 360 degrees turn. Please see Fig.7.

The same procedure should be performed to control the axia l

displacement. Please see Fig.8.

Fig. 7 Fig.8

Radial control Axial control

To correct the alignment, loosen the driver bolts an d move

driver laterally or insert shims to adjust height as required.

Axial and radial alignments should remain within a tolerance

of 0.1 mm with the pump and driver set screws tighten

securely.

If there is no dial indicator available, use a straight edge

placed across the two rims of the sleeve coupling. To control

Meganorm

axially use a feeler gauge. Please see Fig. 9. Observe the

sleeve coupling hub clearance specified by manufacturer.

Fig. 9 – Alignment with straight edge and feeler gauge

9.4.1 Motors without adjustment bolts

For the alignment correction, loosen the bolts from the dri ve

replacing them laterally, or insert shims to correct the height

as required.

9.4.2 Motors with adjustment bolts

To realign the coupling, first loose the four dr ive bolts, as well

as the lock nuts. Turn the adjustment bolt by hand or with a

tool until the coupling alignment is correct. Retighten the bolts

and respective nuts.

9.5 Suction pipeline – Recommendations

To install the suction piping follow these instructions:

a) Connect the suction piping to the pump only after the

complete hardening of the grout in the base plate.

b) The suction piping should be as straight and short as

possible – reducing pressure losses - and totally air tight,

preventing any air leaks.

c) In order to be free of air pockets, the horizontal section of

the suction piping, when negative, should be installed with

gradual rise slope. When positive, the horizontal section

of the pipeline should be installed with a gradual rise

slope to the suction tank.

d) The nominal diameter of the pump suction flange does not

determine the suction pipe nominal diameter. To calculate

the ideal diameter as a reference, the liquid velocity ca n

be defined between 3.2 ft/s and 6.5 ft/s (1 and 2 m/s).

e) If it were necessary to use a reduction, it should be

eccentric, mounted with its taper facing downwards, so

that the reduction upper generatrix stays in a horizontal

position coincident with the pump generatrix, so as to

prevent air pockets.

6

Page 7

f) Curves and accessories, when needed should be

designed and installed reducing pressure losses to a

minimum, i.e. always prefer long or medium radius

curves.

g) The suction line flange should fit to the pump suction

flange without any stress or tension and without applying

any kind of force to the casing. The pump should never

be an anchor point for the suction pipeline. If this

condition is not observed a misalignment may happen,

originating cracks on pump parts and/or other severe

damages.

h) On installations equipped with foot valve, observe that the

free passage area should be 1.5 times the cross sectional

area of the suction pipeline. Normally coupled to the foot

valve there should be a suction strainer with a free

passage area 3 to 4 times larger than the cross section al

area of the suction pipeline.

i) When the liquid being pumped has large temperature

variations, expansion joints should be installed preventing

the effects of contractions and expansions of the suction

pipeline on the pump.

j) With positive suction, it is advisable to install an inlet

valve to close the flow to the pump when necessary.

During the pump operation it should stay totall y open. A

suction with a common header for several pumps should

have an inlet valve for each pump and the connection

between the header and each suction line should be

made with line angle changes less than 45 degrees. In all

these applications of gate valves, the valve stems should

be directed either horizontally or vertically downwards.

k) To prevent turbulence, leakage of air, sand or mud at the

pump suction, all recommendations of the HYDRAULIC

INSTITUTE referred to the these types of installation

should be strictly observed.

l) Even if the coupling alignment has been checked before

tightening, it has to be repeated after the final tightening

of the suction pipeline.

m) To facilitate the mounting of the suction pip eline and the

fitting of the parts, install as necessary, flexible joints of

the following types: Dresser, common or special with tie

bolts.

Meganorm

Fig.11 Positive suction

9.6 Discharge pipeline – Recommendations

To install the discharge pipeline, please follow the instructions

below:

a) If the overpressures caused by the returning of the liquid

in long pipe lines, exceed the limits specified for the line

and the pump, water hammer control devices should be

installed on the discharge pipe line.

b) When the diameters of the pump and pipeline flanges are

different, the connections should be done through a

concentric reduction.

c) On the points where it is necessary to bleed the air in the

pipeline, vent valves should be installed.

d) Install a discharge valve, if possible immediately after the

discharge nozzle of the pump in order to pr operly control

the flow rate and pressure or to prevent driver overloads.

e) When a non-return valve is installed, it should be mounted

between the pump and the discharge valve, preva iling t his

condition over item D.

f) Tie mounting joints should be installed to absorb the

system reaction forces, originated on the applied loads.

g) Safety valves, pressure relief devices and other

operational valves not included up to now, should be

installed as necessary for adequate operation of the

pipeline.

h) The recommendations for the suction pipeline described

on items A, B, F, G are also valid for the discharge

pipeline.

Fig.10 – Negative suction

7

Page 8

9.7 Auxiliary piping and connections

Fig. 12 – Auxiliary piping and connections

Dimension – NPT

Thread Connection Designation

A30 A40 A50 A60

1M.1 Manometer

1M.2 Manometer

3M

6B.1 Drain

8B Dripping

6B.2 Base drain

13D

13B

9.8 Coupling guard

For increased safety in operation, coupling g uards should be

installed. They are made of steel or brass and fixed to the

base.

Check that the coupling guard is not in touch with moving

parts.

Vacuum pressure

gauge

Lubrication

Drain

Table 3

1/4 1/4 1/4 1/4

1/4 1/4 1/4 1/4

1/4 1/4 1/4 1/4

3/8 3/8 1/2 1/2

1/2 1/2 3/4 3/4

1 1 1 1

Ø 20 mm

1/4 1/4 1/4 1/2

9.9 Instruments

It is recommended to use pressure gage and vacuum meter

on discharge and suction pipes respectively for a better

operation control.

Meganorm

Their ranges must correspond to 150% of highest pumping

pressure.

Instruments must be equipped with valves.

When pumping chemicals and agressive liquids, the

instruments and their valves should be made of proper

materials.

In order to obtain a longer useful life the valves should be

open only to read the instruments and then closed again.

10. Operation

10.1 First starting procedure

The following items must be provided for pump first startup:

a) Pump and its driver must be securely fastened to the base

plate;

b) Fix firmly the suction and discharge pipelines;

c) Connect and run auxiliary pipelines and connections (if

any).

d) Wiring should be done upon assuring that all motor

thermal overload protections are securely and adequately

connected and set.

e) Check bearings for cleanliness and dampness. Fill

bearing bracket with oil in quantity and quality as specified

in item 11.

f) Check the rotation direction of driver without coupling the

pump to avoid dry operation.

g) Manually check for the free running of the moving parts.

h) Check that the proper coupling alignment according to

item 9.4 has been performed.

i) Mount coupling guard (if any).

j) Prime p ump by filling it and suction pipeline with water or

with the liquid to be pumped, bleeding internal air

simultaneously.

k) Check that the gland cover nuts are just fitted, without

tightening them (pumps with packing).

l) Fully open suction valve (if any) and close discharge

valve.

10.2 Immediate steps after first start-up

Once the pump has started and is already in normal

operation, please follow the instructions below:

a) Adjust pump to its operation point (pressure and flo w) by

opening slowly the discharge valve shortly after pump

drive has reached its nominal speed.

8

Page 9

b) Motor current consumption (amperage) must be controlled

as well as network voltage value.

c) Assure that suction pressure value corresponds to the

designed one.

d) Assure that pump runs vibration-free and without unusual

noises. Vibration criteria in accordance to Hydraulic

Institute.

e) Check bearing temperature that may reach 122ºF (50ºC)

over ambient temperature. However the sum of bearing

temperature and ambient temperature should not exceed

197ºF (90ºC).

f) Adjust the packing by tightening gland cov er nuts ab out 1/6

turn. Like any new packing, it is required a certain period to

set. The new packing should be checked during the first 5

to 8 hours of operation and in the event of leakage in

excess, the gland cover nuts should be tightene d about 1/6

turn again. During normal operation, packing should drip.

When packing reach the set stage, a weekly inspection

should be enough. The procedure mentione d above shoul d

be practiced every 15 minutes over the first 2 hours of

operation. If all tests pass, new checking should be carried

out every hour, until the first 5 to 8 running hours (p umps

with packing).

g) At the operation beginning, the pum p with mechanical seal

may have a little leakage through that. This leakage must

stop after sealing faces accomodation.

10.3 Operation supervision

Depending on the availability of personal and on the

importance of the pump, we recommend the following

supervision. In case of any irregularity, the maintenance

supervisor should be called immediately.

10.3.1 Weekly supervision

Check:

a) Operating point of the pump.

b) Electric motor consumed current and network voltage.

c) Suction pressure.

d) Vibrations and irregular noises.

e) Oil level.

f) Packing leakage.

10.3.2 Monthly supervision

Check:

a) Oil change interval. Consult chapter 11.2.

b) Bearings temperature.

Meganorm

10.3.3 Semestral supervision

Check:

a) Fixing bolts on pump, driver and base.

b) Alignment of the motor-pump assembly.

c) Coupling lubrication (if an y).

d) Replace packing if necessary (if any).

e) Check the mechanical seal (if any), if their sealing

faces are worn-out, scratched or broken. Replace it if

necessary.

10.3.4 Annual supervision

a) Disassemble the pump for maintenance. After

cleaning, inspect condition of ball and roller bearings

(very carefully), radial seal rings, gaskets, o-rings,

impellers, internal areas of the volute casing (check

also thickness), wear areas and coupling.

10.4 Shutdown procedure

Follow in sequence these instructions:

a) Shut off pump discharge valve.

b) Turn off the driver and observe the gradual and

smooth stop of the rotating assembly.

c) Close the suction valve (if any).

d) Close the auxiliary pipelines (if there is no restriction).

11. Maintenance

11.1 Bearing maintenance

Maintenance purpose here is to increase bearing system

useful life as long as possible. While pump is operating,

the maintenance consists in controlling the ball bearings

temperature and the bearing bracket oil level.

The pumps are delivered from the factory without oil

in the bearing bracket.

NOTE: Table of oil quantity to fill KSB MEGANORM

pumps bearing bracket.

Bearing Bracket Oil quantity - ml (in

A 30 100 (6.10)

A 40 170 (10.37)

A 50 200 (12.2)

A 60 480 (29.30)

Table 4

3

)

9

Page 10

11.2 Lubrication Intervals and oil specification

The first oil change should be made after the first 200 or 300

working hours. The next oil change should be made after 1500

or 2000 working hours. This will avoid dirt particles, which have

not been eliminated by cleaning, to contaminate oil and

damage bearings.

Then, oil change should be made every 8000 effective

working hours or at least once a year (the one that

becomes first). Bearings should be washed every 2

years (as a minimum ).

Manufacturer UP to 3,000 rpm

Atlantic Eureka 68 Eureka 46

Castrol HYS PIN AWS 68 HYS PIN AWS 46

Esso Turbine Oil 68 Turbine Oil 46

Mobil Oil DTE 26 DET 24

Ipiranga IPITUR AW 68 IPITUR AW 46

Petrobrás Marbrax TR 68 Marbrax TR 46

Shell Tellus 68 Tellus 46

Texaco Regal R&O 68 Regal R&O 46

Promax

Bardhal

11.3 Packing maintenance

If the packing has already been pressed an equivalent of one

packing ring thickness and even so the leaking is excessive, it

will need maintenance according to the following instructions:

- Stop the pump;

- Loosen the gland cover and remove it. The removal of

gland cover is easy due to its split design. To remov e it,

just push it in the direction of the bearing cover, and then

pull half of the gland cover to the right and the other half to

the left.

- Remove with the help of a flexible rod all the packing rings

as well as the lantern ring.

- Clean the stuffing box chamber.

- Check the condition of the shaft protecting sleeve. If it is

rough or has grooves that could damage the pack ing, the

sleeve may be remachined on its diameter up to a

maximum of 1 mm, or replaced by a new one.

- Cut new packing rings, if possible with oblique edges (see

Fig. 13). To facilitate this cutting operation a very simple

device may be constructed as shown in Fig. 14.

Maxlub MA 20 Maxlub MA 15

Table 5: Oil specifications

Exceeding 3,000

rpm

Meganorm

Fig. 13 – Slanted cut of the packing

Fig. 14 – Packing rings cutting device

- Lubricate the inner diameter of each packing ring

with grease. Lubricate the outer diameters of the

lantern ring, of the gland bush and of the gland r ing

(if any) with Molykote G;

- Proceed to the assembly in the inverse sequence of

the disassembly, introducing each part into the

stuffing box chamber with the help of the gland

cover. The packing rings should be mounted with

their ends positioned 90 degrees from each other

(see Fig. 15).

Fig. 15 – Ring position with ends positioned 90 degrees

from each other

After all parts have been installed in the stuffing box

chamber, a gap of 0.12" (3 mm) should remain as a gui de

for the gland cover.

11.4 Dismantling instructions

The numbers indicated between parenthesis just after the

name of each part refers to the part list and to the

exploded view drawing (Item 12).

Due to its modern project KSB Meganorm pump offers

several maintenance advantages. The whole set can be

dismantled to the back; bearing bracket, pressure cover

and impeller. The spiral casing (102) and the suction and

discharge piping remain in their place. In case of

installation with spacer coupling, the driver remains also

in its place, during the pump maintenance.

10

Page 11

11.4.1 Dismantling sequence of pump

1) Close the suction and pressure valves. Drain the

pump, taking the threaded plug off. (903.3).

2) Close the valve and disconnect the auxiliary pipi ng (if

any).

3) Remove the coupling cover.

4) Remove the oil level pointer (639) and the threaded

plug (903.6) and drain the oil from the bearing bracket.

5) If the coupling has a spacer, remove it; if it doesn’t

have one, disconnect the sleeve removing the driver.

6) Remove the coupling from the pump shaft, loosening

before the coupling fixing Allen bolt.

7) Loosen the bolts that fix the support foot to the base

plate.

8) Loosen the bolts (901.2) or bolts (901.4) when

necessary.

9) Remove all the set by fastening uniformly the

extracting bolts.

10) Support the overhang side of the set with a piece of

wooden. Lock the shaft using a device in the region of

coupling sleeve key (940.2)

11) Loosen and extract the impeller bolt (906), the flat

gasket (400.4) and the circlip (932).

12) Extract the impeller (230), the key (940.1) and the

gasket (400.1).

13) Loosen the bolts (901.4). Loosen the nuts ( 920.2) and

extract the gland cover (452) (if any). Extract the

discharge cover (163) and the flat gasket (400.2).

Extract the shaft protecting sleeve (524) and the seal

components (433) (if any).

14) Extract the thrower (507) and the key (940.2).

15) Loosen the bolt (901.6) and release the support foot

(183).

16) Loosen the bolts (901.5), extract the bearing cover

(360) and the flat gasket (400.3). Take care not to

damage the radial shaft seal rings (421) which come

outside with the bearing cover.

17) With a piece of lead, strike against the shaft (210)

suction side, in order to make the external surfaces of

the radial ball bearings (321) run inside of the b earing

bracket (330) until the complete extracting.

Meganorm

18a) Extract the parts of the sealing chamber, gland

packing (461) and lantern ring (458). (Pumps with

packing).

18b) Extract the stationary face of mechanical seal (433)

from the pressure cover (163) (pumps with

mechanical seal).

After these instructions are completed, the parts will be

available for analysis and maintenance.

11.4.2 Dismantling sequence of the pump with

mechanical seal and seal gland

Loosen the auxiliary pipings and the s eal gland. Follow

the instructions mentioned in the O&M booklet of the

Mechanical Seal Manufacturer, which will be attached to

the pump, in case of seal supply.

11.5 Assembly instructions

All the parts should be cleaned and deburred befor e the

assembling.

11.5.1 Unauthorized modification and manufacture

of spare parts

Modifications or alterations of the equipment supplied

are only permitted after consultation with the

manufacturer and to the extent permitted by the

manufacturer. Original spare parts and accessories

authorized by the manufacturer ensure safety. The use

of other parts can invalidate any liability of the

manufacturer for consequential damage.

11.5.2 Assembling sequence of the pump

Before the assembly at the shaft, the bearings should be

heated at a furnace or with an oil bath up to a maximum

temperature from 176ºF (80ºC) to 194ºF (90ºC) over the

shaft temperature during 30 minutes, observing the

maximum limit of 257ºF (125ºC).

1) Assemble the radial ball bearings (321) at the shaft.

With a piece of lead, assemble the shaft at the

bearing bracket, from the suction side, making the

external track of the bearing to slide inside the

bearing bracket until it reaches equal

measurements at the both sides of the bearing

bracket in order to allow grooving of the bearing

covers.

2) Assemble the radial shaft seal ring (421) at the

bearing covers (360). Assemble the covers carefully

not to damage the radial shaft seal rings with the

flat gaskets (400.3).

3) Fasten the bolts (901.5). Fit the support foot (183)

and fasten the bolt (901.6) with its washer (554.3).

4) Support the overhang side of the bearing bracket

(330) with a piece of wooden. Introduce the

centrifugal ring at the shaft, without touching the

bearing cover.

11

Page 12

5a) Assemble the studs (902) at the pressure cover (163).

So, assemble the packing (461) at the sealing

chamber (pumps with packing).

5b) Assemble the stationary face of mechanical seal (433)

in the pressure cover (163) (pumps with mechanical

seal).

6a) Assemble the gland cover (452), leaning it against the

nuts (920.2) (pumps with packing).

6b) Assemble the mechanical seal components (433) on

the shaft protecting sleeve (524). Lubricate a l ittle with

oil (SAE 10 or SAE 20) or pure vaseline on the pieces

in contact with the mechanical seal (433) (pumps with

mechanical seal)

7) Assemble the shaft protecting sleeve (524) at the

shaft, having first greased its internal diameter with

Molykote G. Guide the flat gasket (400.2) at the

pressure cover; fit the discharge cover (163) at the

bearing bracket (330) and fix it with bolts (901.4)

(tighten them crossly and uniformly).

8) Assemble the flat gasket (400.1), the key (940.1), the

impeller (230) (grease its internal diameter with

Molykote G), the circlip (932), the flat gasket (400.4),

and the impeller bolt (906).

9) Assemble the key (940.2) at the shaft drive side, lock

the shaft with a device and tight firmly the impeller bolt

(906).

10) Introduce the whole set at the volute casing (102)

guiding the set through the diameter of the pressure

cover (163). Assemble the bolts (901.2) with the

washers (554.1), tightening them, crossly and

uniformly. Check manually if the rotor turn round free.

11.5.3 Pump assembly sequence with mechanical

seal with seal gland

Please see Mechanical Seal O&M Manual, which will be

attached to the pump's manual, in case of mechanical seal

supply.

Meganorm

12

Page 13

12. Exploded view / Part list

12.1 Pumps with packing

Meganorm

Pumps with mechanical seal

Impeller fixing detail

for size 25-150

Fig.16

Fig.17

13

Page 14

Meganorm

Part List

Designation Part nº

Volute casing 102 Shaft protecting sleeve 524

Discharge cover 163

Support foot 183

Shaft 210

Impeller 230

Radial ball bearing 321

Bearing bracket 330

Bearing cover 360

Flat gasket 400.1

Flat gasket 400.2

Flat gasket 400.3

Flat gasket 400.4

Flat gasket (1) 400.5

Radial shaft seal ring 421

Mechanical seal (4) 433

Gland cover (3) 452

Lantern ring (3) 458

Gland packing (3) 461

Casing wear ring 502.1

Impeller wear ring (2) 503

Thrower (3) 507

(1) Only applicable for 25-150

(2) Not applicable for 25-150, 32-125 and 32-125.1

(3) Not applicable for pumps with mechanical seal

(4) Not applicable for pumps with packing

Designation Part nº

Spacer disc (1) 551

Washer 554.1

Washer 554.3

Oil level pointer 639

Hexagon head bolt 901.2

Hexagon head bolt 901.4

Hexagon head bolt 901.5

Stud 901.6

Threaded plug (3) 902

Threaded plug 903.1

Threaded plug 903.2

Threaded plug 903.3

Threaded plug 903.6

Impeller screw 906

Nut 920.6

Nut (3) 920.2

Circlip 932

Key 940.1

Key 940.2

Nameplate 970

13. Recommended spare parts

Spare parts recommended for a continuos 2-year continuous service according to the DIN 24296 Standard.

Number of Pumps (including stand-by ones)

Part nº Designation

2 3 4 5 6 and 7 8 and 9

Quantity of Spare Parts

10 or

more

210 Shaft 1 1 1 2 2 2 20%

230 Impeller 1 1 1 2 2 2 20%

321 Bearing (pair) 1 1 2 2 2 3 25%

330 Bearing bracket - - - - - 1 2 units

421 Rad shaft seal ring (pair) 2 3 4 4 4 5 50%

433 Mechanical seal 1 1 2 2 2 3 25%

461 Gland packing (5 rings) 4 4 6 6 6 8 100%

502 Casing wear ring 2 2 2 3 3 4 50%

503 Impeller wear ring 2 2 2 3 3 4 50%

524 Shaft protecting sleeve 2 2 2 3 3 4 50%

Gasket repair set 4 6 8 8 9 12 150%

Table 6 – Recommended Spare Parts

14

Page 15

14. Special recommendations

14.1 Machining of the impeller external diameter

All impellers made of stainless steel have their vanes

adjusted (sharpened) at the outlet area of the liquid being

pumped, according to the illustration on fig.17, when the

impellers have been trimmed in their external diameter by

machining.

(0.12”)

Meganorm

14.2 Shaft run-out on the impeller region

Verify the shaft run-out. Arrange the bearing bracket

mounted with the shaft on vertical position and check

the run-out on the shaft end with a dial comparator

within the maximum limit of 0,05 mm (0,002”).

(0.787”)

Fig. 17 - Adjusting the Impeller Vanes

15. Pressure limit X Maximum temperature

Shaft sealing

Gland packing

Mechanical seal 194 90 10 / 145

Temperature

º F

-18,4 up to 149 - 28 up to 65 12 / 174

199 93 11 / 160

221 105 10 / 145

Temperature

º C

16. Wearing areas maintenance

Change the wear rings of volute casing and / or casing cove r

(if any) when they are wornout and the impeller in good

condition.

KSB and Dealer Network supply wear rings to repair or as

spare parts to be applied for KSB Meganorm pumps.

These wear rings are supplied with suitable tolerance of the

outside diameter and 2mm (0,05”) of extra material of the

inside diameter.

Note: KSB reserves the right to modify the information presented in this manual without prior notice.

ANSI B16.1 Flange

125 #

Pressure [ bar ] / [psi] Pressure [ bar ] / [psi]

Table 7

16.1 When the exchange mist be made

The wear ring exchange must be made when the

clearance between the impeller and the wear ring is

three times longer than the original clearance that is

0,3mm (0,01”).

ANSI B16.1 Flange

250 #

16 / 232

15

Page 16

KSB Bombas Hidráulicas SA

Rua José Rabello Portella, 400

Várzea Paulista SP 13220-540

Brasil http://www.ksb.com.br

Tel.: 11 4596 8500 Fax: 11 4596 8580

SAK – Serviço de Atendimento KSB

e-mail: gqualidade@ksb.com.br

Fax: 11 4596 8656

Meganorm

A2742.8E/8 09.03.2009

16

Loading...

Loading...