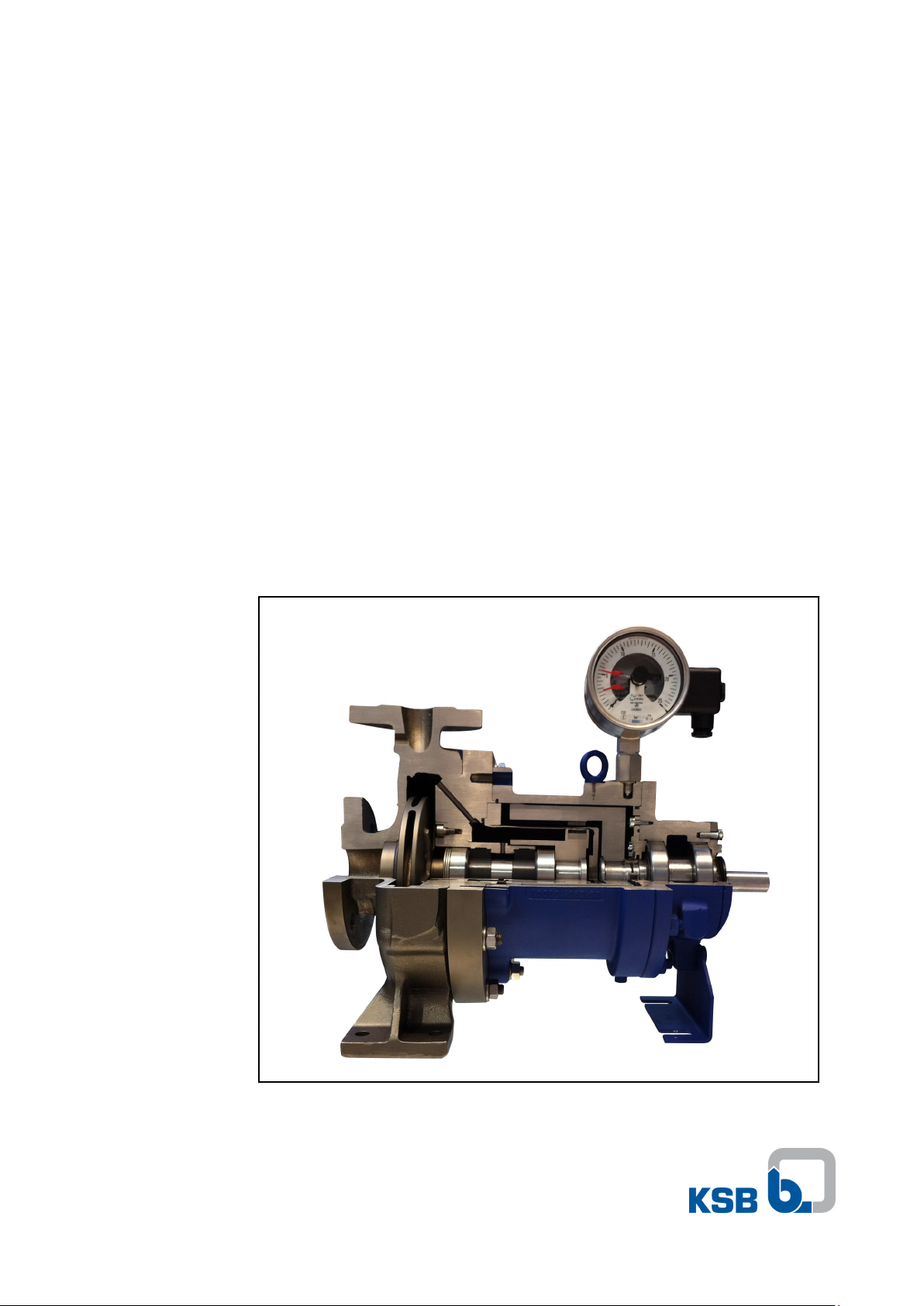

KSB Magnochem-Bloc, Magnochem Supplementary Operating Manual

Monitoring Systems

Magnochem

Magnochem-Bloc

Supplementary Operating

Manual

Legal information/Copyright

Supplementary Operating Manual Monitoring Systems

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced, edited or

processed for any other purpose, nor otherwise transmitted, published or made available to a third party without

the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB Aktiengesellschaft, Frankenthal 14.04.2014

Contents

Contents

1 General ..................................................................................................4

2 Temperature Monitoring Sensors ........................................................5

2.1 Temperature monitoring at the containment shroud via the PT100

resistance thermometer

2.2 Temperature monitoring at the containment shroud via a mineralinsulated thermocouple

3 Fill Level Monitoring Sensors .............................................................22

3.1 Monitoring for dry running/formation of a potentially explosive

atmosphere using a level transmitter

4 Leakage Monitor Sensors ...................................................................28

4.1 Leakage monitoring via level transmitter (Liquiphant) ............................... 28

4.2 Leakage monitoring via pressure switch ....................................................... 31

4.3 Leakage monitoring via contact pressure gauge ......................................... 33

4.4 Leakage monitoring via pressure transmitter ..............................................36

...................................................................................5

................................................................................. 14

........................................................... 22

5 Sensor Accessories ..............................................................................40

5.1 Processing of output signals from analog sensors ....................................... 40

5.2 Additional components in potentially explosive atmosphere ..................... 44

6 Related Documents ............................................................................47

6.1 Circuit diagram for PT100 resistance thermometer .....................................47

6.2 Circuit diagram for mineral-insulated thermocouple .................................. 48

Index ....................................................................................................49

Monitoring Systems

3 of 50

Manufacturer's product

literature

1 General

1 General

This supplementary operating manual accompanies the operating/installation

manual. All information contained in the operating/installation manual must be

observed.

Table 1: Relevant operating manuals

Type series Reference number of the operating/installation

manual

Magnochem 2739.8

Magnochem-Bloc 2749.8

For accessories and/or integrated machinery components observe the relevant

manufacturer's product literature.

4 of 50

Monitoring Systems

2 Temperature Monitoring Sensors

2 Temperature Monitoring Sensors

Temperature monitoring of containment shroud

Eddy currents are induced in the metal containment shroud walls of mag-drive

pumps. This causes the metal containment shroud to heat up. The heat loss

generated is dissipated by a secondary circulation flow. The source of the cooling

flow for the rotor space can be internal or external.

▪ With internal circulation, the cooling flow is bypassed from the main flow. The

main flow passes through the pump's hydraulic system.

▪ With external circulation, the cooling flow is supplied to the rotor space from the

outside via auxiliary connections.

Potentially explosive atmosphere

The cooling flow is sufficiently dimensioned for intended operation. The maximum

permissible surface temperature that is dictated by the temperature class to

EN13463-1 is not exceeded (temperature class and maximum permissible operating

temperature as specified in the data sheet). An impermissible rise in temperature can

occur at the containment shroud when the cooling flow is insufficient or fails

completely.

An insufficient cooling flow or failure of the cooling flow can be caused by the

following:

▪ Fluid properties

▪ Pressure too low

▪ Desynchronisation of magnetic coupling

The maximum surface temperature occurs at the containment shroud tube in the

magnetic coupling area. KSB offers the following measuring instruments to detect an

impermissible increase in temperature at the containment shroud:

▪ PT100 resistance thermometer

For design and operational reasons, the PT100 resistance thermometer cannot

detect the maximum surface temperature that occurs at the containment shroud.

It can monitor the operating status of the pump. A distinction is made between

the following operating statuses:

–

Intended operation: Temperature at containment shroud OK

– Failure: Temperature at containment shroud too high

▪ Mineral-insulated thermocouple

The mineral-insulated thermocouple can be used to monitor the temperature in

this area.

2.1 Temperature monitoring at the containment shroud via the PT100

resistance thermometer

2.1.1 Function

Resistance thermometers are temperature sensors that measure the change in

electrical resistance of metals with changing temperature. Resistance thermometers

use a very thin layer of platinum film on a ceramic substrate. The nominal resistance

of these measuring elements at 0 °C is 100 ohms.

Interpretation of readings

The nominal resistance of the PT100 resistance thermometer at 0 °C is 100 ohms.

Equation for calculating the resistance value at any temperature (T):

Temperature range: T = 0 - 850 °C

R (T) = 100+0.39083×T -5.775×10-5×T

2

Monitoring Systems

5 of 50

M16x1,5

SW17

SW19 (G

1

/4)

T = 80 °C

2 Temperature Monitoring Sensors

Sample calculation:

Measured temperature: T = 80 °C

R (T) = 100+0.39083×80 -5.775×10-5×80

2

R (T) = 130.8968 Ω

The PT100 resistance thermometer has a resistance of approximately 130.9 ohms at a

temperature of 80 °C.

T = 20 °C

Measured temperature: T = 20 °C

R (T) = 100+0.39083×20 -5.775×10-5×20

2

R (T) = 107.7935 Ω

The PT100 resistance thermometer has a resistance of approximately 107.8 ohms at a

temperature of 20 °C.

2.1.2 Technical data of PT100 resistance thermometer

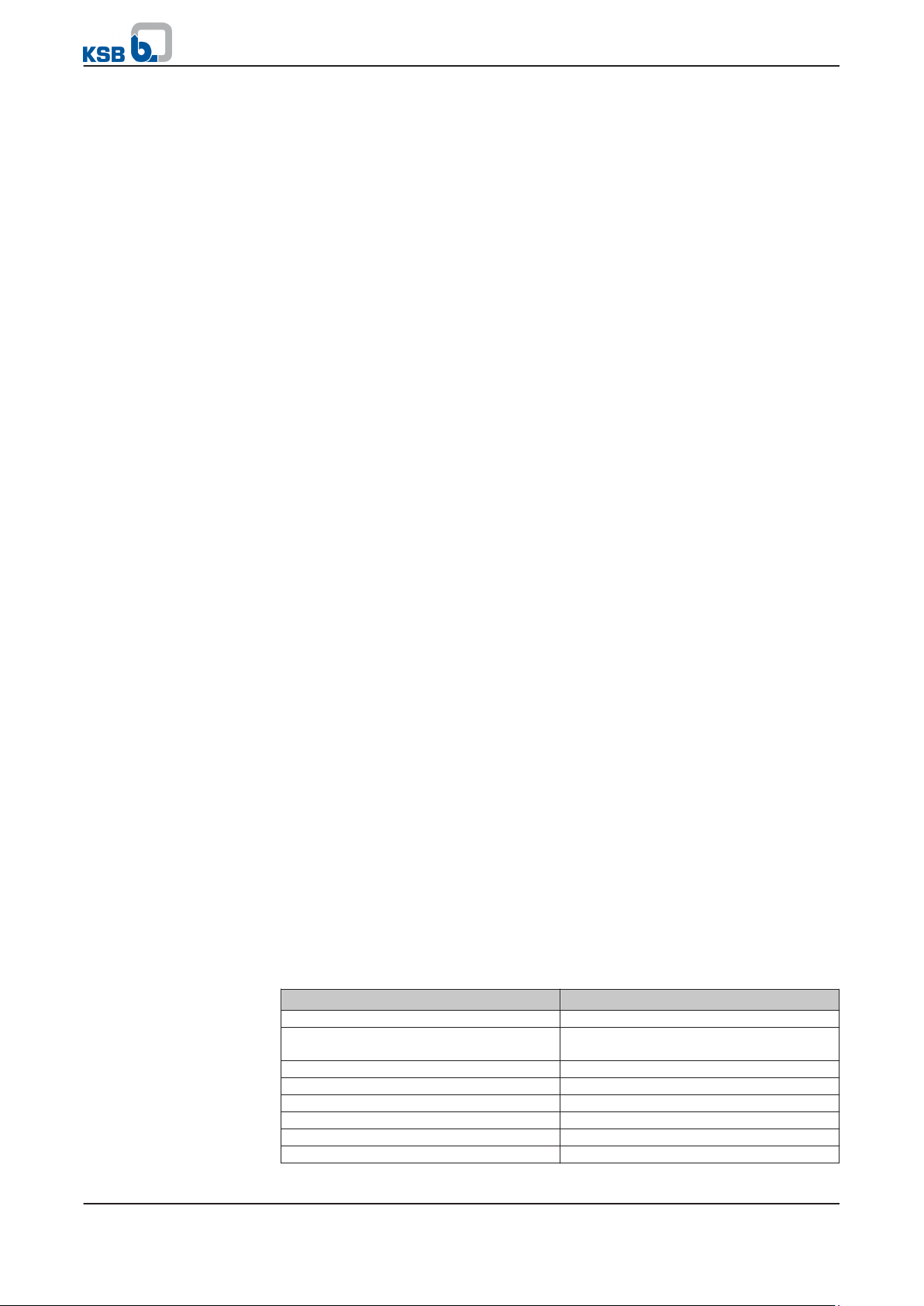

Table 2: Selection aid for resistance thermometer

Resistance thermometer

(type)

Pump design Technical measuring specifications

Leakage barrier Cable lengths Output signal 4

None with ≤ 30 m ≥ 30 m

- 20 mA

TR 55 ✘ - ✘ - Ksb-4,13,xx,02 - ✘ ✘ - Ksb-4,13,xx,01 ✘ ✘ ✘ ✘ ✘

PT100 (TR 55)

1)

For cable lengths up to 30 m

6 of 50

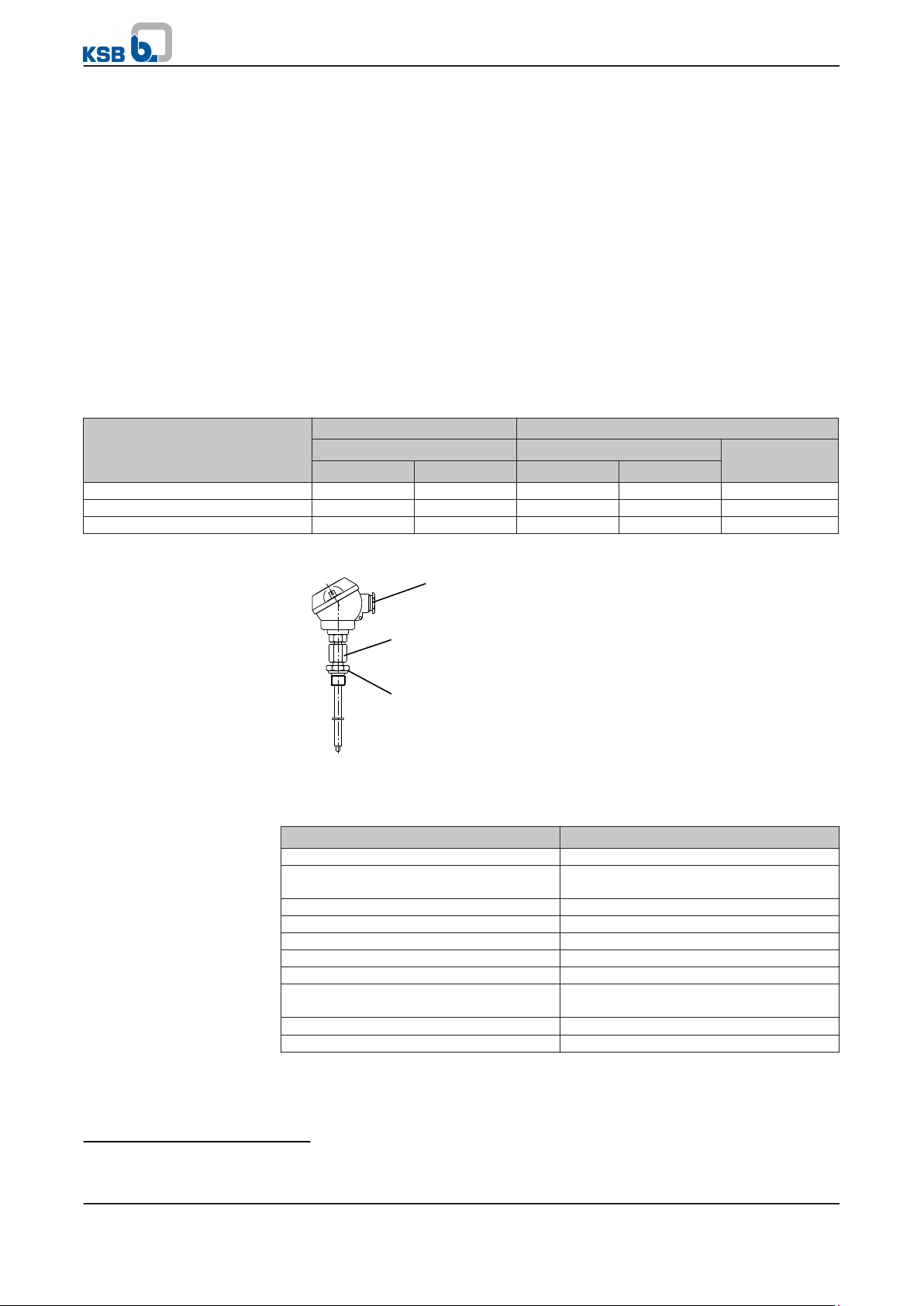

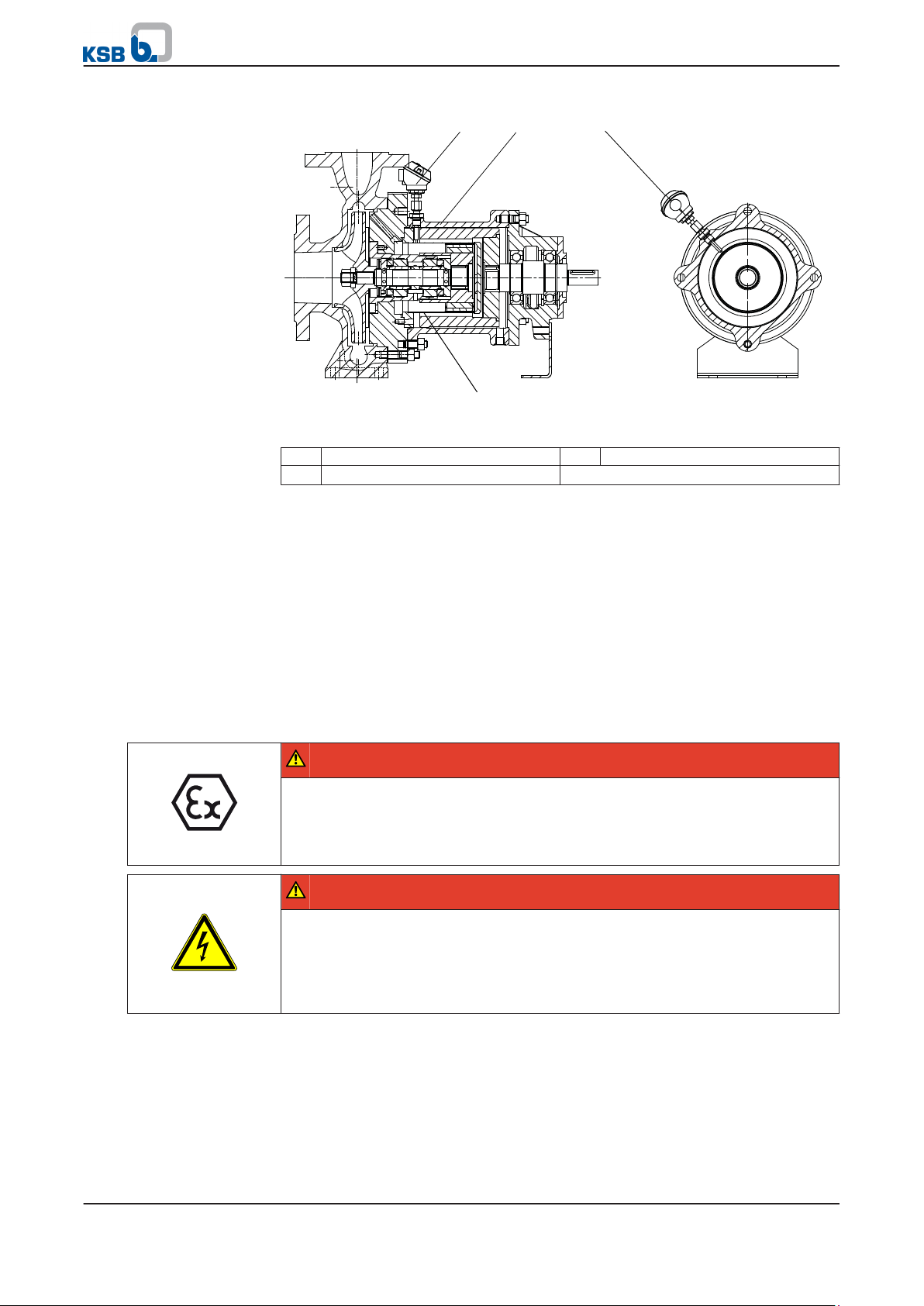

Fig. 1: PT100 resistance thermometer (TR 55)

Table 3: Technical data (TR 55)

Characteristic Value

Sensor type PT100 resistance thermometer

Permissible measuring range (input

-50 ... +450 °C

signal)

Output signal 80 to 268 ohm

Head transmitter None

Type TR 55

Sensor tolerance Class B to IEC 60751

Sealing, sensor tip/support tube Not pressure-proof

Sensor tip Spring-loaded (spring travel approx. 3 to

4 mm)

Wiring

1×4-wire

1)

Process connection G1/4 B/clamping ring

Monitoring Systems

M20x1,5

SW 19 (G

1

/4)

SW 17

2 Temperature Monitoring Sensors

Characteristic Value

Permissible ambient temperature T3/ T4: -40 ... +100 °C

T5: -40 ... +95 °C

T6: -40 ... +80 °C

Nominal length, depending on overall

75, 85 and 125 mm

length

Table 4: Technical data of connection head (TR55)

Characteristic Value

Design, head JS

Enclosure, head IP54

Material Aluminium

Cable connection M16×1.5

Table 5: Characteristic values for explosion protection (TR 55)

Feature Value

Explosion protection, intrinsic safety Ex ib IIC T6

CE conformity marking TÜV 10ATEX 555793 X

Maximum supply current li = 550 mA

Maximum supply power P

maxSensor

= 1.5 W

Maximum supply voltage Ui = 30 V

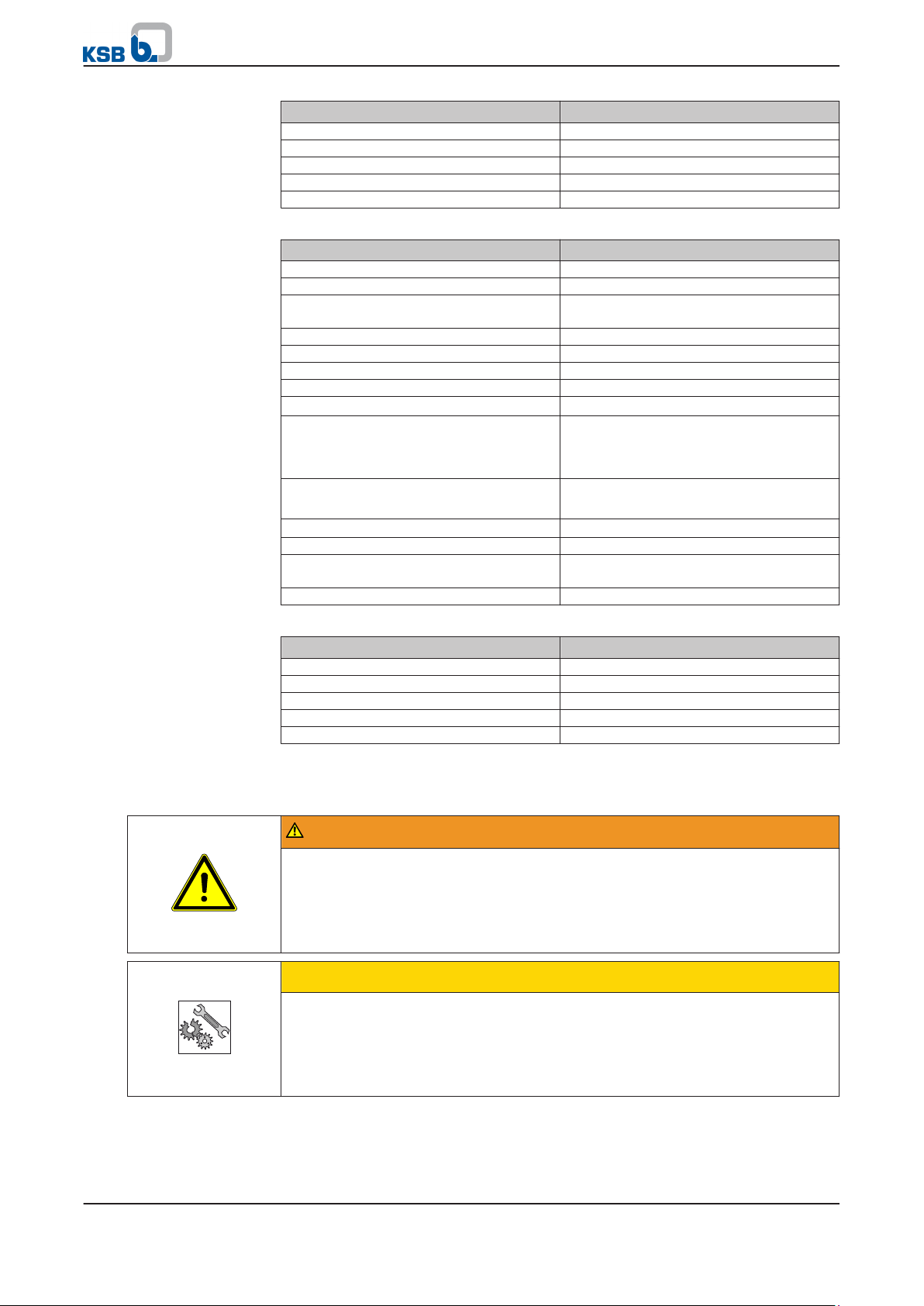

PT100 (Ksb-4,13,xx,02)

2)

This measuring range only applies when the PT100 resistance thermometer is used for designs with a leakage barrier. A

larger measuring range (-40 to +200 °C) is possible for designs without a leakage barrier. Coordination with KSB required.

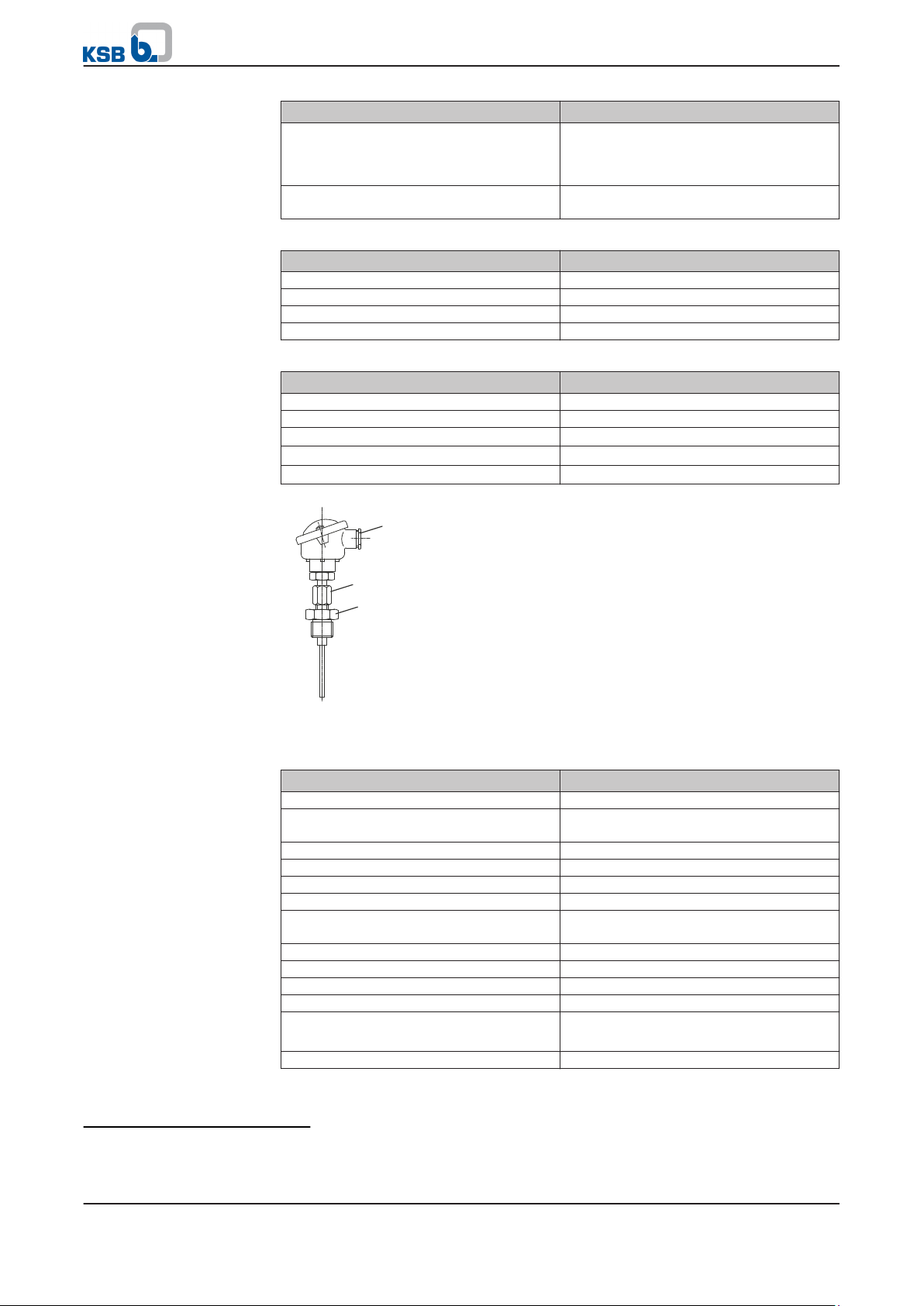

Fig. 2: PT100 resistance thermometer (Ksb-4,13,xx,02)

Table 6: Technical data (Ksb-4,13,xx,02)

Characteristic Value

Sensor type PT100 resistance thermometer

Permissible measuring range (input

-40 ...+120 °C

2)

signal)

Output signal 84 to 146 ohm

Head transmitter None

Type Ksb-4,13,xx,02

Sensor tolerance Class B to IEC 60751

Sealing, sensor tip/support tube Pressure-proof up to 20 bar at a max.

temperature of 120 °C

Sensor tip Spring-loaded (spring travel < 5 mm)

Wiring 1×4-wire

Process connection G1/4B clamping ring

Material: spring-loaded support tube 1.4541

Permissible ambient temperature T5: -40 … +80 °C

T6: -40 … +55 °C

Nominal length, depending on size 120, 135 and 165 mm

Monitoring Systems

7 of 50

M20x1,5

SW 19 (G

1

/4)

SW 17

2 Temperature Monitoring Sensors

Table 7: Technical data of connection head (Ksb-4,13,xx,02)

Feature Value

Design, head BS

Enclosure, head IP65

Material Aluminium

Cable connection M20×1.5

Table 8: Characteristic values for explosion protection (Ksb-4,13,xx,02)

Feature Value

Explosion protection, intrinsic safety 2G Ex ia II C T5/T6

CE conformity marking BVS 03 ATEX E 292

Maximum supply current Ii max = 500 mA (for short circuit)

Maximum supply power P

maxSensor

= 750 mW

Maximum supply voltage Ui = 10 V DC

PT100 (Ksb-4,13,xx,01)

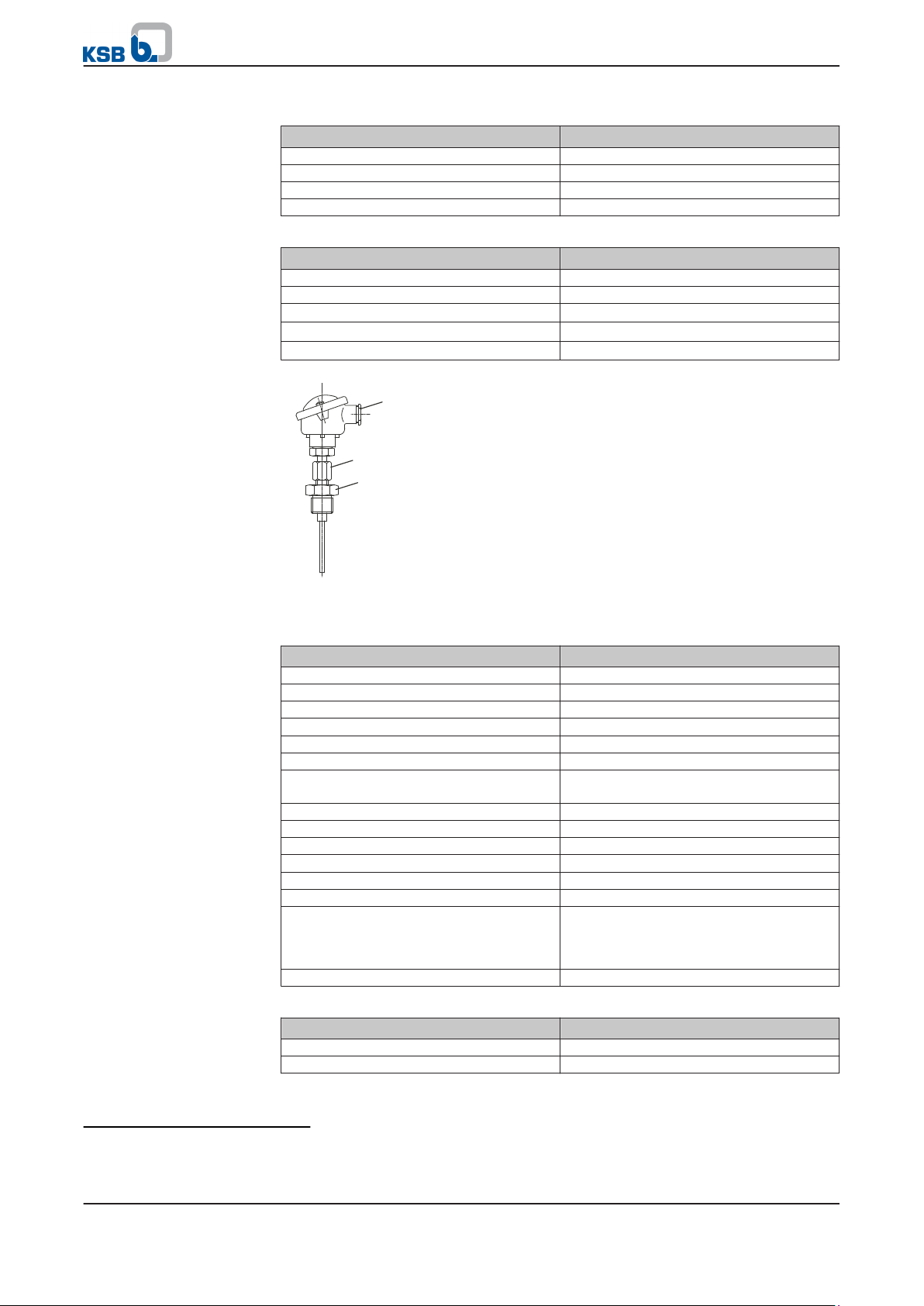

Fig. 3: PT100 resistance thermometer (Ksb-4,13,xx,01)

Table 9: Technical data (Ksb-4,13,xx,01)

Characteristic Value

Sensor type PT100 resistance thermometer

Output signal 4 - 20 mA

Head transmitter T24 WIKA

Permissible measuring range

-40 ... +320 °C

2)3)

Type Ksb-4,13,xx,01

Sensor tolerance Class B to IEC 60751

Sealing, sensor tip/support tube Pressure-proof up to 20 bar at a max.

temperature of 120 °C

Sensor tip Spring-loaded (spring travel < 5 mm)

Wiring 1×4-wire

Process connection G 1/4B clamping ring

Material: spring-loaded support tube 1.4541

Cable connection M20×1.5

Enclosure IP65

Permissible ambient temperature T4: -40 … +85 °C

T5: -40 … +75 °C

T6: -40 … +60 °C

Nominal length, depending on size 120, 135 and 165 mm

Table 10: Technical data of connection head (Ksb-4,13,xx,01)

Feature Value

Design, head BS

Enclosure, head IP65

3)

8 of 50

On designs with a leakage barrier the PT100 resistance thermometer may only be used for temperatures of -40 to 120 °C. If

required, the measuring range may have to be adjusted.

Monitoring Systems

2 Temperature Monitoring Sensors

Feature Value

Material Aluminium

Cable connection M20×1.5

Table 11: Characteristic values for explosion protection (Ksb-4,13,xx,01)

Feature Value

Explosion protection, intrinsic safety 2G E Ex ia II C T5/T6

CE conformity marking BVS 03 ATEX E 292

Maximum supply current Ii max = 120 mA (for short circuit)

Maximum supply power P

maxSensor

= 800 mW

Maximum supply voltage Ui = 30 V DC

Table 12: Technical data of head transmitter

Feature Value

Type T24.10

Design Head-mounted version, explosion-proof

Output Analog, 4 - 20 mA

Fault detection Broken wire, short circuit

Explosion protection 2II 1G EEx ia/ II C T4/T5/T6

Explosion protection type test certificate DMT 02 ATEX E 025 X

Auxiliary energy supply, U

B

DC 9 ... 30 V

Ambient/storage temperature T4: -40 ... +85 °C

T5: -40 ... +75 °C

T6: -40 ... +60 °C

Current-loop circuit (+ and - connections) Ui = 30 V, li = 120 mA, Li = 110 µH

Ci = 6.2 nF, Pi = 800 mW

Material Plastic, PBT, glass-fibre reinforced

Enclosure (to IEC 60529/EN 60529) Housing: IP 66/IP 67

Connection terminals: IP 00

2.1.3 Installing the PT100 resistance thermometer in the pump

WARNING

Leaks and/or corrosion damage on monitoring systems

No fault indications!

Leakage of fluid handled!

▷ Never install damaged or corroded monitoring systems in the pump.

▷ Check monitoring systems for damage and correct function prior to installation.

Monitoring Systems

9 of 50

1 2

3

1

2 Temperature Monitoring Sensors

Fig. 4: Installation location of the PT100 resistance thermometer

1 PT100 resistance thermometer 2 Bearing bracket lantern

3 Containment shroud

1. Remove the screw plug from the 4M.3 connection.

2.

Screw the compression fitting up to the stop.

3. Insert the PT100 resistance thermometer into the fitting up to the stop or until

the tip of the resistance thermometer contacts the containment shroud or its

intermediate piece.

4. Turn the connection head of the PT100 resistance thermometer to the required

position.

5. Pull the PT100 resistance thermometer back by approximately 1 to 2 mm.

6. Tighten the compression fitting to prevent the PT100 resistance thermometer

from loosening and rotating.

2.1.4 Electrical connection of the PT100 resistance thermometer

DANGER

Incorrect electrical installation

Explosion hazard!

▷ For electrical installation, also observe the requirements of IEC 60079-11.

▷ Realise a suitable measuring chain.

DANGER

Work on the pump set by unqualified personnel

Danger of death from electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN 60079.

10 of 50

Monitoring Systems

Red

ϑ

ϑ

Red

Red

White

White

White

Terminal assignment, four-

wire system for TR 55

Terminal assignment, four-

wire system for

Ksb-4,13,xx,02

2 Temperature Monitoring Sensors

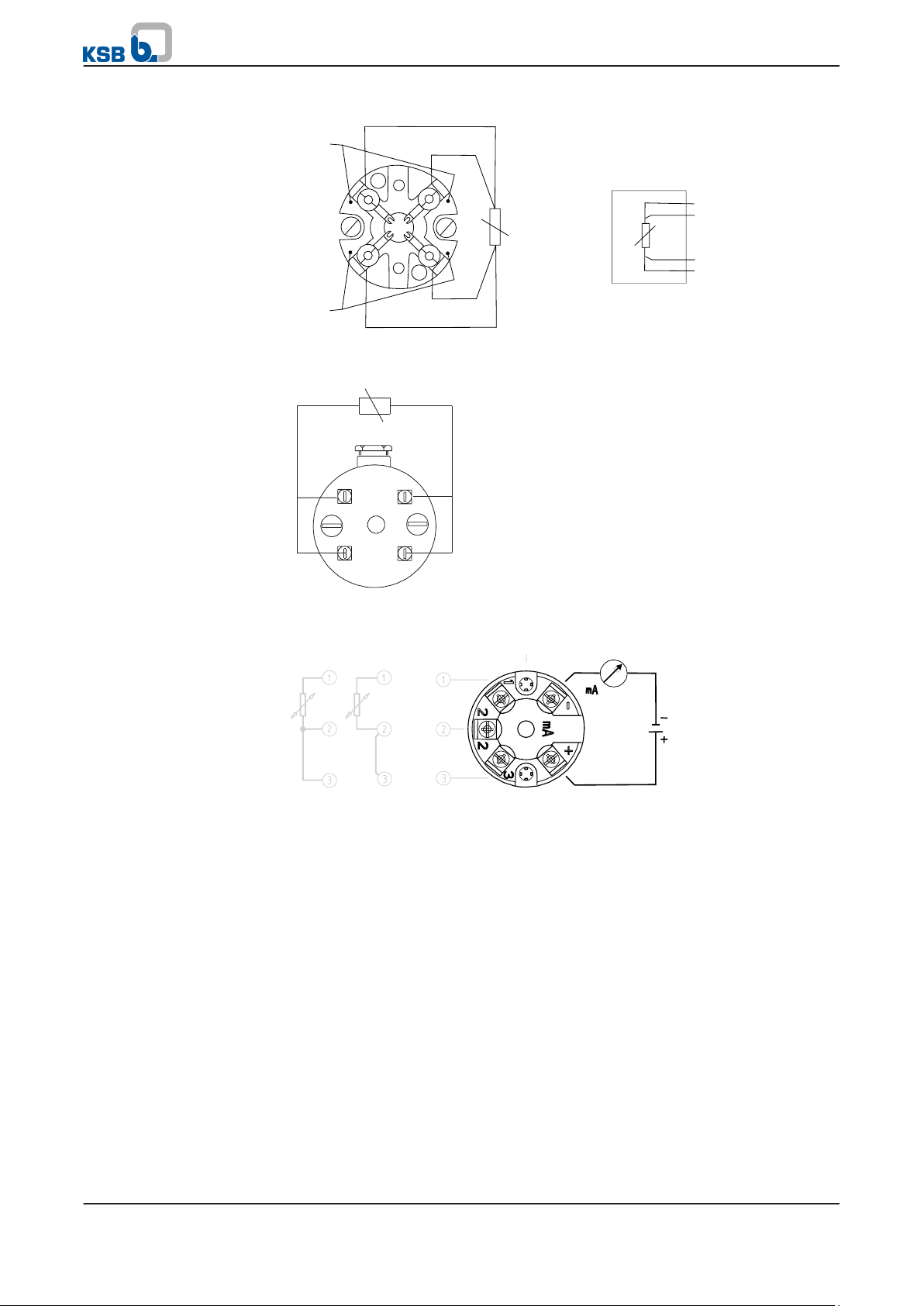

Fig. 5: Terminal assignment, four-wire system for TR 55

Terminal assignment, four-

wire system for

Ksb-4,13,xx,01 (T24)

Design of measuring chain

Fig. 6: Terminal assignment for PT100 four-wire system, pressure-proof (Ksb-4,13,xx,

02)

Fig. 7: Terminal assignment for PT100 including head transmitter (Ksb-4,13,xx,01 with

T24)

Open the connection head.

1.

2. Connect the PT100 resistance thermometer. (Observe terminal assignment. See

illustrations.)

2.1.5 Design of measuring chain

The design of the measuring chain is influenced by the following factors:

▪ Potentially explosive or non-potentially explosive atmosphere

▪ Output signal (Ω or mA)

The measuring chain must be designed and configured in accordance with these

factors. Observe the following illustration for selection.

Monitoring Systems

11 of 50

(ATEX) barrier

Limit switch

Output signal

in Ω

PT100 resistance thermometer

with ceramic terminal block

4...20 m A

(ATEX) transmitter supply unit

Limit switch

Output signal

PT100 resistance thermometer

head transmitter

Limit switch

Output signal

in Ω

PT100 resistance thermometer

with ceramic terminal block

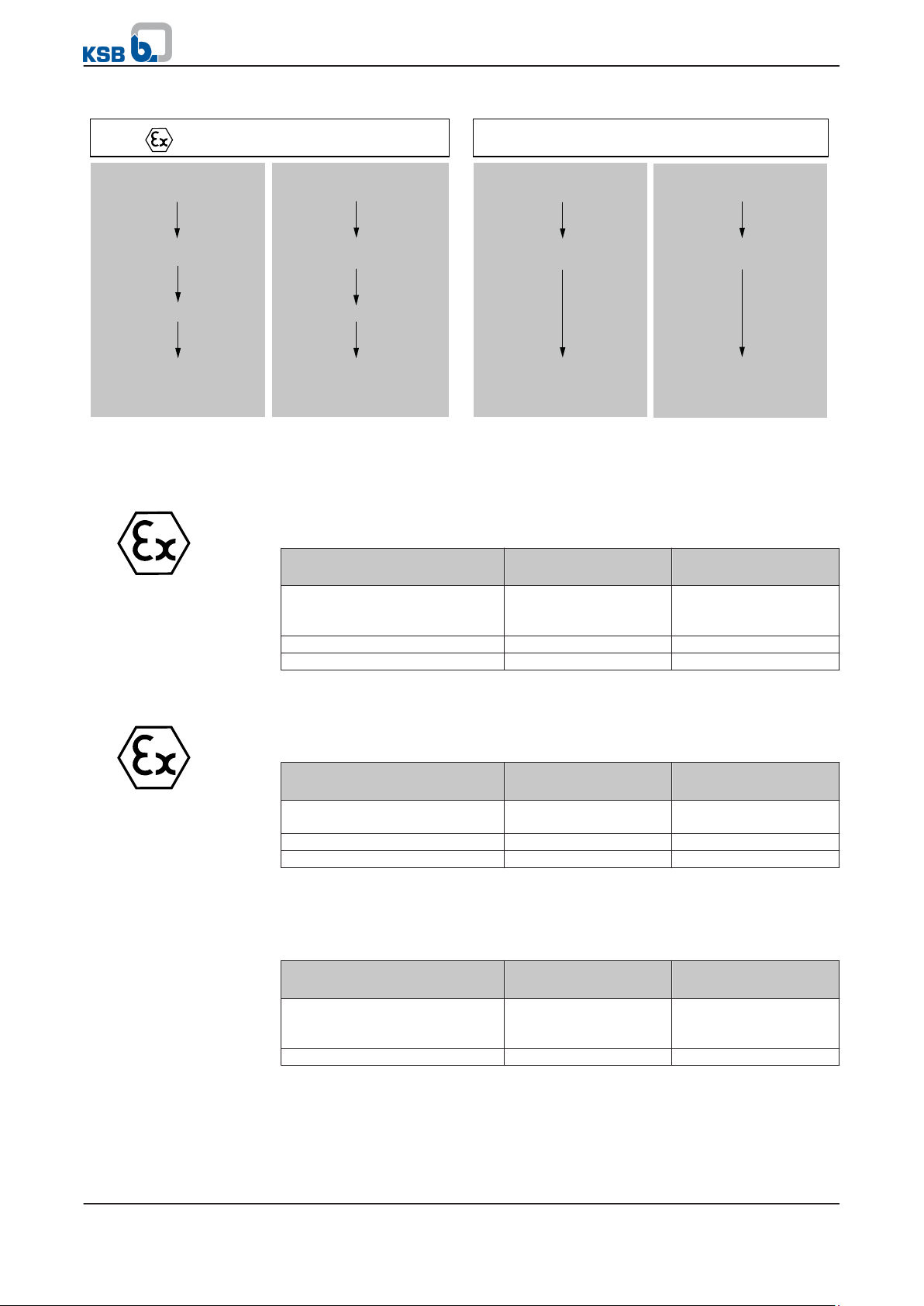

Measuring chain 1 Measuring chain 2 Measuring chain 3

Non-potentially explosive atmosphere

Potentially explosive atmosphere

4...20 m A

Limit switch

Output signal

PT100 resistance thermometer

with head transmitter

Measuring chain 4

2 Temperature Monitoring Sensors

Fig. 8: Design of measuring chain

Non-potentially explosive

atmosphere

Description, measuring chain 1 (potentially explosive atmosphere)

Measuring chain 1 comprises the following elements:

Table 13: Description, measuring chain 1 (potentially explosive atmosphere)

Element KSB device

For details, refer to...

recommendation

PT100 resistance thermometer

without head transmitter

TR 55

or

(⇨ Section 2.1.2 Page 6)

Ksb-4,13,xx,2

(ATEX) barrier Z 954

Limit switch CF1M

(⇨ Section 5.2 Page 44)

(⇨ Section 5.1 Page 40)

Description, measuring chain 2 (potentially explosive atmosphere)

Measuring chain 2 comprises the following elements:

Table 14: Description, measuring chain 2

Element KSB device

For details, refer to...

recommendation

PT100 resistance thermometer

Ksb-4,13,xx,1

(⇨ Section 2.1.2 Page 6)

with head transmitter

(ATEX) transmitter supply unit KFD2-STC4-EX1

Limit switch DGW 1.00 or DWG 4.00

(⇨ Section 5.2 Page 44)

(⇨ Section 5.1 Page 40)

Description, measuring chain 3

Measuring chain 3 comprises the following elements:

Table 15: Description, measuring chain 3

Element KSB device

PT100 resistance thermometer

without head transmitter

Limit switch CF1M or DGW2.0

Description, measuring chain 4

Non-potentially explosive

12 of 50

atmosphere

Measuring chain 4 comprises the following elements:

Monitoring Systems

recommendation

TR55

or

Ksb-4,13,xx,2

For details, refer to...

(⇨ Section 2.1.2 Page 6)

(⇨ Section 5.1 Page 40)

2 Temperature Monitoring Sensors

Table 16: Description, measuring chain 4

Element KSB device

For details, refer to...

recommendation

PT100 resistance thermometer

Ksb-4,13,xx,1

(⇨ Section 2.1.2 Page 6)

with head transmitter

Limit switch DGW 1.00 or DGW 4.00

2.1.6 Analysis of output signals

2.1.6.1 Determining the limit value

(⇨ Section 5.1 Page 40)

In a potentially explosive atmosphere, the maximum permissible surface temperature

is dictated by the temperature class. The maximum permissible operating

temperature of the pump is specified in the data sheet. Observe the following

additional requirements when determining the limit value for the maximum surface

temperature at the containment shroud:

Table 17: Temperature limits

Temperature class to EN13463-1 Maximum permissible surface

temperature at containment shroud

T1 300 °C

T2 290 °C

T3 195 °C

T4 130 °C

T5 On request only

T6 On request only

For design and operational reasons, the PT100 resistance thermometer cannot detect

the maximum surface temperature that occurs at the containment shroud in the

magnetic coupling area. To avoid exceeding the maximum permissible surface

temperatures at the containment shroud (see "Temperature limits" table), a safety

margin to the temperature measured of at least 15 K must be observed. Only the

operating status of the pump can be monitored using the PT100 resistance

thermometer.

A distinction can be made between the following operating statuses:

▪ Intended operation

▪ Failure

Determining the initial value

The initial value and the temperature of the containment shroud or its intermediate

piece during intended operation must first be determined.

NOTE

Observe possible process or rotational speed-related changes in the temperature.

DANGER

Excessive surface temperatures

Explosion hazard!

▷ The limit value for stopping the pump must never exceed the specified surface

temperature of the respective temperature class.

▷ If the specified surface temperature of the respective temperature class is

exceeded, immediately switch off the pump set and determine the cause.

1. Determine the temperature class of the system to EN 13463-1.

Note the maximum permissible surface temperature of the containment shroud

2.

by referring to the "Temperature limits" table.

Monitoring Systems

13 of 50

2 Temperature Monitoring Sensors

3. Transition the pump to the steady state under the intended operating

conditions (see data sheet on the duty point of the pump).

Note the value displayed on the limit switch (= initial value) in the steady state.

4.

5. Check initial value.

The initial value must be at least 15 K below the maximum permissible surface

temperature at the containment shroud (see "Temperature limits" table).

Steady state

Steady state is reached when the temperature rise does not exceed 2 K/h (to EN

13463-1: 2009-07).

If the difference is less, implement the following measures:

▪ Check operating conditions.

▪ Dismantle and clean pump (if required).

▪ Re-determine initial value.

Consultation with KSB/KSB Service is required if the initial value is unchanged.

Determining limit values for operating statuses

Intended operation

The initial value determined corresponds to the temperature at the containment

shroud during intended operation.

Failure

In a failure, an insufficient cooling flow or a failure of the cooling flow can cause the

temperature to rise at the containment shroud. To be able to detect a failure via a

rise in temperature, add a safety margin of 10 K to the initial value determined.

If, during a failure (non-intended operation), the limit value determined is exceeded,

Initial value + 10 K = limit value

the pump is stopped. Depending on the factory setting of the limit switch, the pump

will be started up again after the temperature at the containment shroud has

dropped. The value that is specified as the hysteresis for the output determines the

containment shroud temperature at which the pump is started up again.

A hysteresis of 1 K is factory set for the limit switch CFM1, for example. If the

containment shroud temperature drops 1 K below the limit value here, the pump is

started up again. If the pump must not be re-started after the limit value has been

exceeded, other measures are required on site.

2.2 Temperature monitoring at the containment shroud via a mineralinsulated thermocouple

2.2.1 Functionality of the mineral-insulated thermocouple

The temperature of the containment shroud can be monitored by using an IEC 548compliant mineral-insulated thermocouple fixed to the containment shroud. The

mineral-insulated thermocouple measures in the containment shroud area where the

highest surface temperatures occur: at the containment shroud tube in the magnetic

coupling area. The mineral-insulated thermocouple installed functions as a passive

component in the potentially explosive atmosphere and is designed as a "simple

apparatus" to EN 60079-11.

2.2.2 Technical data of mineral-insulated thermocouple

Table 18: Technical data of mineral-insulated thermocouple with ceramic terminal

block

Characteristic Value

Type K

Explosion protection Intrinsic safety, "simple apparatus" to DIN

EN 60079-11

Sensor type K, NiCr-Ni

Sensor tolerance IEC 584

Measuring point Insulated

Diameter 0.34 mm

Process connection G1/4, compression fitting

Sheath material Austenite steel

14 of 50

Monitoring Systems

2 Temperature Monitoring Sensors

Characteristic Value

Sheath lengths, depending on size 130 and 230 mm

Connection cable material PTFE

Connection cable diameter 3.5 mm

Connection cable length 1 m

Output signal in µV

Table 19: Technical data of head transmitter

Feature Value

Type T12

Design Head-mounted version, explosion-proof

Configuration Pre-configured to type K, NiCr-Ni, IEC 584

ex works

Output Analog, 4 - 20 mA

Fault detection Broken wire, short circuit

Explosion protection II 2 G Ex ib II B / II C T4/T5/T6

Explosion protection type test certificate DMT 98 ATEX E 008X

Auxiliary energy supply, U

B

DC 9 ... 30 V

Ambient temperature T4: -40 °C ... +85 °C

T5: -40 °C ... +75 °C

T6: -40 °C ... +60 °C

Current-loop circuit (+ and - connections) Ui = 30 V, li = 100 mA, Li = 0,65 mH

Ci = 25 nF, Pi = 705 mW

Max. power input For UB = 24 V max. 552 mW

Material Plastic

Enclosure Housing: IP00 IEC 60529/EN 60529

Electronics completely encapsulated

Connection cross-section of terminals 1.5 mm2 max.

Table 20: Technical data of connection head

Feature Value

Type of head BSZ

Enclosure, head IP65

Material Aluminium

Process connection G1/4, compression fitting

Cable connection M20 × 1.5

2.2.3 Installing the containment shroud with fixed mineral-insulated thermocouple

WARNING

Leaks and/or corrosion damage on monitoring systems

No fault indications!

Leakage of fluid handled!

▷ Never install damaged or corroded monitoring systems in the pump.

▷ Check monitoring systems for damage and correct function prior to installation.

CAUTION

Kinking or breaking of the mineral-insulated thermocouple

Damage to the machinery!

▷ Never kink the mineral-insulated thermocouple.

▷ When removing/fitting the bearing bracket lantern, observe the connection

cable of the mineral-insulated thermocouple.

Monitoring Systems

15 of 50

Loading...

Loading...