Page 1

Rainwater Harvesting System

Hya-Rain/Hya-Rain N

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual Hya-Rain/Hya-Rain N

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 21/01/2019

Page 3

Contents

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Target group.....................................................................................................................................................6

1.3 Other applicable documents............................................................................................................................6

1.4 Symbols .............................................................................................................................................................6

1.5 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.3 Personnel qualification and training...............................................................................................................9

2.4 Consequences and risks caused by non-compliance with these operating instructions ..............................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation..................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier...........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................13

4 Description............................................................................................................................................ 14

4.1 General description ........................................................................................................................................14

4.2 Designation.....................................................................................................................................................14

4.3 Name plate......................................................................................................................................................14

4.4 Design details..................................................................................................................................................15

4.5 Configuration and function...........................................................................................................................16

4.6 Noise characteristics .......................................................................................................................................17

4.7 Scope of supply...............................................................................................................................................17

4.8 Dimensions and weights ................................................................................................................................17

5 Installation at Site................................................................................................................................ 18

5.1 Safety regulations...........................................................................................................................................18

5.2 Checks to be carried out prior to installation...............................................................................................18

5.3 Setting up and installing the system.............................................................................................................18

5.4 Connecting the piping ...................................................................................................................................19

5.4.1 Connecting the mains water inlet ....................................................................................................19

5.4.2 Connecting the inlet line...................................................................................................................20

5.4.3 Connecting the discharge line ..........................................................................................................20

5.4.4 Connecting the overflow...................................................................................................................21

5.5 Electrical connection ......................................................................................................................................22

5.5.1 Connecting the float switch ..............................................................................................................22

5.5.2 Connecting the level control system.................................................................................................24

5.5.3 Connecting a booster pump (optional) ............................................................................................25

5.5.4 Connecting the system ......................................................................................................................27

6 Commissioning/Start-up/Shutdown................................................................................................... 28

6.1 Commissioning/Start-up.................................................................................................................................28

6.1.1 Prerequisites for commissioning/start-up .........................................................................................28

6.1.2 Priming and venting the system .......................................................................................................28

6.1.3 Start-up...............................................................................................................................................29

6.1.4 Functional test....................................................................................................................................29

6.2 Operating limits..............................................................................................................................................30

Hya-Rain/Hya-Rain N

3 of 64

Page 4

Contents

6.2.1 Ambient conditions ...........................................................................................................................30

6.2.2 Maximum operating pressure ...........................................................................................................30

6.2.3 Fluid handled .....................................................................................................................................30

6.3 Shutdown/storage/preservation ....................................................................................................................31

6.3.1 Measures to be taken for shutdown ................................................................................................31

6.3.2 Stopping the system ..........................................................................................................................31

7 Operation.............................................................................................................................................. 32

7.1 Control panel..................................................................................................................................................32

7.2 Mode of operation.........................................................................................................................................33

7.2.1 Automatic mode ................................................................................................................................33

7.2.2 Mains water mode (manual mode) ..................................................................................................33

7.2.3 Rainwater mode (manual mode) ......................................................................................................33

7.2.4 Priming ...............................................................................................................................................34

7.3 Level control system (Hya-Rain N only).........................................................................................................35

7.3.1 Calibrating the level control system/ setting the rainwater storage tank design ........................36

7.3.2 Setting the switching level for the rainwater storage tank............................................................37

7.3.3 Setting and displaying the rainwater storage tank water replacement ........................................38

7.3.4 Setting the valve switchover .............................................................................................................39

8 Servicing/Maintenance........................................................................................................................ 40

8.1 General information/safety regulations........................................................................................................40

8.2 Maintenance/inspection.................................................................................................................................41

8.2.1 Replacing the stored mains water ...................................................................................................41

8.2.2 Checking the mains water mode ......................................................................................................41

8.2.3 Checking the pump control unit.......................................................................................................42

8.2.4 Checking the discharge lines.............................................................................................................42

8.3 Drainage/cleaning ..........................................................................................................................................42

8.4 Dismantling the system..................................................................................................................................42

8.4.1 Removing the pump set from the piping.........................................................................................42

8.4.2 Removing the pump control unit .....................................................................................................44

8.4.3 Removing the mechanical seal..........................................................................................................46

8.5 Reassembling the system ...............................................................................................................................47

8.5.1 Installing the mechanical seal ...........................................................................................................47

8.5.2 Installing the pump control unit.......................................................................................................48

8.5.3 Installing the pump set......................................................................................................................49

9 Trouble-shooting.................................................................................................................................. 51

10 Related Documents.............................................................................................................................. 53

10.1 General assembly drawing with list of components ....................................................................................53

10.2 Exploded view with list of components (pump)...........................................................................................54

10.3 Dimensions and connections .........................................................................................................................56

10.3.1 Hya-Rain / Hya-Rain N........................................................................................................................56

10.3.2 Connections........................................................................................................................................57

10.4 Drilling pattern for wall mounting ...............................................................................................................57

10.5 Wiring diagrams .............................................................................................................................................58

10.5.1 Hya-Rain .............................................................................................................................................58

10.5.2 Hya-Rain N..........................................................................................................................................59

11 EU Declaration of Conformity............................................................................................................. 61

12 Certificate of Decontamination........................................................................................................... 62

Index ..................................................................................................................................................... 63

4 of 64

Hya-Rain/Hya-Rain N

Page 5

Glossary

Glossary

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

Rainwater storage tank

Tank for collecting rainwater, for buried

installation or above-floor installation

Hya-Rain/Hya-Rain N

5 of 64

Page 6

1 General

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The operating manual describes the proper and safe use of this equipment in all

phases of operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.3,Page9)

1.3 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Sub-supplier product literature Operating manuals, logic diagram and other

product literature of accessories and integrated

machinery components

1.4 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

⇨ Cross-references

1.

2.

Result of an action

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

6 of 64

Hya-Rain/Hya-Rain N

Page 7

1 General

!

DANGER

!

WARNING

CAUTION

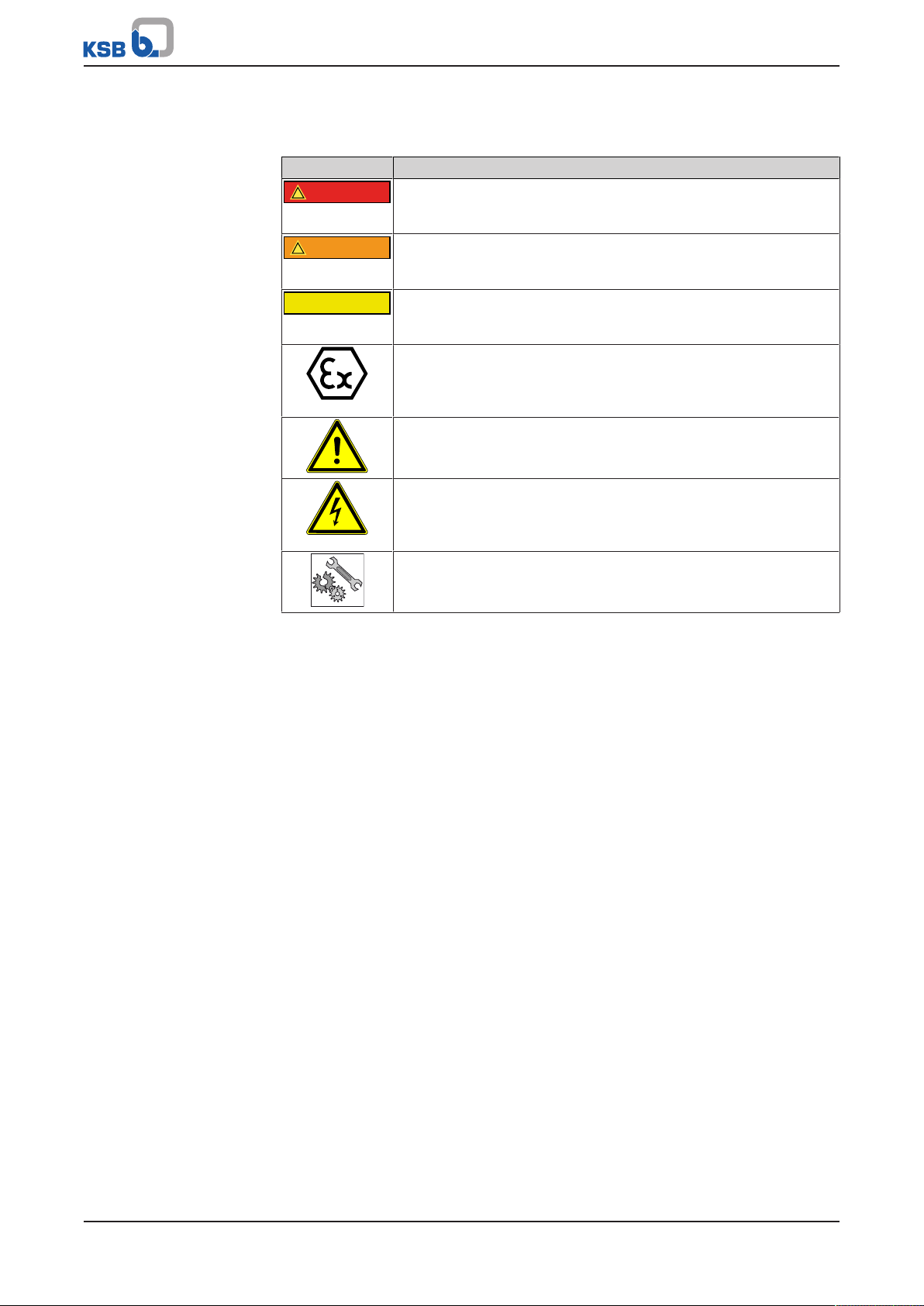

1.5 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EU Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

Hya-Rain/Hya-Rain N

7 of 64

Page 8

2 Safety

!

DANGER

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 General

▪ This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

▪ Comply with all the safety instructions given in the individual sections of this

operating manual.

▪ The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

▪ The contents of this operating manual must be available to the specialist

personnel at the site at all times.

▪ Information and markings attached directly to the product must always be

complied with and kept in a perfectly legible condition at all times. This applies

to, for example:

– Arrow indicating the direction of rotation

– Markings for connections

– Type designation

▪ The operator is responsible for ensuring compliance with all local regulations not

taken into account.

2.2 Intended use

▪ The system must only be operated within the operating limits described in the

other applicable documents.

▪ Only operate systems which are in perfect technical condition.

▪ Do not operate partially assembled systems.

▪ The system may only handle the fluids described in the product literature of the

relevant design variant.

▪ Never operate the system without the fluid to be handled.

▪ Observe the information on minimum flow rates specified in the product

literature (to prevent overheating, bearing damage, etc).

▪ Observe the maximum flow rates indicated in the data sheet or product

literature (to prevent overheating, cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the suction side of the system.

▪ Consult the manufacturer about any other modes of operation not described in

the product literature.

Prevention of foreseeable misuse

▪ Never exceed the permissible application and operating limits specified in the

product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

8 of 64

Hya-Rain/Hya-Rain N

Page 9

2 Safety

2.3 Personnel qualification and training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the equipment this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training at the system must always be supervised by the technical specialist

personnel.

2.4 Consequences and risks caused by non-compliance with these operating instructions

▪ Non-compliance with this operating manual will lead to forfeiture of warranty

cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazard to persons by electrical, thermal and mechanical effects

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

2.5 Safety awareness

In addition to the safety information contained in this operating manual and the

intended use, the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.6 Safety information for the operator/user

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

2.7 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump (set) are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation are

performed by authorised, qualified specialist personnel who are thoroughly

familiar with the manual.

▪ Only carry out work on the system during standstill, with the system de-energised

and secured against unintentional start-up.

▪ When taking the system out of service always adhere to the procedure described

in the manual.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page28)

▪ Make sure the system cannot be accessed by unauthorised persons (e.g. children).

2.8 Unauthorised modes of operation

Always observe the limits stated in the product literature.

Hya-Rain/Hya-Rain N

9 of 64

Page 10

2 Safety

The warranty relating to the operating reliability and safety of the system supplied is

only valid if the system is used in accordance with its intended use.

10 of 64

Hya-Rain/Hya-Rain N

Page 11

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

DANGER

System falling off the pallet

Risk of injury by falling system!

▷ Always transport the system in a vertical position.

▷ Never suspend the system by its power cable.

▷ Use suitable, approved transport equipment, e.g. crane, forklift or pallet trucks.

NOTE

The system and accessories are shipped secured to a wooden pallet and covered

with a cardboard box. For transport two handles are provided on the side of the

cardboard box.

1. Cut the packing straps.

2. Carefully open the upper part of the cardboard box.

3. Take the accessories and padding out of the cardboard box.

4. Lift off the cardboard box.

ð This exposes the system secured to the wooden pallet.

5. Check the packaging contents for completeness.

6. Check the system for any in-transit damage.

7. Select suitable transport equipment.

8. Transport the system to the place of installation.

Hya-Rain/Hya-Rain N

11 of 64

Page 12

3 Transport/Temporary Storage/Disposal

3.3 Storage/preservation

CAUTION

Damage during storage by frost, humidity, dirt, UV radiation or vermin

Corrosion/contamination of the rainwater harvesting system!

▷ Store the system in a frost-proof, roofed area.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage of the rainwater harvesting system!

▷ Only open the openings of the rainwater harvesting system at the time of

installation.

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for storage:

▪ Store the rainwater harvesting system in a dry, protected room with a constant

atmospheric humidity.

▪ For storing a rainwater harvesting system which has already been operated,

observe the measures to be taken for shutdown. (ðSection6.3.1,Page31)

3.4 Return to supplier

1. Drain the system as per operating instructions.

2. Always flush and clean the system.

3. In addition, anhydrous inert gas must be blown through the system to ensure

drying.

4. Always complete and enclose a certificate of decontamination when returning

the system.

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

12 of 64

Hya-Rain/Hya-Rain N

Page 13

3 Transport/Temporary Storage/Disposal

3.5 Disposal

WARNING

Fluids, consumables and supplies posing a health hazard

Hazard to persons and the environment!

▷ Collect and dispose of any preservatives, flushing liquids and fluid residues.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the product.

Collect greases and other lubricants during dismantling.

2. Separate and sort the materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Electrical or electronic equipment marked with the adjacent symbol must not be

disposed of in household waste at the end of its service life.

Contact your local waste disposal partner for returns.

If the used electrical or electronic equipment contains personal data, the user is

responsible for deleting it before the equipment is returned.

Hya-Rain/Hya-Rain N

13 of 64

Page 14

4 Description

1

2

4

3

8

7

9

10

Hya-Rain N

11037303

ZNI1448 P

230 V ~

3,7 A

50 Hz 800 W

IP 44

H

max

:43.0

m Q

max

:4,0 m³/h

2018w09

Made in Germany

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

6

5

26,5 kg

Hya-Rain N

4 Description

4.1 General description

▪ Rainwater harvesting system

▪ Handling clean to slightly contaminated water without aggressive, abrasive and

4.2 Designation

Example: Hya-Rain N

Table4: Designation key

Code Description

Hya-Rain Type series

Hya-Rain With float switch

Hya-Rain N With fill level display and sensor

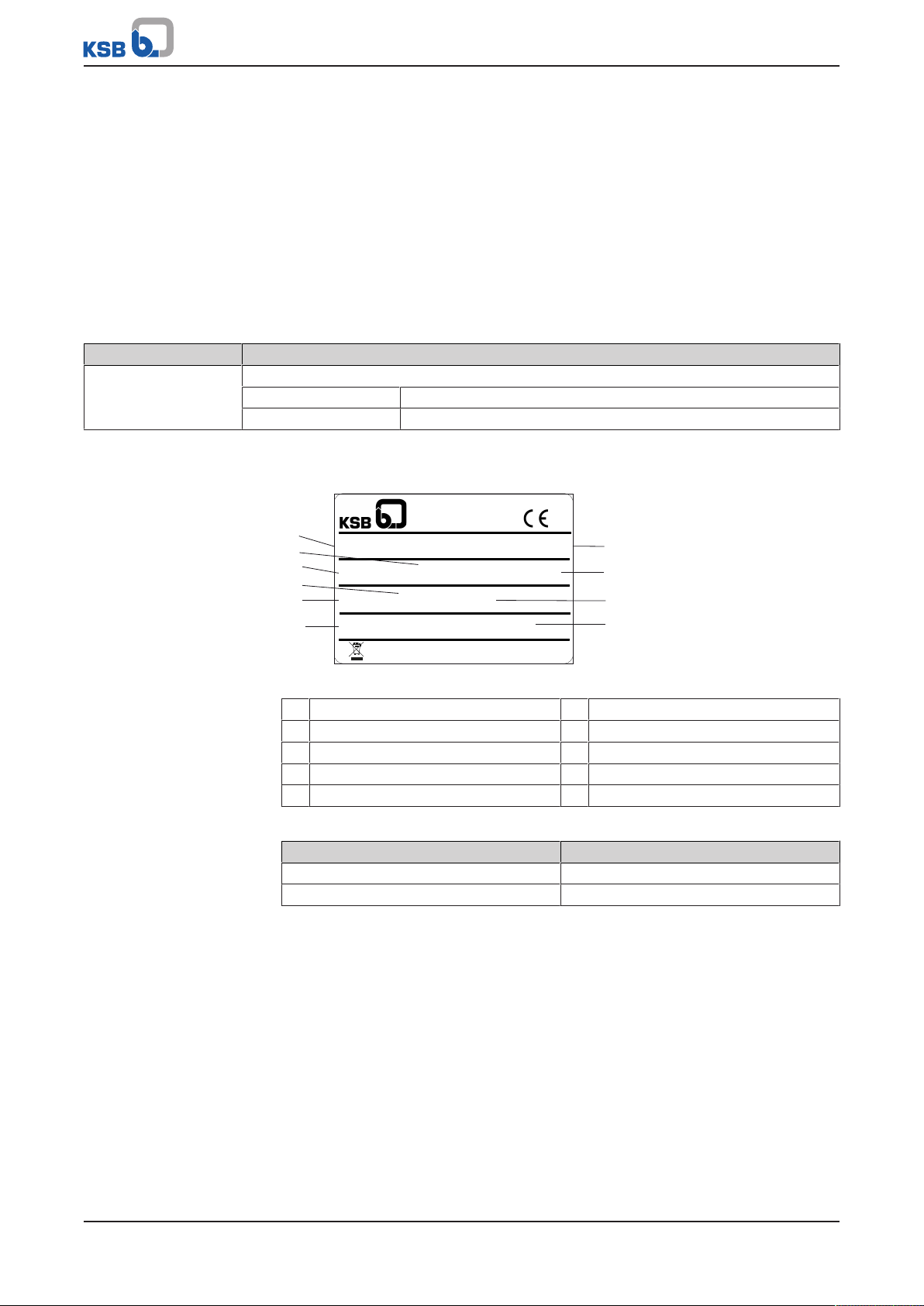

4.3 Name plate

solid particles

Fig.1: Name plate (example)

1 Type series 6 Maximum head

2 Rated current 7 Serial number

3 Rated voltage 8 Total weight

4 Rated power 9 Enclosure

5 Frequency 10 Maximum flow rate

Table5: Key to the serial number

Code Description

2018 Calendar year

09 Calendar week

14 of 64

Hya-Rain/Hya-Rain N

Page 15

4 Description

4.4 Design details

Design

▪ Angled tank designed for wall mounting

▪ Mains water storage tank to EN1717

– Material: PE-LLD, dark

– Storage volume approx. 13l

▪ Float valve for mains water supply (approx. 2.7m³/h)

▪ IP42 enclosure

Pump set

▪ 230V ± 10 %

▪ DOL starting

▪ Thermal class F

▪ Enclosure IP44

▪ Thermal motor protection with automatic reset and start-up

Bearings:

▪ Grease-packed deep groove ball bearings sealed for life

Electrical connection

▪ 230V, 50Hz, 800W

▪ Power input in stand-by mode: 2.5 - 3Watt

▪ 1.5m power cable with shockproof plug

Hya-Rain/Hya-Rain N

15 of 64

Page 16

4 Description

1

2

3

4

5

6

7

8

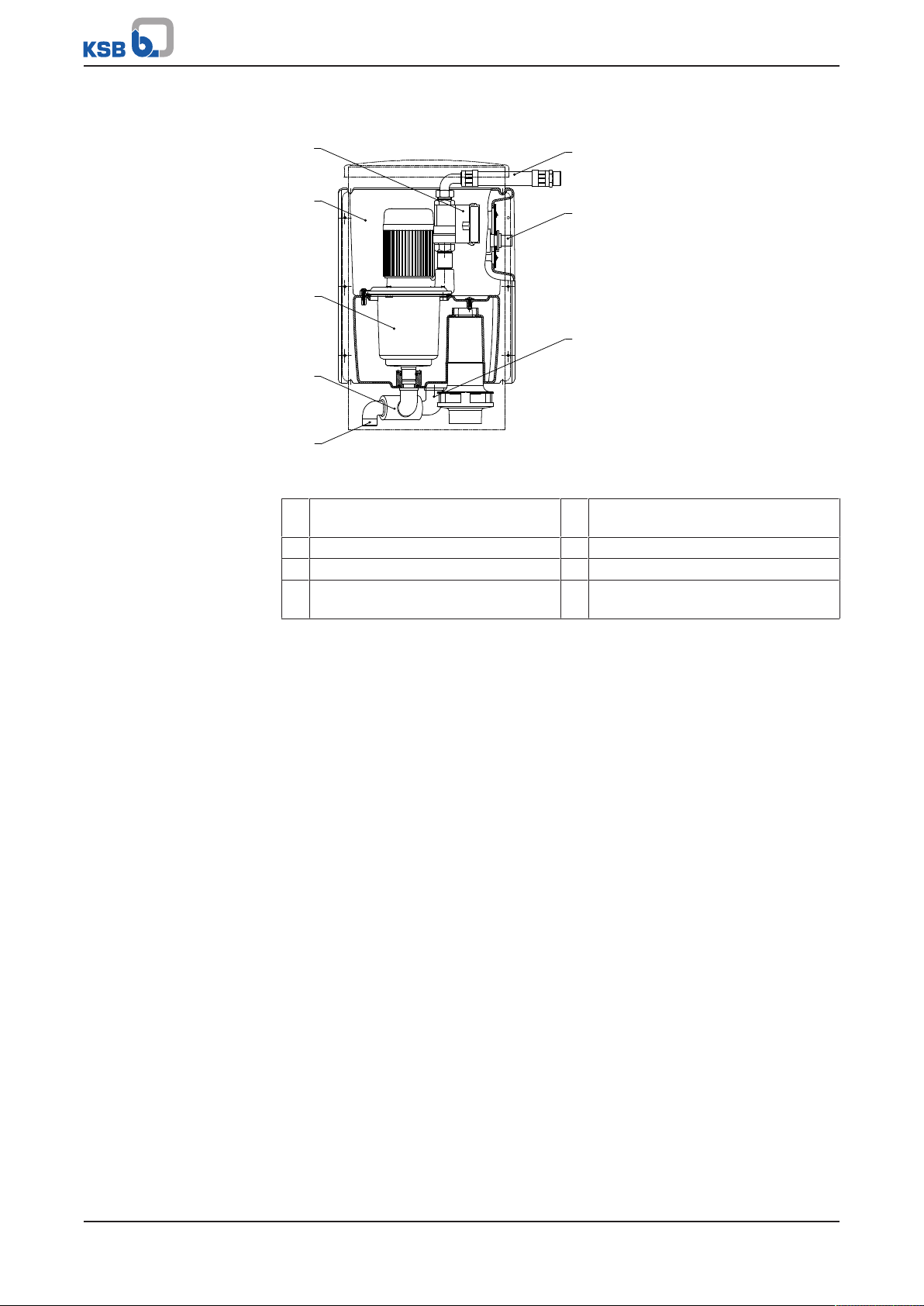

4.5 Configuration and function

Fig.2: Sectional drawing

1 Pump control unit 5 Suction nozzle, rainwater storage

tank

2 Angled tank 6 Discharge outlet

3 High-pressure pump 7 Mains water supply

4 Thee-way valve 8 Suction nozzle, mains water storage

tank

Design A multi-stage self-priming high-pressure pump (3) is installed in an angled tank (2)

designed for wall mounting. Via a three-way valve (4) the high-pressure pump is

connected to a suction nozzle (5) leading out of the system for connection to a

rainwater storage tank.

Function The high-pressure pump (3) withdraws fluid handled from the rainwater storage tank

via the suction nozzle (5). A second suction nozzle (8) leads to an integrated mains

water storage tank, which contains approximately 13l of water. The water in the

mains water storage tank is automatically replenished with drinking water and/or

service water via a float valve. If the sensor fitted in the rainwater storage tank

indicates that the rainwater storage tank is empty, the system will automatically

switch to the mains water storage tank via a three-way valve (4). It will withdraw

water from the mains water storage tank until the rainwater storage tank contains a

sufficient amount of water again. Once the rainwater storage tank contains enough

water again, this condition is signalled to the system, which will then automatically

switch back to withdrawing water from the rainwater storage tank. The pump set is

started and stopped when a consumer installation is opened and closed.

Monitoring equipment For monitoring purposes and for protecting the pump against dry running, the

system is equipped with a pump control unit in the discharge line. When the pressure

falls below approx. 2.5bar (factory setting) the pump control unit starts up the pump

set. When the consumer installation is closed again, the pump control unit stops the

pump set after an after-run time of approx. 10seconds. A lift check valve prevents

the fluid handled from flowing back. The pressure is indicated by a fitted pressure

gauge.

16 of 64

Hya-Rain/Hya-Rain N

Page 17

4 Description

4.6 Noise characteristics

Depending on the operating data of the system, the noise level will be approximately

49-50dB(A).

4.7 Scope of supply

▪ Rainwater harvesting system

– Pump set

– Cervomatic ME control unit and monitoring unit

– Mains water storage tank to EN1717

– Terminals for connecting a booster pump

– Three-way valve with actuator, for automatic switching between rainwater

storage tank and mains water storage tank

– Set of mounting elements for wall mounting (bolts, plug fixings and

mounting brackets)

– Flexible expansion joints for the discharge side as well as for connection to

the mains water supply, length approx. 30/50cm

▪ Bolt hole pattern

▪ Installation/operating manual

Hya-Rain:

▪ Float switch, cable length 20m

Hya-Rain N:

▪ Sensor, cable length 3m, including connection box

4.8 Dimensions and weights

For dimensions refer to the outline drawings. (ðSection10.3.1,Page56)

Table6: Weights

Type series Weight

Without water fill With water fill

[kg] [kg]

Hya-Rain Approx. 26 Approx. 42

Hya-Rain N Approx. 27 Approx. 43

Hya-Rain/Hya-Rain N

17 of 64

Page 18

5 Installation at Site

5 Installation at Site

5.1 Safety regulations

DANGER

Unsuitable electrical installation

Danger to life!

▷ Make sure the electrical installation meets the VDE 0100 installation rules (i.e.

sockets with earthing terminals).

▷ Make sure the electric mains is equipped with a residual current device of

maximum 30 mA.

▷ Always have the electrical connections installed by a trained and qualified

electrician.

5.2 Checks to be carried out prior to installation

Before beginning with the installation check the following:

▪ The system can be operated on the power supply network according to the data

on the name plate. (ðSection4.3,Page14)

▪ The fluid to be handled matches the description of suitable fluids.

(ðSection6.2.3.1,Page30)

▪ The installation room is dry, frost-free and well-ventilated.

▪ The ambient conditions have been met. (ðSection6.2.1,Page30)

▪ The wall (e.g. outside wall) is suitable for accommodating 4plug fixings of

10mm diameter and for carrying the weight of the system.

(ðSection4.8,Page17)

5.3 Setting up and installing the system

ü A suitable installation site has been selected that meets the requirements.

ü Sufficient clearance in all directions is provided for servicing work.

1. Fasten the bolt hole pattern provided to the corresponding wall.

(ðSection10.4,Page57)

2. Drill four holes of 10mm diameter in accordance with the bolt hole pattern.

3. Insert the plug fixings.

4. Mount and align the lower hanging brackets.

5. Undo the nuts. Remove the cover.

6. Place the system on the lower hanging brackets.

7. Fit the upper hanging brackets.

8. Fit the system cover. Fasten it with nuts.

18 of 64

Hya-Rain/Hya-Rain N

Page 19

5 Installation at Site

741.02

5.4 Connecting the piping

5.4.1 Connecting the mains water inlet

CAUTION

Excessive bend of connection line

System defect due to impermissible loads on the system!

Reduced service life!

▷ Connect the connection line without transmitting any stresses or strains.

No forces must act on the connection nozzles and the system.

CAUTION

Pressure higher than mains water back-up limit of 4 bar

System defect due to impermissible load!

▷ Install pressure reducers upstream of the system to make sure that the inlet

pressure of the mains water supply does not exceed 4 bar.

CAUTION

Solid substances in the drinking water (stones, sediments, limescale deposits)

System defect due to impermissible loads!

Reduced service life!

▷ If used in areas where the drinking water quality is affected by the above,

provide a drinking water filter.

NOTE

Fitting a shut-off valve at the site is recommended.

Fig.3: Connecting the mains water inlet

1. Connect the mains water inlet to the mains water supply (float valve 741.02)

R 3/4.

2. Open the mains water supply line.

ð The mains water storage tank will fill automatically once the mains water

supply line is opened.

Hya-Rain/Hya-Rain N

19 of 64

Page 20

5 Installation at Site

5.4.2 Connecting the inlet line

NOTE

The suction-side inlet line (suction hose or suction pipe) must be tightly sealed to

enable self-priming of the pump set.

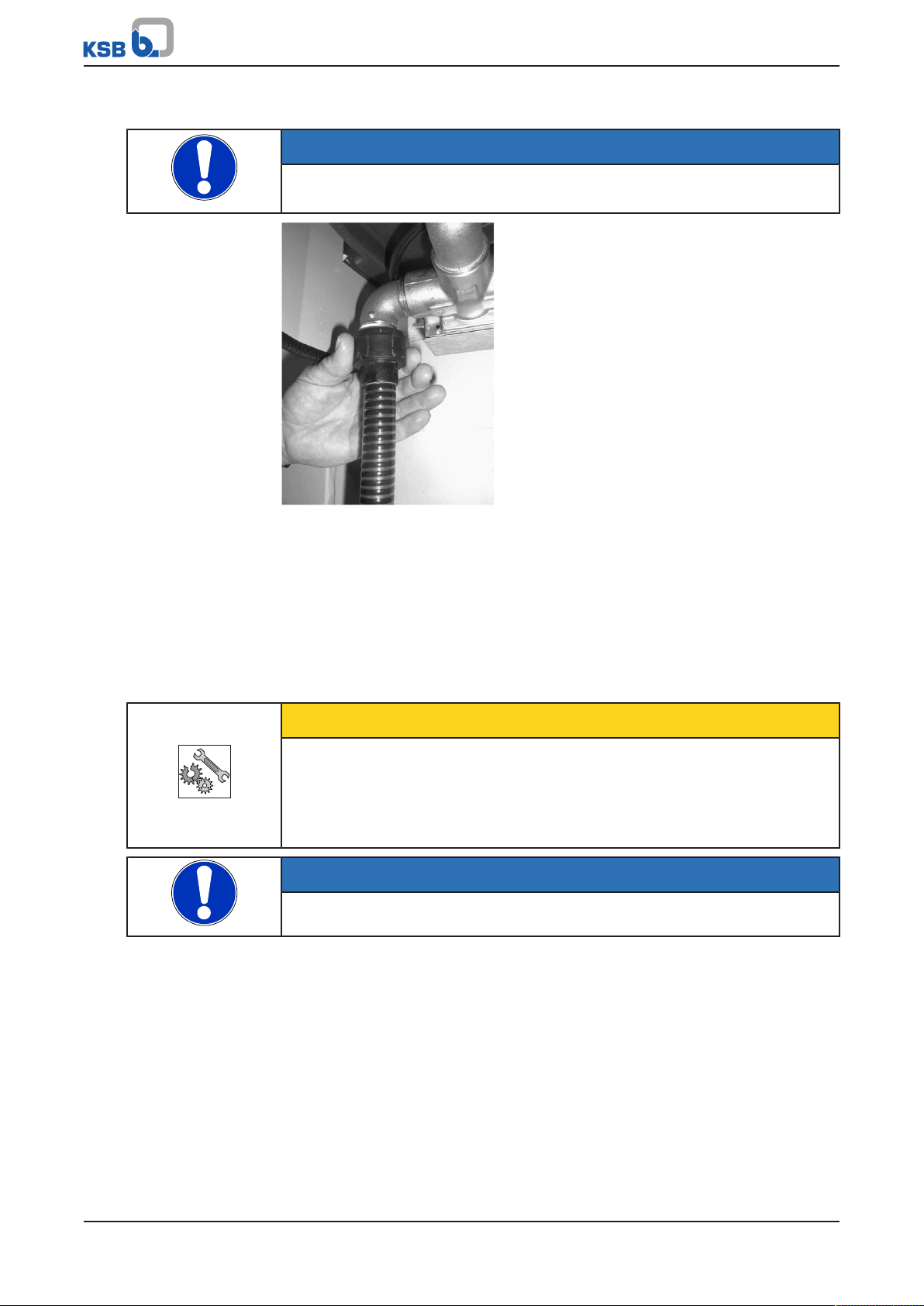

Fig.4: Connecting the inlet line

ü The inlet line (suction hose or suction pipe) has a diameter of at least 1inch.

1. Lay the inlet line coming from the rainwater storage tank with a continuously

rising slope towards the pump set.

2. Screw the inlet line to the suction nozzle at the bottom of the rainwater

harvesting system.

3. Fit a lift check valve at the rainwater storage tank end of the suction line.

5.4.3 Connecting the discharge line

CAUTION

Excessive bend of connection line

System defect due to impermissible loads on the system!

Reduced service life!

▷ Connect the connection line without transmitting any stresses or strains.

No forces must act on the connection nozzles and the system.

NOTE

Fitting a shut-off valve at the site is recommended.

1. Connect hose 719.02, leading it out at the right or left of the rainwater piping

system. Prevent excessive bending of the flexible connection lines.

20 of 64

Hya-Rain/Hya-Rain N

Page 21

5 Installation at Site

A

Fig.5: Connecting the discharge line

5.4.4 Connecting the overflow

NOTE

For permanent connection to the sewage system we recommend the use of a

siphon trap to prevent bad odours.

EN1717 stipulates that for a tank with air gap design an overflow must be provided.

The overflow has a nominal diameter of 70mm. In the event of leakage of the mains

water back-up system, the fluid handled will be discharged via the overflow as soon

as it rises above the maximum fluid level. Operation without backflow protection

from the sewage system is impermissible; such operation voids the DVGW approval

and the warranty.

If no overflow is fitted in the system, the siphon trap available as accessory must be

connected to the sewage system. The siphon trap is not permanently fastened to the

system. Install it as per DIN1986-100, EN1717.

If no drain line is installed, the overflow can be discharged into an open tank fitted

with a water level indicator.

In this case, adequate monitoring by the user/operator is required.

Fig.6: Connecting the overflow (example of a connection)

A Overflow

Hya-Rain/Hya-Rain N

21 of 64

Page 22

5 Installation at Site

≤ 10 cm

≈ 20 cm

≤ 10 cm

5.5 Electrical connection

DANGER

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN60079.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

NOTE

A motor protection device is recommended.

5.5.1 Connecting the float switch

Fig.7: Switching points to be observed when fitting the float switch

1. Fasten the float switch to the conduit, e.g. with cable ties or hose clamps,

observing the switching points.

2. Route the power cable of the float switch to the system through the conduit.

3. Undo the nuts at the terminal box.

22 of 64

Hya-Rain/Hya-Rain N

Page 23

5 Installation at Site

Fig.8: Undoing the nuts at the terminal box

4. Remove the terminal box from the system and open it.

Fig.9: Removing the terminal box from the system and opening it

5. Feed the power cable of the float switch through the cable gland provided.

Make sure the cable gland is pointing down. Fasten it in this position.

Fig.10: Connecting the power cable in the terminal box

6. Tighten the cable gland.

7. Connect the power cable.

8. Close the terminal box.

9. Mount the terminal box on the system.

Hya-Rain/Hya-Rain N

23 of 64

Page 24

5 Installation at Site

Overflow

K

S

K

S

K

S

K

S

min.

10 cm

SENSOR terminals

CABLE terminal

Data cable

Data cable connection

reverse polarity protected

SENSOR terminal

Connect sensor at terminal S.

The cables

must not be twisted.

To tighten the cable

the suspended sensor can end

just above the tank floor.

10 cm

PG2

PG3

PG1

Connect the cable

at terminal K.

100%

reference value

Mark the

sensors at

this point.

5.5.2 Connecting the level control system

5.5.2.1 Connecting the sensor

CAUTION

Liquids entering the terminal box

Damage to the sensors!

System defect!

▷ Mount the terminal box approx. 10cm above the rainwater storage tank

overflow.

24 of 64

Fig.11: Connecting the sensor

1. Mount the terminal box supplied at least 10cm above the overflow. Fasten it to

the rainwater storage tank wall or to a pipe.

ð The sensors hang down straight and can move freely.

2. Cut the sensors, so the weights hang approx. 10cm above the floor of the

rainwater storage tank.

3. Strip the ends of the power cables. Connect the cables to terminals K and S.

4. Tighten the cable glands.

Hya-Rain/Hya-Rain N

Page 25

5 Installation at Site

5.5.2.2 Connecting the power cable

Level control and level measurement are effected by a capacitive system. The sensor

delivered is supplied with a voltage of 12V by means of the optional connection

cable; this voltage is not hazardous to humans. A 2-wire rubber-sheathed cable of

1mm2 to 1.5mm2 is appropriate as connection cable. Already routed float switch

power cables of up to max. 50m length can be used for retrofitting.

1. Undo the nuts at the terminal box.

Fig.12: Undoing the nuts at the terminal box

2. Remove the terminal box from the system and open it.

Fig.13: Removing the terminal box from the system and opening it

3. Feed the stripped end of the power cable through the cable gland provided.

Make sure the cable gland is pointing down. Fasten it in this position.

Fig.14: Connecting the cable in the terminal box

4. Tighten the cable gland.

5. Close the terminal box.

6. Mount the terminal box on the system.

5.5.3 Connecting a booster pump (optional)

A booster pump can be connected if the suction lift or suction losses are larger than

7mWC or the suction line has not been laid with a continuously rising slope. The

booster pump exclusively runs in rainwater mode and only when the pump set of the

Hya-Rain/Hya-Rain N

25 of 64

Page 26

5 Installation at Site

system is running. Its power cable is to be connected to L, N and PE in the same

terminal box as the float switch or level control system. Observe the maximum total

rated power of 800W/ 230V.

ü The operating manual of the booster pump used is on hand.

1. Undo the nuts at the terminal box.

Fig.15: Undoing the nuts at the terminal box

2. Remove the terminal box from the system and open it.

Fig.16: Removing the terminal box from the system and opening it

3. Feed the booster pump connection cable through the provided cable gland.

Make sure the cable gland is pointing down. Fasten it in this position.

Fig.17: Connecting the power cable in the terminal box

4. Tighten the cable gland.

5. Close the terminal box.

6. Mount the terminal box on the system.

7. Install the booster pump as described in the manufacturer's operating manual.

26 of 64

Hya-Rain/Hya-Rain N

Page 27

5 Installation at Site

≈ 40 cm

≤ 10 cm

≤ 10 cm

Fig.18: Installation example for a booster pump

5.5.4 Connecting the system

1. Check the available mains voltage against the data on the name plate.

2. Plug the system into the mains.

Hya-Rain/Hya-Rain N

27 of 64

Page 28

6 Commissioning/Start-up/Shutdown

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/Start-up

6.1.1 Prerequisites for commissioning/start-up

Before commissioning/start-up of the system make sure that the following

requirements are met:

▪ The system has been properly connected to the electric power supply and is

equipped with all protection devices.

▪ All relevant VDE standards and/or regulations applicable in the country of use are

complied with.

6.1.2 Priming and venting the system

Filling

ü Connect the mains water back-up system to the mains water supply.

(ðSection5.4.1,Page19)

ü The system has been properly connected to the power supply.

(ðSection5.5,Page22)

1. Set the operating mode selector switch to mains water mode for approximately

15seconds. (ðSection7,Page32)

ð The mains water storage tank will fill automatically.

Venting

ü The mains water storage tank has been filled.

ü The power plug has been plugged into the socket.

1. Insert the vent hose into the mains water storage tank.

Fig.19: Inserting the vent hose into the mains water storage tank

2. Open a consumer installation.

3. Set the master switch to 1. (ðSection7,Page32)

ð The system will be vented automatically.

4. Close the vent valve.

28 of 64

Hya-Rain/Hya-Rain N

Page 29

6 Commissioning/Start-up/Shutdown

6.1.3 Start-up

Hya-Rain ü The power plug has been plugged into the socket.

1. Set the master switch to 1. (ðSection7,Page32)

ð The pump control unit controls the system automatically:

▪ When a consumer installation is opened, the pump set starts up.

▪ When all consumer installations are closed, the pump set stops.

Table7: Description of indicator lamps

Lamp Description

Green Ready for operation

Red Lack of water: Dry running protection stops the pump set.

Fault: A fault can be reset by pressing the reset key. When the reset key

is pressed and held down, the system is in manual mode.

Hya-Rain N ü The power plug has been plugged into the socket.

1. Set the master switch to 1. (ðSection7,Page32)

2. Calibrate the level display. (ðSection7.3.1,Page36)

6.1.4 Functional test

Dry running protection

ü The system has been properly set up, installed, connected and commissioned.

1. Close the suction-side inlet of the rainwater storage tank.

ð No flow. The pump control unit stops the pump set after an after-run time of

approx. 10seconds.

2. If necessary, repeat the after-run time by pressing the reset key.

Operating modes

ü The system has been properly set up, installed, connected and commissioned.

1. Check the indicator lamps:

Table8: Indicator lamps for operating modes

Operating mode Symbol Indicator lamp

Automatic mode This indicator lamp lights up when the pump automatically switches to the

available water tank.

Mains water mode This indicator lamp lights up when the pump withdraws water from the

mains water storage tank and the mains water back-up system is activated.

Rainwater storage tank This indicator lamp lights up when the pump withdraws water from the

rainwater storage tank.

Hya-Rain/Hya-Rain N

29 of 64

Page 30

6 Commissioning/Start-up/Shutdown

6.2 Operating limits

6.2.1 Ambient conditions

Observe the following parameters and values during operation:

Table9: Permissible ambient conditions

Ambient condition Value

Ambient temperature +40°C maximum

Atmospheric humidity 50% maximum at 40°C

6.2.2 Maximum operating pressure

CAUTION

Permissible operating pressure exceeded

Damage to connections and seals!

▷ Never exceed the operating pressure specified in the data sheet.

The maximum operating pressure is 6 bar.

6.2.3 Fluid handled

6.2.3.1 Permissible fluids to be handled

▪ Service water

▪ Rainwater (not containing abrasive substances)

6.2.3.2 Fluid temperature

Maximum fluid temperature: 35°C

30 of 64

Hya-Rain/Hya-Rain N

Page 31

6 Commissioning/Start-up/Shutdown

6.3 Shutdown/storage/preservation

6.3.1 Measures to be taken for shutdown

WARNING

Unintentional start-up of the rainwater harvesting system

Risk of injury by moving parts!

▷ Only carry out work on the rainwater harvesting system after checking that the

system has been disconnected from the power supply.

▷ Secure the rainwater harvesting system against unintentional starting.

NOTE

To drain the mains water storage tank disconnect the suction line from the system

and set the three-way valve to the middle position.

1. Disconnect the system from the power supply and protect it against inadvertent

start-up.

2. Remove the system as per operating instructions.

3. Shut off the mains water supply and the discharge line.

4. Flush the system as per operating instructions.

5. Leave the system to dry.

6.3.2 Stopping the system

1. Close any valves fitted in the inlet line.

2. Set the master switch to 0.

Hya-Rain/Hya-Rain N

31 of 64

Page 32

7 Operation

3.1

3.2

3.3

1

1.1

1.2

1.3

2

2.2

2.3

3

4

5

2.1

7 Operation

CAUTION

Incorrect operation

Damage to the pump system!

▷ Make sure to comply with all local regulations, particularly the EC Machinery

Directive and the EC Directive on Low-Voltage Equipment.

▷ Check all electric cables prior to commissioning/start-up.

7.1 Control panel

Fig.20: Control panel

1 Operating mode selector switch with operating mode indicator

1.1 Automatic mode

1.2 Mains water mode (manual mode)

1.3 Rainwater mode (manual mode)

2 Level control system (Hya-Rain N only)

2.1 Display

2.2 Percentage setting key

2.3 Timer key

3 Pump control unit

3.1 Lamp (green)

3.2 Lamp (red)

3.3 Reset key

4 Master switch

5 Pressure gauge

32 of 64

Hya-Rain/Hya-Rain N

Page 33

7 Operation

7.2 Mode of operation

7.2.1 Automatic mode

Symbol:

▪ The pump set withdraws the fluid handled from the rainwater storage tank and

pumps it into the consumer system. It is controlled by the pump control unit.

– The rainwater mode lamp is lit in the operating mode indicator.

▪ The pump set is in operation as long as consumer installations (e.g. toilet flush

box, washing machines, garden watering systems) are open. When the consumer

installations are closed, the pump set will continue to run for approx. 10seconds

and will then automatically stop.

▪ When the rainwater storage tank is empty, the pump control unit switches to

mains water mode. As long as the pump set is running, mains water will be

supplied via the float valve. The quantity of mains water supplied will not exceed

current actual requirements. The mains water flow rate depends on the inlet

pressure of the public water supply system.

– The mains water mode lamp is lit in the operating mode indicator.

▪ The system will return to rainwater mode as soon as the water level in the

rainwater storage tank has risen back up to the minimum level.

7.2.2 Mains water mode (manual mode)

Symbol:

▪ The system exclusively withdraws mains water, even if the rainwater storage tank

is filled.

– The mains water mode lamp is lit in the operating mode indicator.

▪ For replacing the mains water in the mains water storage tank or when the

rainwater storage tank requires some maintenance.

7.2.3 Rainwater mode (manual mode)

Symbol:

▪ The system exclusively withdraws rainwater until the rainwater storage tank is

empty.

– The rainwater mode lamp is lit in the operating mode indicator.

▪ The dry running protection may trip the pump set.

– This mode can be used to pump the rainwater storage tank dry.

Hya-Rain/Hya-Rain N

33 of 64

Page 34

7 Operation

7.2.4 Priming

Before withdrawing water from the rainwater storage tank for the first time, the

mains water storage tank must be filled with water. It is filled automatically when

the operating mode selector switch is set to mains water mode for approx.

15seconds and the power plug is connected to a 230V power supply network.

Take the following measures to start the priming process (the process can take up to

4minutes):

ü The mains water storage tank has been filled with water.

1. Open a consumer installation (e.g. water connection in the garden).

2. Set the master switch to 1.

3. Set the operating mode selector switch to rainwater mode.

4. Press and hold down the reset key until the pump set is operating normally.

ð The pressure gauge indicates 2.5 to 4bar.

Should the priming process take longer, verify the following preconditions:

▪ The suction losses correspond to the system specifications.

▪ The suction line is tightly sealed.

▪ The suction line is sufficiently submerged in water.

34 of 64

Hya-Rain/Hya-Rain N

Page 35

7 Operation

1

2

3

7.3 Level control system (Hya-Rain N only)

Fig.21: Level control system

1 Percentage setting key 3 Display

2 Timer key

Table10: Key functions

Key Function

Percentage setting key ▪ Calibrate the fill level.

▪ Set the rainwater storage tank design.

▪ Change values in the menu. (Press down and hold the

key to change a value faster.)

▪ Close the menu.

Timer key ▪ Open the menu.

▪ Go to the next function.

▪ Enable replacement of the water in the rainwater

storage tank.

▪ Display the remaining days until the next module

flushing process.

▪ Display the remaining pump runtime during the

flushing process.

Table11: Level control system display

Display Description

8.8.8 Fill level of the rainwater storage tank and days remaining until the next

rainwater storage tank water replacement

tF Selection of the rainwater storage tank design

75 Fill level in the rainwater storage tank in % (here 75%)

L.. Switching level of the rainwater storage tank (levelxx)

t.. Days remaining until the next rainwater storage tank water replacement

P_ Time of pump operation remaining during rainwater storage tank water

replacement, in minutes

U.. Days until the next automatic valve switchover (protection against

incrustation)

Ei Additional display in the menu and calibration

Err Input signal error (sensor). No fill level can be detected.

Hya-Rain/Hya-Rain N

35 of 64

Page 36

7 Operation

7.3.1 Calibrating the level control system/ setting the rainwater storage tank design

For commissioning of the rainwater harvesting system and replacing the water in the

rainwater storage tank the level control system has to be calibrated and the

rainwater storage tank design has to be set. The level control system has to be

properly installed. (ðSection5.5.2,Page24)

The measured fill level of the rainwater storage tank does not always correspond to

the fill quantity; it depends on the rainwater storage tank design. One of three

rainwater storage tank designs can be selected in the level control system. The level

control system then automatically computes the fill quantity and displays it in%. The

sensor is analysed in steps of 1% with a digital control’s capacitive resistance.

▪ The length of the sensor submerged in the fluid handled is calibrated as 100%.

▪ When the water level drops from 100% to 5%, the system automatically

switches to mains water mode.

▪ When the water level rises again to a level exceeding 7%, the system

automatically switches to rainwater mode.

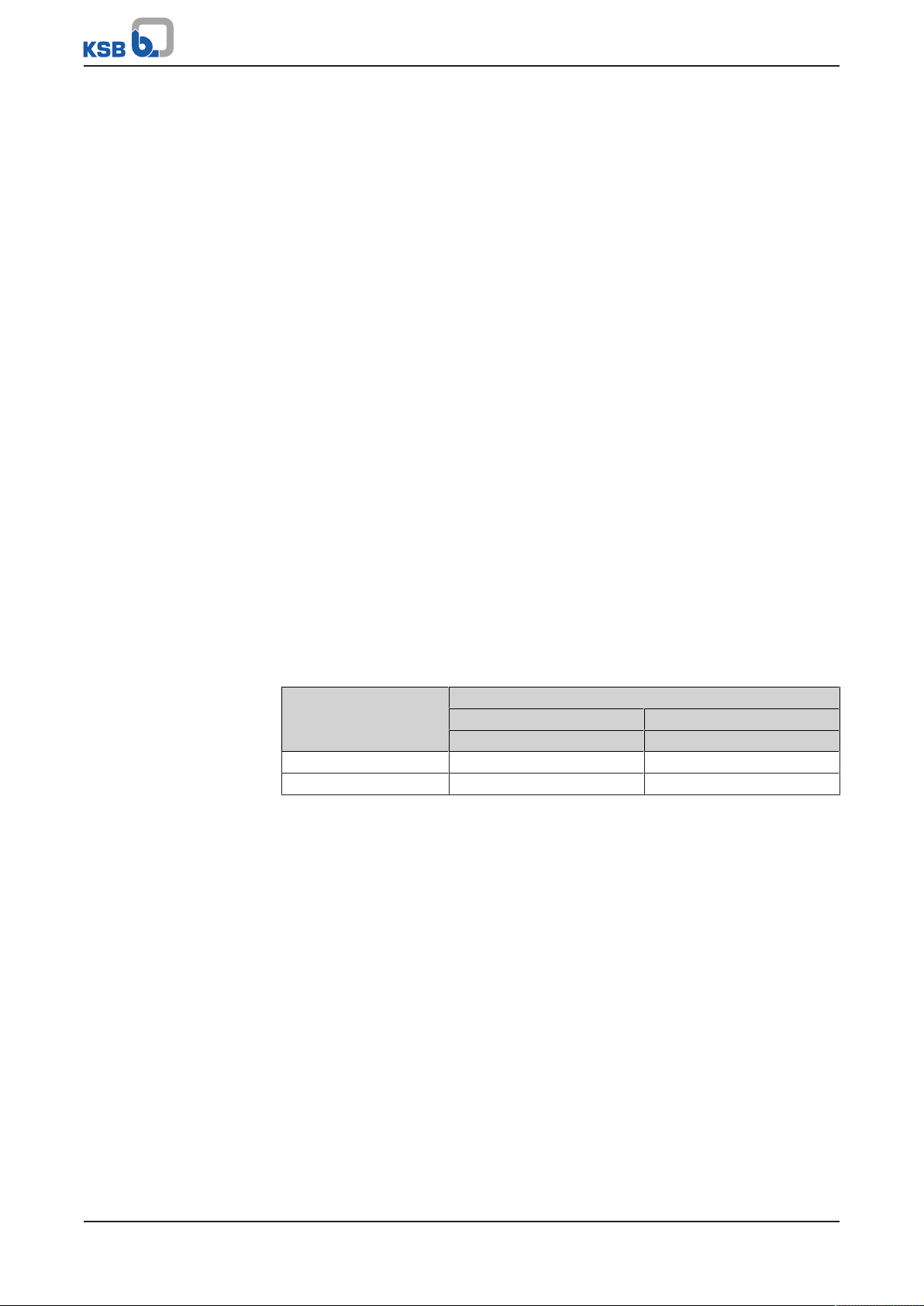

Table12: Fill level depending on the rainwater storage tank design

Display Rainwater storage tank

Fill level

design

tF1 Cylinder, vertical The fill level corresponds to the fill

quantity.

tF2 Cylinder, horizontal The fill level is computed.

tF3 Round tank The fill level is computed.

Factory setting:

▪ Rainwater storage tank design = tF1

Table13: Calibrating the level display and setting the rainwater storage tank design

Step 1: Calibrate the level display.

ü The level control system has been properly installed.

(ðSection5.5.2,Page24)

1. Press down and hold the percentage setting key for 10seconds

until Ei (calibration) is displayed.

Step 2: Setting the fill level as the reference value

1. Release the percentage setting key.

ð The fill level value calculated is permanently saved as the

reference value for 100%.

ð The display shows tF (rainwater storage tank design selection).

Step 3: Setting the rainwater storage tank design

ü The fill level value has been set.

ü tF (rainwater storage tank design selection) flashes on the displays.

1. Press the percentage setting key.

ð Every time the percentage setting key is pressed, the display

moves to the next rainwater storage tank design (tF1, tF2, tF3).

Step 4: Closing the rainwater storage tank design selection

1. To end the selection press the timer key 4×.

ð If none of the keys are pressed for 20seconds, the menu

automatically closes.

2. For setting the next function (ðSection7.3.2,Page37) press the

timer key again.

36 of 64

Hya-Rain/Hya-Rain N

Page 37

7 Operation

7.3.2 Setting the switching level for the rainwater storage tank

The switching level can be set to between 5 and 90%.

When the water level (switching level) in the rainwater storage tank drops below the

lower setpoint of 5%, the control system switches the three-way valve to mains

water mode.

When the water level exceeds the lower setpoint of 5% by 2%, the control system

switches the three-way valve back to rainwater mode..

To prevent frequent switching of the control system, the minimum difference

(hysteresis) of the switching level (mains water storage tank and rainwater storage

tank) always equals 2%.

Factory setting:

▪ Switching level= 5%

Table14: Setting the switching level for the rainwater storage tank

Step 1: Opening the menu

1. Press down and hold the timer key for 3seconds.

ð The menu opens.

Step 2: Choosing the function

1. Press down and hold the timer key until L.. (switching level of the

rainwater storage tank) is displayed.

Step 3: Setting the switching level

1. Press down and hold the percentage setting key to set the

required setpoint in increments of 1% in the range of 5 to 90%.

2. Press down and hold the timer key to save the required setpoint.

Step 3: Setting the next function or closing the menu

When the setting is completed, the menu automatically shows the next

function.

1. Set the next function (ðSection7.3.3,Page38) or close the

menu by briefly pressing the percentage setting key.

ð If none of the keys are pressed for 10seconds, the menu

automatically closes.

Hya-Rain/Hya-Rain N

37 of 64

Page 38

7 Operation

7.3.3 Setting and displaying the rainwater storage tank water replacement

Rainwater storage tank water replacement serves to flush the rainwater storage

tank. It is only enabled when the operating mode has been set to rainwater mode.

The control unit switches to mains water mode after a set interval. Rainwater storage

tank water replacement ends automatically when the pre-set pump runtime has

passed. When the flushing cycle stops, the control unit resets the interval time to the

pre-set value and switches to rainwater mode.

The interval can be set to between 10 and 60days. The pump runtime can be set to

between 1 and 9minutes.

Factory setting:

▪ Interval = 30days

▪ Pump runtime = 3minutes

Table15: Setting the rainwater storage tank water replacement

Step 1: Opening the menu

1. Press down and hold the timer key for 3seconds.

ð The menu opens.

Alternative:

1. After setting some other functions, press the timer key repeatedly

until t.. (days remaining until the next rainwater storage tank

water replacement) is displayed.

Step 2: Choosing the function

1. Press the timer key repeatedly until t.. (days remaining until the

next rainwater storage tank water replacement) is displayed.

Step 3: Setting the interval for rainwater storage tank water

replacement

1. Press the percentage setting key and set the number of days (10 to

60 days) for the flushing interval.

2. Press down and hold the timer key to save the required setpoint.

ð The display shows P_ (pump runtime remaining during

rainwater storage tank water replacement).

Step 4: Setting the pump runtime

ü The interval for tank water replacement has been set.

ü The display shows P_ (pump runtime remaining during rainwater

storage tank water replacement).

1. Press the percentage setting key and set the pump runtime in

minutes (1 to 9minutes).

2. Press down and hold the timer key to save the required setpoint.

Step 5: Setting the next function or closing the menu

When the setting is completed, the menu automatically shows the next

function.

1. Set the next function (ðSection7.3.4,Page39) or close the

menu by briefly pressing the percentage setting key.

ð If none of the keys are pressed for 10seconds, the menu

automatically closes.

38 of 64

Hya-Rain/Hya-Rain N

Page 39

7 Operation

Table16: Displaying the remaining days until the next rainwater storage tank water

replacement

Step 1: Choosing the function

1. Press the timer key.

ð The display shows the days remaining until the next rainwater

storage tank water replacement.

Step 2: Closing the function

▪ If none of the keys are pressed for 10seconds, the display

automatically closes.

7.3.4 Setting the valve switchover

To prevent incrustation of the three-way valve the control unit switches over the

valve for 12seconds after a set interval (forced movement). The valve then

automatically reverts to its previous position. Valve switchover can be set to between

01) and 10days.

Factory setting:

▪ Valve switchover = 2 days

Table17: Setting the valve switchover

Step 1: Opening the menu

1. Press down and hold the timer key for 3seconds.

ð The menu opens.

Alternative:

1. After setting some other functions, press the timer key repeatedly

until U.. (days until next automatic valve switchover) is displayed.

Step 2: Choosing the function

1. Press the timer key repeatedly until U.. (days until next automatic

valve switchover) is displayed.

Step 3: Setting the days until the next automatic valve switchover

1. Press the percentage setting key and set the number of days (1 to

9 days) for the flushing interval.

2. Press down and hold the timer key to save the required setpoint.

ð The menu is closed automatically.

1) 0 = function off

Hya-Rain/Hya-Rain N

39 of 64

Page 40

8 Servicing/Maintenance

8 Servicing/Maintenance

8.1 General information/safety regulations

DANGER

Unintentional start-up of the rainwater harvesting system

Danger to life from live parts!

▷ Always disconnect the rainwater harvesting system from the power supply

before repair or maintenance work is carried out.

▷ Disconnect the plug from the electric mains.

▷ Secure the system against unintentional starting.

WARNING

Unintentional start-up of the rainwater harvesting system

Risk of injury by moving parts!

▷ Only carry out work on the rainwater harvesting system after checking that the

system has been disconnected from the power supply.

▷ Secure the rainwater harvesting system against unintentional starting.

WARNING

Work on the rainwater harvesting system by unqualified personnel

Risk of personal injury!

▷ Always have repair and maintenance work performed by specially trained,

qualified personnel.

WARNING

Insufficient stability

Risk of crushing hands and feet!

▷ During assembly/dismantling, secure the pump (set)/pump parts to prevent

tilting or tipping over.

The operator ensures that maintenance, inspection and installation are performed by

authorised, qualified specialist personnel who are thoroughly familiar with the

manual.

Always observe the safety instructions and information.

A regular maintenance schedule will help avoid expensive repairs and contribute to

trouble-free, reliable operation of the rainwater harvesting system with a minimum

of maintenance expenditure and work.

Never use force when dismantling and reassembling the rainwater harvesting system.

NOTE

40 of 64

All maintenance work, service work and installation work can be carried out by KSB

Service or authorised workshops. For contact details please refer to the enclosed

"Addresses" booklet or visit "www.ksb.com/contact" on the Internet.

Hya-Rain/Hya-Rain N

Page 41

8 Servicing/Maintenance

A

8.2 Maintenance/inspection

KSB recommends the following regular servicing schedule:

Table18: Overview of maintenance work

Maintenance interval Maintenance work

Monthly Replace the stored mains water.

Every 6 months Check the mains water mode.

Check the pump control unit.

Check the discharge lines.

Every 8000 operating hours

approximately

8.2.1 Replacing the stored mains water

Hya-Rain We recommend replacing the stored mains water once a month.

1. Set the operating mode selector switch to mains water mode.

(ðSection7.2.2,Page33)

2. Flush the toilet or activate another consumer installation 2 or 3 times.

ð The noise of the mains water flowing into the tank can be heard.

3. Set the operating mode selector switch back to automatic mode.

(ðSection7.2.1,Page33)

Hya-Rain N The stored mains water is replaced automatically.

Replace the rolling element bearings.

8.2.2 Checking the mains water mode

1. Check the overflow for any escaping water.

ð If water escapes, the float valve could be defective and has to be replaced.

Replacing the float valve

Fig.22: Replacing the float valve

1. Shut off the mains water supply.

2. Undo the four screws (A) at the cover on the side.

3. Remove the cover.

4. Pull out the float valve.

5. Fit a new float valve and new sealing elements.

6. Fit the cover.

7. Screw in the four screws (A) hand-tight at the cover on the side.

Hya-Rain/Hya-Rain N

41 of 64

Page 42

8 Servicing/Maintenance

8.2.3 Checking the pump control unit

1. Open a consumer installation and close it again after the water has been

running for a short time.

ð Check that the pump stops approx. 10seconds after all consumer

installations have been closed.

8.2.4 Checking the discharge lines

1. Check the discharge lines/ discharge hoses for any leakage and damage.

ð In the event of visible leakage or severe damage of the metal sheath, replace

the hoses.

8.3 Drainage/cleaning

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Flush the system.

8.4 Dismantling the system

DANGER

Work on the rainwater harvesting system by unqualified personnel

Hazard from live parts!

▷ The system must only be dismantled and reassembled by a trained and qualified

electrician.

▷ The system must be de-energised before any work is carried out.

▷ Secure the system against unintentional starting.

8.4.1 Removing the pump set from the piping

1. Set the master switch to 0. (ðSection7,Page32)

2. Pull the power plug out of the socket.

3. Shut off the mains water supply and the discharge line.

4. Separate the suction connection. Set the three-way valve to the middle position.

ð Drain the mains water storage tank.

5. Remove the locking pin of the control unit. Push the control unit upwards and

pull it out.

42 of 64

Hya-Rain/Hya-Rain N

Page 43

8 Servicing/Maintenance

Fig.23: Removing the control panel

6. Undo the fixing stud of the mounting plate.

Fig.24: Removing the mounting plate

7. Pull the plate with pressure gauge and hose out sideways.

Fig.25: Removing the plate

8. For Hya-RainN disconnect the power supply of the display panel.

Fig.26: Disconnecting the power supply of the display panel (Hya-RainN)

9. Undo the nuts. Remove the system cover.

10. Disconnect the discharge line with a suitable tool.

Hya-Rain/Hya-Rain N

43 of 64

Page 44

8 Servicing/Maintenance

Fig.27: Disconnecting the discharge line

11. Undo the screws securing the pump.

Fig.28: Undoing the screws securing the pump

12. Pull out the pump set.

Fig.29: Pulling out the pump set

8.4.2 Removing the pump control unit

1. Remove the cable ties.

2. Undo the union nut at the discharge nozzle.

44 of 64

Hya-Rain/Hya-Rain N

Page 45

8 Servicing/Maintenance

Fig.30: Undoing the union nut at the discharge nozzle

Hya-Rain/Hya-Rain N

45 of 64

Page 46

8 Servicing/Maintenance

8.4.3 Removing the mechanical seal

ü The pump set has been properly removed from the system.

(ðSection8.4.2,Page44)

1. Place the pump set with the motor below in a clean assembly area.

2. Undo the hexagon socket head cap screws at the motor. Remove the suction

casing.

Fig.31: Removing the suction casing from the motor

3. Undo the impeller nut.

Fig.32: Undoing the impeller nut

4. Remove the impeller.

ð The mechanical seal is freely accessible.

Fig.33: Removing the impeller

5. Remove the circlip with a suitable tool.

46 of 64

Hya-Rain/Hya-Rain N

Page 47

8 Servicing/Maintenance

Fig.34: Removing the circlip

6. Pull the mechanical seal off the shaft.

7. Clean the removed components, check them for any wear. Replace them if

necessary.

8.5 Reassembling the system

DANGER

Work on the rainwater harvesting system by unqualified personnel

Hazard from live parts!

▷ The system must only be dismantled and reassembled by a trained and qualified

electrician.

▷ The system must be de-energised before any work is carried out.

▷ Secure the system against unintentional starting.

8.5.1 Installing the mechanical seal

ü The components have been cleaned and checked for any wear. They have been

replaced if necessary.

1. Slide the mechanical seal onto the shaft with a suitable tool. Make sure that the

mechanical seal is not damaged by burrs.

2. Fit the circlip.

Fig.35: Slide the mechanical seal onto the shaft.

3. Slide the impeller onto the shaft.

Hya-Rain/Hya-Rain N

47 of 64

Page 48

8 Servicing/Maintenance

Fig.36: Sliding the impeller onto the shaft

4. Fit the impeller nut and tighten it hand-tight.

Fig.37: Tightening the impeller nut

5. Fit an O-ring flush on the motor.

6. Position the suction casing on the motor. Fasten it with hexagon socket head

cap screws.

8.5.2 Installing the pump control unit

1. Fasten the union nut at the discharge nozzle.

Fig.38: Fastening the union nut at the discharge nozzle

2. Connect the cables.

48 of 64

Hya-Rain/Hya-Rain N

Page 49

8 Servicing/Maintenance

412.01

8.5.3 Installing the pump set

1. Grease O-ring 412.01.

2. Hold the pump set in position. Insert the inlet section into the fitting on the

tank floor.

Fig.39: Holding the pump set in position and inserting the inlet section into the

fitting

3. Tighten the screws securing the pump.

Fig.40: Fitting the screws securing the pump

4. Connect hose 719.02, leading it out at the right or left of the rainwater piping

system. Prevent excessive bending of the flexible connection lines.

Fig.41: Connecting the discharge line

5. Fit the system cover. Fasten it with nuts.

6. For Hya-Rain N connect the power cable of the display panel.

Hya-Rain/Hya-Rain N

49 of 64

Page 50

8 Servicing/Maintenance

Fig.42: Connecting the power cable of the display panel (Hya-RainN)

7. Insert the plate with pressure gauge and hose from the side.

Fig.43: Inserting the plate

8. Fit the mounting plate. Tighten the fastening screw hand-tight.

Fig.44: Fitting the mounting plate

9. Insert the control unit. Fasten it with the locking pin.

50 of 64

Fig.45: Inserting the control unit

10. Connect the suction line. Set the three-way valve to the corresponding position.

11. Connect and open the mains water supply and the discharge line.

(ðSection5.4,Page19)

12. Check the available mains voltage against the data on the name plate. Plug the

power plug into the socket.

13. Set the master switch to 1. (ðSection7,Page32)

Hya-Rain/Hya-Rain N

Page 51

9 Trouble-shooting

9 Trouble-shooting

WARNING

Improper work to remedy faults

Risk of injury!

▷ For any work performed to remedy faults, observe the relevant information

given in this instruction manual and/or in the product literature provided by the

accessories manufacturer.

If problems occur that are not described in the following table, consultation with the

KSB customer service is required.

Table19: Trouble-shooting

Fault Possible cause Remedy

Pump is running, but does not

deliver.

Excessive frequency of pump

starts

Pump is running but delivering

insufficient flow rate or

pressure.

Pump stops during operation. ▪ Power failure

Pump stops during operation;

"fault" is indicated.

System does not start. ▪ Pump control unit fault ▪ Press the reset key or interrupt the mains

System does not stop. ▪ Foreign object in pump