Page 1

KSB Guard

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual KSB Guard

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 09/11/2018

Page 3

Contents

Contents

1 General.................................................................................................................................................... 5

1.1 Principles ...........................................................................................................................................................5

1.2 Target group.....................................................................................................................................................5

1.3 Other applicable documents............................................................................................................................5

1.4 Symbols .............................................................................................................................................................5

1.5 Key to safety symbols/markings.......................................................................................................................5

2 Safety...................................................................................................................................................... 7

2.1 General..............................................................................................................................................................7

2.2 Intended use .....................................................................................................................................................7

2.3 Personnel qualification and personnel training.............................................................................................7

2.4 Consequences and risks caused by non-compliance with this operating manual........................................7

2.5 Safety awareness ..............................................................................................................................................8

2.6 Software changes .............................................................................................................................................8

3 Transport/Temporary Storage/Disposal............................................................................................... 9

3.1 Checking the condition upon delivery............................................................................................................9

3.2 Transport...........................................................................................................................................................9

3.3 Storage..............................................................................................................................................................9

3.4 Disposal ...........................................................................................................................................................10

4 Description............................................................................................................................................ 11

4.1 General description ........................................................................................................................................11

4.2 Name plates ....................................................................................................................................................11

4.3 Technical data.................................................................................................................................................11

4.4 Function ..........................................................................................................................................................12

4.5 Gateway ..........................................................................................................................................................13

4.6 Sensor unit ......................................................................................................................................................14

4.7 Transmission and battery unit .......................................................................................................................14

5 Installation/Commissioning................................................................................................................. 15

5.1 Installation ......................................................................................................................................................15

5.1.1 Installing the gateway.......................................................................................................................15

5.1.2 Installing the sensor unit...................................................................................................................18

5.1.3 Establishing a connection between the sensor unit and the transmission and battery unit........20

5.1.4 Commissioning...................................................................................................................................20

5.1.5 Installing the transmission and battery unit ....................................................................................21

5.1.6 Routing the connecting cable ...........................................................................................................21

5.2 Commissioning the gateway..........................................................................................................................22

5.3 Assigning and setting up ...............................................................................................................................23

6 Operation.............................................................................................................................................. 25

6.1 Operating modes of transmission and battery unit.....................................................................................25

6.2 Taking manual measurement and displaying signal strength.....................................................................25

6.3 Reading out the transmission status .............................................................................................................25

7 Changing the Batteries........................................................................................................................ 27

8 Dismantling .......................................................................................................................................... 28

8.1 Dismantling the gateway...............................................................................................................................28

8.2 Dismantling the transmission and battery unit............................................................................................28

8.3 Dismantling the sensor unit...........................................................................................................................29

9 Trouble-shooting.................................................................................................................................. 30

9.1 Trouble-shooting the gateway......................................................................................................................30

9.2 Trouble-shooting the transmission and battery unit/ sensor unit...............................................................30

10 Related Documents.............................................................................................................................. 32

10.1 Recommended mounting position for sensor unit ......................................................................................32

KSB Guard

3 of 40

Page 4

Contents

11 EU Declaration of Conformity............................................................................................................. 35

Index ..................................................................................................................................................... 36

4 of 40

KSB Guard

Page 5

1 General

!

DANGER

!

WARNING

CAUTION

1 General

1.1 Principles

This instruction manual is valid for the type series and variants indicated on the front

cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Target group

This instruction manual is aimed at the target group of trained and qualified

specialist technical personnel.

1.3 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Operating manual for pump/

pump set

For accessories and/or integrated machinery components, observe the relevant

manufacturer's product literature.

Description/operation of pump/pump set

1.4 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

⇨ Cross-references

1.

2.

Result of an action

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

1.5 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

KSB Guard

5 of 40

Page 6

1 General

Symbol Description

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

6 of 40

KSB Guard

Page 7

2 Safety

!

DANGER

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 General

This instruction manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The instruction manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this instruction manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this instruction manual.

2.2 Intended use

▪ The values specified in the technical product literature for the mains voltage and

ambient temperature must not be exceeded. The device must only be operated

in accordance with the instructions provided in the operating manual and other

applicable documents.

2.3 Personnel qualification and personnel training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the equipment this manual refers to. The responsibilities, competence and

supervision of all personnel involved in transport, installation, operation,

maintenance and inspection must be clearly defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the device must always be supervised by specialist technical personnel.

2.4 Consequences and risks caused by non-compliance with this operating manual

▪ Non-compliance with this operating manual will lead to forfeiture of warranty

cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

KSB Guard

7 of 40

Page 8

2 Safety

2.5 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.6 Software changes

The software has been specially created for this product and thoroughly tested.

It is impermissible to make any changes or additions to the software or parts of the

software.

8 of 40

KSB Guard

Page 9

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

CAUTION

Improper transport

Damage to the device!

▷ Always transport the device properly and in its original packaging.

▷ For transport, observe the transport instructions on the original packaging.

▷ Do not throw device.

1. Upon receipt, unpack the device and check for in-transit damage.

2. Report any in-transit damage to the manufacturer immediately.

3. Dispose of packaging material in accordance with local regulations.

3.3 Storage

If the ambient conditions for storage are met, the function of the device will be

ensured even after a prolonged period of storage.

CAUTION

Damage during storage by humidity, dirt or vermin

Corrosion/contamination of the device!

▷ For outdoor storage cover the (packed or unpacked) device and accessories with

water-proof material.

Table4: Ambient conditions for storage

Ambient condition Value

Relative humidity 85% max. (non-condensing)

Ambient temperature -30°C to +60°C

1. Store the device in dry conditions and in its original packaging.

2. Store the device in a dry room in which the atmospheric humidity is maintained

at a constant level (as far as this is possible).

3. Prevent excessive fluctuations in atmospheric humidity (see Ambient conditions

for storage table).

KSB Guard

9 of 40

Page 10

3 Transport/Temporary Storage/Disposal

3.4 Disposal

Electrical or electronic equipment marked with the adjacent symbol must not be

disposed of in household waste at the end of its service life.

Contact your local waste disposal partner for returns.

If the used electrical or electronic equipment contains personal data, the user is

responsible for deleting it before the equipment is returned.

NOTE

Due to certain components it contains, the device is classified as special waste and

meets RoHs 2011/65/EC requirements.

Once decommissioned, the device must be properly disposed of in accordance with

local regulations.

10 of 40

KSB Guard

Page 11

4 Description

KSB SE & Co.KGaA

www.ksb.com

Ambient Temperature:

Protection Class:

Id. No

0 - 90 °C

IP65

01852755

GS118W220001Serial No

KSB Guard Sensor Unit

KSB SE & Co.KGaA

www.ksb.com

Battery Supply: 2 x 1.5V (baby-cell)

0 - 50 °C

IP65

2.4 GHz / < 10mW

Indoor use only

01852758 / 01852753

GT118W260001

Johann-Klein-Str. 9

D-67227 Frankenthal

Protection Class:

KSB Guard Transmission and Battery Unit

Ambient Temperature:

Id. No (Complete System/This Unit):

Serial No

Sensor Network Comm.:

4 Description

4.1 General description

Monitoring device for monitoring vibrations and temperatures of pump sets.

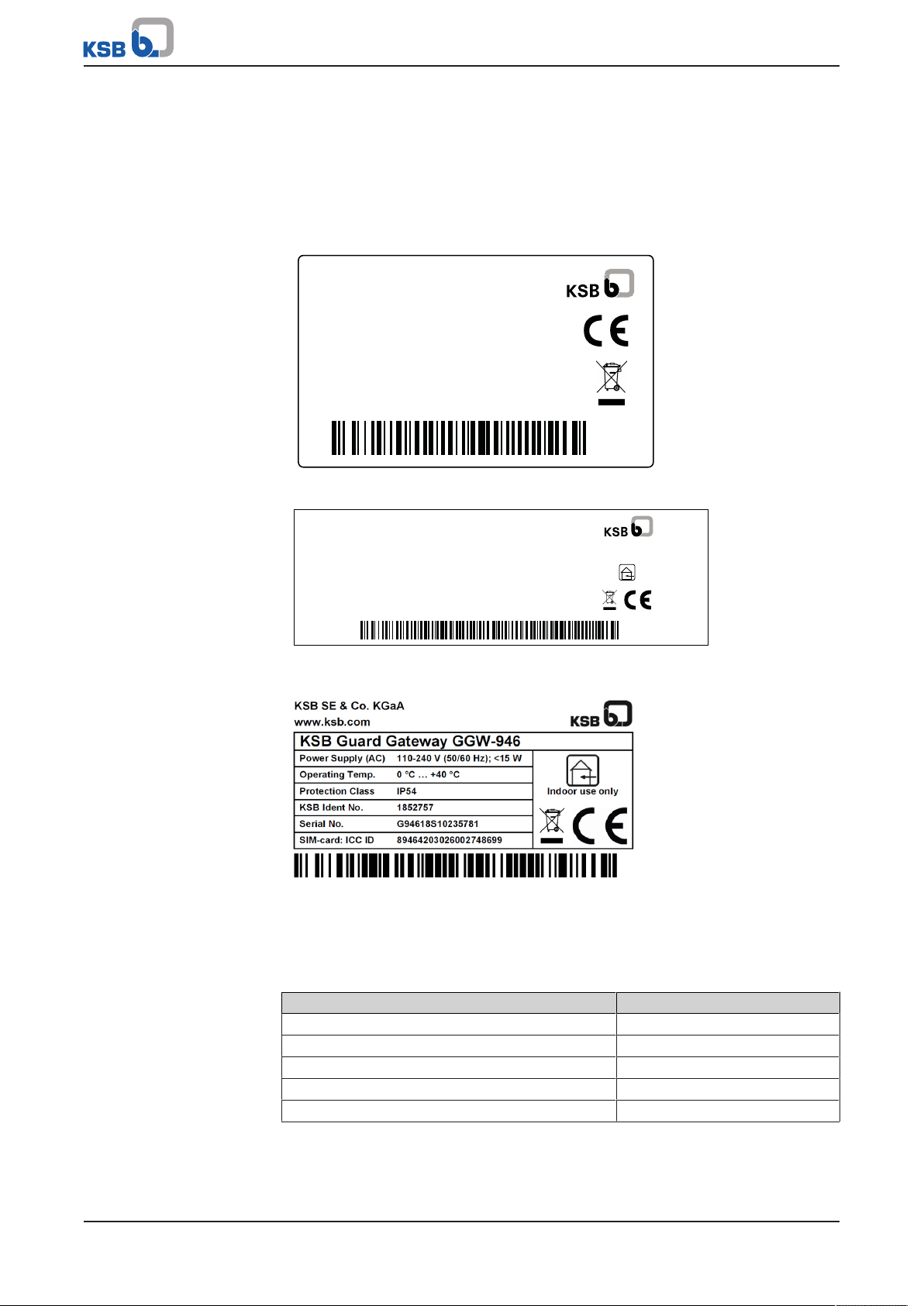

4.2 Name plates

Fig.1: Name plate of sensor unit

Sensor unit Table5: Technical data of sensor unit

Fig.2: Name plate of transmission and battery unit

Fig.3: Name plate of gateway

4.3 Technical data

Characteristic Value

Material Aluminium

Dimensions [mm] 60x45x30

Enclosure IP65

Cable type 1.5m, PUR, 6-pin

Ambient temperature ≤90°C

KSB Guard

11 of 40

Page 12

4 Description

Transmission and battery

unit

Gateway Table7: Technical data of gateway

Table6: Technical data of transmission and battery unit

Characteristic Value

Material Plastic

Dimensions [mm] 120x80x50

Enclosure IP65

Temperature range 0-50°C

Power supply 2 C size batteries (baby), (R14)

Wireless module ISM band, 2.4GHz

Connection M8, 6-pin

Characteristic Value

Mains voltage 110 - 240V, AC voltage

Mains frequency 50/60Hz

Power input <15W

In-service ambient temperature 0 to 40°C

1)

Enclosure IP54

Weight <400g

Dimensions 158×95×45

SMA-RP socket (antenna sensor network) Antenna for 2.4 GHz (WLAN/

Bluetooth)

SMA socket (LTE antenna) Antenna for 2G/3G/4G mobile

data, included in standard

accessories with approx. 5 m

cable

Internal SIM card

2)

Pre-configured

Transmission and battery

unit

Gateway One gateway can process the data of up to 20 transmission and battery units if they

4.4 Function

The sensor unit and transmission and battery unit are connected by a connecting

cable. The sensor unit is installed on the pump’s bearing bracket or drive lantern,

where it measures the pump’s vibration and temperature using built-in sensors.

This data is sent to the transmission and battery unit.

The transmission and battery unit sends the recorded data to the gateway via a radio

signal. From there, the data collected is transferred directly and in encrypted format

to the KSB Cloud for processing.

send data every hour. This number is reduced with more frequent data transmission.

1) Higher temperatures than indicated are possible. Contact KSB Support before installation. Contact: +49 6233 86 6400 and

ksbguard-support@ksb.com.

2) The SIM card is pre-installed and cannot be replaced.

12 of 40

KSB Guard

Page 13

4 Description

1 2 3 4 5

6

4.5 Gateway

Fig.4: Gateway

1 Antenna connection (data

transmission of transmission and

battery unit)

3 Status LED S1 for connection status 4 Level LEDs for mobile network

5 Antenna connection for mobile

data (LTE)

Table8: Description of LED indicators

No. LED Status Description

2 Supply voltage OFF Device is out of operation or in the initialisation phase.

Green Device is in operation. No faults present.

Red Device is in operation. Faults are present.

Flashing red Firmware update is being installed.

3 Connection status OFF No mobile network, no Internet

Yellow Mobile network accessible, no Internet

Green Mobile network and Internet accessible

4 Mobile network

signal strength

4th LED green Signal strength > -75dBm

3rd LED green Signal strength > -85dBm

2nd LED green Signal strength > -95dBm

1st LED green Signal strength < -95dBm

2 Status LED for supply voltage

signal strength (LTE)

6 Power supply connection

KSB Guard

13 of 40

Page 14

4 Description

1

2

1

2

5

6

3

4

4.6 Sensor unit

Fig.5: Sensor unit

1 QR code 2 Connecting cable to transmission

and battery unit

4.7 Transmission and battery unit

Fig.6: Transmission and battery unit

1 Pushbutton 2 Status LED A

3 Status LED B 4 Level LEDs for indicating the signal

strength of the gateway connection

5 Cover for housing screws 6 Connection for connecting cable to

sensor unit

Table9: Description/ function of control elements and LED indicators

Control element/ LED indicator Description

Pushbutton Commissioning, status check, manual measurement

Status LED A Status LEDs for indicating the operating status and for coded output of fault

Status LED B

Level LEDs Signal strength of the gateway connection

messages

14 of 40

KSB Guard

Page 15

5 Installation/Commissioning

5 Installation/Commissioning

5.1 Installation

5.1.1 Installing the gateway

DANGER

Risk of falling when working at a great height

Danger to life by falling from a great height!

▷ Do not step onto the pump (set) during installation work or dismantling work.

▷ Pay attention to safety equipment, such as railings, covers, barriers, etc.

▷ Observe the applicable local health and occupational safety regulations and

accident prevention regulations.

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

CAUTION

Incorrect installation

No data transmission!

▷ Never connect more than 20 transmission and battery units to a gateway.

▷ Maintain a minimum distance of approx. 100m between 2 gateways (or use

separate rooms/ halls).

One gateway can process the data of up to 20 transmission and battery units if they

send data every hour. This number is reduced with more frequent data transmission.

The manufacturer must be consulted if more than 20 transmission and battery units

are connected or if the data transmission rate is higher.

NOTE

Adding another gateway will not serve to increase the data transmission rate or the

number of connected transmission and battery units. If several gateways are within

transmission range of each other, this can lead to overlap and interference.

5.1.1.1 Checking the installation location of the gateway

The installation location of the gateway must meet the following requirements:

▪ Temperature 0-40°C3) (ðSection4.3,Page11)

▪ Only install and operate the gateway in closed rooms.

▪ No direct sunlight

▪ At least 2 m above the ground

▪ Maximum distance between gateway and transmission and battery unit: 30m

▪ Area between gateway and transmission and battery unit with as few obstacles

as possible (e.g. walls).

If possible: Install with a direct visual connection between the pump set to be

connected and the gateway.

3) Higher temperatures than indicated are possible. Contact KSB Support for more information.

KSB Guard

15 of 40

Page 16

5 Installation/Commissioning

1

2

5.1.1.2 Installing the gateway antennas

Fig.7: Installing antennas

1 Rod antenna 2 Magnetic base antenna

The antenna cable should not exceed 20 m in length.

1. Screw the supplied rod antenna onto the left connection (Antenna sensor

network).

2. Screw the magnetic base antenna onto the right connection (Antenna LTE).

3. Place the magnetic base antenna in a location that has sufficiently high mobile

network signal strength. (ðSection5.1.1.4,Page17)

5.1.1.3 Electrically connecting the gateway

Connecting to a shockproof socket

1. Plug the mains power cable supplied into the socket.

2. Check the status LED.

Make sure that at least 2 LEDs are lit. This indicates that the connection to the

mobile network is sufficiently strong.

ð When the mains power cable is connected, the gateway starts automatically and

can then be used.

Alternative connection to customer’s own power supply

DANGER

Improper work on electrical connection

Electric shock!

▷ The gateway may only be opened by a qualified electrical technician.

▷ Electrical work may only be carried out by a qualified electrical technician.

Alternatively, the mains power cable supplied can also be replaced with the

customer’s own mains power cable:

16 of 40

KSB Guard

Page 17

5 Installation/Commissioning

1

Fig.8: Gateway

1 Screw terminals for power supply

1. Insert customer’s own mains power cable into the device through the cable

gland.

2. Connect the mains power cable to the appropriate screw terminals on the circuit

board.

When the customer’s own mains power cable is connected, the gateway starts

automatically and can then be used.

3. Check status LED S1.

Make sure that at least 2 level LEDs are lit. This indicates that the connection to

the mobile network is sufficiently strong.

ð When the mains power cable is connected, the gateway starts automatically and

can then be used.

NOTE

When connecting the cable ensure that the enclosure requirements (IP54) are met

again after installation.

5.1.1.4 Checking the signal strength of the gateway

The signal strength of the mobile data connection can be changed by positioning the

magnetic base antenna. The current signal strength is indicated by the corresponding

level LEDs (see Table: Description of LED indicators). (ðSection4.5,Page13)

▪ Minimum sufficient signal strength is indicated by 2 level LEDs lighting up.

▪ Good signal strength is indicated by 3 level LEDs lighting up.

▪ Maximum signal strength is indicated by 4 level LEDs lighting up.

It is recommended that you position the magnetic base antenna such that 3 or 4 level

LEDs are lit during installation. (ðSection4.5,Page13)

1. Place the magnetic base antenna in a location that has sufficiently high mobile

network signal strength.

2. Check the level LEDs for mobile network signal strength.

3. If necessary, change the position of the magnetic base antenna and check again.

If this condition cannot be met, check whether a more powerful LTE antenna can be

installed using a longer cable (if required). In this scenario, an LTE antenna suitable

for outdoor installation is recommended in particular.

The antenna cable should not exceed 20 m in length.

KSB Guard

17 of 40

Page 18

5 Installation/Commissioning

1

2

NOTE

To improve data transmission between the gateway and the transmission and

battery unit, you can rotate and tilt the gateway antenna (data transmission of

transmission and battery unit). The gateway antenna acts in the plane

perpendicular to the antenna’s axis. The transmission and battery unit should be in

this plane. (ðSection4.5,Page13)

5.1.1.5 Fastening the gateway

Fig.9: Fastening the wall bracket

1 Wall bracket 2 Bolts/screws

ü The gateway antennas have been fitted.

ü The gateway is connected to the power supply.

ü The signal strength at the installation location has been checked and is sufficient.

1. Attach the wall mounting bracket supplied to a suitable wall using 2 screws.

2. Connect the rear adapter of the gateway to the wall bracket.

5.1.2 Installing the sensor unit

DANGER

Strong magnetic field

Danger of death for persons with pacemaker!

Interference with magnetic data carriers, electronic devices, components and

instruments!

Uncontrolled magnetic attraction forces between magnet-equipped components,

tools or similar!

▷ Keep a safety distance of at least 0.3m.

WARNING

18 of 40

Hot surfaces of pump set

Risk of burns!

▷ Observe the manufacturer’s safety instructions for fastening the sensor unit and

using the adhesive.

KSB Guard

Page 19

5 Installation/Commissioning

WARNING

Sensor unit takes on temperature of bearing bracket or drive lantern

Risk of burns!

▷ Observe the operating manual of the pump set.

▷ When the pump set is being operated, only touch the sensor unit using suitable

protective gloves.

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

Positioning the sensor unit Observe the following information when positioning and fastening the sensor unit:

▪ Mount the sensor unit at a suitable location on the bearing bracket or drive

lantern up to a maximum height of 2 m.

Recommended mounting position (ðSection10.1,Page32)

▪ Affix the sensor unit to magnetic material if possible (preferred).

▪ The location on the bearing bracket or drive lantern where the sensor unit is

mounted should be level. Use the adhesive to compensate for minor uneven

spots or curvatures.

▪ The sensor unit must also be glued in addition to the magnetic holders.

▪ (For further information on the correct mounting position, see www.ksb.com/

product/ksbguard).

ü The operating manual for the pump set is accessible and has been observed.

ü All safety instructions for the adhesive have been read and observed.

1. Remove any coarse dirt from the mounting area.

2. Clean the back of the sensor unit using the supplied cleaning pad.

3. Clean the mounting area using the supplied cleaning pad.

4. Spread the supplied adhesive over the back of the sensor unit.

5. Position the sensor unit on the cleaned area of the bearing bracket or drive

lantern. The sensor unit is optimally aligned when one axis of the sensor unit is

parallel to the shaft and the other axis of the sensor unit is horizontal to the

shaft.

6. Firmly press down the sensor unit.

7. Allow the sensor unit to dry on the bearing bracket or drive lantern to ensure

that the position of the sensor unit is not unintentionally changed during

subsequent mounting. The adhesive bond must be able to withstand slight

vibrations at the sensor unit. The waiting time heavily depends on ambient

conditions.

NOTE

At an ambient temperature between +25 °C and +30 °C, the supplied adhesive will

have sufficiently cured after approximately 24 hours. After 3 days, the adhesive will

have fully cured. Increased temperatures (e.g. +60°C to +120°C) accelerate the

curing process.

8. Check that the sensor unit is firmly positioned on the bearing bracket or drive

lantern; re-glue the sensor unit if necessary.

KSB Guard

19 of 40

Page 20

5 Installation/Commissioning

1

2

5

6

3

4

5.1.3 Establishing a connection between the sensor unit and the transmission and battery unit

NOTE

The adhesive bond between the sensor unit and bearing bracket or drive lantern

must be sufficiently cured before continuing to install the connecting cable to avoid

changing the position of the sensor unit.

1. Connect the connecting cable of the sensor unit to the transmission and battery

unit.

5.1.4 Commissioning

Supplied condition The transmission and battery unit is delivered in Deep Sleep mode

(ðSection6.1,Page25) . This operating mode remains active until commissioning

has been completed successfully.

During commissioning, a sensor unit must be detected and a functioning gateway

found within wireless range.

If commissioning is not successful, the device remains in Deep Sleep mode until it is

woken up by pressing and holding down the relevant button.

Commissioning

Fig.10: Transmission and battery unit

1 Pushbutton 2 Status LED A

3 Status LED B 4 Level LEDs for indicating the signal

strength of the gateway connection

5 Cover for housing screws 6 Connection for connecting cable to

sensor unit

ü The gateway has been installed and the signal strength indicated is sufficient.

ü The sensor has been fitted at a suitable location on the pump set.

ü The sensor unit and the transmission and battery unit are interconnected and the

power cable has been connected.

1. Press and hold the pushbutton (1) on the transmission and battery unit for 3

seconds. Release the pushbutton as soon as status LEDs A and B of the

transmission and battery unit briefly light up simultaneously.

ð All LEDs of the transmission and battery unit flash in a predefined sequence and

extinguish. The device is now in stand-by mode and commissioning/ start-up was

successful.

ð Commissioning/ start-up must be repeated if the LEDs of the transmission and

battery unit do not light up after a brief waiting period.

20 of 40

KSB Guard

Page 21

5 Installation/Commissioning

5.1.5 Installing the transmission and battery unit

The transmission and battery unit can be freely positioned as long as the transmission

quality to the gateway is sufficient. (ðSection5.1.4,Page20)

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

The area selected should have the following properties:

▪ Temperature of substrate ≤ 50°C

▪ Position protected

▪ Level

▪ Maximum ground clearance 2 m

ü Electrical connection between sensor unit and transmission and battery unit has

been established.

ü Batteries have been inserted. (Supplied condition)

ü Signal strength at installation location is sufficient. (ðSection6.2,Page25)

1. Position the transmission and battery unit such that there is a line of sight to the

gateway if possible. In the process, ensure that the connecting point of the

connecting cable can be easily accessed.

2. Clean the surface of the transmission and battery unit using the supplied alcohol

pads.

3. Securely attach the transmission and battery unit using the supplied fastening

material.

5.1.6 Routing the connecting cable

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

WARNING

Hot surfaces (Pump and piping take on the temperature of the fluid handled.)

Risk of burns!

▷ Do not touch hot surfaces.

CAUTION

Improper routing

Damage to the connecting cable!

▷ Never kink or crush the connecting cable.

KSB Guard

21 of 40

Page 22

5 Installation/Commissioning

Fig.11: Routing the connecting cable

1. Secure the connecting cable between the sensor unit and the transmission and

battery unit in such a way that no hazard (tripping, entrapment) can arise from

it.

2. Roll up excess length of connecting cable and fasten it using the supplied

fastening material.

5.2 Commissioning the gateway

The device is delivered fully configured and is ready for operation after the power

supply has been connected. The current operating status is indicated by the LED for

the supply voltage. (ðSection4.5,Page13)

22 of 40

KSB Guard

Page 23

5 Installation/Commissioning

5.3 Assigning and setting up

NOTE

The sensor unit must be initially assigned to a pump set.

This assignment cannot be subsequently undone and remains valid for the service

life of the sensor unit.

Correct assignment is key to ensuring proper functionality of the device.

Measurement data can only be saved after the assignment has been made.

You can make the assignment on the KSBGuard Web Portal (www.ksbguard.net) or

in the KSBGuard app (available for iOS and Android).

Further data will be required as you continue setting up the KSB Guard app. We

recommend that you collect the data in advance so that it is readily available when

you need it. The following data is required:

Table10: Data required to register the pump set in the KSBGuard app

Required data Example Notes

Serial number of the sensor unit

(ðSection4.6,Page14)

Designation of the pump set Pump 123

Location of the pump set Hall 2

Functional location of the pump set B2411

Optional: Photo of the pump set/pump

Data from the pump name plate

Manufacturer KSB

Year of construction 2018

Serial number

4)

Type series Etanorm

Size 050-032-161

Nominal head 25 m

Nominal flow rate 50m³/h

Nominal speed 1450rpm

Number of stages 1

Operating hours of the pump set to date (initial

value for the operating hours counter)

Data from the motor name plate

Nominal power 15kW

Nominal speed 1450 rpm

Power factor (cosϕ) 0,86

Other details

Variable speed system (yes or no) No

Application of the pump Heat supply system

Fluid temperature +20°C to +30°C

Density of the fluid handled 997 kg/m³

Bearing type and, if applicable, operating hours

since most recent bearing lubrication/

replacement

GS118W220071

997123456700010000

1000h

Grease, re-lubrication, 1000 h

4) With a pump set from KSB, data on the pump can be accessed when necessary. To do this, it is important that you enter the

KSB serial number in the corresponding field of the app/ web portal. If data is available, it is also displayed in the app or on

the web portal and must be checked to ensure that it is accurate and up to date.

KSB Guard

23 of 40

Page 24

5 Installation/Commissioning

Required data Example Notes

Optional: Optimum flow rate 50 m³/h

Optional: Specification of 7 reference points on

the characteristic curve

ü The KSB Guard app is installed on the mobile device.

ü Data as per table The data required to register the pump set in the KSBGuard app is

available.

1. Start the KSB Guard app or open the KSB Guard Web Portal

(www.ksbguard.net).

2. Select the Add Pump function in the app menu or on the web portal.

3. Follow the instructions in the app dialogue or on the web portal and enter the

requested information.

4. Save the assignment.

25kW, 25m³/h, 25 m;

20kW…

NOTE

The limit values for the pump set are set automatically. Default values can be

checked and, if necessary, changed in the individual view screen of the pump.

NOTE

Once the link has been established, 2 measuring cycles must be run through until

the data transferred from the pump set can be viewed on the web portal or in the

app. This process takes 2 hours at minimum for hourly data transfer (default

setting). If 2 measurements are triggered manually (ðSection6.2,Page25) , the

data can be viewed in just a few minutes’ time.

24 of 40

KSB Guard

Page 25

6 Operation

6 Operation

6.1 Operating modes of transmission and battery unit

▪ Deep Sleep

Status of the device before commissioning and after the batteries have been

removed for more than 10 s.

▪ Stand-by mode

After successful commissioning/ start-up, the device automatically switches to

stand-by mode following each measuring and transfer cycle to save energy. In

this status, all LEDs are off. The device wakes up cyclically (default setting: every

hour) and takes an automatic measurement.

6.2 Taking manual measurement and displaying signal strength

WARNING

Hot surfaces (Pump and piping take on the temperature of the fluid handled.)

Risk of burns!

▷ Do not touch hot surfaces.

WARNING

Sensor unit takes on temperature of bearing bracket or drive lantern

Risk of burns!

▷ Observe the operating manual of the pump set.

▷ When the pump set is being operated, only touch the sensor unit using suitable

protective gloves.

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

ü Commissioning was completed successfully. (ðSection5.1.4,Page20)

1. Briefly press the pushbutton on the transmission and battery unit.

ð The most recent transmission status is displayed.

2. Wait until status LEDs A and B flash slowly (0.5 Hz) together.

3. Briefly press the pushbutton on the transmission and battery unit again.

ð Manual measurement, signal strength is displayed and data is transmitted.

The level LEDs that indicate the signal strength light up briefly after a short

waiting time.

After the measurement is taken, the device automatically switches to stand-by mode

and all LEDs extinguish.

6.3 Reading out the transmission status

ü Commissioning was completed successfully. (ðSection5.1.4,Page20)

1. Briefly press the pushbutton on the transmission and battery unit.

ð The most recent transmission status is displayed.

The transmission status display is complete when status LEDs A and B flash slowly

together (0.5 Hz).

You can now trigger manual measurement if required. (ðSection6.2,Page25)

KSB Guard

25 of 40

Page 26

6 Operation

The device then automatically switches to stand-by mode and all LEDs extinguish.

26 of 40

KSB Guard

Page 27

7 Changing the Batteries

1

1

7 Changing the Batteries

The transmission and battery unit uses two 1.5V batteries.

Only non-rechargeable, standard alkaline batteries (size R14/ baby/ size C) may be

used. Do not insert any other type of battery.

CAUTION

Electrical connection work by unqualified personnel

Damage to the device!

▷ Only trained personnel may open the transmission and battery unit and change

the batteries.

NOTE

During battery replacement, ensure that the foamed-in housing gasket does not

become damaged.

Fig.12: Cover for housing screws

1 Cover for housing screws

1. Remove the glued-on covers for the housing screws (1) from the top of the

housing using a suitable tool.

2. Unscrew the 4 screws in the corners.

3. Pull off the upper part of the housing.

4. Carefully remove the used batteries from the holder, then wait approximately

10 seconds.

5. Insert 2 new batteries. Ensure correct polarity.

The prescribed polarity (+/-) is indicated by corresponding symbols on the circuit

board.

6. Briefly press the pushbutton on the top of the housing and check whether red

status LED A lights up briefly. If status LED A does not light up, check the battery

polarity or insert other batteries.

7. Place the upper part of the housing back on the housing assembly.

8. Screw the 4 screws back into the corners.

9. Glue both covers for the housing screws (1) back on.

10. Restart the transmission and battery unit. (ðSection5.1.4,Page20)

KSB Guard

27 of 40

Page 28

8 Dismantling

8 Dismantling

WARNING

Incorrect dismantling

Crushing, impact injuries, cuts!

▷ Use suitable tools only.

▷ Wear suitable protective equipment.

8.1 Dismantling the gateway

DANGER

Risk of falling when working at a great height

Danger to life by falling from a great height!

▷ Do not step onto the pump (set) during installation work or dismantling work.

▷ Pay attention to safety equipment, such as railings, covers, barriers, etc.

▷ Observe the applicable local health and occupational safety regulations and

accident prevention regulations.

DANGER

Improper work on electrical connection

Electric shock!

▷ The gateway may only be opened by a qualified electrical technician.

▷ Electrical work may only be carried out by a qualified electrical technician.

1. Disconnect the power supply.

2. Detach the rear adapter of the gateway from the wall bracket.

3. Remove the wall-mounting bracket from the wall.

8.2 Dismantling the transmission and battery unit

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

WARNING

Hot surfaces (Pump and piping take on the temperature of the fluid handled.)

Risk of burns!

▷ Do not touch hot surfaces.

28 of 40

1. Disconnect the connecting cable of the sensor unit.

2. Carefully remove the transmission and battery unit from the installation

location. Use a lever tool if necessary.

KSB Guard

Page 29

8 Dismantling

8.3 Dismantling the sensor unit

DANGER

Strong magnetic field

Danger of death for persons with pacemaker!

Interference with magnetic data carriers, electronic devices, components and

instruments!

Uncontrolled magnetic attraction forces between magnet-equipped components,

tools or similar!

▷ Keep a safety distance of at least 0.3m.

WARNING

Work in the immediate vicinity of rotating parts

Risk of hand injury!

▷ Always have this work performed by trained personnel.

▷ Take particular caution when performing this work.

WARNING

Hot surfaces (Pump and piping take on the temperature of the fluid handled.)

Risk of burns!

▷ Do not touch hot surfaces.

ü The connecting cable leading to the transmitter and battery unit has been

removed.

1. Tap off the sensor unit using a soft-face mallet.

KSB Guard

29 of 40

Page 30

9 Trouble-shooting

9 Trouble-shooting

If problems occur that are not described in the following tables, consultation with

KSBGuard Customer Service is required:

▪ 24-h hotline : +49 6233 86 6400

▪ E-mail: ksbguard-support@ksb.com

NOTE

To ensure quick assistance, have the serial number of the sensor unit readily

available.

9.1 Trouble-shooting the gateway

Table11: Gateway trouble-shooting

Error/ defect description Possible cause Remedy

No LED is lit. No connection to mains power

supply

Only one or no green level LED is lit at

the gateway, but status LED S1 is lit

green.

Status LED S1 remains off for more

than 1 minute after the power supply

has been established or is lit yellow.

▪ Solid exterior walls

▪ Great deal of metal in the

surrounding area

▪ Unfavourable position in the

basement of the building

▪ Poor mobile data connection

at the location

Internal fault ▪ Contact KSBGuard Customer

▪ Plug in the mains plug or connect

the mains voltage internally in the

device. (ðSection5.1.1.3,Page16)

▪ Change the position of the

supplied LTE antenna until 3 or 4

level LEDs light up.

▪ If necessary, install an additional

LTE antenna with a longer cable to

achieve a more favourable

position.

(ðSection5.1.1.4,Page17)

▪ Install an outdoor LTE antenna

outside the building.

Service.

9.2 Trouble-shooting the transmission and battery unit/ sensor unit

Table12: Trouble-shooting during commissioning

Error/ defect description Possible cause Remedy

There is no response to a brief press of

the pushbutton.

A brief press of the button produces a

longer flashing sequence (last

transmission status displayed).

▪ The battery is missing or is

discharged.

▪ System error

▪ The system has already been

commissioned.

▪ Change the batteries.

(ðSection7,Page27)

▪ Remove the batteries for 10s, then

reinsert.

▪ Contact KSBGuard Customer

Service.

▪ The device may have been

inadvertently commissioned.

Remove the batteries for 10s, then

reinsert.

Then perform commissioning.

(ðSection5.1.4,Page20)

30 of 40

KSB Guard

Page 31

9 Trouble-shooting

Error/ defect description Possible cause Remedy

After an extended press of the button,

none of the red level LEDs for the

transmission and battery unit light up.

KSG Guard does not send any data to

the KSB Cloud or does not yet appear

there.

Table13: Trouble-shooting during operation

Error/ defect description Possible cause Remedy

KSBGuard does not provide any data

following successful assignment.

Data is suddenly no longer transmitted

during operation, or there are

frequently large time gaps between 2

transfer cycles.

▪ Gateway is switched off. ▪ Switch on gateway.

▪ Gateway is out of range. ▪ If possible, place the transmission

and battery unit within wireless

range of the gateway and test

again.

▪ Sensor unit has not yet been

connected or is defective.

▪ KSB Guard has not been

assigned to a pump set.

▪ Problem in the KSB Cloud

▪ Hardware is defective.

▪ Poor LTE connection ▪ (ðSection9.1,Page30)

▪ The wireless connection

between the transmission and

battery unit and the gateway

is too weak or unstable (local

interference).

▪ Check the connection between the

transmission and battery unit and

the sensor unit, and replace the

sensor if required.

▪ Assign KSB Guard to a pump set

(ðSection5.3,Page23) .

▪ Contact KSBGuard Customer

Service.

▪ Trigger manual measurement

(ðSection6.2,Page25) and check

result. If less than 2 red level LEDs

on the transmission and battery

unit light up, change the position

of the transmission and battery

unit and/or gateway.

(ðSection5.1.5,Page21)

(ðSection5.1.1.1,Page15)

KSB Guard

31 of 40

Page 32

10 Related Documents

10 Related Documents

10.1 Recommended mounting position for sensor unit

The position of the sensor unit as shown in the illustrations is recommended,

depending on the type series.

Fig.13: Etanorm mit Sensoreinheit

Fig.14: Etaline with sensor unit

32 of 40

Fig.15: Etabloc with sensor unit

KSB Guard

Page 33

10 Related Documents

Fig.16: Etaline R with sensor unit

Fig.17: MegaCPK with sensor unit

Fig.18: Movitec with sensor unit

KSB Guard

33 of 40

Page 34

10 Related Documents

Fig.19: Multitec with sensor unit

Fig.20: Omega with sensor unit

Fig.21: Sewatec with sensor unit

34 of 40

KSB Guard

Page 35

11 EU Declaration of Conformity

11 EU Declaration of Conformity

Manufacturer: KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal (Germany)

This Declaration of Conformity is issued under the sole responsibility of the manufacturer.

The manufacturer herewith declares that the product:

KSB Guard

Serial number ranges:

KSB Guard sensor unit: GS118W22xxxx to GS130W52xxxx

KSB Guard transmission and battery unit: GT118W22xxxx to GT130W52xxxx

KSB Guard gateway: G94618S22xxxxxx to G94630S52xxxxxx

▪ is in conformity with the provisions of the following Directives as amended from time to time:

– 2014/53/EU: Radio Equipment Directive (RED)

– 2011/65/EU: Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment

(RoHS)

The manufacturer also declares that the following harmonised international standards have been applied:

▪ KSB Guard sensor unit and KSB Guard transmission and battery unit

– IEC 60529 (2nd edition): 2013-08

– IEC 62368-1: 2014 (2nd edition) and Cor. 1: 2015

– EN 62368-1: 2014/AC: 2015/ A11:2017

– ETSI EN 300 328 V2.1.1

– ETSI EN 301 489-1 V2.2.0: 2017-03

– ETSI EN 301 489-17 V3.2.0: 2017-03

▪ KSB Guard gateway

– ETSI EN 300 328 V2.1.1

– DIN EN 55024:2016-05

– DIN EN 55032:2016-02

– EN 62368-1:2014 + AC:2015-05 + AC:2015-11

The EU Declaration of Conformity was issued in/on:

Frankenthal, 1 Sept. 2018

Thomas Paulus

Head of TPD, Digital Transformation

KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal

KSB Guard

35 of 40

Page 36

Index

Index

numerical

24-h hotline30

A

Adhesive curing19

Antennas16

Assignment

Sensor unit23

Automatic measurement25

B

Batteries27

C

Changing the batteries27

Commissioning20

Connecting cable20

Control elements

Transmission and battery unit14

Cover for housing screws27

Customer’s own mains power cable17

D

Deep Sleep20, 25

Dismantling

Gateway28

Sensor unit29

Transmission and battery unit28

Disposal10

E

EU Declaration of Conformity35

Event of damage5

F

Faults

Trouble-shooting31

Trouble-shooting the gateway30

Trouble-shooting the transmission and battery

unit/ sensor unit30

Function12

G

Gateway13, 17, 18, 22

LED indicators13

I

Improving data transmission18

Installation

Transmission and battery unit21

Installation location

Gateway15

Sensor unit19

Installing the transmission and battery unit21

Intended use7

K

Key to safety symbols/markings5

KSBGuard app24

KSBGuard Customer Service30

L

LED indicators

Gateway13

Transmission and battery unit14

Limits24

M

Magnetic base antenna17

Manual measurement25

Mounting position32

N

Name plate11

O

Operating modes25

Other applicable documents5

P

Positioning the sensor unit19

Power supply16

R

Registration23

Routing the connecting cable22

S

Safety7

Safety awareness8

Sensor unit14, 19

Signal strength of the mobile data connection17

Stand-by mode25

Storage9

Supplied condition20, 21

36 of 40

KSB Guard

Page 37

Index

T

Technical data

Gateway12

Sensor unit11

Transmission and battery unit12

Transmission and battery unit14, 20

LED indicators14

Transmission status25

Transport9

Trouble-shooting30

W

Wall bracket18

Warnings5

Warranty claims5

KSB Guard

37 of 40

Page 38

Page 39

Page 40

KSB SE & Co. KGaA

Johann-Klein-Straße 9 • 67227 Frankenthal (Germany)

Tel. +49 6233 86-0

www.ksb.com

4079.8/01-EN

Loading...

Loading...