Page 1

Operating Instructions

Close-coupled Pumps

Etabloc

Page 2

Page 3

Page

1 General 4

2 Safety 4

2.1 Marking of instructions in the manual 4

2.2 Personnel qualification and training 4

2.3 Non-compliance with safety instructions 4

2.4 Safety awareness 4

2.5 Safety instructions for the operator / user 4

2.6 Safety instructions for maintenance, inspection

and installation work 4

2.7 Unauthorized modification and manufacture of

spare parts 5

2.8 Unauthorized modes of operation 5

3 Transport and interim storage 5

3.1 Transport 5

3.2 Interim storage / Preservation 5

4 Description of the product and accessories 5

4.1 Technical specification 5

4.2 Designation 5

4.3 Design details 6

4.3.1 Pump 6

4.4 Noise characteristics 6

5 Installation at site 6

5.1 Safety regulations 6

5.2 Checks to be carried out prior to installation 6

5.3 Installation method 6

5.4 Installing the pump set 6

5.4.1 Place of installation 6

5.5 Connecting the piping 7

5.5.1 Auxiliary connections 7

5.5.2 Vacuum balance line 7

5.6 Final check 7

5.7 Connection to power supply 7

5.7.1 Motor connection 8

5.7.2 Setting the time relay 8

5.7.3 Checking the direction of rotation 8

6 Commissioning, start-up / shutdown 8

6.1 Commissioning 8

6.1.1 Shaft seal 8

6.1.2 Priming the pump and checks to be carried out 8

6.1.3 Final check 8

6.1.4 Contact guard 8

6.1.5 Start-up 8

6.1.6 Shutdown 8

6.2 Operating limits 9

6.2.1 Temperature of the medium handled 9

6.2.2 Switching frequency 9

6.2.3 Minimum flow 9

6.2.4 Density of medium handled 9

6.3 Shutdown / storage / preservation 9

6.3.1 Storage of new pumps 9

6.3.2 Measures to be taken for prolonged shutdown 9

6.4 Returning to service after storage 9

Page

7 Servicing / maintenance 9

7.1 General instructions 9

7.2 Servicing / inspection 9

7.2.1 Supervision of operation 9

7.2.2 Lubrication and lubricant change 9

7.3 Drainage / disposal 10

7.4 Dismantling 10

7.4.1 Fundamental instructions and recommendations 10

7.4.2 Preparations for dismantling 10

7.4.3 Pump 10

7.4.4 Mechanical seal 10

7.5 Reassembly 11

7.5.1 Pump 11

7.5.2 Mechanical seal 11

7.5.3 Motor for Etabloc N 11

7.5.4 Tightening torques 11

7.6 Spare parts 12

7.6.1 Ordering spare parts 12

7.6.2 Recommended spare parts stock 12

8 Trouble-shooting 13

9 Related documents 14

9.1 Typical Installation Positions 14

9.2 Exploded view and list of components

Etabloc G 15

9.3 Exploded view and list of component Etabloc G 16

9.4 Exploded view and list of components

Etabloc N 17

Etabloc

Contents

2

Page 4

3

Etabloc

Section Page

Auxiliary connections 5.5.1 7

Checking the direction of rotation 5.7.3 8

Checks to be carried out prior to installation 5.2 6

Commissioning 6.1 8

Commissioning, start-up / shutdown 6 8

Connecting the piping 5.5 7

Connection to power supply 5.7 7

Contact guard 6.1.4 8

Density of medium handled 6.2.4 9

Description of the product and accessories 4 5

Design details 4.3 6

Designation 4.2 5

Dismantling 7.4 10

Drainage / disposal 7.3 10

Exploded view and list of components

Etabloc G 9.3 16

Exploded view and list of components

Etabloc G 9.2 15

Exploded view and list of components

Etabloc N 9.4 17

Final check 5.6/ 7/

6.1.3 8

Fundamental instructions and

recommendations 7.4.1 10

General 1 4

General instructions 7.1 9

Installation at site 5 6

Installing the pump set 5.4 6

Installation method 5.3 6

Interim storage / Preservation 3.2 5

Lubrication and lubricant change 7.2.2 9

Marking of instructions in the manual 2.1 4

Measures to be taken for prolonged shutdown 6.3.2 9

Mechanical seal 7.4.4/ 10/

7.5.2 11

Minimum flow 6.2.3 9

Motor connection 5.7.1 8

Motor for Etabloc N 7.5.3 11

Noise characteristics 4.4 6

Non-compliance with safety instructions 2.3 4

Operating limits 6.2 9

Ordering spare parts 7.6.1 12

Personnel qualification and training 2.2 4

Place of installation 5.4.1 6

Preparations for dismantling 7.4.2 10

Priming the pump and checks to be carried out 6.1.2 8

Pump 4.3.1/ 6/

7.4.3/ 10/

7.5.1 11

Reassembly 7.5 11

Recommended spare parts 7.6.2 13

Related documents 9 14

Returning to service after storage 6.4 8

Safety 2 4

Safety awareness 2.4 4

Section Page

Safety instructions for maintenance, inspection

and installation work 2.6 4

Safety instructions for the operator / user 2.5 4

Safety regulations 5.1 6

Servicing / inspection 7.2 9

Servicing / maintenance 7 9

Setting the time relay 5.7.2 8

Shaft seal 6.1.1 8

Shutdown 6.1.6 8

Shutdown / storage / preservation 6.3 9

Spare parts 7.6 12

Start-up 6.1.5 8

Storage of new pumps 6.3.1 9

Supervision of operation 7.2.1 9

Switching frequency 6.2.2 9

Technical specification 4.1 5

Temperature of the medium handled 6.2.1 9

Tightening torques 7.5.4 11

Transport 3.1 5

Transport and interim storage 3 5

Trouble-shooting 8 13

Typical installation positions 9.1 14

Unauthorized modes of operation 2.8 5

Unauthorized modification and manufacture of

spare parts 2.7 5

Vacuum balance line 5.5.2 7

Index

Page 5

Etabloc

1 General

This KSB product has been developed in accor-

dance with state-of-the-art technology; it is manufactured with utmost care and subject to continuous quality

control.

These operating instructions are intended to facilitate familiarization with the unit and its designated use. The manual contains important information for reliable, proper and efficient

operation. Compliance with the operating instructions is of

vital importance to ensure reliability and a long service life of

the unit and to avoid any risks.

These operating instructions do not take into account local

regulations; the operator must ensure that such regulations

are strictly observed by all, including the personnel called in

for installation.

This pump / unit must not be operated beyond the limit

values for the medium handled, capacity, speed, densi-

ty,

pressure, temperature and motor rating specified in the technical documentation. Make sure that operation is in accordance with the instructions laid down in this manual or in the

contract documentation. Contact the manufacturer, if required.

The name plate indicates the type series / size, main operating data and identification number; please quote this information in all queries, repeat orders and particularly when ordering spare parts.If you need any additional information or

instructions exceeding the scope of this manual or in case of

damage please contact KSB’s nearest customer service centre. Noise characteristics see section 4.5.

2 Safety

These operating instructions contain fundamental information

which must be complied with during installation, operation and

maintenance. Therefore this operating manual must be read

and understood both by the installing personnel and the

responsible trained personnel / operators prior to installation

and commissioning, and it must always be kept close to the

location of operation of the machine / unit for easy access. Not

only must the general safety instructions laid down in this

chapter on ”Safety” be complied with, but also the safety

instructions outlined under specific headings.

2.1 Marking of instructions in the manual

The safety instructions contained in this manual whose

non-observance might cause hazards to persons are specially marked with the symbol

general hazard sign to ISO 7000-0434

The electrical danger warning sign is

safety sign to IEC 417 - 5036,

The word

is used to introduce safety instructions whose non-observance may lead to damage to the machine and its functions.

Instructions attached directly to the machine, e.g.

- arrow indicating the direction of rotation

- markings for fluid connections

must always be complied with and be kept in a perfectly legible condition at all times.

2.2 Personnel qualification and training

All personnel involved in the operation, maintenance, inspection and installation of the unit must be fully qualified to carry

out the work involved.

Personnel responsibilities, competence and supervision must

be clearly defined by the operator. If the personnel in question

is not already in possession of the requisite know-how, appropriate training and instruction must be provided. If required,

the operator may commission the manufacturer / supplier to

take care of such training. In addition, the operator is responsible for ensuring that the contents of the operating instructions are fully understood by the responsible personnel.

2.3 Non-compliance with safety instructions

Non-compliance with safety instructions can jeopardize the

safety of personnel, the environment and the machine / unit

itself. Non-compliance with these safety instructions will also

lead to forfeiture of any and all rights to claims for damages.

In particular, non-compliance can, for example, result in:

- failure of important unit/system functions,

- failure of prescribed maintenance and servicing practices,

- hazard to persons by electrical, mechanical and chemical

effects,

- hazard to the environment due to leakage of hazardous

substances.

2.4 Safety awareness

It is imperative to comply with the safety instructions contained

in this manual, the relevant national health and safety regulations and the operator’s own internal work, operation and

safety regulations.

2.5 Safety instructions for the operator / user

- Any hot or cold components that could pose a hazard

must be equipped with a guard by the operator.

- Guards which are fitted to prevent accidental contact with

moving parts (e.g. coupling)must not be removed whilst

the unit is operating.

- Leakages (e.g. at the shaft seal) of hazardous media handled (e.g. explosive, toxic, hot)must be contained so as to

avoid any danger to persons or the environment. All relevant laws must be heeded.

- Electrical hazards must be eliminated. (In this respect

refer to the relevant safety regulations applicable to different countries and/or the local energy supply companies.)

2.6 Safety instructions for maintenance, inspection and

installation work

The operator is responsible for ensuring that all maintenance,

inspection and installation work be performed by authorized,

qualified specialist personnel who are thoroughly familiar with

the manual.

The pump must have cooled down to ambient temperature,

pump pressure must have been released and the pump must

have been drained.

Work on the machine / unit must be carried out only during

standstill. The shutdown procedure described in the manual

for

taking the unit out of service must be adhered to without fail.

Pumps or pump units handling media injurious to health must

be decontaminated.

Caution

!

!

Caution

4

Page 6

5

Immediately following completion of the work, all safety-relevant and protective devices must be re-installed and / or reactivated.

Please observe all instructions set out in the chapter on

“Commissioning/Start-up” before returning the unit to service.

2.7 Unauthorized modification and manufacture of spare

parts

Modifications or alterations of the equipment supplied are only

permitted after consultation with the manufacturer. Original

spare parts and accessories authorized by the manufacturer

ensure safety. The use of other parts can invalidate any liability of the manufacturer for consequential damage.

2.8 Unauthorized modes of operation

The warranty relating to the operating reliability and safety of

the unit supplied is only valid if the equipment is used in accordance with its designated use as described in the following

sections of this manual. The limits stated in the data sheet

must not be exceeded under any circumstances.

3 Transport and interim storage

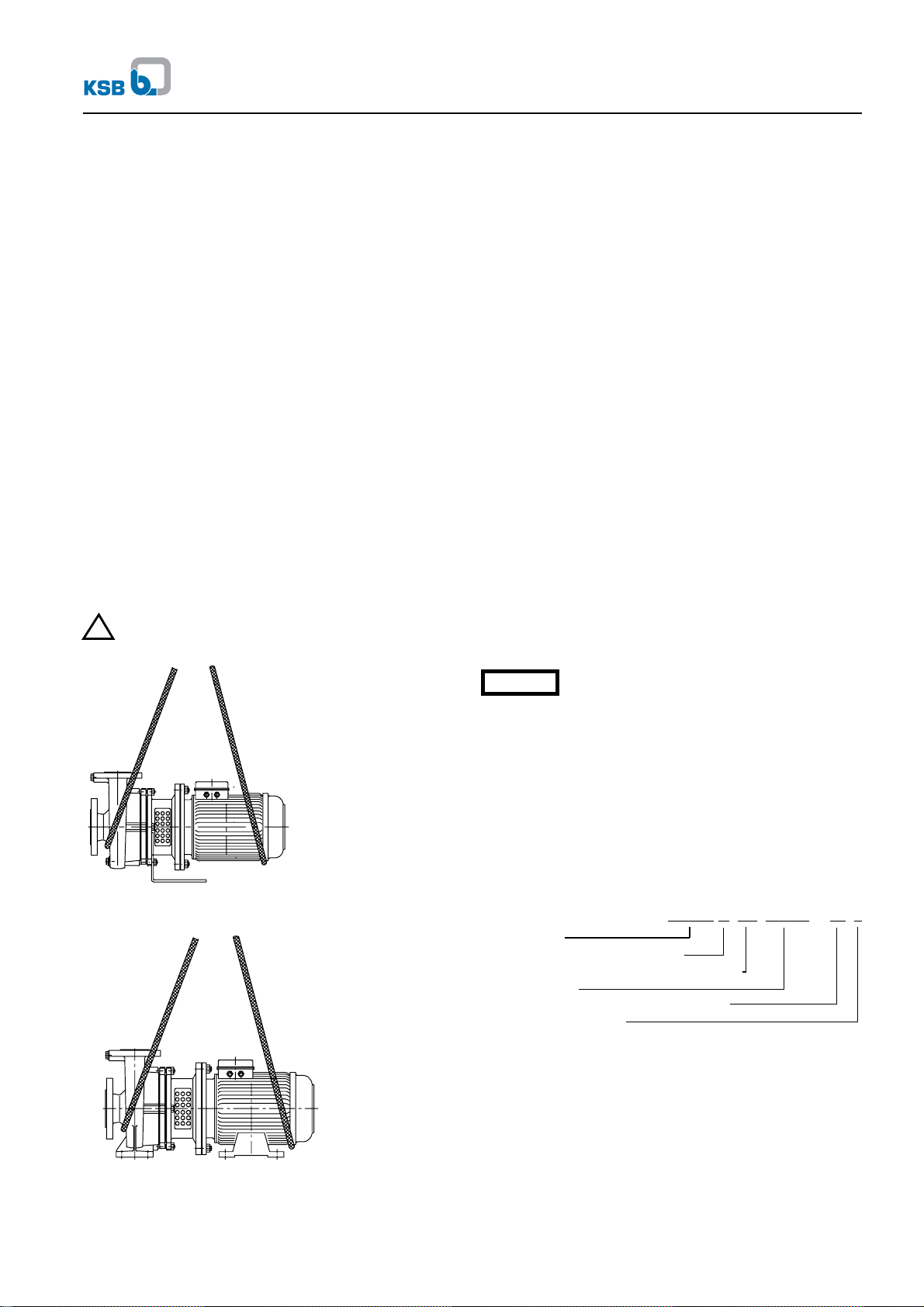

3.1 Transport

Transport of the unit requires proper preparation and handling.

Always make sure that the pump or the unit remains in horizontal position during transport and cannot slip out of the

transport suspension arrangement. Do not use a lifting sling

on the free shaft end of the pump or on the motor eyebolt.

If the pump / unit slips out of the suspension arrangement, it may cause personal injury and damage to

property!

Fig. 3.1-1 Transport of the unit with support foot

Fig. 3.1-2 Transport of the unit with motor/pump foot

During transport the shaft 210 of the pump without motor must

be locked in place.

1.Press cover plates 68-3 slightly together and remove from

drive lantern 341.

2.Insert lock washer 931 into the shaft groove.

Fig. 3.1-3 Transport of the pump

3.2 Interim storage (indoors) / Preservation

When the unit is temporarily put into storage, only the wetted

low alloy components (e.g. grey cast iron JL 10401), nodular

cast iron JS 1025 2)) must be preserved. Commercially available preservatives can be used for this purpose. Please

observe the manufacturer’s instructions for application/removal.

The relevant procedure is described in section 6.3.

The unit / pump should be stored in a dry room where the

atmospheric humidity is as constant as possible.

If stored outdoors, the unit and crates must be covered by

waterproof material to avoid any contact with humidity.

Protect all stored goods against humidity, dirt,

vermin and unauthorized access! All openings of

the assembled unit components are closed and must only be

opened when required during installation.

All blank parts and surfaces of the pump are oiled or greased

(silicone-free oil and grease) to protect them against corrosion.

4 Description of the product and

accessories

4.1 Technical specification

Close-coupled pumps for handling clean or aggressive liquids.

4.2 Designation

Etab

loc G (N) 50-160 / 75 2

Type series

Casing material, e.g. JL 1040 1)

Stub shaft version with standardized motor

Pump size, e.g.

Motor rating: kW x 10 (example 7.5 kW)

Number of motor poles

1) to EN 1561 = GJL-250

2) to EN 1563 = GJS-400-18-LT

Etabloc

!

Caution

167:452

1

1167:453/2

Page 7

4.3 Design details

4.3.1 Pump

Design: Volute casing pumps, single-stage with rat-

ings to EN 733. [The shaft is fitted with a

replaceable shaft sleeve in the shaft seal

area. Volute casing and impeller with

replaceable casing / impeller wear rings

1)

]

1) Etabloc G only.

Etabloc N

Pump and motor flanged together to form a

close-coupled unit; with standardised motor.

Pump shaft and motor shaft are rigidly connected.

Etabloc G

Pump and motor flanged together to form a

close-coupled unit with common

pump/motor shaft.

Shaft seal: Mechanical seal to EN 12 756.

4.4 Noise characteristics

Rated power A-weighted surface sound pressure level pA

input PN Pump with motor

(kW) 1450 1/min 2900 1/min

dB 3) dB 3)

0.25 53.0 -

0.37 54.0 -

0.55 55.0 -

0.75 56.0 66.0

1.1 57.0 66.0

1.5 58.0 67.0

2.2 59.0 67.0

3.0 60.0 68.0

4.0 61.0 68.0

5.5 62.0 70.0

7.5 64.0 71.0

11.0 65.0 73.0

15.0 67.0 74.0

18.5 68.0 75.0

22.0 69.0 76.0

30.0 70.0 77.0

37.0 71.0 78.0

45.0 73.0 78.0

3) measured at a distance of 1 m from the pump outline (as per ISO 3744)

The above noise characteristics apply to non-cavitating pump

operation in the Qopt range.

5 Installation at site

5.1 Safety regulations

Electrical equipment operated in hazardous locations

must comply with the relevant explosion protection regulations. This is indicated on the motor rating plate.

If the equipment is installed in hazardous locations, the

applicable local explosion protection regulations and

the regulations of the test certificate supplied with the

equipment and issued by the responsible approval

authorities must be observed and complied with. The

test certificate supplied must be kept close to the location of operation for easy access (e.g. foreman’s

office).

5.2 Checks to be carried out prior to installation

All structural work required must have been prepared in accordance with the dimensions stated in the dimension table / general arrangement drawing.

The concrete foundations shall have sufficient strength (min.

class X0) to ensure safe and functional installation in accordance with DIN 1045.

Make sure that the concrete foundation has set firmly before

placing the unit on it. Its surface shall be truly horizontal and

even.

5.3 Installation method

For safety reasons the arrangement of “motor

below” is not permitted.

Etabloc pumps up to 4 kW, or explosion-proof units up to

3.3 kW, can either be flanged into the piping (remove support

foot 183) or mounted with the support foot. Installation examples see 9.1.

Etabloc pumps from 5.5 kW or explosion-proof units from

4.6 kW are fixed by means of the motor foot.

Etabloc 4 pole, 30 kW and above are fixed by means of the

pump foot and a motor support.

5.4 Installing the pump set

After placing the unit on the foundation, align it with the help

of a spirit level placed on the discharge nozzle.

If the volute casing is turned, a drain hole must be drilled in the

volute casing.

On Etabloc G, the position of the condensation water drain

holes on the motor must be observed meticulously (see 9.1).

The screwed plug needs to be changed depending on the

installation position.

5.4.1 Place of installation

The volute casing and discharge cover take on rough-

ly the same temperature as the medium handled. The

discharge cover and the drive lantern must not be insulated.

Take the necessary precautions to avoid burns!

!

Etabloc

Caution

6

Page 8

7

5.5 Connecting the piping

Never use the pump itself as an anchorage point

for the piping.

The pump must not be subjected to any pipeline forces and

moments (for example by torsion, thermal expansion).

Suction lift lines shall be laid with a rising slope towards the

pump and suction head lines with a downward slope towards

the pump. The pipelines shall be anchored in close proximity

to the pump and connected without transmitting any stresses

or strains.

With short pipelines, the nominal diameters should be at least

equal to the nominal diameters of the pump nozzles. For long

pipelines, the most economical nominal diameter has to be

determined from case to case.

Adapters to larger diameters should have a diffuser angle of

approx. 8 in order to avoid any increase in pressure losses.

It is recommended to install check and shut-off elements in

the system, depending on the type of plant and pump.

Thermal expansions of the pipelines must be compensated by

appropriate measures so as not to impose any extra loads on

the pump exceeding the permissible pipeline forces and

moments.

An excessive, impermissible increase in the pipeline

forces may cause leaks on the pump where the medium

handled can escape into the atmosphere.

Danger of life when hot media are handled!

The flange covers on the pump suction and discharge nozzles

must be removed prior to installation in the piping.

Before commissioning new installations thoroughly clean,

flush and blow through all vessels, pipelines and connections.Often welding beads, scale and other impurities only

come off after a certain period of operation. Fit a strainer in the

suction line to prevent them from entering the pump.The total

cross-section of the holes in the strainer shall be three times

the cross-section of the pipeline in order to avoid excessive

pressure loss across the strainer due to clogging. Conical

strainers with laid-in wire mesh having a mesh width of 0.5

mm and a wire diameter of 0.25 mm, of corrosion-resistant

material, shall be used.

1 Strainer housing

2 Fine screen

3 Perforated plate

4 Pump suction nozzle

5 Differential pressure gauge

Fig. 5.5-1 Conical strainer for the suction line

5.5.1 Auxiliary connections

The dimensions and location of the auxiliary connection (drain

line) are indicated on the general arrangement drawing or piping layout.

5.5.2 Vacuum balance line

Where liquid has to be pumped out of a vessel under vacuum,

it is advisable to install a vacuum balance line. This line shall

have a nominal diameter of at least 25 mm and must be

arranged to lead into the vessel at a point above the highest

permissible liquid level.

An additional pipeline fitted with a shut-off valve – from the

pump discharge nozzle to the balance line – facilitates venting

of the pump before start-up.

A Main shut-off valve

B Vacuum balance line

C Shut-off valve

E Vacuum-tight shut-off valve

R Swing check valve

V Vessel under vacuum

Z Intermediate flange

Fig. 5.5-2 Suction line and vacuum balance line

5.6 Final check

Check the integrity and proper functioning of all

connections.

5.7 Connection to power supply

Connection to the power supply must be effected by a trained

electrician only.

The applicable DIN VDE regulations 0100 and, for explosionproof units, 0165 must be complied with.

Check available mains voltage against the data on the motor

rating plate and select appropriate start-up method.

All connections shall be effected in accordance with the

technical specifications issued by the local energy supply company.

We strongly recommend to use a motor protection device.DIN

VDE 0170/0171 stipulates that explosion-proof motors, type of

protection IP 54, increased safety Ex EEx, temperature class

T3, must always be connected via a motor protection switch.

Etabloc

!

Caution

Caution

1211:19/4

Page 9

5.7.1 Motor connection

In compliance with DIN VDE 0530 – Part 8, the three-phase

motors are always wired for clockwise rotation (looking at the

motor shaft stub).

The pump’s direction of rotation is anti-clockwise (looking at

the suction flange).

For the motor’s direction of rotation to match the pump’s direction of rotation, the motor must be connected as shown in fig.

5.7-1 or 5.7-2, as applicable.

n configuration (low voltage)

Fig. 5.7-1 Connection diagram for three-phase motors,

n configuration

Y configuration (high voltage)

Fig. 5.7-2 Connection diagram for three-phase motors,

Y configuration

If required, connect the PTC resistors as per DIN

44081/44082 with the tripping unit in accordance with fig. 5.7-

3.

Fig. 5.7-3 Connection diagram for PTC resistors

5.7.2 Setting the time relay

Make sure that in the case of three-phase motors with stardelta starting method switching over from star to delta will be

effected at very short intervals. Prolonged switch-over intervals will result in pump damage.

Time relay setting for star-delta starting: <3 s.

5.7.3 Checking the direction of rotation

The motor’s direction of rotation must correspond to the direction indicated by the arrow on the pump’s volute casing (clockwise seen from the motor end). Verify by switching the motor

on and then off again immediately.

If the pump runs in the wrong direction of rotation, interchange

any two phases L1, L2 or L3 of the power cable in the motor

terminal box.

6 Commissioning, start-up / shutdown

6.1 Commissioning

Before starting up the pump make sure that

- the pump unit has been properly connected to the electric

power supply and is equipped with all protection devices;

- the pump has been primed with the liquid to be pumped;

- the direction of rotation has been checked;

- all auxiliary connections have been properly connected.

6.1.1 Shaft seal

Shaft seal (see sections 7.4.4 and 7.5.2)

6.1.2 Priming the pump and checks to be carried out

Before start-up, the pump and the suction line must be vented

and primed with the liquid to be pumped.

The shut-off valve in the suction line must be fully open.

Open the shut-off valve in the vacuum balance line (if any),

and close the vacuum-tight shut-off valve E (fig. 5.5-2).

Dry-running will result in increased wear and

must be avoided.

6.1.3 Final check

It must be easy to rotate the shaft by hand.

Check the integrity and proper functioning of all connections.

6.1.4 Contact guard

In compliance with the accident prevention regulations

the pump must not be operated without a contact guard.

6.1.5 Start-up

Always make sure that the shut-off valve in the discharge line

is closed before the pump is started up! Only after the pump

has reached full rotational speed shall the shut-off valve in the

discharge line be opened slowly and adjusted to comply with

the duty point.

After the operating temperature has been reached and/or in

the event of leakage, switch off the unit and retighten hex. nuts 920.2 or .3 or .4.

6.1.6 Shutdown

Close the shut-off valve in the discharge line.

If the discharge line is equipped with a non-return or check

valve, the shut-off element may remain open if there is back

pressure.

The shut-off valve in the suction line must not be closed

when switching off the pump.

Switch off the motor, making sure that the unit runs down

smoothly to a standstill.

Depending on the type of installation, the pump should have a

sufficient after-run time – with the heat source shut off – until

the medium handled has cooled down sufficiently to avoid a

heat build-up in the pump.

For prolonged shutdown, close the shut-off valve in the suction line. Close the auxiliary connections.

In the event of frost and/or prolonged shutdowns, the pump

must be drained or otherwise protected against freezing.

pp g g

!

!

Etabloc

Caution

Caution

Caution

8

3/2

0910:

Page 10

9

6.2 Operating limits

6.2.1 Temperature of the medium handled

Do not operate the pump at product temperatures exceeding those specified on the data

sheet or the name plate.

6.2.2 Switching frequency

To prevent high temperature increases in the motor and

excessive loads on the pump, motor, seals and bearings, the

switching frequency shall not exceed the following number of

start-ups per hour (h).

Etabloc G, M: 15 start-ups/h

Etabloc GN, MN, SN: 15 start-ups/h

Etabloc BN, CN: 6 start-ups/h

6.2.3 Minimum flow

If the plant configuration is such that the pump might be

operated against a closed discharge side valve, a minimum

flow of

t -30to+ 70C ≈ 15 % of Qopt.

t >70 to +140 C ≈ 25 % of Qopt.

must be ensured during this period.

6.2.4 Density of medium handled

The power input of the pump will increase in proportion to

the density of the medium handled. To avoid overloading of

the motor and pump, the density of the medium must comply

with the data specified on the purchase order.

6.3 Shutdown / storage / preservation

Each KSB pump leaves the factory carefully assembled. If

commissioning is to take place some time after delivery, we

recommend that the following measures be taken for pump

storage.

6.3.1 Storage of new pumps

- New pumps are supplied by our factory duly prepared for

storage.

Maximum protection for up to 12 months, if the pump is

properly stored indoors.

- Store the pump in a dry location.

6.3.2 Measures to be taken for prolonged shutdown

1.The pump remains installed; periodic check of operation

In order to make sure that the pump is always ready for

instant start-up and to prevent the formation of deposits

within the pump and the pump intake area, start up the

pump set regularly once a month or once every 3 months

for a short time (approx. 5minutes) during prolonged shutdown periods.

Prior to an operation check run ensure that there is sufficient liquid available for operating the pump.

2.The pump is removed from the pipe and stored

Before putting the pump into storage, carry out all checks

specified in sections 7.1 to 7.4. Then apply appropriate

preservatives:

Spray-coat the inside wall of the pump casing, and in particular the impeller clearance areas,with a preservative.

Spray the preservative through the suction and discharge

nozzles. It is advisable to close the pump nozzles (e.g.with

plastic caps or similar).

6.4 Returning to service after storage

Before returning the pump to service, carry out all checks

and maintenance work specified in sections 7.1 and 7.2.

In addition, the instructions laid down in the sections

on “Commissioning” (6.1) and ”Operating limits” (6.2)

must be observed.

Immediately following completion of the work, all safety-relevant and protective devices must be re-installed

and/or re-activated.

7 Servicing / maintenance

7.1 General instructions

The operator is responsible for ensuring that all maintenance, inspection and installation work be performed by

authorized, qualified specialist personnel who are thoroughly familiar with the manual.

A regular maintenance schedule will help avoid expensive

repairs and contribute to trouble-free, reliable operation of

the pump with a minimum of maintenance expenditure and

work.

Work on the unit must only be carried out with the

electrical connections disconnected. Make sure

that the pump set cannot be switched on accidentally

(danger to life!).

Pumps handling liquids posing health hazards

must be decontaminated. When draining the medi

um see to it that there is no risk to persons or the environment. All relevant laws must be adhered to (danger to

life)!

7.2 Servicing / inspection

7.2.1 Supervision of operation

The pump must run quietly and free from vibrations at all times.

The pump must never be allowed to run dry.

Do not run the pump against a closed shut-off valve for

prolonged periods of time so as to avoid heating up of

the fluid pumped.

Max. permissible room temperature 40 ºC.

Bearing temperature may exceed room temperature by up to

50 ºC but must never rise above +90 ºC (measured external-

ly on the motor housing).

For required minimum flows please refer to section 6.2.3.

During pump operation the shut-off valve in the suction

line must not be closed.

The mechanical seal shows only slight or invisible (vapour)

leakage during operation. It is maintenance-free.

Any stand-by pumps installed shall be switched on and then

immediately off again once a week to keep them operational.

Attention shall be paid to the correct functioning of the auxil-

iary connections.

7.2.2 Lubrication and lubricant change

7.2.2.1 Lubrication

The rolling element bearings in the KSB IEC motor are

grease-lubricated. The lubricant change intervals as well as

the required quantity and quality are specified below.

!

!

!

!

!

Etabloc

Caution

Caution

Page 11

7.2.2.2 Grease quality / grease change

The bearings are packed with high-quality lithium-soap

grease. Under normal conditions the grease-lubricated bearings will run for 15,000 operating hours or 2 years. Under

unfavourable operating conditions, e.g. high room temperature, high atmospheric humidity, dust-laden air, aggressive

industrial atmosphere etc., the bearings shall be checked

earlier and cleaned and re-lubricated, if required.

Use a high-quality lithium-soap grease, free of resin and acid,

not liable to crumble and with good rust-preventive characteristics. The grease should have a penetration number

between 2 and 3, corresponding to a worked penetration

between 220 and 295 mm/10. Its drop point must not be

below 175ºC. The bearing cavities must only be half-filled

with grease.

If required, the bearings may be lubricated with greases of

other soap bases. Since greases of differing soap bases must

not be mixed, the bearings must be thoroughly cleaned

beforehand. The re-lubrication intervals required must then

be adjusted to the greases used.

Please observe the local laws applicable to the

disposal of such substances!

7.2.2.3 Deep-groove ball bearings/ Lubricant quantity for

KSB IEC motor

Deep-groove ball bearings to DIN 625

Code Grease g

6004 C3 2

6205 C3 3

6206 C3 4

6208 C3 6

6209 C3 7

6210 C3 7

6212 C3 7

6213 C3 11

- for KSB motor with extended shaft

Deep-groove ball bearings to DIN 625

Code

6305 C3

6306 C3

6308 C3

6309 C3

Closed bearings greased for life (2 Z or 2 RS bearings) cannot be washed out and refilled. They will have to be replaced

by new ones.

7.3 Drainage / disposal

If the pump was used for handling liquids posing health

hazards, see to it that there is no risk to persons or the

environment when draining the medium. All relevant laws

must be heeded. If required, wear safety clothing and a protective mask!

The flushing liquid used and any liquid residues in the pump

must be properly collected and disposed of without posing

any risk to persons or the environment.

7.4 Dismantling

Before dismantling the pump, secure it so as to make

sure it cannot be switched on accidentally . The shut-of f

valves in the suction and discharge lines must be closed.

The pump must have cooled down to ambient temperature,

pump pressure must have been released and the pump must

have been drained.

Dismantling and reassembly must always be carried out in

accordance with the relevant exploded view.

7.4.1 Fundamental instructions and recommendations

Repair and maintenance work to the pump must only be carried out by specially trained personnel, using original spare

parts

(see 2.7).

Observe the safety regulations laid down in section 7.1.

Any work on the motor shall be governed by the specifications and regulations of the respective motor supplier.

Dismantling and reassembly must always be carried out

in the sequence shown in the relevant exploded views on

pages 16 to 23.

In the case of damage or pump failure please contact our

nearest customer service centre.

For customer service centres please refer to the attached list

of addresses.

7.4.2 Preparations for dismantling

1 Interrupt power supply.

2 Dismantling the complete unit:

2.1 Disconnect the motor from the power supply.

2.2 Unbolt the discharge and suction nozzle from the piping.

2.3 Depending on the pump /motor size, unscrew the bolts

that fix the support foot and/or motor foot to the foundation.

2.4 Remove the complete unit from the piping.

3 The pump casing remains in the piping during disman-

tling.

3.1 Disconnect the motor from the power supply.

3.2 Unscrew hex. nuts 920.2/.3/.4.

3.3 Depending on the pump /motor size, unscrew the bolts

that fix the support foot and/or motor foot to the foundation.

3.4 Withdraw the complete rotating assembly with the motor

from the pump casing.

4 Pump (Etabloc-N only) remains in the piping,motor is

removed

4.1 Disconnect the motor from the power supply.

4.2 Press cover plates 68-3 slightly together and remove

from drive lantern 341.

4.3 Undo hex. nuts 920.5.

4.4 Undo hex. head bolts 901.3.

4.5 Insert both lock washers 931 into the groove in shaft 210.

4.6 Tighten hex. head bolts 901.

4.7 Remove the motor.

After a prolonged period of operation the individual components may be hard to pull off the shaft. If this is the case, use

a brand name penetrating agent and/or - if possible - an

appropriate pull-off device.

Under no circumstances use force.

7.4.3 Pump

Dismantle the pump in the sequence shown in the exploded

views on pages 16 to 23.

7.4.4 Mechanical seal

In order to replace the mechanical seal the pump must be

dismantled.

After removing impeller 230 pull mechanical seal 433 off the

shaft by hand.

Prior to reassembly, clean the shaft sleeve 523 and touch up

score marks or scratches, if any, with a polishing cloth. If the

score marks are still visible, fit a new shaft sleeve. Clean the

seat ring location.

Etabloc

!

!

Caution

10

Page 12

11

7.5 Reassembly

7.5.1 Pump

The pump shall be reassembled in accordance with the rules

of sound engineering practice.

The locating surfaces of the individual components must be

coated with graphite or similar before reassembly. The same

applies to bolted connections.

O-rings shall be examined for signs of damage and replaced

by new ones, if necessary.

Gaskets shall always be replaced by new ones.Make sure that

new gaskets have the same thickness as the old ones.

Gaskets of asbestos-free materials or graphite must always

be fitted without using lubricants.

Avoid the use of mounting aids as far as possible. Should a

mounting aid be required after all, use a commercially available contact adhesive (e.g. Pattex) or sealing agent (HYLOMAR or Epple 33).The adhesive shall only be applied at

selected points and in thin layers. Do not use cyanoacrylate

adhesives (quick-setting adhesives).

If the seal area between the impeller neck and the casing

wear ring is worn, the casing wear rings 502.1 and 502.2 (if fitted) must be replaced by new ones.

Clearances:

new 0.3 mm in diameter

max. permissible enlargement to 0.9 mm in diameter

Reassembly is effected in reverse order to dismantling. Make

sure to assemble the components in their correct sequence.

7.5.2 Mechanical seal

Reassembly is effected in reverse order to dismantling.

The following rules must be observed when fitting a mechan-

ical seal:

Extreme care and cleanliness.

The protective wrapping of the contact faces shall only be

removed immediately before assembly takes place.

Take care not to damage the seal faces and O-rings.

Clean the shaft and the seat ring location in the discharge

cover and gently remove any deposits.

When fitting the seal, shaft sleeve 523 may be wetted with

water to reduce the friction forces.

Ethylene propylene rubber elastomers must

never come into contact with oil or grease. Water

shall be used as a lubricant during fitting.

Press the seat ring into discharge cover 163 by hand or fin-

gers only. Make sure that the pressure is applied evenly.

7.5.3 Motor for Etabloc N

Reassembly is effected in reverse order to dismantling.

When mounting shaft 210 onto the motor shaft

stub, make sure that the keyway of the motor

shaft end aligns with the slot in shaft 210.

7.5.4 Tightening torques

Fig. 7.5-2 Tightening points, pump set

Position Thread size Tightening torque

1)

mm MA [Nm]

M 10 40

A

M 12 55

M 12 x 1.5 25

B

M 20 x 1.5 85

M 30 x 1.5 140

M 8 15

C

M 10 30

M 12 45

M 16 80

D

M 6 10

M 8 25

1) for unlubricated threads

A = bolted connections at the casing components

B = impeller nut

C = bolts between drive lantern and motor

D = screw between taper lock ring and stub shaft

Etabloc

Caution

Caution

Page 13

7.6 Spare parts

7.6.1 Ordering spare parts

When ordering spare parts please always quote the following

data stated on the name plate, e.g.

Type

Serial No

7.6.2 Recommended spare parts stock for 2 years’ continuous operation in accordance with DIN 24 296

Number of pumps (including stand-by pumps)

2 3 4 5 6 and 7 8 and 9 10 and more

Part No. Description Quantity of spare parts

210 Shaft

1)

1 1 1 2 2 2 20 %

230 Impeller (including casing wear ring 502.2)2)1 1 1 2 2 2 20 %

400.1/.2 Gaskets (set) 4 6 8 8 9 12 150 %

433 Mechanical seal: 1 1 2 2 2 3 25 %

502.1 Casing wear ring

2)

2 2 2 3 3 4 50 %

523 Shaft sleeve

2)

2 2 2 3 3 4 50 %

1) not for Etabloc G

2) Casing wear rings and shaft sleeve applicable only to Etabloc G

Etabloc

12

Page 14

13

Cause Remedy

1)

D Pump delivers against an excessively high discharge Re-adjust to duty point.

pressure

.

D Excessively high back pressure. Check plant for impurities.

D D D Pump or piping are not completely vented or primed. Vent and/or prime.

D Suction line or impeller clogged Remove deposits in the pump and/or piping.

D Formation of air pockets in the piping. Alter piping layout.

Fit a vent valve.

D D D Suction head is too high/NPSH- available Check/alter liquid level.

(positive suction head) is too low. Fully open shut-off valve in the suction line.

Change suction line, if the friction losses in the suction line

are too high.

Check any strainers installed/suction opening.

D Wrong direction of rotation. Interchange two of the phases of the power supply cable.

D D Wear of internal pump parts. Replace worn components by new ones.

D D D Pump back pressure is lower than specified in the purchase Adjust to duty point.

order.

D The density or viscosity of the fluid pumped is higher than

2)

specified in the order.

D Defective gasket Fit new gasket between volute casing and discharge cover.

D Worn shaft seal. Fit new shaft seal.

D D Score marks or roughness on shaft sleeve. Fit new shaft sleeve.

Fit new shaft seal.

D Vibrations during pump operation Improve suction conditions.

Increase pressure at the pump suction nozzle.

D D D Pump is warped Check pipeline connections and secure fixing of pump; if required,

reduce the distances between the pipe clamps.

Fix the pipelines using anti-vibration material.

D Increased axial thrust.

2)

Clean balancing holes in the impeller.

Fit new wear rings.

D Insufficient or excessive quantity of lubricant or unsuitable Top up, reduce or change lubricant.

lubricant.

D D Motor is running on two phases only. Replace the defective fuse.

Check the electric cable connections.

D Rotor is out of balance. Clean the impeller.

Re-balance the impeller.

D Defective bearing(s). Fit new bearings.

D D Insufficient rate of flow. Increase the minimum rate of flow.

D Incorrect setting of motor protection switch Check setting.

Fit new motor protection switch

D D Transport lock has not been removed from the shaft groove. Remove.

1) Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

2) Request particulars.

8 Trouble-shooting

Etabloc

Pump delivers insufficient flow rate

Motor is overloaded

Motor protection switch trips the pump

Excessive bearing temperature

Leakage at the pump

Excessive leakage at the shaft seal

Vibrations during pump operation

Excessive rise of temperature inside the pump

Page 15

9 Related documents

9.1 Typical installation positions

Etabloc G

up to motor size 112 = 4 kW up to motor size 132 = 5.5 kW to

180 = 22 kW

As-delivered condition

Horizontal installation, attachment below

up to motor size 112 = 4 kW

For vertical installation with motor on top please contact KSB

Position of condensate holes o = open

x = closed

Horizontal installation, attachment above

Motor has to be turned through 180º

Etabloc N

up to motor size 180 = 22 kW

Etabloc

to180=22 kW

For vertical installation a vent valve must be fitted

to prevent dry running of the mechanical seal

14

1165:21/4

1167:22/5

1167:72

1167:68

1167:69

For vertical installation a vent valve must be fitted

to prevent dry running of the mechanical seal.

Page 16

15

9.2 Exploded view and list of components Etabloc G

Version with bolted-on discharge cover

Etabloc

Supplied in packaging units only

Part No. Description

102 Volute casing

163 Discharge cover

183

2)

Support foot

230 Impeller

400.1/.2 Gasket

412.1 O-ring

423.1/.2 Labyrinth seal

433 Mechanical seal

502.1/.2 Casing wear ring

Part No. Description

523 Shaft sleeve

550.1 1)Disc

802 Motor for close coupling

902.1/.2/.4

2)

Stud

903.1 Screwed plug

920.1-.3 Hex. nut

920.4

2)

Hex. nut

930 Spring washer

940 Key

Auxiliary connections

1M Pressure gauge

6B Casing drain

6 D Priming and venting

1) for Etabloc with shaft unit 25 only.

2) up to motor size 112 = 4 kW only, (from motor size 132 = 5.5 kW upwards with motor foot, not shown in exploded view)

Page 17

Etabloc

Supplied in packaging units only

Part No. Description

102 Volute casing

163 Discharge cover

183

2)

Support foot

230 Impeller

400.1/2 Gasket

412.1 O-ring

423.1/2 Labyrinth seal

433 Mechanical seal

502.1/.2 Casing wear ring

Part No. Description

523 Shaft sleeve

550.1

1)

Disc

802 Motor for close coupling

902.3/.4

2)

Stud

903.1 Screwed plug

920.1/.4 Hex. nut

930 Spring washer

940 Key

Auxiliary connections

1M Pressure gauge

6B Casing drain

6D Priming and venting

9.3 Exploded view and list of components Etabloc G

Version with clamped discharge cover

1) for Etabloc with shaft unit 25 only.

2) up to motor size 112 = 4 kW only

(from motor size 132 = 5.5 kW upwards with motor foot, not shown in exploded view)

16

Page 18

9.4 Exploded view and list of components Etabloc N

Supplied in packaging units only

Part No. Description

102 Volute casing

163 Discharge cover

210 Shaft

230 Impeller

341 Drive lantern

400.1 Gasket

411.5 Joint ring

433 Mechanical seal

Part No. Description

801 Flanged motor

902.1/.3.4.5 Stud

903.1/.2 Screwed plug

920.1/.4/.5 Hex. nut

930 Spring washer

940 Key

Auxiliary connections

1M Pressure gauge

6B Casing drain

6D Priming and venting

Etabloc

17

Page 19

Page 20

Etabloc

Gartone Press: Tel: (011) 440-6126 29.6.2004 Subject to technical modification without prior notice

Loading...

Loading...