KSB ECOLINE GLB, ECOLINE PTF, ECOLINE SCF, ECOLINE GTB, ECOLINE GTV Operating Manual

...

ECOLINE GLF/GTF/PTF/SCF/FYF

ECOLINE GLB/GTB

ECOLINE GLV/GTV/SCV

ECOLINE GLC/GTC/SCC/FYC

Operating Manual

Legal information/Copyright

Operating Manual

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB Valves Changzhou Co., Ltd., China12/12/2016

Contents

3 of 100

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Target group.....................................................................................................................................................6

1.3 Other applicable documents............................................................................................................................6

1.4 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 7

2.1 Key to safety symbols/markings.......................................................................................................................7

2.2 General..............................................................................................................................................................7

2.3 Intended use .....................................................................................................................................................8

2.4 Personnel qualification and training...............................................................................................................8

2.5 Consequences and risks caused by non-compliance with this manual .........................................................8

2.6 Safety awareness ..............................................................................................................................................8

2.7 Safety information for the operator/user.......................................................................................................9

2.8 Safety information for maintenance, inspection and installation ................................................................9

2.9 Unauthorised modes of operation..................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 10

3.1 Checking the condition upon delivery..........................................................................................................10

3.2 Transport.........................................................................................................................................................10

3.3 Storage/preservation......................................................................................................................................11

3.4 Return to supplier...........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................12

4 Valve Description ................................................................................................................................. 13

4.1 General description ........................................................................................................................................13

4.2 Marking...........................................................................................................................................................13

4.3 Globe Valves to ANSI/ASME with Gland Packing .........................................................................................14

4.4 Bellows-type Globe Valves to ANSI/ASME.....................................................................................................30

4.5 Gate Valves to ANSI/ASME.............................................................................................................................38

4.6 Lift Check Valves to ANSI/ASME ....................................................................................................................57

4.7 Swing Check Valves to ANSI/ASME................................................................................................................64

4.8 Strainers to ANSI/ASME..................................................................................................................................76

5 Installation at Site................................................................................................................................ 81

5.1 General information/Safety regulations .......................................................................................................81

5.2 Installation position and location..................................................................................................................82

5.3 Welding into the pipeline..............................................................................................................................83

5.4 Valves with actuator.......................................................................................................................................83

5.5 Insulation ........................................................................................................................................................84

6 Commissioning/Start-up/Shutdown................................................................................................... 85

6.1 Commissioning/start-up .................................................................................................................................85

6.2 Shutdown........................................................................................................................................................87

7 Servicing/Maintenance........................................................................................................................ 88

7.1 Safety regulations...........................................................................................................................................88

7.2 Maintenance...................................................................................................................................................88

8 Trouble-shooting.................................................................................................................................. 90

9 EU Declaration of Conformity............................................................................................................. 91

9.1 EU Declaration of Conformity for ECOLINE FYF 800, GLF 2500, GLB 800, GTF 2500, GTB 800, PTF 2500,

SCF 2500 ..........................................................................................................................................................91

9.2 EU Declaration of Conformity for ECOLINE GTC, GLC, SCC, GLF, GTF, SCF, PTF .........................................92

9.3 EU Declaration of Conformity for ECOLINE FYC...........................................................................................93

9.4 EU Declaration of Conformity for ECOLINE GLV, GTV, SCV.........................................................................94

Contents

4 of 100

9.5 EU Declaration of Conformity for ECOLINE GLB 150-600 ............................................................................95

Index ..................................................................................................................................................... 96

Glossary

5 of 100

Glossary

PED

The 97/23/EC or 2014/68/EU directive, also known

as the Pressure Equipment Directive, sets out the

requirements to be met by pressure equipment

intended to be placed on the market in the

European economic area.

Technical literature

Refer to the product catalogue for the technical

literature on our products at www.ksb.com.

1 General

6 of 100

1 General

1.1 Principles

This operating manual is supplied as an integral part of the type series and variants

indicated on the front cover. The manual describes the proper and safe use of this

equipment in all phases of operation.

In the event of damage, immediately contact the KSB sales organisation responsible

in order to maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.3 Other applicable documents

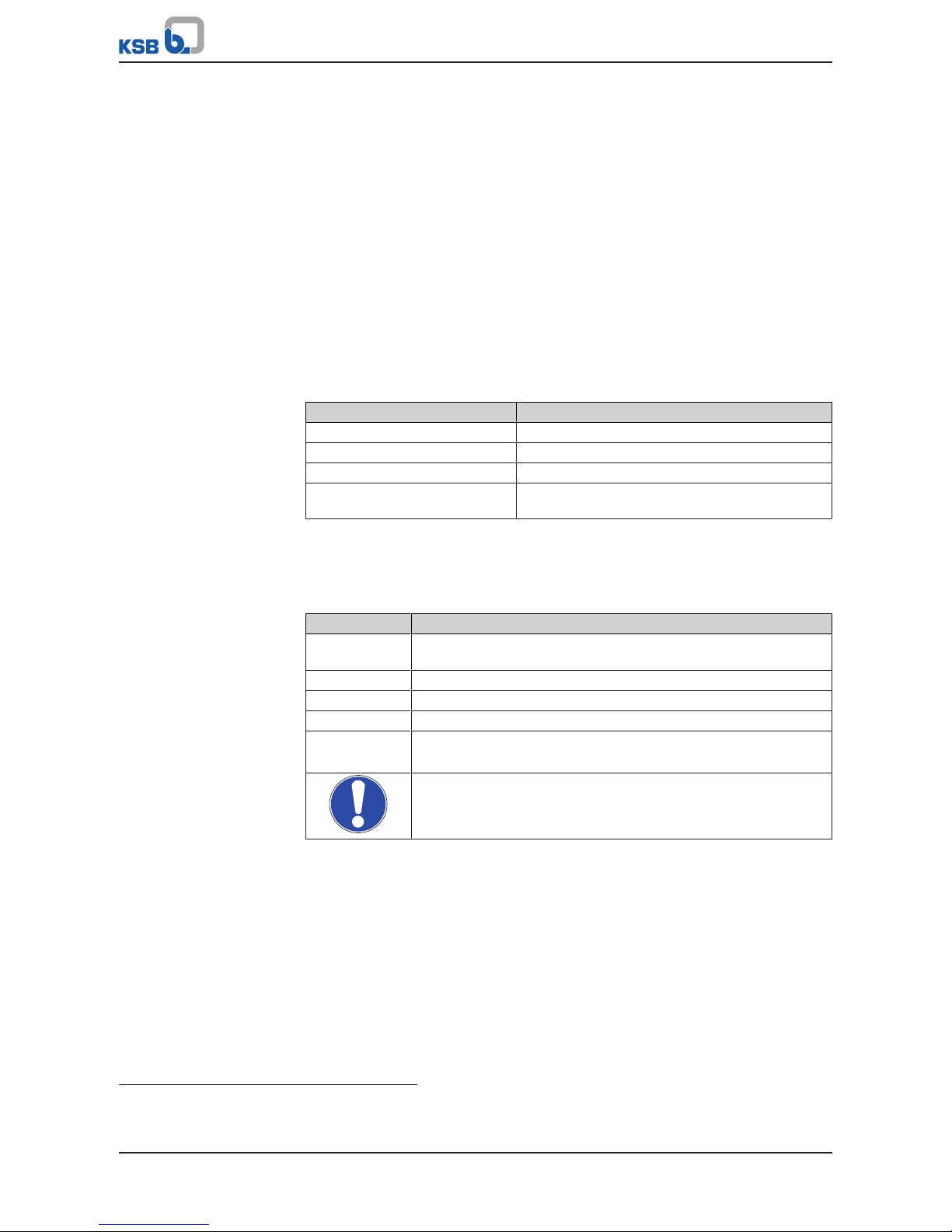

Table1: Overview of other applicable documents

Document Contents

Type series booklet Description of the valve

Flow characteristics

1)

Information on Kv and zeta values

General assembly drawing

2)

Sectional drawing of the valve

Sub-supplier product literature3)Operating manuals and other product literature

for the accessories

Observe the relevant manufacturer's product literature for the accessories.

1.4 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

1) If any

2) If inclusion in the scope of supply has been agreed; otherwise refer to the type series booklet.

3) If inclusion in the scope of supply has been agreed.

2 Safety

7 of 100

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

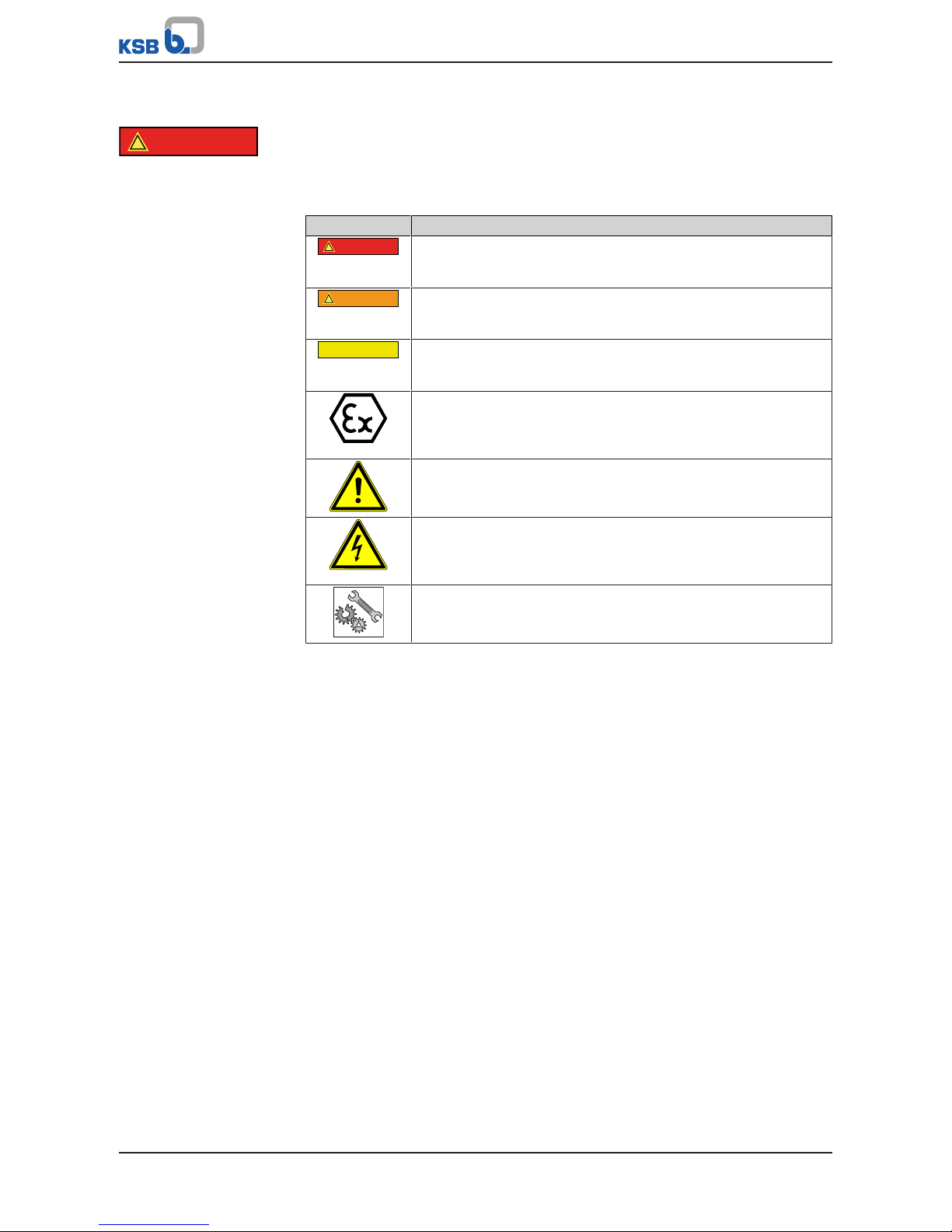

2.1 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This manual contains general installation, operating and maintenance instructions

that must be observed to ensure safe valve operation and prevent personal injury

and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and fully understood by the specialist personnel/

operators responsible prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Instructions and information attached directly to the valve must always be complied

with and kept in a perfectly legible condition at all times. This applies to, for

example: flow direction arrow, manufacturer, type designation, nominal pressure,

nominal size, year of construction and material.

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this manual.

The design, manufacture and the testing of the valves are subject to a QM system to

DINENISO9001 as well as the European Pressure Equipment Directive 97/23/EC.

Compliance with these requirements, however, is based on normal, predominantly

static loading.

Valves exposed to creep-rupture conditions have a limited service life and have to

meet the applicable regulations stipulated in the technical codes.

In the case of customised special variants, further restrictions may apply with regard

to the operating mode and service life. Please refer to the relevant sales literature for

this information.

2 Safety

8 of 100

This operating manual does not take into account:

▪ Any eventualities or incidents which may occur during installation performed by

the customer, operation and maintenance.

▪ Local regulations; the operator must ensure that such regulations are strictly

observed by all, including the personnel called in for installation.

2.3 Intended use

▪ Only operate valves which are in perfect technical condition.

▪ Do not operate partially assembled valves.

▪ The valve must only handle the fluids specified in the product literature.

▪ Only operate the valve within the permissible operating range specified for

pressure and temperature.

▪ Consult the manufacturer about any other modes of operation not described in

the product literature.

Prevention of foreseeable misuse

▪ Never exceed the permissible operating limits specified in the data sheet or

product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this operating manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the product this manual refers to and be fully aware of the interaction

between the valve and the system.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Hands-on training at the valve must always be supervised by specialist technical

personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with this operating manual will lead to forfeiture of warranty

cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2 Safety

9 of 100

2.7 Safety information for the operator/user

Actuator-operated valves are intended for use in areas which cannot be accessed by

unauthorised persons. Operation of these valves in areas which can be accessed by

unauthorised persons is only permitted if appropriate protective devices are fitted at

the site. This must be ensured by the operator.

▪ The operator shall fit contact guards for hot, cold and moving parts and check

that the guards function properly.

▪ Do not remove any contact guards during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the stem seal) of hazardous fluids (e.g. explosive, toxic,

hot) so as to avoid any danger to persons and the environment. Adhere to all

relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the valve require the manufacturer's prior

consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Carry out work on the valve during standstill only.

▪ The valve body must have cooled down to ambient temperature.

▪ The pressure in the valve body must have been released and the valve must have

been drained.

▪ When taking the valve out of service always adhere to the procedure described

in the manual.

▪ Decontaminate valves which handle fluids posing a health hazard.

▪ As soon as the work has been completed, re-install and/or re-activate any safety-

relevant and protective devices. Before returning the product to service, observe

all instructions on commissioning.

2.9 Unauthorised modes of operation

Never operate the valve outside the limits stated in the data sheet and in this

operating manual.

The warranty relating to the operating reliability and safety of the valve supplied is

only valid if the valve is used in accordance with its intended use.

(ðSection2.3,Page8)

Shut-off valves are not suitable for regulating volume flow.

Gate valves are used in such a way that they are either fully open or fully closed. An

intermediate position (throttling function) is not permitted.

3 Transport/Temporary Storage/Disposal

10 of 100

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer (as applicable) and the insurer about the

damage in writing immediately.

3.2 Transport

Always close the valve manually before transporting it. The valve is delivered ready

for operation and its line connection ports may still be closed with caps, if applicable.

Original spare parts are only ready for operation following assembly/installation and

subsequent shell and leak testing of the valve.

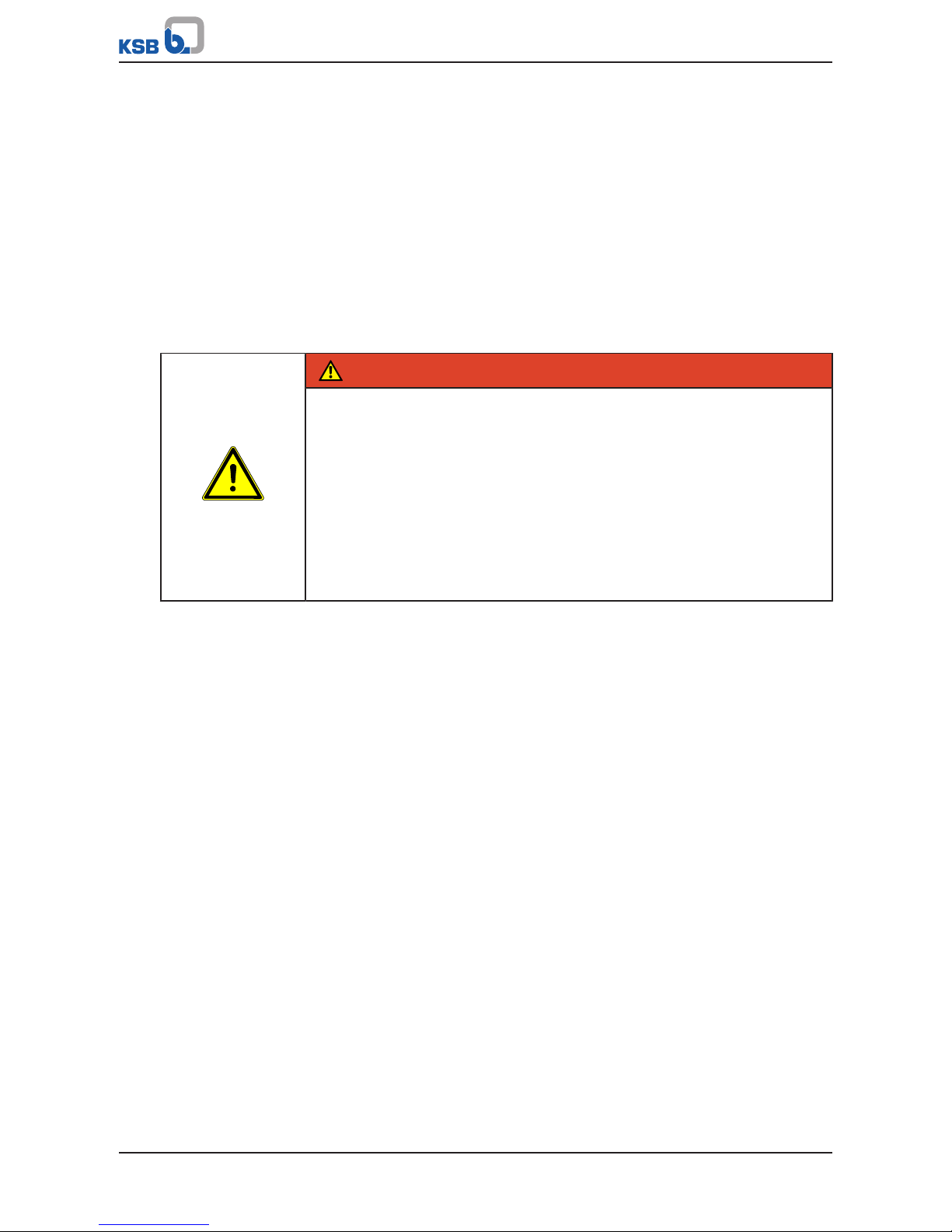

DANGER

The valve could slip out of the suspension arrangement

Danger to life from falling parts!

▷ Only transport the valve in the specified position.

▷ Never suspend the valve from its handwheel.

▷ Pay attention to the weight data and the centre of gravity.

▷ Observe the applicable local accident prevention regulations.

▷ Use suitable, permitted lifting accessories.

▷ Transport devices (if any) on the actuator may not be suitable for being

attached to a suspension arrangement in order to transport the valve/actuator

assembly. Refer to the actuator operating manual for the permissible loads.

To transport the valve, suspend it from the lifting tackle as illustrated.

3 Transport/Temporary Storage/Disposal

11 of 100

Fig.1: Transporting the valve

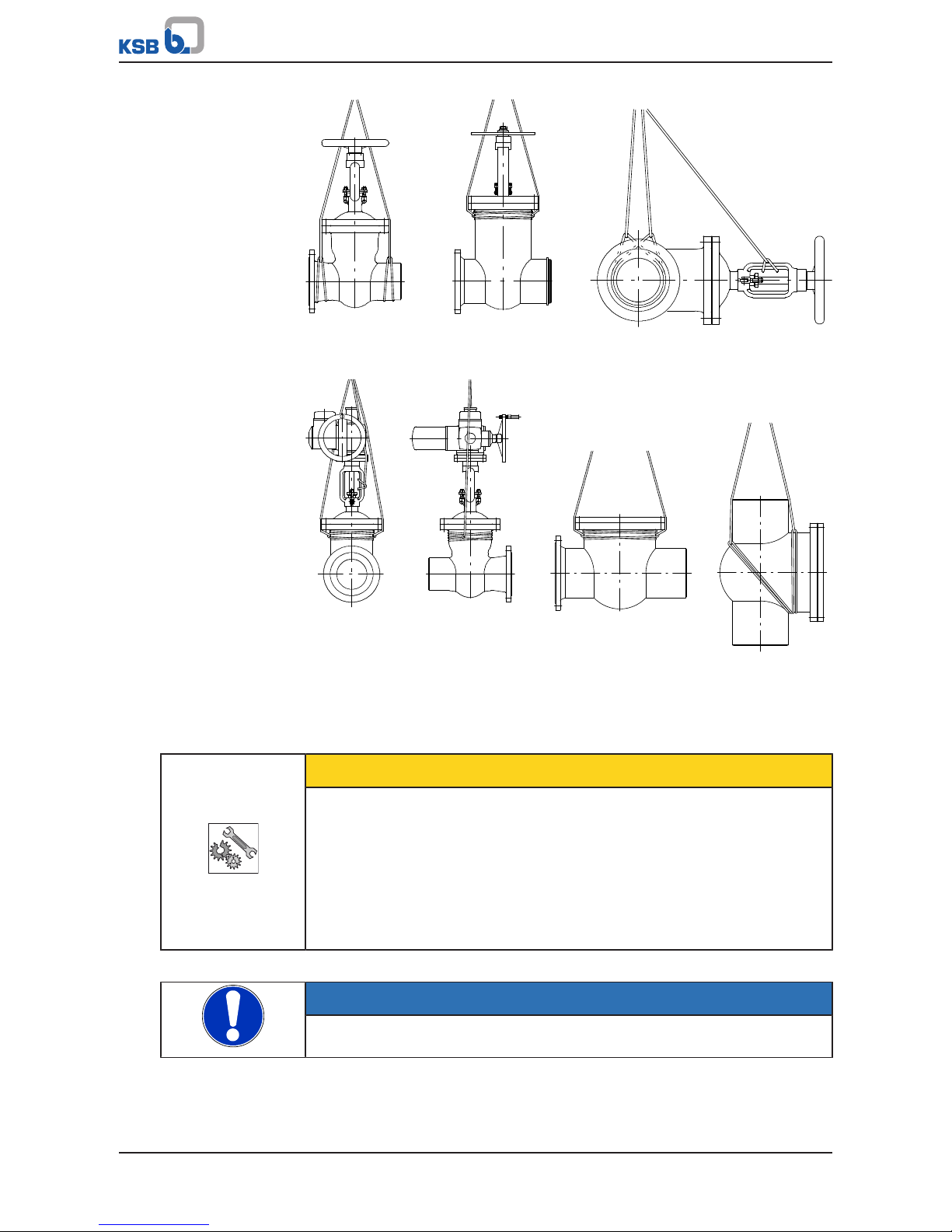

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for storing the valve:

CAUTION

Incorrect storage

Damage to the valve due to dirt, corrosion, moisture and/or frost!

▷ Store the valve in a dust- and vibration-free, frost-proof room where the

atmospheric humidity is as constant as possible (use suitable caps or film for

protection).

▷ Close the valve using little force and store in the closed position.

▷ Protect the valve from contact with solvents, lubricants, fuels or other

chemicals.

If properly stored indoors, the equipment is protected for a maximum of 12 months.

NOTE

For actuated valves, also observe the actuator's operating manual.

3 Transport/Temporary Storage/Disposal

12 of 100

3.4 Return to supplier

1. Drain the valve as described in the manual.

2. Always flush and clean the valve, particularly if it has been used for handling

noxious, explosive, hot or other hazardous fluids.

3. If the fluids handled by the system leave residues which might lead to corrosion

damage when coming into contact with atmospheric humidity, or which might

ignite when coming into contact with oxygen, the valve must also be neutralised

and blown through with anhydrous inert gas for drying purposes.

4. When returning valves used for handling Fluids in Group 1 always complete and

enclose a certificate of decontamination.

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

KSB web site at: www.ksb.com/certificate_of_decontamination

3.5 Disposal

WARNING

Fluids, consumables and supplies which are hot and/or pose a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the valve.

Collect greases and other lubricants during dismantling.

2. Separate and sort the valve materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with current regulations or in another

controlled manner.

4 Valve Description

13 of 100

4 Valve Description

4.1 General description

The sectional drawings below provide examples of the general design/configuration

of the valve. For additional and more detailed information, refer to the respective

type series booklet.

4.2 Marking

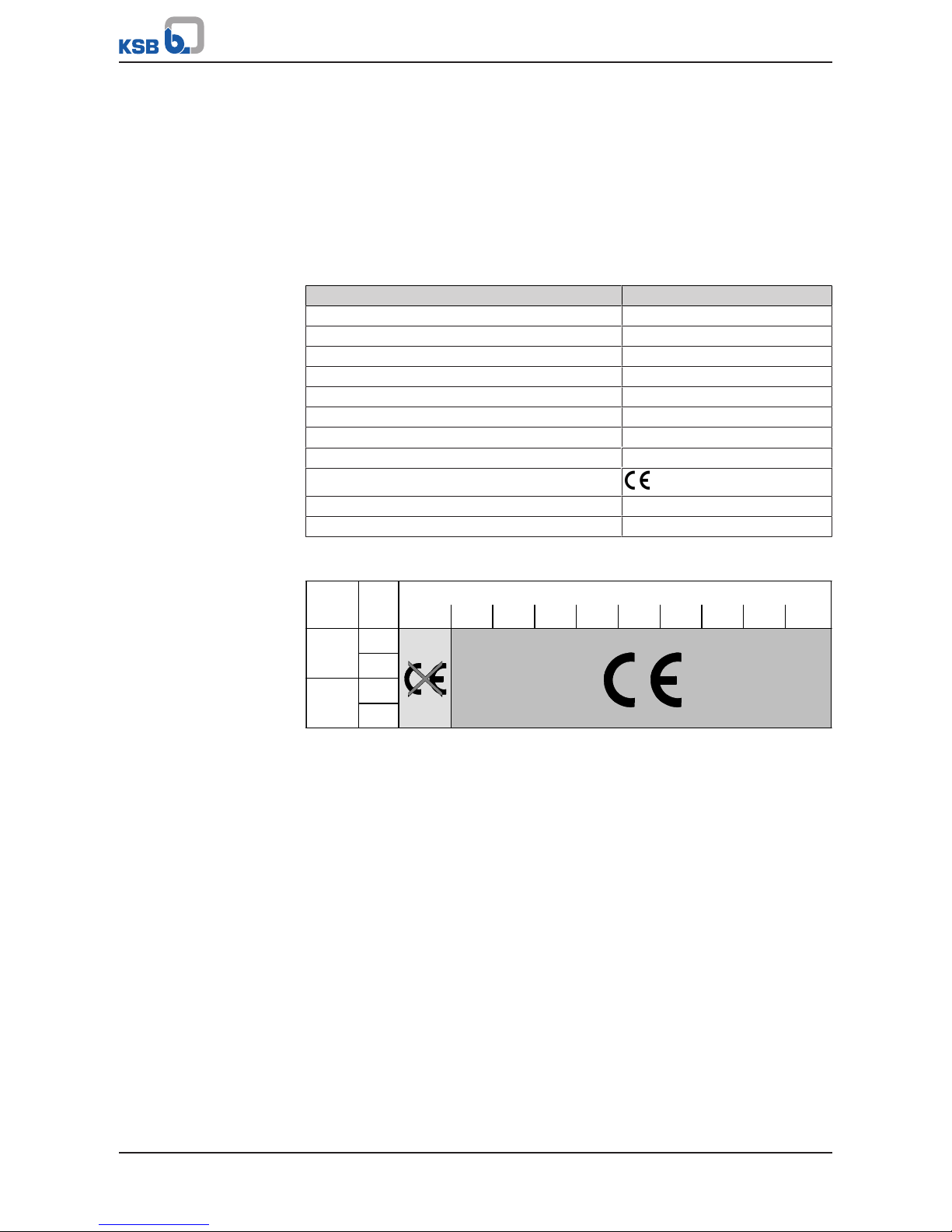

Table4: General marking

Parameter Value/Marking

Nominal size NPS (inch) ...

Nominal pressure class Class ...

Manufacturer KSB

Type series/Model ECOLINE...

Year of construction 20..

Material .......

Flow direction arrow →

Traceability of the material .......

CE markingPED

Identification number of the notified body 0036

Customer's marking e.g. plant/system No., etc.

The CE marking on the valve indicates that it is in conformity with the European

Pressure Equipment Directive 97/23/EC.

Fluids in Groups 1 and 2

Class PN DN

≤25 32 40 50 65 80 100 125 150 ≥200

10

16

25

≥

≥40

150

300

Fluid groups

Group 1 comprises fluids defined as

▪ Explosive

▪ Extremely flammable

▪ Highly flammable

▪ Flammable: The maximum allowable temperature is above flashpoint

▪ Very toxic

▪ Toxic

▪ Oxidising

Group 2 comprises all other fluids not referred to in Group 1.

4 Valve Description

14 of 100

4.3 Globe Valves to ANSI/ASME with Gland Packing

4.3.1 ECOLINE GLC 150-600

4.3.1.1 Operating data

Table5: Operating properties

Characteristic Value

Nominal pressure Class 150 - 600

Nominal size NPS 2'' - 12''

Max. permissible pressure 106 bar / 1500 PSI

Min. permissible temperature 0°C /32 °F

Max. permissible temperature 816 °C / 1500 °F

Temperatures < 0°C on request

Selection as per pressure/temperature ratings (ðSection4.3.1.4,Page16)

4.3.1.2 Fluids handled

▪ Steam

▪ Fluids containing gas

▪ Fluids containing mineral oils

▪ Gas

▪ High-temperature hot water

▪ Feed water

▪ Oil

4 Valve Description

15 of 100

4.3.1.3 Design details

Design

▪ Globe valve to BS 1873

▪ Tested to API 598

▪ Body made of cast steel or stainless steel

▪ Bolted bonnet

▪ Outside screw

▪ Rotating stem

▪ Non-rotating stem (8'' and 10'' Class 300/600)

▪ Rising stem

▪ Stem with burnished shank

▪ Solid flat disc (plug-type valve disc for 8" and 10" Class 600)

▪ Stem sealed by gland packing

▪ Two-piece self-aligning gland follower

▪ Stem nut made of nickel steel

▪ Valve seat made of wear-resistant and corrosion-proof materials

▪ Back seat

▪ Hardened back seat bush

▪ Die-moulded graphite gland packing, packing end rings made of braided

graphite

▪ Stainless steel/graphite gaskets

▪ Outside yoke

▪ Yoke head suitable for mounting electric and pneumatic actuators (DIN ISO 5210)

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 97/23/EC (PED) for fluids in Groups 1 and 2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, Group II, category2 (zones1+21) and

category3 (zones2+22) to ATEX 2014/34/EU.

Variants

▪ Position indicator

▪ Limit switch(es)

▪ Locking device

▪ Throttling plug

▪ Hard-faced back seat

▪ Drain plug

▪ Bypass

▪ Version in compliance with TA-Luft (German Clean Air Act) to VDI 2440 for

temperatures up to 400 °C

▪ Version with free stem end and top flange to ISO 5210

▪ Gearboxes

▪ Electric actuators

▪ Non-destructive testing, e.g. radiographic testing

▪ Inspections to technical codes such as AD2000 or IBR

▪ NACE standard

▪ Other flanged end designs or butt weld ends to ASME B16.25

▪ Larger nominal sizes and other variants on request

4 Valve Description

16 of 100

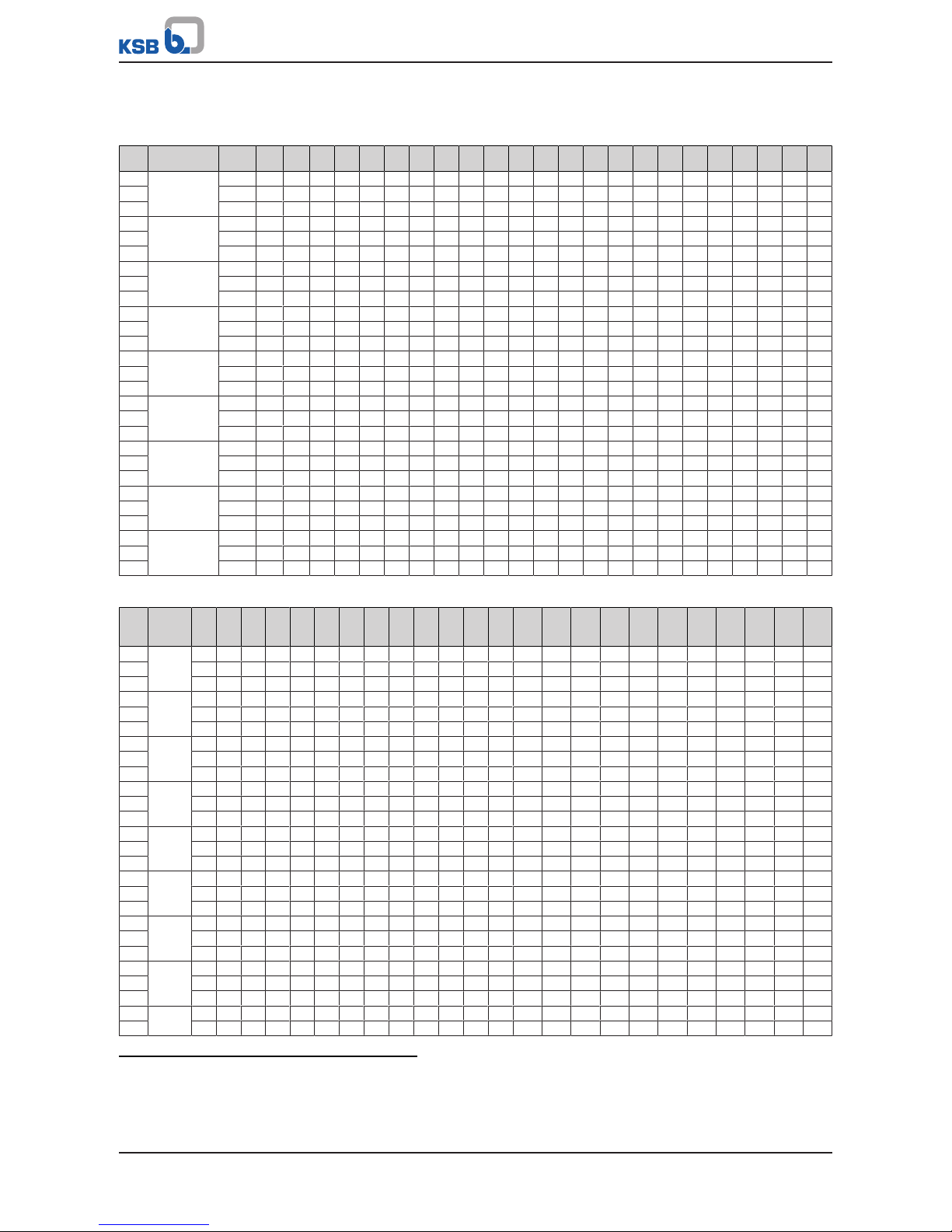

4.3.1.4 Pressure/temperature ratings

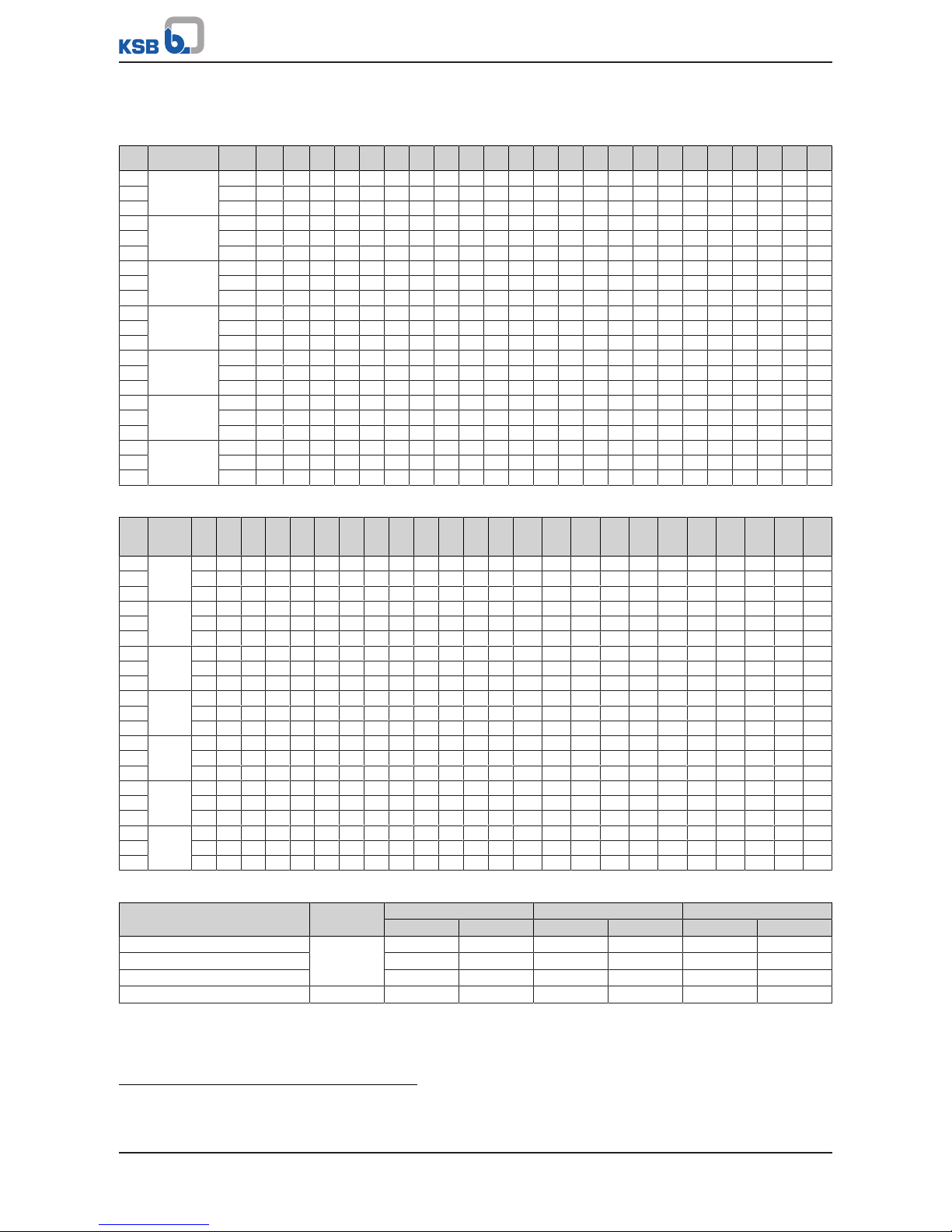

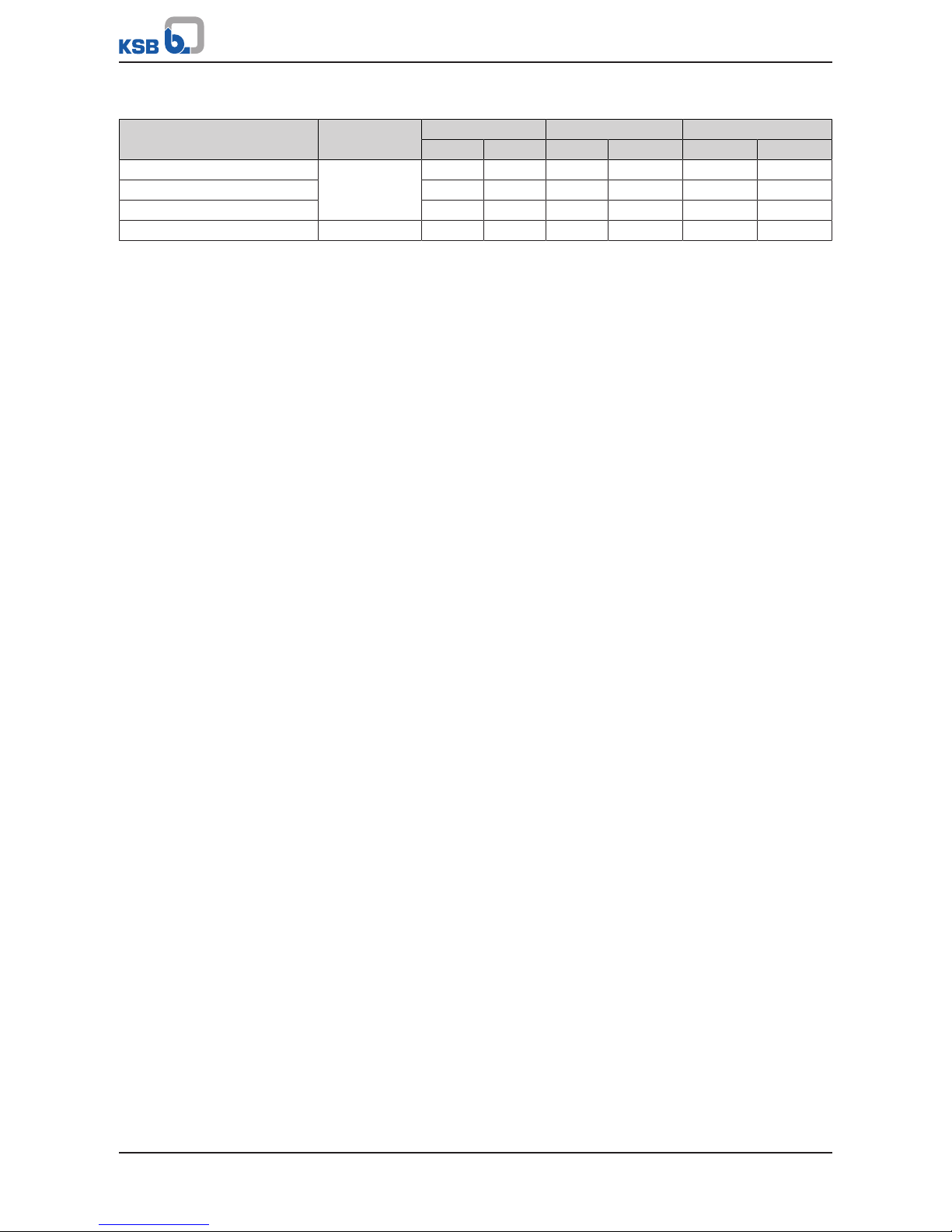

Table6: Permissible operating pressures in bar at temperatures in °C (to ASME B16.34)

Class

Material -29 to3893 149 204 260 316 343 371 399 427 454 482 510 538 566 593 621 649 677 704 732 760 788 816

150 A 216 WCB4)19,7 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 - - - - - - - - - 300 51,0 46,9 45,2 43,8 41,7 39,3 37,9 36,5 34,8 28,3 22,1 15,9 9,3 5,9 - - - - - - - - - 600 102,0 93,8 90,3 87,2 83,1 78,3 75,8 73,1 70,0 56,9 44,1 31,7 19,0 11,7 - - - - - - - - - 150 A 217 WC65)20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)- - - - - - - 300 51,7 51,7 49,6 47,9 45,9 41,7 40,7 39,3 36,5 35,2 33,4 31,0 22,1 14,8 10,0 6,6 - - - - - - - 600 103,4 103,4 99,6 95,5 91,7 83,4 81,0 78,3 73,4 70,0 67,2 62,1 44,1 29,6 20,0 13,1 - - - - - - - 150 A 217 WC9 20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)- - - - - - - 300 51,7 51,7 50,3 48,6 45,9 41,7 40,7 39,3 36,5 35,2 33,4 31,0 26,5 18,3 12,1 7,6 - - - - - - - 600 103,4 103,4 100,3 97,2 91,7 83,4 81,0 78,3 73,4 70,0 67,2 62,1 52,1 36,9 24,1 15,2 - - - - - - - 150 A 217 C5 20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)1,46)1,06)- - - - - 300 51,7 51,7 50,3 48,6 45,9 41,7 40,7 39,3 36,5 35,2 33,4 25,9 19,0 13,8 10,0 6,9 4,1 2,4 - - - - - 600 103,4 103,4 100,3 97,2 91,7 83,4 81,0 78,3 73,4 70,0 67,2 51,4 37,9 27,6 20,0 13,8 8,6 4,8 - - - - - 150 A 217 C12 20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)1,46)1,46)- - - - - 300 51,7 51,7 50,3 48,6 45,9 41,7 40,7 39,3 36,5 35,2 33,4 31,0 25,9 17,6 11,7 7,9 5,2 3,4 - - - - - 600 103,4 103,4 100,3 97,2 91,7 83,4 81,0 78,3 73,4 70,0 67,2 62,1 52,1 34,8 23,8 15,5 10,3 7,2 - - - - - 150 A 352 LCB7)18,3 17,6 15,9 13,8 11,7 9,7 8,6 - - - - - - - - - - - - - - - - 300 47,9 45,5 44,1 42,4 40,3 37,9 36,9 - - - - - - - - - - - - - - - - 600 96,2 91,0 87,9 84,8 81,0 76,2 73,4 - - - - - - - - - - - - - - - - 150 A 352 LCC 20,0 17,9 15,9 13,8 11,7 9,7 8,6 - - - - - - - - - - - - - - - - 300 51,7 51,7 50,3 48,6 45,9 41,7 40,7 - - - - - - - - - - - - - - - - 600 103,4 103,4 100,3 96,6 91,7 83,4 81,0 - - - - - - - - - - - - - - - - 150 A 351 CF88)19,0 15,9 14,1 13,1 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,0

6)

300 49,6 41,4 37,2 34,1 32,1 30,3 29,6 29,0 28,6 27,9 27,2 26,9 26,2 24,5 22,4 17,6 14,1 11,4 9,3 7,9 6,6 5,2 4,1 2,8

600 99,3 82,7 74,1 68,6 64,1 61,0 59,6 58,3 56,9 55,8 54,5 53,8 52,7 49,0 44,8 35,5 28,3 22,8 18,3 15,5 12,8 10,3 7,9 5,9

150 A 351 CF8M8)19,0 16,2 14,8 13,4 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,46)1,0

6)

300 49,6 42,7 38,6 35,5 33,1 31,0 30,3 30,0 29,3 29,0 29,0 28,6 26,5 25,2 24,8 21,0 16,2 12,8 10,0 7,9 6,6 5,2 4,1 2,8

600 99,3 85,5 77,2 70,7 65,8 62,1 61,0 60,0 59,0 58,3 57,6 57,2 53,4 50,0 49,6 42,1 32,8 25,5 20,3 16,2 13,1 10,3 7,9 5,9

Table7: Permissible operating pressures in PSI at temperatures in °F (to ASME B16.34)

Class

Material

-20

to

100

200 300 400 500 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

150 A 216

WCB

4)

285 260 230 200 170 140 125 110 95 80 65 50 35 20 - - - - - - - - - 300 740 680 655 635 605 570 550 530 505 410 320 230 135 85 - - - - - - - - - 600 1480 1360 1310 1265 1205 1135 1100 1060 1015 825 640 460 275 170 - - - - - - - - - 150 A 217

WC6

5)

290 260 230 200 170 140 125 110 95 80 65 50 35 20 206)206)- - - - - - - 300 750 750 720 695 665 605 590 570 530 510 485 450 320 215 145 95 - - - - - - - 600 1500 1500 1445 1385 1330 1210 1175 1135 1065 1015 975 900 640 430 290 190 - - - - - - - 150 A 217

WC9

290 260 230 200 170 140 125 110 95 80 65 50 35 20 206)206)- - - - - - - 300 750 750 730 705 665 605 590 570 530 510 485 450 385 265 175 110 - - - - - - - 600 1500 1500 1455 1410 1330 1210 1175 1135 1065 1015 975 900 755 535 350 220 - - - - - - - 150 A 217 C5 290 260 230 200 170 140 125 110 95 80 65 50 35 20 206)206)206)156)- - - - - 300 750 750 730 705 665 605 590 570 530 510 485 375 275 200 145 100 60 35 - - - - - 600 1500 1500 1455 1410 1330 1210 1175 1135 1065 1015 975 745 550 400 290 200 125 70 - - - - - 150 A 217

C12

290 260 230 200 170 140 125 110 95 80 65 50 35 20 206)206)206)206)- - - - - 300 750 750 730 705 665 605 590 570 530 510 485 450 375 255 170 115 75 50 - - - - - 600 1500 1500 1455 1410 1330 1210 1175 1135 1065 1015 975 900 755 505 345 225 150 105 - - - - - 150 A 352

LCB

7)

265 255 230 200 170 140 125 - - - - - - - - - - - - - - - - 300 695 660 640 615 585 550 535 - - - - - - - - - - - - - - - - 600 1395 1320 1275 1230 1175 1105 1065 - - - - - - - - - - - - - - - - 150 A 352

LCC

290 260 230 200 170 140 125 - - - - - - - - - - - - - - - - 300 750 750 730 705 665 605 590 - - - - - - - - - - - - - - - - 600 1500 1500 1455 1405 1330 1210 1175 - - - - - - - - - - - - - - - - 150 A 351

CF8

8)

275 230 205 190 170 140 125 110 95 80 65 50 35 20 206)206)206)206)206)206)206)206)206)15

6)

300 720 600 540 495 465 440 430 420 415 405 395 390 380 355 325 255 205 165 135 115 95 75 60 40

600 1440 1200 1075 995 930 885 865 845 825 810 790 780 765 710 650 515 410 330 265 225 185 150 115 85

150 A 351

CF8M

8)

275 235 215 195 170 140 125 110 95 80 65 50 35 20 206)206)206)206)206)206)206)206)206)15

6)

300 720 620 560 515 480 450 440 435 425 420 420 415 385 365 360 305 235 185 145 115 95 75 60 40

4) Permissible but not recommended for prolonged use above 427°C (800°F).

5) Cannot be used for temperatures above 593°C (1100°F).

6) For butt weld end valves only. Flanged end ratings terminate at 538°C (1000°F).

7) Cannot be used for temperatures above 343°C (650°F).

8) At temperatures over 538°C (1000°F), use only when carbon content is 0.04% or higher.

4 Valve Description

17 of 100

Class

Material

-20

to

100

200 300 400 500 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

600 1440 1240 1120 1025 955 900 885 870 855 845 835 830 775 725 720 610 475 370 295 235 190 150 115 85

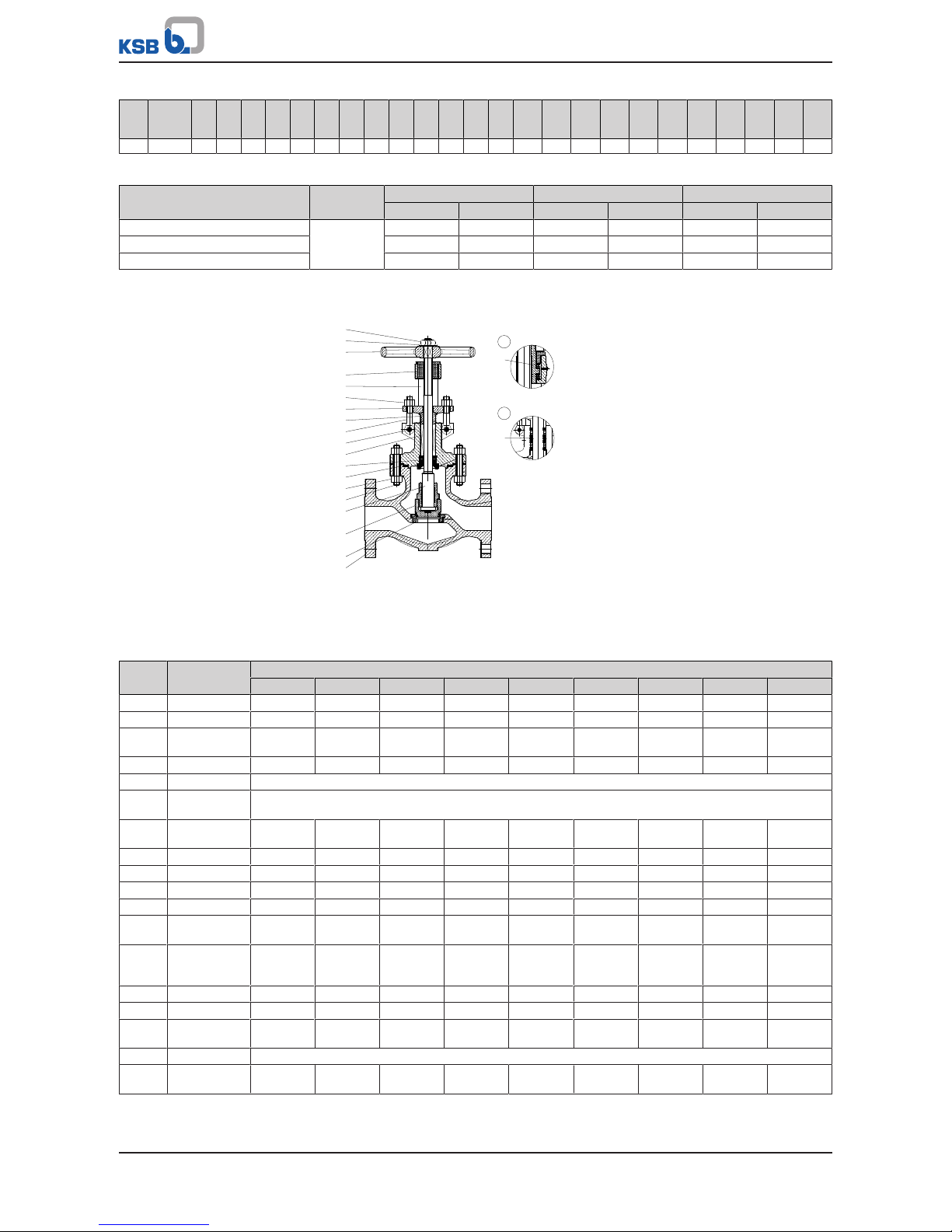

Table8: Test pressures

Test Test medium Class 150 Class 300 Class 600

[bar] [psi] [bar] [psi] [bar] [psi]

Shell Water 32 450 78 1125 153 2225

Leak test (back seat) 23 315 56 815 112 1630

Leak test (seat) 23 315 56 815 112 1630

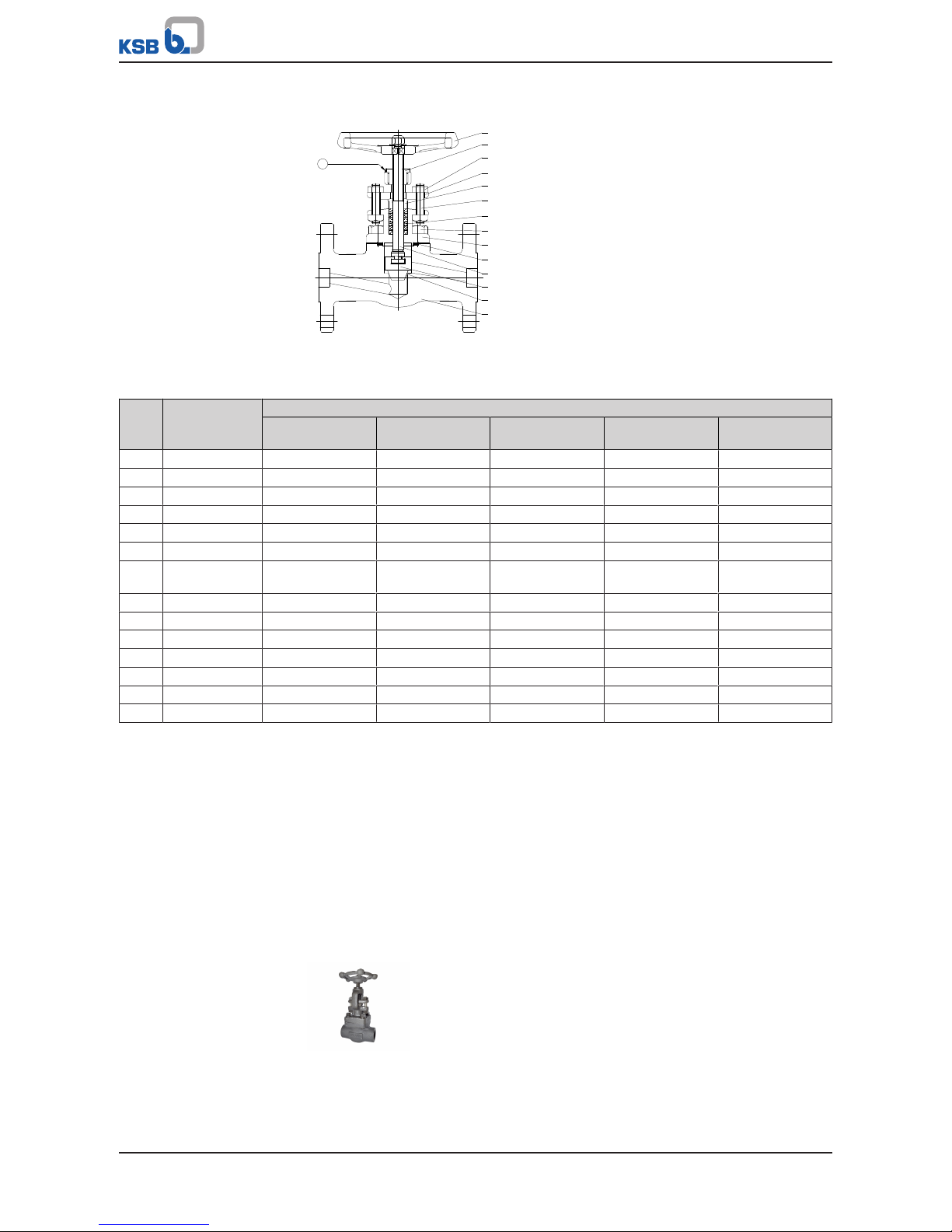

4.3.1.5 Materials

1

2

920.3

920.1

411

166

900

465

450

461

560

452

920.2

544

961

554

458

300

100

515

350

200

902

① Bearing (8''-12'' Class 300, 6''-12'' Class 600)

② Lantern ring (optional)

Table9: Parts list

Part

No.

Description Material

A 216 WCB A 217 WC6 A 217 WC9 A 217 C5 A 217 C12 A 352 LCB A 352 LCC A 351 CF8 A 351 CF8M

100 Body A 216 WCB A 217 WC6 A 217 WC9 A 217 C5 A 217 C12 A352 LCB A 352 LCC A 351 CF8 A 351 CF8M

166 Yoke A 216 WCB A 217 WC6 A 217 WC9 A 217 C5 A 217 C12 A352 LCB A 352 LCC A 351 CF8 A 351 CF8M

350 Lower valve disc

section

A 216 WCB A 217 WC6 A 217 WC9 A 217 C5 A 217 C12 A352 LCB A 352 LCC A 351 CF8 A 351 CF8M

515 Seat ring A 105 A 182 F11 A 182 F22 A 182 F5 A 182 F9 A 182 LF2 A 350 LF2 A 182 F304 A 182 F316

200 Stem See "Trim materials" table

450 Back seat

bush

See "Trim materials" table

465 Lower gland

section

13Cr 13Cr 13Cr 13Cr 13Cr 304 304 304 316

452 Gland follower A 216 WCB A 216 WCB A 216 WCB A 351 CF8 A 351 CF8 A 351 CF8 A 351 CF8 A 351 CF8 A 351 CF8

544 Threaded bush A 439 D2C A 439 D2C A 439 D2C A 439 D2C A 439 D2C A 439 D2C A 439 D2C A 439 D2C A 439 D2C

902 Stud A 193 B7 A 193 B16 A 193 B16 A 193 B16 A 193 B16 A 320 L7 A 320 L7 A 193 B8 A 193 B8

920.1 Nut A 194 2H A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 8 A 194 Gr. 8

461 Gland

packing

Graphite Graphite Graphite Graphite Graphite Graphite Graphite Graphite Graphite

411 Joint ring Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

Graphite +

stainless

steel

900 Eyebolt A 307 B A 193 B16 A 193 B16 A 193 B16 A 193 B16 A 320 L7 A 320 L7 A 193 B8 A 193 B8

920.2 Nut A 194 2H A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 7 A 194 Gr. 8 A 194 Gr. 8

560 Pin Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon steel Carbon

steel

Stainless

steel

Stainless

steel

961 Handwheel Nodular cast iron or malleable cast iron or cast steel

920.3 Handwheel nut Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Stainless

steel

Stainless

steel

4 Valve Description

18 of 100

Part

No.

Description Material

A 216 WCB A 217 WC6 A 217 WC9 A 217 C5 A 217 C12 A 352 LCB A 352 LCC A 351 CF8 A 351 CF8M

554 Washer Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Carbon

steel

Stainless

steel

Stainless

steel

300 Bearing Steel Steel Steel Steel Steel Steel Steel Steel Steel

458 Lantern ring 13Cr 13Cr 13Cr 13Cr 13Cr 304 304 304 316

Table10: Trim materials

Part No. Description Trim 1 Trim 2 Trim 5 Trim 8 Trim 10

13% chrome steel (Cr) /

13% chrome steel (Cr)

304 / 304 Stellite / Stellite Stellite / 13% chrome

steel (Cr)

316 / 316

350 Lower valve disc

section

13% chrome steel (Cr) 304 stainless steel Stellite 13% chrome steel (Cr) 316 stainless steel

515 Seat ring 13% chrome steel (Cr) 304 stainless steel Stellite Stellite 316 stainless steel

200 Stem 13% chrome steel (Cr) 304 stainless steel 13% chrome steel (Cr) 13% chrome steel (Cr) 316 stainless steel

450 Back seat

bush

13% chrome steel (Cr) 304 stainless steel 13% chrome steel (Cr) 13% chrome steel (Cr) 316 stainless steel

4.3.1.6 Function

The main components of the globe valves are the body (100), the yoke (166), the

valve disc (350), the stem (200) and the actuating unit.

Stem seal

The gland packing (461), which seals off the stem (200), is tightened via the gland

follower (452) by means of eyebolts (900) and nuts (920.2). The yoke (166) is

equipped with a back seat bush (450) which seals off the valve when the stem (200) is

fully retracted.

Seat/disc interface

The hard-faced seat ring (515) is welded into the body (100). The seating surface of

the valve disc (350) is hard-faced.

Bonnet/cover seal

The body (100) and the yoke (166) are connected by studs (902) and nuts (920.1). The

joint is sealed by means of a joint ring (411).

4.3.2 ECOLINE GLF 150-600

4.3.2.1 Operating data

Table11: Operating properties

Characteristic Value

Nominal pressure Class 150 - 600

Nominal size NPS ½'' - 2''

Max. permissible pressure 104 bar / 1480 PSI

Min. permissible temperature 0°C /32 °F

Max. permissible temperature 816 °C / 1500 °F

Temperatures < 0°C on request

Selection as per pressure/temperature ratings (ðSection4.3.2.4,Page20)

4 Valve Description

19 of 100

4.3.2.2 Fluids handled

▪ Steam

▪ Fluids containing gas

▪ Gas

▪ High-temperature hot water

▪ Fluids containing mineral oils

▪ Oil

▪ Feed water

4.3.2.3 Design details

Design

▪ Globe valve to API 602

▪ Tested to API 598

▪ Body made of forged steel

▪ Bolted bonnet

▪ Outside screw

▪ Outside yoke

▪ Rotating stem

▪ Rising handwheel

▪ Stem sealed by gland packing

▪ Reduced bore

▪ Two-piece self-aligning gland follower

▪ Graphite gland packing

▪ Stem with burnished shank

▪ Fully confined bonnet gasket

▪ Back seat

▪ Solid valve disc

▪ Integral seat - ST6 (HF)

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 97/23/EC (PED) for fluids in Groups 1 and 2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, Group II, category2 (zones1+21) and

category3 (zones2+22) to ATEX 2014/34/EU.

Variants

▪ Seal-welded body/bonnet joint

▪ Full bore

▪ Hard-faced back seat

▪ Extended bonnet

▪ Locking device

▪ Position indicator

▪ Electric actuators

▪ Version in compliance with TA-Luft (German Clean Air Act) to VDI 2440 for

temperatures up to 400 °C

▪ Butt weld ends

▪ NACE standard

▪ Other flanged end designs or butt weld ends to ASME B16.25

▪ Other trims

4 Valve Description

20 of 100

4.3.2.4 Pressure/temperature ratings

Table12: Permissible operating pressures in bar at temperatures in °C (to ASME B16.34)

Class

Material 0 to 38 93 149 204 260 316 343 371 399 427 454 482 510 538 566 593 621 649 677 704 732 760 788 816

150 A 105 19,7 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 - - - - - - - - - - - - - 300 51,0 46,9 45,2 43,8 41,7 39,3 37,9 36,5 34,8 28,3 - - - - - - - - - - - - - 600 102,0 93,8 90,3 87,2 83,1 78,3 75,8 73,1 70,0 56,9 - - - - - - - - - - - - - 150 A 182 F11 9)20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

10)

1,4

10)

- - - - - - - 300 51,7 51,7 49,6 47,9 45,9 41,7 40,7 39,3 36,5 35,2 33,4 31,0 22,1 14,8 10,0 6,6 - - - - - - - 600 103,4 103,4 99,6 95,5 91,7 83,4 81,0 78,3 73,4 70,0 67,2 62,1 44,1 29,6 20,0 13,1 - - - - - - - 150 A 182 F304

11)

19,0 15,9 14,1 13,1 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,0

10)

300 49,6 41,4 37,2 34,1 32,1 30,3 29,6 29,0 28,6 27,9 27,2 26,9 26,2 24,5 22,4 17,6 14,1 11,4 9,3 7,9 6,6 5,2 4,1 2,8

600 99,3 82,7 74,1 68,6 64,1 61,0 59,6 58,3 56,9 55,8 54,5 53,8 52,7 49,0 44,8 35,5 28,3 22,8 18,3 15,5 12,8 10,3 7,9 5,9

150 A 182 F22 20,0 17,9 15,9 13,8 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

10)

1,4

10)

- - - - - - - 300 51,7 51,7 50,3 48,6 45,9 41,7 40,7 39,3 36,5 35,2 33,4 31,0 26,5 18,3 12,1 7,6 - - - - - - - 600 103,4 103,4 100,3 97,2 91,7 83,4 81,0 78,3 73,4 70,0 67,2 62,1 52,1 36,9 24,1 15,2 - - - - - - - 150 A 182 F316

11)

19,0 16,2 14,8 13,4 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,4

10)

1,0

10)

300 49,6 42,7 38,6 35,5 33,1 31,0 30,3 30,0 29,3 29,0 29,0 28,6 26,5 25,2 24,8 21,0 16,2 12,8 10,0 7,9 6,6 5,2 4,1 2,8

600 99,3 85,5 77,2 70,7 65,8 62,1 61,0 60,0 59,0 58,3 57,6 57,2 53,4 50,0 49,6 42,1 32,8 25,5 20,3 16,2 13,1 10,3 7,9 5,9

150 A 182 F304L 15,9 13,4 12,1 11,0 10,3 9,7 8,6 7,6 7,6 5,5 - - - - - - - - - - - - - 300 41,4 35,2 31,4 30,0 27,2 25,5 25,2 24,8 24,5 23,8 - - - - - - - - - - - - - 600 82,7 70,3 62,7 57,9 54,1 51,4 50,3 49,6 48,6 47,6 - - - - - - - - - - - - - 150 A 182 F316L 15,9 13,4 12,1 11,0 10,3 9,7 8,6 7,6 7,6 5,5 4,5 - - - - - - - - - - - - 300 41,4 35,2 31,4 29,0 27,2 25,5 25,2 24,8 24,5 23,8 23,4 - - - - - - - - - - - - 600 82,7 70,3 62,7 57,9 54,1 51,4 50,3 49,6 48,6 47,6 46,5 - - - - - - - - - - - - -

Table13: Permissible operating pressures in PSI at temperatures in °F (to ASME B16.34)

Class

Material

32

to

100

200 300 400 500 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

150 A 105 285 260 230 200 170 140 125 110 95 80 - - - - - - - - - - - - - 300 740 680 655 635 605 570 550 530 505 410 - - - - - - - - - - - - - 600 1480 1360 1310 1265 1205 1135 1100 1060 1015 825 - - - - - - - - - - - - - 150 A 182

F11

9)

290 260 230 200 170 140 125 110 95 80 65 50 35 20 20

10)

20

10)

- - - - - - - 300 750 750 720 695 665 605 590 570 530 510 485 450 320 215 145 95 - - - - - - - 600 1500 1500 1445 1385 1330 1210 1175 1135 1065 1015 975 900 640 430 290 190 - - - - - - - 150 A 182

F304

11)

275 230 205 190 170 140 125 110 95 80 65 50 35 20 20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

15

10)

300 720 600 540 495 465 440 430 420 415 405 395 390 380 355 325 255 205 165 135 115 95 75 60 40

600 1440 1200 1075 995 930 885 865 845 825 810 790 780 765 710 650 515 410 330 265 225 185 150 115 85

150 A 182

F22

290 260 230 200 170 140 125 110 95 80 65 50 35 20 20

10)

20

10)

- - - - - - - 300 750 750 730 705 665 605 590 570 530 510 485 450 385 265 175 110 - - - - - - - 600 1500 1500 1455 1410 1330 1210 1175 1135 1065 1015 975 900 755 535 350 220 - - - - - - - 150 A 182

F316

11)

275 235 215 195 170 140 125 110 95 80 65 50 35 20 20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

20

10)

15

10)

300 720 620 560 515 480 450 440 435 425 420 420 415 385 365 360 305 235 185 145 115 95 75 60 40

600 1440 1240 1120 1025 955 900 885 870 855 845 835 830 775 725 720 610 475 370 295 235 190 150 115 85

150 A 182

F304L

230 195 175 160 150 140 125 110 110 80 - - - - - - - - - - - - - 300 600 510 455 420 395 370 365 360 355 345 - - - - - - - - - - - - - 600 1200 1020 910 840 785 745 730 720 705 690 - - - - - - - - - - - - - 150 A 182

F316L

230 195 175 160 150 140 125 110 110 80 65 - - - - - - - - - - - - 300 600 510 455 420 395 370 365 360 355 345 340 - - - - - - - - - - - - 600 1200 1020 910 840 785 745 730 720 705 690 675 - - - - - - - - - - - - -

Table14: Test pressures

Test Test medium Class 150 Class 300 Class 600

[bar] [psi] [bar] [psi] [bar] [psi]

Shell Water 31,0 450 77,6 1125 153,4 2225

Leak test (back seat) 22,4 325 56,9 825 113,8 1650

Leak test (seat) 22,4 325 56,9 825 113,8 1650

Leak test (seat) Air 5,5 80 5,5 80 5,5 80

9) Use normalised and tempered materials only.

10) Flanged end ratings terminate at 538°C (1000°F).

11) At temperatures over 538°C (1000°F), use only when carbon content is 0.04% or higher.

4 Valve Description

21 of 100

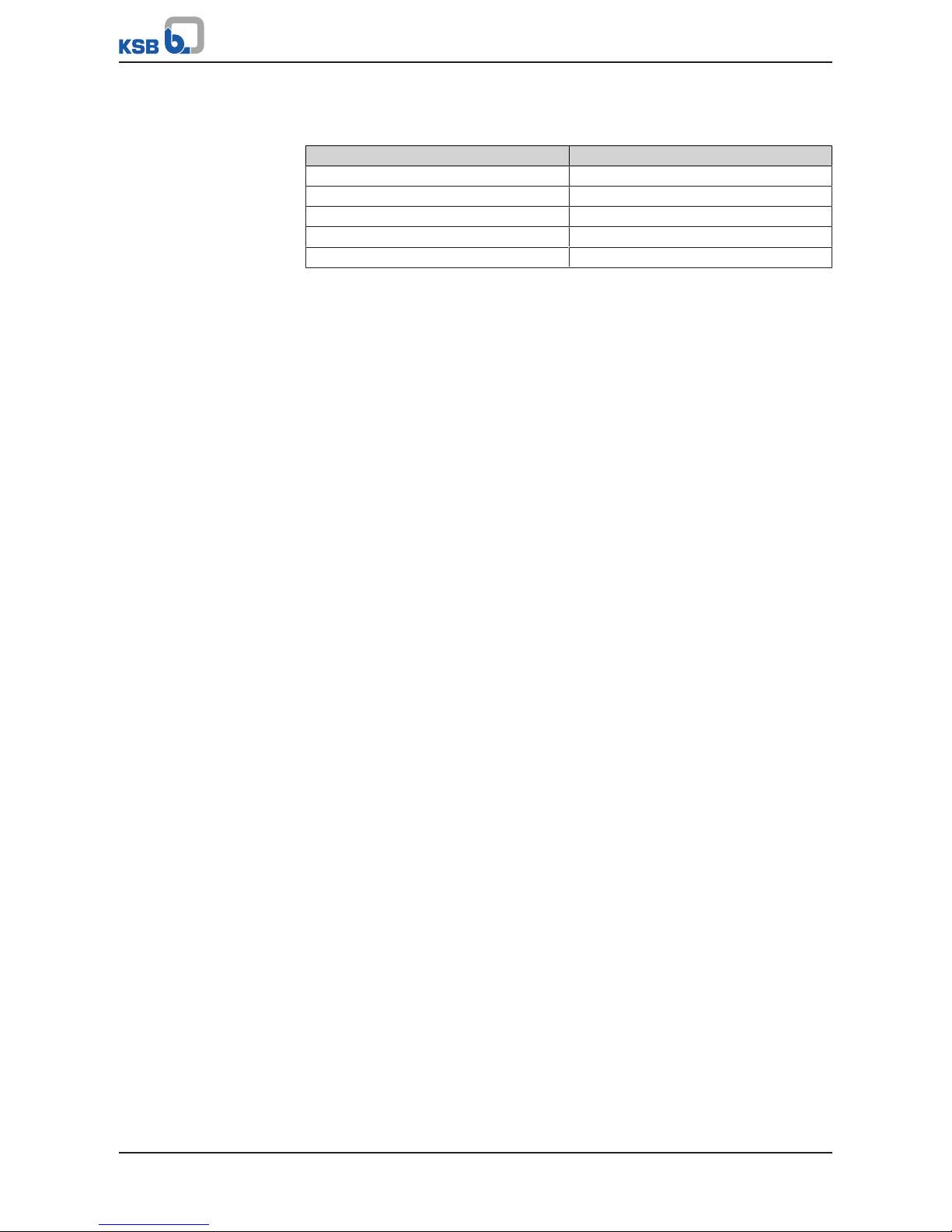

4.3.2.5 Materials

961

544

920

452

465

902

461

901

166

411

200

350

515

100

1

① Tack-welded

Table15: Parts list

Part No.

Description Material

A 105

Trim 8

A 182 F11

Trim 5

A 182 F22

Trim 5

A 182 F304

Trim 2

A 182 F316

Trim 10

100 Body A 105 A 182 F11 A 182 F22 A 182 F304 A 182 F316

166 Yoke A 105 A 182 F11 A 182 F22 A 182 F304 A 182 F316

200 Stem A 182 F6a A 182 F6a A 182 F6a A 182 F304 A 182 F316

350 Valve disc A 182 F6a A 182 F6a + STL6 A 182 F6a + STL6 A 182 F304 A 182 F316

411 Joint ring 304 + graphite 304 + graphite 304 + graphite 304 + graphite 316 + graphite

452 Gland follower A 105 A 105 A 105 A 182 F304 A 182 F316

465 Lower gland

section

A 276 410 A 276 410 A 276 410 A 276 304 A 276 316

461 Gland packing Flexible graphite Flexible graphite Flexible graphite Flexible graphite Flexible graphite

515 Seat ring STL6 (integral) STL6 (integral) STL6 (integral) 304 (integral) 316 (integral)

544 Threaded bush A 276 410 A 276 410 A 276 410 A 276 410 A 276 410

901 Bolt A 193 B7 A 193 B16 A 193 B16 A 193 B8 A 193 B8M

902 Stud A 193 B8 A 193 B16 A 193 B16 A 193 B8 A 193 B8

920 Nut A 194 2H A 194 8 A 194 8 A 194 8 A 194 8M

961 Handwheel A 197 A 197 A 197 A 197 A 197

4.3.2.6 Function

The main components of the globe valves are the body (100), the yoke (166), the

valve disc (351), the stem (200) and the actuating unit.

Stem seal

The gland packing (461), which seals off the stem (200), is tightened via the gland

follower (452) by means of studs (902) and nuts (920). The yoke (166) features an

integral back seat which seals off the valve when the stem (200) is fully retracted.

Seat/disc interface

The integral seating surfaces in the body (100) are hard-faced. The valve disc (351) is

connected to the stem (200) by a "T" joint.

Bonnet/cover seal

The yoke (166) is bolted to the body (100). The joint is sealed by a joint ring (411).

4.3.3 ECOLINE GLF 800-2500

4 Valve Description

22 of 100

4.3.3.1 Operating data

Table16: Operating properties

Characteristic Value

Nominal pressure Class 800 - 2500

Nominal size NPS ½" - 2"

Max. permissible pressure 431 bar / 6250 PSI

Min. permissible temperature 0°C /32 °F

Max. permissible temperature +538 °C / +1500 °F

Temperatures < 0°C on request

Selection as per pressure/temperature ratings (ðSection4.3.3.4,Page24)

4.3.3.2 Fluids handled

▪ Steam

▪ Fluids containing gas

▪ Gas

▪ High-temperature hot water

▪ Fluids containing mineral oils

▪ Oil

▪ Feed water

4.3.3.3 Design details

Design

▪ Globe valve to API 602

▪ Tested to API 598

▪ Body made of forged steel

▪ Bolted bonnet (Class 800)

▪ Welded bonnet

▪ Outside screw

▪ Outside yoke

▪ Rotating stem

▪ Rising handwheel

▪ Stem sealed by gland packing

▪ Reduced bore

▪ Two-piece self-aligning gland follower

▪ Graphite gland packing

▪ Stem with burnished shank

▪ Fully confined bonnet gasket (Class 800)

▪ Back seat

▪ Solid valve disc

▪ Integral seat - ST6 (HF)

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 97/23/EC (PED) for fluids in Groups 1 and 2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, Group II, category2 (zones1+21) and

category3 (zones2+22) to ATEX 2014/34/EU.

4 Valve Description

23 of 100

Variants

▪ Full bore

▪ Hard-faced back seat

▪ Extended bonnet

▪ Locking device

▪ Position indicator

▪ Electric actuators

▪ Version in compliance with TA-Luft (German Clean Air Act) to VDI 2440 for

temperatures up to 400 °C

▪ Butt weld ends

▪ NACE standard

▪ Other threaded ends or butt weld ends to ASME B16.25

▪ Other trims

▪ Other material variants

4 Valve Description

24 of 100

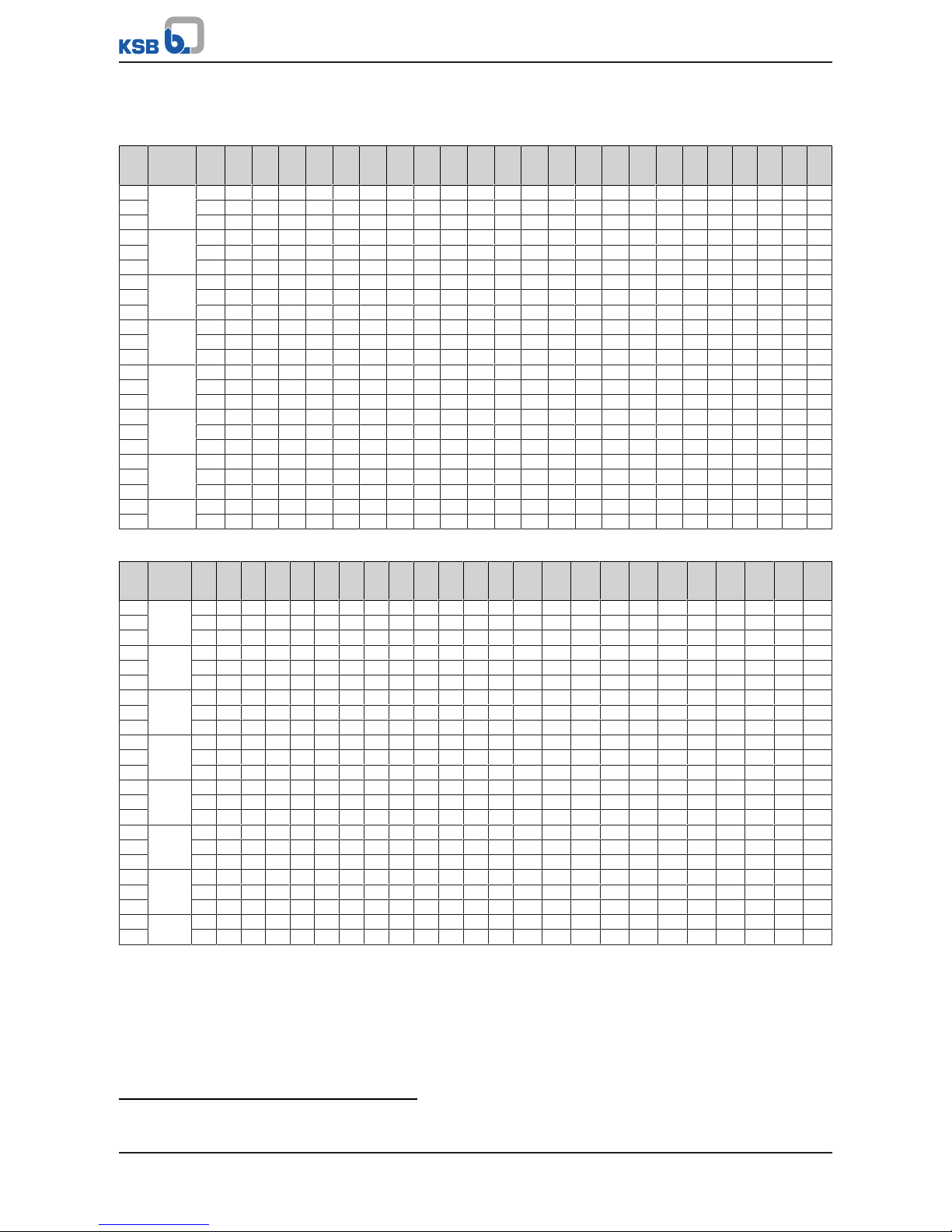

4.3.3.4 Pressure/temperature ratings

Table17: Permissible operating pressures in bar at temperatures in °C (to ASME B16.34)

Class

Material

0 to3893 149 204 260 316 343 371 399 427 454 482 510 538 566 593 621 649 677 704 732 760 788 816

800 A 105 136,0 124,8 120,5 116,4 110,9 104,5 101,1 97,4 93,2 75,7 - - - - - - - - - - - - - 1500 255,3 233,0 225,4 219,0 209,7 193,6 187,8 181,8 173,6 143,8 - - - - - - - - - - - - - 2500 425,5 388,3 375,6 365,0 349,5 322,6 313,0 303,1 289,3 239,7 - - - - - - - - - - - - - 800 A 182

F11

12)

137,9 137,9 132,7 127,4 122,2 111,2 108,1 104,5 97,8 93,4 89,5 82,7 58,6 39,8 26,4 17,7 - - - - - - - 1500 258,6 257,4 248,7 239,8 231,8 206,6 201,1 194,1 183,1 175,1 169,0 158,2 128,6 74,5 44,0 30,5 - - - - - - - 2500 430,9 429,0 414,5 399,6 386,2 344,3 335,3 323,2 304,9 291,6 281,8 263,9 214,4 124,1 73,4 50,9 - - - - - - - 800 A 182 F22 137,9 137,9 133,9 129,6 122,2 111,2 108,1 104,5 97,8 93,4 89,5 82,7 70,7 49,1 32,2 20,2 - - - - - - - 1500 258,6 257,6 250,8 243,4 231,8 206,6 201,1 194,1 183,1 175,1 169,0 158,2 140,9 92,2 52,6 34,4 - - - - - - - 2500 430,9 429,4 418,2 405,4 386,2 344,3 335,3 323,2 304,9 291,6 281,8 263,9 235,0 153,7 87,7 57,4 - - - - - - - 800 A 182

F304

13)

132,4 110,3 98,9 91,4 85,5 81,2 79,4 77,6 76,0 74,5 72,9 71,5 70,2 65,3 59,8 47,2 37,7 30,3 24,5 20,8 17,1 13,8 10,7 7,7

1500 248,2 204,3 185,0 172,4 162,4 151,1 148,1 145,2 142,2 140,0 137,0 134,7 132,4 122,1 104,2 84,4 68,9 56,3 46,7 40,1 33,8 28,9 17,4 14,1

2500 413,7 340,4 308,4 287,3 270,7 251,9 246,9 241,9 237,0 233,3 228,4 224,5 220,7 203,6 173,7 140,7 114,9 93,8 77,9 66,9 56,3 48,1 29,2 23,8

800 A 182

F316

13)

132,4 114,0 102,9 94,3 87,9 82,9 81,2 80,0 78,5 77,6 76,9 76,3 71,2 66,7 66,2 56,1 43,6 34,0 27,0 21,5 17,7 13,8 10,7 7,7

1500 248,2 211,0 192,5 178,3 166,9 154,4 151,6 149,4 147,2 145,7 144,2 143,4 140,9 125,5 119,7 99,5 79,1 63,3 51,6 41,9 34,9 29,3 17,4 14,1

2500 413,7 351,6 320,8 297,2 278,1 257,4 252,7 249,0 245,3 242,9 240,4 238,9 235,0 208,9 199,5 165,9 131,8 105,5 86,0 69,8 58,2 48,9 29,2 23,8

800 A 182

F304L

110,3 94,0 83,9 77,2 72,3 68,4 67,1 66,2 64,9 63,4 - - - - - - - - - - - - - 1500 206,8 173,9 157,0 145,8 137,3 127,4 125,4 123,8 121,5 119,3 - - - - - - - - - - - - - 2500 344,7 289,9 261,6 243,0 228,9 212,3 208,9 206,3 202,5 198,8 - - - - - - - - - - - - - 800 A 182

F316L

110,3 94,0 83,9 77,2 72,3 68,4 67,1 66,2 64,9 63,4 62,2 - - - - - - - - - - - - 1500 206,8 173,9 157,0 145,8 137,3 127,4 125,4 123,8 121,5 119,3 117,1 - - - - - - - - - - - - 2500 344,7 289,9 261,6 243,0 228,9 212,3 208,9 206,3 202,5 198,8 195,1 - - - - - - - - - - - - 1500 A 182 F91 258,6 257,6 250,8 243,4 231,8 206,6 201,1 194,1 183,1 175,1 169,0 158,2 140,9 125,5 119,7 97,5 73,0 49,6 - - - - - 2500 430,9 429,4 418,2 405,4 386,2 344,3 335,3 323,2 304,9 291,6 281,8 263,9 235,0 208,9 199,5 162,5 121,7 82,7 - - - - - -

Table18: Permissible operating pressures in PSI at temperatures in °F (to ASME B16.34)

Class

Material

32

to

100

200 300 400 500 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

800 A 105 1973 1810 1747 1688 1608 1515 1467 1413 1352 1098 - - - - - - - - - - - - - 1500 3705 3395 3270 3170 3015 2840 2745 2665 2535 2055 - - - - - - - - - - - - - 2500 6170 5655 5450 5280 5025 4730 4575 4425 4230 3430 - - - - - - - - - - - - - 800 A 182

F11

12)

2000 2000 1925 1848 1773 1613 1568 1515 1418 1355 1298 1200 850 577 383 257 - - - - - - - 1500 3750 3750 3610 3465 3325 3025 2940 2840 2660 2540 2435 2245 1595 1080 720 480 - - - - - - - 2500 6250 6250 6015 5775 5540 5040 4905 4730 4430 4230 4060 3745 2655 1800 1200 800 - - - - - - - 800 A 182

F22

2000 2000 1942 1880 1773 1613 1568 1515 1418 1355 1298 1200 1025 712 467 293 - - - - - - - 1500 3750 3750 3640 3530 3325 3025 2940 2840 2660 2540 2435 2245 1930 1335 875 550 - - - - - - - 2500 6250 6250 6070 5880 5540 5040 4905 4730 4430 4230 4060 3745 3220 2230 1455 915 - - - - - - - 800 A 182

F304

13)

1920 1600 1435 1325 1240 1178 1152 1125 1102 1080 1057 1037 1018 947 867 685 547 440 355 302 248 200 155 112

1500 3600 3000 2690 2485 2330 2210 2160 2110 2065 2030 1980 1945 1910 1770 1630 1285 1030 825 670 565 465 380 290 205

2500 6000 5000 4480 4140 3880 3680 3600 3520 3440 3380 3300 3240 3180 2950 2715 2145 1715 1370 1115 945 770 630 485 345

800 A 182

F316

13)

1920 1653 1493 1368 1275 1203 1178 1160 1138 1125 1115 1107 1032 968 960 813 632 493 392 312 257 200 155 112

1500 3600 3095 2795 2570 2390 2255 2210 2170 2135 2110 2090 2075 1930 1820 1800 1525 1185 925 735 585 480 380 290 205

2500 6000 5160 4660 4280 3980 3760 3680 3620 3560 3520 3480 3460 3220 3030 3000 2545 1970 1545 1230 970 800 630 485 345

800 A 182

F304L

1600 1363 1217 1120 1048 992 973 960 942 920 - - - - - - - - - - - - - 1500 3000 2555 2280 2100 1970 1860 1825 1800 1765 1730 - - - - - - - - - - - - - 2500 5000 4260 3800 3500 3280 3100 3040 3000 2940 2880 - - - - - - - - - - - - - 800 A 182

F316L

1600 1363 1217 1120 1048 992 973 960 942 920 902 - - - - - - - - - - - - 1500 3000 2555 2280 2100 1970 1860 1825 1800 1765 1730 1690 - - - - - - - - - - - - 2500 5000 4260 3800 3500 3280 3100 3040 3000 2940 2880 2820 - - - - - - - - - - - - 1500 A 182

F91

3750 3750 3640 3530 3325 3025 2940 2840 2660 2540 2435 2245 1930 1820 1800 1510 1115 720 - - - - - 2500 6250 6250 6070 5880 5540 5040 4905 4730 4430 4230 4060 3745 3220 3030 3000 2515 1855 1200 - - - - - -

12) Use normalised and tempered materials only.

13) At temperatures over 538°C (1000°F), use only when carbon content is 0.04% or higher.

4 Valve Description

25 of 100

Table19: Test pressures

Test Test medium Class 800 Class 1500 Class 2500

[bar] [psi] [bar] [psi] [bar] [psi]

Shell Water 205,1 2975 396 5625 660 9375

Leak test (back seat) 149,8 2173 291 4125 484 6875

Leak test (seat) 149,8 2173 291 4125 484 6875

Optional leak test (seat) Air 5,5 80 4 to 7 58 to 100 4 to 7 58 to 100

4 Valve Description

26 of 100

4.3.3.5 Materials

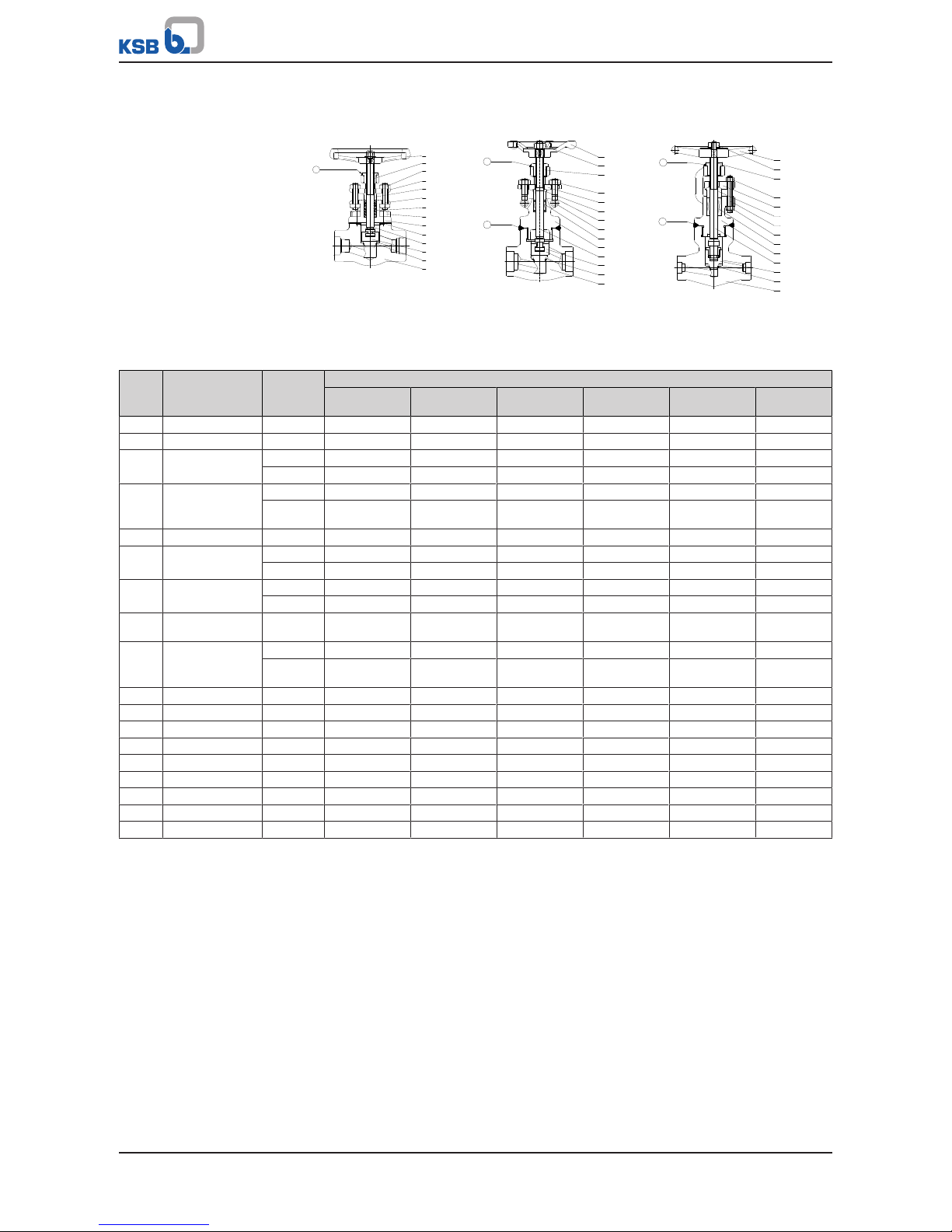

Class 800 Class 1500 Class 2500

1

961

544

920

452

465

902

461

901

166

411

200

350

515

100

1

2

961

544

920.3

920.2

452

465

900

560

461

166

200

350

515

100

1

2

961

544

920.3

920.2

452

465

900

920.2

461

166

200

350

515

100

① Tack-welded

② Seal-welded

Table20: Parts list

Part No.

Description Class Material

A 105

Trim 8

A 182 F11

Trim 5

A 182 F22

Trim 5

A 182 F304

Trim 2

A 182 F316

Trim 10

A182F91

Trim 5

100 Body A 105 A 182 F11 A 182 F22 A 182 F304 A 182 F316 A 182 F91

166 Yoke A 105 A 182 F11 A 182 F22 A 182 F304 A 182 F316 A 182 F91

200 Stem 800 A 182 F6a A 182 F6a A 182 F6a A 182 F304 A 182 F316

1500/2500 A 479-410-2 A 479-410-2 A 479-410-2 A 182 F304 A 182 F316 A479-XM19

350 Valve disc 800 A 182 F6a A 182 F6a + STL6 A 182 F6a + STL6 A 182 F304 A 182 F316

1500/2500 A276-410/

A276-410+ST6

A276-410/

A276-410+ST6

A276-410/

A276-410+ST6

A276-304/

A276-304+ST6

A276-304/

A276-304+ST6

A276-410/

A276-410+ST6

411 Joint ring 304 + graphite 304 + graphite 304 + graphite 304 + graphite 316 + graphite

452 Gland follower 800 A 105 A 105 A 105 A 182 F304 A 182 F316

1500/2500 A 105 A 105 A 105 A 182 F304 A 182 F304 A 182 F22

465 Lower gland

section

800 A 276-410 A 276-410 A 276-410 A 276-304 A 276-316

1500/2500 A 276-420 A 276-420 A 276-420 A 276-304 A 276-316 A 276-420

461 Gland packing Flexible graphite Flexible graphite Flexible graphite Flexible graphite Flexible graphite Flexible

graphite

515 Seat ring 800 A 276-410 + ST6 A 276-410 + ST6 A 276-410 + ST6 A 276-304 A 276-316

1500/2500 A276-410/

A276-410+ST6

A276-410/

A276-410+ST6

A276-410/

A276-410+ST6

A276-304/

A276-304+ST6

A276-304/

A276-304+ST6

A276-410/

A276-410+ST6

544 Threaded bush A 276-410 A 276-410 A 276-410 A 276-410 A 276-410 A 276-410

560 Pin 1500/2500 A 276-410 A 276-410 A 276-410 A 276-410 A 276-410 A 276-410

900 Eyebolt 1500/2500 A 193 B8 A 193 B8 A 193 B8 A 193 B8 A 193 B8 A 193 B8

901 Bolt 800 A 193 B7 A 193 B16 A 193 B16 A 193 B8 A 193 B8M

902 Stud 800 A 193 B8 A 193 B16 A 193 B16 A 193 B8 A 193 B8

920 Nut 800 A 194 2H A 194 8 A 194 8 A 194 8 A 194 8M

920.2 Nut 1500/2500 A 194 2H A 194 2H A 194 2H A 194 8 A 194 8 A194 4/7

920.3 Handwheel nut 1500/2500 A 194 2H A 194 2H A 194 2H A 194 8 A 194 8 A 194 2H

961 Handwheel A 197 A 197 A 197 A 197 A 197 A 197

4.3.3.6 Function

The main components of the globe valves are the body (100), the yoke (166), the

valve disc (351), the stem (200) and the actuating unit.

Stem seal

The gland packing (461), which seals off the stem (200), is tightened via the gland

follower (452) by means of studs (902) and nuts (920). The yoke (166) features an

integral back seat which seals off the valve when the stem (200) is fully retracted.

Seat/disc interface

The integral seating surfaces in the body (100) are hard-faced. The valve disc (351) is

connected to the stem (200) by a "T" joint.

Bonnet/cover seal

On Class 800 valves, the yoke (166) is bolted to the body (100). The joint is sealed by a

joint ring (411). On Class 1500 and Class 2500 valves, the yoke (166) is screwed into

the body (100) and the joint is seal-welded.

4 Valve Description

27 of 100

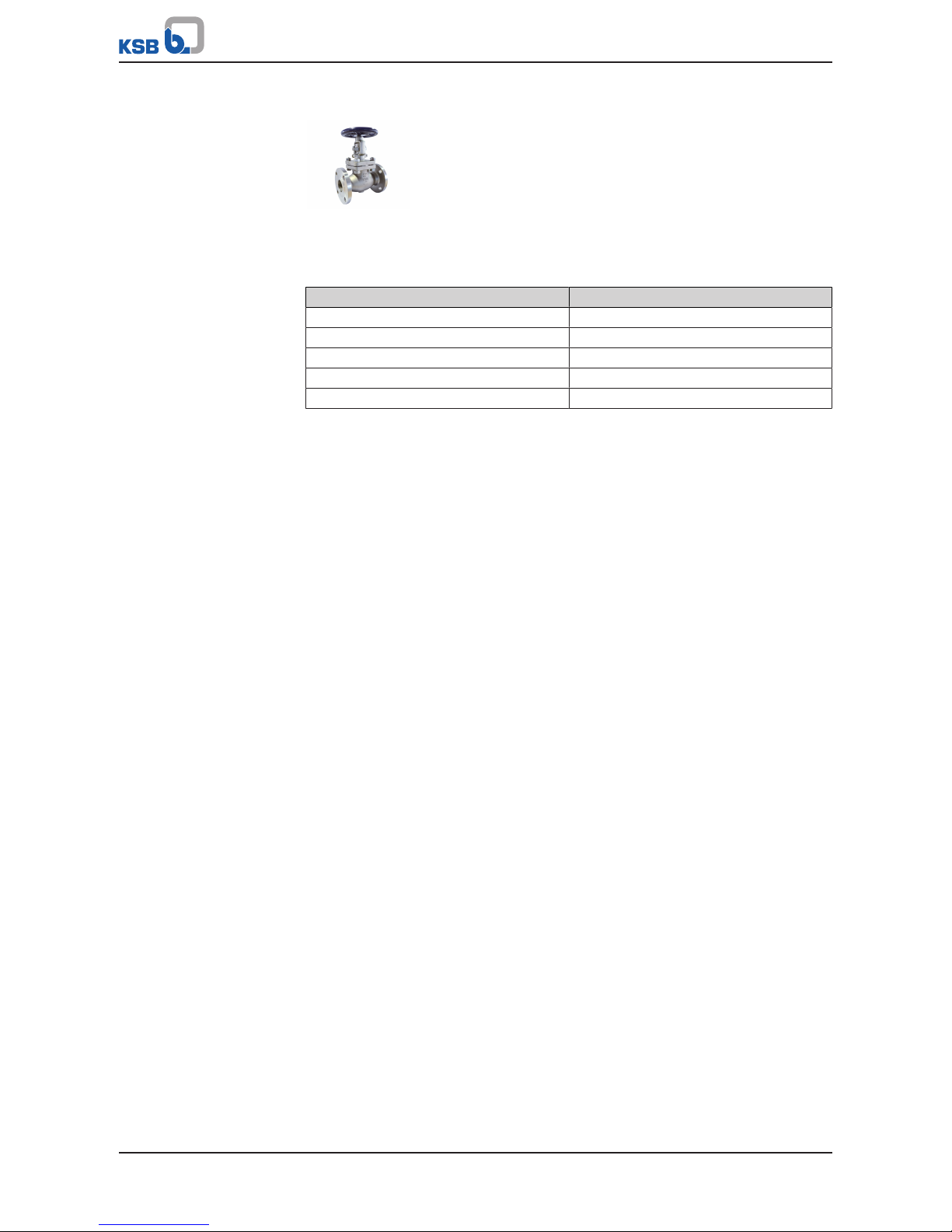

4.3.4 ECOLINE GLV 150-300

4.3.4.1 Operating data

Table21: Operating properties

Characteristic Value

Nominal pressure Class 150 - 300

Nominal size NPS 2'' - 12''

Max. permissible pressure 50 bar / 720 PSI

Min. permissible temperature 0°C /32 °F

Max. permissible temperature 816 °C / 1500 °F

Temperatures < 0°C on request

Selection as per pressure/temperature ratings (ðSection4.3.4.4,Page29)

4.3.4.2 Fluids handled

▪ Steam

▪ Gas

▪ Fluids containing gas

▪ High-temperature hot water

▪ Fluids containing mineral oils

▪ Oil

▪ Feed water

4 Valve Description

28 of 100

4.3.4.3 Design details

Design

▪ Globe valve to ASME B16.34

▪ Tested to API 598

▪ Compact design to API 603

▪ Valve made of corrosion-resistant materials

▪ Body made of stainless steel

▪ Bolted bonnet

▪ Outside screw

▪ Rotating stem

▪ Stem with burnished shank

▪ Stem nut made of nickel steel

▪ Rising handwheel

▪ Outside yoke

▪ Yoke head suitable for mounting electric and pneumatic actuators (DIN ISO 5210)

▪ Fully confined bonnet gasket

▪ Stem sealed by gland packing

▪ Two-piece self-aligning gland follower

▪ Die-moulded graphite gland packing, packing end rings made of braided

graphite

▪ Stainless steel/graphite gaskets

▪ Back seat

▪ Integrated seat ring

▪ Minimum wall thickness as per ASME B16.34

▪ The valves satisfy the safety requirements of Annex I of the European Pressure

Equipment Directive 97/23/EC (PED) for fluids in Groups 1 and 2.

▪ The valves do not have a potential internal source of ignition and can be used in

potentially explosive atmospheres, Group II, category2 (zones1+21) and

category3 (zones2+22) to ATEX 2014/34/EU.

Variants

▪ Hard-faced back seat

▪ Hard-faced sealing surface (single or double)

▪ PTFE packing

▪ PTFE gasket

▪ Drain plug

▪ Locking device

▪ Position indicator

▪ Limit switches

▪ Grease-free version

▪ Version with free stem end and top flange to ISO 5210

▪ Gearboxes

▪ Electric actuators

▪ Non-destructive testing, e.g. radiographic testing

▪ NACE standard

▪ Other flange designs

▪ Larger nominal sizes and other variants on request

4 Valve Description

29 of 100

4.3.4.4 Pressure/temperature ratings

Table22: Permissible operating pressures in bar at temperatures in °C (to ASME B16.34)

Class

Material -29 to3893 149 204 260 316 343 371 399 427 454 482 510 538 566 593 621 649 677 704 732 760 788 816

150 A 351 CF8

14)

19,0 15,9 14,1 13,1 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,0

15)

300 49,6 41,4 37,2 34,1 32,1 30,3 29,6 29,0 28,6 27,9 27,2 26,9 26,2 24,5 22,4 17,6 14,1 11,4 9,3 7,9 6,6 5,2 4,1 2,8

150 A 351 CF8M

14)

19,0 16,2 14,8 13,4 11,7 9,7 8,6 7,6 6,6 5,5 4,5 3,4 2,4 1,4 1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,4

15)

1,0

15)

300 49,6 42,7 38,6 35,5 33,1 31,0 30,3 30,0 29,3 29,0 29,0 28,6 26,5 25,2 24,8 21,0 16,2 12,8 10,0 7,9 6,6 5,2 4,1 2,8

Table23: Permissible operating pressures in PSI at temperatures in °F (to ASME B16.34)

Class

Material

-20

to

100

200 300 400 500 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

150 A 351

CF8

14)

275 230 205 190 170 140 125 110 95 80 65 50 35 20 20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

15

15)

300 720 600 540 495 465 440 430 420 415 405 395 390 380 355 325 255 205 165 135 115 95 75 60 40

150 A 351

CF8M

14)

275 235 215 195 170 140 125 110 95 80 65 50 35 20 20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

20

15)

15

15)

300 720 620 560 515 480 450 440 435 425 420 420 415 385 365 360 305 235 185 145 115 95 75 60 40

Table24: Test pressures

Test Test medium Class 150 Class 300

[bar] [psi] [bar] [psi]

Shell Water 32 450 78 1125

Leak test (seat) 23 315 56 815

Leak test (back seat) 23 315 56 815

Leak test (seat) Air 4 to 7 60 to 100 4 to 7 60 to 100

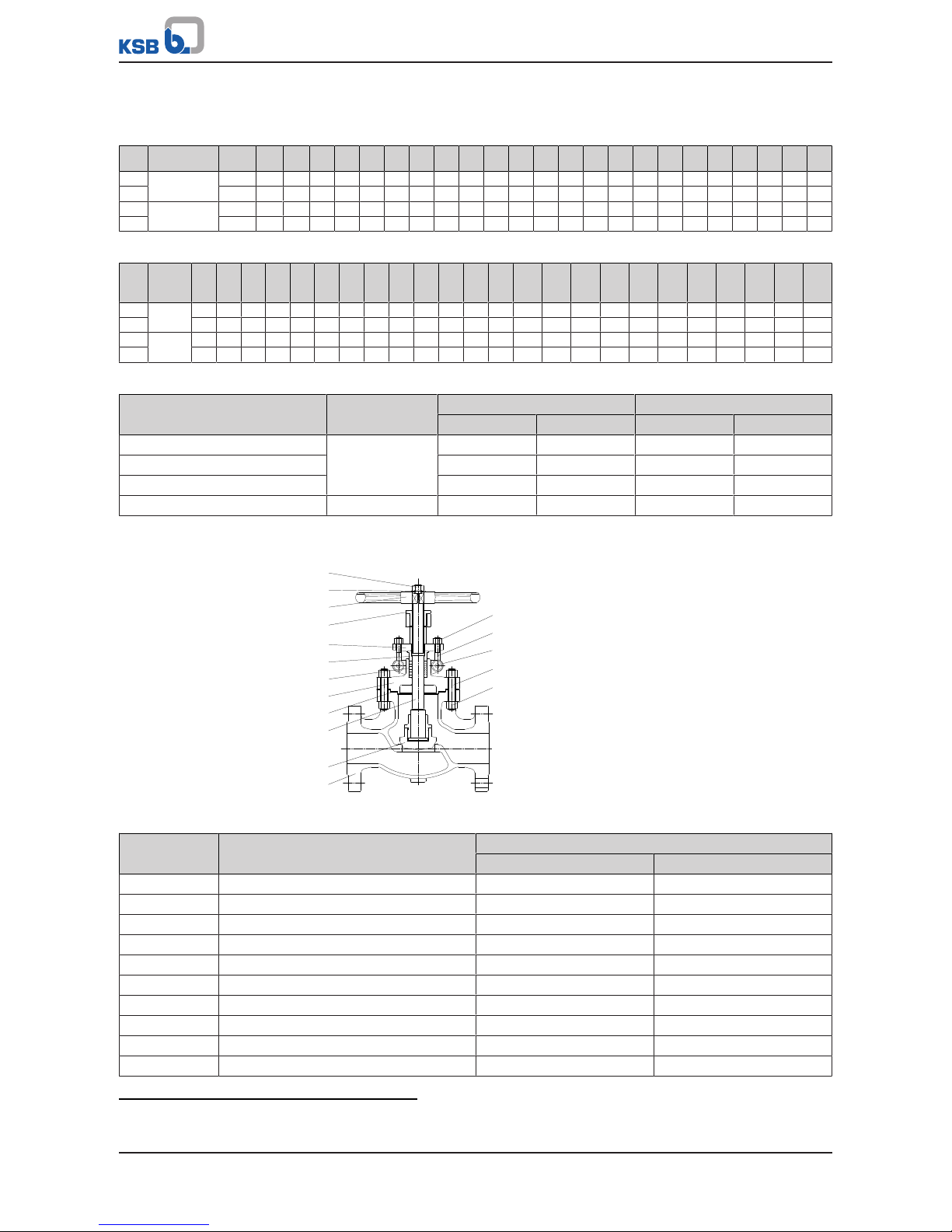

4.3.4.5 Materials

920.1

350

452

544

200

461

465

166

411

961

554

100

560

920.2

902

900

920.3

Table25: Parts list

Part No. Description Material

A 351 CF8 A 351 CF8M

100 Body A 351 CF8 A 351 CF8M

350 Valve disc A 276 304 A 276 304

200 Stem A 276 304 A 276 316

411 Joint ring Stainless steel/graphite Stainless steel/graphite

166 Yoke A 351 CF8 A 351 CF8M

461 Gland packing Graphite Graphite

465 Lower gland section A 276 304 A 276 316

452 Gland follower A 351 CF8 A 351 CF8

544 Threaded bush A 439 D2 A 439 D2

961 Handwheel A 395 65 45 15 A 395 65 45 15

14) At temperatures over 538°C (1000°F), use only when carbon content is 0.04% or higher.

15) For butt weld end valves only. Flanged end ratings terminate at 538°C (1000°F).

4 Valve Description

30 of 100

Part No. Description Material

A 351 CF8 A 351 CF8M

554 Washer A 276 420 A 276 420

920.1 Handwheel nut A 194 8 A 194 8

920.2 Nut A 194 8 A 194 8

902 Stud A 193 B8 A 193 B8

560 Pin A 276 304 A 276 304

900 Eyebolt A 193 B8 A 193 B8

920.3 Nut A 194 8 A 194 8

Table26: Trim materials

Part No. Description Trim 2 Trim 10

304 / 304 316 / 316

100 Body 304 stainless steel 316 stainless steel

350 Valve disc 304 stainless steel 316 stainless steel

200 Stem 304 stainless steel 316 stainless steel

4.3.4.6 Function

The main components of the globe valves are the body (100), the yoke (166), the

valve disc (350), the stem (200) and the actuating unit.

Stem seal

The gland packing (461), which seals off the stem (200), is tightened via the gland

follower (452) by means of eyebolts (900) and nuts (920.3). The yoke (166) features

an integral back seat which seals off the valve when the stem (200) is fully retracted.

Seat/disc interface

The seat ring is an integral part of the body (100). The seating surface of the valve

disc (350) is machined.

Bonnet/cover seal

The body (100) and the yoke (166) are connected by studs (902) and nuts (920.2). The

joint is sealed by means of a joint ring (411).

4.4 Bellows-type Globe Valves to ANSI/ASME

4.4.1 ECOLINE GLB 150-600

4.4.1.1 Operating data

Table27: Operating properties

Characteristic Value

Nominal pressure Class 150 - 600

Nominal size NPS 2'' - 12''

Max. permissible pressure 106 bar

Min. permissible temperature 0 °C

Max. permissible temperature 427 °C

Temperatures < 0°C on request

Selection as per pressure/temperature ratings (ðSection4.4.1.4,Page32)

Loading...

Loading...