Page 1

Control Valve Actuators

EA-C

For Type Series BOA-CVE H and BOA-H Mat E

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual EA-C

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 10/08/2018

Page 3

Contents

3 of 44

EA-C

Contents

1 General.................................................................................................................................................... 5

1.1 Principles ...........................................................................................................................................................5

1.2 Target group.....................................................................................................................................................5

1.3 Symbols .............................................................................................................................................................5

2 Safety...................................................................................................................................................... 6

2.1 Key to safety symbols/markings.......................................................................................................................6

2.2 General..............................................................................................................................................................6

2.3 Intended use .....................................................................................................................................................7

2.4 Personnel qualification and training...............................................................................................................7

2.5 Consequences and risks caused by non-compliance with this manual .........................................................7

2.6 Safety awareness ..............................................................................................................................................7

2.7 Safety information for the user/operator.......................................................................................................7

2.8 Safety information for maintenance, inspection and installation ................................................................8

2.9 Unauthorised modes of operation..................................................................................................................8

3 Transport/Temporary Storage/Disposal............................................................................................... 9

3.1 Checking the condition upon delivery............................................................................................................9

3.2 Transport...........................................................................................................................................................9

3.3 Storage/preservation........................................................................................................................................9

3.4 Disposal/recycling .............................................................................................................................................9

4 Description............................................................................................................................................ 10

4.1 General description ........................................................................................................................................10

4.2 Designation.....................................................................................................................................................10

4.3 Name plate......................................................................................................................................................10

4.4 Design details..................................................................................................................................................11

4.5 Installation types ............................................................................................................................................12

4.6 Noise characteristics .......................................................................................................................................12

4.7 Dimensions and weights ................................................................................................................................12

5 Reassembly........................................................................................................................................... 13

5.1 Safety regulations...........................................................................................................................................13

5.2 Checking prior to installation/assembly........................................................................................................13

5.3 Mounting the actuator ..................................................................................................................................14

5.4 Electrical connection ......................................................................................................................................16

5.5 Interfaces.........................................................................................................................................................19

5.6 Heating resistor (optional).............................................................................................................................21

5.7 Setting the limit switches...............................................................................................................................21

6 Commissioning/Start-up/Shutdown................................................................................................... 23

6.1 Prerequisites for commissioning/start-up......................................................................................................23

6.2 Commissioning/Start-up.................................................................................................................................23

6.3 Operating limits..............................................................................................................................................24

6.4 Shutdown........................................................................................................................................................24

6.5 Returning to service .......................................................................................................................................24

7 Servicing/Maintenance........................................................................................................................ 25

7.1 Safety regulations...........................................................................................................................................25

7.2 Removing the actuator ..................................................................................................................................26

7.3 Maintenance/inspection.................................................................................................................................26

7.4 Lubrication......................................................................................................................................................27

7.5 Cleaning ..........................................................................................................................................................27

7.6 Mounting the actuator ..................................................................................................................................27

7.7 Spare parts stock.............................................................................................................................................27

Page 4

Contents

4 of 44

EA-C

8 Trouble-shooting.................................................................................................................................. 28

9 Related Documents.............................................................................................................................. 30

9.1 General assembly drawing, handwheel on top (EA-C 20 to 140)................................................................30

9.2 General assembly drawing, side-mounted handwheel (EA-C 200 to 250)..................................................31

9.3 Wiring diagrams .............................................................................................................................................32

9.4 Technical data.................................................................................................................................................35

10 EU Declaration of Conformity............................................................................................................. 40

11 Declaration of Incorporation of Partly Completed Machinery ......................................................... 41

Index ..................................................................................................................................................... 42

Page 5

1 General

5 of 44

EA-C

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.3 Symbols

Table1: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

Page 6

2 Safety

6 of 44

EA-C

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

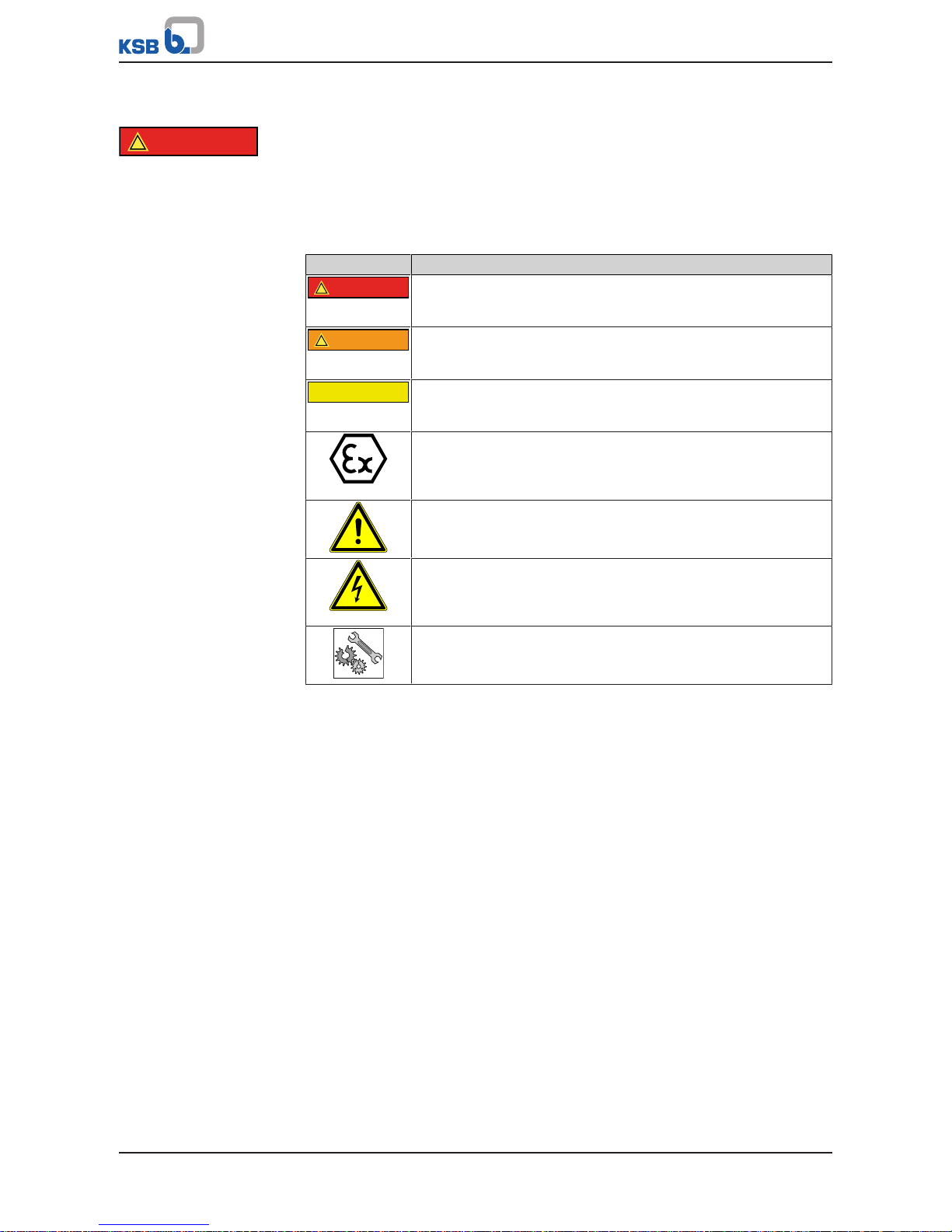

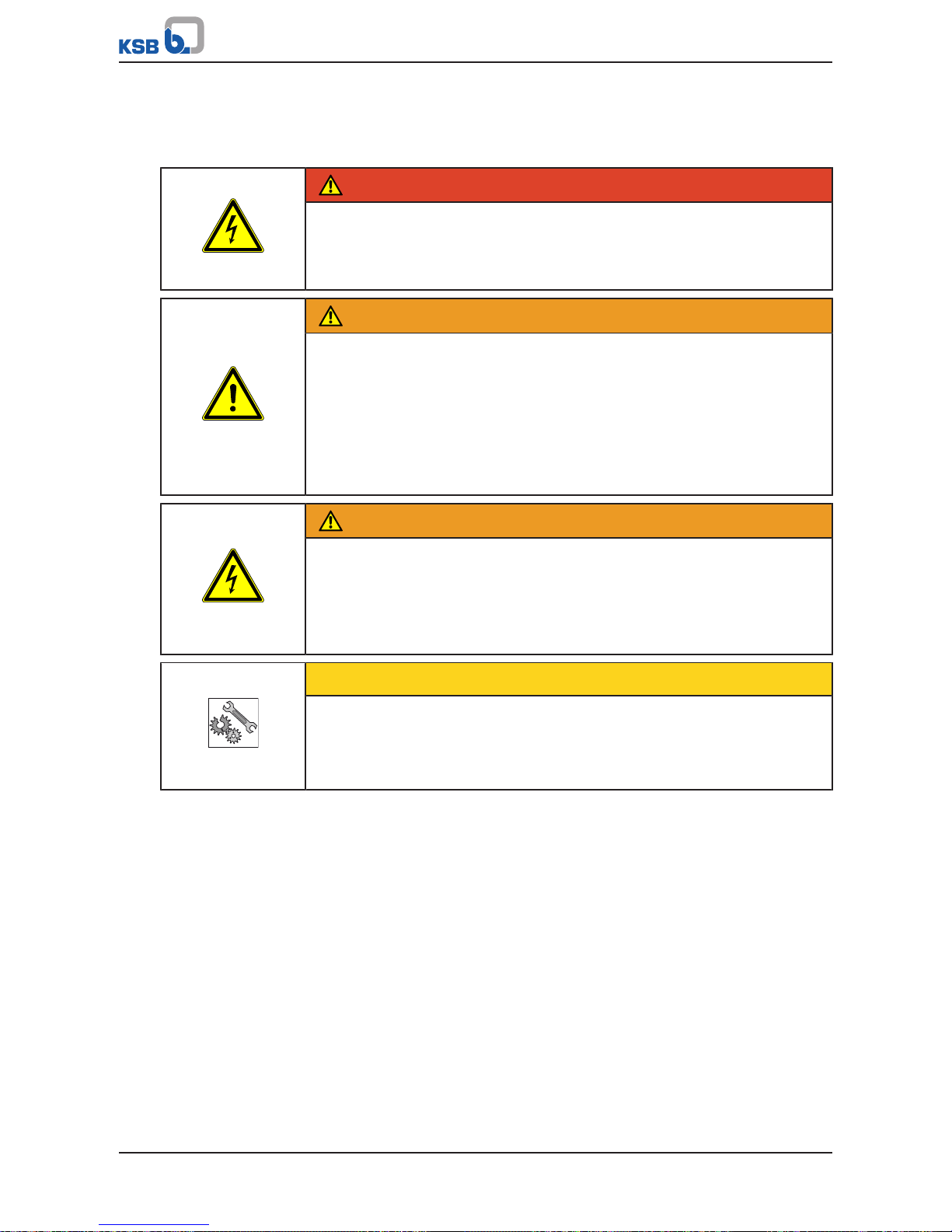

2.1 Key to safety symbols/markings

Table2: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EU Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

This electric motor has been designed and constructed in accordance with the

requirements of Directive 2014/35/EU (“Low-voltage Directive”). It is intended for use

in industrial plants.

If the motor is used in countries outside the European Community, adhere to the

regulations applicable to the relevant country. Also observe any local and industryspecific regulations governing installation and safety.

Page 7

2 Safety

7 of 44

EA-C

2.3 Intended use

▪ Only operate actuators which are in perfect technical condition.

▪ Do not operate partially assembled actuators.

▪ Generally observe the operating limits given.

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

Prevention of foreseeable misuse

▪ Never exceed the permissible application and operating limits specified in the

data sheet or product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the product this manual refers to. The responsibilities, competence and

supervision of all personnel involved in installation, operation, maintenance and

inspection must be clearly defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the product must always be supervised by specialist technical personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.7 Safety information for the user/operator

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

Page 8

2 Safety

8 of 44

EA-C

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the actuator are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Any work on the product shall only be performed when it has been disconnected

from the power supply (de-energised).

▪ Carry out work on the product during standstill only.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.2,Page23)

2.9 Unauthorised modes of operation

Never operate the product outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the product supplied

is only valid if the product is used in accordance with its intended use.

Page 9

3 Transport/Temporary Storage/Disposal

9 of 44

EA-C

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

CAUTION

Impacts against the coupling when placing in a horizontal or vertical position

Damage to the coupling!

▷ Place a suitable support underneath the coupling half when placing it in a

horizontal or vertical position.

Transport the actuator carefully and in its original packaging. Avoid damaging the

coating.

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken:

Table3: Ambient conditions for storage

Ambient condition Value

Storage temperature -20°C to +80°C

Humidity 5 % to 95 % rH

▪ Well-ventilated

▪ Dry

▪ Dust-free

▪ Shock-free

▪ Vibration-free

3.4 Disposal/recycling

Due to some components, the product is classified as special waste.

1. Dismantle the product.

2. Separate and sort the materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner. PCBs, power electronics, capacitors and electronic

components are all hazardous waste.

Page 10

4 Description

10 of 44

EA-C

4 Description

4.1 General description

▪ Actuator for the automation of a control valve

Actuator with continuous-action or 3-point actuation in 24VAC/DC, 230VAC and

400VAC 3~. Actuator for valve type series BOA-CVE H and BOA-H Mat E.

Versions

Continuous-action actuators in 24VAC/DC, 230VAC and 400VAC 3~ versions and a

24VAC 3-point version

Variable speed actuator

control

▪ 24VDC motor, controlled by pulse-width modulation (PWM)

▪ Absolute-coded feedback via precision potentiometer

▪ Positioning function

▪ Active feedback function

▪ Automatic commissioning

▪ Comprehensive diagnosis options

Parameterisation by

software

▪ Actuator functions can be adapted to a wide variety of process conditions by

means of current and voltage monitoring.

▪ Setting of valve-specific details

▪ Setting of actuating force and actuating moment

▪ Setting of stroke and actuating speed

▪ Configuration of messages

▪ Freely programmable characteristic curve corrections

3-point actuators in 230VAC and 400V AC 3~ versions

▪ The actuator can be set by limit switches in both opening and closing direction

▪ Torque transmission by disc spring stack in closing direction.

▪ 2 limit switches for visualising the limit positions included as standard

4.2 Designation

Example: EA-C 250

Table4: Designation key

Code Description

EA-C Product name

250 Actuator size and maximum actuating force of 25kN

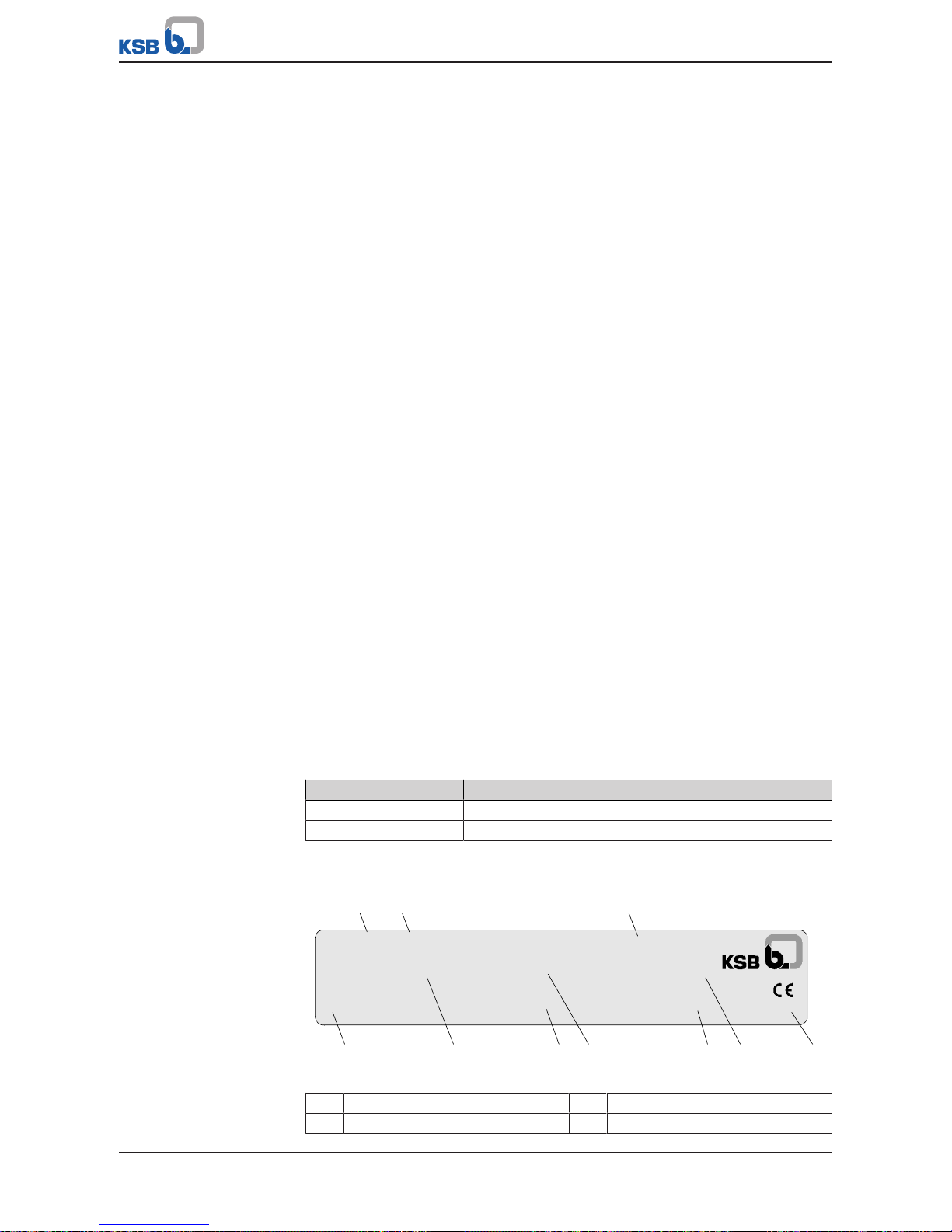

4.3 Name plate

EA-C Antrieb

Auftrag / Pos.:

order No. / pos.:

2120000000 / 0000

Stellkraft:

act. force:

....... N

Istwert:

feedback:

.......

Sollwert:

set value:

.......

Antrieb:

actuator:

EA- C ....

IP..

Betriebsspannung:

power supply:

....... V

Antriebsnummer:

actuator no.:

............

1 2 3

4 5 6 7 8 9 10

Fig.1: Actuator name plate (example)

1 Order number 2 Order item number

3 Product name 4 Supply voltage

Page 11

4 Description

11 of 44

EA-C

5 Actuating force 6 Actual value

7 Setpoint 8 Actuator number

9 Actuator size 10 Enclosure

4.4 Design details

Operating modes

▪ IEC 34-1, 8: S2 for short-time duty

▪ IEC 34-1, 8: S4 for control duty

Actuating force

2kN to 25kN

Actuating speed

1)

▪ Continuous-action actuation: 0.2mm/s to 1.3mm/s

▪ 3-point actuation: 0.45mm/s to 1.4mm/s

Enclosure

▪ EA-C 20: IP65 to EN 60529

▪ EA-C 40: IP65 to EN 60529

▪ EA-C 80: IP65 to EN 60529

▪ EA-C 140: IP67 to EN 60529

▪ EA-C 200: IP65 to EN 60529

▪ EA-C 250: IP65 to EN 60529

Design

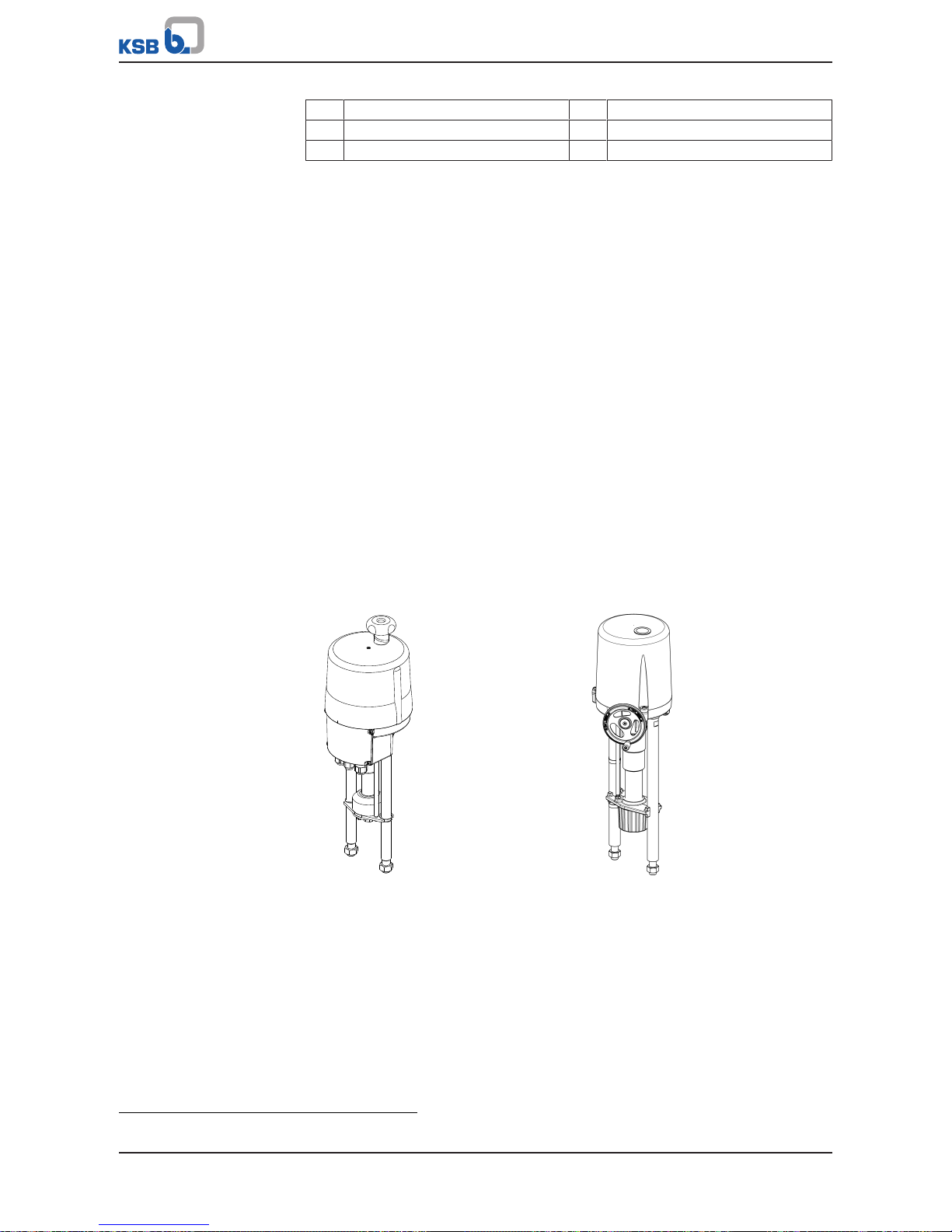

Handwheel on top (EA-C 20 to 140) Side-mounted handwheel (EA-C 200 to

250)

▪ Configurable, microprocessor-controlled actuators

– Supply voltage: 24VAC/DC, 230VAC, 400VAC 3~

– Position setpoint: 4-20 mA, 0/2-10V

– Actual-position feedback: 4-20 mA, 0/2-10V

– Limit switching is torque-dependent in closing direction and stroke-

dependent in opening direction.

▪ 3-point actuators

– Supply voltage: 230VAC, 400VAC 3~

1) Depending on the actuator type

Page 12

4 Description

12 of 44

EA-C

– Actual-position feedback: 2 limit switches

– Stopping via limit switches in closing and opening direction

▪ Actuating time between 23 and 150seconds, depending on the stroke

▪ Operating data stored in permanent memory

▪ After a power failure, operation is resumed in accordance with the operating

data.

Variants

▪ Actuator configured to match the order specification

▪ Integrated process controller

▪ Power back-up unit

▪ Heating of the motor space

▪ Local control unit

▪ Additional limit switch for continuous-action actuators

▪ Optional potentiometer for 3-point actuators

▪ PSPT2) for 3-point actuators

4.5 Installation types

The installation position as shown in the drawing below must be adhered to.

Fig.2: Types of installation for EA-C actuator

4.6 Noise characteristics

The sound pressure level depends on the local conditions and the duty point. It is

≤70dB(A).

4.7 Dimensions and weights

For dimensions and weights please refer to the type series booklet.

2) Optional potentiometer with printed circuit board for converting the resistance into a 4-20 mA output current signal

(additional 24V DC power supply required)

Page 13

5 Reassembly

13 of 44

EA-C

5 Reassembly

5.1 Safety regulations

DANGER

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have any work on the connection to the power supply performed by a

trained electrician.

WARNING

Improper handling of an electric actuator

Crushing of fingers!

Damage to the actuator or the valve!

▷ When mounting the actuator onto the valve make sure that the power supply

has not yet been connected or that the actuator is secured against

unintentional start-up.

▷ Ensure that any objects and parts of the body are removed from the actuator

coupling area prior to starting the actuator.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

▷ Inspect the power cable for visible damage.

▷ Never connect damaged power cables.

CAUTION

Painting of pipes

Impairment of the valve's function and loss of information!

▷ Protect stem and plastic components prior to applying paint.

▷ Protect printed name plates prior to applying paint.

5.2 Checking prior to installation/assembly

▪ Check the actuator's compatibility with the valve.

▪ Check whether the valve has been prepared for assembly to the actuator.

▪ Check whether the actuator cover needs to be dismantled.

– The actuator cover on EA-C actuator sizes 200 to 250 and EA-C 3-point

actuators needs to be dismantled. (ðSection5.4,Page16)

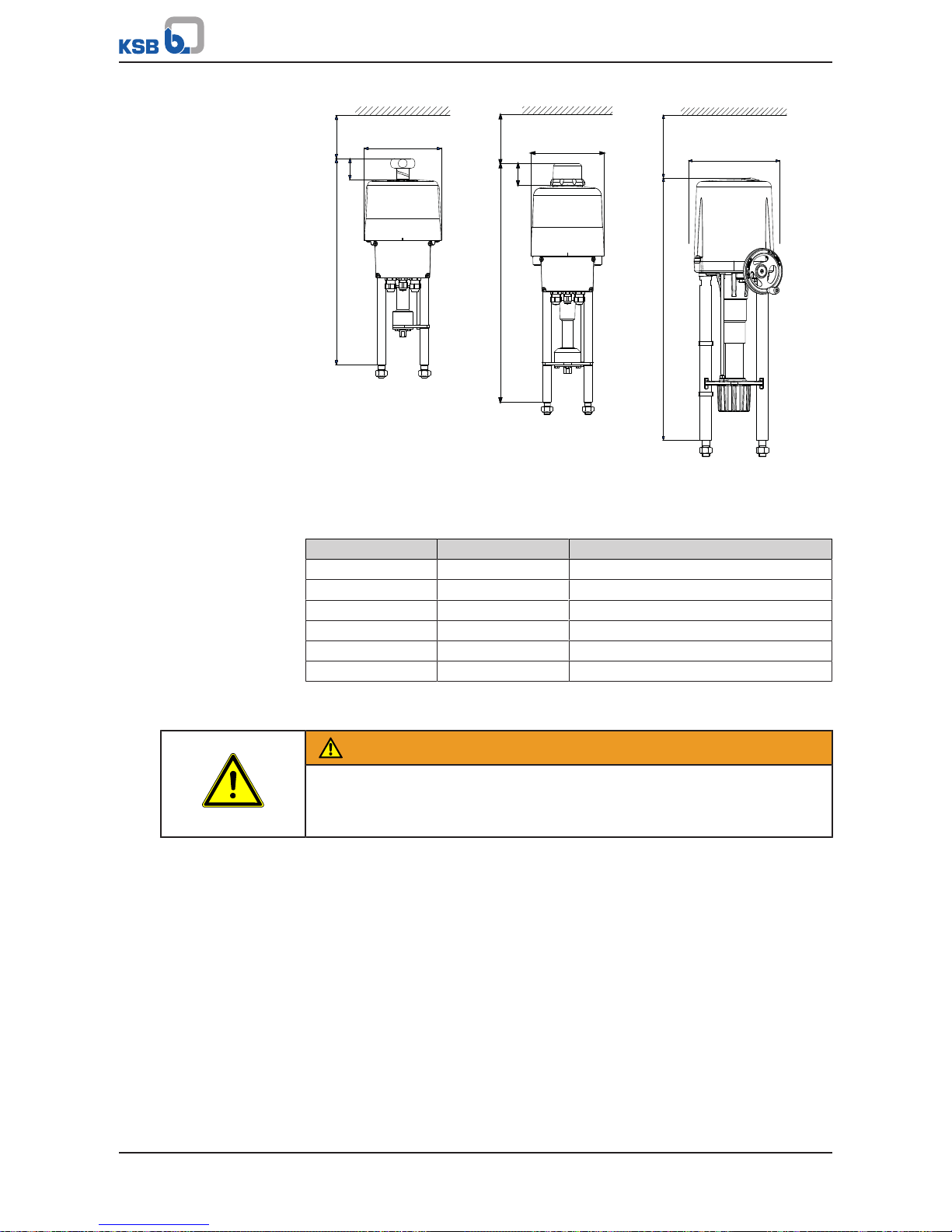

▪ Make sure that there is a minimum wall clearance for removing the actuator

cover.

Page 14

5 Reassembly

14 of 44

EA-C

A

X

X

X

Ø 180

Ø 180

Ø 250

A

A

50

52

EA-C 20, 40, 80 EA-C 140 EA-C 200, 250

Fig.3: Actuator with minimum wall clearance X

Table5: Dimensions [mm]

Actuator A Minimum wall clearance X

EA-C 20 478,2 100

EA-C 40 481 100

EA-C 80 510,3 100

EA-C 140 579 120

EA-C200 720 230

EA-C250 720 230

5.3 Mounting the actuator

WARNING

Electrical operation of the actuator

Crushing of hands!

▷ Use only the handwheel to operate the actuator during assembly/dismantling.

Page 15

5 Reassembly

15 of 44

EA-C

a

b

c

d

e

f

g

h

i

EA-C 20 - 140 EA-C 200 - 250

Fig.4: Mounting of EA-C actuator sizes 20 to 250

a Coupling

b Coupling nut

c Tensioning screw

d Screwed insert

e Pillar

f Stem

g Locknut

h Top flange

3)

i Pillar nut

ü The handwheel4) has been used to move the coupling (a) into its top starting

position.

1. Check that the coupling nut (b) can be turned by hand. If it cannot be rotated,

loosen either the 4 tensioning screws (c) or the screwed insert (d), depending on

the design.

CAUTION

Tensioning screws or screwed insert too loose

Internal coupling parts may fall out!

▷ Reinsert the internal coupling parts in accordance with the disc spring

arrangement diagram.

2. Insert the actuator pillars (e) in the drilled holes provided in the top flange3) (h).

3. Screw the pillar nuts (i) onto the threads of the pillars (e). Make sure to keep a

distance of approx. 5mm from the top flange3) (h).

4. Turn the handwheel to extend the coupling (a) until the coupling nut (b) rests

on the stem (f).

5. Keep on turning until the gap between the pillar shoulders and the top flange

3)

(h) is approx. 5mm.

3) Control valve flange for mounting the actuator

4) To turn the handwheel of EA-C 200 to 250 actuators, press the coupling button on the top of the actuator cover until it

latches in the down position.

Page 16

5 Reassembly

16 of 44

EA-C

6. Use an open-ended wrench to screw the coupling nut (b) onto the stem (f) until

the pillar shoulders rest on the top flange3) (h).

7. Continue until the stem thread is screwed into the coupling nut (b).

ð Thread engagement depth for M10: 12mm

ð Thread engagement depth for M14: 16mm

8. Secure the coupling nut (b) with the locknut (g).

9. For EA-C 20 to 140 actuators, tighten the tensioning screws (c) crosswise to a

torque of 8Nm. On EA-C 200 to 250 actuators, tighten the screwed insert (d)

hand-tight as far as it will go using a pin-type face wrench.

10. Operate the coupling (a) with the handwheel until the pillar shoulders rest on

the top flange3) (h).

1

2

Fig.5: Illustration of correct screwed condition

1 Pillar shoulder 2 Top flange

3)

11. Tighten the pillar nuts (i) to a torque of 56Nm.

EA-C 20

EA-C 40

EA-C 140

EA-C 200 - 250

EA-C 80

Fig.6: Disc spring arrangement diagrams of EA-C 20 to 250 actuators

5.4 Electrical connection

DANGER

Electrical connection work by unqualified personnel

Danger of death from electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC60364.

DANGER

Work performed on an energised terminal box

Danger of death from electric shock!

▷ Switch off the power supply at least 5minutes prior to commencing work and

ensure that it cannot be switched on again unintentionally.

Page 17

5 Reassembly

17 of 44

EA-C

WARNING

Sudden start-up of the continuous-action actuator with power back-up unit after

disconnection from the mains.

Crushing of hands!

▷ Disconnect the equipment from the power supply.

▷ Secure against unauthorised start-up.

CAUTION

Pressing down the actuator cover with force

Damage to components!

▷ Turn the actuator cover gently to and fro until you can feel it lock in position.

NOTE

The terminal box has terminals for connecting solid and flexible electrical cables

with cross-sections from 0.14mm2 to 2.5mm2 as well as a PE terminal on the

housing.

Depending on the actuator, the terminal box is located behind the terminal box

cover or under the actuator cover.

Terminal box behind the terminal box cover (on continuous-action actuators and

24V 3-point actuators)

Fig.7: Undo the screws.

1. Undo and store the terminal box screws.

2. Remove the terminal box cover.

3. Unscrew the cable gland.

4. Choose the supply voltage and control signals in accordance with the data on

the name plate.

5. Connect the cables for power supply and control to the terminals as shown in

the wiring diagram. (ðSection9.3,Page32)

ð Use separate power cables for this purpose.

Fig.8: Power cable and control cable

6. Mechanically secure the power cable and the control cable before the terminals

against loosening.

7. Fasten the cable gland.

8. Fasten the terminal box cover with the screws.

ð Only tighten the screws until resistance can be felt.

Page 18

5 Reassembly

18 of 44

EA-C

Terminal box under the actuator cover (handwheel on top - on 230V and 400V 3point actuators)

Fig.9: Loosen the protective

cap of EA-C 140

Fig.10: Undo the fastening

screw of EA-C 20

1. For EA-C 140 actuators, unscrew the protective cap.

2. Loosen and store the fastening screw of the handwheel.

3. Remove the handwheel.

4. For EA-C 140 actuators, loosen and store the hexagon socket head cap screws of

the actuator cover.

5. Use both hands to gently lift off the actuator cover.

6. Unscrew the cable gland.

7. Choose the supply voltage and control signals in accordance with the data on

the name plate.

8. Connect the cables for power supply and control to the terminals as shown in

the wiring diagram. (ðSection9.3,Page32)

ð Use separate power cables for this purpose.

Fig.11: Power cable and control cable

9. Mechanically secure the power cable and the control cable before the terminals

against loosening.

10. Tighten the cable gland up to one full turn.

11. A thin coat of grease may be applied to the joint ring to facilitate fitting of the

actuator cover.

12. Properly place the joint ring in the groove of the housing.

Fig.12: Markings on

actuator cover / housing

13. Slip the actuator cover over the handwheel shaft.

14. Observe the marking.

15. Do not press down the actuator cover by force. Turn the actuator cover gently

to and fro until you can feel it lock in position.

16. Slide the actuator cover over the joint ring as far as it will go. When properly

seated, the actuator cover cannot be turned any more, and its lower edge is

flush with the housing edge.

17. Mount the handwheel on the handwheel shaft until it has seated. Secure the

handwheel with the fastening screw onto the flattened area of the shaft.

18. Fasten the actuator cover with the screws.

19. For EA-C 140 actuators, tighten the protective cap.

20. Fasten the cable gland.

Terminal box under the actuator cover (side-mounted handwheel, on EA-C 200 and

250 actuators)

Fig.13: Open the actuator

cover.

1. Undo the hexagon socket head cap screws from the actuator cover and store

them.

2. Use both hands to gently lift off the actuator cover.

3. Unscrew the cable gland.

4. Choose the supply voltage and control signals in accordance with the data on

the name plate.

5. Connect the cables for power supply and control to the terminals as shown in

the wiring diagram. (ðSection9.3,Page32)

ð Use separate power cables for this purpose.

Page 19

5 Reassembly

19 of 44

EA-C

Fig.14: Power cable and control cable

6. Mechanically secure the power cable and the control cable before the terminals

against loosening.

Fig.15: Close the actuator

cover.

7. Fasten the cable gland.

8. A thin coat of grease may be applied to the joint ring to facilitate fitting of the

actuator cover.

9. Properly place the joint ring in the groove of the housing.

10. Observe the marking.

11. Do not press down the actuator cover by force.

12. Slide the actuator cover over the joint ring as far as it will go. When properly

seated, the actuator cover cannot be turned any more, and its lower edge is

flush with the housing edge.

13. Fit the actuator cover and fasten it with the hexagon socket head cap screws.

14. Fasten the cable gland.

5.5 Interfaces

Communication

interface

A

Fig.16: Communication interface

The communication interface A is factory-set. A parameterisation kit (ident. No.:

46001269) for actuator communication and parameter setting can be ordered from

KSB. The PC is connected to the actuator via a USB interface and an RJ45 socket using

the communication cable supplied. All actuator parameters can be set with the

software (included in the parameterisation kit). The operating manual is also

included in the scope of supply.

Inputs

1

2

3

Fig.17: Galvanically isolated setpoint input

The parameterisable setpoint for closed-loop control is supplied to terminals 1 to 3

via 4-20mA or 0/2-10V signals.

Page 20

5 Reassembly

20 of 44

EA-C

15

16

17

Fig.18: Actual process value for process controller (optional)

Terminals 15 to 17 serve to connect the parameterisable actual process value via

4-20mA or 0/2-10V signals supplied by the process sensor, if the optional process

controller in the actuator is used.

NOTE

The binary inputs described below take priority over the setpoint supplied: If the

actuator parameters are set for closed-loop control, the actuator will not follow the

setpoint supplied as long as binary signals are received. Only after the signal has

been removed will the actuator return to the position stipulated by the setpoint.

9 10 11

Fig.19: Galvanically isolated binary inputs

The binary Open/Close signals are connected to terminals 9 to 11. These inputs are

rated for 24VAC/DC as standard. (ðSection9.3.3,Page34) The actuator is

operated in open-loop control mode in this configuration.

Outputs

4

5

6

Fig.20: Continuous actual-position feedback

Terminals 4 to 6 can be used for transmitting the parameterisable actual-position

value as a 4-20mA or 0/2-10V signal.

14

17

Fig.21: Power supply for process sensor (optional)

Page 21

5 Reassembly

21 of 44

EA-C

The output (terminals 14 and 17) supplies 21-40VDC unregulated voltage, 100mA

max.. If a feedback value transmitter is used to supply a setpoint signal for the

optional process controller, a fixed-voltage regulator must be used for 24VDC

voltage supplies. A fixed-voltage regulator is also required when using BOATRONIC

MS-420. For voltage tolerances please refer to the relevant product literature.

5.6 Heating resistor (optional)

On option, a heating resistor can be installed to heat the actuator's terminal

compartment. Condensation inside the actuator if used outdoors, in environments

with highly fluctuating ambient temperatures or high atmospheric humidity will thus

be prevented. The heating resistor inside the actuator is powered by the actuator's

power supply, i.e. separate mains connection is not required.

ü The power supply has been disconnected.

ü The actuator has been secured against unauthorised start-up.

ü The actuator has been moved into the set limit position.

ü The operating manual for the heating resistor included in the scope of supply is

on hand.

1. Open the actuator cover. (ðSection5.4,Page16)

2. For all other steps, see the operating manual supplied.

3. The internal cable must be routed in such a way that it cannot come into

contact with the actuator cover seal and/or moving components.

5.7 Setting the limit switches

The standard limit switches (1) and (2) of the 3-point actuator serve to stop the motor

when the limit positions have been reached. The additional limit switches (3) and (4)

are designed as volt-free changeover contacts for open/closed position feedback.

3

1

2

4

5

6

Fig.22: Setting the switching cams

1 Limit switch for CLOSED position 4 Switching cam for OPEN signal

2 Limit switch for OPEN position 5 Locking screw

3 Switching cam for CLOSED signal 6 Gear screw

Page 22

5 Reassembly

22 of 44

EA-C

Fitting of optional limit switches for continuous actuation

ü The power supply has been disconnected.

ü The actuator has been secured against unauthorised start-up.

ü The coupling has been fully extended using the handwheel.

ü The operating manual for the limit switches included in the scope of supply is on

hand.

1. Open the actuator cover. (ðSection5.4,Page16)

2. For all other steps, see the operating manual supplied.

NOTE

For straight-way valves, first set the CLOSED position force-dependent / stroke

dependent, then set the OPEN position stroke-dependent.

1. Use the handwheel to move the actuator into the limit position until the valve

disc touches the valve seat.

ð The position is reached when the valve stem starts to move axially against

the disc spring force in the stem nut.

2. Continue to operate the actuator until the disc springs are slightly precompressed (approx. 1.5mm).

3. Loosen the locking screw of the corresponding switching cam.

4. Turn the gear screw to move the switching cam towards the limit switch until

you hear the limit switch click.

5. Tighten the locking screw.

6. Check the setting by repeating the closing action electrically.

ð If the setting for the position is too low, the slip coupling will start making a

rattling noise. Re-adjust the cam as required.

7. On the basis of the lower limit position, read the required stroke on the scale to

set the OPEN position. Set the limit switch to this position.

8. Set the 2 volt-free changeover contacts so that they switch slightly before the

standard switches.

Page 23

6 Commissioning/Start-up/Shutdown

23 of 44

EA-C

6 Commissioning/Start-up/Shutdown

6.1 Prerequisites for commissioning/start-up

NOTE

Do not operate the actuator electrically before it has been mounted onto a valve.

Before commissioning/starting up the drive, make sure that the following conditions

are met:

▪ Check that the actuator has been properly installed and aligned

(ðSection4.5,Page12) .

▪ Make sure that the operating conditions correspond to the data specified and

those provided on the name plate.

▪ All fastening bolts, connecting elements, and electrical connections have been

properly tightened to the specified tightening torques.

▪ Implement all measures preventing accidental contact with moving and live

parts.

6.2 Commissioning/Start-up

6.2.1 Automatic commissioning of continuous-action and 24V AC/DC 3-point

actuators

The actuator is delivered in "initialised" mode and the green LED is lit. In this mode

the actuator responds to the setpoint supplied or to other operating commands.

If the actuator has been replaced, automatic commissioning must be performed.

Power supply must not be interrupted during commissioning.

If the actuator stroke is blocked during commissioning before the actuator has

reached a set stroke-dependent limit position, the value reached will be saved.

If no torque limit is found during commissioning, or the stroke determined is below

the permissible minimum stroke of 5mm, commissioning is aborted. The actuator

returns to the "non-initialised" state, which is indicated by the green LED flashing

slowly. This will also happen if the actuator has not been initialised correctly.

1

2

3

Fig.23: Commissioning button and LEDs

1 Commissioning button 2 Green LED

3 Red LED

ü Check whether the terminal box cover or the actuator cover needs to be

dismantled, see the selection table. (ðSection5.2,Page13)

1. Dismantle the terminal box cover or the actuator cover, depending on the

design. (ðSection5.4,Page16)

2. Press and hold the commissioning button (1) inside the terminal box for 3

seconds.

3. The initialisation process starts, the green LED (2) flashes and the actuator

completes a full cycle between the set limit positions.

Page 24

6 Commissioning/Start-up/Shutdown

24 of 44

EA-C

4. The green LED (2) lights up continuously.

ð The actuator has now been commissioned and is ready for operation.

5. Close the actuator cover or the terminal box cover, depending on the design.

(ðSection5.4,Page16)

6.2.2 Mechanical commissioning of 3-point actuators

ü Check whether the terminal box cover or the actuator cover needs to be

dismantled, see the selection table. (ðSection5.2,Page13)

1. Dismantle the terminal box cover or the actuator cover, depending on the

design. (ðSection5.4,Page16)

2. Use the handwheel to move the actuator to the middle of the valve travel.

3. Operate the actuator in both directions using the actuating signals until the

respective limit switches stop the actuator.

4. If limit switching is not correct, re-adjust the limit switches.

(ðSection5.7,Page21)

5. The green LED (2) is lit.

6. Close the actuator cover or the terminal box cover, depending on the design.

(ðSection5.4,Page16)

6.3 Operating limits

6.3.1 Ambient temperature

Observe the following parameters and values during operation:

Table6: Permissible ambient temperatures

Ambient condition Value

Ambient temperature -20°C to +60°C

Humidity 5 % to 95 % rH

6.4 Shutdown

1. Disconnect the equipment from the power supply.

ð If a power back-up unit is fitted, the stem moves into the set limit position.

2. Secure against unauthorised start-up.

ð If a power back-up unit is fitted, allow the capacitors to fully discharge

before further work is done. The discharge time is 3hours.

6.5 Returning to service

After maintenance work has been carried out on the actuator and/or valve during

which the stem coupling and disc spring stack were dismantled, the following points

must be observed after proper reassembly.

▪ An initialisation run must always be performed for continuous-action actuators.

(ðSection6.2.1,Page23)

▪ The limit switches of 3-point actuators must be checked. (ðSection5.7,Page21)

Page 25

7 Servicing/Maintenance

25 of 44

EA-C

7 Servicing/Maintenance

7.1 Safety regulations

The operator ensures that maintenance, inspection and installation is performed by

authorised, qualified specialist personnel who are thoroughly familiar with the

manual.

WARNING

Unintentional starting of the drive or driven machine

Risk of injury by moving components and shock currents!

▷ Always make sure the electrical connections are disconnected before carrying

out work on the drive or driven machine. In addition to the main circuits,

ensure that supplementary and auxiliary circuits are also disconnected.

▷ Mind the capacitor discharge time. After switching off the frequency inverter,

wait 10 minutes until dangerous voltages have discharged.

▷ Ensure that the drive cannot be started unintentionally.

WARNING

Insufficient stability

Risk of crushing hands and feet!

▷ Secure the motor against tilting or tipping over during assembly/dismantling.

A regular maintenance schedule will help avoid expensive repairs and contribute to

trouble-free, reliable operation of the drive with a minimum of maintenance

expenditure and work.

NOTE

All maintenance work, service work and installation work can be carried out by KSB

Service or authorised workshops. For contact details please refer to the enclosed

"Addresses" booklet or visit "www.ksb.com/contact" on the Internet.

Never use force when dismantling and reassembling the drive.

Page 26

7 Servicing/Maintenance

26 of 44

EA-C

7.2 Removing the actuator

a

b

c

d

e

f

g

h

i

EA-C 20 - 140 EA-C 200 - 250

Fig.24: Removing the actuators

a Coupling

b Coupling nut

c Tensioning screw

d Screwed insert

e Pillar

f Stem

g Locknut

h Top flange

5)

i Pillar nut

ü The power back-up unit of continuous-action actuators has been disconnected

separately.

1. Remove the actuator cover or the terminal box cover, depending on the

actuator. (ðSection5.4,Page16)

2. Disconnect the power cable and the control cable from the terminals.

3. Undo the pillar nuts (i).

4. For EA-C 20 to 140, loosen the tensioning screws (c). For EA-C 200 to 250, loosen

the screwed insert (d) with a pin-type face wrench.

5. Undo the locknut (g).

6. Tighten the coupling nut (b) with an open-ended wrench.

7. Use the handwheel to move the coupling (a) into its top starting position. If it

cannot be turned, loosen the 4 tensioning screws (c) or the screwed insert (d)

further, depending on the design.

8. Pull the actuator pillars (e) out of the drilled holes provided in the top flange

5)

(h) .

7.3 Maintenance/inspection

EA-C actuators are maintenance-free.

5) Control valve flange for mounting the actuator

Page 27

7 Servicing/Maintenance

27 of 44

EA-C

7.4 Lubrication

The gearing is lubricated for life and does not need to be relubricated.

The moving parts such as the stem and the coupling nut must be lubricated using

standardised lubricants to DIN 51825.

7.5 Cleaning

CAUTION

Improper cleaning of actuators

Damage to the actuator covers!

▷ Clean the actuators in dry condition only.

▷ Do not use solvents.

▷ Use a soft cloth.

▷ Do not use abrasive substances.

7.6 Mounting the actuator

After maintenance / inspection, the actuator must be mounted back onto the valve.

See (ðSection5.3,Page14) Connect the power cable and the control cable and

mechanically secure them before the terminals against loosening.

(ðSection5.4,Page16) For returning the actuator into service after maintenance

and mounting, see (ðSection6.5,Page24)

7.7 Spare parts stock

In the case of damage and malfunction, a full replacement is recommended.

Page 28

8 Trouble-shooting

28 of 44

EA-C

8 Trouble-shooting

WARNING

Improper work to remedy faults

Risk of injury!

▷ For any work performed to remedy faults, observe the relevant information

given in this operating manual and/or in the product literature provided by the

accessories manufacturer.

If problems occur that are not described in the following table, consultation with the

KSB customer service is required.

Faults are indicated by a green and a red LED inside the terminal box. For this

purpose, the terminal box cover or the actuator cover must be dismantled,

depending on the design. (ðSection5.4,Page16)

A The red LED lights up continuously.

B The red LED flashes rapidly.

C The red LED flashes slowly.

D Red LED not lit.

E The green LED lights up continuously.

F The green LED flashes rapidly.

G The green LED flashes slowly.

H Green LED not lit.

Table7: Trouble-shooting for statuses

A B C D E F G H Status Possible cause Remedy

- - - ✘ - - - ✘ Actuator does not respond;

both status LEDs are off.

No power supply Check mains connection.

Voltage supplied does not

match the supply voltage

indicated on the name plate.

Apply correct supply voltage.

- - - ✘ ✘ - - - Actuator does not cover the

full valve travel.

Initialisation has not been

performed correctly.

Repeat initialisation

procedure.

Insufficient stroke has been

set for stroke-dependent limit

position.

Check valve travel parameter

settings.

- - - ✘ ✘ - - - Actuator does not provide

correct valve shut-off.

Initialisation has not been

performed correctly.

Repeat initialisation

procedure.

Actuator's closing force /

closing torque is insufficient.

Verify actuator selection.

- - - ✘ ✘ - - - Actuator is in normal

operating mode but does not

respond to setpoint

modifications.

Actuator has been configured

as process controller.

Connect the process sensor.

- - - ✘ ✘ - - - Actuator position does not

match the setpoint supplied.

A non-linear characteristic has

been parameterised.

Check parameters of

characteristic.

Table8: Trouble-shooting for operating modes

A B C D E F G H Operating modes Possible cause Remedy

- - - ✘ ✘ - - - Normal operating mode - -

- - - ✘ - ✘ - - Actuator is in initialisation

mode.

- Initialisation mode is exited

automatically upon

completion.

- - - ✘ - - ✘ - Actuator has not been

initialised.

- Run automatic initialisation.

Page 29

8 Trouble-shooting

29 of 44

EA-C

Table9: Trouble-shooting for faults in the actuator's environment

A B C D E F G H Faults in the actuator's

environment

Possible cause Remedy

- - ✘ - ✘ - - - An excessive torque has been

measured when the actuator

is run to its limit positions.

Actuator has not been

initialised correctly for the

valve actuated.

Repeat initialisation

procedure.

Actuator stroke is blocked

mechanically.

Check valve and actuator for

smooth operation.

Incorrect actuator selection Verify actuator selection.

- - ✘ - - ✘ - - No or incorrect actual process

value signal

Maximum control range is

exceeded.

No or incorrect actual process

value signal

Apply correct actual process

value signal, check polarity of

actual process value signal.

Actual process value not

within set range

Ensure correct actual process

value.

No signal provided by process

sensor.

Check process sensor or power

supply.

- - ✘ - - - ✘ - Actuator moves to a pre-set

position.

A signal has been applied to

the fail-safe binary input.

Disconnect signal.

Mains power failure on

actuator options with

rechargeable battery pack

(Accupack)

Check power supply.

- - ✘ - - - - ✘ Setpoint signal not applied or

not within set range

Setpoint signal not applied Apply setpoint signal.

Wrong polarity of setpoint

signal

Check polarity of setpoint

signal.

Setpoint signal not within the

set range

Check setpoint range.

- ✘ - - ✘ - - - The limit position stored

during initialisation has not

been reached.

Dirt deposits on valve seat or

loosened valve seat

Check valve seat.

- ✘ - - - ✘ - - The limit position stored

during initialisation has been

exceeded.

Worn or defective valve seat Check valve seat.

- ✘ - - - - ✘ - Insufficient supply voltage in

the actuator

Incorrect mains connection Check mains connection.

Supply voltage fluctuations Check power supply. See data

sheet

Insufficient voltage supplied

by rechargeable battery (on

actuator options with

"accupack" rechargeable

battery pack)

Contact KSB Service.

Table10: Trouble-shooting for actuator faults

A B C D E F G H Actuator faults Possible cause Remedy

✘ - - - ✘ - - - Actuator has reached service

limit.

Wear and/or operating hours Contact KSB Service.

✘ - - - - ✘ - - Electronics fault/Invalid

parameter data

Power supply has been

interrupted during

initialisation.

Contact KSB Service.

Damaged electronic

component

✘ - - - - - ✘ - Critical or maximum actuator

temperature has been

reached.

Excessive frequency of starts Check control settings.

Ambient temperature too

high

Check ambient temperature

and reduce if possible. See

data sheet

✘ - - - - - - ✘ Mechanical actuator fault Damaged mechanical

component

Contact KSB Service.

Page 30

9 Related Documents

30 of 44

EA-C

9 Related Documents

9.1 General assembly drawing, handwheel on top (EA-C 20 to 140)

100

400

500

200

600

300

Fig.25: General assembly drawing, handwheel on top (EA-C 20 to 140)

Table11: List of components

Part No. Description Material

100 Handwheel Plastic

200 Actuator cover Plastic/Aluminium

300 Terminal box cover Plastic

400 Pillars Steel

500 Coupling Brass/PA

600 Double-ear clamps Steel

Page 31

9 Related Documents

31 of 44

EA-C

9.2 General assembly drawing, side-mounted handwheel (EA-C 200 to 250)

100

400

500

200

600

Fig.26: General assembly drawing, side-mounted handwheel (EA-C 200 to 250)

Table12: List of components

Part No. Description Material

100 Handwheel Plastic

200 Actuator cover Plastic / Aluminium

400 Pillars Steel

500 Coupling Brass / PA

600 Double-ear clamps Steel

Page 32

9 Related Documents

32 of 44

EA-C

9.3 Wiring diagrams

9.3.1 Wiring diagram, 230V AC 3-point (single-phase AC)

X10

X5

X9

X4

X6

X1

X11 X0

1

2

1

6

7

4

2

1

2

3

1

2

1

2

3

4

5

6

X2

X3

X7

PE

1

2

4

X5

PE

N

L2

L1

t

X1 Internal wiring

X2 Internal wiring

X3 Internal wiring

X4 Potentiometer 1

X5/1 Neutral

X5/2 Motor phase to open

X5/4 Motor phase to close

X5/6 Temperature switch as volt-free contact

X5/7 Temperature switch as volt-free contact

X6 Additional limit switches

X7 Not used

X8 Heating resistor

X9 Potentiometer 2

PE Earth connection on housing

Page 33

9 Related Documents

33 of 44

EA-C

9.3.2 Wiring diagram, 400VAC 3-point (three-phase AC)

X2

X7

4

3

2

2

1

1

X0

X10

S2

S1

X5 X4

X5_3

X5_2

X5_1

11

12

13

14

15

16

17

18

19

20

15

14

16

13

14

15

16

11

12

17

18

19

20

X5

t

PE

L3

L1

L2

N

1) 2)

1) Closed 2) Open

X5_1/17 Limit switch Closed

X5_1/18 Limit switch Closed

X5_1/19 Limit switch Open

X5_1/20 Limit switch Open

X5_2/13 Neutral conductor

X5_2/14 Phase L1 (400V AC)

X5_2/15 Phase L3 (400V AC)

X5_2/16 Phase L2 (400V AC)

X5_3 Temperature switch

X4 Potentiometer

Page 34

9 Related Documents

34 of 44

EA-C

9.3.3 Terminal configuration EA-C 20 to 250 with terminal box

Continuous-action actuation 24 V AC/DC, 230 V AC and 400 V AC 3~

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 RJ-45

TTL

Pushbutto

n

L1 L2 L3

↑ ↑ ↑ ↓ ↓ ↓ ↑↓ ↑↓ ↑ ↑ ↑ ↑ ↑ ↓ ↑ ↑ ↑ ↑↓ ↑↓ ↑↓ ↑↓ ↑ ↑ ↑ ↑ ↑

+0(2) - 10V

+0(4) - 20 mA

GND

+0(2) - 10 V

+0(4) - 20 mA

GND

Max. load

100mA at 24VDC

L OPENNL CLOSE

L (24V AC/DC)

N (24V AC/DC)

24V DC / 100mA

+0(2) - 10V

+0(4) - 20mA

GND

(Optional)

(Optional)

(Optional)

(Optional)

L (see name plate)

N (see name

plate)PE(Optional)

400 V AC 3~

400 V AC 3~

400 V AC 3~

PE

24 V AC/DC □

115V AC □

230V AC □

Ⓐ Ⓑ Ⓒ Ⓓ Ⓔ Ⓕ Ⓖ Ⓗ Ⓘ Ⓙ Ⓚ Ⓛ Ⓜ Ⓠ

Ⓝ Ⓞ Ⓟ

In continuous-action configuration, only the terminals in columns Ⓐ, Ⓑ and Ⓙ

are active.

3-point actuation 24V AC/DC

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 RJ-45

TTL

Pushbutto

n

↑ ↑ ↑ ↓ ↓ ↓ ↑↓ ↑↓ ↑ ↑ ↑ ↑ ↑ ↓ ↑ ↑ ↑ ↑↓ ↑↓ ↑↓ ↑↓ ↑ ↑

+0(2) - 10V

+0(4) - 20mA

GND

+0(2) - 10V

+0(4) - 20mA

GND

Max. load

100mA at 24VDC

L OPENNL CLOSE

L (24V AC/DC)

N (24V AC/DC)

24 V DC / 100 mA

+0(2) - 10V

+0(4) - 20mA

GND

(Optional)

(Optional)

(Optional)

(Optional)

L (see name plate)

N (see name plate)

PE

(Optional)

24 V AC/DC

□

115V AC □

230V AC □

Ⓐ Ⓑ Ⓒ Ⓓ Ⓔ Ⓕ Ⓖ Ⓗ Ⓘ Ⓙ Ⓚ Ⓛ Ⓜ

Ⓝ Ⓞ Ⓟ

In 3-point configuration, only the terminals in columns Ⓑ, Ⓓ and Ⓙ are active. Ⓓ

equals 24V AC/DC by default.

Table13: Key

Ⓐ Setpoint input Ⓙ Supply voltage: single-phase alternating current or

direct current

Ⓑ Active actual-position feedback Ⓚ Field bus connection (optional)

Ⓒ Volt-free fault message (optional) Ⓛ Communication with PC

Ⓓ Binary control (standard 24V AC/DC) Ⓜ Commissioning

Ⓔ Power failure signal

6)

Ⓝ Galvanically isolated 1 kV

Ⓕ Supply Ⓞ Process sensor (optional)

Ⓖ Actual value Ⓟ Limit switch, volt-free contact

Ⓗ Closed Ⓠ Power supply: three-phase current

Ⓘ Open

6) Optional connections for external power back-up unit.

Page 35

9 Related Documents

EA-C

35 of 44

9.4 Technical data

9.4.1 Technical data of EA-C 20 to 40 (continuous-action and 24VAC 3-point)

Table14: Technical data of EA-C 20 to 40 (continuous-action and 24VAC 3-point)

Characteristic EA-C 20 continuous-action EA-C 20 continuous-

action and 3-point

EA-C 40 continuous action EA-C 40 continuous-action

and 3-point

Actuating force [N] 2000 4000

Stroke [mm] 50

Handwheel turns [/10mm

stroke]

12

Actuating speed [mm/s] 0,45 - 0,9

Power supply [V] 230VAC 1~ 320 - 575VAC 3~ 24 V AC 1~ 230VAC 1~ 320 - 575VAC 3~ 24VAC 1~

Frequency [Hz] 50

Nominal current

7)

[A] 0,07 0,08

8)

0,7 (AC) / 0,4 (DC) 0,11 0,11

8)

1,1 (AC) / 0,7 (DC)

Maximum current

7)

[A] 0,1 0,11

8)

0,9 (AC) / 0,6 (DC) 0,14 0,14

8)

1,4 (AC) / 0,9 (DC)

Maximum power input9)[W] 13 22

8)

12 (AC) / 11 (DC) 19 28

8)

18 (AC) / 16 (DC)

Duty cycle

10)

IEC 60034-1,8 S2 30 minutes, S4 50% operating time - 1200 c/h

11)

Enclosure EN 60529 IP65

Allow. ambient

temperature

[°C] -20 to +60

Motor protection Thermal monitoring and overload protection

Weight (without

accessories)

[kg] 8

7) Values may be higher depending on accessories used.

8) At 400V 3-phase and 50Hz

9) At maximum actuating force; Values may be higher depending on accessories used.

10) At 25 °C ambient temperature

11) Cycles per hour

Page 36

9 Related Documents

36 of 44

EA-C

9.4.2 Technical data of EA-C 80 to 140 (continuous-action and 24VAC 3-point)

Table15: Technical data of EA-C 80 to 140 (continuous-action and 24VAC 3-point)

Characteristic EA-C 80 continuous-action EA-C 80 continuous-

action and 3-point

EA-C 140 continuous-action EA-C 140 continuous-action

and 3-point

Actuating force [N] 8000 14000

Stroke [mm] 50 65

Handwheel turns [/10mm

stroke]

12 40

Actuating speed [mm/s] 0,3 - 0,7 0,65 - 1,3

Power supply [V] 230VAC 1~ 320 - 575VAC 3~ 24 V AC 1~ 230VAC 1~ 320 - 575VAC 3~ 24VAC 1~

Frequency [Hz] 50

Nominal current

12)

[A] 0,22 0,18

13)

2,1 (AC) / 1,3 (DC) 0,48 0,35

13)

4,6 (AC) / 2,9 (DC)

Maximum current

12)

[A] 0,29 0,23

13)

2,7 (AC) / 1,7 (DC) 0,62 0,45

13)

6 (AC) / 3,7 (DC)

Maximum power input

14)

[W] 38 47

13)

35 (AC) / 32 (DC) 88 91

13)

82 (AC) / 69 (DC)

Duty cycle

15)

IEC 60034-1,8 S2 30 minutes, S4 50% operating time - 1200 c/h

16)

Enclosure EN 60529 IP65 IP67

Allow. ambient

temperature

[°C] -20 to +60

Motor protection Thermal monitoring and overload protection

Weight (without

accessories)

[kg] 10 12

12) Values may be higher depending on accessories used.

13) At 400V 3-phase and 50Hz

14) For maximum actuating force; Values may be higher depending on accessories used.

15) At 25 °C ambient temperature

16) Cycles per hour

Page 37

9 Related Documents

EA-C

37 of 44

9.4.3 Technical data of EA-C 20 to 140 (230VAC and 400 V 3~ 3-point)

Table16: Technical data of EA-C 20 to 140 (230VAC 3-point)

Characteristic EA-C 20 3-point EA-C 40 3-point EA-C 80 3-point EA-C 140 3-point

Actuating force [N] 2000 4000 8000 14000

Stroke [mm] 50 65

Handwheel turns [/10mm

stroke]

12 31 28

Actuating speed [mm/s] 0,5 1,4 0,5 1,4 0,65 0,45

Power supply [V] 230VAC 1~ 400VAC 3~ 230VAC 1~ 400VAC 3~ 230VAC 1~ 400VAC 3~ 230VAC 1~ 400VAC 3~

Frequency [Hz] 50 / 60

Nominal current

17)

[A] 0,5 0,13 0,08 0,21 0,23 0,13 0,23 0,13

Maximum current

17)

[A] 0,07 0,18 0,08 0,26 0,27 0,15 0,27 0,15

Maximum power input

18)

[W] 12 30 18 51 52 30 52 30

Duty cycle

19)

IEC 60034-1,8 S2 30 minutes, S4 50 % operating time - 1200 c/h

20)

Enclosure EN 60529 IP65 IP67

Allow. ambient temperature [°C] S2: -20 to +80, S4: -20 to +60

Motor protection Anti-jam

design

Temperature switch Anti-jam

design

Temperature switch Temperature switch

Weight (without accessories) [kg] 5,5 8 10

17) Values may be higher depending on accessories used.

18) For maximum actuating force; values may be higher depending on accessories used.

19) At 25 °C ambient temperature

20) Cycles per hour

Page 38

9 Related Documents

38 of 44

EA-C

9.4.4 Technical data of EA-C 200 to 250 (continuous-action and 24VAC 3-point)

Table17: Technical data of EA-C 200 to 250 (continuous-action and 24VAC 3-point)

Characteristic EA-C 200

continuous-action

and 3-point

EA-C 200

continuous-

action

EA-C 200

continuous-

action

EA-C 250

continuous-action

and 3-point

EA-C 250

continuous-

action

EA-C 250

continuous-

action

Actuating force [N] 20000 25000

Maximum positioning force

21)

[N] 10000 12500

Stroke [mm] 95

Handwheel turns [/10mm stroke] 50

Actuating speed [mm/s] 0,2 - 0,4

Power supply [V] 24VAC/DC 230VAC 320-575VAC 3~ 24VAC/DC 230VAC 320-575VAC 3~

Frequency [Hz] 50 (AC)

Nominal current

22)

[A] 4,2 (AC) / 2,6 (DC) 0,44 0,32

23)

4,6 (AC) / 2,9 (DC) 0,48 0,35

23)

Maximum current

22)

[A] 5,5 (AC) / 3,4 (DC) 0,57 0,42

23)

6 (AC) / 3,7 (DC) 0,62 0,42

23)

Maximum power input

24)

[W] 76 (AC) / 63 (DC) 81 85

23)

82 (AC) / 69 (DC) 88 91

23)

Duty cycle

25)

IEC 60034-1,8 S2 30minutes, S4 50% operating time

26)

Enclosure EN 60529 IP65

Allow. ambient temperature [°C] -20 to +60

Motor protection Electronic motor current monitoring incl. safety tripping

Weight (without accessories) [kg] 23

21) Permissible average actuating force over the entire stroke range

22) Values may be higher depending on accessories used.

23) At 400V 3-phase and 50Hz

24) For maximum actuating force; values may be higher depending on accessories used.

25) At 25 °C ambient temperature

26) Cycles per hour

Page 39

9 Related Documents

EA-C

39 of 44

9.4.5 Technical data of EA-C 200 to 250 (230 V and 400V AC 3-point)

Table18: Technical data of EA-C 200 to 250 (230 V and 400V AC 3-point)

Characteristic EA-C 200 3-point EA-C 200 3-point EA-C 250 3-point EA-C 250 3-point

Actuating force [N] 20000 25000

Maximum positioning force

27)

[N] 10000 12500

Stroke [mm] 95

Handwheel turns [/10mm stroke] 50

Actuating speed [mm/s] 1,0

Power supply [V] 230VAC 400VAC 3~ 230VAC 400VAC 3~

Frequency [Hz] 50

Nominal current

28)

[A] 0,58 0,4 0,62 0,5

Maximum current [A] 0,95 0,6 0,95 0,6

Maximum power input

29)

[W] 137 120 145 140

Duty cycle

30)

IEC 60034-1,8 S2 30minutes, S4 50% operating time

31)

Enclosure EN 60529 IP65

Allow. ambient temperature [°C] S2: -20 to +80, S4: -20 to +60

Motor protection Temperature switch

Feedback via 2 limit switches Provided

Weight (without accessories) [kg] 23

27) Permissible average actuating force over the entire stroke range

28) Values may be higher depending on accessories used.

29) For maximum actuating force; values may be higher depending on accessories used.

30) At 25 °C ambient temperature

31) Cycles per hour

Page 40

10 EU Declaration of Conformity

40 of 44

EA-C

10 EU Declaration of Conformity

Manufacturer: KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal (Germany)

The manufacturer herewith declares that the product:

KSBEA-C20, KSBEA-C40, KSBEA-C80, KSBEA-C140,

KSBEA-C200, KSBEA-C250

▪ is in conformity with the provisions of the following Directives as amended from time to time:

– 2011/65/EU: Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment

(RoHS)

– 2014/30/EU: Electromagnetic Compatibility (EMC)

– 2014/35/EU: Electrical Equipment Designed for Use within Specific Voltage Limits (Low Voltage)

The manufacturer also declares that

▪ the following harmonised international standards have been applied:

– EN61000-6-2:2005

– EN61000-6-3:2007+A1:2011

– EN61010-1:2010

The EU Declaration of Conformity was issued in/on:

Frankenthal, 1 February 2018

Wolfgang Glaub

Integrated Management Germany

Dieter Hanewald

Product Management and Product Development II

Frankenthal

KSB SE & Co. KGaA

Johann-Klein-Str. 9

67227 Frankenthal

KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal

Page 41

11 Declaration of Incorporation of Partly Completed Machinery

41 of 44

EA-C

11 Declaration of Incorporation of Partly Completed Machinery

Manufacturer: KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal (Germany)

The manufacturer herewith declares for the partly completed machinery:

KSBEA-C20, KSBEA-C40, KSBEA-C80, KSBEA-C140,

KSBEA-C200, KSBEA-C250

▪ The following essential requirements of the Machinery Directive 2006/42/EC, Annex I, have been applied and

fulfilled:

– 1.1.2, 1.1.3, 1.1.5

– 1.2.1, 1.2.2, 1.2.6

– 1.3.2, 1.3.4, 1.3.7, 1.3.9

– 1.5.1, 1.5.4, 1.5.5, 1.5.6

– 1.7.1, 1.7.3, 1.7.4

▪ The relevant technical documentation has been compiled in accordance with Part B of Annex VII. This

documentation or parts hereof will be transmitted by post or electronically in response to a reasoned request

by the national authorities.

The partly completed machinery must not be put into service until the final machinery into which it is to be

incorporated has been declared in conformity with the provisions of the Machinery Directive 2006/42/EC, where

appropriate.

Person authorised to compile the technical file:

Dieter Hanewald

Product Management and Product Development II Frankenthal

KSB SE & Co. KGaA

Johann-Klein-Str. 9

67227 Frankenthal (Germany)

The Declaration of Incorporation was issued in/on:

Frankenthal, 1 February 2018

Dieter Hanewald

Product Management and Product Development II Frankenthal

KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal

Page 42

Index

42 of 44

EA-C

Index

C

Commissioning23

Commissioning/start-up23

D

Design11

Designation10

Disposal9

E

Event of damage5

F

Faults

Causes and remedies28

I

Installation/assembly13

K

Key to safety symbols/markings6

M

Misuse7

O

Operating modes11

P

Personnel7

Personnel qualification7

Preservation9

S

Safety6

Safety awareness7

Servicing/Maintenance25

Specialist personnel7

Storage9

T

Terminal configuration34

Training7

W

Warnings6

Warranty claims5

Page 43

Page 44

KSB SE & Co. KGaA

Johann-Klein-Straße 9 • 67227 Frankenthal (Germany)

Tel. +49 6233 86-0

www.ksb.com

7525.83/01-EN

Loading...

Loading...