KSB DYNACTAIR 200, DYNACTAIR 400, DYNACTAIR 800 Installation Manintenance

Maintenance

8519.83/3--EN

DYNACTAIR 200 to 800 -- MAINTENANCE

INSTALLATION

MAINTENANCE

1 -- General overview

2 -- Recommended tools

3 -- Installation / Safety / Exhaust ports of springs cartridges

4 -- Adjustment of adjustable end stops

5 -- Actuator disassembly

6 -- Actuator re--assembly

7 -- Actuator / Valve coupling and protection

8 -- Trouble shooting

AMRI is ISO 9001 approved

DYNACTAIR 200 to 800 -- MAINTENANCE

1 -- GENERAL OVERVIEW

The purpose of this manual is to describe the installation / maintenance procedures and actions to be carried out in

case of breakdowns or faulty operations of DYNACTAIR 200 to 800 type pneumatic actuators.

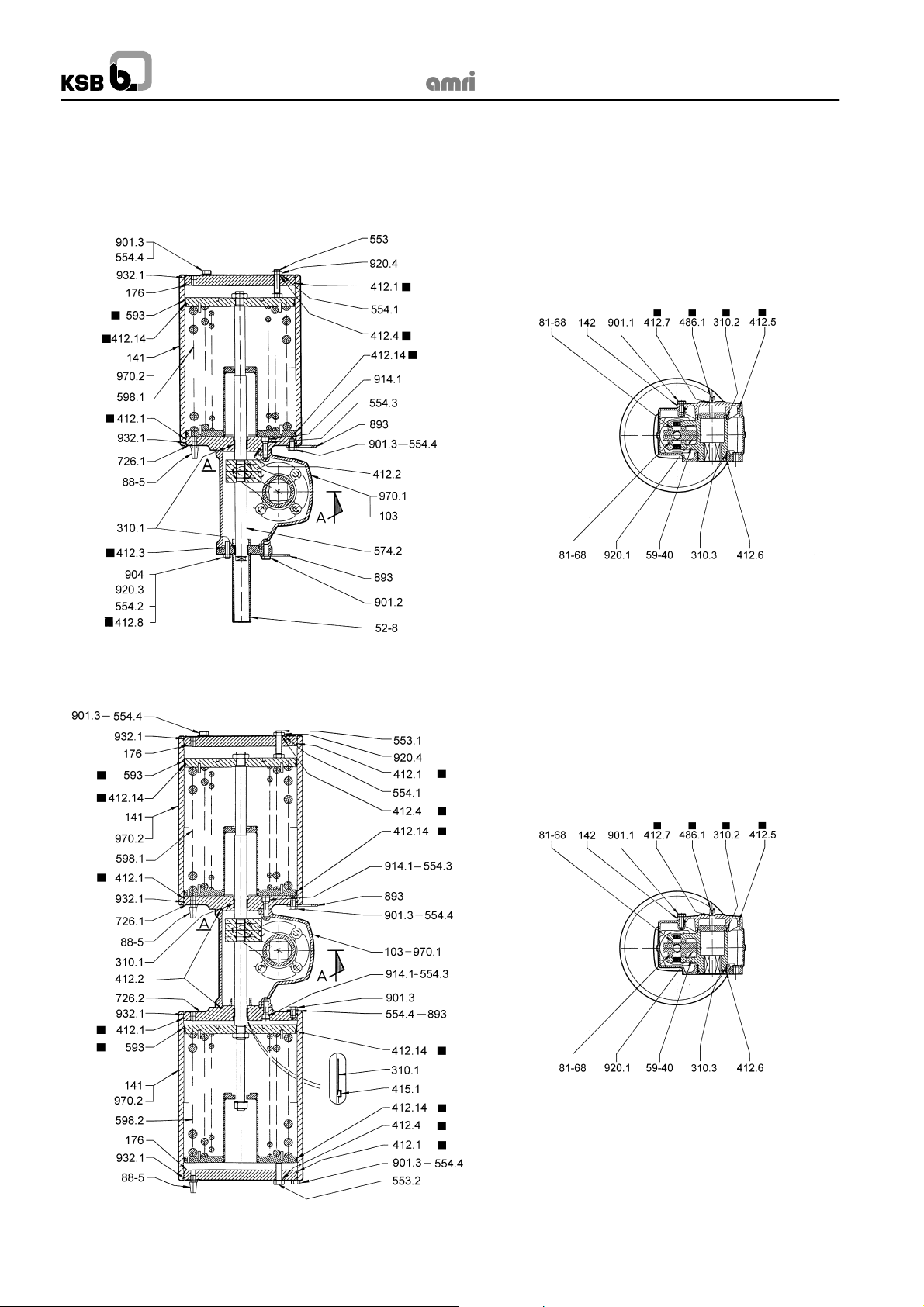

DYNACTAIR 200 – Closure function by lack of control fluid

Section A--A

DYNACTAIR 400 and 800 – Closure function by lack of control fluid

Section A--A

2

Parts included in the spare part kit

DYNACTAIR 200 to 800 -- MAINTENANCE

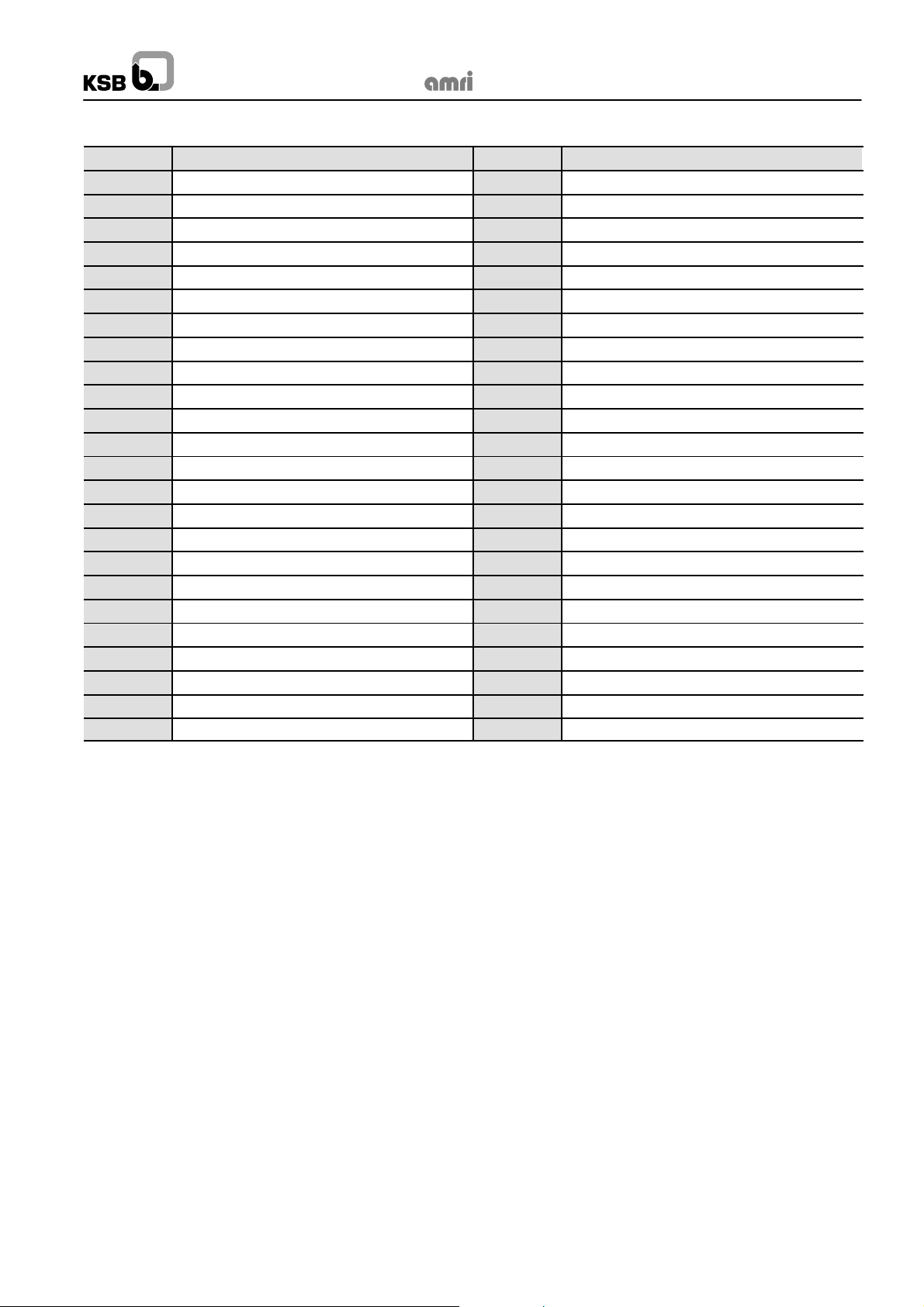

Item Designation Item Designation

52--8 Protection sleeve 553.1 Thrust insert

59--40 Mandrel 553.2 Thrust insert

81--68 Pressure pad 554.1 Washer

88--5 Silencer 3/8” G 554.2 Washer

103 Housing 554.3 Washer

141 Cylinder 554.4 Washer

142 Cover 574.2 Rod

176 Cylinder head 593 Guiding strip

310.1 Self--lubricating bearing 598.1 Sub assembly springs cartridge

310.2 Self--lubricating strip 598.2 Sub assembly springs cartridge

310.3 Self--lubricating strip 726.1 Cylinder guiding flange

412.1 O--Ring 726.2 Cylinder guiding flange

412.2 O--Ring 893 Support plate

412.3 O--Ring 901.1 Hexagon head screw

412.4 O--Ring 901.2 Hexagon head screw

412.5 O--Ring 901.3 Hexagon head screw

412.6 O--Ring 904 Travel stop

412.7 O--Ring 914.1 Hexagon socket head screw

412.8 O--Ring 920.1 Operating nut

412.14 O--Ring 920.3 Hexagon nut

415.1 Lip seal ring 920.4 Hexagon nut

486.1 Ball 932.1 Spring retaining ring

970.1 Identity plate *

991 Grease 970.2 Safety instructions plate

* NOTE : The identity plate 970.1 indicates the actuator references. These are needed any requested for information

and spares.

3

DYNACTAIR 200 to 800 -- MAINTENANCE

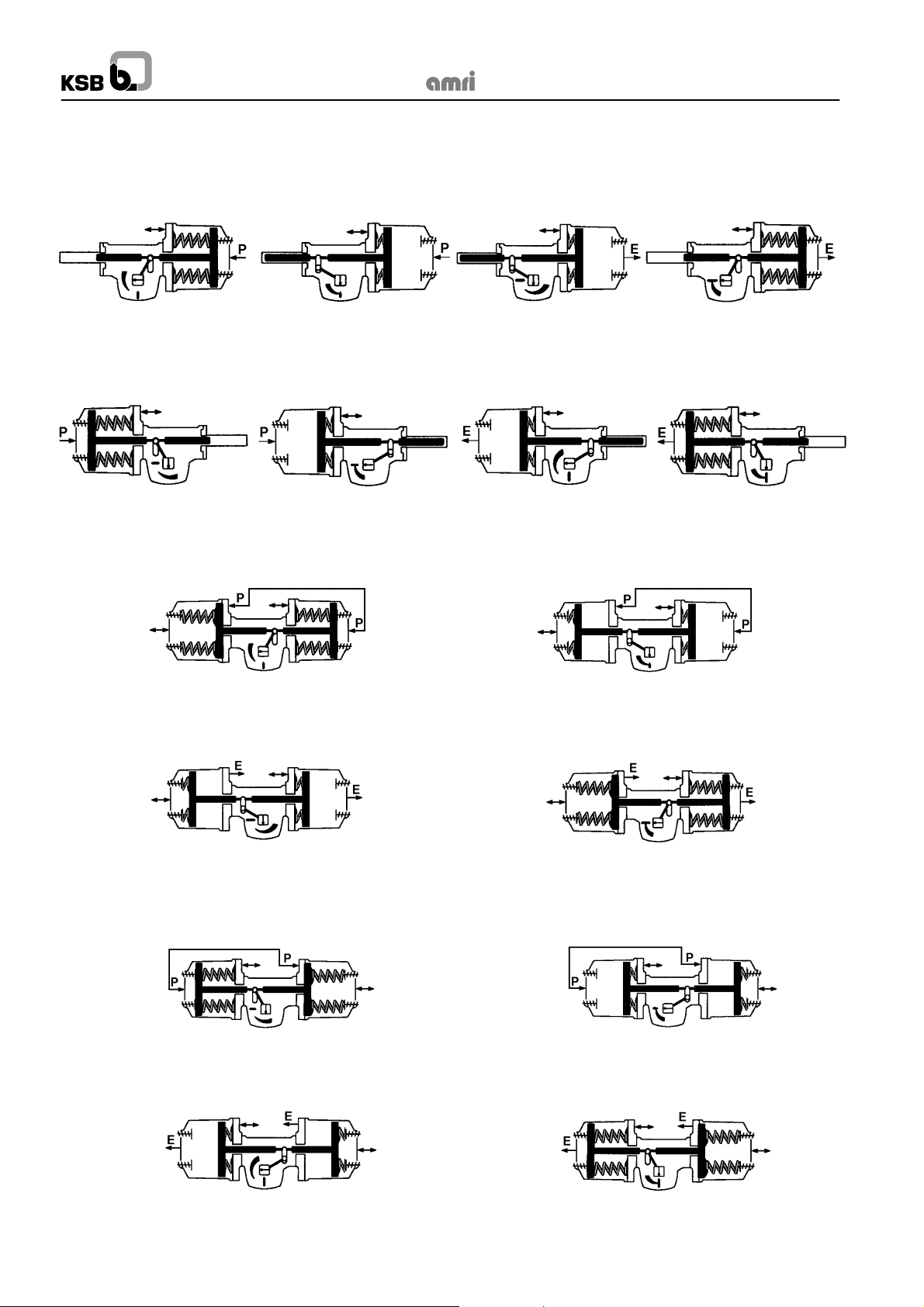

Closure and opening functions by lack of control fluid of these actuators are defined following drawings thereafter:

DYNACTAIR 200 Closure function by lack of control fluid

Opening operation under fluid pressure Closing function under springs action

Actuator/Valve closed Actuator/Valve open Actuator/Valve open Actuator/Valve closed

DYNACTAIR 200 Opening function by lack of control fluid

Closing operation under fluid pressure Opening function under springs action

Actuator/Valve open Actuator/Valve closed Actuator/Valve closed Actuator/Valve open

DYNACTAIR 400 and 800 Closure function by lack of control fluid

Opening operation under fluid pressure

Actuator/Valve closed Actuator/Valve open

Closing operation under springs action

Actuator/Valve open Actuator/Valve closed

DYNACTAIR 400 and 800 Opening function by lack of control fluid

Closing operation under fluid pressure

Actuator/Valve open Actuator/Valve closed

Opening operation under springs action

Actuator/Valve closed Actuator/Valve open

During the operation under pressure, the actuator is maintened in position by the air supply.

4

DYNACTAIR 200 to 800 -- MAINTENANCE

2 -- RECOMMENDED TOOLS (not supplied)

-- Pneumatic screwing machine

-- Flat spanners 24 and 30

-- Allen key 8, 10 and 14

-- Screw driver

-- Mallet

-- 2 brushes for grease: the brushes must not loose its hair (one for cleaning out the old grease and one for greasing)

HANDLING MEANS (not supplied)

-- Handling means (crane, hoist, travelling crane, etc...)

-- Slings

CONSUMABLE

-- Grease Multis MS2 (Total) or RETINAX AM (Shell) or RENOLIT MO2 (Fuchs).

-- Specific grease may be used for special application.

Needed quantity of grease: 400 ml.

-- Iamsub Spalmatura mastic (Veneziani) or Sikaflex 227 or equivalent.

-- Glue Loctite 242 or equivalent.

-- Flange sealant Loctite 58--14 or 58--31, Omnifit FD30 or equivalent

-- KSB spare parts kits, according to the actuator size.

3 -- INSTALLATION -- SAFETY

3.1 -- Safety instruction

The user is responsible for ensuring that all maintenance, inspection and installation work is carried out by authorized,

adequately qualified staff who are thoroughly familiar with this manual.

Any work on an actuator may only be performed after the deconnecting pneumatic energy supply.

ATTENTION

3.2 -- Inadmissible modes of operation

Operational safety and reliability of the actuator supplied is only warranted for its designated use as defined in the

type series booklet.

The limits stated in the technical documentations must not be exceeded under any circumstances.

3.3 -- Before any action

-- Index the mounting position of the actuator onto the valve (Position N o r M)

-- Index the position of the pointer 629 on mandrel 59--40

-- The disassembly of the actuator must be performed with be careful.

-- The device retrieval system stores mechanical energy (Cartridge springs 598.1 / 598.2), the dismantling of

this cartridge springs is strictly PROHIBITED.

-- If the maintenance of the spring cartridge (598.1 / 598.2) is necessary, it must be carried out by KSB Service.

: this actuator contains strong compressed springs. The dismantling of the actuator must be careful.

5

Loading...

Loading...