KSB Delta Primo, Delta Primo K, Delta Primo VP, Delta Primo SVP Installation And Operating Manual

Page 1

Pressure Booster System

KSBDeltaPrimo

KSB Delta Primo K

KSB Delta Primo VP

KSB Delta Primo SVP

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual KSBDeltaPrimo

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB B.V., Alphen aan den Rijn, Nederland 13/09/2018

Page 3

Contents

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.2.1 Prevention of foreseeable misuse.......................................................................................................8

2.3 Personnel qualification and personnel training.............................................................................................8

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation................................................................................................................10

3 Software Changes................................................................................................................................ 11

4 Transport/Temporary Storage/Disposal............................................................................................. 12

4.1 Checking the condition upon delivery..........................................................................................................12

4.2 Transport.........................................................................................................................................................12

4.3 Storage/preservation......................................................................................................................................12

4.4 Return to supplier ..........................................................................................................................................13

4.5 Disposal ...........................................................................................................................................................13

5 Description............................................................................................................................................ 14

5.1 General description ........................................................................................................................................14

5.2 Designation.....................................................................................................................................................14

5.3 Name plate......................................................................................................................................................14

5.4 Design details..................................................................................................................................................15

5.5 Configuration and function...........................................................................................................................16

5.6 Noise characteristics .......................................................................................................................................17

5.7 Scope of supply...............................................................................................................................................17

5.8 Dimensions and weights ................................................................................................................................18

5.9 Terminal wiring diagram ...............................................................................................................................18

5.10 Potential equalisation ....................................................................................................................................18

6 Installation at Site................................................................................................................................ 19

6.1 Installation ......................................................................................................................................................19

6.2 Checks to be carried out prior to installation...............................................................................................19

6.3 Installing the pressure booster system..........................................................................................................19

6.4 Connecting the piping ...................................................................................................................................20

6.4.1 Fitting an expansion joint .................................................................................................................20

6.4.2 Installing a pressure reducer .............................................................................................................20

6.5 Connection to power supply..........................................................................................................................21

6.5.1 Sizing the power cable ......................................................................................................................21

6.5.2 Connecting the pressure booster system..........................................................................................22

6.5.3 Volt-free contacts...............................................................................................................................22

7 Commissioning/Start-up/Shutdown................................................................................................... 23

7.1 Commissioning/Start-up.................................................................................................................................23

7.1.1 Prerequisites for commissioning/start-up .........................................................................................23

7.1.2 Dry running protection......................................................................................................................23

KSBDeltaPrimo

3 of 60

Page 4

Contents

7.1.3 Commissioning/start-up of pressure booster system .......................................................................23

7.2 Switching on the pressure booster system....................................................................................................24

7.3 Checklist for commissioning/start-up ............................................................................................................25

7.4 Shutdown........................................................................................................................................................25

8 Operating the Pressure Booster System............................................................................................. 26

8.1 KSB Delta Primo K, VP, SVP............................................................................................................................26

8.1.1 Control panel .....................................................................................................................................26

8.1.2 Menu structure...................................................................................................................................28

8.1.3 Access levels........................................................................................................................................29

8.1.4 Displaying and changing parameters ...............................................................................................30

8.1.5 Displaying messages ..........................................................................................................................31

8.1.6 Description of parameters.................................................................................................................31

8.1.7 Quick menu ........................................................................................................................................36

8.1.8 Saving and restoring settings............................................................................................................36

8.1.9 Alerts and warnings...........................................................................................................................36

8.1.10 Connecting the Remote OFF contact................................................................................................37

8.1.11 Connecting the fire alert ...................................................................................................................37

8.1.12 Charging the accumulator.................................................................................................................38

8.1.13 Energy-saving mode ..........................................................................................................................38

8.1.14 Flow detection ...................................................................................................................................38

8.1.15 Connecting the ambient temperature monitoring device (option) ...............................................38

8.1.16 Digital inputs for remote reset, setpoint changeover and check run (option)..............................39

9 Servicing/Maintenance........................................................................................................................ 40

9.1 General information/Safety regulations .......................................................................................................40

9.1.1 Inspection contract ...........................................................................................................................41

9.2 Servicing/Inspection........................................................................................................................................41

9.2.1 Supervision of operation ...................................................................................................................41

9.2.2 Checklist for inspection work............................................................................................................42

9.2.3 Setting the pre-charge pressure........................................................................................................42

9.2.4 Replacing the non-return valve ........................................................................................................43

9.2.5 Mounting the manifold in a mirrored position ...............................................................................45

10 Trouble-shooting.................................................................................................................................. 49

11 Related Documents.............................................................................................................................. 51

11.1 General assembly drawings/exploded views with list of components ........................................................51

11.1.1 KSB Delta Primo K..............................................................................................................................51

11.1.2 KSB Delta Primo VP............................................................................................................................52

11.1.3 KSB Delta Primo SVP ..........................................................................................................................53

12 EU Declaration of Conformity............................................................................................................. 54

13 Certificate of Decontamination........................................................................................................... 55

14 Commissioning report ......................................................................................................................... 56

Index ..................................................................................................................................................... 57

4 of 60

KSBDeltaPrimo

Page 5

Glossary

Glossary

Accumulator

The accumulator serves to compensate for

pressure losses in the piping system downstream

of the pressure booster system which may be

caused by the consumption of small quantities of

water. As a result, the frequency of starts of the

pressure booster system is minimised.

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

Charging the accumulator

Option offered by speed-controlled pressure

booster systems of filling a discharge-side

accumulator before the last pump stops.

Energy-saving mode

Setting designed to avoid the energetically

inefficient operation of a pump at minimum water

consumption.

IE3

Efficiency class to IEC60034-30: 3=Premium

Efficiency (IE = International Efficiency)

KSBDeltaPrimo

5 of 60

Page 6

1 General

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB refer to the sub-sections under

Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.3,Page8)

1.4 Other applicable documents

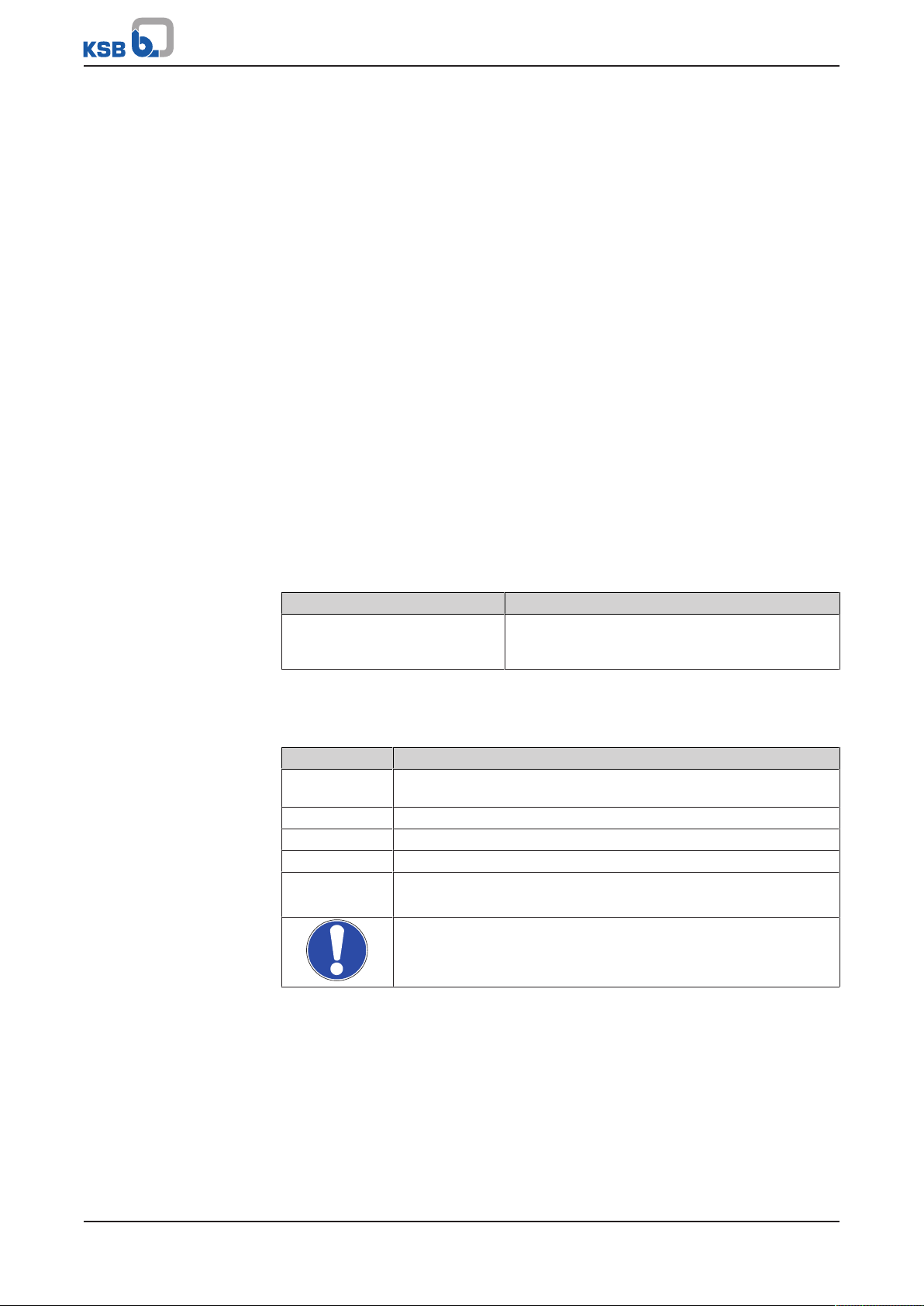

Table1: Overview of other applicable documents

Document Contents

Sub-supplier product literature Operating manuals, logic diagram and other

product literature of accessories and integrated

machinery components

1.5 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

⇨ Cross-references

1.

2.

Result of an action

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

6 of 60

KSBDeltaPrimo

Page 7

1 General

!

DANGER

!

WARNING

CAUTION

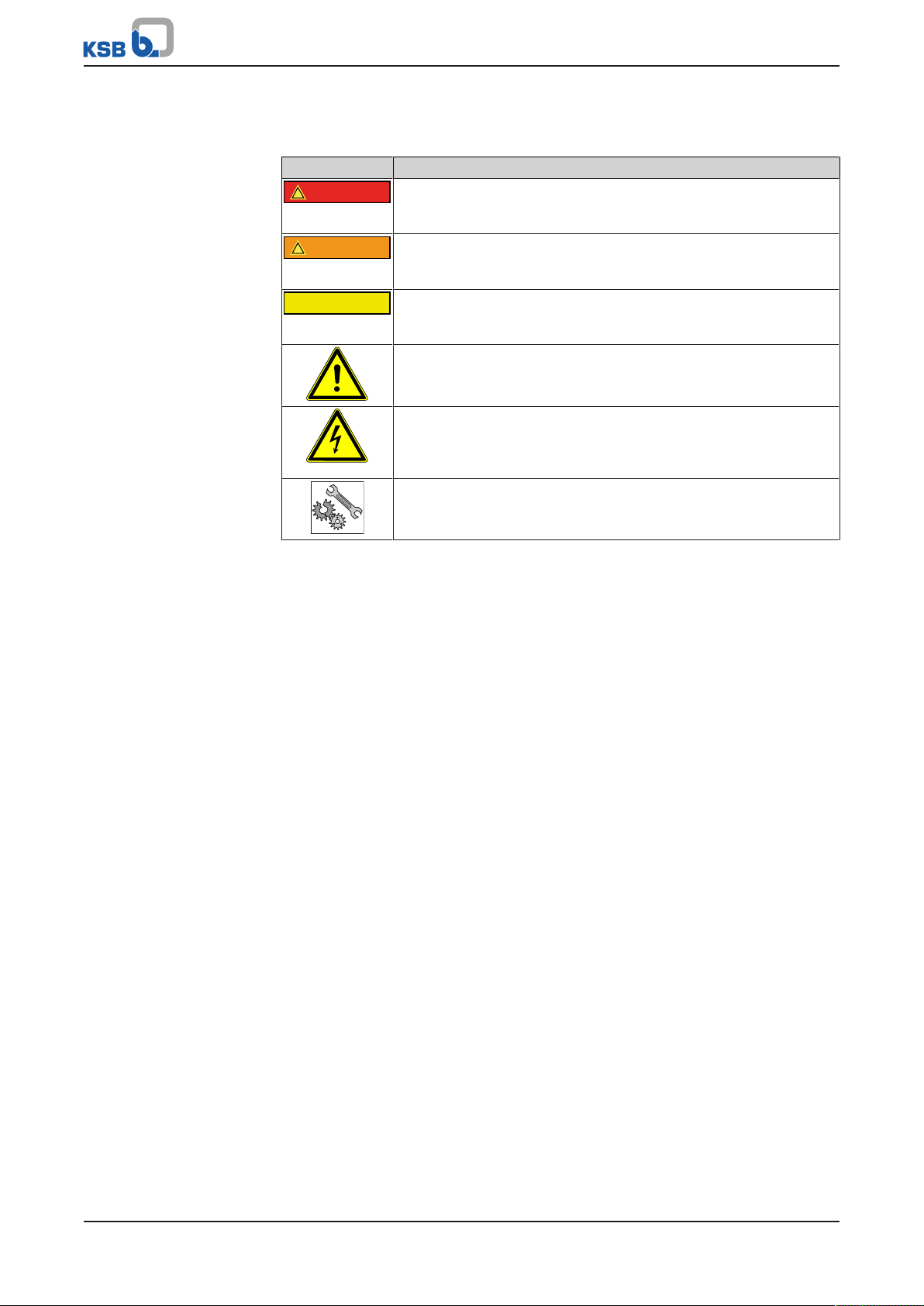

1.6 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

KSBDeltaPrimo

7 of 60

Page 8

2 Safety

!

DANGER

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Arrow indicating the direction of rotation

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

2.2 Intended use

▪ The pressure booster system must only be operated within the operating limits

described in the other applicable documents.

▪ Only operate pressure booster systems which are in perfect technical condition.

▪ Do not operate partially assembled pressure booster systems.

▪ The pressure booster system must only handle the fluids described in the product

literature of the respective design variant.

▪ Never operate the pressure booster system without the fluid to be handled.

▪ Observe the information on minimum flow rates specified in the product

literature (to prevent overheating, bearing damage, etc).

▪ Observe the maximum flow rates indicated in the data sheet or product

literature (to prevent overheating, cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the suction side of the pressure booster system

(to prevent cavitation damage).

▪ Consult the manufacturer about any other modes of operation not described in

the product literature.

2.2.1 Prevention of foreseeable misuse

▪ Never exceed the permissible application and operating limits specified in the

product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

8 of 60

2.3 Personnel qualification and personnel training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

installation, operation, maintenance and inspection must be clearly defined by the

operator.

KSBDeltaPrimo

Page 9

2 Safety

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the pressure booster system must always be supervised by technical

specialist personnel.

2.4 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.5 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.6 Safety information for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

2.7 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pressure booster system are only permitted

with the manufacturer's prior consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Carry out work on the pressure booster system during standstill only.

▪ The pump casing must have cooled down to ambient temperature.

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the pressure booster system out of service always adhere to the

procedure described in the manual.

▪ Decontaminate pressure booster systems which handle fluids posing a health

hazard.

KSBDeltaPrimo

9 of 60

Page 10

2 Safety

▪ As soon as the work has been completed, re-install and/or re-activate any safety-

relevant and protective devices. Before returning the product to service, observe

all instructions on commissioning.

▪ Make sure the pressure booster system cannot be accessed by unauthorised

persons (e.g. children).

▪ Prior to opening the device, pull the mains plug and wait for at least 10minutes.

2.8 Unauthorised modes of operation

Always observe the limits stated in the product literature.

The warranty relating to the operating reliability and safety of the pressure booster

system supplied is only valid if the equipment is used in accordance with its intended

use. (ðSection2.2,Page8)

10 of 60

KSBDeltaPrimo

Page 11

3 Software Changes

3 Software Changes

The software has been specially created for this product and thoroughly tested.

Making changes or additions to the software or parts of the software is prohibited.

This does not, however, apply to software updates supplied by KSB.

KSBDeltaPrimo

11 of 60

Page 12

4 Transport/Temporary Storage/Disposal

4 Transport/Temporary Storage/Disposal

4.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

4.2 Transport

NOTE

The pressure booster system is bolted to a pallet and wrapped in plastic film for

shipping and temporary storage. All connecting points are capped.

DANGER

Pressure booster system tipping over

Danger to life from falling pressure booster system!

▷ Never suspend the pressure booster system by its power cable.

▷ Do not lift the pressure booster system by its manifold.

▷ Observe the applicable local accident prevention regulations.

▷ Observe the information on weights, centre of gravity and fastening points.

▷ Use suitable and permitted transport equipment, e.g. crane, forklift or pallet

jack.

ü The pressure booster system has been checked for in-transit damage.

1. Make sure the transport equipment is suitable for safely carrying the indicated

load.

2. Transport the pressure booster system to the place of installation.

3. Attach the pressure booster system to the lifting tackle. Lift it off the pallet.

Dispose of the pallet.

4. Use suitable lifting equipment to lift the pressure booster system and carefully

place it down at the place of installation.

4.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken when storing the pressure booster system:

CAUTION

Damage during storage due to frost, moisture, dirt, UV radiation or vermin

Corrosion/contamination of pressure booster system!

▷ Store the pressure booster system in a frost-proof room. Do not store outdoors.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage of the pressure booster system!

▷ Only open the openings of the pressure booster system at the time of

installation.

12 of 60

Store the pressure booster system in a dry, protected room where the atmospheric

humidity is as constant as possible.

KSBDeltaPrimo

Page 13

4 Transport/Temporary Storage/Disposal

4.4 Return to supplier

1. Drain the pressure booster system as per operating instructions.

2. Always flush and clean the pressure booster system, particularly if it has been

used for handling noxious, explosive, hot or other hazardous fluids.

3. If the pressure booster system has handled fluids whose residues could lead to

corrosion damage in the presence of atmospheric humidity or could ignite upon

contact with oxygen, the pressure booster system must also be neutralised and

treated with anhydrous inert gas to ensure drying.

4. Always complete and enclose a certificate of decontamination when returning

the pressure booster system. (ðSection13,Page55)

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

4.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the pressure booster system.

Collect greases and other lubricants during dismantling.

2. Separate and sort the pump materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

KSBDeltaPrimo

13 of 60

Page 14

5 Description

ID PN

Prod. IP

RDP PO

U Kalkovenweg 13

F Alphen a/d Rijn, NL

Imax www.ksb.com

KSB B. V.

Made in NL

KSB Delta Primo 3/1508

SVP

48278756

56.1A

50 Hz

3x400V

PT

01/2018 1234567-01

123456789

54

16

1

14

13

12

6

11

10

9

8

7

2

5

4

3

5 Description

5.1 General description

▪ Pressure booster system

5.2 Designation

Example: KSB Delta Primo 3/1508 SVP

Table4: Designation key

Code Description

KSB Delta Primo Type series

3 Number of pumps

15 Pump size

08 Number of pump stages

SVP Design

K Fixed speed pressure booster system

VP Pressure booster system with cabinet-mounted variable speed

SVP Pressure booster system with variable speed system and

system

KSB SuPremE motor

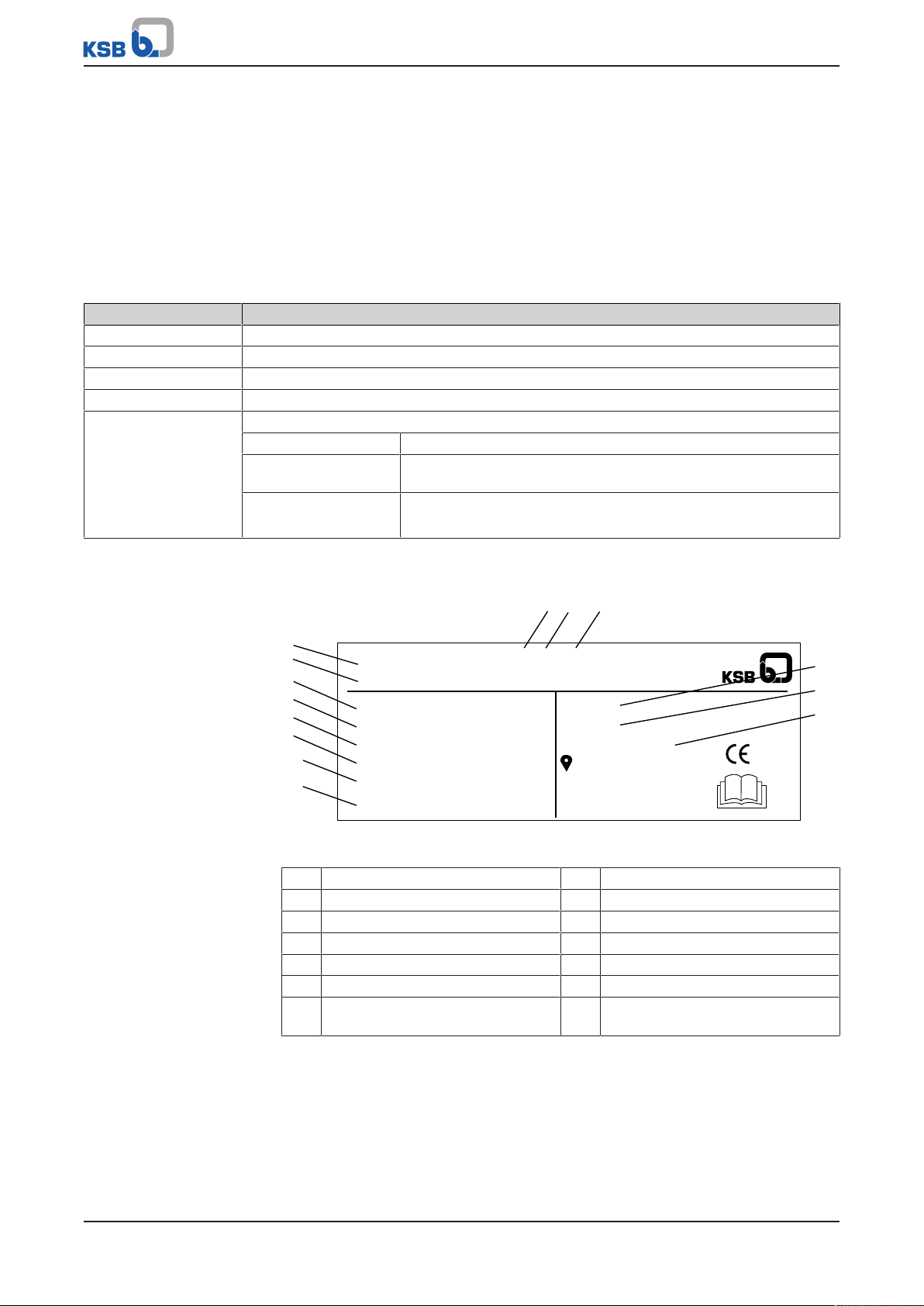

5.3 Name plate

Fig.1: Name plate (example)

1 Type series 8 Dry running protection

2 Design 9 Power supply voltage

3 Number of pumps 10 Power supply frequency

4 Size 11 Maximum current input

5 Number of pump stages 12 Max. operating pressure

6 Serial number 13 Enclosure

7 Month of production/ year of

production, consecutive number

14 Order number

14 of 60

KSBDeltaPrimo

Page 15

5 Description

5.4 Design details

Design

▪ Compact system mounted on a common base frame

▪ One or more vertical high-pressure pumps with variable speed system

▪ Hydraulic components made of stainless steel/ brass for high operating reliability

Multiple pump system:

▪ Check valve per pump

▪ Discharge-side gate valve per pump

▪ Suction-side gate valve per pump

KSB Delta Primo K:

▪ Power contactor per pump

KSB Delta Primo VP, SVP:

▪ One frequency inverter per pump

Installation

▪ Stationary dry installation

Drive

KSB Delta Primo K, VP:

▪ Electric motor

▪ Efficiency class IE3 to IEC60034-30

KSB Delta Primo SVP:

▪ Magnetless synchronous reluctance motor

▪ Efficiency class IE5 to IEC60034-30

▪ KSB SuPremE

Automation

▪ Control cabinet IP54

– Sheet steel housing: colour RAL7035

– BoosterControl Advanced

– Graphical display with operating panel

– Three LEDs signalling the operating status

– Lockable master switch (repair switch)

– Motor protection switch per pump

– Service interface for KSB ServiceTool

KSBDeltaPrimo

15 of 60

Page 16

5 Description

1

2

3

4

5

6

1

2

3

4

5

6

5.5 Configuration and function

Fig.2: KSB Delta Primo

1 Control cabinet

2 Control unit

3 Vertical high-pressure pumps

4 Membrane-type accumulator

5 Manifold

6 Baseplate

Design Fully automatic pressure booster system with two or three vertical high-pressure

pumps (3) for ensuring the required supply pressure

Function KSB Delta Primo K:

Either 2 or 3 pumps are controlled and monitored by a micro-processor control unit

(BoosterControl Advanced). The first pump is started up when the pressure falls

below the set start-up pressure. Additional pumps are sequenced in automatically in

line with actual demand. When demand decreases, the pumps are sequenced out

again as the stop pressure (start-up pressure+ deltap) is reached. The pump that has

been started up first will be stopped first. The pumps are automatically started up in

a different order for each new cycle. The actual pressure is measured by an analog

pressure measuring device (pressure transmitter). The function of this pressure

transmitter is monitored (live-zero).

This ensures equal distribution of pump operating hours.

If a duty pump fails, the next pump is started up immediately. A fault is output,

which can be reported via volt-free contacts (e.g. to the control station).

The operating status is displayed via LEDs.

▪ Green: system ready for operation

▪ Yellow: warning

▪ Red: alert

2 volt-free contacts on terminals are provided for reporting warnings and alerts.

KSB Delta Primo VP, SVP:

Either 1 or more pumps are controlled and monitored by a micro-processor control

unit (BoosterControl Advanced). Each pump is operated on a frequency inverter and

controlled by the control unit so as to ensure a constant discharge pressure of the

pressure booster system.

As the demand increases or decreases, peak load pumps are started and stopped

automatically. As soon as the demand increases again after one pump has been

stopped, another pump which has not been in operation before is started up. When

16 of 60

KSBDeltaPrimo

Page 17

5 Description

the last pump has been stopped and the demand increases again, the next pump in

line is started up on a frequency inverter. The stand-by pump is also included in the

alternating cycle.

The standard setting is for the pressure booster system to start automatically as a

function of pressure. As long as the pressure booster system is in operation, the

pumps are started and stopped as a function of demand (standard setting). In this

way it is ensured that the individual pumps operate only in line with actual demand.

If the demand drops towards 0, the pressure booster system slowly runs down to the

stop point.

The operating status is displayed via LEDs.

▪ Green: system ready for operation

▪ Yellow: warning

▪ Red: alert

2 volt-free contacts on terminals are provided for reporting warnings and alerts.

5.6 Noise characteristics

The pressure booster systems are available with different numbers of pumps and

different pump sizes.

Therefore, the expected total sound pressure level in dB(A) needs to be calculated.

1. Refer to the pumps' operating manual for the noise characteristics of the

individual pumps.

2. Calculate the expected total sound pressure level.

Table5: Calculating the expected total sound pressure level

Number of pumps Expected total sound pressure level

Single pump See pump operating manual

2 pumps +3dB(A)

3 pumps +4,5dB(A)

Total dB(A)

Table6: Example of calculating the expected total sound pressure level

Number of pumps Expected total sound pressure level

Single pump 48dB(A)

2 pumps +3dB(A)

Total 51dB(A)

The expected total sound pressure level of 51dB(A) for this configuration may

develop when both pumps are running under full-load conditions.

5.7 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ 2 or 3 vertical high-pressure centrifugal pumps with oval flange

▪ Powder-coated / epoxy resin-coated steel baseplate

▪ Integrated check valve per pump

▪ Discharge-side gate valve per pump

▪ Suction-side gate valve per pump

▪ Suction-side manifold and discharge-side manifold made of stainless steel

▪ Pressure transmitter on the discharge side

▪ Pressure gauge

▪ Dry running protection switch on the inlet pressure side

▪ Membrane-type accumulator on the discharge side, approved for drinking water

▪ Control cabinet IP54

– Sheet steel housing: colour RAL7035

KSBDeltaPrimo

17 of 60

Page 18

5 Description

1

2

– Parameterisable BoosterControl Advanced control unit

– Graphical display with operating panel

– Three LEDs signalling the operating status

– Lockable master switch (repair switch)

– Motor protection switch per pump

– One frequency inverter per pump

– Service interface for KSB ServiceTool

5.8 Dimensions and weights

For dimensions and weights refer to the outline drawings of the pressure booster

system.

5.9 Terminal wiring diagram

For the terminal assignment refer to the circuit diagram.

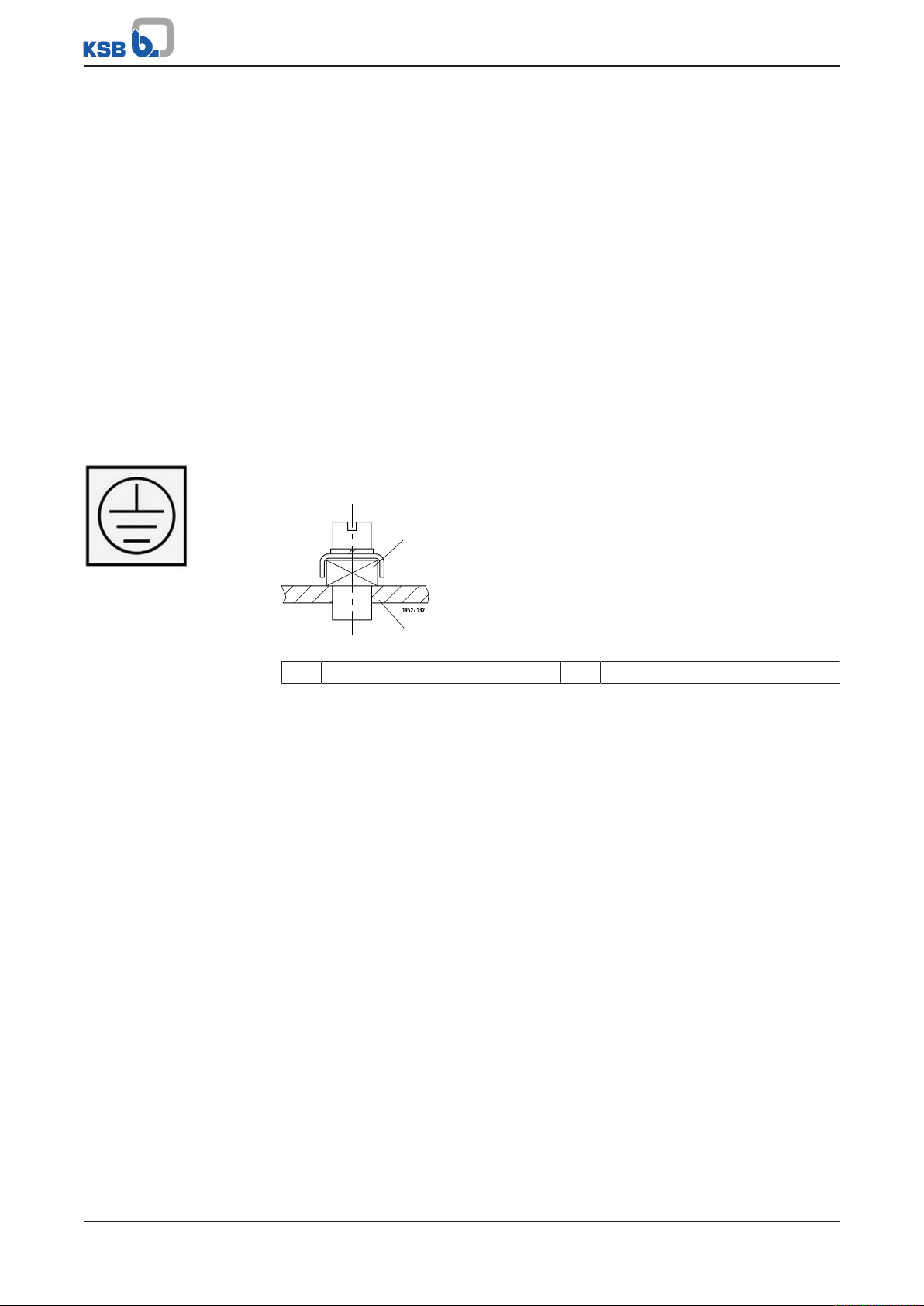

5.10 Potential equalisation

A terminal marked with the earth symbol is provided on the baseplate for connecting

a PE conductor.

Fig.3: Earth symbol

Fig.4: PE terminal

1 Earthing terminal 2 Baseplate

18 of 60

KSBDeltaPrimo

Page 19

6 Installation at Site

6 Installation at Site

6.1 Installation

Install pressure booster systems either in the technical equipment room or in a wellventilated, frost-free, lockable room used for no other purpose. No harmful gases are

allowed to enter the installation room. An adequately sized drain (leading to a sewer

or equivalent) must be provided.

The pressure booster system is designed for a maximum ambient temperature of 0°C

to +40°C1) at a relative humidity of 50%.

NOTE

Do not install pressure booster systems next to sleeping or living quarters.

The anti-vibration mounting of the pressure booster system provides adequate

insulation against solid-borne noise. If expansion joints (see accessories) are used for

damping vibrations, their fatigue strength (endurance limit) must be given due

consideration. Expansion joints must be easily replaceable.

6.2 Checks to be carried out prior to installation

Place of installation

WARNING

Installation on mounting surfaces which are unsecured and cannot support the

load

Personal injury and damage to property!

▷ Use a concrete of compressive strength class C12/15 which meets the

requirements of exposure class X0 to EN206-1.

▷ The mounting surface must have set and must be completely horizontal and

even.

▷ Observe the weights indicated.

NOTE

The anti-vibration mounts of the pressure booster system provide adequate

insulation against solid-borne noise.

1. Check the structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing.

6.3 Installing the pressure booster system

1) KSB Delta Primo VP: +30°C

WARNING

Top-heavy pressure booster system

Risk of personal injury by pressure booster system tipping over!

▷ Pressure booster systems awaiting final installation must be secured against

tipping over.

▷ Firmly anchor the pressure booster system.

Remove all packaging before installing the pressure booster system. Connect the

pressure booster system's inlet line and discharge line to the corresponding site

distribution lines.

KSBDeltaPrimo

19 of 60

Page 20

6 Installation at Site

NOTE

In order to avoid transmission of piping forces onto the pressure booster system

and transmission of solid-borne noise, we recommend installing length-limited

expansion joints.

Allow sufficient space for maintenance and repair work.

ü All structural work required has been checked.

ü The dimensions of the concrete foundation are correct, and the concrete has set

firmly.

1. Mark out the anchoring holes on the floor as shown in the outline drawing.

2. Drill the holes (max. diameter: 12mm).

3. Insert plug fixings of appropriate size.

4. Set the pressure booster system down in its correct installation position.

5. Use suitable bolts to firmly anchor the pressure booster system.

6.4 Connecting the piping

Make sure that piping is installed without transmitting any stresses or strains. The use

of length-limited expansion joints (KSB accessory) is advisable.

6.4.1 Fitting an expansion joint

DANGER

Sparks and radiant heat

Fire hazard!

▷ Take suitable precautions to protect the expansion joint if any welding work is

carried out nearby.

CAUTION

Leaking expansion joint

Flooding of installation room!

▷ Regularly check for cracks or blisters, exposed fabric or other defects.

ü The expansion joint has a length limiter with solid-borne sound insulation so as

to be able to absorb reaction forces.

1. Install the expansion joint in the piping free of twist or distortion. Never use the

expansion joint to compensate for misalignment or mismatch of the piping.

2. Tighten the bolts evenly and crosswise during assembly. The ends of the bolts

must not protrude from the flange.

3. Do not apply paint to the expansion joint. Protect it from any contact with oil.

4. The position of the expansion joint within the pressure booster system must

allow easy access and inspection and it must, therefore, not be insulated along

with the piping.

5. Expansion joints are subject to wear.

20 of 60

6.4.2 Installing a pressure reducer

NOTE

A pipe length of approximately 600 mm must be provided on the inlet side to

accommodate a pressure reducer, if necessary.

KSBDeltaPrimo

Page 21

6 Installation at Site

NOTE

A pressure reducer must be installed

- if the inlet pressure fluctuation is too high for the pressure booster system to

operate as intended or

- if the total pressure (inlet pressure plus shut-off head) of the pressure booster

system exceeds the design pressure.

The maximum pump discharge pressure at zero flow point is reached in manual

mode.

A minimum pressure gradient of 5 metres is required for the pressure reducer to

fulfill its function. The pressure downstream of the pressure reducer (downstream

pressure) is the basic parameter for determining the pump head.

For example:

The inlet pressure fluctuates between 4 and 8 bar. A pressure reducer is needed

upstream of the pressure booster system on the inlet side.

Min. inlet pressure (p

Min. pressure gradient=0.5bar

Downstream pressure=3.5bar.

6.5 Connection to power supply

)=4bar

inl

DANGER

Electrical connection work by unqualified personnel

Danger of death from electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC60364.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

NOTE

A motor protection device is recommended.

NOTE

If a residual current device is installed, observe the operating manual for the

frequency inverter.

The circuit diagrams for the pressure booster system are included in the control

cabinet, where they must remain when not in use.

The product literature of the switchgear and controlgear assembly supplied with the

pressure booster system includes a list of the electrical components installed. When

ordering spare parts for electrical components, please always indicate the circuit

diagram number.

6.5.1 Sizing the power cable

The cross-section of the power cable must be sized for the total rated power

requirement.

KSBDeltaPrimo

21 of 60

Page 22

6 Installation at Site

6.5.2 Connecting the pressure booster system

Connect the pressure booster system to the power supply as per the enclosed circuit

diagram.

Observe the data on the name plate.

6.5.3 Volt-free contacts

Volt-free contacts are provided for the following messages:

▪ Warning

▪ Alert

The terminals are marked in the circuit diagram and in the switchgear and

controlgear assembly.

22 of 60

KSBDeltaPrimo

Page 23

7 Commissioning/Start-up/Shutdown

7 Commissioning/Start-up/Shutdown

7.1 Commissioning/Start-up

7.1.1 Prerequisites for commissioning/start-up

Before commissioning/start-up of the pressure booster system make sure that the

following requirements are met:

▪ The pressure booster system has been properly connected to the electric power

supply and is equipped with all protection devices.

▪ All relevant regulations applicable in the country of use are complied with.

NOTE

The competent authorities must be informed in due time prior to commissioning/

test running the system.

7.1.2 Dry running protection

Pressure booster systems are fitted with a pressure switch as dry running protection

device.

A float switch whose volt-free contact closes the circuit in upper float position can be

connected to the control system as dry running protection. Follow the float switch

manufacturer's instructions on how to set the float switch levels.

Table7: Levels for dry running protection

Dry running protection device Stop pressure Start-up pressure

[bar] [bar]

Pressure switch 0,2 1,1

7.1.3 Commissioning/start-up of pressure booster system

NOTE

The pressure booster systems undergo hydraulic testing with water at the factory

and are drained carefully before shipment. However, for technical reasons the

presence of some residual water is unavoidable.

The hydraulic connections are closed in as-supplied condition. They must only be

opened immediately before installation.

Refer to EN806 before commissioning/starting up the pressure booster system.

After an extended pre-installation period, in particular, flushing or even

professional disinfection is recommended. For extensive or branched piping systems

the pressure booster system should preferably be flushed either before installation,

or flushing should be restricted to a limited area.

CAUTION

Foreign matter in the piping

Damage to the pumps/pressure booster system!

▷ Before commissioning/starting (or even test running) the pressure booster

system, make sure that there is no foreign matter in the pressure booster

system or piping.

NOTE

Commissioning of the pressure booster system - even test running - shall only be

carried out in full compliance with all pertinent VDE (German Association of

Electrical Engineers) regulations.

KSBDeltaPrimo

23 of 60

Page 24

7 Commissioning/Start-up/Shutdown

CAUTION

Operation without the fluid to be handled

Damage to the pump!

▷ Prime the pressure booster system with the fluid to be handled.

ü The pipe unions between the pump and the piping have been re-tightened.

ü The flange bolting has been checked for firm seating.

ü The cooling air inlet and outlet openings on the motor are unobstructed.

ü All shut-off valves of the pressure booster system are open.

ü The pre-charge pressure of the membrane-type accumulator has been checked.

(ðSection9.2.3,Page42)

1. Set the master switch to "0"; unlock all motor protection switches (if

applicable).

2. Provide connection to power supply.

3. Open/loosen the vent plugs on the pumps (refer to the pump's installation/

operating manual).

4. Slowly open the inlet-side shut-off element and prime the pressure booster

system until the fluid to be handled escapes through all vent holes.

5. Insert and slightly tighten the pump vent plugs.

6. Switch on all motor protection switches.

7. Switch on the master switch.

8. Start one pump after the other in manual mode, checking the direction of

rotation. The direction of rotation must match the rotation arrow on the motor.

If the pump runs in the wrong direction of rotation, interchange two phases at

the motor terminal strip.

9. Open the discharge-side shut-off element.

10. Then re-tighten the vent plug firmly.

11. Check that the pumps are running smoothly.

12. Close the discharge-side shut-off element, causing all pumps to stop.

NOTE

Minor leakage of the mechanical seals during commissioning is normal and will

cease after a short period of operation.

7.2 Switching on the pressure booster system

Switch on the master switch to energise the pressure booster system. The green LED

on the control panel lights up, indicating the system's readiness for operation.

CAUTION

Pressure booster system not set to requirements

Damage to the pump/pressure booster system!

▷ Adjust the settings of the pressure booster system to the pressure conditions at

the site.

▷ Set the functions as required.

24 of 60

KSBDeltaPrimo

Page 25

7 Commissioning/Start-up/Shutdown

7.3 Checklist for commissioning/start-up

Table8: Checklist

Actions Done

1 Read the operating manual.

2 Verify the power supply against the name plate data.

3 Check the earthing system (taking measurements).

4 Check the mechanical connection to the water mains.

Re-tighten the flange bolting and pipe unions.

5 Prime and vent the pressure booster system from the inlet side.

6 Check the inlet pressure.

7 Check whether all cables are still firmly connected to the terminals inside the control unit.

8 Compare the set values of the motor protection switches with the name plate data; if

required, readjust.

9 Briefly start up one pump after the other in manual mode and compare the direction of

rotation at the fanwheel with the arrow indicating the direction of rotation.

10 Check the start and stop pressure; re-adjust if necessary.

11 Check that the dry running protection equipment is working properly.

12 Vent the pumps for a second time after they have been running for 5 to 10minutes.

13 Check the pre-charge pressure of the (membrane-type) accumulator.

14 Record all system conditions that do not correspond to our specifications or to the purchase

order in the commissioning report (i.e. no dry running protection or inlet pressure + max.

pressure of pressure booster system higher than 16bar).

15 Complete the commissioning report together with the operator/user and instruct the operator/

user as to the function of the unit.

7.4 Shutdown

NOTE

As long as the pressure booster system is out of operation, water is supplied directly

at p

through the pressure booster system.

inl

Set the master switch to "0".

NOTE

Drain the pressure booster system for prolonged shutdown.

KSBDeltaPrimo

25 of 60

Page 26

8 Operating the Pressure Booster System

1

2

3

4

5

8 Operating the Pressure Booster System

8.1 KSB Delta Primo K, VP, SVP

CAUTION

Incorrect operation

Water supply is not assured!

▷ Make sure to comply with all local regulations, particularly the EC Machinery

Directive and the EC Directive on Low-Voltage Equipment.

The pressure booster system is factory-set to the start-up pressure and stop pressure

indicated on the name plate.

The settings can be modified via the control panel if necessary.

NOTE

The factory settings are permanently stored in the control unit. Should an incorrect

setting result in pressure booster system failure, the factory settings can be

restored. (ðSection8.1.8.2,Page36)

NOTE

The settings made at the site can be saved and loaded when required.

(ðSection8.1.8.1,Page36) (ðSection8.1.8.2,Page36)

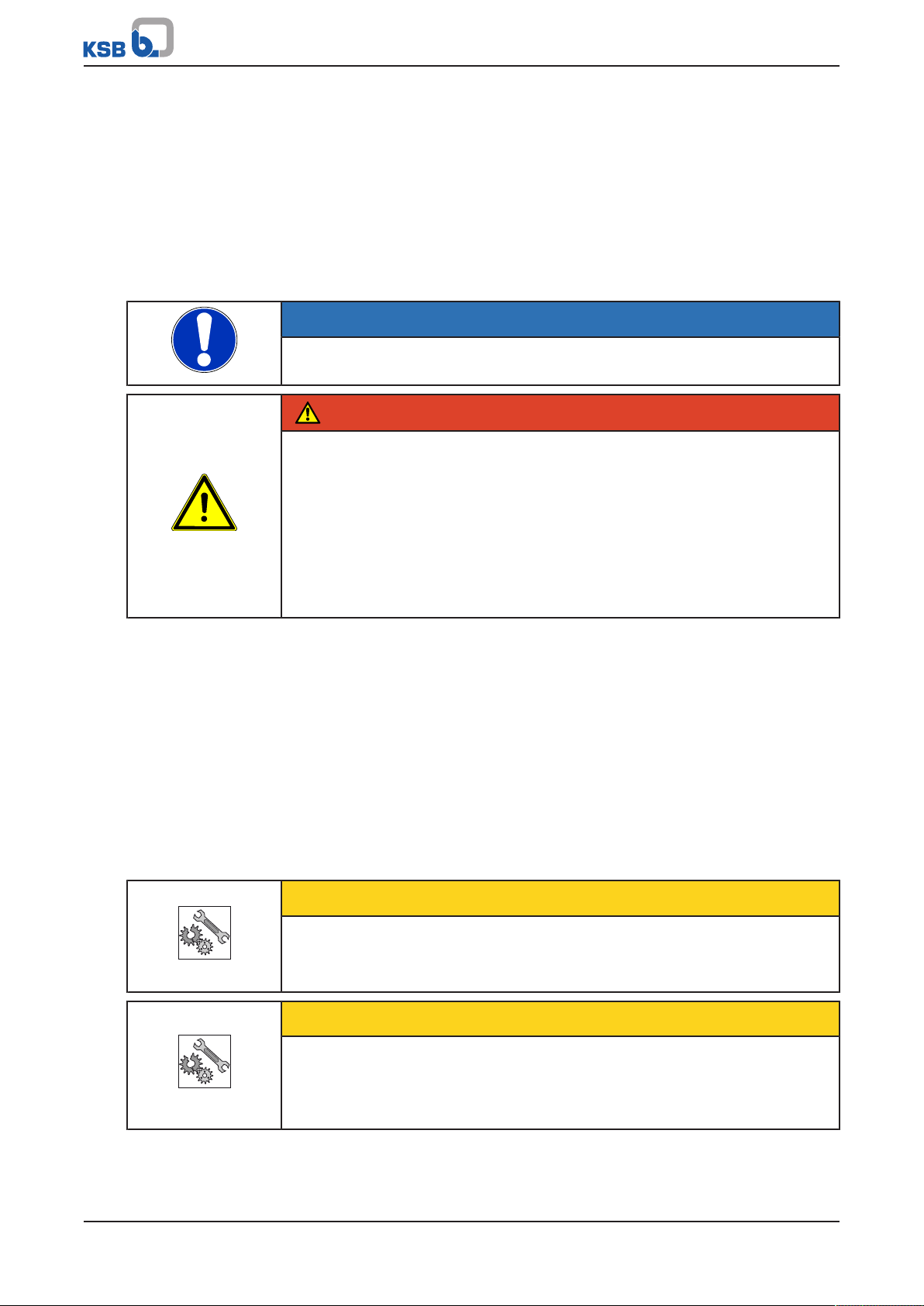

8.1.1 Control panel

The control panel comprises a back-lit display, LEDs, function and navigation keys,

and an access point for the service interface.

The display shows important information for operating the pressure booster system.

Plain-text data can be accessed and parameters can be set.

26 of 60

Fig.5: BoosterControl Advanced control panel

KSBDeltaPrimo

Page 27

8 Operating the Pressure Booster System

3-5

C

Pressure

Setpoint

Bandwidth

Accumulator pressure

Max. setpoint

22-05 13:40

1 Display 2 "Traffic light" LEDs

3 Function keys 4 Navigation keys

5 Service interface

8.1.1.1 Display

The six-row display contains the following information:

Fig.6: Control unit: Display elements

Display element Description

Parameter No./Pump Shows the number of the parameter or pump

selected

Current selection Shows the current parameter in plain text

Parameter information List of selectable parameters/parameter

information

Access level Shows the current access level:

Blank = Standard

(limited access to parameters)

C = Customer, access to main parameters

S = Service

F = Factory

Date, time Shows the set date and time

Example: Setpoint adaptation at "Customer" access level:

Fig.7: Display: Setpoint adaptation

The number of the current menu or parameter is always displayed at the top left of

the screen. This number indicates the path through the menu levels and thus enables

the user to quickly locate parameters. See "Displaying and changing parameters".

(ðSection8.1.4,Page30)

8.1.1.2 LEDs

The "traffic light" LEDs provide information about the pump system's operating

status.

KSBDeltaPrimo

27 of 60

Page 28

8 Operating the Pressure Booster System

Esc

OK

?

Table9: LED description

LED Description

Red: One or more than one alert is active

Amber: One or more than one warning is active

Green: Trouble-free operation

8.1.1.3 Function keys

You can use the menu keys to access the elements at the first menu level directly.

Table10: Assignment of menu keys

Key Menu

Operation

Diagnosis

Settings

Information

8.1.1.4 Navigation keys

For navigating through the menus and confirming settings:

Table11: Control unit: Navigation keys

Key Description

Direction keys:

▪ Move up/down in the menu options

▪ Increase/decrease a numerical value

▪ Scroll up or down

Escape key:

▪ Cancel an entry without saving it.

▪ Move up one menu level.

OK key:

▪ On the start display: Open the quick menu.

▪ Confirm settings.

▪ Confirm a menu selection.

▪ When entering numbers: Go to the next digit.

Help key:

▪ Displays a help text for each selected menu option.

8.1.1.5 Service interface

The service interface allows a PC/Notebook to be connected via a special cable (USB RS232).

The pressure booster system can be parameterised by using the Service-Tool

software.

The control unit can also be updated via this interface.

28 of 60

8.1.2 Menu structure

Main menu: KSB logo/actual value display

KSBDeltaPrimo

Page 29

8 Operating the Pressure Booster System

Main menu Key Sub-menu Information displayed

➡ Operation ➡ General System pressure

System load %

RDP switch present/not present

Inlet pressure

Level content %

Level height m

Ambient temp.

Digital inputs

➡ Pumps Operating mode of pumps

Display pump load

Display thermal protection

➡ Time and statistics Operating hours

Service interval

Current min. runtime

➡ Diagnosis ➡ General Display messages

Show history

Acknowledge faults

Clear history

➡ Settings ➡ Control panel Basic settings

CAN configuration

Service interface

Logo

➡ Control unit Login

Service

➡ System configuration Number of pumps

Configuration suction side

Configuration operating mode

➡ System settings Suction side

Discharge side

Configuration of frequency inverter

➡ Pressure configuration Configuration setpoint and dry running protection

➡ Timer settings Operation check run/alternative setpoint

➡ Time/date

➡ Program outputs

➡ Messages

➡ Main menu

➡ Information ➡ Control module Serial number

Material number

Firmware

Parameter set

Hardware version

8.1.3 Access levels

Various access levels have been defined to prevent unintentional or unauthorised

access to the pressure booster system parameters.

"Standard" level Unless users log on to one of the other access levels, they will only have limited access

to parameters.

"Customer" level Access level for expert users.

This level enables access to all the parameters required for commissioning. You must

enter the password under (3-2-1-1) Login to gain access.

"C" is displayed.

If password protection is deactivated via parameter 3-2-1-2, this access level becomes

the "Standard" access level.

The password is "7353".

"Service" level Access level for service personnel.

You must enter the password under (3-2-1-1) Login to gain access.

"S" is displayed.

KSBDeltaPrimo

29 of 60

Page 30

8 Operating the Pressure Booster System

"Factory" level Access level for the manufacturer only.

"F" is displayed.

NOTE

If no keys are pressed for ten minutes, the system will automatically return to the

"Standard" access level.

8.1.4 Displaying and changing parameters

The parameter numbers contain the navigation path, which helps you find a

particular parameter quickly and easily.

The first digit of the parameter number indicates the first menu level, which is called

up directly via the four function keys.

Table12: Function keys

Operation

Diagnosis

Settings

Information

Subsequent steps are carried out via the navigation keys.

Example: Parameter 3-5-1 Setpoint

First, enter the customer password. (ðSection8.1.3,Page29)

Then change the setpoint as follows:

First digit of parameter number: 3-5-1

Press the third function key for Settings.

3-1 appears on the top left of the screen.

Second digit of parameter number: 3-5-1

Change the display 3-1 (top left) to 3-5 by pressing the navigation

keys.

To confirm the selection, press OK. 3-5-1 appears on the top left of

the screen. You have reached the required parameter.

To change this parameter, press OK again.

Numbers can then be entered digit by digit from left to right.

Increase value.

Reduce value.

30 of 60

The bar above the entry displays the value currently being entered in relation to the

value range.

Confirm the selected value by pressing OK. The cursor moves to the

next position (second position from the left).

Make the settings for the subsequent positions as described above and then

KSBDeltaPrimo

Page 31

8 Operating the Pressure Booster System

press OK to save the new parameter value.

Press ESC several times to return to the main display.

The new setpoint is now active.

8.1.5 Displaying messages

All monitoring and protective functions trigger warnings or alerts. These are

signalled by the yellow or red LED and connected to the relay outputs.

▪ All current messages can be displayed in the Diagnosis menu under 2-1-1 and

acknowledged individually if the cause of the fault has gone.

▪ The history of messages can be accessed in the Diagnosis menu under 2-1-2. It

indicates the start and end of a fault.

▪ The list of fault messages can be acknowledged in the Diagnosis menu under

2-1-3.

▪ The history of messages can be deleted in the Diagnosis menu under 2-1-4. For

this step, you have to login at the "Service" level.

When the pressure booster system is reset (by switching the pressure booster system

off and on with the master switch), all alerts are acknowledged automatically.

Acknowledging alerts may cause the system to re-start.

8.1.6 Description of parameters

8.1.6.1 Parameter group 1 "Operation"

Access via "Operation" key

Parameters starting with the digit "1" indicate current operating conditions.

Exception: Parameter 1-2-1, which can be used to start and stop individual pumps in

Fig.8: Operation key

Parameter Description

1-1-1 System pressure

1-1-2 System load 0 to 300%, depending on the number of pumps in operation.

1-1-3 Indicates whether a dry running protection device is connected or not.

1-1-7 Ambient temperature, if "Temperature" function has been selected under 3-3-4, WSD.

1-1-8 For Service only: Status of digital inputs.

1-1-10 Power down speed. If the rotational speed of the variable-speed pump drops below this speed (set

under 3-11-3), the pump will stop. Only active if energy-saving mode has been activated under 3-11-1.

1-2-1 Operating mode. After the pump has been selected (by entering the pump number), it can be run

either in automatic mode, in manual mode (for 10 seconds), or switched off. If the pump was

switched off via this parameter, the same parameter will have to be used to return the pump to

automatic mode again.

This pump cannot be switched on again by means of a voltage reset!

If a pump has been operated in manual mode via this parameter, it will automatically return to its

previous operating mode after 10seconds.

1-2-2 Pump load indicates the load per pump.

1-2-3 For Service only: Thermal fail. flags.

1-2-4 Running hours pump.

1-2-5 For Service only: Number of pumpstarts and failures.

manual mode.

KSBDeltaPrimo

31 of 60

Page 32

8 Operating the Pressure Booster System

8.1.6.2 Parameter group 2 "Diagnosis"

Access via "Diagnosis" key

Parameters starting with the digit "2" are used for fault diagnosis.

Fig.9: Diagnosis key

Parameter Description

2-1-1 Displaying messages. Current faults are displayed.

A ring next to the fault means that the fault has gone but has not been acknowledged yet.

A ring filled with a dot means that the fault is still active but cannot be acknowledged.

2-1-2 Displaying history. The last six faults are displayed.

A ring next to the fault means that the fault has gone but has not been acknowledged yet.

A ring filled with a dot means that the fault is still active but cannot be acknowledged.

2-1-3 Acknowledging faults.

2-1-4 For Service only: Deleting the fault history.

8.1.6.3 Parameter group 3 "Settings"

Access via "Settings" key

This key is used to change parameters which are required to adjust the pressure

booster system to site conditions if the data specified in the purchase order no longer

Fig.10: Settings key

Parameter Description

3-1 Control panel

3-1-1 Basic settings of the control panel. Parameters 3-1-1-1 and 3-1-1-2 can be changed at the Standard

access level.

3-1-1-1 Language settings

3-1-1-2 Backlight settings for the display: 3-1-1-2-1 serves to select the backlighting modes "Always ON“ or

"Timer-based". If "Timer-based" is selected, the backlight time can be set from 0 to 999seconds

under 3-1-1-2-2.

3-1-1-3 Service only: Displayed units for pressure (3-1-1-3-1), fill level (3-1-1-3-2) and temperature (3-1-1-3-3).

3-1-2 Service only: Fieldbus type and address.

3-1-3 Factory only: Service interface settings.

3-1-4 Factory only: Logo on start screen.

3-2 Control unit

3-2-1 Login. The various login levels can be selected under 3-2-1-1. The password for the "Customer" level is

7353. The password prompt for this access level can be deactivated under 3-2-1-2.

3-2-2 Service. 3-2-2 provides access to the parameters required for saving and restoring settings.

3-2-2-1 "Customer" level. Resetting the pressure booster system to the factory settings it was delivered with.

3-2-2-2 "Service" level. Resetting the service interval.

3-2-2-3 "Customer" level. Resetting to the settings made at the site and saved under 3-2-2-4.

3-2-2-4 "Customer" level. Saving the settings made at the site.

3-2-2-5 "Factory" level. Saving the factory settings the pressure booster system is delivered with.

3-2-2-6 "Factory" level. Resetting to default settings.

3-3 System configuration

All parameters can be changed at "Service" level.

3-3-1 Number of pumps in the system.

3-3-2 The "inlet" configuration defines the type of dry running protection used (by pressure switch,

pressure sensor or flow monitoring), or whether the individual inlet tank levels are processed and

whether inflow into the tank is controlled by means of a proportional valve or gate valve (on/off

valve).

3-3-3 "Discharge" configuration. Defines the control method (cascade operation, frequency inverter, jockey

pumps).

applies or if accessories or supplementary equipment have been retrofitted.

32 of 60

KSBDeltaPrimo

Page 33

8 Operating the Pressure Booster System

Parameter Description

3-3-4 WSD. Presently, only the ambient temperature can be analysed. If "Temperature" has been selected,

a Pt1000 sensor can be connected and the temperature measured can be displayed. If the

temperature exceeds the value entered under 3-4-4-3, a warning is output.

3-4 System settings

All parameters can be changed at "Service" level.

3-4-1 Inlet

3-4-1-1 Sensor press. 4 mA. Lower sensor limit, factory setting: 0bar.

3-4-1-2 Sensor press. 20mA. Upper sensor limit. Factory setting: 10bar.

3-4-1-3 Automatic RDP reset. Control unit response when lack of water signal has gone. Factory setting:

automatic reset.

3-4-1-4 Inlet tank configuration if inlet tank has been selected under 3-3-2.

3-4-1-4-1 0% level. Input of inlet tank level in cm or m (depending on setting made under 3-1-1-3-2) at 0% of

sensor signal.

3-4-1-4-2 100% level. Input of inlet tank level in cm or m (depending on setting made under 3-1-1-3-2) at

100% of sensor signal.

3-4-1-4-3 Sensor level. Sensor distance from tank floor.

3-4-1-4-4 Low level shut down. At this level the pressure booster system stops owing to lack of water.

3-4-1-4-5 Low level reset. At this level the pressure booster system starts again.

3-4-1-4-6 Critical water level. Level at which a warning is output: tank is almost empty.

3-4-1-4-7 High water level. Level at which a warning is output: high-water level is reached.

3-4-1-4-8 Threshold

3-4-1-4-8-1 Threshold1: ON

3-4-1-4-8-2 Threshold1: OFF

3-4-1-4-8-3 Threshold2: ON

3-4-1-4-8-4 Threshold2: OFF

3-4-1-4-9 Supply valve ON/OFF. These parameters define the levels at which the supply valve is opened and

closed, respectively. Level 1A is an alternative level which is activated under 3-7-9 and 3-7-10.

3-4-1-4-9-1 Level 1 open. Level at which the gate valve is to open.

3-4-1-4-9-2 Level 1 closed. Level at which the gate valve is to close.

3-4-1-4-9-3 Level 1A open. Level at which the gate valve is to open.

3-4-1-4-9-4 Level 1A closed. Level at which the gate valve is to close.

3-4-1-4-10 Supply valve prop.

3-4-1-4-10-1 Level setpoint 1. This parameter defines the level at which the proportional valve is fully open.

3-4-1-4-10-2 Level setpoint1A. This parameter defines the alternative level at which the proportional valve is fully

open. The alternative level is activated under 3-7-9 and 3-7-10.

3-4-1-4-10-3 Hysteresis

3-4-1-4-10-4 Sample time

3-4-2 Discharge side

3-4-2-1 Sensor press. 4 mA. Lower sensor limit, factory setting: 0bar.

3-4-2-2 Sensor press. 20mA. Upper sensor limit. Factory setting: 16bar.

3-4-2-3 Pumps ON sensor fail. This parameter defines the control unit response if the sensor current drops

below 4mA. A number between 0 and 6 is input. 0means that all pumps are stopped, 1means that

one pump is running, 6means that six pumps are running.

3-4-2-4 Max power. This parameter defines the maximum number of pumps allowed to run at the same time.

Input is in number of pumps x 100%.

3-4-3 Variable freq. drive.

3-4-3-1 Communication. Configuration of communication protocol used by control unit and frequency

inverter.

3-4-3-2 Proportional const. Proportional amplification factor of controller. The higher the value, the higher

the amplification.

3-4-3-3 Integral time. Integration time of controller. The higher the value, the faster the controller.

3-4-3-4 Differential const. Not used in pressure boosting applications.

KSBDeltaPrimo

33 of 60

Page 34

8 Operating the Pressure Booster System

Parameter Description

3-4-3-5 No-flow detection. Parameters determining the pressure booster system's stopping behaviour at zero

flow.

3-4-3-5-1 No-flow bandwidth. Permissible deviation of actual value from setpoint (settable from 2to18%)

interpreted as constant pressure at zero flow by the control unit.

3-4-3-5-2 No-flow time. Period (settable from 4to20s) during which the deviation set under 3-4-3-5-1 must be

valid for the control unit to identify zero flow.

3-4-3-5-3 No-flow step. Value must not be changed for pressure booster systems!

3-4-4 WSD settings. Only the temperature monitoring function is supported at the moment.

3-4-4-3 Average room temp. A warning is output if this temperature is exceeded.

3-5 Pressure

3-5-1 "Customer" level. Setpoint. Pressure at which the pumps start.

3-5-3 "Customer" level. Bandwidth. Value in bar (standard: 0.05bar) of permissible deviation of actual value

from setpoint.

3-5-4 "Customer" level. Accumulation press. Value added to the actual value before the last pump is

stopped.

3-5-5 "Service" level. Max. setpoint

3-5-6 "Service" level. Hmax. Maximum pump head at zero flow.

3-5-8 "Service" level. Average inlet press. This parameter indicates the inlet pressure of the system if a

pressure switch is used as dry running protection device.

3-5-9 "Customer" level. Adapt. setpoint. Activated under 3-7-8, Adapt. setpoint.

3-5-10 Delta p. This parameter defines by how many bar the setpoint is increased or decreased per running

pump.

For difficult site conditions only.

3-5-11 "Customer" level. High pressure alarm. This parameter defines the maximum pressure at which a

warning is to be output.

3-5-12 "Customer" level. High pressure action. This parameter defines the control unit's response when the

pressure set under 3-5-11 is reached. Selection options: "Stop pumps" or "Message only".

3-5-13 "Customer" level. Low pressure alarm. This parameter defines the minimum pressure at which a

warning is to be output.

3-5-14 "Service" level. Low pressure action. This parameter defines the control unit's response when the

pressure set under 3-5-13 is reached. Selection options: "Stop pumps" or "Message only".

3-5-15 "Service" level. Shut down RDP. Can only be selected if a pressure sensor has been selected for dry

running protection. This parameter defines the pressure at which lack of water is to be signalled.

3-5-16 "Service" level. Reset RDP. Can only be selected if a pressure sensor has been selected for dry running

protection. This parameter defines the pressure at which the lack of water has gone.

3-5-17 "Service" level. Press. Flow Control. Can only be selected if flow monitoring has been selected for dry

running protection. Lack of water is detected when the flow sensor detects zero flow and the

pressure on the discharge side falls below the setpoint minus the value entered here.

3-6 Timer settings

All parameters can be changed at "Service" level.

3-6-1 Opt. pump starts/h. Permissible pump starts per hour.

3-6-2 Min. run time. Minimum run time of the pump, even if the period between the start and stop

command is shorter.

3-6-3 Min. run time corr. Value added to the minimum run time if the number of pump starts is exceeded.

3-6-4 Max. run time. Period after which the pumps will be changed over in any case.

3-6-5 Start delay. Time between the start command and the actual pump start.

3-6-6 Stop delay. Time between the stop command and the actual pump stop.

3-6-8 RDP delay. Time between lack-of-water signal and pump stop.

3-6-9 High/low alarm delay. Time between the occurrence of a fault and the associated warning/alert.

3-7 Time/Date

All parameters except 3-7-7 and 3-7-11 can be changed at "Customer" level.

3-7-1 Date

3-7-2 Time

34 of 60

KSBDeltaPrimo

Page 35

8 Operating the Pressure Booster System

Parameter Description

3-7-3 Check run mode. Set according to requirements: System does not perform check run (set to OFF),

performs check run at given interval (set to "Interval-based"), every day at the same time (Time of

day based) or at a given time on a given day of week (Time of week based).

3-7-4 Check run interval. Can only be selected if "Interval-based" has been selected under 3-7-3. Enter the

interval in seconds.

3-7-5 (Daily) Check run at. Can only be selected if "Time of day based" has been selected under 3-7-3. Enter

hour and minute.

3-7-6 (Weekly) Check run at. Can only be selected if "Time of week based" has been selected under 3-7-3.

Enter hour, minute and weekday.

3-7-7 Check run duration. Duration of check run of each pump.

3-7-8 Clock adapt setp.

3-7-8-1 Adaptation mode. Set according to requirements: no alternative setpoint (set to OFF), every day at

the same time ("Adapt ON/OFF ev. day") or at a given time on a given day of week ("Adapt. ON/OFF

per day").

3-7-8-2 Change ON/OFF times. Can only be selected if "Adapt ON/OFF ev. day" has been selected under

3-7-8-1. Enter hour and minute for activating and deactivating the alternative setpoint.

3-7-8-3 Select day of week. Can only be selected if "Adapt ON/OFF per day" has been selected under 3-7-8-1.

Enter the weekday.

3-7-8-4 Change ON/OFF times. Can only be selected if "Adapt ON/OFF per day" has been selected under

3-7-8-1. Enter hour and minute for activating and deactivating the alternative setpoint.

3-7-9 Date adapt level ON. Month from which the alternative level specified under 3-4-1-4, Level

configuration, is to be activated.

3-7-10 Date adapt level OFF. Month from which the alternative level specified under 3-4-1-4, Level

configuration, is to be deactivated.

3-7-11 Maintenance interval. Enter the number of operating hours after which maintenance is to be

performed.

3-10 Main menu

"Customer" level. Set the information to be displayed in the main menu.

3-11 Energy Saving Mode

All parameters can be changed at "Service" level.

3-11-1 Energy Saving Mode ON/OFF. This parameter serves to activate/deactivate the energy-saving mode.

3-11-2 Direct Off. This parameter defines whether, upon reaching the "power down speed", the pressure

booster system stops after the delay set under 3-11-4 or flow detection is started.

3-11-3 Power down speed. Enter the pump load at which the last pump is to stop.

3-11-4 Time Direct Off.

8.1.6.4 Parameter group 4 "Information"

Access via "Information" key